Patents

Literature

1334 results about "Corn meal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corn meal is made by grinding corn kernels into a coarse powder. Unlike flour made from wheat grains, corn meal does not contain gluten, so it makes for a safe cooking ingredient for those suffering from celiac disease or gluten intolerance, according to Colorado State University.

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

Low carbohydrate direct expanded snack and method for making

A method for making a low carbohydrate high protein puffed snack food product. Ingredients comprising soy isolate, soy concentrate, corn meal, and water are introduced into an extrudate. The ingredients are extruded through a die orifice at a high specific mechanical energy. The ingredient formula ranges have been determined that maximize volumetric expansion and the set operating conditions and keep texture, color, and flavor acceptable. The puffed snack is then dried and seasoned. There are minimal off-flavors in the product.

Owner:FRITO LAY NORTH AMERICA INC

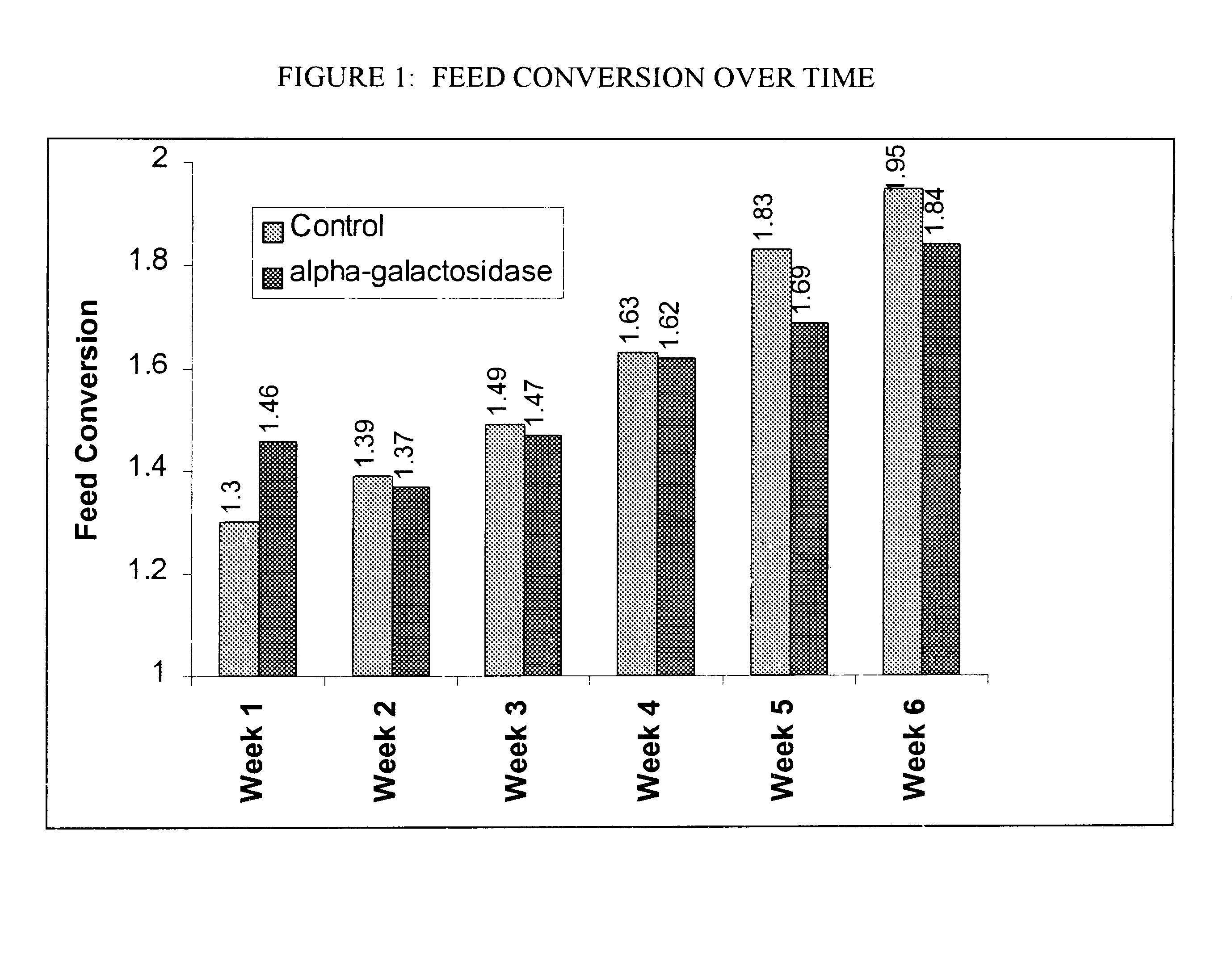

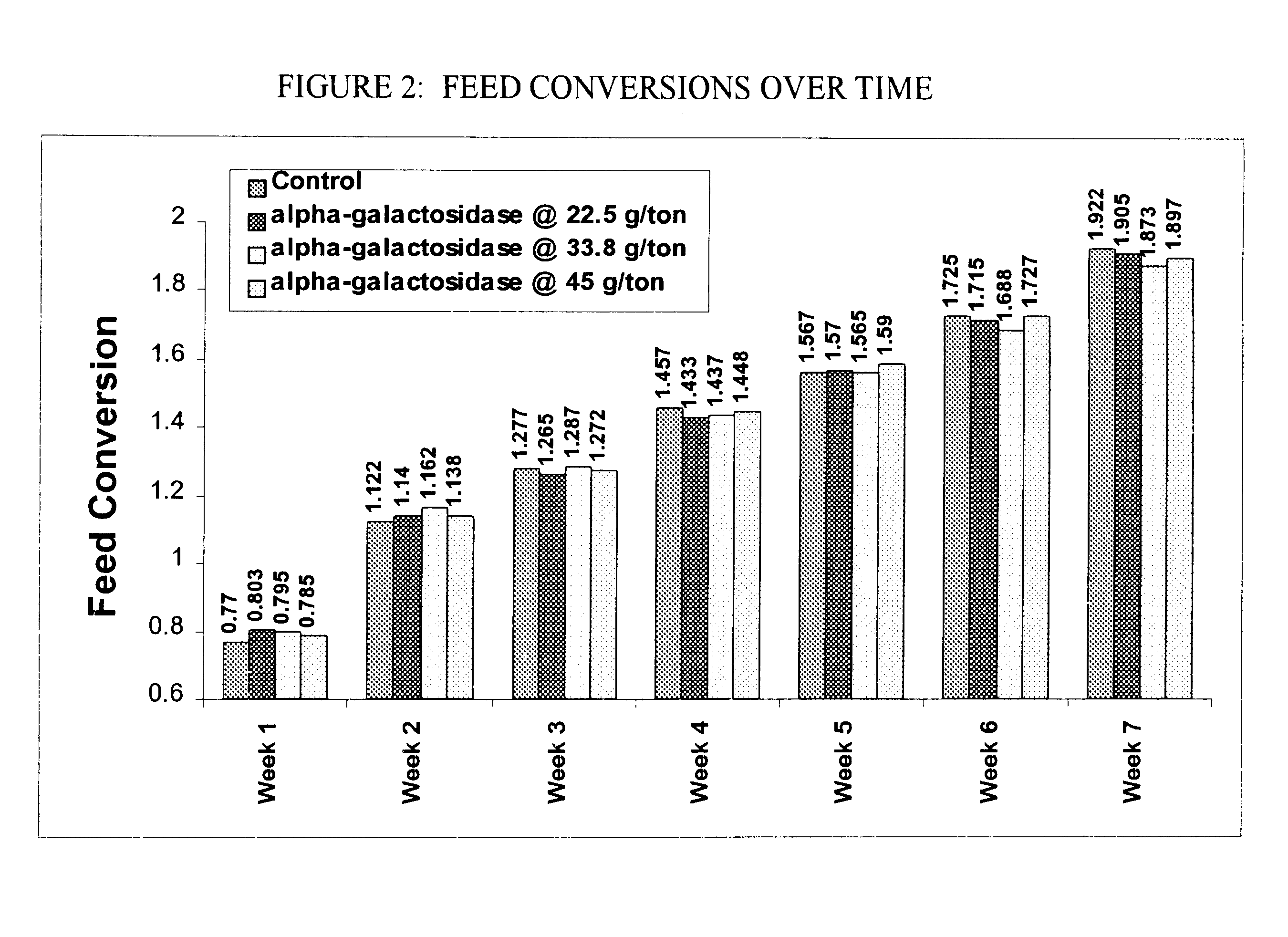

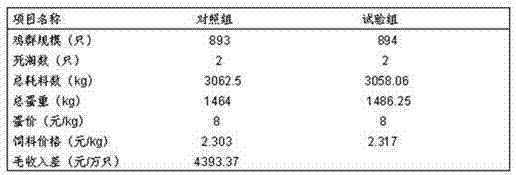

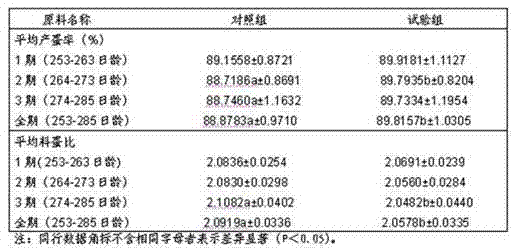

Method for increasing breast meat yields in poultry

A poultry feed composition including protein, vitamins and minerals, and a source of carbohydrates from the group consisting of soybean meals and corn supplemented with an alpha-galactosidase that catalyzes the degradation of the galactoside. The addition of the alpha-galactosidase increases the ratio of gain to feed, increases the amount of white meat, or decreases the amount of fat deposited during growth of a chicken fed the feed composition, relative to the chicken fed on an identical feed composition absent the alpha-galactosidase.

Owner:KEMIN IND INC

Method of producing fermentation-based products from corn

InactiveUS7083954B2Excellent extractabilityIncrease usable surface areaProtein composition from vegetable seedsClimate change adaptationCorn mealFermentation

Corn oil and corn meal obtained from corn are included in useful products. A method for producing fermentation-based products comprises combining corn meal with water and an enzyme, and mixing the combination with a micro-organism capable of fermenting a carbon source to produce a fermentation-based product. The corn meal is produced by cracking whole corn, conditioning the whole corn and extracting the whole corn to produce corn meal without flaking the corn during processing. The corn grain process generally includes the steps of cracking corn grain having a total oil content of from about 3% by weight to about 30% by weight and extracting a corn oil from the cracked corn grain.

Owner:RENESSEN

Freshwater fish feed and preparation method thereof

ActiveCN103340334AMeeting nutritional needsImprove immunityFood processingAnimal feeding stuffEgg proteinPhytase

The invention discloses freshwater fish feed and a preparation method thereof. The feed comprises the following materials in percentage by weight: 5%-17% of import fish powder, 8%-22% of flour, 3%-16% of potato starch, 3%-18% of beer yeast, 5%-15% of bean pulps, 5%-15% of peanut pulps, 5%-10% of rape seed cakes, 2%-8% of corn powder, 3%-9% of cooked egg protein, 5%-8% of dried meat floss powder, 1%-2% of liquid phytase, 1%-3% of non-starch polysaccharase, 0.5%-1.9% of glutamine, 1%-2% of microecological preparation and 1%-3% of immune polysaccharides. The preparation process comprises a crushing step, a mixing step, a pelletizing step and a spraying step. The freshwater fish feed has the beneficial effects of being capable of well satisfying the nutrition needs of freshwater fish, improving the immunity of the freshwater fish, prompting intestinal absorption and improving the production performance of the freshwater fish.

Owner:射阳六和饲料有限公司

High-dietary fiber five-cereal puffing powder and preparation process thereof

The invention relates to high-dietary fiber five-cereal puffing powder and a preparation method, and belongs to the field of food processing. The five-cereal puffing powder comprises the following raw materials: coarse rice powder, wheat meal, oatmeal, millet meal, glutinous corn meal, soybean meal, wheat bran meal, calcium lactate, ferrous gluconate, zinc gluconate, vitamin B1, vitamin B2 and vitamin B6. A method for processing the five-cereal puffing powder comprises the following steps of: screening coarse cereals, grinding, milling, sieving with an 80-mesh sieve, mixing uniformly in a ratio, adjusting the moisture of materials, balancing the moisture, extruding and puffing by using double screws, drying, crushing, and sieving with a 100-mesh sieve, enhancing mineral elements and the vitamins. The high-dietary fiber five-cereal puffing powder has the characteristics that the puffing powder is prepared from natural grain coarse cereals, emulsifying agents and sweeteners are not added, the mineral elements and the vitamins are enhanced, the content of dietary fibers reaches the specified standard of national high-dietary fiber foods, and the puffing powder can be eaten only by being infused by boiling water, so that the high-dietary fiber five-cereal puffing powder is an ideal nutritional and convenient food which is suitable to be eaten by middle and old-aged people.

