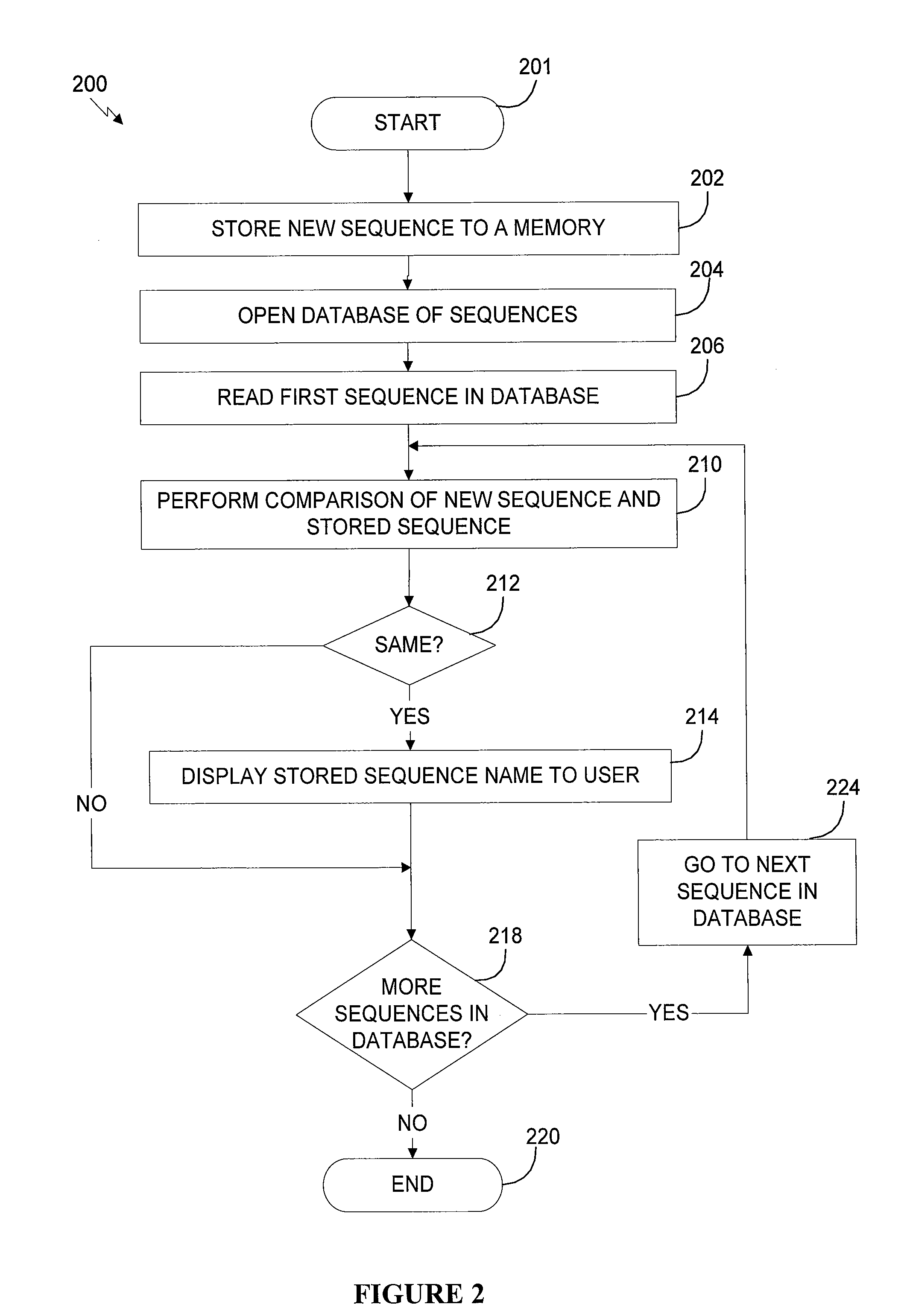

Patents

Literature

246 results about "Carboxy methyl cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carboxy Methyl Cellulose (CMC) is used as a thickeners in non-volatile eye drops (artificial tears). Sometimes it is methyl cellulose (CMC) which is used, but its non-polar methyl groups (-CH3) do not add any solubility or chemical reactivity to the base cellulose.

