Method of bonding a metal to a substrate

A metal and substrate technology, applied in the direction of metal material coating process, coating, hot-dip coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

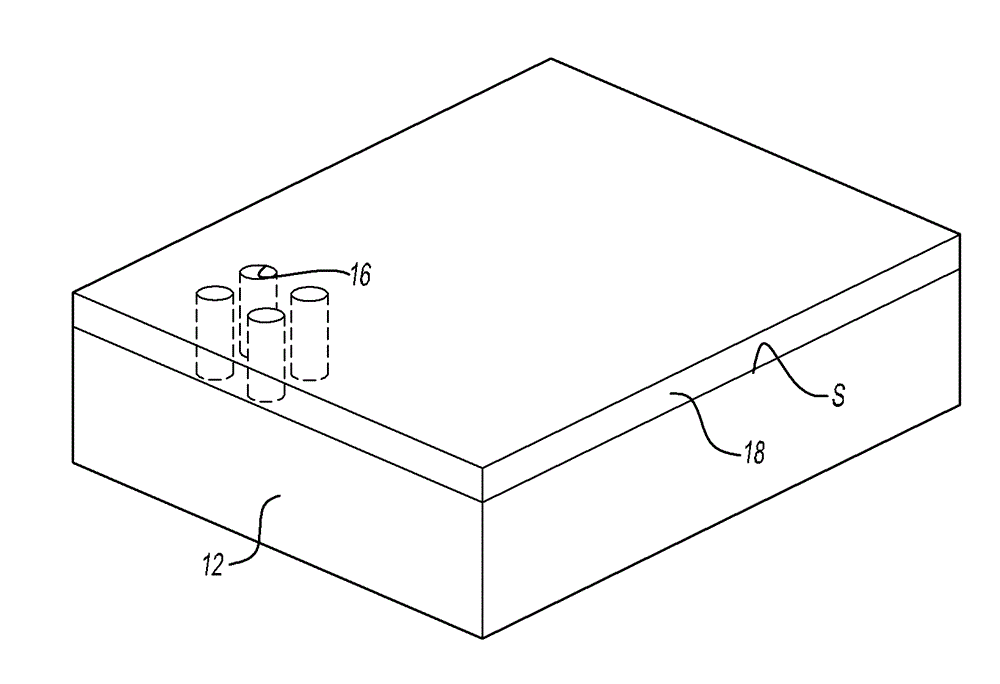

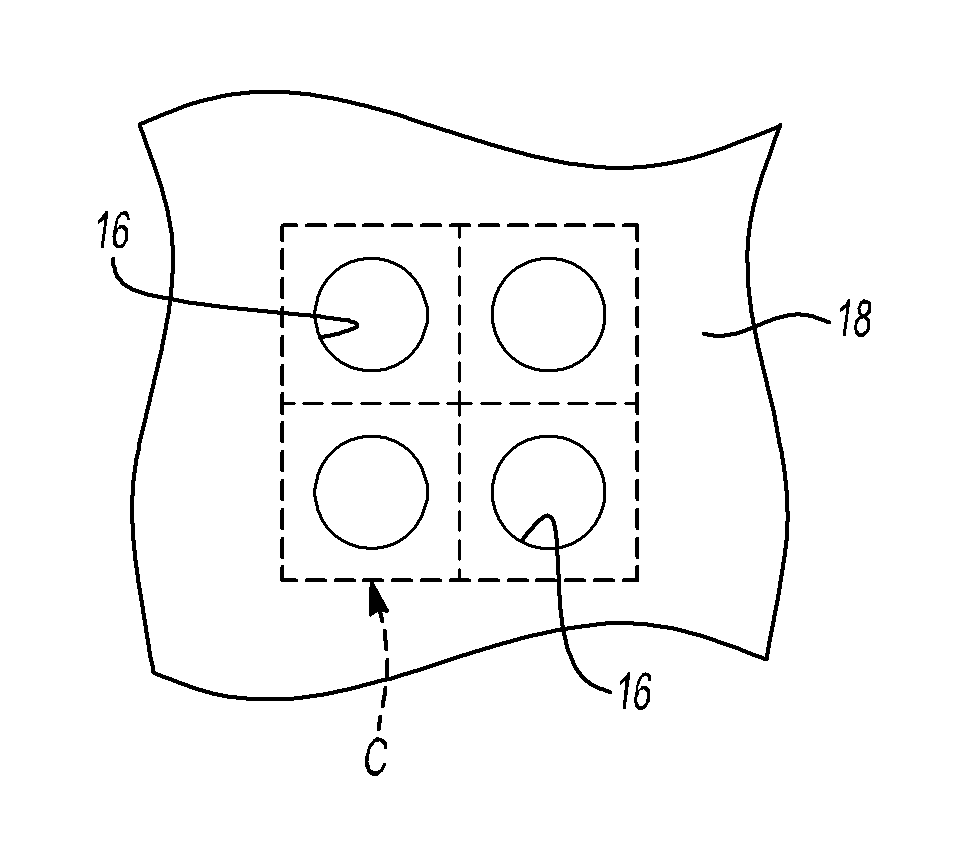

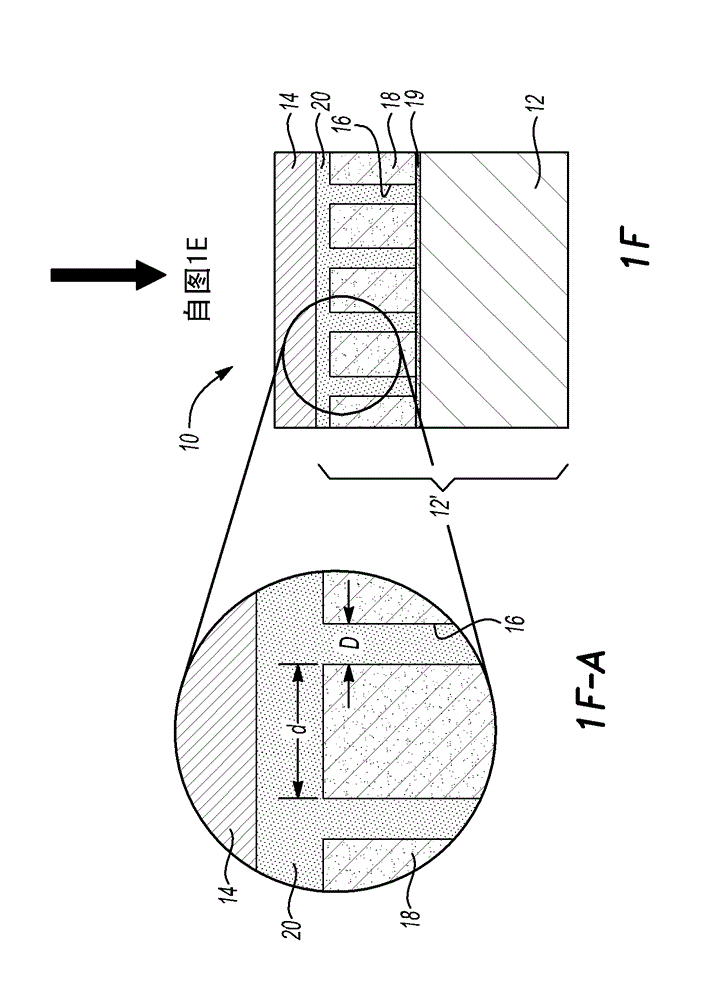

[0041] Aluminum and steel can be used to make different car parts, at least because these materials have mechanical strength that contributes to the structural integrity of the part. It has been found that some aluminum or steel in the parts can be replaced with lighter weight materials such as magnesium. It is believed that the presence of lighter weight materials will reduce the total weight of automotive parts in some cases.

[0042] It has been found that magnesium can be incorporated into aluminum or steel parts via a casting method such as a method called overflow casting. It has also been found that in some cases magnesium cannot be metallurgically bonded to the underlying aluminum or steel, at least not to the extent necessary to form parts that are considered structurally sound and can be used in automobiles. For example, aluminum may include a dense oxide surface layer (e.g., aluminum oxide) formed thereon, which prevents metallurgical bonding of magnesium to aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com