Patents

Literature

137results about How to "Guaranteed texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion grade aesthetical resin possessing metal color effect and its preparation method

The invention relates to an extrusion grade aesthetical resin possessing metal color effect and its preparation method, which comprises the following ingredients by weight content: 100 parts of matrix resin, 0.1-3.0 parts of metal pigment, 0.1-3.0 parts of pearlescent pigment, 0.1-3.0 parts of molecular sieve adsorbent, 0.1-3.0 parts of lubricant and 0.1-1.0 parts of anti-oxidant. The method comprises the following steps: stirring and mixing the above raw materials in a high speed mixer, sending in a double screw extruder, under the conveying, shearing and mixing of a screw, fusing the raw materials, compositing, extruding, bracing, cooling, cutting into granule to obtain the extrusion grade aesthetical resin possessing the metal color effect. Compared with prior art, the extrusion surface effect of the extrusion grade aesthetical resin possessing metal color effect is close to metal spray paint effect, thereby the energy saving and environmental protection scheme without spraying can be realized, the aesthetical resin possessing metal color effect enables large market potential in the fields of automobile, household electrical appliance, consumer electronics and the like which possess high appearance requirement.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

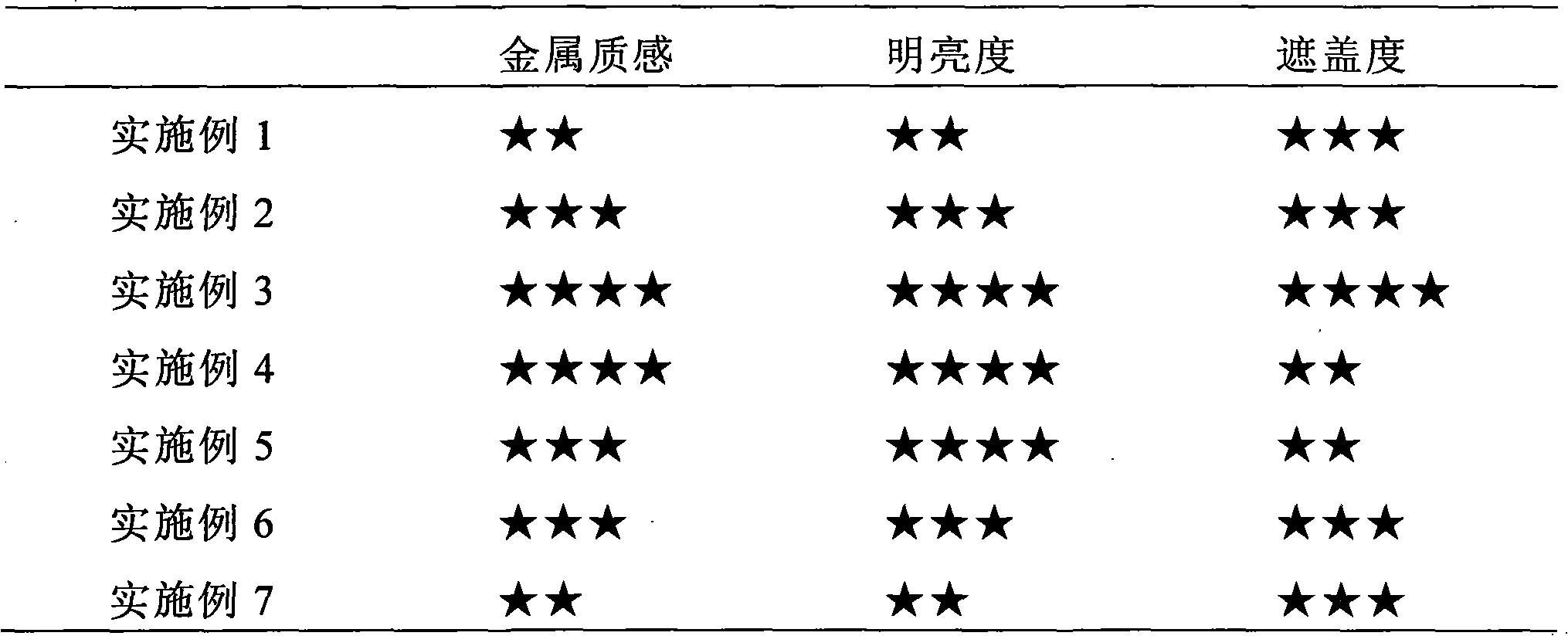

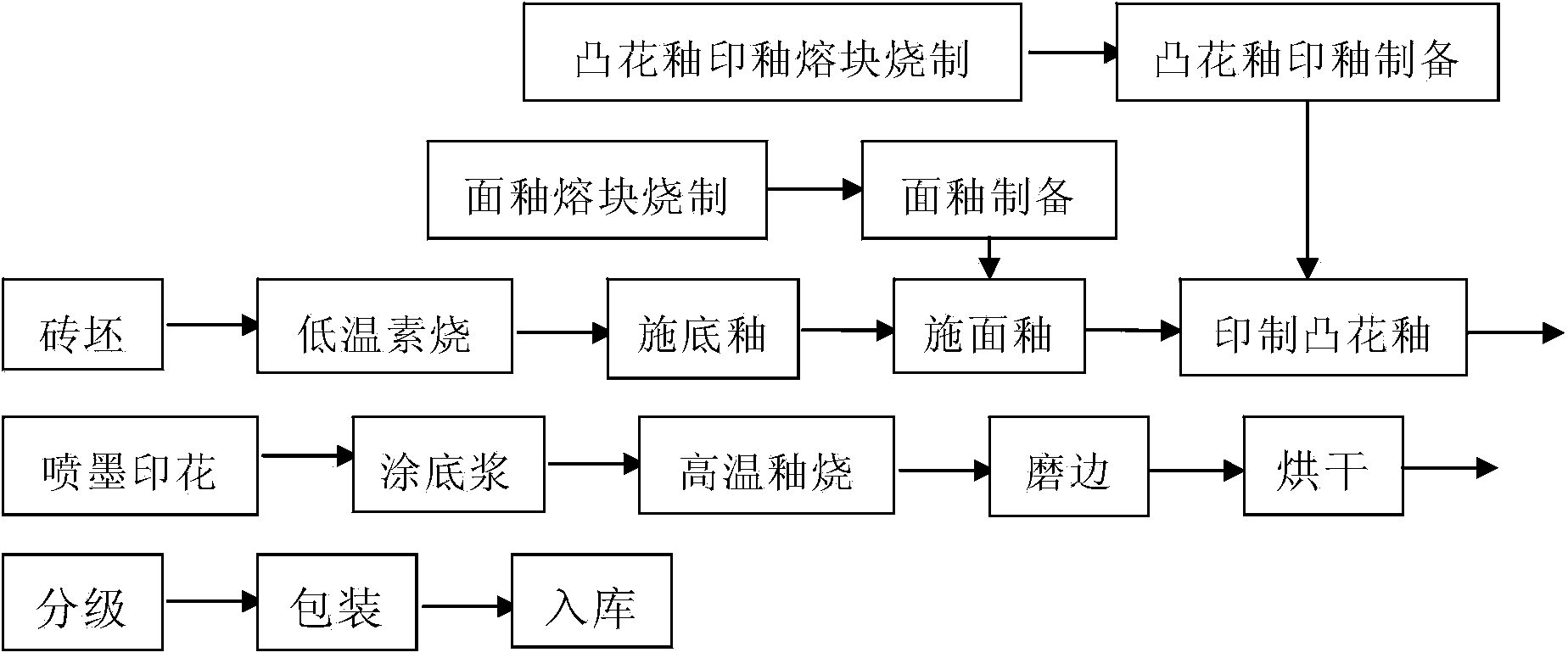

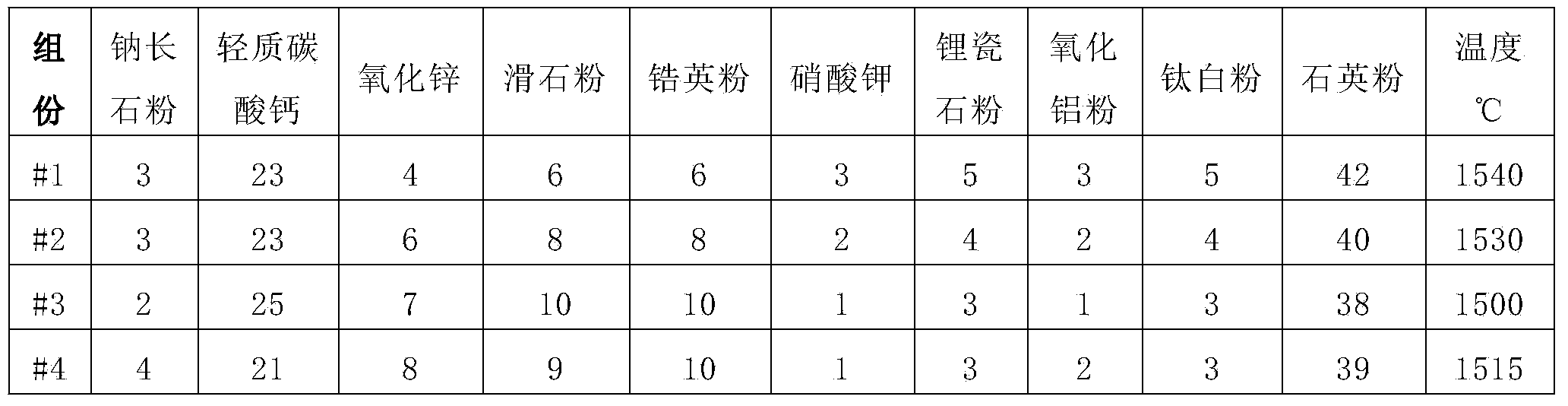

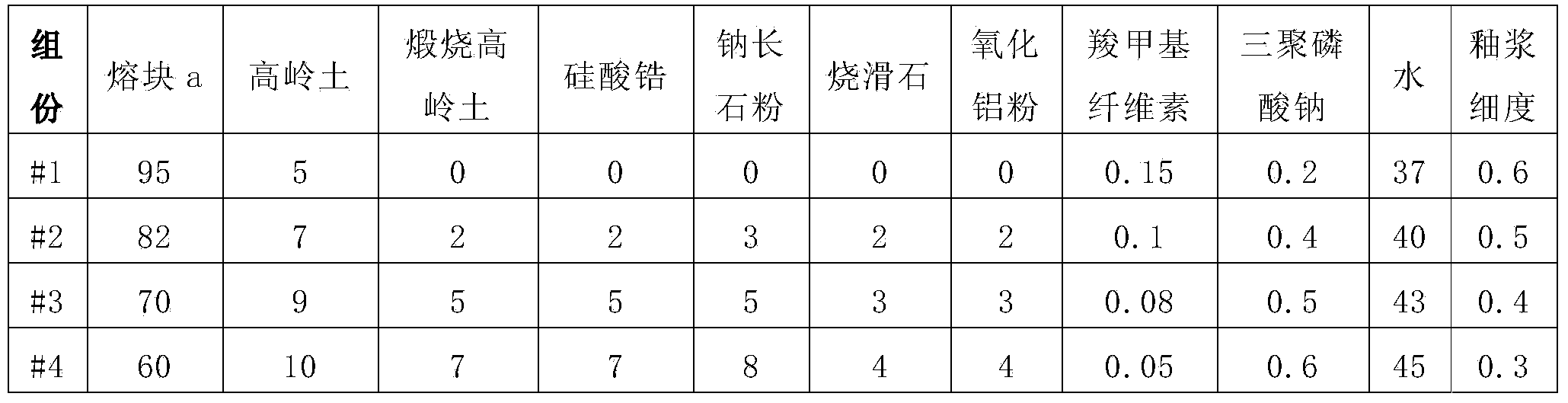

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

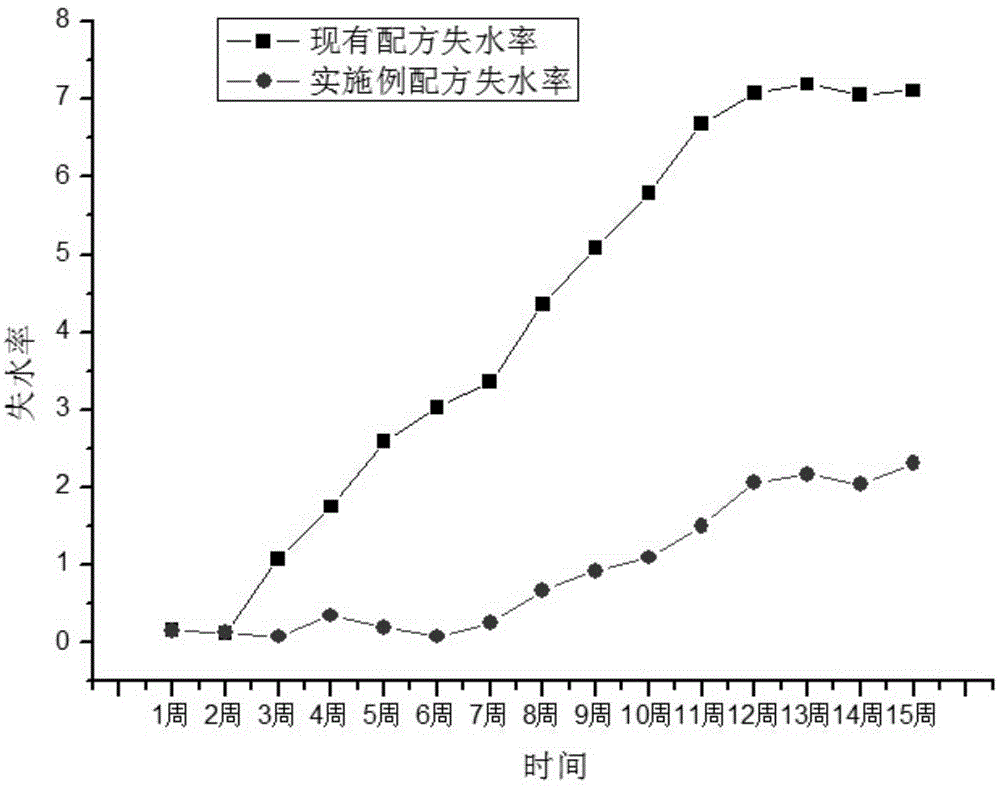

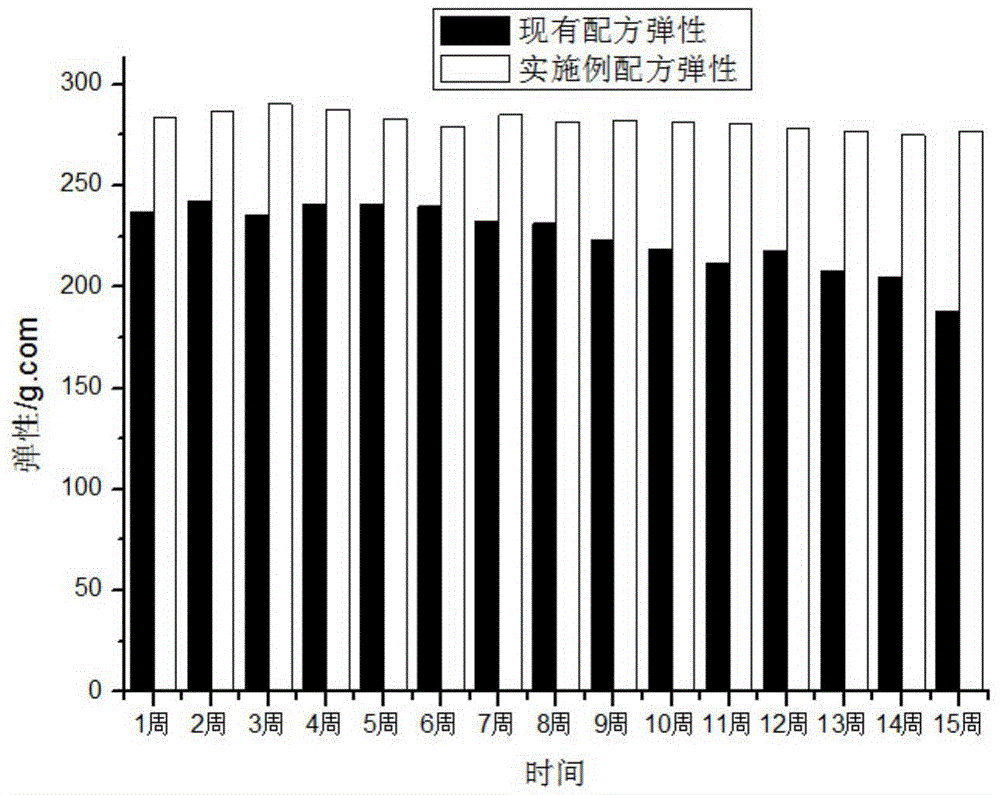

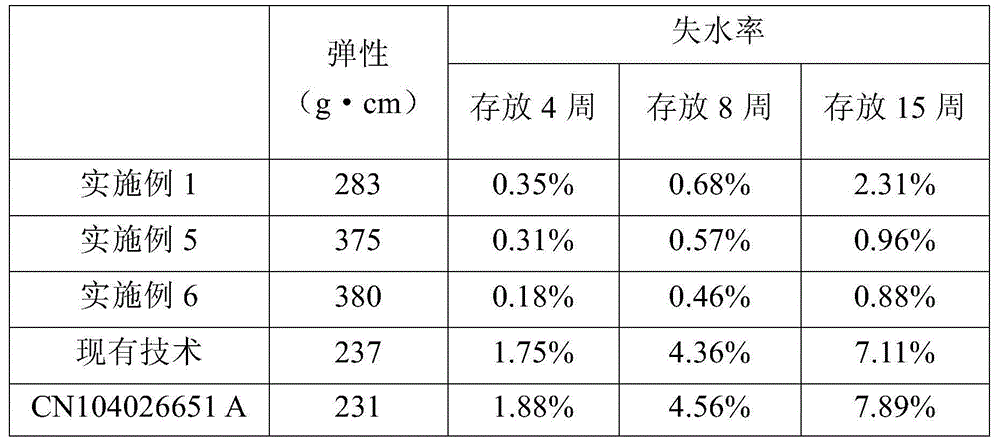

Method for processing high-quality emulsion sausage rich in diary fiber

The invention discloses a method for processing high-quality emulsion sausage rich in diary fiber, and belongs to the technical field of meat product processing. Aiming at the problems that the texture is hardened, the storage period is shortened and the like caused by adding diary fiber into the conventional emulsion sausage in the product storage process, the invention provides a method for preparing the high-quality emulsion