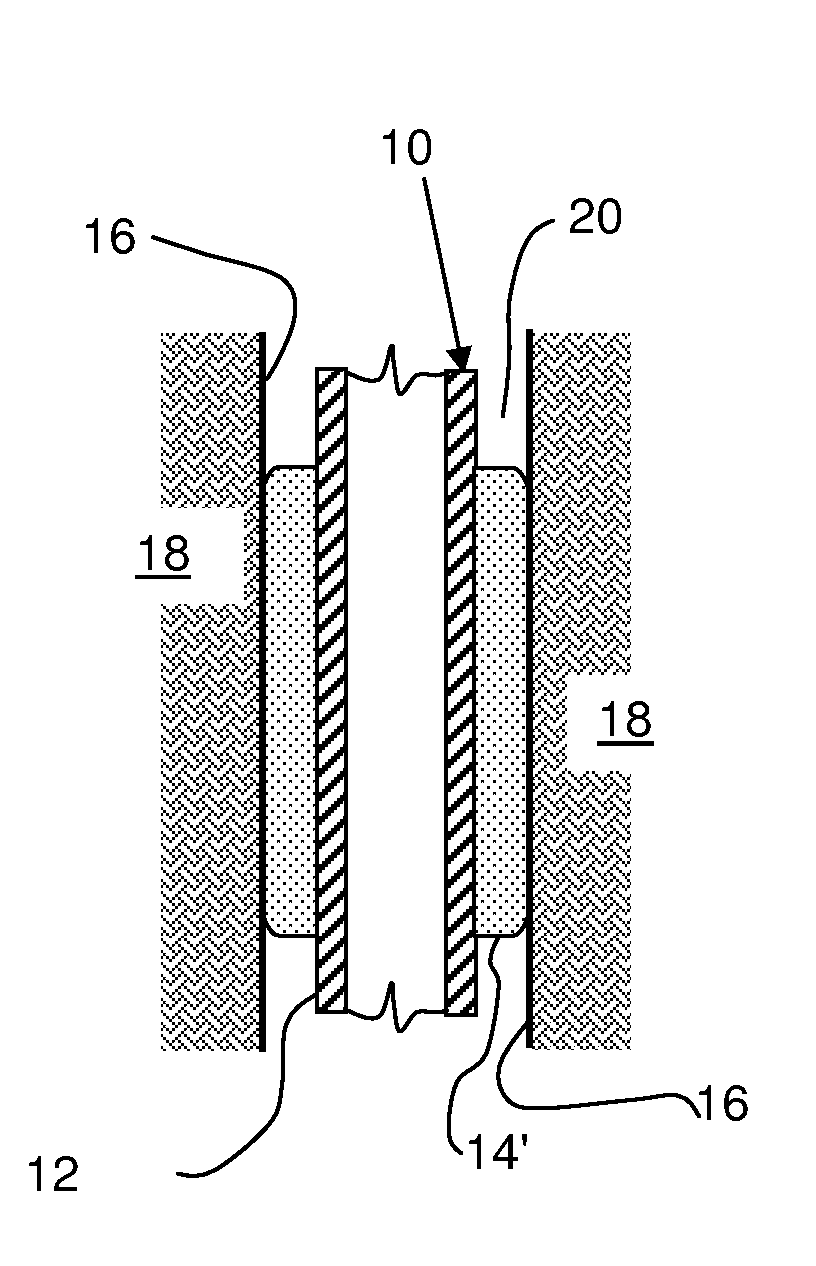

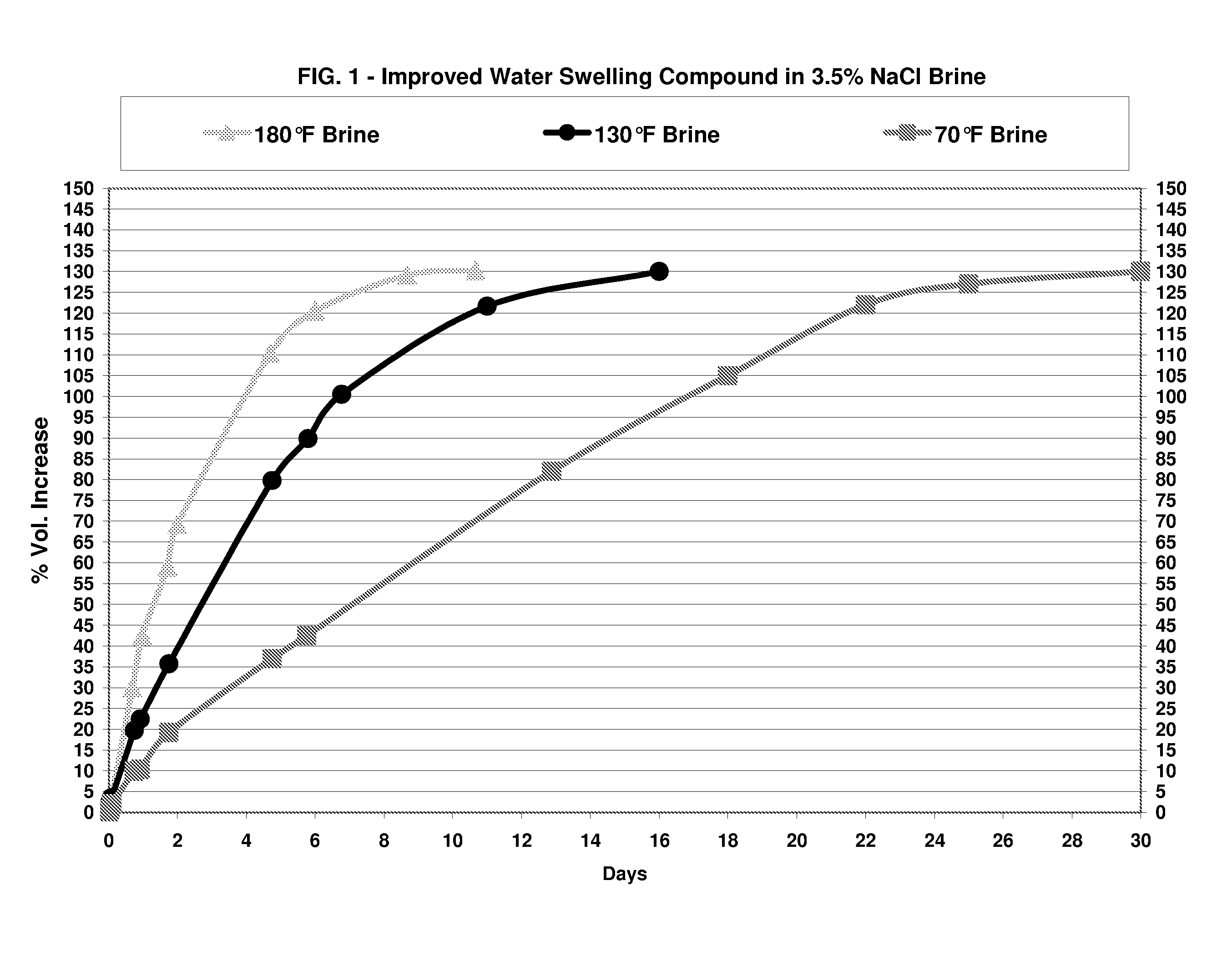

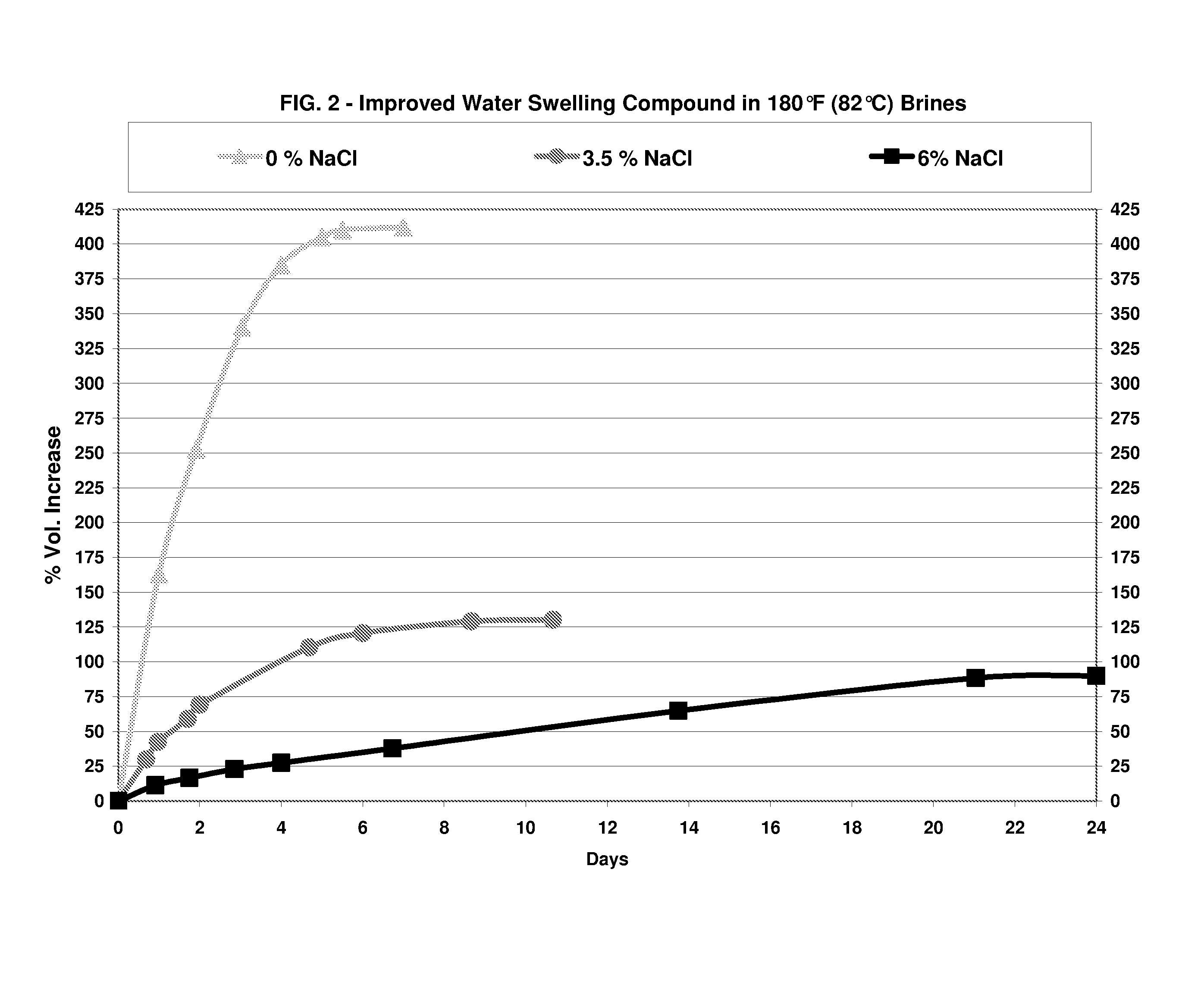

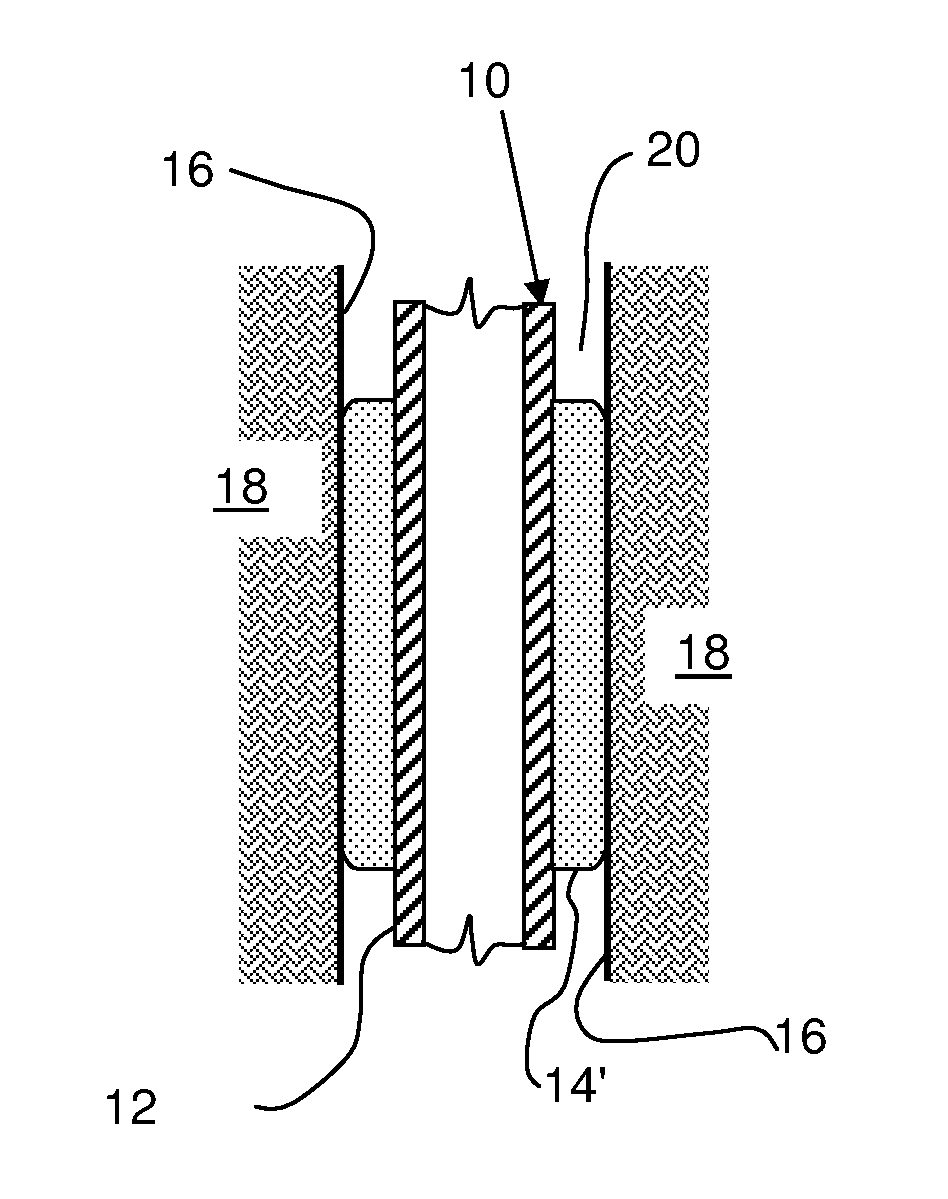

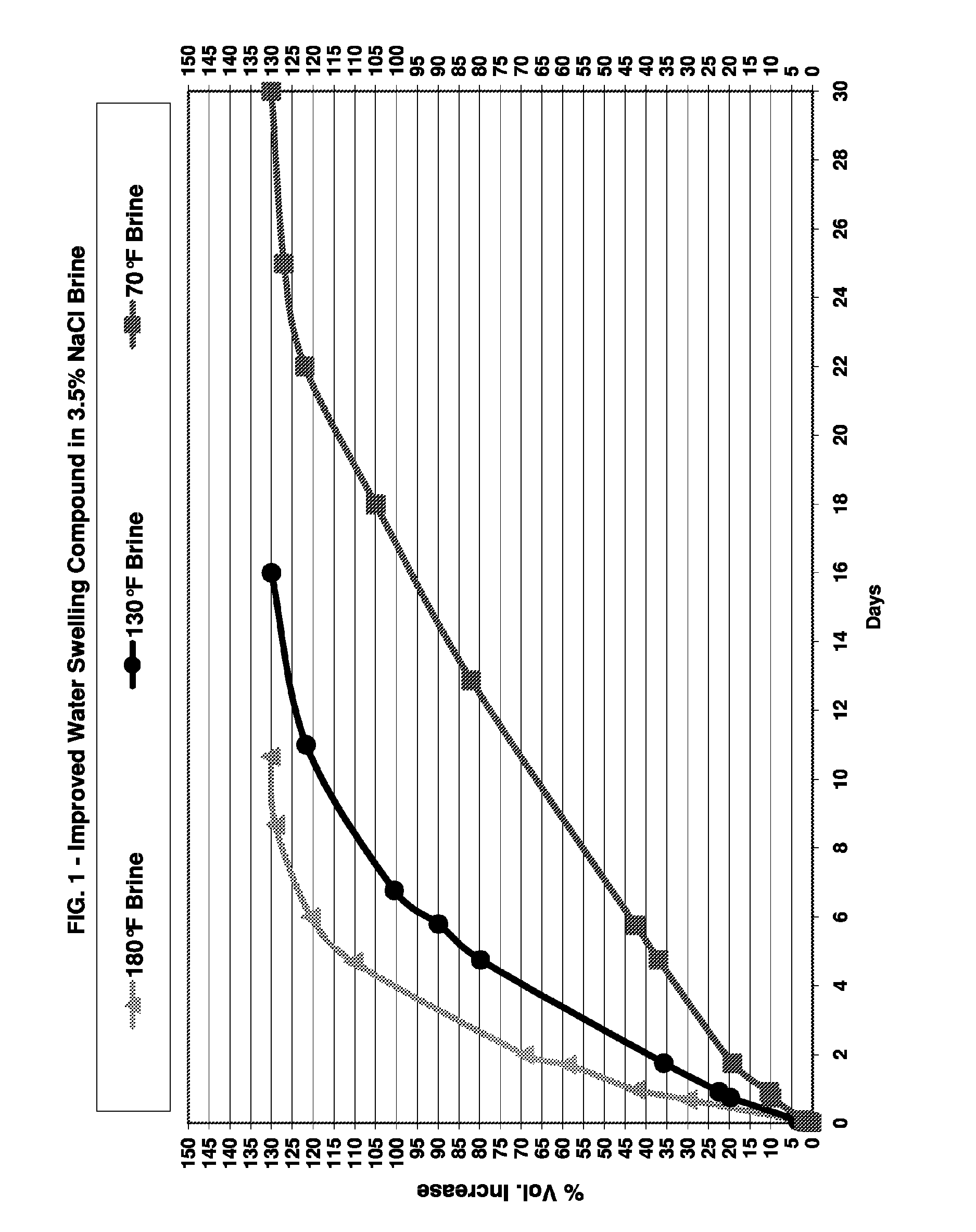

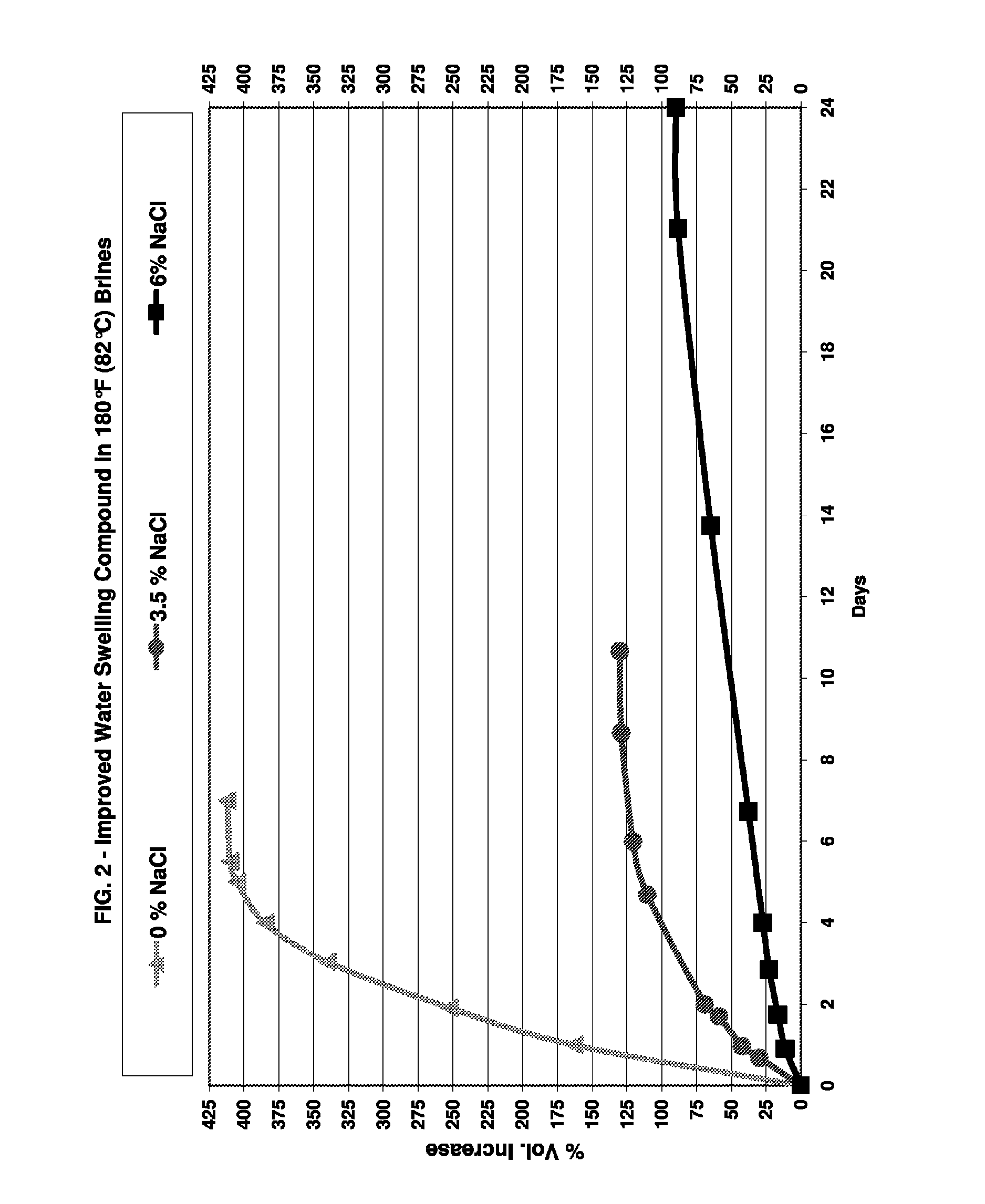

Water Swelling Rubber Compound for Use In Reactive Packers and Other Downhole Tools

