Patents

Literature

1091 results about "Plasma jet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

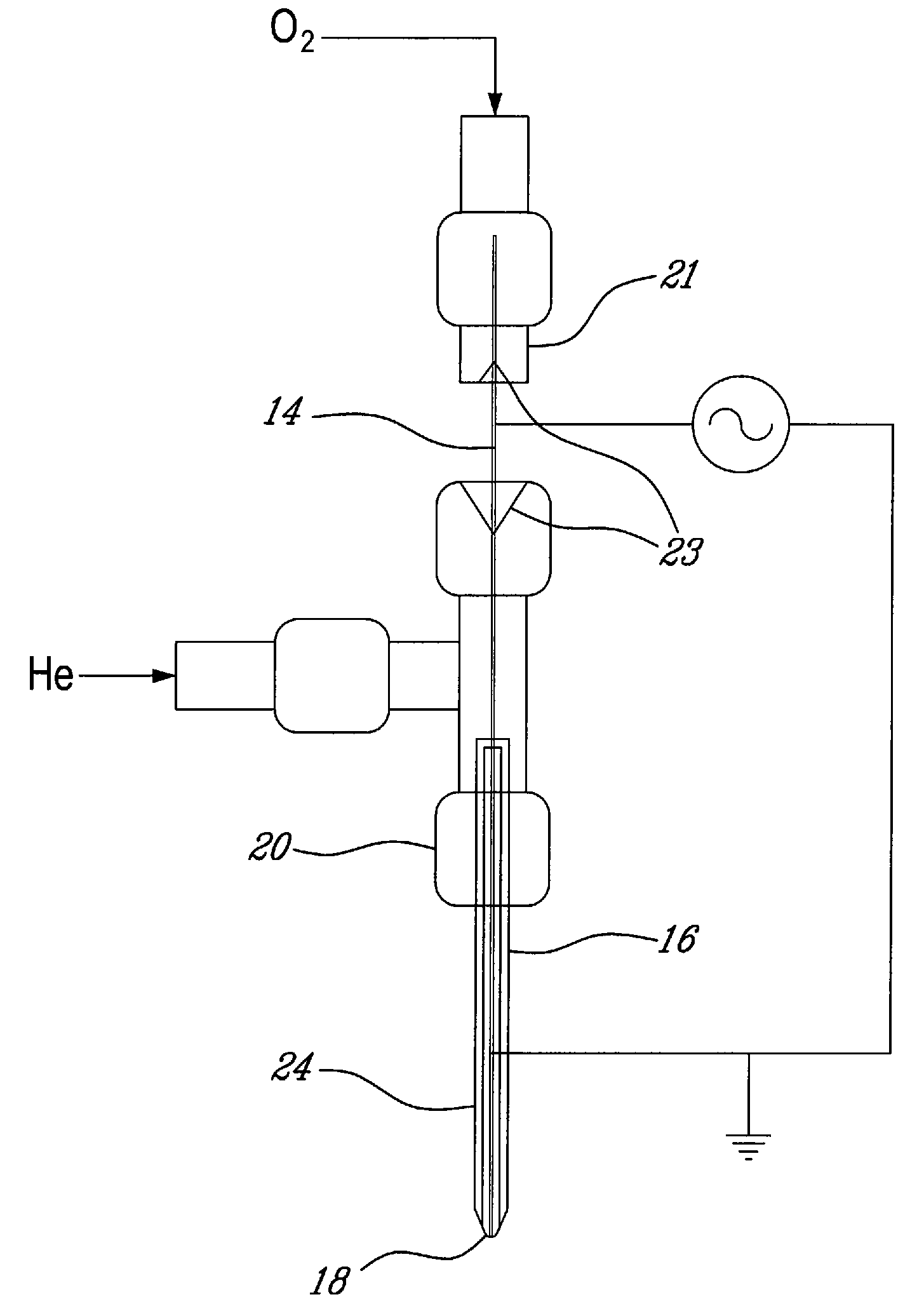

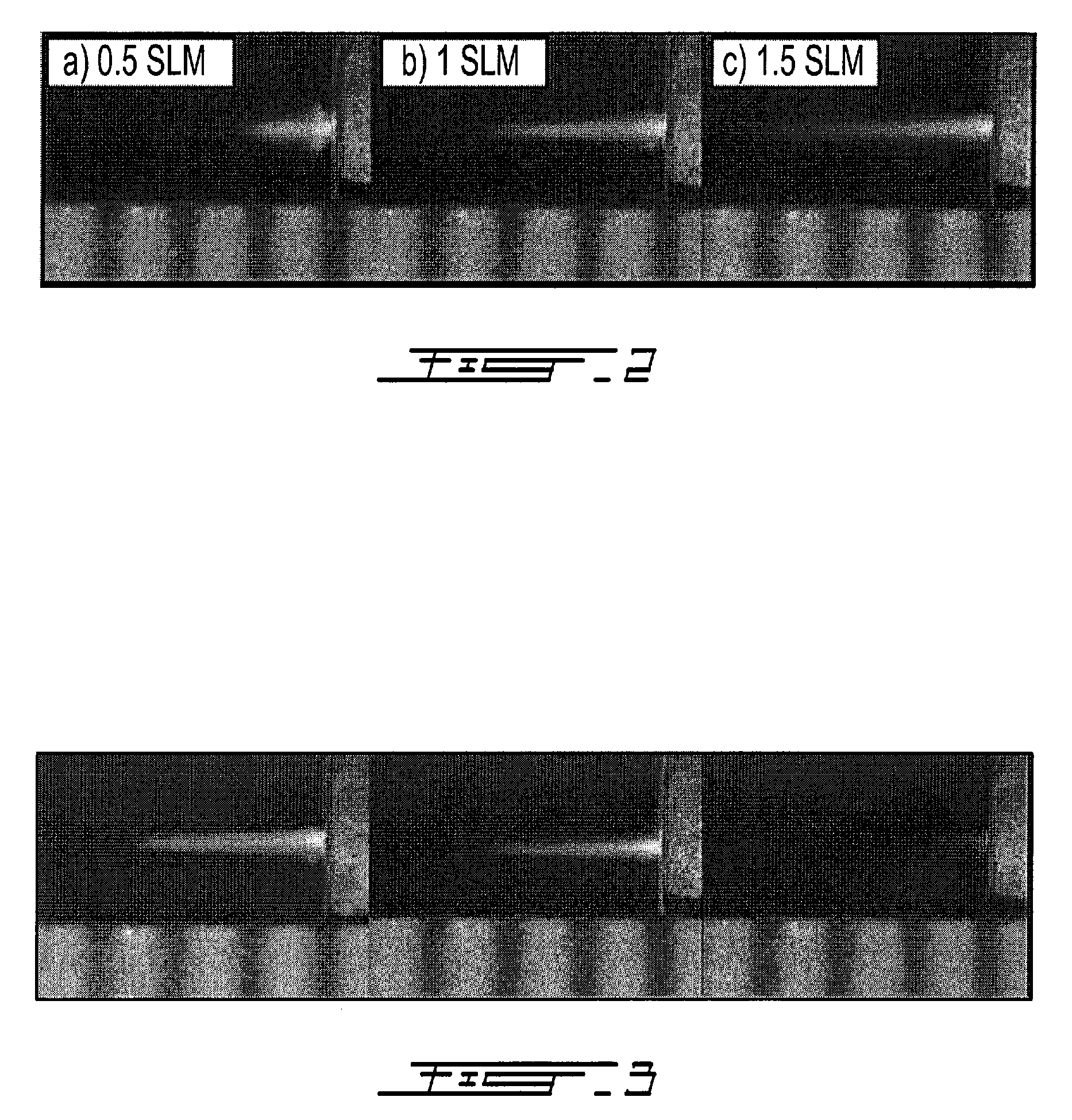

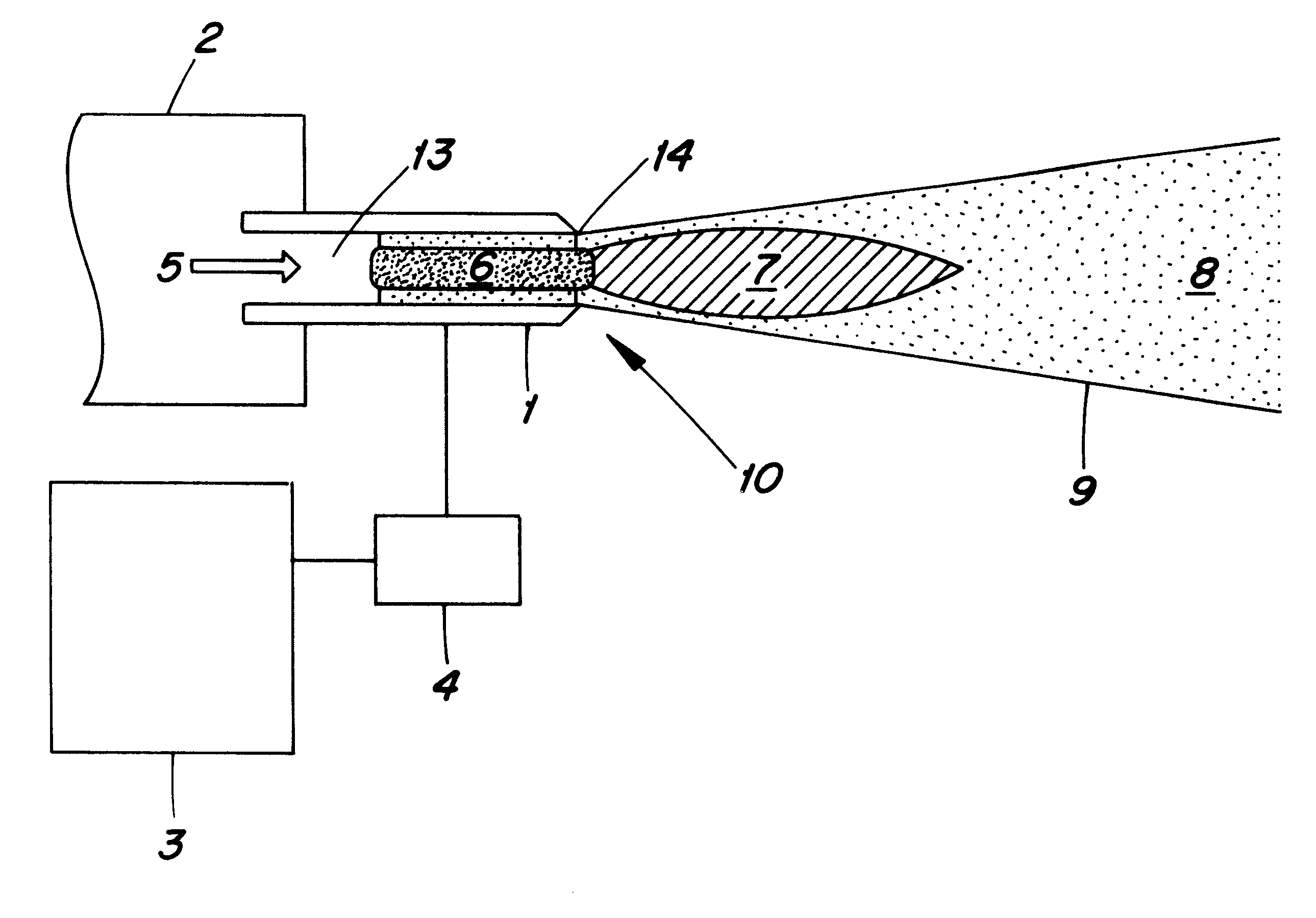

Plasma source and applications thereof

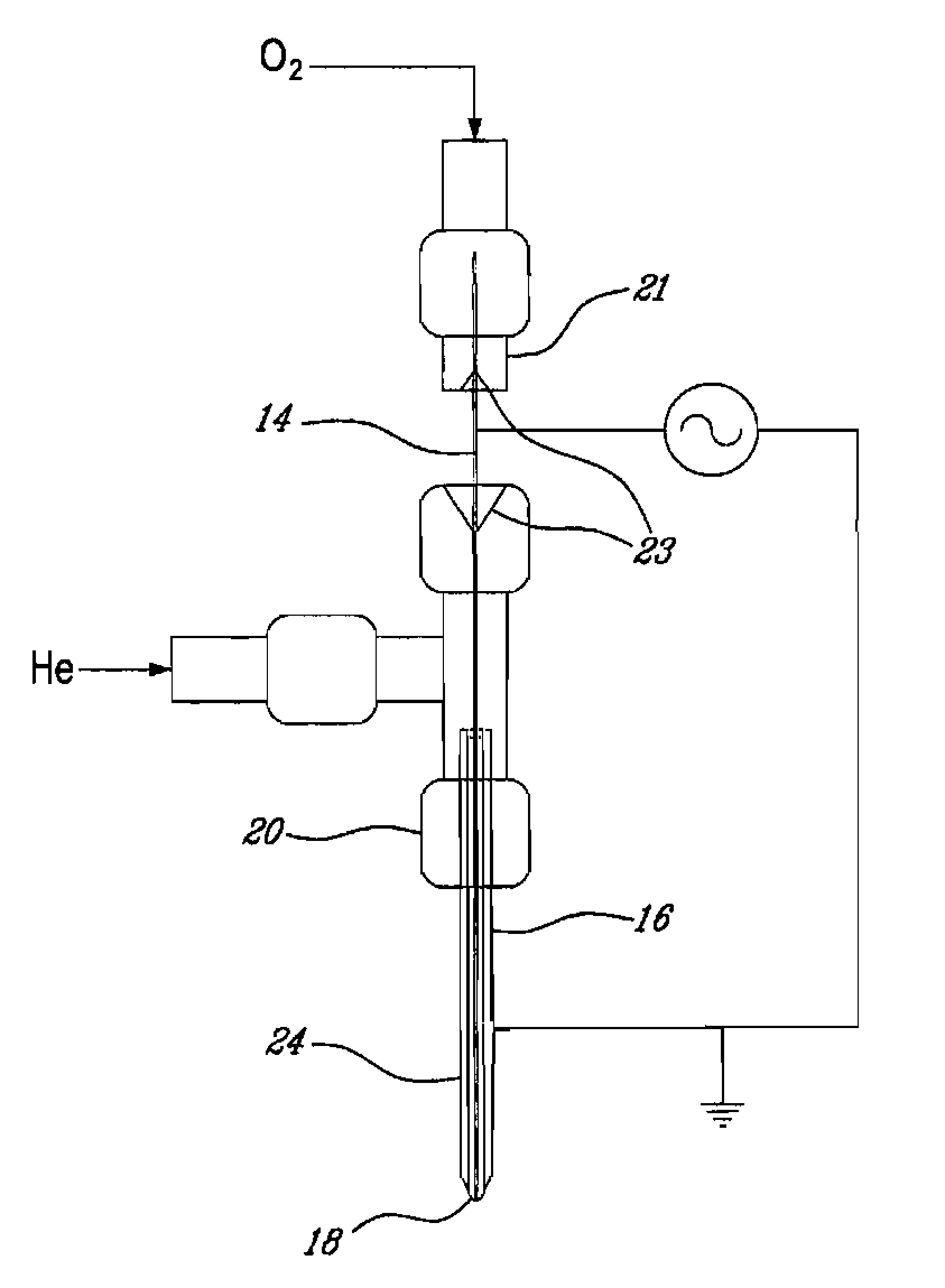

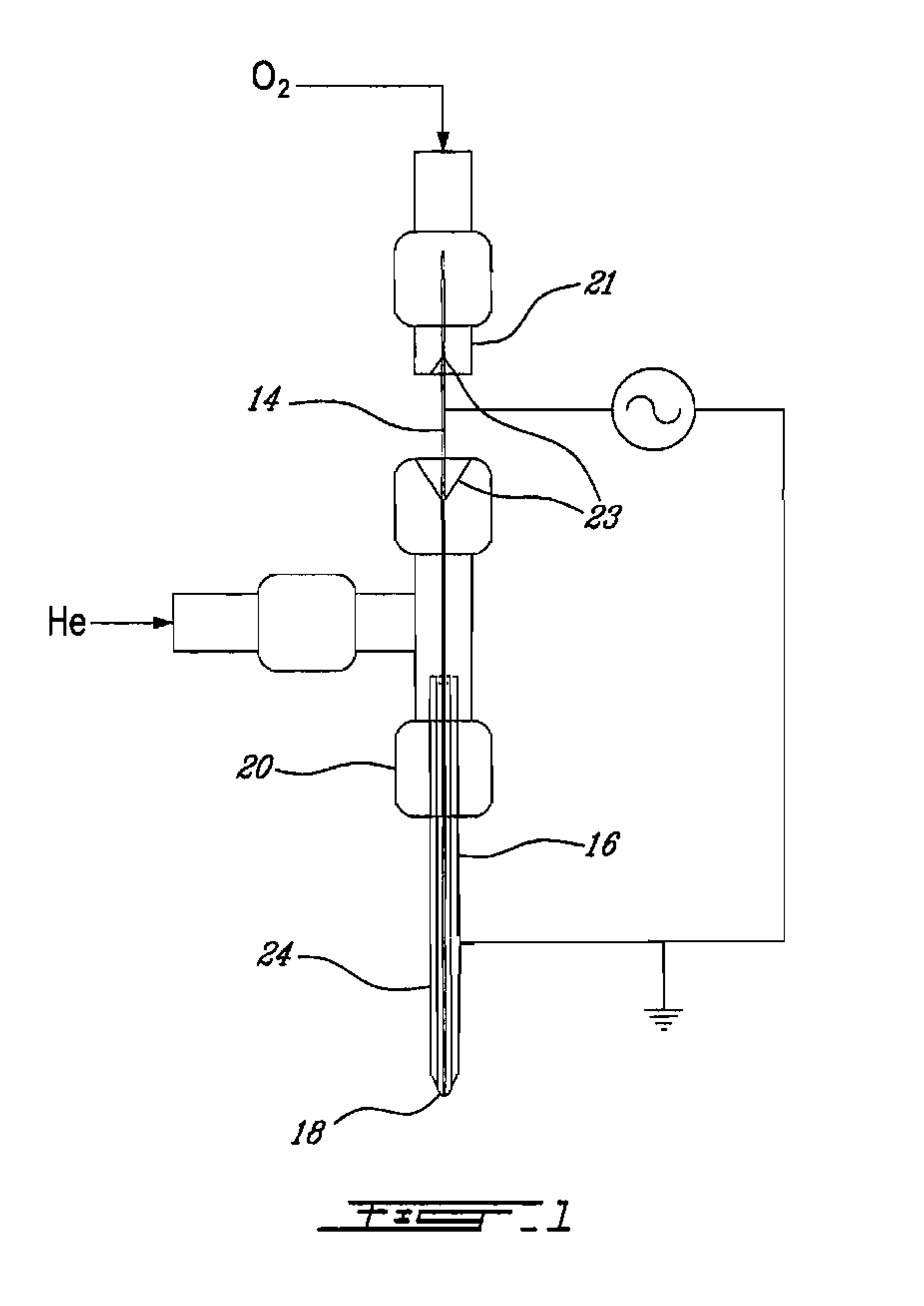

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may found applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

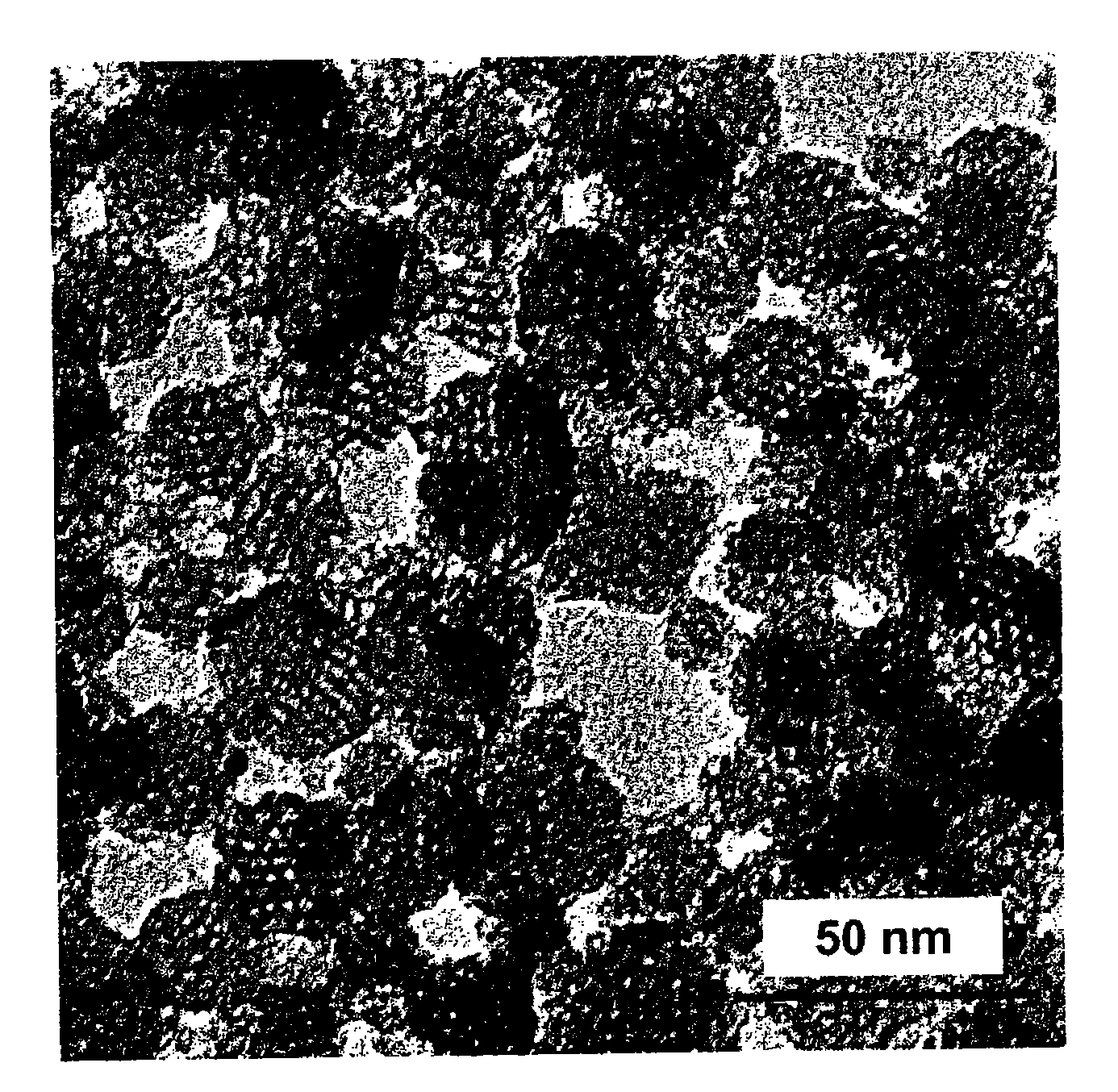

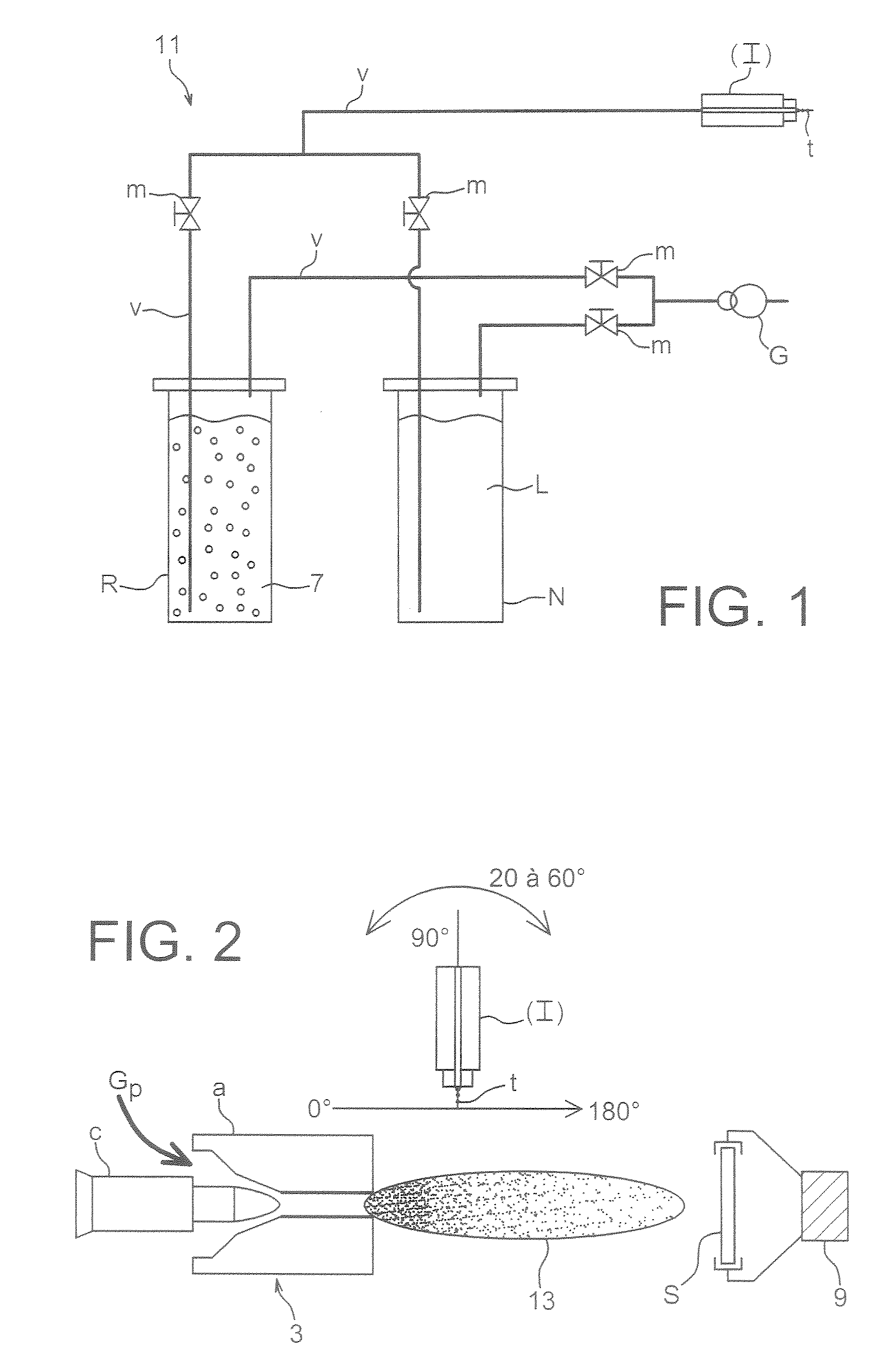

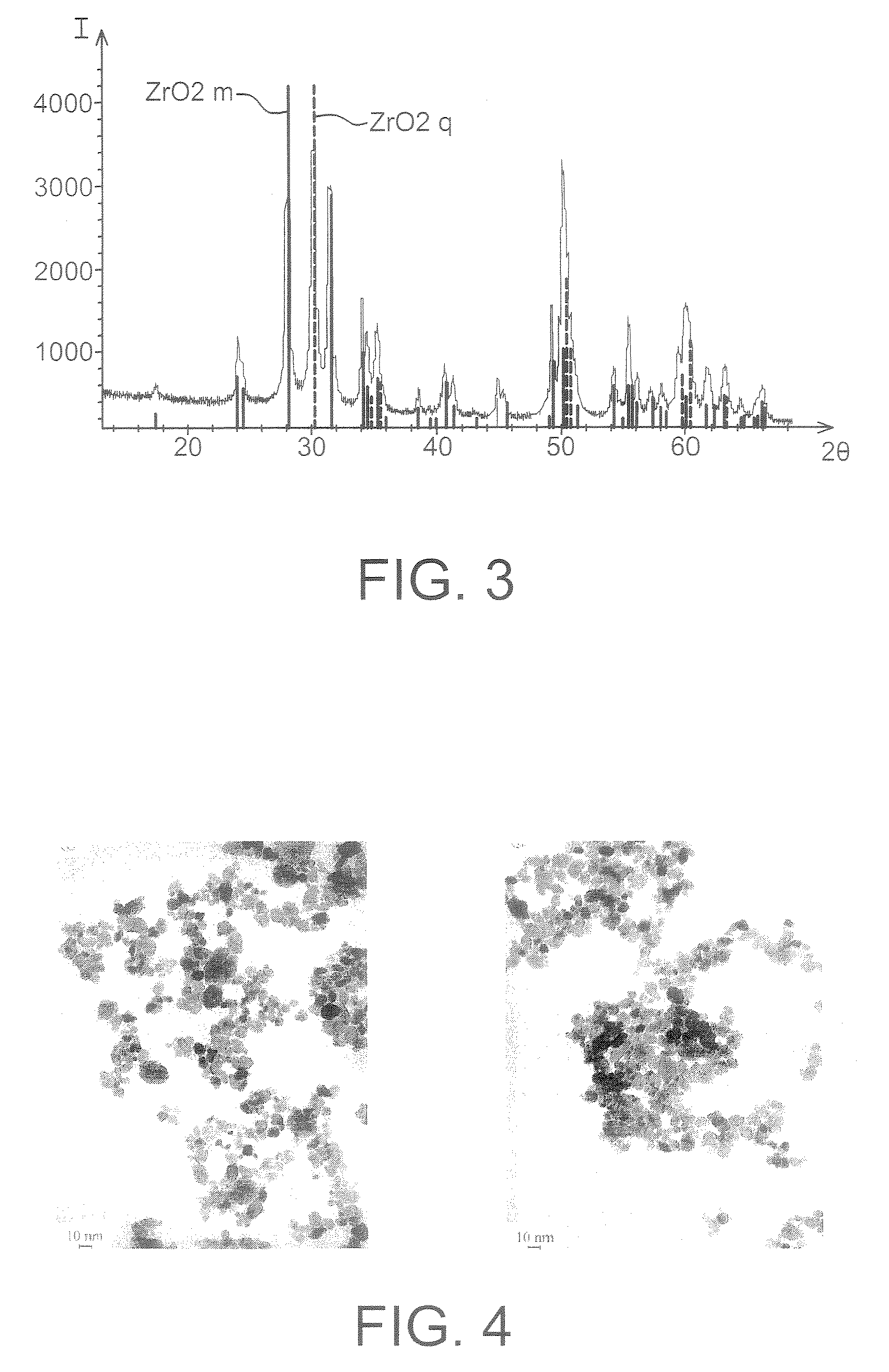

Process for Producing a Nanoporous Layer of Nanoparticles and Layer Thus Obtained

ActiveUS20090241496A1Easy to carryImprove performanceCombination devicesLiquid surface applicatorsPlasma jetNanoparticle

Process for producing at least one nanoporous layer of nanoparticles chosen from nanoparticles of a metal oxide, nanoparticles of metal oxides, and mixtures of said nanoparticles, on a surface of a substrate, in which at least one colloidal sol, in which said nanoparticles are dispersed and stabilized, is injected into a thermal plasma jet which sprays said nanoparticles onto said surface.Nanoporous layer and device, especially a separation device, comprizing said layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source of reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may find applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

