Patents

Literature

136results about "Molten casting coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

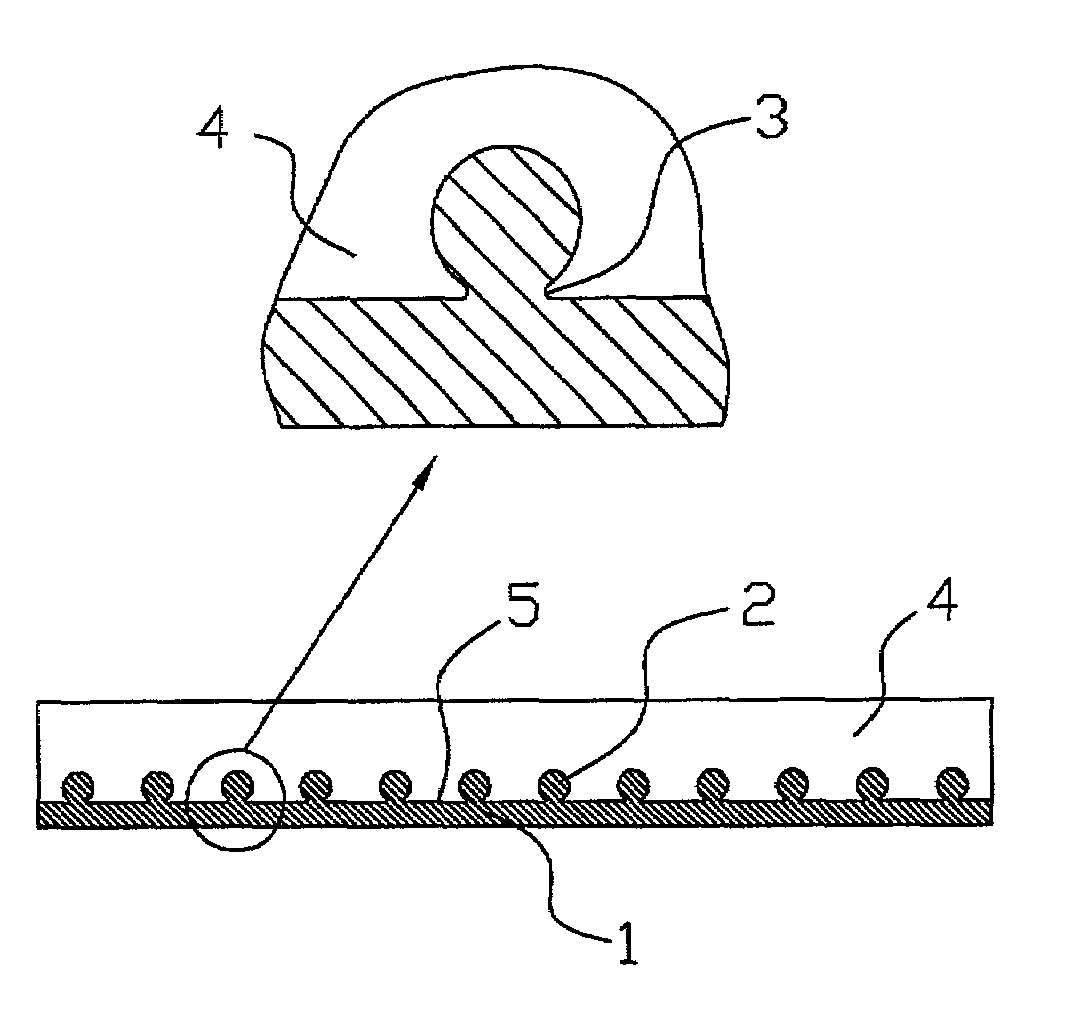

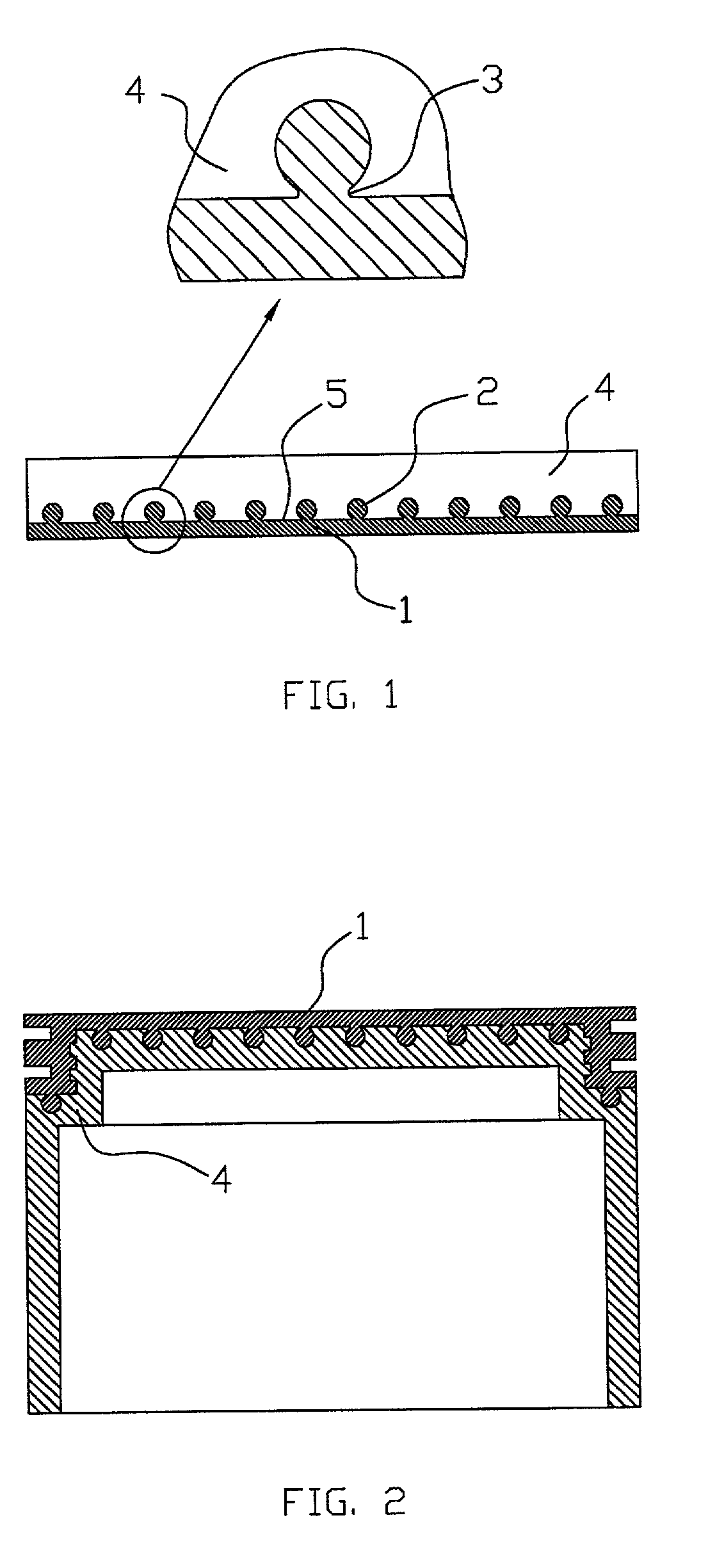

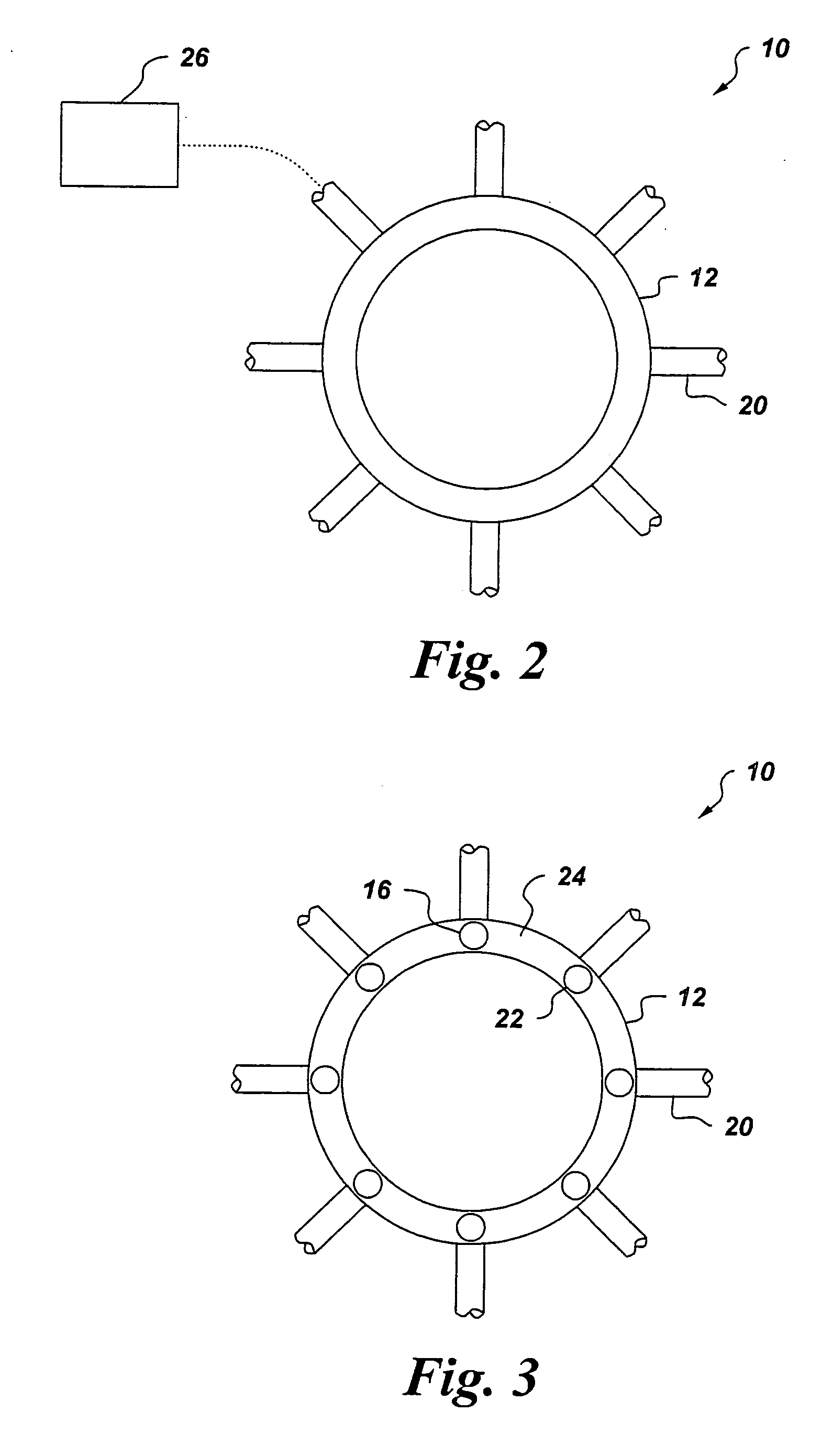

Method for manufacturing clad components

A method for manufacturing a clad component in which a cladding workpiece having a section comprising a first metal onto which a number of metal beads are rigidly bonded is inserted into a mold. A molten second metal is poured into the mold, where it flows about and covers the beads and is then permitted to cool. This process forms an article made of the second metal, which is mechanically interlocked to the beads, clad by the first metal. Typically the first metal is a high-melting point strong metal, such as steel, and the second metal is a lower-melting point, weaker, but lighter metal, such as aluminum.

Owner:NANOMETAL

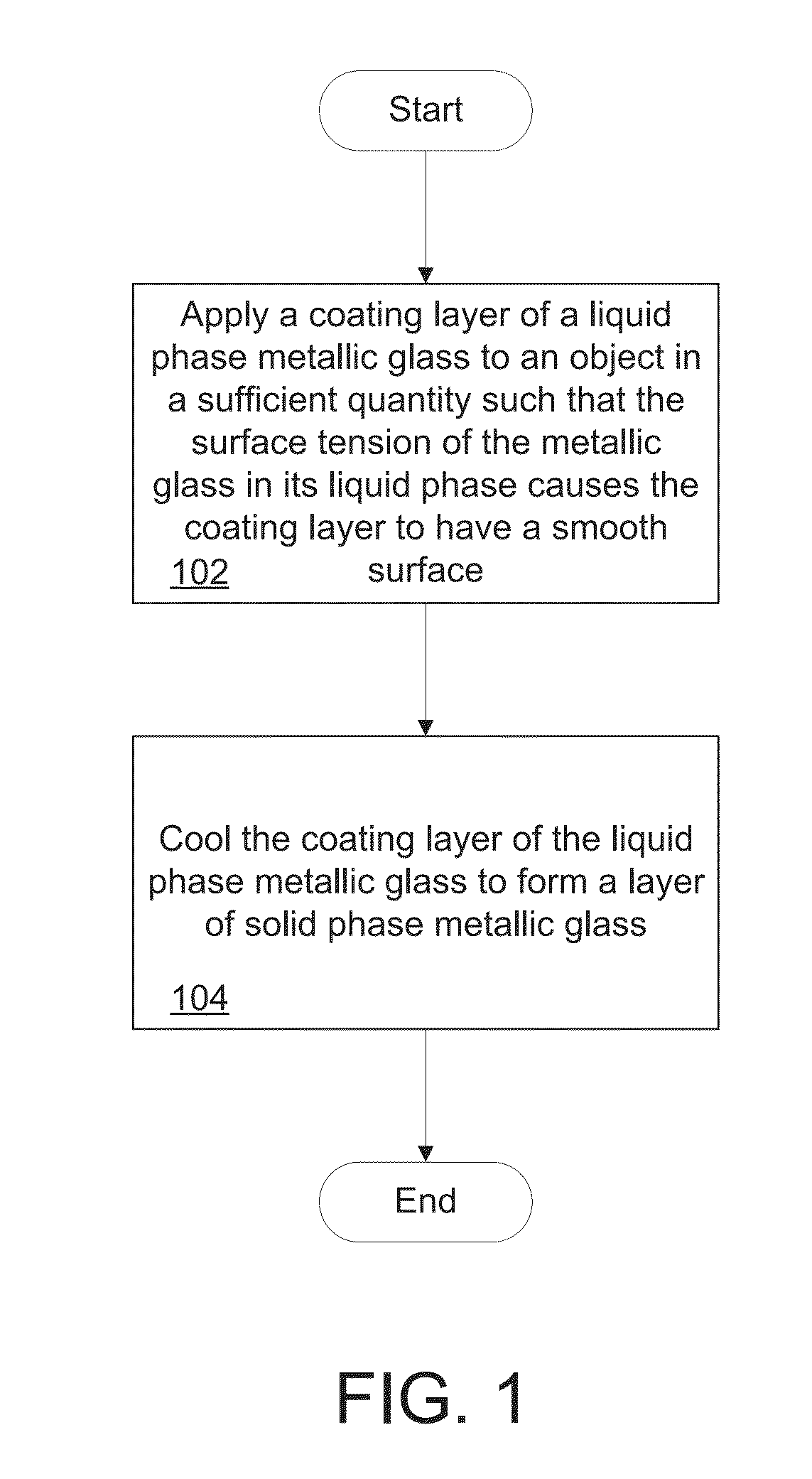

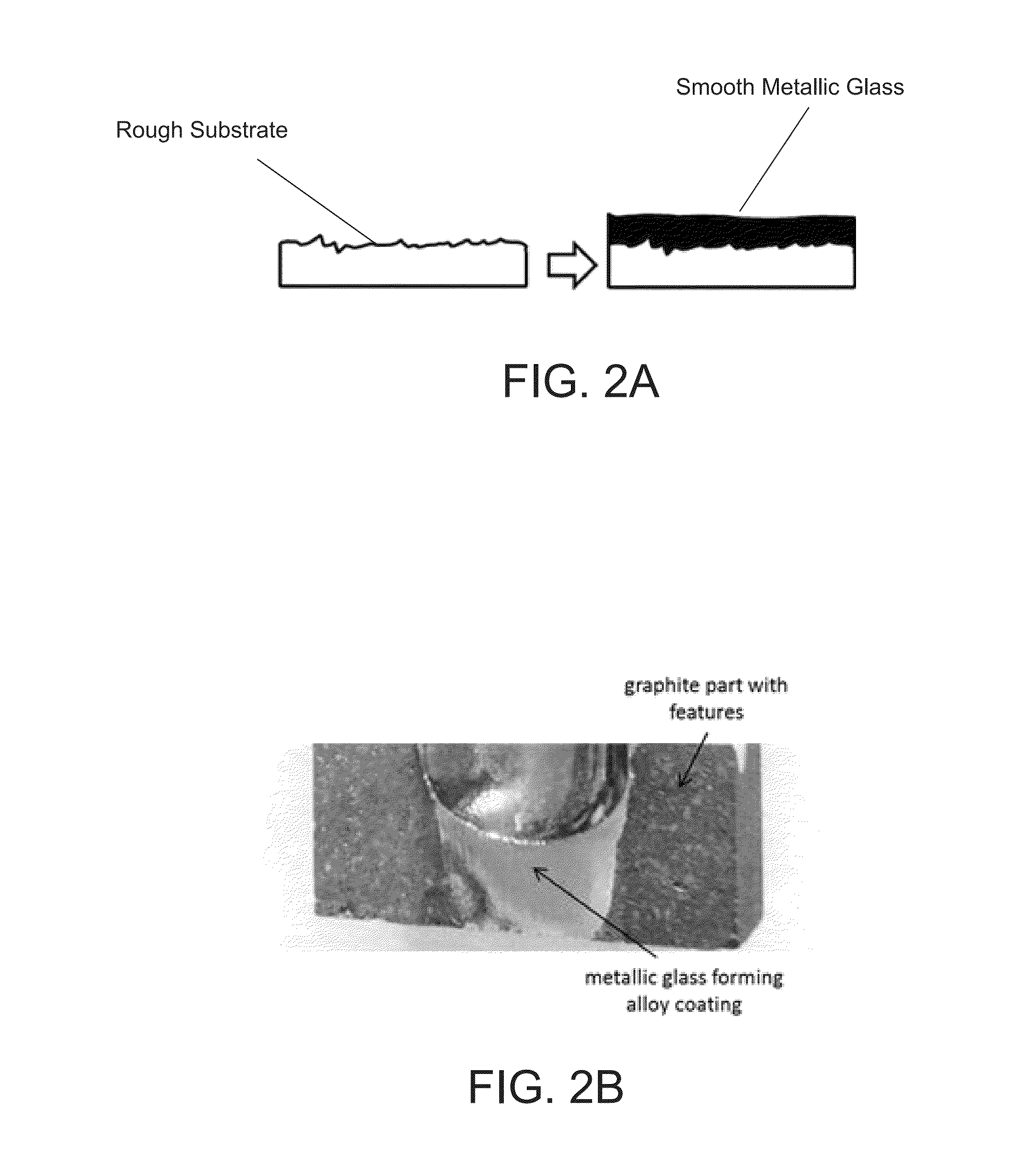

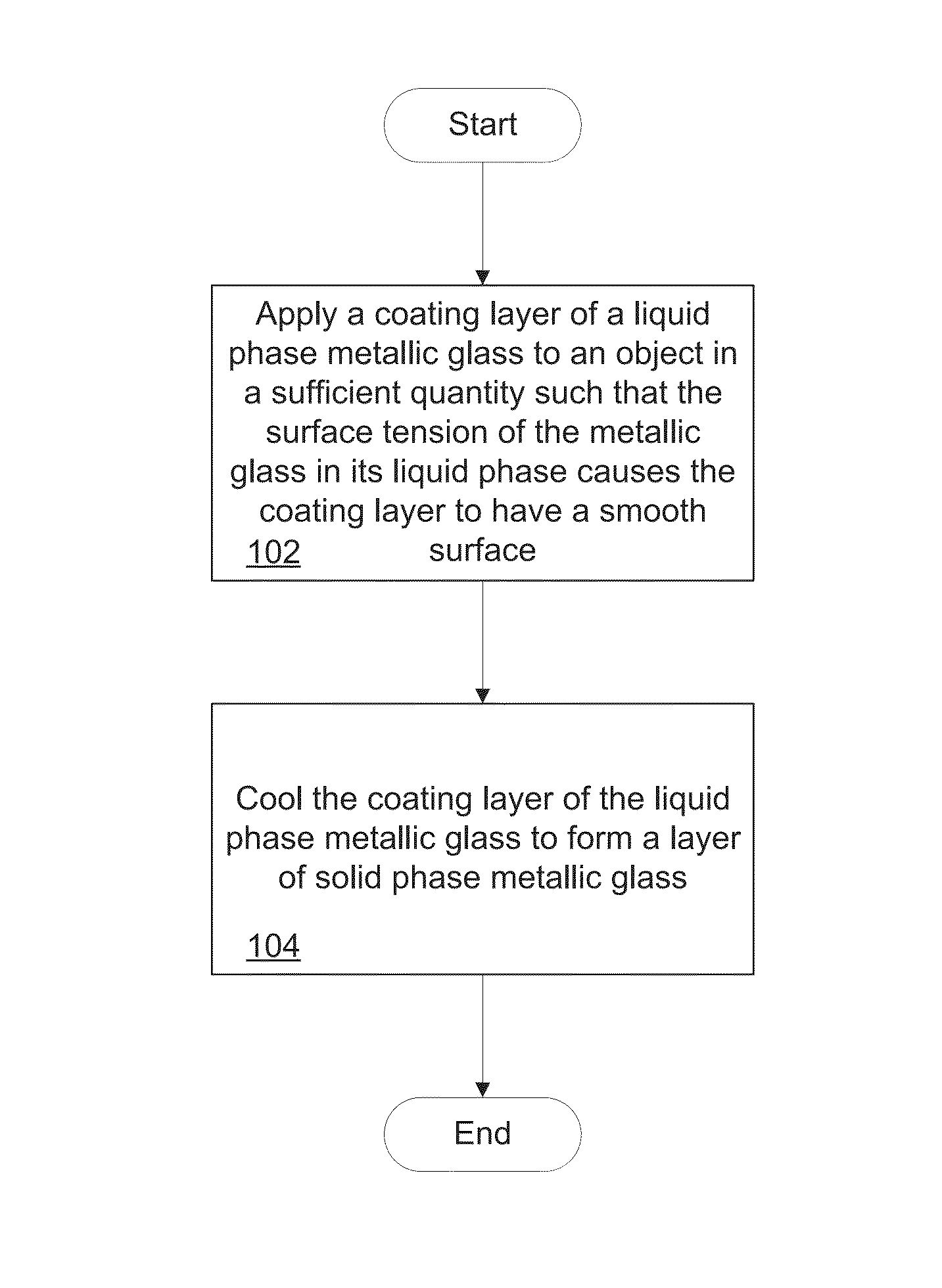

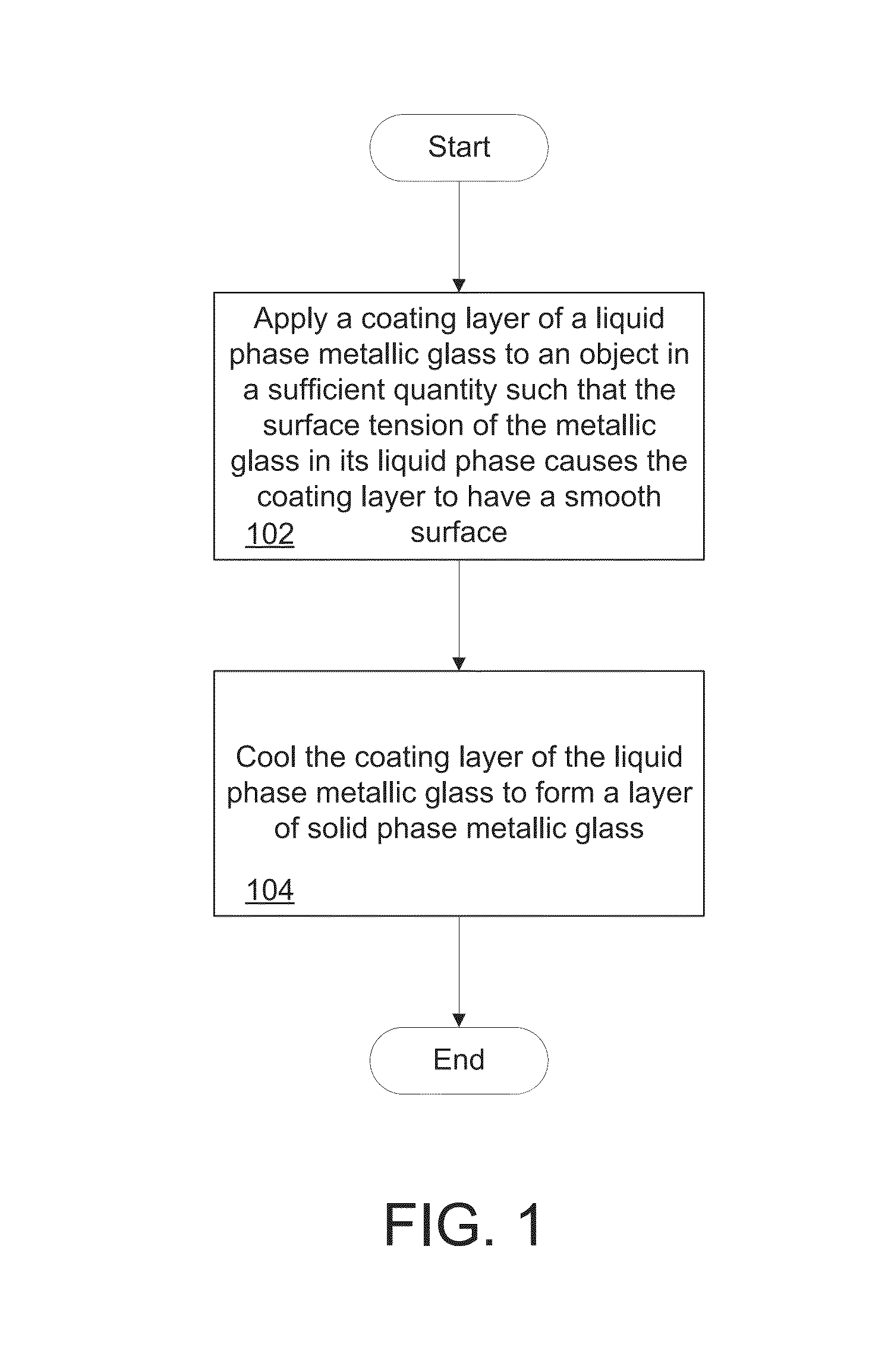

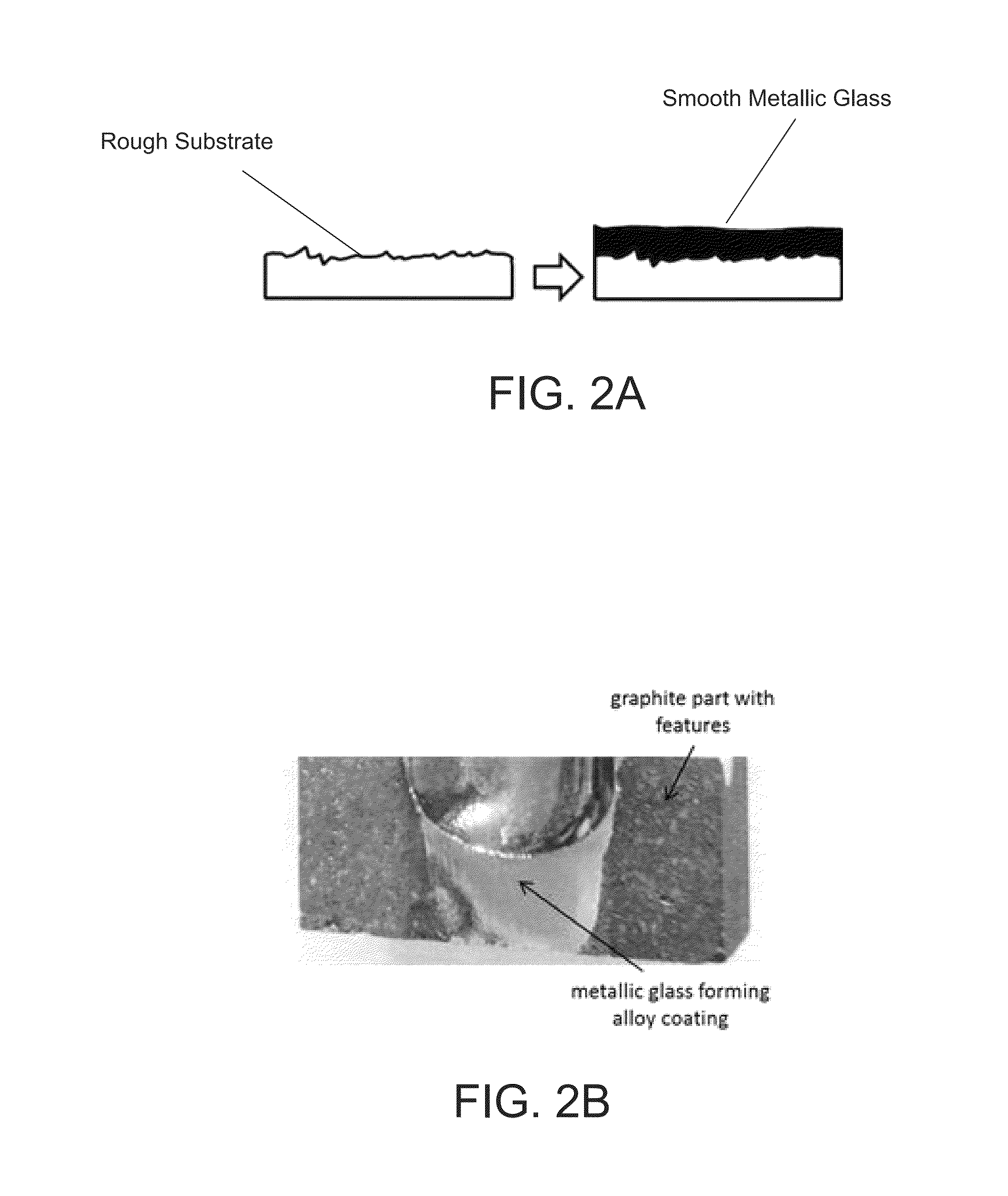

Systems and Methods Implementing Layers of Metallic Glass-Based Materials

ActiveUS20140141164A1Eliminate excessLower melting temperatureHot-dipping/immersion processesMolten spray coatingMetalMaterial system

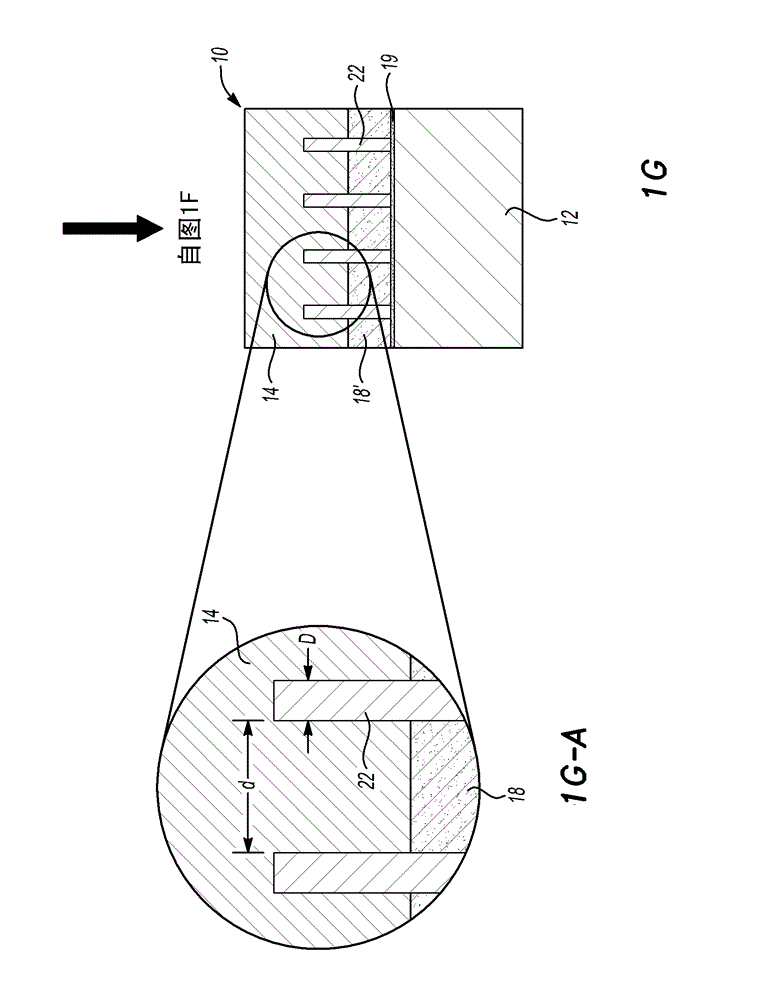

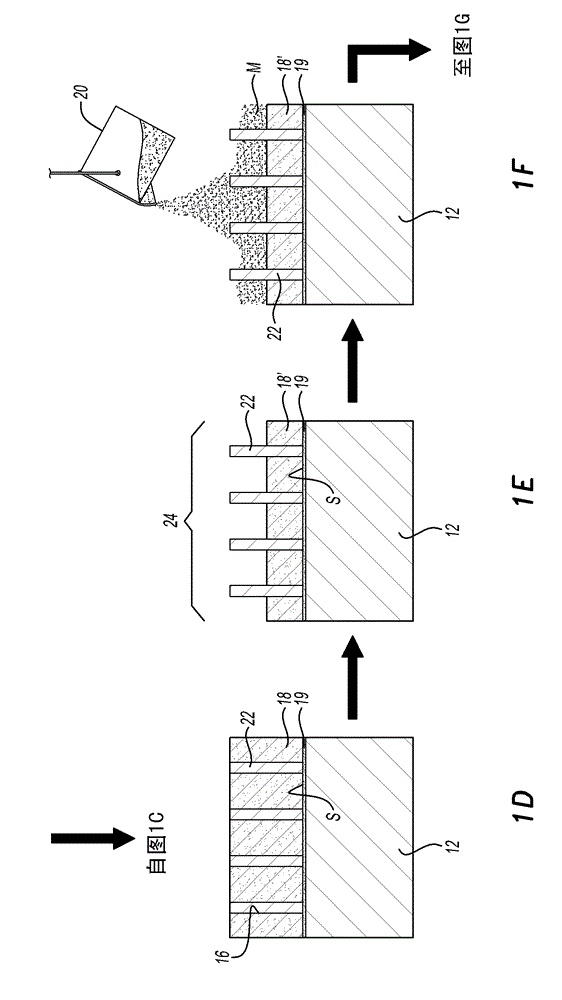

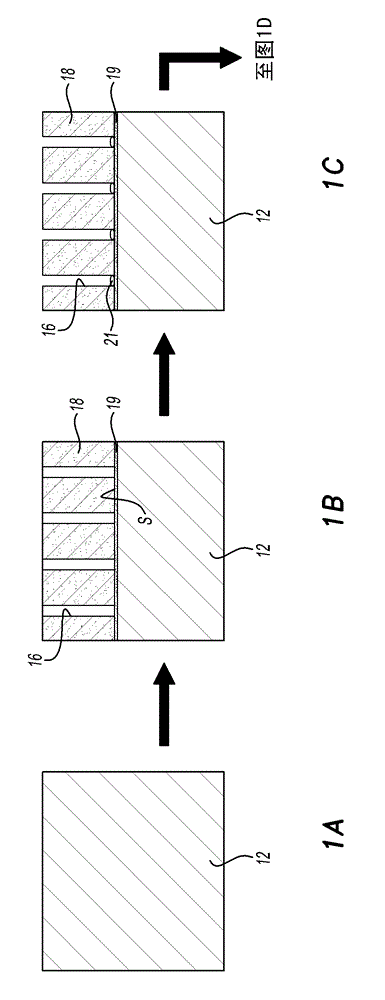

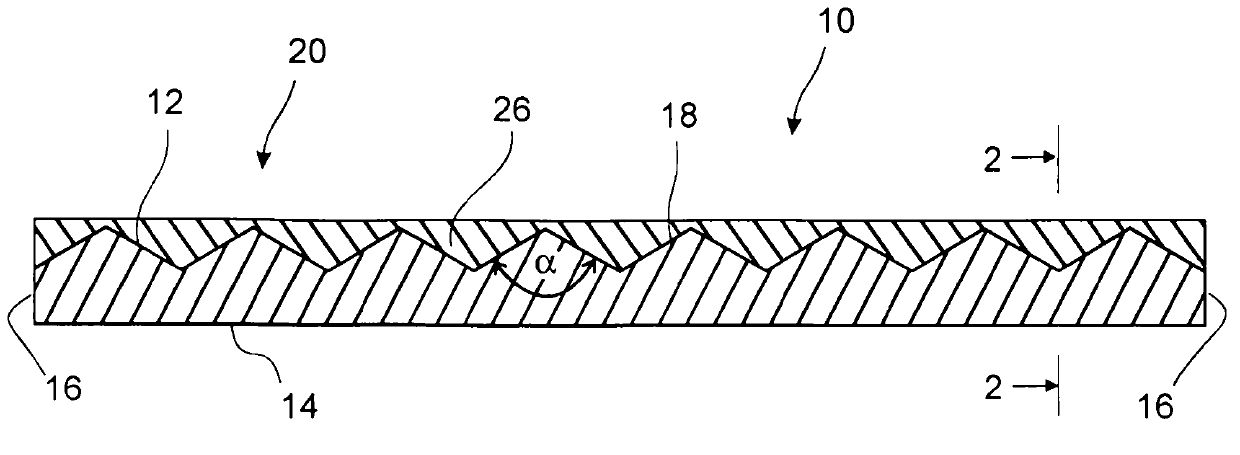

Systems and methods in accordance with embodiments of the invention implement layers of metallic glass-based materials. In one embodiment, a method of fabricating a layer of metallic glass includes: applying a coating layer of liquid phase metallic glass to an object, the coating layer being applied in a sufficient quantity such that the surface tension of the liquid phase metallic glass causes the coating layer to have a smooth surface; where the metallic glass has a critical cooling rate less than 1000 K / s; and cooling the coating layer of liquid phase metallic glass to form a layer of solid phase metallic glass.

