Method for preparing nonsolvent of high-purity natamycin

A technology of natamycin and filter aid, which is applied in the field of green and environmentally friendly preparation, to achieve high sample yield, shorten the process cycle, and reduce the effect of pigment ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

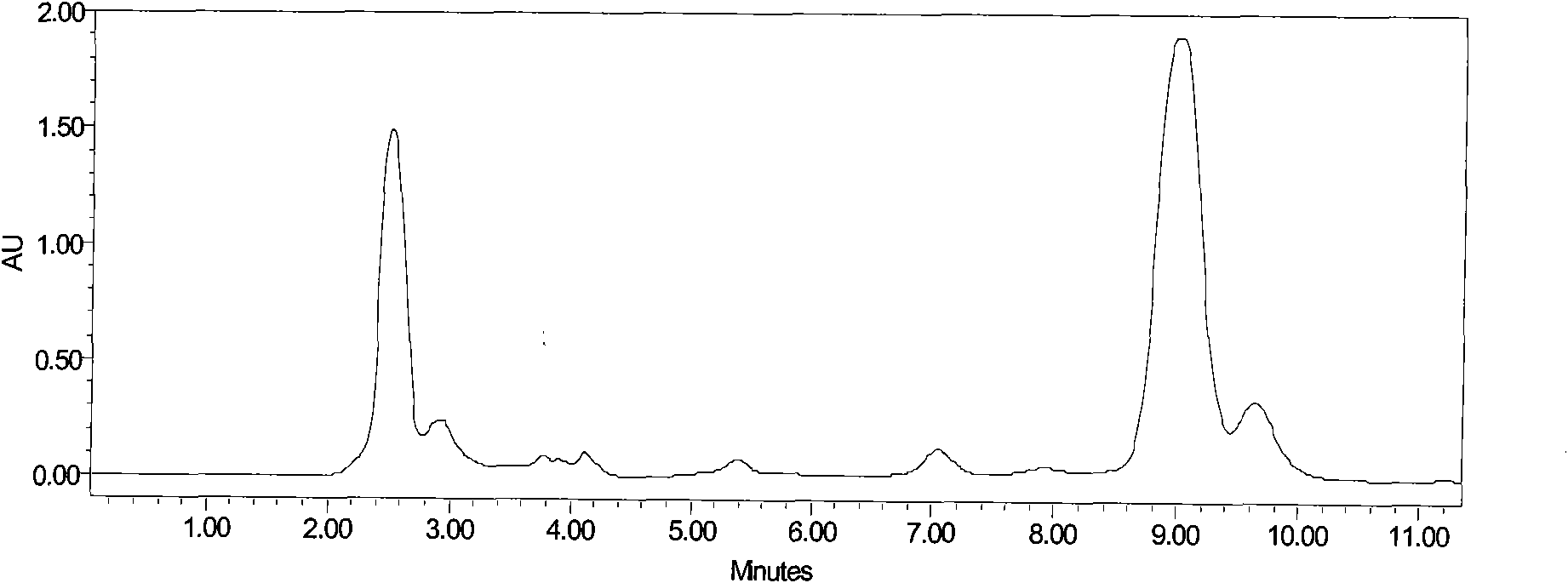

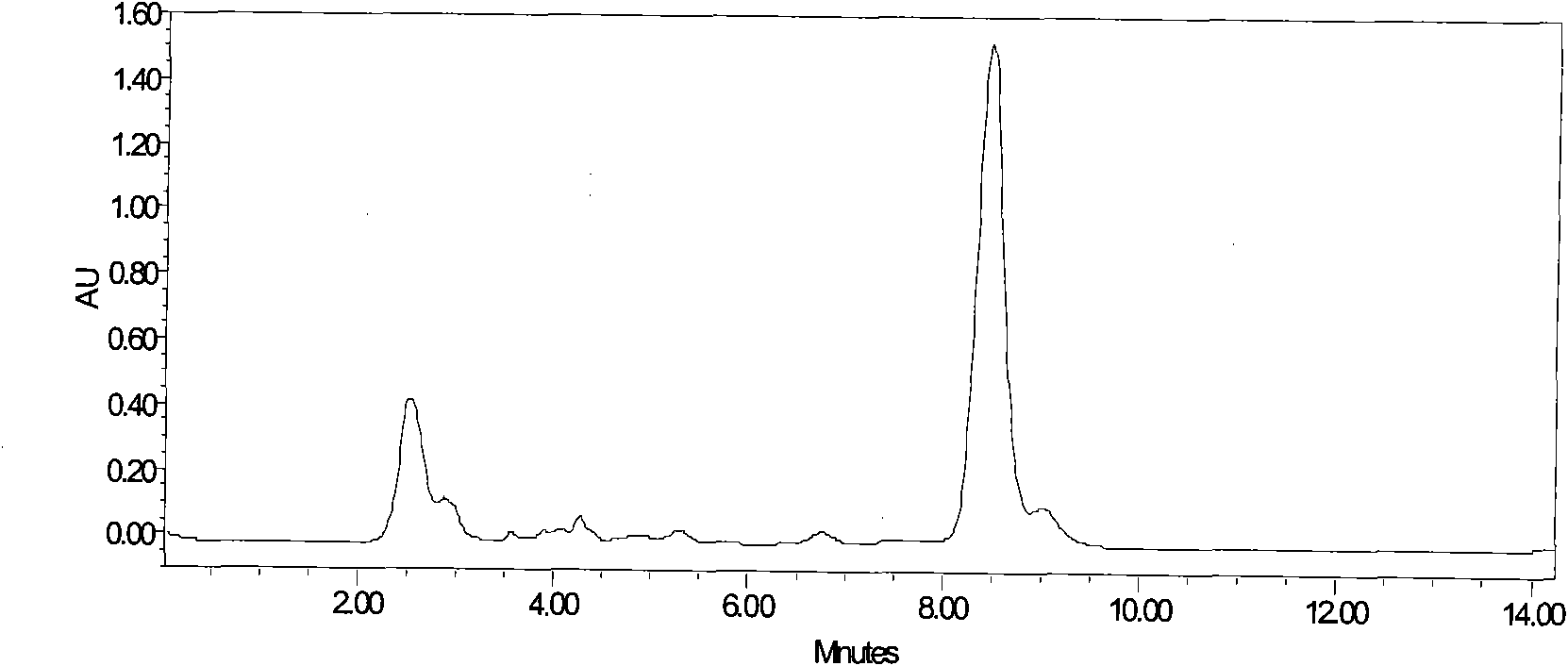

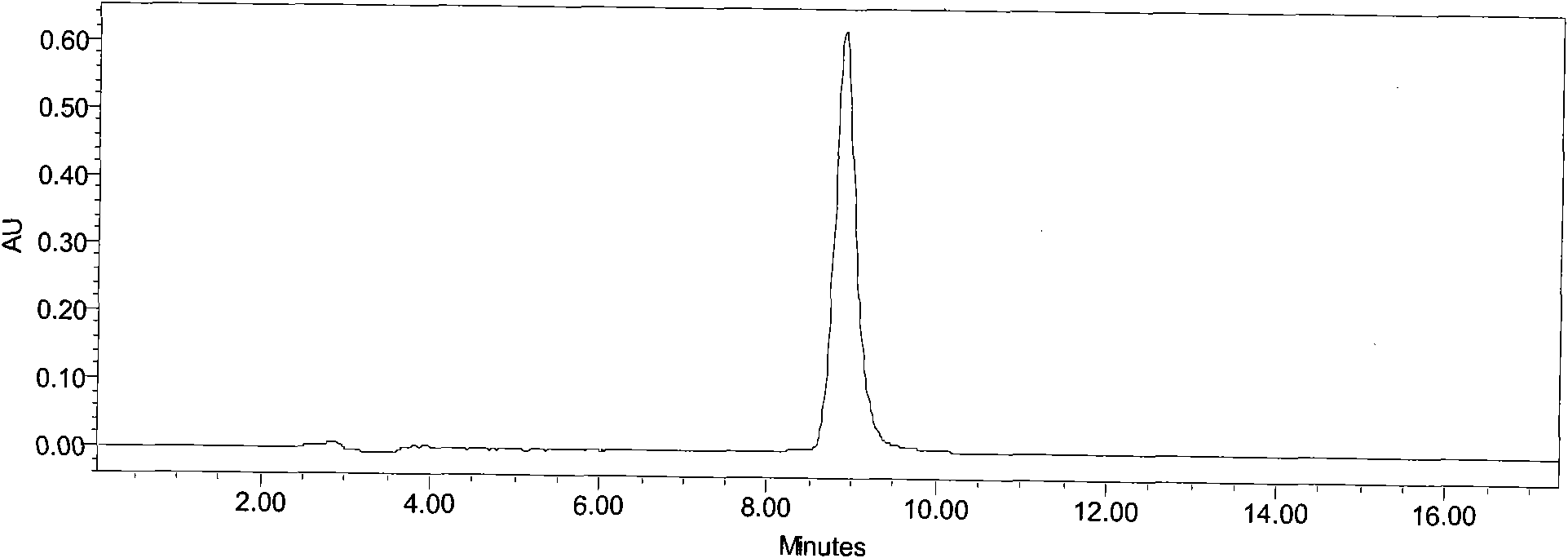

[0040] Take 10.0L of natamycin fermentation liquid, and the fermentation unit is 5.2g / L. In the fermentation broth (see attached figure 1 ) was added 500g of perlite, stirred for 30 minutes and then vacuum-filtered to obtain 2.08kg of mycelium. Add 8 L of alkaline water with NaOH to adjust the pH value to 11.5 in the mycelia, keep the temperature at 20°C and stir for 1 hour, then vacuum filter and collect the filtrate (see attached figure 1 ). The filtrate was decolorized through a resin column with a height of 50 cm, a diameter of 10 cm, and a loading capacity of 500 ml of D290 resin at a flow rate of 1000 mL / h. Collect the decolorization solution (see attached figure 2 ), importing high 50cm, diameter is the