sausage rich in the diary fiber by pre-emulsification technology. The processing process comprises the following steps of: mincing and mixing raw material meat; mixing the minced and mixed meat, pre-emulsified diary fiber and various seasoners in a ratio; salting; filling; baking; cooking; drying; cooling; and packaging, wherein the diary fiber is rice bran diary fiber or soybean diary fiber; and the pre-emulsification treatment comprises the following steps of: fully moistening stabilized diary fiber powder and a proper amount of water; adding plant oil rich in unsaturated fatty acid, of which the volume is 1 to 5 times that the mixture; and performing the pre-emulsification treatment by utilizing void effect of ultrasonic waves. The emulsion sausage prepared from the pre-emulsified diary fiber has the advantages of low fat content, rich nutrient, good edible quality and safety and health.

Owner:SHANDONG HUIFA FOODS

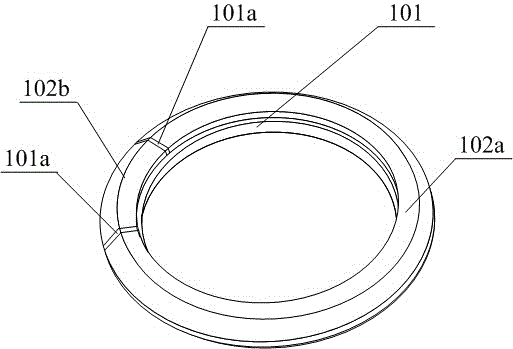

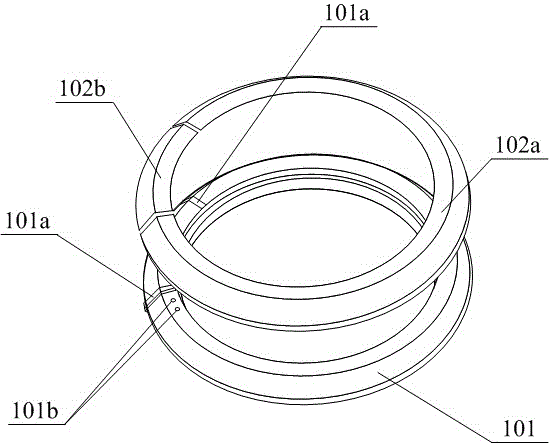

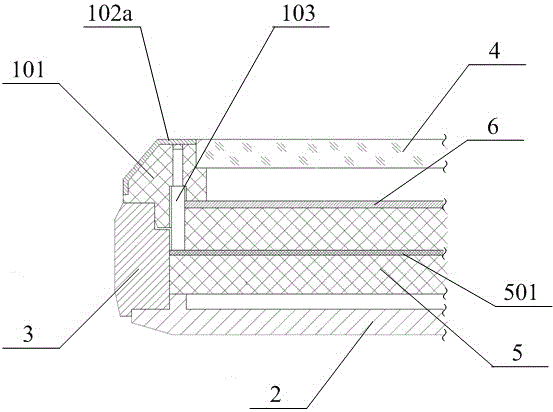

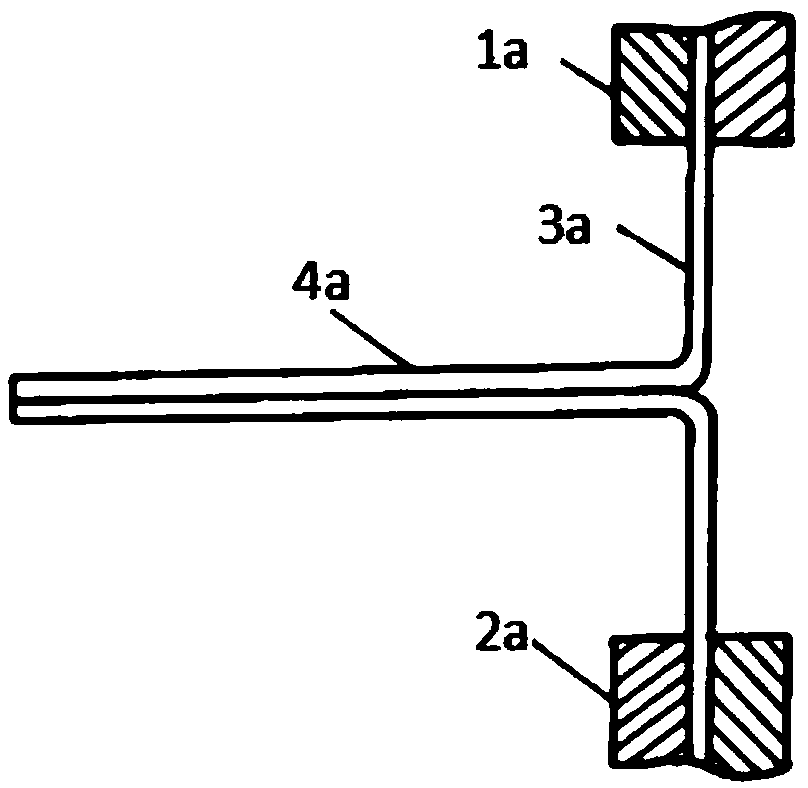

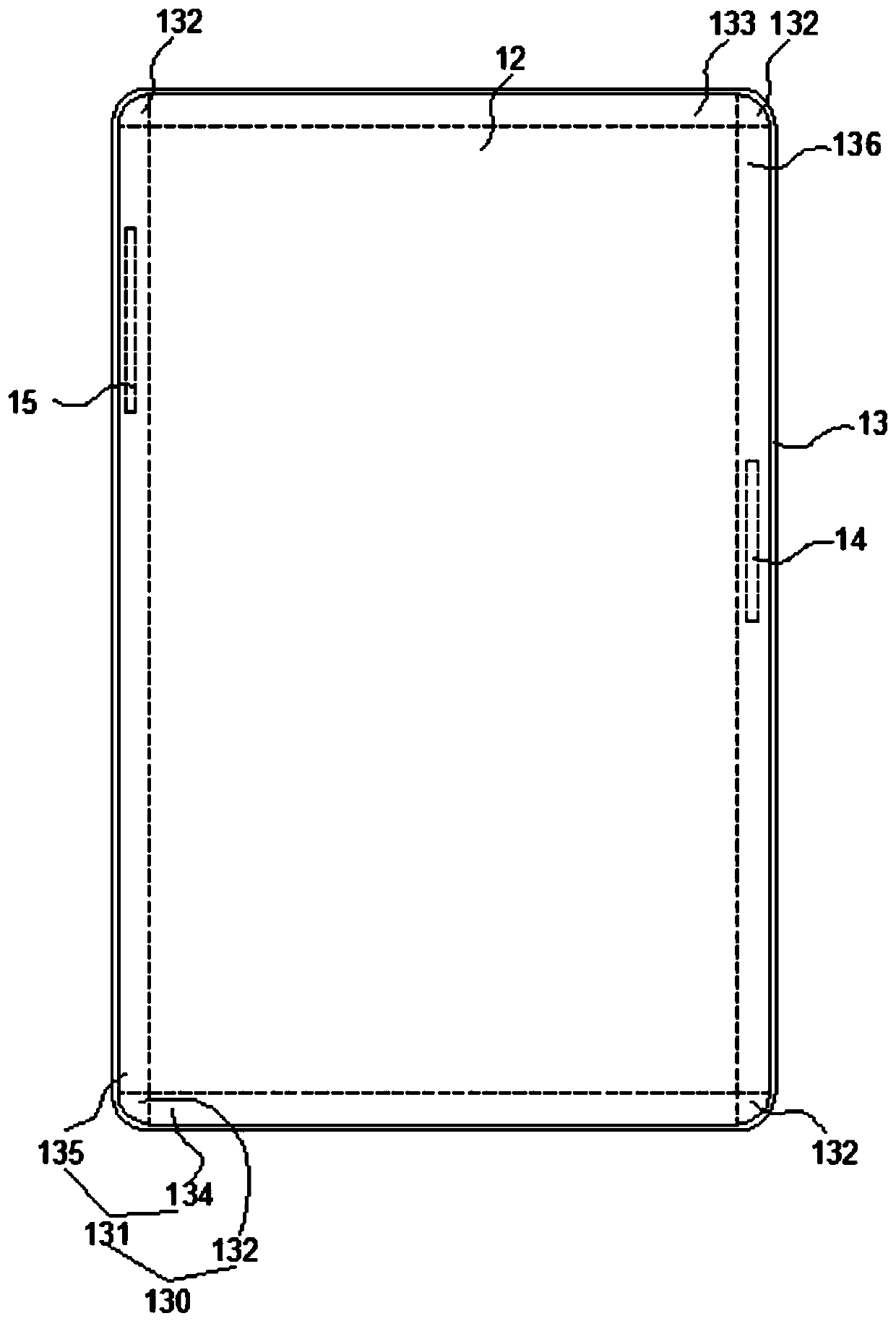

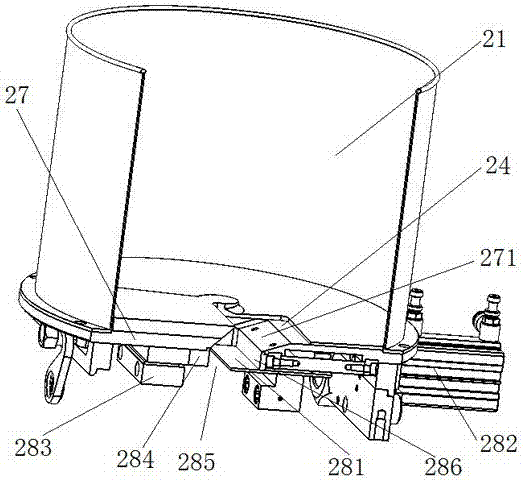

Intelligent watch antenna and intelligent watch structure with external antenna

InactiveCN106207381AExquisite structureGuaranteed textureAntenna supports/mountingsRadio-controlled time-piecesElectrical and Electronics engineering

The invention relates to the field of intelligent watches and discloses an intelligent watch antenna and an intelligent watch structure with an external antenna. A watch frame is changed into the watch antenna, the receiving face of the antenna can be externally arranged, in this way, the shielding influences of a metal watch shell and other components can be greatly reduced, the receiving effect can be improved, the situation that the antenna occupies the internal space of a watch can be avoided, and an internal movement and the whole watch can be miniaturized. In addition, material limit is not produced on the metal watch shell or the other components, the texture of the intelligent watch can be guaranteed, the intelligent watch has the advantages that the cost is low, and the overall structure is attractive and descent, and the intelligent watch can be conveniently applied and popularized in reality.

