Patents

Literature

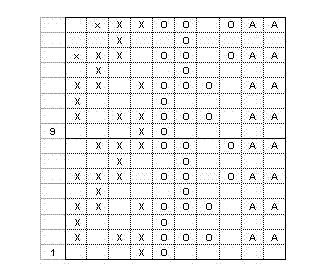

725 results about "Puncture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Puncture resistance denotes the relative ability of a material or object to inhibit the intrusion of a foreign object. This is defined by a test method, regulation, or technical specification. It can be measured in several ways ranging from a slow controlled puncture to a rapid impact of a sharp object or a rounded probe.

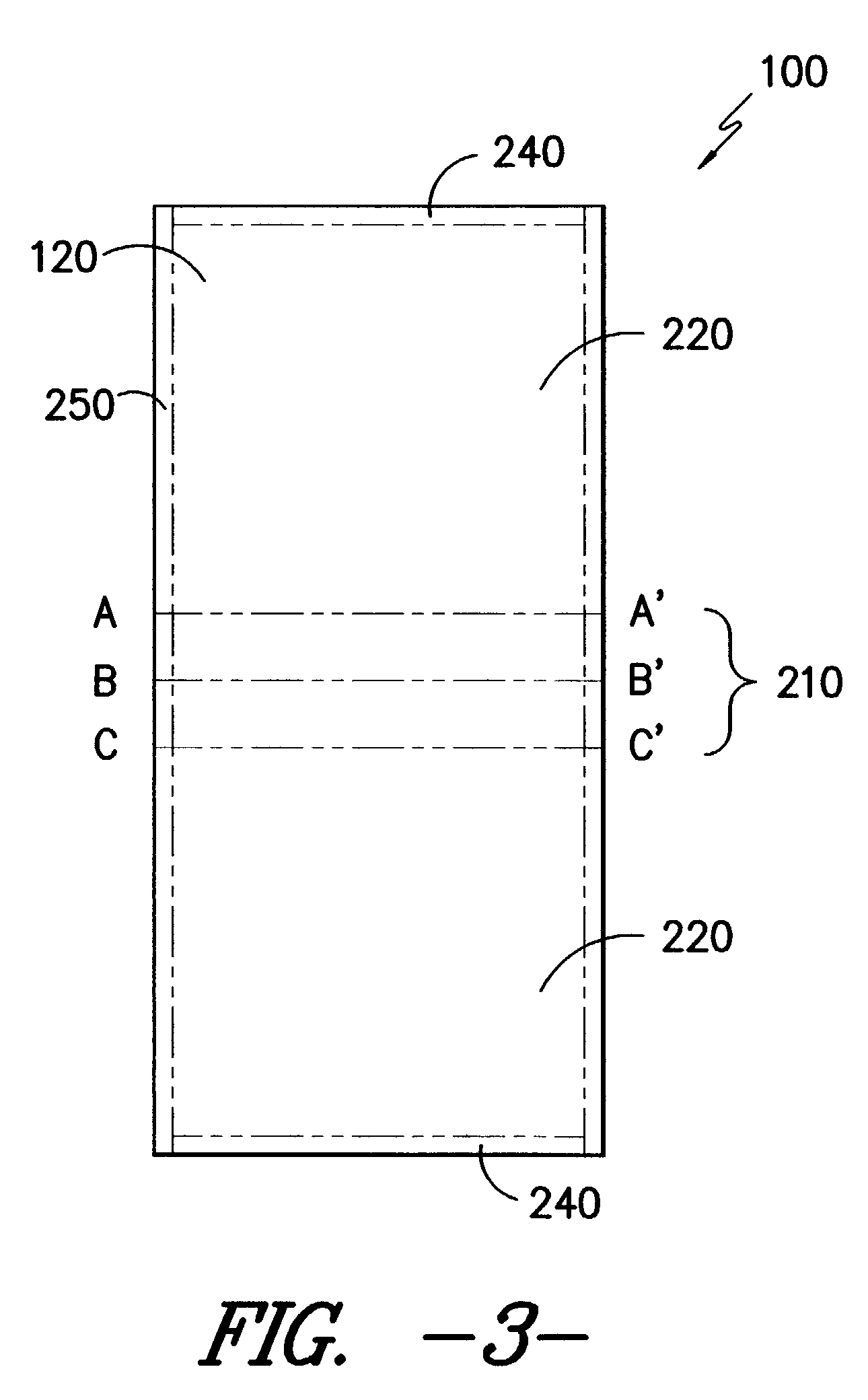

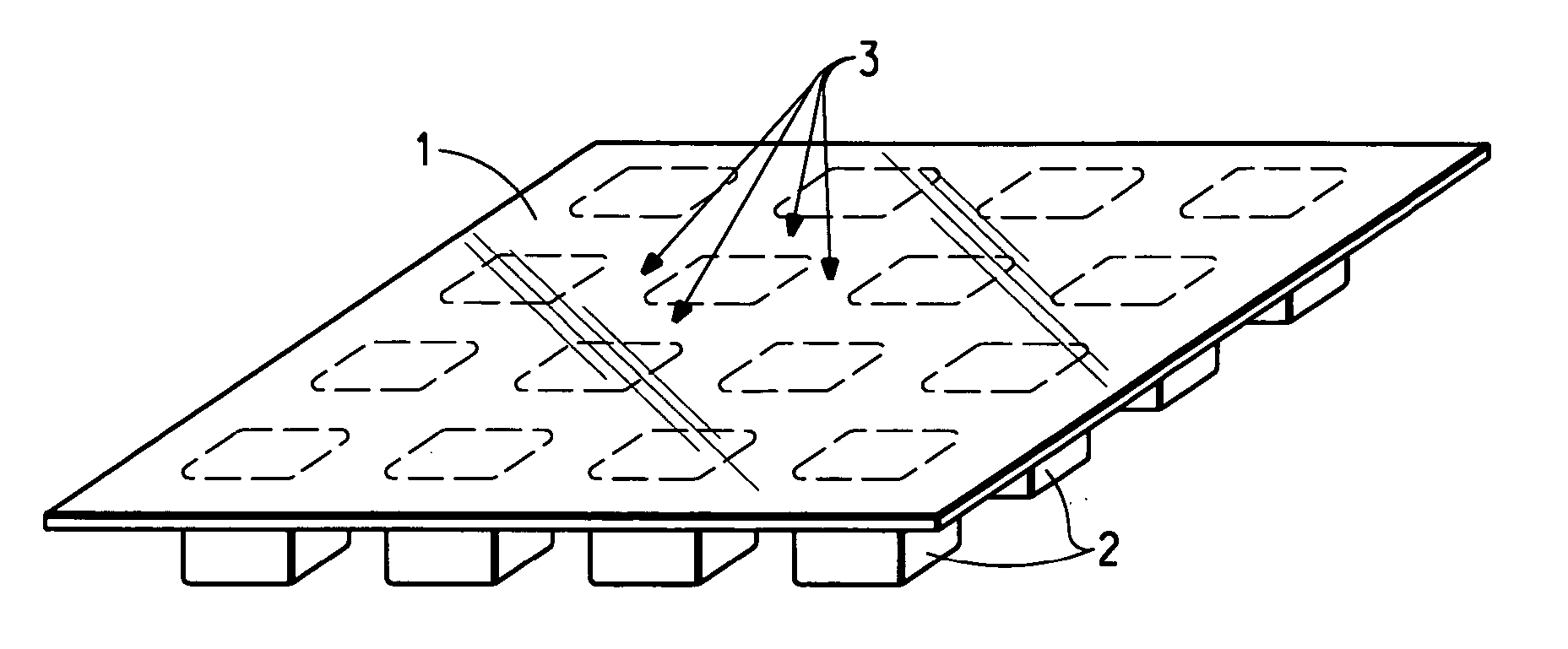

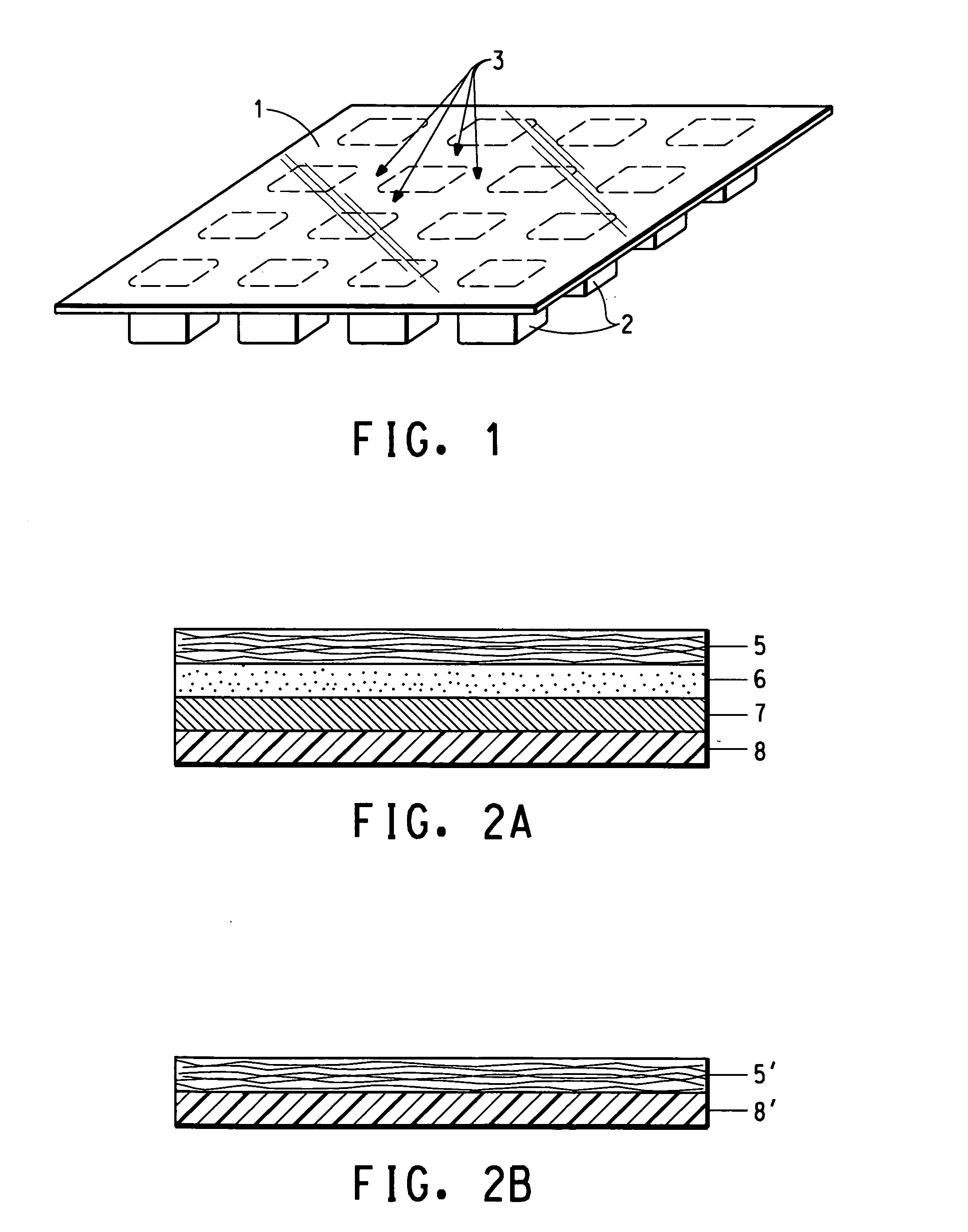

Insulating sheathing with tough three-ply facers

InactiveUS6093481AImprove insulation performanceHighly controllableSynthetic resin layered productsHeat proofingPuncture resistanceHardness

A method for continuously manufacturing an insulation board by facing a foam-forming composition with one or two facing sheets to form a singly or doubly faced composite, at least one sheet comprising either a tough polymeric layer or a laminate of a tough polymeric layer with at least one other facing material, the tough polymeric layer of at least one sheet facing to the outside of the composite, and foaming and curing the faced foam-forming mixture to produce an insulation board having an exceptional hardness and puncture resistance.