D312 resin column adsorption of 10cm, and D312 resin loading capacity is 500ml, and saturated resin is washed and purified with water, and then the ethanol-alkaline aqueous solution that is 80% mass percentage concentration with pH value to be 11.0 is analyzed, analy...

Embodiment 2

[0042] Get natamycin fermentation liquid 100L, fermentation unit 6.7g / L. 6 kg of diatomaceous earth was added to the fermented liquid, stirred for 40 minutes and then vacuum-filtered to obtain 22.6 kg of mycelium. Add 65 L of alkaline water with ammonia water to adjust the pH value to 11.0 into the mycelia, keep the temperature at 15° C. and stir for 1 hour, then plate and frame press filter, and collect the filtrate. The filtrate is decolorized through a resin column with a height of 1.2m, a diameter of 12cm, and a D303 resin loading capacity of 4000mL, and the decolorization flow rate is 6L / h. The decolorizing solution is introduced into a HZ816 resin column with a height of 1.2m, a diameter of 12cm, and a resin loading capacity of 4000mL for adsorption. The saturated resin is washed and purified with water, and then analyzed with a 70% ethanol-alkaline aqueous solution with a pH value of 11.5 and a mass percentage concentration of 11.5. The analytical flow rate is 3L / h. C...

Embodiment 3

[0044] Get 1000L of natamycin fermented liquid, the fermentation unit is 7.3g / L. 45 kg of diatomaceous earth was added to the fermented liquid, stirred for 50 minutes and then vacuum-filtered to obtain 172 kg of mycelia. Add 700L of alkaline water with KOH to adjust the pH value to 11.5 into the mycelium, keep the temperature at 20°C and stir for 1 hour, then plate and frame filter, and collect the filtrate. The filtrate is decolorized through a resin column with a height of 2.4m, a diameter of 50cm, and a loading capacity of 50L of D290 resin at a flow rate of 80L / h. Collect the decolorizing solution, introduce it into a resin column with a height of 2.4m and a diameter of 50cm for adsorption, the HZ818 resin loading capacity is 50L, and the saturated resin is washed and purified with water, and then the pH value is 11.0 and the mass percentage concentration is 90% ethanol-alkali aqueous solution. Analytical, the analytical flow rate is 40L / h. Adjust the pH value to 6.0-6.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com