Preparation method of vanadium tetrasulfide/graphene composite material used for electrode of sodium ion battery

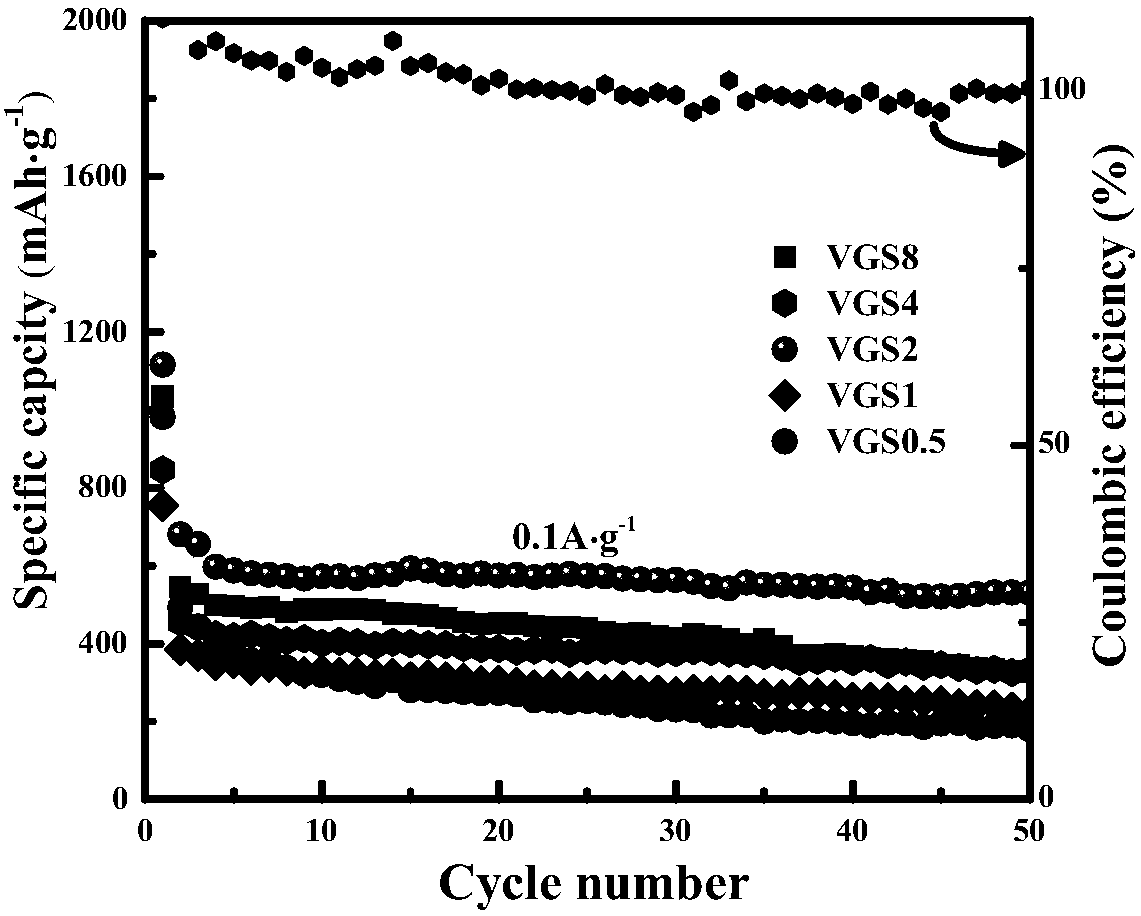

A sodium-ion battery, vanadium tetrasulfide technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem that the electrochemical performance cannot meet the performance standards of commercialized sodium-ion batteries , to meet the requirements of commercial sodium-ion battery electrode applications, excellent electrochemical performance of sodium-ion batteries, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