Through the combination of at least two polymer families, and the optimization of other components, a rubber compound has been developed for use in downhole applications that will swell in water-based fluids. A cellulose component, such as carboxy methyl cellulose (CMC), is used together with an acrylate copolymer (AC) that can increase the swelling capacity of an acrylonitrile butadiene rubber (NBR) in water to over 1000%. The amount of swelling achieved depends on physical boundaries and limitations, the salinity of the water, and the temperature.

Owner:BAKER HUGHES INC

Rice ball modifier and preparation method thereof

The invention discloses a rice ball modifier comprising the following raw materials in proportions by weight: 1-3 parts of sodium polyacrylate, 2-5 parts of sodium carboxy methyl cellulose, 3-7 parts of xanthan gum, 80-87 parts of guar gum and 7-10 parts of glycerin monostearate. Through the rice ball modifier provided by the invention, the problem that the strength of water-milled glutinous riceflour which is used for making wrappers of the rice balls is insufficient can be solved.

Owner:ZHENGZHOU SYNEAR FOOD

Stabilizer composition of co-attrited microcrystalline cellulose and carboxymethylcellulose, method for making, and uses

Methods of making a high gel strength, water-dispersible, stabilizing colloidal microcrystalline cellulose composition are disclosed. This stabilizer composition is useful in many food and non-food applications.

Owner:DUPONT NUTRITION USA INC

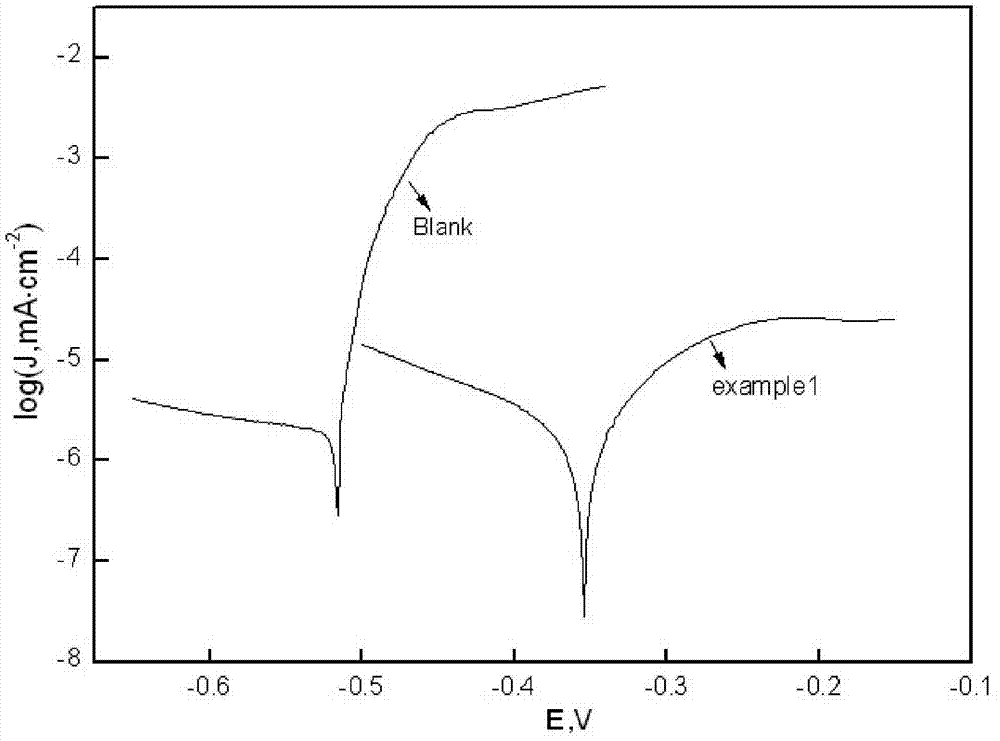

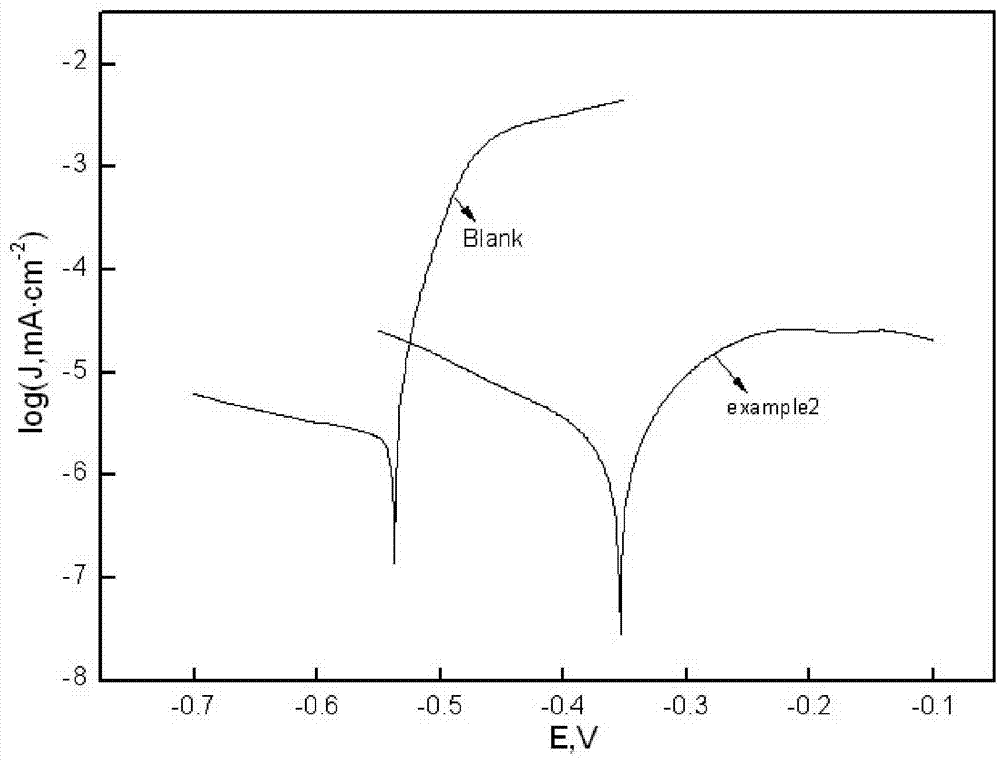

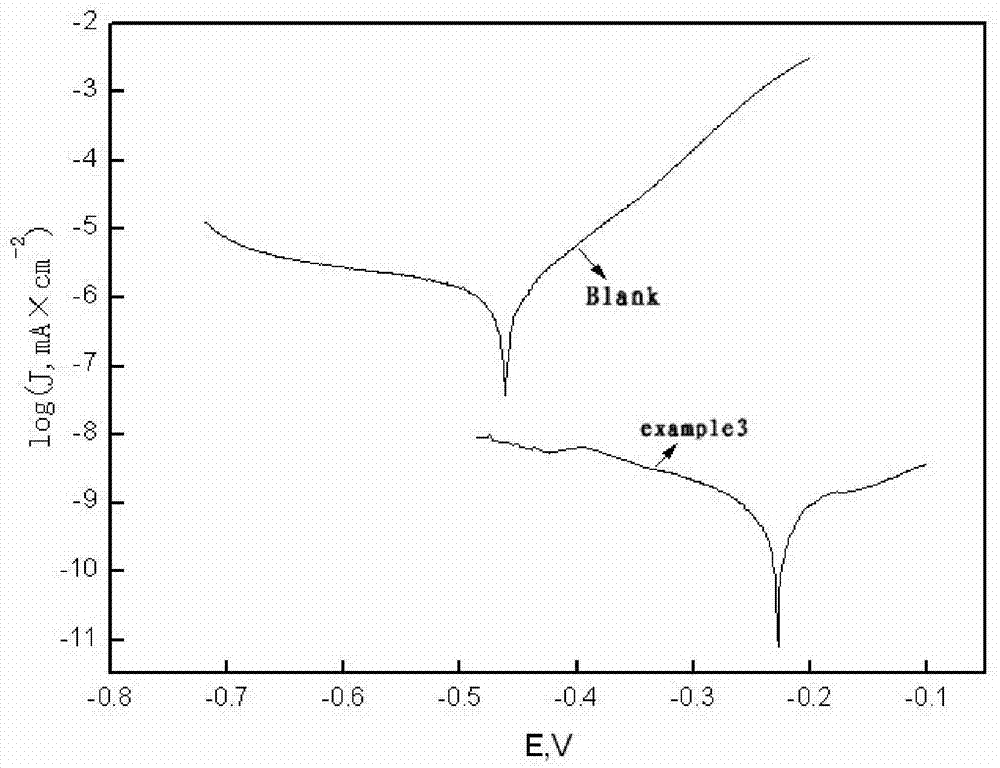

Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

The invention discloses a deformed steel bar compound corrosion-inhibited quenching agent and a usage method thereof. The compound corrosion-inhibited quenching agent is obtained by mixing the following compositions in parts by weight: 0-1 part of sodium carboxy methyl cellulose, 0-1 part of sodium polyacrylate, 0.1-1 part of sodium benzoate, 0.1-2 parts of triethanolamine, 0-0.1 part of sodium molybdate, 0-5 parts of sodium hydroxide, 0-10 parts of sodium carbonate, 5-15 parts of sodium silicate, and 70-90 parts of water. In use, the non-rusted deformed steel bar is subjected to quenching treatment in the corrosion-inhibited quenching agent for 1-2s at 100-200 DEG C, thereby being capable of slowing down the corrosion of the deformed steel bar under the atmosphere. The corrosion-inhibited quenching agent does not contain nitrite and chromate, has no S and P atoms, and is green and environment-friendly, low in cost, and recyclable.

Owner:HEFEI UNIV OF TECH

Hydrogel fire extinguishing agent and use method thereof

InactiveCN107497088AIncrease coverageImprove isolationFire rescueFire extinguisherHydrogel filmFire retardant

The invention discloses a hydrogel fire extinguishing agent. The hydrogel fire extinguishing agent is white powder and obtained in the manner that 5-10 parts of acrylic polymers, 10-15 parts of carboxy methyl cellulose, 10-15 parts of corn starch, 5-10 parts of dispersing agent, 10-20 parts of fire retardant, 1-3 parts of hydrocarbon surfactant and the like undergo modified treatment. The obtained fire extinguishing agent has the conventional water cooling fire extinguishment function, and the fire extinguishing agent and water can form a hydrogel film resistant to high temperature, good in fire resistance and high in coverage performance and adhesion performance, and the hydrogel film can isolate air, extinguish fire by smothering and effectively prevent the fire from burning again; if the fire extinguishing agent is sprayed to an unburned area close to the fire, an isolation strip can form, so that the spreading tendency of the fire can be effectively controlled, and the fire extinguishing efficiency can be significantly improved. Besides, fire extinguishment residues are free of pollution, easy to degrade, safe, environmentally friendly and free of doing harm to human beings, plants and the like. In this way, the hydrogel fire extinguishing agent is wide in application range, can be applied to civil facilities, public facilities, plant-station disaster relief, forest fire and the like, the dosage of the fire extinguishing agent is small, and therefore the hydrogel fire extinguishing agent has significant advantages.

