Patents

Literature

399results about How to "Improve the bonding force between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

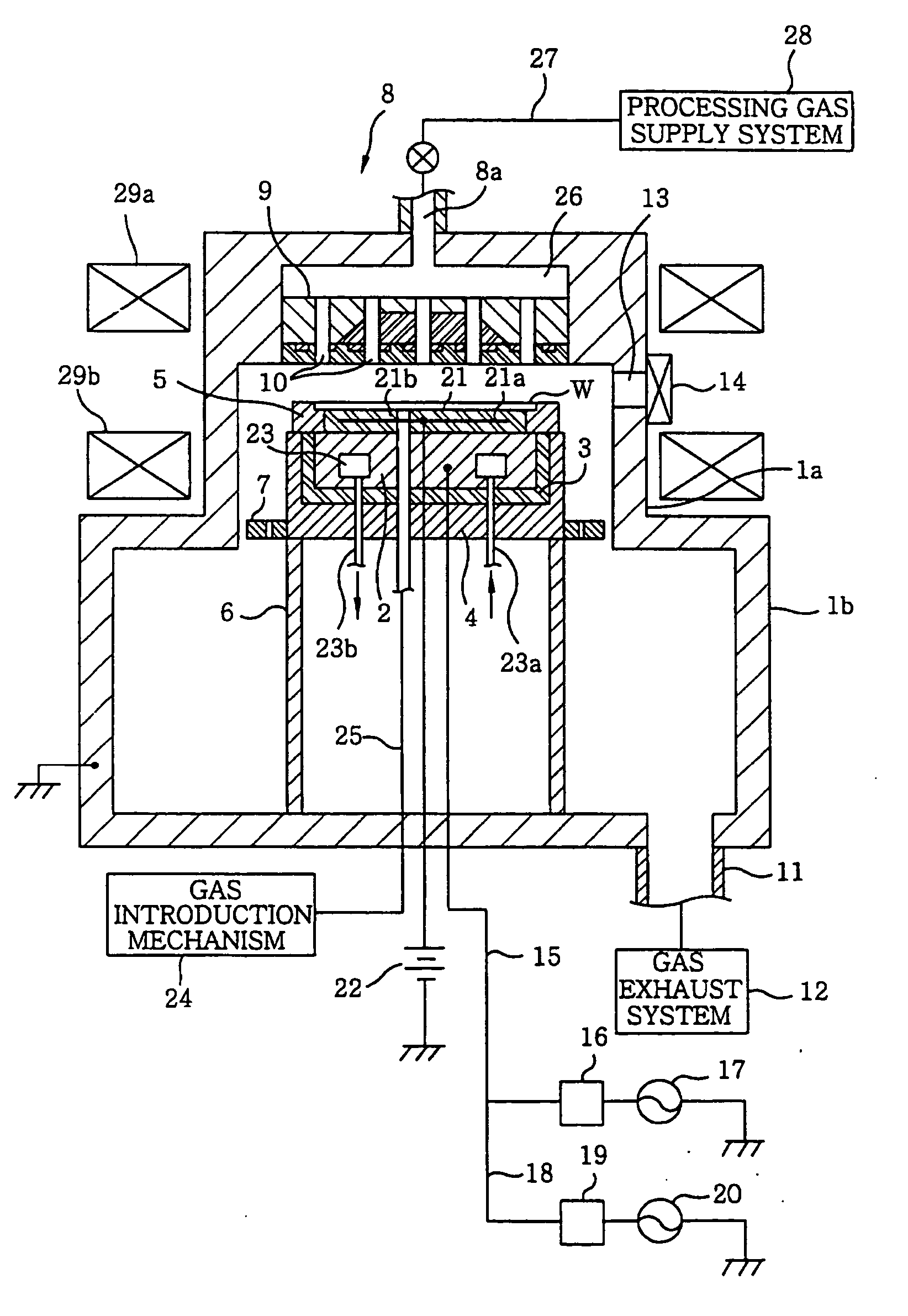

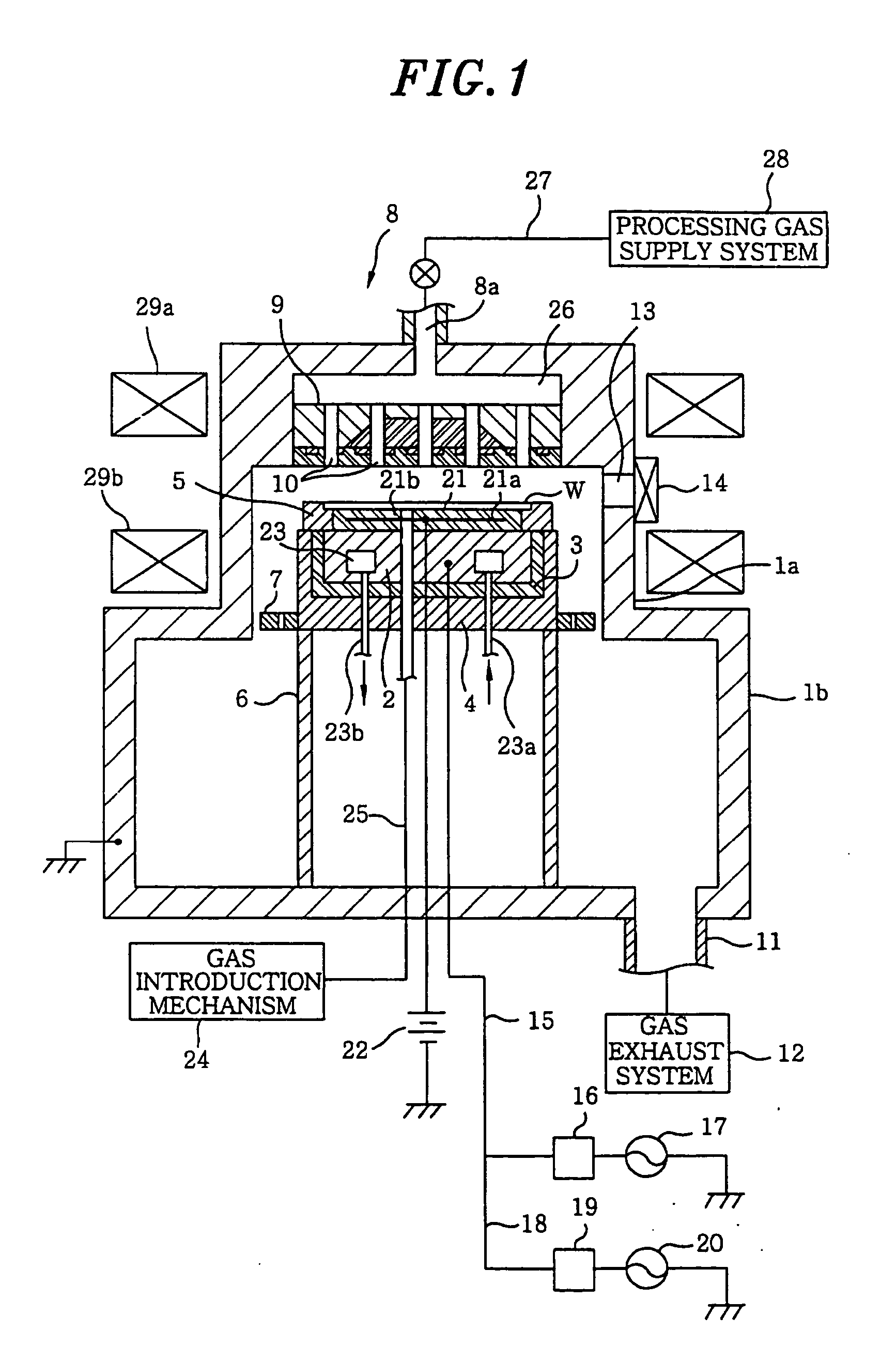

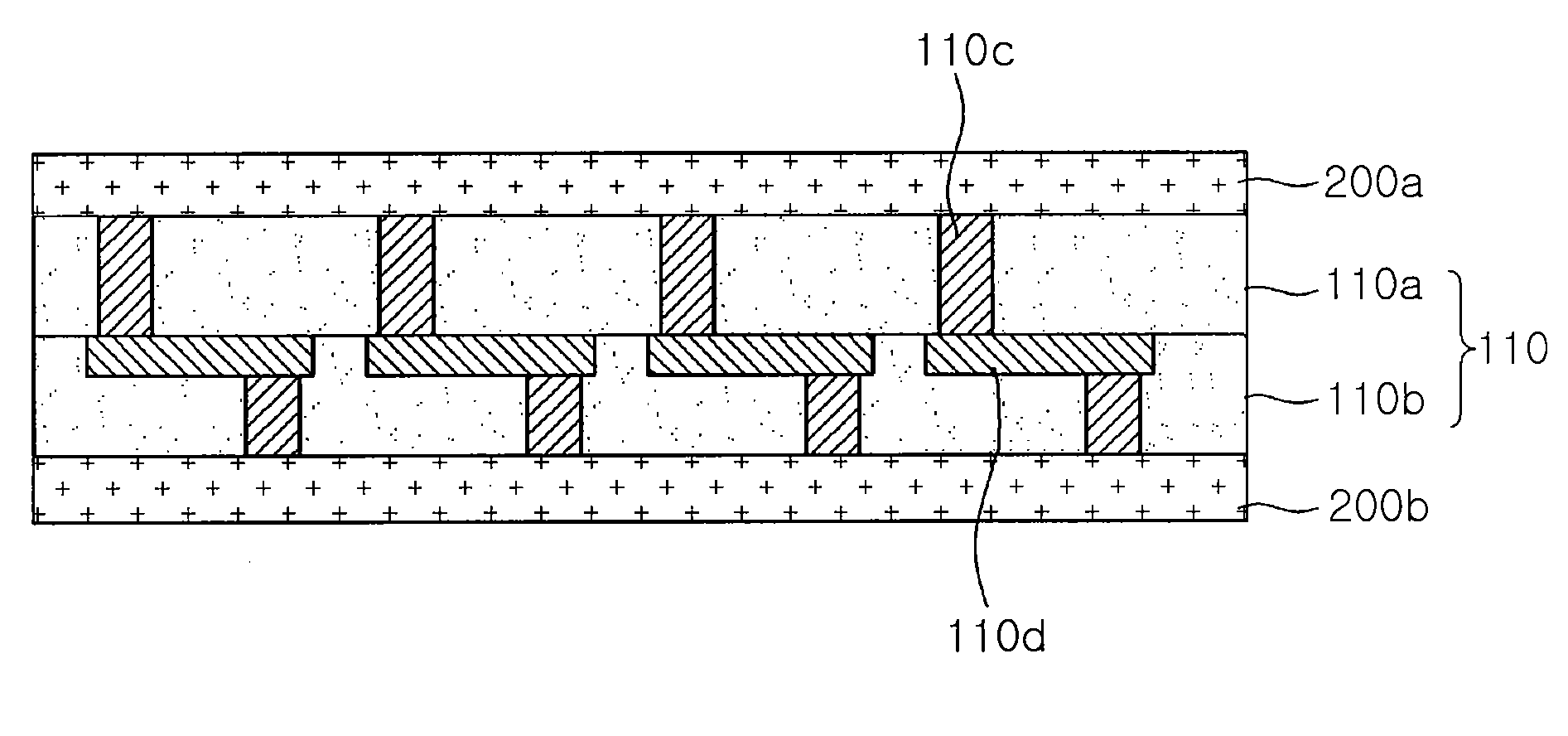

Thermally sprayed member, electrode and plasma processing apparatus using the electrode

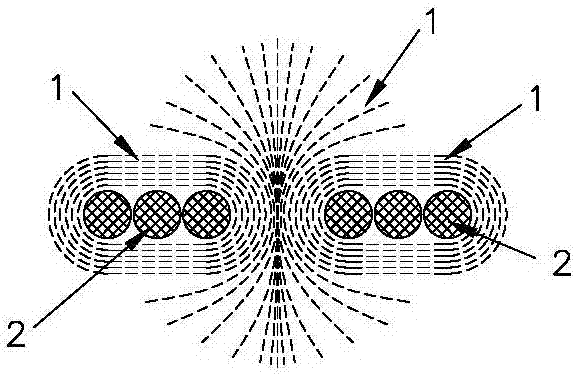

ActiveUS20050211384A1High-frequency powerAvoid flowMolten spray coatingElectric discharge tubesThermal sprayingInter layer

A thermally sprayed member or an electrode includes a basic material, a thermally sprayed film formed on the surface of the basic material, the thermally sprayed film being made of an insulating ceramic and a metallic intermediate layer provided between the basic material and the thermally sprayed film for increasing a bonding force therebetween, wherein the thermally sprayed film side of the member is exposed to a high frequency plasma atmosphere and the electrode is intended to form a high frequency plasma on the side of the thermally sprayed film. The basic material includes a base portion made of a conductive material and a dielectric portion provided to include a part of a surface of the basic material. Further, the intermediate layer is comprised of a plurality of island-shaped parts isolated from each other.

Owner:TOKYO ELECTRON LTD

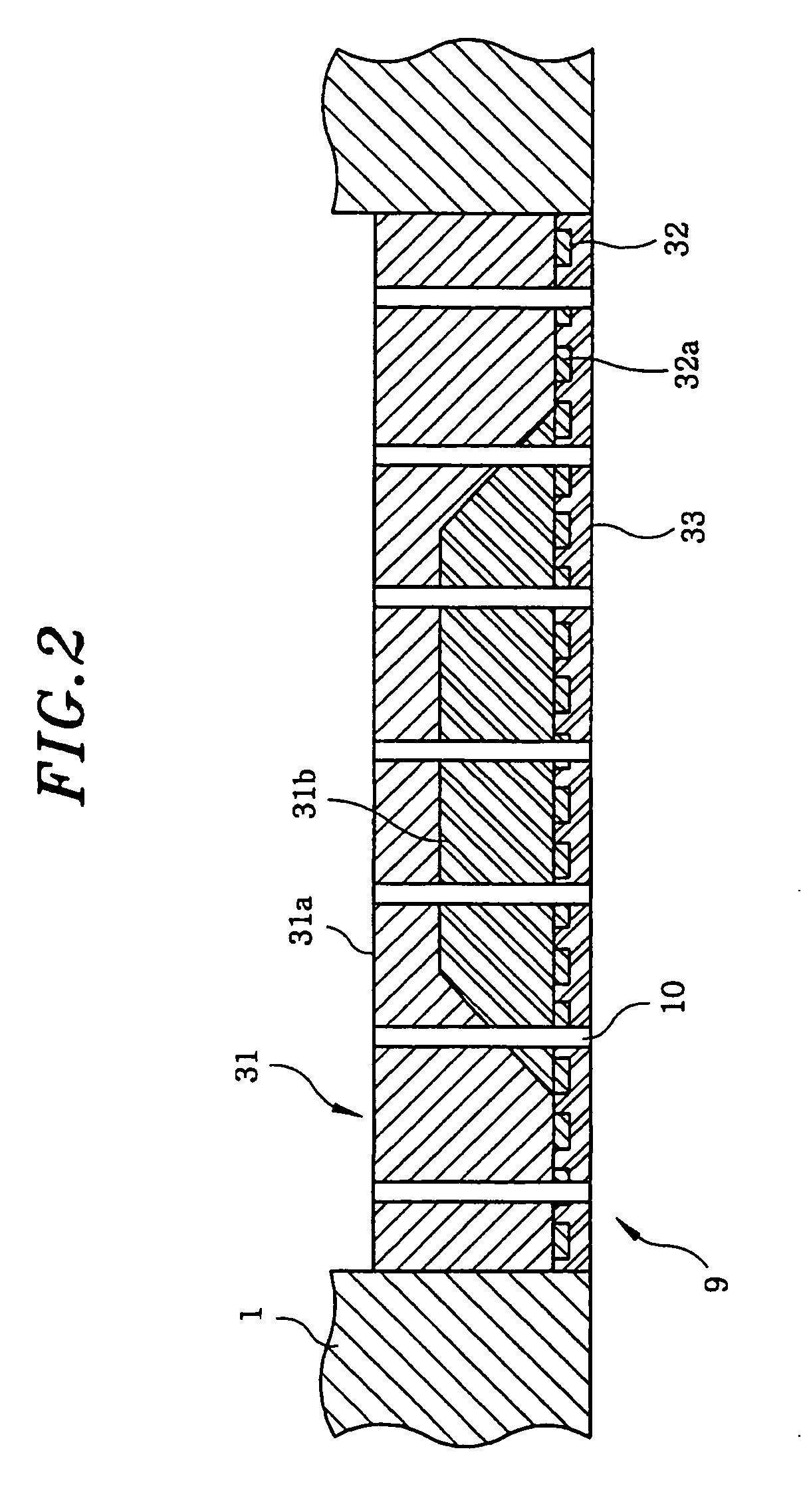

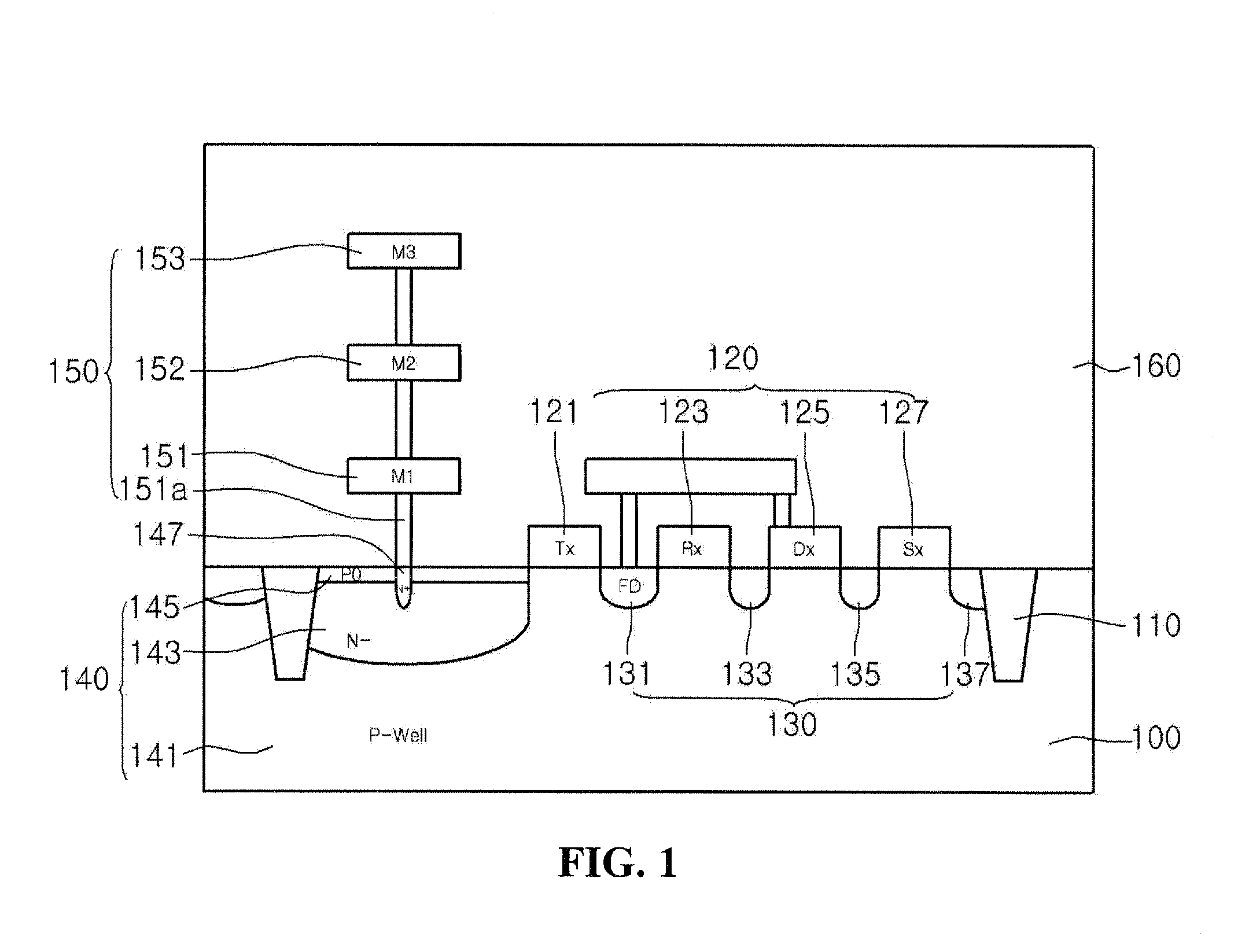

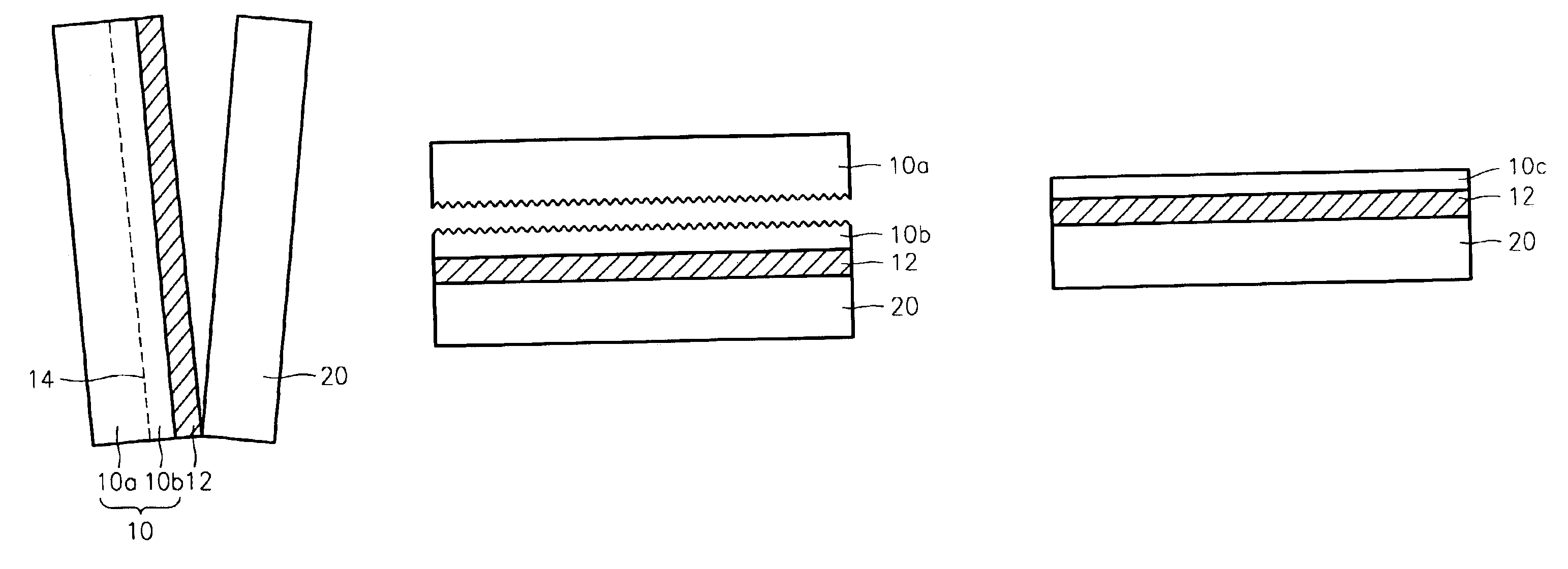

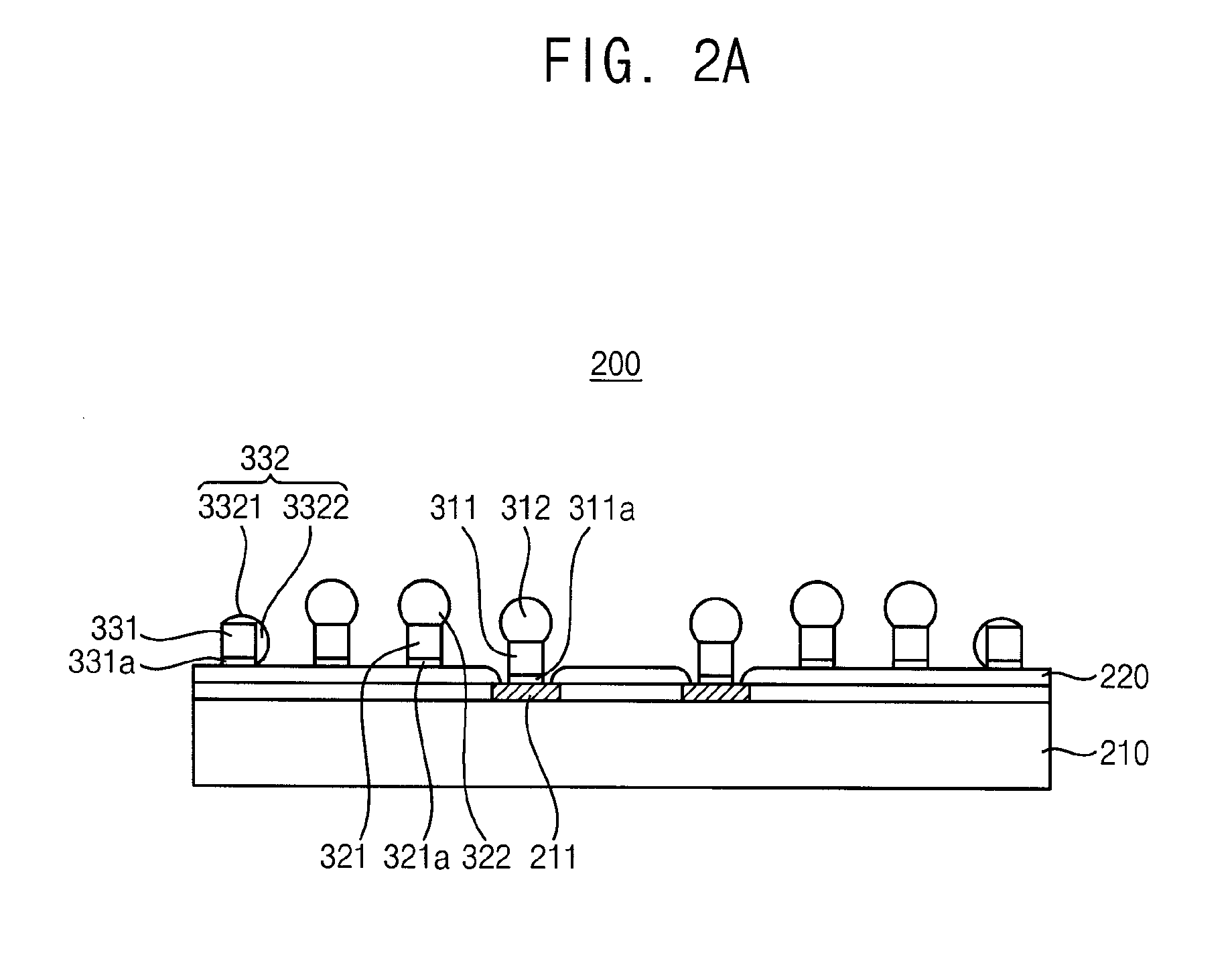

Image Sensor and Manufacturing Method Thereof

InactiveUS20090065827A1Improve bonding forceImprove the bonding force between layersSolid-state devicesSemiconductor/solid-state device manufacturingImage sensorDielectric

Provided is an image sensor. The image sensor can include a readout circuitry on a first substrate. An interlayer dielectric is formed on the first substrate, and comprises a lower line therein. A crystalline semiconductor layer is bonded to the interlayer dielectric. A photodiode can be formed in the crystalline semiconductor layer, and comprises a first impurity region and a second impurity region. A via hole can be formed passing through the crystalline semiconductor layer and the interlayer dielectric to expose the lower line. A plug is formed inside the first via hole to connect with only the lower line and the first impurity region. A device isolation region can be formed in the crystalline semiconductor layer to separate the photodiode according to unit pixel.

