Patents

Literature

3042 results about "Sodium molybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium molybdate, Na₂MoO₄, is useful as a source of molybdenum. It is often found as the dihydrate, Na₂MoO₄·2H₂O. The molybdate(VI) anion is tetrahedral. Two sodium cations coordinate with every one anion.

Liquid fertilizer with pyroligneous liquor and oxalacetic liquor and production thereof

InactiveCN1778773AMagnesium fertilisersFertilisers by pryogenic processesRare-earth elementPlant regulators

A liquid fertilizer containing wood vinegar liquid or oxalic vinegar liquid and its production are disclosed. The liquid fertilizer consists of urea 1í½20.0%, potassium phosphate 1í½20.0%, potassium nitrate 1í½20.0%, lime nitrate 0.1í½10.0%, magnesium sulfate 0.1í½5.0%, ferrous sulfate 0.1í½5.0%, manganous sulfate 0.1í½5.0%, zinc sulfate 0.1í½5.0%, cupric sulfate 0.1í½5.0%, boron sand or boric acid 0.1í½2.0%, sodium molybdate or ammonium molybdate 0.1í½1.0%, plant hormone or plant regulator, rare earth element or humus acid or pesticide auxiliaries etc. The process is carried out by proportioning and mixing. It can improve bacterium inhibiting and plant growth regulating functions.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

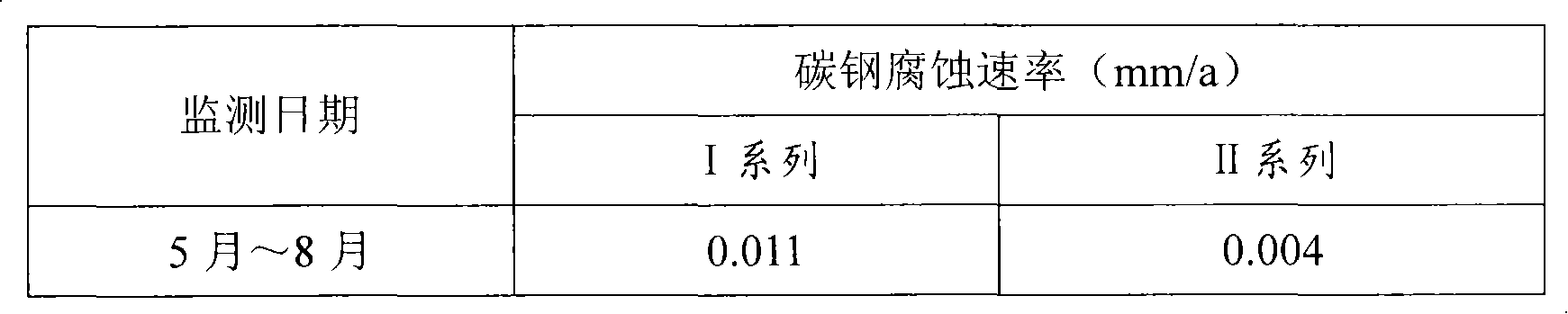

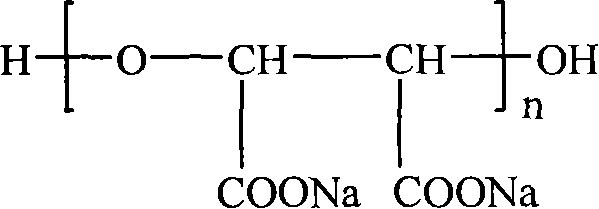

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

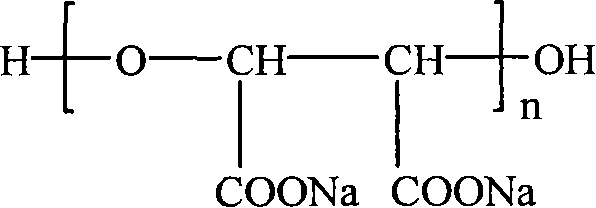

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

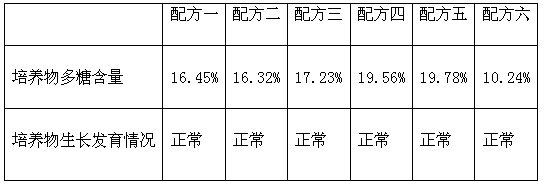

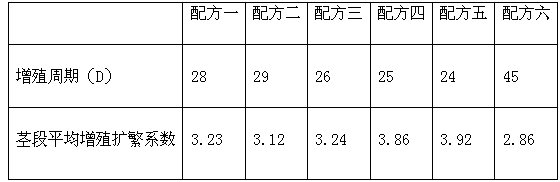

Dendrobium officinale culture solution

ActiveCN102976848AHigh in polysaccharidesHigh in amino acidsFertilizer mixturesEthylenediamineManganese

The invention discloses a Dendrobium officinale culture solution and belongs to the technical field of agricultural planting. The culture solution comprises the following ingredients: potassium nitrate, ammonium nitrate, magnesium sulfate, manganese sulfate, zinc sulfate, monopotassium phosphate, copper sulfate, potassium iodide, cobalt dichloride, boric acid, sodium molybdate, vitamin VB1, vitamin VB6, vitamin VB5, glycine, ferrous sulfate, disodium ethylenediamine tetraacetic acid, calcium chloride, naphthylacetic acid, mashed banana, mashed potato, white sugar, inositol, and powdered agar. The dendrobium officinale culture solution is reasonable in compatibility, can provide comprehensive nutrition for a Dendrobium officinale stem, fast promote the stem to grow out of a root, increase the polysaccharide content and the amino acid content in the Dendrobium officinale, shorten the time for culturing the Dendrobium officinale stem to a complete plant to about 25 days, and significantly improve the transplanting survival rate of the Dendrobium officinale.

Owner:杭州富阳文曲生态农业开发有限公司

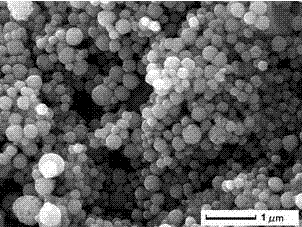

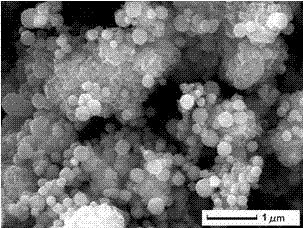

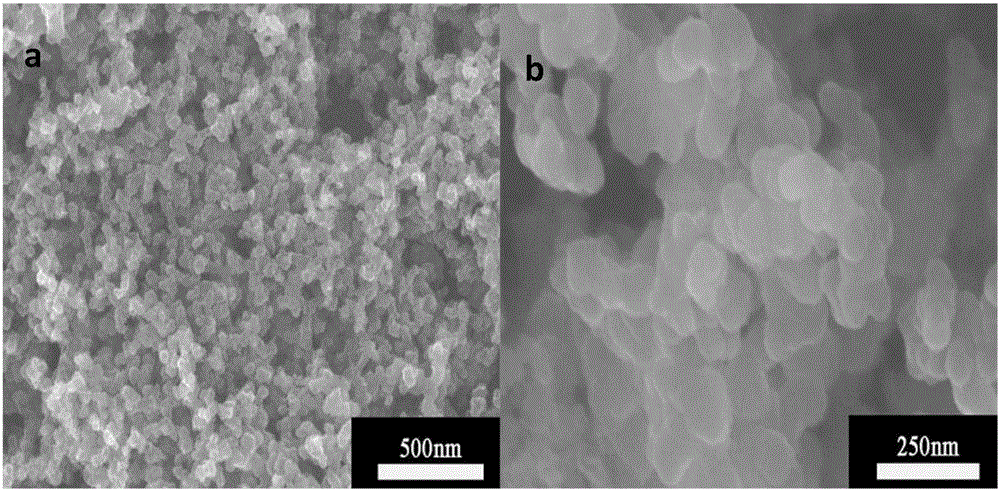

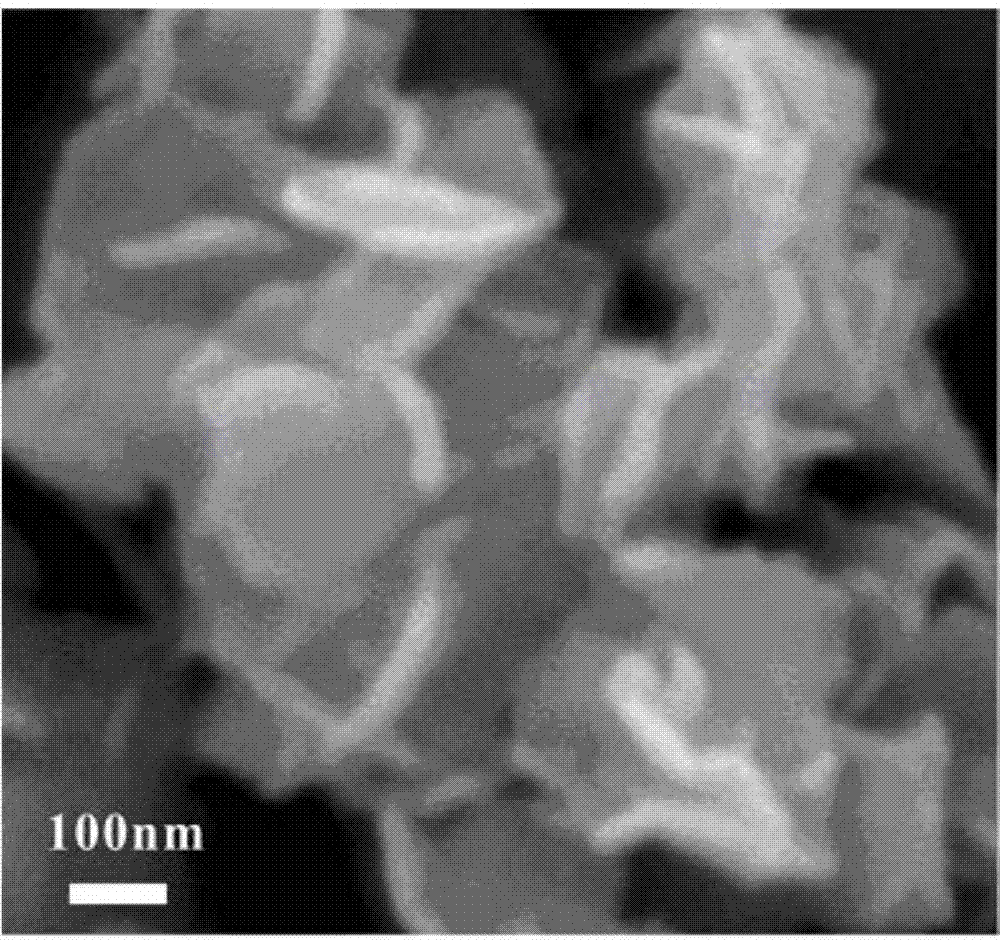

Preparation method for synthesizing MoS2/Fe3O4 nano composite material

InactiveCN103028352ASimple processHigh crystallinityInorganic material magnetismMicroballoon preparationSodium thiocyanateCrystallinity

The invention provides a preparation method of a MoS2 / Fe3O4 nano composite material, belonging to the technical field of preparation of nano inorganic functional materials. The preparation method taking Fe3O4 nano particles as the raw material comprises the following specific steps of: dispersing the Fe3O4 nano particles in de-ionized water, adding sodium molybdate, sodium chloride, sodium thiocyanate and a surface active agent CTAB (Cetyltrimethyl Ammonium Bromide), after stirring for a period of time, adjusting pH by using hydrochloric acid, then, pouring the mixture into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and naturally cooling after reacting at the pre-set temperature for a period of time; and centrifugally washing a reaction product by using the de-ionized water for several times, and drying the product to obtain the MoS2 / Fe3O4 nano composite material. The method disclosed by the invention has the advantages of being simple in process, rapid, high-efficiency and the like; MoS2 is well wrapped on the Fe3O4 nano particles; and the MoS2 / Fe3O4 nano composite material prepared by the invention is good in crystallinity, controllable in morphology and size and good in adsorption property.