Owner:RUNTAI RESCUE EQUIP TECH HEBEI CO LTD

Glucanases, Nucleic Acids Encoding Them and Methods for Making and Using Them

InactiveUS20110117067A1Low viscosityImprove textureAntibacterial agentsFungiNucleotideExoxylanase activity

The invention relates to polypeptides having glucanase, e.g., endoglucanase, mannanase, xylanase activity or a combination of these activities, and polynucleotides encoding them. In one aspect, the glucanase activity is an endoglucanase activity (e.g., endo-1,4-beta-D-glucan 4-glucano hydrolase activity) and comprises hydrolysis of 1,4-beta-D-glycosidic linkages in cellulose, cellulose derivatives (e.g., carboxy methyl cellulose and hydroxy ethyl cellulose) lichenin, beta-1,4 bonds in mixed beta-1,3 glucans, such as cereal beta-D-glucans or xyloglucans and other plant material containing cellulosic parts. In addition, methods of designing new enzymes and methods of use thereof are also provided. In alternative aspects, the new glucanases e.g., endoglucanases, mannanases, xylanases have increased activity and stability, including thermotolerance or thermostability, at increased or decreased pHs and temperatures.

Owner:BP CORP NORTH AMERICA INC

Water soluble cellulose etherified derivatives styptic materials

InactiveUS7262181B2Improved water solubility and biologic absorbencyOrganic active ingredientsBiocideCelluloseEther

Owner:BEIJING TEXTILE RES INST

Environment-friendly diatom emulsion interior wall decorative material and preparation method thereof

The invention discloses environment-friendly diatom emulsion interior wall decorative material. The environment-friendly diatom emulsion interior wall decorative material comprises, by mass ratio, 9%-15% of diatomite, 6%-10% of attapulgite powder, 7%-10% of calcined kaolin, 1.7%-3% of titanium dioxide, 0.2%-0.4% of nano-titania, 5%-9% of calcite powder, 0.3%-0.4% of carboxy methyl cellulose, 0.3% of flatting agent, 0.3% of dispersant, 0.3% of preservative, 0.6%-1.2% of mildew preventive, 8%-12% of re-dispersible emulsion powder, and the balance of distilled water. The invention also discloses a preparation method of the environment-friendly diatom emulsion interior wall decorative material. The preparation method includes proportionally adding the ingredients into a dispersing barrel, using a high-speed disperser to evenly disperse, and filtering to obtain the finished product. The preparation method of the environment-friendly diatom emulsion interior wall decorative material is simple, construction is simple and convenient, materials are saved, and the environment-friendly diatom emulsion interior wall decorative material is higher in efficiency of absorbing harmful matters in air.

Owner:HUNAN LANTIDEN ENVIRONMENTAL BUILDING MATERIAL LTD

Paint remover for plane aluminium alloy skin depainting treatment

The invention relates to a paint remover for plane aluminium alloy skin depainting treatment; the paint remover comprises more than two kinds of 70-80 parts of main solvent, two kinds of 12-18 parts of accelerators, 4-5 parts of thickening agents and 0.5-2 parts of corrosion inhibitors; the main solvent includes N-methylpyrrolidone (N-P), alpha-pyrrolidone (alpha-P), benzyl alcohol and dimethyl sulfoxide; the accelerator is soluble organic acid with lower than 1000 of molecular weight, and the molecular weight includes methanoic acid, salicylic acid, p-toluenesulfonic acid and terephthalic acid; the thickening agent is carboxymethylcellulose or carboxyethyl cellulose; and the corrosion inhibitor is p-methyl pyrrodiazole, thiazole and benzotriazole. The paint remover can remove the paint film on the surface of the plane aluminium alloy skin in a short time (within 35min) in a in-situ way, and the paint remover has no over etching to the surface of the aluminium alloy and has recoatability.

Owner:合肥华清方兴表面技术有限公司

Adhesive controlled release fertilizer and preparation method thereof

ActiveCN101985409ASimple production processReduce manufacturing costFertilizer mixturesCellulosePolyvinyl alcohol

The invention provides an adhesive controlled release fertilizer and a preparation method thereof. The adhesive controlled release fertilizer consists of the following components in percentage by weight: 4 to 10 percent of pregelatinized starch, 2 to 4 percent of tung oil, 3 to 6 percent of disproportionated rosin, 7 to 15 percent of attapulgite powder, 0 to 15 percent of lignosulfonate, 0 to 15 percent of weathered coal, 0 to 6 percent of polyvinyl alcohol, 0 to 6 percent of carboxy methyl cellulose, and the balance of fertilizer. The preparation method comprises the following steps of: adding water which is 10 to 20 percent based on the total weight of the materials into the fertilizer to ensure that partial fertilizer is dissolved; adding an adhesive material with stirring in the process of heating until the solution is boiling; fully mixing uniformly, continuously stirring to ensure that the mixture is dried till the moisture is less than 10 percent; and granulating by using a granulator, or melting the mixture for spraying granulation. The adhesive controlled release fertilizer can release the fertilizer nutrient releasing speed to improve the nutrient utilization rate, the production process is simple, and the production cost is relatively low.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI +1

