Patents

Literature

731 results about "Crude fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crude fibre. A measurement of fibre content. Also known as Weende cellulose, crude fibre is the insoluble residue of an acid hydrolysis followed by an alkaline one. This residue contains true cellulose and insoluble lignin.

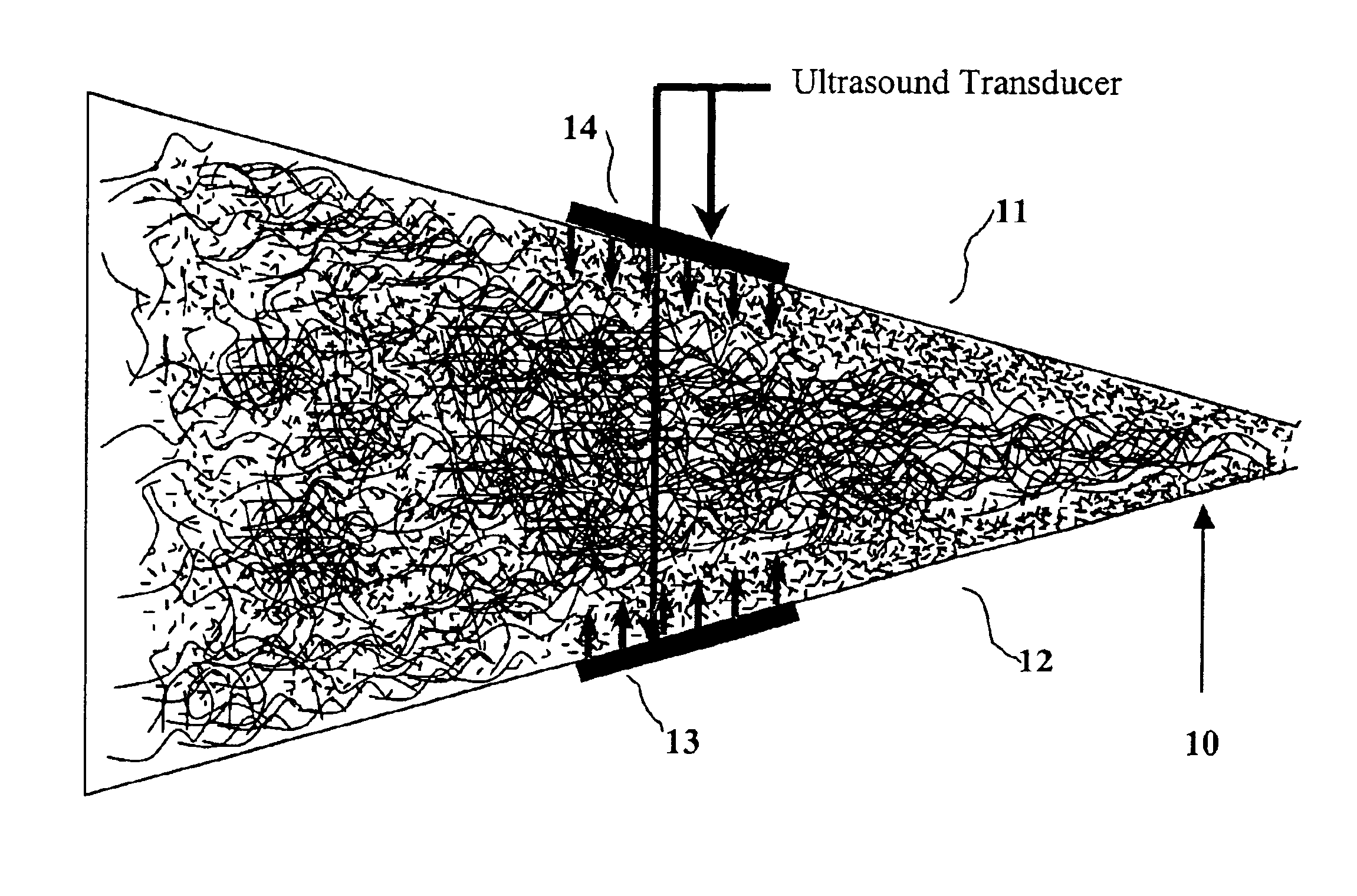

Filter material construction and method

InactiveUS6872431B2Improve efficiencyExtend filter lifeCombination devicesDispersed particle filtrationFiberFilter media

A preferred filter media is provided. The media includes a fine fiber web secured to the surface of a coarse fiber support. A preferred filter media, comprising multiple layers of fine fiber media separated by coarse fiber support, is provided. Advantageous filter constructions result and are provided. Also according to the disclosure, methods for using such arrangements to filter are provided.

Owner:DONALDSON CO INC

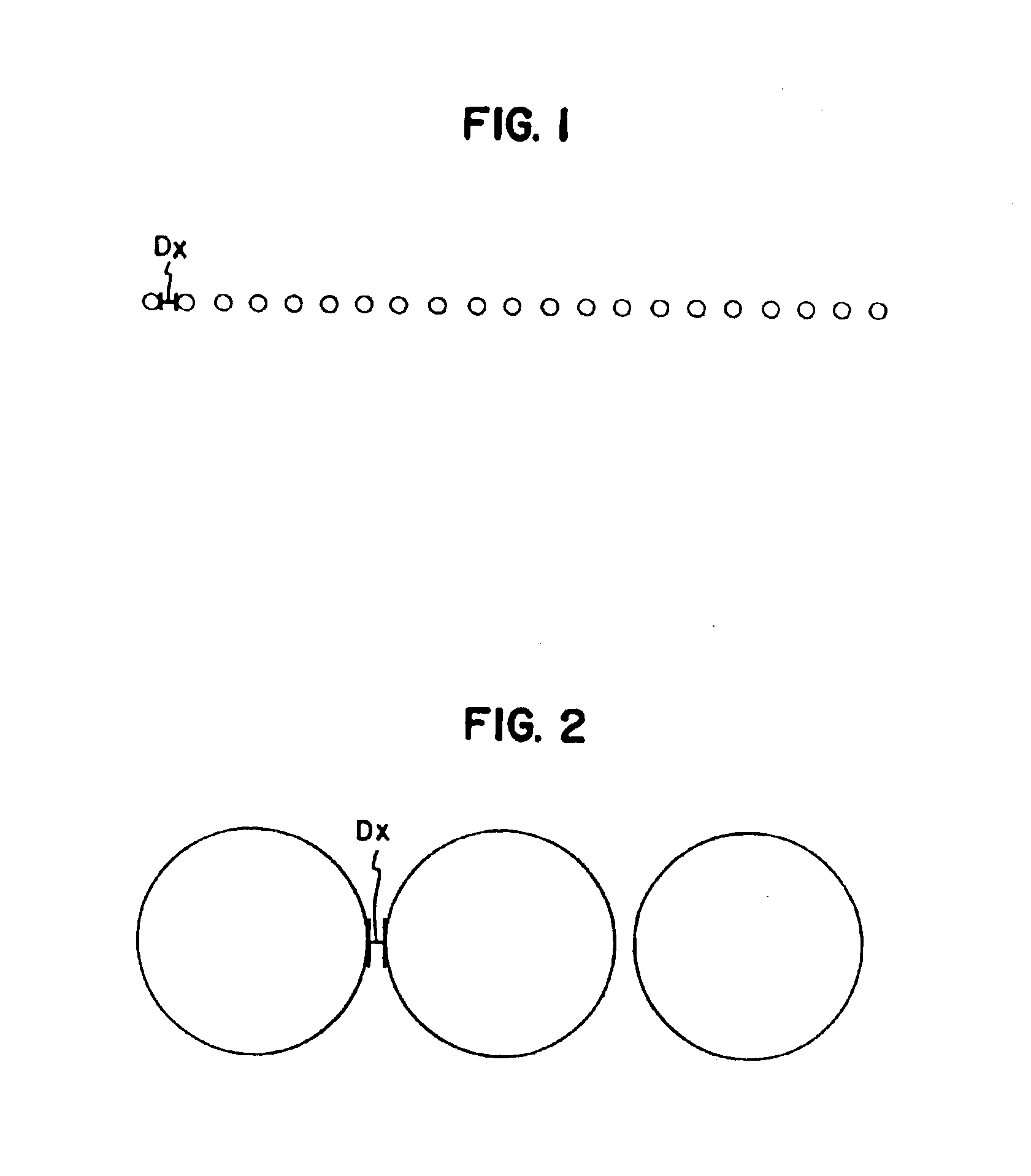

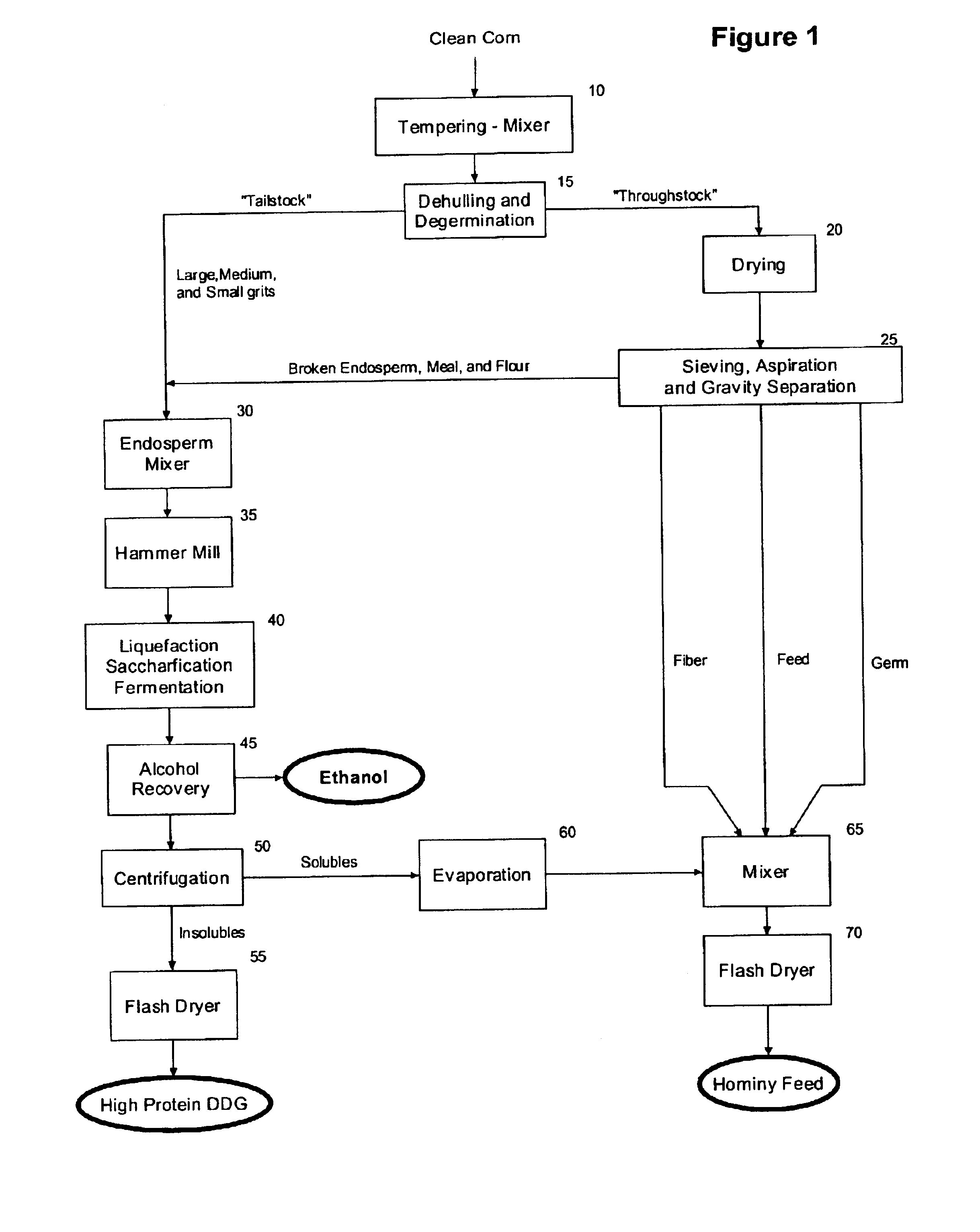

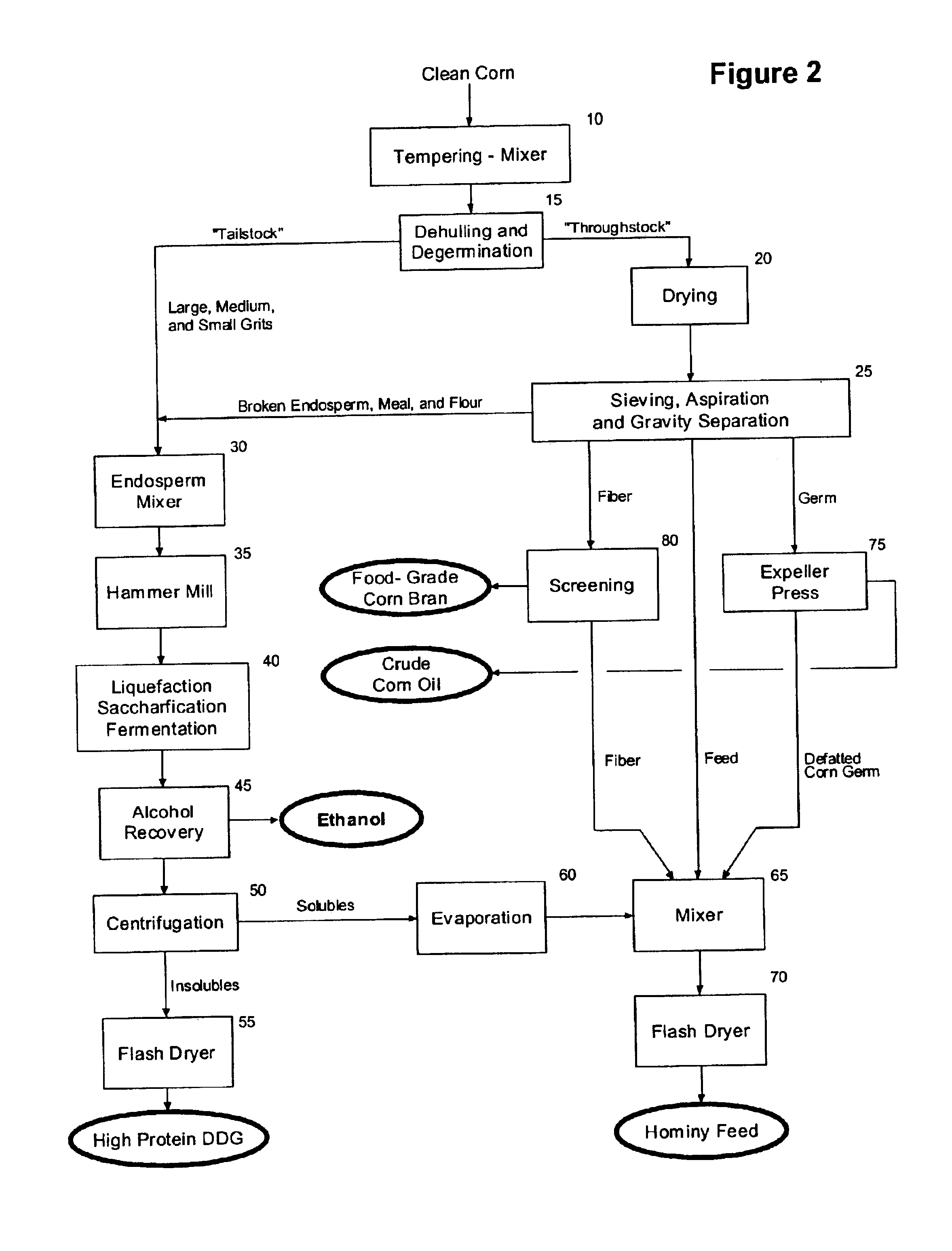

High protein corn product production and use

InactiveUS6962722B2Improve palatabilityImprove digestibilityFood processingClimate change adaptationWeight gainingFiber

The present invention relates to the production of a highly digestible, high protein product (high protein distillers dried grains or high protein DDG) from corn endosperm, and more particularly to a method for the recovery of high protein DDG by using: (i) dehulling and degermination to isolate a low fat, low fiber corn endosperm fraction, (ii) enzymatic hydrolysis to solubilize and alcoholic fermentation to assimilate the starch and non-starch carbohydrates present in the corn endosperm, and (iii) filtration and / or centrifugation to recover the dealcoholized insoluble solids that remain after fermentation of the corn endosperm. The present invention provides an alternative to the traditional dry mill method of processing corn to produce ethanol, and results in the production and recovery of a distillers' by-product (high protein DDG) with increased value and range of use as an ingredient in feeds for farm-raised ruminants and non-ruminants and pet foods. The product of the present invention contains less than about 2.0 weight percent starch, from about 55.0 to about 65.0 weight percent protein, from about 4.5 to about 7.5 weight percent fat, from about 3.0 to about 5.0 weight percent crude fiber, and from about 78.0 to about 90.0 percent total digestible nutrients, and improves the palatability and digestibility of animal feeds and / or pet foods into which it is incorporated, and aids in the management of the health and weight gain of the animal.

