Patents

Literature

396results about How to "Reduced shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

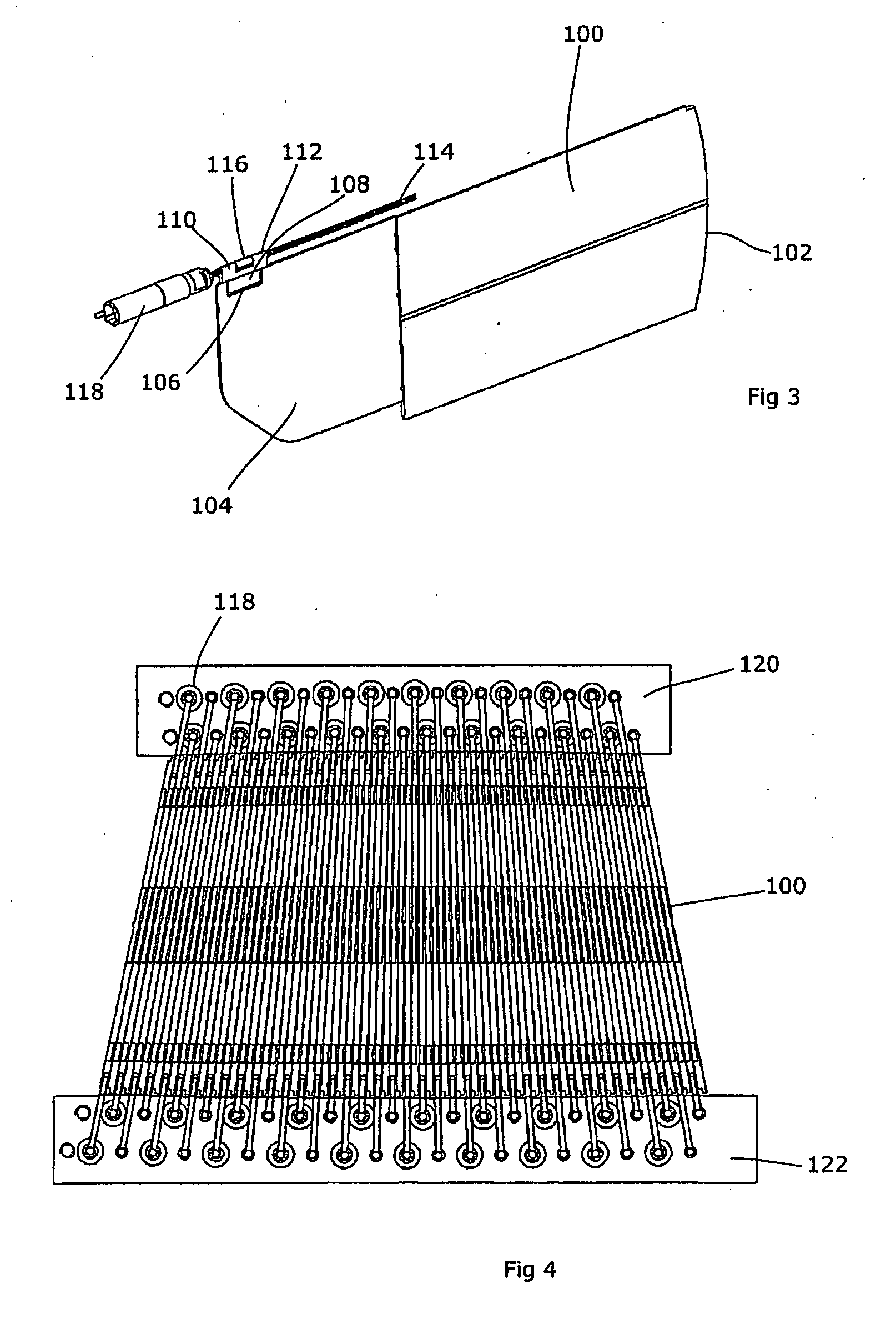

Target density imaging using discrete photon counting to produce high-resolution radiographic images

InactiveUS7166844B1Avoid flowRapid, non-invasiveMaterial analysis by optical meansMachines/enginesParallaxImage resolution

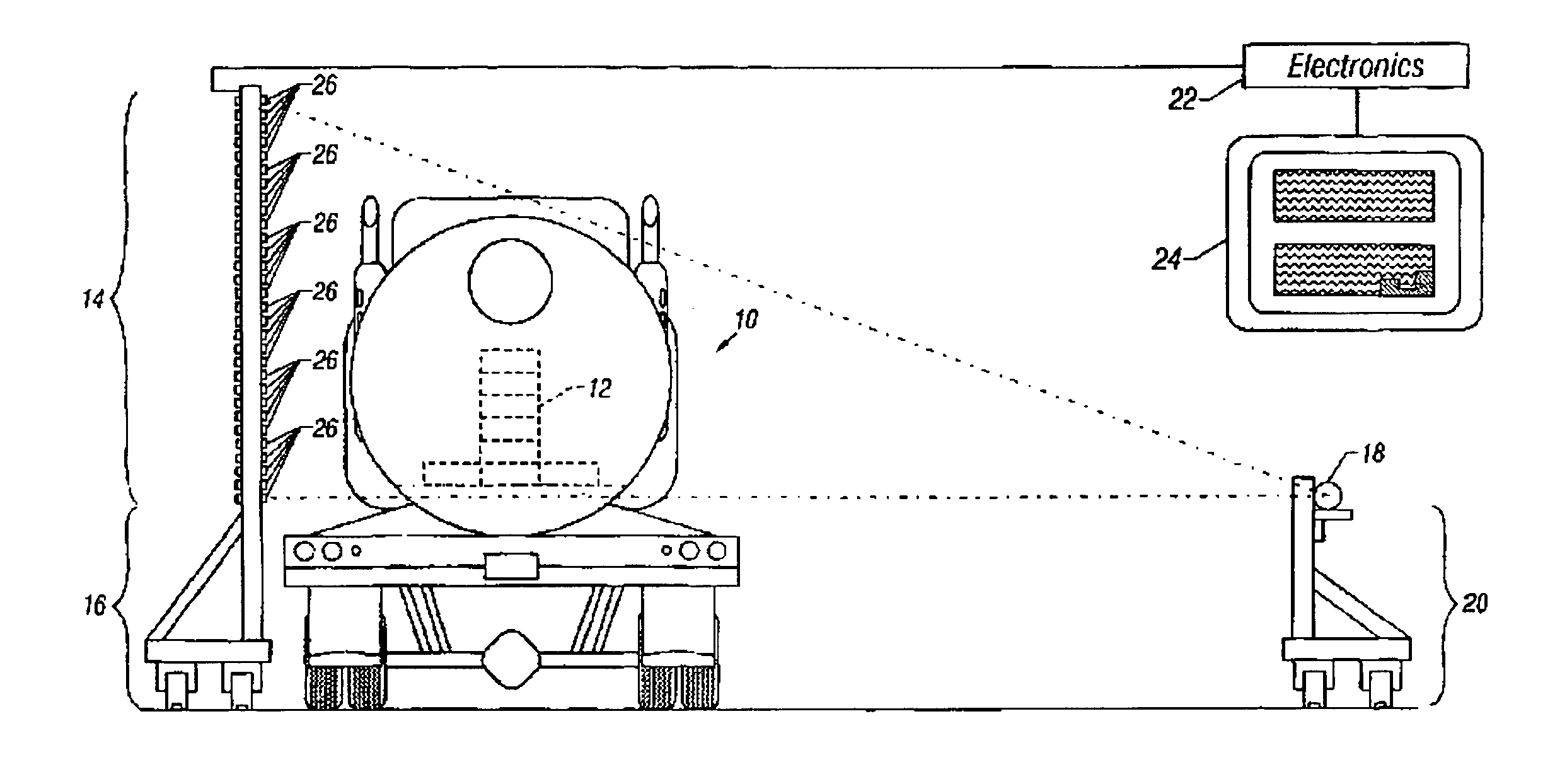

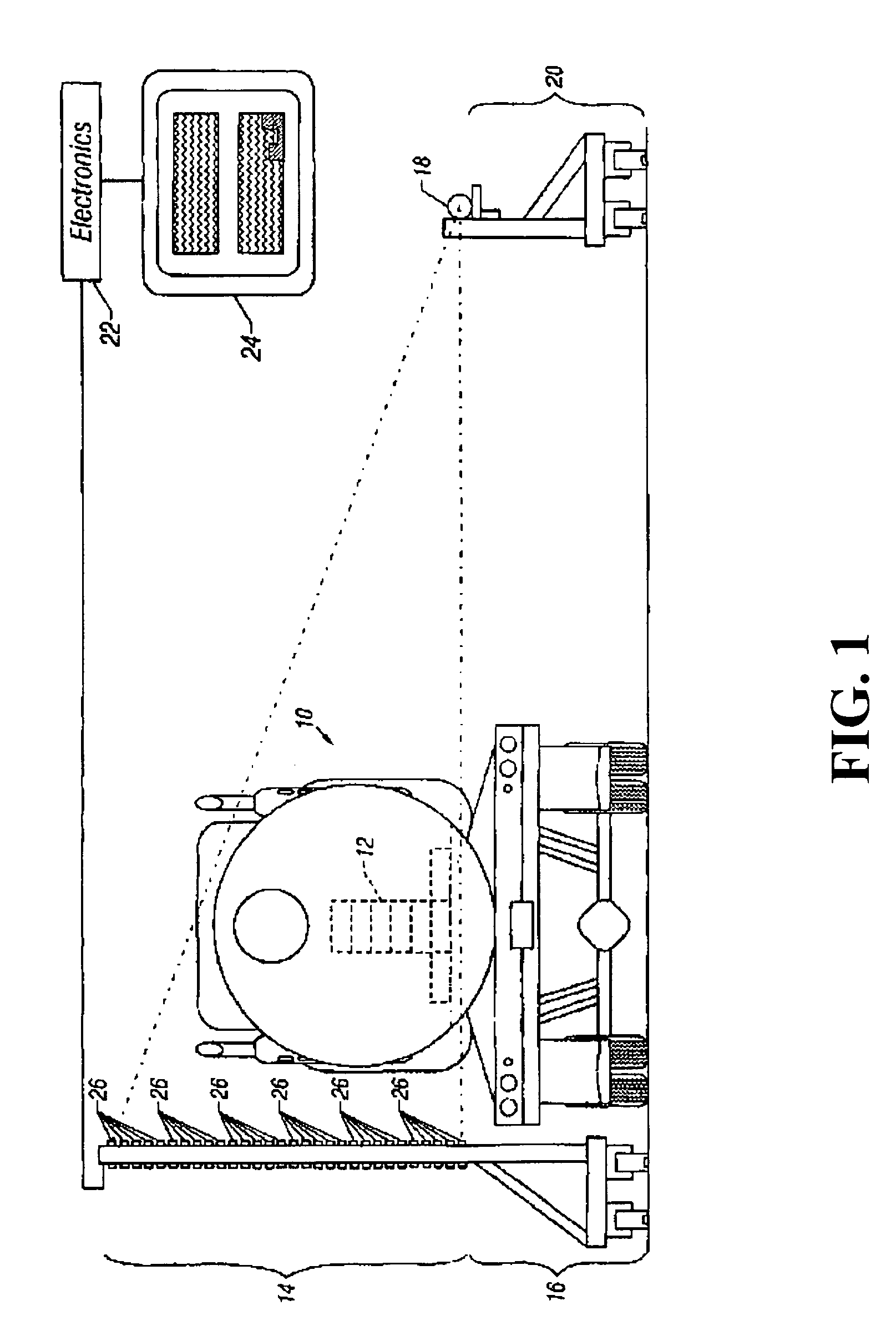

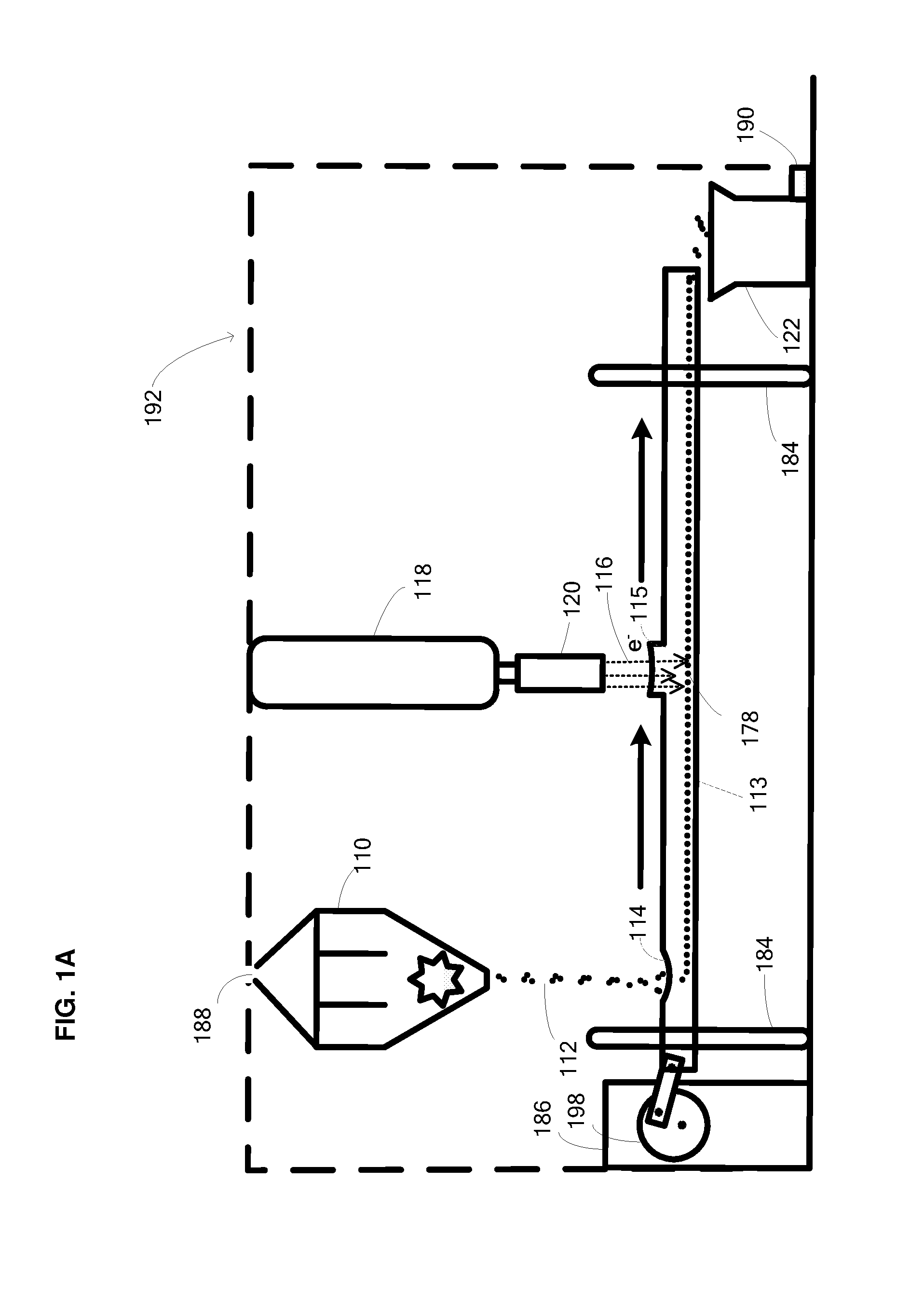

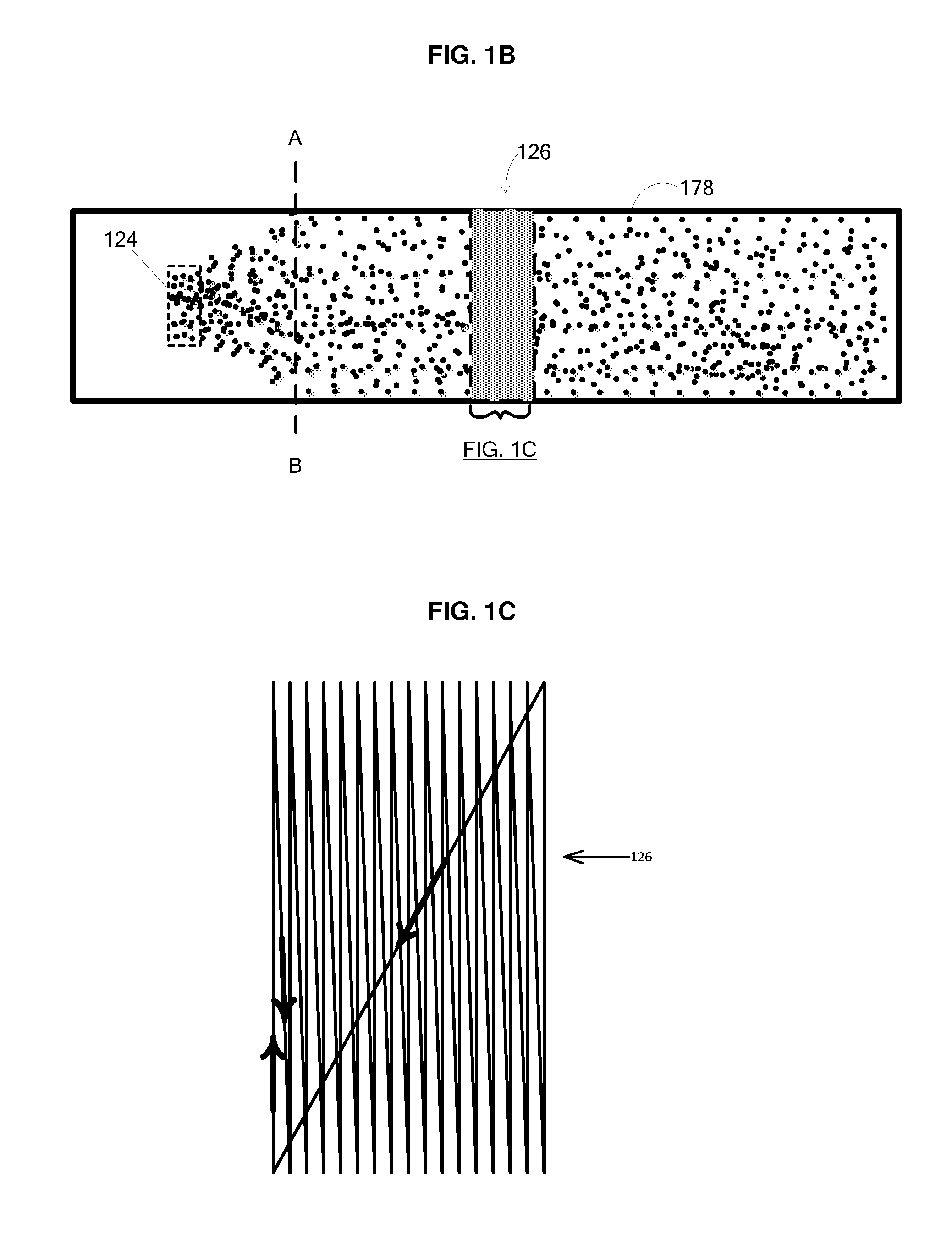

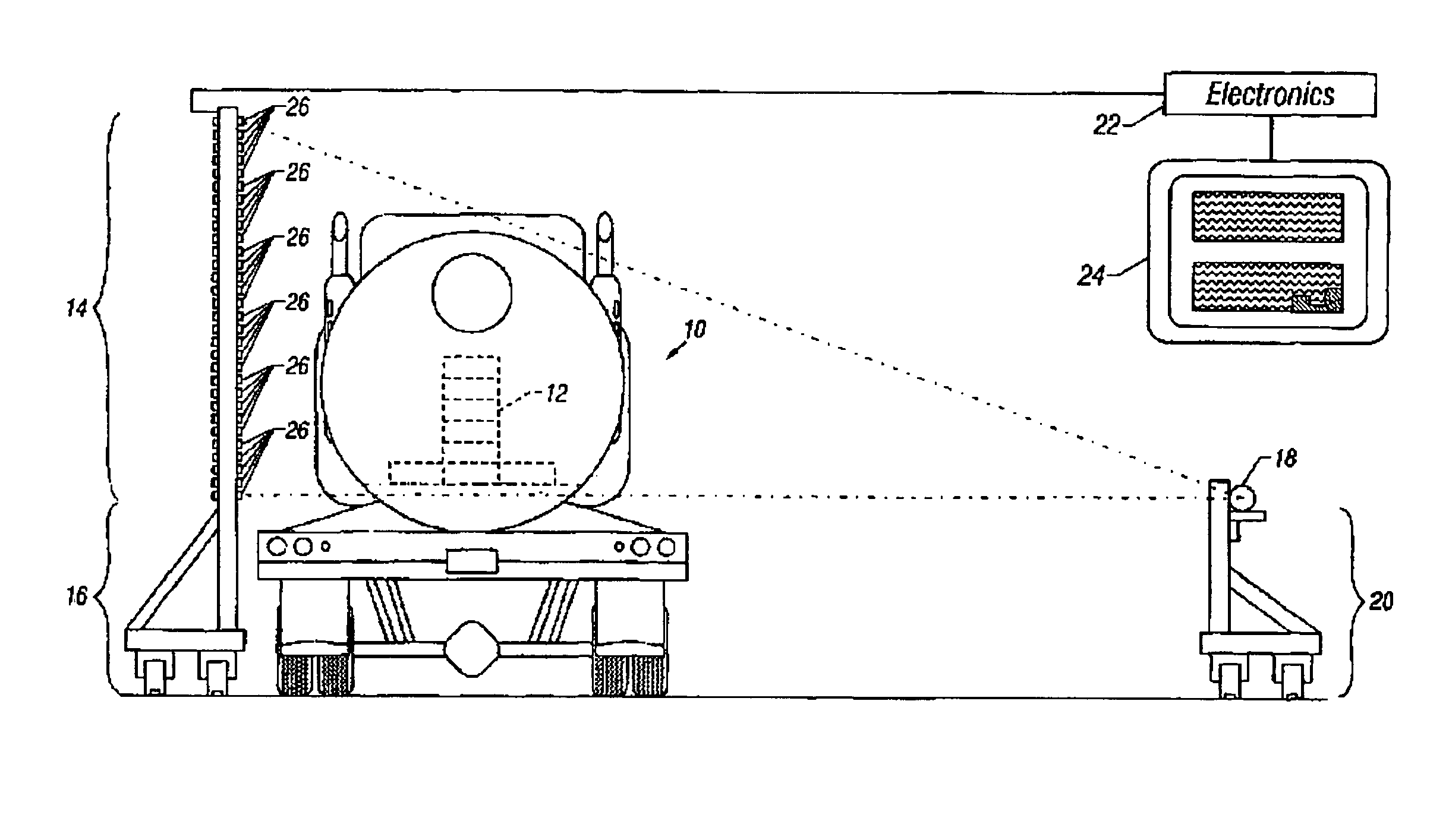

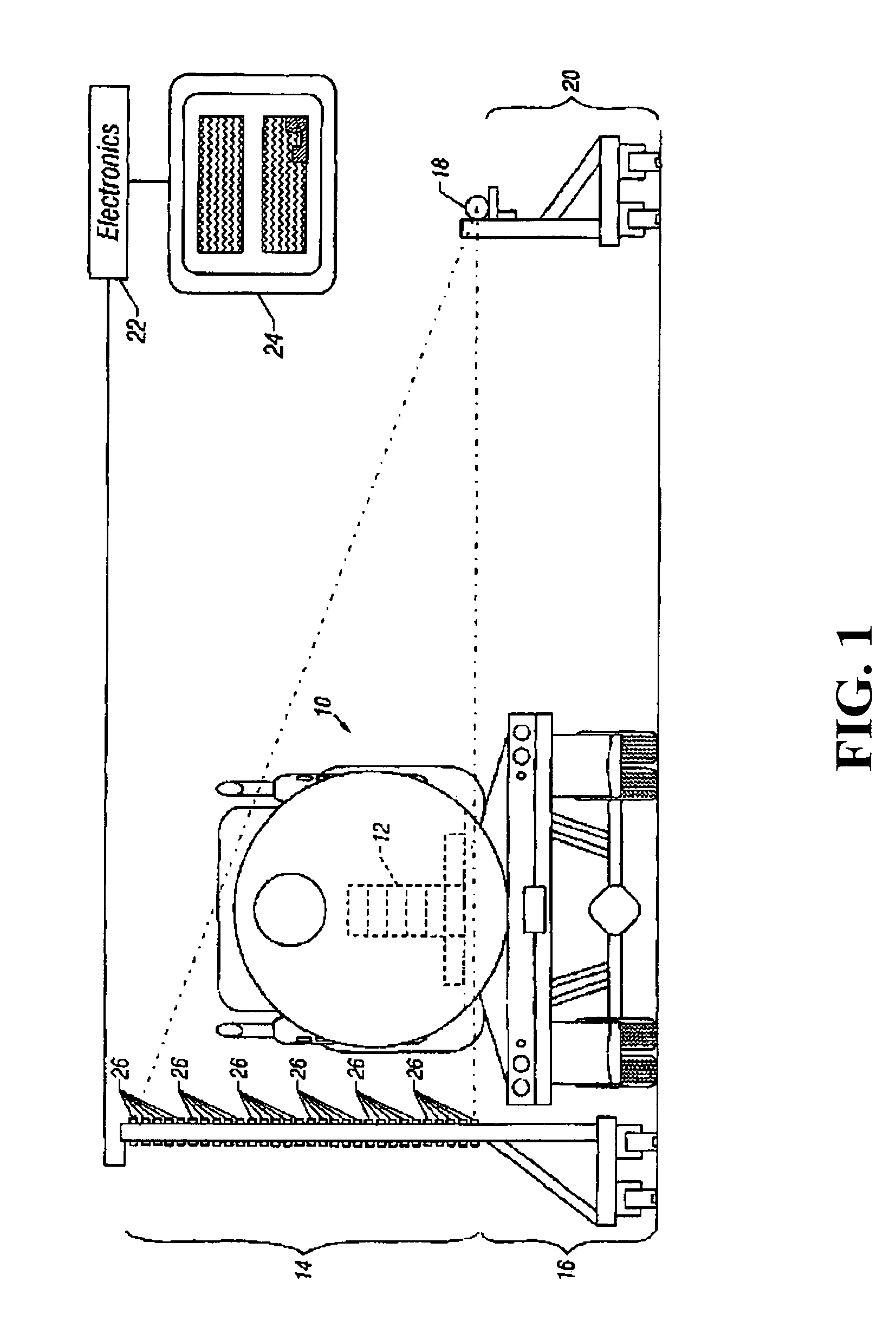

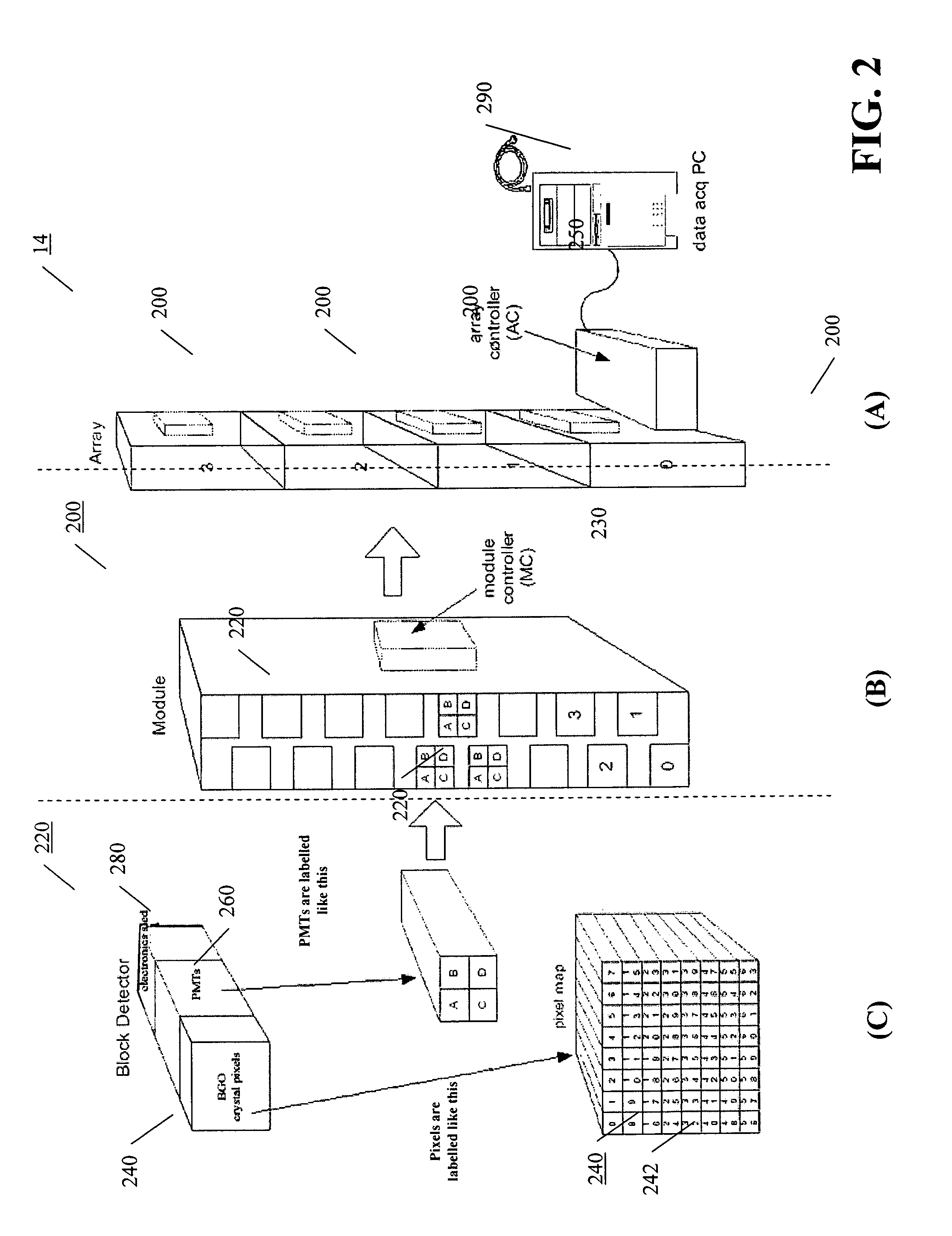

The present invention relates to a system and method for using discrete photon counting to produce transmission radiographic images of a target object with improved spatial resolution and high system sensitivity. The system comprises a radiation source for directing photons at a target object and a detector array for receiving photons passing through the target in order to provide an image of the target density. The detector array is configured to enhance spatial resolution and maintain high system sensitivity. To correct the parallax effect that may be induced by such configuration of the detector array, a process can be computer implemented or program coded to parallax correction.

