Patents

Literature

45results about How to "Q-factor can be increased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

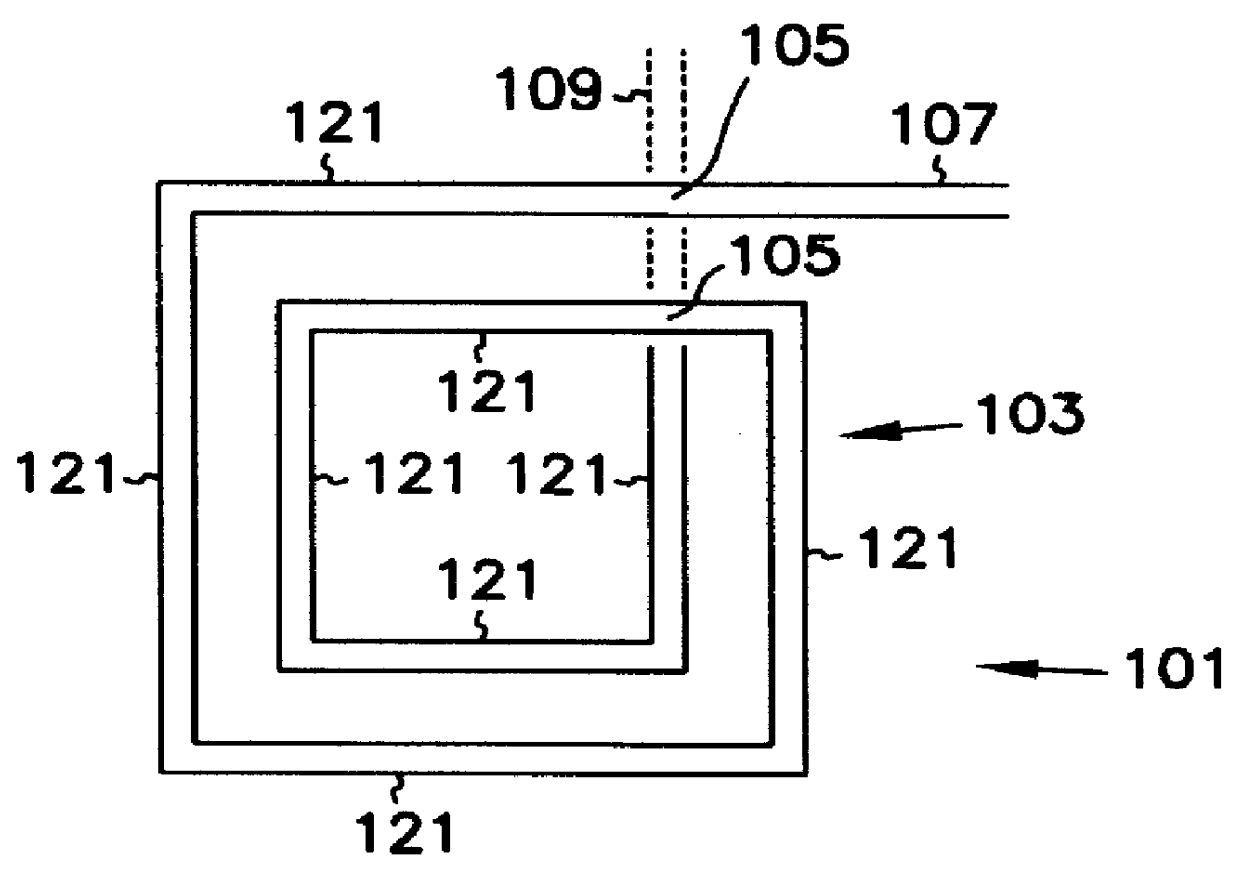

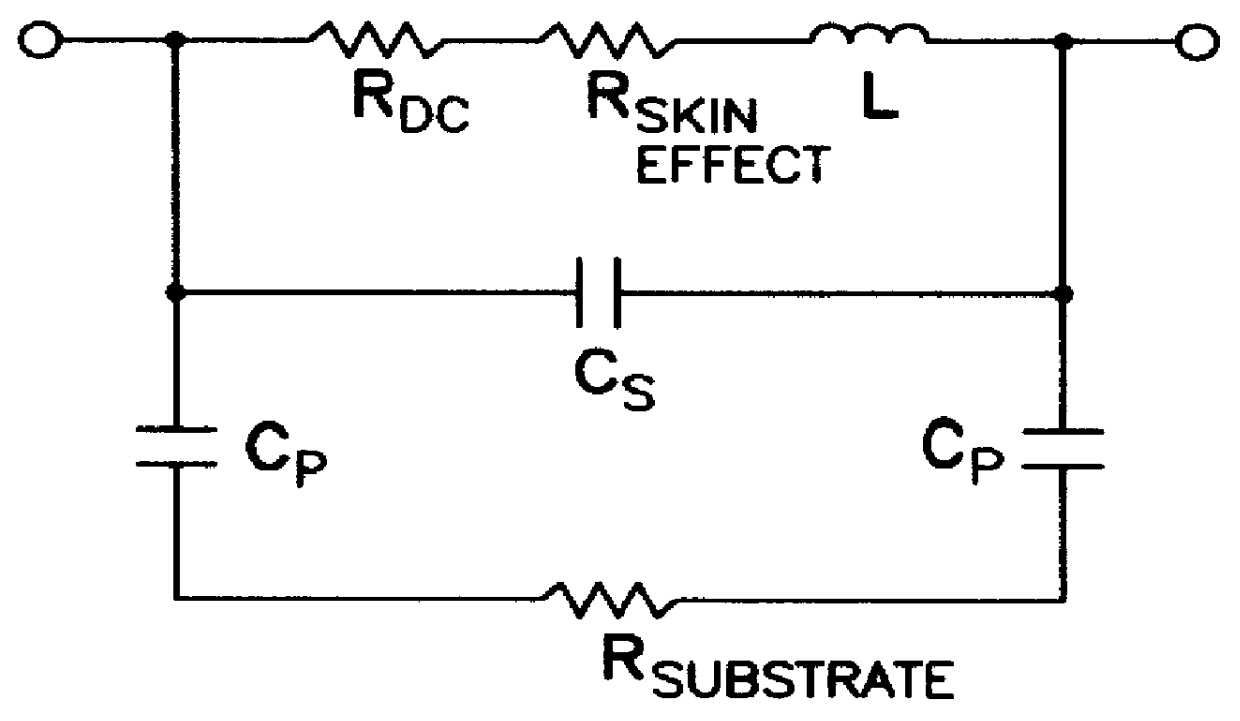

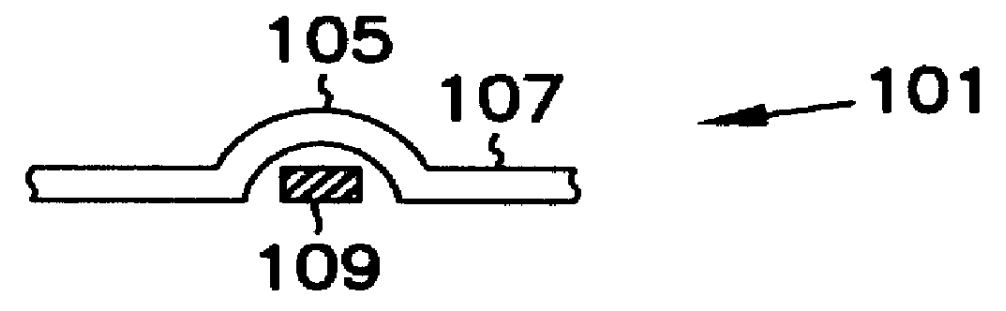

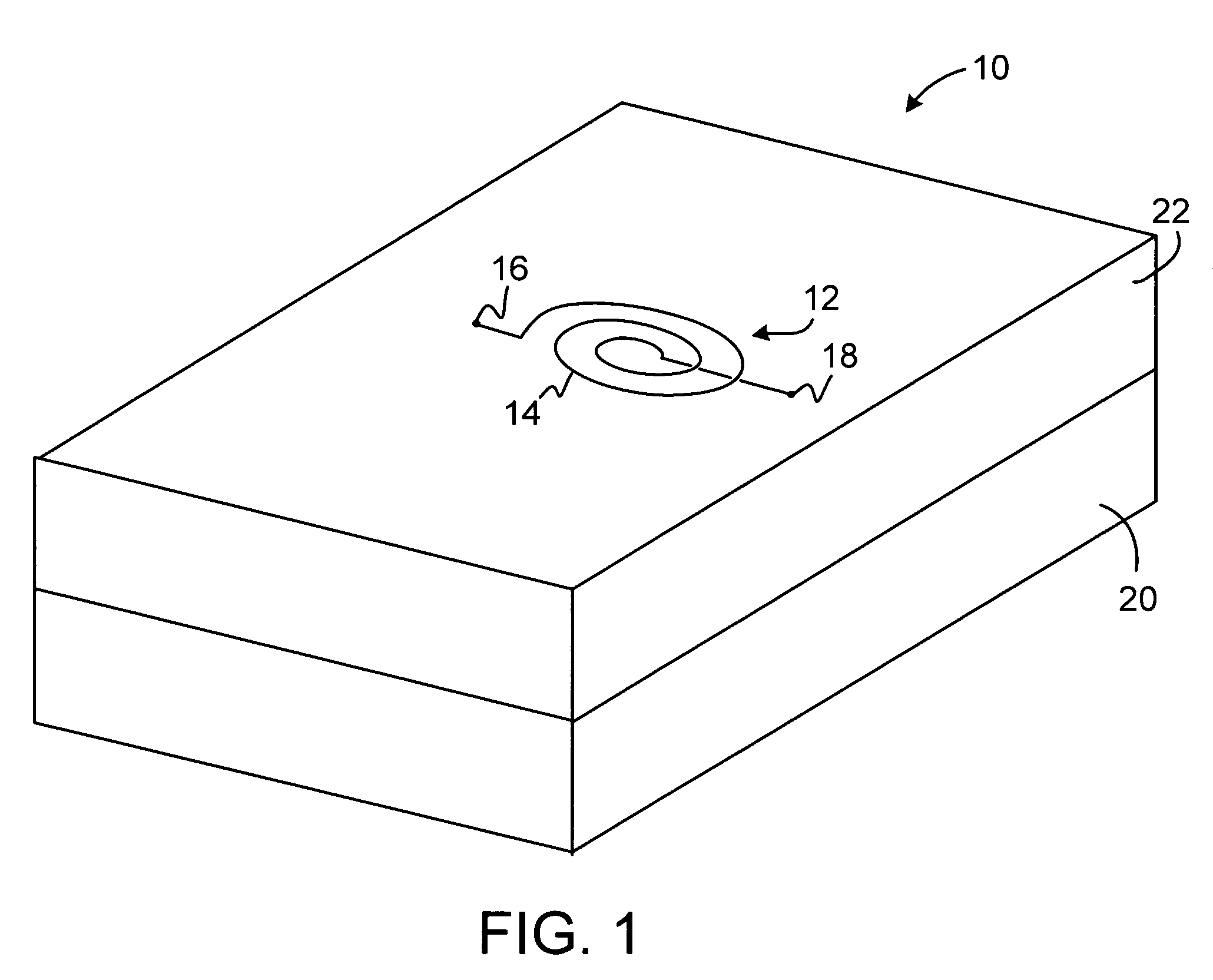

Method for making high-Q inductive elements

InactiveUS6025261ARaise the self-resonant frequencyHigh selectivitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInductance

Owner:MICRON TECH INC

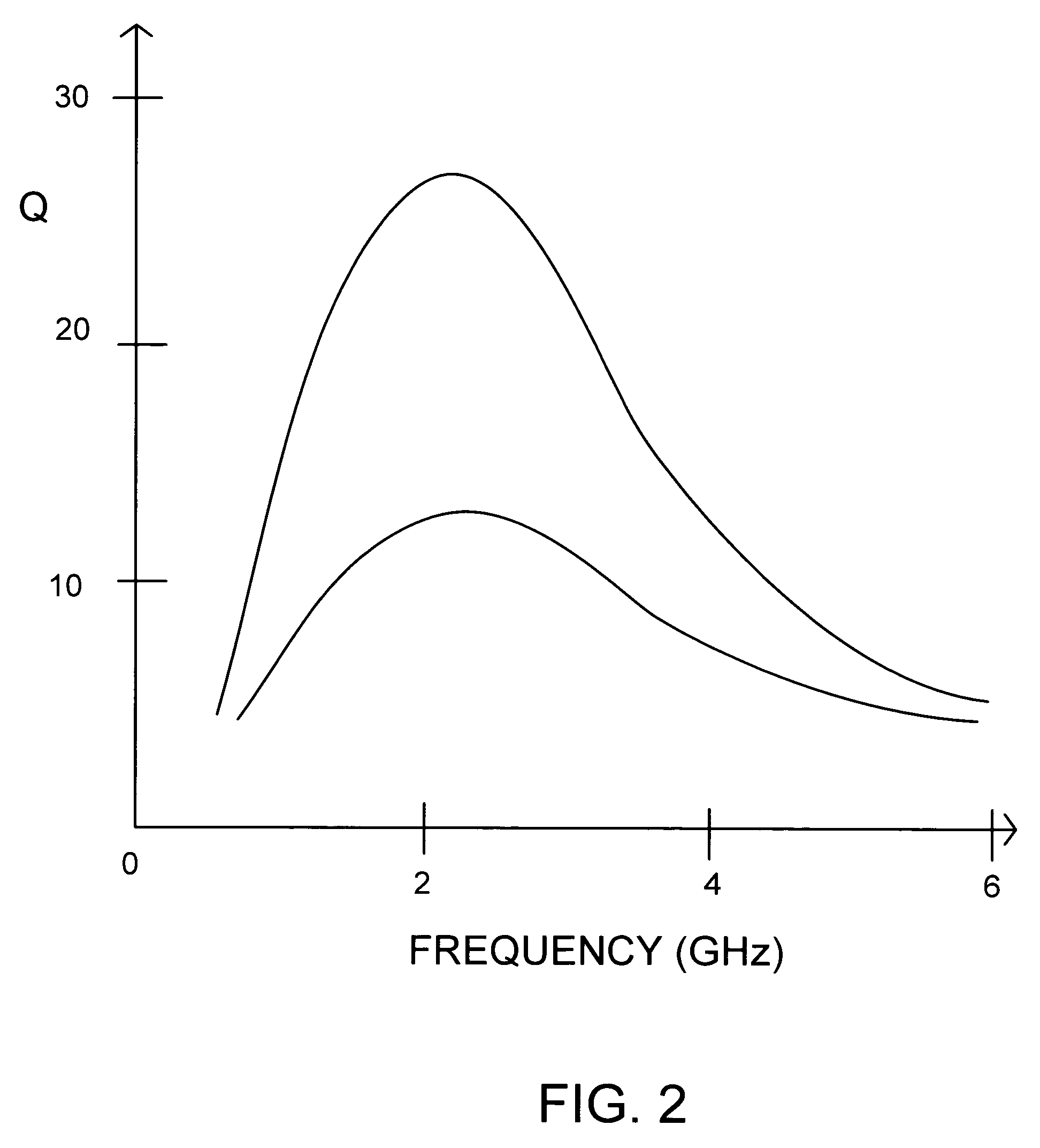

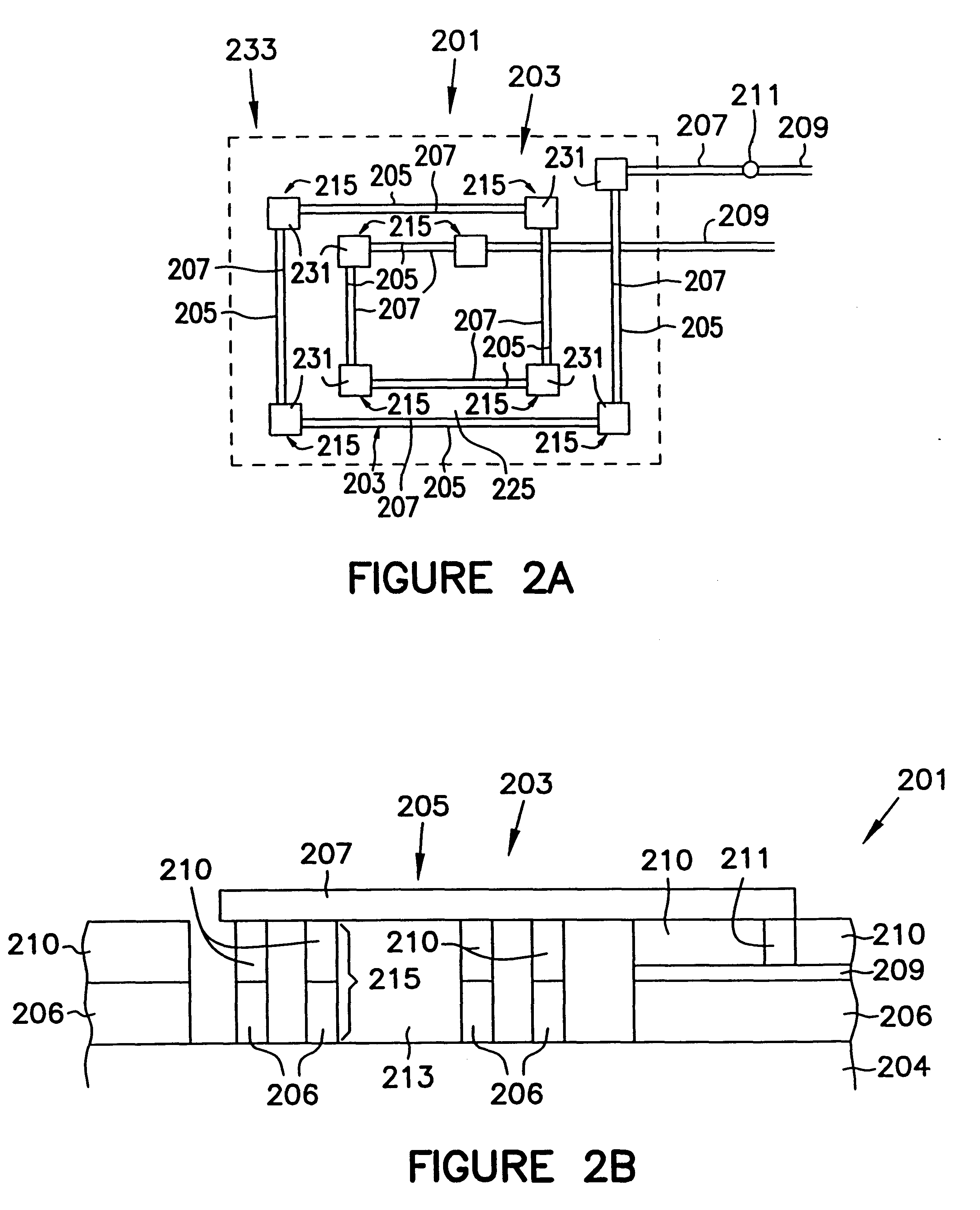

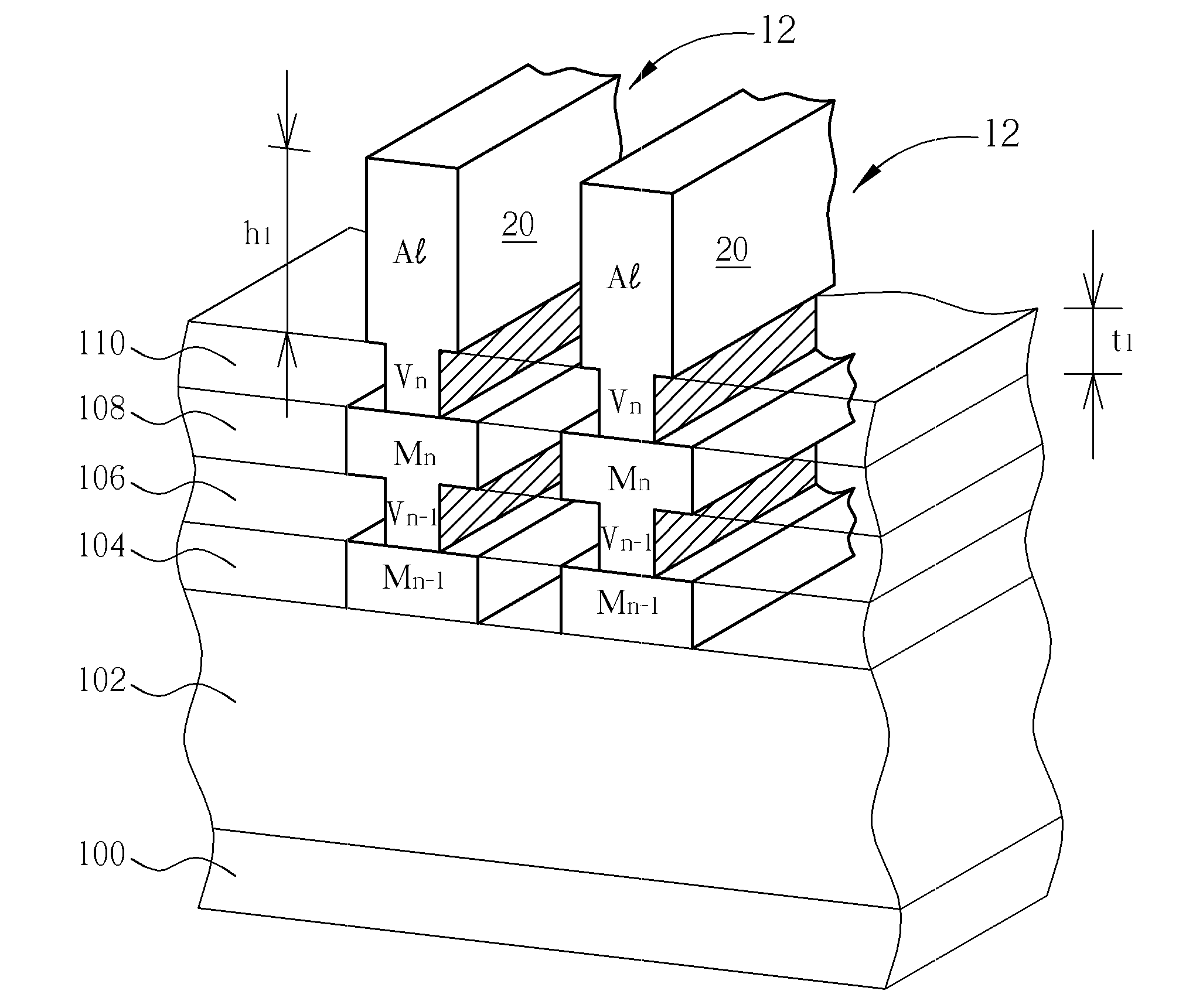

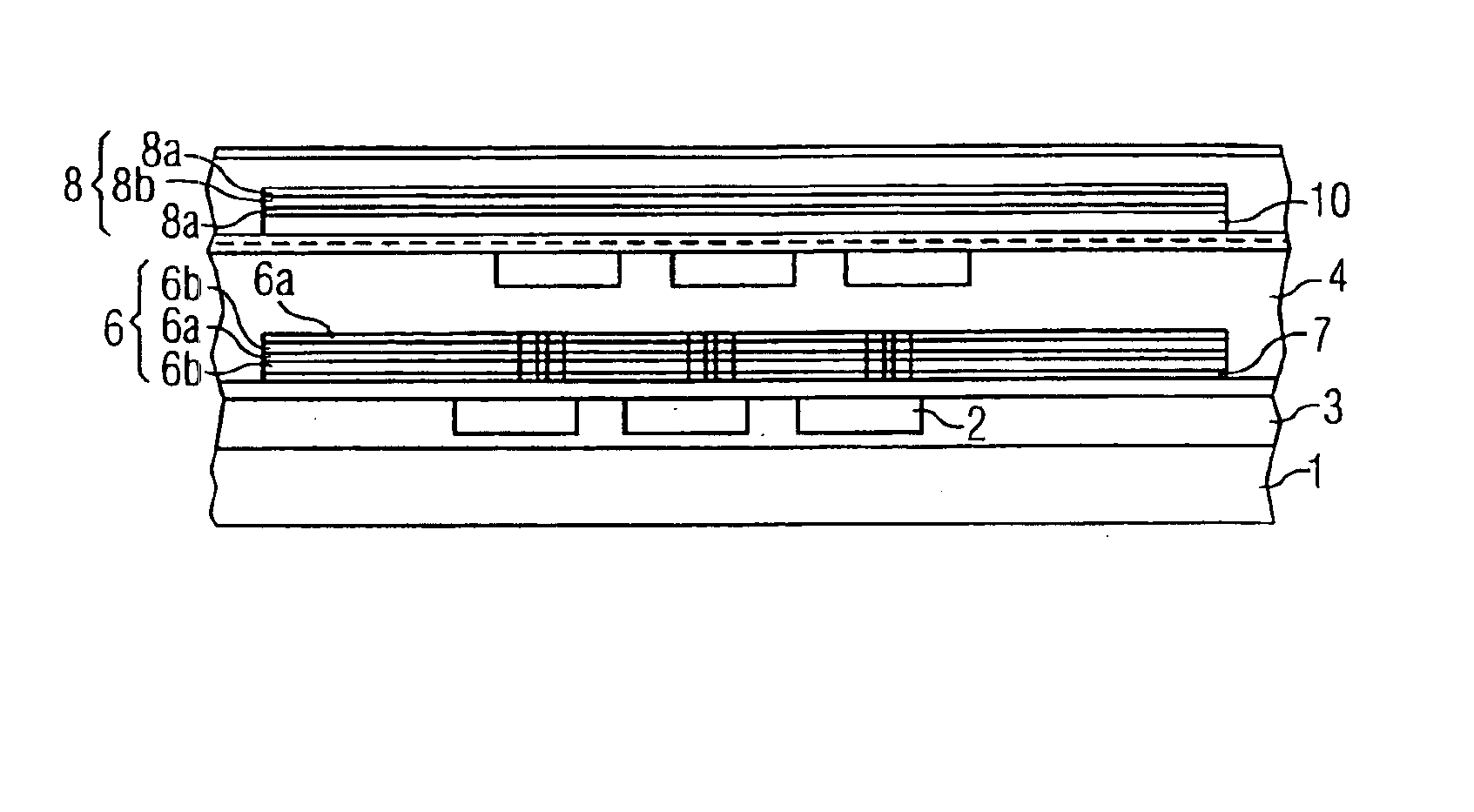

Integrated circuit inductors

InactiveUS7135951B1Q-factor of the integrated circuit may be enhancedLower on-resistanceSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsDielectricElectrical resistance and conductance

Integrated circuit inductors may be formed using a spiral layout on the surface of an interconnect dielectric stack. Conductive lines from two or more metal layers in the interconnect stack may be electrically connected using one or more via trenches. The via trench interconnection arrangement reduces the resistance of the inductor and increases the inductor's Q-factor. The Q-factor of the inductor may also be increased by placing a region of n-type and p-type wells or a metal plate region beneath the inductor to reduce power losses during operation. Shallow trench isolation may be used to reduce eddy currents and increase Q. The effects of copper dishing and trench blow-out may be used during inductor fabrication. A dual damascene fabrication process may be used.

Owner:ALTERA CORP

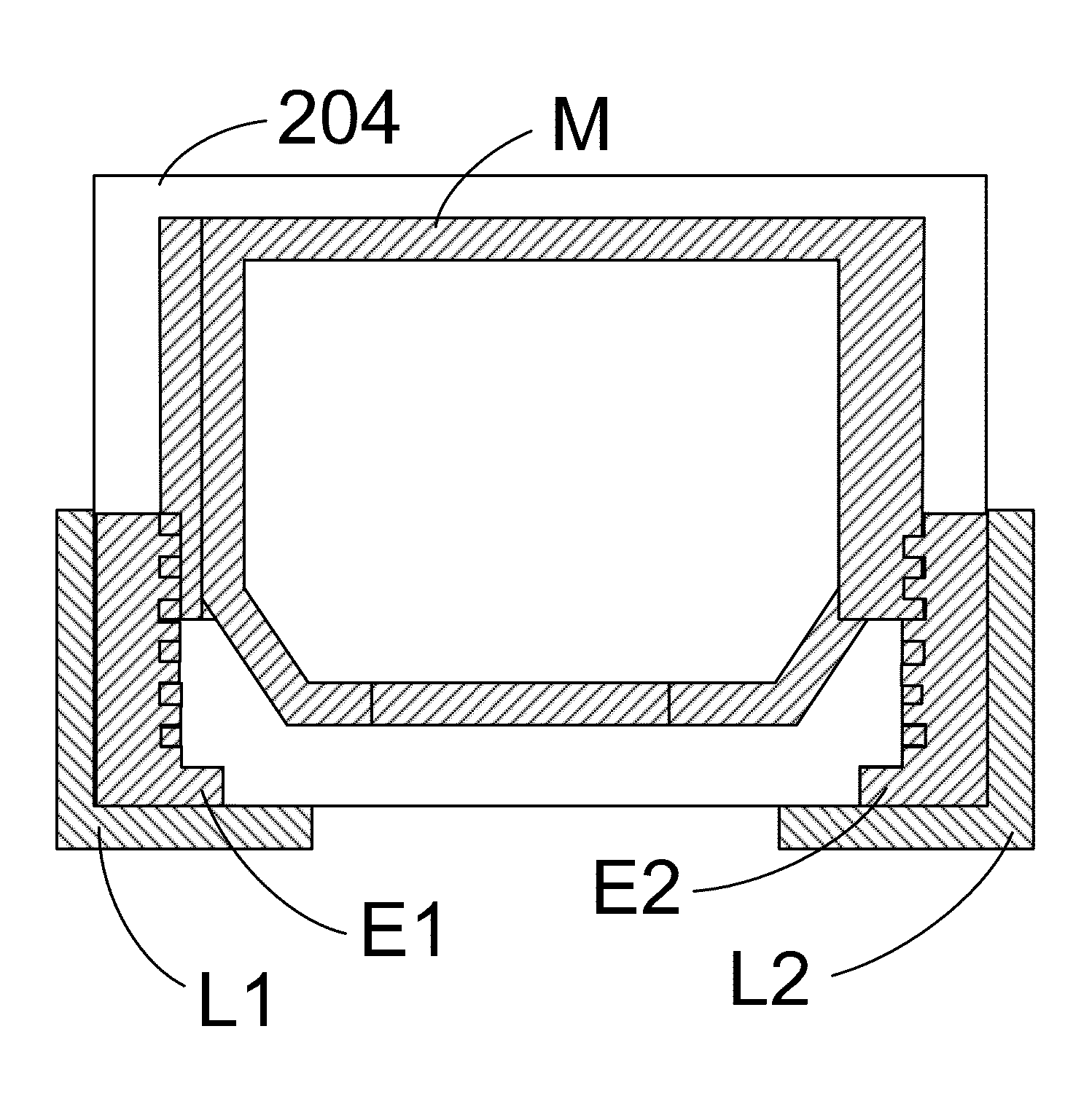

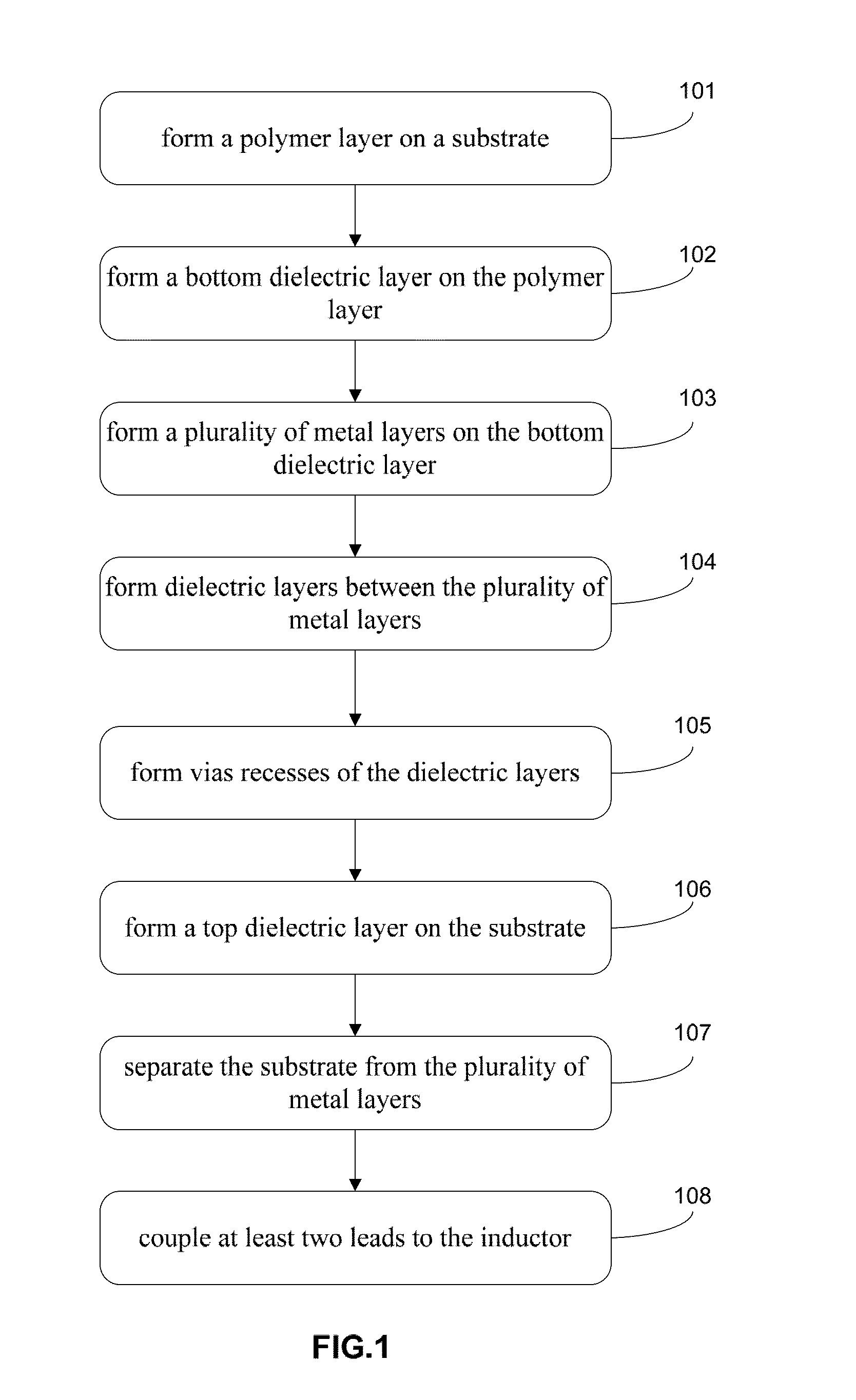

Substrate-less electronic component and the method to fabricate thereof

InactiveUS20160141102A1Q-factor can be increasedLower quality factorTransformers/inductances coils/windings/connectionsCoils manufactureElectronic componentElectron

An electronic component is disclosed, the electronic component comprising: a conductive structure, comprising a plurality of conductive layers separated by a plurality of insulating layers, wherein the plurality of conductive layers and the plurality of insulating layers are stacked in a vertical direction, wherein the plurality of conductive layers forms at least one coil, wherein each of the coil is formed along the vertical direction across said plurality of conductive layers, wherein the plurality of insulating layers are not supported by a substrate.

Owner:CYNTEC

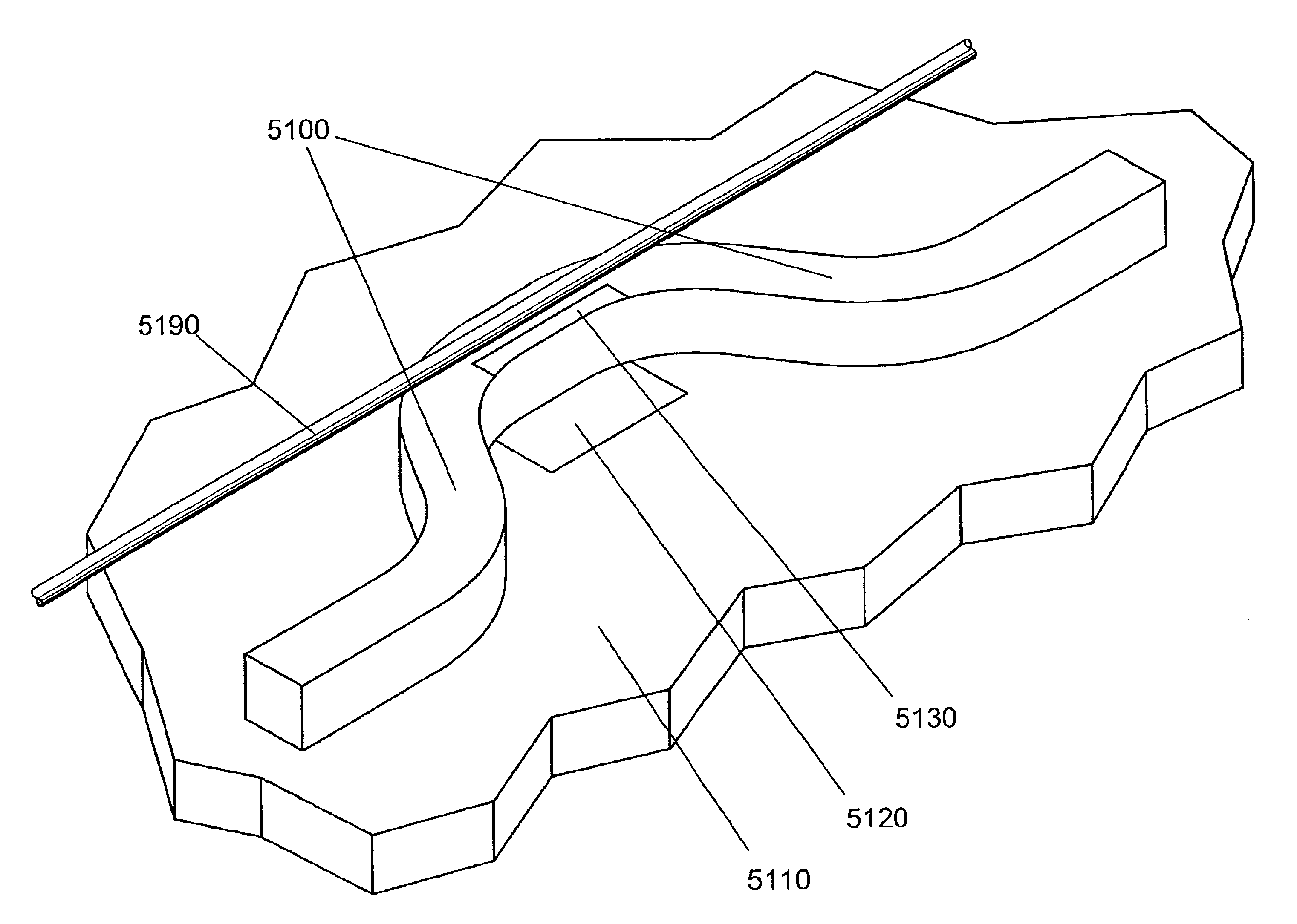

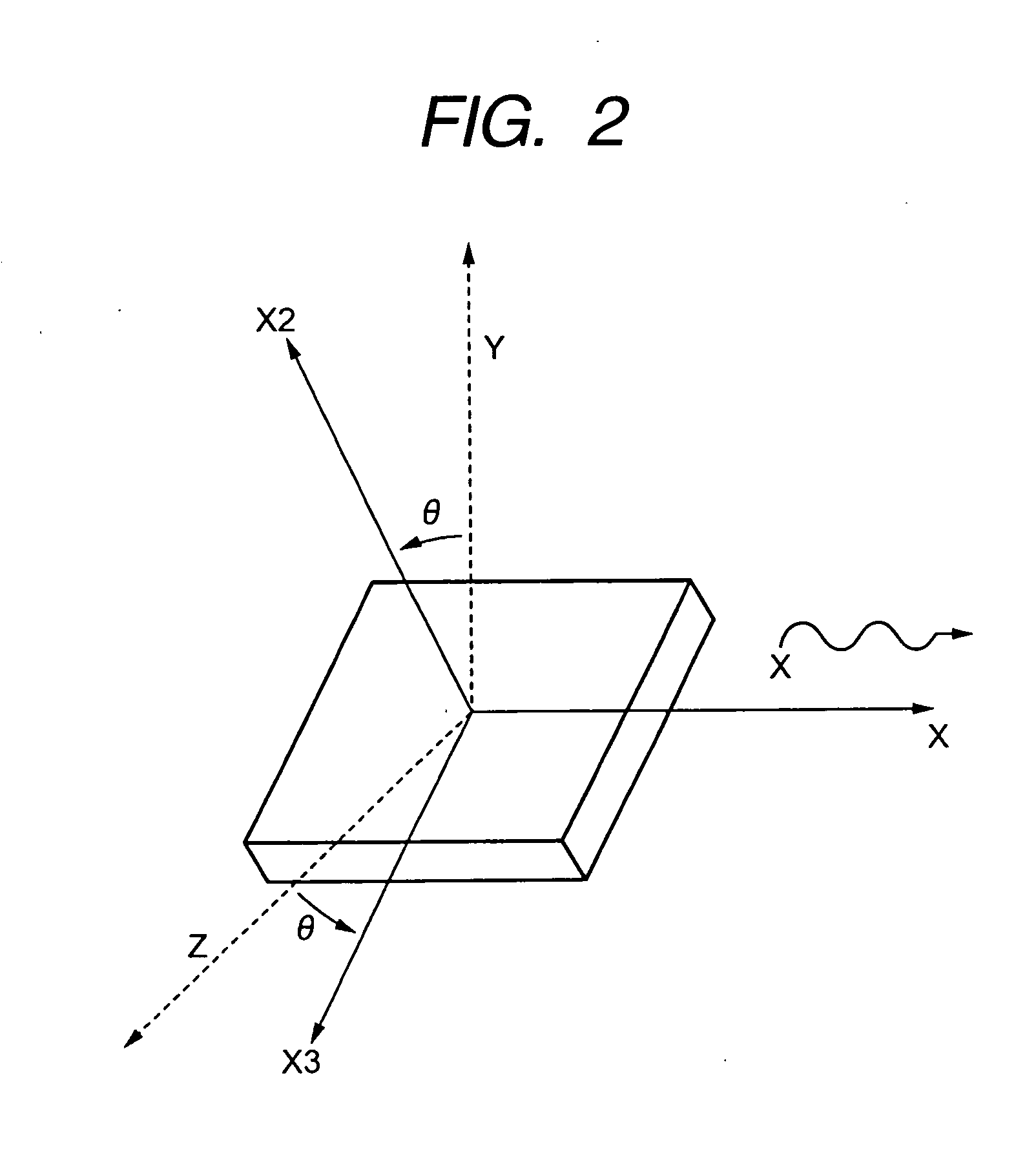

Multi-layer dispersion-engineered waveguides and resonators

InactiveUS6839491B2Large modal index shiftLarge indexNanoopticsCoupling light guidesControl signalLow voltage

A multi-layer laterally-confined dispersion-engineered optical waveguide may include one multi-layer reflector stack for guiding an optical mode along a surface thereof, or may include two multi-layer reflector stacks with a core therebetween for guiding an optical mode along the core. Dispersive properties of such multi-layer waveguides enable modal-index-matching between low-index optical fibers and / or waveguides and high-index integrated optical components and efficient transfer of optical signal power therebetween. Integrated optical devices incorporating such multi-layer waveguides may therefore exhibit low (<3 dB) insertion losses. Incorporation of an active layer (electro-optic, electro-absorptive, non-linear-optical) into such waveguides enables active control of optical loss and / or modal index with relatively low-voltage / low-intensity control signals. Integrated optical devices incorporating such waveguides may therefore exhibit relatively low drive signal requirements.