Owner:GREENSTOCK RESOURCES

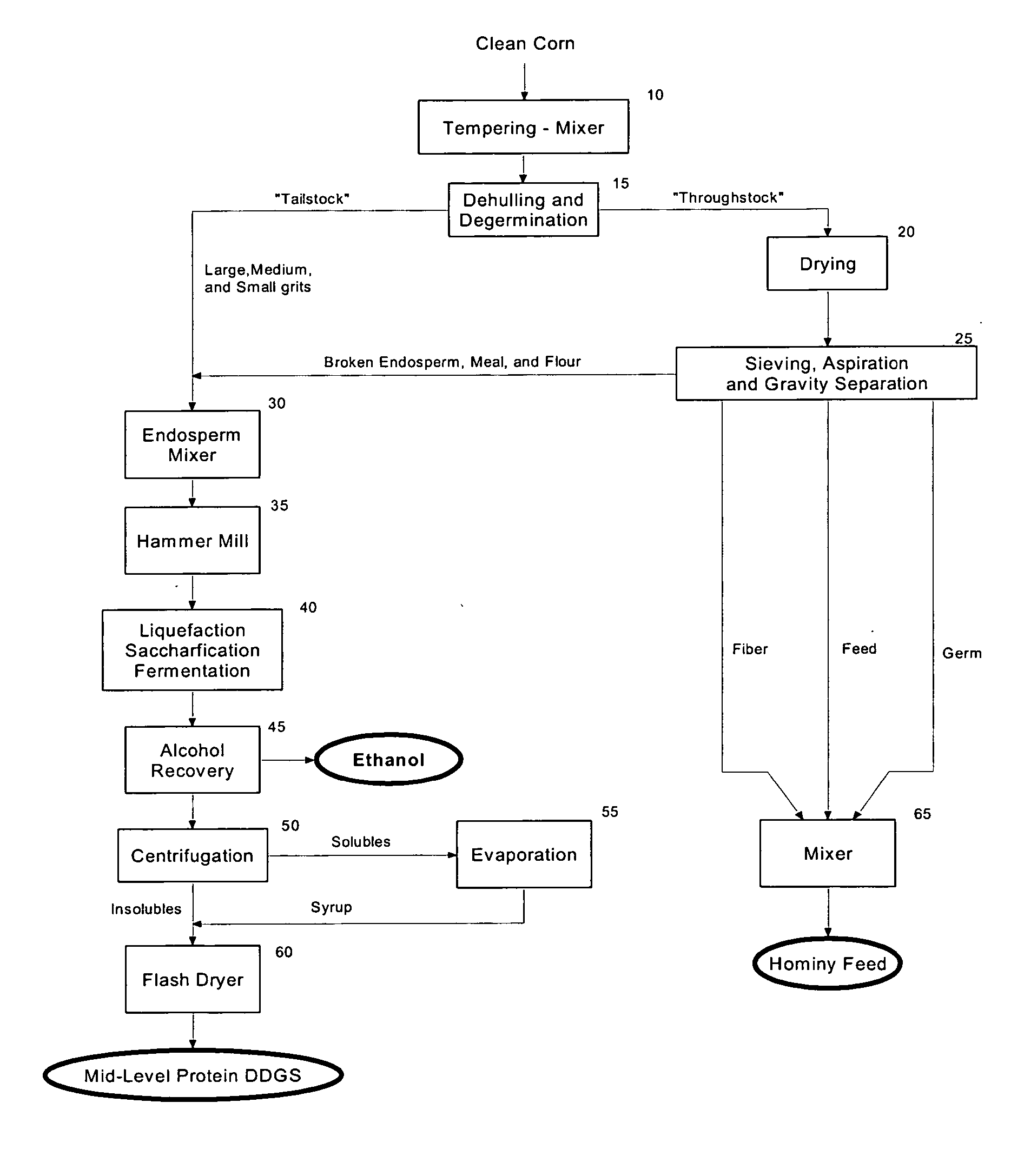

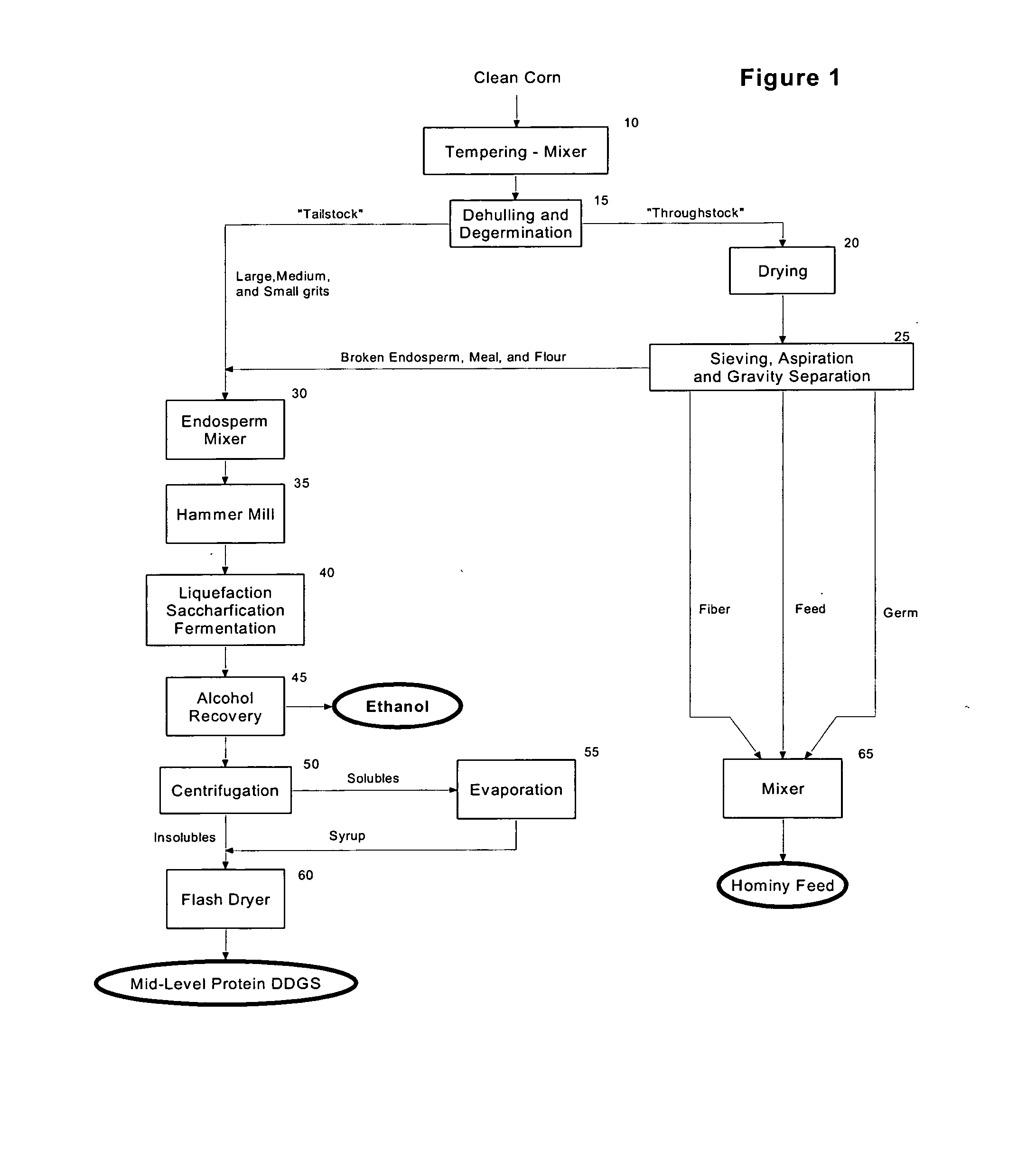

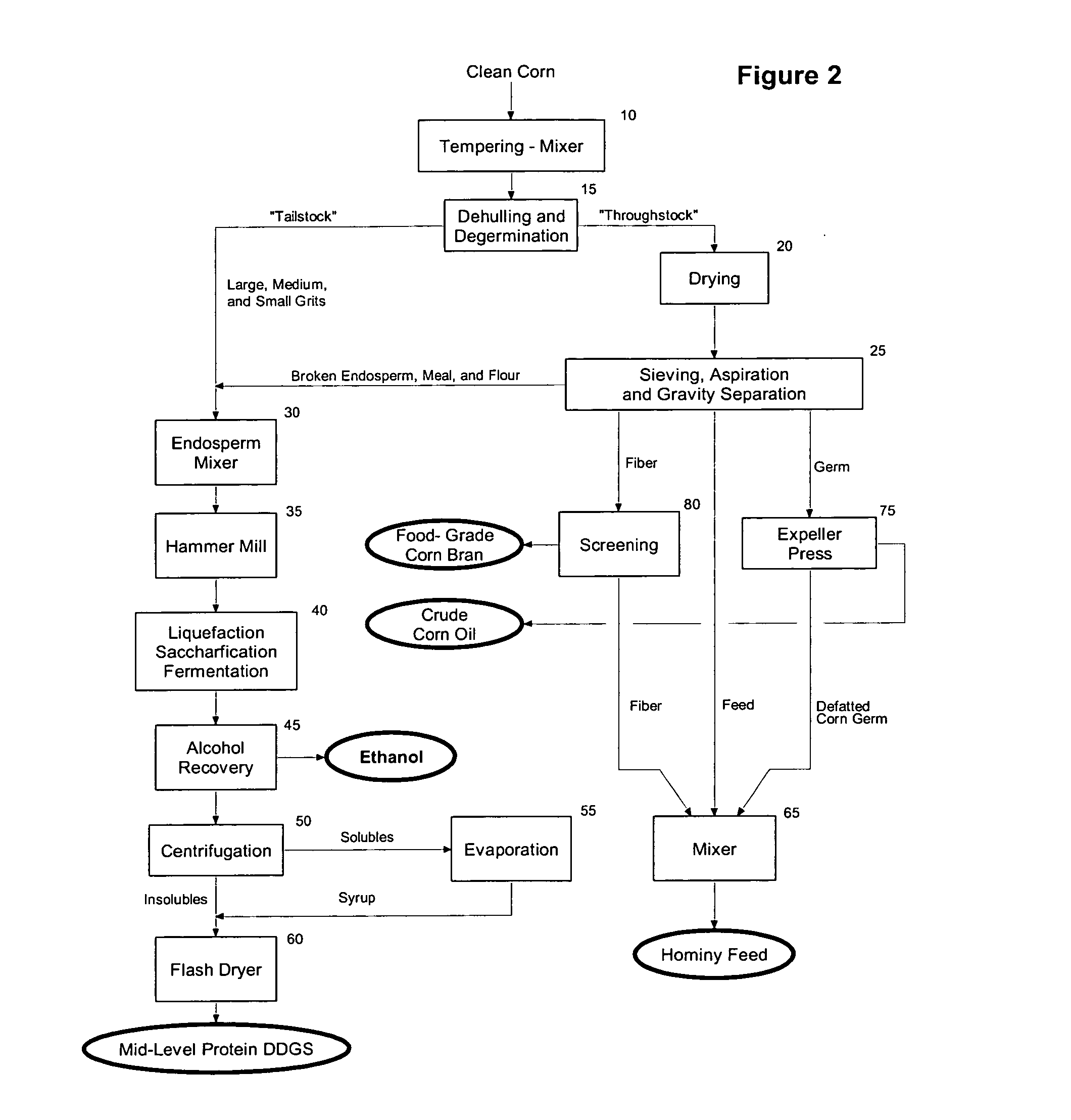

Mid-level protein distillers dried grains with solubles (DDGS) - production and use

InactiveUS20060057251A1Improve palatabilityImprove digestibilityFood processingClimate change adaptationFiberFiltration

The present invention relates to the production of a highly digestible, mid-level protein DDGS from corn endosperm, and more particularly to a method for the recovery of mid-level protein DDGS by using: (i) dehulling and degermination to isolate a low fat, low fiber corn endosperm fraction, (ii) enzymatic hydrolysis to solubilize and alcoholic fermentation to assimilate the starch and non-starch carbohydrates present in the corn endosperm, and (iii) filtration, centrifugation and / or evaporation to recover the dealcoholized insoluble and soluble solids that remain after fermentation of the corn endosperm. The product of the present invention contains less than about 5.0 weight percent starch, from about 40.0 to about 52.5 weight percent protein, from about 4.5 to about 8.5 weight percent fat, from about 3.0 to about 6.0 weight percent crude fiber, and from about 78.0 to about 90.0 percent total digestible nutrients.

