Preionization atmos low-temperature plasma jet generator

A low-temperature plasma and jet generator technology, applied in the direction of plasma, electrical components, circuits, etc., can solve the problems of low batch processing efficiency, maintenance voltage rise, and limited processing efficiency, and achieve long continuous working time and discharge The effect of stabilizing and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

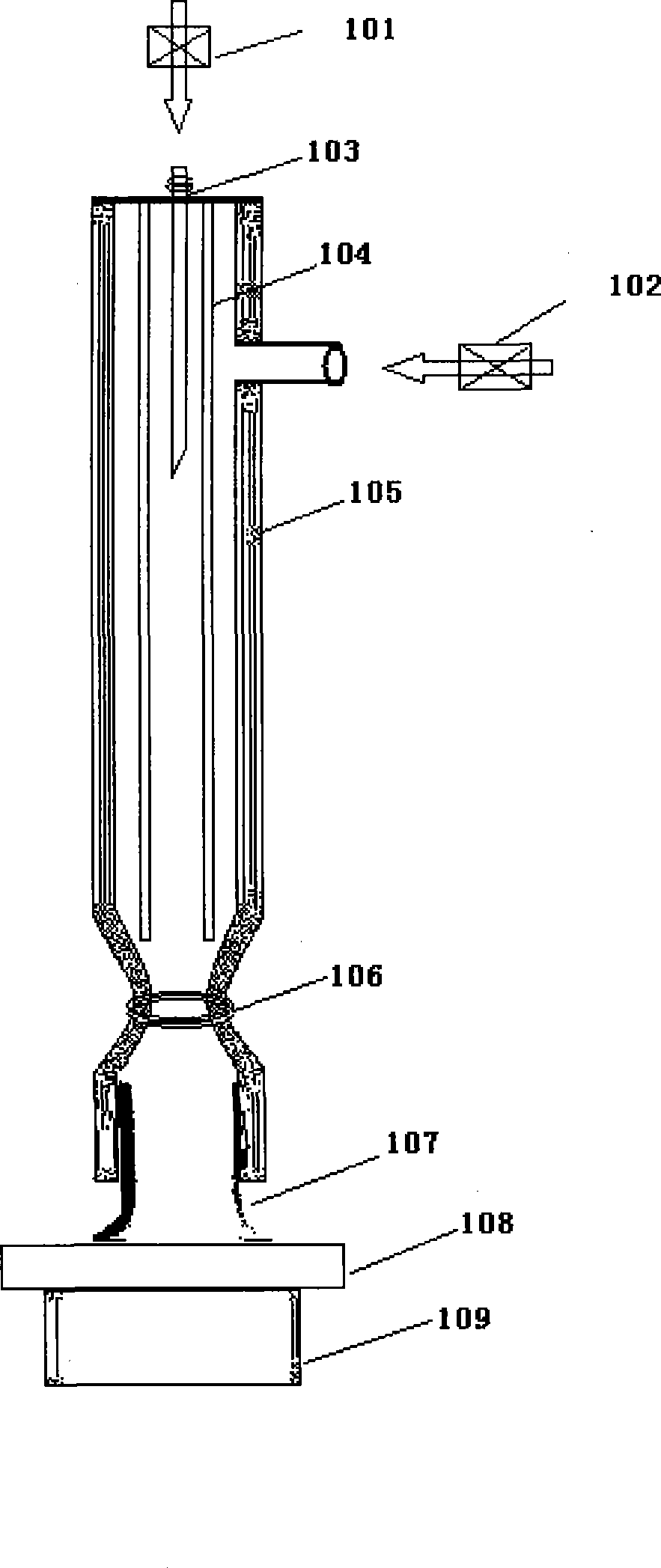

Image

Examples

Embodiment

[0023] Choose argon gas (purity 99.999%) as the working gas of single needle electrode, and the lower limit of the flow rate that can produce steady-state jet is 0.08m 3 / h. Using oxygen as the working gas of the ring electrode, the maximum flow rate is 0.13m 3 / h. Now select the argon flow as 0.26m 3 / h, the oxygen flow rate is 0.13m 3 / h:

[0024] 1. When a voltage of 4.0kV is applied, a single-needle pre-ionization discharge is generated, and then the voltage is increased to 8.0kV, and then a ring electrode discharge is generated.

[0025] 2. If the voltage is further increased, the discharge can be maintained stably. The maximum voltage is 12kV. If this voltage is exceeded, the discharge will become unstable, and arc discharge will occur, and the temperature of the discharge plasma jet will rise rapidly.

[0026] 3. Within the parameter range of stable discharge, the measured maximum oxygen atom concentration is 9.8×10 17 / cm 3 .

[0027] 4. Use this device to clean the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com