Patents

Literature

431 results about "Natamycin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natamycin is used to treat fungal eye infections.

Natamycin dosage form, method for preparing same and use thereof

InactiveUS20050042341A1Sustained releaseReduce releaseDough treatmentEggs preservation by coatingFood productsDosage form

The present invention relates to a novel natamycin dosage form for the food industry, and more particularly to microcapsules where natamycin is encapsulated within a physiologically acceptable shell to provide a protected natamycin product. The present invention relates also to novel processes for preparing the capsules according to the invention, as well as to the use of the capsules of the present invention. The invention further relates to food products containing natamycin in encapsulated form.

Owner:AS DE DANSKE SUKKERFABRIKKER

Lichee natural coating antistaling agent and its preparation method

InactiveCN102388957AGood fresh-keeping effectSimple planFruits/vegetable preservation by coatingRough surfaceAdditive ingredient

The invention discloses a lichee natural coating antistaling agent which is characterized in that the coating antistaling agent comprises an antistaling agent A and an antistaling agent B. The antistaling agent employs fresh-keeping components of chitosan, citric acid, natamycin, tea polyphenol, ascorbic acid and the like. In the fresh-keeping process, the antistaling agent is coated on lichee twice for keeping fresh, each fresh-keeping component can be effectively kept on the fruit rough surface of whole lichee, the condition of uneven thickness caused by downward fresh-keeping liquid in thesubsequent treatment and operation processes of placing, air drying and the like can be avoided, the uniform thickness of the film can be effectively controlled, simultaneously, the fresh-keeping effect of each fresh-keeping component is fully performed, and the antistaling agent has good fresh-keeping effect and long fresh-keeping time. In addition, the antistaling agent has the advantages of safety, no toxicity, simple scheme and easy operation, and is convenient for industrial production.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Mushrooms

A substrate for mushroom cultivation comprises a polyene fungicide, in particular, natamycin. Mushrooms cultivated in such substrates can be harvested earlier than mushrooms cultivated in substrates which do not include polyene fungicides. Alternatively, mushrooms grown in a substrate comprising a polyene fungicide achieve a greater size than mushrooms grown for the same amount of time in a substrate which does not include a polyene fungicide.

