Environment friendly biological preservative film and preparation method thereof

A bio-preservation and environmental-friendly technology, applied in bio-packaging, food preservation, food science, etc., can solve the problems of weak marketization and high cost, and achieve good antibacterial and fresh-keeping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

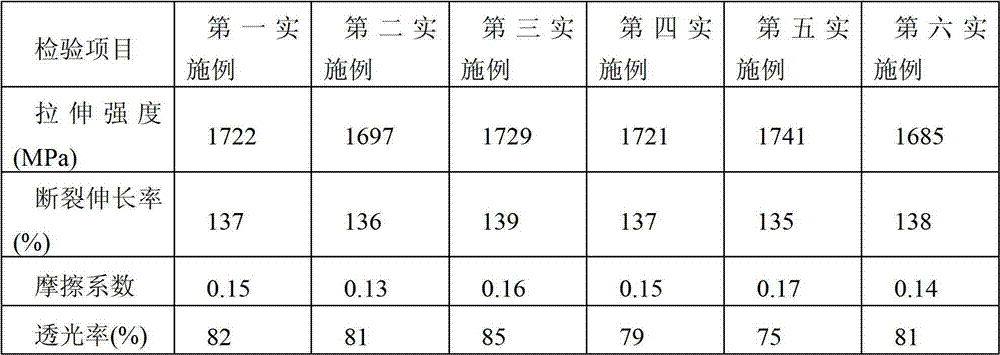

Examples

no. 1 example

[0026] A kind of environmental protection biological preservative film, is made of the raw material of following mass parts,

[0027] Average molecular weight is 100 parts of polylactic acid of 148kDa;

[0028] Straw fiber 5 parts;

[0029] 1 part of glycerin;

[0030] 1 part of polydiphenylmethane diisocyanate;

[0031] Nisin 1 part;

[0032] 10 parts of dichloromethane;

[0033] Natamycin 1 part.

[0034] Firstly, the straw fiber, glycerin and polydiphenylmethane diisocyanate were fully mixed and homogenized at room temperature for 1 hour, and left for 24 hours to prepare a mixed fiber component; then 2 parts by mass of polylactic acid, dichloromethane, lactic acid Streptin and natamycin were mixed evenly and stirred for 50 minutes to prepare an antibacterial preservative; 98 parts by mass of polylactic acid particles were mixed with 50 parts by mass of mixed fiber components, and the diameter of the screw rod was 18mm, and the length-to-diameter ratio of the screw rod ...

no. 2 example

[0036] A kind of environmental protection biological preservative film, is made of the raw material of following mass parts,

[0037] Average molecular weight is 100 parts of polylactic acid of 148kDa;

[0038] 4 parts straw fiber;

[0039] 1.5 parts of glycerin;

[0040] 0.8 part of polydiphenylmethane diisocyanate;

[0041] Nisin 0.8 part;

[0042] 15 parts of dichloromethane;

[0043] Natamycin 1.2 parts.

[0044] Its specific manufacturing steps are the same as those of the first embodiment, and will not be repeated here.

no. 3 example

[0046] A kind of environmental protection biological preservative film, is made of the raw material of following mass parts,

[0047] Average molecular weight is 100 parts of polylactic acid of 148kDa;

[0048] 3 parts straw fiber;

[0049] 2 parts of glycerin;

[0050] 0.5 part of polydiphenylmethane diisocyanate;

[0051] Nisin 0.5 part;

[0052] 20 parts of dichloromethane;

[0053] Natamycin 1.5 parts.

[0054] Its specific manufacturing steps are the same as those of the first embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com