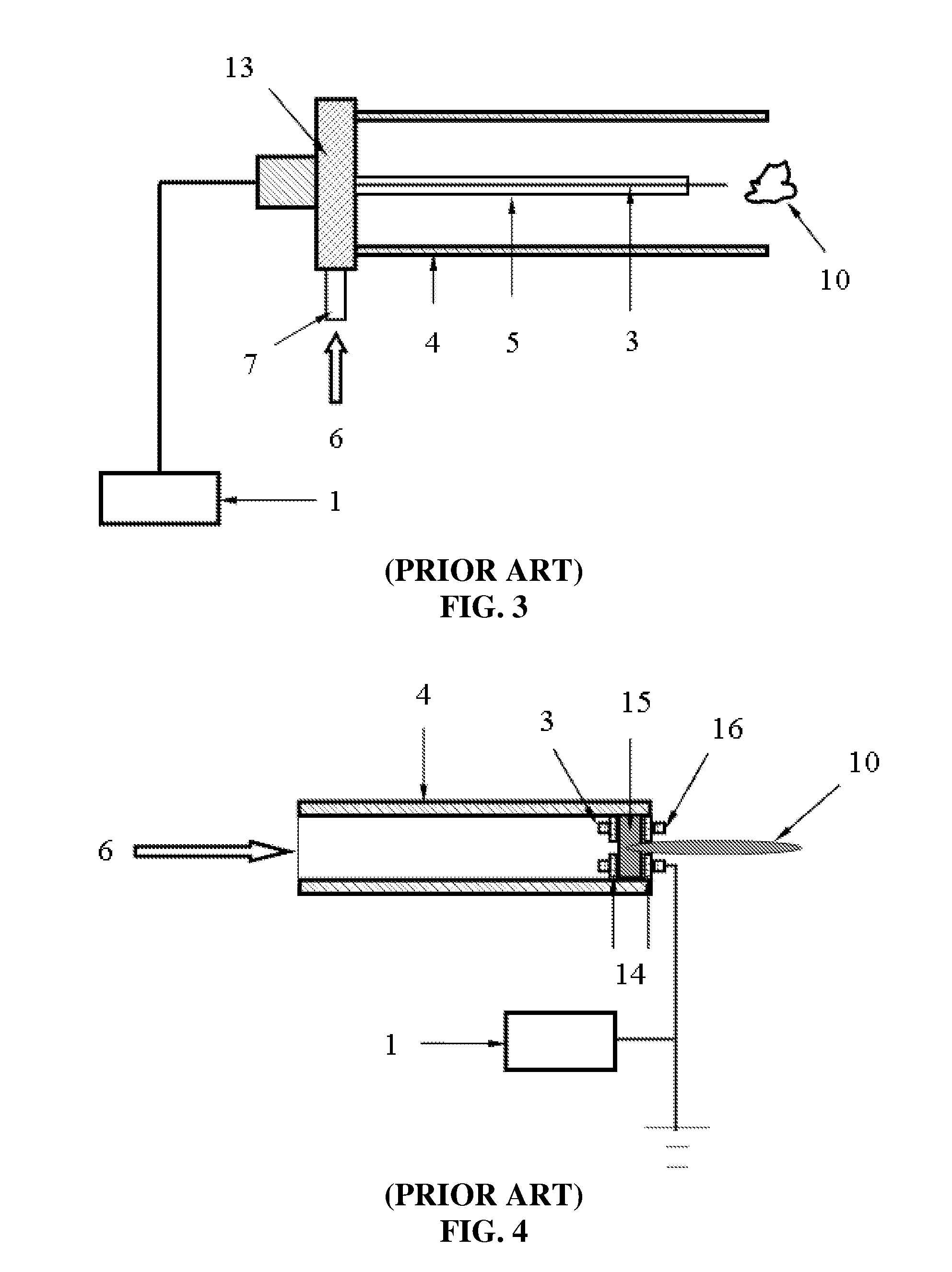

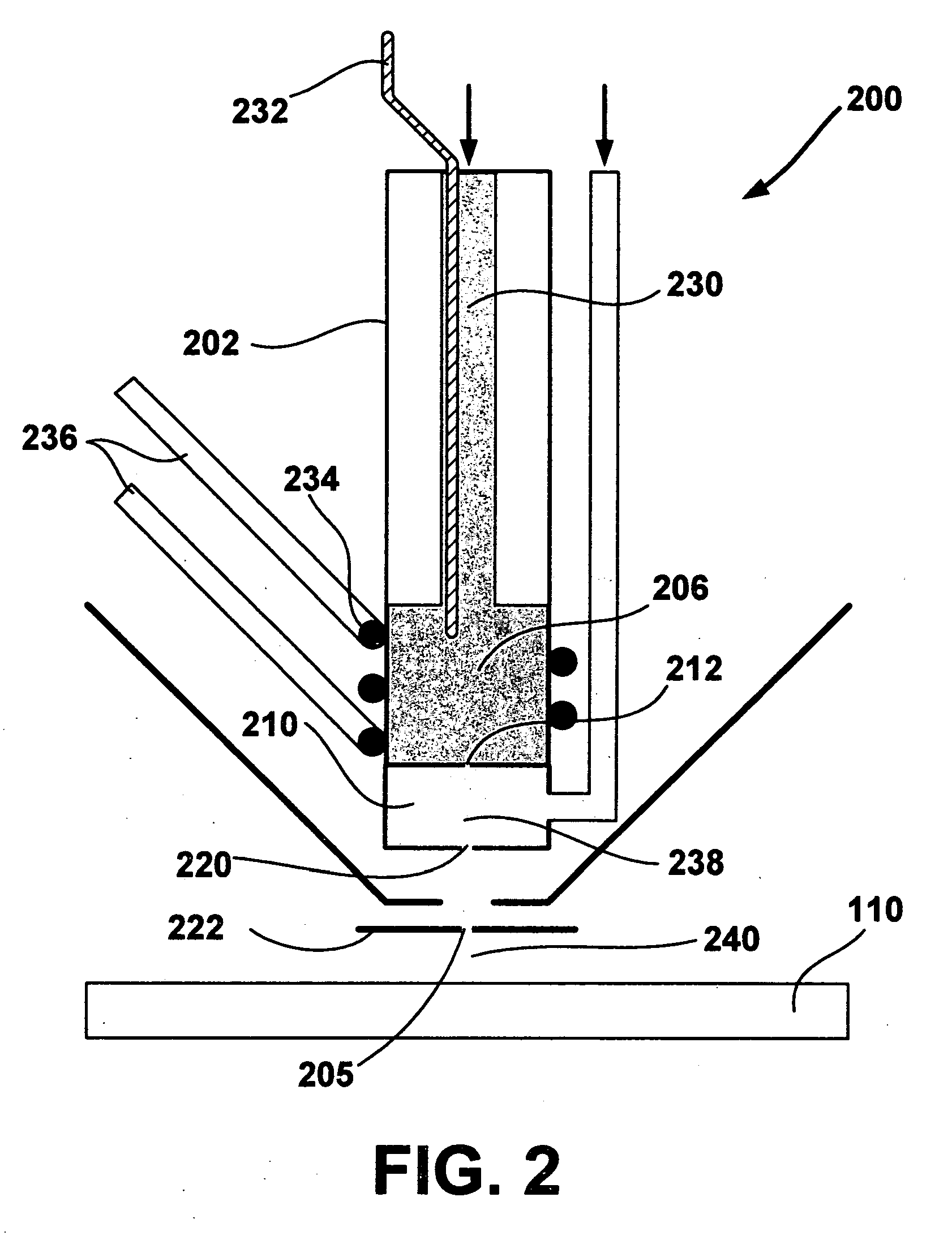

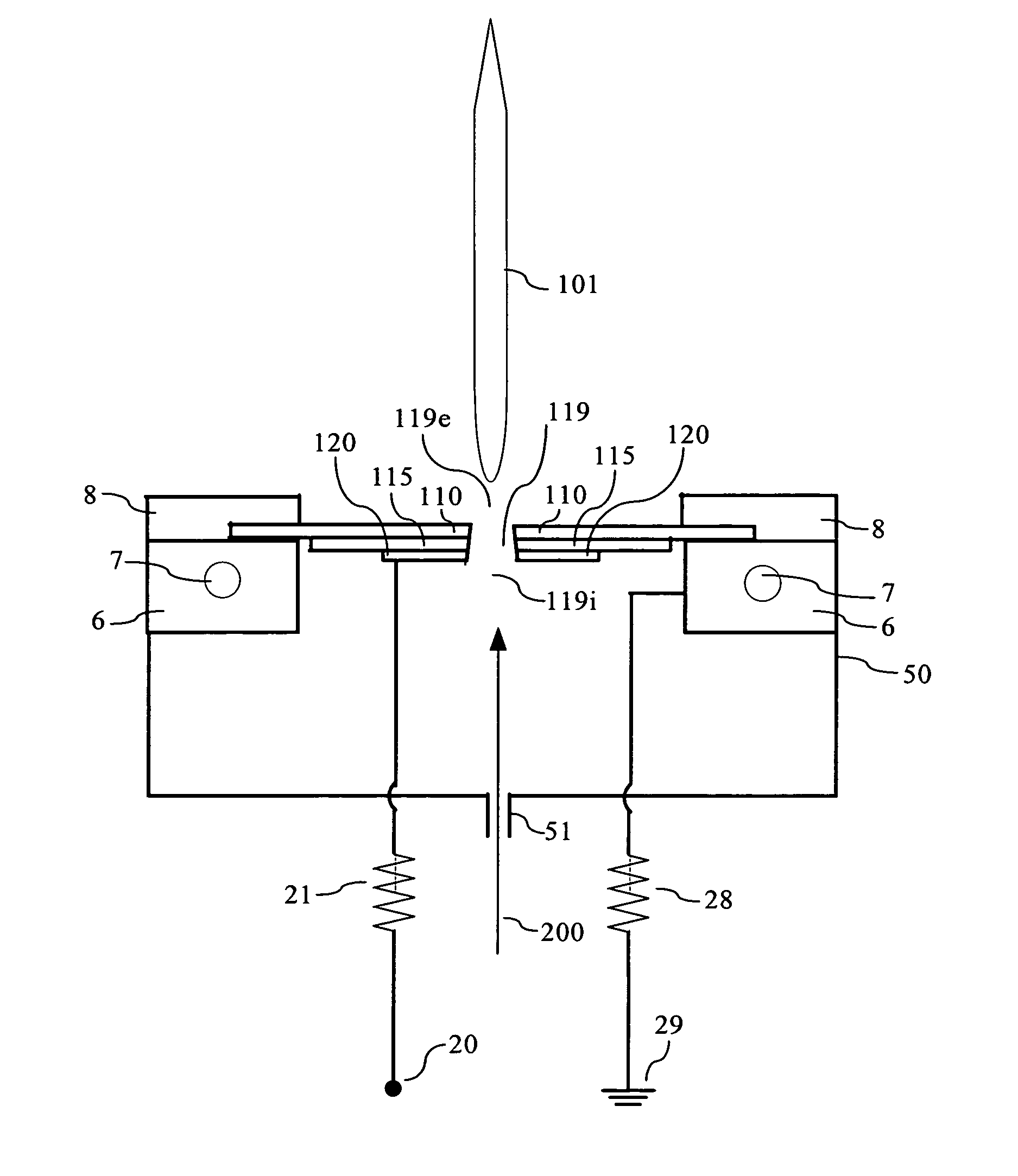

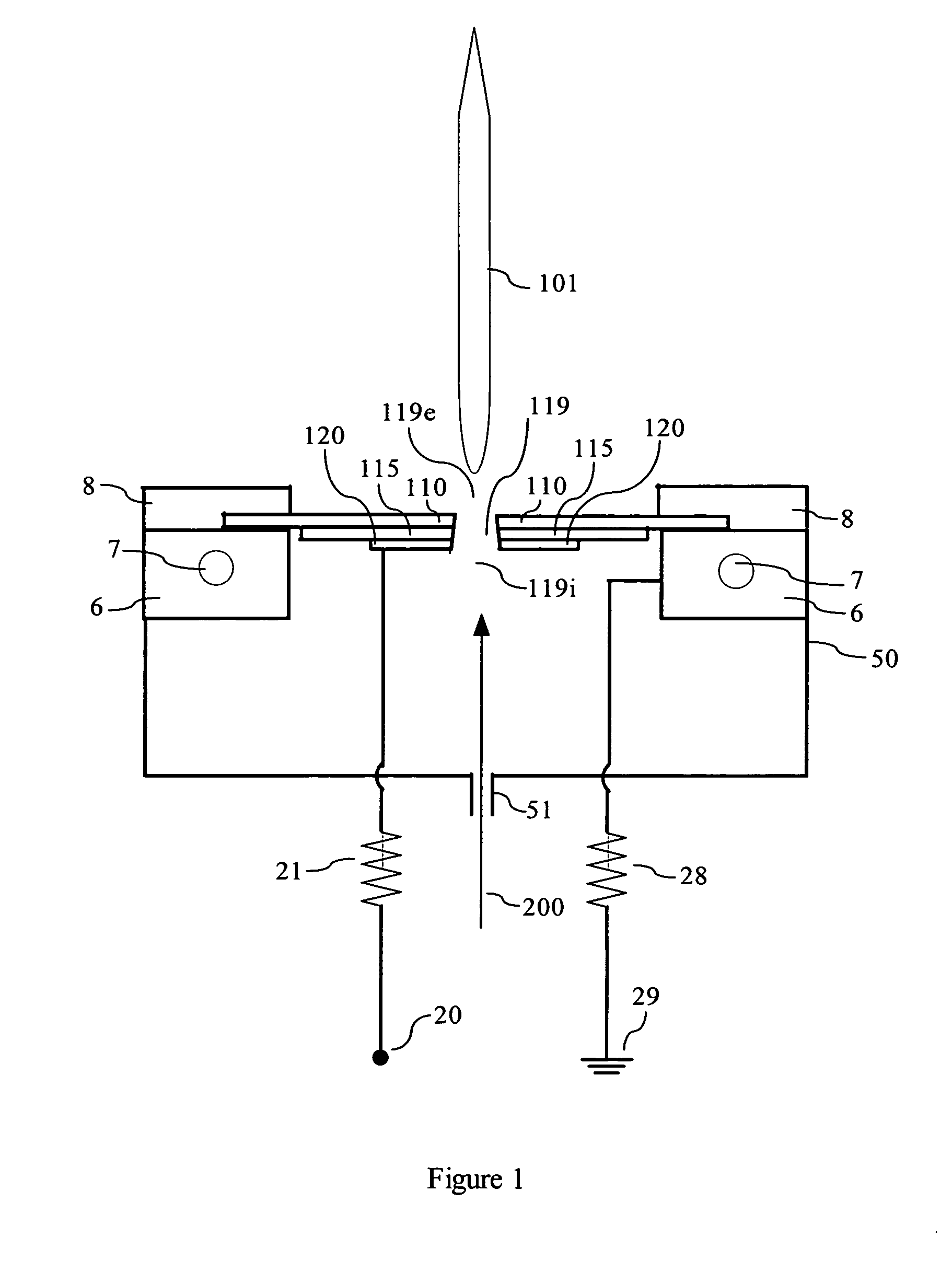

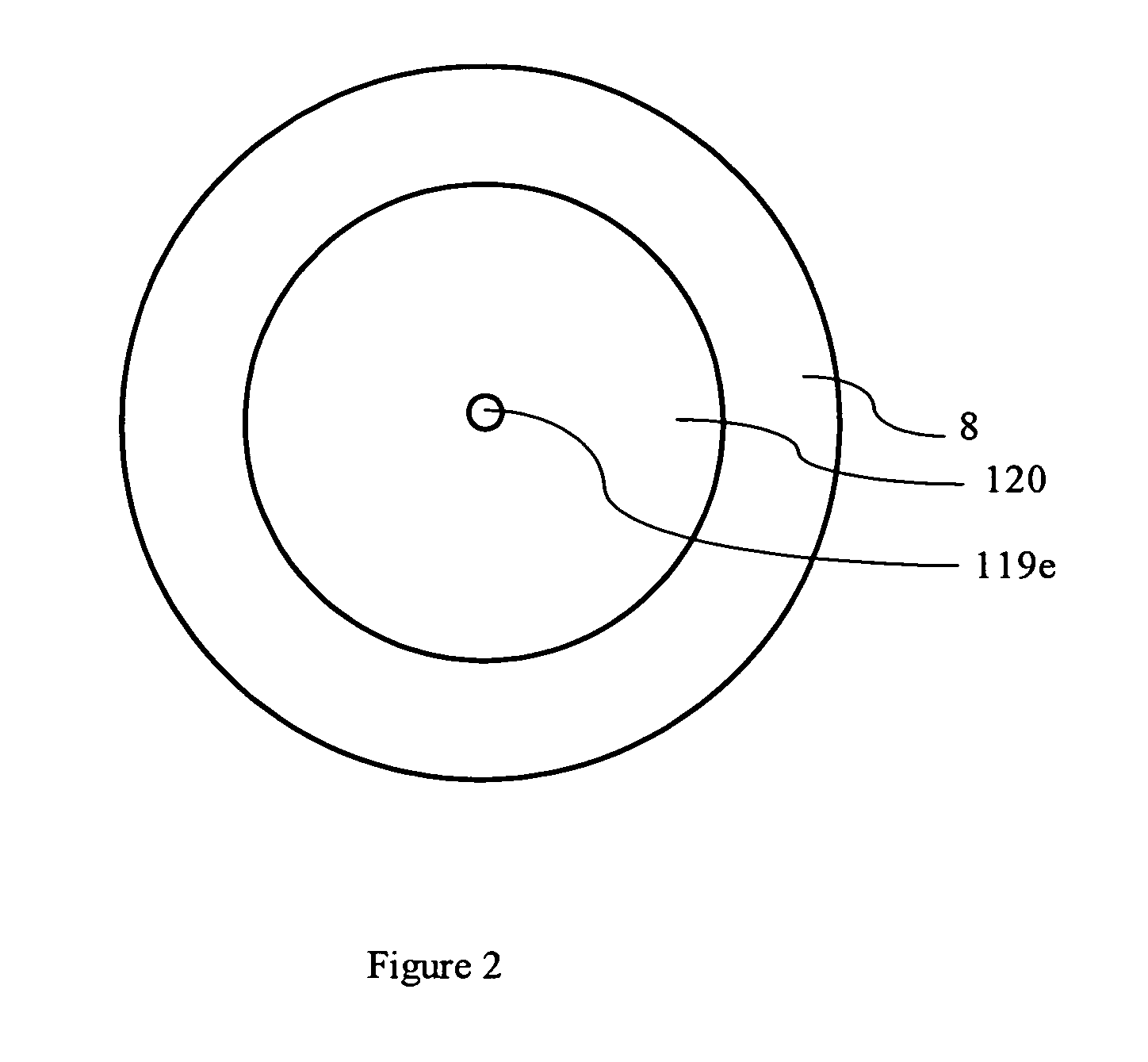

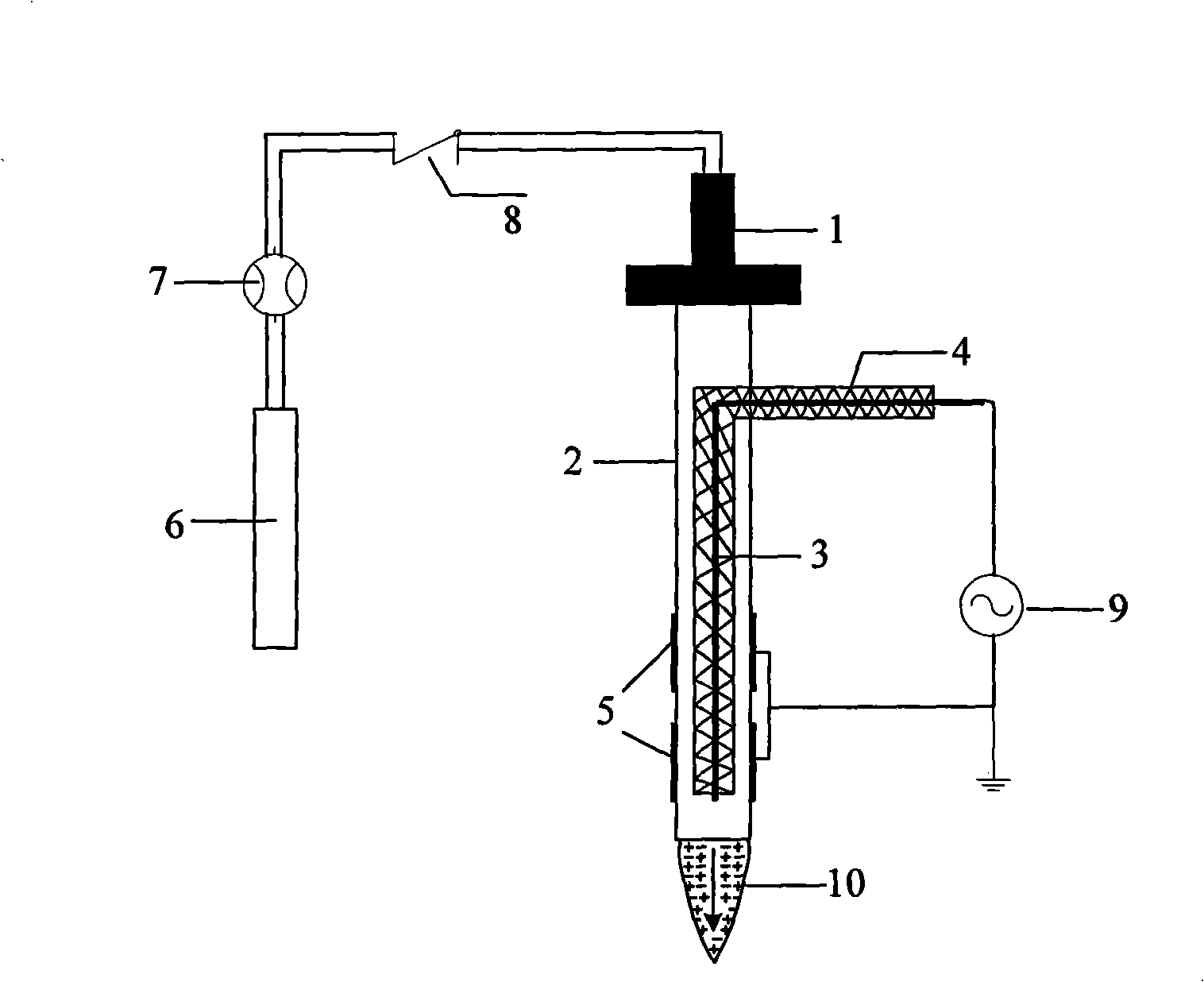

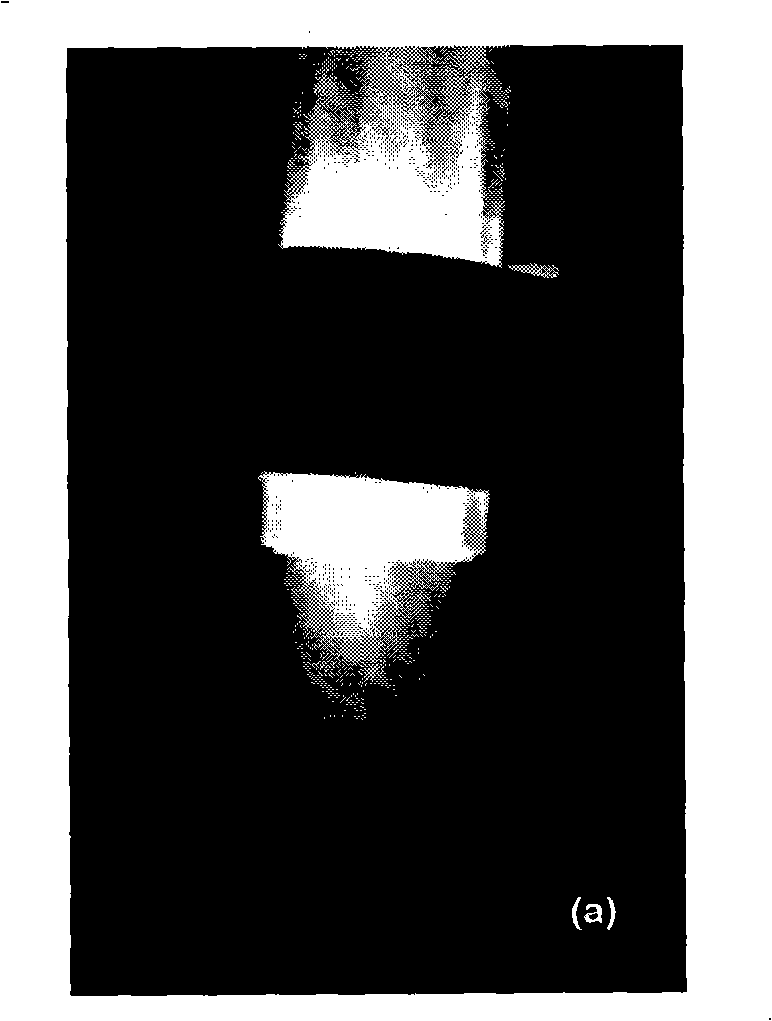

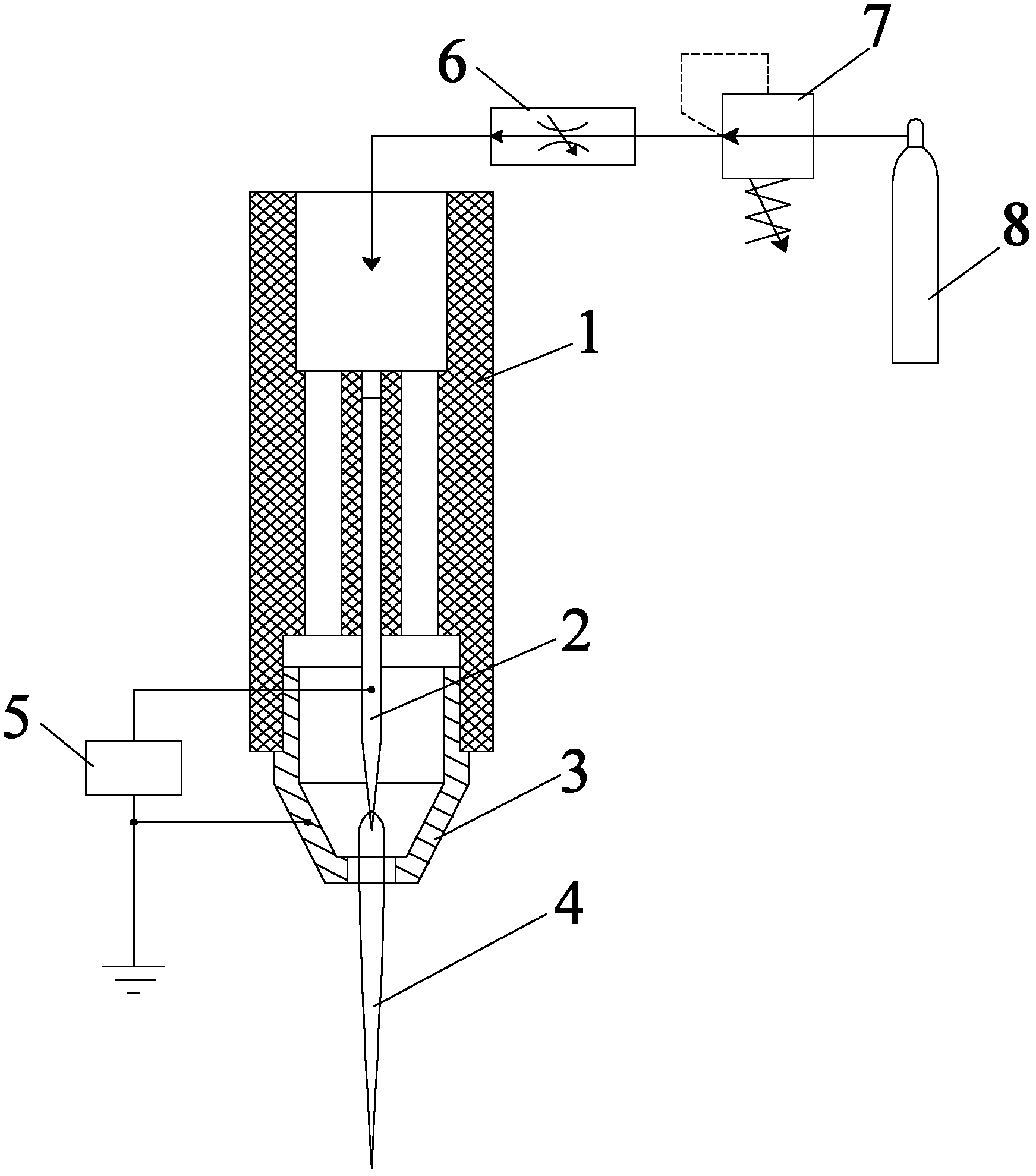

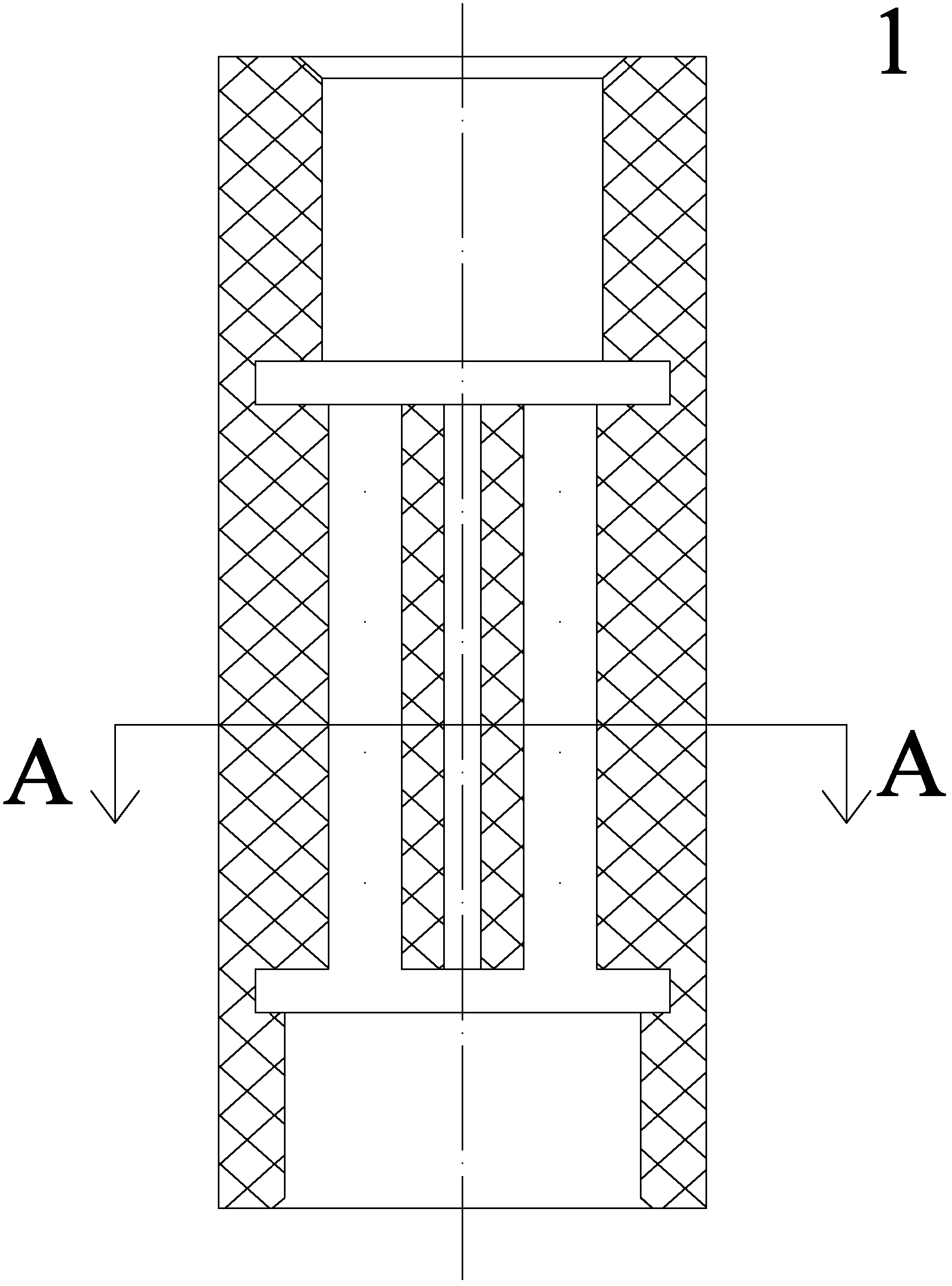

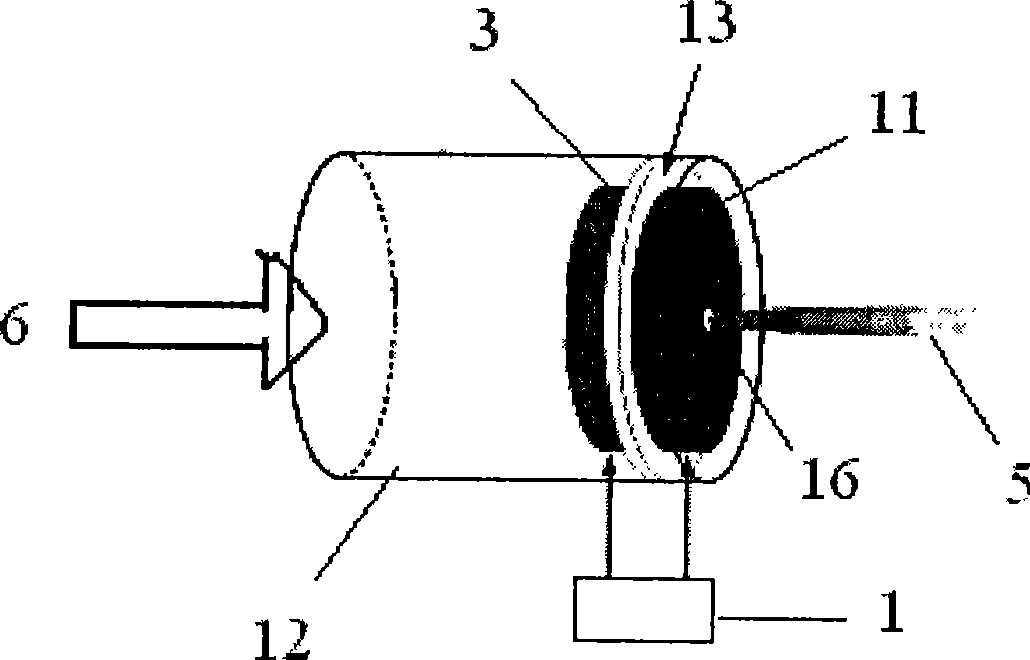

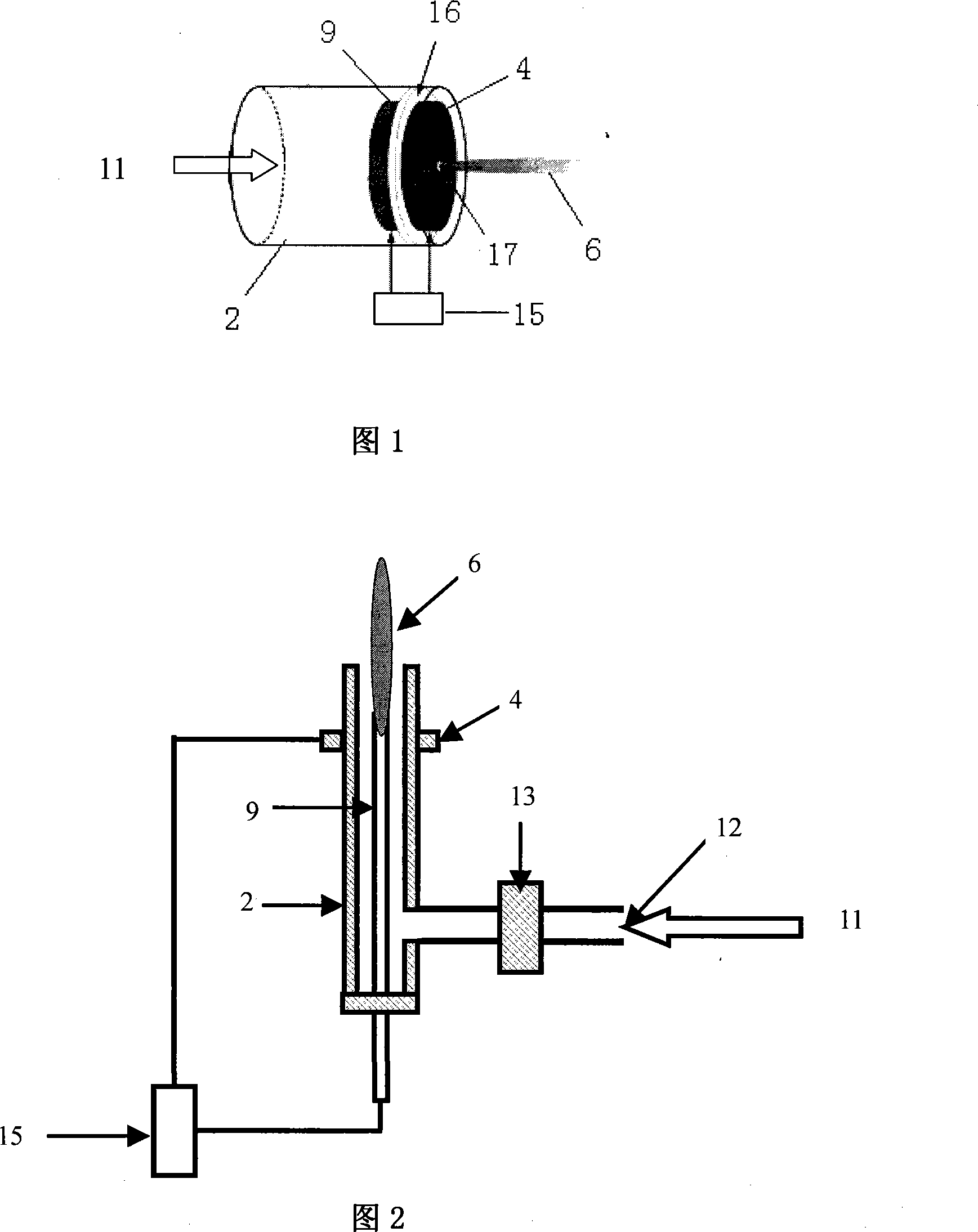

Plasma jet device

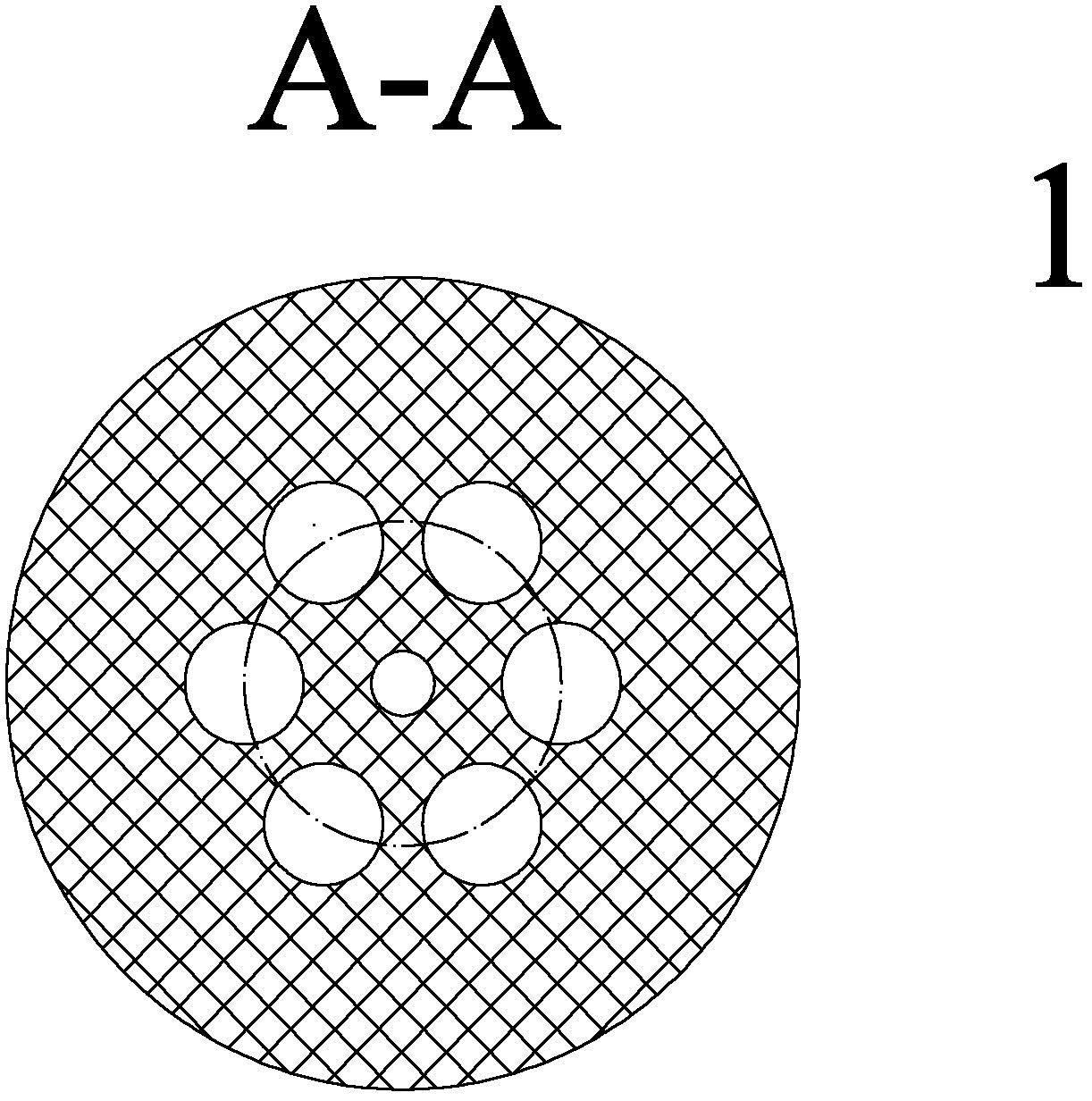

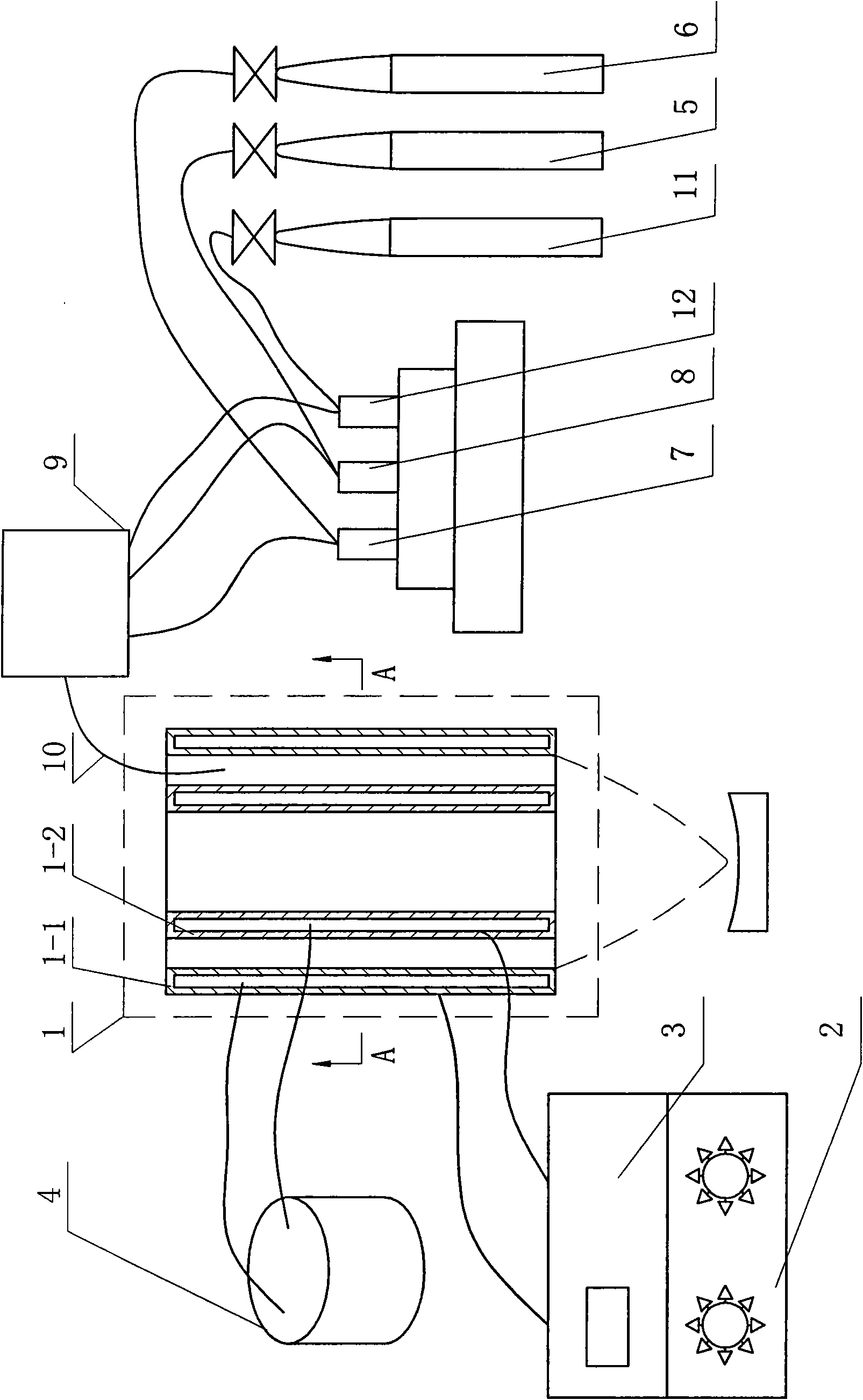

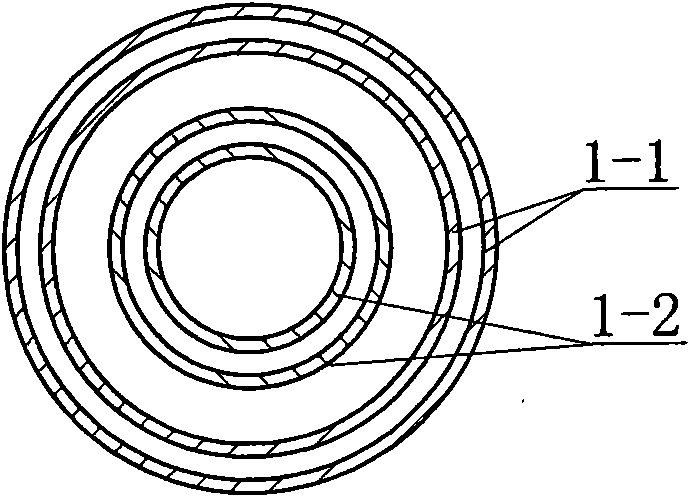

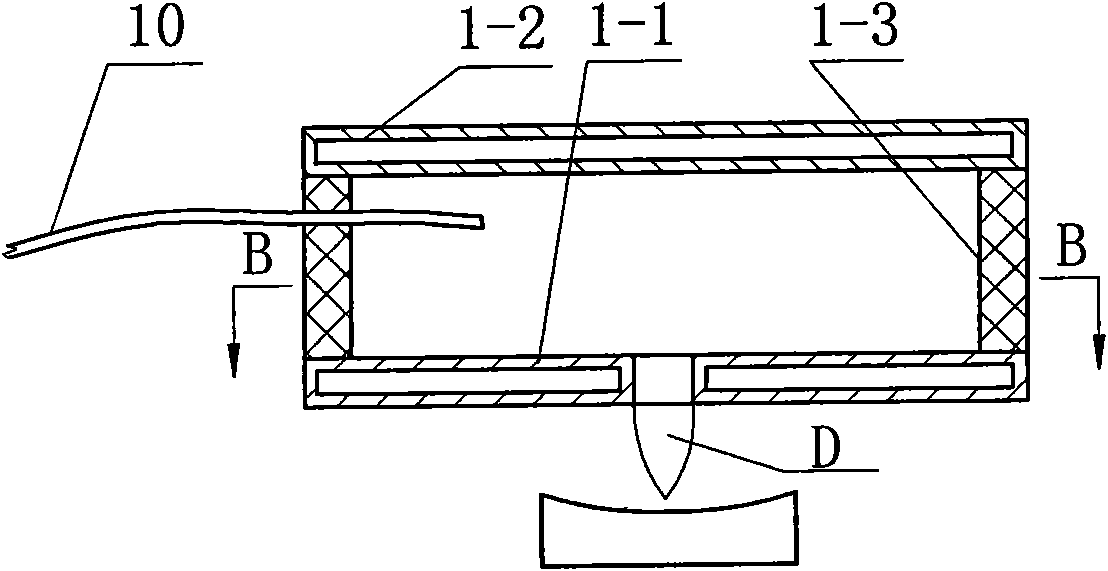

InactiveUS20090188626A1Broaden applicationGood curative effectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma jetDielectric layer

A plasma jet device, comprising a dielectric container comprising a gas inlet and a plasma jet outlet, and an electrode. The electrode, which is completely covered by dielectric material, is inserted into the dielectric container and connected to the power supply. The dielectric material is in the form of a hollow tube with one end closed and another end opened. The power supply is connected to the electrode from the open end of the dielectric material. The dielectric material can also be a coated dielectric layer, which covers the electrode completely except one end for connecting to the power supply. A grounding electrode can be added downstream, outside the dielectric container or the nozzle. There also can be multiple electrodes inside the dielectric container arranged in a row or multiple rows, or in the shape of a circle or disk.