Owner:HEFEI UNIV OF TECH

Method for planting selenium-enriched pleurotus eryngii and culture medium thereof

InactiveCN101182266AHas a therapeutic effectExcellent biological source of seleniumHorticultureFertilizer mixturesSaccharumAgricultural science

The invention discloses a selenium-enriched pleurotus eryngii planting method and a culture medium, comprising the following steps of confecting the culture medium, bagging, sterilizing, inoculating, fungus growing, bud hastening, producing mushroom and harvesting. The materials of the culture medium is manufactured according the weight portions of 70 to 90 portions of cotton seed shell, 8 to 10 portions of bran, 2 to 3 portions of corn meal, 0.6 to 1.2 portions of sucrose, 0.6 to 1.2 portions of gypsum, 4.5 to 6.5 portions of lime, 100 to 140 portions of water and 0.0011 to 0.0014 portion of sodium selenite. The method of the invention domesticates and cultivates the pleurotus eryngii seeds capability of absorbing and enriching selenium to ensure that the selenium-enriched pleurotus eryngii achieves the balanced production and is on the market all year, which improves the output and increases the economic benefit.

Owner:HANGZHOU NONGFA SCI & TECH DEV

Environment-friendly sea cucumber streak feed and preparation method thereof

ActiveCN101971922AImprove stabilityEasy to prepareFood processingClimate change adaptationAquatic productMultivitamin

The invention relates to an environment-friendly sea cucumber streak feed and a preparation method thereof, and belongs to the technical field of feed. The feed comprises the following raw materials in percentage by weight: 20 to 35 percent of algae powder, 10 to 20 percent of kelp powder, 5 to 15 percent of fish meal, 10 to 30 percent of bean pulp, 5 to 10 percent of zeolite powder, 5 to 10 percent of corn meal, 5 to 10 percent of shell powder, 1 to 3 percent of composite vitamin and mineral substance, and plant immune reinforcing agent and microbial preparation added as required. The preparation method comprises the following steps of: pre-treating and drying the raw materials of the feed, coarsely crushing the raw materials to 40 to 60 meshes, then adding a proper amount of auxiliary agent into the coarse powder, treating the mixture by micro shearing-auxiliary agent technology to obtain an ultra-micro powder raw material of 200 to 300 meshes, adding water into the ultra-micro powder raw material in a weight ratio of 1:1, mixing the raw material and the water uniformly, extruding the mixture into streaks, and drying at the temperature of 20 DEG C to obtain the streak feed with different lengths and widths. The feed is suitable for aquatic product culture such as sea cucumber and the like, and has the advantages of environmental protection, long soaking time, low nutrient loss, strong trapping property, quick weight increment and excitability reduction.

Owner:DALIAN UNIV OF TECH

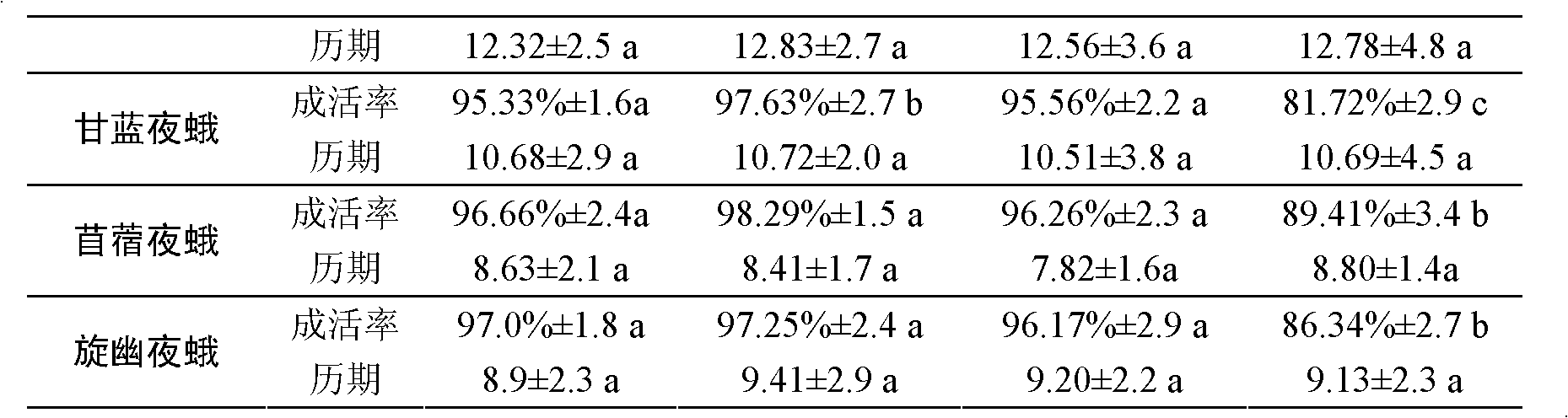

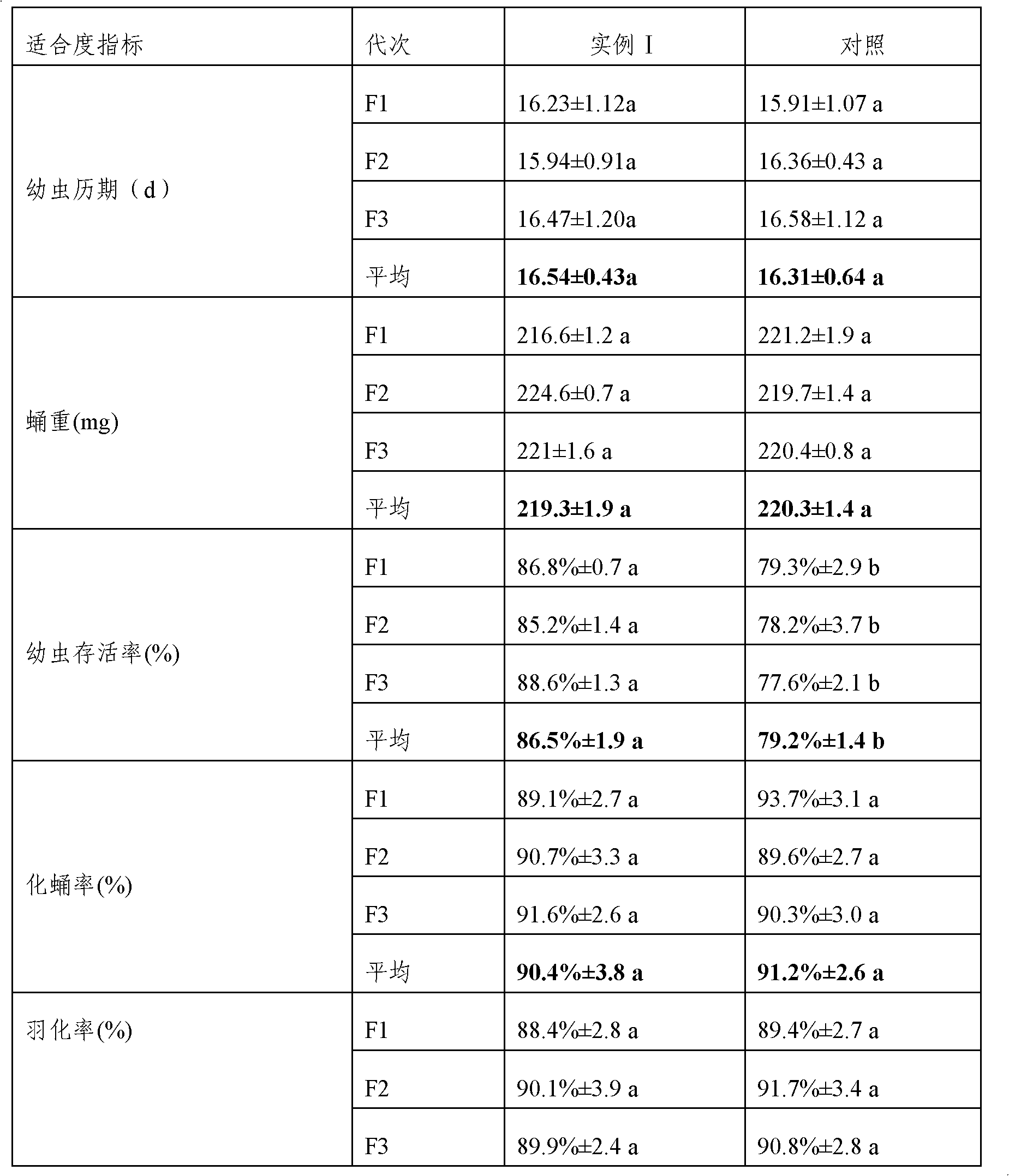

Artificial feed of sesamia inferens walker as well as preparation method and feeding method thereof

InactiveCN101971931ANormal growth and developmentGreat tasteAnimal feeding stuffAccessory food factorsShootCorn meal

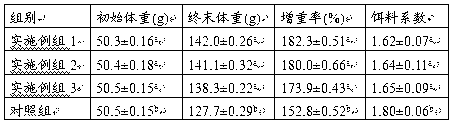

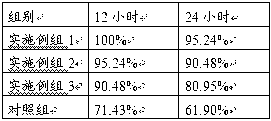

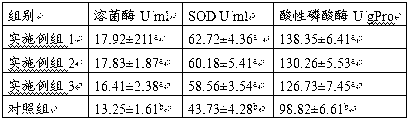

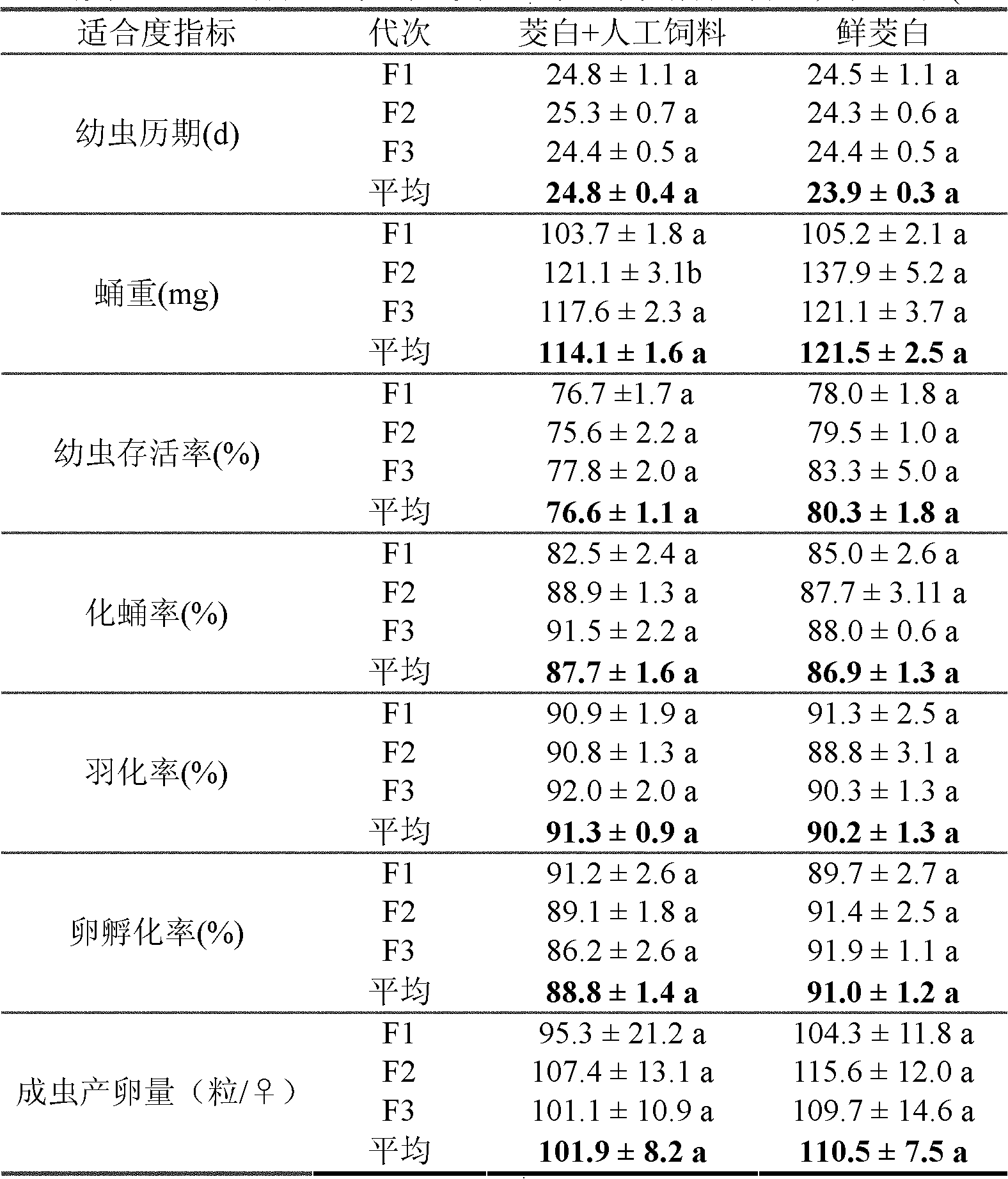

The invention relates to an artificial feed of sesamia inferens walker as well as a preparation method and a feeding method thereof, belonging to the technical field of insect feeding. The artificial feed comprises soybean meal, corn meal, wheat germ, yeast powder, casein, cane sugar, honey, fresh wild rice shoots or fresh rice stems, ascorbic acid, cholesterol, choline chloride, Fiske salt, vitamin B complex, vitamin E, sorbic acid, methyl parahydroxybenzoats, 40 percent formaldehyde, 98.18 percent rice ketone, agal-agal and water. A long-term and successive feeding method of the sesamia inferens walker is carried out by adopting a wild rice shoots (young larva) and artificial feed (old larva until pupation). The fed larva of the sesamia inferens walker have development period of 24.8 days, larva survival rate of 76.6 percent, percentage of pupation of 87.7 percent, eclosion rate of 91.3 percent, egg laying amount of 101.9 for single adult and egg hatching rate of 88.8 percent. The invention has the advantages of low cost, practicability, simple preparation, and the like, and is suitable for massive, long-term and successive feeding of standard test sesamia inferens walkers.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Method for cultivating lucid ganoderma by using mulberry branches