Owner:JIANGSU UNIV

Descaling method of phospheric acid concentration heat exchanger

ActiveCN1724965AEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

Coating sustained-released disposable fertilizer

ActiveCN101362662AReduce uneven dispersionReduce clumpingAgriculture gas emission reductionOrganic fertilisersPotassiumNutrient

The invention discloses a coating slow-release disposable fertilizer which consists of a coating formed by basis fertilizers and masking liquid on the surface of the basis fertilizers, wherein, the composition of the masking liquid on the coating is expressed according to the ratio of quality portions: 0.5-10 portions of humate, 0.1-2.5 portions of natural gum, 0.1-2.5 portions of modified starch, 5-20 portions of carbamide, 0.5-4 portions of zinc sulfate, 0.5-3 portions of manganous sulfate, 0.5-20 portions of green copperas, 0.5-1 portion of boric acid, 0.1-1 portion of sodium molybdate, 2.5-3 portions of organic acid regulators, 2.5-3 portions of ammonium citrate and 87.2-30 portions of water. The masking liquid is evenly coated on the particle surface of the basis fertilizers in a coating machine. Referring to the proposal of soil measurement and fertilizer preparation, the invention can adjust prescription flexibly, organize production quantitively, keeps the fertilizer effect tobe stable in a long time, reduces the slow-release cost, realizes the modification of three main nutrients of nitrogen, phosphorus and potassium and has complete functions of slow-releasing and synergy; besides, the fertilizer improves the utilization of the fertilizer and is suitable for mechanized application and standard production.

Owner:阎宗彪

Special composite fertilizer for tea

InactiveCN102816017AIncrease productionImprove qualityBio-organic fraction processingOrganic fertiliser preparationShort termsBran

The invention discloses a special composite fertilizer for tea. The composite fertilizer is prepared from the following components according to a certain weight ratio: an oil tea cake, peanut bran, Chinese herbal medicine residue, humic acid, manure of livestock and poultry, a biological bacterial preparation, a nitrogen-phosphorus-potassium fertilizer, a biological insecticide, zinc sulfate, magnesium sulfate, sodium molybdate and calcium superphosphate. According to the invention, an organic fertilizer, medium trace elements and a quick-acting inorganic fertilizer are organically combined, the Chinese herbal medicine residue is added at the same time, and therefore, the characteristic of combined fertilizer effects and insecticide effects of the composite fertilizer is obtained. The special composite fertilizer provided by the invention has the advantages of a reasonable formula, balanced nutrition, safety, no pollution, capacity of completely satisfying short-term and long-term demands of tea trees for nutrients and effects of balanced fertilization, soil improvement, environmental protection and effective promotion of output and quality of tea.

