Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

A quenching agent and rebar technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., to achieve the effect of overcoming environmental pollution and human health hazards, low price, and high corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 0.3 parts of sodium carboxymethylcellulose, 0.5 parts of sodium benzoate, 0.5 parts of triethanolamine, 5 parts of sodium carbonate, 1.3 parts of sodium hydroxide and 7 parts of water glass into 77.2 parts of tap water while stirring at room temperature, and all substances are dissolved Then continue to stir until the solution is uniform and transparent to obtain the compound corrosion inhibitor and quenching agent of the present invention, with a pH value of 13.45 and a viscosity of 7.1 mPa·S.

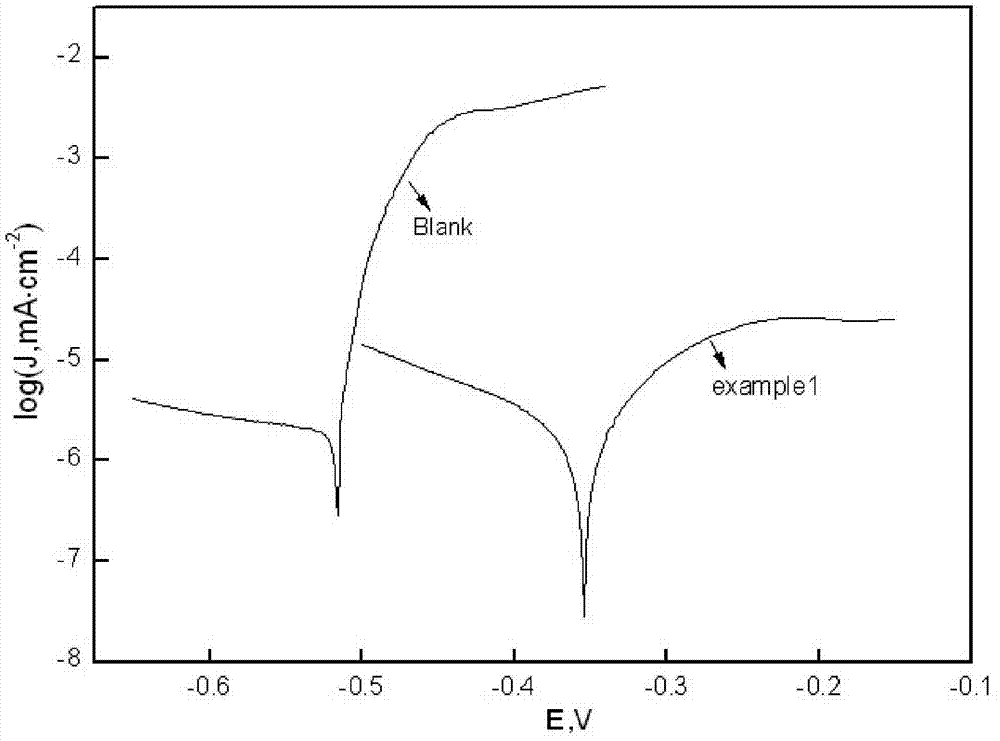

[0034]The corrosion resistance of rebar was evaluated by CCT and ET respectively, and the corrosion inhibition rate is shown in Table 1. It can be seen from Table 1 that the corrosion inhibition rates of CCT and ET reach 45% and 99% respectively, and the corrosion resistance of rebar after quenching with the compound corrosion inhibitor and quenching agent of the present invention is greatly improved. Tafel line of electrochemical method see figure 1 ,Depend on figure 1 I...

Embodiment 2

[0036] Add 0.1 parts of sodium polyacrylate, 0.5 parts of sodium benzoate, 1.5 parts of triethanolamine, 3 parts of sodium carbonate, 1.3 parts of sodium hydroxide and 10 parts of water glass into 76.2 parts of tap water while stirring at room temperature, and continue stirring after all substances are dissolved Until the solution is uniform and transparent, the compound corrosion inhibitor quenching agent of the present invention is obtained, the pH value is 13.32, and the viscosity is 7.76mPa·S.