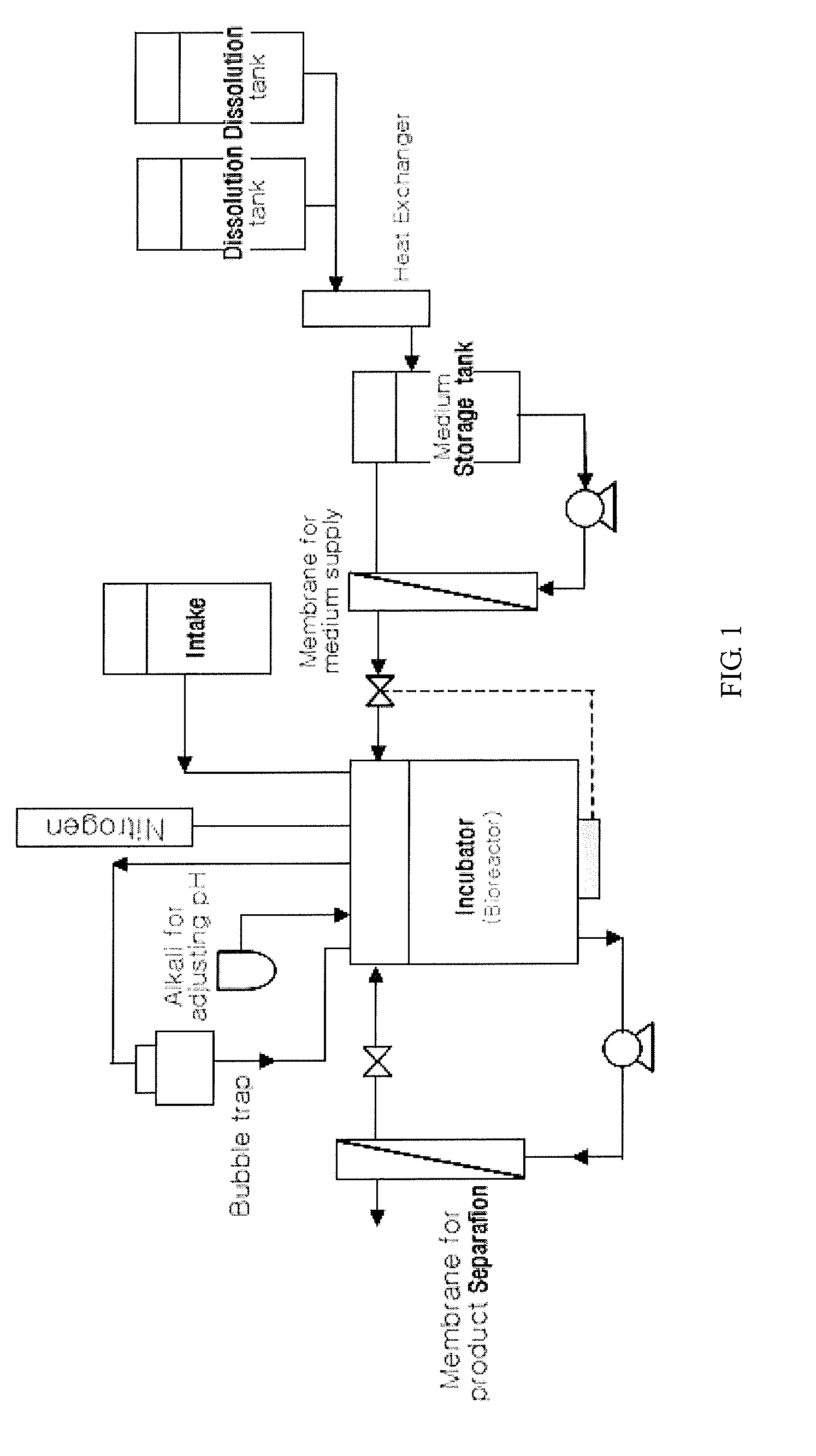

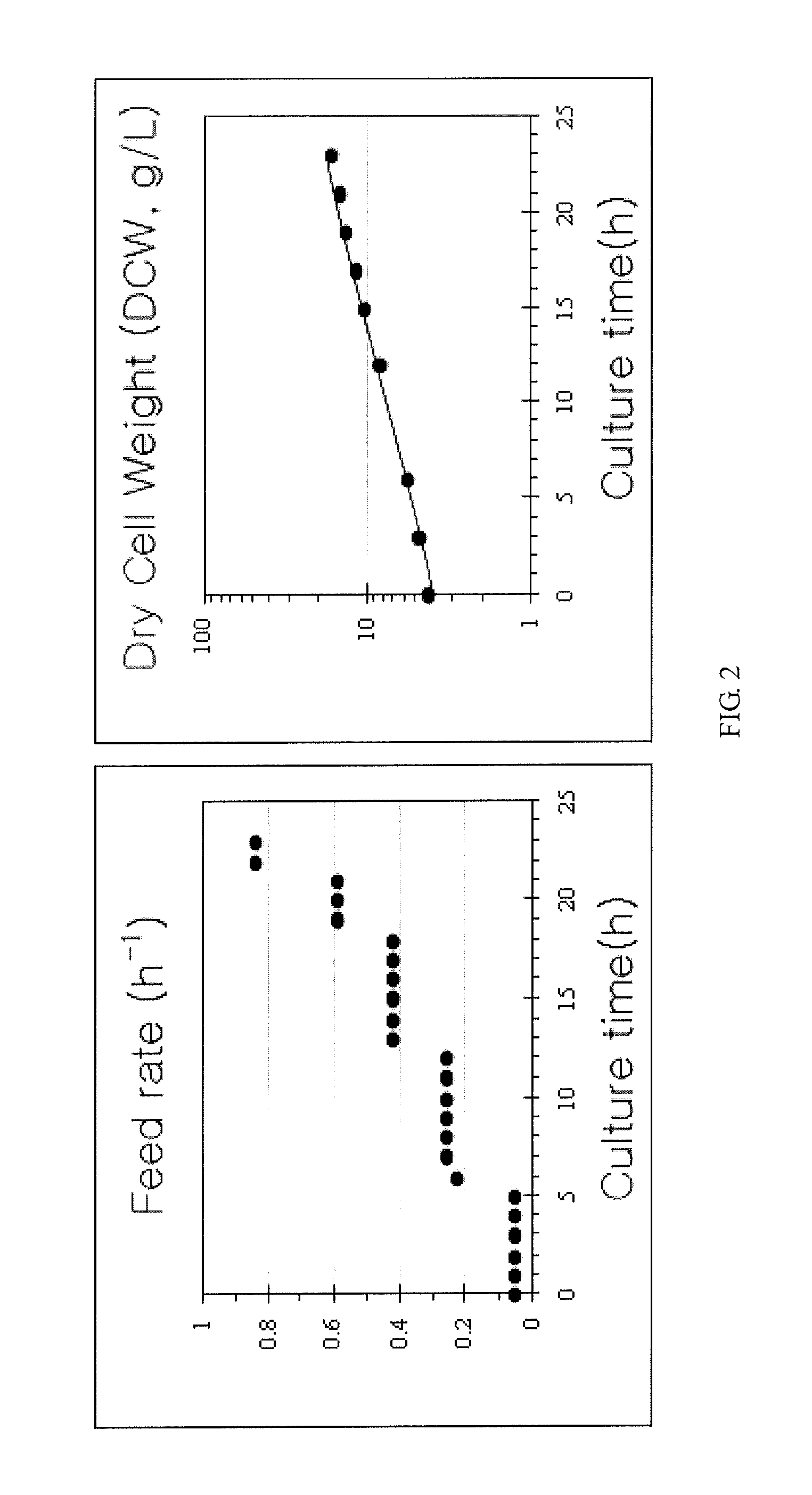

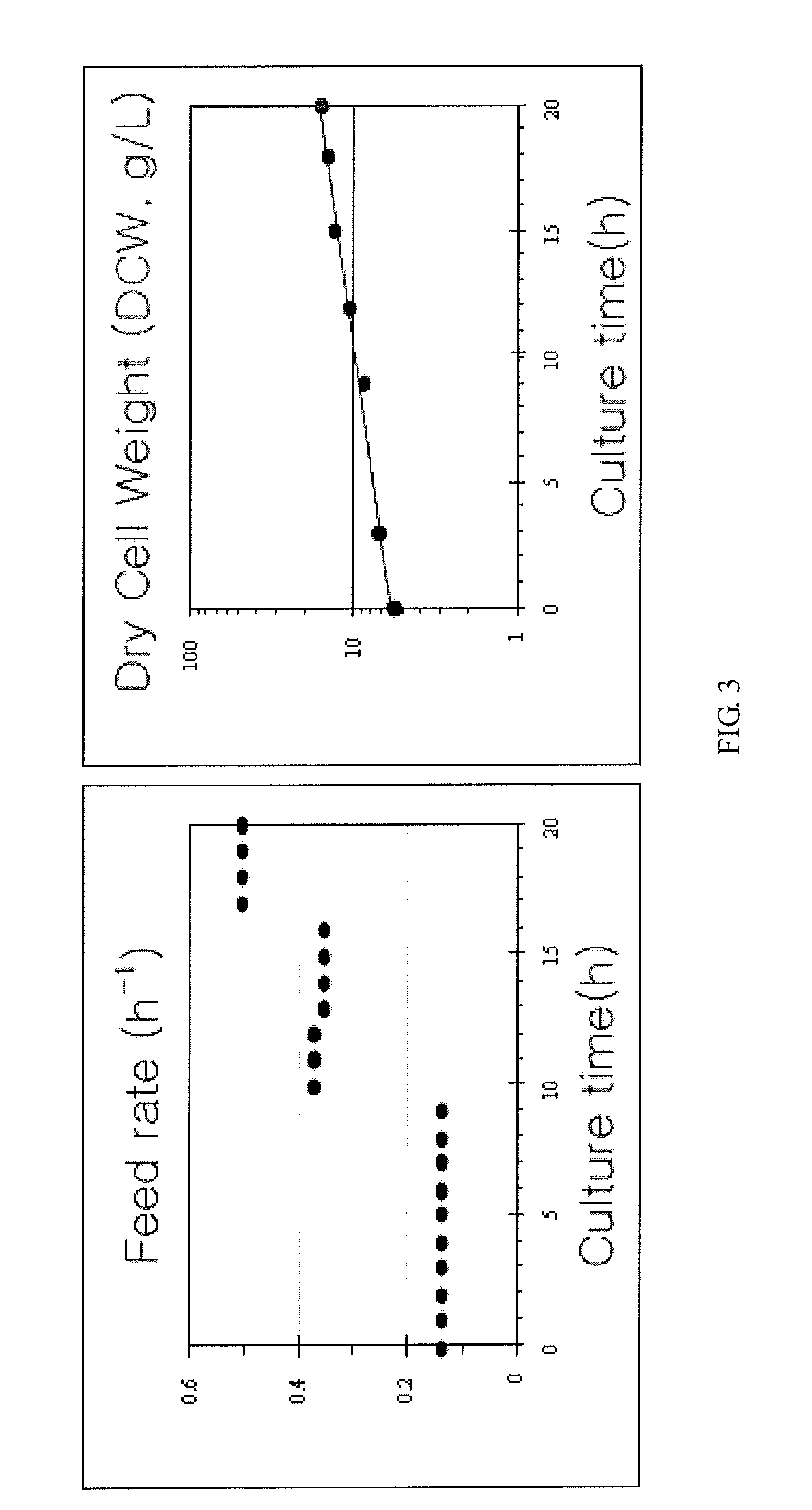

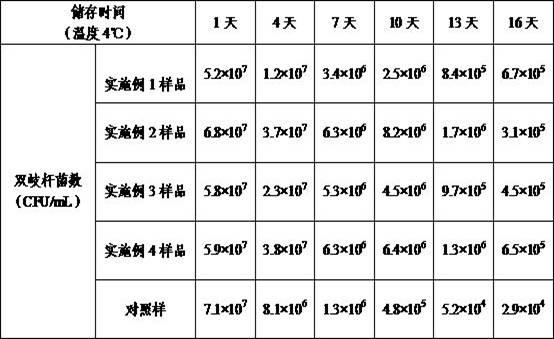

Method for producing high concentrate lactic acid bacteria with membrane bioreactor and freeze-dried, lactic acid bacteria powder

InactiveUS20120064606A1Good chemical stabilityImprove physical stabilityBacteriaUnicellular algaeHigh concentrationLactic acid bacterium

The present invention relates to a method for producing lactic acid bacteria of a high concentration continuously using a membrane bioreactor. Specifically, the present invention relates to a method for producing lactic acid bacteria of a high concentration in a membrane bioreactor that comprises the steps of cultivating lactic acid bacteria in a membrane bioreactor including a membrane for product separation and a medium supply apparatus; supplying culture media to the bioreactor through the medium supply apparatus; continuously separating and discharging culture filtrate through the membrane for product separation; and recycling lactic acid bacteria continuously to the bioreactor. Additionally, the present invention relates to a method for producing lactic acid bacteria powder by freeze drying the bacteria produced in the membrane bioreactor using a freeze drying preservative composition. The lactic acid bacteria obtained through the membrane bioreactor is obtained in pellet form with a centrifugal separator, and is subjected to freeze-drying using the composition for freeze drying preservative containing certain amounts of trehalose, maltodextrin, starch and sodium carboxy methyl cellulose to form lactic acid powder. The lactic acid bacteria that have been converted into powder by such method exhibit superior stability chemically and physically compared to lactic acid bacteria powder that has been subjected to simple freeze drying.

Owner:LACTOMASON CO LTD

High-performance moderate-temperature phase-change energy-storage material and preparation method thereof

InactiveCN103045175AHigh densityImprove solubilityHeat-exchange elementsSodium phosphatesPhase change

The invention relates to a high-performance moderate-temperature inorganic phase-change energy-storage material and a preparation method thereof. The material comprises the following components by weight percent: 95-99% of sodium phosphate dibasic dodecahydrate and 1-5% of sodium salt additive, wherein the sodium salt additive comprises sodium metasilicate nonahydrate, sodium salt of carboxy methyl-cellulose and sodium polyacrylate. According to the invention, as an improvement of a traditional inorganic phase-change energy-storage material, the material provided by the invention has larger phase change latent heat larger than 210 J / g and appropriate phase change temperature 30-40 DEG C, is an energy storage material with good performance within the temperature range, and has a wide application prospect.

Owner:TIANJIN UNIV OF SCI & TECH

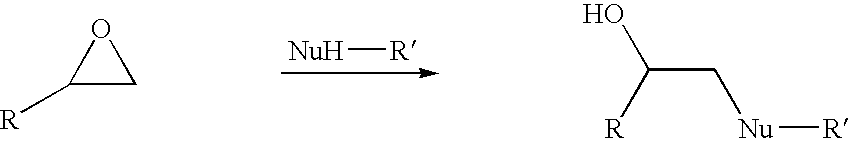

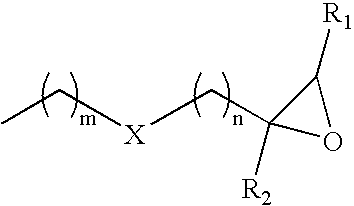

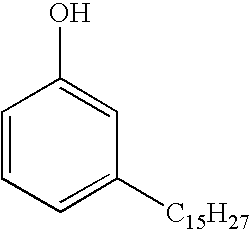

Hydrophobically modified fluid loss additives and viscosifier products

A wellbore fluid that includes an oleagninous continuous phase; a non-oleaginous phase; and a polymeric additive formed by reaction of at least one lipophilic epoxy modifier and at least one epoxide-reactive agent, wherein the at least one epoxide-reactive agent comprises at least one selected from lignins, tannins, biopolymers, starches, carboxy methyl cellulose, polyacrylates, polyacrylamides, and synthetic polymers is disclosed.

Owner:MI

Water swelling rubber compound for use in reactive packers and other downhole tools

Owner:BAKER HUGHES INC

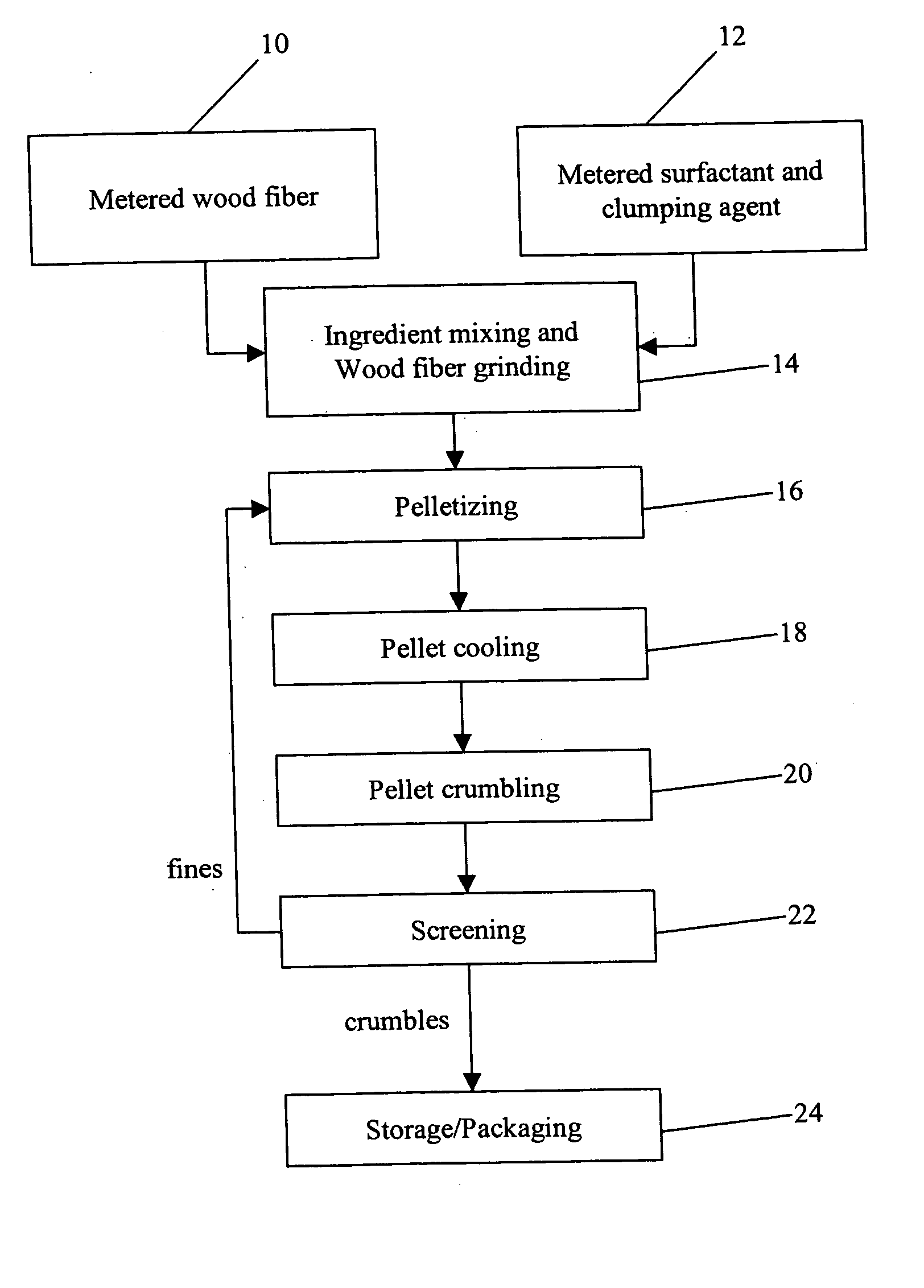

Clumping animal litter and method for making same

ActiveUS20050160996A1Improve absorption qualityCost controlAnimal housingOther apparatusFiberAdditive ingredient

A clumping animal litter comprises an organic material, a surfactant, and a clumping agent. The clumping agent may be a combination of carboxymethylcellulose (CMC) and guar gum. The material may comprise 1-2% CMC, 3-6% guar gum, 1-5% surfactant, and the remainder wood fiber. The material is formed into pellets with a uniform distribution of the various ingredients. The pellets are then crumbled to improve absorption characteristics. The mixture results in a fully-biodegradable, organic-based litter product with improved clumping abilities, natural odor control, and ease of litter pan maintenance.