Owner:SCI APPL INT CORP

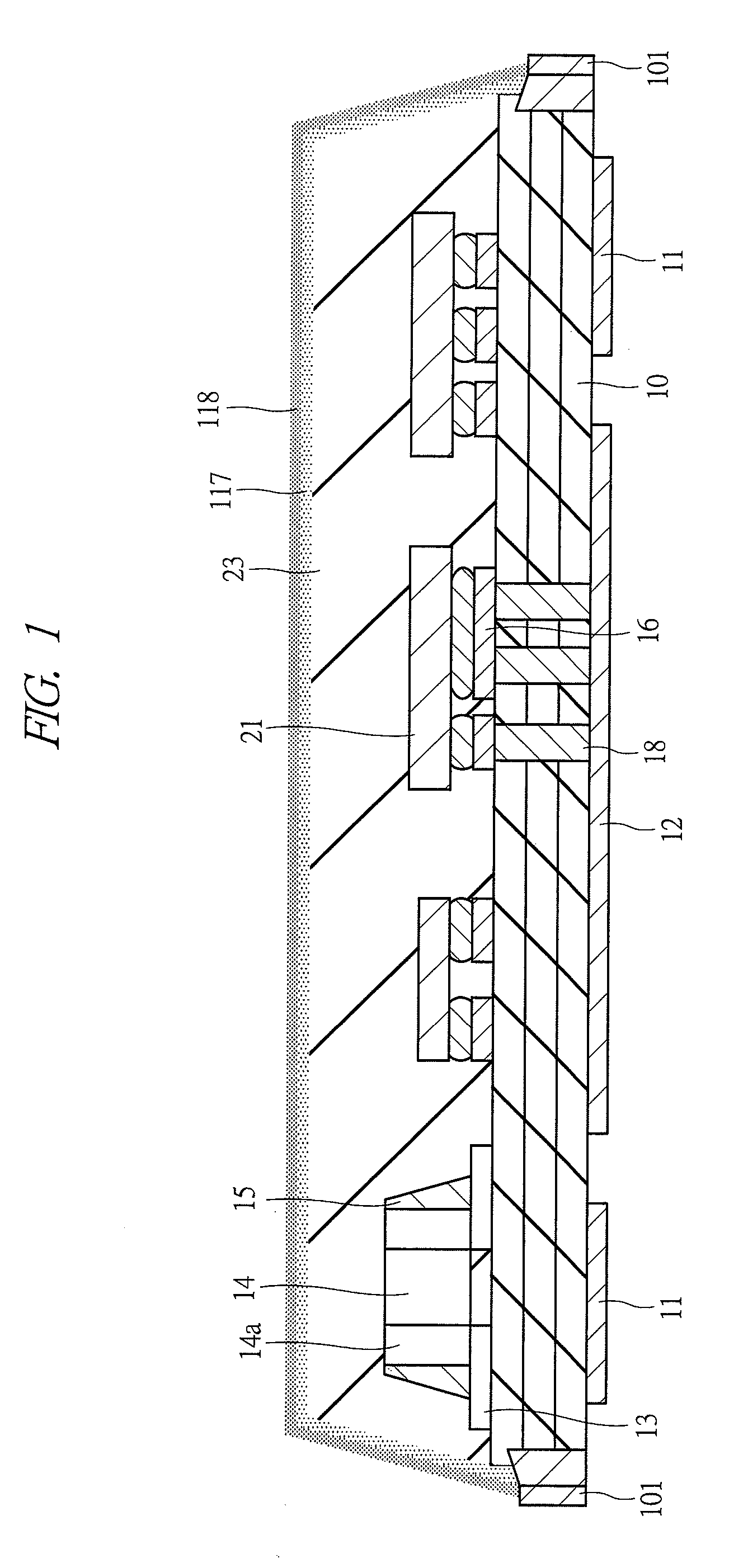

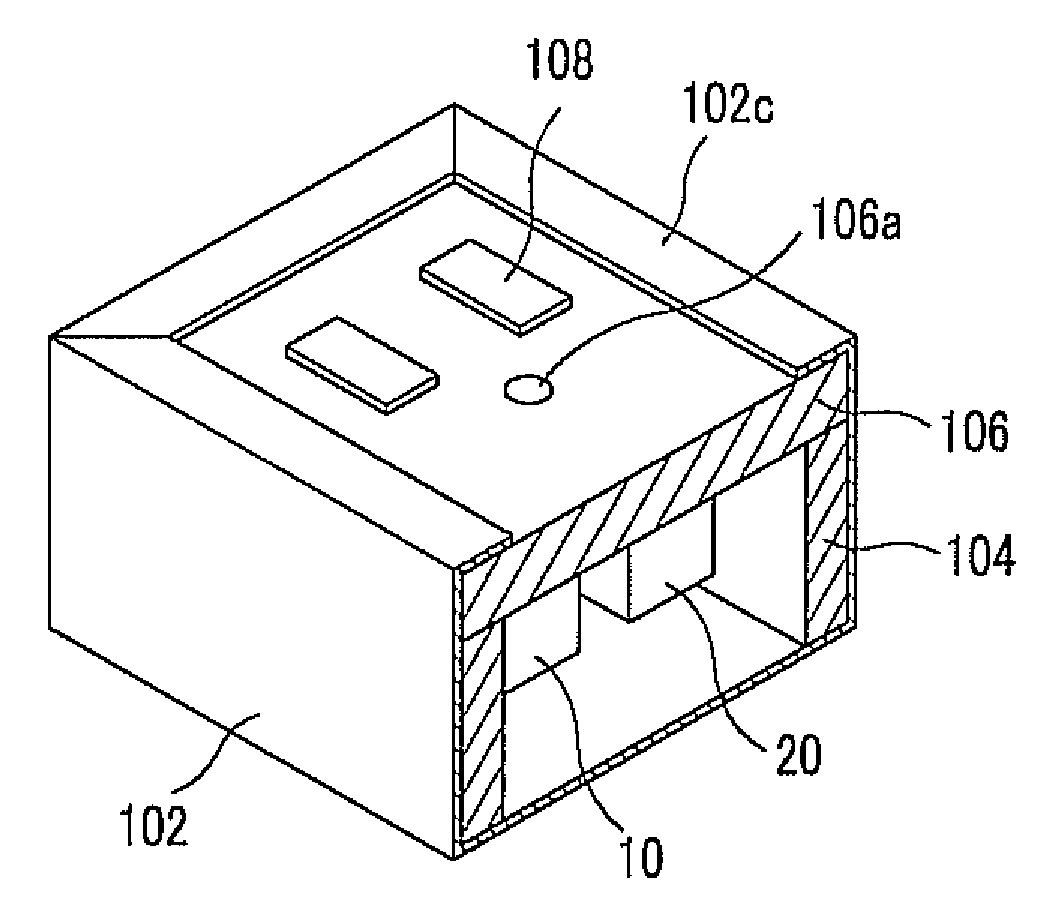

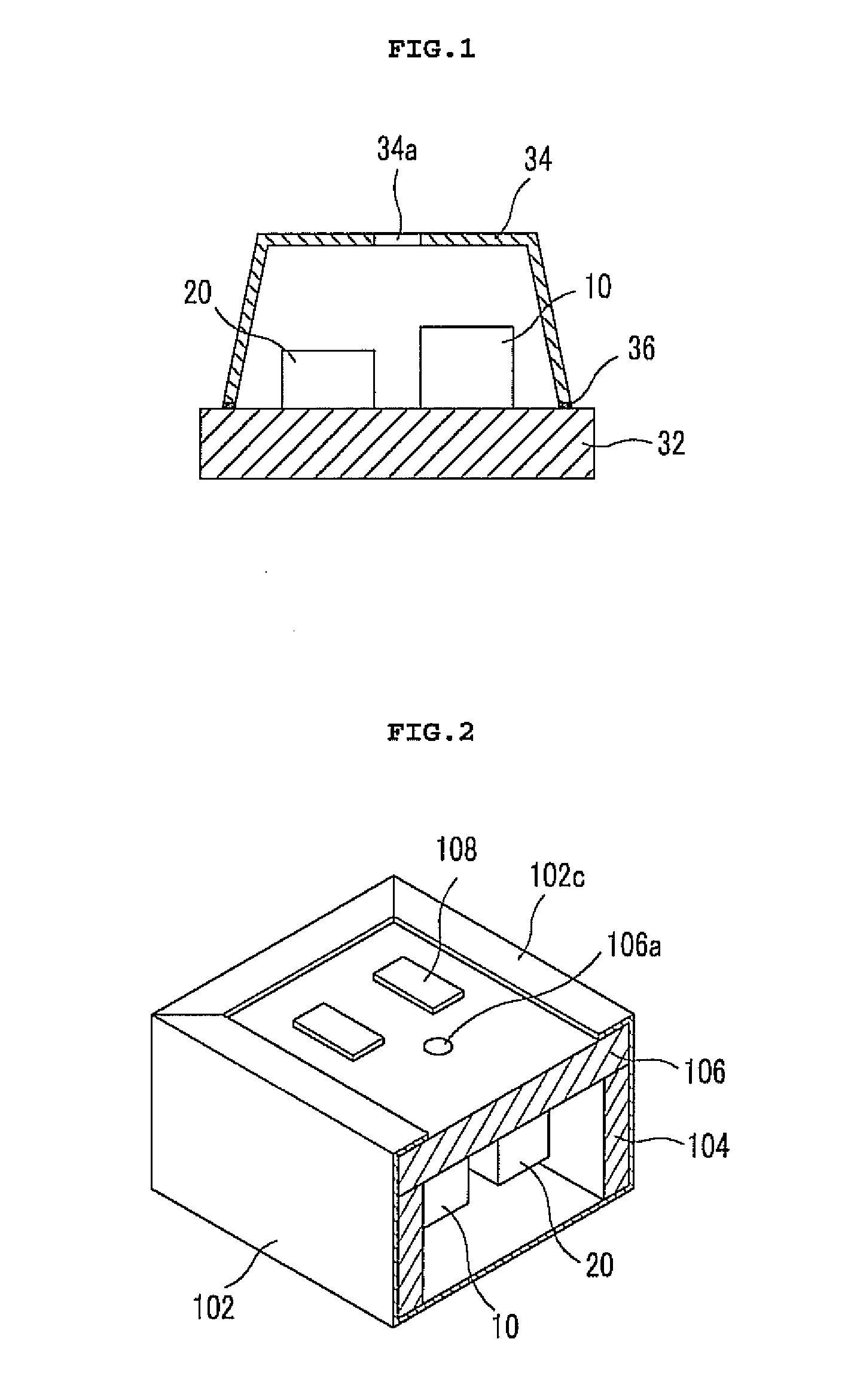

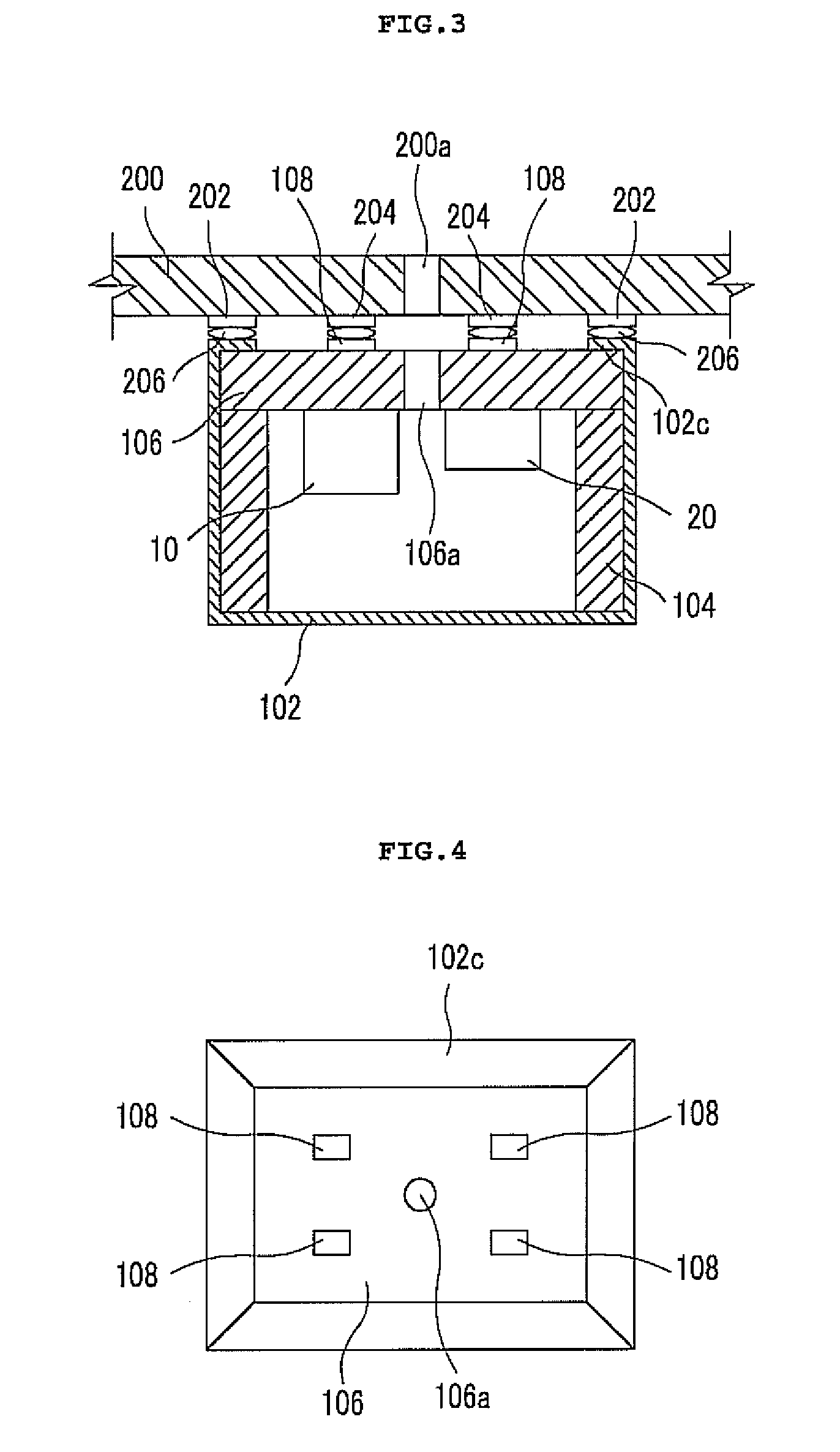

Shielded electronic components and method of manufacturing the same

InactiveUS20100172116A1Improve reliabilityImprove adhesionPrinted circuit assemblingMagnetic/electric field screeningPre treatmentNickel

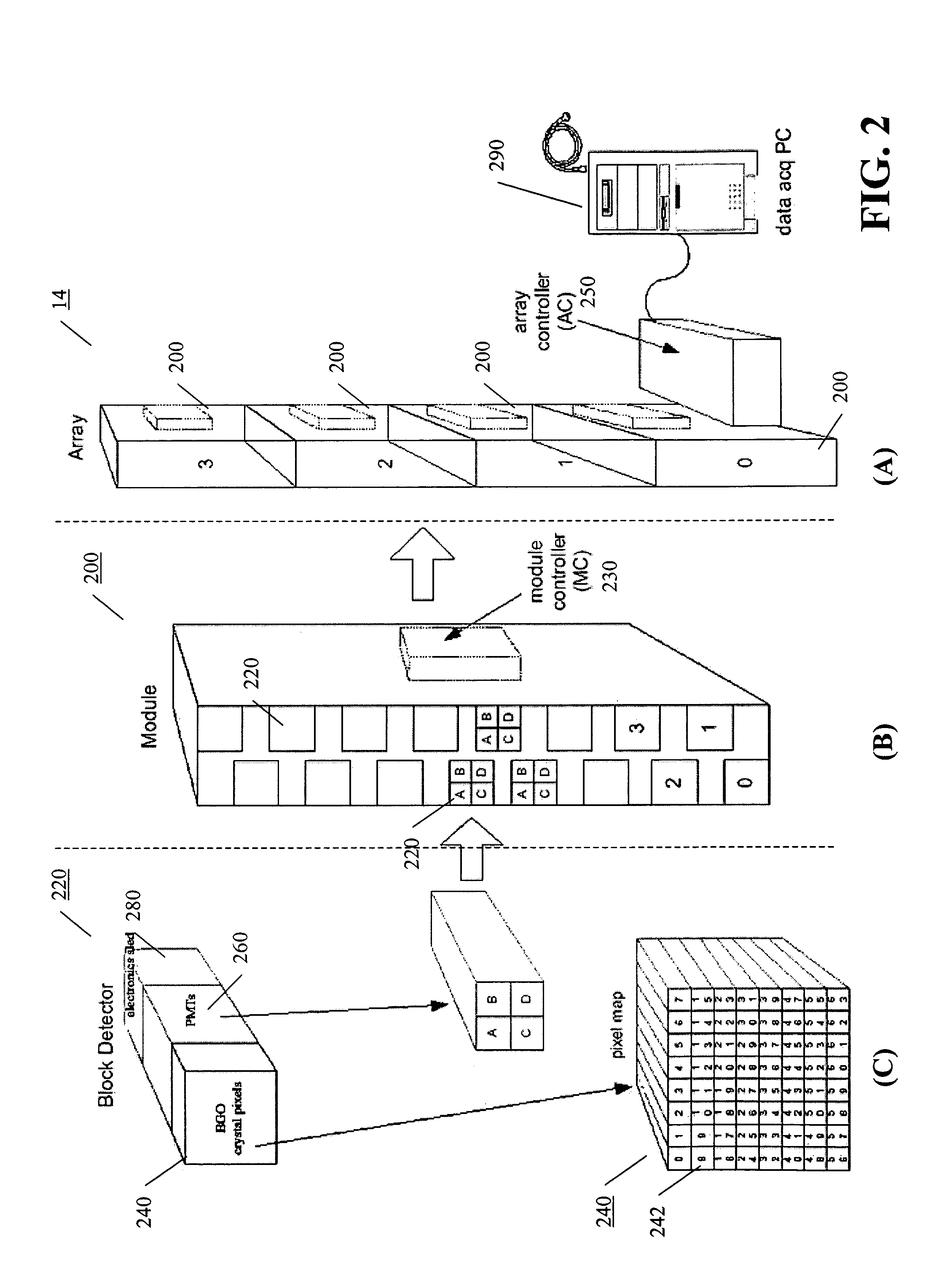

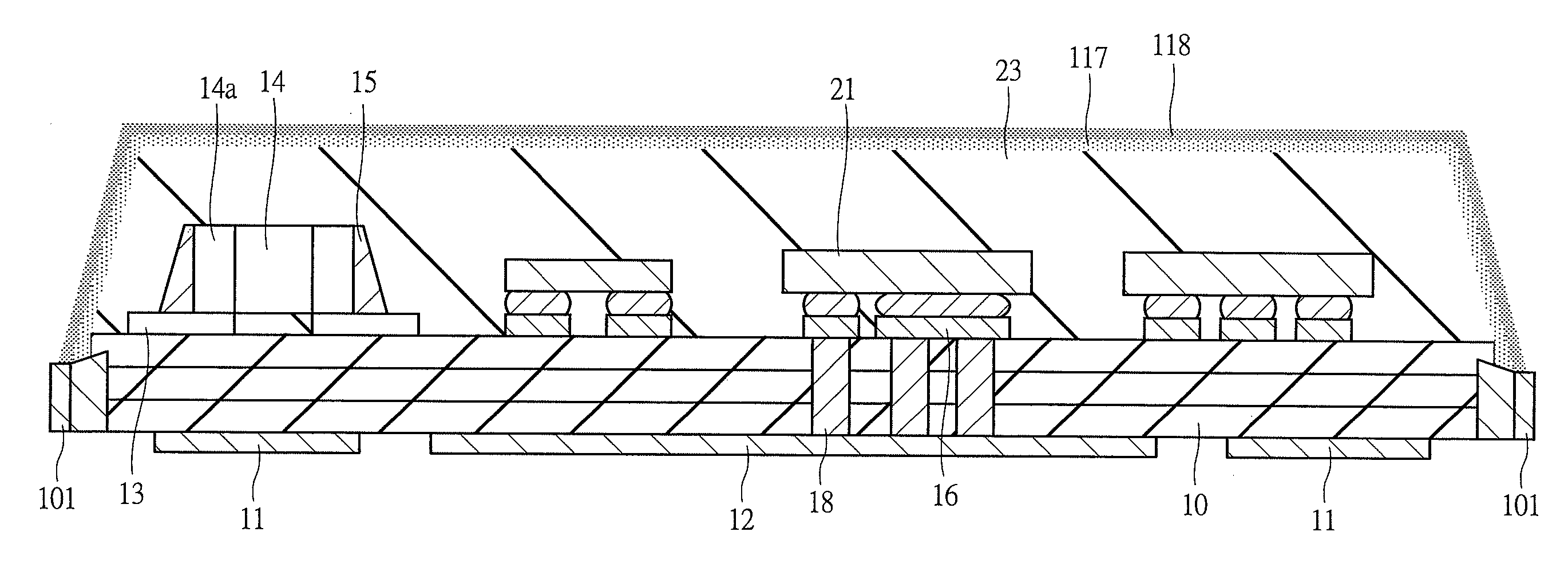

A shielded electronic component including a wiring board, at least one semiconductor chip mounted on a main surface of the wiring board, a sealant which seals the whole of an upper surface of the wiring board, and a nickel (Ni) plating film formed on an upper surface of the sealant is provided. The Ni plating film is formed on a palladium (Pd) pretreatment layer formed on the upper surface of the sealant with using high-pressure CO2 in a state of protecting a back surface of the wiring board, and is electrically connected with an end portion of a ground wiring layer of the wiring board or a ground (GND) connection through-hole connected with the end portion of the ground wiring layer.

Owner:RENESAS ELECTRONICS CORP

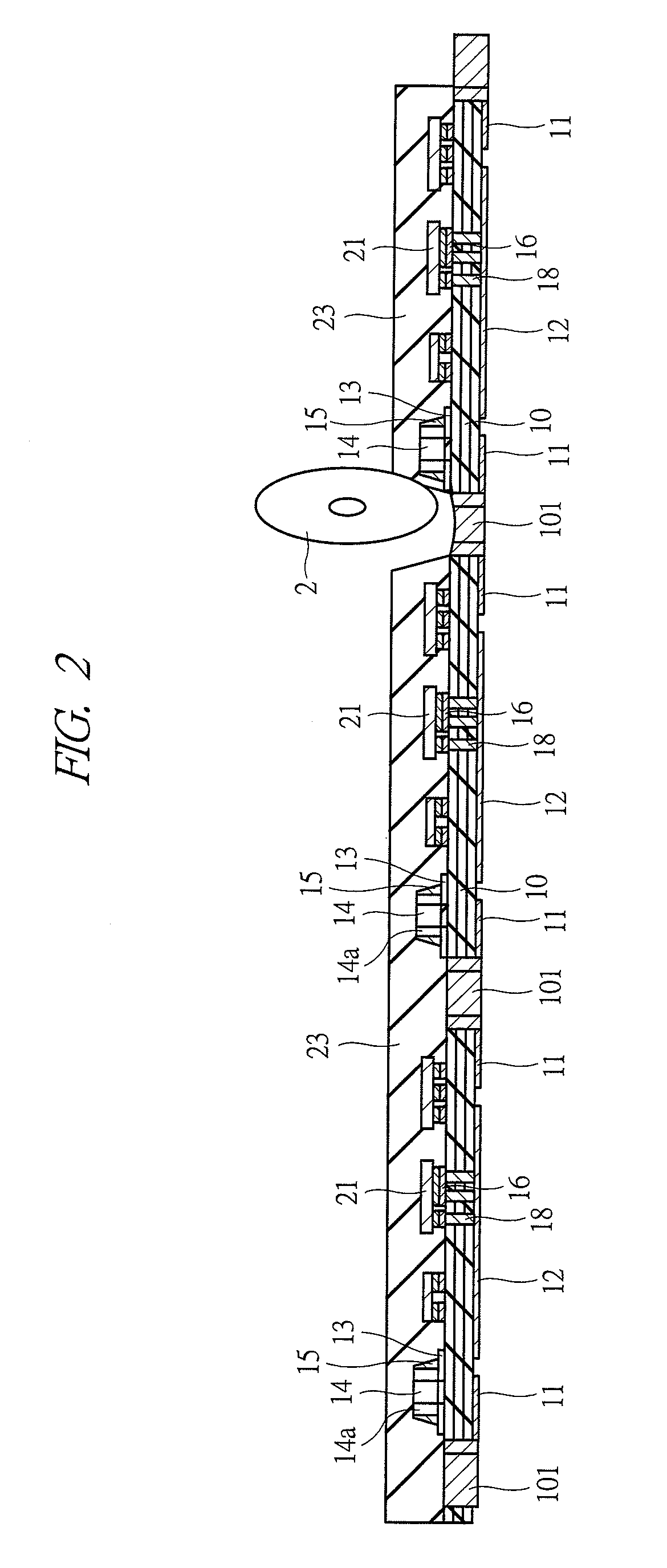

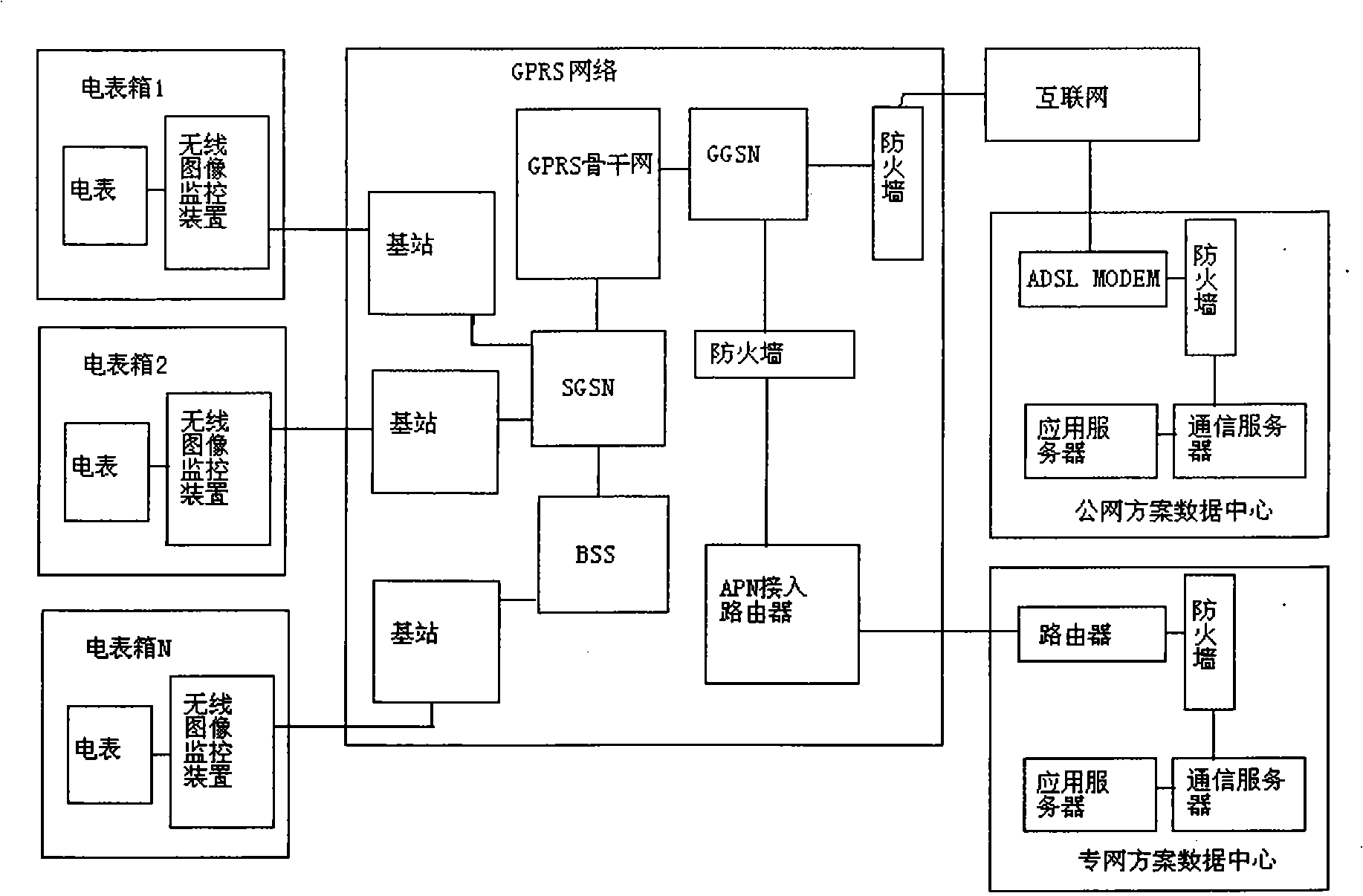

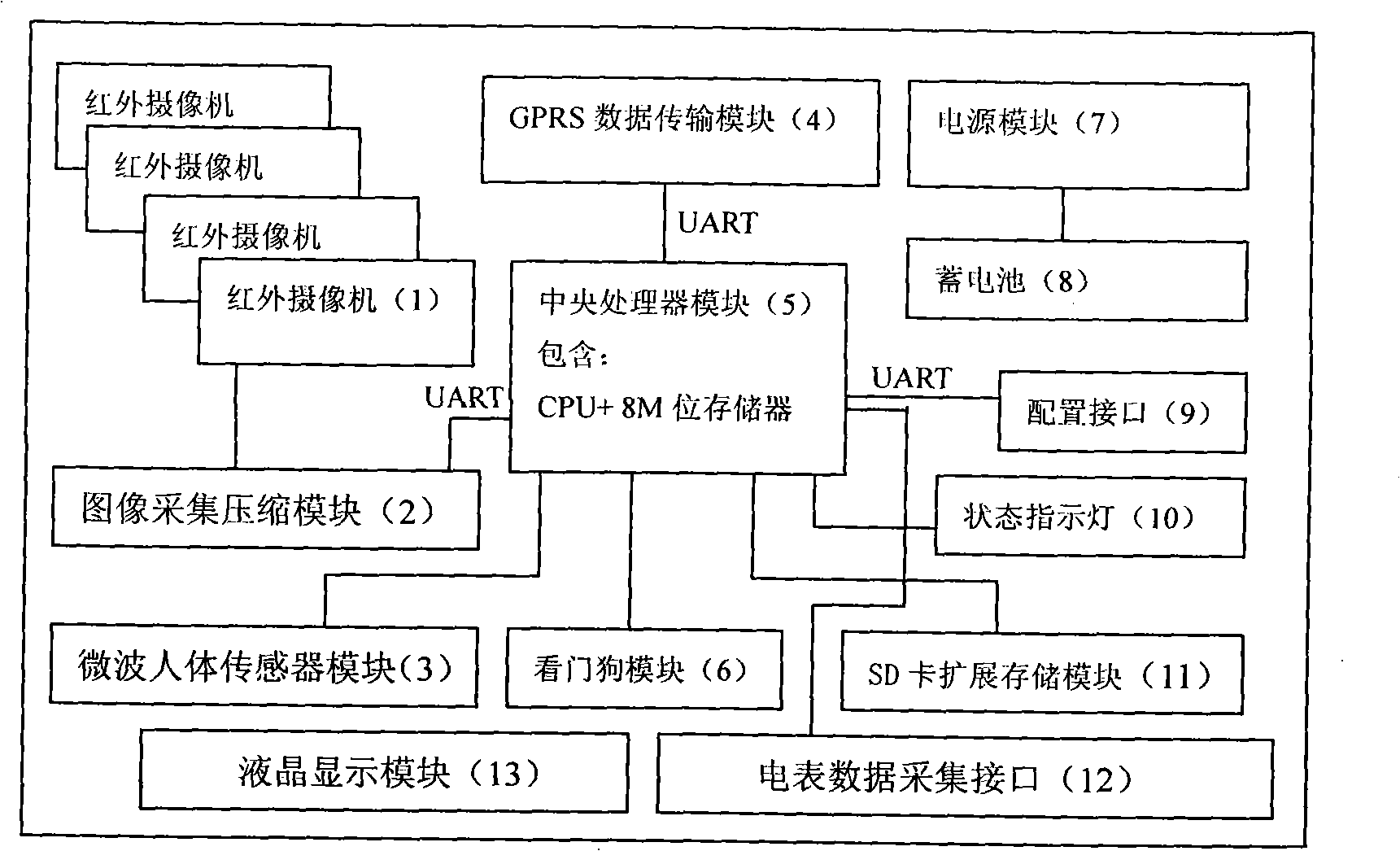

Wireless data and image double-acquisition anti-electricity theft monitoring system and method thereof

InactiveCN101320053AAcquisition timingReal-time acquisitionTransmissionBurglar alarmElectricityMicrowave

The invention discloses a wireless data-image dual acquirement anti-electricity-theft monitoring system and method which uses a microwave body sensor to conduct the real time detection to activities of people around an electricity meter box. Based on the method of the image shooting of a camera, the monitoring system provided by the invention uses a camera to continuously shoot and store the images of the activities of people around the electricity meter box and can real time transmit alarming information, electricity meter data and image information to a motoring server through GPRS network; and then, the motoring server can send the received alarming information to the mobile phones or computers of users in time, and users can read the alarming information from the mobile phones or computers of users in distance. Besides the functions of remote electricity meter data acquiring, the anti-electricity-theft monitoring and real-time alarming, the monitoring system also can transmit field images in time and obtain images stored by field equipment later for providing convincible proofs during handling the electricity theft of illegal users.