Owner:HOYA USA

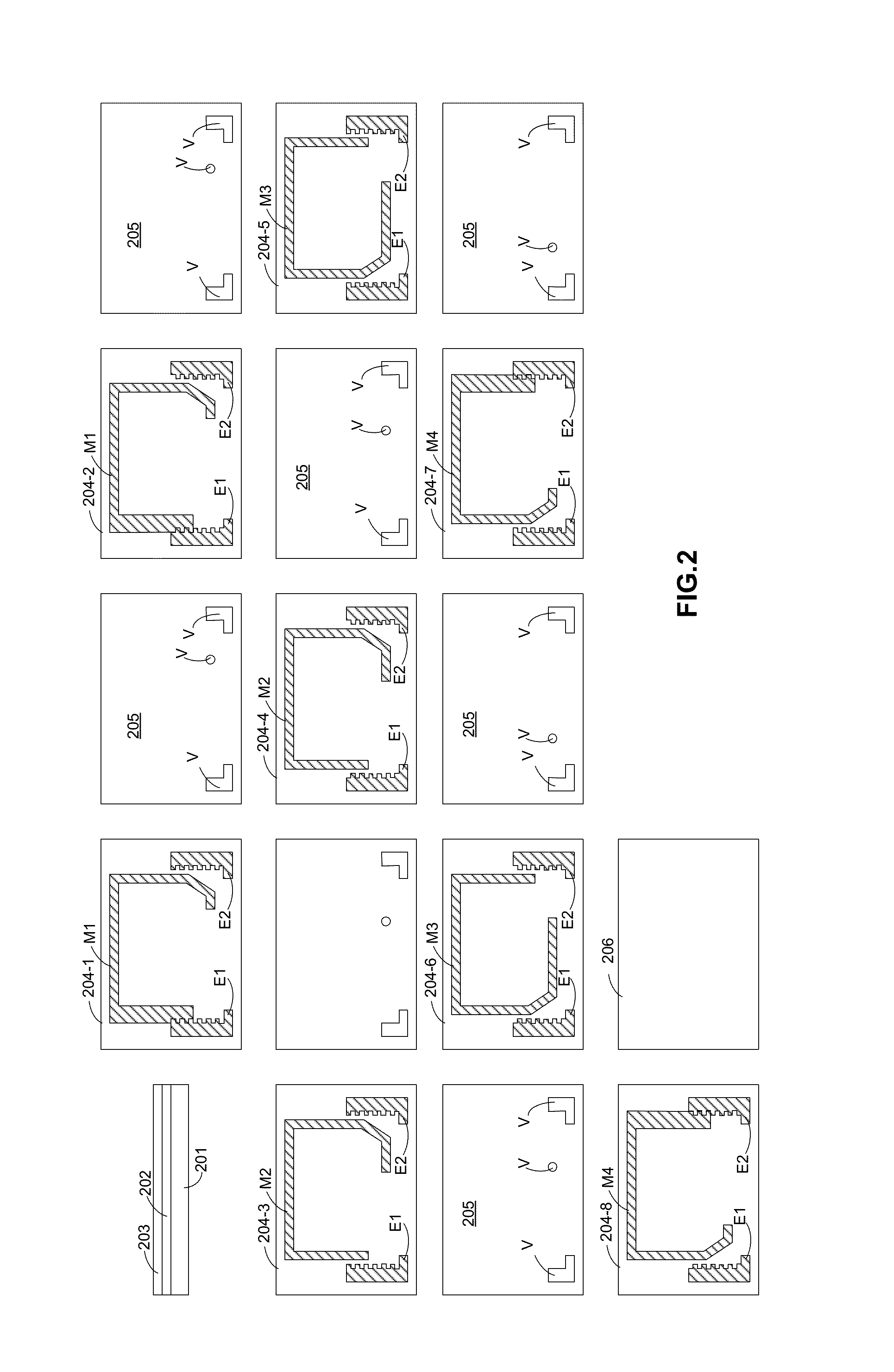

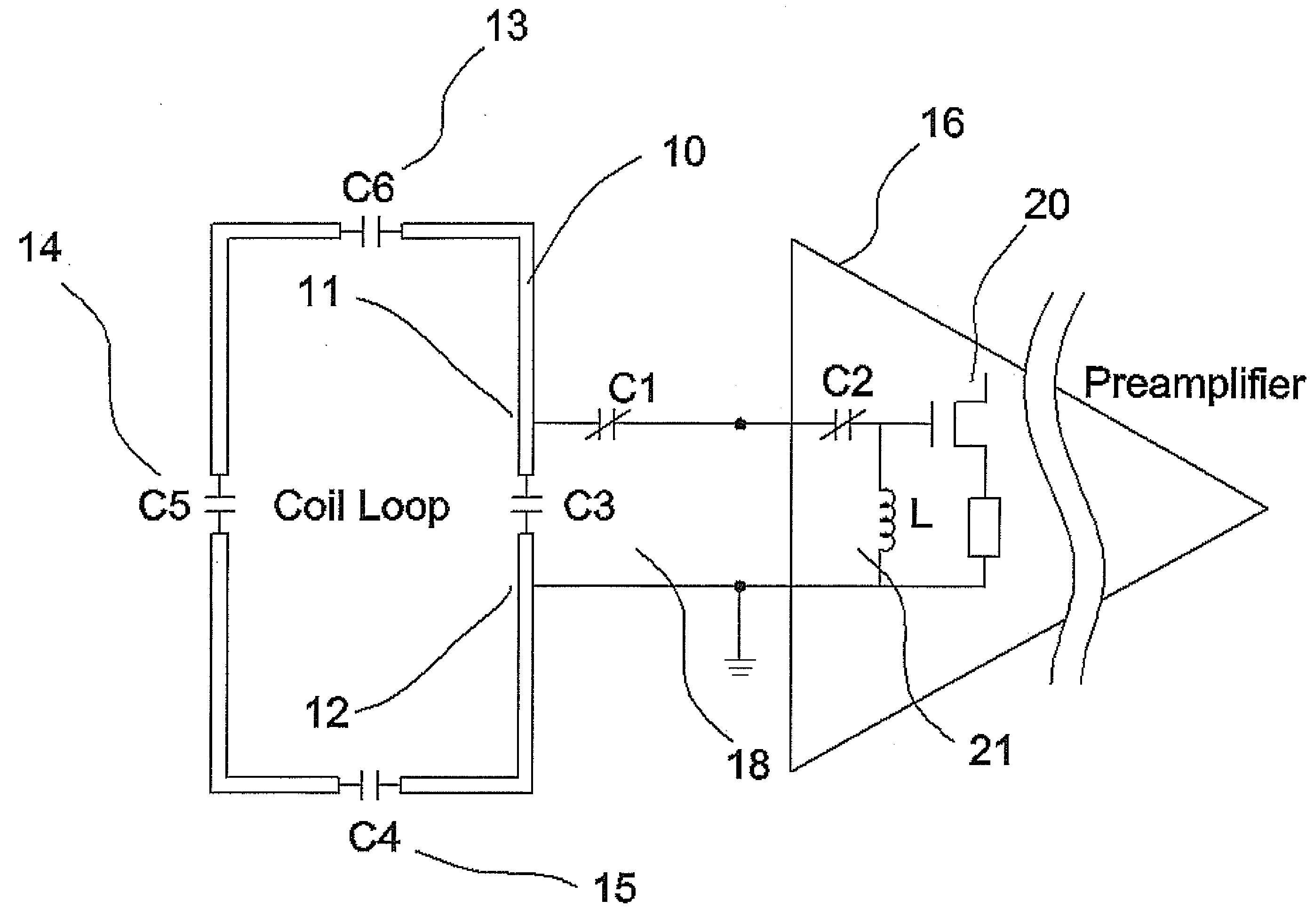

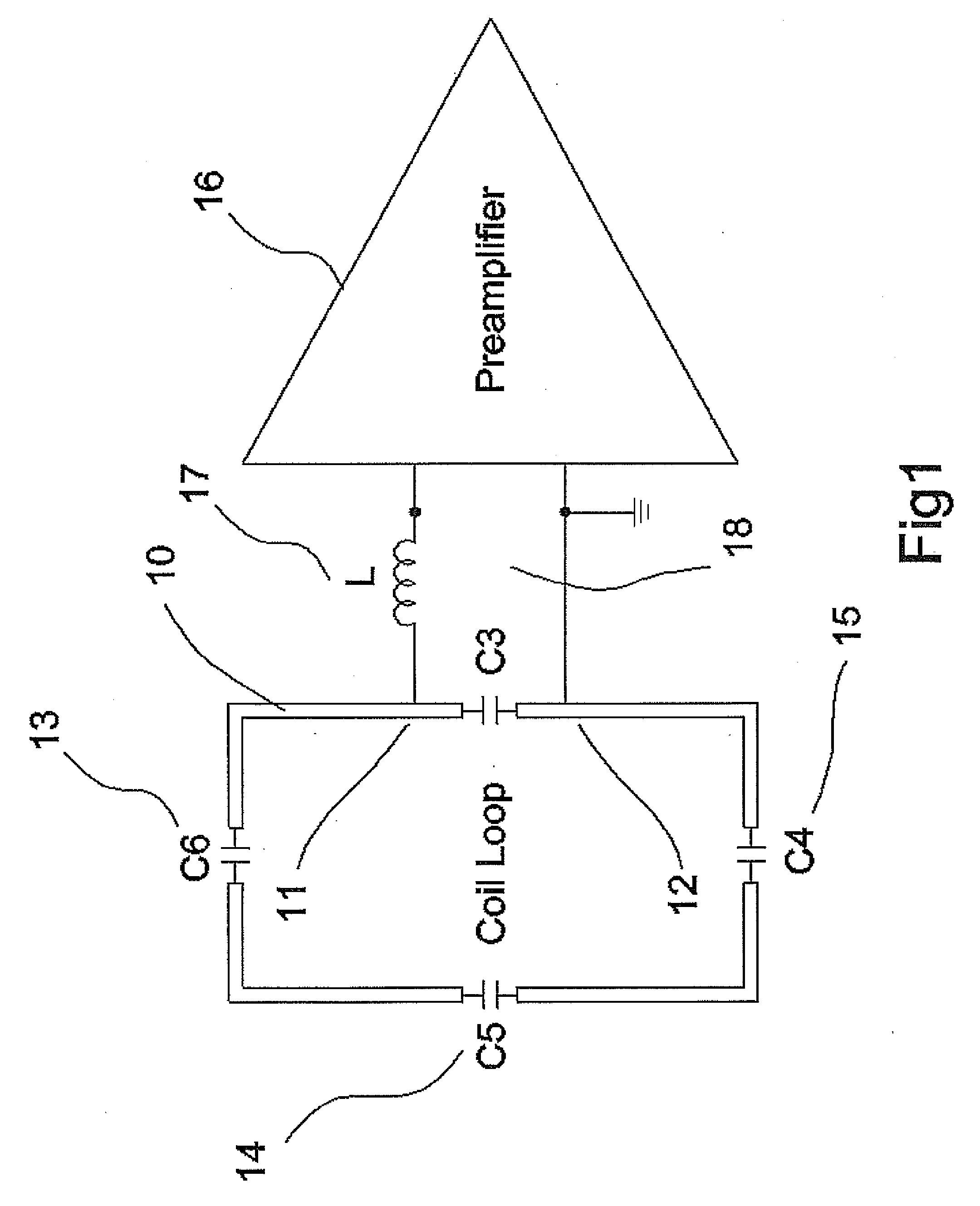

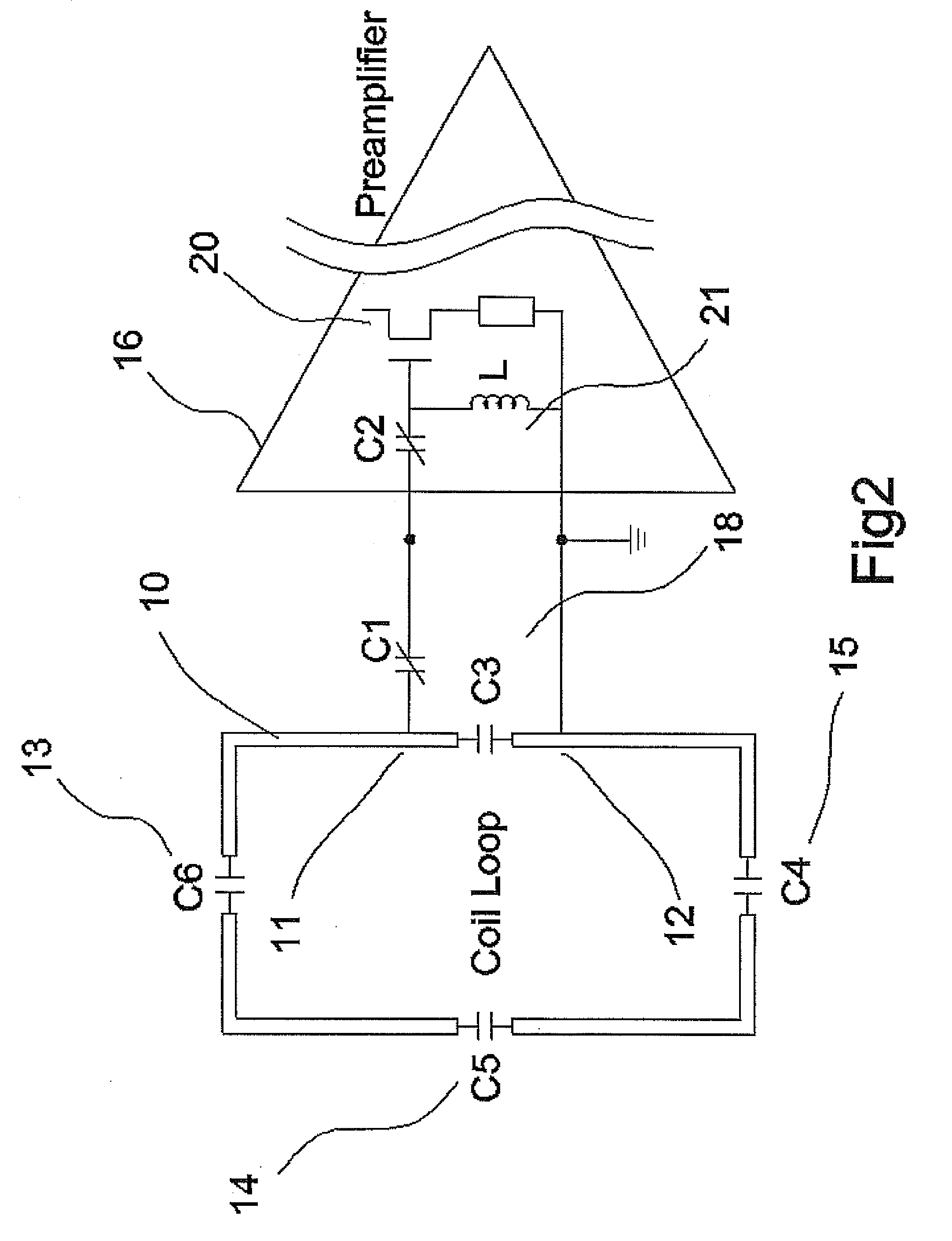

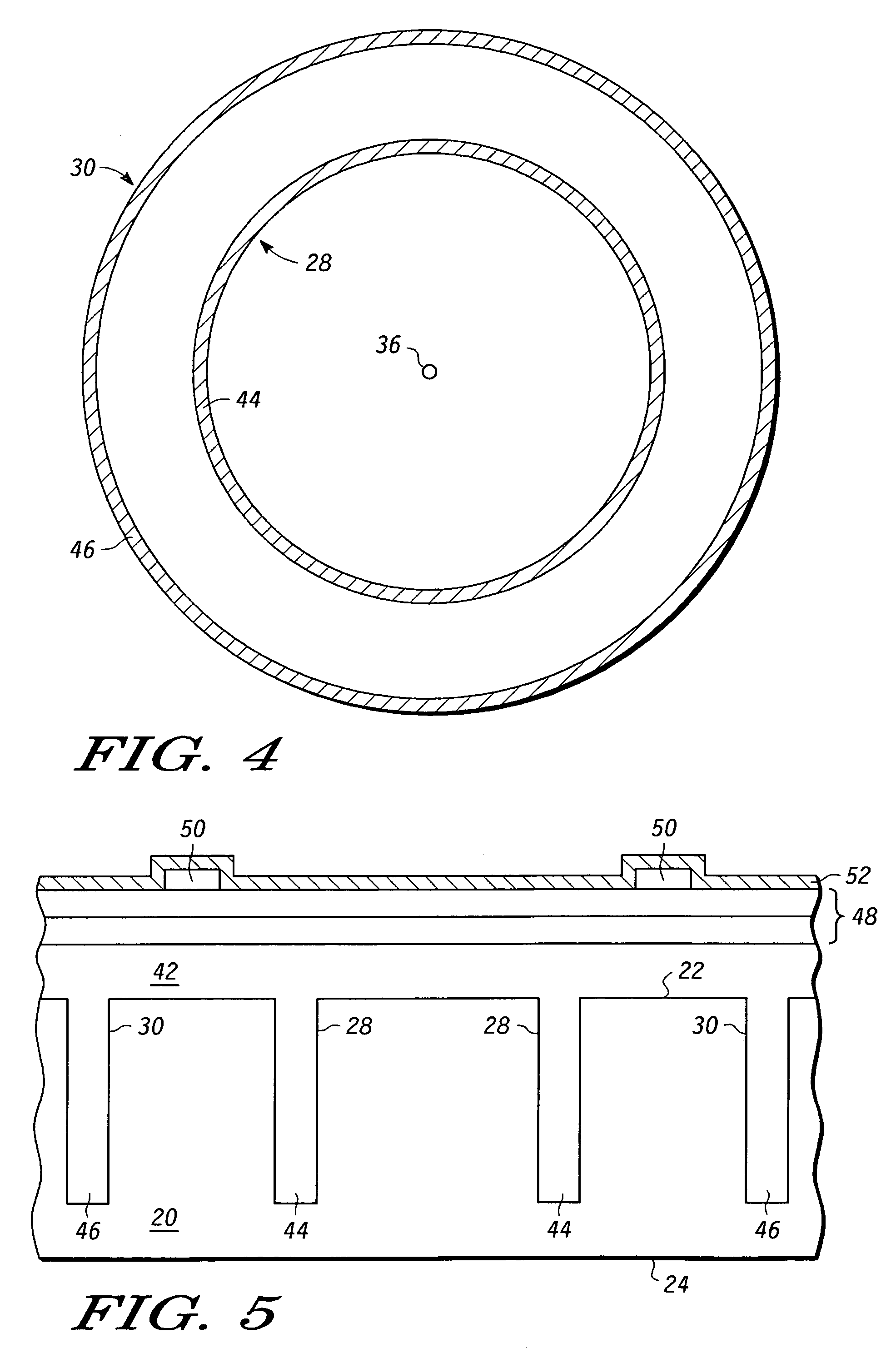

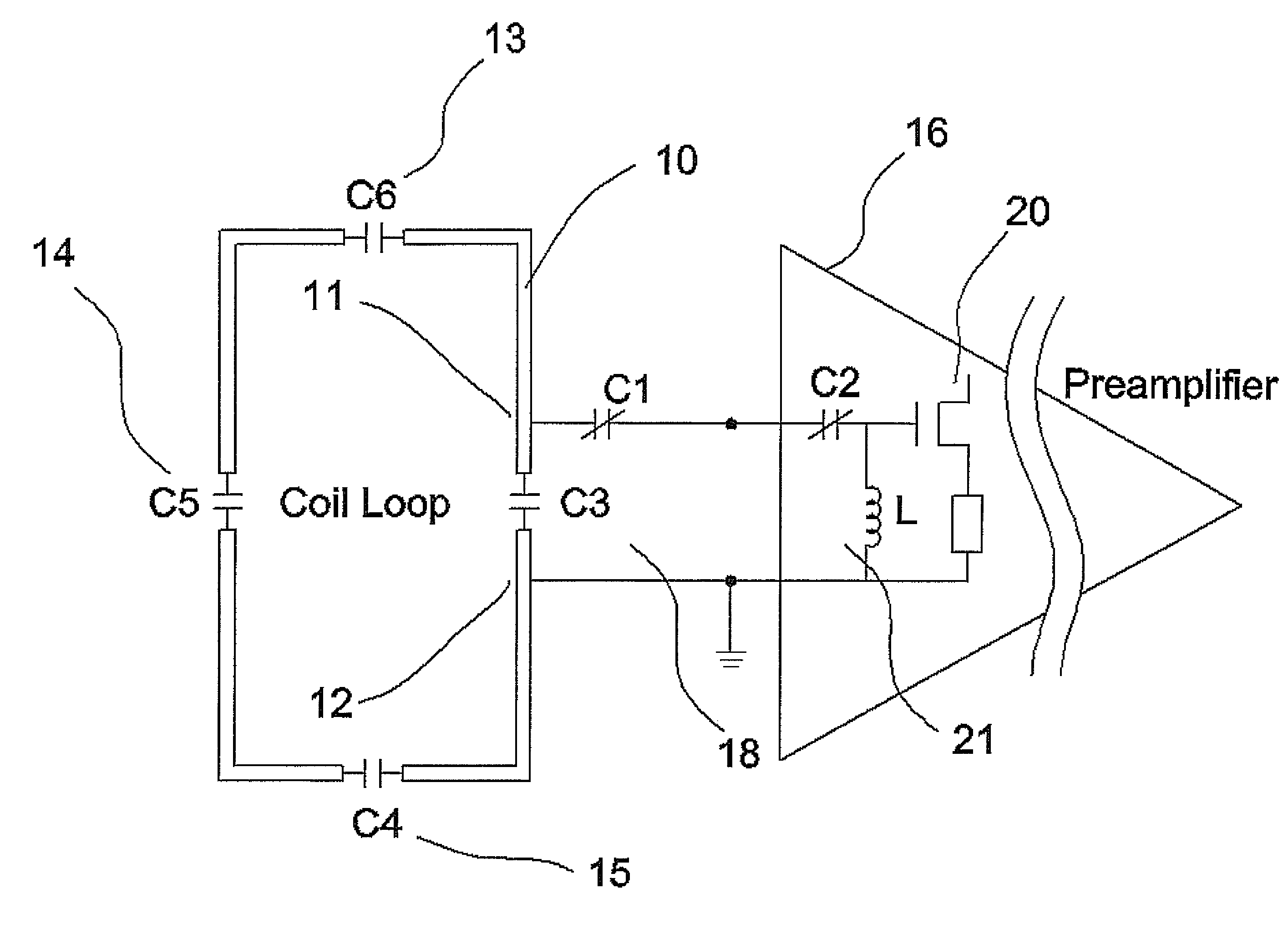

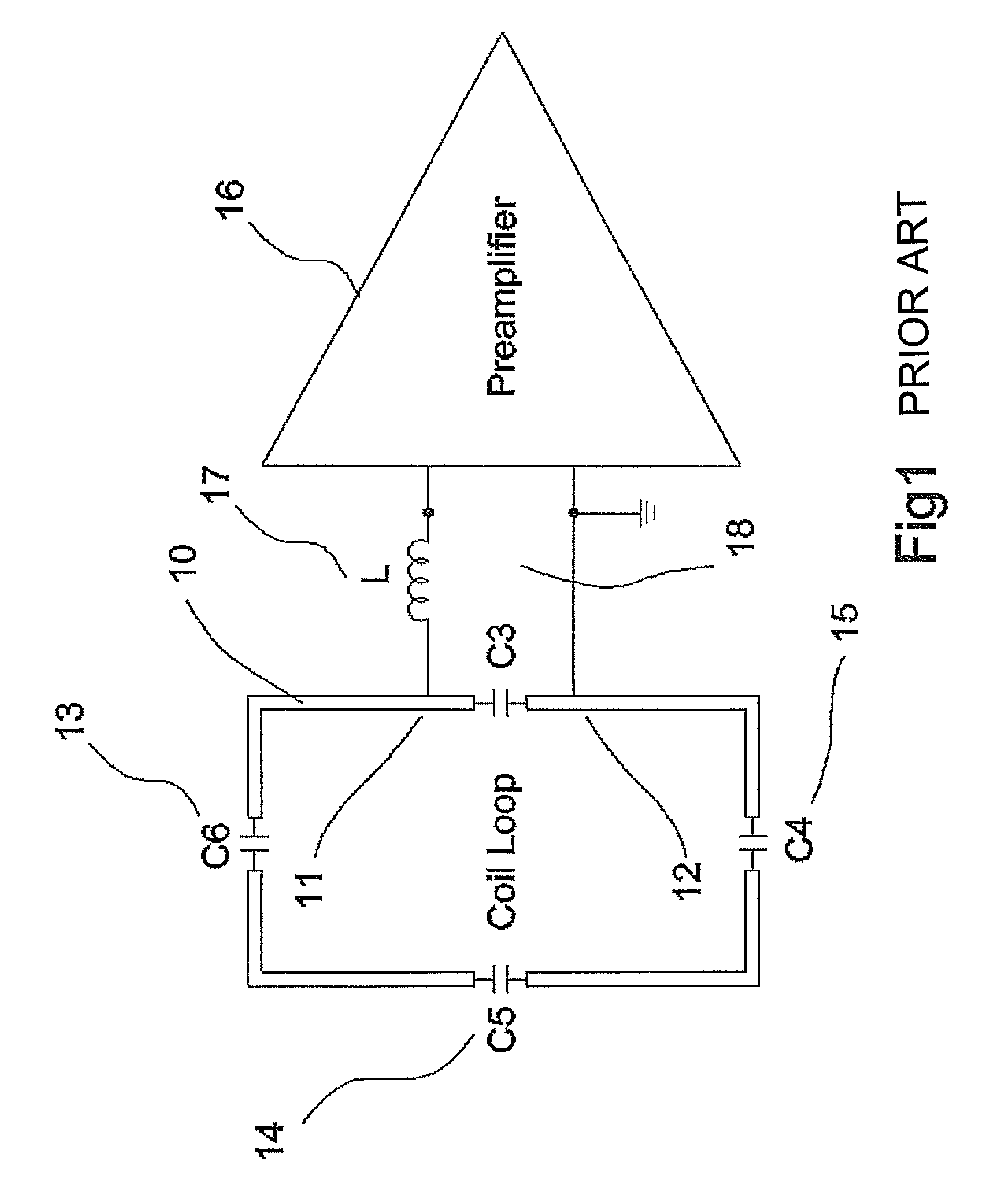

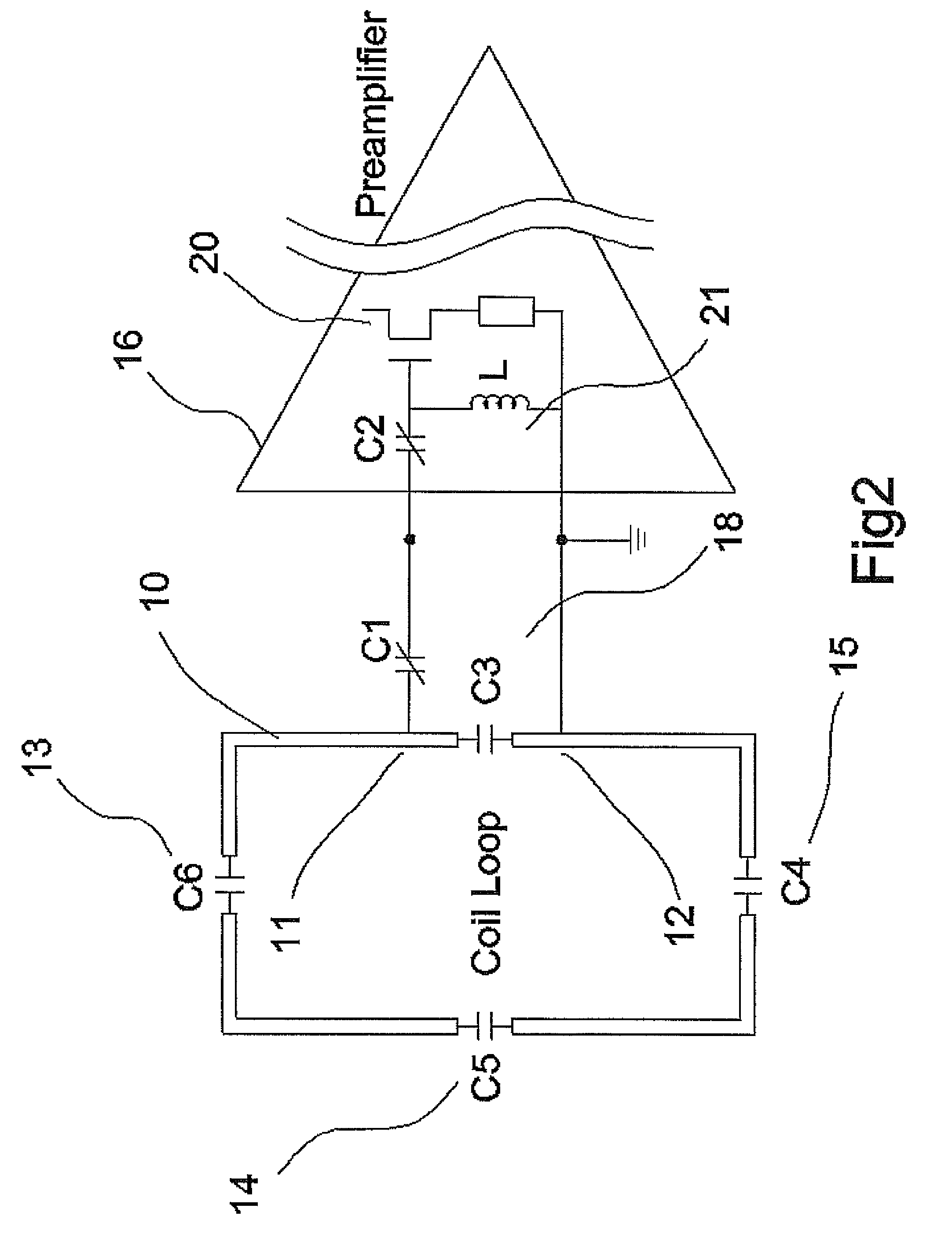

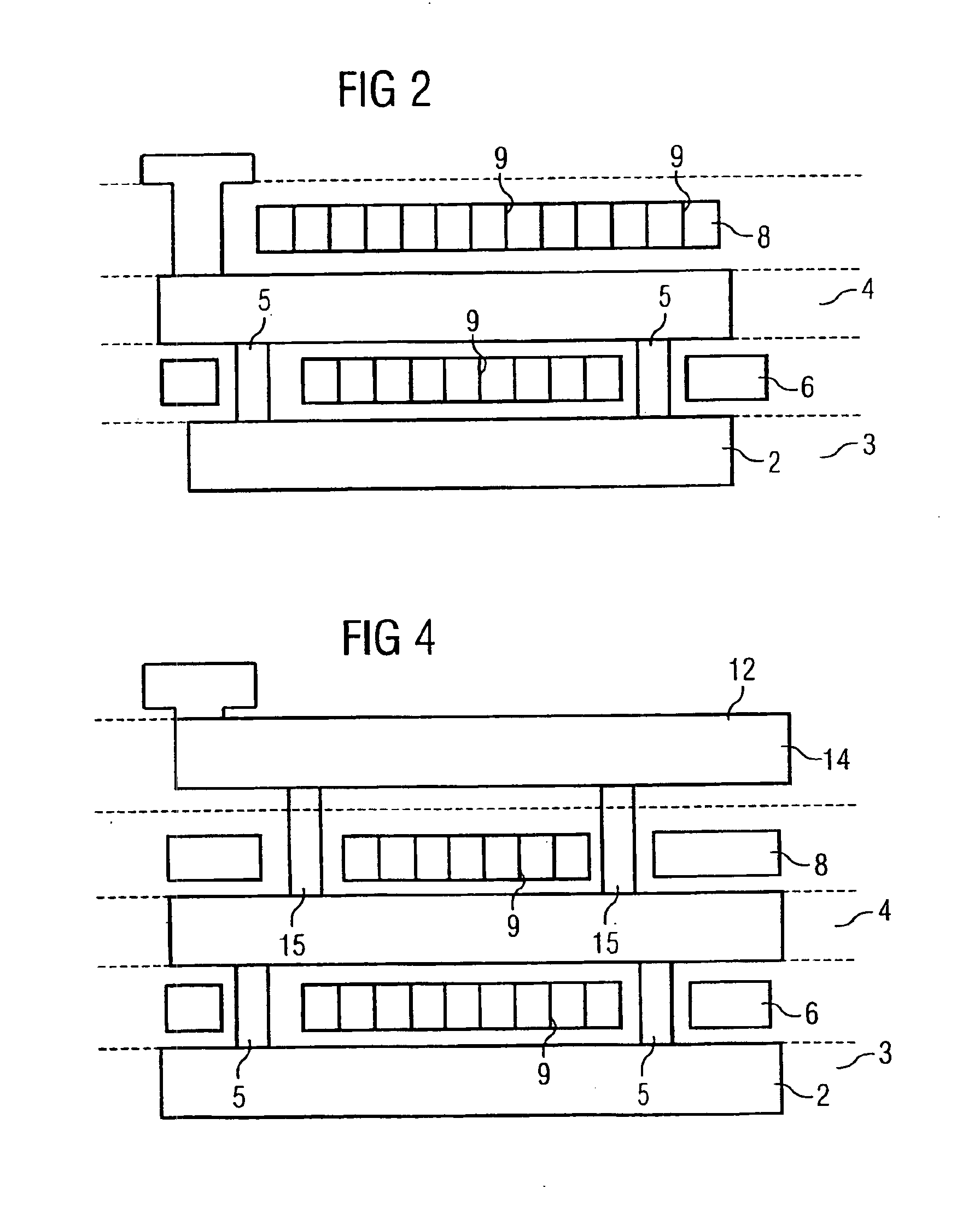

Coil decoupling for an RF coil array

ActiveUS20110043209A1Reduce parallel resistanceEliminating number of componentElectric/magnetic detectionMeasurements using NMRCapacitanceRadio frequency

An MRI phase RF coil array includes a plurality of separate RF coil elements where each coil element has a pre-amplifier circuit with a conditioning circuit in advance of the transistor including an inductor and capacitors connected across the input of preamplifier. Each of the coil elements has a preamplifier decoupling parallel resonant circuit for generating a tuned high impedance across the ends of the coil so as to inhibit coupling in the coil from signals in adjacent and non-adjacent coils of the array. The decoupling circuit comprises a fixed first capacitor across the ends, a second variable capacitor in one of the leads, a further capacitor in the conditioning circuit, all of which define a capacitance which co-operates with the inductance defined by the inductor of the conditioning circuit of preamplifier to form the parallel resonant circuit to generate the high impedance.