Owner:THE DOW CHEM CO

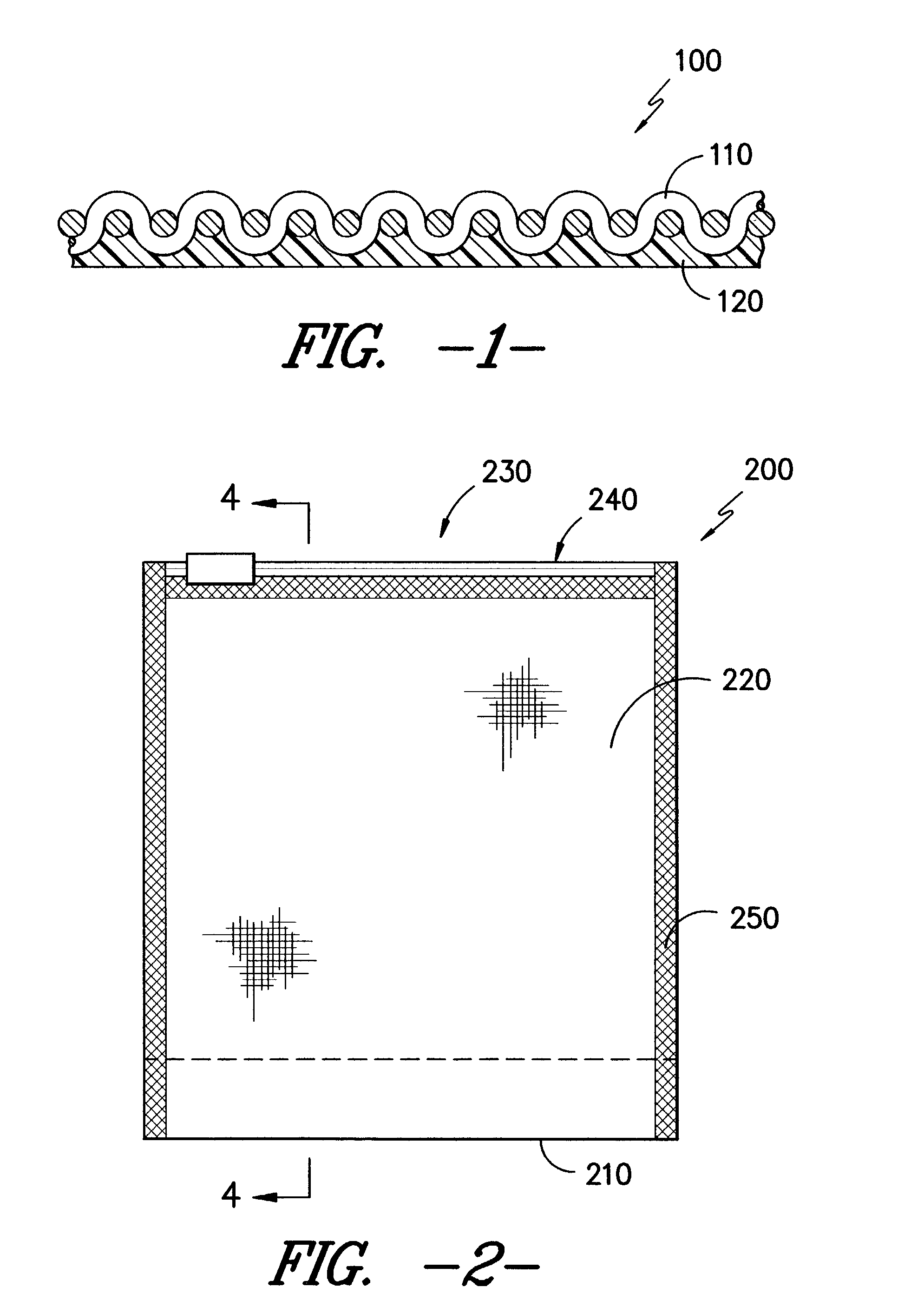

Packaging material and containers formed therefrom

The flexible, reusable packaging container of the present invention is comprised of a packaging material. The packaging material is comprised of one or more layers of coating disposed on one or more layers of textile substrate. The coating layer may be comprised of a stiffening agent for providing support to the packaging container. The stiffening agent may provide a gas and / or liquid impermeable barrier between the contents of the container and the textile substrate. The stiffening agent may also include chemicals which impart antifungal or antibacterial properties to container. The textile substrate typically provides an aesthetically pleasing feel and appearance to the outside of the packaging container, as well as providing functional attributes such as water repellence, stain resistance, and / or anti-static resistance. The resulting packaging container possesses increased strength, puncture resistance, and resistance to de-lamination over the current paper or plastic packaging containers.