Owner:安徽金农生态农业科技发展有限公司

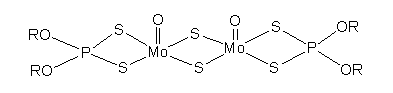

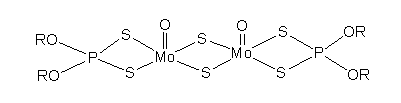

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

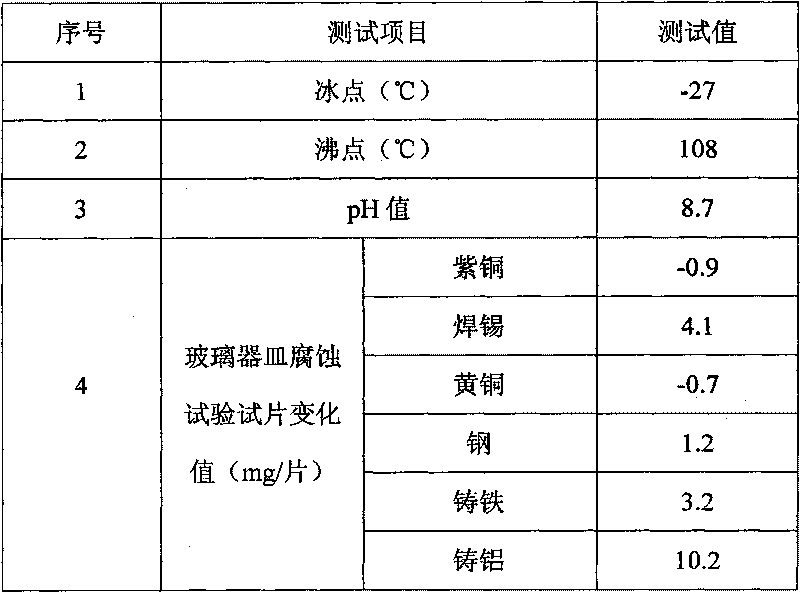

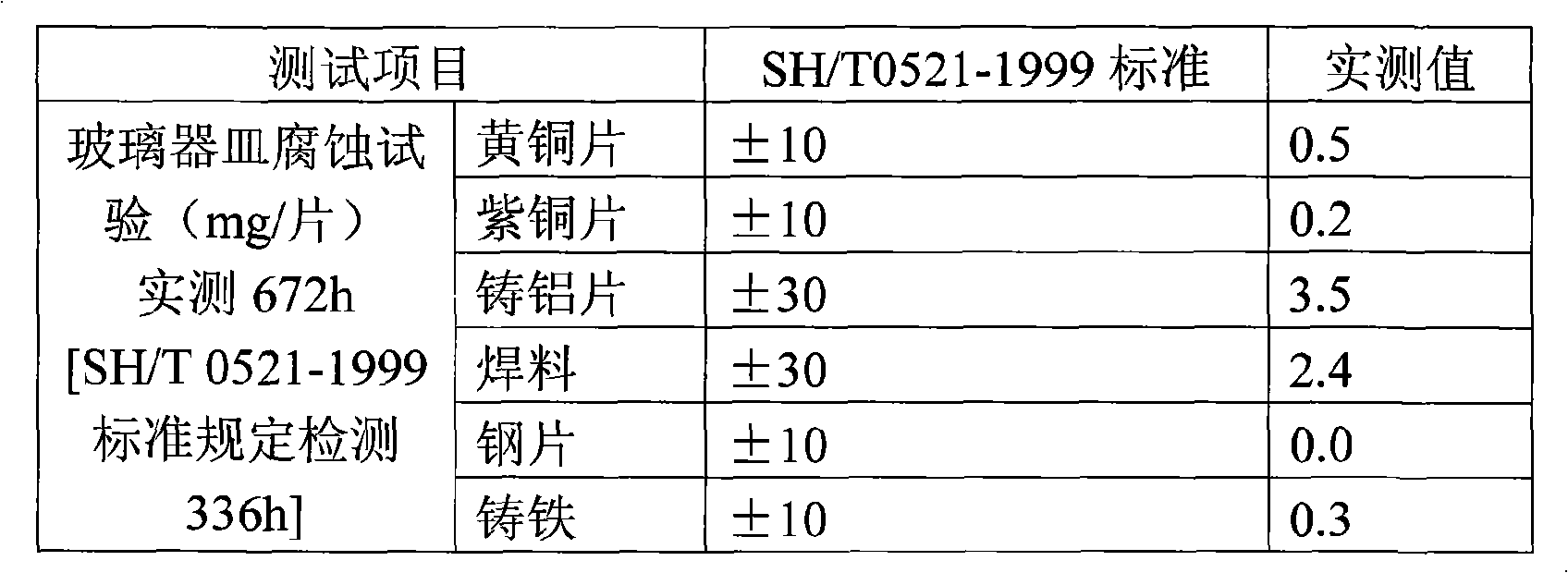

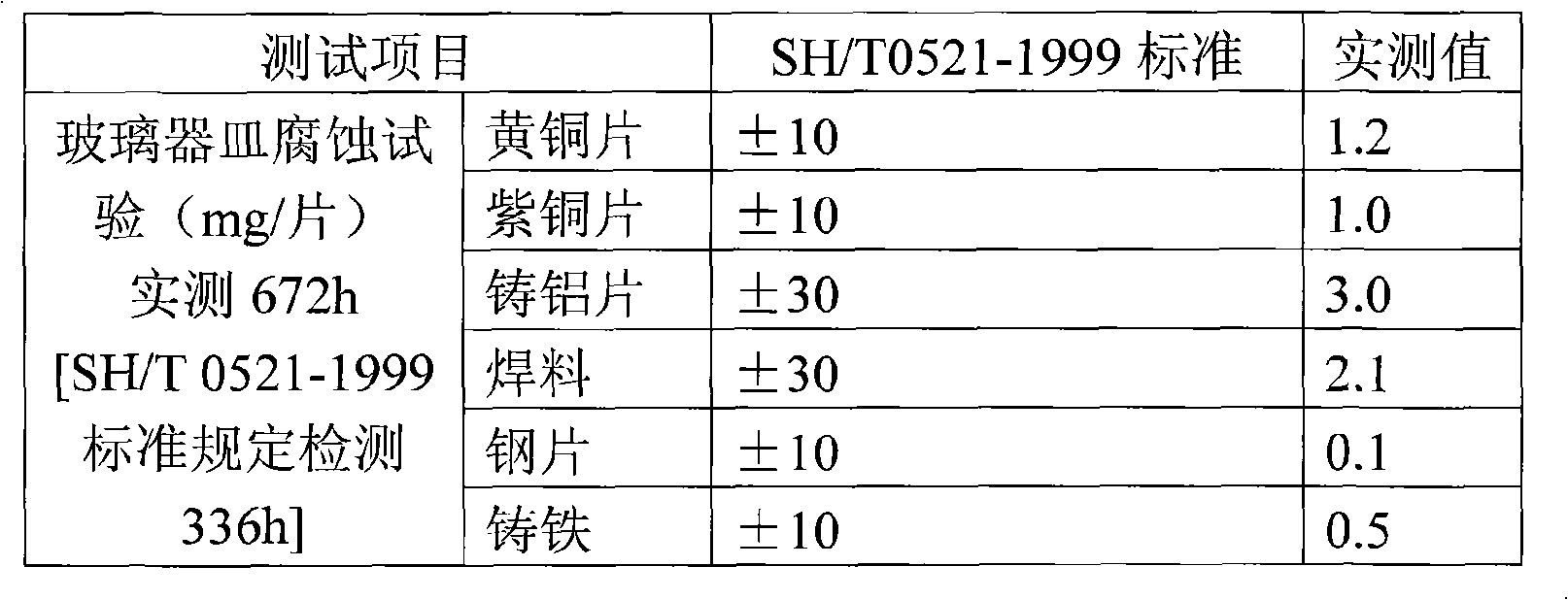

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

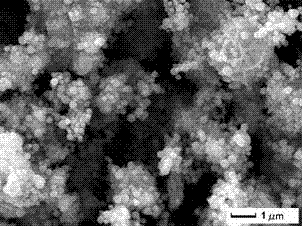

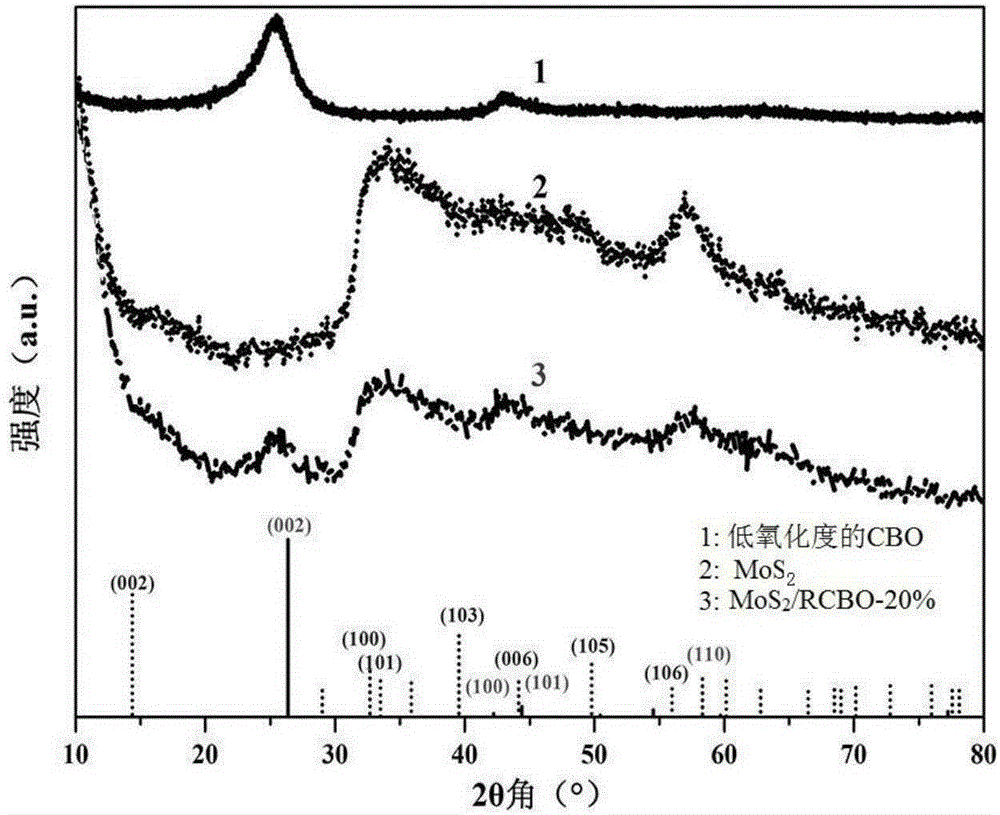

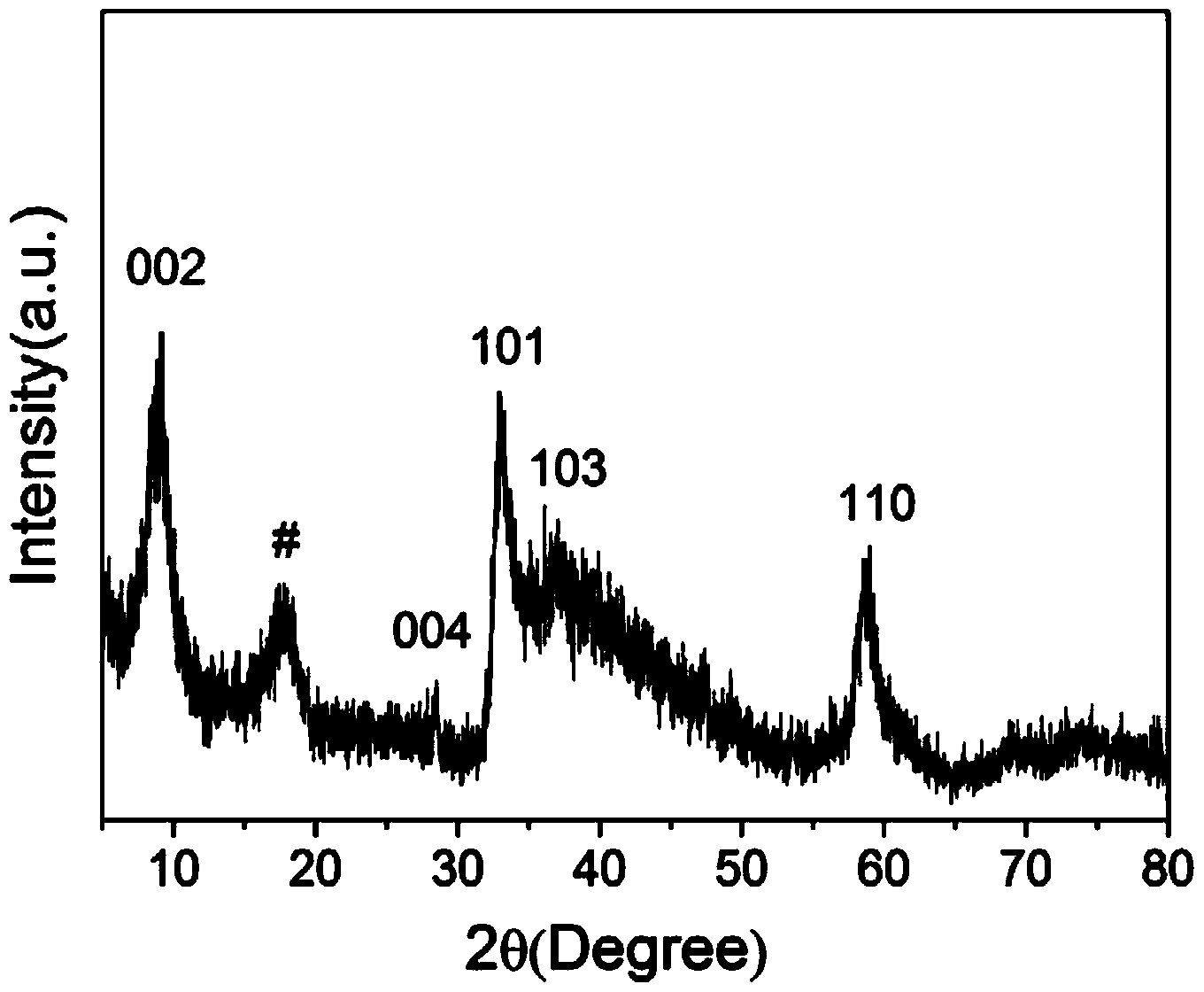

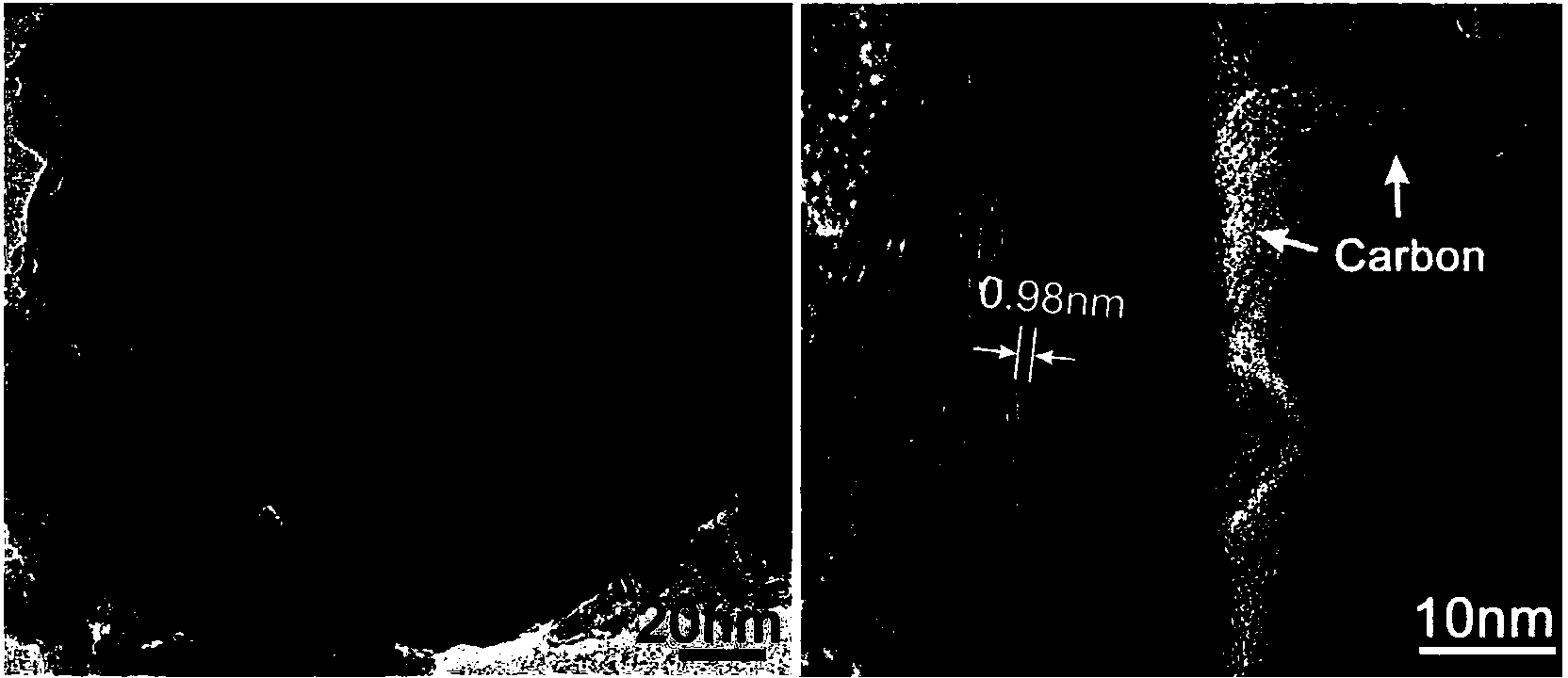

Molybdenum disulfide/carbon black composite hydrogen-evolution electrocatalytic material and preparation method therefor

InactiveCN105200450AHigh yieldLow pricePhysical/chemical process catalystsElectrodesSolvothermal reactionMaterials science

The invention relates to a molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material and a preparation method therefor and belongs to the field of electrocatalytic hydrogen evolution. According to the preparation method, firstly, a carbon black oxide with low degree of oxidation is prepared by adopting an improved Hummer method; and then, the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is prepared through one-step solvothermal reaction at the temperature of 220 DEG C in a manner of taking sodium molybdate crystals as a molybdenum source, taking sulfourea as a sulfur source and taking dimethylformamide as a solvent. According to the method provided by the invention, the carbon black oxide with low degree of oxidation is simple in preparation process and high in yield; the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is prepared by adopting a simple, convenient and mild one-step solvothermal method, the cost is low, the repeatability is high, and large-scale synthesis is facilitated. When the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is applied to electrocatalytic hydrogen evolution reaction, excellent catalysis performance is shown, the reduced current density reaches 25.0mA / cm<2> when tested overpotential is 200mV, and the reduced current density reaches 36.2mA / cm<2> when tested overpotential is 226mV; the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material has good electrocatalytic stability.

