Patents

Literature

4025results about "Meat/fish preservation using chemicals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and composition for washing poultry during processing

InactiveUS6514556B2Reduce Microbial ContaminationHigh degreeBiocideDough treatmentBiologyMicrobial contamination

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

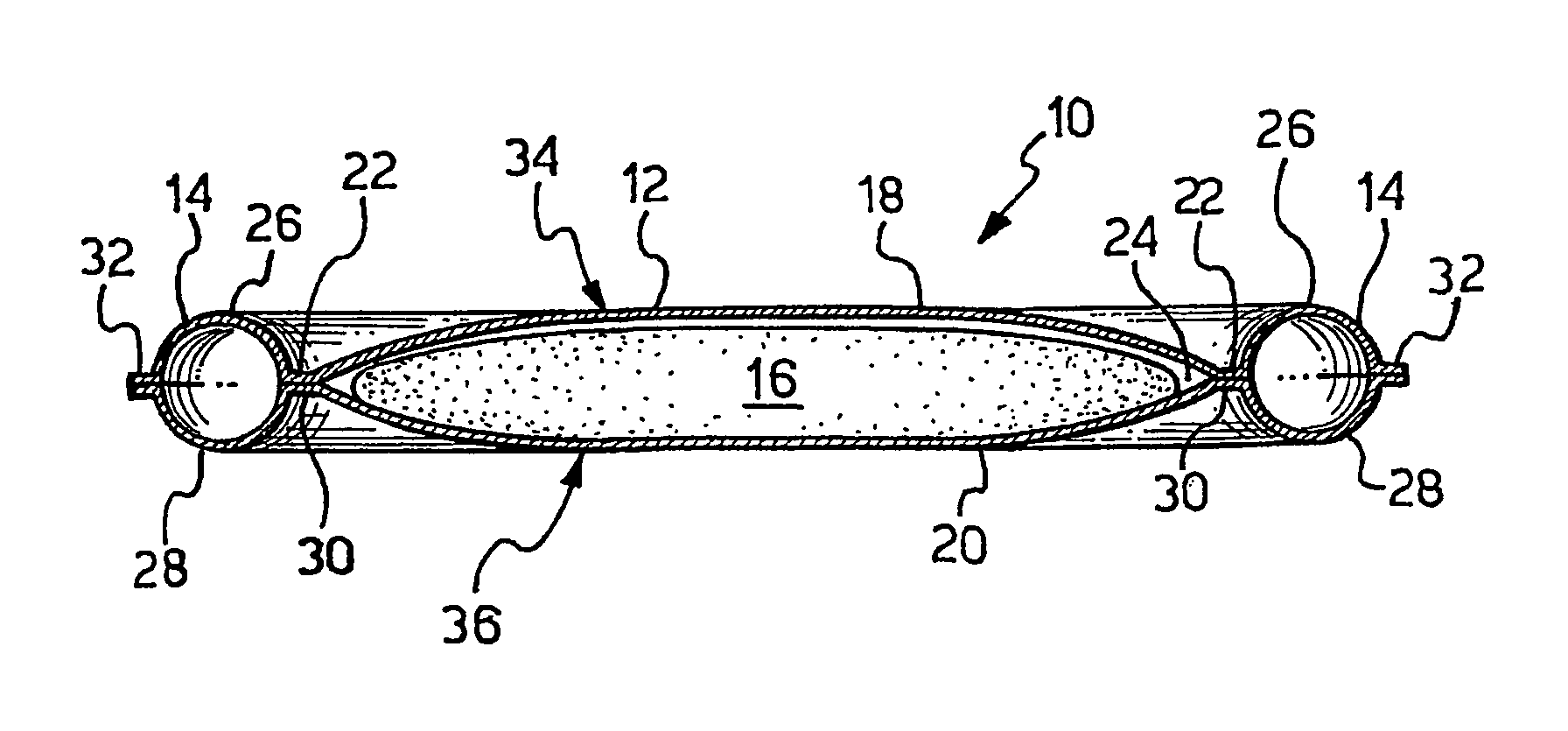

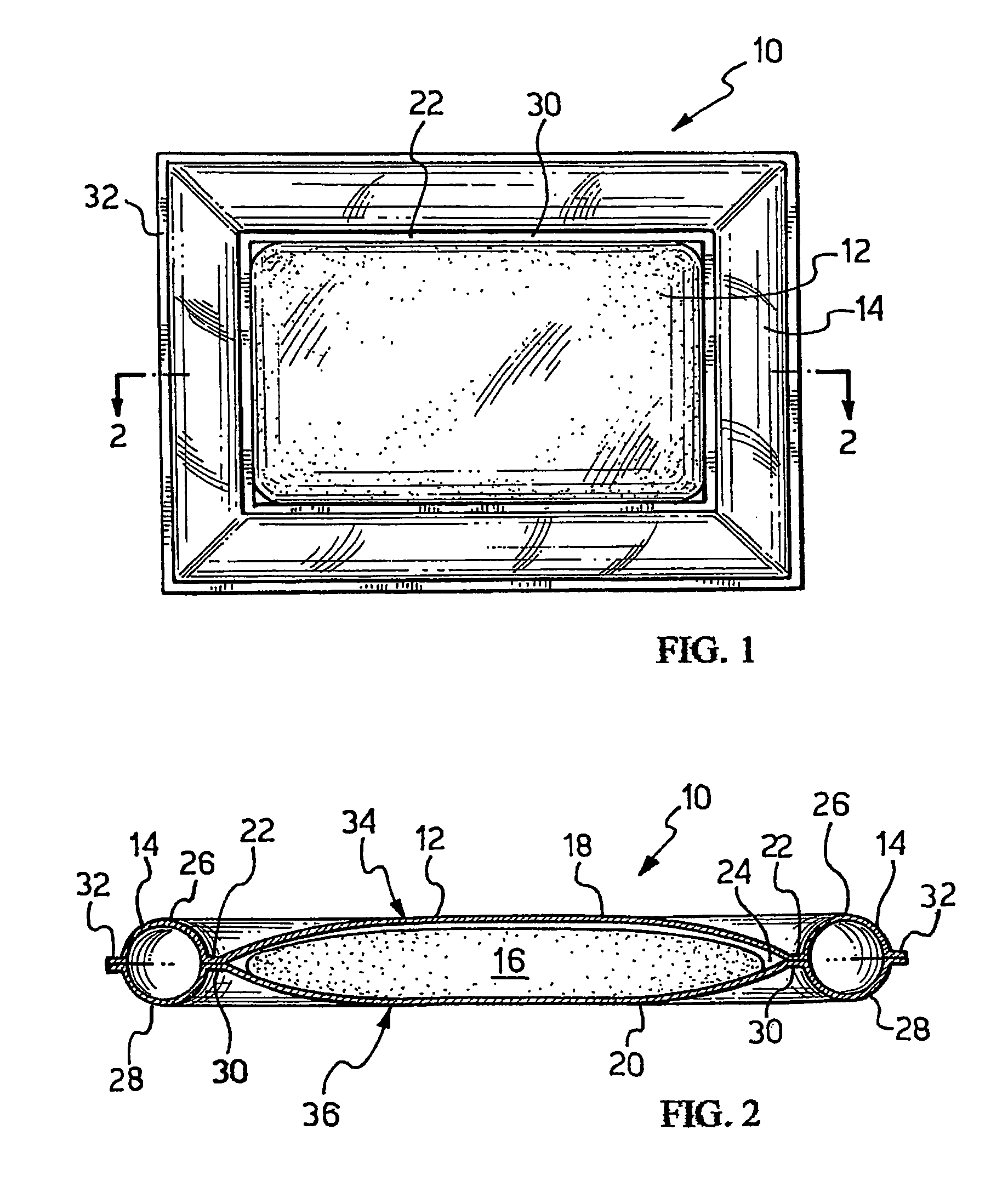

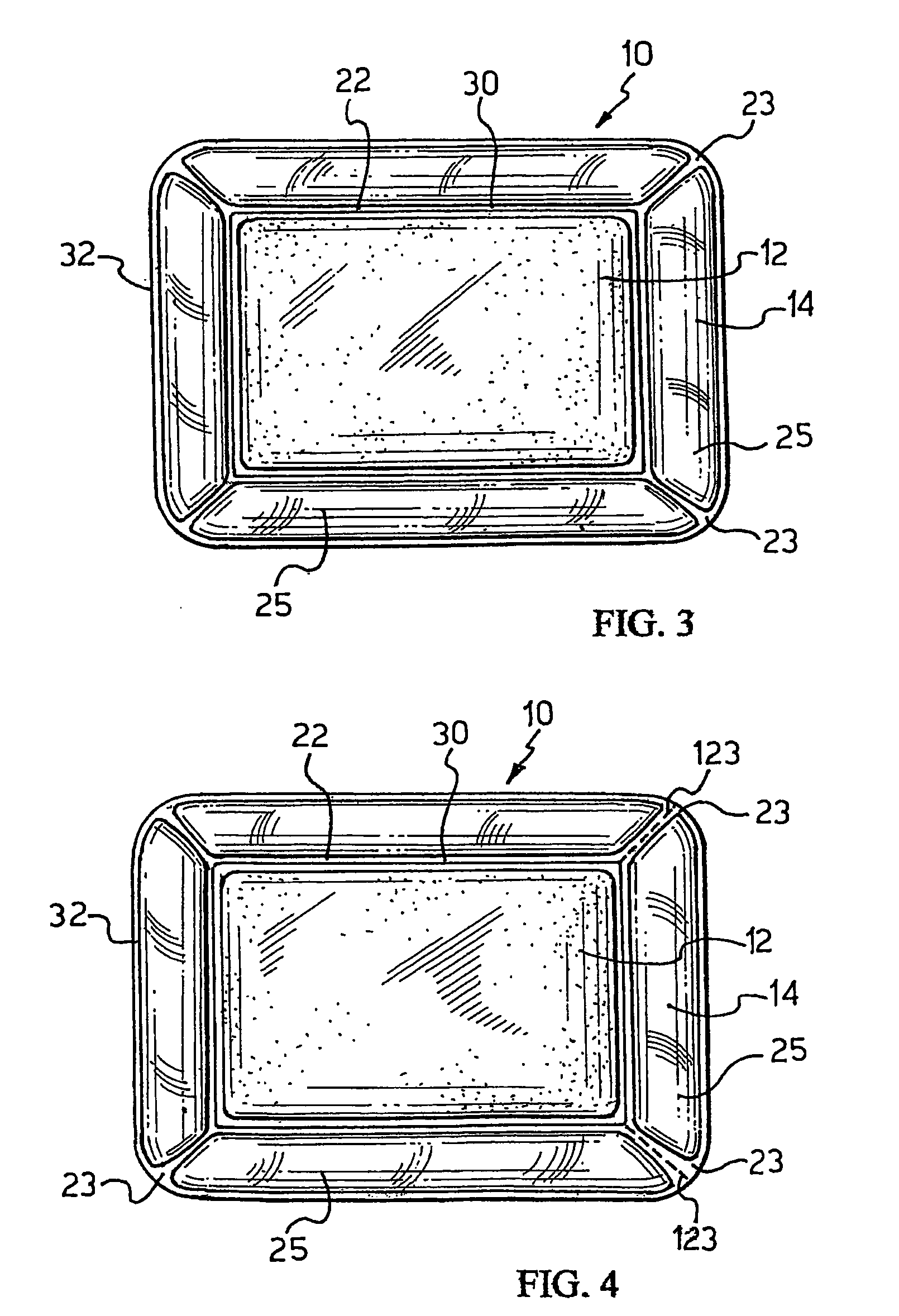

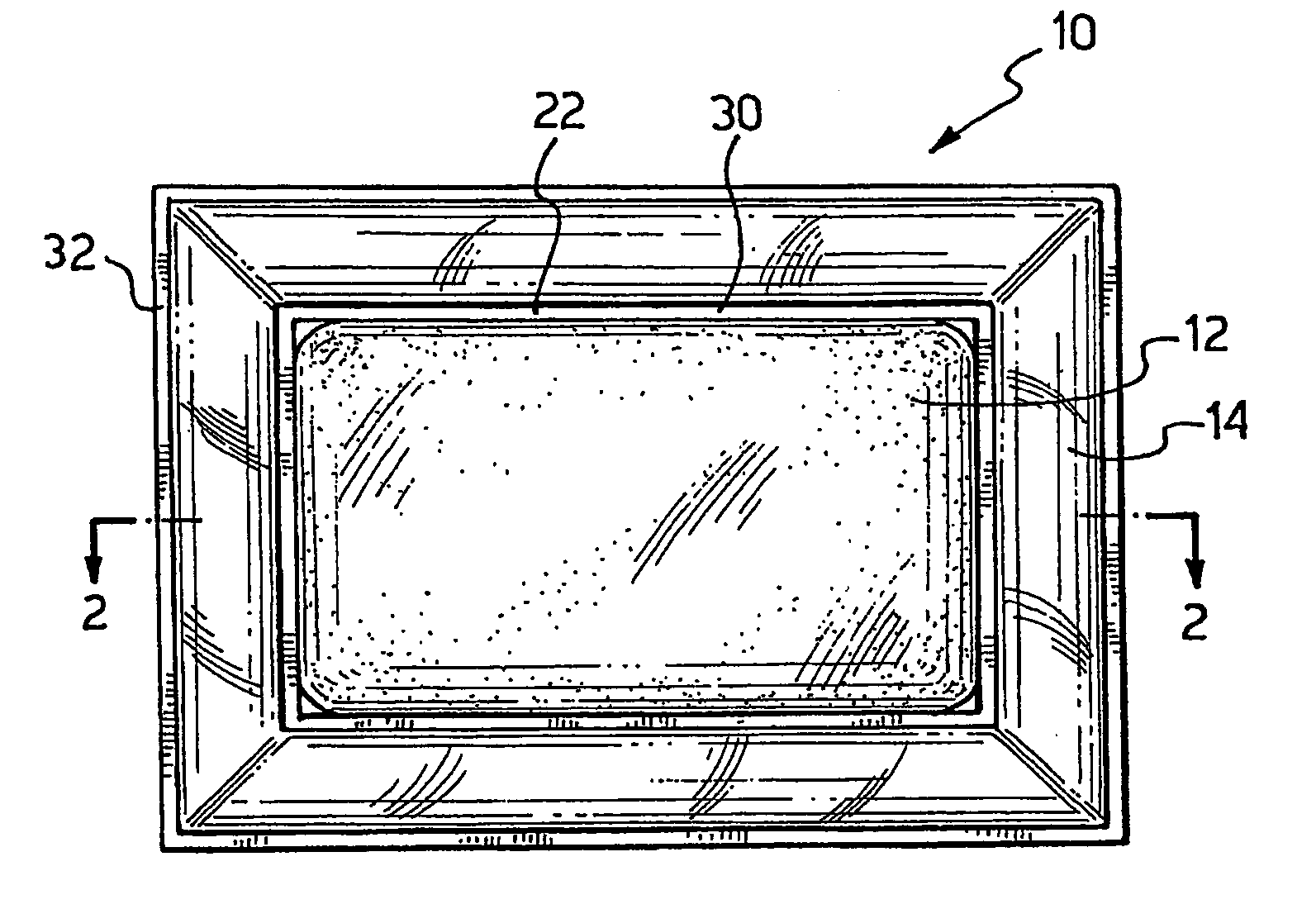

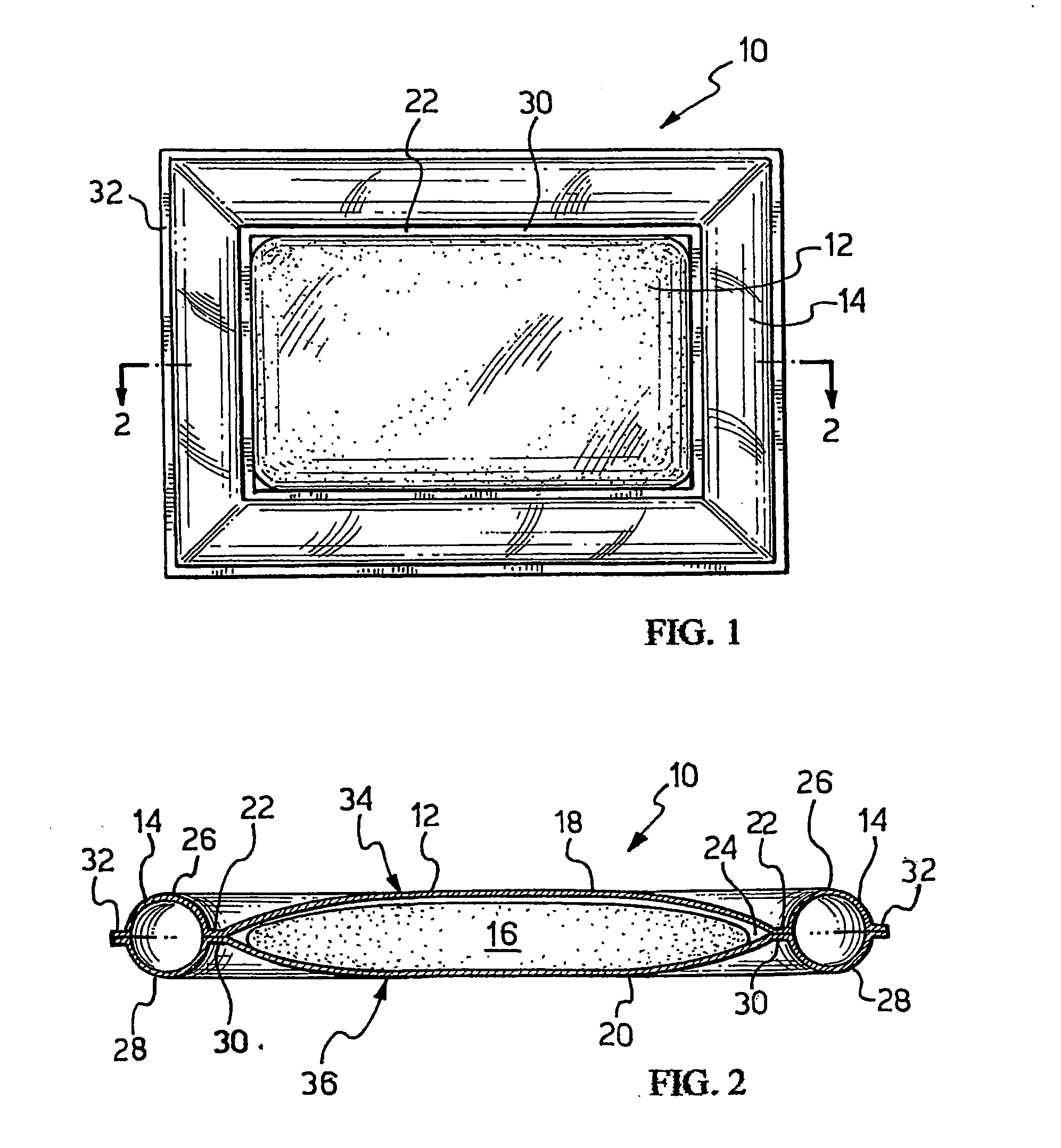

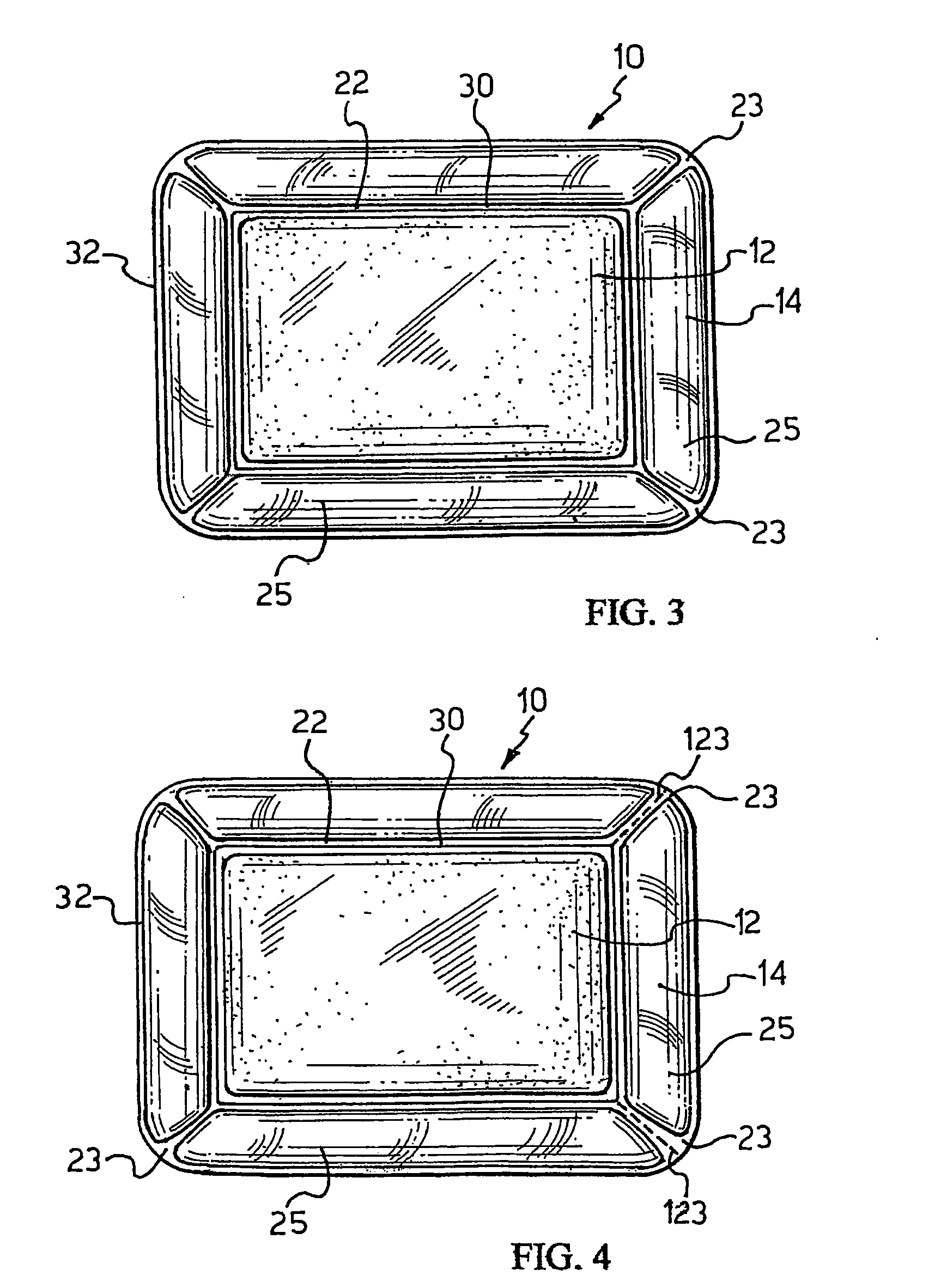

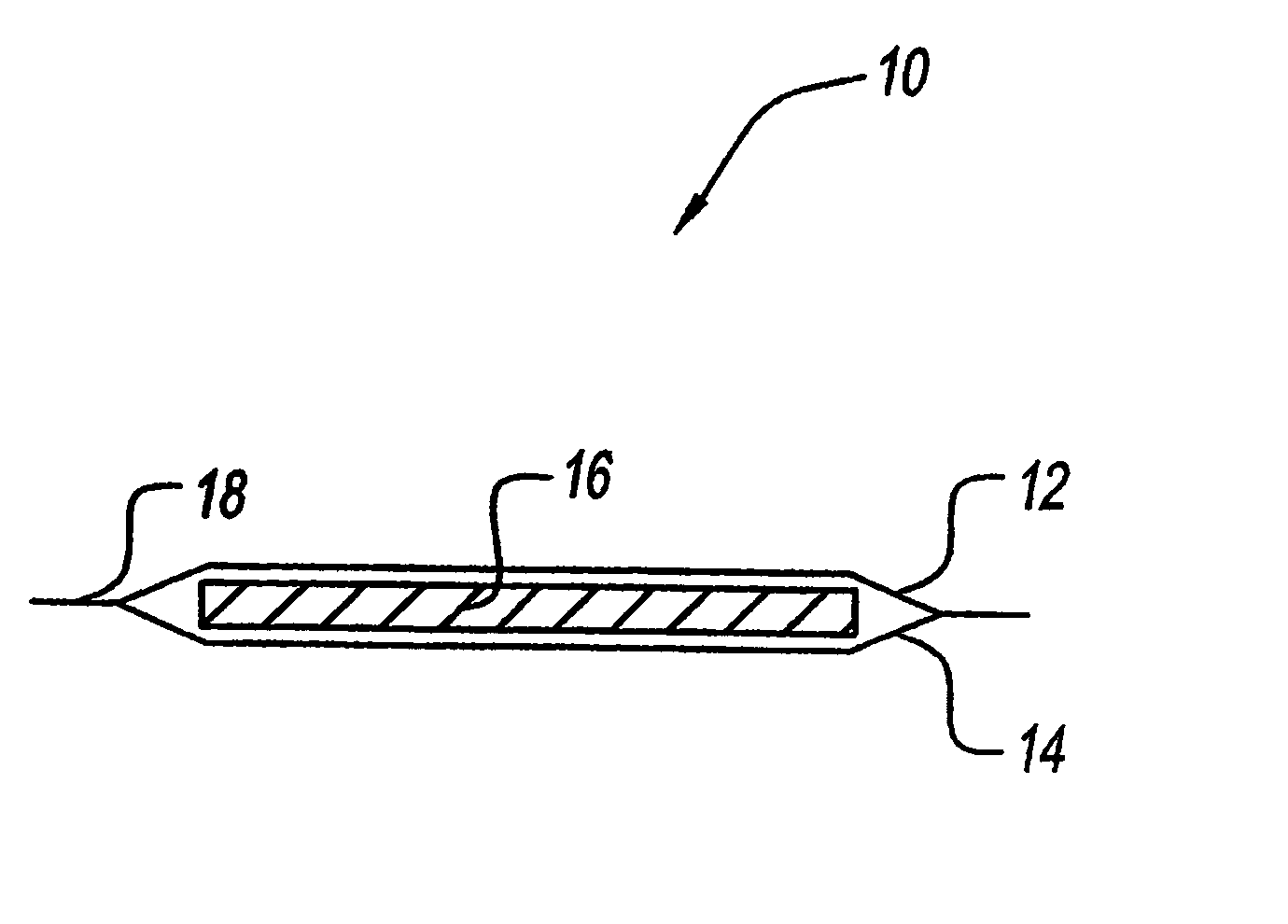

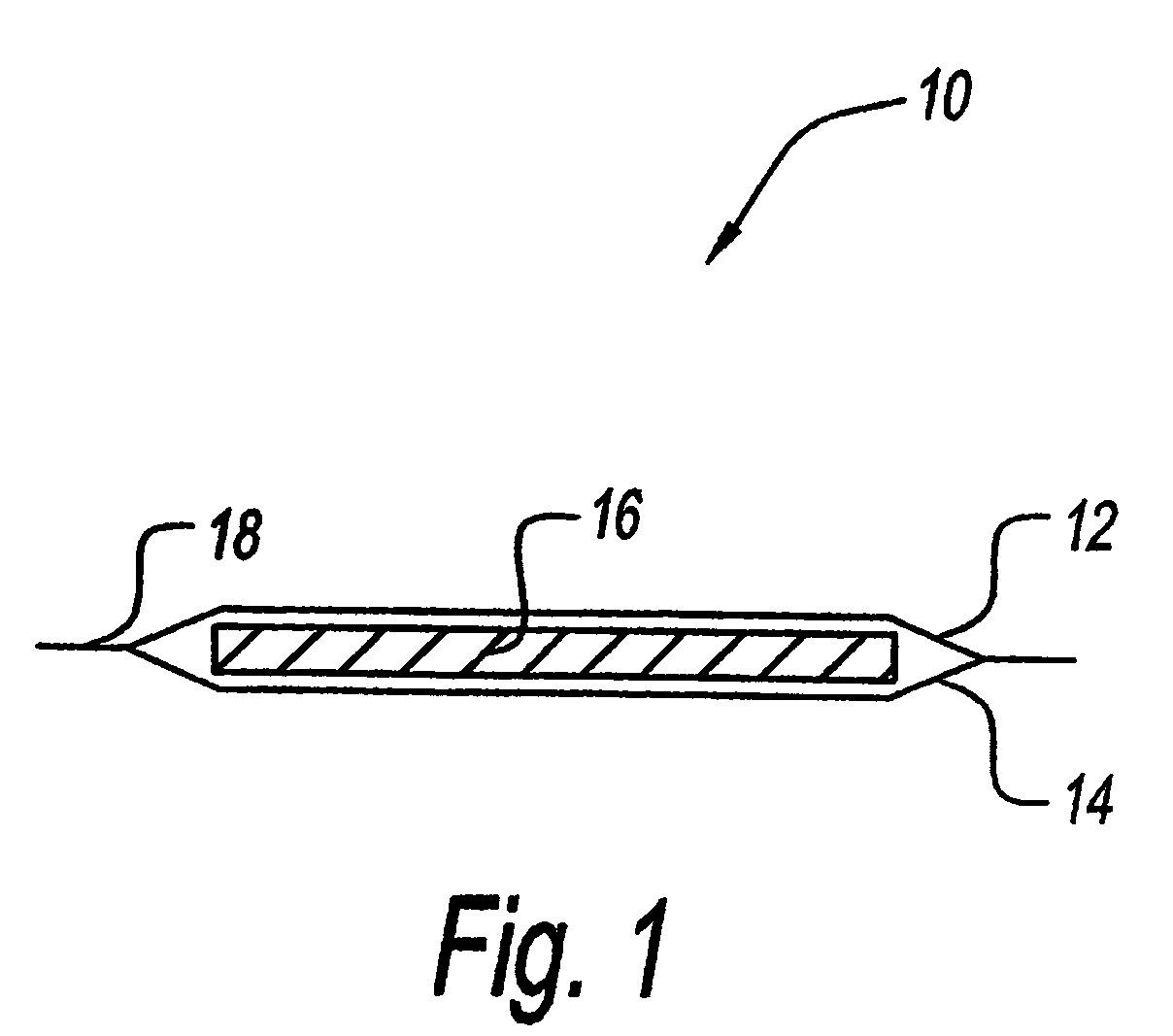

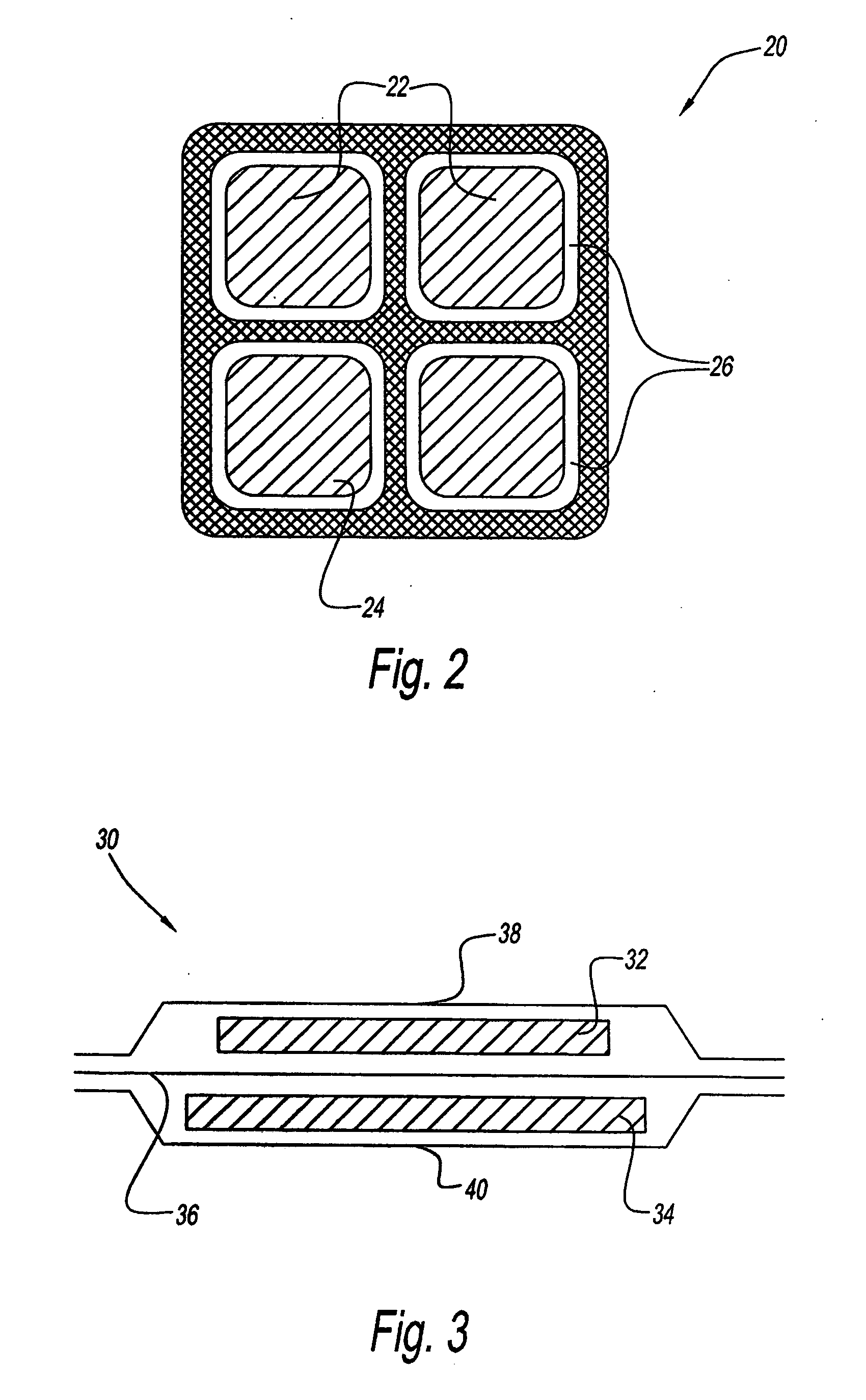

Package having an inflated frame

A package for containing a product such as meat. The package includes top and bottom opposing flexible chamber sheets. These sheets are sealed together in a selected chamber seal zone to define a watertight chamber portion that is capable of containing the product. A hollow frame circumscribes the chamber portion. The frame supports the chamber portion when the frame is inflated. The need for a rigid tray may be eliminated by the inventive package.

Owner:CRYOVAC ILLC

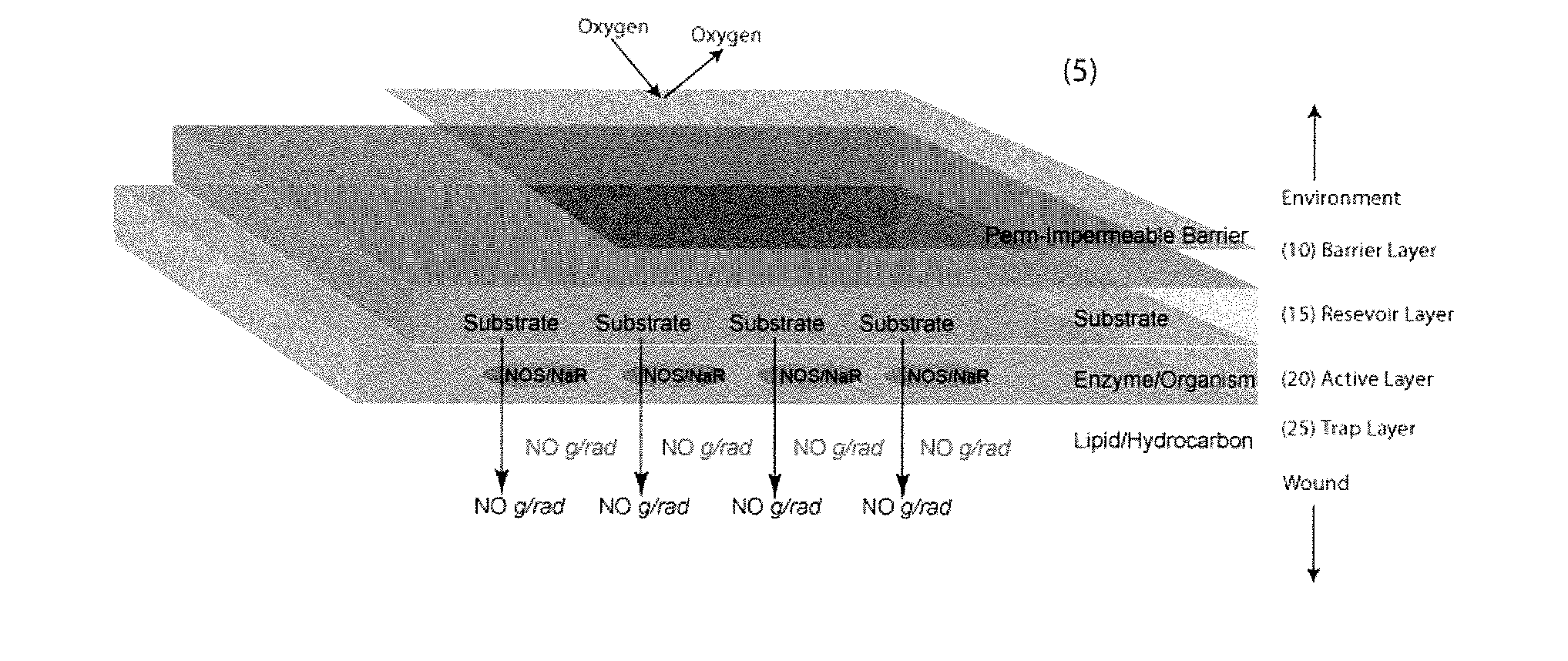

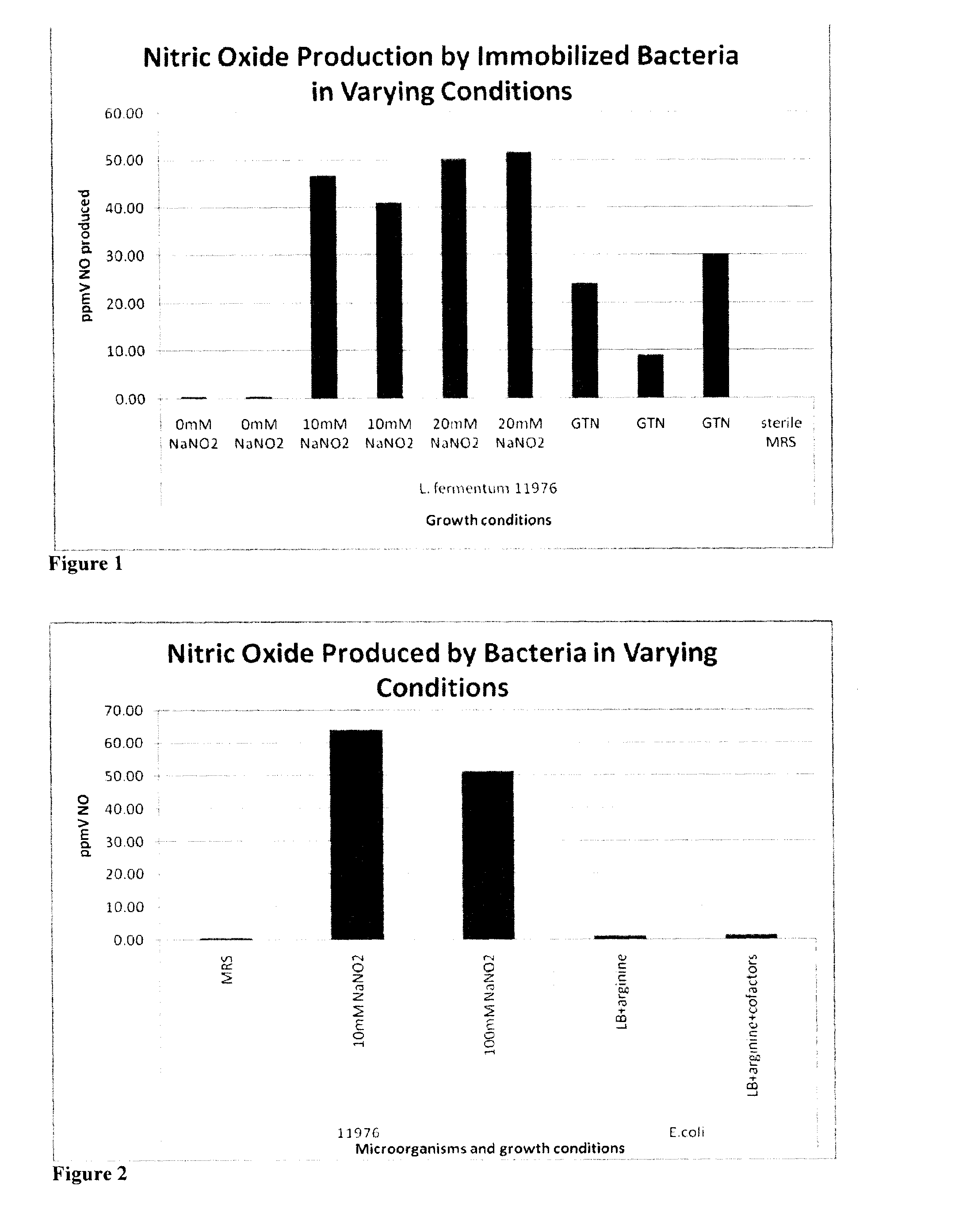

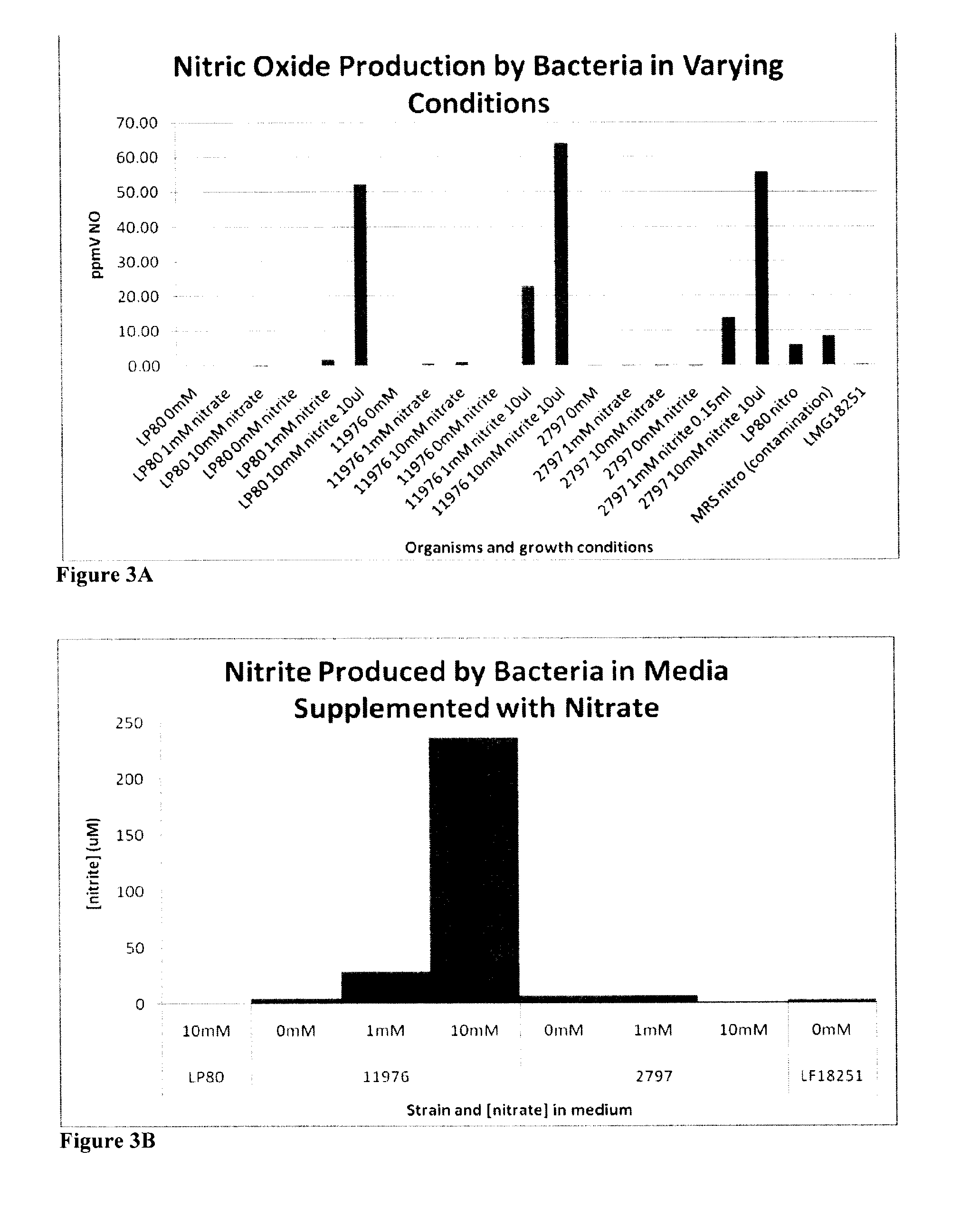