Owner:SYLVAN +1

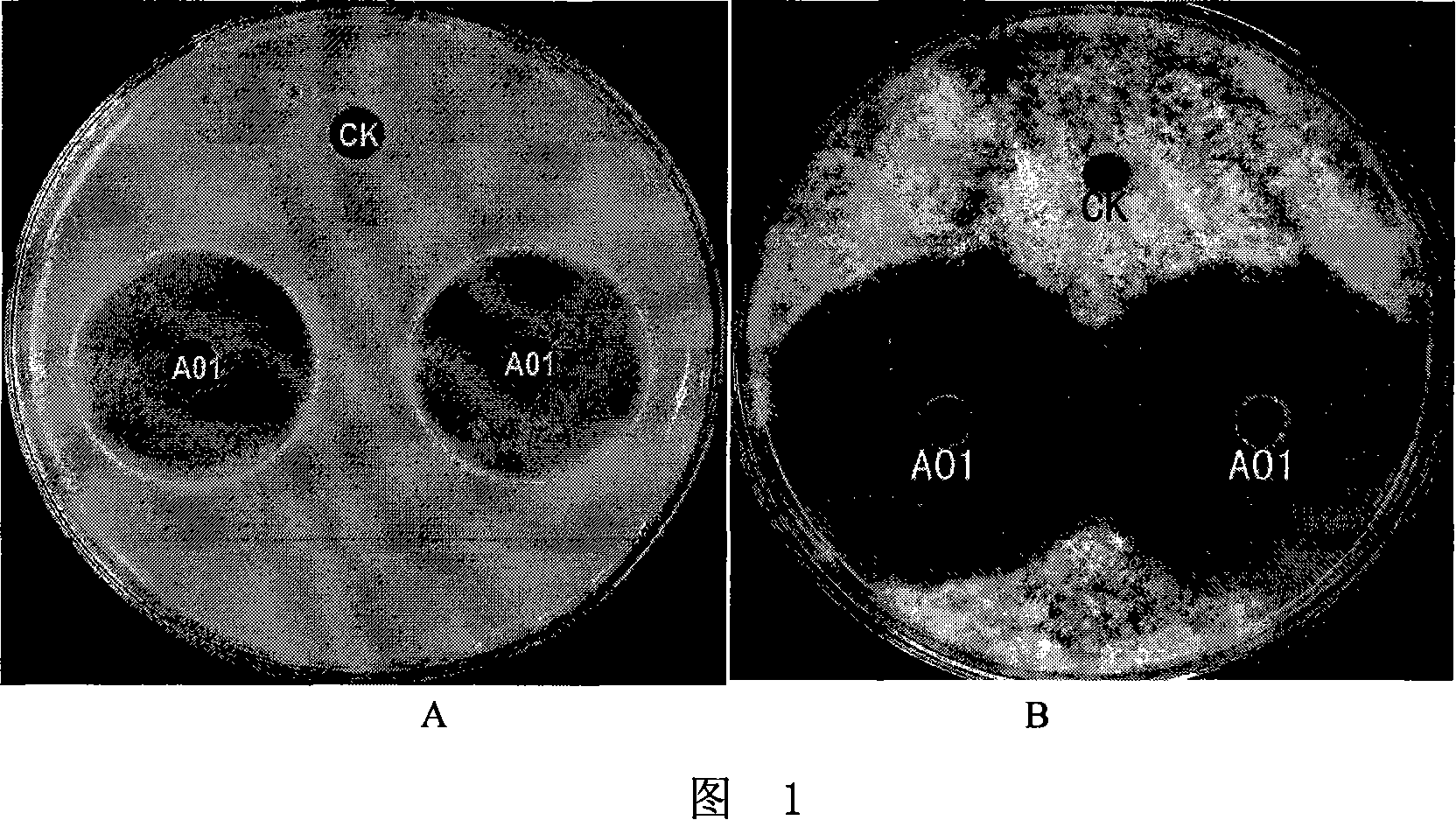

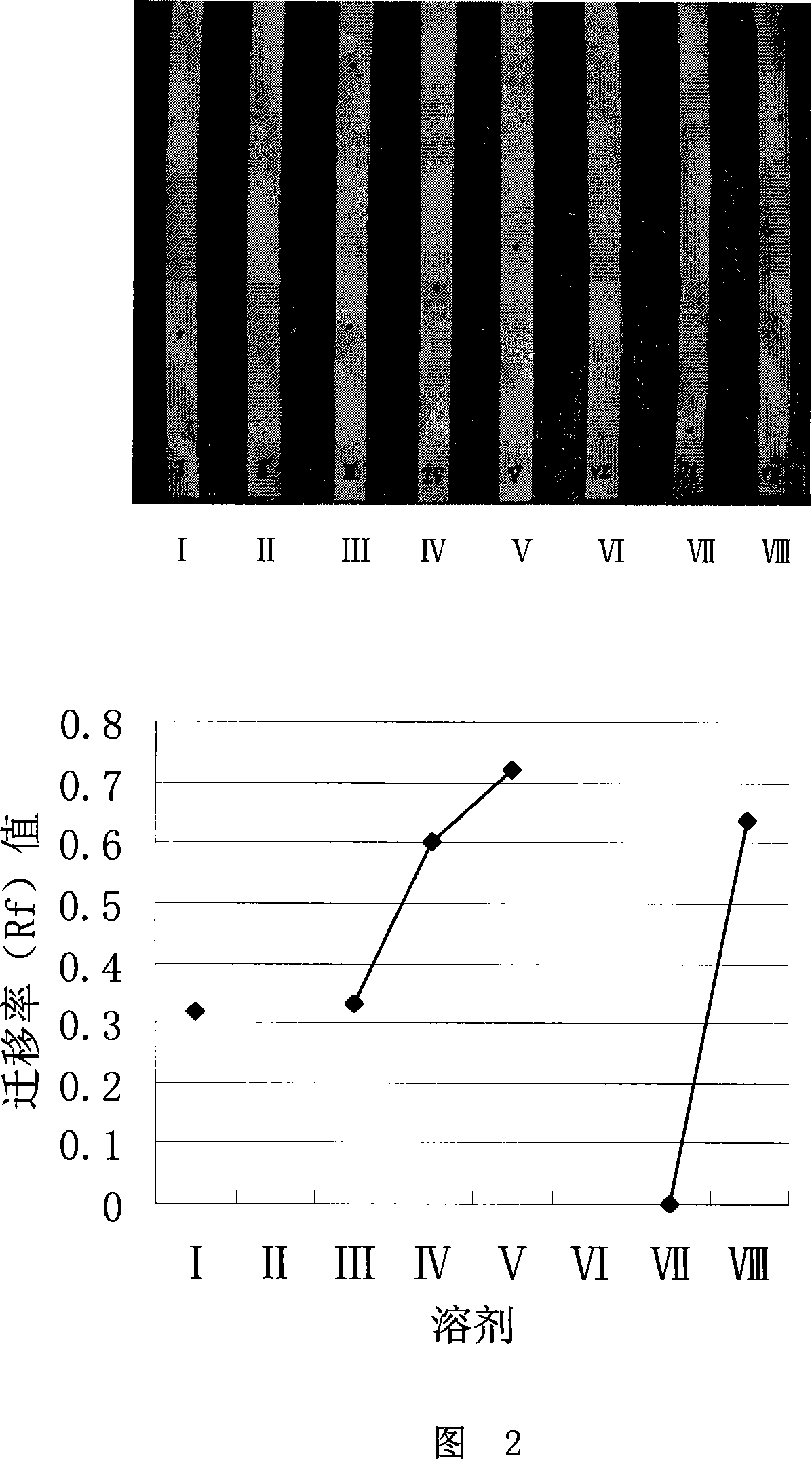

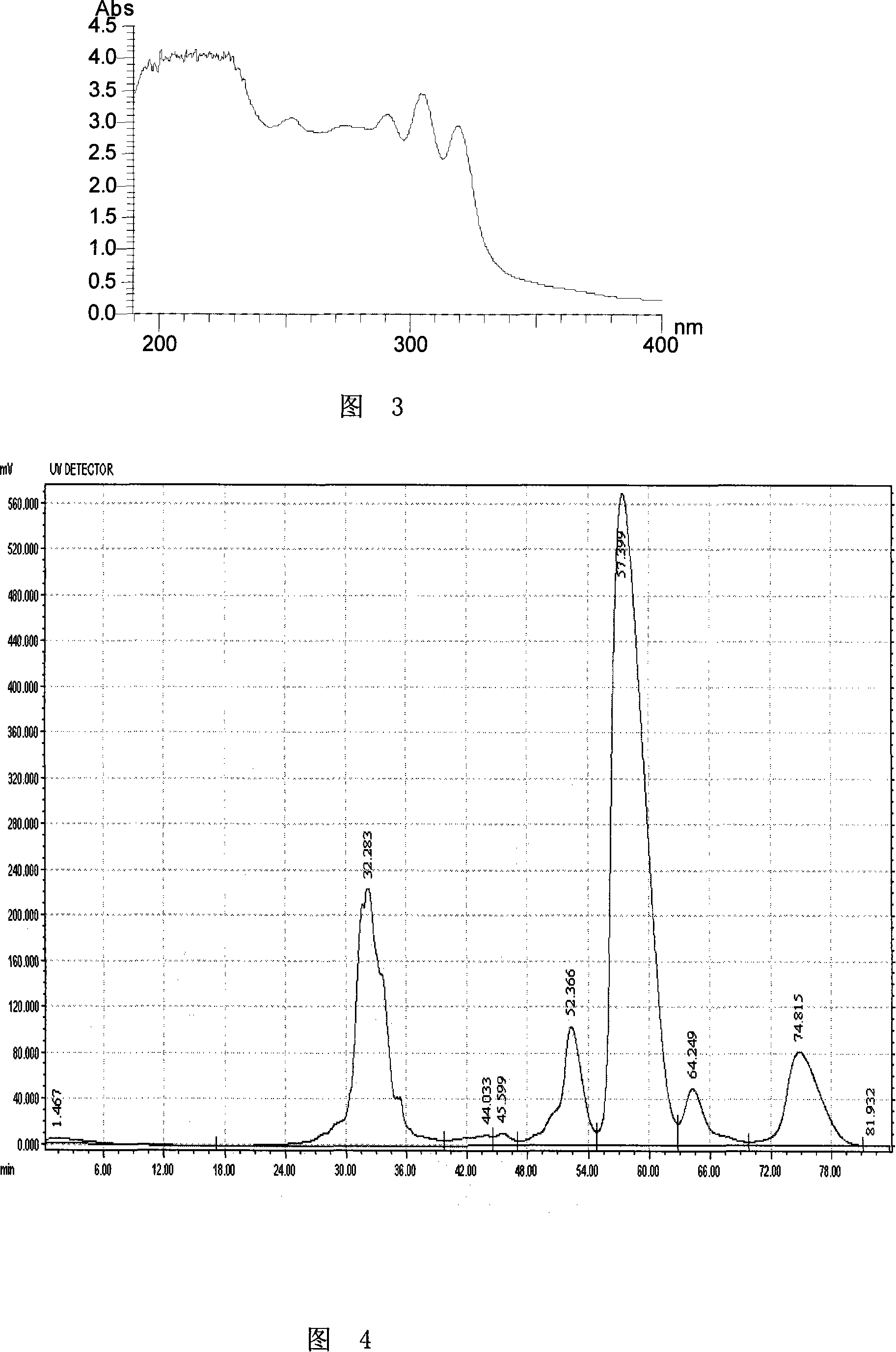

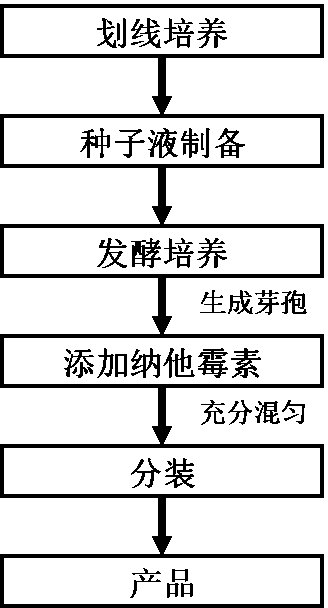

Streptomyces lydicus producing natamycin and uses thereof

The invention discloses a strain of Streptomyces lydidii and its application. The strain is Streptomyces lydicus A01 CGMCC No.1653. The bacterial strain can produce natamycin and will be widely used in the preparation of inhibitors of natamycin-sensitive bacteria.

Owner:中农绿康(北京)生物技术有限公司

Room-temperature litchi storage preservative, and preparation method and application of preservative

ActiveCN103564039ASimple and fast operationSuitable for assembly line productionFruit and vegetables preservationPesticide residuePhytic acid

The invention relates to the technical field of litchi preservation, and particularly discloses a room-temperature litchi storage preservative, and a preparation method and an application of the preservative. The preservative mainly comprises carboxymethyl-chitosan, nisin, natamycin, tea polyphenol, epsilon-polylysine, citric acid and phytic acid; litchi fruit is soaked in a preservation solution, and then aired, so that the litchi fruit can be stored at a room temperature; the quality and low level browning of the litchi fruit can be kept for a long time at the room temperature. Litchi treated by the preservative has the characteristics that the preservative is good in preservation effect, safe, environment-friendly, simple to operate and convenient to use; the preservative is extensive in source, low in cost, edible, and easy to degrade; no pesticide residue risk exists; short-term preservation during room-temperature storage and room-temperature logistics can be achieved; the preservative is a novel preservation material with a great development potential.