Owner:LU XINPEI +1

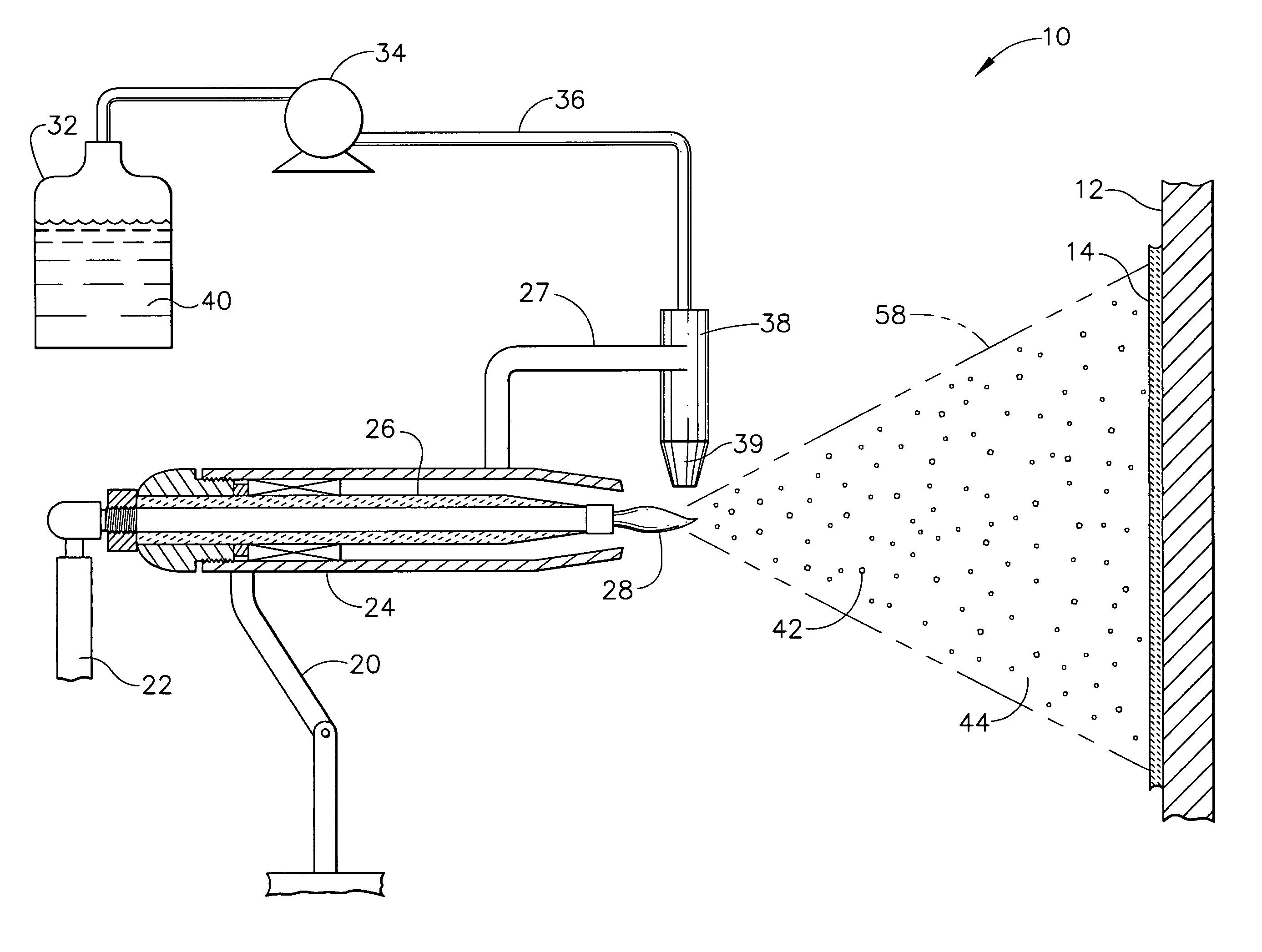

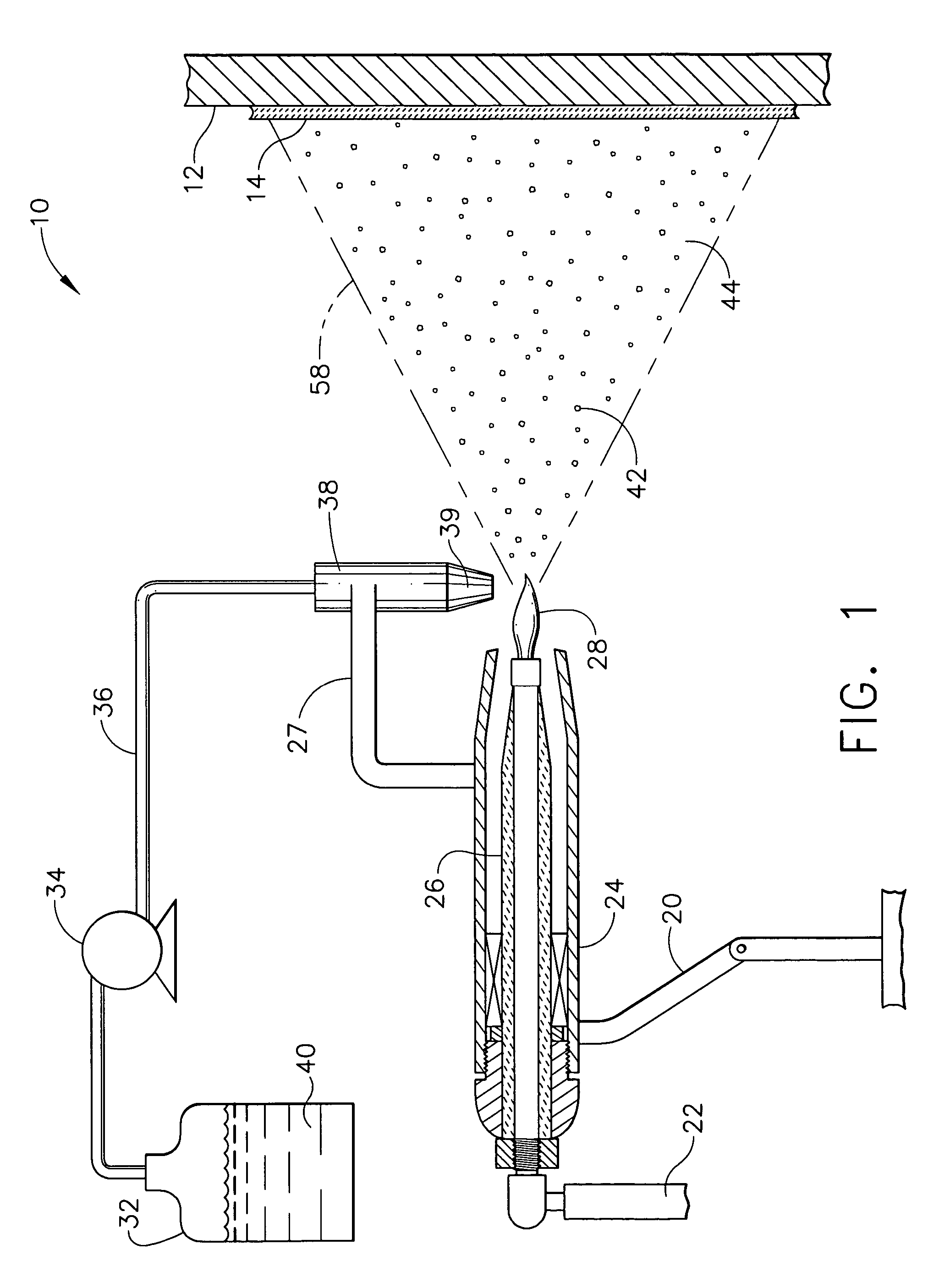

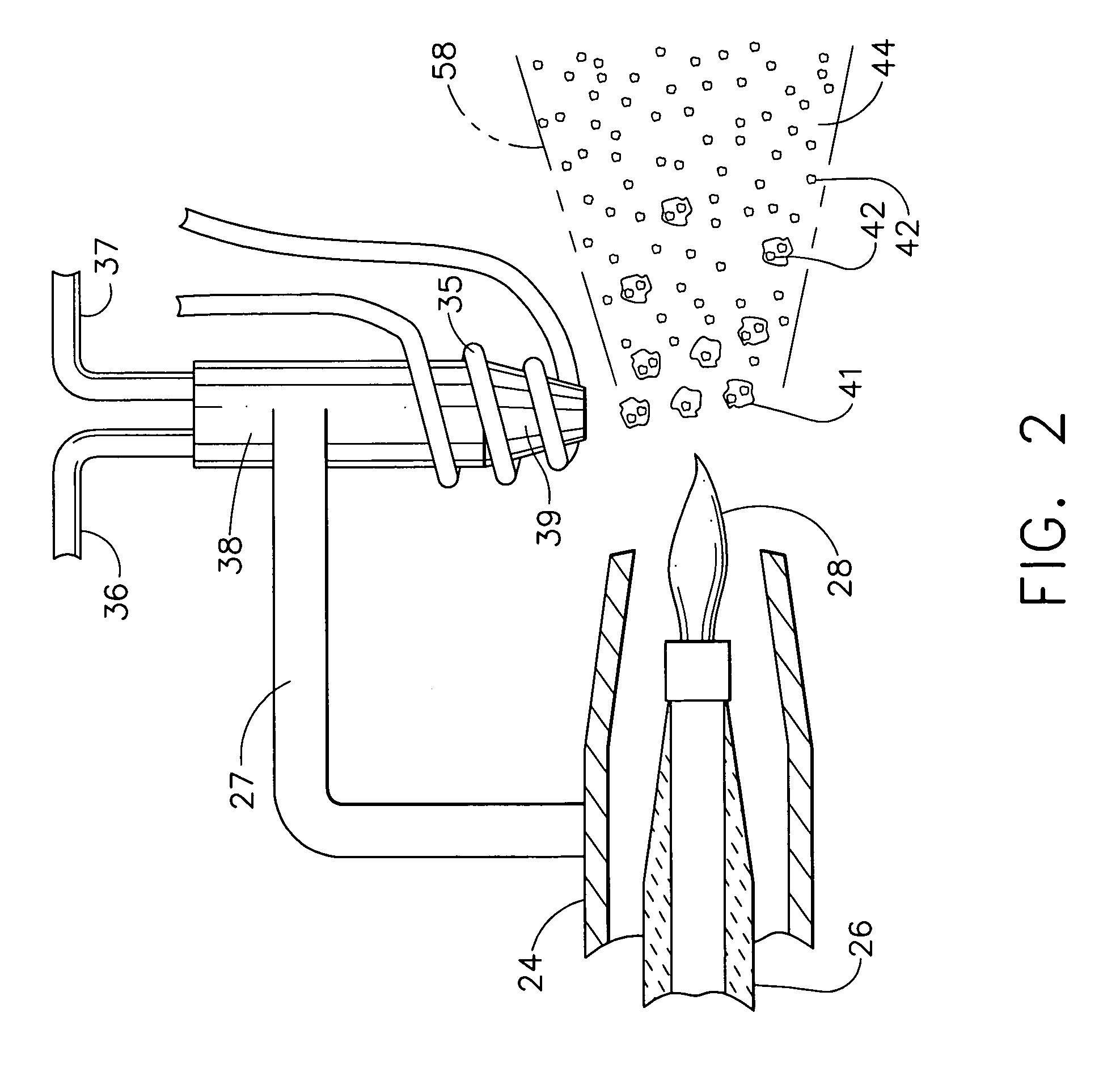

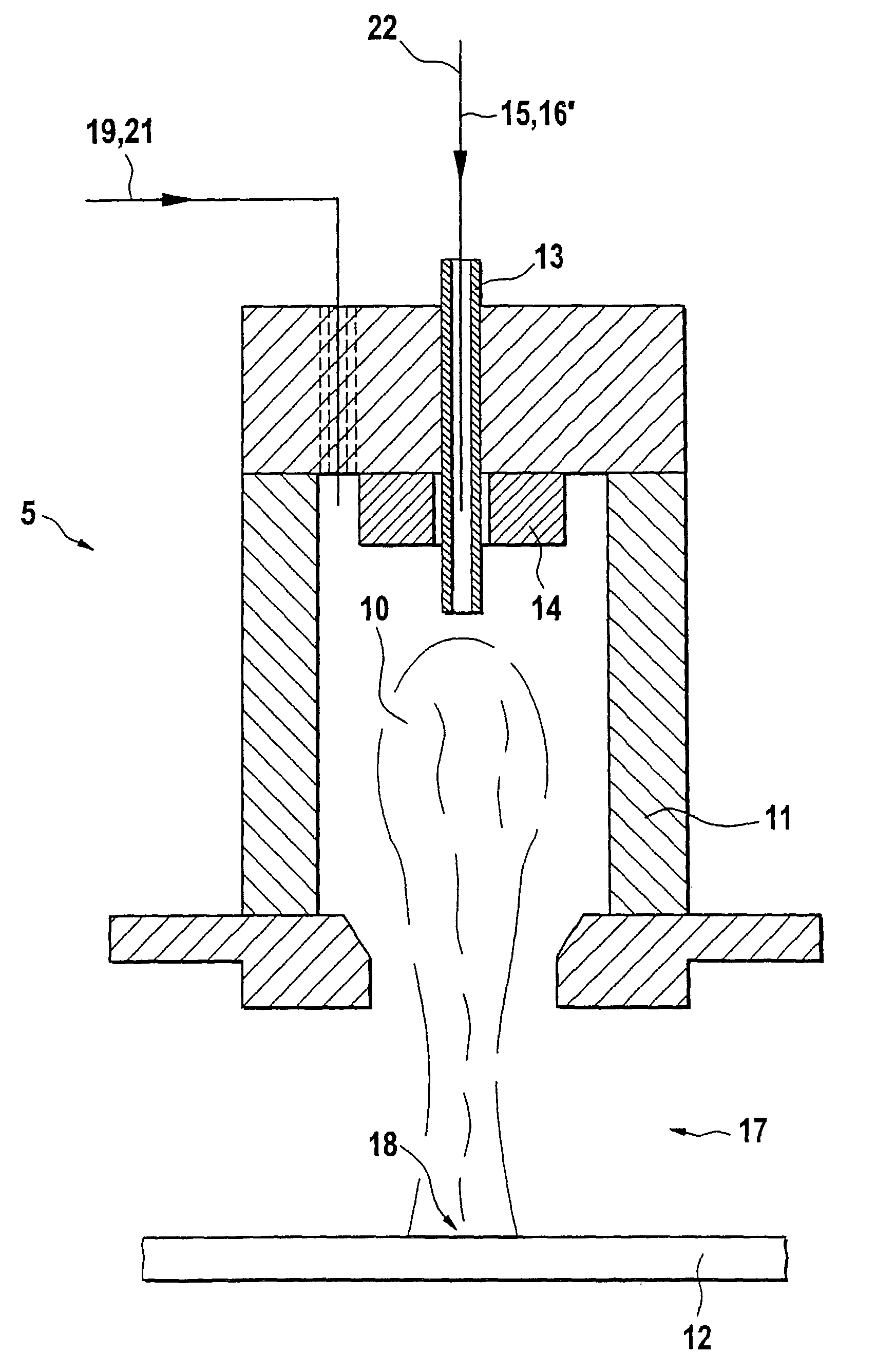

Method for applying a plasma sprayed coating using liquid injection

InactiveUS20060222777A1Improve processing efficiencyReduce the amount requiredLiquid surface applicatorsMolten spray coatingPlasma jetPlasma sprayed coating

A method for applying a plasma prayed coating using liquid injection is disclosed. The method includes providing a mixture of a liquid and solid particles. The solid particles are constituents of a thermal barrier coating. The mixture is injected into a plasma jet of a plasma spray device and the plasma jet is directed toward a substrate to deposit a gradient film formed from the constituents onto the substrate.

Owner:GENERAL ELECTRIC CO

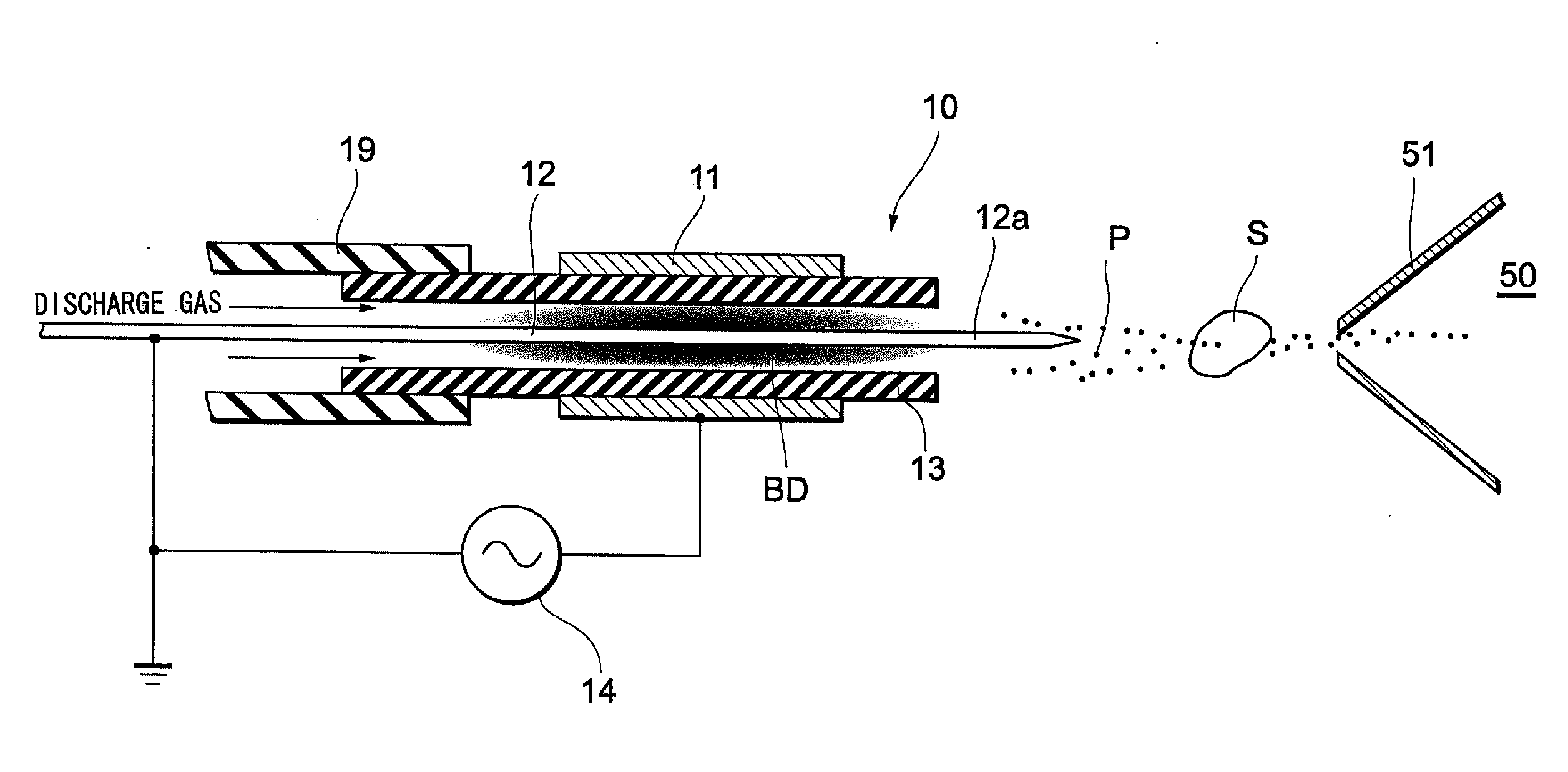

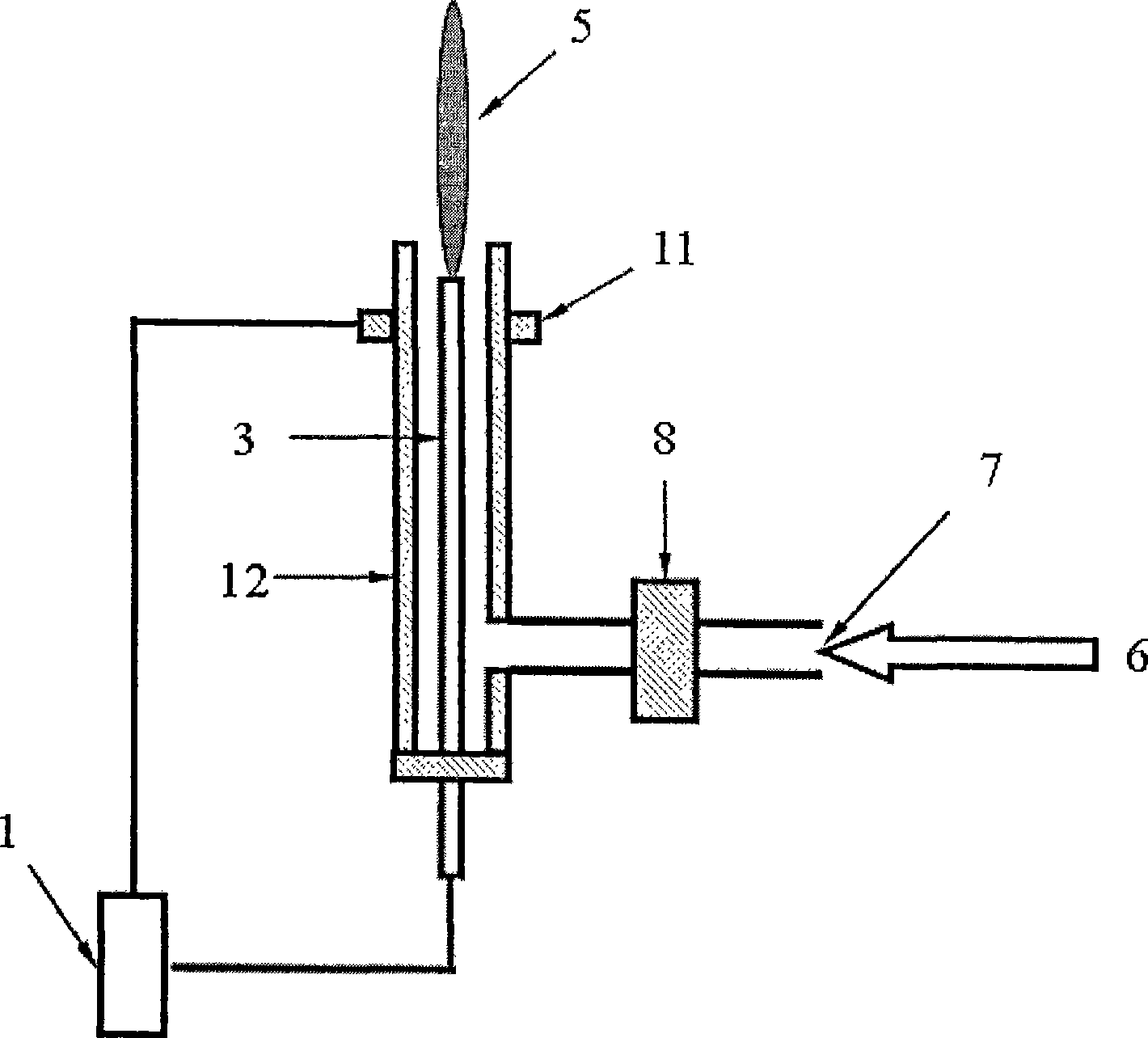

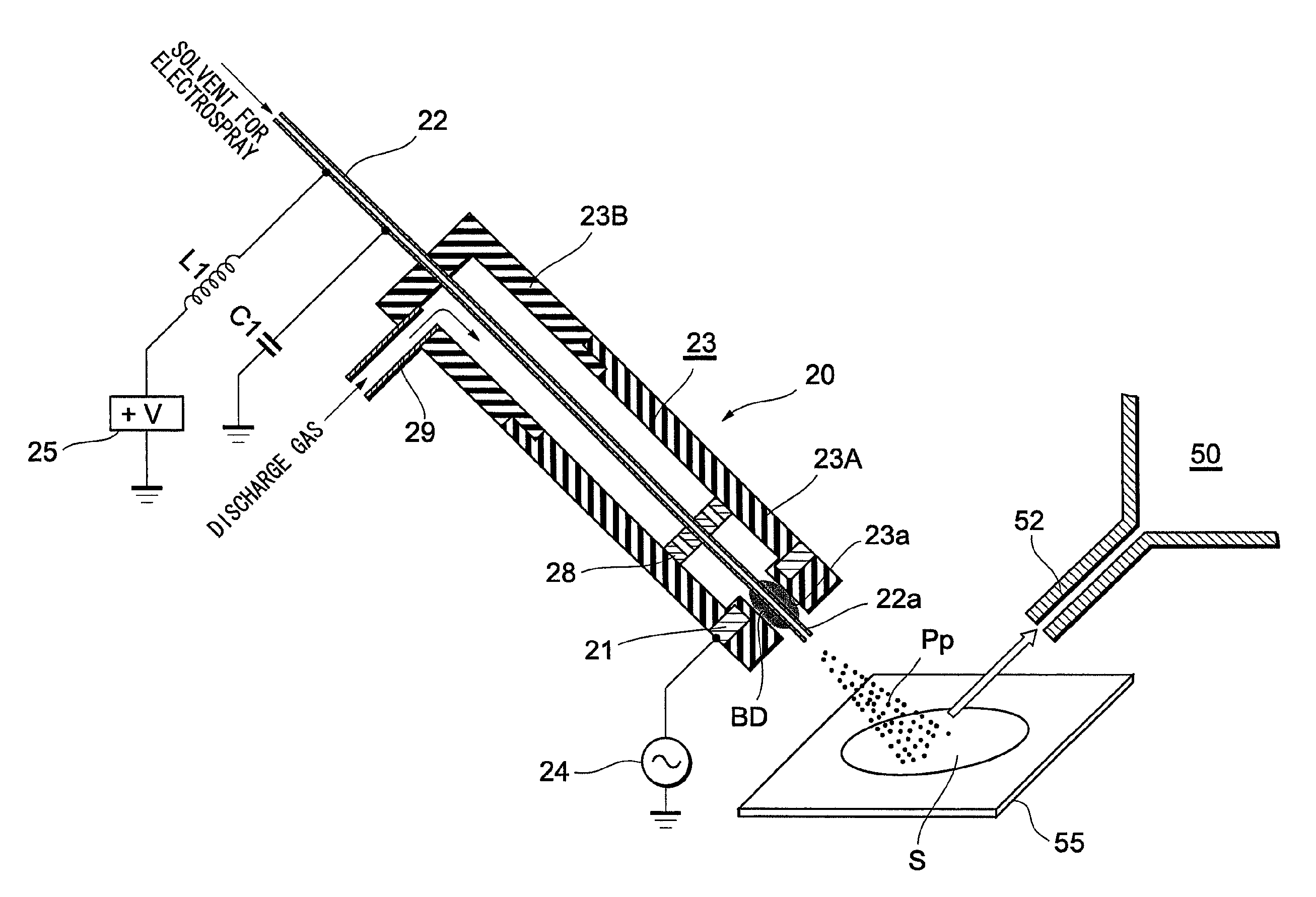

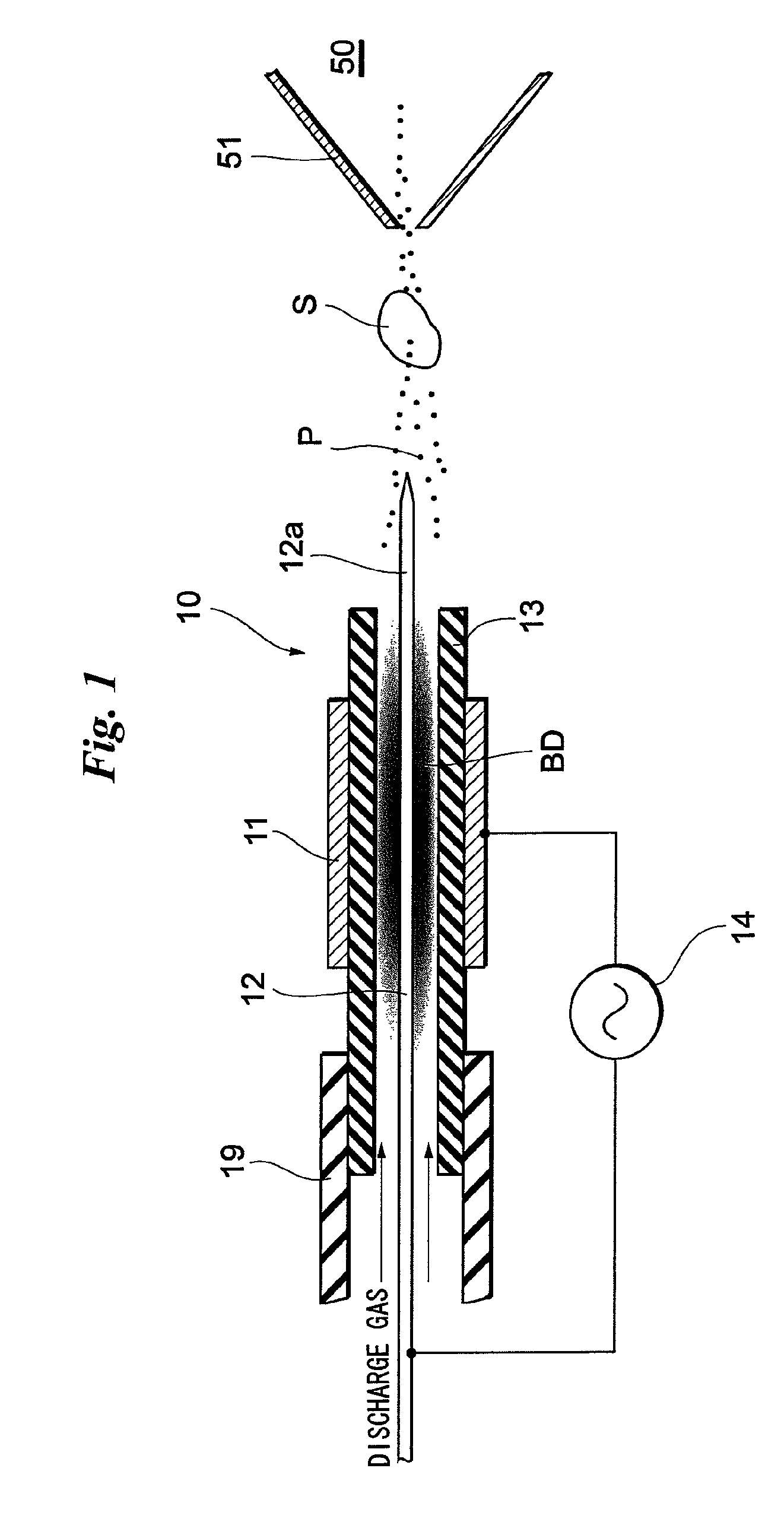

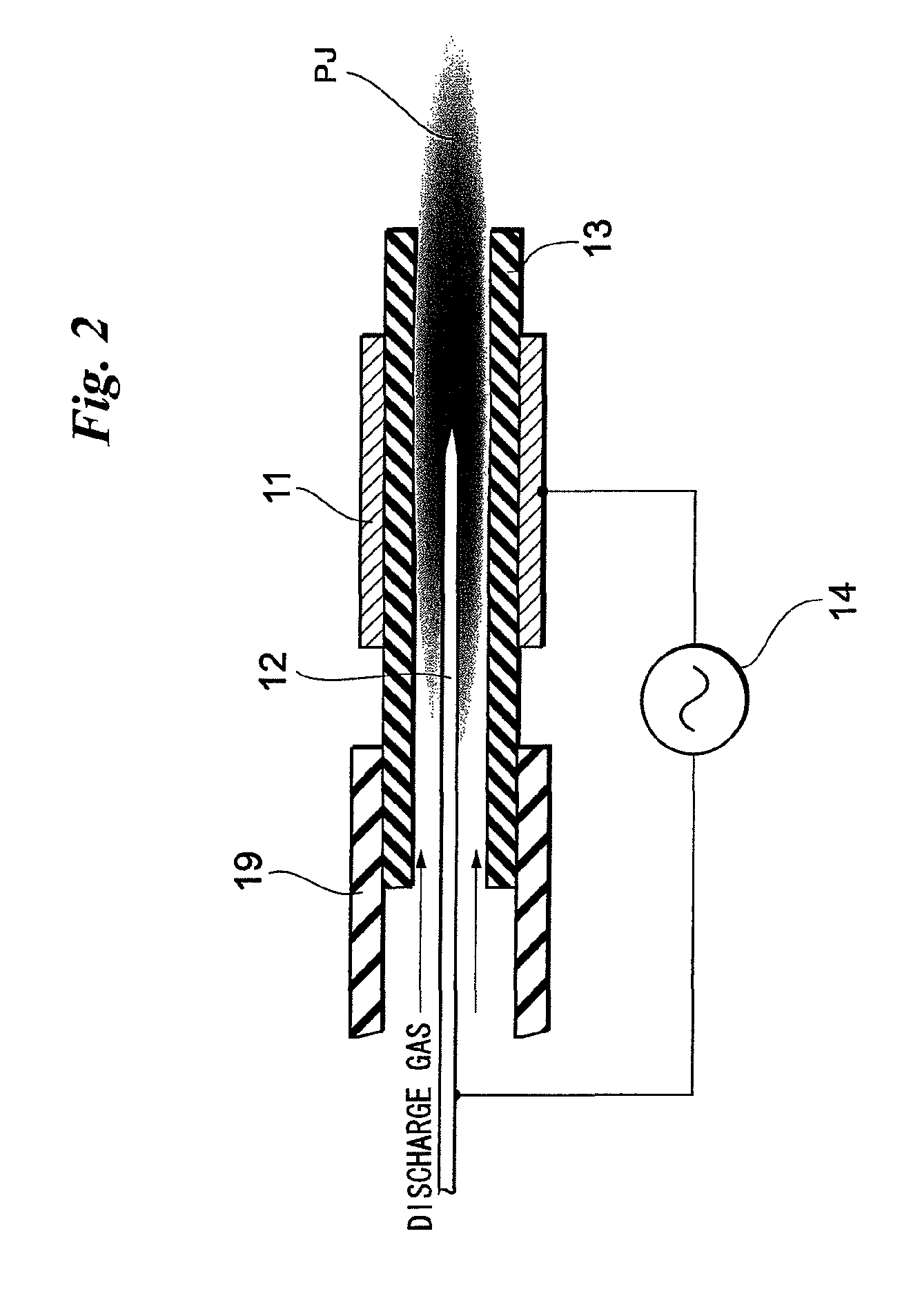

Ionization analysis method and apparatus

ActiveUS20110108726A1Ultra high sensitivitySufficient ion intensityParticle separator tubesMaterial analysis by optical meansPlasma jetElectron temperature

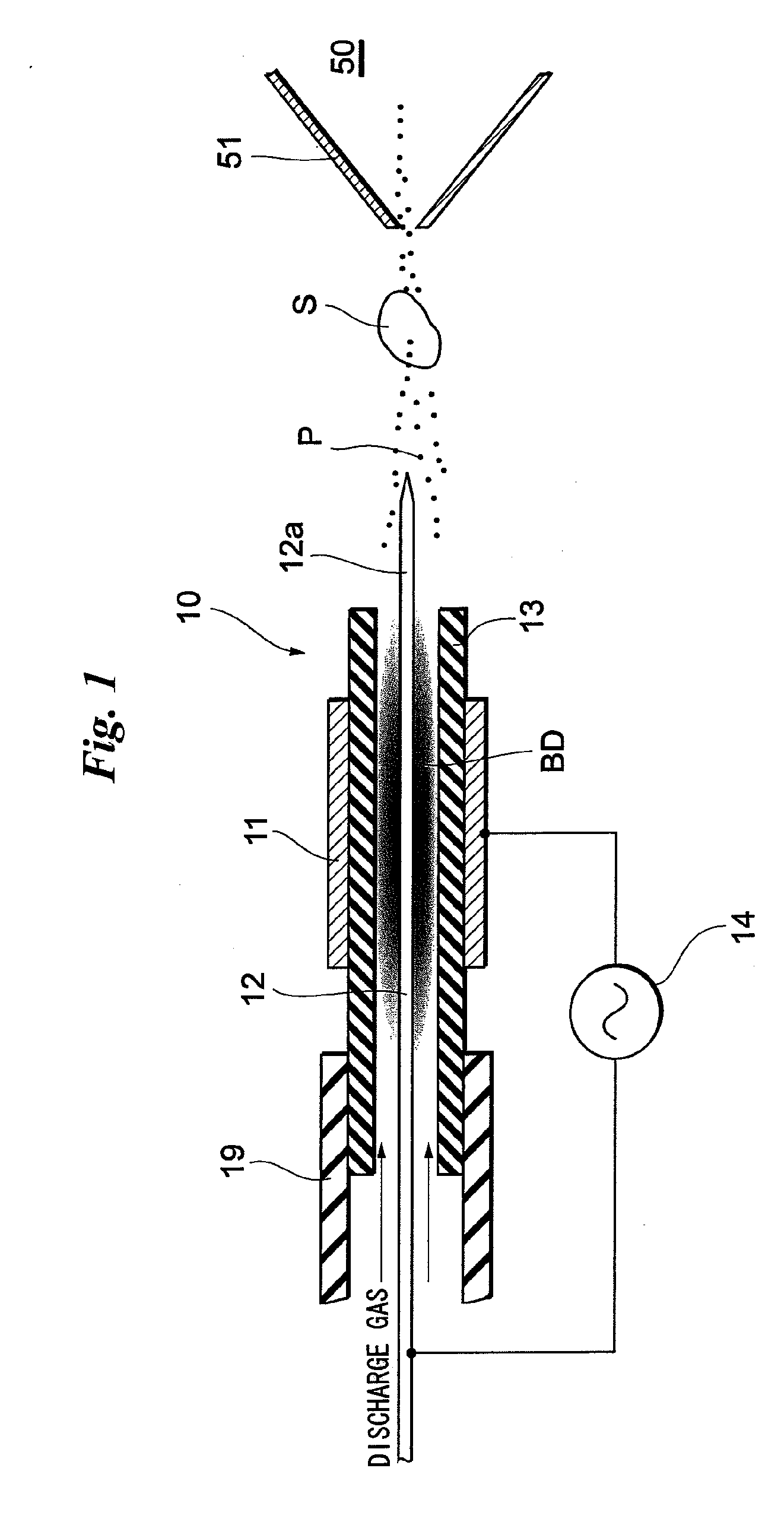

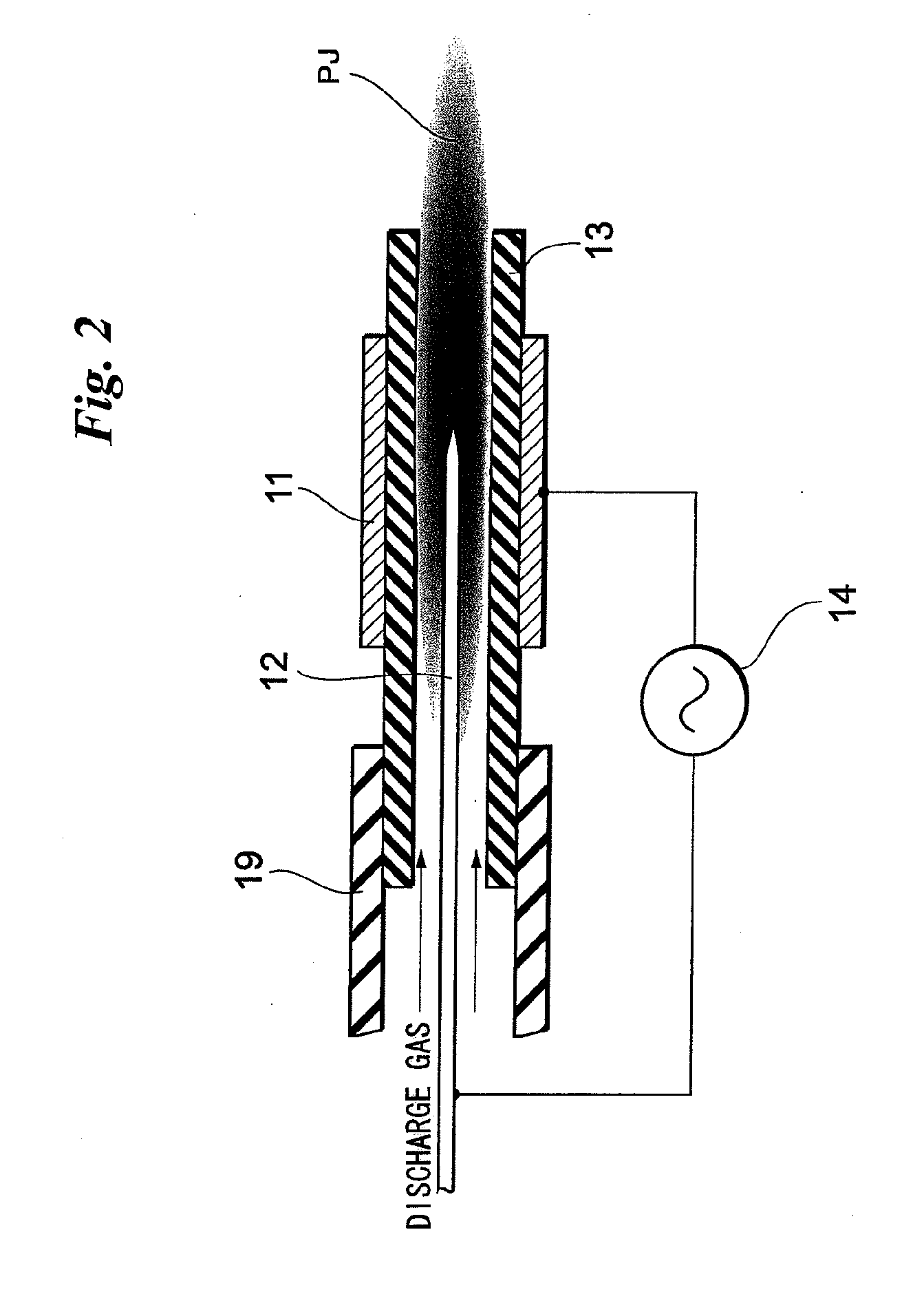

It is arranged so that ions can be analyzed accurately and with high sensitivity. A first electrode 11 is provided on the outer periphery of a dielectric cylindrical body 13 and a second electrode 12 is placed inside the cylindrical body 13 leaving a clearance between itself and the inner surface of the cylindrical body 13. When an AC high voltage is impressed across the first electrode 11 and second electrode 12, a barrier discharge occurs within the cylindrical body 13. When a distal end portion 12a of the second electrode 12 projects outwardly from the distal end of the cylindrical body 13, a thermal equilibrium plasma P having a low electron temperature is generated outwardly of the distal end of the cylindrical body 13 without a plasma jet ascribable to the barrier discharge emerging outwardly from the distal end of the cylindrical body 13. By exposing a sample S to the thermal equilibrium plasma P, particles (atoms, molecules) desorbed from the sample S undergo soft ionization without being decomposed or polymerized. The ions generated are introduced to a mass analyzer 50.

