Patents

Literature

90results about How to "Large discharge capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonaceous material for electrode and non-aqueous solvent secondary battery using this material

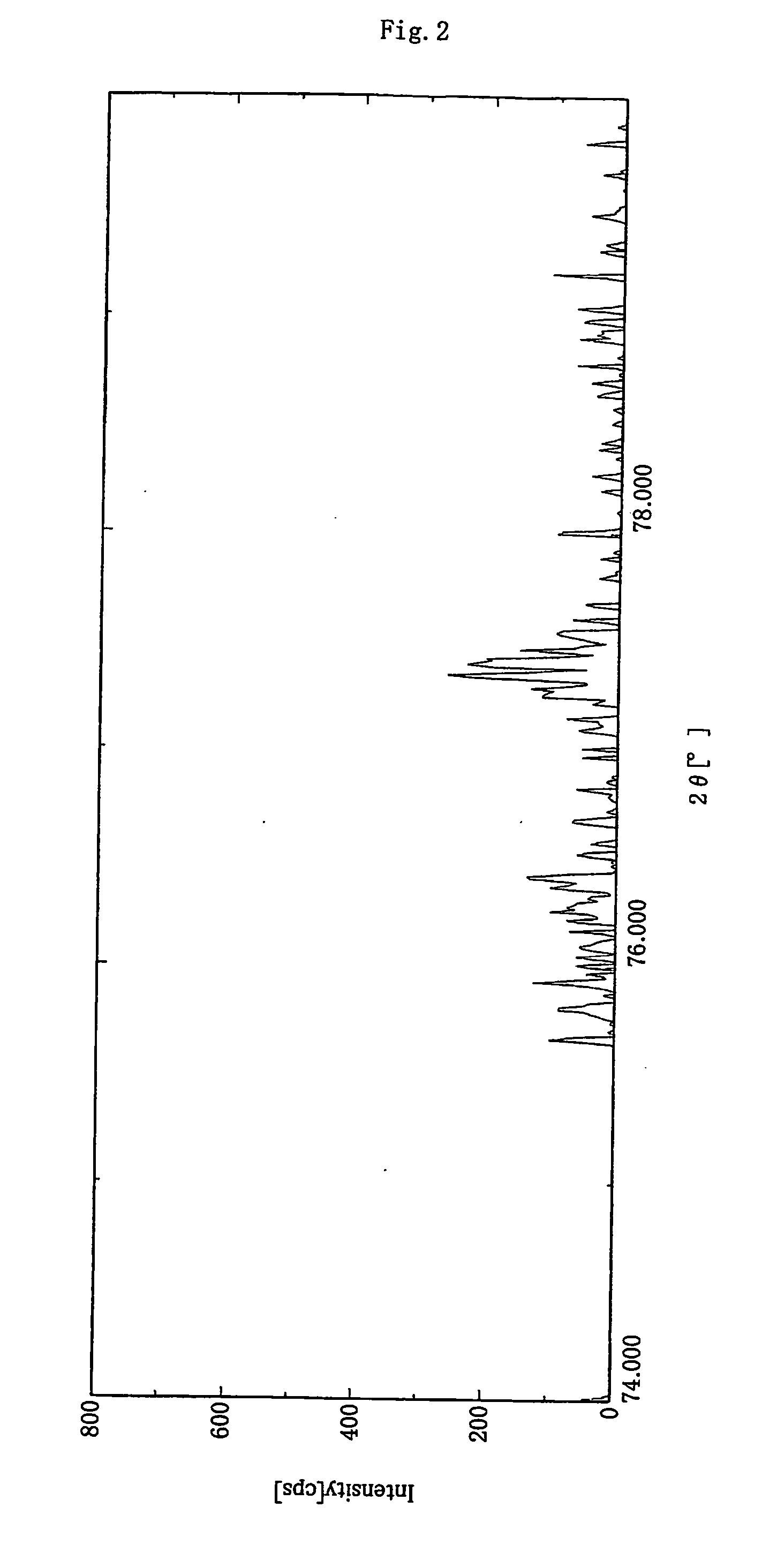

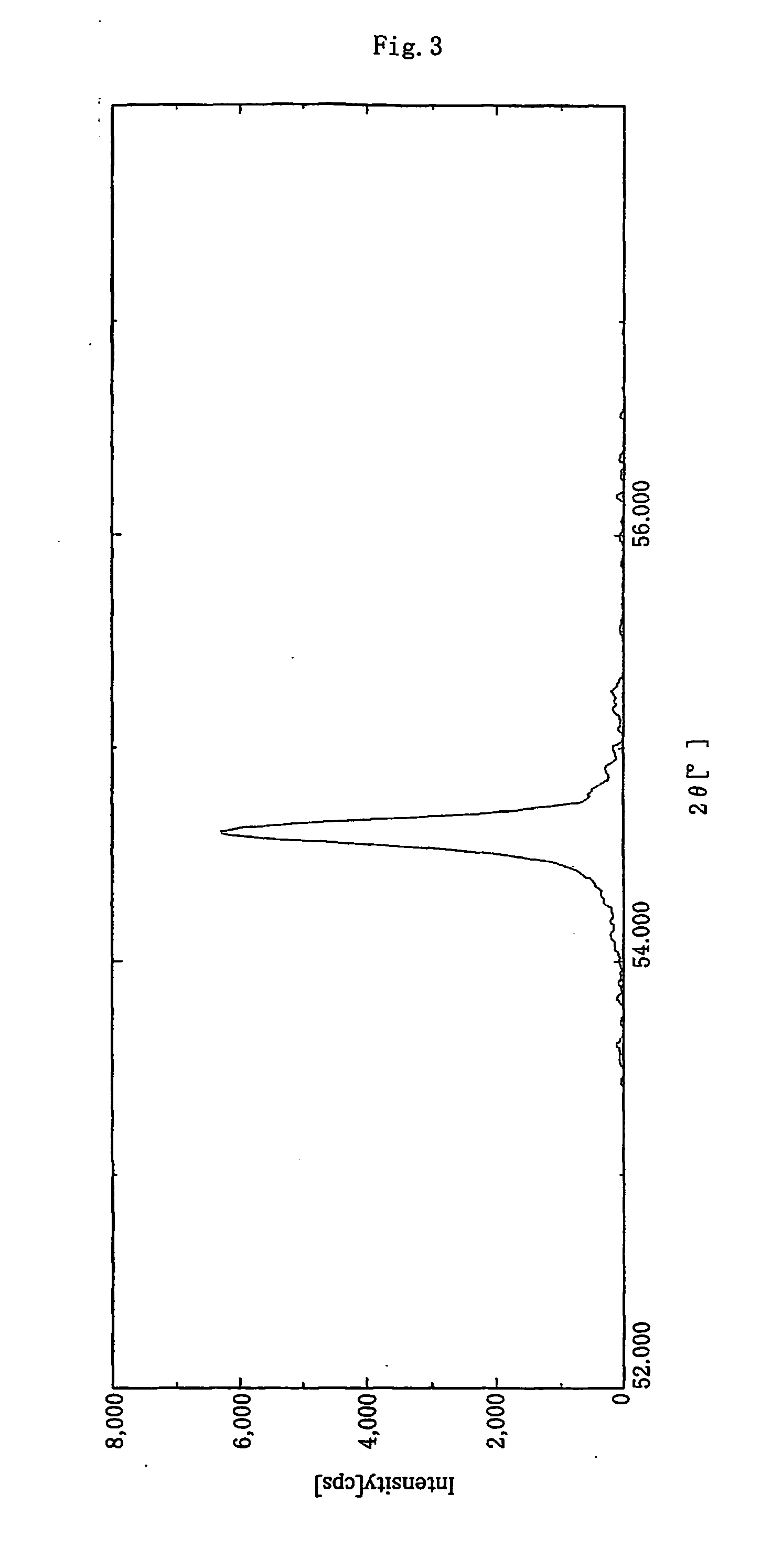

InactiveUS6632569B1Large discharge capacityImprove propertiesAlkaline accumulatorsConductive materialX-rayPeak value

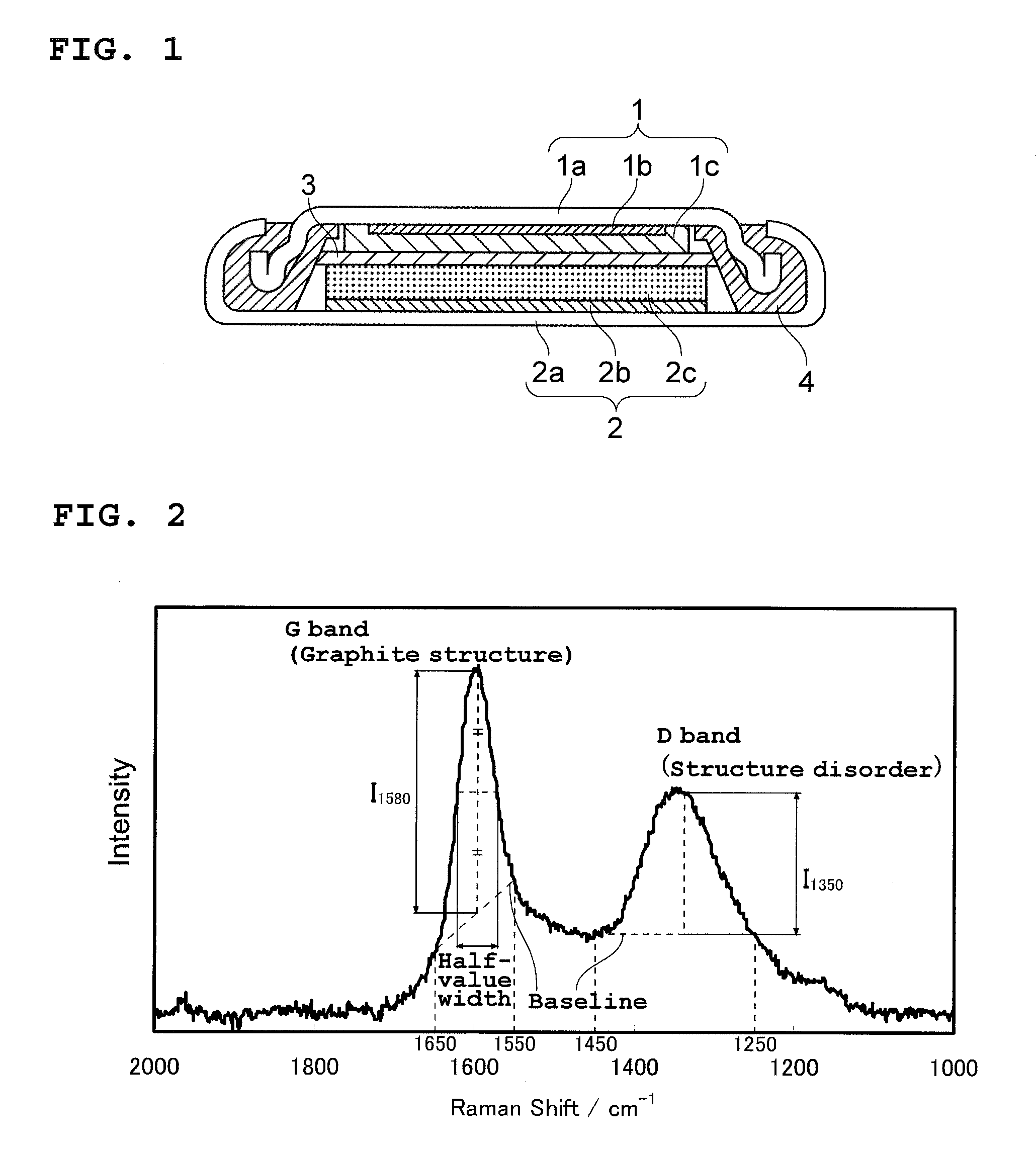

A carbonaceous material has a plane space d002 of a (002) plane less than 0.337 nm in an X-ray wide angle diffraction method, a crystallite size (Lc) of 90 nm or higher, an R value, as a peak intensity ratio of a peak intensity of 1360 cm<HIL><−1 < / SP><PDAT>to a peak intensity of 1580 cm<HIL><−1 < / SP><PDAT>in a Raman spectrum in use of an argon ion laser, of 0.20 or higher, and a tap density of 0.75 g / cm<HIL><3 < / SP><PDAT>or higher. Also disclosed is a multilayer structure carbonaceous material for electrode, which is manufactured by carbonizing some organic compounds where the carbonaceous material for electrode is mixed with the organic compounds. The battery using the carbonaceous material for electrode or the multilayer structure carbonaceous material for electrode has a large capacity, a small irreversible capacity admitted in the initial cycle, excellent capacity maintaining rate of the cycle, and particularly, largely improved quick charging and discharging characteristics.< / PTEXT>

Owner:MITSUBISHI CHEM CORP

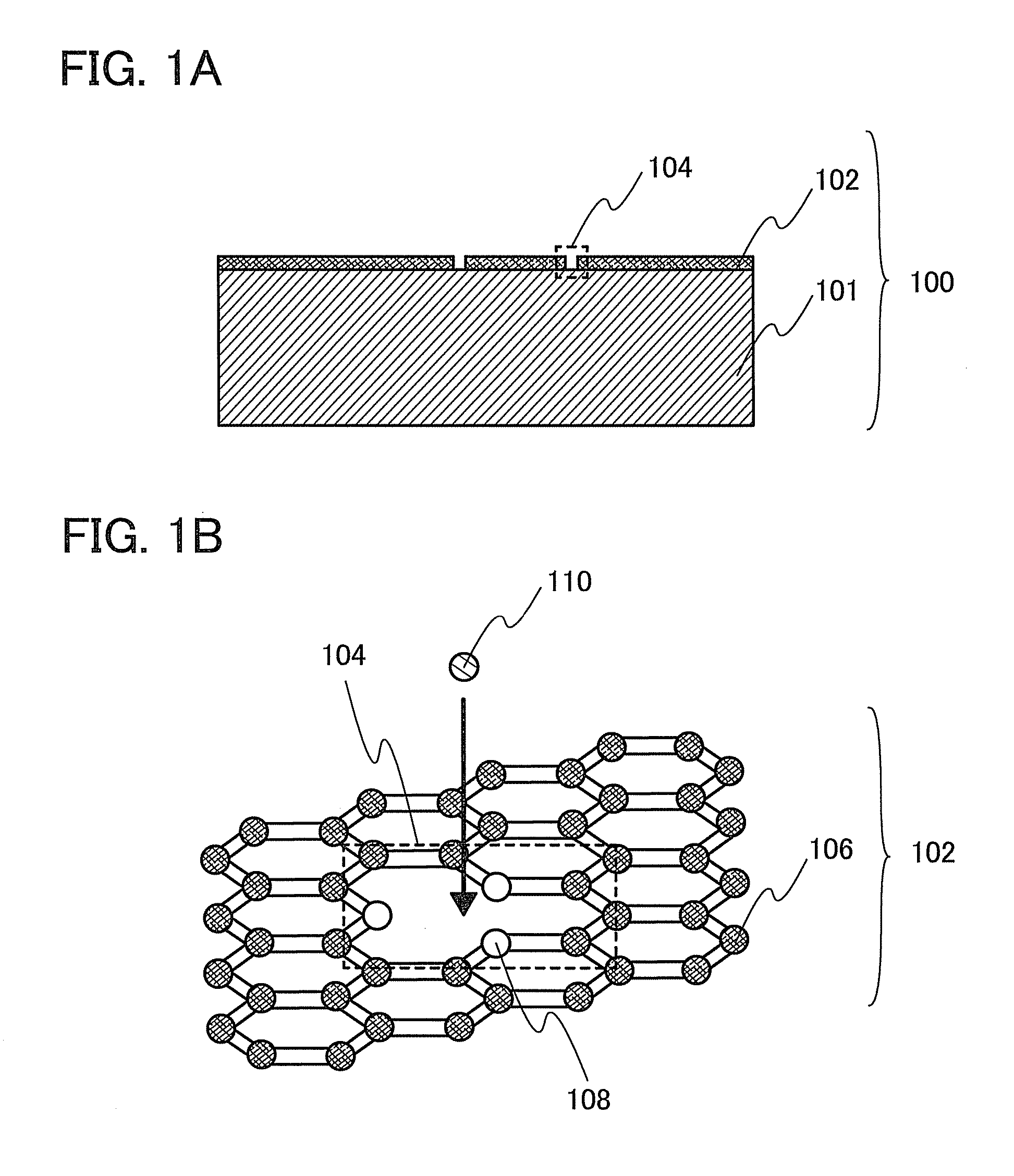

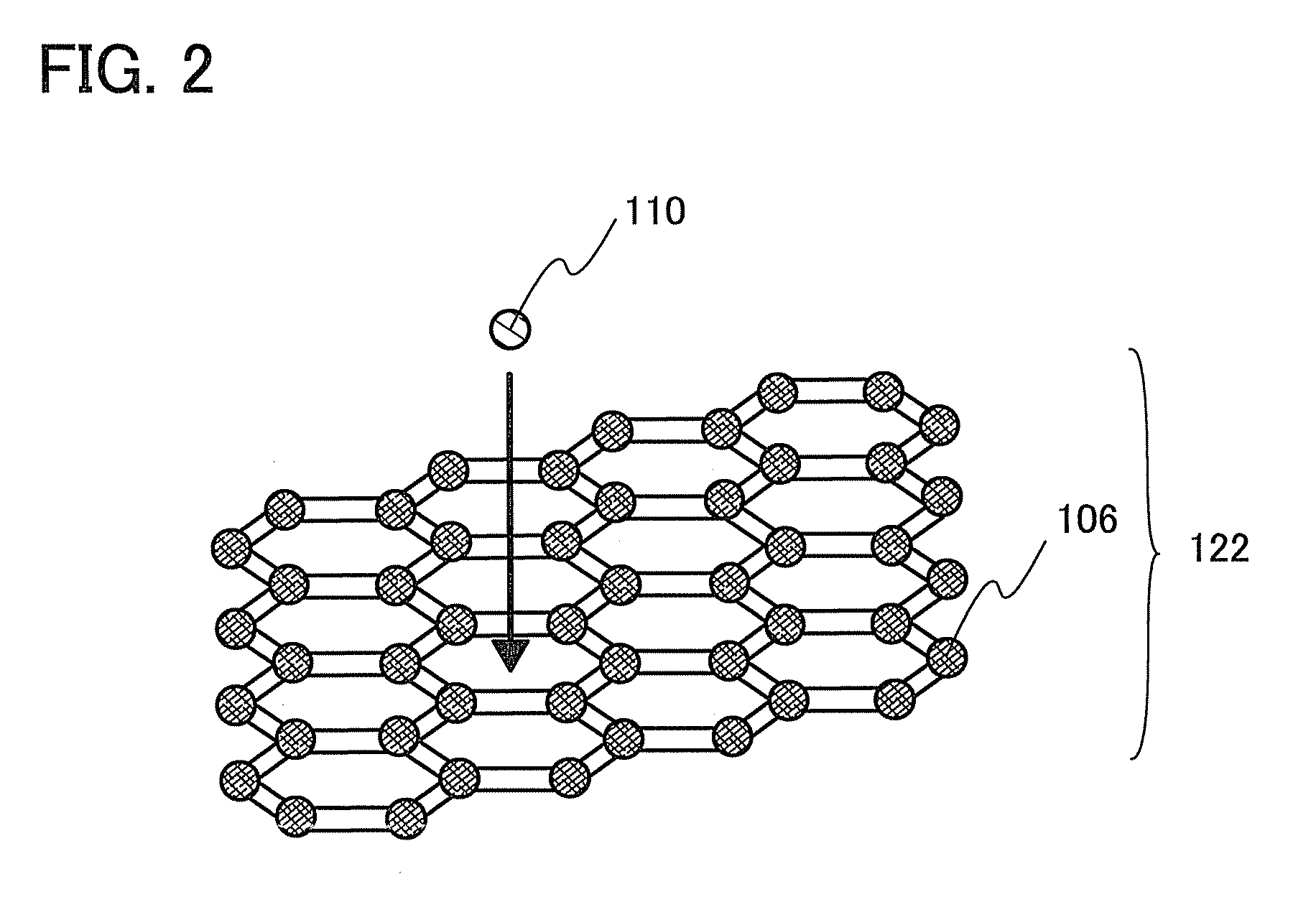

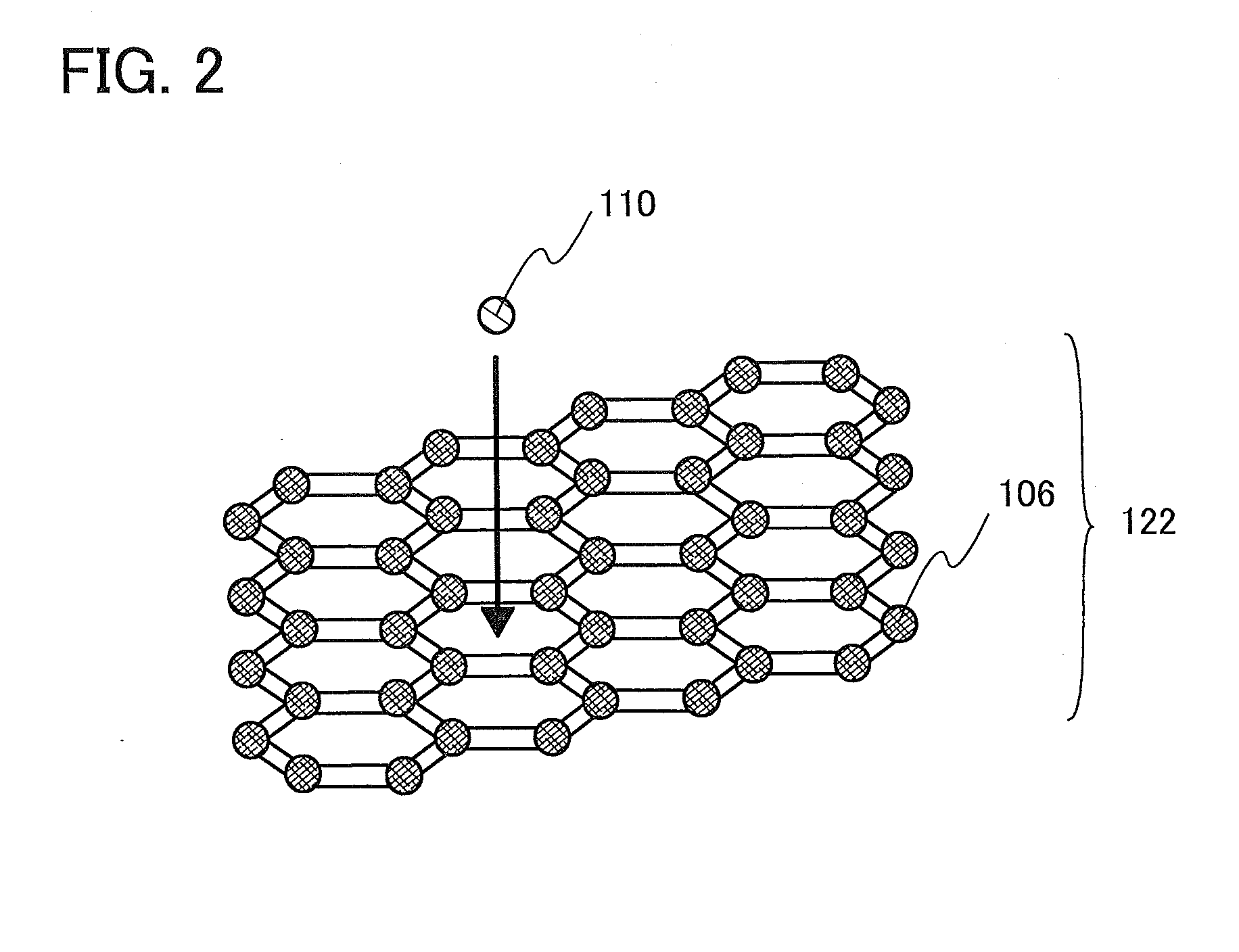

Positive-electrode active material and power storage device

InactiveUS20120088151A1High electrical conductivityImprove conductivityMaterial nanotechnologyActive material electrodesPower storageOxide

A positive-electrode active material with improved electrical conductivity, and a power storage device using the material are provided. A positive-electrode active material with large capacity, and a power storage device using the material are provided. A core including lithium metal oxide is used as a core of a main material of the positive-electrode active material, and one to ten pieces of graphene is used as a covering layer for the core. A hole is provided for graphene, whereby transmission of a lithium ion is facilitated, resulting in improvement of use efficiency of current.