Owner:CHENGDUSCEON ELECTRONICS

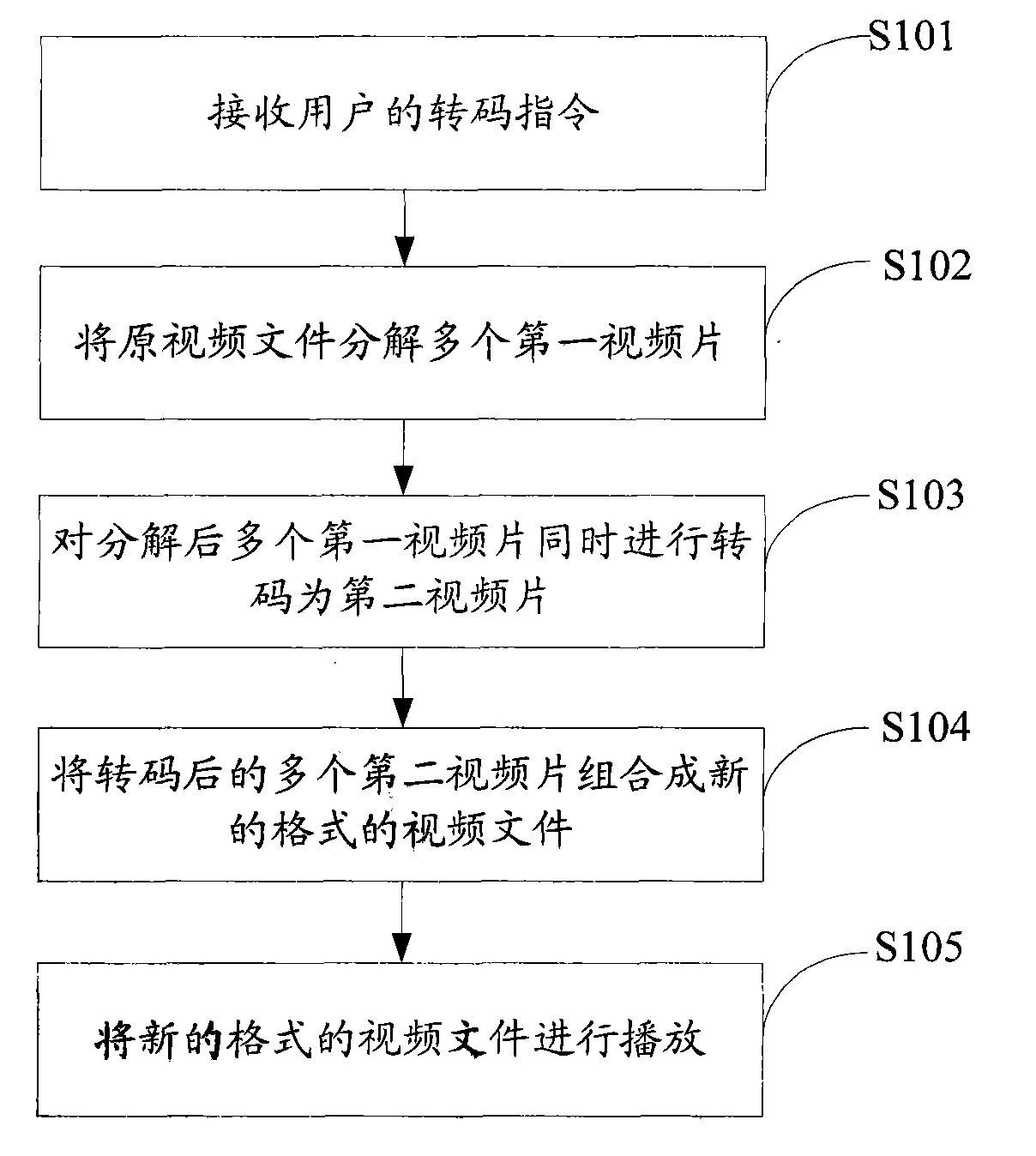

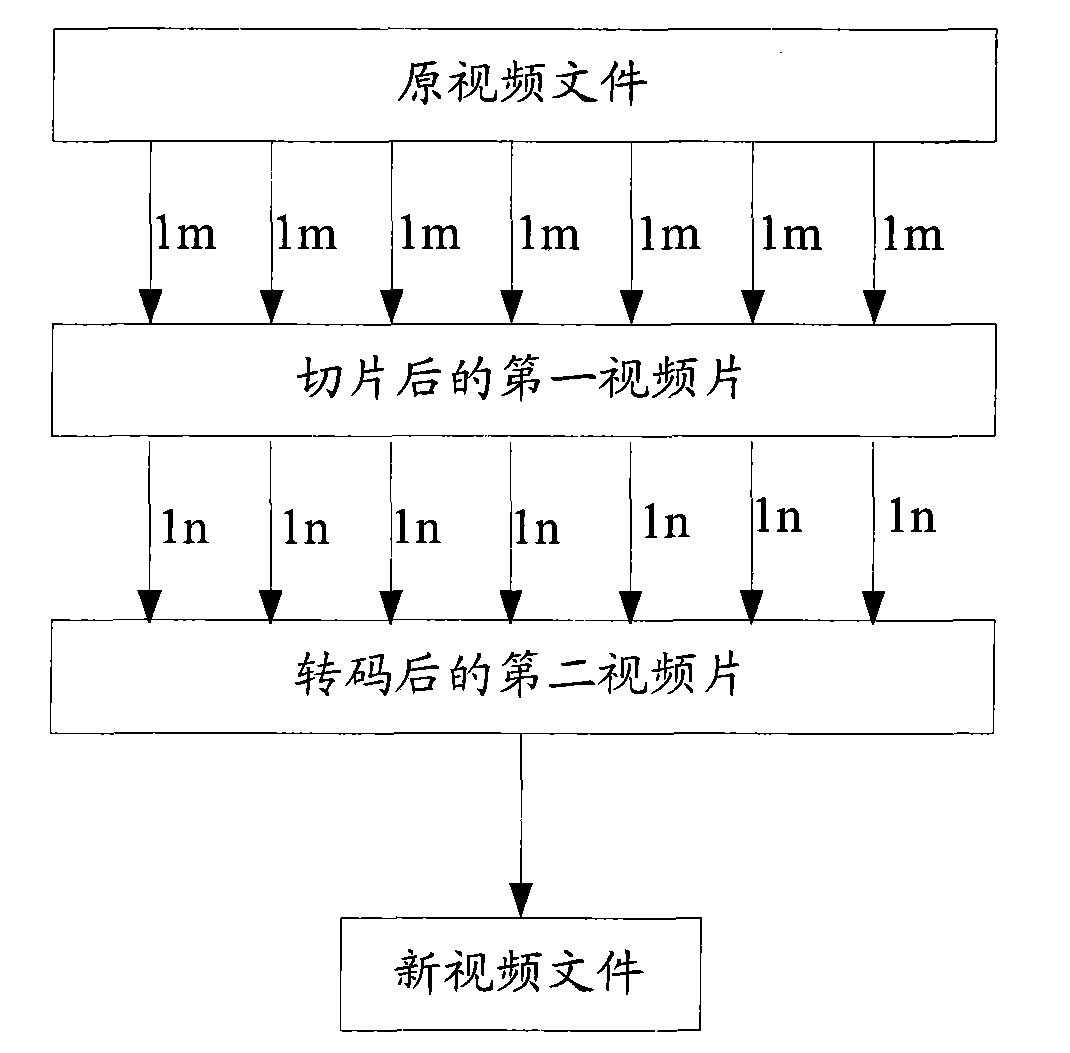

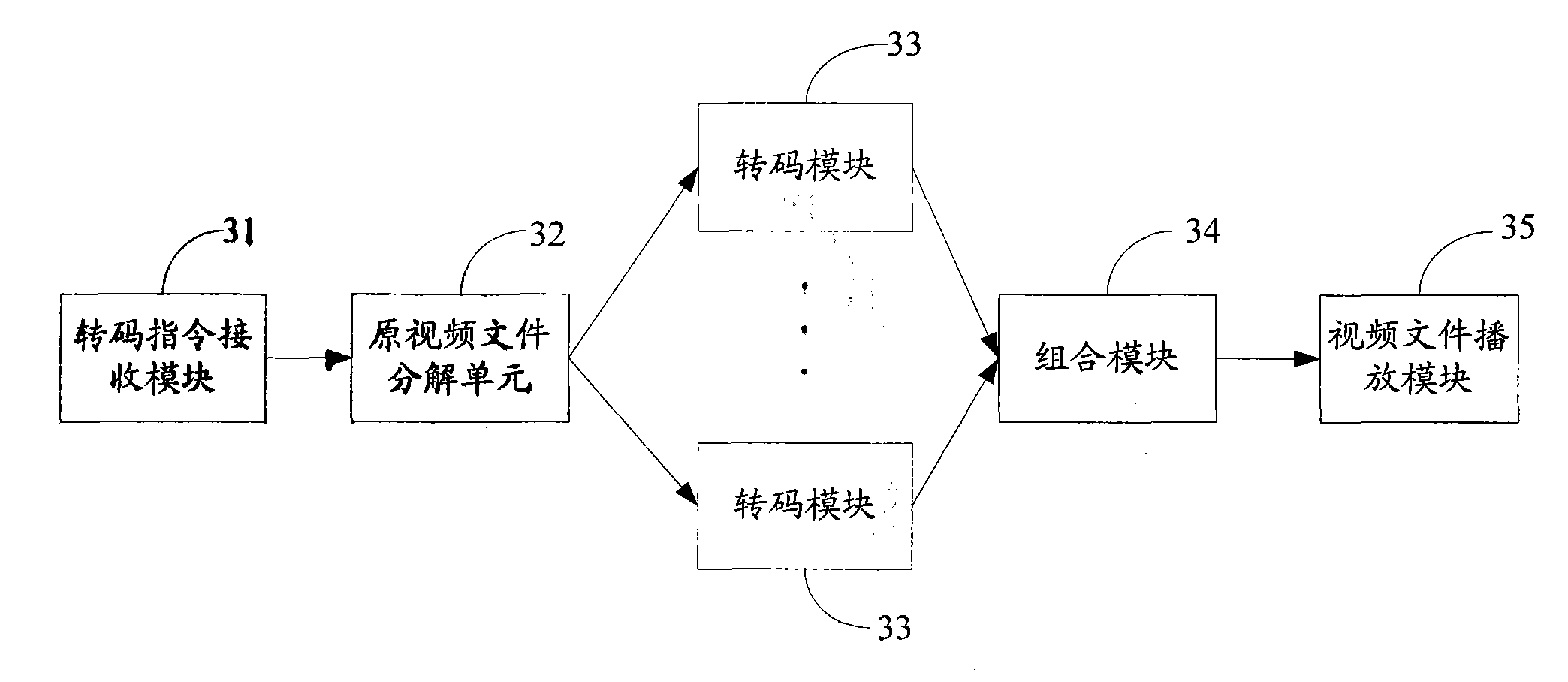

Method and system for parallel trans-coding of video slicing

ActiveCN101964894AGuaranteed textureSave transcoding timeTelevision system detailsColor television detailsComputer graphics (images)

The invention is suitable for the technical field of audio-video playing, and discloses a method and a system for parallel trans-coding of video slicing. The method comprises the following steps of: disassembling an original video file into a plurality of first video segments; simultaneously trans-coding the first video segments after disassembling into second video segments; and assembling a plurality of the second video segments after trans-coding into a video file with a new format. In the method, by disassembling the original video file into the plurality of the first video segments, simultaneously trans-coding the first video segments after disassembling into the second video segments, and assembling the plurality of the second video segments after trans-coding into the video file with the new format, not only the trans-coding time is saved and the trans-coding efficiency is improved, but also the texture of a picture is well ensured, and the method and the system are favorable for popularizing an audio-video playing device.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Gas conditioning method for chicken wings

The invention provides a gas conditioning method for chicken wings, which comprises the following steps of: salting and marinating the chicken wings serving as raw materials sequentially to obtain cooked chicken wings; packaging the cooked chicken wings by using a polyester-biaxially-oriented polyamide-aluminum-chlorinated polypropylene (PET-BOPA-AL-CPP) composite membrane, filling nitrogen and sealing; and sterilizing the chicken wings in a multi-stage warming and quick cooling mode to obtain soft package instant products of the chicken wings. In the method, a process is simple and convenient, the operation is feasible, and a preservative is not used; each gram of raw materials contains about 10<6> to 10<7> bacteria, and after the raw materials are sterilized, the number of the bacteria can be reduced to be between 10<1> and 10<3>; the processed chicken wings have complete wing shapes, long quality guarantee period and high safety, are convenient to eat, and can be stored at normal temperature for two years; by the method, the texture of the food is kept, and the mouthfeel, taste and nutrition of the food can be well kept; and nitrogen-filled packages can well protect the shapes of the chicken wings in bags, so that the chicken wings are prevented from being crushed in the process of transportation.

Owner:NAVY MEDICINE RES INST OF PLA

Anti-freezing mashed shrimp and preparation method thereof

ActiveCN104382105AImprove frost resistanceImprove qualityFood ingredientsFood preparationAnti freezingPhosphate

The invention discloses an anti-freezing mashed shrimp and a preparation method thereof. The mashed shrimp mainly comprises the following raw materials in parts by mass: 75-90 parts of shrimp meat, 5-10 parts of potato starch, 3-5 parts of frozen egg white, 3-6 parts of water, 0.5-1.5 parts of salt, 0.5-2.5 parts of white granulated sugar, 0.02-0.05 part of composite phosphate and 0.02-0.05 part of sorbitol. The anti-freezing mashed shrimp is smooth in taste and rich in nutrition; the shrimp meat is obvious in granular sensation. The invention also provides a preparation method of the anti-freezing mashed shrimp. The method is simple and convenient in process and liable to operate; the protein denaturation of the mashed shrimp in the preservation process can be delayed; the severe dehydration of the mashed shrimp after being unfrozen can be effectively avoided.

Owner:福州百洋海味食品有限公司

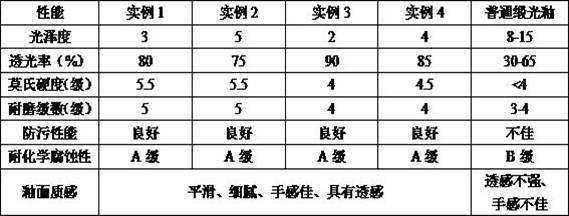

High-wear-resistance high-transparency satin glaze, preparation method and large-specification satin rock plate

The invention relates to the technical field of building ceramic new materials, and particularly discloses a high-wear-resistance high-transparency satin glaze which comprises the following componentsin parts by weight: 4-10 parts of clay, 5-20 parts of high-temperature transparent frit, 5-15 parts of lepidolite, 1-6 parts of corundum powder, 0-10 parts of strontium carbonate, 0-10 parts of barium carbonate, 5-15 parts of spodumene, 10-15 parts of dolomite, 2-10 parts of calcite, 0-6 parts of zinc oxide, 0-5 parts of lithium carbonate, and 30-70 parts of low-temperature fluxing agent. The low-temperature fluxing agent is composed of potassium feldspar and albite, and the weight ratio of the potassium feldspar to the albite is (2-9): 1, and meanwhile, the invention further discloses a preparation method of the high-wear-resistance high-transparency satin glaze and a large-specification satin rock plate produced by using the high-wear-resistance high-transparency satin glaze. The precipitation of crystals is inhibited and the sizes of the crystals are controlled by adjusting the formula composition of the glaze, the glaze surface loses gloss due to scattering, and the transparency,the color development and the wear resistance of the glaze surface are improved on the basis of ensuring the texture of the glaze surface.

