Fruit seed protoplasm liquid preparation method and beverage prepared from fruit seed protoplasm liquid

A fruit seed and slurry technology, applied in the field of fruit seed slurry preparation, can solve the problems of organic solvent residue, low utilization rate of proanthocyanidins and anthocyanins, high production cost of proanthocyanidins and anthocyanins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

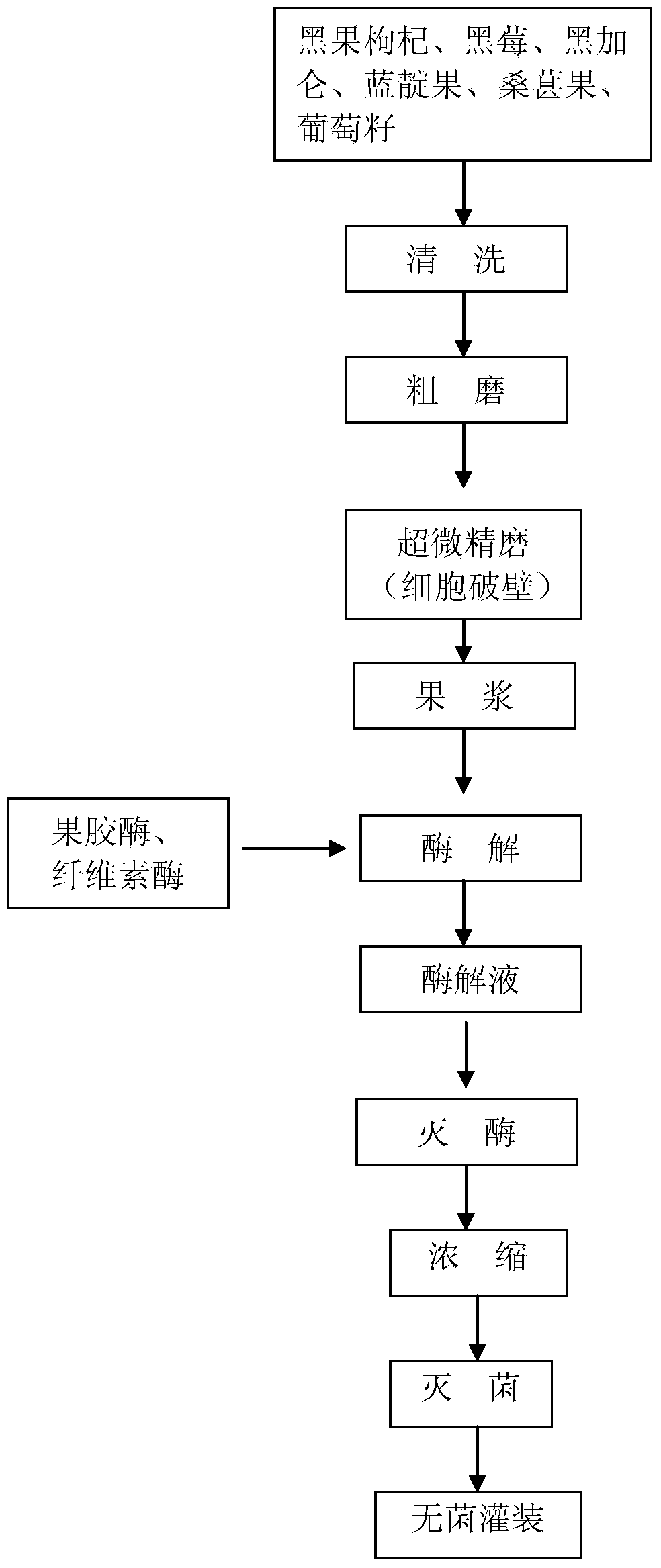

[0039] Such as figure 1 Shown: a method for preparing fruit seed stock solution, including the following steps: cleaning the sorted dried fruit, the dried fruit is black wolfberry, blackberry, blackcurrant, indigo fruit, mulberry fruit and grape seed, the above-mentioned dried fruit The parts by weight are: 1-20 parts of black wolfberry, 1-20 parts of blackberry, 5-10 parts of blackcurrant, 2-20 parts of indigo fruit, 5-30 parts of mulberry fruit and 5-30 parts of grape seed.

[0040] Add 5-10 times of water to the total weight of dried fruit, soak and grind, firstly use a coarse grinder for rough grinding, and then use an ultra-fine grinder for fine grinding, so that the coarse fibers are refined and the plant cells are broken, and the particle size of the refined grinding liquid is ≤ 10 μm. , Fruit seed puree with solid content ≥ 10wt%.

[0041] Carry out enzymatic hydrolysis to the slurry, the enzymes of the enzymolysis are pectinase and cellulase, the consumption of pecti...