Owner:DEERFIELD IMAGING INC

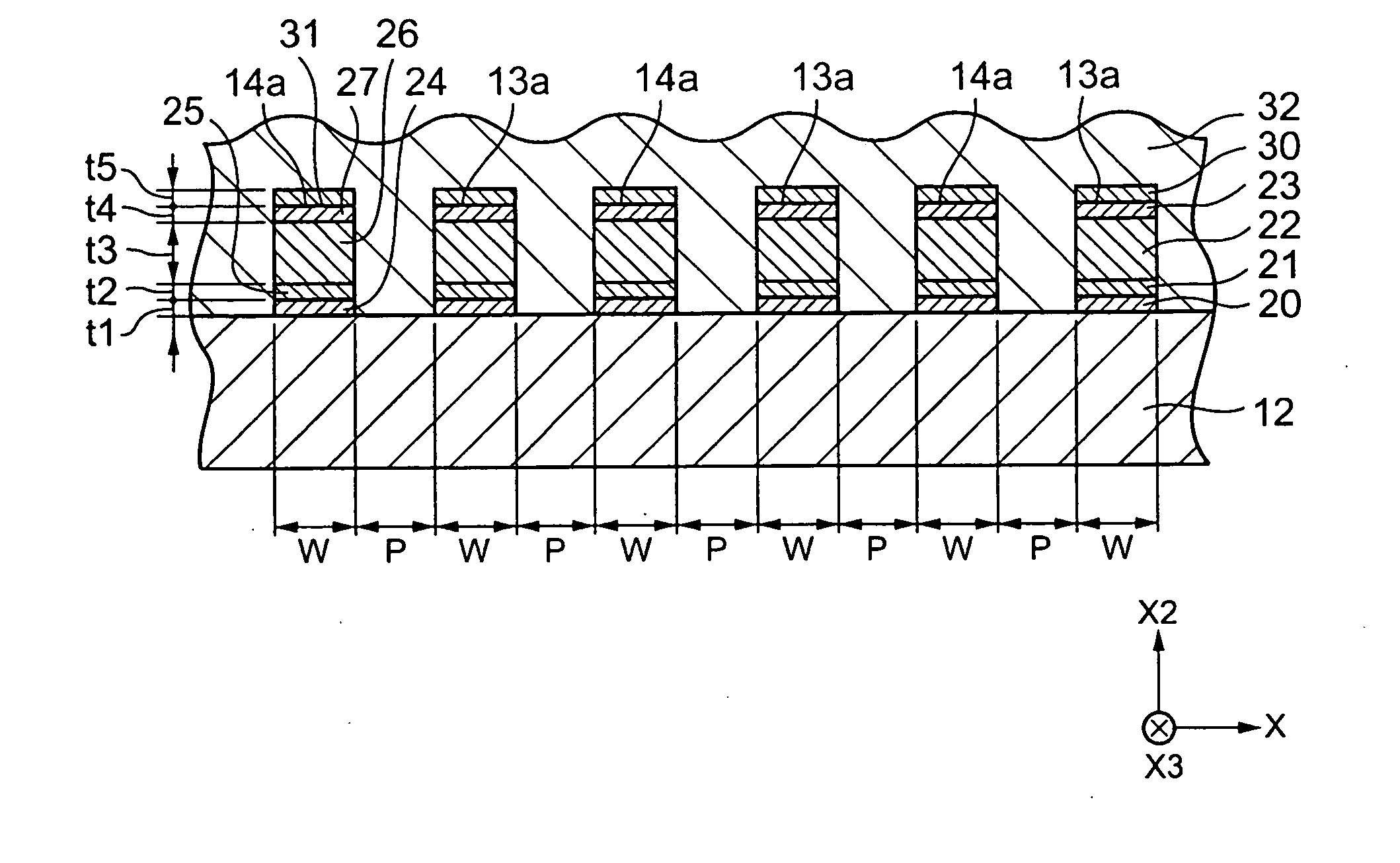

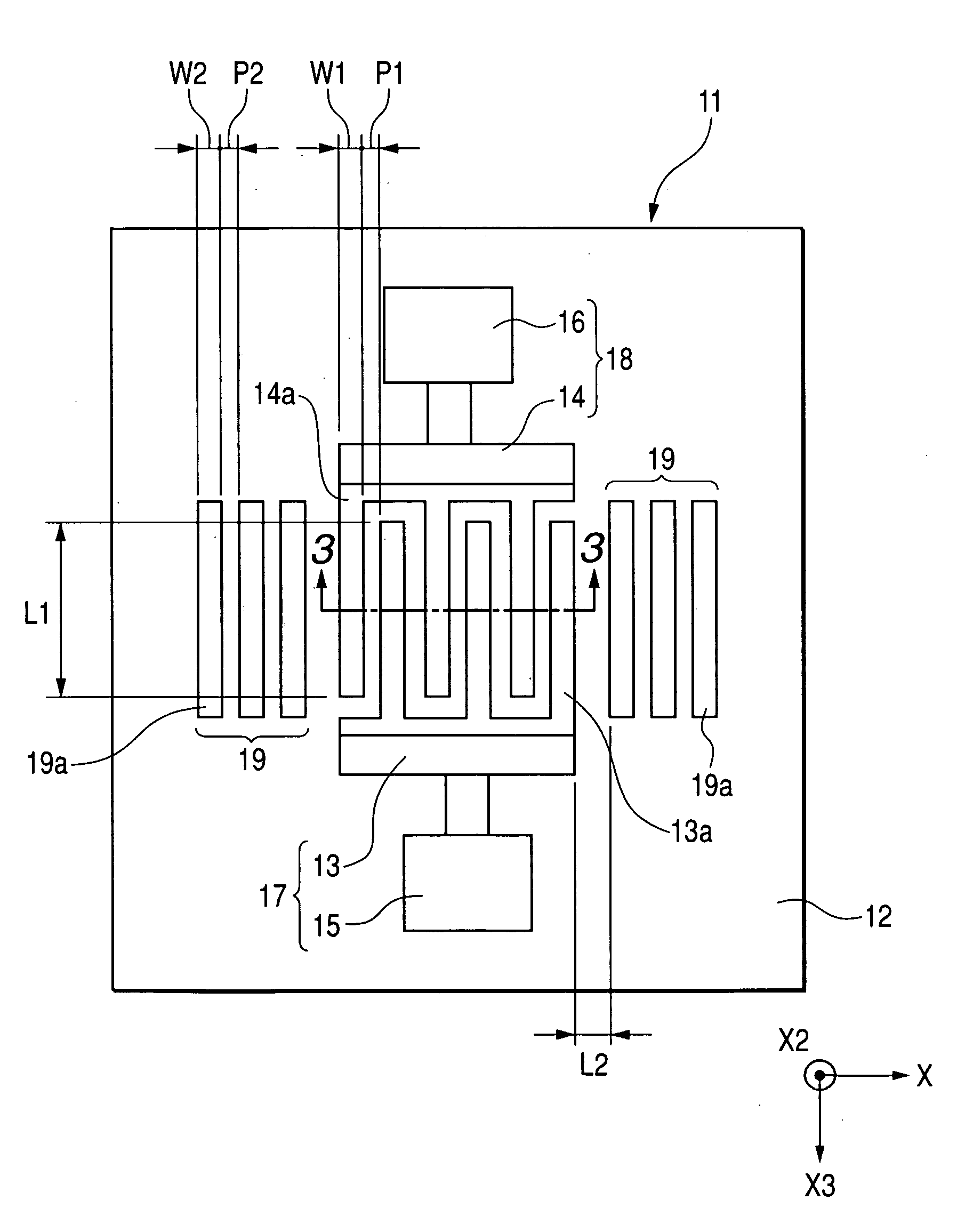

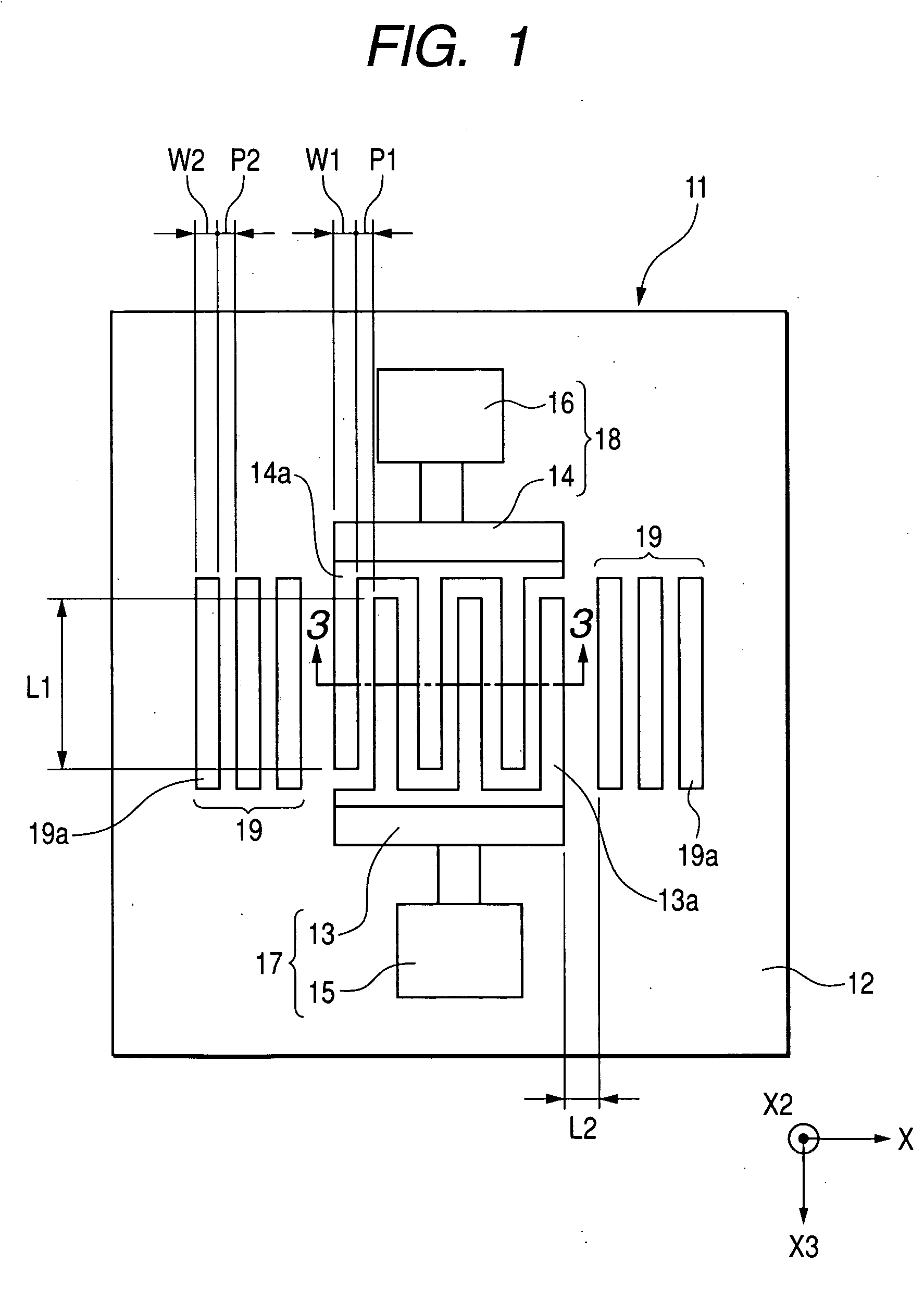

Surface acoustic wave device and method of manufacturing the same

ActiveUS20060273687A1Suppress electromigrationSuppress stress migrationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksResonanceParallel resonance

First base layers made of TiN or TiOxNy (where, 0<x<0.2, x+y=1) and second base layers made of Cr are provided between interdigital transducer portions and a piezoelectric substrate, and accordingly, it is possible to prevent voids from being generated in the interdigital transducer portions, which improves a power resistance of the surface acoustic wave device. In addition, since it is possible to prevent the voids from being generated in the interdigital transducer portions, it is possible to suppress the resistance of the interdigital transducer portions from increasing, which can reduce the loss of power. In addition, it is also possible to reduce the variations in a serial resonance frequency and a parallel resonance frequency.

Owner:QORVO US INC

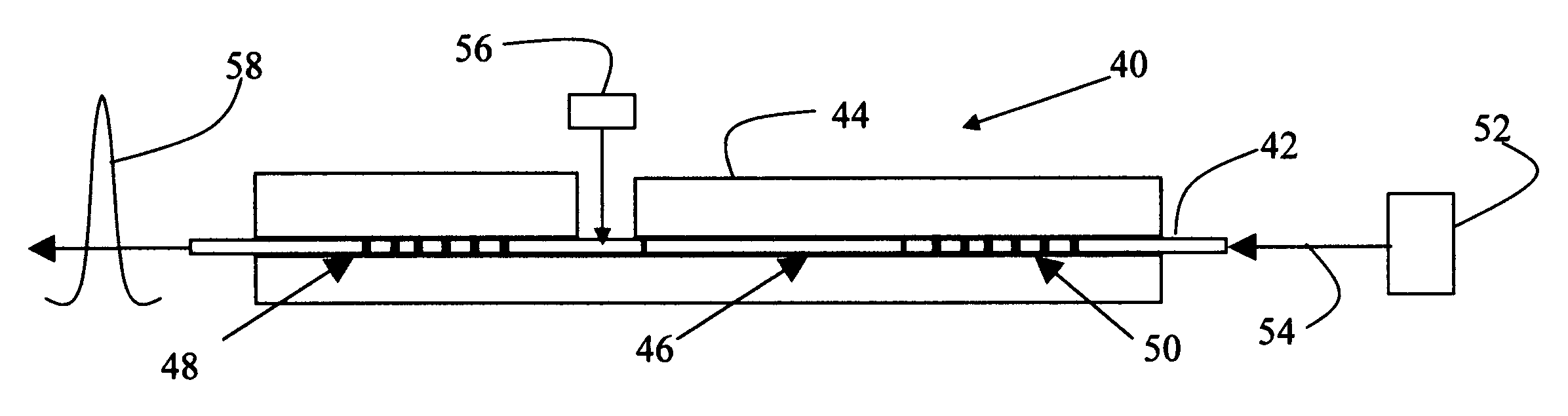

All-fiber Q-switched laser

ActiveUS7130319B1Narrow pulse widthFast repetition rateLaser using scattering effectsQ factorBroadband

An all-fiber Q-switched laser includes a gain fiber spliced between narrowband and broadband fiber gratings that define a polarization-dependent resonant cavity. The narrowband grating is, for example, formed in a PM fiber to create a polarization-dependent reflection band. A modulator applies stress to the fiber chain to induce birefringence and switch the cavity Q-factor to alternately store energy in the gain fiber and then release the energy in a laser pulse.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

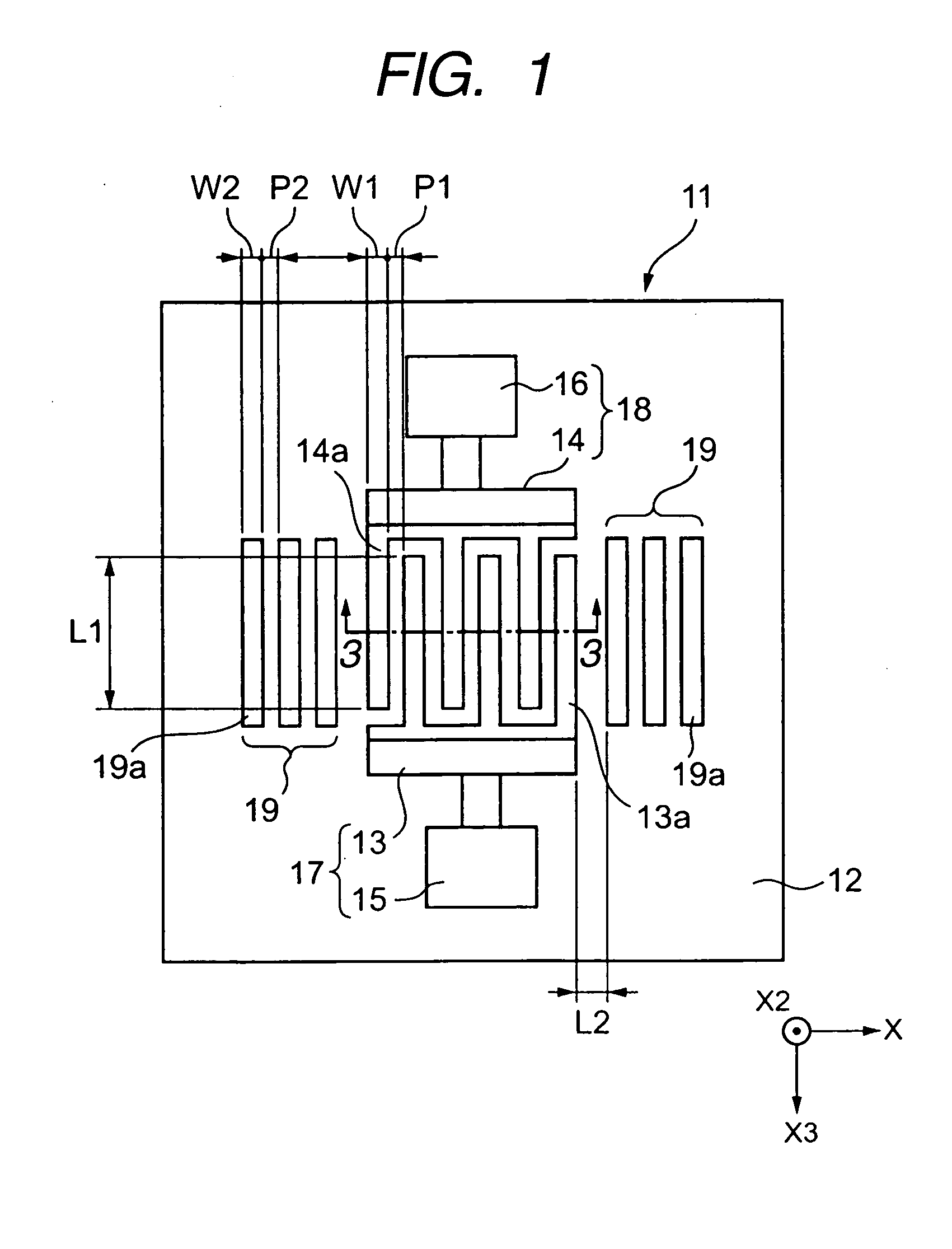

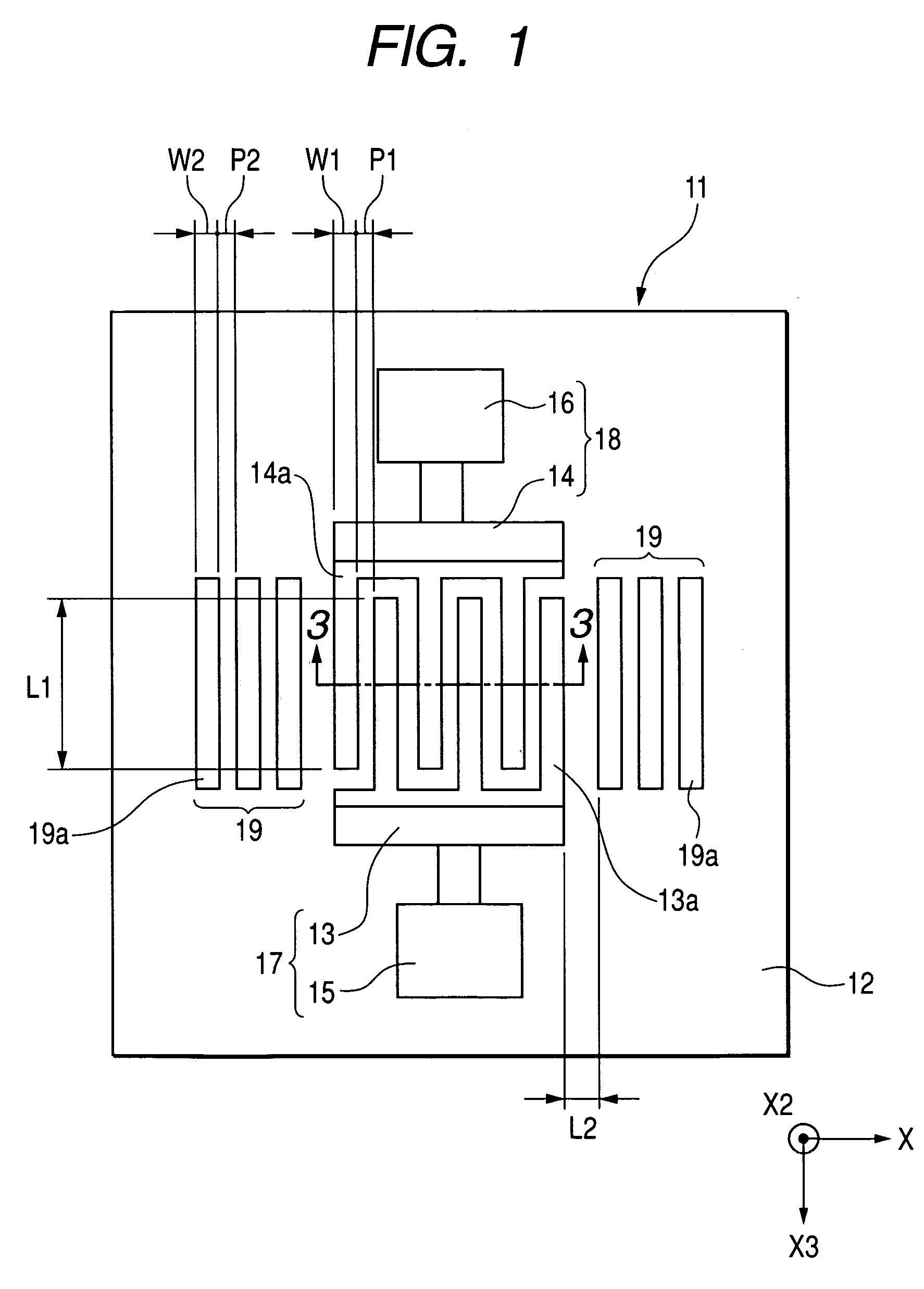

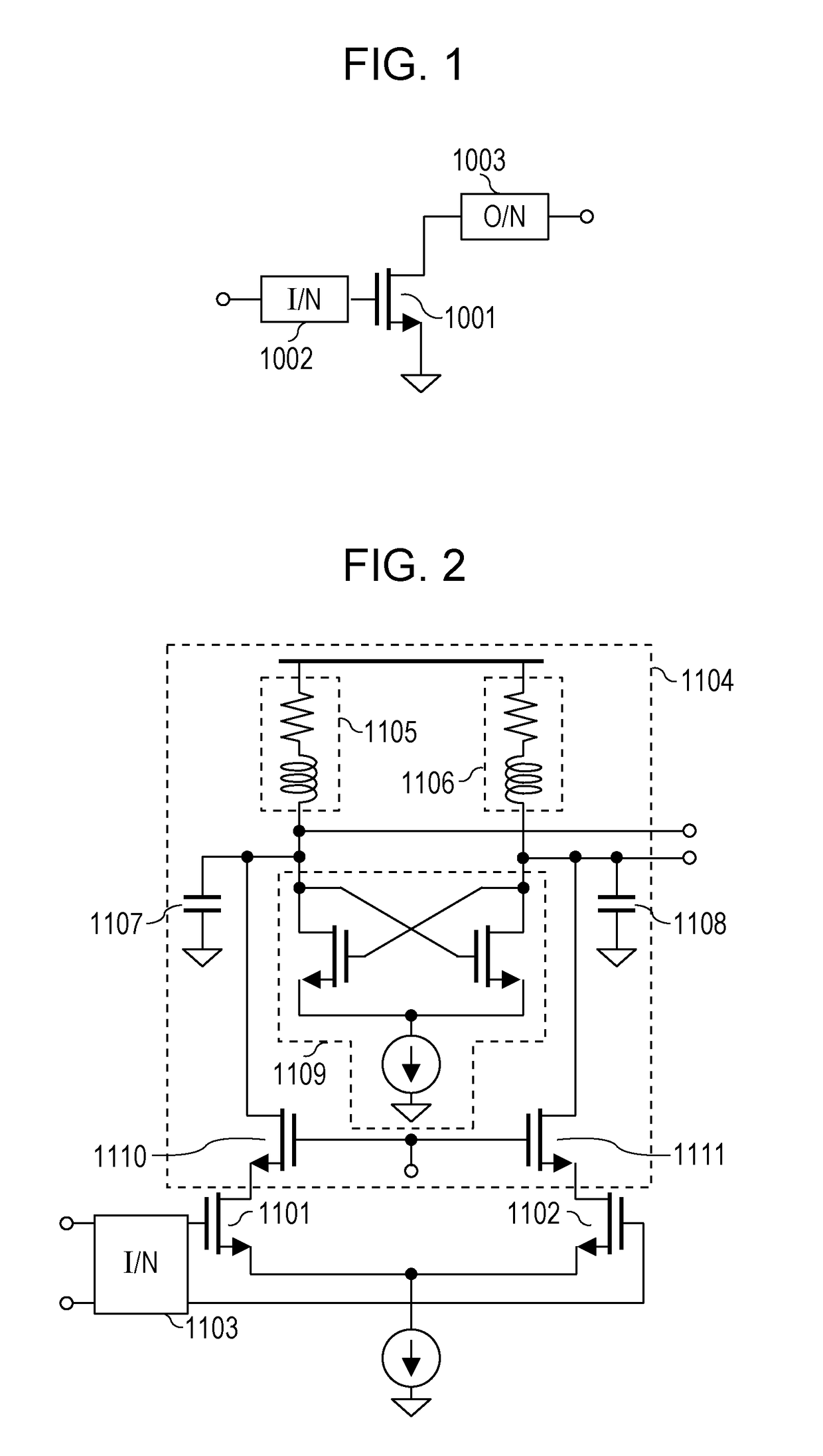

Transistor voltage-controlled oscillator

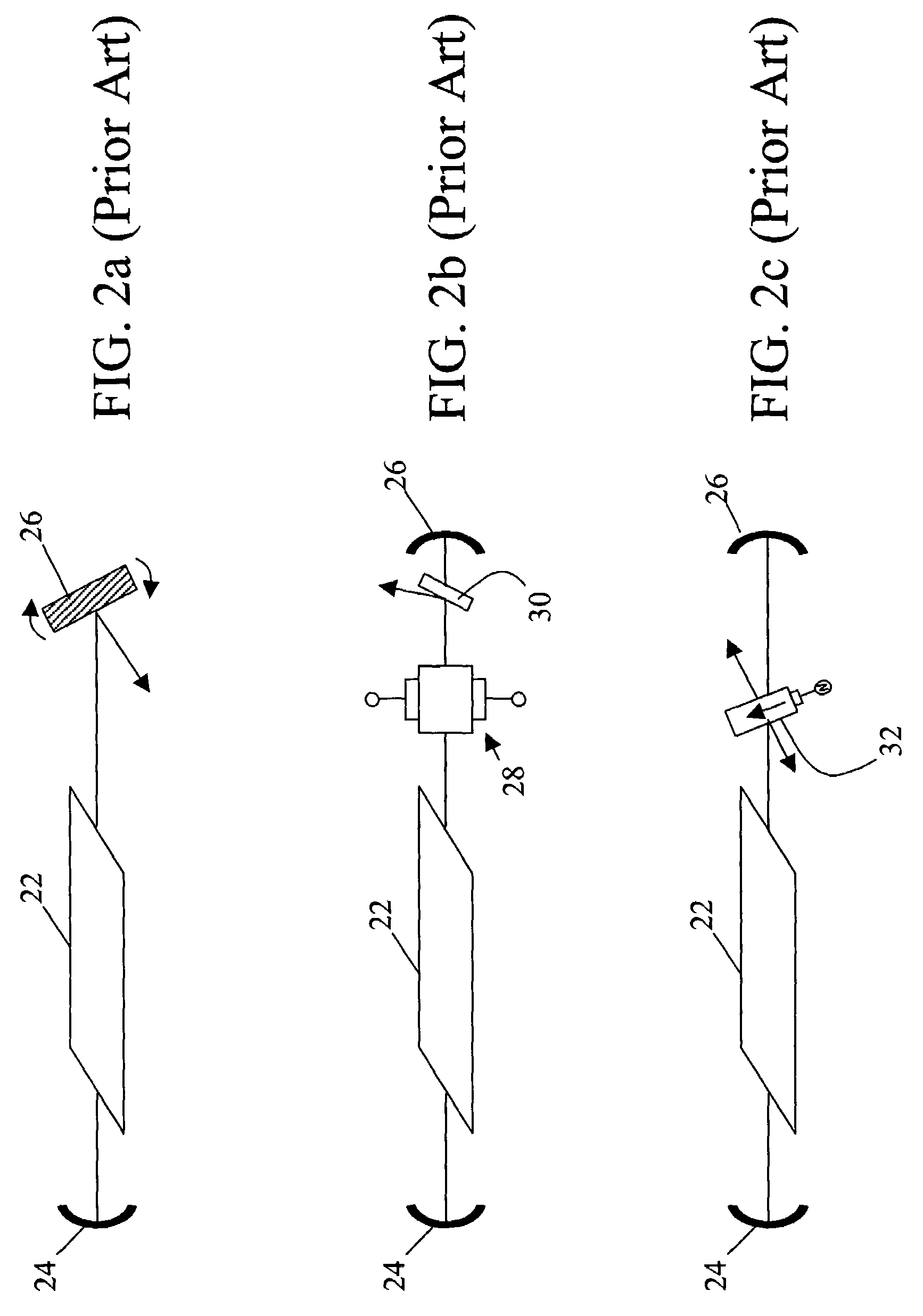

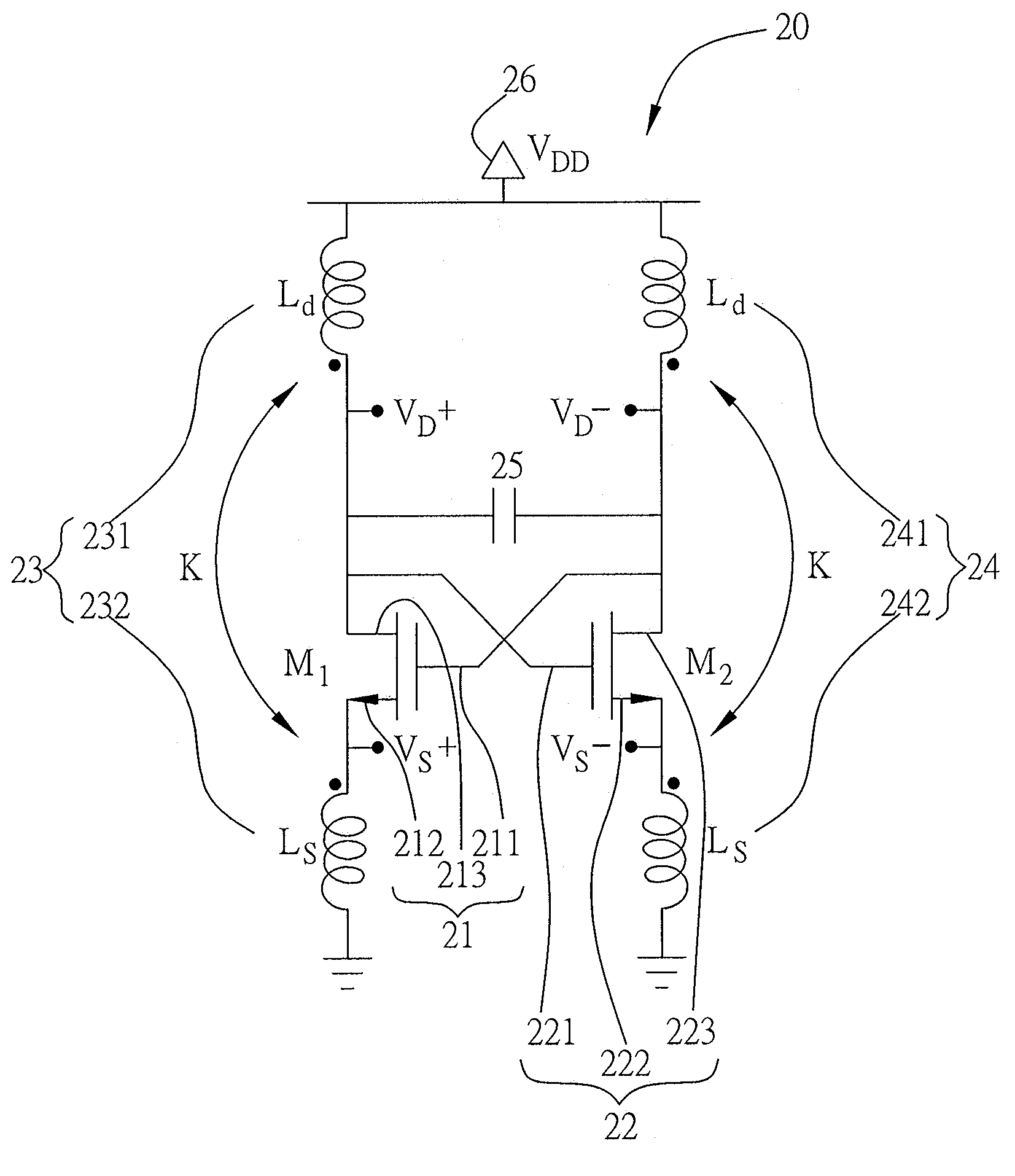

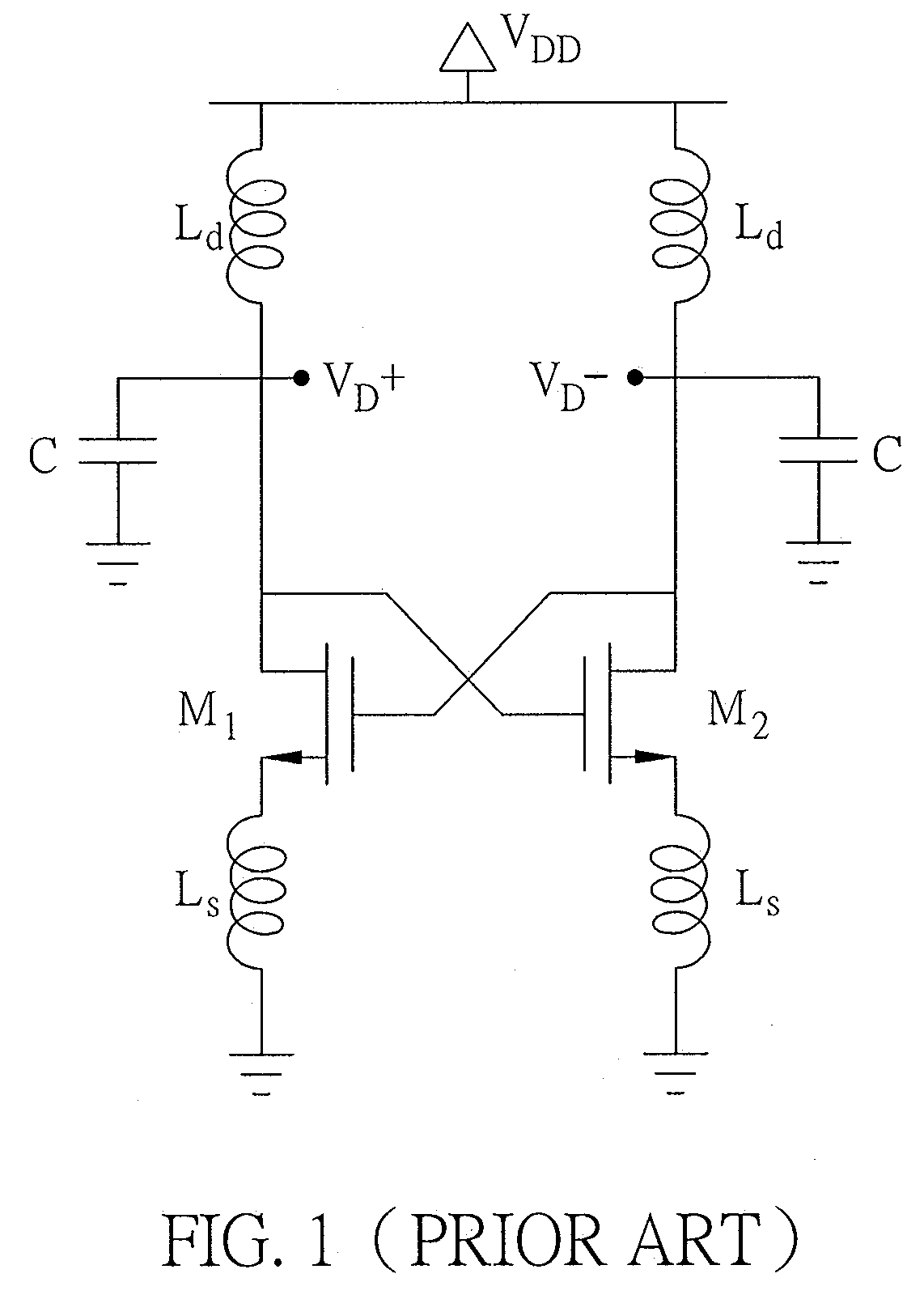

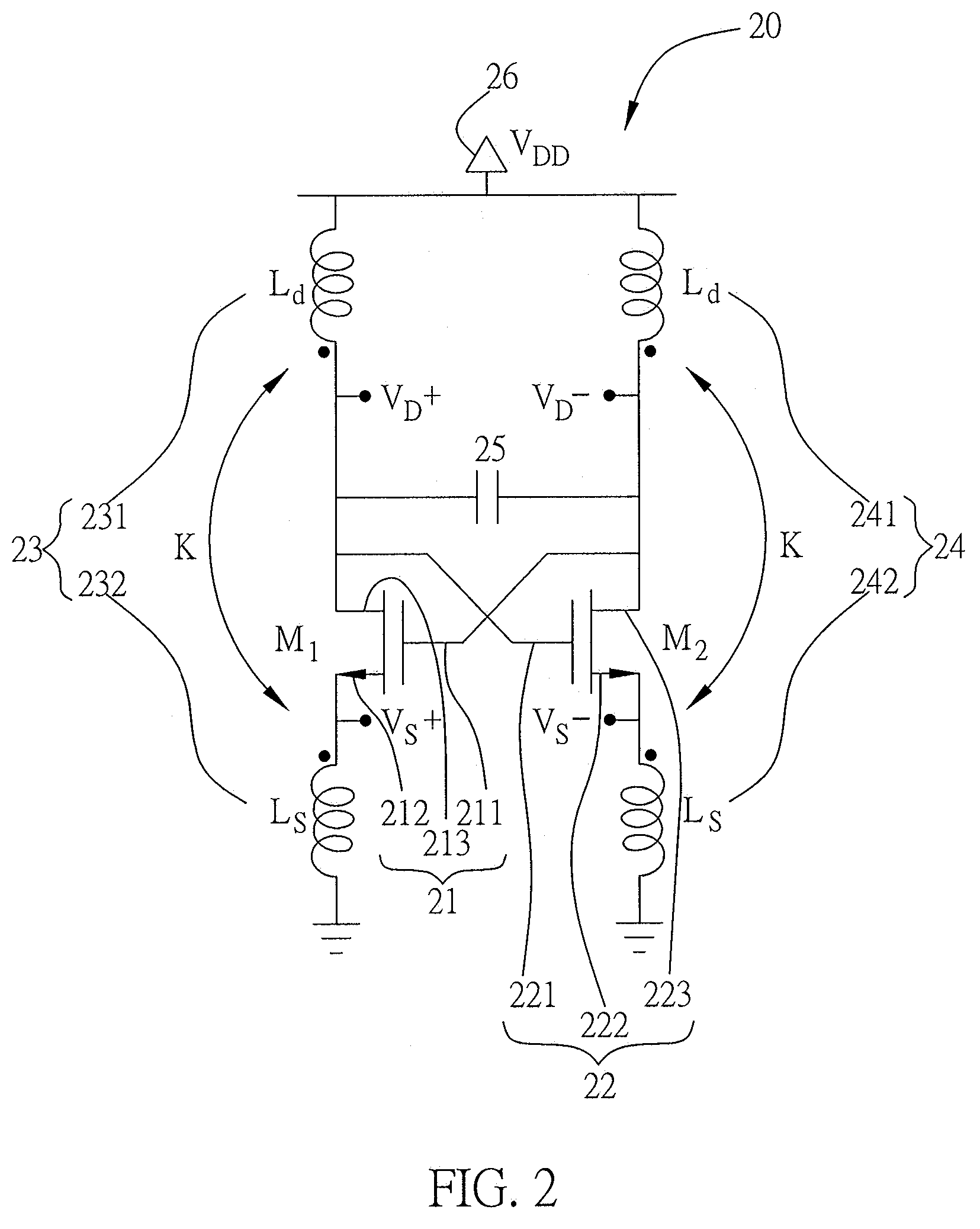

InactiveUS20090184774A1Reduce mold sizeReduce power consumptionElectric pulse generatorOscillations generatorsTransformerParasitic capacitance

A transistor voltage-controlled oscillator includes a cross-coupled LC-tank transistor voltage-controlled oscillating circuit composed of two transistors, a capacitor set, and a first transformer inductor having a first inductor coil and a second inductor coil coupled to the first inductor coil; and a second transformer inductor having a third inductor coil and a fourth inductor coil coupled to the third inductor coil. The first transformer inductor and the second transformer inductor are both used as a coupling inductor for the cross-coupled LC-tank transistor voltage-controlled oscillating circuit. As a result, the inductor area of the transistor voltage-controlled oscillator is greatly reduced and the parasitic capacitance between the inductors and the silicon substrate is reduced accordingly such that the power consumption is greatly reduced and the quality factor of the inductor is increased.