Owner:佛山市玉矶材料科技有限公司

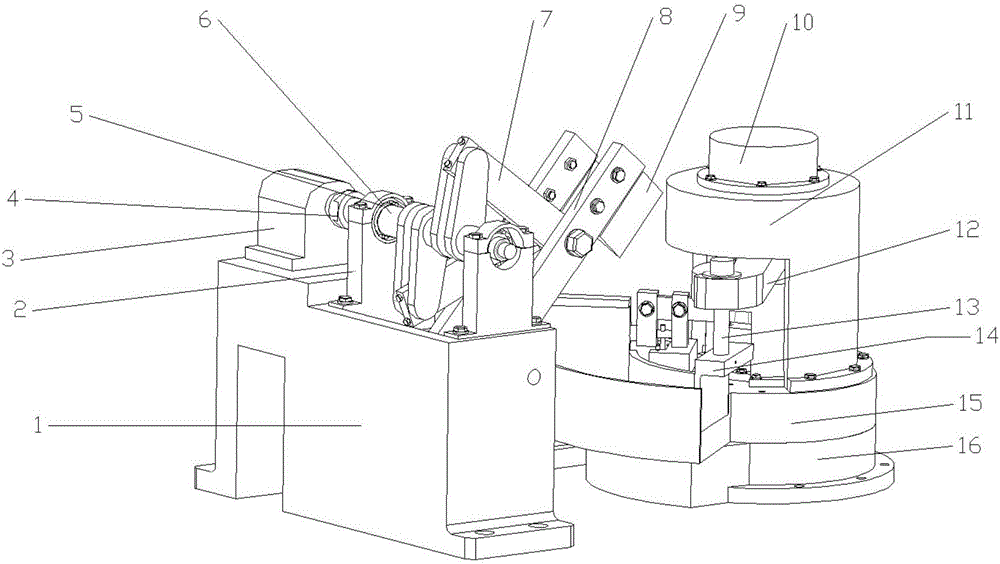

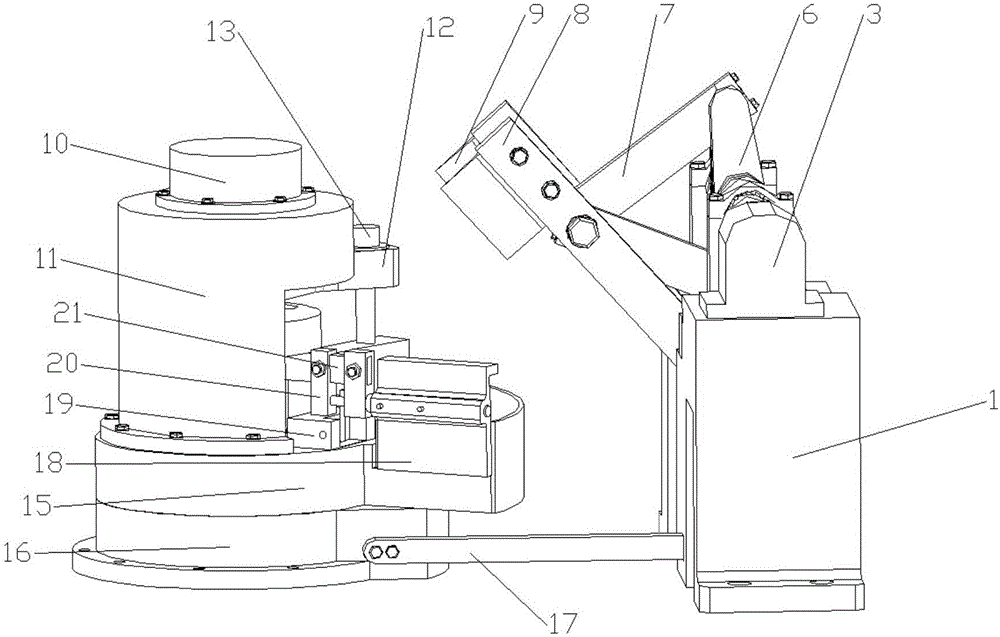

Meat mincing machine capable of automatically overturning meat

The invention discloses a meat mincing machine capable of automatically overturning meat. When a conventional meat grinder is used for grinding the meat, the skin texture of the meat can be destroyed, and a conventional meat mincing machine imitates manual meat mincing, so that the fiber of the meat can be reserved, and the texture of the meat is improved. The conventional meat mincing machine is difficult to realize fully-automatic overturning of the meat. The meat mincing machine disclosed by the invention comprises a knife rest mechanism, a meat overturning mechanism and a cutting board mechanism, wherein the knife rest mechanism comprises a meat mincing base, a bearing seat, a first motor, a coupling, a bearing, a crankshaft, a connecting rod, rockers and blades; the cutting board mechanism comprises a cutting board frame, a cutting board base, a cutting board and a second motor; and the meat overturning mechanism comprises a motor seat, a first rotating arm, a connecting column, a vertical blocking board, an oblique blocking board, an electromagnet mounting frame, a first connecting block, a second rotating arm, a motor housing, a second connecting block, a fixing frame, a third motor, a fourth motor, a cylindrical pin and a supporting column. The meat mincing machine disclosed by the invention imitates the movements during manually mincing meat, so that the texture of the minced meat is guaranteed; and the meat mincing machine can overturn the meat in the process of meat mincing, so that the meat is more uniformly minced.

Owner:泰州博瑞企业管理咨询有限公司

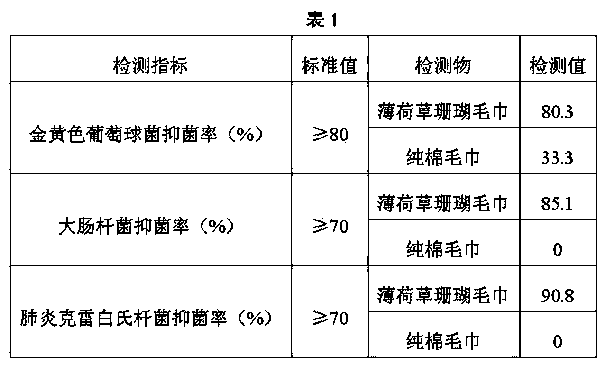

Blended yarn containing sarcandra glabra fiber and mint fiber and production method thereof

ActiveCN103741305AGood antibacterial health care performanceExcellent Yarn Physical IndexYarnYarnFiber

The invention relates to the technical field of blended yarn production, and provides a blended yarn containing sarcandra glabra fiber and mint fiber and a production method thereof. The blended yarn comprises 10 to 40 wt% of mint fiber, 10 to 40 wt% of sarcandra glabra fiber and balance of combed cotton. The blended yarn has excellent antibiotic and health protective properties and excellent yarn physical indicators, surface softness and dye properties of blended yarn finished products of towels and bath towels are optimized, texture and thickness of the finished products of towels and bath towels are guaranteed, and product added value can be improved greatly.

Owner:河北瑞春纺织科技有限公司

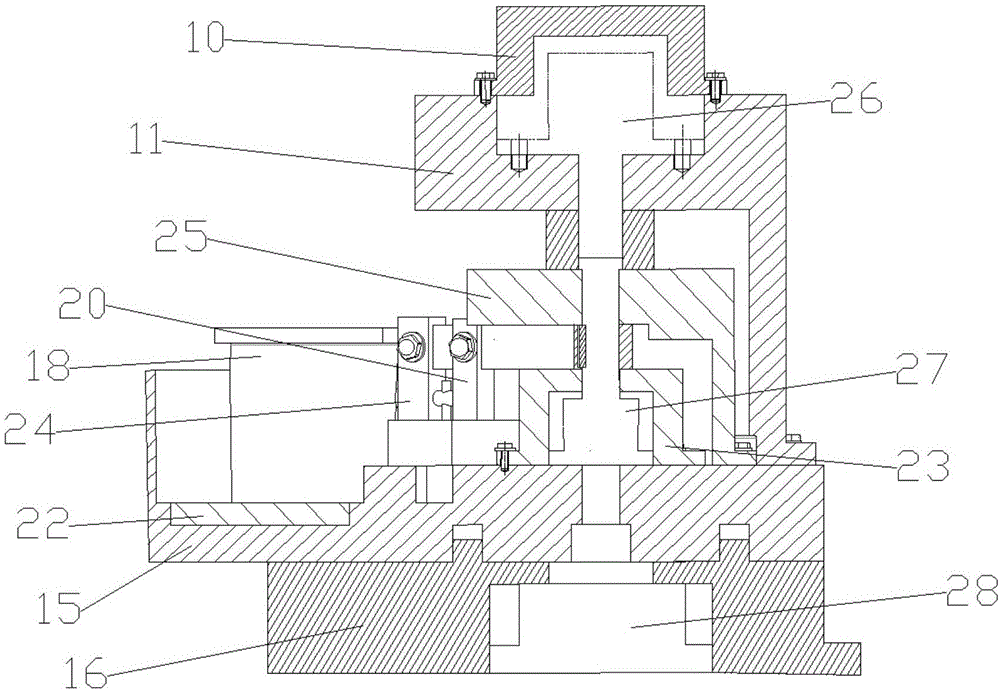

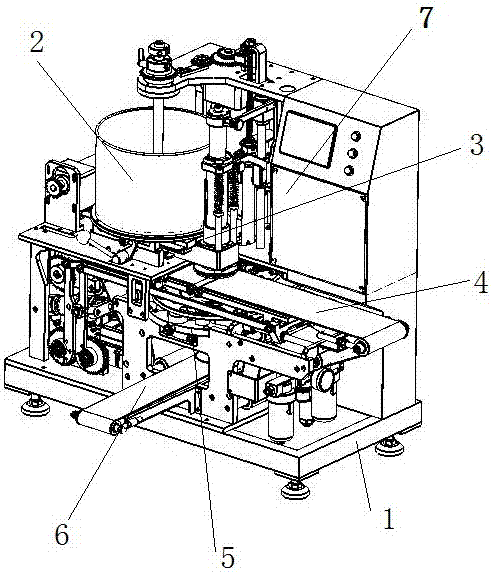

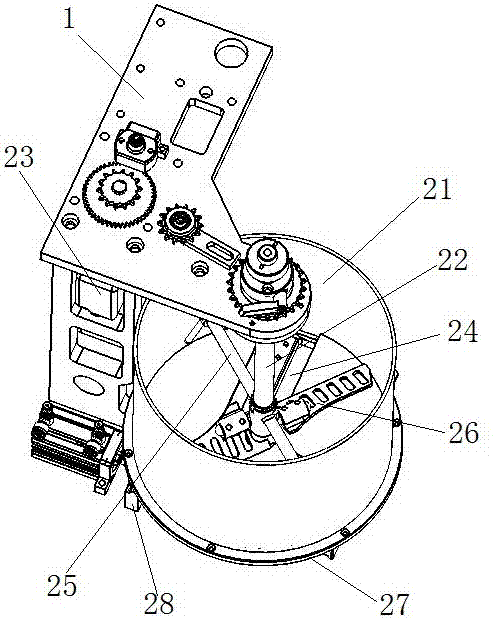

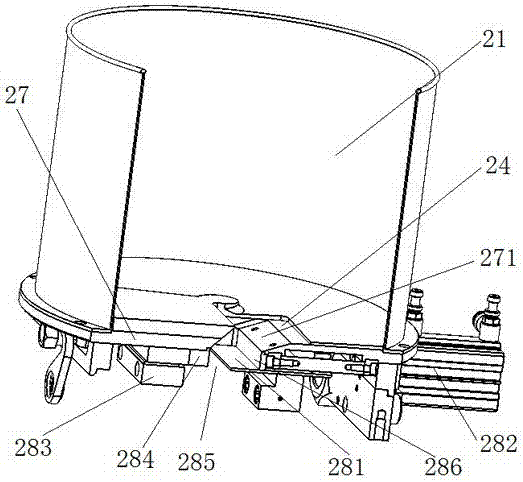

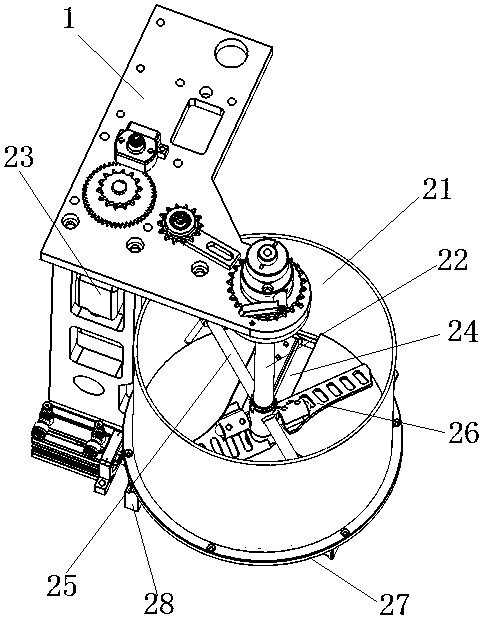

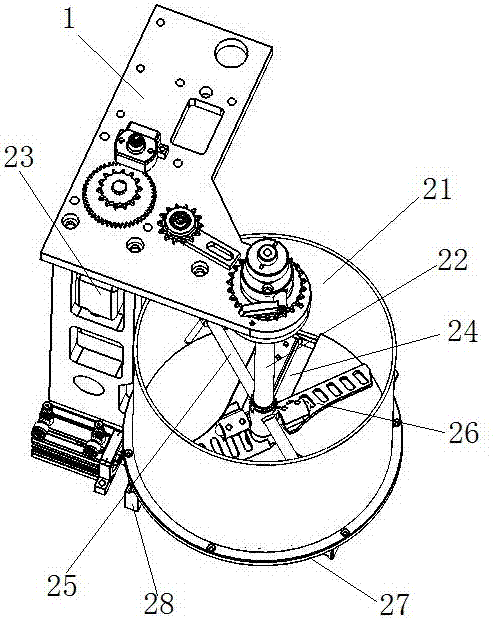

Pattern pinching forming device of steamed stuffed bun machine

ActiveCN107372693AAdjust the amount of fillingOvercoming the lack of stuffing that cannot be adjustedDough processingMachinePower apparatus

The invention provides a pattern pinching forming device of a steamed stuffed bun machine. The pattern pinching forming device comprises a pattern pinching fixing disc, the pattern pinching fixing disc is arranged on a cutter support, is of an annular plate structure and is provided with a pattern pinching cutter block, a downward pattern pinching limiting shaft is arranged in the middle of the pattern pinching cutter block, an inner hole of the annular pattern pinching fixing disc is internally provided with a pattern pinching turntable, the pattern pinching turntable can rotate relative to the pattern pinching fixing disc, and is provided with a pattern pinching limiting slide groove corresponding to the pattern pinching limiting shaft, the pattern pinching limiting shaft is installed in the pattern pinching limiting slide groove in a penetrated mode, the lower end face of the pattern pinching turntable is connected with a pattern pinching power plate, and the pattern pinching power plate is connected with a pattern pinching power device. The pattern pinching forming device is applicable to a simulation steamed stuffed bun machine, can pinch patterns, seal and form fallen cylindrical steam stuffed bun wrappers and seal and pinch the steamed stuffed buns into wrinkles of simulation of manual pinching.

Owner:HENAN WANJIE INTELLIGENT TECH

A kind of processing method of semi-dried fresh salted fish

InactiveCN102273663AShorten production timeInhibits growth and enzyme activityFood preparationFlavorGill

The invention discloses a method for processing semi-dried fresh salted fish, which comprises the steps of selecting fish, removing viscera and gills, washing and pickling, air-drying, and refrigerating in a freezer. Compared with the salted fish products produced by the traditional method, the semi-dried fresh salted fish processing method of the present invention has the advantages of unique flavor, good meat taste, hygiene and safety, and the like.

Owner:林孟德

Working liquid for fabricating preserved flowers of peony and Chinese herbaceous peony, and method for fabricating preserved flowers and preserved leaves of peony and Chinese herbaceous peony by using same

InactiveCN103843760ANot affectedStay resilientDead plant preservationEnvironment effectPolypropylene glycol

The invention relates to a working liquid for fabricating preserved flowers of peony and Chinese herbaceous peony, and a method for fabricating preserved flowers and preserved leaves of peony and Chinese herbaceous peony by using the same. The working liquid comprises one or a mixture of more than two of 50-80% methanol, ethanol, normal propyl alcohol, n-butyl alcohol and isopropanol, 20-50% polyethylene glycol 200-1000 and polypropylene glycol 200-1000; and the polyethylene glycol accounts for 60-80%, and the polypropylene glycol accounts for 20-40%. The preserved flowers and preservative liquid of the peony and the Chinese herbaceous peony fabricated by the working liquid can be stored for a long period of time in a state of being close to fresh flowers / fresh leaves, the natural gesture, the flexibility and the texture can be kept, the external environment effect is avoided, and the ornamental value is greatly enhanced.

Owner:洛阳甲天下牡丹园艺有限公司

Preparation method of bombax ceiba three-dimensional dried flowers

The invention discloses a preparation method of bombax ceiba three-dimensional dried flowers. The preparation method comprises following steps: (1), pretreatment, wherein fresh bombax ceiba flowers are immersed in a color retention agent so as to maintain original color and quality of bombax ceiba flowers in subsequent drying processes, and the color retention agent is a mixture of citric acid and glycerin; (2) embedding, wherein gaps of the bombax ceiba flowers processed via step (1) are filled with degreasing cotton, the whole bombax ceiba flowers are coated with degreasing cotton, and the obtained bombax ceiba flowers are coated with granular silica gel; (3) drying, wherein vacuum freeze drying or refrigerator freeze drying are used to dry the coated bombax ceiba flowers so as to remove water in the bombax ceiba flowers; and (4), the granular silica gel and the degreasing cotton are removed so as to obtain the bombax ceiba three-dimensional dried flowers. The preparation method is used for preparing the bombax ceiba three-dimensional dried flowers; original shape, color, texture, softness, and straight shape of the bombax ceiba flowers are basically maintained; the bombax ceiba three-dimensional dried flowers can be further made into bombax ceiba three-dimensional dried flower souvenirs in forms of single flower, flowering branch, or other forms; and supply of the bombax ceiba flowers all year round becomes possible.