Owner:BEIHANG UNIV

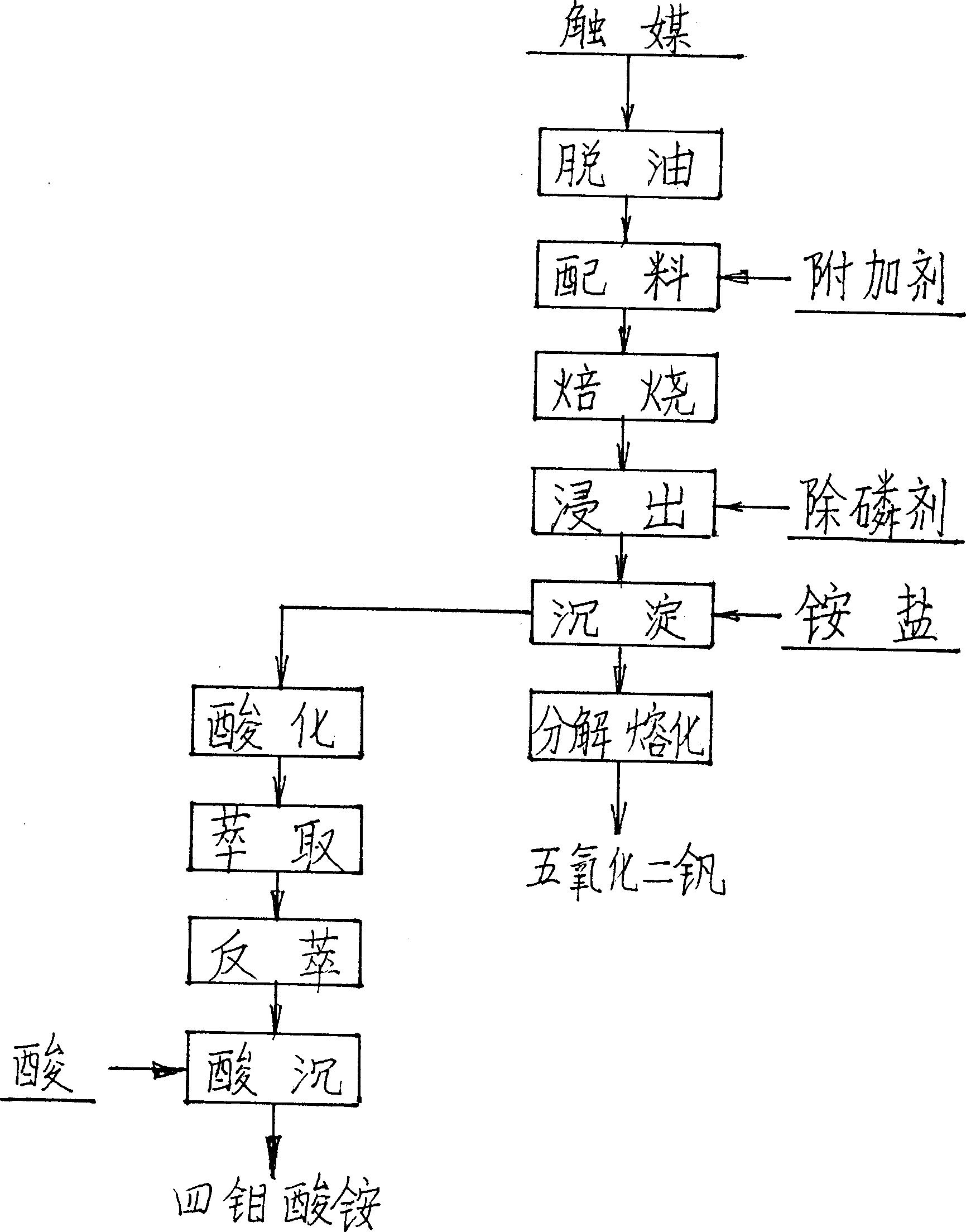

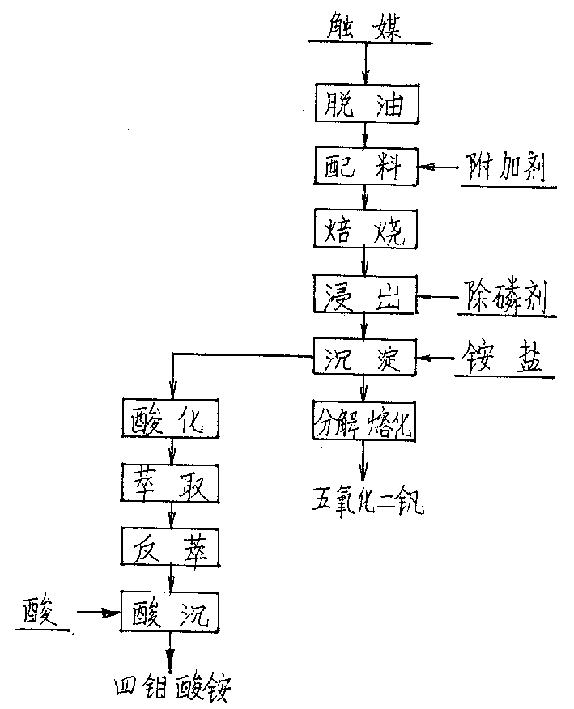

Method for reclaiming metals from molybdenum-containing waste catalyst

ActiveCN102051483APrevents the problem of easy leachingSolve pollutionProcess efficiency improvementFiltrationImpurity

The invention discloses a method for reclaiming metals from a molybdenum-containing waste catalyst, which comprises the following steps of: mixing the waste catalyst and a magnesium-containing compound, roasting, degreasing, removing carbon, then crushing, mixing the powder and sodium carbonate, roasting the mixture, and leaching the roasted materials by using aqueous solution, wherein ammonium salt or aqueous ammonia is added in the aqueous solution leaching step, the molybdenum in the waste catalyst enters the solution in a form of sodium molybdate or ammonium molybdate, the impurities such as silicon, phosphorus and the like entering the aqueous solution form sediment, and the sediment is kept in solid residue in a filtration step; and after the solid is separated, performing acidification, extraction, re-extraction and the like to reclaim the molybdenum and other metals. The method solves the pollution problem caused by sulfur dioxide in the discharged gas in the roasting, degreasing and carbon removal processes; and the salts formed by the reclaimed sulfur and magnesium can play a role in removing impurities in the subsequent steps so as to save the consumption of chemical reagents in the metal reclaiming process and reduce the cost. In addition, the method reduces the operation steps, reduces equipment, improves the operation effect, and also can improve the molybdenum yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special fertilizer for oil tea

InactiveCN102816015APromote growthImprove disease resistanceBio-organic fraction processingOrganic fertiliser preparationPaulowniaCamellia oleifera

The invention discloses a special fertilizer for oil tea. The fertilizer is prepared from the following components according to a certain weight ratio: an oil tea cake, peanut bran, sawdust of paulownia, bone meal, Chinese herbal medicine residue, humic acid, a nitrogen-phosphorus-potassium fertilizer, a biological bacterial preparation, a biological insecticide, zinc sulfate, magnesium sulfate, sodium molybdate and borax. According to the invention, long-term demands of oil tea for nutrients can be completely satisfied when the special fertilizers for the oil tea with different proportions of N, P and K are applied in different growth stages of the oil tea, and the special fertilizer provided by the invention has the advantages of a reasonable formula, balanced nutrition, safety, no pollution and capacity of promoting better growth of the oil tea, enhancing soil environment and improving quality and oil output of the oil tea.

Owner:安徽金农生态农业科技发展有限公司

Soilless vegetable culture nutrient solution and preparation method

InactiveCN106699386AImprove stabilityHigh content of effective nutrientsCalcareous fertilisersMagnesium fertilisersAdditive ingredientNutrient solution

The invention relates to the field of nutrient solutions, in particular to a soilless vegetable culture nutrient solution and a preparation method. The soilless vegetable culture nutrient solution is prepared from sodium nitrate, urea phosphate, potassium nitrate, ammonium sulfate, magnesium chloride, Fe-EDTA, boric acid, manganese chloride, zinc sulfate, copper sulfate, sodium molybdate, mixed nitrogen-fixing bacterium solution and a nostoc extracting solution. The nutrient solution is simple and convenient to prepare, comprehensive in nutrient ingredient, high in biological activity and good in homogeneity, can decompose self-toxic materials produced by vegetables, remarkably improve the resistance, yield and the quality of the vegetables.

Owner:GUIZHOU UNIV

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

Multifunctional preparation for controlling biological corrosion and blockage of oilfield production system

ActiveCN101875839AEliminate pollutionEliminate cloggingDrilling compositionDisinfectantSulfate-reducing bacteria

The invention relates to a multifunctional preparation for controlling biological corrosion and blockage of an oilfield production system. The contents of functional preparations in the treating water are as follows: 20 to 200 ppm of disinfectant: glutaraldehyde, acrolein, dodecyldimethylbenzyl ammonium chloride or dodecyldimethylbenzyl ammonium bromide, 10 to 100 ppm of inhibitor: sodium nitrateor sodium nitrite; and / or 10 to 20 ppm of sodium molybdate, sodium tungstate or lithium molybdate; 10 to 20 ppm of corrosion inhibitor: imidazoline quaternary ammonium; or / and 20 to 50 ppm of desulphurizing reagent: trihydroxymethyl nitromethane; or / and 10 to 20 ppm of penetrating agent: alkylpheol ethoxylates. The components undergo synergistic action so that the concentration of the single component is reduced obviously and reaches 25 to 90%, and the efficiency of killing the SRB (Sulfate Reducing Bacteria) reaches more than 90%.