Owner:NAT TAIWAN UNIV

Inductor and method of manufacturing the same

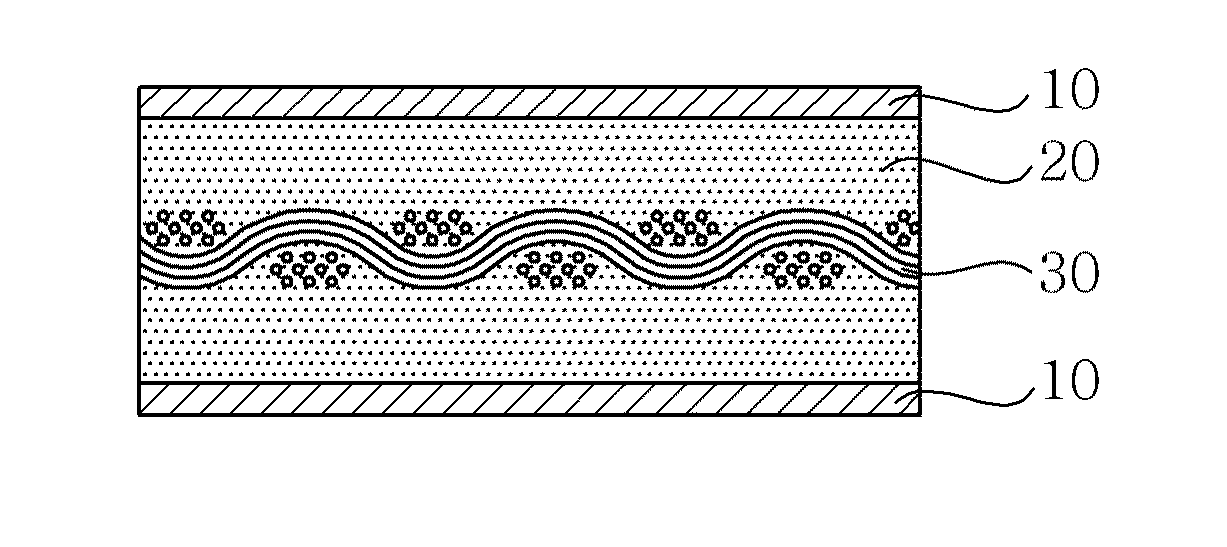

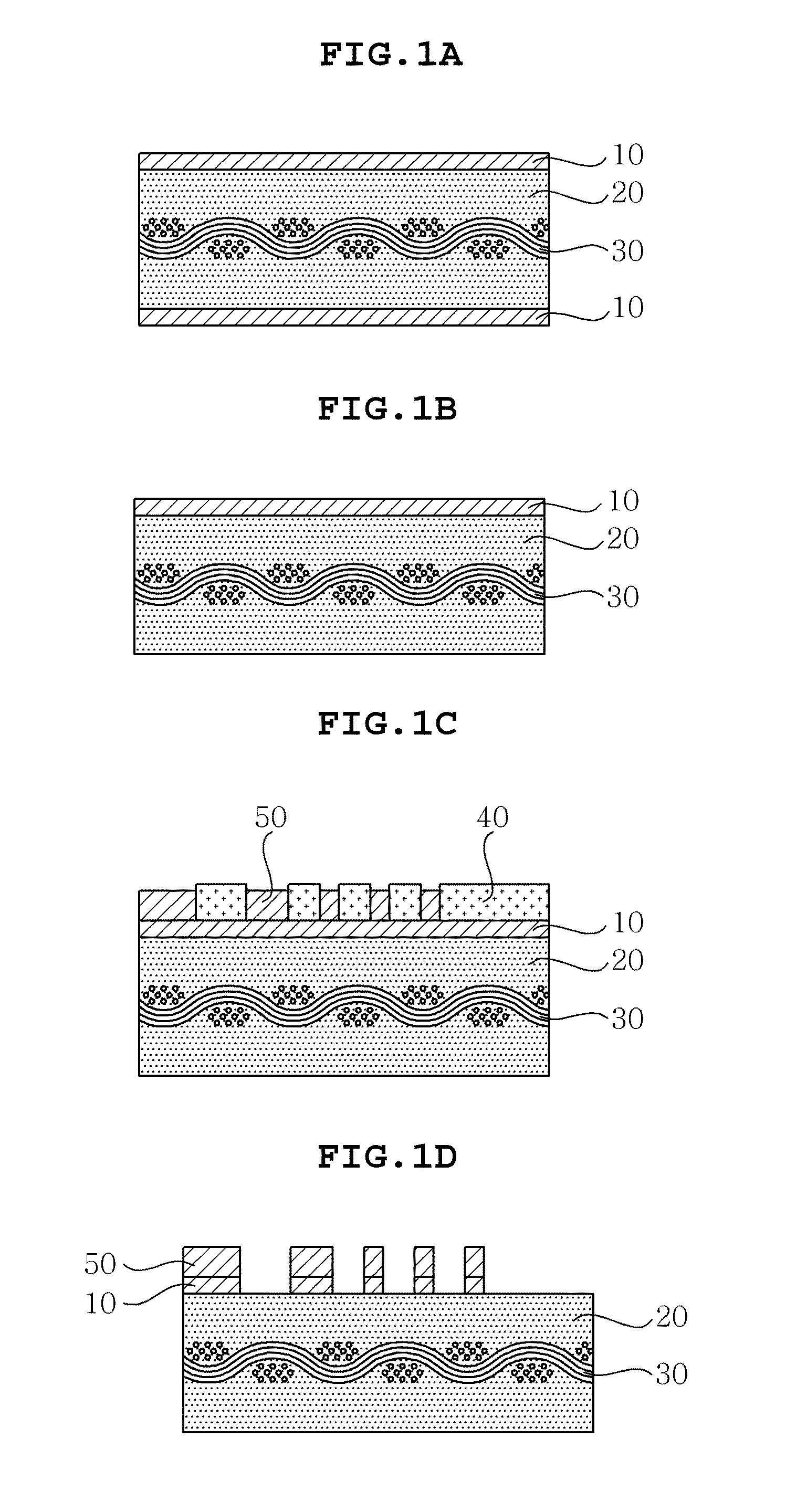

InactiveUS20140002226A1Low dielectric lossQ-factor can be increasedTransformers/inductances detailsCable/conductor manufactureInductorLiquid crystal

Disclosed herein are an inductor and a method of manufacturing the same. More specifically, in the inductor according to the present invention, a coil with a fine pattern may be formed, and an insulating resin composite including liquid crystal oligomer for reducing occurrence of deformation of the coil may be used for an insulating substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

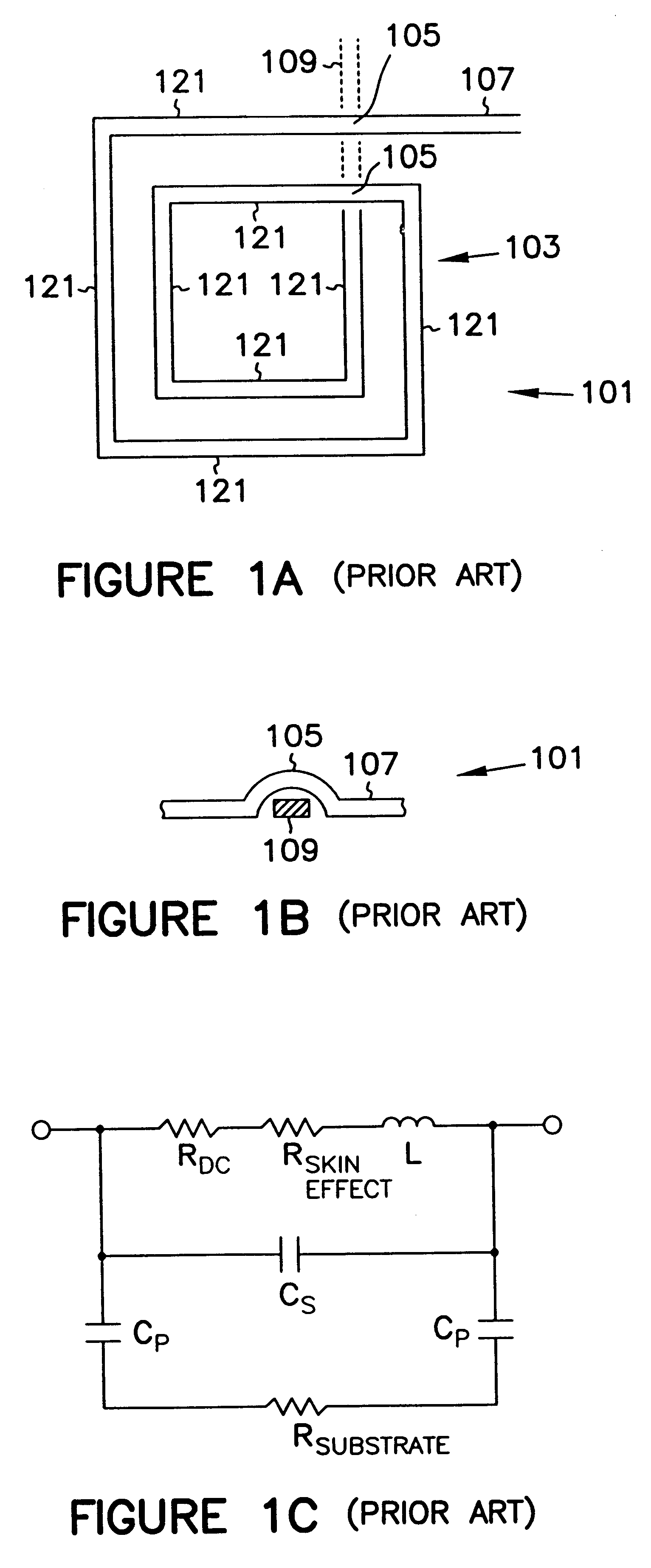

High-Q inductive elements

InactiveUS6239684B1Q-factor can be increasedRaise the self-resonant frequencyTransformers/inductances coils/windings/connectionsSolid-state devicesElectrical conductorEngineering

Owner:MICRON TECH INC

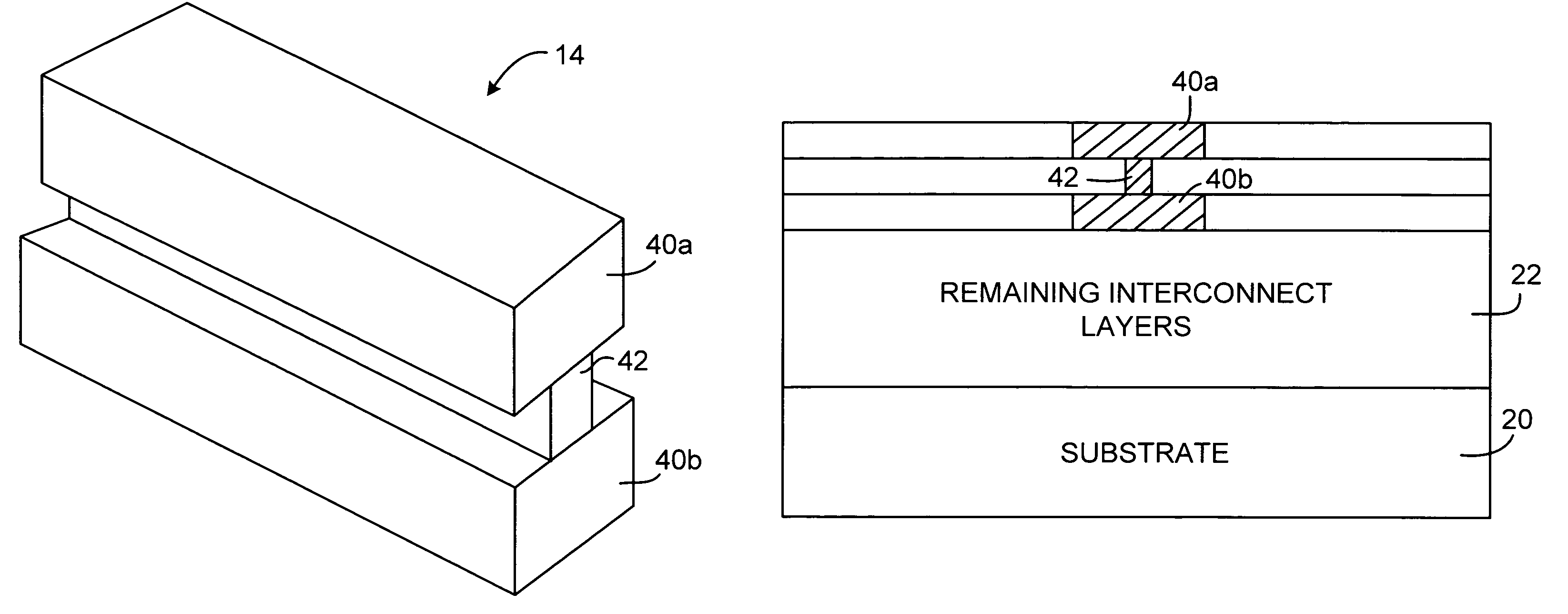

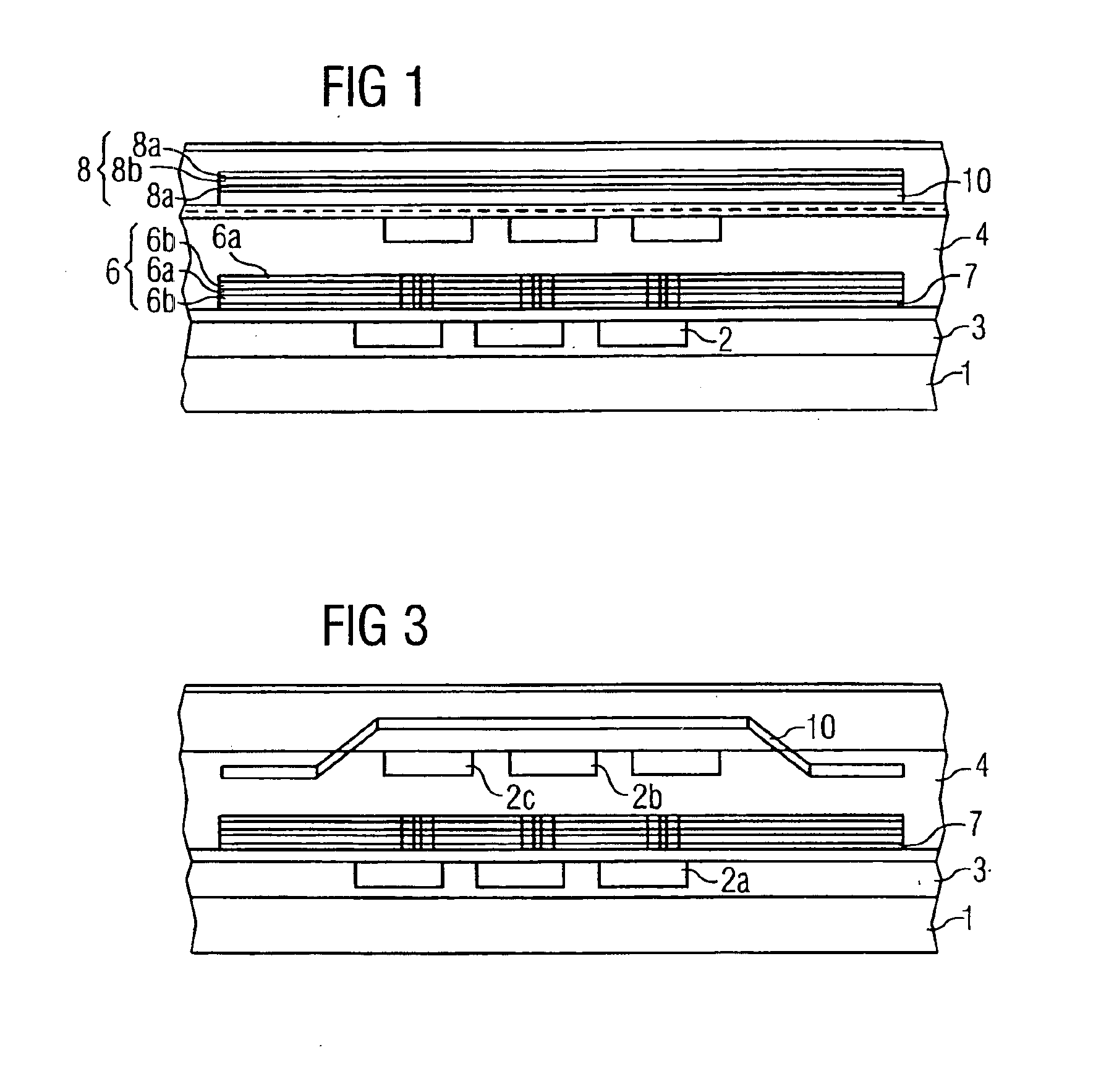

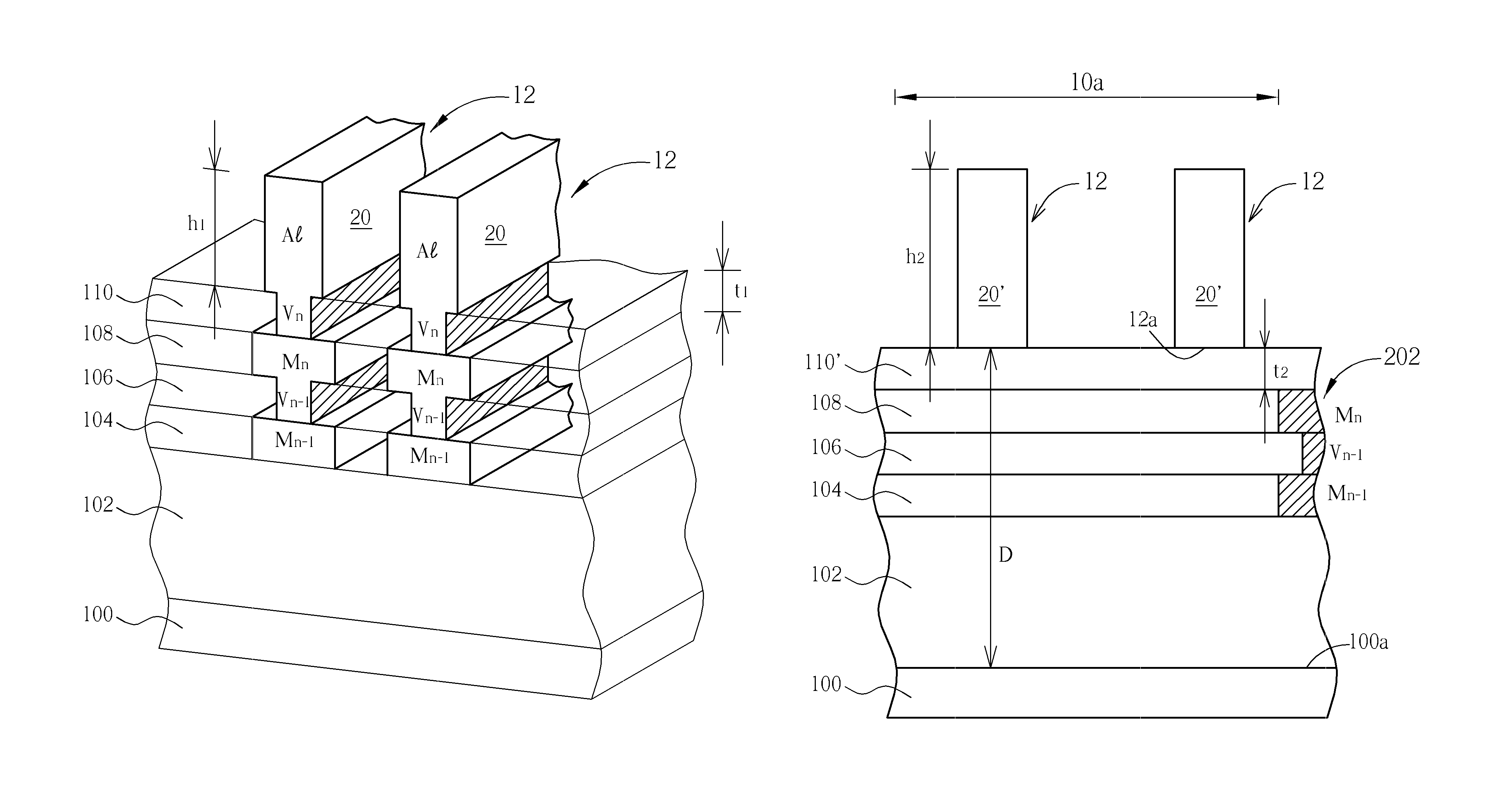

Microelectronic assembly and method for forming the same

InactiveUS7264986B2Q-factor can be increasedSolid-state devicesSemiconductor/solid-state device manufacturingInductorEngineering

Owner:TAIWAN SEMICON MFG CO LTD

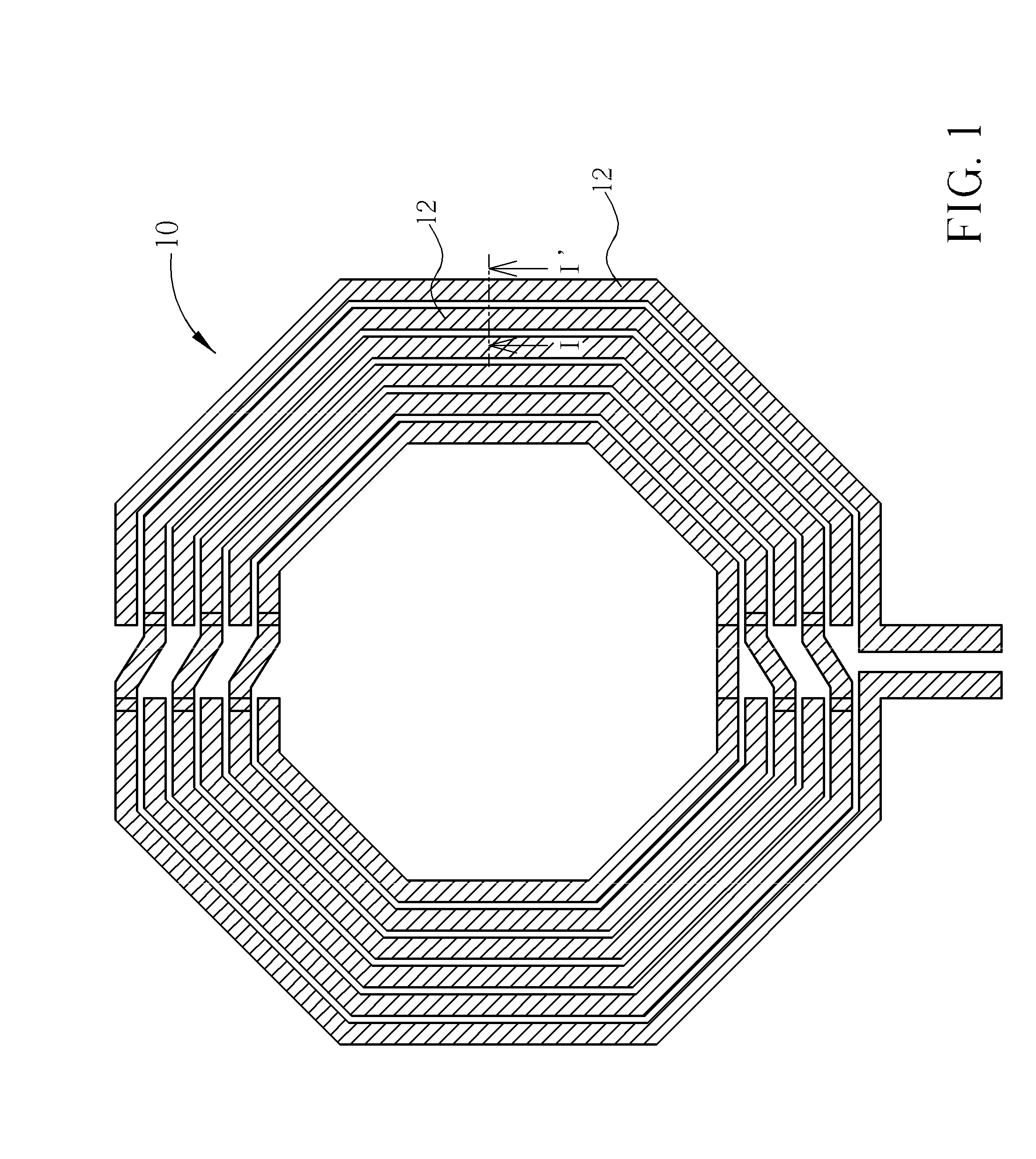

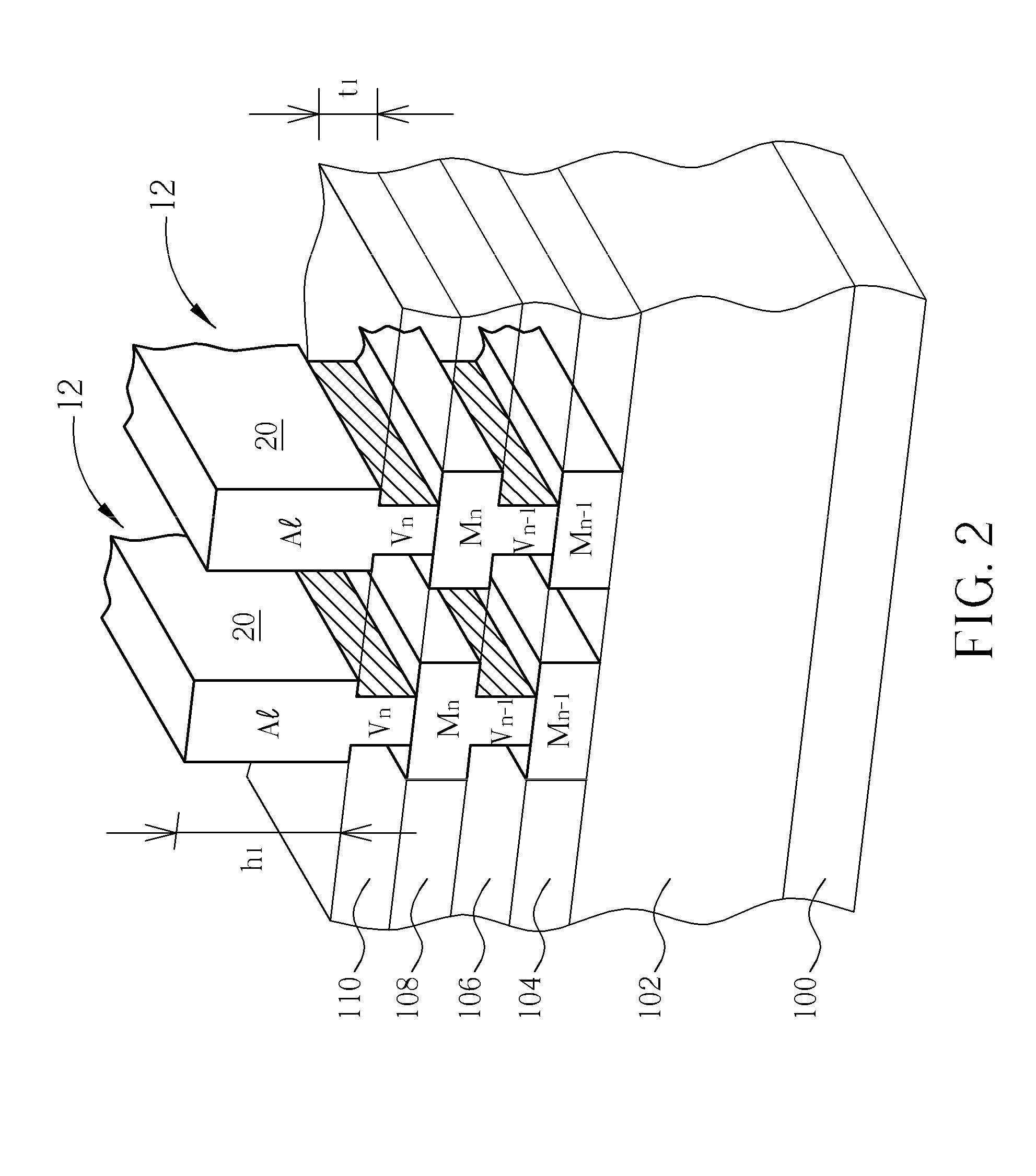

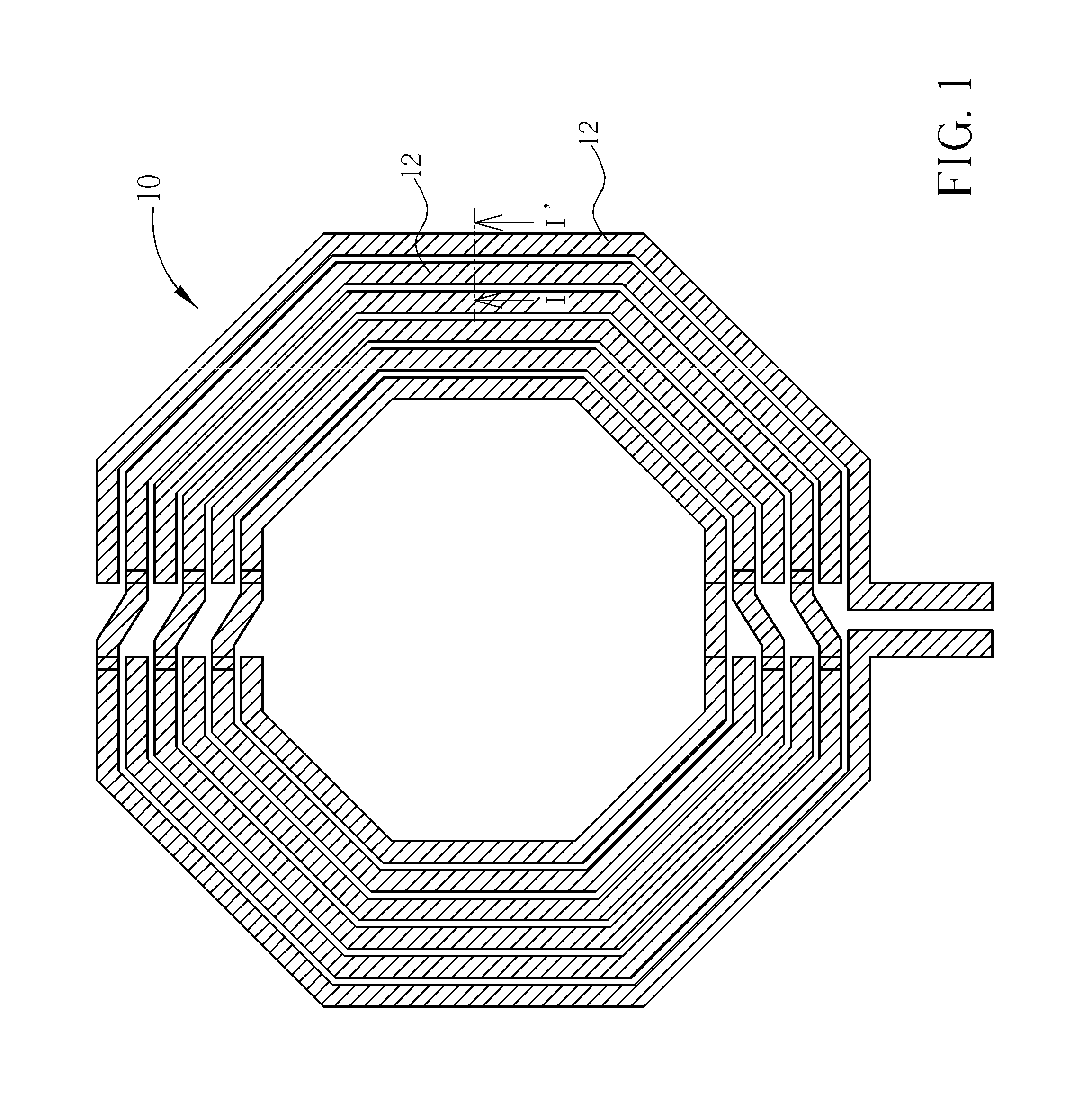

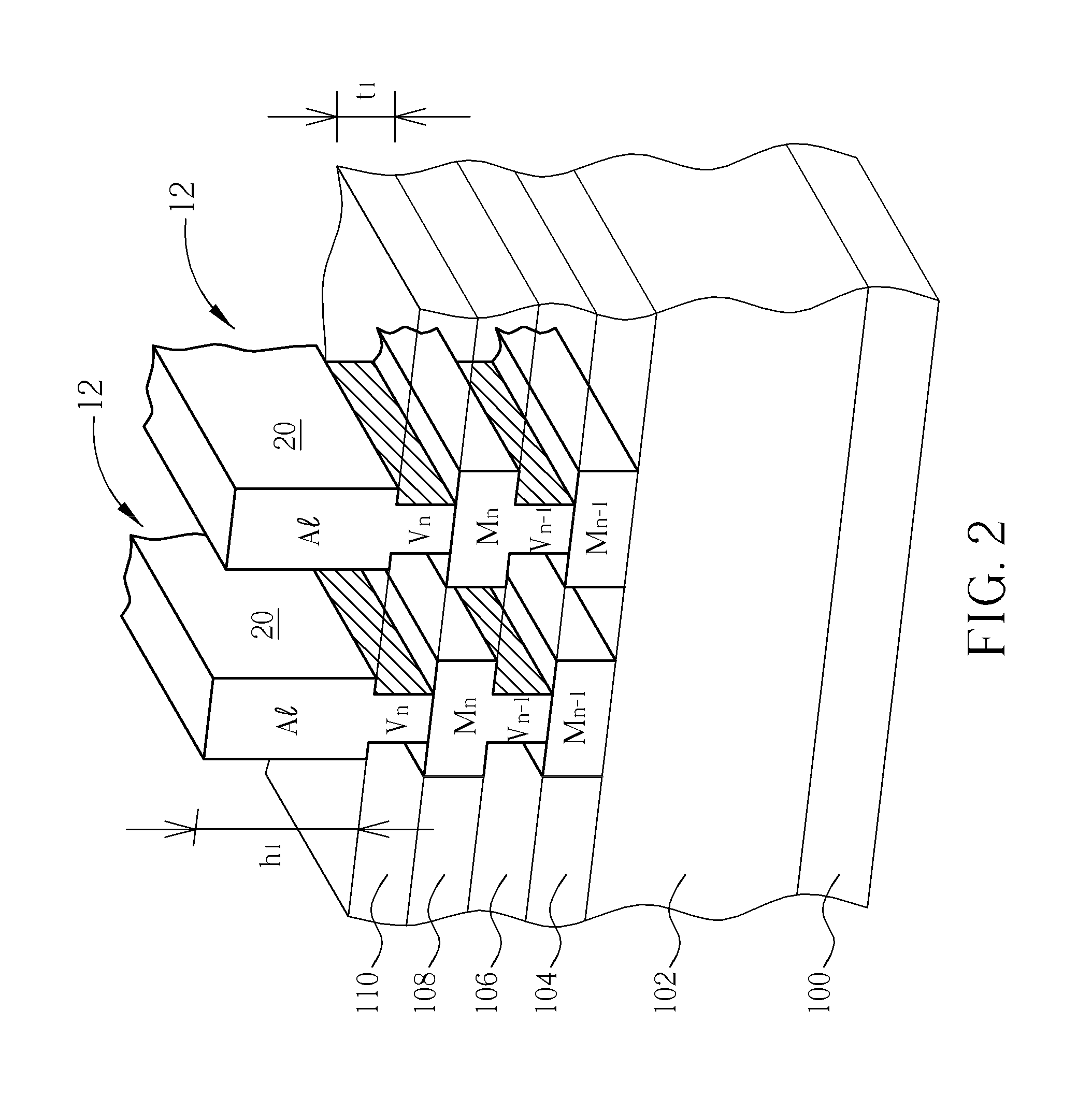

Integrated inductor

ActiveUS20090261937A1Simple processLow costSemiconductor/solid-state device detailsSolid-state devicesMicrometerInductor

An integrated inductor includes a winding consisting of an aluminum layer atop a passivation layer, wherein the aluminum layer does not extend into the passivation layer and has a thickness that is not less than about 2.0 micrometers. The passivation layer has a thickness not less than about 0.8 micrometers. By eliminating copper from the integrated inductor and increasing the thickness of the passivation layer, the distance between the bottom surface of the inductor structure and the main surface of the semiconductor substrate is increased, thus the parasitic substrate coupling may be reduced and the Q-factor may be improved. Besides, the increased thickness of the aluminum layer may help improve the Q-factor as well.