Owner:MARVELL ASIA PTE LTD

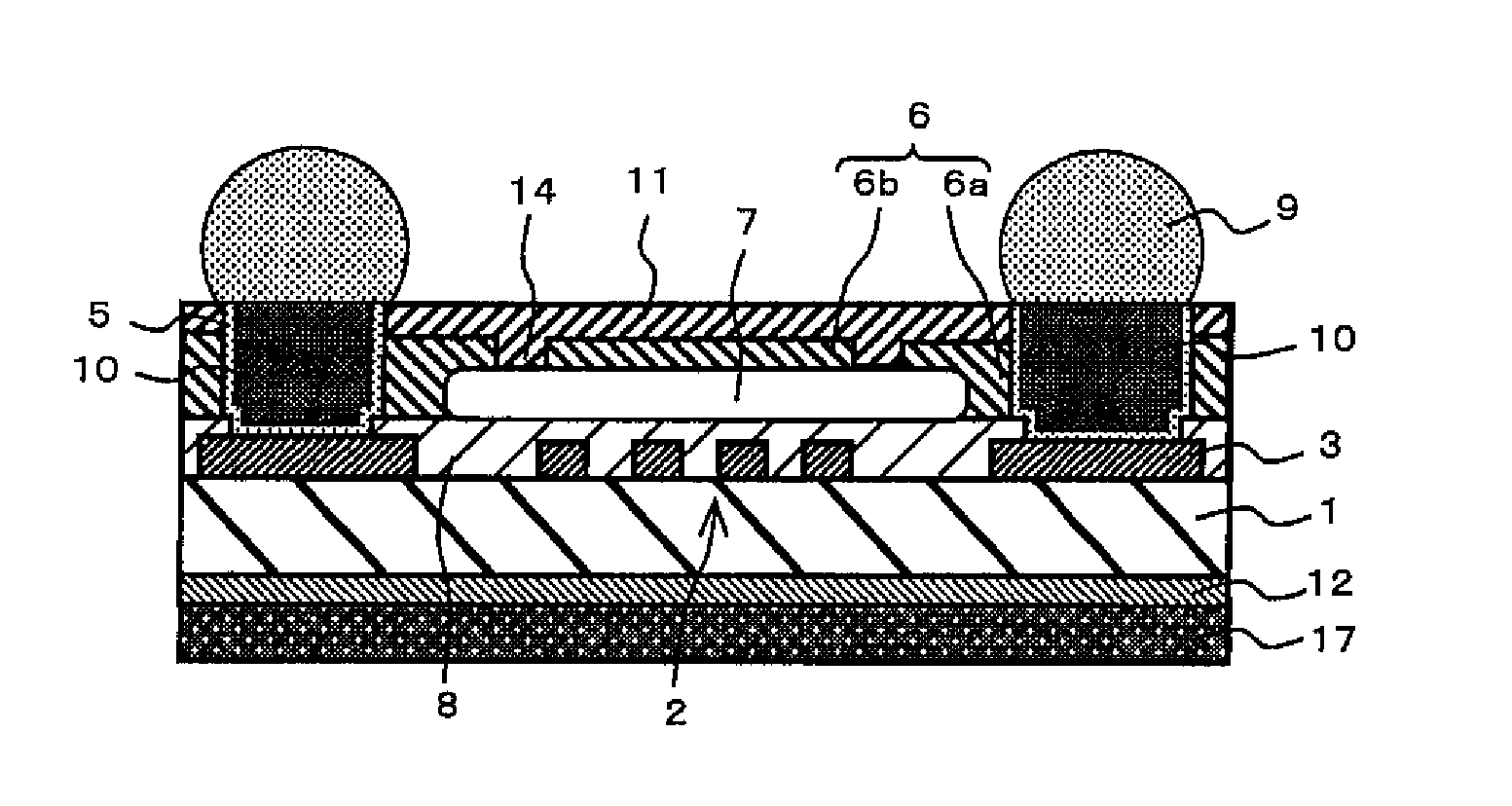

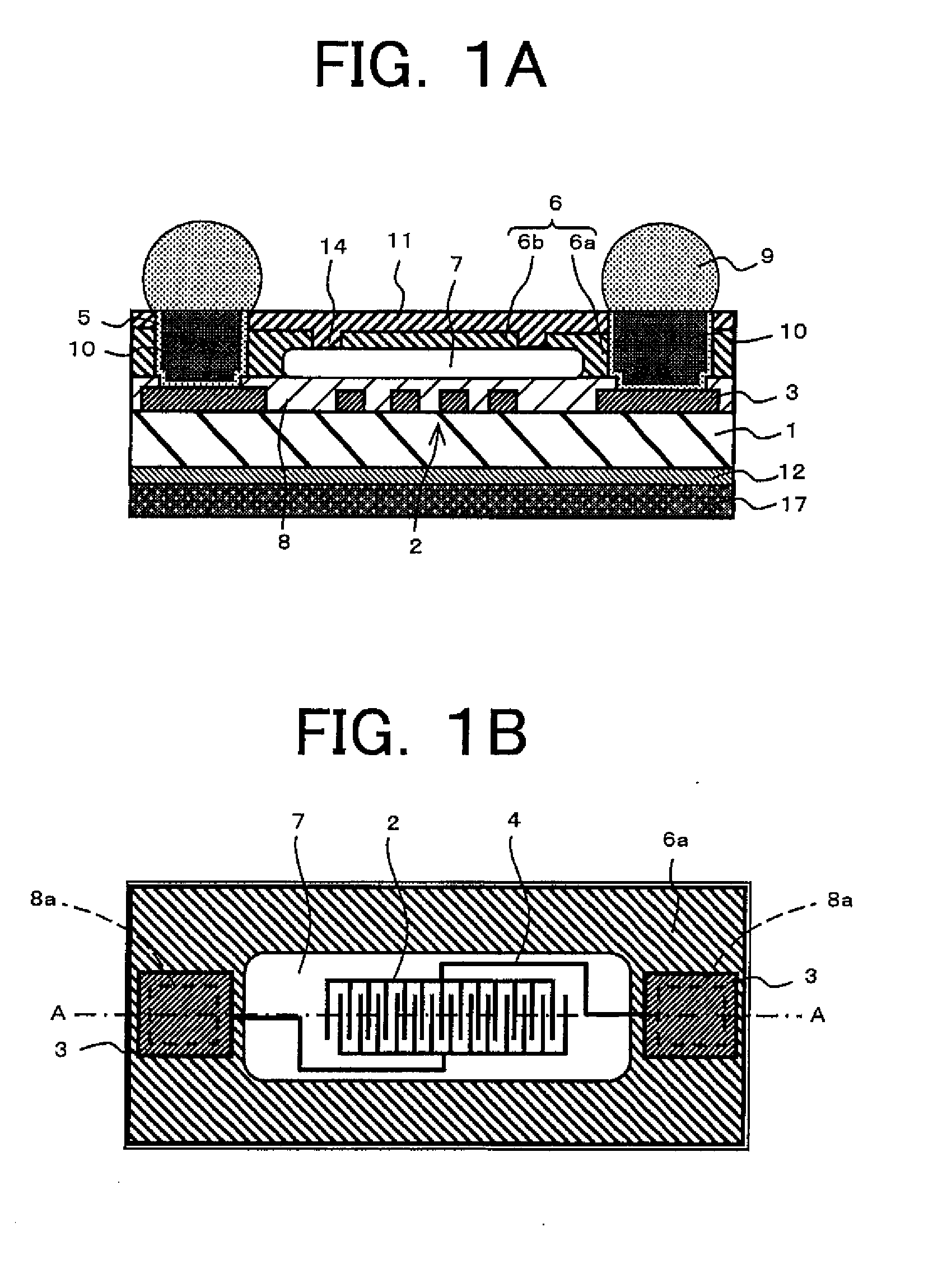

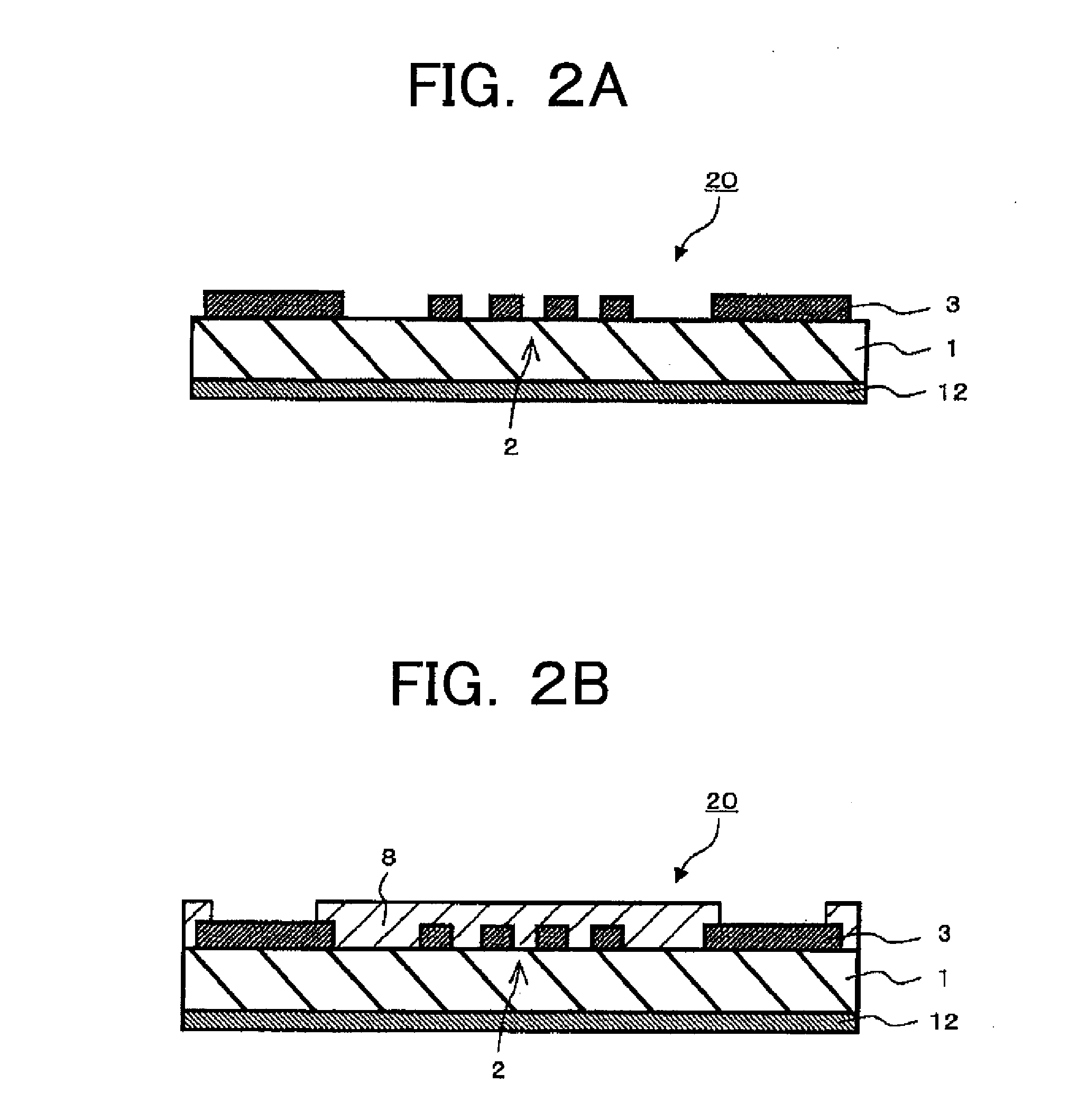

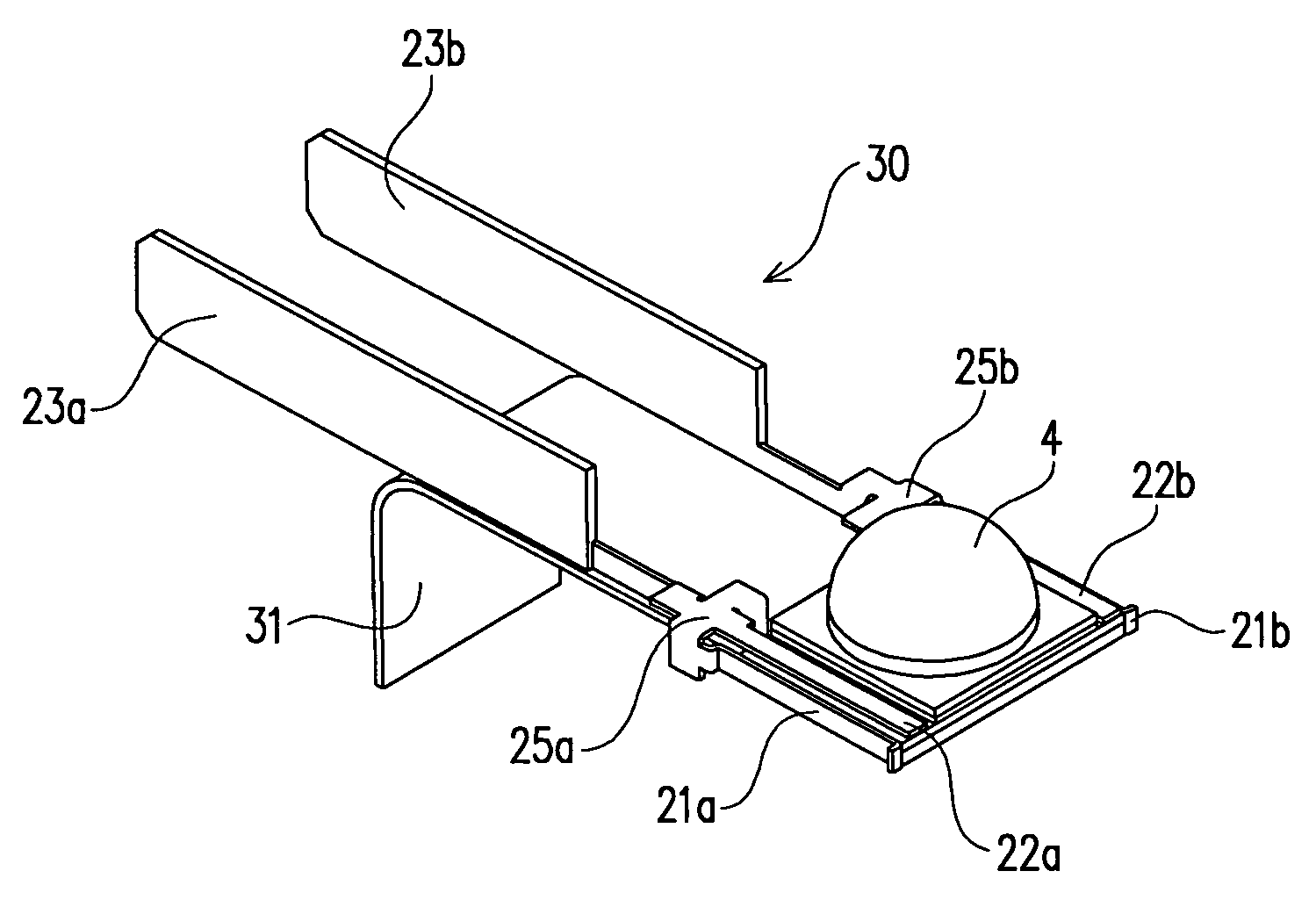

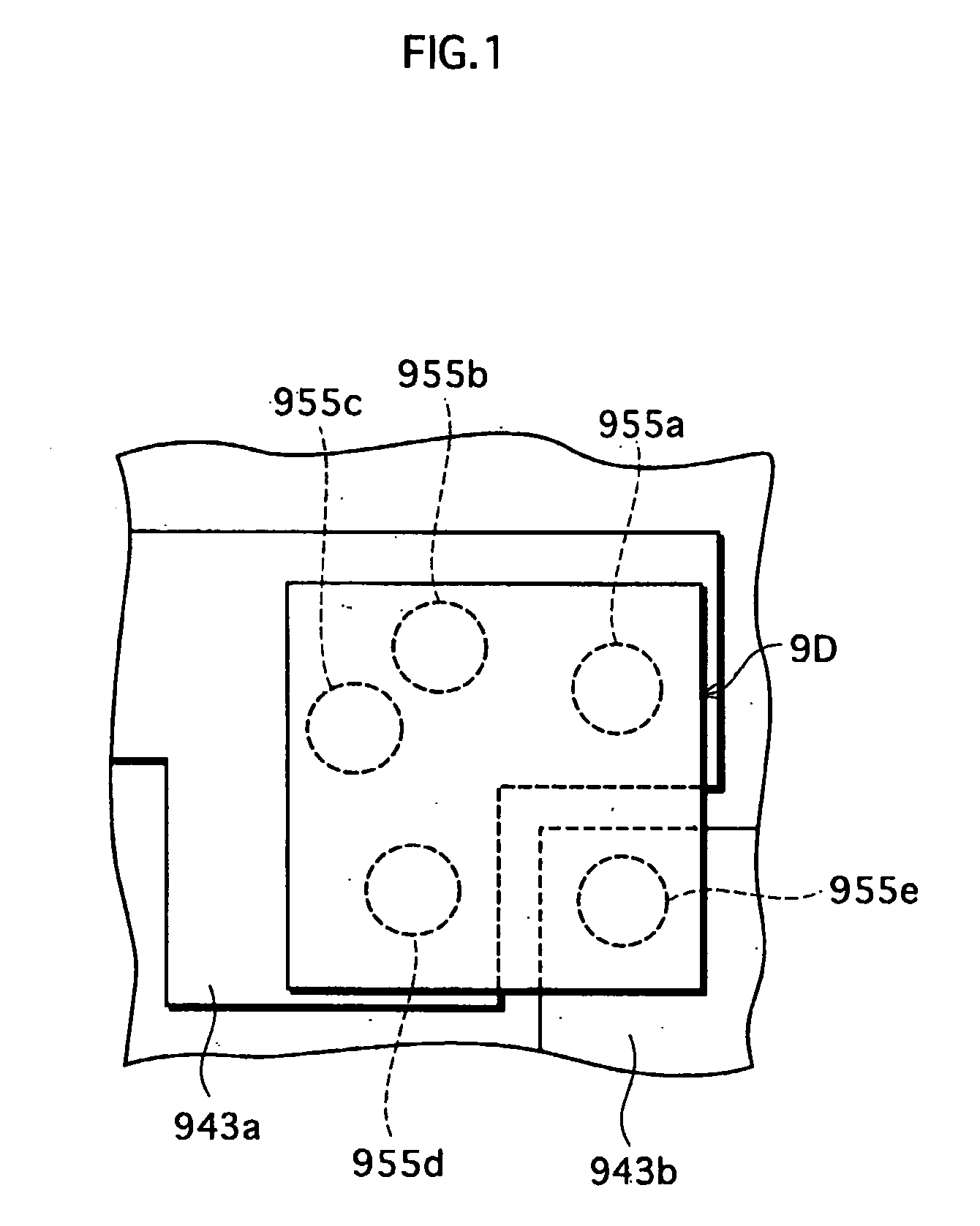

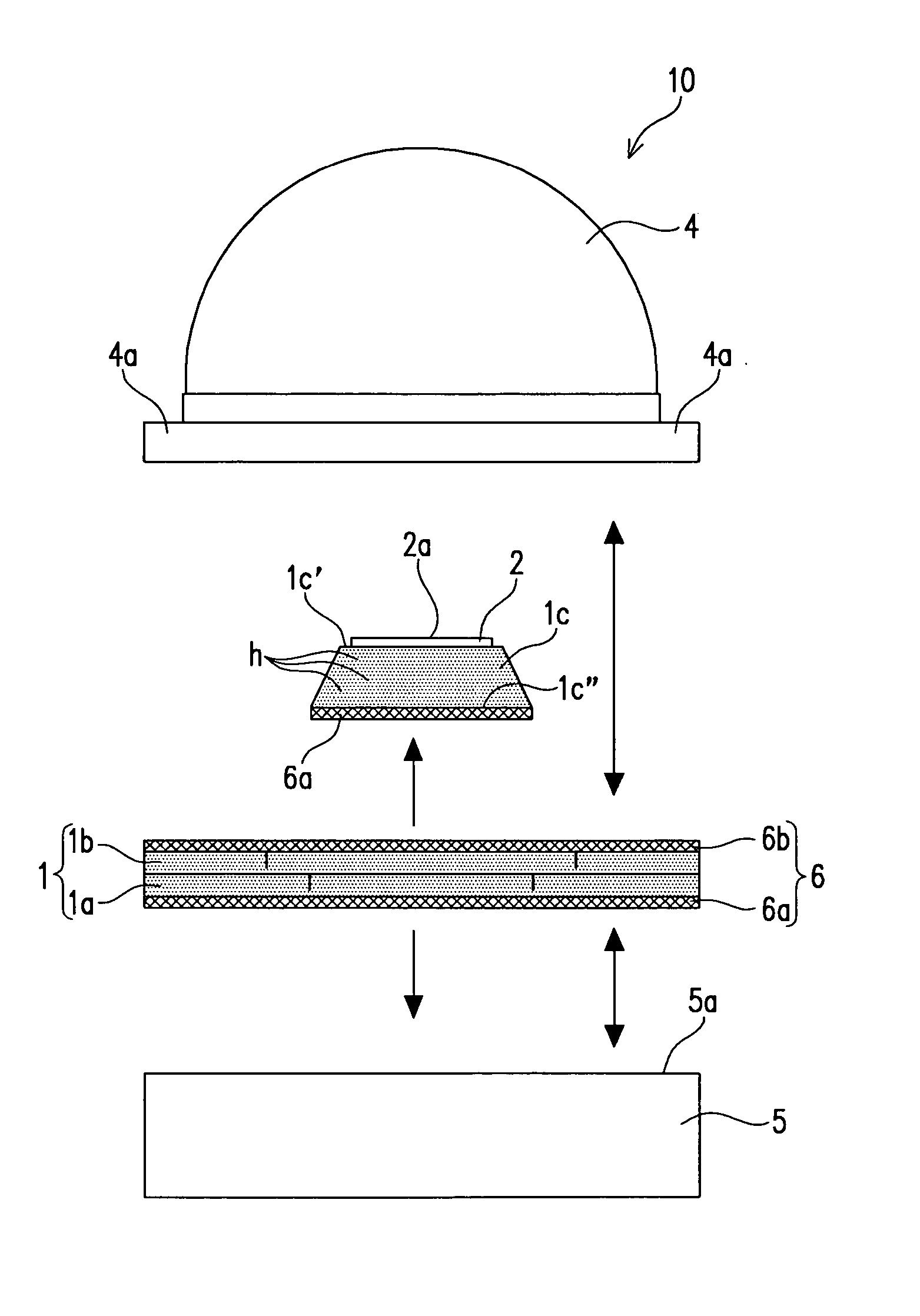

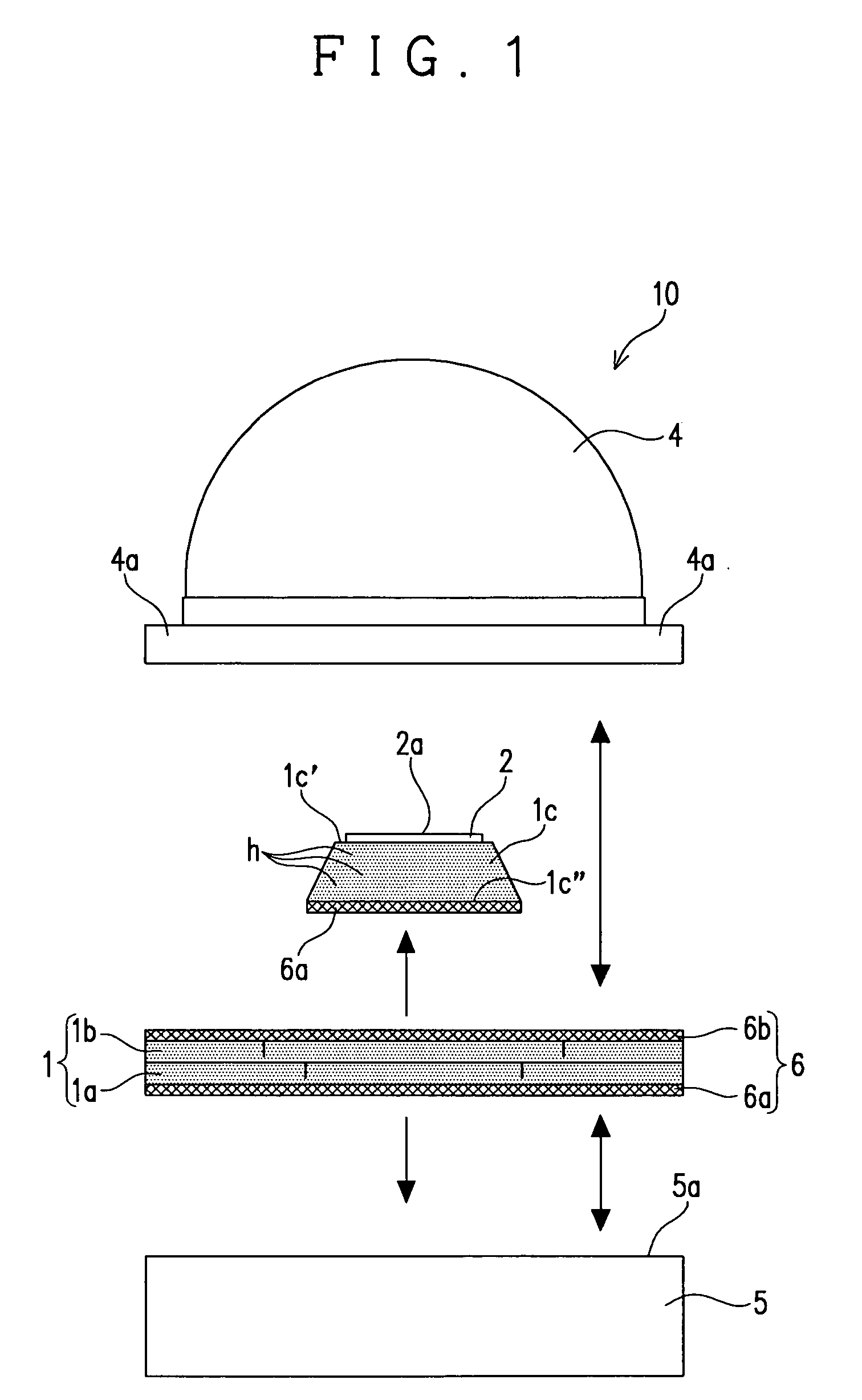

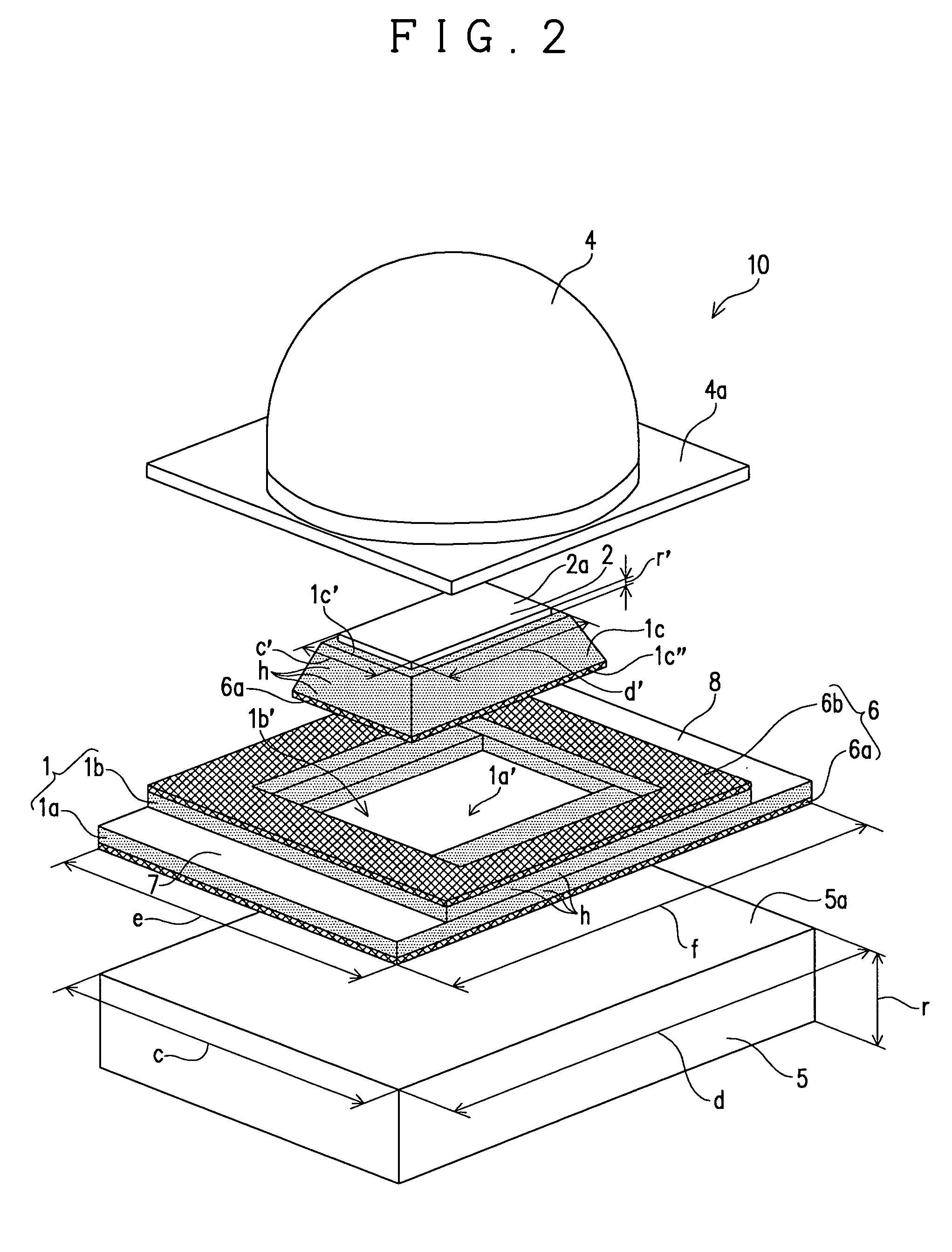

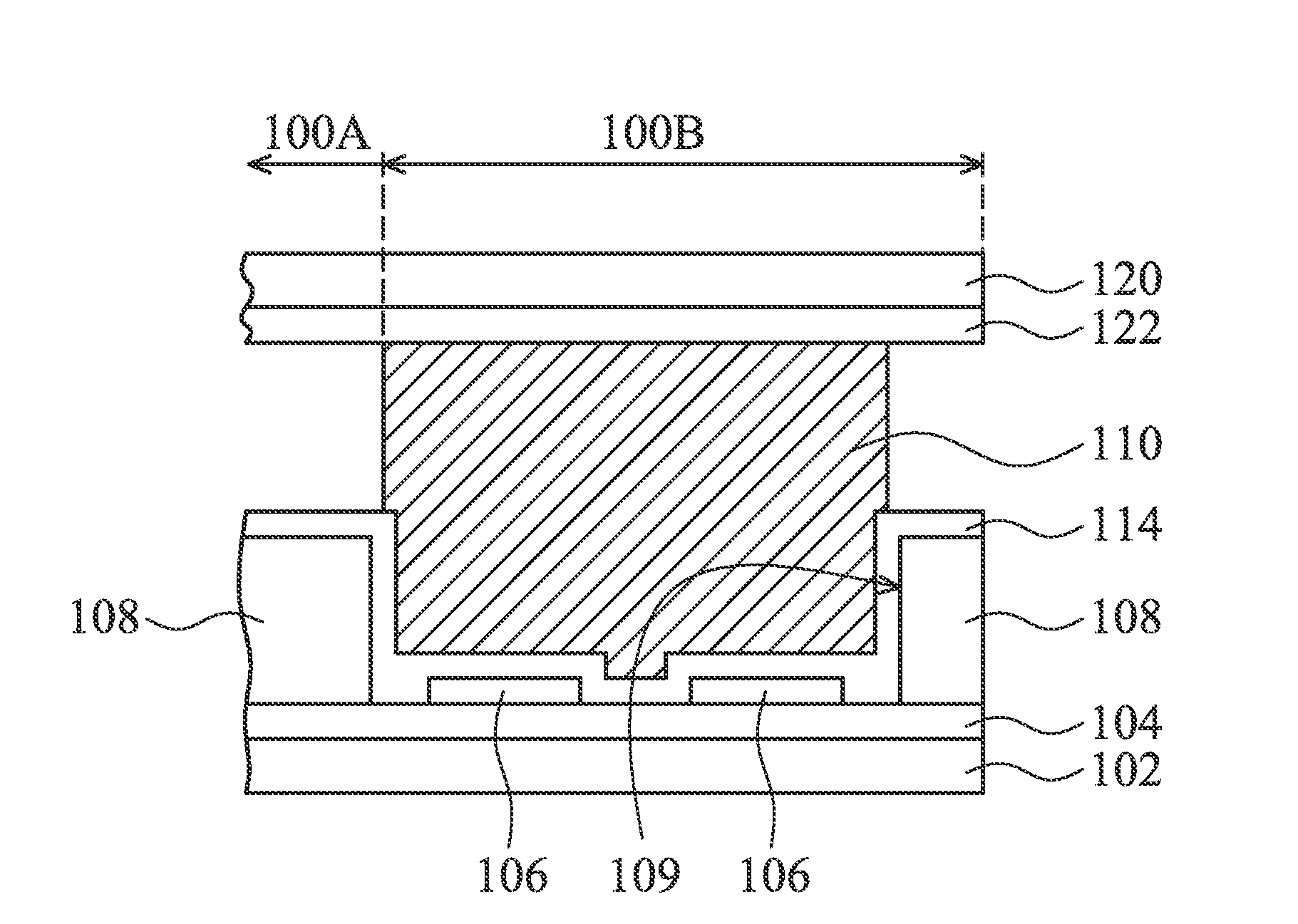

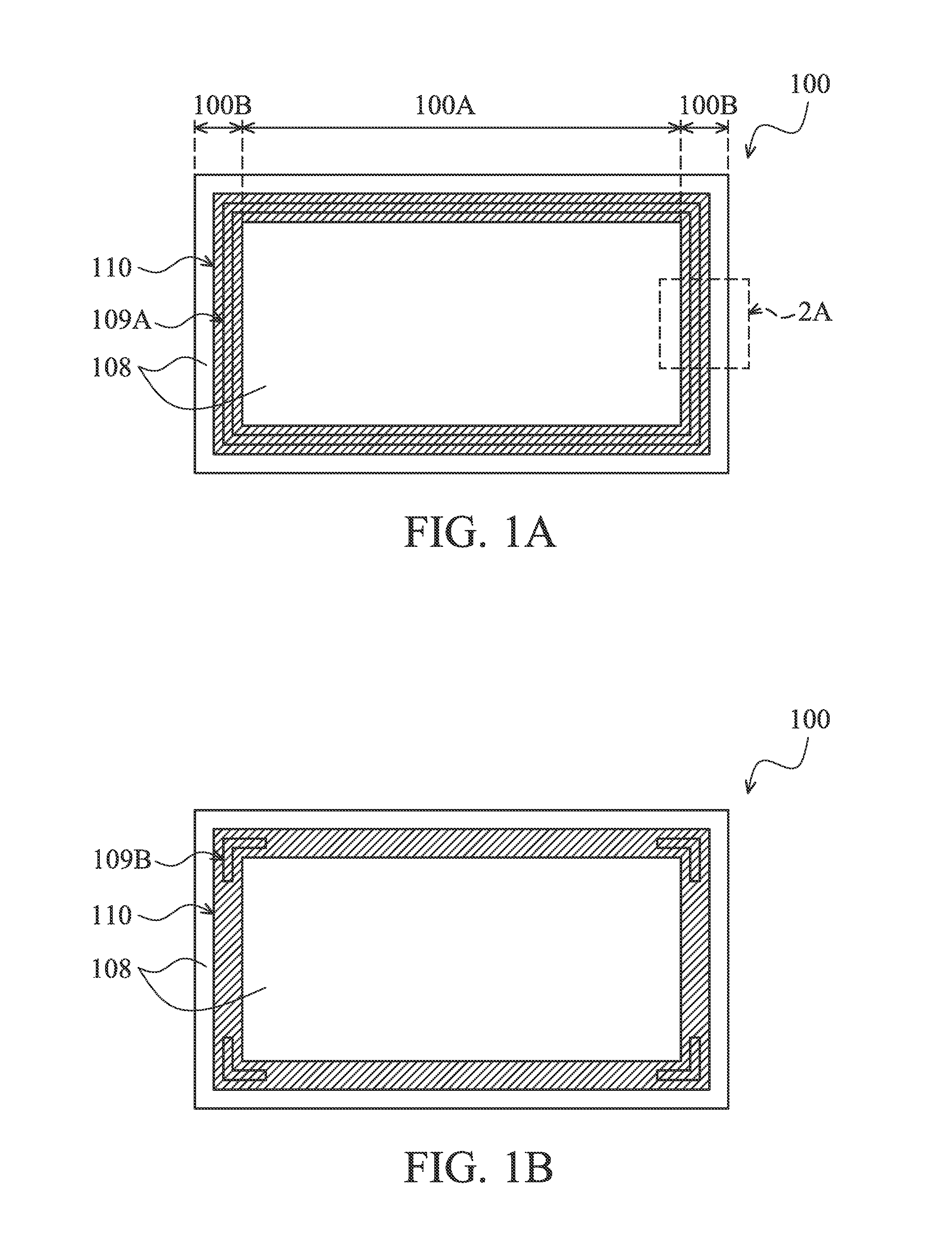

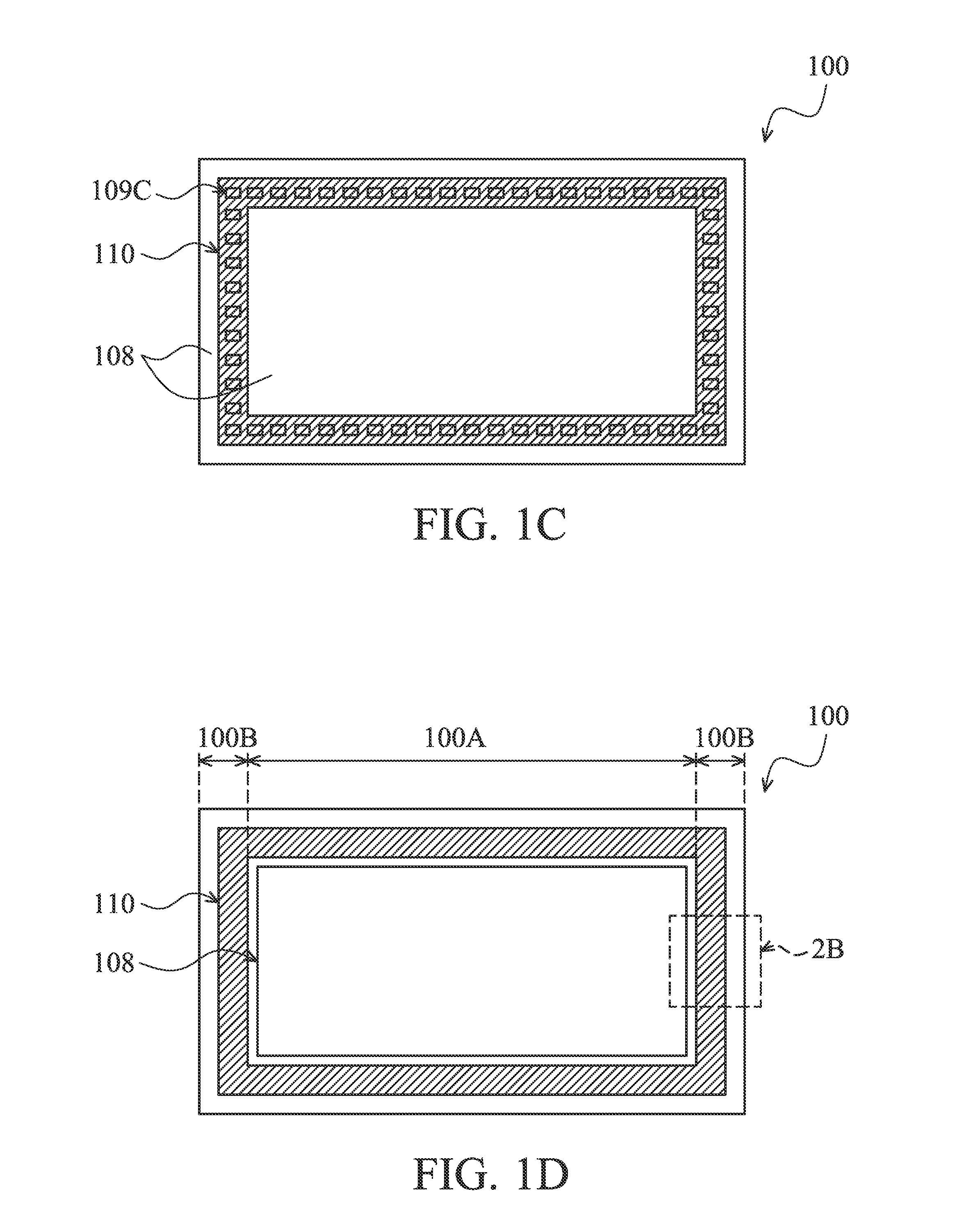

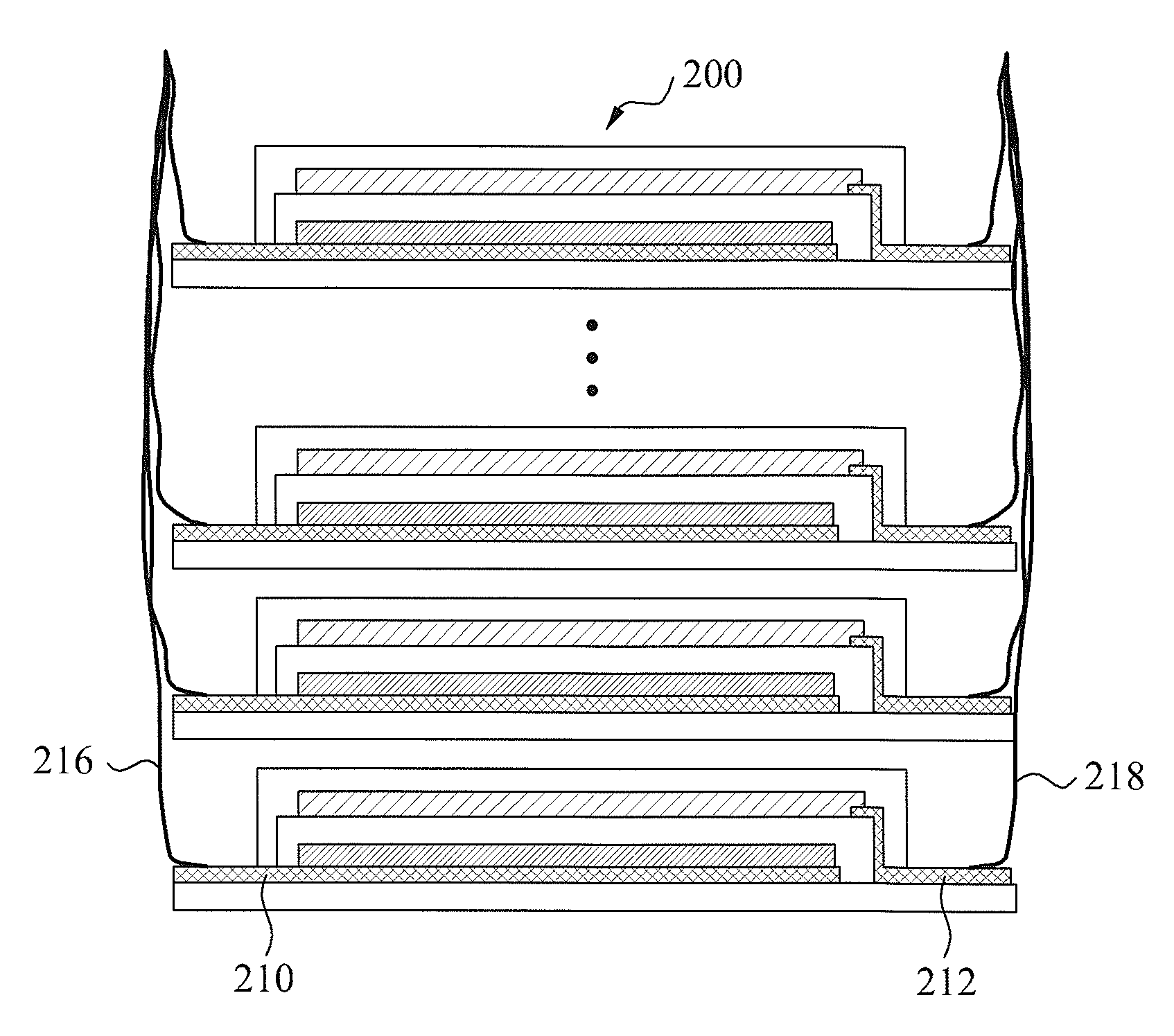

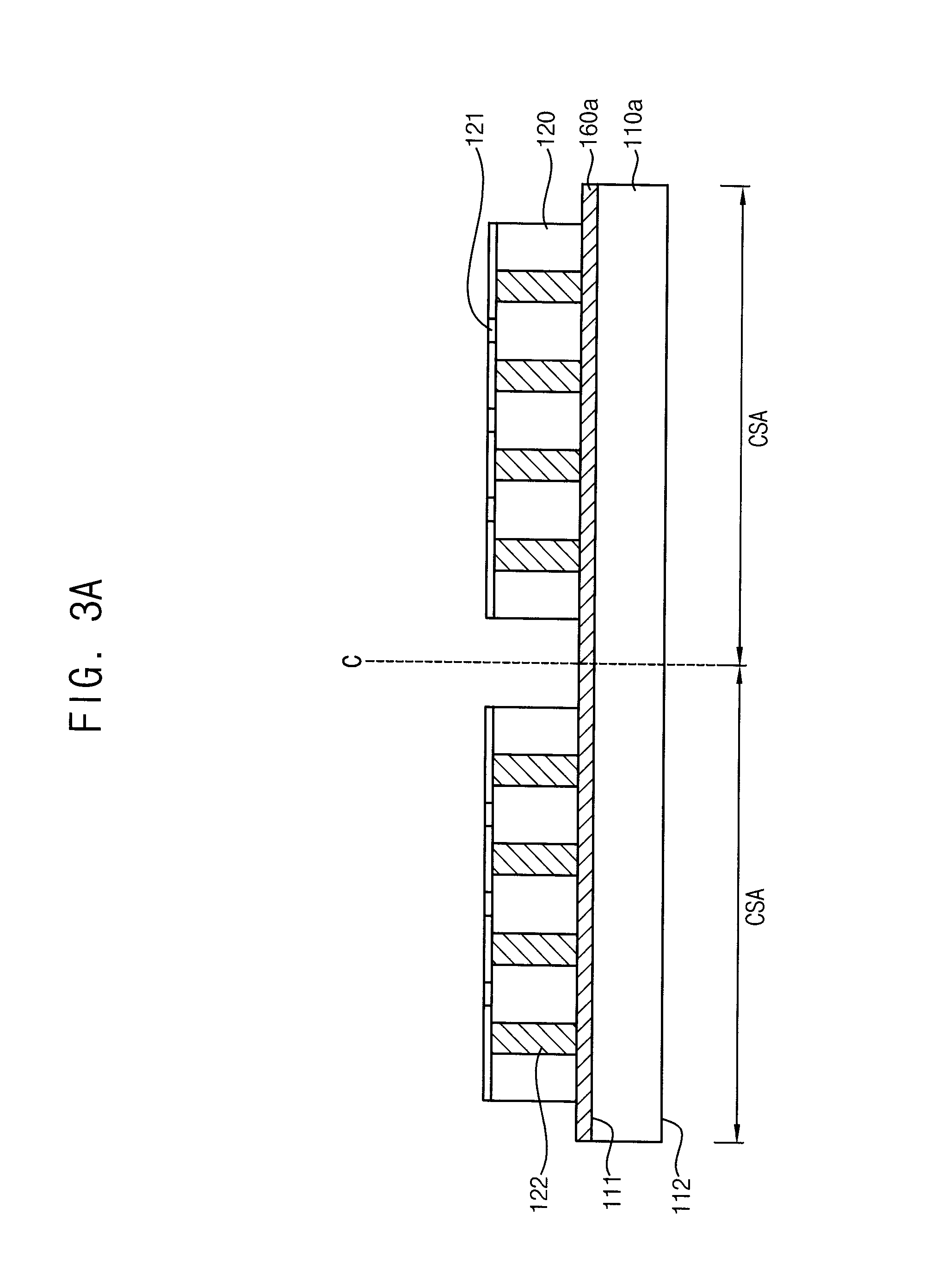

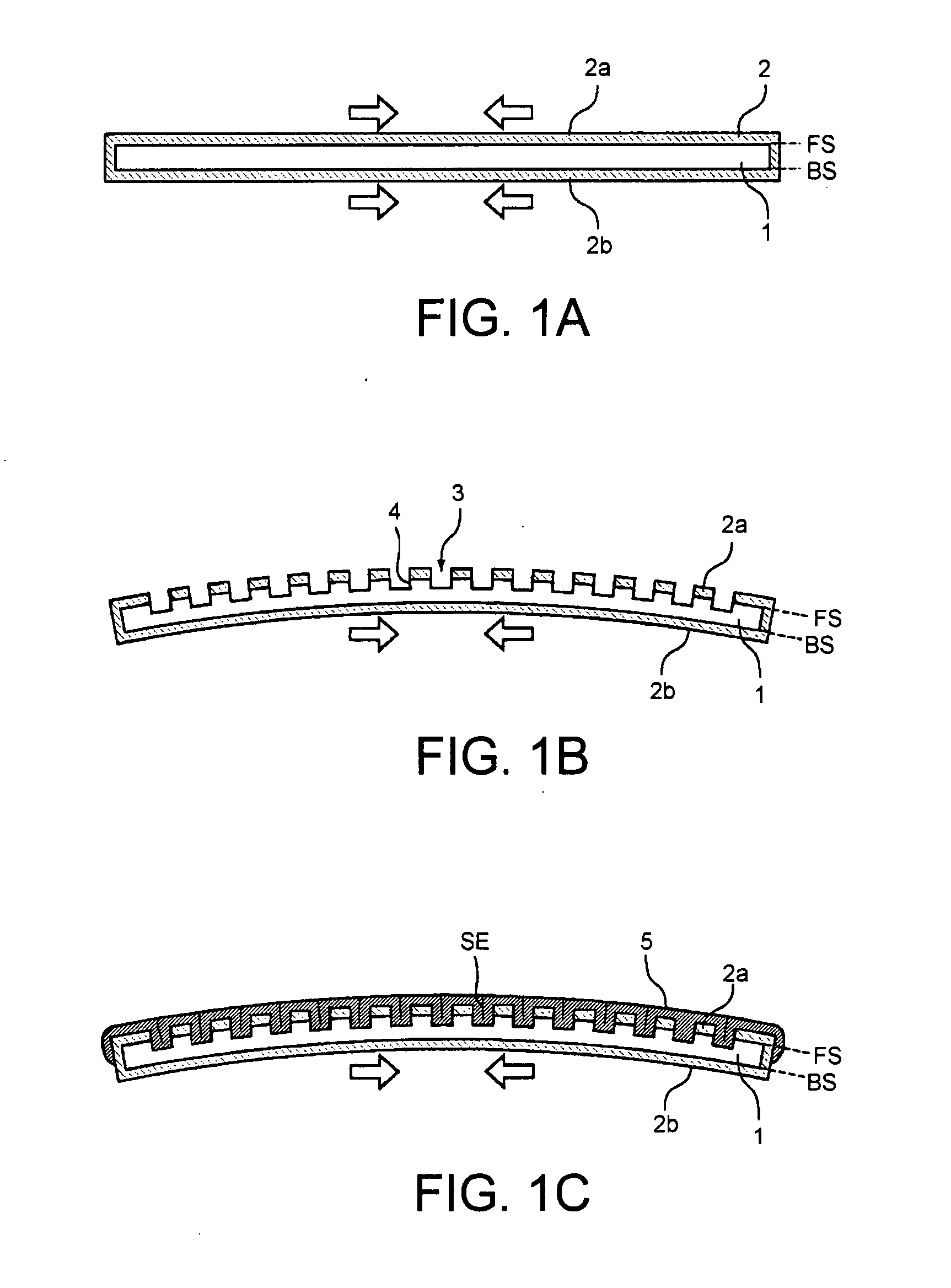

Acoustic Wave Device and Method for Production of Same

ActiveUS20110018389A1Stably keep tight sealImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