Owner:STATE GRID SHANDONG ELECTRIC POWER

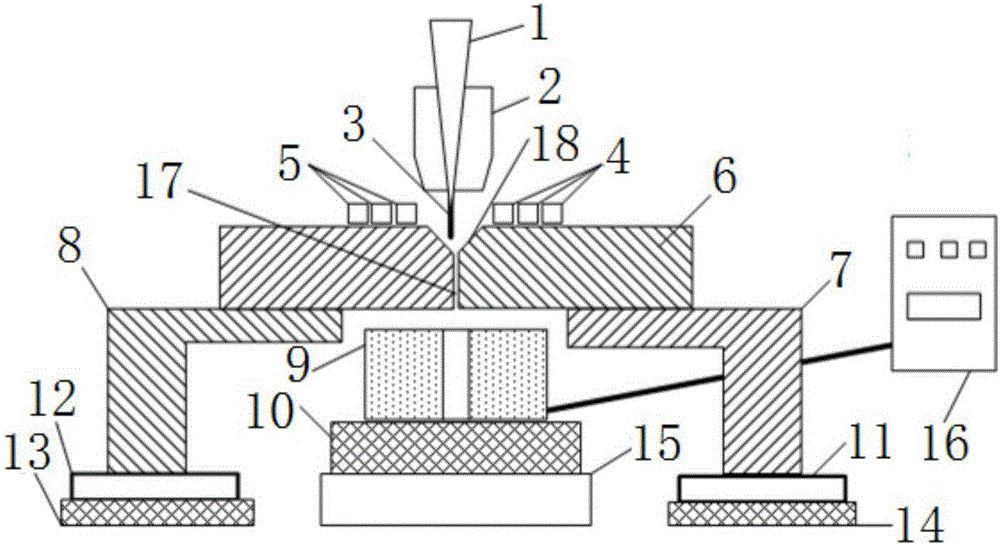

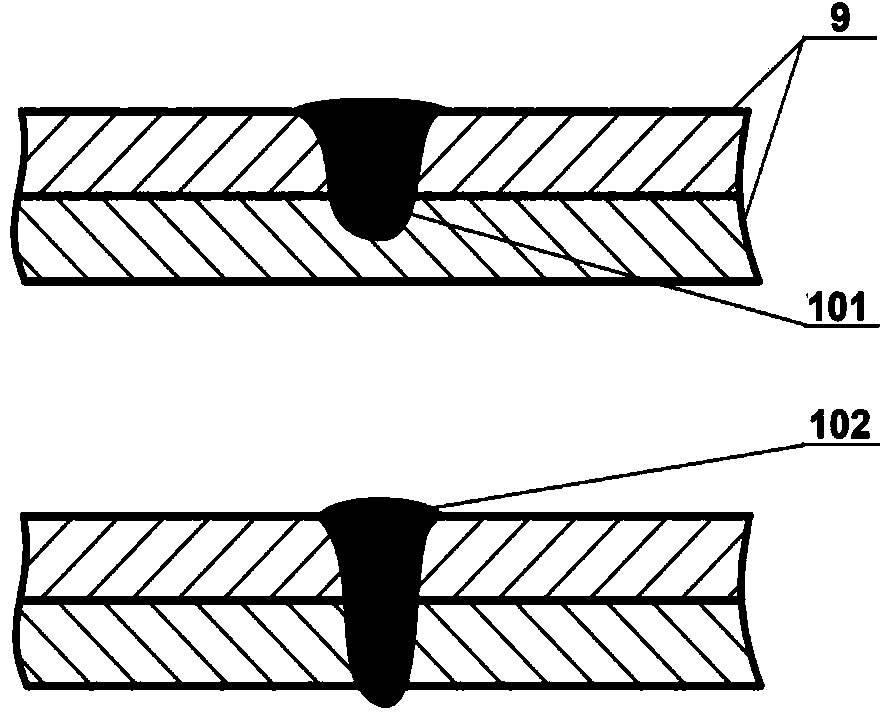

Welding device and method for avoiding high-nitrogen steel welding air holes and improving connector strength

ActiveCN105772944AImprove toughnessImprove stabilityWelding/soldering/cutting articlesLaser beam welding apparatusMagnetEngineering

The invention discloses a welding device and method for avoiding high-nitrogen steel welding air holes and improving connector strength, and belongs to the technical field of welding. Two welded workpieces are fixed to a first workpiece supporting plate and a second workpiece supporting plate in a butt joint manner. A welded workpiece connector gap is formed between the two welded workpieces. A groove is formed in the front faces of the welded workpieces and the position of the welded workpiece connector gap. The pipe wall of a first water passing copper pipe and the pipe wall of a second water passing copper pipe are closely attached to the two sides of the groove. Magnet exciting coils are arranged on the back faces of the welded workpieces, a laser beam vertically irradiates the front faces of the welded workpieces, a welding gun is arranged on the front faces of the welded workpieces, and the laser beam, the welded workpiece connector gap and the magnet exciting coils are coaxial. The problems that in the high-nitrogen steel welding process in the prior art, gas is prone to being generated, nitride, carbide and carbonitride are likely to be separated out, and the grain of a weld line is thick are solved, accordingly, the mechanical performance of a high-nitrogen steel welding connector is improved, and the tenacity of a welding heat affected zone is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Substrate-less electronic component and the method to fabricate thereof

InactiveUS20160141102A1Q-factor can be increasedLower quality factorTransformers/inductances coils/windings/connectionsCoils manufactureElectronic componentElectron

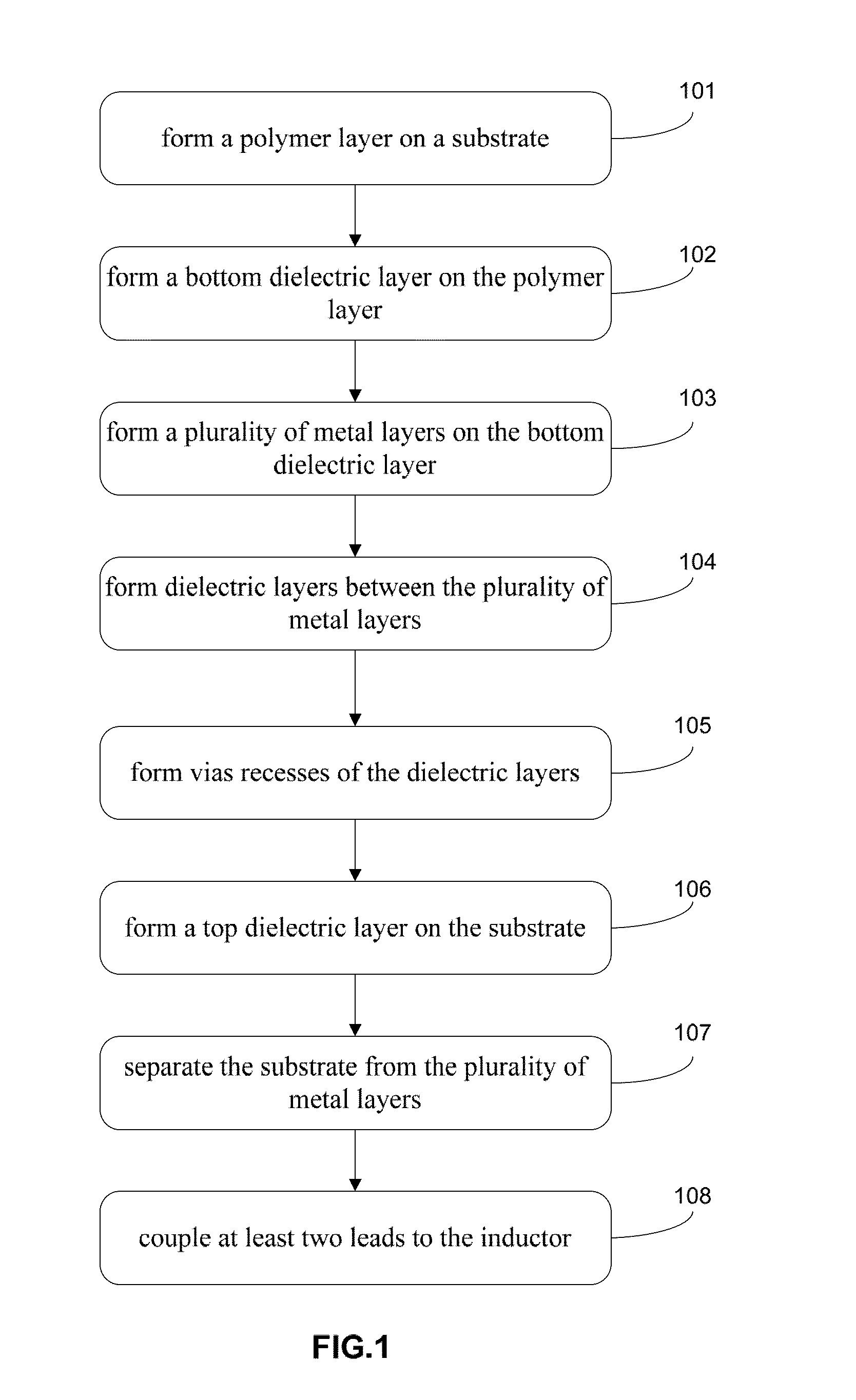

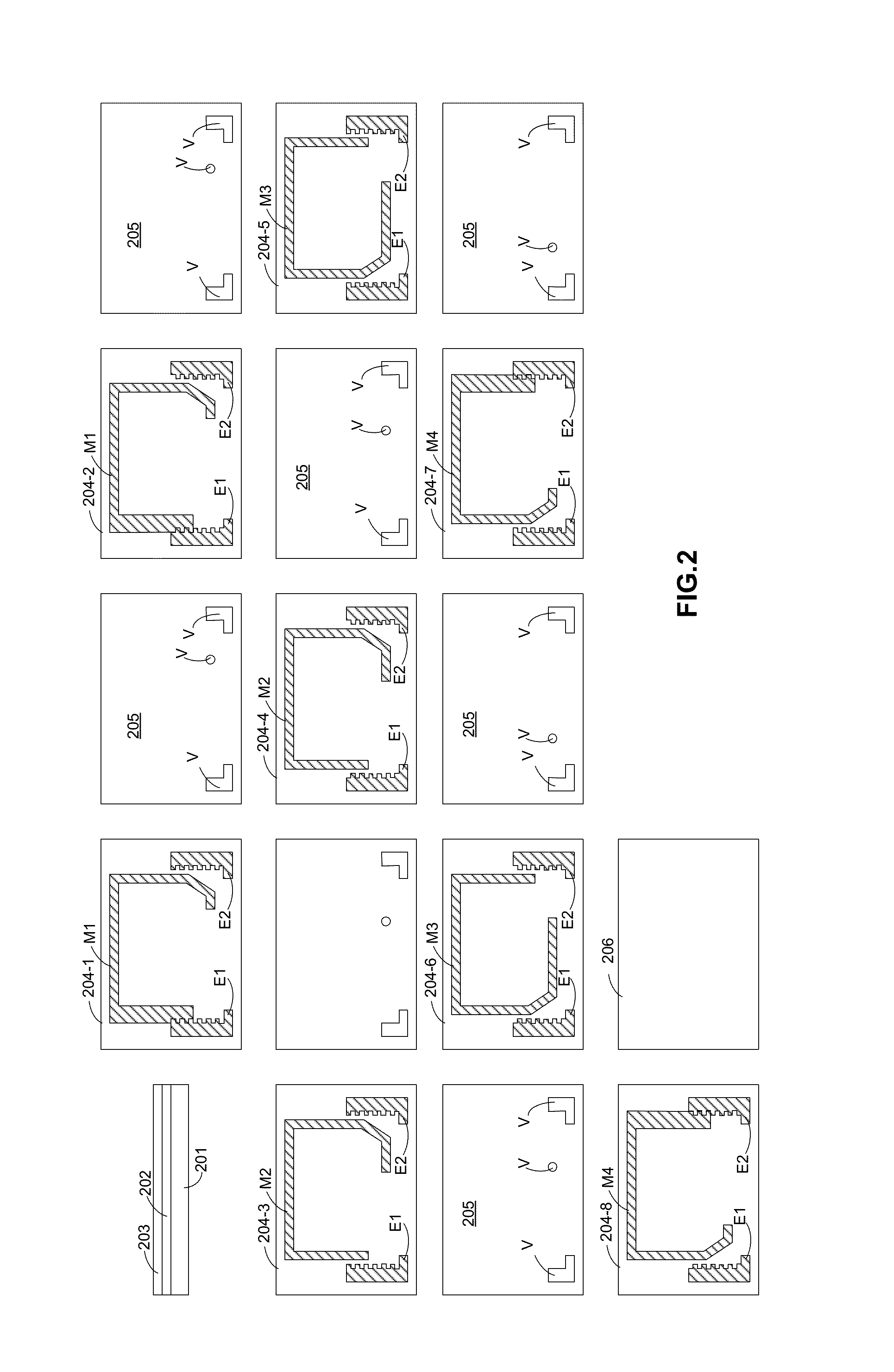

An electronic component is disclosed, the electronic component comprising: a conductive structure, comprising a plurality of conductive layers separated by a plurality of insulating layers, wherein the plurality of conductive layers and the plurality of insulating layers are stacked in a vertical direction, wherein the plurality of conductive layers forms at least one coil, wherein each of the coil is formed along the vertical direction across said plurality of conductive layers, wherein the plurality of insulating layers are not supported by a substrate.

Owner:CYNTEC

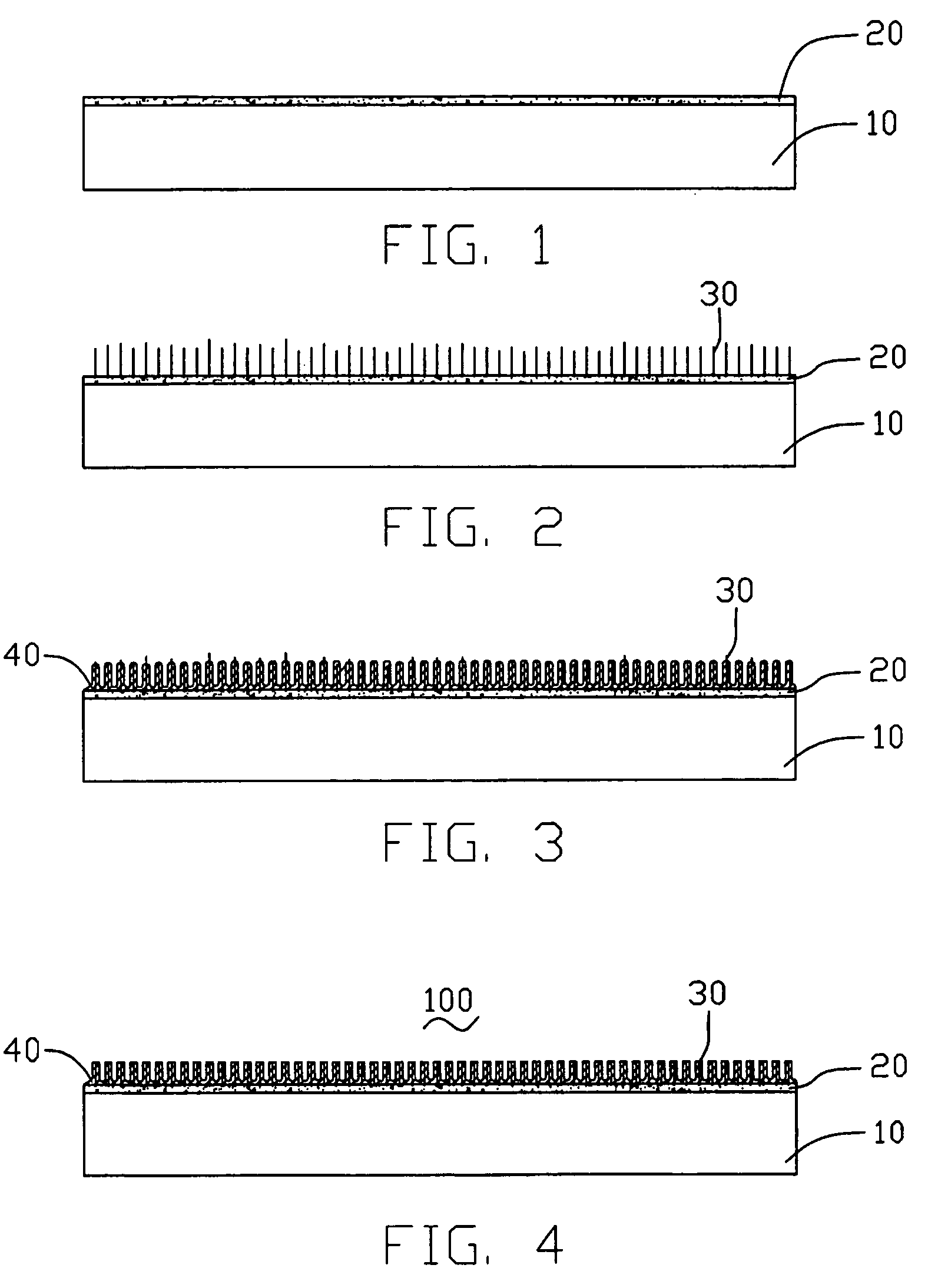

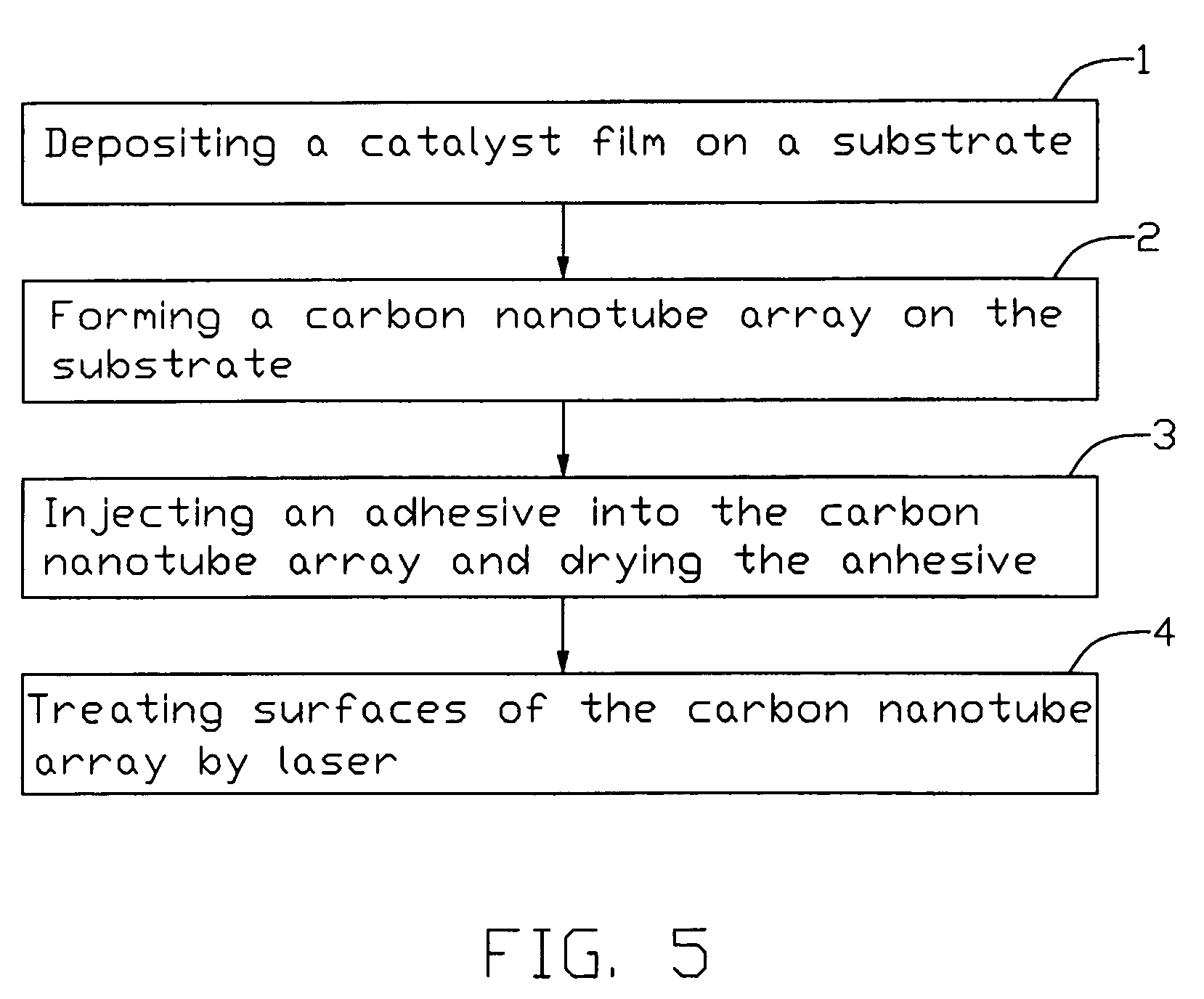

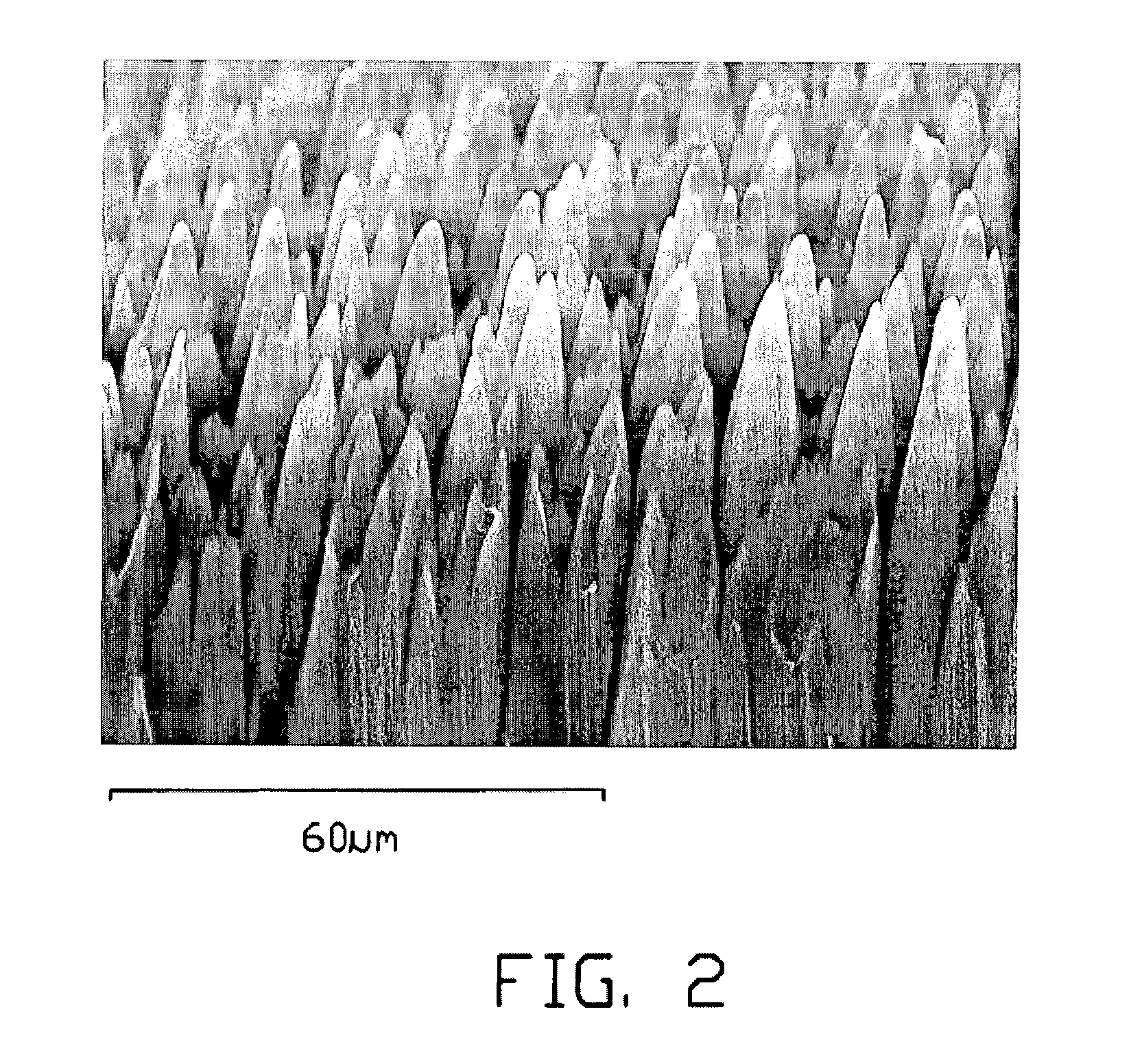

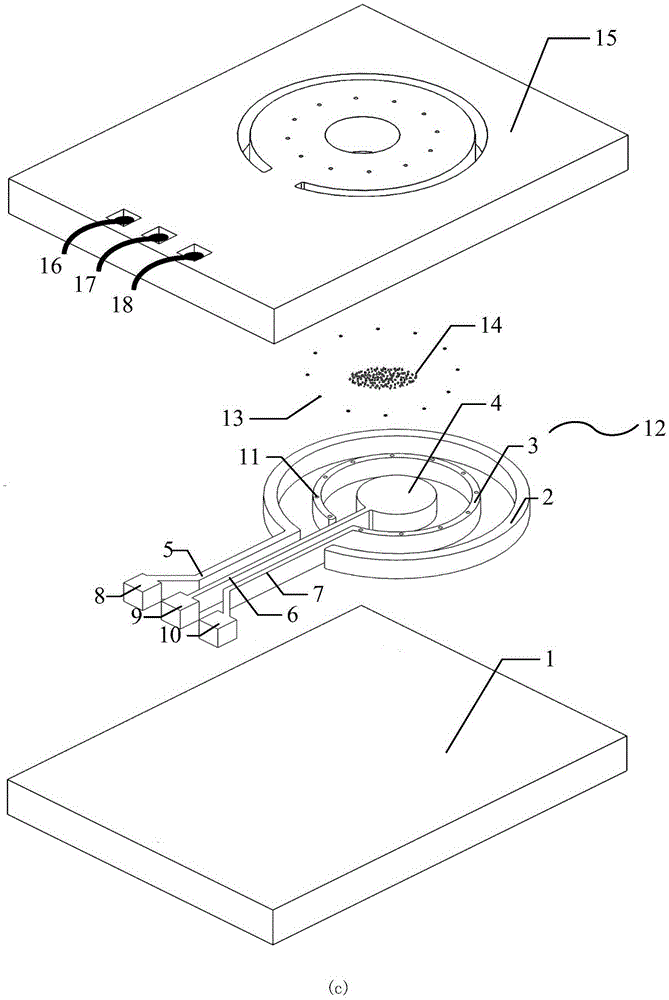

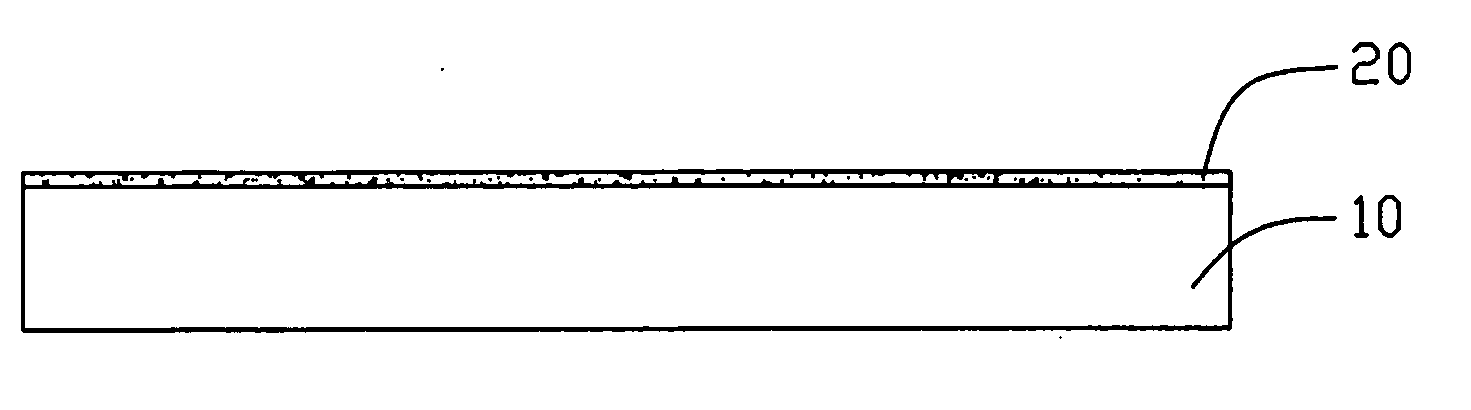

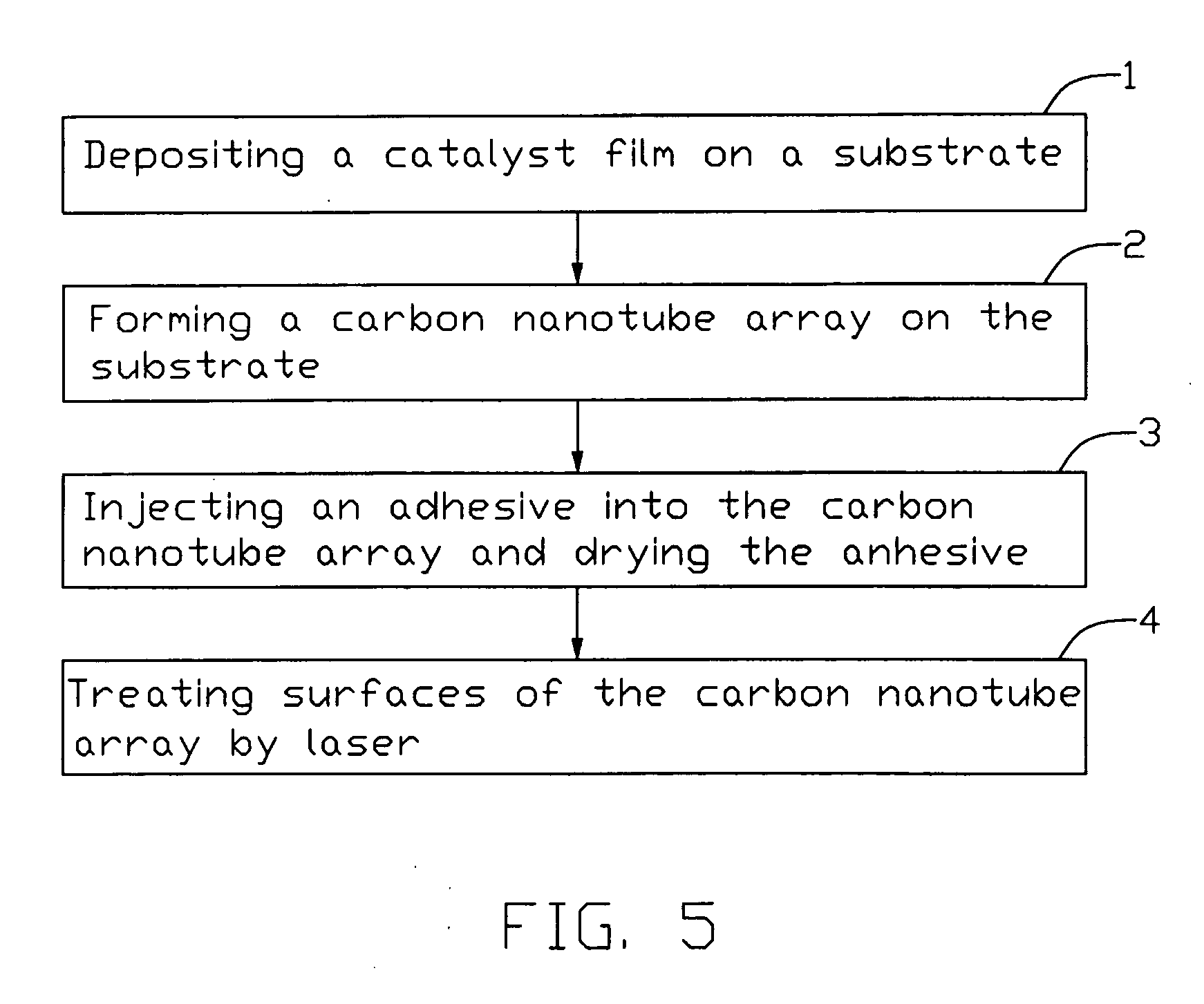

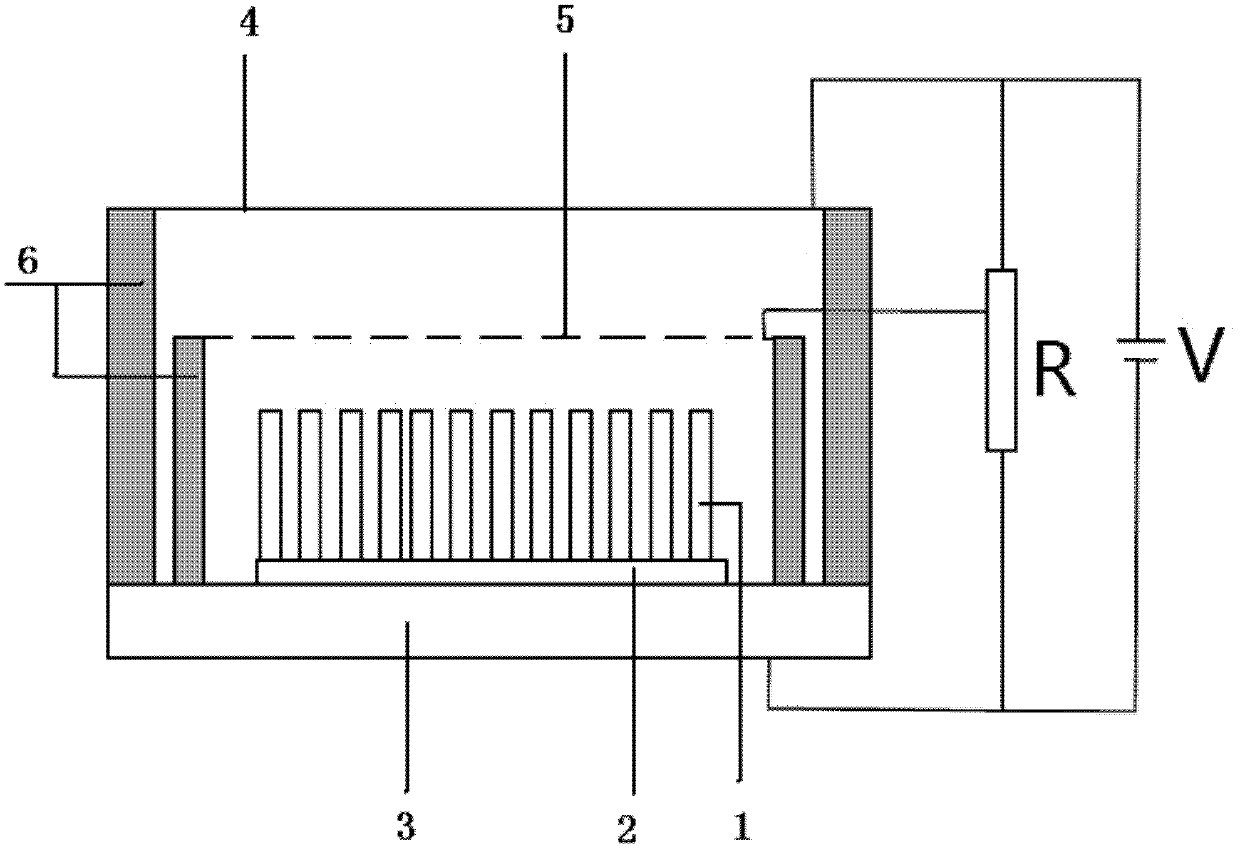

Method for manufacturing carbon nanotube field emission device

ActiveUS7448931B2Avoid separationReduced shieldingLiquid surface applicatorsDischarge tube luminescnet screensField emission deviceField emission current

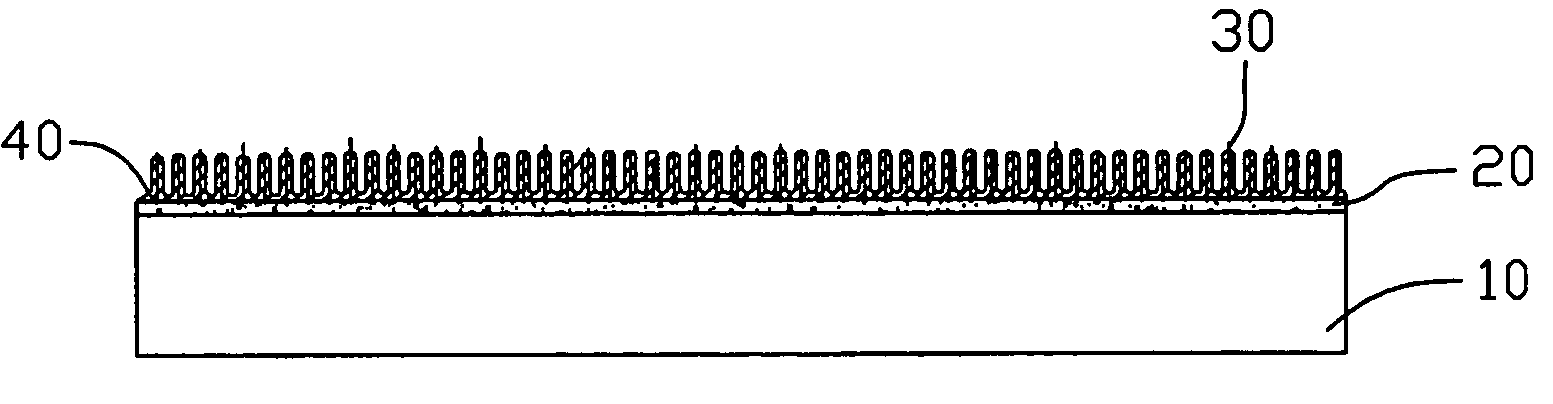

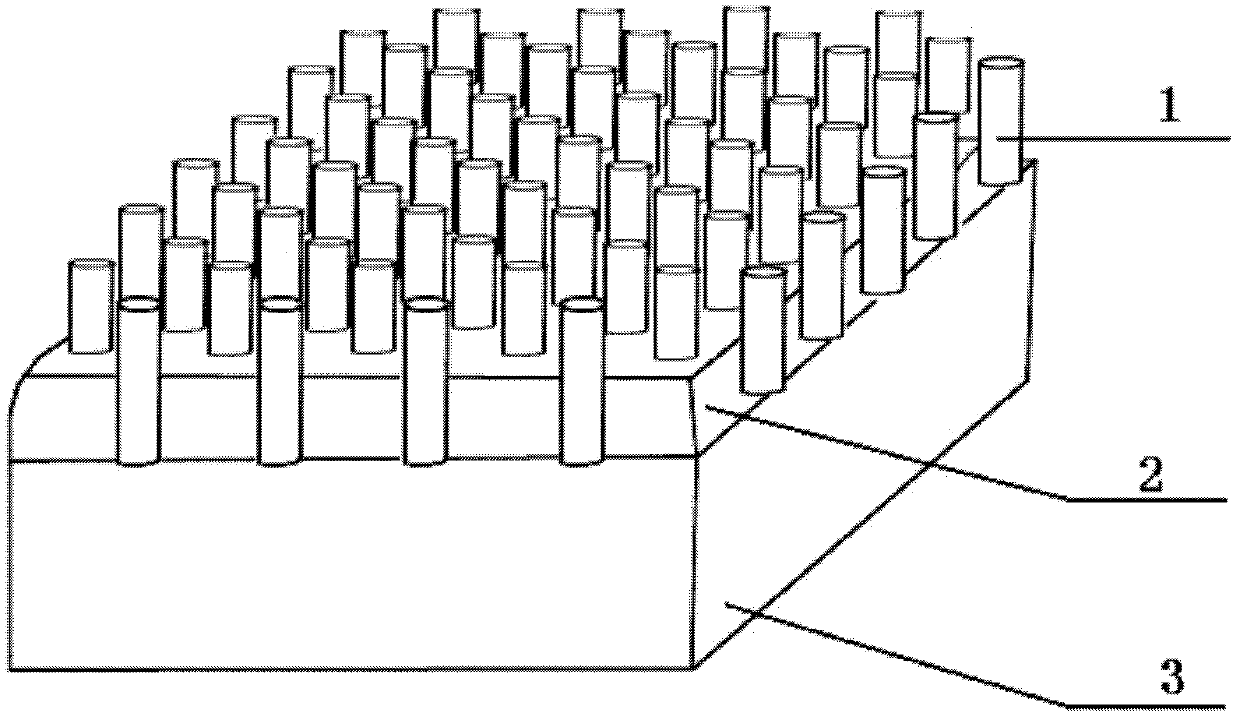

A carbon nanotube field emission device (100) includes a substrate (10), and a carbon nanotube array (30) formed on and secured to the substrate. This avoids separation of the carbon nanotubes from the substrate by electric field force in a strong electric field. Tips of the carbon nanotubes are exposed. A method for manufacturing the carbon nanotube field emission device includes the steps of: (a) depositing a catalyst film (20) on a substrate; (b) forming a carbon nanotube array on the substrate; (c) injecting an adhesive into the carbon nanotube array, and drying the adhesive; and (d) treating surfaces of the carbon nanotube array by laser. The carbon nanotube field emission device has reduced shielding between adjacent carbon nanotubes, reduced threshold voltage, and increased field emission current.