Owner:MILLIKEN & CO

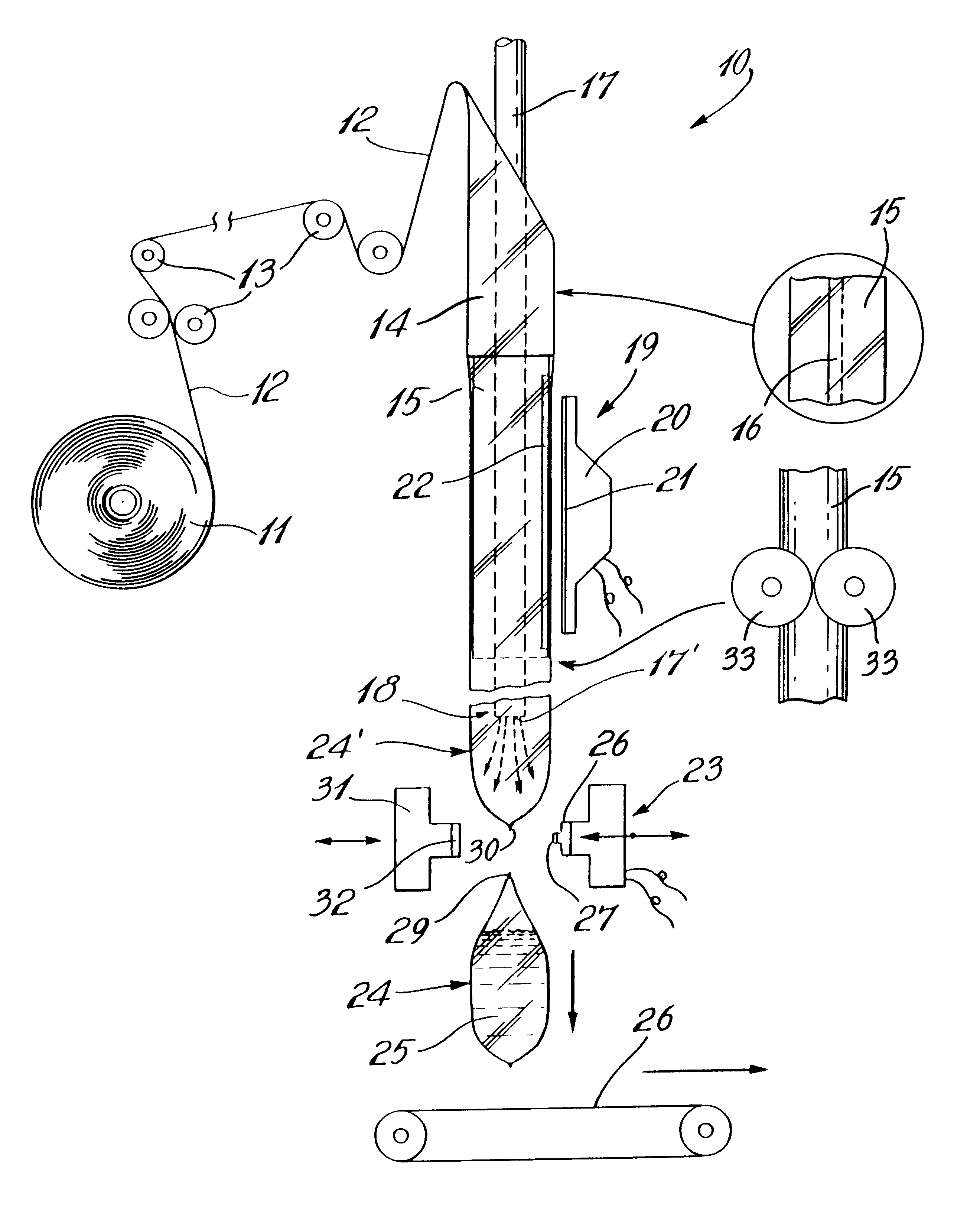

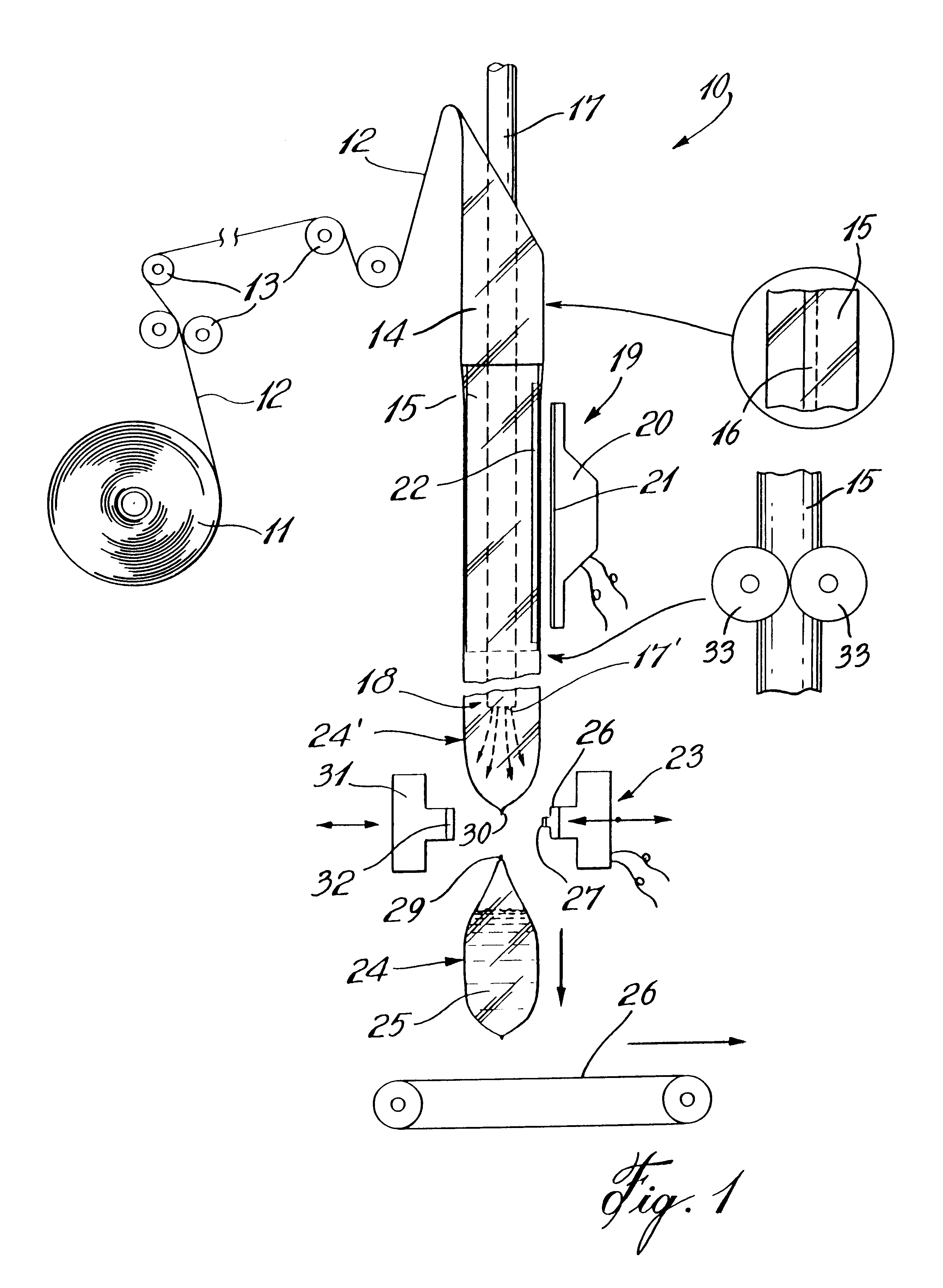

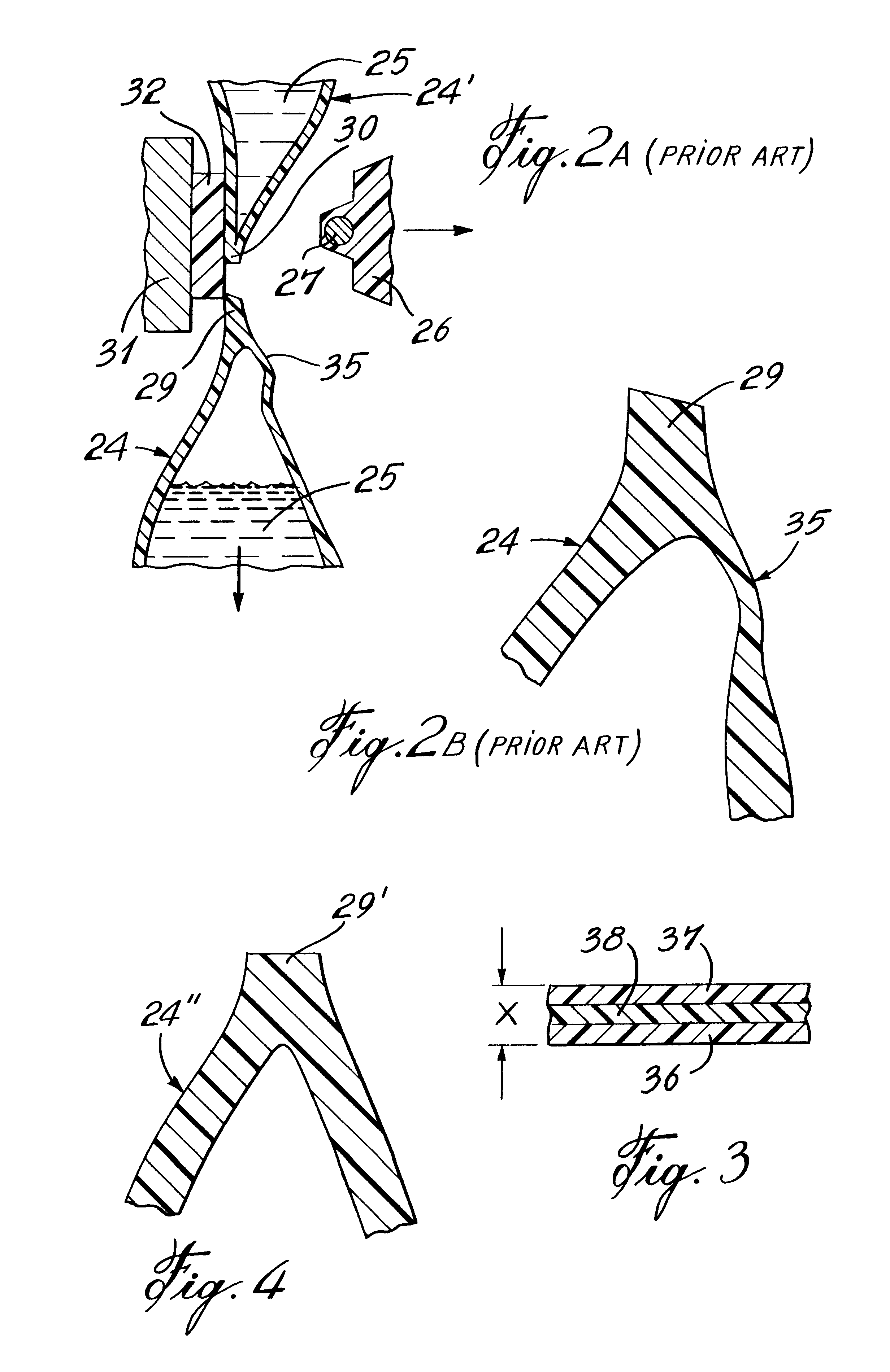

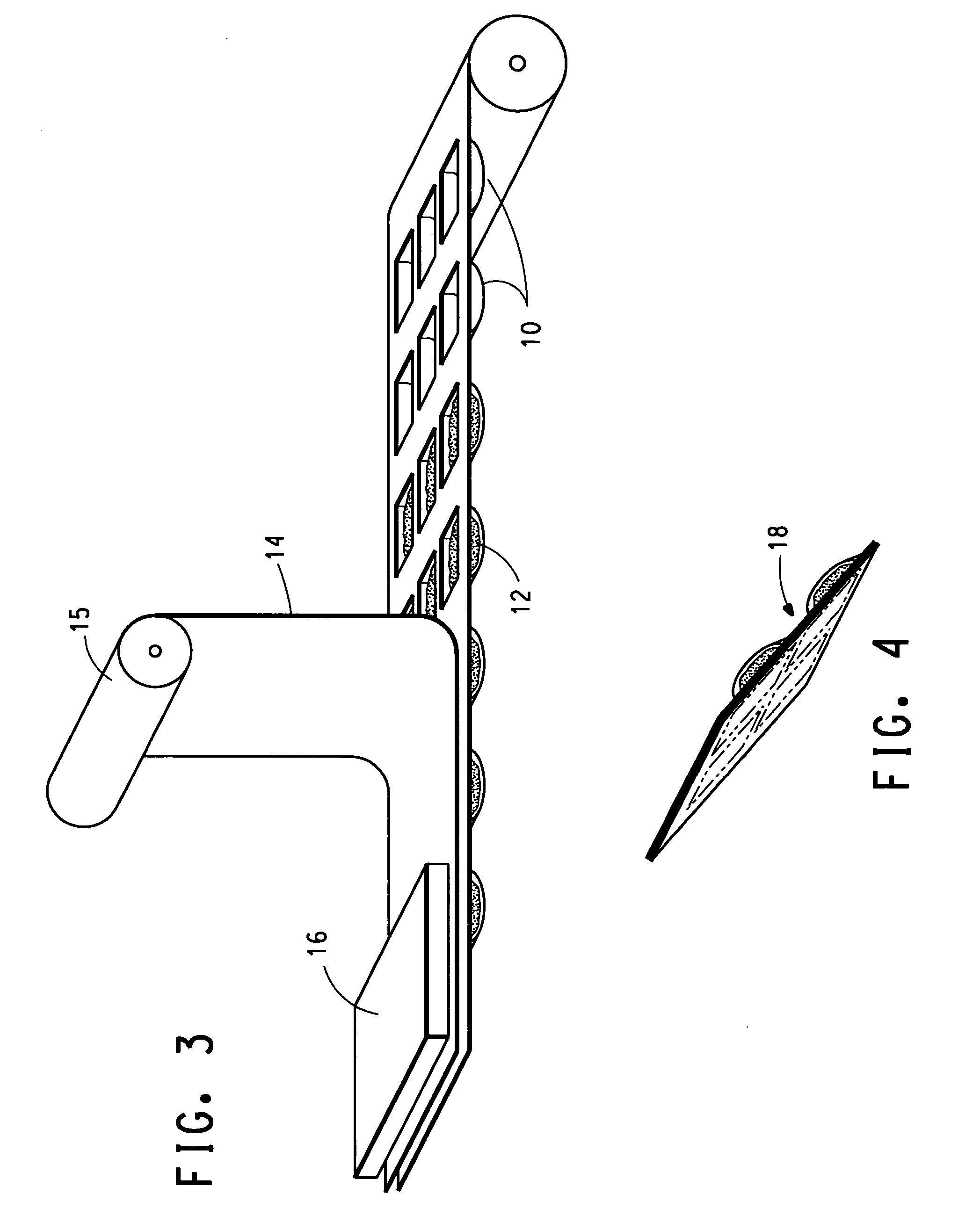

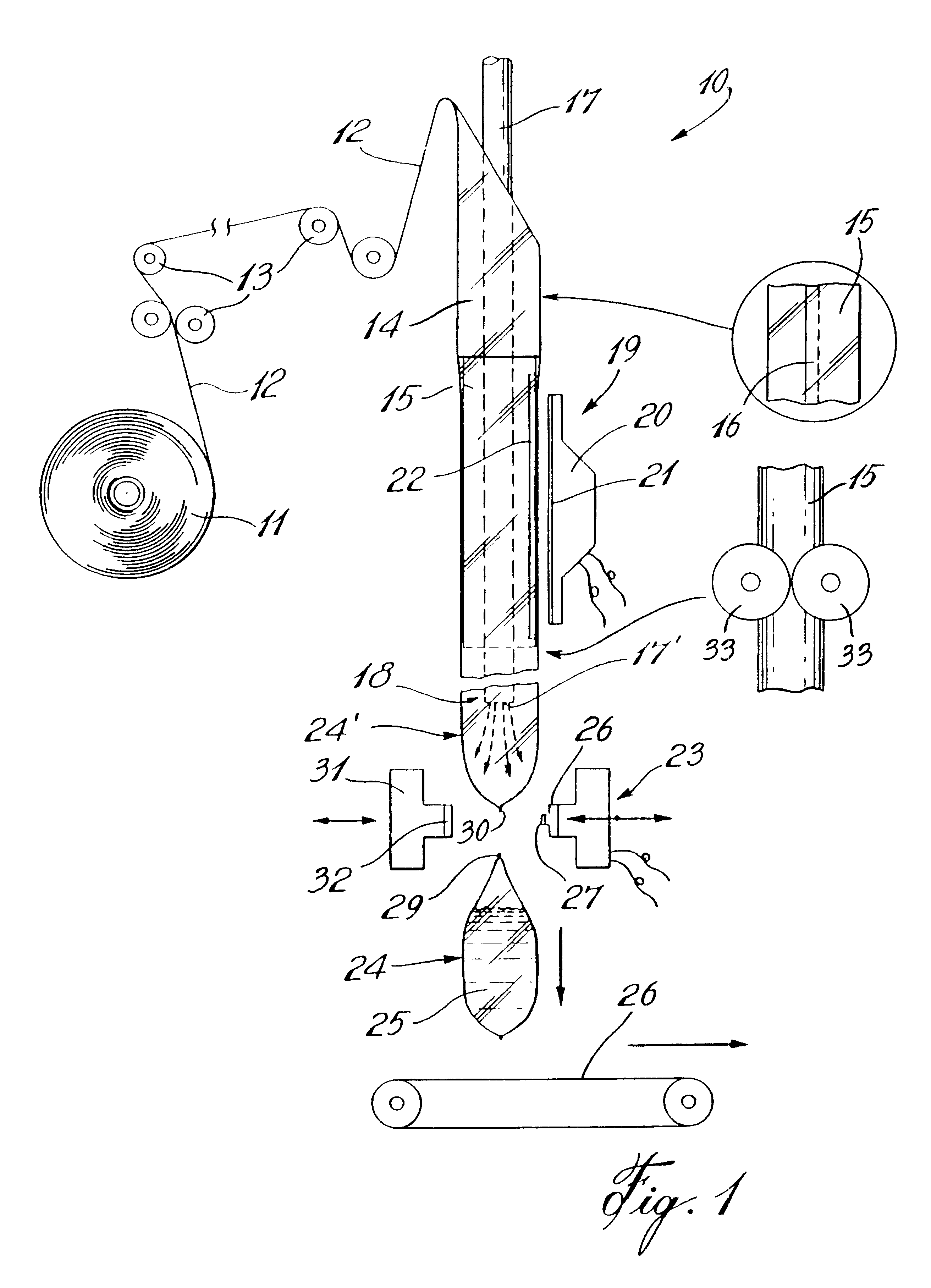