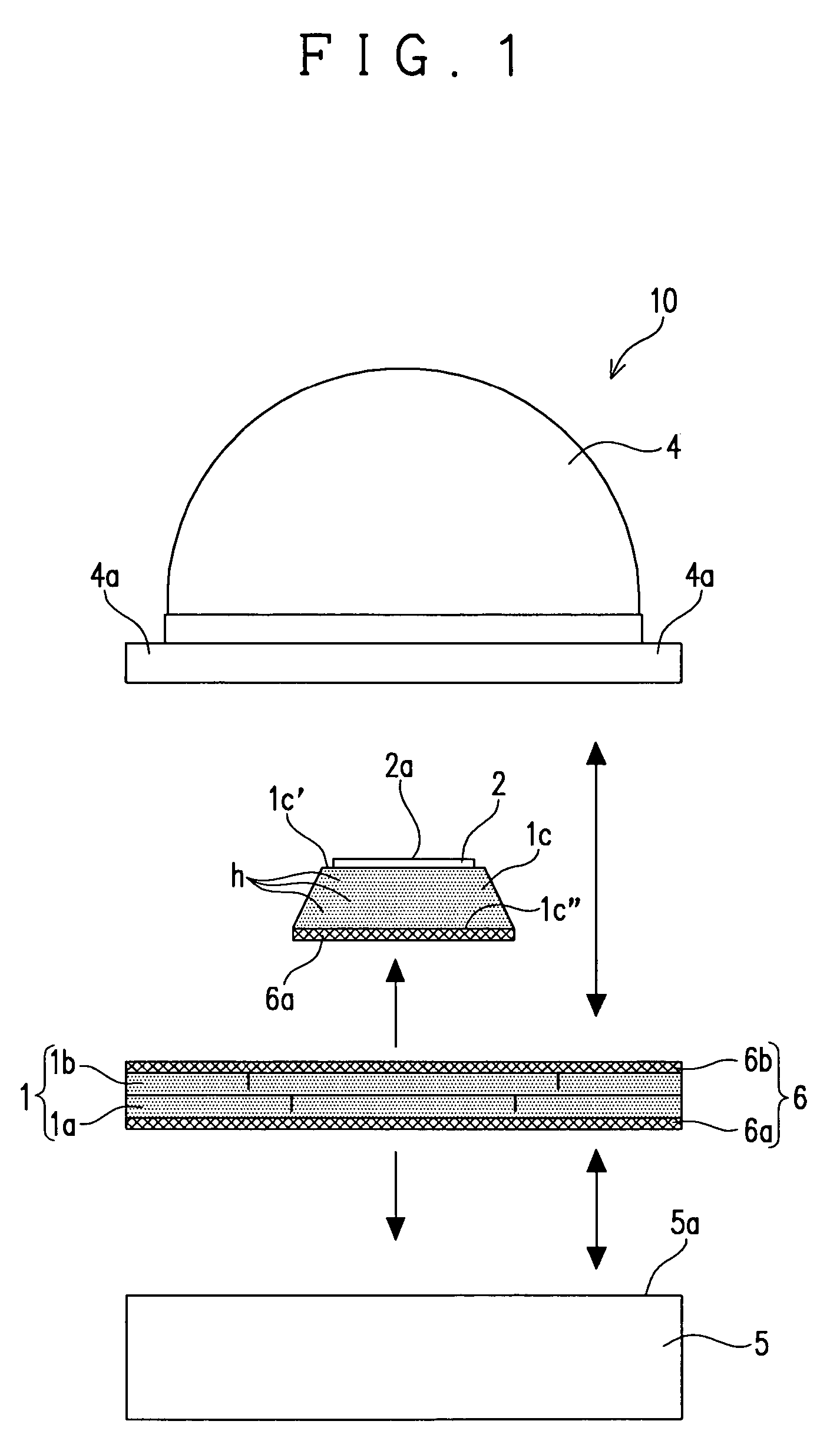

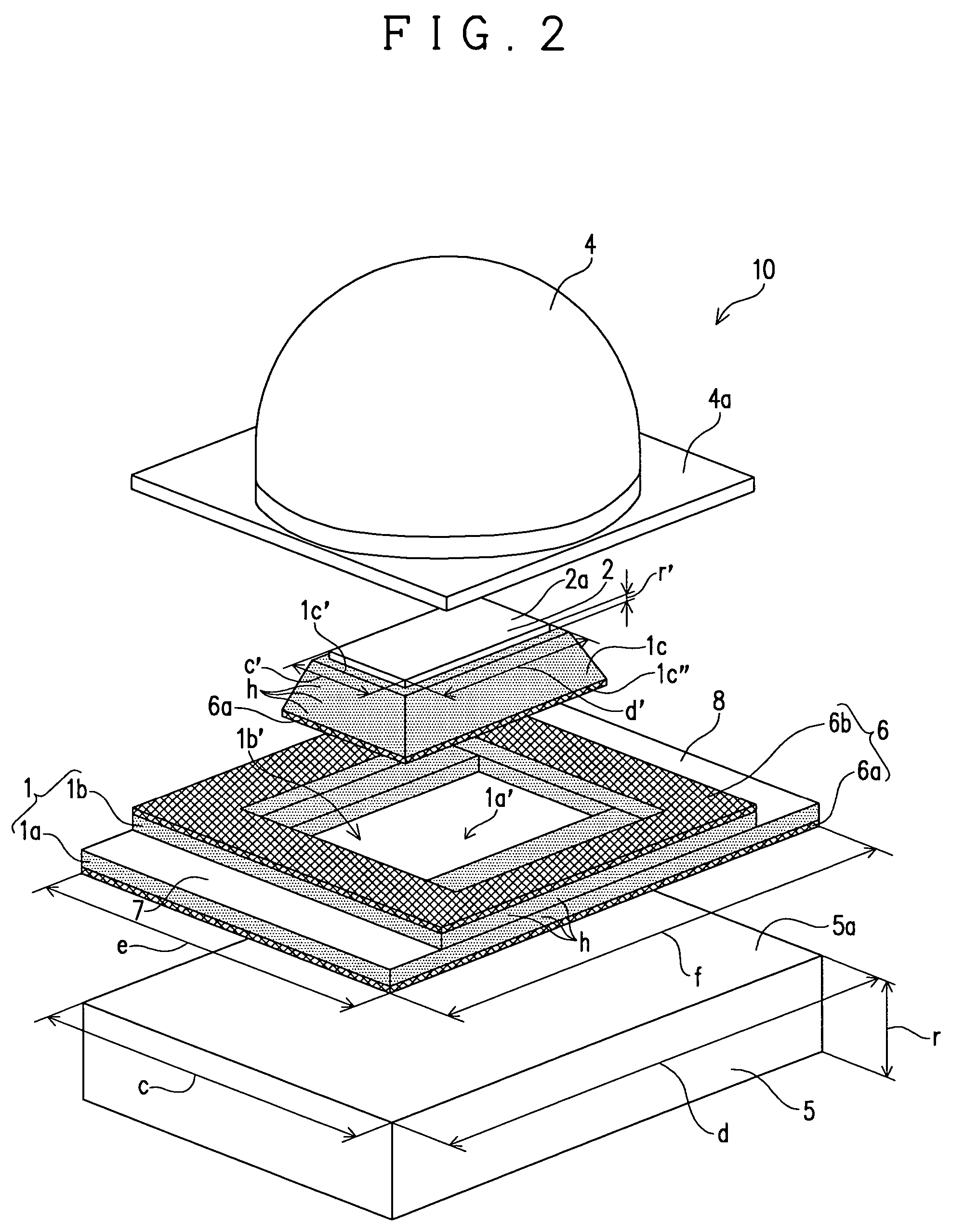

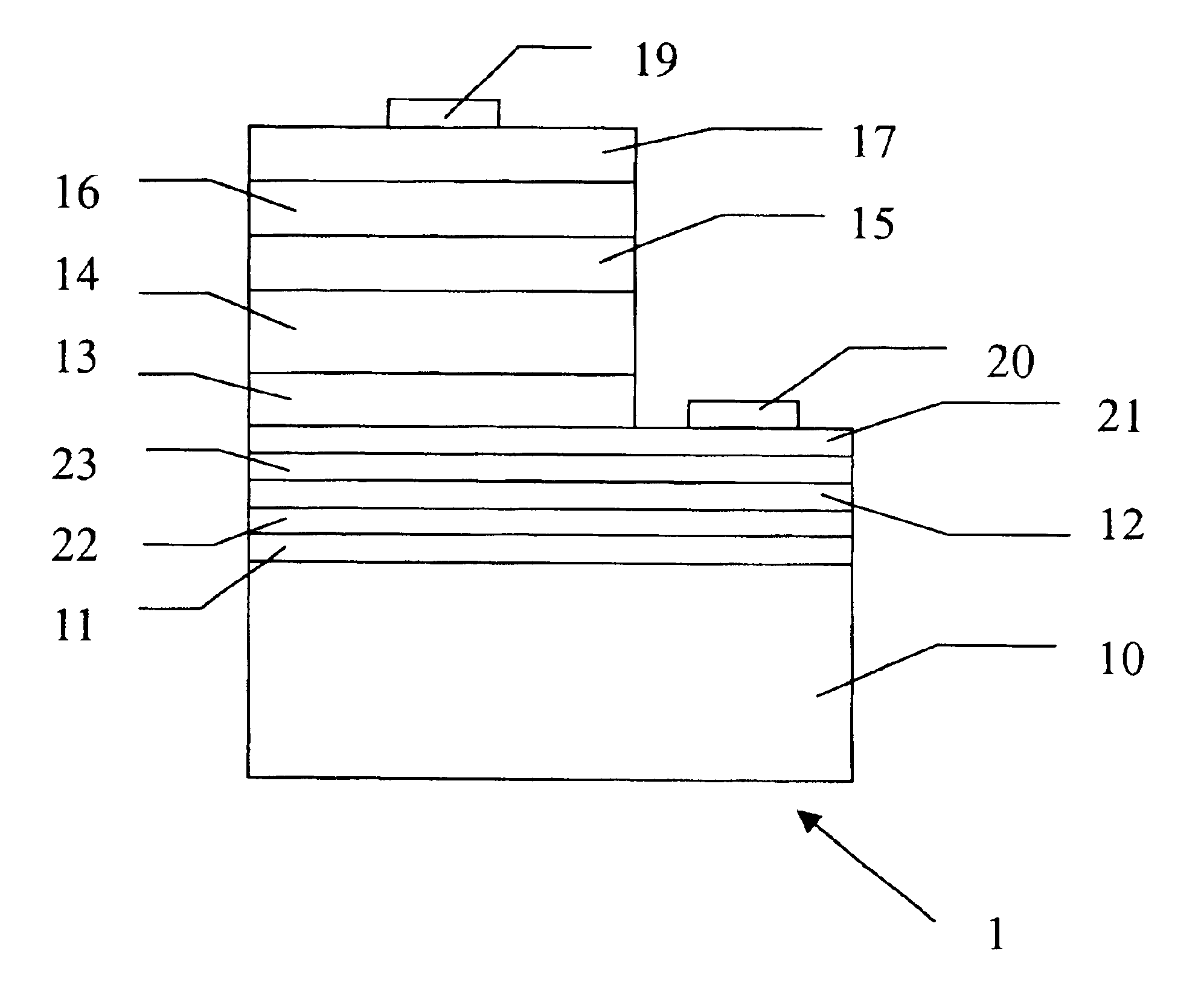

Light emitting device, method of manufacturing the same and lighting equipment

ActiveUS7211835B2InhibitionImprove the bonding force between layersVehicle headlampsPoint-like light sourceLight equipmentEffect light

In a light emitting device with a heat-release metallic part made of metal and a packaging ceramic part made of ceramics bonded to the metallic part via an adhesive, the adhesive is a hot melt that melts with heat at a melting temperature higher than a given temperature and has flexibility when it has been hardened and formed a bond, and the ceramic part has pores at least in a given bonding surface region so that the hot melt is impregnated into the pores.

