Fermented abandoned vegetable feedstuff and preparation method thereof

A technology of discarded vegetables and feed, applied in animal feed, animal feed, application, etc., can solve the problems of vegetable waste and straw waste, and achieve the effect of strong adaptability and wide range of applicable raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

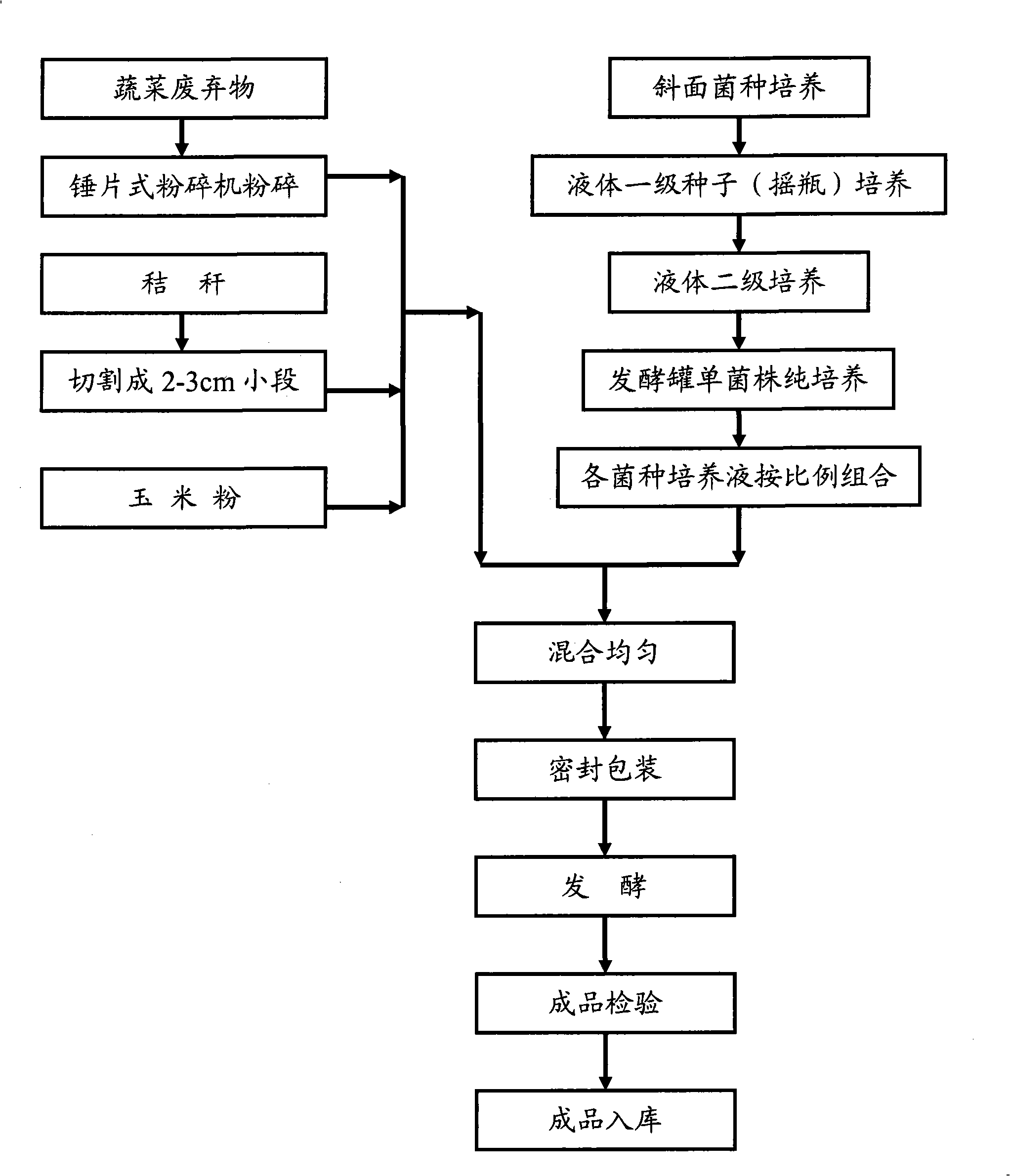

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 (high dose)

[0041] It is composed of mixed raw materials and microbial live bacteria liquid. The mixed raw materials are composed of vegetable waste, straw and corn flour. , rice stalks, sorghum stalks, peanut stalks or potato stalks, the mixed raw materials are composed of 80% waste vegetables, 25% straws, 6% corn flour, and live microorganisms are added to each ton of mixed raw materials 40 milliliters of liquid, each milliliter of microbial living bacteria liquid contains by volume: 30% of Bacillus coagulans, 25% of Lactobacillus acidophilus, 25% of Lactobacillus plantarum, 25% of Lactobacillus brevis, and 25% of Candida utilis.

[0042] The live bacteria content per milliliter of microbial live bacteria liquid is 1.0×10 9 cfu / mL~1.0×10 11 cfu / mL, live bacteria content: Bacillus coagulans ≥1.0×10 11 cfu / mL, Lactobacillus acidophilus ≥1.0×10 11 cfu / mL, Lactobacillus plantarum ≥1.0×10 11 cfu / mL, Lactobacillus breve microcapsules ≥1.0×10 11 cfu / mL, ...

Embodiment 2

[0043] Embodiment 2 (low dosage)

[0044] It is composed of mixed raw materials and microbial live bacteria liquid. The mixed raw materials are composed of vegetable waste, straw and corn flour. , rice stalks, sorghum stalks, peanut stalks or potato stalks, the mixed raw materials are composed by weight (w / w) per ton: 70% of discarded vegetables, 20% of straw, 4% of corn flour, and live microorganisms are added to each ton of mixed raw materials 30 milliliters of liquid, each milliliter of microbial living bacteria liquid contains by volume: 20% of Bacillus coagulans, 20% of Lactobacillus acidophilus, 15% of Lactobacillus plantarum, 15% of Lactobacillus brevis, and 15% of Candida utilis.

[0045] The live bacteria content per milliliter of microbial live bacteria liquid is 1.0×10 9 cfu / mL~1.0×10 11 cfu / mL, live bacteria content: Bacillus coagulans ≥1.0×10 11 cfu / mL, Lactobacillus acidophilus ≥1.0×10 11 cfu / mL, Lactobacillus plantarum ≥1.0×10 11 cfu / mL, Lactobacillus breve...

Embodiment 3

[0046] Embodiment 3 (medium dose)

[0047] It is composed of mixed raw materials and microbial live bacteria liquid. The mixed raw materials are composed of vegetable waste, straw and corn flour. , rice stalks, sorghum stalks, peanut stalks or potato stalks, mixed raw materials per ton by weight ratio (w / w): 75% of discarded vegetables, 22.5% of straw, 5% of corn flour, added live microorganisms per ton of mixed raw materials 35 milliliters of liquid, each milliliter of microbial living bacteria liquid contains by volume: 25% of Bacillus coagulans, 22.5% of Lactobacillus acidophilus, 20% of Lactobacillus plantarum, 20% of Lactobacillus brevis, and 20% of Candida utilis.

[0048] The live bacteria content per milliliter of microbial live bacteria liquid is 1.0×10 9 cfu / mL~1.0×10 11 cfu / mL, live bacteria content: Bacillus coagulans ≥1.0×10 11 cfu / mL, Lactobacillus acidophilus ≥1.0×10 11 cfu / mL, Lactobacillus plantarum ≥1.0×10 11 cfu / mL, Lactobacillus breve microcapsules ≥1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com