ActiveCN102835248AStrong complementarityNutritional diversityHorticultureFertilizer mixturesBiotechnologyEconomic benefits

The invention discloses a method for cultivating lucid ganoderma by using mulberry branches. A formula for cultivating the lucid ganoderma by using the mulberry branches comprises the following raw materials in parts by weight: 70-80 parts of mulberry branches, 1-10 parts of bran, 1-5 parts of rice bran, 1-5 parts of corn meal, 1-5 parts of bean cake meal, 1-5 parts of gypsum powder, 1-5 parts of lime powder, 0.1-1 part of calcium carbonate, 1-5 parts of sugar, 0.1-1 part of magnesium sulfate and 5-10 parts of miscellaneous fine sawdust. The method for cultivating the lucid ganoderma by using the mulberry branches has the advantages of adequate source of raw materials, simple technology, low cost and quick response. In addition, according to the method for cultivating the lucid ganoderma by using the mulberry branches, the contradiction between fungus and forest can be solved, and the forest log is substituted by the mulberry branches for cultivating the lucid ganoderma, so that the waste is changed into things of value, the economic benefit for production of silkworm is improved, and the method has a great significance to protection of forest resources.

Owner:颍上县鸿涛菌业专业合作社

Compound coarse grain instant food and preparation method thereof

ActiveCN102389084ARetain nutrientsImprove digestion and absorption rateFood preparationBiotechnologyNutritive values

The invention relates to the technical field of instant foods and particularly relates to a compound coarse grain instant food. The ingredients of the food include rice flour, core flour, bean flour, oat flour, buckwheat flour, wheat spout flour and barley malt flour. The preparation method comprises the steps as follows: grinding at a low temperature, hydrolyzing with compound enzymes, concentrating under vacuum, pre-freezing, freeze-drying, and grinding. The low-temperature grinding procedure can retain various nutrients in coarse grains to the greatest extent. The compound enzyme enzymolysis procedure can hydrolyze certain insoluble functional active components to form soluble components, so as to increase digestion and absorption rate of nutrients in vivo. The low-temperature vacuum concentration procedure and the freeze-drying procedure can prevent loss of nutrients and functional active components to the greatest extent during the process, so as to increase the nutritional valueand health-care function of the product and improve the product quality. Therefore, the product has the characteristics of being convenient to eat and good in instant solubility and preparing property.

Owner:JINAN HUALU FOOD

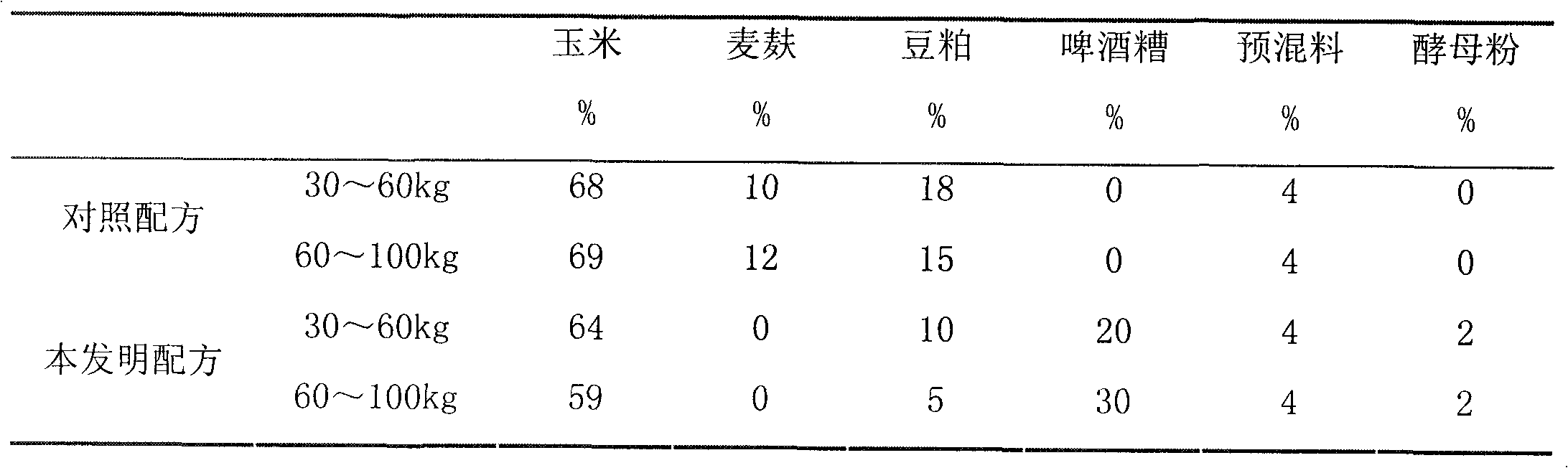

Production method for adding brewer grain fattening pannage

ActiveCN101779749ARich varietyLow costFood processingAnimal feeding stuffAdditive ingredientCorn meal

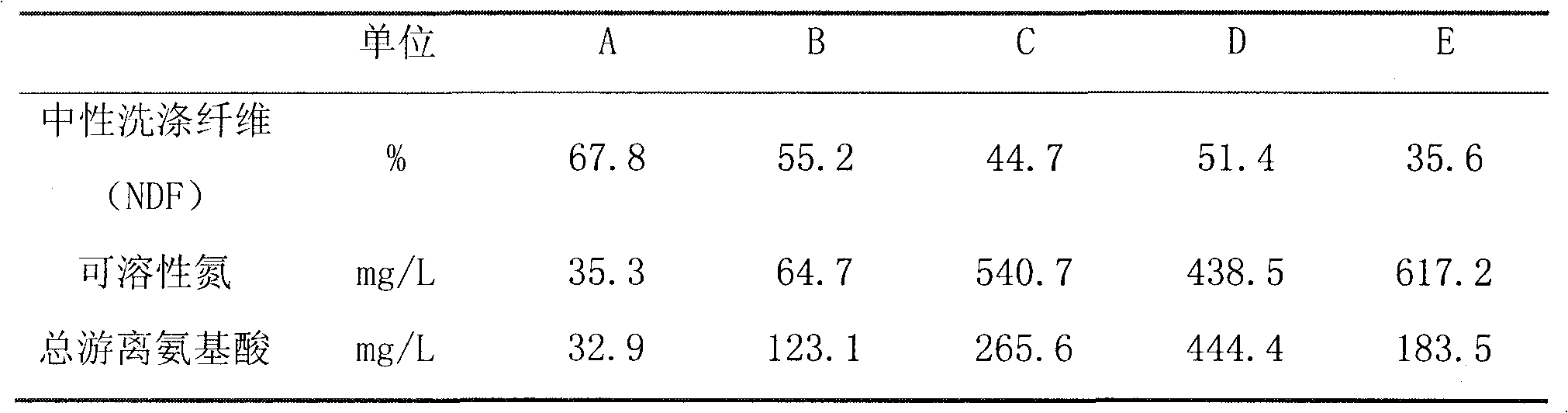

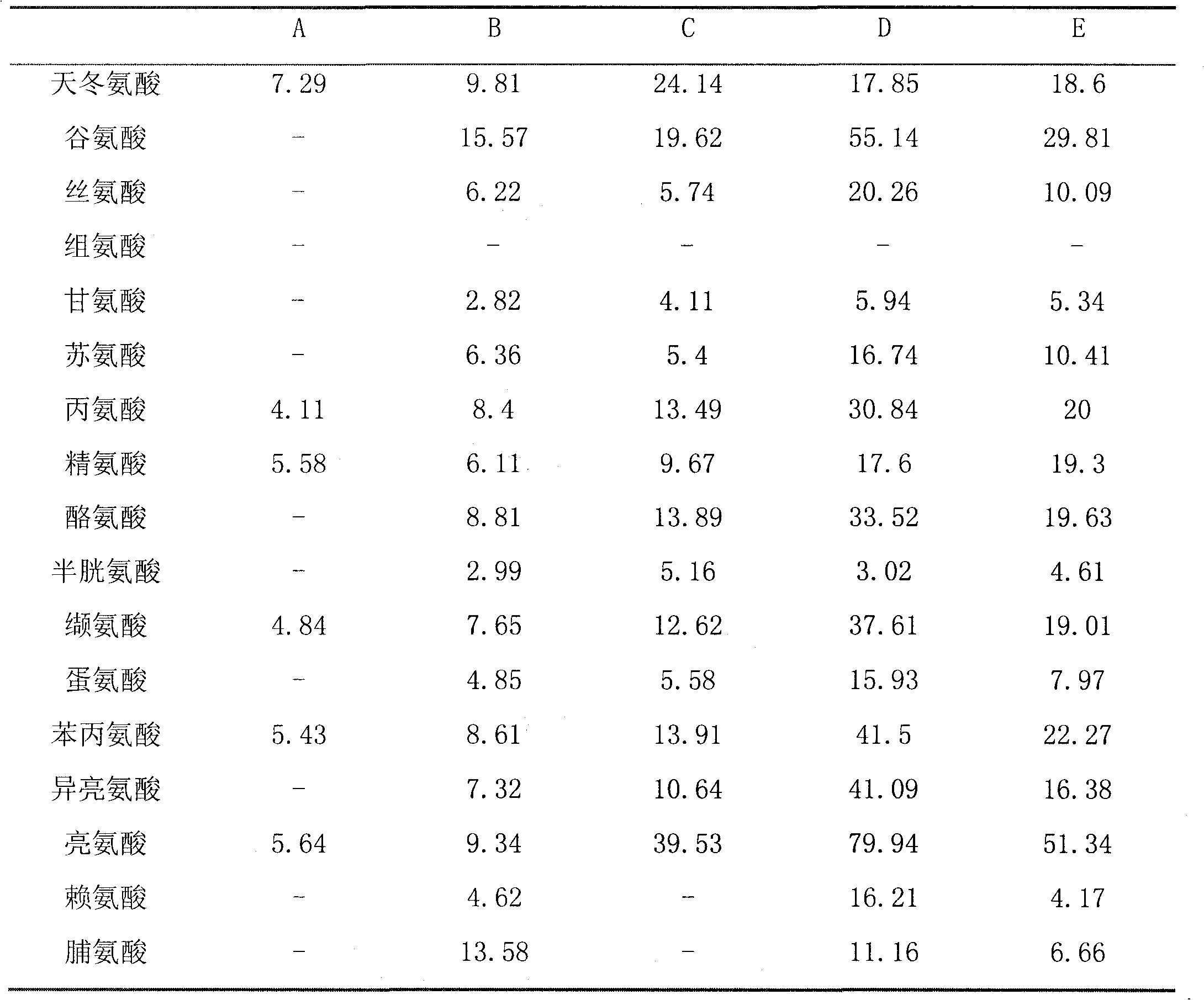

The invention belongs to a production method for adding brewer grain fattening pannage, which belongs to the technical field of the feed processing. The production method comprises the following steps that: the brewer grain is undertaken the steam explosion pretreatment and is added with mixed bacteria and / or complex enzyme to be undertaken the solid anaerobic fermentation so as to degrade the fiber content in the brewer grain and to improve the soluble nitrogen content of the brewer grain, so the quality is better, and the nutrition is more balanced; then the fermented brewer grain, waste yeast powder, corn meal, soybean meal and pre-mixed material are uniformly mixed to obtain the fattening pannage being added with brewer grain. The source of the brewer grain and the waste yeast is abundant, the nutrition for matching the brewer grain and the waste yeast is balanced, and the cost of the feed can be reduced; and the brewer grain is processed with the steam explosion pre-treatment technology, the enzymolysis technology and the biological fermentation technology, so the fiber content is reduced, the protein quality is improved, and the type of the aminoacid is more abundant; and the production method can reduce the grain ratio, improves the daily gain, reduces the feed compositions, and is free from influencing the feed intake and the growth of the fatty pigs.