Owner:SOUTH CHINA AGRI UNIV

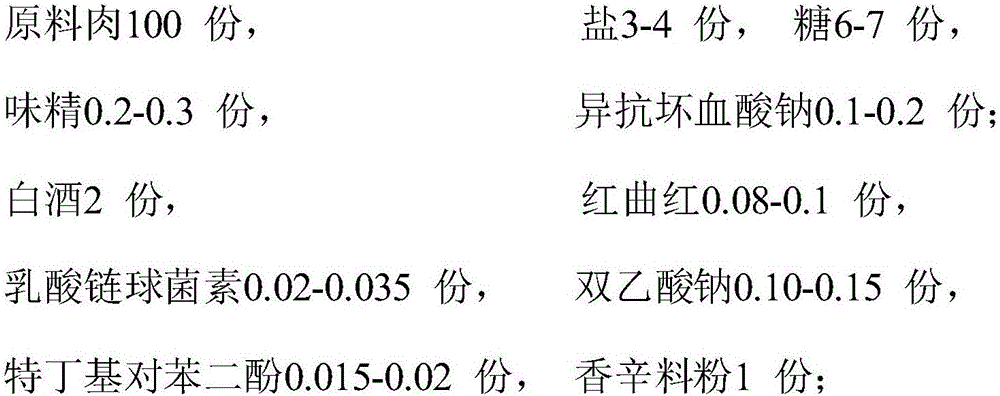

Nitrite-substituted meat processing method

InactiveCN106071907AGood effectGood muscle toneFood ingredient as antioxidantFood ingredient as taste affecting agentBetaninEthyl maltol

The invention discloses a nitrite-substituted meat processing method, and belongs to the technical field of food processing. The nitrite-substituted meat processing method comprises the following steps: selecting raw materials, carrying out pickling treatment and processing a meat product, so that the final products of the meat product are prepared; and the nitrite is substituted by a nitrite substitute during the step of carrying out pickling treatment. The nitrite substitute comprises the following components in parts by weight: 4-5 parts of monascorubin, 0.7-1.3 parts of betanin, 4-6 parts of potassium sorbate, 2-3 parts of D-sodium isoascorbate, 1.5-2.5 parts of nisin, 9-11 parts of sodium lactate, 1-2 parts of natamycin, 5-6 parts of natural vitamin E, 1-2 parts of a rosemary extract, 0.5-1.5 parts of sage essential oil, 1-2 parts of tea polyphenols, 15-16 parts of L-sodium glutamate, 0.5-1.5 parts of flavoring 5'-disodium ribonucleotide, 40-43 parts of a yeast extract, 4-5 parts of sodium tripolyphosphate and 0.5-1.5 parts of ethyl maltol. The nitrite-substituted meat processing method disclosed by the invention is simple, easy to operate and free of nitrite addition; and the prepared meat products are very good in qualities, color, luster and taste.

Owner:邯郸市锦园食品有限公司

Compound antistaling agent and fresh-keeping method of glutinous rice cake

InactiveCN101473991AGood fresh-keeping effectLight quality is beautiful and aesthetically pleasingClimate change adaptationFood preservationMicroorganismAcetic acid

The invention relates to a compound rice cake antistaling agent and a fresh keeping method. The compound antistaling agent comprises 0.03-0.1wt% of nisin, 0-0.1wt% of lysozyme, 0.03-0.1wt% of natamycin and a film forming agent; and the film forming agent comprises chitosan, acid and water, the specific proportions are 1-3wt% of the chitosan, 0.5-1wt% of the acid and the water, and a pH value of the film forming agent is controlled at 3.0-5.0, wherein, the acid is selected from lactic acid, citric acid or glacial acetic acid. The rice cake is soaked into 3-4 folds of the compound antistaling agent by volume for 1-5minutes, and then the rice cake is packaged in vacuum. The fresh keeping method can help better preserve the quality of the rice cake, inhibit external microbe invasion, sterilize the rice cake inside, and effectively solve the problem of relatively hard texture of the rice cake.

Owner:刘青梅 +1

Preparation method of R-polysaccharide fermentation liquor and preparation method of composite preservative of R-polysaccharide fermentation liquor

InactiveCN101974601ASimple processNo smellFood preservationMicroorganism based processesBiotechnologyCellulose

The invention discloses to a preparation method of R-polysaccharide fermentation liquor and a preparation method of a composite preservative of the R-polysaccharide fermentation liquor, relating to a preparation of fermentation liquor and a preparation method of a composite preservative of the fermentation liquor, which solves the problems of complex preparation technology of the traditional R-polysaccharide preparation, and high production cost and low yield of the preparation of a preservative of the traditional R-polysaccharide preparation. The preparation method of the R-polysaccharide fermentation liquor comprises the following steps of activating bacillus subtilis, streptococcus thermophilus and brewers' yeast; collecting and washing after being centrifuged; fermenting and cultivating the thalluses after mixing; and purifying the fermentation liquor. The preparation method of the preservative is as follows: mixing nisin, natamycin, propionic acid, antioxidant of bamboo-leaf, chitosan, ethylene diamine tetraacetic acid (EDTA), cellulose, ethanol, sorbitol and oxygen-enriched active water; and mixing the mixed liquor and the R-polysaccharide fermentation liquor to be reacted. The preparation of the R-polysaccharide fermentation liquor has the advantages of simple technology, no three-waste generation, no pollution discharge and no peculiar smell. The R-polysaccharide fermentation liquor is prepared into a composite preservative, the production cost is ** yuan / ton, and the yield is high.

Owner:王心礼

Nisin composite biological preservative and preparation method thereof

The invention discloses a Nisin composite biological preservative and a preparation method thereof. The preservative comprises the fermentation broth of lactic streptococci and components consisting of, on the basis of the weight of the fermentation broth of lactic streptococci, 0.2 to 0.6% of chitosan, 0.1 to 0.2% of antioxidant bamboo leaves, 1 to 5% of sodium hexametaphosphate, 0.5 to 1% of natamycin, 0.1 to 0.2% of garlicin, 0.05 to 0.1% of sodium ascorbate, 1 to 3% of maltodextrin and 0.5 to 2% of NaCl. The preservative provided by the invention does not contain any chemical preservative, overcomes the defects of a narrow antibacterial spectrum and low dependence on a pH value of pure Nisin, has the characteristics of high efficiency, a wide spectrum, good stability and high security, greatly improves the preservative effect and the application range of Nisin and produces high economic benefits and social benefits.

Owner:山东省蓝源生物工程有限公司

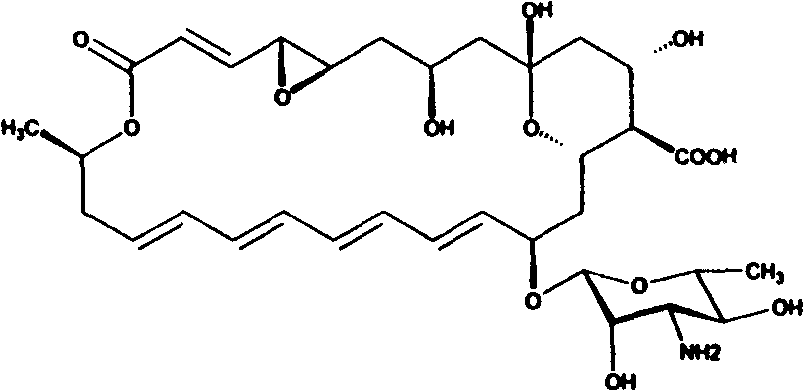

Stable aqueous solution of natamycin fungicide

The present invention provides an aqueous composition comprising—water; —a water miscible solvent; —and a polyene fungicide which is dissolved in the water and water miscible solvent. The present invention further provides a method for the production of the composition of the invention. The composition of the invention may be used as an antifungal treatment for a variety of products including food, feed, agricultural products, growth substrates and in- or outsides of buildings.

