Patents

Literature

287results about How to "Good rate characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Synthesis and surface modification method of lithium excessive laminar oxide anode material

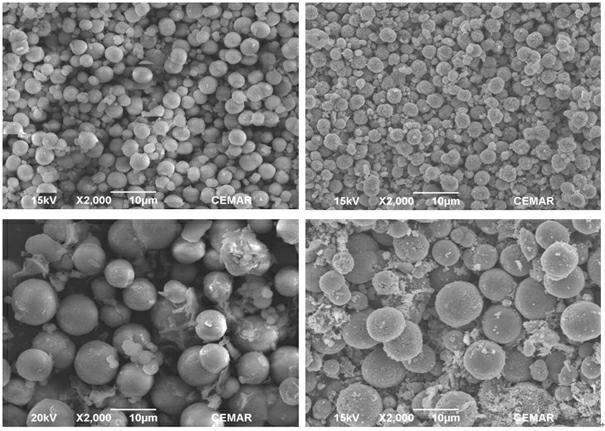

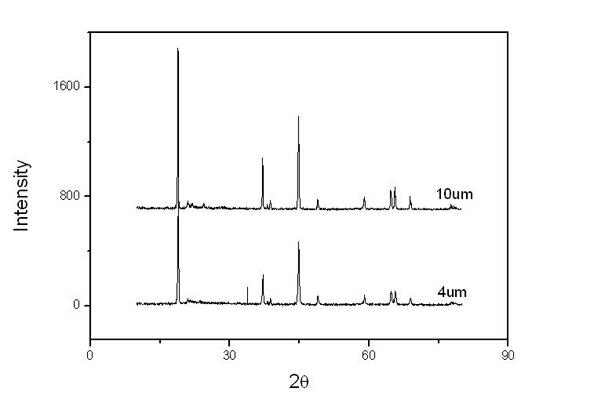

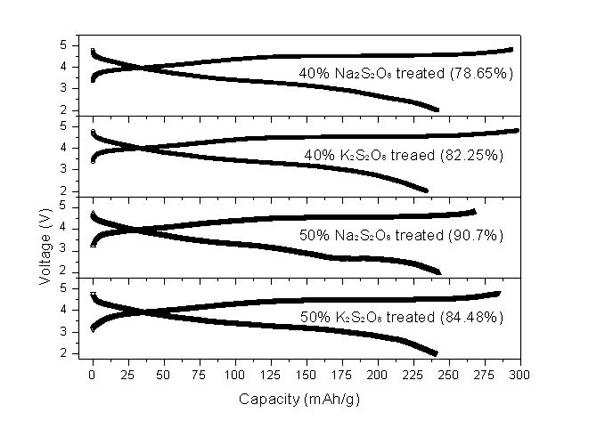

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

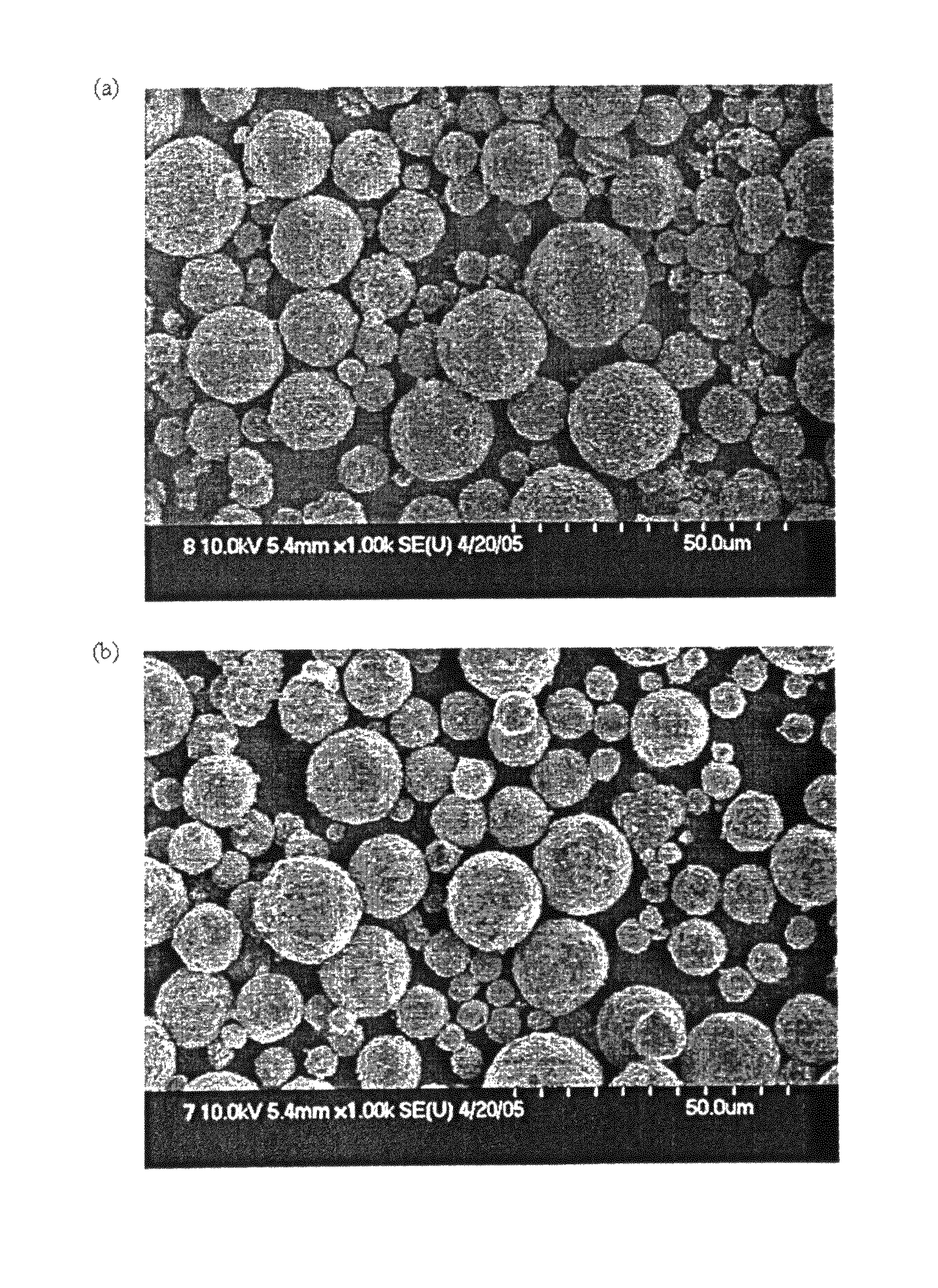

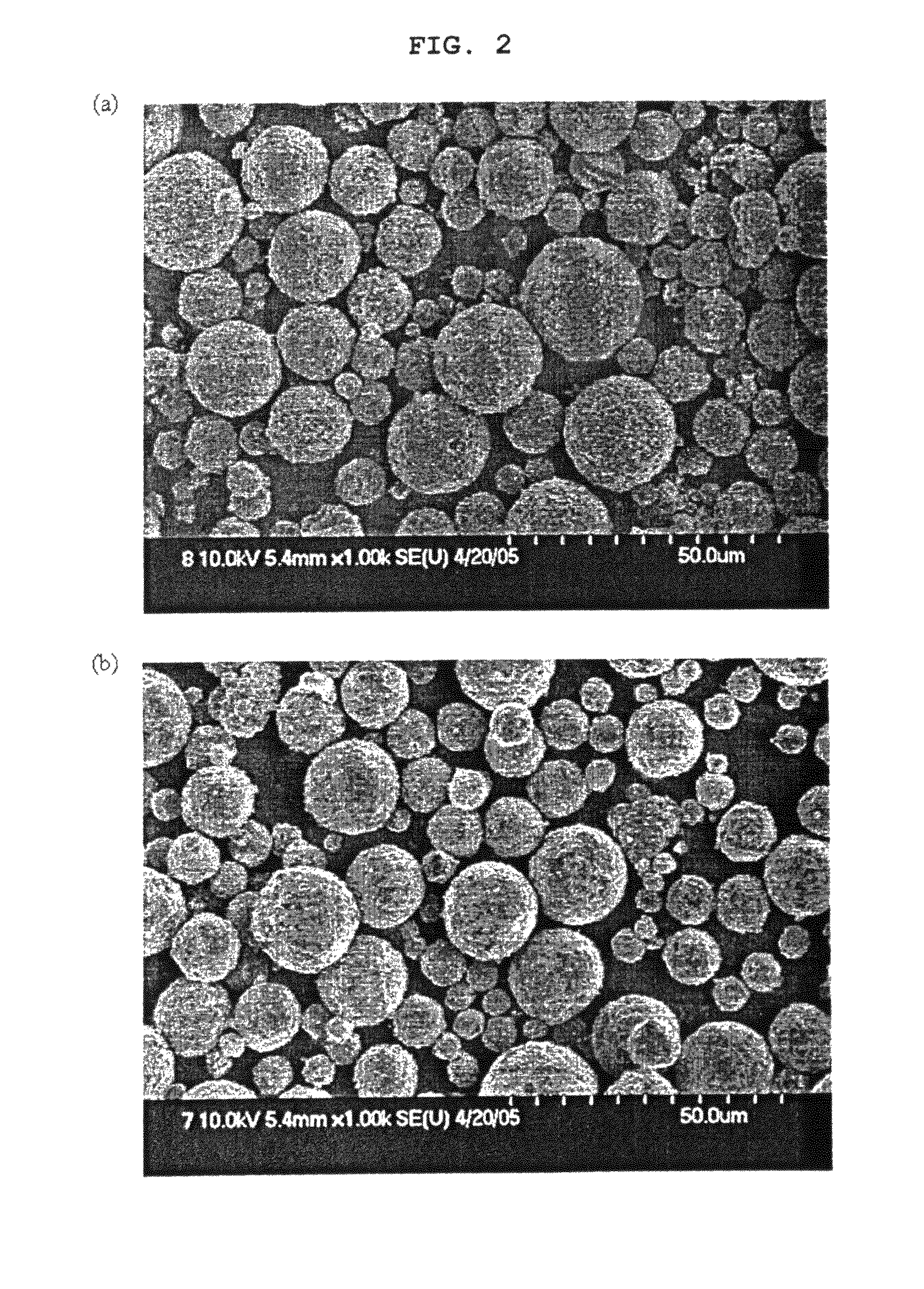

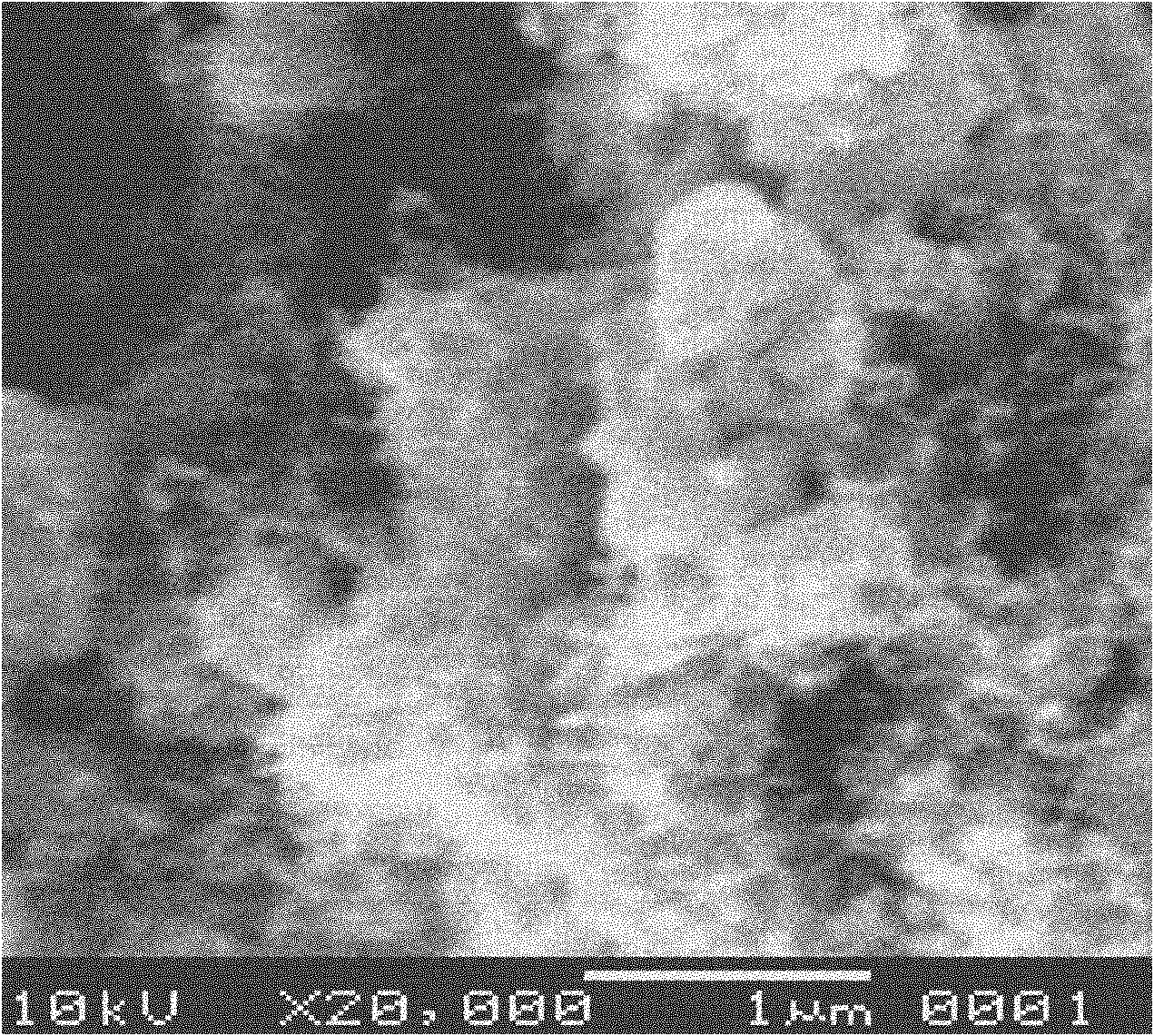

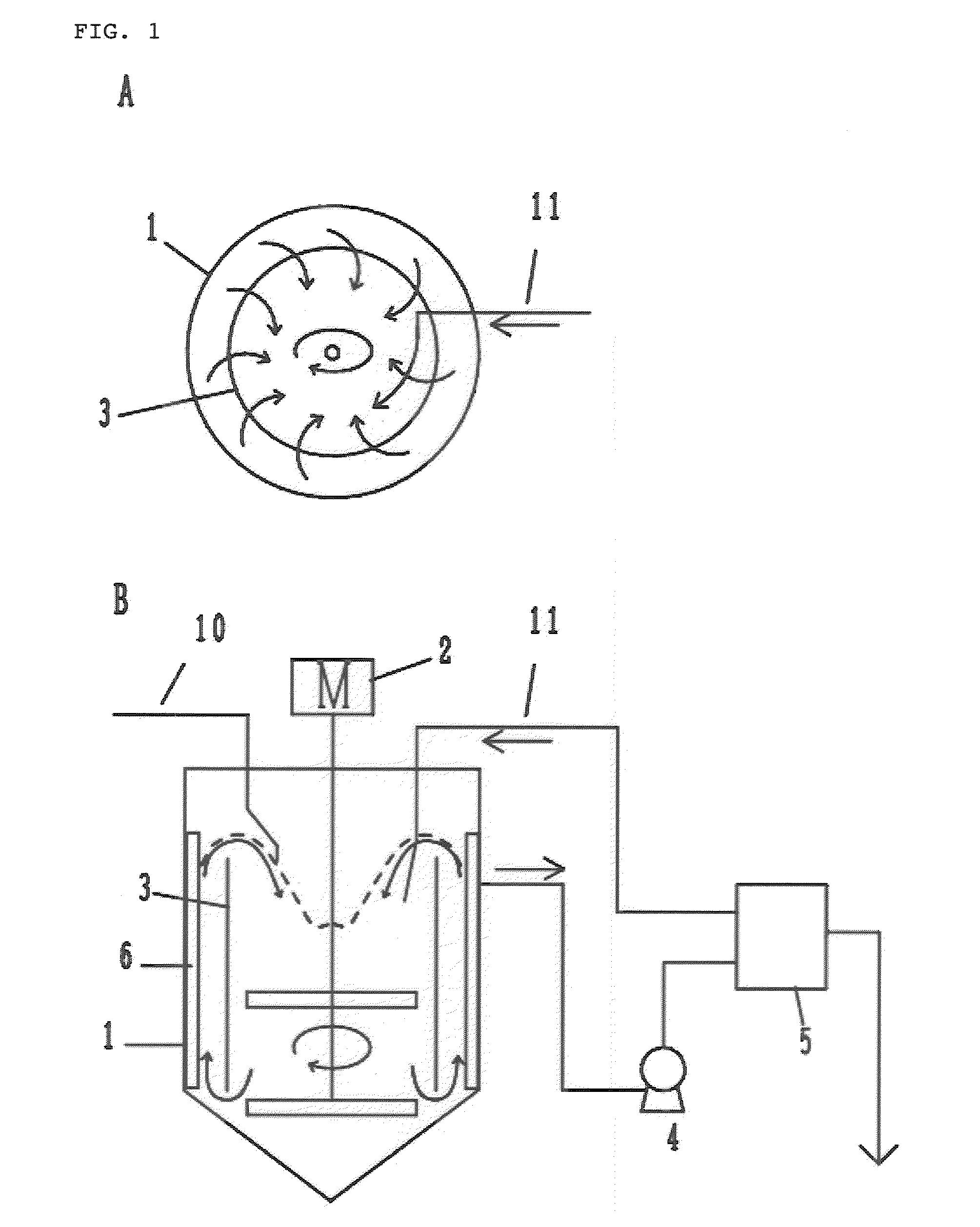

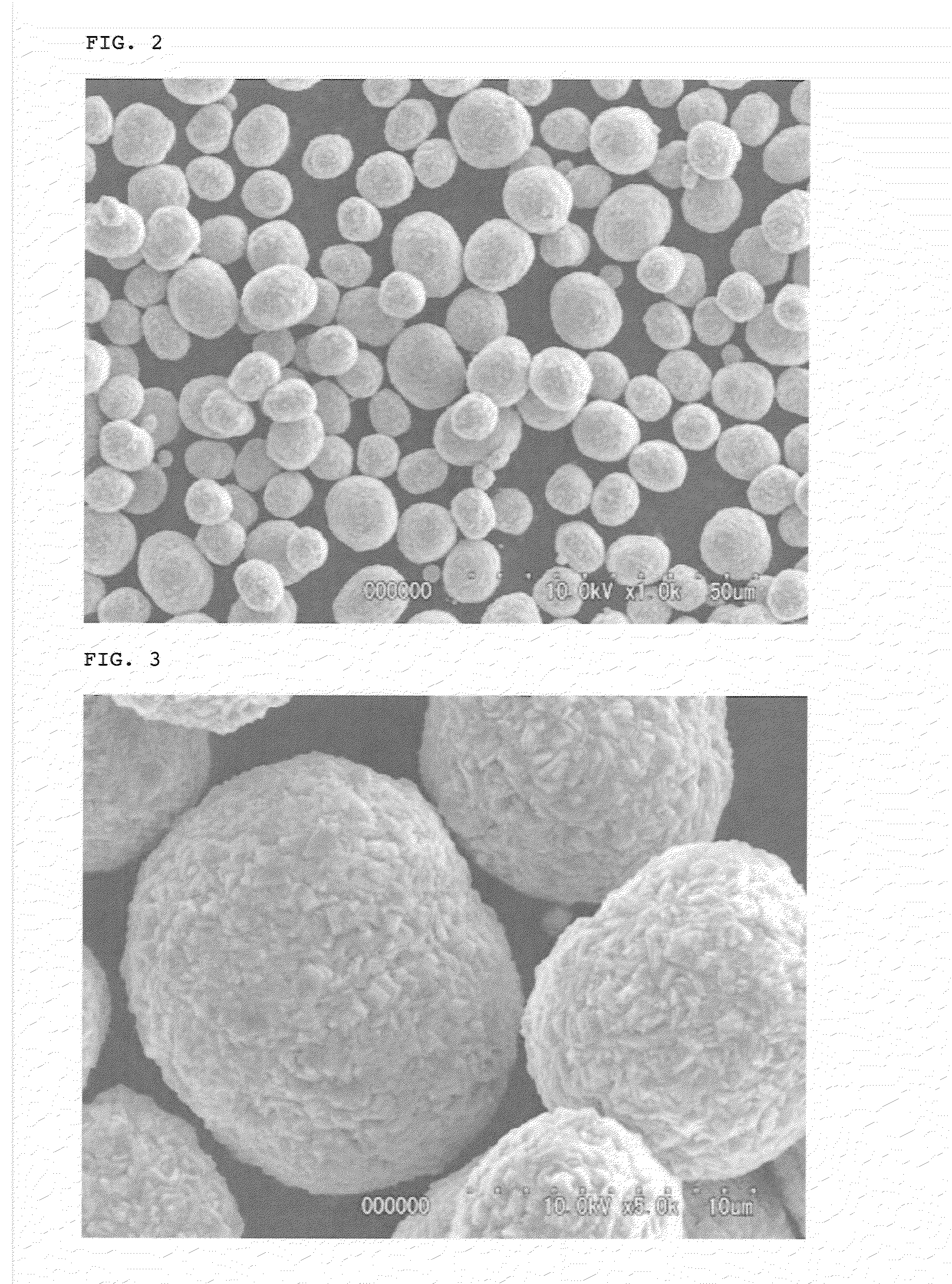

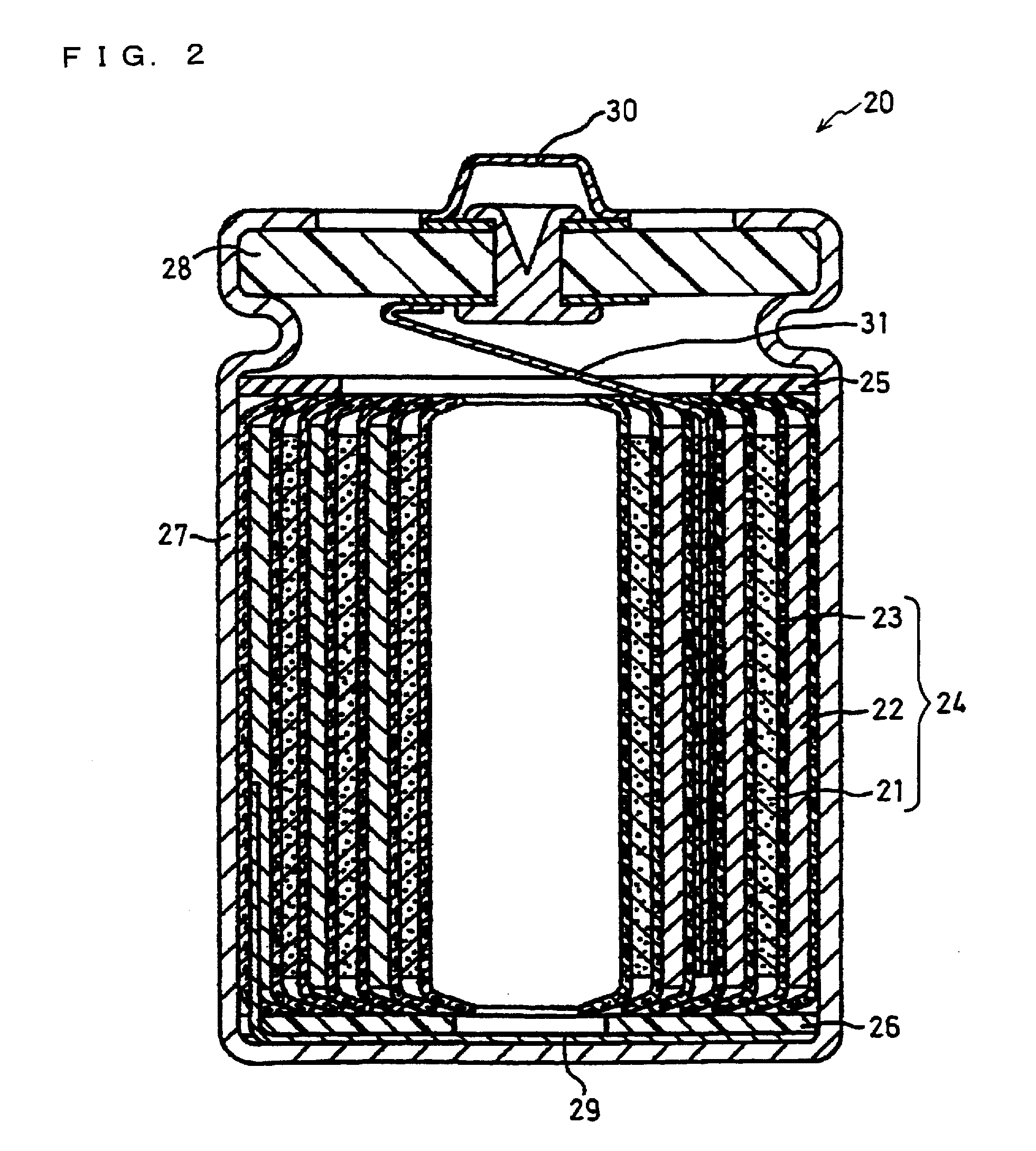

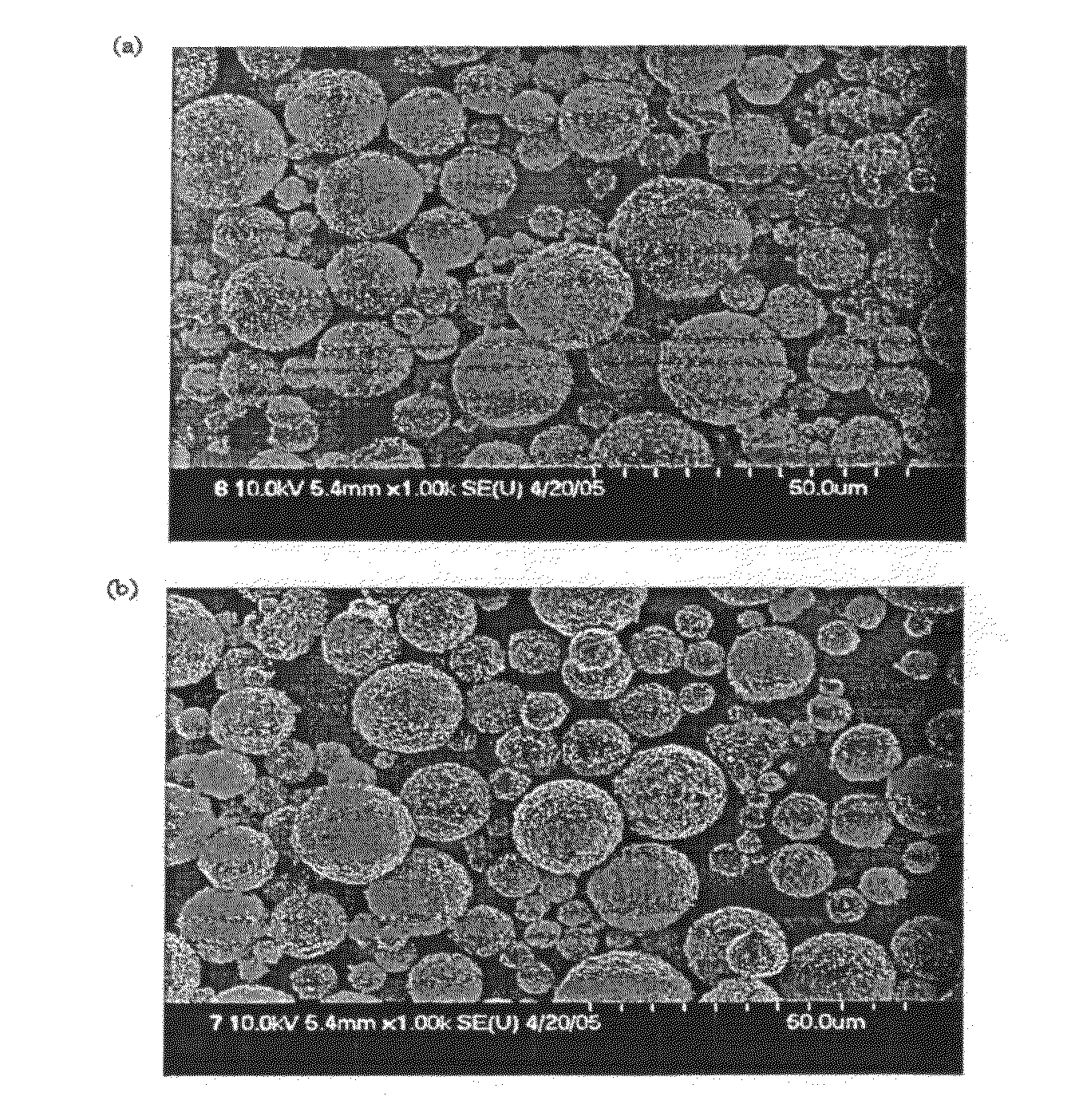

Layered lithium-nickel-based compound oxide powder and its production process

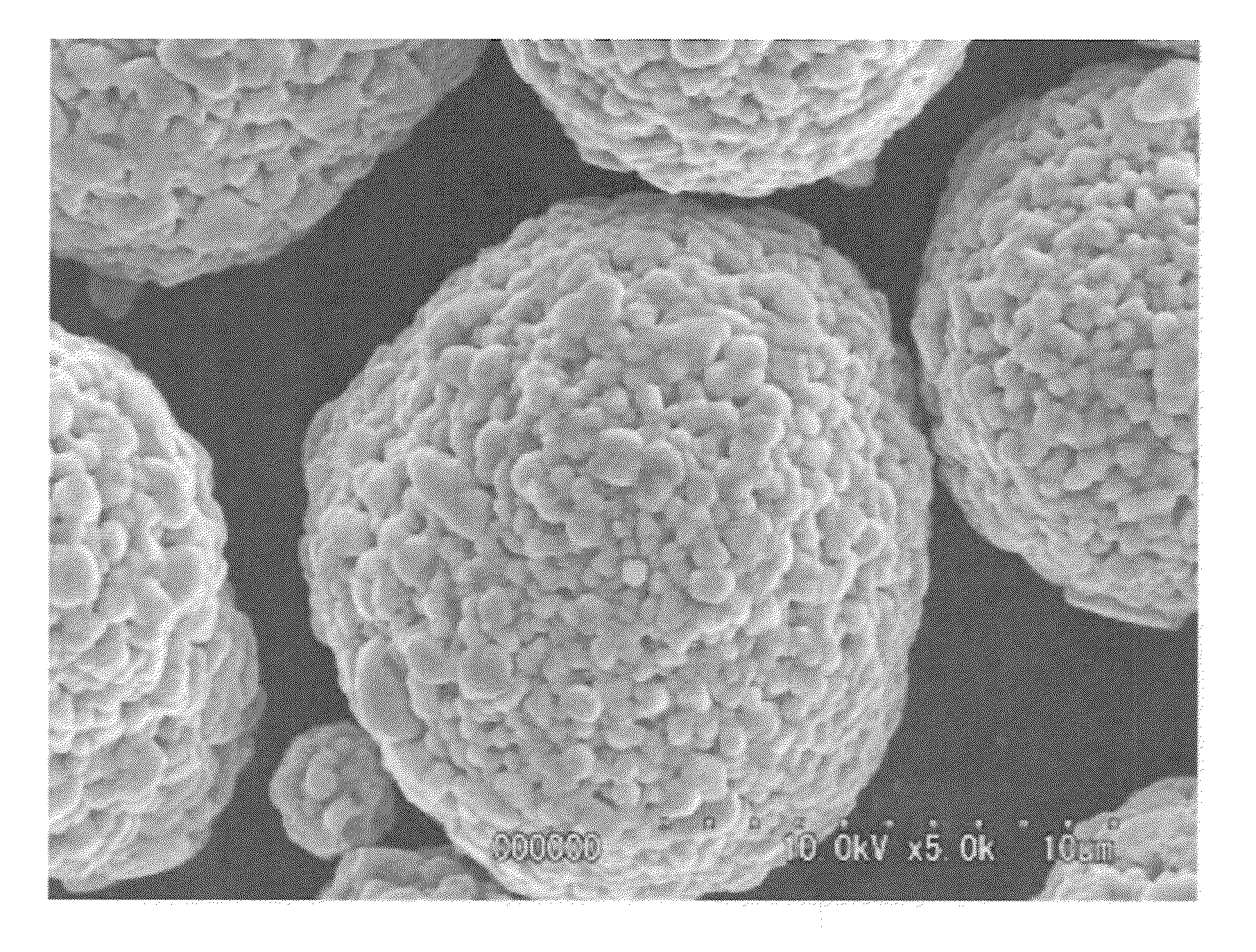

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

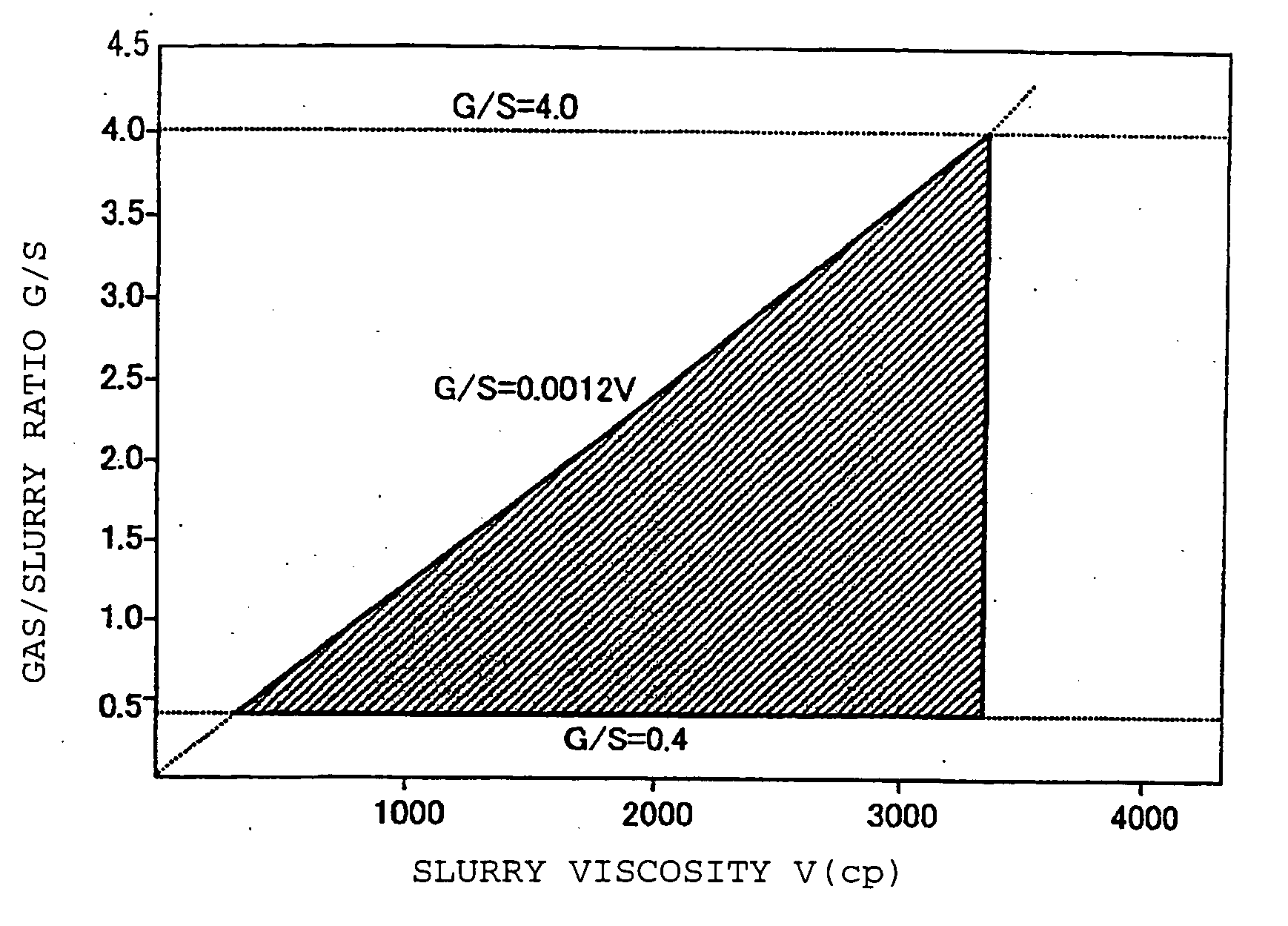

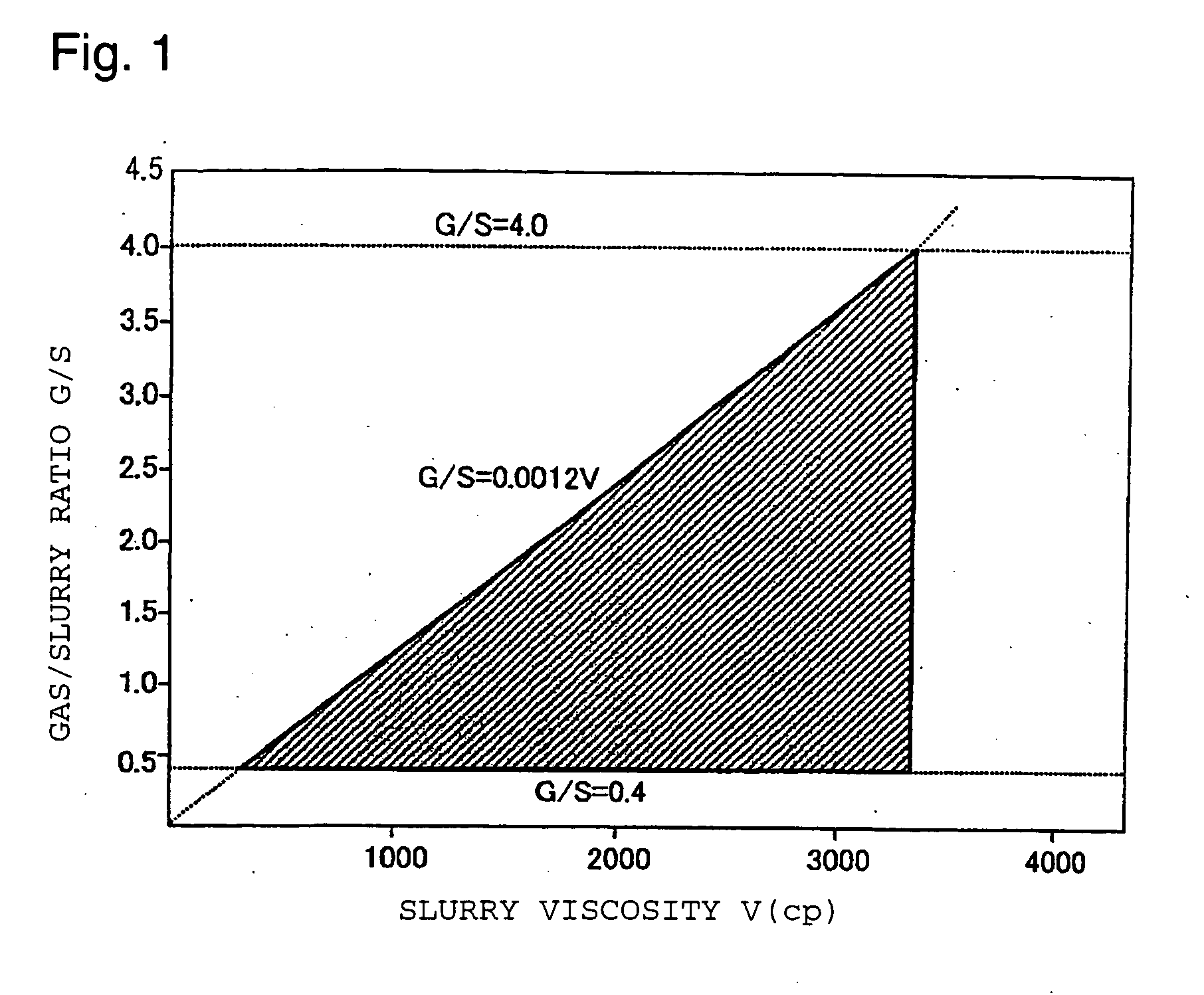

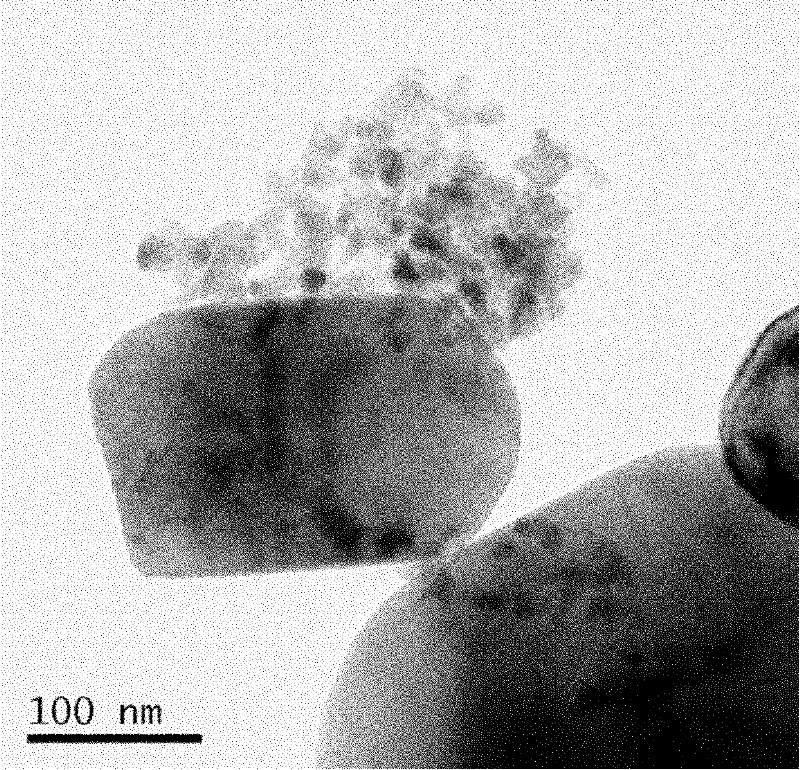

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

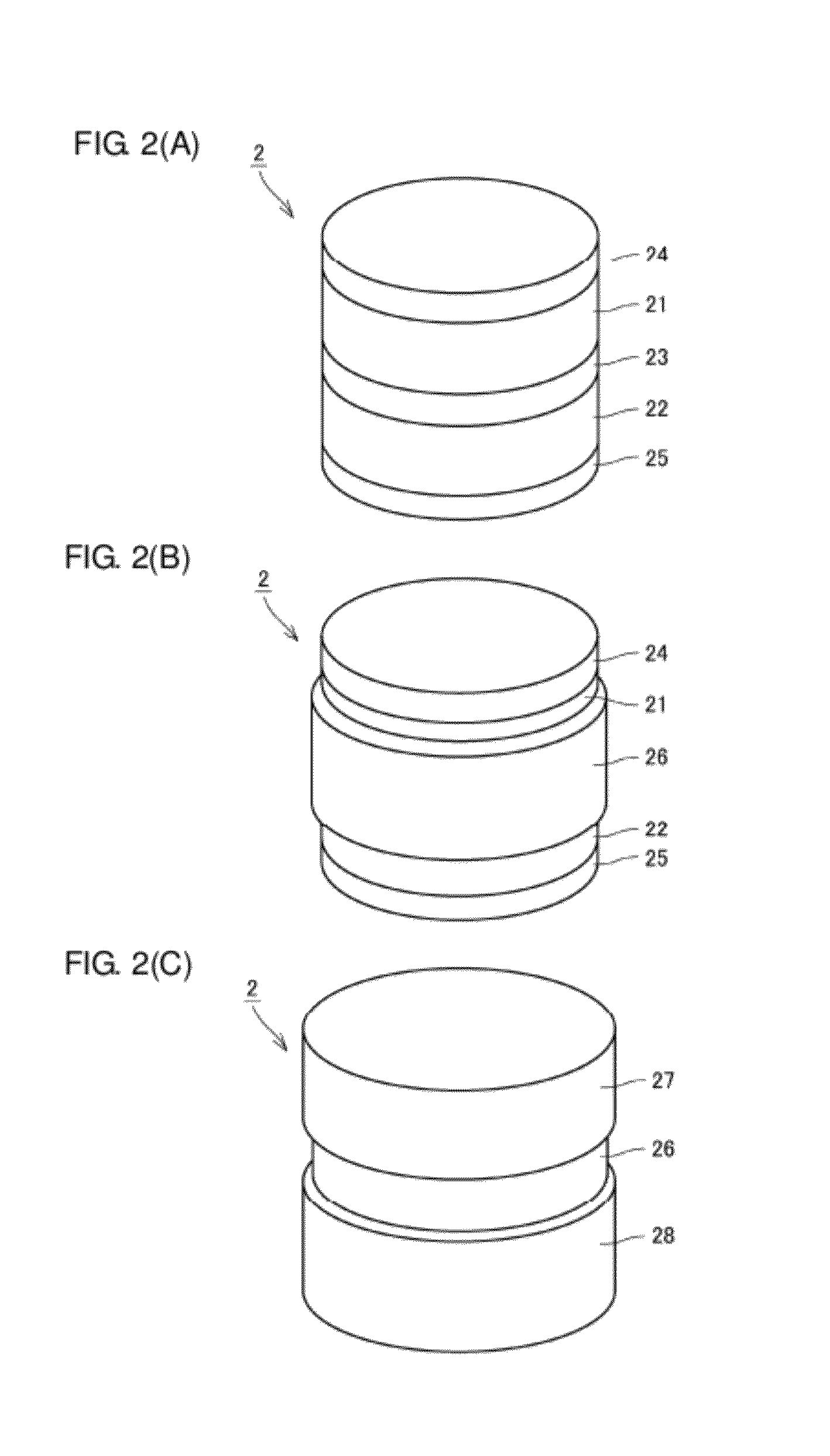

Positive electrode active material for lithium secondary battery and positive electrode including same

ActiveUS20150093580A1Increase volumetric energy densityGood rate characteristicsCell electrodesSynthetic resin layered productsLithium-ion batteryMaterials science

There is provided a positive electrode active material capable of achieving a high volume energy density and yet superior rate characteristics when configured as a positive electrode for lithium secondary batteries. This positive electrode active material comprises a plurality of secondary particles each comprising primary particles composed of a lithium-nickel based complex oxide having a layered rock-salt structure. The plurality of secondary particles have a volume-based average particle diameter D50 of 5 to 100 μm, and at least part of the plurality of secondary particles are coarse secondary particles having a particle diameter of 9 μm or greater. The coarse secondary particles have a voidage of 5 to 25%, and the ratio of through holes among all voids in the coarse secondary particles is 70% or greater.