Owner:ZHONGKAI UNIV OF AGRI & ENG

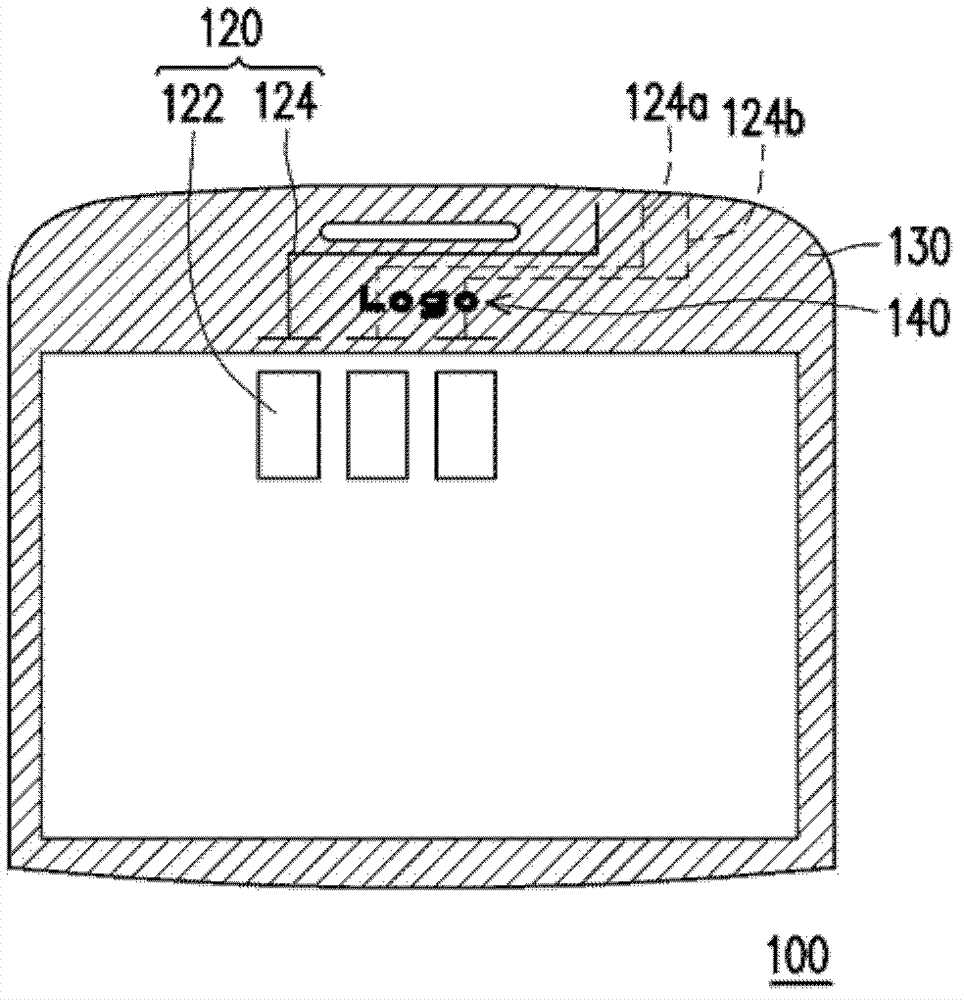

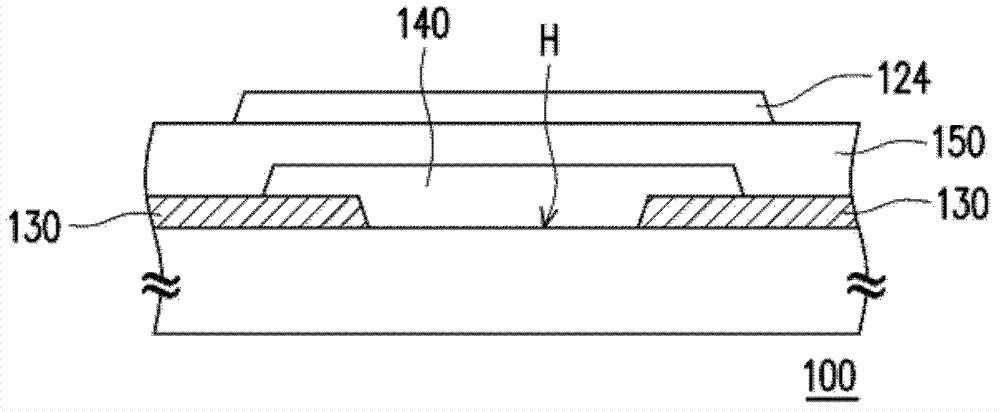

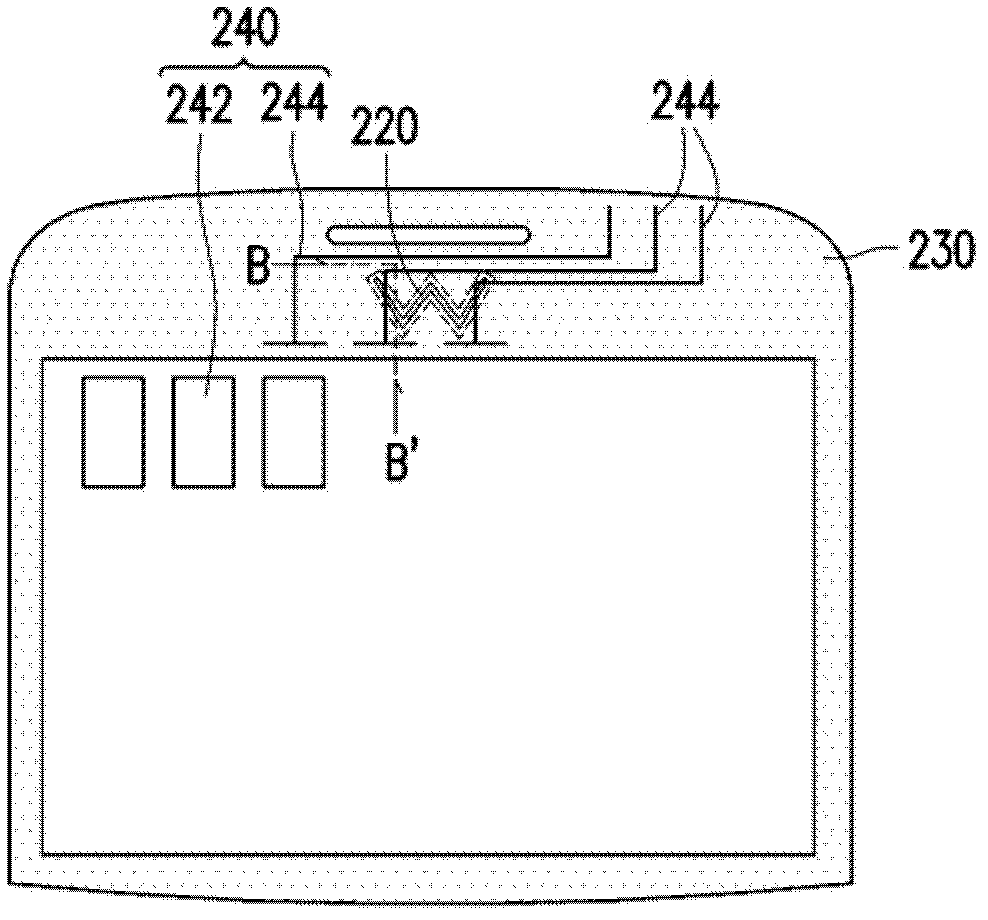

Touch panel and touch display device

InactiveCN102955598AGuaranteed textureIncrease flexibilityInput/output processes for data processingDisplay deviceComputer science

The invention relates to a touch panel which comprises a substrate, a logo, a decorative layer and a touch element. The logo is positioned on the substrate and between the substrate and the decorative layer, the decorative layer is positioned at the peripheral edge of the surface of the substrate, and the touch element is positioned on the substrate. Flexibility of the touch panel in terms of wiring and manufacturing can be improved, and the sense of design of the touch panel is improved. The invention further provides a touch display device with the touch panel.