Owner:PLANETWISE PROD

Method for preparing gold nanoparticles based on environmentally-friendly chemical method

InactiveCN102225470AGreenSimple and fast operationMaterial nanotechnologyChemical synthesisMetallic materials

The invention provides a method for preparing spherical, polypodia-shaped and linear gold nanoparticles based on an environmentally-friendly chemical method. The method provided by the invention is characterized by comprising the following steps: on the basis of adopting sodium carboxy methyl cellulose (CMC) as a reducing agent and a protective agent, reducing HAuC14 into the spherical, polypodia-shaped and linear gold nanoparticles. During the reaction process, the CMC and HAuC14 can play a role in controlling the shape and dimension of the gold nano materials. After being subjected to high-speed centrifugation, the reaction product is precipitated and washed with water to obtain the gold nanoparticles which have better particle size distribution and special appearance. The method provided by the invention belongs to the technical field of preparation of nano materials in metal materials. The method has the characteristics that the nano dimension and shape of the product can be controlled, and the conventional reducing agent during thermochemical synthesis of the gold nano materials are omitted, so that the method is environment-friendly, easy to separate and simple and convenient to operate.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Glucanases, Nucleic Acids Encoding Them and Methods for Making and Using Them

ActiveUS20140295523A1Low viscosityImprove textureAntibacterial agentsBiofuelsNucleotideExoxylanase activity

The invention relates to polypeptides having glucanase, e.g., endoglucanase, mannanase, xylanase activity or a combination of these activities, and polynucleotides encoding them. In one aspect, the glucanase activity is an endoglucanase activity (e.g., endo-1,4-beta-D-glucan 4-glucano hydrolase activity) and comprises hydrolysis of 1,4-beta-D-glycosidic linkages in cellulose, cellulose derivatives (e.g., carboxy methyl cellulose and hydroxy ethyl cellulose) lichenin, beta-1,4 bonds in mixed beta-1,3 glucans, such as cereal beta-D-glucans or xyloglucans and other plant material containing cellulosic parts. In addition, methods of designing new enzymes and methods of use thereof are also provided. In alternative aspects, the new glucanases e.g., endoglucanases, mannanases, xylanases have increased activity and stability, including thermotolerance or thermostability, at increased or decreased pHs and temperatures.

Owner:BP CORP NORTH AMERICA INC

Environment-friendly diatom ooze exterior wall coating and preparation method thereof

The invention relates to an exterior wall decoration material, in particular to an environment-friendly diatom ooze exterior wall coating and a preparation method thereof. The environment-friendly diatom ooze exterior wall coating comprises raw materials in percentage by mass as follows: 8%-15% of diatomite, 8%-12% of calcined kaolin, 2%-10% of titanium dioxide, 0.2%-0.6% of nano-titanium dioxide, 0.2%-0.6% of carboxy methyl cellulose, 0.3% of a dispersing agent, 0.2% of a preservative, 0.3%-0.6% of a mildew preventive, 40%-55% of an odorless emulsion, 0.1%-0.3% of a coalescing agent and the balance of distilled water. The preparation method is simple, the construction method is identical to that of common wall paint, the roller coating can be thinner, materials are saved, the coating has high absorption efficiency for harmful substances in the air, and negative oxygen ions can be released.

Owner:HUNAN LANTIDEN ENVIRONMENTAL BUILDING MATERIAL LTD

Porous silicon-carbon composite material for lithium ion battery and preparation method of material

InactiveCN106450246ARich sourcesLow priceCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a porous silicon-carbon composite material for a lithium ion battery and a preparation method of the material. According to the preparation method, CMC (sodium carboxy methyl cellulose) serves as template agents and enwrapping agents, a porous silicon-carbon material is prepared by the aid of microwave drying technologies, the porous silicon-carbon material and graphite materials are composited to obtain the porous silicon-carbon composite material, the porous silicon-carbon composite material is used for negative electrode materials of the lithium ion battery, the graphite materials are one or more in mesocarbon micro-beads, natural graphite and artificial graphite, porous silicon is carbon-coating nano-scale porous silicon, porous characteristics of the porous silicon are beneficial to absorption and storage of electrolyte solution, a space for volume expansion is provided in the charge and discharge process of the silicon materials, the porous silicon is the nano-scale porous silicon, so that volume effect of silicon particles is relieved, and the porous silicon-carbon composite material has the advantages of high reversible capacity, good circulation performance and excellent rate performance.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

Preparation method of health-care active lactobacillus beverage

InactiveCN102177966APromote growthImprove protectionMilk preparationVitamin CIsomaltooligosaccharide

The invention discloses a preparation method of health-care active lactobacillus beverage. The preparation method includes the steps as follows: A. pretreatment of milk; B. mixing: adding white granulated sugar and / or isomaltooligosaccharide in the milk obtained from the step A and stirring the mixture to full dissolution; C. homogenization and sterilization; D. fermentation; E. temperature reduction of fermented milk; F. secondary mixing: heating purified water to 95-100 DEG C, mixing sodium carboxy methyl cellulose, vitamin C and natural fruit powder, uniformly dispersing the materials by a high-speed material mixer and a colloid mill, and dissolving the materials in hot water, thus preparing stabilizer sol, then reducing the temperature of the stabilizer sol to 30-40 DEG C by a heat exchanger, and uniformly mixing the stabilizer sol with the fermented milk obtained from the step E; G. secondary homogenization; H. secondary temperature reduction; and I. filling. By the preparation method, probiotics with a health-care function obtains a good survival condition in the lactobacillus beverage and the nutrient health-care function of the fermented type lactobacillus beverage is improved greatly.

Owner:王玉良

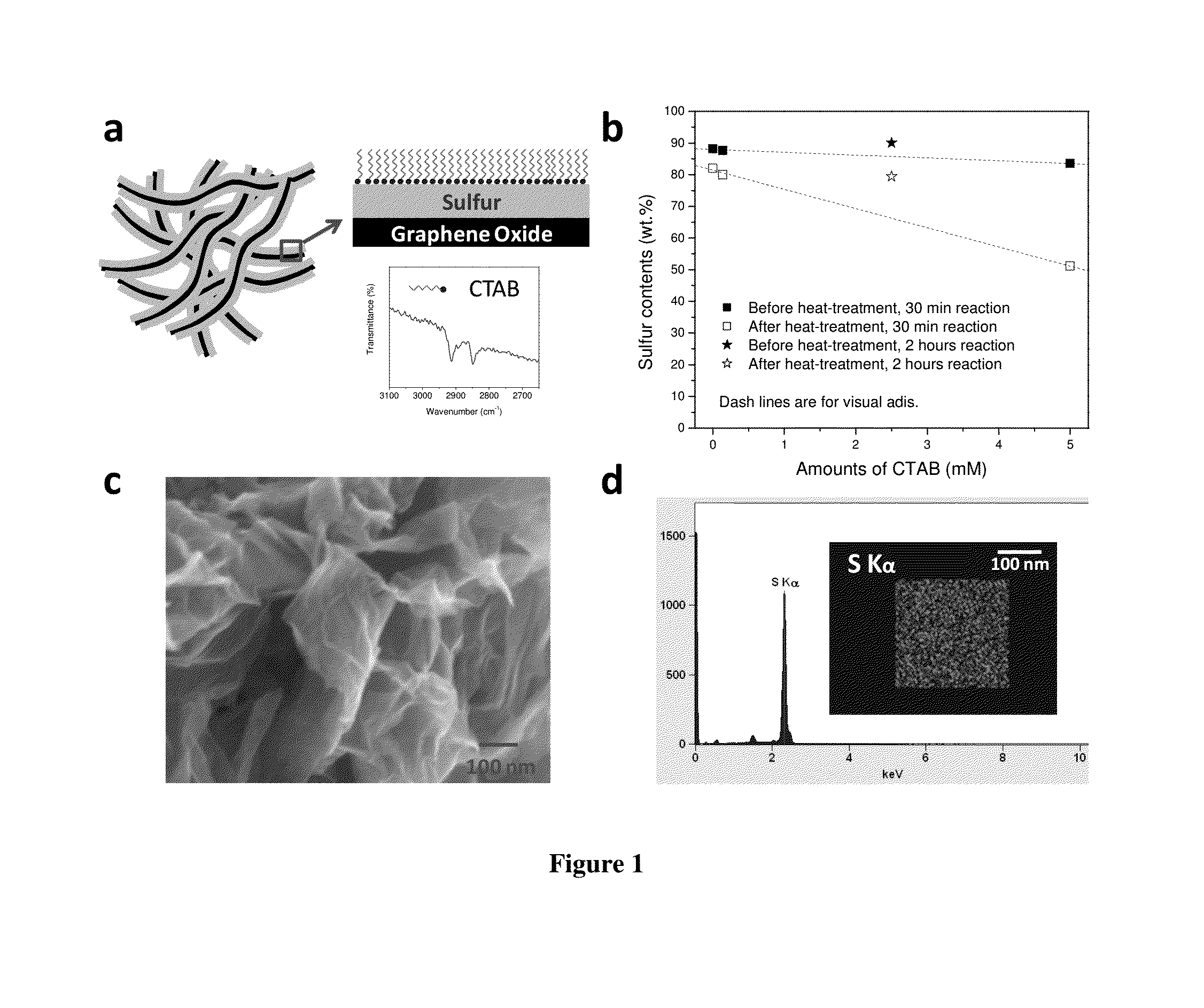

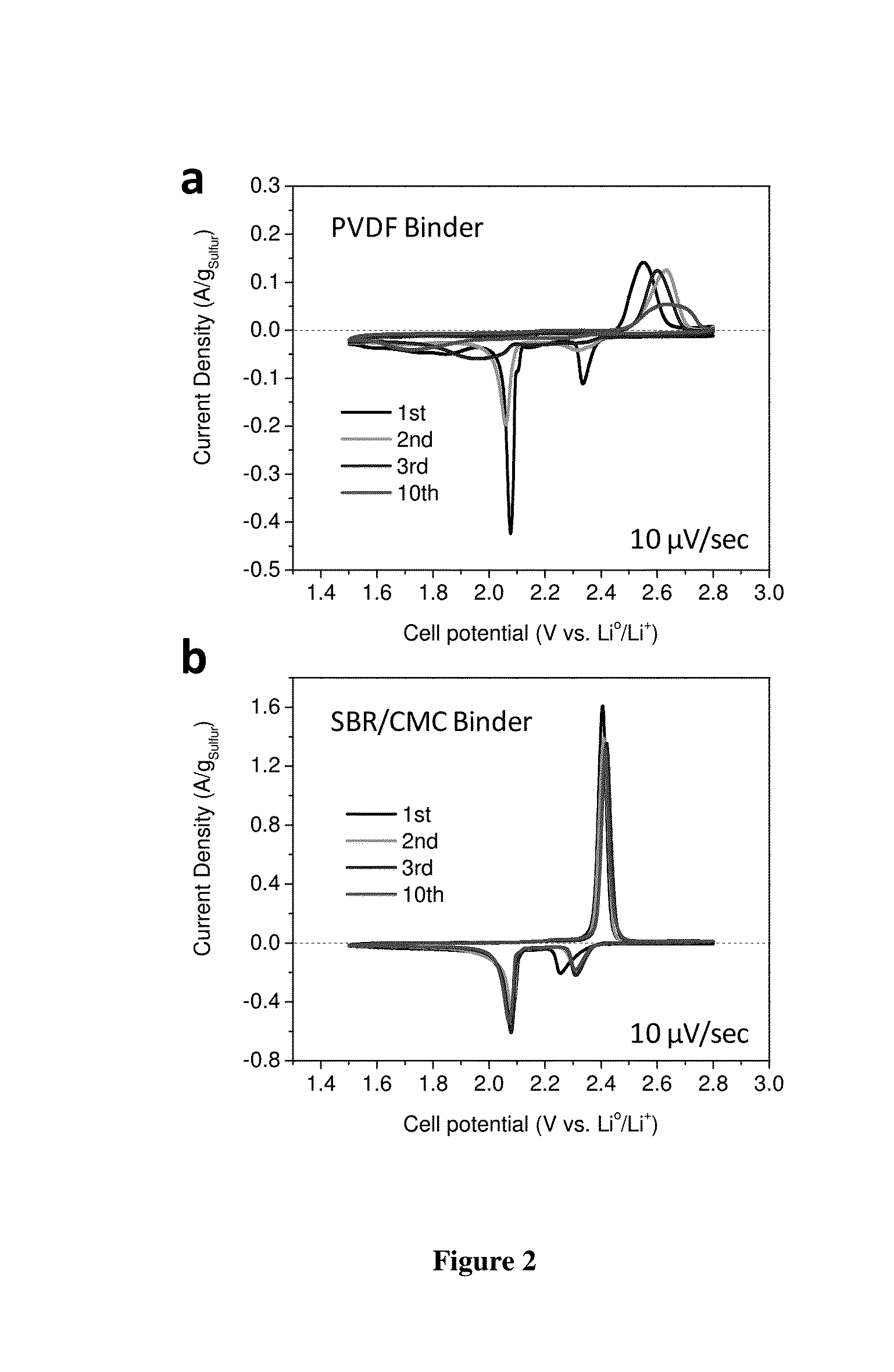

A long-life, high-rate lithium/sulfur cell utilizing a holistic approach to enhancing cell performance