Nitric Oxide Device and Method for Wound Healing, Treatment of Dermatological Disorders and Microbial Infections

InactiveUS20110104240A1Reduce concentrationAntibacterial agentsImmobilised enzymesWound healingDermatological disorders

The present disclosure provides a device having a casing with a barrier surface and a contact surface and a composition in the casing having a nitric oxide precursor and an isolated enzyme or live cell expressing an endogenous enzyme, for converting the nitric oxide gas precursor to nitric oxide gas or having activity on a substrate that produces a catalyst that causes the conversion of the nitric oxide gas precursor to nitric oxide gas. The present disclosure also provides methods and uses for treating wounds, microbial infections and dermatological disorders and for preserving meat products.

Owner:MICROPHARMA

Treatment of meat products

InactiveUS6113963AReduce microbial countPrevent browningBiocideDough treatmentCarboxylic acidNuclear chemistry

Described is a method of sanitizing meat product using aqueous streams having an antimicrobial composition added to the stream. Preferably, the antimicrobial composition includes a mixture of one or more carboxylic acids having up to 18 carbon atoms and one or more peroxycarboxylic acids having up to 12 carbon atoms, preferably a mixture of a C.sub.2-4 peroxycarboxylic acid and a C.sub.8-12 peroxycarboxylic acid.