Owner:HON HAI PRECISION IND CO LTD +1

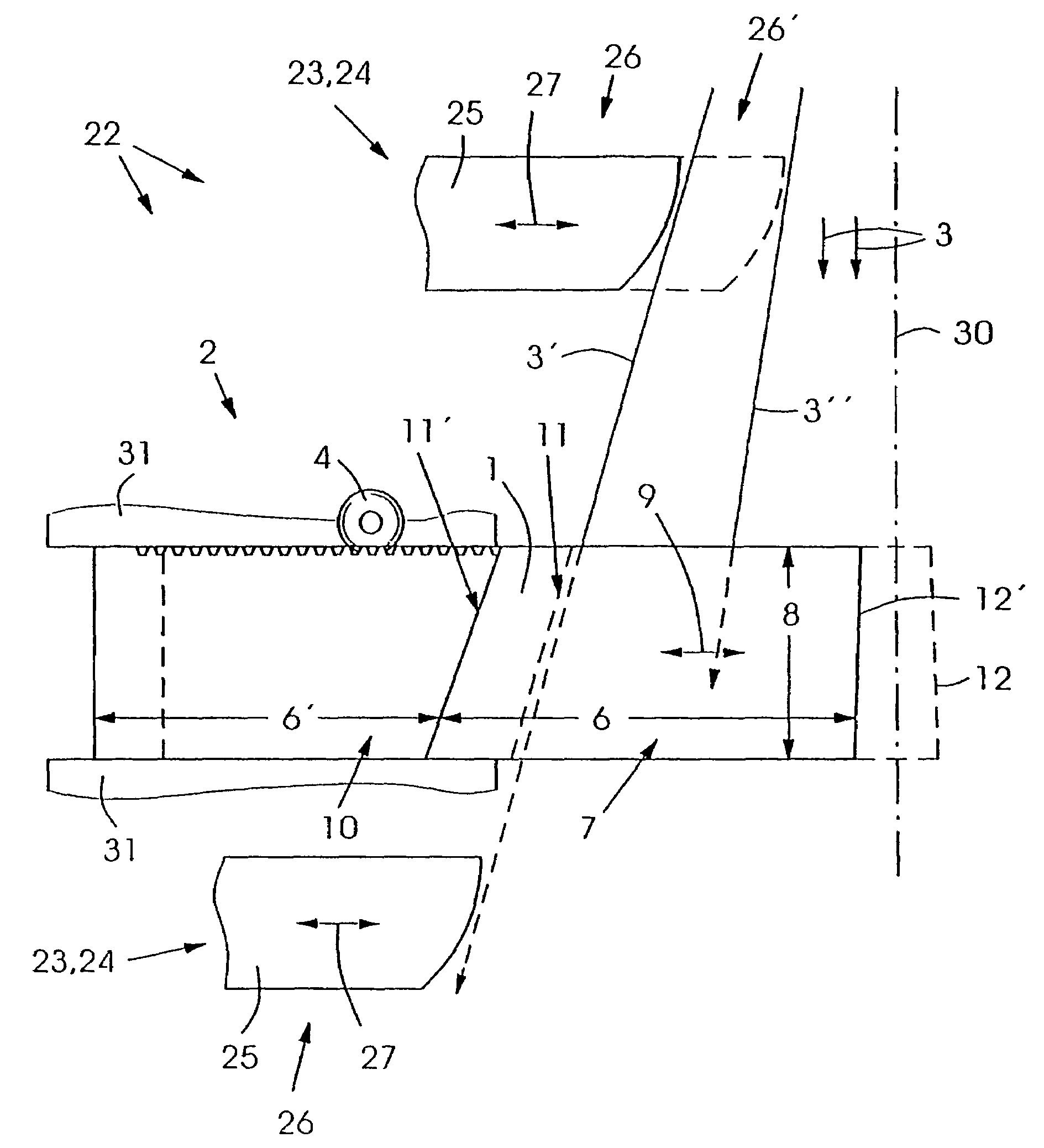

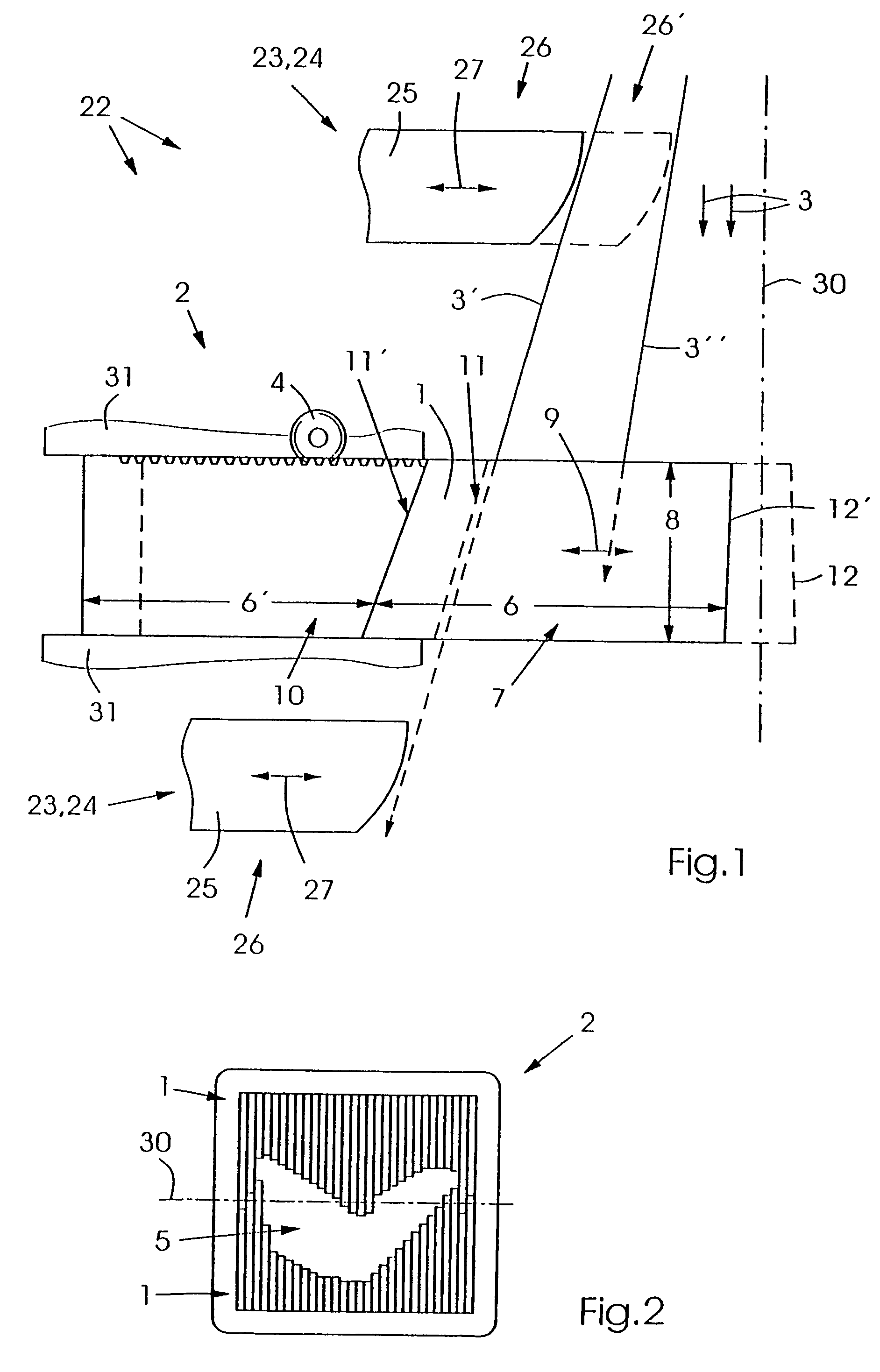

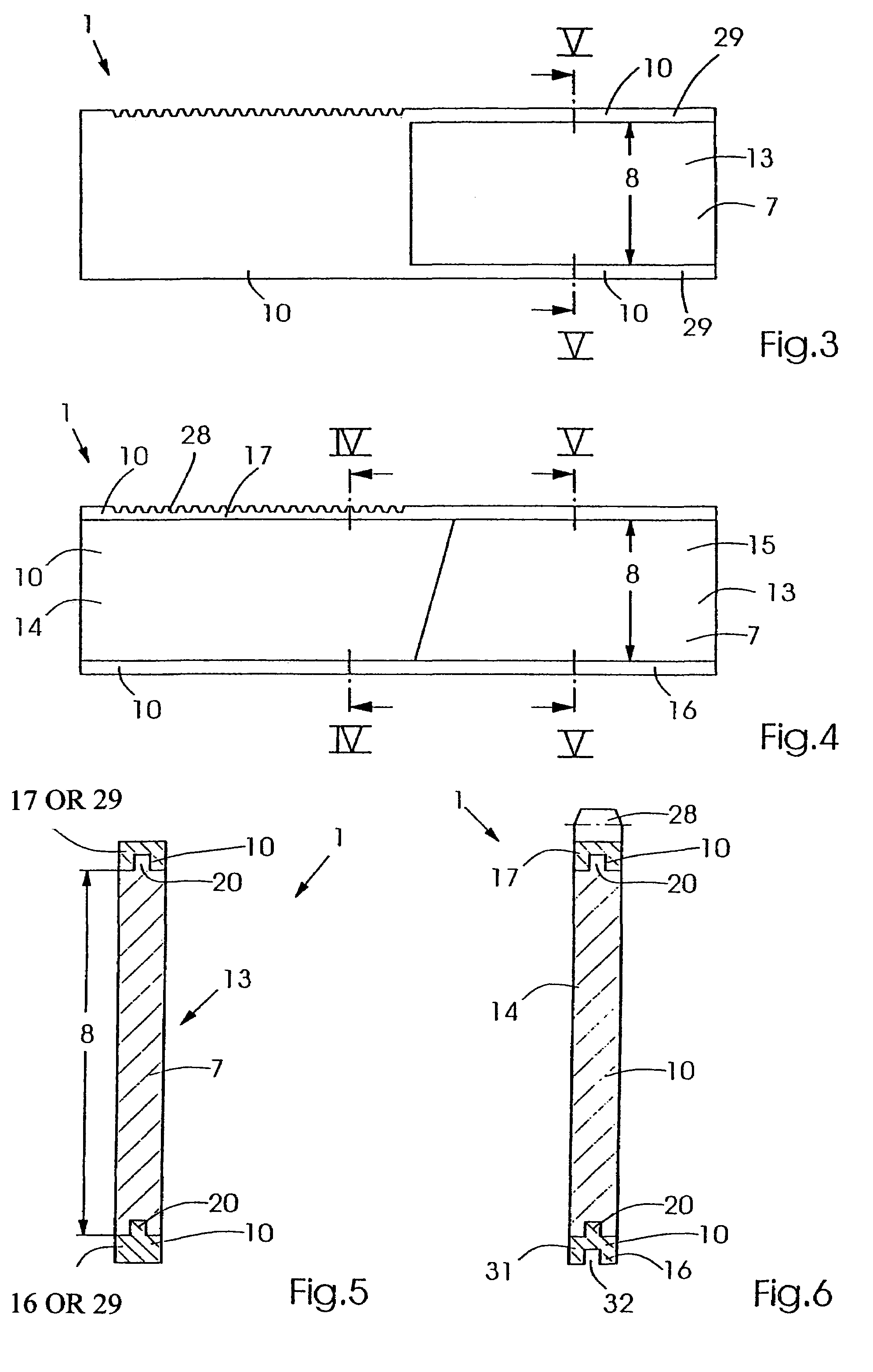

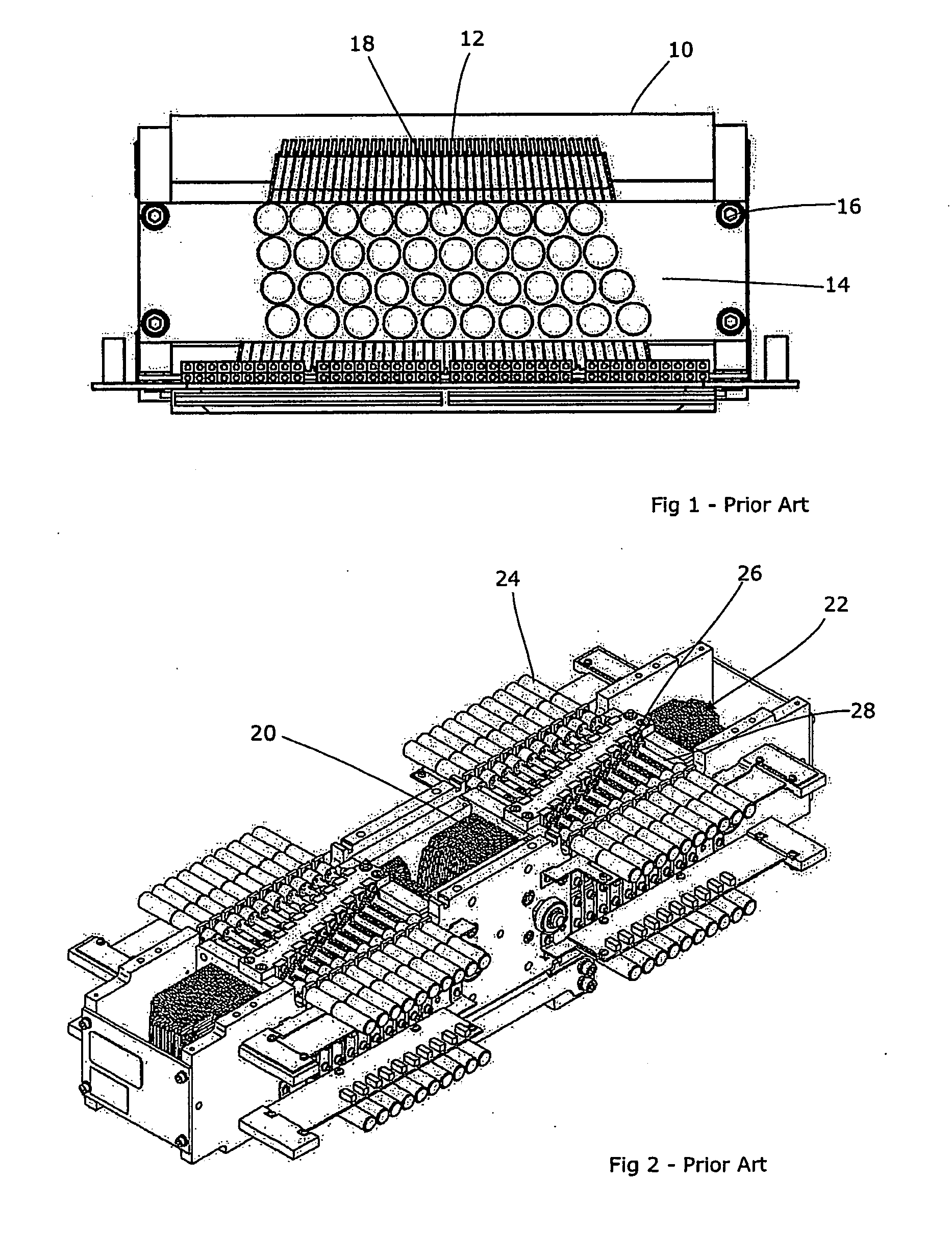

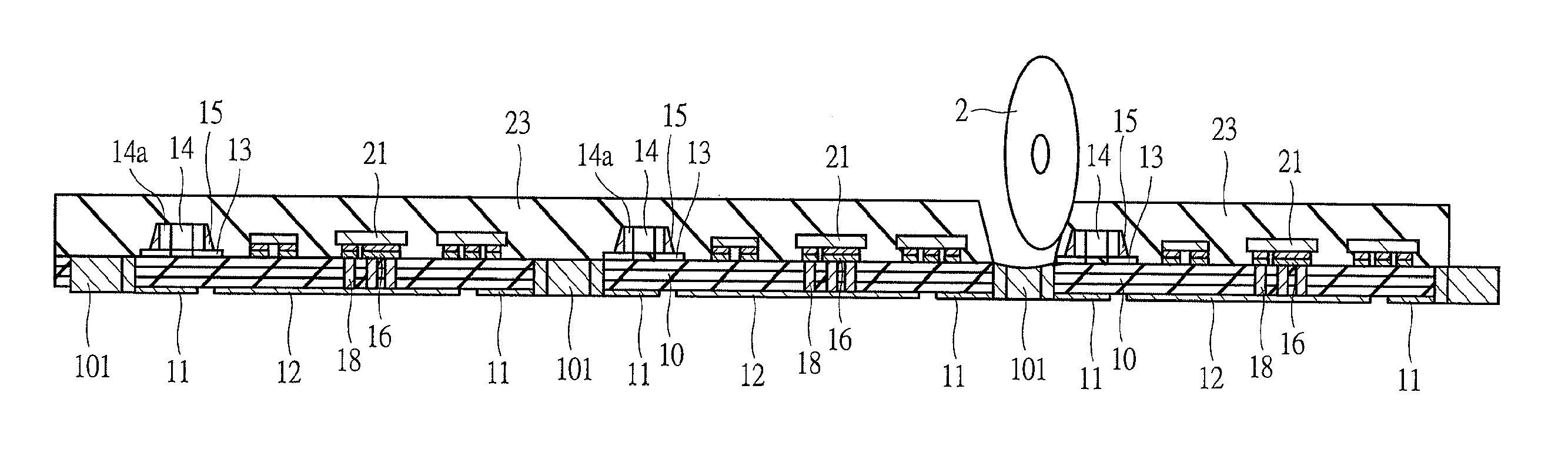

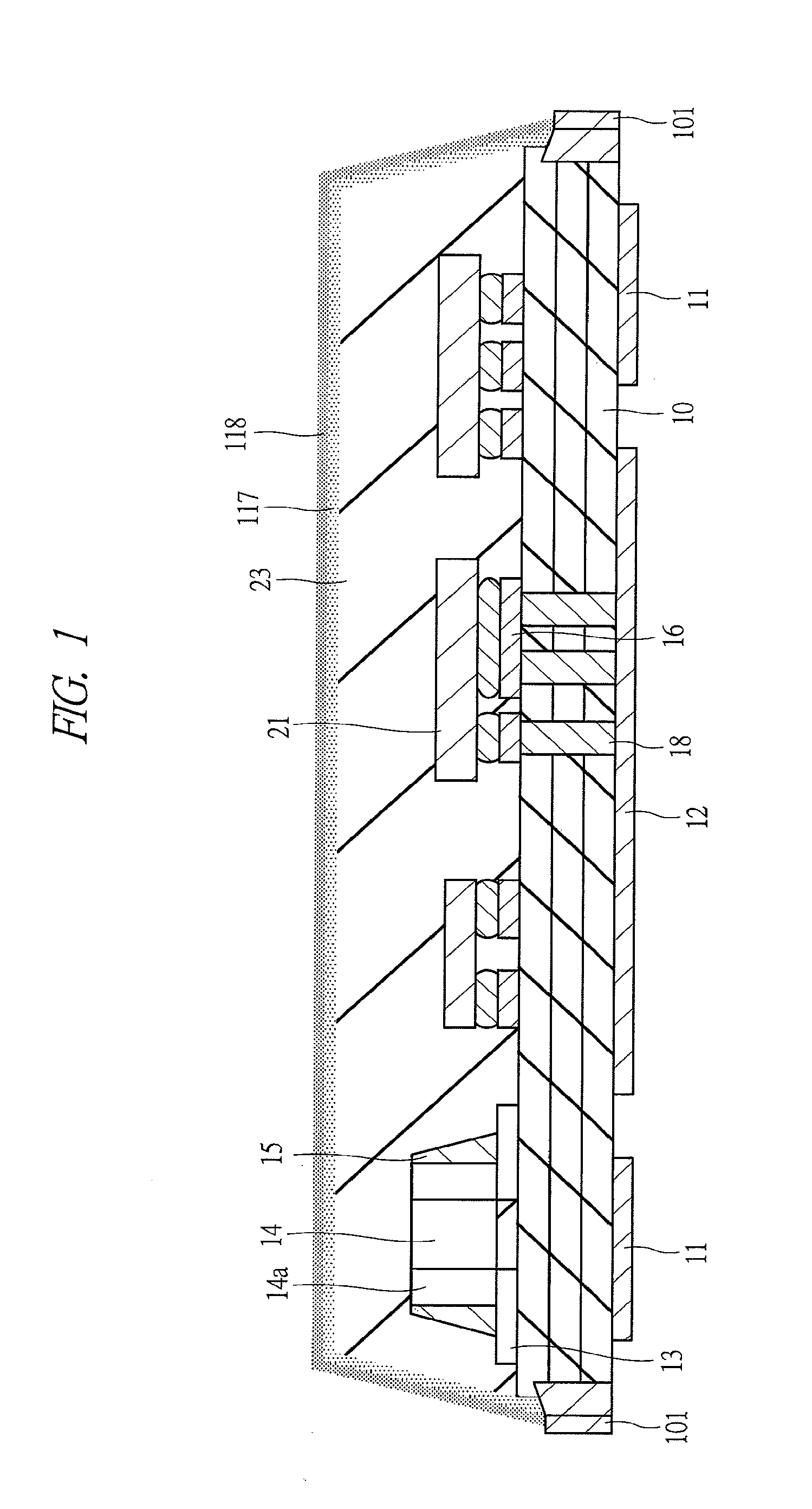

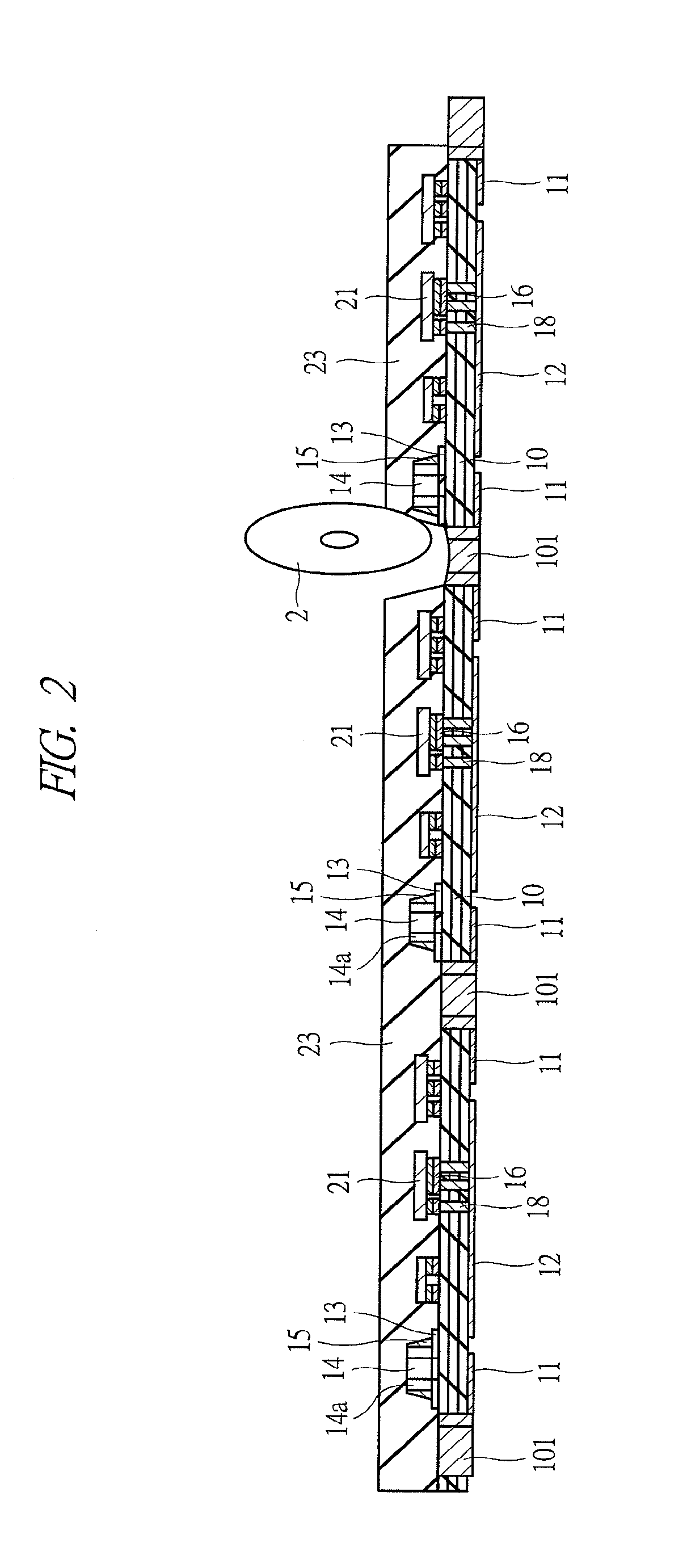

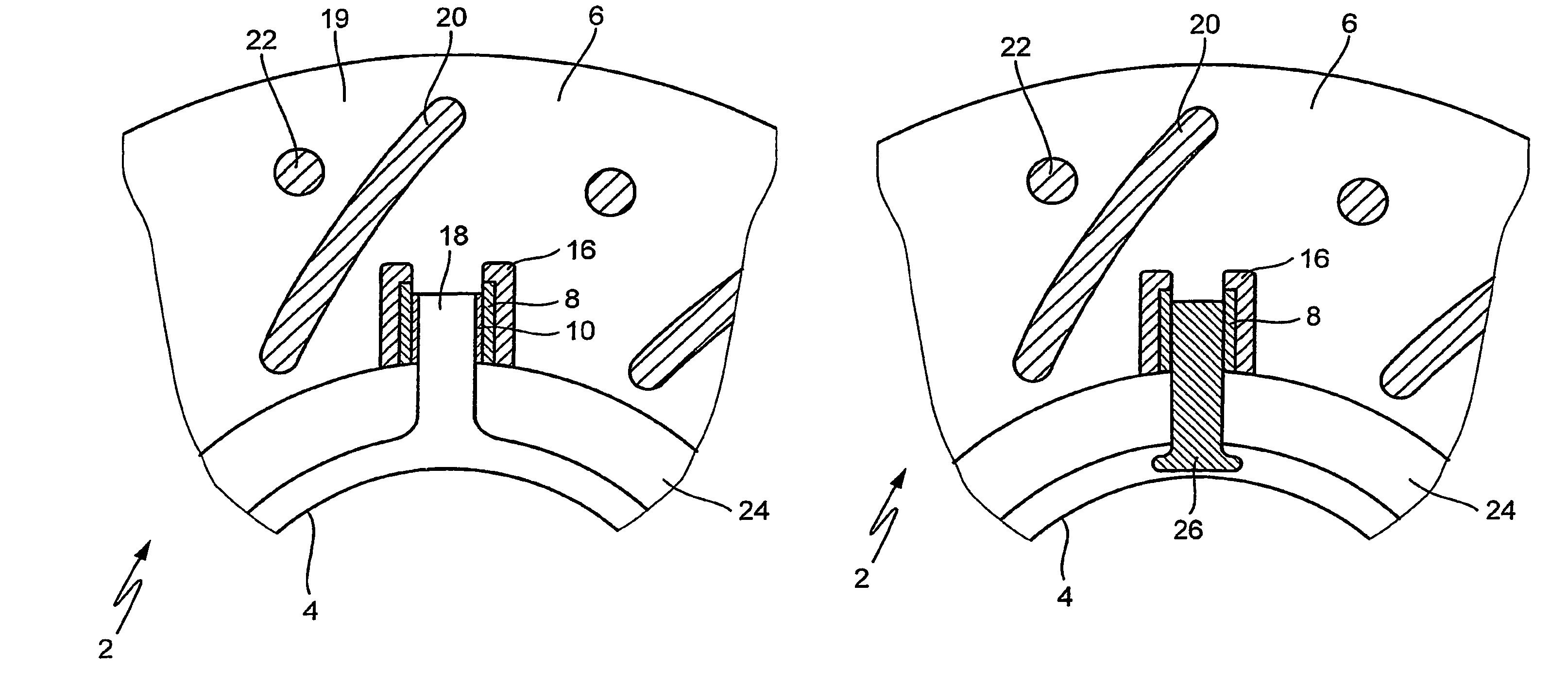

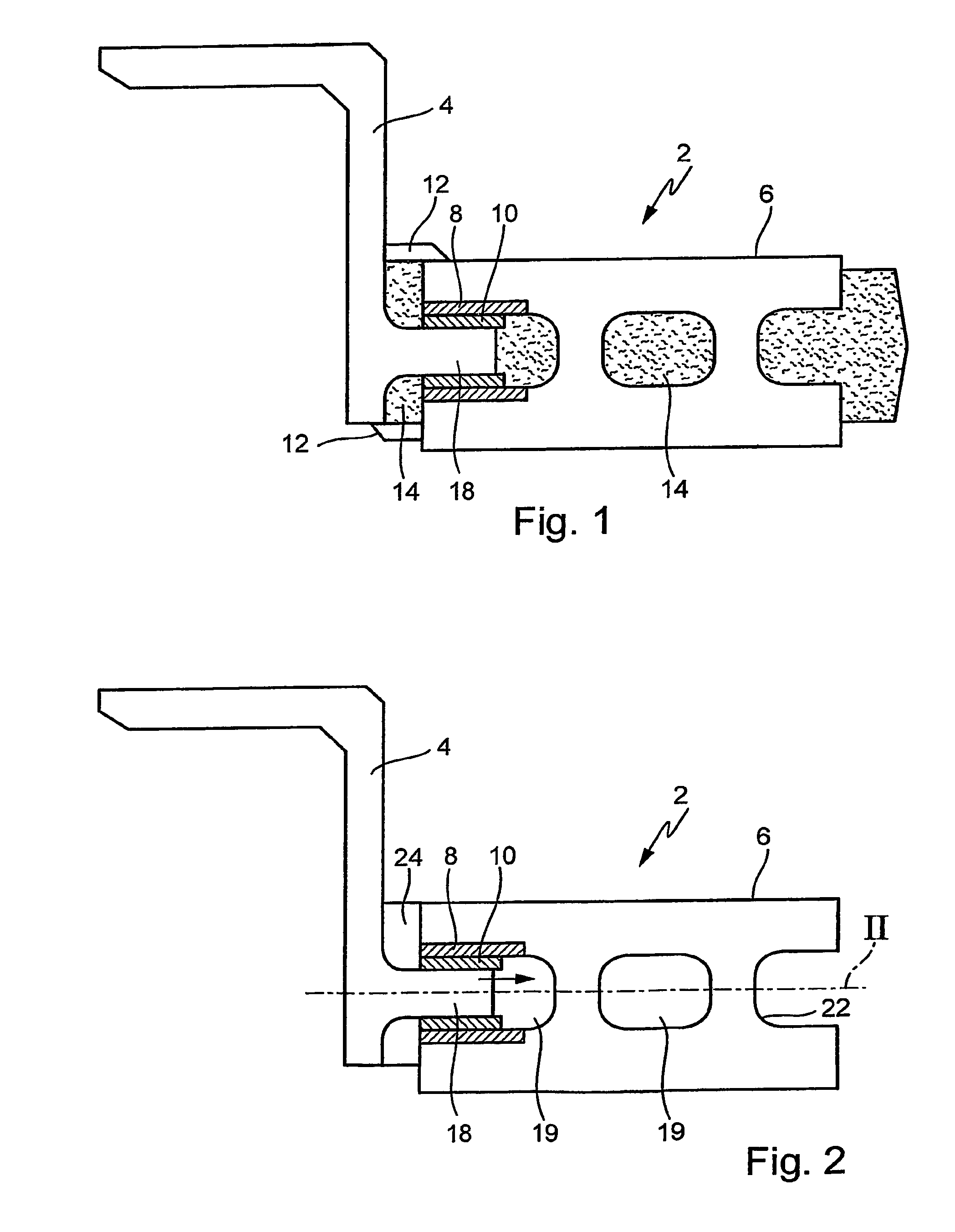

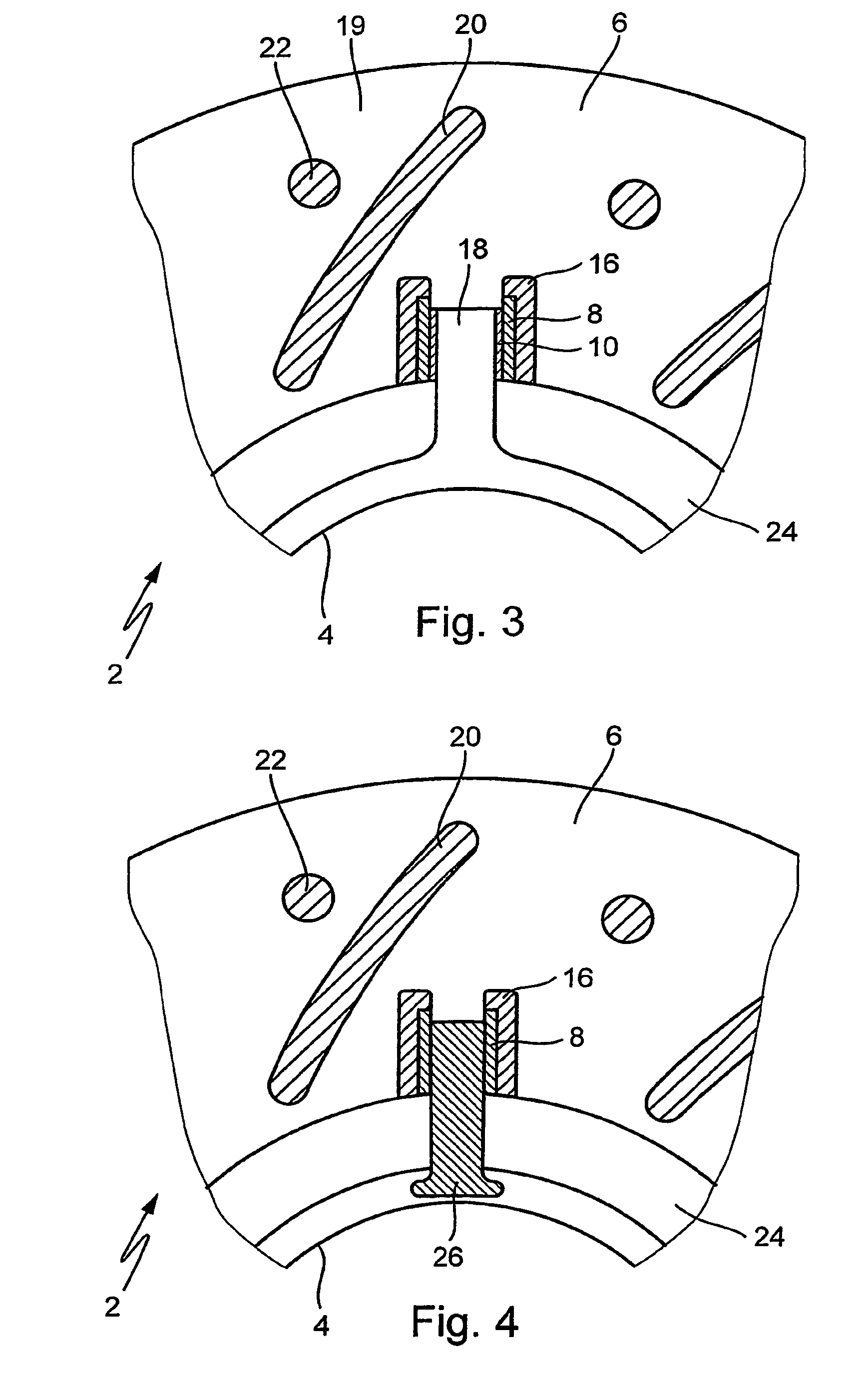

Leaf, multi-leaf collimator, device for delimiting beams and irradiation device

ActiveUS7397902B2Reduce weightReduce materialElectrode and associated part arrangementsHandling using diaphragms/collimetersMulti leaf collimatorLight beam

The invention relates to a leaf (1) for a multi-leaf collimator (2) for delimiting a high-energy beam (3, 3′, 3″) of an irradiation device, in particular for conformational radiation therapy. According to the invention, the multi-leaf collimator (2) comprises a plurality of opposing leaves (1), which can be brought into the beam path (3, 3′, 3″) by means of drives (4), in such a way that the contour (5) of said path can be shaped in accordance with the volume to be irradiated. The need for beam-absorbent material (7) is reduced, as the leaf (1) essentially only comprises a beam-absorbent material (7) of an appropriate thickness (8) in a region (6) that is brought into the path (3, 3′, 3″) of the high-energy beam (3) during the course of all possible positional displacements (9). The invention also relates to a corresponding multi-leaf collimator (2), a device (22) for delimiting beams, and an irradiation device.