Owner:DSM IP ASSETS BV

Preparation method of natamycin

The preparation method of natamycin belongs to a technique for producing and extracting natamycin by using luteofuscus spore streptomycete as strain and adopting fermentation process. It includes the following steps: adopting luteofuscus spore streptomycete, preparing spore suspension liquor, culturing seed, making femrentation, extracting, controlling pH value and dissolved oxygen level, and adopting glucose-feeding mode in batches in the period of fermentation to prepare natamycin. In order to raise its yield, adopting low-temp. evaporation methanol-removing process to extract natamycin.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

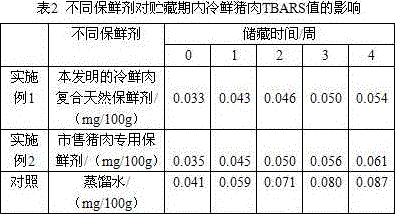

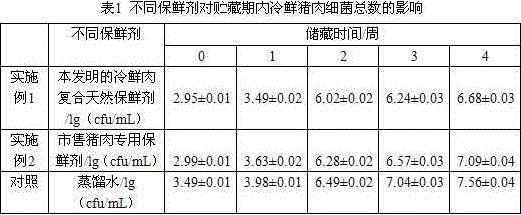

Composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent

InactiveCN106212635ABroad antibacterial spectrumRich sourcesMeat/fish preservation using chemicalsVitamin CNon toxicity

The invention relates to a composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent. The composite natural fresh-keeping agent for the cold fresh meat is characterized by comprising tea polyphenol, chitosan, nisin, natamycin, lysozyme, oregano essential oil, vitamin C, vitamin E, erythorbic acid, a spice extract and water in certain proportions by weight, wherein the spice extract is obtained by extracting ginger, garlic, cinnamon, cardamom, clove and rosemary in certain proportions by weight through ethanol extraction. The composite natural fresh-keeping agent for the cold fresh meat is prepared from biological-source raw materials by a simple preparation method, has the advantages of non-toxicity, safety, broad antibacterial spectrum and the like, is convenient to operate during using and prominent in fresh-keeping effect, and has an important industrial value.

Owner:宋晓燕

Antimicrobial Composition

ActiveUS20070264394A1Preserve safetyPreserve stabilityBiocideDough treatmentAdditive ingredientNisin

Owner:DSM IP ASSETS BV

Red bayberry preserving agent and method for energy saving transportation

InactiveCN1582684AImprove freshnessMeet the requirements of transportation to the whole countryFood processingFruits/vegetable preservation by freezing/coolingBiotechnologyYeast

An antistaling agent for red bayberry, peach, strawberry, etc contains components A for treating fungus and yeast and component B for treating anerobic bacteria. said component A is chosen from sorbic acid, sodium dehydroacetate, and natamycin. Said component B is chosen from Nisin and lysozyme. An energy-saving antistaling method for red bayberry indudes such steps as precooling fresh red bayberry to 0+ / -1 deg.C, freezing the ozone solution in plastic containers to obtain ozone ice, and storing the red bayberry along with said ozone ice.

Owner:ZHEJIANG WANLI UNIV

Method for increasing natamycin action efficiency

InactiveCN101491240AMaintain antibacterial activityGood water solubilityBiocideFood preservationSolubilityRoom temperature

The invention relates to a method for improving the natamycin action efficiency. The method comprises the following steps: taking cyclodextrin and derivatives as the supermolecule host compounds to prepare a natamycin / cyclodextrin supermolecule clathrate; and keeping the bacteriostatic activity of natamycin and improving the water solubility and stability of natamycin. The preparation method for the natamycin / cyclodextrin supermolecule clathrate comprises the following steps: preparing an aqueous solution of the cyclodextrin and the derivatives through ultra pure water to reach certain solubility; adding a certain amount of natamycin into the aqueous solution of the cyclodextrin and the derivatives, and carrying out ultrasonic treatment for 5 minutes to improve the complexation efficiency; and covering a layer of aluminum-foil paper on the container of the suspension, placing the container on a shaking table at a room temperature for reaction, and obtaining the homogenous solution of the natamycin / cyclodextrin supermolecule clathrate after reaching the balance. The method has the advantages of improving the solubility and stability of natamycin in the aqueous solution, improving the natamycin bioavailability, solving the problem of poor water solubility of natamycin, and improving the action efficiency of the biological bacteriocide natamycin.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

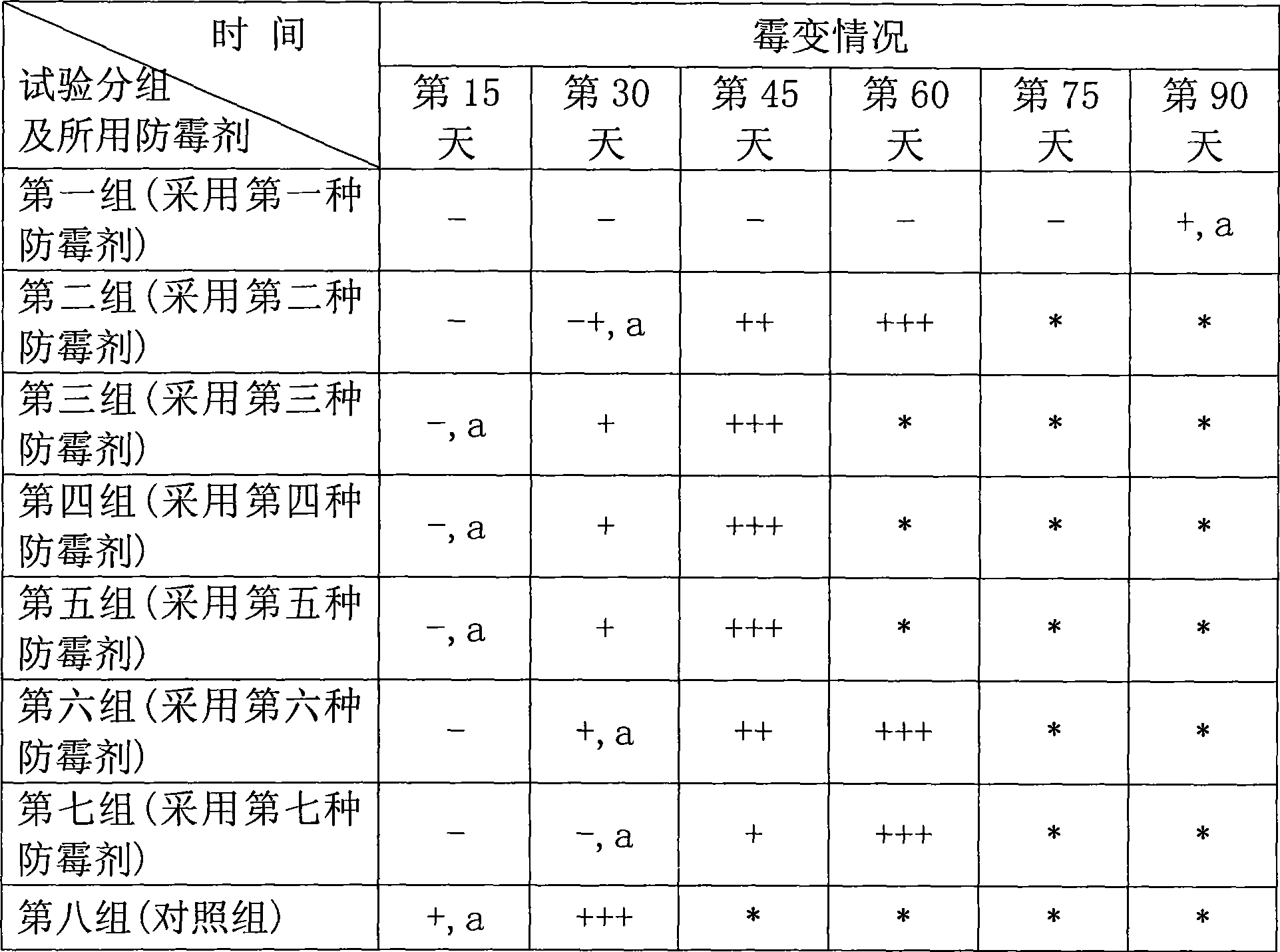

Preparing method for mildew inhibitor for feed

ActiveCN101543264AEasy to prepareEasy to operateFood preservationAnimal feeding stuffAcetic acidIrritation

The invention relates to a preparing method for mildew inhibitor for feed. The proportioning by weight of the mildew inhibitor for feed is 10-25 clove oil, 10-20 oil of chinese cinnamon, 5-15 natamycin, 5-15 acetic acid or ethylformic acid and 35-60 transporting species. The preparing method is throwing clove oil, oil of chinese cinnamon and acetic acid or ethylformic acid into the reactor by proportion, heating to 50-60degrees at the condition of mixing round, adding matching weight natamycin to total solubilization, mixing the above material and matching weighttransporting species in mixing machines, and then comminuting, siftting out, checking up and packaging after cooling down the above material. The product is more conform to environmental-protection with its less irritation and more security, and has good effect on mildew resistance, strong bacteriostatic effect and palatability as its principal raw material is clove oil and oil of chinese cinnamon with matching some natural bacteriostatics natamycin.