Owner:ECOLAB USA INC

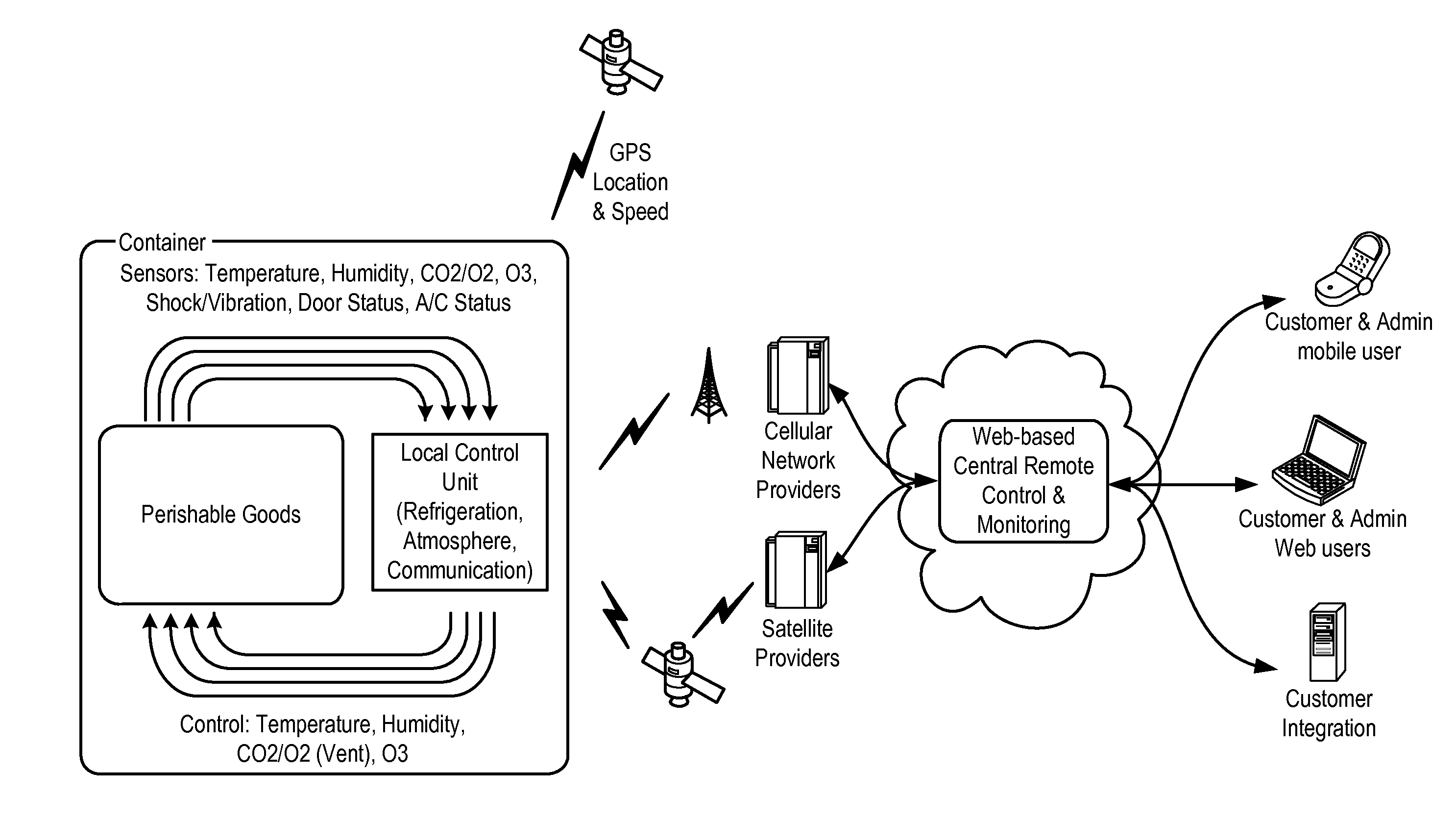

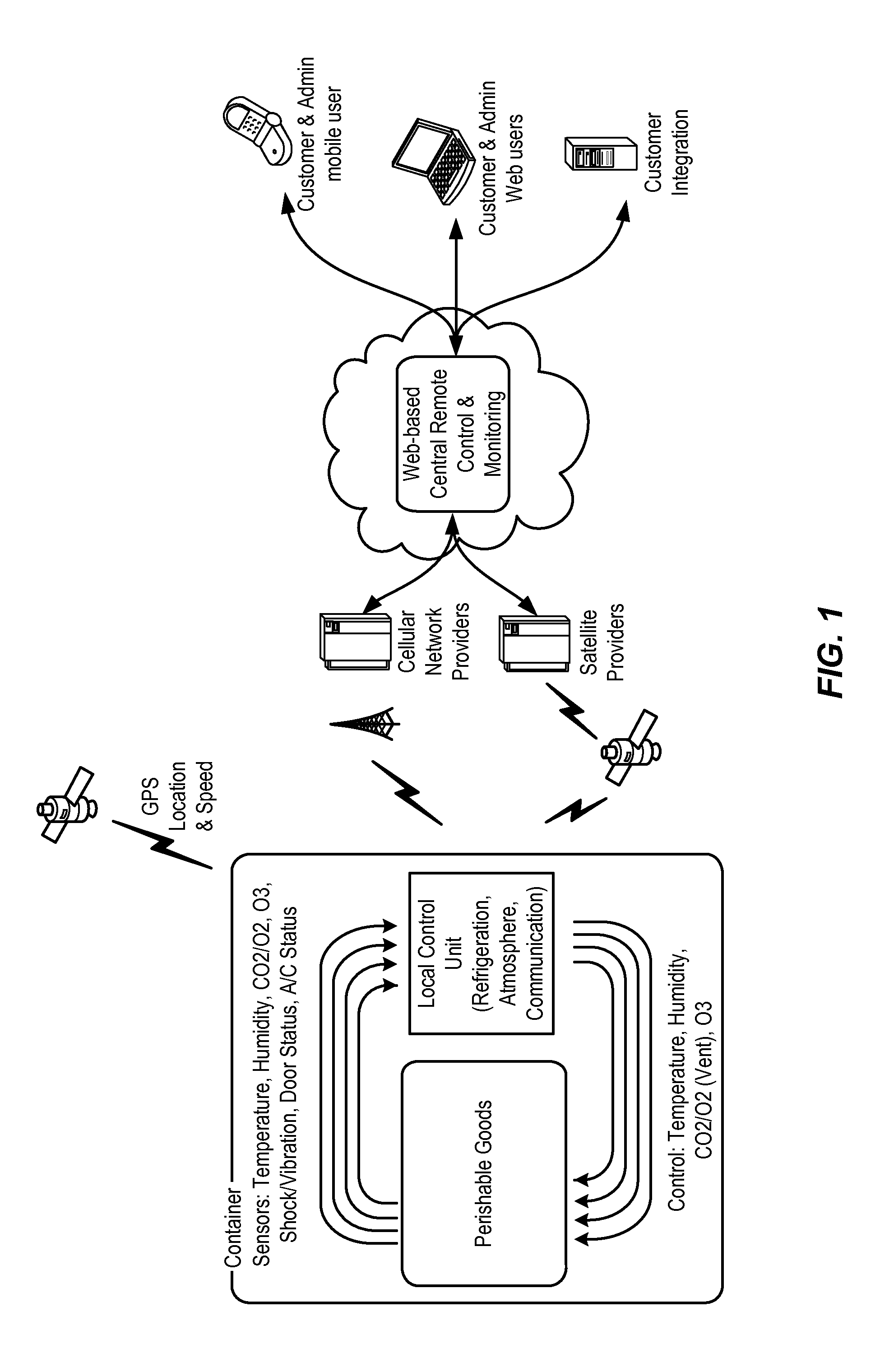

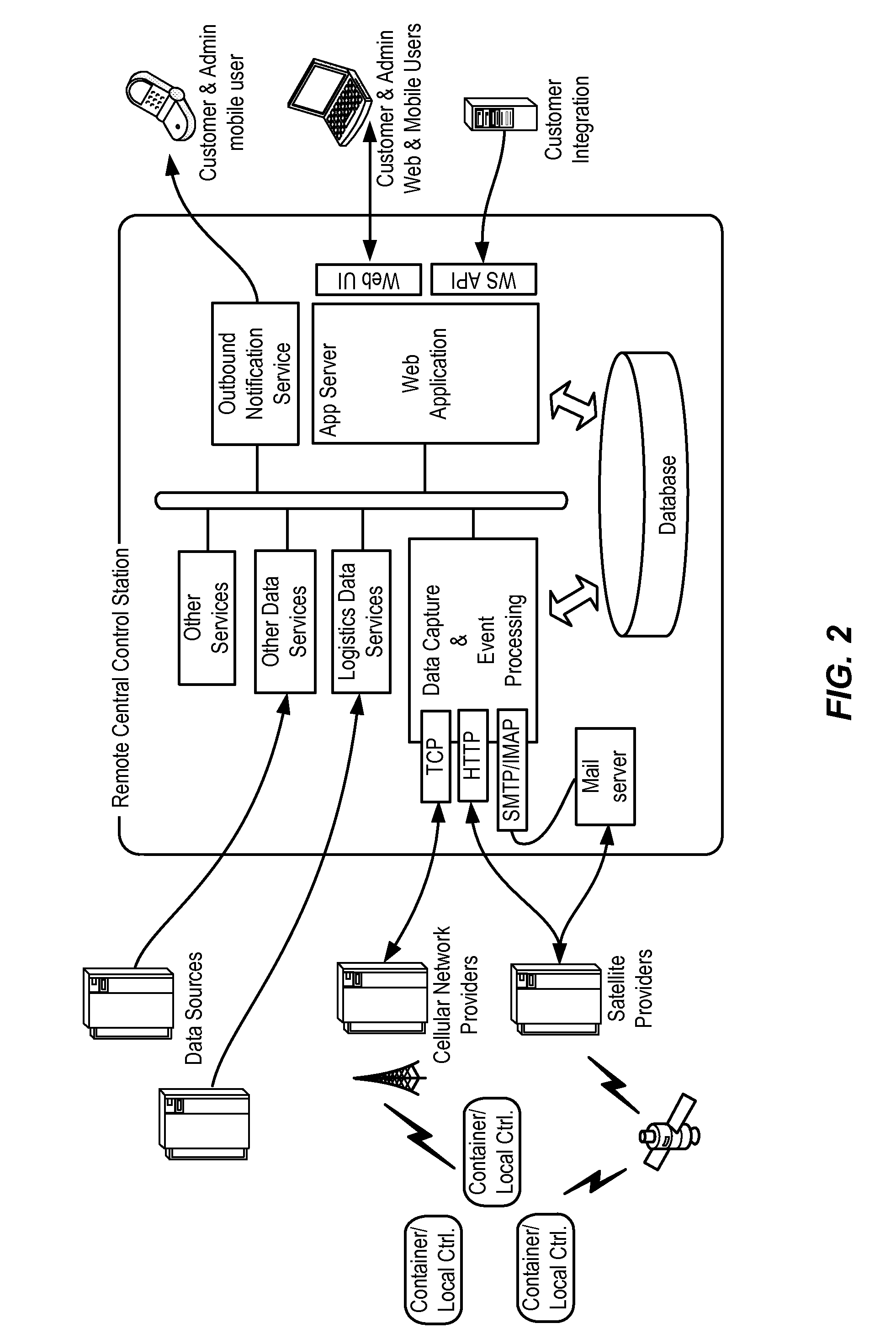

Methods and systems for controlled distribution of perishable goods

A system for distributing perishable goods includes a remote central control station, a plurality of local control units, and a plurality of mobile storage containers. By wirelessly transmitting information between the remote central control system and local control units, controlled conditions within the associated mobile storage containers can be optimized to preserve the perishable goods within the containers during lengthy transport trips.

Owner:PURFRESH

Natamycin dosage form, method for preparing same and use thereof

InactiveUS20050042341A1Sustained releaseReduce releaseDough treatmentEggs preservation by coatingFood productsDosage form

The present invention relates to a novel natamycin dosage form for the food industry, and more particularly to microcapsules where natamycin is encapsulated within a physiologically acceptable shell to provide a protected natamycin product. The present invention relates also to novel processes for preparing the capsules according to the invention, as well as to the use of the capsules of the present invention. The invention further relates to food products containing natamycin in encapsulated form.

Owner:AS DE DANSKE SUKKERFABRIKKER

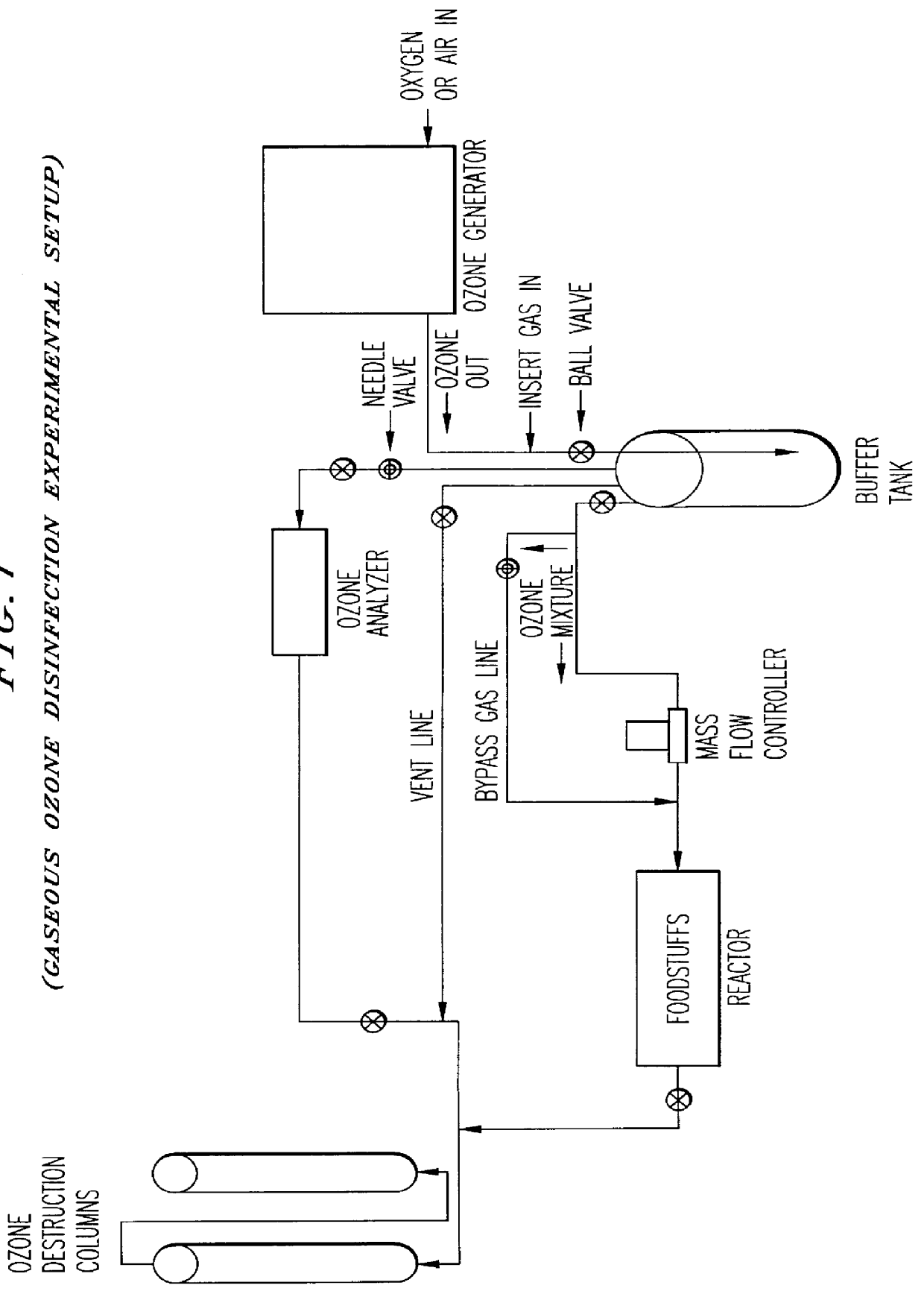

Method of disinfecting a foodstuff using gaseous ozone

The present invention provides a method of disinfecting a foodstuff using a gaseous mixture containing ozone in an amount and for a time sufficient to effect disinfection.

Owner:AIR LIQUIDE AMERICA INC

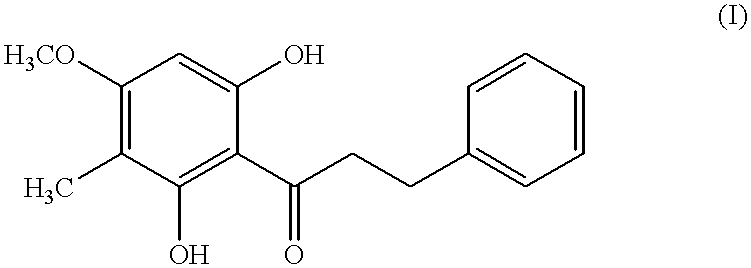

Bactericides

An object of the present invention is to provide a bactericide (and a fungicide) that is highly safe and has strong bactericidal power even when used in low concentration, and that can be used repeatedly in a sterilizing process.The object can be achieved by the bactericide (or the fungicide) comprising a polar solvent extract of leaves of eucalyptus plants and chitosan. The polar solvent is preferably chosen from the group consisting of lower alcohols and glycols.

Owner:OJI PAPER CO LTD

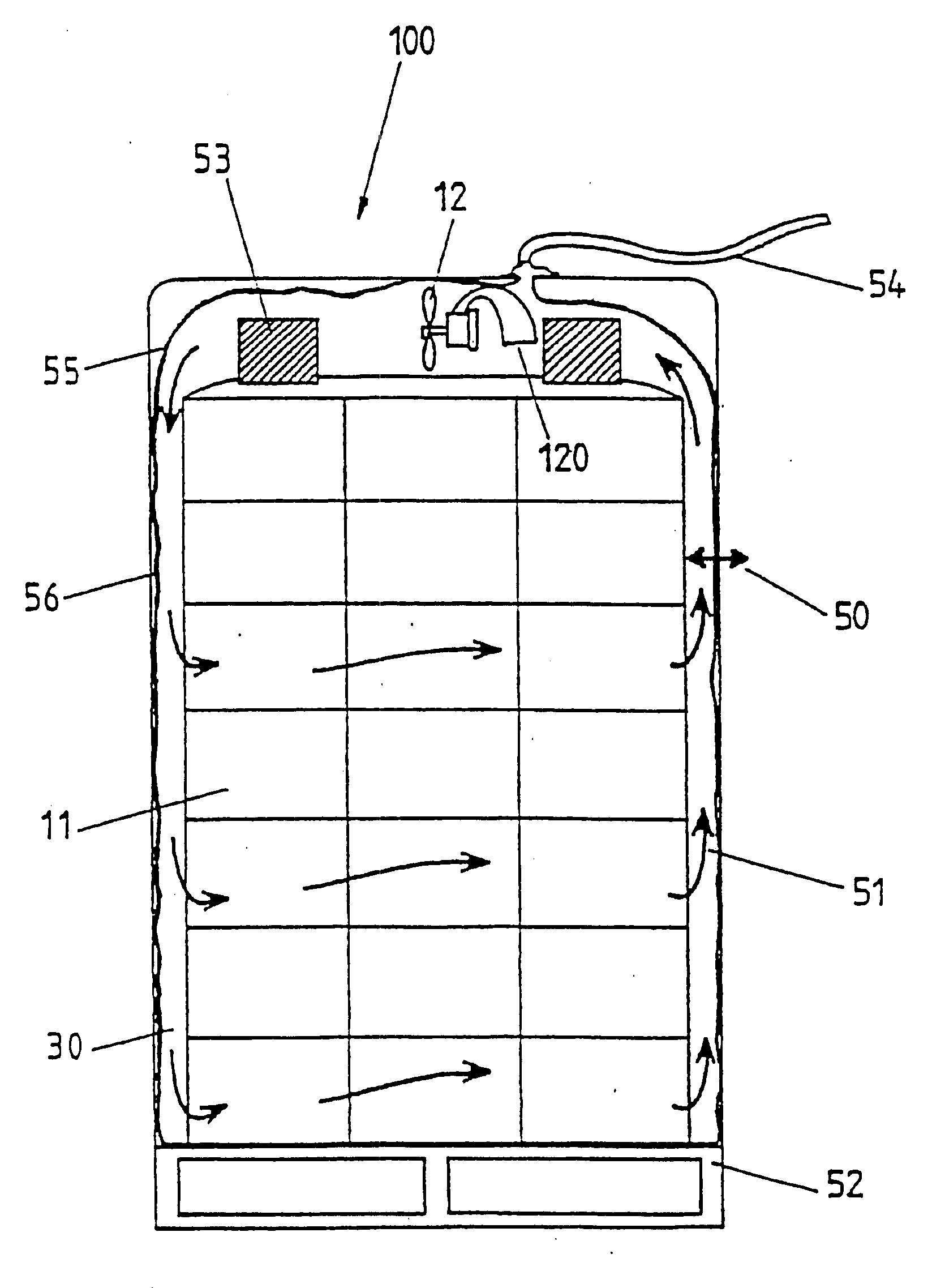

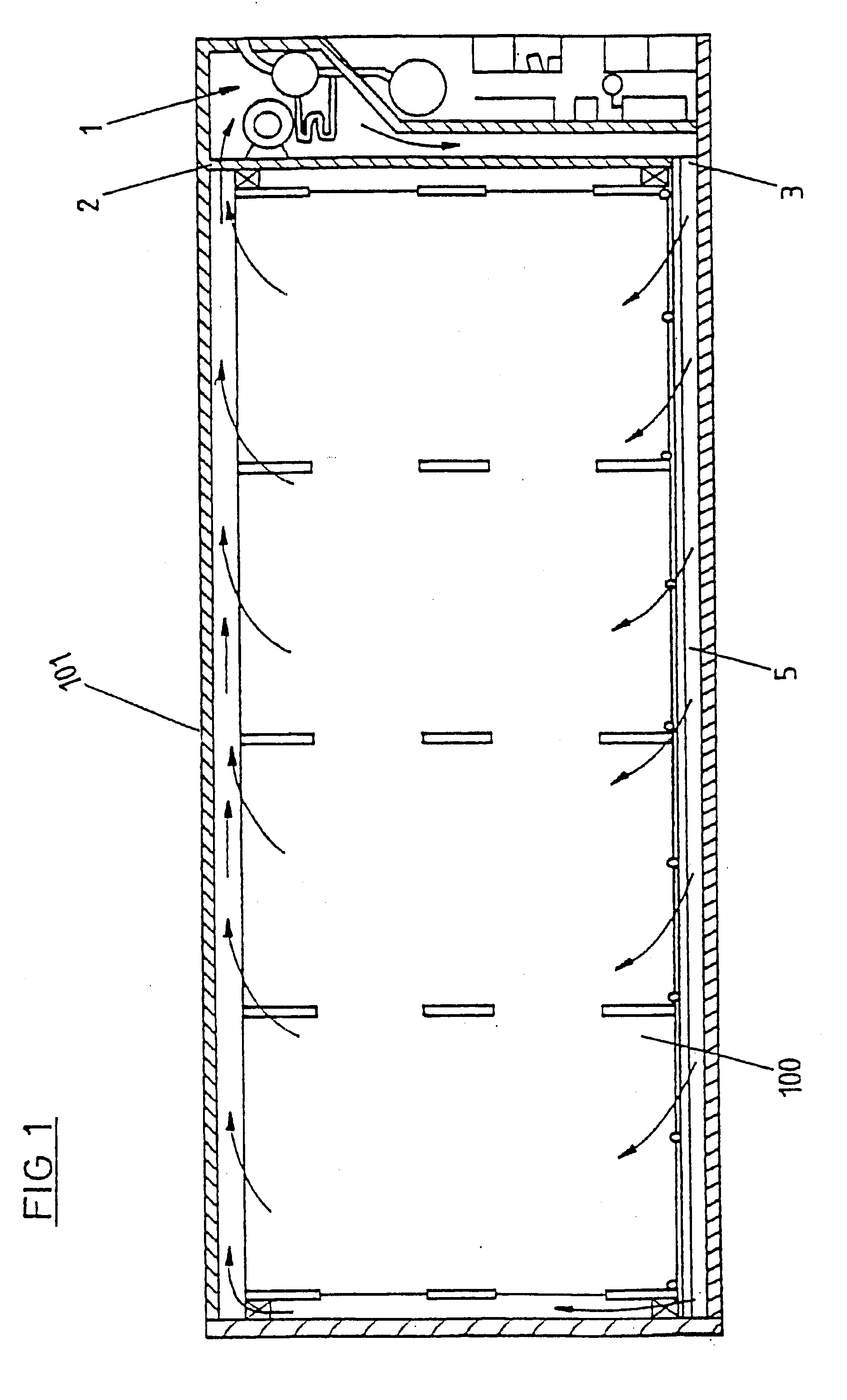

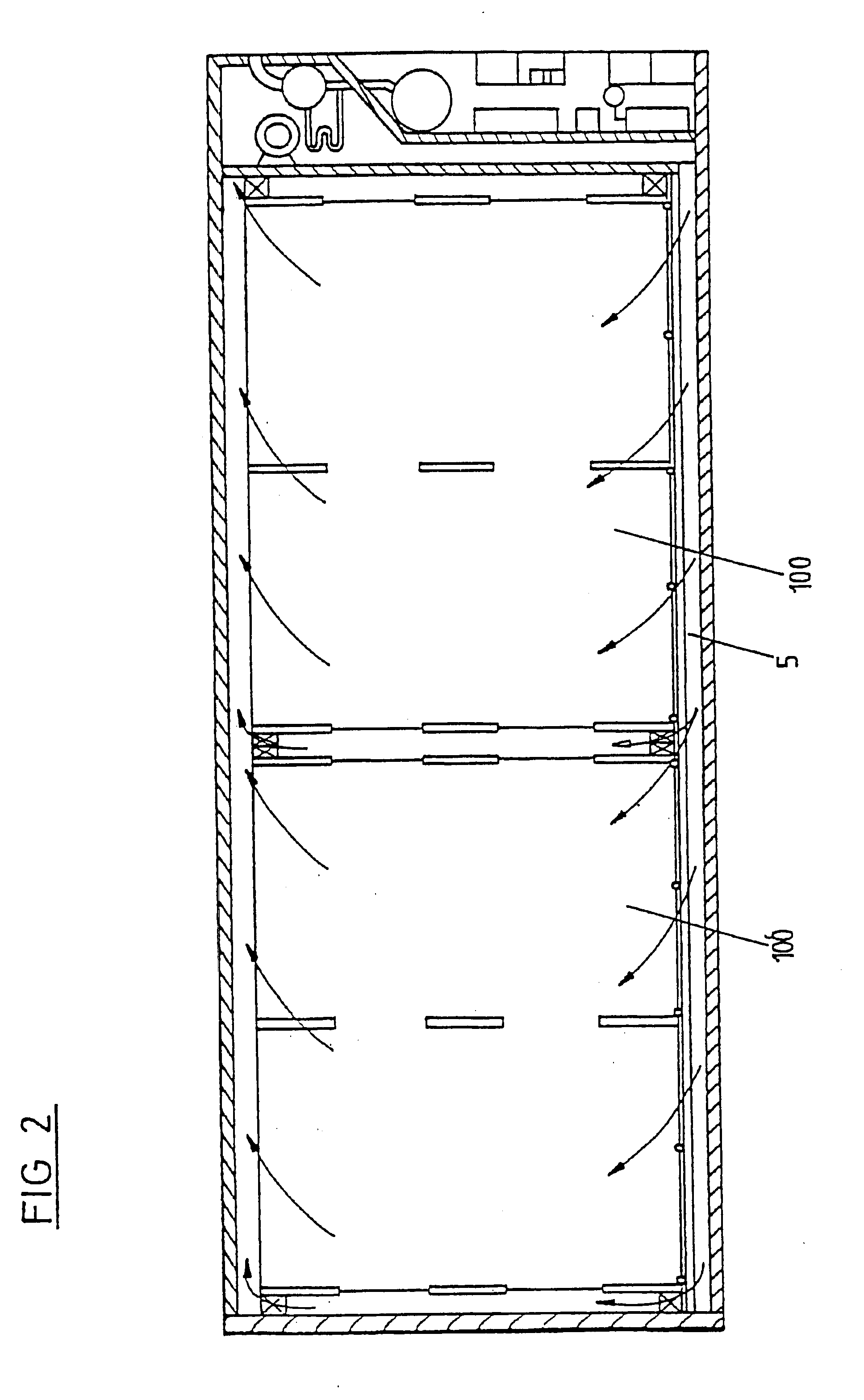

Method of transporting or storing perishable produce

InactiveUS6615908B1Convenient infusionIncrease humiditySpace heating and ventilationOperation mode of machinesGas compositionProduct gas

The invention allows cool rooms or sea containers designed for frozen goods to handle produce requiring more precisely controlled temperatures and conditions, e.g., vegetables and fruits requiring temperatures in the chilling range and often also needing control or modification of the atmosphere. Each load of produce (100) (e.g. of pallet size) is held in the sea container or cool room but is sealed from the air of the refrigerated environment by, for example, a plastics bag (56). The atmosphere within the bag is then circulated by a fan (12) (or by convection currents from a heating element) so as to pass through the load and around it via ducts (30) provided adjacent the bag (56). Heat exchange (50) between the circulating gas and the refrigerated environment, via the plastics film, serves to cool the load. However, if cooling is excessive a heating element can be used to raise the temperature of the circulating atmosphere. Gas composition of the atmosphere can be controlled by scrubbing, flushing, etc. via pipes from a central unit or at each load individually or by choosing semi-permeable plastic for the sealing bags.

Owner:TRANSPHERE SYST

Packaging for meat and foodstuff

InactiveUS6447826B1Preventing inflationMaintain internal pressureReady-for-oven doughsFlexible coversFood packagingLow oxygen

Methodology for packaging and packages for meat or other foodstuffs in a carbon dioxide rich low oxygen environment by including without the packages carbon dioxide generating material and oxygen removing material where the production of carbon dioxide is not dependent upon removal of oxygen.