Owner:SIEMENS HEALTHCARE GMBH

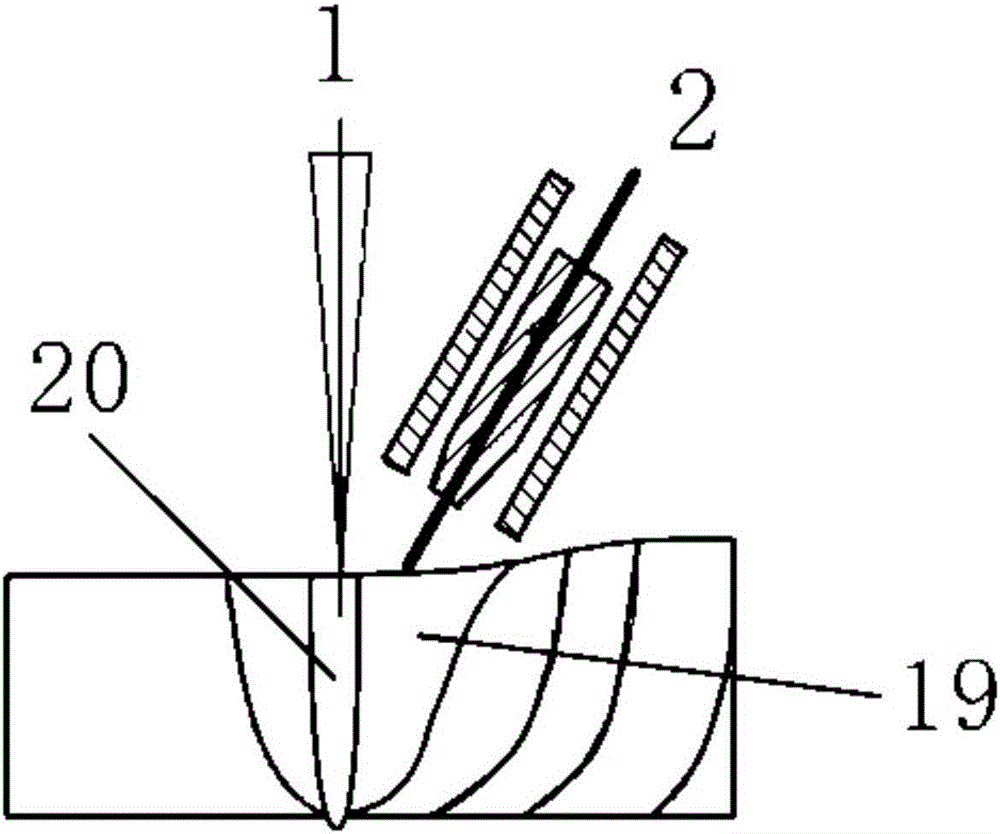

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

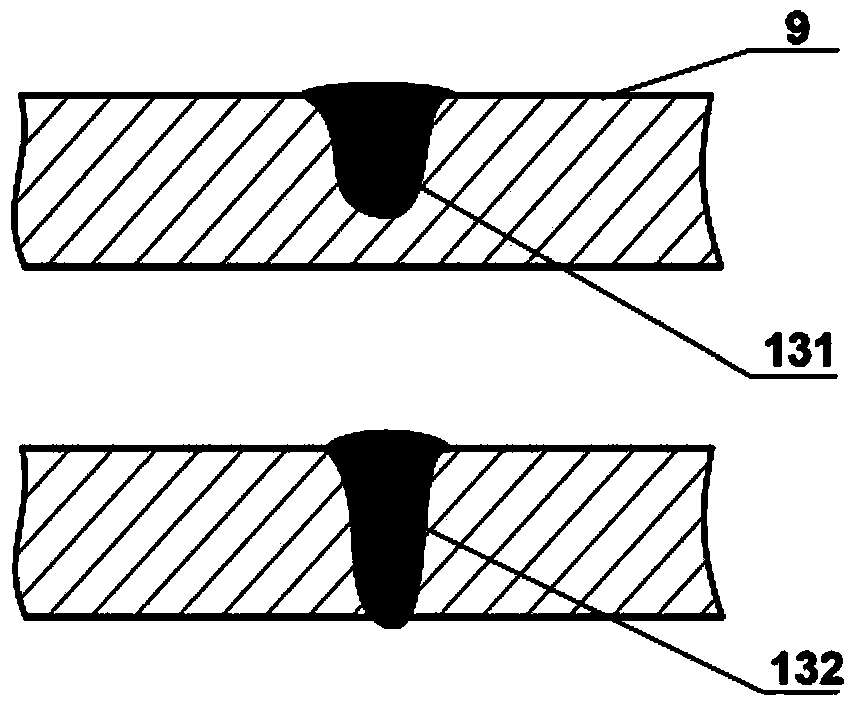

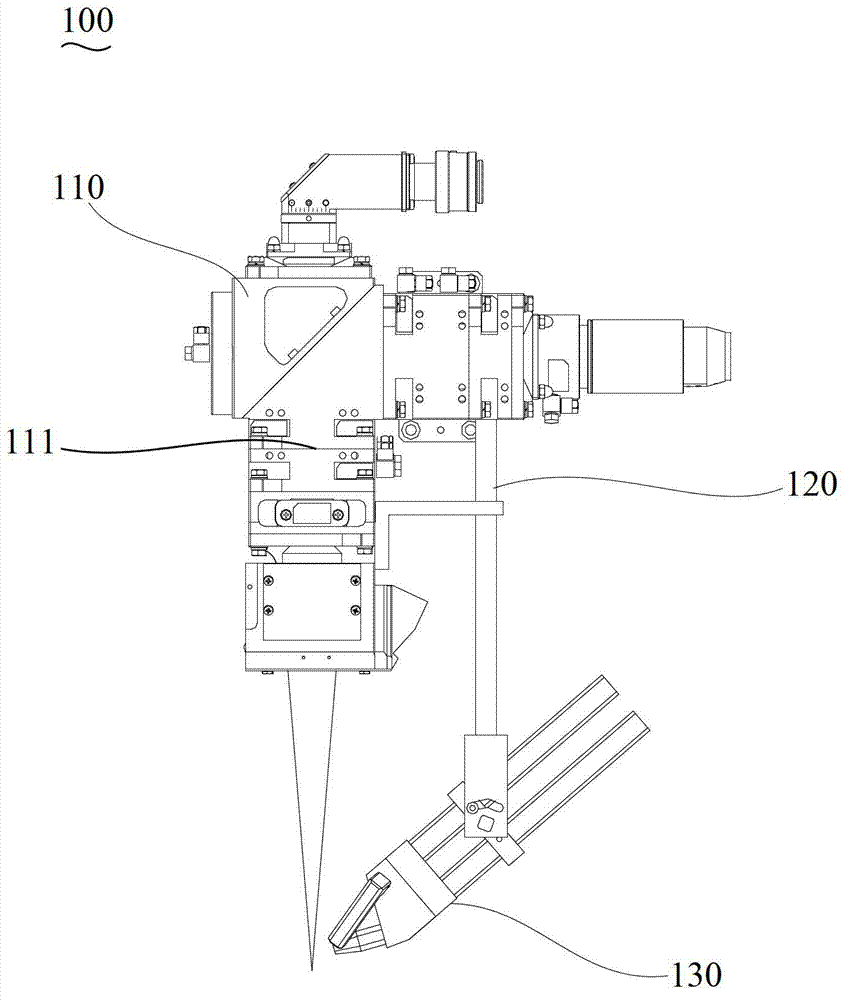

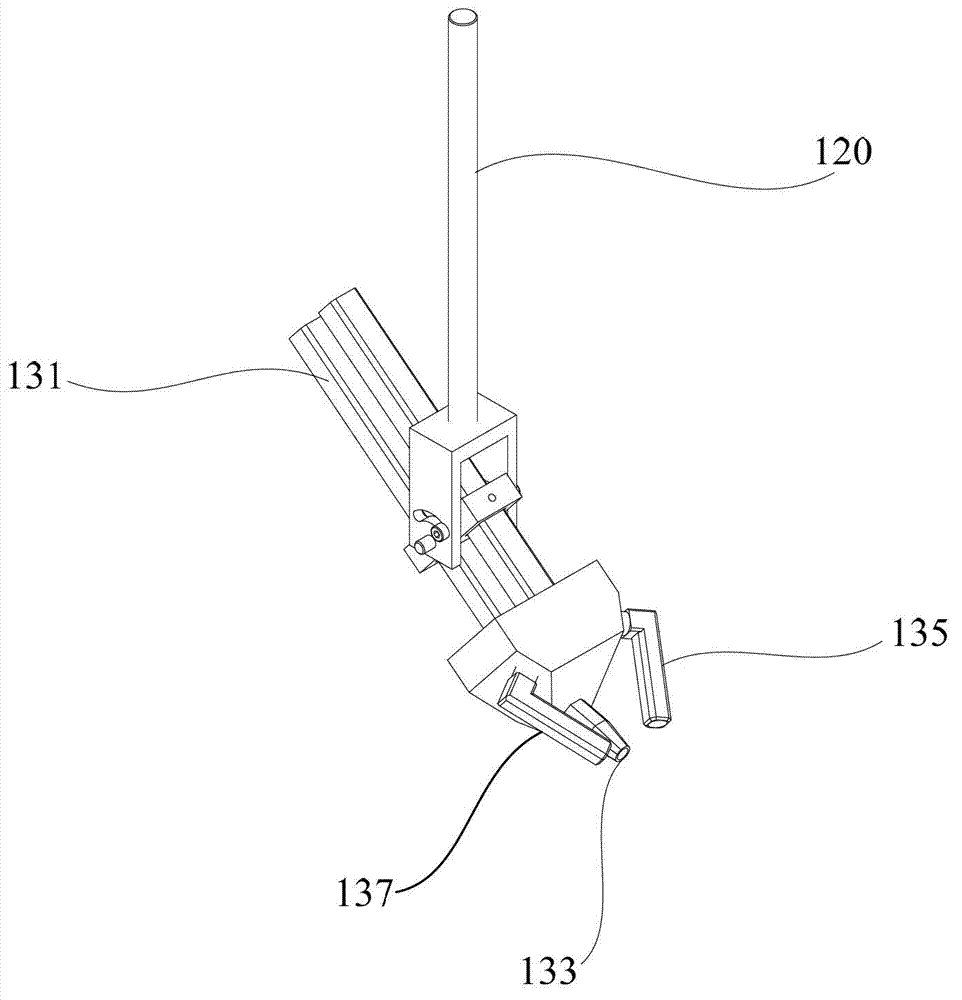

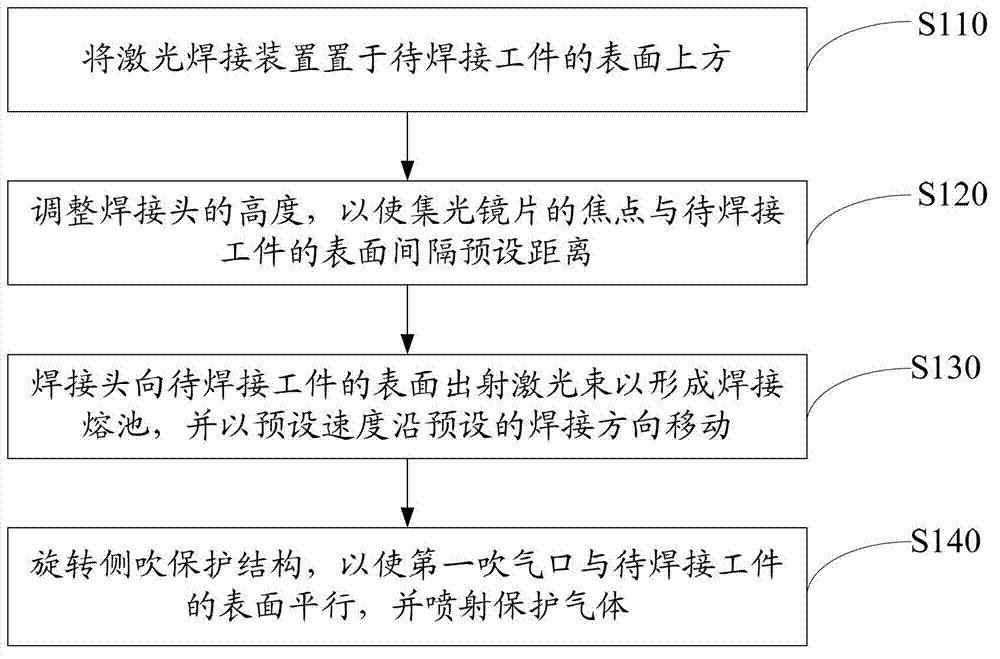

Laser welding device and welding method

ActiveCN103170744AReduce focus driftFix focus driftLaser beam welding apparatusLong-focus lensThick plate

The invention discloses a laser welding device. According to the invention, the aggregating lens of a welding head is a long-focus lens, so that the welding head can be placed at a position far away from a welding pool during welding, the influence of thermal radiation of the welding pool on optical devices in the welding head can be reduced and the focus drifting of the aggregating lens is avoided; in addition, a first air blowing port of a side-blow protecting structure is capable of spraying protective gas into the welding pool during the welding and plasma above the welding pool can be blown away, so that the height of plasma flame can be reduced, the shielding effect of the plasma on laser beams is reduced and humps are avoided; and in conclusion, the laser welding device is capable of effectively improving the welding stability in a thick plate welding process. In addition, the invention also provides a welding method.

Owner:HANS LASER TECH IND GRP CO LTD

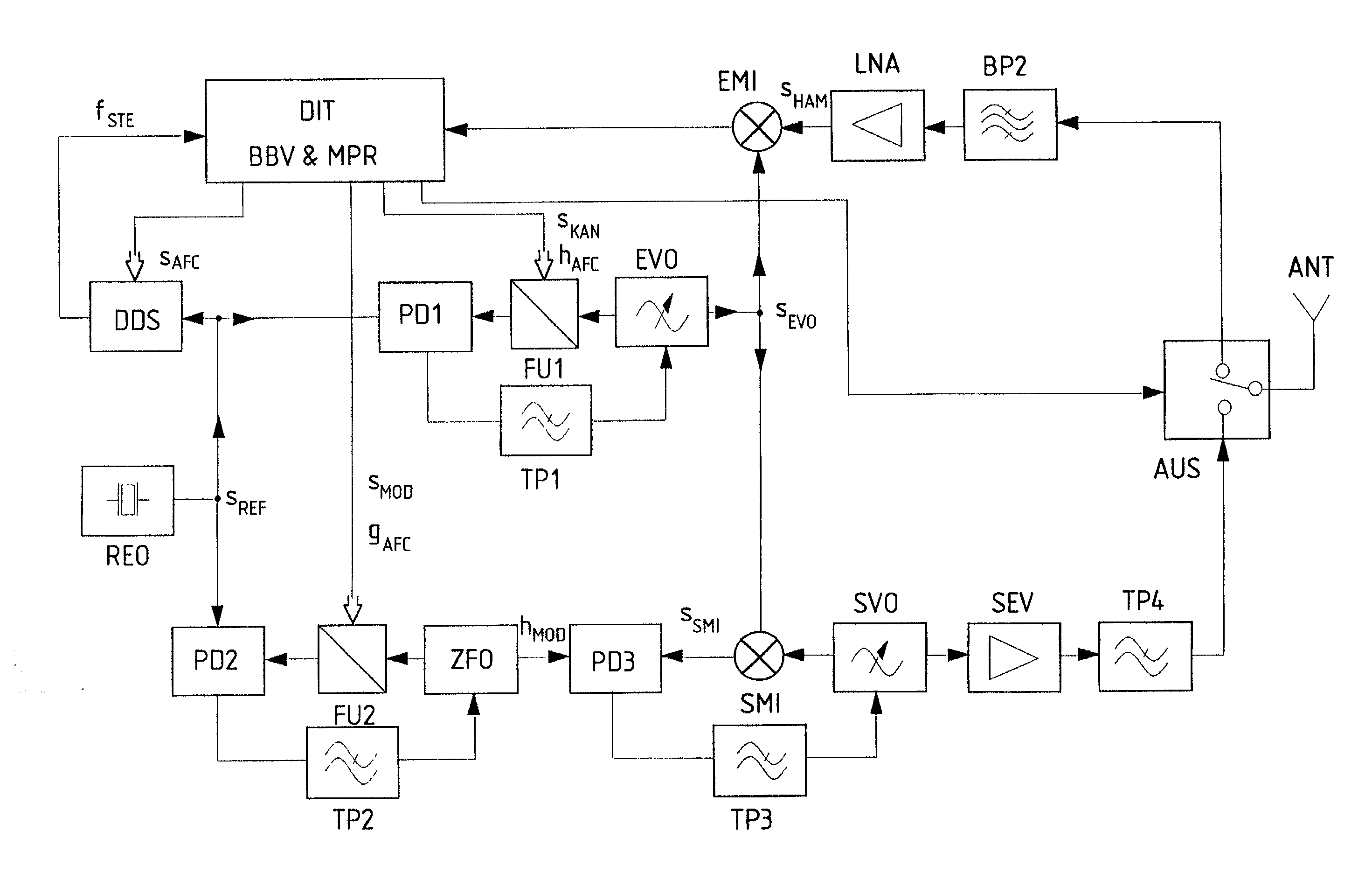

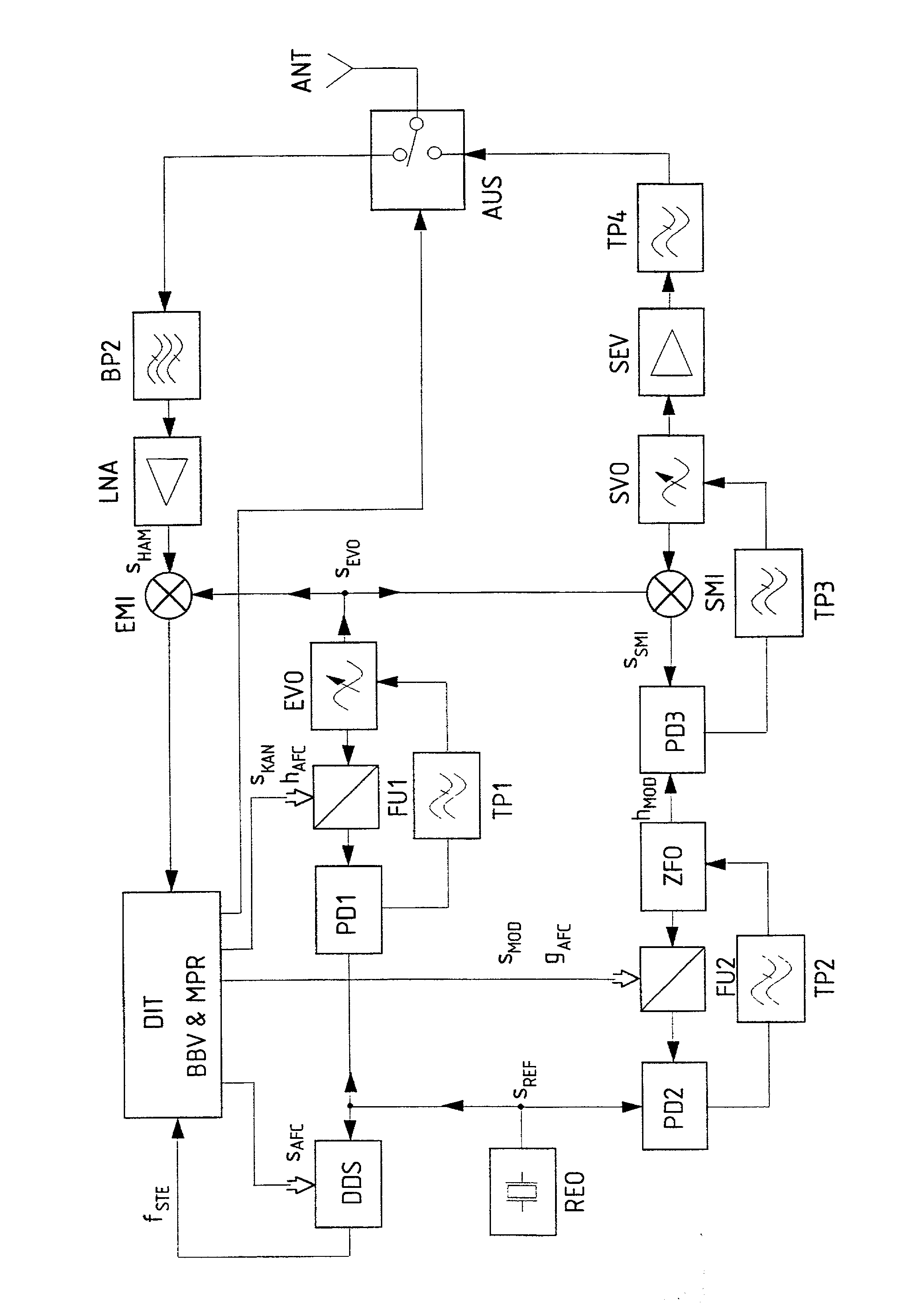

Transmitter-receiver

InactiveUS7076215B1Avoid harmonicsReduced shieldingPulse automatic controlElectrial characteristics varying frequency controlDigital tuningDiscriminator

A transceiver having an RF receiver, in particular VHF receiver, with digital signal processing in a digital part. The transceiver having an input part, at least one mixer and an intermediate frequency / baseband processing device, having a local channel oscillator, to which a first phase locked loop with a phase discriminator and an adjustable first frequency converter are assigned, and having a reference oscillator for the phase locked loop and the control clock of the digital signal processing device, in which, in order to acquire the control clock, a digital clock synthesizer is provided to which an output signal of the reference oscillator is supplied, and a control signal is supplied by the digital part in the form of a digital tuning word, the frequency of the reference oscillator being selected such that its order of magnitude is at least equal to the bandwidth of one or more of the reception bands used, and none of its harmonics occur in a reception channel.