Owner:WINTEK CHINA TECH LTD +1

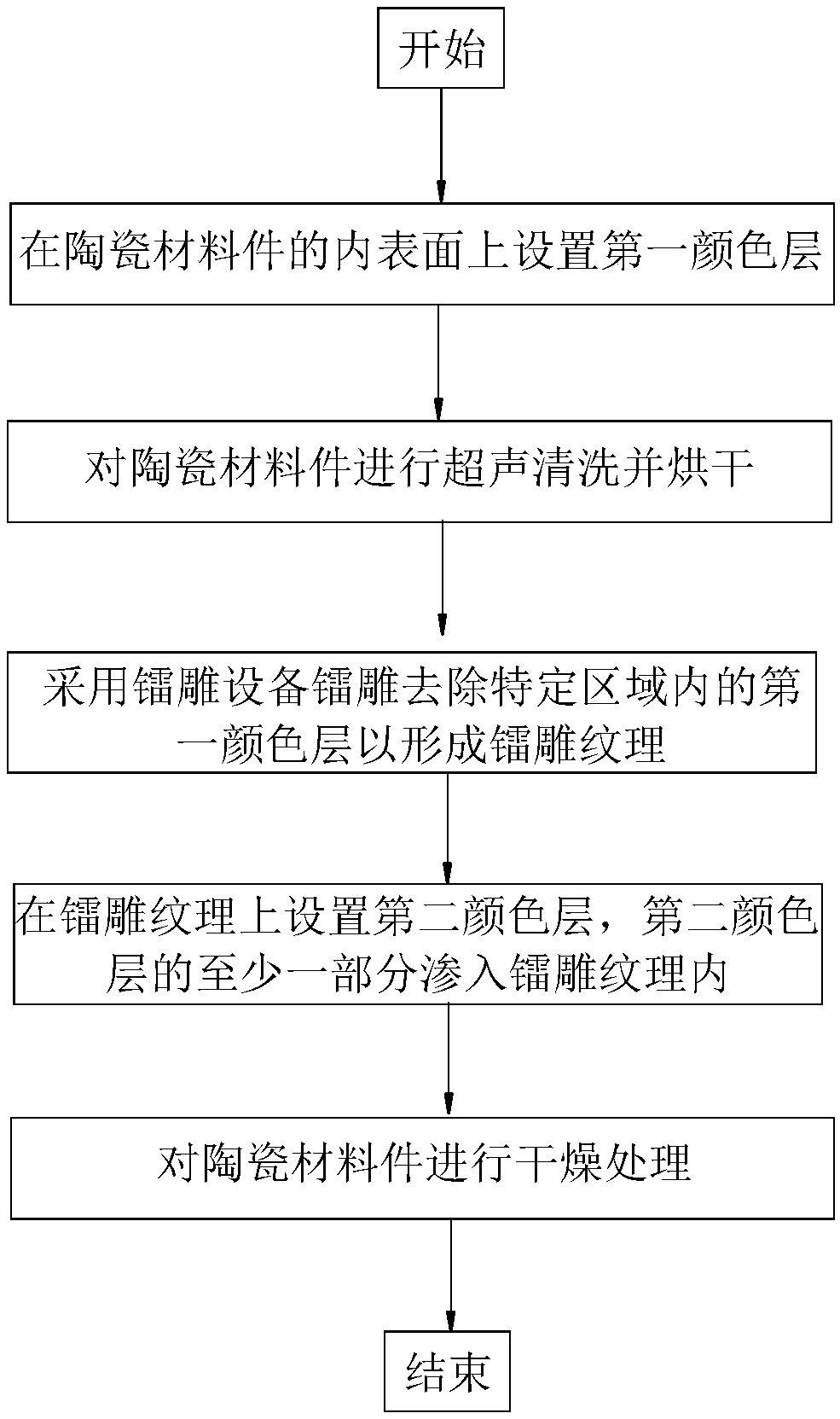

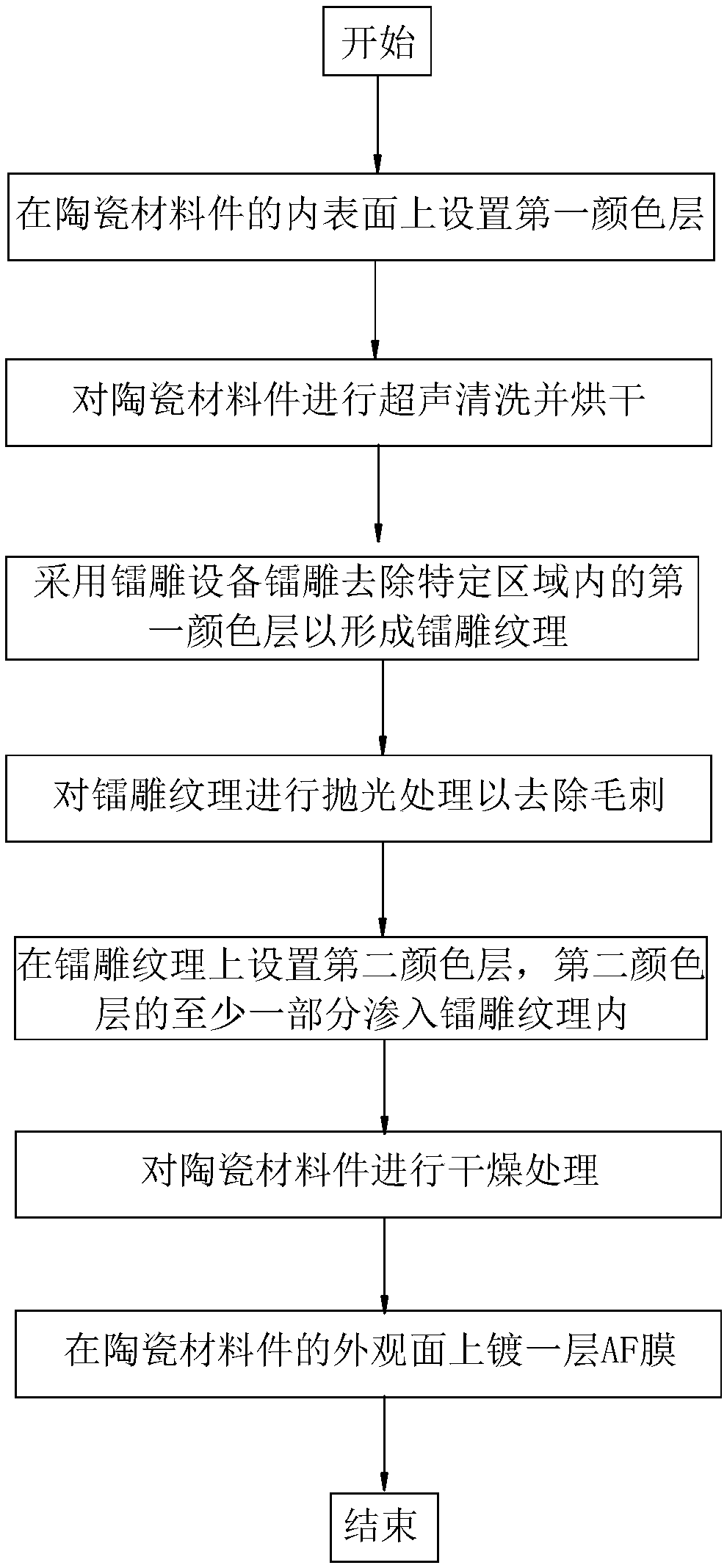

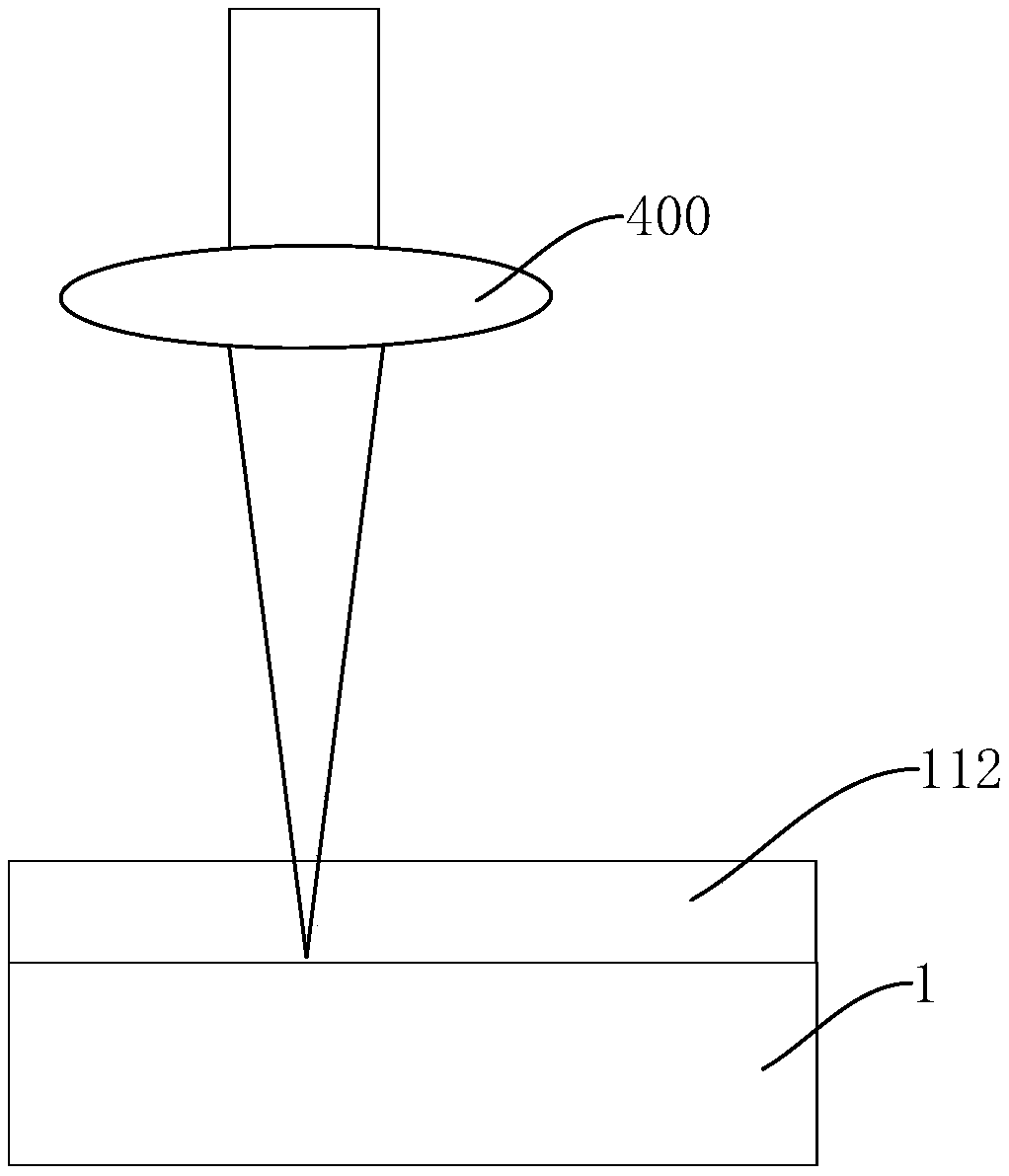

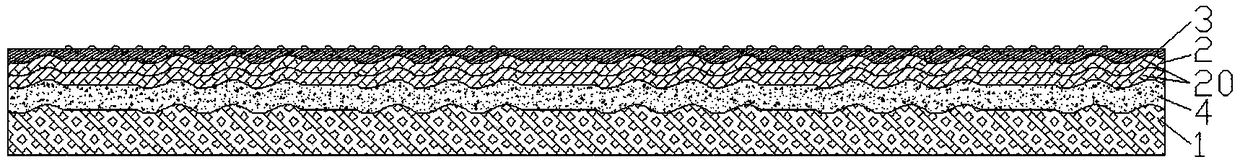

Surface treatment method for ceramic material piece, housing assembly and electronic device

InactiveCN109050139AImprove aestheticsGuaranteed glossDecorative surface effectsCasings/cabinets/drawers detailsLaser engravingPartial filling

The invention discloses a surface treatment method for a ceramic material piece, a housing assembly and an electronic device. The surface treatment method of the ceramic material piece comprises the following steps: providing a first color layer on the inner surface of the ceramic material piece; performing laser engraving on the first color layer by using a laser engraving device to remove the first color layer in a specific area to form a laser engraving texture; providing a second color layer on the laser engraving texture, filling at least a portion of the second color layer into the laserengraving texture; and drying the ceramic material piece. According to the surface treatment method of the ceramic material piece of the present application, by providing the first color layer and the second color layer on the inner surface of the ceramic material piece, at least a portion of the second color layer is filled into the laser engraving texture on the first color layer. Therefore, itis possible to present a clear, rounded and gradient laser engraved texture on the appearance of the ceramic material piece, improving the aesthetic appearance of the ceramic material piece.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

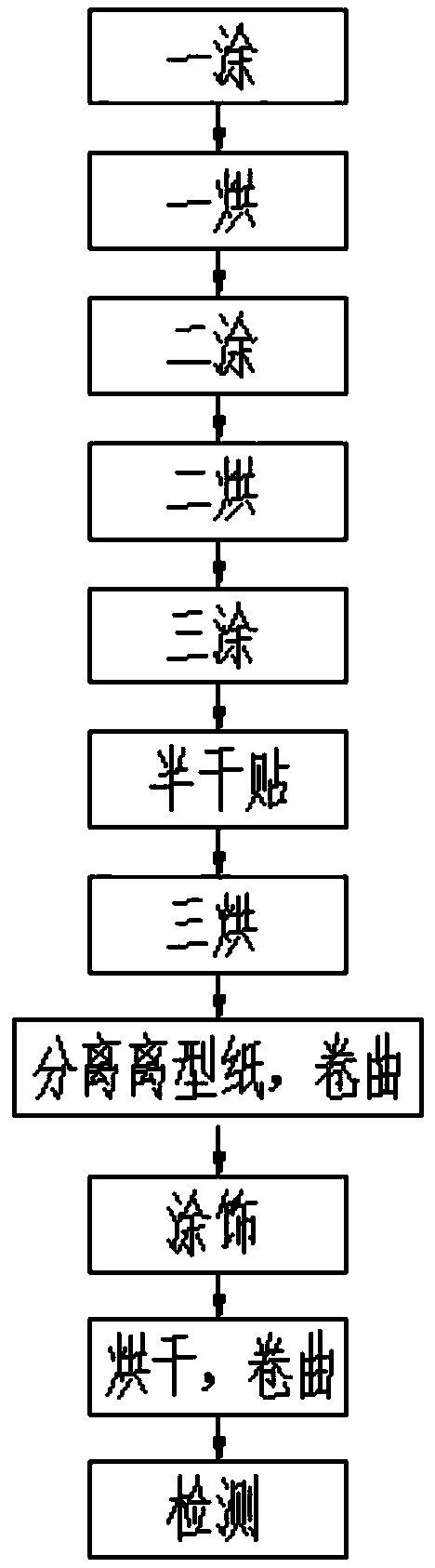

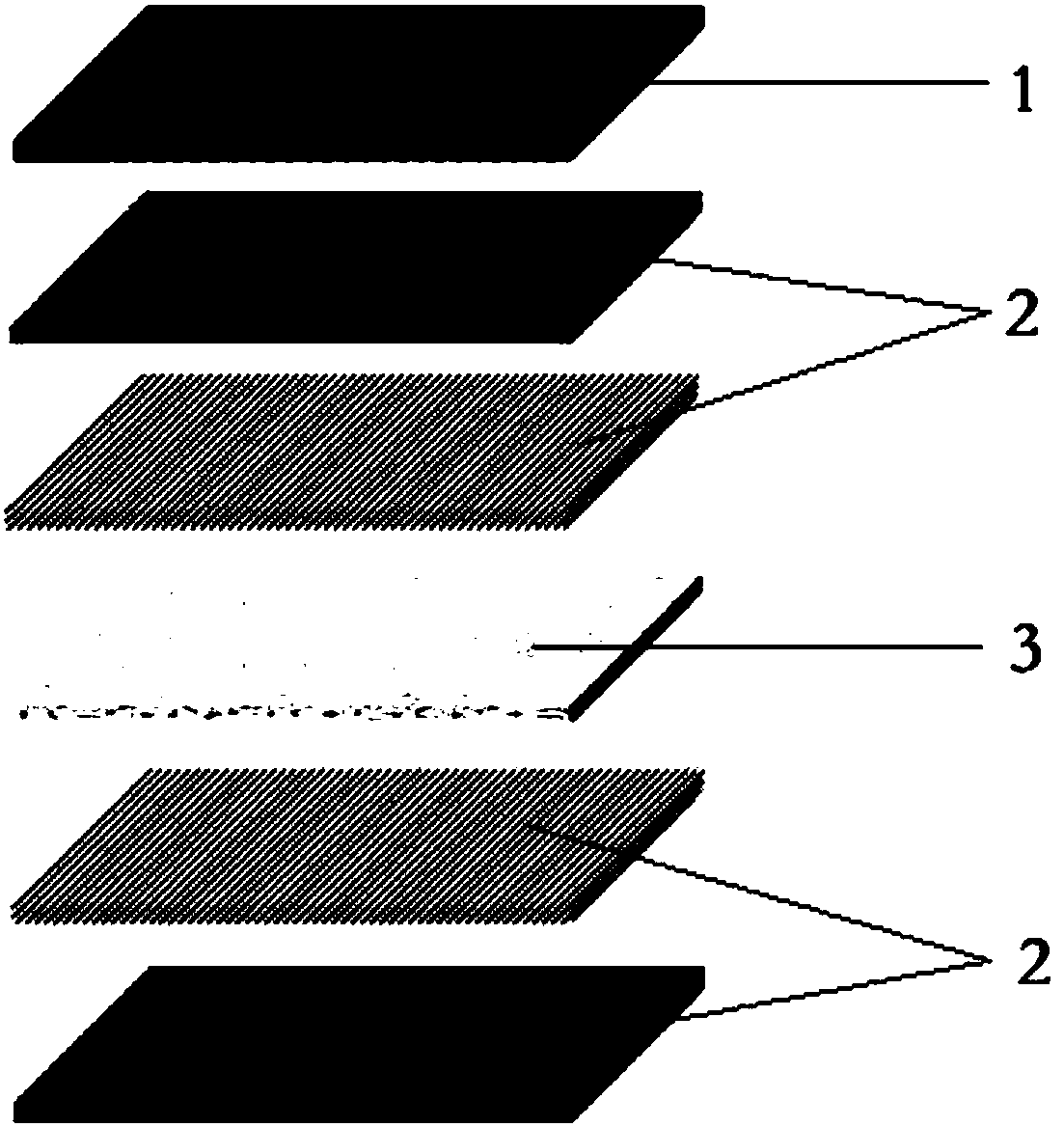

High laminating degree PU leather, and preparation method thereof

InactiveCN109109419ACompact structureHierarchical stabilityLamination ancillary operationsSynthetic resin layered productsAdhesiveIn vehicle

The invention discloses a high laminating degree PU leather. The high laminating degree PU leather comprises a base cloth layer, a PU layer, and a coating decorative layer successively; an adhesive layer is arranged between the base cloth layer and the PU layer; the adhesive layer is prepared from a solvent-free PU adhesive; the coating decorative layer is a water- based coating decorative layer;the PU layer comprises two PU single layers; the PU layer comprises, by weight, 90 to 105 parts of PU resin, 62 to 72 parts of DMF, 12 to 16 parts of ethyl acetate, and 19 to 25 parts of color paste;the coating decorative layer comprises, by weight, 4 to 6 parts of a semi-bright delustering surface treatment agent, 4.5 to 6 parts of a delustering surface treatment agent, 0.5 to 0.8 part of a dryslide handfeel wear resisting agent, 0.6 to 0.75 part of a wet slide handfeel wear resisting agent, 0.6 to 0.85 part of a antifouling agent, 0.25 to 0.32 part of a levelling agent, 0.6 to 0.85 part ofa cross-linking agent, and 2.5 to 4 parts of industrial distilled water. A preparation method of the high laminating degree PU leather is capable of avoiding layering phenomenon after material heating force loading in coating moulding process of the PU material, and satisfying moulding requirements of irregular interior decorative parts in vehicles; and extremely excellent durability and fastnessare achieved.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

Method for treating and fresh-keeping sciaenops ocellatus by using acidic electrolyzed water

ActiveCN102960425AReasonable designPH controlMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAquatic productChemistry

The invention provides a method for treating and fresh-keeping sciaenops ocellatus by using acidic electrolyzed water and belongs to the technical field of preservation of aquatic products. The method comprises the following steps of: 1) pre-treating the sciaenops ocellatus; 2) carrying out spraying treatment by using the acidic electrolyzed water; 3) carrying out immersing treatment by using the acidic electrolyzed water; 4) carrying out freezing point injection treatment; 5) packaging in vacuum; and 6) preserving at an ice temperature. According to the method for treating and fresh-keeping the sciaenops ocellatus by using the acidic electrolyzed water, disclosed by the invention, the kill ratio of common bacteria on the surface of the sciaenops ocellatus is more than 99%; and the freshness degree, the flavor and the texture of the sciaenops ocellatus can be guaranteed to the greatest extent within 40-50 days.

Owner:ZHEJIANG OCEAN UNIV

Method for preparing nitrogen-filled instant sea cucumber

InactiveCN102342548AExtended shelf lifePreserve health and nutrition functionsFood preparationFlavorPreservative

The invention discloses a method for preparing a nitrogen-filled instant sea cucumber. The preparation method comprises the following steps of: eviscerating, foaming and seasoning the fresh sea cucumber sequentially, packaging the treated sea cucumber by a compound film, filling nitrogen and sterilizing to obtain the nitrogen-filled instant sea cucumber. The process of the preparation method is simple, the operation is feasible, no preservative is required, the thorn shape of the sea cucumber filled with nitrogen is complete, so the original quality, taste, flavor and nutrition of the sea cucumber can be retained well; meanwhile, the quality guarantee period is long, the safety is higher and the nitrogen-filled instant sea cucumber is more convenient to eat.