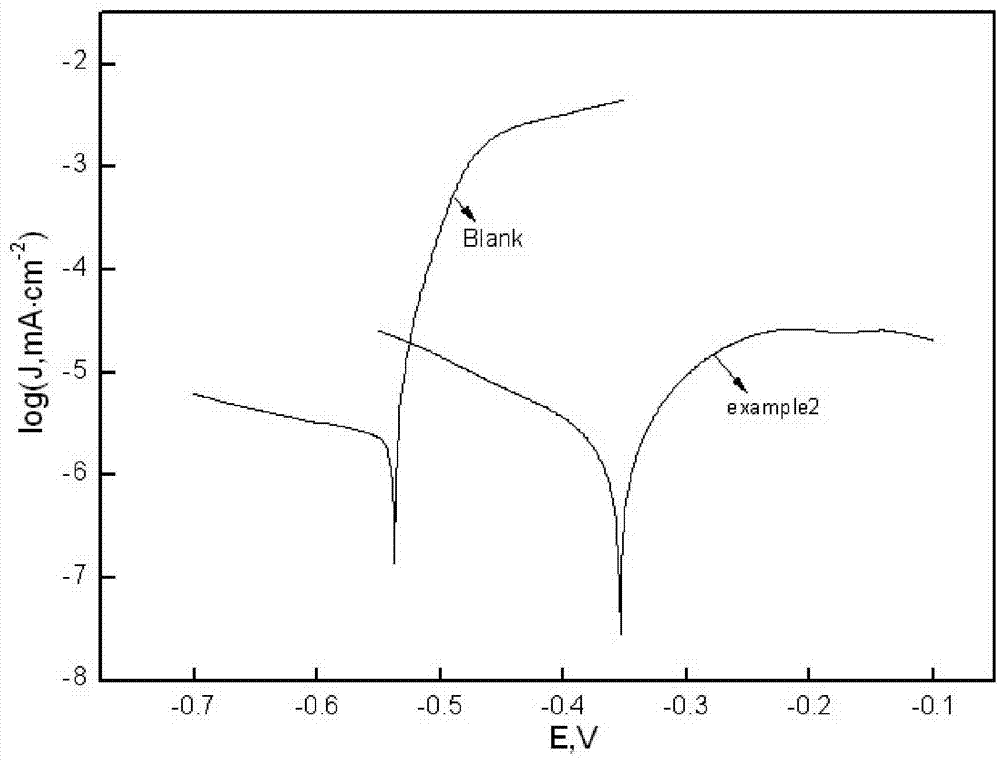

[0037] The corrosion resistance of rebar was evaluated by CCT and ET respectively. The corrosion inhibition rate is shown in Table 1. As can be seen from Table 1, the corrosion inhibition rates of CCT and ET reach 49% and 91.7% respectively, and the corrosion resistance of the threaded steel after the quenching treatment of the compound corrosion inhibiting quenching agent of the present invention is greatly improved. improvement. Tafel line of electrochemical method see figure ...

Embodiment 3

[0039] At room temperature, add 0.3 part of sodium polyacrylate, 0.5 part of sodium benzoate, 0.5 part of triethanolamine and 12 parts of water glass into 87.9 parts of tap water while stirring, and continue stirring until the solution is uniform and transparent after all the substances are dissolved to obtain the composite compound of the present invention. Corrosion inhibitor quenching agent, pH value is 11.86, viscosity is 5.7mPa·S.

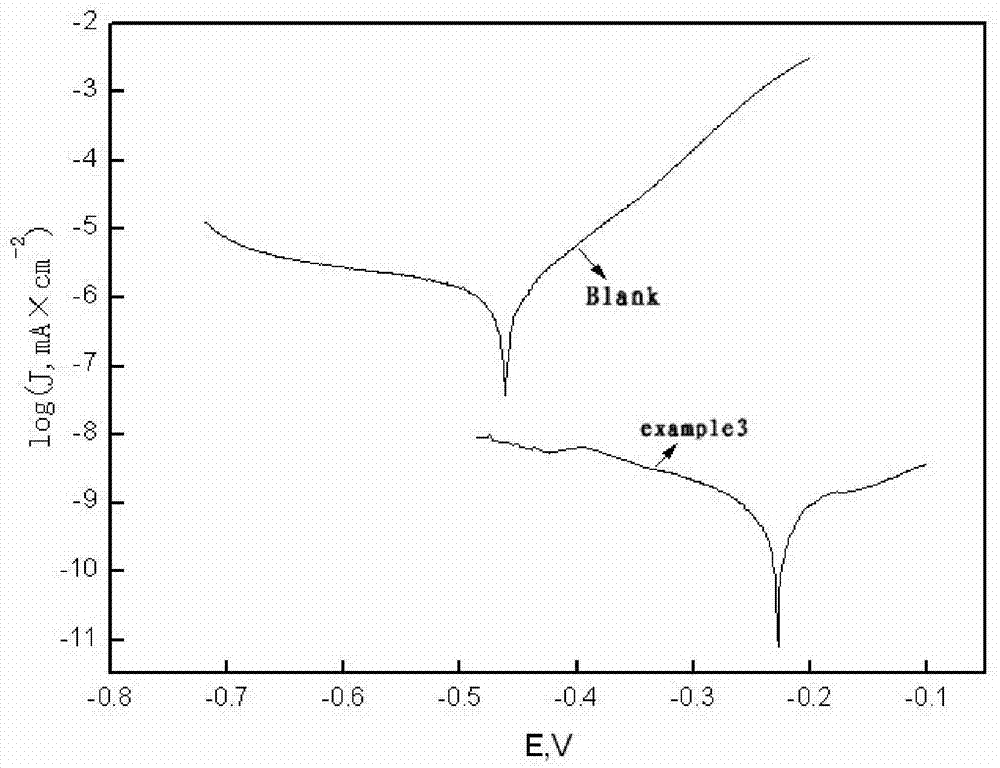

[0040] The corrosion resistance of rebar was evaluated by CCT and ET respectively. The corrosion inhibition rate is shown in Table 1. It can be seen from the corrosion inhibition rate in Table 1 that the corrosion inhibition rates of CCT and ET reach 67.6% and 99.9% respectively. be greatly improved. Tafel line of electrochemical method see image 3 . Depend on image 3 It can be seen that the self-corrosion potential of the carbon steel sheet after the quenching treatment of the corrosion inhibitor and quenching agent is obviously shifted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com