Owner:NICHIA CORP

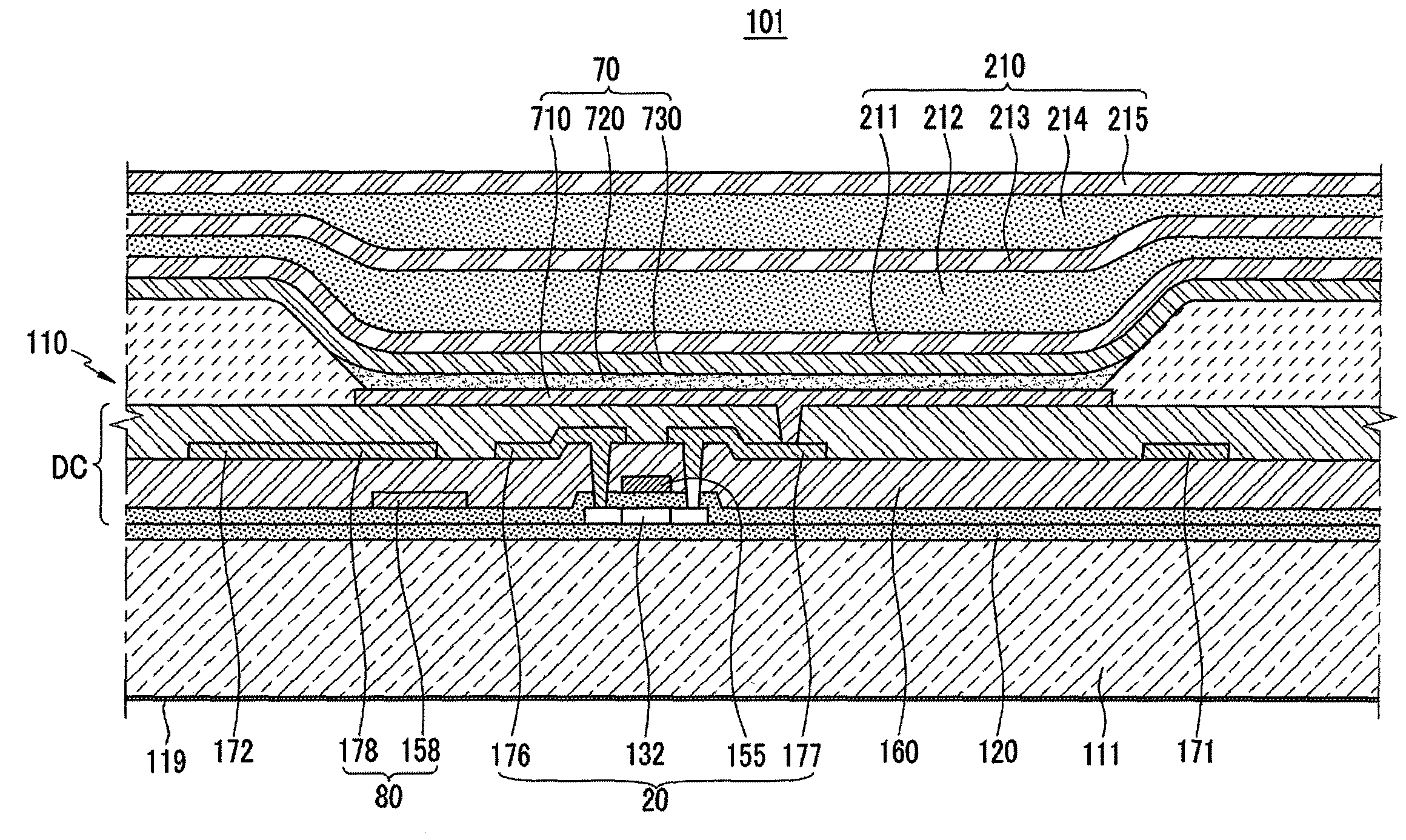

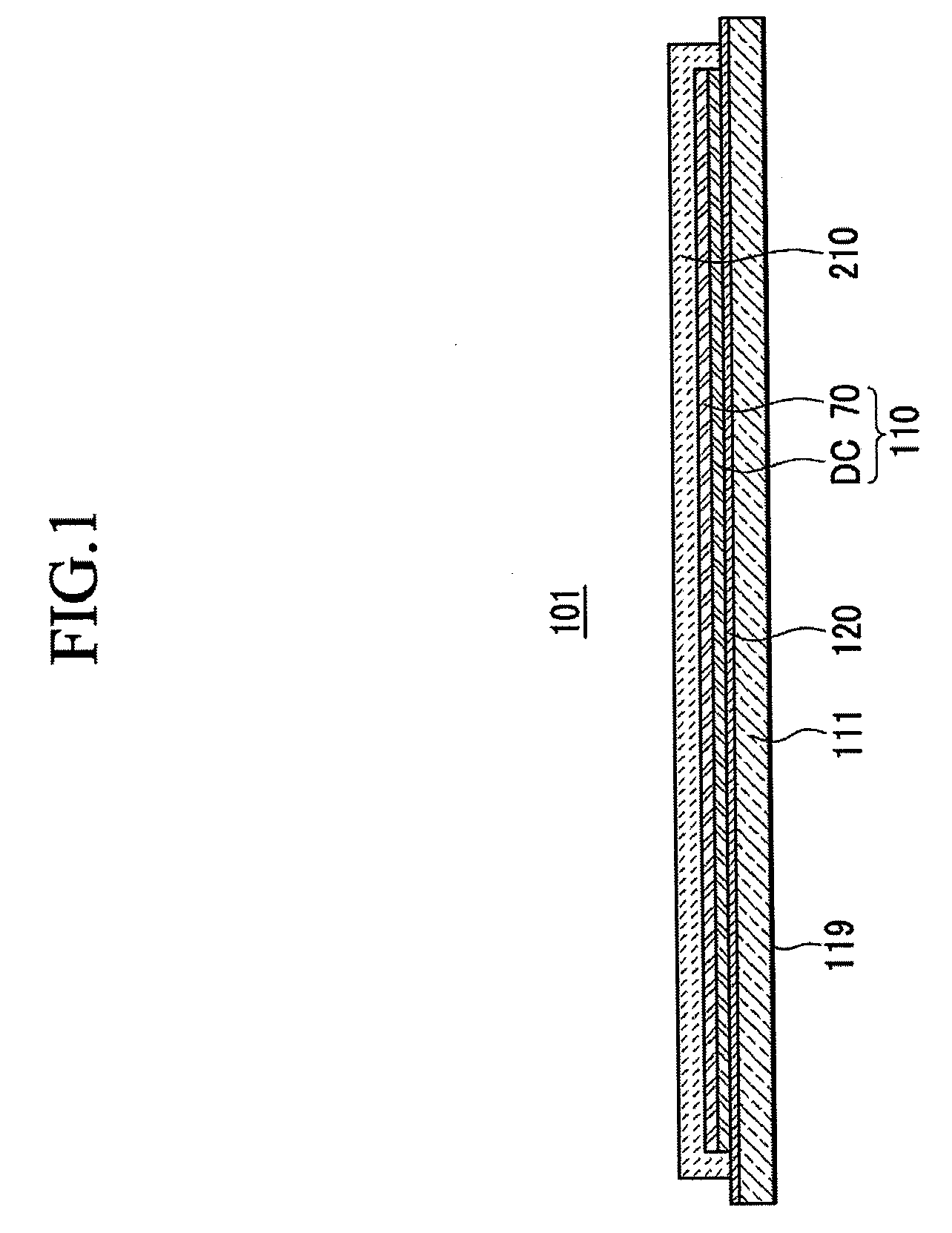

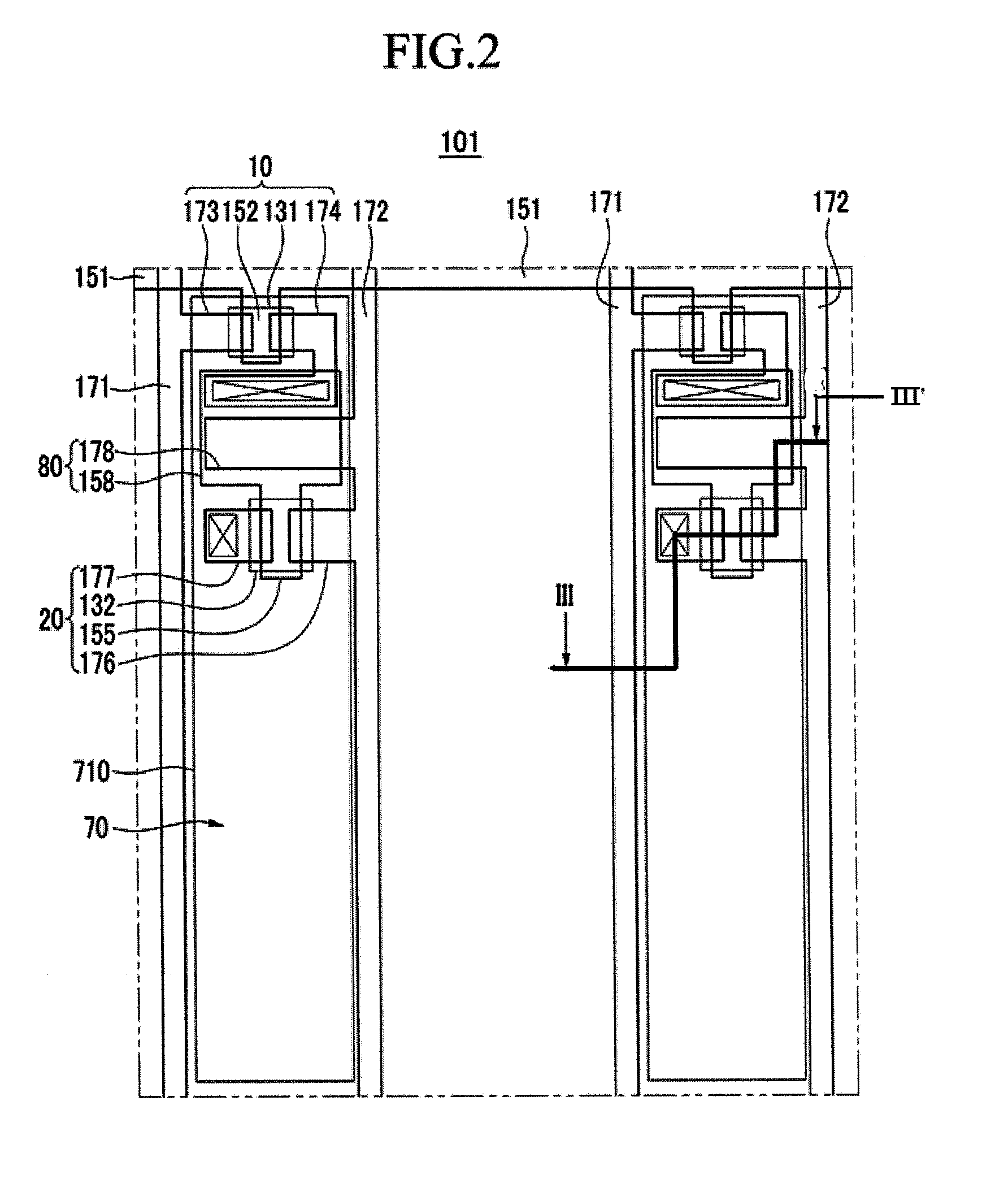

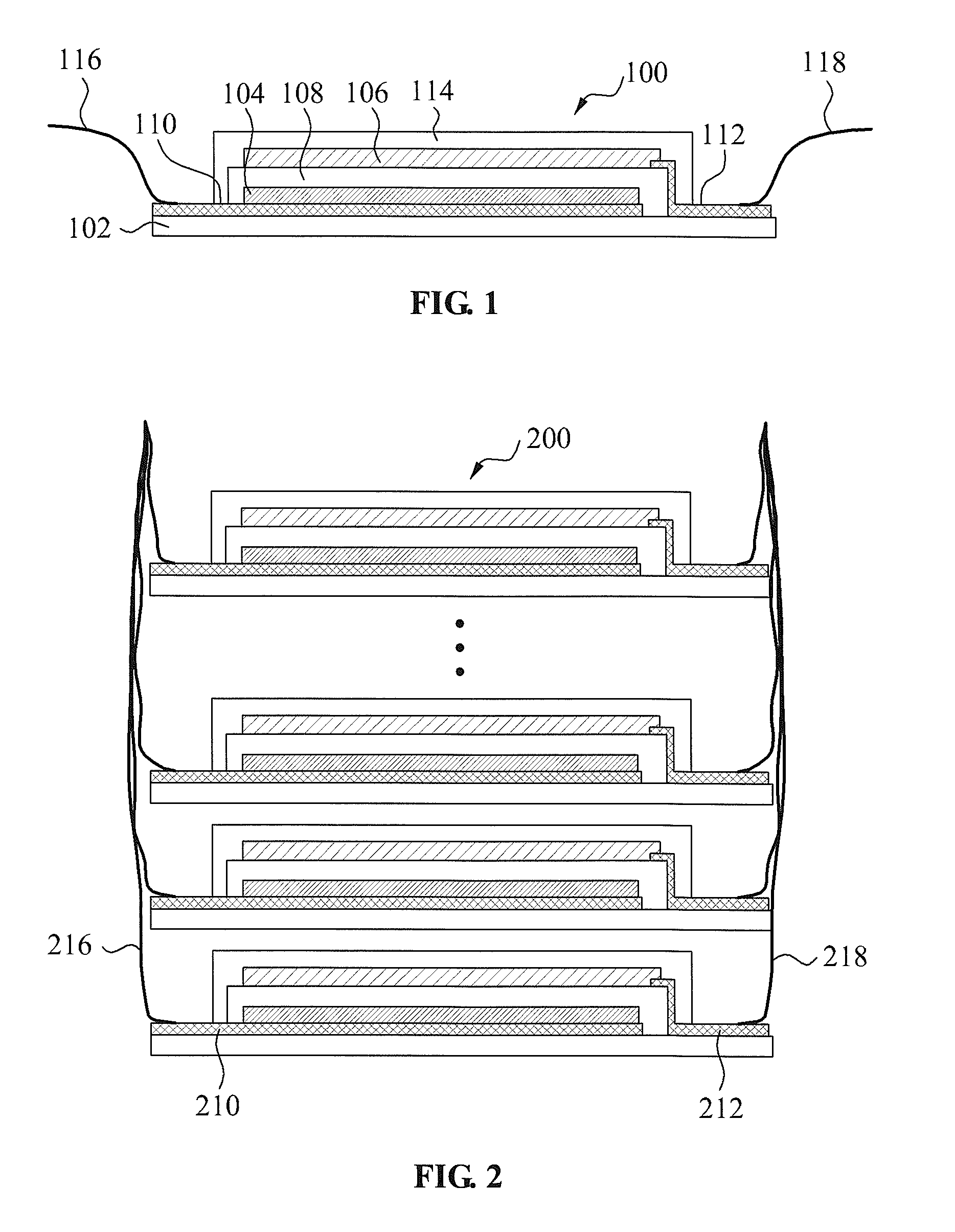

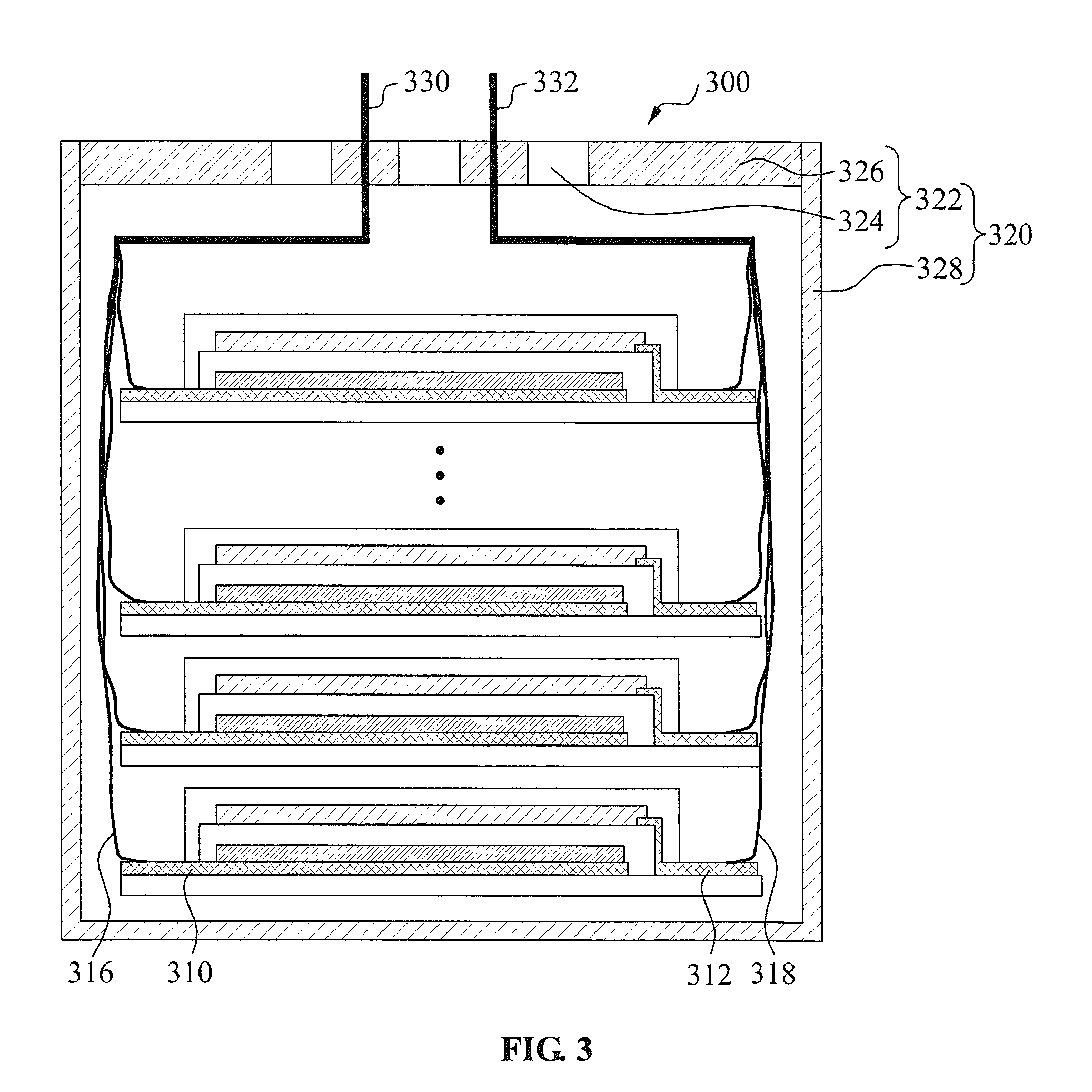

Flexible display and method for manufacturing the same

InactiveUS20110052836A1Inhibition of defect generationImprove the bonding force between layersLiquid crystal compositionsFinal product manufacturePlastic materialsMetallic materials

A flexible display comprises a flexible substrate made of plastic material, a display element on a first surface of the flexible substrate, and a surface residual film containing at least one of a metal material or a metal oxide material. The surface residual film is bonded to at least a part of a second surface of the flexible substrate. The second surface is opposed to the first surface. A method for manufacturing a flexible display comprises preparing a glass substrate, forming adhesive material film on the glass substrate, the adhesive material film being made of at least one of a metal material or a metal oxide material, and forming a flexible substrate from plastic material on the adhesive material film.

Owner:SAMSUNG DISPLAY CO LTD

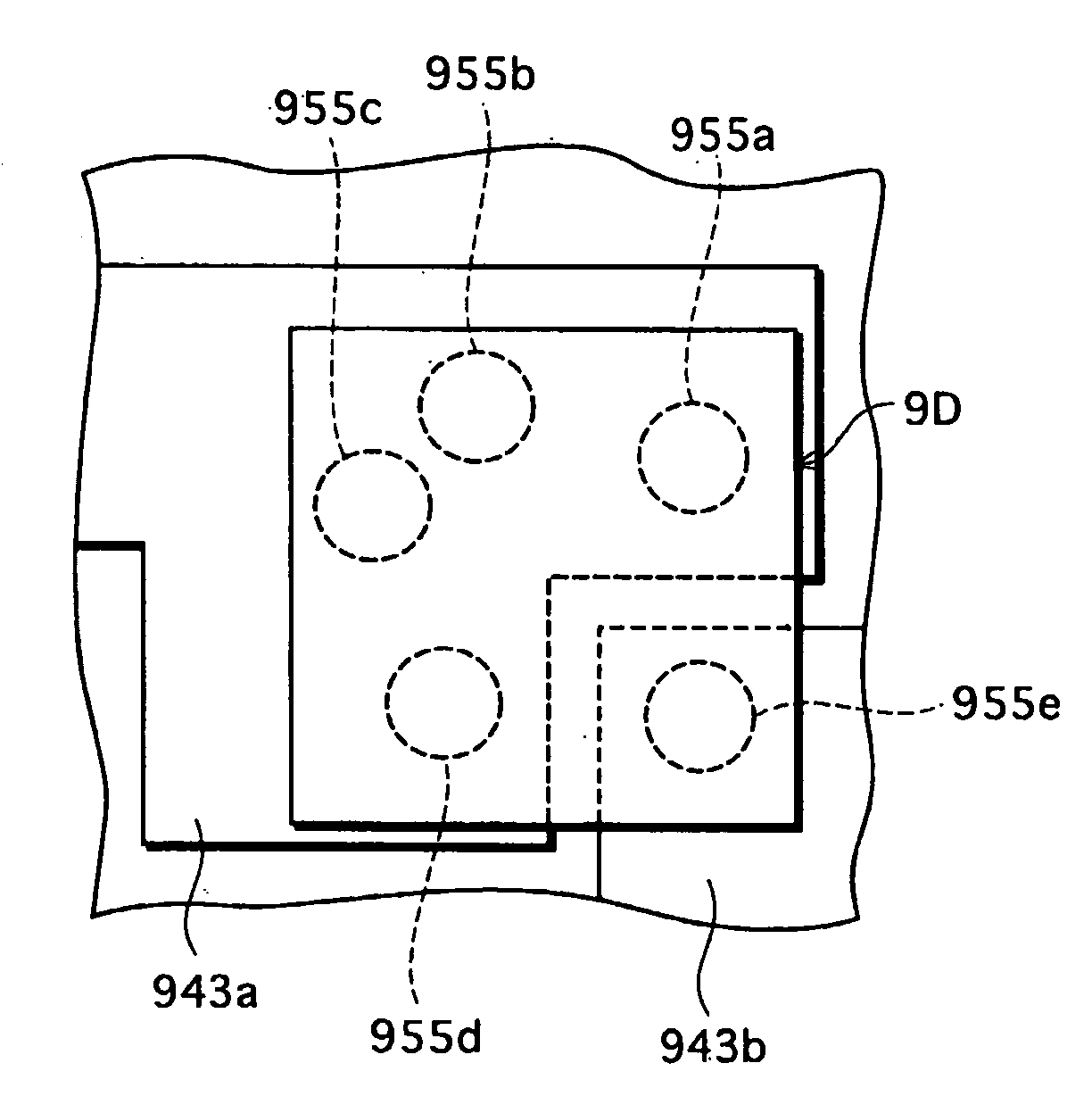

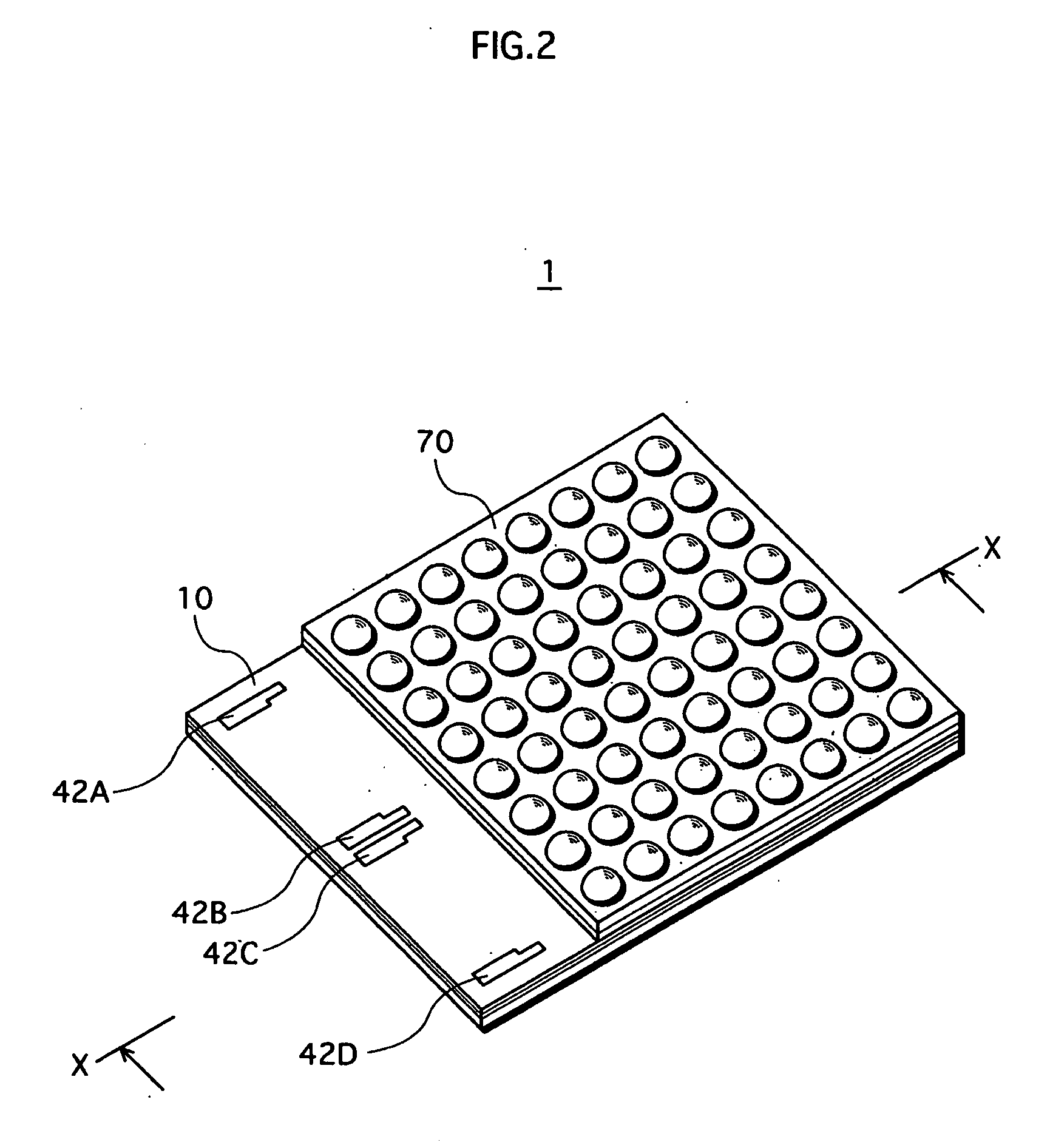

Light source, manufacturing method of light source, lighting apparatus, and display apparatus

ActiveUS20090039376A1Improve bindingReduce the possibilityPlanar light sourcesPoint-like light sourceLight emitting deviceLight source

Provided is a light source that has high reliability and hardly causes conductivity failure between a light emitting device and a conductive land. In an LED light source of the present invention, an LED bare chip is mounted to conductive lands of a substrate, using bumps (55a, 55b). The LED bare chip (D65) is provided with a p-electrode (Lp) and an n-electrode (Ln) on a rear surface. The p-electrode (Lp) is larger in area than the n-electrode (Ln). The p-electrode (Lp) is bonded to a corresponding conductive land via four bumps (55a), whereas the n-electrode (Ln) is bonded to a corresponding conductive land via one bump (55b). A bonded area (Sn) between the n-electrode (Ln) and the bump (55b) is larger than a bonded area (Sp) between the p-electrode (Lp) and one of the bumps (55a).

Owner:PANASONIC CORP

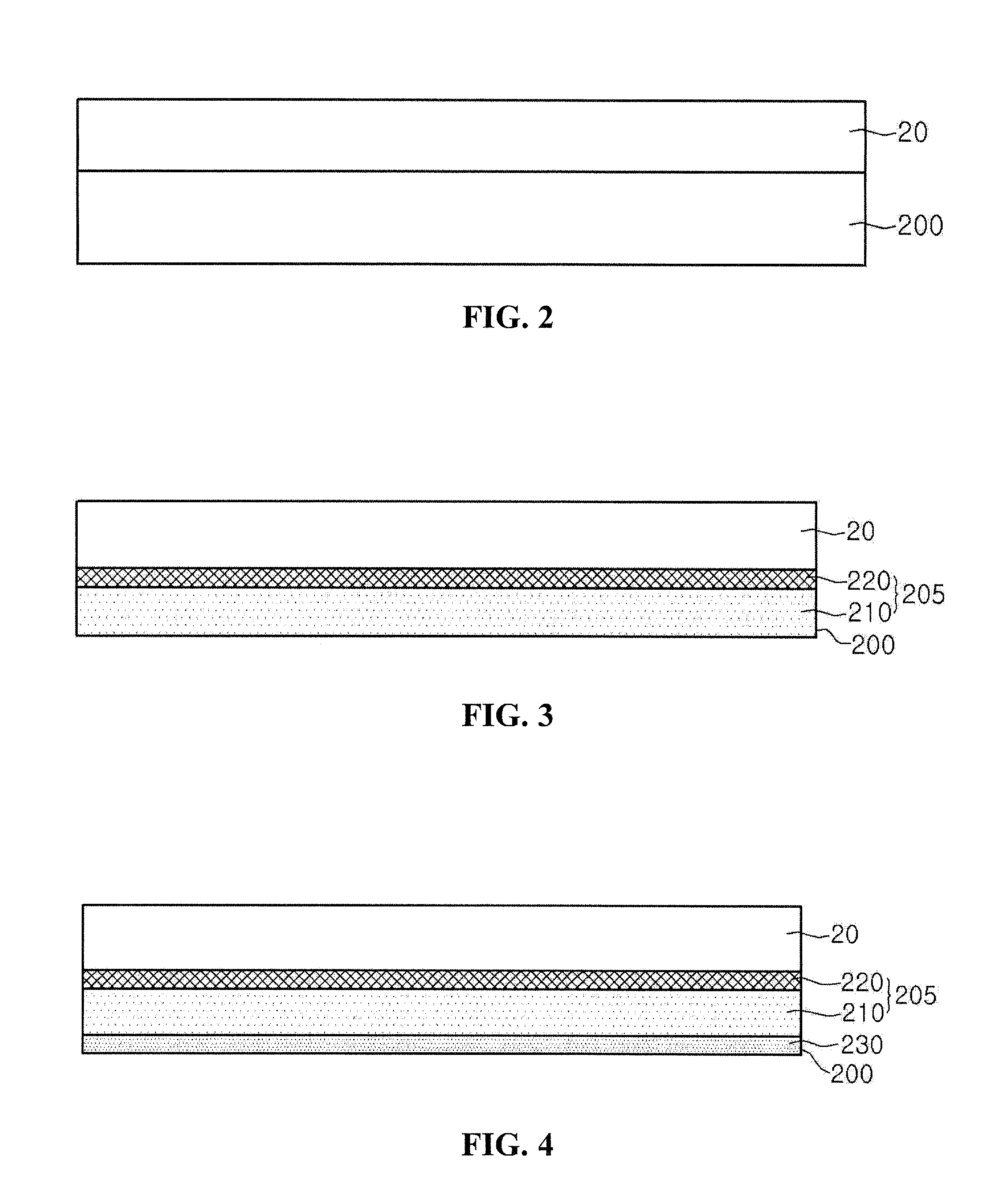

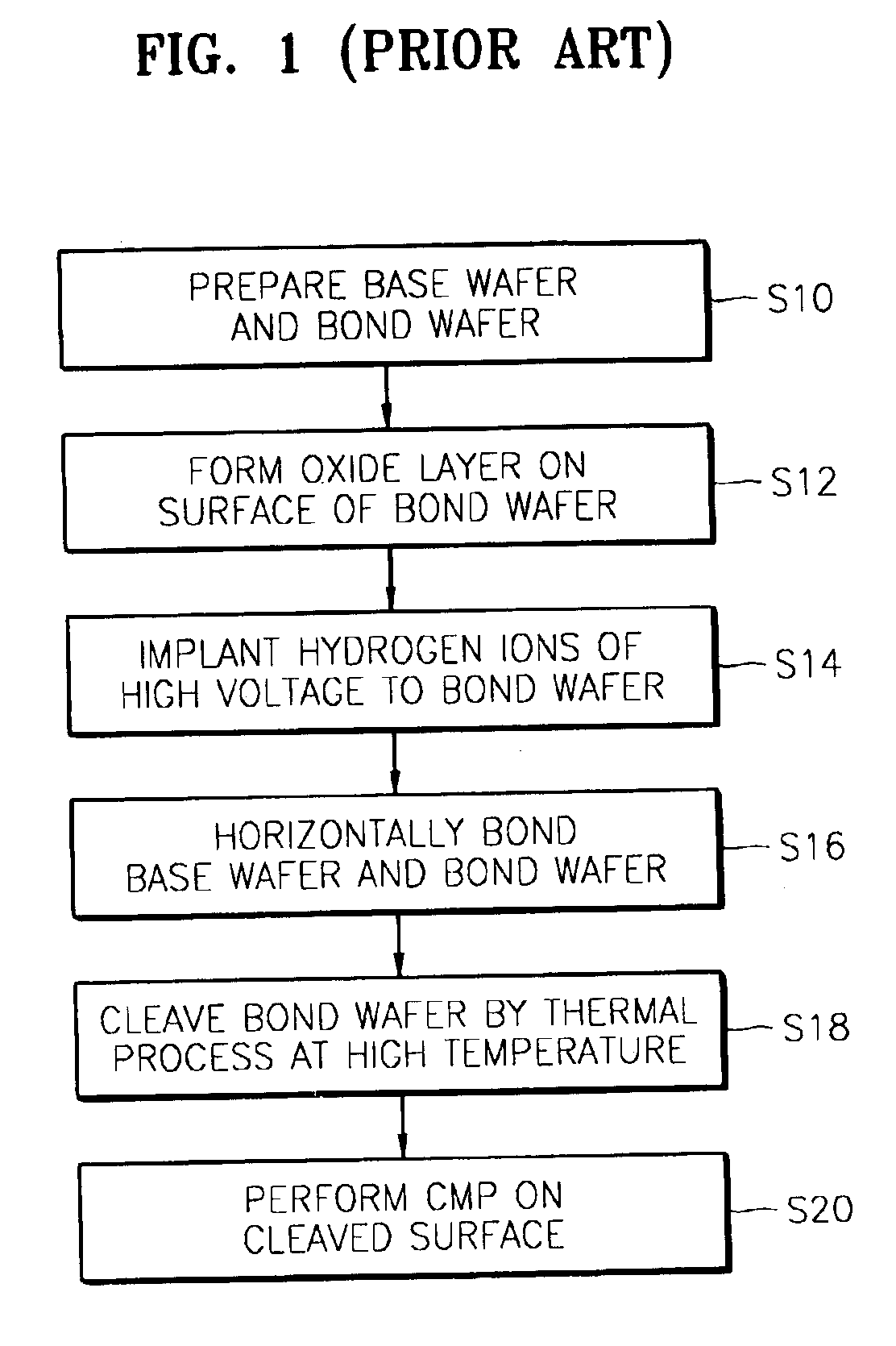

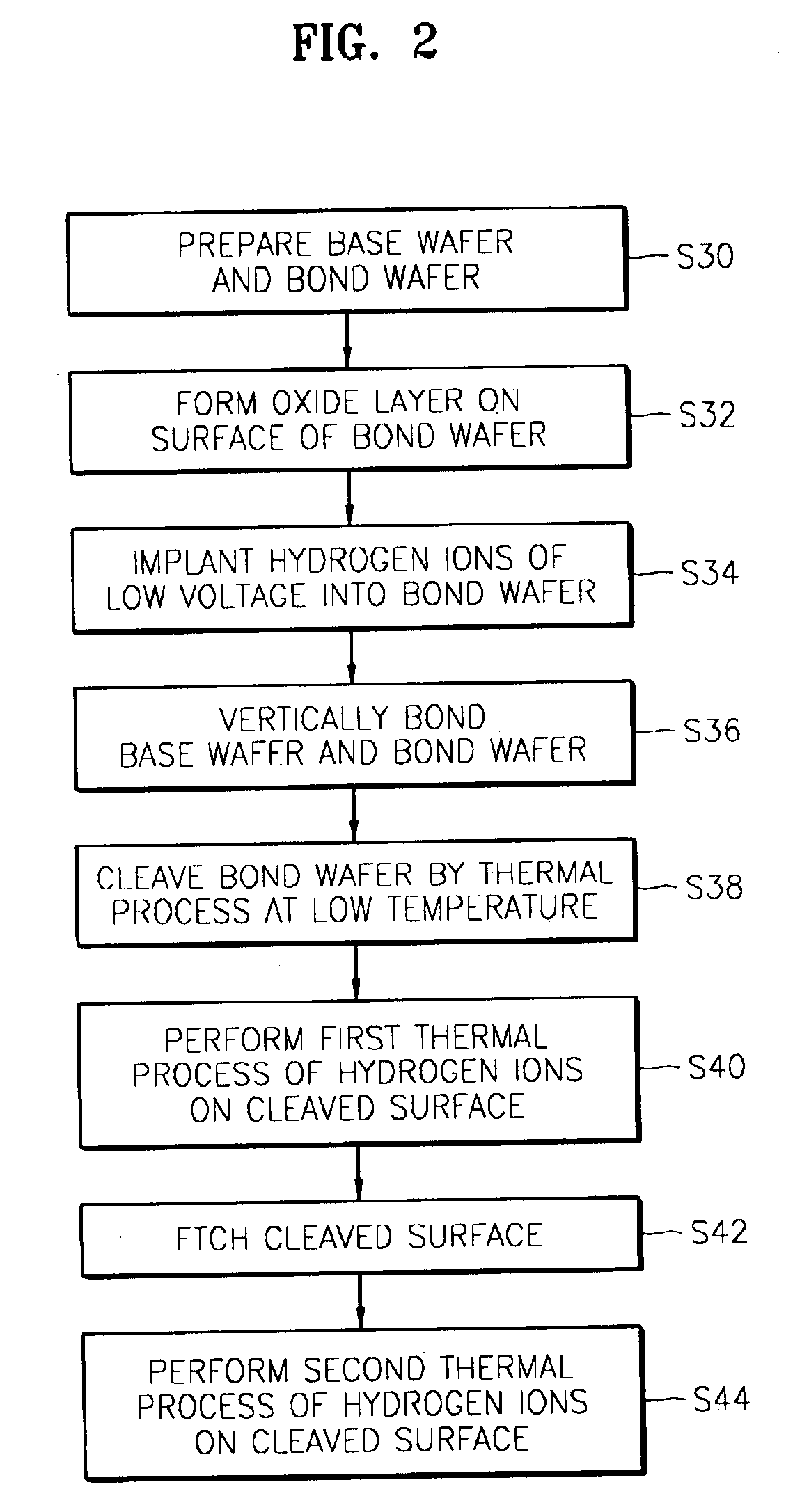

Method of fabricating nano SOI wafer and nano SOI wafer fabricated by the same

InactiveUS6884694B2Improve the bonding force between layersEtch thickness can be made uniformSolid-state devicesSemiconductor/solid-state device manufacturingDielectricNano silicon

A method of fabricating a nano silicon on insulator (SOI) wafer having an excellent thickness evenness without performing a chemical mechanical polishing (CMP) and a wafer fabricated by the same are provided. The provided method includes preparing a bond wafer and a base wafer, and forming a dielectric on at least on surface of the bond wafer. Thereafter, an impurity ion implantation unit is formed by implanting impurity ions into the bond wafer to a predetermined depth from the surface of the bond wafer at a low voltage. The dielectric of the bond wafer and the base wafer contact each other in order to be bonded. Next, a thermal process of low temperature is performed to cleave the impurity ion implantation unit of the bond wafer. In addition, the cleaved surface of the bond wafer bonded to the base wafer is etched to form a nano scale device region. Here, the cleaved surface may be etched by performing a hydrogen surface process and a wet etching.

Owner:LG SILTRON +1

Light emitting device, method of manufacturing the same and lighting equipment

ActiveUS20050007783A1Suppress occurrenceInhibitionVehicle headlampsPoint-like light sourceCeramicPliability

In a light emitting device with a heat-release metallic part made of metal and a packaging ceramic part made of ceramics bonded to the metallic part via an adhesive, the adhesive is a hot melt that melts with heat at a melting temperature higher than a given temperature and has flexibility when it has been hardened and formed a bond, and the ceramic part has pores at least in a given bonding surface region so that the hot melt is impregnated into the pores.

Owner:NICHIA CORP

System for display images

InactiveUS20130003006A1Improve the bonding force between layersBlock display panelNon-linear opticsComputer science

A system for displaying images including a display panel is provided. The display panel has a display area and a peripheral area. The display panel includes a metal layer disposed on a first substrate. A patterned planarization layer is disposed on the metal layer, having at least one opening corresponding to the peripheral area, wherein a portion of the metal layer is exposed through the opening. A second substrate is disposed opposite to the first substrate. A seal is disposed at the peripheral area and between the first and the second substrates, wherein the seal covers the metal layer through the opening of the patterned planarization layer.

Owner:INNOLUX CORP +1

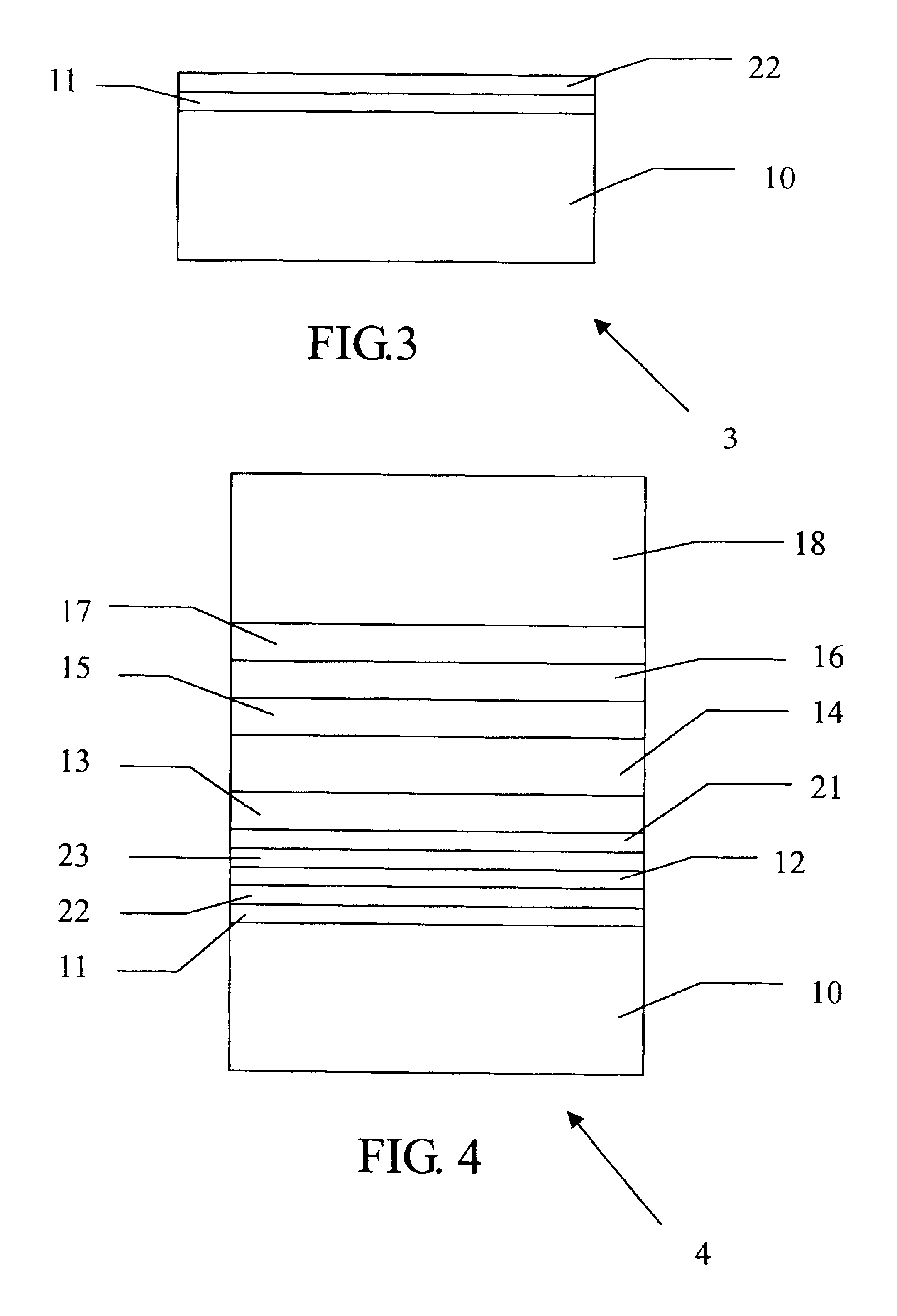

Thin film battery and method of connecting electrode terminal of thin film battery

InactiveUS20100330411A1Bonding forceReduce heat damagePrimary cell to battery groupingFinal product manufactureEngineeringAnode

Provided is a thin film battery, including: a base substrate; a cathode current collector pattern and an anode current collector pattern being formed on the base substrate and being electrically separate from each other; a cathode terminal and an anode terminal being directly bonded with the cathode current collector pattern and the anode current collector pattern; a cathode and an anode being disposed on the cathode current collector pattern and the anode current collector pattern; and an electrolyte layer being disposed between the cathode and the anode.