Owner:MEDIATEK INC

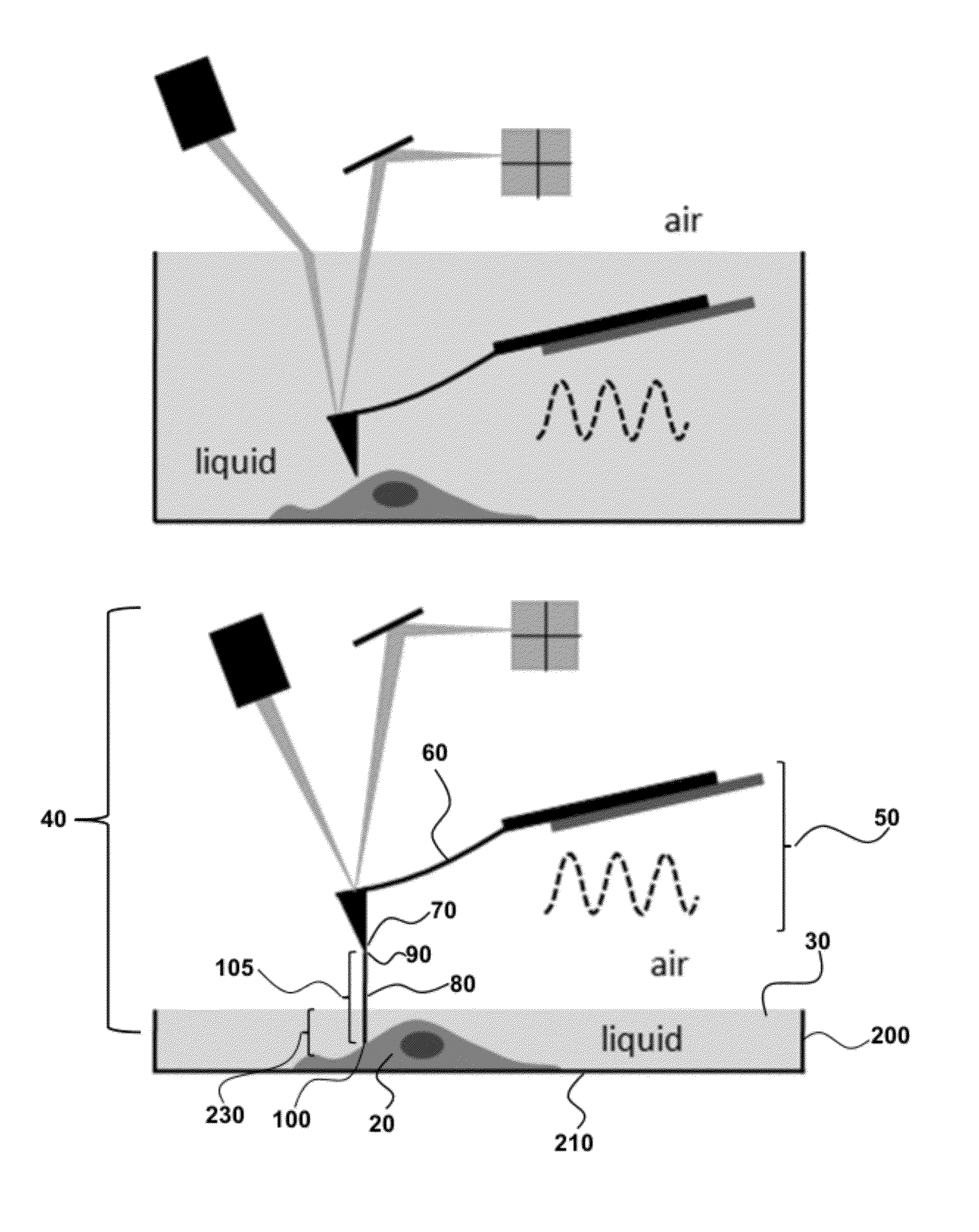

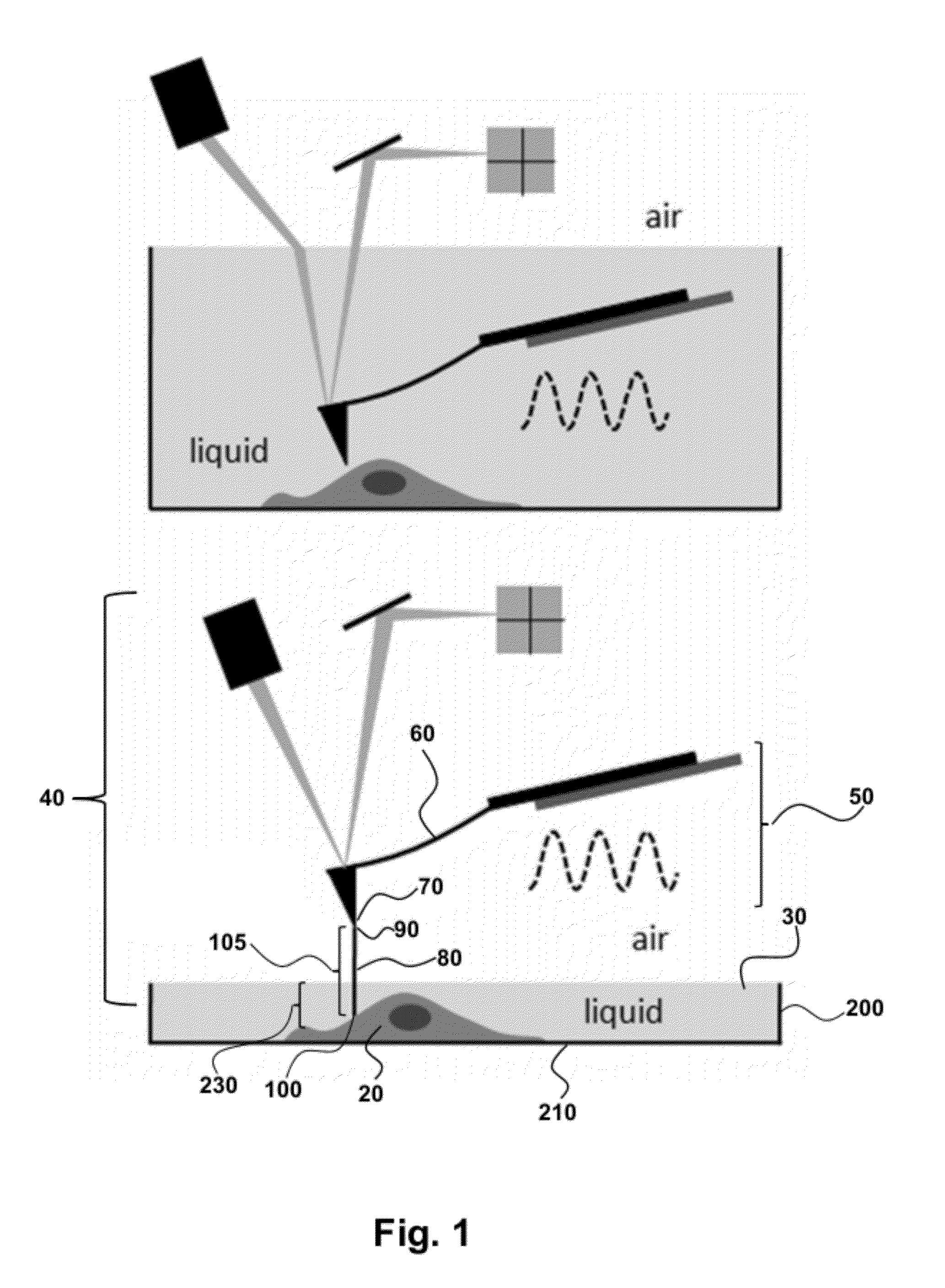

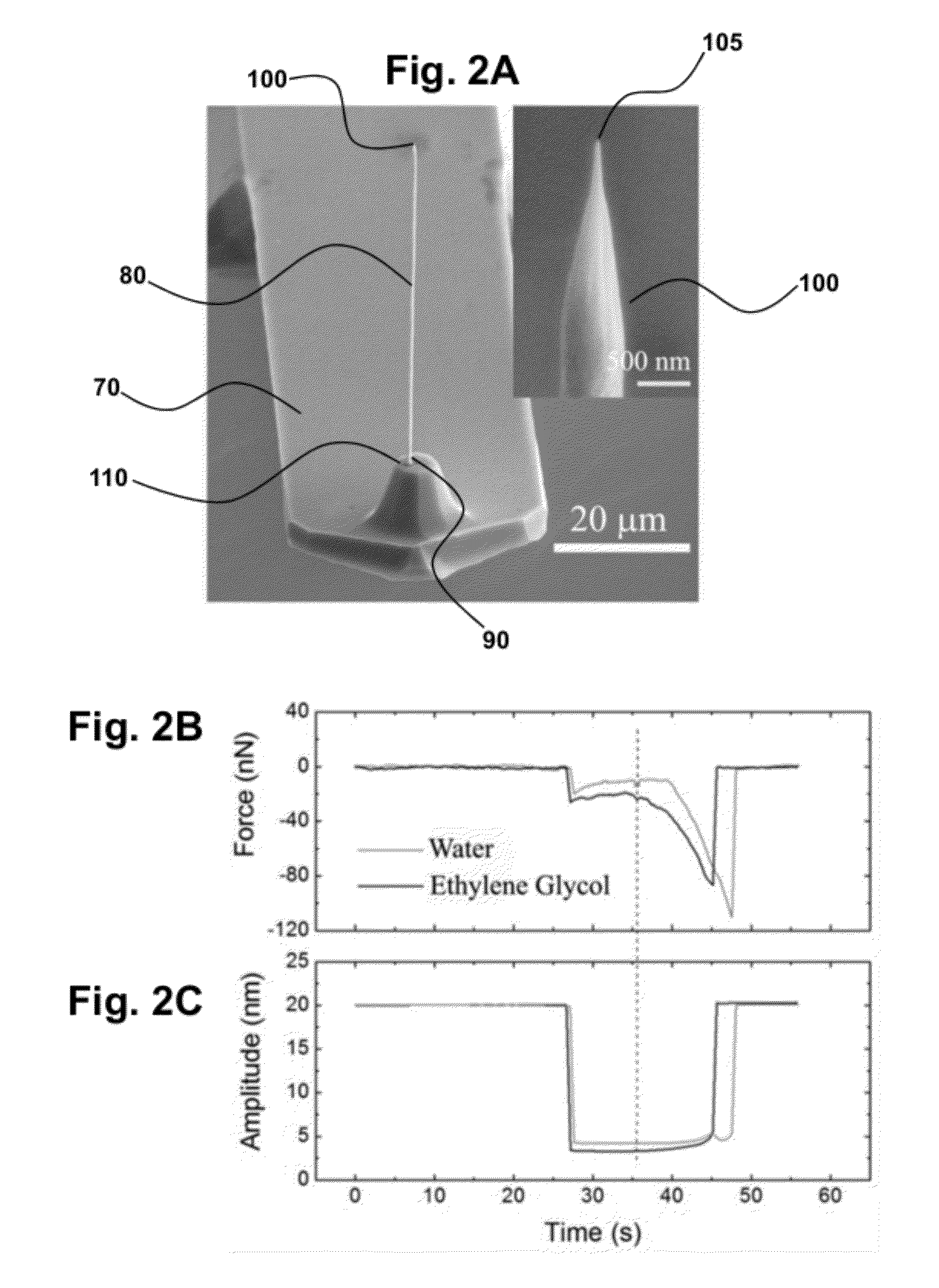

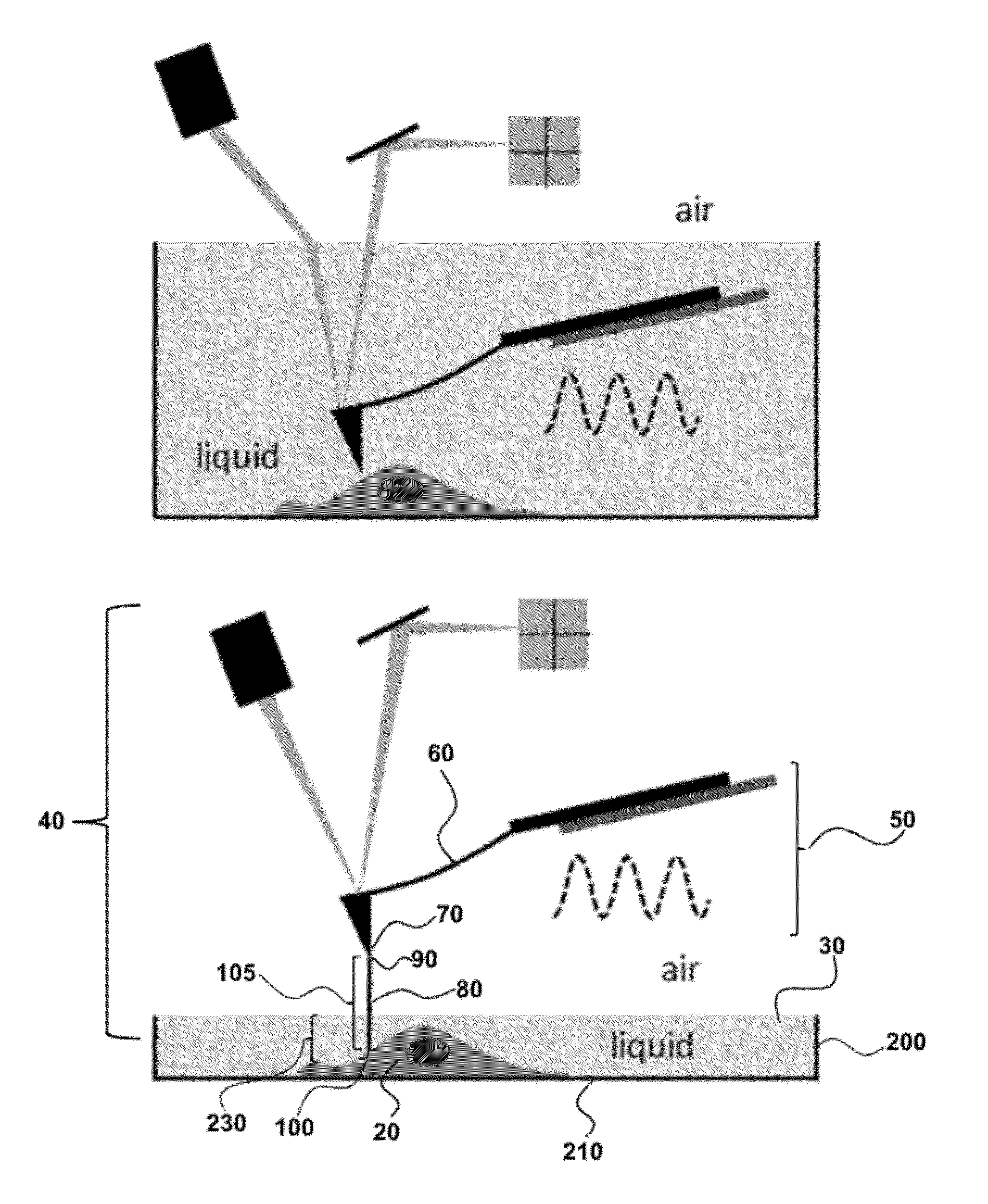

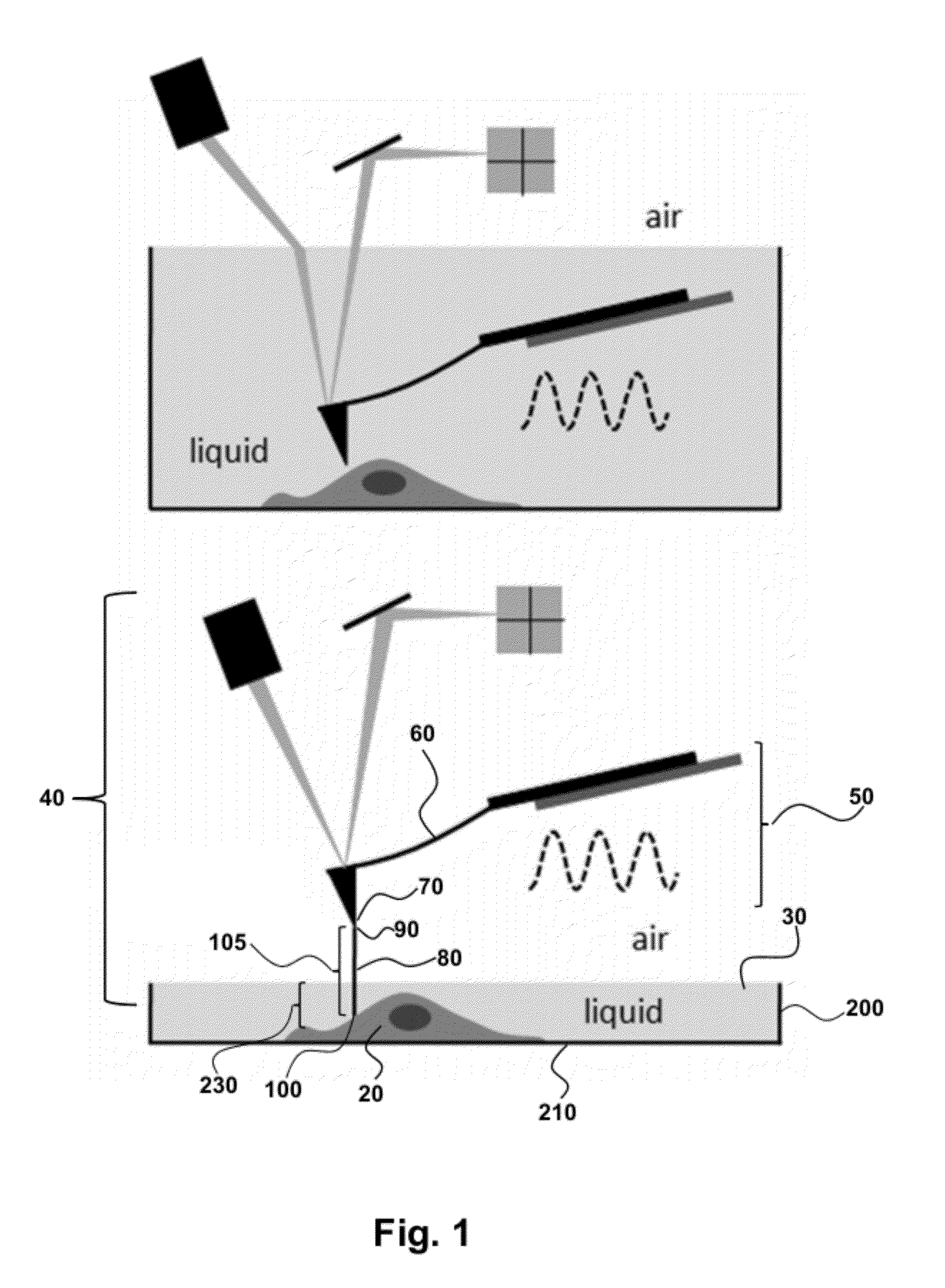

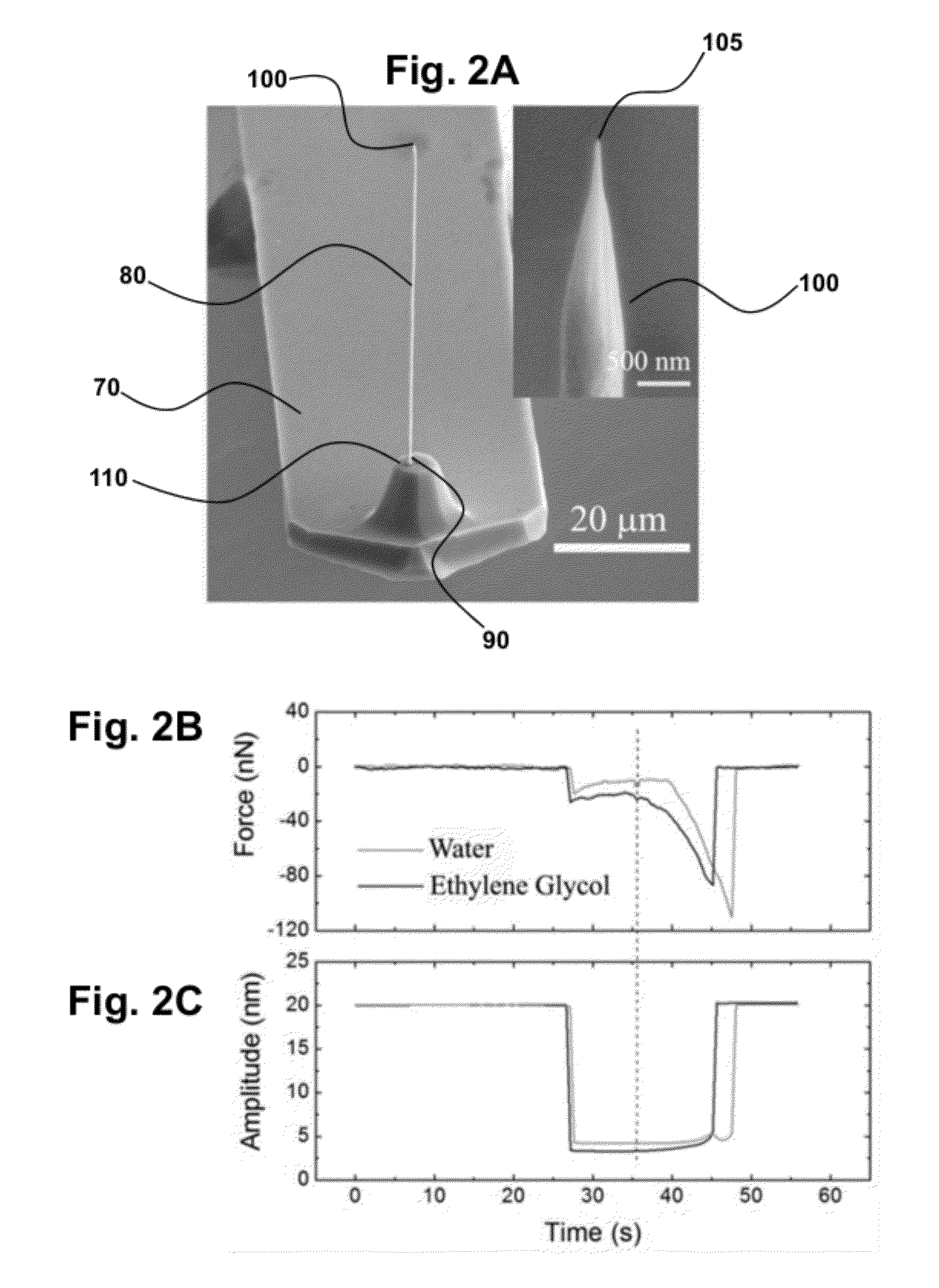

Ultra-Low Damping Imaging Mode Related to Scanning Probe Microscopy in Liquid

InactiveUS20120278958A1Ultra-low dampingHigh resolution imagingNanosensorsScanning probe microscopyAtomic force microscopyHigh resolution imaging

Provided are methods and systems for high resolution imaging of a material immersed in liquid by scanning probe microscopy. The methods further relate to imaging a material submersed in liquid by tapping mode atomic force microscopy (AFM), wherein the AFM has a microfabricated AFM probe comprising a nanoneedle probe connected to a cantilever beam. The nanoneedle probe is immersed in the liquid, and the rest of the AFM probe, including the cantilever beam to which the nanoneedle probe is attached, remains outside the liquid. The cantilever is oscillated and the nanoneedle probe tip taps the material to image the material immersed in liquid. In an aspect, the material is supported on a shaped substrate to provide a spatially-varying immersion depth with specially defined regions for imaging by any of the methods and systems of the present invention.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Coil decoupling for an RF coil array

ActiveUS8138762B2Decrease compromiseImprove the level ofMagnetic measurementsElectric/magnetic detectionCapacitanceCoil array

Owner:DEERFIELD IMAGING INC

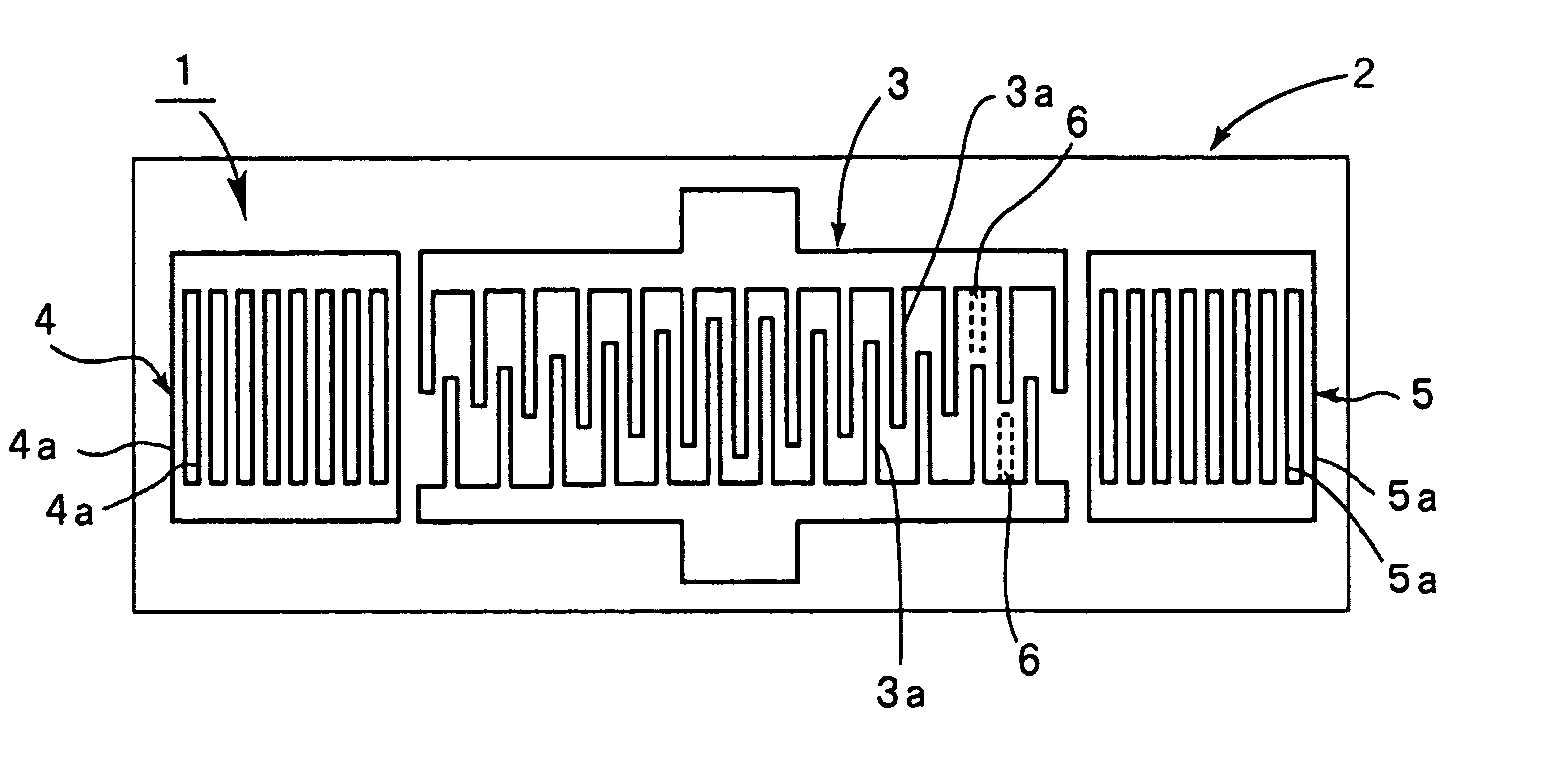

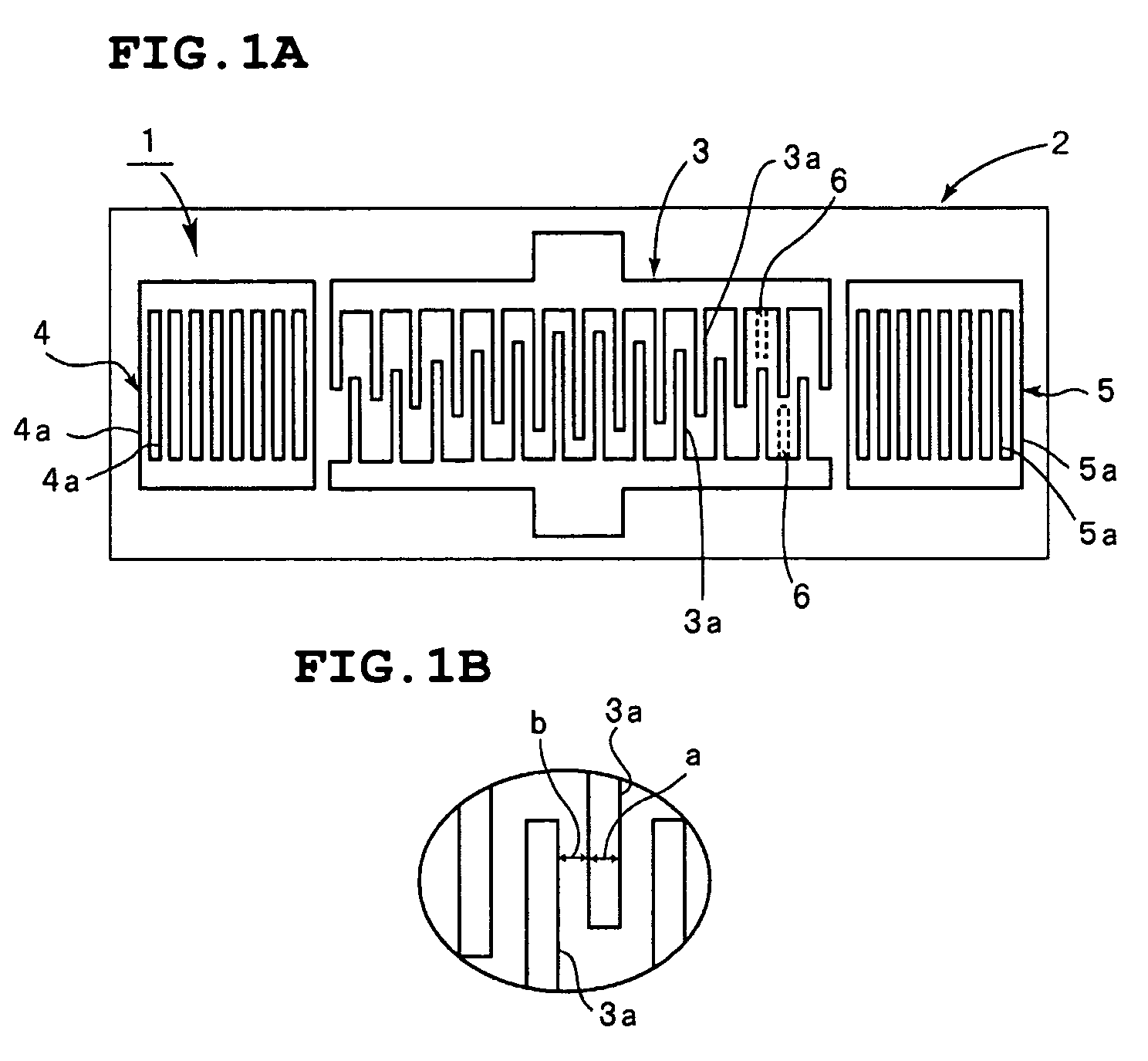

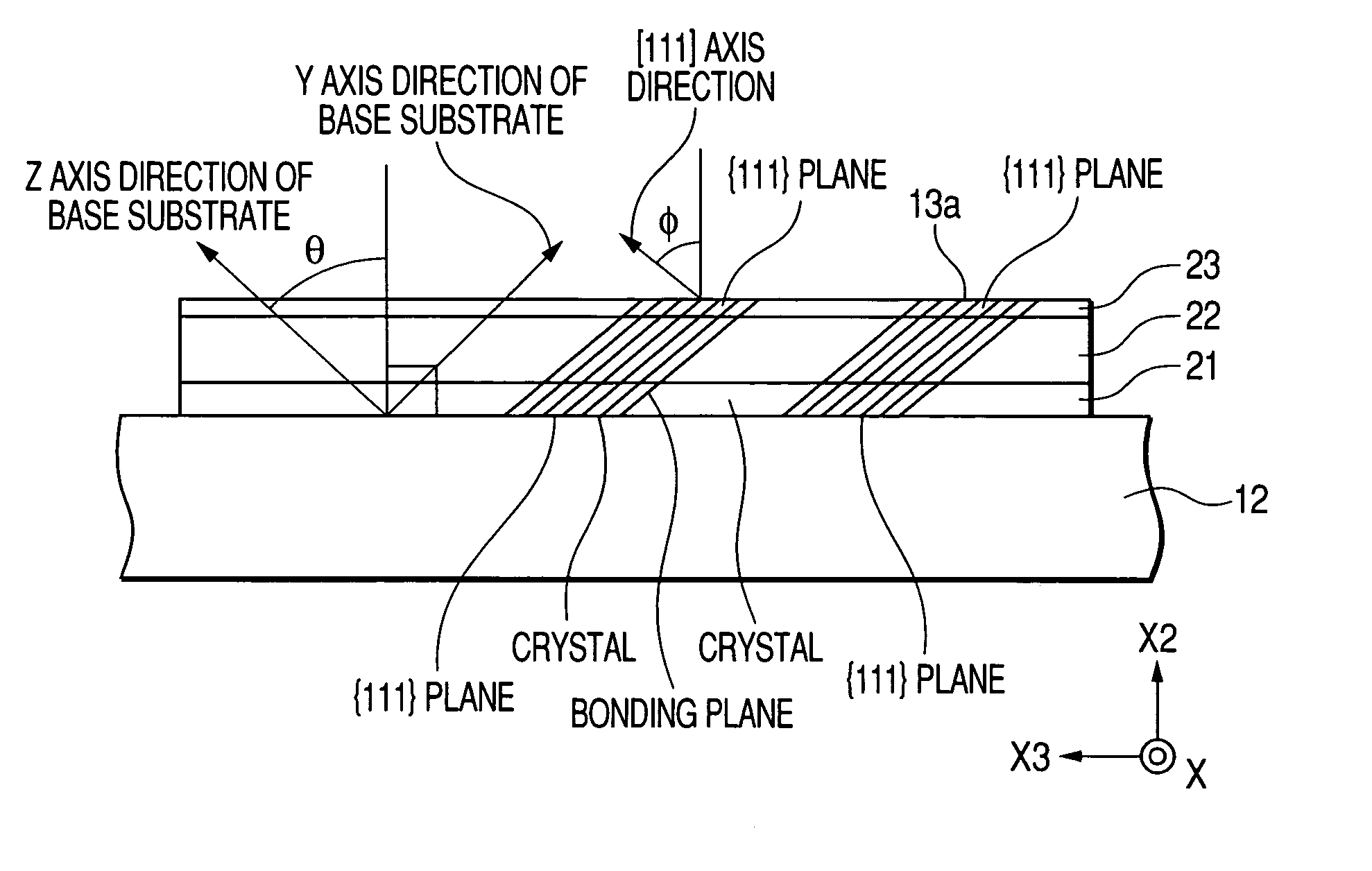

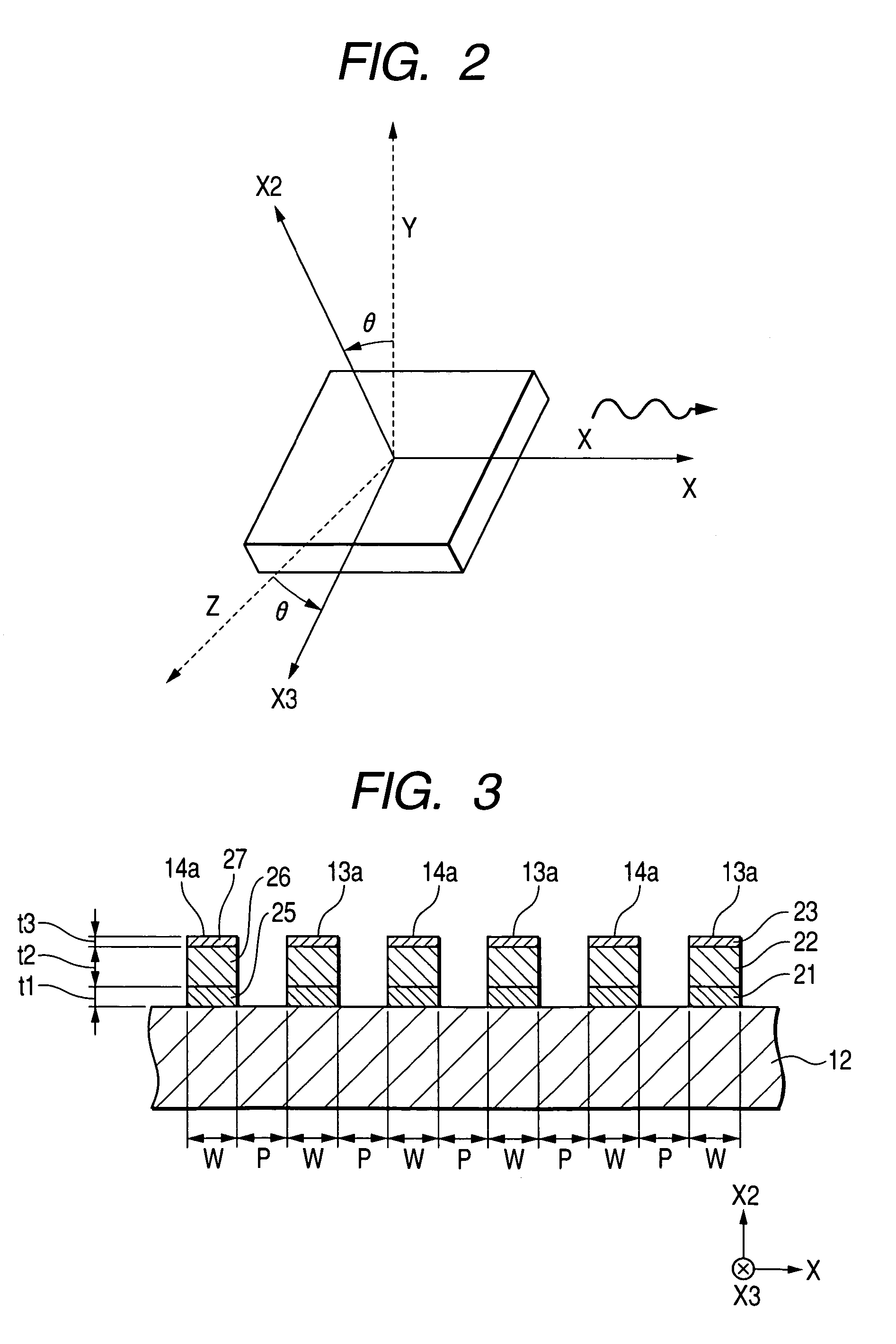

Surface acoustic wave device

ActiveUS20050174012A1Electromigration be suppressedSuppress stressPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTitanium nitrideAcoustic wave

There is provided a surface acoustic wave device which can prevent a breakage of electrodes and electrical breaks, decrease an insertion loss of elements, and enhance a Q-factor of resonators. Interdigital electrode sections and each have a laminated structure of a base layer made of TiN (titanium nitride) or TiOxNy and a main electrode layer deposited to come in contact with an upper surface of the base layer. The main electrode layer is deposited such that a {111} plane as a closest-packed plane of the main electrode layer has a constant gradient with respect to a surface of a substrate, and thus electromigration or stress migration can be suppressed in the interdigital electrode sections.

Owner:QORVO US INC

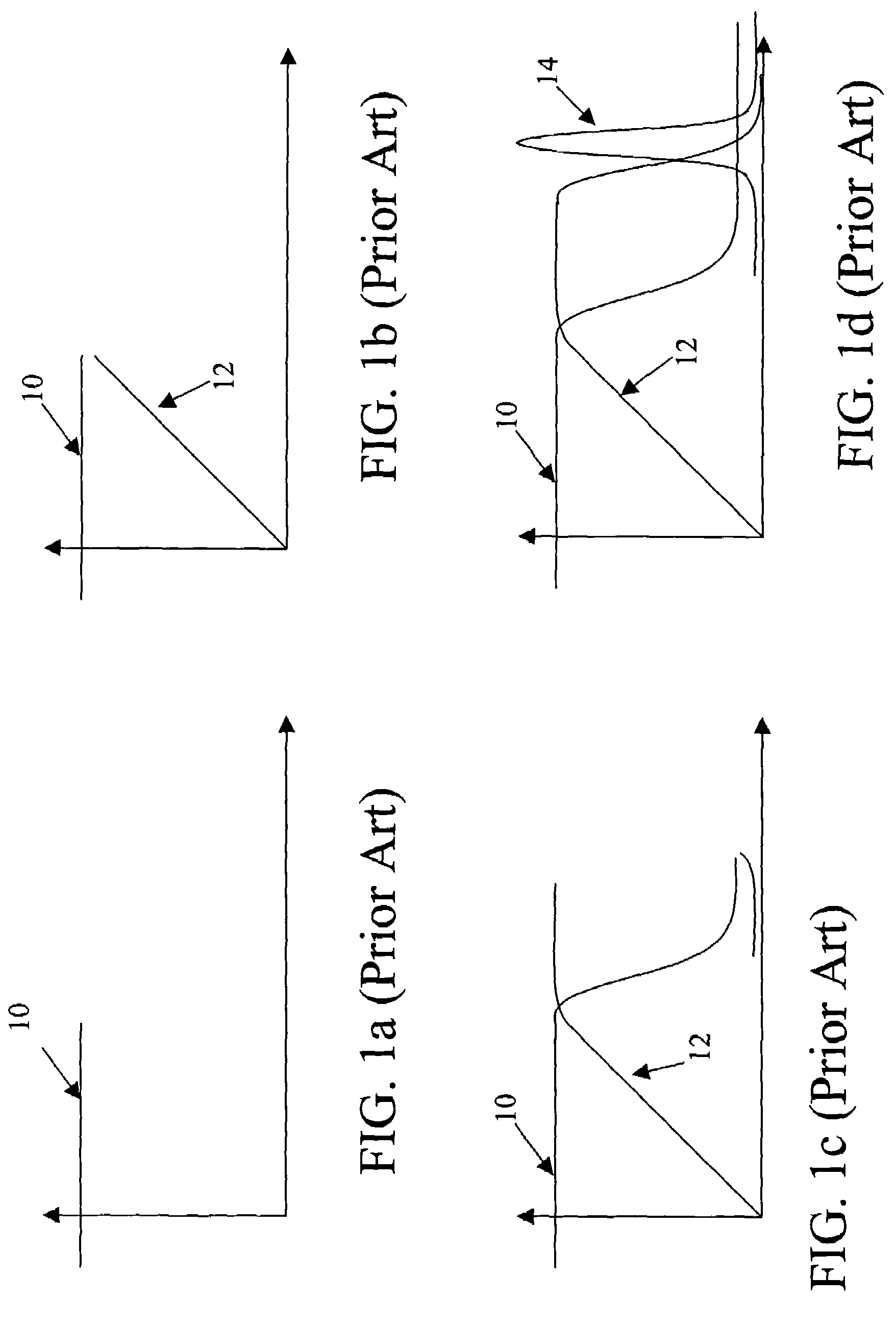

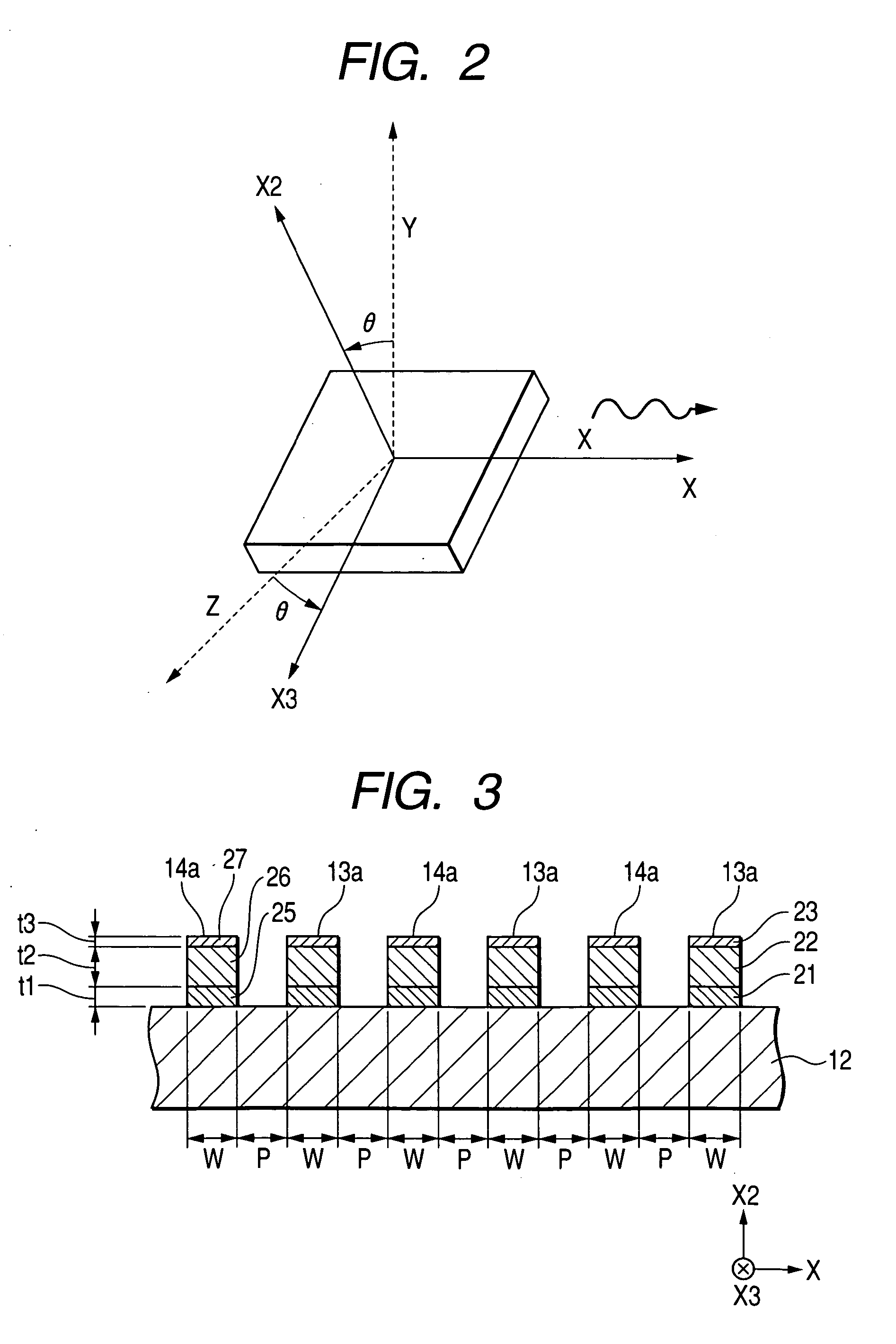

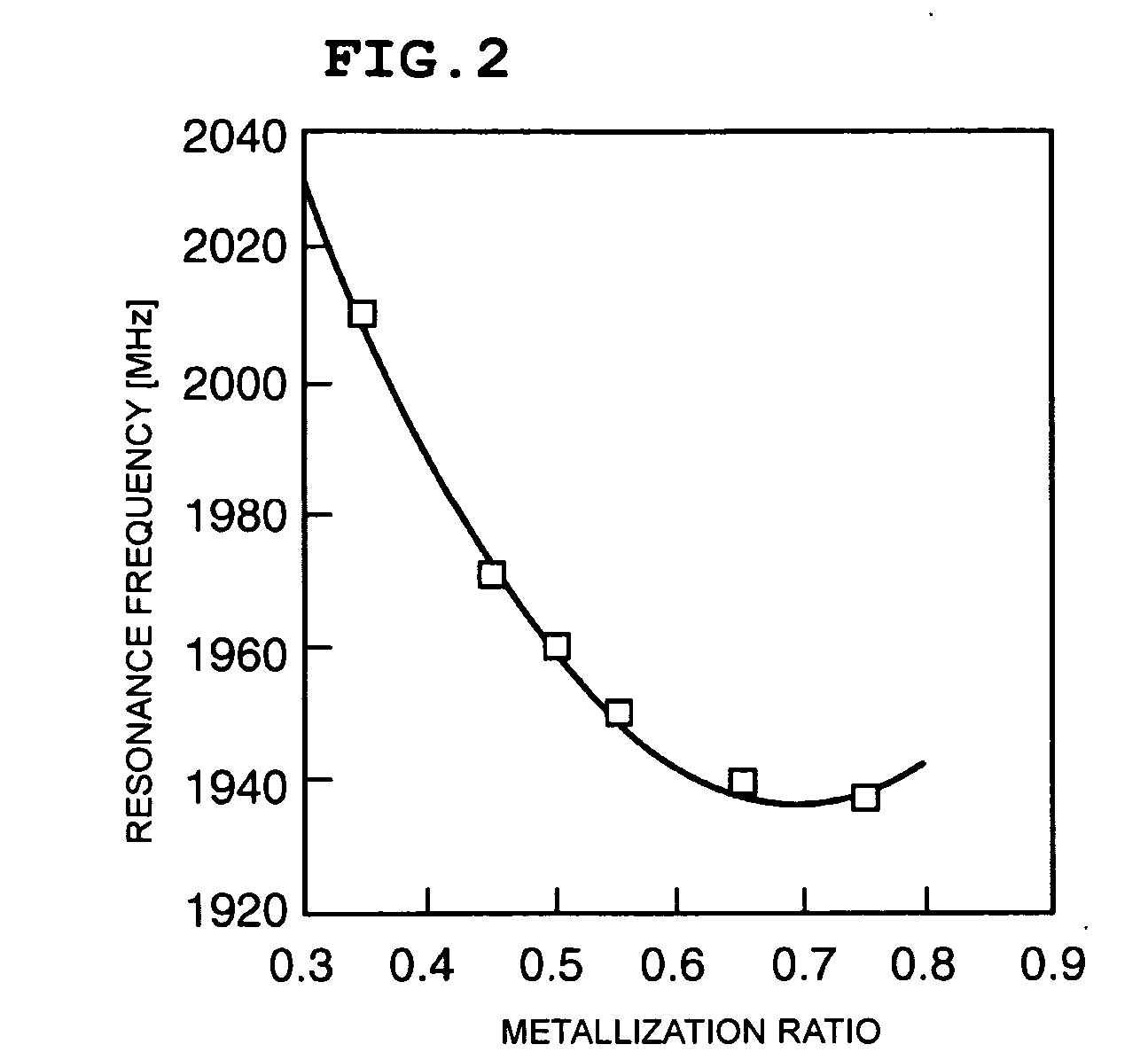

One-port surface acoustic wave resonator and surface acoustic wave filter

InactiveUS20060131992A1High frequencyReduce frequency fluctuationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTransducerAcoustic wave

A one-port surface acoustic wave resonator includes a rotated Y-cut LiTaO3 substrate, an interdigital electrode transducer disposed on the LiTaO3 substrate, and reflectors disposed on both sides of the interdigital electrode transducer in the surface acoustic wave propagation direction of the interdigital electrode transducer. When the electrode finger width of the interdigital electrode transducer is denoted by a and the gap between the electrode fingers is denoted by b, the metallization ratio, a / (a+b), is in the range of about 0.55 to about 0.85 and the interdigital electrode transducer is overlapping-length weighted.