Owner:UNIVERSITY OF YAMANASHI

Plasma processing device for surfaces

InactiveUS6265690B1Rapid and efficient pretreatmentLow equipment costPretreated surfacesArc welding apparatusPlasma jetEngineering

Owner:PLASMATREAT GMBH

Method and device to synthesize boron nitride nanotubes and related nanoparticles

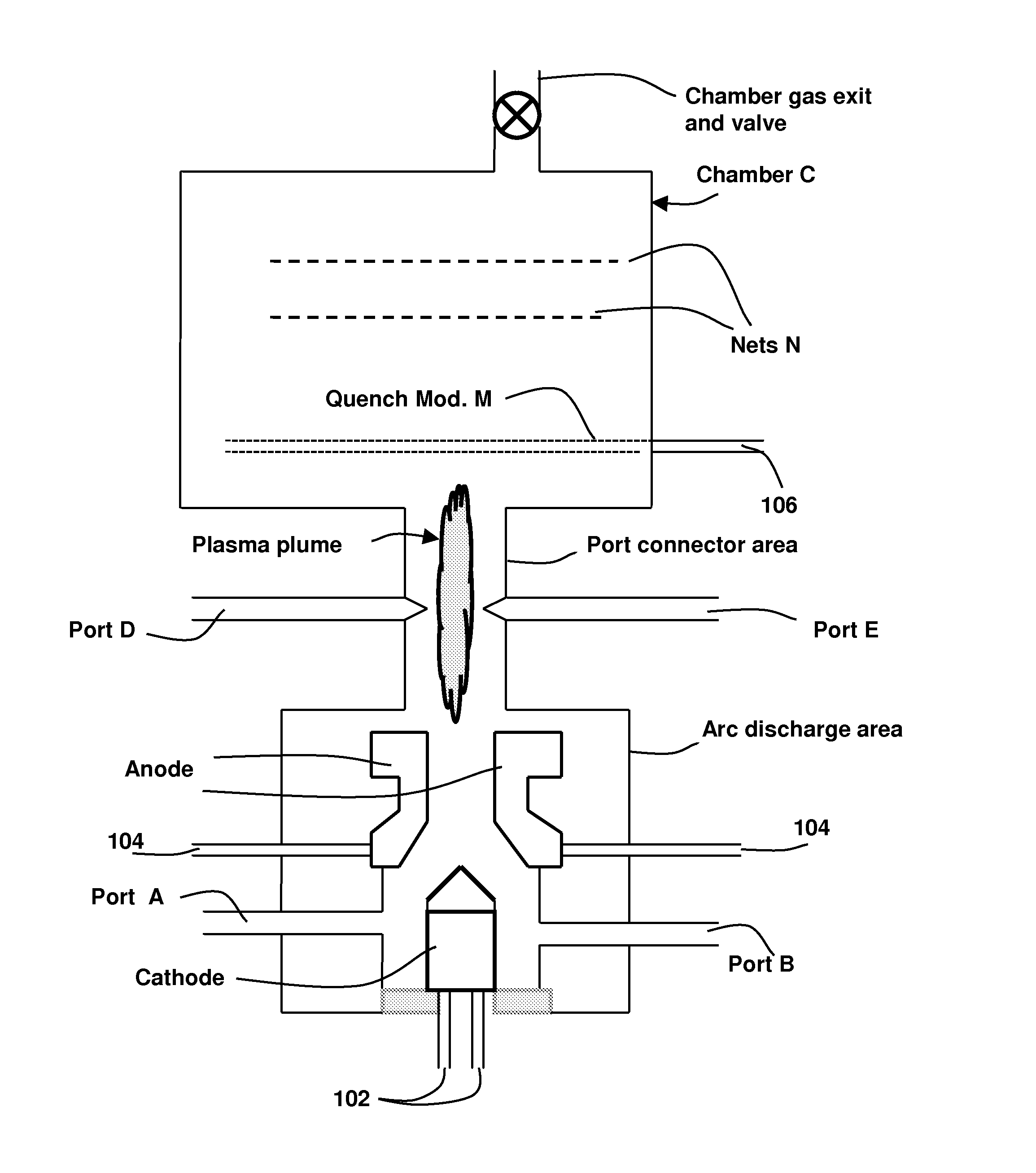

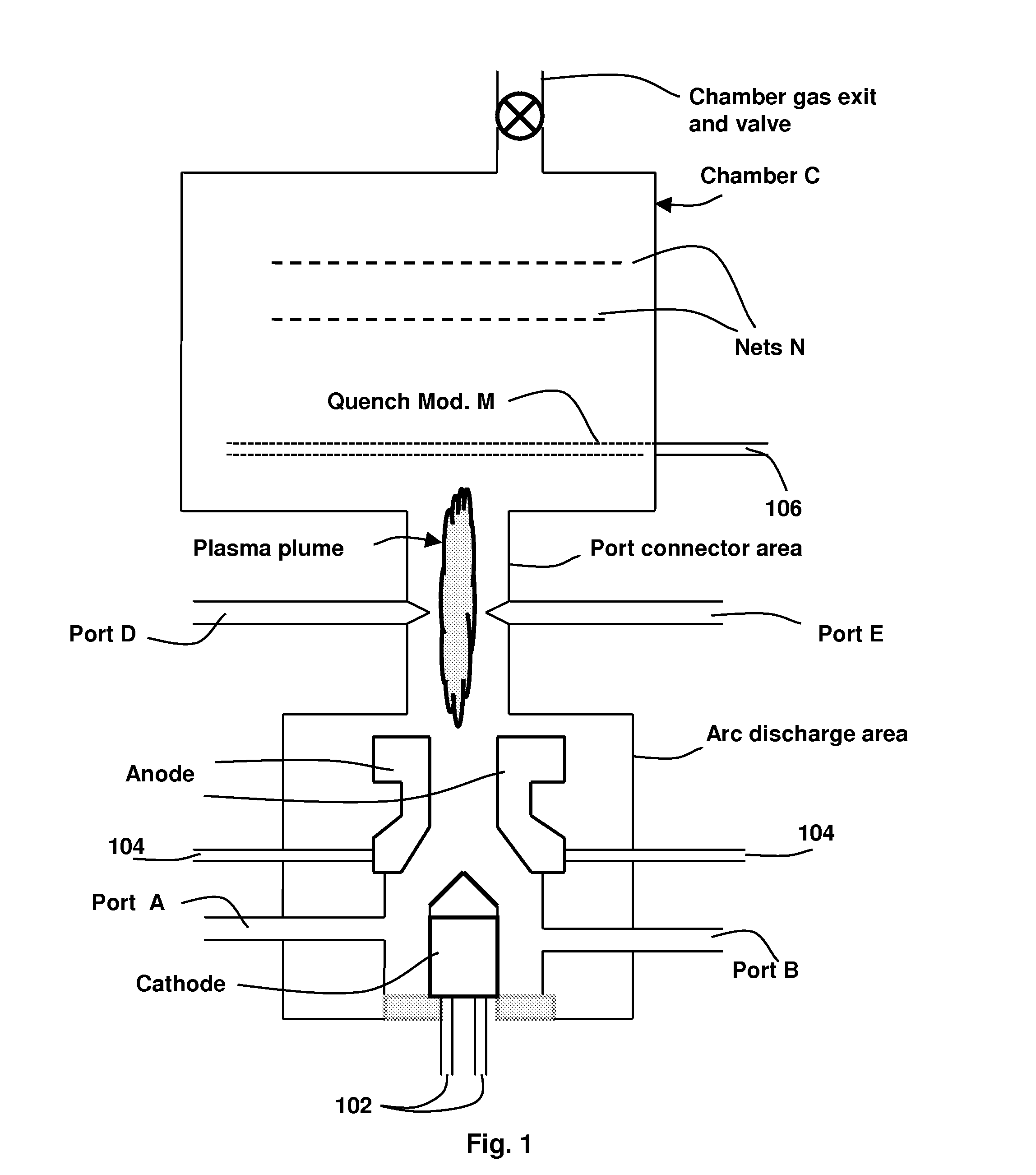

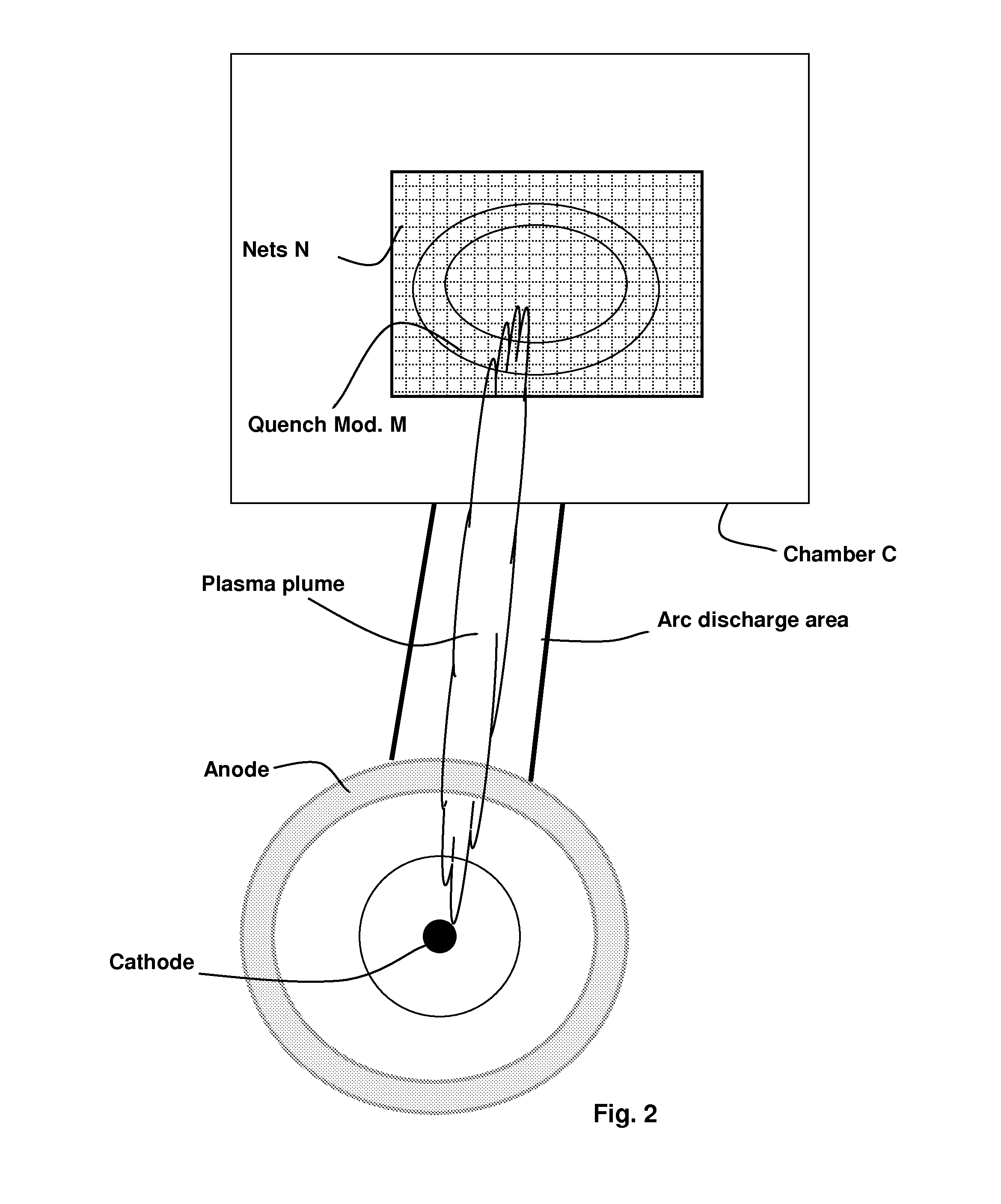

Methods and apparatus for producing chemical nanostructures having multiple elements, such as boron and nitride, e.g. boron nitride nanotubes, are disclosed. The method comprises creating a plasma jet, or plume, such as by an arc discharge. The plasma plume is elongated and has a temperature gradient along its length. It extends along its length into a port connector area having ports for introduction of feed materials. The feed materials include the multiple elements, which are introduced separately as fluids or powders at multiple ports along the length of the plasma plume, said ports entering the plasma plume at different temperatures. The method further comprises modifying a temperature at a distal portion of or immediately downstream of said plasma plume; and collecting said chemical nanostructures after said modifying.