Owner:SEMICON ENERGY LAB CO LTD

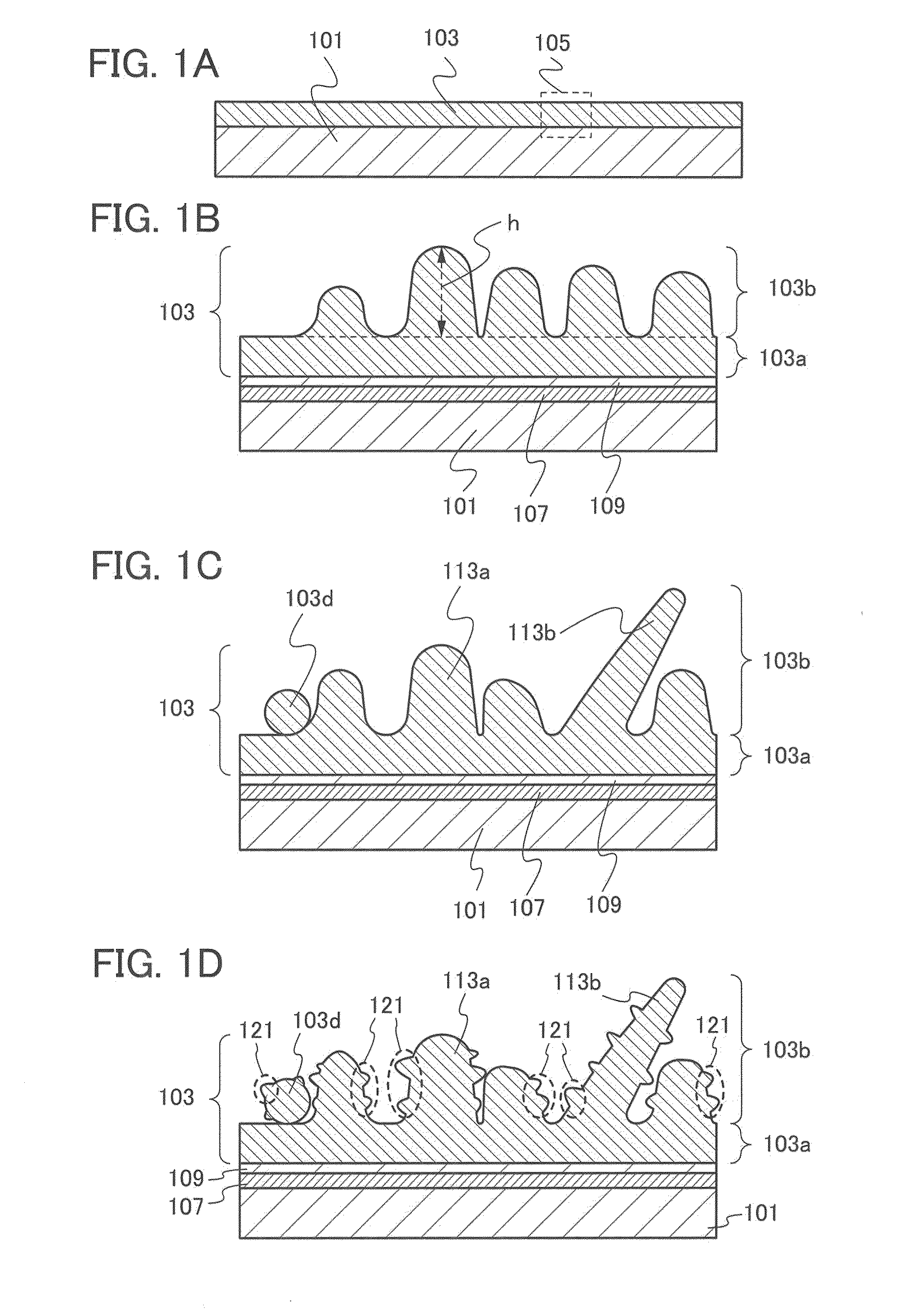

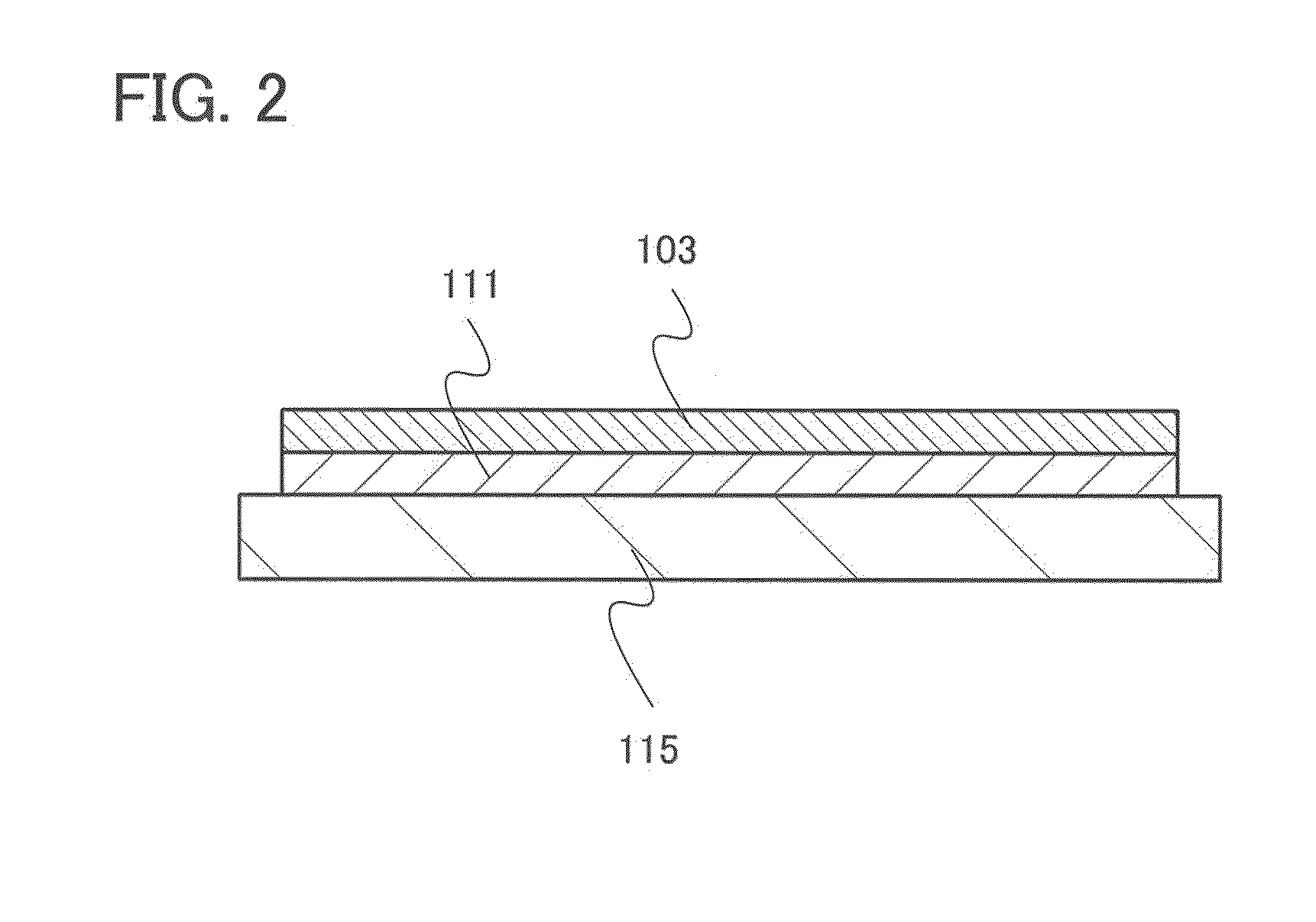

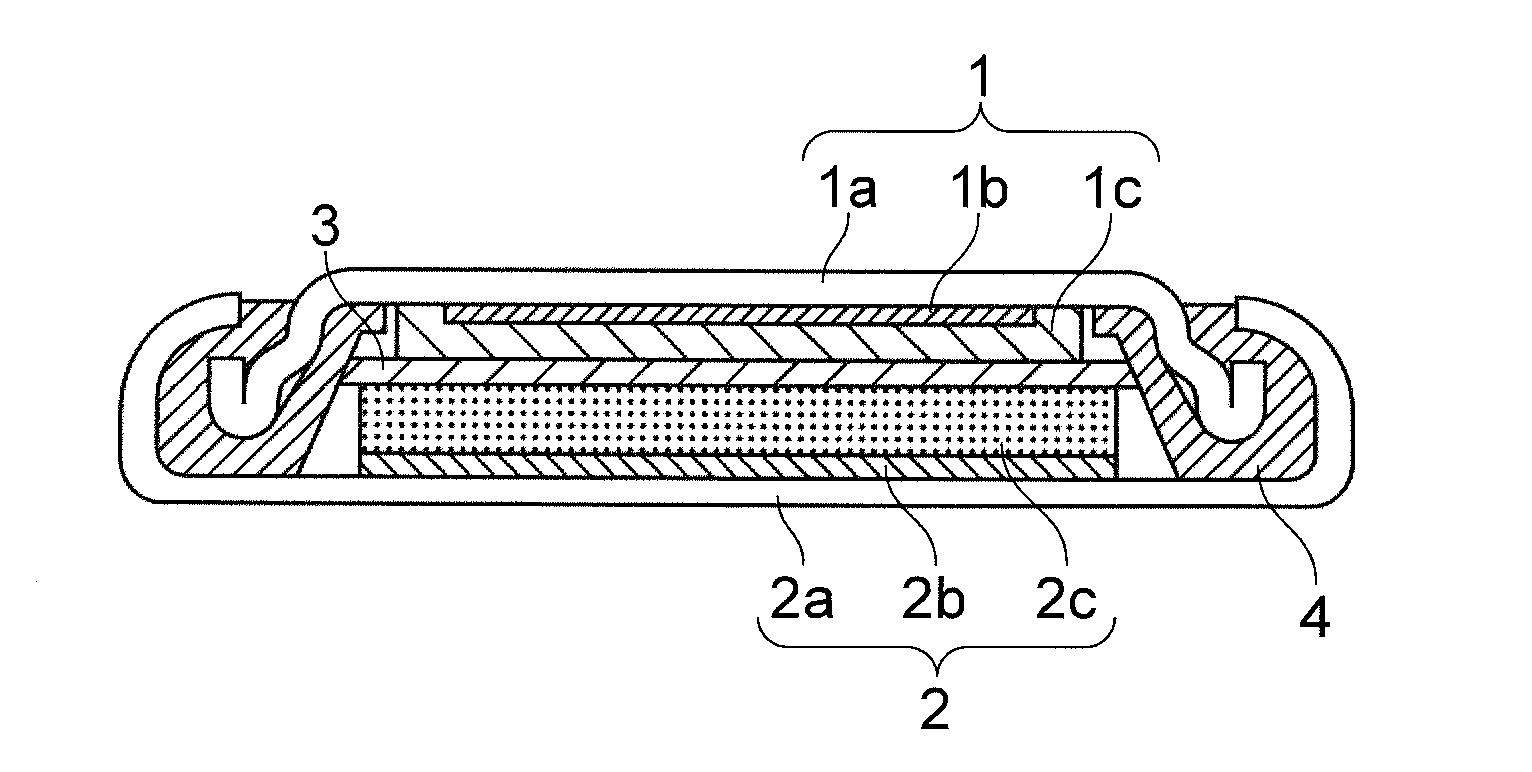

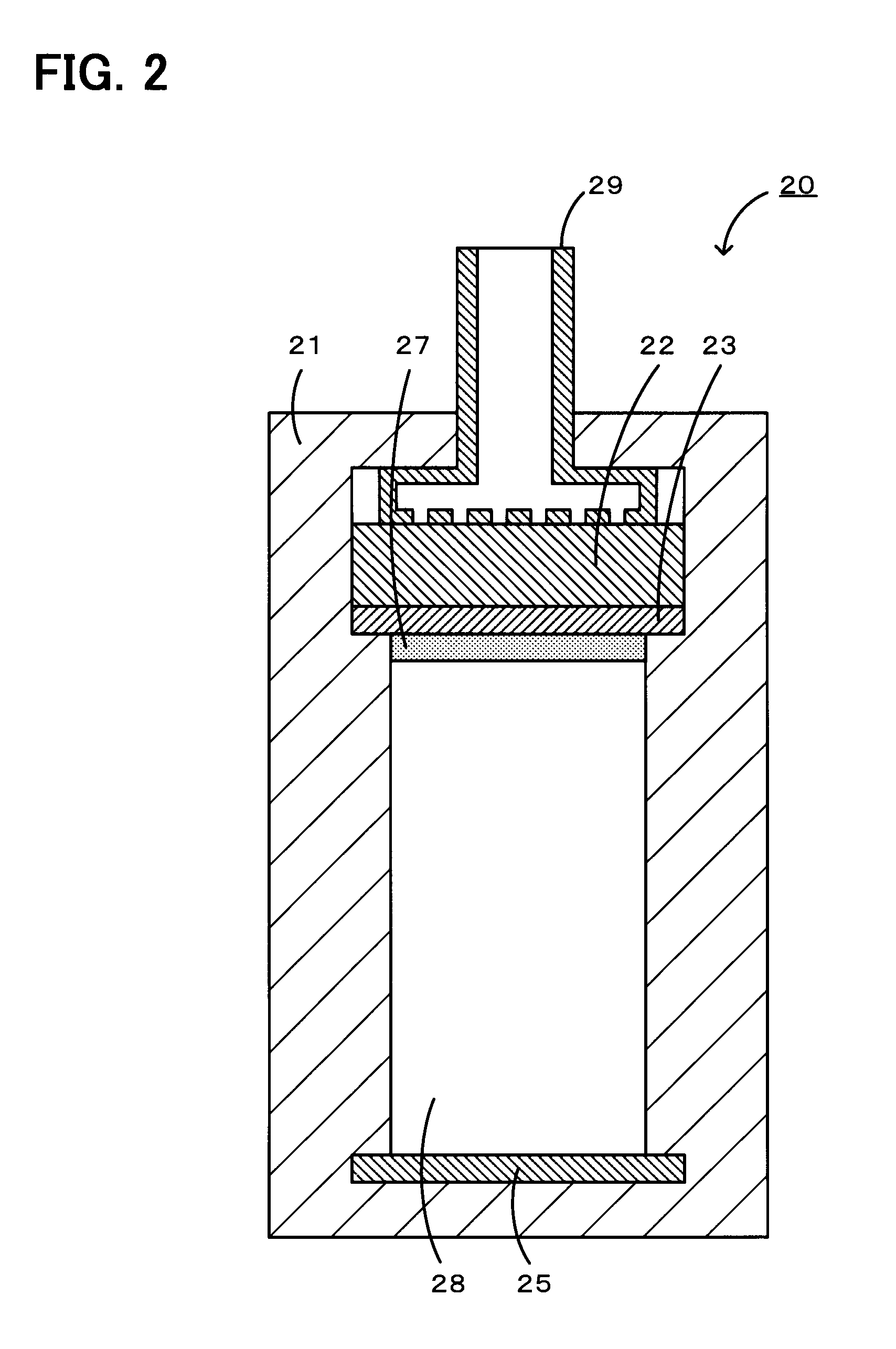

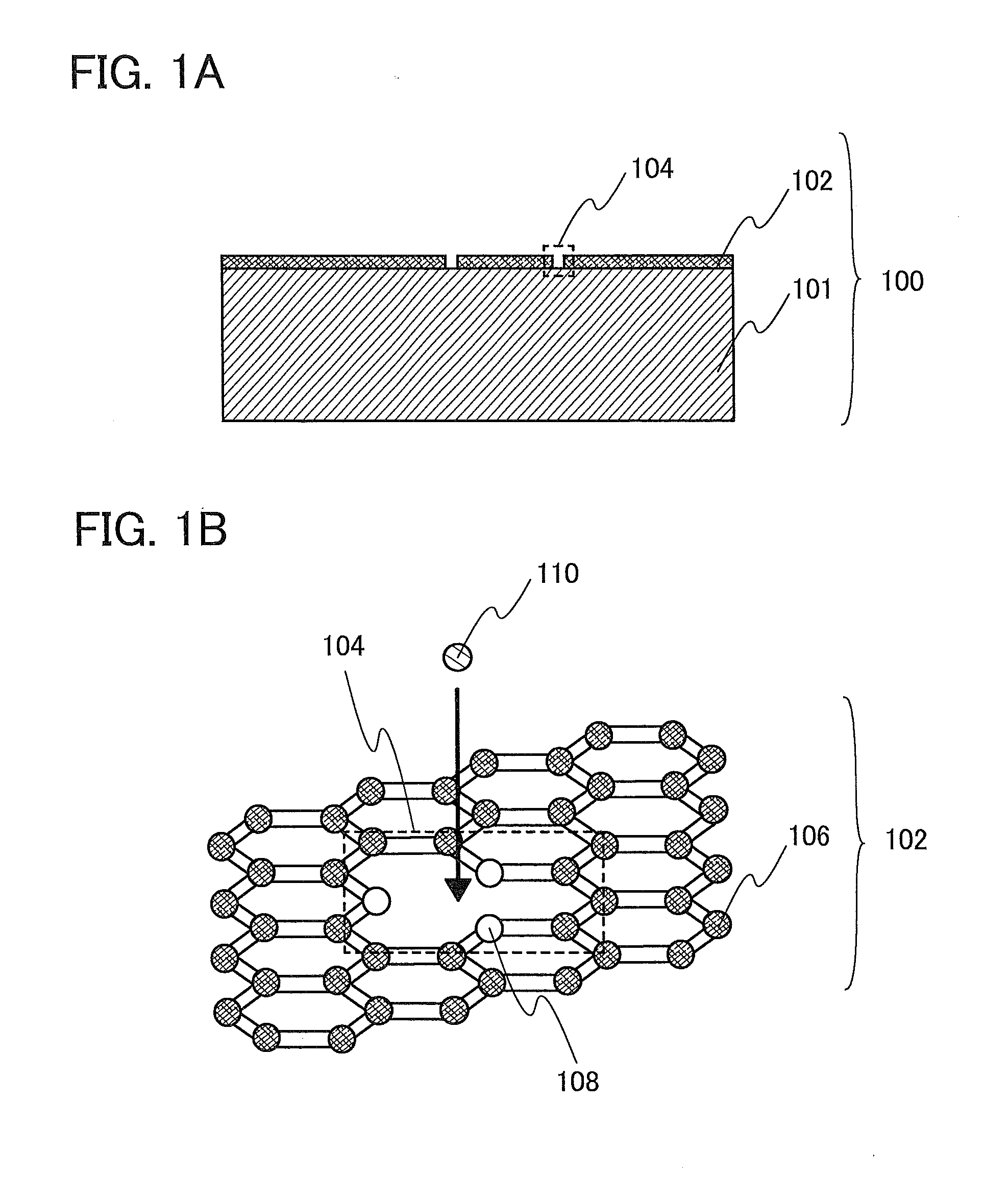

Power storage device and method for manufacturing the same

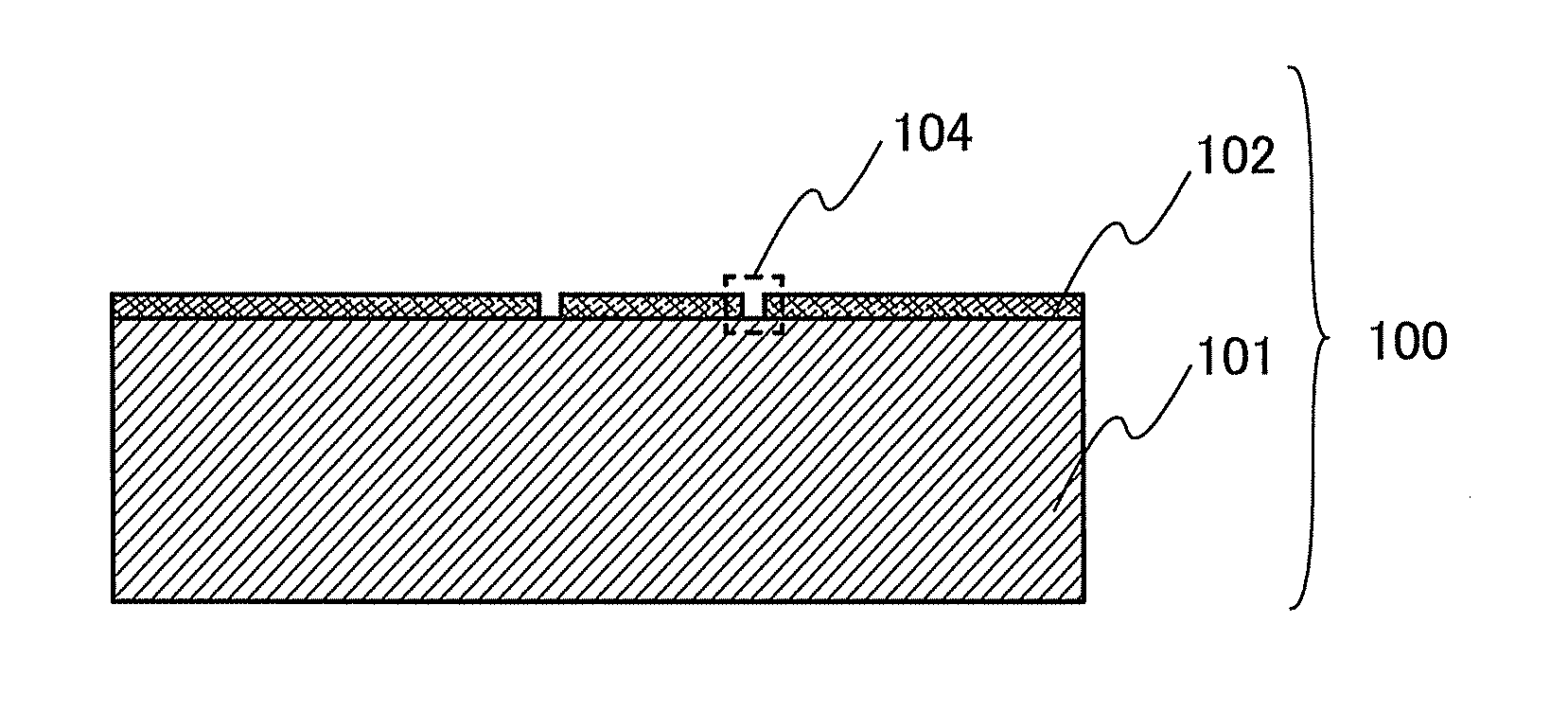

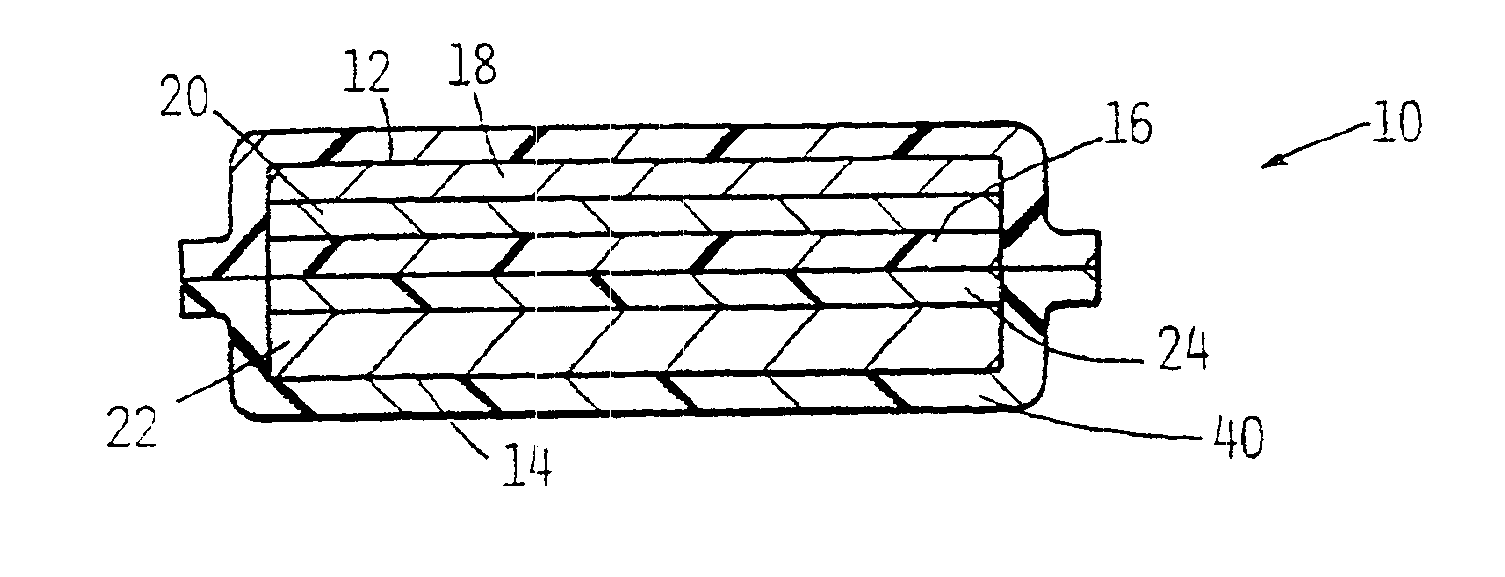

ActiveUS20110266654A1Improving interface characteristicResistanceFuel and secondary cellsFinal product manufactureEngineeringWhiskers

Provided is a method for manufacturing a power storage device in which a crystalline silicon layer including a whisker-like crystalline silicon region is formed as an active material layer over a current collector by a low-pressure CVD method in which heating is performed using a deposition gas containing silicon. The power storage device includes the current collector, a mixed layer formed over the current collector, and the crystalline silicon layer functioning as the active material layer formed over the mixed layer. The crystalline silicon layer includes a crystalline silicon region and a whisker-like crystalline silicon region including a plurality of protrusions which project over the crystalline silicon region. With the protrusions, the surface area of the crystalline silicon layer functioning as the active material layer can be increased.

Owner:SEMICON ENERGY LAB CO LTD

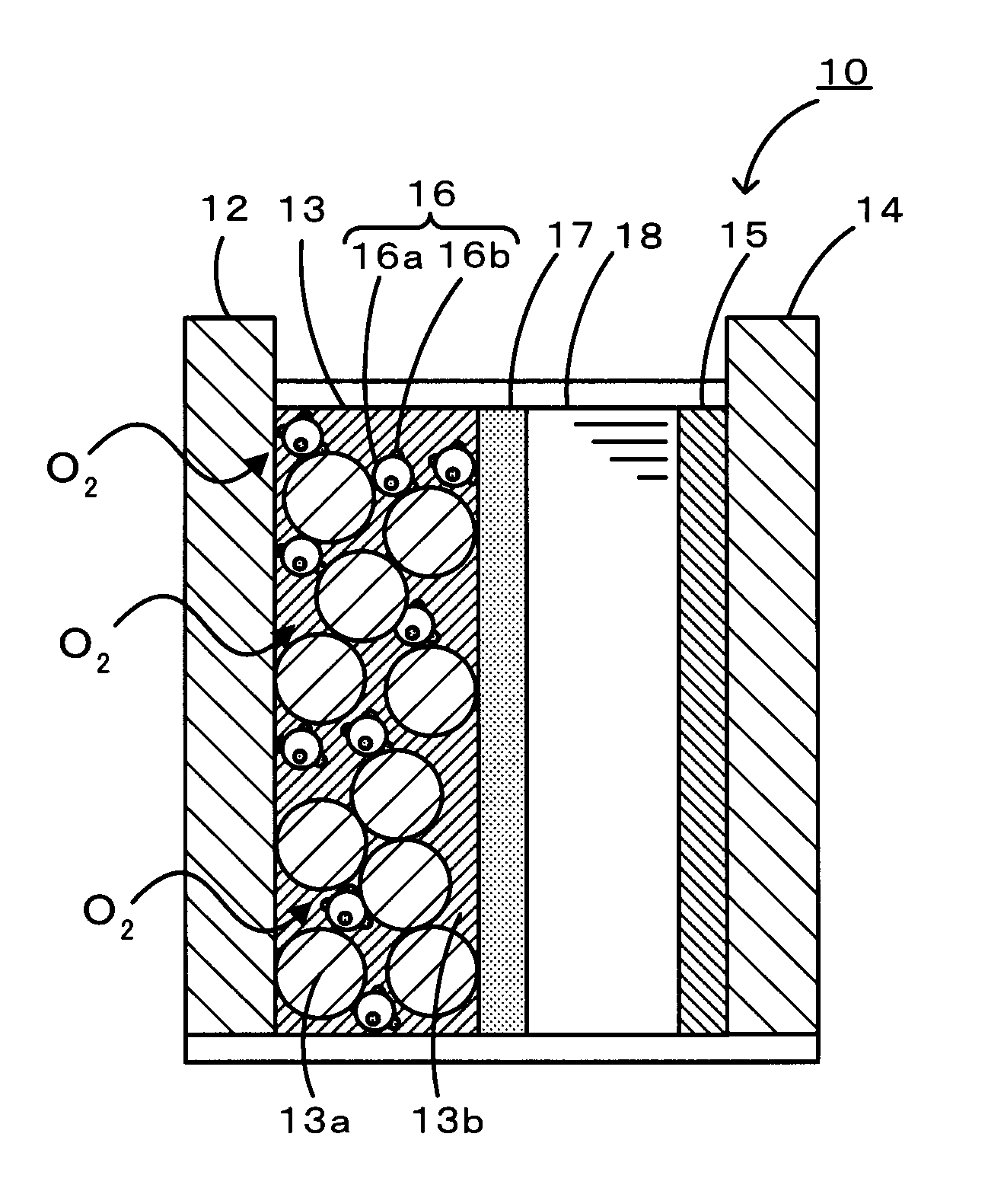

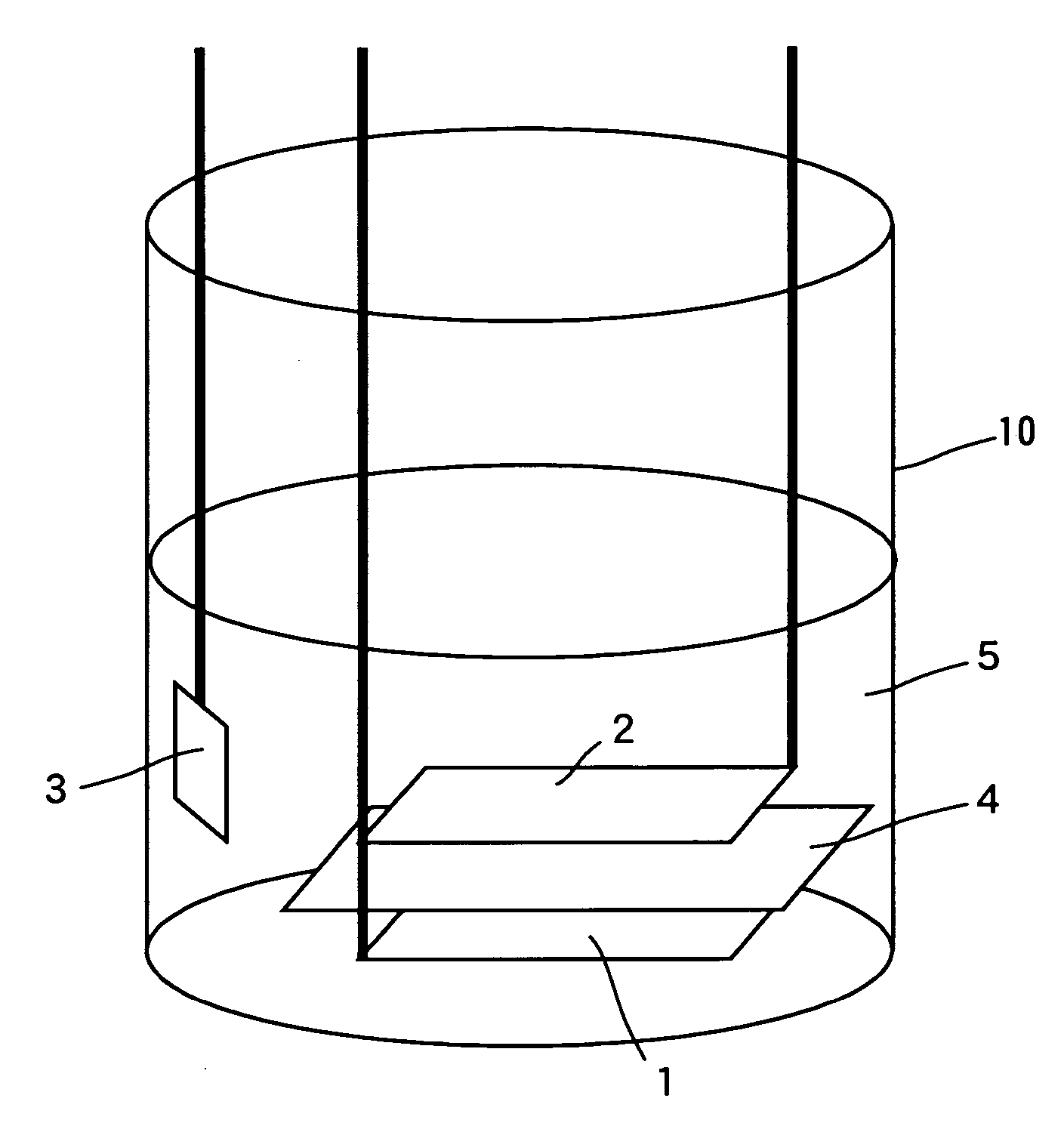

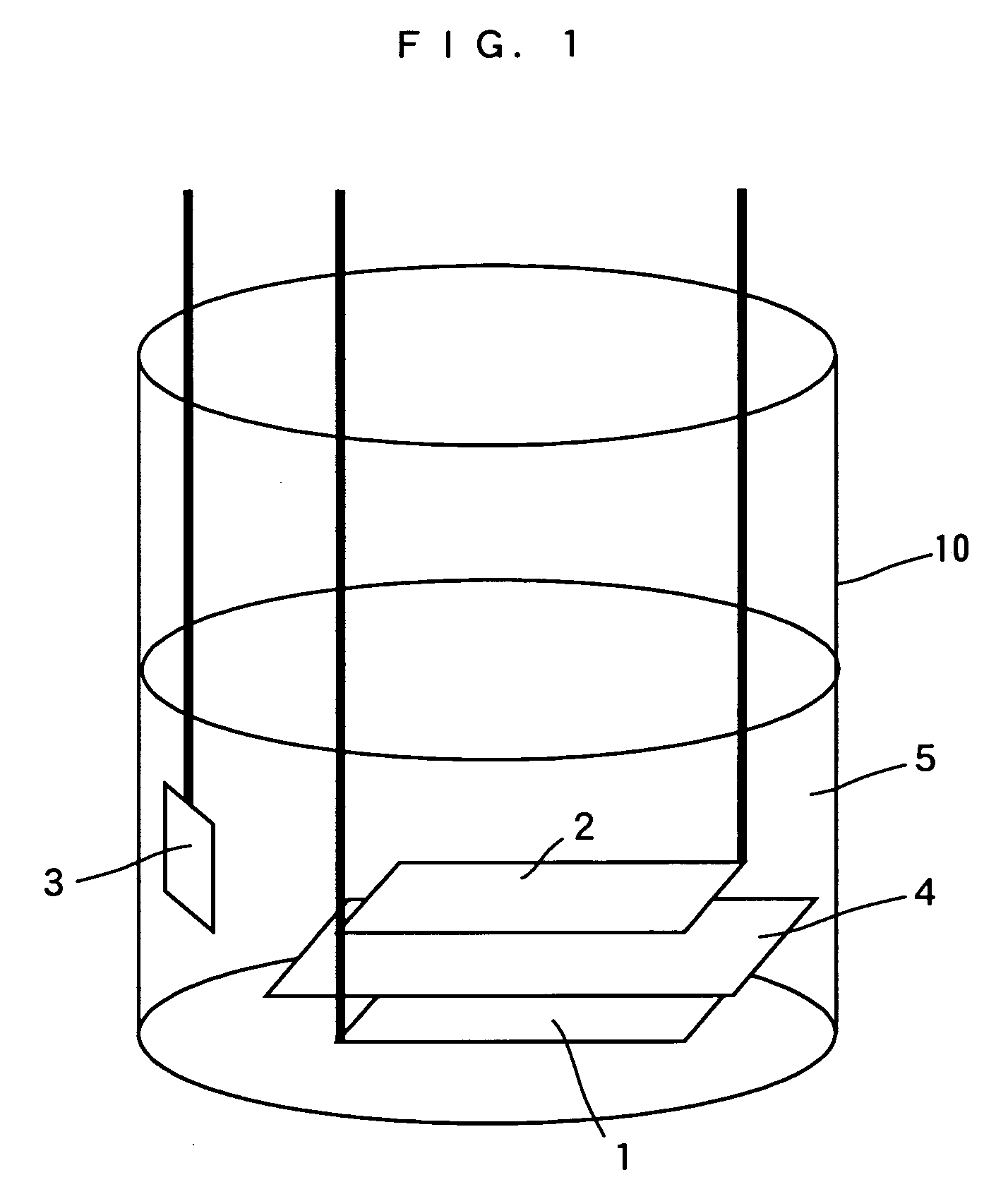

Lithium-air battery

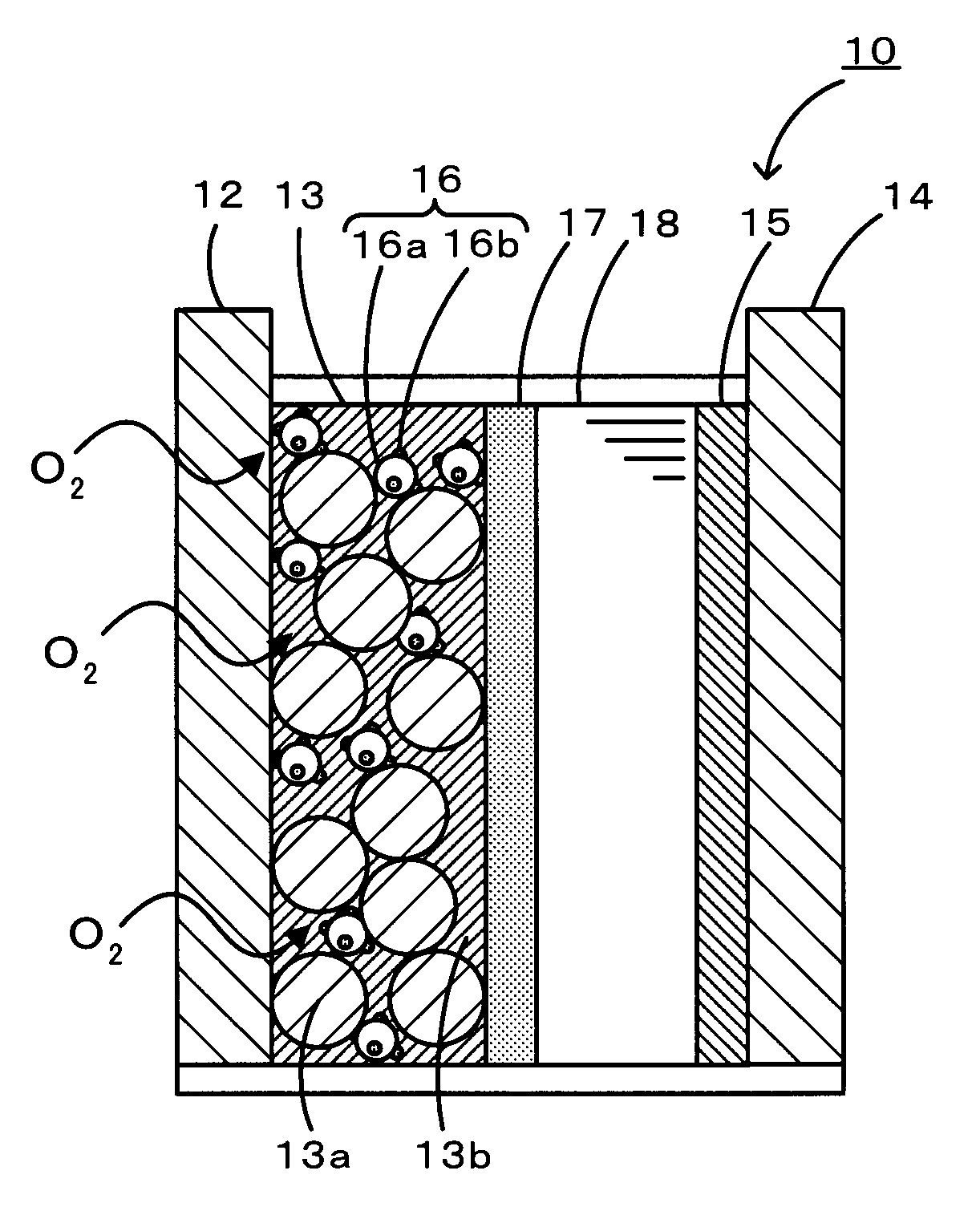

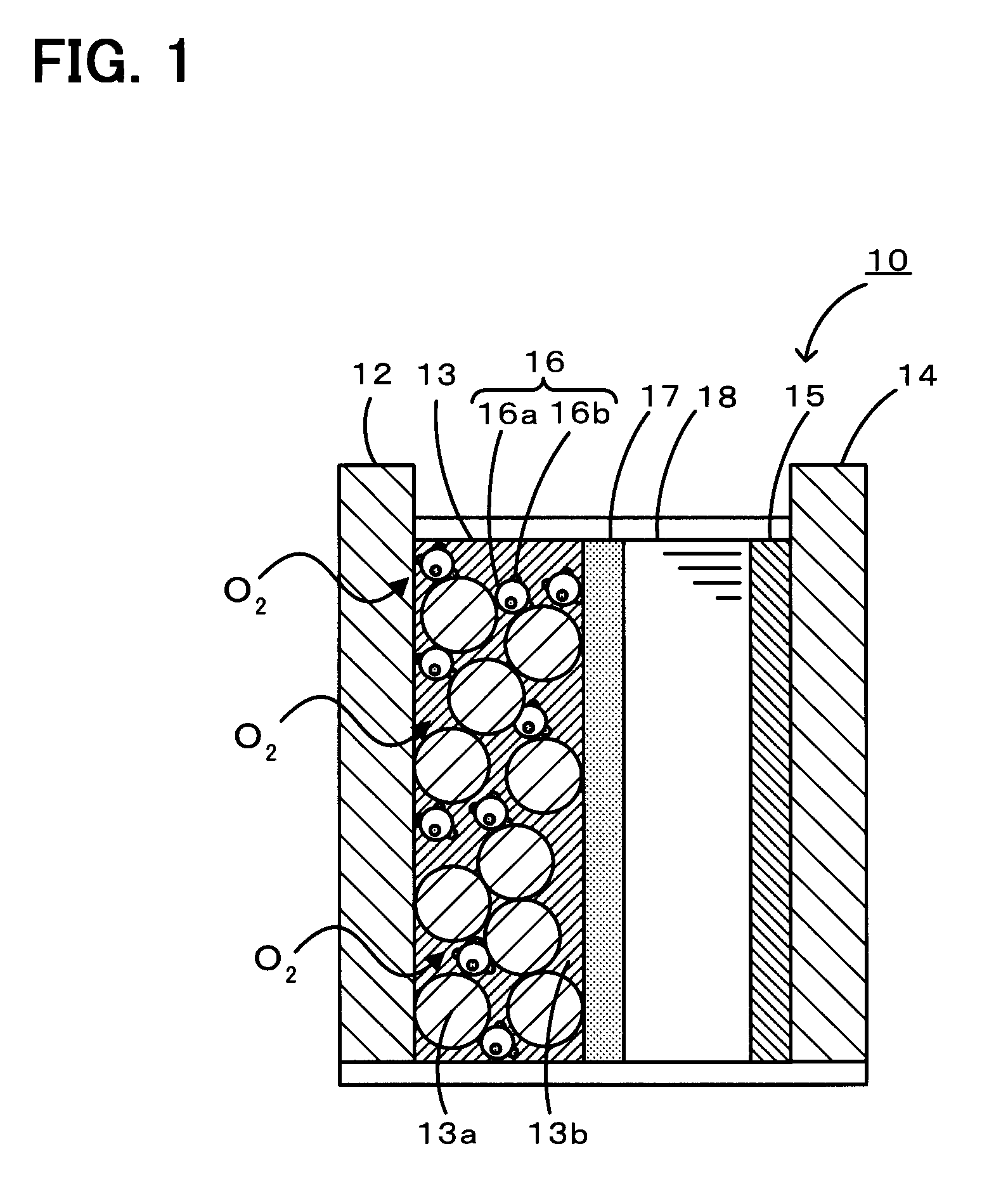

InactiveUS20080176124A1High cell potentialLarge discharge capacityFuel and primary cellsFuel and secondary cellsOxideNon aqueous electrolytes

A lithium-air battery includes a lithium negative electrode, a positive electrode including a catalyst containing gold, and a non-aqueous electrolyte interposed between the positive electrode and the lithium negative electrode. The catalyst includes gold supported on a cerium-containing oxide, such as a cerium-zirconium compound oxide or a cerium-aluminum compound oxide. The amount of catalyst of the positive electrode is in the range of 0.01 to 50 weight percent relative to the total weight of the positive electrode.