Owner:CALIFORNIA INST OF TECH

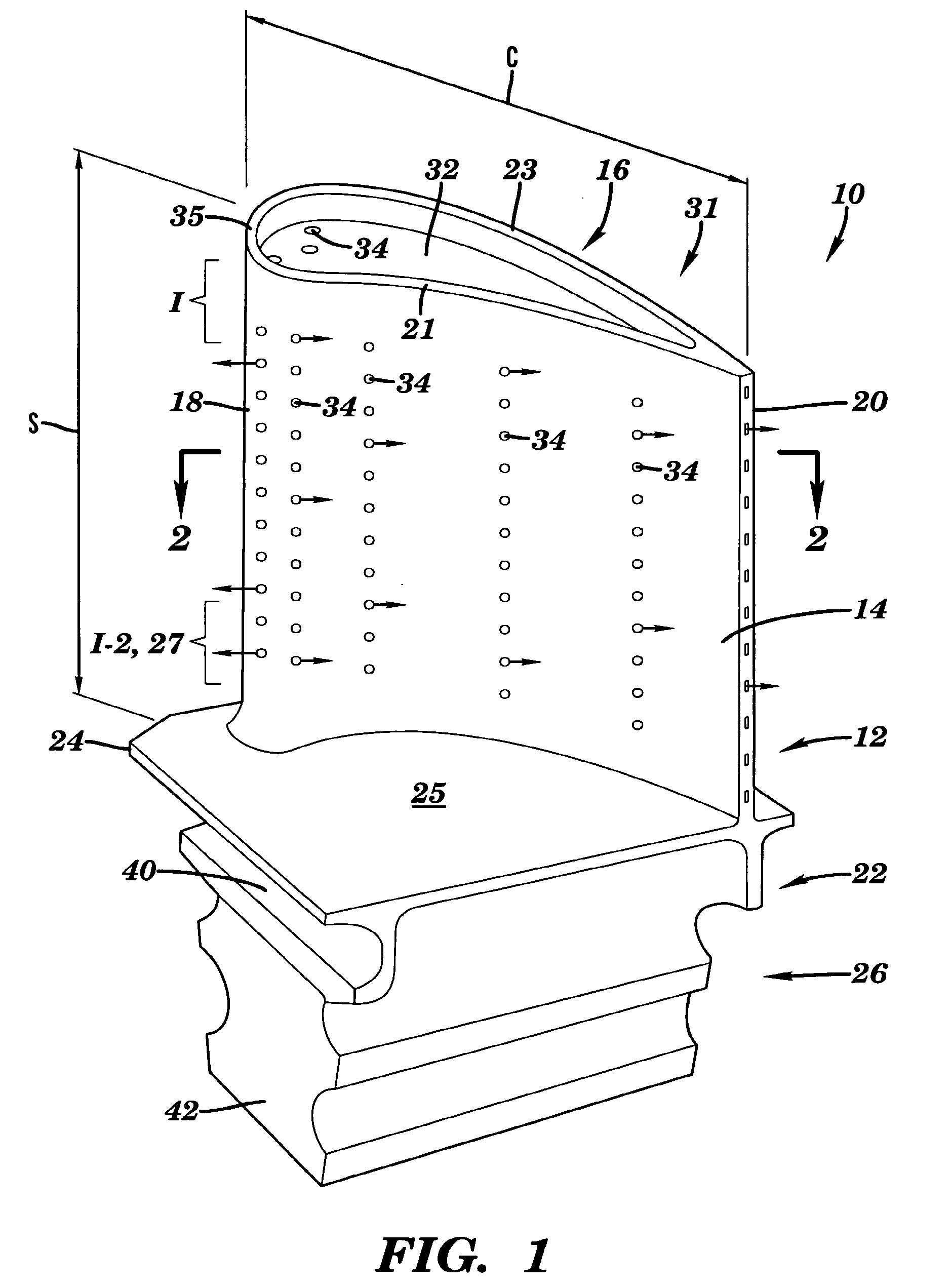

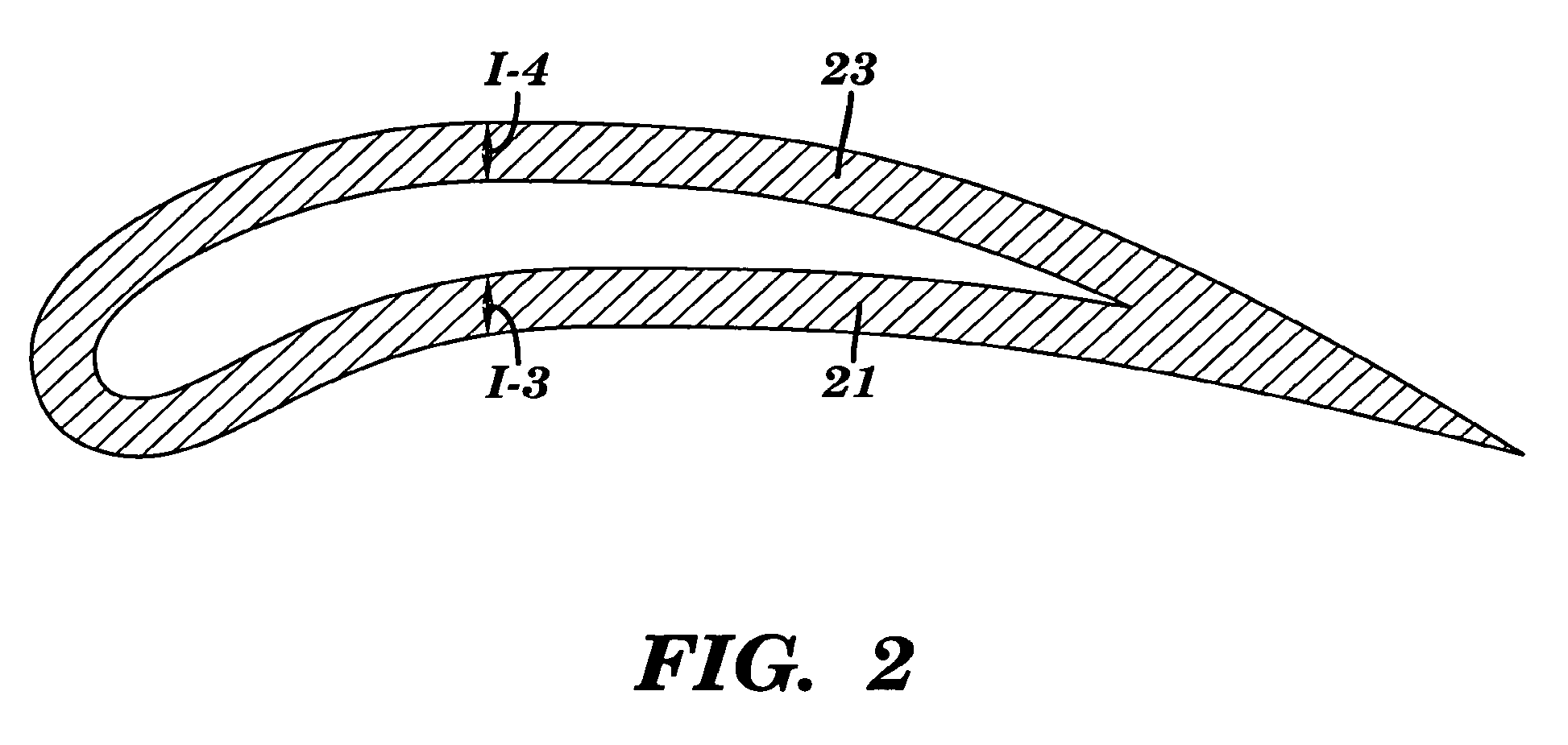

Niobium silicide-based turbine components, and related methods for laser deposition

A turbine component formed from a niobium silicide-based composition is described. The component can be compositionally-graded through at least a portion of its structure. A turbine blade formed from a composition which includes a niobium silicide alloy is also described. The blade includes an airfoil; an airfoil tip region; a platform on which the airfoil is mounted; and a dovetail root attached to an underside of the platform. The niobium silicide alloy in at least one portion of the turbine blade is compositionally different from the niobium silicide alloy in another portion of the blade. Processes for fabricating a niobium silicide-based turbine article are also described, using laser cladding techniques. Repair methods are also set forth in the application.

Owner:GENERAL ELECTRIC CO

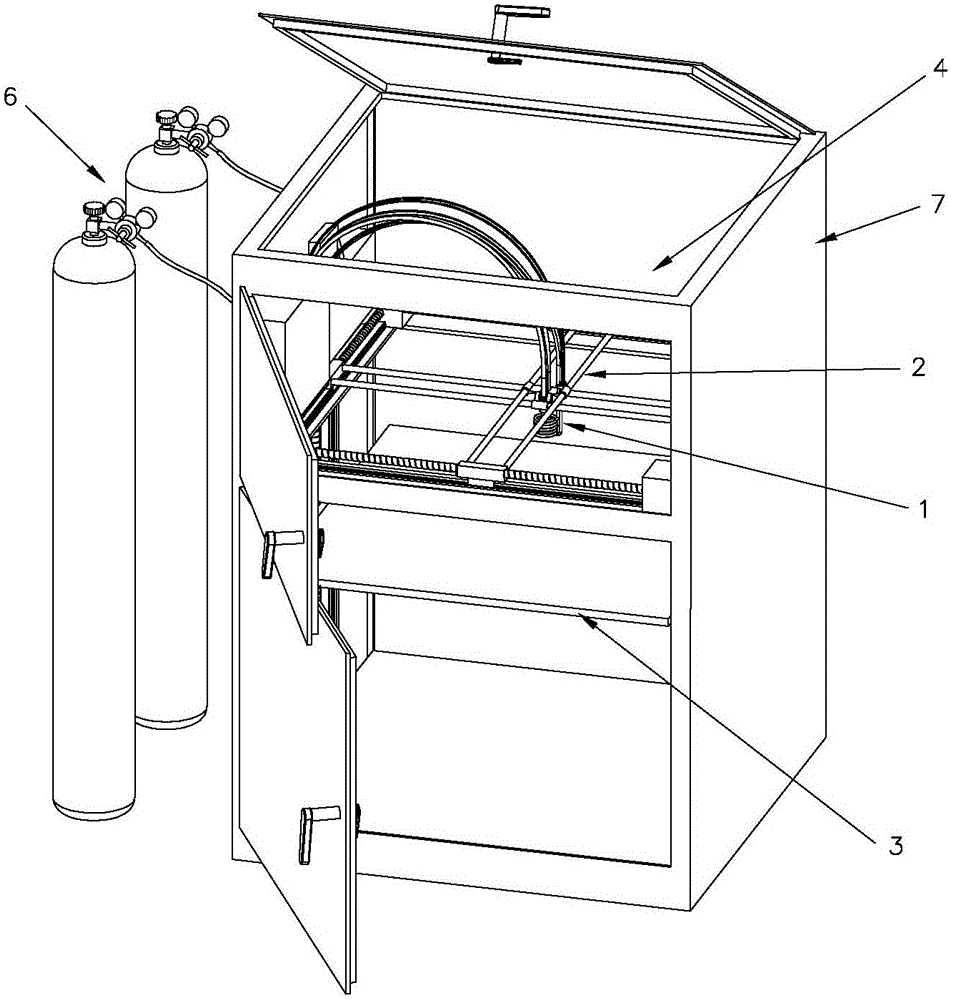

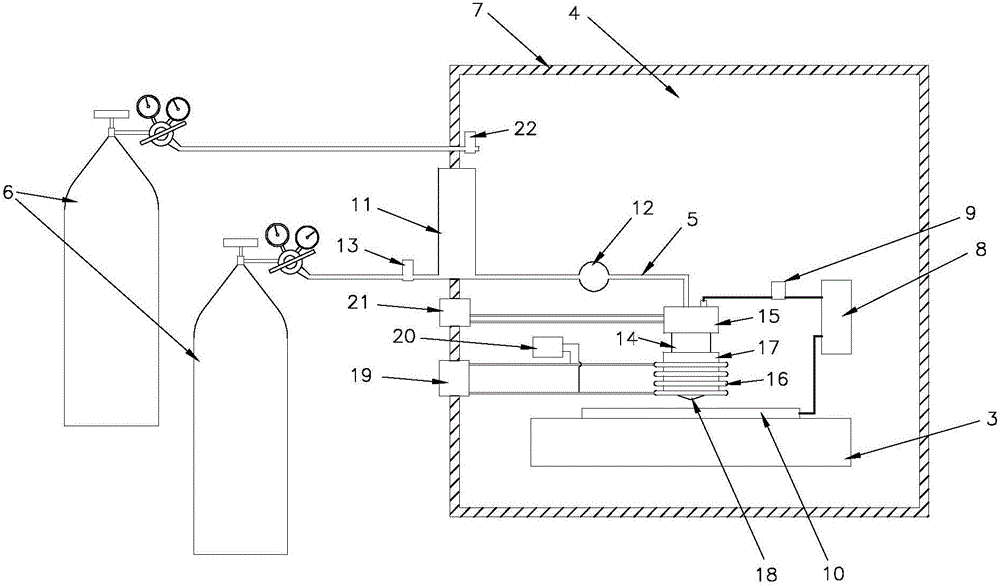

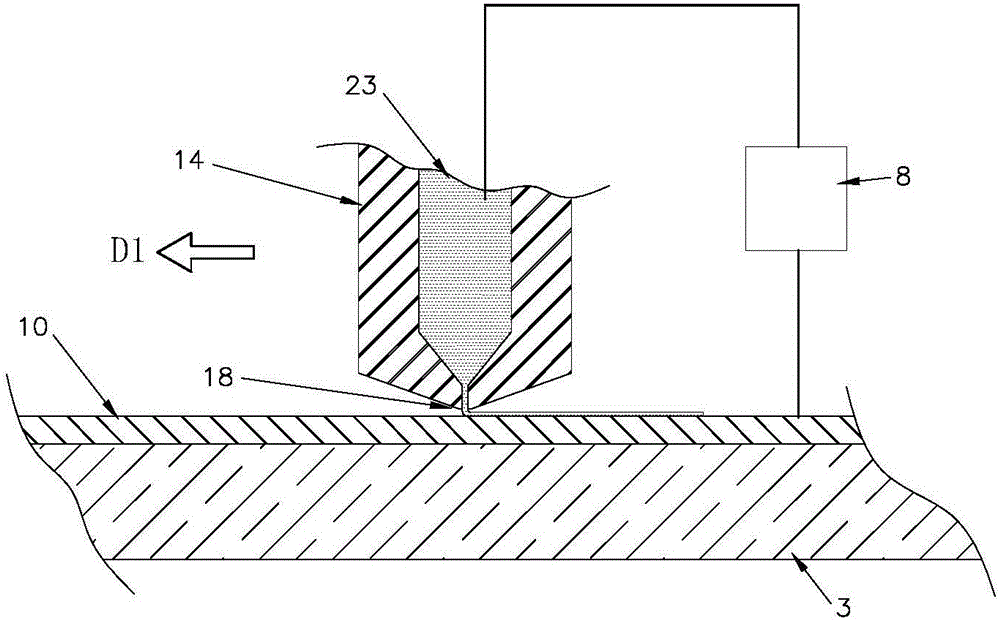

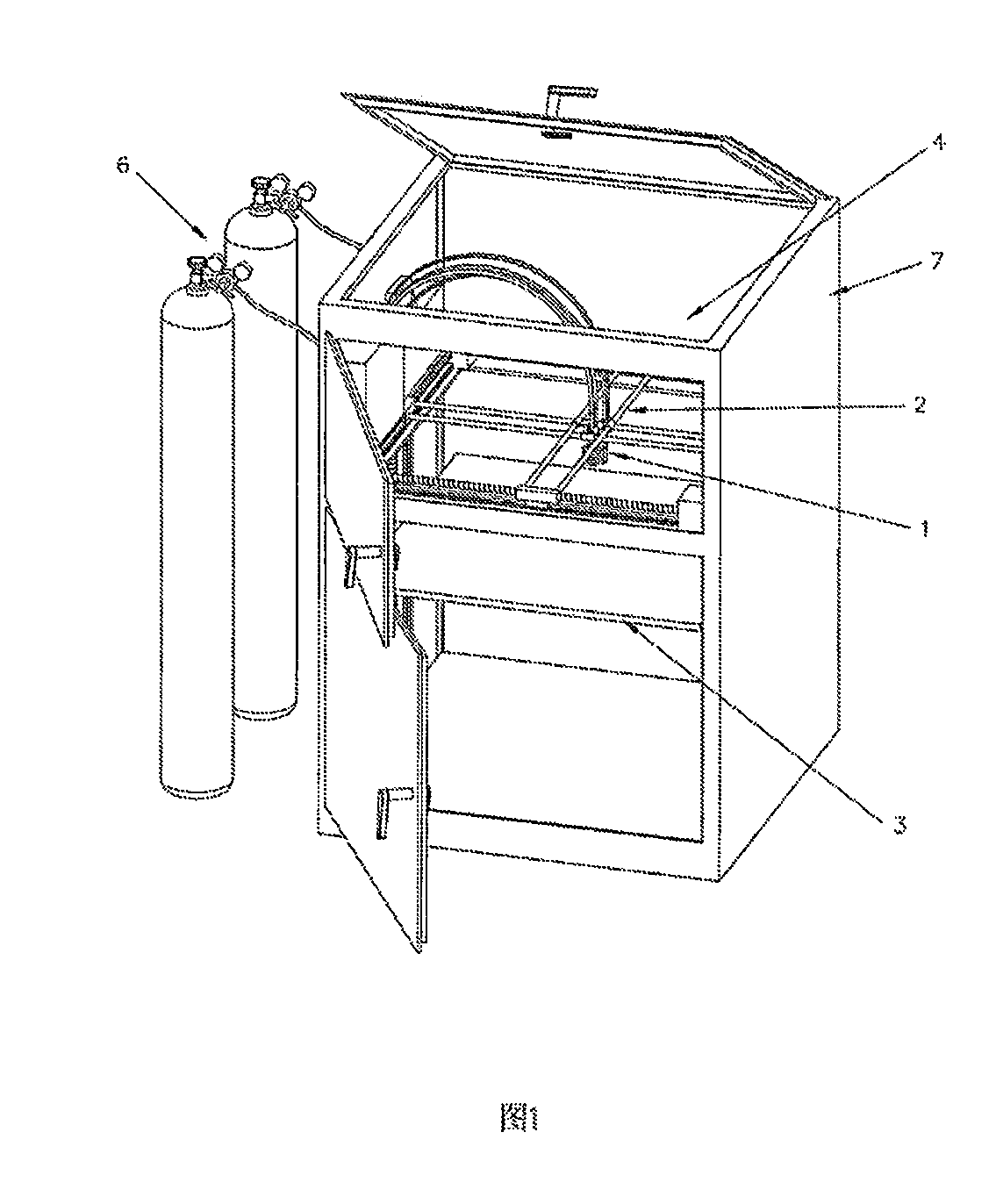

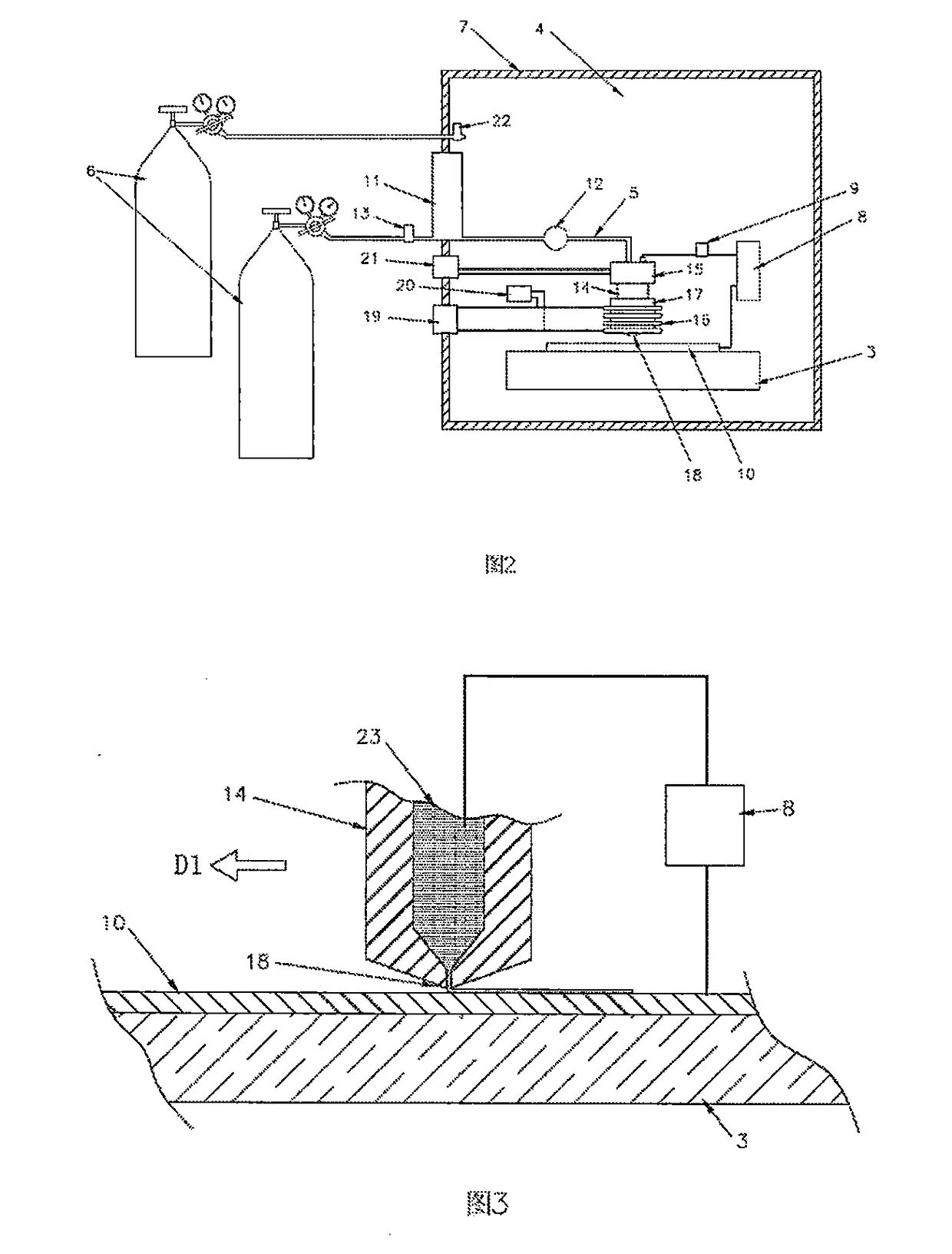

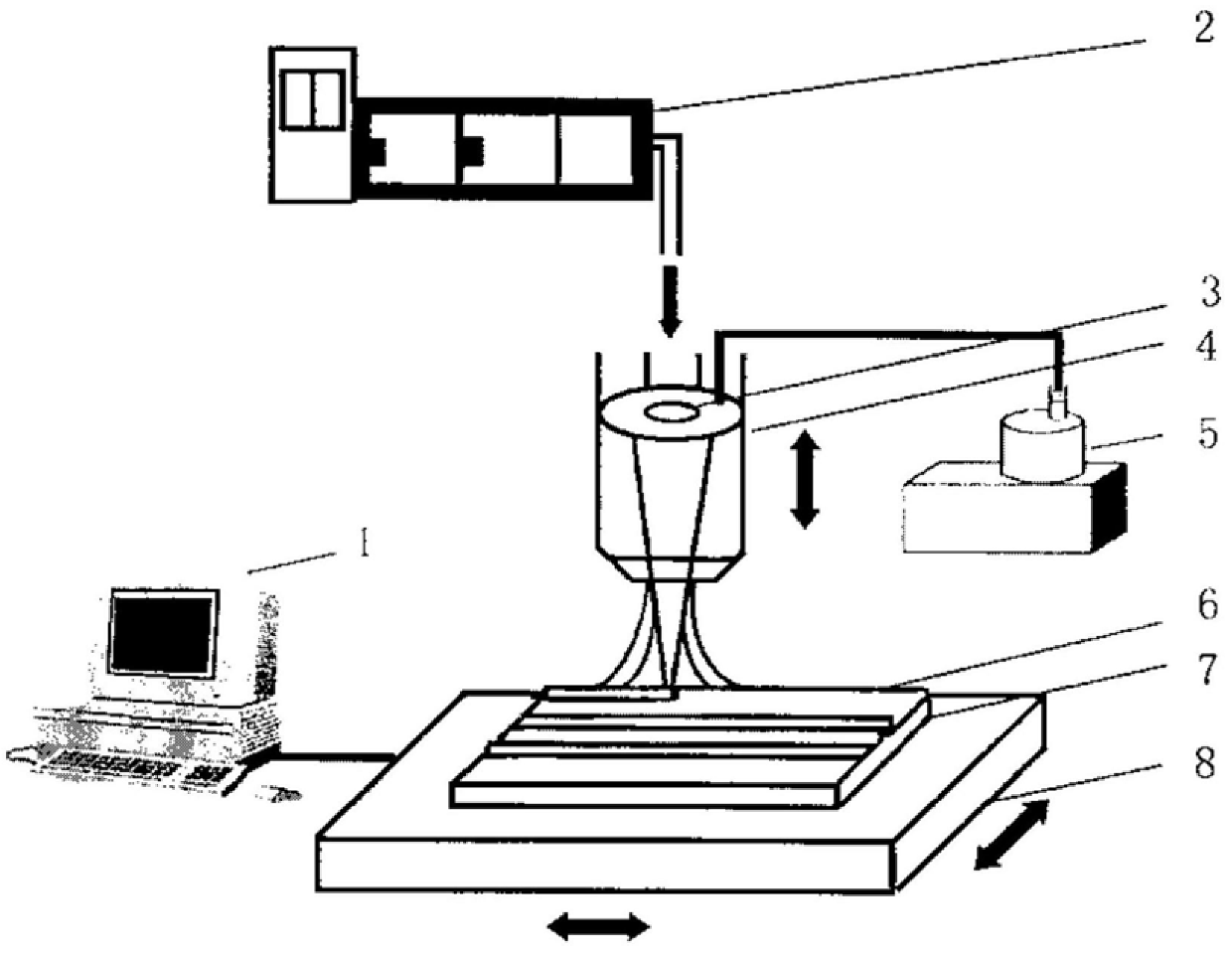

Metal three-dimensional printing method and equipment thereof

ActiveCN105880598AHigh strengthImprove the bonding force between layersAdditive manufacturing apparatusMolten casting coatingElectrical resistance and conductanceUltimate tensile strength

The invention discloses a metal three-dimensional printing method and equipment thereof. The metal three-dimensional printing method comprises the following steps that melted and flowable metal or softened and flowable metal is put into a molding area used by three-dimensional printing equipment; after not having the flowability, the melted and flowable metal or the softened and flowable metal is converted into printed and molded metal; the melted and flowable metal or the softened and flowable metal is accumulated based on the printed and molded metal until an object to be printed is molded; the object to be printed is formed by the accumulated printed and molded metal. The key characteristics of the metal three-dimensional printing method disclosed by the invention lie in that during molding, binding force between layers and binding force between pixel points are changed in a manner of resistance radiation, and a printing area for performing resistance radiation can be set; a metal part generated by the metal three-dimensional printing method disclosed by the invention is high in strength, high in density, and high in molding accuracy; molding process of each pixel point is monitored; a dismountable assisting bracket can be synchronously generated; a large-scale part can be printed; the equipment is simple in structure and low in cost. The metal three-dimensional printing method and the equipment thereof disclosed by the invention have a substantive progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

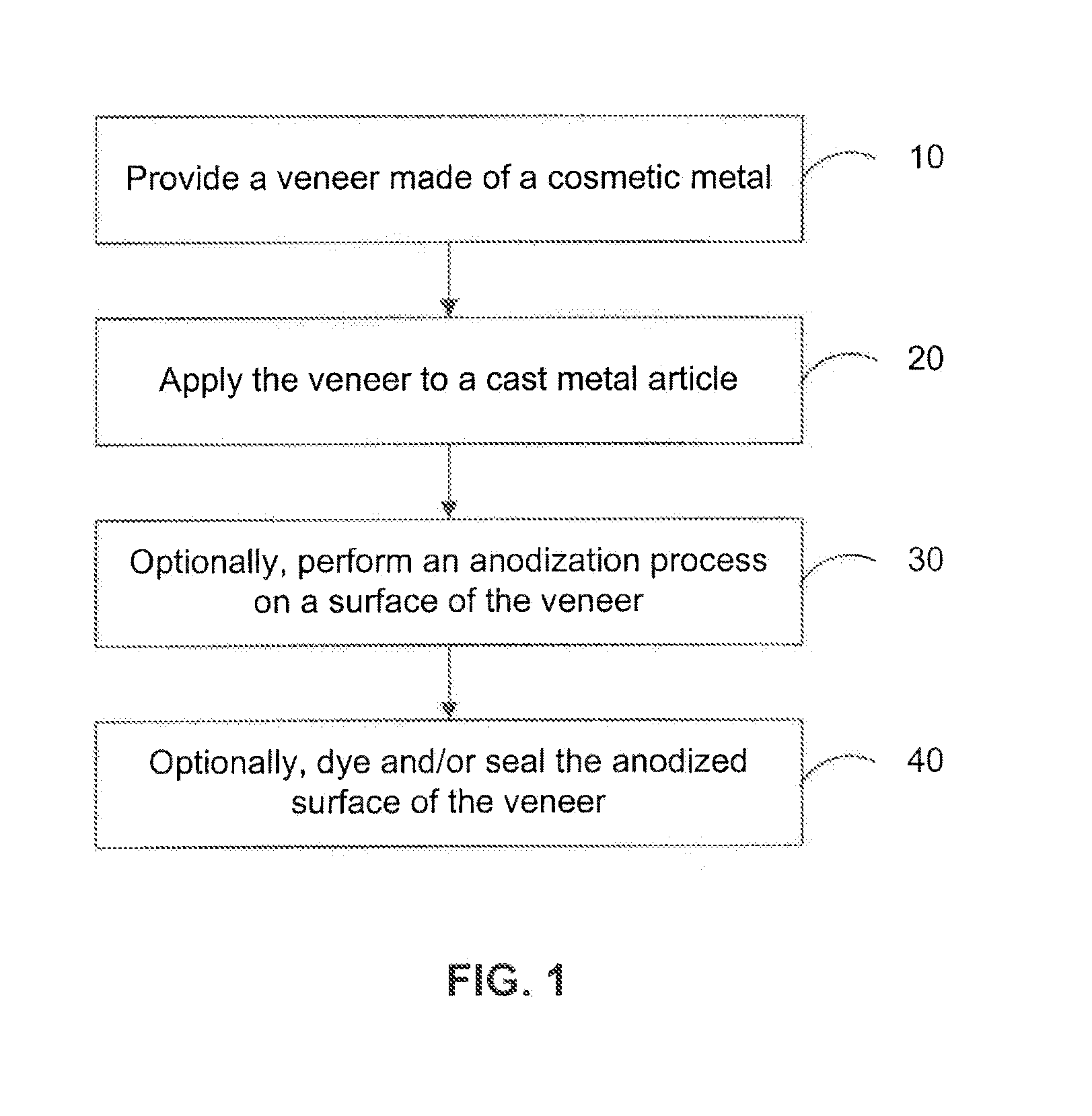

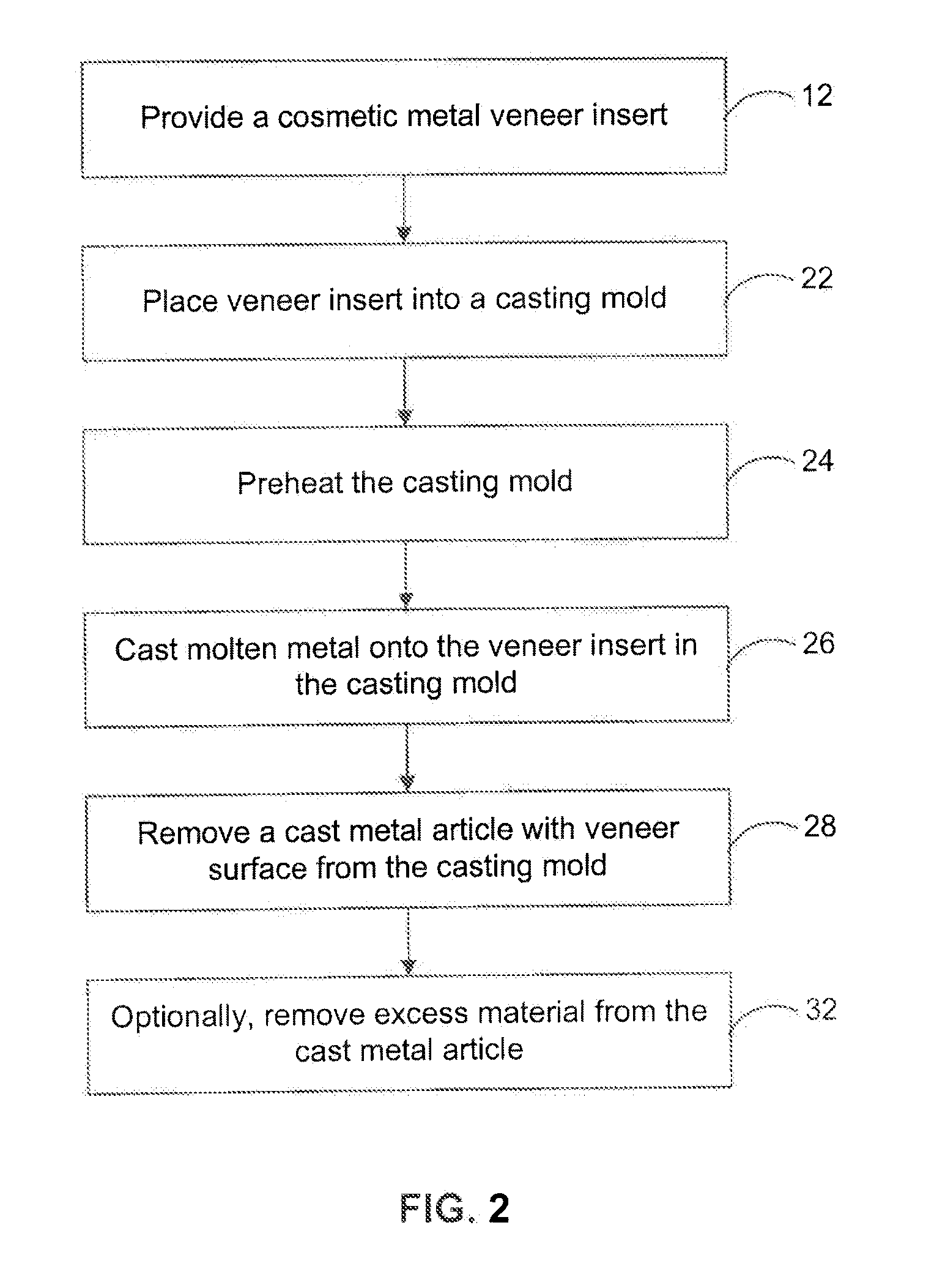

Cast Metal Parts With Cosmetic Surfaces And Methods Of Making Same

InactiveUS20110195271A1Improved and desired functional propertyImprove corrosion resistanceCooking-vessel materialsExhaust apparatusDie castingCasting mold

A cast metal part has a veneer made of cosmetic metal applied thereto so that the cast metal part has a cosmetic surface. A method for producing a cast metal part with a cosmetic surface comprises applying a veneer of cosmetic metal to a surface of the cast metal part. The cast metal part can be a die cast part, such as die cast aluminum or zinc. The veneer can be thin gauge highly cosmetic aluminum. The veneer of cosmetic metal can be applied to the surface of the cast metal part by placing the veneer into a casting mold used for forming the cast metal part, and casting molten metal onto the veneer in the casting mold. The veneer of cosmetic metal can also be applied to the surface of the cast metal part by solid-state welding, e.g., diffusion bonding, the veneer and the cast metal part together.