A long-life, high-rate lithium sulfur (Li / S) cell with high specific energy uniquely combines cetyltrimethyl ammonium bromide (CTAB)-modified sulfur-graphene oxide (S-GO) nanocomposites with an elastomeric styrene butadiene rubber (SBR) / carboxy methyl cellulose (CMC) binder and an ionic liquid-based novel electrolyte with the LiNO3 additive. A Li / S cell employing a CTAB-modified S-GO nanocomposite cathode can be discharged at rates as high as 6C (1C=1.675 A / g of sulfur) and charged at rates as high as 3C while still maintaining high specific capacity (˜800 mAh / g of sulfur at 6C), with a long cycle life exceeding 1500 cycles, the longest cycle life with extremely low decay rate (0.039% per cycle) demonstrated so far for a Li / S cell.

Owner:RGT UNIV OF CALIFORNIA

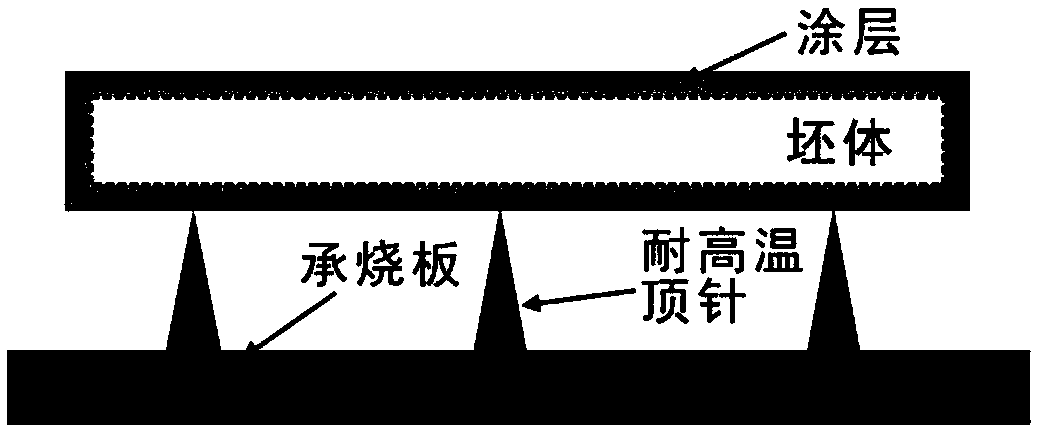

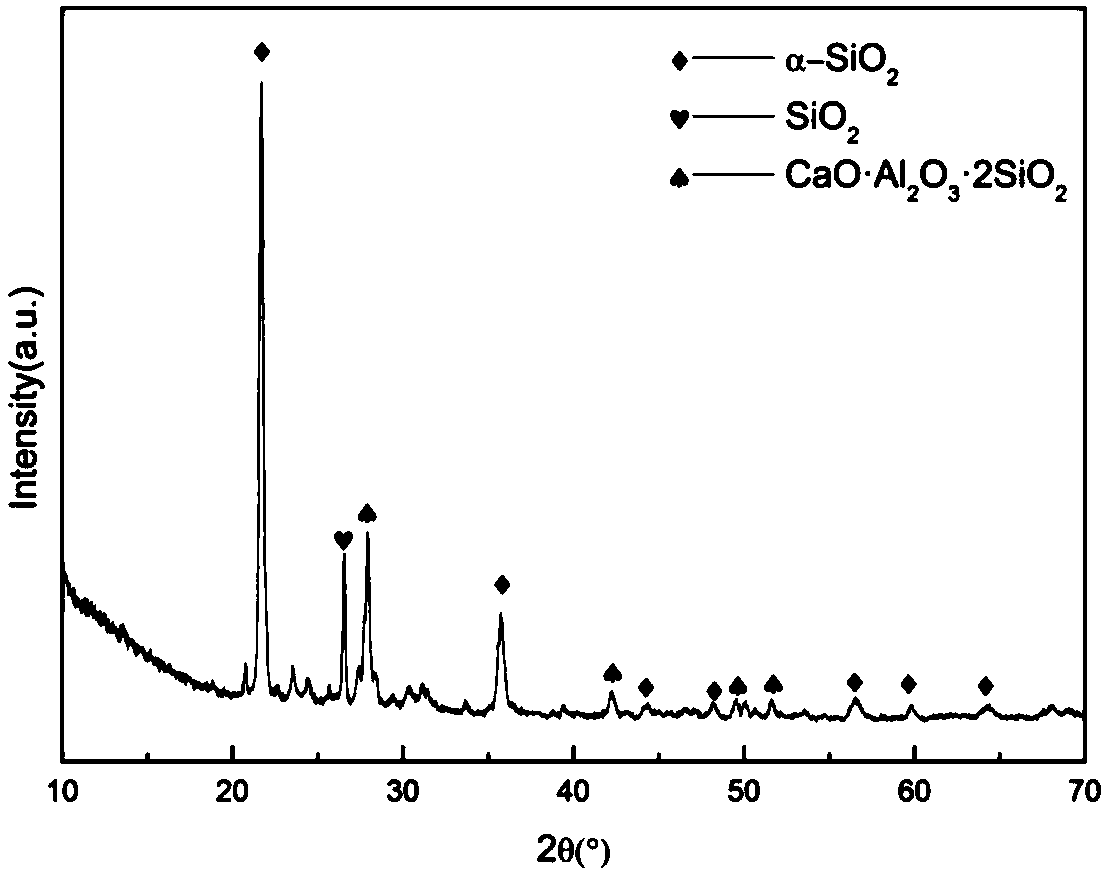

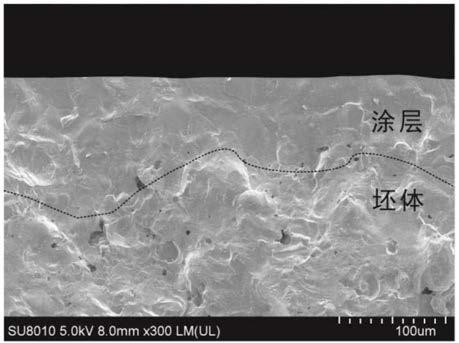

Coating slurry for enhancing prestress of building ceramic and preparation method and building ceramic product of coating slurry

The invention discloses coating slurry for enhancing prestress of a building ceramic. The coating slurry consists of aggregate and an adhesive in a weight ratio of 1 to 4, wherein the aggregate is a combination of oxides, hydroxides and oxygen containing salts of Si, Al, Mg, Ca and Zn; the aggregate comprises the following chemical components: 50-75% of SiO2, 10-30% of Al2O3, 0-20% of MgO, 0-25% of CaO and 0-10% of ZnO; the adhesive is one or a combination of CMC (Carboxy Methyl Cellulose Sodium), PVA (Polyvinyl Acetate), PVB (Polyvinyl Butyral) and sodium silicate. In addition, the inventionfurther discloses a preparation method and a building ceramic product of the coating slurry. The coating slurry disclosed by the invention is adopted to completely coat the surface of a building ceramic blank, by exerting prestress, the strain that the ceramic blank is stressed and broken is increased, so that the strength and the performance of the building ceramic product can be greatly improved. The preparation and the application of the coating slurry are simple in production, easy to control, low in cost and beneficial to popularization and application, and have very high practical valuesand application prospects.