Owner:RGT UNIV OF CALIFORNIA

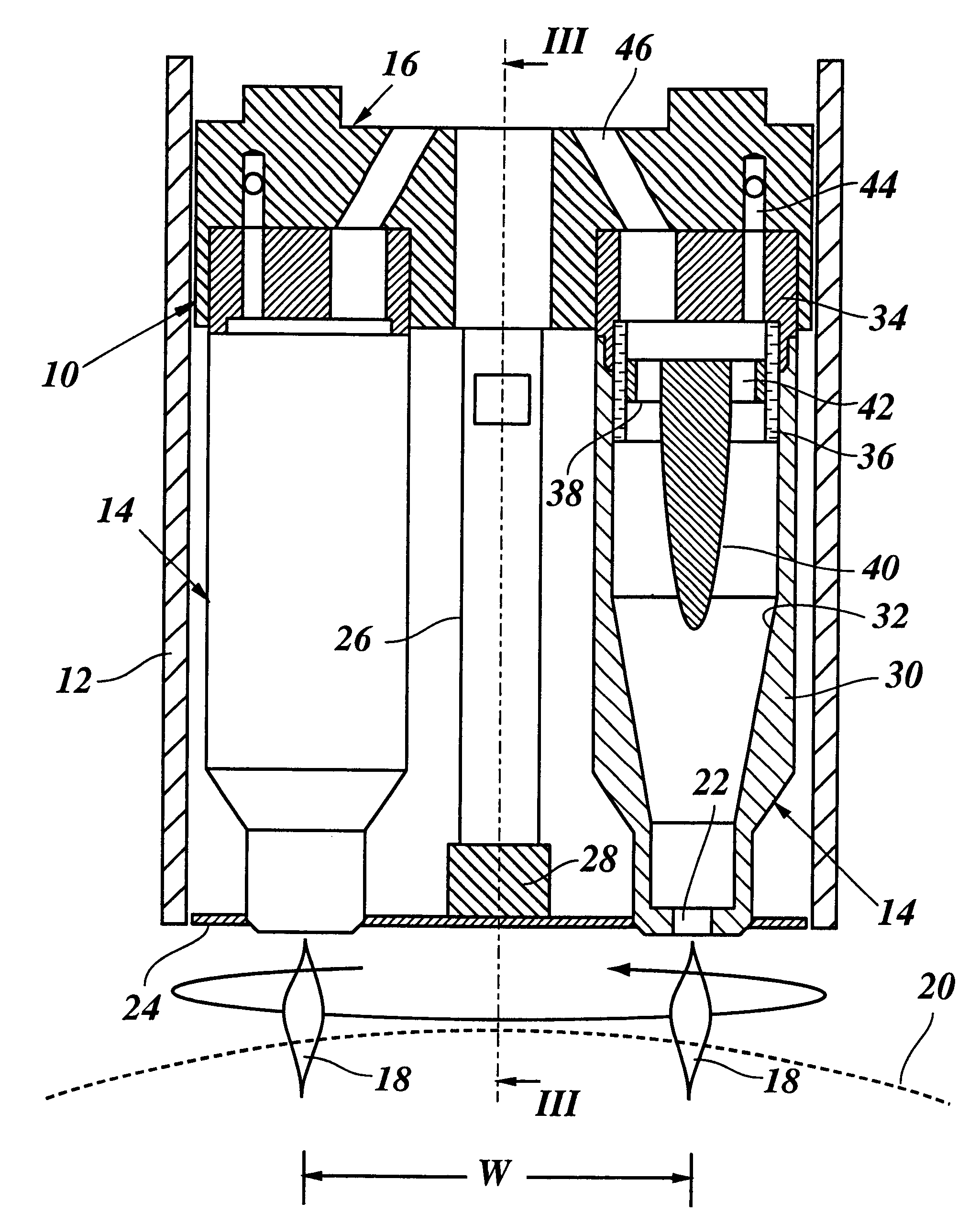

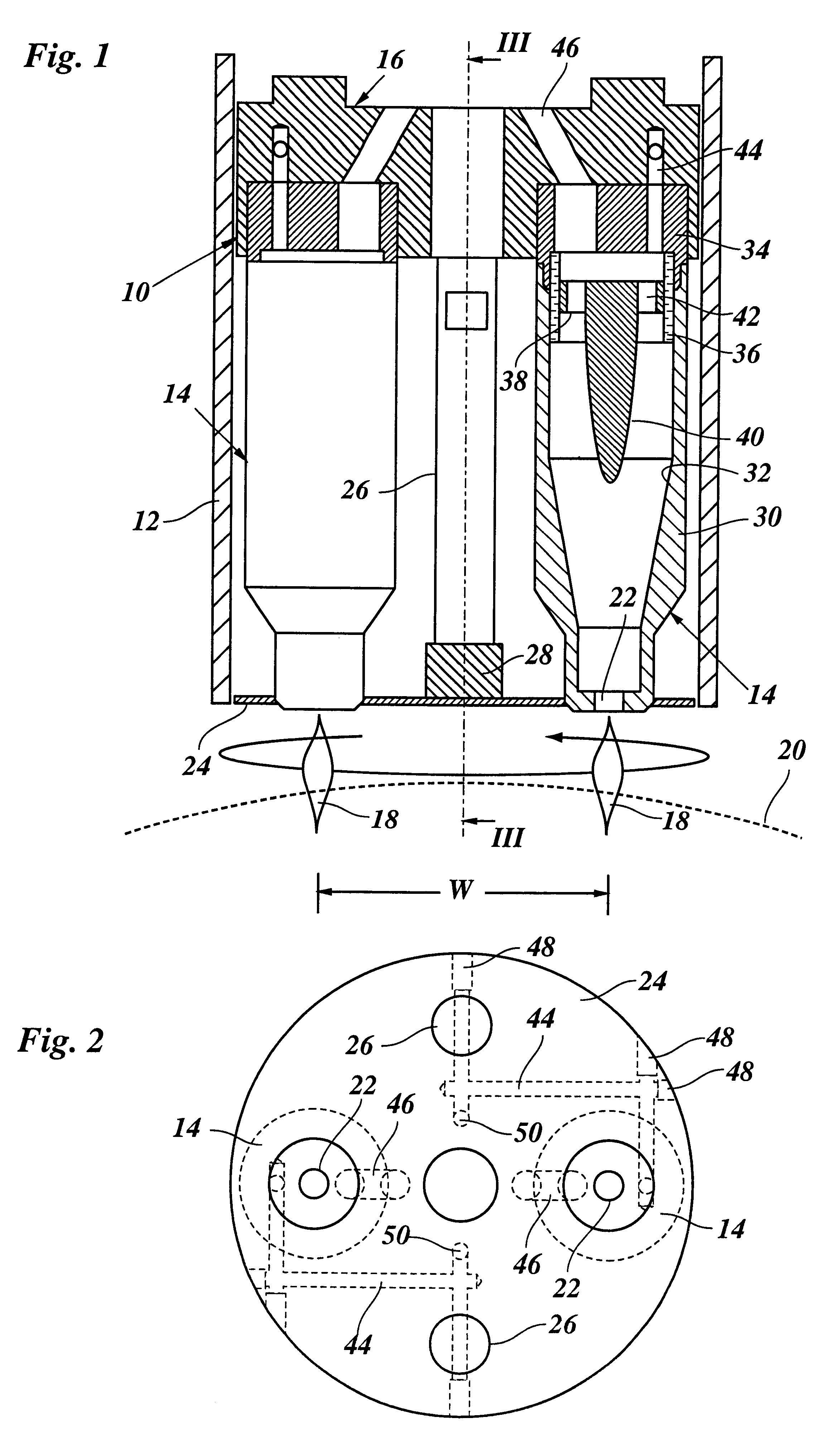

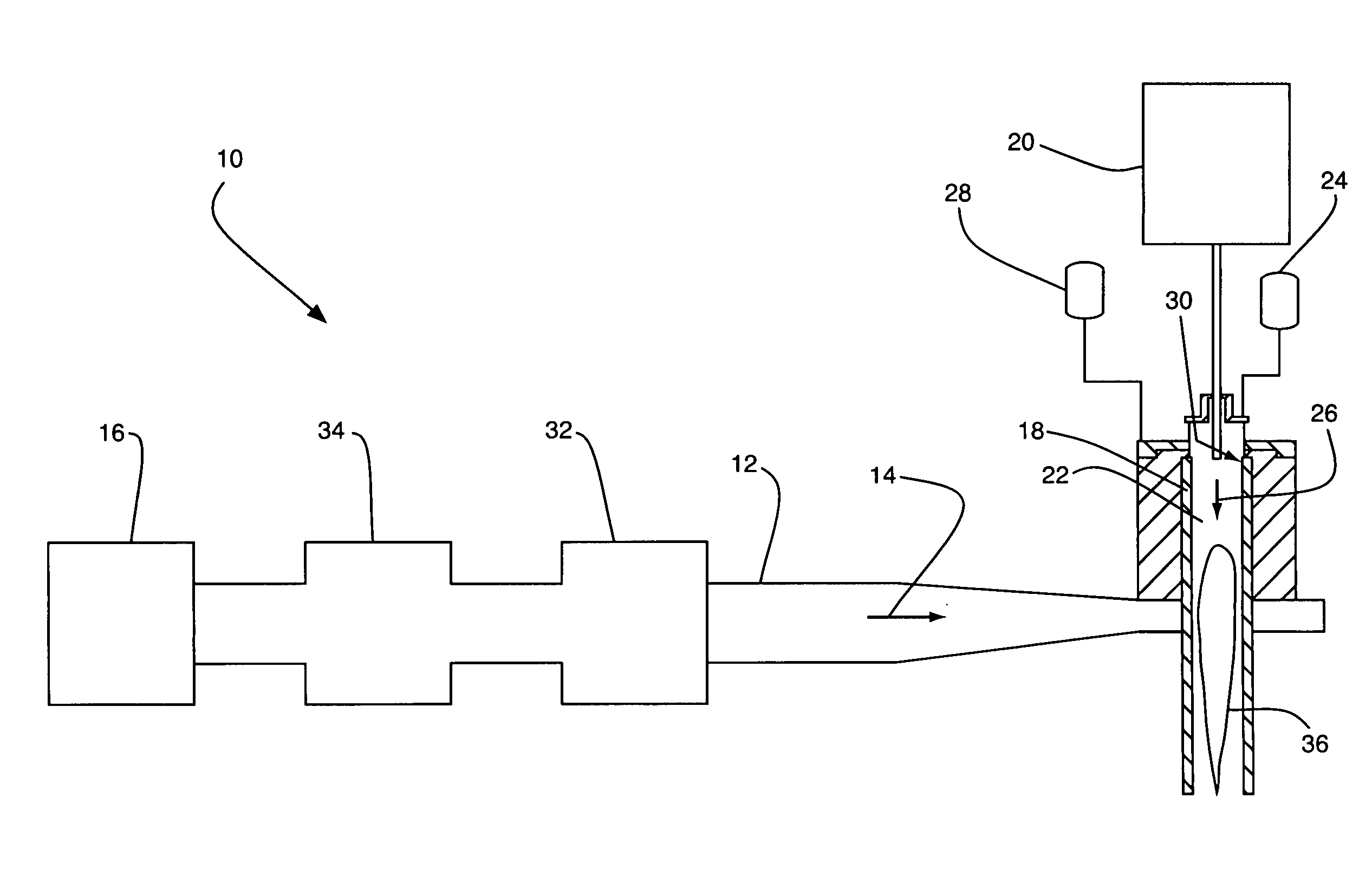

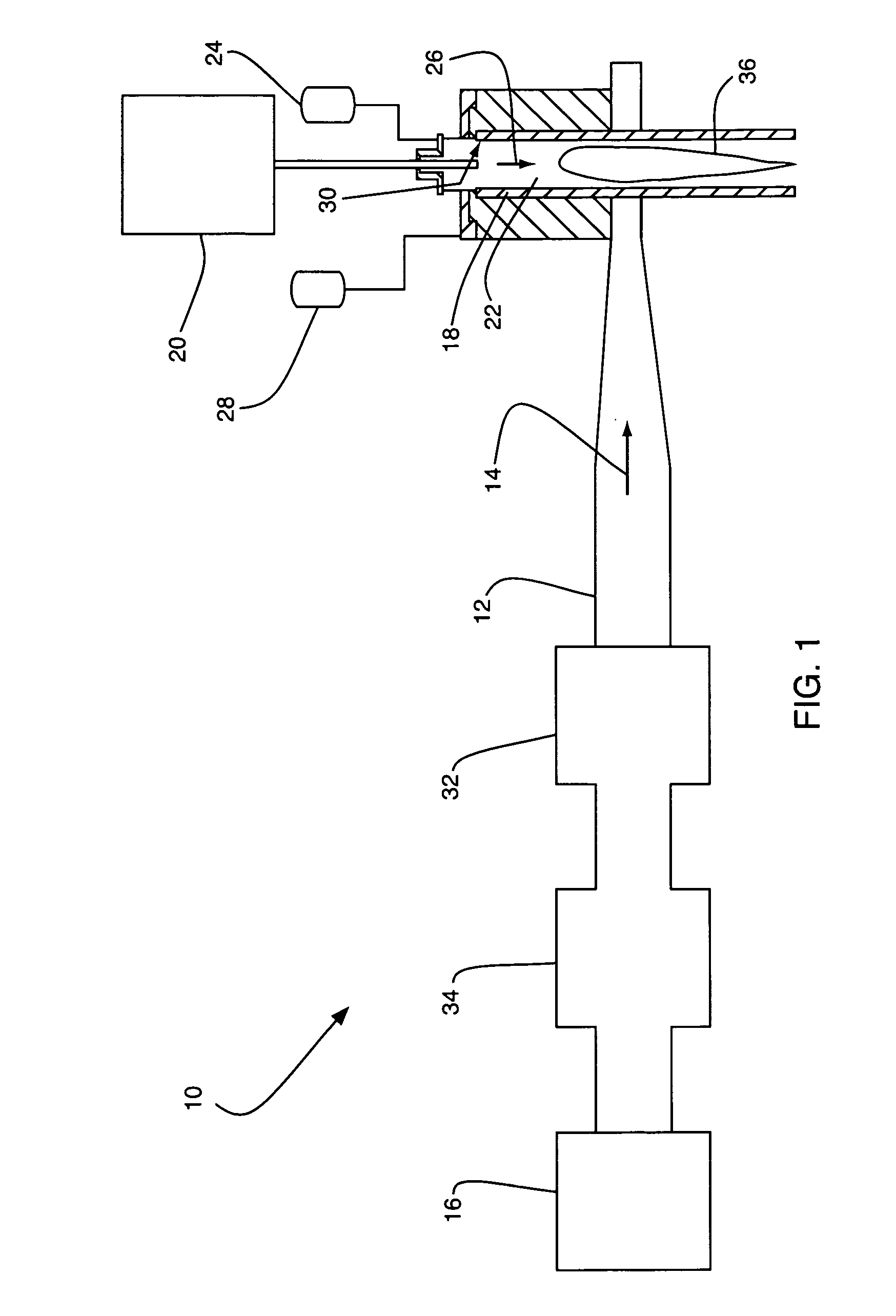

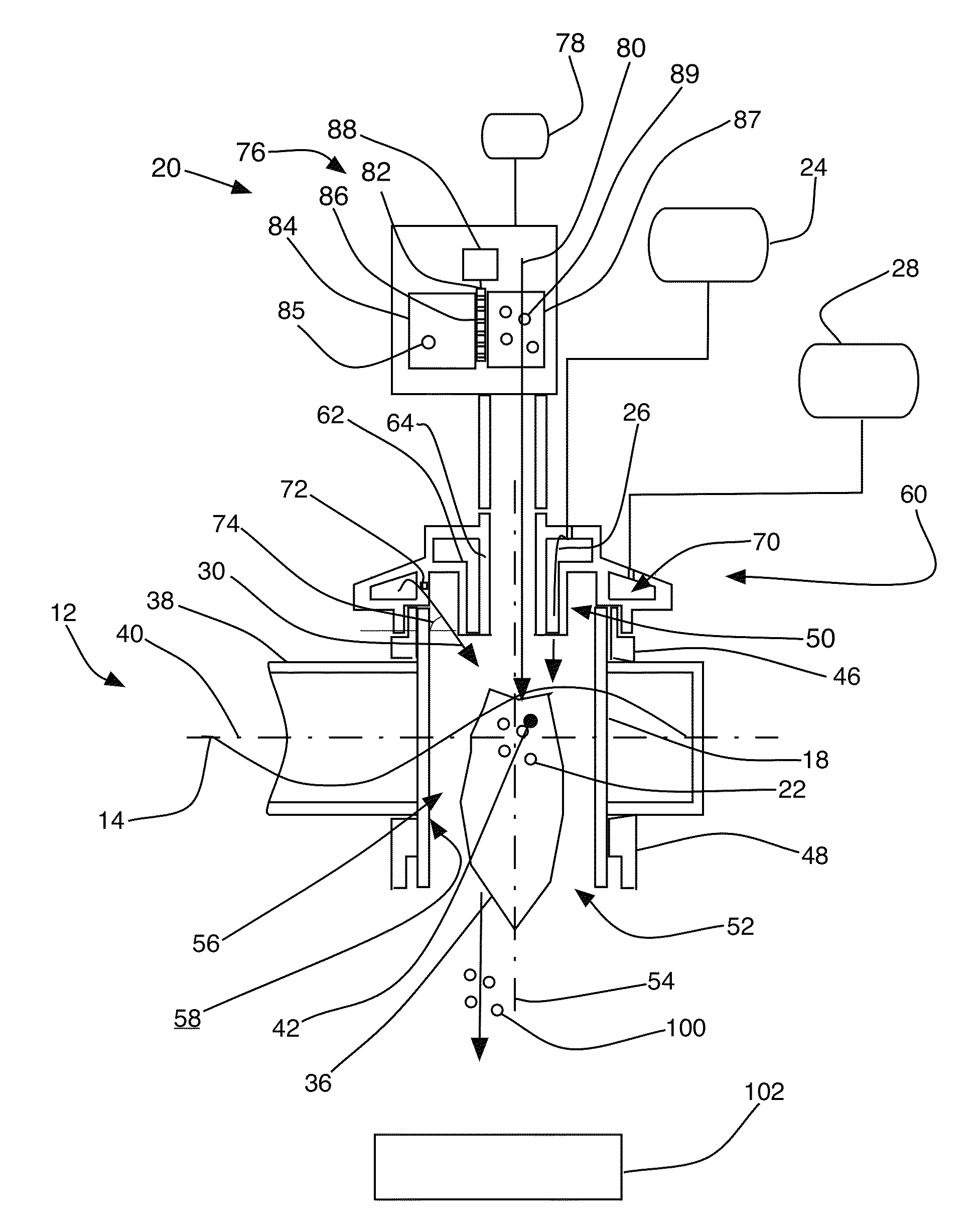

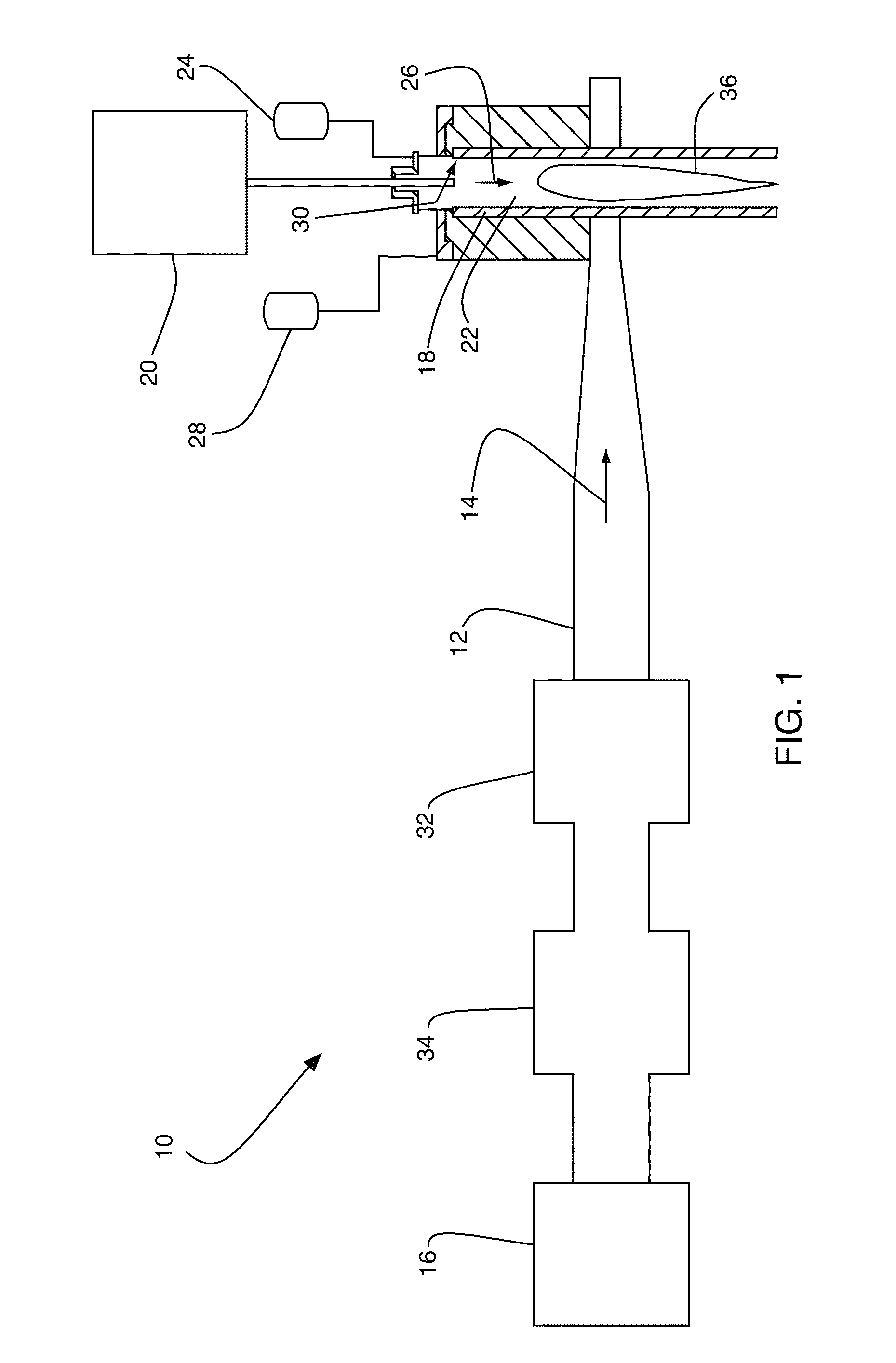

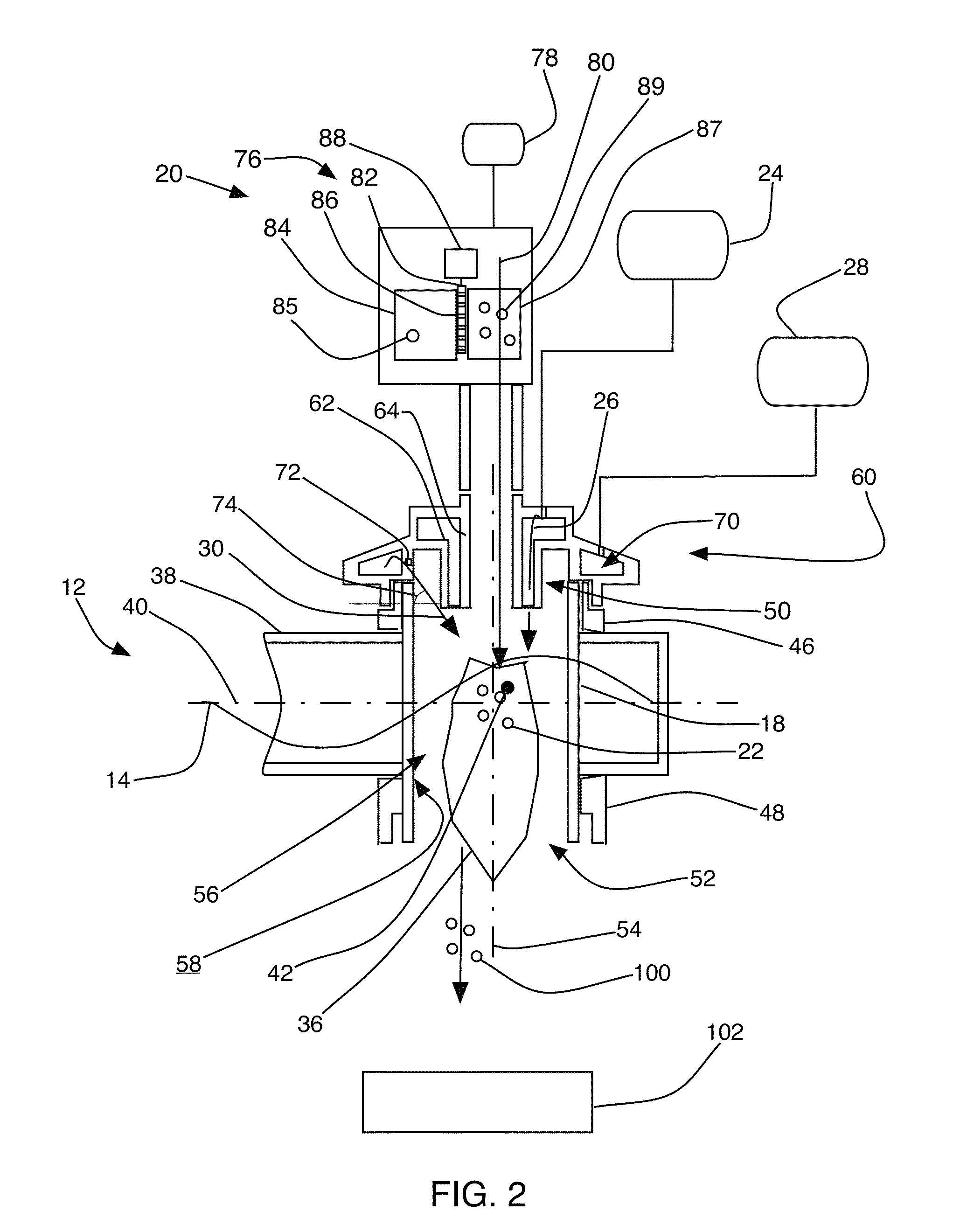

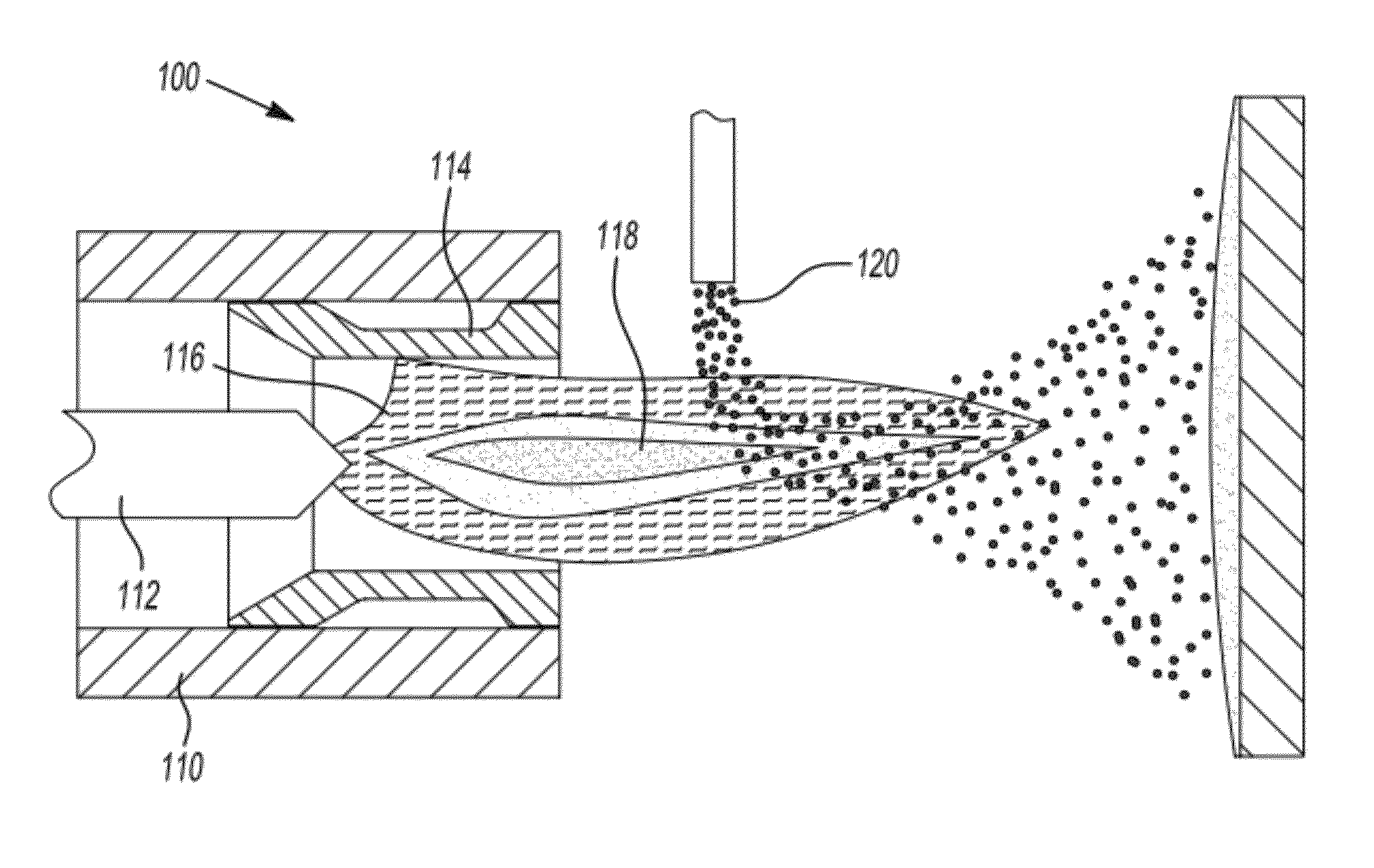

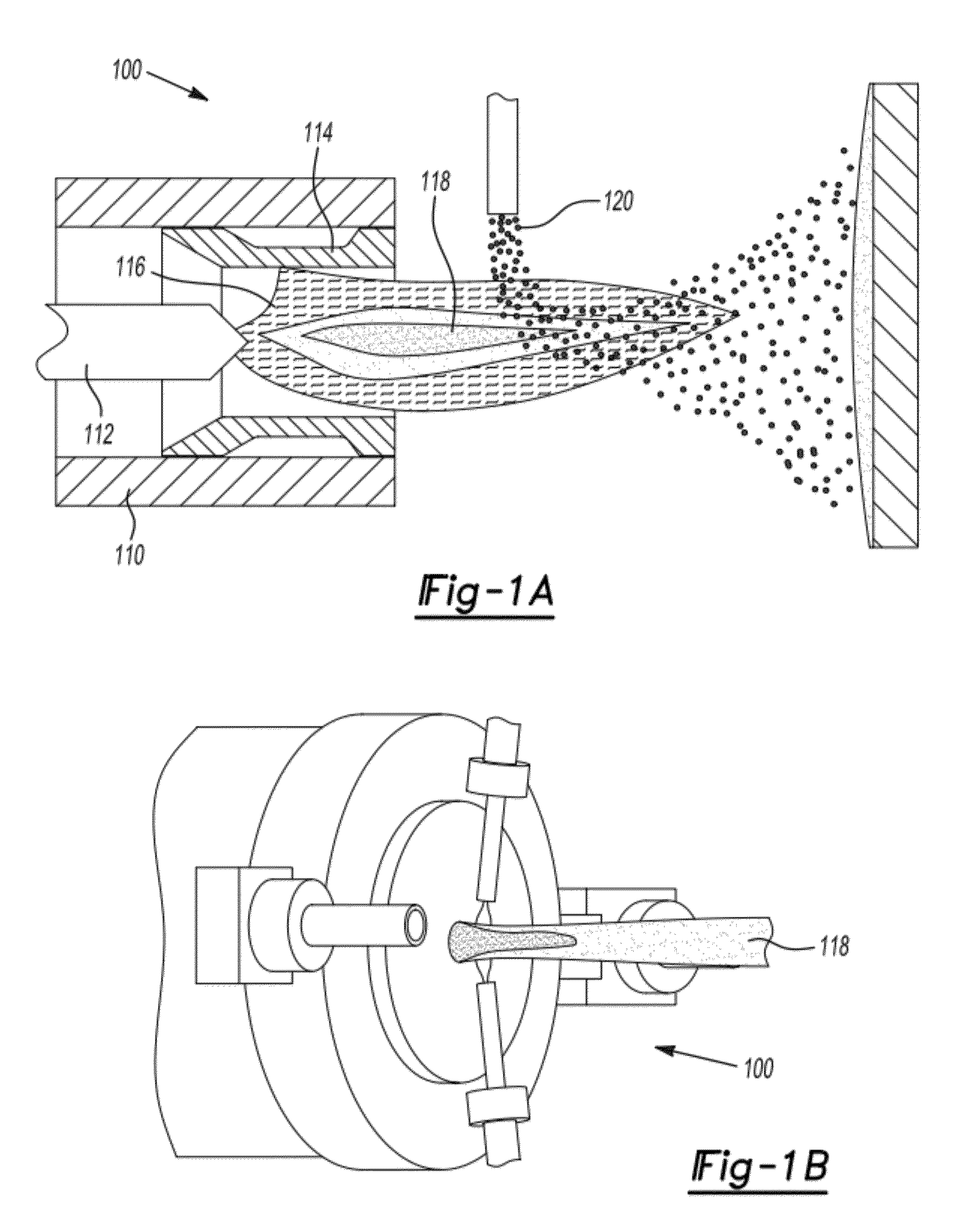

Microwave plasma apparatus and method for materials processing

ActiveUS20080173641A1Enhanced couplingReduce leakageMolten spray coatingArc welding apparatusMolten statePlasma jet

A microwave plasma apparatus for processing a material includes a plasma chamber, a microwave radiation source, and a waveguide guiding microwave radiation from the microwave radiation source to the plasma chamber. A process gas flows through the plasma chamber and the microwave radiation couples to the process gas to produce a plasma jet. A process material is introduced to the plasma chamber, becomes entrained in the plasma jet, and is thereby transformed to a stream of product material droplets or particles. The product material droplets or particles are substantially more uniform in size, velocity, temperature, and melt state than are droplets or particles produced by prior devices.

Owner:6K INC +1

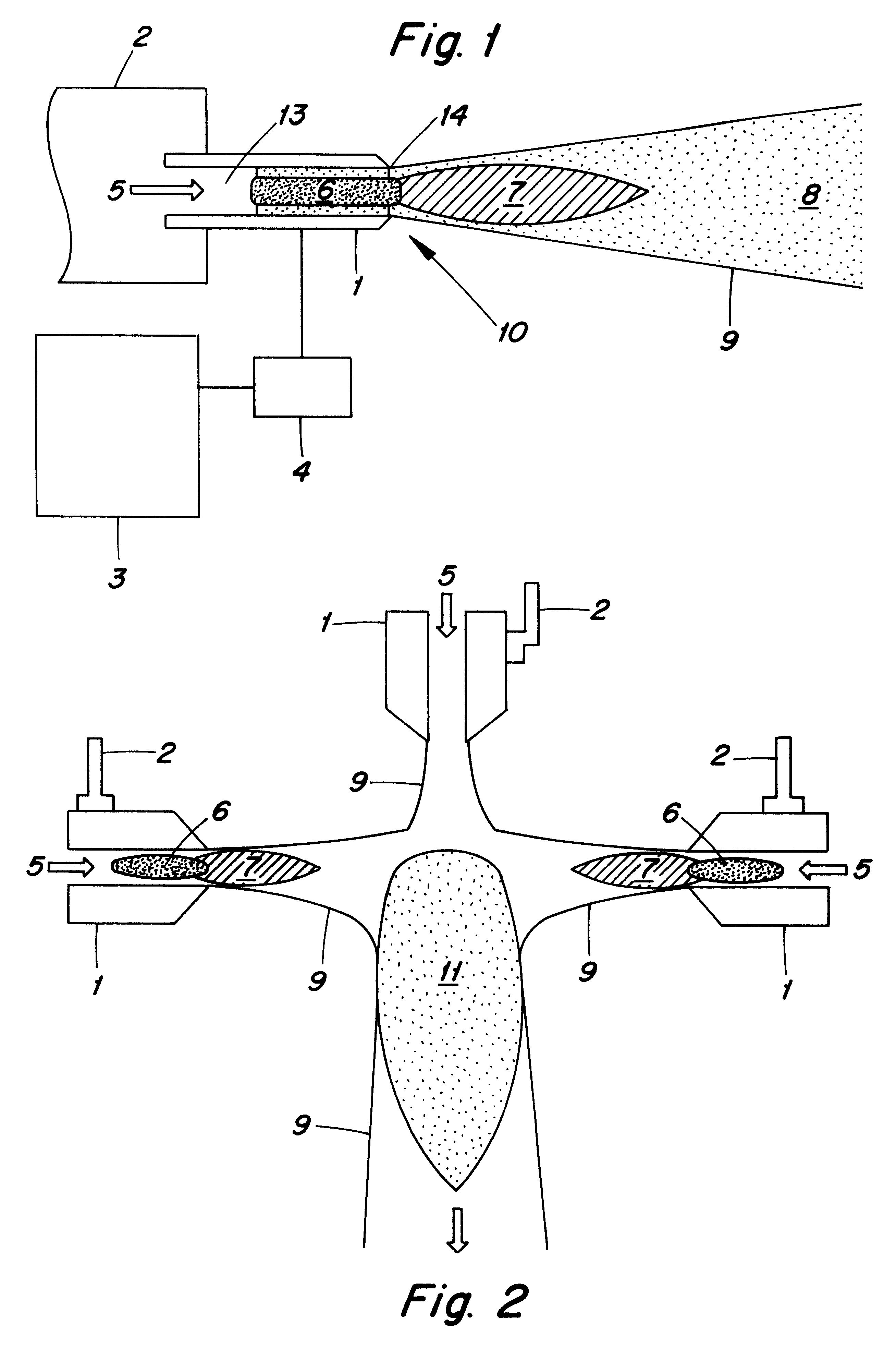

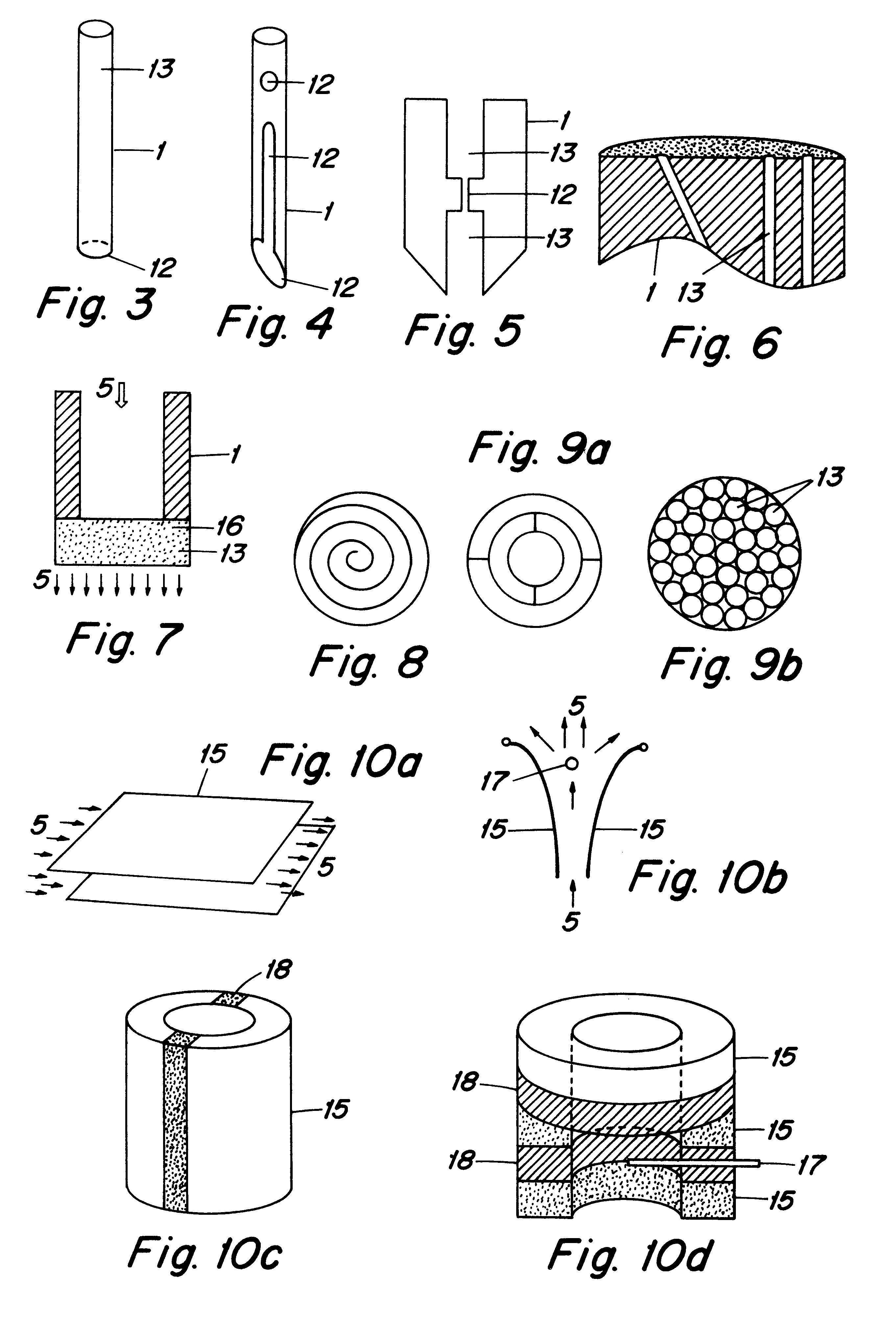

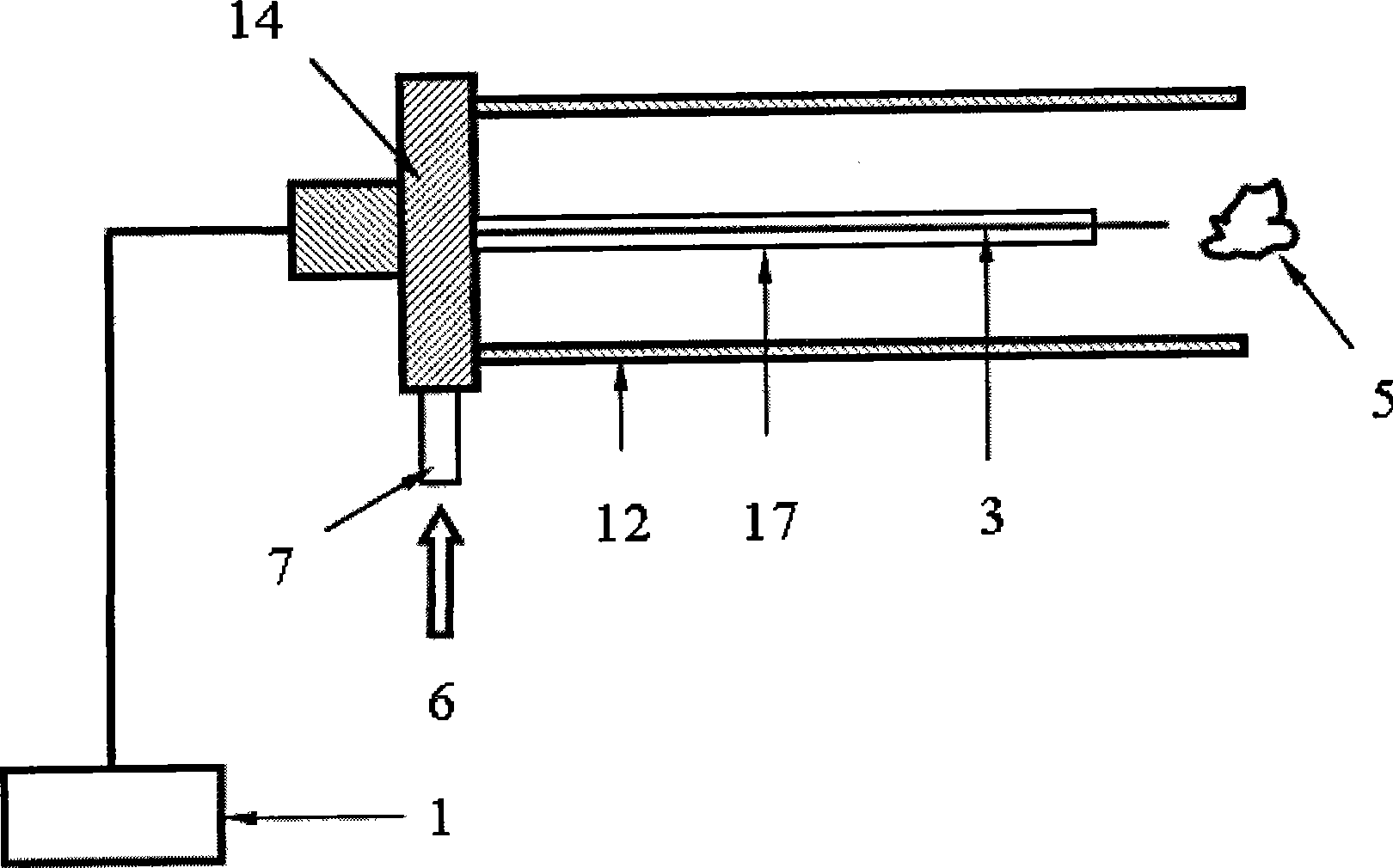

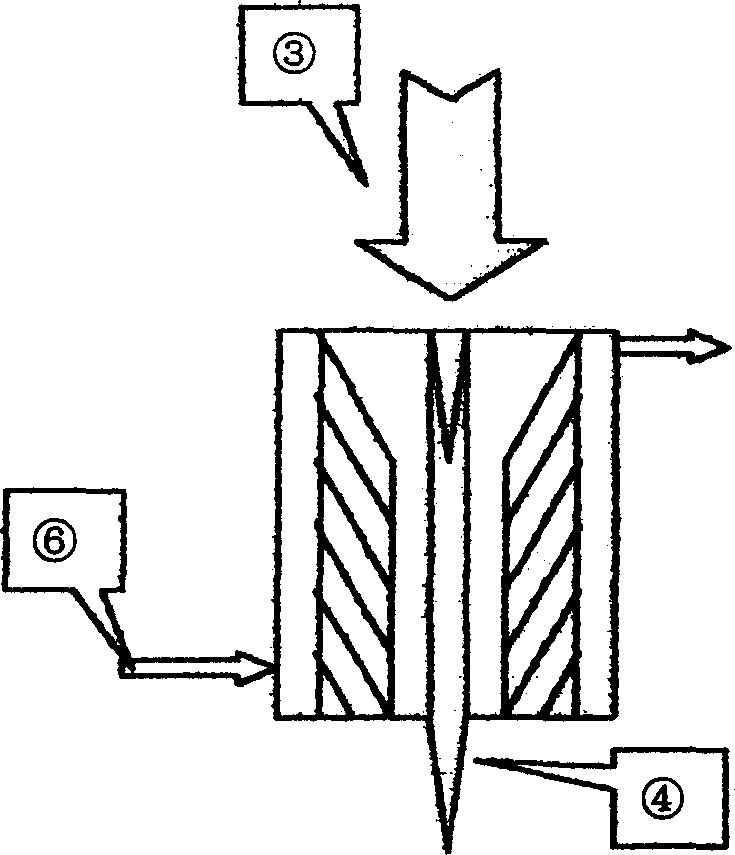

Method of making a physically and chemically active environment by means of a plasma jet and the related plasma jet

The method consists in the fact that from at least one external source (3) electromagnetic energy is conducted to at least one hollow electrode (1) with elements (14) locally increasing the density of electromagnetic energy, by which, inside the cavities of the electrode (1) and / or at its orifice and in the external environment an intensive discharge is generated. The plasma jet consists of at least one hollow electrode (1) of conductive or conductive and dielectric material with at least one element (14) locally increasing the density of electromagnetic energy inside the hollow electrode (1) and / or at its orifice and / or outside, which consists of a design element (12) and / or a physical element (17) acting in the transversal and / or the longitudinal direction with respect to the streaming working medium (5) and is further constituted by at least one source (3) or electromagnetic energy attached via the impedance adapting member (4) consisting of a system of regulatory transformation and transfer elements, onto the conductive part of the hollow electrode (1).

Owner:MASARYK UNIVERSITY

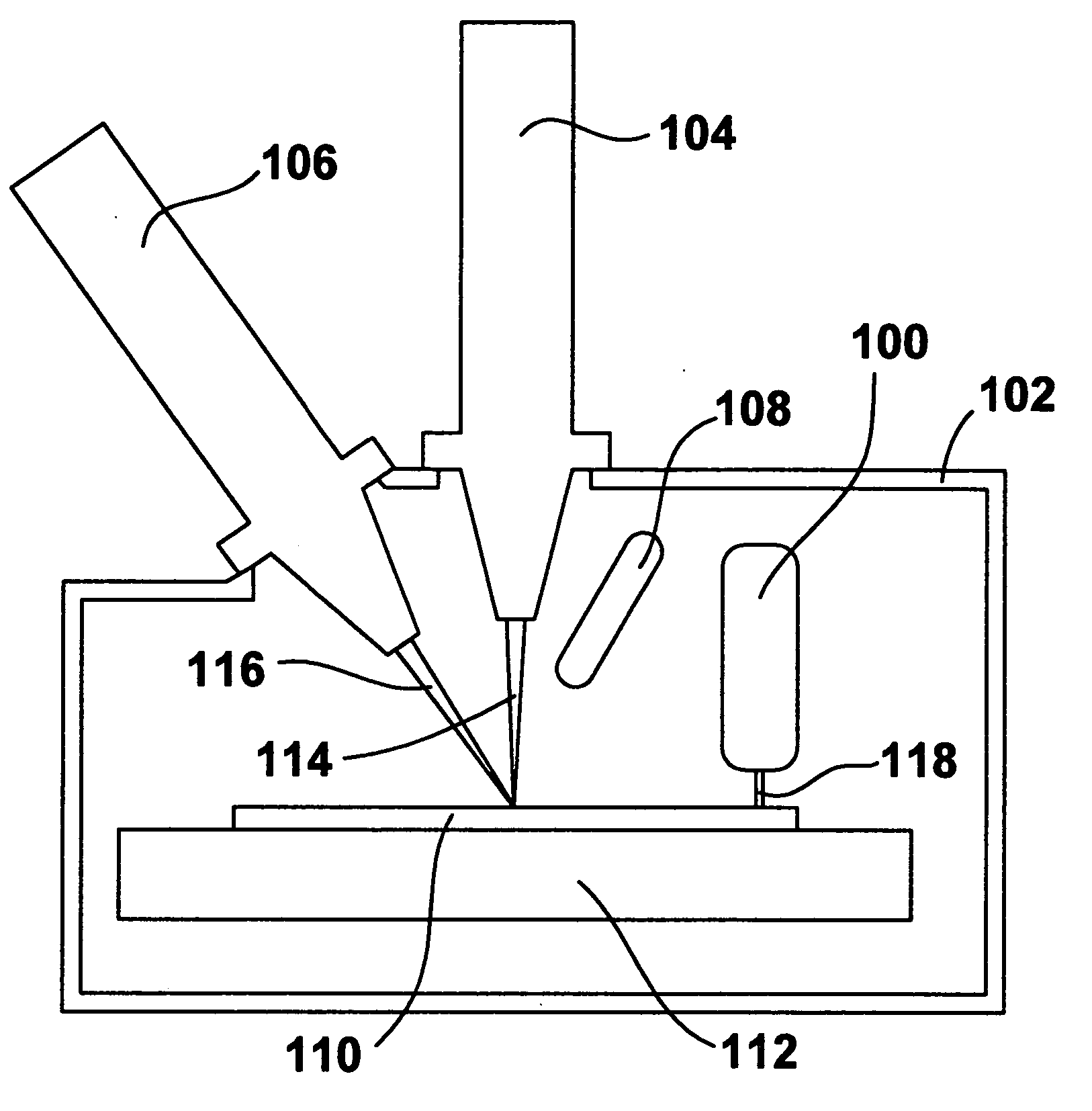

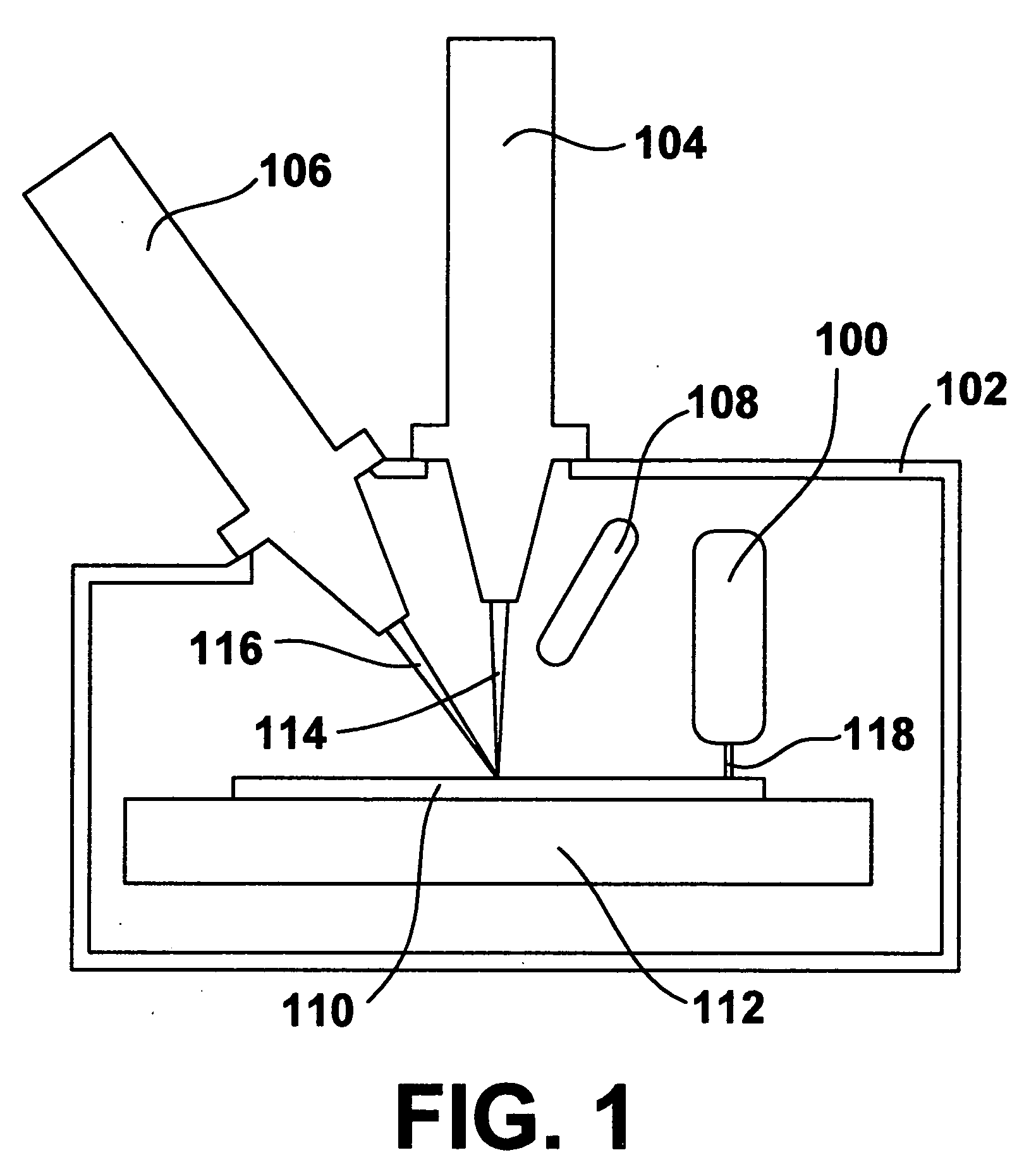

Localized plasma processing

ActiveUS20060045987A1Minimal damageHigh rateElectric discharge tubesDecorative surface effectsPlasma jetEtching

A method of localized plasma processing improves processing speed and reduces work piece damage compared to charged particle beam deposition and etching. In one embodiment, a plasma jet exits a plasma generating chamber and activates a reactive gas. A jet of plasma and reactive gas impacts and processes the work piece. Because the plasma and the ions in the reactive gas can have low kinetic energy, there can be little or no surface damage. This is particularly useful for deposition processes. When it is desired to etch material, the reactive ions can be more energetic to enhance etching.

Owner:FEI CO

Microwave plasma apparatus and method for materials processing

ActiveUS8748785B2Enhanced couplingReduce leakagePolycrystalline material growthMolten spray coatingMolten statePlasma jet

A microwave plasma apparatus for processing a material includes a plasma chamber, a microwave radiation source, and a waveguide guiding microwave radiation from the microwave radiation source to the plasma chamber. A process gas flows through the plasma chamber and the microwave radiation couples to the process gas to produce a plasma jet. A process material is introduced to the plasma chamber, becomes entrained in the plasma jet, and is thereby transformed to a stream of product material droplets or particles. The product material droplets or particles are substantially more uniform in size, velocity, temperature, and melt state than are droplets or particles produced by prior devices.

Owner:6K INC +1

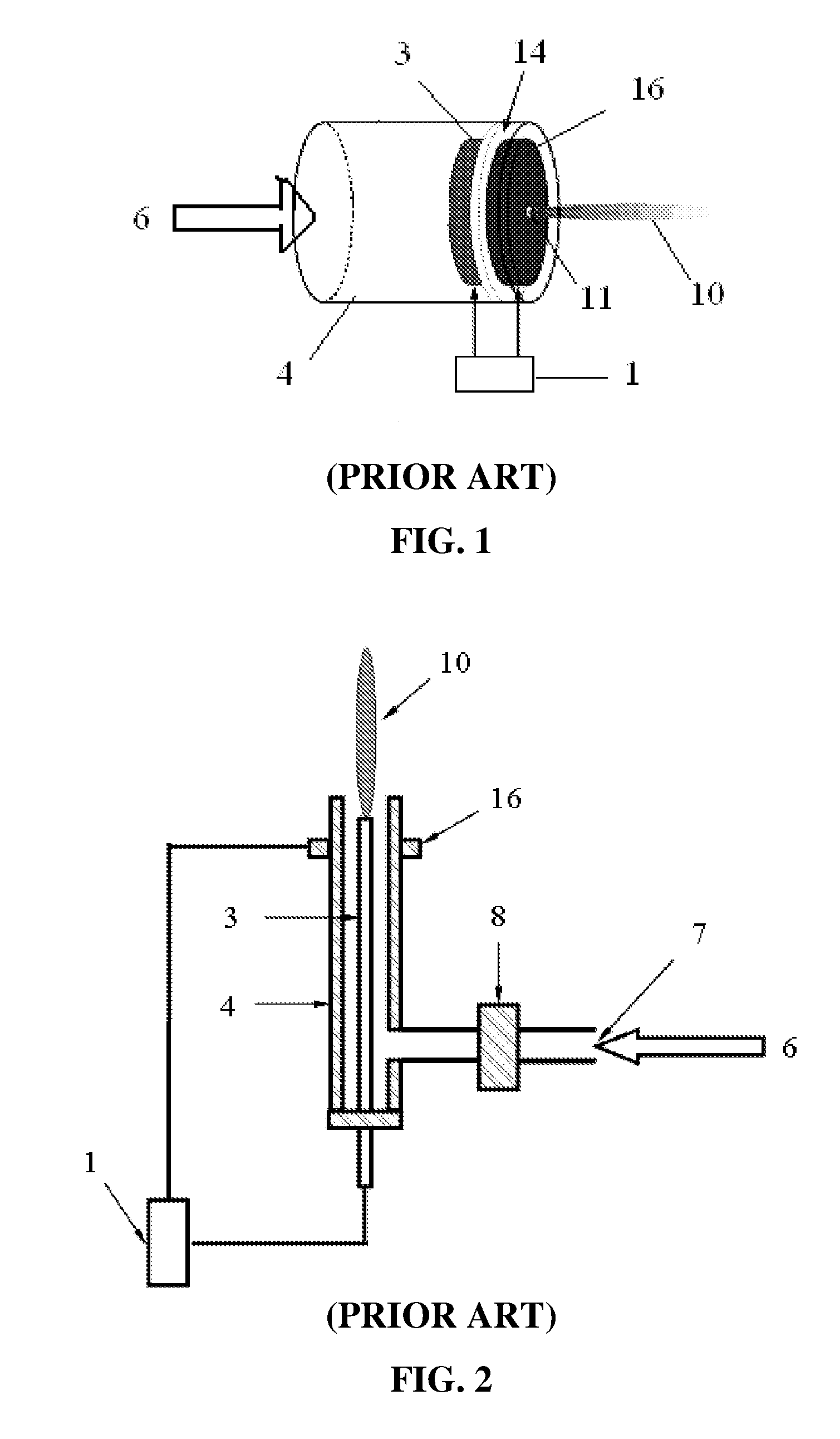

Method and device for creating a micro plasma jet

ActiveUS20060028145A1Reduce the possibilityIncrease electron densityElectric arc lampsArc welding apparatusDielectricPlasma jet

A microhollow cathode discharge assembly capable of generating a low temperature, atmospheric pressure plasma micro jet is disclosed. The microhollow assembly has at two electrodes: an anode and a cathode separated by a dielectric. A microhollow gas passage is disposed through the three layers, preferably in a taper such that the area at the anode is larger than the area at the cathode. When a potential is placed across the electrodes and a gas is directed through the gas passage into the anode and out the cathode, along the tapered direction, then a low temperature micro plasma jet can be created at atmospheric pressure.