Owner:BEIJING YANJING BREWERY

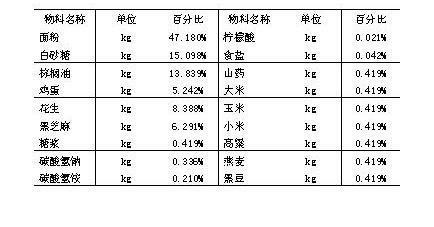

Cereal nutrient biscuit and preparation method thereof

InactiveCN101779690AAnti agingReasonable nutritionDough treatmentBakery productsBiotechnologySodium bicarbonate

The invention relates to a leisure food, namely a cereal nutrient biscuit and a preparation method thereof, belonging to the technical filed of food processing, which is composed of flour, white sugar, edible vegetable oil, black sesame seed, broken peanut, black soy milk powder, yam flour, rice powder, millet powder, corn powder, sorghum powder, oatmeal, fresh hen eggs, salt, sodium bicarbonate, ammonium bicarbonate and citric acid. The preparation method is as follows: evenly mixing the raw materials and stirring into paste; rolling the paste into the shape of biscuit and then baking; spraying palm oil on the surface of biscuits; cooling at room temperature; detecting the biscuits by a metal detector, removing biscuits containing metal chips or metal particles; picking out damaged biscuits; and packaging and warehousing the biscuits. In the invention, multiple grains such as sesame, peanuts and black beans are added to ensure more reasonable nutrition, no fumet is added to let the biscuits keep natural fragrance of rice; and the biscuit has the advantages of rich nutrition, multiple disease prevention, beautifying and body building, prolonging life, thin and crisp mouth feeling and the like, thus is a convenient leisure food suitable for people at all ages.

Owner:WEIHAI DONGWANG FOOD

Production process of germ and corn composite nutritional powder and product of production process

ActiveCN102754764AIncrease nutritional contentIncrease the content of gamma-aminobutyric acidFood preparationNutritive valuesAdditive ingredient

The invention relates to a production process of germ and corn composite nutritional powder and the product of the production process, and belongs to the technical field of food processing. The production process is characterized in that mixing corn which sprouts in stress with wheat germ which is subjected to microwave enzyme inactivation; performing extrusion and superfine grinding to prepare germ and corn meal; adding carrot meal, spirulina meal, white granulated sugar, maltodextrin and vegetable fat powder into the germ and corn meal; and sterilizing and packaging to prepare the germ and corn composite nutritional powder. The production process is simple and high in industrial degree, so that the germ resource can be further utilized, corn can be completely utilized, and the additional value of agricultural products can be increased. The germ and corn composite nutritional powder produced by the production process is good in dissolubility, fine in taste and high in nutritional value, is rich in gamma-aminobutyric acid, glutathione, octacosanol, dietary fiber and other components, has the functions of improving brain functions, calming nerves, improving sleeping, resisting oxidation, delaying senescence, improving body immunity and the like, and is an ideal health-care nutritional food, wherein the content of gamma-aminobutyric acid in the product is between 20 and 60mg / 100g.

Owner:JIANGSU HENGHUI FOOD CO LTD

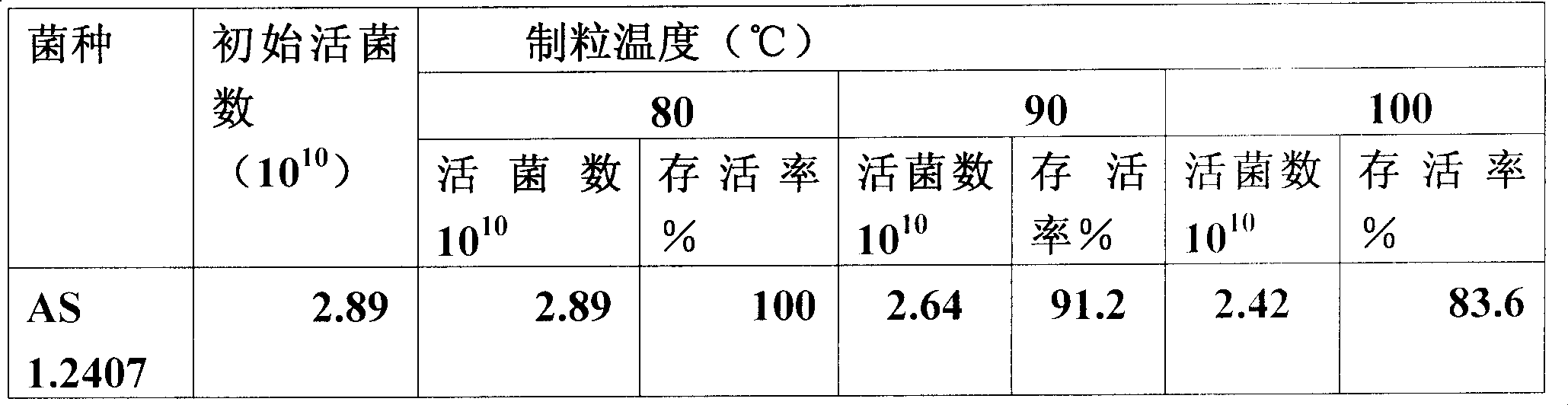

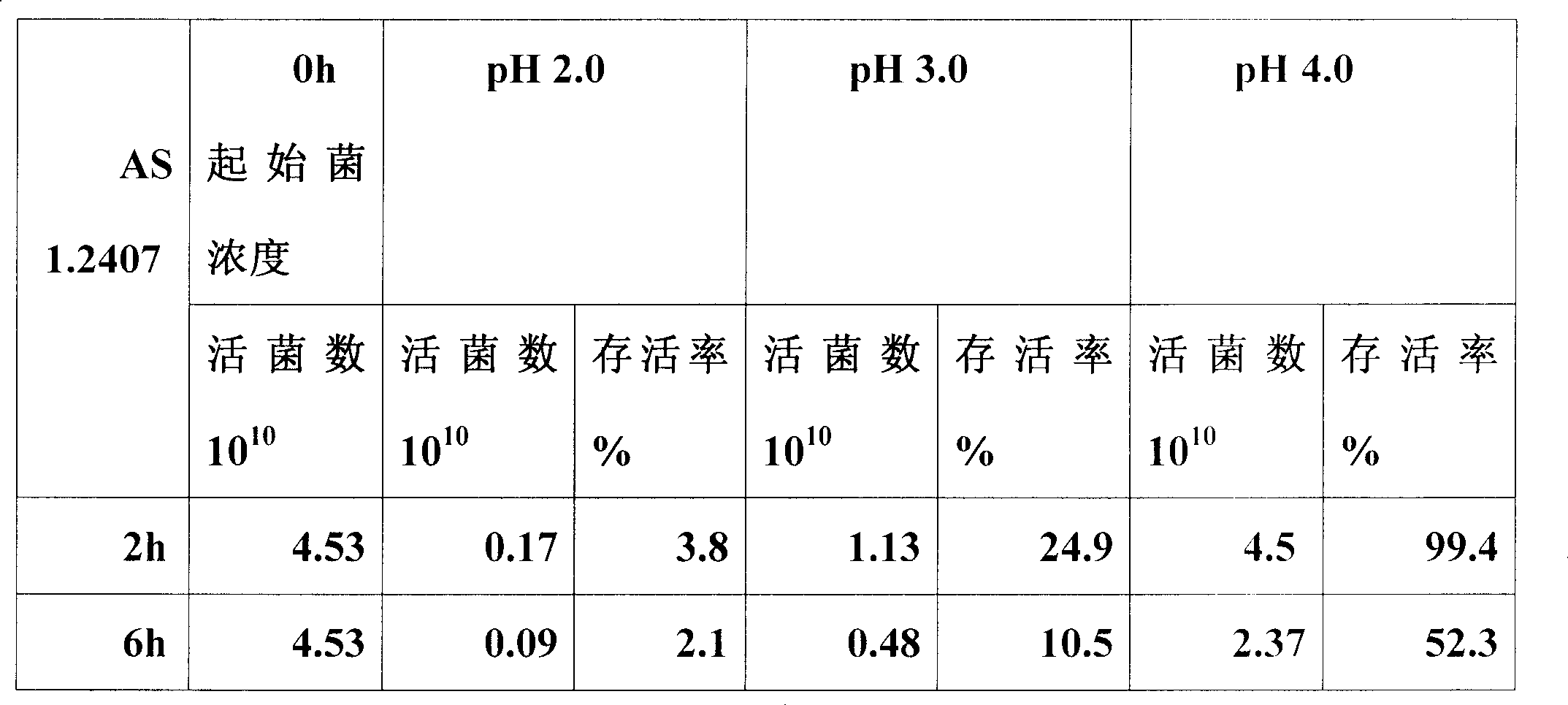

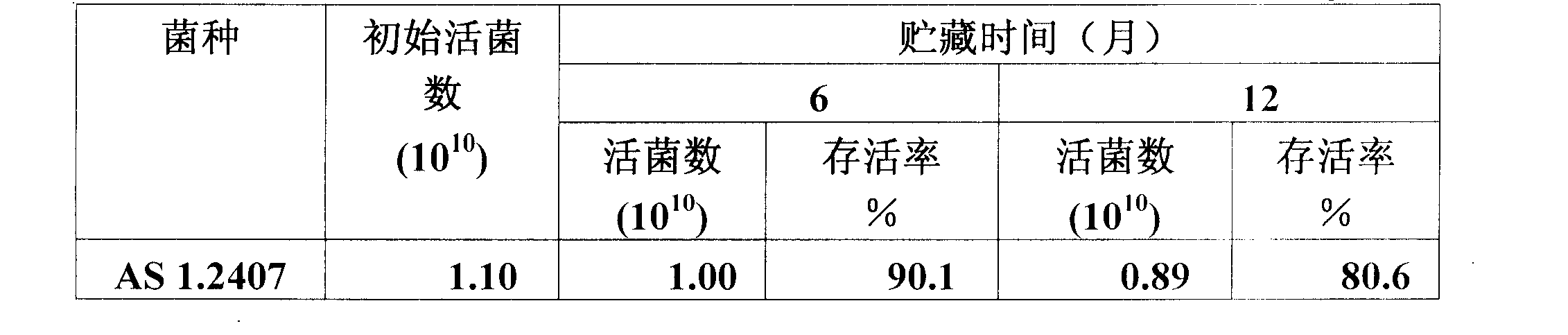

Coagulation bacillus feedstuff supplement and preparation method thereof

ActiveCN101390571AImprove stress resistanceHigh viable countFungiAnimal feeding stuffSucroseCorn meal

The invention relates to a condensate bacillus feed additive and a preparation method, belonging to the technical field of microbial feed additives. The additive uses one or several of the fish meal, soybean meal, cottonseed meal, urea, ammonium sulfate, diammonium hydrogen phosphate, soybean peptone and yeast extract as the nitrogen source, and also takes one or several of the glucose, lactose, starch, cane sugar, maize flour and bran as the carbon source for fermentation; the number of viable bacteria reaches more than 1 multiplying 109 CFU / ml; after the additive is further concentrated and dried or directly adsorbed to the carrier, bacillus powder is obtained through spray-drying, and the number of viable bacteria reaches more than 1 multiplying 1010 CFU / g. The novel bacillus product produced with the submerged liquid fermentation method provided in the invention is free from toxic side effects, drug resistance and residue; the product can endure processing, intestinal habitat and storage.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Compound microbial fermented fodder nutrient additive and its preparing method

InactiveCN1813562AEasy to prepareLower requirementFood processingAnimal feeding stuffMicroorganismAdditive ingredient

The present invention relates to a composite microbial fermented feed nutrient additive and its preparation process. Its composition includes the following ingredients: (by wt%) rice husk powder 20-30, maize meal 15-22, oil meal 4.5-10, soybean cake 5-11, cotton seed cake 2-5, rape cake 1.5-5, fish meal 0-4, clean water 28-35, compound microbial fermentation agent 0.55-0.75 and nutrient agent 1.8-3.6. Said invention also provides the concrete steps of its preparation method.