Owner:APPLE INC

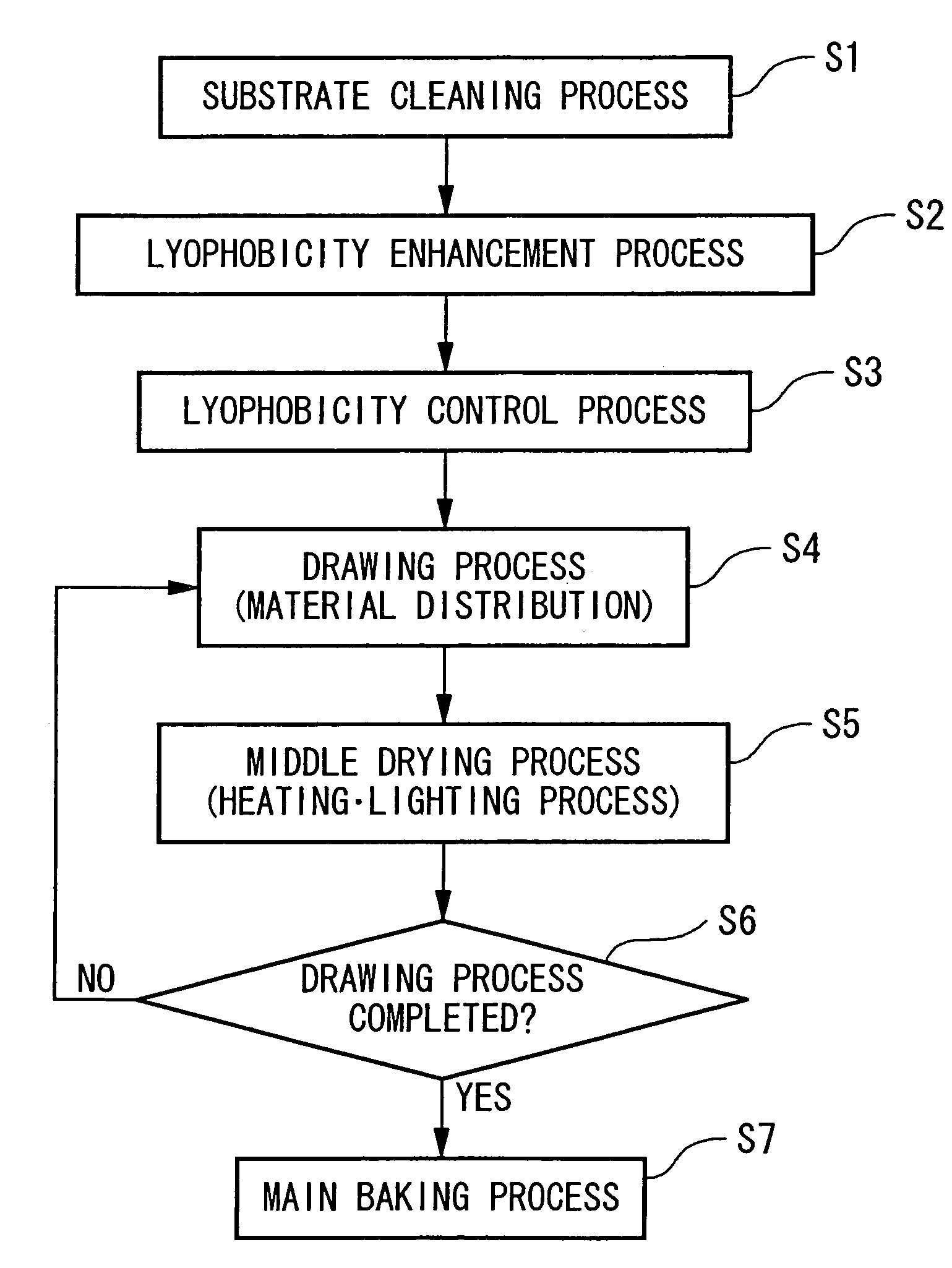

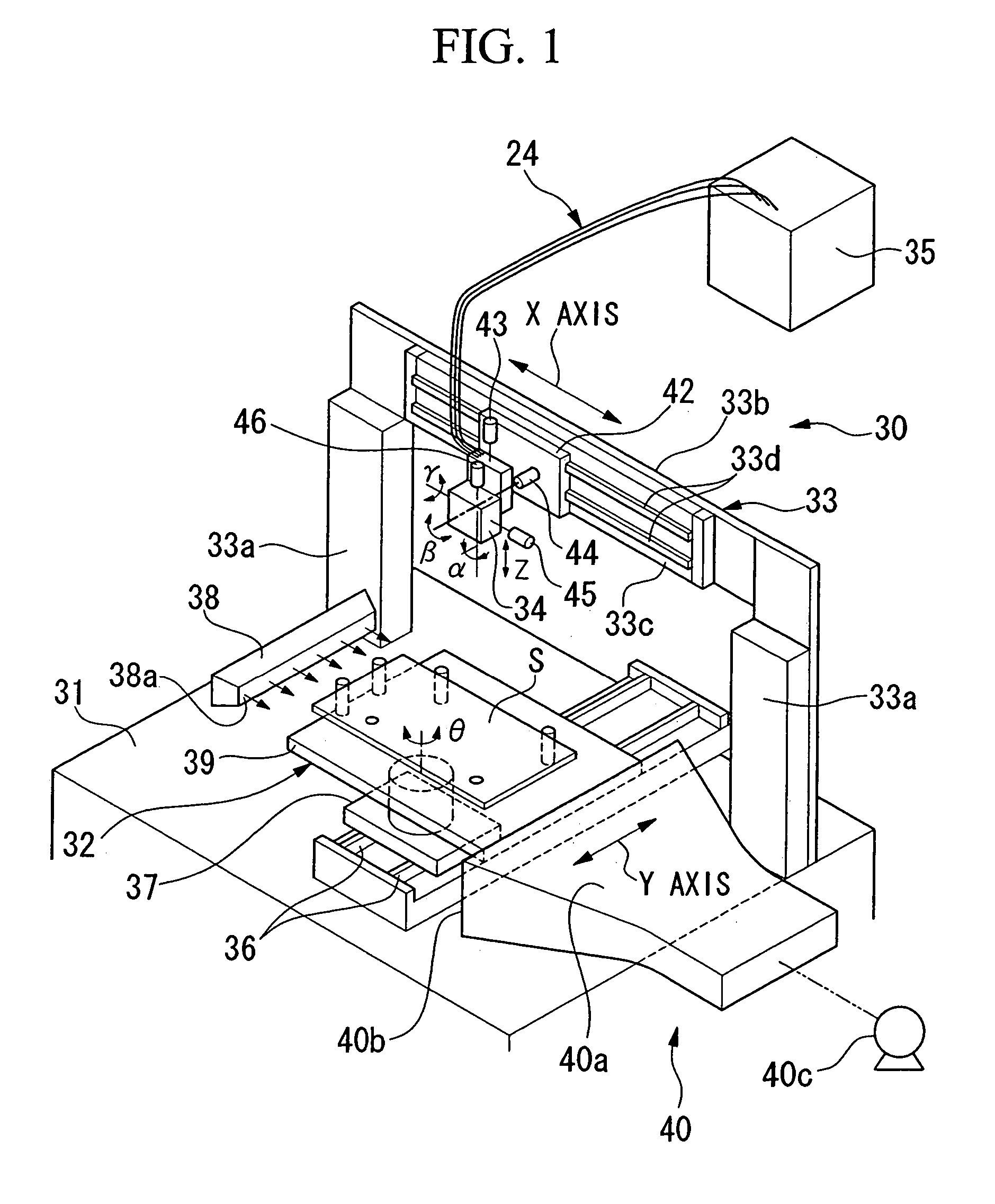

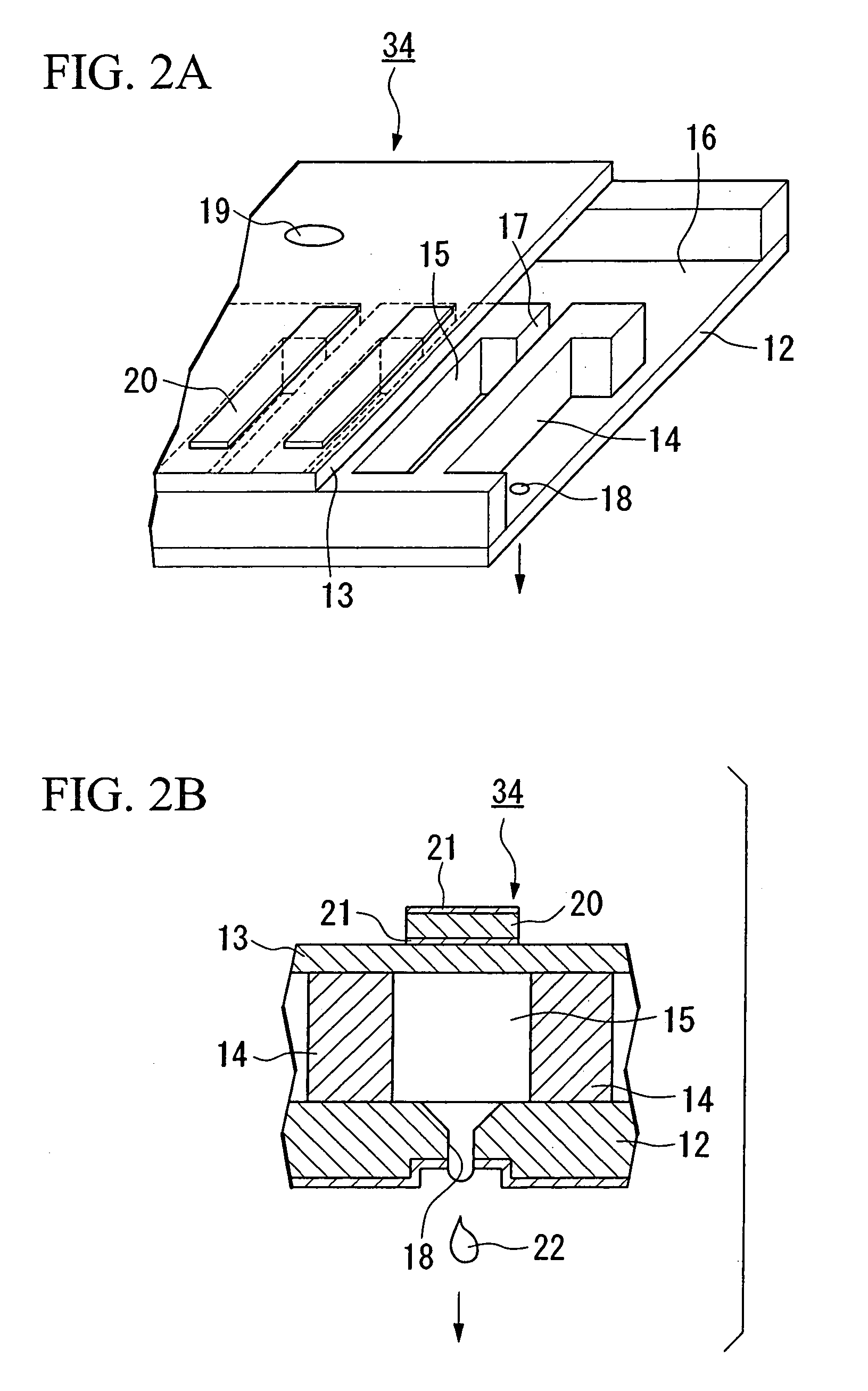

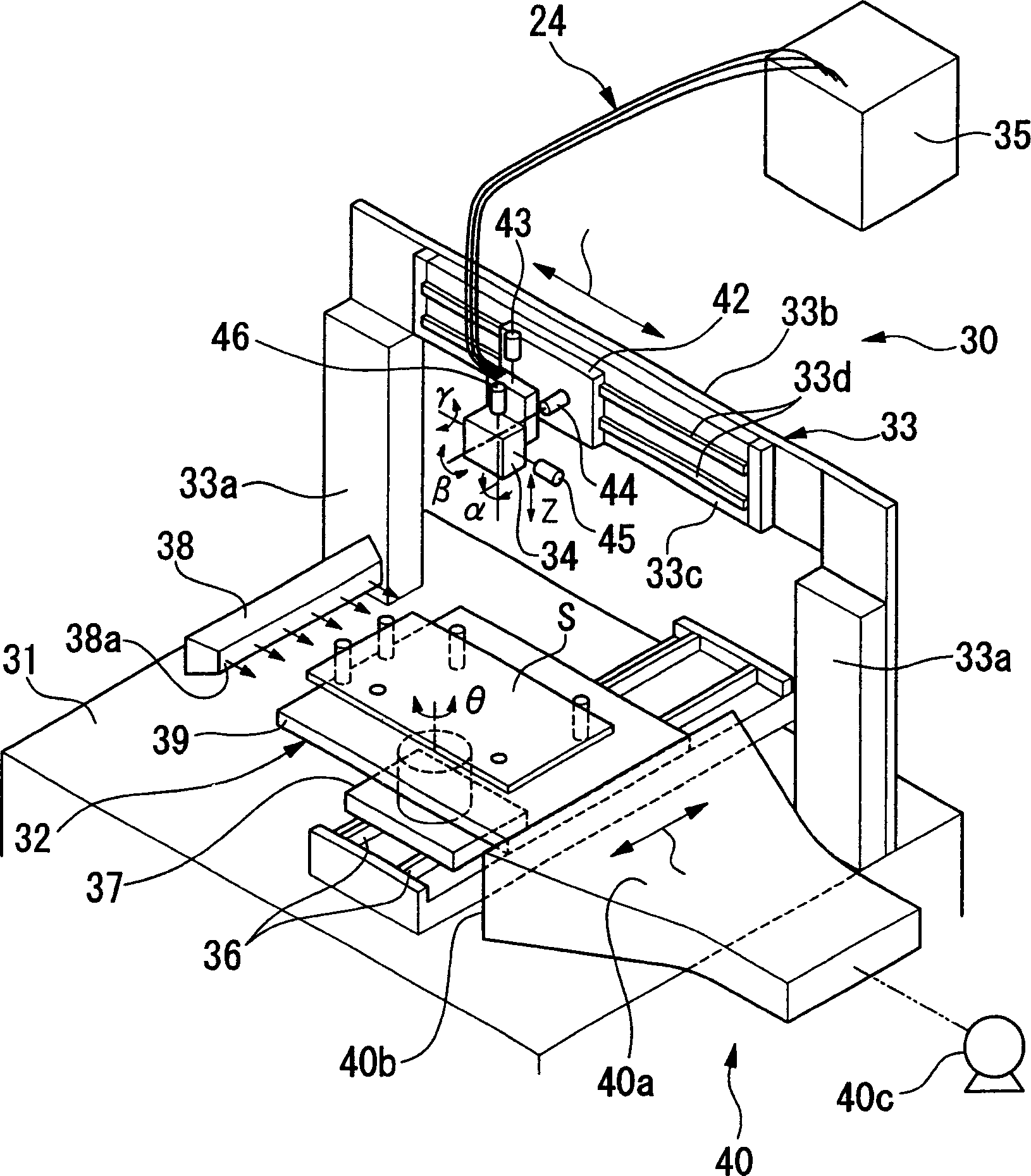

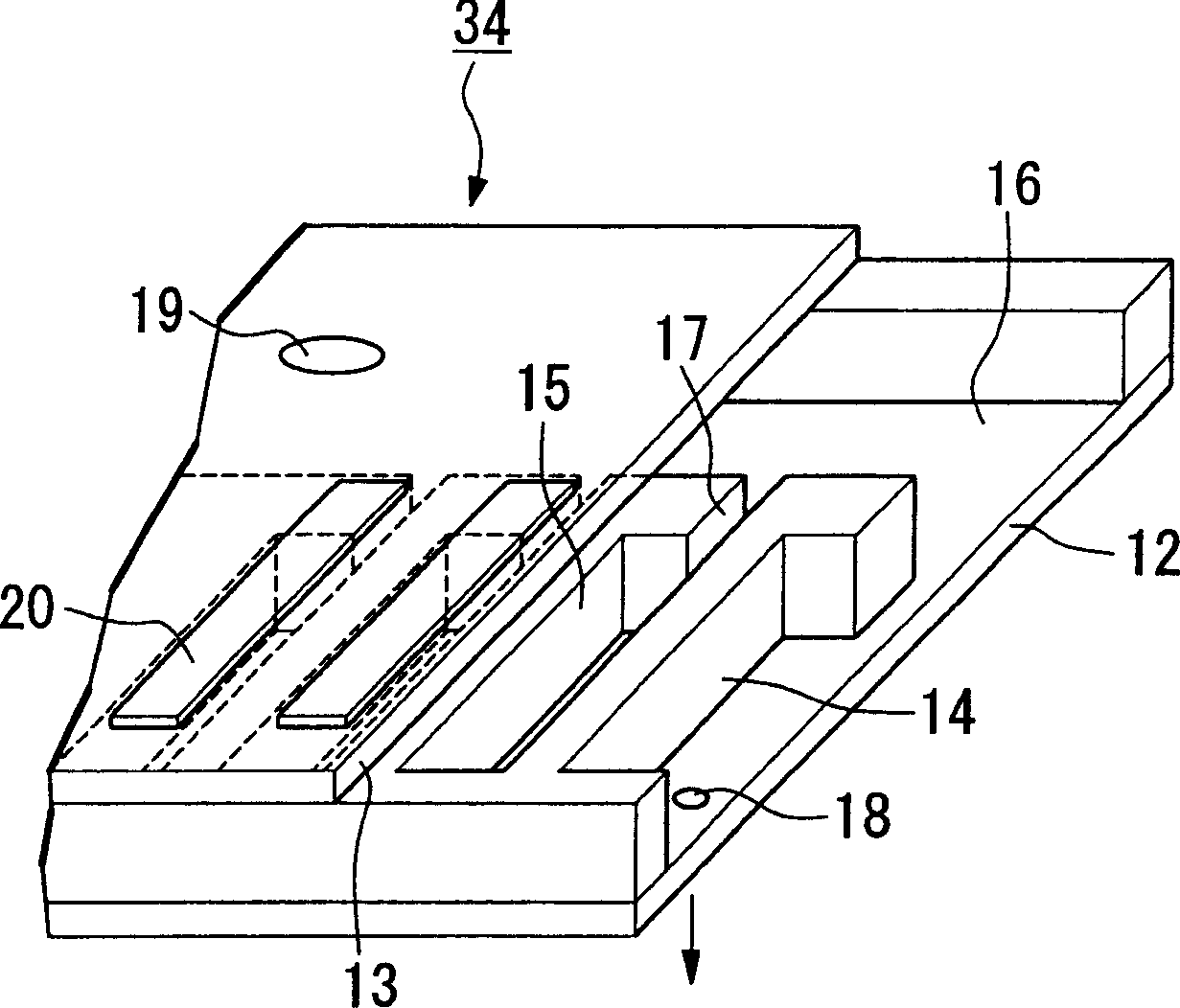

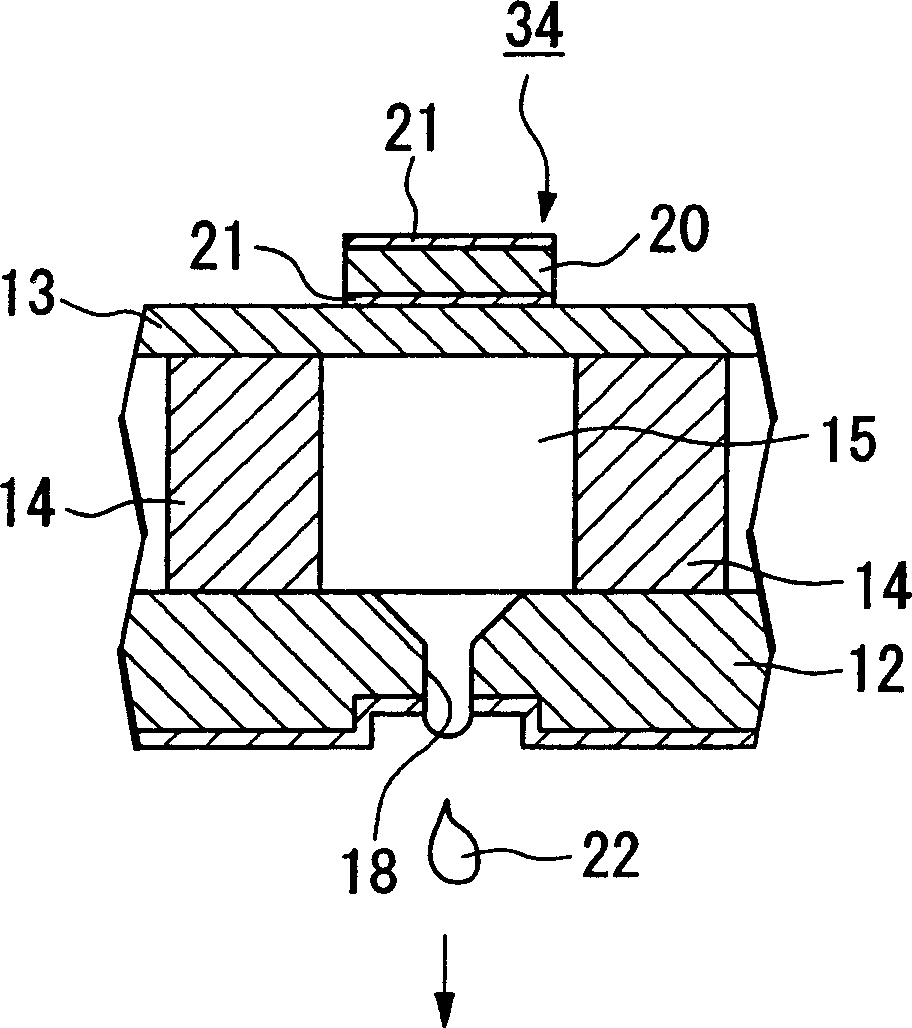

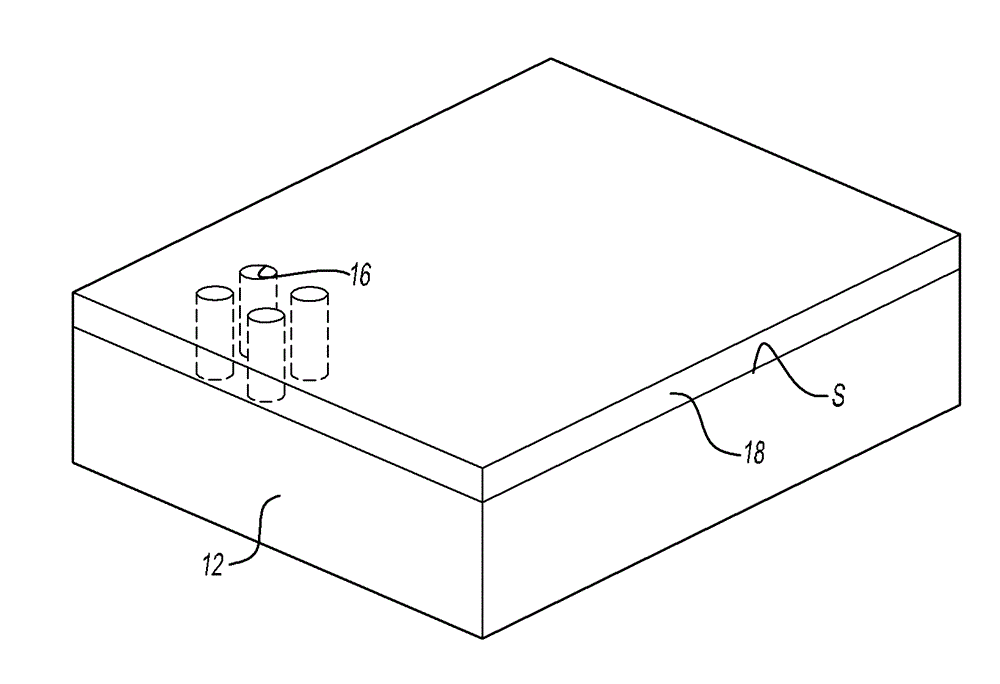

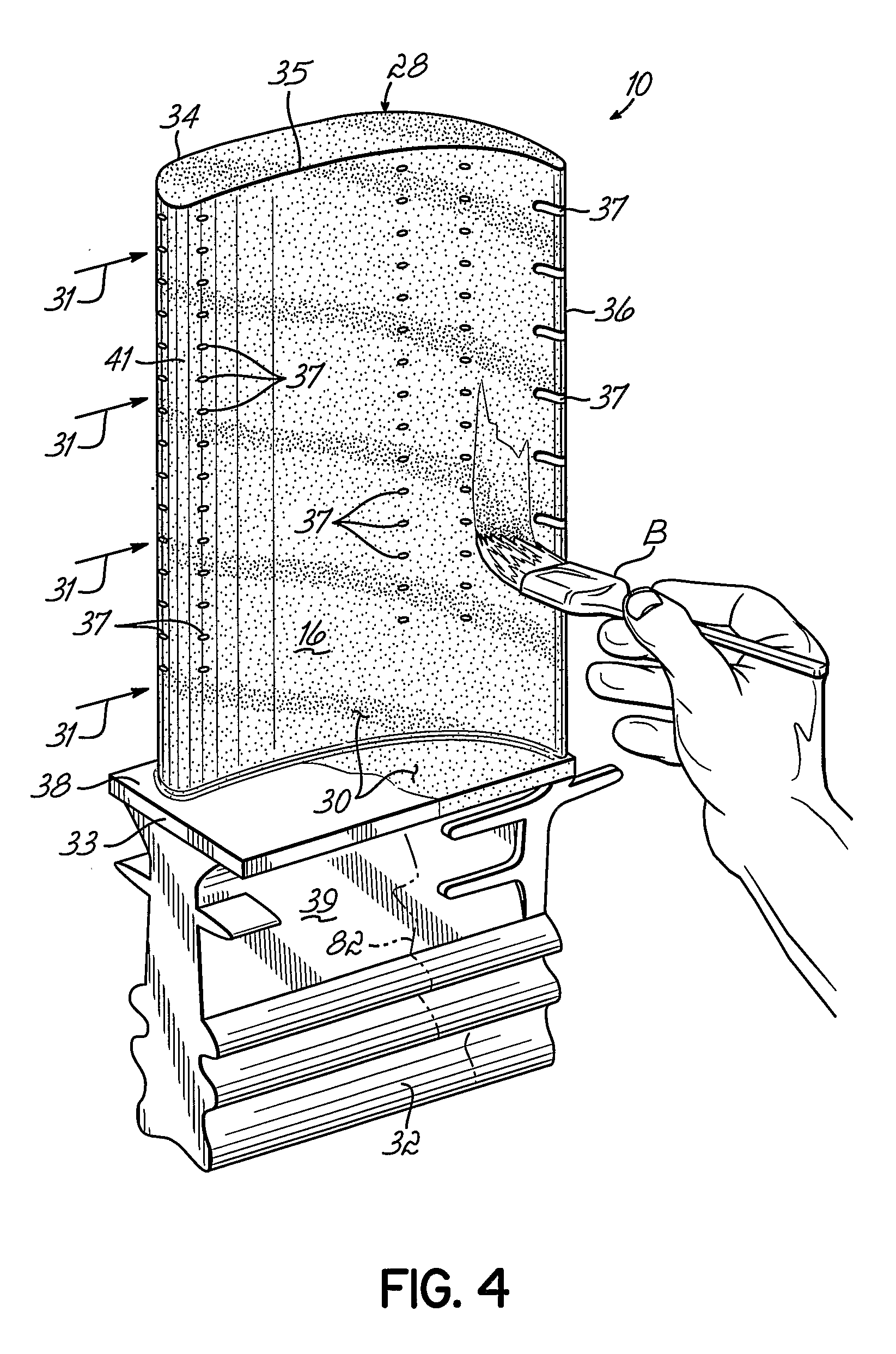

Liquid material discharging method, liquid material discharging apparatus, and electronic device manufactured thereby

ActiveUS7156515B2Easy to chargeImprove reliabilityMelt-holding vesselsMolten spray coatingEngineeringElectron

A discharging apparatus has a substrate holding part 32 which holds a substrate S; an discharging head 34 which discharges a liquid material onto the substrate S; an ion producing device 38 which provides an ionized wind on the substrate S; an exhaust device 40 which is placed on a direction where the ionized wind from the ionized wind producing device 38 is blowing, and the ionized wind is provided toward the liquid material on the substrate S, at least, immediately after discharging the liquid material onto the substrate S.

Owner:KATEEVA

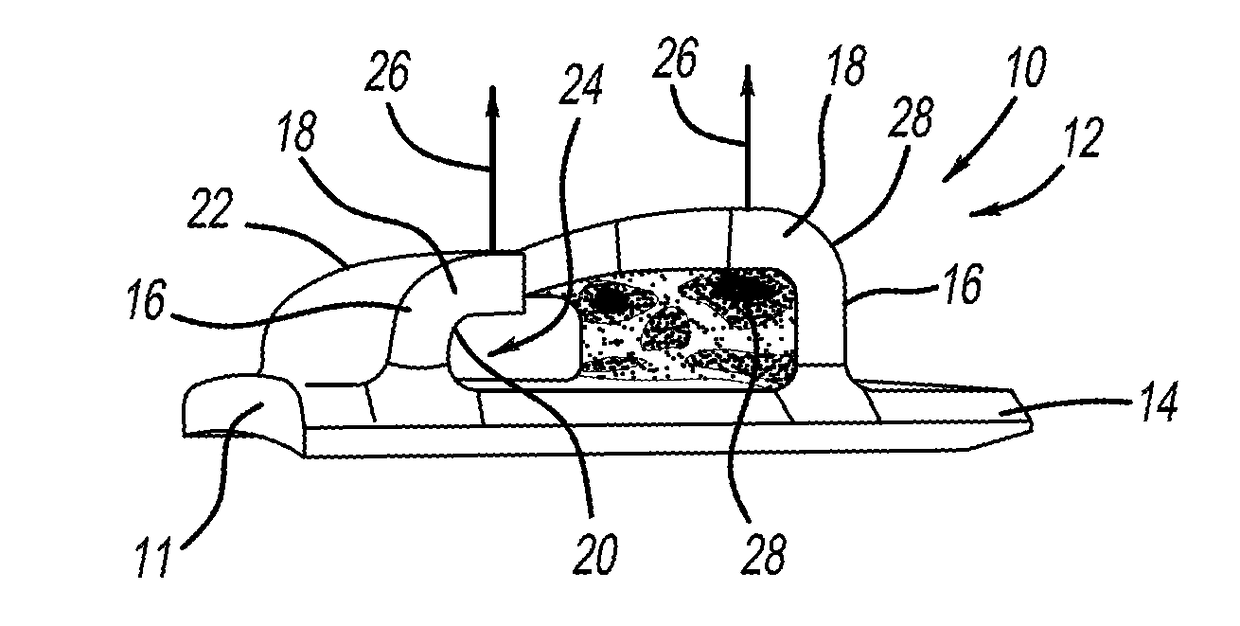

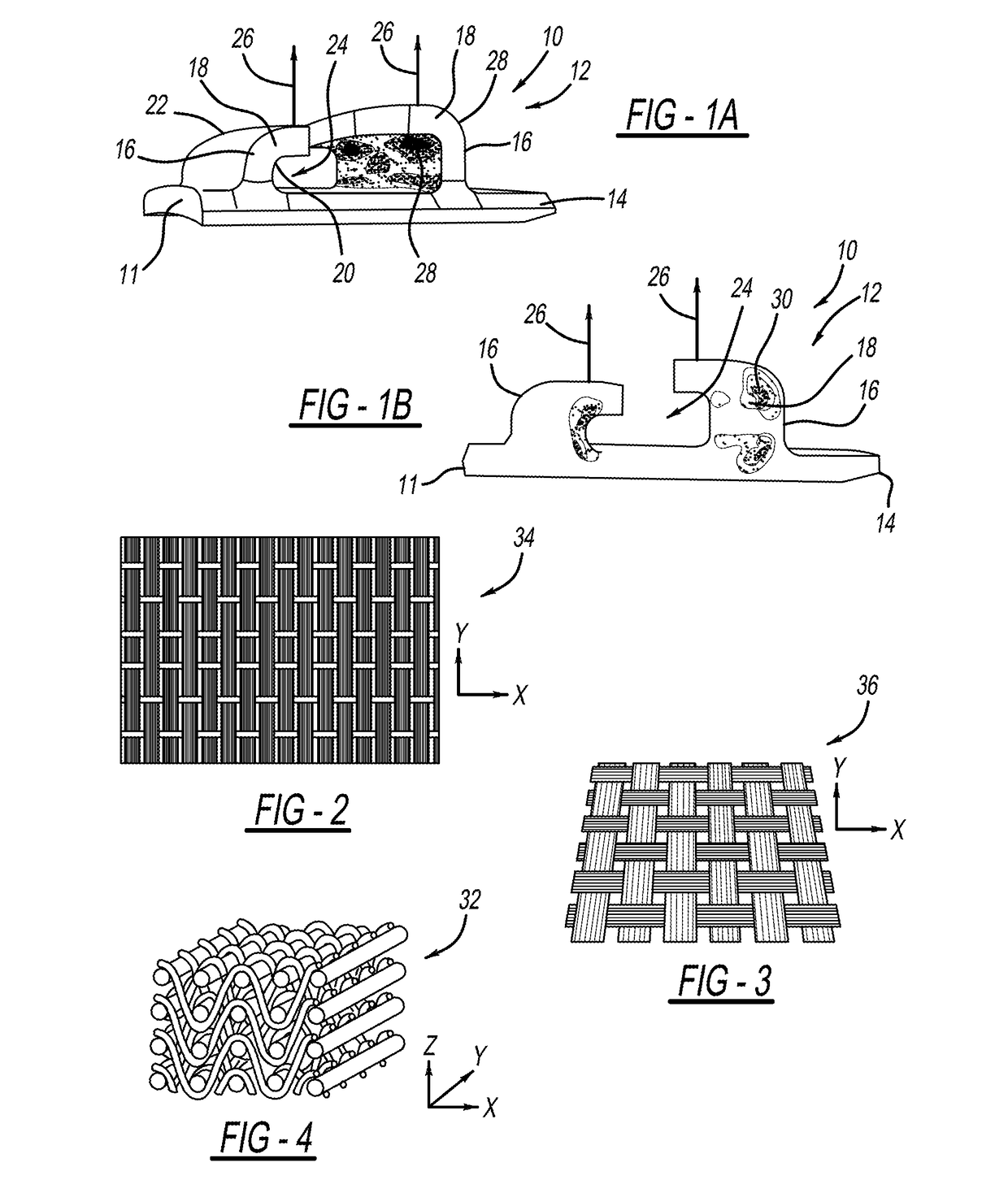

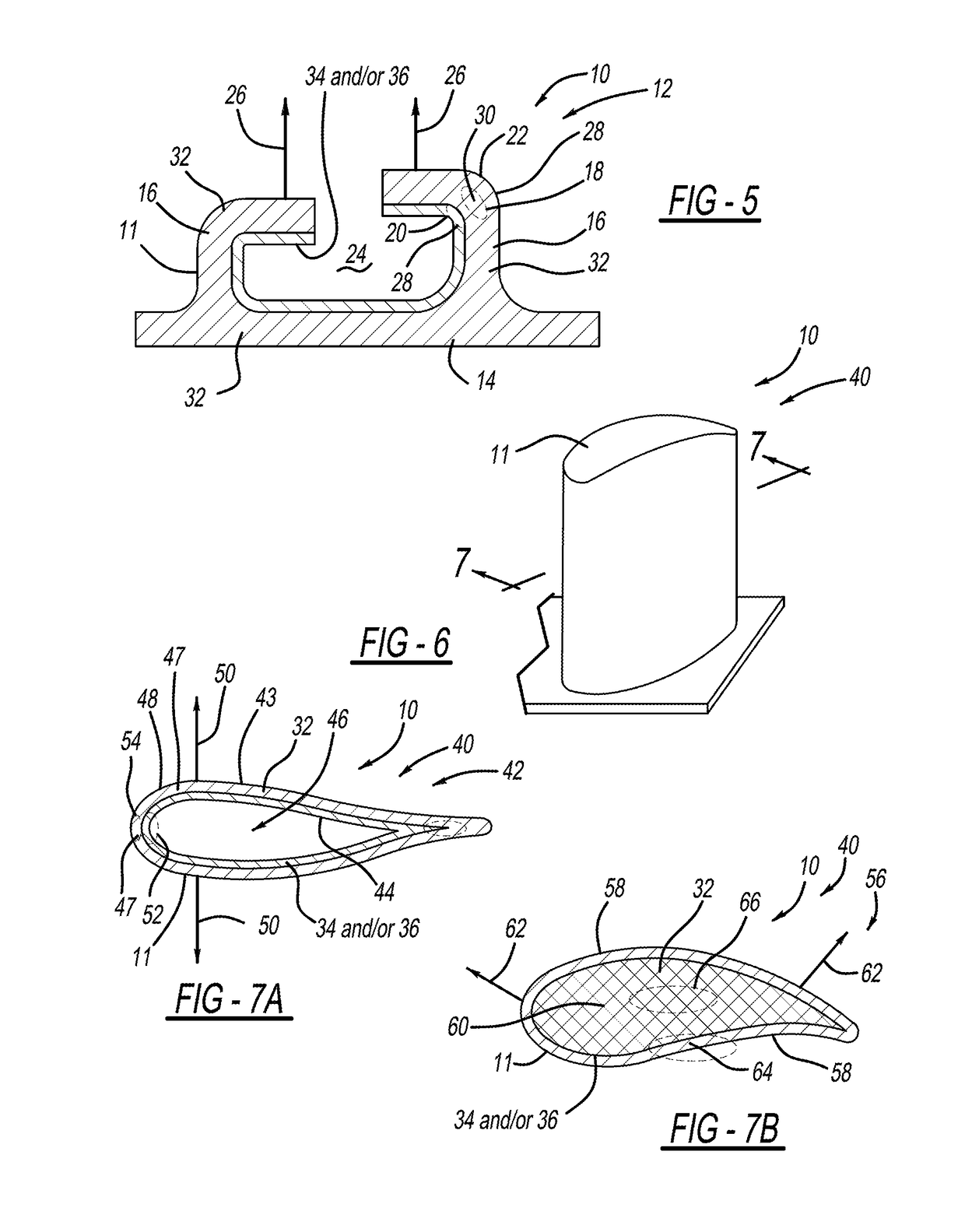

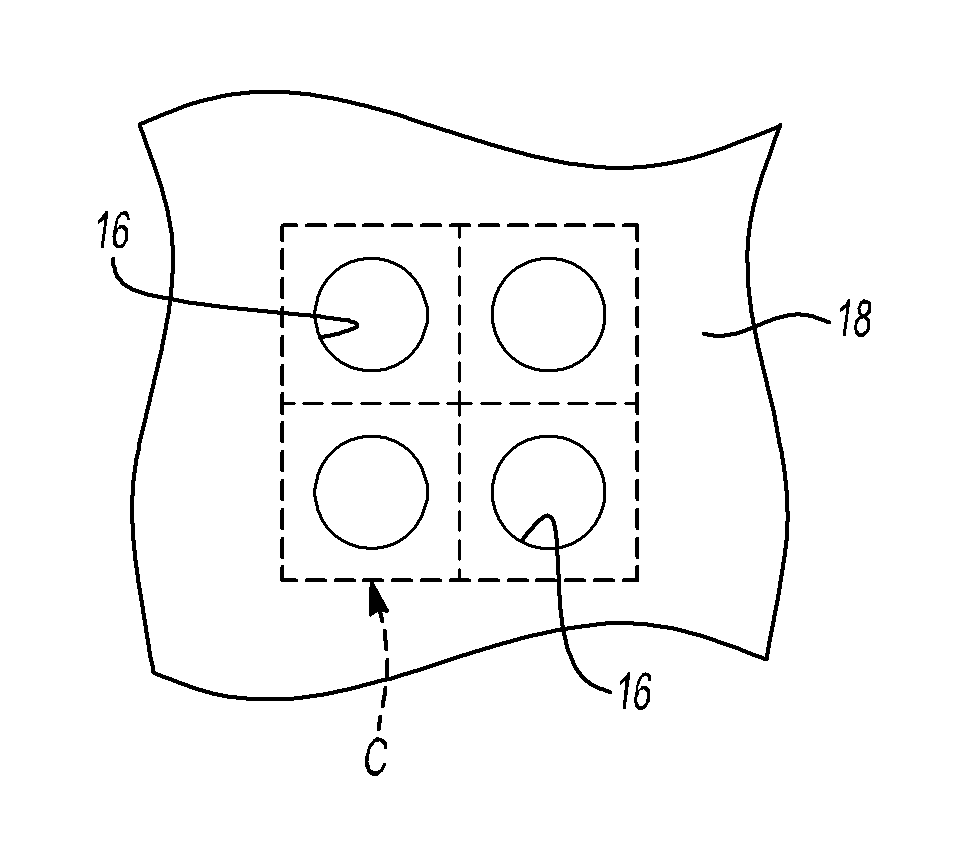

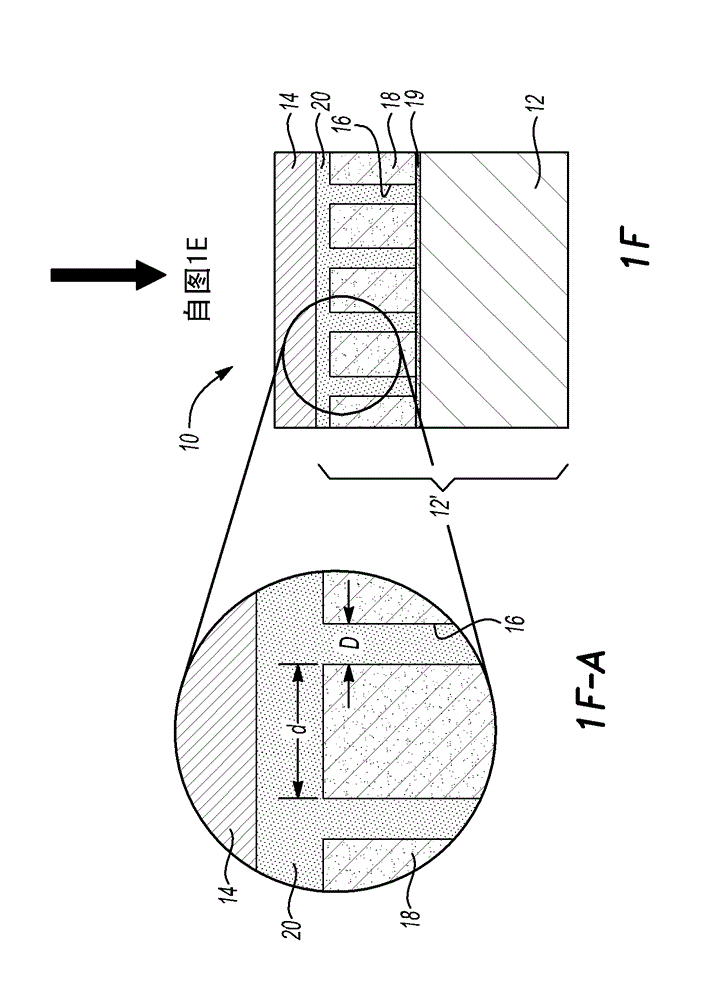

Ceramic matrix composite components reinforced for managing multi-axial stresses and methods for fabricating the same