Owner:MOHAMED ABDEL ALEAM H +2

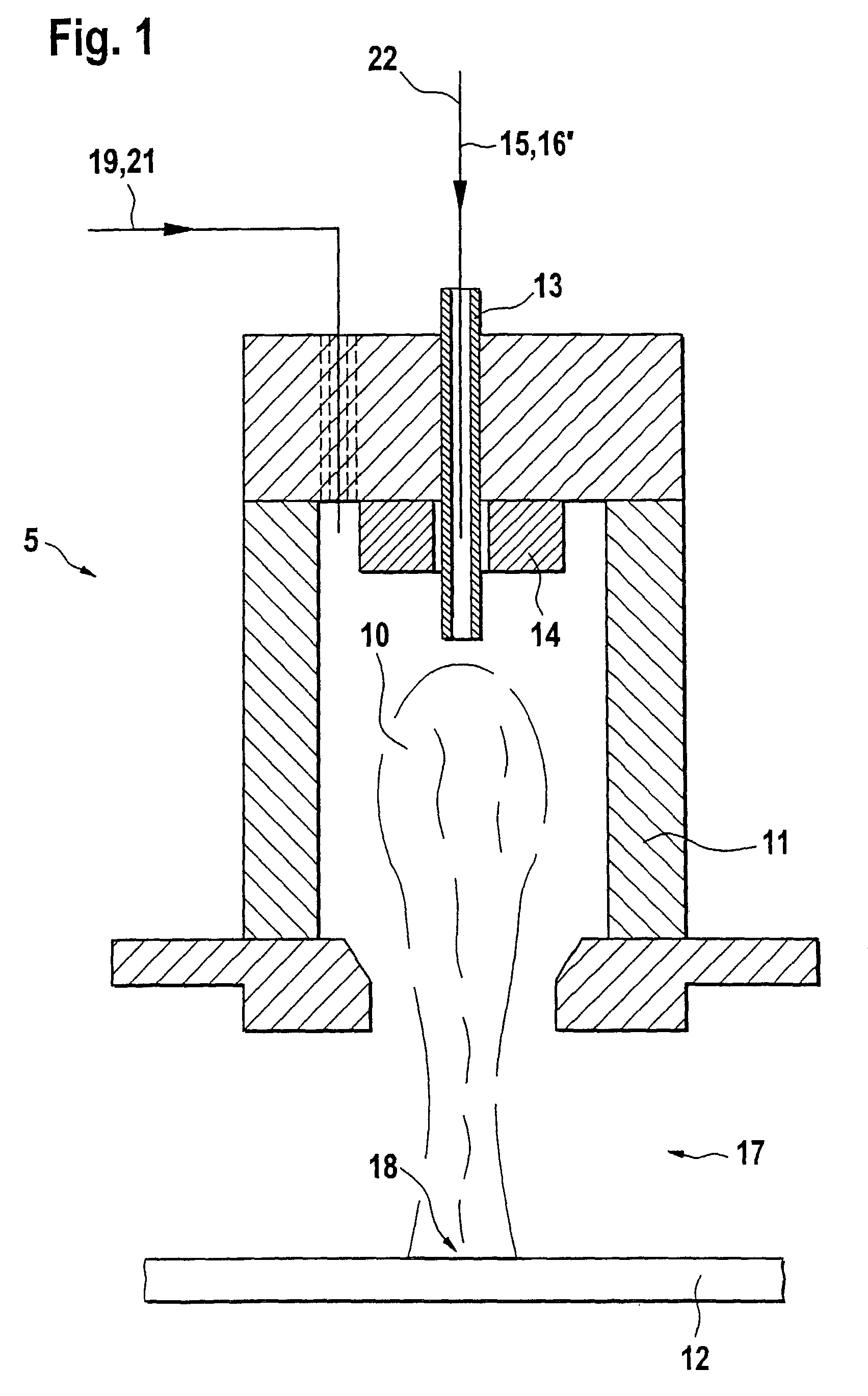

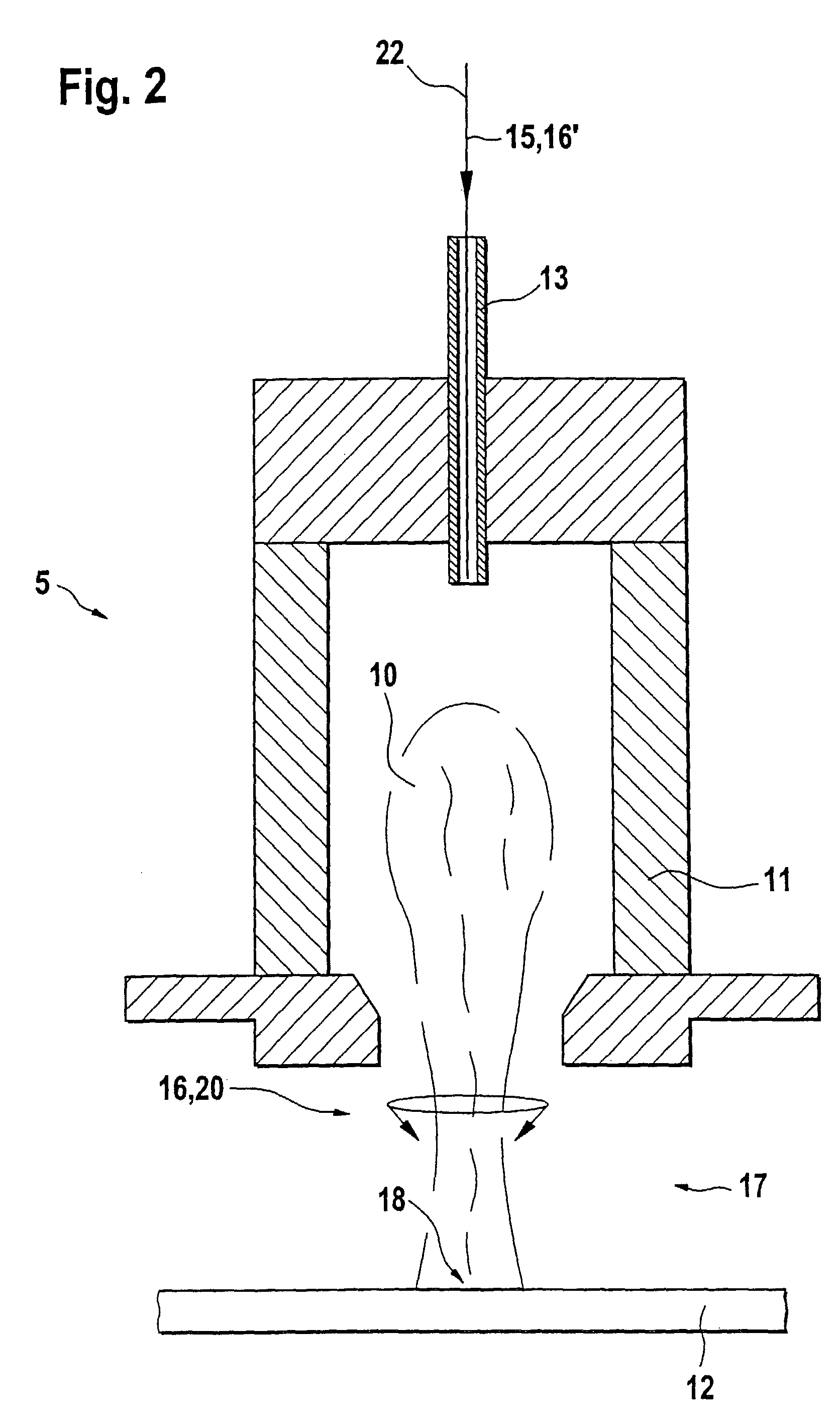

Method for producing composite layers using a plasma jet source

A method is for producing a functional coating, e.g., composite layers or metal alloys, on a substrate using at least one plasma jet source able to be operated in a fine vacuum up to an almost atmospheric pressure range. For this purpose, the plasma jet source produces a plasma, which emerges from the plasma jet source in the form of a plasma jet and acts on a substrate. In this context, at least two precursor materials, which are modified or fused in the plasma jet and subsequently deposited on the substrate, are introduced into the plasma.

Owner:ROBERT BOSCH GMBH

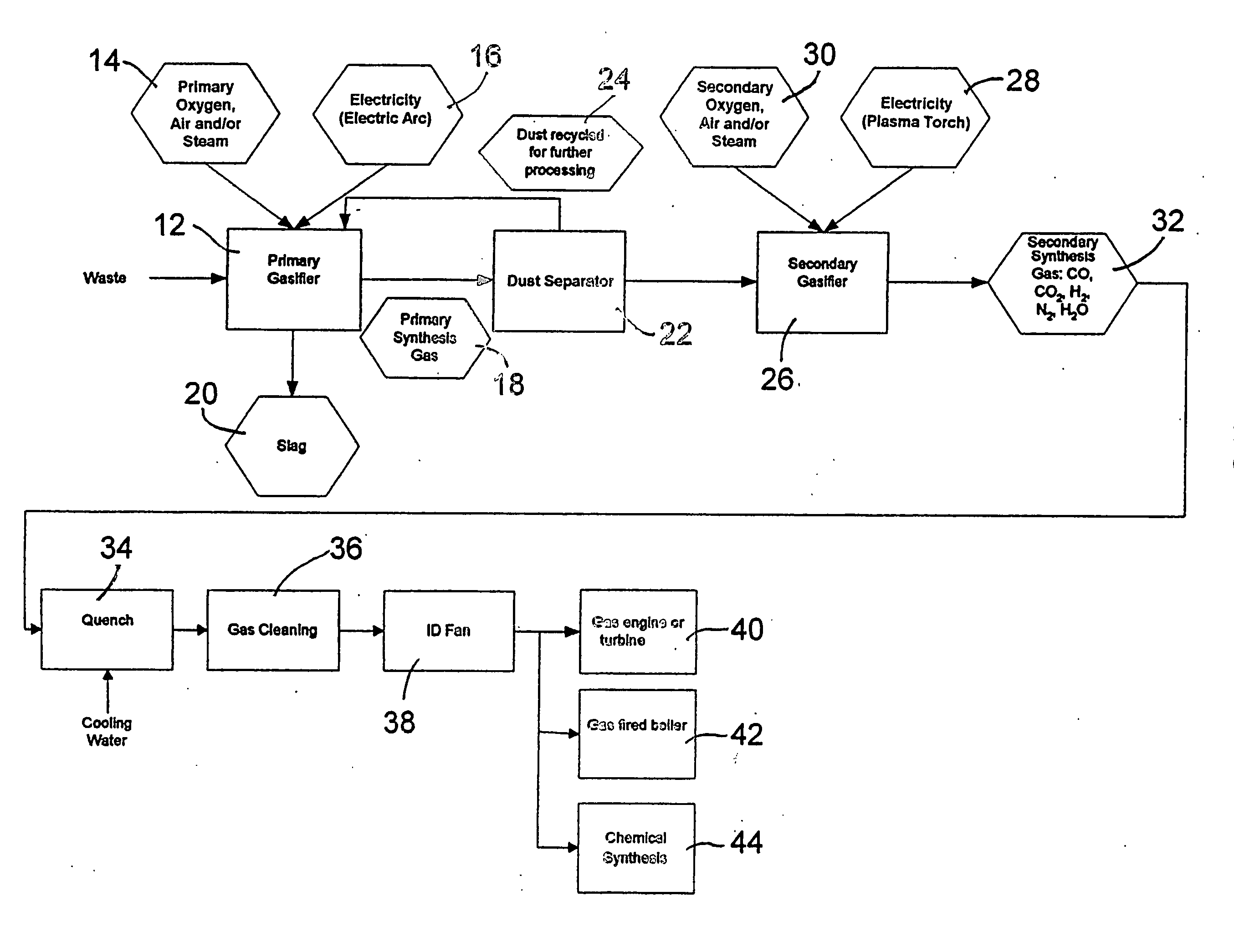

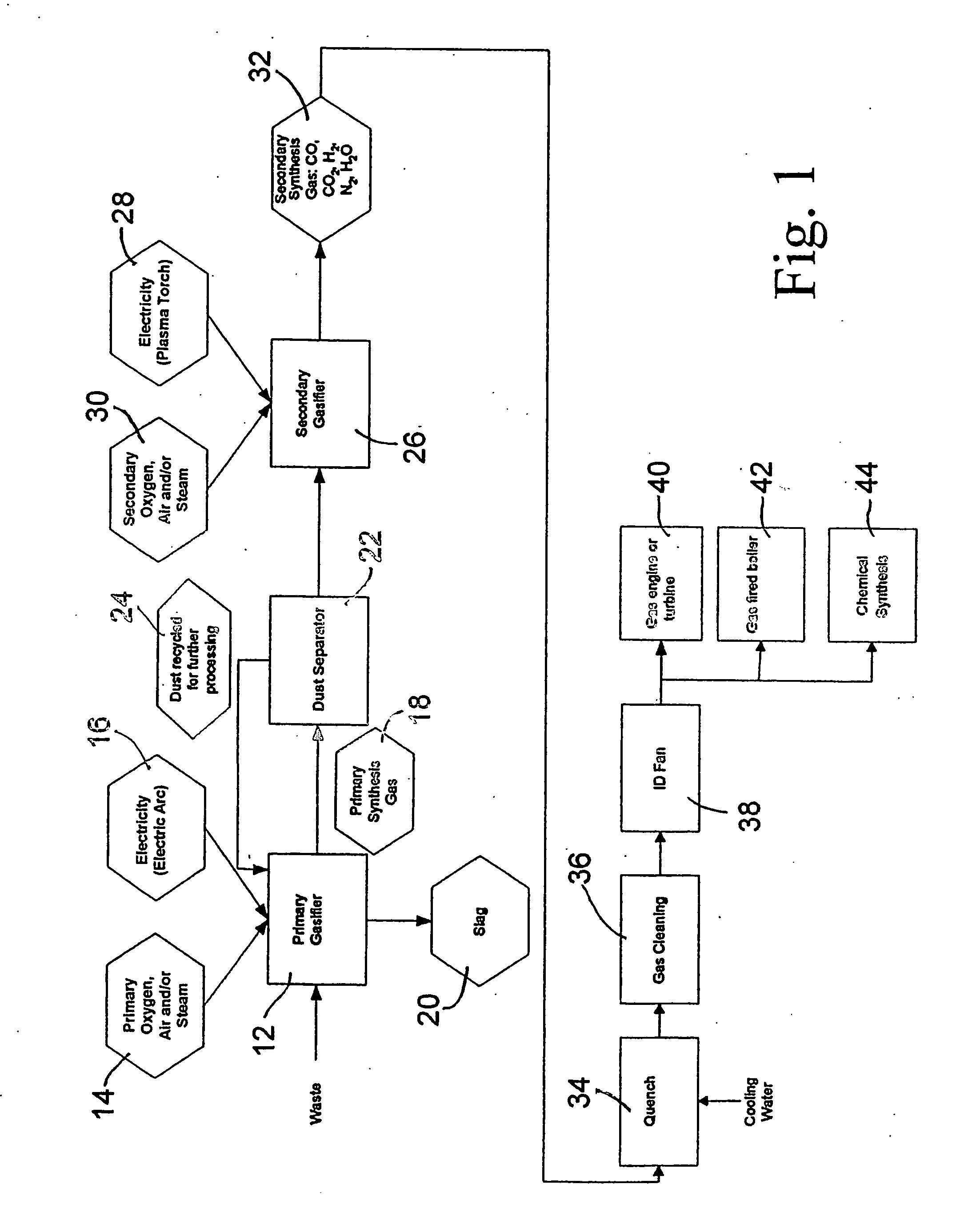

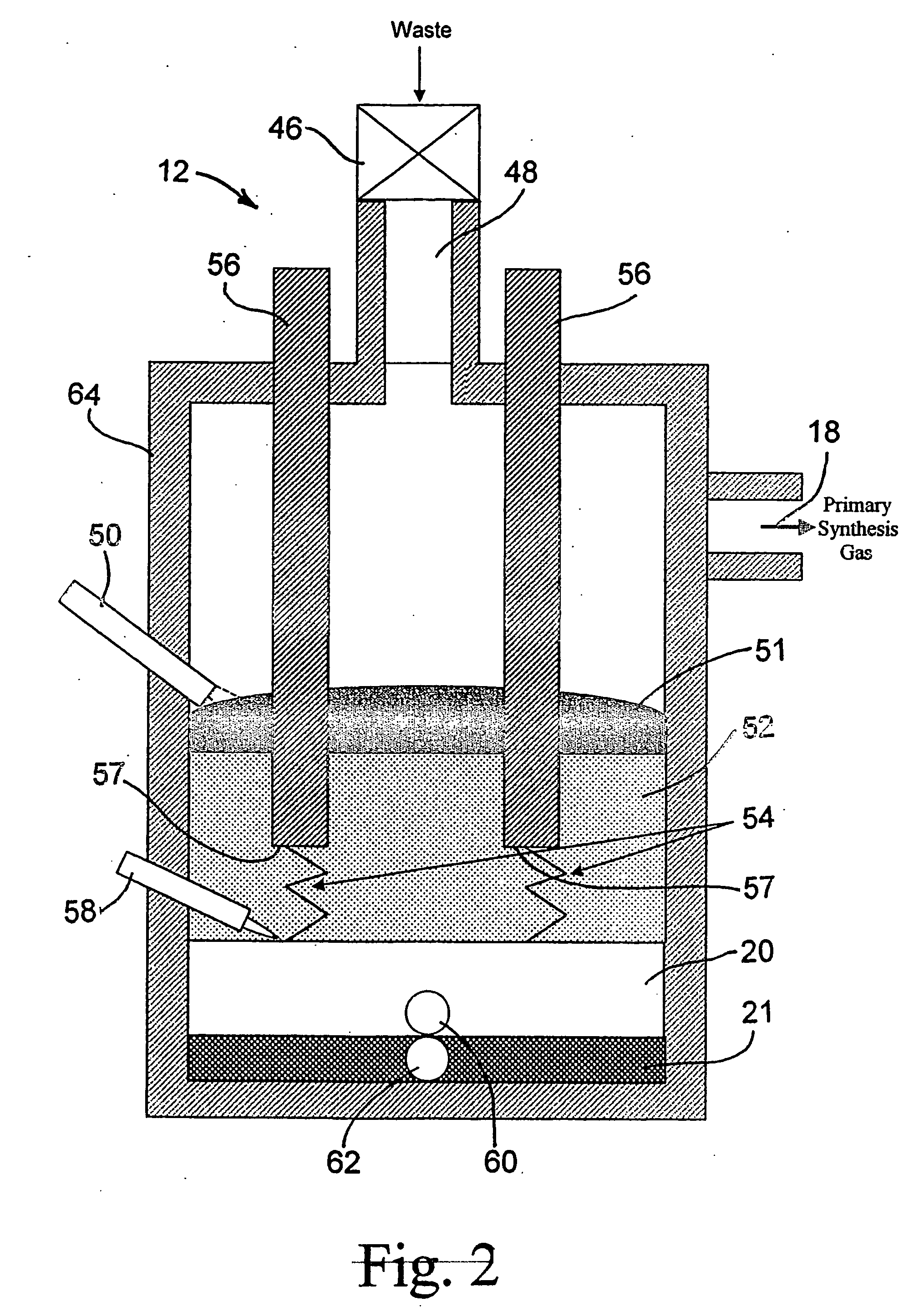

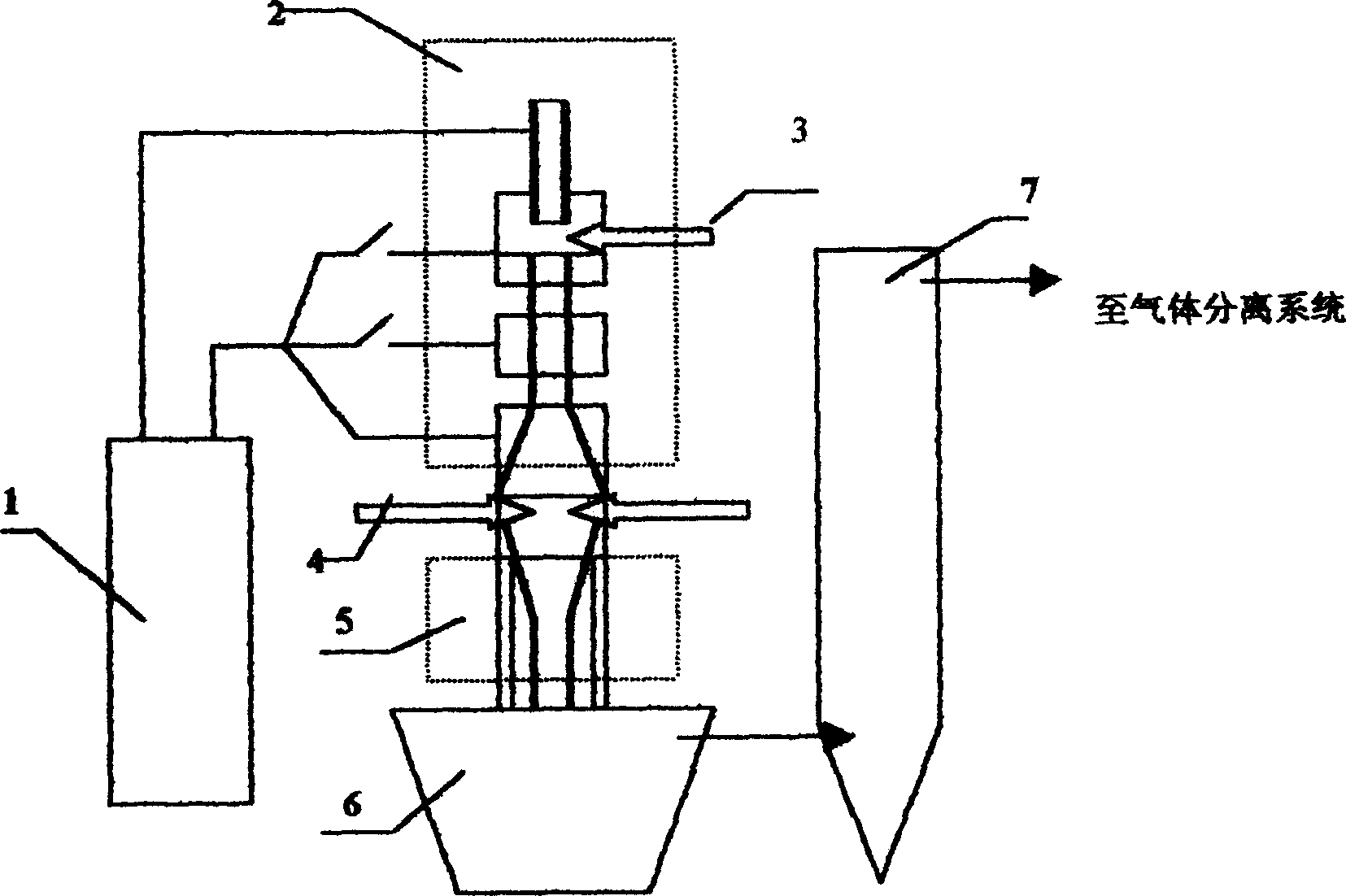

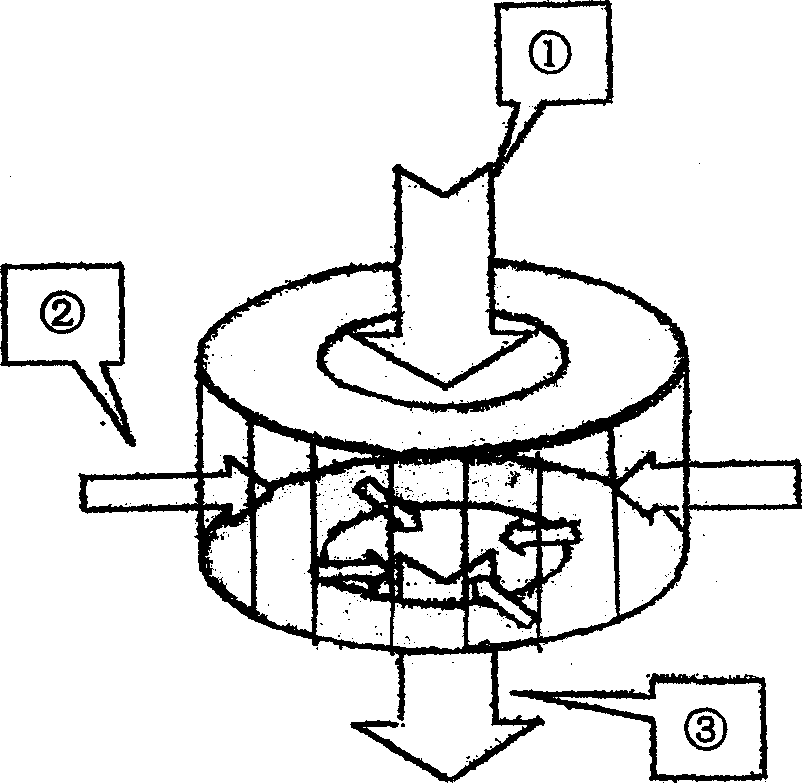

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

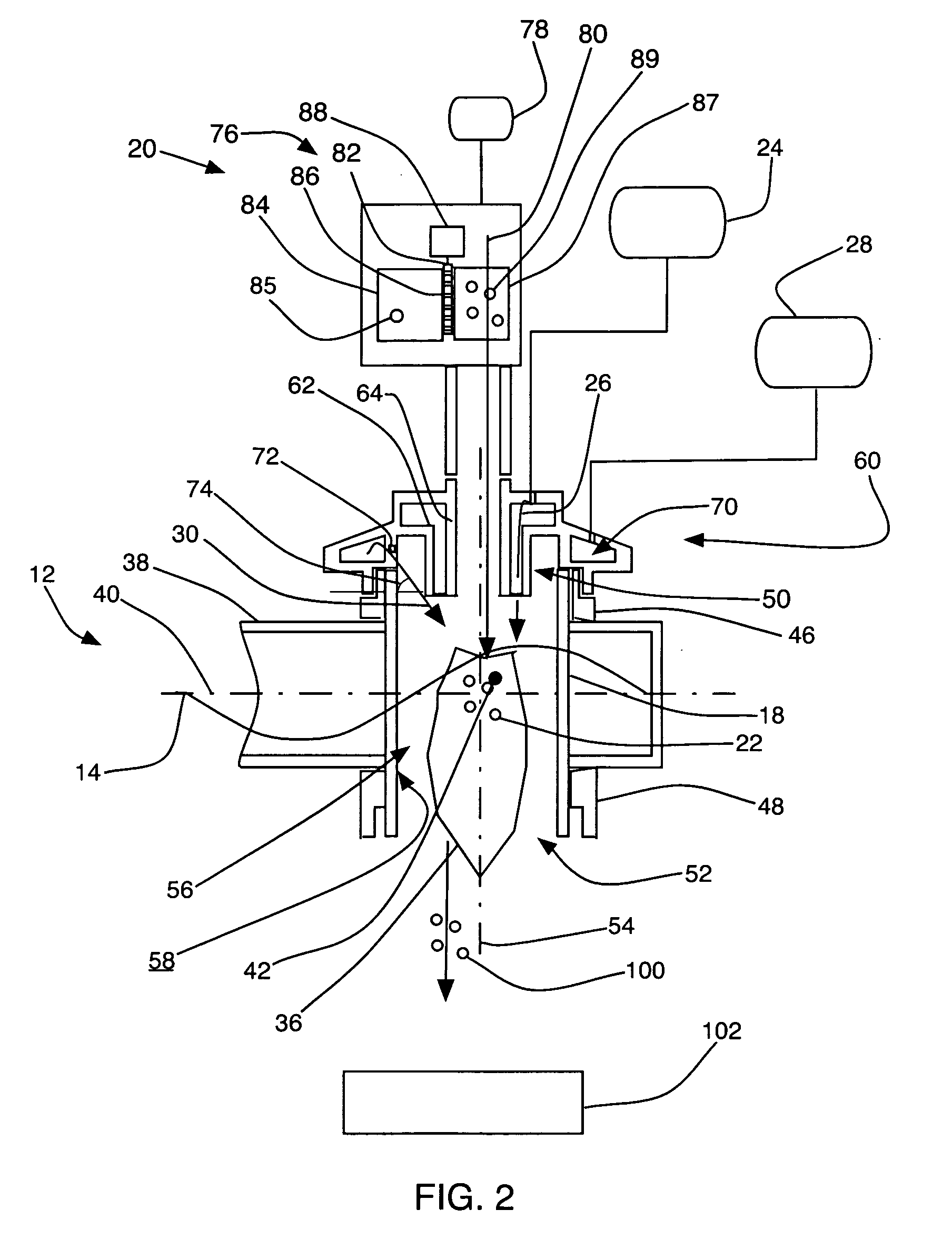

In-situ plasma/laser hybrid scheme

ActiveUS8294060B2Good coating performanceIncrease deposition rateArc welding apparatusX-ray apparatusPlasma jetLaser source

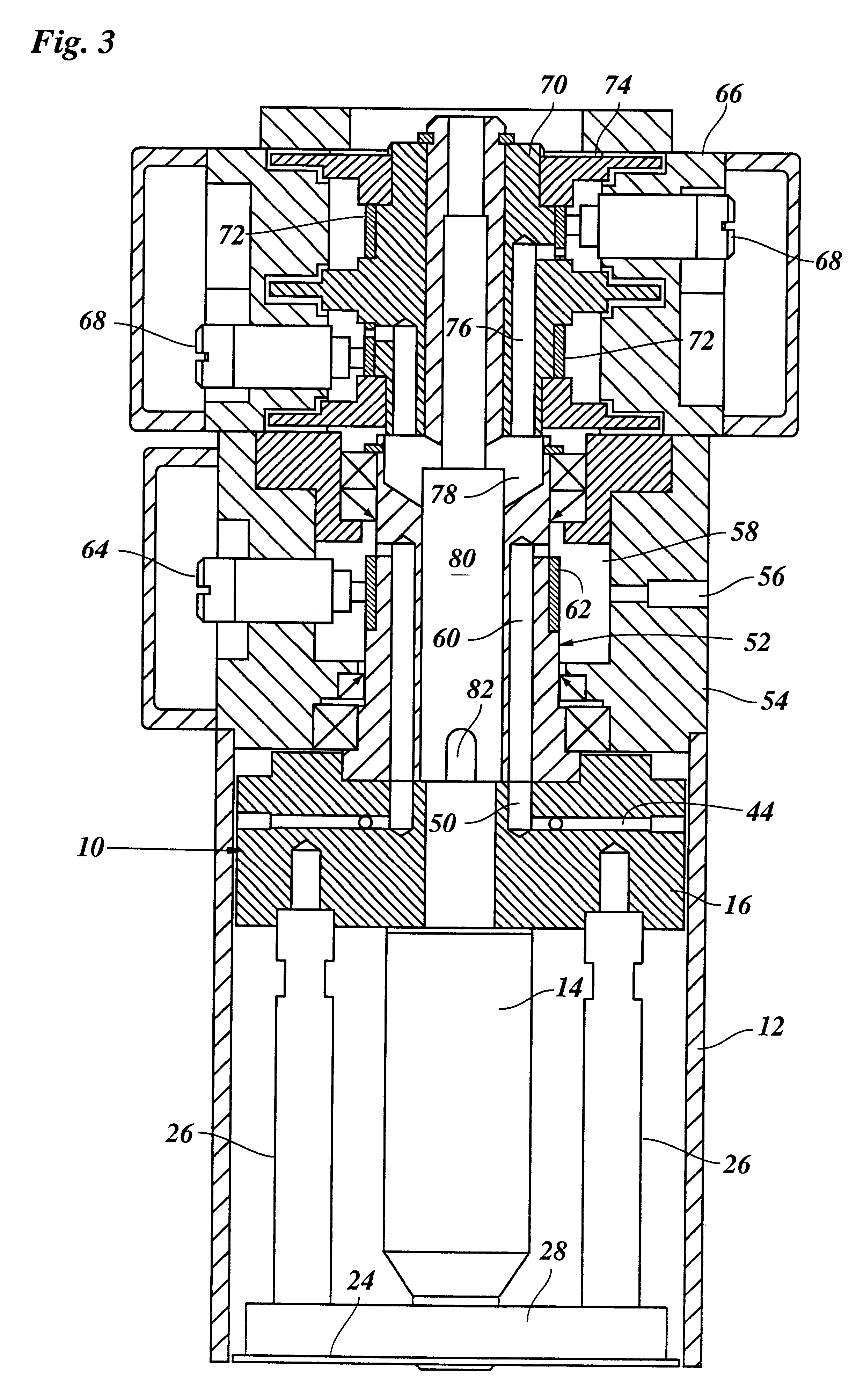

A method and apparatus for forming layers on a target. The apparatus and method employ a direct current plasma apparatus to form at least one layer using a plasma jet containing precursors. In some embodiments, the direct current plasma apparatus utilizes axial injection of the precursors through the cathode (in an upstream and / or downstream configuration) and / or downstream of the anode. In some embodiments, the direct current plasma apparatus can comprise a laser source for remelting the layer using a laser beam to achieve in-situ densification thereof.

Owner:RGT UNIV OF MICHIGAN

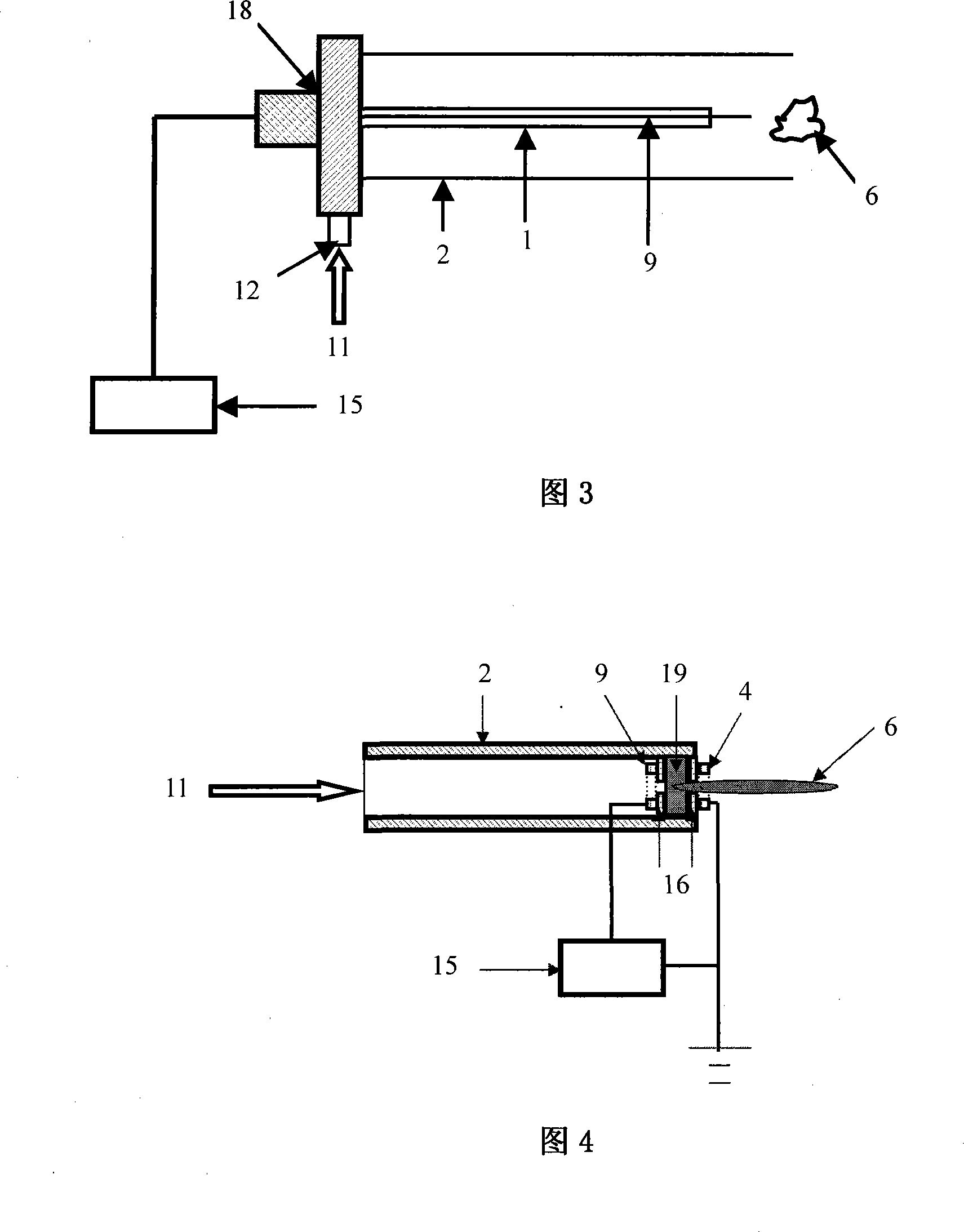

Jet apparatus capable of blocking discharging from generating low temperature plasma by atmos medium

InactiveCN101330794ASolve the problem of limited application rangeEasy to modifyPlasma techniquePlasma jetParallel plate

A jetting device for a low-temperature plasma generated by the atmospheric dielectric barrier discharge relates to the technical field of the application of gas discharge plasma. Inert gas and air are used as working gas; the plasma generated in a discharge area is blown out in the form of jet; the problem of limited application range caused by the narrow parallel-plate dielectric barrier discharge area and a high plasma macroscopic temperature can be solved. The device has the structural characteristics that a hollow pipe-shaped connector is connected with a hollow dielectric pipe; an electrode coated with insulation dielectric is fixed at the center of the dielectric pipe; an annular electrode is closely attached to the outer wall of the dielectric pipe; the working gas enters the dielectric pipe from a flow meter and a retaining valve through the connector; the plasma is blown out to form the plasma jetting. The jetting device has the advantages of low plasma macroscopic temperature, large electron energy, wide expanded range, low cost, low energy consumption and high reliability; furthermore, the jetting device can used in the fields of sterilization and disinfection, the surface modification of complex-shaped material, waste gas treatment, ozone synthesis, as well as the physical and chemical fields of the discharge light source plasma.

Owner:XI AN JIAOTONG UNIV

Preionization atmos low-temperature plasma jet generator

InactiveCN101466194AReduce breakdownIncrease discharge powerElectric discharge tubesPlasma techniquePlasma jetHigh concentration

The invention relates to an atmospheric pressure low-temperature plasma jet reactor with preionization structure, which belongs to plasma discharge reactor technical field, and the reactor is characterized in that: the device main body is a millimeter magnitude main silica tube with one open end; a part is arranged above the open end at the lower part with 15 to 25mm, and the part becomes the thinnest at 20mm part, and a ring-shaped electrode is wound on the part; a thin silica tube is connected at the closed end arranged in the inner part thereof through the closed end arranged at the upper part of the silica tube; and a needle electrode is arranged in the thin silica tube. An earthing electrode is arranged below the open end of the main silica tube; and the argon gas is filled into the needle electrode, and the oxygen gas is filled into the main silica tube. The needle electrode and the ring-shaped electrode can be exerted with the same high voltage; the needle electrode discharge can supply the seed electrons for the ring-shaped electrode discharge, and a stable glowing discharge plasma jet is arranged between the ring-shaped electrode and the earthing electrode. The reactor has the beneficial effects that the obtained plasma jet can generate high-concentration chemical activity species, and the reactor has practical value.