Embodiment 1

[0048] A kind of fruit seed puree preparation method of the present invention comprises the following steps:

[0049] 1) Take 15 kg of sorted black fruit wolfberry, 15 kg of blackberry, 25 kg of blackcurrant, 5 kg of indigo fruit, 20 kg of mulberry fruit, and 20 kg of grape seed according to the weight of dried fruit.

[0050] 2) Wash the black fruit wolfberry, blackberry, black currant, indigo fruit, mulberry fruit and grape seed, and soak in water at 80° C. by weight for 10 times the total weight for 30 minutes.

[0051] 3) Coarsely grind black fruit wolfberry, blackberry, blackcurrant, indigo fruit, mulberry fruit and grape seed with a coarse grinder.

[0052] 4) The coarse grinding slurry is finely ground with a fine grinder to obtain a fine grinding liquid with a particle size of ≤8 μm.

[0053] 5) Put the finely ground slurry in an enzymatic hydrolysis tank, adjust the pH of the slurry to 5.0 with citric acid, supply 95°C hot water to the interlayer of the enzymatic hyd...

Embodiment 2

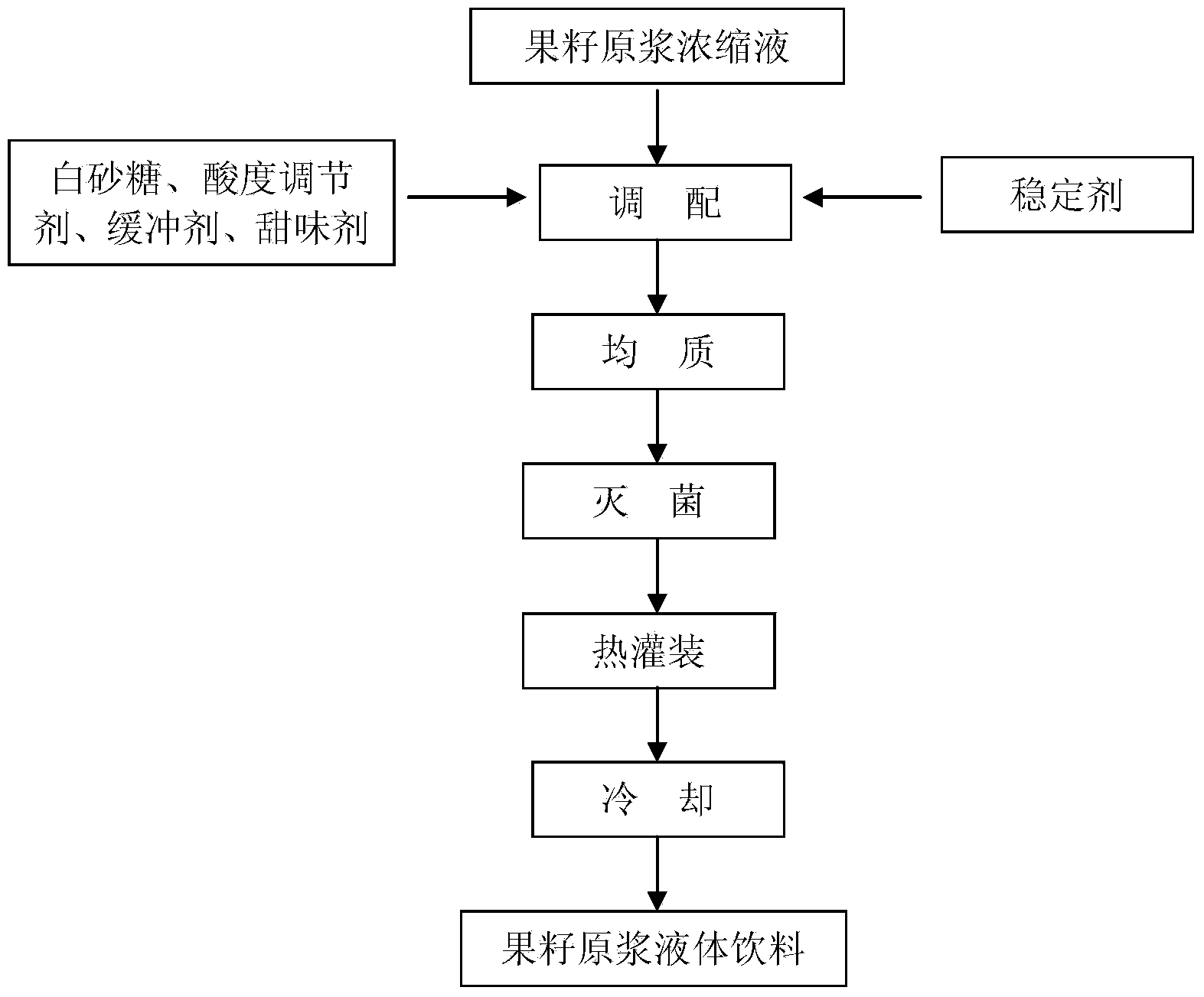

