Three-electrode integrated electrochemical sensor based on microelectrode array

A technology of microelectrode array and integrated electrochemistry, applied in the direction of material electrochemical variables, can solve the problems of reducing detection repeatability and accuracy, large test samples, cumbersome operation, etc., to achieve reduced shielding effect, low detection limit, The effect of simple interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

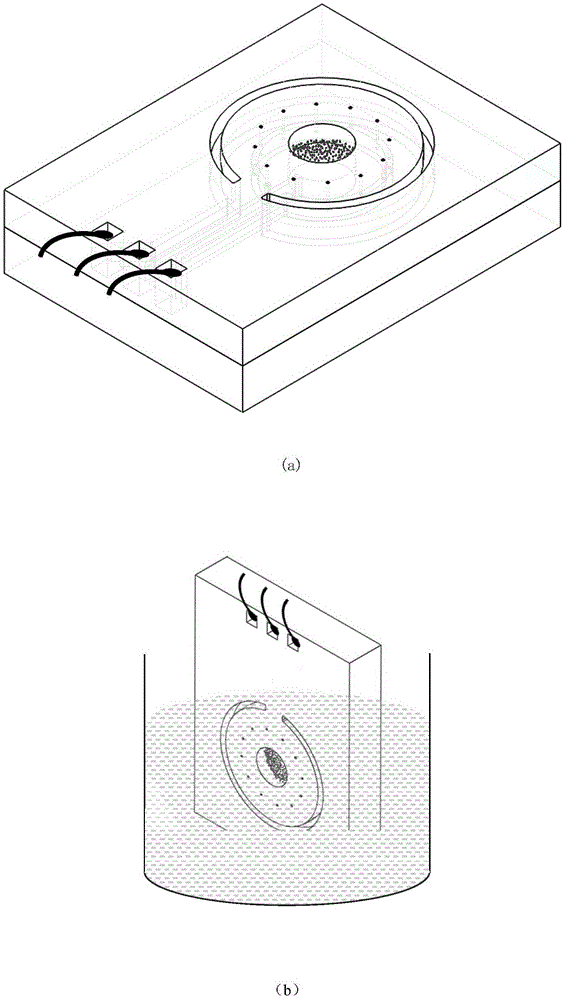

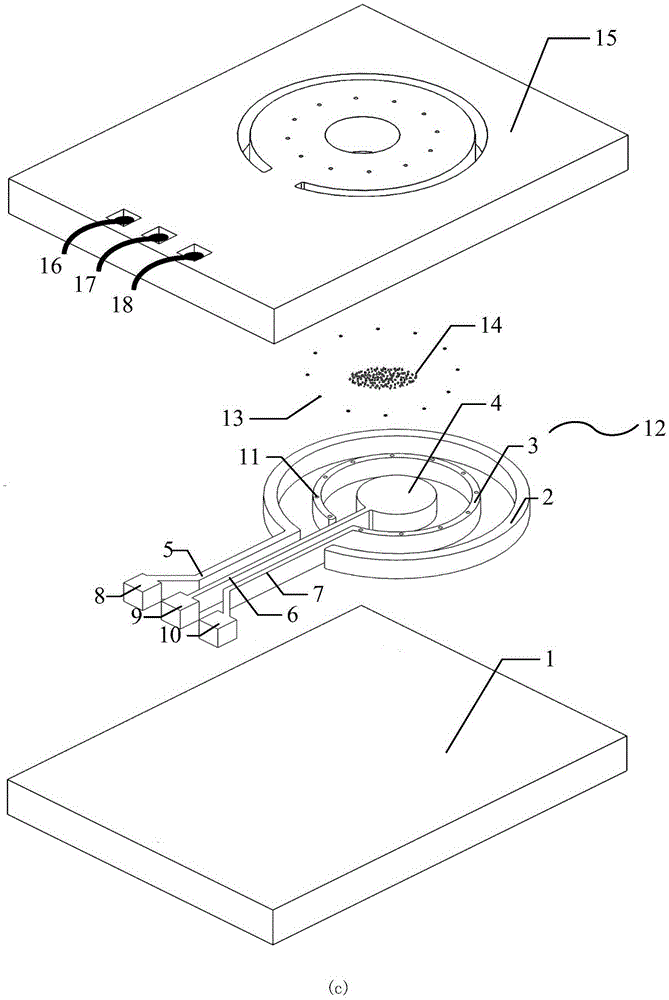

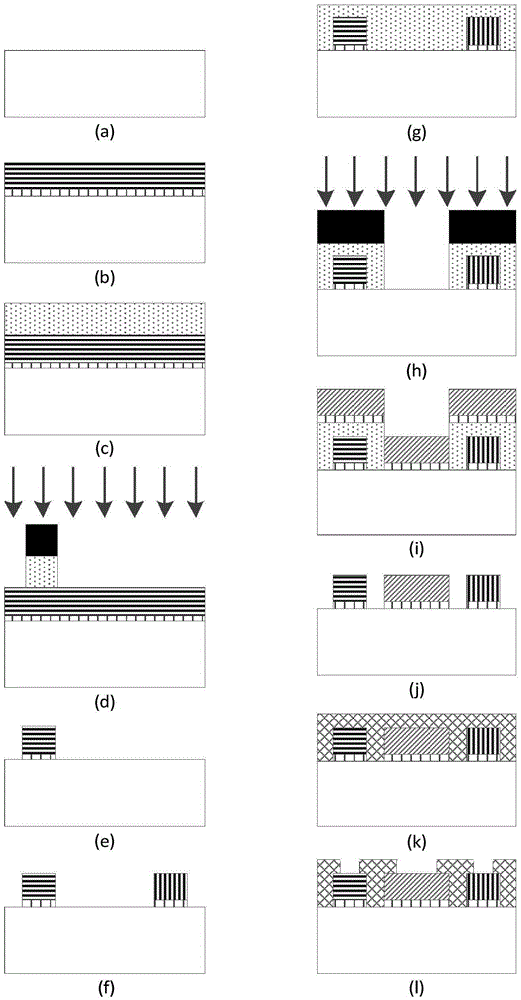

[0028] One, in figure 1 In (a), the surface of the microelectrode array is pre-coated with bismuth film to form the working electrode, the surface of the silver electrode is electroplated with silver chloride to form the reference electrode, and the platinum electrode is used as the counter electrode; the three electrodes are fabricated on a quartz substrate by MEMS technology. It can be connected with the external heavy metal electrochemical detector through the relevant auxiliary wire. figure 1 (c) shows the internal structure and association of the sensor, wherein the gold electrode 3, the gold lead 7, the gold pad 10 and the third wire 18 are sequentially connected and conducted, and the platinum electrode 2, the platinum lead 5, the platinum pad 8 and the first The wires 16 are sequentially connected and conducted, and the silver e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com