Owner:PETROCHINA CO LTD

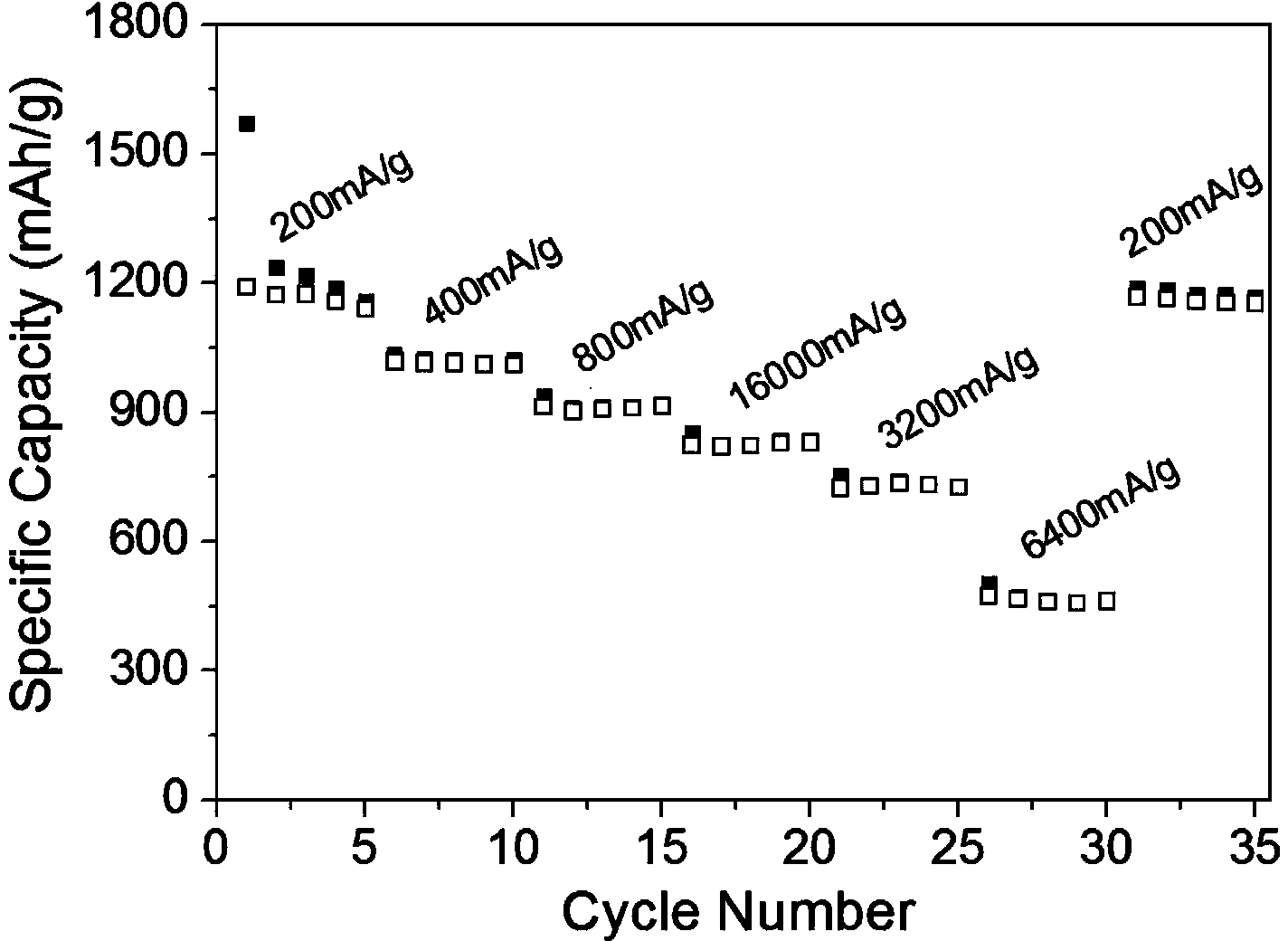

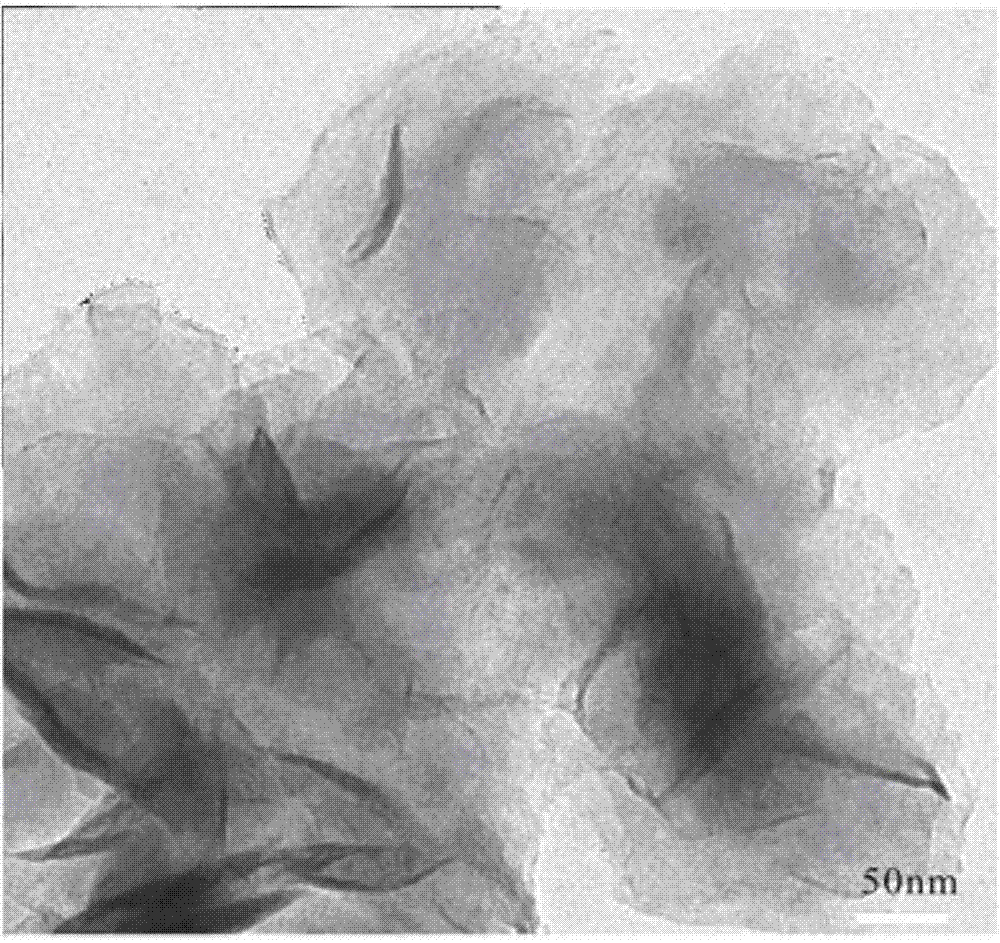

Molybdenum disulfide/mesoporous carbon composite electrode material as well as preparation method and application thereof

ActiveCN103915630AImprove the utilization rate of electrochemical activityIncrease spacingCell electrodesSecondary cellsChemical reactionThiourea

The invention discloses a molybdenum disulfide / mesoporous carbon composite electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing an oleic acid molecule intercalation molybdenum disulfide precursor through a hydrothermal reaction by adopting oleic acid and sodium oleate as a structure-directing agent and sodium molybdate and thiourea as a molybdenum source and a sulfur source; introducing dopamine into an interlayer by virtue of a chemical reaction of dopamine and oleic acid molecules; self-polymerizing molybdenum disulfide interlayer dopamine to form poly(dopamine) by adopting a tri-block copolymer, polyoxyethylene-polypropylene oxide-polyxyethylene, as a soft template, and then performing a high-temperature carbonization process to prepare the mesoporous carbon-embedded molybdenum disulfide interlayer nano hybrid material. By embedding mesoporous carbon, not only can the interlayer distance of molybdenum disulfide be increased and the re-accumulation of nano-sheets be effectively prevented, but also the electronic conductivity of molybdenum disulfide can be remarkably improved. An electrochemical test result proves that as a lithium ion battery negative material, the molybdenum disulfide / mesoporous carbon composite electrode material has high specific capacity, excellent rate performance and excellent cycling performance, and can be widely applied to the field of lithium ion batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

Composite fertilizer special for dragon fruits

The invention relates to a composite fertilizer special for dragon fruits. The composite fertilizer consists of urea, ammonium nitrate, monoammonium phosphate, potassium sulfate, humic acid salt, chitosan, borax, zinc chloride, sodium molybdate, manganese sulfate, ferrous sulfate, magnesium sulfate, copper sulfate, salicylic acid, sodium dodecyl benzene sulfonate, dimethyl sulfoxide, monosodium glutamate waste liquor, an EM (effective microorganism) liquid and the like. The composite fertilizer disclosed by the invention is used for overcoming the defects that the specially applied fertilizer is lack in the current dragon fruit cultivation production, the fertilizer use amount is high and organic nutrition components are few.