Owner:SEALED AIR NZ +1

Antimicrobial salt solutions for food safety applications

ActiveUS7090882B2Reduce in quantityInhibit microorganismsMilk preservationDough treatmentBiologyFood processing

Owner:CARGILL INC

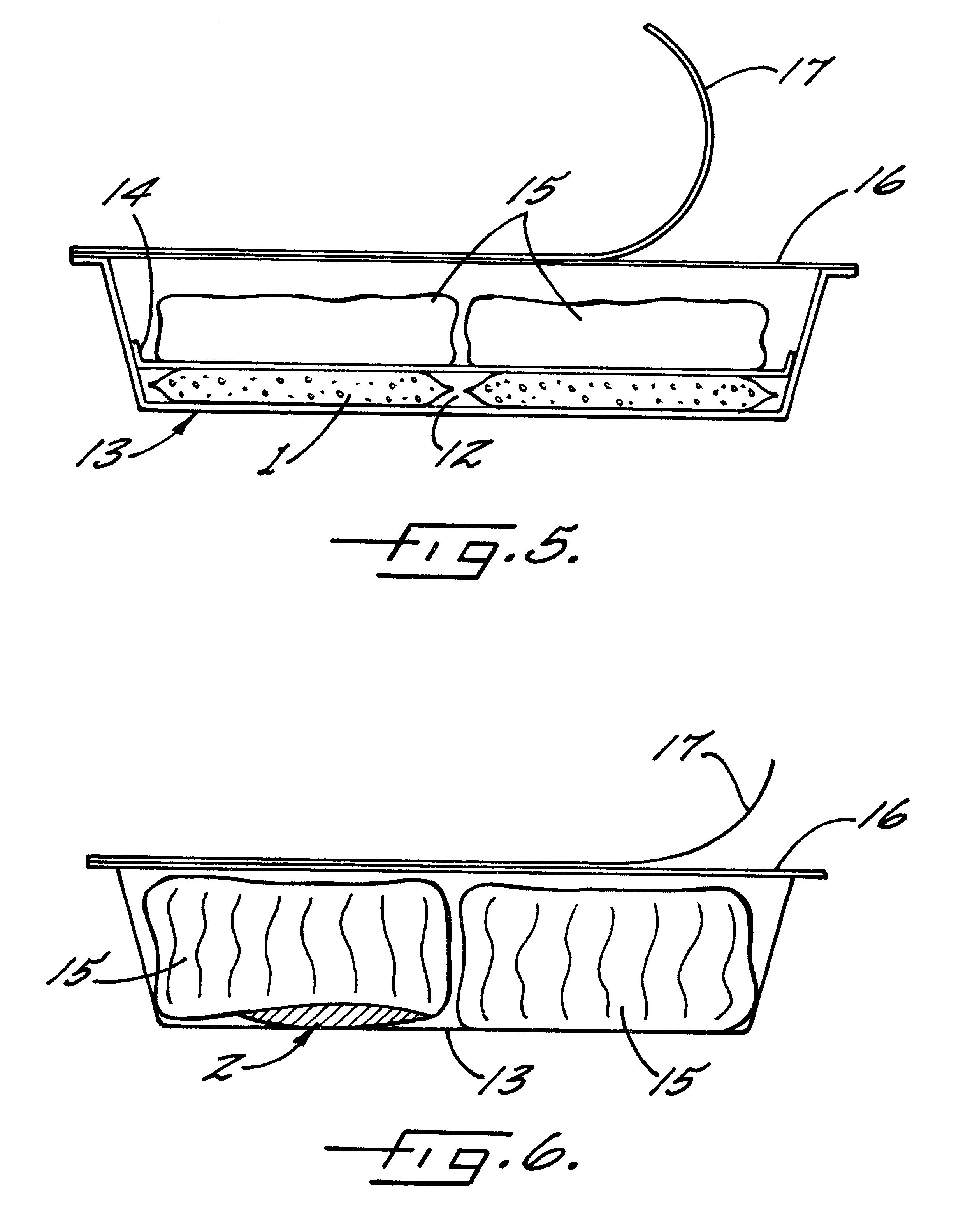

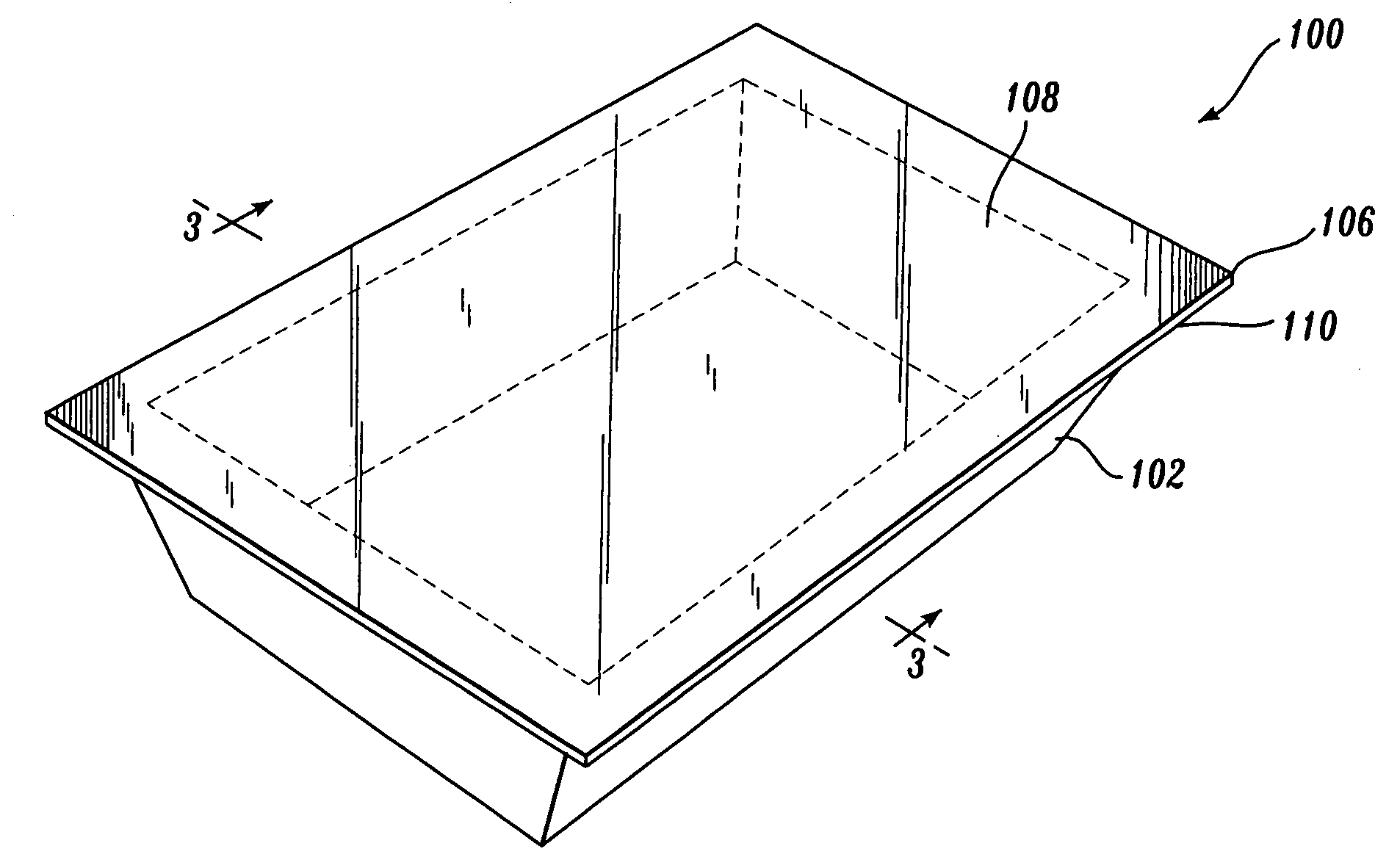

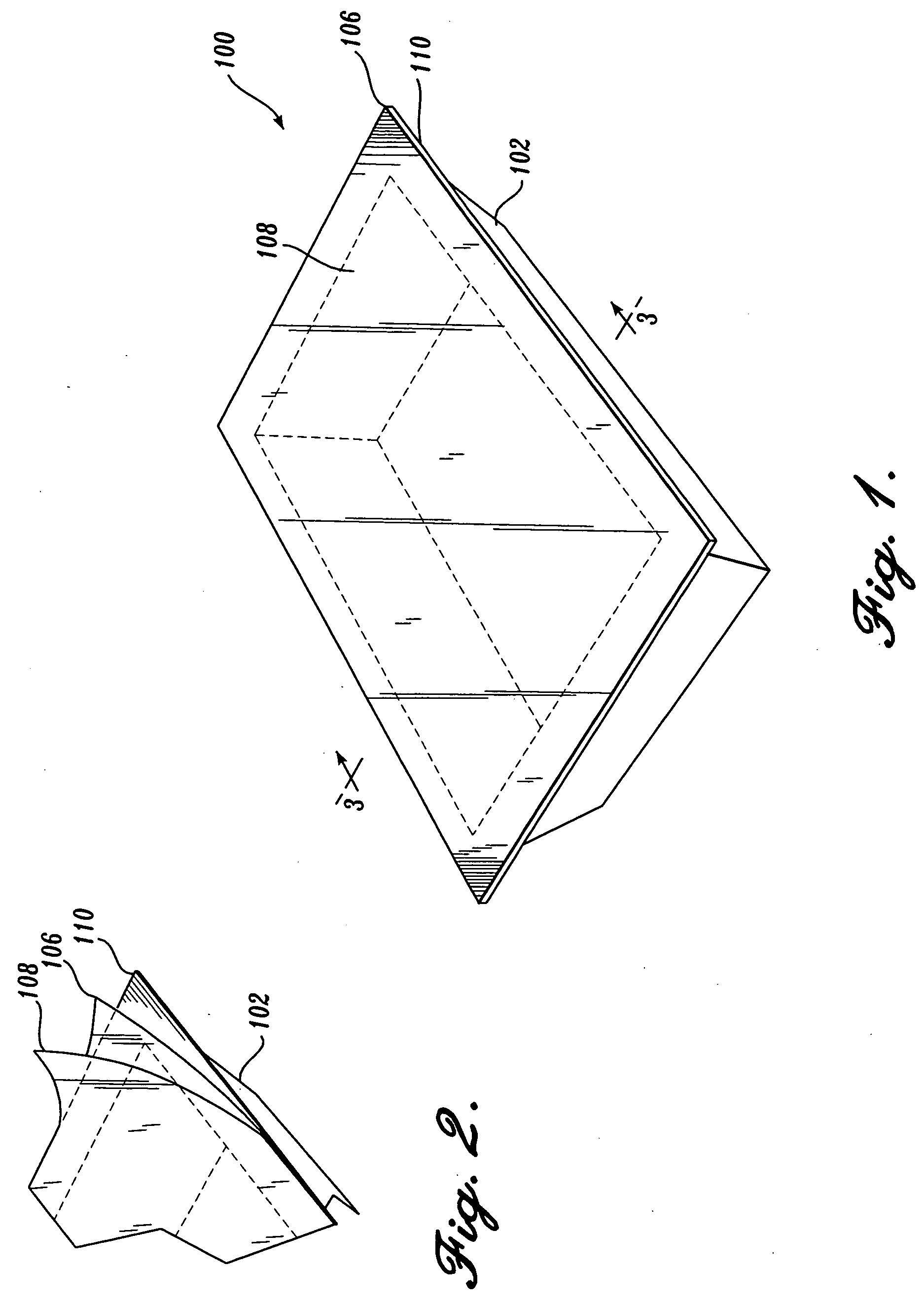

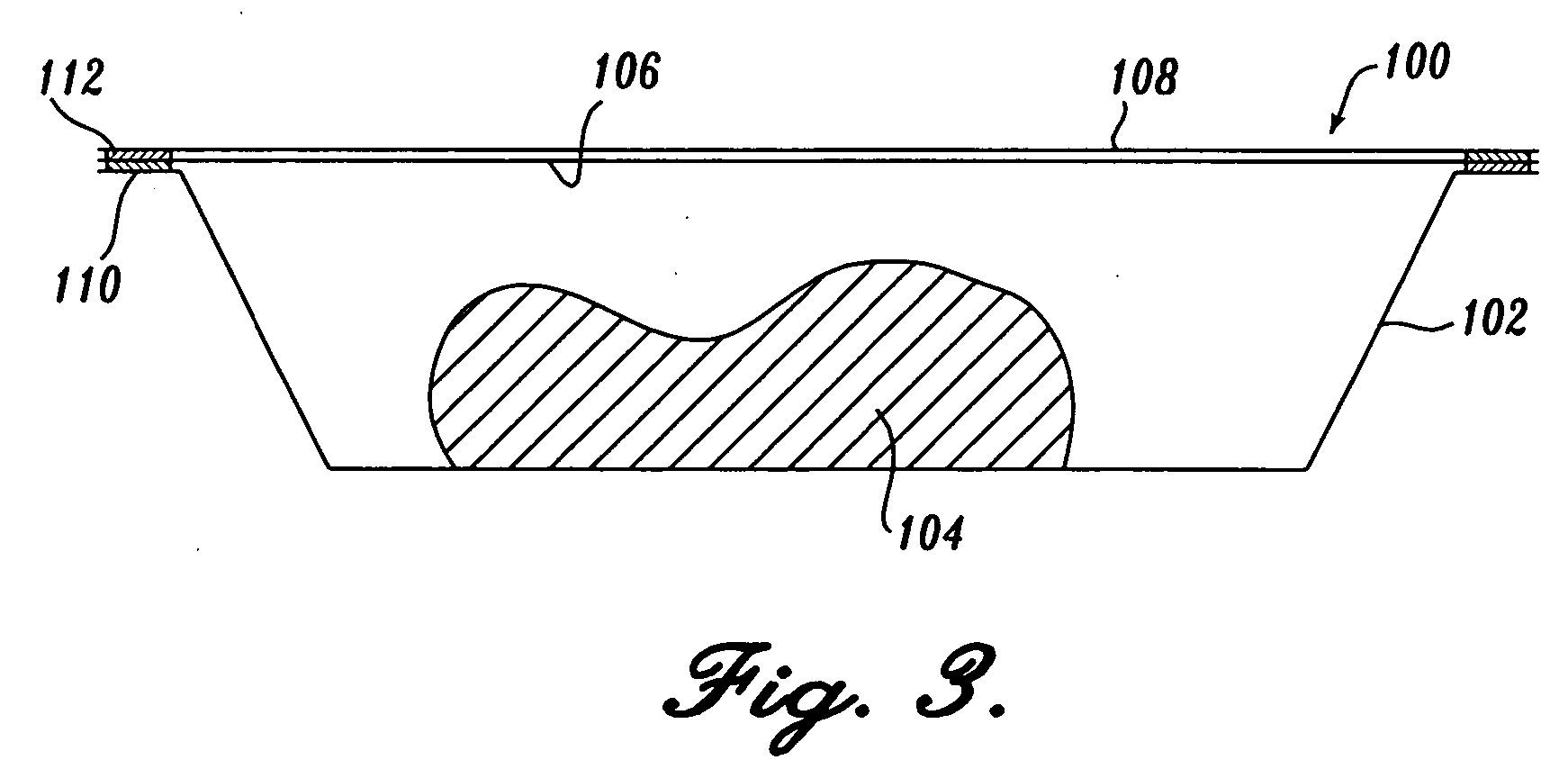

Package having an inflated frame

InactiveUS20050126941A1Eliminate needContainer/bottle contructionPackaging foodstuffsEngineeringSheet material

A package for containing a product such as meat. The package includes top and bottom opposing flexible chamber sheets. These sheets are sealed together in a selected chamber seal zone to define a watertight chamber portion that is capable of containing the product. A hollow frame circumscribes the chamber portion. The frame supports the chamber portion when the frame is inflated. The need for a rigid tray may be eliminated by the inventive package.

Owner:CRYOVAC ILLC

Meat processing in a controlled gas environment

InactiveUS6054161AIncrease flexibilityImprove efficiencyReady-for-oven doughsPackaging under vacuum/special atmosphereSufficient timeProduct gas

A meat treatment method and apparatus for handling, storage, transportation and sale of meat exposes the meat to a controlled gas environment. This environment includes oxygen under pressure in excess of atmospheric wherein the meat is exposed for a predetermined period of time. The method may also includes the step of pre-treating the meat in a substantially anaerobic environment for a sufficient time to achieve a predetermined close down of aerobic bacteria on the meat and suspension of most biochemic effects of oxygen on the meat. Subsequently, the method includes the treating of the meat under aerobic conditions including the step of supplying oxygen under pressure. The method also includes the prepackaging of meat in at least partially gas permeable packaging suitable for use in a retail sale environment, prior to aerobic gas pressure treatment. The method improves shelf life and appearance of meat over a traditionally handled product.

Owner:FOODCAP INT

Compositions and methods of treating edible matter and substrates therefor

There are provided methods of treating edible matter comprising applying a composition comprising performic acid to the edible matter or a substrate therefor. Other embodiments are also disclosed.

Owner:BEN YEHUDA NIMROD

Labiatae herb extracts and hop extracts for extending the color life and inhibiting the growth of microorganisms in fresh meat, fish and poultry

InactiveUS20040131709A1Good colorDecreases color lifeBiocideUnknown materialsHops extractMicroorganism

Compositions comprising a Labiatae herb extract and a hop extract containing beta acids and methods of using them to extend the color life and retard the growth of microorganisms in fresh meat, fish and poultry stored in an atmosphere that contains 20% or more oxygen.

Owner:KALSEC

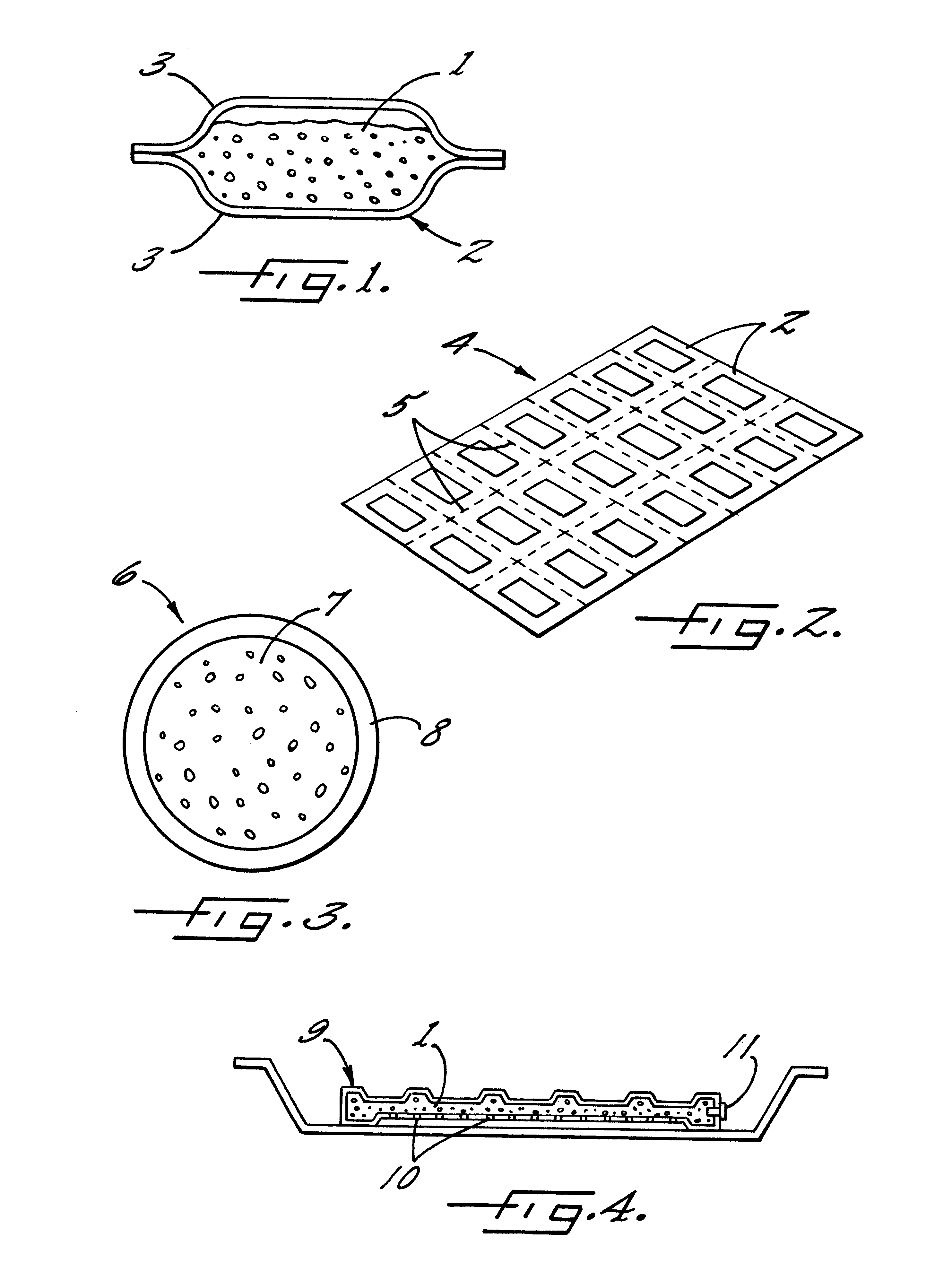

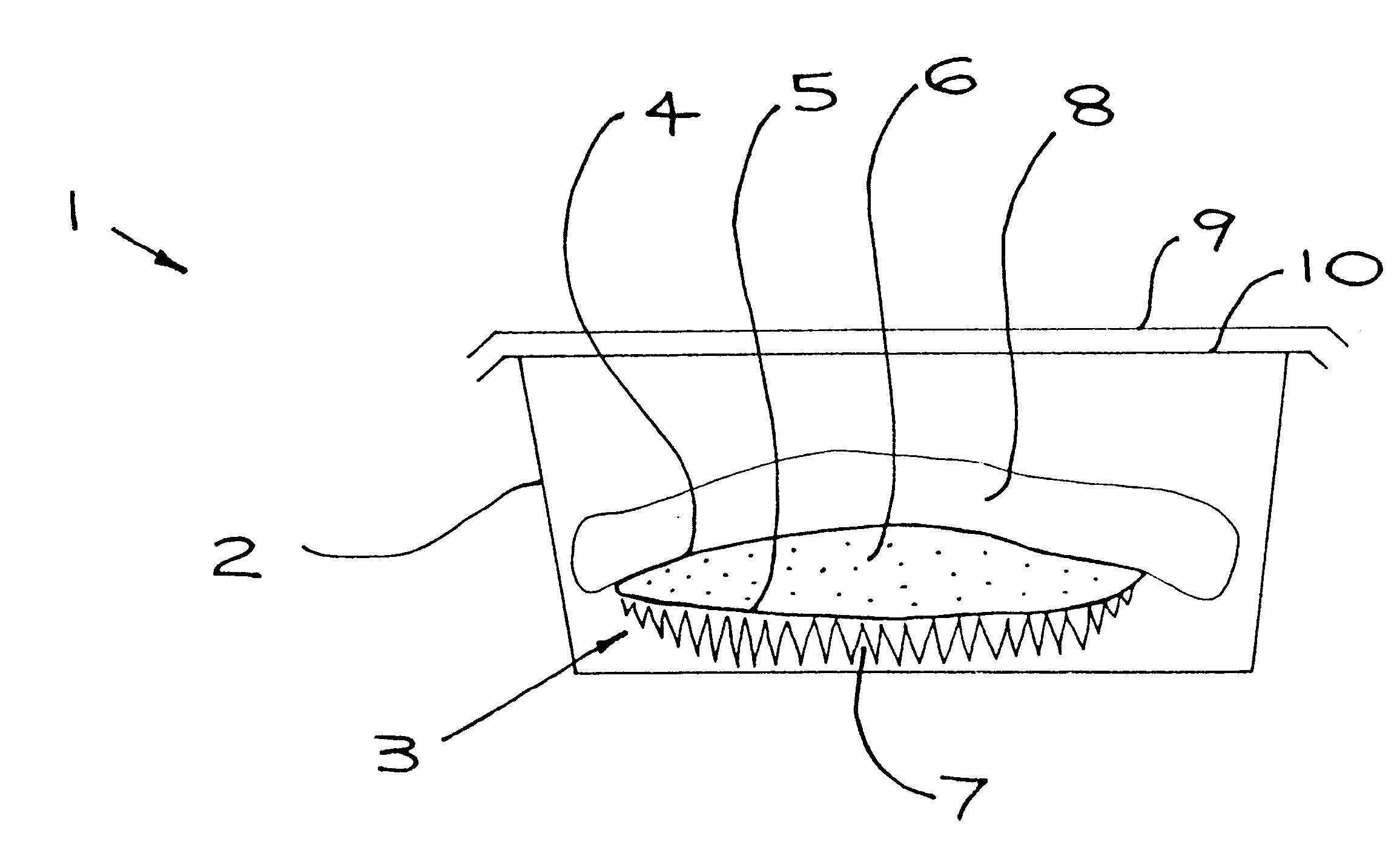

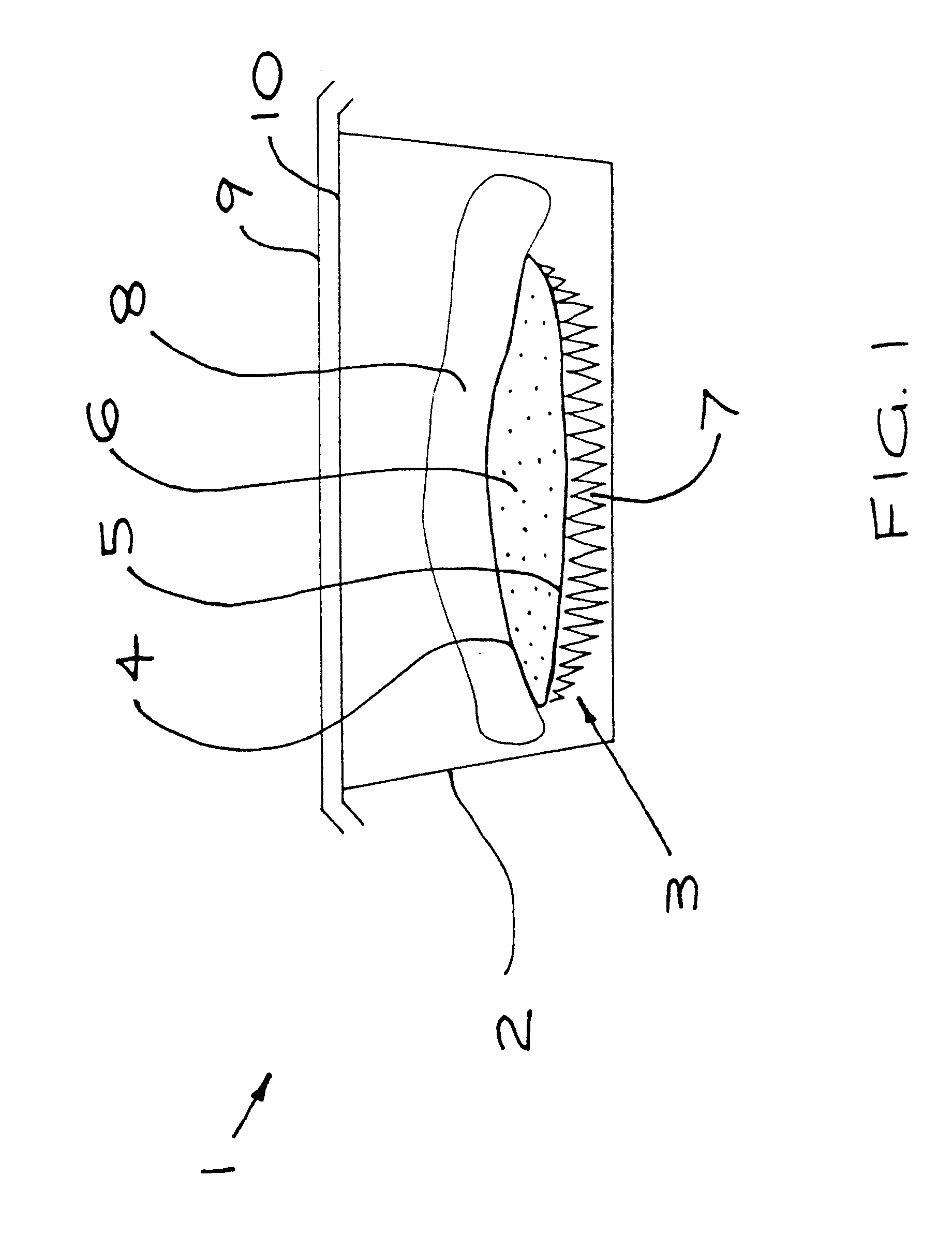

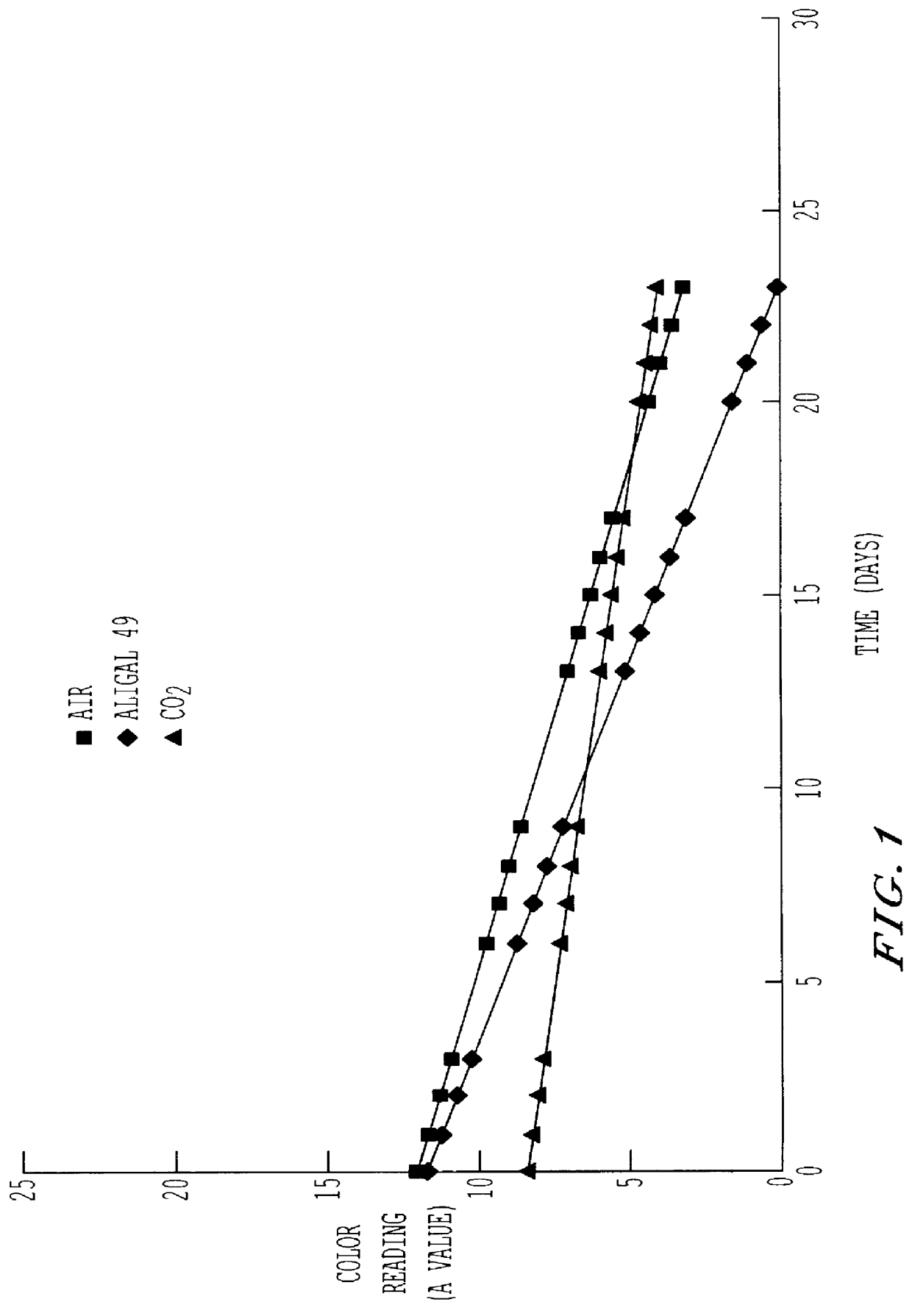

Carbon dioxide atmosphere modifiers for packaging

InactiveUS6592919B1Avoid Sealing ProblemsReady-for-oven doughsPackaging under vacuum/special atmosphereWater vaporPorous layer

A device or sachet (3) for maintaining or modifying the atmosphere in a package suitable for meat, beef, lamb, pork, etc. the device including at least two containing layers (4, 5), a moisture activated chemical substance (6) contained by the containing layers, and at least one absorbent layer (7). Moisture within the package is soaked up by the absorbing layer. The moisture is then transferred from the absorbing layer to permeate through a micro-porous layer (5) as water vapor and activate the chemicals. The gas produced by the chemicals then passes through the sachet and into the package's atmosphere. This modifies the atomosphere to ensure that there is an adequate quantity of CO2 for achieving the desired shelf life of the packaged food.