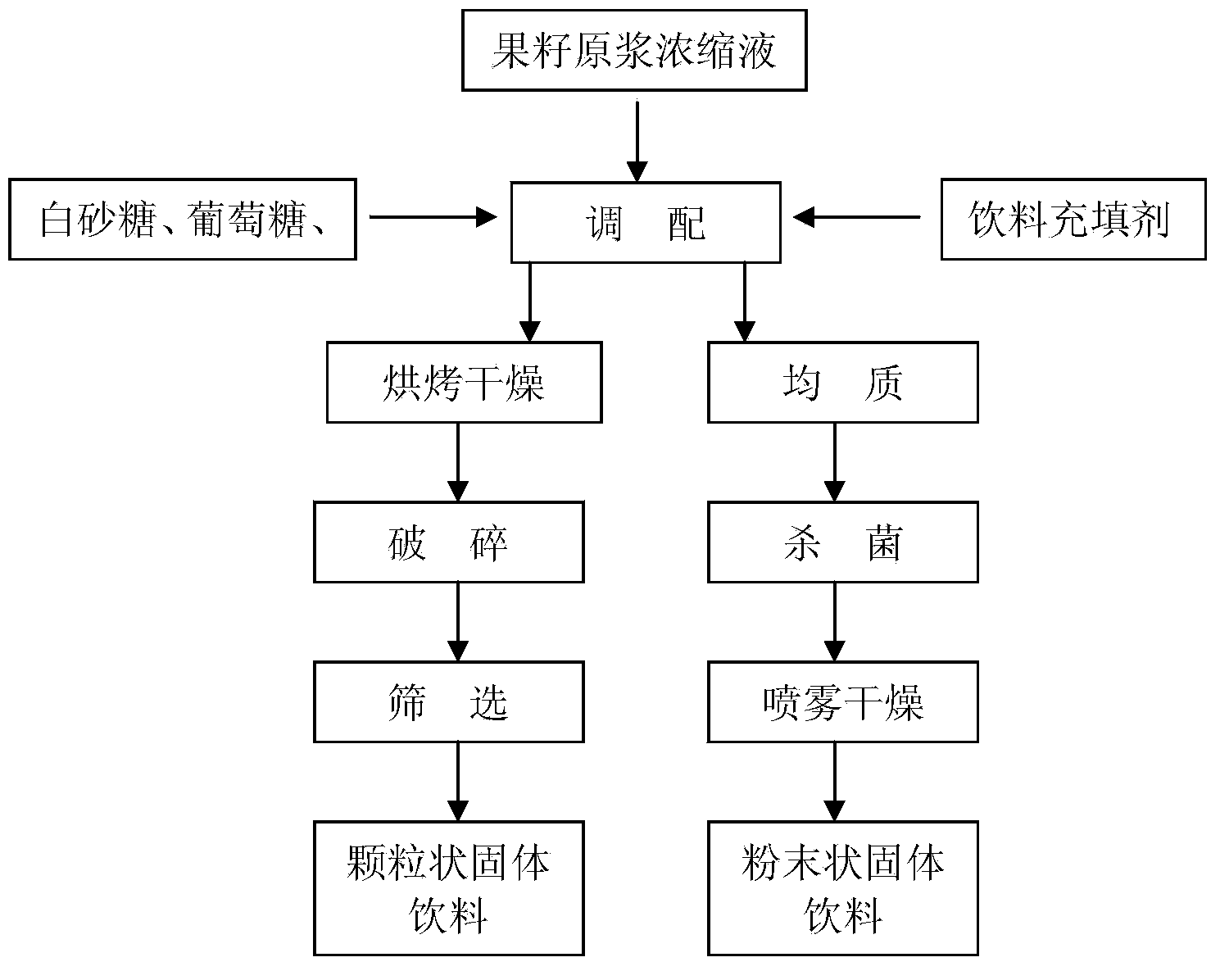

[0071] A kind of preparation method of fruit seed puree functional liquid beverage of the present invention, comprises the following steps:

[0072] 1) 100L product ingredients: 30 kg of fruit seed puree concentrate with a solid content of 65% prepared in Example 1, 6 kg of white sugar, 120 grams of citric acid, 50 grams of sodium citrate, 50 grams of pectin, xanthan gum 70 grams, 60 grams of sodium carboxymethylcellulose, 40 grams of glyceryl monostearate, 50 grams of polyoxyethylene sorbitan monopalmitate, 10 grams of cyclamate, and 5 grams of stevia.

[0073] 2) Take 50 grams of pectin, 70 grams of xanthan gum, 60 grams of sodium carboxymethylcellulose, 40 grams of glyceryl monostearate, and 50 grams of polyoxyethylene sorbitan monopalmitate according to the ingredients of the product. 5L pure water at 80°C is fully emulsified in the emulsification tank.

[0074] 3) Take 6 kg of white granulated sugar, 10 grams of cyclamate, and 5 grams of stevia according to the ingredien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com