Owner:NGK INSULATORS LTD

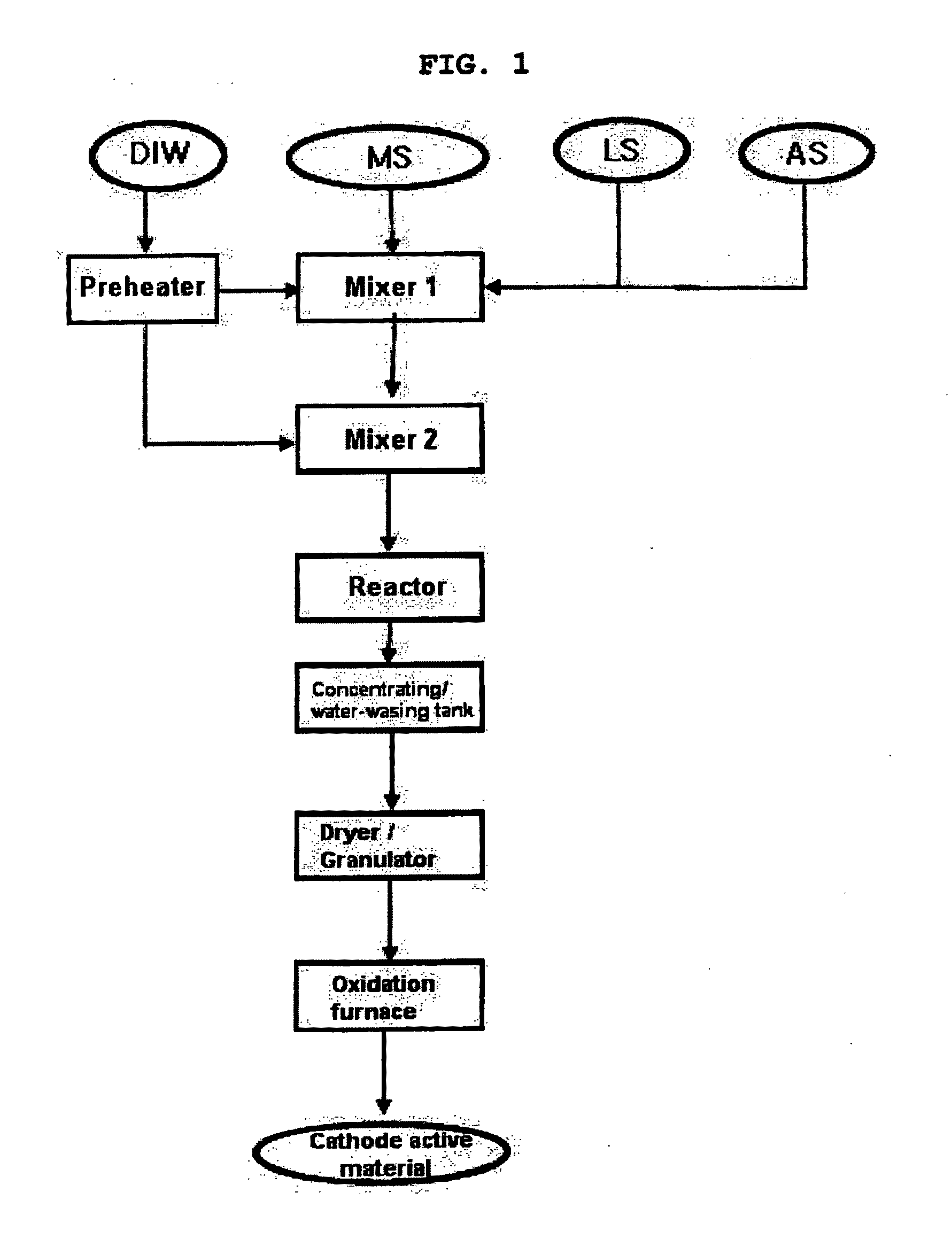

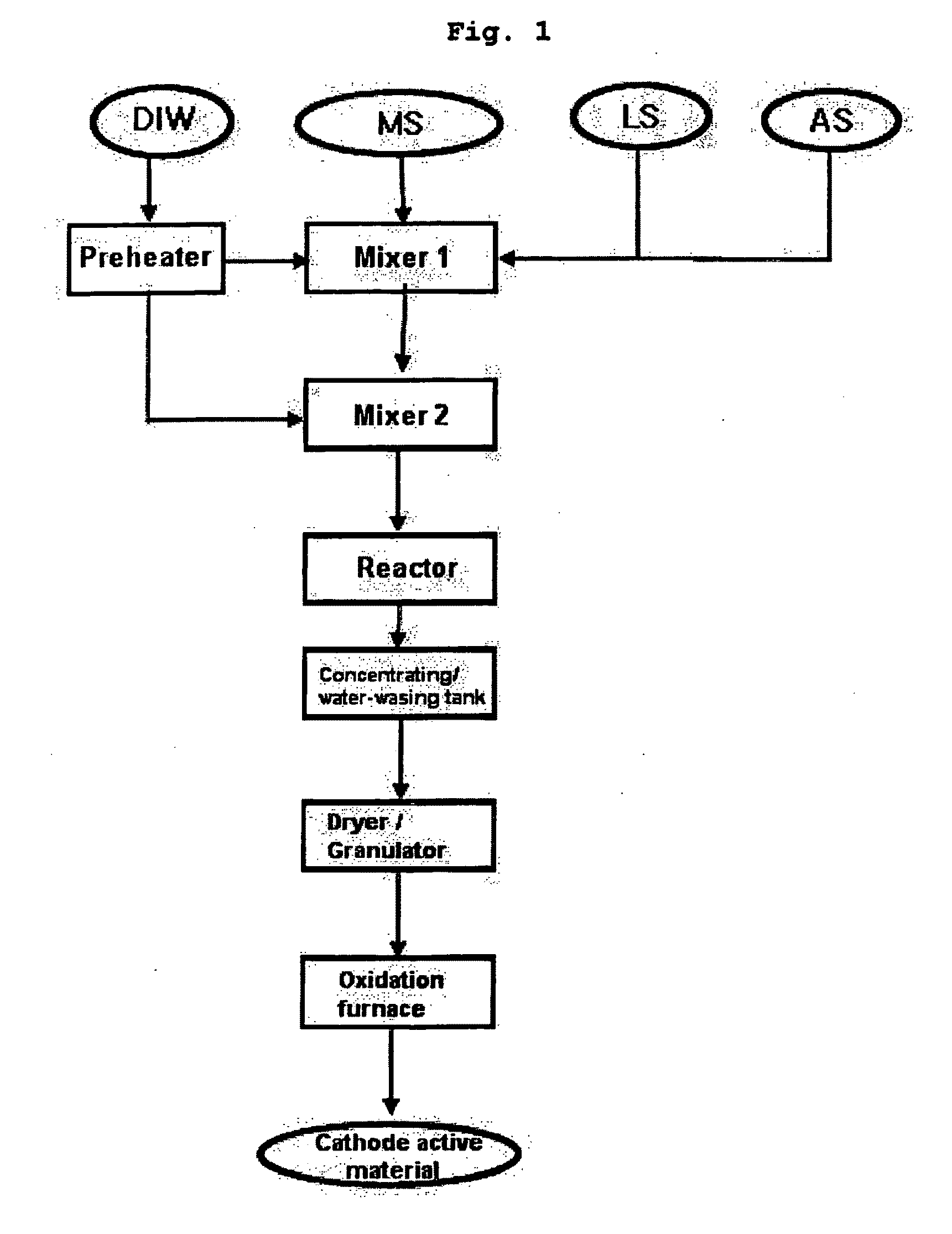

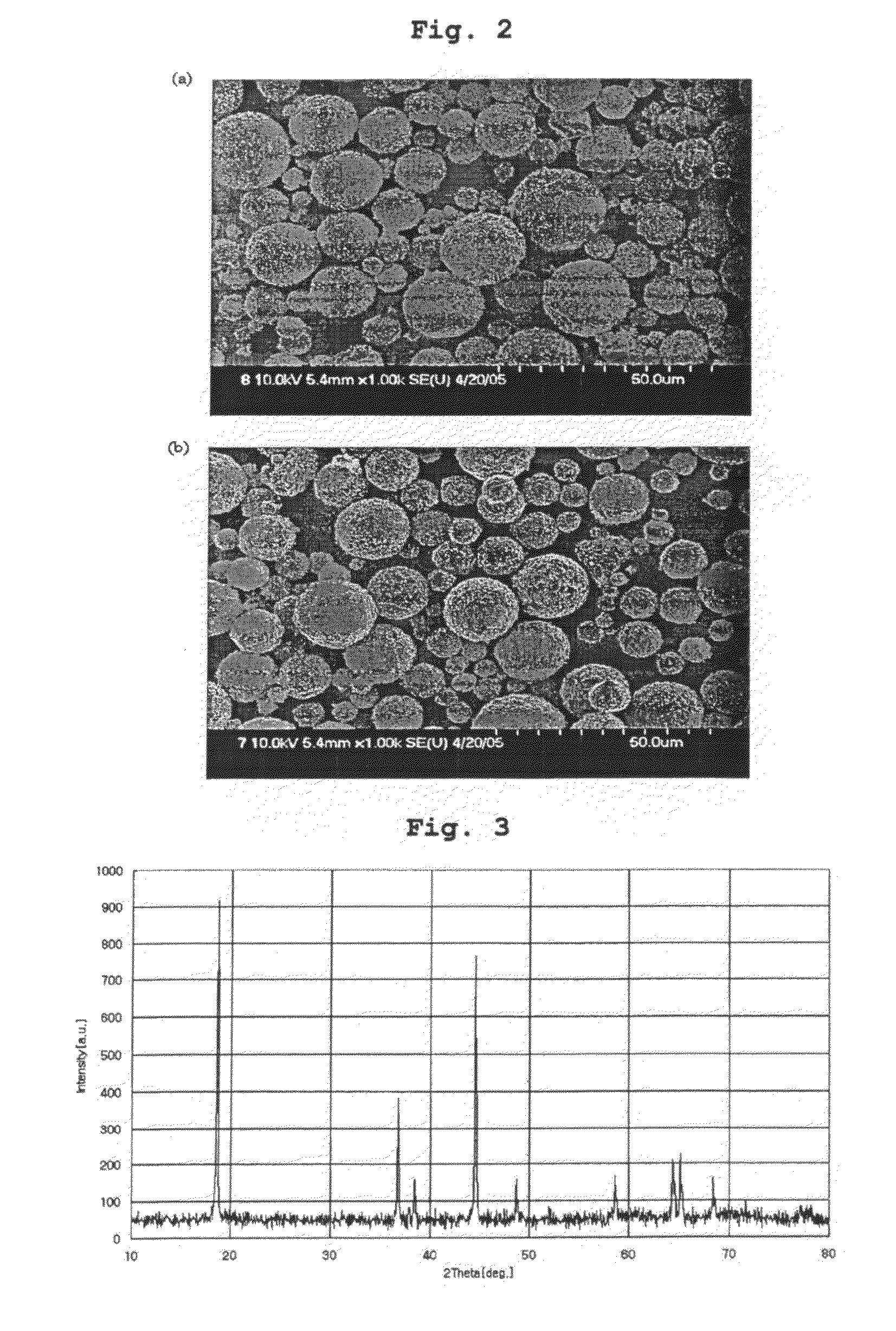

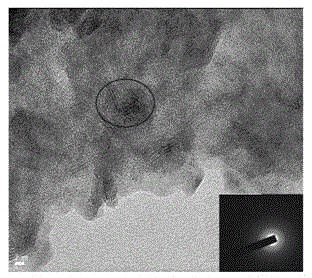

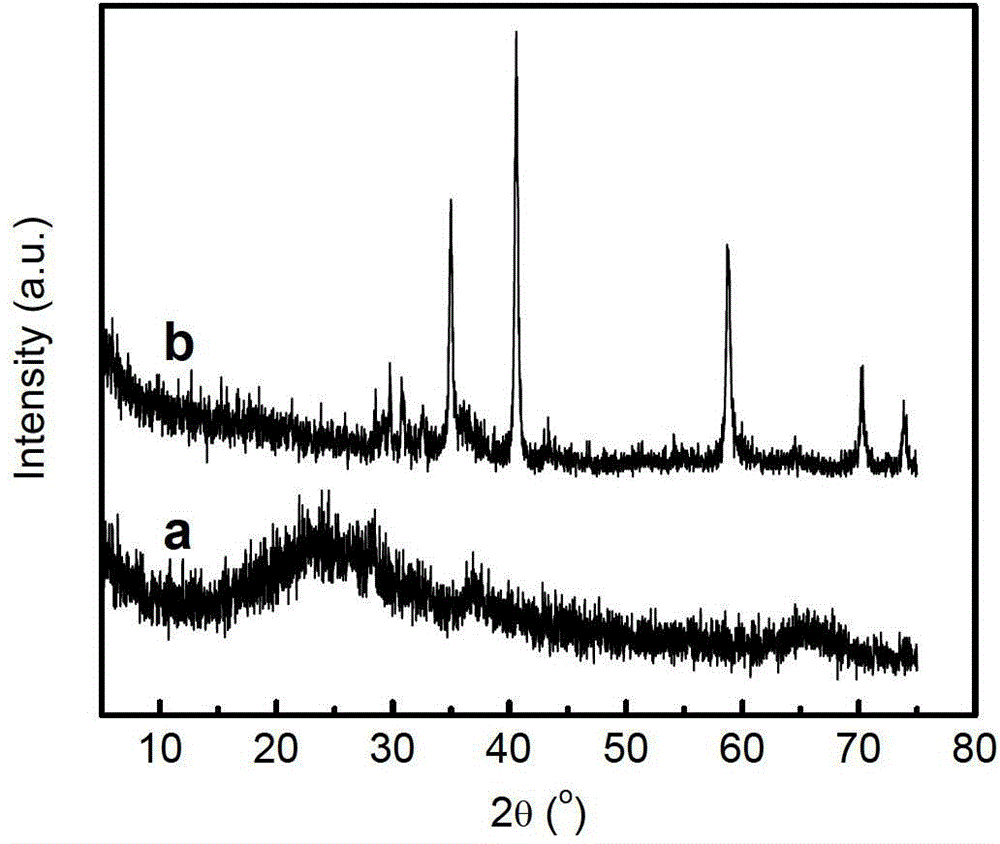

Preparation Method of Lithium-Metal Composite Oxides

ActiveUS20100227221A1High Capacity FeaturesImproved cycle life characteristicsLithium compoundsActive material electrodesLithium metalElectrochemistry

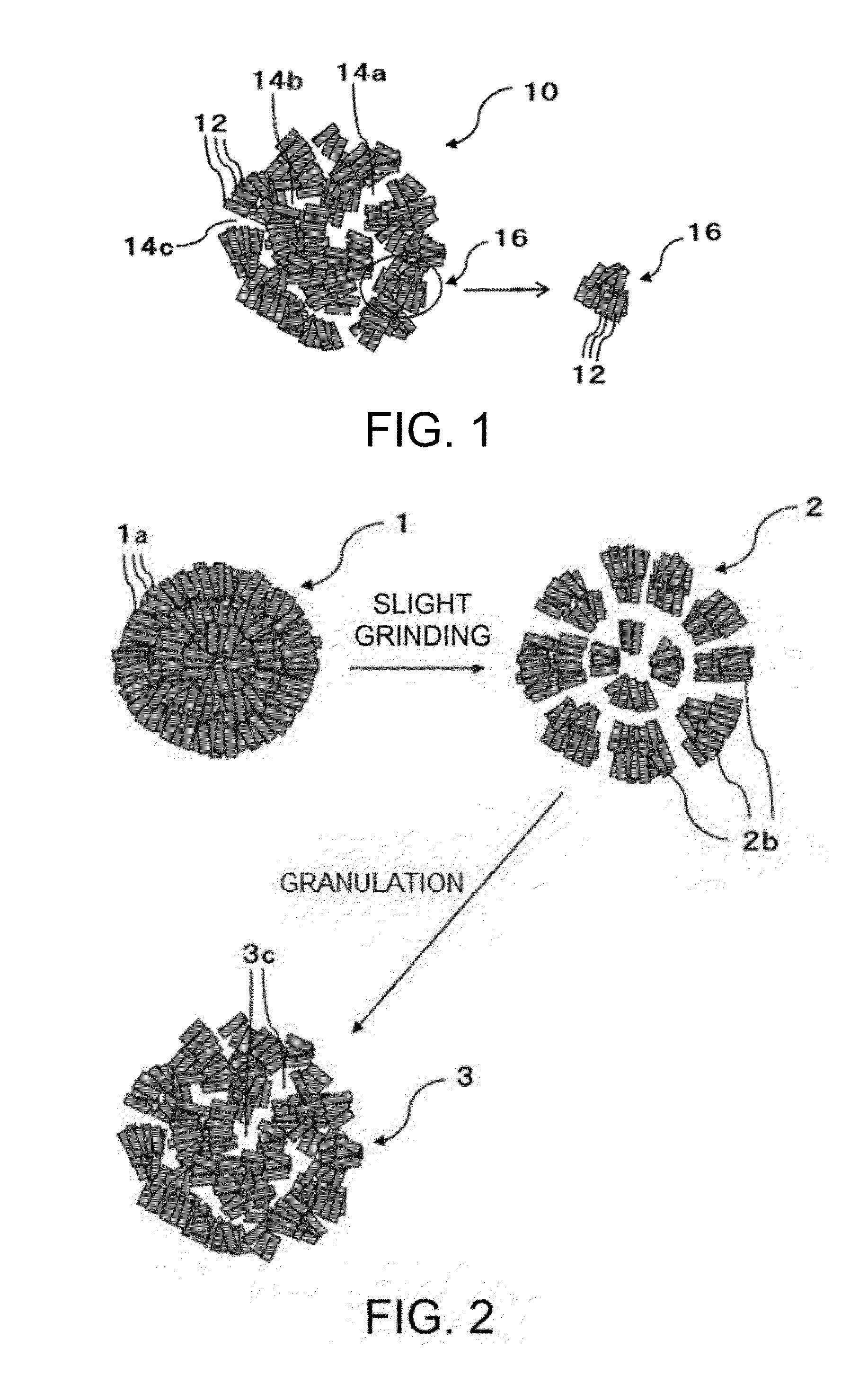

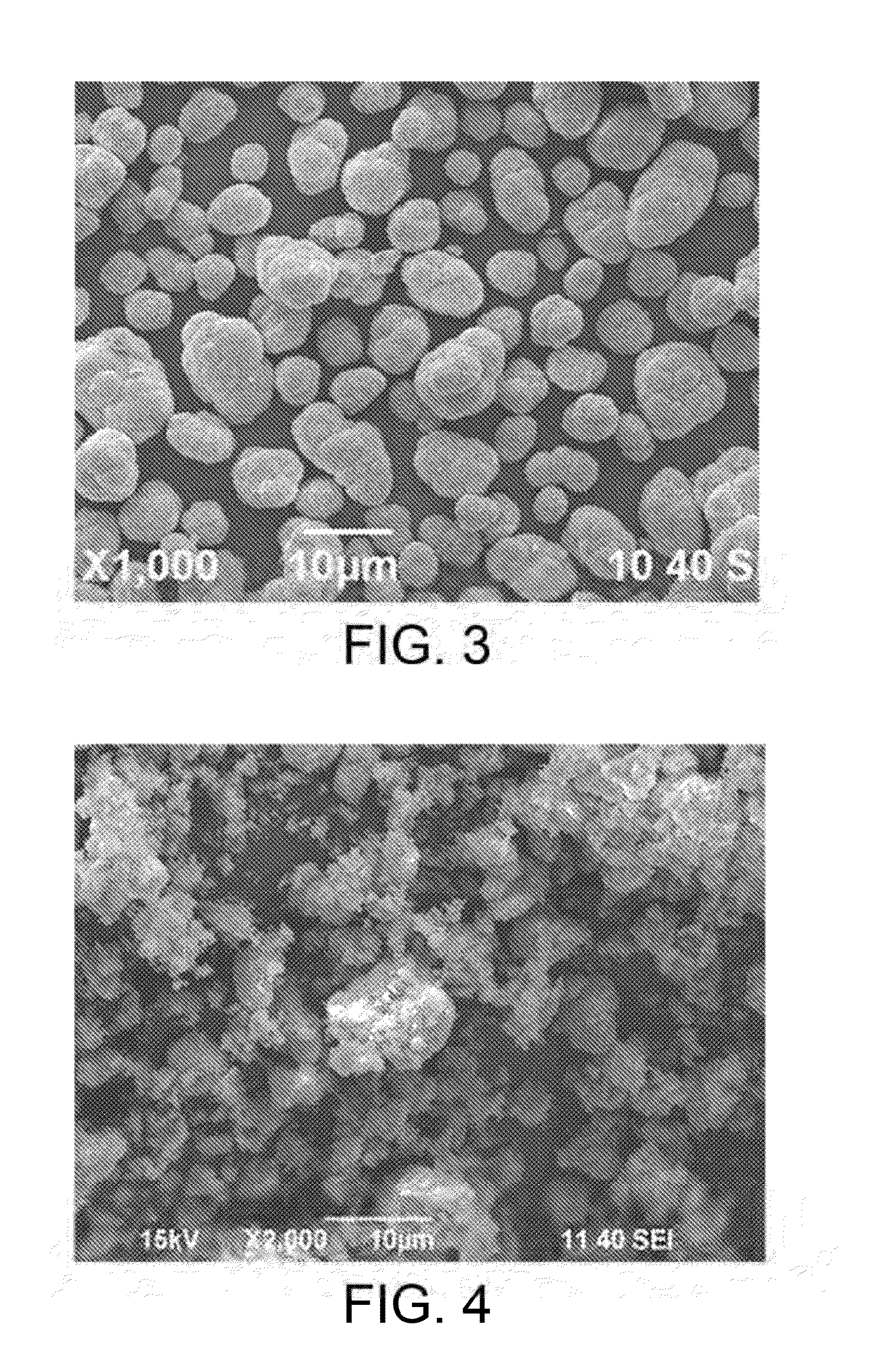

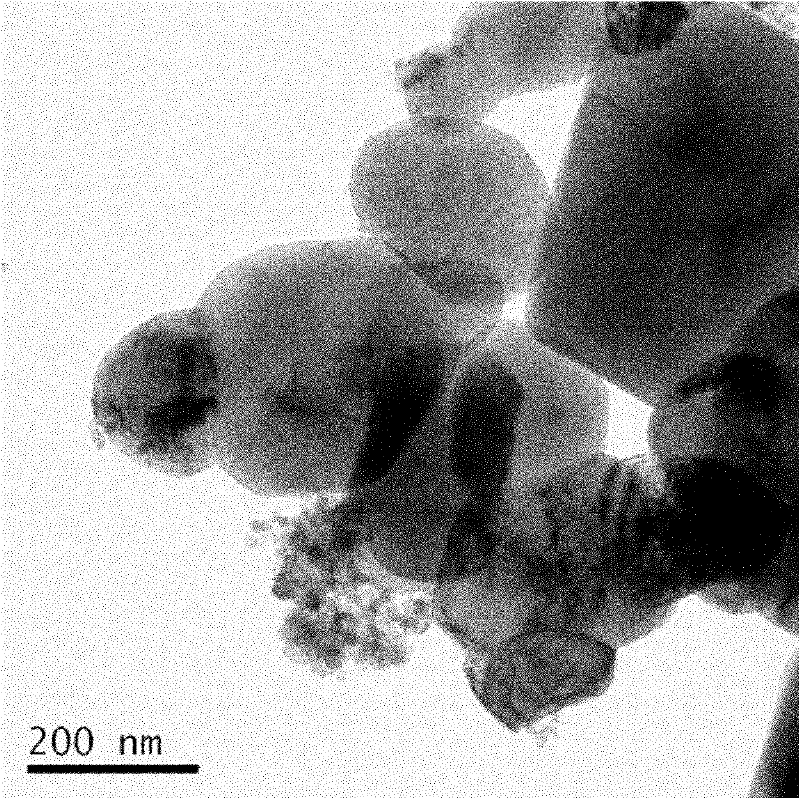

Disclosed is a method for preparing a lithium-metal composite oxide, the method comprising the steps of: (a) mixing an aqueous solution of one or more transition metal-containing precursor compounds with an alkalifying agent and a lithium precursor compound to precipitate hydroxides of the transition metals; (b) mixing the mixture of step (a) with water under supercritical or subcritical conditions to synthesize a lithium-metal composite oxide, and drying the lithium-metal composite oxide; and (c) subjecting the dried lithium-metal composite oxide either to calcination or to granulation and then calcination. Also disclosed are an electrode comprising the lithium-metal composite oxide, and an electrochemical device comprising the electrode. In the disclosed invention, a lithium-metal composite oxide synthesized based on the prior supercritical hydrothermal synthesis method is subjected either to calcination or to granulation and then calcination. Thus, unlike the prior dry calcination method or wet precipitation method, a uniform solid solution can be formed and the ordering of metals in the composite oxide can be improved. Accordingly, the lithium-metal composite oxide can show crystal stability and excellent electrochemical properties.