Owner:蚌埠行时知识产权运营有限公司

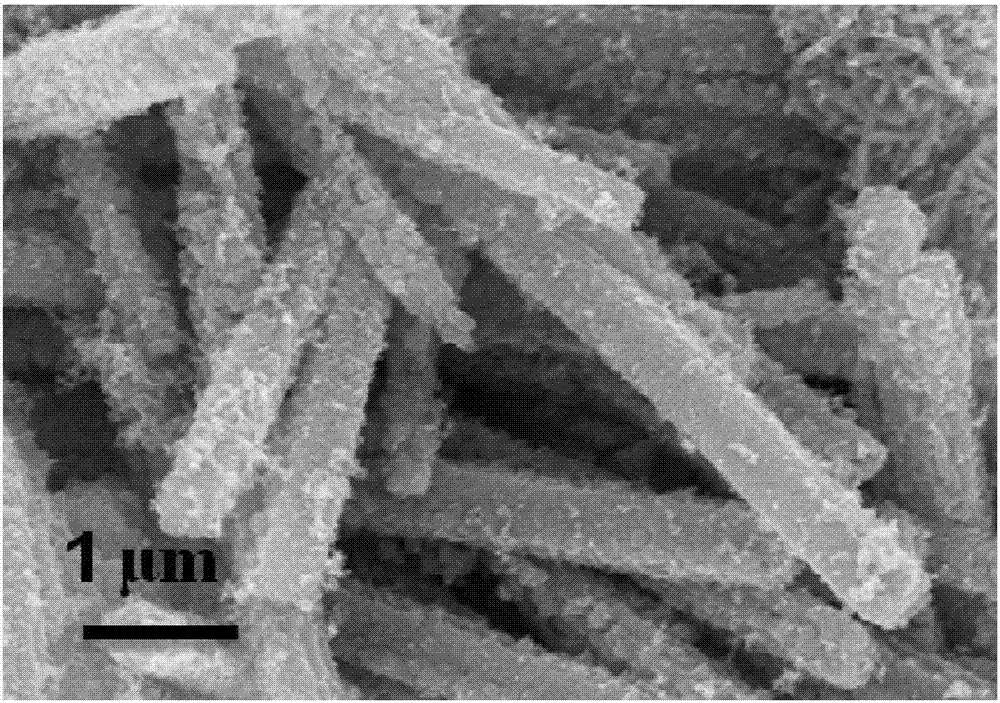

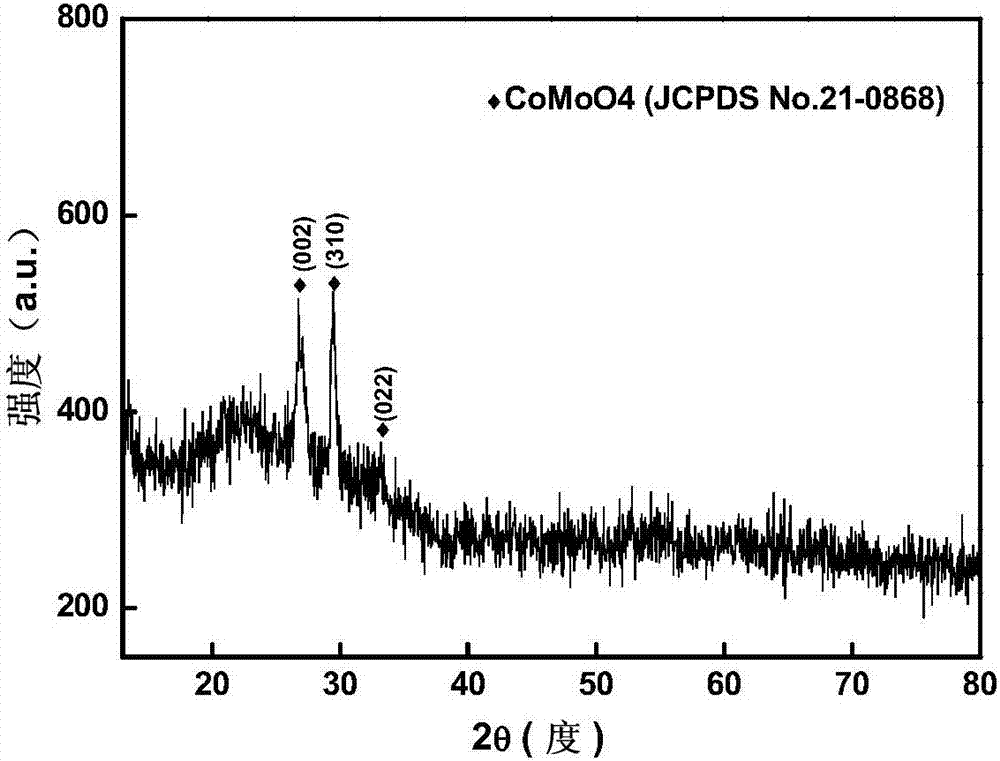

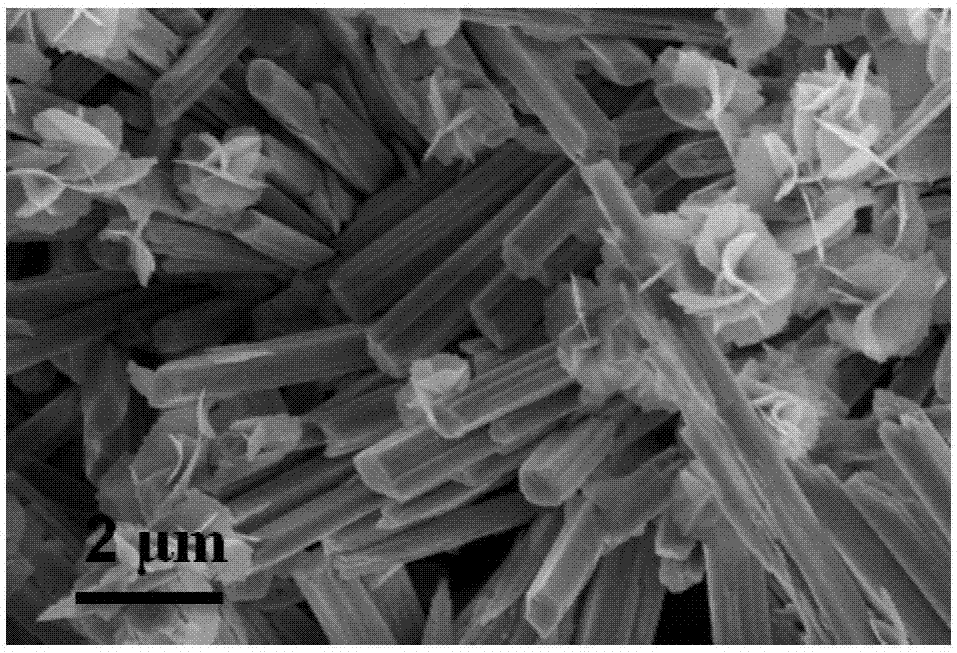

MoSe2/Co0.85Se composite material for electrocatalytic water decomposition as well as preparation method and application thereof

InactiveCN107051550AFor subsequent applicationFacilitate catalytic performance testingPhysical/chemical process catalystsElectrodesDecompositionCobalt

The invention relates to a MoSe2 / Co0.85Se composite material for electrocatalytic water decomposition. The microtopography of the composite material is that a micron / nano rod of a MoSe2 / Co0.85Se compound is loaded with a nano sheet of a molybdenum selenide / cobaltous selenide compound; the micron / nano rod has the length of is 1.5 to 3.5 microns and a diameter of 0.2 to 0.5 micron. A composite-material precursor CoMoO4 is firstly prepared and obtained through a hydrothermal reaction by using cobalt nitrate and sodium molybdate as reactive raw materials; afterwards, the composite material is made through the hydrothermal reaction by using sodium borohydride, selenium powder and the prepared composite-material precursor as raw materials. A preparation method of the MoSe2 / Co0.85Se composite material is simple; the raw materials are easily obtained; the cost is low; the industrialized production is easily realized; the prepared and obtained composite material is good in electrocatalytic effect, and further, has favorable stability.

Owner:SHANDONG UNIV

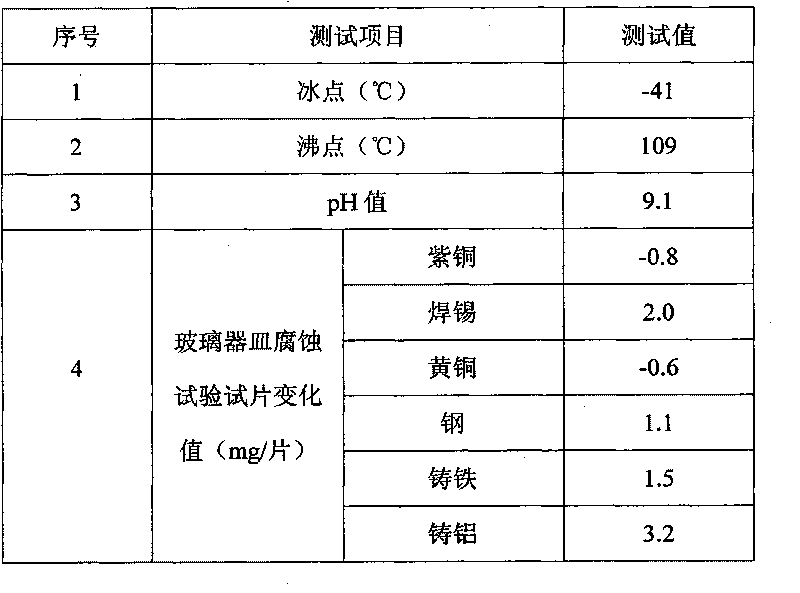

Anti-freezing fluid

ActiveCN101302424ATo achieve long-term goalsTo achieve the characteristics of green environmental protectionHeat-exchange elementsSodium molybdateAnti freezing

The invention discloses anti-freeze fluid. The compositions by weight percentage of the anti-freeze fluid are: 35 to 85 percent of glycol, 0.25 to 0.06 percent of sodium molybdate, 0.4 to 0.1 percent of sodium nitrate, 3.5 to 0.8 percent of potassium hydroxide, 1.2 to 0.2 percent of 85 percent phosphoric acid, 0.3 to 0.02 percent of metyl benzotriazole, 0.5 to 0.05 percent of benzotriazole, 3.5 to 0.8 percent of sebacic acid, 1.0 to 0.25 percent of undecanedioic acid, 1.0 to 0.2 percent of octanoic acid, 3.0 to 0.8 percent of sodium benzoate, 0.2 to 0.05 percent of hydrolytic-polymeric maleic anhydride, 0.003 to 0.01 percent of antifoaming agent, the balance being deionized water. The anti-freeze fluid is characterized by long effect and environmental protection, and can perform all-around multi-layer protection on an automobile cooling system.