Owner:GUILIN WANKANG BIOCHEM

High-efficiency broad-spectrum food composite preservative

The invention provides a high-efficiency broad-spectrum food composite preservative and aims to solve the technical problem that most of the food preservatives now used in food processing are potassium sorbate and sodium benzoate, cannot achieve ideal preservation effect when use alone due to certain limitation to antibacterial spectrum and suffers certain limitation on use. The key point of the preservative lies in that the preservative contains nisin, natamycin, potassium sorbate, sodium diacetate and sodium dehydroacetate or also one or all of d-sodium erythorbate and d-glucono-delta-lactone. The use of the preservative is to be added in various foods.

Owner:SHENYANG HONGMEI BIOTECH

Bakery product which is protected against spoilage and process for preventing mould spoilage of bakery products

InactiveUS20060165857A1Equally distributedEffective amountPreservation by coatingBakery productsViscosityChemistry

The present invention relates to a bakery product, which is protected by natamycin against spoilage, as well as to a process for preventing mould spoilage of bakery products. The viscosity of the natamycin suspension is increased by a thickener before it is sprayed onto the bakery product. The thickener ensures that the natamycin is evenly distributed on the surface of the bakery product.

Owner:AS DE DANSKE SUKKERFABRIKKER

A kind of natural food preservative of light bamboo leaf extract and preparation method thereof

The invention discloses a common lophatherum herb extract natural food preservative and a preparation method thereof, belonging to the technical field of food preservatives. The preservative is formed by mixing the following raw materials: a common lophatherum herb extract, streptococcus lactis peptide, natamycin and chitosan, wherein the common lophatherum herb extract is prepared by drying common lophatherum herb extraction solution; and the preparation method comprises the following steps: cleaning and crushing bamboo leaves of common lophatherum herb; soaking in sodium hydroxide solution;regulating the pH value; hydrolyzing; extracting; filtering; concentrating; drying; and mixing for getting the natural food preservative which takes the common lophatherum herb extract as a main raw material. The preservative is completely produced from natural ingredients, has no toxicity or side effects, is further wide in a antimicrobial spectrum and can be widely applied in the preservatives in a variety of food fields, and the invention further provides the preparation method of the preservative.

Owner:四川高金翔达食品有限公司

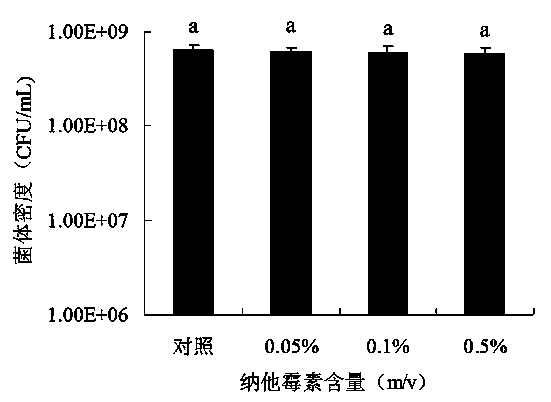

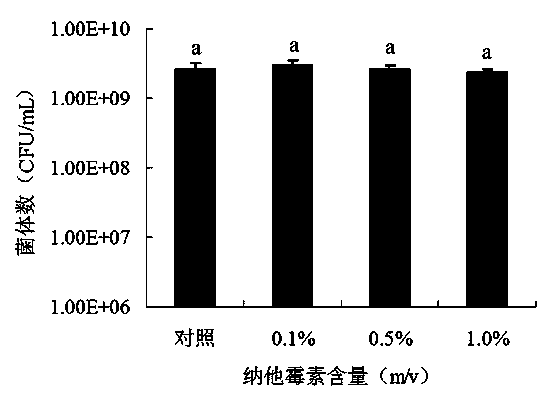

Compound biological preservative and application method thereof

ActiveCN103621621AHigh viable countHigh spore survival rateFruit and vegetables preservationBacteriaAntibiotic YPlant disease

The invention discloses a compound biological preservative. The compound biological preservative comprises the components as follows: 0.1-5 g of component B is added in each 1L of component A, the component A is fermentation liquor of Bacillusamyloliquefacienssubsp.plantarum BGP20 strains, and the component B is natamycin. The compound biological preservative is used for preventing and controlling diseases of fruits and vegetables in a storage period and particularly can be used for simultaneously preventing and treating bacterial soft rot and various fungal diseases (for example, phytophthora capsici, rhizopus soft rot, pythium blight and the like) of fruits and vegetables in the storage period, avoiding or reducing residual chemical pesticides and agricultural antibiotics and maintaining the quality of the fruits and vegetables in the storage period, so that the compound biological preservative has good economic and social benefits.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Making method of hand tear bread

InactiveCN105901059AEasy to manufactureExtended shelf lifeFood preservationBakery productsFood materialFermentation

The invention discloses a making method of hand tear bread. The method comprises the following steps that 1, 100 parts of high gluten flour, 20-27 parts of low gluten flour, 60-70 parts of butter, 18-25 parts of granulated sugar, 1-2.5 parts of salt, 2-3 parts of yeast, 10-15 parts of eggs and 65-80 parts of milk are weighed and prepared; 2, all the food materials except the butter are poured into a stirrer for stirring, and dough is formed; 3, the dough is subjected to flattening and put into a refrigerator for refrigeration; 4, the butter is wrapped by the dough subjected to refrigeration, and the dough is folded multiple times; 5, the treated dough is put into the refrigerator for refrigeration; 6, the dough subjected to refrigeration is folded multiple times and then compacted; 7, shaping treatment is conducted on the dough; 8, the dough subjected to shaping is put at room temperature for fermentation; 9, natamycin is sprayed on the surface of the dough; 10, the dough is put into an oven finally. The hand tear bread made through the method is soft and delicious, making is easy and convenient, and the refreshing time of the hand tear bread is long.

Owner:欧福泉

Method for preparing nonsolvent of high-purity natamycin

ActiveCN102040638AQuality improvementHigh claritySugar derivativesSugar derivatives preparationFermentationCrystallization

The invention discloses a method for preparing natamycin by using natamycin fermentation liquor. The crystals of natamycin can be obtained by extracting, decoloring, absorbing, crystallizing and the like in the presence of a filter aid. The method has the advantages of environment-friendly preparation process and the obtainment of high-purity natamycin.

Owner:NCPC NEW DRUG RES & DEV

Artificial feed of rice leaf folder and preparation method of artificial feed

InactiveCN102907577AGood anti-mildew effectNo growthAnimal feeding stuffAccessory food factorsBiotechnologyPhospholipid

The invention relates to an artificial feed of a rice leaf folder and a preparation method of the artificial feed. The artificial feed belongs to the technical field of insect raising. The formula is prepared from the following components of water, rice leaf powder, wheat germ powder, corn meal, soybean meal, casein, granulated sugar, agar, yeast, mildew inhibitor, antioxidant, insect feed oil, antibiotic, choline chloride, wade-salt, cholesterol and vitamine. The mildew inhibitor used in the formula is composed of 2-3 of natamycin, sorbic acid, nipagin, tebuconazole and azoxystrobin; the antioxidant is mixture of ascorbic acid and phospholipid; the insect feed oil is the mixture of linseed oil, rice bran oil and germ oil, and the antibiotic may be streptomycin or chloramphenicol or aureomycin. Survival rates of larvas can be obviously improved by raising the rice leaf folder by the feed in the formula, and a foundation is created for an indoor research of the rice leaf folder.