Owner:HANWHA CHEMICAL CORPORATION +1

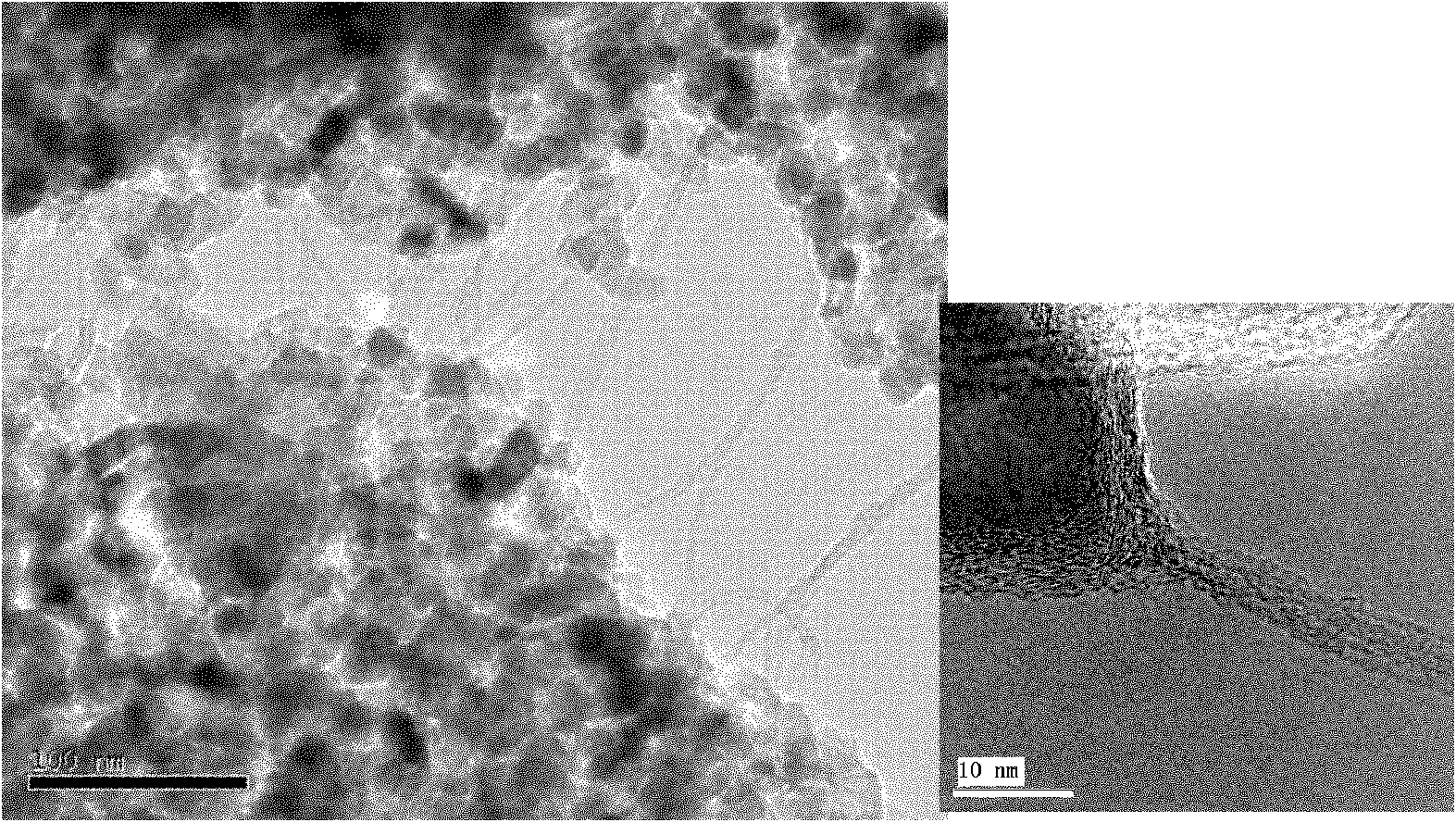

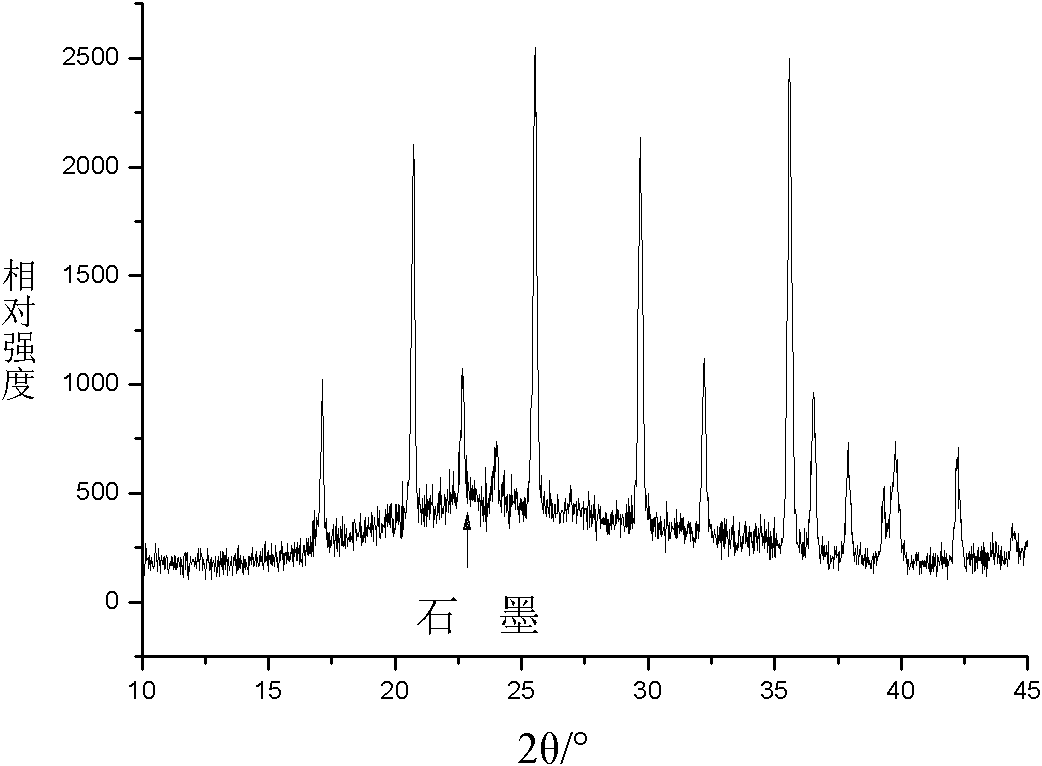

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

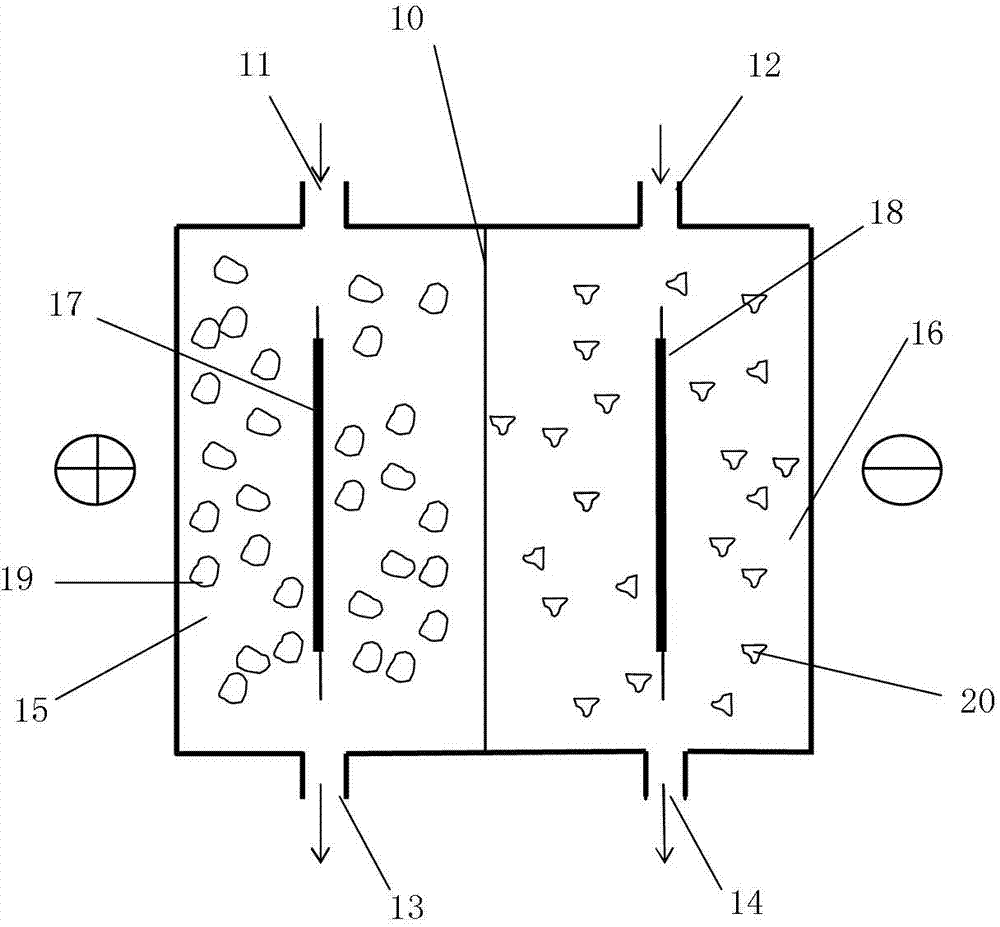

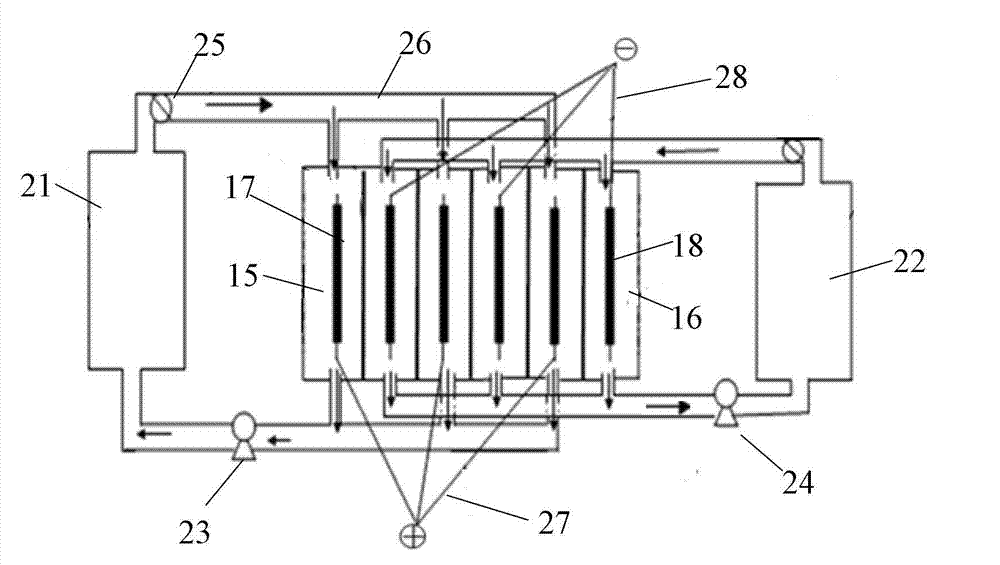

Semi-solid flow cell

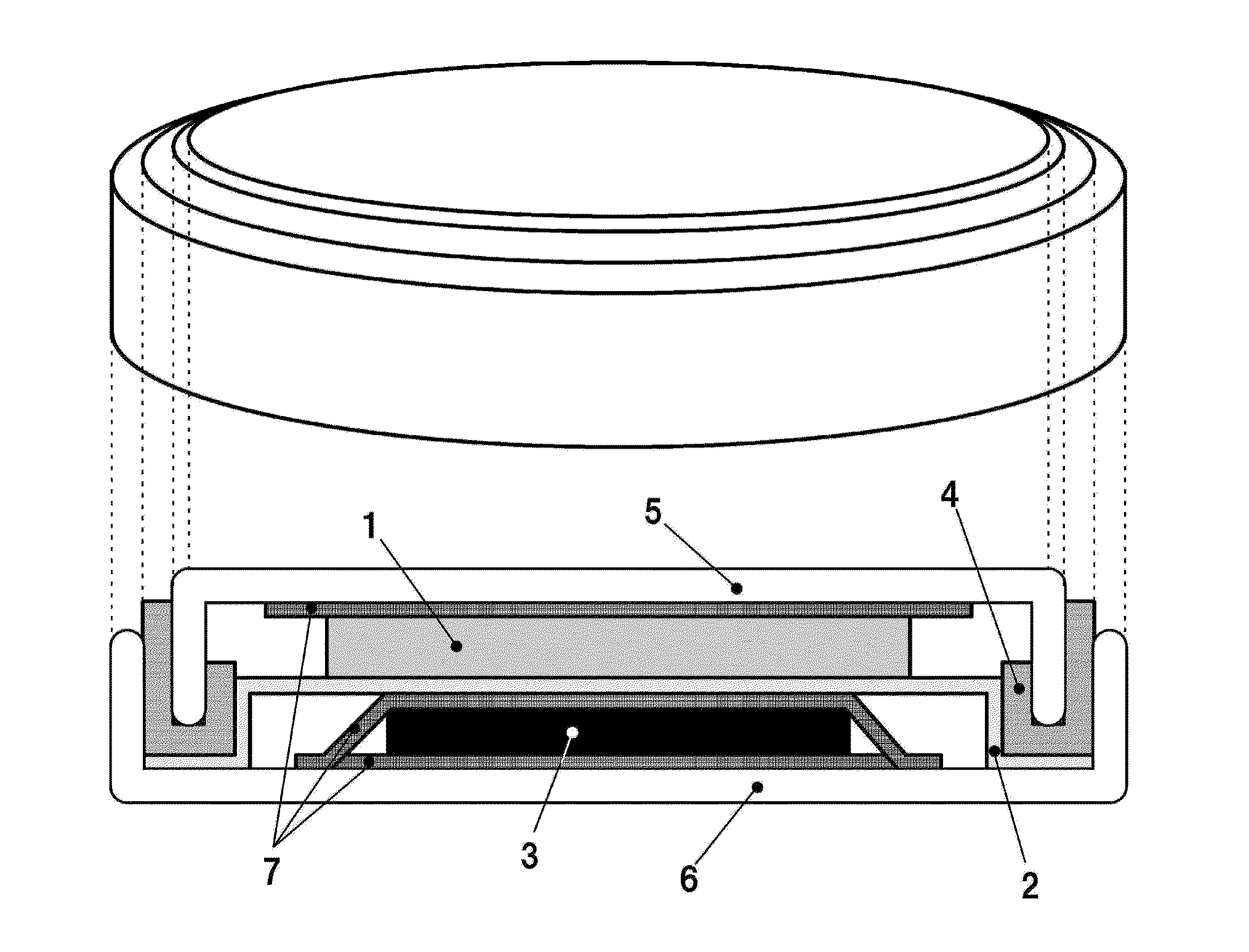

ActiveCN103247816AIncrease working current densityGood rate characteristicsFinal product manufactureRegenerative fuel cellsElectrochemical responseElectrical battery

Owner:南京竞予能源有限公司

Nickel-cobalt-maganese-based compound particles and process for producing the nickel-cobalt-manganese-based compound particles, lithium composite oxide particles and process for producing the lithium composite oxide particles, and non-aqueous electrolyte secondary battery

ActiveUS20130045421A1Good thermal stabilityLess thermal stabilitySynthetic resin layered productsCellulosic plastic layered productsComposite oxideChemistry

The present invention relates to nickel-cobalt-manganese-based compound particles which have a volume-based average secondary particle diameter (D50) of 3.0 to 25.0 μm, wherein the volume-based average secondary particle diameter (D50) and a half value width (W) of the peak in volume-based particle size distribution of secondary particles thereof satisfy the relational formula: W≦0.4×D50, and can be produced by dropping a metal salt-containing solution and an alkali solution to an alkali solution at the same time, followed by subjecting the obtained reaction solution to neutralization and precipitation reaction. The nickel-cobalt-manganese-based compound particles according to the present invention have a uniform particle size, a less content of very fine particles, a high crystallinity and a large primary particle diameter, and therefore are useful as a precursor of a positive electrode active substance used in a non-aqueous electrolyte secondary battery.