Owner:DALIAN UNIV OF TECH

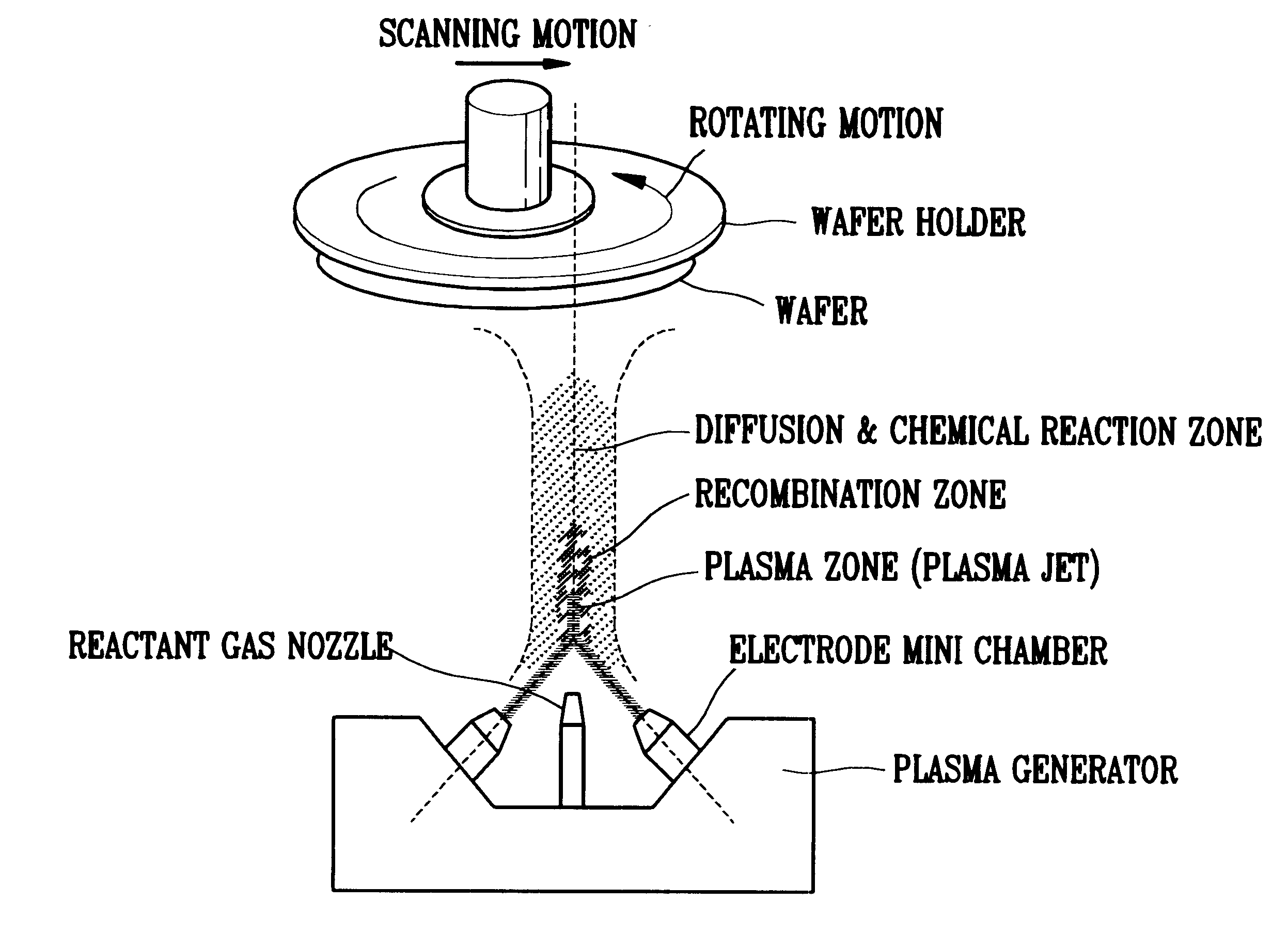

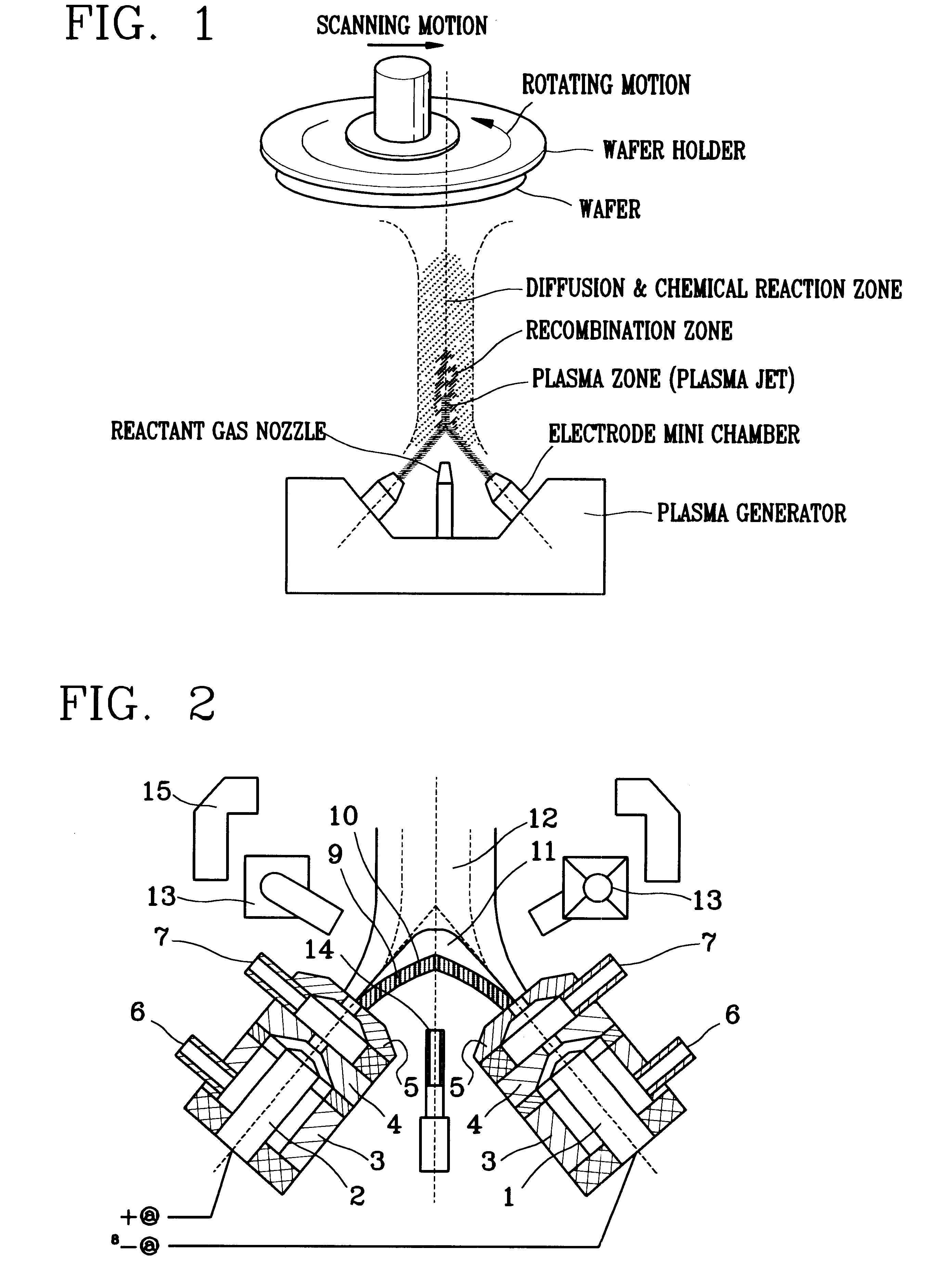

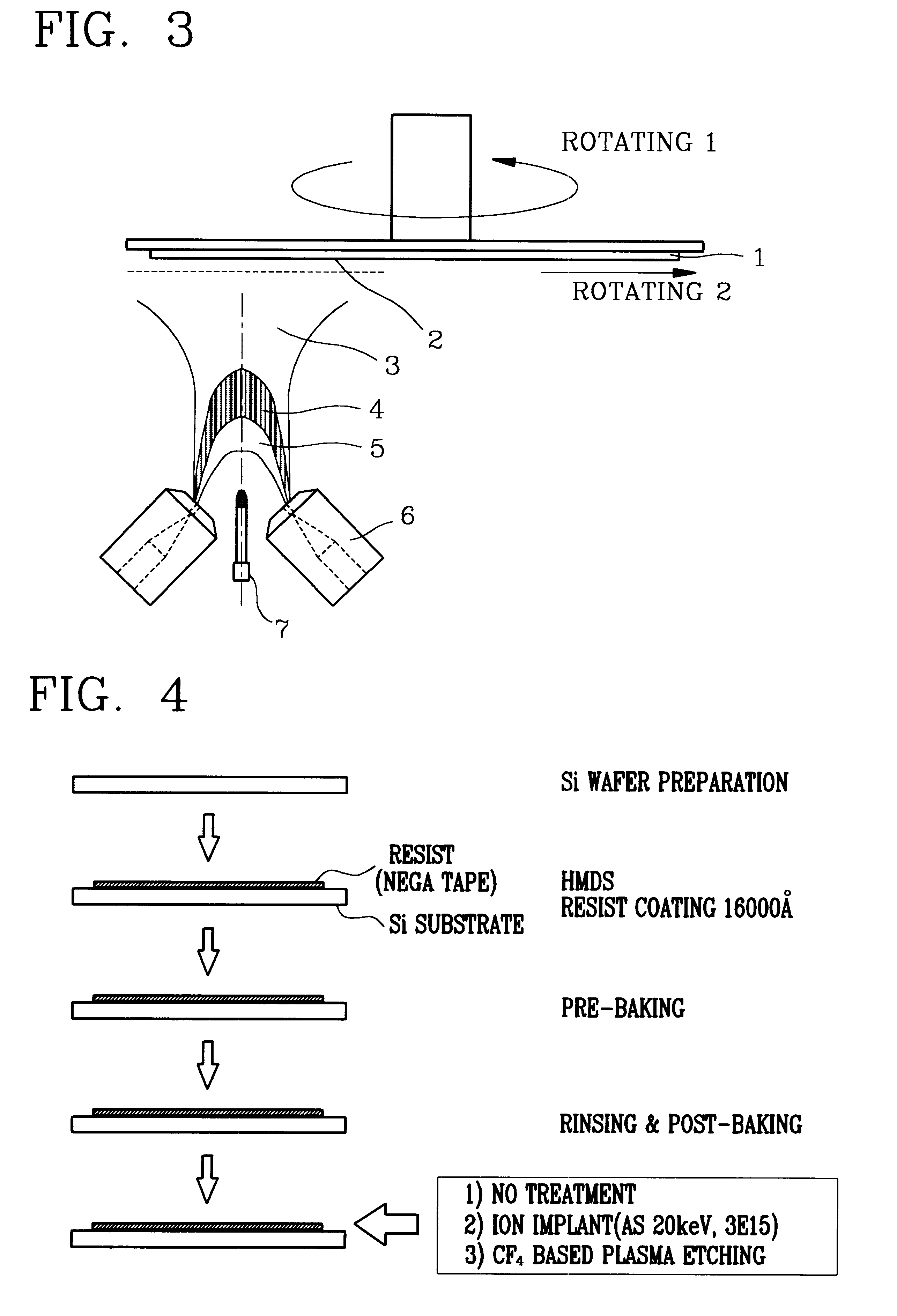

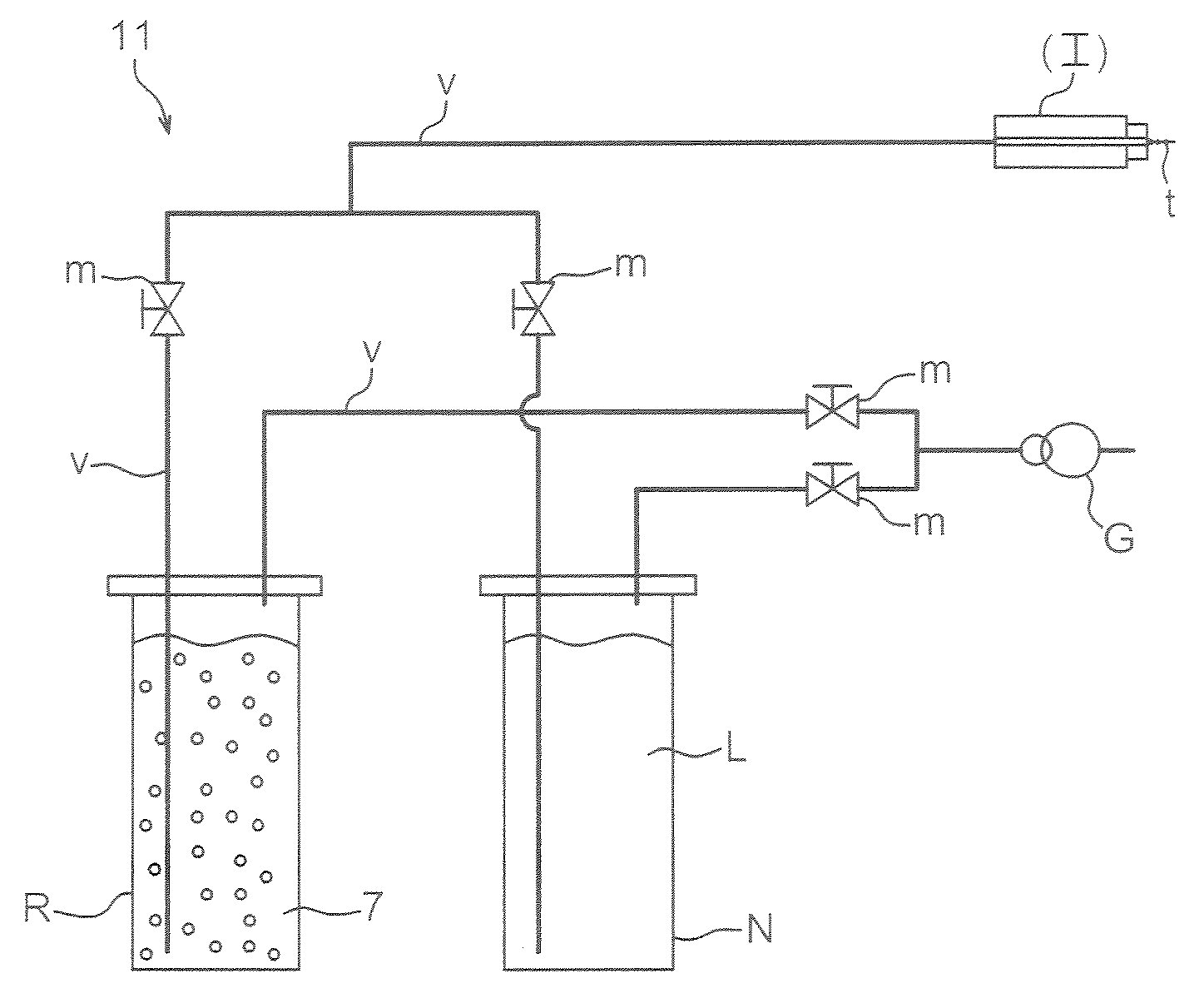

Method for removing residual metal-containing polymer material and ion implanted photoresist in atmospheric downstream plasma jet system

A method of removing metal-containing polymeric material and ion implanted or plasma damaged photoresist from a surface using a plasma jet system, by generating radicals having high energy and high density from atmospheric plasma by introducing a reactant gas to the plasma, and placing the surface at a distance from the plasma, whereby ionic reaction on the surface is minimized while the removing action of the radicals on the surface is maintained.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanosturctured Coating and Coating Method

InactiveUS20080090071A1Increase probabilityImproved performance characteristicsLiquid surface applicatorsMolten spray coatingPlasma jetNanoparticle

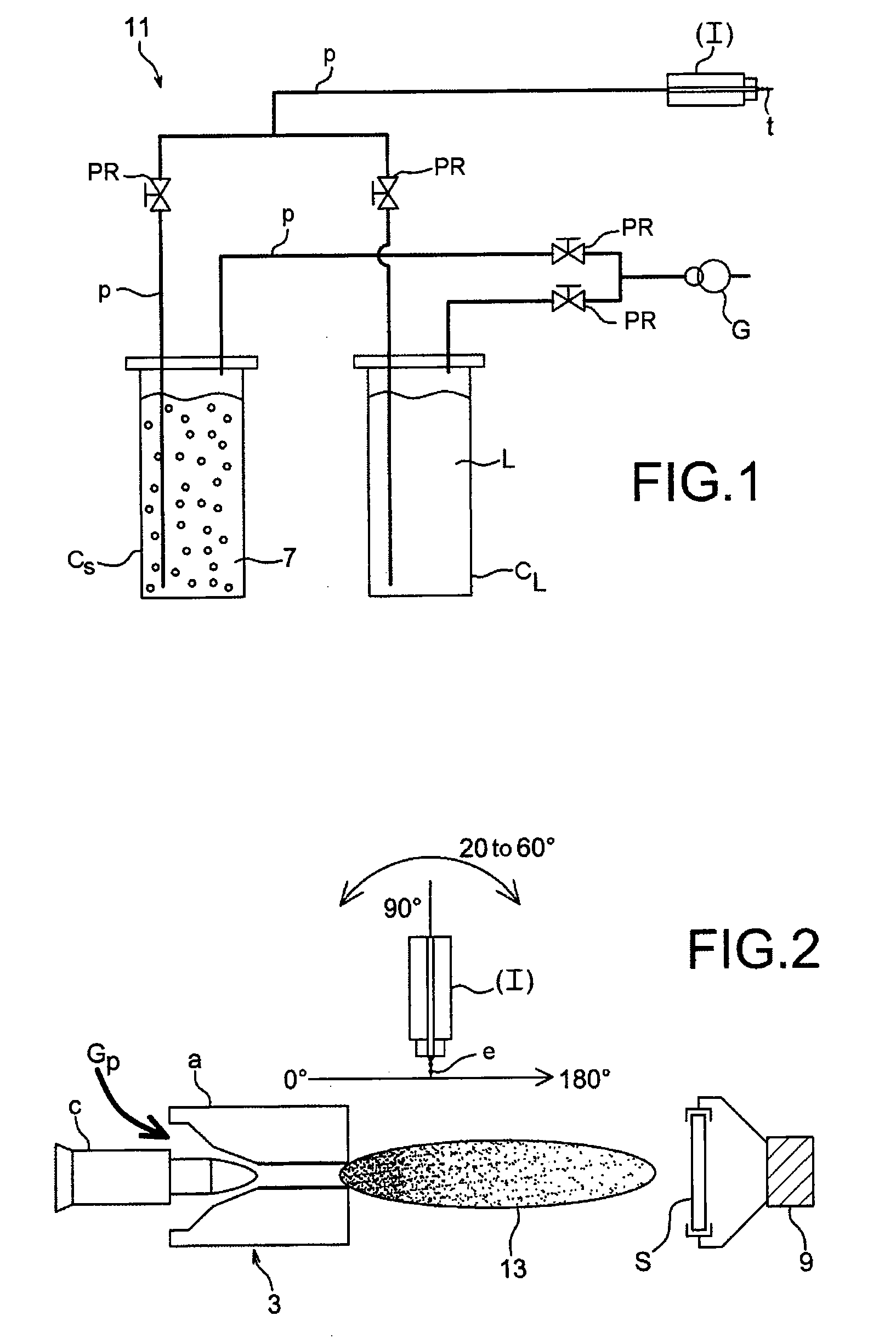

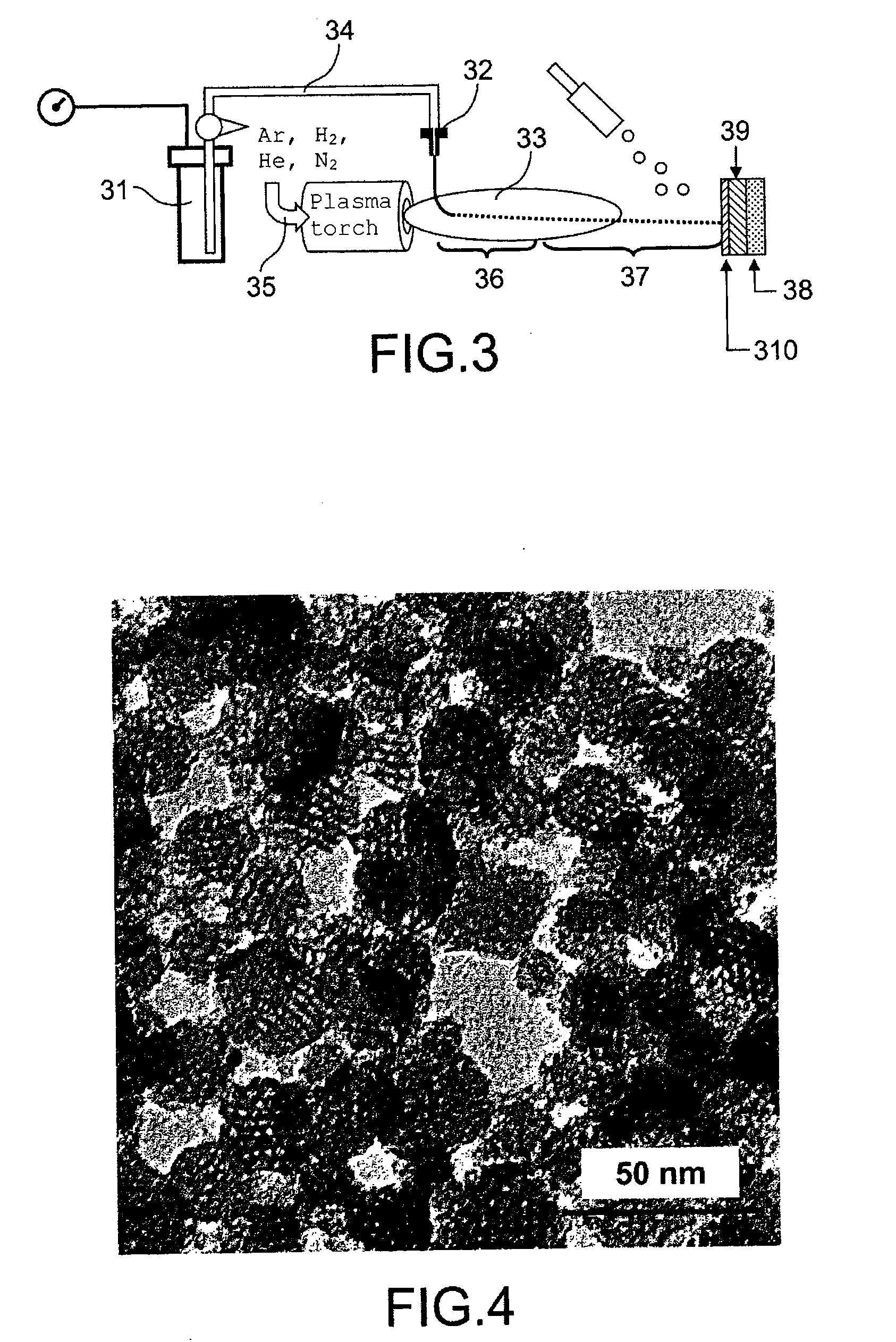

The present invention relates to a method of coating a surface with nanoparticles, to a nanostructured coating that can be obtained by this method, and also to a device for implementing the method of the invention. The method is characterized in that it comprises an injection of a colloidal sol of said nanoparticles into a plasma jet that sprays them onto said surface. The device (1) comprises: a plasma torch (3); at least one container (5) containing the colloidal sol (7) of nanoparticles; a device (9) for fixing and for moving the substrate(S); and a device (11) for injecting the colloidal sol into the plasma jet (13) of the plasma torch. The present invention has applications in optical, electronic and energy devices (cells, thermal barriers) comprising a nanostructured coating that can be obtained by the method of the invention.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

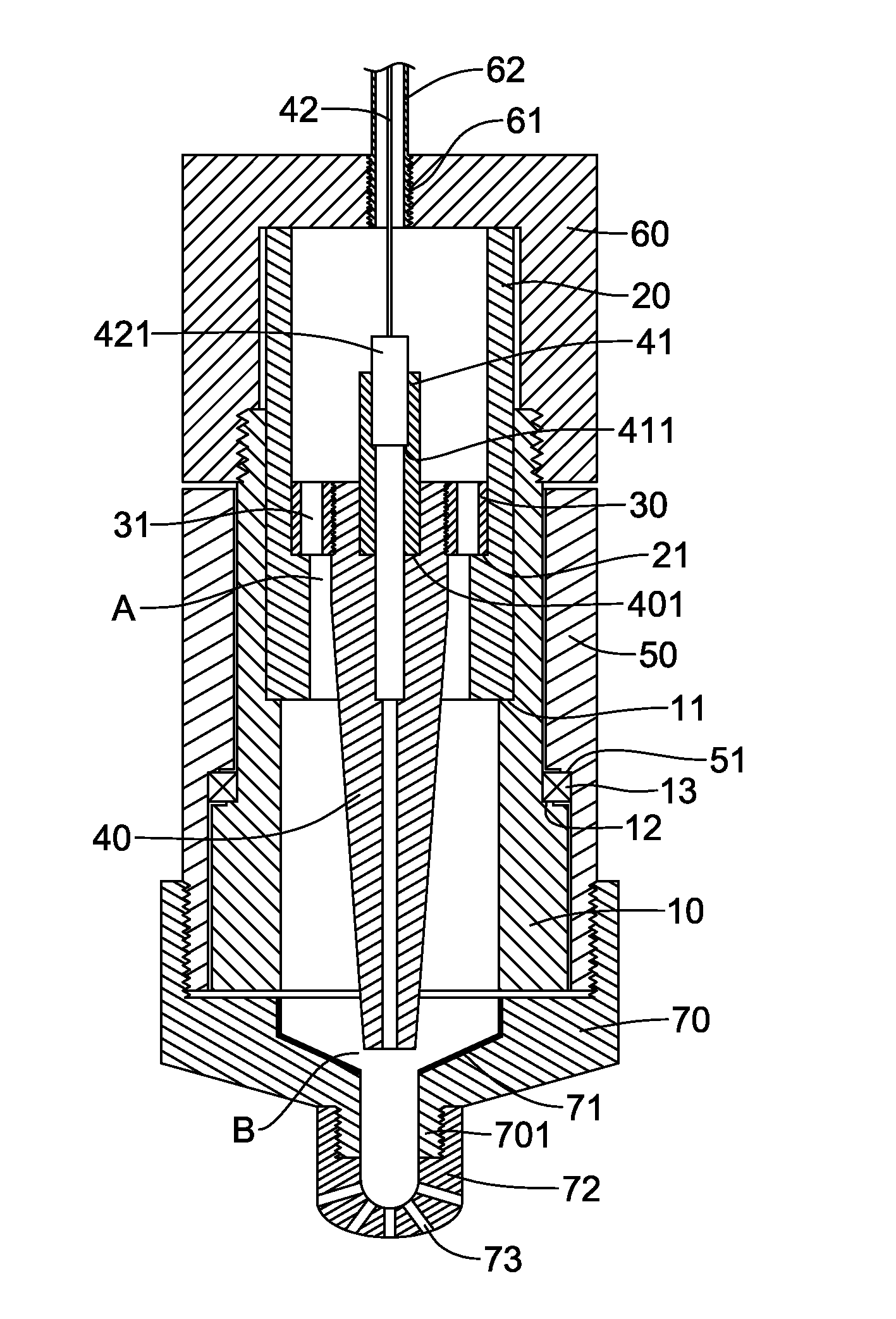

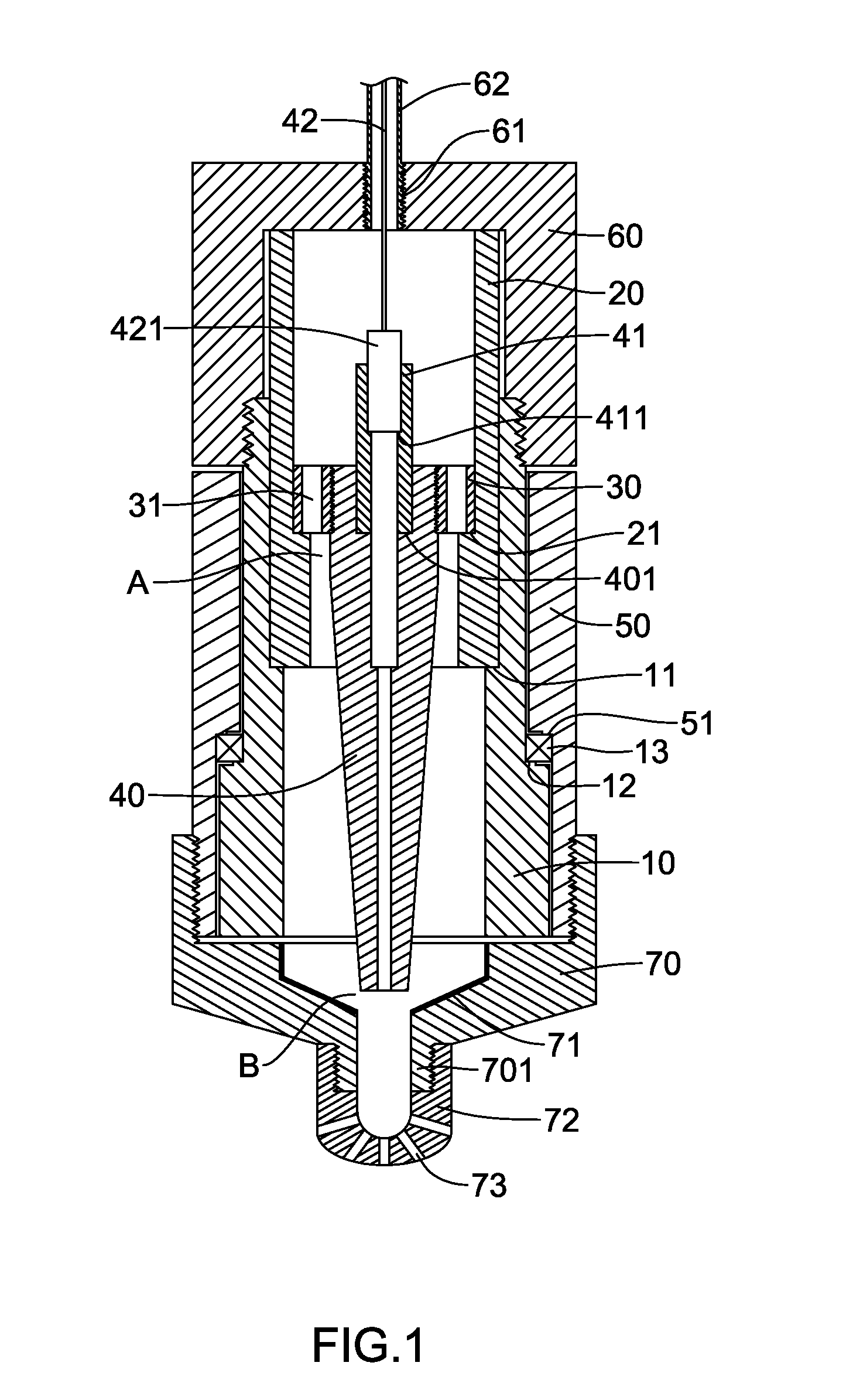

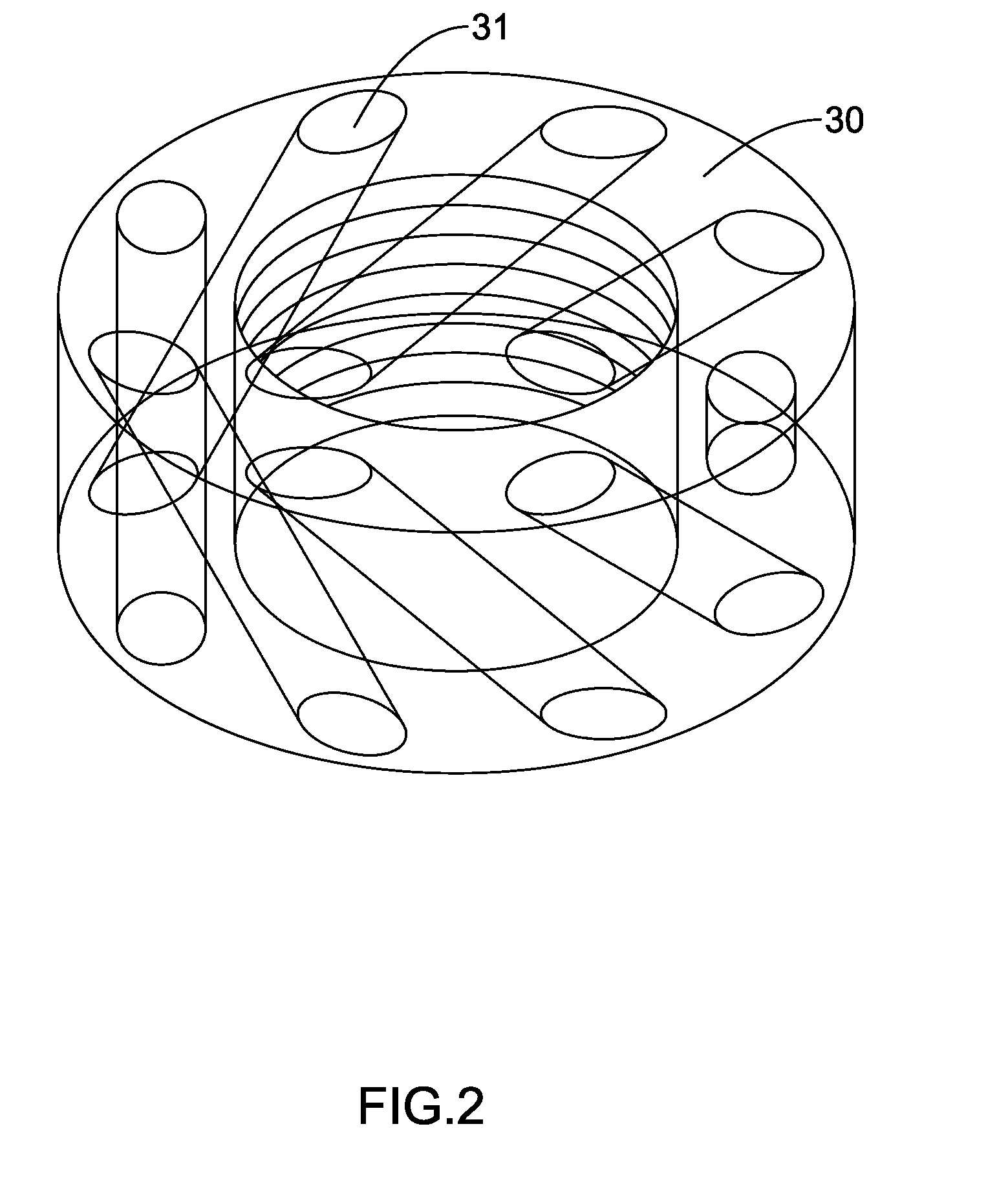

Generating device for atmospheric bare electrode cold plasma jet

The invention provides a generating device for an atmospheric bare electrode cold plasma jet. The generating device comprises a working gas source, a pressure reducing valve, an adjustable flow meter, a high-voltage power supply, a cylindrical shell, a nozzle electrode and a pin electrode, wherein the tail part of the cylindrical shell made of insulating material is connected with a gas supply system; the front end of the cylindrical shell is connected with the nozzle electrode through a thread; the pin electrode is fixedly arranged in a central hole of the cylindrical shell; a certain discharging clearance is kept between the tip of the pin electrode and the nozzle electrode; a plurality of through holes parallel to the central hole of the cylindrical shell are distributed around the central hole; the through holes are used for conveying the working gas to a discharging area in the nozzle electrode; a high-voltage output end of the high-voltage power supply is connected with the pin electrode; and a low-voltage output end of the high-voltage power supply is connected with the nozzle electrode and is grounded. Cold plasma is generated at the tip of the pin electrode by adjusting the high-voltage power supply and the flow of the working gas, and the cold plasma is jetted from an outlet of the nozzle electrode so as to form the cold plasma jet. According to the generating device provided by the invention, uniform and stable cold plasma jet can be obtained under an atmospheric open air environment.

Owner:DALIAN UNIV OF TECH

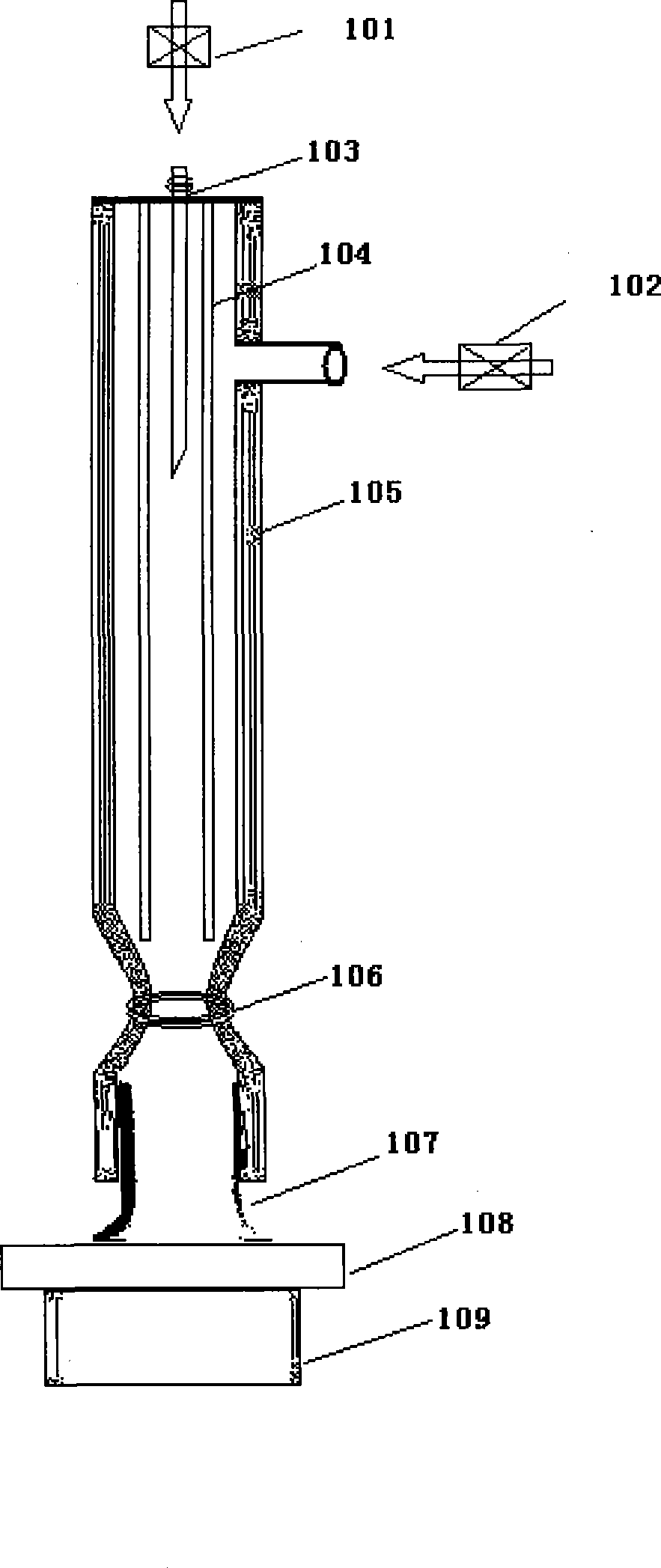

Atmospheric plasma chemical processing method of WC and SiC optical molding molds

ActiveCN101659568AIncreased durabilityEfficient removalGlass pressing apparatusPlasma jetChemical reaction

The invention relates to an atmospheric plasma chemical processing method of WC and SiC optical molding molds, which belongs to the atmospheric plasma chemical processing methods of the optical molding molds. The atmospheric plasma chemical processing method can solve the problems that the grinding and polishing technology which is used for processing after processing and forming of the optical molding molds made of SiC and WC materials has the disadvantages of low processing efficiency, poor surface quality, damage of a sub-surface layer and short service life of the molds. The method comprises the steps of: introducing a mixture of plasma gas, reaction gas and oxygen into space between a cathode and an anode of a plasma generator, imposing radio frequency power signals on the cathode andthe anode, producing the plasma discharge between the two electrodes, then placing the surface to be processed of the WC or SiC optical molding mold in a plasma jet region for carrying out chemical reaction and realizing the optical surface processing of the optical molding molds made of the SiC and WC materials. The method is used for carrying out the optical processing on the surfaces of the WCand SiC optical molding molds.

Owner:HARBIN INST OF TECH

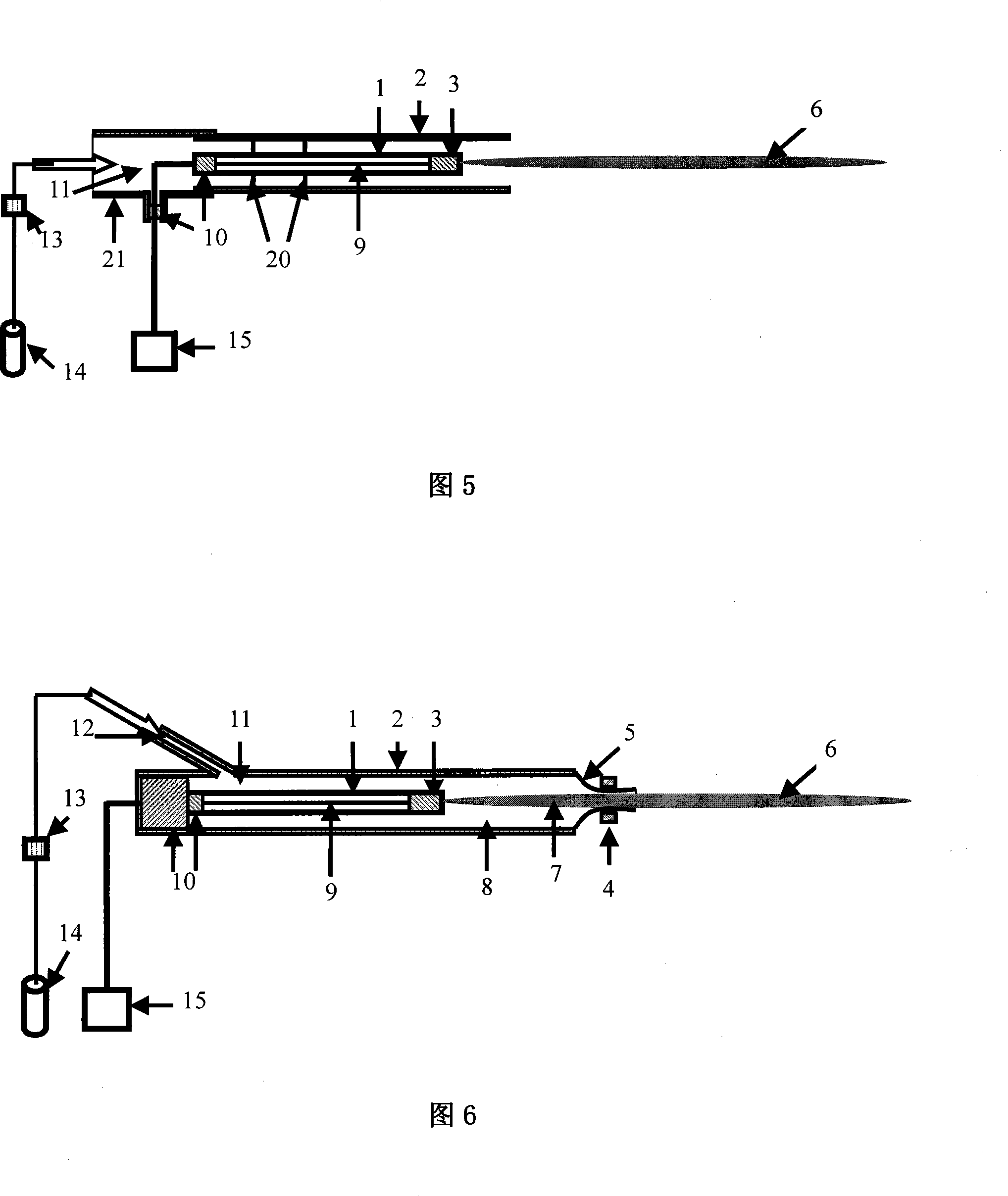

Plasma jet device

ActiveCN101426327AIncrease varietyIncrease the number ofElectric discharge tubesPlasma techniqueCapacitancePlasma jet

A plasma jet device belongs to a plasma generator and settles the problem the unsafe electrode and the likely generation of arc discharging between the electrode and the grounding existing in the prior plasma jet device. The plasma jet device according to the invention comprises a power supply, a working gas source and an electrode. The working gas of the working gas source enters the electrode from the gas input port of the electrode. The electrode is in the shape of empty tube, is provided with a gas input port at one end and is provided with a gas output port at the other end. The electrode is connected with the power supply through a resistor and a capacitor. The plasma jet device according to the invention has the advantages of easy manufacture, easy maintenance, convenient use, low cost and easy carrying. The temperature of the generated plasma jet can be different when resistor with different resistance, capacitor with different capacitance, different driving power supply and different working gas are selected. The human body can touch with the plasma jet safely when the temperature of the plasma jet is approximate to the room temperature. At the same time the plasma jet can be provided with different shapes and can diffuse to different directions simultaneously. The specific application with large scale and large area in normal temperature and normal pressure can be realized.