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation method of duck feet with pickled chili

InactiveCN103315317ANutritional balanceShorten the production cycleFood preparationMonosodium glutamateNutritive values

The invention discloses a preparation method of duck feet with pickled chili. The method comprises the following components: 50% of duck feet, 20% of wild rod chili, 0.3% of lactic acid, 1.57% of spice, 12% of monosodium glutamate, 0.5% of calcium chloride, 0.6% of white spirit, 0.23% of water-soluble chili extract, 0.2% of duck paste, 8.44% of a seasoning; 0.15g / kg of epsilon-polylysine, 0.4g / kg of Nisin, and 0.3g / kg of natamycin. The invention aims at solving existing pickled chili duck feet quality problems caused by poor taste and short shelf life. Through the improvement upon the formula, the pickled chili duck feet are tasty, appetizing, fragrant, and crispy. With a biological preservative and with an ultrahigh-pressure sterilization technology, natural flavor and nutritive values of pickled chili duck feet can be sufficiently maintained. Finally, convenient, nutritional, and safe product with short production period can be obtained. The product is important for healthy body and for the fast-pace modern life.

Owner:SICHUAN AGRI UNIV

Compound biological preservative, preparation method thereof and application thereof

InactiveCN101606745AAdd lessImprove anti-corrosion performanceFood preservationEscherichia coliSodium phosphates

The invention relates to a compound biological preservative, a preparation method thereof and an application thereof. Each 100g of compound biological preservative comprises 20 to 80g of epsilon-polylysine, 1 to 30g of nisin, 1 to 20g of natamycin, 1 to 20g of nipagin ester, 1 to 10g of sodium propionate, 0.01 to 0.5g of ascorbic acid, 5 to 20g of malic acid and 0.1 to 1g of trimeric sodium phosphate. The compound biological preservative is used in Guang type seasoned sausage products, and the addition amount is 5 to 15g per 50 kg. The compound biological preservative prepared mainly from the epsilon-polylysine can effectively reduce the use amount of salt and white granulated sugar in Guang type seasoned sausages, and has the characteristics of low toxicity, high efficiency and less addition amount. With the advantages of wide antimicrobial spectrum and high bacteriostasis, the compound biological preservative has favorable effect for inhibiting Gram-negative escherichia coli and salmonella which are not easy to inhibit by other natural preservative, and also has inhibiting effect on heat-resist bacillus and some viruses.

Owner:GUANGDONG INST OF MICROORGANISM +1

Cation adhesion type natamycin nano eye drops

ActiveCN101385703AImprove solubilityIncrease corneal resorptionOrganic active ingredientsSenses disorderSolubilityPhospholipid

A cationic adhesive-type natamycin nanometer eye drop comprises natamycin, a proper amount of osmoregulator and pH regulator. The eye drop is characterized by further comprising chitosan, pluronic F-68 and phospholipid, wherein, the mass percent concentration of the phospholipid in the eye drop is 0.01-2%, the mass percent concentration of the pluronic F-68 in the eye drop is 0.1-20%, and the mass percent concentration of the chitosan in the eye drop is 0.01-4%. The molecular weight of the chitosan is 5000-300000, and the deacetylation degree of the chitosan is greater than 85%. The natamycin nanometer eye drop is characterized by making a common natamycin suspension into suspension particles with the diameter ranging from 10nm to 1000nm, thus increasing solubility of the eye drop and enhancing safety and effectiveness. The natamycin particles of the common suspension are modified by the phospholipid and the chitosan to cause the particles to be positively charged, which is helpful to improve absorption of the eye drop by cornea, enhances drug effect and prolongs the action time of the eye drop. And the chitosan has bioadhesion function, which enhances the adhesiveness between medicinal particles and the cornea.