Owner:GREENSTOCK RESOURCES

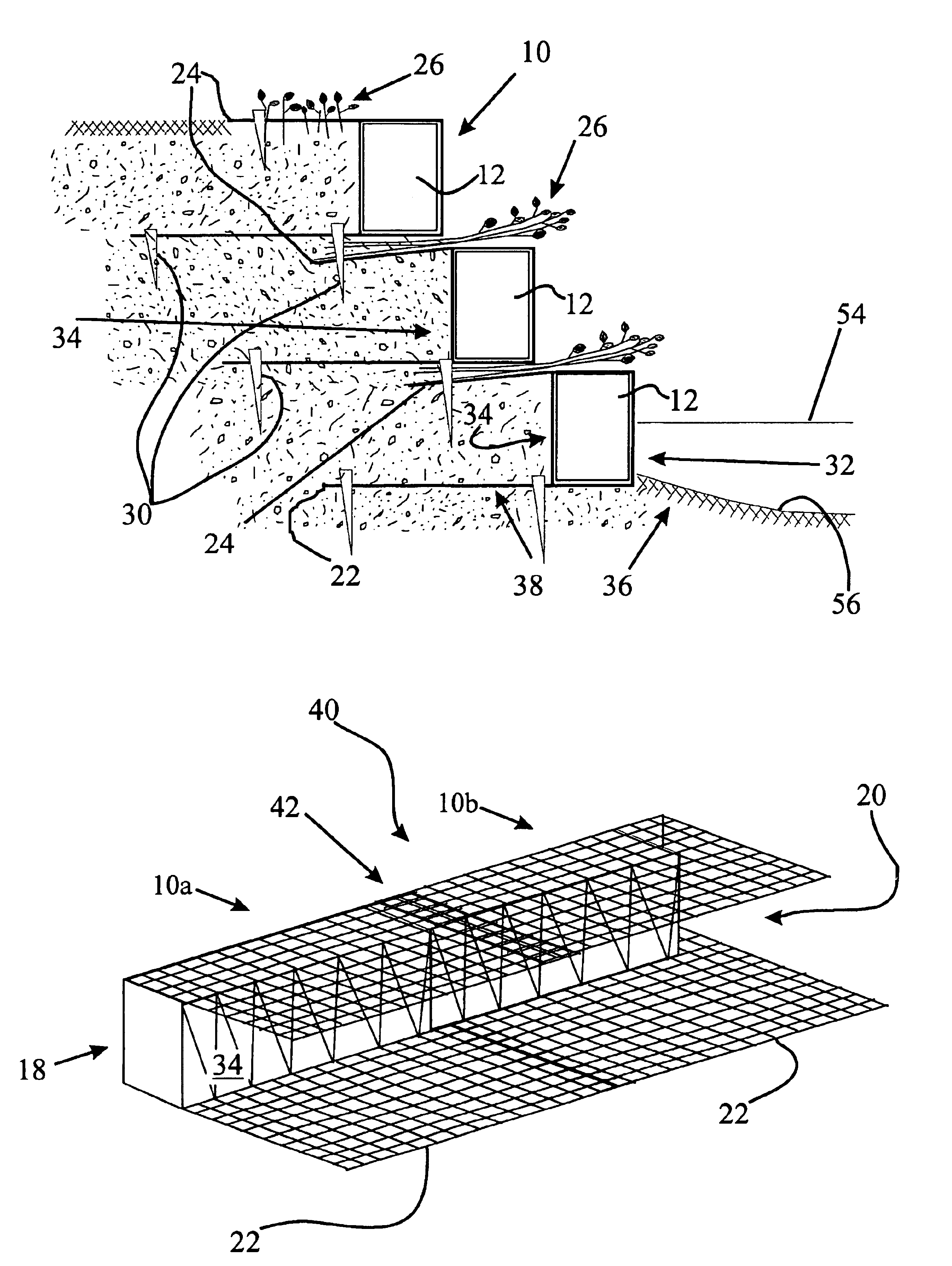

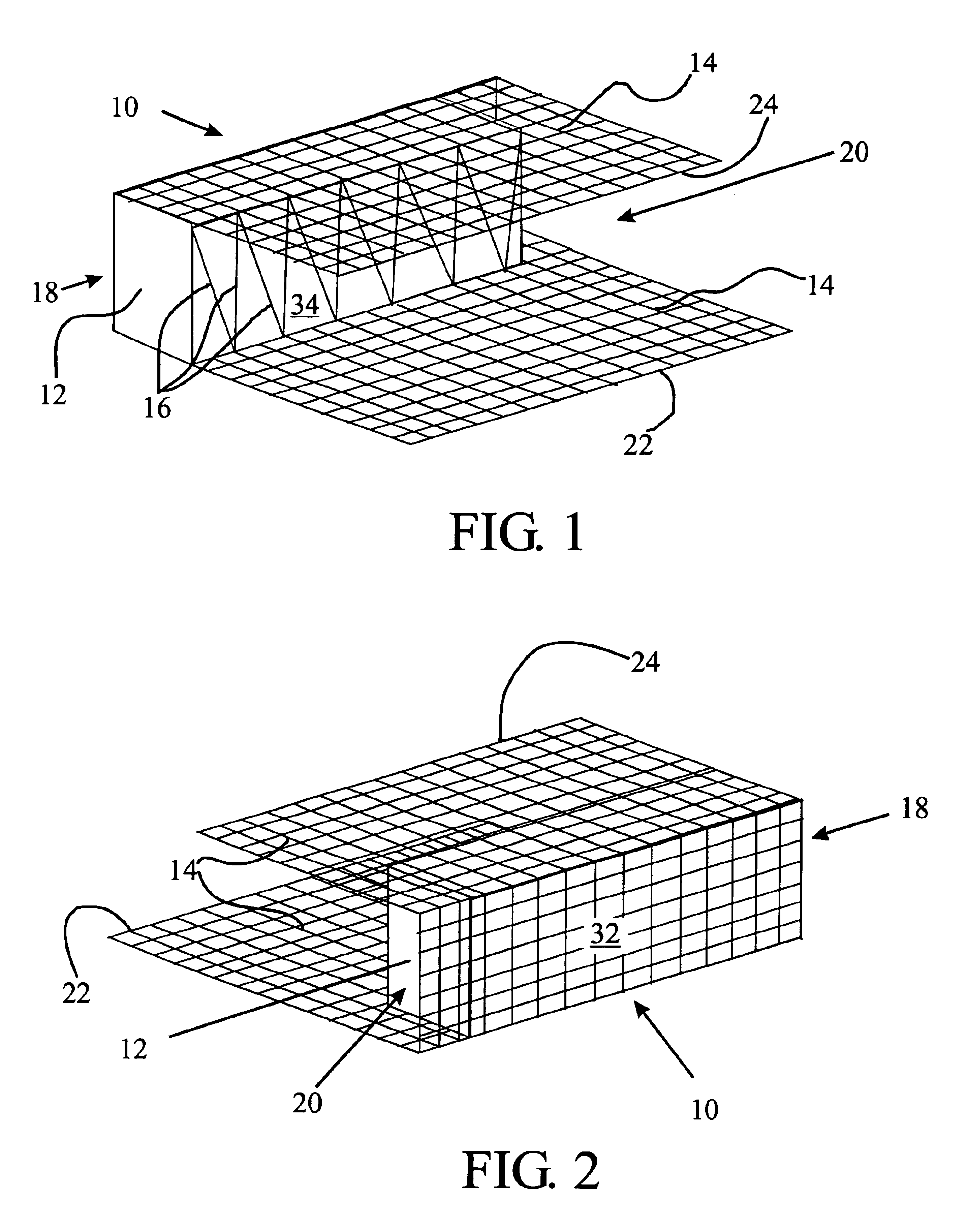

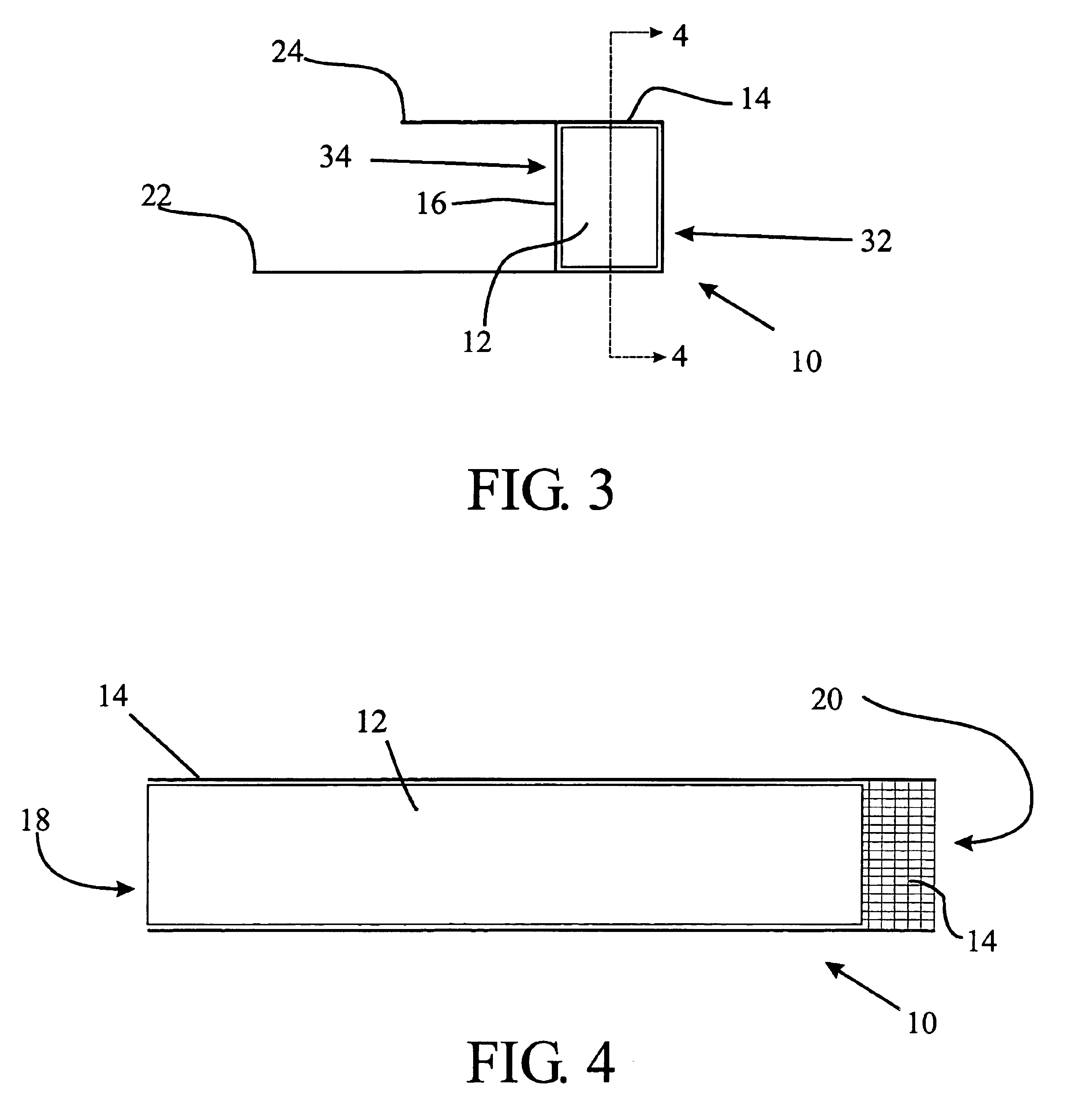

Self-anchoring fiber block system

InactiveUS6893193B2Promote vegetation growthEasy to installArtificial islandsClimate change adaptationFiberEngineering

A fiber block segment suitable for controlling erosion and stabilizing soil is described that comprises an elongated fiber block formed of a densely packed elongated thick fibrous material. The fiber block is wrapped with a fabric around three sides so that the fabric defines a top anchor portion and a bottom anchor portions extending from the block. The fiber block is securely attached to the wrapped fabric by another fabric or twine spanning the fourth side of the block. Additionally, the fabric is wrapped only up to the edges defining one end (a male end) and beyond the edges defining the opposite end (the female end) to define a pouch-like structure at the female end. The fiber block is made of coconut fibers (coir). The fabric is woven from coir twine, and coir twine secures the fabric to the fiber block.

Owner:SANTHA B LANKA

Method of making a stratified paper

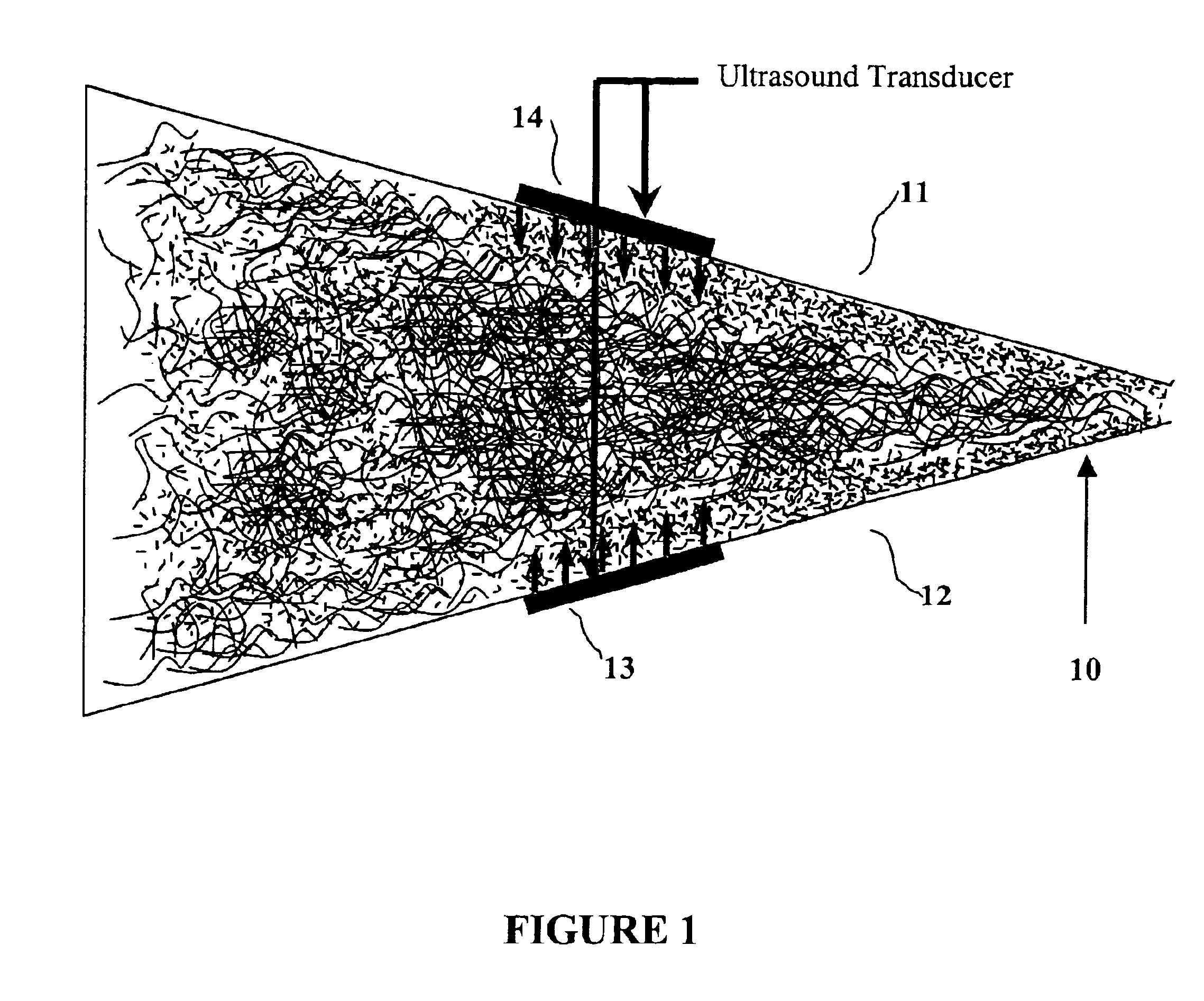

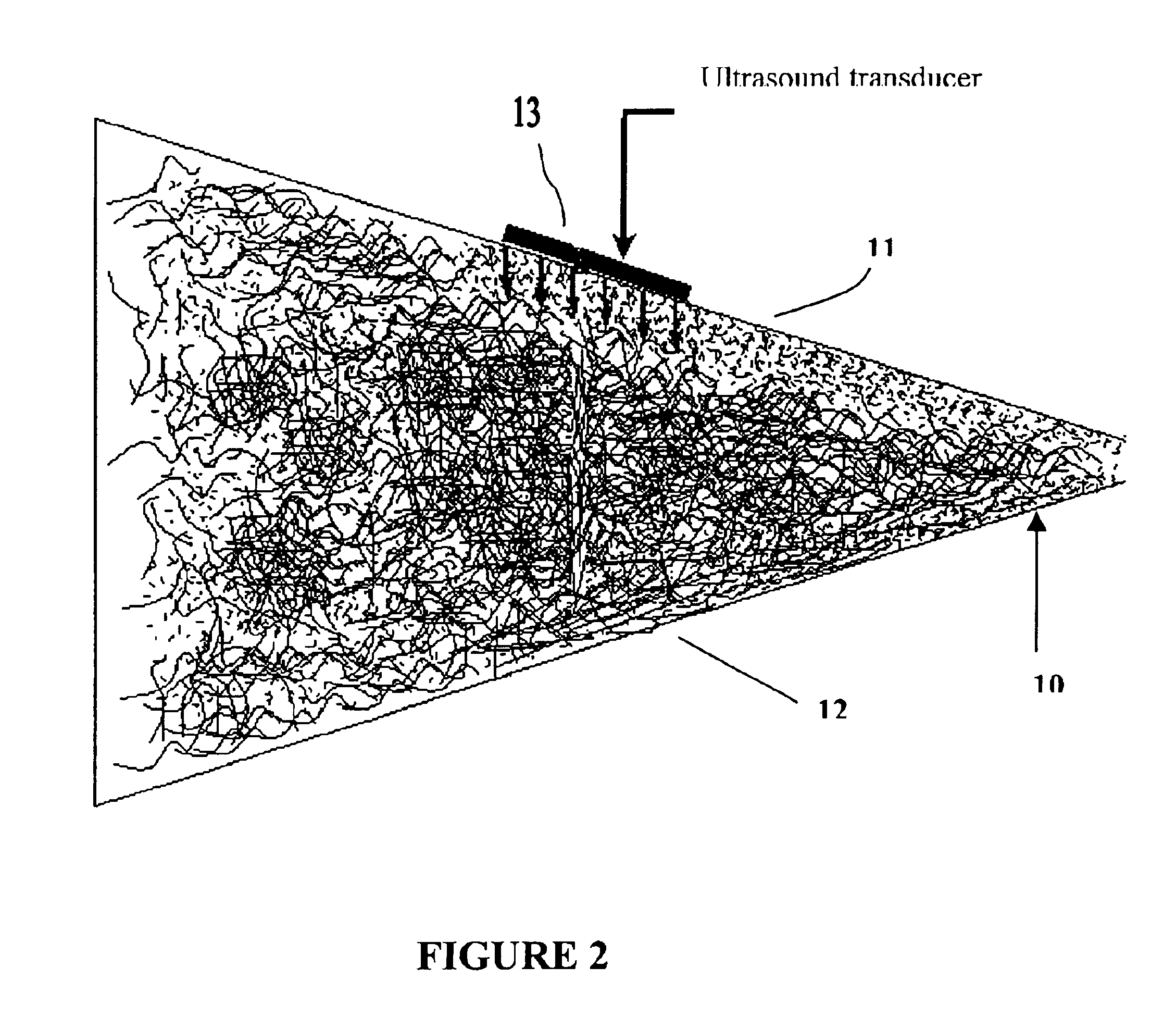

The present invention provides a method making stratified paper by redistributing the pulp suspension inside the headbox nozzle using acoustic radiation waves. Acoustic radiation forces fractionate fibers based on fiber radius. The acoustic radiation waves separate the fibers by pushing the coarse and longer fibers to the inner area while fines and smaller fibers remain in the outer area. This has a similar effect of multi-layer stratification headbox, and provides paper with a smoother surface.