Owner:MURATA MFG CO LTD

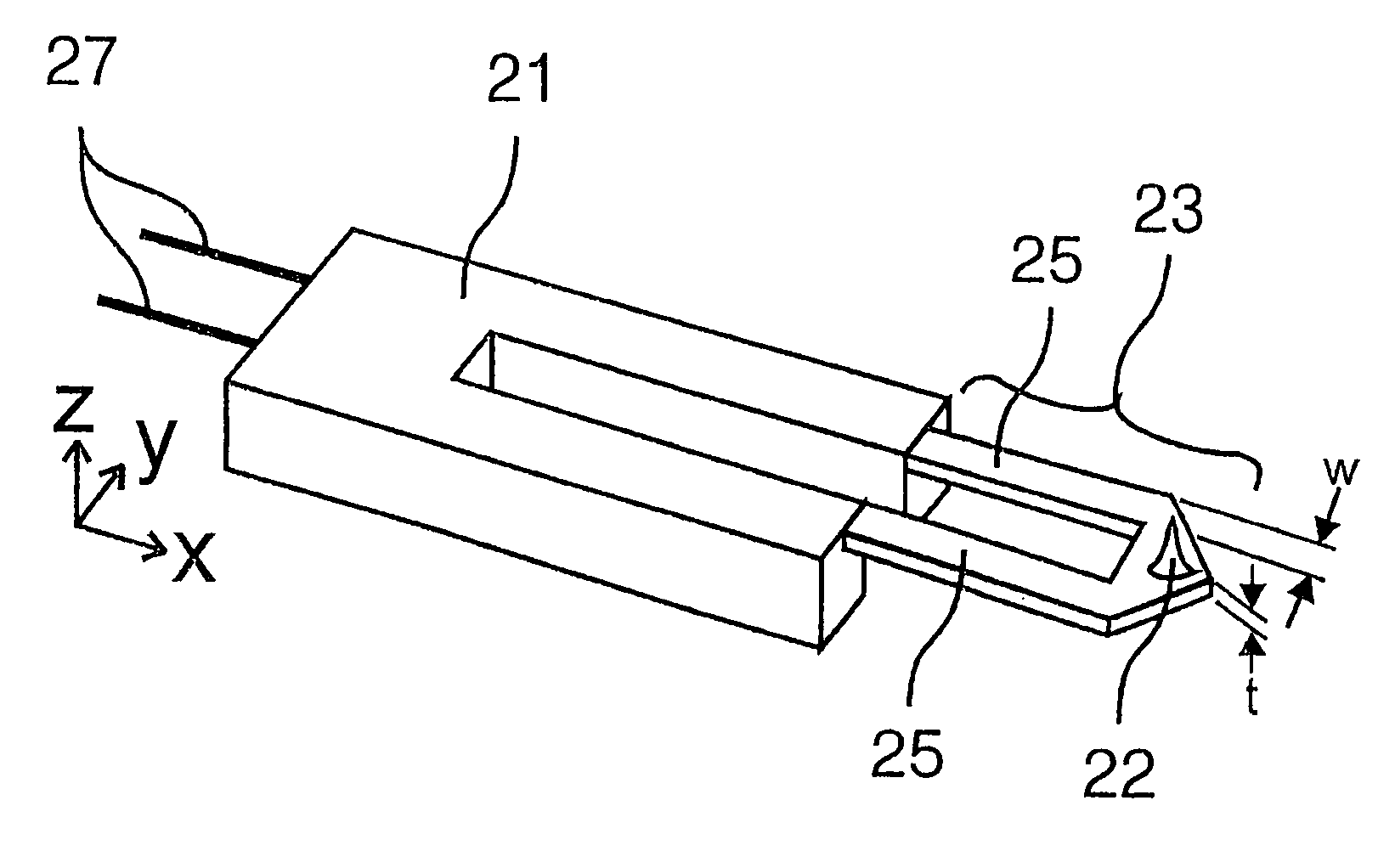

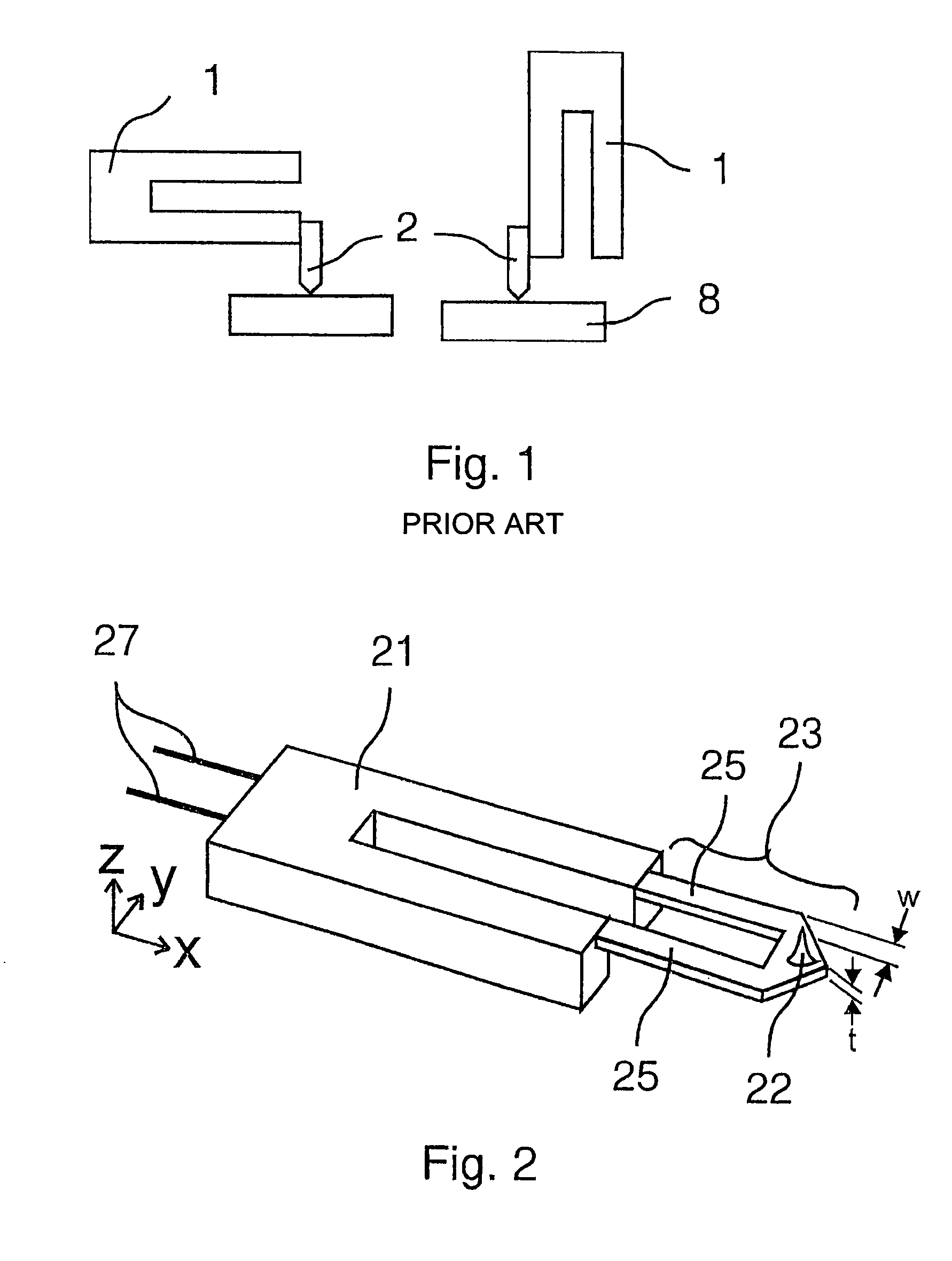

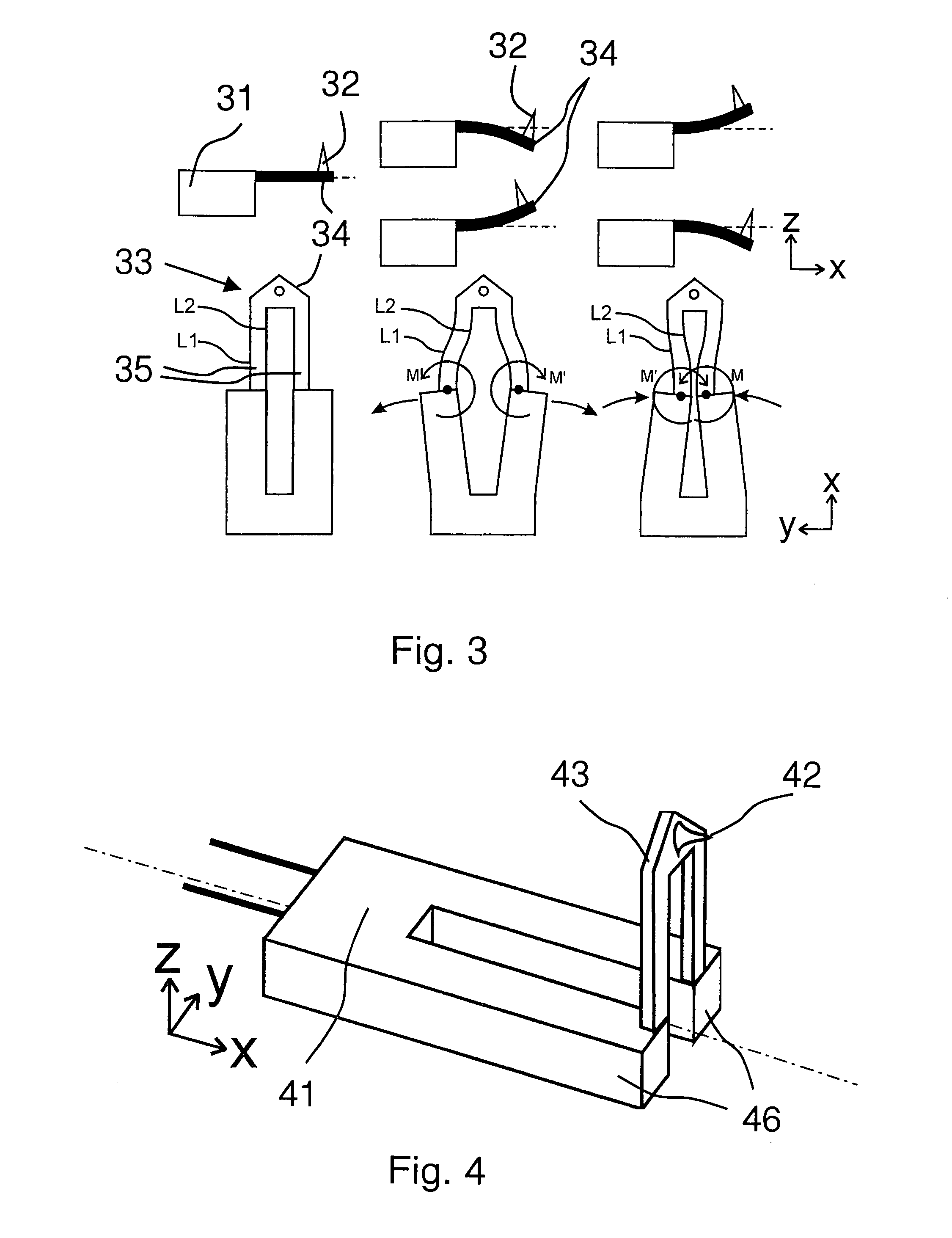

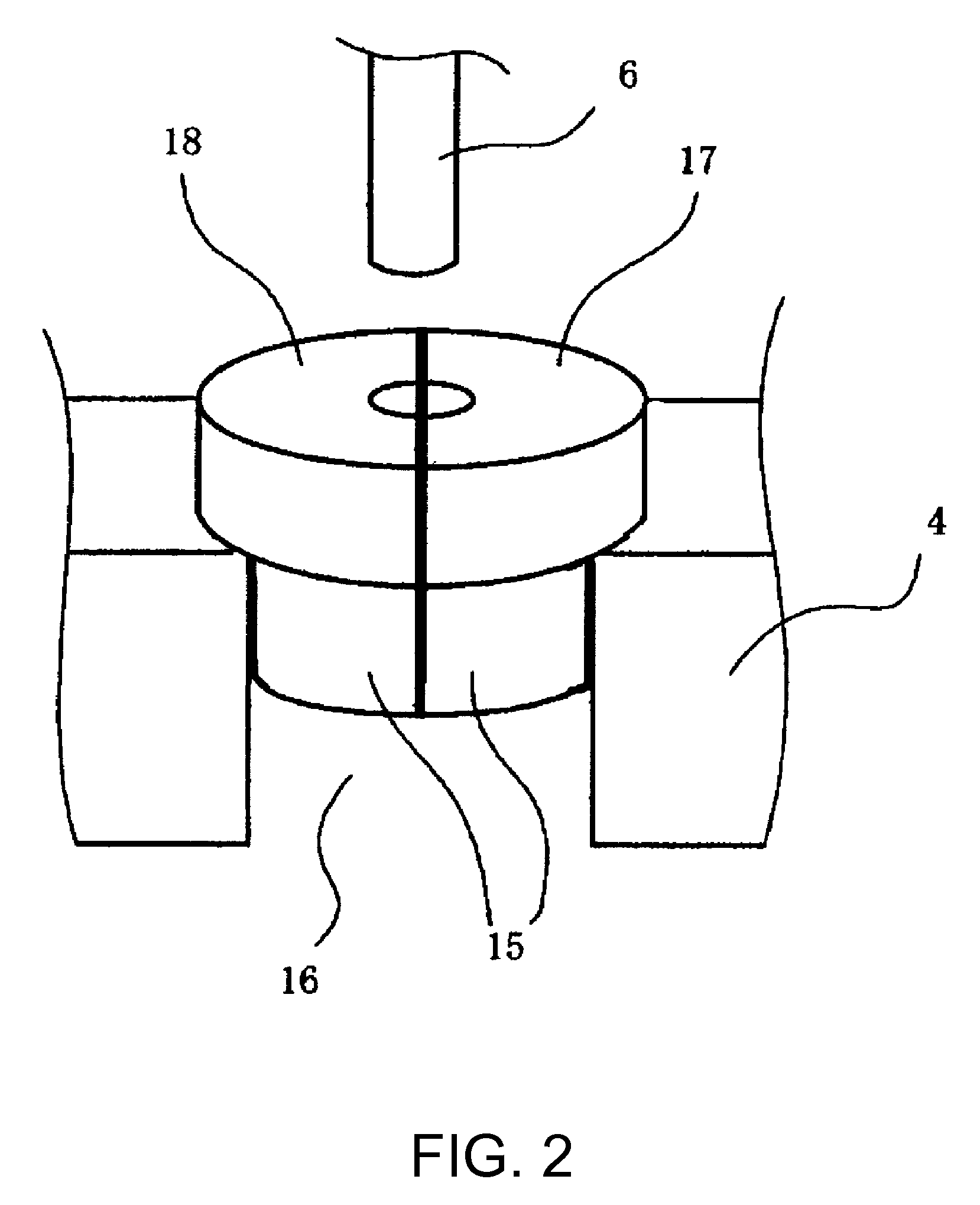

Actuating and sensing device for scanning probe microscopes

InactiveUS7051582B2Improving QMore forceMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsTuning forkEngineering

An actuating and sensing device for scanning probe microscopes includes a tuning fork (21) containing two prongs, a connection device (23) such as a spring, and a probing tip (22). The tip (22) is connected to both prongs of the tuning fork (21) with the connection device (23). The tuning fork (21) is used as a mechanical resonator to vibrate. The movements of the prongs are transformed via the connection device (23) into movements of the tip (22), wherein the tip movements can be in different planes than the movement plane of the prongs.

Owner:UNIV DE NEUCHATEL INSTITUT DE MICROTECHN

Magnetic component

InactiveUS6873242B2Prevent penetrationIncrease inductanceTransformersSemiconductor/solid-state device detailsMagnetic fluxQ factor

The magnetic component uses at least two different layers of magnetic material for carrying and amplifying the magnetic flux. The use of two different layers which may, however, have the same material composition allows the magnetic conductors to form a magnetic circuit with a locally matched domain alignment. The magnetic component accordingly allows considerable improvements to be achieved in the component parameter, in particular a considerable increase in the Q-factor.

Owner:INFINEON TECH AG

Surface acoustic wave device

ActiveUS7180223B2Improve enduranceElectromigration be suppressedPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTitanium nitrideAcoustic wave

Owner:QORVO US INC

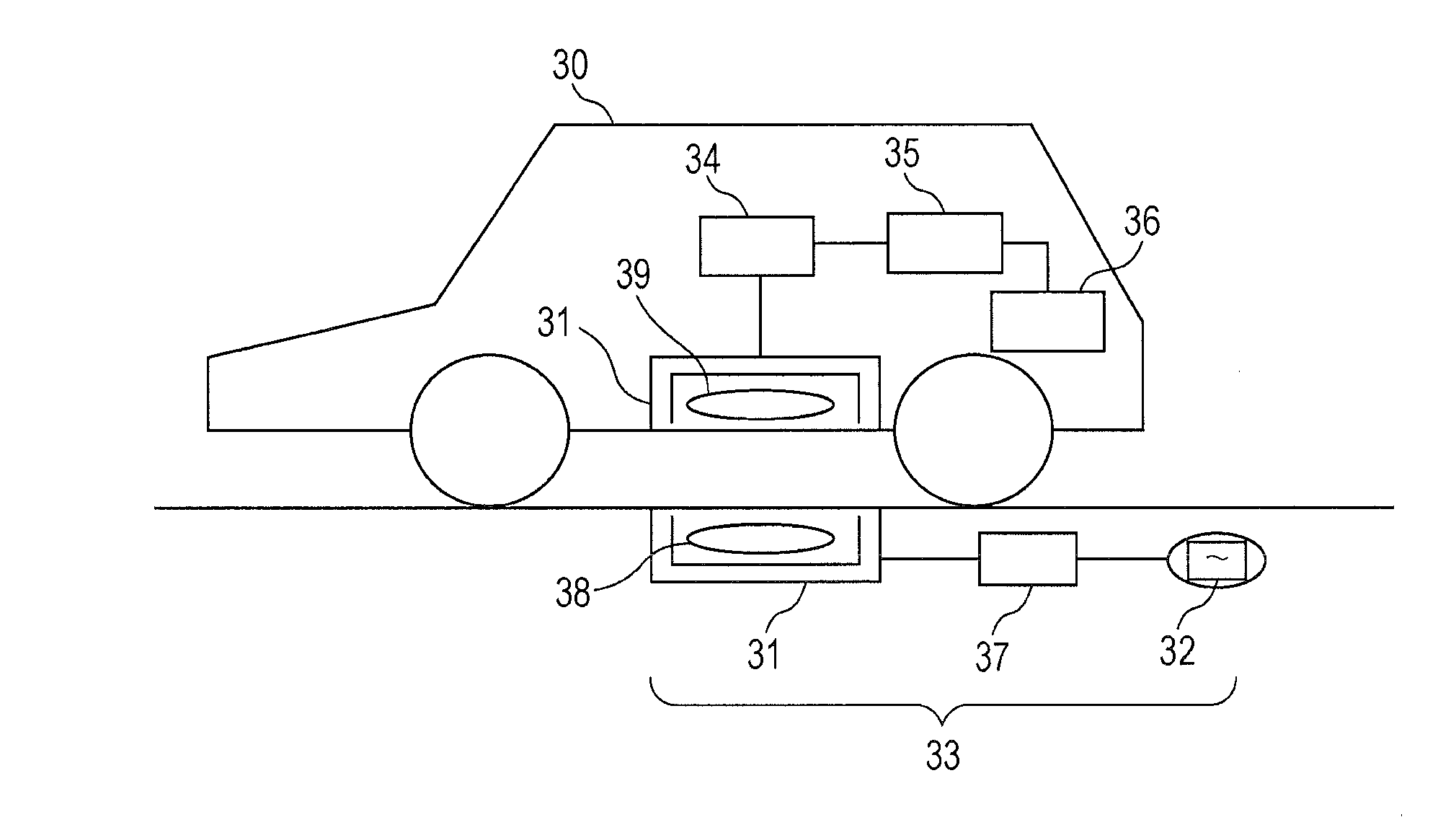

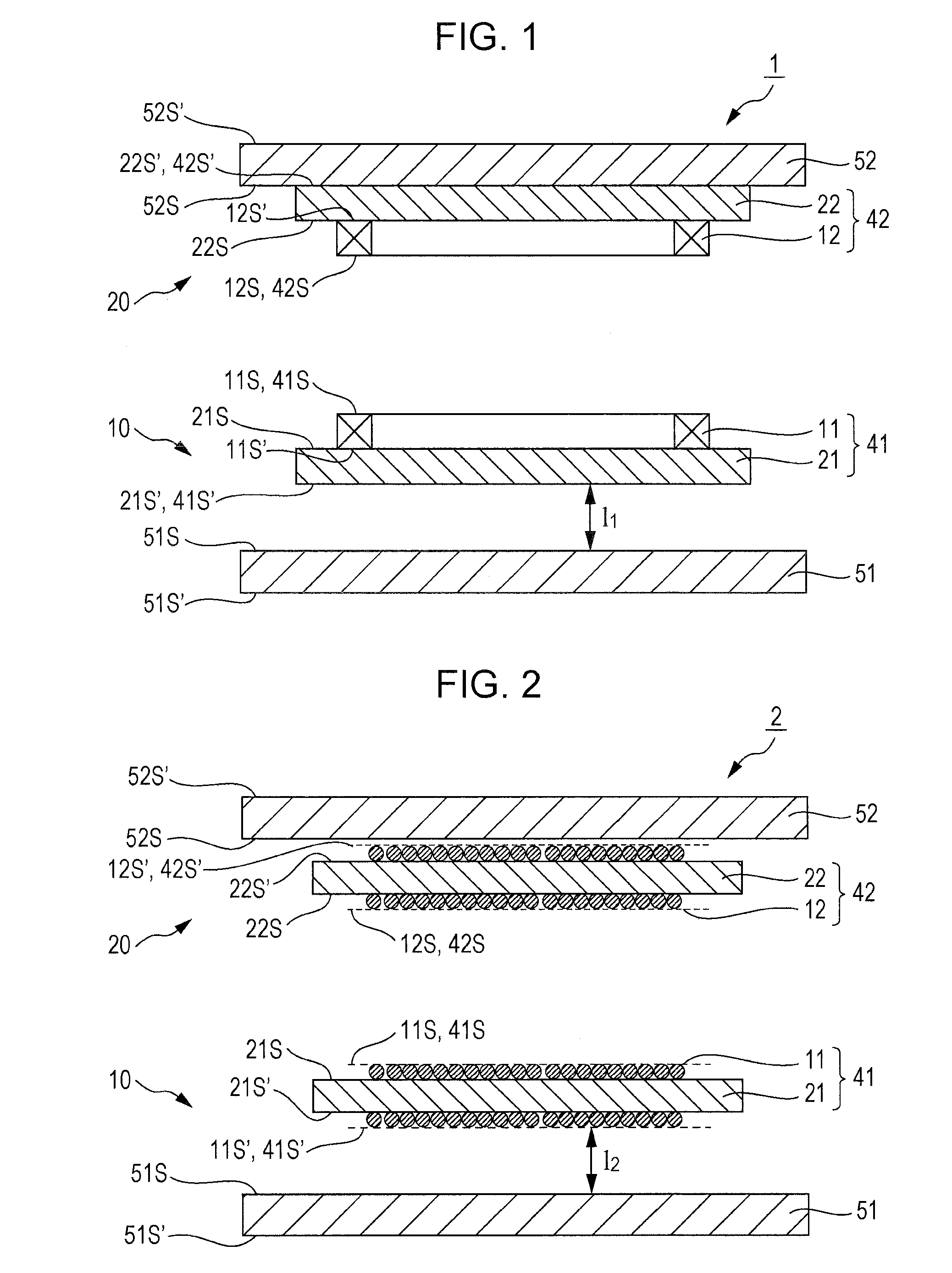

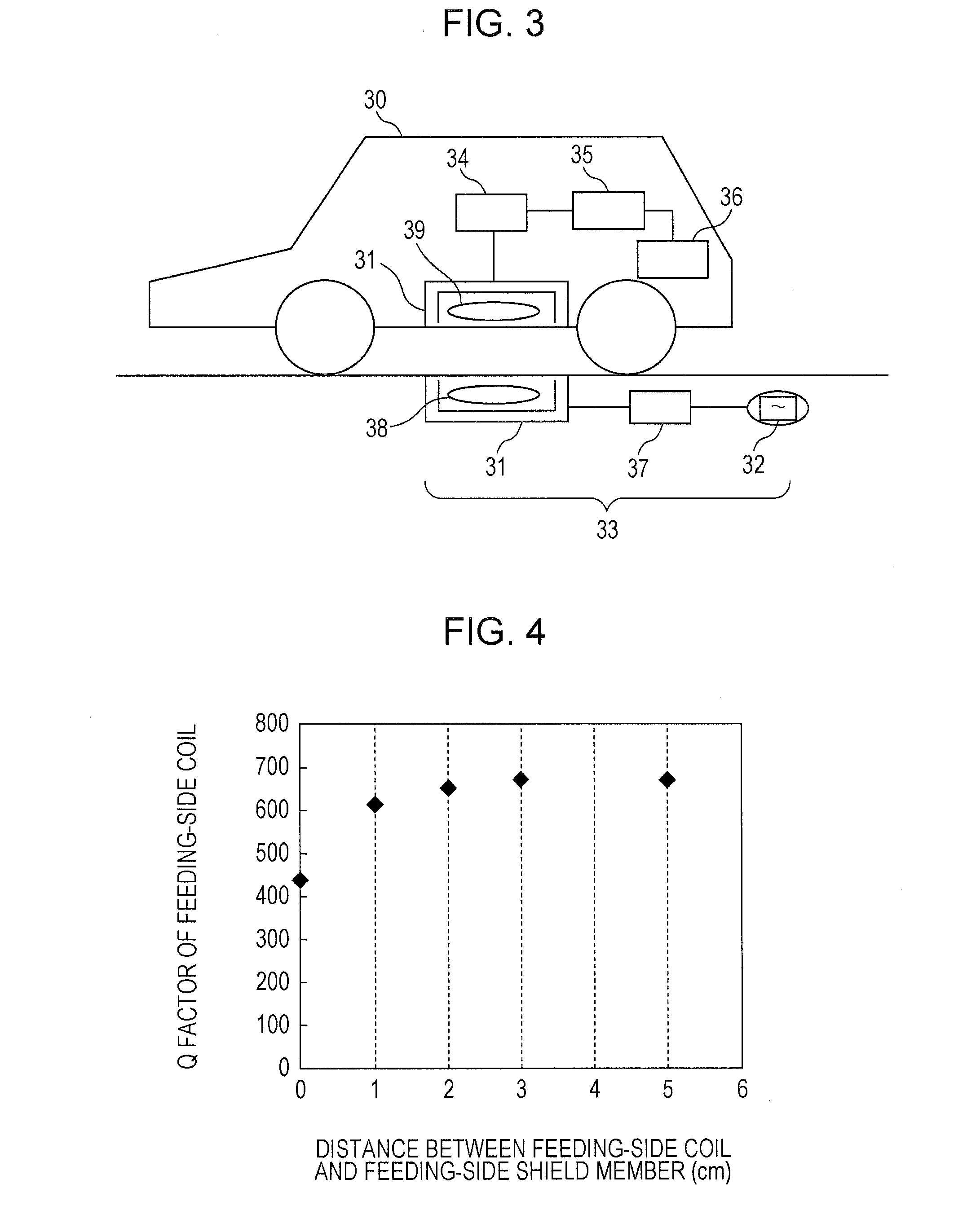

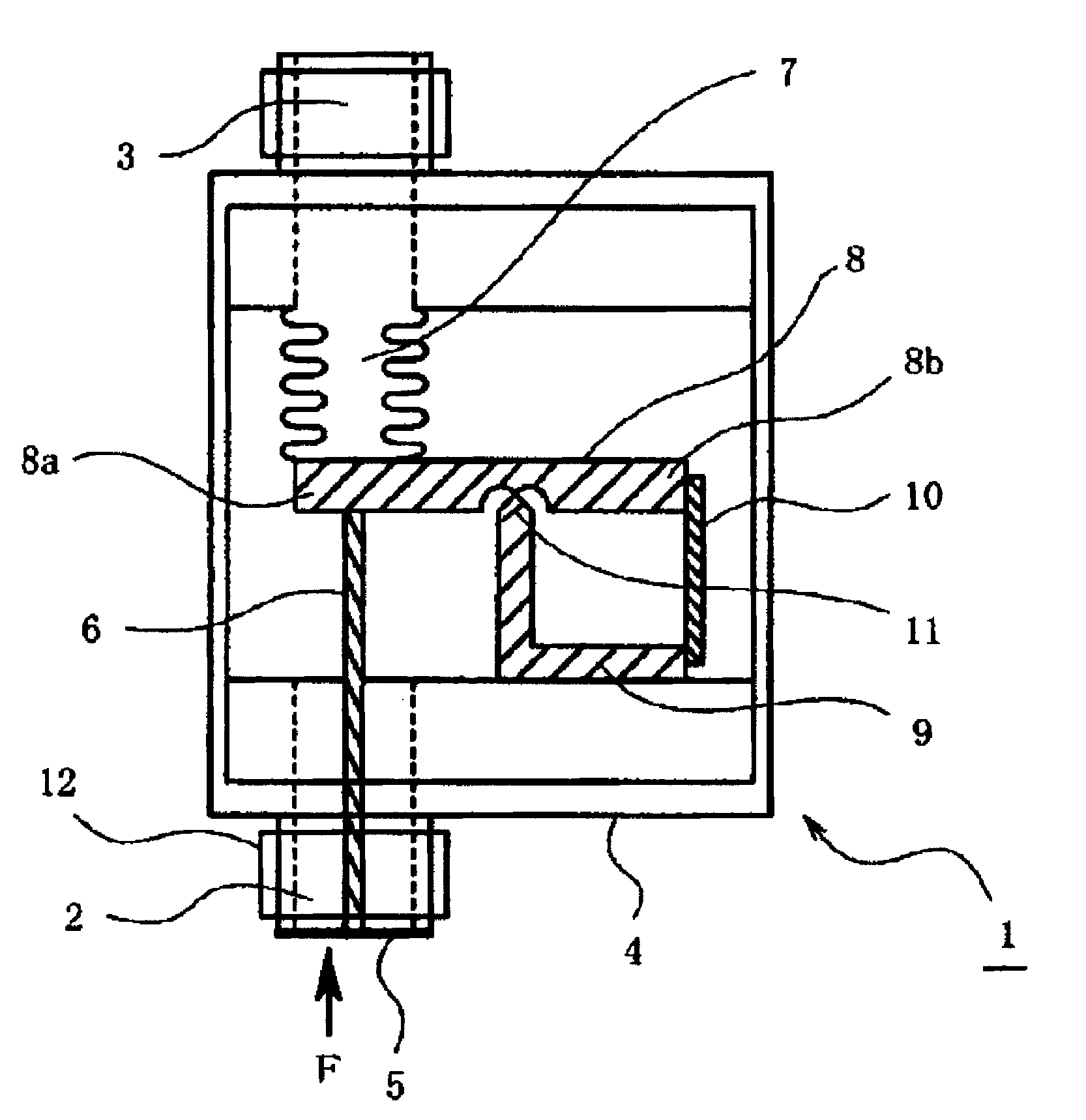

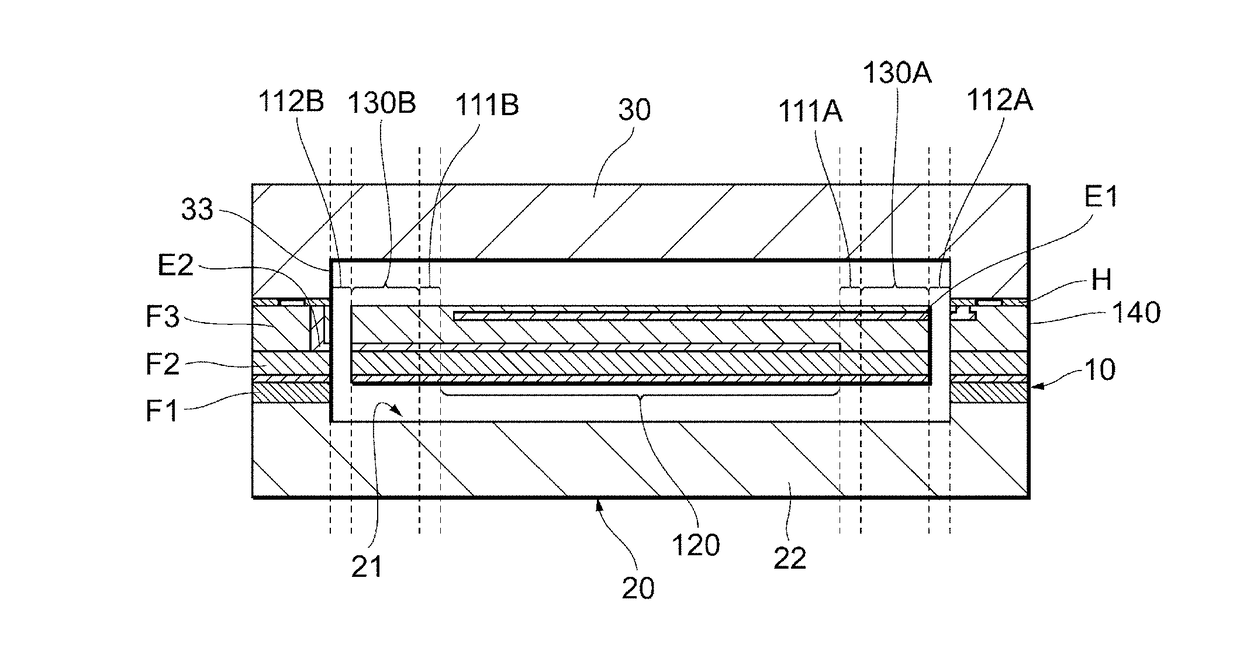

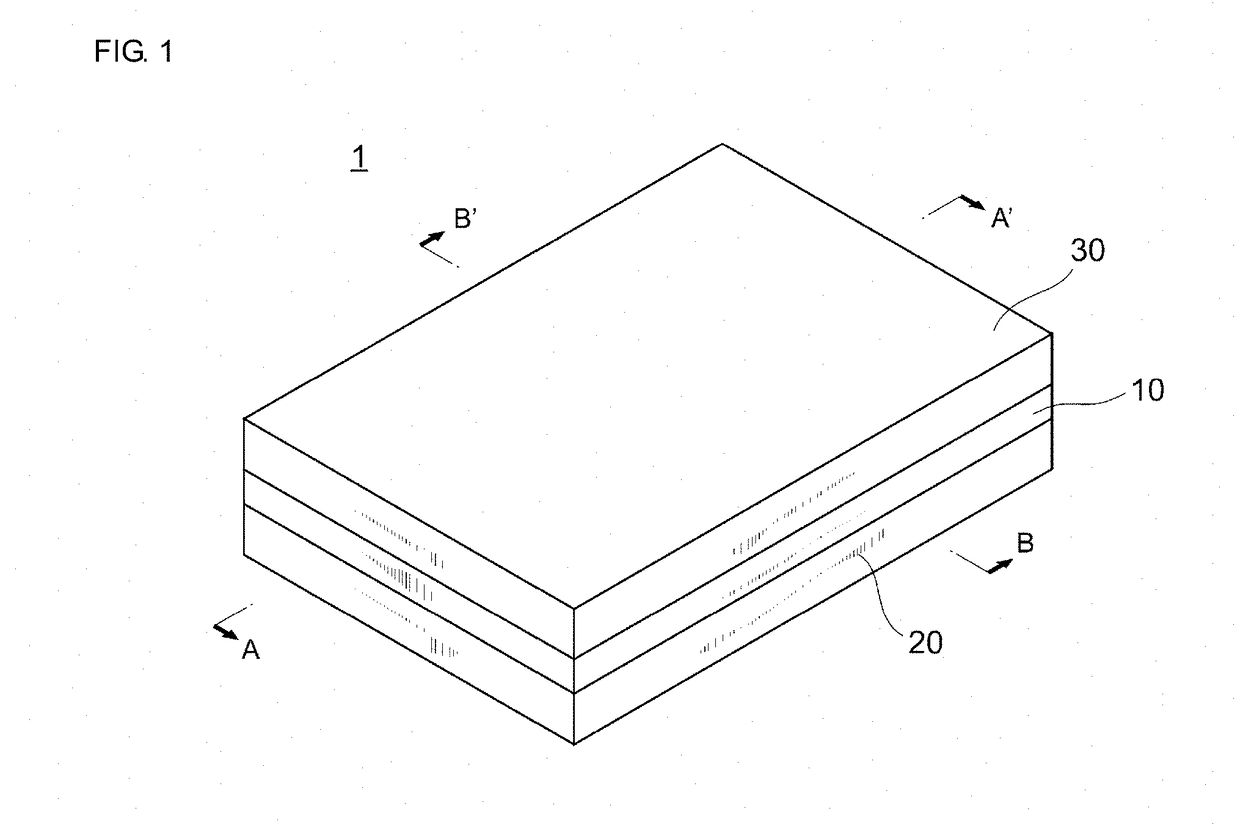

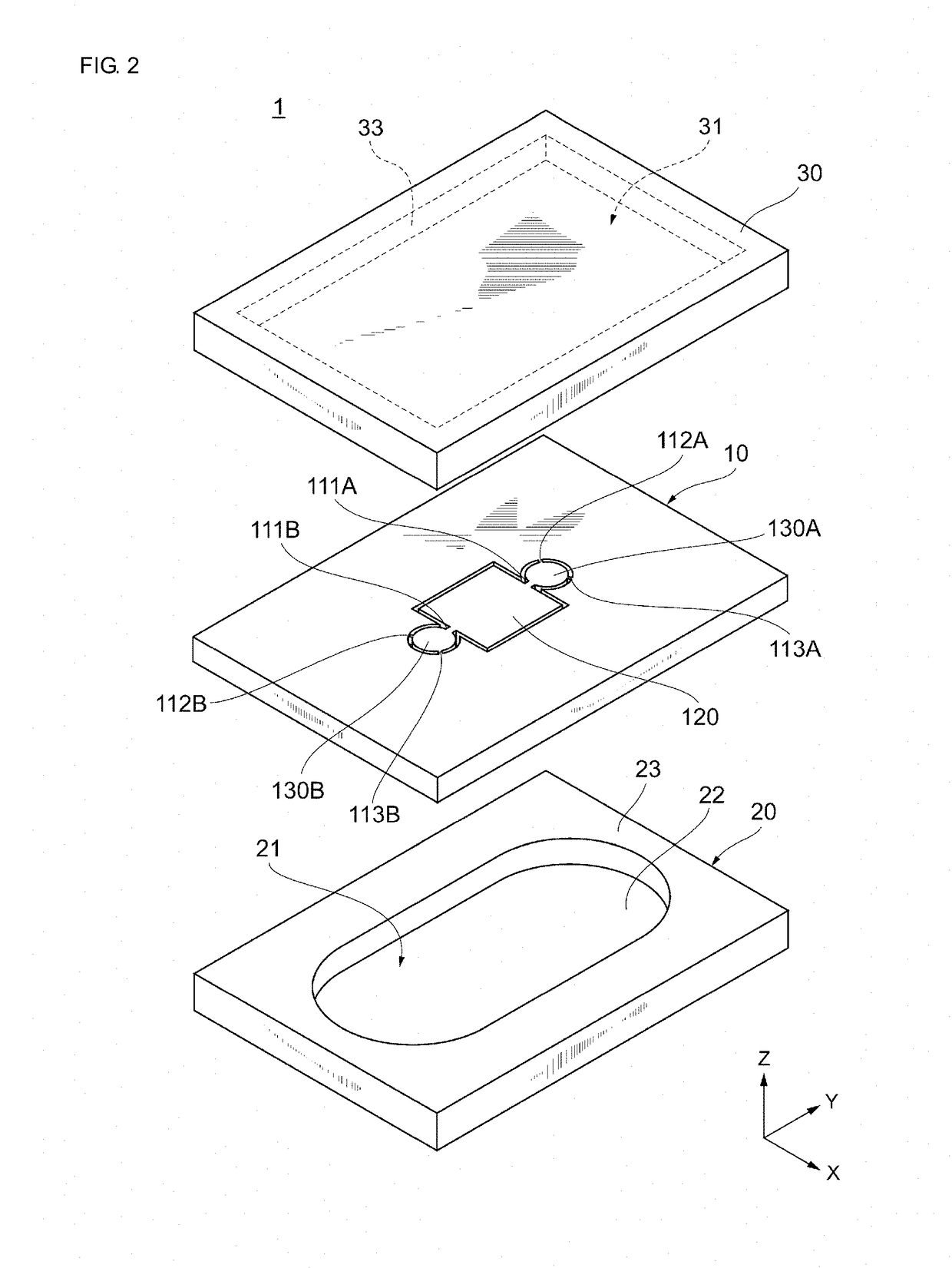

Wireless power transmission device

ActiveUS20150001953A1High power transmission efficiencyEasy to optimizeTransformersTransformers/inductances circuitsElectric power transmissionConductor Coil

A wireless power transmission device includes a power feeding unit and a power receiving unit. The power feeding unit and the power receiving unit are disposed so that a principal surface of a primary magnetic core and a principal surface of a secondary magnetic core face each other across a primary winding and a secondary winding. The distance from a surface of a feeding-side shield member which faces a feeding-side coil to a surface of the feeding-side coil which faces the feeding-side shield member, is longer than the distance from a surface of a receiving-side shield member which faces a receiving-side coil to a surface of the receiving-side coil which faces the receiving-side shield member.