Owner:SHANDONG EYE INST

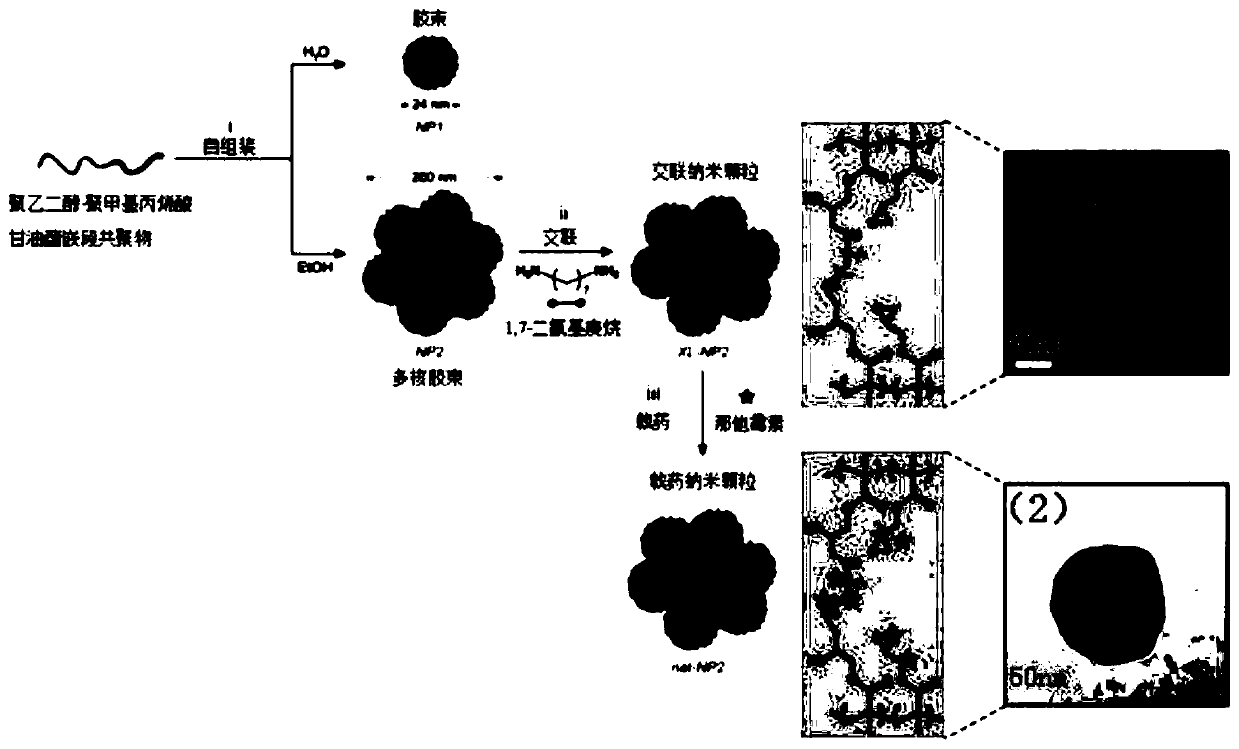

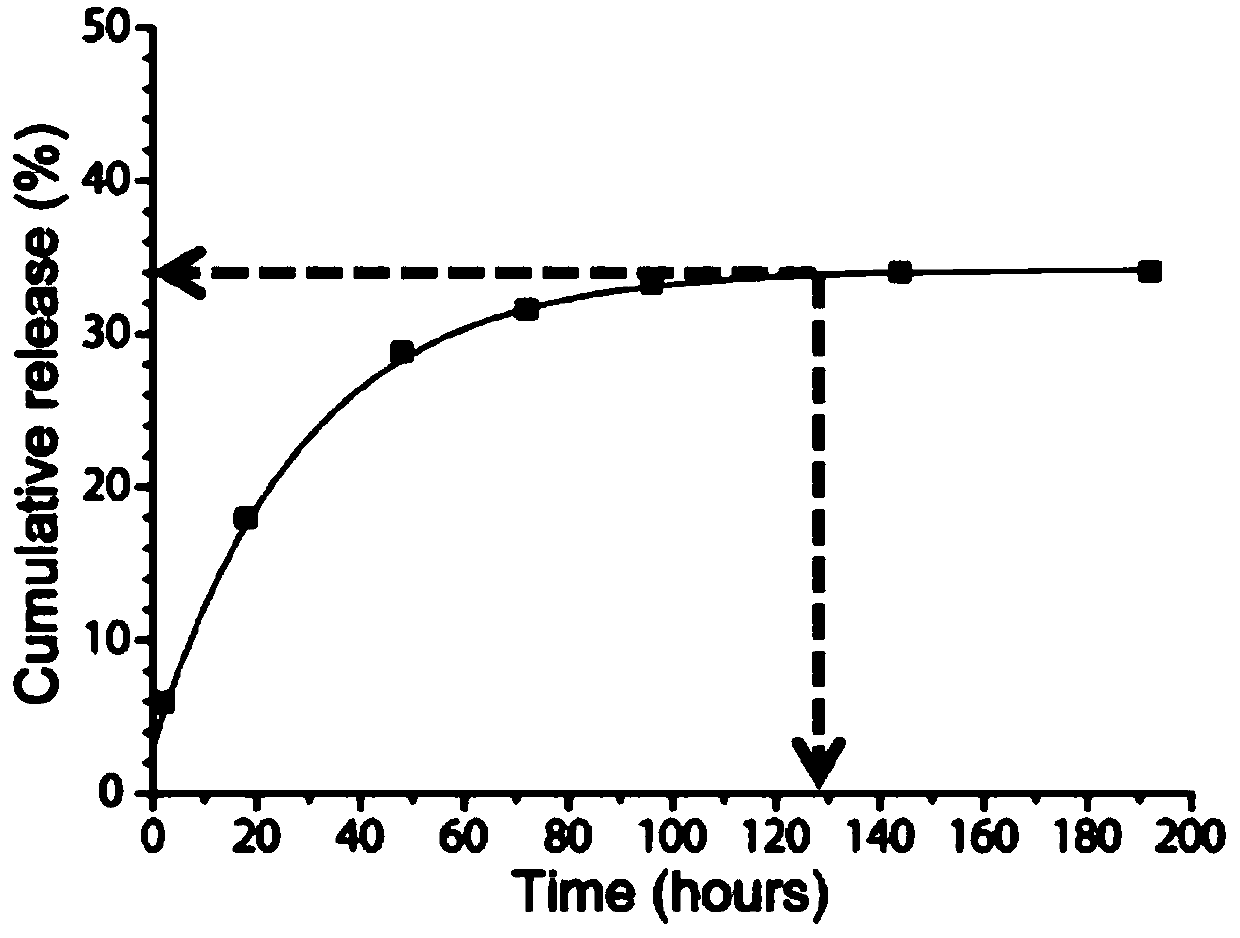

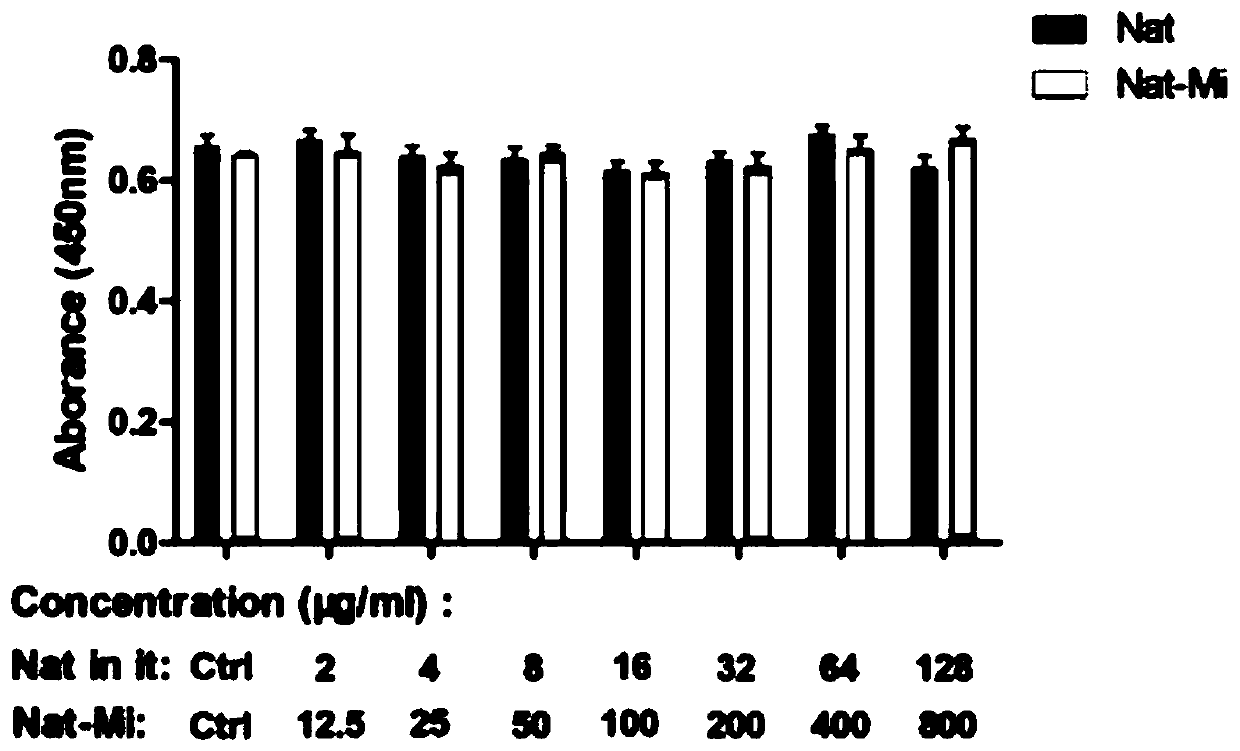

Natamycin polymer micelle eye drop and preparation method thereof

ActiveCN110664752AExtended release timeAddressing poor adherenceOrganic active ingredientsSenses disorderMycotic keratitisPolythylene glycol

The invention relates to a natamycin polymer micelle eye drop and a preparation method thereof, belongs to the technical field of ophthalmic disease treatment and aims to solve the problem that a conventional natamycin eye drop is too high in use frequency. The invention provides the natamycin polymer micelle eye drop which comprises a natamycin polymer micelle and a phosphate buffer in a certainmass volume ratio, wherein the natamycin polymer micelle comprises 10-30% in mass percentage of natamycin and the balance of a polyethylene glycol-polymethylacrylic acid glyceride block copolymer. Thepolyethylene glycol-polymethylacrylic acid glyceride block copolymer is put into ethanol to form a cross-linking micelle through self assembling, and the natamycin is coated by the micelle to preparethe natamycin polymer micelle eye drop, so that the release time of the natamycin can be prolonged, the medicine use times can be reduced, the problem that the patient compliance is poor because of frequent medicine use can be solved, the eye drop has excellent properties of high medicine carrying, slow release, safety, non-toxicity, and the like, and mycotic keratitis can be treated with eye dropping of low frequency.