Owner:周选忠

Feed and method for raising black pigs

The invention relates to a feed and method for raising black pigs. The feed is prepared from 55-65% of corn meal, 10-20% of bean pulp, 5-15% of wheat bran, 2-6% of fish meal, 0.1-0.5% of salt and 5-10% of auxiliary materials by weight, wherein the auxiliary materials include fructus cannabis, almonds, fructus perillae and pumpkin seeds and also include schisandra chinensis, acanthopanax, pine leaves, horsetail, purslane and peony. The method comprises the following steps of: keeping the concentration of anions in the raising environment not to be less than 1000-1500 per cubic centimeter; selecting black pigs or binary or ternary hybrid pigs of the black pigs and boars; ensuring the culture cycle to be 9-16 months; and beginning feeding the feed every other day 40-45 days before marketing until marketing. The feed and the method have the following advantages that: the pigs cultured by the method have pure fragrant and tender meat and the meat is fat but not greasy and lean but not bonyand is rich in omega-3 unsaturated fatty acid and omega-6 linoleic acid.

Owner:于永林

Feed for crabs

InactiveCN103284016AMeet the needs of growthIncrease appetiteAnimal feeding stuffBiotechnologyAnimal science

The invention belongs to the technical field of feeds and particularly relates to a feed for crabs. The feed for crabs is characterized by comprising the following materials in parts by weight: 30-60 parts of pork skin, 20-50 parts of fat pork, 5-15 parts of lean pork, 6-9 parts of corn meal, 3-5 parts of soybean meal, 1-5 parts of edible oil, 0.1-1 part of garlic cloves, 1-2 parts of fish scale powder and 0.5-1.5 parts of rape seed cakes. The main problems that since the feed for crabs is difficult to absorb, the crabs grow slowly and the water quality is contaminated in the prior art are solved; the feed disclosed by the invention has the beneficial effects of being rich in nutrition and aromatic in smell, containing antiviral components, and enabling the crabs to grow fast after the feed is eaten; the feed is simple to prepare and all the materials of the feed are rich in supply.

Owner:陈瑜 +7

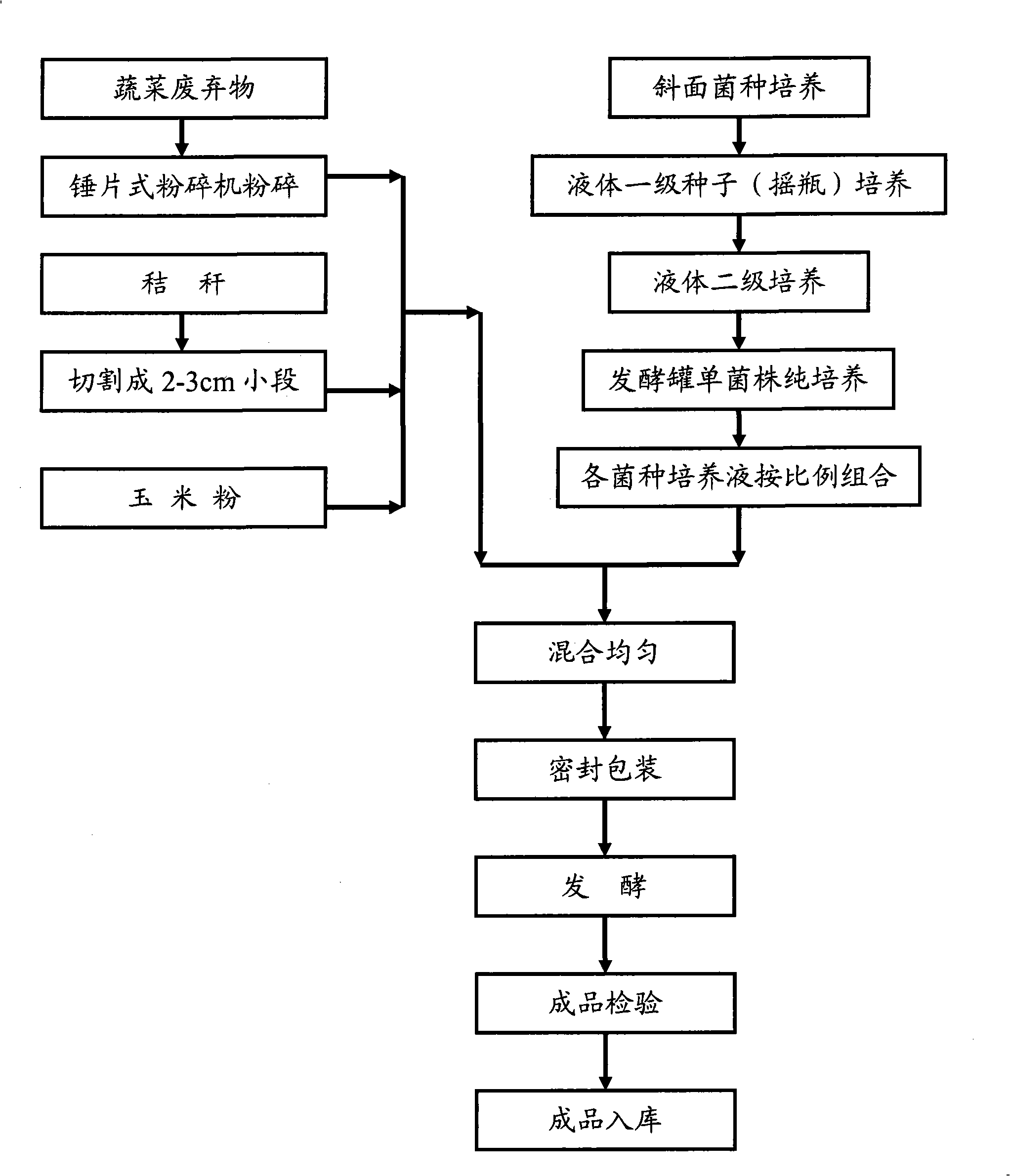

Fermented abandoned vegetable feedstuff and preparation method thereof

InactiveCN101401616AAdaptableSuitable for a wide range of raw materialsFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to fermentation waste vegetables feed and a preparation method. The fermentation waste vegetables feed consists of mixed raw materials and microorganism living bacteria liquid, wherein the mixed raw materials consist of vegetable waste materials, straw and corn powder; and each ton of the mixed raw materials are formed according to the weight ratio (w / w): 70 to 80 percent of waste vegetables, 20 to 25 percent of straw, and 4 to 6 percent of corn powder. Each ton of the mixed raw materials are added with 30 to 40 milliliters of the microorganism living bacteria liquid, and the content of living bacteria for the microorganism living bacteria liquid is between 1.0x10<9>cfu / mL and 1.0x10<11>cfu / mL. The fermentation waste vegetables feed and the preparation method have the advantages of reasonable formulation, scientific production method, wide applicable areas, simple operation, easy master, low cost, reasonable formula design, convenient production, suitability for broad peasant households and livestock breeding plants, safe and no toxity, and great adaptability to fermentation conditions, and can be used as feed of cows, sheep, geese, and so on, make full use of side products in agriculture industry, realize reasonable use of the resources, and provide new techniques for clean and sustainable agricultural industry.

Owner:北京阔利达生物技术开发有限公司 +1

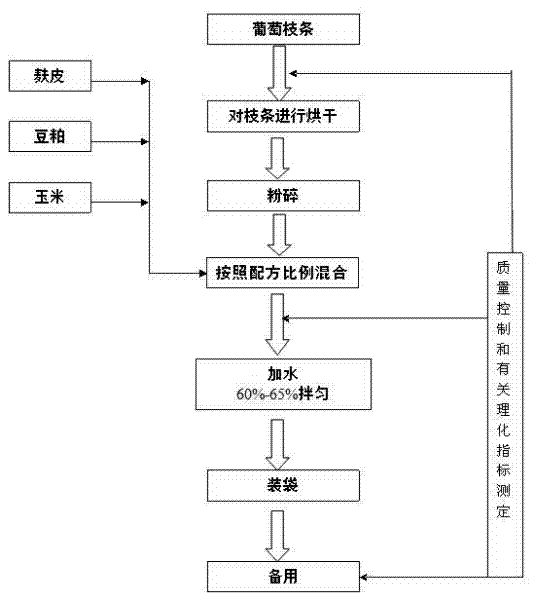

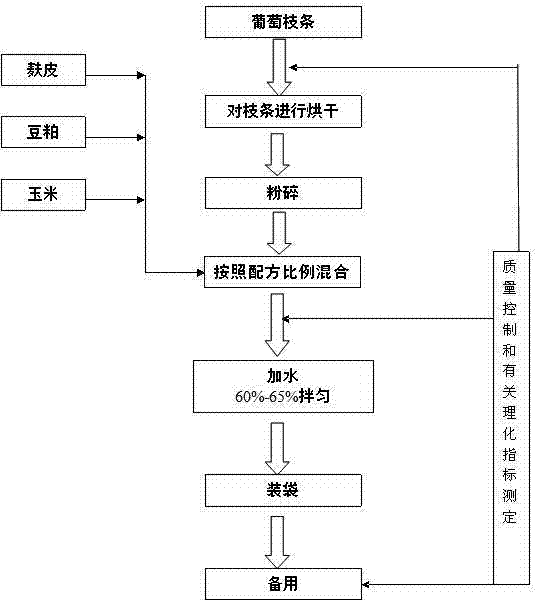

Medium for growing pleurotus eryngii by using grape branches

The invention relates to an edible fungi culture medium, in particular to a medium for growing pleurotus eryngii by using grape branches. The medium for growing the pleurotus eryngii by using the grape branches is characterized in that: each 100 weight parts of culture medium comprises 63.89 to 79.69 weight parts of grape branches, 15.27 to 26.66 weight parts of bran, 3 to 8.16 weight parts of bean pulp and 3 to 6.85 weight parts of corn meal; and each 100g of culture medium comprises 68.03g of grape branches, 20.41g of bran, 8.16g of bean pulp and 3.40g of corn meal. The grape branches are taken as a main material and properly added with other biological nitrogen sources to form the medium for producing wooddecay fungi; and the culture medium can degrade cellulose, hemicelluloses and lignin in the grape branches, and produce high-quality edible fungi.

Owner:NORTHWEST A & F UNIV

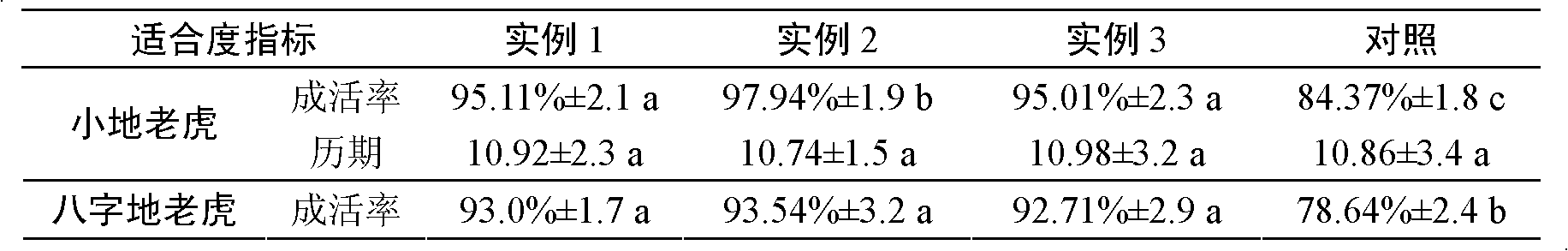

Artificial diet for Lepidopterous young larvae, preparation method for artificial diet and application of artificial diet

The invention provides an artificial diet for Lepidopterous young larvae. The artificial diet for the Lepidopterous young larvae is prepared from the following raw materials in percentage by weight: 2.0 to 3.0 percent of soybean cake meal, 7.0 to 10.0 percent of corn flour, 2.0 to 3.0 percent of Saccharomyces cerevisiae Hansen, 7.0 to 10.0 percent of tomato sauce, 0.8 to 1.2 percent of sucrose, 1.2 to 1.4 percent of agar, 0.2 to 0.5 percent of sorbic acid, 0.05 to 0.1 percent of vitamin B complex, 0.2 to 0.4 percent of ascorbic acid, 0.1 to 0.2 percent of ethyl p-hydroxybenzoate, 0.2 to 0.4 percent of propionic acid and 71.0 to 77.0 percent of water. The invention also provides a method for preparing the artificial diet and application of the artificial diet. The artificial diet is low in manufacturing cost, easy to operate and high in practicability; and by the artificial diet and the raising method for raising the Lepidopterous young larvae, the survival rate of the larvae is high, the workload is low, and manpower and material resources are greatly saved.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Fermented organic fertilizer

InactiveCN104744087AReduce usageImprove filtration efficiencyBio-organic fraction processingOrganic fertiliser preparationMicrobial agentCorn meal

The invention discloses a fermented organic fertilizer. The fermented organic fertilizer comprises the following components in parts by mass: 1000-1500 parts of stalk, 1000-1300 parts of chicken manure, 1000-1500 parts of cattle manure, 800-1200 parts of pig manure, 1200-1800 parts of soybean meal, 35-50 parts of a microbial agent, 10-20 parts of peat humic acid, 50-80 parts of corn meal, 60-90 parts of composite enzyme preparation and 30-60 parts of complex bacteria. The invention also discloses a fermentation method of the fermented organic fertilizer. As the method adopts the microbial bacteria and the composite enzyme preparation, the fermentation efficiency is improved, the fermentation time is effectively reduced, the consumption amount of water, electricity and steam is reduced, the production cost is lowered, and the method is suitable for industrial large-scale production; the fermented organic fertilizer disclosed by the invention has no malodor when used in fields, is cost-saving due to the reduction in the consumption, does not result in soil impoverishment, hardening and salinization, and meets the trend of energy-saving, environment-friendly and sustainable development.