Owner:INT PAPER CO

Preparation method of surface-modified ball-milling refined plant fibers

InactiveCN102978984ABall milling method is simpleBall milling method is convenientPulping with inorganic basesGrain treatmentsChemical industryCrude fibre

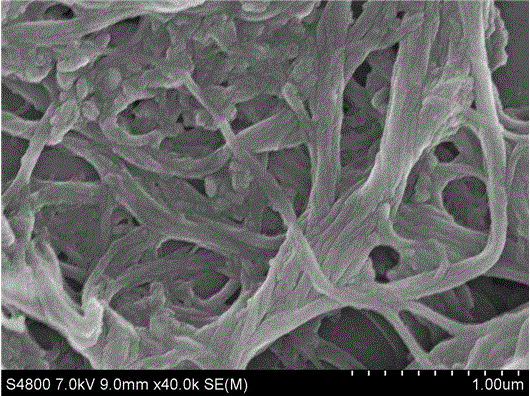

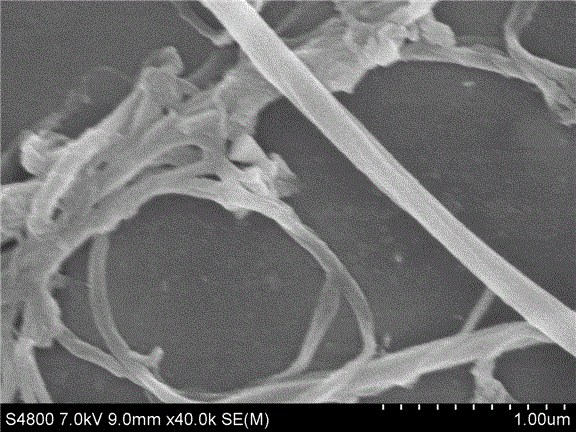

The invention relates to a preparation method of surface-modified ball-milling refined plant fibers. According to the preparation method, natural plant fibers are subjected to wet method ball milling after pretreatment, and the original micro-fibers can be scattered along the long-axis direction and broken along the diameter direction, so that the refined plant fibers are obtained. Compared with nano-celluloses prepared by a hydrolysis method, the refined long fibers obtained by the preparation method have the characteristics that the length is long, the length-diameter ratio is greater, and by controlling the ball milling condition, fine fibers and coarse fibers in the product are interconnected to from a net-like structure, and separated single fibers can be obtained. The fiber product does not contain acidic groups remained during preparation by the hydrolysis method. The plant fibers are subjected to appropriate surface modification, and then the surface-modified ball-milling refined plant fibers are prepared. The surface-modified ball-milling refined plant fibers have good application prospects in construction foods, medicaments, chemical industry, papermaking, spinning, new material preparation and the like.

Owner:SUN YAT SEN UNIV

Premix feed for relieving astriction of sows

ActiveCN102178112ARelieve constipationPromote proliferationAnimal feeding stuffAccessory food factorsFiberDietary fiber

The invention discloses a premix feed for relieving astriction of sows, which is prepared by mixing 5 to 7 weight parts of premix feed and 93 to 95 weight parts of main ingredient. The premix feed comprises the following components in part by weight: 0.8 to 1 part of liquoric root, 0.8 to 1.0 part of Bacillus subtillis and lactic acid bacteria preparation, 0.3 to 0.6 parts of antibacterial peptide and 1.2 to 1.6 part of choline chloride. The premix feed can relieve astriction of sows by adding a raw material with high crude fiber content or adding mineral substance aperients, microecological preparation, functional oligosaccharide, dietary fibers, antibacterial peptides and various green additives, thereby improving the production performance of sows.

Owner:SHENZHEN PREMIXINVE NUTRITION CO LTD

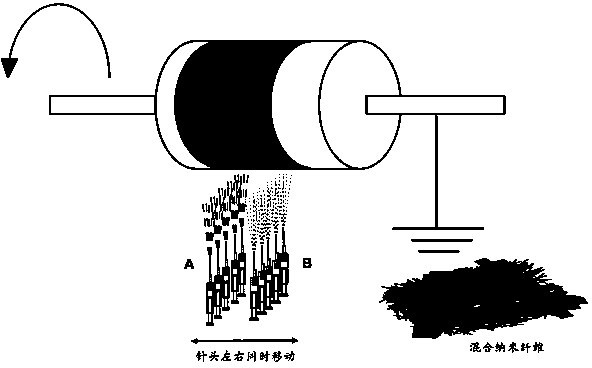

Preparation method for efficient low-impedance antibacterial air purification filter membrane

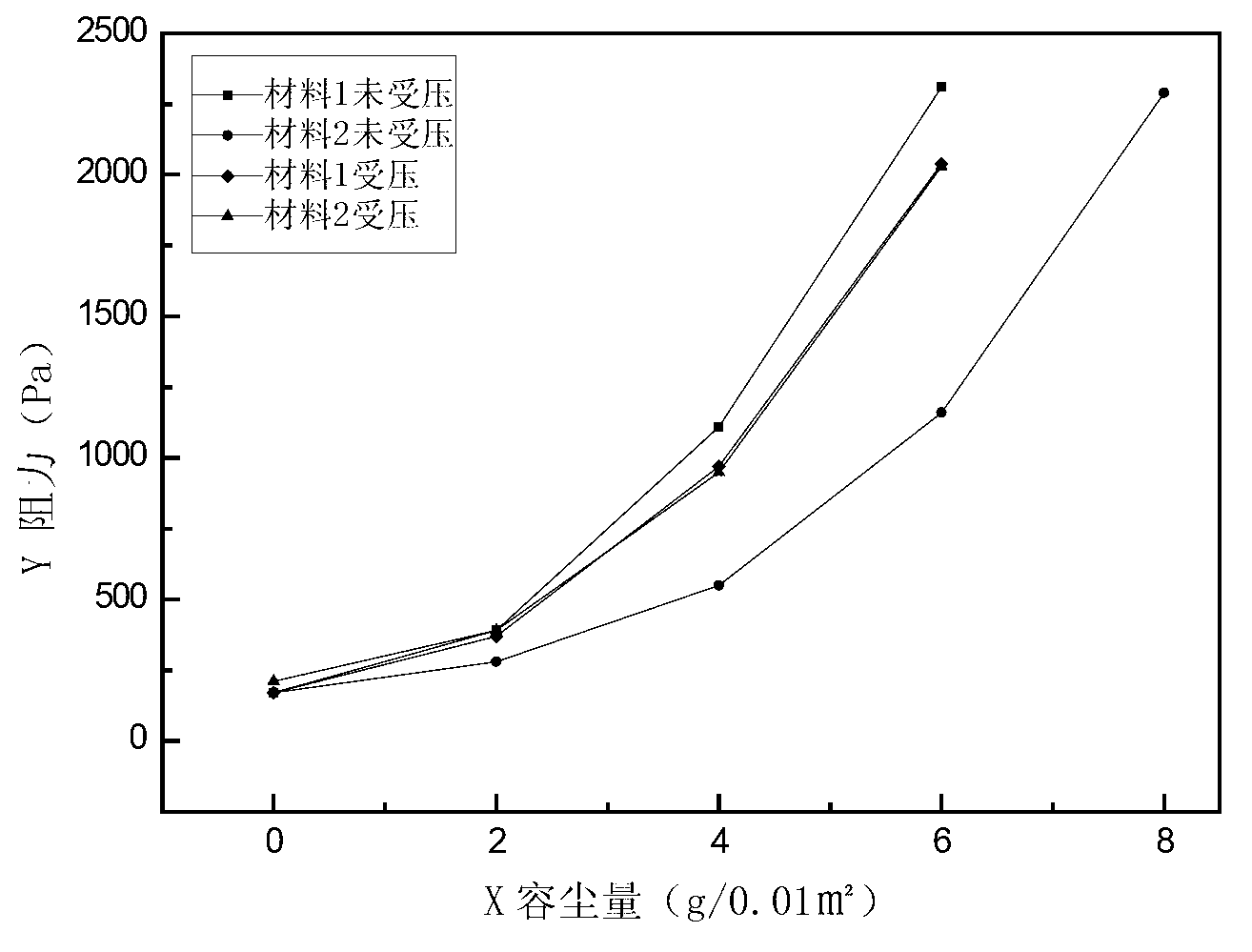

ActiveCN103774345ANo reduction in filtration efficiencySmall filter resistanceDispersed particle filtrationFiltration separationEscherichia coliCrude fibre

The invention discloses a preparation method for an efficient low-impedance antibacterial air purification filter membrane. Two polymers A and B which can be used for preparing nanofibers with great diameter differences by an electrostatic spinning technology are selected, and are mixed with graphene oxide and a solvent to prepare two spinning solutions respectively, and a composite nanofiber filter membrane with a multilayer composite structure is prepared in a parallel electrospinning way. According to the preparation method, the graphene oxide is doped, so that the prepared nanofiber filter membrane is antibacterial; rough fiber layers are inserted into fine fiber layers to enable the fine fiber layers to be looser, so that the filter resistance of the membrane is reduced without reduction in the filter efficiency of the membrane; the filter membrane is detected to have sodium chloride aerosol particle rejection rate of over 96 percent, pressure drop of a less-than-28mm water column and Escherichia coli inhibition rate of over 90 percent.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Sand badger fattening forage and preparation method thereof

InactiveCN103222553AFattening promotionImprove disease resistanceAnimal feeding stuffBiotechnologyAnimal science

Owner:徐玉文

Method for quickly fermenting paper mulberry leaves to produce protein feed

The invention relates to a method for quickly fermenting paper mulberry leaves to produce a protein feed. Paper mulberry leaf powder is used as a main nitrogen source raw material, corn meal is used as a carbon source raw material, and the paper mulberry leaves are quickly converted into the protein feed through a complex microorganism mixing solid fermentation technology. The method is mainly characterized in that: the corn meal is taken as a carbon source, so the decomposition conversion of microorganisms on the paper mulberry leaves can be speeded up, the production time is obviously shortened, the production efficiency is improved, and the fermentation facility investment is reduced. The proportion of the corn meal and the paper mulberry leaf powder 1-6 / 100, the protein content of the obtained protein feed after the conversion is larger than 28%, the carbohydrate content is less than 40%, the crude fibre content is less than 9%, the crude fat content is less than 4%, the LD 50 is more than 16g / kg, so the method is safe and non-toxic.

Owner:HUBEI GOLE BIO TECH DEV

Health-care growth-promoting fermented feed additive and preparation method thereof

The invention discloses a health-care growth-promoting fermented feed additive and a preparation method thereof. The fermented feed additive comprises, by weight, 10-40% of edible fungus chaff, 5-10% of traditional Chinese medicine residues, 10-30% of corncobs, 10-30% of bean pulp, 0.2-1% of fermentation strains and 20-30% of water. The fermented feed additive has the advantages that the edible fungus chaff and the traditional Chinese medicine residues are added into feed, so that the usage amount of cereal feed is reduced, and the feed cost is lowered; mycelia, saccharomycetes and other probiotics in the edible fungus chaff are utilized for performing solid fermentation treatment on the traditional Chinese medicine residues, so that both the medicinal value and the edible value of the medicine residues are brought into full play; crude protein, crude fat and crude fiber in the fungus chaff and medicinal ingredients not extracted from the medicine residues are fully degraded through a fermentation technology, so that the made fermented feed additive contains rich protein, saccharides, fat, microelements and other nutrient substances and also has the effects of improving immunity and promoting digestion.