Owner:TODA IND

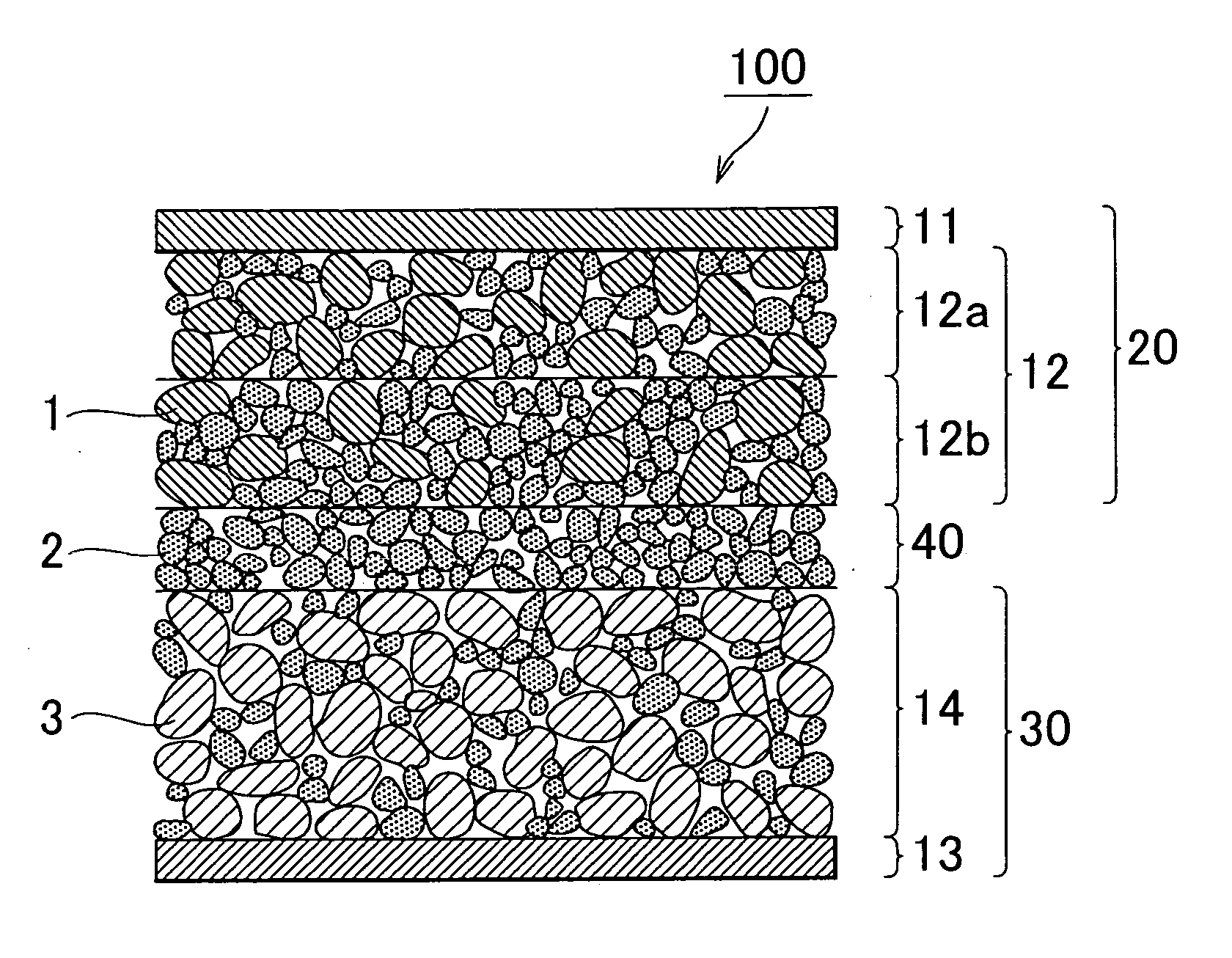

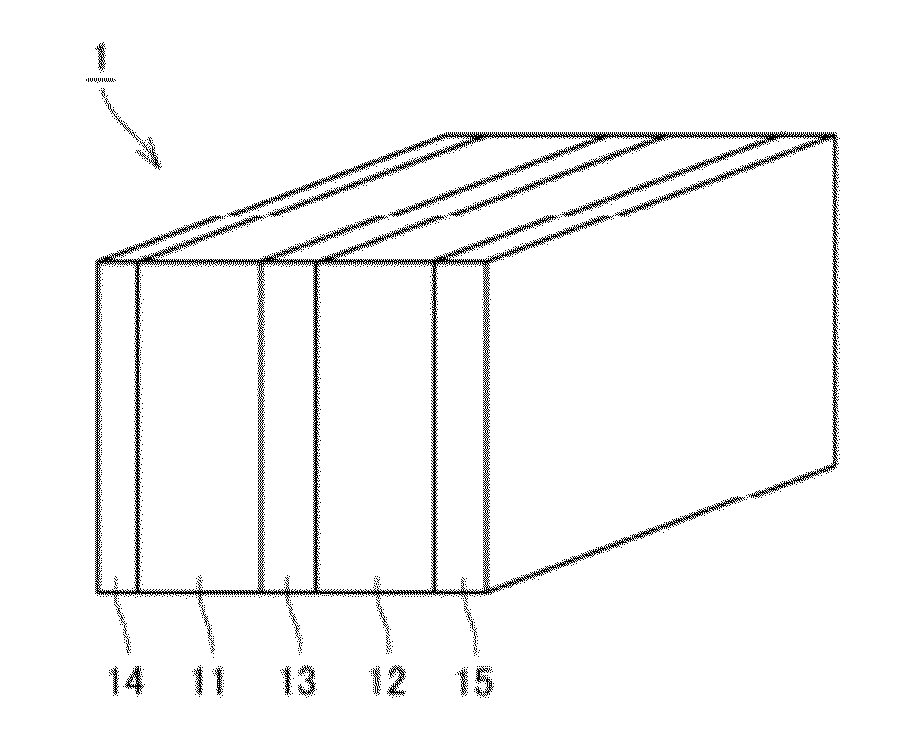

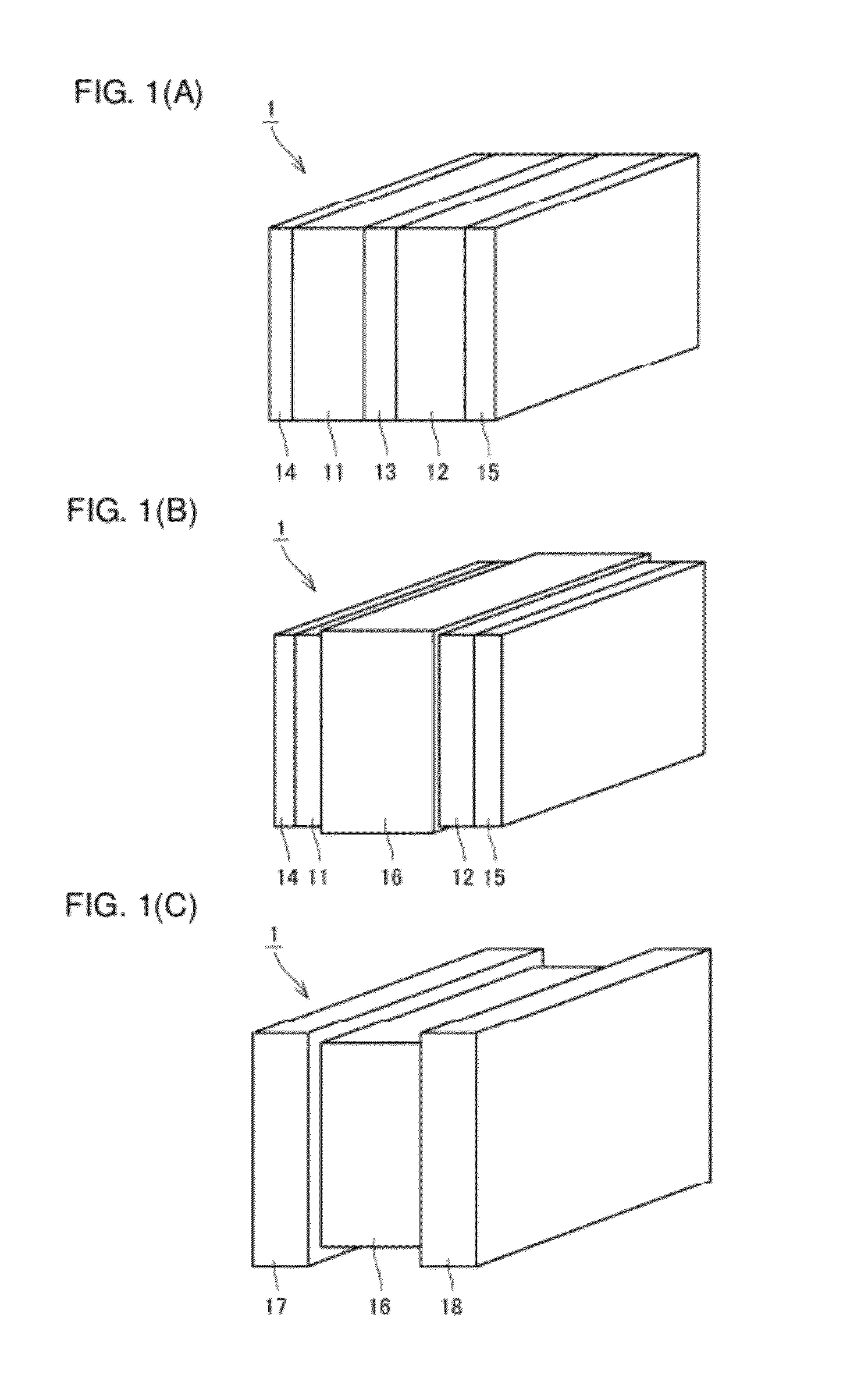

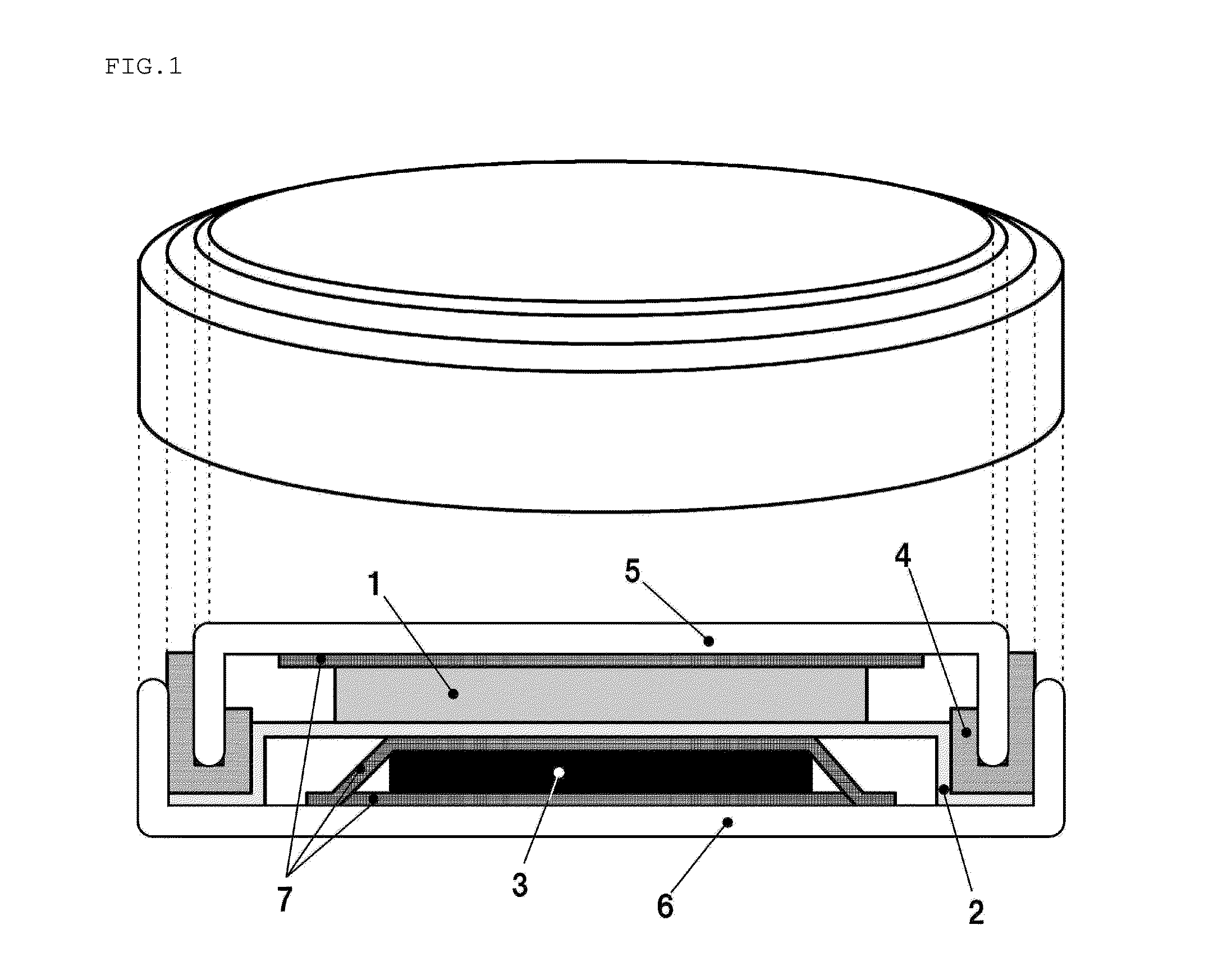

All-solid battery

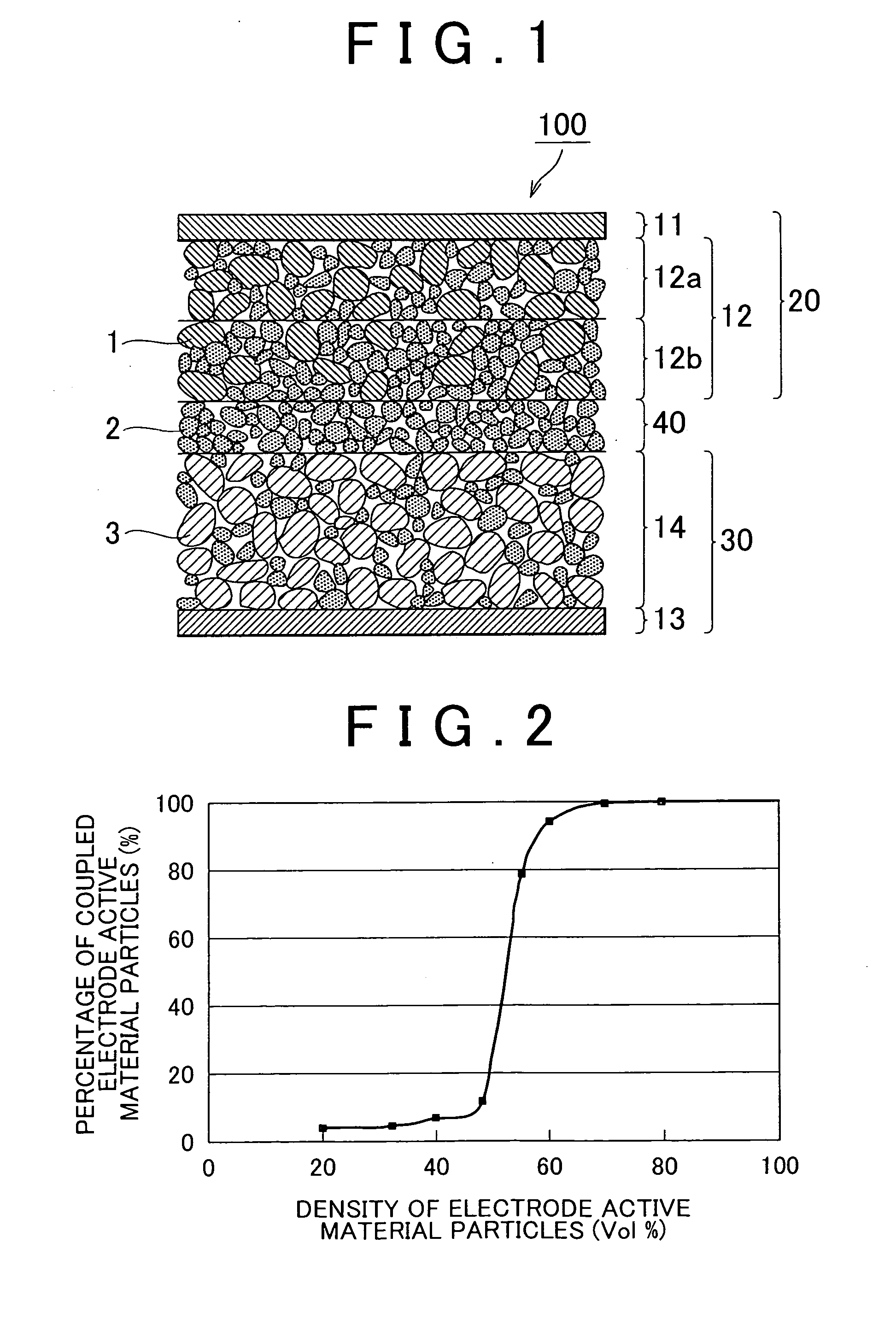

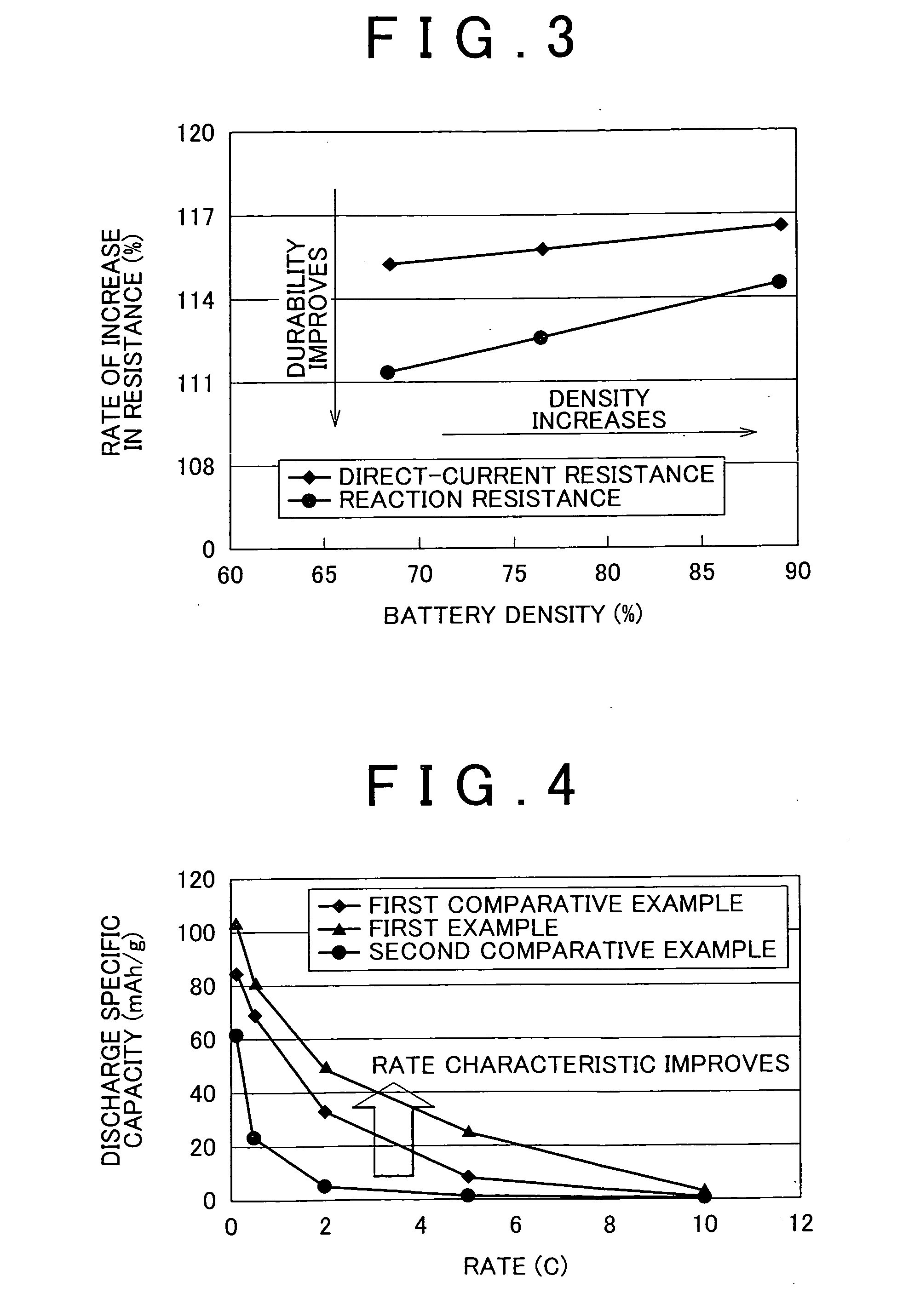

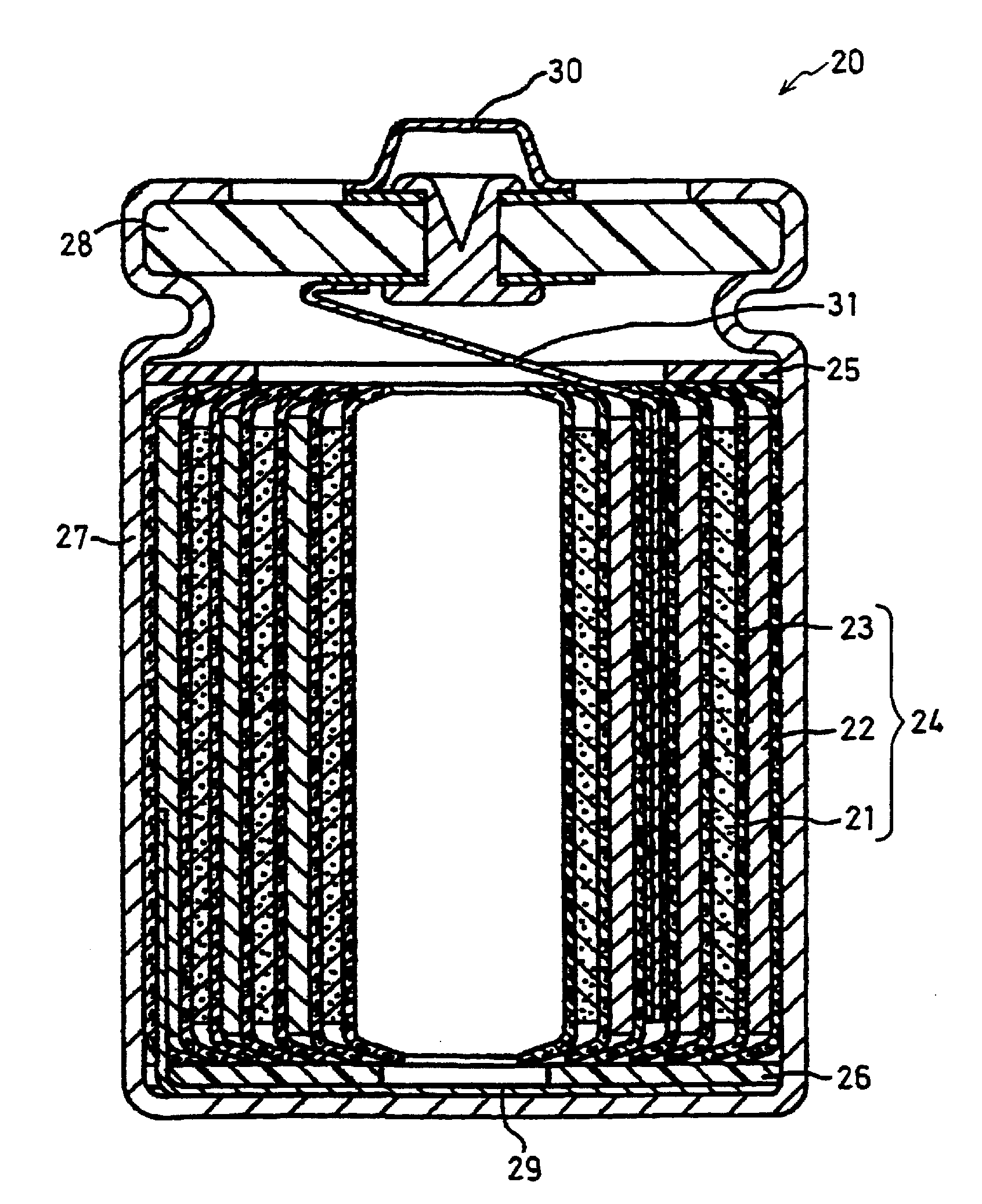

ActiveUS20120115028A1Reduced diffusion resistanceEnhanced rate characteristicFinal product manufactureActive material electrodesSolid-state batteryCurrent collector

An all-solid battery is formed so that an electrode active material layer of at least one of positive and negative electrodes has a composition distribution such that a local volume ratio, expressed by a ratio of a volume of an electrode active material contained in a part of the electrode active material layer with respect to a volume of a solid electrolyte material contained in the part of the electrode active material layer, increases as the part of the electrode active material layer approaches from an interface of the solid electrolyte layer toward an interface of a current collector in a thickness direction of the electrode active material layer, and a voidage of the electrode active material layer increases as the part of the electrode active material layer approaches from the interface of the solid electrolyte layer toward the interface of the current collector in the thickness direction.