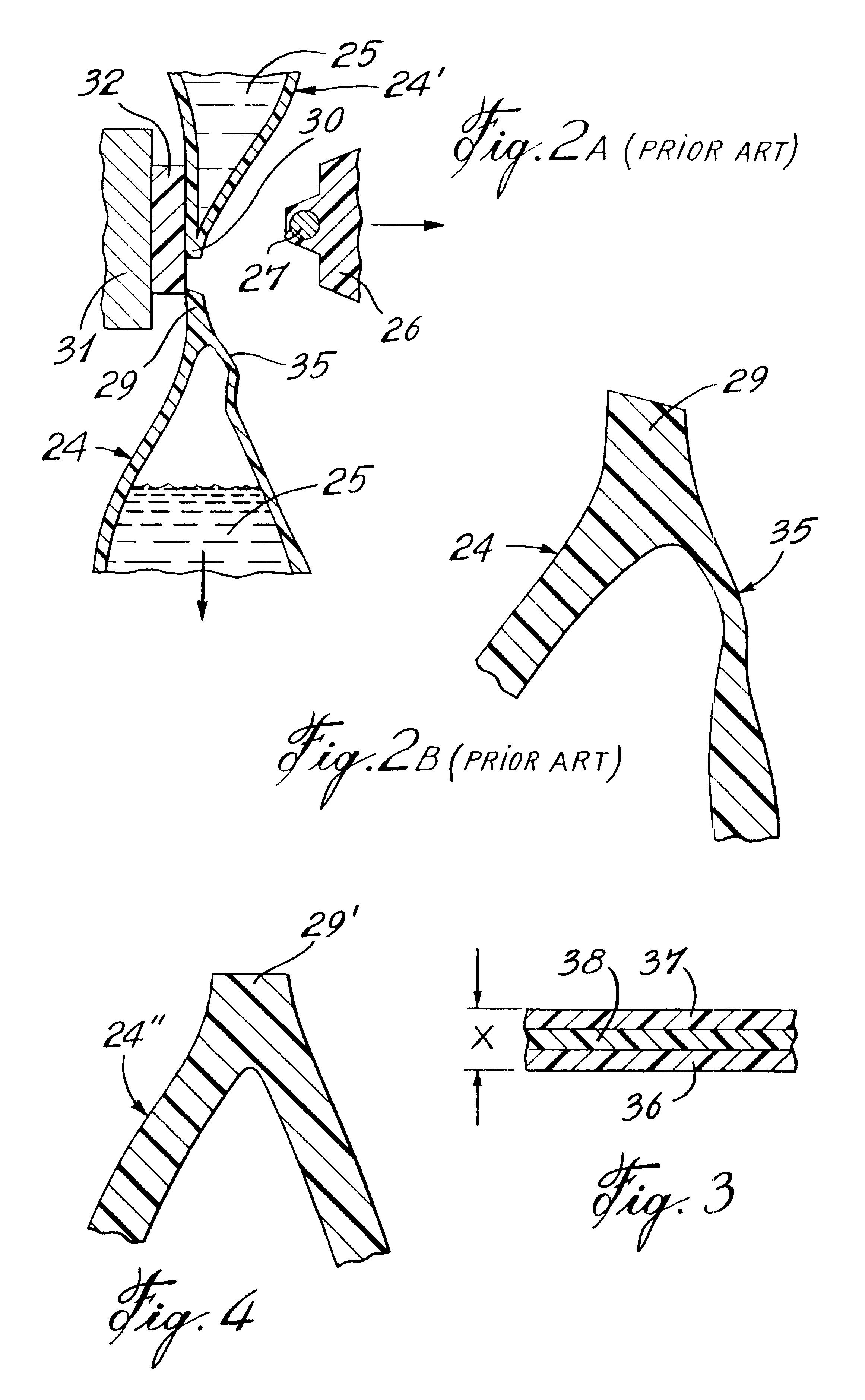

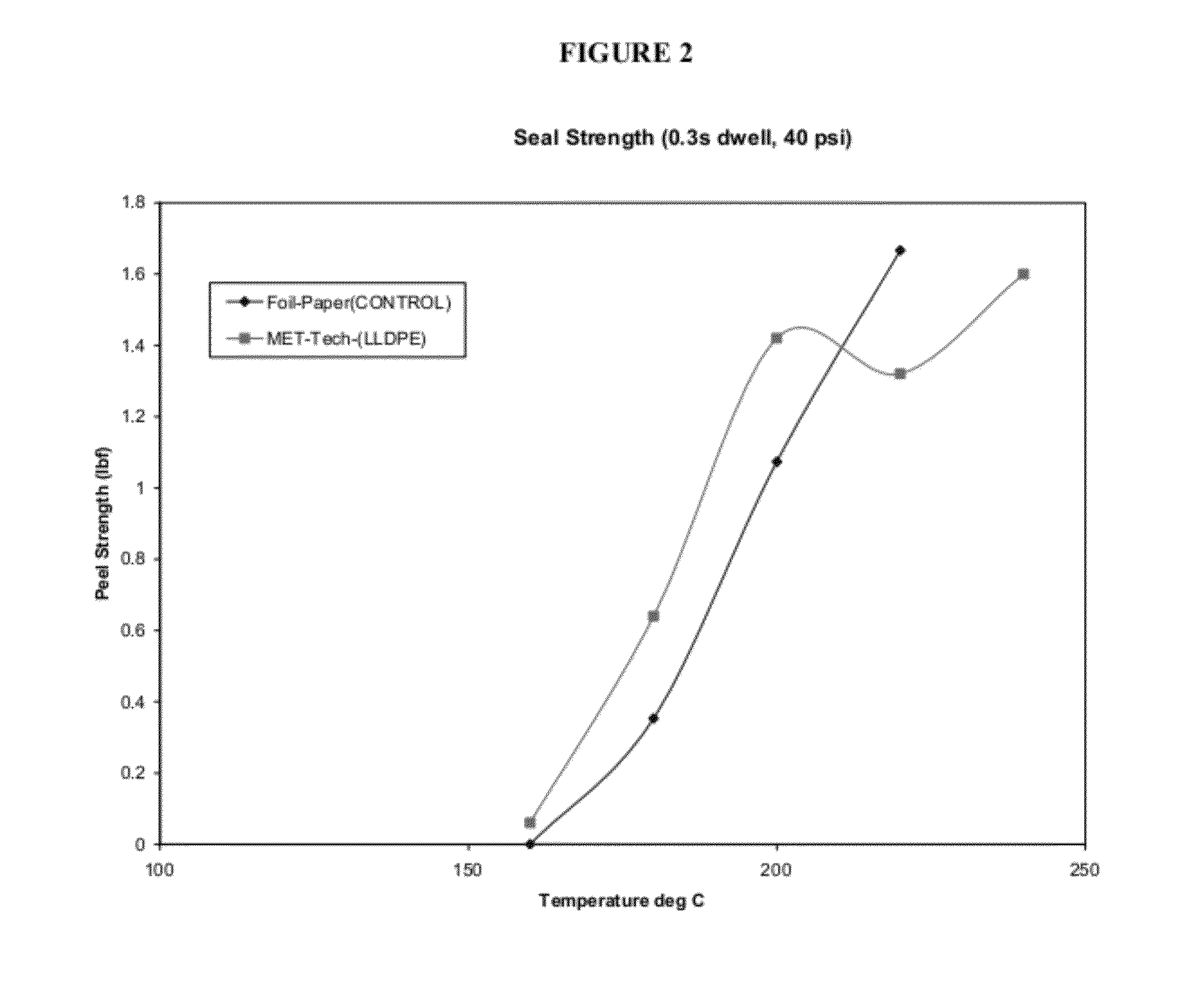

High-speed pouch forming, sealing and filling machine, method of operation, and multi-layer film therefore

InactiveUS6237308B1Improve methodImprove throughputSynthetic resin layered productsWrapper twisting/gatheringPuncture resistanceEngineering

The multi-layer film structure having an inner sealing layer which comprises metallocene resin, a core which includes polypropylene copolymer and an outer layer and wherein the multi-layer film structure has a thickness within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.