Owner:河南亚卫动物药业有限公司

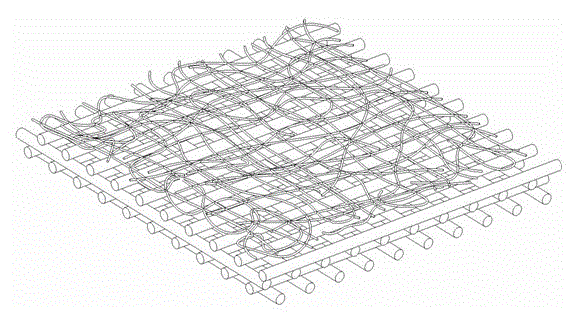

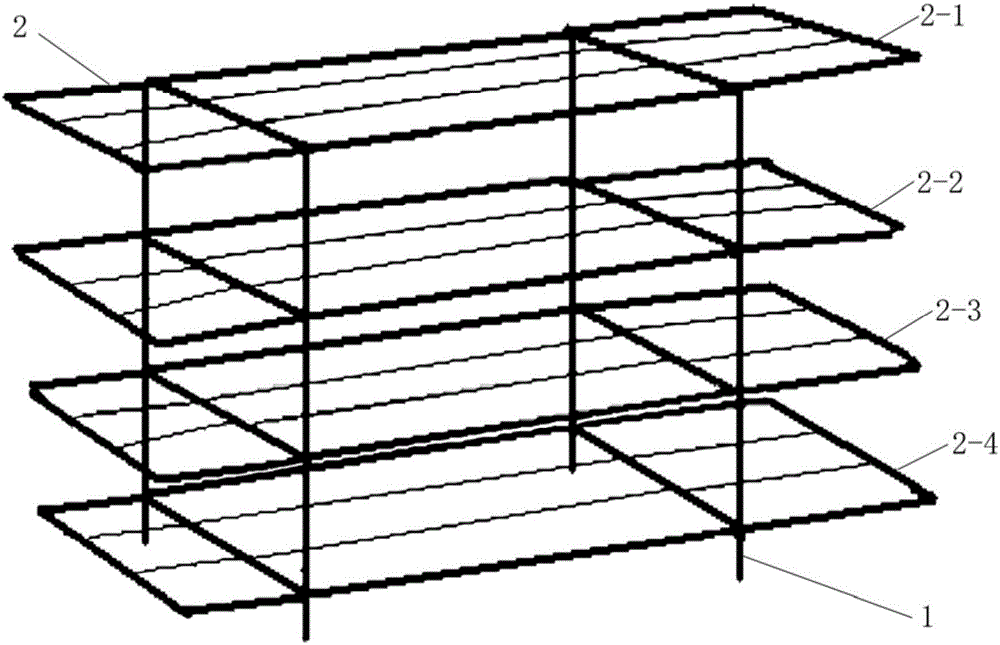

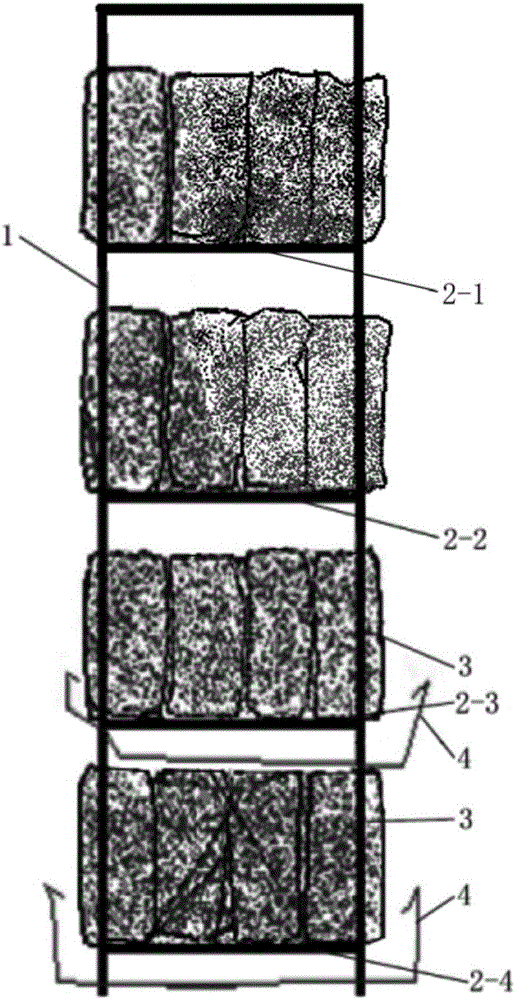

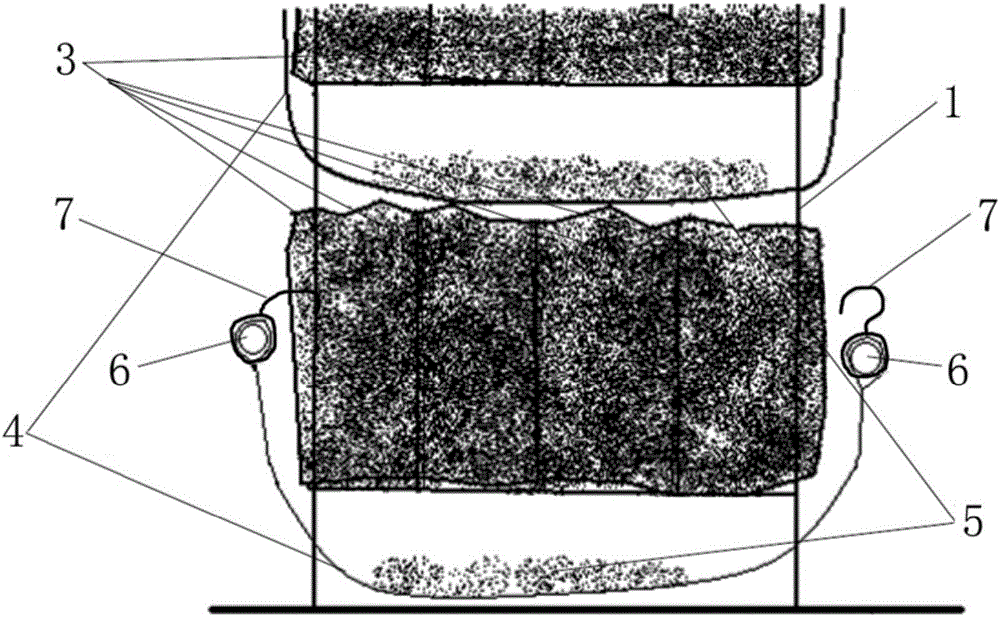

Diphasic porous three-dimensional cell culture scaffold

InactiveCN102719391AImprove adsorption capacityImprove inoculation efficiencyTissue cultureMicroorganism fixing/supporting apparatusNanofiberCultured cell

The invention relates to a diphasic porous three-dimensional cell culture scaffold which is formed by a coarse fiber phase and a fine fiber phase which are entirely different in diameter. The coarse fiber phase is larger than cultured cells in size while the fine fiber phase is smaller than the cultured cells in size, the coarse fiber phase comprises multilayer coarse fiber structures, each two adjacent coarse fiber structures are arranged according to a certain angle, and the fine fiber phase is individually combined on one side or multiple sides of the coarse fiber phase and is averagely or intensively distributed in hole structures of the three-dimensional cell culture scaffold formed by the coarse fiber phase. In the diphasic porous three-dimensional cell culture scaffold, the fine fiber phase is much smaller than the cells in diameter, so that the cells can attach to nanofibers quite easily, and differentiation of stem cells on the nanofibers can be effectively promoted. Therefore, by means of adding the fine fibers on the three-dimensional cell culture scaffold, cell vaccination efficiency can be improved, and the cells grown on the fine fibers, particularly growth and differentiation of the stem cells, can be promoted and regulated.

Owner:JIANGYIN RECONGENE BIOMEDICAL TECH

Preparation method of biological feed of banana stem leaves

InactiveCN101579041AHas a clear fragranceLower pHFood processingAnimal feeding stuffBiotechnologyFully developed

The invention discloses a preparation method of a biological feed of banana stem leaves, which comprises the following steps of: cutting up the banana stem leaves, then pre-drying till the water content is 70 to 75 percent, adding minor ingredients into the banana stem leaves, then adding cellulase, tannase and third class seed liquid of lactobacillus plantarum, mixing evenly, extracting air, sealing, storing and preparing to obtain the biological feed of banana stem leaves; and the minor ingredients are pineapple peels, papaya peels or molasses. The preparation method uses the banana stem leaves as major raw materials, generates an acid environment by fermentation of lactobacillus to inhibit spoilage micro-organisms, and can fully develop and utilize by products of fruits, reduce tannin content and coarse fibre content of the by product of banana and improve the palatability, digestibility and nutritional value of the feed.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Culture medium for breeding earthworms and stereoscopic earthworm breeding method and device

ActiveCN106577556ASuitable for growthSuitable for breedingFood processingAnimal feeding stuffFiberFeces

The invention relates to a culture medium for breeding earthworms and a stereoscopic earthworm breeding method and device and belongs to the technical field of earthworm breeding. The culture medium is prepared through the following method that firstly, a base material and EM bacterium liquid are mixed, humidity is adjusted to 80%-90% to obtain a mixed material, and the base material is mainly composed of livestock feces, coarse fiber materials and sludge; secondly, the mixed material is subjected to closed anaerobic fermentation for 22-26 h, and after temperature is lowered to 28-32 DEG C, the EM bacterium liquid is added to continue the closed anaerobic fermentation for 22-26 h, and a fermented material is obtained; and thirdly, net bags are filled with the fermented material, and after compacting, the culture medium is obtained after piling and thorough decomposing are performed for 1-3 days. The culture medium achieves that pollution is treated through cultivation and achieves effective recycling of organic solid waste, nutrient substances in the base material are reserved to the maximum extent, and the culture medium is suitable for growing and breeding of the earthworms; and a three-dimensional stereoscopic space is provided for activity and breeding of the earthworms, adult earthworms are not needed to be separated manually, and intensified stereoscopic breeding of the earthworms in a greenhouse or in an indoor environment can be achieved easily.

Owner:海南晟延农业投资有限公司

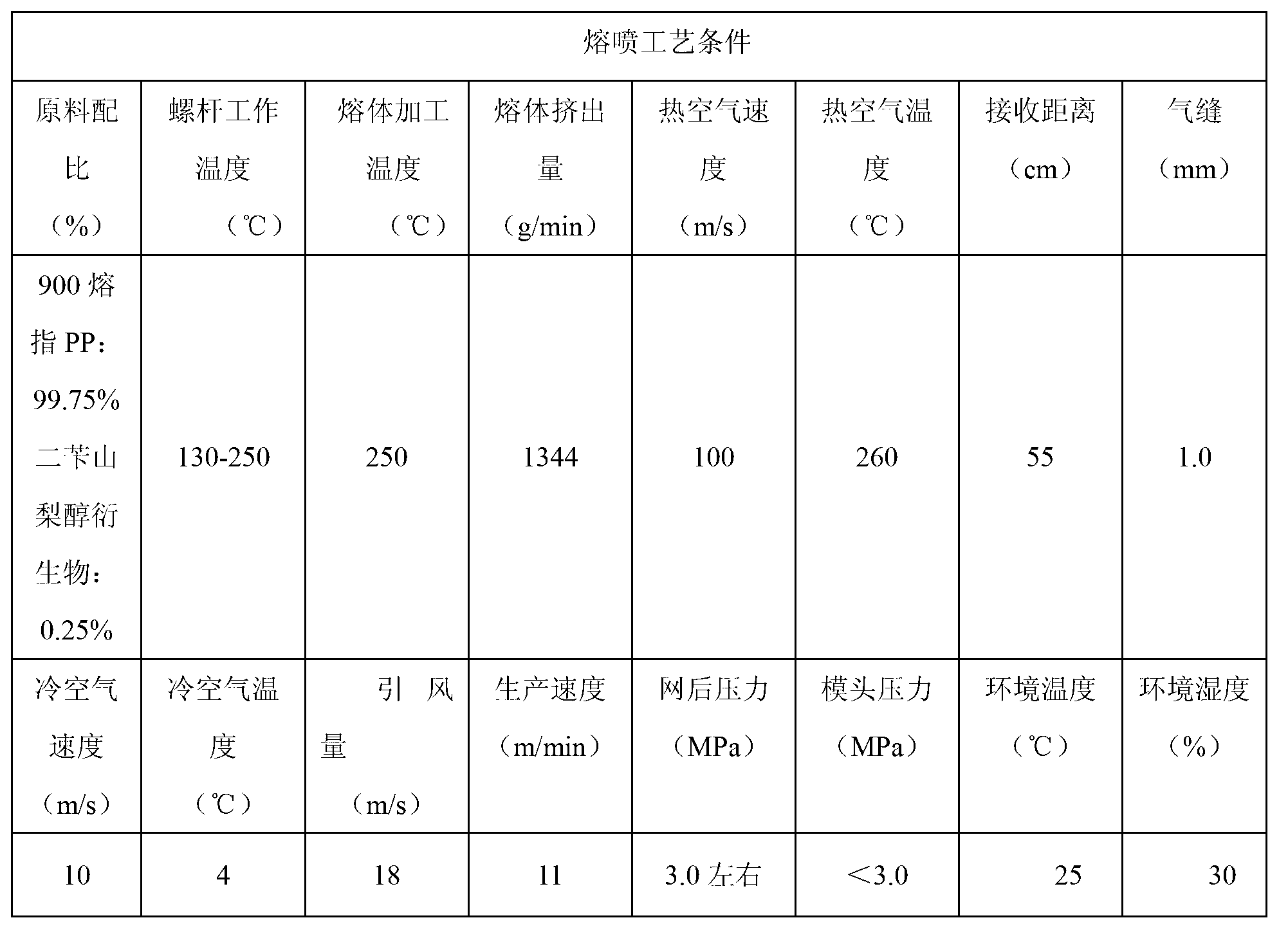

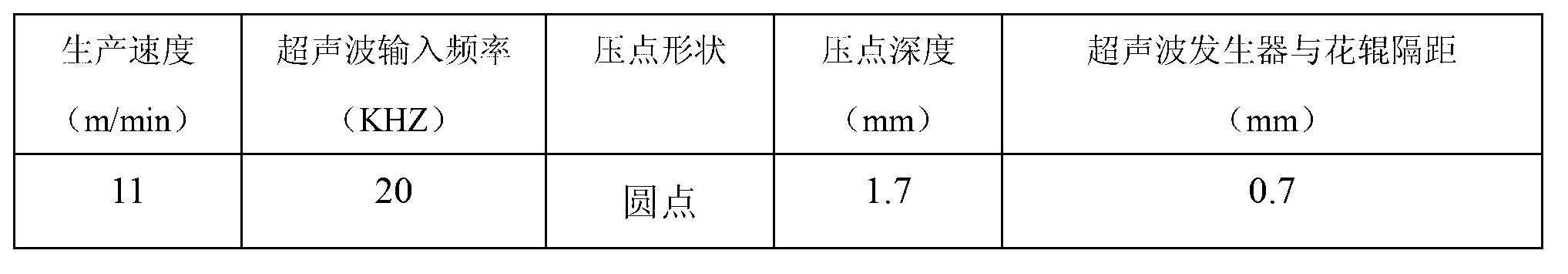

Melt spinning non-woven material and production method and application thereof

InactiveCN103046231AImprove interception effectSmall pressure lossSuction filtersLayered productsCrude fibrePolymer science

A melt spinning non-woven material is characterized in that the weight of the non-woven material weights 35 to 500 g / m<2> and being obtained by a polymer slice being directly melting to spin and the spine being weaved into webs. The melt spinning non-woven material consists of superfine fibers and crude fibers, the crude fibers are used as a framework and the superfine fibers are filled into the framework to form a fiber web to form a thickness matching structure. The fiber web has one layer or more, and when the layer number of the fiber web is more than one, a thickness increasing or gradient structure is formed through a multilayer structure. By means of the optimization of raw materials and process, the melt spinning non-woven material and a production method and an application of the melt spinning non-woven material can control a fiber web structure of the melt spinning non woven material: the distribution of fiber finenesses is controlled in a reasonable range, the fiber web has a large amount of superfine fibers and a certain amount of crude fibers; the crude fibers being used as a framework and the superfine fibers being filled into the framework improve the fluffiness of the material, and the material can still maintain some recovery capability when in use; and the fiber web forms a structure with some gradients.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

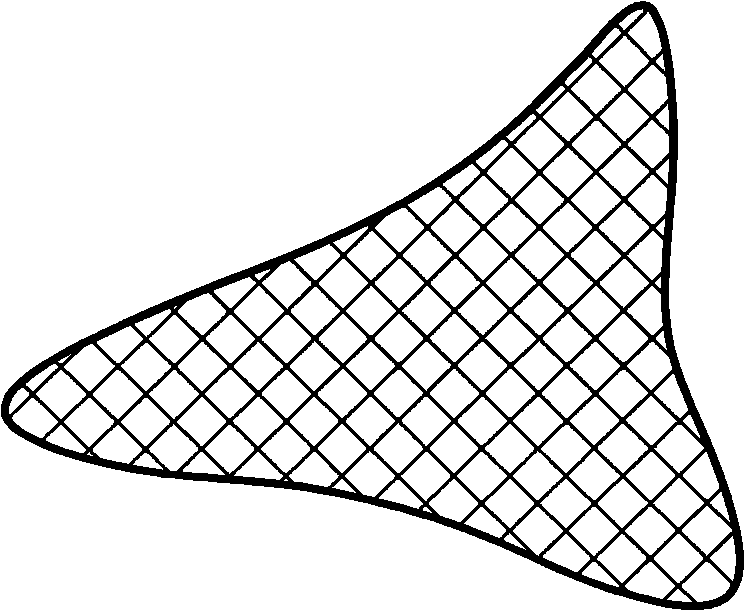

Bi-component polyester coarse fibre, filter material and preparation thereof

InactiveCN101302659AImprove breathabilityGood water permeabilityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyester

The invention relates to a coarse polyester fiber, a filter material made of the coarse fiber and a preparation method thereof. The double-component coarse polyester fiber is skin-warped-core structure, wherein, the skin is polymer with low-melting point, the core is polyester with high-melting point, and the coarseness of fiber is 4-8 dpf; the melting point difference between the high-melting point polyester and the low-melting point polymer is not less than 15 DEG C. The preparation method of the double-component coarse polyester fiber consists of the following steps: the low-melting point polymer and the high-melting point polyester are extruded from two different extruders under melting condition and the double-component coarse polyester fiber is formed by composite spinneret spinning. The double-component coarse fiber and the polyester spun-bond filter material of the invention have excellent air permeability and water permeability, outstanding mechanical properties, low pressure loss, long service life and striking economic benefits.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