Owner:TOYOTA CENT RES & DEV LAB INC

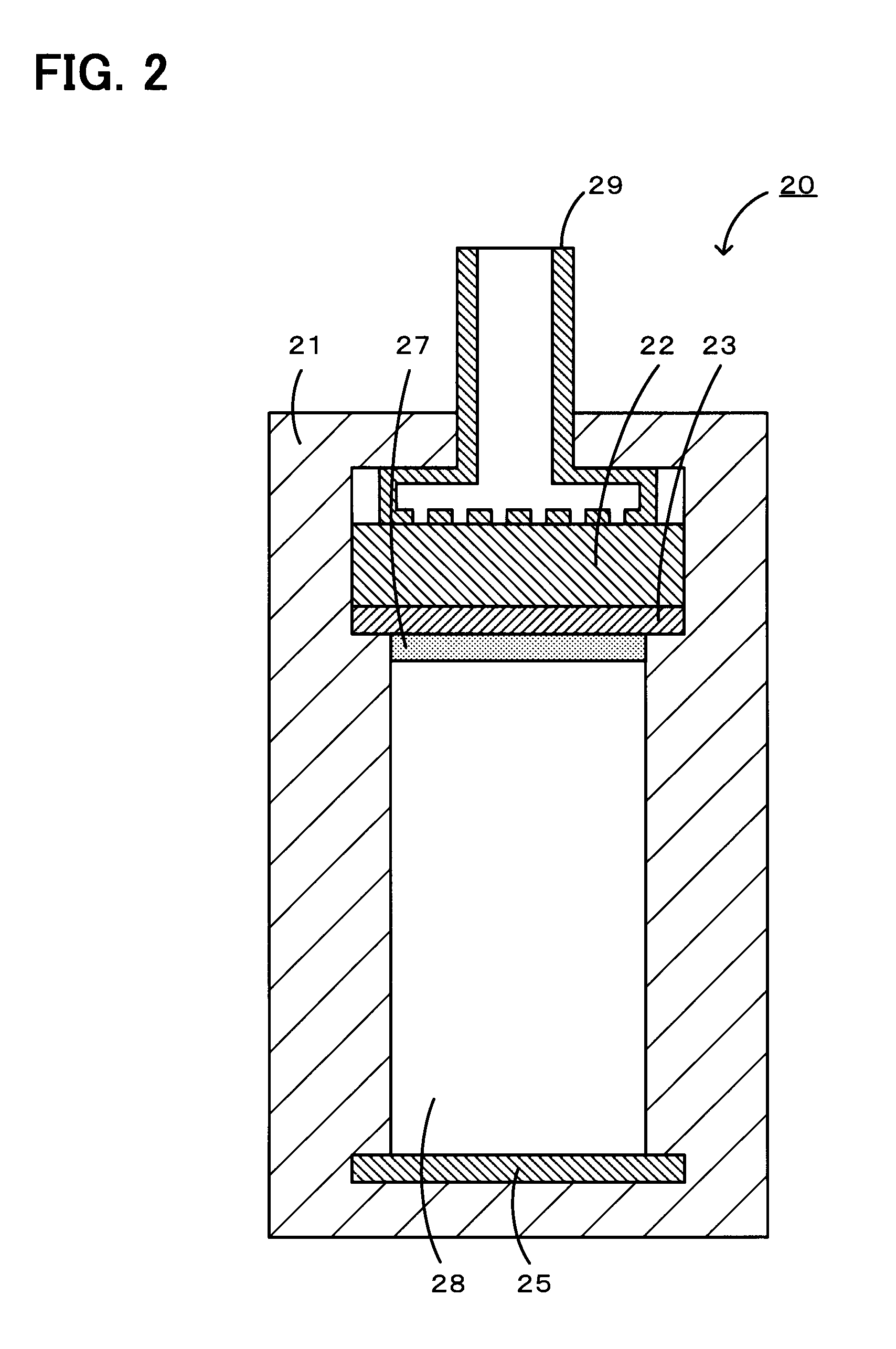

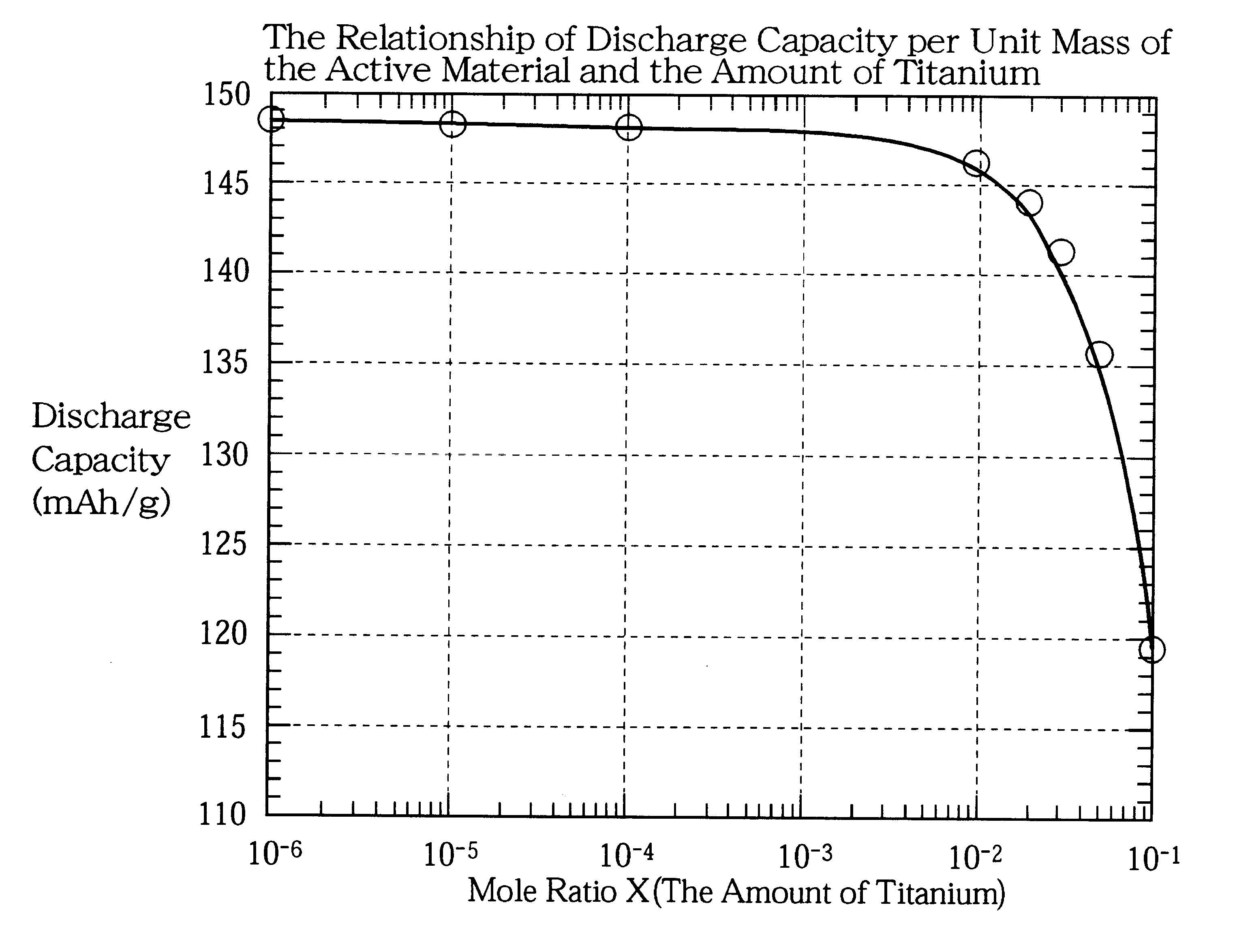

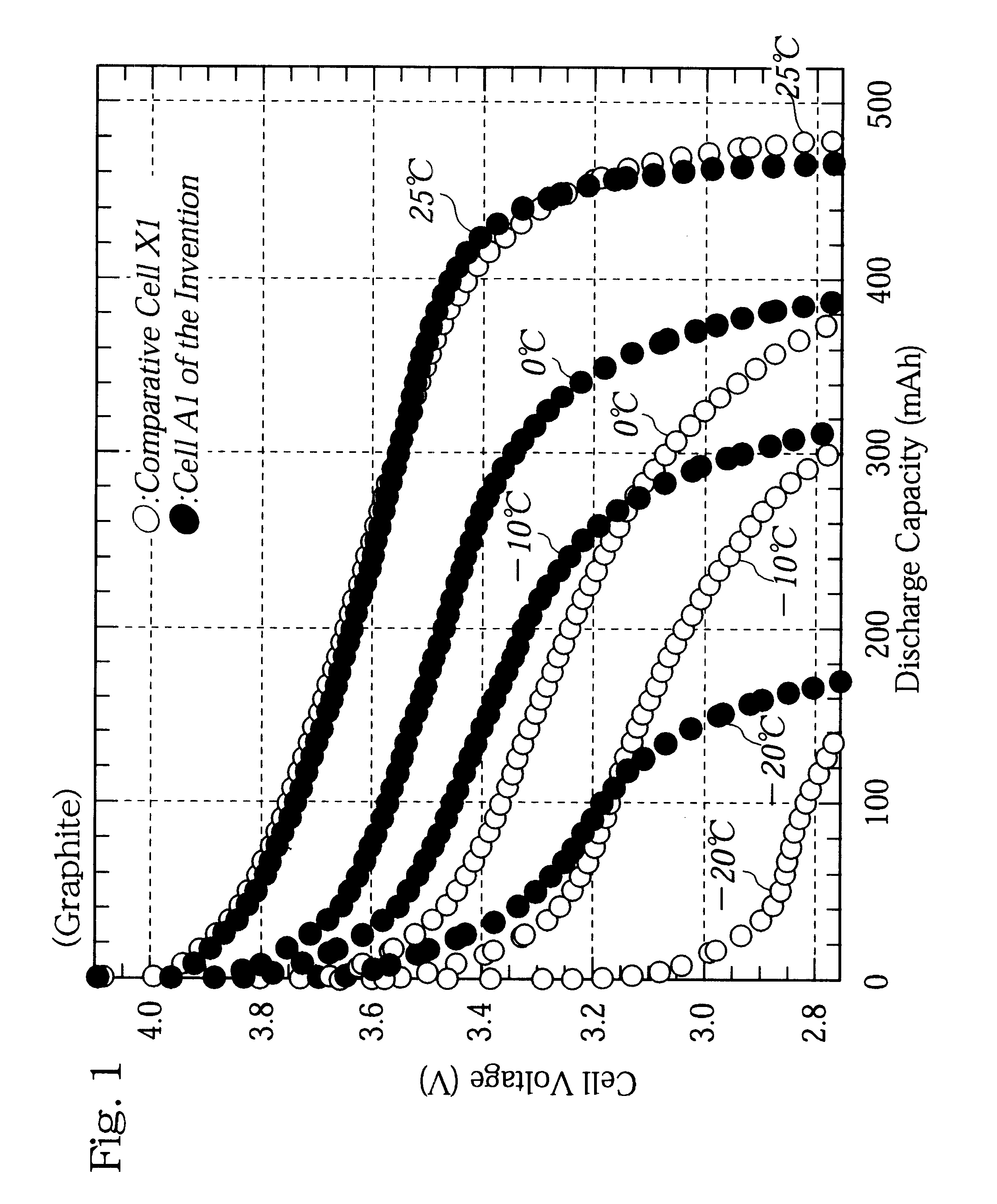

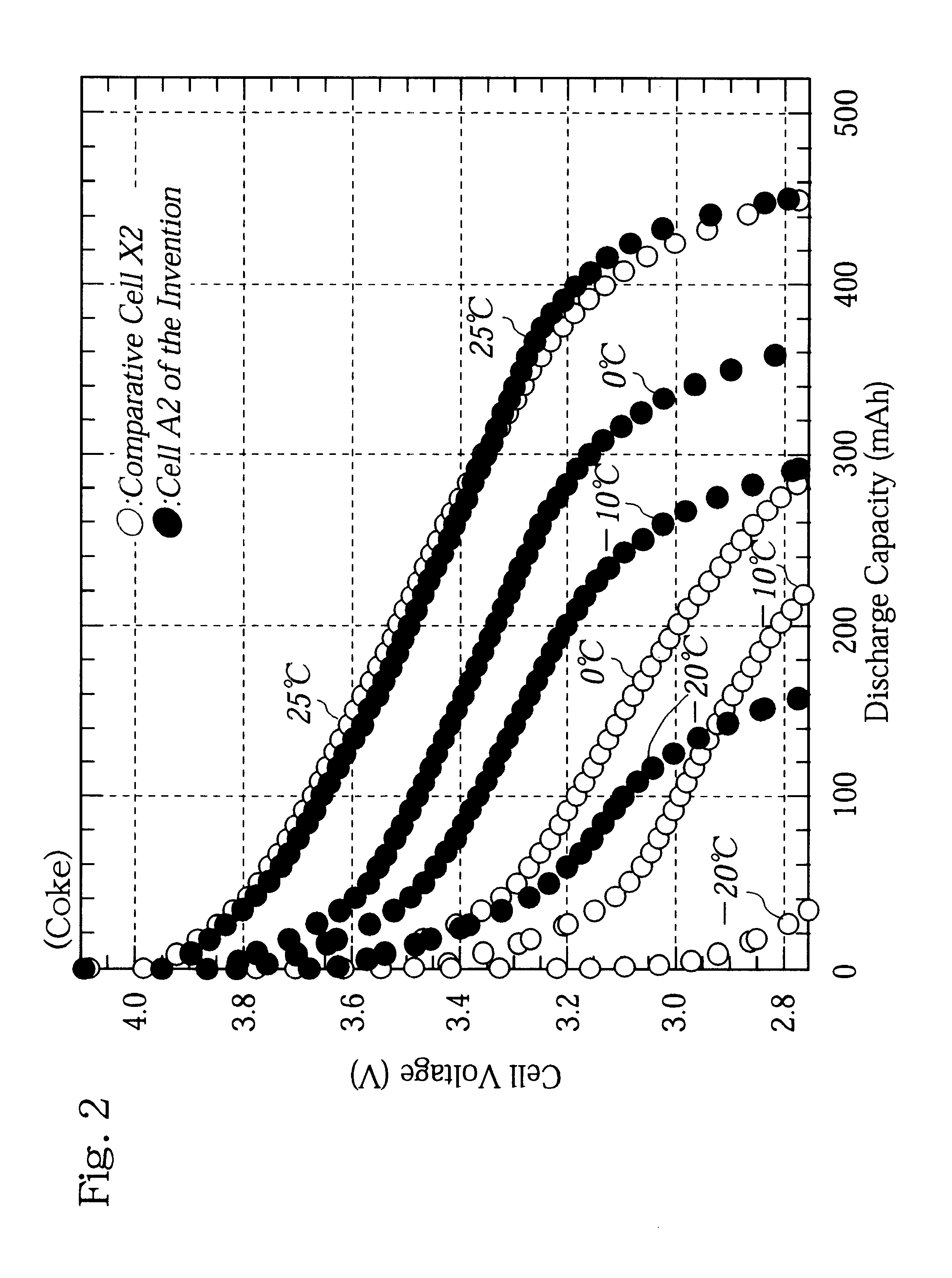

Non-aqueous electrolyte cell having a positive electrode with Ti-attached LiCoO2

InactiveUS6395426B1Easy to transformImprove reliabilityNon-aqueous electrolyte accumulatorsFinal product manufactureTitaniumPropylene carbonate

The invention provides a non-aqueous electrolyte cell having a high working voltage in a low temperature range of 0° C. or below and thereby attaining excellent low temperature discharge characteristics, a reduced internally-generated gas, and an excellent safety against heat. This is achieved by a cell comprising a non-aqueous electrolyte containing propylene carbonate and LiN(SO2C2F5)2 as an electrolyte salt, a graphite negative electrode, and a positive electrode having a positive electrode active material comprising a Ti-attached LiCoO2 in which a particle of titanium and / or titanium compound is attached on a surface of a particle of lithium cobalt oxide and a mole ratio of titanium and / or titanium compound in the Ti-attached LiCoO2 is within the range of from 0.00001 to 0.02.

Owner:SANYO ELECTRIC CO LTD

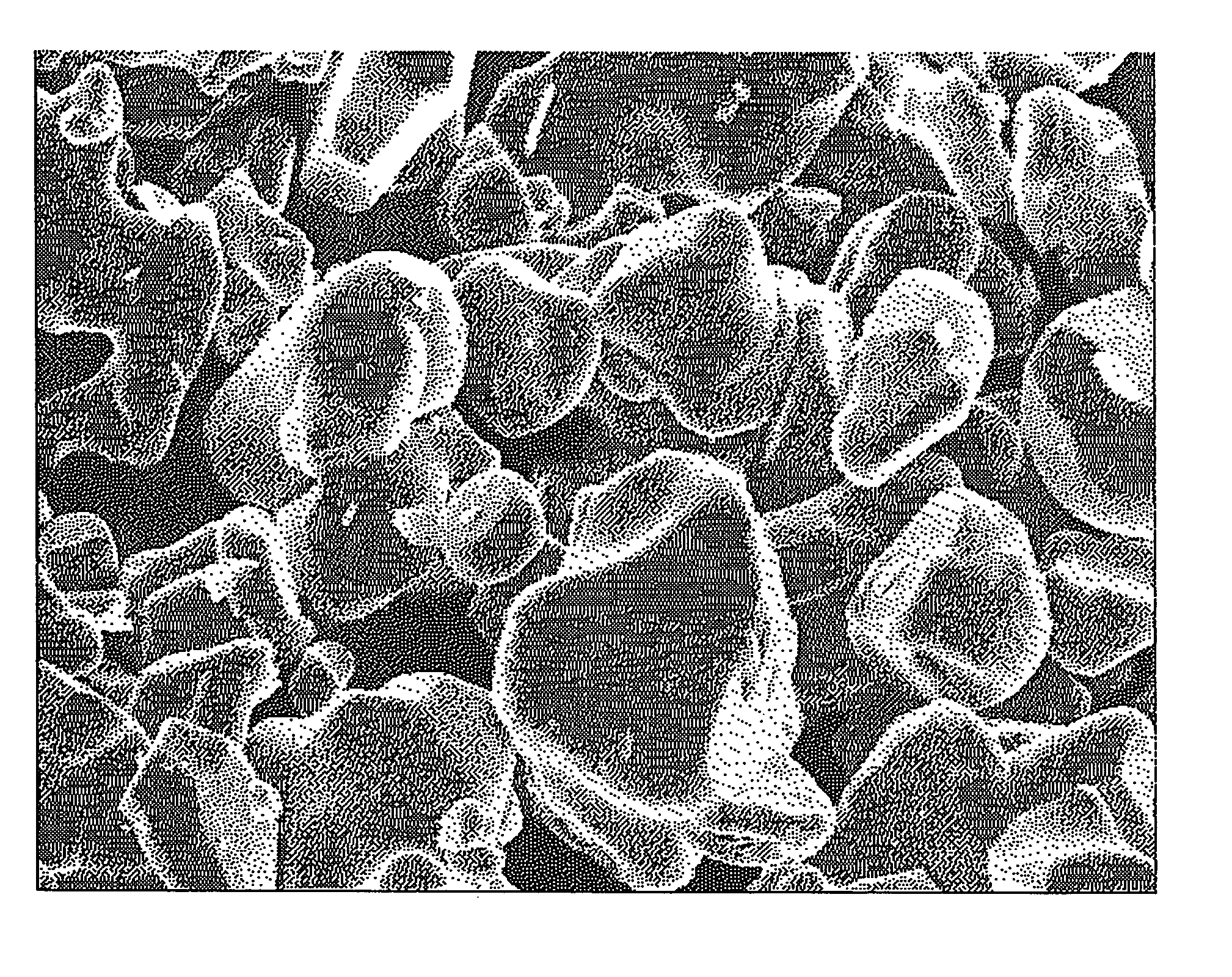

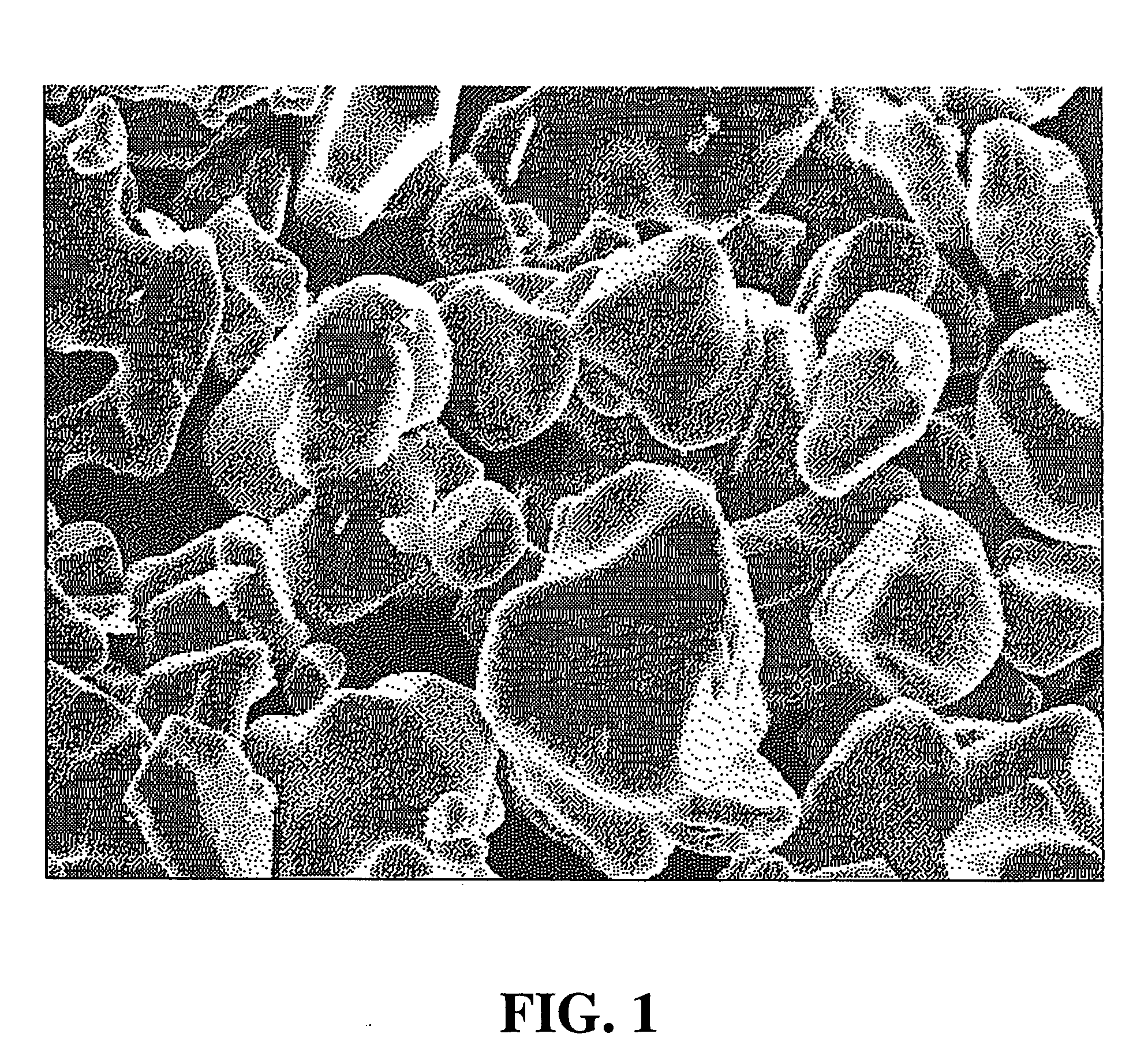

Surface graphitized carbon material and process for producing the same

InactiveUS6022518AImprove low temperature performanceLarge discharge capacitySecondary cellsCarbon preparation/purificationCharge and dischargeLithium

A surface graphitized carbon material comprising a graphitic surface and a carbonaceous internal part. This surface graphitized carbon material can be produced by contacting a carbon material with a metal having catalytically graphitizing activity or a compound thereof to thereby cause the metal or compound thereof to be present in a surface of the carbon material and heating the carbon material at 300 to 1500 DEG C. in an inert atmosphere. By virtue of the possession of a graphitic surface and a carbonaceous internal part, the surface graphitized carbon material of the present invention simultaneously has the properties of the carbon material such that, when used in a negative electrode for lithium-ion secondary battery, a negative electrode having high charge and discharge capacities, being excellent in performance at low temperature, and facilitating a display of residual capacity can be obtained, and the properties of the graphite material such that a negative electrode whose cycle deterioration of charge and discharge capacities is slight can be obtained.

Owner:PETOCA

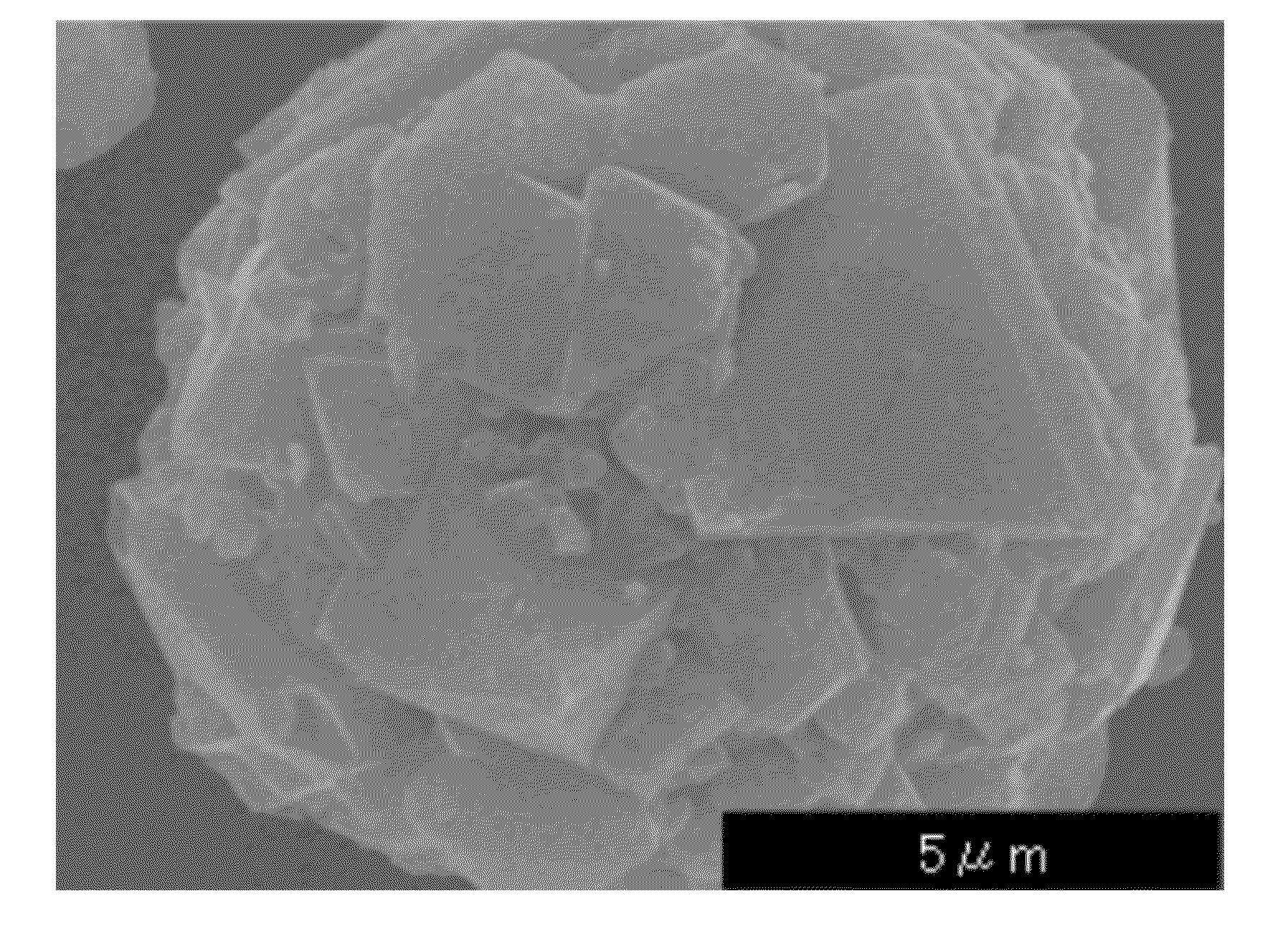

Positive electrode active substance precursor particles, positive electrode active substance particles and non-aqueous electrolyte secondary battery

InactiveUS20130032753A1Increase discharge voltageLarge discharge capacityElectrode manufacturing processesSecondary cellsAmount of substanceNon aqueous electrolytes

The present invention relates to positive electrode active substance particles comprising a compound having a spinel type structure comprising at least Li, Ni and Mn, and having an Li content which is controlled such that a molar ratio of Li(Ni+Mn) therein is 0.3 to 0.65, an Ni content of 5 to 25% by weight, an Na content of 0.05 to 1.9% by weight and an S content of 0.0005 to 0.16% by weight, a sum of the Na content and the S content being 0.09 to 1.9005% by weight. The positive electrode active substance particles according to the present invention can be suitably used as positive electrode active substance particles for non-aqueous electrolyte secondary batteries which can exhibit a high discharge voltage and an excellent discharge capacity.