Owner:CINTERION WIRELESS MODULES

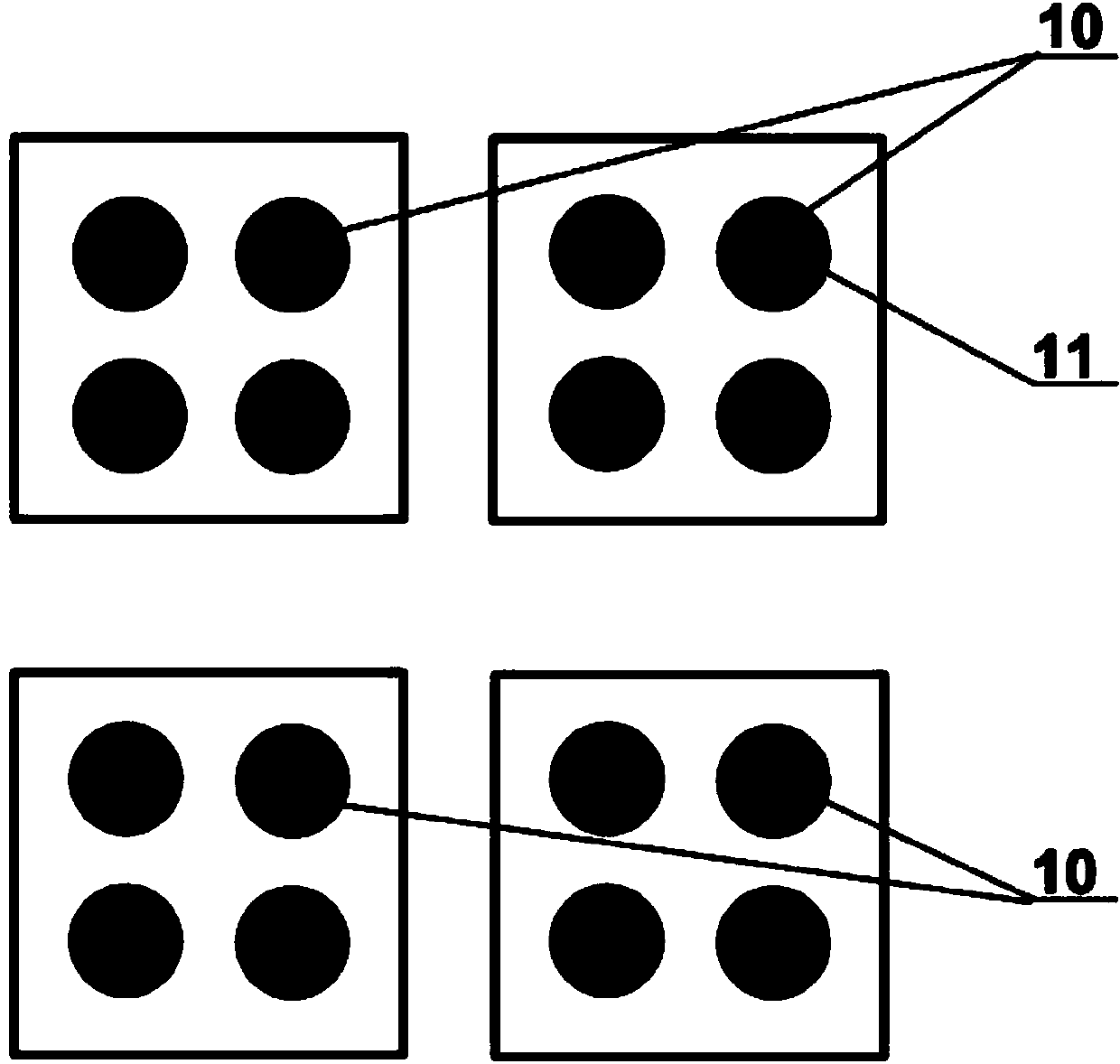

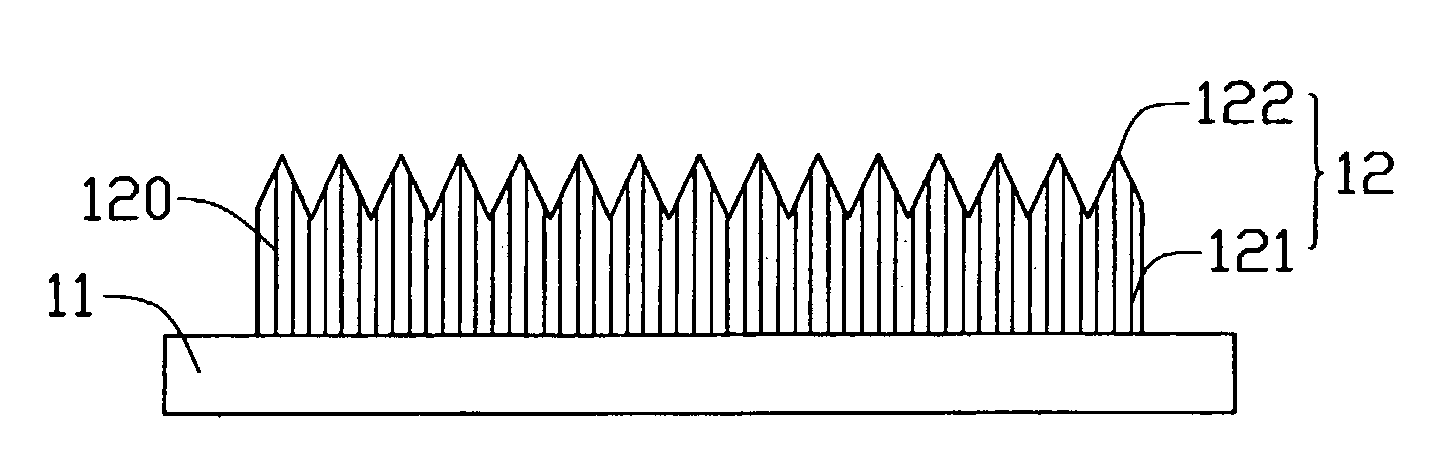

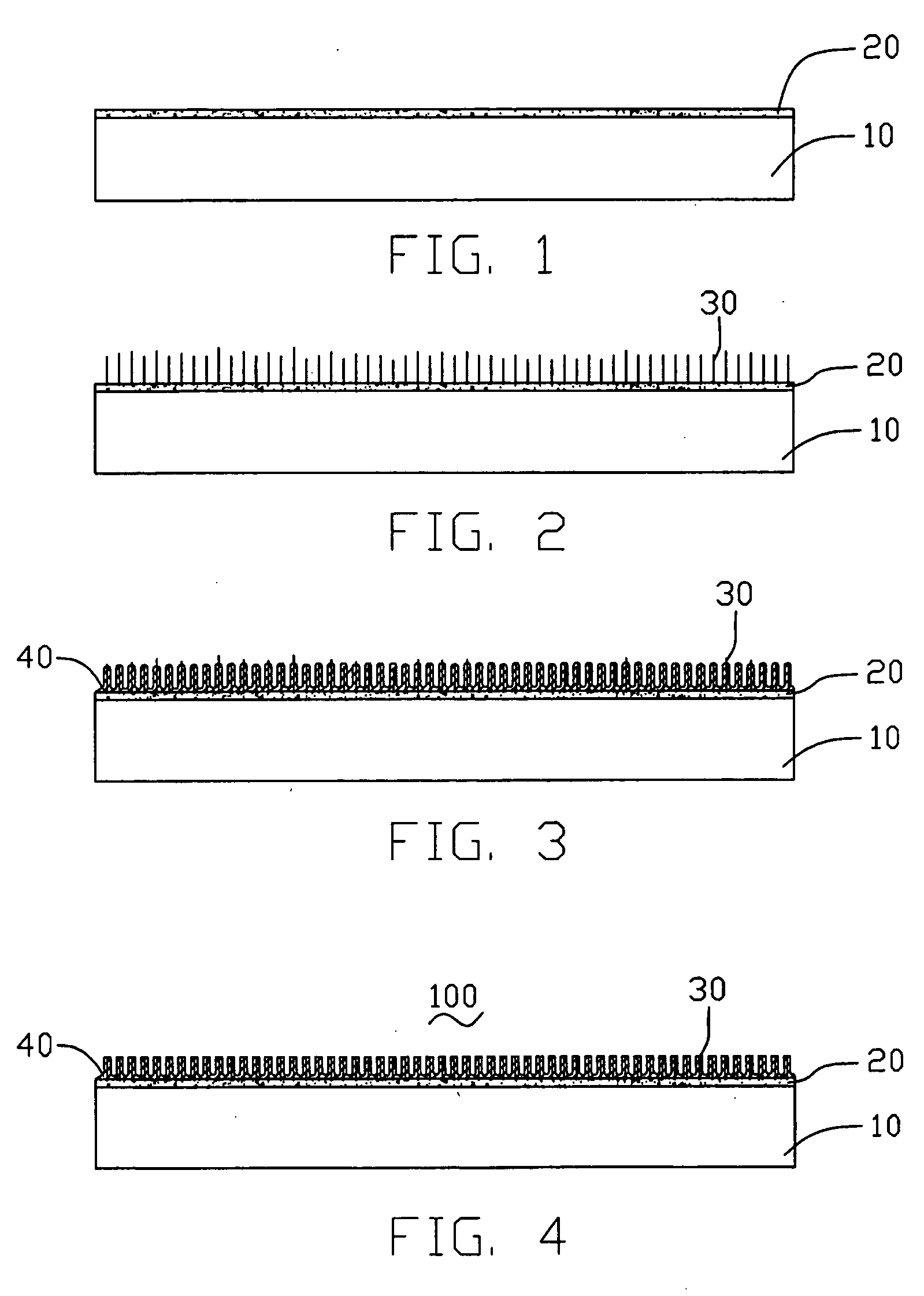

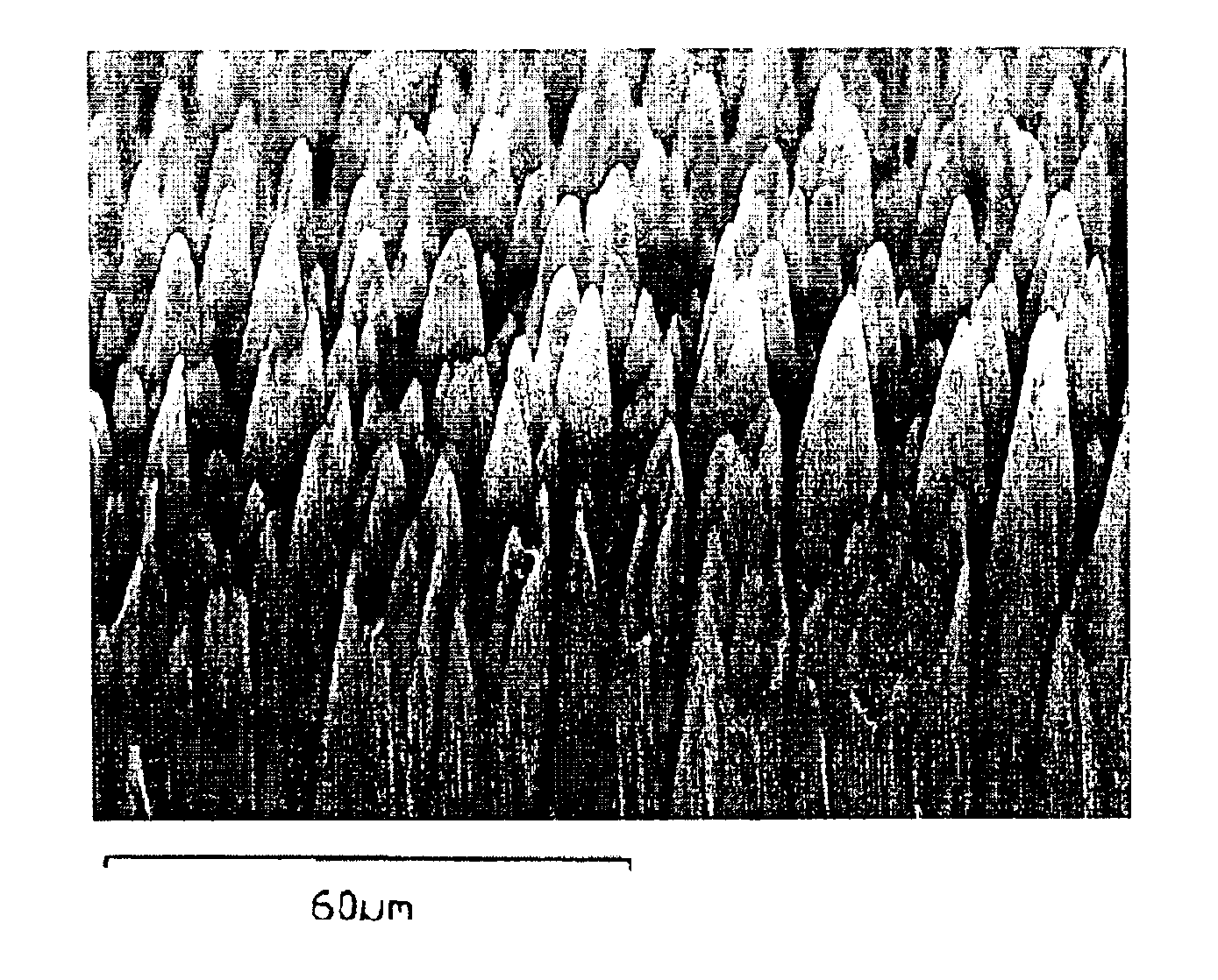

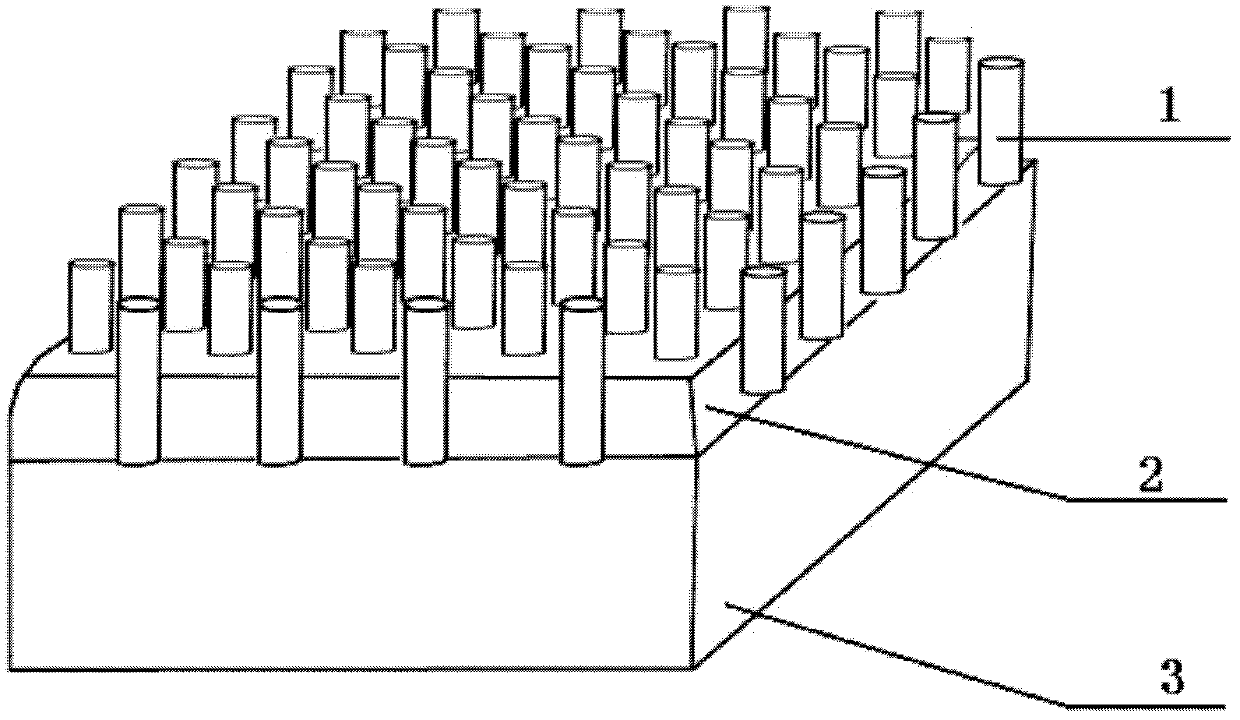

Carbon nanotube array and field emission device using same

InactiveUS7064474B2Reduced shieldingImproved field emission concentration and efficiencyMaterial nanotechnologyElectric discharge tubesField emission deviceMicrometer

A field emission device includes a substrate (11) and a carbon nanotube array (12) formed thereon. Carbon nanotubes (120) of the carbon nanotube array are parallel to each other and cooperatively form a plurality of substantially rod-shaped lower portions (121, 121′) and a plurality of corresponding tapered tips (122, 122′) above the lower portions. Each lower portion and tapered tips have a plurality of carbon nanotubes. Distances between adjacent tips are approximately uniform, and are more than one micrometer. Preferably, the distance is in the range from 1 to 30 micrometers. The field emission device with this structure has reduced shielding between adjacent carbon nanotubes and has decreased threshold voltage required for field emission by the carbon nanotubes. The field emission device also contributes to an improved field emission concentration and efficiency.

Owner:TSINGHUA UNIV +1

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

Multi-leaf collimators

InactiveUS20090262901A1Drive great amountReduced shieldingHandling using diaphragms/collimetersRadiation therapyMulti leaf collimatorEngineering

A multi-leaf collimator for a radiotherapy apparatus comprises at least one array of laterally-spaced elongate leaves, each leaf being driven by an associated motor connected to the leaf via a drive means so as to extend or retract the leaf in its longitudinal direction, the drive means comprising a sub-frame on which at least a subset of the motors are mounted, the sub-frame being mounted at a location spaced from the leaf array in a direction transverse to the lateral and longitudinal directions, and including a plurality of leadscrews disposed longitudinally, each being driven by a motor and being operatively connected to a leaf thereby to drive that leaf.

Owner:ELEKTA AB

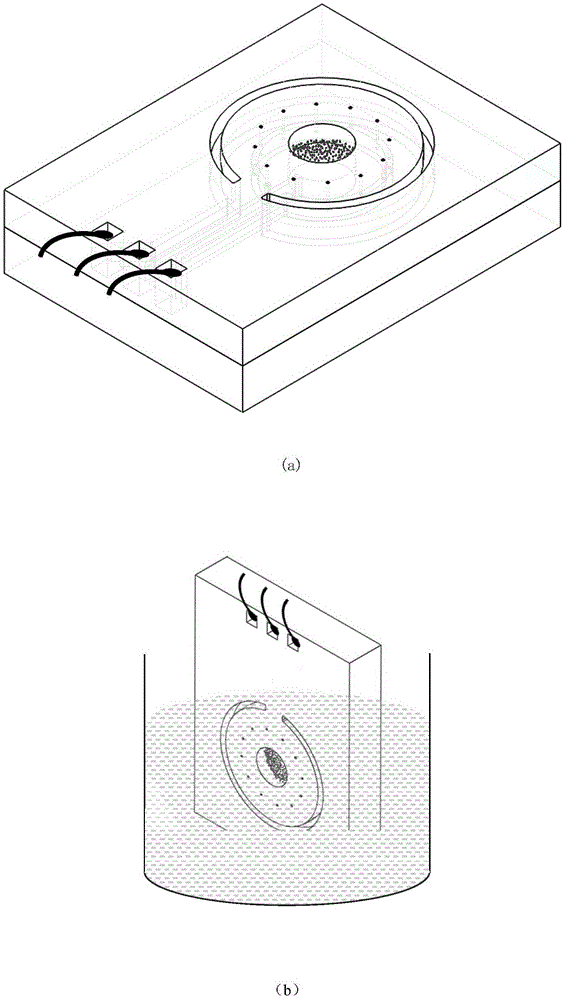

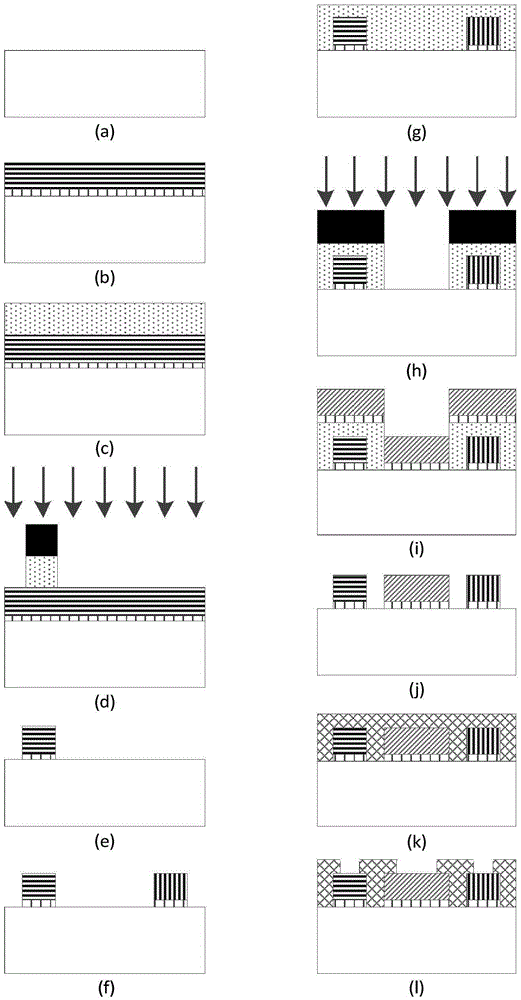

Three-electrode integrated electrochemical sensor based on microelectrode array

InactiveCN105388201ASmall sizeCommon materialMaterial electrochemical variablesElectrochemical gas sensorSurface modification

The invention discloses a three-electrode integrated electrochemical sensor based on a microelectrode array. The sensor comprises the bismuth film modified microelectrode array (gold working electrode), a silver / silver chloride electrode (reference electrode) and a platinum electrode (counter electrode). The three electrodes are prepared through a standard MEMS technology, and multiple discs at equal intervals are evenly distributed on the gold electrode to serve as the microelectrode array. In the electrochemical detection process, heavy metal gathering and dissolving-out reacting occur on the microelectrode array, and the surface of the microelectrode array is modified with a bismuth film in order to increase the detection type of heavy metal and expand the detection range of the heavy metal. The surface of the silver electrode is electroplated with silver chloride to form the Ag / AgCl reference electrode. The platinum electrode serves as the counter electrode and forms an access with the working electrode. Difference pulse stripping voltammetry is utilized for determining the concentration of the heavy metal, and a result shows that the sensor is high in detection sensitivity, low in detection limit and high in signal-to-noise ratio; the sensor is easy and convenient to operate, needs a small quantity of samples, can be used for rapidly detection heavy metal on site and is capable of efficiently monitoring environmental pollution in real time.

Owner:ZHEJIANG UNIV

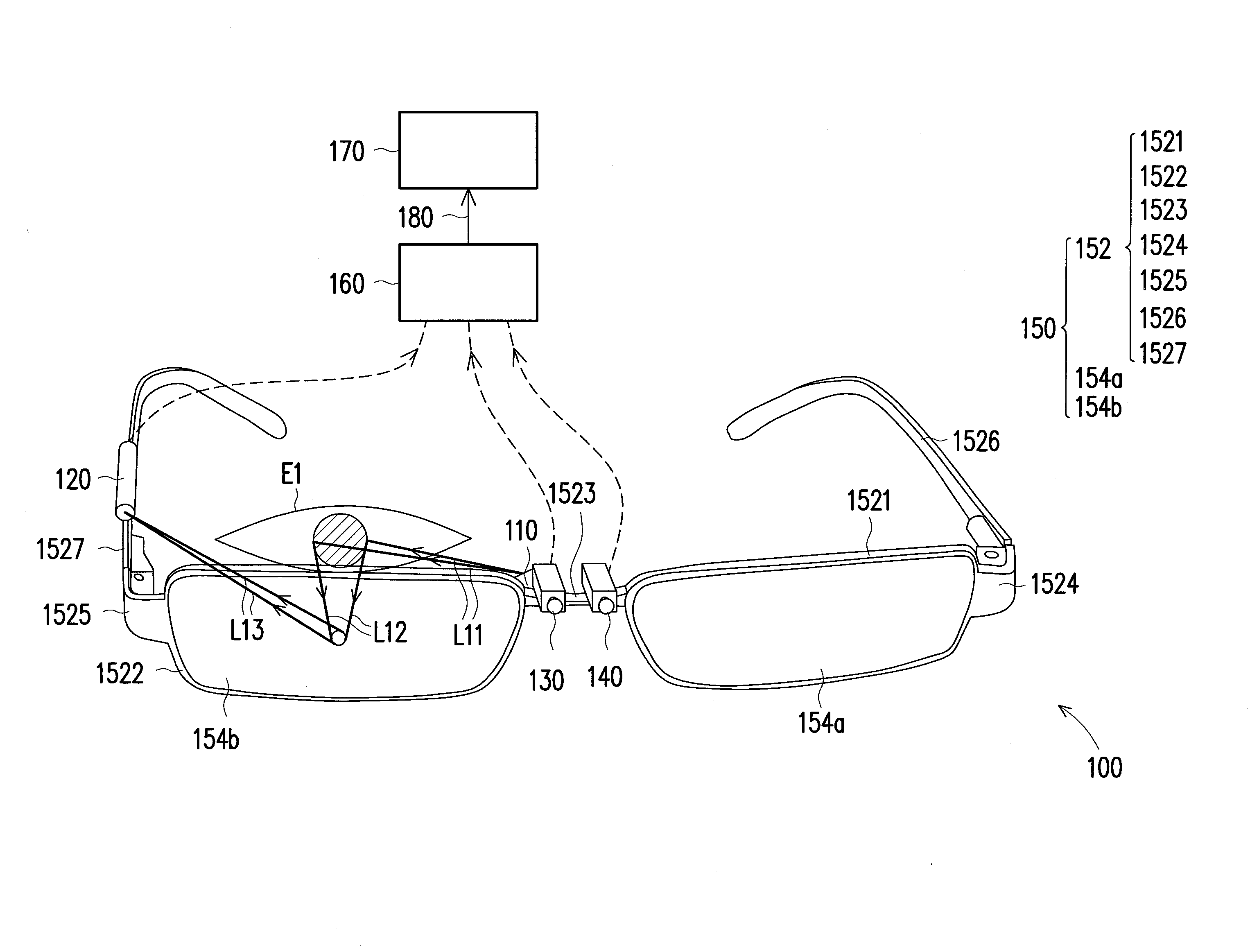

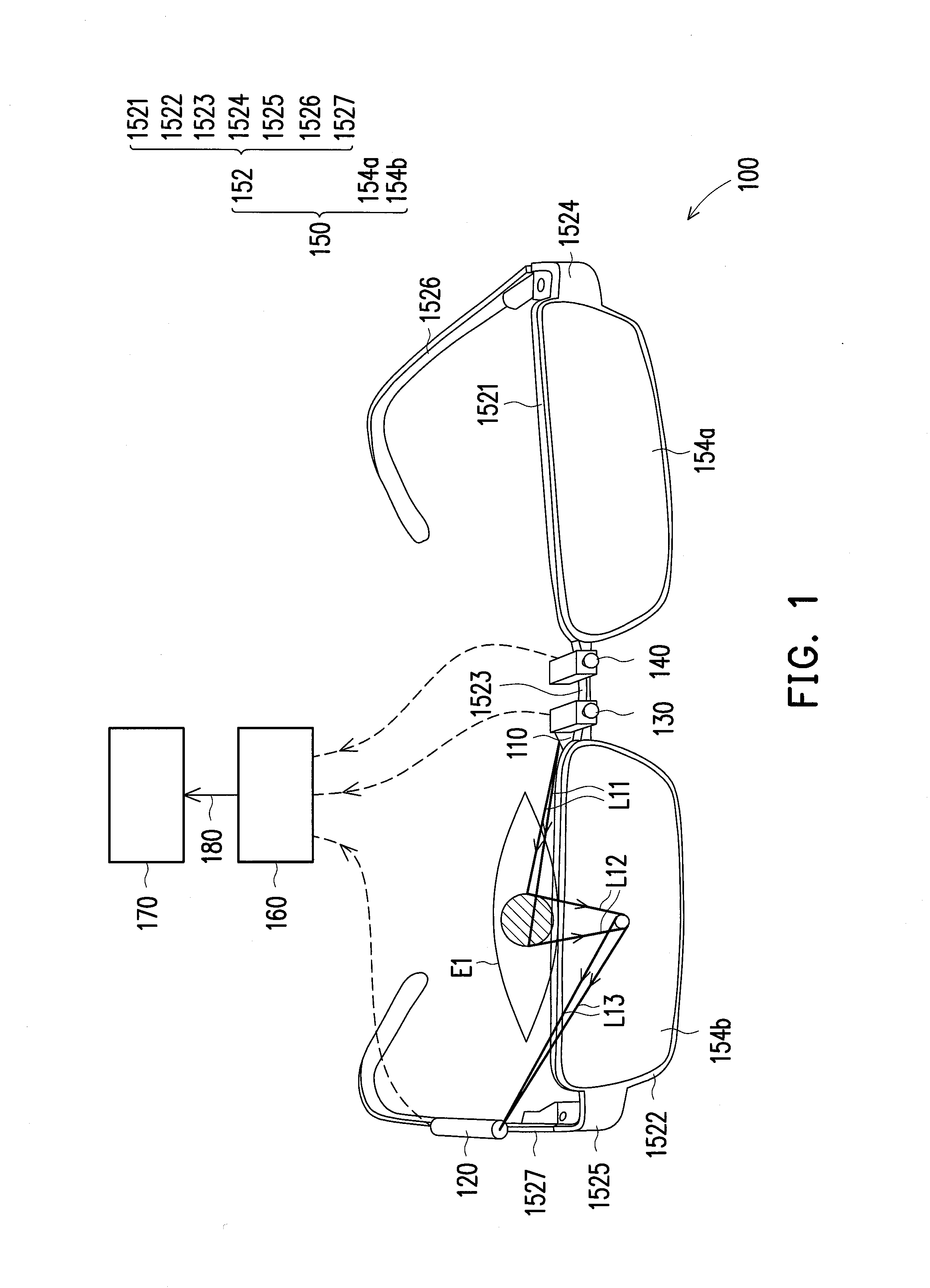

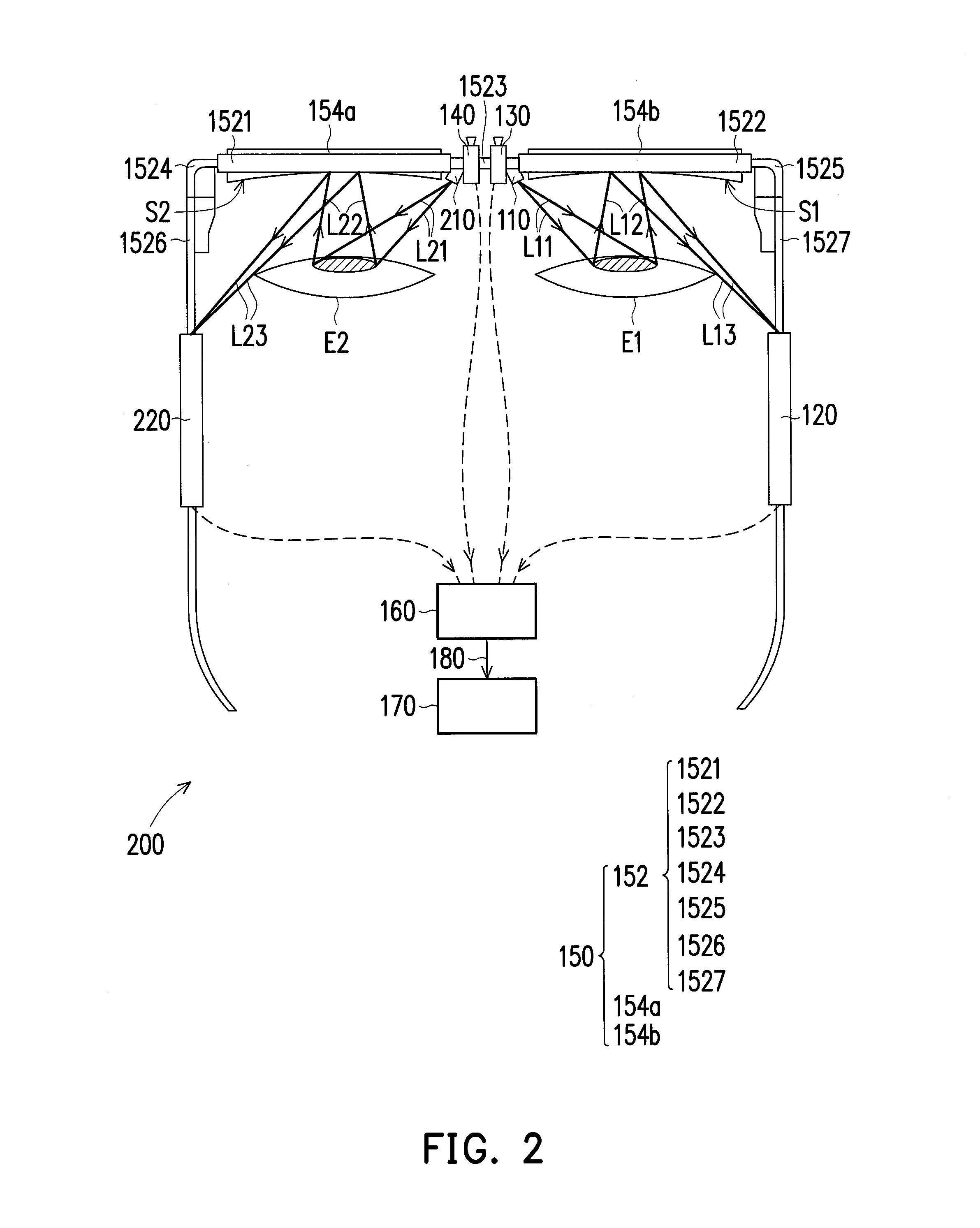

Head-mount eye tracking system

ActiveUS20150035745A1Reduce decreaseReduced shieldingInput/output for user-computer interactionCathode-ray tube indicatorsPupilEye tracking system

A head-mount eye tracking system including a first light source, a first pupil image capturing device, a first and a second environmental image capturing devices, a fixing device and an image identification system. The first light source is applied to illuminate a first eye of a user. The first pupil image capturing device is applied to capture a first pupil image of the first eye. The first and the second environmental image capturing devices are respectively applied to capture a first and a second environmental images in front of the user. The fixing device is mounted to the head of the user to fix the first light source, the first pupil image capturing device, the first and the second environmental image capturing devices on the head of the user. The image identification system is applied to map the first or the second environmental images to the first pupil image.

Owner:NAT CHIAO TUNG UNIV

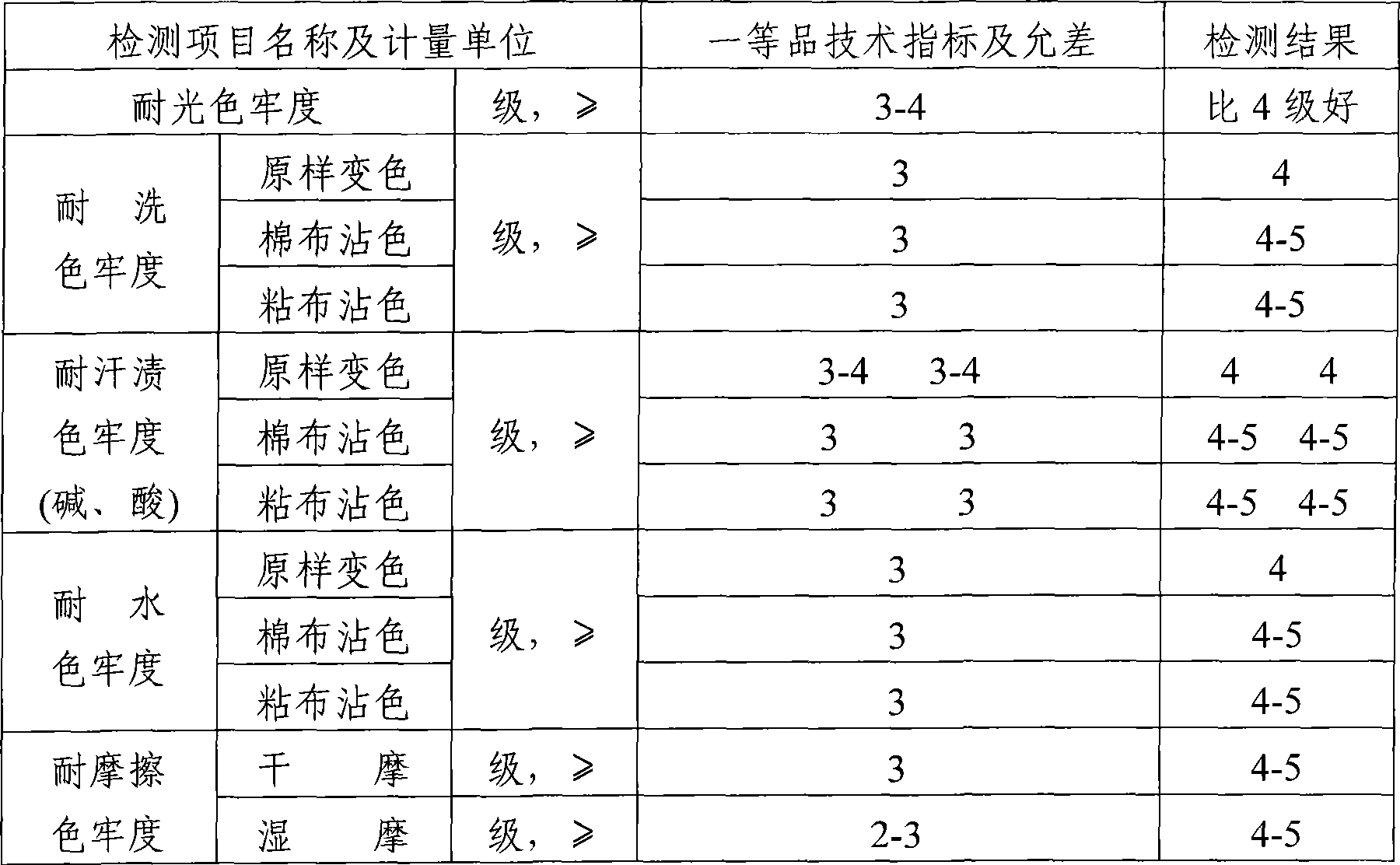

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

MEMS microphone package having sound hole in PCB

InactiveUS20090116669A1Reduced shieldingIncrease construction costsPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersMems microphoneApplication-specific integrated circuit

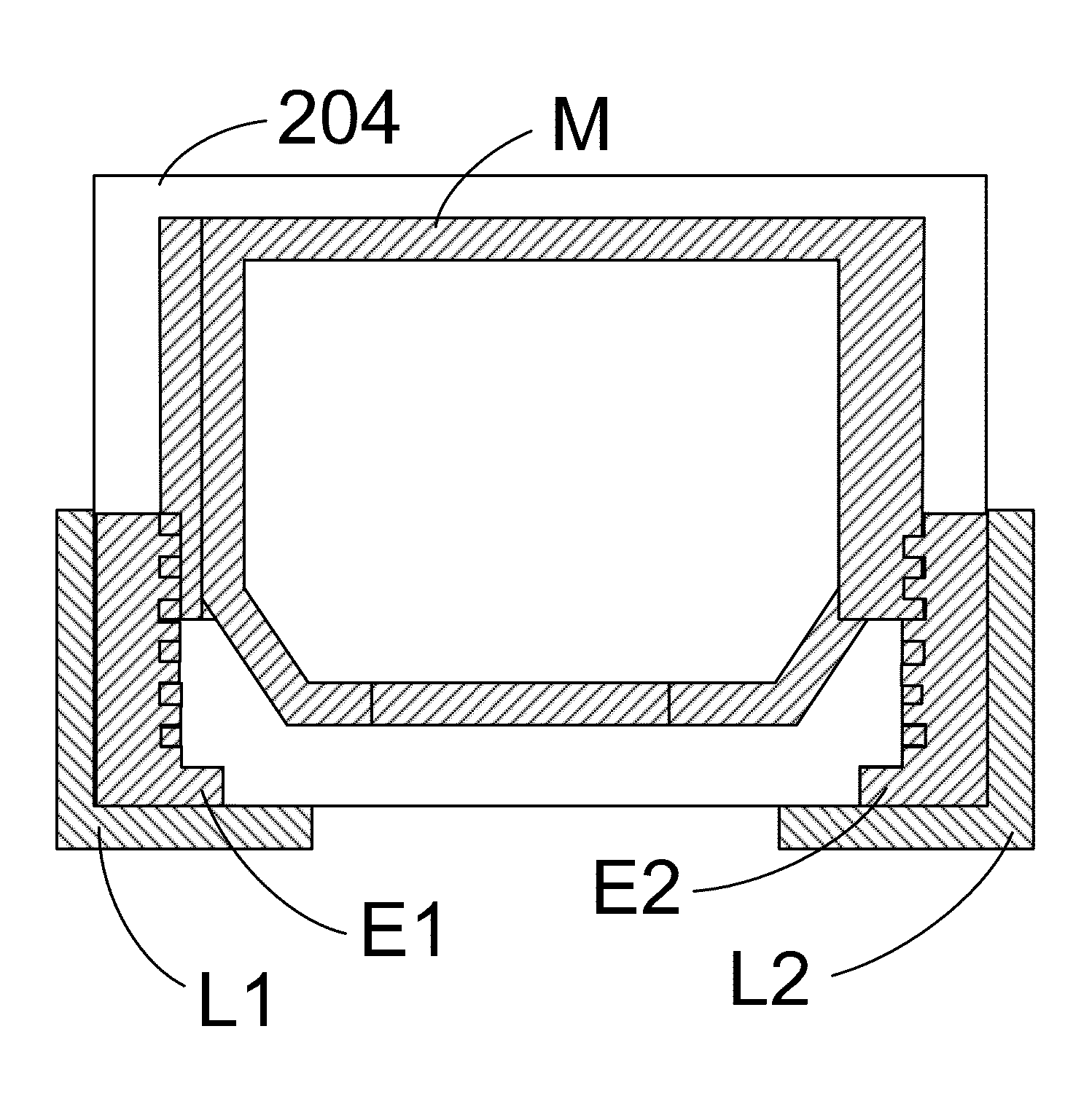

Provided is a MEMS microphone package having a sound hole in a PCB, which can ground-connect a metal case to a main board using an assembly process including bending and clamping an end of the case. The MEMS microphone package includes a tetragonal container-shaped metal case having an open-side to insert components into an inner space, and a chamfered end on the open-side to easily perform a curling operation, a printed circuit board (PCB) substrate to which a MEMS microphone chip and an application specific integrated circuit (ASIC) chip are mounted, the PCB substrate being inserted into the metal case and having a sound hole for introducing an external sound, and a support configured to support the PCB substrate in the curling operation and define a space between the metal case and the PCB substrate.