Owner:TDK CORPARATION

Integrated inductor

ActiveUS8860544B2Simple processLow costSemiconductor/solid-state device detailsSolid-state devicesMicrometerInductor

An integrated inductor includes a winding consisting of an aluminum layer atop a passivation layer, wherein the aluminum layer does not extend into the passivation layer and has a thickness that is not less than about 2.0 micrometers. The passivation layer has a thickness not less than about 0.8 micrometers. By eliminating copper from the integrated inductor and increasing the thickness of the passivation layer, the distance between the bottom surface of the inductor structure and the main surface of the semiconductor substrate is increased, thus the parasitic substrate coupling may be reduced and the Q-factor may be improved. Besides, the increased thickness of the aluminum layer may help improve the Q-factor as well.

Owner:MEDIATEK INC

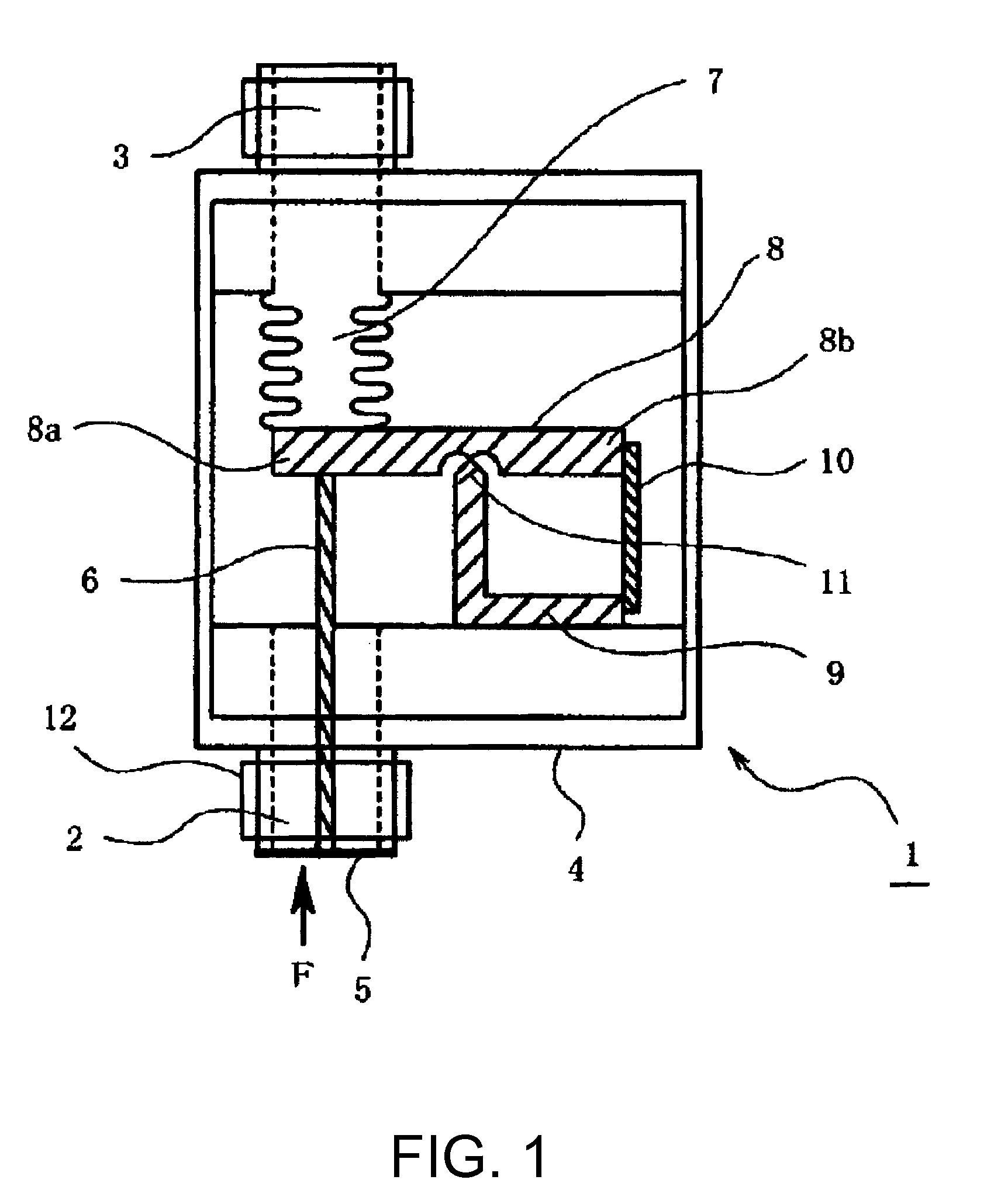

Pressure sensor and method for manufacturing the same

InactiveUS7942062B2Eliminate needGood temperature characteristicsFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsPressure senseEngineering

A pressure sensor includes: a housing; an attachment having a pressure input orifice communicating with an interior of the housing; a first diaphragm that seals an opening of the pressure input orifice of the attachment, an external surface of the first diaphragm being a pressure receiving surface; a force transmitting member having an end which is coupled approximately perpendicular to a main surface of the first diaphragm, the main surface being opposite from the pressure receiving surface; a swing arm which is joined to the force transmitting member and is held to a retainer at a pivoting point as a fulcrum; and a pressure sensing element having a first end coupled to the retainer and a second end coupled to the swing arm, so that a displacement direction of the force transmitting member is the same direction as a line joining the first end and the second end. In this pressure sensor, the force transmitting member, the swing arm, the pressure sensing element, and the retainer are housed inside the housing, and the retainer is fixed to an inner wall of the housing.

Owner:SEIKO EPSON CORP

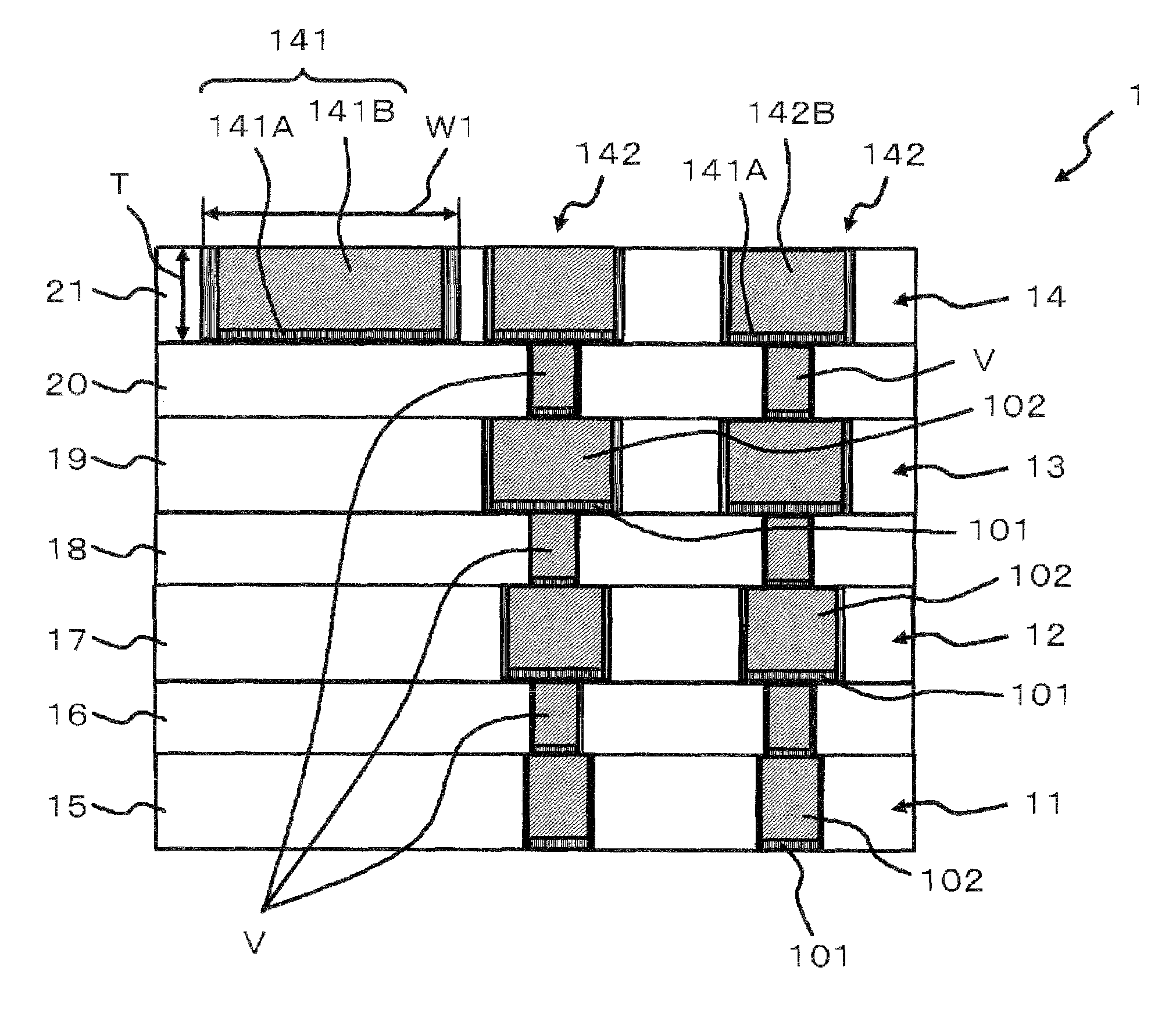

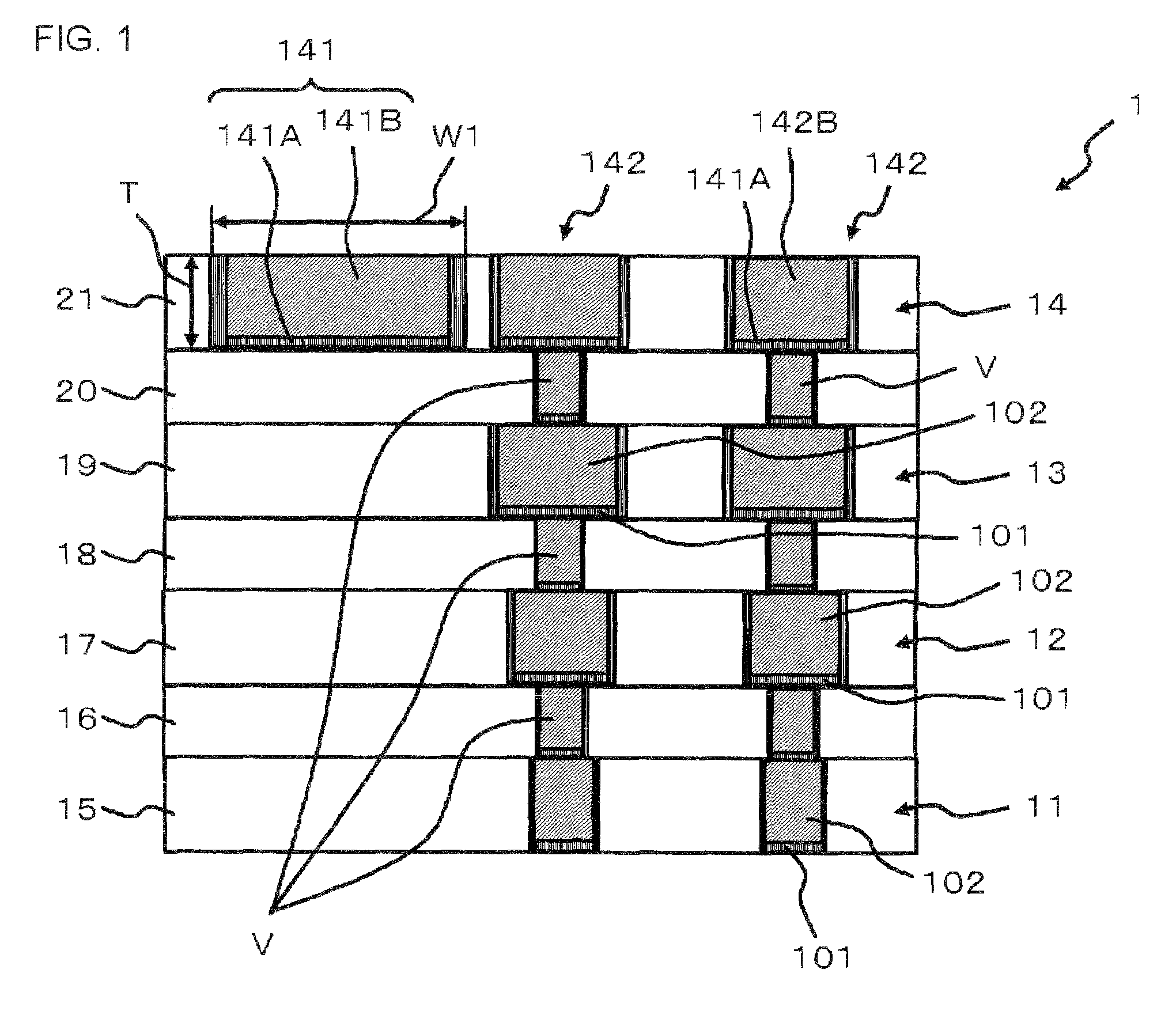

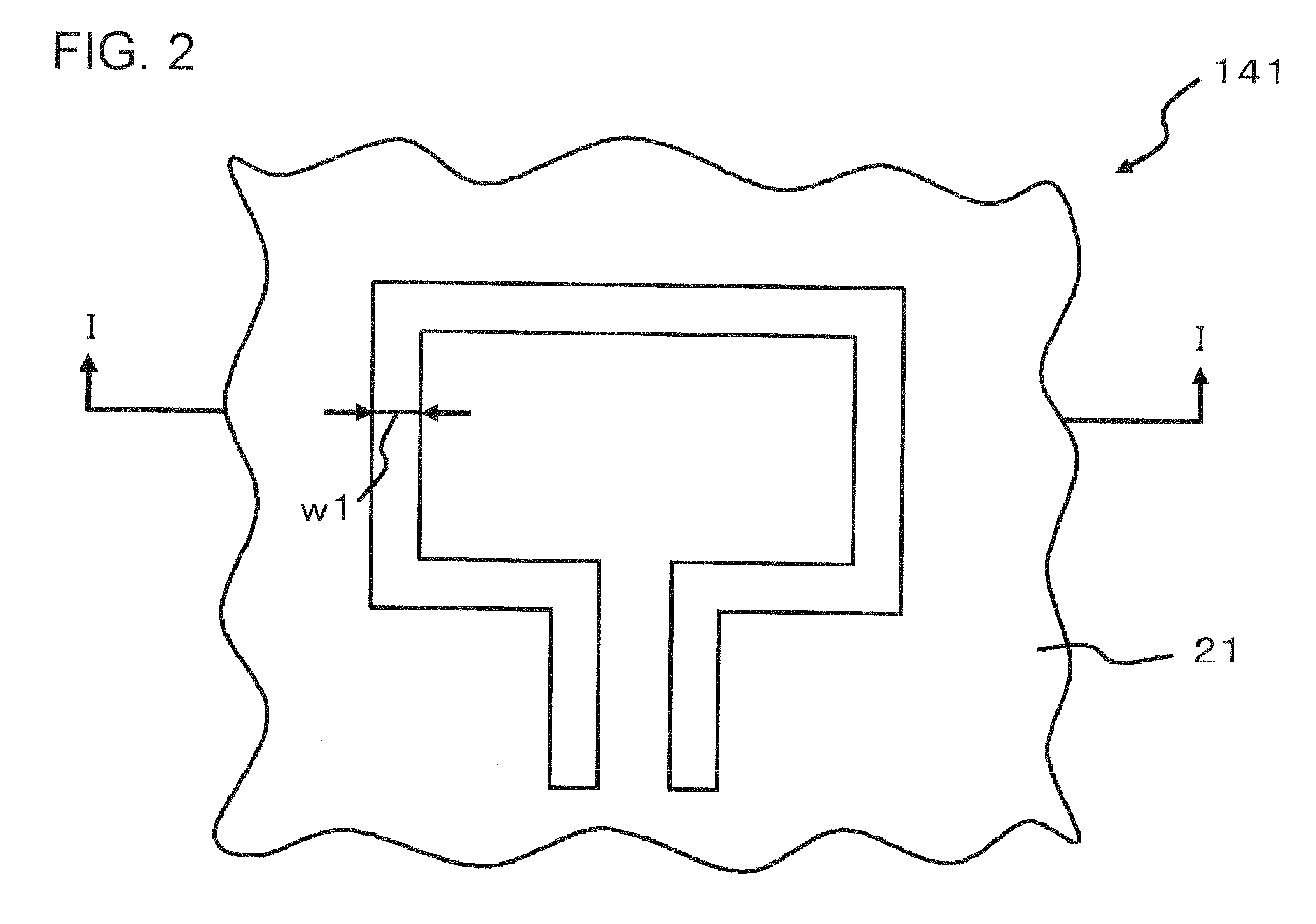

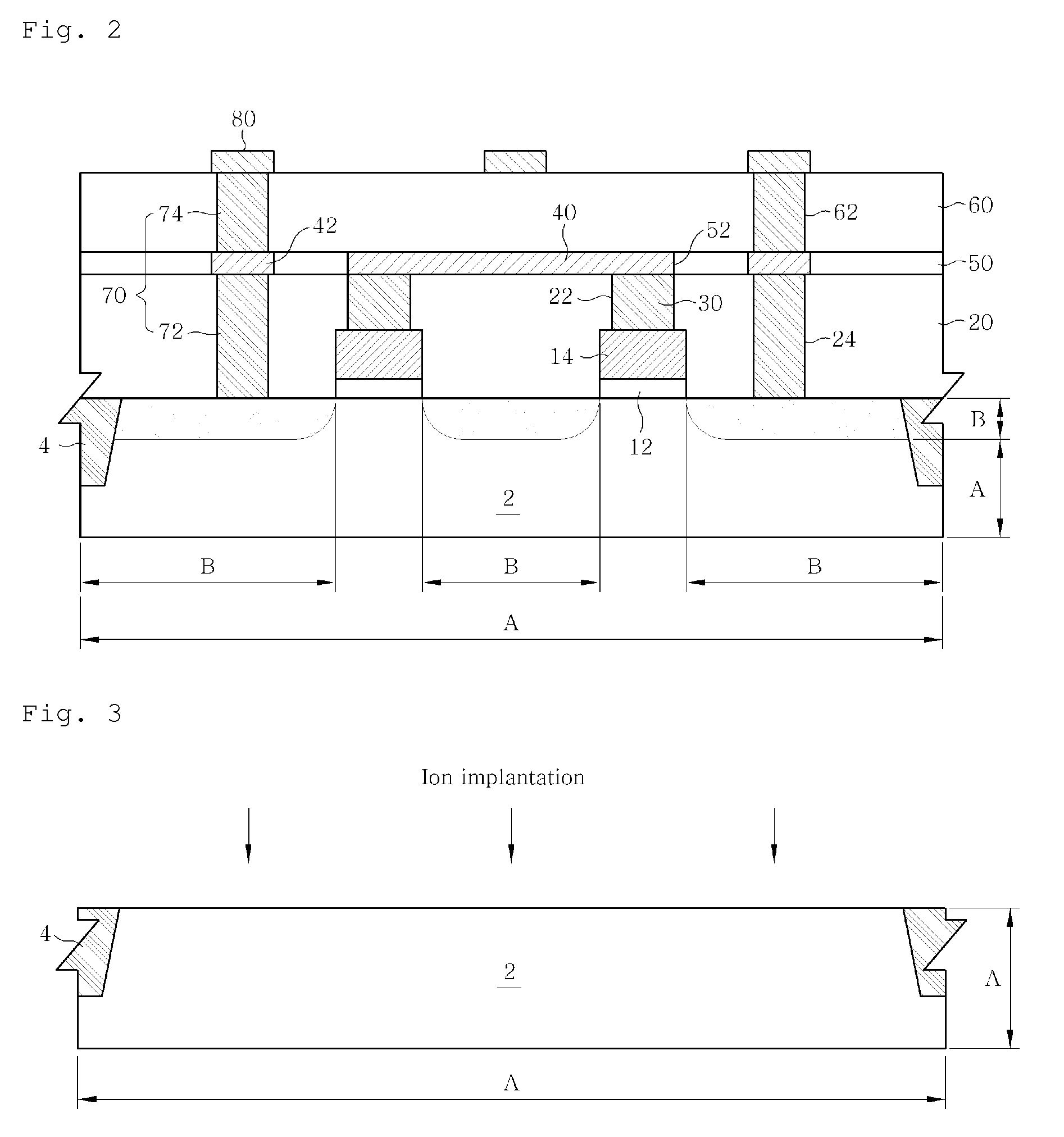

Semiconductor device

InactiveUS20090115022A1Reduce resistanceQ-factor can be increasedSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectSemiconductor

A semiconductor device 1 includes: a copper interconnect layer 14 that has an interconnect containing an inductor 141, which is buried in an interconnect trench formed in an insulating layer 21; and copper interconnect layers 11 to 13, which include no inductor and are buried in interconnect trenches formed in other insulating layers 15, 17 and 19, respectively. An average grain size of the inductor 141 is larger than average grain sizes of the interconnects in the copper interconnect layers 11 to 13 that contain no inductor

Owner:RENESAS ELECTRONICS CORP

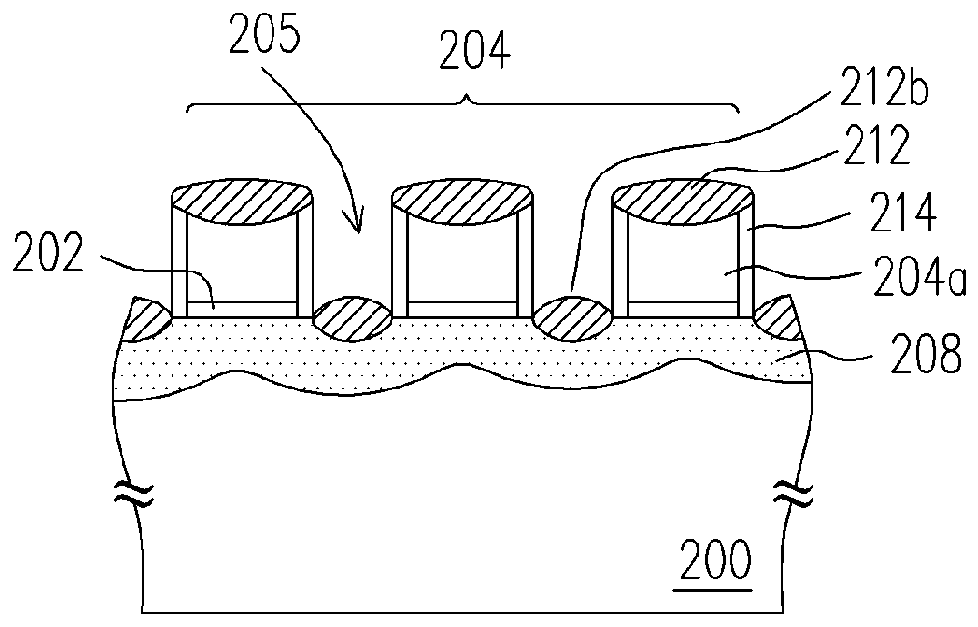

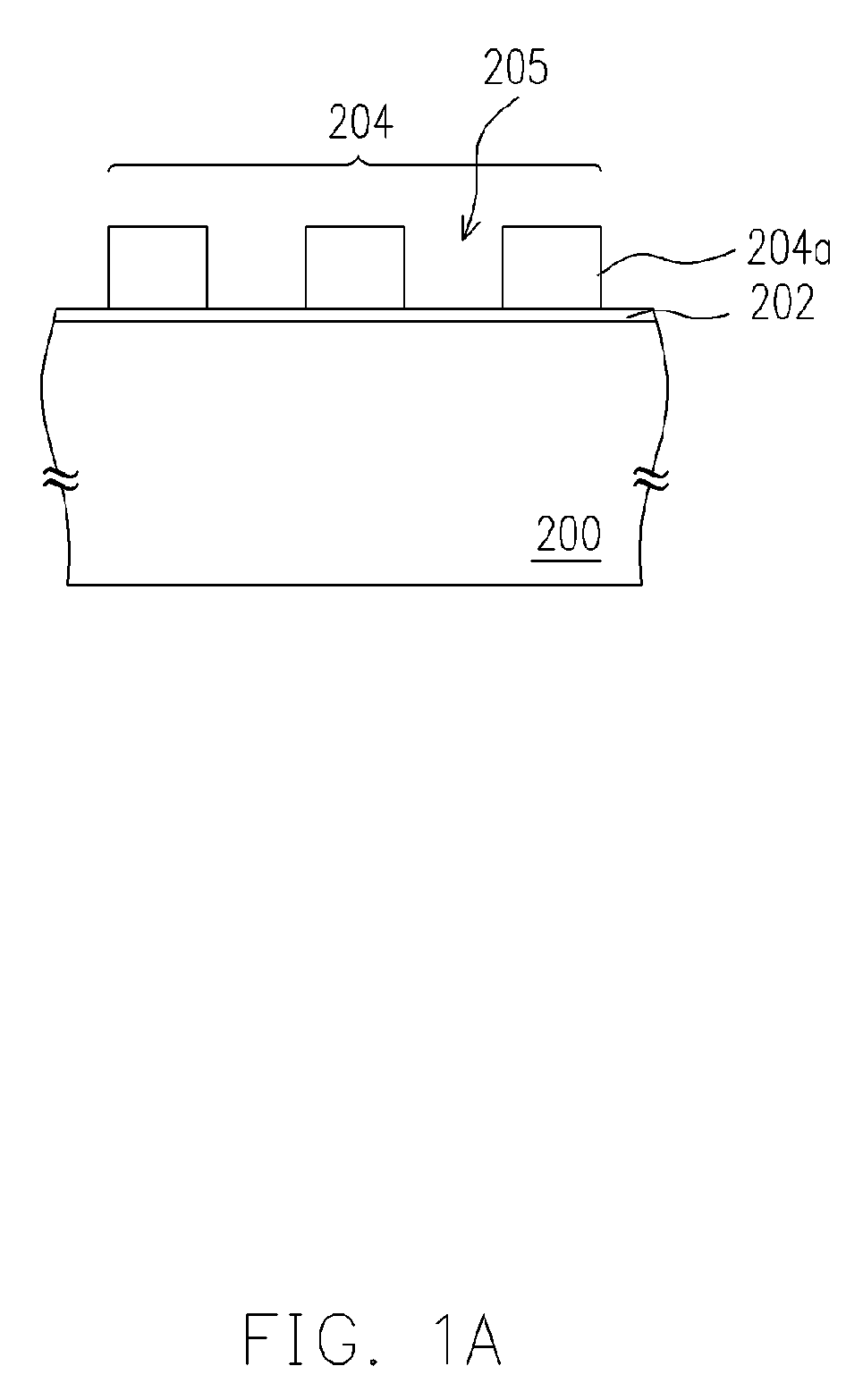

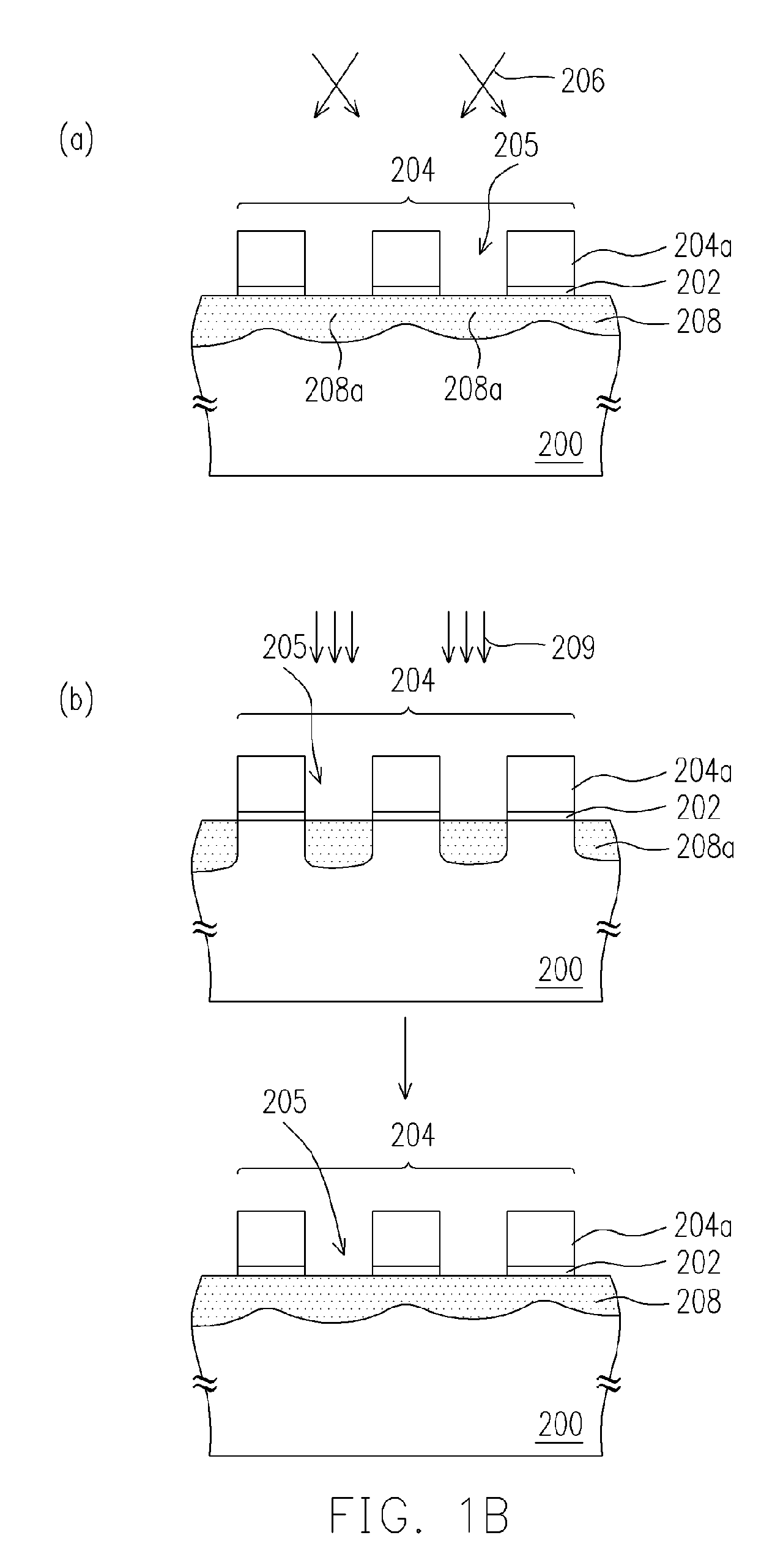

Method of fabricating capacitor

ActiveUS7071070B2Quality improvementReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsDielectric layer

A method of fabricating a capacitor is described. A dielectric layer is formed over a substrate. An upper electrode having multiple openings therein is formed over the dielectric layer. Then, a doping step is performed to the substrate through the openings to form a single doped region as a lower electrode in the substrate under the upper electrode.

Owner:UNITED MICROELECTRONICS CORP

Resonator and resonance device

ActiveUS20180191329A1Reducing anchor lossQ-factor can be increasedImpedence networksResonanceEngineering

A resonator that includes a piezoelectric vibrating portion; a retainer provided in at least part of an area surrounding the piezoelectric vibrating portion; a first node generating portion disposed between the piezoelectric vibrating portion and the retainer; a first connecting arm that connects the first node generating portion to a region in the piezoelectric vibrating portion that faces the first node generating portion; and a first retaining arm that connects the first node generating portion to a region in the retainer that faces the first node generating portion. The first node generating portion is substantially symmetrical with respect to each of two lines passing through a center of the first node generating portion along a first direction and a second direction orthogonal to the first direction, with the first direction being a direction that the first connecting arm connects the first node generating portion to the piezoelectric vibrating portion.