Owner:TODA IND

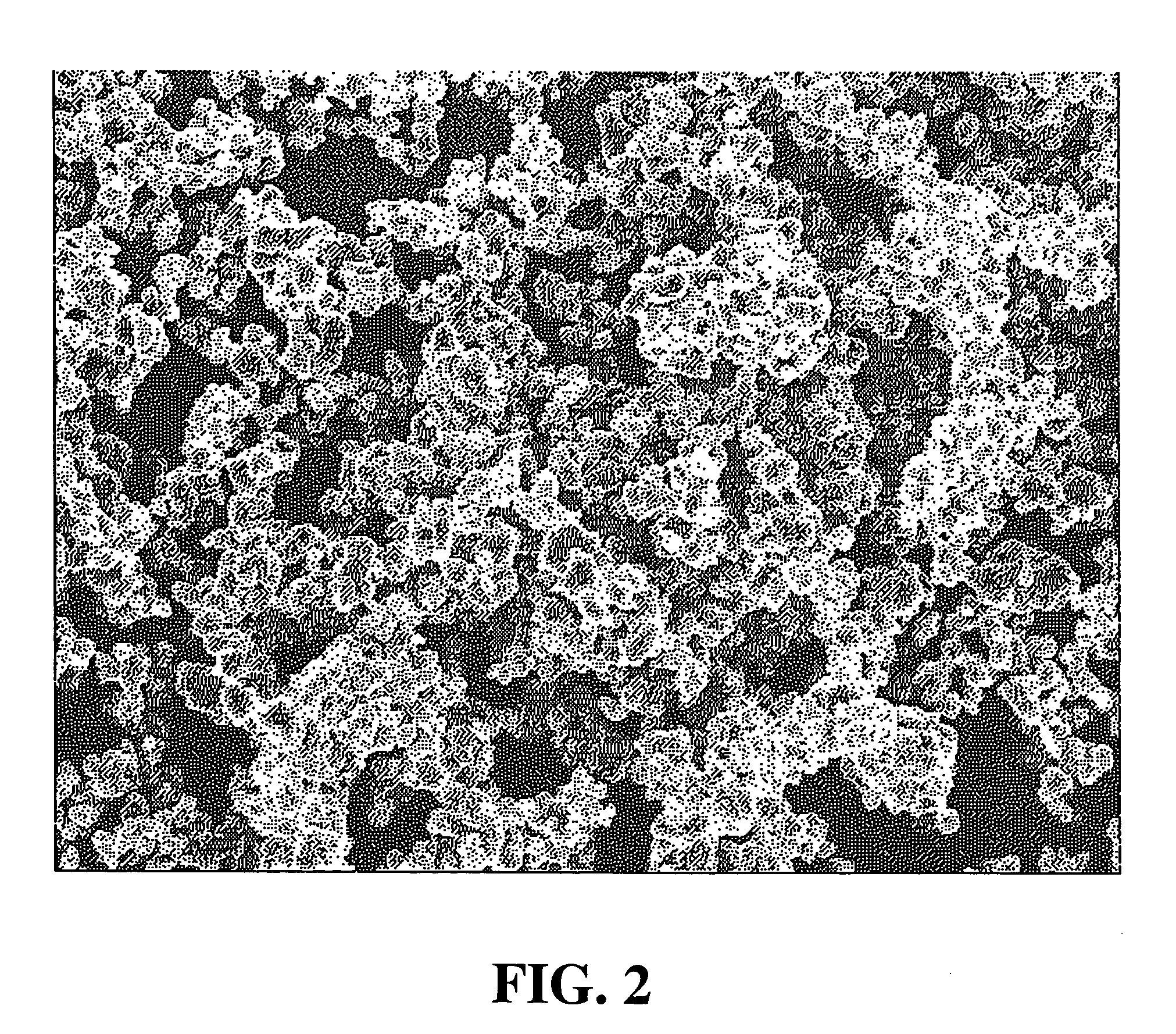

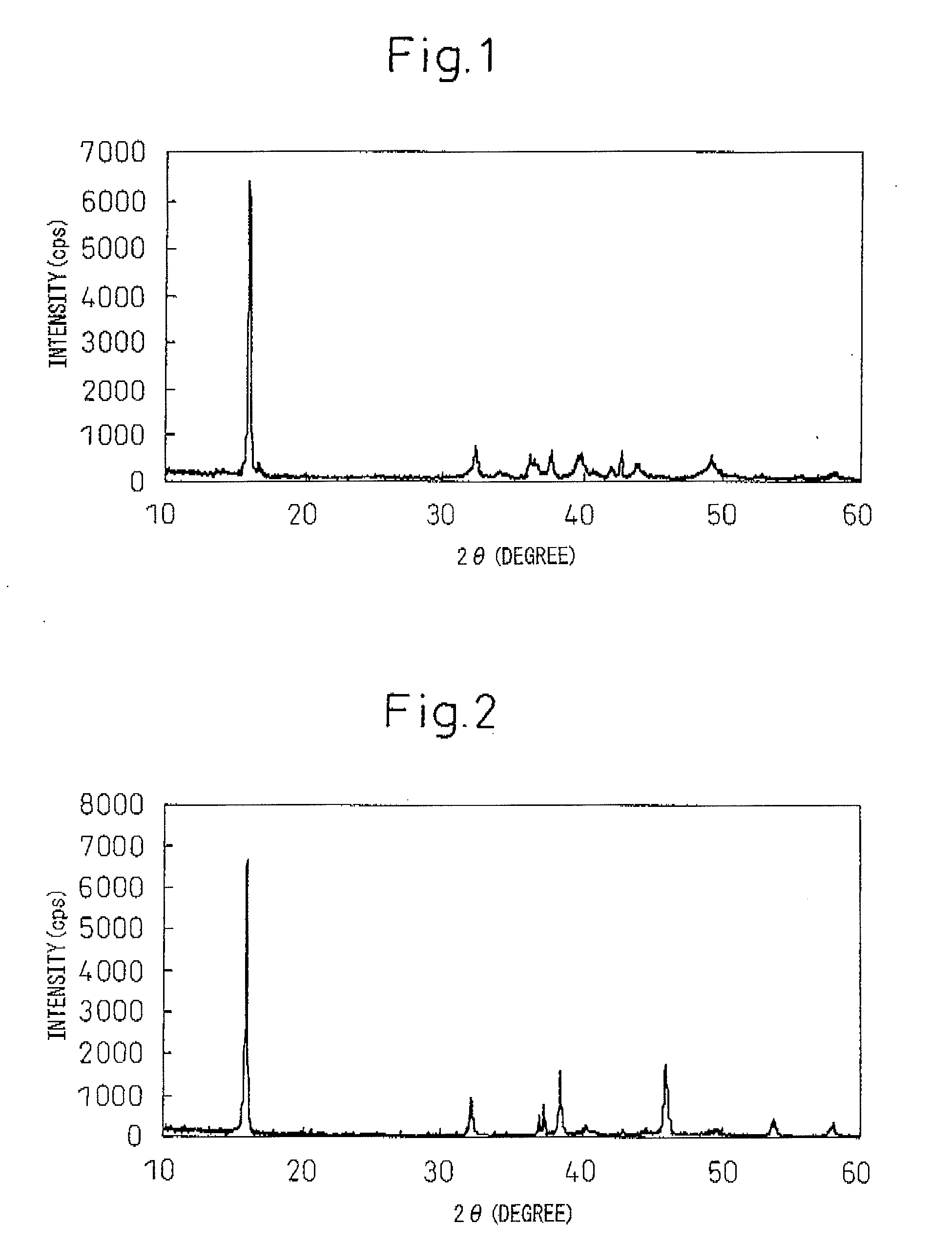

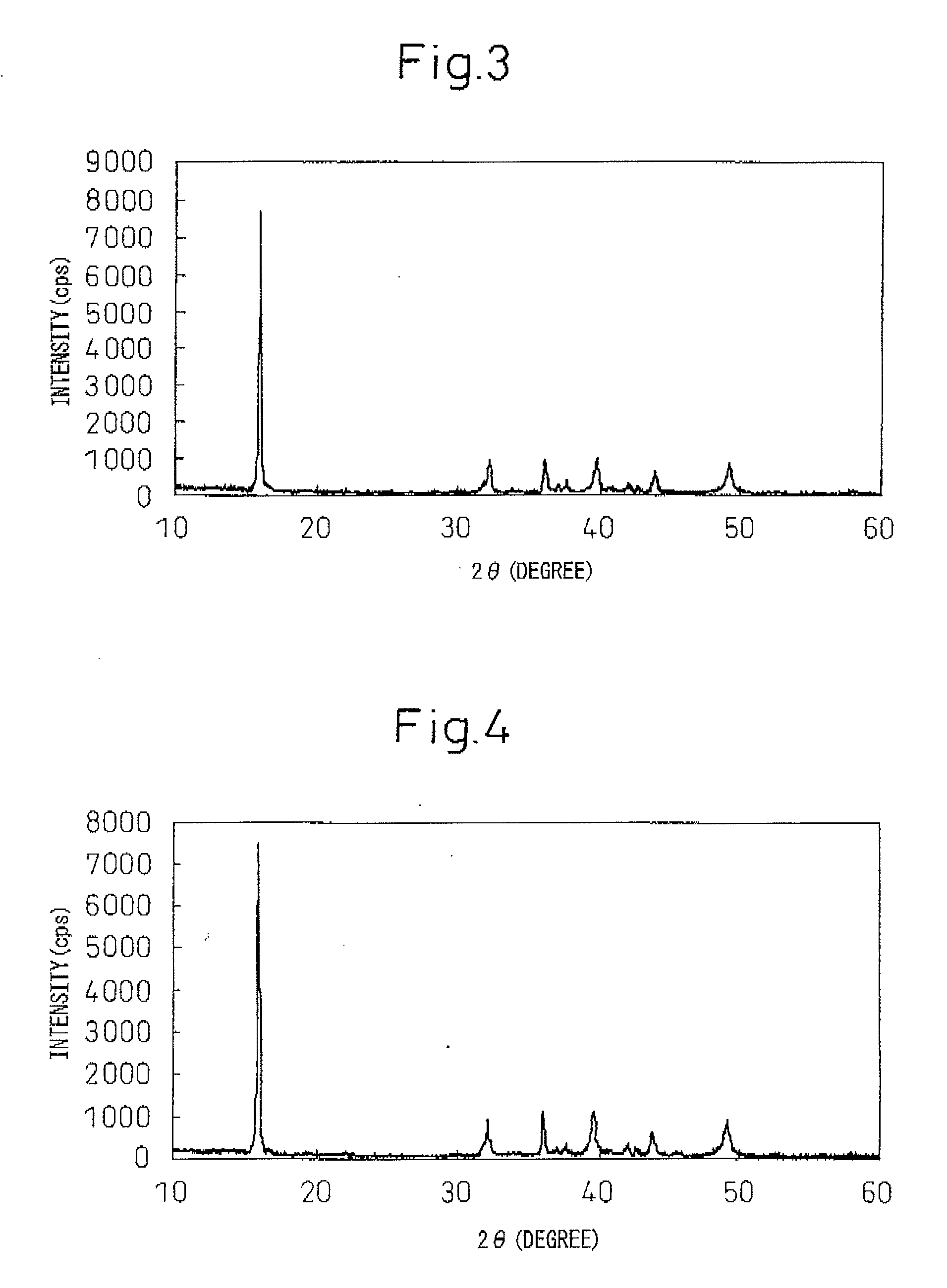

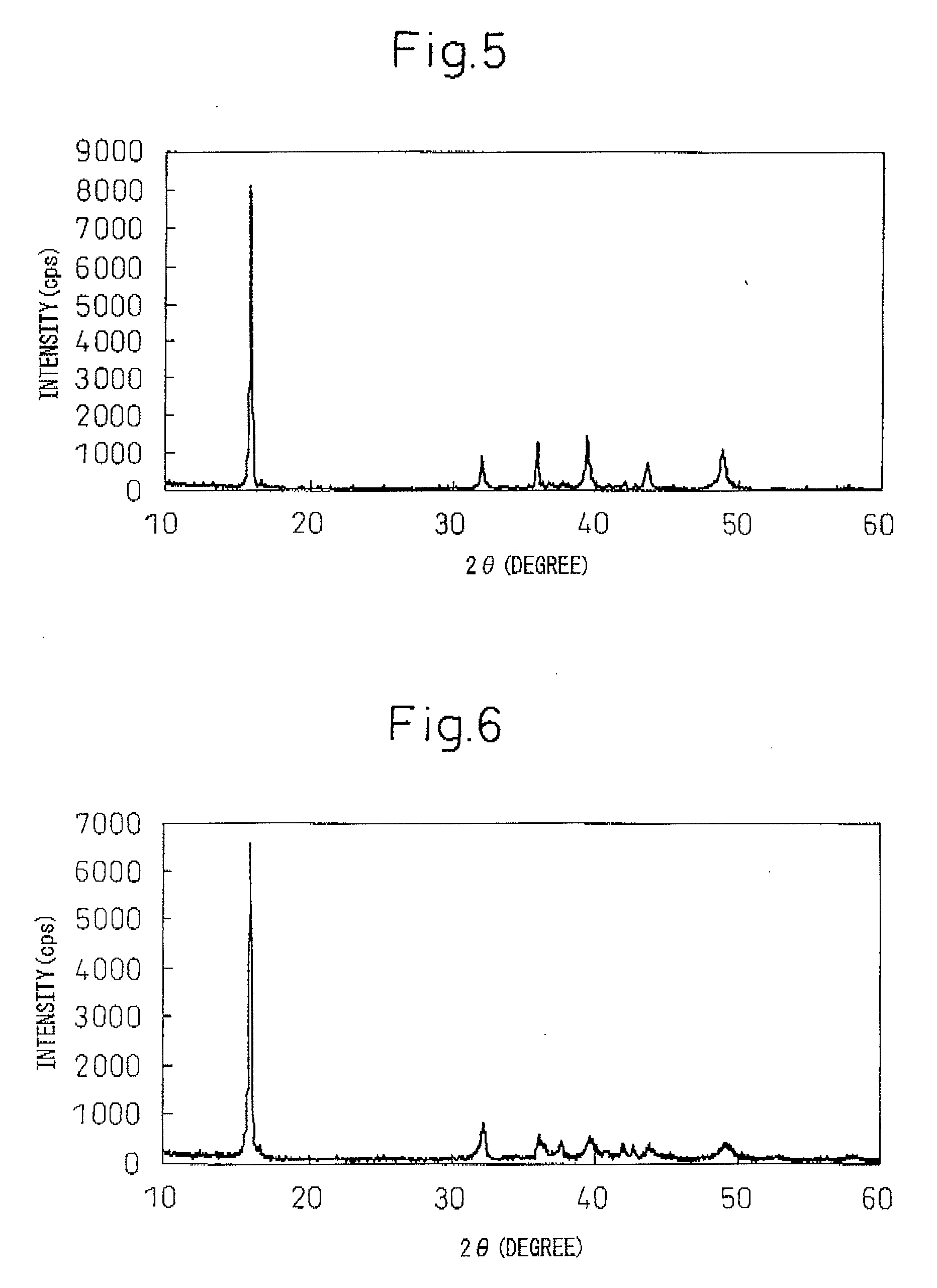

Carbon material for battery electrode and production method and use thereof

InactiveUS20070092428A1Less deformation/orientationLarge discharge capacityGraphiteSecondary cellsPolymer scienceSource material

The invention provides a carbon material for a battery electrode, which comprises a carbon powder material as a composite of carbonaceous particles and an a carbon material derived from an organic compound prepared by allowing the organic compound serving as a polymer source material to deposit onto and / or permeate into the carbonaceous particles to thereby polymerize the polymer material and then heating at 1,800 to 3,300° C., and which has an intensity ratio of 0.1 or more for peak intensity attributed to a (110) plane to peak intensity attributed to a (004) plane determined through X-ray diffraction spectroscopic analysis on a mixture of the carbon material and a binder resin when pressed at 103 kg / cm2 or higher. The carbon material which undergoes less deformation / orientation due to application of pressure, has high discharge capacity and small irreversible capacity and exhibiting excellent coulombic efficiency, cycle characteristics and leakage-current load characteristics.

Owner:SHOWA DENKO KK

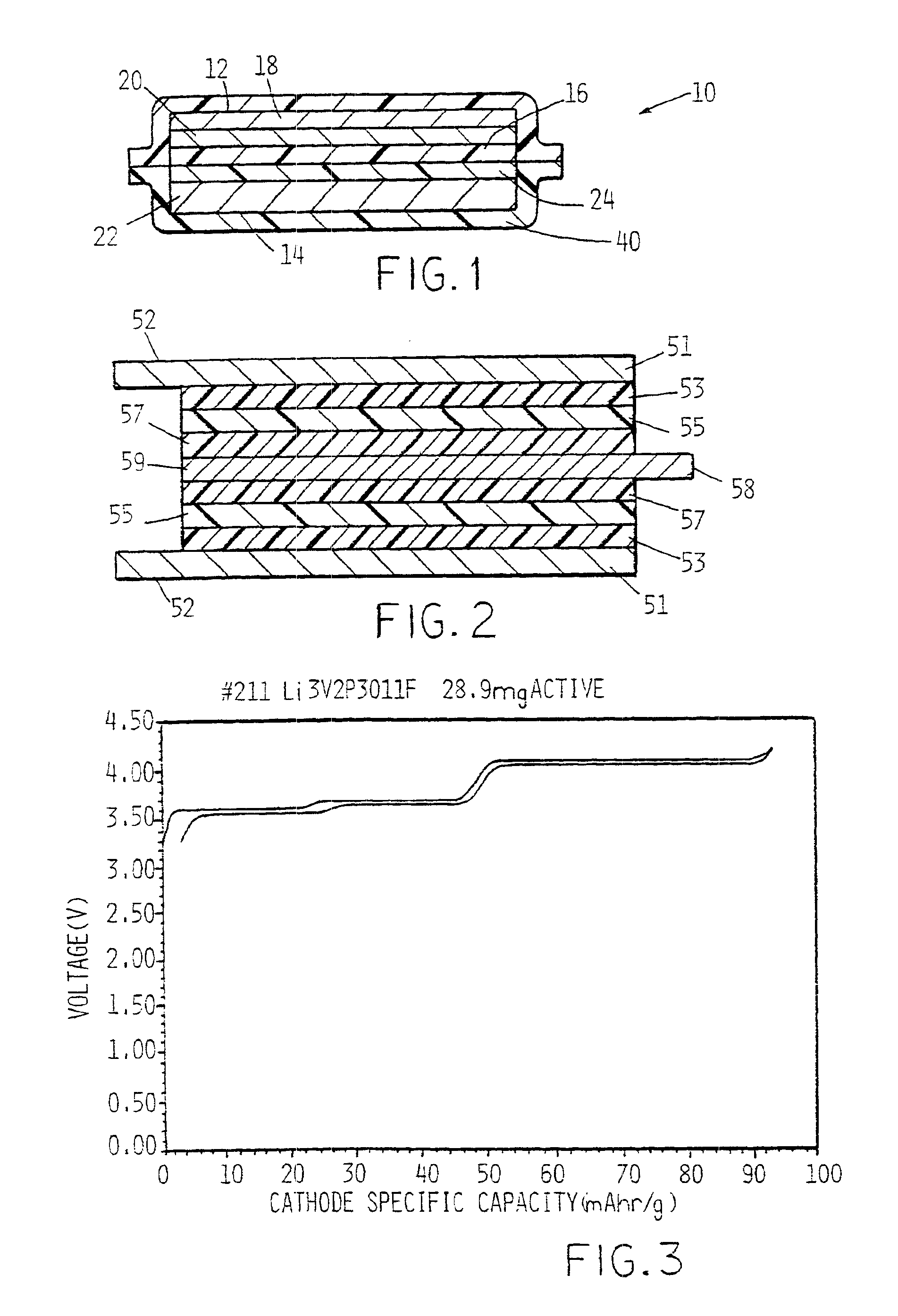

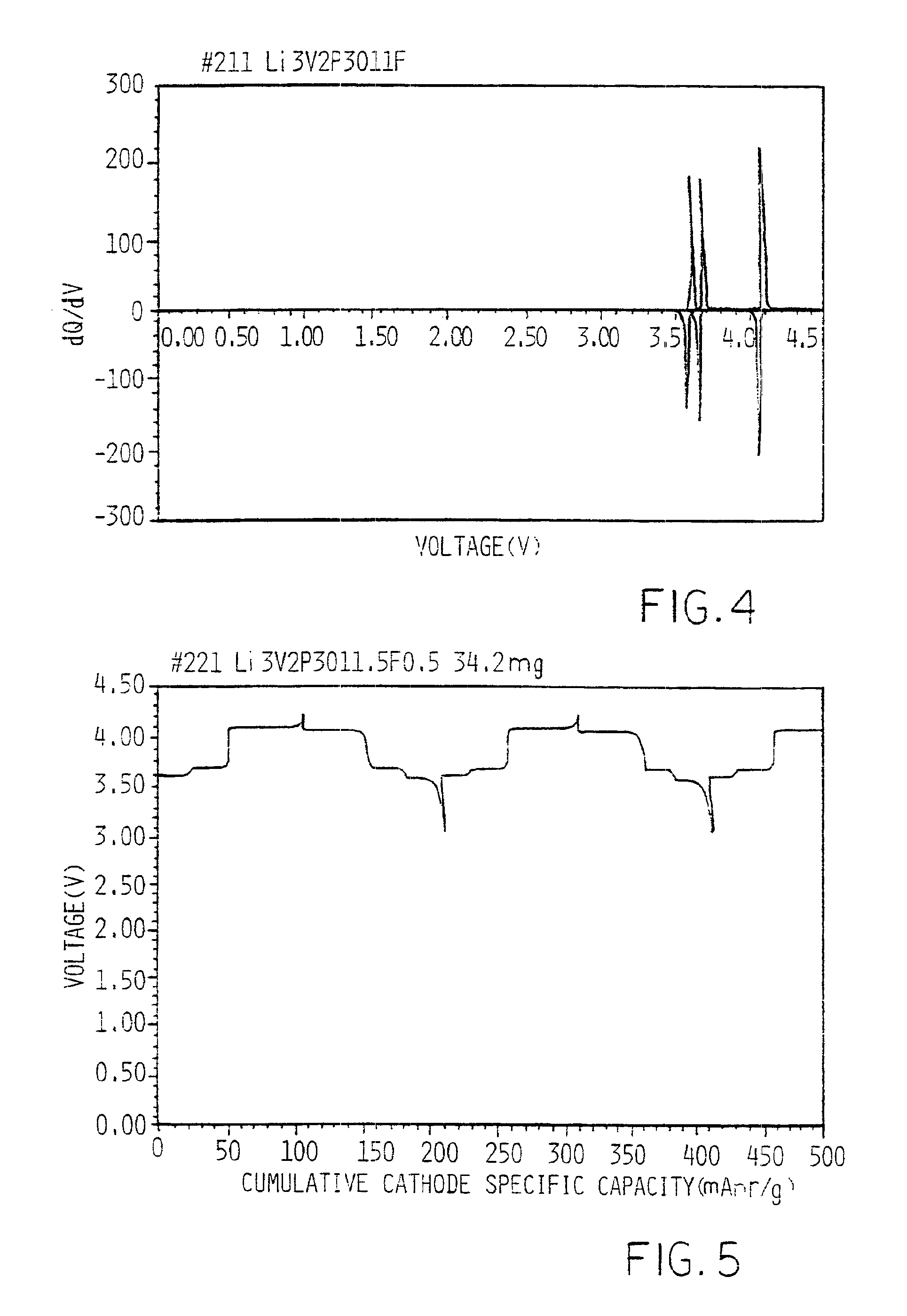

Lithium-containing phosphate active materials

InactiveUS6890686B1Simple processEasy to adaptFinal product manufactureSecondary cellsPhosphateElectrochemistry

The invention provides novel lithium-containing phosphate materials having a high proportion of lithium per formula unit of the material. Upon electrochemical interaction, such material deintercalates lithium ions, and is capable of reversibly cycling lithium ions. The invention provides a rechargeable lithium battery which comprises an electrode formed from the novel lithium-containing phosphates.

Owner:VALENCE TECH INC

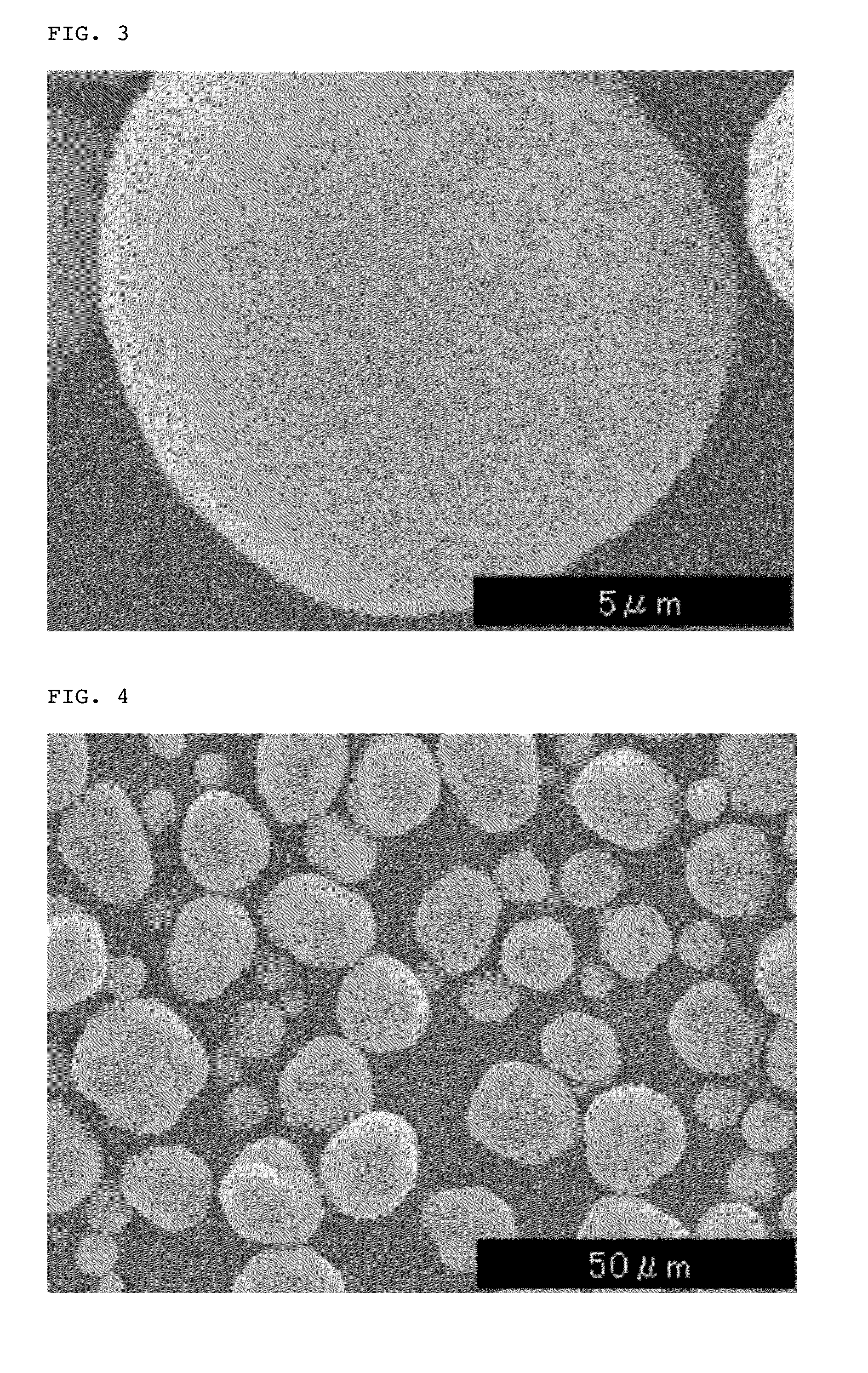

Cathode active material powder for lithium secondary battery

ActiveUS7429434B2Increase volume capacity densityImprove securityPositive electrodesCobalt compoundsAlkaline earth metalComposite oxide

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

Electrolyte, electrolyte solution for lithium-ion secondary battery comprising the electrolyte, and lithium-ion secondary battery using the electrolyte solution

ActiveUS20100003597A1Excellent cycle characteristicsImprove securityAlkaline accumulatorsElectrolytic capacitorsPhosphoniumLithium-ion battery

An object of the present invention is to provide an electrolyte solution for lithium-ion secondary batteries comprising a tetraalkylphosphonium salt which improves the cycle characteristics and safety of lithium-ion batteries, and to provide a lithium-ion secondary battery using the electrolyte solution. Disclosed is an electrolyte comprising a tetraalkylphosphonium salt represented by general formula (1)wherein R1 represents a linear, branched or alicyclic alkyl group having 2 to 6 carbon atoms and R2 represents a linear, branched or alicyclic alkyl group having 1 to 14 carbon atoms, provided that R1 and R2 are different from each other and the total number of carbon atoms in the phosphonium cation is 20 or less; and X represents an anion.

Owner:NIPPON CHECMICAL IND CO LTD

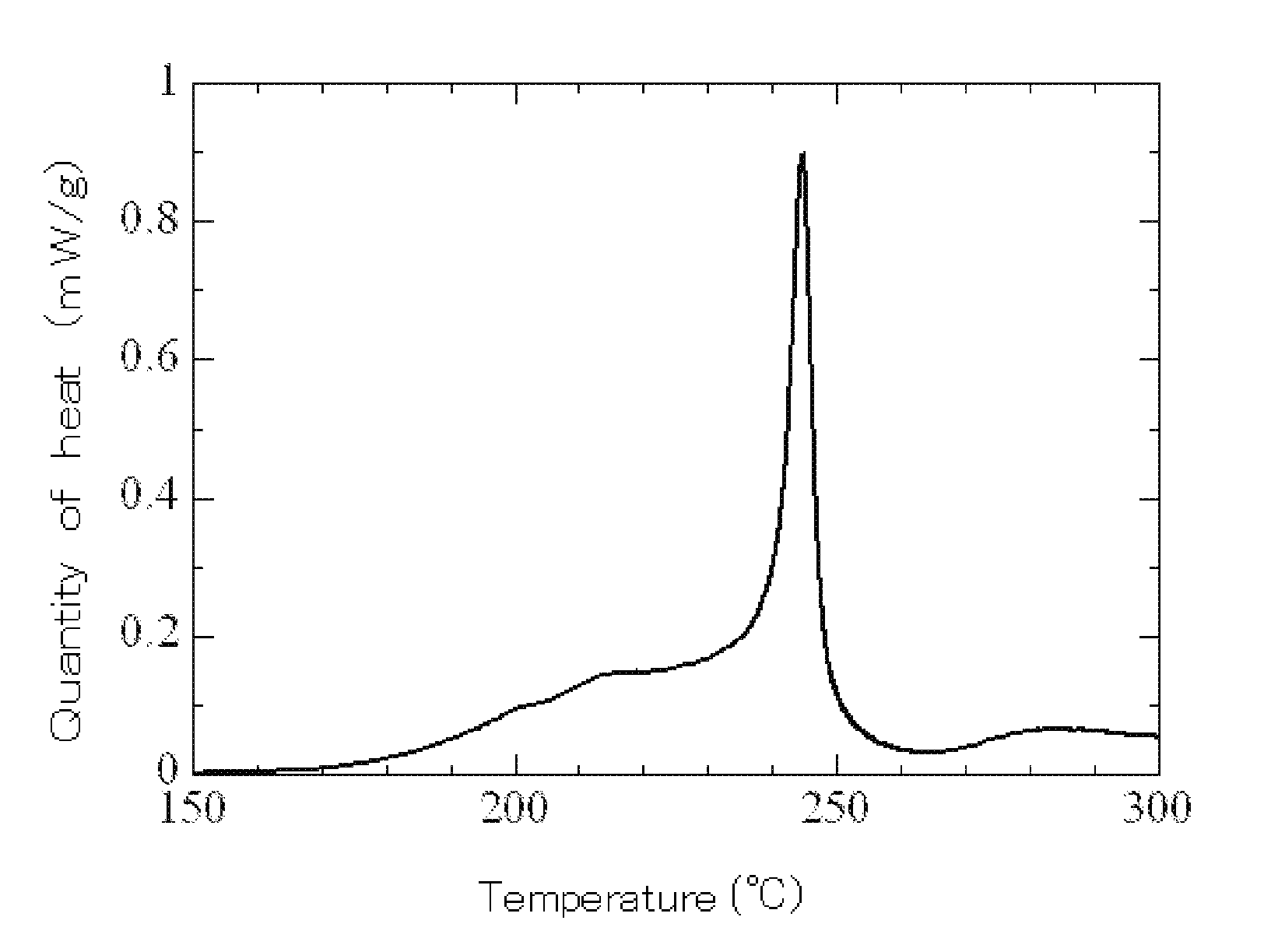

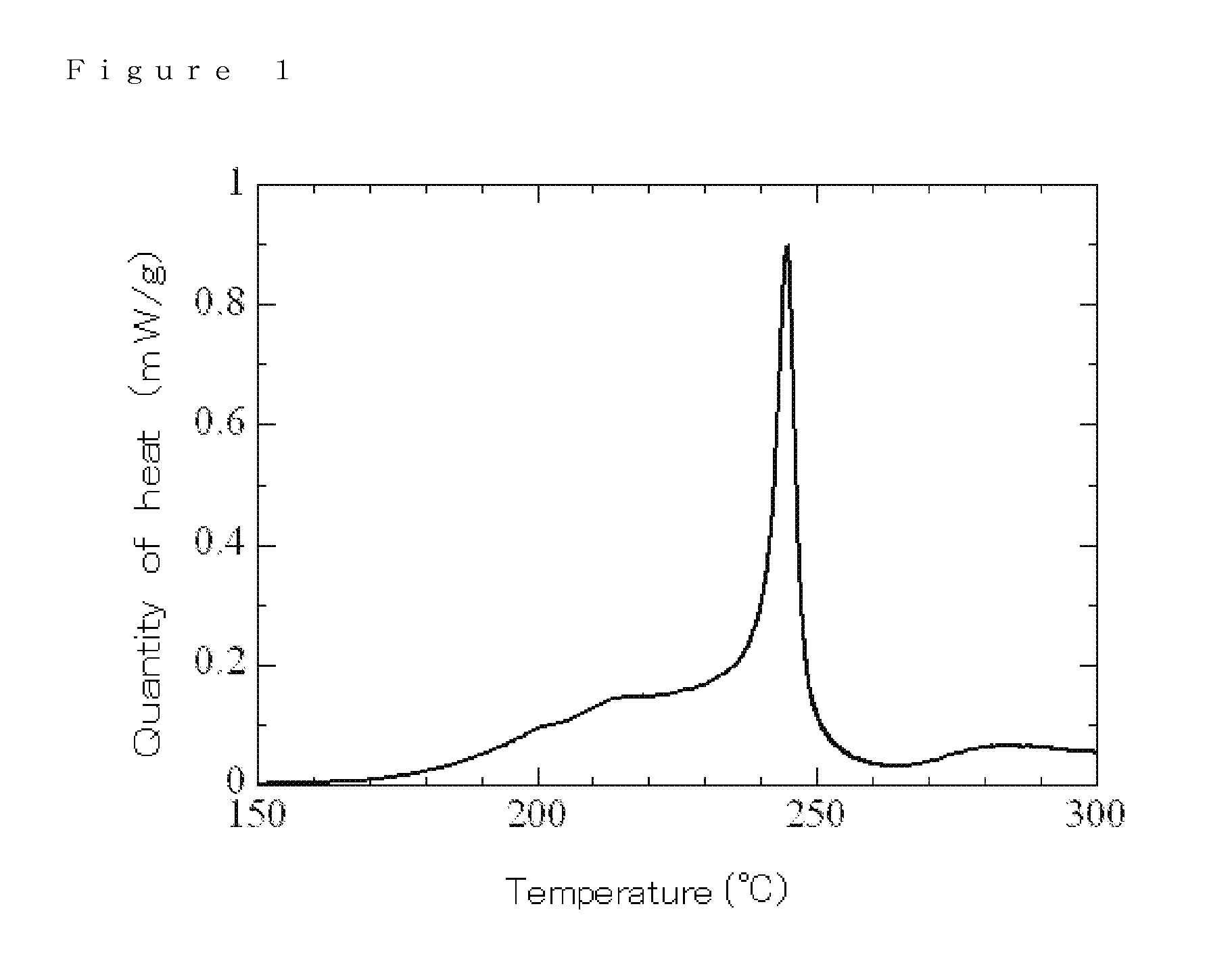

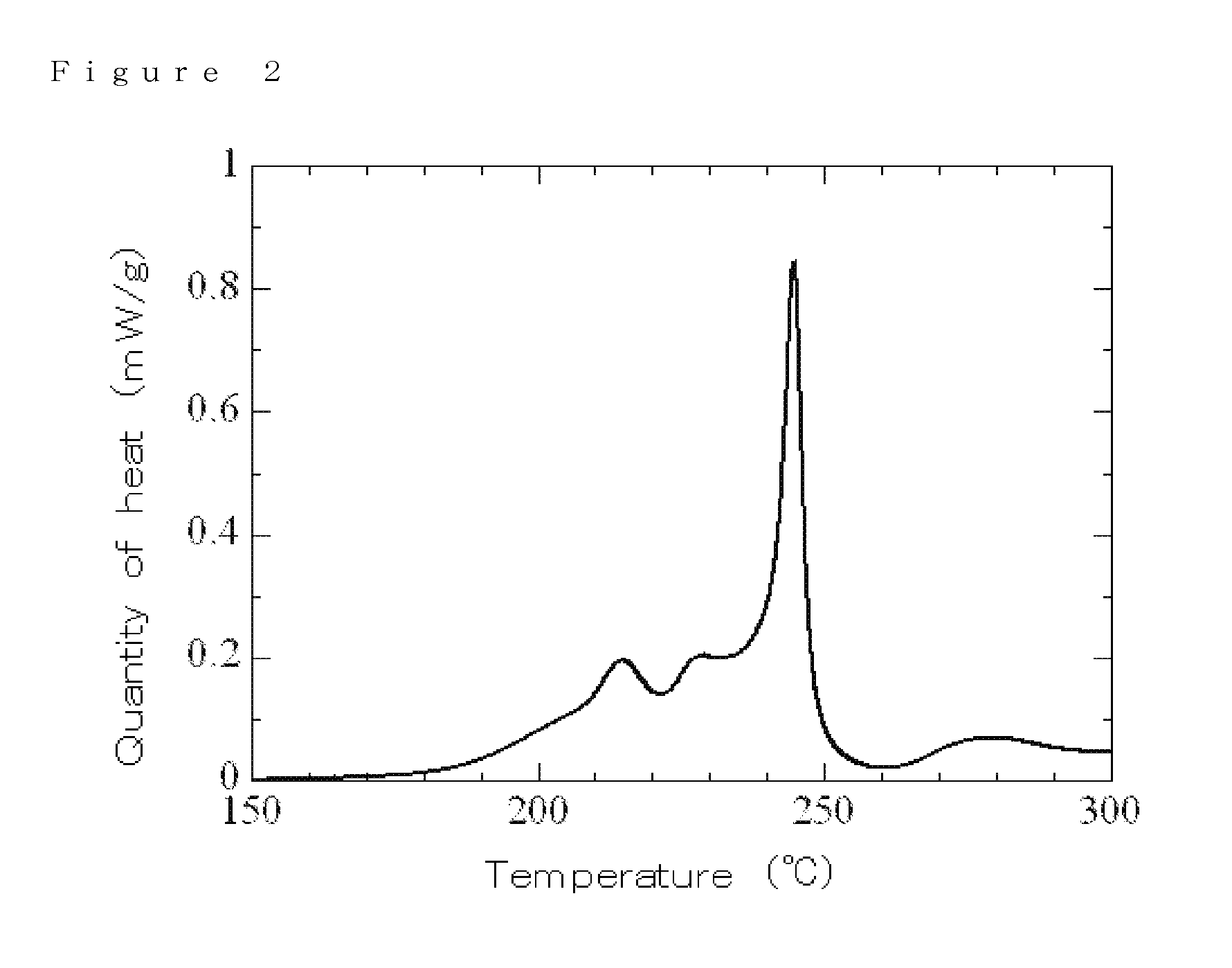

Lithium cobalt oxide, method for manufacturing the same, and nonaqueous electrolyte secondary battery

ActiveUS20050271576A1Increase the pressing densityIncrease electrode densitySecondary cellsActive material electrodesElectrolyteMaterials science

Lithium cobalt oxide, which can provide a nonaqueous electrolyte secondary battery having an excellent initial capacity and an excellent capacity retention, and a method for manufacturing the same are provided. The lithium cobalt oxide has a tap density of at least 1.7 g / cm3 and a pressed density of 3.5 to 4.0 g / cm3. A method for manufacturing the lithium cobalt oxide includes the step of selecting a lithium cobalt oxide (A) and a lithium cobalt oxide (B) so that a difference in the tap density between the lithium cobalt oxide (A) and the lithium cobalt oxide (B) is at least 0.2 g / cm3; and mixing the lithium cobalt oxide (A) and the lithium cobalt oxide (B).