Owner:TOYOTA JIDOSHA KK

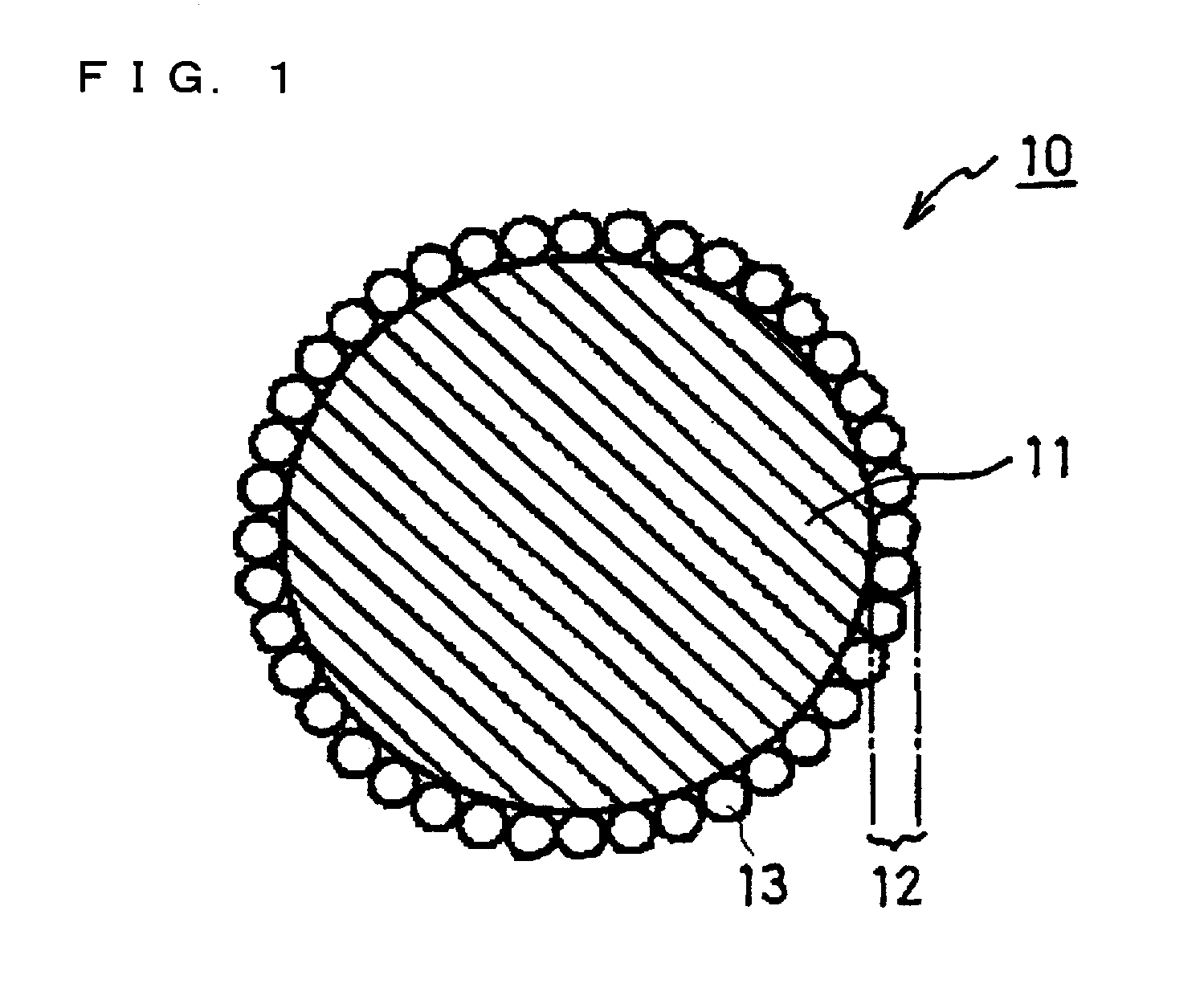

Positive electrode active material particles for lithium ion secondary batteries, positive electrode using the same, and lithium ion secondary battery

ActiveUS20120231334A1Rate characteristic be improveImprove characteristicMaterial nanotechnologyElectrode carriers/collectorsOlivinePhosphate

Positive electrode active material particles for lithium ion secondary batteries include: a core particle including a first olivine-structured, lithium-containing phosphate compound which includes Fe and / or Mn and Li; and a shell layer attached to the surface of the core particle. The shell layer includes a second olivine-structured, lithium-containing phosphate compound which includes Fe and / or Mn and Li. At least the core particle includes a phosphorous compound represented by the formula (1): MemPnOp, where Me is Fe and / or Mn, 0<m≦3, 0<n≦3, and 0≦p≦5; a content C1 of the phosphorous compound in the core particle is 0.5 to 3 mol %; and when the shell layer includes the phosphorous compound represented by the formula (1), a content C2 of the phosphorous compound in the shell layer is smaller than the C1.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Slurry composition for secondary cell positive electrode, secondary cell positive electrode and secondary cell

InactiveUS20040020763A1Large capacityImprove rate characteristicsCellsNon-aqueous electrolyte accumulatorsLithiumLiquid medium

A slurry composition for a positive electrode for a lithium ion secondary battery, comprising a polymer A wherein a HOMO value by a semiempirical method molecular orbital calculation is -13.5 eV to -10 eV and a content of ethylene repeatingunits is 30 mol % to 95 mol %; apolymer B wherein a HOMO valueby a semi empirical method molecular orbital calculation is -13.5 eV to -10 eV, a glass transition temperature is -80° C. to 0° C., and a gel content is 50 wt % or more; an active material for a positive electrode; a conductivity adding agent; and a liquid medium C in which the polymer A dissolves but the polymer B does not dissolve. According to the composition, a lithium ion secondary battery having a large battery capacity, a good charge / discharge cycle characteristic and an improved rate characteristic can be realized.

Owner:ZEON CORP

Lithium-Metal Composite Oxides and Electrochemical Device Using the Same

ActiveUS20100227222A1High Capacity FeaturesImproved cycle life characteristicsLithium compoundsMagnetic materialsLithium metalElectrochemistry

Disclosed is a lithium-containing metal composite oxide comprising paramagnetic and diamagnetic metals, which satisfies any one of the following conditions: (a) the ratio of intensity between a main peak of 0±10 ppm (Io PPm) and a main peak of 240±140 ppm (I240 pPm), Uoppm / 124o PPm), is less than 0.117·Z wherein Z is the ratio of moles of the diamagnetic metal to moles of lithium; (b) the ratio of line width between the main peak of 0±10 ppm (Io PPm) and the main peak of 240+140 ppm (I24o PPm), (W24o PPm / WO ppm), is less than 21.45; and (c) both the conditions (a) and (b), the peaks being obtained according to the 7Li—NMR measurement conditions and means disclosed herein. Also, an electrode comprising the lithium-containing metal composite oxide, and an electrochemical device comprising the electrode are disclosed. The lithium-containing multicomponent metal composite oxide shows crystal stability and excellent physical properties as a result of an improved ordering structure of metals, in which the components of the composite oxide are uniformly distributed. Thus, it can provide a battery having high capacity characteristics, long cycle life characteristics and improved rate characteristics.

Owner:HANWHA CHEMICAL CORPORATION +1

Slurry composition, electrode and secondary cell

ActiveUS7316864B2Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

Owner:ZEON CORP

Lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery

ActiveCN104347853AHigh specific capacityCapacity decaySecondary cellsPositive electrodesManganeseManganate

The invention provides a lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery. The composite positive electrode material is of a core-shell structure. The inner layer of the composite positive electrode material is an in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate LiMn2O4-LiNi1-x-yCox(Al / Mn)yO2, wherein x is more than 0 and less than or equal to 0.25, and y is more than 0 and less than or equal to 0.15; the outer shell of the composite positive electrode material is a metal oxide coated layer. According to the lithium manganate composite positive electrode material and the preparing method thereof, the in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate is obtained after in-site sintering of a manganese source, a nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate precursor, and a lithium source, then shell-layer metal oxide is cladded by using spray drying, and finally the composite positive electrode material is obtained by combining a microwave sintering process. The composite positive electrode material provided by the invention has relatively high specific capacity, and excellent high temperature cycling and storage performances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electrode active material for all solid state secondary battery and all solid state secondary battery

ActiveUS20120308870A1Good rate characteristicsImprove battery performanceElectrode carriers/collectorsSolid electrolyte cellsAll solid stateCompression molding

An electrode active material for an all solid state secondary battery, which is able to have the controlled orientation of a crystal face at the interface between an electrode layer and an electrolyte layer in order to enhance the battery performance, and an all solid state secondary battery including the electrode active material. The electrode active material includes a carbon material having an intensity ratio (P002 / P100) of 600 or less between the X-ray diffraction peak intensity P002 in the (002) plane and the X-ray diffraction peak intensity P100 in the (100) plane, which are obtained when a surface of a compact prepared by compression molding of a powder of the carbon material at a pressure of 110 MPa is irradiated with X-ray. The all solid state secondary battery includes a positive electrode, a negative electrode, and a solid electrolyte, and the negative electrode contains the electrode active material.

Owner:MURATA MFG CO LTD

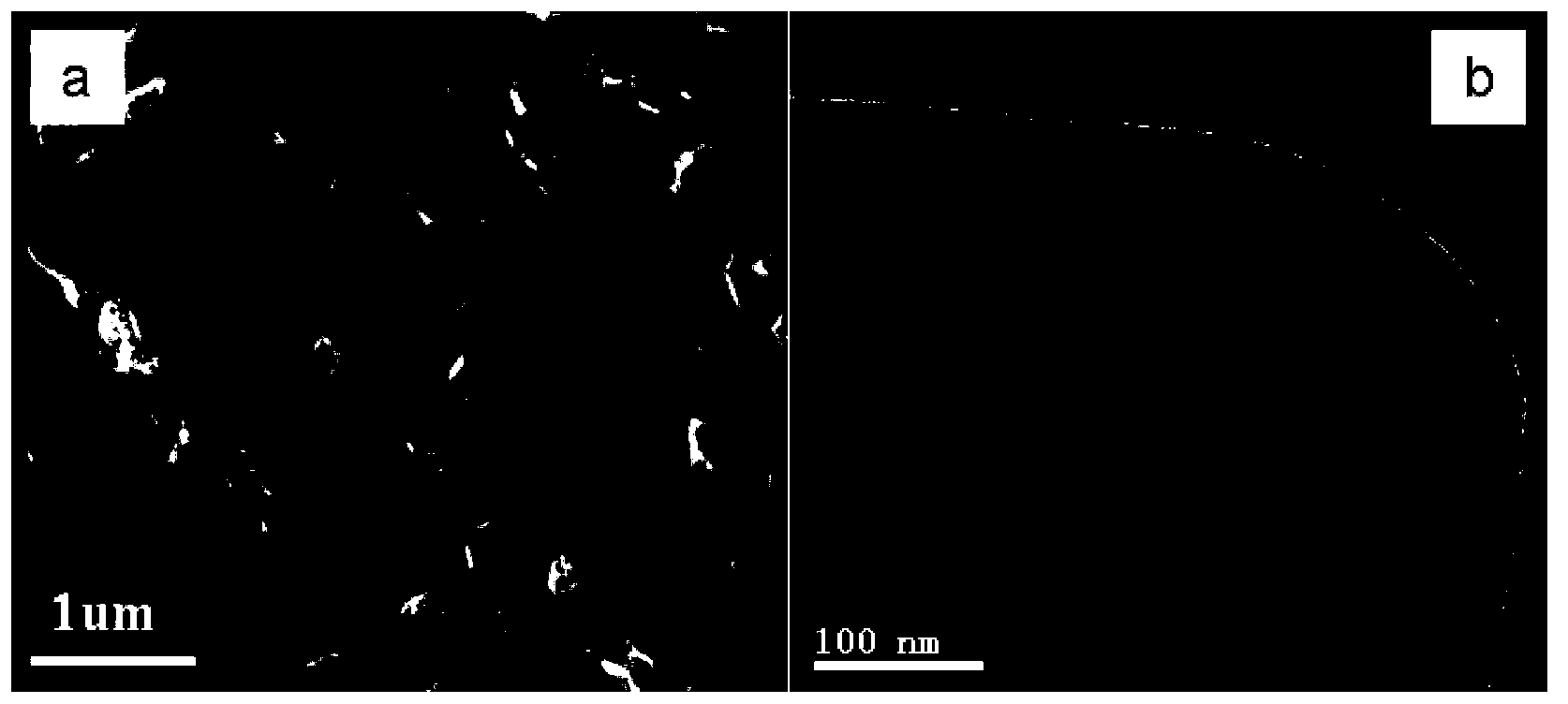

Preparation method of graphene quantum dot/nanometer silicon negative electrode material for lithium-ion battery

InactiveCN105742586ASimple methodLow costMaterial nanotechnologyCell electrodesCvd grapheneCapacitance

The invention provides a preparation method of a graphene quantum dot / nanometer silicon negative electrode material for a lithium-ion battery. Amino acid functional graphene quantum dots are prepared by high-temperature pyrolysis of a mixture of a citric acid and an amino acid as a carbon source; and then a graphene quantum dot / nanometer silicon compound is obtained by coating the graphene quantum dots on the surface of nanometer silicon particles. A research shows that the electron / ion conductivity of a silicon negative electrode is improved by introduction of the graphene quantum dots; and the compound has significantly improved specific capacitance and high rate capability and cycling stability as the negative electrode material for the lithium-ion battery. The preparation method can be widely applied to various high-capacity lithium-ion batteries.

Owner:JIANGNAN UNIV

Foam metal matrix oxide electrode used in lithium-ion battery cathode and preparation method thereof

ActiveCN102013470AExtended service lifeIncrease capacityElectrode carriers/collectorsOxide compositeAlloy

The invention relates to a preparation method of a foam metal matrix oxide electrode used in the lithium-ion battery cathode, relating to a metal electrode used in the lithium-ion battery cathode and a preparation method thereof. The invention aims to solve the problems of the existing lithium-ion battery anode material that the specific capacity is low, the cycle performance is poor and the preparation method is complicated. The foam metal matrix oxide electrode uses one or two of foam metals comprising Cu, Ni and Fe as the matrix. The preparation method of the foam metal matrix oxide electrode comprises the following steps: 1) cleaning with acid solution; 2) soaking with alkaline solution; and 3) generating one or two of the corresponding transition metal oxides, namely CuO, Cu2O, NiO, Ni2O, Fe2O3 and Fe3O4 on the foam metal in situ through low-temperature roasting and other steps to obtain the foam metal / transition metal oxide composite electrode. The preparation method is simple, the electrode has high specific capacity, long cycle life and excellent rate performance; and the electrode is suitable for the lithium-ion battery system of an electric vehicle.

Owner:HARBIN INST OF TECH

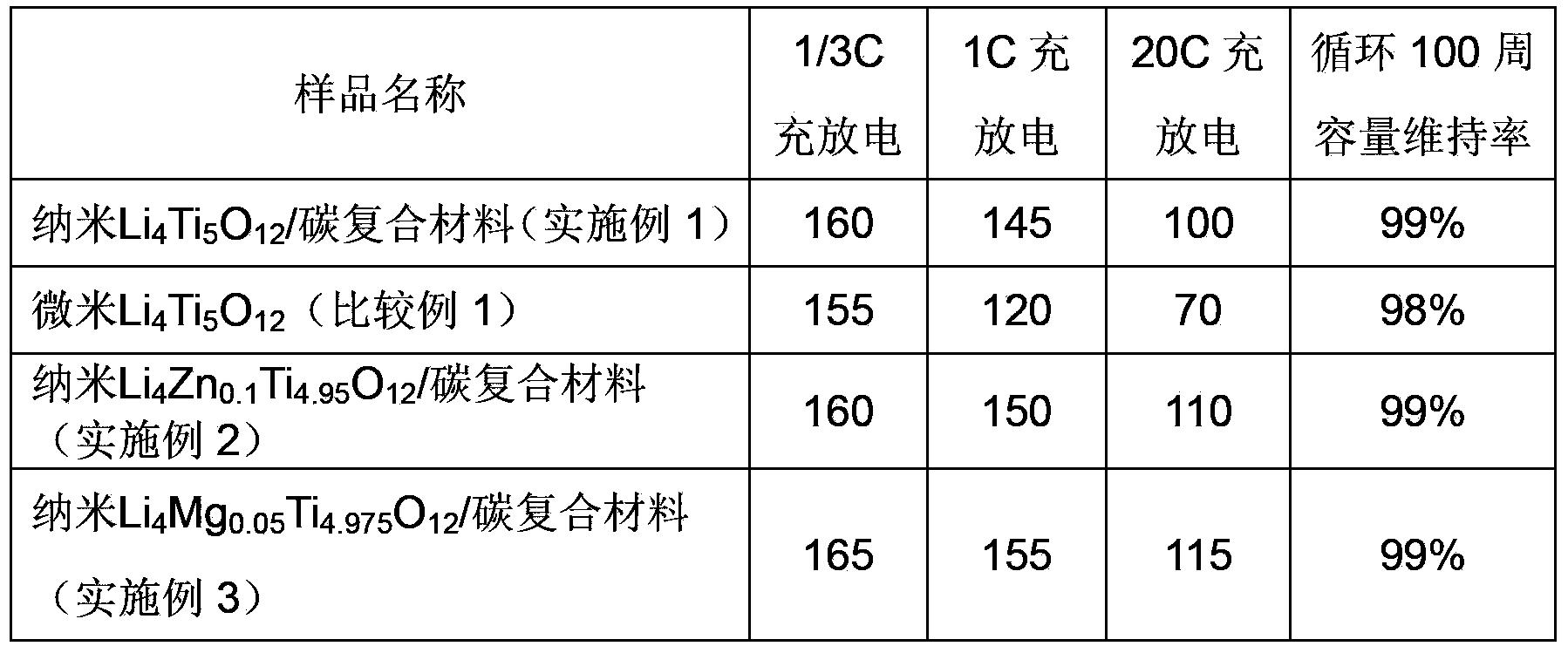

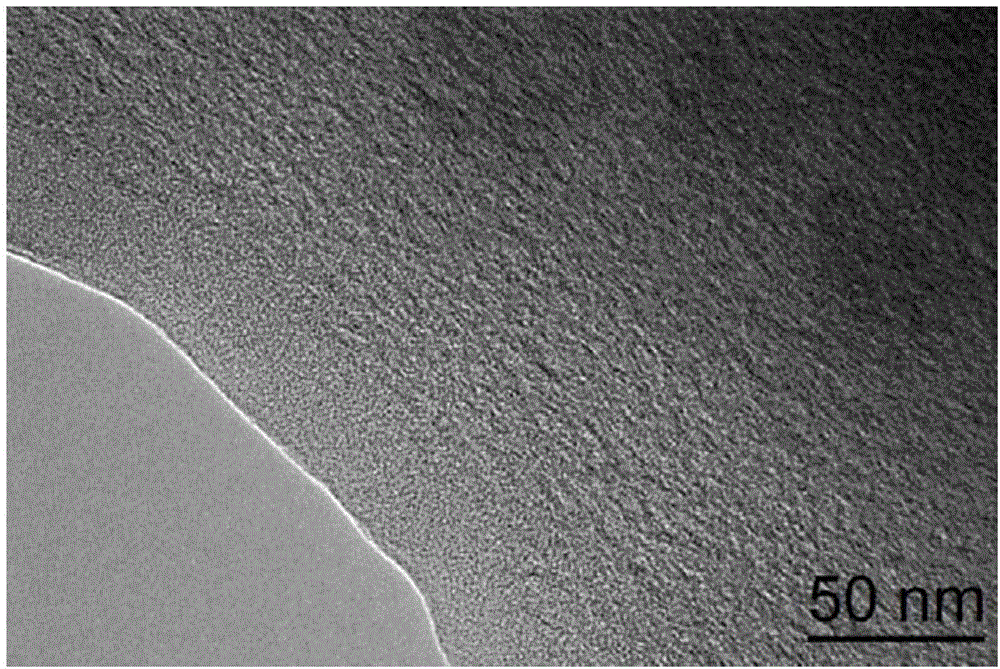

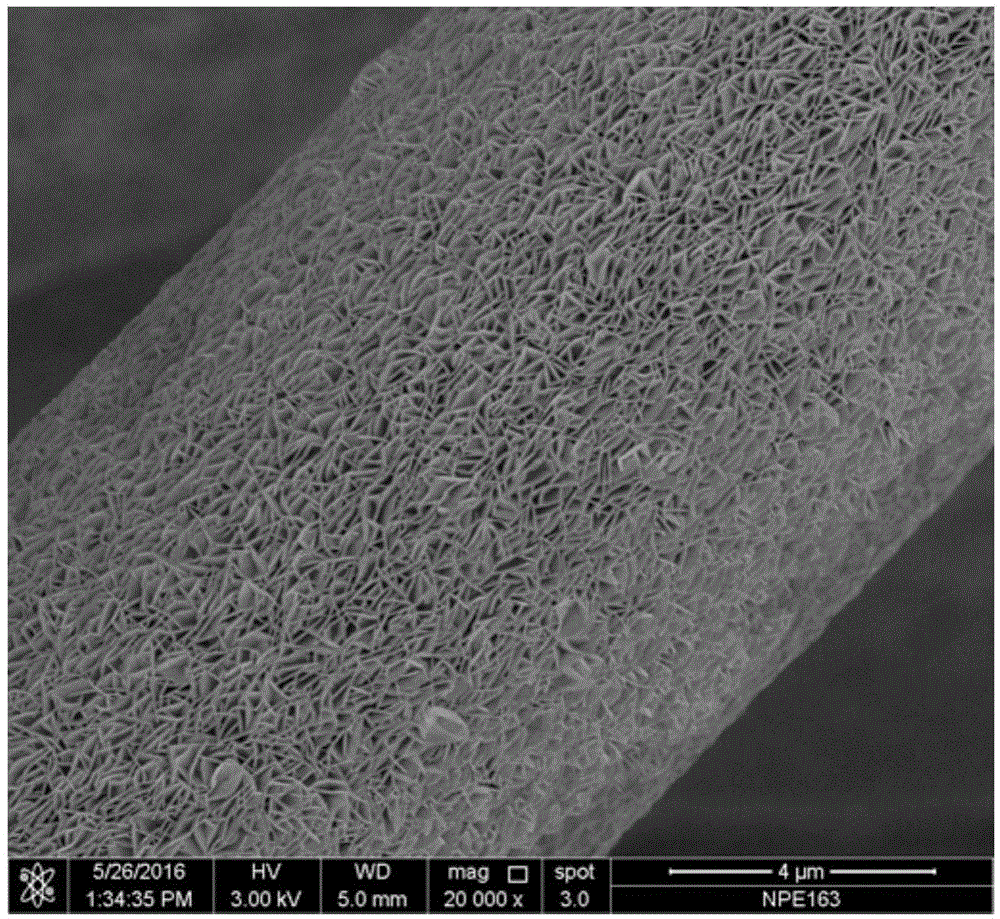

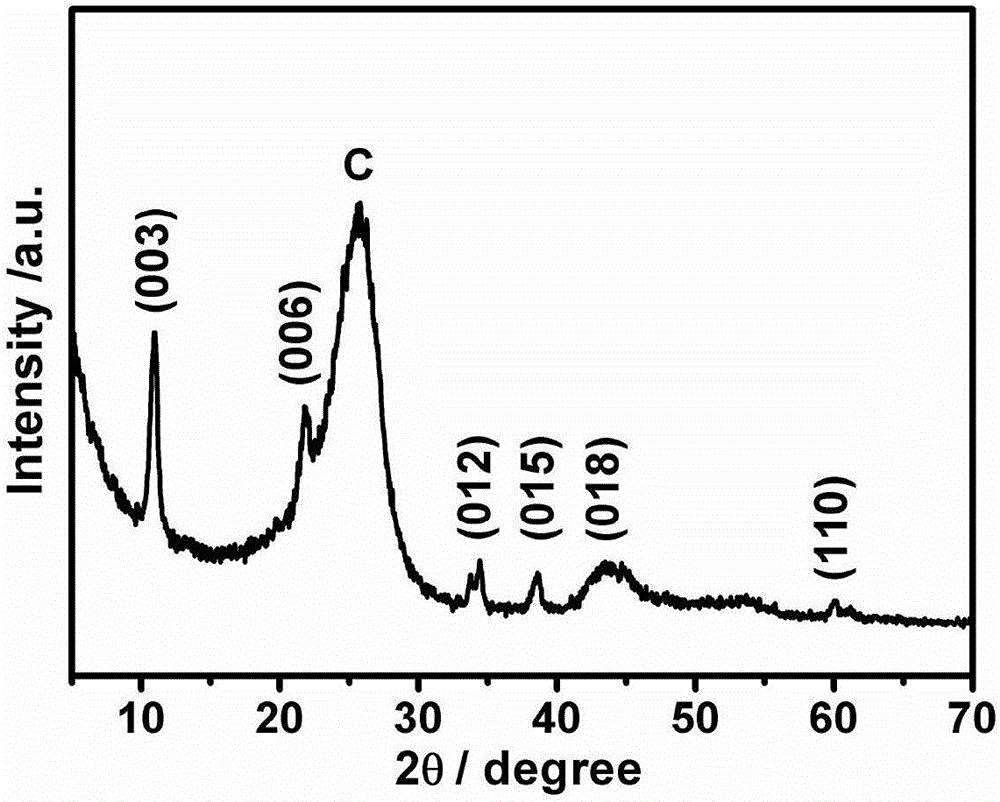

Carbon-clad spinel lithium titanate material, production method and application thereof

InactiveCN104253267AImprove power performanceGood rate characteristicsCell electrodesSecondary cellsCarbon compositesSolvent

The invention relates to a carbon-clad spinel lithium titanate Li4MxTiyO12 material used as a lithium ion battery cathode material, a production method and an application thereof. The cathode material is spinel type Li4MxTiyO12 or a mono or multiple other metallic element-doped compound Li4MxTiyO12. A synthetic method comprises the following steps: mixing an organic titanium solution and lithium salt liquid to prepare sol; aging the sol to obtain a lithium titanate gel predecessor; calcining the gel predecessor, and being conversed to the spinel lithium titanate material with nano size; or comprises the following steps: dispersing the prepared lithium titanate in a carbon source organic solution, removing the solution, and calcining to obtain the spinel lithium titanate / carbon composite material with nano size. Compared with lithium titanate Li4Ti5O12 prepared by a conventional method, the spinel lithium titanate material has better multiplying power characteristic, when the spinel lithium titanate material is used as a lithium ion battery cathode, the power performance of the cell can be obviously increased.