Owner:福州百洋海味食品有限公司

Remolding-realizable carbon fiber sheet material with weaving texture on whole surface and preparation method thereof

ActiveCN108215413AHigh strengthImprove rigiditySynthetic resin layered productsLaminationFiberCarbon fibers

The invention relates to a remolding-realizable carbon fiber sheet material with a weaving texture on a whole surface. The remolding-realizable carbon fiber sheet material comprises a carbon fiber sheet main body, wherein the carbon fiber sheet main body comprises multiple thermosetting carbon fiber prepreg layers and a filled interlayer; the glass bead filled interlayer is arranged in the middleof the multiple thermosetting carbon fiber prepreg layers; the carbon fiber sheet material also comprises a thermoplastic carbon fiber woven fabric prepreg layer arranged at the uppermost layer of thecarbon fiber sheet main body; moreover, the edge of the thermoplastic carbon fiber woven fabric prepreg layer is in an arc shape. The sheet material provided by the invention has favorable strength and rigidity below the softening point of a base material, and also has plasticity anew above the softening point; due to the arc-shaped structure of the edge, when the sheet material is subjected to subsequent processing or combined with other structures, the weaving texture of the entire surface can be maintained; the post forming processing speed of the remolding-realizable carbon fiber sheet material is quick; the production efficiency is high; the production cost is low; the large-batch production can be realized; the impact resistance is good; a product can have post forming ability, andthe remolding-realizable carbon fiber sheet material has the carbon fiber weaving texture on the whole surface.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

Composition for adjusting concrete color

A composition for adjusting concrete pigment consists of pure propyl-emulsion 26-35 wt%, water 10-15 wt%, dispersant 0.3-0.4 wt%, anti-freezing agent 2-4 wt%, antiseptics 0.1-0.3 wt%, titanium pigment 8-10 wt%, filler 37-53 wt%, filming accessory 2-3 wt%, hydrophobic agent 2-5 wt%, thickener 0.2-0.5 wt% and pH regulator 0.1-0.3 wt%. The color paste comprises red, yellow and black three kinds, each kinds occupies 0.03-0.06 wt%. It has excellent weather resistance.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

Preparation method of dried crawfishes

InactiveCN106551294AEasy to storeLess nutrient lossFood dryingMeat/fish preservation by dryingCold chainShrimp

The invention discloses a preparation method of dried crawfishes. The method comprises the following steps of (1) selection and classification; (2) soaking and decontamination; (3) boiling with a salt solution; (4) cooling; (5) hot air drying; (6) microwave drying; and (7) sealed packaging. According to the preparation method of the dried crawfishes, combined processing through hot air and microwaves is adopted, the preparation method for a crawfish instant product which can be preserved at the room temperature and contains the high moisture content is provided, the limit that the crawfish product needs a cold-chain guarantee is broken through, and the product can be preserved at the room temperature and convenient to transport, carry and eat.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Production process of super waterproof leather

ActiveCN106480241AGuaranteed textureTexture does not destroyTanning treatmentPre-tanning chemical treatmentPhysical strengthDyeing

The invention discloses a production process of super waterproof leather. Backwater, retanning, neutralization, filling, dyeing, stuffing, fixing, skin layer and resin layer combination and the like are performed on two-layer leather. The process comprises a plurality of waterproof processing steps of the leather, and a skin layer and a resin layer which have good air permeability are combined with the surface of a base material of the two-layer leather, so that the texture of the leather is guaranteed, the effect of increasing the physical strength of the leather is achieved, therefore, the leather which is produced by using the process has the advantages of super waterproof performance and high air permeability, and the texture of the leather is not destroyed.

Owner:福建省永建皮革科技股份有限公司

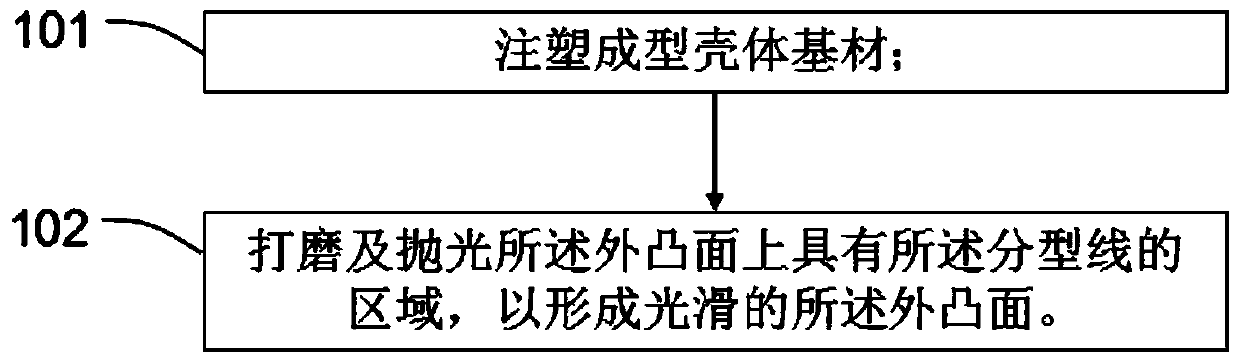

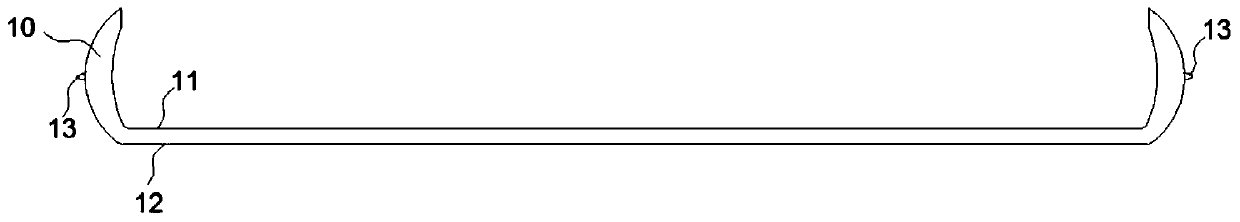

Processing method of shell, shell and electronic equipment

InactiveCN110253380AGuaranteed textureLow costEdge grinding machinesDomestic articlesConvex sideEngineering

The invention provides a processing method of a shell. The processing method comprises the following steps that 1, injection molding of a shell base material is performed, wherein the shell base material is provided with an inner concave surface and an outer convex surface which are oppositely arranged, and the outer convex surface is provided with a parting line; and 2, the area with the parting line on the outer convex surface is ground and polished so as to form a smooth outer convex surface. By injecting and molding the shell base material, the area with the parting line arranged on the base material is ground and polished, so that the parting line on the outer convex surface of the shell base material is removed, the shell base material with a smooth outer convex surface is formed, the texture of the shell base material is improved, the edge of the shell base material is smooth and round, the shell base material is glittering and translucent, and the outer convex surface of the shell base material is smooth like a mirror surface.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

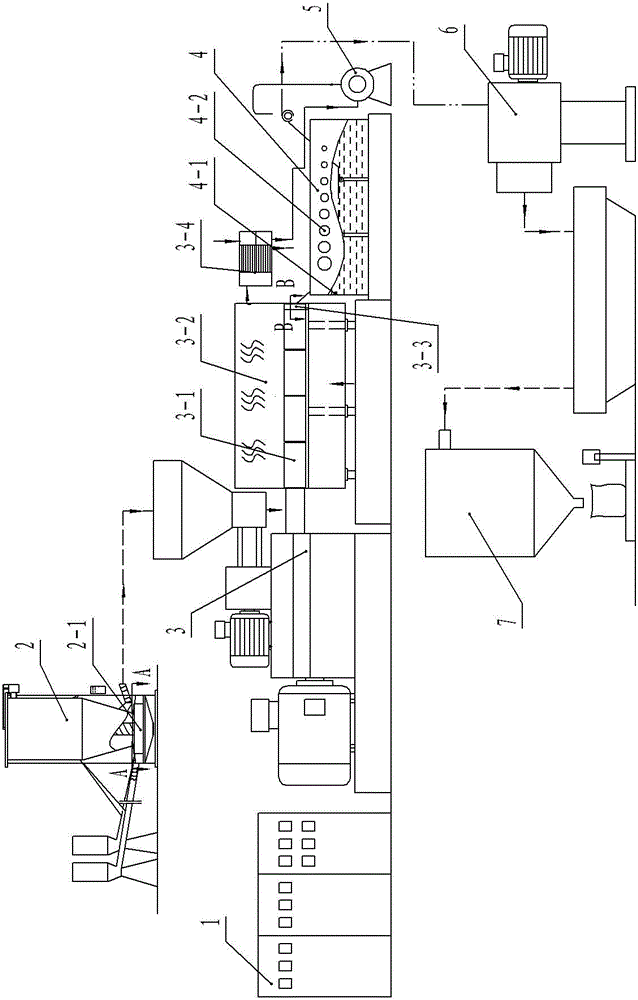

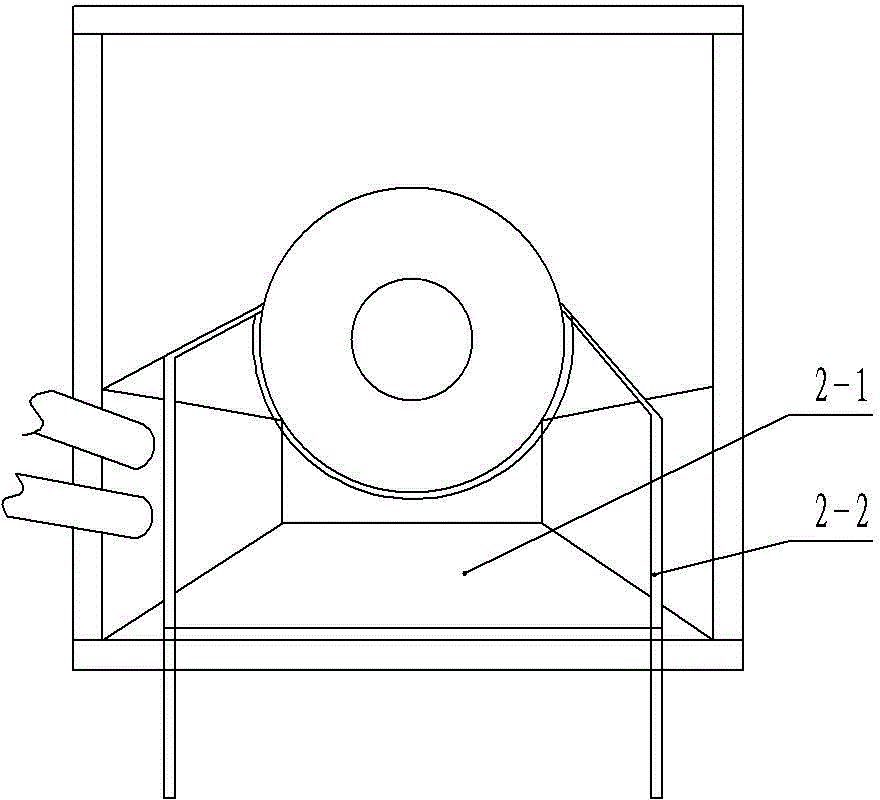

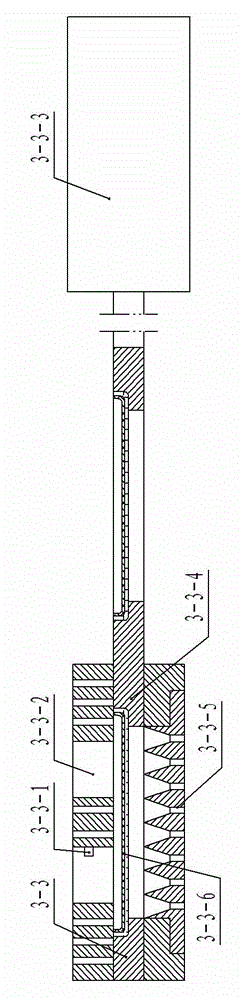

Production line of modified plastic granules

The invention discloses a production line of modified plastic granules, belonging to the technical field of plastic machine manufacture. The production line comprises a mixing feeder, an extruder, a cooling water tank, a drying fan, a traction dicing cutter and a packaging machine which are connected in sequence, and an electric control cabinet connected with all the devices, wherein a dustproof cover is arranged at a feeding hole of the mixing feeder; a smoke-proof cover is defined at the periphery of a heating unit of the extruder; a smoke discharge hole of the smoke-proof cover is connected with a heat exchange device by an exhaust fan; the heat exchange device is connected with the drying fan by a heated end outlet; the tail end of the heating unit is connected with a die head main body comprising an internal filter screen replacement plate; the die head main body is internally provided with a sensor which is connected with the electric control cabinet and is capable of removing the filter screen replacement plate from the die head main body by a cylinder; a plurality of water inlets and a plurality of water outlets are formed in the two opposite side walls of the cooling water tank, respectively. The problems that the environment is polluted, the production is influenced after a filter screen of a die head of the extruder is blocked and the performance of plastic finished products is influenced by the non-uniform temperature of water in the cooling water tank can be solved.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