Owner:GSNANOTECH

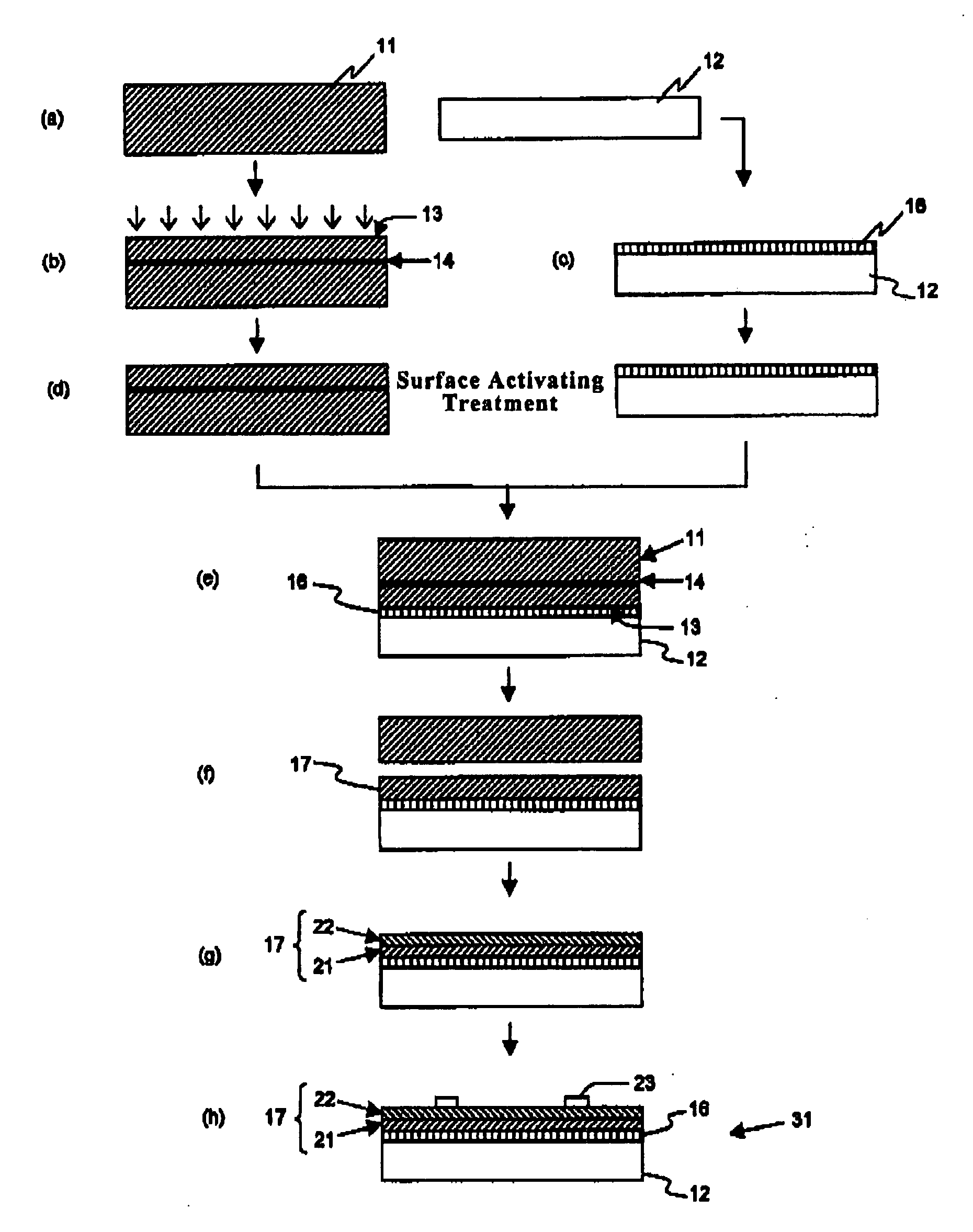

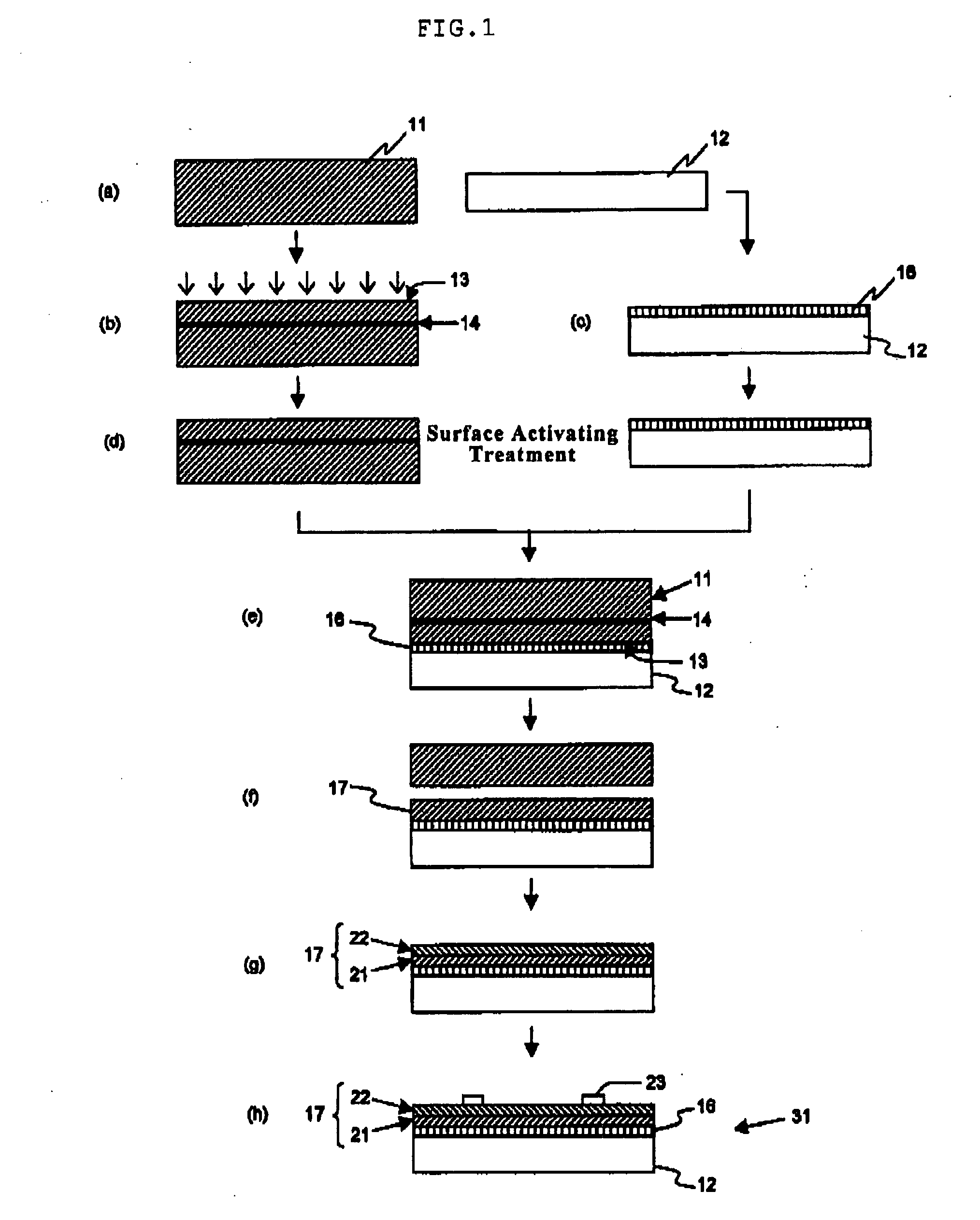

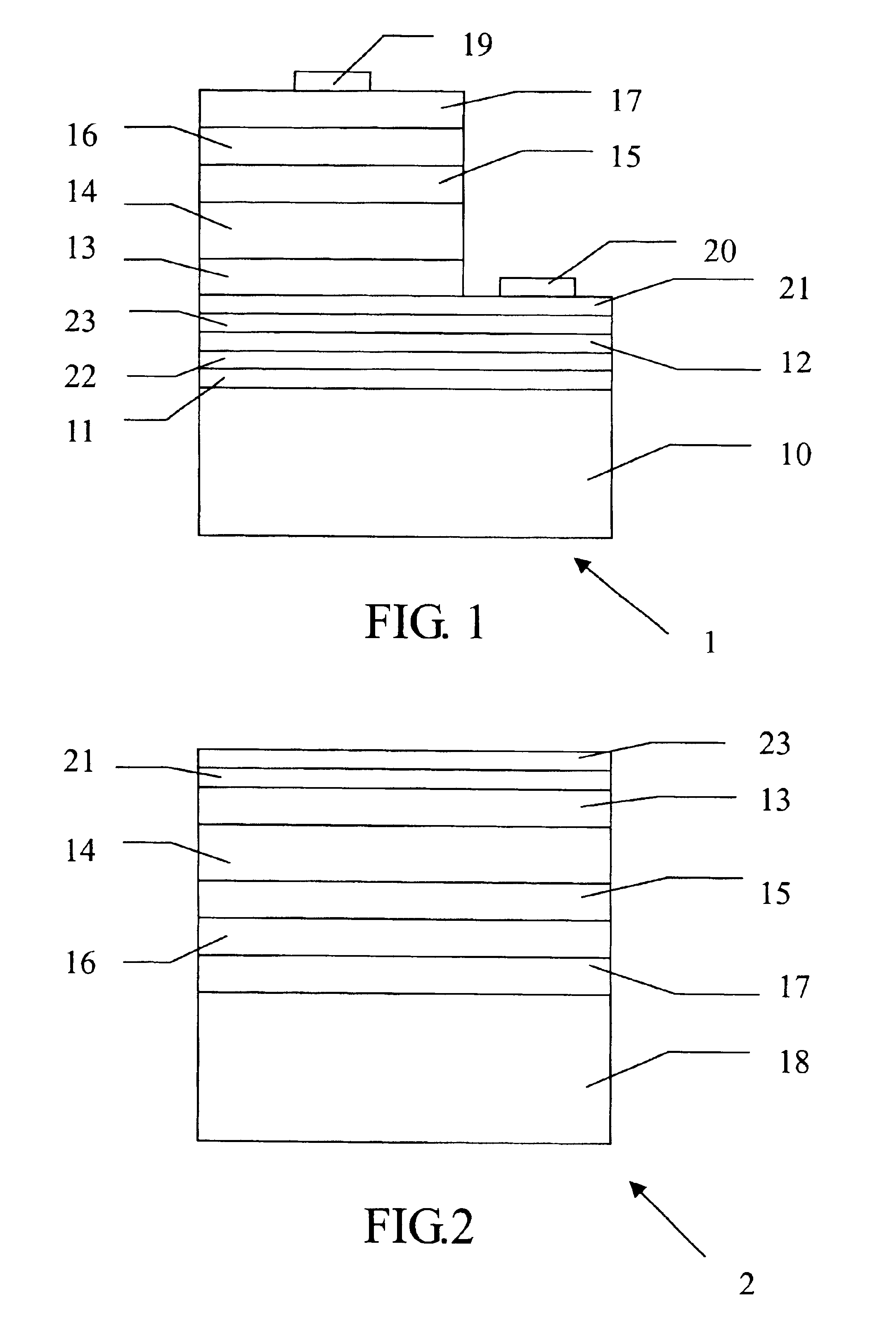

Method for producing single crystal silicon solar cell and single crystal silicon solar cell

InactiveUS20080099065A1High crystallinityImprove conversion efficiencyLamination ancillary operationsFinal product manufactureNoble gasLight irradiation

There is disclosed a method for producing a single crystal silicon solar cell comprising the steps of: implanting hydrogen ions or rare gas ions into a single crystal silicon substrate through an ion implanting surface thereof to form an ion implanted layer in the single crystal silicon substrate; forming a transparent electroconductive film on a surface of a transparent insulator substrate; conducting a surface activating treatment for the ion implanting surface of the single crystal silicon substrate and / or a surface of the transparent electroconductive film on the transparent insulator substrate; bonding the ion implanting surface of the single crystal silicon substrate and the surface of the transparent electroconductive film on the transparent insulator substrate to each other; applying an impact to the ion implanted layer to mechanically delaminate the single crystal silicon substrate thereat to leave a single crystal silicon layer; and forming a p-n junction in the single crystal silicon layer. There can be provided a single crystal silicon solar cell where a light conversion layer is provided as a thin-film for effective utilization of silicon as a starting material of the silicon solar cell, which single crystal silicon solar cell is excellent in conversion characteristics and is less in degradation due to light irradiation, and which single crystal silicon solar cell is provided as a see-through type solar cell that is usable as a natural lighting window material of a house or the like.

Owner:SHIN ETSU CHEM IND CO LTD

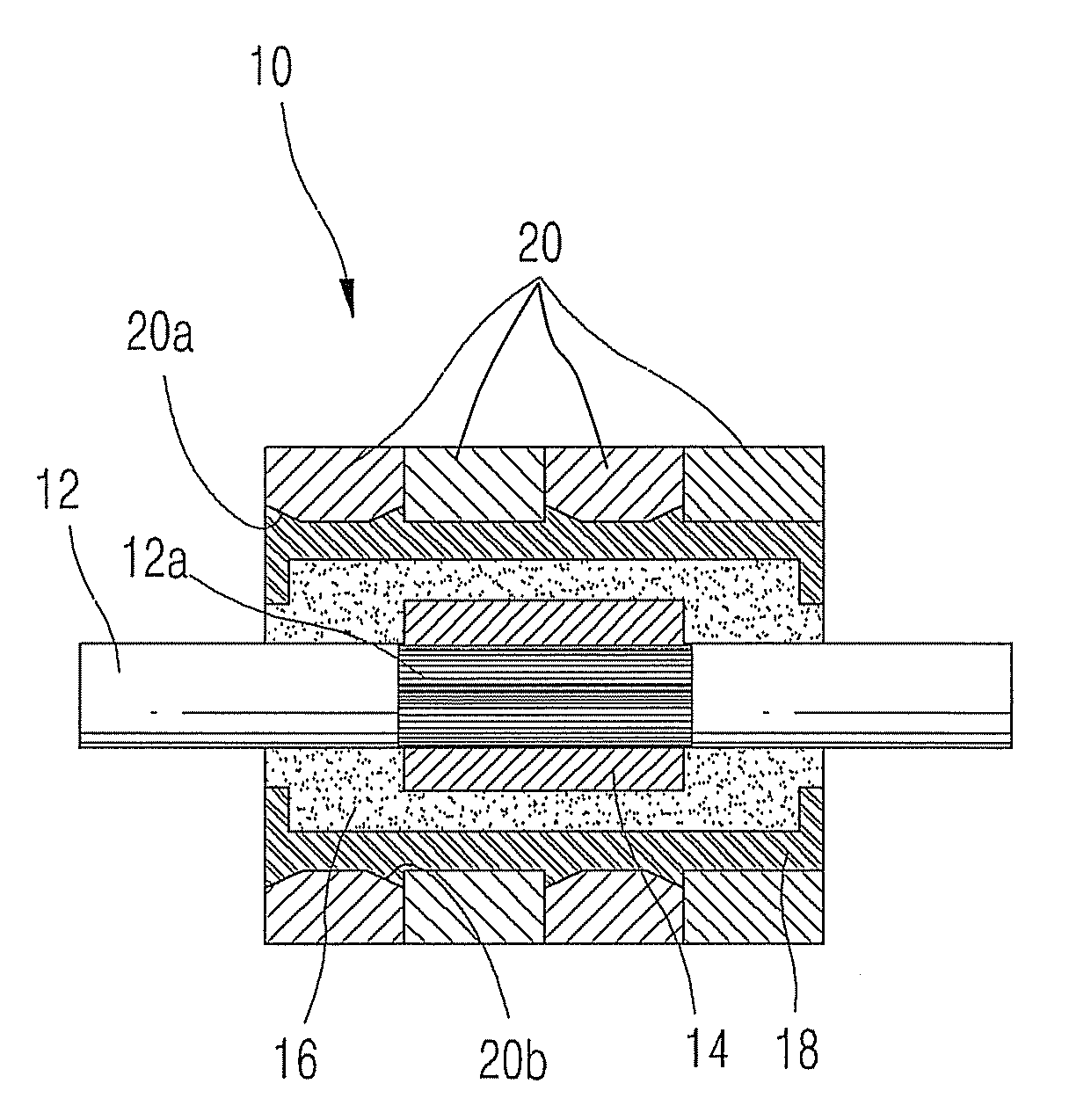

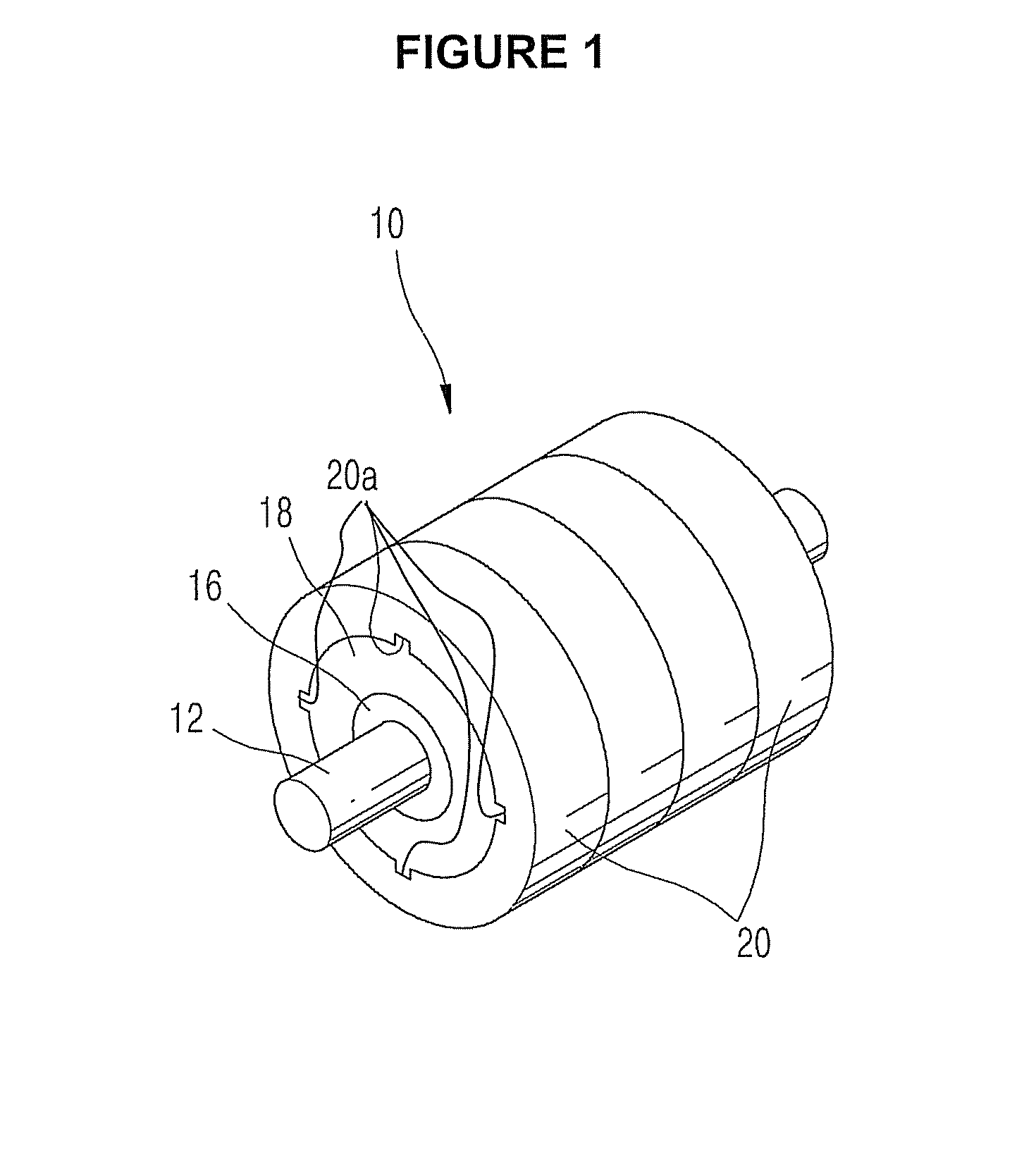

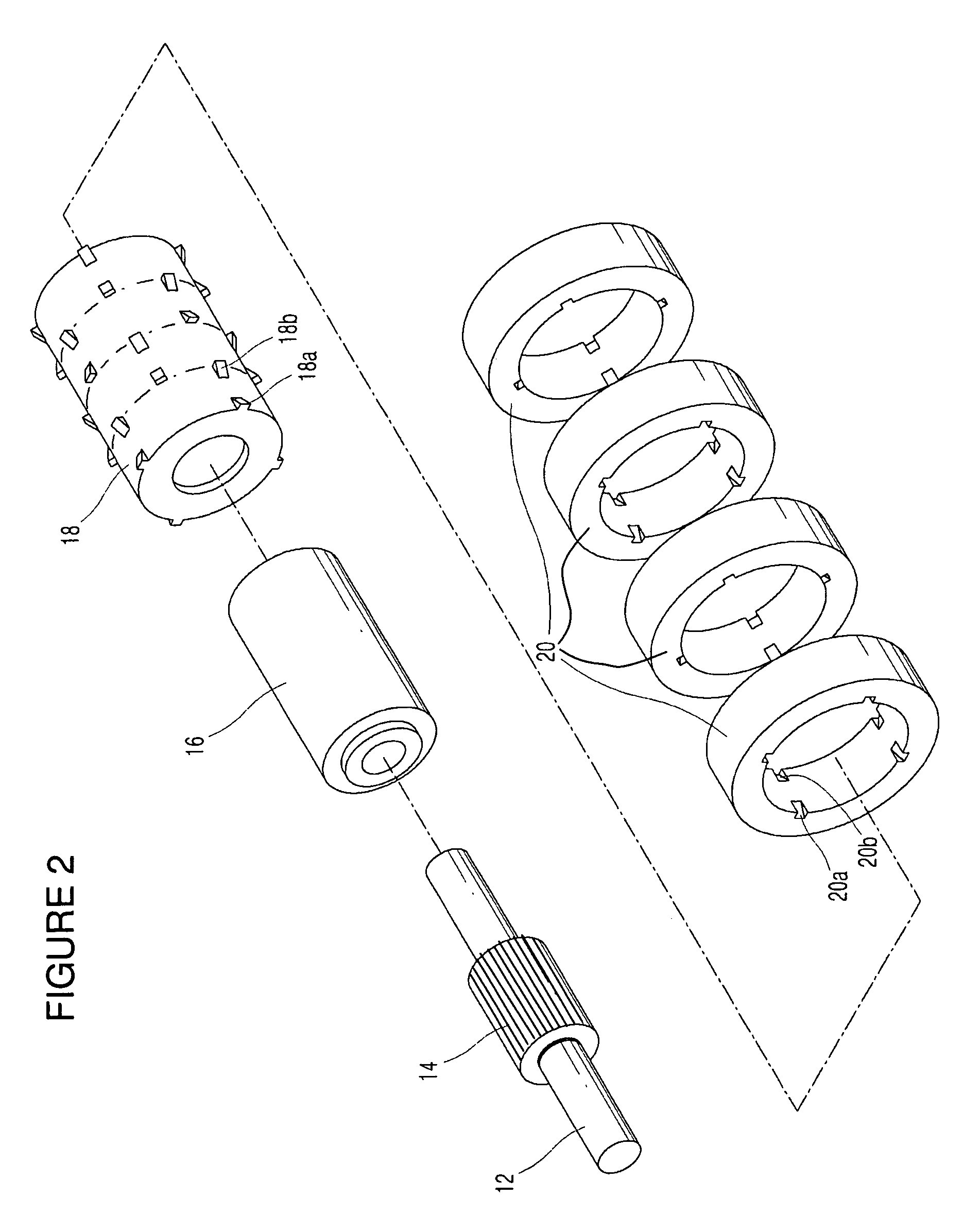

Rotor of brushless (BL) motor

ActiveUS8080907B2Improve the bonding force between layersMagnetic circuit rotating partsMagnetic circuit characterised by insulating materialsEngineering plasticHigh intensity

Owner:BLUFFTON MOTOR WORKS

Slurry composition, electrode and secondary cell

ActiveUS7316864B2Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

Owner:ZEON CORP

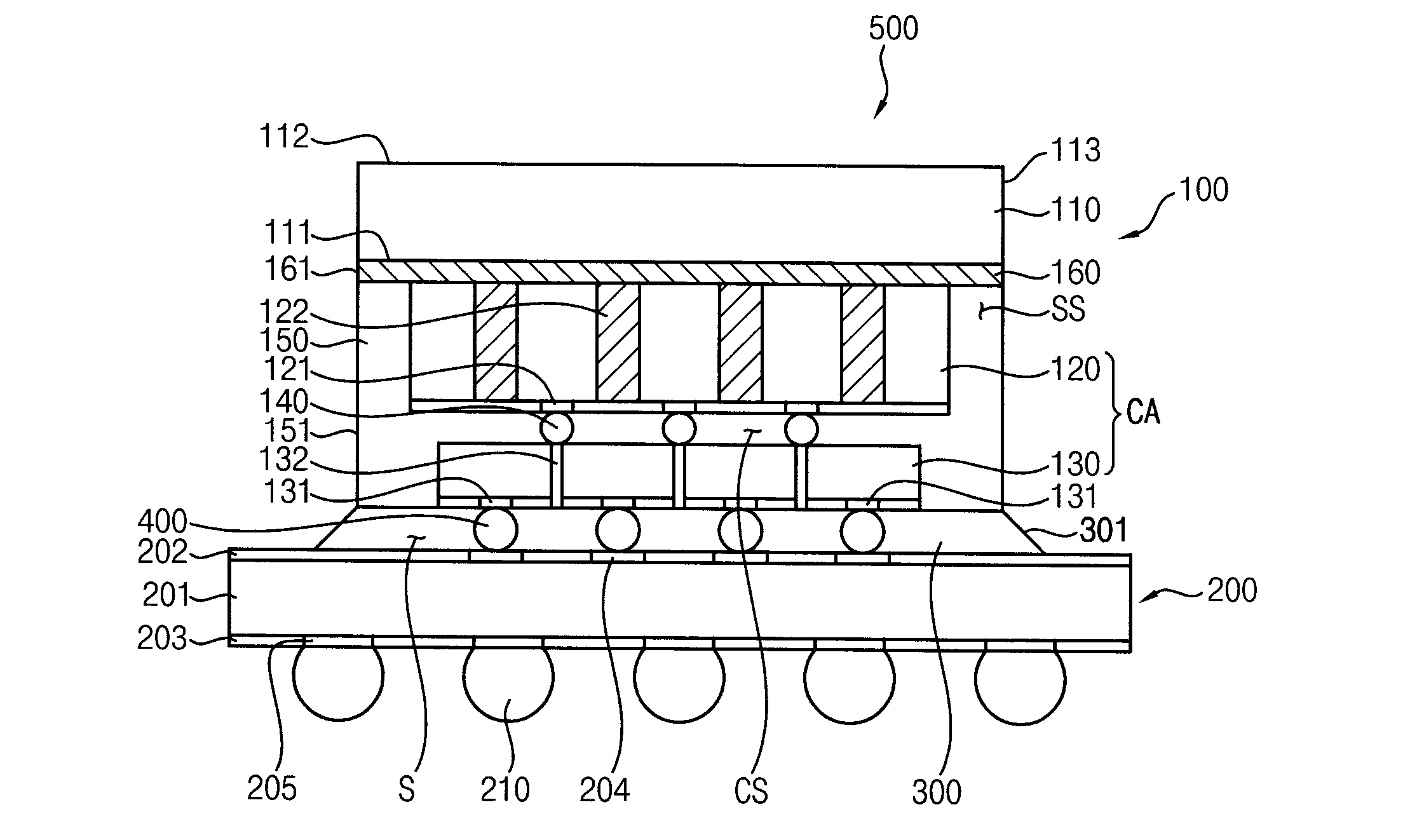

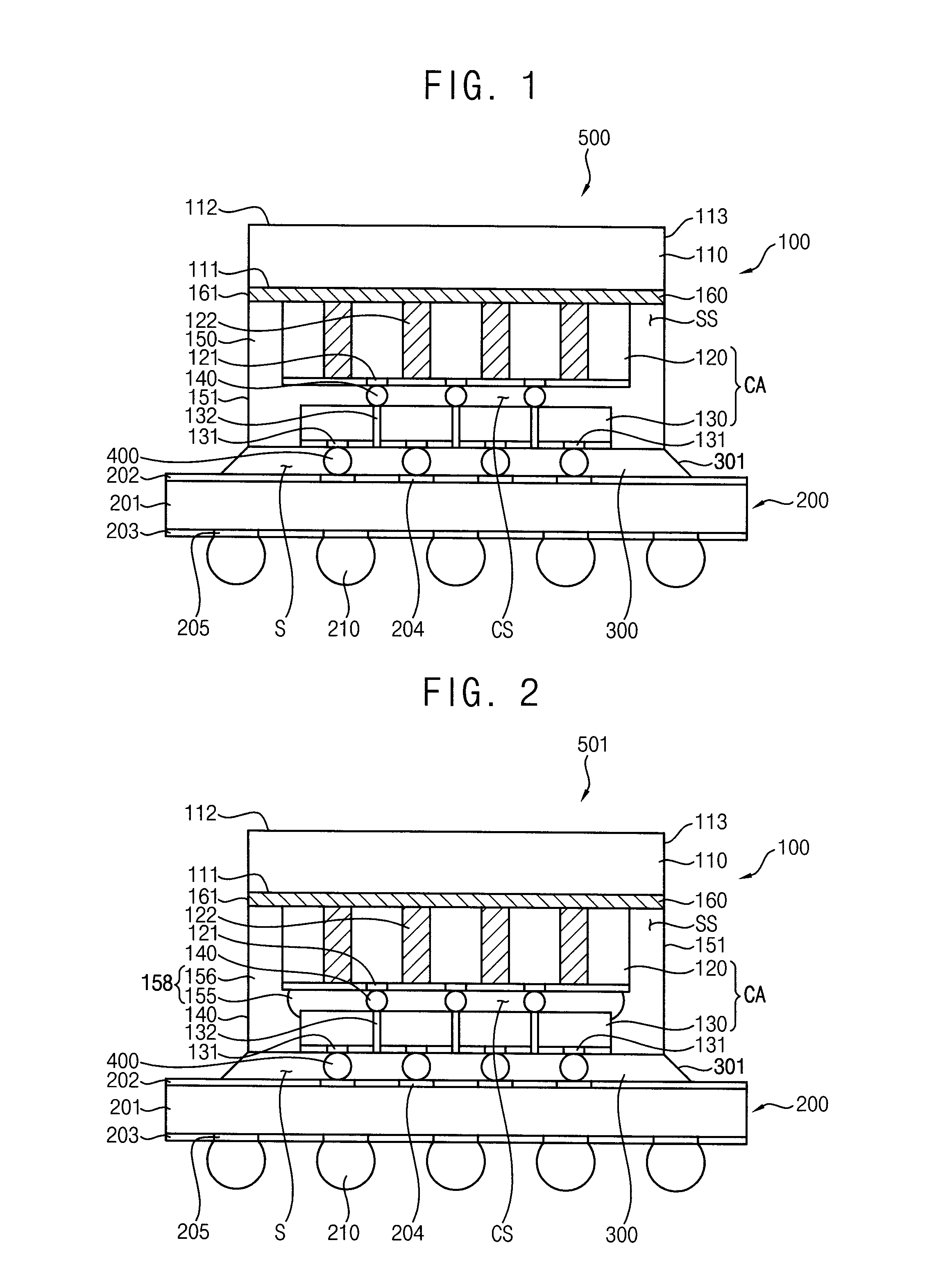

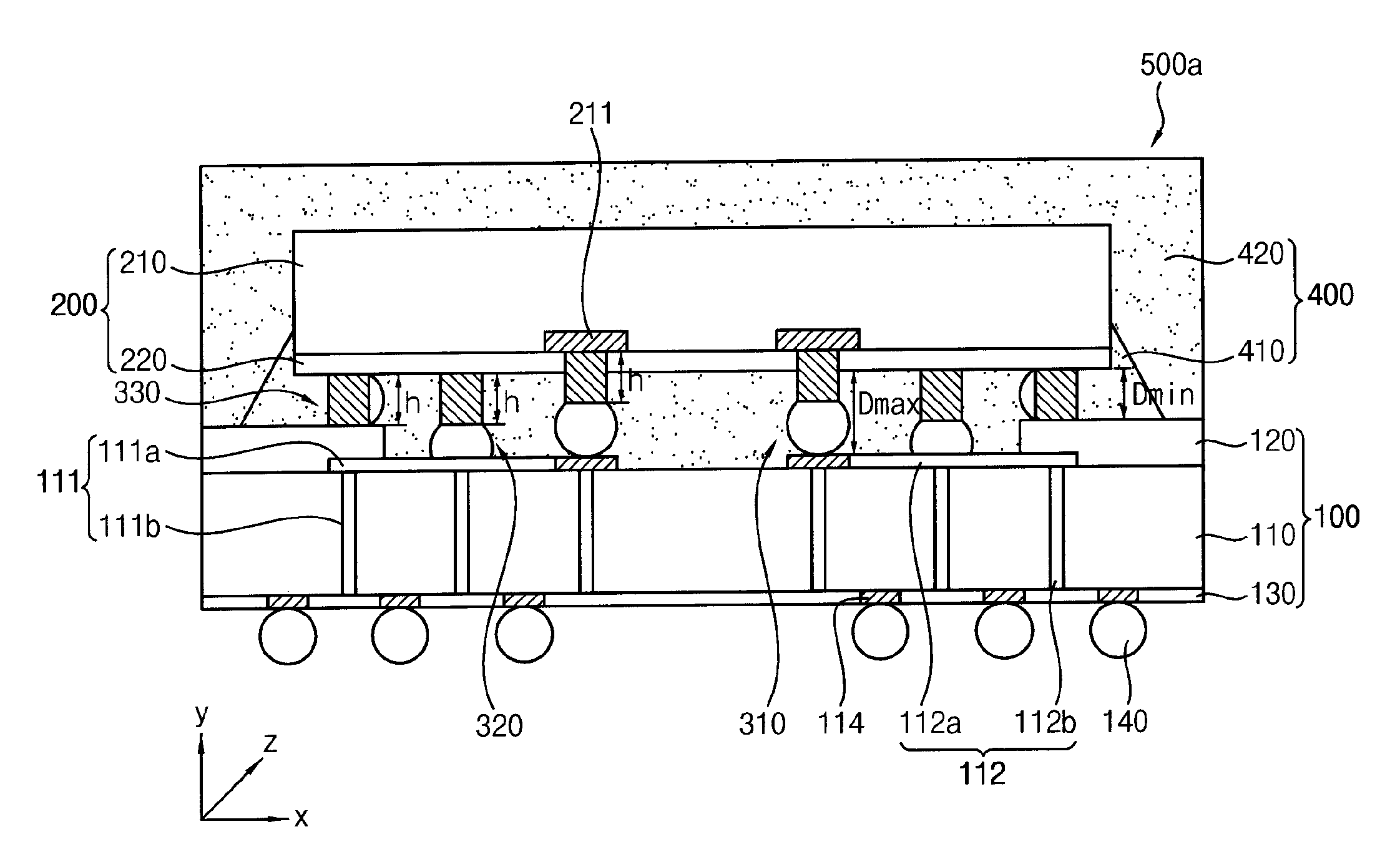

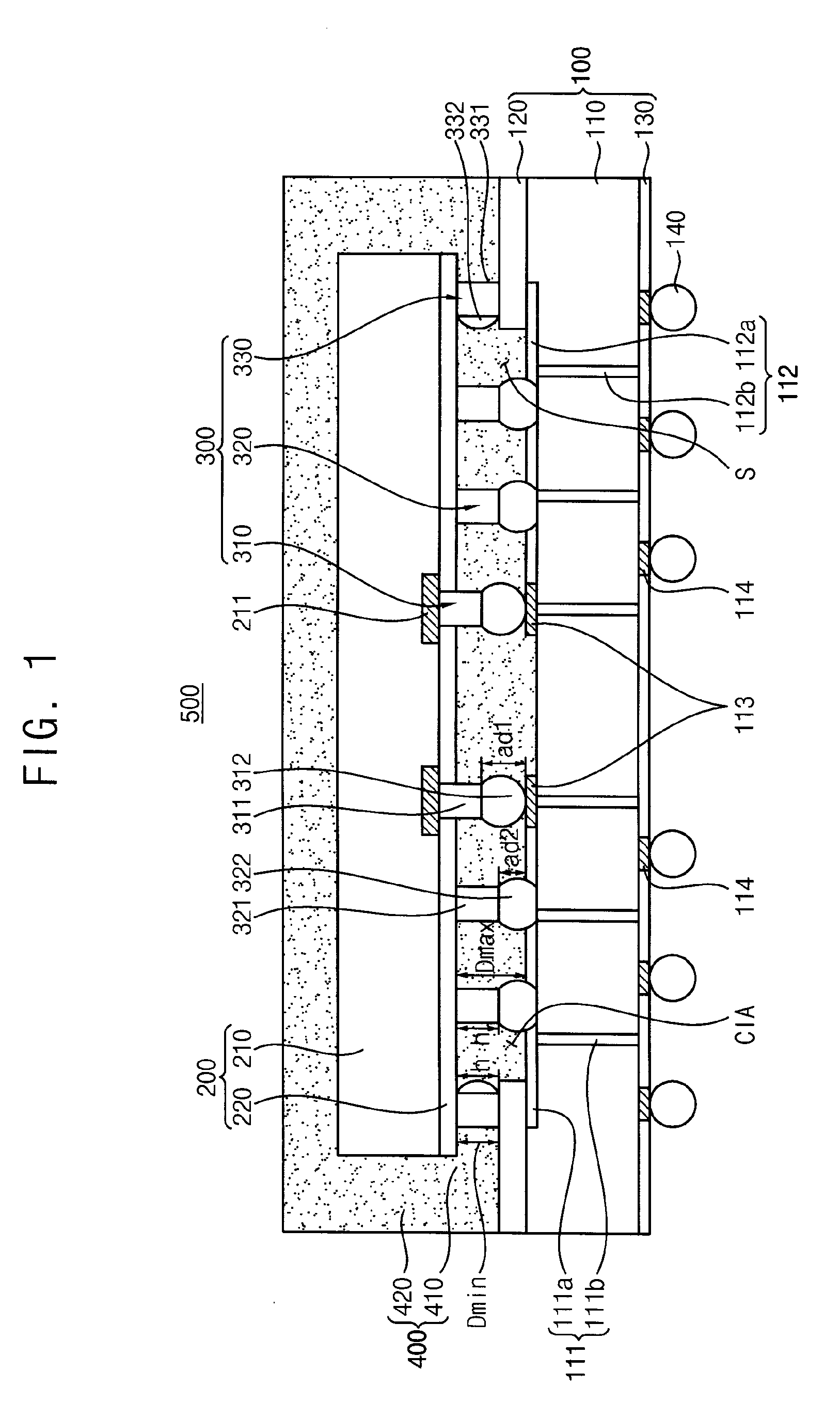

Semiconductor package and method of manufacturing the same

InactiveUS20150228591A1Circuit board warpage is mitigated or prevented in the semiconductor packageGuaranteed uptimeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package including a chip stack structure having first and second chips that are secured to a dissipating plate by using a mold layer such that the second chip is combined to the dissipating plate and the first chip is bonded to the second chip, and the first chip has a smaller thickness than the second chip, a circuit board onto which the chip stack structure is mounted in a bonded manner, and an under-fill layer filling a gap space between the circuit board and first chip, a side surface of the under-fill layer being connected to a sidewall of the mold layer may be provided. Due to this bulk mounting structure, the warpage and bonding failures of the semiconductor package may be substantially reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

Light emitting diode having an adhesive layer and a reflective layer

InactiveUS6987287B2Increase brightnessReduce reflectivitySolid-state devicesSemiconductor devicesReflective layerLight-emitting diode

A light emitting diode having an adhesive layer and a reflective layer and a manufacturing method thereof featured by adhering together a light emitting diode stack and a substrate having a reflective metal layer by use of a transparent adhesive layer so that the light rays directed to the reflective metal layer can be reflected therefrom to improve the brightness of the light emitting diode.