ActiveUS20180251921A1High stress regionIncrease pressureTurbinesContinuous combustion chamberIn planeMetallurgy

Ceramic matrix composite components and methods for fabricating ceramic matrix composite components are provided. In one example, a ceramic matrix composite component includes a ceramic matrix composite body. The ceramic matrix composite body includes a layer-to-layer weave of ceramic fibers and a layer of 1-directional and / or 2-directional (1D / 2D) fabric of ceramic fibers disposed adjacent to the layer-to-layer weave. When stressed, the ceramic matrix composite body forms a relatively high through-thickness stress region and a relatively high in-plane bending stress region. The layer-to-layer weave is disposed through the relatively high through-thickness stress region and the layer of 1D / 2D fabric is disposed through the relatively high in-plane bending stress region.

Owner:ROLLS ROYCE CORP

Highly active liquid melts used to form coatings

ActiveUS8070894B2Reduce layeringHot-dipping/immersion processesLiquid surface applicatorsProtective oxideUltimate tensile strength

An alloy suitable for coating metal surfaces is provided in which the alloy provides a liquid melt which contains a fraction of dissolved oxide forming additives as deoxidizers. The alloyed combination of elements in the liquid melt resists compound formation thus preserving the chemical activity of the individual elements. In a coating application, the alloy may form a coating that can interact with and remove the oxide or residual oxide coating of the base metal to be coated, i.e., scrub the surface of the metal clean. This results in increased coating bond strength and the ability to bond effectively to normally difficult alloys such as stainless steel, refractory metals (W, Ti, Ta etc.), or aluminum alloys which form protective oxide layers.

Owner:THE NANO CO INC +1

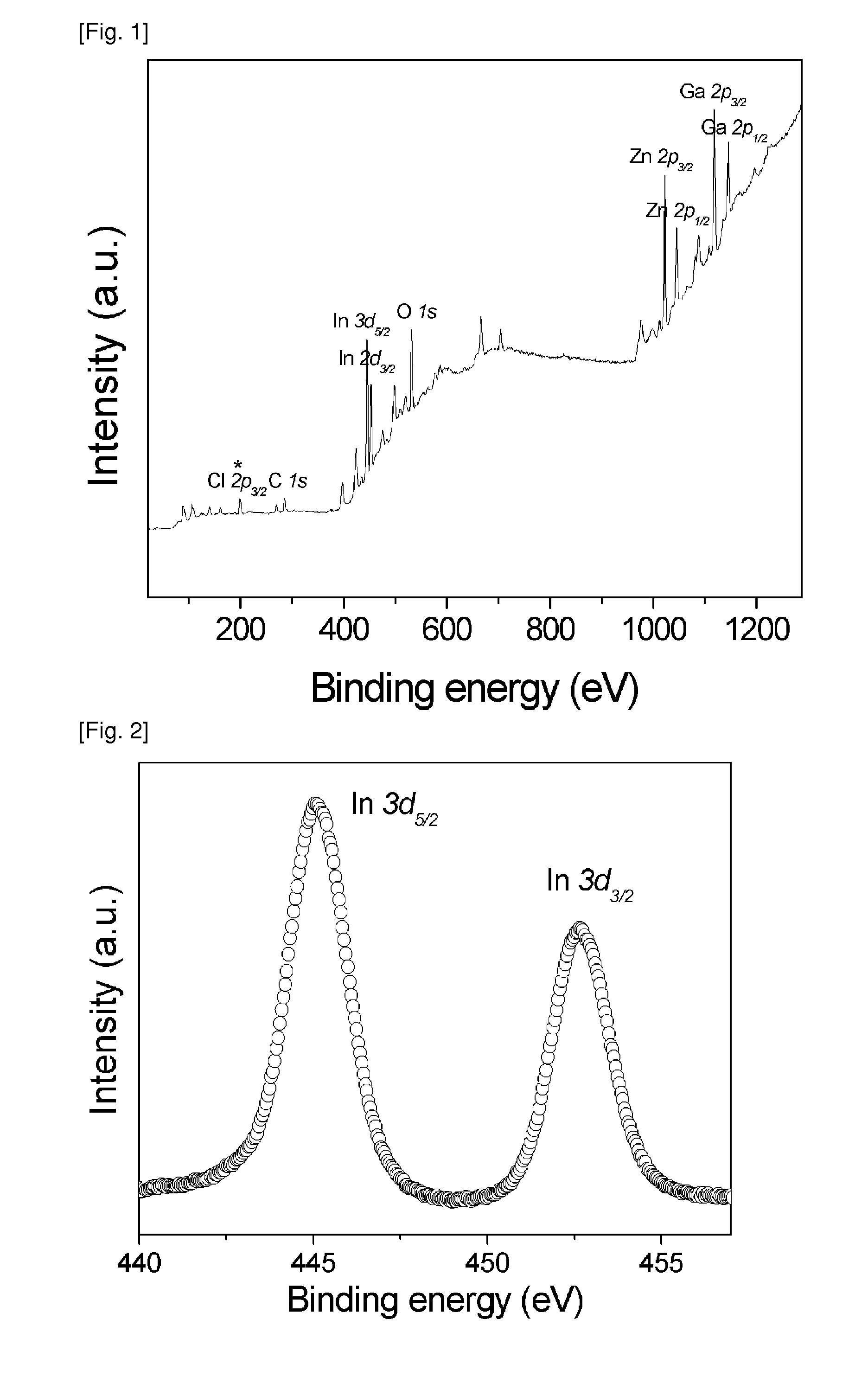

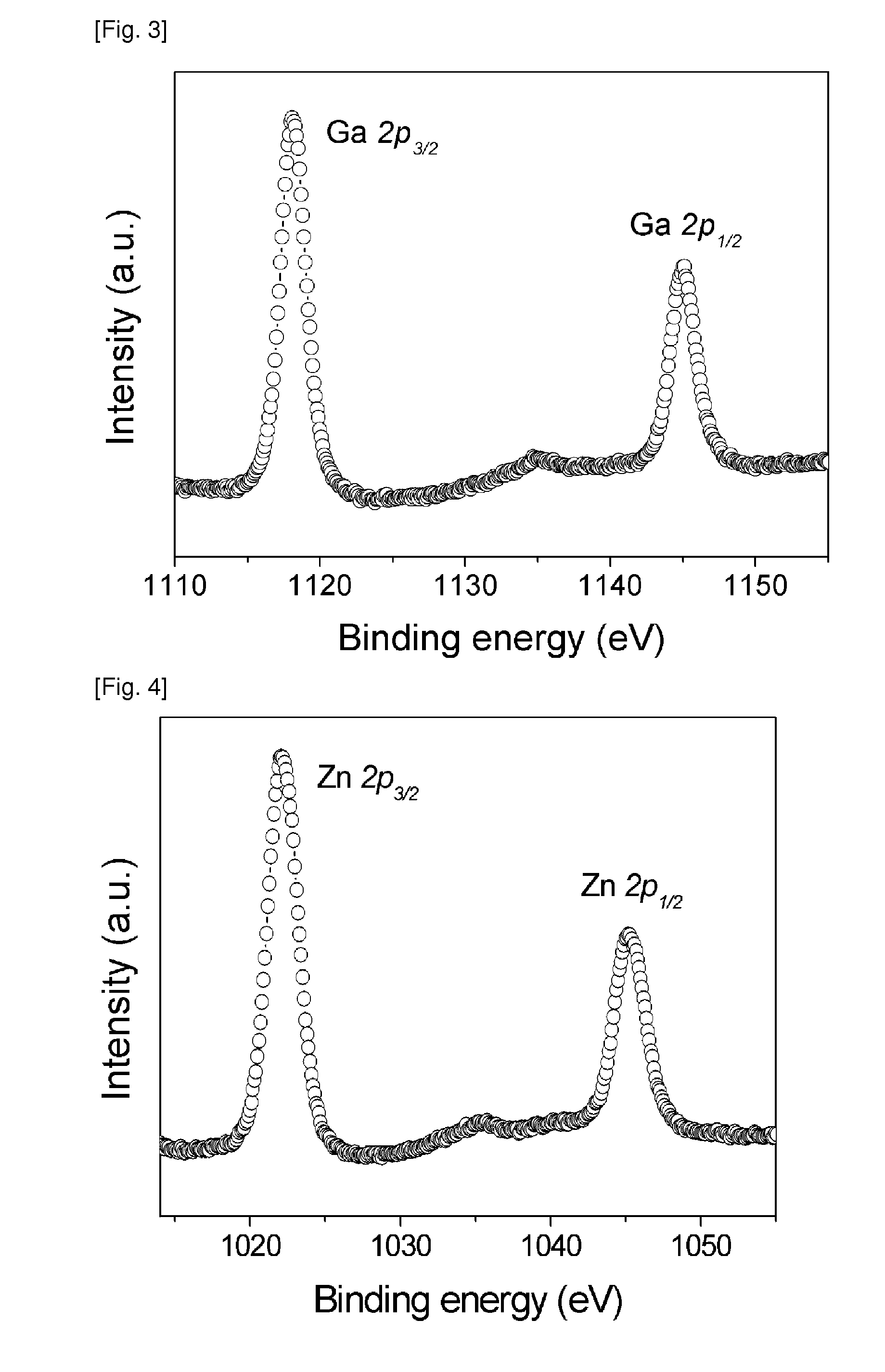

Method of fabricating liquid for oxide thin film

ActiveUS20100251936A1Simple and low-costSemiconductor/solid-state device manufacturingMolten casting coatingZinc compoundsIndium

A method of fabricating a liquid for an oxide thin film is provided, which includes mixing at least two kinds of dispersoids selected from the group consisting of a Zinc compound, an Indium compound, a Gallium compound, a Tin compound and a Thallium compound, with dispersion media corresponding to the selected dispersoids to form a dispersion system, and stirring and aging the dispersion system at a predetermined temperature for a predetermined time, wherein a molar ratio of the Zinc compound to each of the Indium compound, Gallium compound, Tin compound and Thallium compound is 1:0.1 to 1:2. According to the present invention, the liquid for the oxide thin film may be fabricated by a sol-gel method making it capable of being implemented in mass production in a simple and low-cost manner as opposed to the conventional vacuum deposition method.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

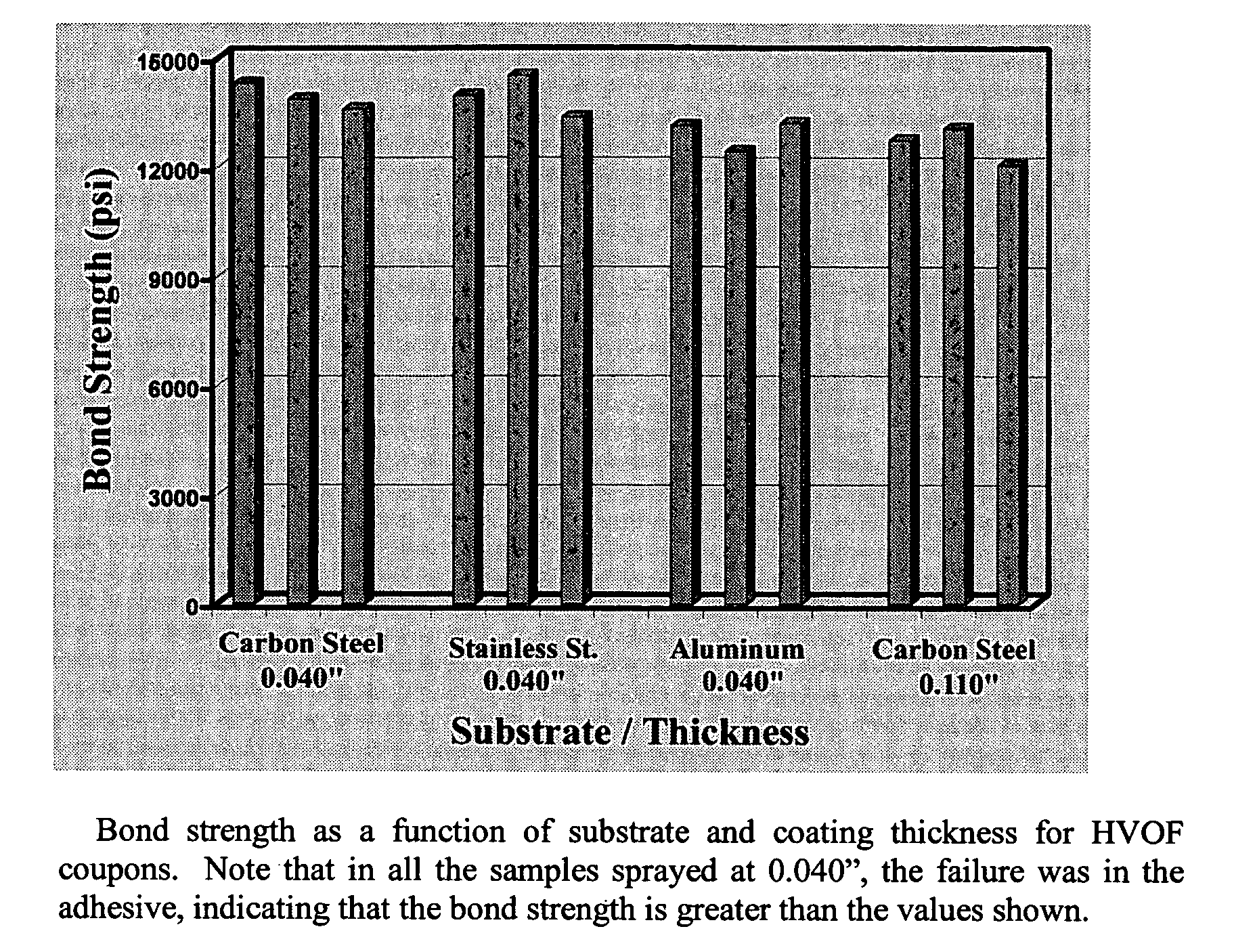

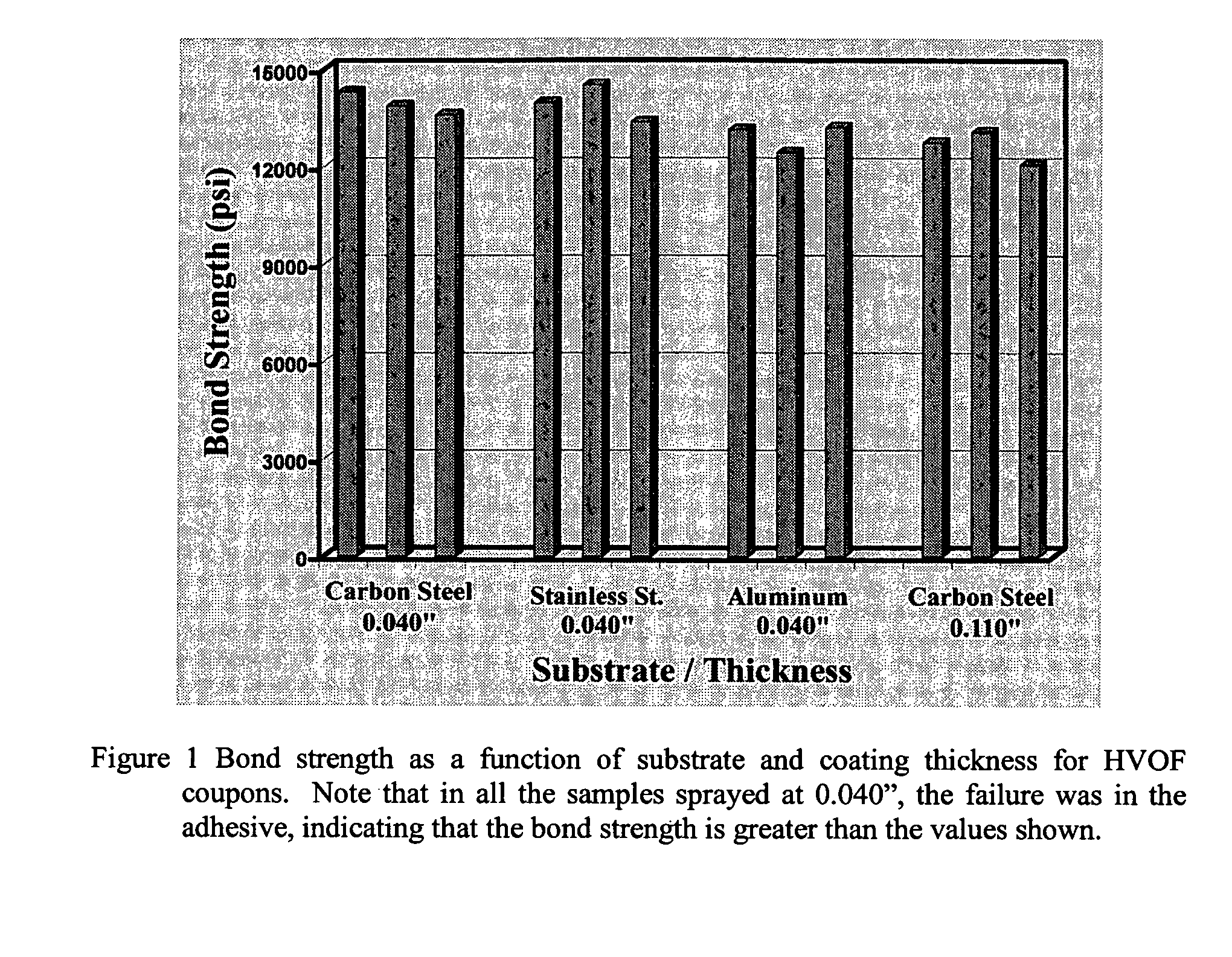

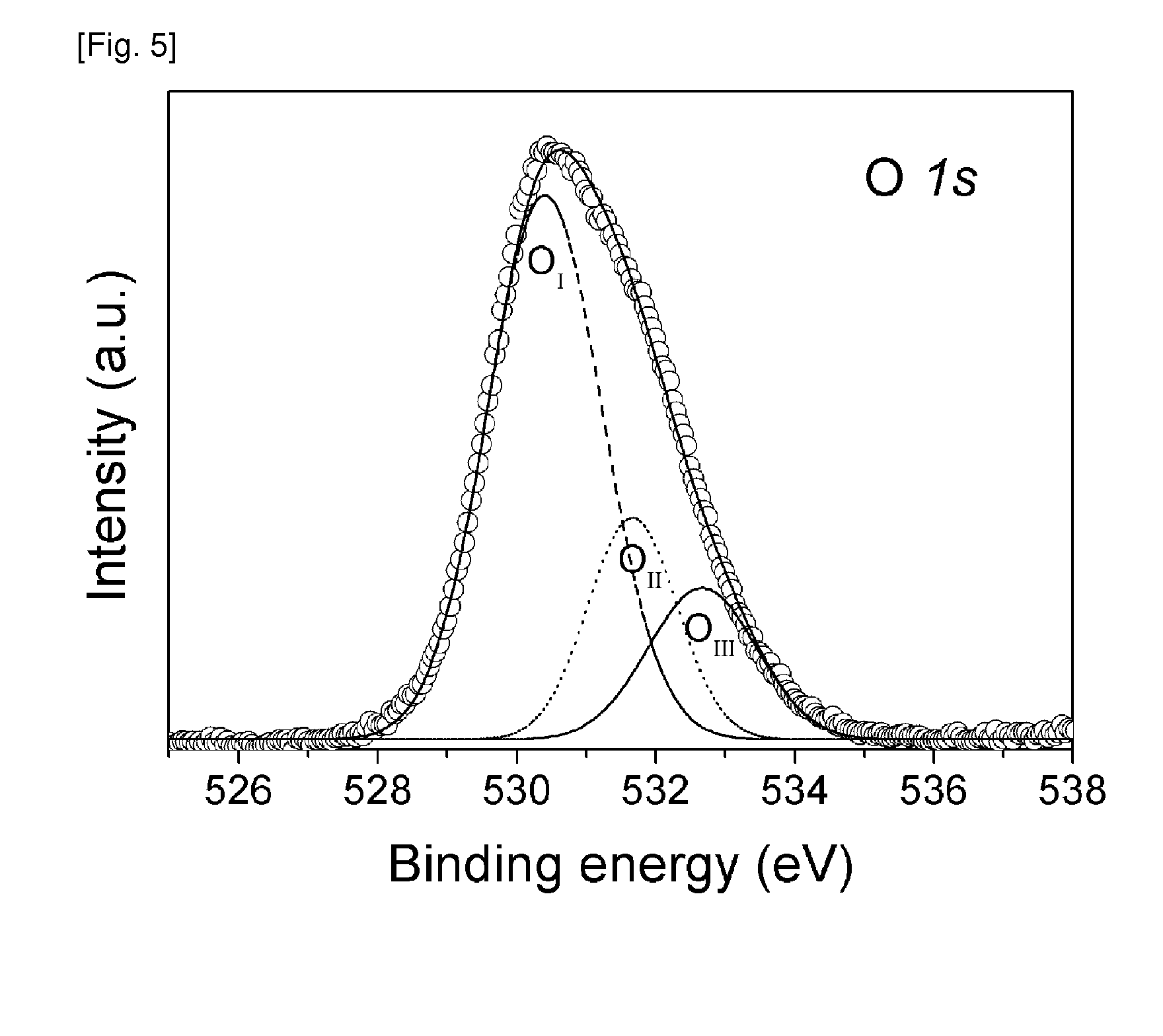

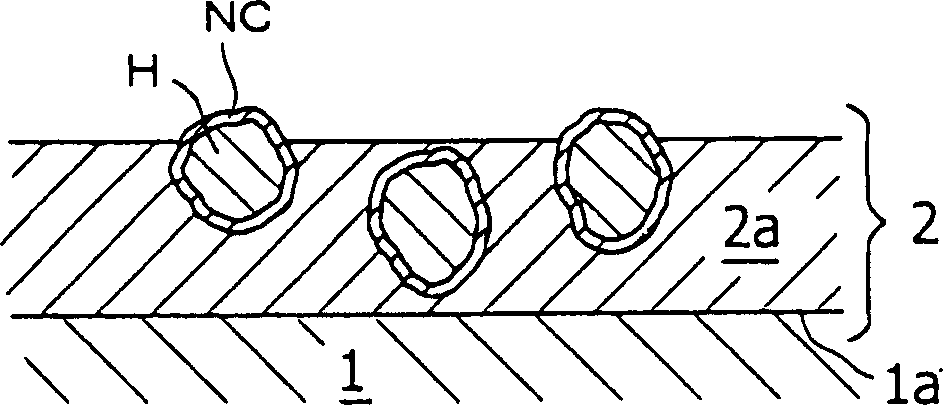

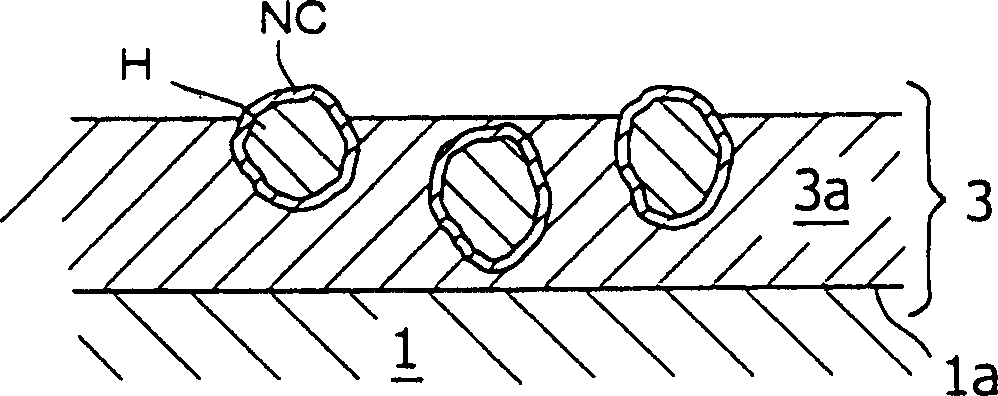

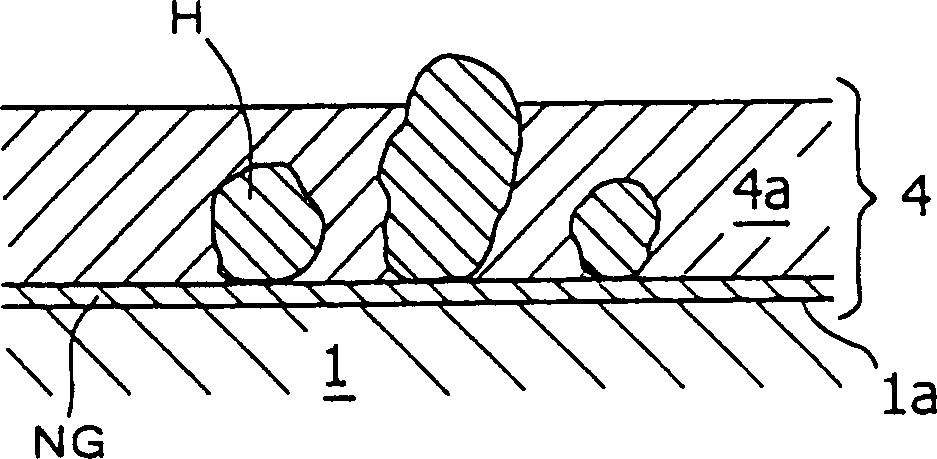

Wear-resistant coating and method fr applying it

InactiveCN1457375ALow costImprove antioxidant capacityPump componentsBlade accessoriesBond coatingWear resistant

The present invention provides an abrasion-resistant coating which has high oxidation resistance and durability and can be applied easily at a low cost. The abrasion-resistant coating in accordance with the present invention is formed at the tip end of a base material forming a gas turbine blade. The abrasion-resistant coating at the tip end has a thickness of 300 microns. On the tip end, hard particles H consisting of CBN are fixed in a bond coating formed by heating, melting, and solidification of a mixture of a brazing filler metal and M-Cr-Al-Y (M designates a metal element such as Co and Ni). The hard particles H are Ni and Co coated to improve wettability relative to the brazing filler metal, and are arranged so that some of them are partially protruded from the surface of bond coating to exhibit the grindability.