Owner:SEALED AIR NZ

Method for increasing the tenderness of a meat product

A method for preserving a food product, such as meat, including the steps of inoculating meat with an effective amount of euhygienic non-pathogenic, non-spoilage bacteria in order to competitively inhibit the growth of undesired pathogenic and spoilage bacteria. Edible films that incorporate and / or cover euhygenic bacteria on the food product are used to ensure competitive inhibition of undesired spoilage and pathogenic bacteria.

Owner:SWIFT BEEF +1

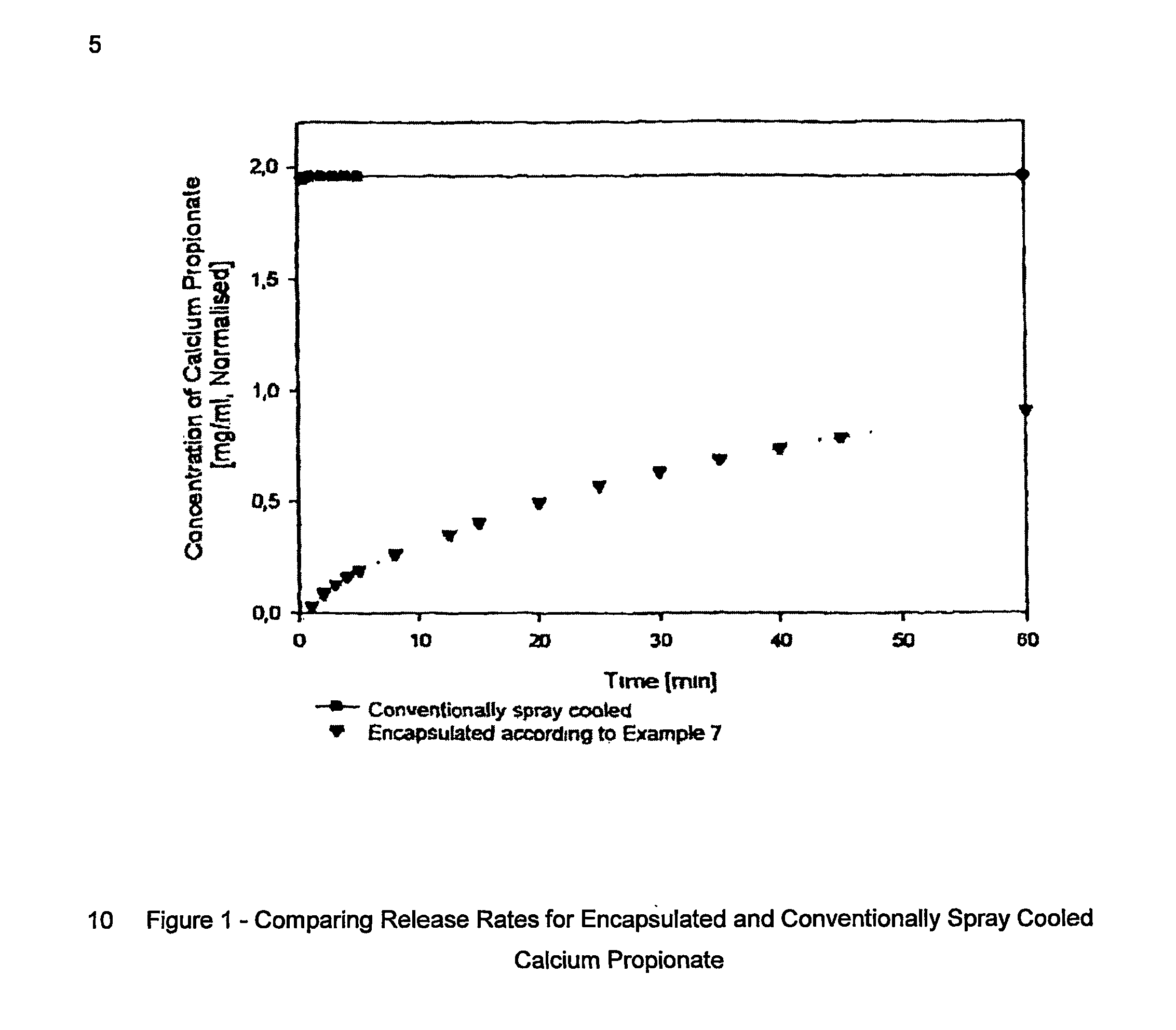

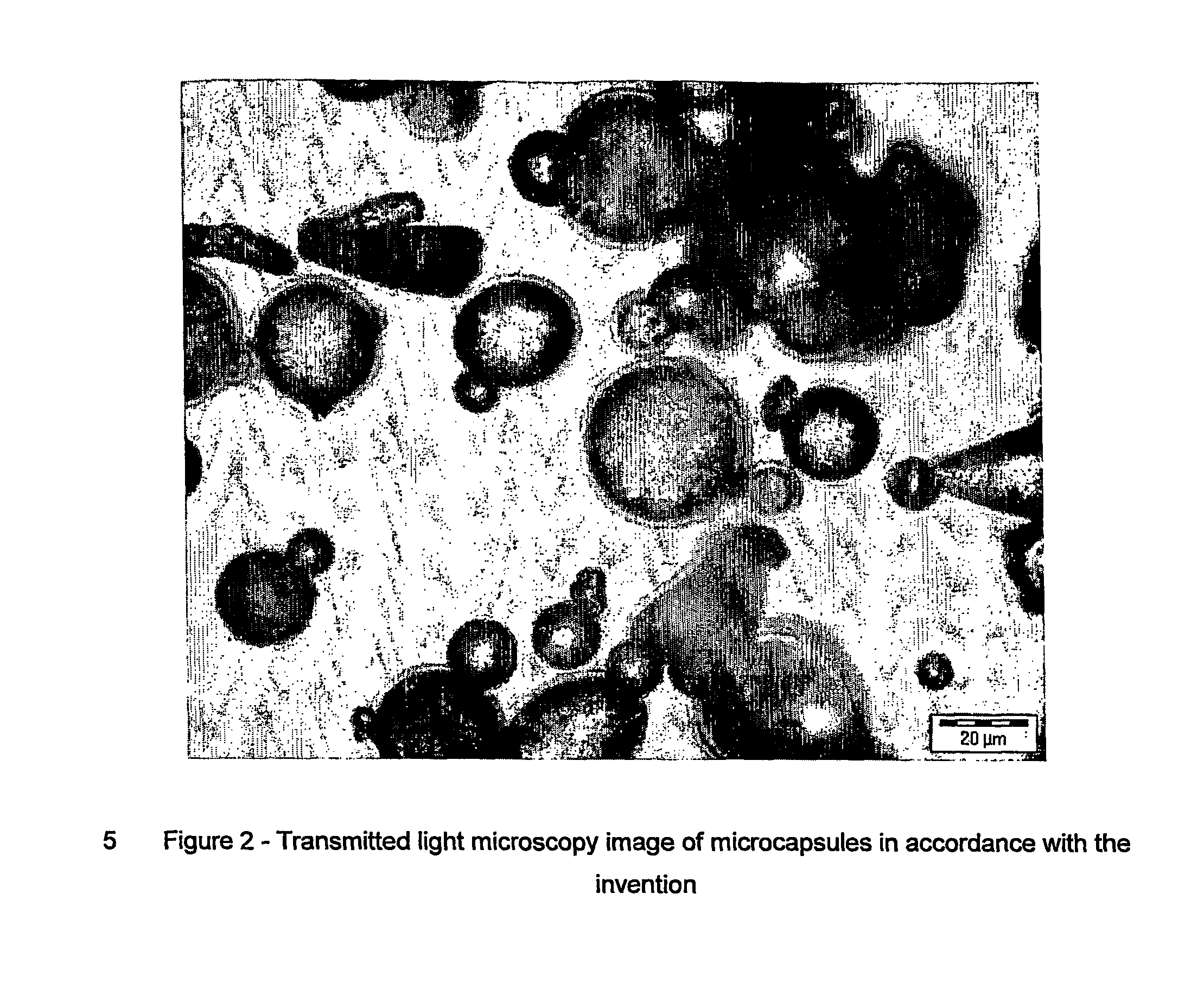

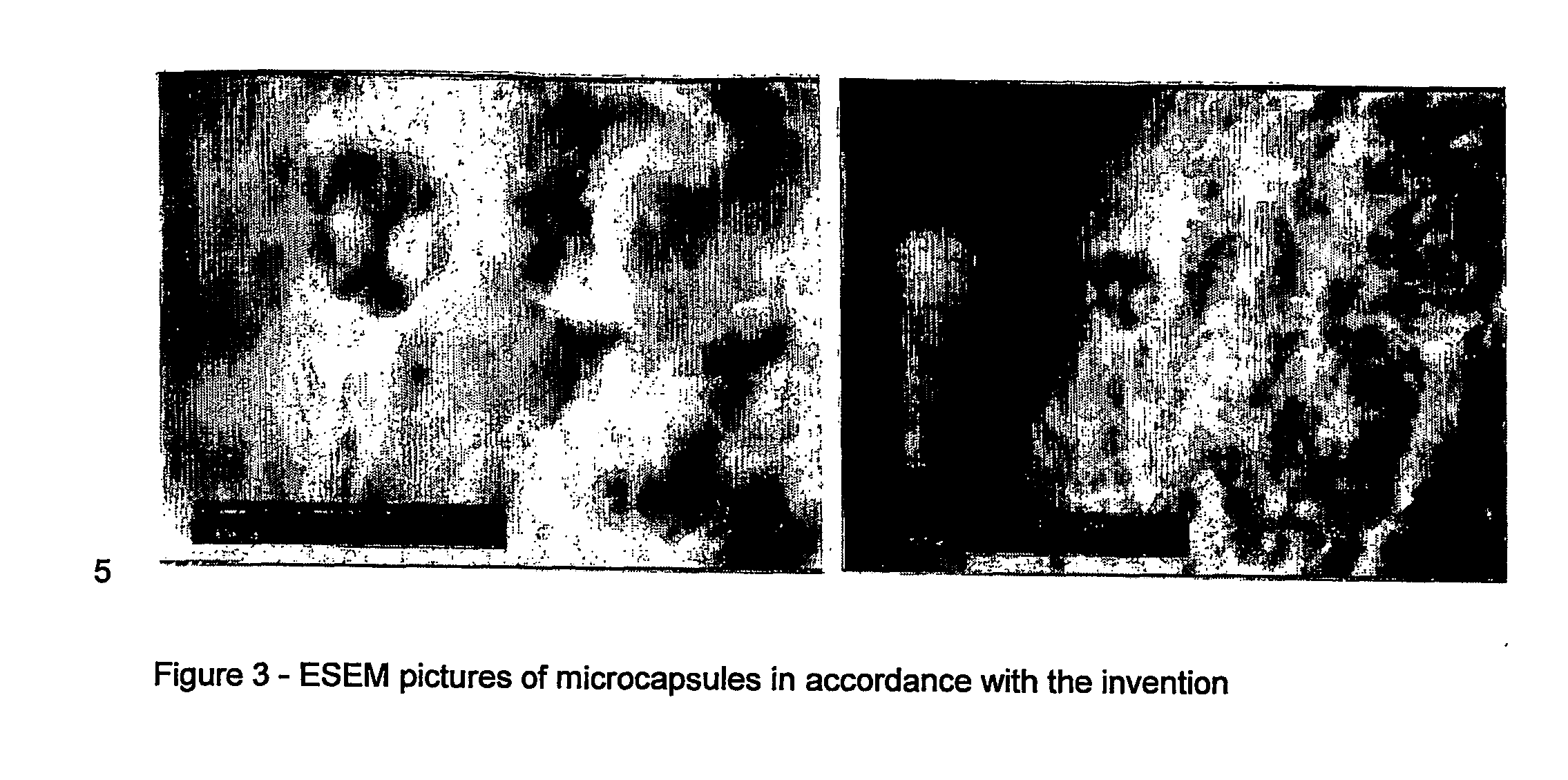

Microcapsules

InactiveUS20070042184A1Increase release rateControl releaseBiocideEggs preservation by coatingBULK ACTIVE INGREDIENTActive ingredient

The present invention relates to microcapsules, and more particularly to microcapsules where an aqueous bead or beads comprising the active ingredient is encapsulated in or by a hydrophobic shell matrix. The present invention relates also to novel methods for preparing the microcapsules according to the invention, as well as to the use of the microcapsules of the present invention. A microcapsule of the present invention comprises a solidified hydrophobic shell matrix, an encapsulated aqueous bead or beads which is / are encapsulated in or by the solidified hydrophobic shell matrix, and an active ingredient or active ingredients dissolved or incorporated in the encapsulated aqueous bead or beads.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Method of preserving foods using noble gases

InactiveUS6342261B1Inhibit enzymeAvoid reactionFruit and vegetables preservationEdible seed preservationNoble gasPreserved Foods