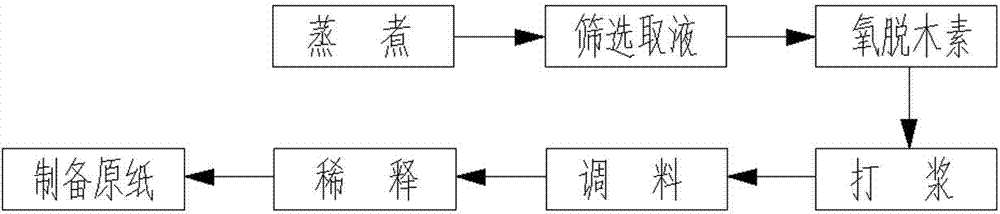

Method for preparing natural color bamboo pulp fiber household paper

InactiveCN103882758AIncrease brightnessCompact structureNatural cellulose pulp/paperPaper-making machinesCrude fibreFiber

The invention relates to a method for preparing natural color bamboo pulp fiber household paper. The method includes the steps that firstly, digesting is conducted, natural clustered bamboo chips are placed in a specially-made digesting container, NaOH and Na2S are added to the container, and then steaming is conducted on the bamboo chips; secondly, large bulks of undigested bamboo chips, undigested bamboo joints, undigested crude fibers, gravels in raw materials and the like are removed through a screening and purifying device, black liquor in crude pulp is extracted through a pulp washing device, and then bamboo pulp fibers are primarily obtained; thirdly, the oxygen delignification working process is conducted on the obtained bamboo pulp fibers to further remove residual lignin in the bamboo pulp fibers, the bamboo pulp fibers are completely washed through the pulp washing device, and eventually natural color bamboo fibers are obtained; fourthly, the natural color bamboo fibers are pulped, pulp is placed in a pulp mixing pool, and coniferous long fibers are mixed into the pulp mixing pool; fifthly, additives are added to the pulp generated in the fourth step according to different products; sixthly, the pulp is fully stirred; seventhly, the mixed natural color bamboo pulp is online diluted and then processed through a purification system to further remove impurities; eventually, pulp is placed on a screen, paper is manufactured with the pulp, a layer of wet paper sheet is formed and processed, and then natural color bamboo pulp fiber household paper body paper is obtained. The method has the advantages that the prepared paper is greener, more environmentally friendly and healthier.

Owner:SHAONENG GRP SHAOGUAN NANXIONG ZHUJI PAPER IND CO LTD

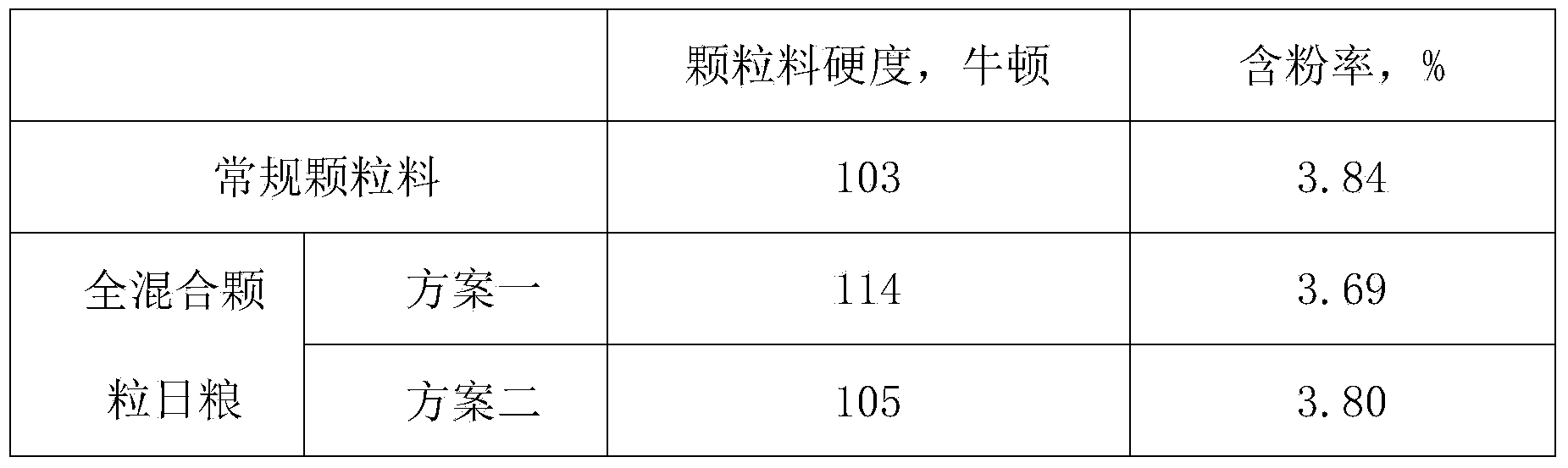

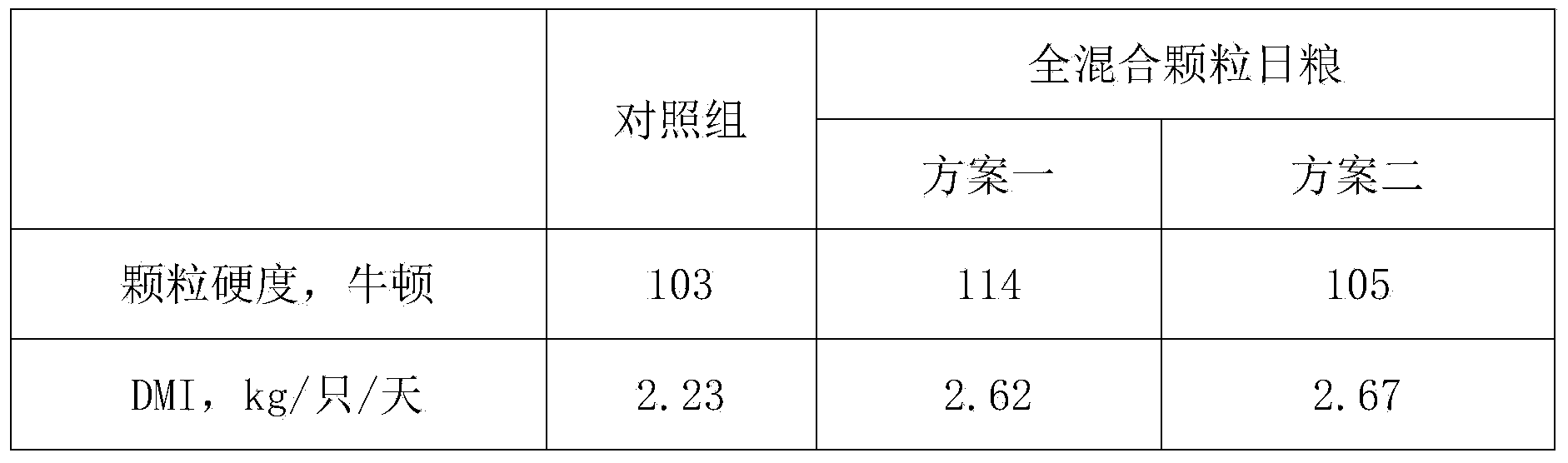

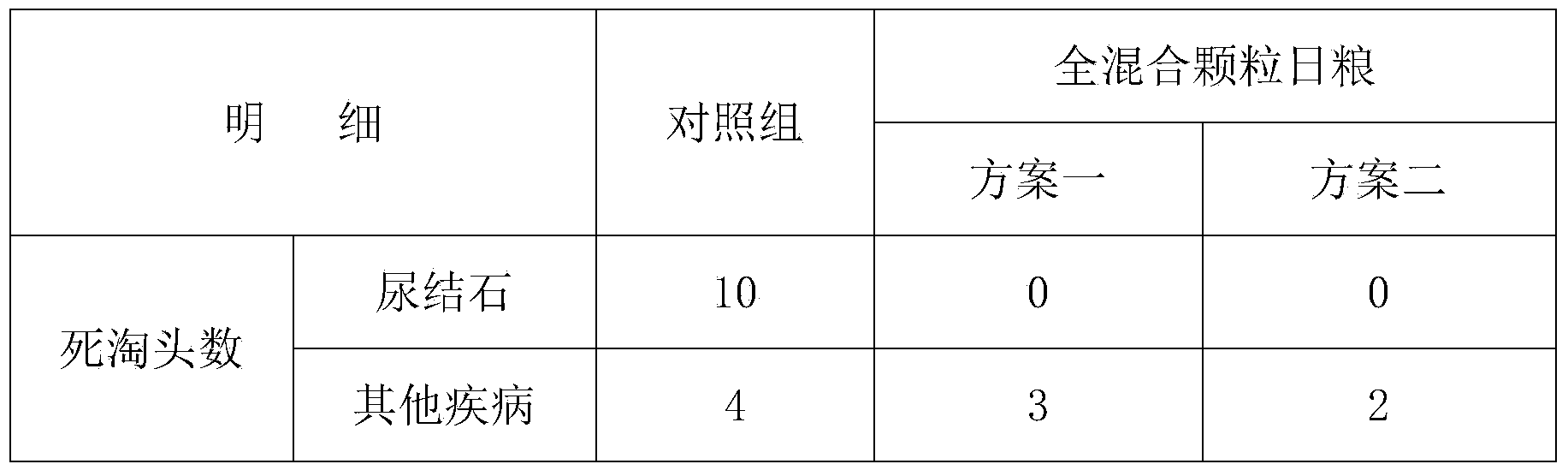

Granular total mixed ration for fattening meat sheep and processing process thereof

ActiveCN104304822AIncrease the rate of weight gainReduce feeding costsFood processingAnimal feeding stuffFiberAnimal science

A granular total mixed ration for fattening meat sheep is characterized by comprising 10-15% of corns, 5-8% of barley, 10-13% of corn bran, 5-6% of corn germ meal, 5-7% of DDGS (Distillers Dried Grains with Soluble), 4-7% of double-low rapeseed meal and 1.5-2.5% of mountain flour. The granular total mixed ration for fattening the meat sheep, provided by the invention, has the advantages that the palatability is good, the total mixed ration is rich in energy, crude protein, crude fiber, vitamins and trace elements, the weight increasing speed of the meat sheep can be effectively increased, the feeding cost is reduced and urinary stone in the fattening process is eliminated.

Owner:LIAONING WELLHOPE AGRI TECH

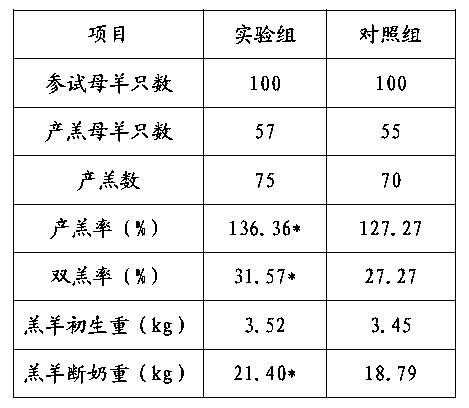

Breeding ewe complete pellet feed and preparation method thereof

InactiveCN104256186AFine grainIncrease productionFood processingAnimal feeding stuffBiotechnologyAgricultural science

The invention discloses cultivation feed, particularly relates to breeding ewe complete pellet feed and belongs to the technical field of feed cultivation. The breeding ewe complete pellet feed has the benefits that the nutrition collocation is reasonable, a positive combined effect between roughage (peanut shells, soybean hulls, brewer's grain, apple pomace and the like) and concentrated feed is utilized, the dietary nutrition is balanced and completely meets the production and breeding demands of breeding ewes, the digestion and the utilization of coarse-fibered raw materials are greatly improved, the normal physiological functions of rumens of the breeding ewes are ensured, the feeding process of farmers are greatly reduced at the same time, the production efficiency is improved, the market demands and the benefits are huge, and meanwhile, the multiple coarse-fibered raw materials are utilized by adopting a special processing mode and other measures, so that the social value is higher.

Owner:SICHUAN TQLS IND

Biological organic fertilizer produced from fermented traditional Chinese medicine residue and method for producing fertilizer

InactiveCN102910976AModernize operationsLabor savingBio-organic fraction processingOrganic fertiliser preparationBiotechnologyWater Hyacinths

The invention relates to a biological organic fertilizer produced from fermented traditional Chinese medicine residue and a method for producing the fertilizer. The method comprises the following steps of: carrying out dry-wet treatment on the traditional Chinese medicine residue serving as a main raw material; then adding crude fiber degrading bacteria, water hyacinth, platycodon grandiflorum and other plant fiber or turf for mixed stack retting and fermentation, so as to prepare semi-finished fermented traditional Chinese medicine residue organic fertilizer; based on a dry material, preparing a finished product from 85-90wt% of semi-finished organic fertilizer and 10-15wt% of microbial active bacteria. The product not only contains organic materials and active effective bacteria, but also contains trace element inorganic components, wherein the content of the organic materials accounts for more than 25%; and the product has the characteristics of no pollution, no public hazard, scientific formula, rich nutrient, high efficiency and the like. According to the invention, the problem that medicine residue pollutes environment is solved, waste is turned into wealth, good benefits of environmental protection and comprehensive development and utilization of energy sources and fertilizers are realized, and the process technology has innovation, scientificity and advancement.

Owner:GUANGDONG FUERKANG CHEM TECH

Microbial flocculant as well as preparation method and application thereof

InactiveCN103525870AImprove flocculation performanceWide variety of sourcesMicroorganism based processesFermentationWater contentChemistry

The invention discloses a microbial flocculant as well as a preparation method and application thereof. The preparation method comprises the following steps: inoculating flocculant-producing bacteria in a coarse fiber raw material to prepare a fermentation substrate with water content of 50-80 percent and pH (potential of Hydrogen) of 2-7; performing aerobic fermentation and anaerobic fermentation in sequence to obtain a fermentation product; leaching the fermentation product by using alkali liquor; filtering and drying leaching liquor to prepare the microbial flocculant. The fiber raw material is biologically converted by using the specific flocculant-producing bacteria, and meanwhile, a large amount of metabolites are produced during growth of the flocculant-producing bacteria, so that the obtained microbial flocculant has higher flocculation performance; the microbial flocculant is especially suitable for high-efficiency economic treatment on low-concentration heavy metal wastewater; the waste vegetables and crop straws are used as the raw materials which are low in cost, readily available and have wide sources, so that the recycling of the large amount of waste straws is realized; no wastewater is produced during production of the microbial flocculant, energy conservation and environmental friendliness are realized, the production process is simple, and the operation is convenient.