Owner:MITSUBISHI HEAVY IND LTD

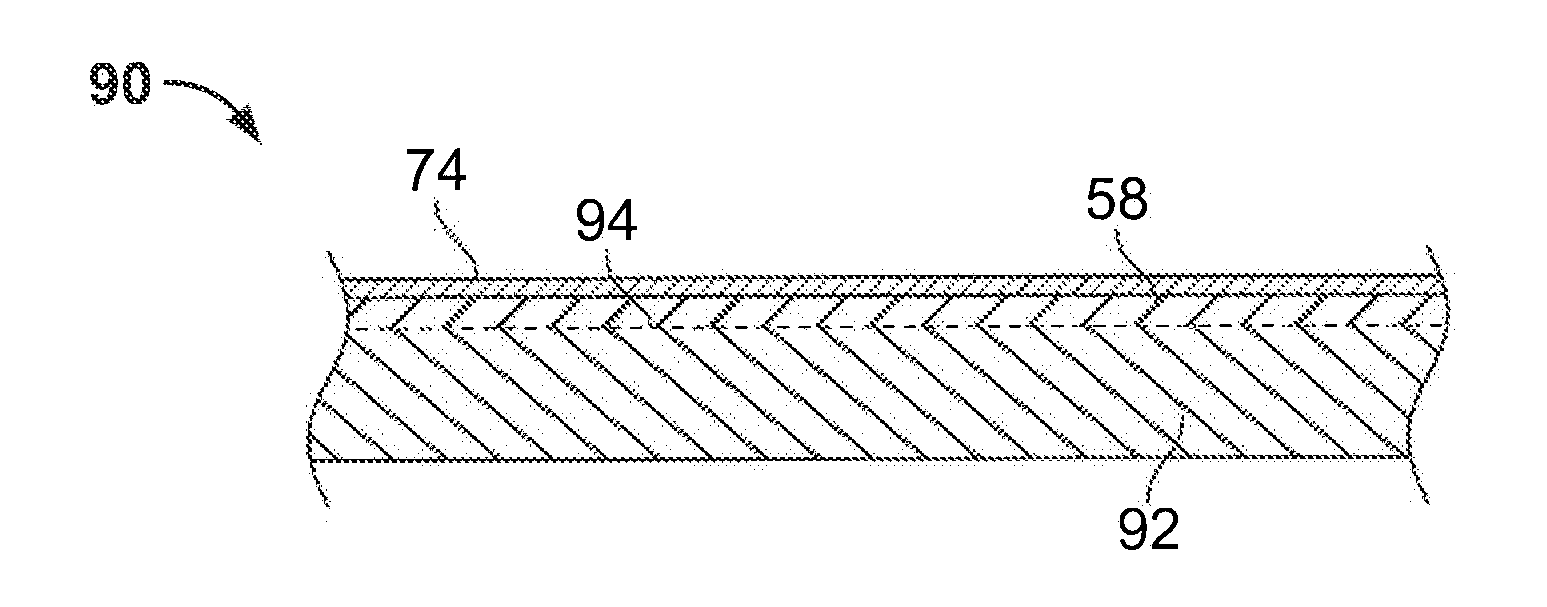

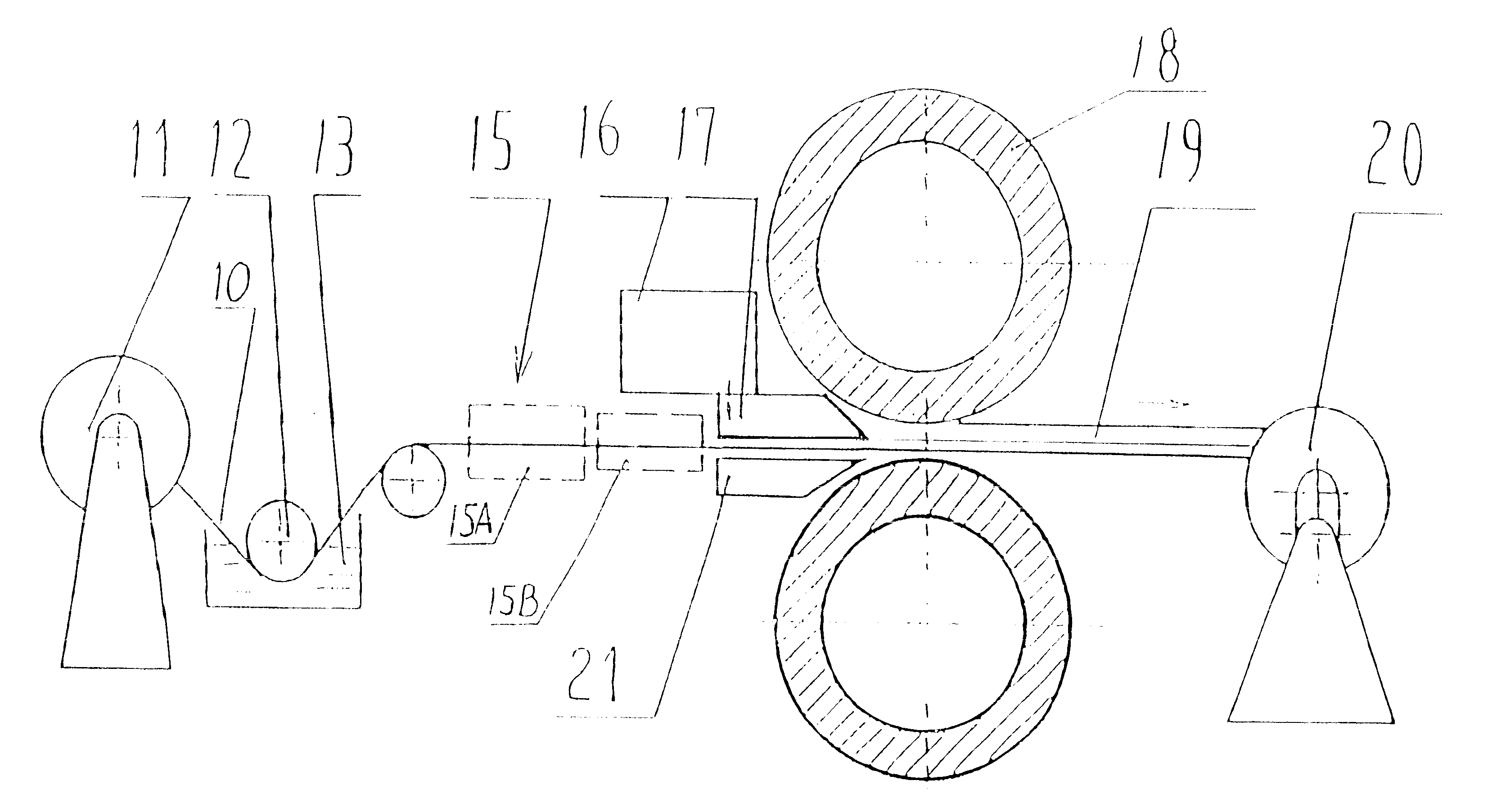

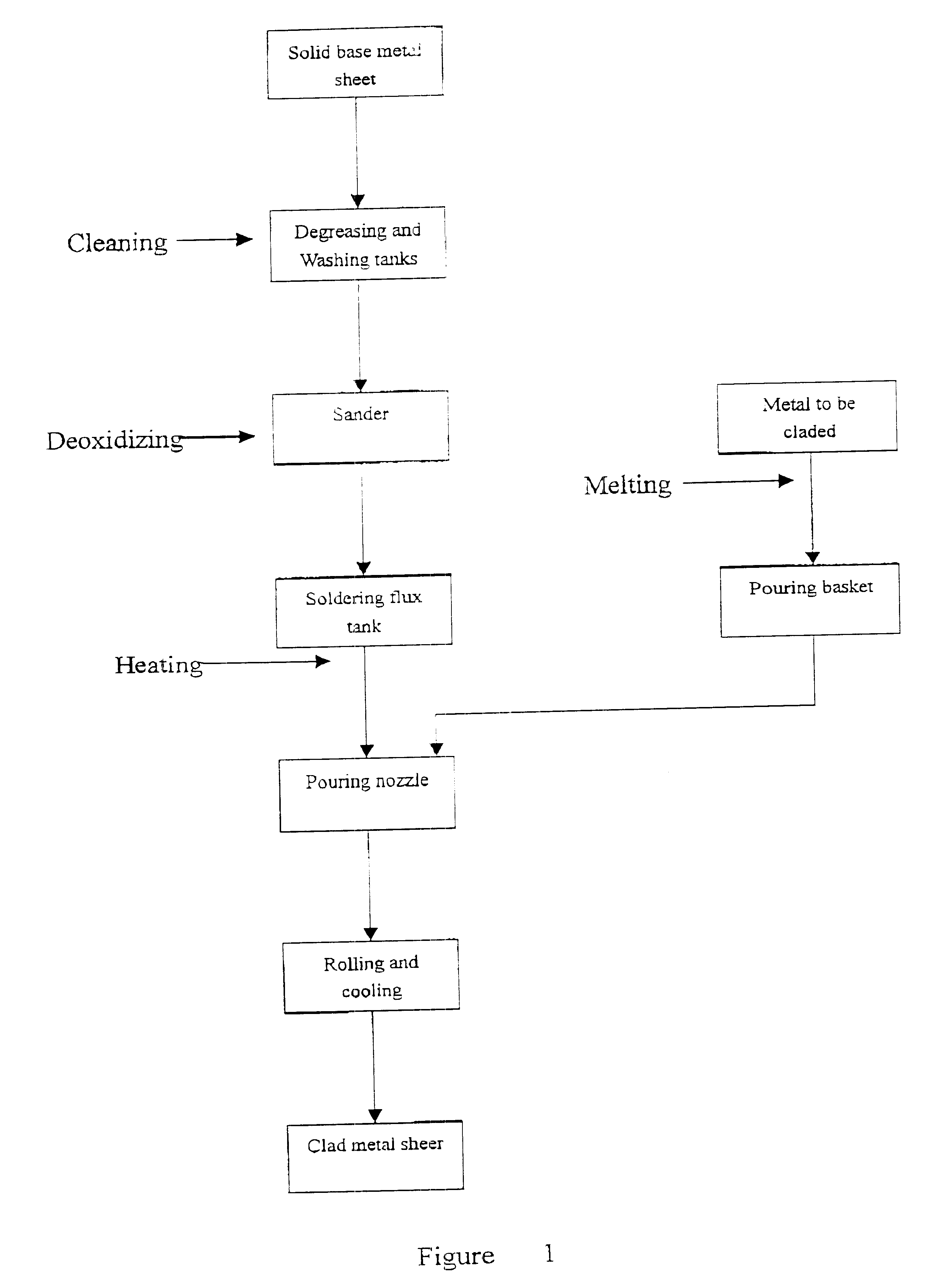

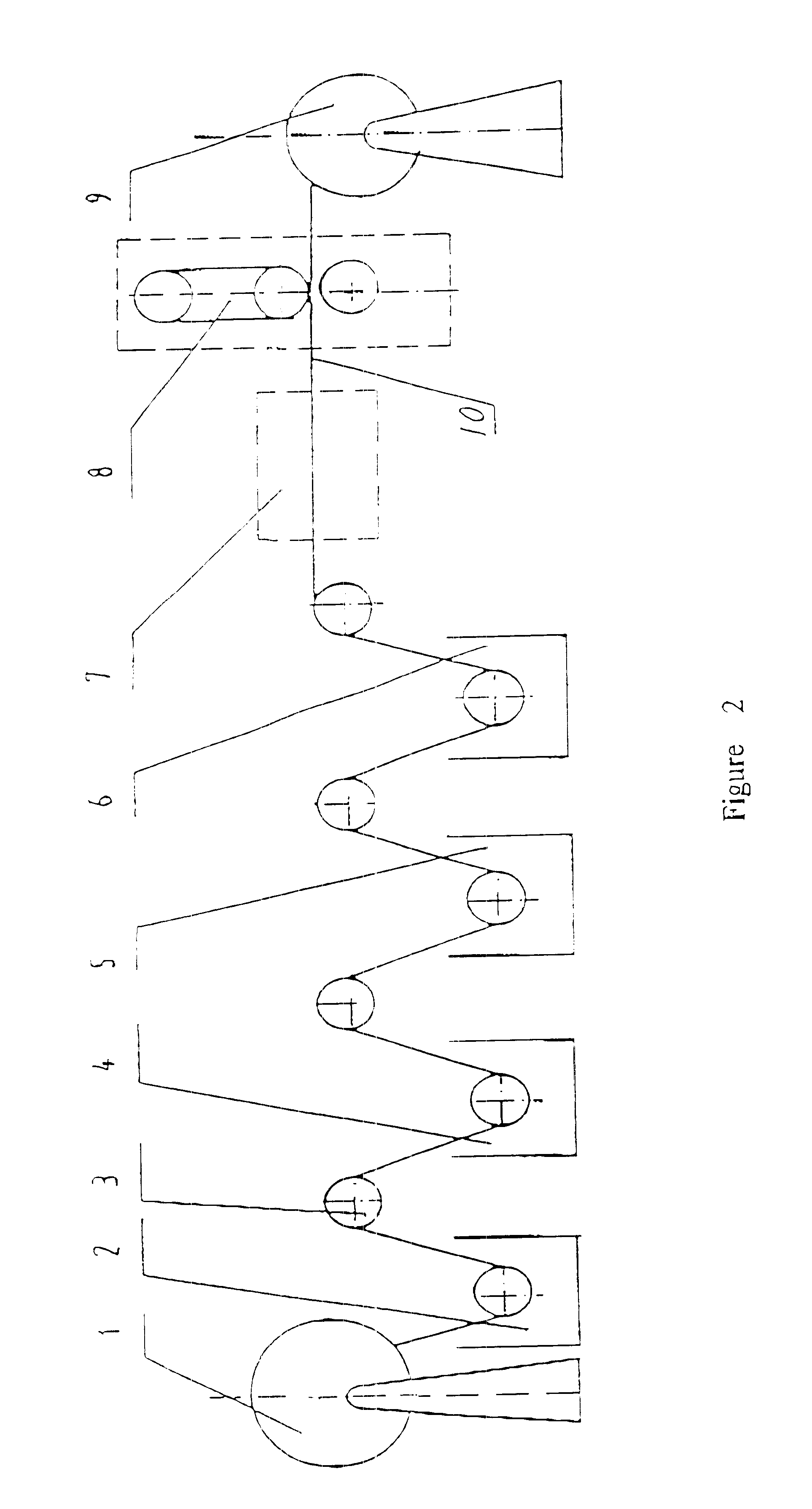

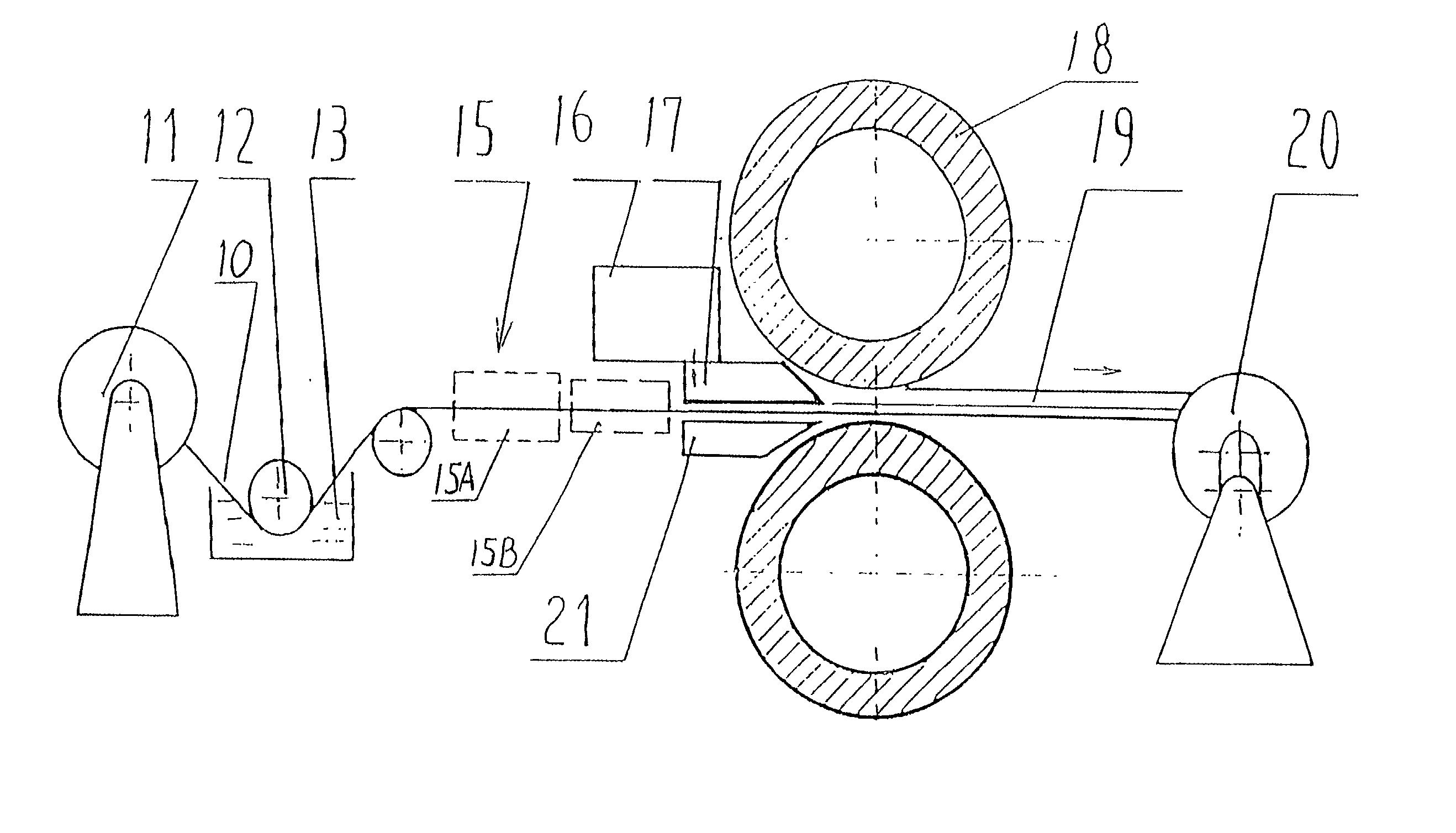

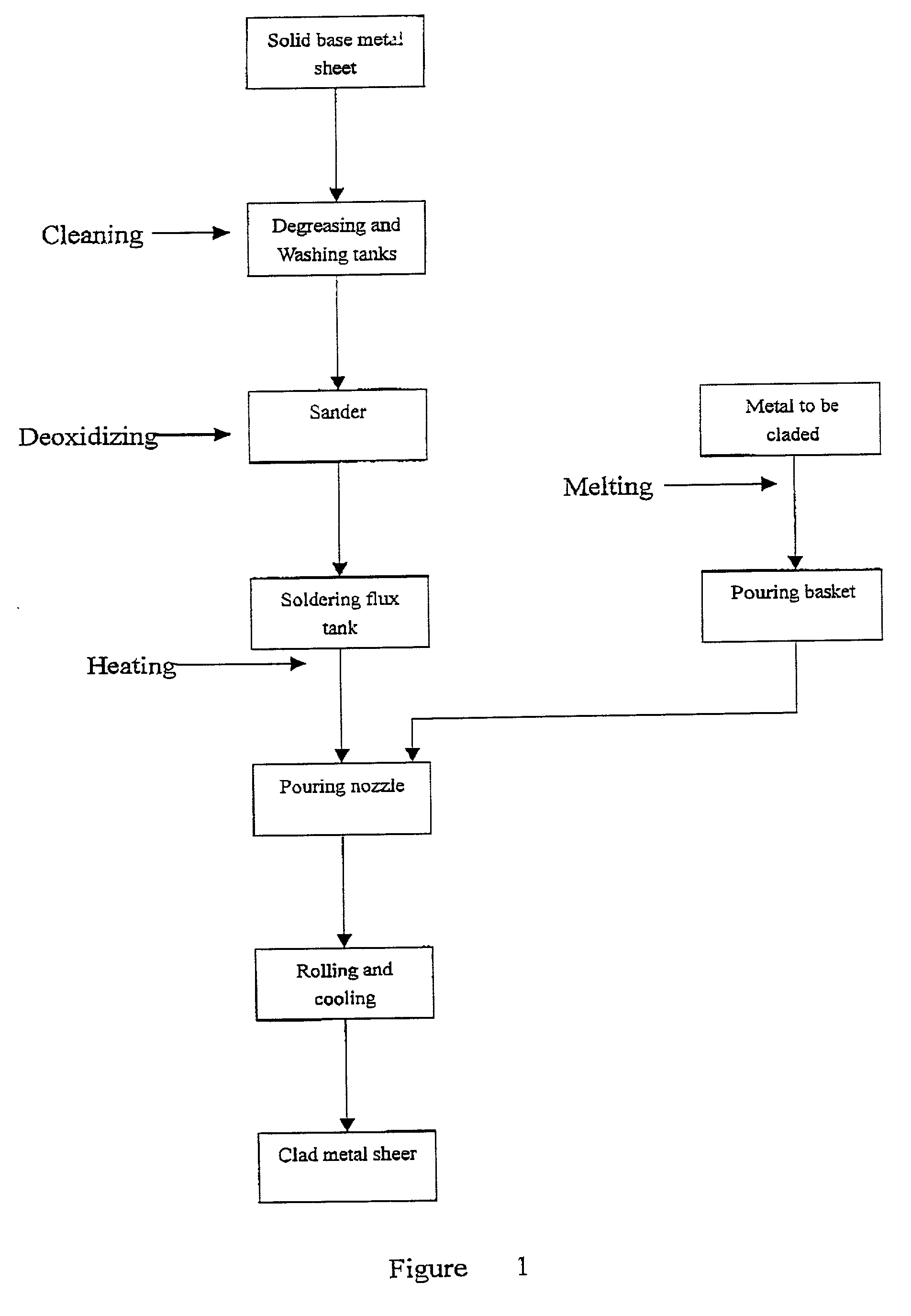

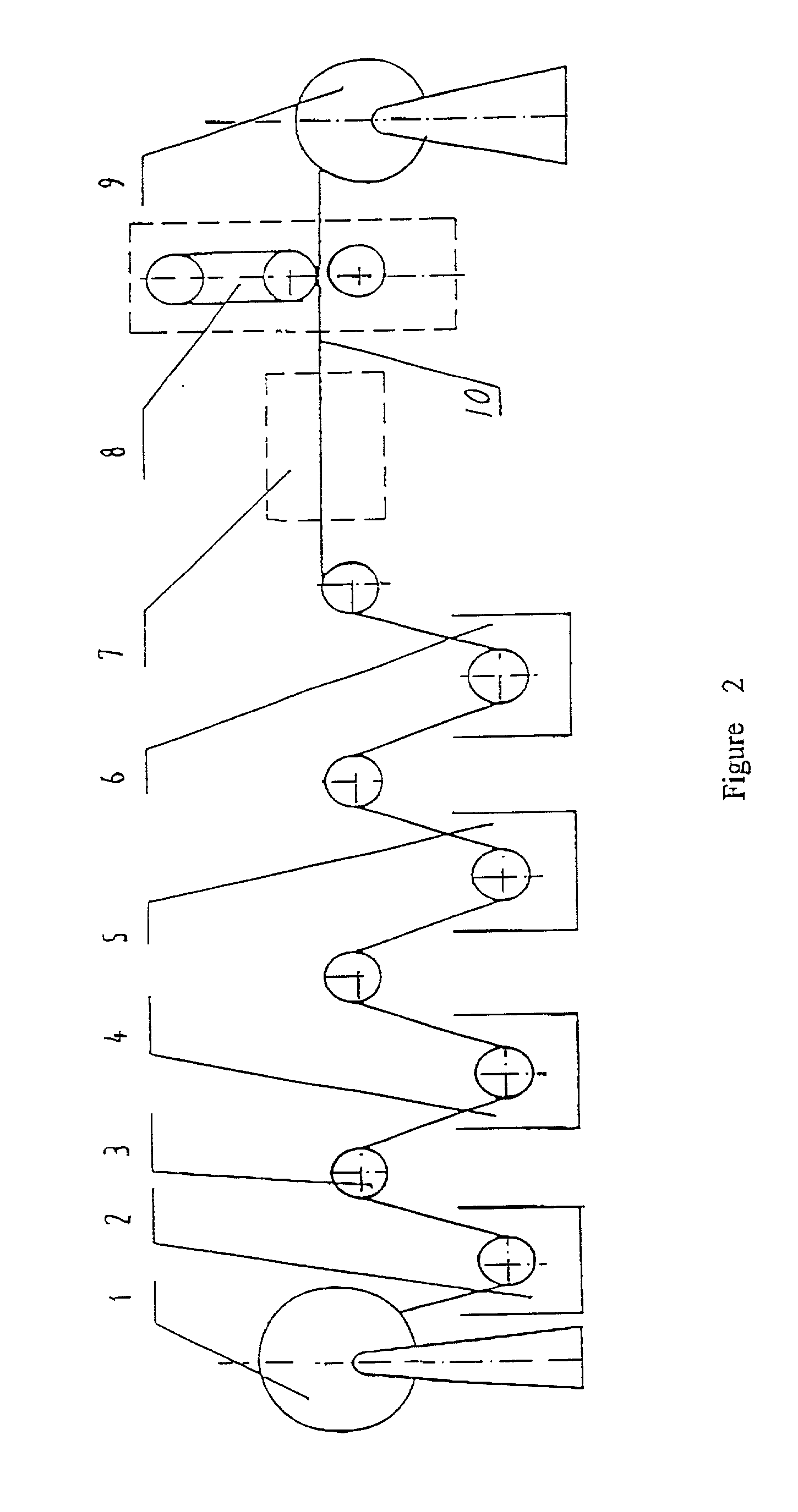

Liquid-solid rolling bonding method for different kinds of metals and the apparatus therefor

InactiveUS6681838B2High bonding strengthSimple procedureHot-dipping/immersion processesMolten casting coatingLiquid metalSurface binding

The present invention relates to a liquid-solid rolling bonding method for heterogeneous metals and an apparatus therefor. The method comprises: pouring a liquid metal onto the surface of a heterogeneous solid base metal coated with a soldering flux; rolling the liquid metal and the solid metal under pressure; solidifying the liquid metal and making it bond to the surface of the solid base metal under rapid cooling to realize metallurgical bonding of the two or more metals. The apparatus comprises an unrolling machine, a soldering flux tank, a drying-heating apparatus, a pouring nozzle, an interior water-cooling rollers and a roll-collecting machine arranged in order, a pouring basket is disposed above the pouring nozzle and a base frame is disposed below the pouring nozzle. The present invention has the advantages of high bonding strength, lower production cost, high production efficiency, good product quality, fewer investment for the apparatus and lower consumption of energy. The method of the present invention can replace the convention rolling bonding method in solid-solid phase and is suitable for the production of various clad metal sheets and strip.

Owner:NORTHEASTERN UNIV +1

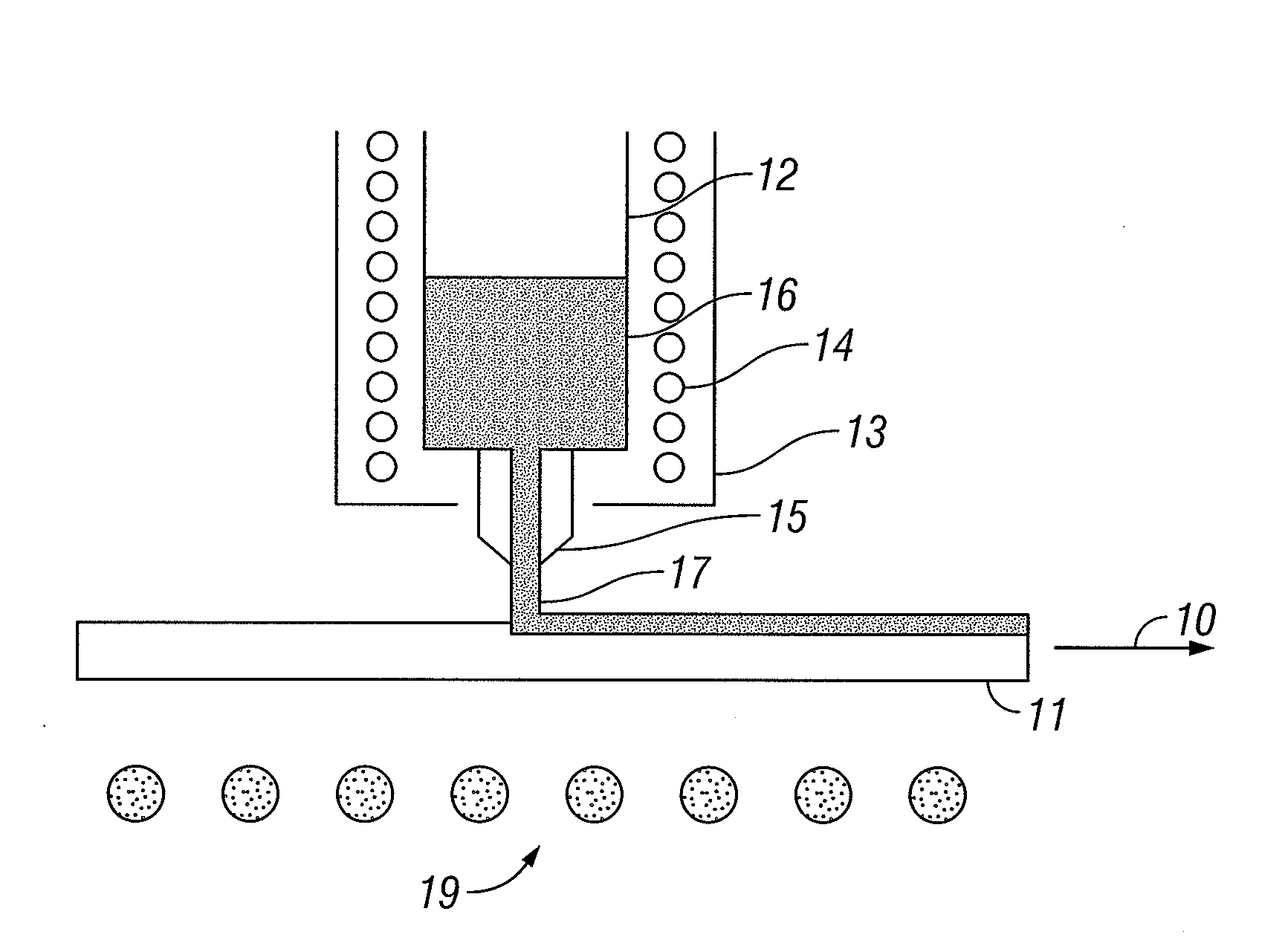

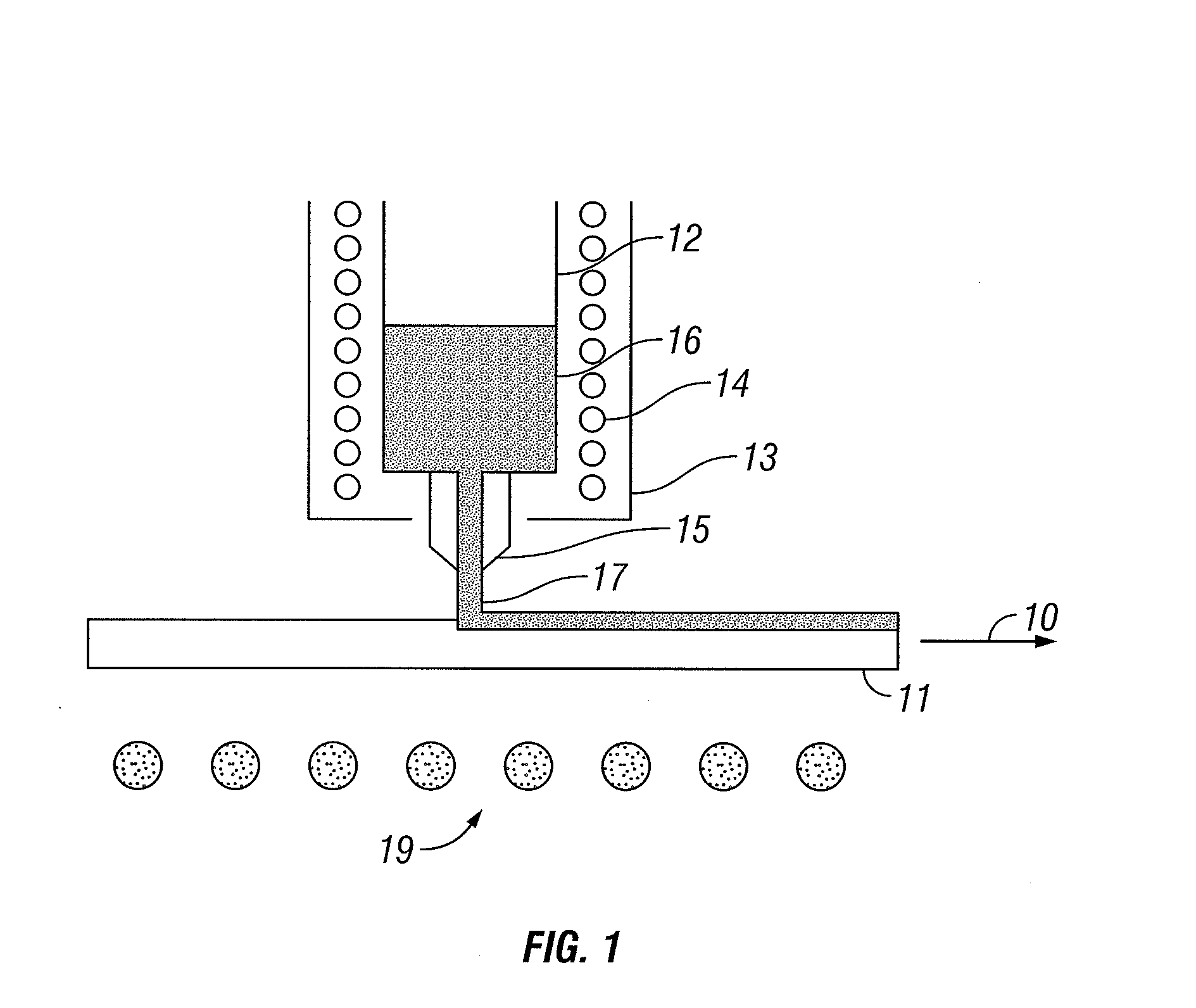

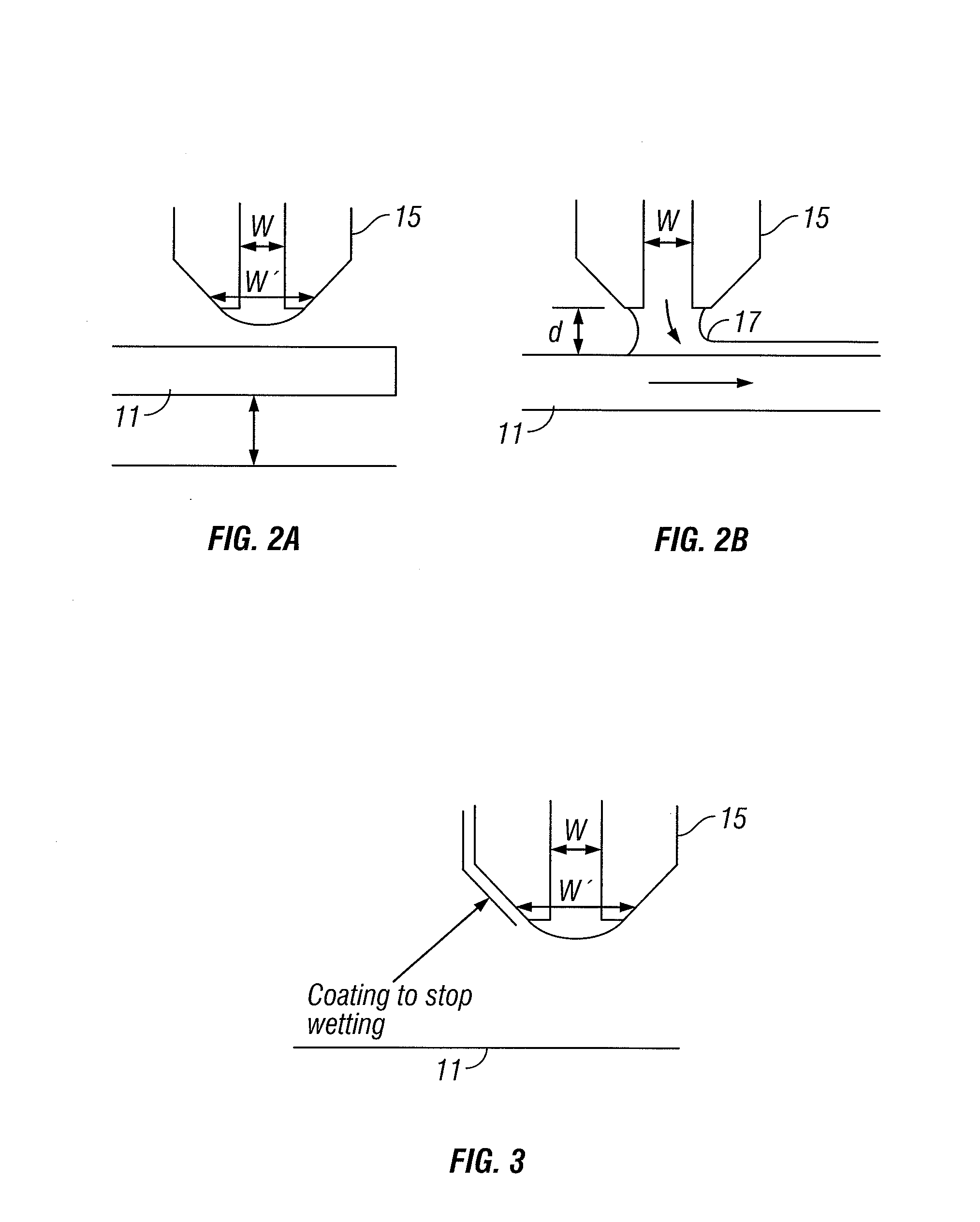

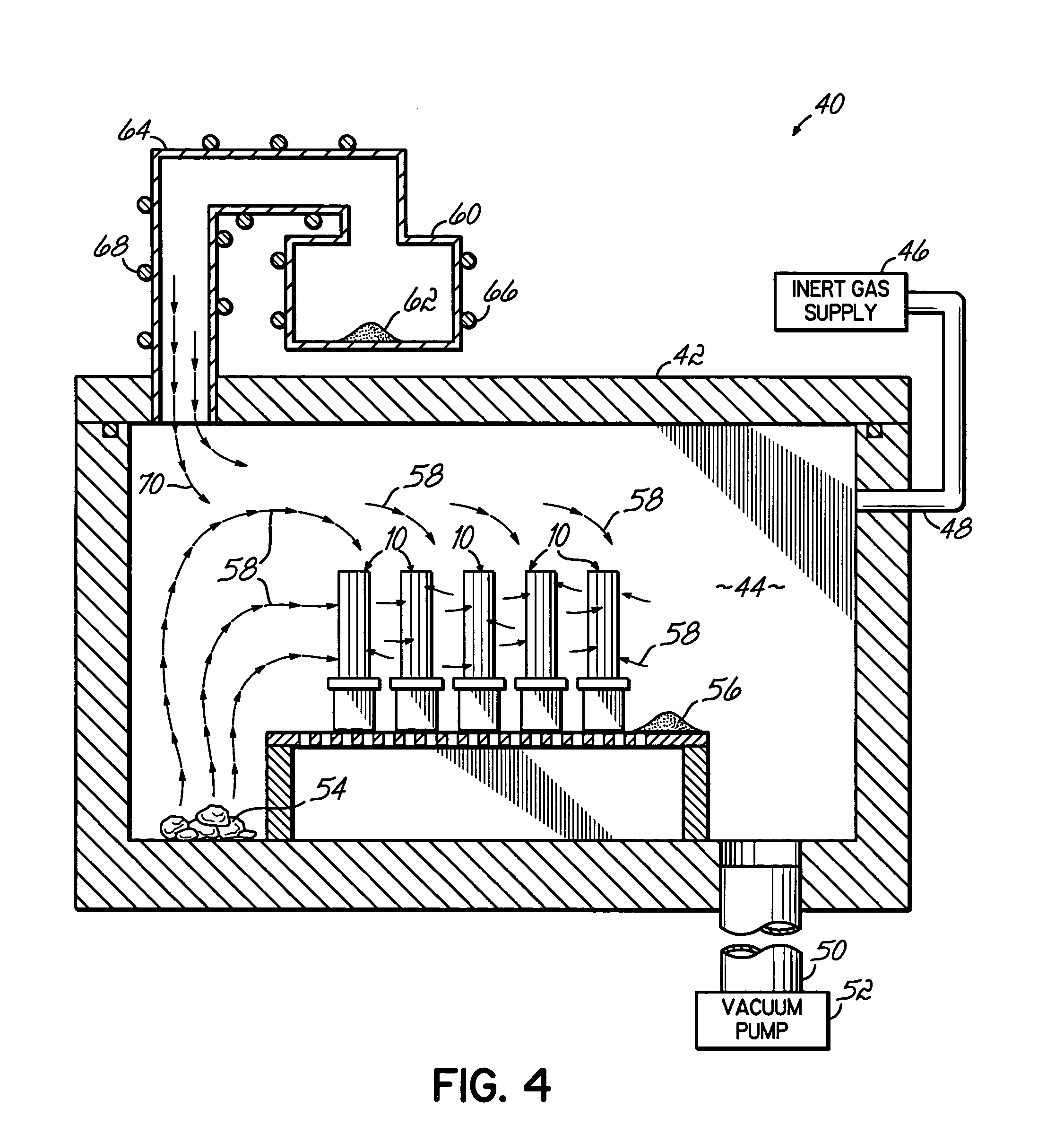

Methods of fabricating a layer of metallic glass-based material using immersion and pouring techniques

ActiveUS9211564B2Easy to castEliminate excessHot-dipping/immersion processesLiquid surface applicatorsMetalLiquid phase