Owner:AIR LIQUIDE AMERICA INC

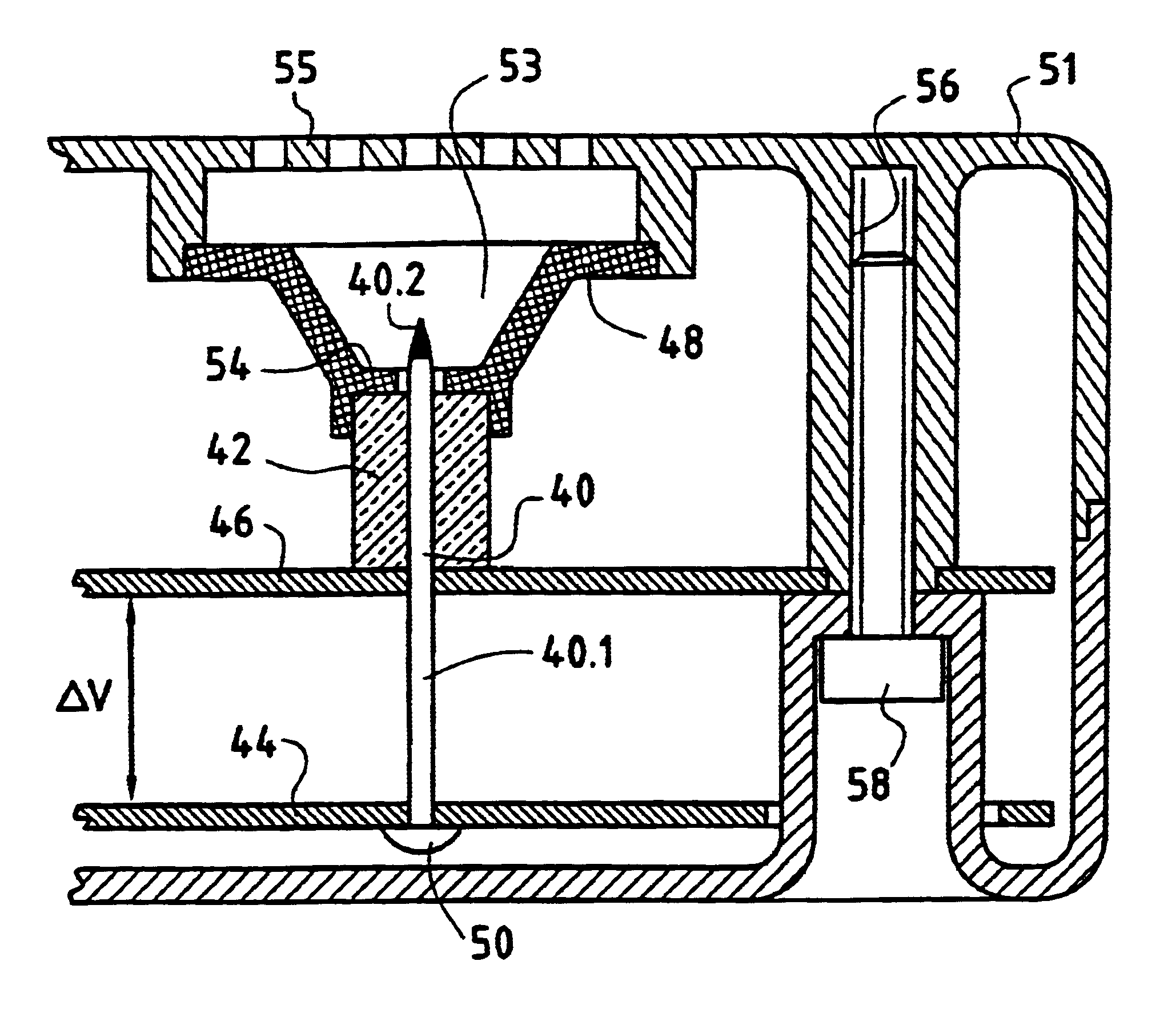

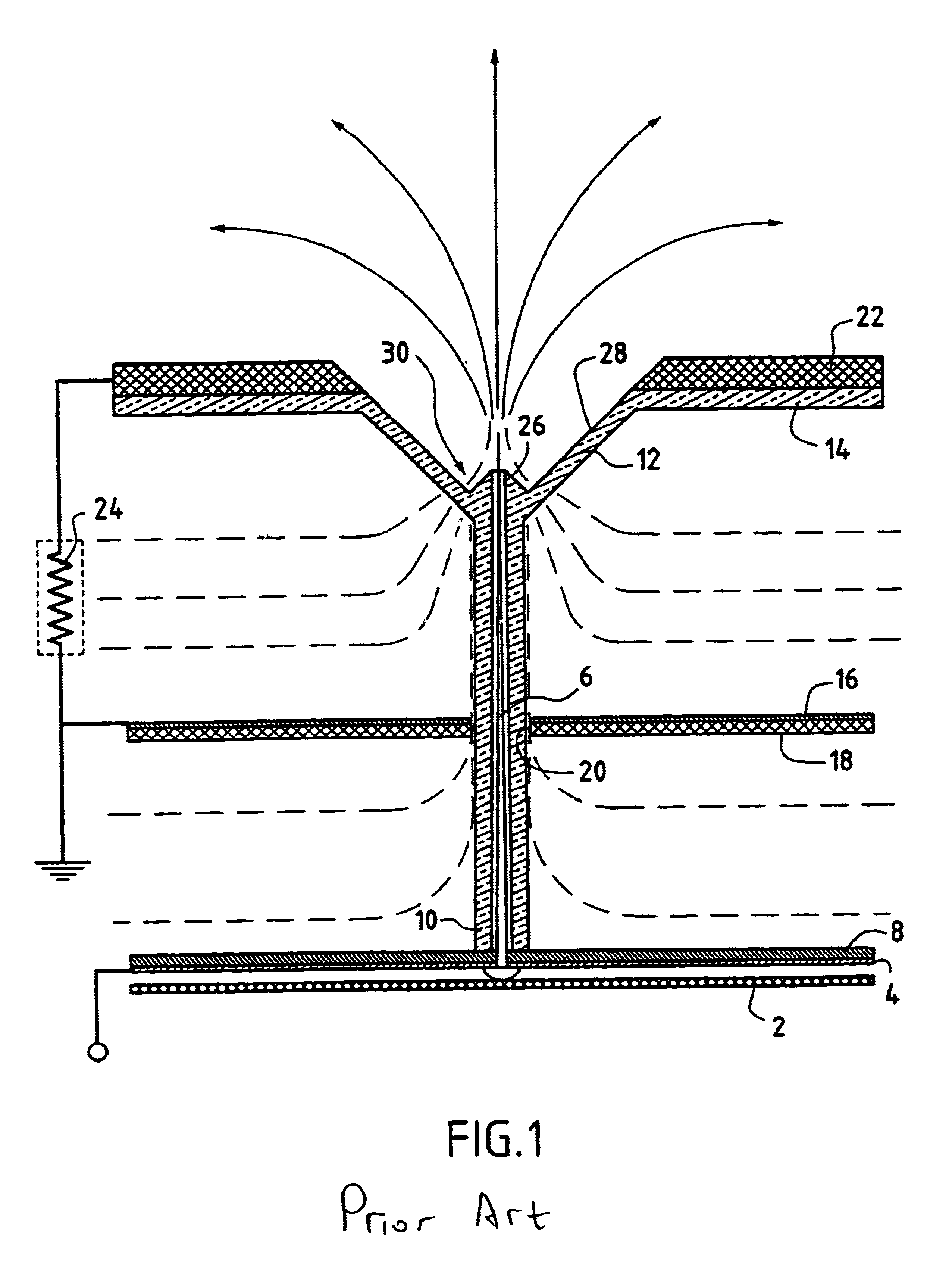

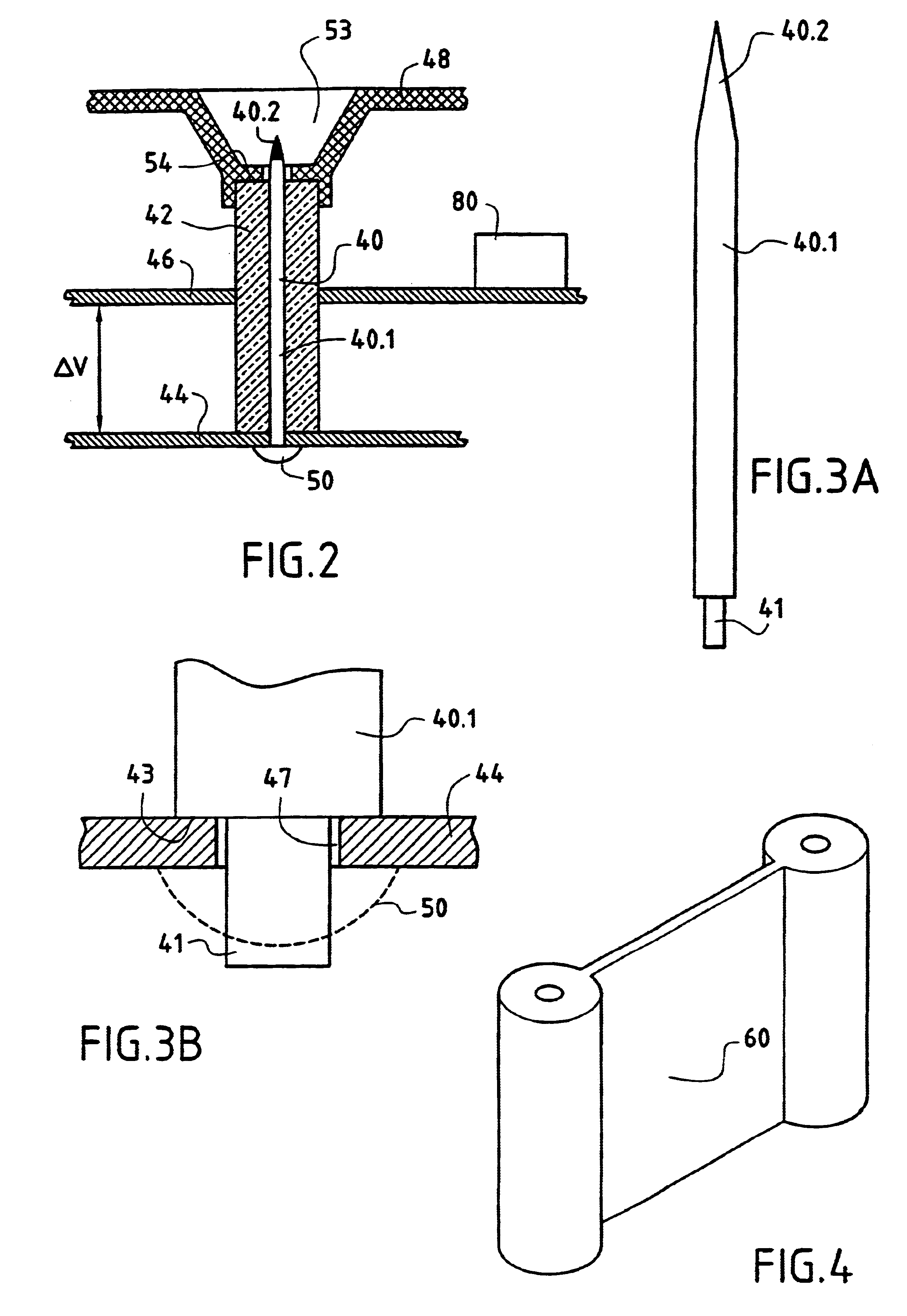

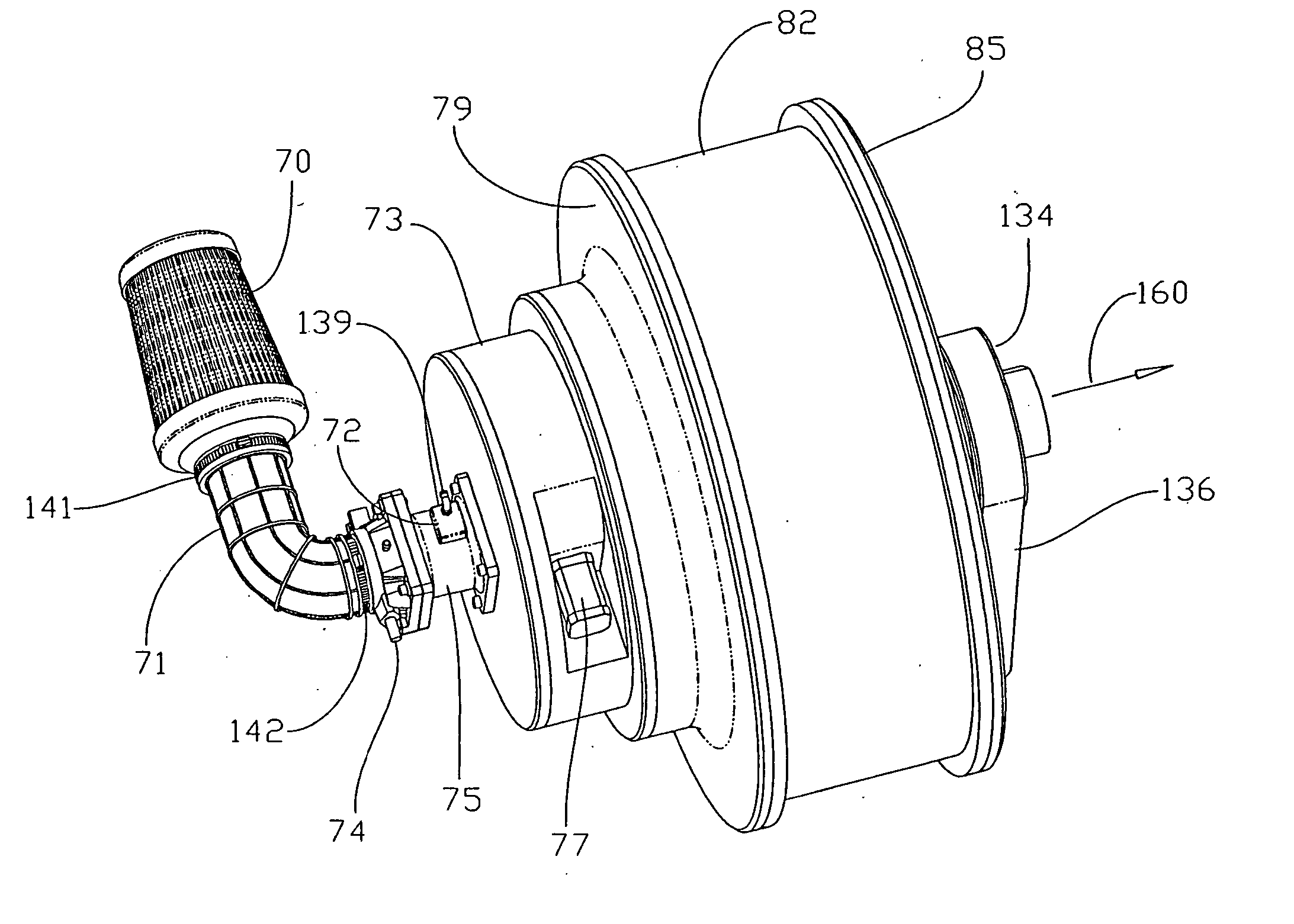

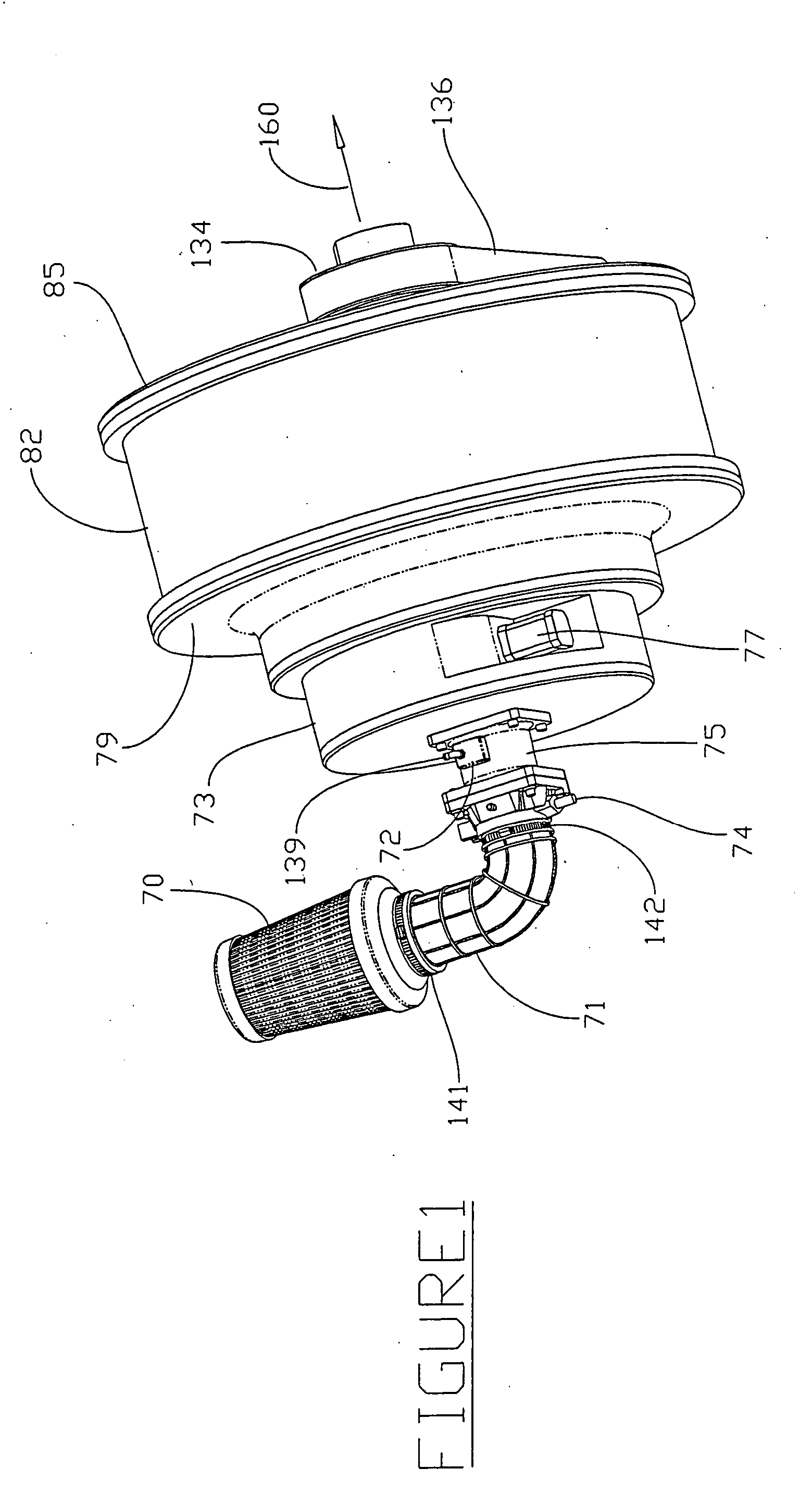

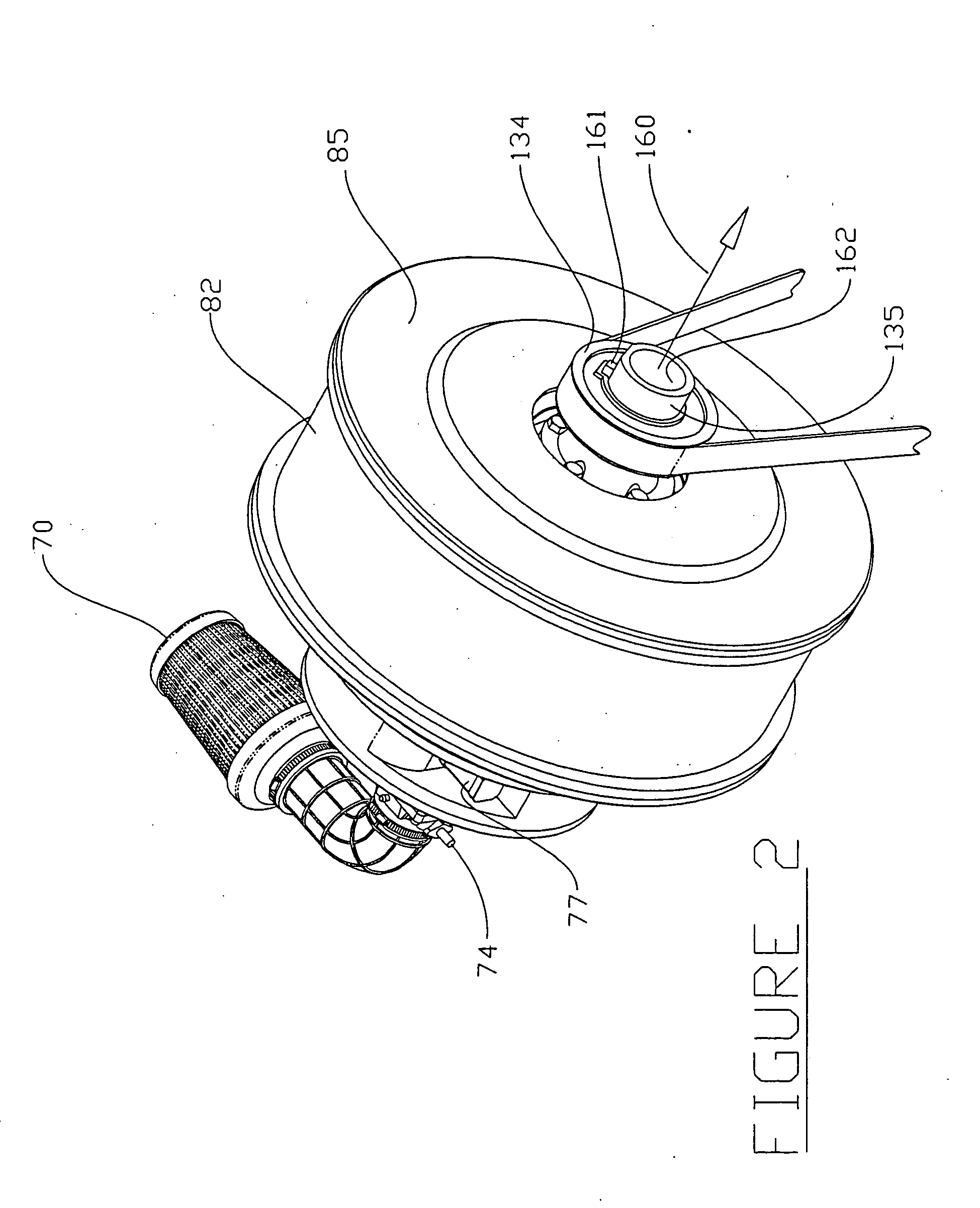

Ion generating device

InactiveUS6735830B1Material analysis by optical meansVessels or leading-in conductors manufacturePolyesterGlass fiber

The invention relates to apparatus for generating ions in a gaseous medium, the apparatus comprising one or more needles (40) each presenting a shank (40.1) and an emitter end (40.2), a sheath (42) of composite material comprising glass fiber reinforced unsaturated polyester surrounding the shank (40.1) of each needle, and means (44, 46, 80) for applying a voltage between two portions of the shank of each needle.

Owner:GENIE & ENVIRONNEMENT

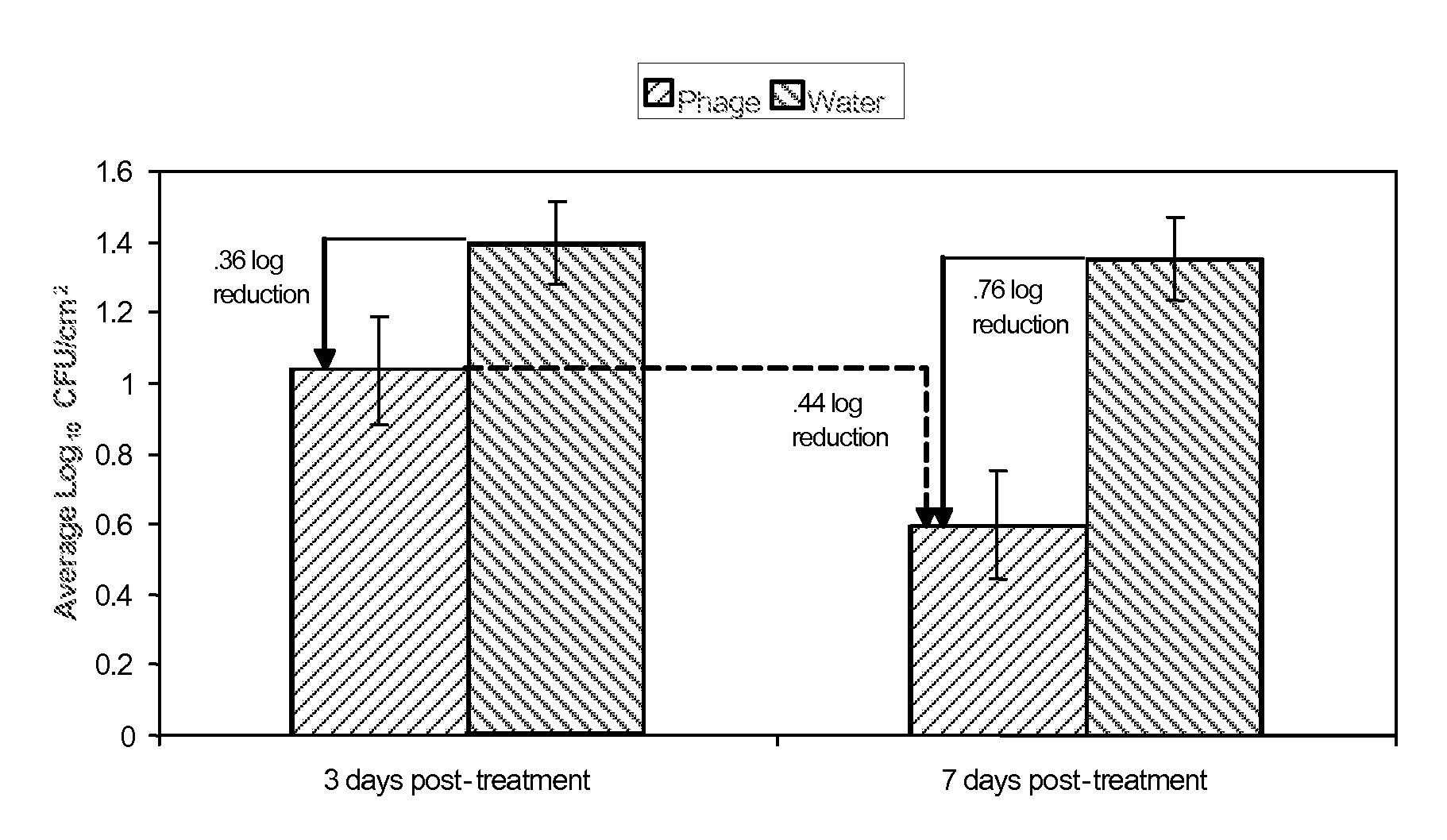

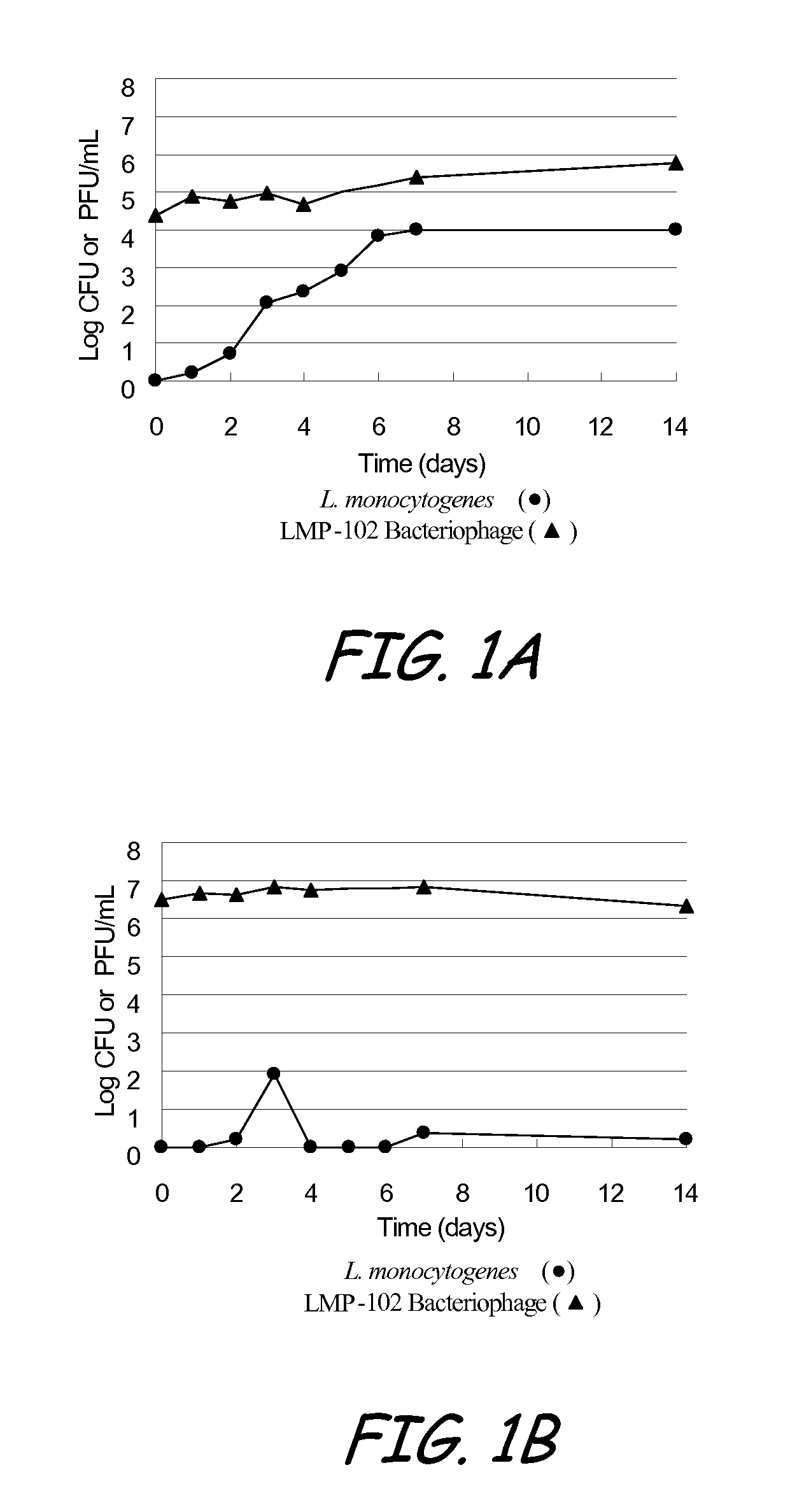

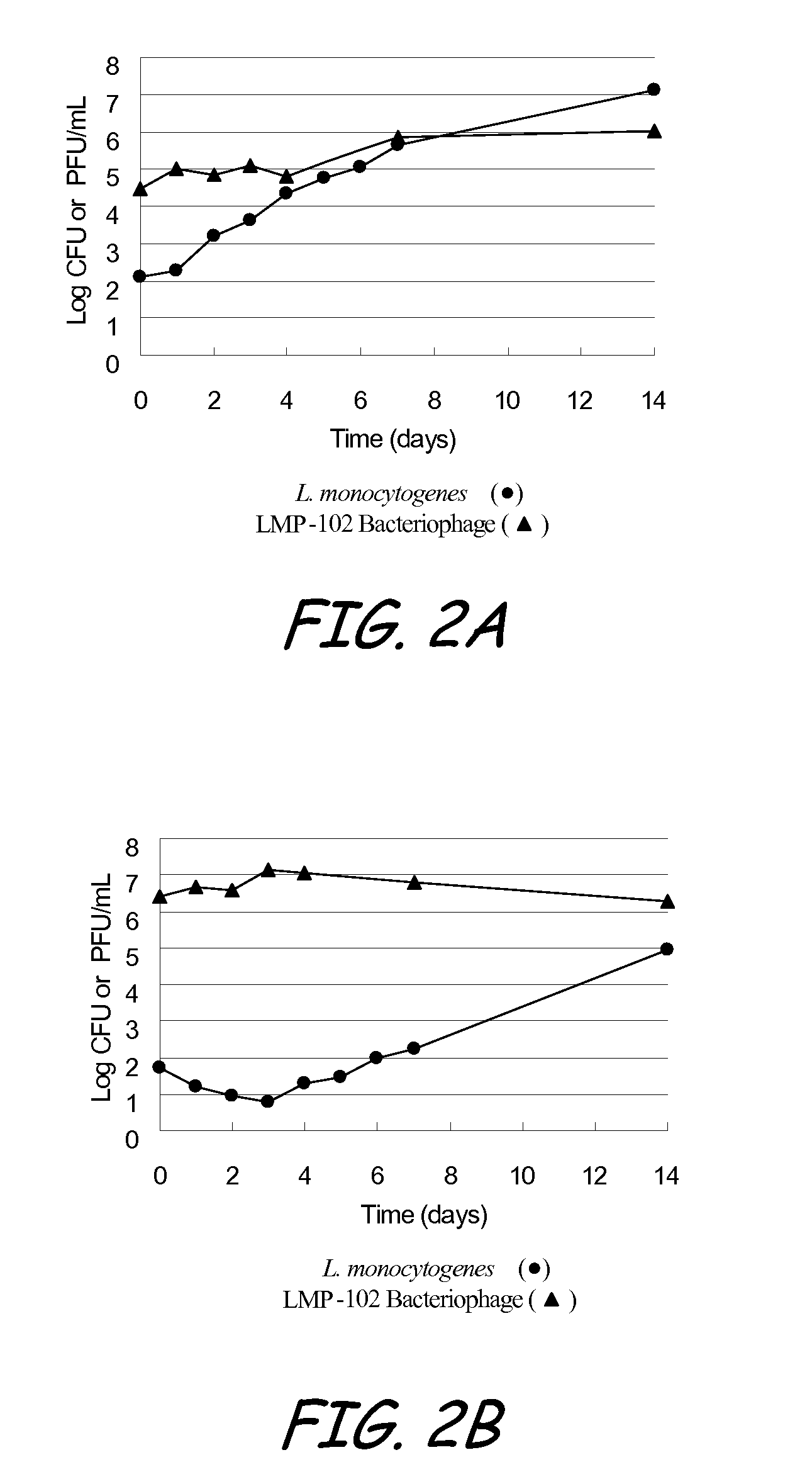

Bacteriophage treatment for reducing and preventing bacterial contamination

ActiveUS20090246336A1Process stabilityImprove performanceBiocideMilk preservationBacteroidesAdjuvant

A system and method for reducing or preventing bacterial contamination in food includes application of a bacteriophage treatment to any type of food product at any stage of processing the food product. The bacteriophage treatment may also be applied to non-food surfaces and water systems, which may be susceptible to bacterial contamination and subsequent spread of bacteria. The bacteriophage treatment comprises at least one bacteriophage in a concentration sufficient to reduce or prevent bacterial contamination from pathogenic bacteria and / or spoilage bacteria. In some embodiments, the bacteriophage is able to reduce or eliminate bacteria introduced to a food product after the bacteriophage treatment was applied to the food product. In some embodiments, the bacteriophage treatment includes a buffering agent to maintain the bacteriophage at a pH level that sustains the bacteriophage. In some embodiments, the bacteriophage treatment includes a surfactant and / or a thickener to aid in applying the bacteriophage. Additional adjuvants and enhancers may be used in some embodiments to stabilize the bacteriophage or enhance its performance as an antibacterial agent.