Owner:JIAXING UNIV

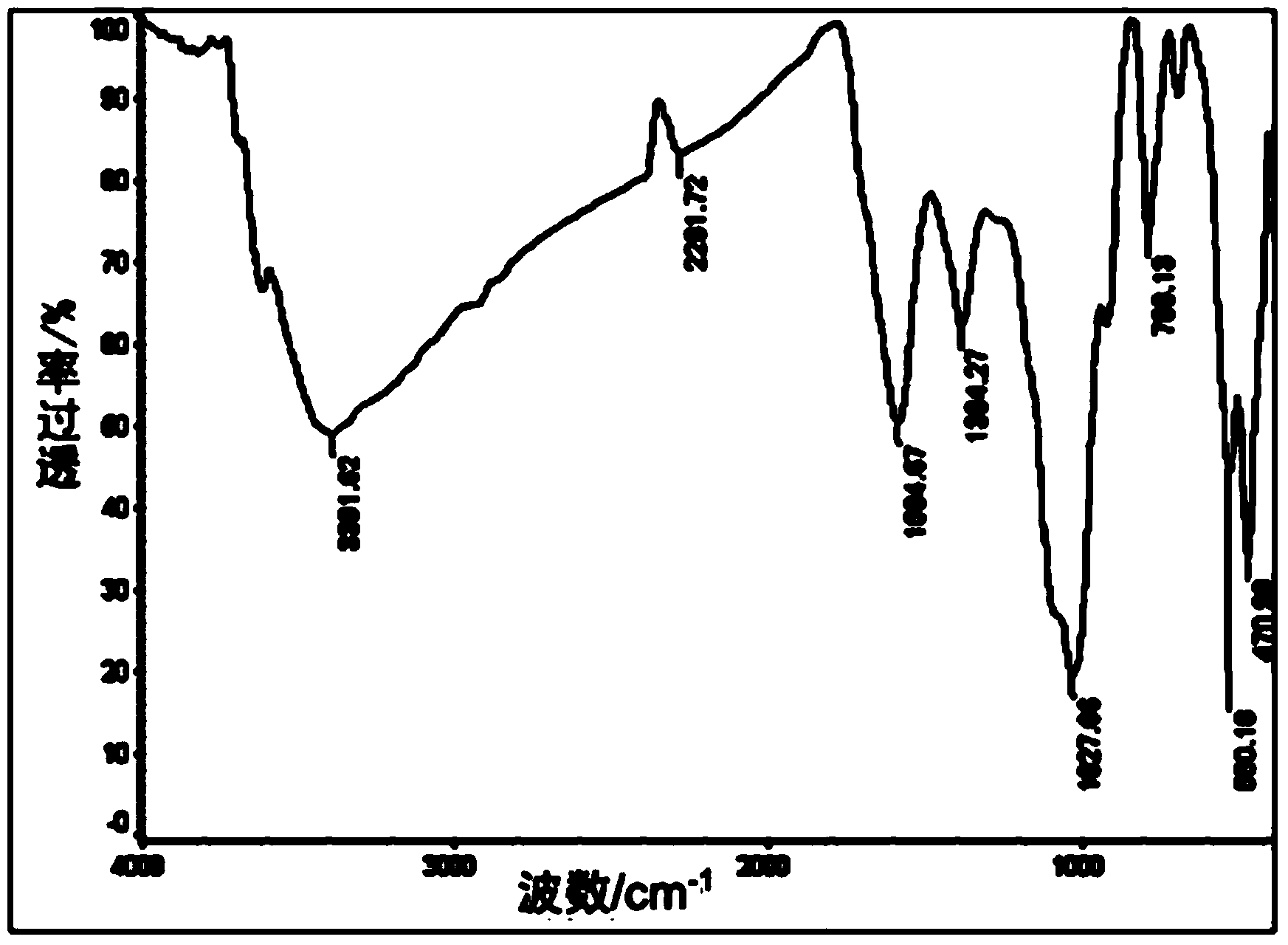

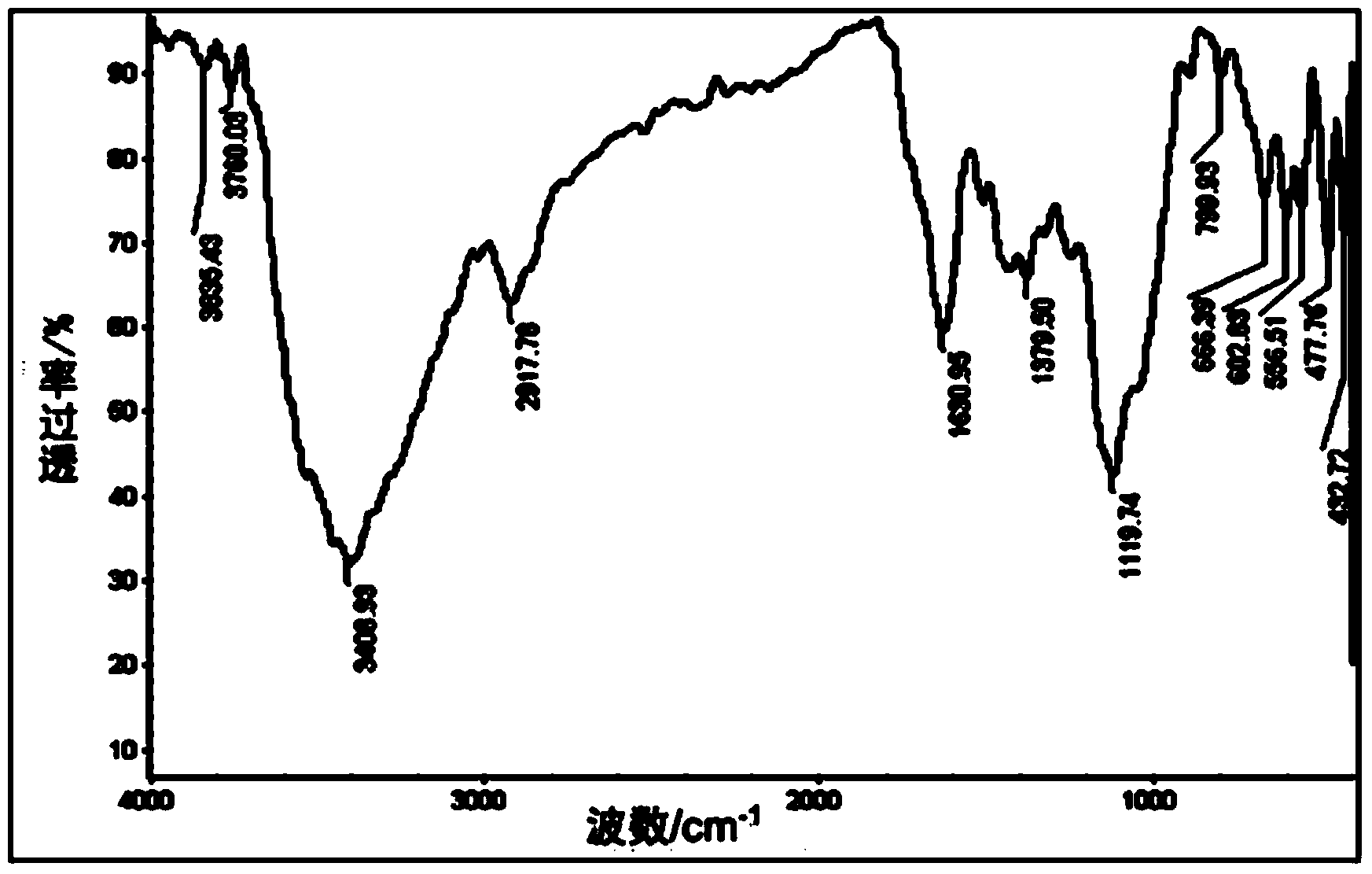

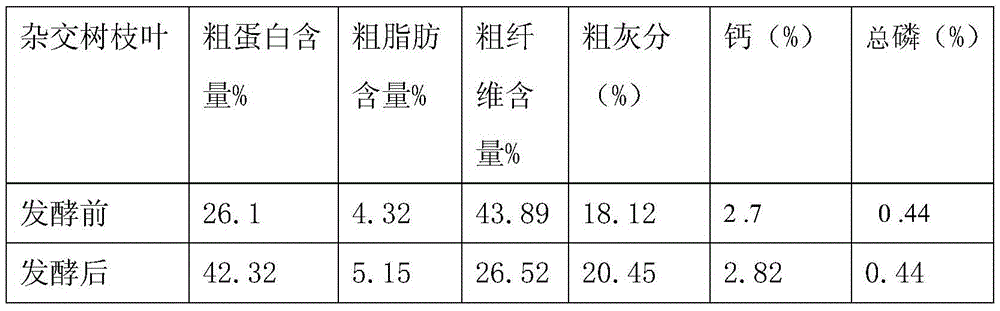

Hybrid paper mulberry tree leaf and shoot fermentation feed and preparation method thereof

InactiveCN105533160AIncrease crude protein contentReduce crude fiber contentAnimal feeding stuffAccessory food factorsAnimal feedPaper mulberry tree

The invention provides a preparation method of a hybrid paper mulberry tree leaf and shoot fermentation feed. The preparation method comprises the following steps of firstly crushing raw materials, performing soaking treatment with alkali, then performing high-temperature boiling, performing cooling and enzymolysis, and finally performing microbial fermentation so as to obtain finished products. The method disclosed by the invention is short in fermentation time, the obtained fermentation feed is high in the content of crude protein, reduced in the content of crude fibers, high in raising efficiency and environmentally-friendly, and animals fed with the fermentation feed grow quickly and are low in attack rate.

Owner:ANHUI ZHONGKE ANYUE FORESTRY TECH DEV CO LTD

Feed fermentation agent and fermented feed

InactiveCN104605167AEnhance physical fitnessImprove the immunityAnimal feeding stuffPichia pastorisBiotechnology

The invention discloses a feed fermentation agent and a fermented feed, the feed fermentation agent includes the following components by mass: 20-25% of pichia pastoris, 15-20% of lactobacillus, 10-15% of enterococcus faecalis, 3-10% lactobacillus plantarum, 10-15% of cellobiose lactobacillus and 15%-25% a compound enzyme agent. The fermented feed is a fermented product of soybean meal, corn and wheat bran, mulberry-rich plants and a mixture of mulberry-rich plants and soybean meal by use of the feed fermentation agent, after fermentation of the soybean meal or corn or wheat bran and other traditional feed by use of the feed fermentation agent, harmful materials such as accumulated stool and the like cumulated in pig intestines can be decomposed and removed by cooperation of crude fiber in the traditional feed and microorganism, so that the intestinal absorption efficiency of nutrients can be provided.