Owner:张家港迪克汽车化学品有限公司

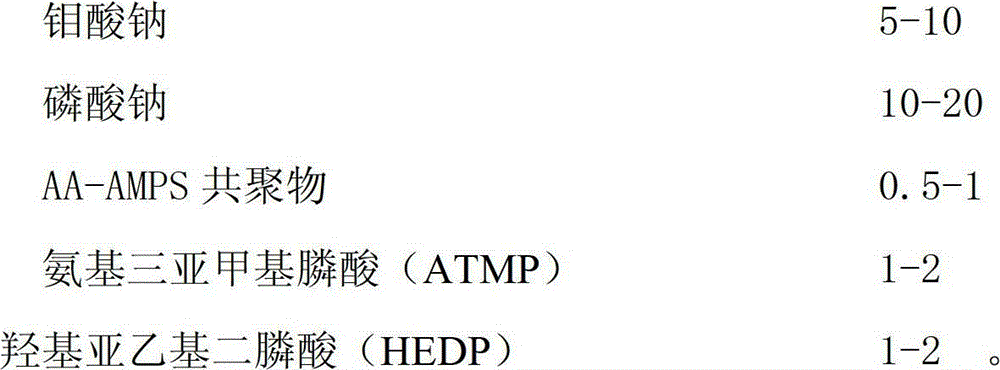

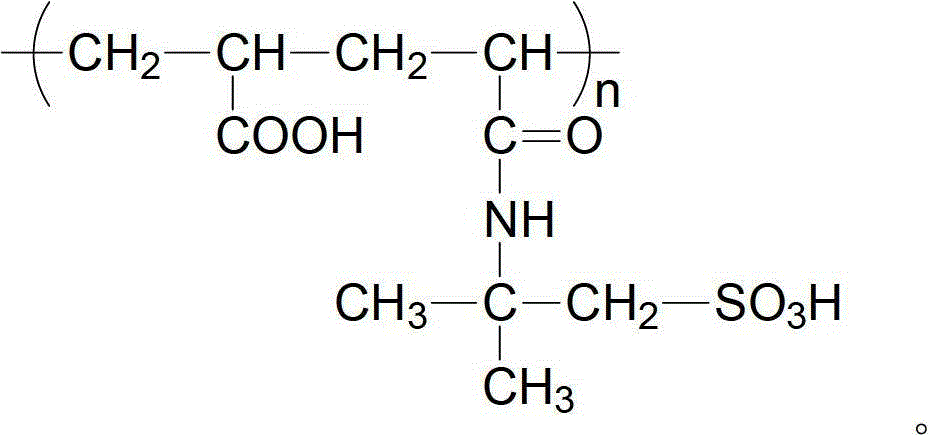

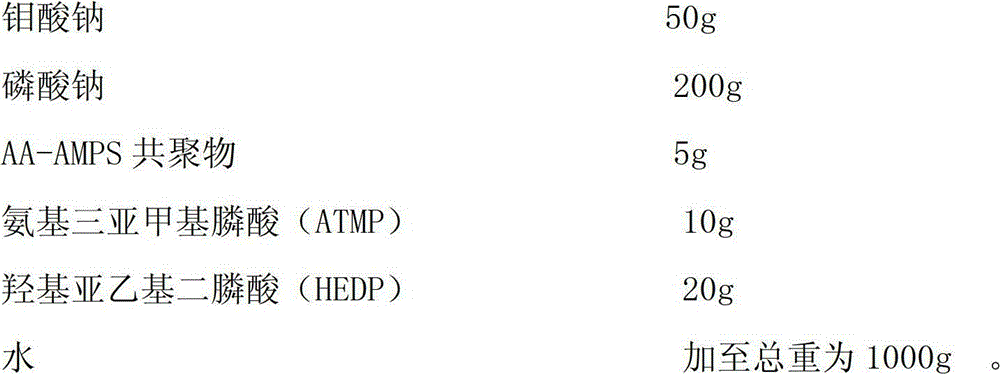

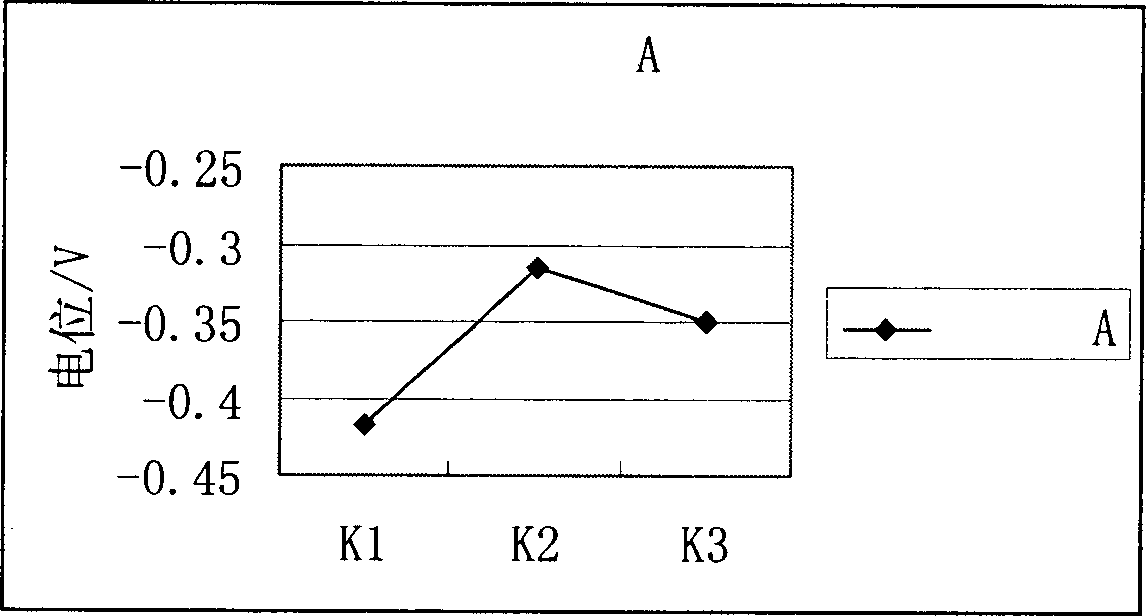

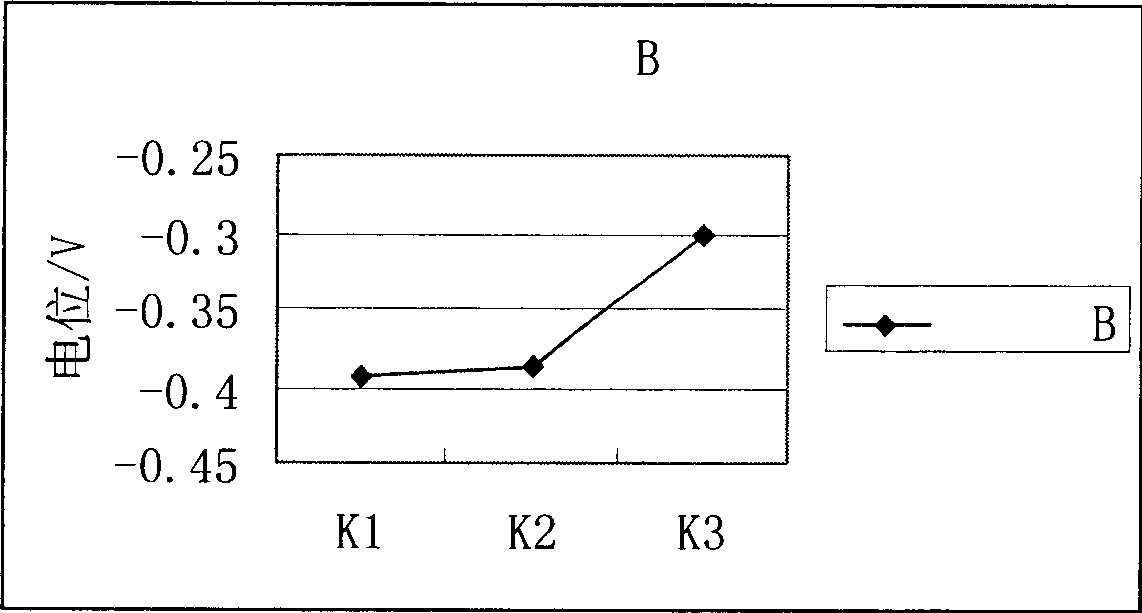

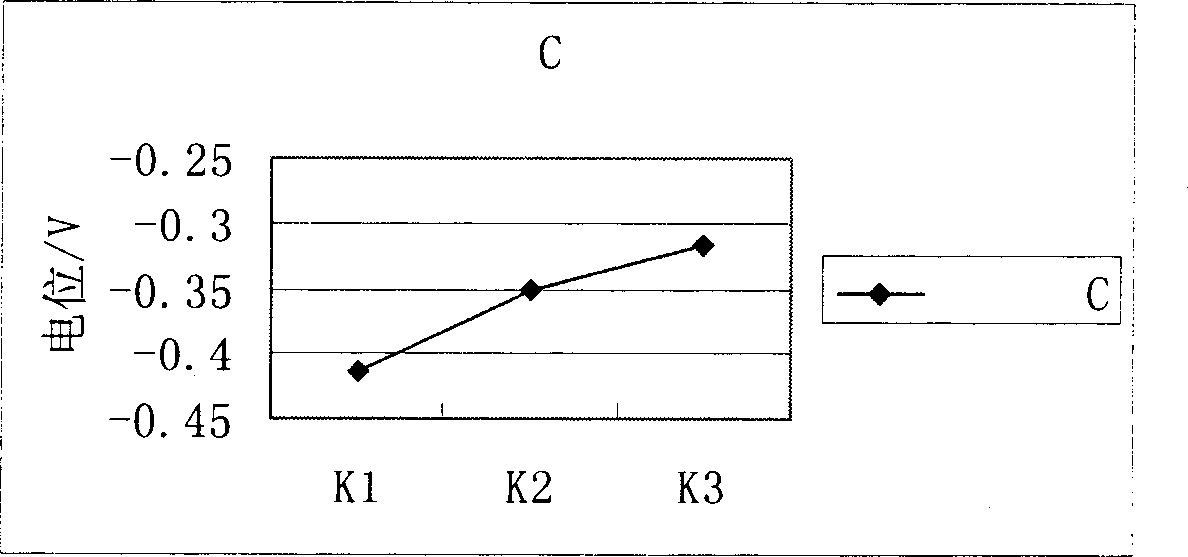

Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102911651AGood synergyGood scale and corrosion inhibitionBorehole/well accessoriesSodium phosphatesSimple component

The invention relates to an oil field compound type anti-scale corrosion inhibitor and a preparation method thereof, belonging to the technical field of corrosion inhibitor. The oil field compound type anti-scale corrosion inhibitor is characterized by comprising the components by mass percent: 5-10% of sodium molybdate, 10-20% of sodium phosphate, 0.5-1% of acrylic acid-2-acrylamido-2-methyl propane sulfonic acid (AA-AMPS) copolymer, 1-2% of amino trimethylene phosphonic acid and 1-2% of hydroxyl ethylidene diphosphonic acid (HEDP). The preparation method comprises the steps of: firstly, completely dissolving sodium molybdate and sodium phosphate by using water; then, adding the AA-AMPS copolymer under the condition of stirring until the copolymer is completely dissolved; subsequently, adding ATMP and the HEDP, and further stirring for dissolving; and finally, adding water until the concentration of the mixed solution is in accordance with the requirement, so as to obtain the oil field compound type anti-scale corrosion inhibitor. The inhibitor disclosed by the invention has the advantages of simple components, available raw materials, simple technology, high efficiency, low cost, low dosage, good scale inhibition, descaling and corrosion inhibition effects and the like, and is convenient to prepare, rapid.

Owner:E TECH ENERGY TECH DEV CORP

Antirust for reinforced concrete

This invention relates to an antirust agent for reinforced concrete. The antirust agent is composed of: sodium molybdate 0.01-0.05 wt.%, diethylenetriamine 0.9-4.5 wt.%, allylthiourea 0.08-0.19 wt.%, 1,4-butynediol 0.15-0.75 wt.%, and water as balance. The antirust agent can effectively alleviate and prevent the rusting of the steel bars in the reinforced concrete, as well as alleviate or inhibit the damage to the passivated film of the steel bars by chloric ions. Besides, the antirust agent has such advantages as low application amount.