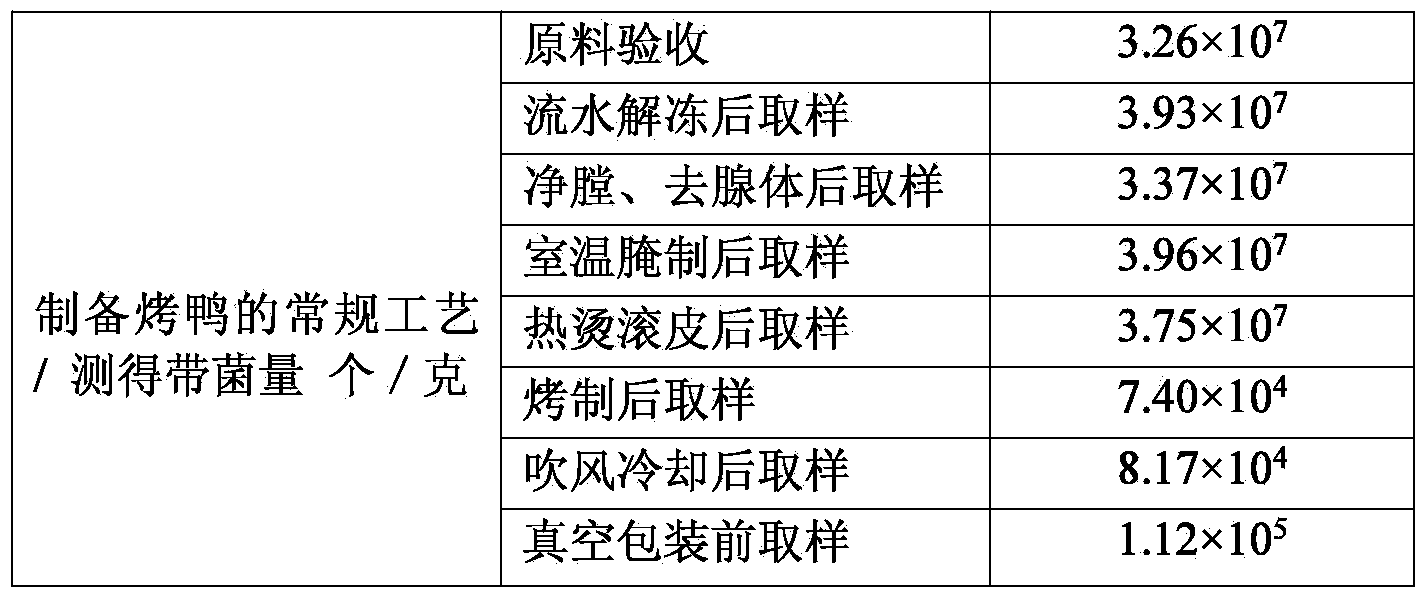

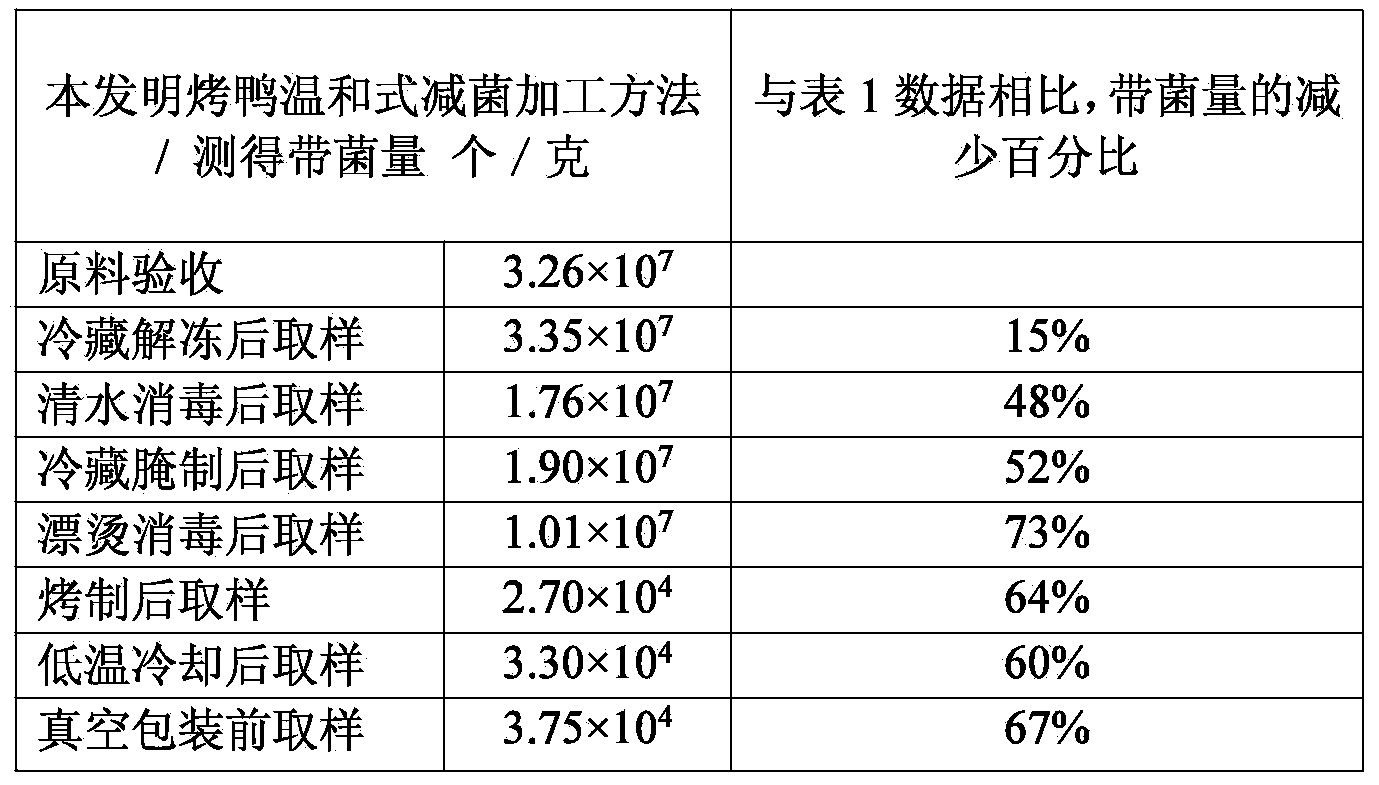

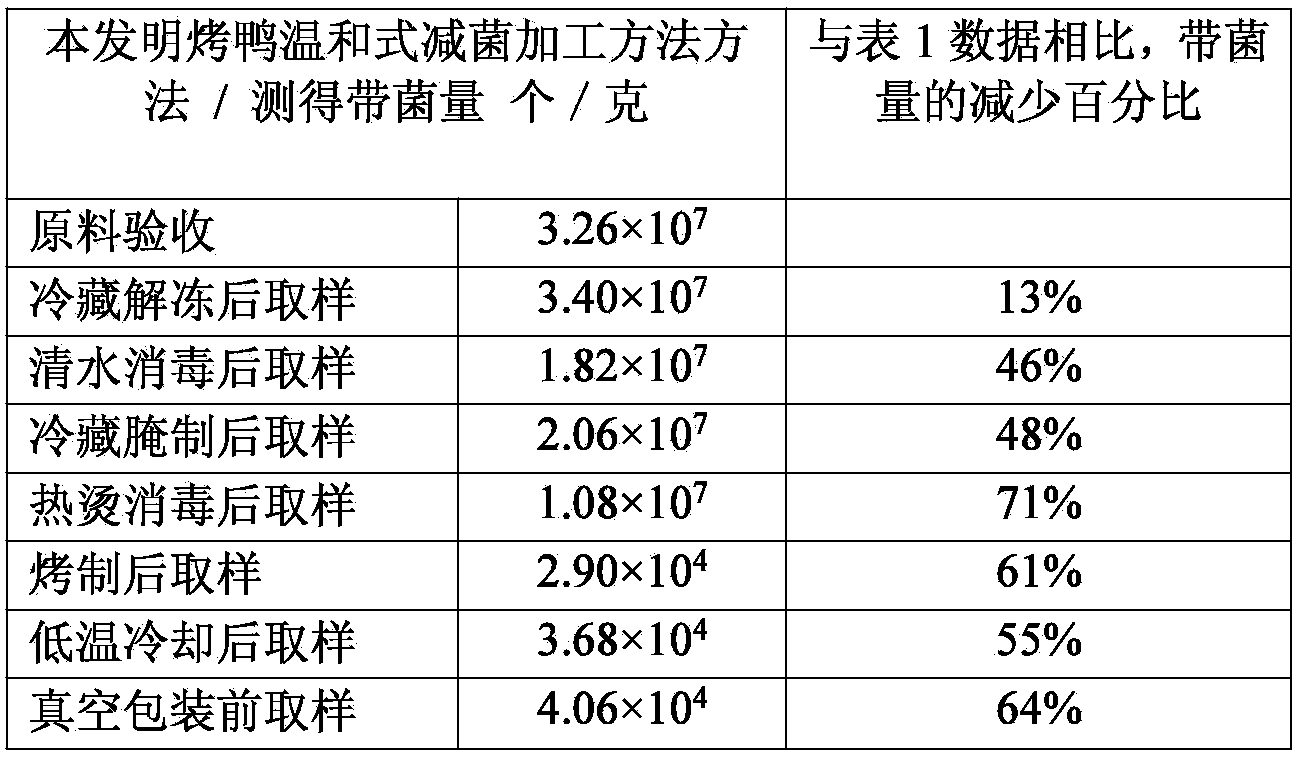

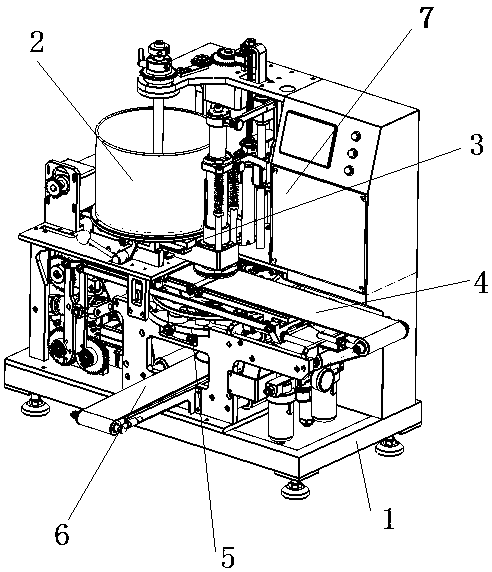

Gentle type decontamination processing method for meat product

ActiveCN103719231AGuaranteed textureGuaranteed tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsCooking & bakingAdditive ingredient

The invention provides a gentle type decontamination processing method for a meat product. The gentle type decontamination processing method comprises the following flow: checking and accepting raw materials; putting into a storage and refrigerating and storing; delivering and checking; refrigerating and thawing; washing and disinfecting; refrigerating and pickling; blanching, disinfecting and baking or marinating; cooling at low temperature; metering and dividing; packaging in vacuum; sterilizing; cooling by cold flow water; airing outer water; and checking and storing. According to the gentle type decontamination processing method for the meat product, a series of decontamination measures are added in a raw material meat processing process; the bacteria carrying amount of the meat product packaged in vacuum is reduced and the sterilization strength in a terminal high-temperature sterilization process is reduced; the color, the aroma, the taste and the shape, and the nutritional ingredients of the meat product are kept unchanged to the greatest extent. Correspondingly, the gentle type decontamination processing method for the meat product provided by the invention is also applicable to processing vegetables with long shelf lives.

Owner:北京中农探味科技有限公司

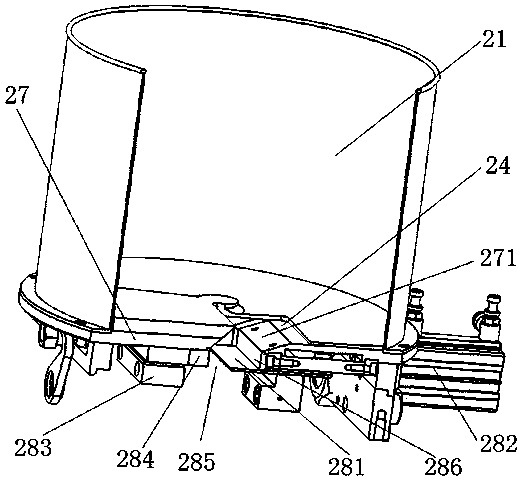

Wrapper positioning device of steamed-stuffed bun making machine

ActiveCN107549229AAdjust the amount of fillingOvercoming the lack of stuffing that cannot be adjustedDough processingEngineeringMechanical engineering

The invention discloses a wrapper positioning device of a steamed-stuffed bun making machine. The wrapper positioning device comprises wrapper cutter blocks, wherein a wrapper cutter block fixing plate is arranged on a cutter disc bracket and is connected with the wrapper cutter blocks swinging relative to the wrapper cutter block fixing plate; cutter disc limiters are arranged on the wrapper cutter block fixing plate; the wrapper cutter block and the cutter disc limiters are alternatively distributed; upward wrapper positioning and limiting shafts are arranged at the middle parts of the wrapper cutter blocks; a wrapper-adjusting rotary disc is of a ring-shaped plate structure, is arranged above the wrapper cutter blocks and is provided with rotary chutes, wrapper positioning and limitingchutes and a power chaining plate; the wrapper positioning and limiting shafts are arranged in the wrapper positioning and limiting chutes in a penetrating manner; the cutter disc limiters are arranged in the rotary chutes in a penetrating manner; and the power chaining plate is connected with the wrapper-adjusting rotary disc and a wrapper-positioning power device. The wrapper positioning devicedisclosed by the invention has the advantages that falling steamed-stuffed bun wrappers and stuffing are pushed to a steamed-stuffed bun falling channel, so that the steamed-stuffed bun wrappers are prevented from falling in a biased manner; and under the action of the wrapper cutter blocks, the peripheries of the steamed-stuffed bun wrappers are pushed and extruded towards the middle parts so asto form drum-shaped structures with folds.

Owner:HENAN WANJIE INTELLIGENT TECH

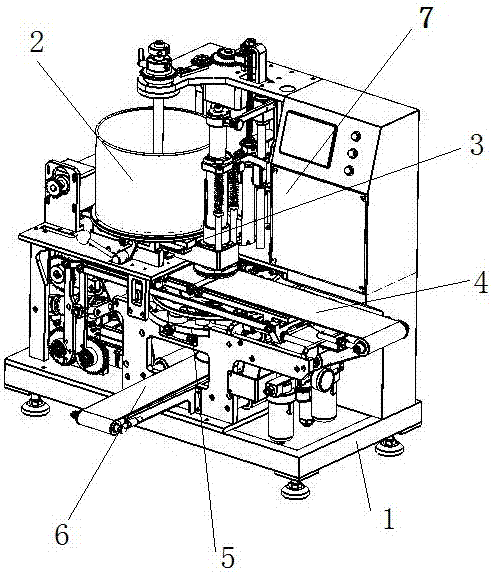

Wrapper conveying mechanism of stuffed bun making machine

ActiveCN107568285AAdjust the amount of fillingOvercoming the lack of stuffing that cannot be adjustedDough processingEngineeringMechanical engineering

The invention provides a wrapper conveying mechanism of a stuffed bun making machine. The wrapper conveying mechanism comprises a conveying belt, a driving roller, a conveying motor, a reversing support roller, a left driven roller, a right driven roller, a left moving roller, a right moving roller, a right discharging device, a left discharging device and a conveying belt moving device. The conveying belt is used for conveying hand-made bun wrappers to the lower end of a stuffing feeding mechanism; then, under the action of the conveying belt moving device, the conveying belt is divided fromthe middle to two sides so as to form a space for bun wrappers and bun stuffing to fall off; and under the action of a falling stuffing pushing shaft, the bun wrappers and the bun stuffing are pushedto a patterning and forming mechanism of a bionic stuffed bun making machine. The wrapper conveying mechanism provided by the invention is original in conception and smart in design; and by manually preparing the bun wrappers, the chewiness of the wrappers can be adequately protected, the wrappers can not be damaged, and the texture of the stuffed buns can be ensured.

Owner:HENAN WANJIE INTELLIGENT TECH

Ceramic glazed tile glaze prepared from coal gangue, and preparation method and use method of ceramic glazed tile glaze

The invention relates to the technical field of ceramic glazed tiles, in particular to a ceramic glazed tile glaze prepared from coal gangue, and a preparation method and use method of the ceramic glazed tile glaze. The ceramic glazed tile glaze is prepared from 1-5 parts of zinc oxide, 4-10 parts of barium carbonate, 4-12 parts of zirconium silicate, 30-40 parts of potassium feldspar, 2-10 partsof desiliconized aluminum powder, 6-14 parts of calcined talc, 2-8 parts of calcite, 6-12 parts of kaolin, 6-12 parts of dolomite, 3-8 parts of quartz and 5-12 parts of coal gangue waste residues, wherein the fineness of the coal gangue waste residues is that screening residues of 60 meshes is 10-20%, and the mass content of water is 1-2%. According to the glaze, the cheap coal gangue waste residues are adopted to replace high-cost calcined kaolin, so that cost of the glaze is greatly reduced, and raw material cost per ton can be reduced by 60% or above. In addition, the texture and luster ofthe glaze surface are finally ensured to meet use requirements by controlling the glaze slurry performance, the glaze formula and the glazing conditions.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Tea oil-mushroom oil chili pepper and preparation method thereof

The invention discloses tea oil-mushroom oil chili pepper and a preparation method thereof, wherein the tea oil-mushroom oil chili pepper comprises the following raw materials in parts by weight: 12-14 parts of rapeseed oil, 9-11 parts of tea seed oil, 5-6 parts of fermented soya beans, 3-5 parts of chili pepper, 2-3 parts of shiitake mushroom, 3-5 parts of crushed peanut kernels, 2-4 parts of sweet flour paste, 2-4 parts of raw ginger, 0.7-0.9 part of garlic, 0.2-0.4 part of Sichuan pepper, 0.08-0.12 part of star anise, 0.5-1.5 parts of monosodium glutamate, 1.3-1.6 parts of chicken essence,0.2-0.4 part of edible salt, 0.7-0.9 part of white sugar, 0.4-0.6 part of sesame seeds, and 0.6-0.8 part of soy sauce. The oil chili pepper prepared through material selection, low temperature soaking, steaming, Ciba chili pepper preparation, stir-frying, filling and other steps retains the nutrient substances of the raw materials and glossy appearance, full flavor and soft and chewy mouthfeel offlavor products.

Owner:贵州老外婆风味食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com