Owner:哈尔滨医科大学科技开发总公司 +1

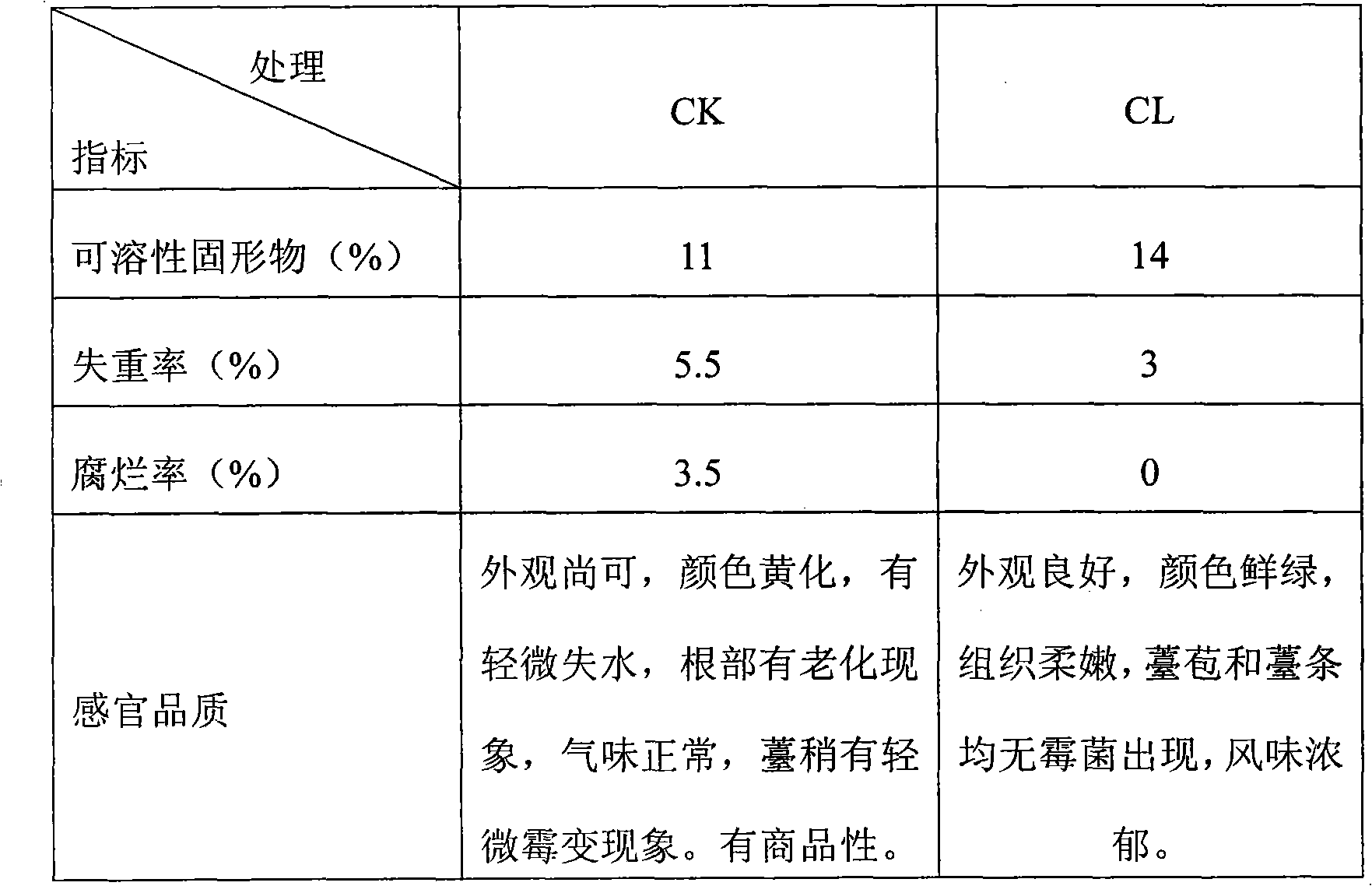

High-efficiency mould-proof preservative special for preserving garlic stems

InactiveCN101965864AGood antibacterial effectImprove anti-corrosion performanceFruit and vegetables preservationPreservativeModified atmosphere

The invention discloses a high-efficiency mould-proof preservative special for preserving garlic stems, which consists of the following components in percentage by weight: 1 to 5 percent of chitosan, 0.05 to 0.1 percent of nipagin ester, 0.001 to 0.01 percent of natamycin, 0.05 to 0.1 percent of thiabendazole and the balance of water. The garlic stem preservative has low cost and is convenient to apply and high-efficiency and safe; by combining measures and technology such as low temperature, spontaneous modified atmosphere packaging and the like, the garlic stems treated by the preservative are bright green, have tender tissues and are still fresh after being stored for 6 to 8 months, and mould does not grow in garlic involucre and strips; the commodity rate reaches 95 percent; and the preservation effect is good.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

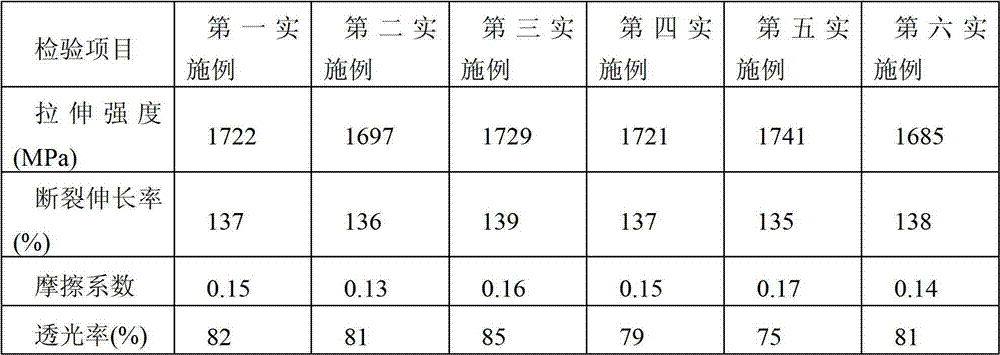

Environment friendly biological preservative film and preparation method thereof

ActiveCN102827464AHigh strengthReduce manufacturing costFlexible coversWrappersFiberFrictional coefficient

The invention discloses an environment friendly biological preservative film. The environment friendly biological preservative film comprises polylactic acid, straw fiber, glycerol, polydiphenylmethane diisocyanate, lactic streptococci peptide, dichloromethane and natamycin. The preparation method comprises the steps of: preparing a synthetic fabric component by using straw fiber, oat fiber, glycerol, distilled water and polydiphenylmethane diisocyanate; preparing an antibacterial preservative by polylactic acid, dichloromethane, lactic streptococci peptide and natamycin; then mixing the synthetic fabric component with particles of polylactic acid, carrying out melt extrusion, blow molding and cooling to prepare a biological film; and uniformly coating the antibacterial preservative. With the adoption of the biological preservative film provided by the invention, high strength of the thin film can be maintained while the production cost of the polylactic acid thin film is greatly reduced, so that the tensile strength, the elongation at break, the frictional coefficient and the light transmittance of the environment friendly biological preservative film meet the national state, and the environment friendly biological preservative film further has good antibacterial preservative performance of food package.

Owner:TIANJIN SHENGTIANLI MATERIAL TECH

Method for preparing biogenic biphase coating anti-staling agent for pickle stem tuber raw materials

InactiveCN102405965ADoes not affect flavorGood fresh-keeping effectFruits/vegetable preservation by coatingPropolisFermentation

The invention discloses a method for preparing a biogenic biphase coating anti-staling agent for pickle stem tuber raw materials. The method comprises the following steps of: preparing an ethanol-water solution, regulating the pH value to be 6.1-6.6, and adding chitosan, propolis and porous starch into the ethanol-water solution based on the mass of the ethanol-water solution; adding natamycin, nisin and poly-L-lysine; and stirring by using an electric stirrer at constant temperature for 1 to 2 hours at a stirring rate of 900r / min, adding cinnamon oil, clove oil and rosemary oil, adding 1.0 to 3.0 percent of Tween-80 emulsifier, stirring by using the electric stirrer for 1 to 2 hours at a stirring rate of 1,200r / min to make the mixed oil uniformly dispersed, and homogenizing at a rate of 1.6*10<4>-2.0*10<4>r / min for 30 minutes to obtain the coating anti-staling agent. Product pollution because mixed bacteria are attached to the raw materials in the fermentation process is avoided, themature periods of pickle products are consistent, and product quality is stable.

Owner:XIHUA UNIV +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com