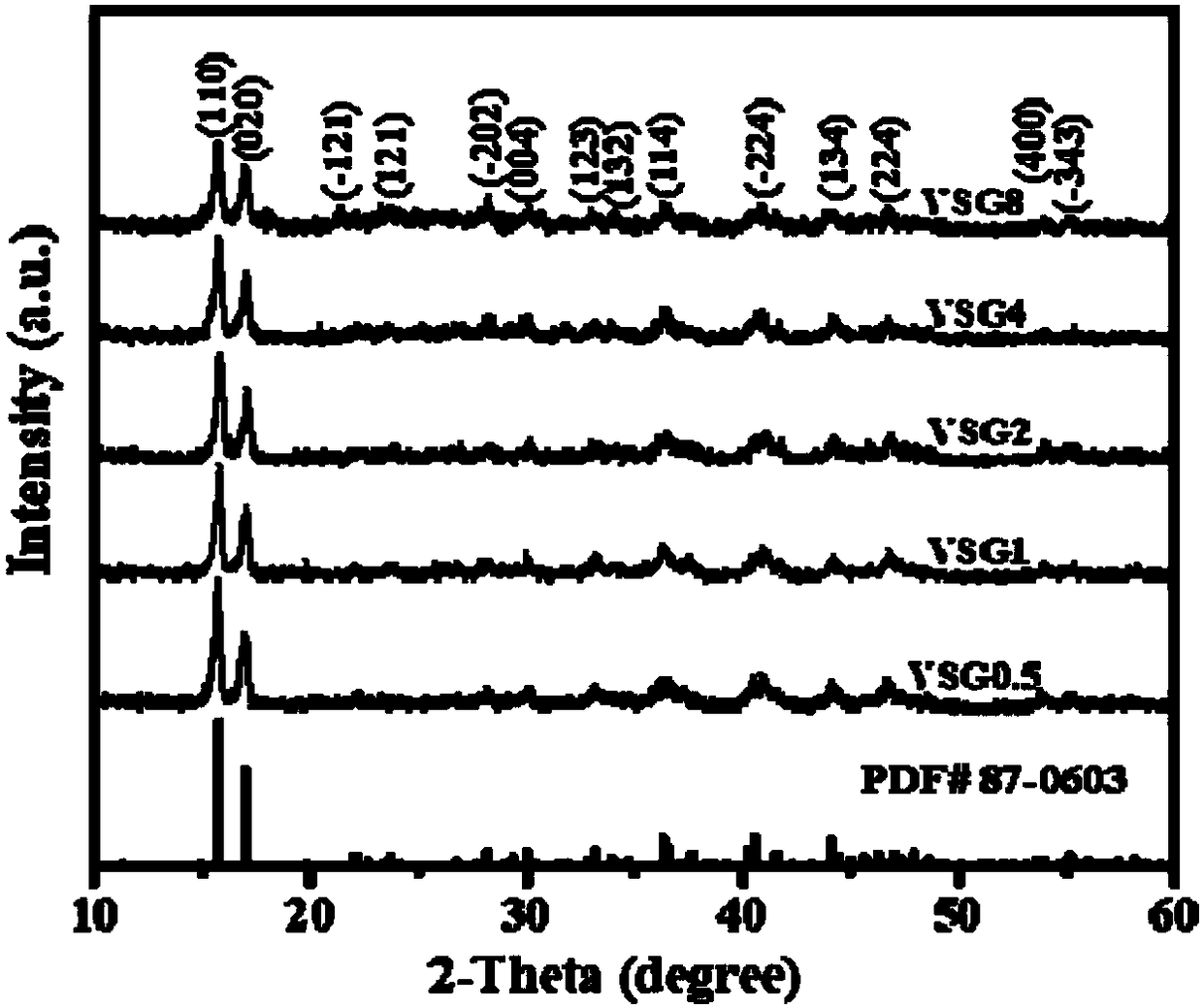

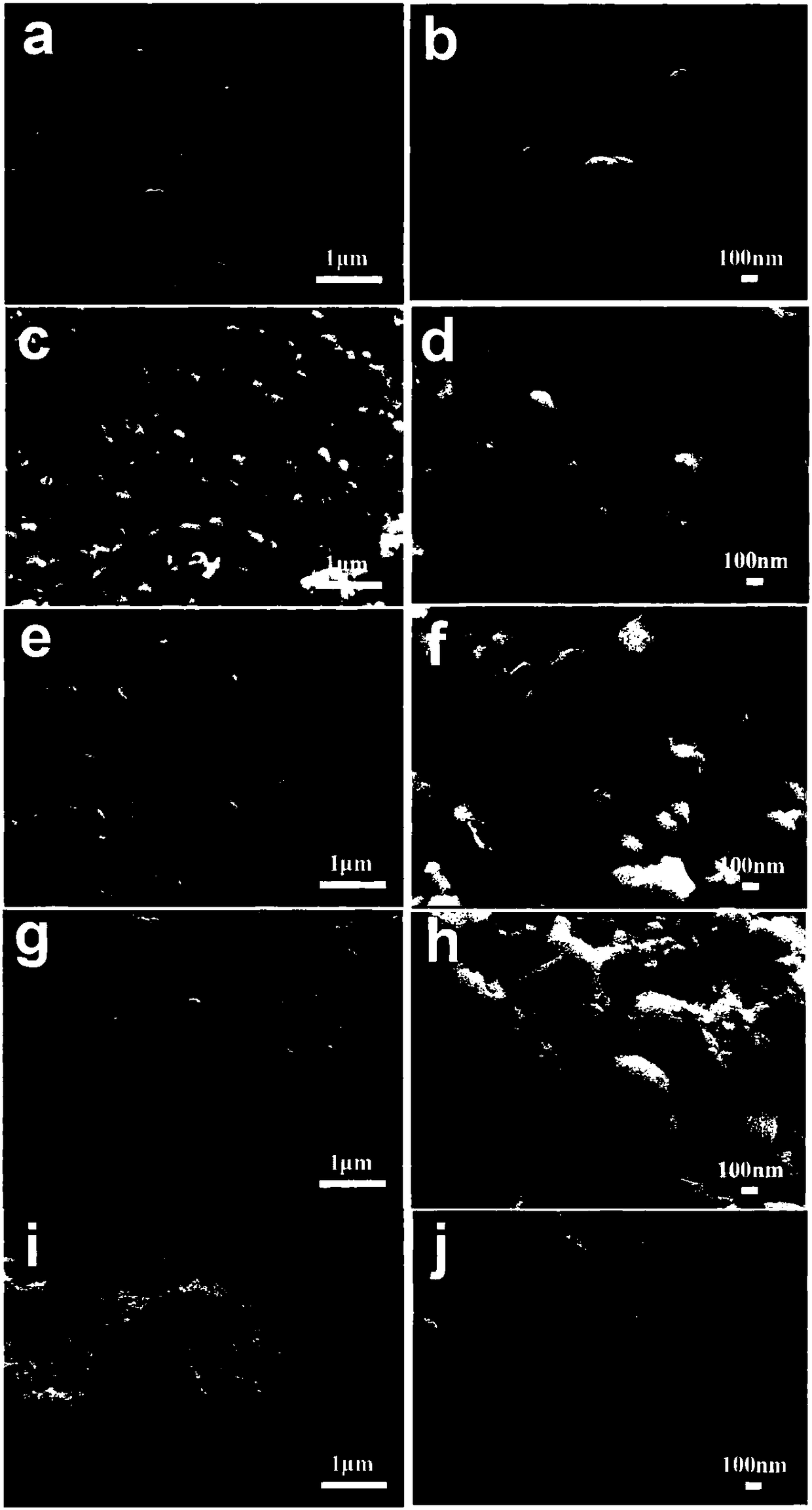

[0026] The present embodiment provides a method for preparing a vanadium tetrasulfide / graphene composite material for an electrode of a sodium ion battery, which specifically includes the following steps:

[0027] (1) 0.5 mg / ml graphene oxide was dissolved in deionized water, and after ultrasonic dispersion for 30 minutes, it was configured into a graphene oxide solution;

[0028] (2) 10mmol sodium orthosulfate and 50mmol thioacetamide were sequentially added to the dispersed 0.5mg / ml graphene oxide solution, and stirred for 0.5h to form a mixed solution;

[0029] (3) Transfer the above mixed solution to the inner tank of the reactor, and form a mixed product after hydrothermal reaction at 180°C for 24 hours;

[0030] (4) After the reactor was cooled to room temperature, the resulting product was alternately washed 10 times with alcohol and deionized water in a fume hood, and then dried at 80°C in a vacuum oven to obtain a vanadium tetrasulfide / graphene electrode material.

Embodiment 2

[0032] This embodiment provides a kind of preparation method of the vanadium tetrasulfide / graphene composite material that is used for the electrode of sodium ion battery, and its basic steps are identical with embodiment 1, difference is: in the step (1), graphene oxide concentration is changed from "0.5 mg / ml" is changed to "1mg / ml", and the stirring time in step (2) is changed from "0.5h" to "1h".

Embodiment 3

[0034] This embodiment provides a kind of preparation method of the vanadium tetrasulfide / graphene composite material that is used for the electrode of sodium ion battery, and its basic steps are identical with embodiment 1, difference is: in the step (1), graphene oxide concentration is changed from "0.5 mg / ml" is changed to "2mg / ml", and the stirring time in step (2) is changed from "0.5h" to "2h".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com