Owner:BSE CO LTD

Carbon nanotube field emission device and method for manufacturing same

ActiveUS20050264155A1Avoid separationReduced shieldingDischarge tube luminescnet screensElectric discharge tubesField emission deviceField emission current

Owner:HON HAI PRECISION IND CO LTD +1

Method for producing amino acid fertilizer by means of waste water and meat and bone meal generated by livestock harmless treatment

ActiveCN104003766AReduced shieldingReduce addAnimal corpse fertilisersClimate change adaptationDiseaseSide chain

The invention provides a method for producing an amino acid fertilizer by means of waste water and meat and bone meal generated by livestock harmless treatment, and particularly relates to a method for producing the amino acid fertilizer by hydrolyzing the organic waste water and the meat and bone meal generated due to harmless treatment of livestock died from diseases in a enzyme-acid two-step method. Firstly, the meat and bone meal and soluble protein in the organic waste water are hydrolyzed by means of trypsin, polypeptide generates small-molecule peptide chains through enzymolysis, the shielding function of side-chain radicals on peptide is weakened, the space repression effect between the side-chain radicals and the peptide is reduced, and then complete hydrolysis is carried out with dilute hydrochloric acid. The method has the advantages that the soluble protein and amino acid in the organic waste water generated due to harmless treatment of the livestock died from the diseases are fully used, and waste is turned to wealth; the hydrolyzed meat and bone meal generates a large amount of calcium, phosphorus and microelements and is chelated with the free amino acid, and addition of extra microelements, calcium and phosphorus is reduced; besides, the content of the amino acid generated by the meat and bone meal after hydrolysis is more comprehensive and balanced.

Owner:FOSHAN YANHUI BIOTECH CO LTD

Intelligent watch antenna and intelligent watch structure with external antenna

InactiveCN106207381AExquisite structureGuaranteed textureAntenna supports/mountingsRadio-controlled time-piecesElectrical and Electronics engineering

The invention relates to the field of intelligent watches and discloses an intelligent watch antenna and an intelligent watch structure with an external antenna. A watch frame is changed into the watch antenna, the receiving face of the antenna can be externally arranged, in this way, the shielding influences of a metal watch shell and other components can be greatly reduced, the receiving effect can be improved, the situation that the antenna occupies the internal space of a watch can be avoided, and an internal movement and the whole watch can be miniaturized. In addition, material limit is not produced on the metal watch shell or the other components, the texture of the intelligent watch can be guaranteed, the intelligent watch has the advantages that the cost is low, and the overall structure is attractive and descent, and the intelligent watch can be conveniently applied and popularized in reality.

Owner:CHENGDUSCEON ELECTRONICS

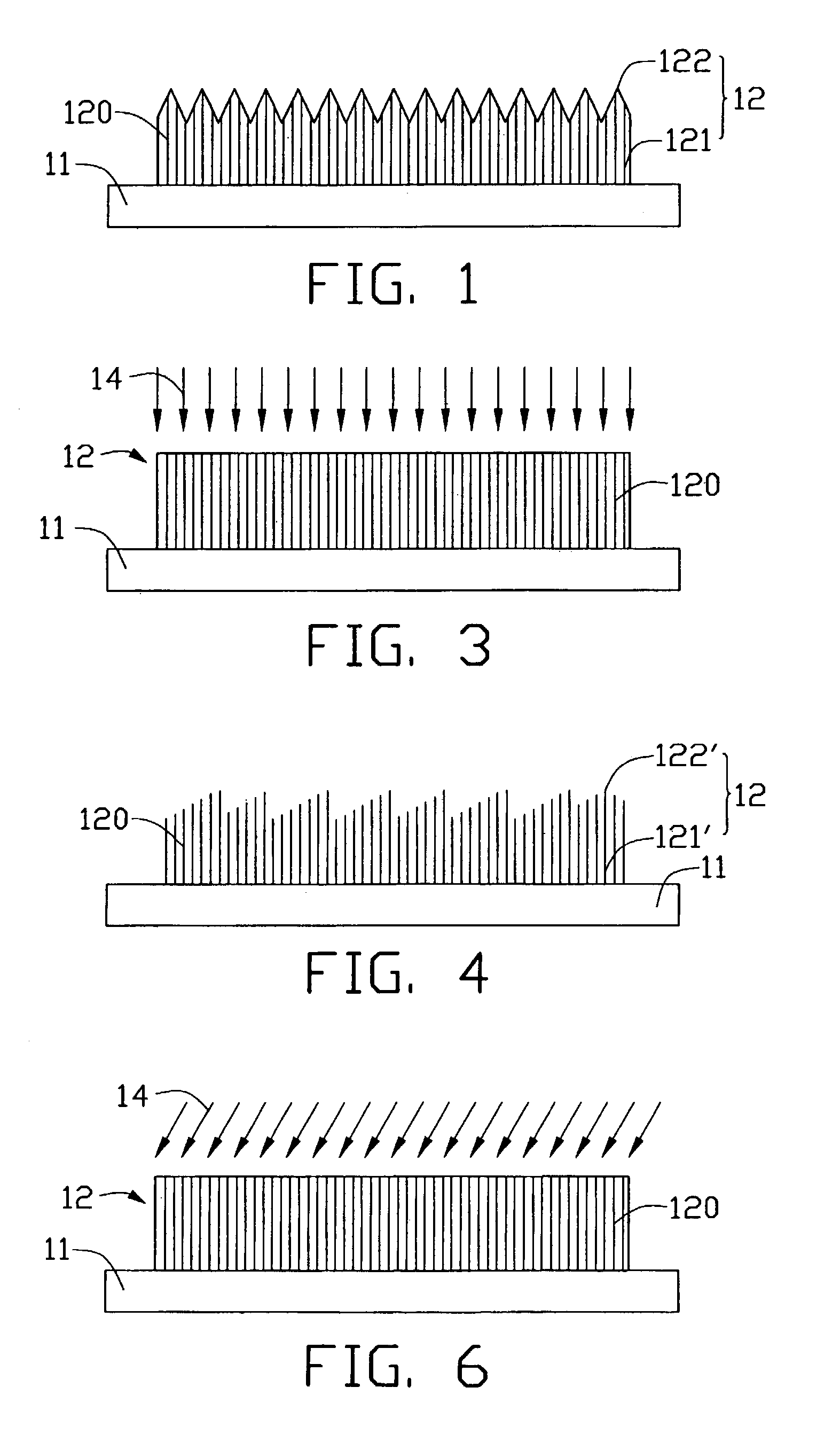

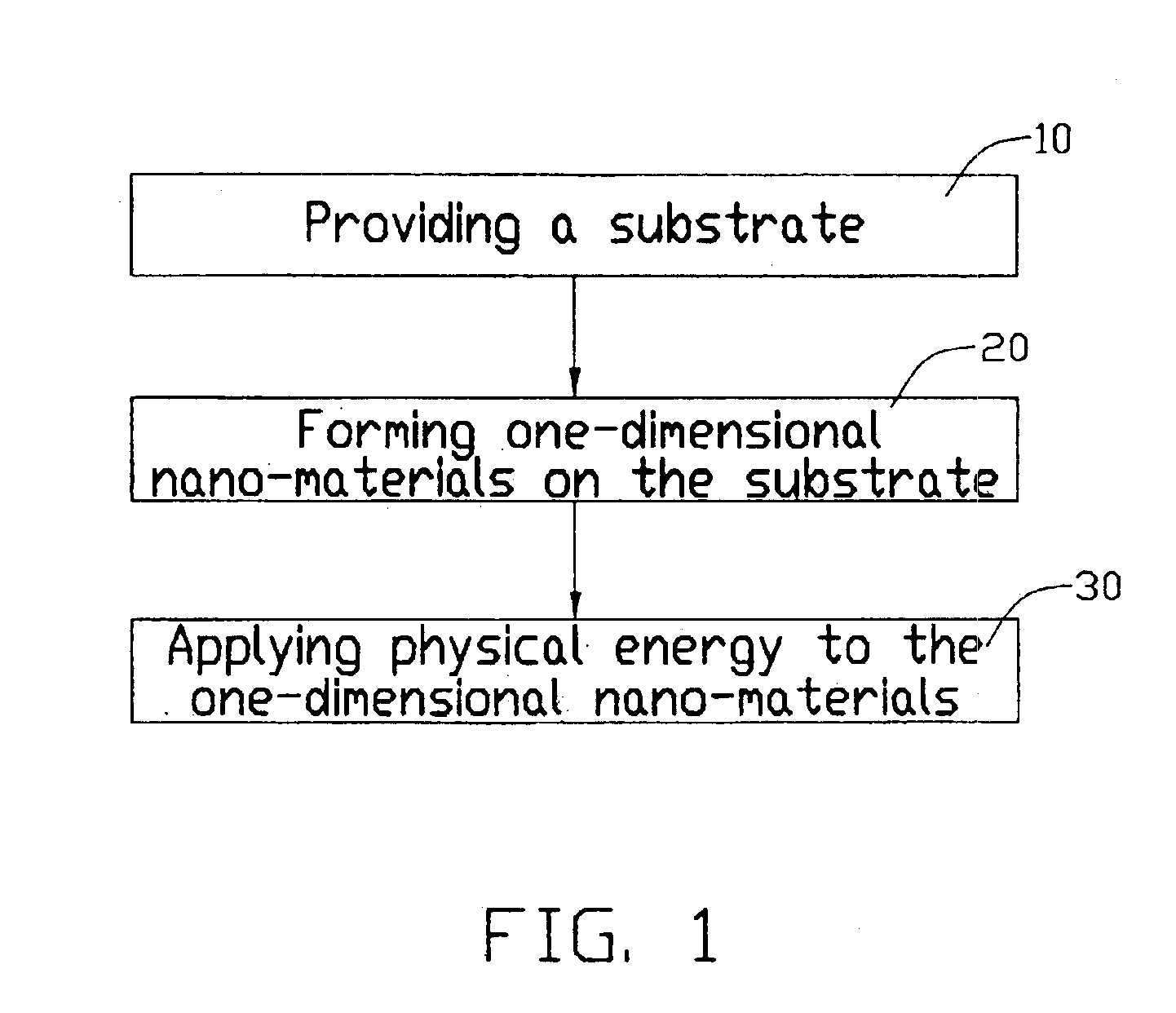

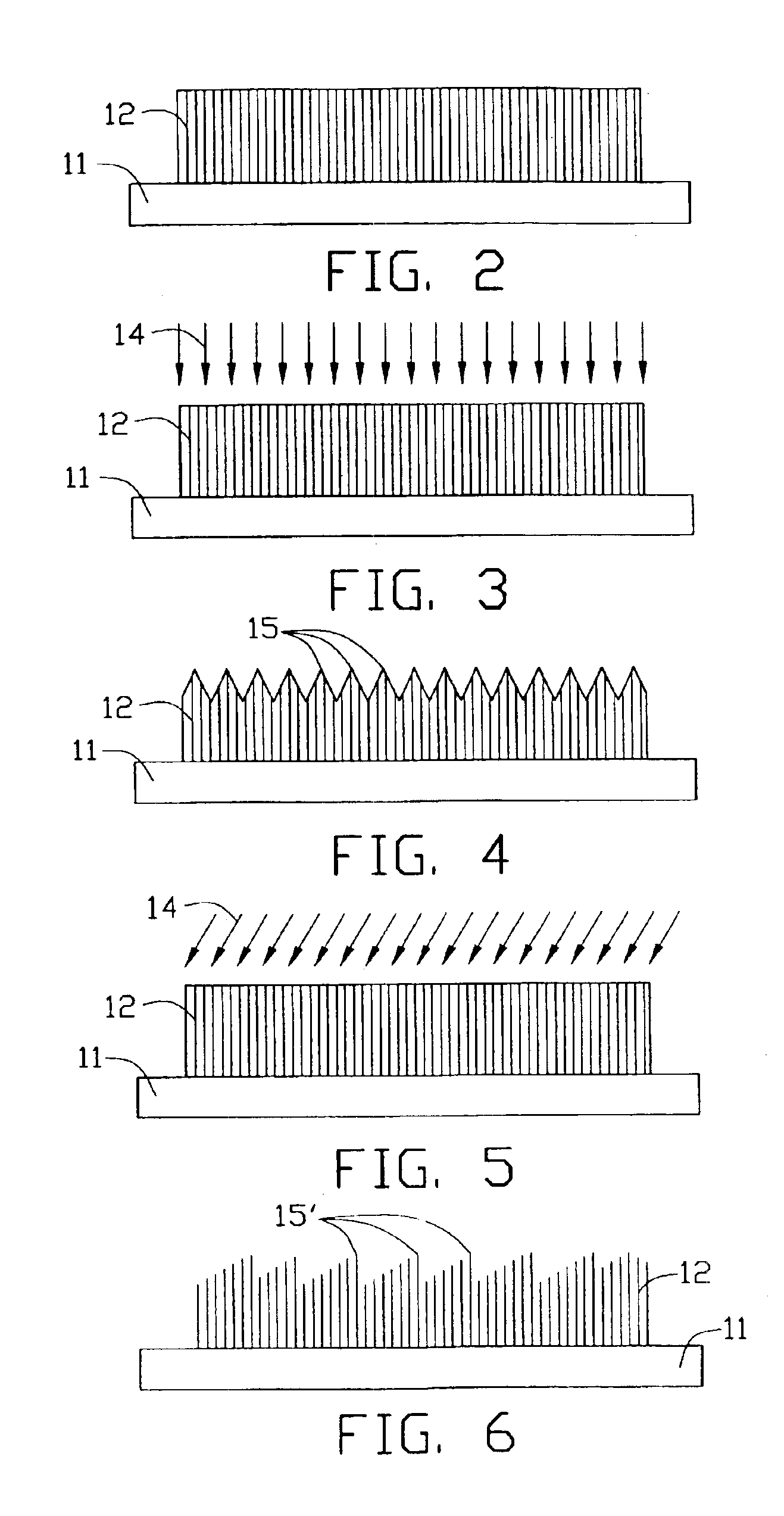

Method for processing one-dimensional nano-materials

InactiveUS6893886B2Reduced shieldingLower threshold voltageMaterial nanotechnologyPolycrystalline material growthHigh energyEngineering

A method for processing one-dimensional nano-materials includes the following steps: providing a substrate (11); forming one-dimensional nano-materials (12) on the substrate, the one-dimensional nano-materials being substantially parallel to each other and each being substantially perpendicular to the substrate, the one-dimensional nano-materials cooperatively defining a top surface distal from the substrate; and applying physical energy (14) by means of a high-energy pulse laser beam to the top surface of the one-dimensional nano-materials. The resulting one-dimensional nano-materials have sharp, tapered tips (15, 15′). Distances between adjacent tips are approximately uniform, and are relatively large. This reduces shielding between adjacent one-dimensional nano-materials. The tips also contribute to a decreased threshold voltage required for field emission by the one-dimensional nano-materials.

Owner:TSINGHUA UNIV +1

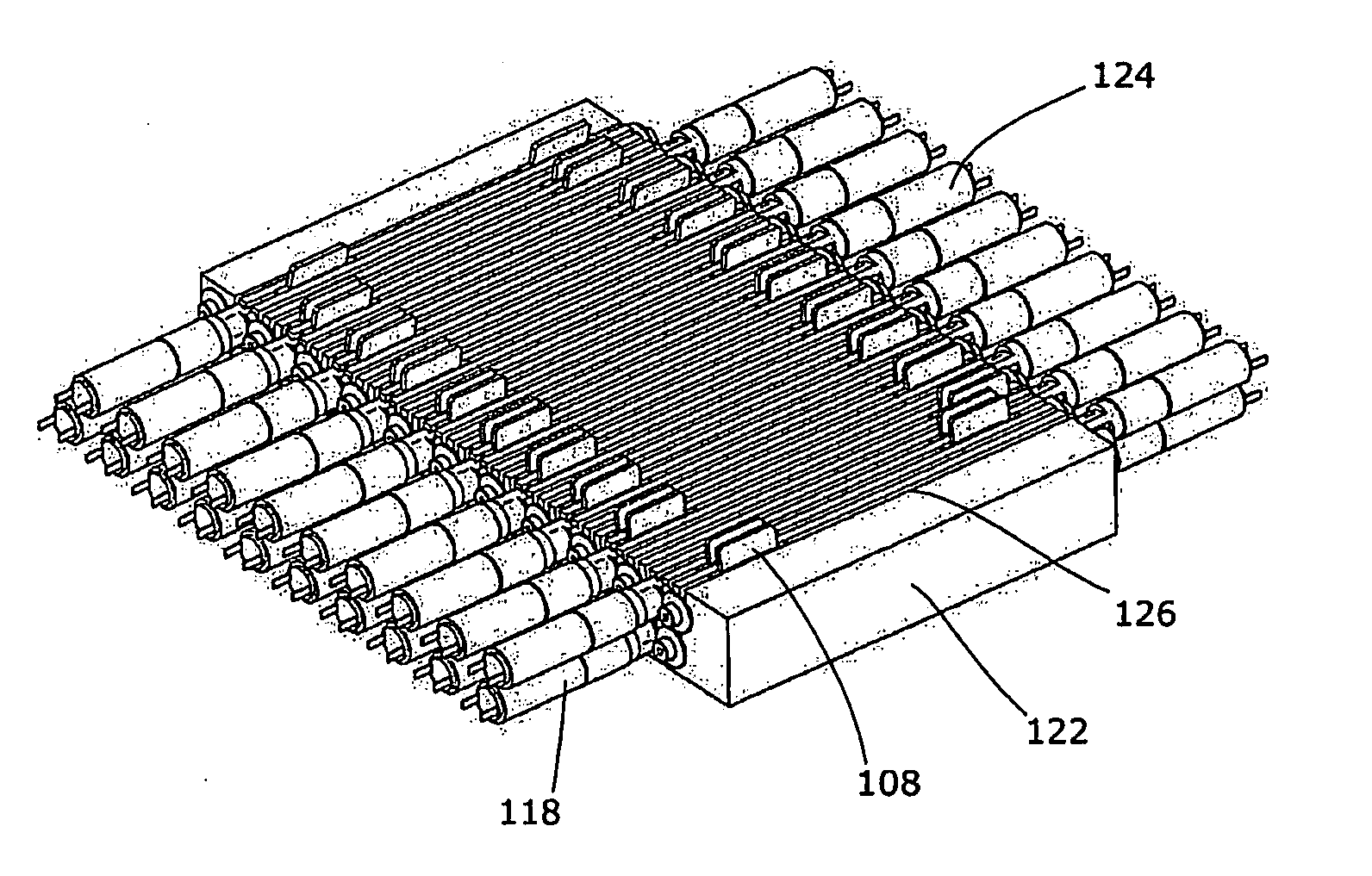

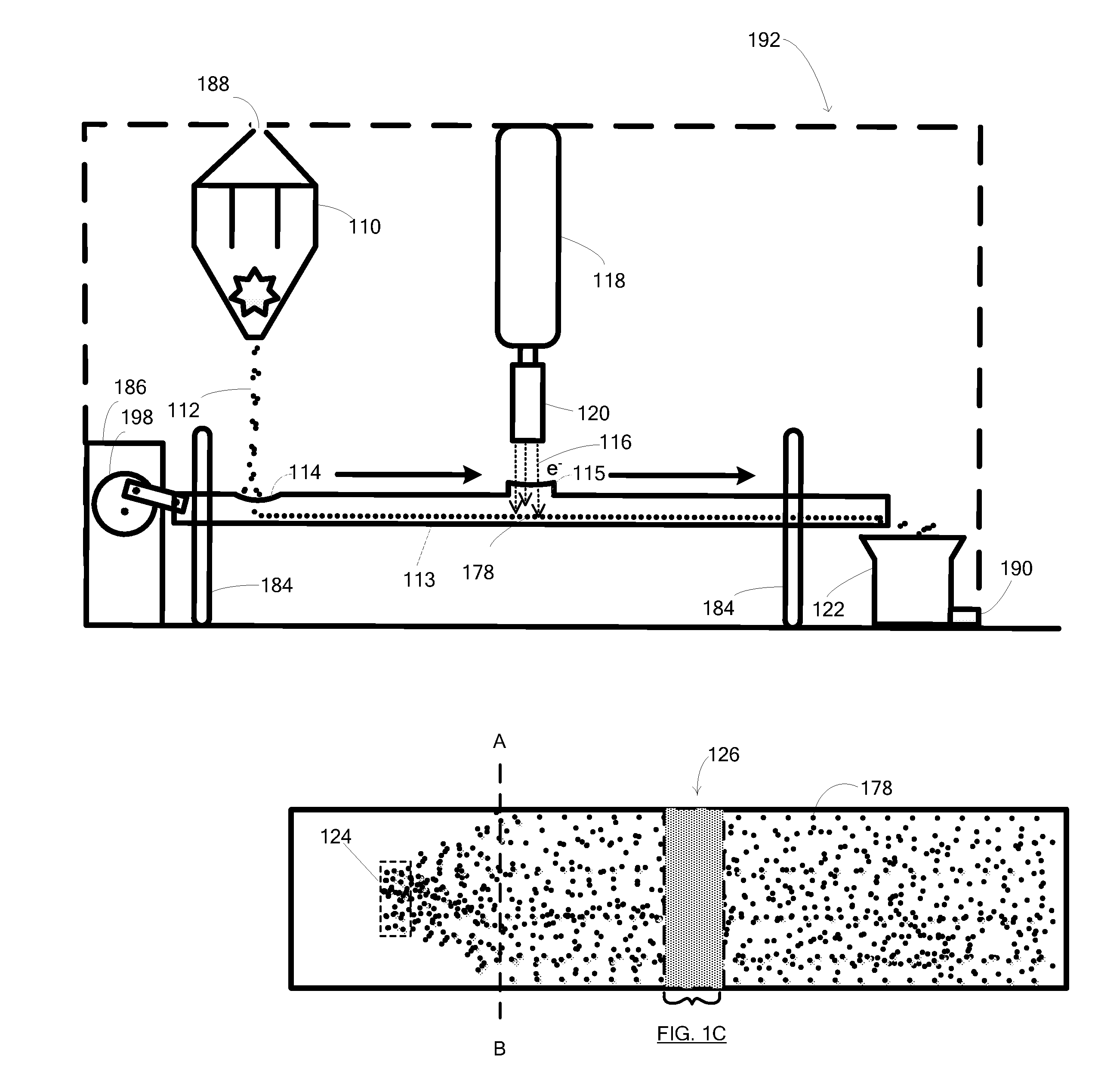

Processing biomass

Methods and systems are described for processing cellulosic and lignocellulosic materials into useful intermediates and products, such as energy and fuels. For example, conveying systems and methods, such as highly efficient vibratory conveyors, are described for the processing of the cellulosic and lignocellulosic materials.

Owner:XYLECO INC

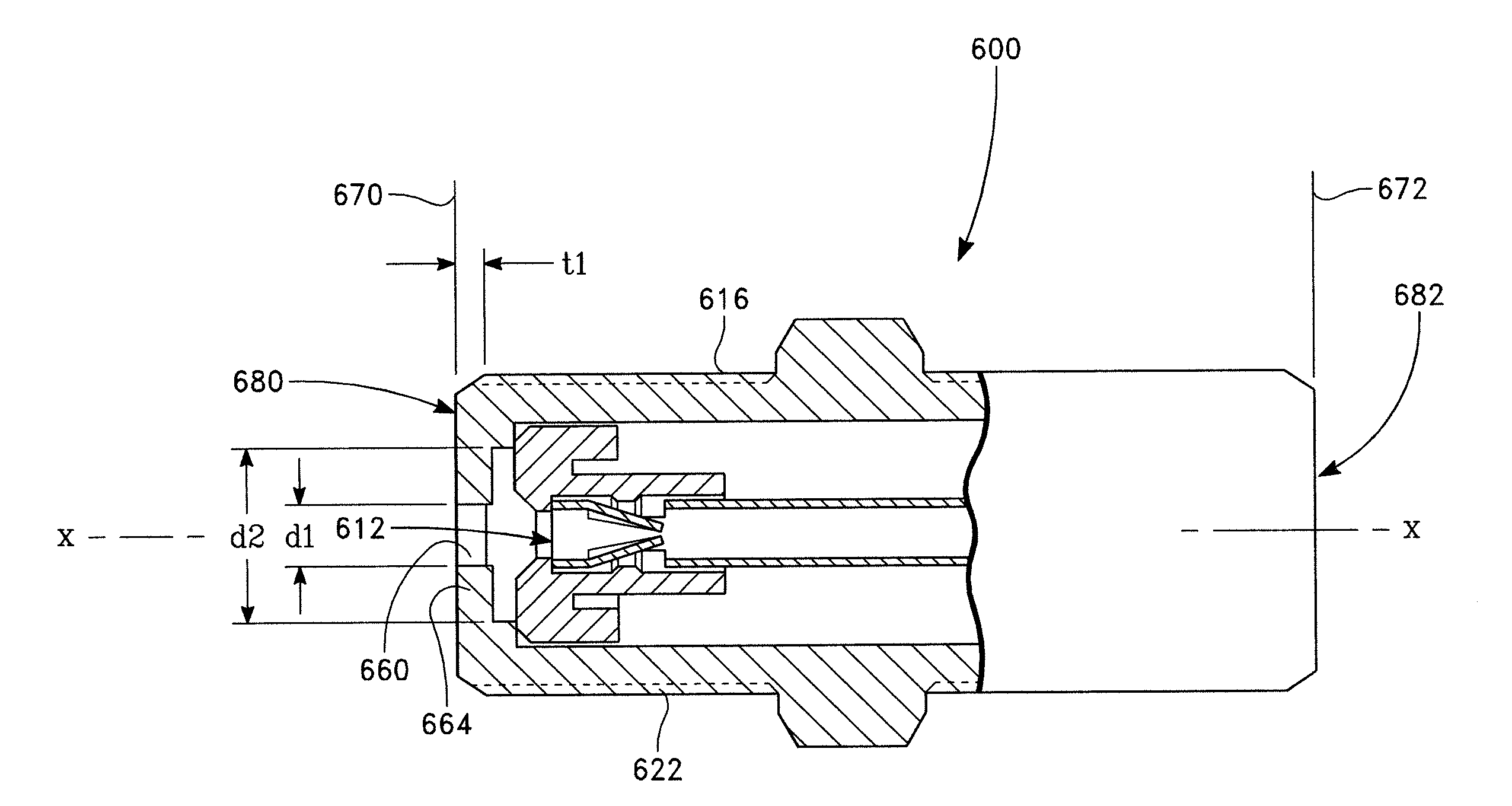

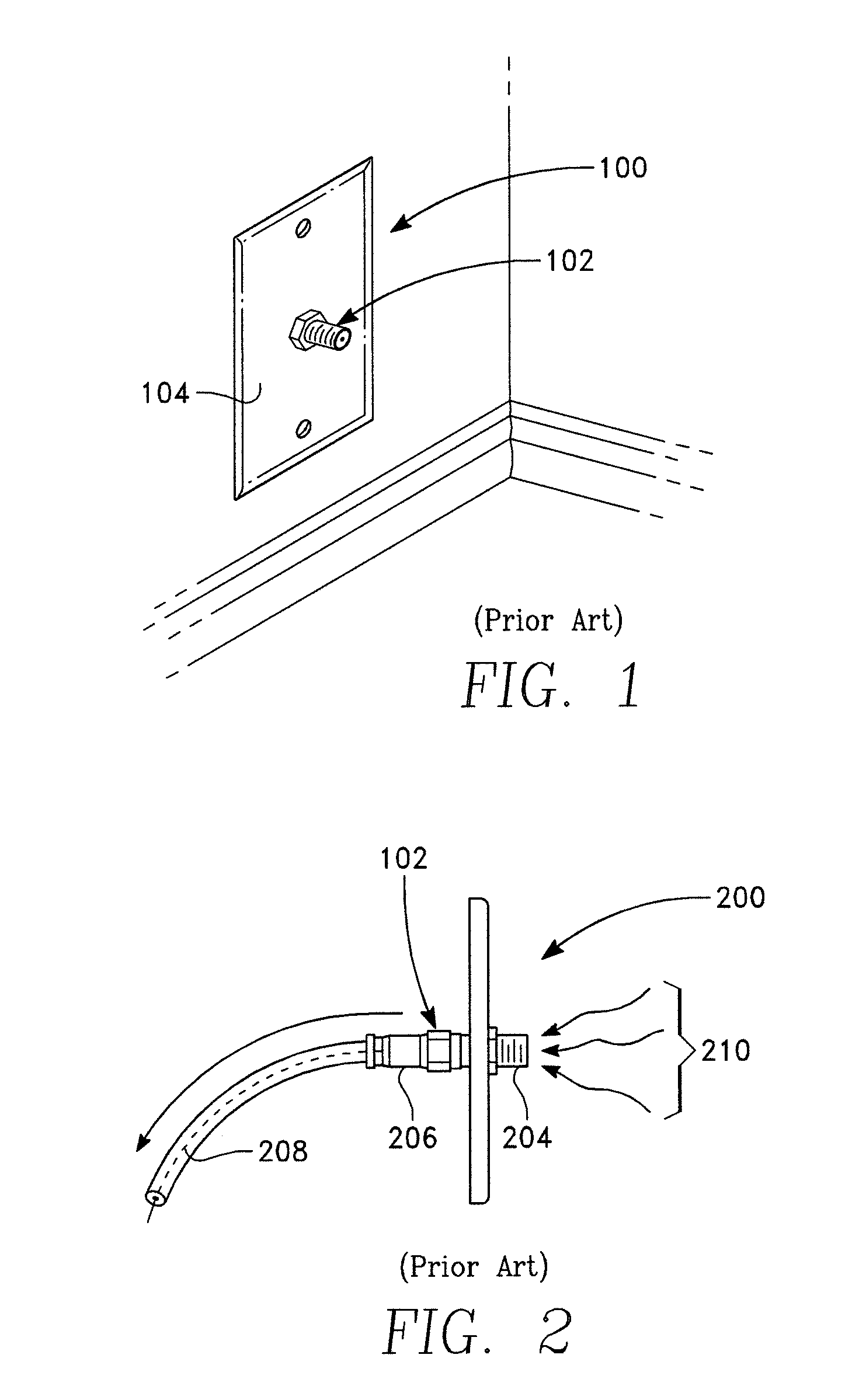

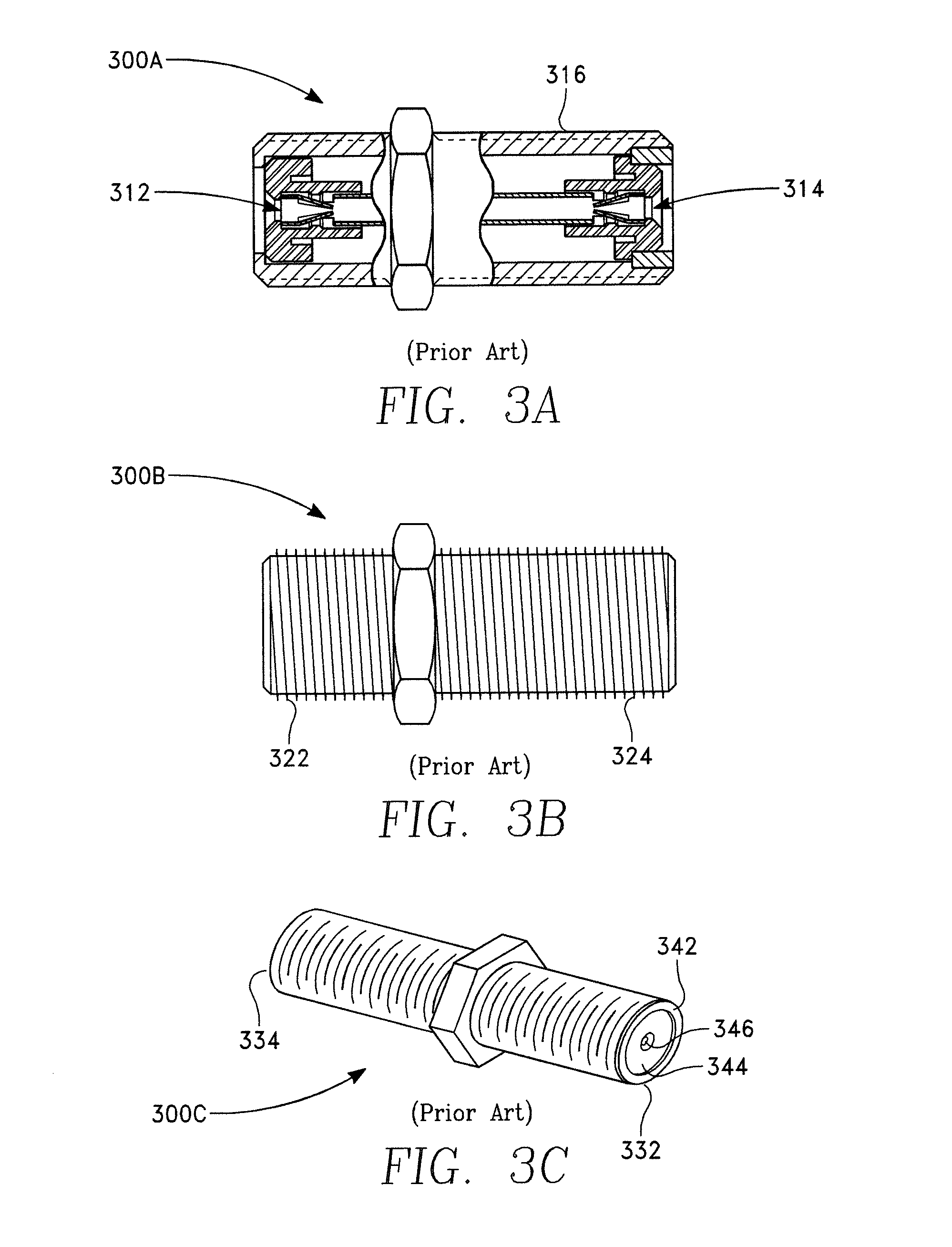

Coaxial connector with ingress reduction shield

InactiveUS20130266275A1Increasing the thicknessImproving impedanceTwo-part coupling devicesCoupling light guidesEngineeringElectrical and Electronics engineering