Owner:EPISTAR CORP

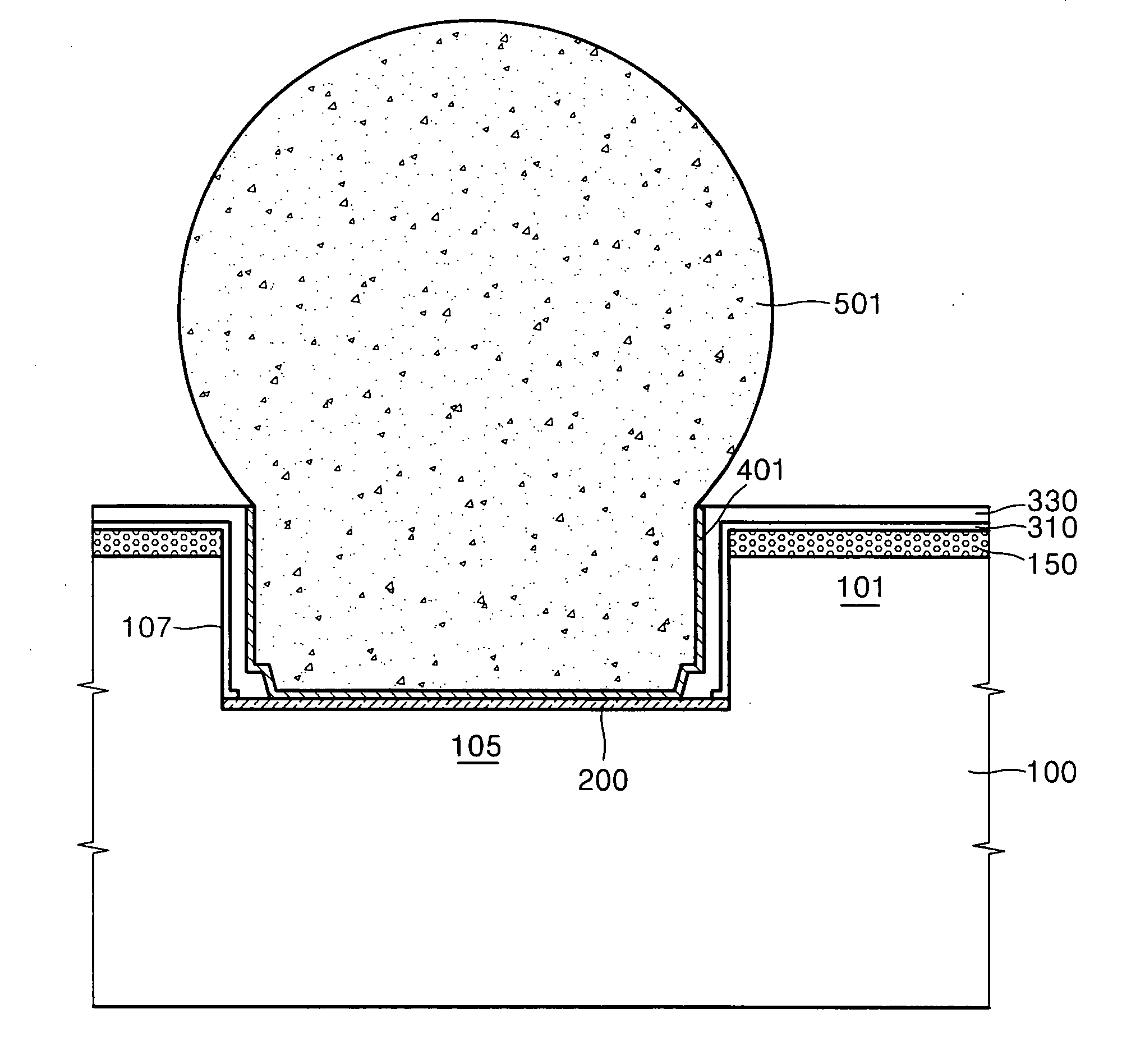

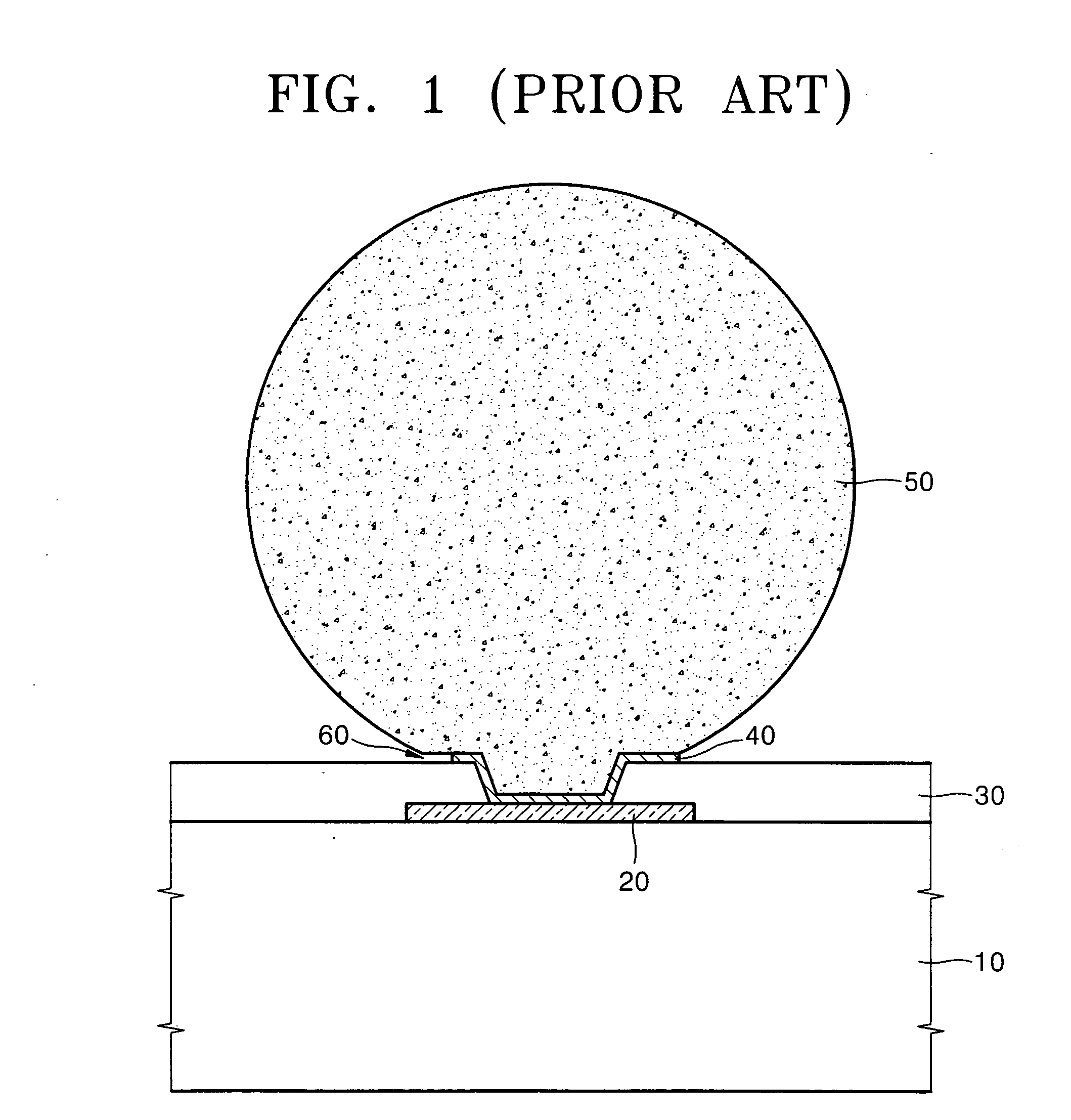

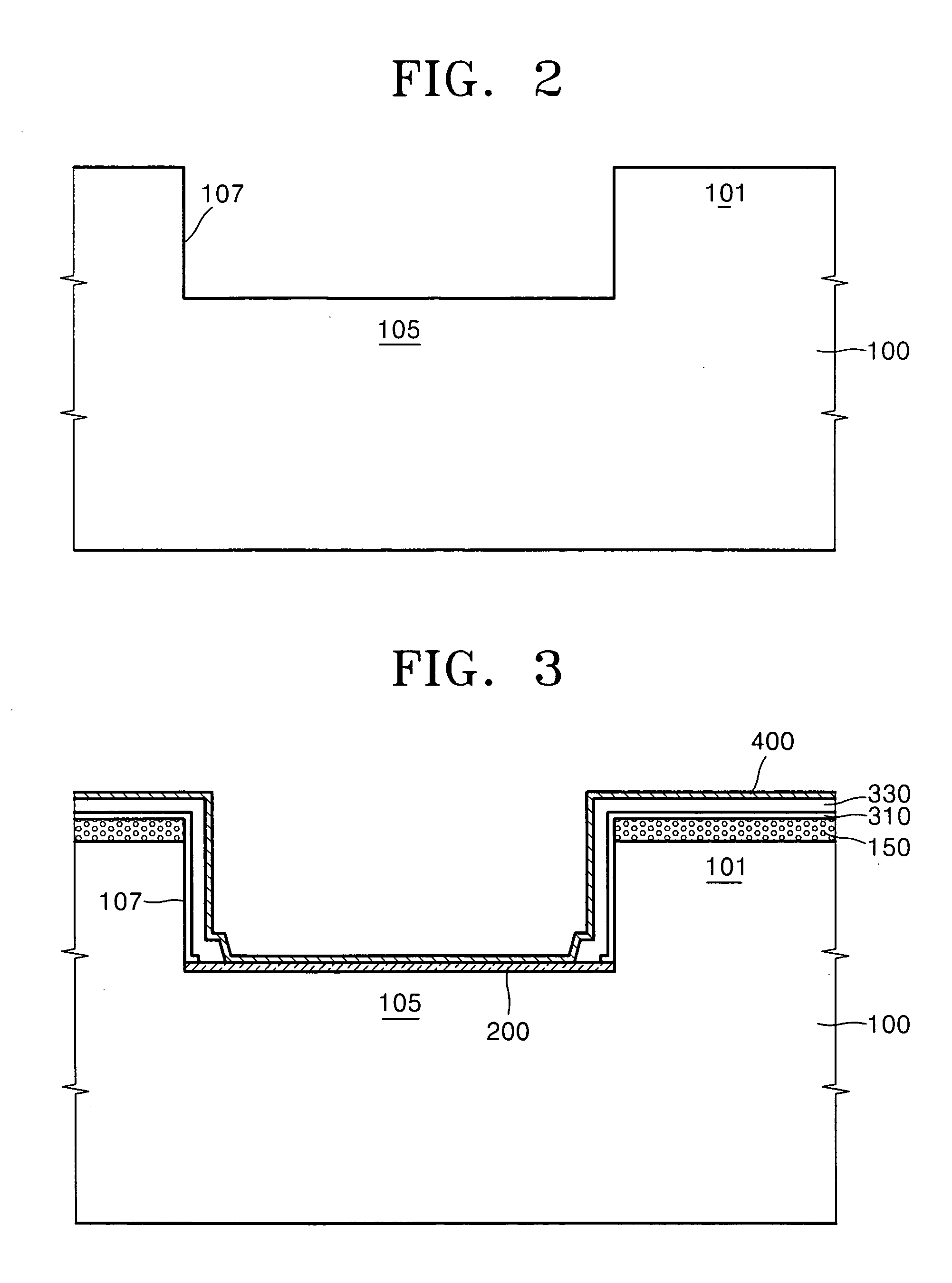

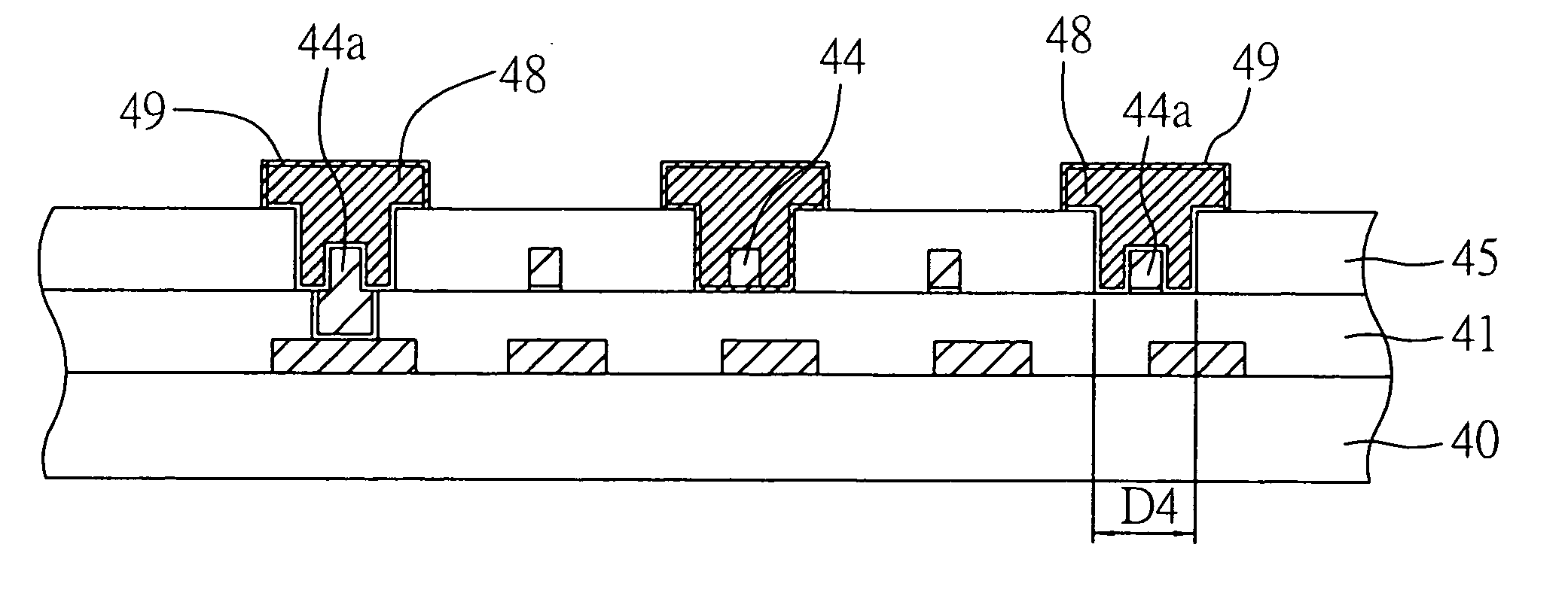

Bump structure of semiconductor device and method of manufacturing the same

InactiveUS20060170102A1Improve the bonding force between layersAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

In connection with a bump of a semiconductor device and a manufacturing method thereof, a groove is formed in a bump pad region of a semiconductor substrate. An under bump metal layer is then formed in the groove, and a lower end portion of the bump fills the groove on the under bump metal layer.

Owner:SAMSUNG ELECTRONICS CO LTD

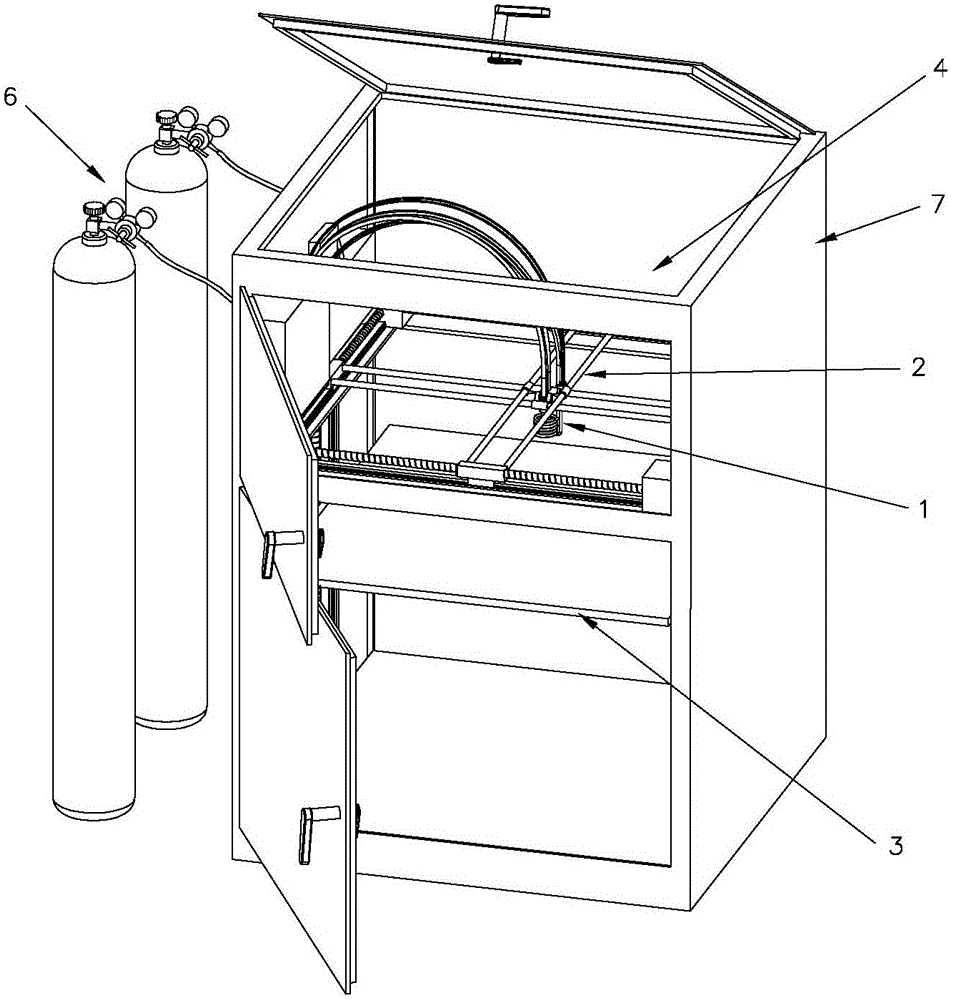

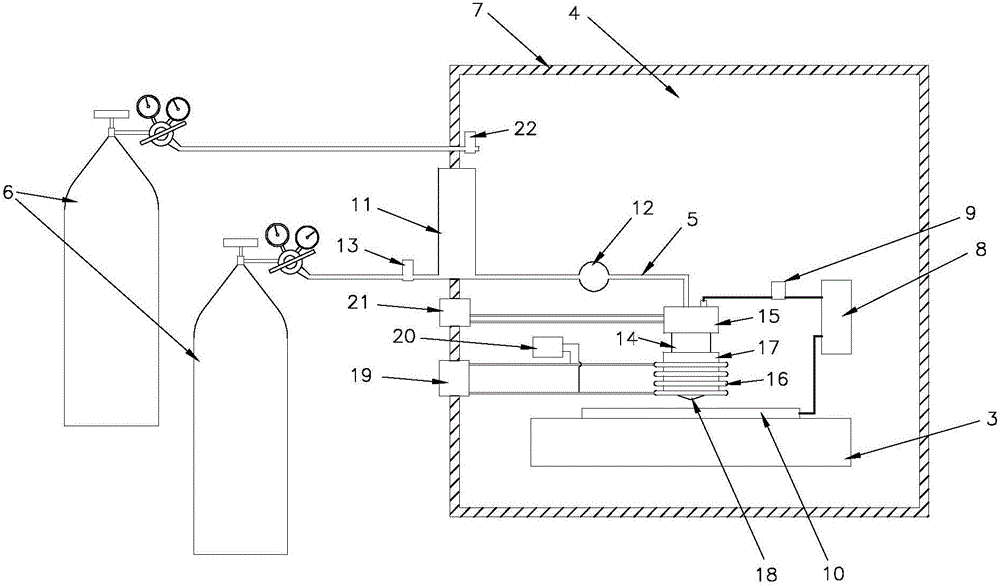

Three-dimensional printing method

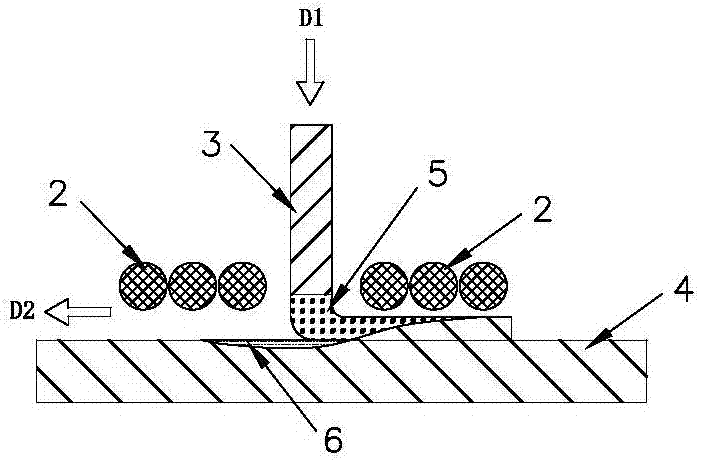

ActiveCN106965421AImprove the bonding force between layersImprove structural strengthManufacturing heating elementsCeramic shaping apparatusBinding forceElectromagnetic induction

The invention discloses a three-dimensional printing method. According to the main process of the three-dimensional printing method, fused raw materials are placed in a forming area adopted by a three-dimensional printing device, the fused raw materials are accumulated and converted into a printed body in the forming area, and the fused raw materials are accumulated on the basis of the printed body until an object to be printed is formed. The three-dimensional printing method is characterized in that in the process of accumulating the fused raw materials, the portion, where the fused raw materials are to be accumulated, of the printed body is fused or softened through an electromagnetic induction heating manner, and / or the portion, where the fused raw materials are being accumulated, of the printed body is fused or softened. The three-dimensional printing method has the beneficial effects that the interlayer binding force of the printed body is high, and the structural strength of the printed body is high; a detachable auxiliary supporting body can be generated synchronously so that printing of a complicated structure can be achieved; an equipment structure is simple; a large-sized component can be printed; the three-dimensional printing method is suitable for multiple types of materials, and three-dimensional printing of electrically-conducive materials such as metal, metal ceramics and plastics mixed metal power can be achieved; cost is low; and the three-dimensional printing method has the substantial improvement.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

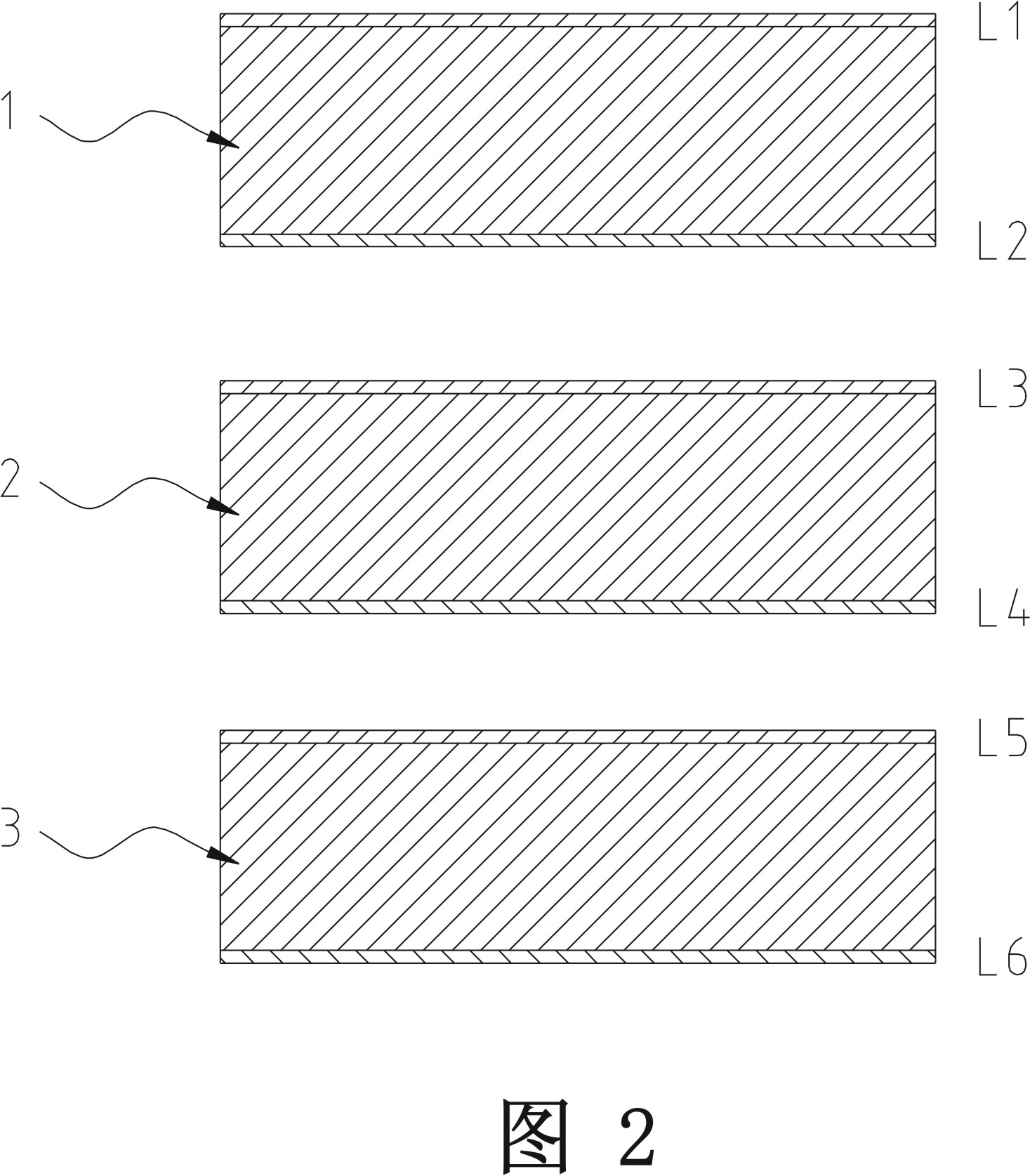

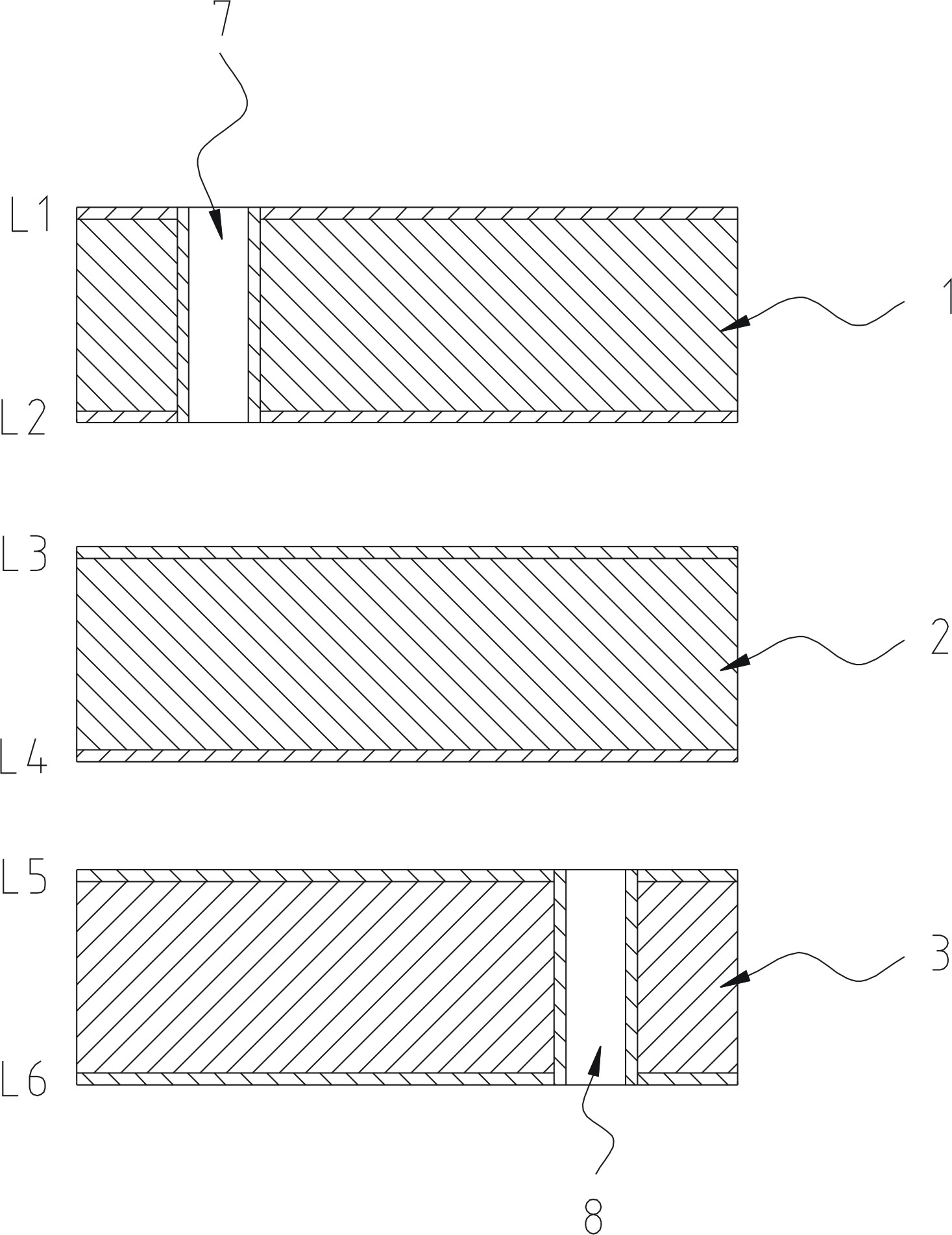

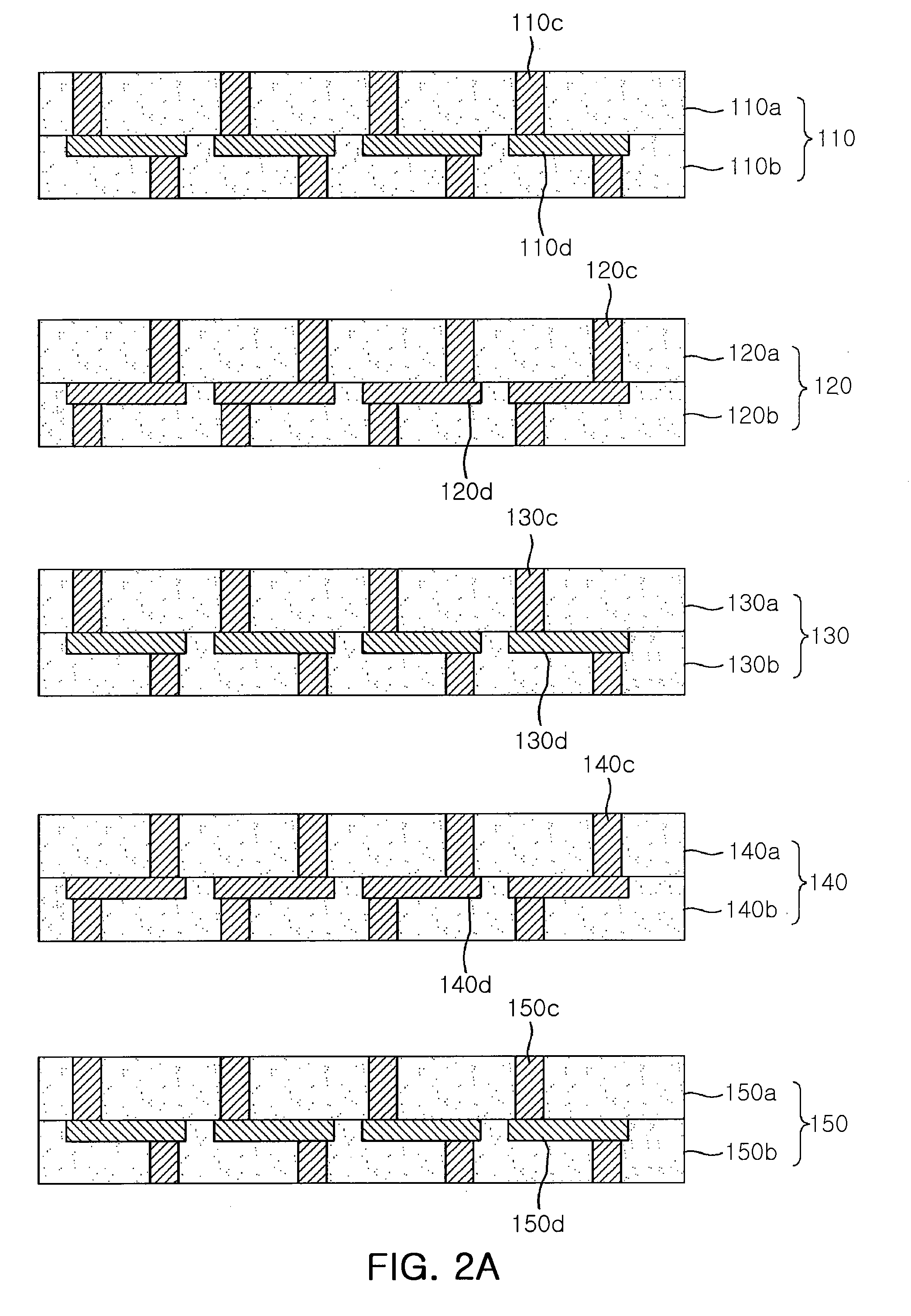

Production method of high-density laminated printed circuit board of high-frequency material