Owner:福建亚森农业综合开发股份公司

Method for culturing stropharia rugoso-annulata and compost thereof

InactiveCN101723758AIncrease productionSave energyHorticultureFertilizer mixturesBiotechnologyPhosphate

The invention discloses compost for stropharia rugoso-annulata, which is prepared by taking maize straws as main materials. The invention also provides a safe and environmentally-friendly method for culturing the stropharia rugoso-annulata. The compost of the stropharia rugoso-annulata is characterized by consisting of the following components in part by weight:63 to 70 parts of maize straws, 15 to 17 parts of sorghum husk, 8 to 10 parts of wheat bran, 1 to 3 parts of corn meal, 1 to 2 parts of pulse flour, 1 part of salt, 1 to 3 parts of quicklime, 1 to 2 parts of potassium dihydrogen phosphate and 1 to 2 parts of plaster. Compared with the prior art, the high-yield formulation of the invention adopting the maize straws as raw materials takes full use of the advantages of maize straw resources and needs no farm chemicals for weed prevention by a natural culturing method.

Owner:SHANDONG FANGLV AGRI SCI & TECH

Edible mushroom culture medium

The invention relates to the technical field of edible mushroom cultivation, in particular to an edible mushroom culture medium, which is prepared by mixing the following raw materials in part by weight: 20 to 90 parts of oat husk, 5 to 25 parts of corn meal, 0.25 to 6.5 parts of inorganic fertilizer, 0.25 to 4 parts of lime and 0.25 to 4 parts of plaster, wherein the inorganic fertilizer is one of or a mixture of several of potassic fertilizer, phosphatic fertilizer and nitrogen fertilizer. The oat husk serves as the substrate of the edible mushroom cultivation, so the raw material is wide in resource and low in cost. When used for culturing edible mushroom, the medium has the advantages of high safety, good yield stability, environmental friendliness, high economic efficiency, fresh andsweet taste, crisp and smooth mouthfeel and the like.

Owner:李文胜

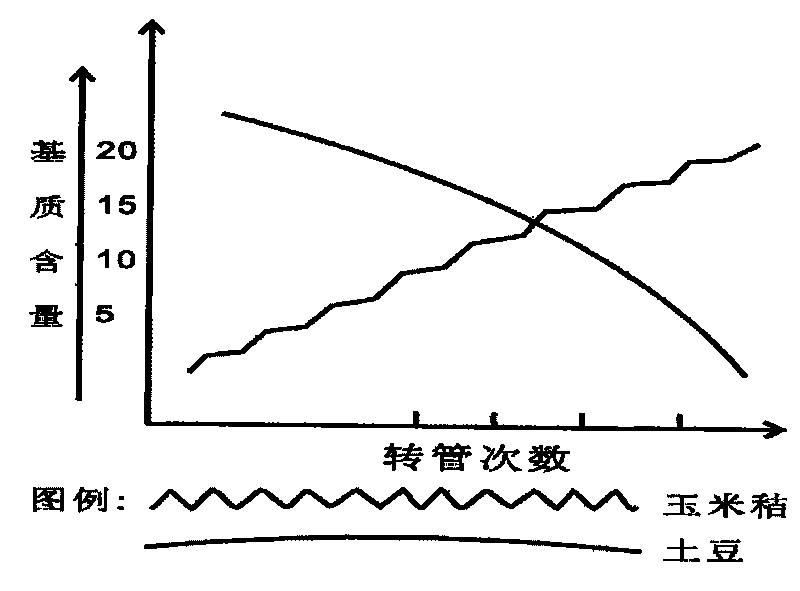

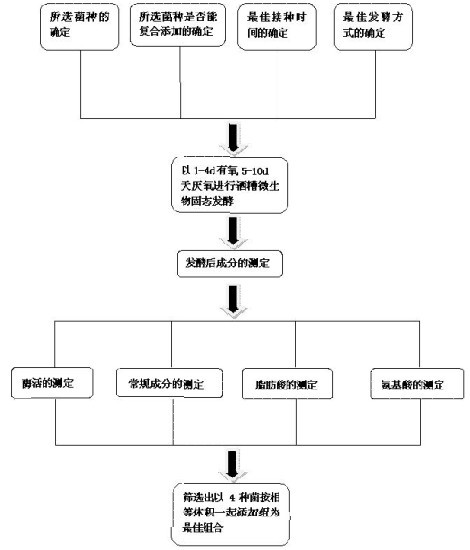

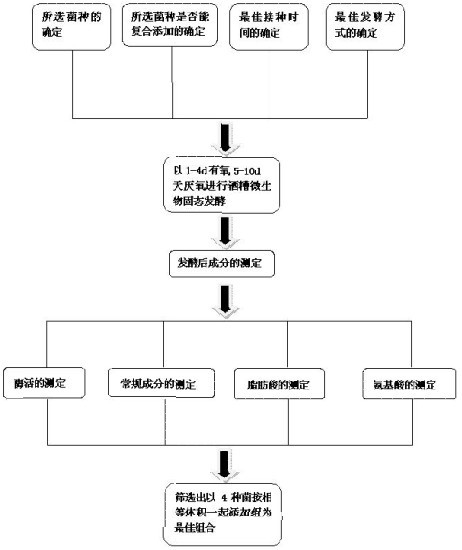

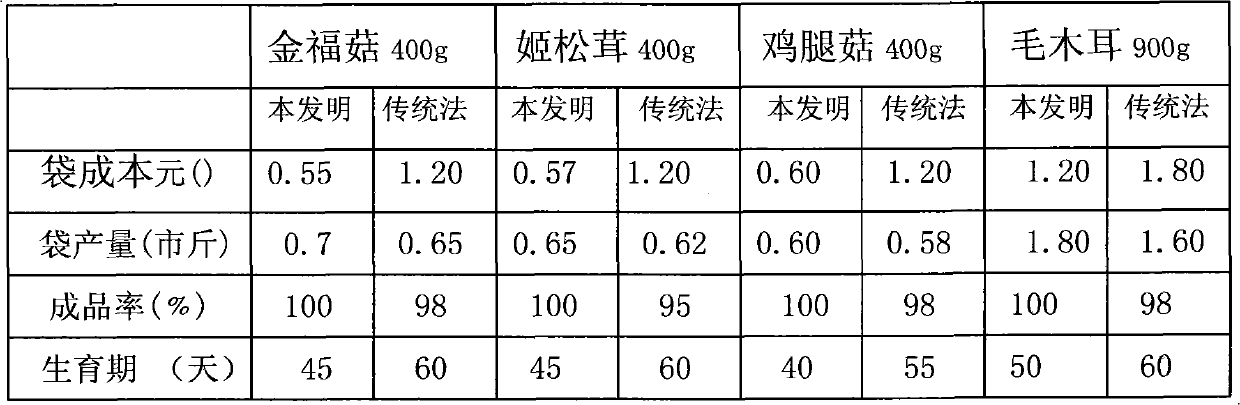

Combined strain formula for producing grain stillage biological feed through fermenting grain stillage and screening method of the combined strain formula

InactiveCN102630809AImprove palatabilityHigh in nutrientsFood processingAnimal feeding stuffBiotechnologyManganese

The invention discloses a strain combined formula for producing grain stillage biological ferment feed through fermenting grain stillage and a screening method of the combined strain formula. The strain combined formula comprises a grain stillage culture medium and strains; the formula of the grain stillage culture medium comprises 60 percent of fresh grain stillage, 10 percent of maize flour, 10 percent of rapeseed meal and 20 percent of water; 15mg of ferrous sulfate, 12mg of zinc sulfate, 10mg of manganese sulfate, 15mg of copper sulfate and 2g of calcium hydrogen phosphate are additionally added into each 100g of the grain stillage culture medium; the strains comprise Bacillus subtilis, Trichoderma viride, Lactobacillus acidophilus and Brettanomyces custersianus, the inoculum concentration is 1.5 percent for each strain; and the viable count of Bacillus subtilis is 1.33*10<11>cfu / mL, the viable count of Trichoderma viride is 7.0*10<10>cfu / mL, the viable count of Brettanomyces custersianus is 3.5*10<11>cfu / mL, and the viable count of Lactobacillus acidophilus is 2.1*10<10>cfu / mL.

Owner:GUIZHOU UNIV

Method for quickly fermenting paper mulberry leaves to produce protein feed

The invention relates to a method for quickly fermenting paper mulberry leaves to produce a protein feed. Paper mulberry leaf powder is used as a main nitrogen source raw material, corn meal is used as a carbon source raw material, and the paper mulberry leaves are quickly converted into the protein feed through a complex microorganism mixing solid fermentation technology. The method is mainly characterized in that: the corn meal is taken as a carbon source, so the decomposition conversion of microorganisms on the paper mulberry leaves can be speeded up, the production time is obviously shortened, the production efficiency is improved, and the fermentation facility investment is reduced. The proportion of the corn meal and the paper mulberry leaf powder 1-6 / 100, the protein content of the obtained protein feed after the conversion is larger than 28%, the carbohydrate content is less than 40%, the crude fibre content is less than 9%, the crude fat content is less than 4%, the LD 50 is more than 16g / kg, so the method is safe and non-toxic.

Owner:HUBEI GOLE BIO TECH DEV

Edible fungus compost, production method thereof and edible fungus culture process

InactiveCN102696458ASolve the technical problems of repeated recyclingPromote sustainable developmentCultivating equipmentsSoilless cultivationSocial benefitsAdditive ingredient

The invention relates to an edible fungus compost, a production method thereof and an edible fungus culture process. The edible fungus compost disclosed by the invention consists of 40 to 90 parts of residual waste (spent mushroom substrate) left over after the harvest of edible fungi, 5 to 40 parts of cottonseed hulls, 3 to 20 parts of bran, 2 to 8 parts of corn meal, 1 to 2 parts of gypsum powder, 0 to 5 parts of quicklime, 0 to 2 parts of superphosphate and 0.05 to 0.8 parts of fungus-strengthening substance, and the pH value is 6 to 9. The invention adopts the residual waste (spent mushroom substrate) left over after the harvest of edible fungi as main material ingredient to produce the edible fungus compost. By implementing the invention, the residual waste of edible fungi cannot pollute the environment any more, and is made profitable, and the resource can be recycled; an edible fungus material resource is added, the economic burden caused by the shortage and higher prices of edible fungus materials is decreased for edible fungus farmers, the production cost of the method is reduced by more than 50 percent in comparison with the production cost of the conventional method, the yield is increased by 10 to 15 percent, the bioconversion rate reaches 80 to 120 percent, and economic income and social benefit are increased. The method is applicable to a variety of edible fungi.

Owner:江山市金福食用菌专业合作社

Loach compound feed and preparation method thereof

InactiveCN102919569AMeet all nutritional needsSatisfy eating habitsFood processingAnimal feeding stuffFeed conversion ratioRapeseed

The invention discloses loach compound feed and a preparation method thereof. The loach compound feed is prepared from flour, puffed dehulled soybean meal, rapeseed meal, cottonseed meal, fish meal, peanut meal, distiller's corn meal, rice bran, soybean oil, soybean phospholipid oil, choline chloride, ammonia absorber zeolite, monocalcium phosphate, table salt, a compound pre-mixing agent for crucian and an aquatic product bacillus feed additive. The loach compound feed as loach special-purpose feed can satisfy all nutritional requirements, satisfy a loach ingestion habit, reduce feed wasting and environmental pollution, improve a water environment, has a high feed conversion rate and a feed coefficient of 1.5 to 1.9, and realizes good vitality of loaches and obvious economic benefits.