Owner:CALIFORNIA INST OF TECH

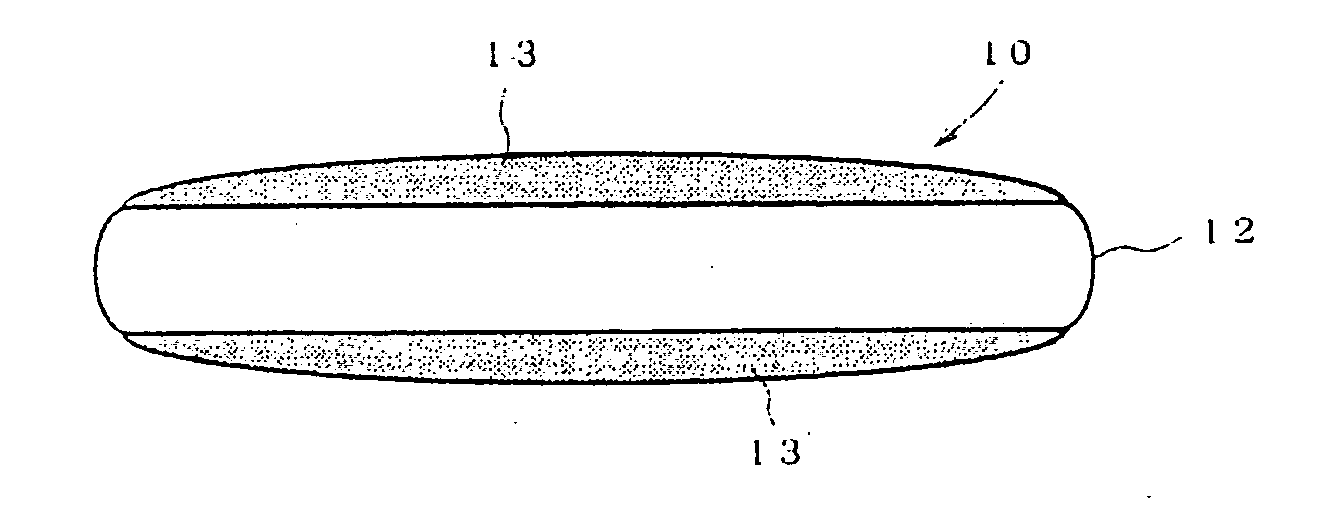

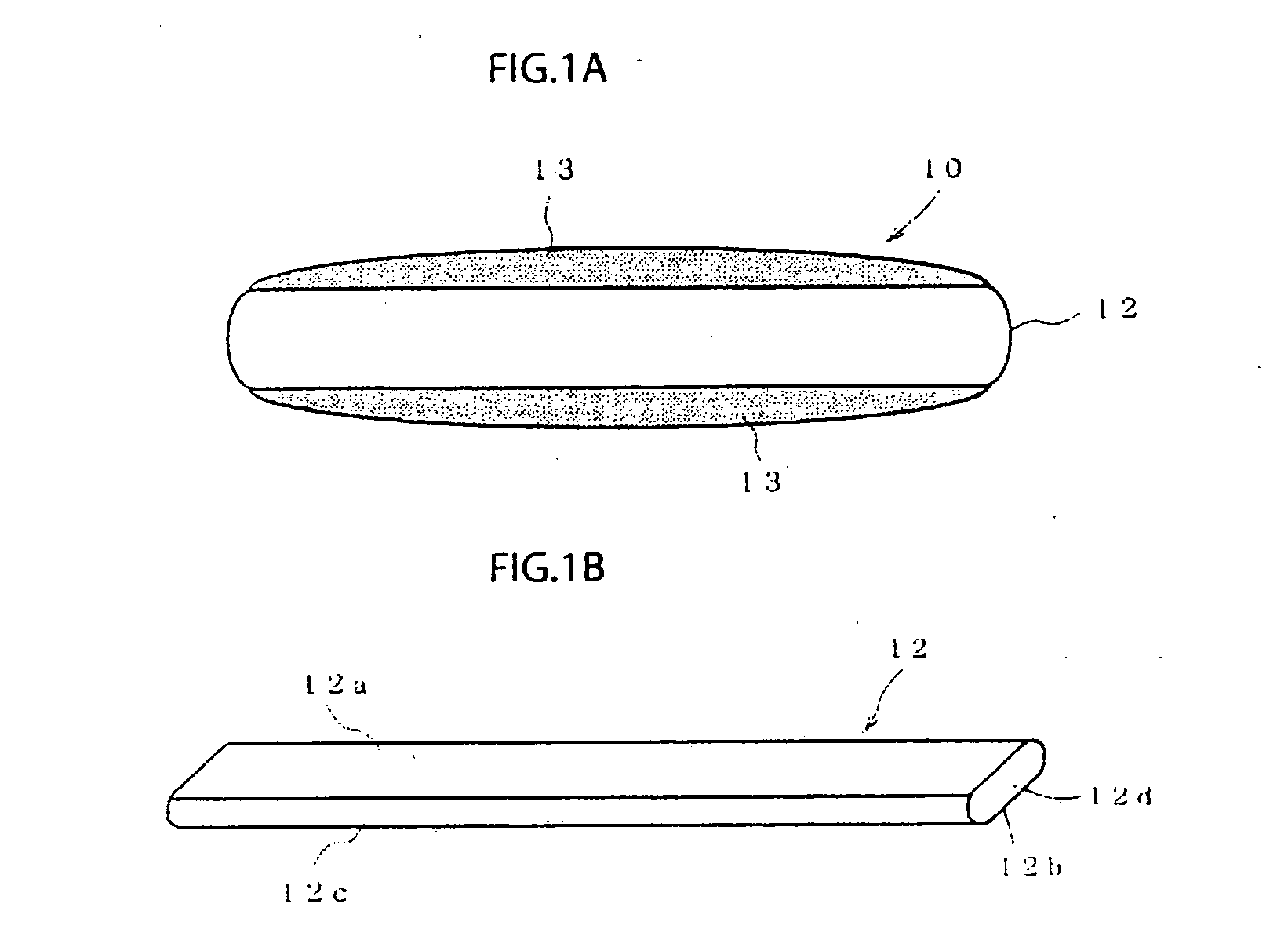

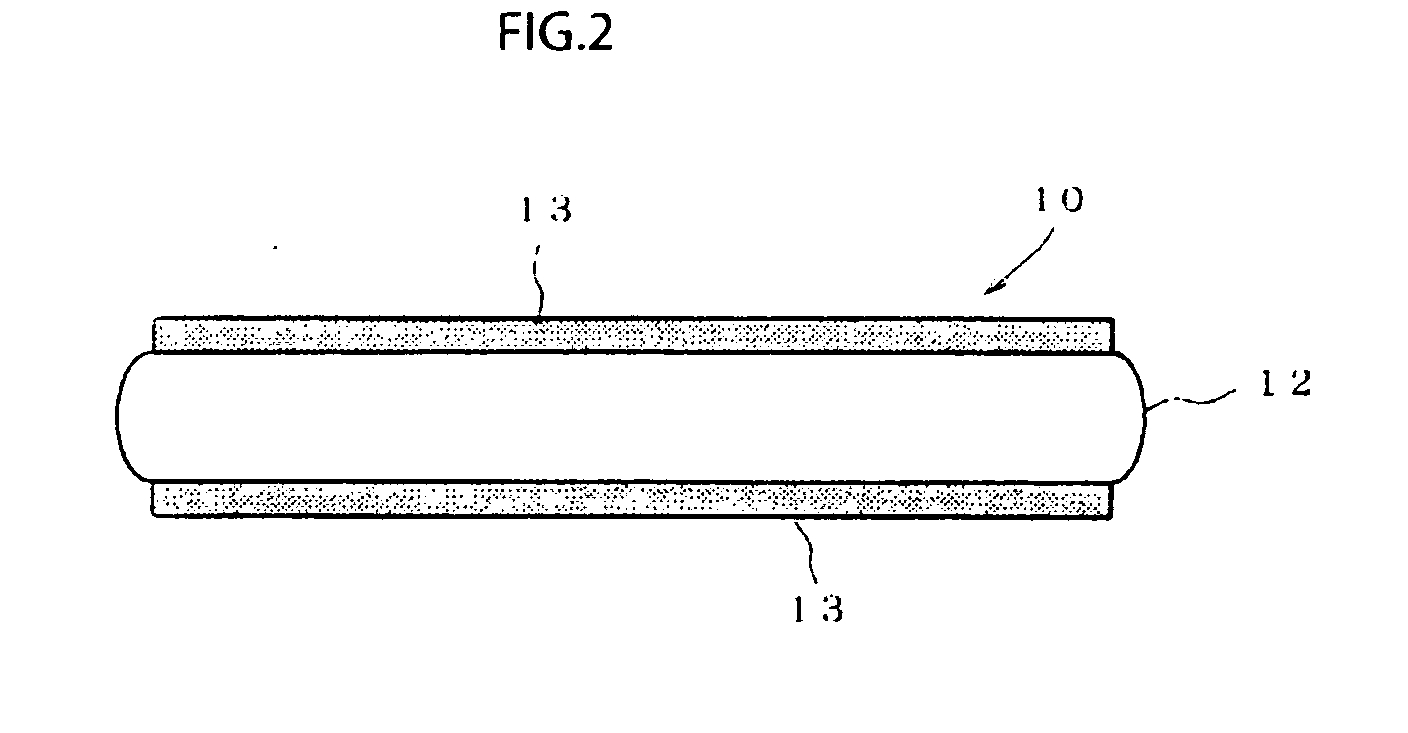

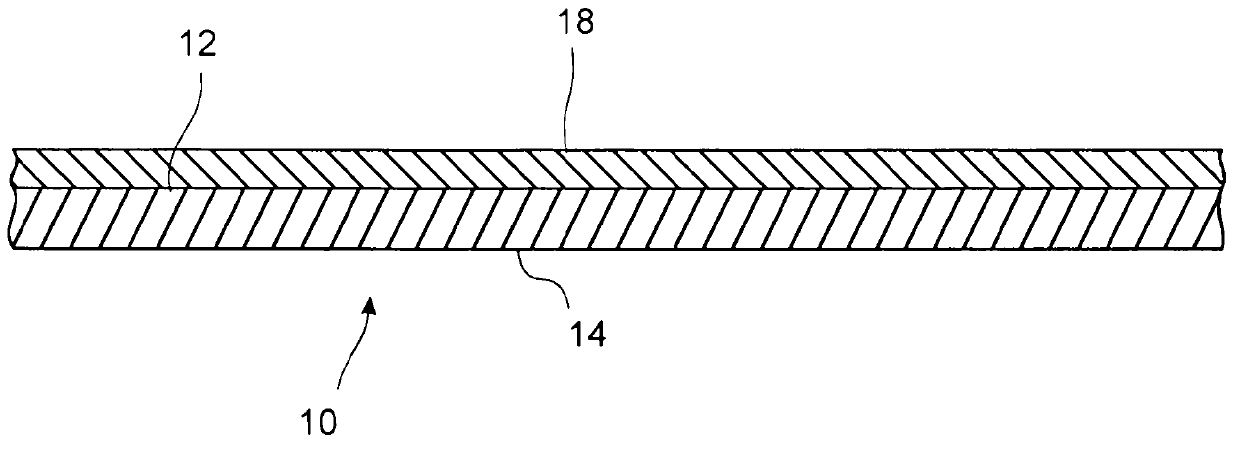

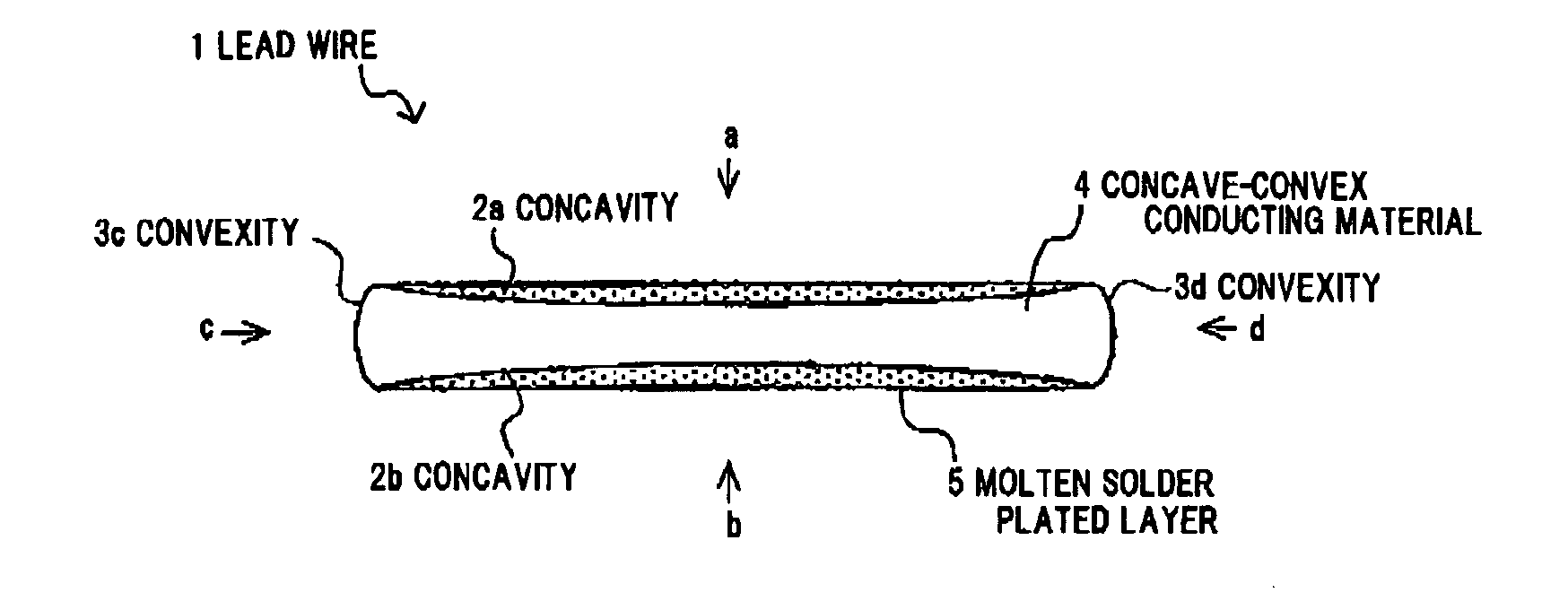

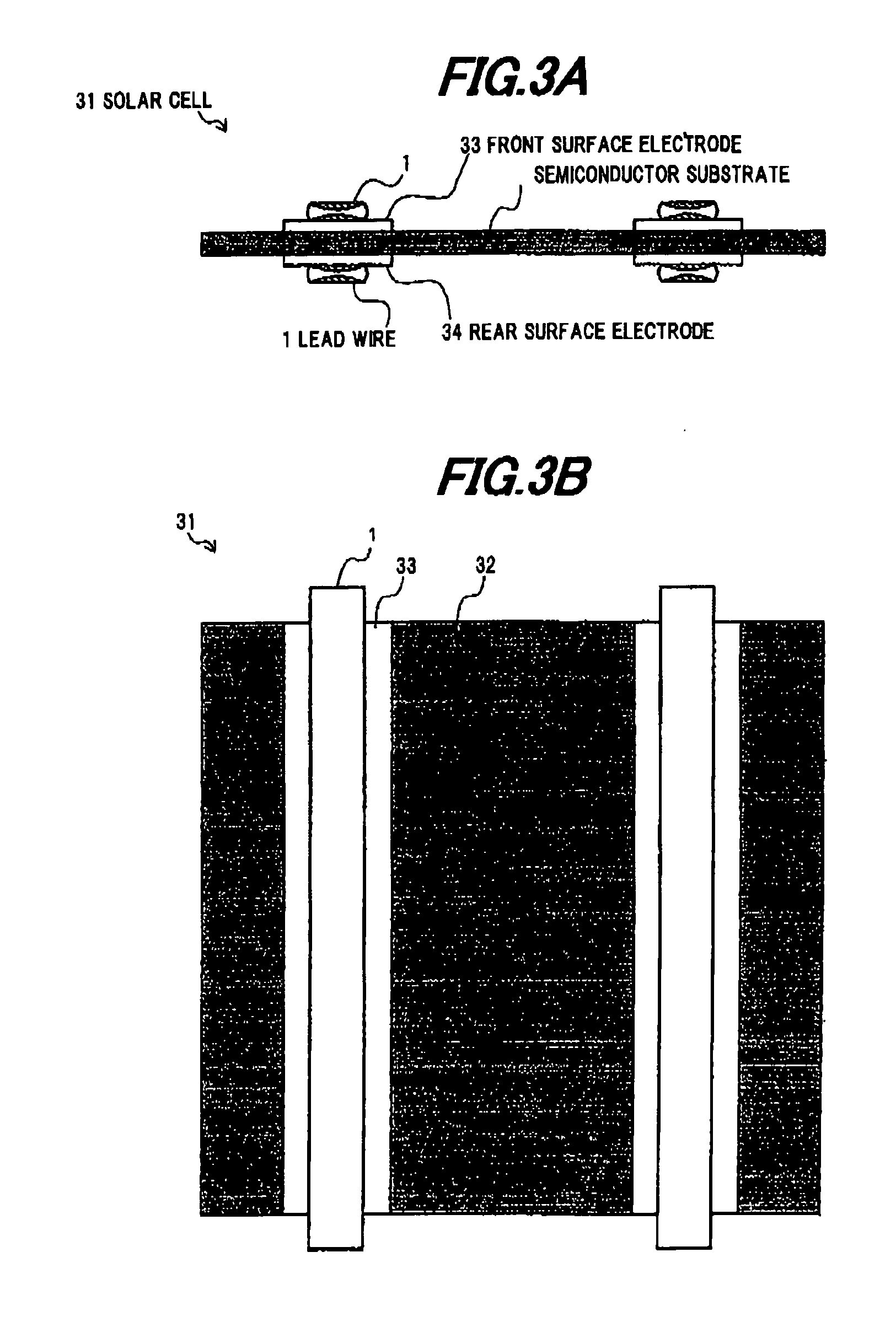

Lead wire for solar cell, manufacturing method and storage method thereof, and solar cell

ActiveUS20110220196A1Improve adhesionHot-dipping/immersion processesNon-insulated conductorsSolar cellMaterials science

Disclosed is a lead wire for a solar cell having excellent bondability with a solar cell. The solar cell lead wire (10) has a band plate-shaped electroconductive material (12) that is formed with straight-angled cross-sectional shape and is covered by a molten solder plating layer (13), with the thickness of the oxide film on the surface of the molten solder plating layer (13) being 7 nm or less.

Owner:HITACHI METALS LTD

Liquid spurting method, its spurting device and electronic instrument thereof

InactiveCN1498685AAvoid electrostatic damageImprove reliabilityMolten spray coatingOptical filtersElectronic instrumentEngineering

A discharging apparatus has a substrate holding part 32 which holds a substrate S; an discharging head 34 which discharges a liquid material onto the substrate S; an ion producing device 38 which provides an ionized wind on the substrate S; an exhaust device 40 which is placed on a direction where the ionized wind from the ionized wind producing device 38 is blowing, and the ionized wind is provided toward the liquid material on the substrate S, at least, immediately after discharging the liquid material onto the substrate S.

Owner:KATEEVA DISPLAY TECH (SHAOXING) LTD

Method for Rapid Liquid Phase Deposition of Crystalline Si Thin Films on Large Glass Substrates for Solar Cell Applications

InactiveUS20080236665A1Improve efficiencyPropels solar electricity penetrationFinal product manufactureVacuum evaporation coatingElectrical batteryAmorphous silicon

A method for liquid phase deposition of crystalline silicon thin films, and a high efficiency solar cell that is fabricated using crystalline silicon thin film technology, has the performance of a crystal silicon solar cell, but at the cost level per unit area of a solar cell fabricated using an amorphous silicon thin film. The crystal thin film uses only 10% or less of the amount of silicon used in a wafer-based solar cell. Because of the maturity of silicon technology in semiconductor industry, this approach not only enables high volume, automated production of solar cells on a very large, low-cost substrate, but also increases the area throughput up to 10000 cm2 / min from 942 cm2 / min in case of CZ crystal growth.

Owner:SIERRA SOLAR POWER

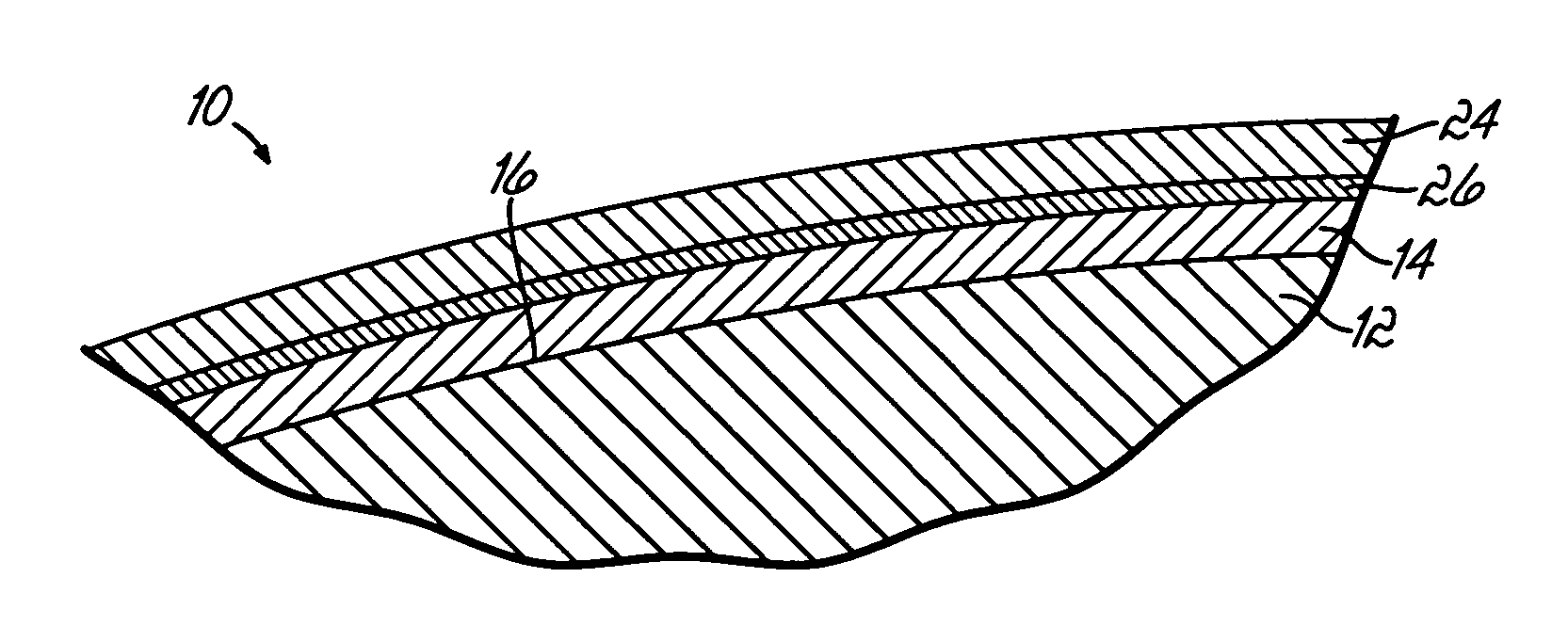

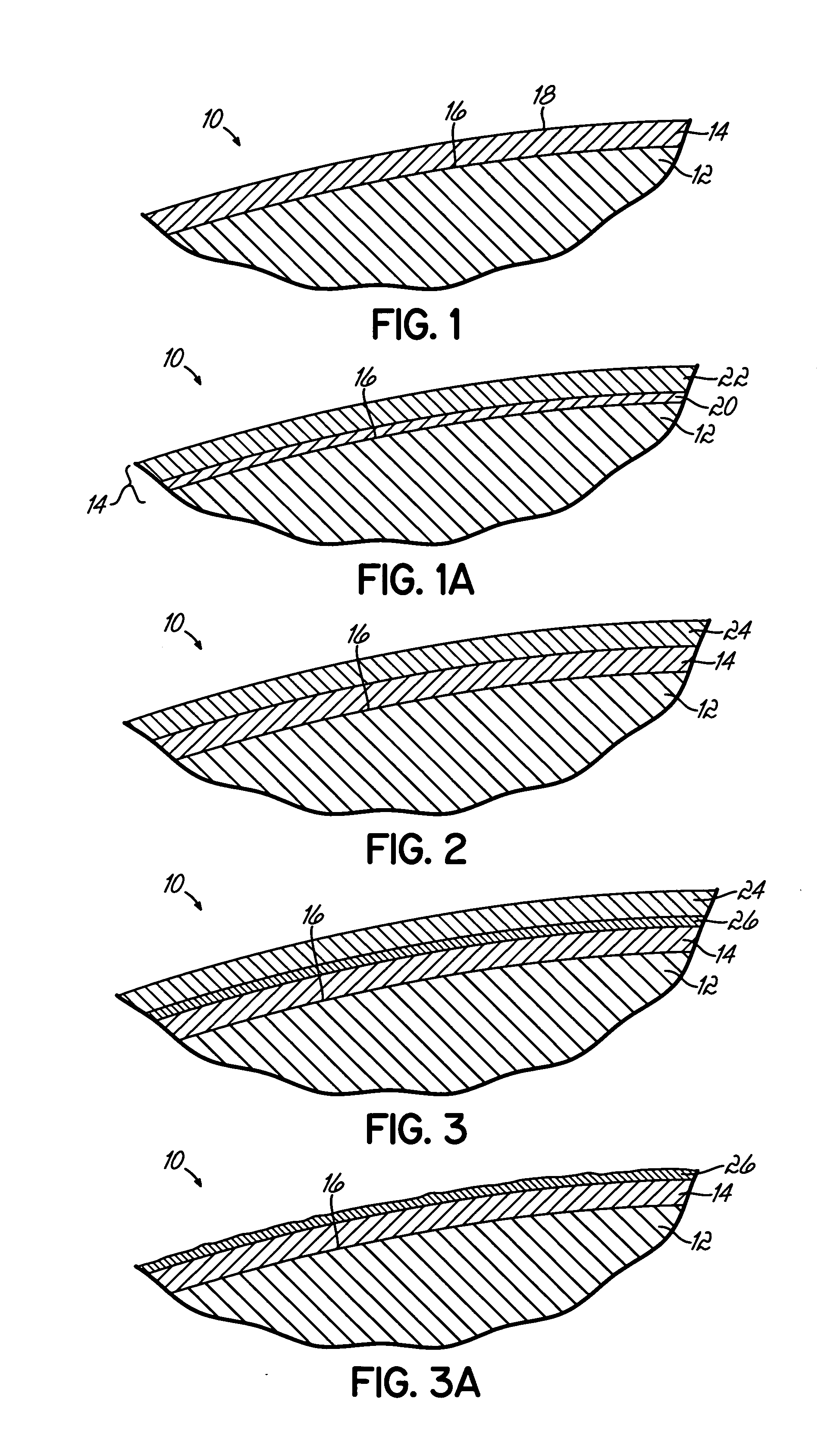

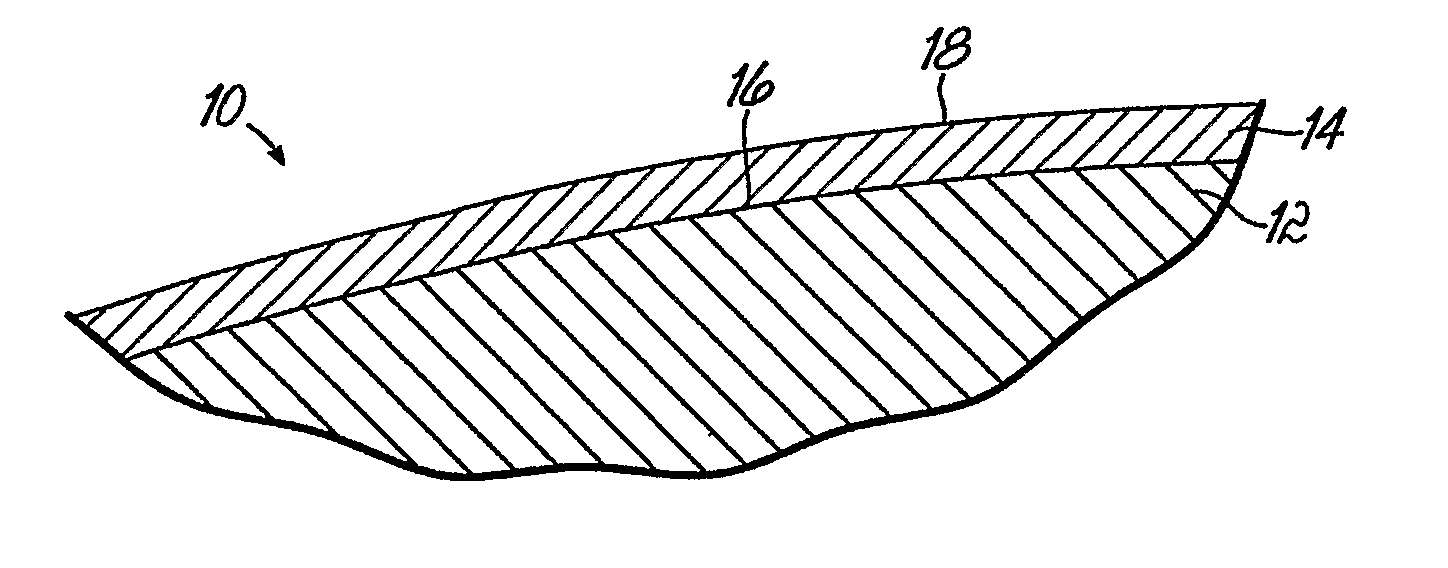

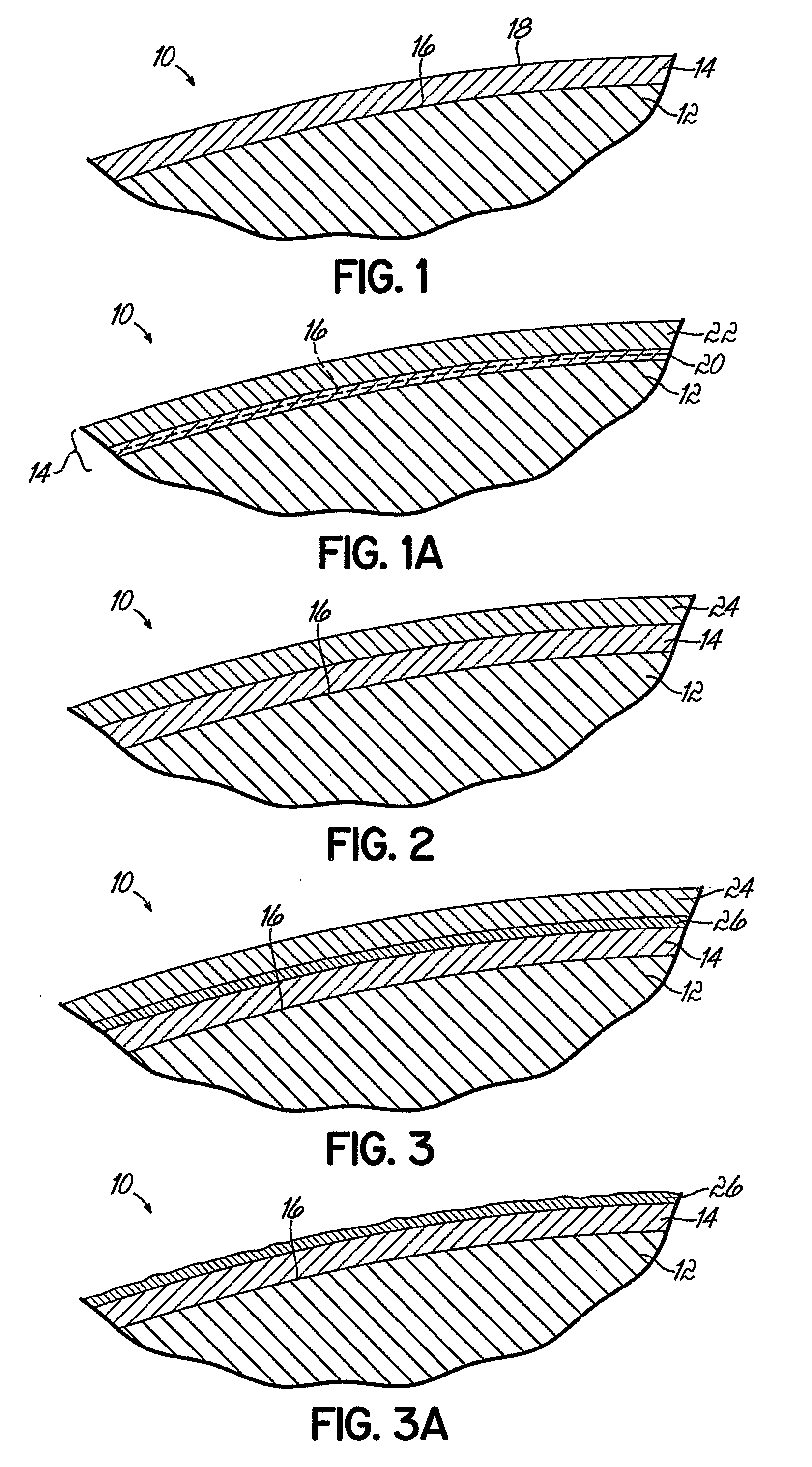

Alluminide coatings containing silicon and yttrium for superalloys and method of forming such coatings

InactiveUS20060057418A1Competitive performanceLess-expensive to produceAnodisationEfficient propulsion technologiesJet engineGas phase

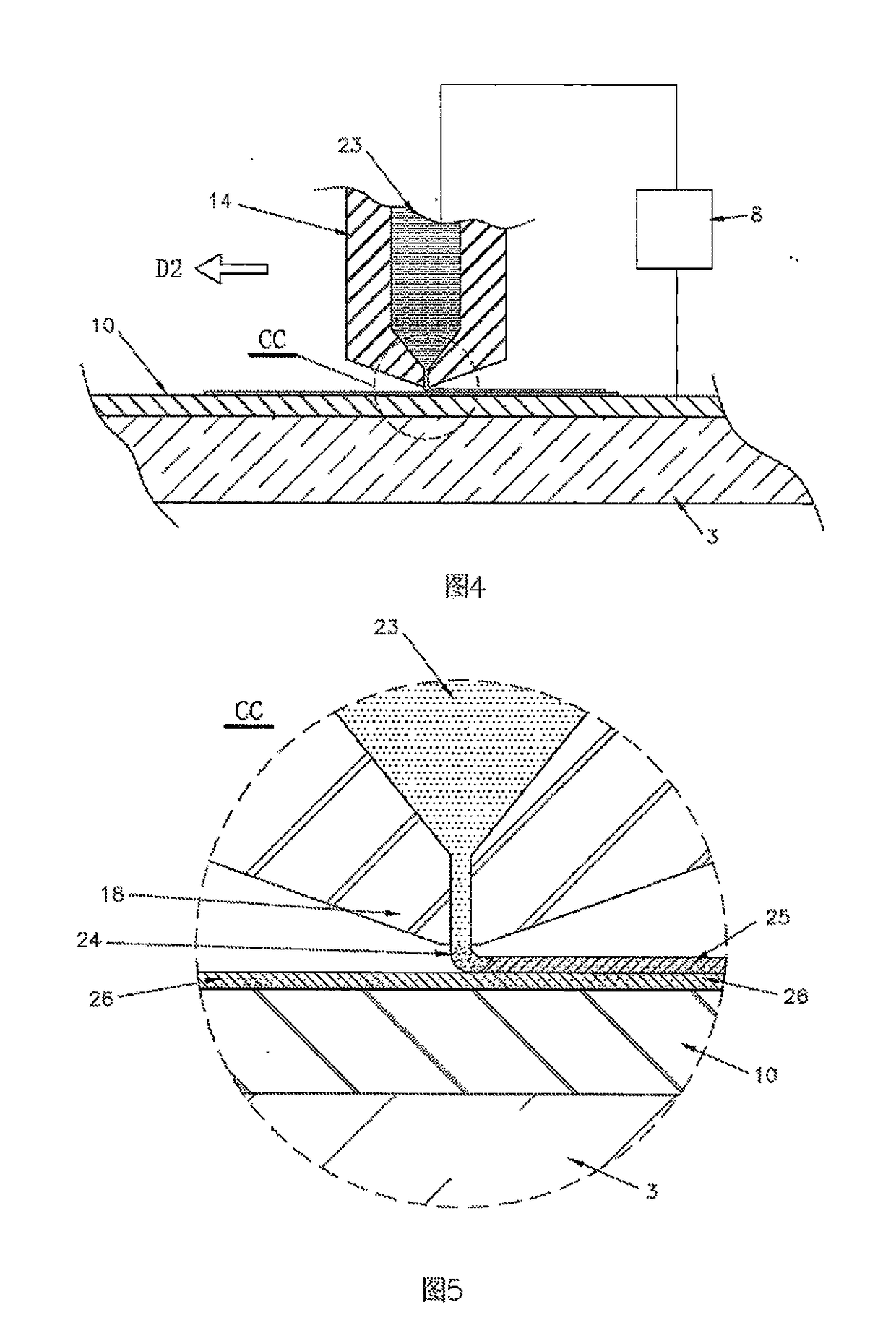

Aluminide coatings or layers (14) for jet engine components (10) and a process for forming aluminide layers (14) that include additions of silicon and yttrium. A superalloy substrate (12) of the component (10) is initially coated with a layer of a silicon-containing material. The substrate (12) is then aluminided, for example by a chemical vapor deposition process, and is exposed to a yttrium-containing material during the aluminiding process to form the aluminide layer (14) containing silicon and yttrium. A ceramic thermal barrier layer (24) of yttria-stabilized zirconia may be optionally applied over the aluminide layer (14). Another optional zirconia layer (26) maybe provided between the aluminide layer (14) and the ceramic thermal barrier layer (24). The present invention provides a silicon- and yttrium-containing aluminide layer (14) having improved durability, either as a standalone environmental coating or as a bond coat for a subsequently-applied ceramic thermal barrier layer (24).