Owner:ECOLAB USA INC

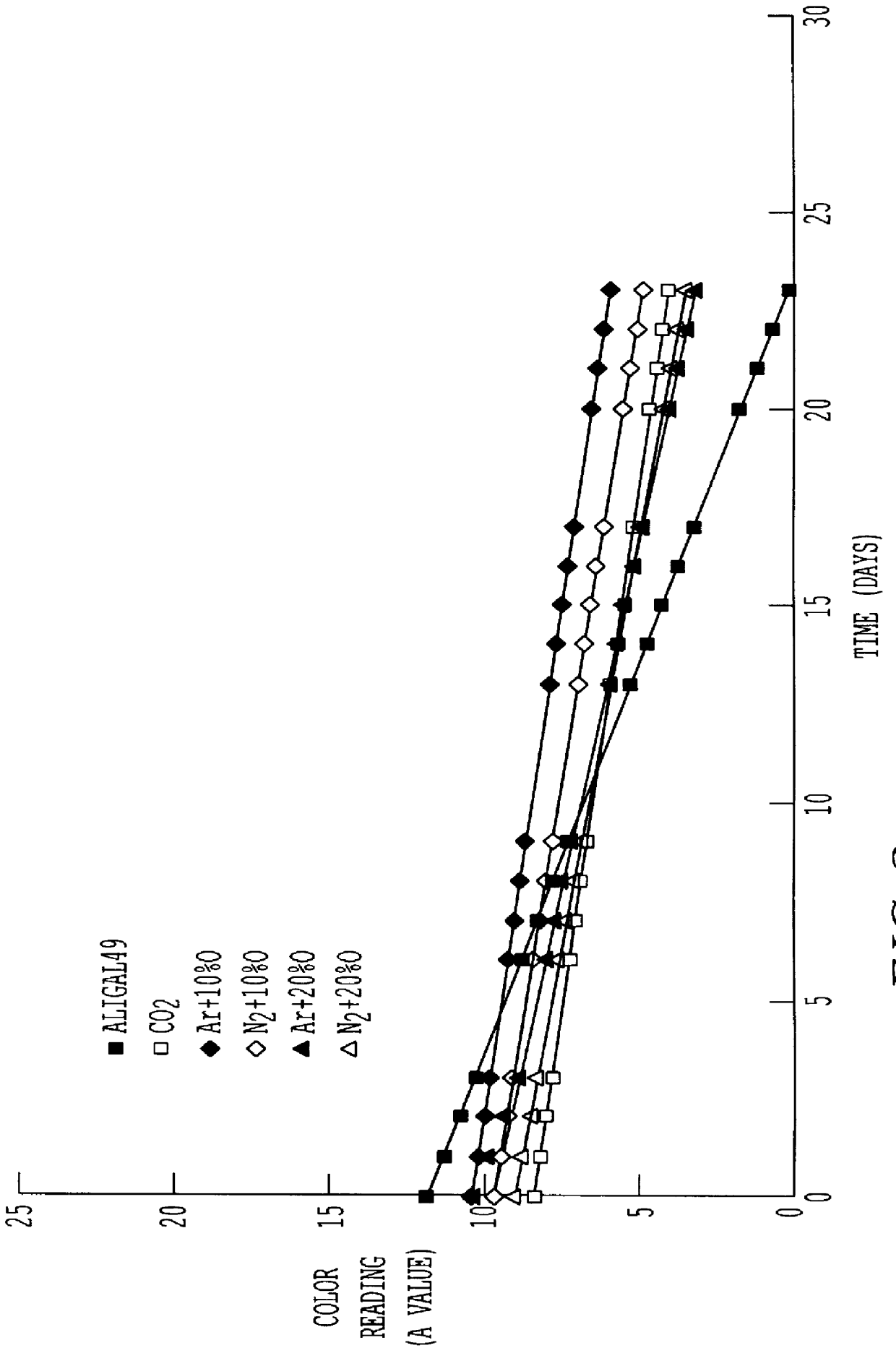

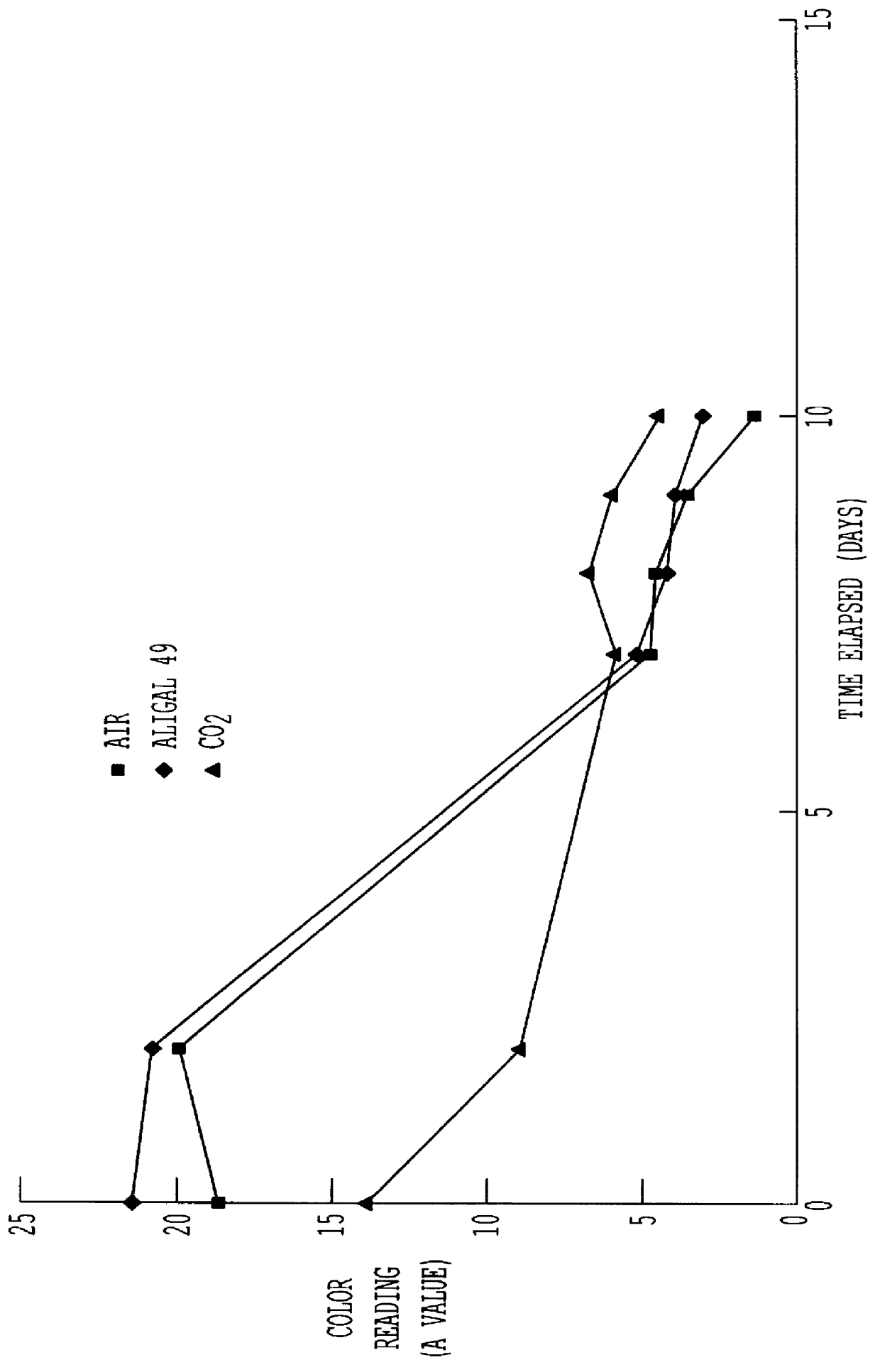

Preservation of color of stored meat using noble gases

A process for preserving the color of red meat, which entails contacting the meat with an effective amount of an atmosphere selected from the group consisting of a noble gas, a mixture of noble gases and a mixture containing at least one noble gas and a carrier gas, the noble gas in the mixture with the carrier gas being selected from the group consisting of argon, neon, xenon an krypton and being present in said mixture in an amount of greater than about 10% by volume.

Owner:AIR LIQUIDE AMERICA INC

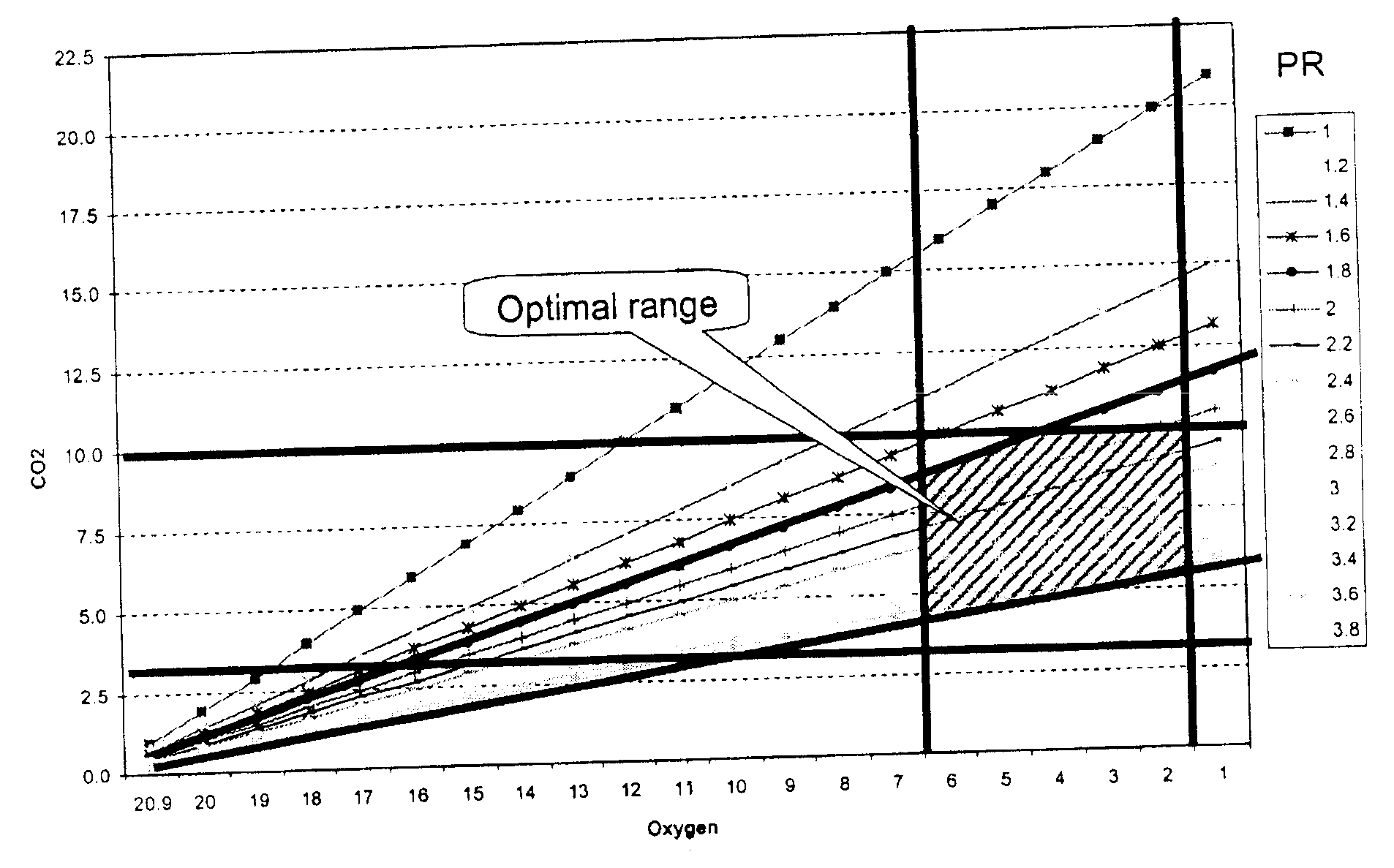

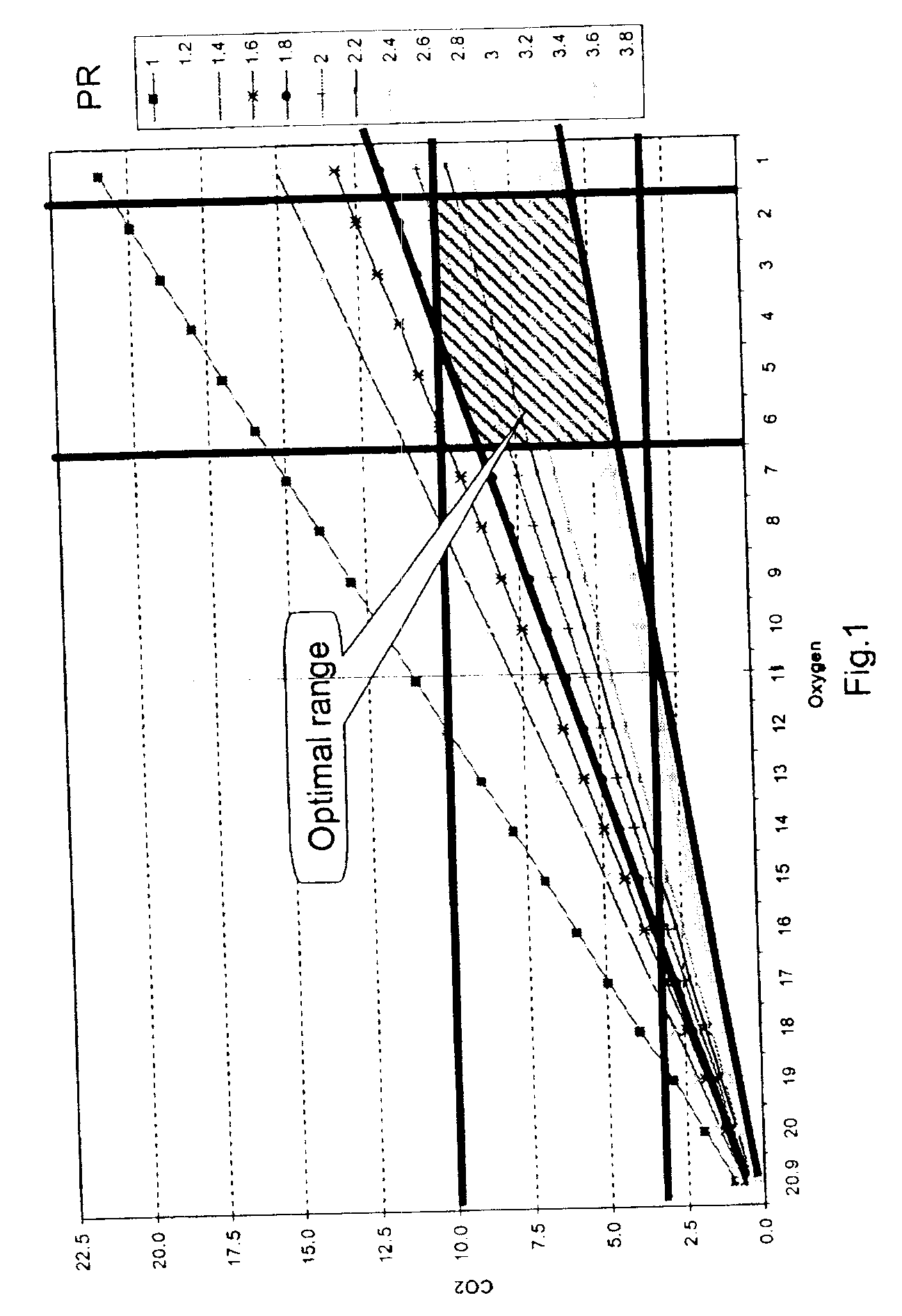

Method for Storing Bananas During Ripening

InactiveUS20080008793A1Improve flavor profileKeep for a long timeReady-for-oven doughsFruit and vegetables preservationCellular respirationRipening

A method for storing respiring produce, particularly bananas, during ripening is disclosed. The method allows bananas to remain in the ripened condition for an extended period of time while, at the same time, having improved sweetness and taste characteristics. In this method, during ripening, the produce is maintained in a gas medium which comprises oxygen and carbon dioxide and has the following characteristics: PR=ratio of oxygen to carbon dioxide=(20.94−B) / C=from about 1.8 to about 3.8; wherein B is the percentage (by weight) of oxygen in the gas medium and C is the percentage (by weight) of carbon dioxide is the gas medium, and the percentage (by weight) of oxygen (in the gas medium) is from about 1.0 to about 6.0, and the percentage (by weight) of carbon dioxide in the gas medium is from about 3.0 to about 10.0

Owner:CHIQUITA BRANDS LLC +1

Products, methods and apparatus for fresh meat processing and packaging

InactiveUS20060147588A1Lower display costsReduce packaging costsPackaging meatMeat/fish preservation using chemicalsAtmospheric oxygenRed meat

Improved processing and packaging for perishable goods such as red meats providing a processing system wherein ambient air is excluded and suitable gases such as carbon dioxide are provided at a suitable pressure and in such a manner as to increase the quantity of the gases dissolved in the perishable goods. Then providing a base and placing the perishable goods over the base. A flexible web of plastic wrapping material (second web) is then applied over the base and the goods and air or gas evacuated therefrom and replaced with a suitable gas. The base includes a cup-shaped tray with a recess (first web), of plastics or other suitable material, with side walls extending upwardly to connect to a narrow horizontally disposed flange. The first web, goods and second web are located inside a depression in a third web of gas barrier material and there together placed into an enclosed evacuation chamber. A suitable gas is provided in the chamber in such a manner as to displace substantially all other gas and particularly atmospheric oxygen that may be present with the enclosed goods and web materials. The third web is then sealed so as to enclose the goods with first and second webs. that the pressure of the gas may be increased to a level above atmospheric pressure. Most preferably the quantity of gas dissolved into the goods will be increased. Most preferably the gas introduced into the chamber and the space will enhance preservation of the packaging goods when contacting the goods. The first web, second web and third web are sealed together thereby producing a hermetically sealed package with the goods and a gas filled space contained therein to provide a sealed package. The sealed package can be stored for any convenient period of time after which the third web is can be removed so as to allow ambient air to contact the goods. The invention further includes the method and apparatus for producing the processed goods and packaging.

Owner:STONE MICHAEL

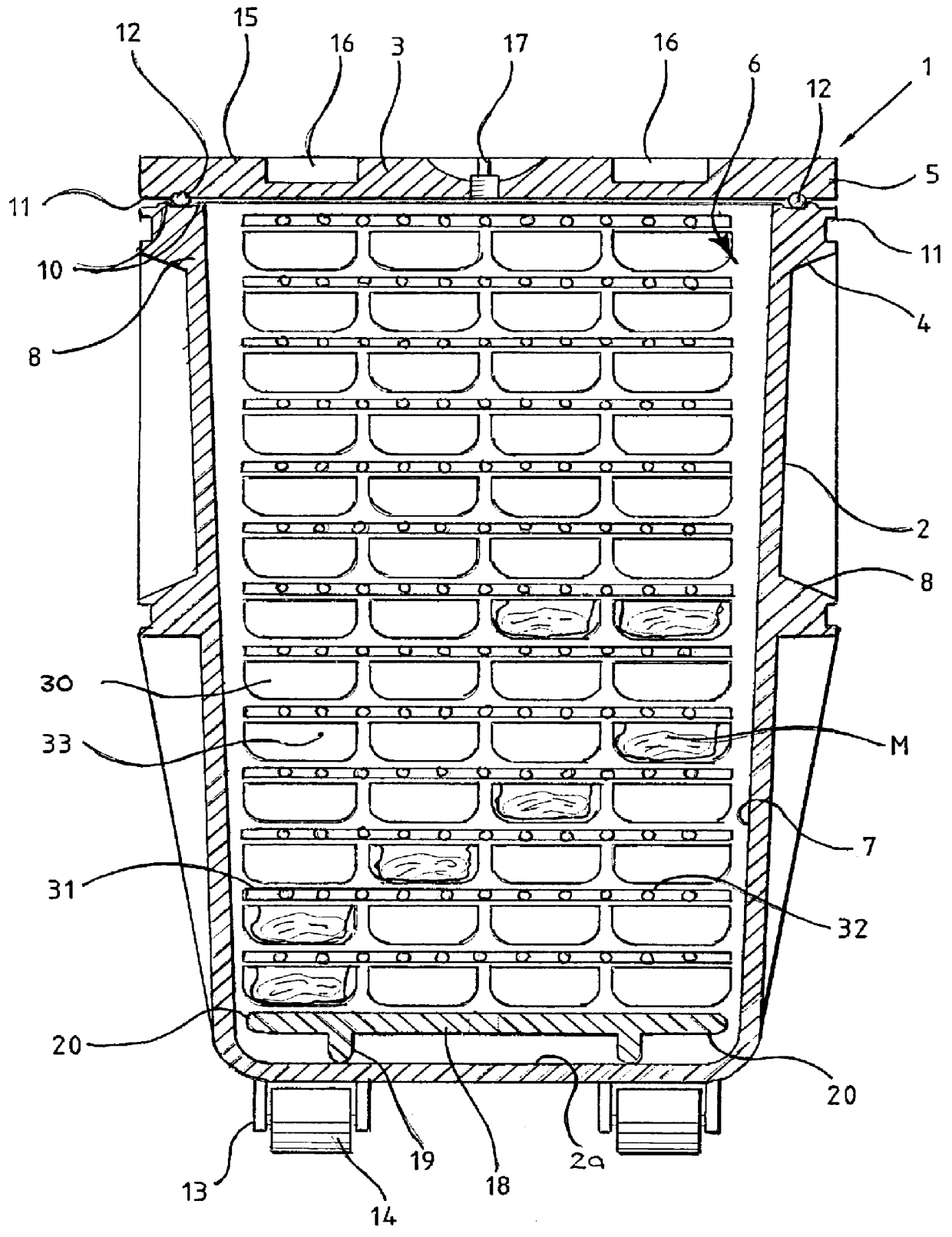

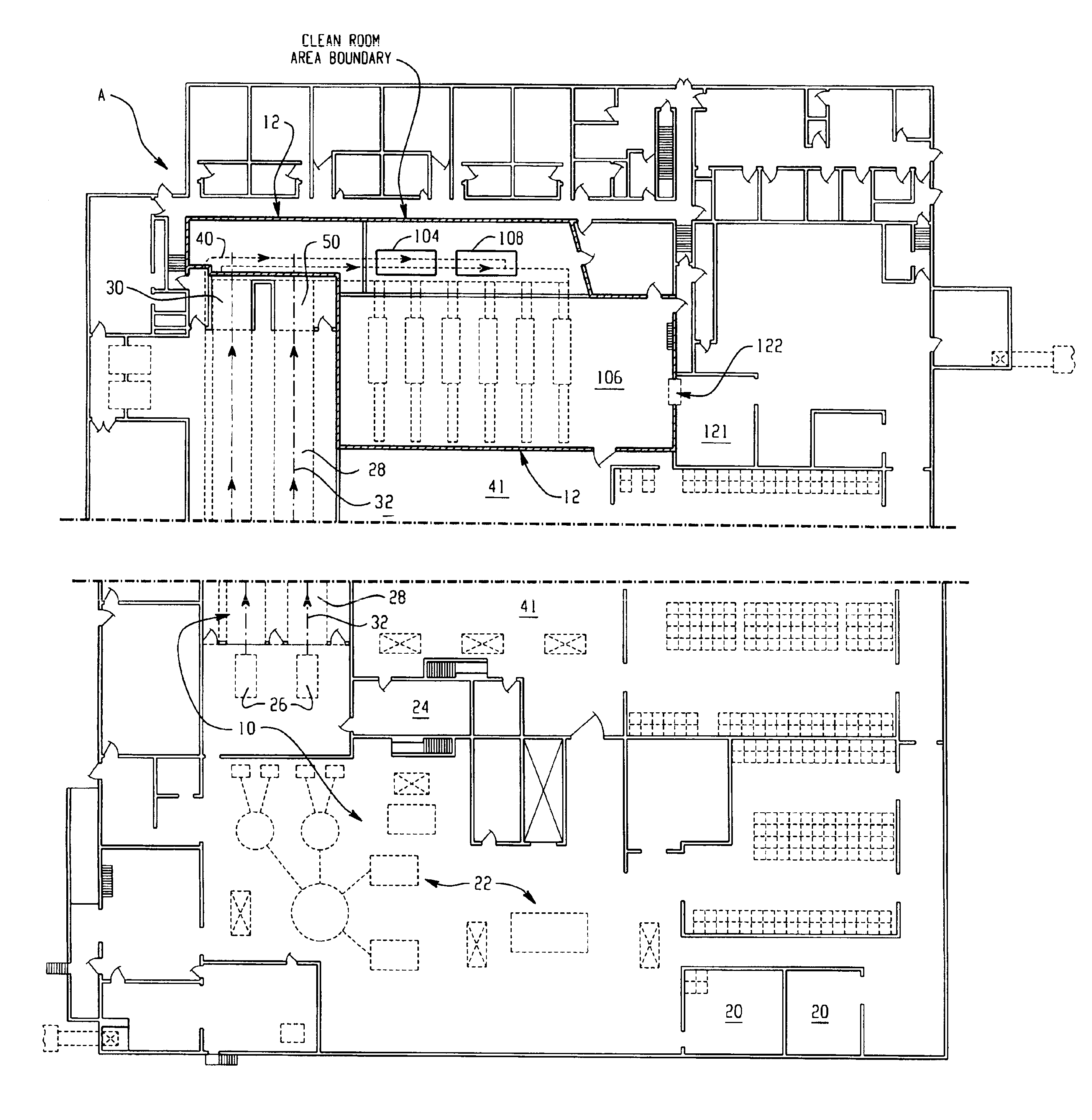

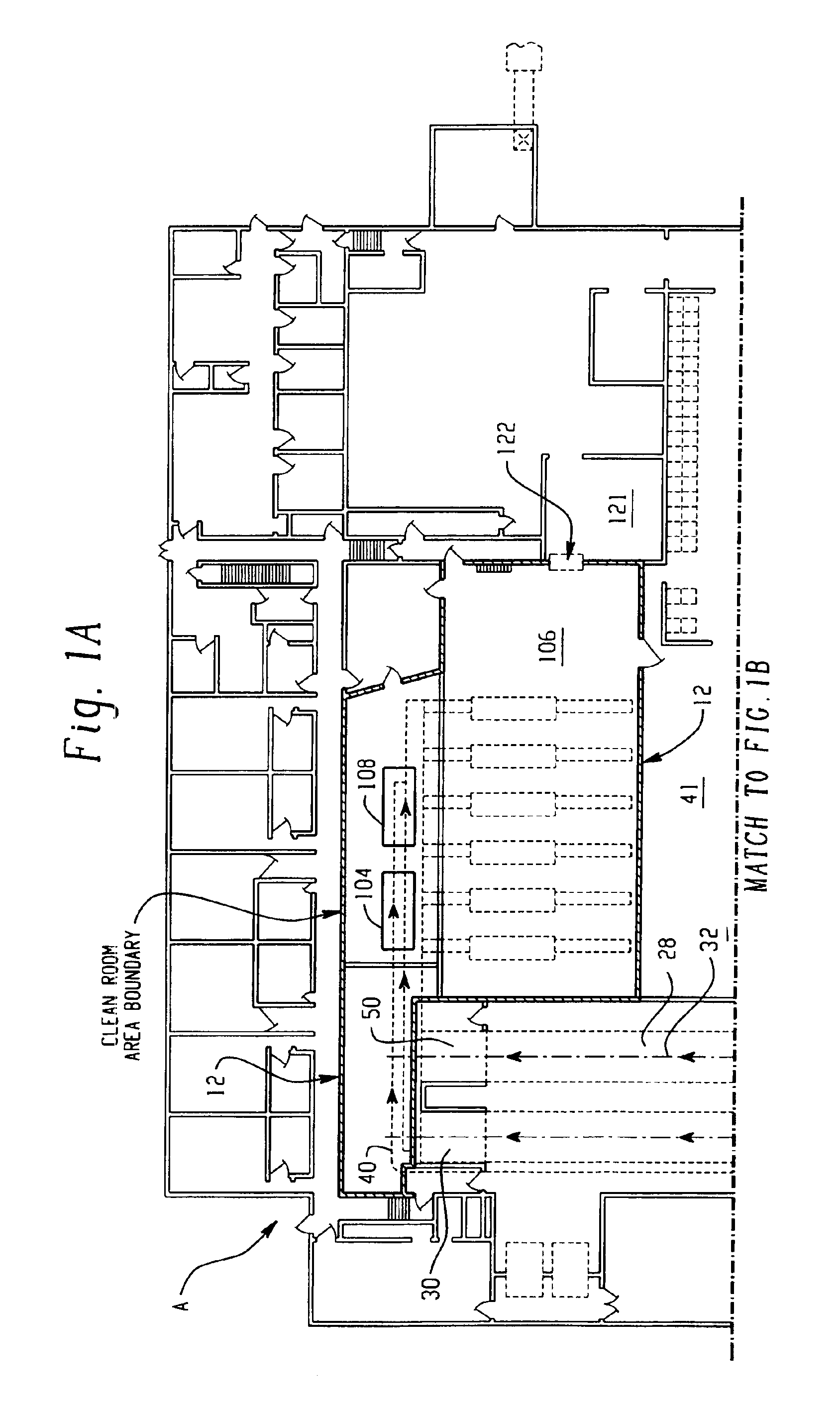

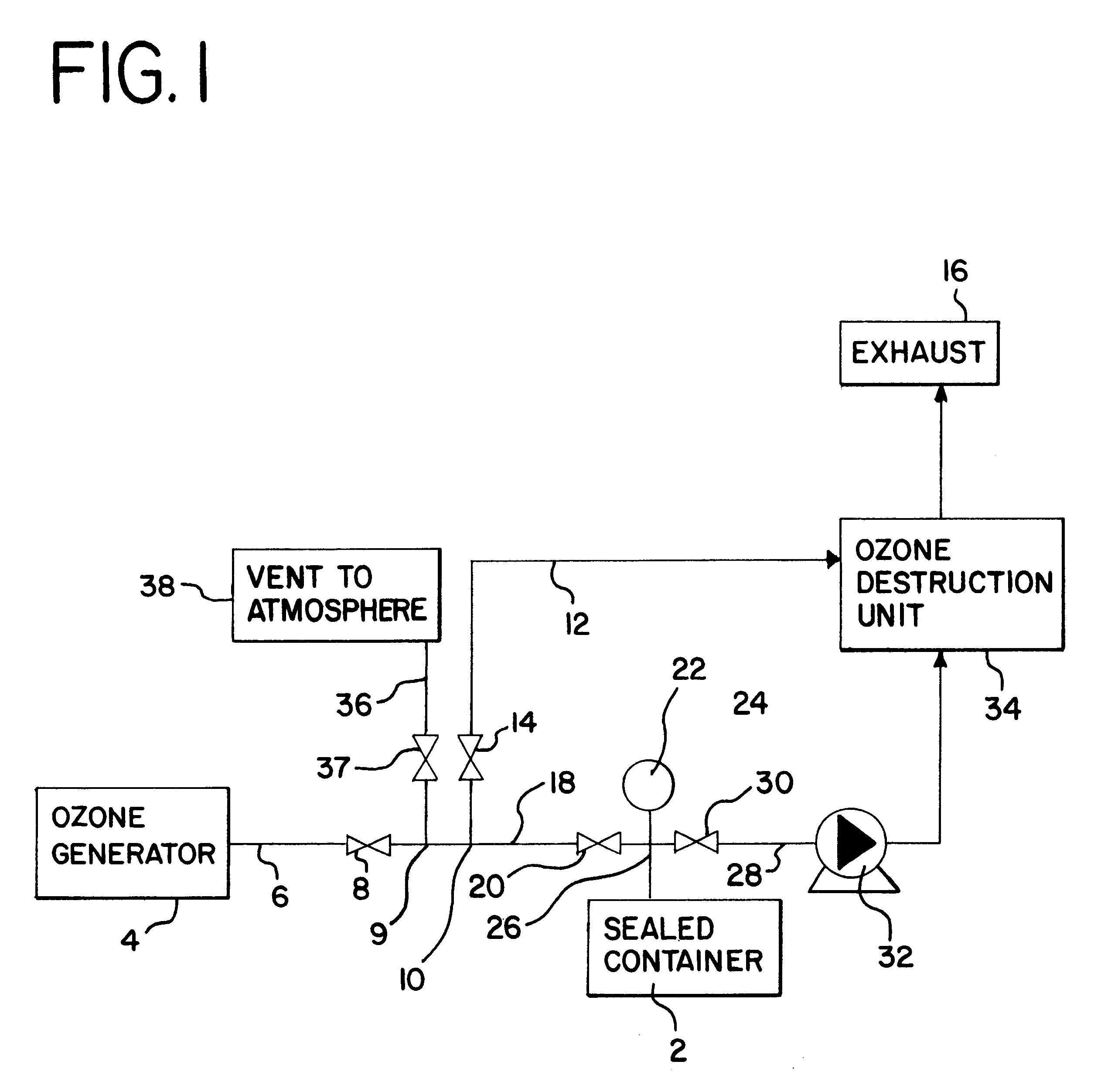

System for handling processed meat and poultry products

InactiveUS6964788B2Apparent advantageObvious advantagesMeat/fish preservation using liquidsSausage casingsPathogenic microorganismPoultry product