Owner:NIPPON CHECMICAL IND CO LTD

Negative electrode material powder for lithium-ion secondary battery, negative electrode for lithium-ion secondary battery and negative electrode for capacitor using the same, and lithium-ion secondary battery and capacitor

InactiveUS20130149606A1Large discharge capacitySatisfactory cycle characteristicHybrid capacitor electrodesLiquid electrolytic capacitorsTarPeak value

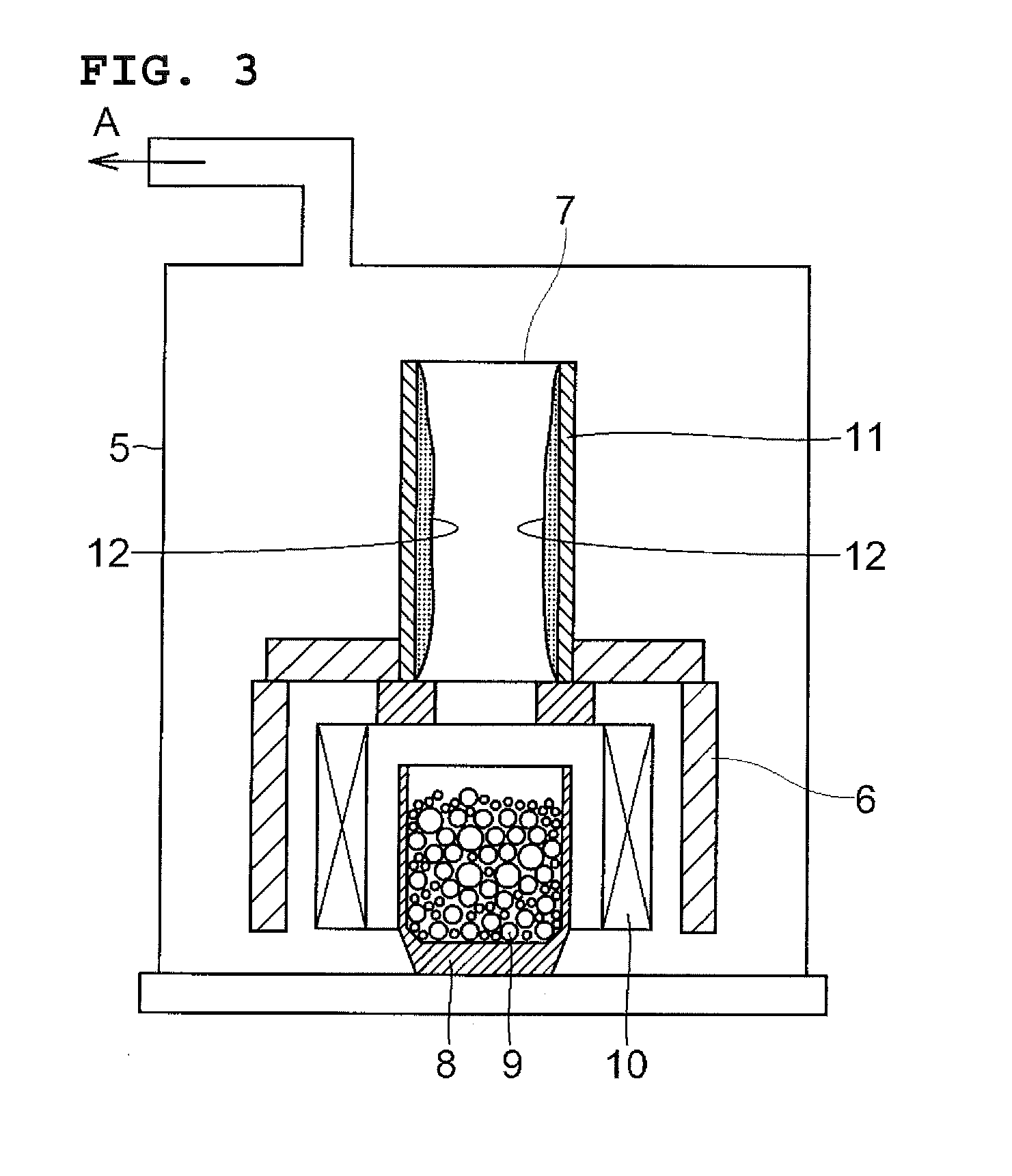

Provided is a negative-electrode material powder for a lithium-ion secondary battery including a conductive carbon film on the surface of a silicon oxide powder, in which the total content of tar components is not less than 1 ppm and not more than 4000 ppm, and in the Raman spectrum, peaks exist at 1350 cm−1 and 1580 cm−1, while the peak at 1580 cm−1 has a half-value width of not less than 50 cm−1 and not more than 100 cm−1. In the negative-electrode material powder, a specific surface area is preferably not less than 0.3 m2 / g and not more than 40 m2 / g, and the proportion of the conductive carbon film is preferably not less than 0.2 mass % and not more than 10 mass %. This makes it possible to provide a negative-electrode material powder which can be used to obtain a lithium-ion secondary battery with large discharge capacity and satisfactory cycle characteristics.

Owner:OSAKA TITANIUM TECHNOLOGIES

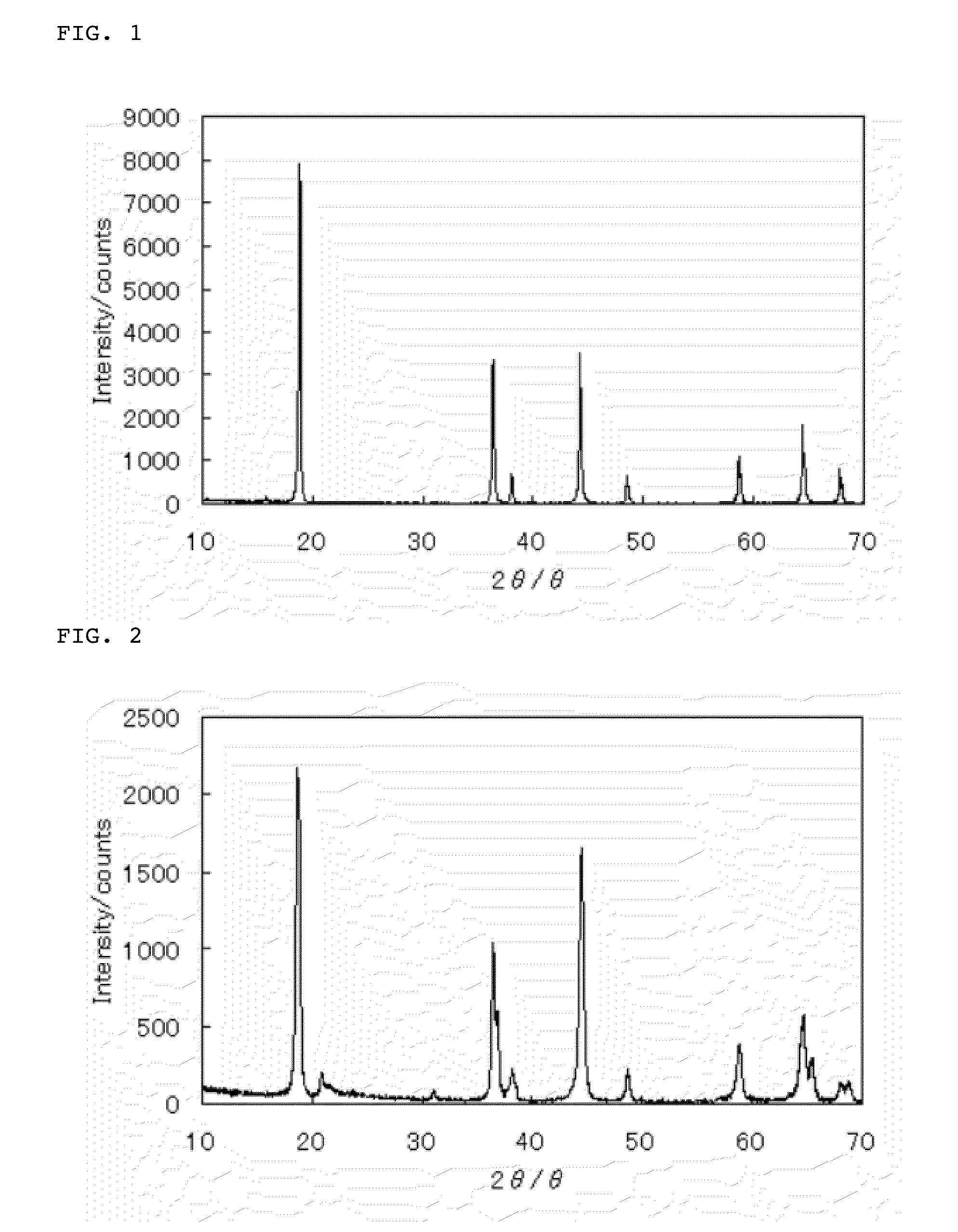

Graphite material for negative pole of lithium secondary battery, method of manufacturing the graphite material, and lithium secondary battery

InactiveUS7141229B2Large discharge capacityLittle loss in capacityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsVolumetric Mass DensityGraphite

This invention relates to a graphite material for negative electrode of lithium secondary battery. This graphite material is obtained by carbonizing the pulverized green coke to yield coke, adding one kind or more of boron or a compound thereof to the coke, graphitizing the resulting mixture and controlling the particle size of the product graphite. This graphite material for negative electrode is characterized by showing a tap density of 0.95 g / cm3 or more after tapping 20 times or 1.15 g / cm3 or more after tapping 300 times and a BET specific surface area of 1.5 m2 / g or less. A lithium secondary battery made by the use of this graphite material for negative electrode has a large discharge capacity and suffers little loss during charging and discharging.

Owner:NIPPON STEEL CHEMICAL CO LTD

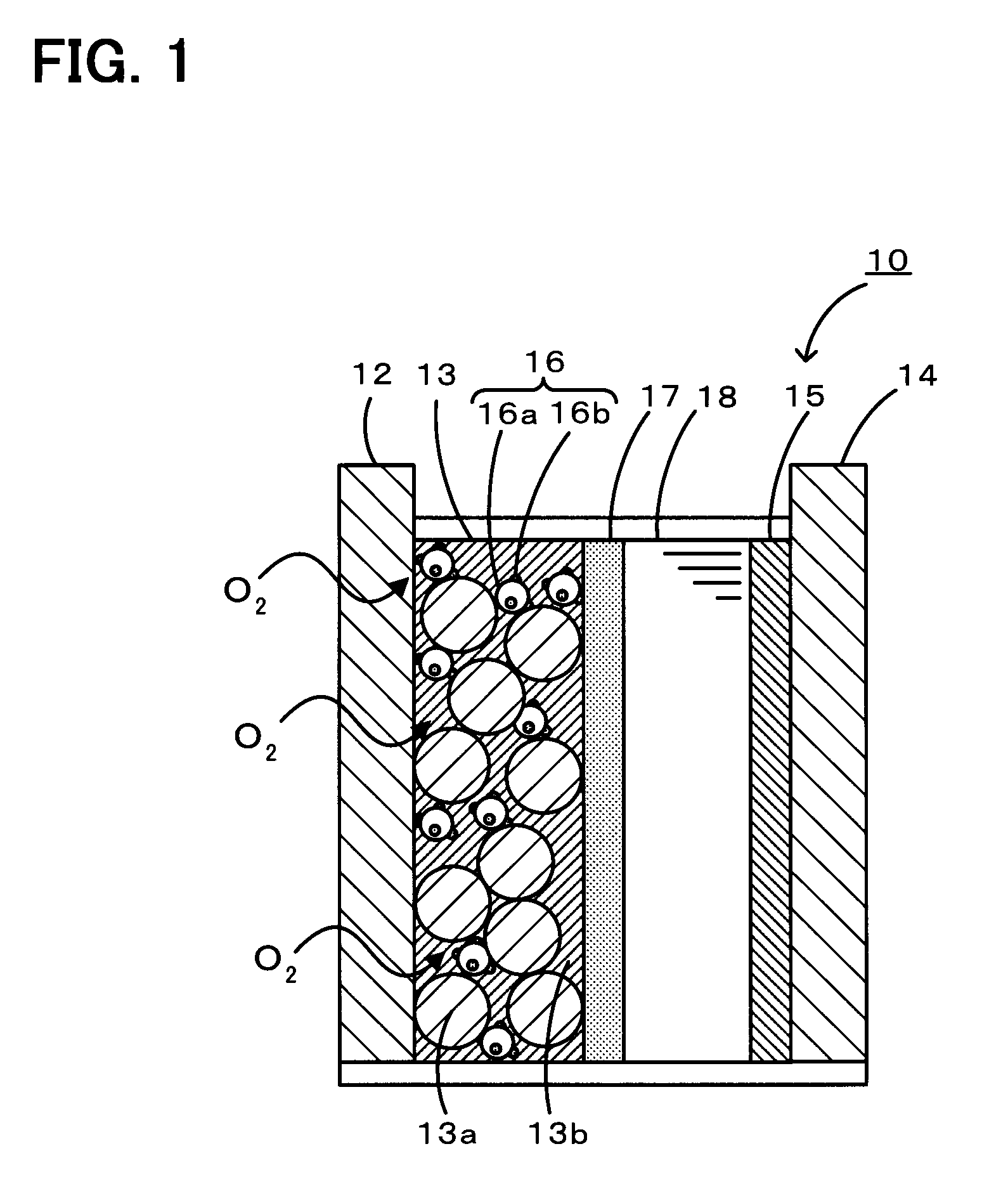

Lithium-air battery

InactiveUS7767345B2Large discharge capacityHigher cell potentialFuel and primary cellsFuel and secondary cellsLithium–air batteryCerium

A lithium-air battery includes a lithium negative electrode, a positive electrode including a catalyst containing gold, and a non-aqueous electrolyte interposed between the positive electrode and the lithium negative electrode. The catalyst includes gold supported on a cerium-containing oxide, such as a cerium-zirconium compound oxide or a cerium-aluminum compound oxide. The amount of catalyst of the positive electrode is in the range of 0.01 to 50 weight percent relative to the total weight of the positive electrode.

Owner:KK TOYOTA CHUO KENKYUSHO

Non-aqueous electrolyte secondary battery

InactiveUS20070054192A1More stabilityHeat stability is moreActive material electrodesSecondary cells testingMulti materialManganese

A positive electrode active material including lithium (Li), nickel (Ni), manganese (Mn) and a transition metal that can be in the hexavalent state is used. As the transition metal that can be in the hexavalent state, for example, one or both of tungsten (W) and molybdenum (Mo) can be used. As the positive electrode active material including a plurality of materials as mentioned above, LiNi0.5Mn0.5O2 can be used. As a negative electrode, a carbon material or a silicon material capable of storing and releasing lithium ions can be used.

Owner:SANYO ELECTRIC CO LTD

Negative-electrode material for nonaqueous - electrolyte secondary battery production process for the same, negative electrode for nonaqueous-electrolyte secondary battery, and nonaqueous-electrolyte secondary battery

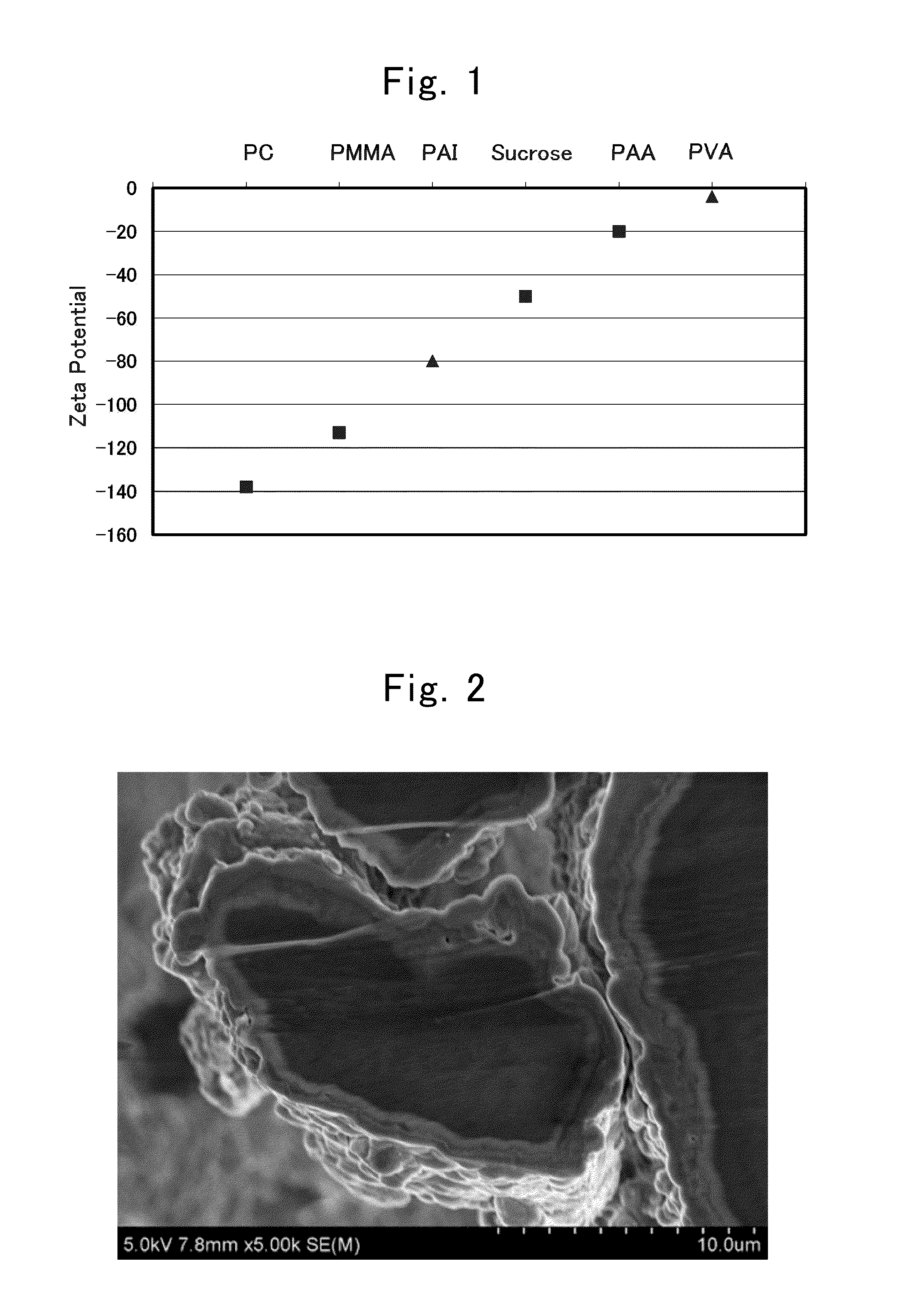

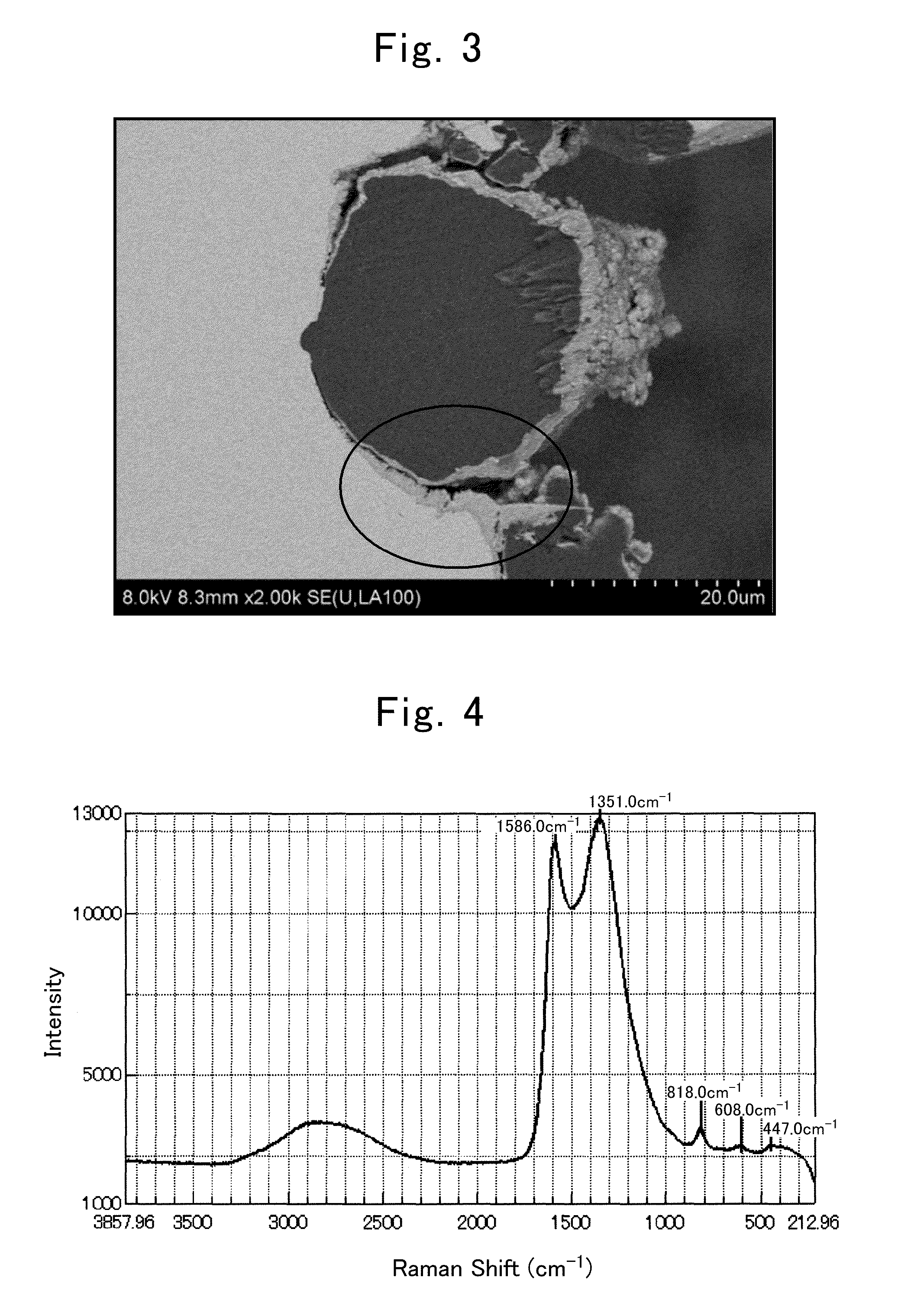

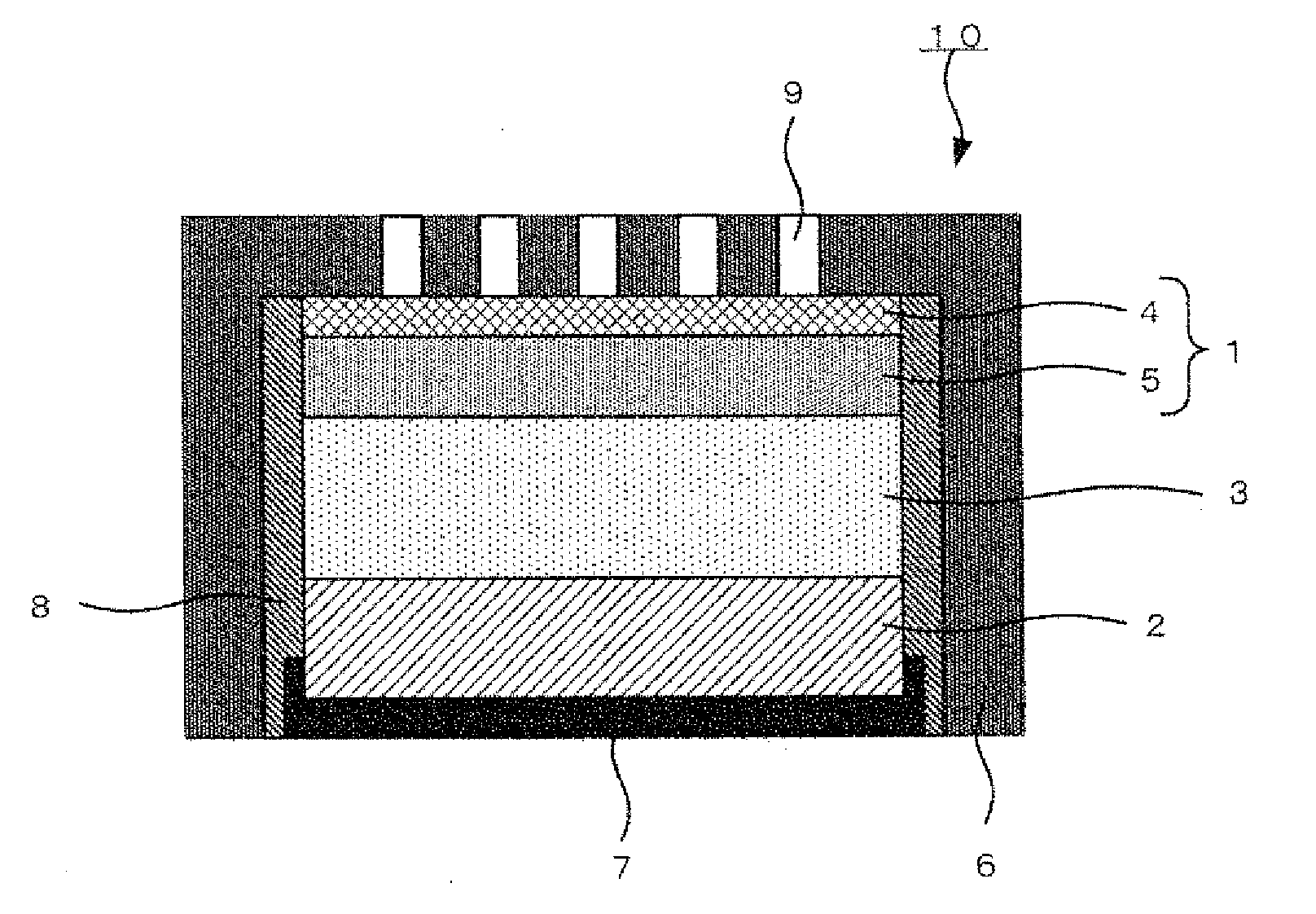

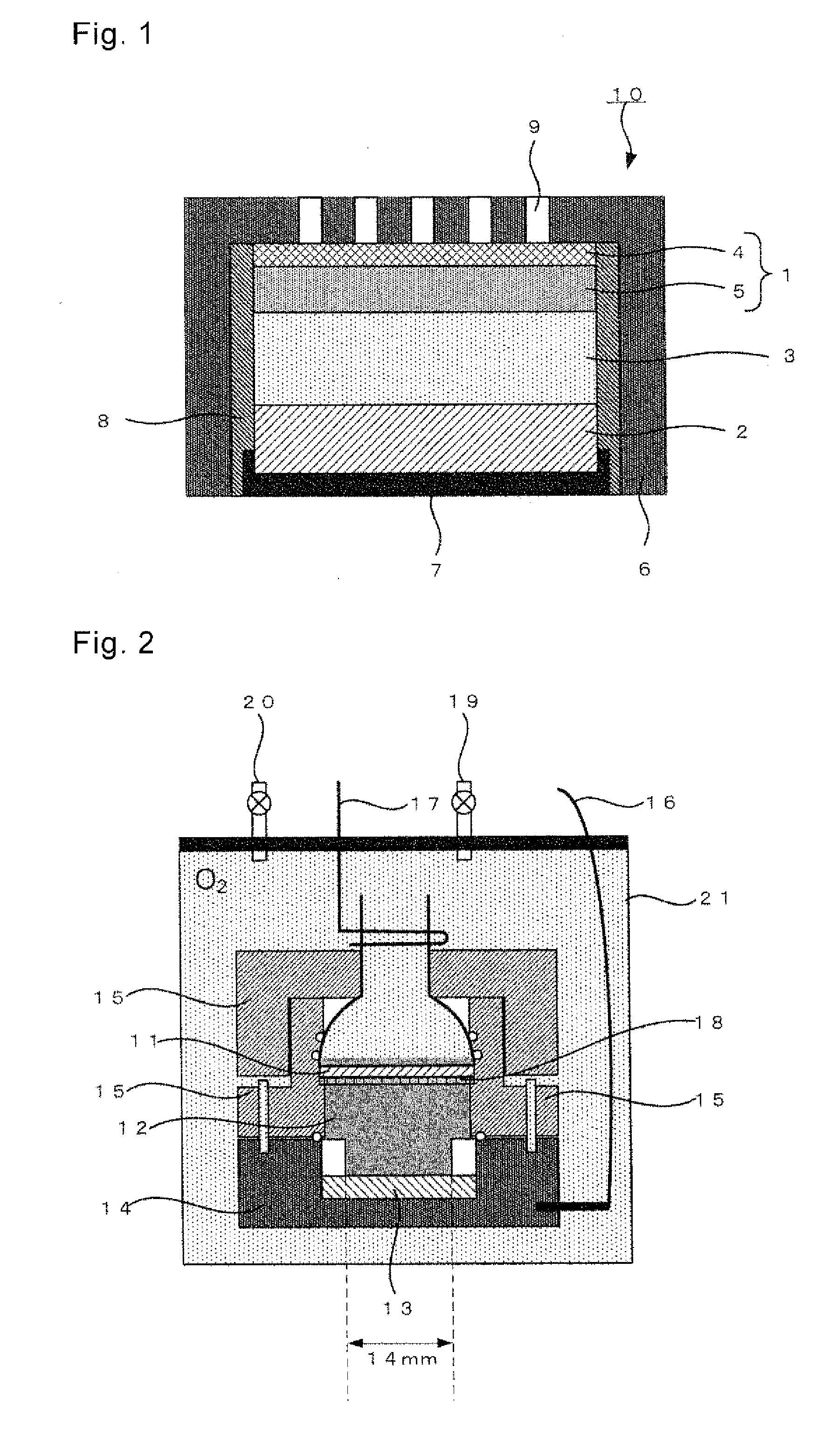

InactiveUS20150188127A1Reduce irreversible capacityLarge discharge capacityElectrode thermal treatmentNegative electrodesZeta potentialLithium

Providing a negative-electrode material for nonaqueous-electrolyte secondary battery, the negative-electrode material including lithium silicate particles coated by a carbonaceous substance, a production process for the same, a negative electrode for nonaqueous-electrolyte secondary battery, and a nonaqueous-electrolyte secondary battery.A negative-electrode material for nonaqueous-electrolyte secondary battery includes lithium silicate particles having a surface at least some of which is coated by a carbonaceous substance formed by heating a carbon-containing compound at a thermal decomposition temperature of the carbon-containing compound or more and 1,100° C. or less, the carbon-containing compound being a solid at ordinary temperature and exhibiting a zeta-potential absolute value being 60 or more against N-methyl-2-pyrrolidone (or NMP).