Owner:AEROMET TECH

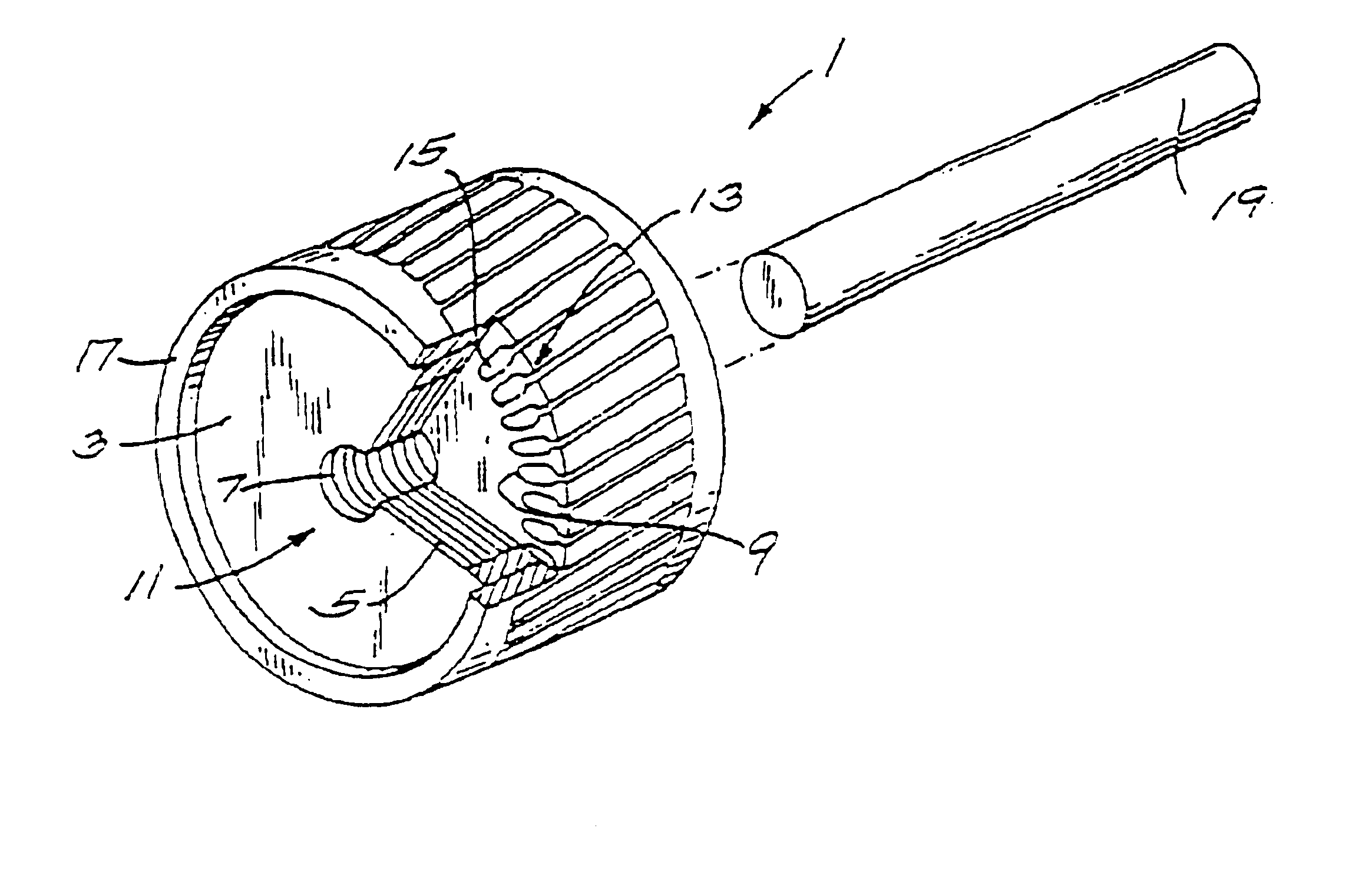

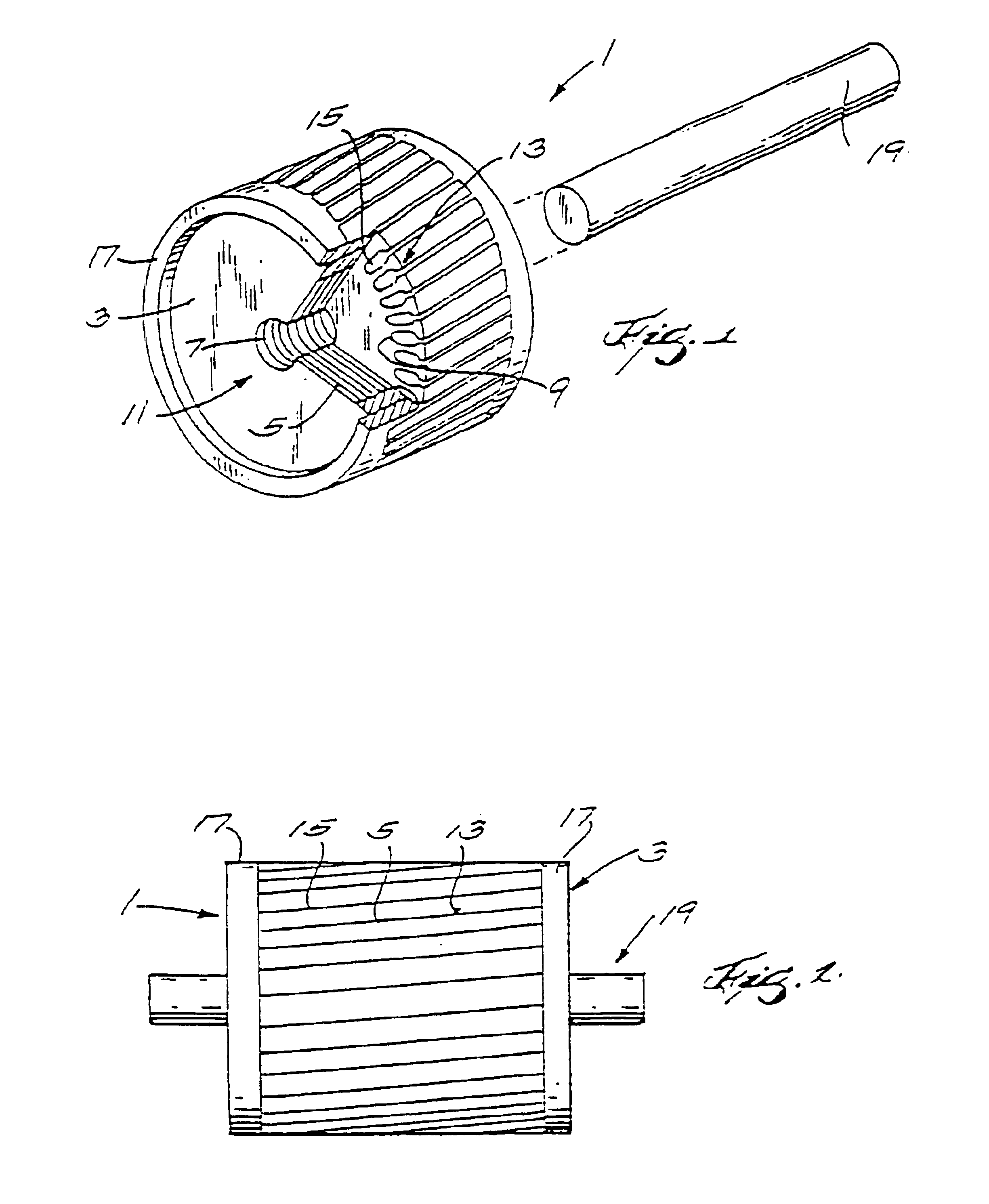

Coating compositions for electronic components and other metal surfaces, and methods for making and using the compositions

InactiveUS6995484B1Eliminate solderingImprove motor performanceHot-dipping/immersion processesNanotechTransformerEngineering

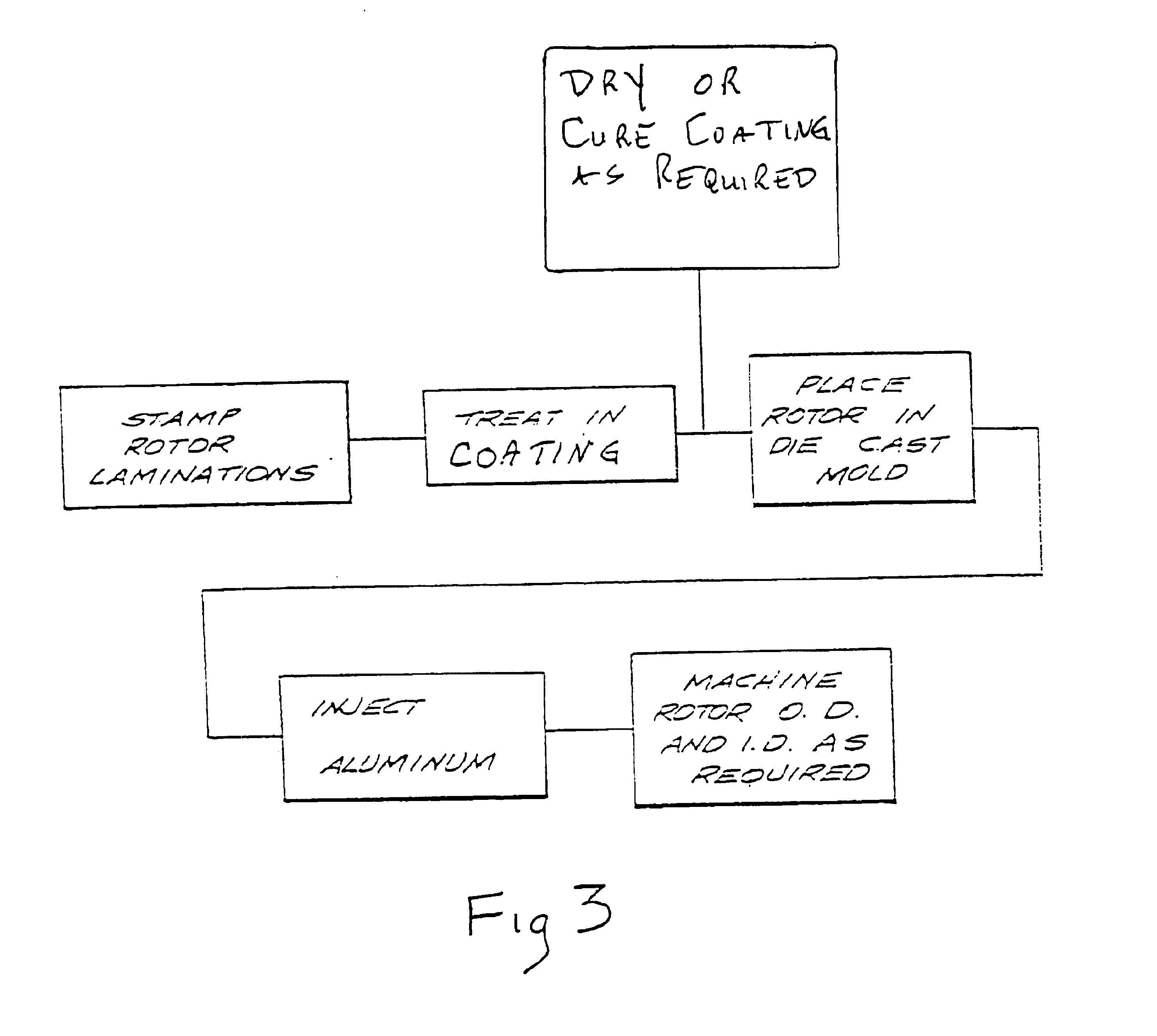

A method is disclosed for providing inorganic and / or organic coating compositions onto rotor cores to eliminate soldering during aluminum injection. These coatings can also be applied upon electric motor rotors and / or stators laminates as well as other electronic components such as transformers. The disclosed method provides at least one film or layer of a coating composition within channels or bar slots defined by the rotor of the electric motor core / rotor (depending upon the design of the motor the slots can be defined within the rotor or open ended along the longitudinal axis of the rotor). The coating composition is also typically applied upon all exposed surfaces of the rotor, e.g., within the channels and exterior surfaces of the rotor. The coated rotor is then contacted with a molten metal. The coating composition functions to isolate the laminates (e.g., steel) of the rotor from a molten metal (e.g., aluminum and its alloys), which surrounds the rotor and fills the channels thereby embedding the rotor, and prevents the metal from forming an undesirable conductive path typically termed soldering among the individual laminates.

Owner:ELISHA HLDG LLC

Surface and composition enhancements to high aspect ratio C-MEMS

ActiveUS7534470B2Increase surface areaHigh aspect ratioMaterial nanotechnologyMolten casting coatingVitrificationForming gas

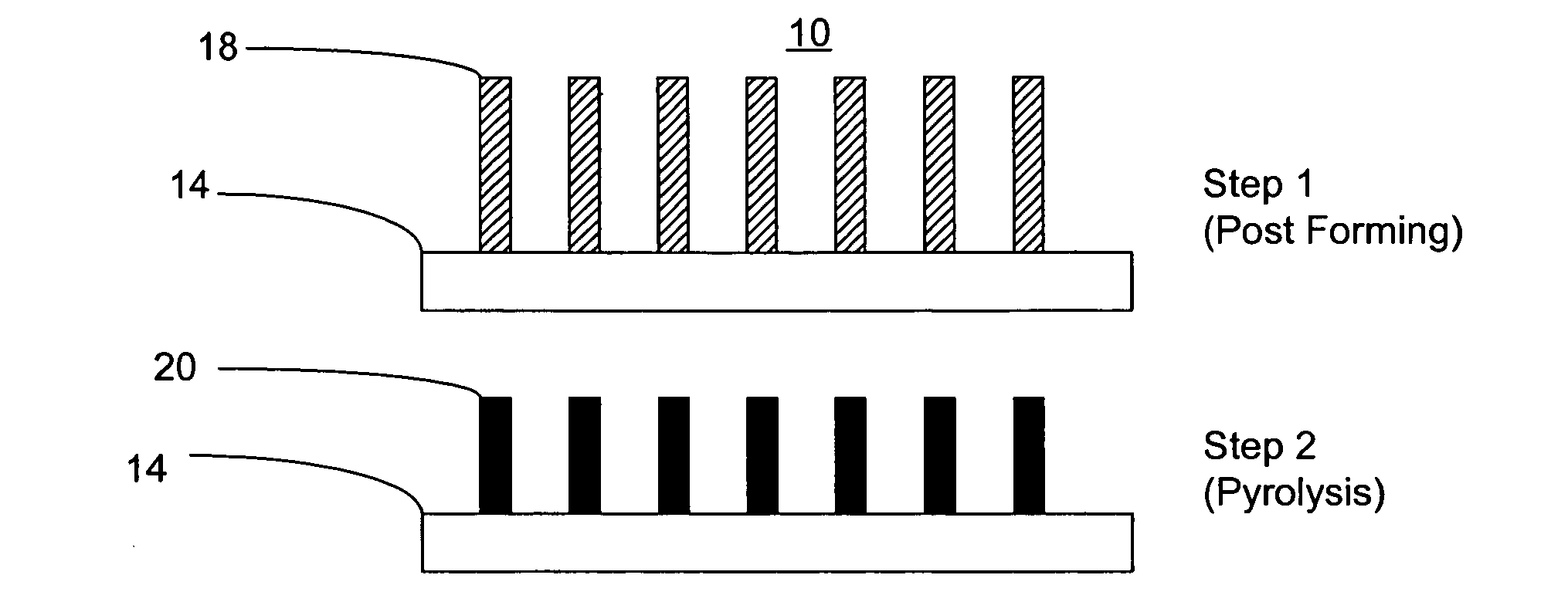

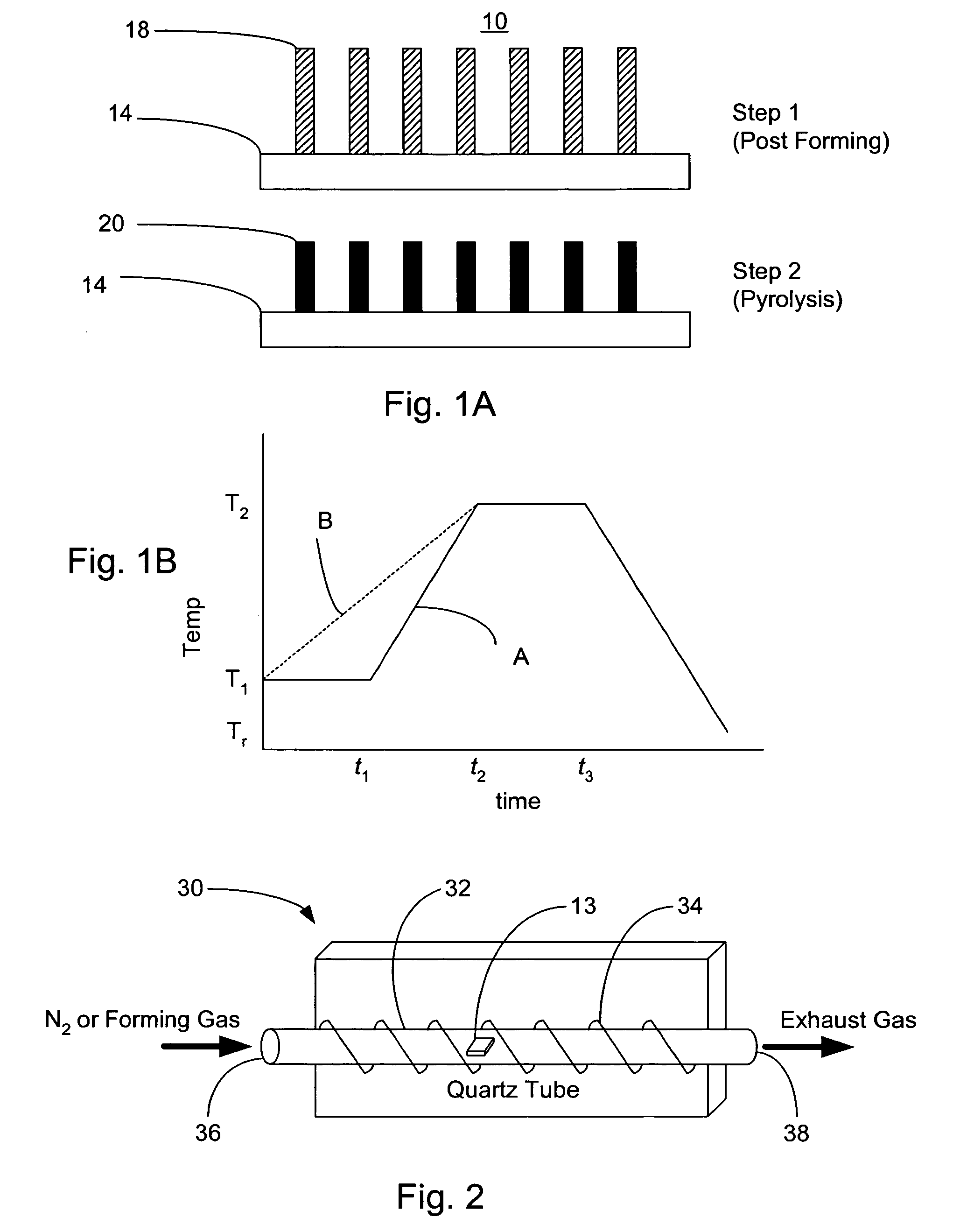

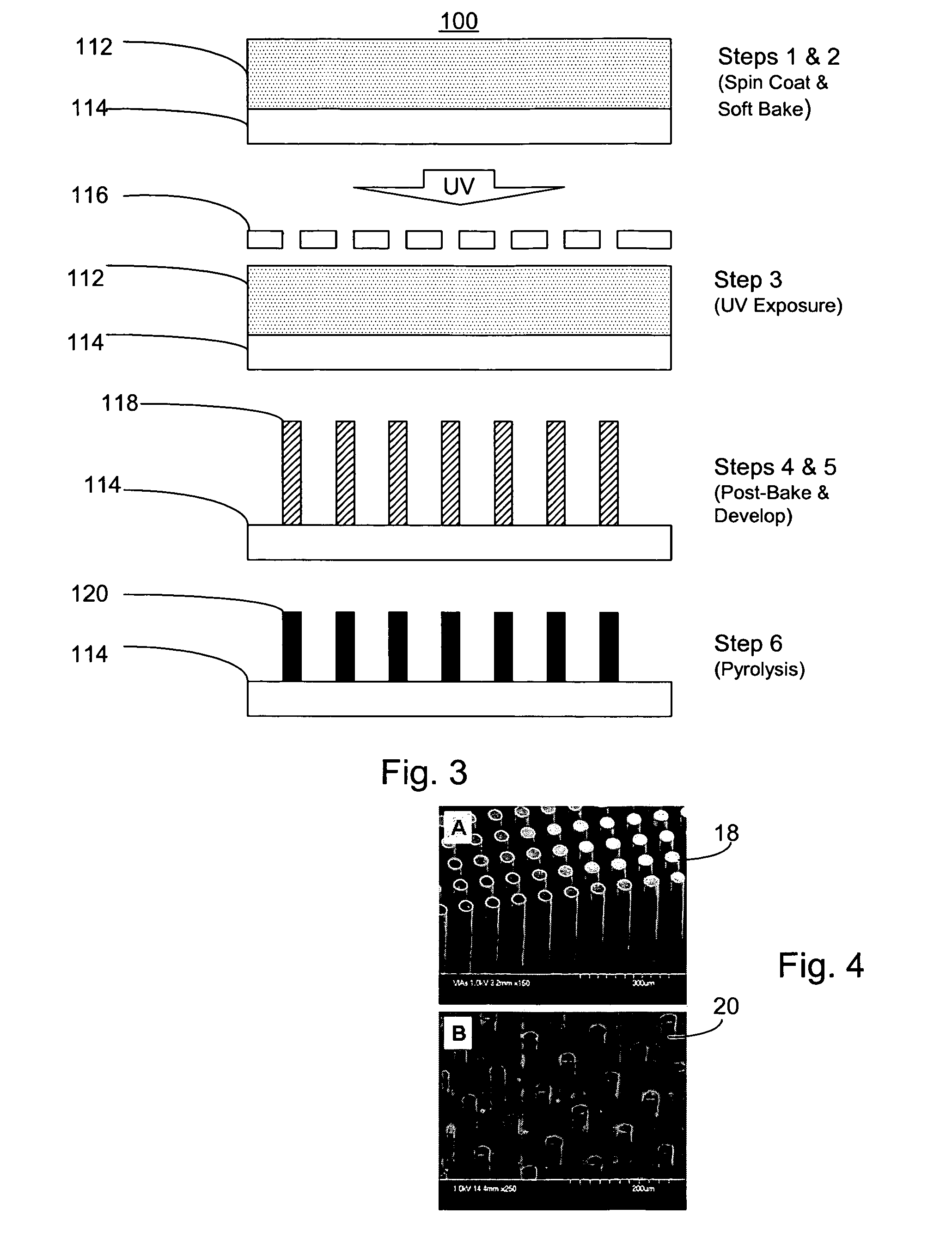

C-MEMS architecture having carbon structures with high surface areas due to high aspect ratios and nanoscale surface enhancements, and improved systems and methods for producing such structures are provided. Specifically, high aspect ratio carbon structures are microfabricated by pyrolyzing a patterned carbon precursor polymer. Pyrolysing the polymer preferably comprises a multi-step process in an atmosphere of inert and forming gas at high temperatures that trail the glass transition temperature (Tg) for the polymer. The surface area of the carbon microstructures is increases by nanotexturing the surface through oxygen plasma exposure, and by integrating nanoscale structures with the carbon microstructures by exposing the carbon microstructures and a catalyst to hydrocarbon gas. In a preferred embodiment, the carbon microstructures are the source of carbon gas.

Owner:RGT UNIV OF CALIFORNIA

Liquid - solid rolling bonding method for different kinds of metals and the apparatus therefor

InactiveUS20020069998A1High bonding strengthSimple procedureHot-dipping/immersion processesMolten casting coatingLiquid metalSurface binding

The present invention relates to a liquid-solid rolling bonding method for heterogeneous metals and an apparatus therefor. The method comprises: pouring a liquid metal onto the surface of a heterogeneous solid base metal coated with a soldering flux; rolling the liquid metal and the solid metal under pressure; solidifying the liquid metal and making it bond to the surface of the solid base metal under rapid cooling to realize metallurgical bonding of the two or more metals. The apparatus comprises an unrolling machine, a soldering flux tank, a drying-heating apparatus, a pouring nozzle, an interior water-cooling rollers and a roll-collecting machine arranged in order, a pouring basket is disposed above the pouring nozzle and a base frame is disposed below the pouring nozzle. The present invention has the advantages of high bonding strength, lower production cost, high production efficiency, good product quality, fewer investment for the apparatus and lower consumption of energy. The method of the present invention can replace the convention rolling bonding method in solid-solid phase and is suitable for the production of various clad metal sheets and strip.

Owner:NORTHEASTERN UNIV +1

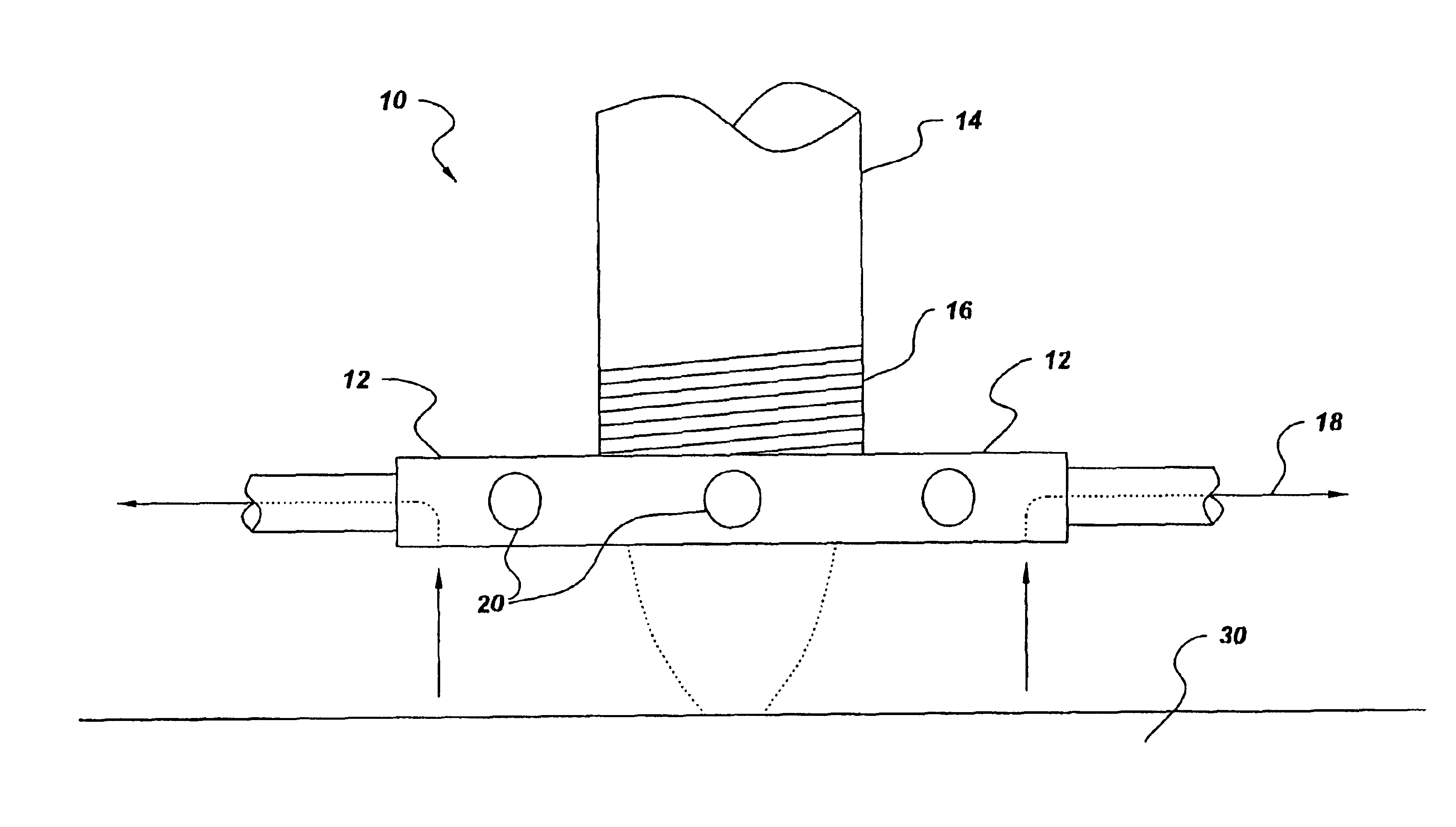

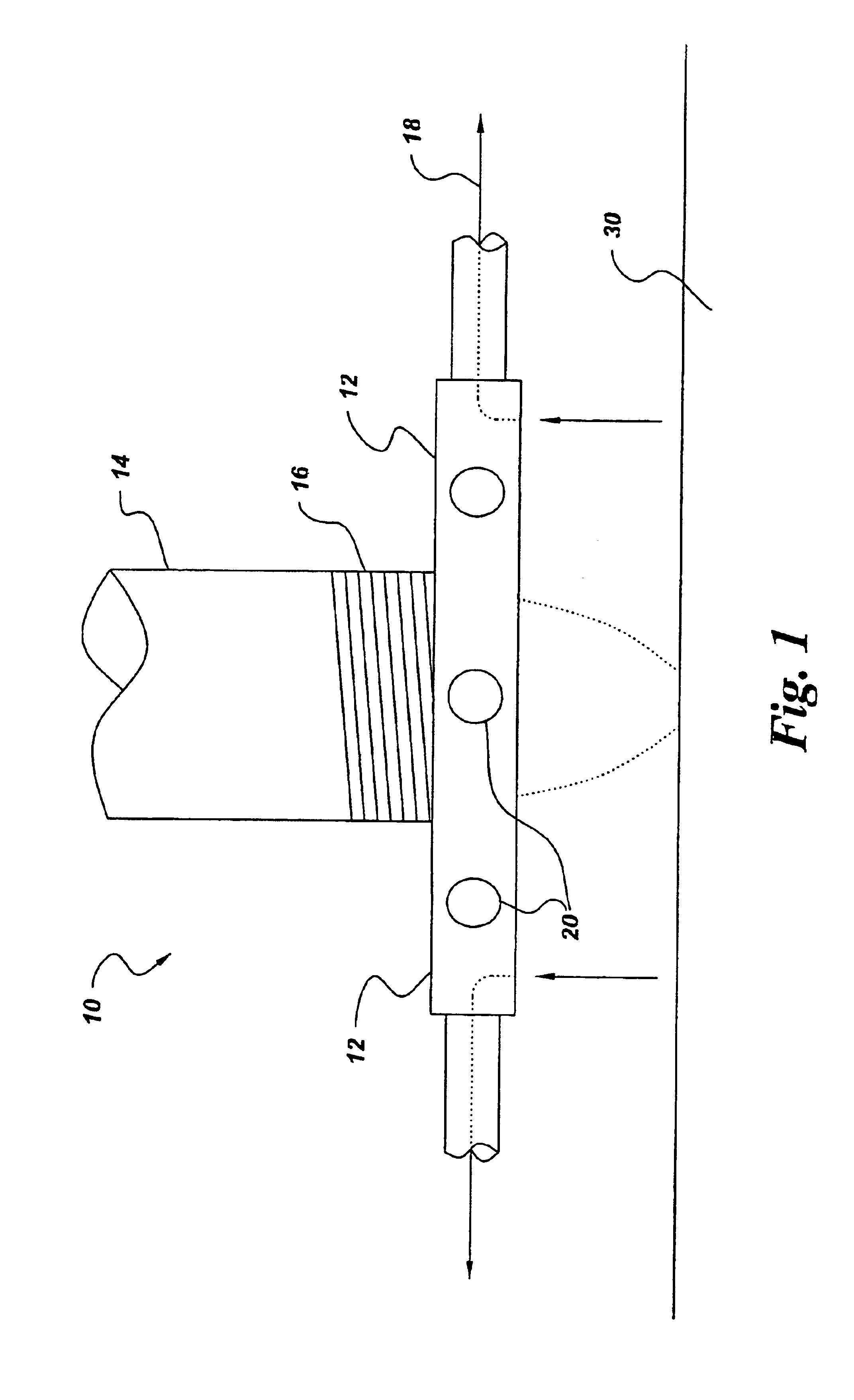

Method of bonding a metal to a substrate

A method of bonding a metal to a substrate involves forming an oxide layer on a surface of the substrate, and in a molten state, over-casting the metal on the substrate surface. The over-casting drives a reaction at an interface between the over-cast metal and the oxide layer to form another oxide. The other oxide binds the metal to the substrate surface upon solidification of the over-cast metal.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and apparatus for metal three-dimensional printing

InactiveUS20180141151A1Simple driving mechanismRaw materials are simpleAdditive manufacturing apparatusMolten casting coatingElectrical resistance and conductanceHigh density

The invention discloses a method and an apparatus for metal three-dimensional printing, in which the method for metal three-dimensional printing comprises the following steps: molten or softened flowable metal is placed in a build area used by a three-dimensional printing device, after having no fluidity, the molten or softened flowable metal is converted into metal built by printing, the molten or softened flowable metal is accumulated on the basis of the metal built by printing, until an object to be printed is built, and the accumulated metal built by printing forms the object to be printed; the key characteristics are as follows: in the building process, the interlayer binding force and the binding force between pixel points are changed through a manner of resistance heating; and a printing area for implementing resistance heating can be set. The metal component generated has high strength, high density, and high building precision, the building process of each pixel point is monitored, a removable auxiliary support can be generated synchronously, a large-scale component can be printed, and the apparatus is simple in structure and low in cost. The present invention possesses a substantial progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