Owner:郭旭华

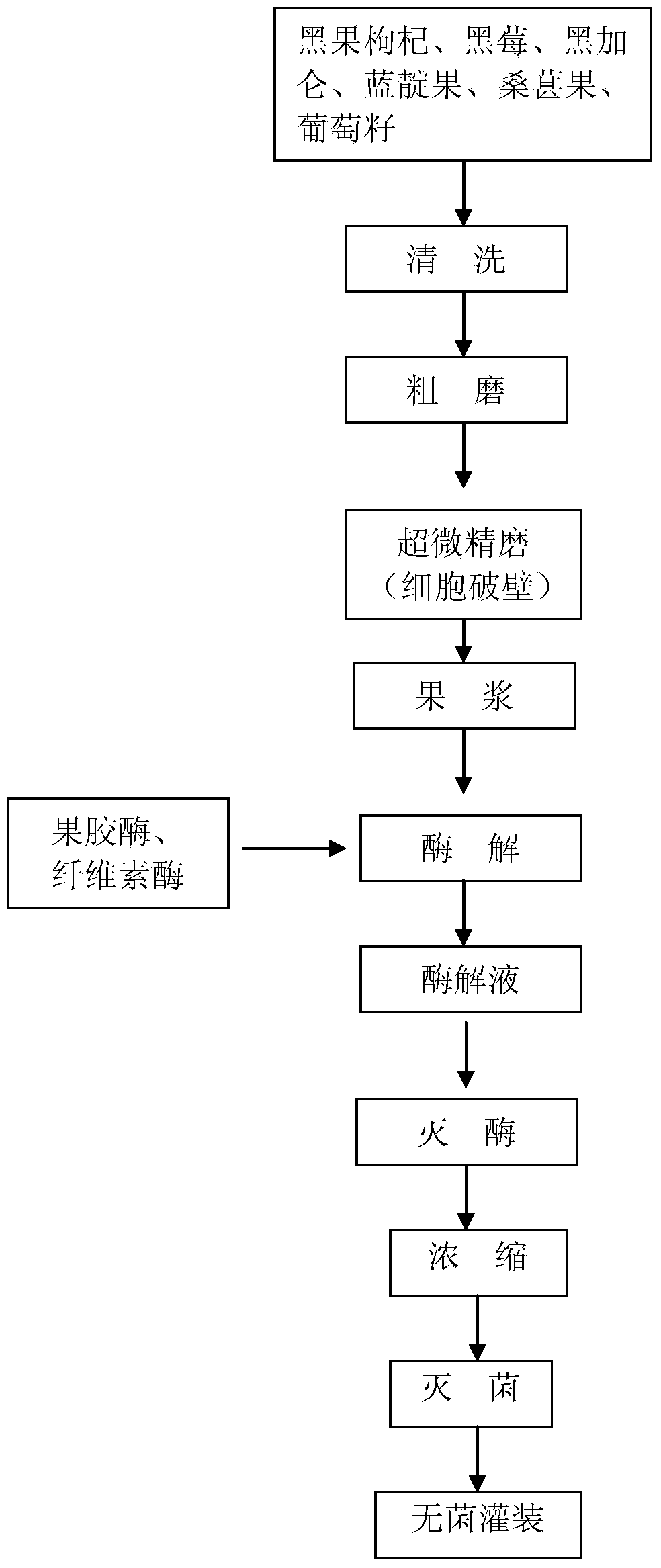

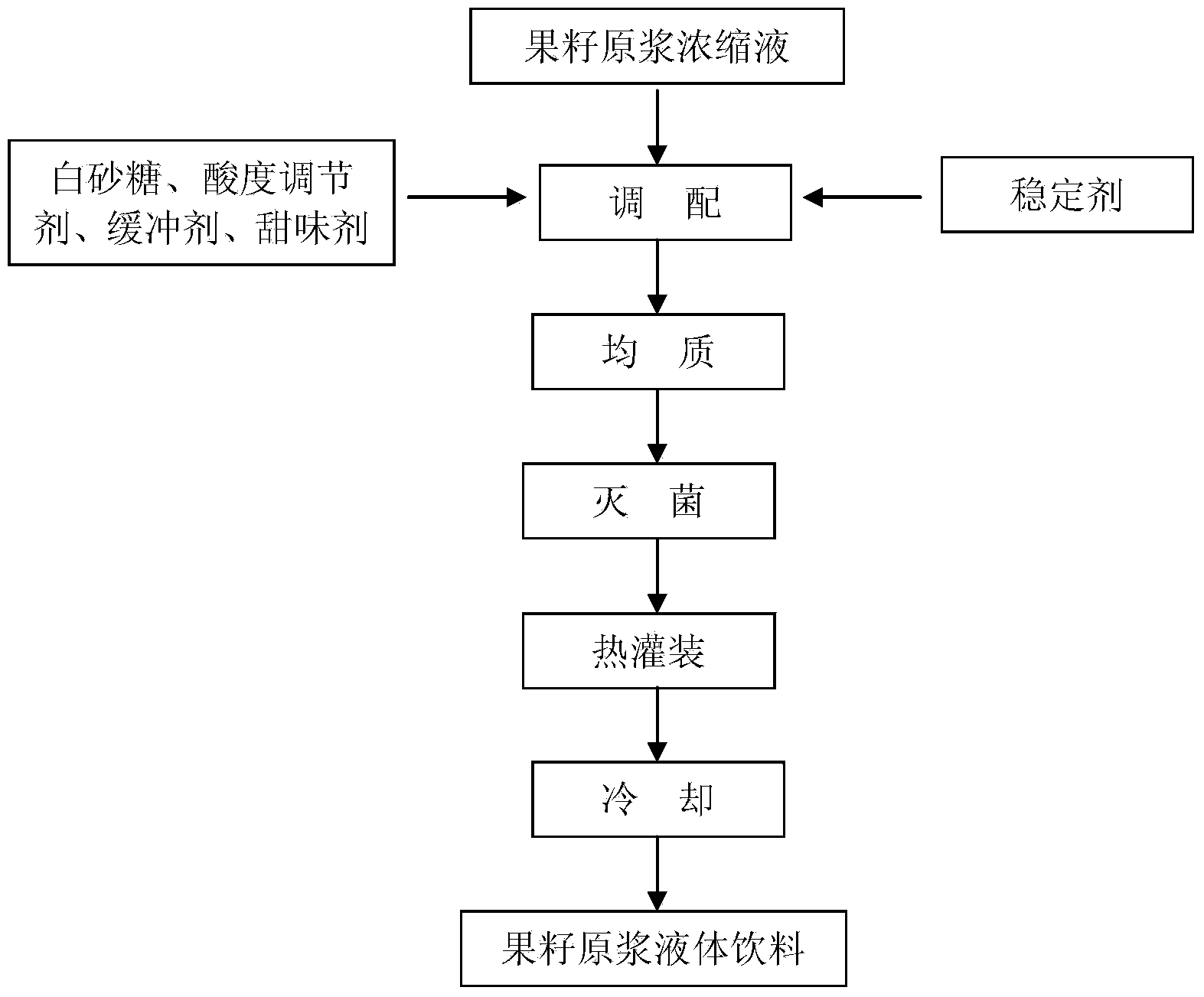

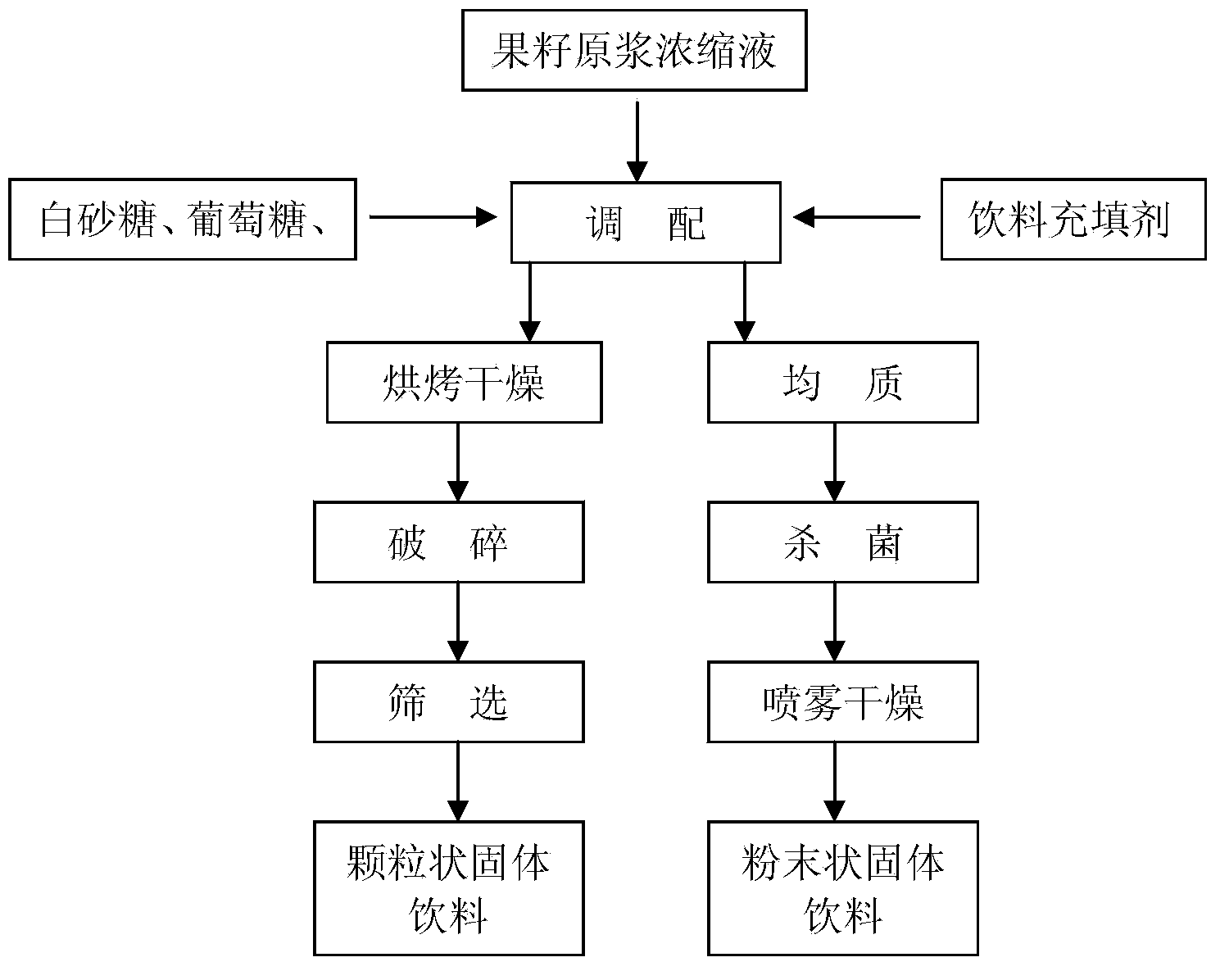

Fruit seed protoplasm liquid preparation method and beverage prepared from fruit seed protoplasm liquid

The invention relates to a fruit seed protoplasm liquid preparation method and a beverage prepared from the fruit seed protoplasm liquid. The fruit seed protoplasm liquid preparation method comprises the following steps: cleaning dried fruit which are sorted, wherein the dried fruit is one or several of black wolfberry fruit, blackberry, blackcurrant, lonicera edulis, mulberry fruit and grape seeds; adding 5 to 10 times of water for soaking according to the weight part of the dried fruit, and grinding pulp, wherein a rough grinding machine is adopted for rough grinding and an ultrafine grinding machine is adopted for fine grinding, so that crude fibers are thinned, plant cells are crushed, and the protoplasm liquid of which the fine grinding liquid grain size is less than or equal to 10 mu m, and the fruit seed protoplasm solid content is greater than or equal to 10 percent in parts by weight is obtained; concentrating the protoplasm after the protoplasm is subjected to enzymolysis and enzyme deactivation into the fruit seed protoplasm concentrate of which the solid content is 50 to 70 percent for later use, or performing aseptic filling after the fruit seed protoplasm concentrate is subjected to ultra-high temperature sterilization. By adopting the method disclosed by the invention, functional components, namely procyanidine and anthocyanin, of the original fruit do not lose, and meanwhile, fruit peels and fruit seeds are subjected to enzymolysis through the enzymolysis technology, so that the fruit peels and the fruit seeds which cannot be absorbed by a human body can be subjected to enzymolysis to form nutritional components and functional components which can be absorbed by the human body.

Owner:杨红利

Processing method for dried tuna meat floss

The invention relates to a processing method for producing dried tuna meat floss with tunas as material. The processing method includes the following steps: material acceptance check and processing; filleting; flavoring; drying; roasting; rolling; floss making; drying; packaging; and finished product. The processing method has the advantages that: the processing method overcomes the defect of tuna food that tuna food cannot be conveniently eaten by infants and old people due to rough meat and unpalatableness, the dried tuna meat floss is so processed as to be crisp and flavorful and not to be as rough as fibers, and moreover, because the coarse fiber content of the convenient-to-eat dried tuna meat floss is little, the dried tuna meat floss is easy to digest and absorb, and is particularly suitable for infants and old people to eat. The process is reasonable, the production is simple, and the cost is low.

Owner:吴延飞

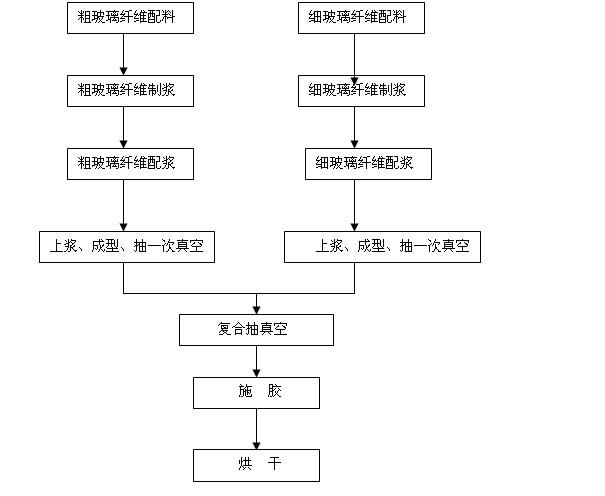

Double-layer filter material, preparation method thereof and multilayer product

ActiveCN102059025AExtended service lifeImprove filtration efficiencyGlass/slag layered productsFiltration separationGlass fiberCrude fibre

The invention relates to the field of wet paper making, in particular to a double-layer filter material, a preparation method thereof and a multilayer material. The double-layer filter material consists of a coarse glass fiber layer and a fine glass fiber layer, wherein the thickness of the double-layer filter material is between 0.35 and 0.45mm; and the double-layer filter materials are compounded to prepare a multilayer filter material, or are compounded with nonwoven fabrics for filtering liquid. The preparation method comprises the steps of preparation of a coarse fiber layer semi-finished product and a fine fiber semi-finished product, preparation of a composite fiber layer semi-finished product and drying. In the double-layer filter material, the service life is prolonged to 133 percent, the filter efficiency is improved by 50 percent, and the resistance is reduced by 10 percent. The double-layer filter material can be compounded with the nonwoven fabrics and other filter materials once more to prepare a filter material with better performance and effectively filter impurities and microorganisms in the liquid; and the preparation method is easy to operate, has high yield, and is suitable for scale production.

Owner:CHONGQING ZAISHENG TECH CORP

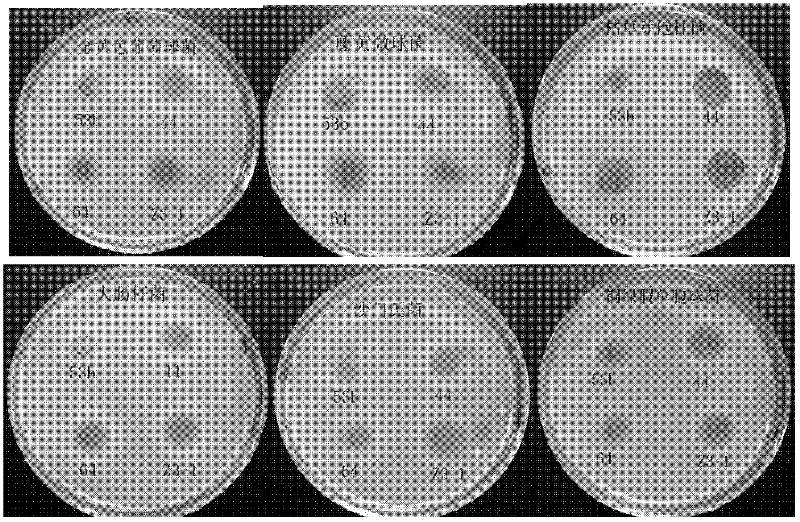

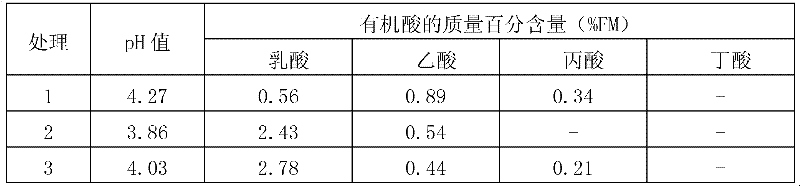

Lactobacillus plantarum and application thereof in fermenting and ensiling sweet potato stem and leaf

InactiveCN102643767AImprove efficiencyLow costBacteriaAnimal feeding stuffWater contentLaboratory culture

The invention discloses a lactobacillus plantarum and application thereof in fermenting and ensiling sweet potato stem and leaf. The strain is the Lactobacillus plantarum Z3-1, and has the accession number of CGMCC (China General Microbiological Culture Collection Center) No.5027 in the China General Microbiological Culture Collection Center. The strain can improve a nutrition value after the sweet potato stem and leaf are fermented, and compared with the natural fermentation, the sweet potato stem and leaf are subjected to strain fermentation for 3 days-7days, so that amino acid total quantity, crude protein and soluble total sugar content of the sweet potato stem and leaf are high, and crude fiber content is low. The sweet potato stem and leaf with the bran or the corn grits are mixed to prepare a mixture with the water content of 60%-70% to inoculate the strain for ensiling for 30 days-60days, and then unsealing is carried out, thus pH is low, and lactic acid content is high. The lactobacillus plantarum with the accession number of CGMCC No.5027 provided by the invention can be used for fermenting or ensiling the sweet potato stem and leaf and has the advantages that efficiency is high, cost is low and the like. The lactobacillus plantarum can be used for producing fermented food or green environment-friendly biological feed.

Owner:ZHENGZHOU UNIV

Moringa oleifera pig feed

InactiveCN102805253ALow in crude fatReduce cholesterolFood processingAnimal feeding stuffBiotechnologyLean meat

The invention provides moringa oleifera pig feed, which is characterized by consisting of the following components in percentage by mass: 38 to 60 percent of corn, 10 to 16 percent of bean pulp, 12 to 18 percent of rice bran, 7 to 38 percent of moringa oleifera powder and 0.2 to 1 percent of salt. The moringa oleifera pig feed contains rich crude protein, crude fiber, mineral substances, vitamine, and multiple antioxidative, antibacterial and antiphlogistic active ingredients such as moringa oleifera flavone; the content of crude fat is low; the ratio of amino acid is appropriate; any chemical medicine or chemical raw material is not added; the moringa oleifera pig feed does not have toxic or side effects; after being fed, pigs gain weight quickly; the metabolic capacity of pig organisms can be improved; immunity and disease resistance are strengthened; the marketing time is short; the lean meat percentage is high; the cholesterol is low; acidification can be lightened; the generation of pale soft exudative (PSE) pork is prevented; and quality of the pork is improved.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Preparation process of beef concentrated feed

InactiveCN104171293AGrow fastMeet the need for weight gainFood processingAnimal feeding stuffSodium bicarbonateAmino acid

The invention discloses a preparation process of a beef concentrated feed. The beef concentrated feed is prepared from the following raw materials: 20 percent of corn, 10 percent of soybean meal, 10 percent of silkworm excrement, 23 percent of fresh stillage, 10 percent of rape seed cake, 8.07 percent of cottonseed meal, 1.02 percent of amino acid, 0.6 percent of vitamins, 10.3 percent of molasses, 2 percent of traditional Chinese medicine, 1 percent of salt, 1 percent of sodium bicarbonate, 2 percent of microelements and 1.01 percent of calcium phosphate. The prepared beef concentrated feed is high in the energy and protein, is capable of satisfying the needs of beefs in rapidness in growth and weight increment, contains rich digestible crude fibers, makes up for the insufficient mineral substances, vitamins and microelements in a feed by virtue of the addition of enough mineral substances, vitamins, microelements and traditional Chinese medicines and is capable of improving the immunity of the beefs and enabling weights of the beefs to be increased by 1.2-1.5 kilograms per day.

Owner:云南七彩田园牧业有限公司

Mixed culture base material for pleurotus eryngii culture

InactiveCN104829336AImprove food safetyPromote growthFertilizer mixturesNutrients substancesWheat Brans

The invention discloses a mixed culture base material for pleurotus eryngii culture. The base material comprises the following components in parts by weight: 3 to 5 parts of nutritional inorganic fertilizer, 60 to 70 parts of weed tree sawdust, 20 to 90 parts of oat husk, 10 to 40 parts of wood bran, 10 to 40 parts of peanut shell, 5 to 15 parts of cotton seed husk, 26 to 30 parts of calcium carbonate, 35 to 40 parts of corn core, 10 to 20 parts of sugarcane dreg, 15 to 25 parts of wheat bran, 3 to 8 parts of corn flour, 20 to 30 parts of calcium sulfate, 5 to 10 parts of magnesium sulfate, 5 to 10 pats of lime, 0.25 to 4 parts of gypsum, 5 to 10 parts of urea with a nitrogen content of 46%, 5 to 10 parts of triacontanol, and 2 to 7 parts of soybean meal. The water content of the mixed culture material after pre-wetting is 65% + / - 1%, and the pH value is 7.5 to 9. The nutritional inorganic fertilizer is a boron-potassium mixed fertilizer, and the mass ratio of boron fertilizer to potassium fertilizer is 1:1.5. The provided mixed culture base material is rich in nutrients such as vitamin B1, vitamin B, crude fiber, proteins, mineral substances, trace elements, and the like, and is beneficial for the growth of edible fungi. The edible fungi cultured by the provided mixed culture base material have a fresh and sweet flavor and a crispy and smooth taste.

Owner:吴中区胥口精益生物医药研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com