Owner:TOYOTA IND CORP

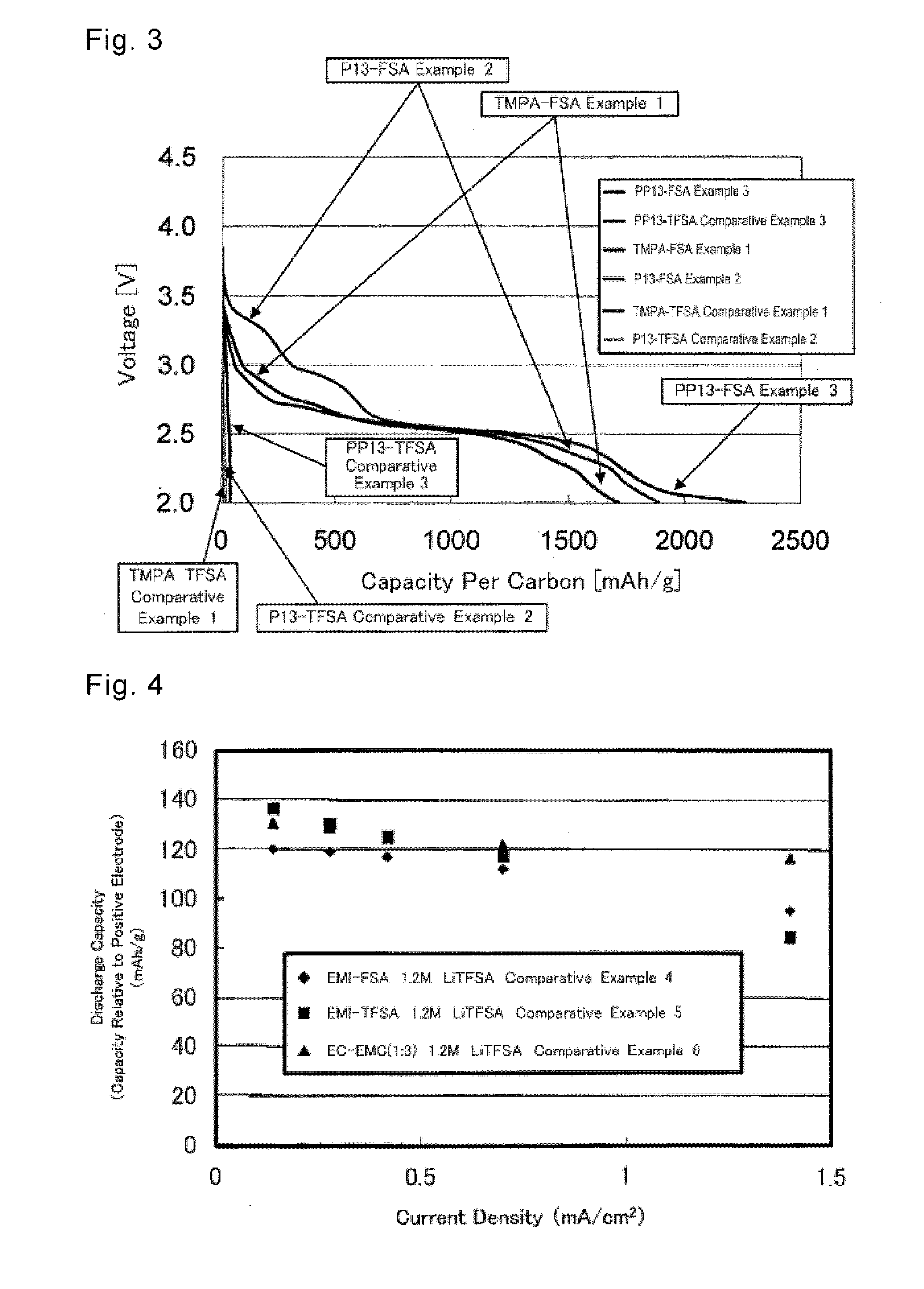

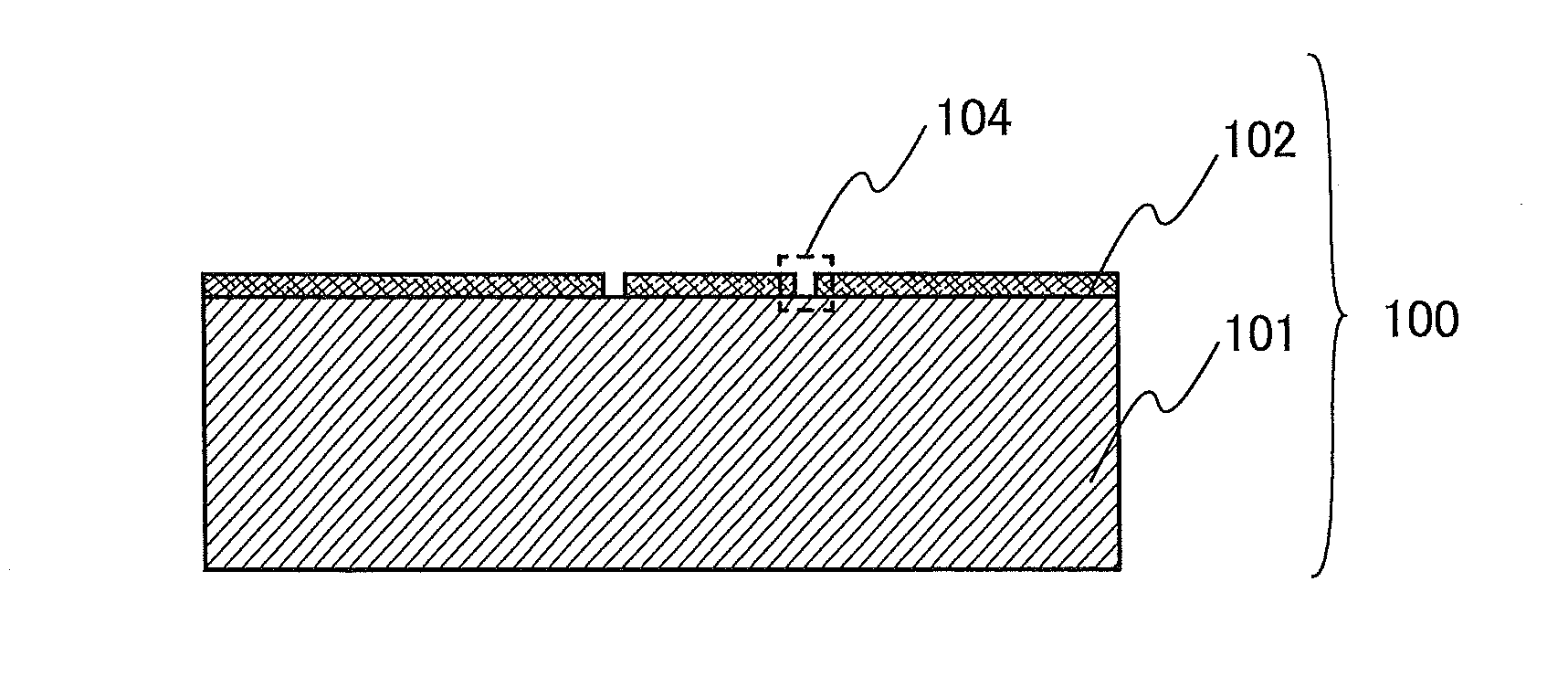

Non-aqueous electrolyte air battery

ActiveUS20140004429A1Large discharge capacityGood rate characteristicsFuel and secondary cellsFuel cellsSolventAir cathode

An object of the present invention is to provide a non-aqueous electrolyte air battery with large discharge capacity and excellent rate characteristics. Disclosed is a non-aqueous electrolyte air battery including an air cathode, an anode and a non-aqueous electrolyte present between the air cathode and anode, wherein the non-aqueous electrolyte includes an ionic liquid as the solvent, the ionic liquid including bis(fluorosulfonyl)amide as the anion portion.

Owner:TOYOTA JIDOSHA KK

Positive-Electrode Active Material and Power Storage Device

InactiveUS20150123050A1Improve conductivityOvercome lack of conductivityMaterial nanotechnologyNon-metal conductorsElectric forceLithium metal

Owner:SEMICON ENERGY LAB CO LTD

Negative electrode material for lithium-ion battery, and use therefor

ActiveUS20170040610A1Low initial irreversible capacityLarge emissionsNegative electrodesSecondary cellsSilicon oxideGraphitic carbon

A negative electrode material for a lithium ion battery containing a composite material, the composite material including silicon-containing particles, graphitic carbon material particles, and a carbonaceous carbon material, in which the composite material has a ratio (A / B) of an area (A) of a peak near 100 eV derived from metal Si to an area (B) of a peak near 103 eV derived from silicon oxide, as measured by XPS, of not less than 0.10 and not more than 2.30. Also disclosed is a paste including the negative electrode material, as well as a negative electrode for a lithium ion battery including a formed body of the paste and a lithium ion battery including the negative electrode.

Owner:UMICORE AG & CO KG

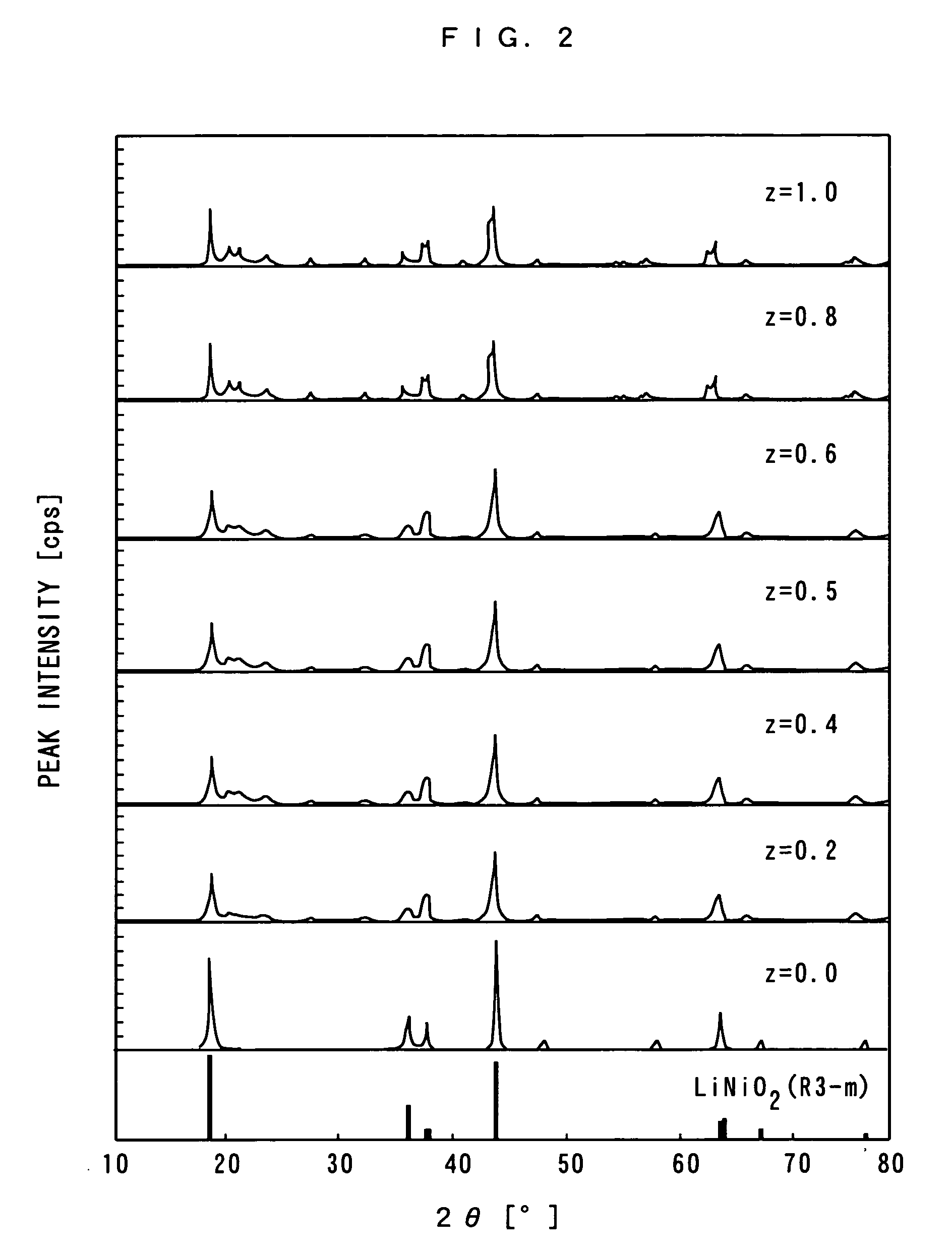

Mixed metal oxide and sodium secondary battery

ActiveUS20110003192A1Reduce amountLarge discharge capacityCell electrodesSecondary cellsLithiumMixed metal

The present invention provides a sodium secondary battery capable of reducing the amount used of a scarce metal element such as lithium and cobalt and moreover, ensuring a larger discharge capacity after repeating charge / discharge as compared with conventional techniques, and a mixed metal oxide usable as the positive electrode active material therefor. The mixed metal oxide of the present invention comprises Na, Mn and M1 wherein M1 is Fe or Ni, with a Na:Mn:M1 molar ratio being a:(1-b):b wherein a is a value falling within the range of more than 0.5 and less than 1, and b is a value falling within the range of from 0.001 to 0.5. Another mixed metal oxide of the present invention is a mixed metal oxide represented by the following formula (1): NaaMn1-bM1bO2 (1) wherein M1, a and b each have the same meaning as above. The positive electrode active material for sodium secondary batteries of the present invention comprises the mixed metal oxide above.

Owner:SUMITOMO CHEM CO LTD

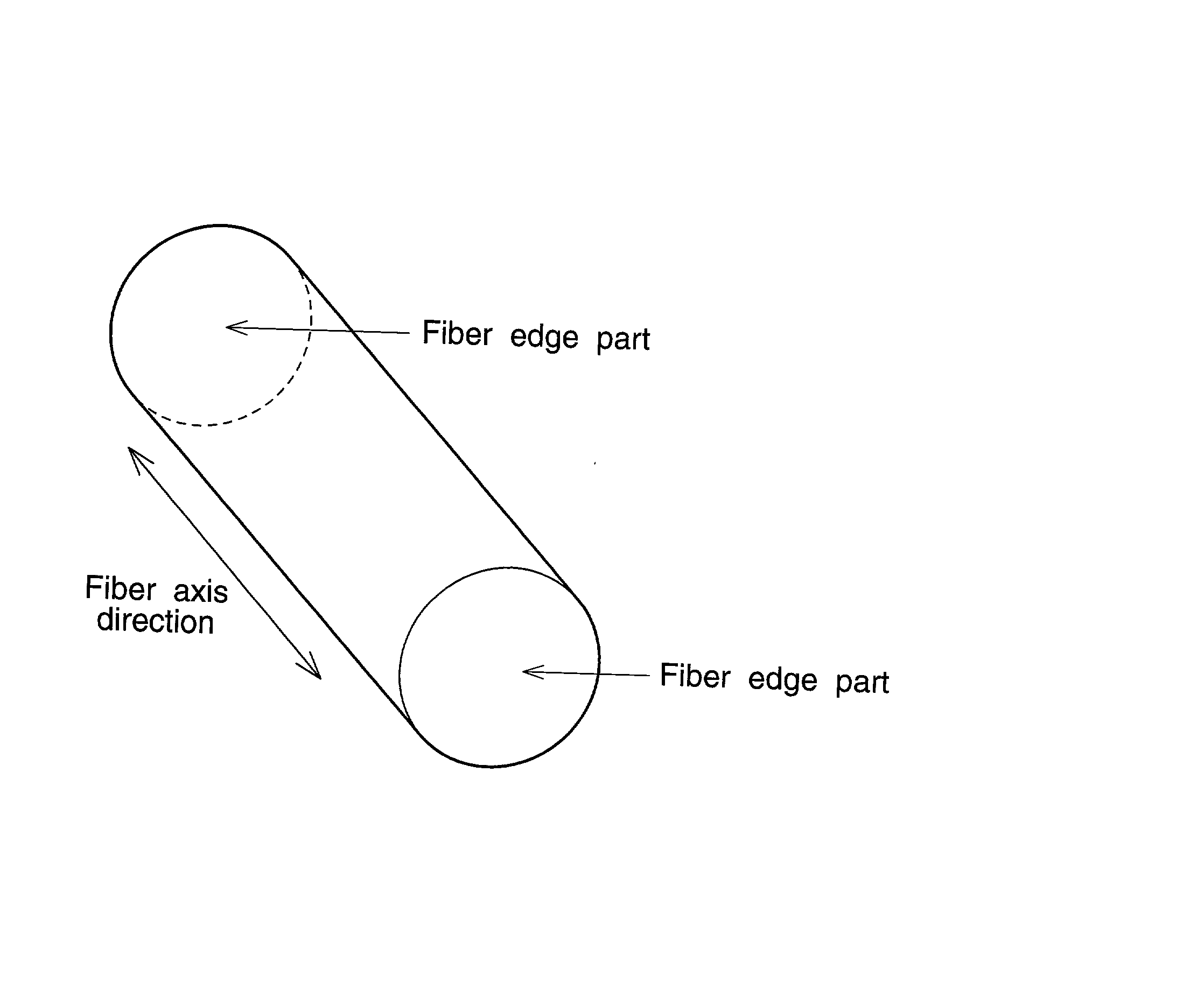

Graphite material for negative electrode of lithium ion secondary battery and process for producing the same

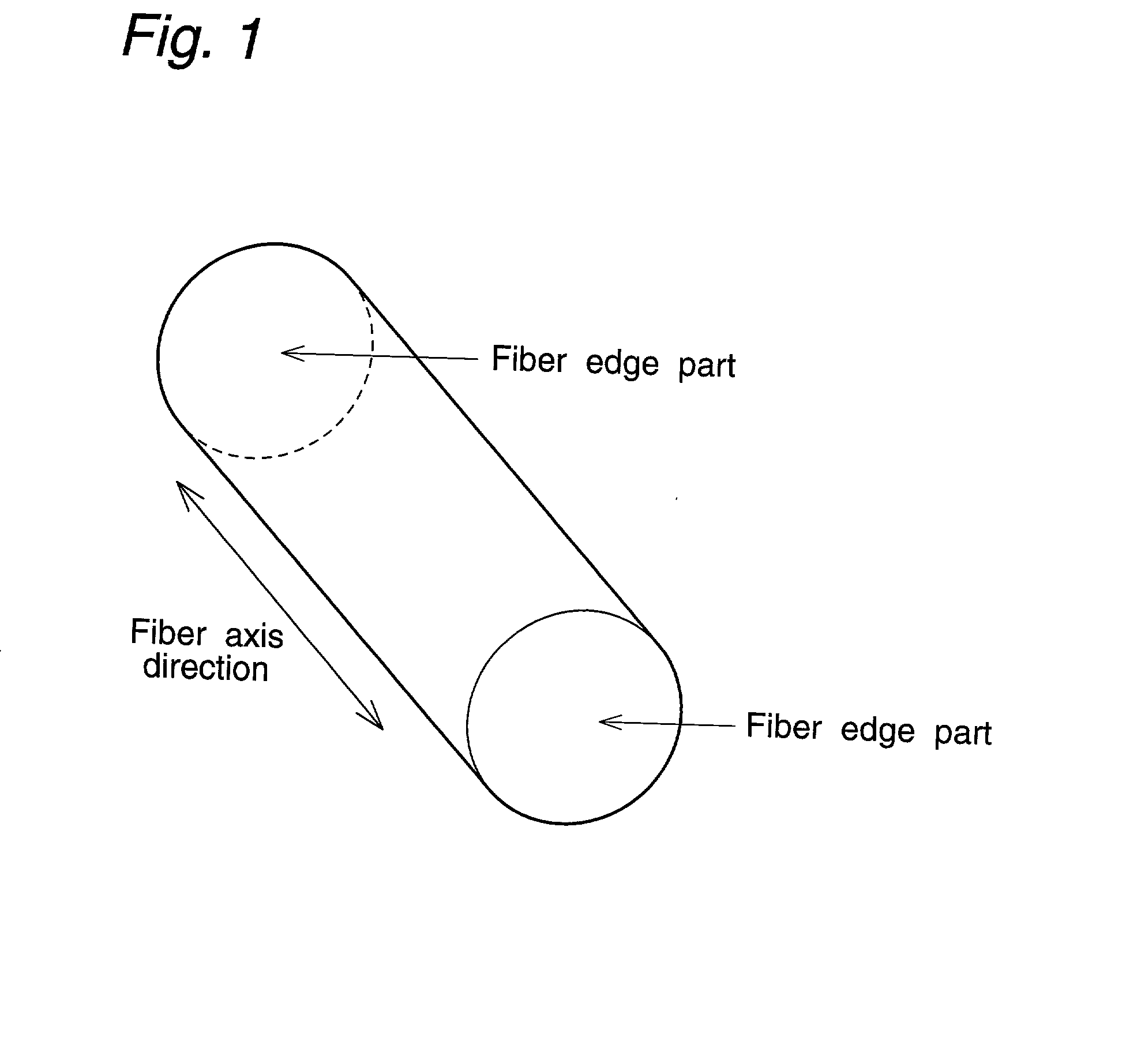

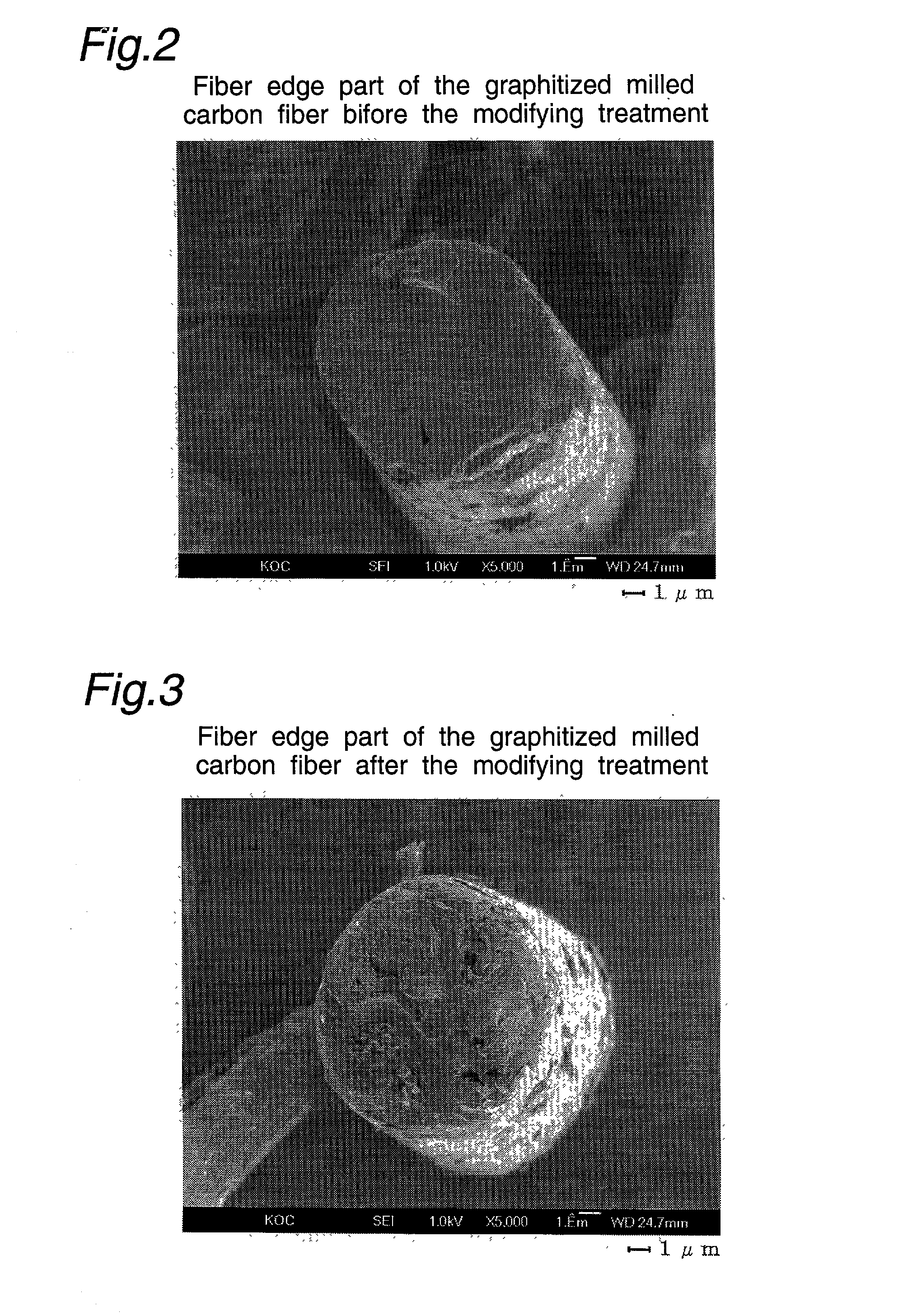

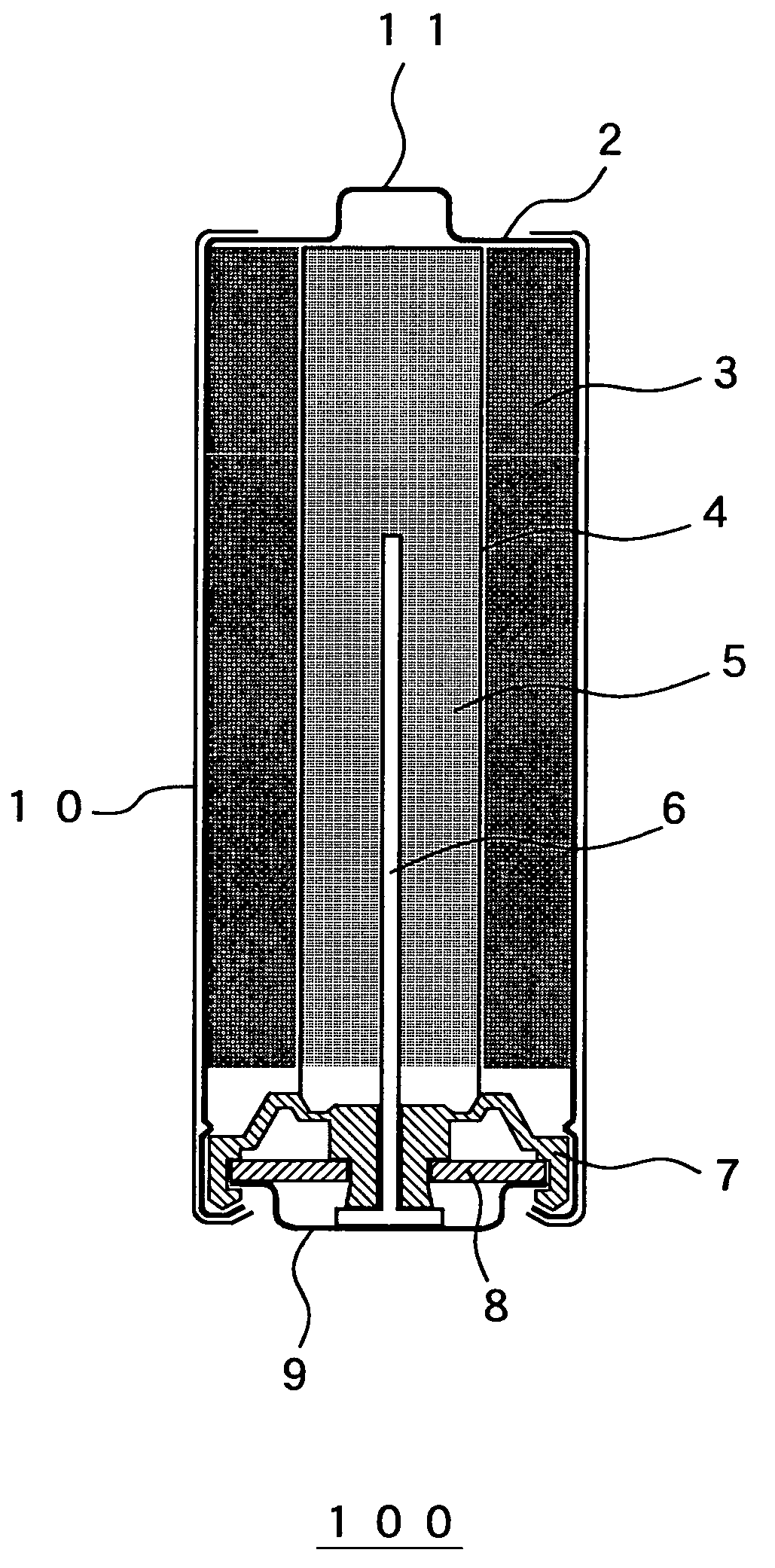

InactiveUS20020160266A1Large discharge capacityHigh charge-discharge efficiencyGraphiteSecondary cellsLithiumFiber

According to the present invention, milled carbon fiber is mixed with a boron compound and graphitized in the presence of nitrogen, and thereafter subjected to modifying treatment by applying impact selectively to fiber edge parts of the carbon fiber. The present invention can provide a graphite material produced in such a way that the milled carbon fiber is highly graphitized and the fiber edge parts of the graphitized milled carbon fiber is subjected to a modifying treatment in the above procedure. The graphite material is suitable for a negative electrode of a lithium secondary battery capable of facilitating entering and leaving (doping and undoping) of lithium ions, having large discharge capacity and high charge / discharge efficiency and excellent charge / discharge cyclability. The present invention also provides a process for producing such graphite materials.