Owner:HOLLAND ELECTRONICS

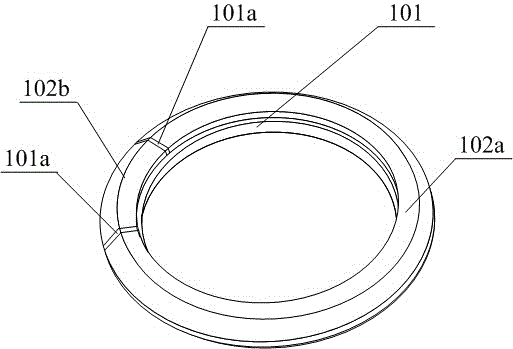

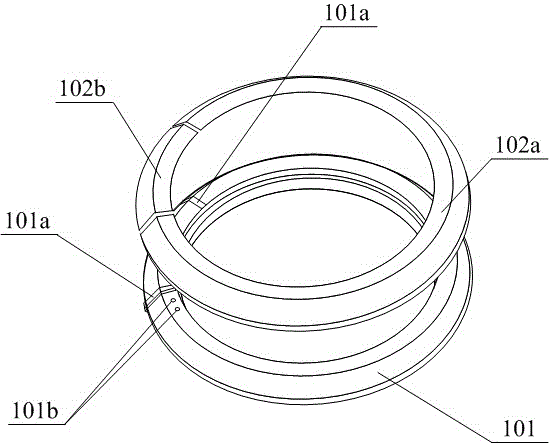

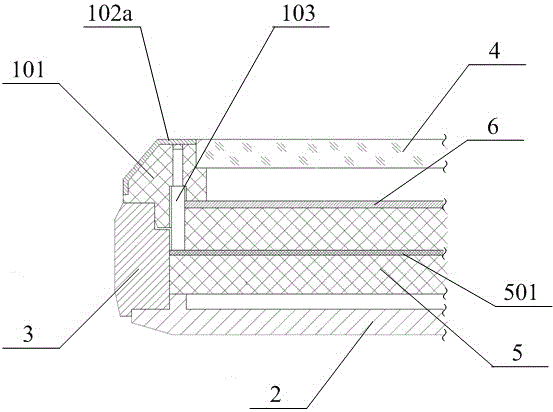

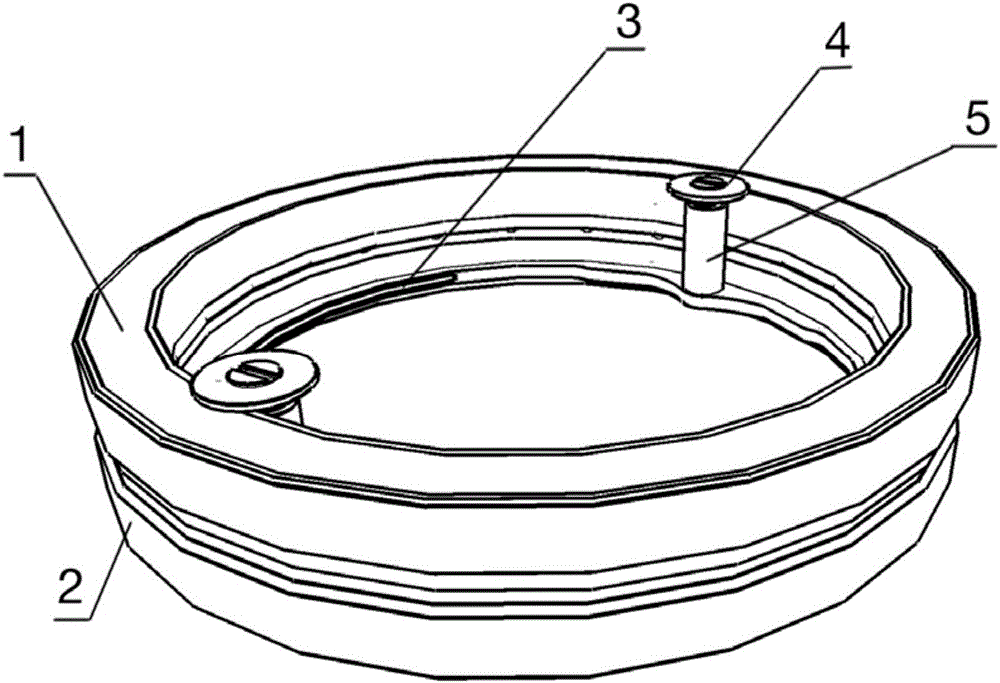

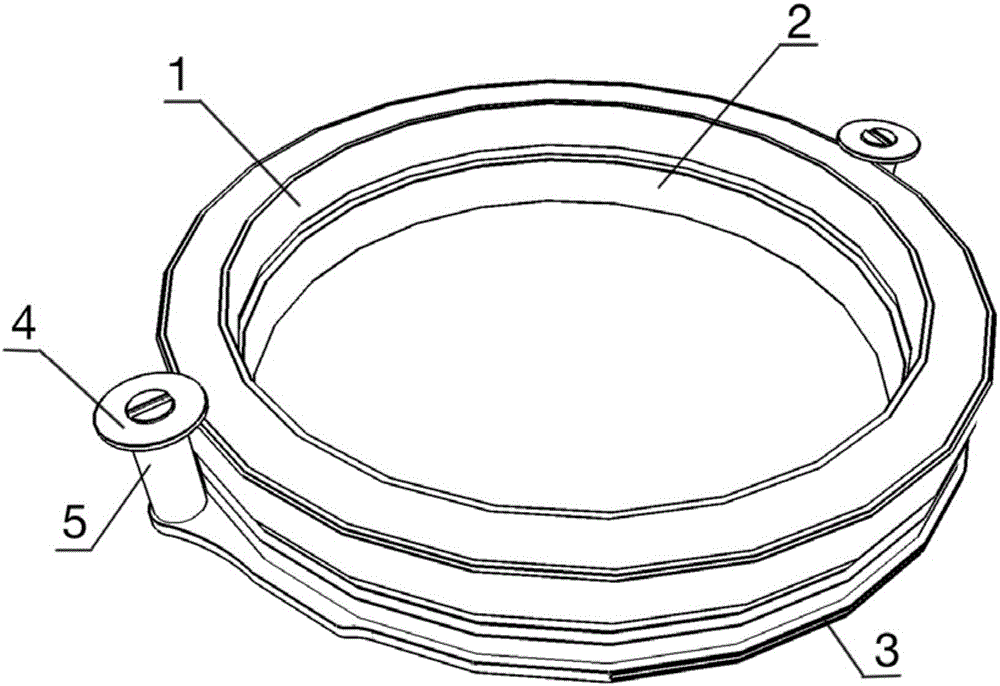

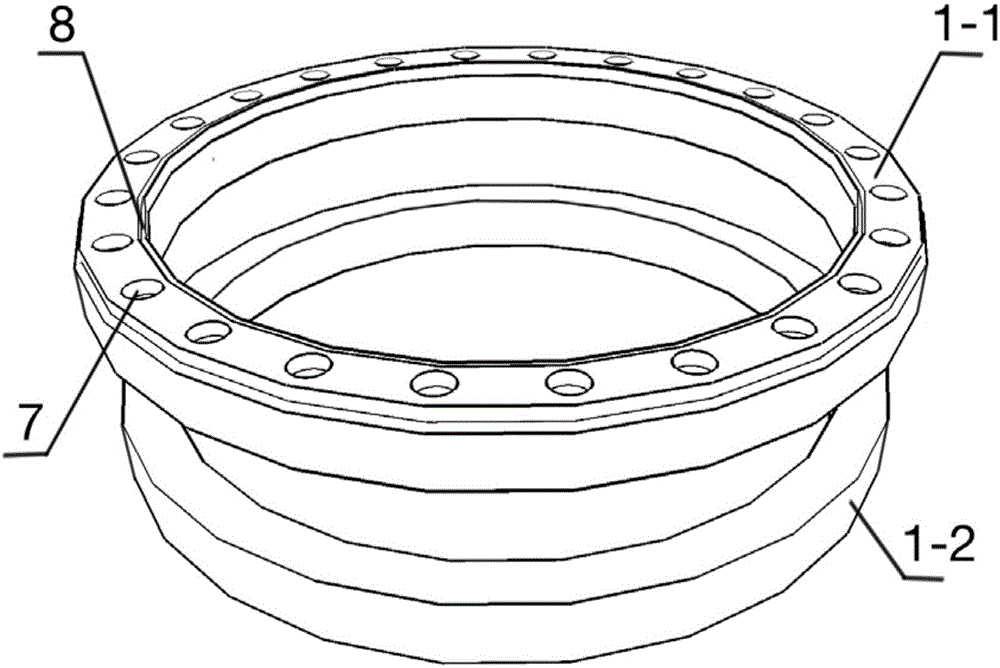

Fastening-type micro-nail magnetic-squeezing anastomosis ring

A fastening-type micro-nail magnetic-squeezing anastomosis ring comprises a bolting ring and an upper ring connected to the upper part of the bolting ring and contains a circular knife, the inner side or the outer side of the bolting ring is integrally provided with more than two fixed nuts, and bolts which are connected with the fixed nuts and are used for clamping the upper ring contains the circular knife on the upper surface of the bolting ring firmly, and the upper ring and the bolt magnet ring are both elliptical or circular ring structures. The fastening-type micro-nail magnetic-squeezing anastomosis ring is fastened by the bolts, the healing quality is guaranteed, the anastomosis window is bigger, and the clinical application safety is improved; the cast that anastomotic orifice and the hemorrhoids tissues are penetrated and torn, and the anastomotic orifice bleeds and is torn and the like is avoided; and the anastomosis ring can be buckled with others easily; the circular knife is hidden in the inner rim of one side of the magnet ring, and surrounding tissues can be prevented from being damaged; and the anastomosis is not penetrating without residual foreign matter. According to the invention, the magnetic shielding effect can be reduced at the most extent, and the magnetic force is not obviously affected.

Owner:广东省虚拟医学科技有限公司

Shielded electronic components and method of manufacturing the same

ActiveUS20120292772A1Reduced shieldingGood effectMagnetic/electric field screeningCross-talk/noise/interference reductionSemiconductor chipEngineering

A shielded electronic component including a wiring board, at least one semiconductor chip mounted on a main surface of the wiring board, a sealant which seals the whole of an upper surface of the wiring board, and a nickel (Ni) plating film formed on an upper surface of the sealant is provided. The Ni plating film is formed on a palladium (Pd) pretreatment layer formed on the upper surface of the sealant with using high-pressure CO2 in a state of protecting a back surface of the wiring board, and is electrically connected with an end portion of a ground wiring layer of the wiring board or a ground (GND) connection through-hole connected with the end portion of the ground wiring layer.

Owner:RENESAS ELECTRONICS CORP

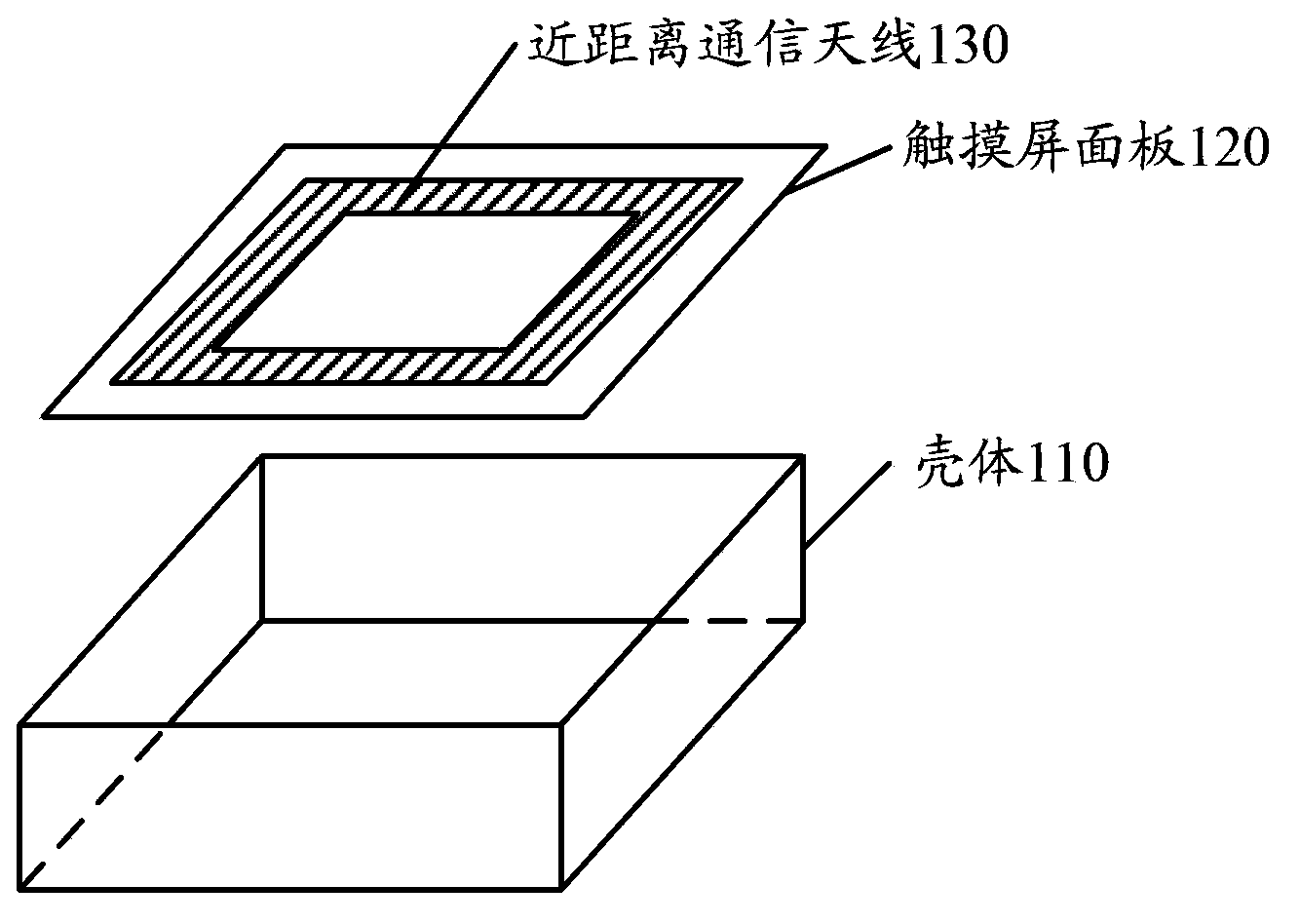

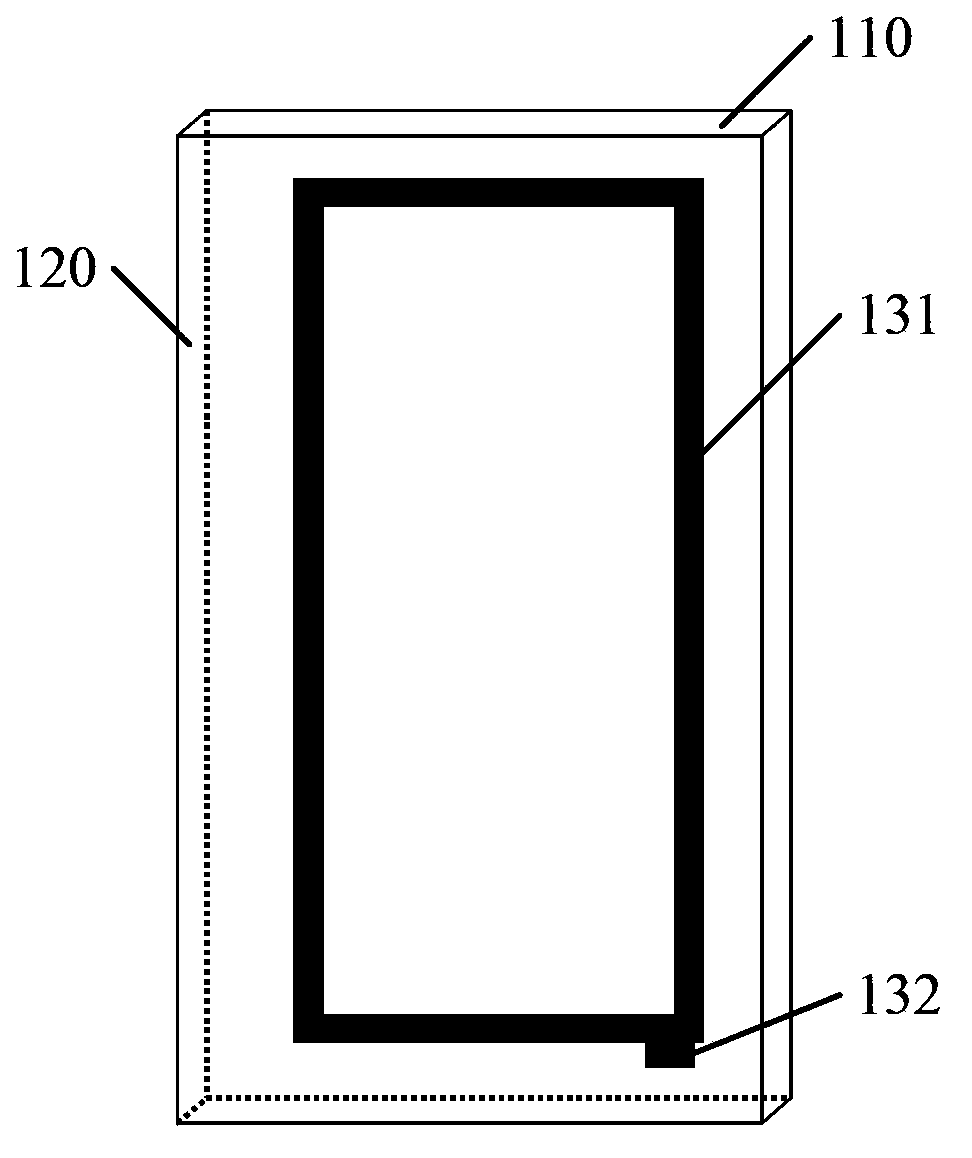

Electronic equipment and method for distributing near field communication antennas

ActiveCN103905095AReduced shieldingMagnetic/electric field screeningAntenna supports/mountingsConductive materialsOperating frequency

The invention provides electronic equipment and a method for distributing near field communication antennas. The electronic equipment comprises a shell with at least a part being made of electric conducting material, a touch screen panel comprising a first face and a second face, and the near field communication antennas. The work frequency of the near field communication antennas is lower than a preset frequency, the near field communication antennas are located on the second face of the touch screen panel, and therefore the shielding effect of the electric conducting material is avoided. According to the technical scheme, the near field communication antennas which occupy large space can be distributed in the electronic equipment, and the shielding effect of the electric conducting outer shell of the electronic equipment on the near field communication antennas is lowered.

Owner:LENOVO (BEIJING) LTD

Method for the production of a brake disk and brake disk

InactiveUS7467694B2Improve mobilityReduced shieldingBraking discsActuatorsEngineeringMechanical engineering

A method for the production of a brake disk and a brake disk which are characterized by the following features: several pairs of bushings inserted into each other are placed into a core box. The core is closed about the bushings in such a way that they form an integral component of the core. The core is inserted into a casting tool and the brake disk is cast. After the core is removed, the brake disk hub and the friction ring are decoupled from each other and can expand in relation to each other without shielding the brake disk.

Owner:DAIMLER AG

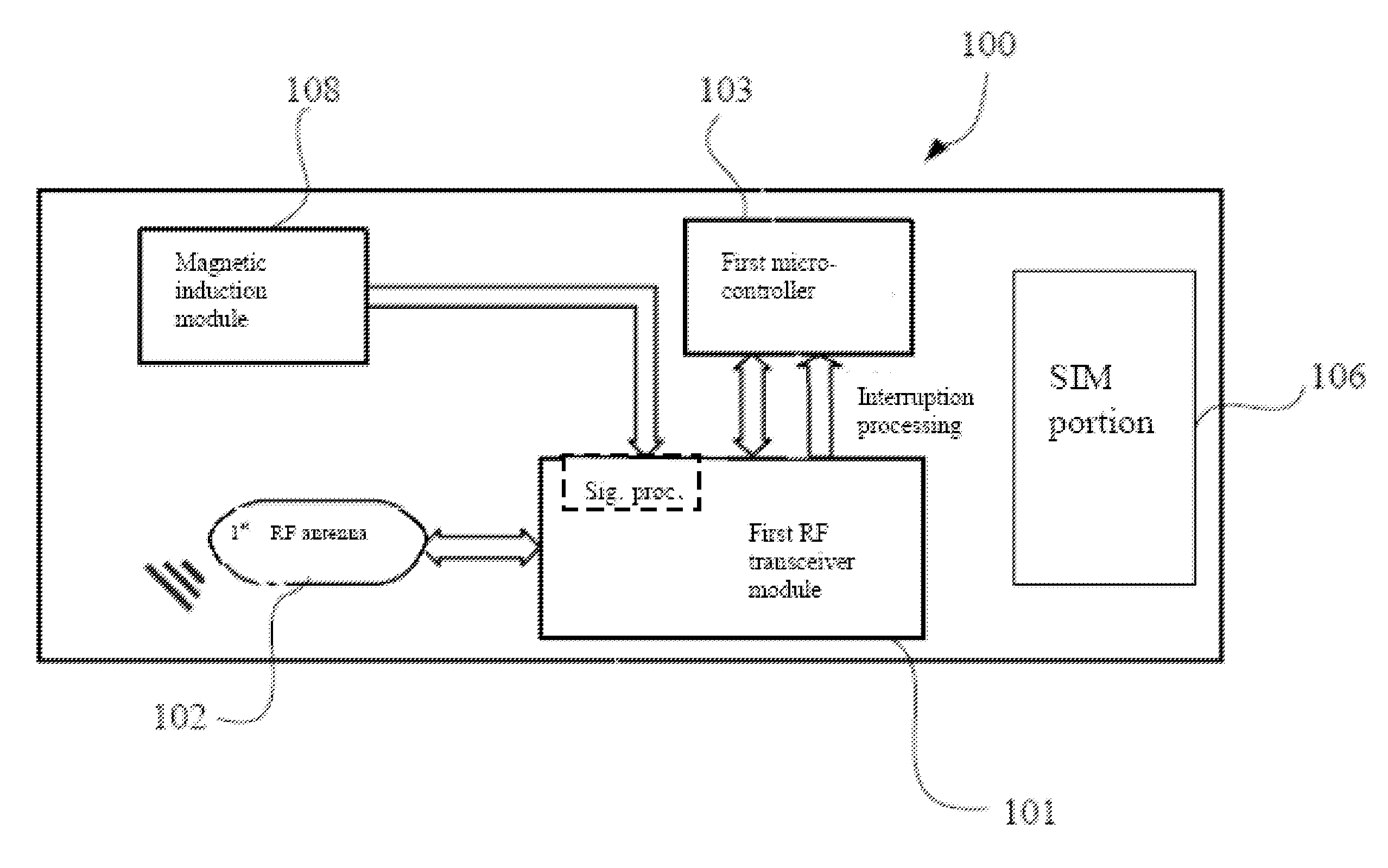

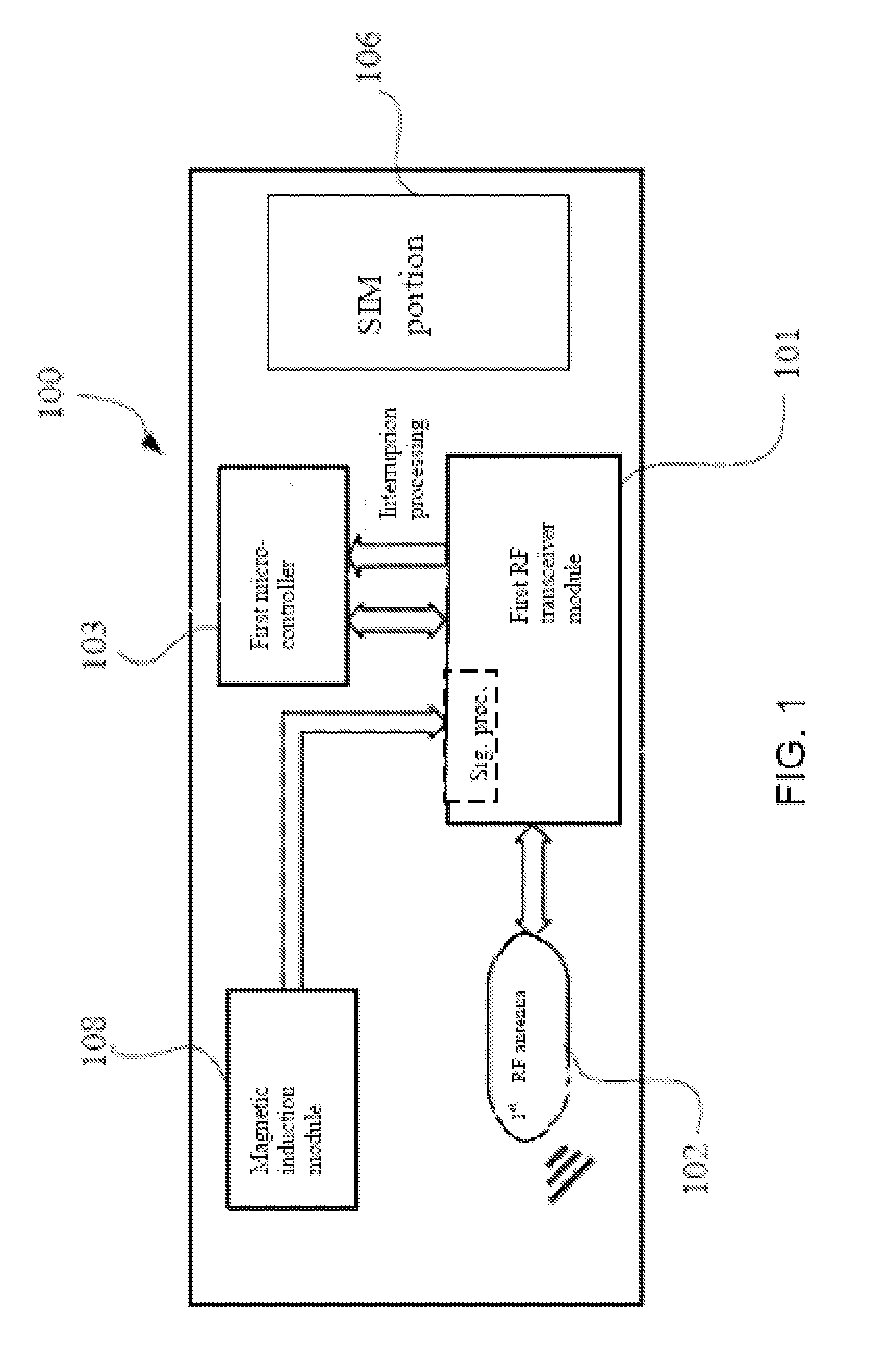

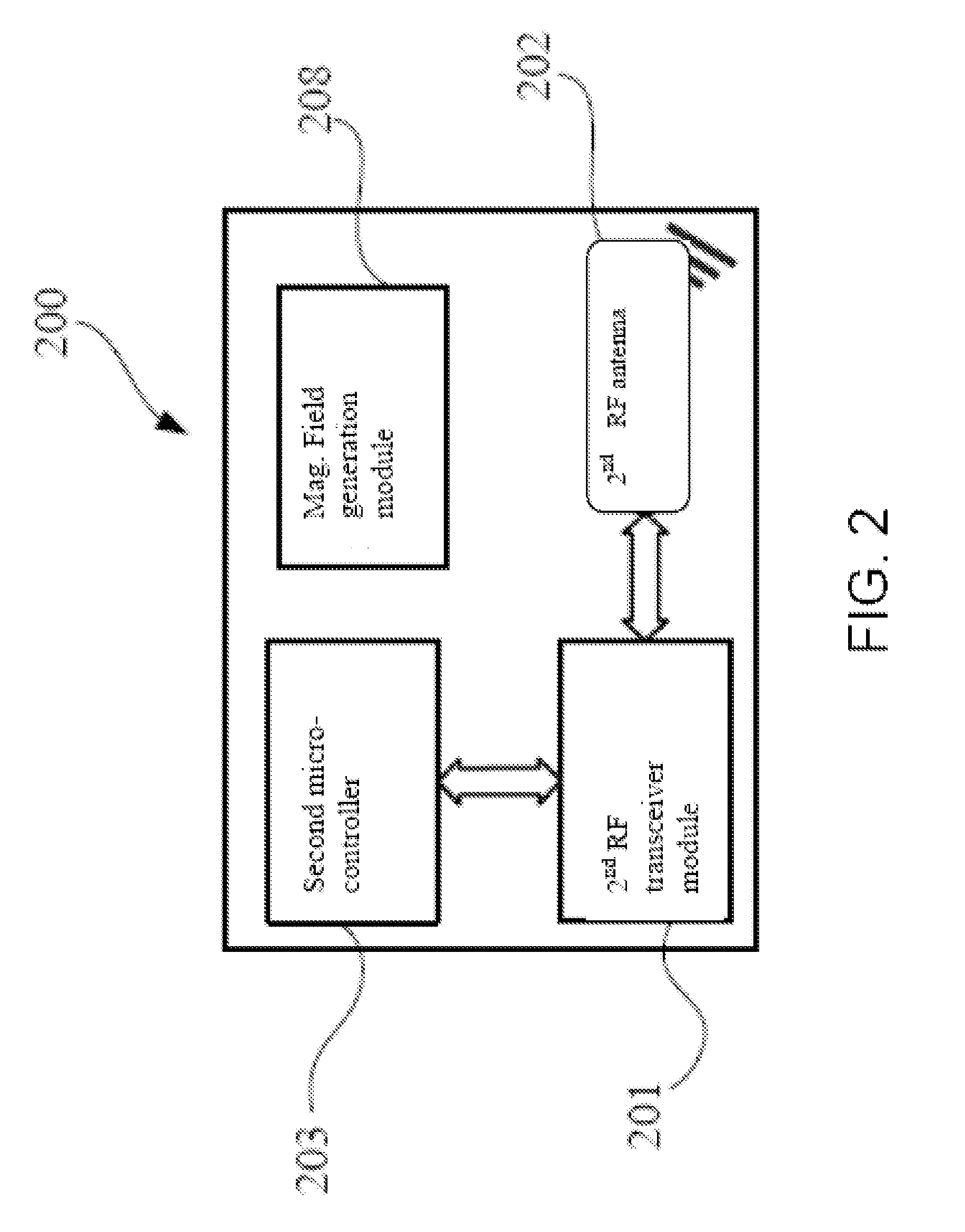

RF SIM card, card reader, and communication method

ActiveUS8630584B2Reduced shieldingExpand communication rangeElectric signal transmission systemsNear-field transmissionTransceiverEngineering

A radio frequency (RF) device includes an RF transceiver, an RF antenna, and a magnetic signal detector. The RF is selected to be in the very high frequency (VHF), ultrahigh frequency (UHF), or super high frequency (SHF) bands such that the shielding effect is reduced and the RF device can be configured as a SIM card disposed inside a cellular phone with an increased RF communication range. The magnetic signal detector is used to sense a magnetic field signal from an RF reader, which includes an RF transceiver, an RF antenna, and a magnetic signal transmitter. The longer communication range afforded by the VHF, UHF, or SHF bands is reduced by the sensing of the magnetic field, thereby providing a communication range control, while the RF device and the RF reader exchange information through the RF channel with improved security as a result of the range control.

Owner:NATIONZ TECH INC

Target density imaging using discrete photon counting to produce high-resolution radiographic images

ActiveUS7388209B1Avoid flowRapid, non-invasiveMaterial analysis by optical meansRadiation intensity measurementParallaxImage resolution

The present invention relates to a system and method for using discrete photon counting to produce transmission radiographic images of a target object with improved spatial resolution and high system sensitivity. The system comprises a radiation source for directing photons at a target object and a detector array for receiving photons passing through the target in order to provide an image of the target density. The detector array is configured to enhance spatial resolution and maintain high system sensitivity. To correct the parallax effect that may be induced by such configuration of the detector array, a process can be computer implemented or program coded to parallax correction.

Owner:LEIDOS

Preparation method of carbon nanotube field emission cathode

ActiveCN102386042AReduce hole diameterHigh aspect ratioCold cathode manufacturePhosphoric acidEvaporation

The invention relates to a preparation method of a carbon nanotube field emission cathode and belongs to the field of nanomaterial preparation and application. The method comprises the following steps of: preparing a porous anodized aluminum template by secondary anodic oxidation process, soaking the template in a nickel chloride or cobalt chloride solution, taking out and air-drying to obtain a template (2); preparing carbon nanotubes in the pores of the template (2) by chemical vapor deposition process to obtain a template (3); adding dropwise a phosphoric acid solution to the surface on which the carbon nanotubes are not deposited to obtain a template (4); forming a silver coating on a stainless steel substrate by evaporation and then sticking the carbon nanotube-grown surface of the template (4) onto the silver coating, to produce the carbon nanotube field emission cathode. The pressure reduction method is adopted in the late stage of the preparation of the porous anodized aluminum template, so as to reduce the diameters of the pores at the bottom of the porous anodized aluminum template and thus to increase the length-diameter ratio of the carbon nanotubes and improve the field emission characteristics of the carbon nanotube field emission cathode.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com