Owner:MURATA MFG CO LTD

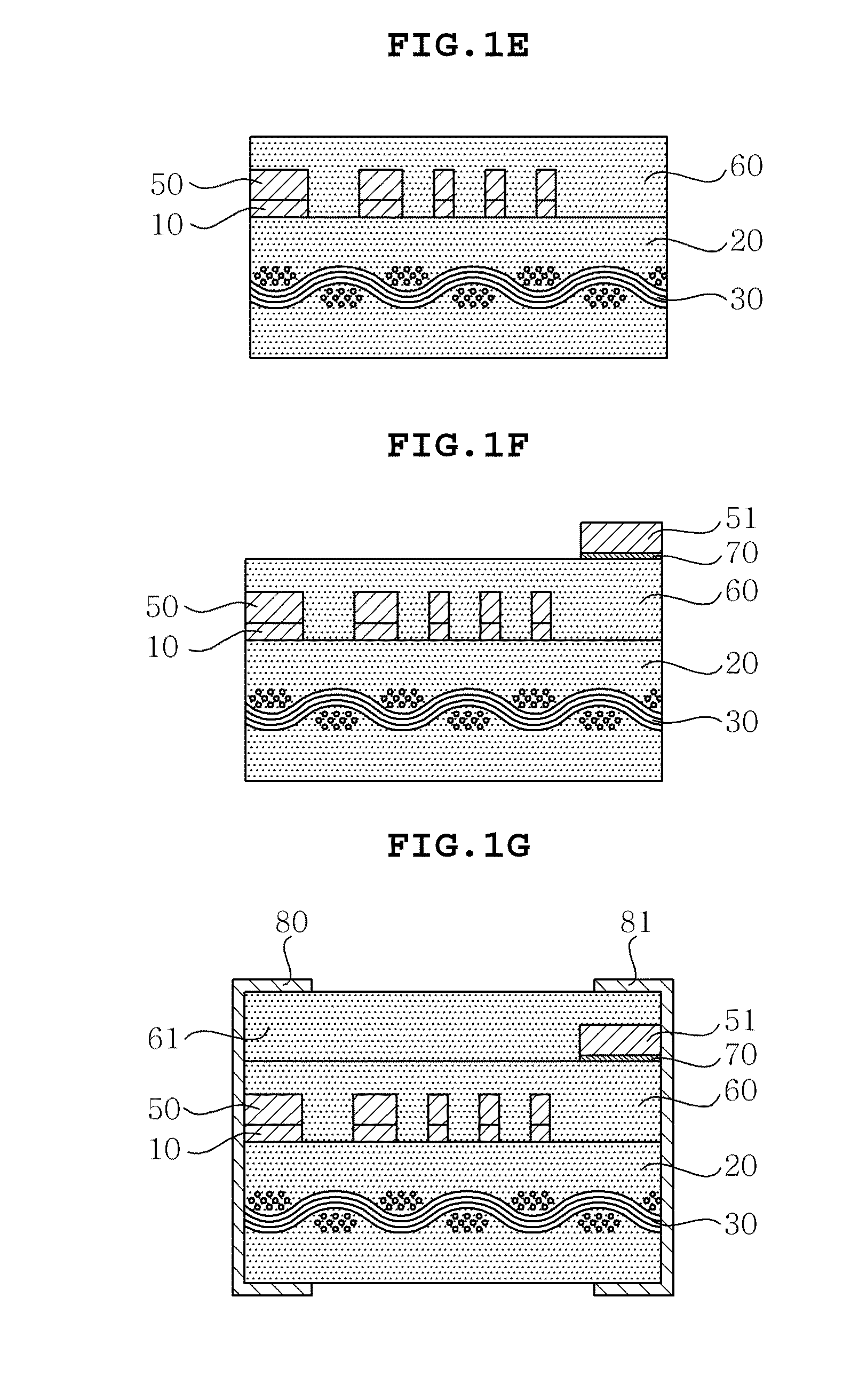

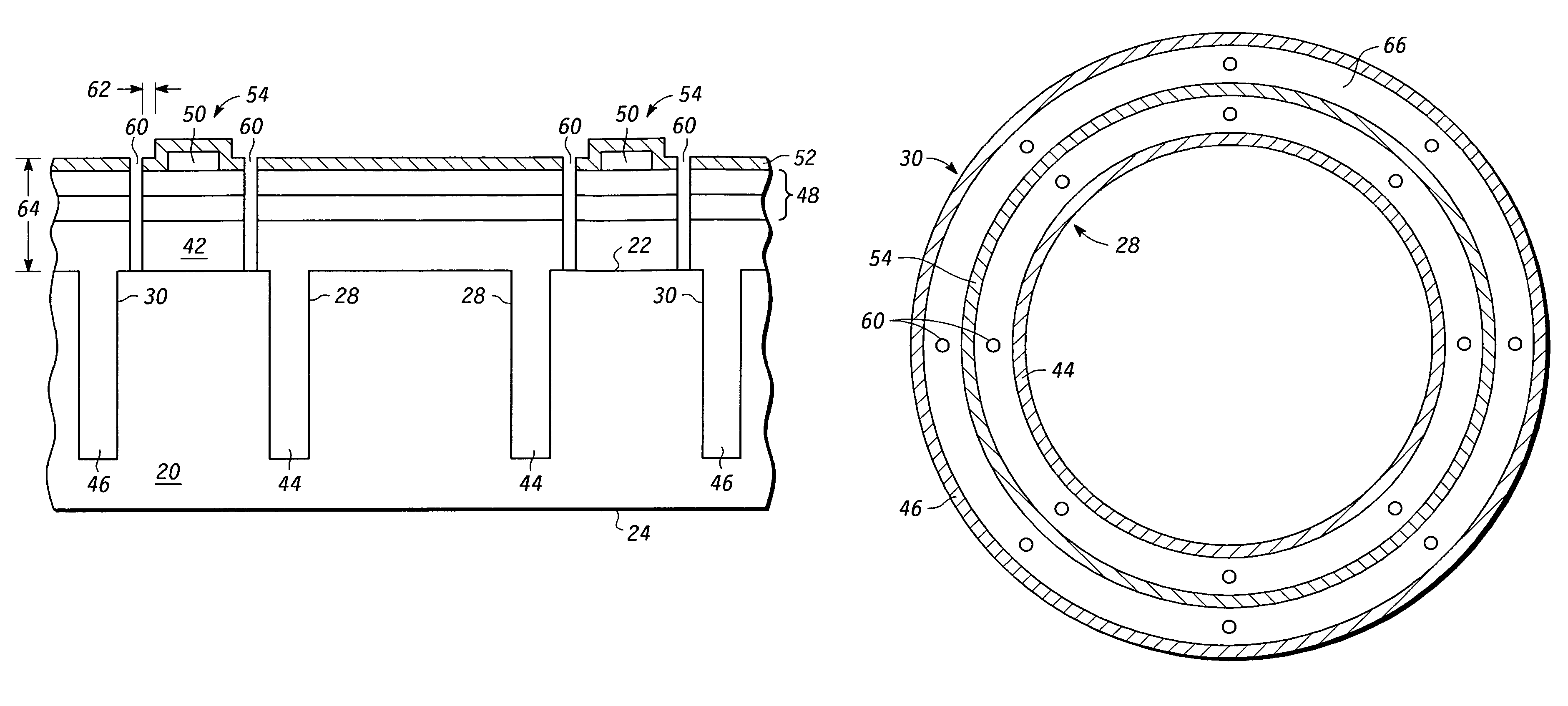

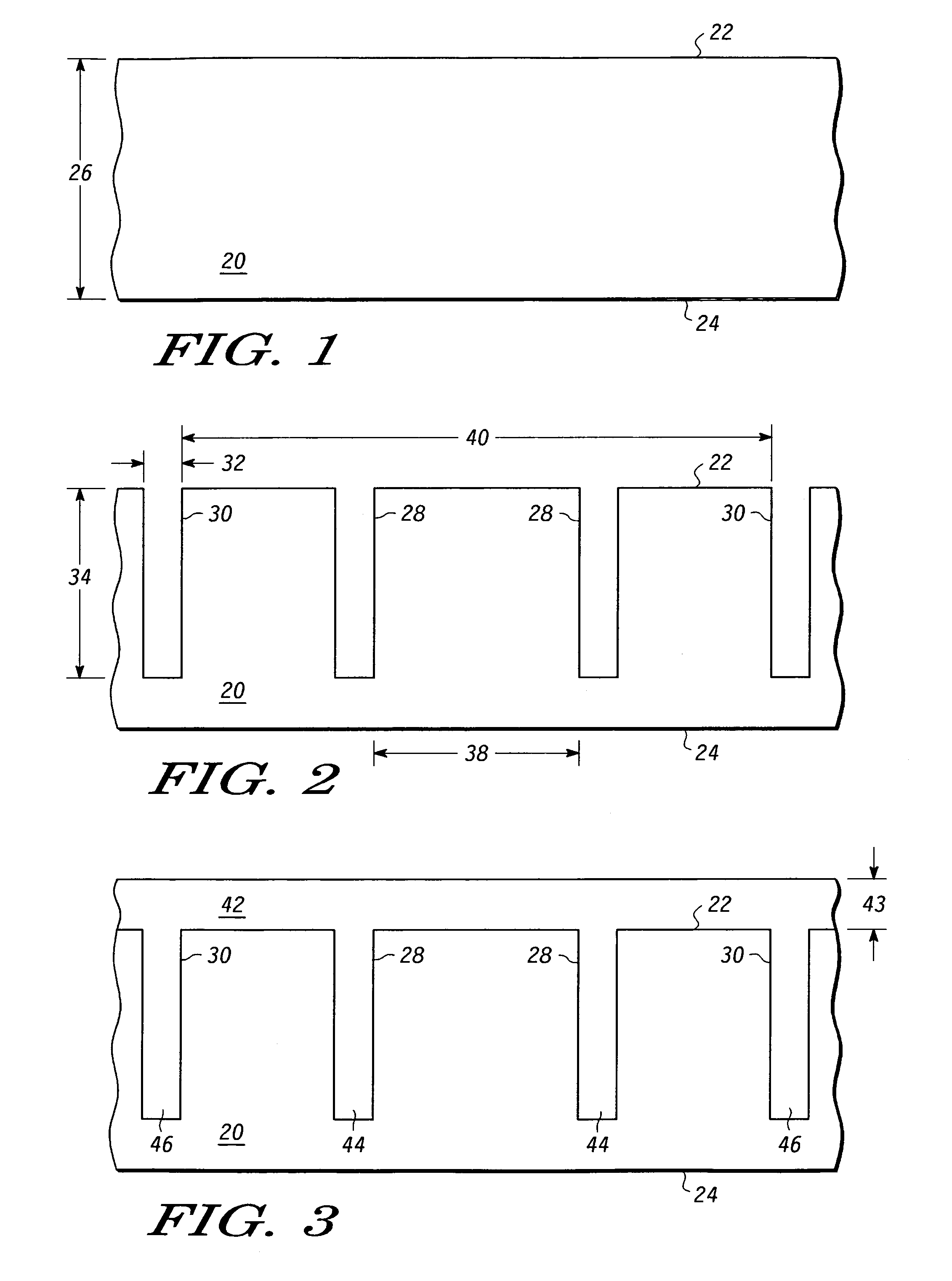

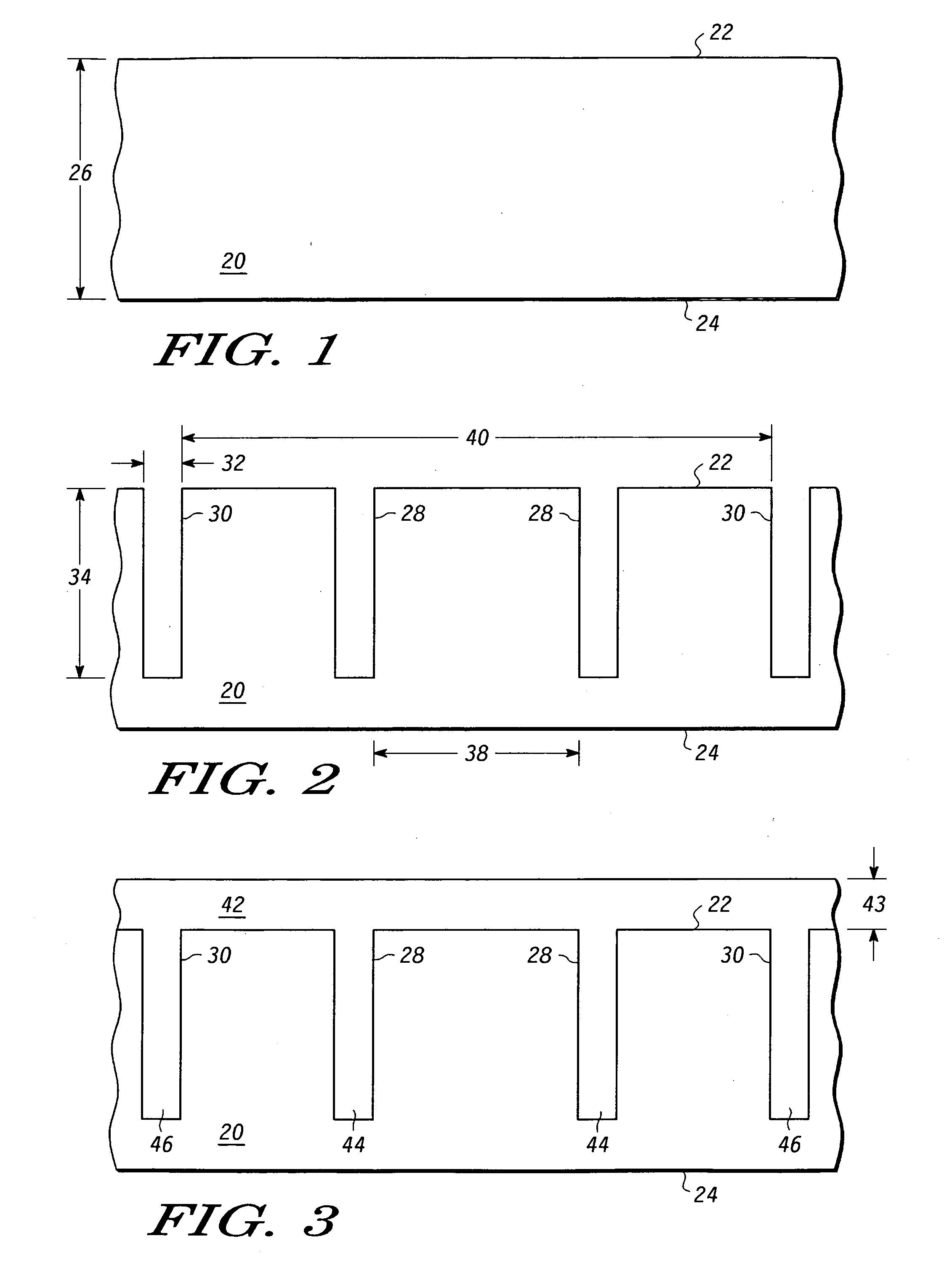

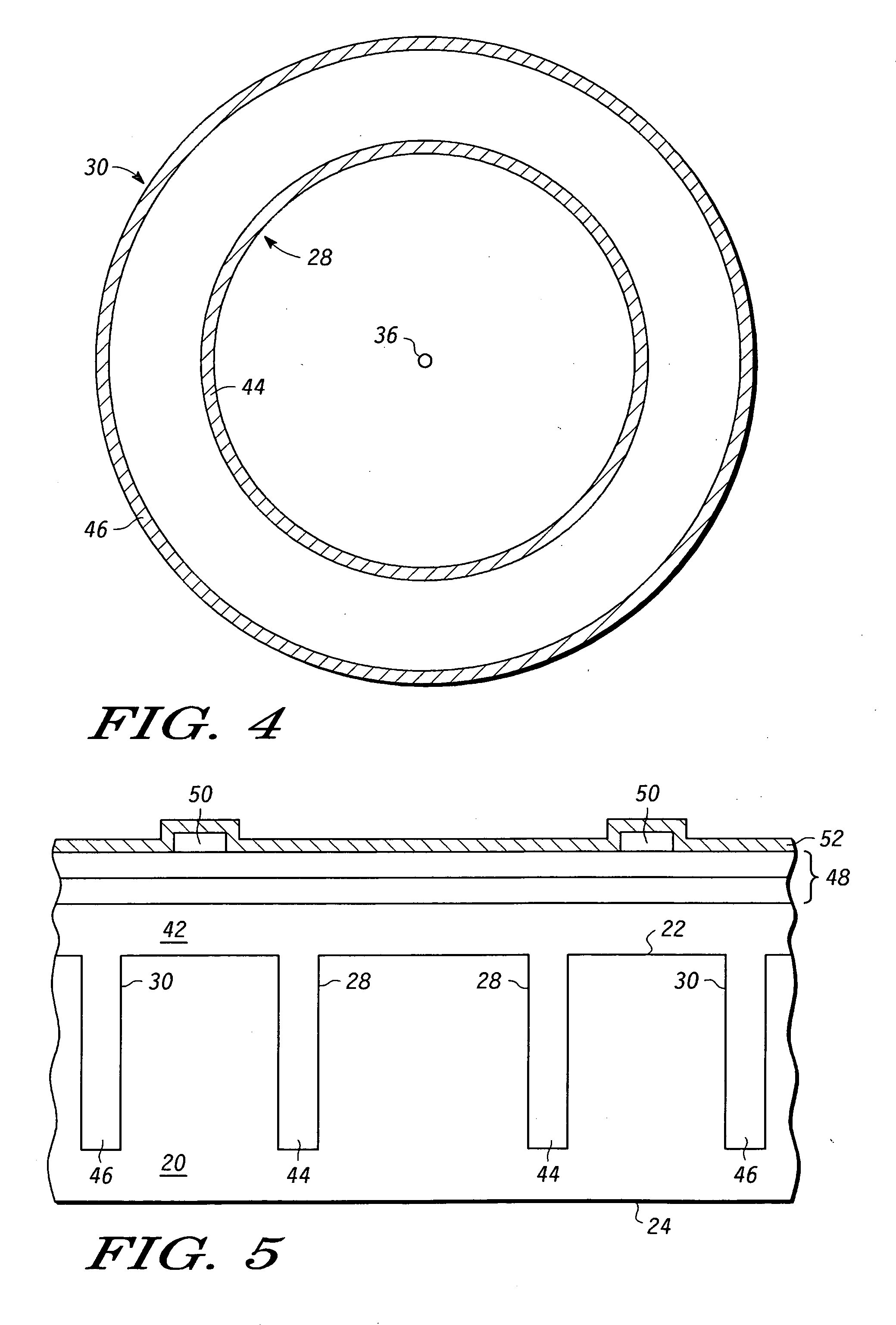

Method for forming microelectronic assembly

InactiveUS7425485B2Q-factor can be increasedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringInductor

A microelectronic assembly and a method for forming the same are provided. The method includes forming first and second lateral etch stop walls in a semiconductor substrate having first and second opposing surfaces. An inductor is formed on the first surface of the semiconductor substrate and a hole is formed through the second surface of the substrate to expose the substrate between the first and second lateral etch stop walls. The substrate is isotropically etched between the first and second lateral etch stop walls through the etch hole to create a cavity within the semiconductor substrate. A sealing layer is formed over the etch hole to seal the cavity.

Owner:NORTH STAR INNOVATIONS

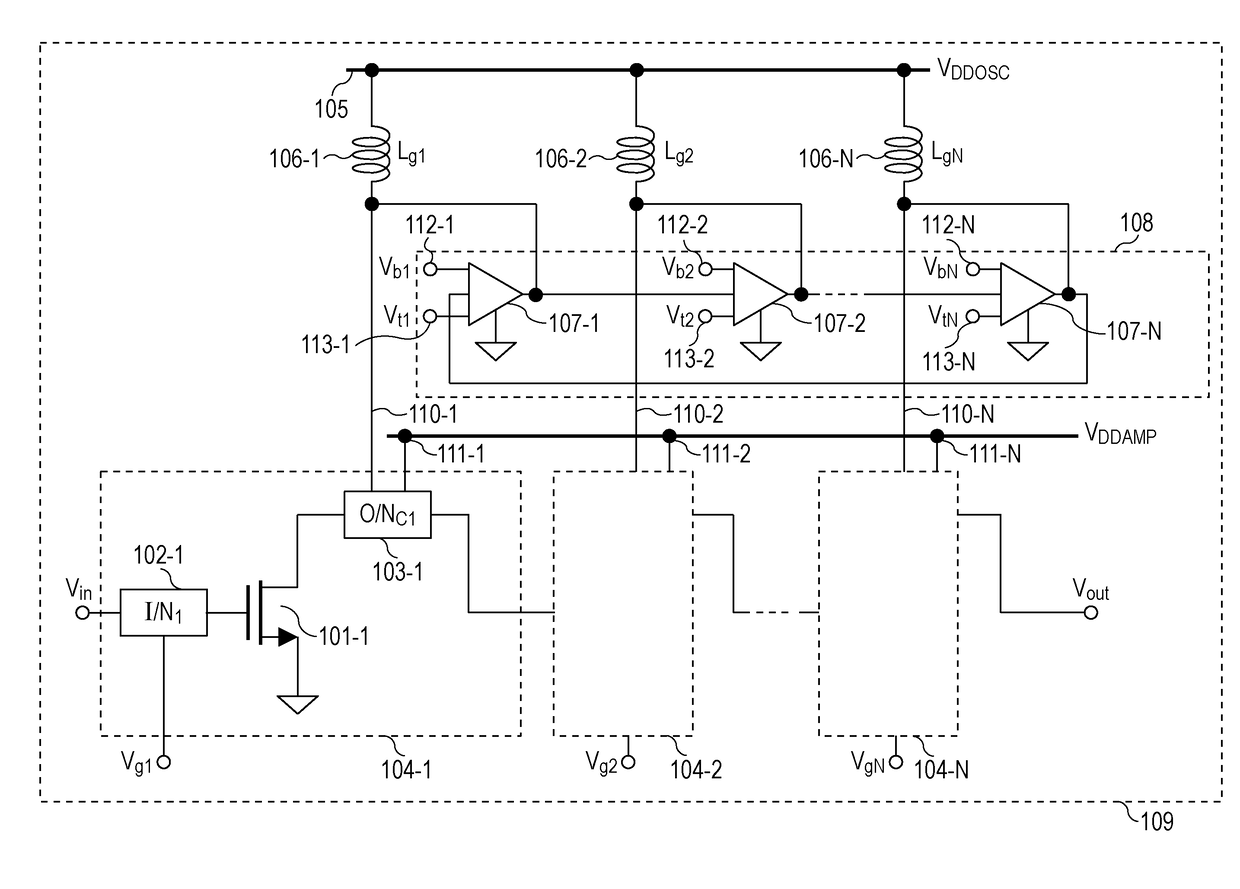

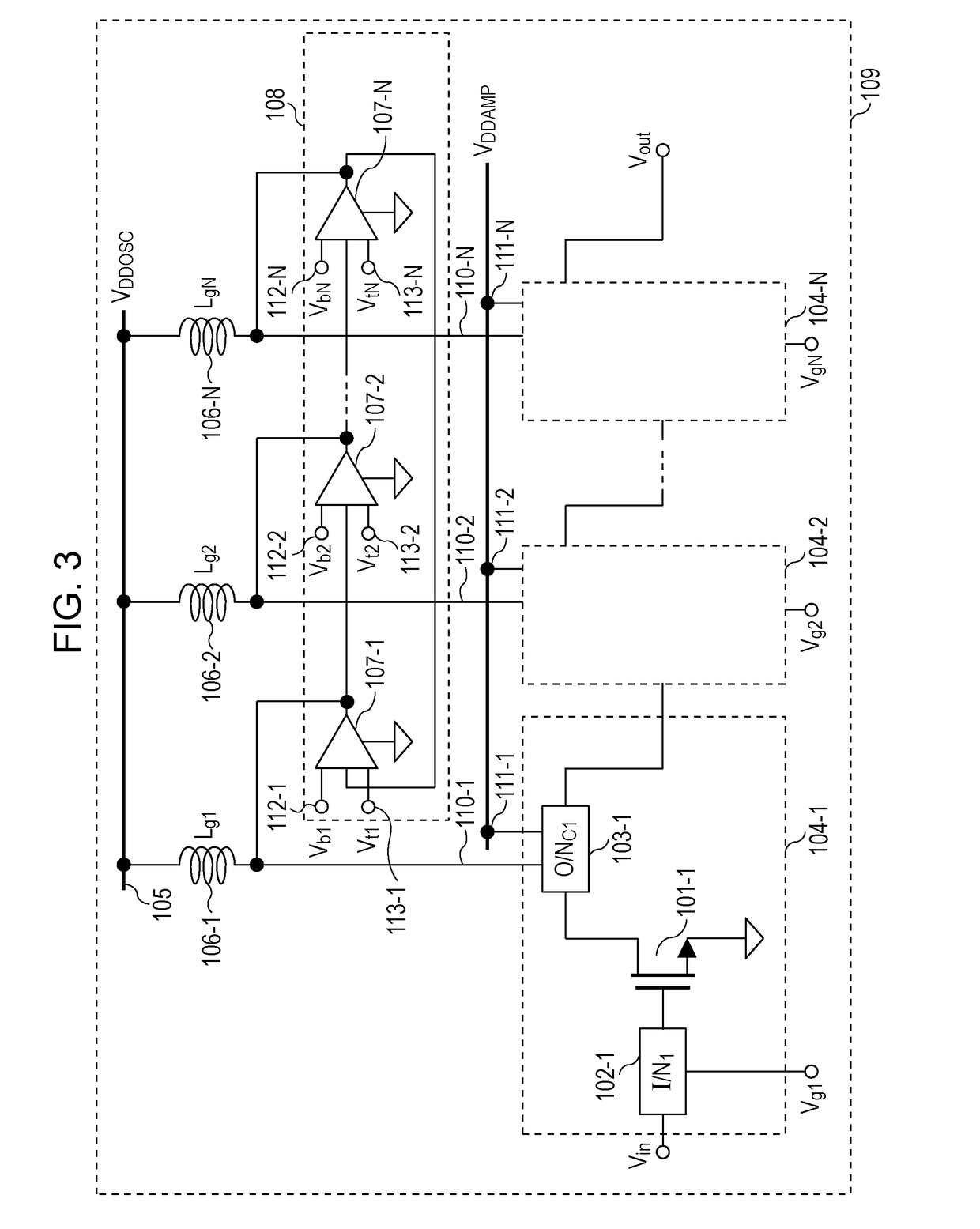

Power amplifier circuit

InactiveUS20170222604A1Increase power gainQ-factor can be increasedAmplifier modifications to reduce temperature/voltage variationPower amplifiersAudio power amplifierEngineering

A power amplifier circuit includes N (N is an integer equal to or greater than 2) power amplifier circuit cores, which in operation, amplify power of an input signal, N inductors, which in operation, are connected to the N power amplifier circuit cores, and ring-oscillator-type transconductance (gm) generation circuitry, which in operation, generates transconductance (gm) for compensating power loss of the N inductors.

Owner:PANASONIC CORP

MOS varactor and fabricating method of the same

ActiveUS7989868B2Reduced series resistanceQ-factor can be increasedTransistorSolid-state devicesElectrical resistance and conductanceAND gate

A MOS varactor for use in circuits and elements of a millimeter-wave frequency band, which is capable of reducing series resistance and enhancing a Q-factor by using a plurality of island-like gates seated in a well region of a substrate and gate contacts directly over the gates, includes: gate insulating layers arranged at equal intervals in the form of a (n×m) matrix, and a gate electrode placed on the gate insulating layers in a well region of a substrate; a gate contact which contacts the gate electrode; a first metal wire, which is electrically connected to the gate contact; source / drain contacts arranged at equal intervals in a matrix to form apexes of a square centered at the gate electrode and contact a doping region except for the bottom of the gate insulating layers; and a second metal wire, which is electrically connected to the source / drain contacts.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

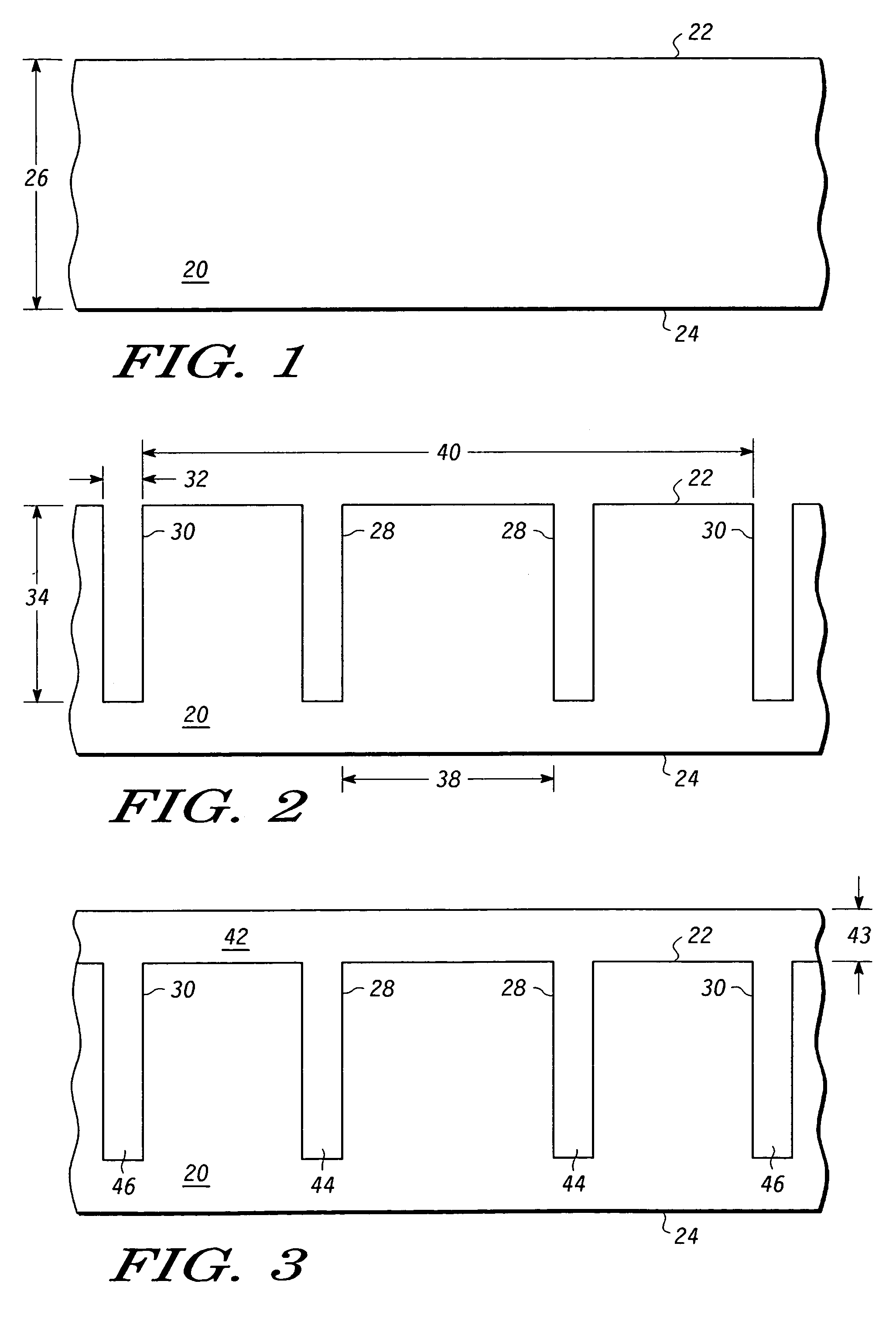

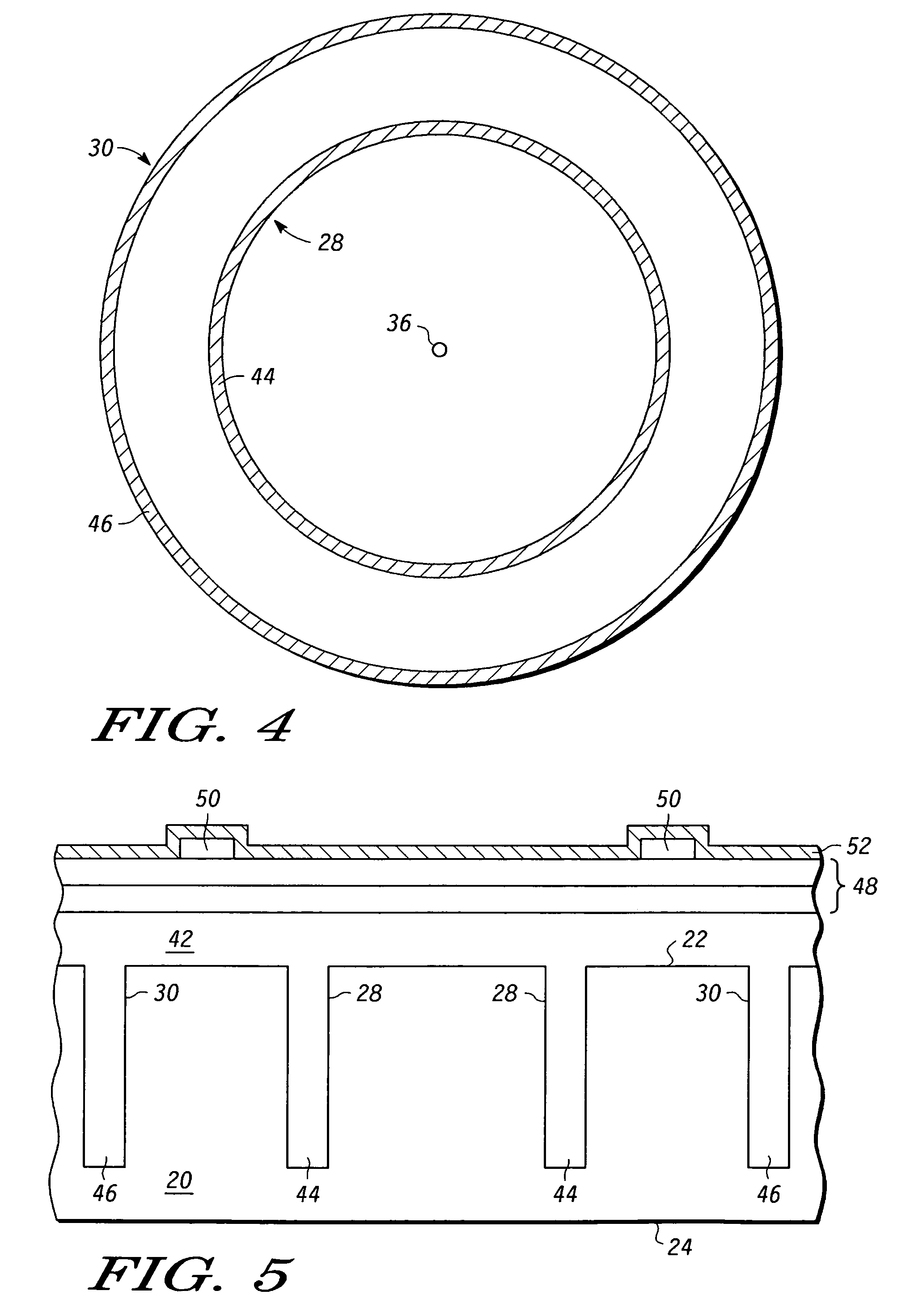

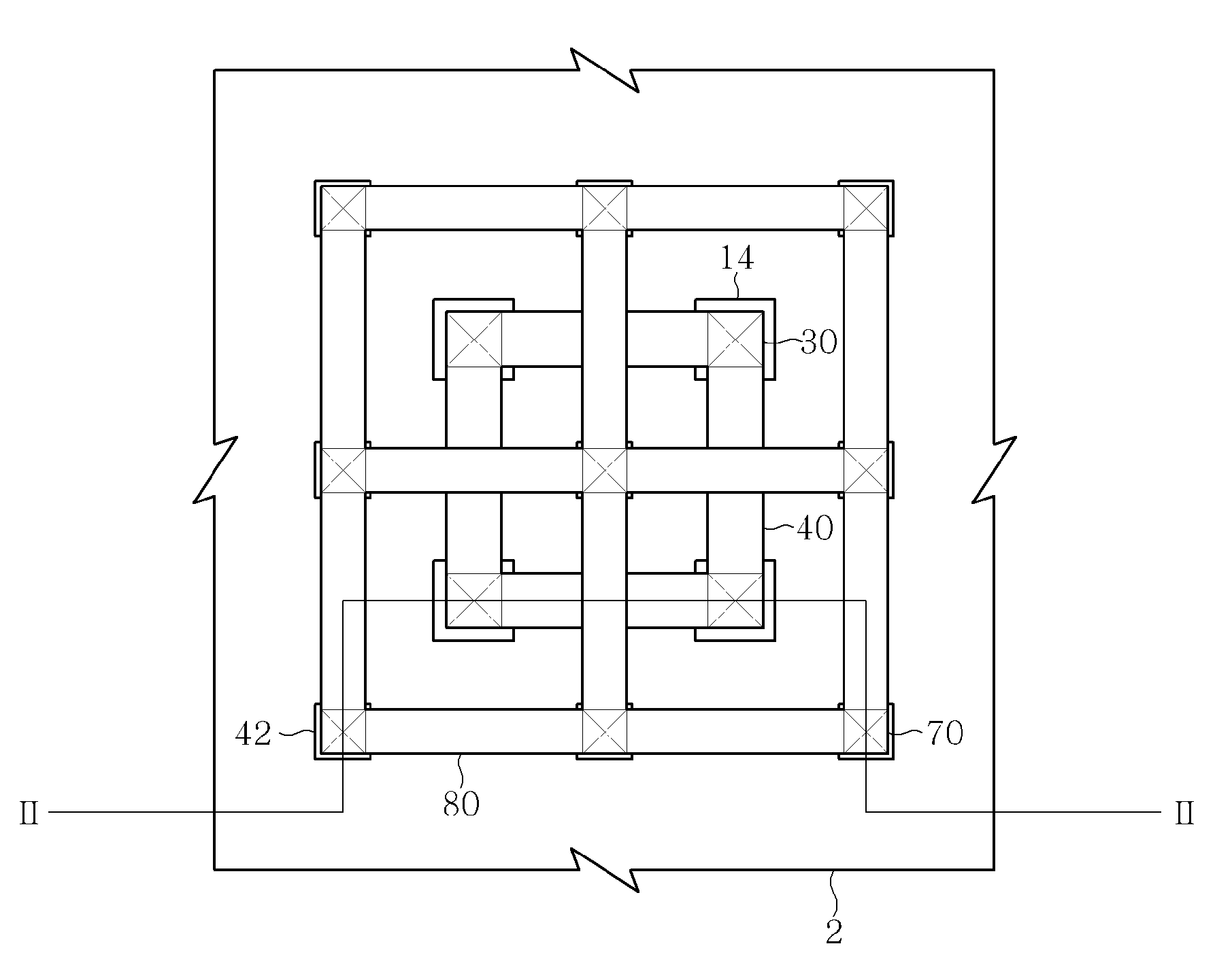

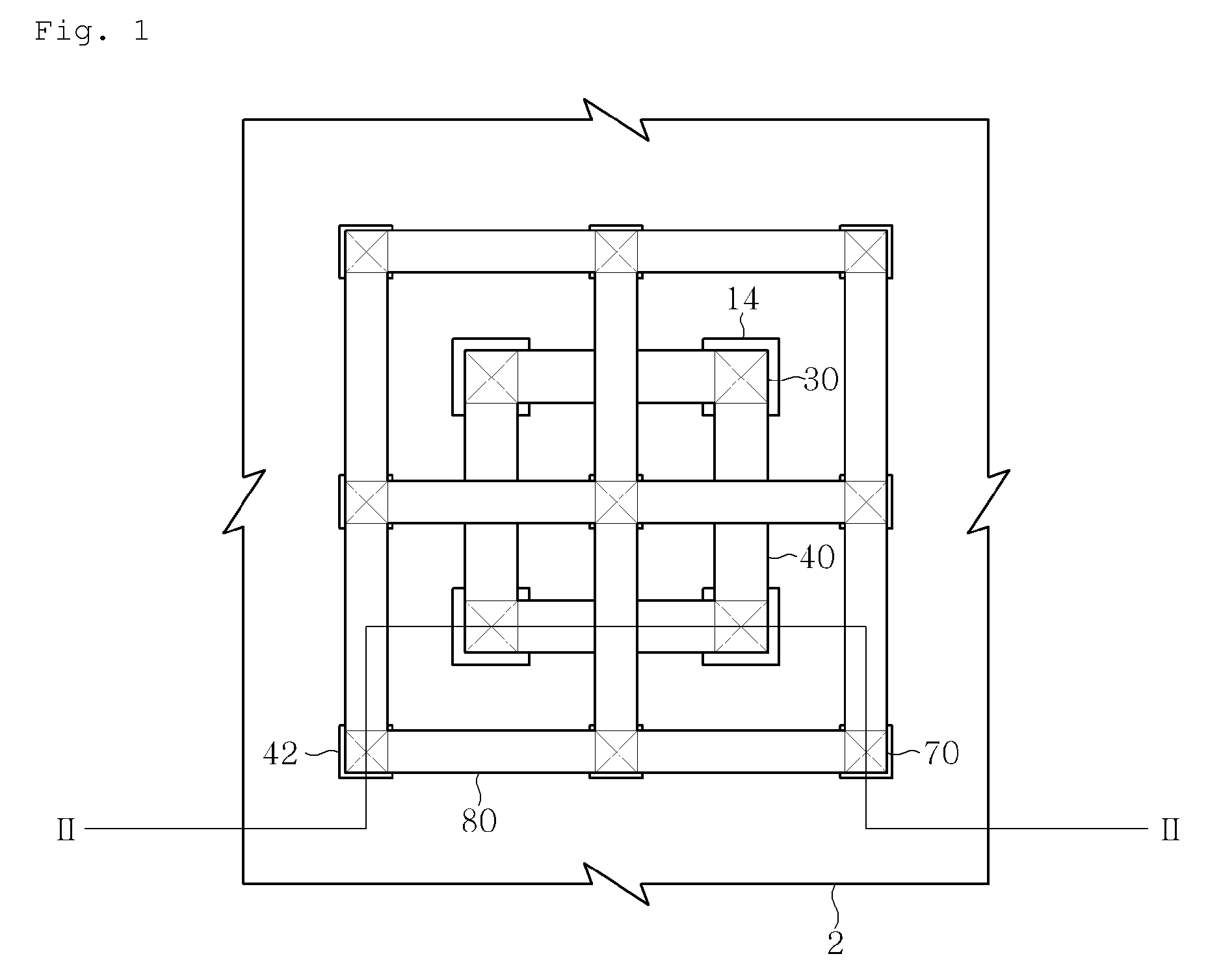

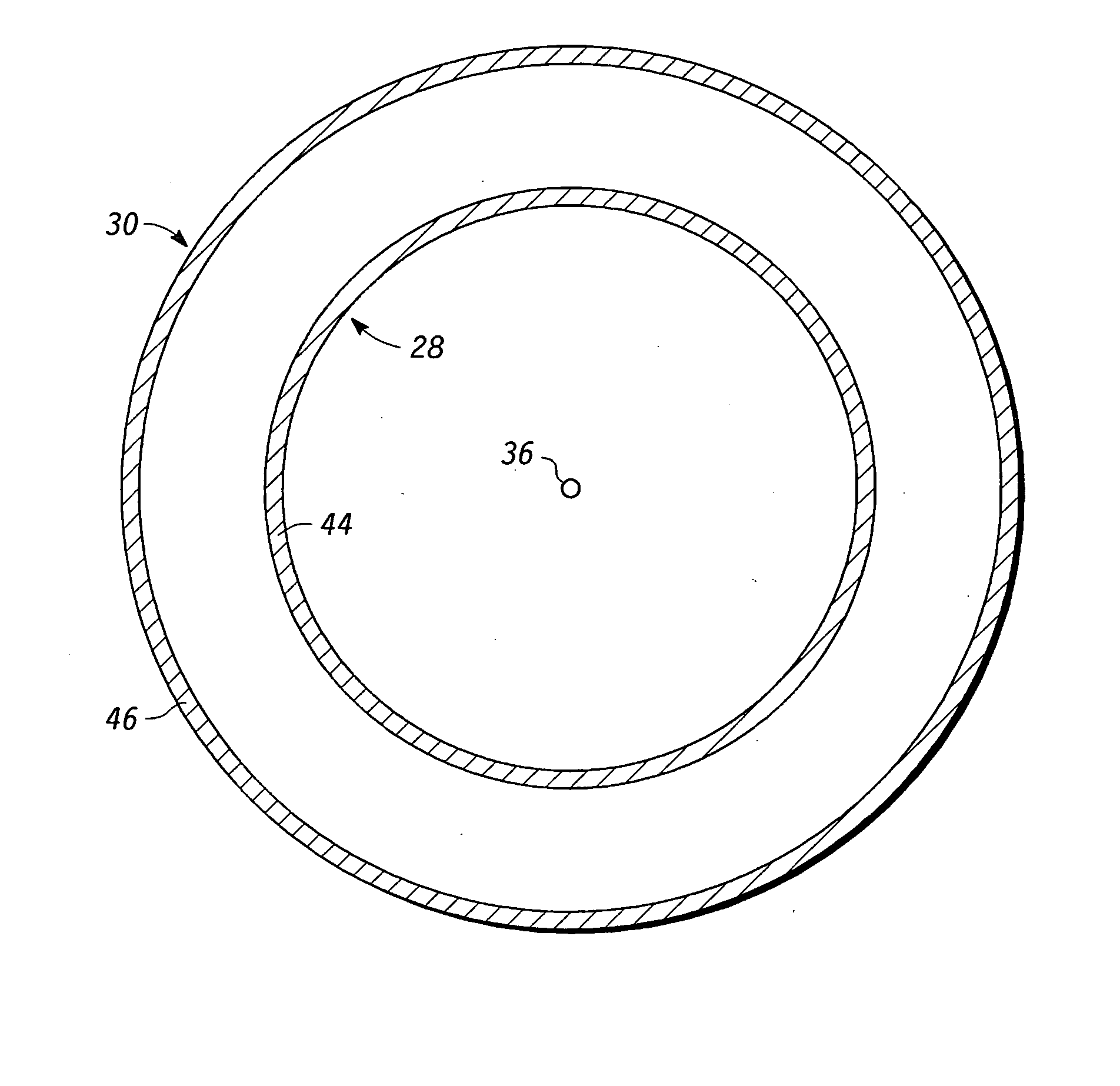

Microelectronic assembly and method for forming the same

InactiveUS20070075445A1Q-factor can be increasedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringInductor

According to one aspect of the present invention, a method is provided for forming a microelectronic assembly. The method comprises forming first and second trenches on a semiconductor substrate, filling the first and second trenches with an etch stop material, forming an inductor on the semiconductor substrate, forming an etch hole in at least one of the etch stop layer and the semiconductor substrate to expose the substrate between the first and second trenches, isotropically etching the substrate between the first and second trenches through the etch hole to create a cavity within the substrate, and forming a sealing layer over the etch hole to seal the cavity.

Owner:TAIWAN SEMICON MFG CO LTD

Ultra-low damping imaging mode related to scanning probe microscopy in liquid

InactiveUS8479309B2Ultra-low dampingHigh resolution imageNanosensorsScanning probe microscopyAtomic force microscopyHigh resolution imaging

Provided are methods and systems for high resolution imaging of a material immersed in liquid by scanning probe microscopy. The methods further relate to imaging a material submersed in liquid by tapping mode atomic force microscopy (AFM), wherein the AFM has a microfabricated AFM probe comprising a nanoneedle probe connected to a cantilever beam. The nanoneedle probe is immersed in the liquid, and the rest of the AFM probe, including the cantilever beam to which the nanoneedle probe is attached, remains outside the liquid. The cantilever is oscillated and the nanoneedle probe tip taps the material to image the material immersed in liquid. In an aspect, the material is supported on a shaped substrate to provide a spatially-varying immersion depth with specially defined regions for imaging by any of the methods and systems of the present invention.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com