Owner:PETOCA MATERIALS

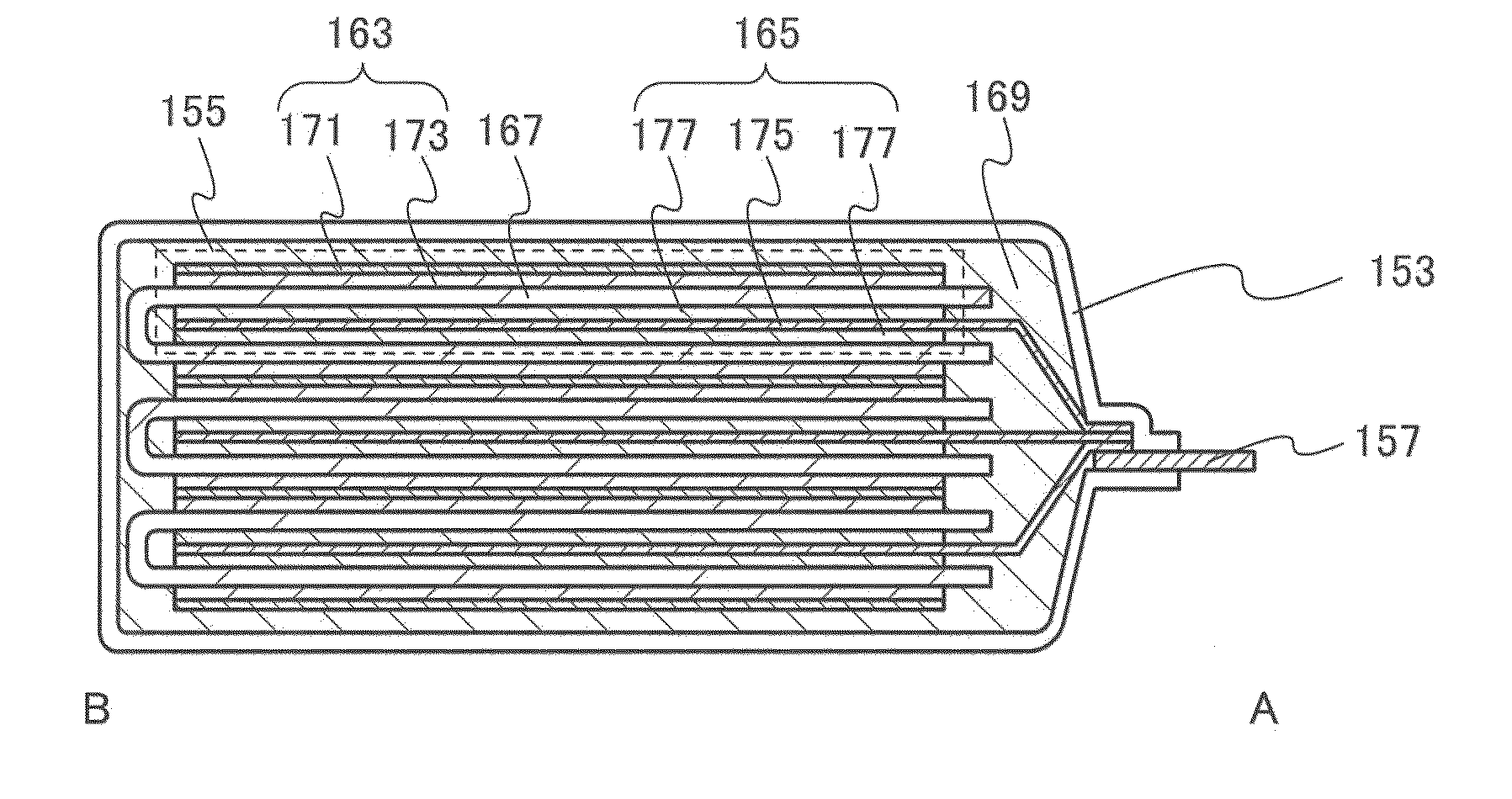

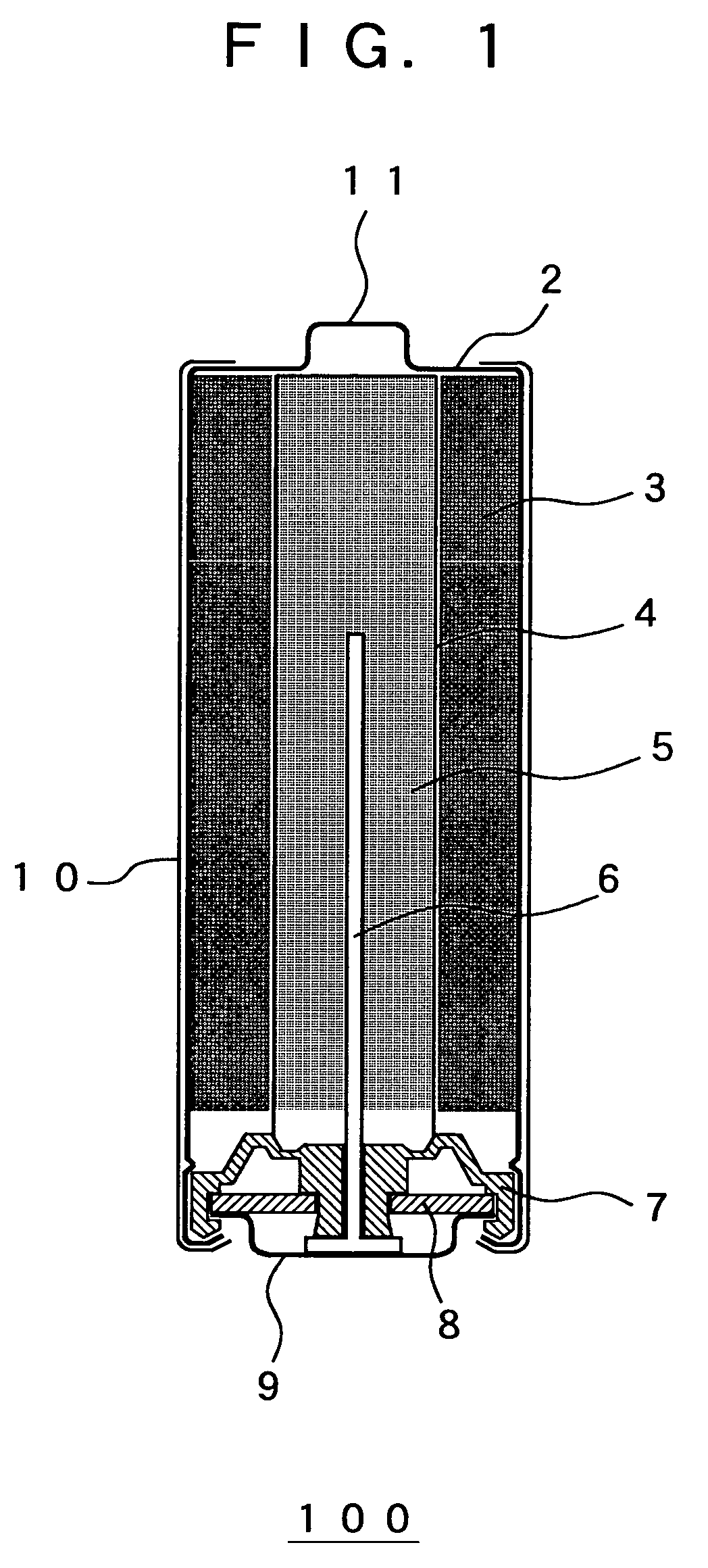

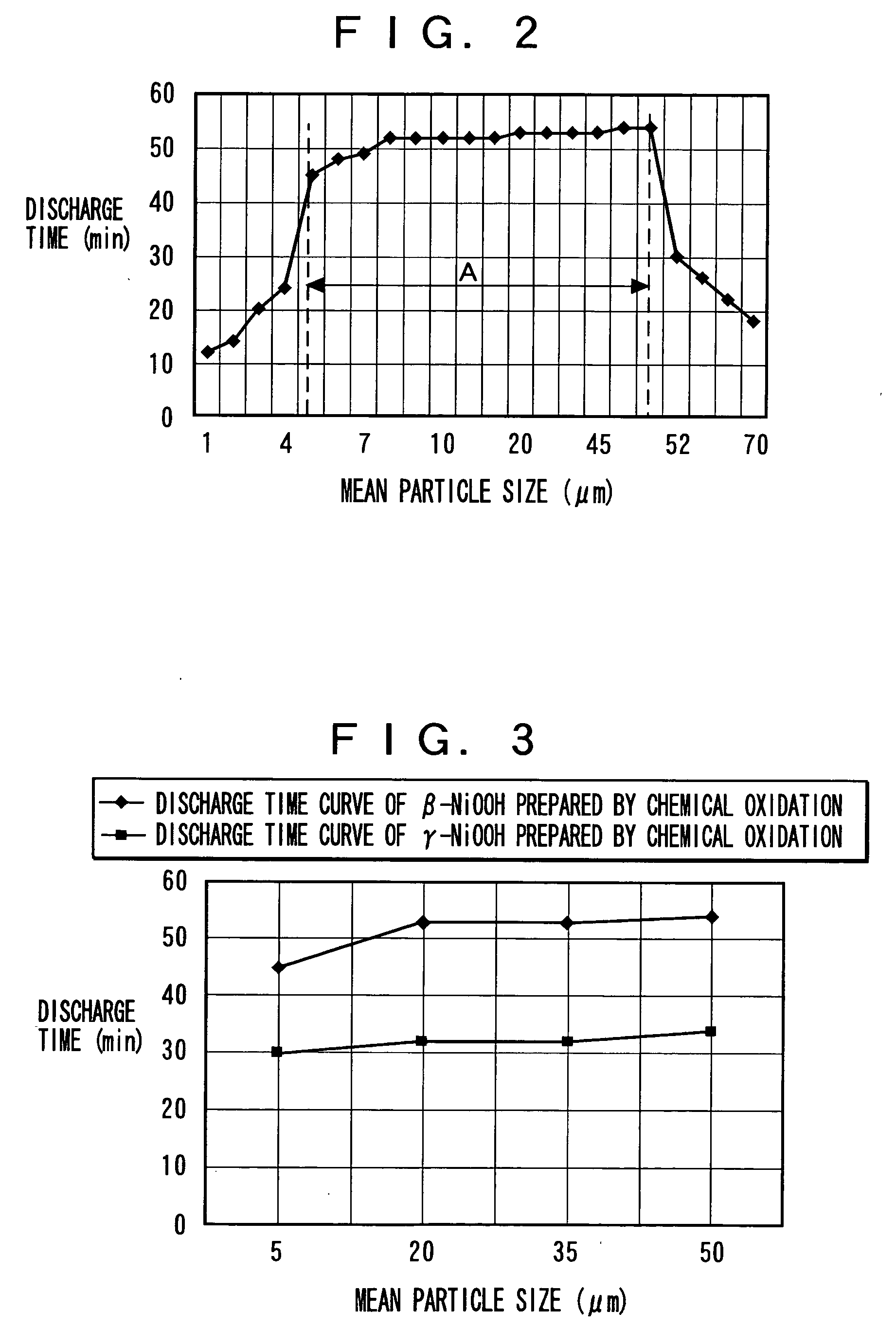

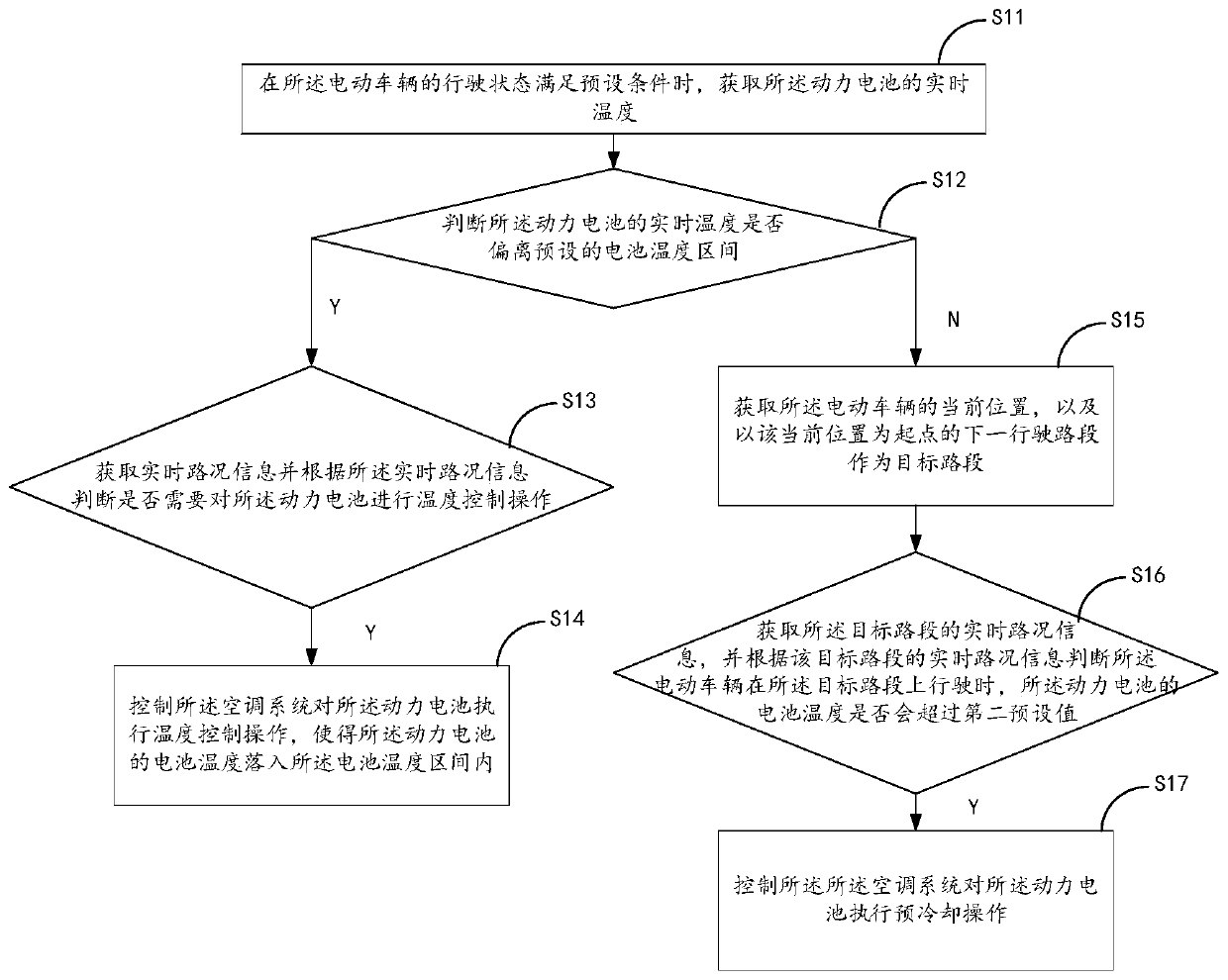

Alkaline battery

InactiveUS20050008936A1Excellent cycle characteristicsReduce conductivityElectrode carriers/collectorsAlkaline accumulator electrodesPotassium hydroxideEngineering

The present invention provides an alkaline battery suitable for use as a primary or secondary battery as a power source of electronic appliances. The battery is excellent in discharge characteristics under a heavy load and in cycle characteristics. The alkaline battery (100) comprises a cathode mix (3) containing β-nickel oxy-hydroxide, an anode mix (5) containing zinc as a main component of anode active material, and an alkali solution as an electrolyte, wherein the cathode mix (3) includes a mixture of β-nickel oxy-hydroxide, graphite powder, and a potassium hydroxide solution in a given weight ratio. The β-nickel oxy-hydroxide is prepared by chemical oxidation and has an approximately spherical shape of particle with a mean particle size in the range of 5 to 50 μm.

Owner:SONY CORP

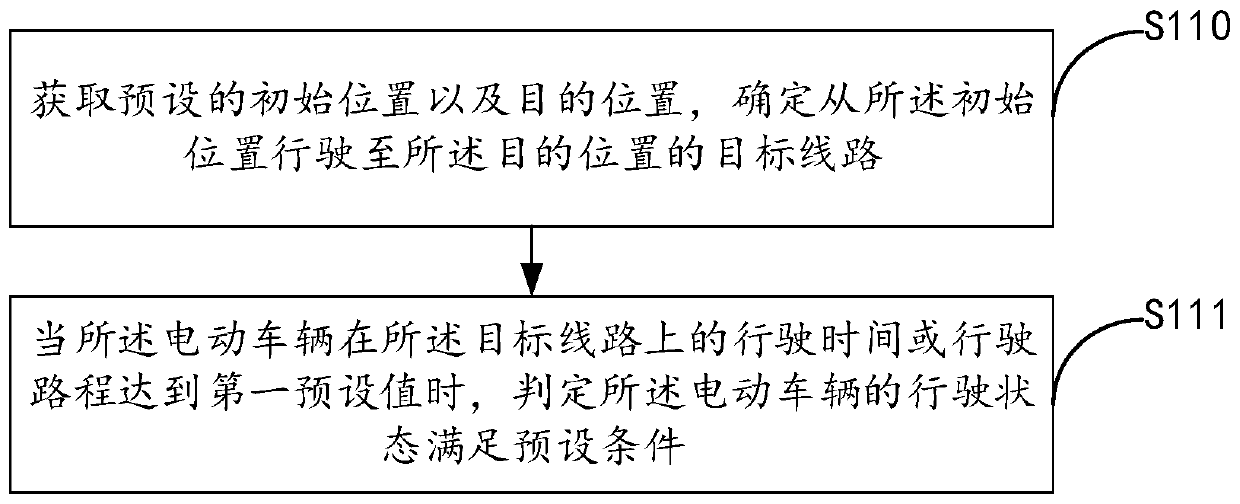

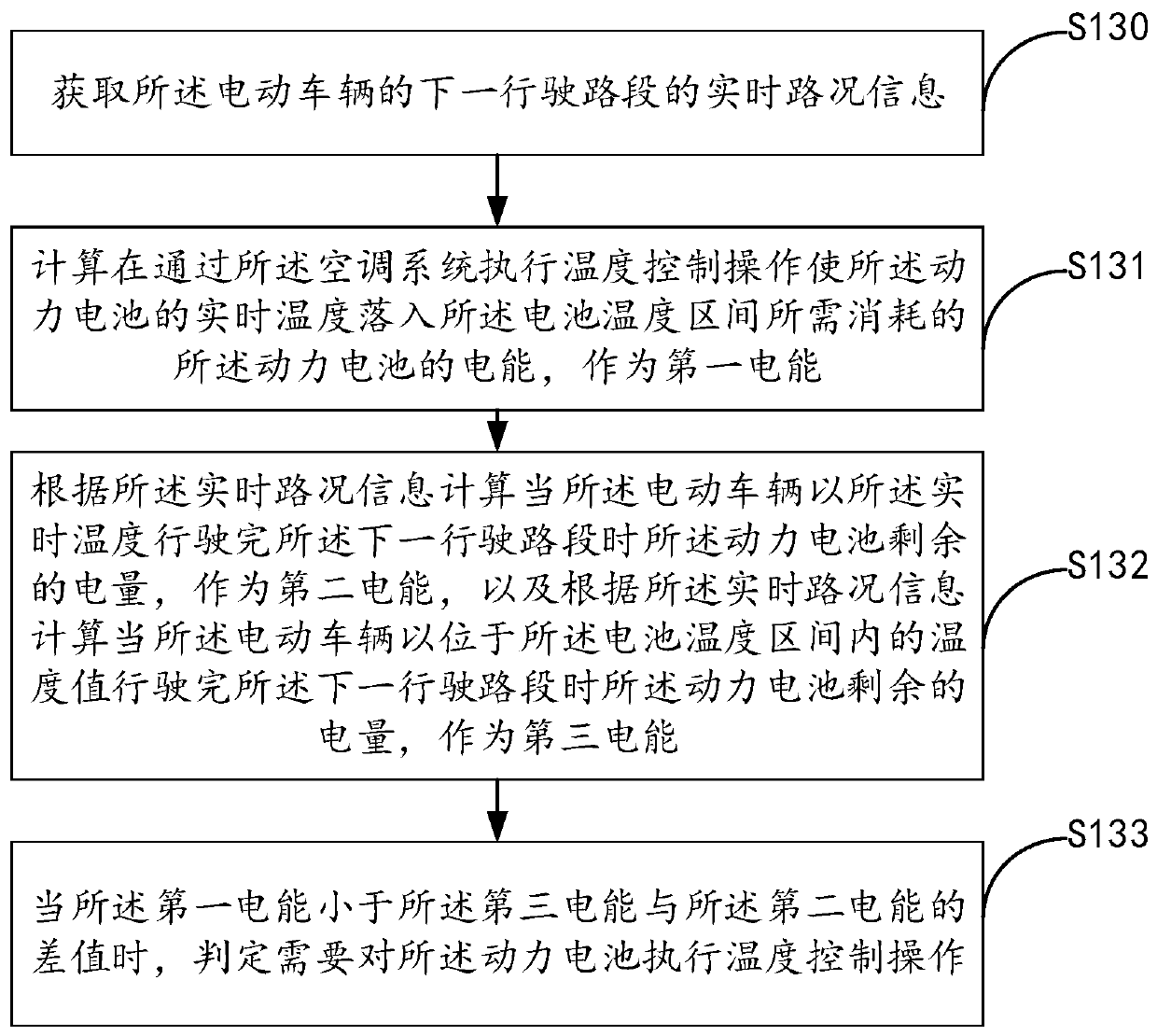

Heat management method and device

ActiveCN110176657ALarge discharge capacityImprove energy conversion efficiencySecondary cellsVehicular energy storagePower batteryTemperature control

Embodiments of the invention provide a heat management method and device, which is applied to a heat management system in an electric vehicle. The heat management method comprises the steps of, when arunning state of the electric vehicle meets a preset condition, obtaining a real-time temperature of a power battery; judging whether the real-time temperature of the power battery is deviated from apreset battery temperature interval or not; when the real-time temperature of the power battery deviates from the preset battery temperature interval, acquiring real-time road condition information and judging whether temperature control operation needs to be performed on the power battery or not according to the real-time road condition information; and if the temperature control operation needsto be performed on the power battery, controlling an air conditioning system to perform the temperature control operation on the power battery, so that the battery temperature of the power battery falls into the battery temperature interval. The energy conversion rate of the power battery can be effectively improved.

Owner:HUATING HEFEI POWER TECH

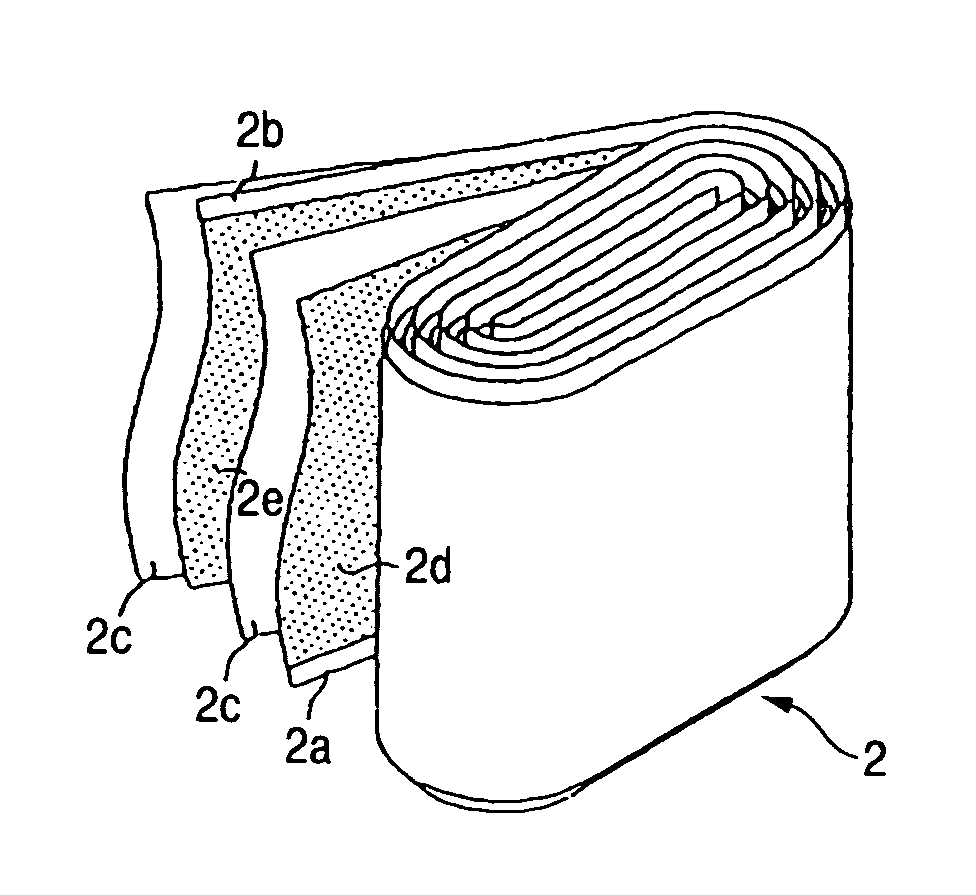

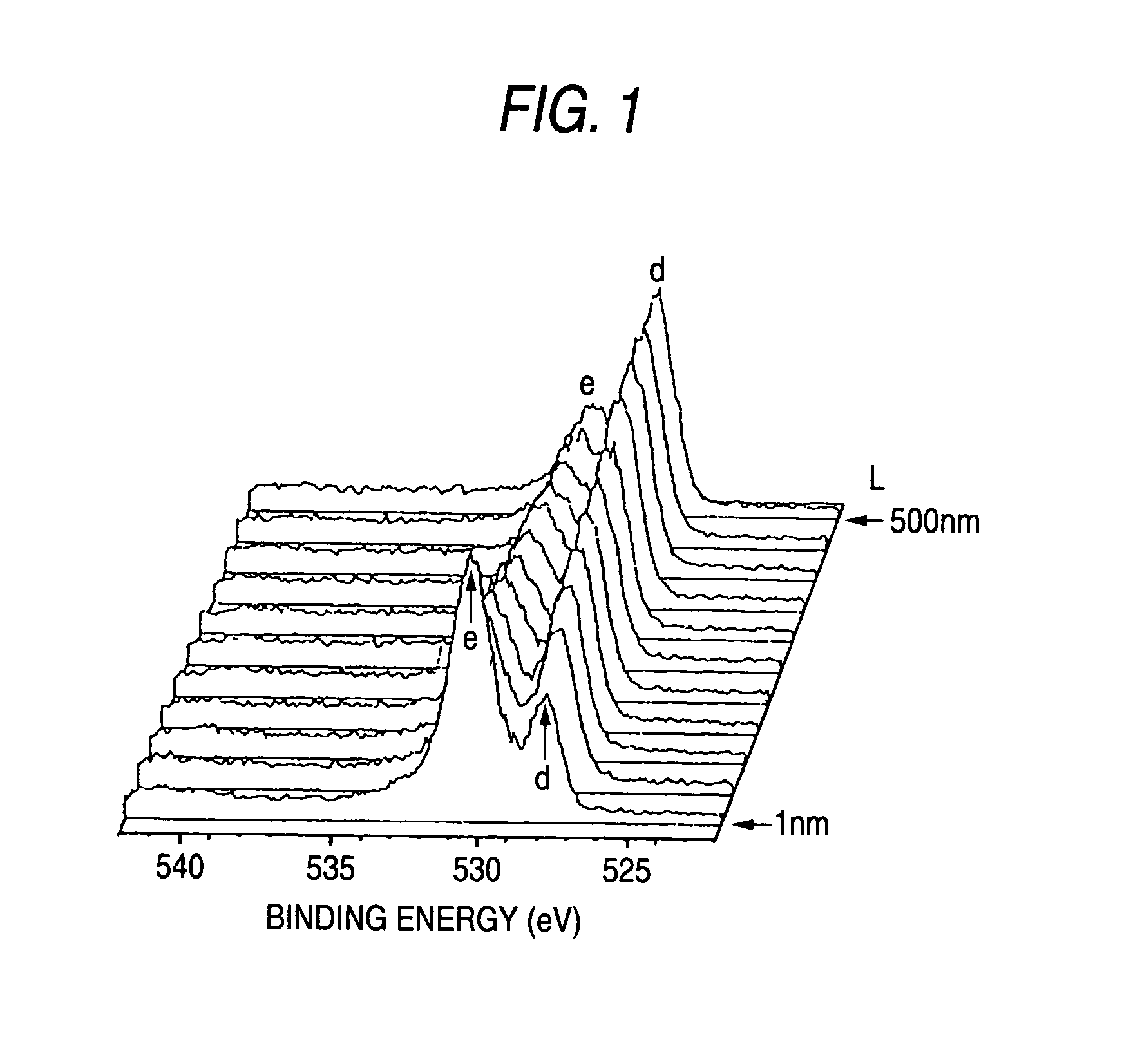

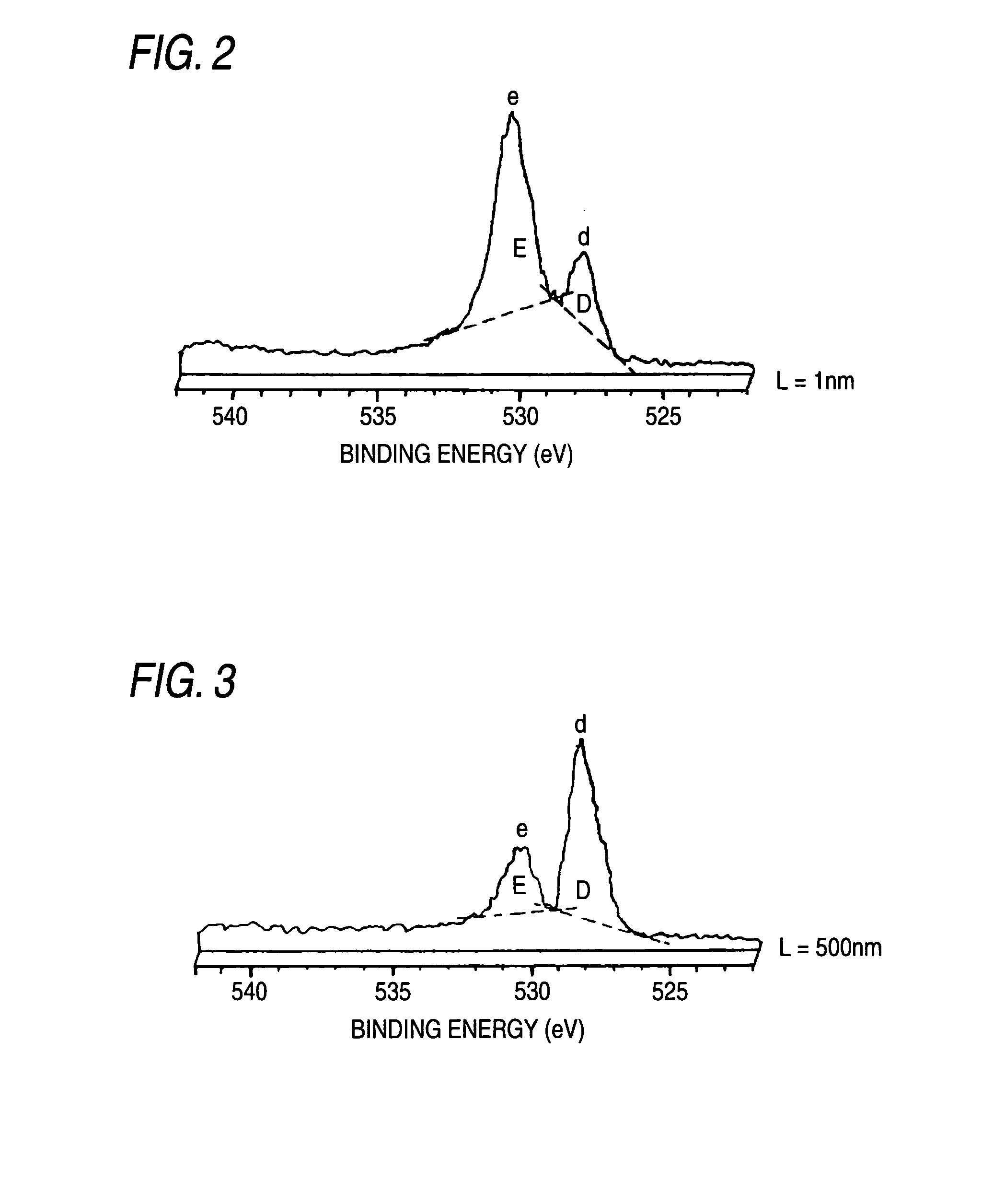

Nonaqueous electrolyte secondary battery

ActiveUS20060286457A1Improve battery performanceImprove discharge capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumOxygen

A nonaqueous electrolyte secondary battery which comprises a positive electrode including particles of lithium-containing layered nickel oxide represented by a general formula LiaNixCoyAlzMbO2, wherein 0.3≦a≦1.05, 0.7≦x≦0.87, 0.1≦y≦0.27, 0.03≦z≦0.1, 0≦b≦0.1; M is at least one selected from metallic elements except Ni, Co and Al. In the binding energy of the oxygen 1s spectrum when measuring the particles by XPS, if the peak area appearing at 529 eV is set to D; the peak area appearing at 531 eV is set to E; oxygen concentration ratio is set to D / (D+E); and the oxygen concentration ratios at depths of L1 nm and L2 nm from the particle surface are respectively set to αL1 and αL2, the combination of L1 and L2 in which (αL2−αL1) / αL2≦0.1, L1≦100, L2≧500 is present.

Owner:GS YUASA INT LTD

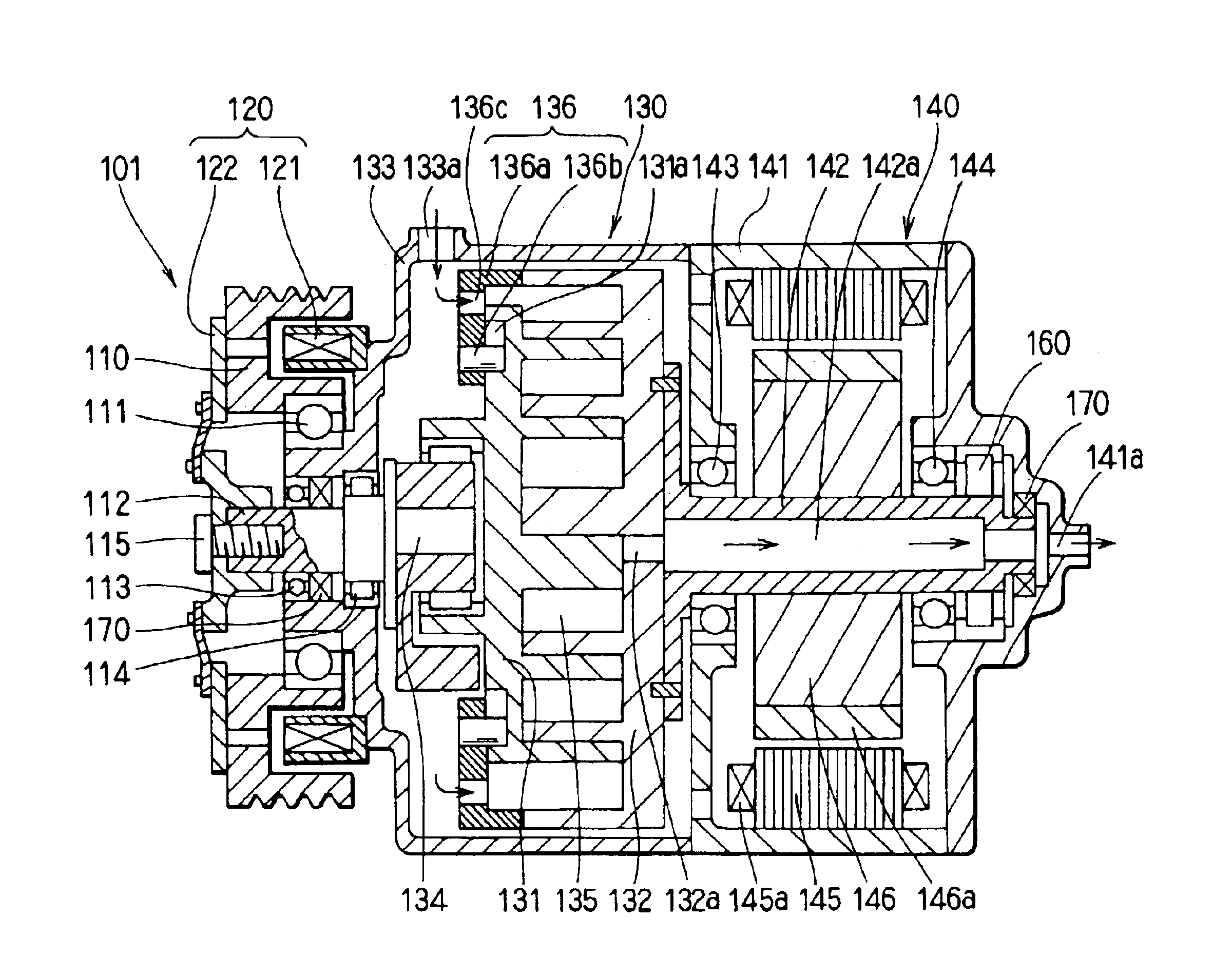

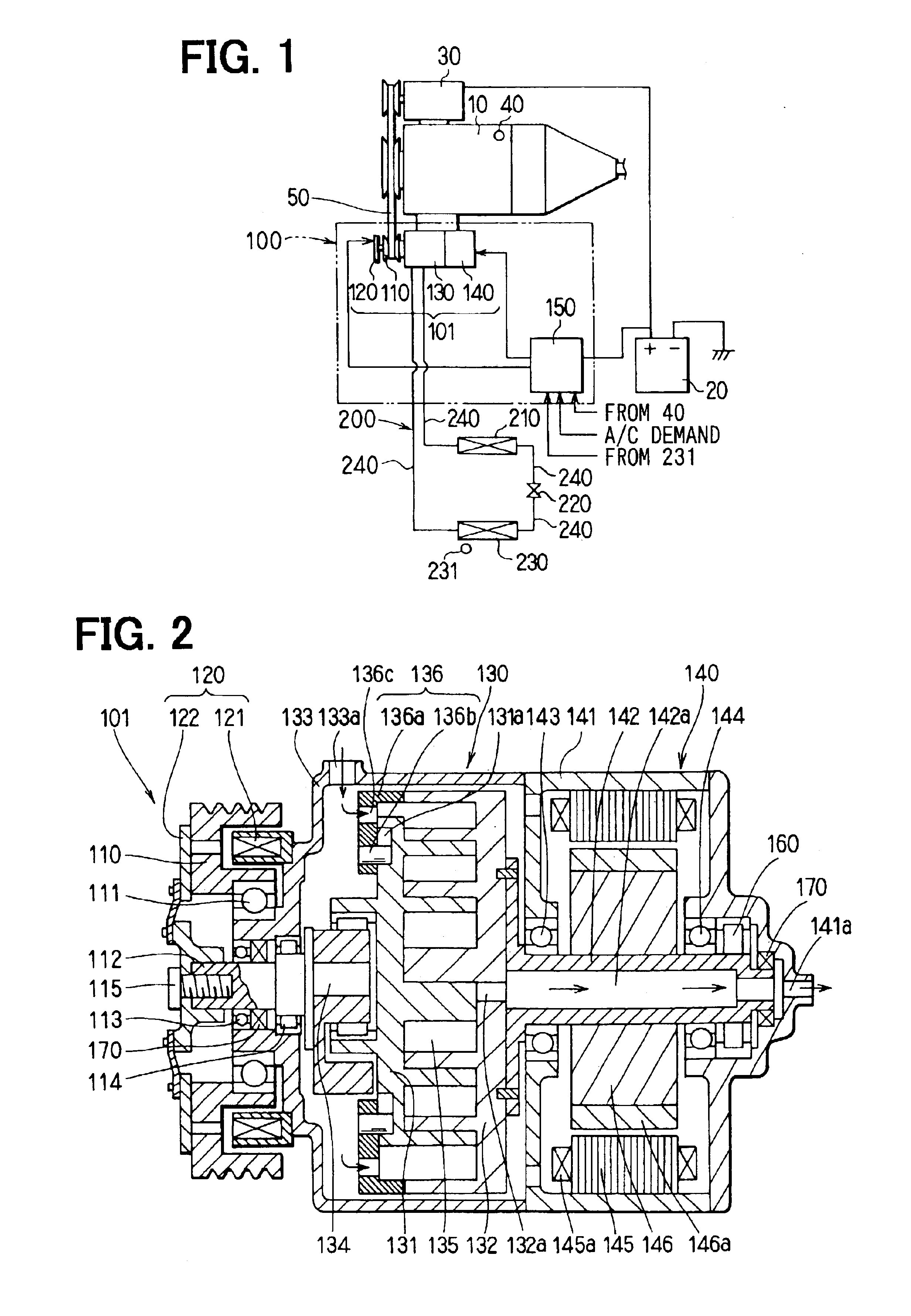

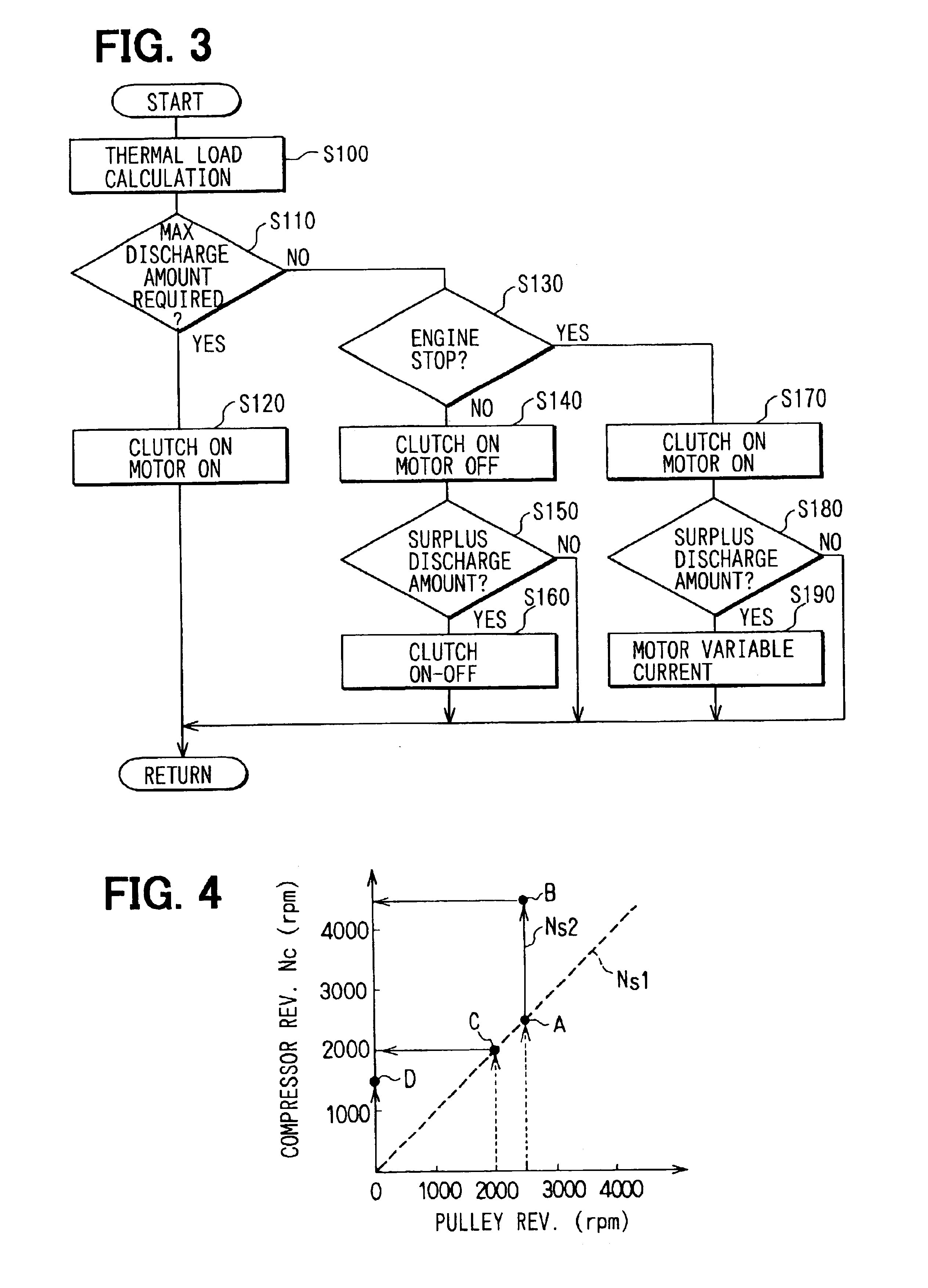

Compressor having independently driven members

InactiveUS6874996B2Compact bodyEasy to operateRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesEngineeringCompression member

The hybrid compressor apparatus is composed of a compressor in which fluid is compressed by varying a volumetric capacity of a compression space provided between a first compression member and a second compression member, which are movable independently of each other, according to rotation of the first compression member relative to the second compression member, a motor rotatable upon receipt of power of an external electric source, and a driven member rotatably driven by motive force transmitted from an external driving source. The first compression member is connected with the driven member and the second compressor is connected with the motor. If maximum discharge amount is required for the compressor, the motor is driven separately by a control device when the driven member drives the first compression member so that the second compression member is rotated in a direction opposite to that of the first compression member.