Owner:JINGDEZHEN CERAMIC UNIV

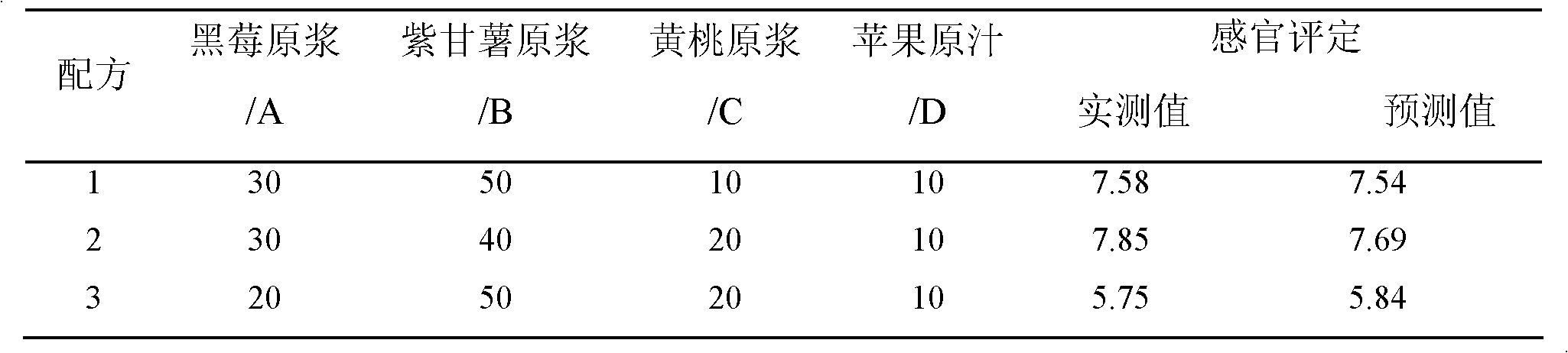

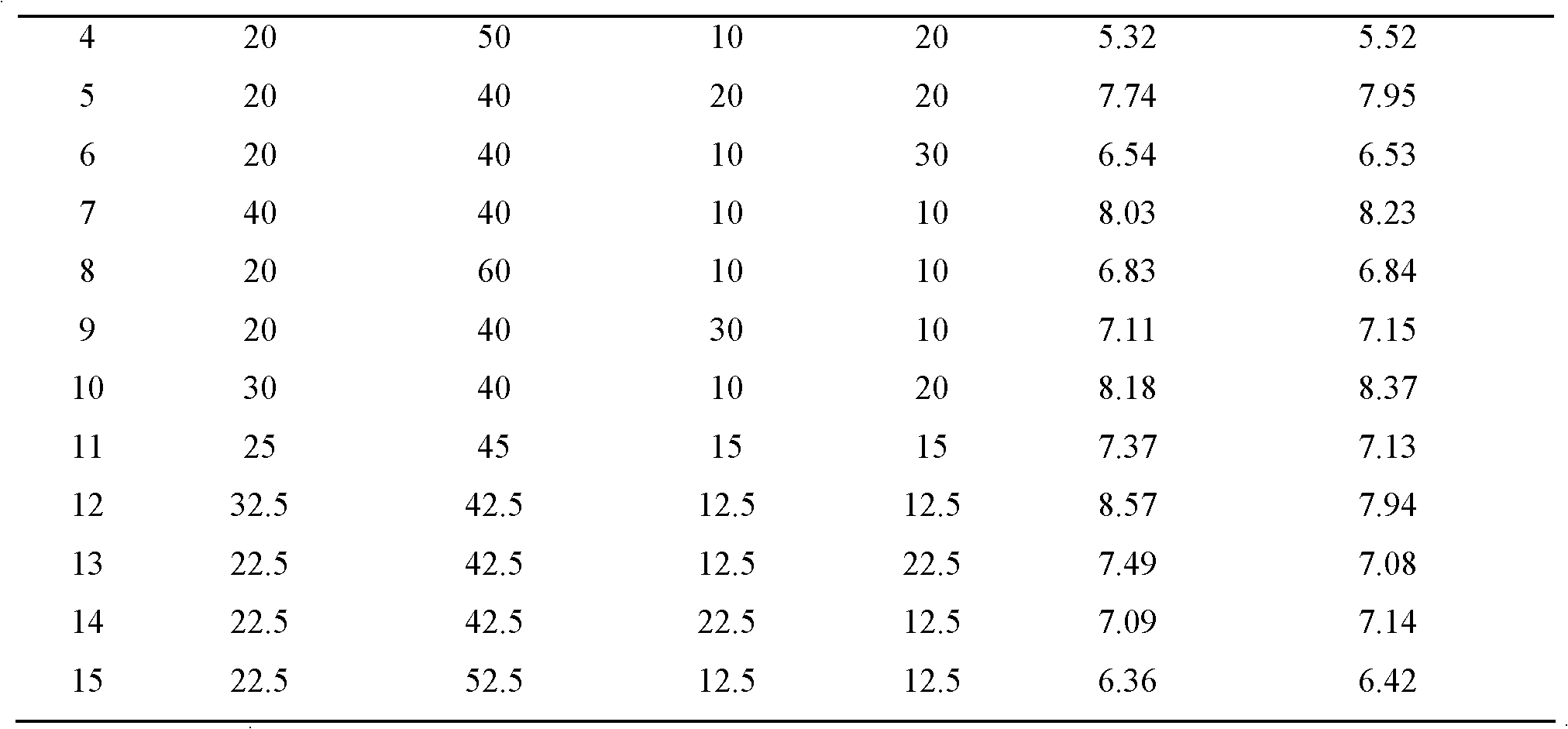

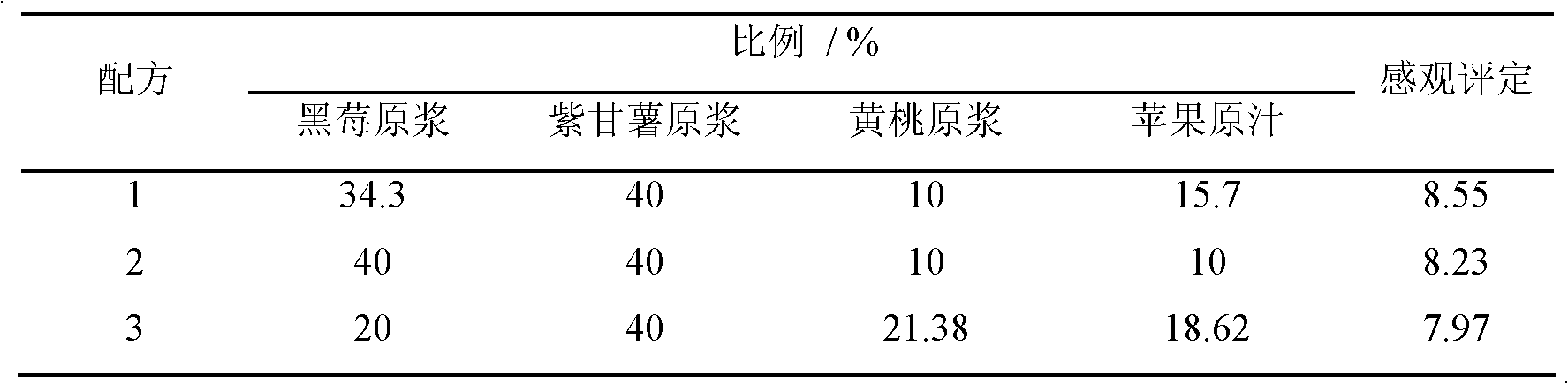

Purple sweet potato-blackberry composite pulp beverage and its preparation method

The invention discloses a purple sweet potato-blackberry composite pulp beverage and its preparation method. The beverage comprises composite pulp and stabilizing agents. The beverage is characterized in that: the composite pulp consists of purple sweet potato primary pulp, blackberry primary pulp, yellow peach primary pulp and apple juice in a volume ratio of 40-60:30-40:10-20:10-20; and the stabilizing agents include acid resistant CMC (carboxy methyl cellulose) accounting for 0.03-0.06% of the total volume of the beverage, gellan gum accounting for 0.005%-0.01% of the total volume of the beverage and xanthan gum accounting for 0.01-0.05% of the total volume of the beverage. The beverage product of the invention highlights the unique coordinated flavor from the mixing of purple sweet potatoes and blackberries as well as the stable color and biological activity generated from the interaction of anthocyanins in purple sweet potatoes and blackberries. Meanwhile, being rich in the nutritional components of yellow peaches and apples, the beverage provided in the invention has uniform appearance and stable color, and is a novel composite fruit-vegetable beverage boasting broad market prospects.

Owner:连云港每日食品有限公司

Sodium secondary battery electrode and sodium secondary battery

InactiveUS20140065492A1Large discharge capacityReduce discharge capacityElectrode thermal treatmentConductive materialState of artEngineering

The present invention provides an electrode that can be used for a sodium secondary battery having a larger discharge capacity when charging and discharging are performed repeatedly than that of the prior art. This sodium secondary battery electrode contains tin (Sn) powder as an electrode active material. The electrode, particularly, further contains one or more electrode-forming agents selected from the group consisting of poly(vinylidene fluoride) (PVDF), poly(acrylic acid) (PAA), poly(sodium acrylate) (PAANa), and carboxymethylcellulose (CMC), thereby making it possible to provide a sodium secondary battery having even greater electrode performance.

Owner:TOKYO UNIVERSITY OF SCIENCE +1

Environment-friendly hair-care hair dye and preparation method thereof

ActiveCN102824283ANeutralize damageGood dyeabilityCosmetic preparationsHair cosmeticsPolyphenolHair care

The invention provides an environment-friendly hair-care hair dye which consists of three agents A, B and C. The agent A comprises the following components: L-cysteine, Na2CO3, triethanolamine, sodium carboxy methyl cellulose, glycerin and water; the agent B comprises the following components; metal salt, the sodium carboxy methyl cellulose, a surfactant, an odorant and the water; and the agent Ccomprises the following components: pigment, the sodium carboxy methyl cellulose, the surfactant, citric acid, fragrance and the water. The hair dye uses the plant pigment such as tea polyphenol and the like as a dye, has easily obtained raw materials, is low in cost, has no toxicity, is easy to color and also has a hair care effect.

Owner:章华化妆品科技有限公司

Glucanases, nucleic acids encoding them and methods for making and using them

The invention relates to polypeptides having glucanase, e.g., endoglucanase, mannanase, xylanase activity or a combination of these activities, and polynucleotides encoding them. In one aspect, the glucanase activity is an endoglucanase activity (e.g., endo-1,4-beta-D-glucan 4-glucano hydrolase activity) and comprises hydrolysis of 1,4-beta-D-glycosidic linkages in cellulose, cellulose derivatives (e.g., carboxy methyl cellulose and hydroxy ethyl cellulose) lichenin, beta-1,4 bonds in mixed beta-1,3 glucans, such as cereal beta-D-glucans or xyloglucans and other plant material containing cellulosic parts. In addition, methods of designing new enzymes and methods of use thereof are also provided. In alternative aspects, the new glucanases e.g., endoglucanases, mannanases, xylanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

Monochromatic color bubble solution capable of fading

InactiveCN102371075ASimple production processRaw materials are simpleToysSodium bicarbonateMonochromatic color

The invention provides a monochromatic color bubble solution capable of fading. The monochromatic color bubble liquid comprises the following components in weight percent: 99.5230 percent of distilled water, 1.8524 percent of color-changing agent (phenolphthalein, thyme phenolphthalein / thymolphthalein and o-cresolphthalein), 0.3756 percent of sodium bicarbonate, 0.1523 percent of lauryl sodium sulfate and 0.2215 percent of sodium carboxy methyl cellulose (food grade), wherein the solution is basic; and a used indicator is phenolphthalein, thyme phenolphthalein / thymolphthalein or o-cresolphthalein. The monochromatic color bubble solution capable of fading is a basic solution, and can be used for producing monochromatic color bubbles capable of fading by blowing.

Owner:SHANGHAI FUYUN CULTURE TRANSMISSION

Rhubarb toothpaste

ActiveCN102579292AImprove immunityEasy to solveAntibacterial agentsCosmetic preparationsToothpasteMENTHOL CRYSTALS

The invention relates to a rhubarb health care toothpaste and is applied to teeth cleaning and health care of users in daily life. The rhubarb toothpaste comprises, by weight, 40-50kg of calcium carbonate, 15-25kg of sorbitol, 0.2-1.5kg of sodium carboxy methyl cellulose, 0.1-1kg of guar gum, 0-0.5kg of saccharin sodium, 0.5-2.5kg of sodium lauryl sulfate, 0-1kg of sodium pyrophosphate, 1-5kg of silicon dioxide, 0-0.5kg of sodium methyl, 1-3.5kg of propylene glycol, 15-30kg of deionized water, 0-0.8kg of essence, 0-1kg of menthol crystal, 0.2-1.5kg of rhubarb biological extract, and 0-0.8kg of sea-buckthorn extract. A preparation method of the rhubarb toothpaste includes adding and evenly mixing the sorbitol, the sodium carboxy methyl cellulose, the guar gum, the sodium lauryl sulfate, the sodium pyrophosphate, the silicon dioxide, the sodium methylparaben and the propylene glycol in a vacuum unguent machine; adding deionized water; adding sequentially the rhubarb biological extract, the sea-buckthorn extract, the saccharin sodium, the calcium carbonate, the menthol crystal and the essence; and performing stirring in high speed, fully emulsification and even mixing in a vacuum state.

Owner:孟庆海

Wool and cashmere printing and dyeing auxiliary

The invention relates to the field of production auxiliaries of wool products, in particular to a wool and cashmere printing and dyeing auxiliary. The wool and cashmere printing and dyeing auxiliary comprises sodium carboxy methyl cellulose, sodium diethylhexyl sulfosuccinate, citric acid, ethylene oxide, amino silicon oil, di-rhamnolipid, peroxidase and deionized water. The wool and cashmere printing and dyeing auxiliary comprises, by mass, 10-15 parts of sodium carboxy methyl cellulose, 3-8 parts of sodium diethylhexyl sulfosuccinate, 12-16 parts of citric acid, 8-14 parts of ethylene oxide, 5-10 parts of amino silicon oil, 3-6 pars of di-rhamnolipid, 1-3 parts of peroxidase and 40-60 parts of deionized water. According to the wool and cashmere printing and dyeing auxiliary, due to the combination ratio of the carboxy methyl cellulose, the citric acid and the amino silicon oil, dyeing and fixation of the dye on a wool and cashmere product are effectively improved, color fastness is improved, the color increasing and protecting performance can be improved, and the dyeing effect is ensured.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Melt-extruded film

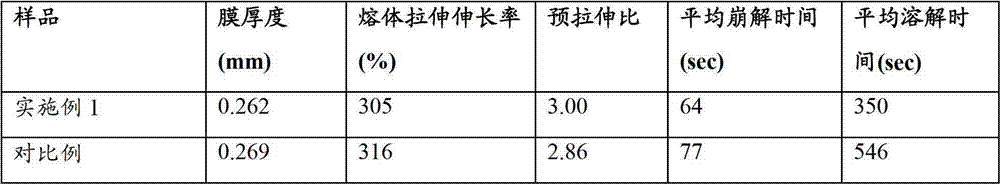

A mono-layer or multi-layer film wherein at least one of the layers has a thickness of at least 0.125 mm is produced from a melt-extruded polymer composition comprising a) a water-soluble polymer, b) an active ingredient and c) an adjuvant selected from the group consisting of mono- and disaccharides, sugar alcohols, low molecular weight water soluble polymers, and salts of cross-linked carboxymethylcellulose, with the proviso that the adjuvant c) is different from the water-soluble polymer a).

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com