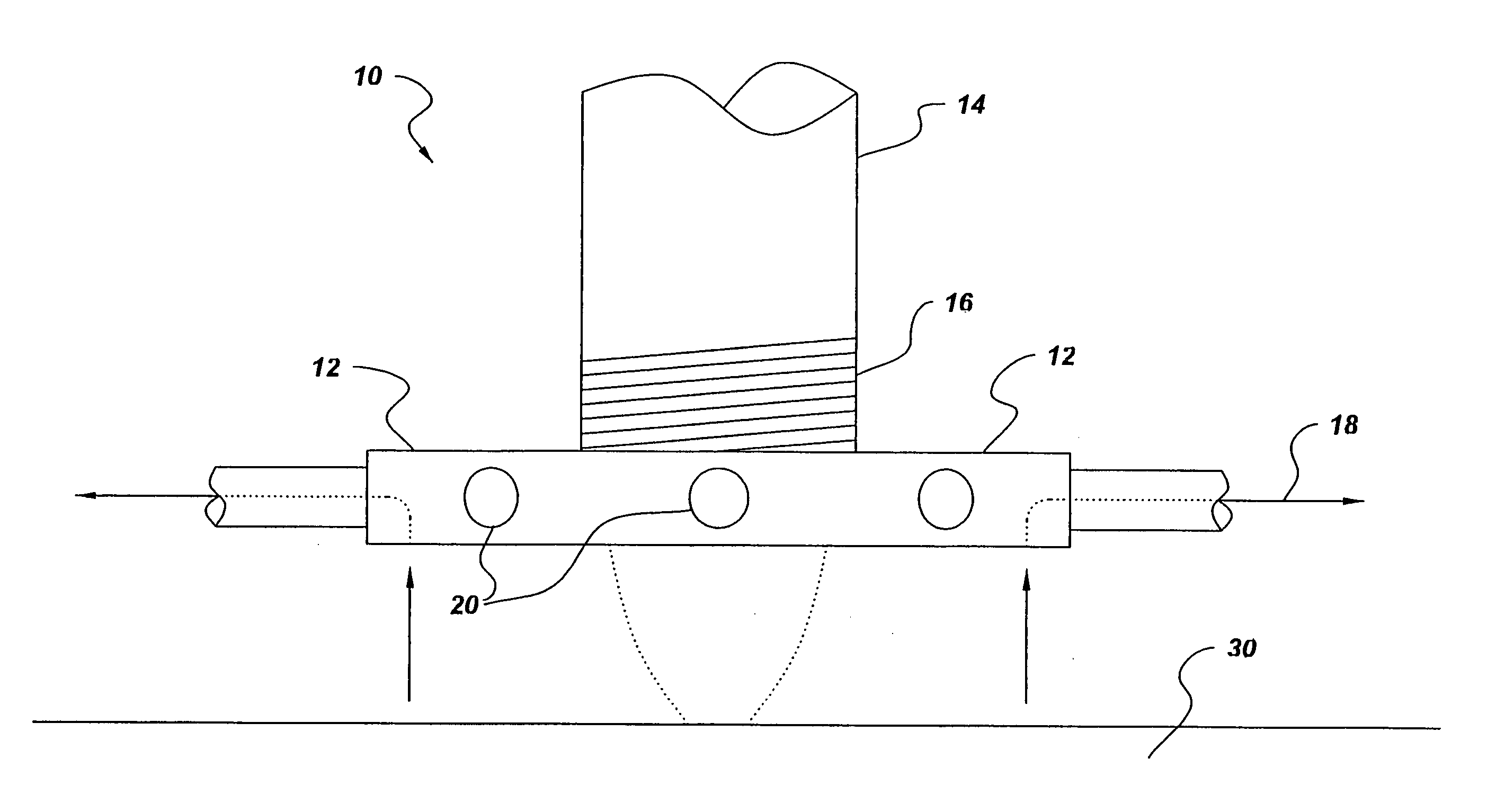

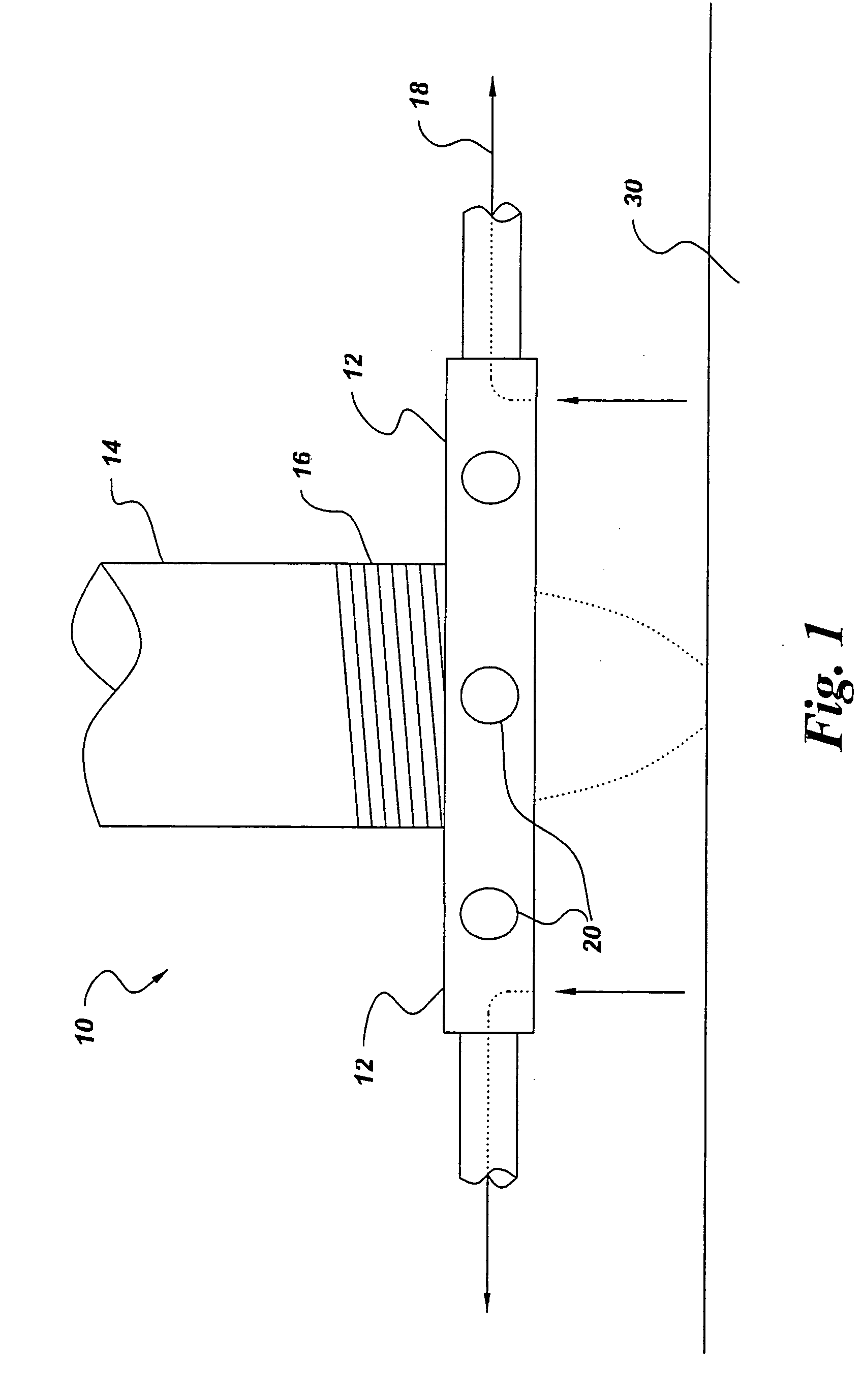

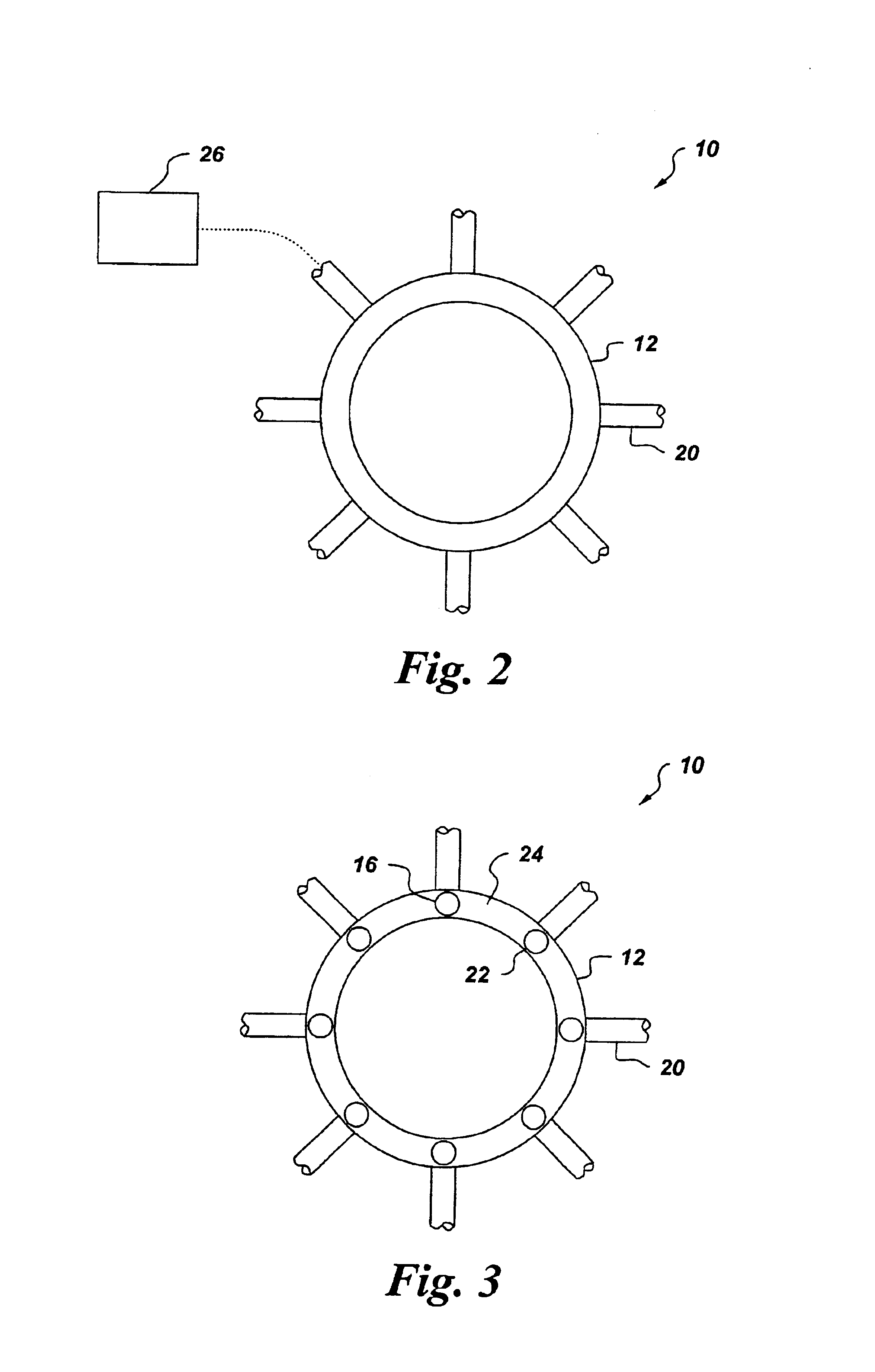

Coating apparatus and processes for forming low oxide coatings

A local environmental cell for a welding spray gun includes an annular ring having a top surface and a bottom surface, wherein the annular ring is adapted for attachment to an outer perimeter of the spray gun; and a plurality of fluid passageways radially disposed about the annular ring comprising a plurality of openings in the bottom surface of the ring in fluid communication with a vacuum source for providing a vacuum thereto. The use of the local environmental cell permits deposition of local bond coats as well as minimizes the number of steps associated with welding repair processes. For example, the use of the local environmental cell permits welding and formation of a low oxide bond coat during the welding process, thereby eliminating the need for placing the substrate subsequent to a welding process in a separate spray cell to deposit the bond coating.

Owner:GENERAL ELECTRIC CO

Method of bonding a metal to a substrate

A method of bonding a metal to a substrate is disclosed herein. The method involves forming a nano-brush on a surface of the substrate, where the nano-brush includes a plurality of nano-wires extending above the substrate surface. In a molten state, the metal is introduced onto the substrate surface, and the metal surrounds the nano-wires. Upon cooling, the metal surrounding the nano-wires solidifies, and during the solidifying, at least a mechanical interlock is formed between the metal and the substrate.

Owner:GM GLOBAL TECH OPERATIONS LLC

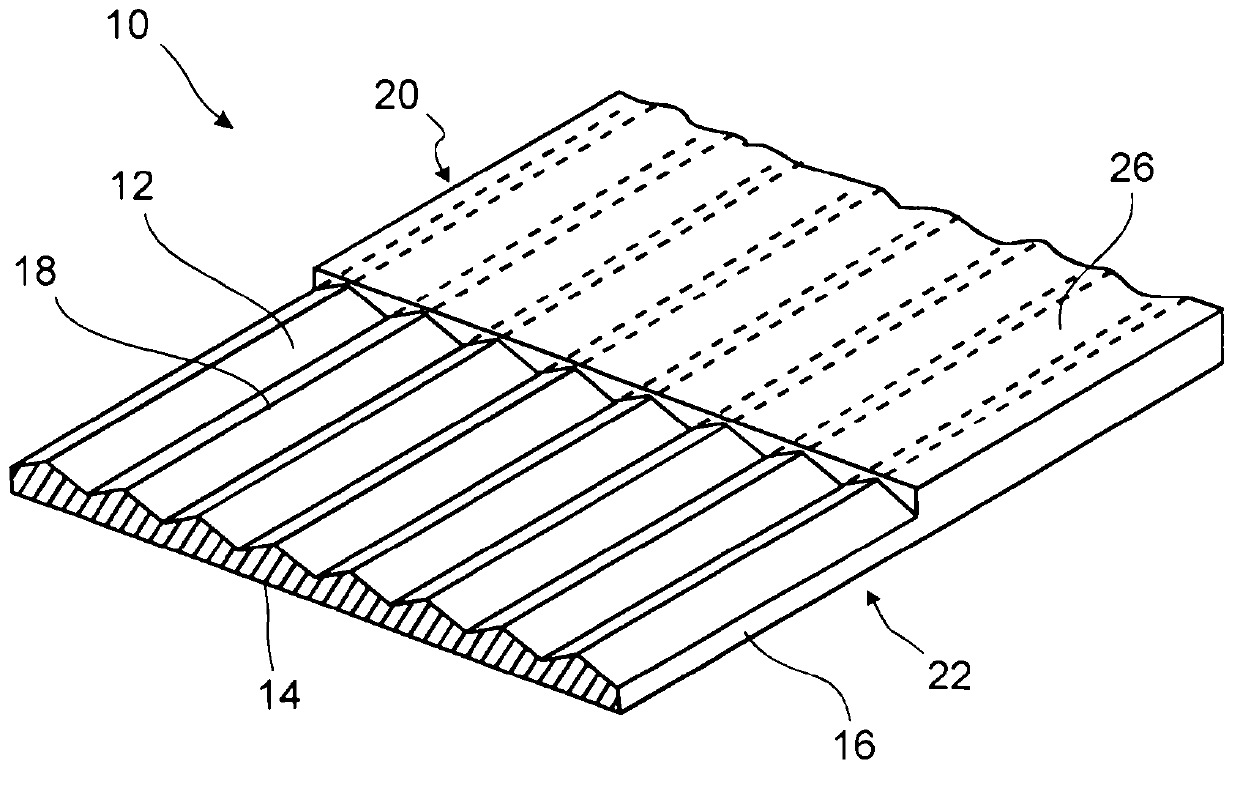

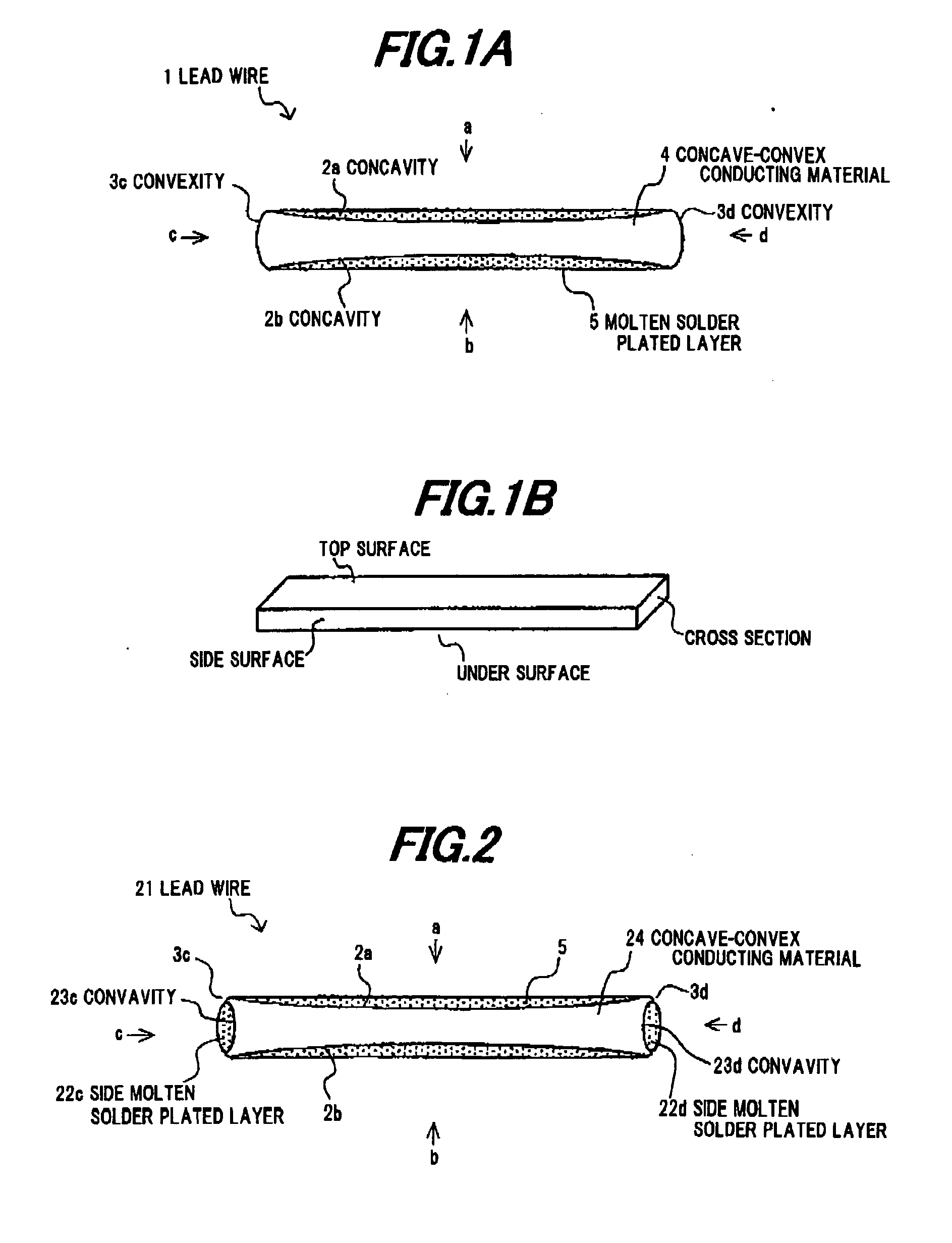

Process for producing pre-tin-plated connectors for pv cells and metal foil having a groove structure running in one direction

To produce pre-tin-plated strips of connectors for PV cells, a metal foil (30) is guided through a roll gap (46) of a roll unit, in which at least one roll (48) has a surface with a groove structure, such that a groove structure having ridges or vertices and valleys is pressed at least into one side of the metal foil (30), tin solder in the form of solder preforms (54) is applied to that side of the metal foil (30) which has the impressed groove structure, wherein the soldering flux required for the tin plating has previously been applied to the solder preforms or the metal foil, the solder preforms (54) are connected to the metal foil (30) or applied thereto and melted, and the tin-plated metal foil (30) which has the impressed groove structure is separated into parallel strips.; The solder preforms (54) have such a thickness that the groove structure is at least filled up after the solder preforms (54) have been melted.

Owner:SCHLENK METALLFOLIEN

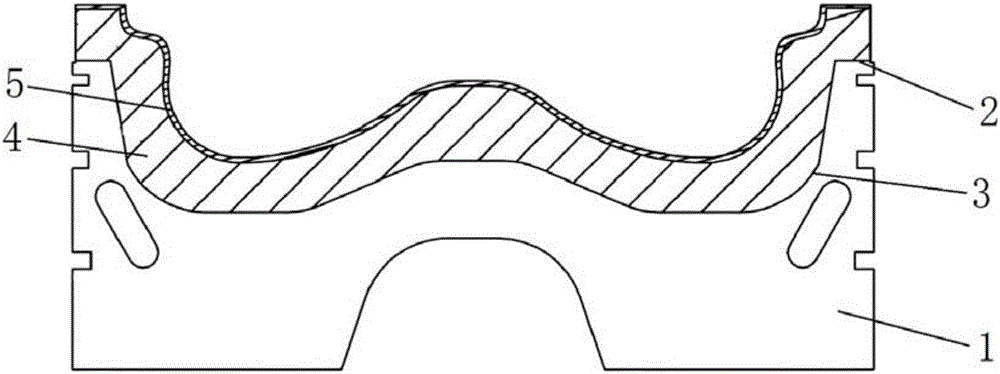

Heat insulating piston

InactiveCN106194483AReduce heat lossLow thermal conductivityMolten spray coatingMolten casting coatingCombustion chamberEngineering

The invention relates to the technical field of internal combustion engines, in particular to a heat insulating piston. The heat insulating piston comprises a piston substrate. A groove used for forming a combustion chamber is formed in the top of the piston substrate. A foam metal layer is arranged on the top face of the piston substrate and the surface of the groove. According to the heat insulating piston provided by the invention, the foam metal layer is arranged on the top face of the piston substrate and the surface of the groove used for forming the combustion chamber correspondingly; on the one hand, the specific heat capacity of the foam metal layer is low, and heat stored by the foam metal layer during working of the piston is small, so that the heat absorbed from the combustion chamber is small; and on the other hand, the heat conduction coefficient of the foam metal layer is low, so that the speed of heat transfer from the combustion chamber to the piston substrate is low, and the heat loss of the combustion chamber is effectively reduced.

Owner:WEICHAI POWER CO LTD

Gas Turbine Engine Components With Aluminide Coatings And Method Of Forming Such Aluminide Coatings On Gas Turbine Engine Components

ActiveUS20080220165A1Reduce transportationLess-expensive to producePretreated surfacesEfficient propulsion technologiesBond coatingHafnium

A turbine engine component (10) with a protective aluminide coating (14) that include additions of silicon and a dopant, such as yttrium and / or hafnium, in an amount effective to reduce sulfidation and a deposition process for forming such aluminide coatings (14). A silicon-containing layer (30) may be applied to the superalloy substrate (12) of the component (10) and the aluminide coating (14) formed by exposing component (10) and layer (30) to a vapor phase reactant containing the dopant. The aluminide coating (14), which contains dopant from the layer (30), may operate as a standalone environmental coating or as a bond coating for an optional ceramic thermal barrier layer (24). An optional zirconia layer (26) maybe provided between the aluminide coating (14) and the ceramic thermal barrier layer (24). Alternatively, the dopant may be included in the silicon-containing layer (30) applied to the component (10) before the aluminide coating (14) is formed and no vapor phase reactant containing the dopant is required.

Owner:AEROMET TECH

Solar cell lead wire, method of making the same, and solar cell

InactiveUS20090260689A1Avoid crackingHot-dipping/immersion processesNon-insulated conductorsMetallurgyDying processes

A solar cell lead wire includes a conducting material, and a molten solder plated layer formed on the conducting material. The conducting material includes a concave-convex conducting material that includes a concavity on top and under surfaces thereof, respectively, and a convexity on a side surface thereof, and that is formed by die processing a strip-shaped conducting material, and the molten solder plated layer comprises a flat surface formed by supplying a molten solder to the concavity of the concave-convex conducting material.

Owner:HITACHI METALS LTD

A method of repairing parts with laser directional solidification technology

InactiveCN106342014BIntegrity guaranteedEnsure consistencyMolten casting coatingLaser beam welding apparatusNumerical controlLaser coating

The invention is a method for repairing parts by laser directional solidification technology. In order to overcome the deficiency in the prior art that the columnar crystal or single crystal structure in the repaired area is consistent with the original part structure, the present invention slices and processes the three-dimensional information of the part to be repaired into a series of two-dimensional plane data information, The CNC machine tool scans according to the scanning trajectory determined by the two-dimensional plane data. The laser beam forms a laser molten pool in the repair area of the part. Covering and stacking layer by layer, so as to realize the repair of parts by using epitaxial laser metal forming method. By adopting the technical solution of the present invention, a directionally solidified columnar crystal or single crystal repair layer can be obtained in the repair area, which is epitaxially grown from the original part tissue, which ensures the integrity and orientation consistency of the repair layer and the matrix grains, and has good applicability .

Owner:NORTHWESTERN POLYTECHNICAL UNIV

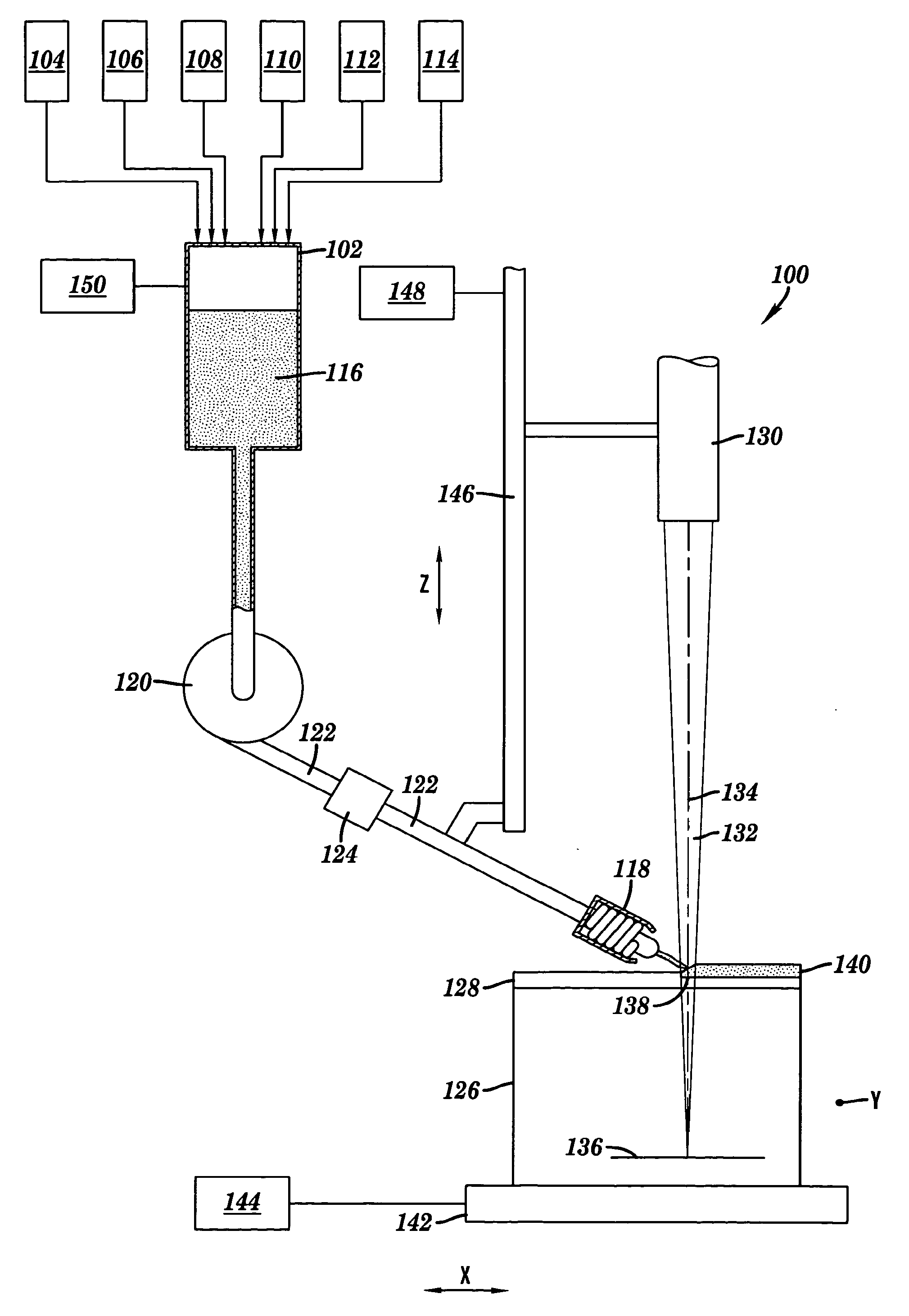

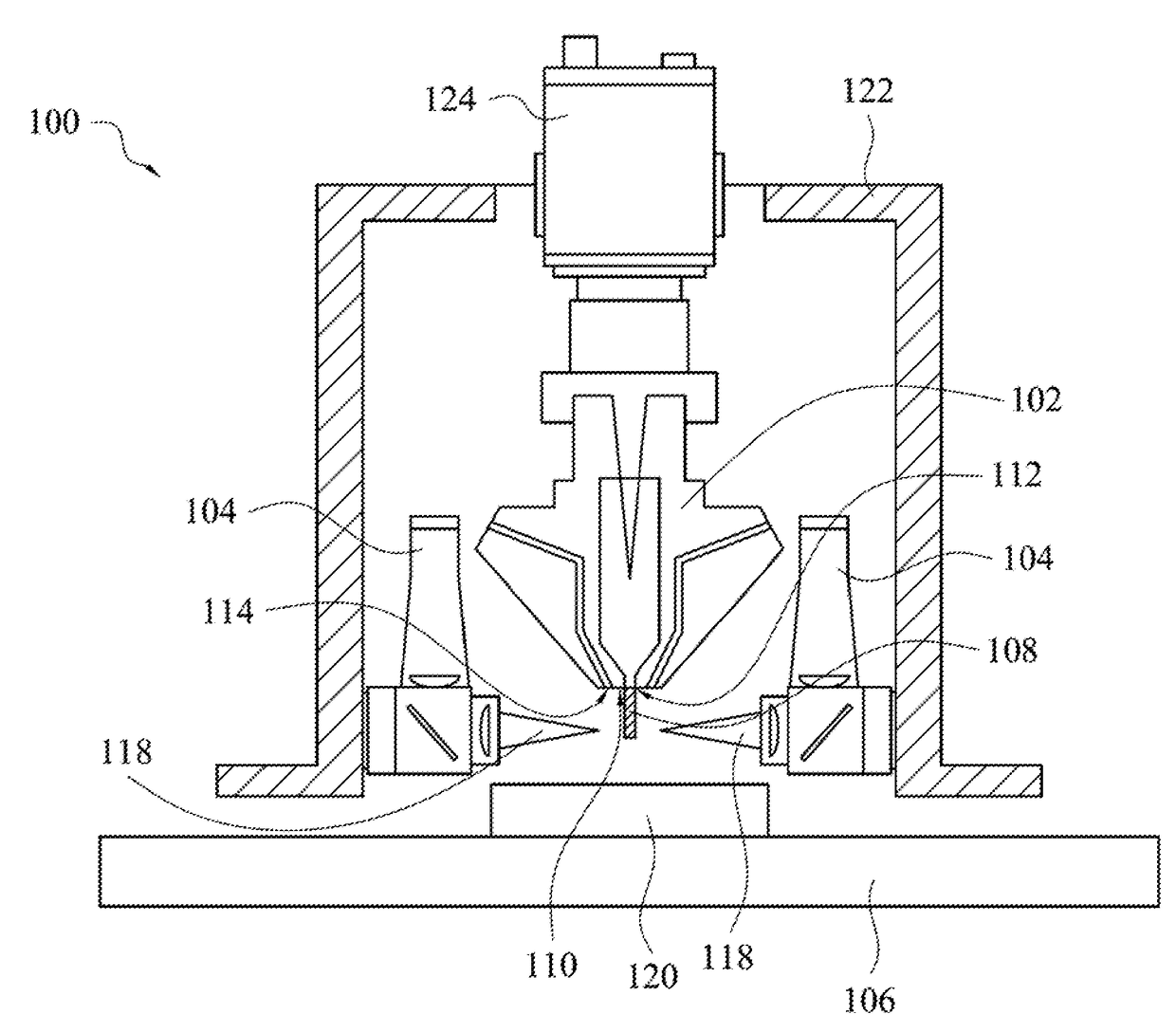

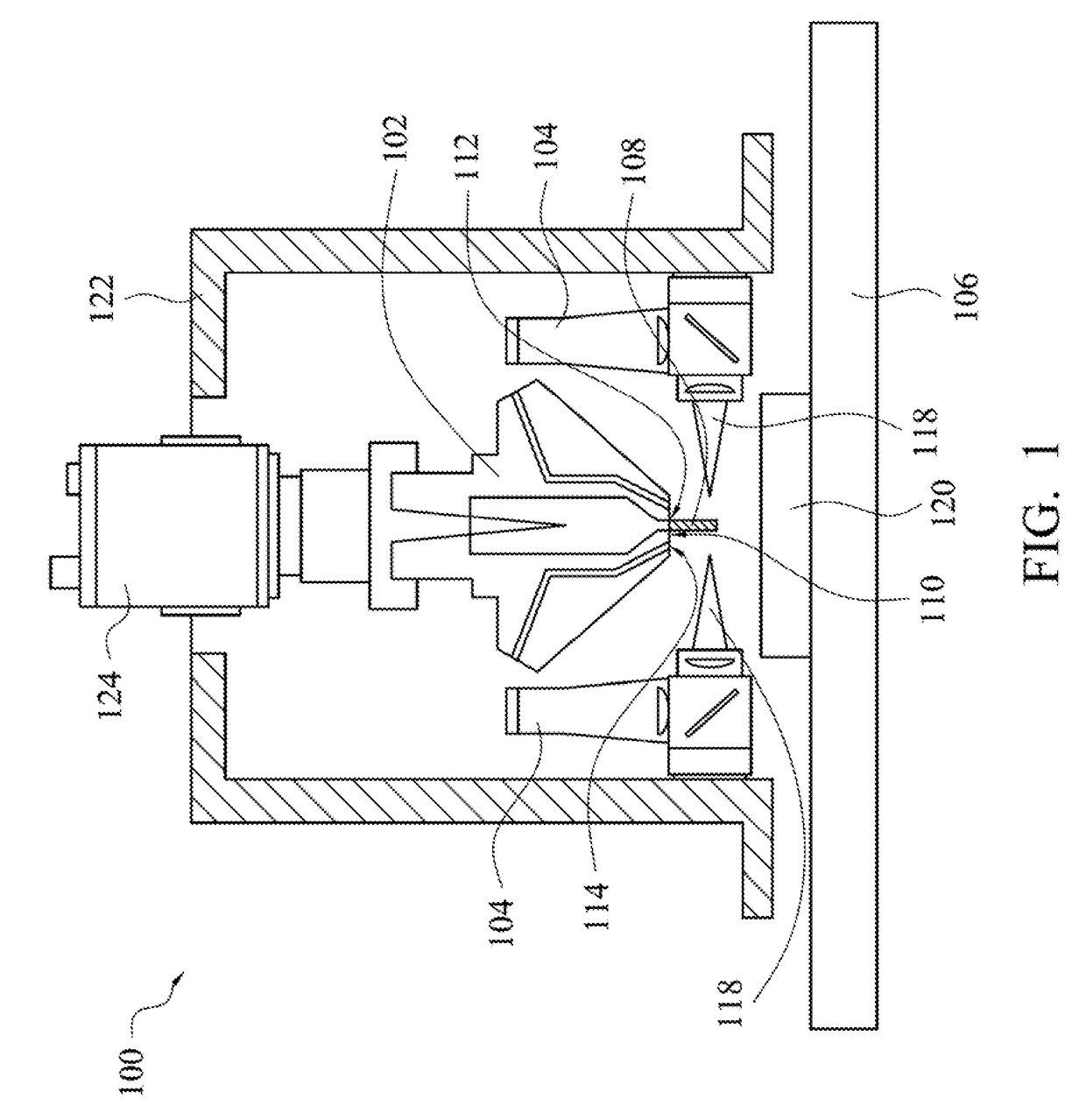

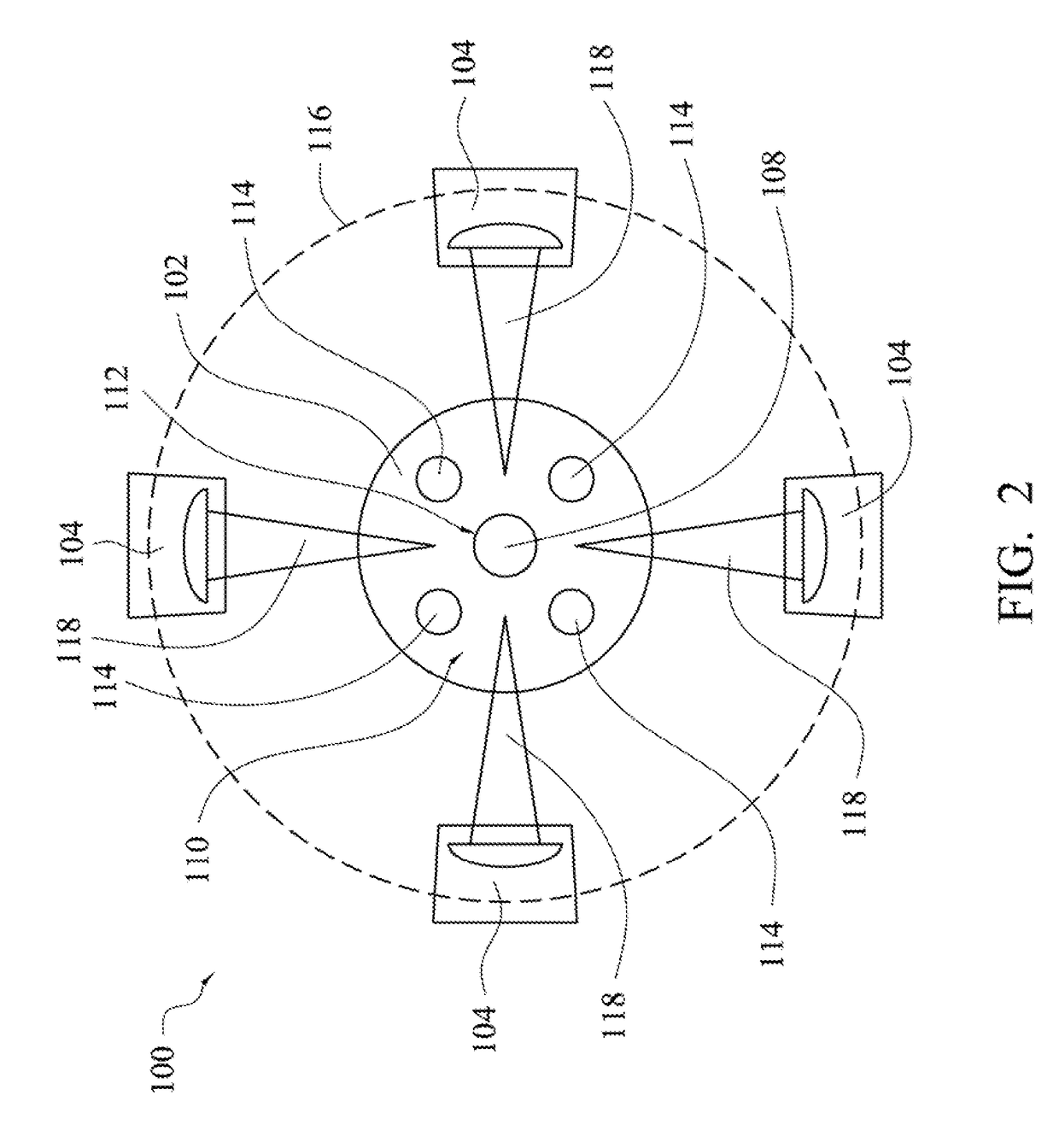

Deposition apparatus and deposition method

InactiveUS20170361404A1Low costSimple materialAdditive manufacturing apparatusMolten spray coatingEngineeringLaser beams

A deposition apparatus and a deposition method are described. The deposition apparatus includes an accommodating element, a plurality of lasers and a carrier. The accommodating element is configured to accommodate a material. The lasers are disposed at a periphery of the accommodating element, and are configured to simultaneously emit a plurality of laser beams toward the material to melt the material to form a deposition liquid. The carrier is disposed under the accommodating element and the lasers, and are configured to carry the deposition liquid.

Owner:NAT CHENG KUNG UNIV

Coating apparatus and processes for forming low oxide coatings

A local environmental cell for a welding spray gun includes an annular ring having a top surface and a bottom surface, wherein the annular ring is adapted for attachment to an outer perimeter of the spray gun; and a plurality of fluid passageways radially disposed about the annular ring having a plurality of openings in the bottom surface of the ring in fluid communication with a vacuum source for providing a vacuum thereto. The use of the local environmental cell permits deposition of local bond coats as well as minimizes the number of steps associated with welding repair processes. For example, the use of the local environmental cell permits welding and formation of a low oxide bond coat during the welding process, thereby eliminating the need for placing the substrate subsequent to a welding process in a separate spray cell to deposit the bond coating.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com