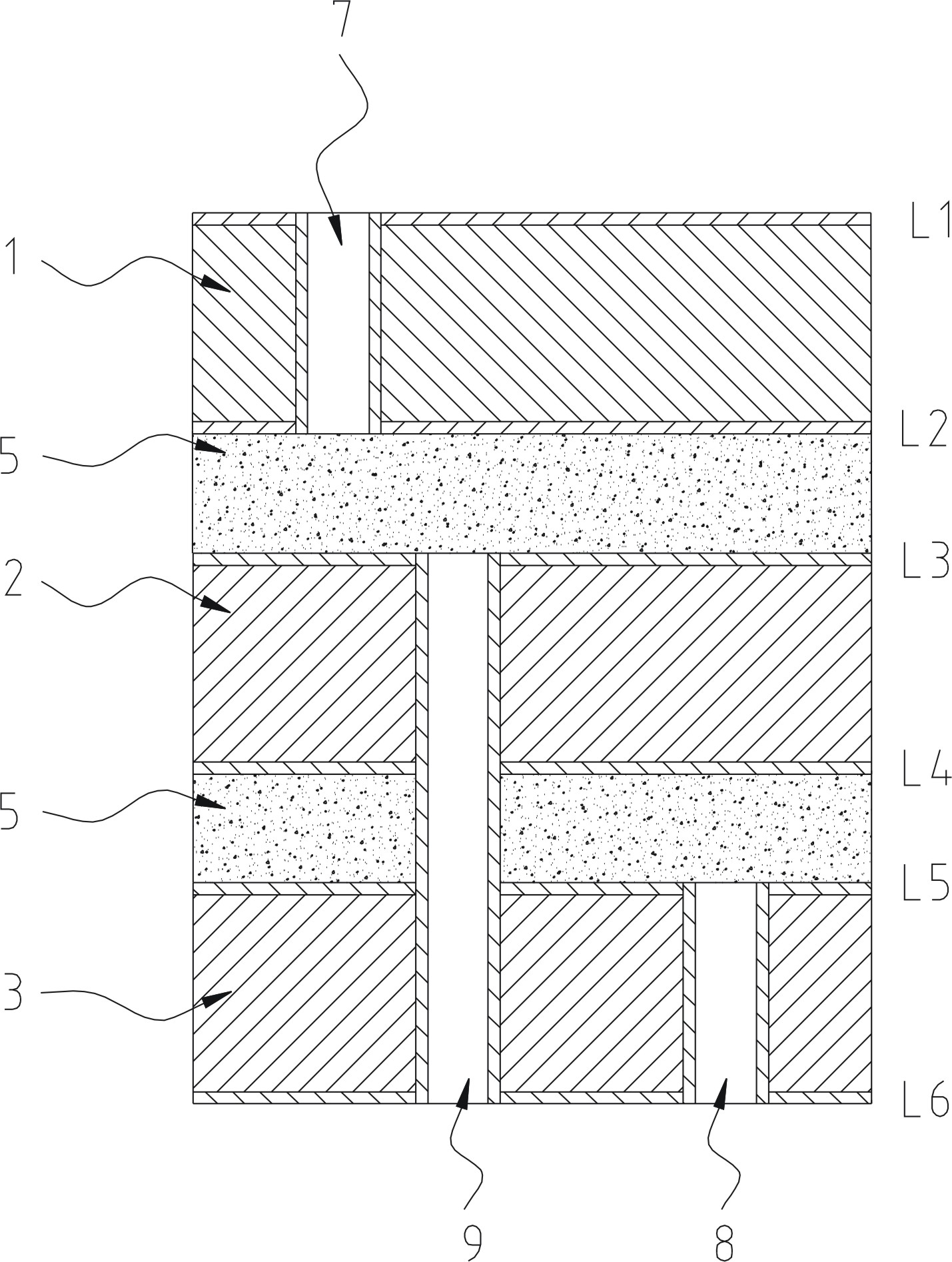

InactiveCN102065651ASolve the problem of difficult glue removal after laminationImprove bindingMultilayer circuit manufactureResistScreen printing

The invention discloses a production method of a high-density laminated printed circuit board of a high-frequency material. The production method comprises the following steps of: (1) drilling: drilling blind holes for interlaminar electrical connection on a layer or a plurality of layers of daughter boards; (2) screen printing solder resist: coating solder resist printing ink on the surface of outer copper foil of the layer or the plurality of layers of daughter boards with the blind holes, ensuring that the blind holes are filled with the solder resist printing ink, and exposing and developing to solidify the solder resist printing ink; (3) laminating: laminating the layer or the plurality of layers of daughter boards having the solder resist printing ink with other daughter boards into a whole by high-frequency prepregs; and (4) taking off the solder resist printing ink. The production method provided by the invention can commendably solve the problem that glue is difficult to remove when the high-density laminated printed circuit board of the high-frequency material is laminated and has the advantages of simpleness and safety of operation and low cost. In addition, the production method can play a role of glue resistance so that resin can not overflow to the board surface and is kept on interlamination, thereby effectively strengthening interlaminar bonding force and improving reliability of a product.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH

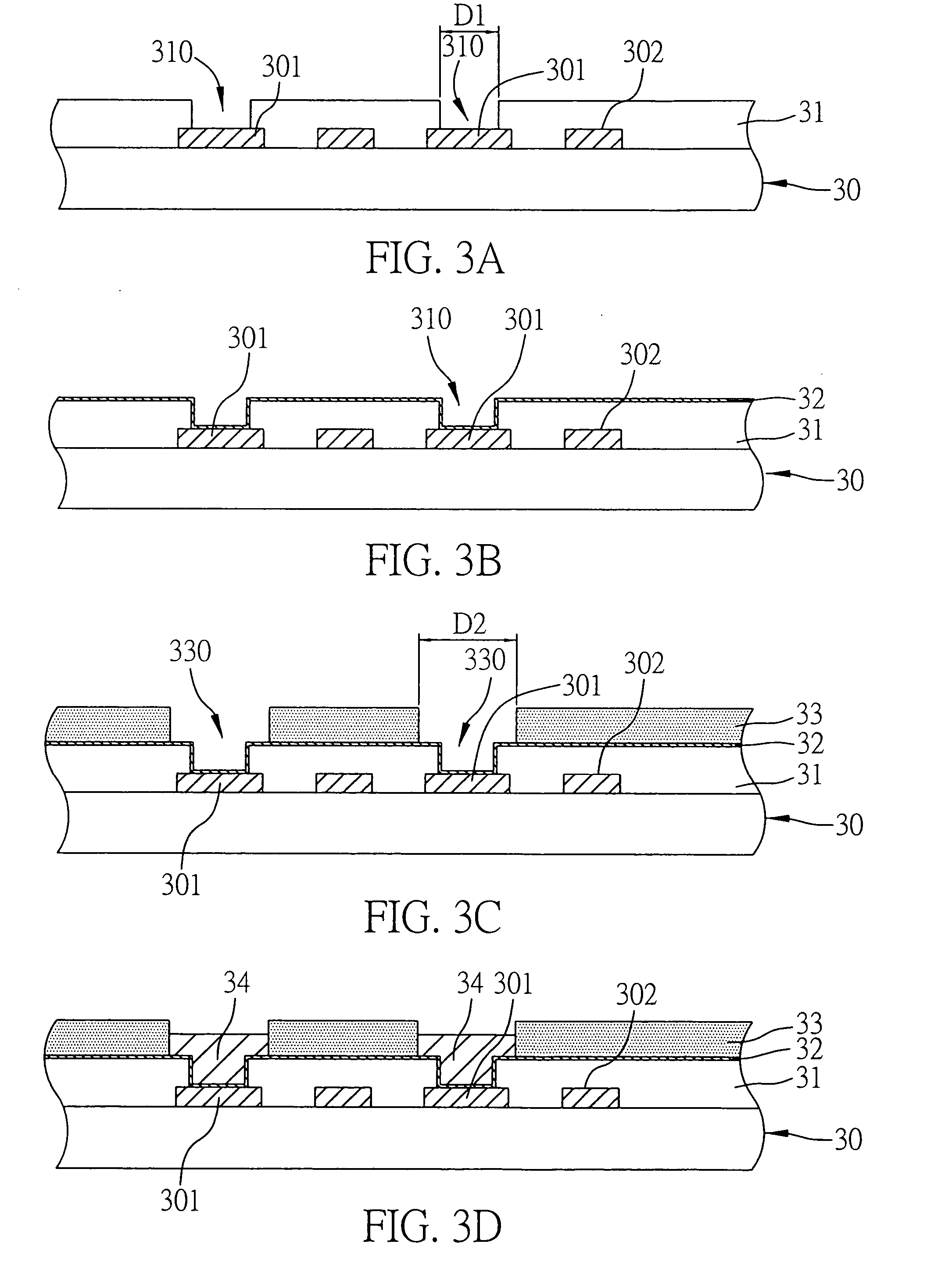

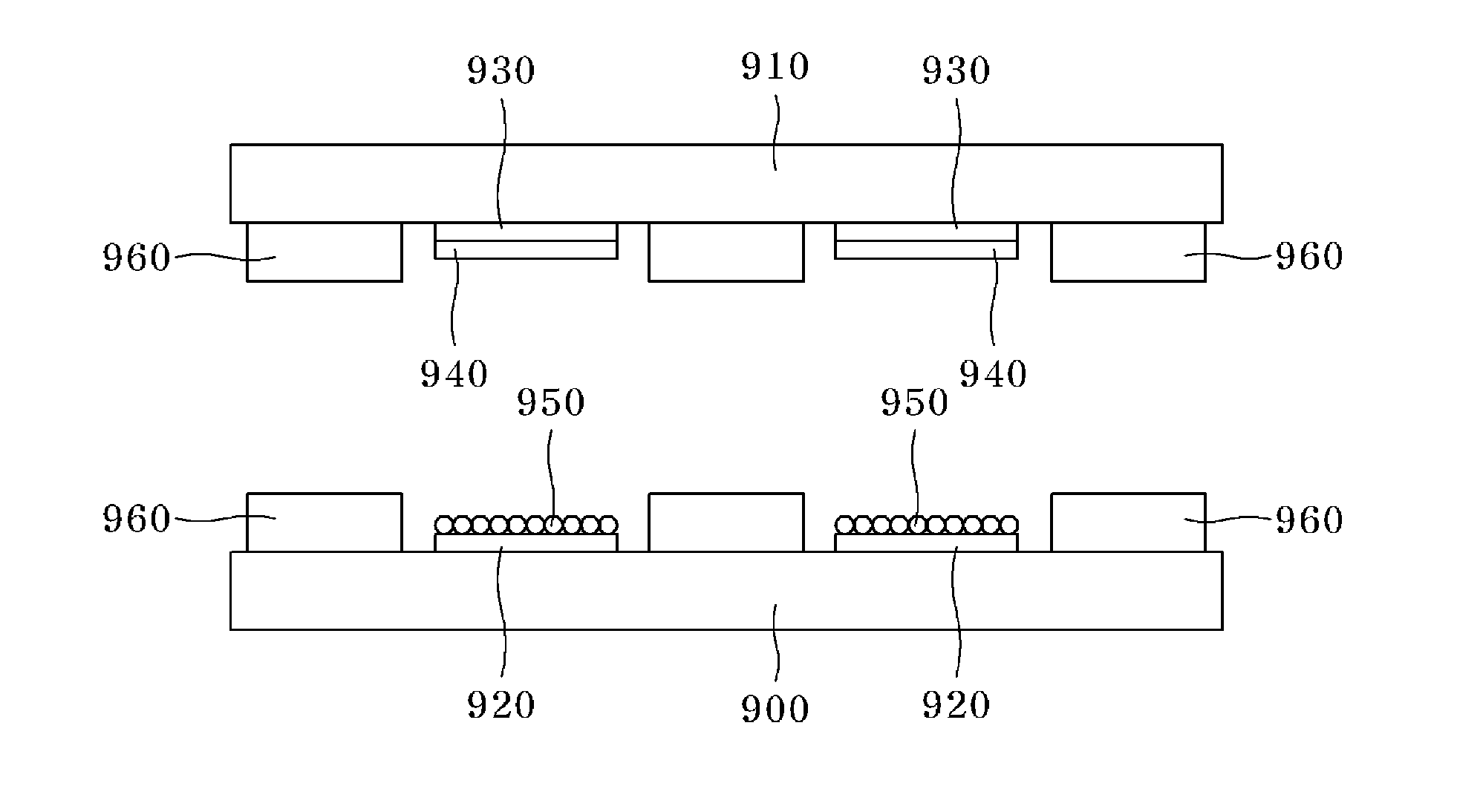

Semiconductor package and method of manufacturing the same

InactiveUS20160005707A1Reinforce bond forceImprove the bonding force between layersSemiconductor/solid-state device detailsSolid-state devicesContact padStorage cell

A semiconductor package includes a package board that includes an circuit pattern and a plurality of contact pads electrically connected to the circuit pattern; a semiconductor chip having a plurality of chip pads; and a bump structure including a plurality of connecting bumps electrically connected with the semiconductor chip and the circuit pattern and a plurality of gap adjusting bumps bonded to the semiconductor chip and shaped into a slender bar between the semiconductor chip and the package board, the gap adjusting bumps spacing the semiconductor chip from the package board such that a gap space, S, is maintained between the package board and the semiconductor chip. A method of fabrication and a memory unit are disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

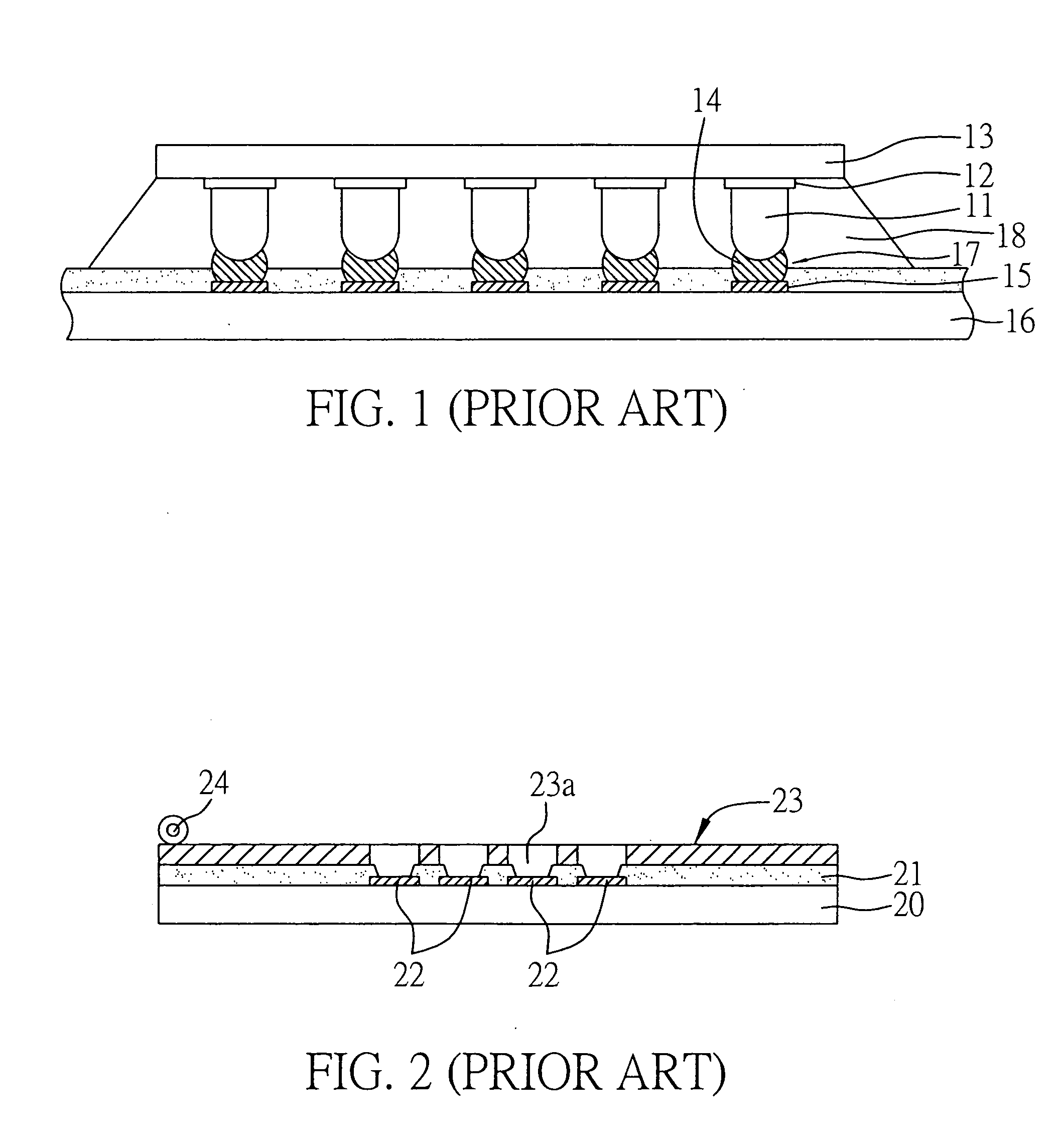

Conductive bump structure of circuit board and fabrication method thereof

InactiveUS20060225917A1High strengthAvoid it happening againElectrically conductive connectionsPrinted circuit aspectsResistEngineering

A conductive bump structure of a circuit board and a fabrication method thereof are proposed. The circuit board is formed with conductive circuits on a surface thereof An insulating protection layer having a plurality of openings to expose terminals of the conductive circuits is formed on the circuit board. A conductive layer is formed on the insulating protection layer and in the openings thereof. A patterned resist layer is formed on the conductive layer and has a plurality of openings corresponding in position to the terminals of the conductive circuits. Conductive bumps are formed by electroplating in the openings of the resist layer. Then, the resist layer and the conductive layer underneath the resist layer are removed. An adhesive layer is formed on the conductive bumps and completely covers exposed surfaces of the conductive bumps respectively. The circuit board can be electrically connected to electronic elements through the conductive bumps.

Owner:PHOENIX PRECISION TECH CORP

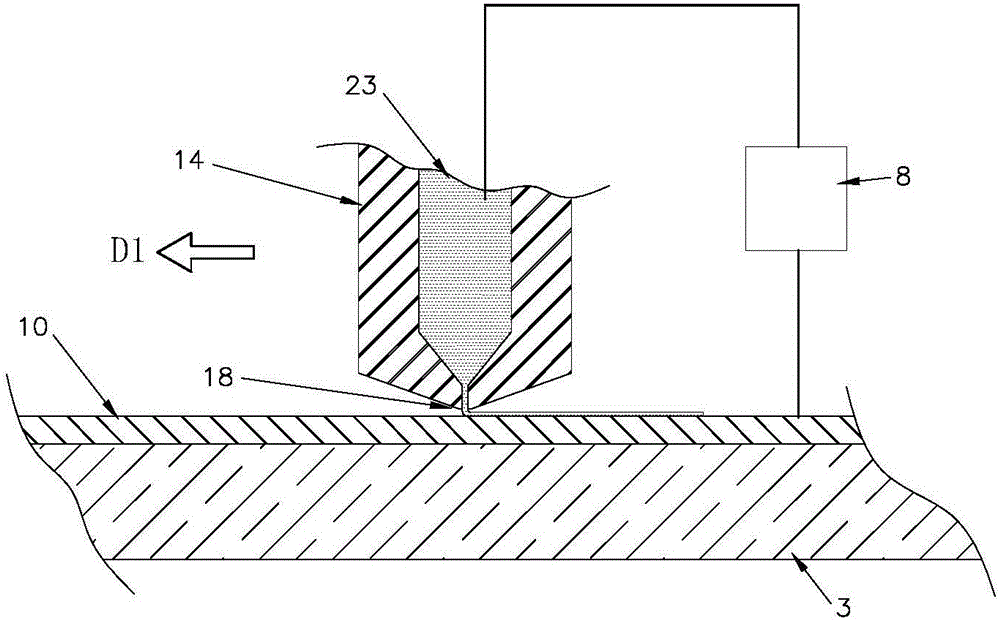

Metal three-dimensional printing method and equipment thereof

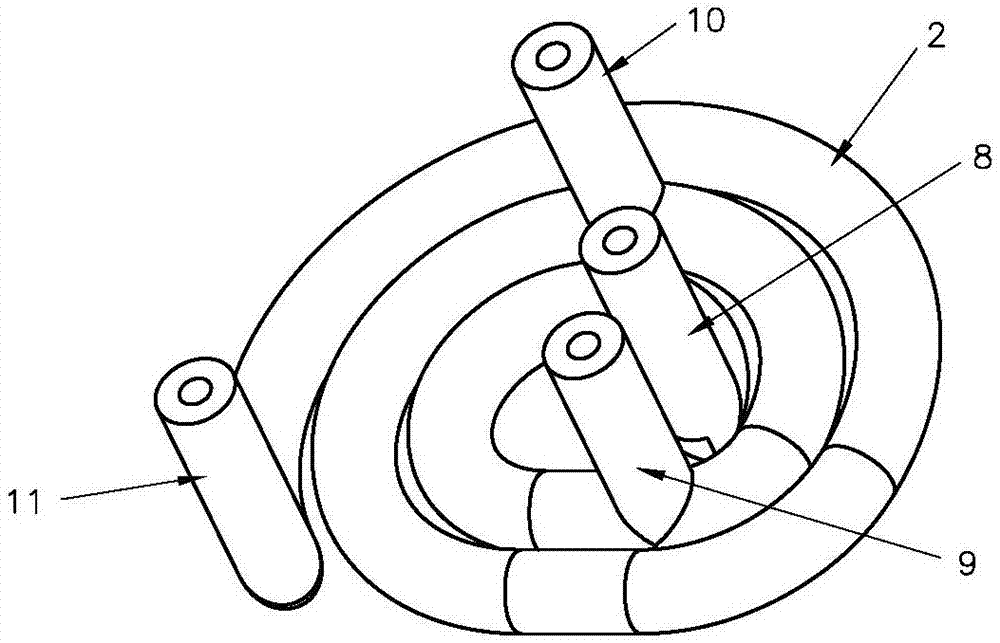

ActiveCN105880598AHigh strengthImprove the bonding force between layersAdditive manufacturing apparatusMolten casting coatingElectrical resistance and conductanceUltimate tensile strength

The invention discloses a metal three-dimensional printing method and equipment thereof. The metal three-dimensional printing method comprises the following steps that melted and flowable metal or softened and flowable metal is put into a molding area used by three-dimensional printing equipment; after not having the flowability, the melted and flowable metal or the softened and flowable metal is converted into printed and molded metal; the melted and flowable metal or the softened and flowable metal is accumulated based on the printed and molded metal until an object to be printed is molded; the object to be printed is formed by the accumulated printed and molded metal. The key characteristics of the metal three-dimensional printing method disclosed by the invention lie in that during molding, binding force between layers and binding force between pixel points are changed in a manner of resistance radiation, and a printing area for performing resistance radiation can be set; a metal part generated by the metal three-dimensional printing method disclosed by the invention is high in strength, high in density, and high in molding accuracy; molding process of each pixel point is monitored; a dismountable assisting bracket can be synchronously generated; a large-scale part can be printed; the equipment is simple in structure and low in cost. The metal three-dimensional printing method and the equipment thereof disclosed by the invention have a substantive progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

Ceramic multi-layer circuit substrate and manufacturing method thereof

InactiveUS20100059266A1Improved electrical connectionImproved yieldPrinted circuit aspectsCeramic layered productsCeramicElectrode

Provided is a method of manufacturing a ceramic multi-layer circuit substrate. A plurality of ceramic blocks, in each of which one or more ceramic green sheets having via-electrodes are layered one atop the other, are formed and are then fired. The fired ceramic blocks are aligned with each other. One or more bonding green sheets each having bonding electrodes in positions corresponding to the via-electrodes of the ceramic blocks are prepared. Each of the bonding green sheets is interposed between a pair of the ceramic blocks opposing each other. The ceramic blocks and the bonding green sheets are bonded and are then fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Slurry composition, electrode and secondary cell

ActiveUS20050069769A1Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

A slurry composition for electrode comprising a binder, an active material, and a liquid medium, characterized in that the binder comprises a polymer (X) comprising 60 to 95 mole % of repeating units derived from acrylonitrile or methacrylonitrile and 5 to 30 mole % of repeating units derived from at least one kind of a monomer selected from 1-olefins and compounds represented by the following general formula (1): CH2═CR1—COOR2 wherein R1 represents a hydrogen atom or a methyl group and R2 represents an alkyl group; and the liquid medium is capable of dissolving the polymer (X). The slurry composition allows the manufacture of a lithium ion secondary battery having enhanced capacity and good charge-discharge cycle characteristics and good charge-discharge rate characteristics.

Owner:ZEON CORP

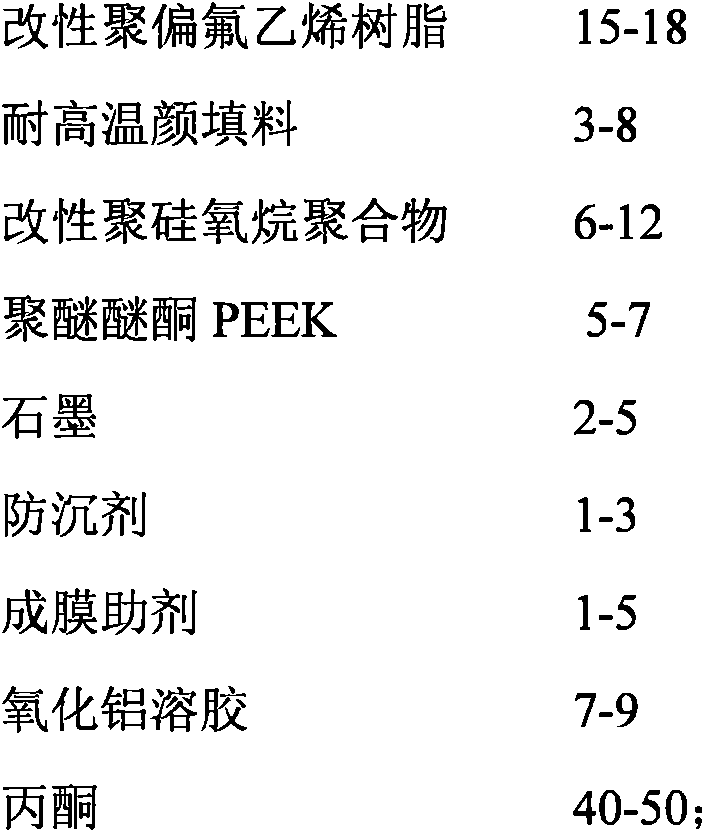

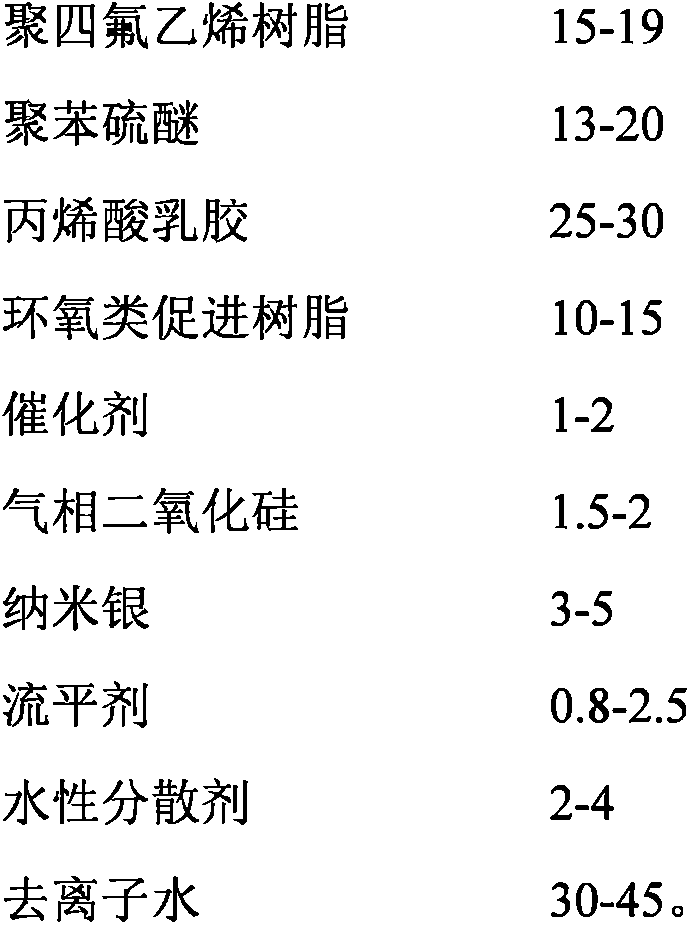

Wear-resistant and mildewproof non-stick pan coating

ActiveCN105111926AChemically stableDoes not generate PFOACooking-vessel materialsAntifouling/underwater paintsEpoxyWear resistant

The present invention relates to a wear-resistant and mildewproof non-stick pan coating. The coating comprises a bottom layer and a surface layer; The bottom layer consists of the following materials in parts by weight: polyimide resin, modified polyvinylidene fluoride resin, a high-temperature-resistant pigment filler, modified polyorganosiloxane polymer, polyetheretherketone PEEK and graphite. The surface layer consists of the following materials in parts by weight: polytetrafluoroethylene resin, phenylene sulfide, acrylate rubber latex, epoxy accelerated resin, a catalyst, fumed silica, nano silver and the like. The wear-resistant and mildewproof non-stick pan coating prepared in the invention is chemically stable at the cooking temperature and does not generate hazardous substance PFOA. The coating has relatively great hardness and the damages of spatulas or spoons to the surface coating of the non-stick pan can be avoided. The non-stick pan prepared from the coating has low cost and a long service life.

