Nitrite-substituted meat processing method

A technology for nitrite and meat processing, which is applied in the field of meat processing to replace nitrite, can solve problems such as hidden dangers of food safety, and achieve the effects of enhancing fresh taste, obvious effect, and tenderizing meat quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

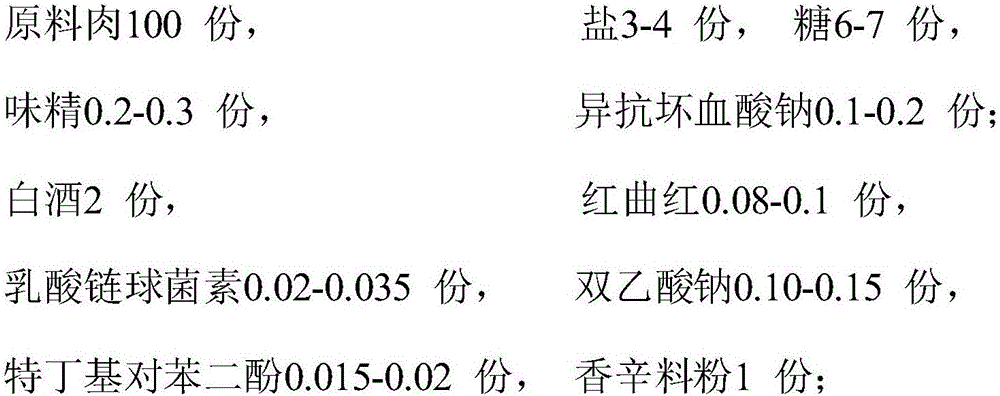

Method used

Image

Examples

Embodiment 1

[0050] Nitrite substitutes are in parts by weight, including 4 parts of Monascus Red, 0.7 parts of Beetroot Red, 4 parts of Potassium Sorbate, 2 parts of D-Sodium Erythorbate, 1.5 parts of Nisin, 9 parts of Sodium Lactate, Nata 1 part of mycin, 5 parts of natural vitamin E, 1 part of rosemary extract, 0.5 parts of sage essential oil, 1 part of tea polyphenols, 15 parts of L-sodium glutamate, 5'-taste nucleotide disodium 0.5 parts, yeast extract 40 parts, sodium tripolyphosphate 4 parts, ethyl maltol 0.5 parts.

Embodiment 2

[0052] The nitrite substitutes are in parts by weight, including 5 parts of Monascus Red, 1.3 parts of Beetroot Red, 6 parts of Potassium Sorbate, 3 parts of D-Sodium Erythorbate, 2.5 parts of Nisin, 11 parts of Sodium Lactate, Nata 2 parts of mycin, 6 parts of natural vitamin E, 2 parts of rosemary extract, 1.5 parts of sage essential oil, 2 parts of tea polyphenols, 16 parts of L-sodium glutamate, disodium 5′-flavored nucleotide 1.5 parts, yeast extract 43 parts, sodium tripolyphosphate 5 parts, ethyl maltol 1.5 parts.

Embodiment 3

[0054] The nitrite substitutes are in parts by weight, including 4.5 parts of Monascus Red, 0.9 parts of Beetroot Red, 5 parts of Potassium Sorbate, 2.5 parts of D-Sodium Erythorbate, 2 parts of Nisin, 10 parts of Sodium Lactate, Nata 1.5 parts of mycin, 5.5 parts of natural vitamin E, 1.5 parts of rosemary extract, 1 part of sage essential oil, 1.5 parts of tea polyphenols, 15.5 parts of L-sodium glutamate, 5'-flavored nucleotides 1 part of disodium, 41 parts of yeast extract, 4.5 parts of sodium tripolyphosphate, 1 part of ethyl maltol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com