Owner:DENSO CORP

Sodium secondary battery electrode and sodium secondary battery

InactiveUS20140065492A1Large discharge capacityReduce discharge capacityElectrode thermal treatmentConductive materialState of artEngineering

The present invention provides an electrode that can be used for a sodium secondary battery having a larger discharge capacity when charging and discharging are performed repeatedly than that of the prior art. This sodium secondary battery electrode contains tin (Sn) powder as an electrode active material. The electrode, particularly, further contains one or more electrode-forming agents selected from the group consisting of poly(vinylidene fluoride) (PVDF), poly(acrylic acid) (PAA), poly(sodium acrylate) (PAANa), and carboxymethylcellulose (CMC), thereby making it possible to provide a sodium secondary battery having even greater electrode performance.

Owner:TOKYO UNIVERSITY OF SCIENCE +1

Lithium composite metal oxide and positive electrode active material

ActiveUS20120015231A1Large discharge capacityIron compoundsNon-aqueous electrolyte accumulator electrodesLithiumMaterials science

A lithium mixed metal oxide, shown by the following formula (A): Lix(Mn1-y-z-dNiyFezMd)O2 (A) wherein M is one or more elements selected from the group consisting of Al, Mg, Ti, Ca, Cu, Zn, Co, Cr, Mo, Si, Sn, Nb and V; x is 0.9 or more and 1.3 or less; y is 0.3 or more and 0.7 or less; z is more than 0 and 0.1 or less, and d is more than 0 and 0.1 or less. A positive electrode active material, including the lithium mixed metal oxide. A positive electrode, including the positive electrode active material. A nonaqueous electrolyte secondary battery, including the positive electrode.

Owner:SUMITOMO CHEM CO LTD

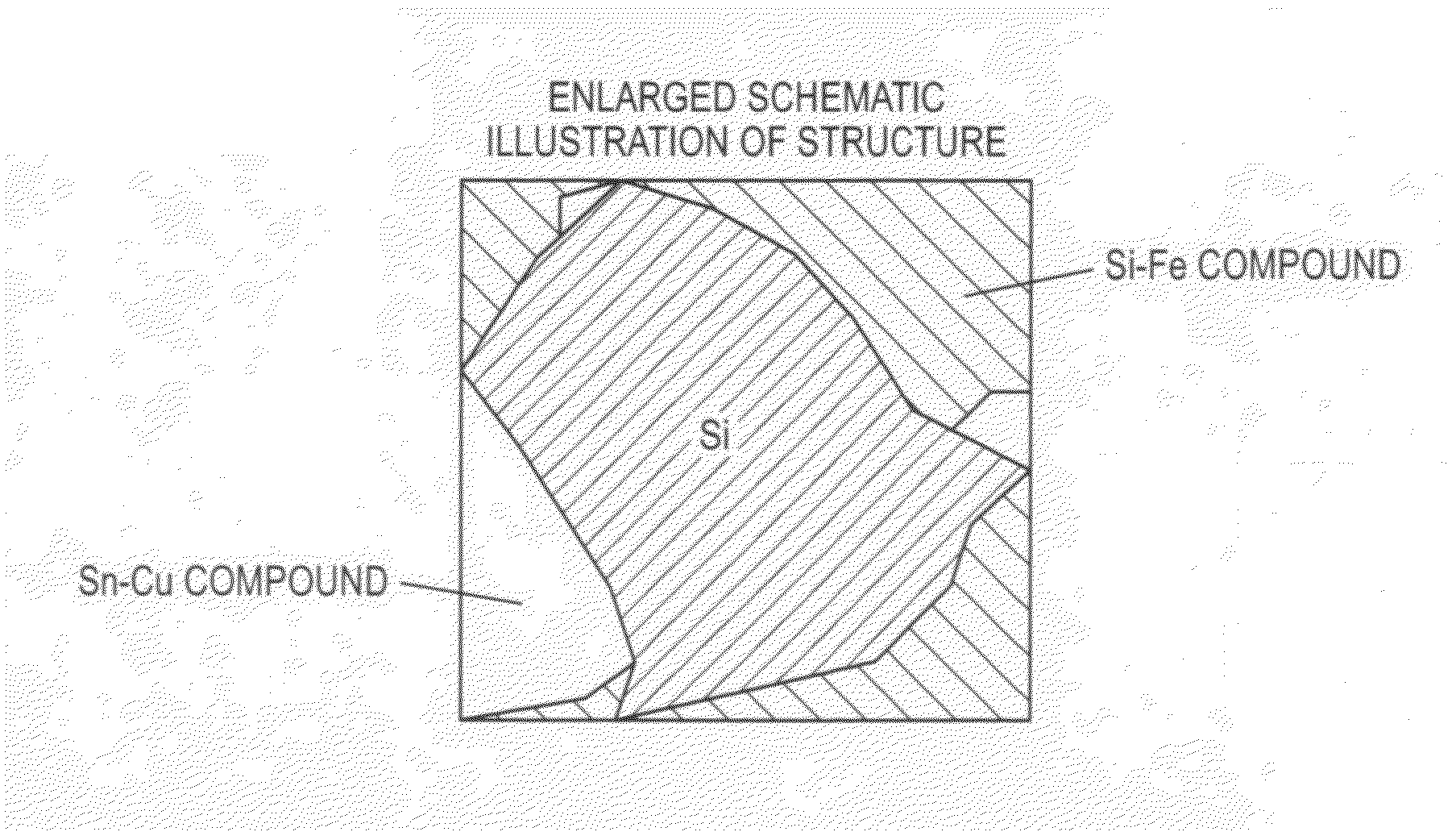

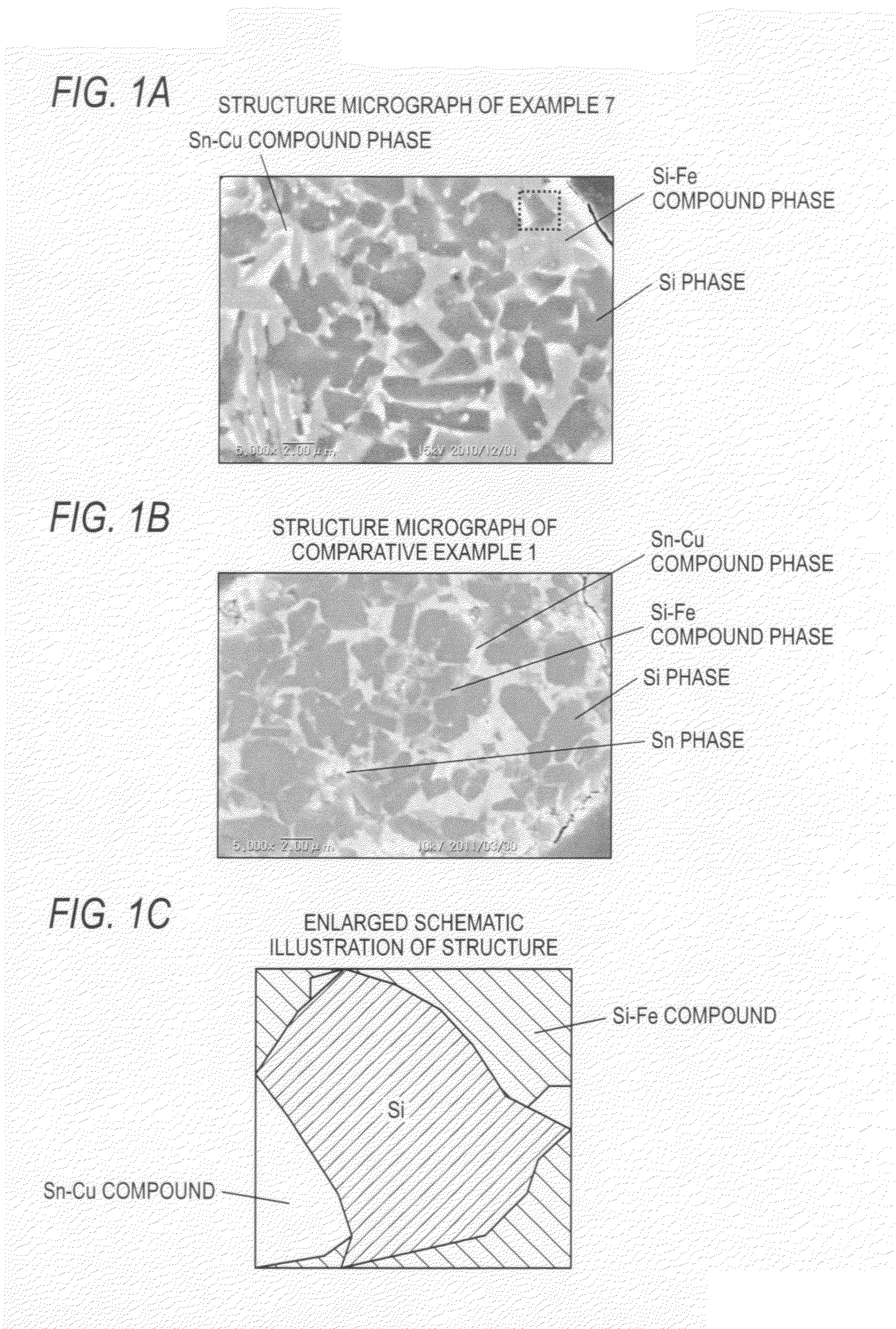

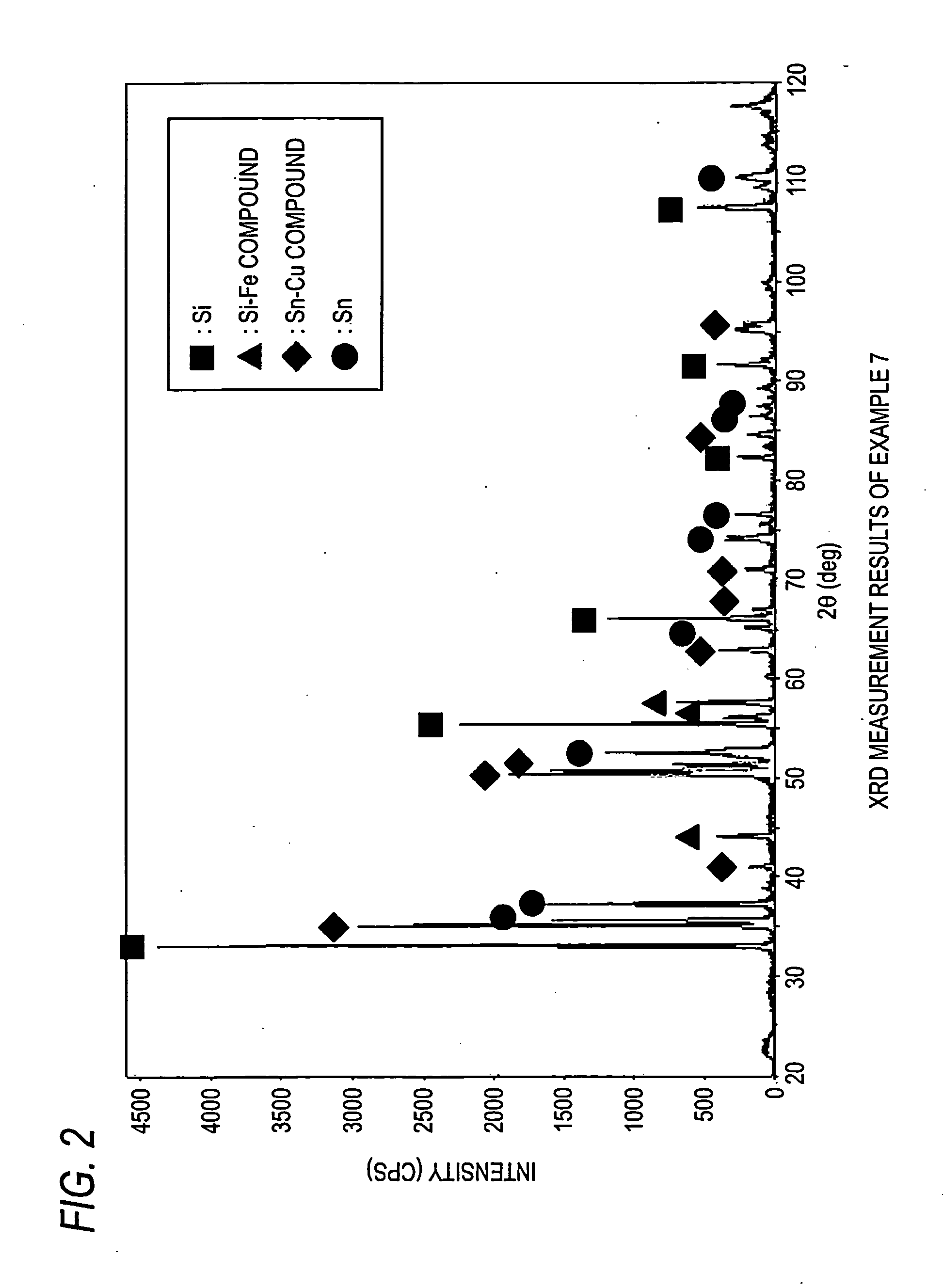

Negative electrode active material for lithium ion battery, and negative electrode for lithium ion battery using the same

ActiveUS20130084498A1Large discharge capacityImprove featuresConductive materialNon-conductive material with dispersed conductive materialElectrical batteryAlloy

The present invention relates to a negative electrode active material including an Si—Sn—Fe—Cu based alloy, in which an Si phase has an area ratio in a range of from 35 to 80% in the entire negative electrode active material, the Si phase is dispersed in a matrix phase, the matrix phase contains an Si—Fe compound phase crystallized around the Si phase and further contains an Sn—Cu compound phase crystallized to surround the Si phase and the Si—Fe compound phase, the Si—Fe compound phase is crystallized in a ratio of from 35 to 90% in terms of an area ratio in the entire matrix phase, and the matrix phase further contains an Sn phase unavoidably crystallized in the matrix phase in a ratio of 15% or less in terms of an area ratio in the entire matrix phase,

Owner:DAIDO STEEL CO LTD

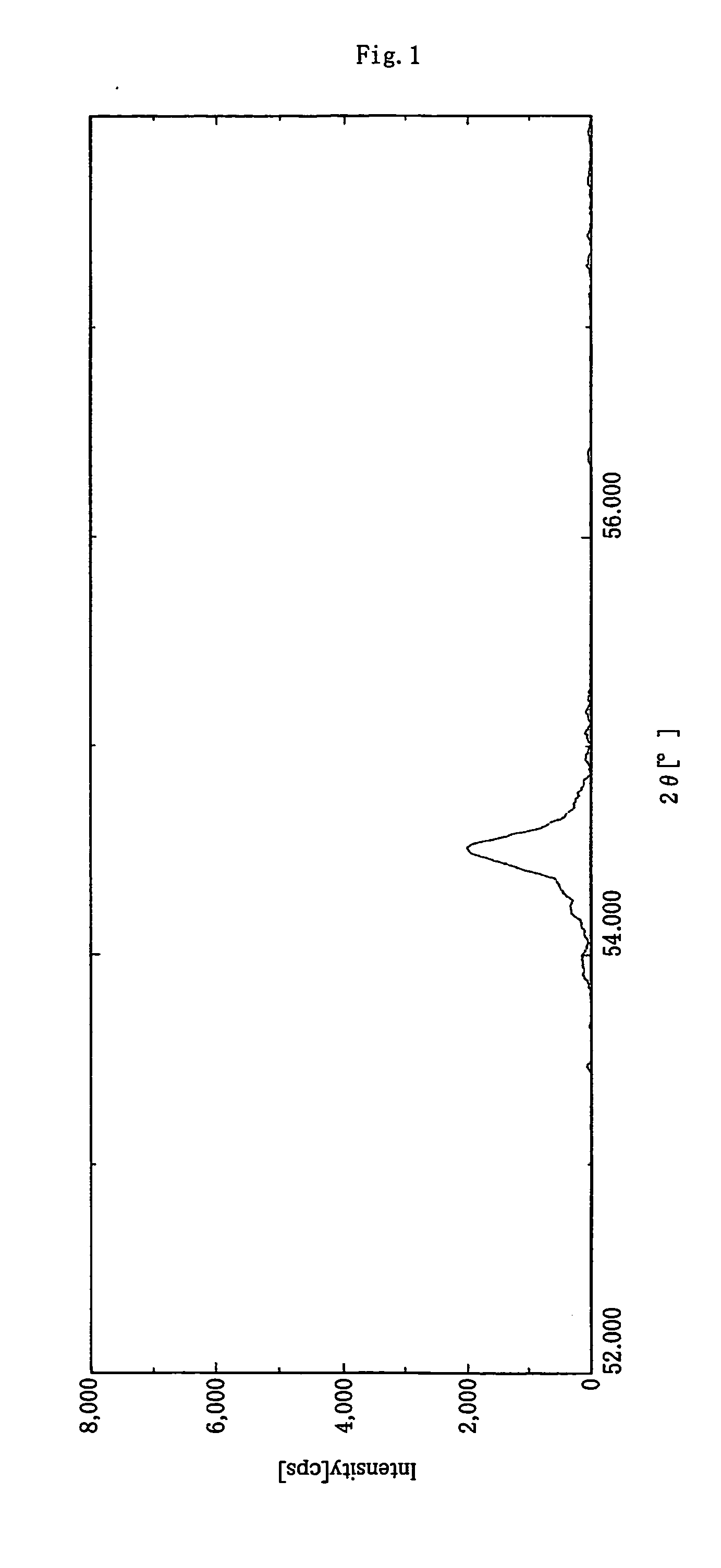

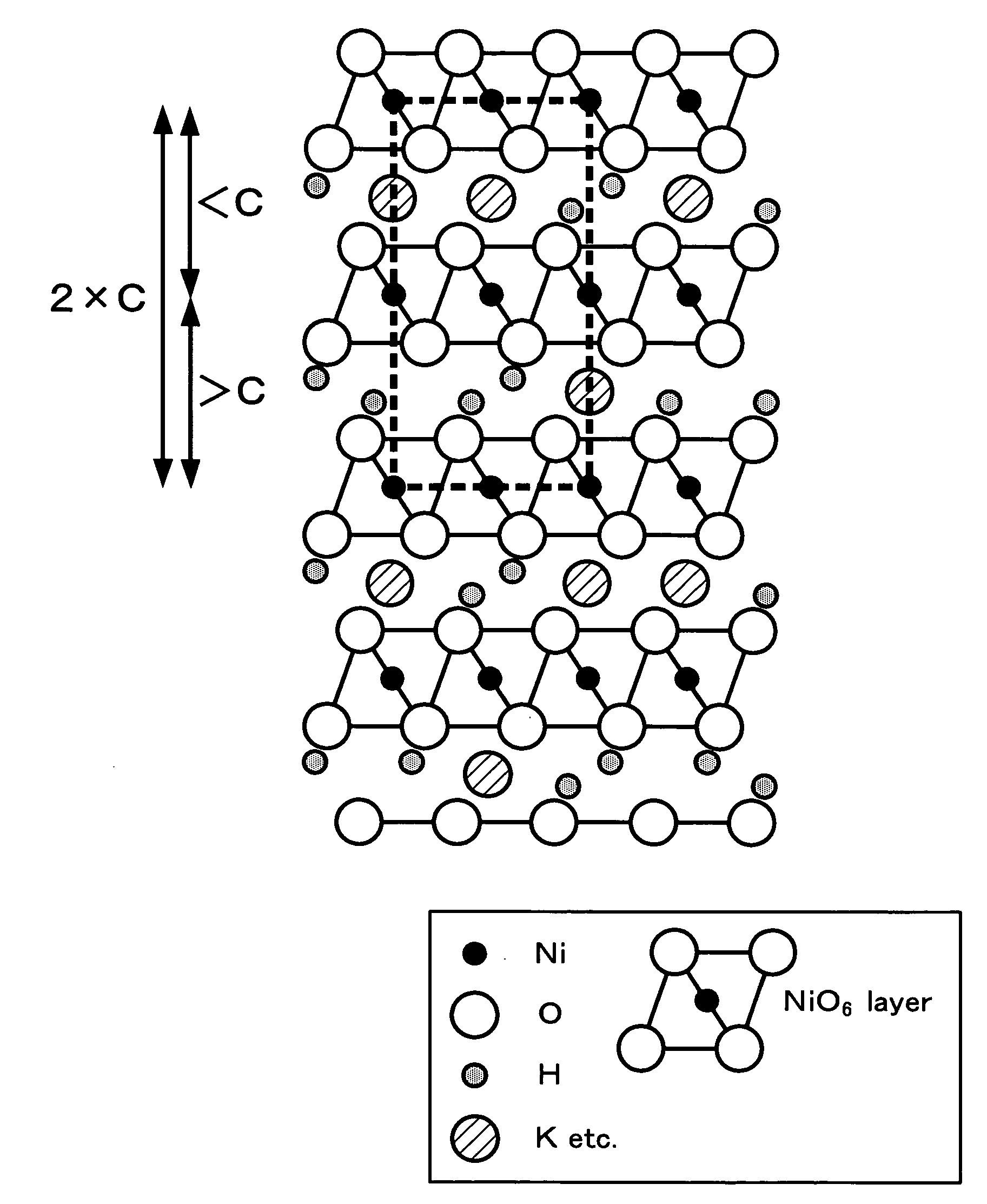

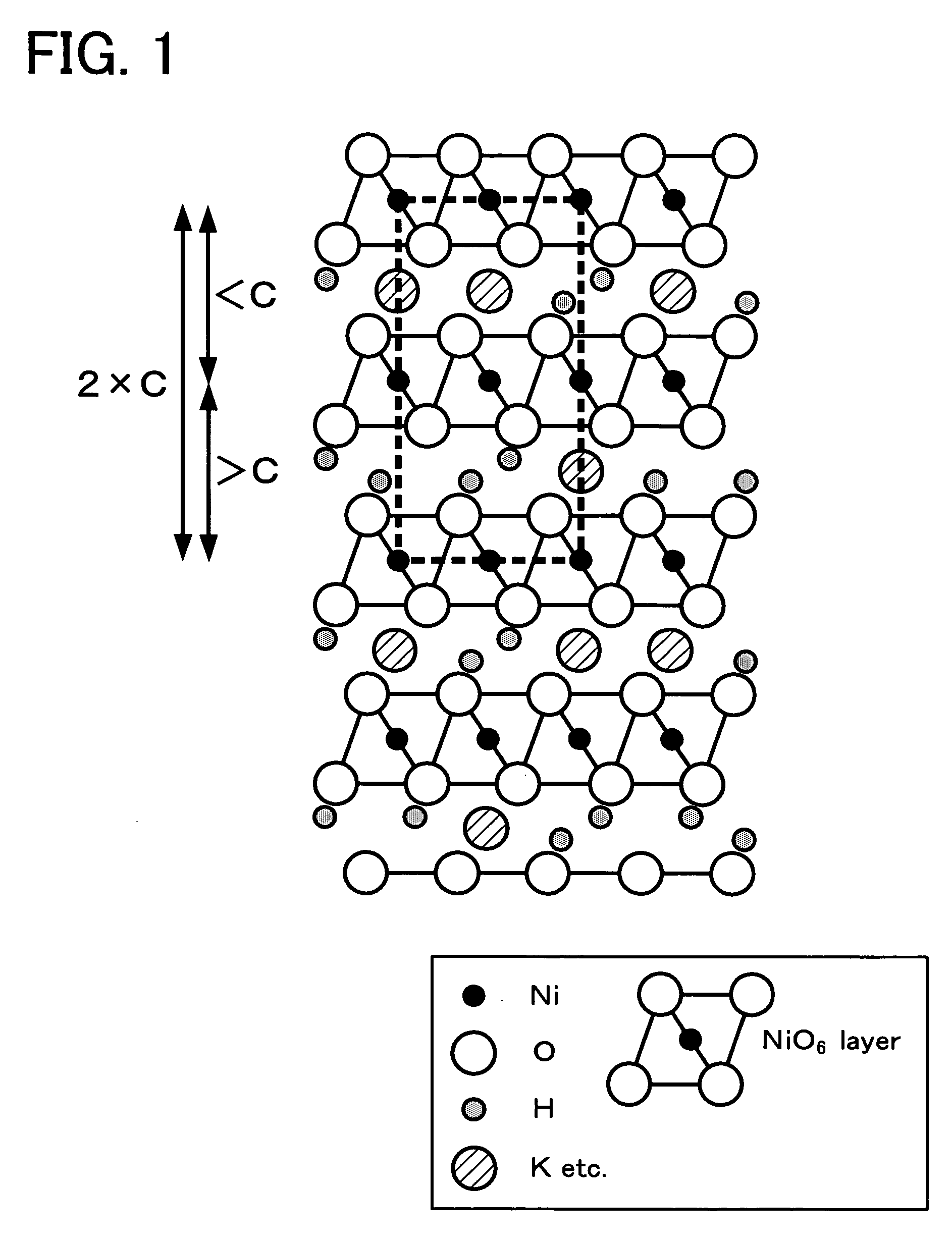

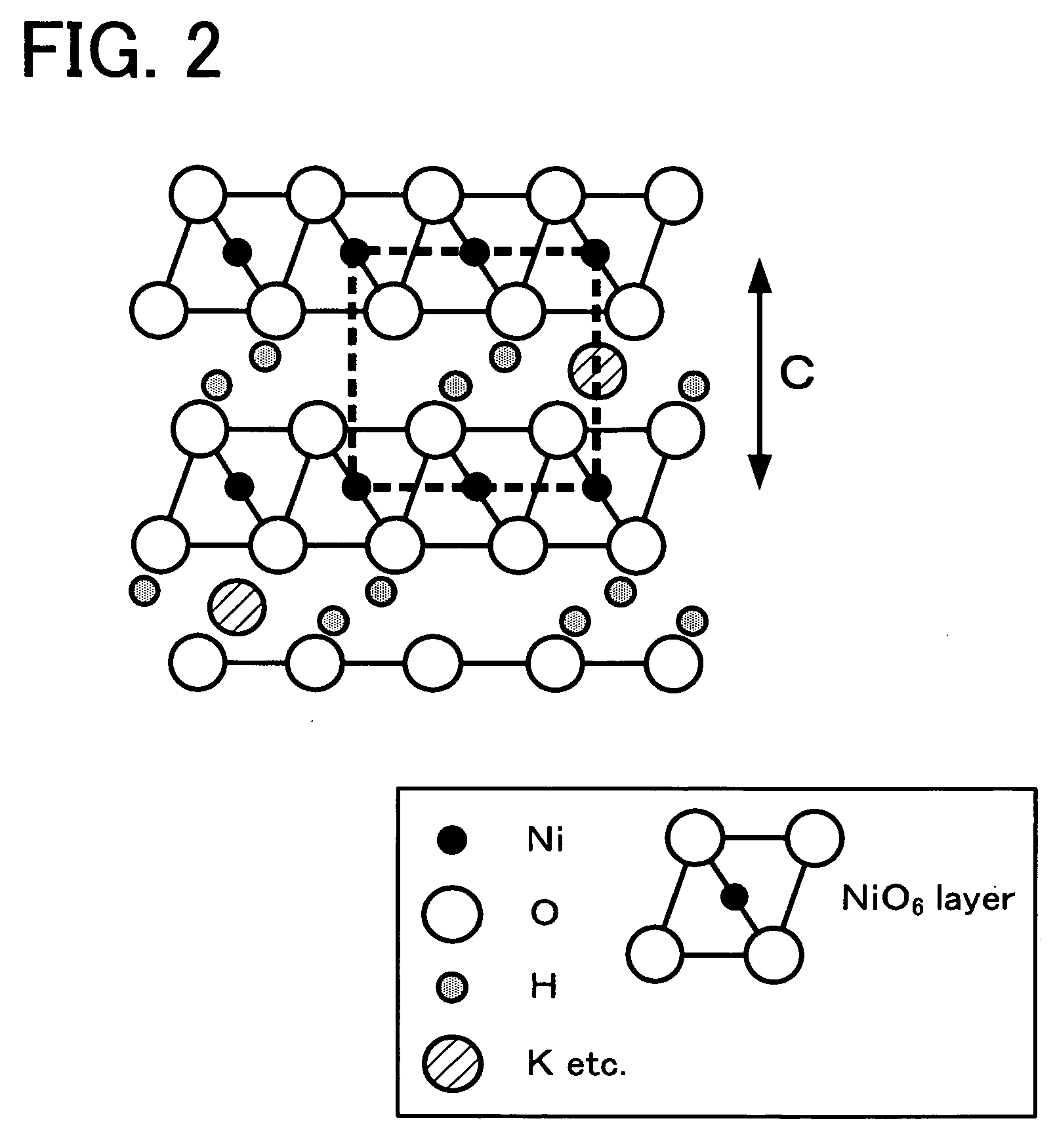

Cathode Active Material for Alkaline Battery and Manufacturing Method Thereof, and Alkaline Battery

InactiveUS20080274405A1High Ni valenceLarge discharge capacityElectrode carriers/collectorsPositive electrodesLamellar crystalsAlkaline water

The present invention is to provide a cathode active material for an alkaline battery with a lamellar crystal structure including nickel oxyhydroxide. The cathode active material has a diffraction peak at a position that ranges from 8.4 degrees to 10.4 degrees in diffraction angle 2θ by X-ray diffraction using CuKα-rays. In addition, the present invention provides an alkaline battery having a cathode having a cathode active material, an anode having an anode active material, and an alkaline water solution as an electrolytic solution. Furthermore, the present invention provides a manufacturing method for a cathode active material for an alkaline battery with a lamellar crystal structure including nickel oxyhydroxide. The manufacturing method has an oxidation process for manufacturing the cathode active material by oxidizing a starting material made from β-type nickel hydroxide with a lamellar crystal structure in an airstream including alkaline water solution or alkali.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com