Owner:HUAIAN ZHENGCHANG FEED

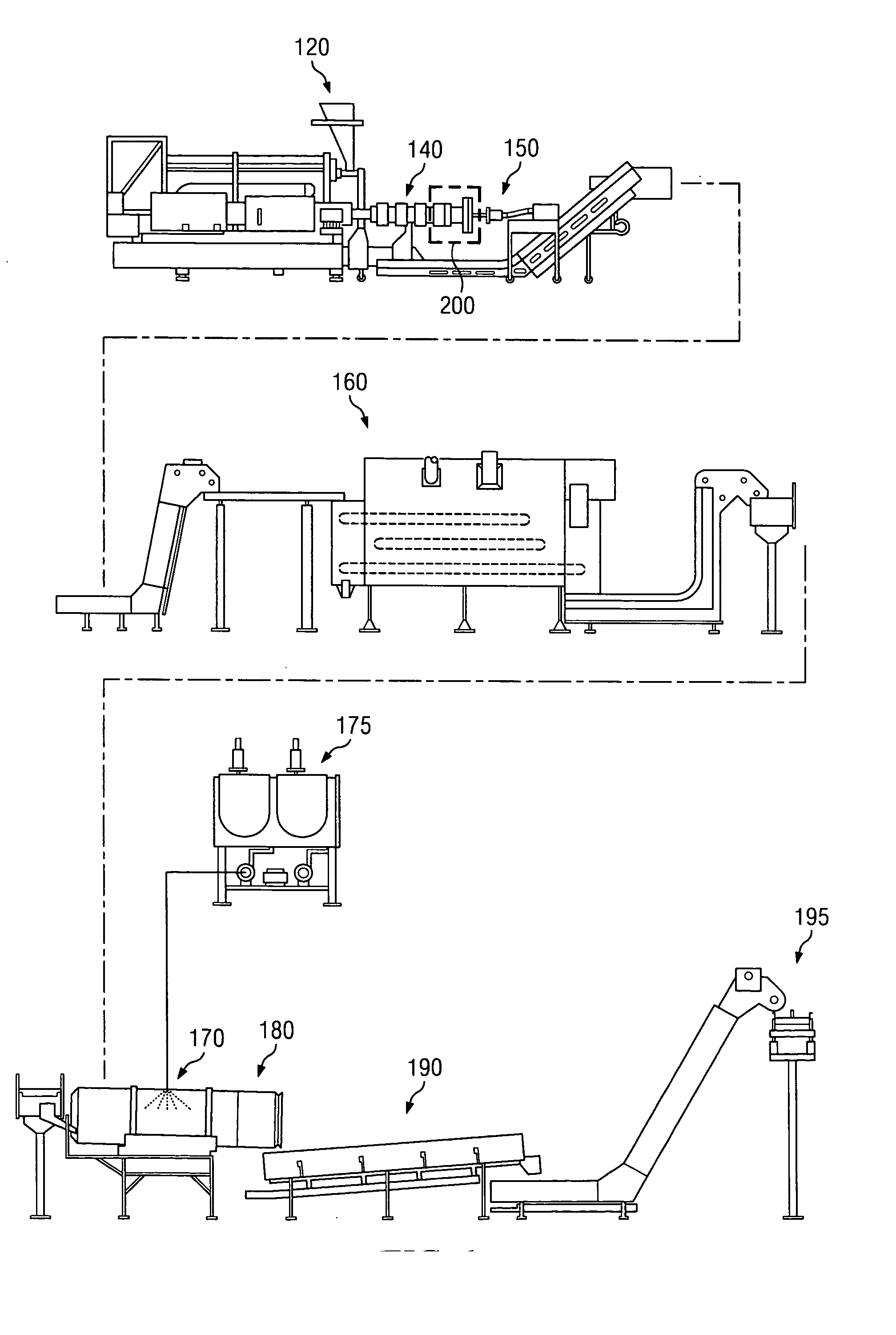

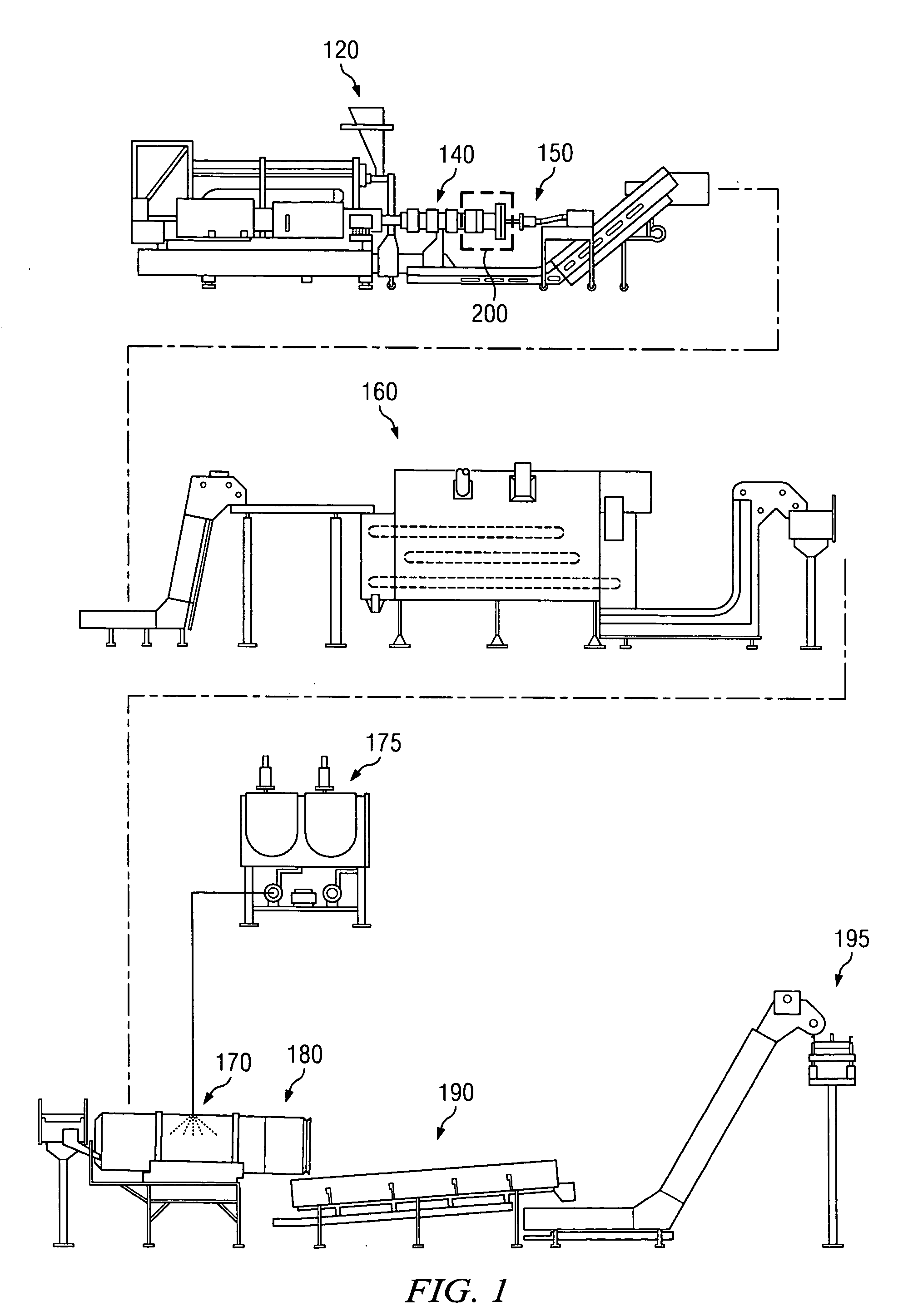

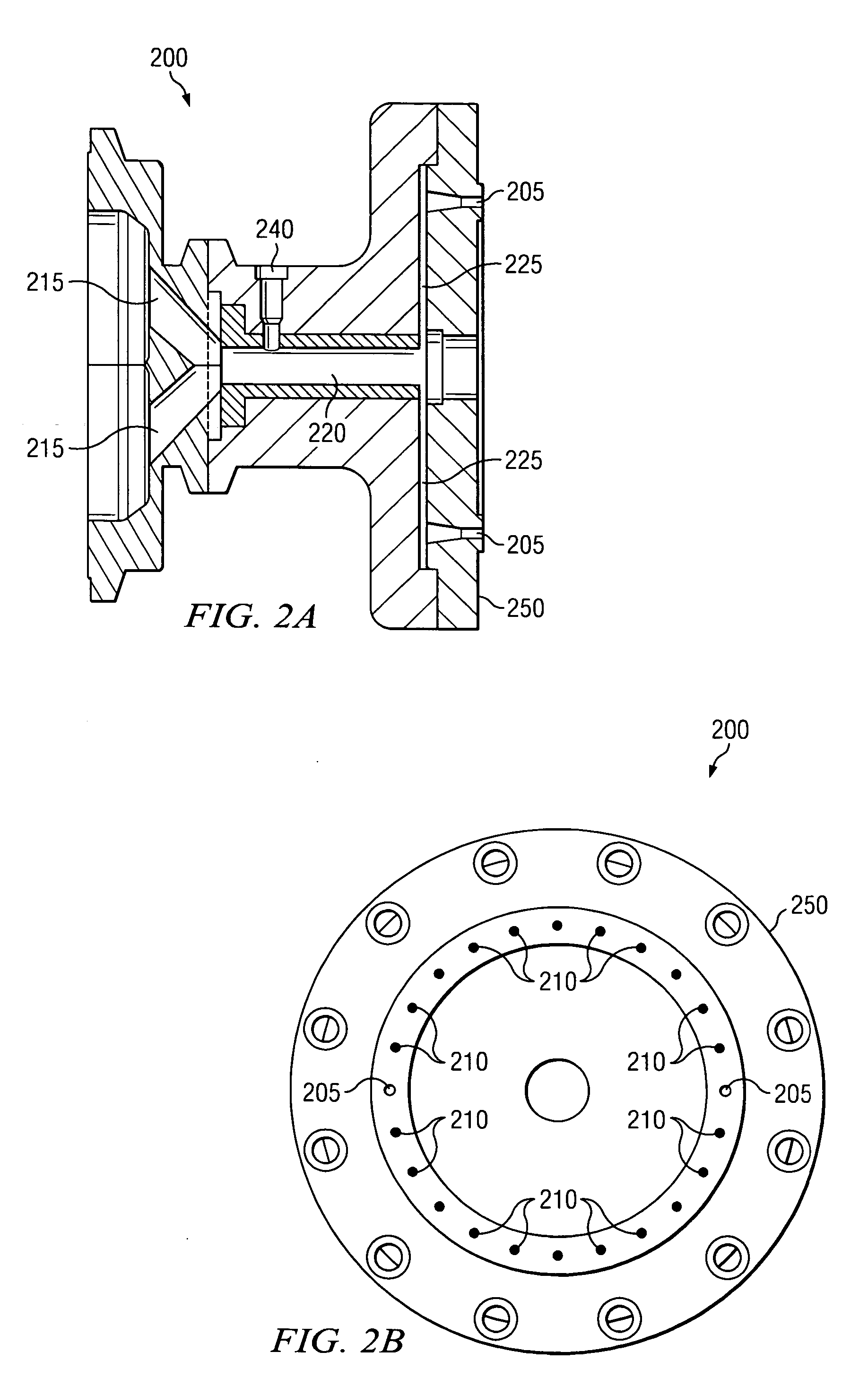

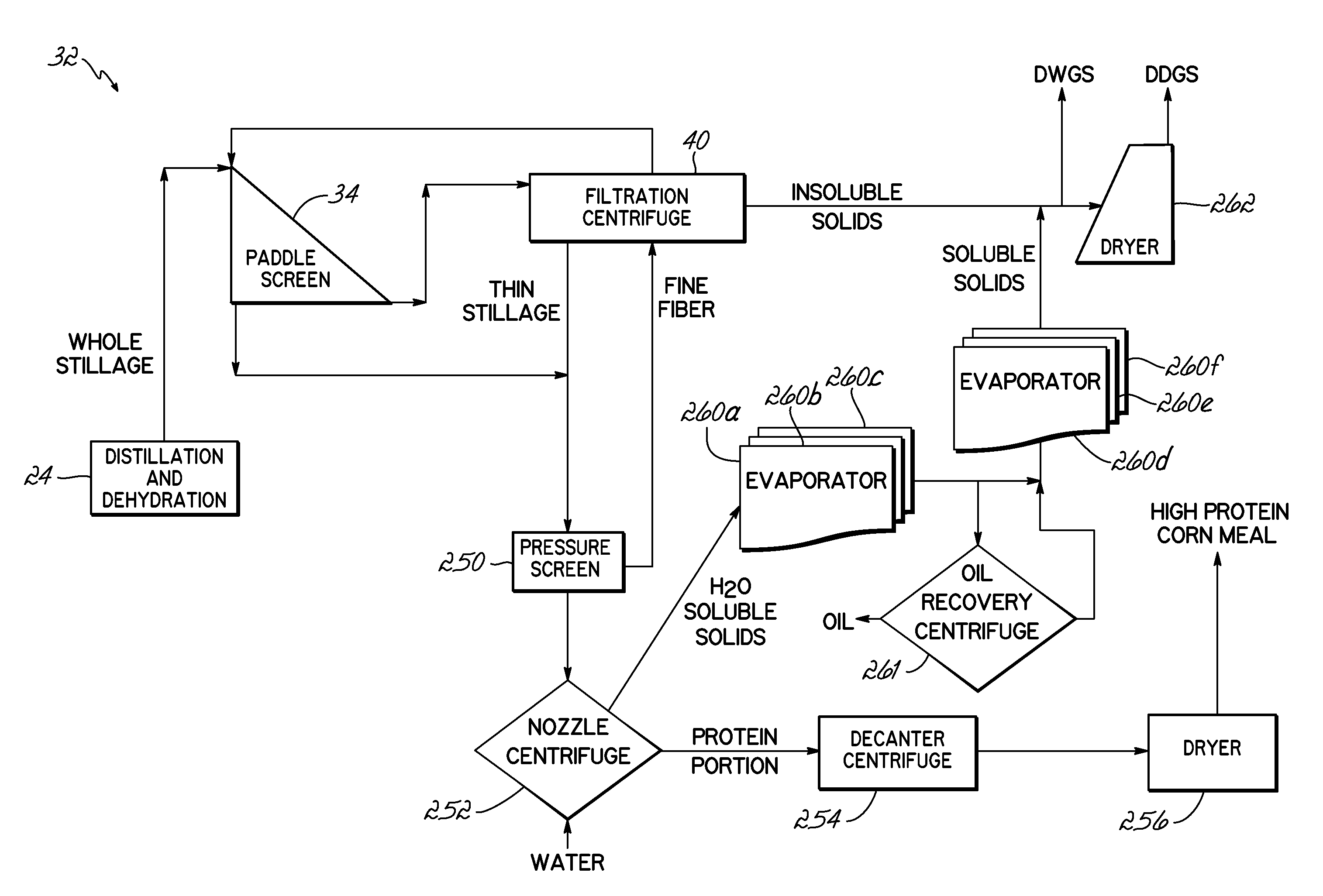

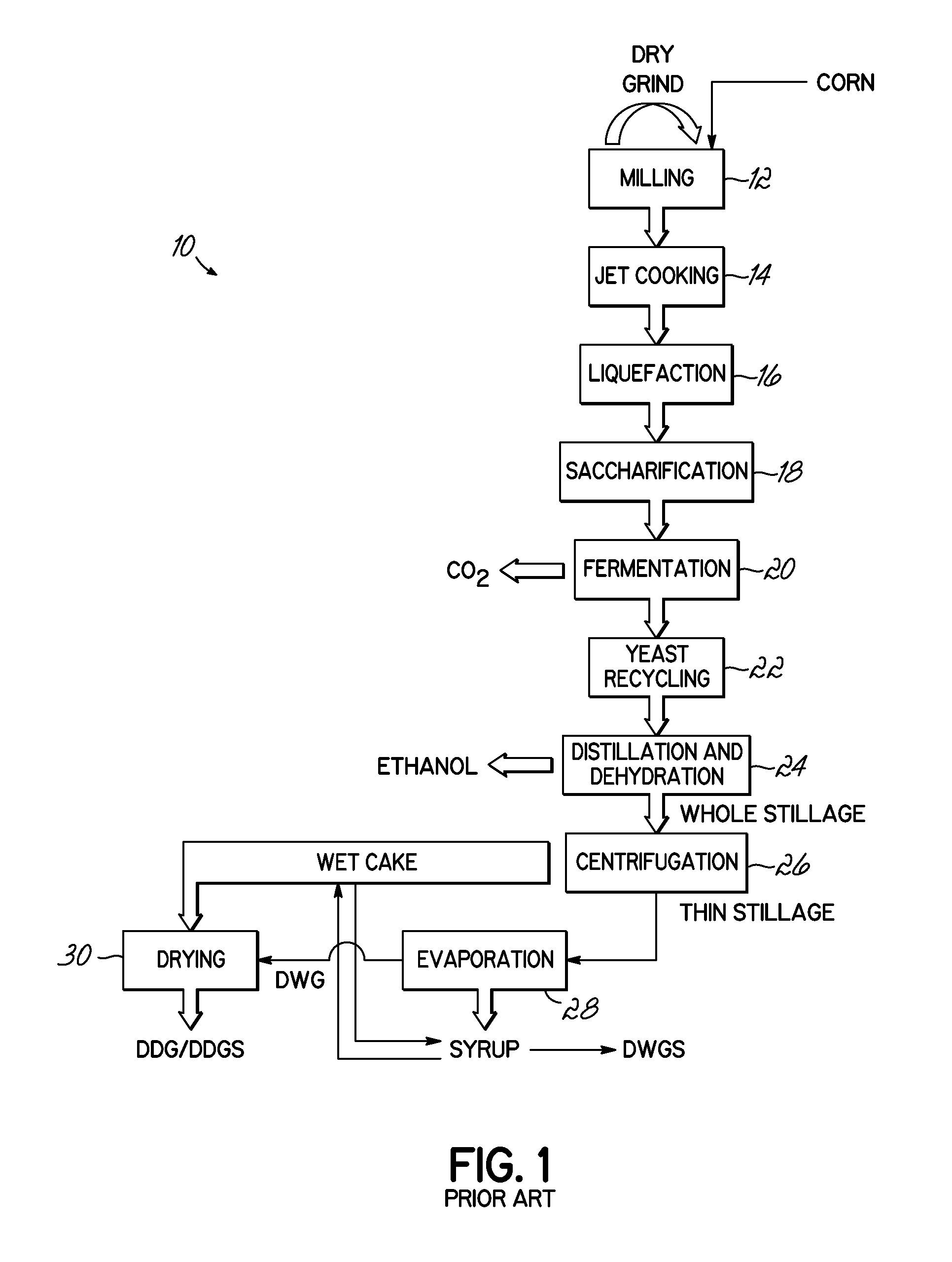

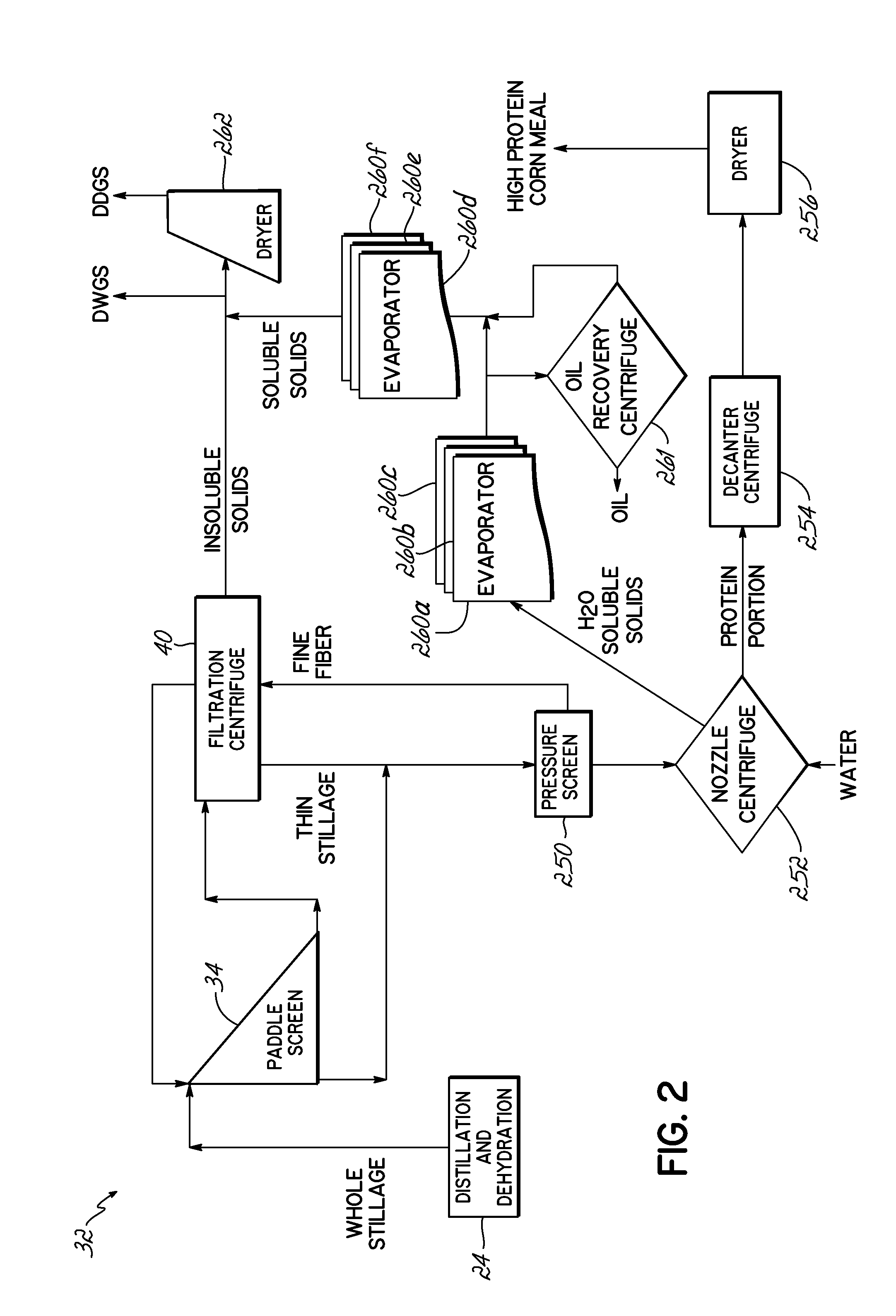

Methods for producing a high protein corn meal from a whole stillage byproduct and system therefore

ActiveUS20120064213A1High in proteinFatty oils/acids recovery from wasteBy-product recoveryWater solubleCorn meal

The present invention relates generally to corn dry-milling, and more specifically, to methods for producing a high protein corn meal from a whole stillage byproduct produced in a corn dry-milling process for making ethanol and a system therefore. In one embodiment, a method for producing a high protein corn meal from a whole stillage byproduct includes, in a corn dry-milling process for making ethanol, separating the whole stillage byproduct into an insoluble solids portion and a thin stillage portion. The thin stillage portion is separated into a protein portion and a water soluble solids portion. Next, the protein portion is dewatered then dried to define a high protein corn meal that includes at least 40 wt % protein on a dry basis.

Owner:FLUID QUIP TECH LLC

Laying hen compound feed and preparation method thereof