Owner:SHANGHAI ELECTRICGROUP CORP +1

Slurry composition, electrode and secondary cell

ActiveUS20050069769A1Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

A slurry composition for electrode comprising a binder, an active material, and a liquid medium, characterized in that the binder comprises a polymer (X) comprising 60 to 95 mole % of repeating units derived from acrylonitrile or methacrylonitrile and 5 to 30 mole % of repeating units derived from at least one kind of a monomer selected from 1-olefins and compounds represented by the following general formula (1): CH2═CR1—COOR2 wherein R1 represents a hydrogen atom or a methyl group and R2 represents an alkyl group; and the liquid medium is capable of dissolving the polymer (X). The slurry composition allows the manufacture of a lithium ion secondary battery having enhanced capacity and good charge-discharge cycle characteristics and good charge-discharge rate characteristics.

Owner:ZEON CORP

Functionalized polydopamine derived carbon layer coated carbon substrate preparation method and application

InactiveCN106340399AStable structureHigh specific capacitanceHybrid capacitor electrodesCell electrodesCarbon layerCapacitance

The invention relates to the technical field of preparation of nanometer materials, and discloses a functionalized polydopamine derived carbon layer coated carbon substrate preparation method and application. The preparation method comprises the following steps: 1) immersing a carbon substrate into a trihydroxymethyl aminomethane aqueous solution, the pH value of which is adjusted to be alkaline, and then, reacting with dopamine hydrochloride to obtain a polydopamine coated carbon substrate; 2) carrying out high-temperature carbonization on the obtained polydopamine coated carbon substrate to obtain a polydopamine derived carbon layer coated carbon substrate; and 3) enabling the obtained polydopamine derived carbon layer coated carbon substrate to react with a bimetallic saline solution to obtain a functionalized polydopamine derived carbon layer coated carbon substrate. The functionalized polydopamine derived carbon layer coated carbon substrate is stable in structure, is high in electrochemical activity, and has a series of advantages of high specific capacitance and good rate capability and the like when serving as the electrode material of a super capacitor; and the preparation method thereof is simple and easy to operate.

Owner:DALIAN UNIV OF TECH

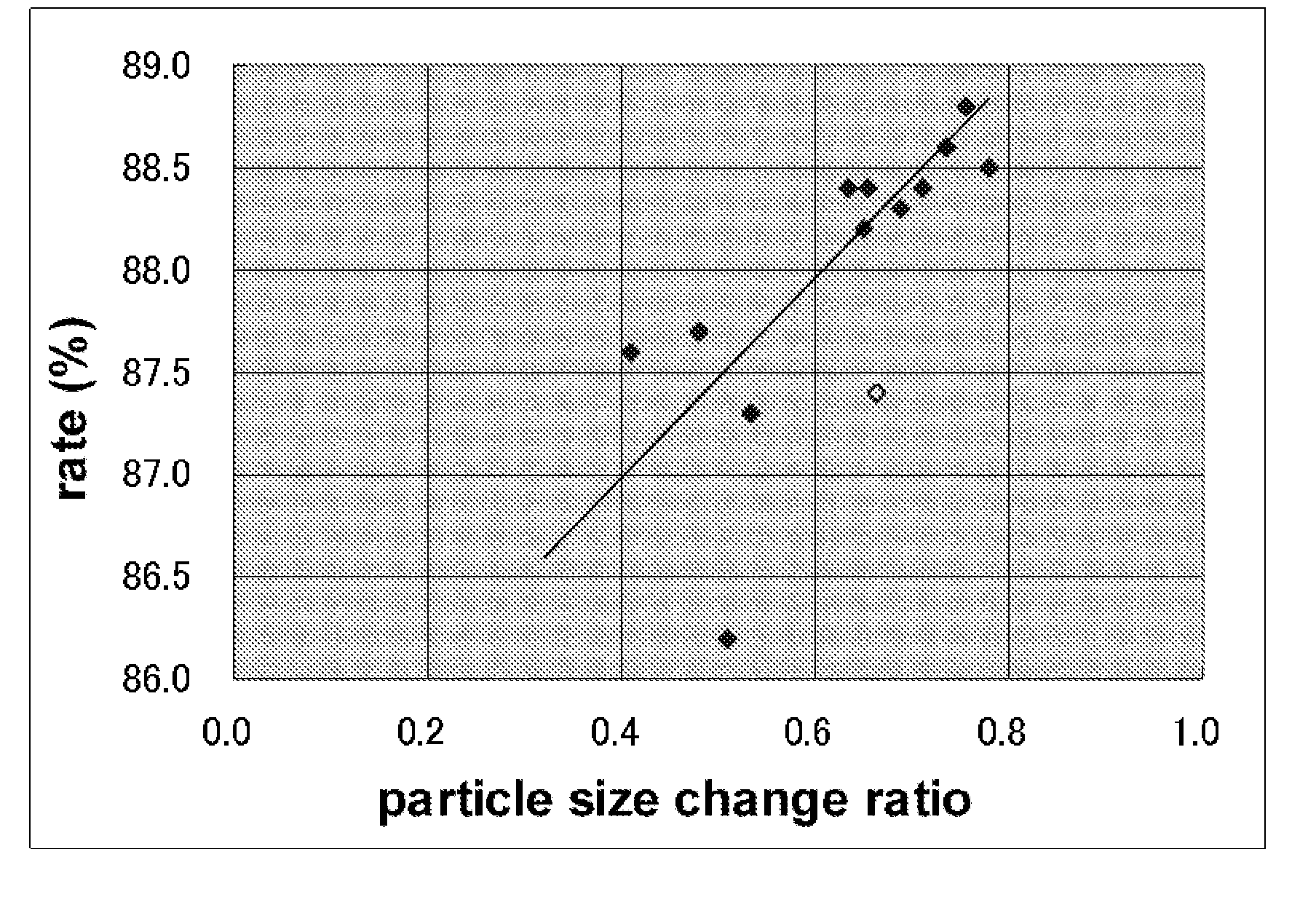

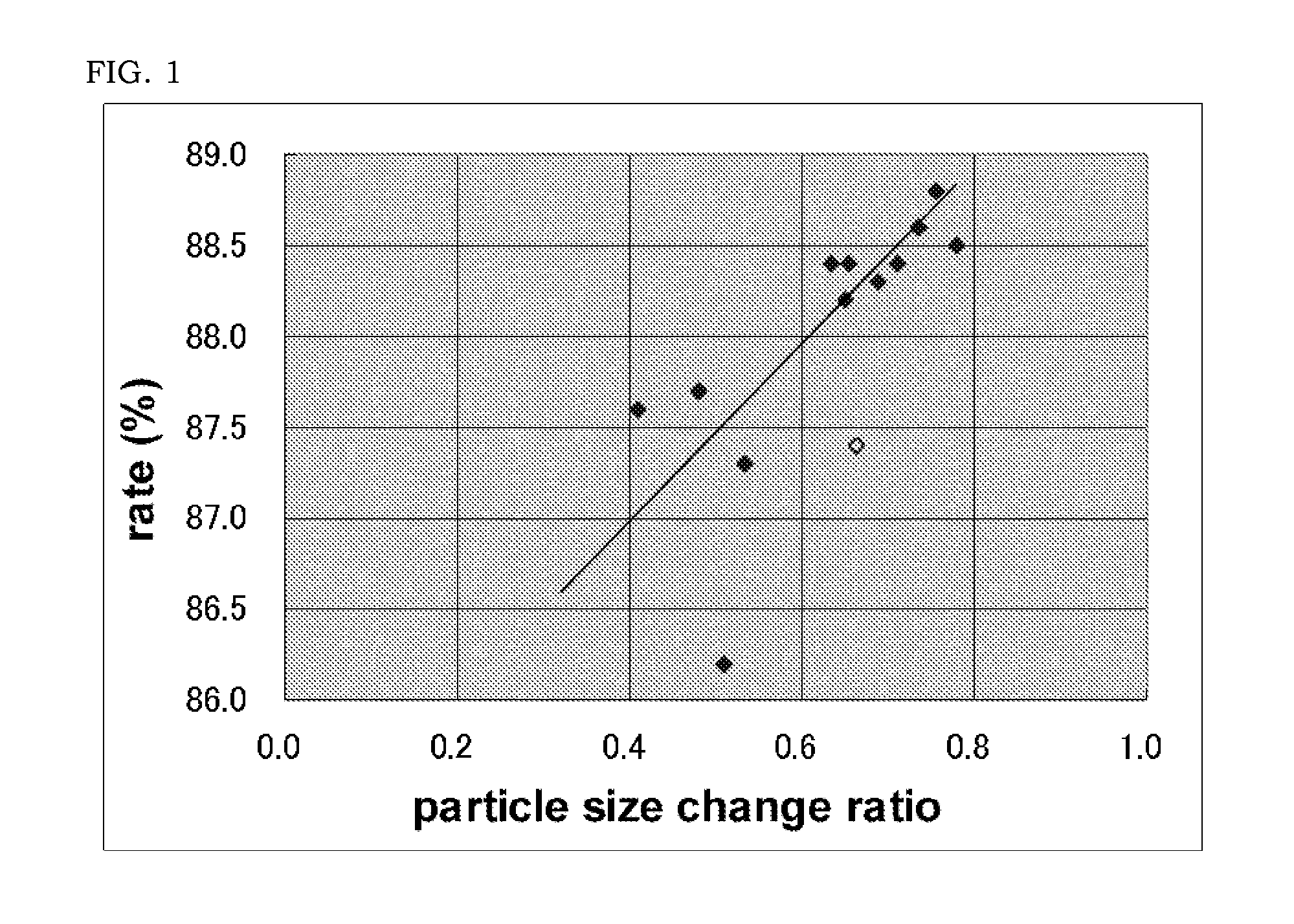

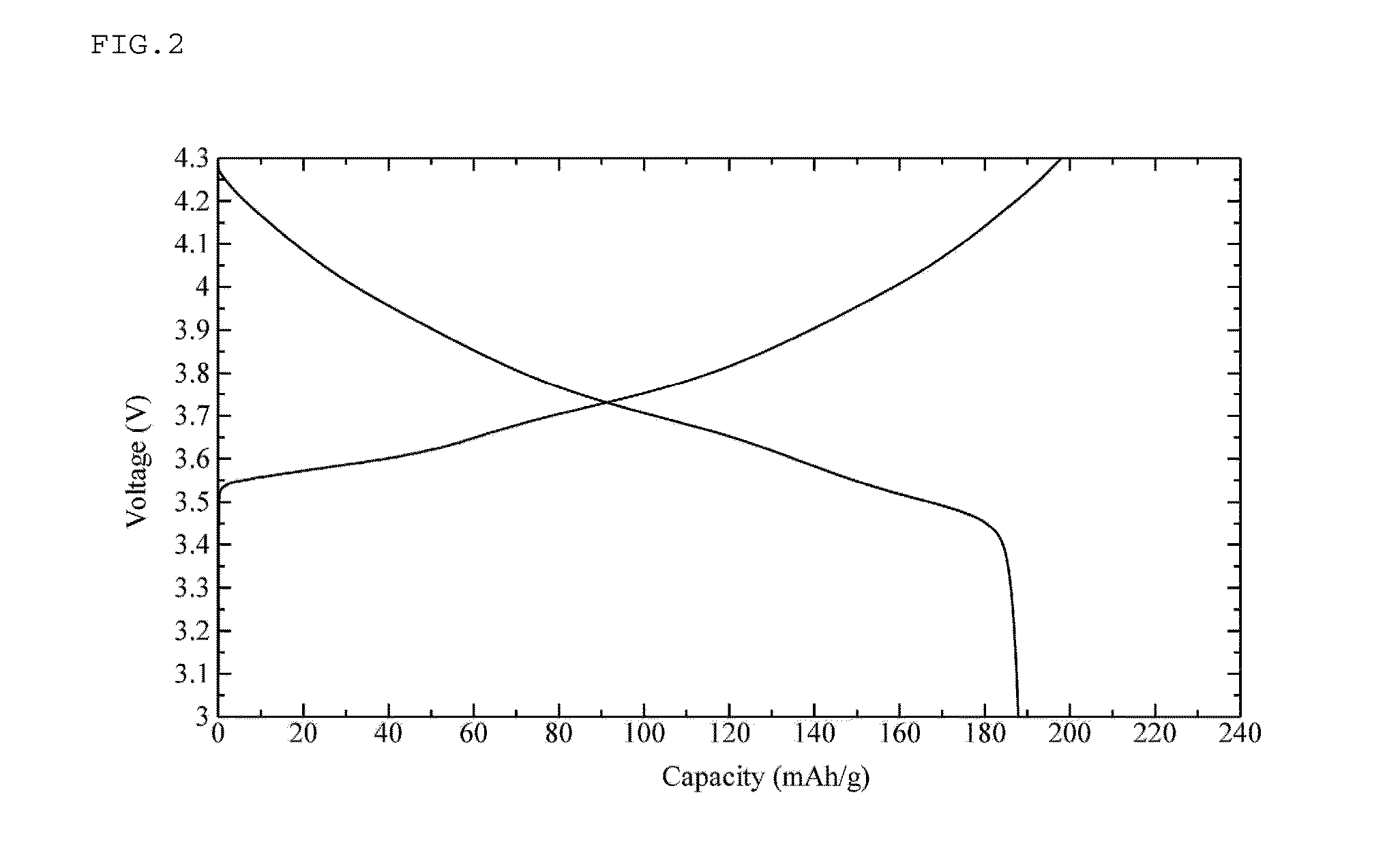

Positive Electrode Active Material For Lithium-Ion Battery, Positive Electrode For Lithium-Ion Battery, And Lithium-Ion Battery

ActiveUS20130004849A1Good rate characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryLithium electrode

The present invention provides a positive electrode active material for lithium ion battery having good rate characteristics. The positive electrode active material for lithium ion battery has a layer structure expressed by a composition formula: Lix(NiyMi1-y)Oz, wherein M represents Mn and Co, x represents 0.9 to 1.2, y represents 0.6 to 0.9, and z represents 1.8 to 2.4. The positive electrode active material has a particle size ratio D50P / D50 of 0.60 or more, wherein D50 is the average secondary particle size of the positive electrode active material powder, and D50P is the average secondary particle size of the positive electrode active material powder after pressing at 100 MPa. The positive electrode active material contains 3% or less particles having a particle size of 0.4 μm or less in terms of the volume ratio after pressing at 100 MPa.

Owner:JX NIPPON MINING& METALS CORP

Preparation method of manganese dioxide/carbon material/conducting polymer composite material

InactiveCN102977602AGood rate characteristicsImprove cycle performanceHybrid capacitor electrodesConductive polymerPotassium

The invention relates to a preparation method of a manganese dioxide / carbon material / conducting polymer composite material. The preparation method comprises the following steps: 1, water phase comprising an aqueous solution of potassium hypermanganate and a colloidal solution of a carbon material and organic phase formed by dispersing monomers of the conducting material in an organic solvent are subjected to the interfacial oxidative polymerization to obtain the manganese dioxide / carbon material / conducting polymer composite material; and 2, the manganese dioxide / carbon material / conducting polymer composite material obtained from step 1 is calcined with the existence of an inert gas to obtain the target composite material. The outstanding advantage of the preparation method is that, by subjecting the composite materials of the conductive materials, such as the manganese dioxide, the carbon material, and / or the conducting polymer, to the post-treatment of calcination, not only is the carbon material reduced, but also hydrate can be removed from the manganese dioxide to form a stable crystal structure, so that the electrochemical performance of the composite material is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Lithium Nickel Manganese Cobalt Composite Oxide and Lithium Rechargeable Battery

ActiveUS20090200508A1Improve featuresGood rate characteristicsCell electrodesCobalt compoundsManganeseCrystal structure

This invention provides a lithium nickel manganese cobalt composite oxide having a composition of LiaNixMnyCozO2 (x+y+z=1, 1.05<a<1.3), wherein, in the data obtained by measuring a Raman spectrum of the composite oxide, the peak intensity of an Eg oscillation mode of a hexagonal crystal structure located at 480 to 495 cm−1 and the peak intensity of an F2g oscillation mode of a spinel structure located at 500 to 530 cm−1 in relation to the peak intensity of an A1g oscillation mode having a hexagonal crystal structure in which the main peak is located at 590 to 610 cm−1 are respectively 15% or higher and 40% or lower than the peak intensity of the A1g oscillation mode of a hexagonal crystal structure as the main peak. Thereby, the Raman spectrum can be used for the identification of the crystal structure to clarify the characteristics of a positive electrode precursor composed of lithium nickel manganese cobalt composite oxide. In particular, it is possible to obtain lithium nickel manganese cobalt composite oxide and a lithium rechargeable battery superior in rate characteristics and cycle characteristics.

Owner:JX NIPPON MINING& METALS CORP

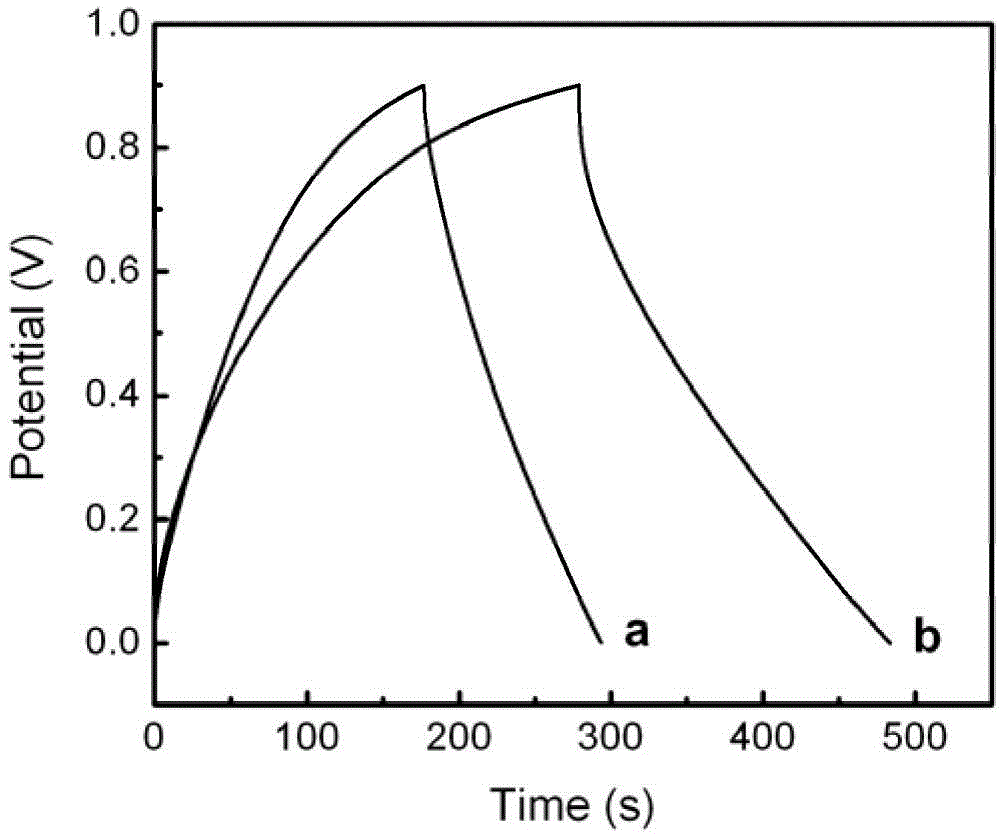

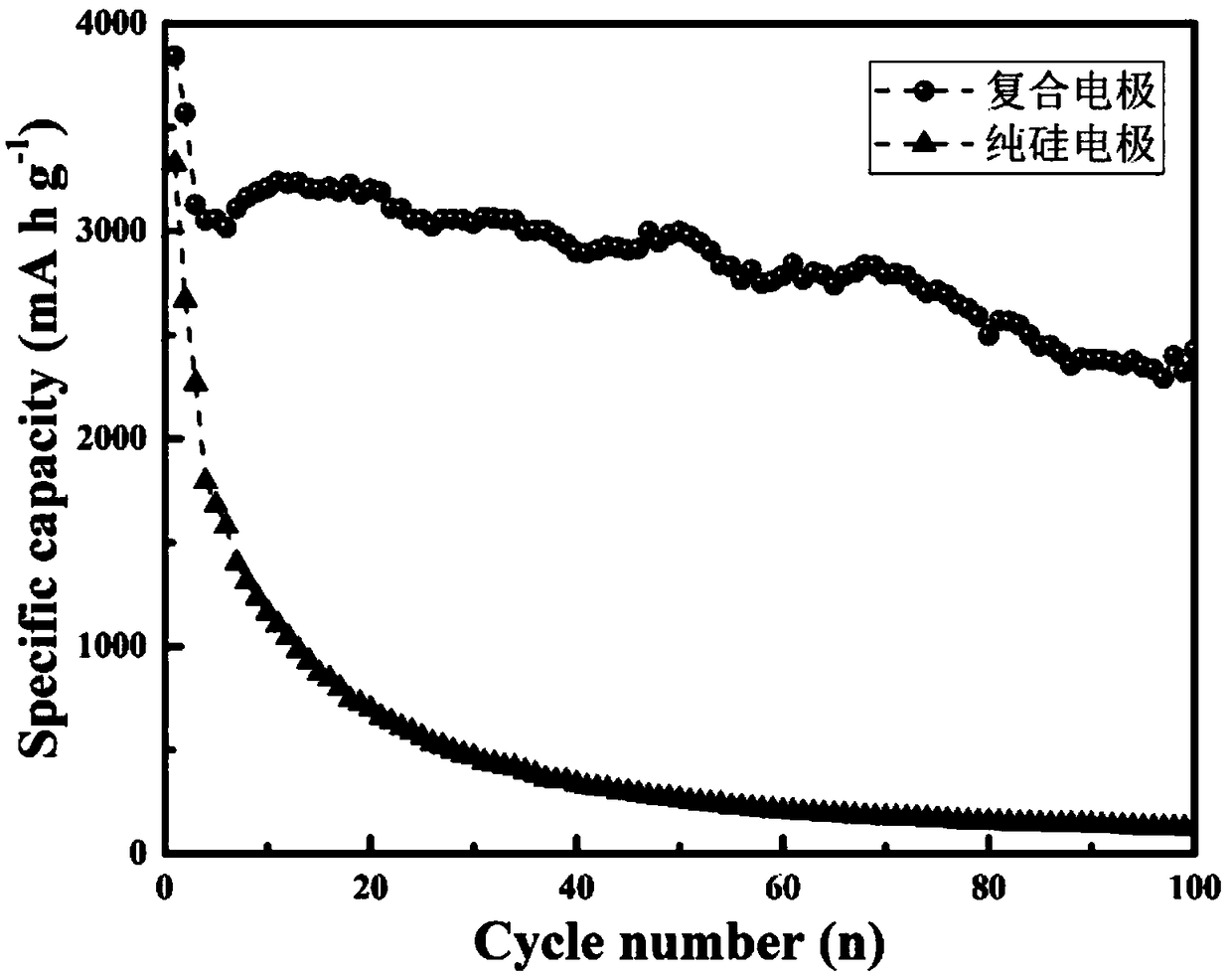

Lithium-ion-battery composite material and preparing method of composite electrode of lithium ion battery