Owner:武汉海思普莱生命科技有限公司

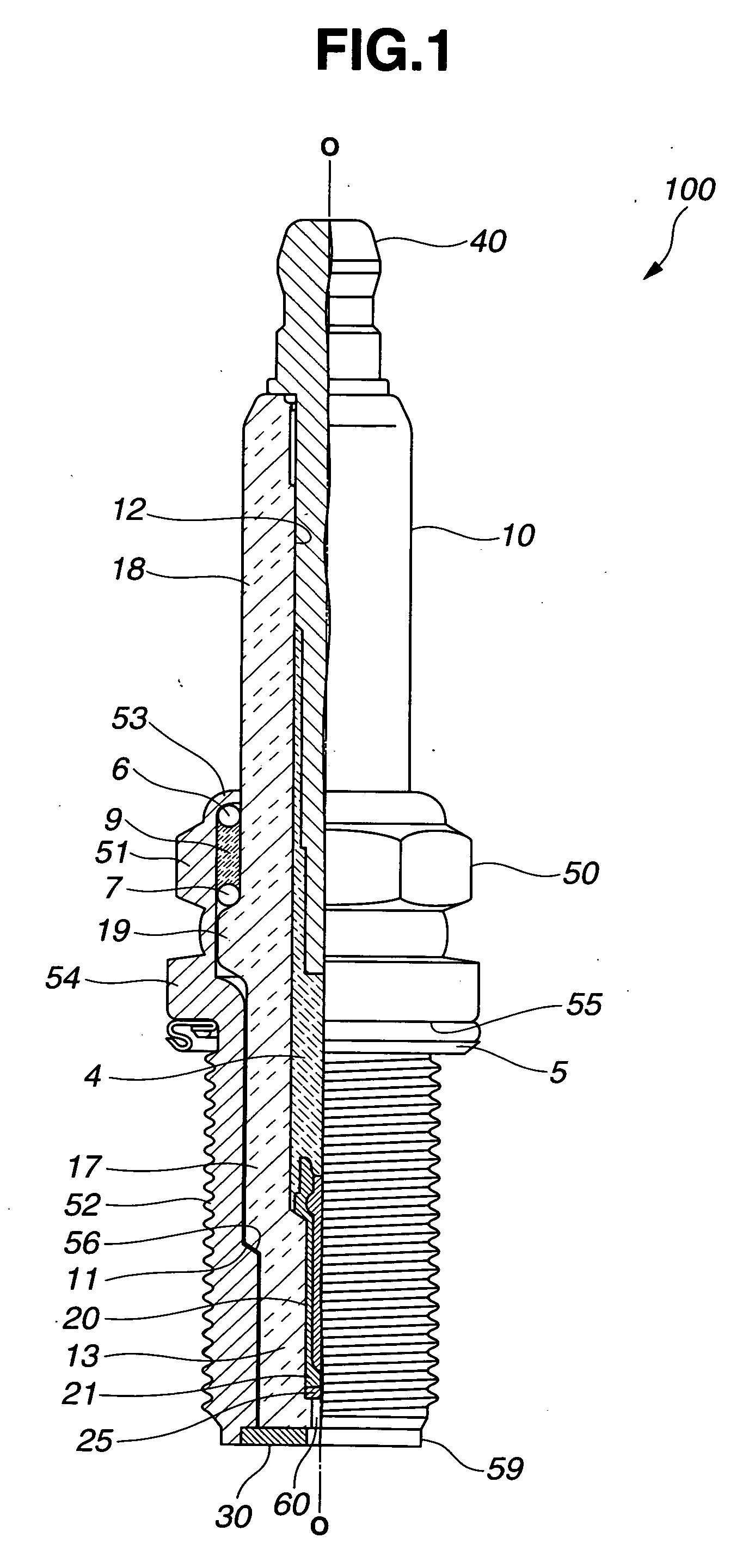

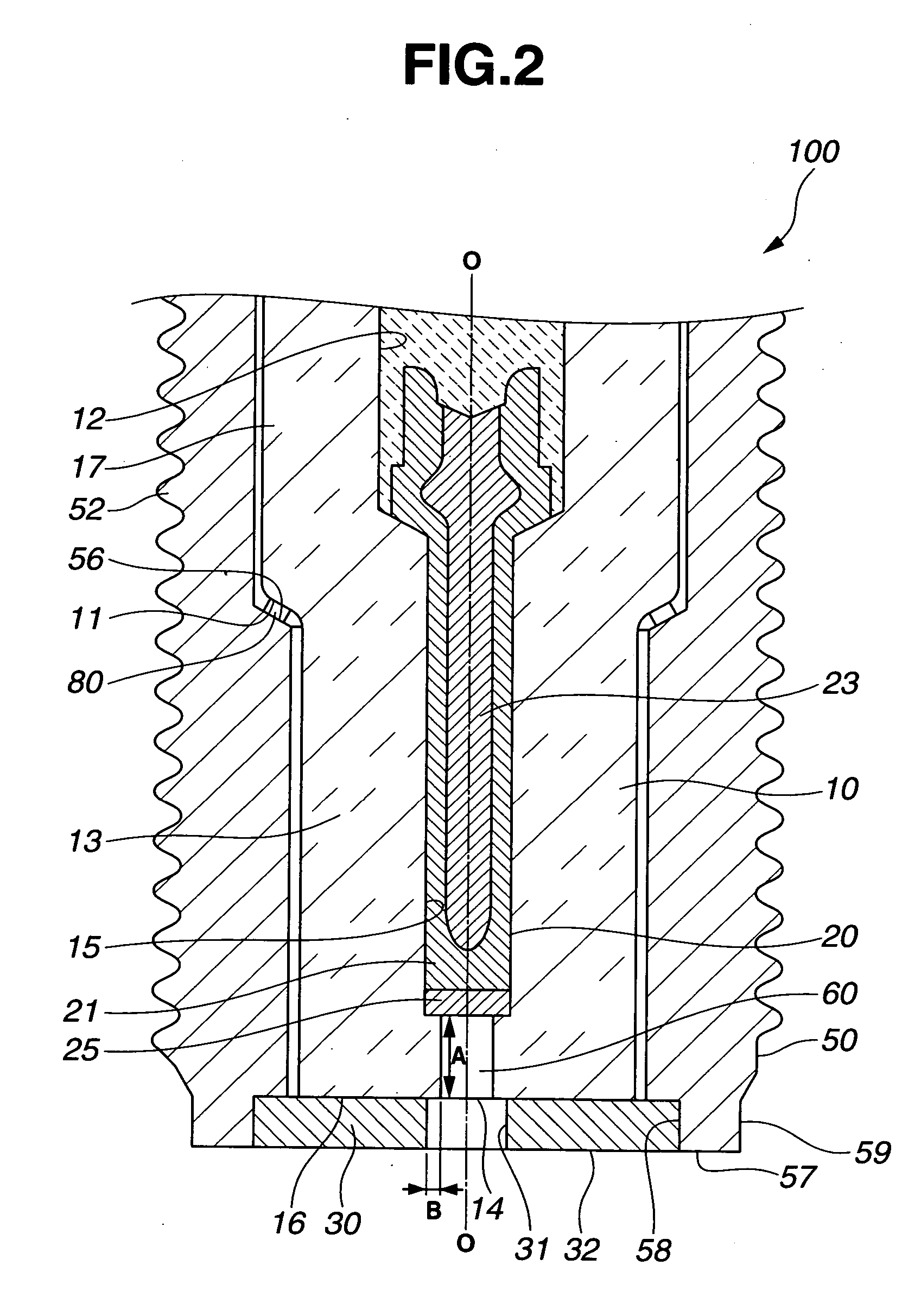

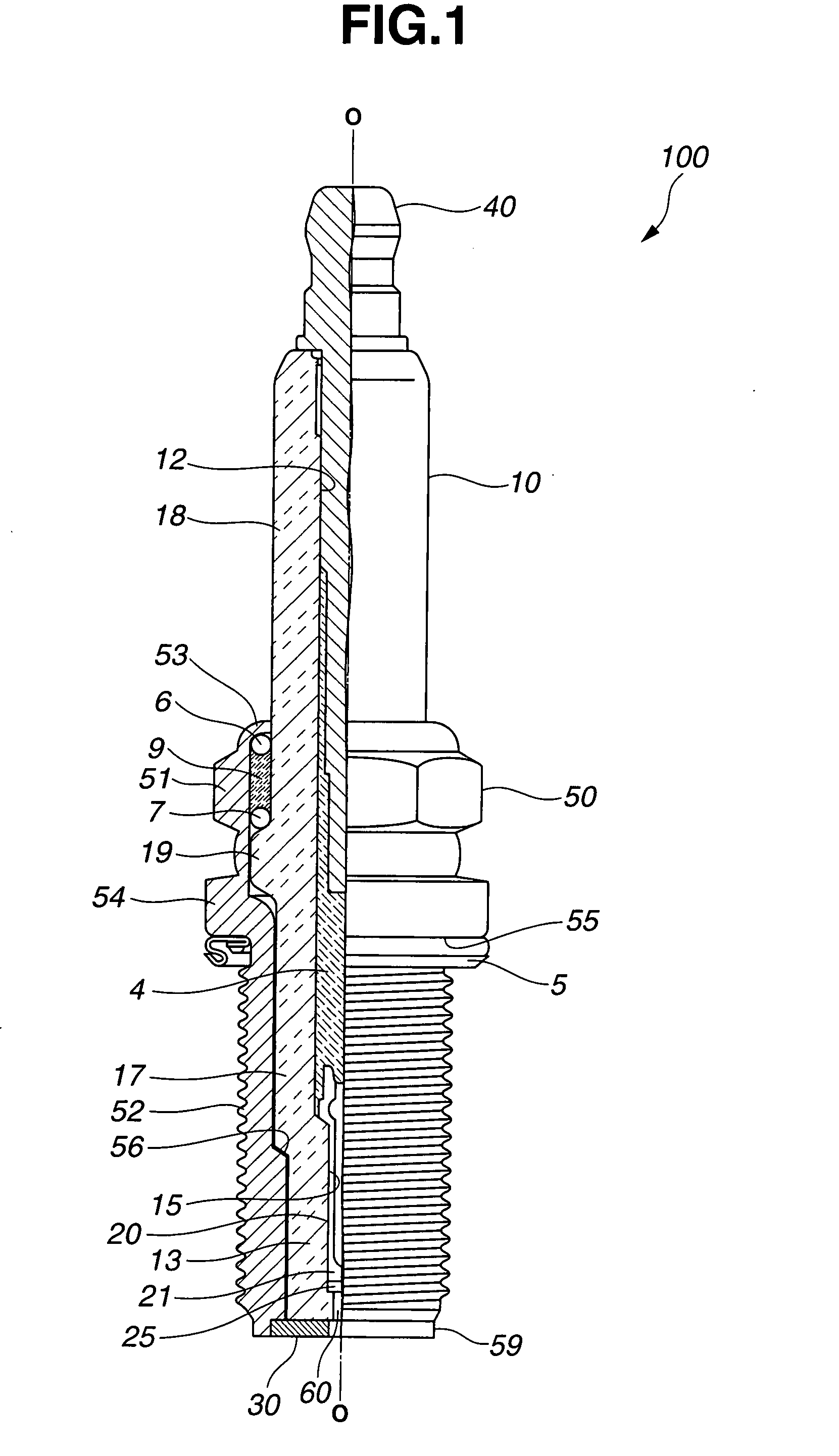

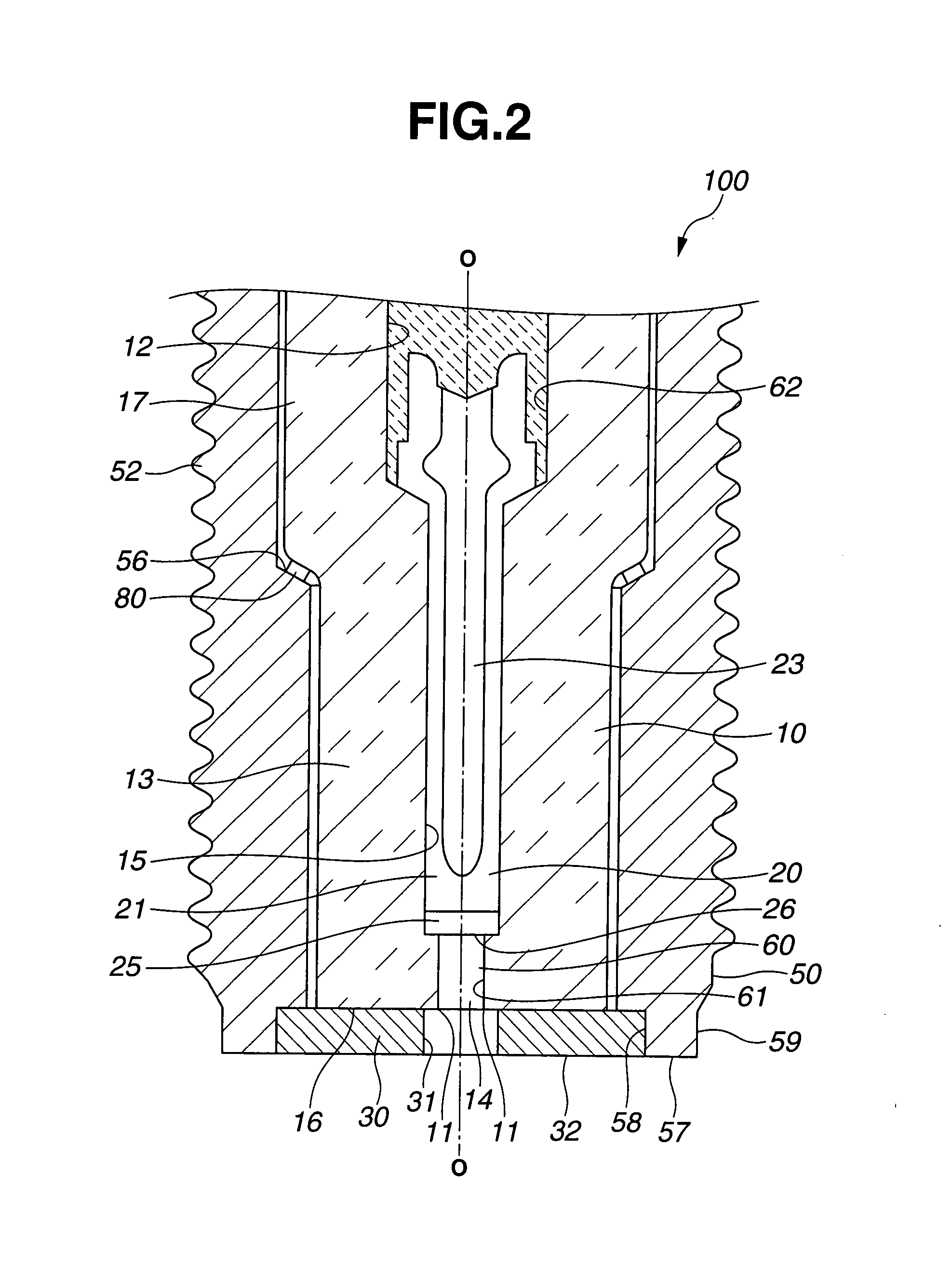

Plasma-jet spark plug control method and device

There is provided a method for controlling a plasma-jet spark plug in a four-stroke internal combustion engine, including the steps of: causing the spark plug to generate a primary discharge during either a compression stroke or an expansion stroke of the engine in such a manner as to produce a plasma by the primary discharge; and causing the spark plug to generate a secondary discharge during a time after the primary discharge and before the completion of a subsequent intake stroke of the engine.

Owner:NGK SPARK PLUG CO LTD

Ionization analysis method and apparatus

ActiveUS8253098B2High sensitivityReduce the temperatureMaterial analysis by optical meansIon sources/gunsElectron temperaturePlasma jet

An ionization apparatus comprises a first electrode provided on the outer periphery of a dielectric cylindrical body and a second cylindrical electrode placed inside at a center of the cylindrical body. When an AC high voltage is impressed across the first electrode and the second cylindrical electrode, a barrier discharge occurs within the cylindrical body. A distal end portion of the second cylindrical electrode projects outwardly from the distal end of the cylindrical body, a thermal equilibrium plasma P having a low electron temperature is generated outwardly from the distal end of the cylindrical body without a plasma jet ascribable to the barrier discharge emerging outwardly from the distal end of the cylindrical body. By exposing a sample S to the thermal equilibrium plasma P, particles (atoms, molecules) desorbed from the sample S undergo soft ionization without being decomposed or polymerized.

Owner:UNIVERSITY OF YAMANASHI

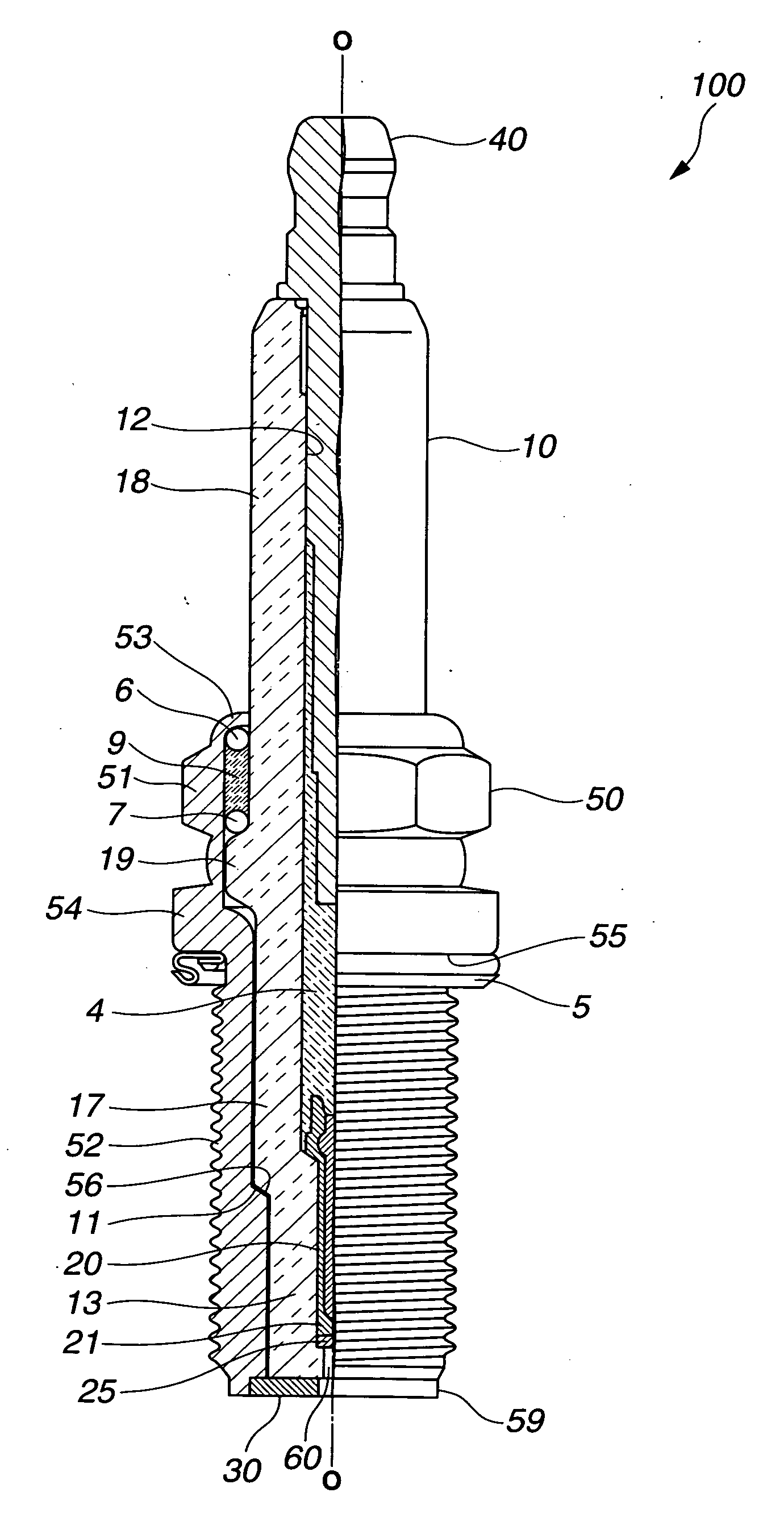

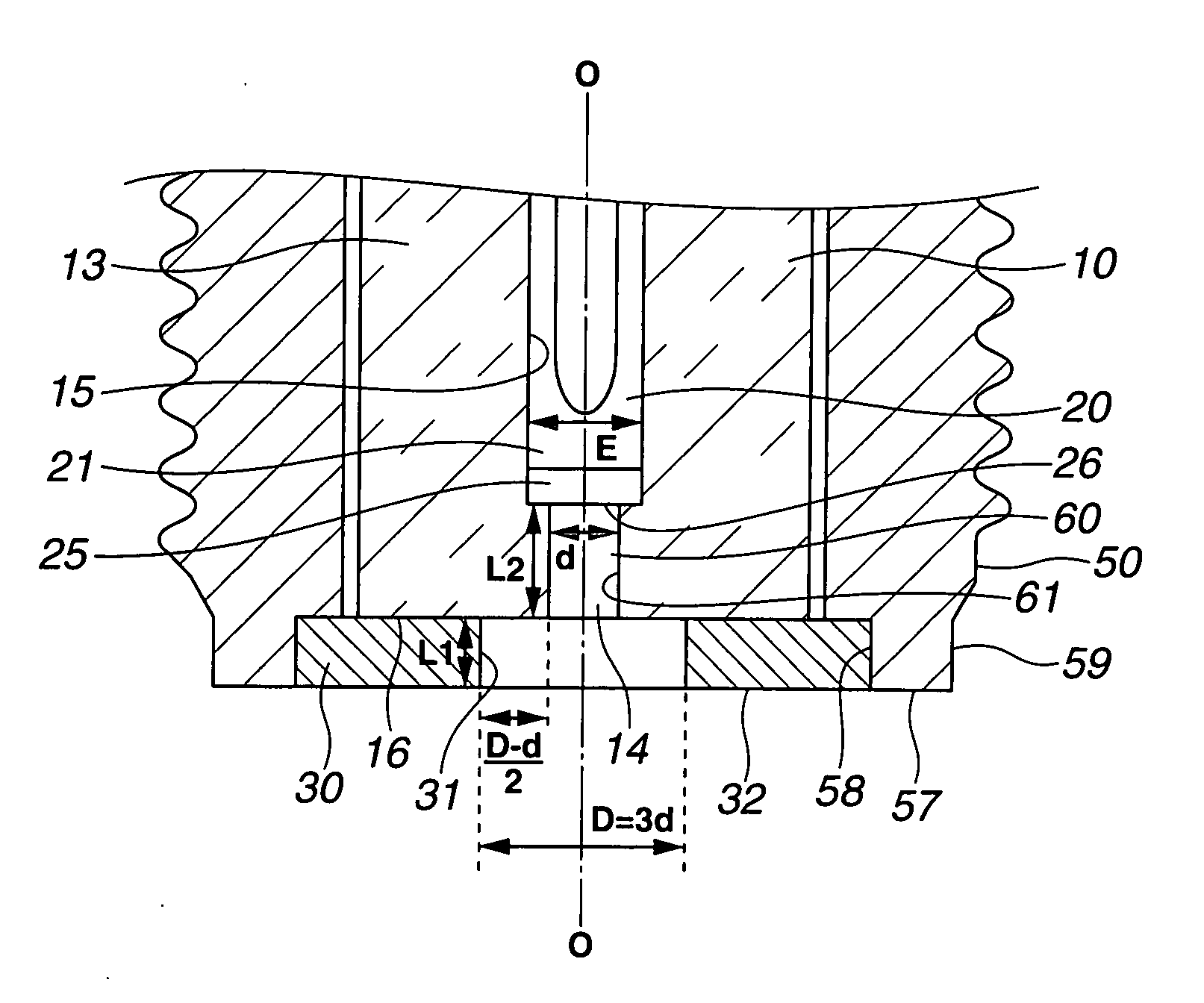

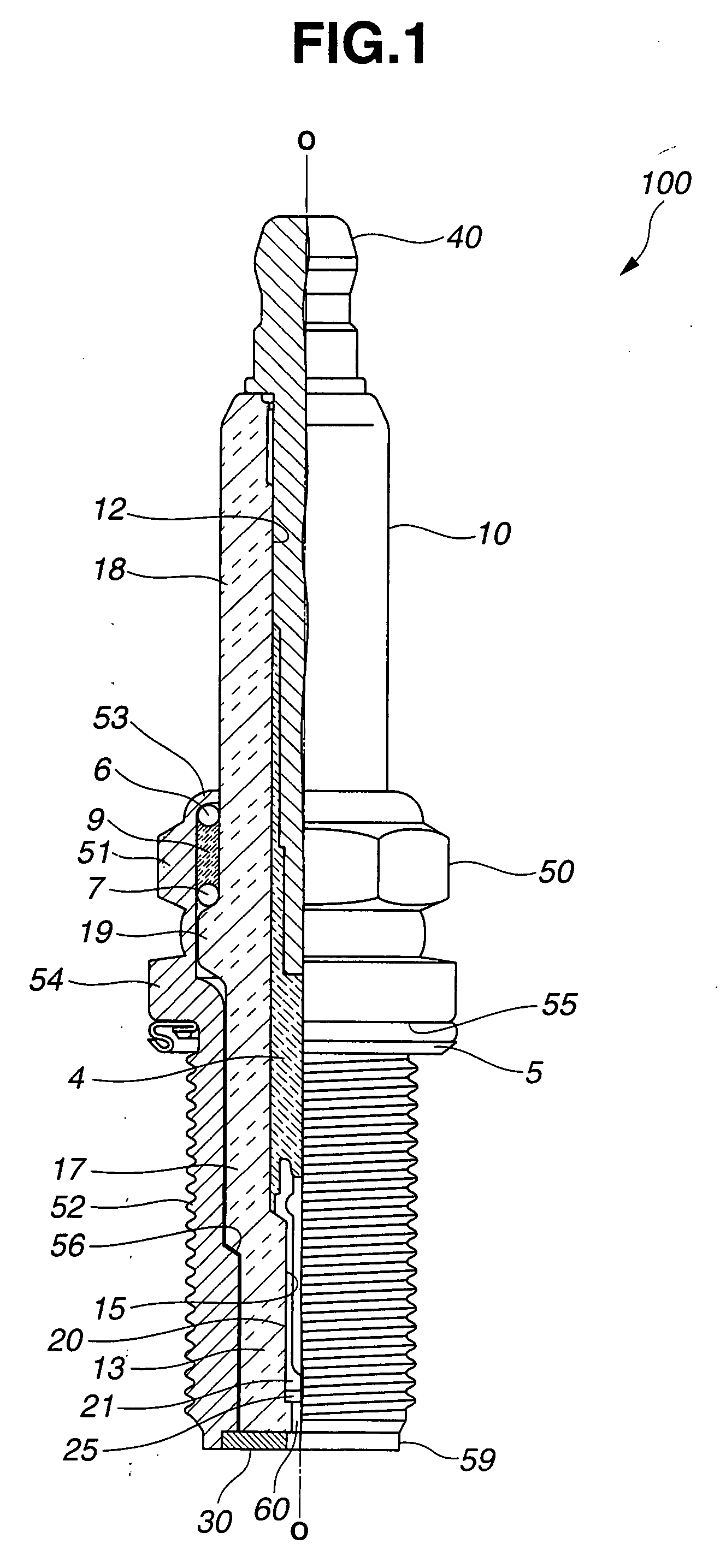

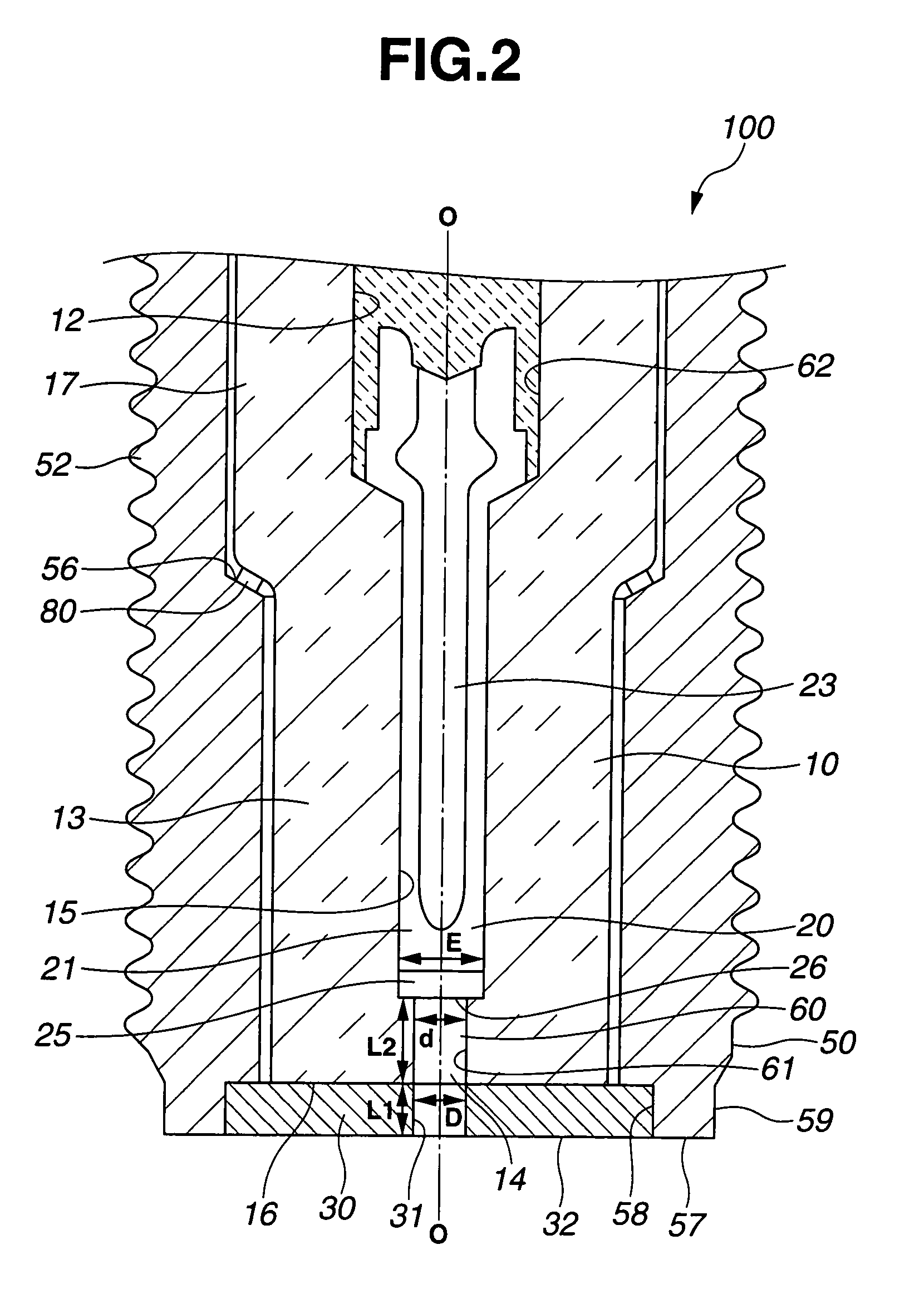

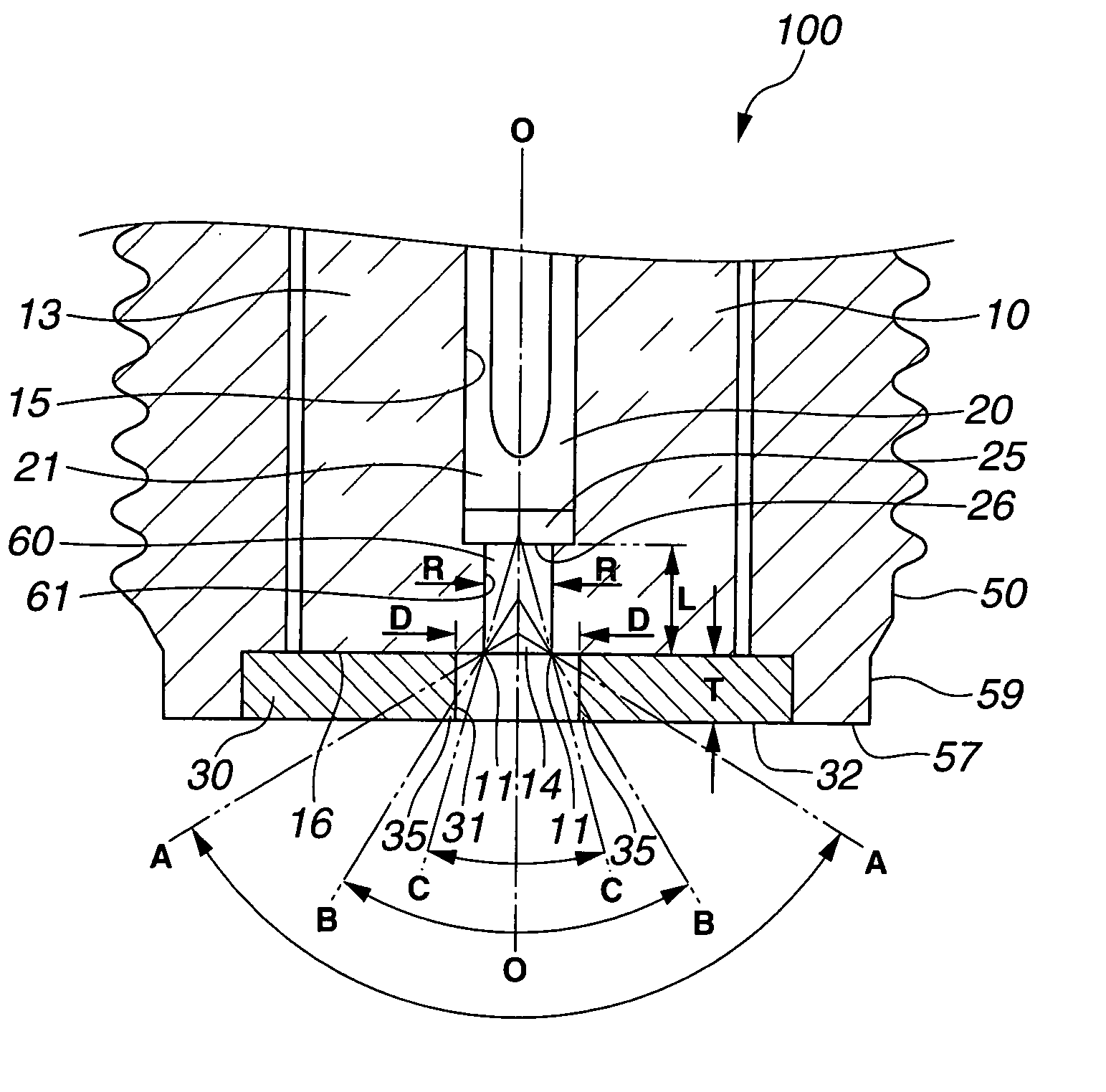

Plasma-jet spark plug and ignition system

A plasma-jet spark plug includes a metal shell, an electrical insulator retained in the metal shell, a center electrode held in an axial hole of the electrical insulator to define a cavity by a front end face of the center electrode and an inner circumferential surface of the insulator axial hole and a ground electrode fitted to a front end face of the electrical insulator and formed with an opening for communication between the cavity and the outside of the spark plug and satisfies the following dimensional relationships:d≦D≦3d;0.5 mm≦d≦1.5 mm;L1≦1.5 mm;2d≦L2≦3.5 mm; andL2+{(D−d) / 2}≦3.5 mmwhere D is a diameter of the ground electrode opening; L1 is a thickness of the ground electrode; d is a diameter of the cavity; and L2 is a depth of the cavity.

Owner:NGK SPARK PLUG CO LTD

Plasma Jet Electrode Device and System thereof

InactiveUS20070235417A1Large treatment areaImprove uniformityWelding/cutting media/materialsSolid cathode detailsPlasma jetEtching

A plasma jet electrode device includes an orientation base, a ceramic pipe, a round plate having a plurality of tilted through holes thereon and a high-voltage metal electrode. A dielectric discharging plasma area is formed between the high-voltage metal electrode and the ceramic pipe. The plasma jet electrode device further has a rotating base, a bottom plate, and a grounding electrode. A low-temperature non-equilibrium plasma area is formed between the grounding electrode and the high-voltage metal electrode. The round plate has a spray head praying low-temperature non-equilibrium plasma. The plasma treatment area is increased, and the uniformity is improved. The present plasma jet electrode system has a frame for fixing at least one plasma jet electrode device. It evidently increases the effective plasma treatment area. The system can also provide additional functions of cooling, guiding, plating and etching, etc.

Owner:KUO YUEH YUN

Plasma-jet spark plug and ignition system

InactiveUS20070221156A1Maximize ignition performanceImprove flammabilitySparking plugsFuel testingPlasma jetFront edge

A plasma-jet spark plug includes a metal shell, an electrical insulator retained in the metal shell, a center electrode held in an axial hole of the electrical insulator to define a cavity by a front end face of the center electrode and an inner circumferential surface of the insulator axial hole and a ground electrode arranged on a front end of the electrical insulator. The ground electrode has an opening defining portion defining an opening for communication between the cavity and the outside of the spark plug. The opening defining portion is located radially inside of or in contact with a first imaginary circular conical surface where the first imaginary circular conical surface has an axis coinciding with an axis of the spark plug and a vertex angle of 120° opening toward a front end of the spark plug and passing through a front edge of the insulator axial hole.

Owner:NGK SPARK PLUG CO LTD

Method for preparing acetylene by hot plasma cracking methane containing gas

InactiveCN1552680AAvoid adverse consequencesIndustrial method improvementHydrocarbon by hydrocarbon crackingPlasma jetPlasma generator

A process for preparing acetylene by using hot plasma to crack the gas containing methane includes such steps as using plasma generator to ionize the argon or N2 or H2 to form a plasma jet, spraying raw gas via a gas inlet ring in reactor, mixing the plasma jet with the raw gas in the reactor, cracking reacting, and quickly cooling the cracked gas in an expansion cavity of cooler to obtain acetylene, carbon black and H2.

Owner:德阳市旌能天然气有限公司 +1

Plasma jet apparatus

ActiveCN101227790AIncrease varietyIncrease the number ofElectric discharge tubesPlasma techniquePlasma jetConductive materials

A plasma body jet flow device belongs to a plasma body generating device and aims at producing plasma body jet flows with long distance, low temperature and rich active compositions, the electrode position is safe, the device is applied in a plurality of discharge. The high voltage electrode of the invention is arranged in an inner dielectric tube and commonly located in an outer dielectric container, power supply is connected with the high voltage electrode, the outer dielectric container is communicated with a working gas source, the inner dielectric tube takes a hollow tubular shape with a sealed single end, the sealed end of the inner dielectric tube is provided with conducting materials which are communicated with one end of the high voltage electrode, the other end of the high voltage electrode in the inner dielectric tube is provided with an insulating plug, and the high voltage electrode is fixed by the insulating block head and the conducting materials. The invention has easy manufacture, good maintenance, safe and convenient use, wide working gas range and changeable temperature, length and thickness of the plasma body jet flows, further develops the range of application of a plasma body technique, and increases the application effects of the plasma body.

Owner:武汉海思普莱生命科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com