ActiveCN102258153AImprove digestion and absorption ratePromote excess secretionFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention provides a compound feed for a laying hen in egg-laying period and a preparation of the compound. The compound feed comprises the following ingredients: 64-66 wt% of corn, 20-22 wt% of soybean meal, 2-4 wt% of wheat bran, 0.5-1 wt% of fish steak powder, 0.4-1 wt% of cottonseed meal, 0.1-0.15 wt% of phytase (5000), 7-10 wt% of clamshell powder, 1-2 wt% of mountain meal, 0.5-1 wt% of calcium hydrogen phosphate, 0.3-1 wt% of salt, 0.2-0.4 wt% of 65%-lysine, 0.1-0.2 wt% of solid methionine, 0.06-0.1 wt% of choline chloride, 0.3-0.5 wt% of vitamin C, 0.2-0.4 wt% of trace element premix, and 0.2-0.4 wt% of vitamin premix, and is prepared by the following steps: extracting raw materials, carrying out fine grinding to on the raw materials with 2.0 mm sieves, and mixing the feed for 200 s, with the grain size of corn of 5.4 mm. The compound feed has scientific allocated proportion and simple preparation, reduces the usage of antibiotics, reduces drug residue in the laying hen body, has positive influences effects on the laying hen, and is economical and practical.

Owner:贵阳新希望农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com