ActiveCN108565406AImprove hydrophilicityHigh activityMaterial nanotechnologyNegative electrodesAluminium-ion batteryElectrical battery

The invention relates to a lithium-ion-battery composite material and a preparing method of a composite electrode of a lithium ion battery. Nanometer silicon is added into a dopamine hydrochloride solution, and a polydopamine wrapping layer is formed on the surface of silicon; meanwhile, graphene quantum dots are prepared with the one-step solvothermal method, and are doped into sodium alginate binding agent, and a composite electrode material is prepared. In the lithium-ion-battery composite material and the preparing method of the composite electrode of the lithium ion battery, the polydopamine wrapping layer can buffer enormous volume expansion of a silicon ball, and the stability of a silicon-based cathode material is effectively improved. As the graphene quantum dots are doped, a binding agent layer has the higher mechanical performance and the elasticity, the product has the more lasting swelling property in electrolyte accordingly, and can develop the reversible buffering effecton enormous volume changes of silicon after multiple times of cycling, and the structural integrity of an electrode in the charging and discharging process is further guaranteed; meanwhile, the graphene quantum dots have certain conductivity, and therefore the conductivity of the binding agent layer is improved. The electrode shows the good electrochemical performance, and can be widely applied to various high-capacity lithium ion batteries.

Owner:安普瑞斯(无锡)有限公司

Nonaqueous electrolyte secondary battery separator, nonaqueous electrolyte secondary battery laminated separator, nonaqueous electrolyte secondary battery member, and nonaqueous electrolyte secondary battery

InactiveUS20170155120A1Inhibit deteriorationGood rate characteristicsNon-aqueous electrolyte accumulatorsCell component detailsMicrowavePolyolefin

Provided is a nonaqueous electrolyte secondary battery separator including a porous film containing polyolefin as a main component, the nonaqueous electrolyte secondary battery separator having a time until temperature rise cessation with respect to an amount of resin per unit area of 2.9 sec·m2 / g to 5.7 sec·m2 / g, the time being obtained in a case where the nonaqueous electrolyte secondary battery separator is impregnated with N-methyl pyrrolidine containing 3 wt % water and is subsequently irradiated, at an output of 1,800 W, with a microwave having a frequency of 2,455 MHz, the nonaqueous electrolyte secondary battery separator having an excellent initial rate characteristic and being capable of preventing a deterioration in rate characteristic which deterioration is caused by repeated charge and discharge.

Owner:SUMITOMO CHEM CO LTD

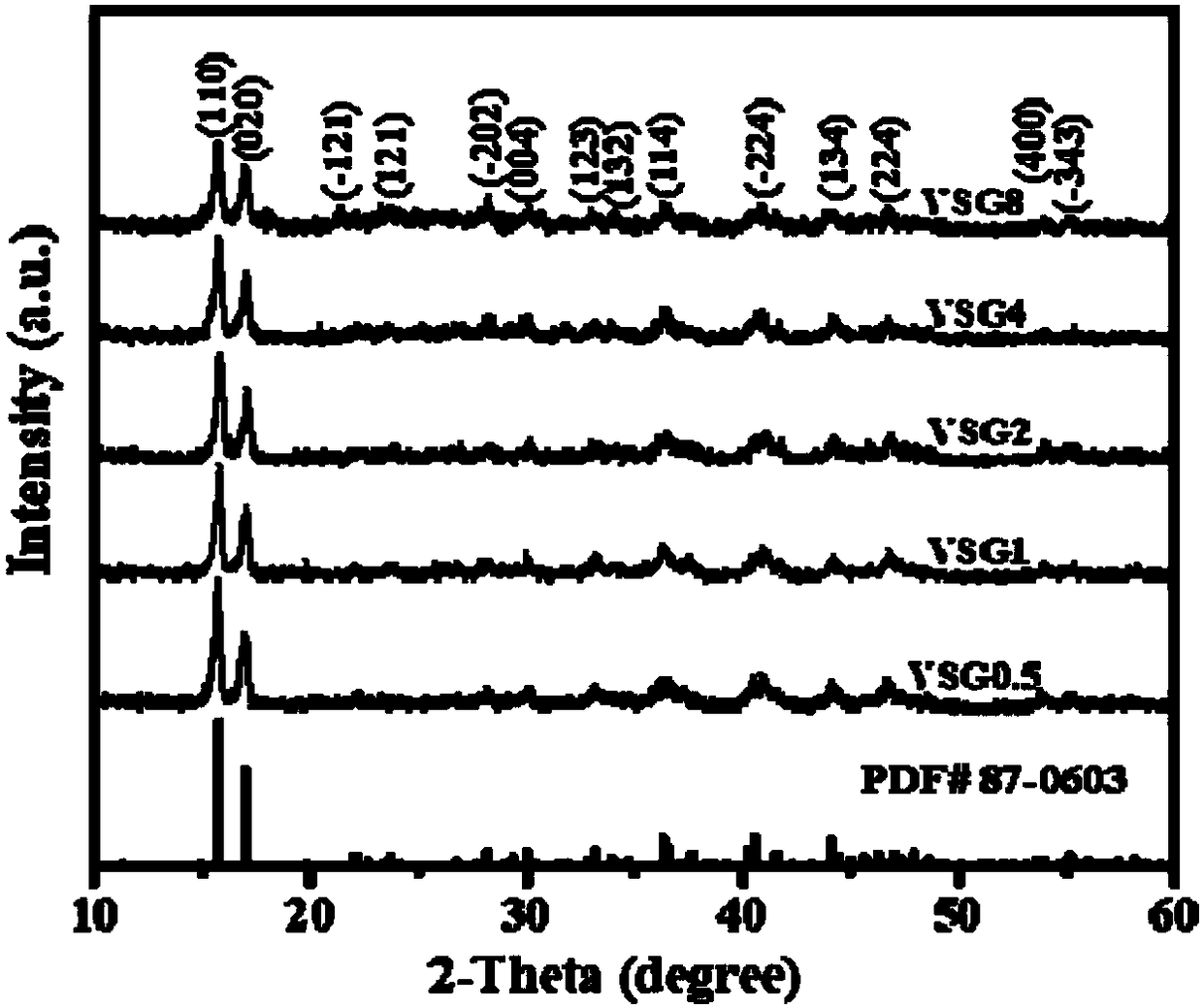

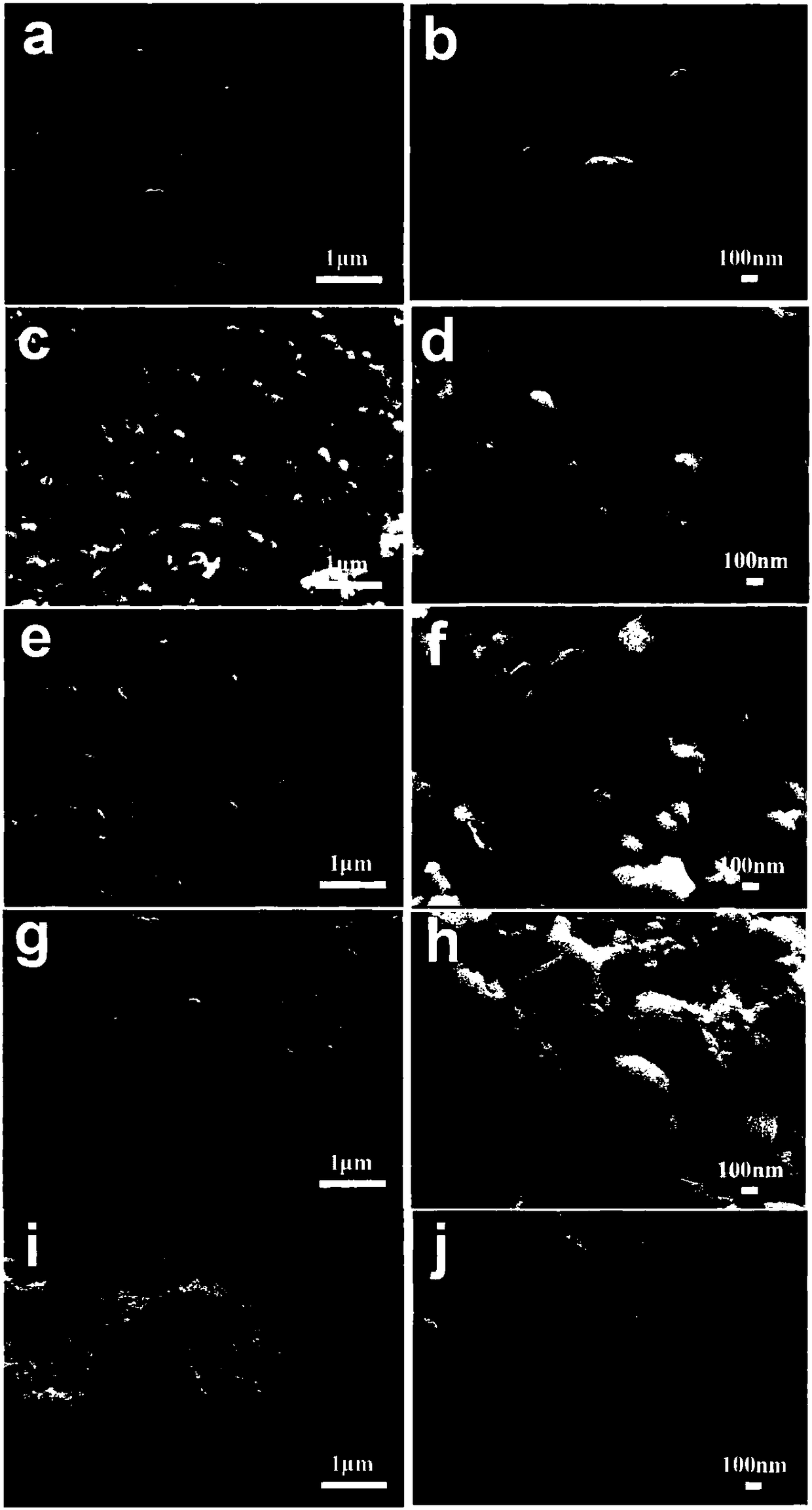

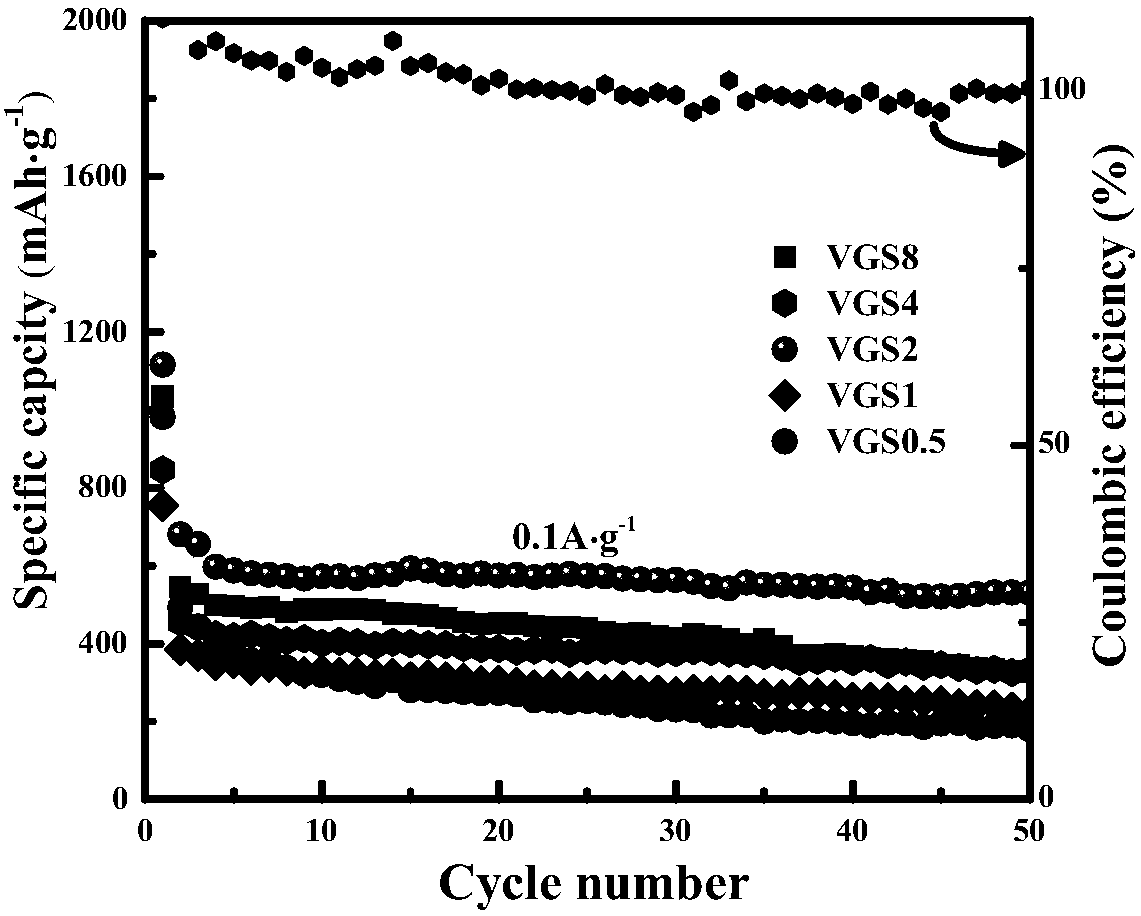

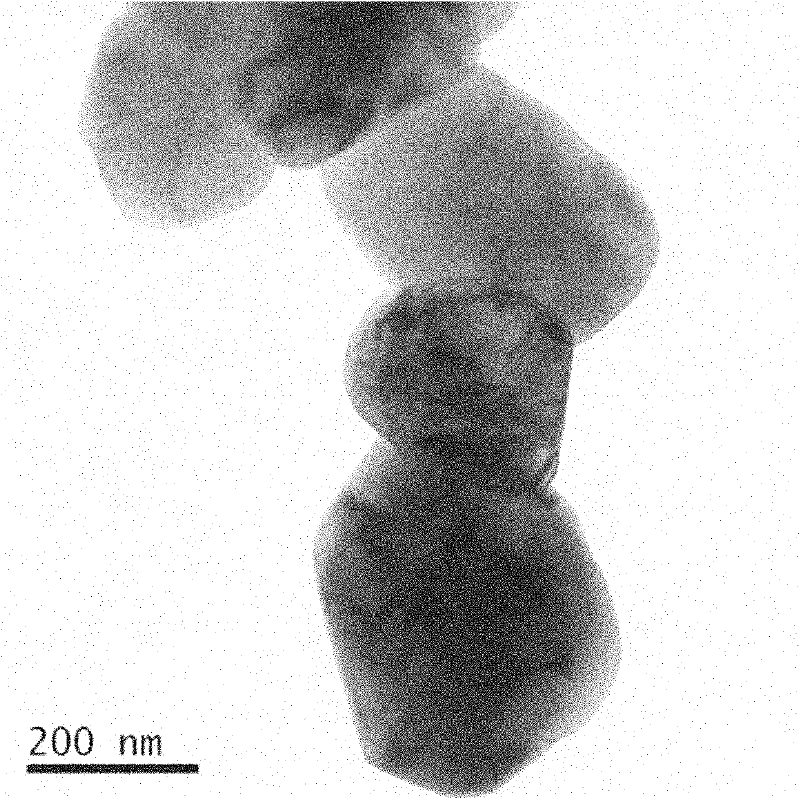

Preparation method of vanadium tetrasulfide/graphene composite material used for electrode of sodium ion battery

InactiveCN108598432AImprove conductivitySimple processMaterial nanotechnologyCell electrodesHigh rateNew energy

The invention belongs to the technical field of a new energy material, specifically a preparation method of a vanadium tetrasulfide / graphene composite material used for an electrode of a sodium ion battery. By adopting a hydrothermal synthesis method and by adopting layered graphene as a template, vanadium tetrasulfide is grown on the layered graphene template (or vanadium tetrasulfide particles are coated with graphene) so as to form the vanadium tetrasulfide / graphene composite material; the method is simple in process, low in cost, high in repeatability, and suitable for a commercial application of the electrode material of the sodium ion battery; according to the preparation method, by virtue of a graphene thin film sheet layers, the nanometer vanadium tetrasulfide particles are connected between the sheet layers to form a stable solid electrolyte interface film, thereby effectively improving conductivity of the composite electrode material, and showing high rate capability and cycle stability; and the reversible specific capacity in charging and discharging cycles at the current of 0.2A.g<-1> can reach 580mAh.g<-1>, and high-current charging and discharging capability of as high as 20A.g<-1> can be realized, so that the commercial electrode application of the sodium ion battery can be satisfied.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Cathode material of secondary battery and preparation method thereof as well as anode and secondary battery

InactiveCN102544456AHigh discharge specific capacityGood rate characteristicsSecondary cellsNon-aqueous electrolyte accumulator electrodesMetallurgyElectron

The invention provides a cathode material of a secondary battery. The cathode material comprises LiMPO4 and Lil+xMnyNizCo1-x-y-zO2, wherein M is any one of Fe, Co, Ni and Mn, x is more than 0 and less than 0.3, y is more than 0.5 and less than 0.8, and z is more than 0 and less than 0.3; and LiMPO4 is accumulated or dispersed on the surface of the Lil+xMnyNizCo1-x-y-zO2. The cathode material provided by the invention is not reduced in electron conduction rate. The secondary battery prepared from the cathode material has high cyclability and multiplying power property. The invention also provides a preparation method of the cathode material as well as an anode and the secondary battery.

Owner:SUZHOU UNIV

Silicon-containing high-energy-density lithium ion battery

ActiveCN109713367AEnhanced complexationEnergy barrier increaseFinal product manufactureSecondary cells servicing/maintenanceSolubilityHigh energy

The invention relates to a silicon-containing lithium ion battery with high energy density. The lithium ion battery comprises a positive electrode, a silicon-containing negative electrode, a fluorine-containing electrolyte, a diaphragm, electrode lugs and a packaging material. The silicon-containing negative electrode takes a silicon-based material as a whole or a part of electrochemical active substances. The electrolyte contains lithium salt, a non-aqueous organic solvent capable of dissolving the lithium salt, an SEI film-forming additive and hydrofluoroether. The solubility of the lithiumsalt in the non-aqueous organic solvent capable of dissolving the lithium salt is higher than 2 mol / L. The solubility of the lithium salt in the hydrofluoroether is lower than 0.3 mol / L, wherein the non-aqueous organic solvent capable of dissolving the lithium salt is mutually dissolved with the hydrofluoroether, the non-aqueous organic solvent capable of dissolving the lithium salt and the liquidSEI film-forming additive are mutually dissolved, so the solid SEI film-forming additive can be dissolved. The silicon-containing lithium ion battery has the advantages of high energy density, long cycle life, good rate capability, high safety performance, difficulty in expansion and deformation and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

Separator

ActiveUS20100112432A1Improve heat resistanceImprove discharge characteristicsFinal product manufactureCell component detailsChemistryHeat resistant

Provided is a separator made of a laminated porous film in which a heat-resistant layer that comprises a heat-resistant resin and a shut-down layer that comprises a thermoplastic resin are laminated, wherein the heat-resistant layer further comprises two or more fillers, and the value of D2 / D1 is 0.15 or less where among values each obtained by measuring the average particle diameter of particles that constitute one of the two or more fillers, the largest value is let be Di and the second largest value is let be D2.

Owner:SUMITOMO CHEM CO LTD

Positive electrode active substance for nonaqueous electrolyte secondary cell, method for producing same, and nonaqueous electrolyte secondary cell using positive electrode active substance

ActiveUS20150188136A1Large capacityReduce irreversible capacityPositive electrodesNon-aqueous electrolyte accumulator electrodesDischarge efficiencyOccupancy rate

A positive electrode active material is provided that has a high capacity, a low irreversible capacity, an excellent initial charge / discharge efficiency, and excellent rate characteristics. This positive electrode active material comprises a hexagonal lithium nickel complex oxide having a layer structure and represented by the general formula LixNi1-y-zCoyMzO2 (0.98≦x≦1.04, 0.25≦y≦0.40, 0≦z≦0.07, and M is at least one element selected from Al, Ti, Mn, Ga, Mg, and Nb), wherein a lithium occupancy rate in a lithium main layer as obtained by Rietveld analysis from the x-ray diffraction pattern is at least 98.7%, and a crystallite diameter as calculated from the peak for the (003) plane in x-ray diffraction is 50 to 300 nm.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com