Food products, such as precooked meats, sausages, and the like are microbially decontaminated in their cooking packages to remove surface microorganism contamination from the packages. The cooking packages are removed and the food products optionally subjected to further processing, such as slicing, and then packaged in aseptic packaging. The microbial decontamination step, further processing and packaging are carried out in a clean room which is maintained to a high level of sterilization or disinfection to minimize or eliminate contamination of the food products with pathogenic microorganisms such as Listeria Monocytogenes. The food products thus leave the packaging plant with a much higher assurance of food safety than is found in a conventional packaging plant.

Owner:STERIS CORP

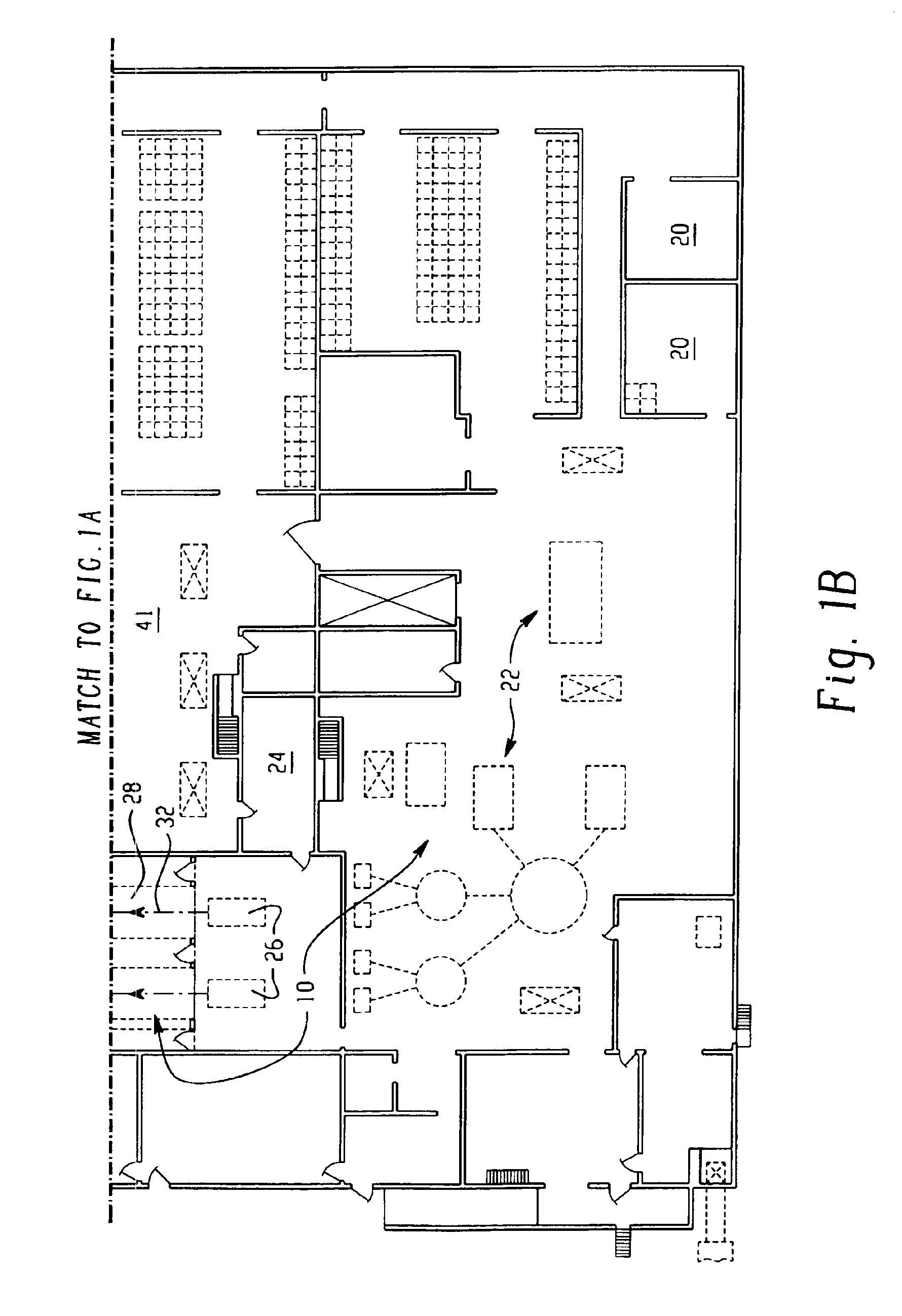

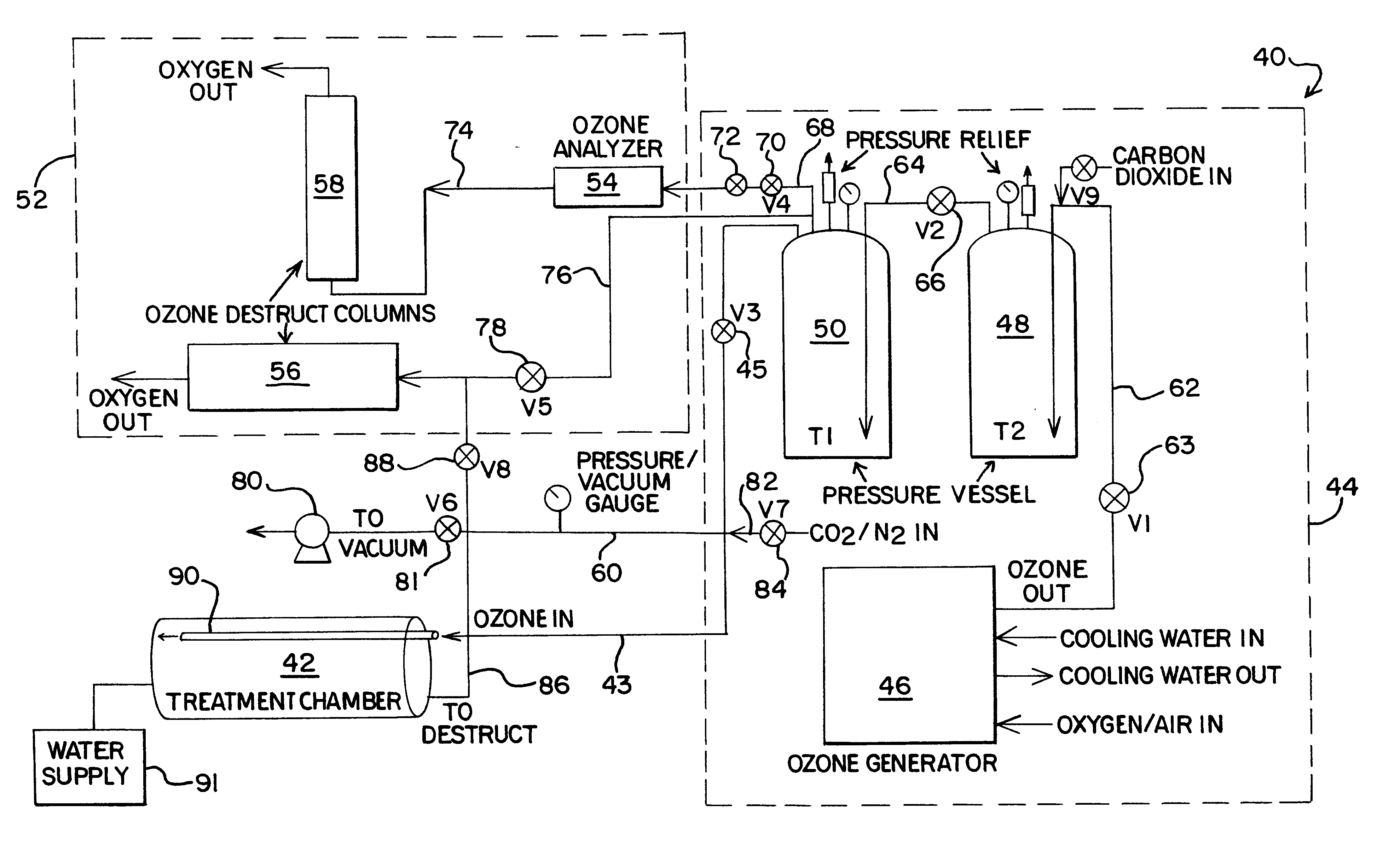

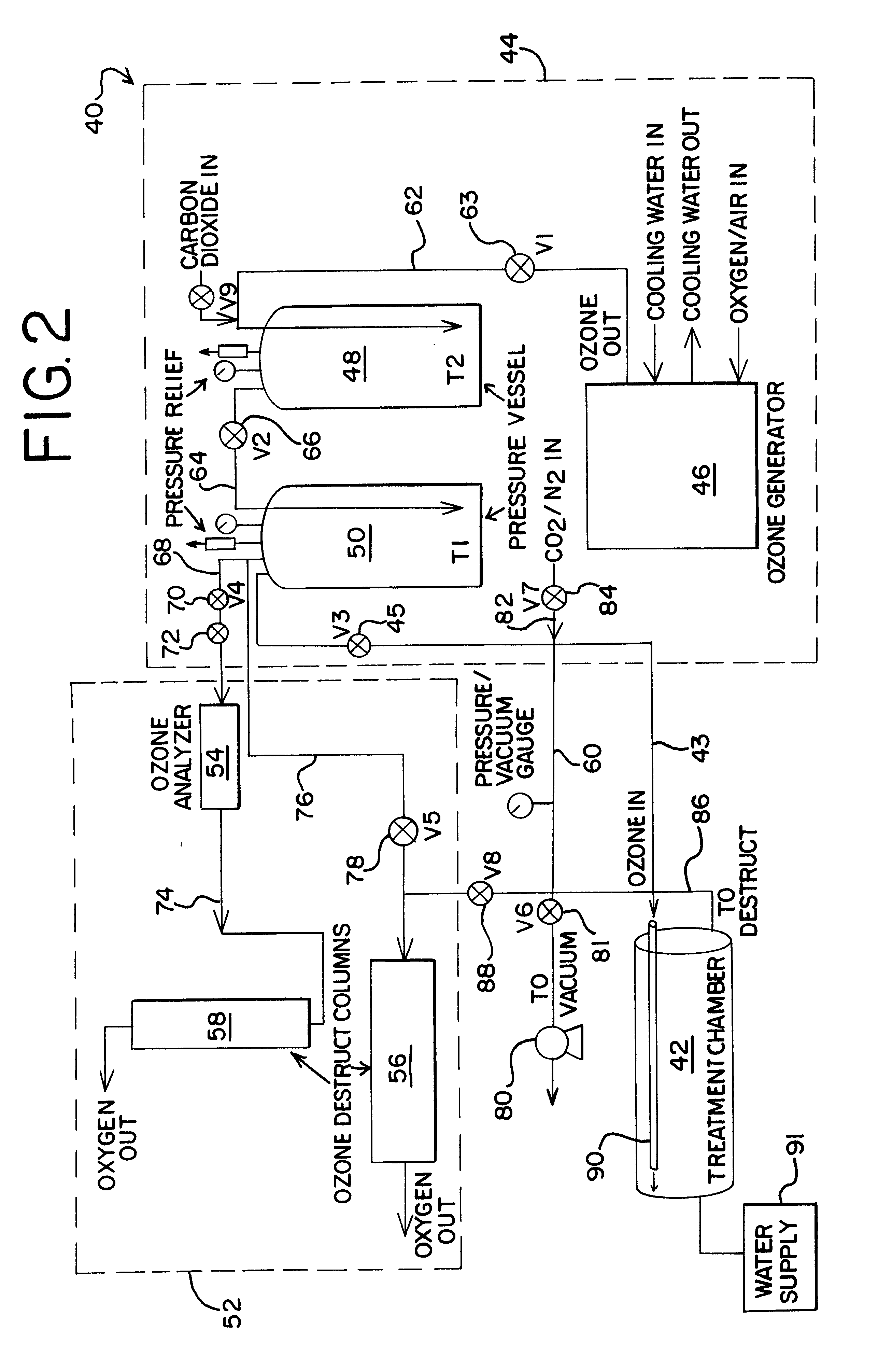

Food disinfection using ozone

Methods and apparatus are provided for decreasing the bacteria count of a food commodity without affecting its overall organoleptic quality (taste, odor, and color). This is accomplished using a treatment fluid comprising ozone, which is injected into a treatment chamber containing the food commodity. Some water is preferably added to obtain better contact of the ozone with the food by forming a thin film of ozonated water on the food surface. Spices and / or other ingredients may preferably be added with the water. The food is placed in a tumbler and the tumbler is set in motion. During treatment good contact between the treatment fluid and the food commodity is obtained by reversibly oscillating the tumbler. A log reduction of 40% or more in bacteria count may be obtained as compared without the ozone.

Owner:AIR LIQUIDE AMERICA INC +2

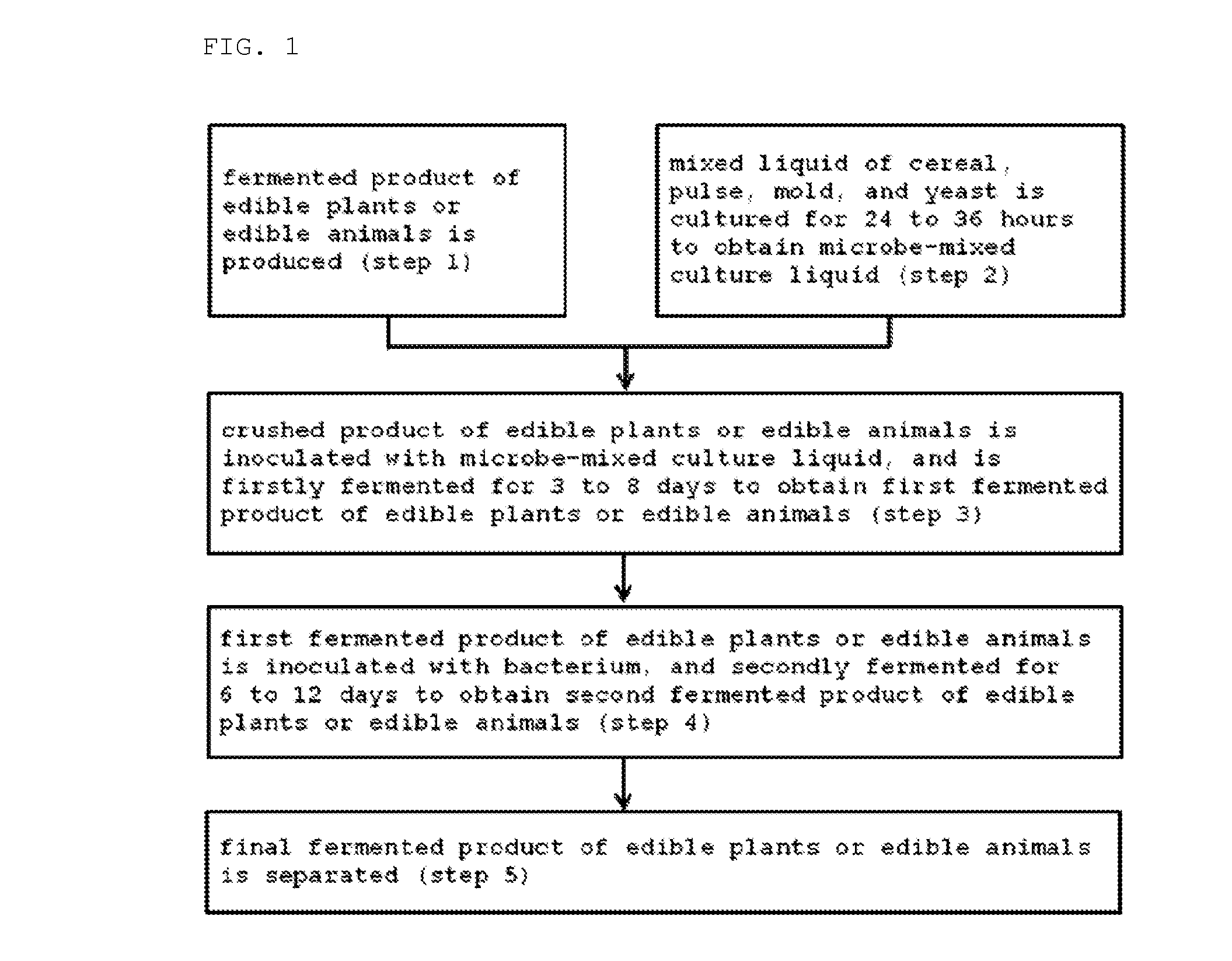

Method for producing fermented edible plants or edible animal/plants, fermented edible plants or edible animal/plants produced by same, and foods containing same

ActiveUS20100316763A1Increase heightPrevent invasionDough treatmentEdible seed preservationFood flavorOrganism

The present invention relates to a method for producing fermented edible plants or edible animal / plants, to fermented edible plants or edible animal / plants produced by same, and to foods containing same. The method for producing fermented edible plants or edible animal / plants includes the steps of: producing crushed edible plants or edible animal / plants; culturing a liquid mixture of grains, saccharides, filamentous fungi, and yeast for 24 to 36 hours to produce a mixed microbial broth; inoculating the edible plants or edible animal / plants with the mixed microbial broth, and firstly fermenting the edible plants or edible animal / plants for 3 to 8 days to produce first fermented edible plants or edible animal / plants; and inoculating the first fermented edible plants or edible animal / plants with bacteria, and secondly fermenting the first fermented edible plants or edible animal / plants for 6 to 12 days to produce second fermented edible plants or edible animal / plants. Whereby, a fermentation period can be shortened, and food deterioration and the growth of pathogenic microorganisms can be suppressed. Further, adding the fermented edible plants or edible animal / plants produced by the above-described method into foods can provide storage stability, increase bioavailability, and improve flavor.

Owner:PHARVIS R&D KOREA

Method and composition for washing poultry during processing

InactiveUS7381439B2Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationMachining processBiology

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

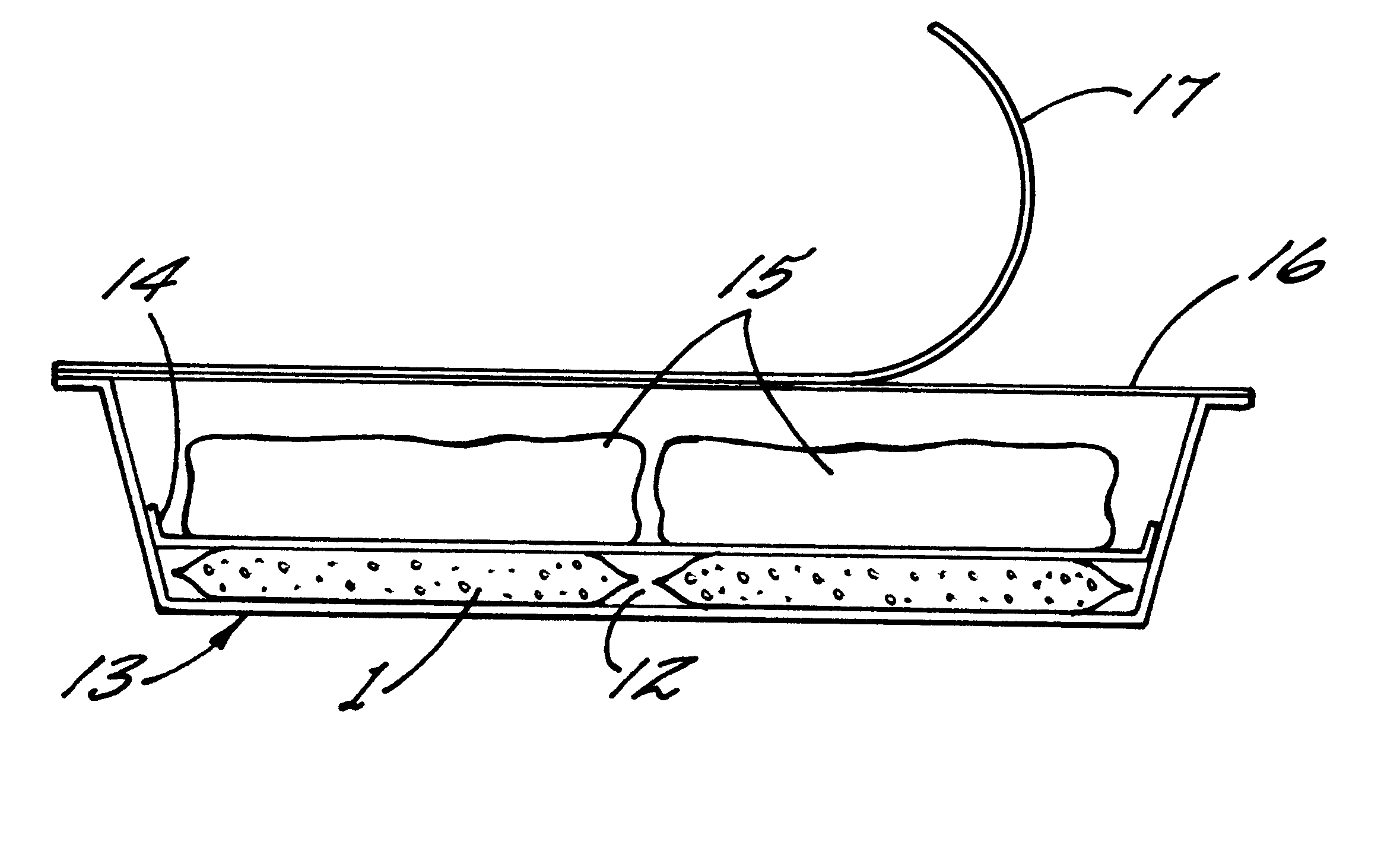

Food preservation systems

ActiveUS20060172048A1Large capacityIncreased physical sizeContainer/bottle contructionFruits/vegetable preservation using acidsFood safetyFood preservation

The present invention provides a food preservation system that includes a multi-phase bacterial inhibition food pad. The food pad includes absorbent media and / or material to absorb fluids emanating from the packaged food. The absorbent media / material includes one or more bacterial inhibitors that may possess bacteriostatic and / or bactericidal properties. In addition, the food pad may also include an atmosphere modification system capable of modifying an atmosphere in a food package. Optionally, one or more reaction promoters and / or one or more mechanisms to protect the food preservation system may also be included in the food pad. Overall, the food preservation system inhibits bacterial growth, thereby enhancing food preservation and / or food safety.

Owner:NOVIPAX INC

Method of processing waste product into fuel

InactiveUS20050142250A1Efficient conversionControlled and adjustable resistanceMilk preparationSolid fuelsWaste streamWaste product

Fuels used may be derived from existing waste streams such as animal wastes and streams of discarded or unwanted animal byproducts generated at animal slaughterhouses. A method of processing organic waste products into fuel includes homogenizing the waste products. The waste products are heated and pressurized. Water is removed from the waste products. Selected constituent of the waste products are separated from the waste products into a waste stream. The waste stream is blended with a fuel to form a bio-fuel mixture.

Owner:STONE MICHAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com