Owner:邢士波

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

Alkaline fertilizer

InactiveCN104761322AGood characterPrevent acidificationFertilizer mixturesPotassium hydroxideManganese

The invention discloses an alkaline fertilizer composed of the following components in percentage by weight: 31-99.4% of macroelements, 0.5-50% of medium elements, 0.1-15% of microelements and 0-50% of synergic components, wherein the macroelements include two and even more selected from urea, diammonium phosphate, ammonium polyphosphate, dipotassium phosphate, tripotassium phosphate, potassium pyrophosphate, potassium tripolyphosphate, potassium nitrate, potassium carbonate, potassium sulfate, potassium chloride, potassium formate, potassium silicate and potassium hydroxide; the medium elements are one or more selected from calcium nitrate, calcium chloride, magnesium chloride, magnesium sulfate, EDTA calcium and EDTA magnesium; the microelements are one or more selected from ferrous sulfate, zinc sulfate, manganese sulfate, copper sulfate or an EDTA chelate of iron, zinc, manganese and copper, EDDHA iron, borax, disodium octaborate tetrahydrate and sodium molybdate; and the synergic components include one or more selected from sodium humate, potassium humate, sodium fulvate, potassium fulvate, sodium alginate, potassium alginate and a plant growth regulator.

Owner:于书强

Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

The invention discloses a deformed steel bar compound corrosion-inhibited quenching agent and a usage method thereof. The compound corrosion-inhibited quenching agent is obtained by mixing the following compositions in parts by weight: 0-1 part of sodium carboxy methyl cellulose, 0-1 part of sodium polyacrylate, 0.1-1 part of sodium benzoate, 0.1-2 parts of triethanolamine, 0-0.1 part of sodium molybdate, 0-5 parts of sodium hydroxide, 0-10 parts of sodium carbonate, 5-15 parts of sodium silicate, and 70-90 parts of water. In use, the non-rusted deformed steel bar is subjected to quenching treatment in the corrosion-inhibited quenching agent for 1-2s at 100-200 DEG C, thereby being capable of slowing down the corrosion of the deformed steel bar under the atmosphere. The corrosion-inhibited quenching agent does not contain nitrite and chromate, has no S and P atoms, and is green and environment-friendly, low in cost, and recyclable.

Owner:HEFEI UNIV OF TECH

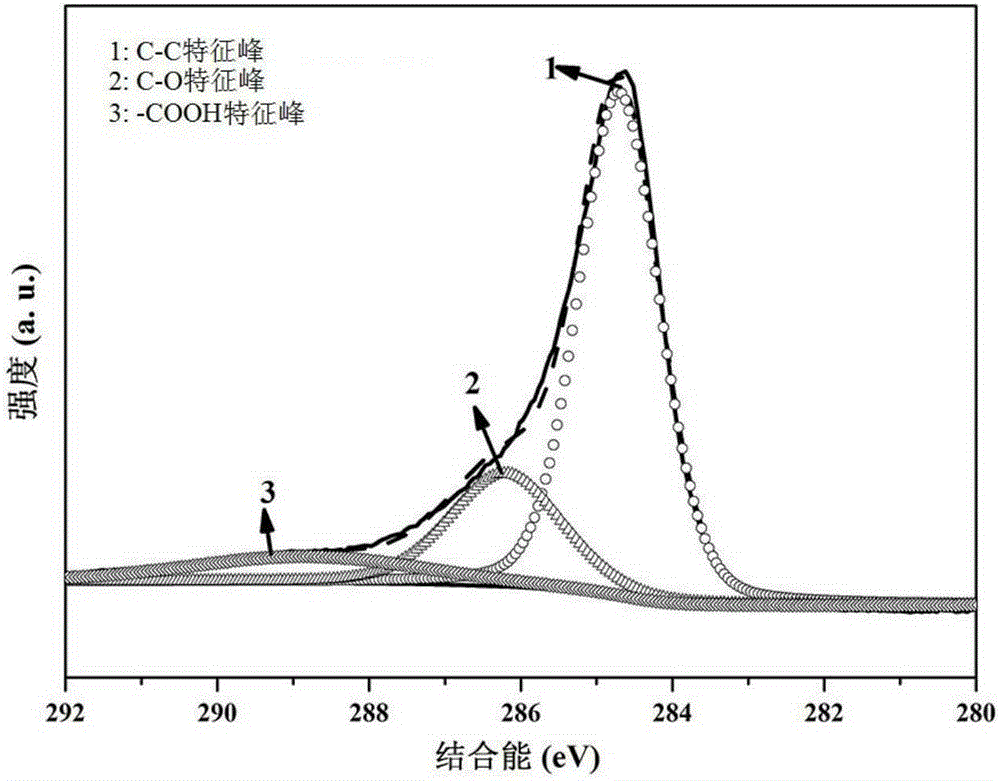

Preparation method of carbon-doped molybdenum disulfide nanometer material

InactiveCN104495937AImprove cycle stabilityLittle change before and afterMaterial nanotechnologyMolybdenum sulfidesSodium acetateDispersity

The invention provides a preparation method of a carbon-doped molybdenum disulfide nanometer material. The method comprises the following steps: weighing sodium molybdate, ammonium molybdate or molybdenum oxide and thiourea, sodium sulphide, potassium rhodanate or dithiocyano sodium acetate to be firstly dissolved into an ethylene glycol solution, then dissolved into ultrapure water, and fully stirring, so as to prepare a mixed solution; adjusting the pH value of a mixed solution with ammonia water and hydrochloric acid; transferring the mixed solution into a reaction kettle, and carrying out solvothermal reaction; taking out the mixed solution after reaction, and naturally cooling to room temperature; sequentially washing with ultrapure water and ethyl alcohol, and collecting a black substance; and drying the black substance in a vacuum drying oven, so as to prepare the carbon-doped molybdenum disulfide nanometer material. According to the carbon-doped MoS2 nanometer material prepared by the method, the sheet is uniform in size, good in dispersity, small in pollution in preparation process, and free of harmful air; and the molybdenum disulfide nanometer material with good dispersity can be greatly prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Metal anti-rust agent

The invention relates to a metal anti-rust agent which is characterized by comprising the following components in parts by weight: 10-20 parts of inositol hexaphosphate, 8-15 parts of acrylamide, 6-14 parts of diethanol amine, 5-10 parts of a polymer film-forming agent, 4-8 parts of sodium molybdate, 1-3 parts of cresyl triazole, 0.5-1.5 parts of a surfactant and the balance amount of water. The metal anti-rust agent has the characteristics of wide application range, stable anti-rust effect, convenience in use, high efficiency, safety, environmental friendliness and the like.

Owner:GUANGXI DOCTOR HAIYI INFORMATION TECH

Plant nutrient solution

InactiveCN103724072AWill not polluteCause some damagesCultivating equipmentsSoilless cultivationSodium iodideNutrition

The invention provides a plant nutrient solution which consists of the following components: potassium nitrate, urea, ammonium nitrate, magnesium sulphate, ammonium dihydrogen phosphate, calcium nitrate, manganese sulfate, zinc sulfate, ferric citrate, boric acid, sodium molybdate, sodium iodide, folic acid, asparagine and deionized water. According to the invention, the plant nutrient solution is comprehensive in nutrition, has no poisonous substance, cannot pollute the environment after being used, cannot cause harm to human body, and is free from undesirable odor. Through the adoption of the plant nutrient solution to cultivate foliage plants such as monstera deliciosa and rohdea japonica without soil, the leaf color is dark green, the growth is vigorous, death is hard, and compared with the conventional plant nutrient solution in the market, the growth rate is increased by 20%.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

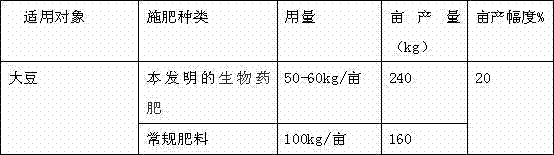

Organic-inorganic composite biological fertilizer pesticide special for soybean and preparation method thereof

ActiveCN102951962AImprove fertilizer efficiencyLow costFertilizer mixturesNutritionMonocalcium phosphate

The invention provides an organic-inorganic composite biological fertilizer pesticide special for soybean. The organic-inorganic composite biological fertilizer pesticide is prepared from the following materials in parts by weigh: 40-50 parts of household garbage, 30-40 parts of mushroom slag, 20-25 parts of vinasse, 15-20 parts of humic acid, 10-13 parts of monocalcium phosphate, 12-14 parts of urea, 10-12 parts of potassium nitrate, 10-12 parts of quail feather, 20-24 parts of modified sepiolite, 3-4 parts of quispualis indica, 3-4 parts of stone-like omphalia, 4-6 parts of broom cypress fruit, 4-6 parts of rhizome nardostachyos, 4-6 parts of radix euphorbiae lantu, 0.1-0.2 part of boric acid, 0.05-0.1 part of sodium molybdate, 1-1.5 parts of zinc sulfate, 0.7-1.0 part of manganese sulfate, 5-7 parts of magnesium sulfate, 1-2 parts of nitrogen-fixing bacteria preparation and 3-5 parts of wintergreen oil. According to the invention, multiple organic wastes are mixed and then fermented so as to be changed into green organic fertilizer, environmental pollution is reduced, fermenting organic matter are mixed with inorganic fertilizer, and Chinese herbal medicine juice with insecticide function is added, therefore, the nutrition is more complete, and the sterilizing effect is increased. By applying the fertilizer, the quality of the soybean can be effectively improved, the soybean has green leaves and more flowers, the flowering period is prolonged, and the yield is improved.

Owner:东至县神山化肥有限责任公司 +1

Environment-friendly type composite pre-film reagent used for recirculated cooling water system pre-film processing and method of use thereof

InactiveCN101182643AReduce total usageUse low concentrationScale removal and water softeningLiquid wasteTricarboxylic acid

The invention belongs to the circulating cooling water treatment technical field, and refers in detail to an environment-protecting composite pretreatment filming agent used for the pre-treatment filming in a circulating cooling water system and a use method thereof. The environment-protecting composite pretreatment filming agent comprises the main components of 2-phosphonobutane- 1, 2, 4-tricarboxylic acid and sodium of polyepoxysuecinic acid as well as a proper amount of carboxylic acid copolymer, benzotriazole, sodium molybdate, zinc sulphate and so on. When used, the composite pre-treatment filming agent is added into the circulating cooling water directly, and a corrosion-resistant protecting film is formed after 48 years of operation, the corrosion resistance of which to the standard copper sulphate drip solution is far better than the traditional phosphor-zinc pretreatment filming agent. The total phosphor content of the environment-protecting composite pretreatment filming agent is less than 7.5mg / l, and the water pH value does not have to be adjusted. After the pretreatment filming, the water is clear and transparent, and the normal operation can be started without replacing the water. Thus, not only the water to be replaced is saved, but also the chemical base investment expense during the normal operation after the water replacement is reduced. Meanwhile, no waste liquor of pretreatment filming is discharged, so the invention belongs to the environment-friendly pretreatment filming method.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com