Owner:NINGBO GRAMMY KITCHENWARE

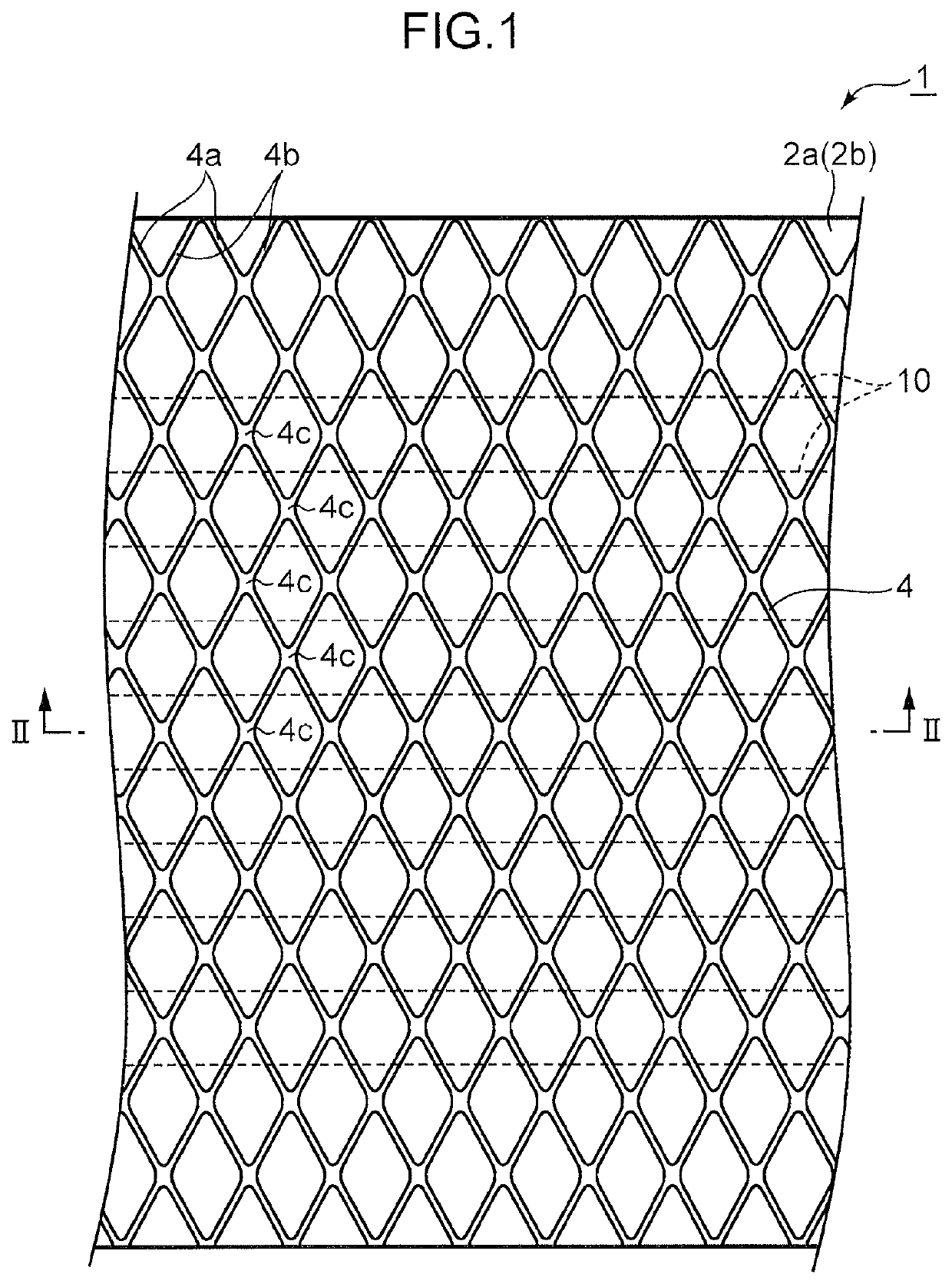

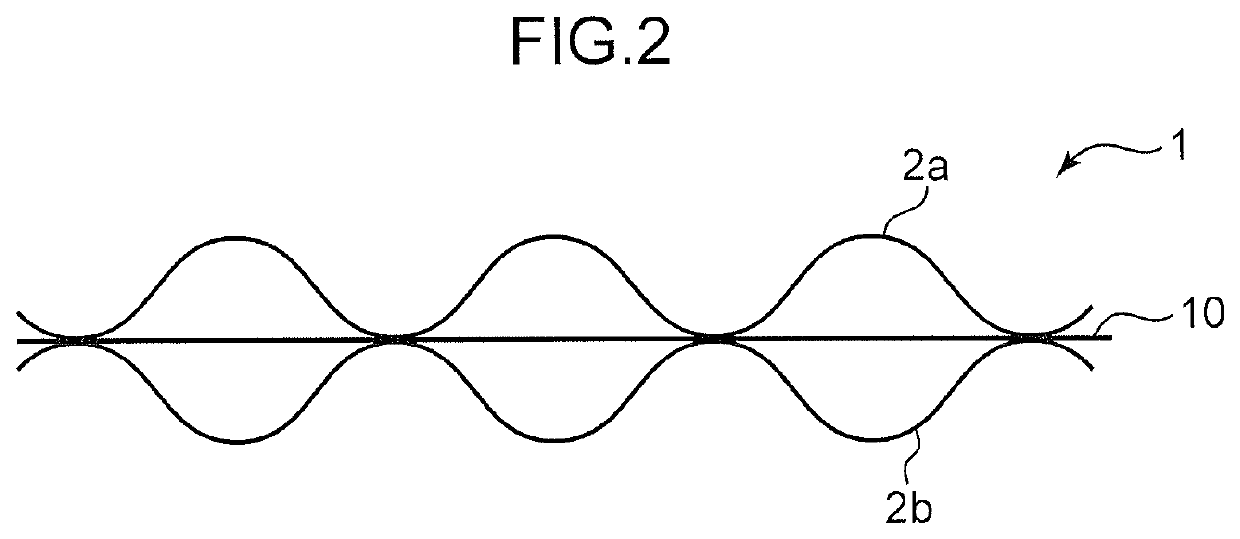

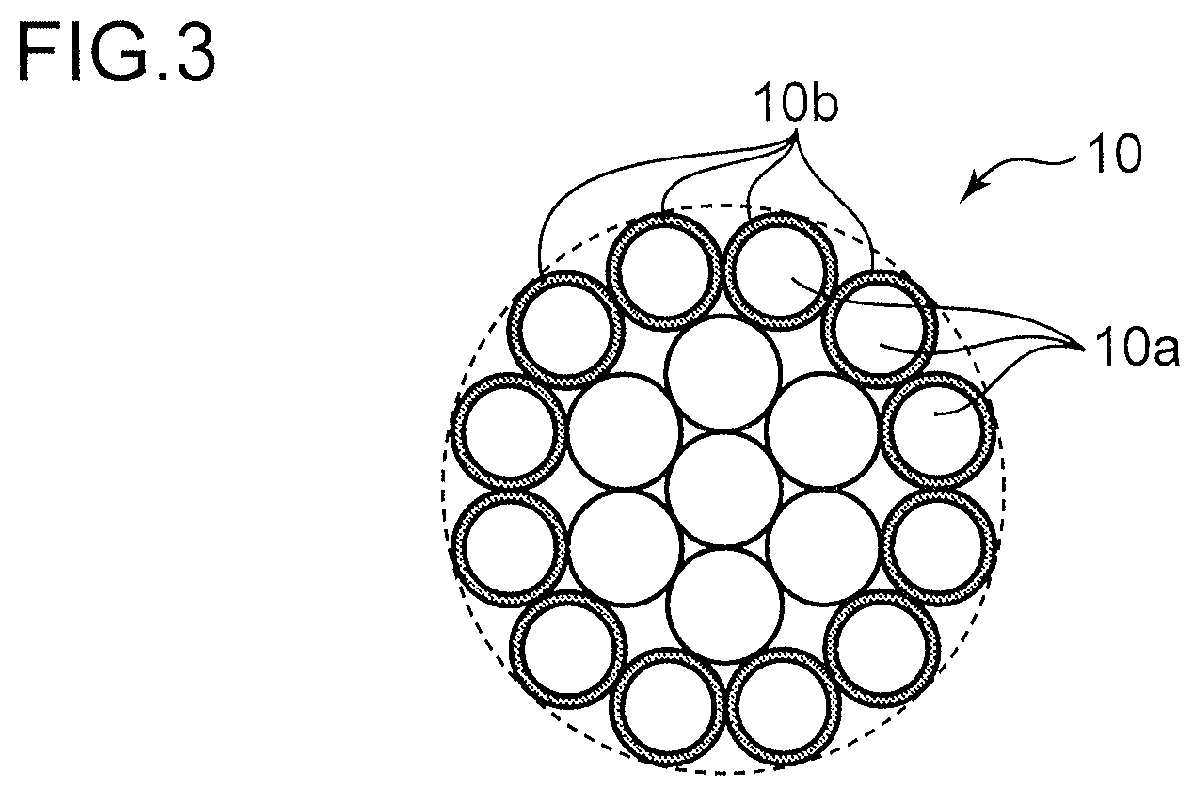

Composite stretchable member, wearable article, and method for producing wearable article

ActiveUS10596045B2Improve the bonding force between layersLayered productsAbsorbent padsStructural engineeringMechanical engineering

Owner:ZUIKO CORP

Technique for producing sheet-type electronic component paper carrying base paper by using waste paper pulp

InactiveCN101100830AReduce consumptionImprove protectionPure paperDryer sectionHigh concentrationPulp and paper industry

The invention relates to paper technology used waste pulp to produce sheet electronic component paper characteristic carried band base paper. It includes the following steps: mixing 50-80% broadleaf pulp, 0-35% need pulp, 0-15% mechanism ground pulp and sending them into high concentration pulping machine to pump to 40-48 degree SR; adding 0.8-1wt% starch and 0.5-1wt% sizing agent to form cover pulp; de-inking, de-sanding, de-dusting for the waste pulp; sending them into the pulping machine; putting into core pulp storing pool; adding 0.8-1wt% starch and 0.5-1wt% sizing agent to form core pulp; distributing the cover and core pulp into cover net and core net by splitting box to form many paper sheet; spraying a layer of starch on them; folding them to form base paper; rolling; drying; dehydrating; surface sizing; cooling; balancing moisture; coiling up. The invention has the advantages of reasonable technology, convenient production, stable quality, practicality, and environmental protection.

Owner:方隽云

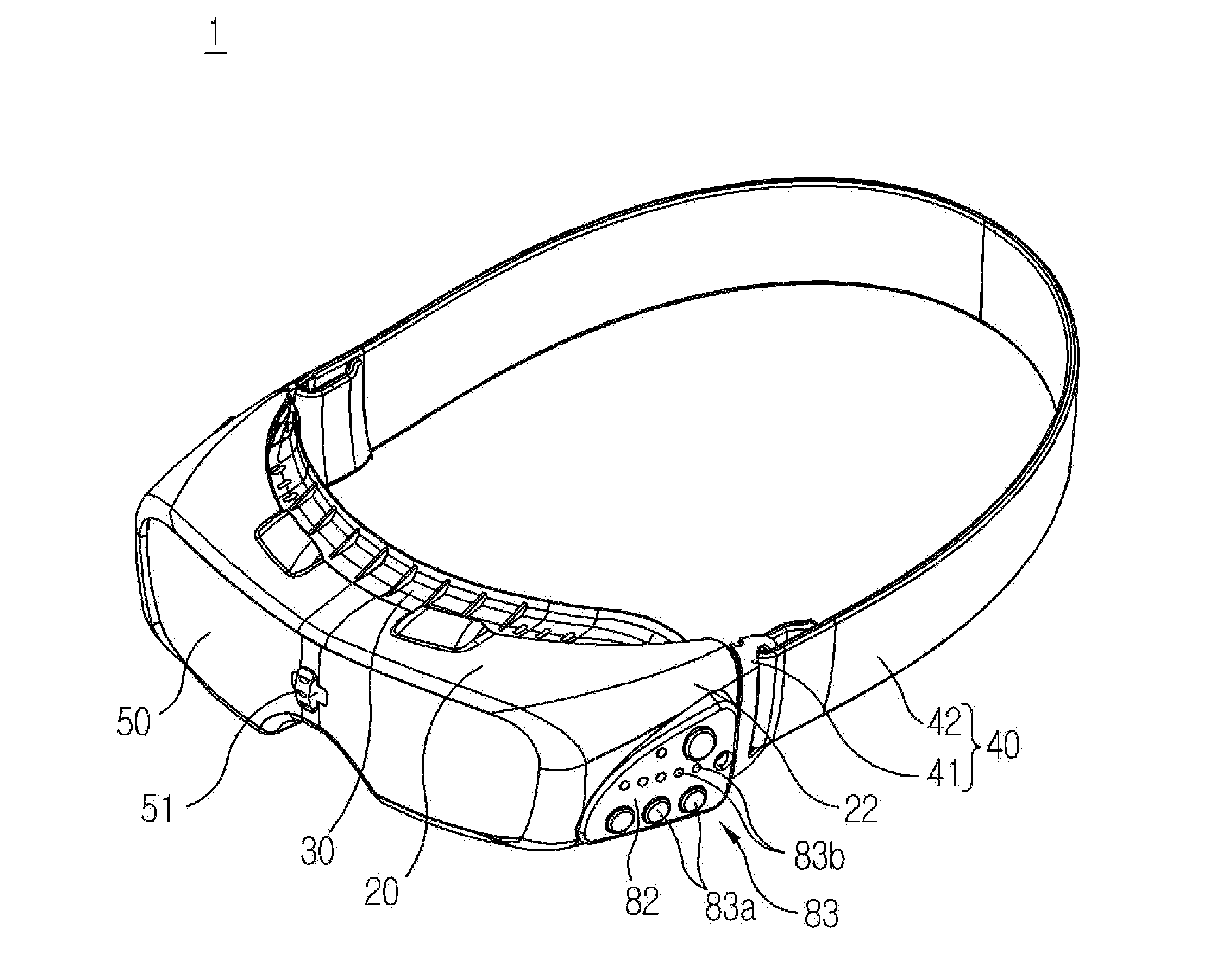

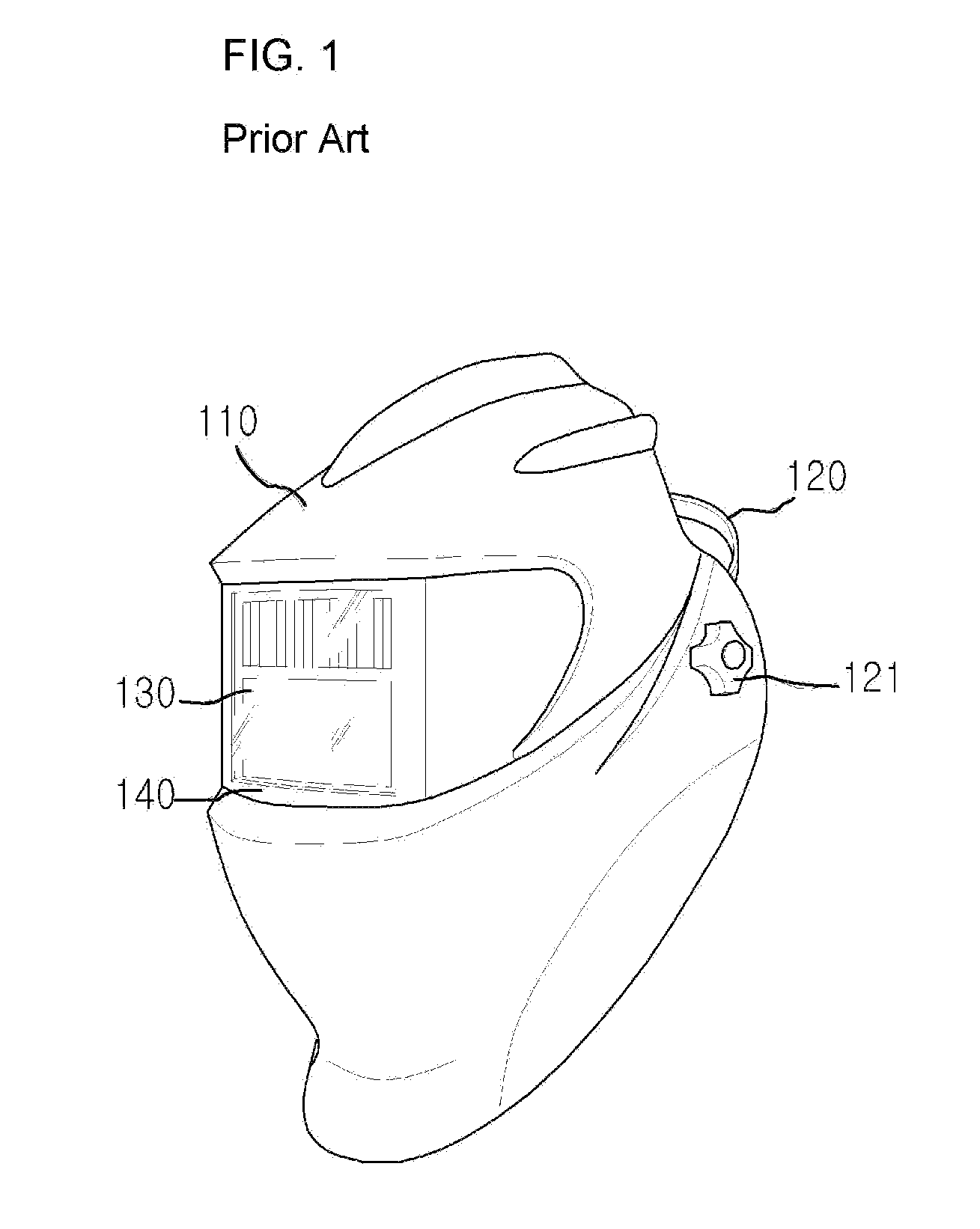

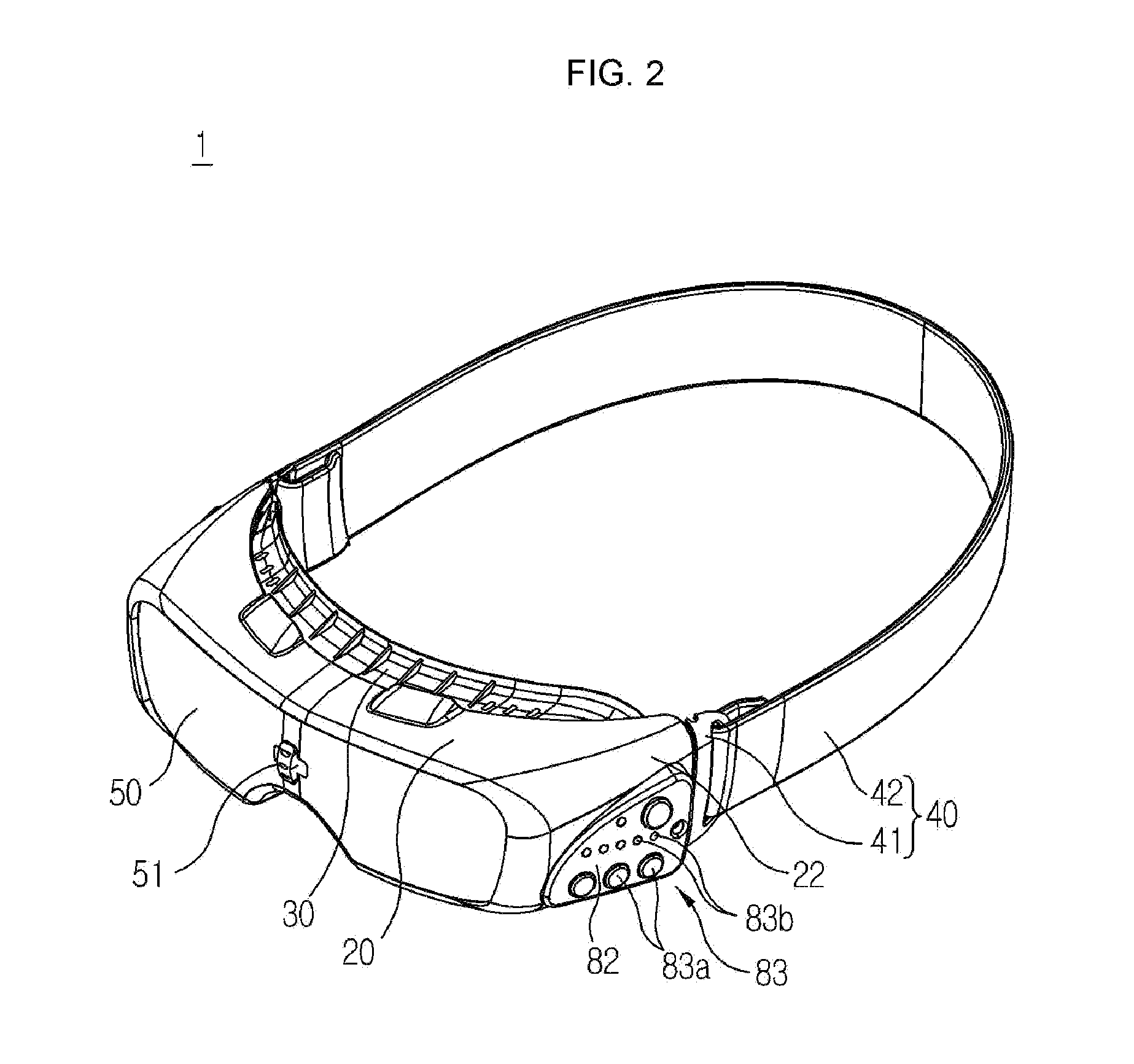

Automatic shading goggles

ActiveUS20120204303A1Reduce the burden onEasy to distinguishGogglesEngineering safety devicesEngineeringWelding helmet

Provided is automatic shading goggles in that a welding helmet is manufactured in a goggle shape, so that the size thereof is compact and the weight thereof is light and a shading degree of a LCD lens can be selectively adjusted in any one mode of a welding mode for shielding a harmful light generated during welding operation and a security mode for shielding a visible ray, so that it can reduce a burden of the weight applied to a worker, block a strong light during welding operation, and easily distinguish the surrounding objects, when the welding operation is not performed.

Owner:SERVORE

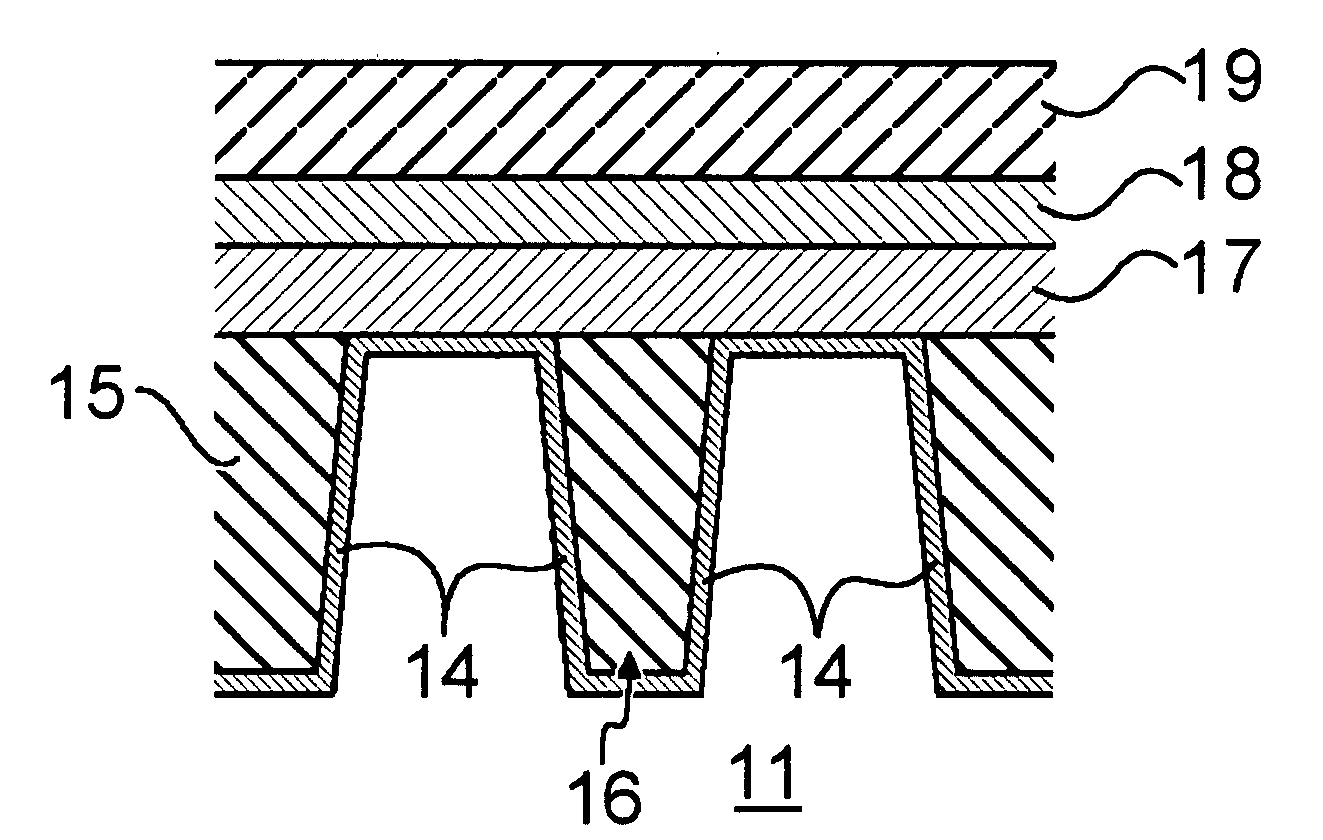

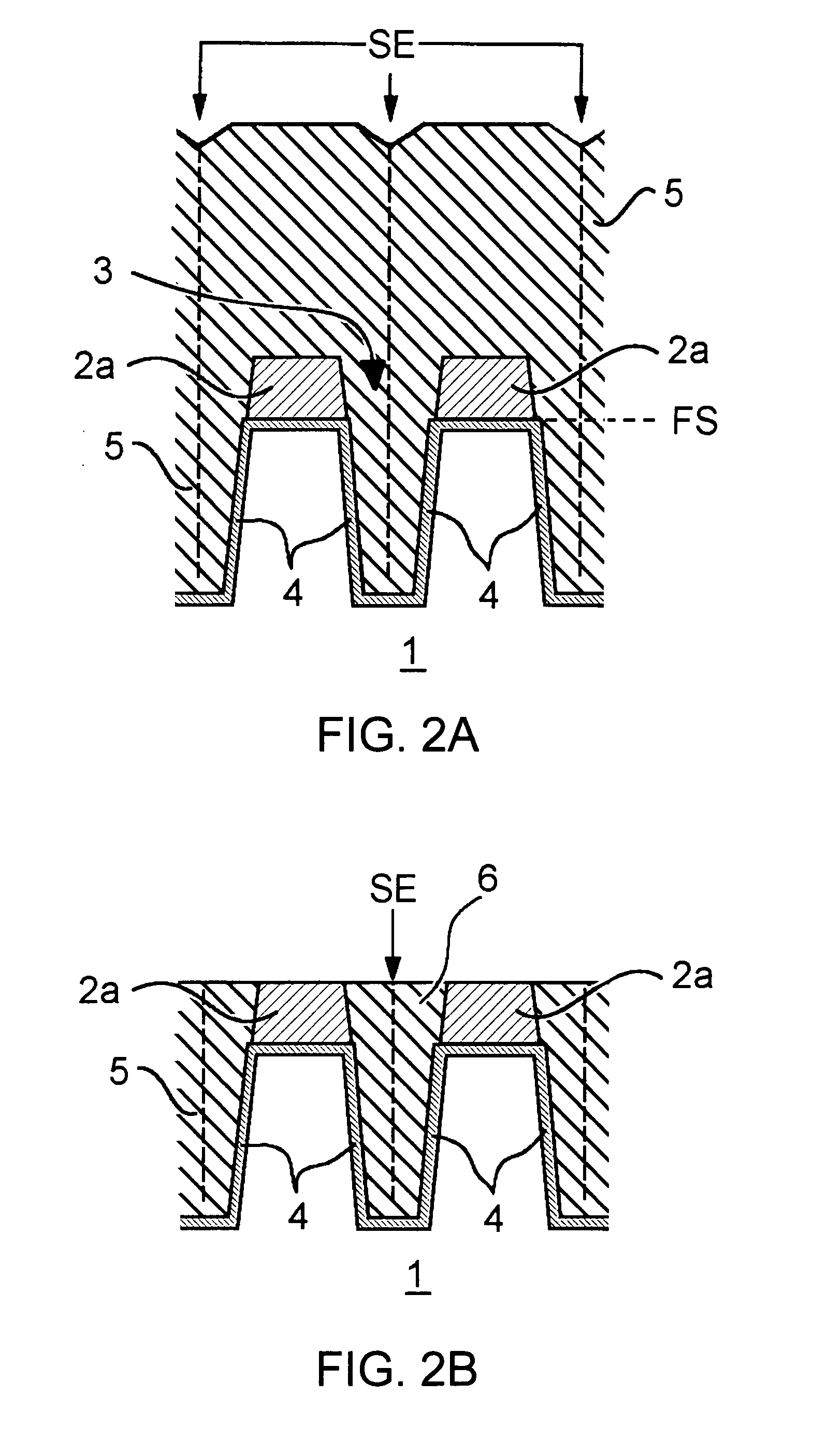

Method of producing semiconductor device

ActiveUS20080050886A1Easy to disassembleIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringNitride

A method of producing a semiconductor device according to the present invention comprises steps of:(A) forming trenches (13) on the front surface (FS) of a semiconductor substrate (11) on the back surface (BS) of which a nitride film (12b) is formed;(B) depositing an insulating film (15) to bury the trenches (13);(C) removing the nitride film (12b) on the back surface (BS) of the semiconductor substrate (11) after the step (B); and(D) annealing before the insulating film (15) is etched after the step (C).

Owner:MICRON TECH INC

Photocurable resin-based ceramic composite material and ceramic green body degreasing method

ActiveCN108218440AReduce disengagementHigh affinityAdditive manufacturing apparatusCeramic compositeMetallurgy

The invention discloses a photocurable resin-based ceramic composite material and a ceramic green body degreasing method. By optimizing the design of a resin system, the method increases the penetration depth of a ceramic slurry system and reduces the molding dimensional error while maintaining the system reaction activity; furthermore, the interlayer bonding force of a ceramic green body and theadhesion between the ceramic green body and a printing platform are improved, and the detachment between the ceramic green body and the platform as well as the cracks on the surface of the ceramic green body are reduced.

Owner:深圳长朗智能科技有限公司

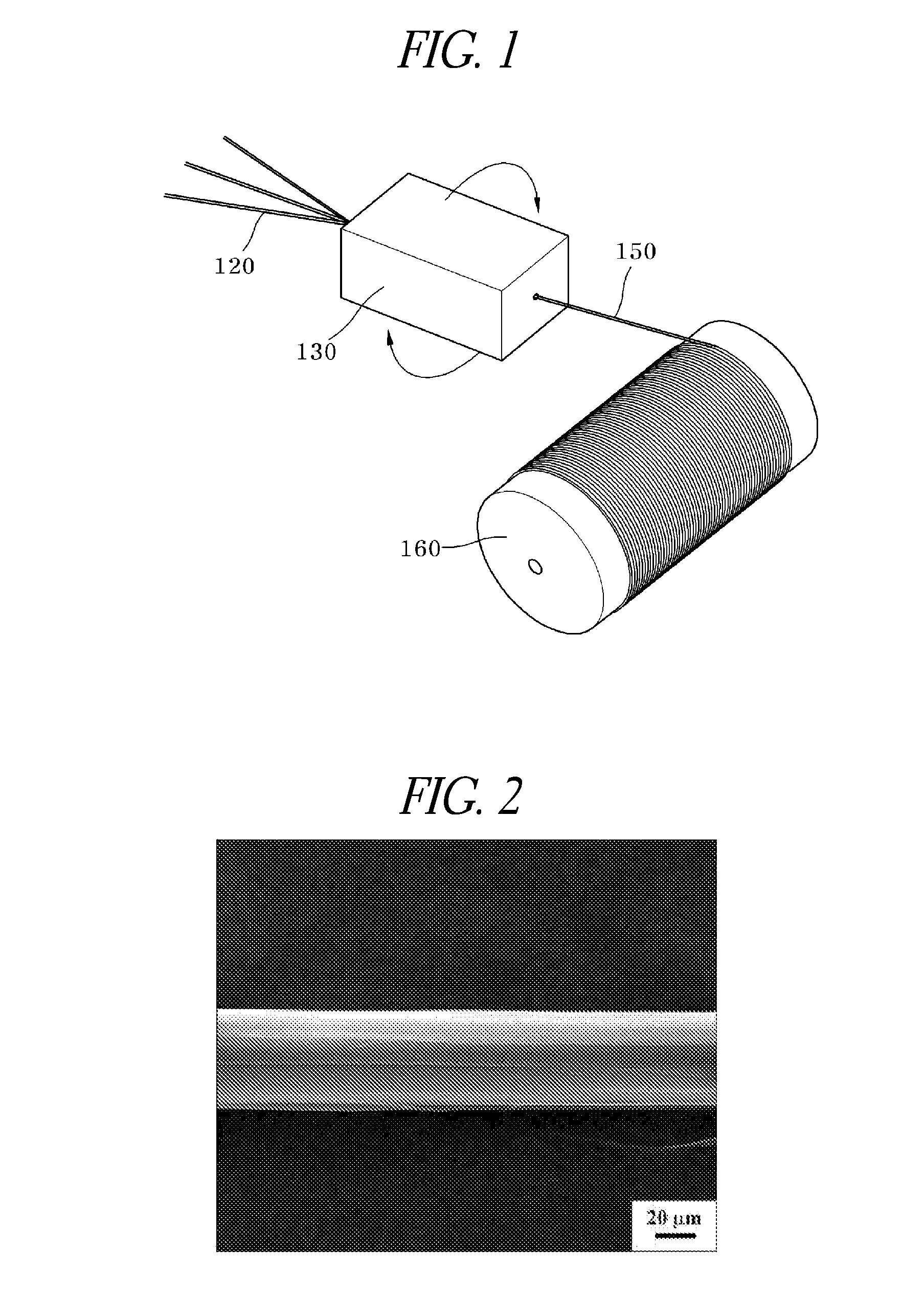

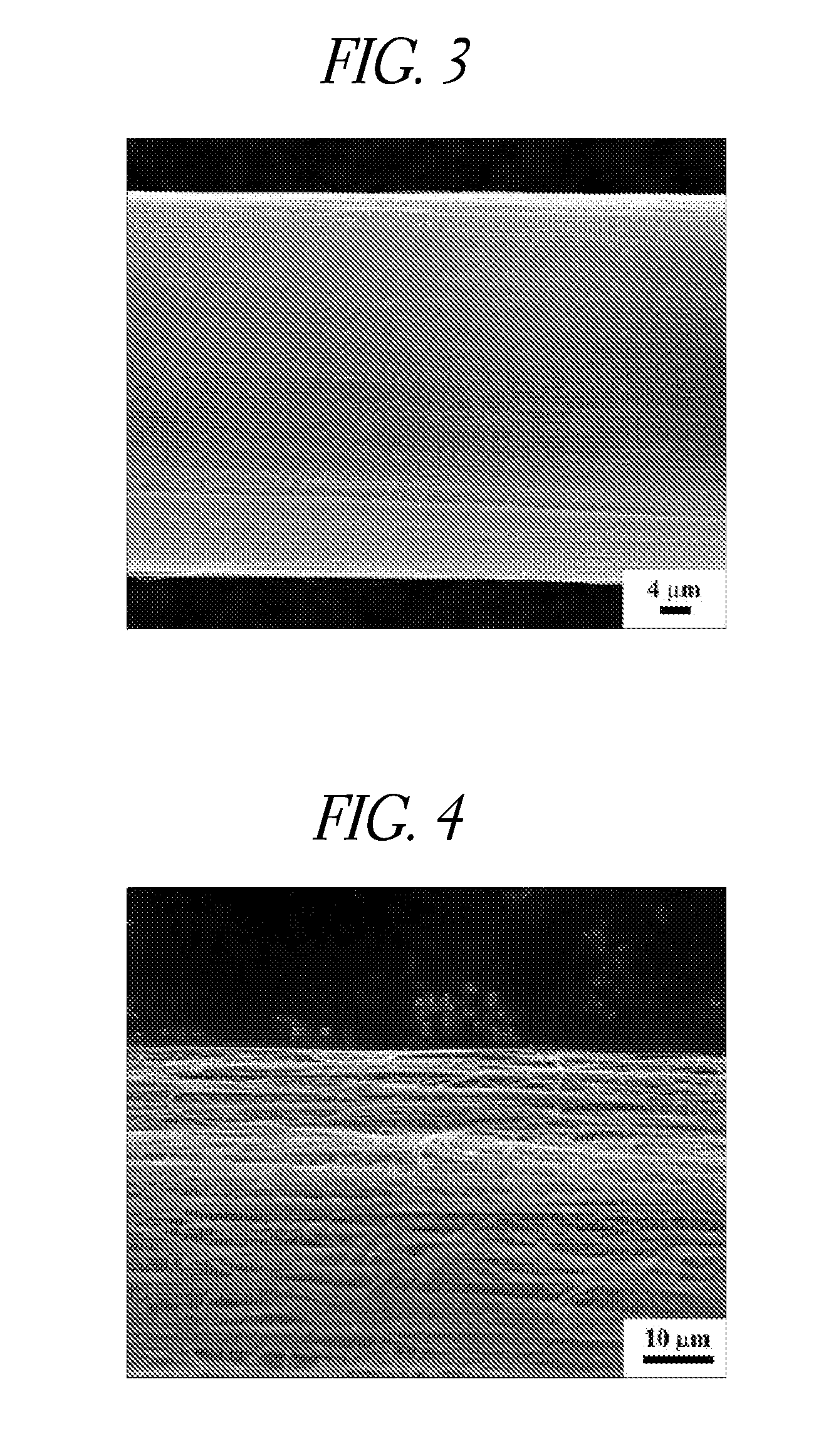

Surface field electron emitters using carbon nanotube yarn and method of fabricating carbon nanotube yarn thereof

ActiveUS20100181896A1Improve homogeneityGood reproducibilityCarbon fibresThermionic cathodesCarbon nanotube yarnLight emitting device

Surface field electron emitters using a carbon nanotube yarn and a method of fabricating the same are disclosed. To fabricate the carbon nanotube yarn for use in fabrication of simple and efficient carbon nanotube field electron emitters, the method performs densification of the carbon nanotube yarn during rotation of a plying unit and heat treatment of the carbon nanotube yarn that has passed through the plying unit without using organic or inorganic binders or polymer pastes. The method fabricates the carbon nanotube yarn with excellent homogeneity and reproducibility through a simple process. The carbon nanotube yarn-based surface field electron emitters can be applied to various light emitting devices.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com