Owner:GLOPAK INC

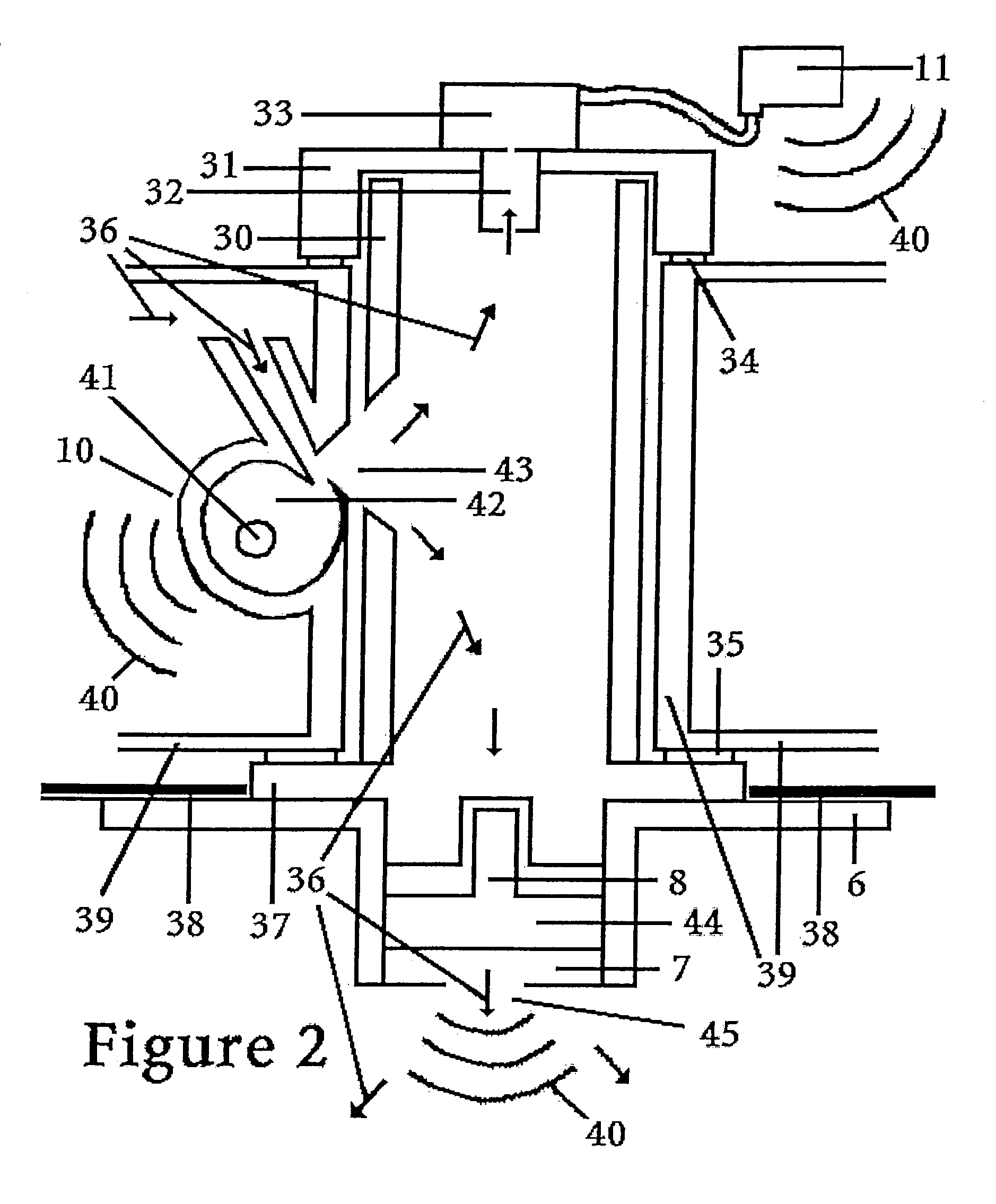

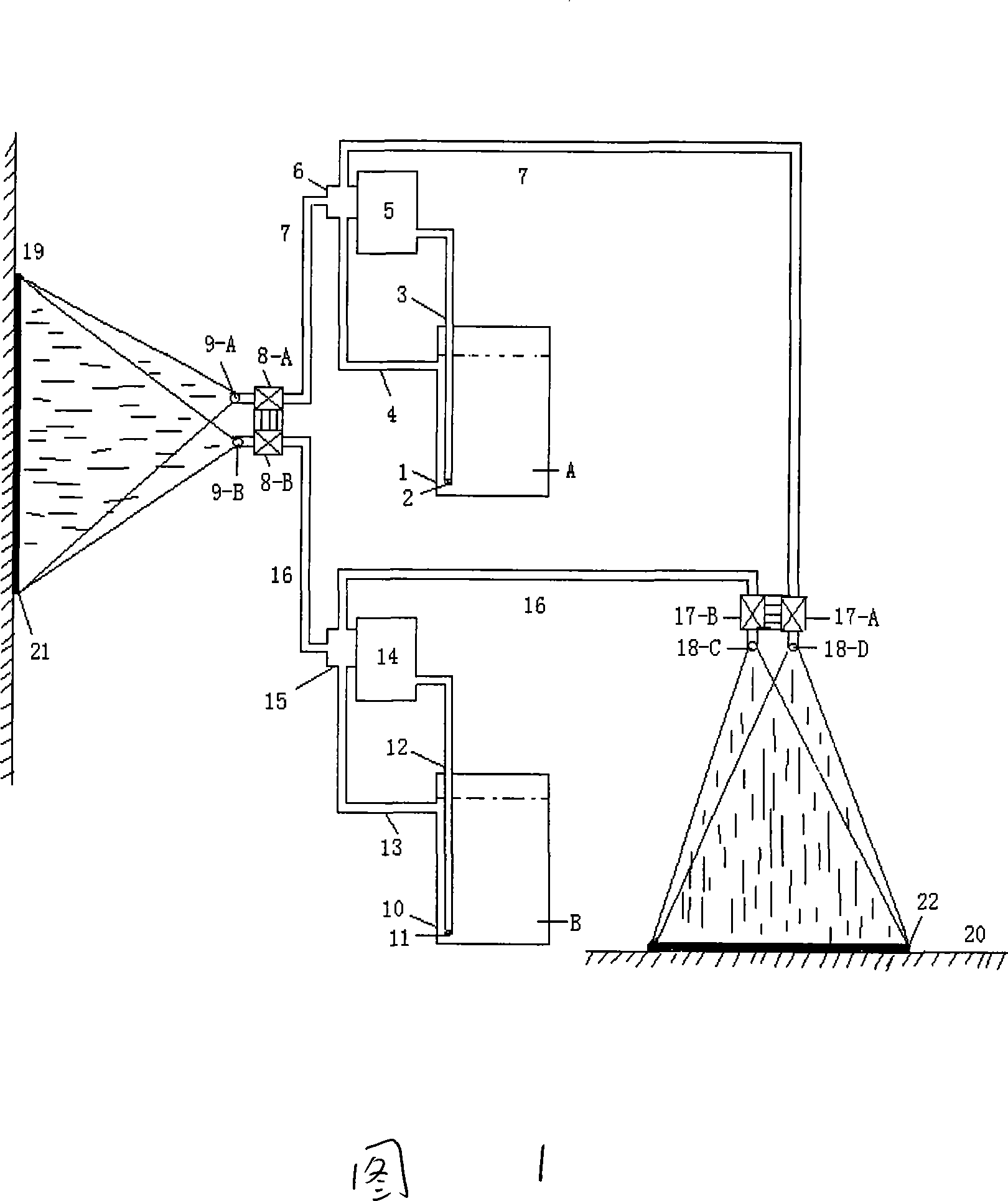

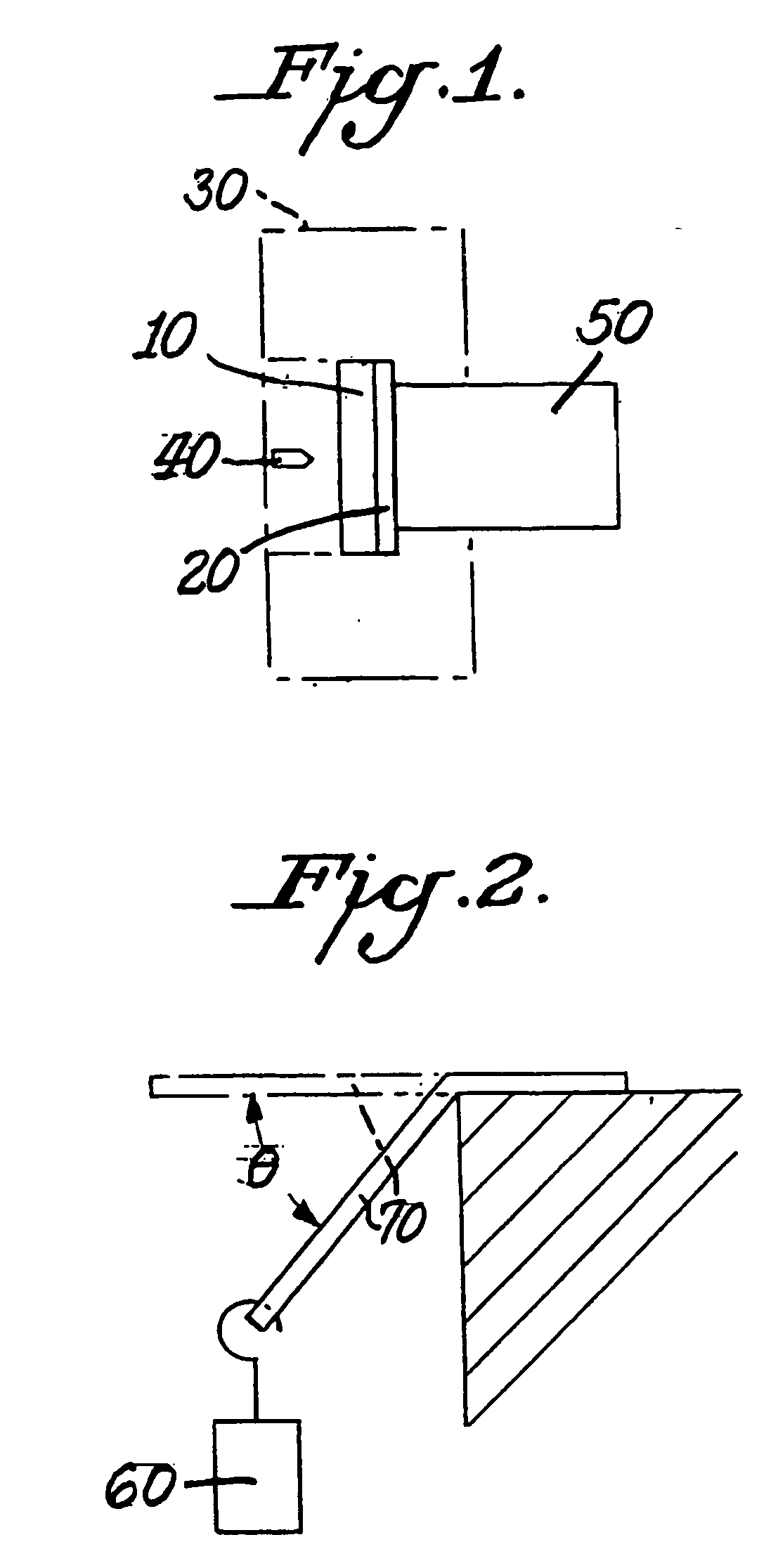

Combination inflator and manifold assembly

InactiveUS7056179B2Extend working lifePrevent moistureLife-raftsAudible signalling devicesPuncture resistanceSeawater

A variable volume raft containing adjustable ratio and amounts of air and or water. The buoyancy and ballast of the raft are routinely adjusted to accommodate additional occupants and changing weather conditions. A manual pump can be the primary or back up source for initial inflation. The torque pump twisted by hand or amplified by a lever arm generates air pressure for maintenance and repairing deflating lacerations at sea. The pumps collector gathers and pressurizes rain water for drinking in one chamber while pressurizing sea water as a stabilizing ballast in another chamber. A double hull or full floor chamber allows huge variations in buoyancy or ballast as dictated by changing needs for stability versus mobility. A compressed liquid or two-part foam confers puncture resistance to a portion of the raft. A thrown self-righting manual air horn, worn water-activated air horns and water activated transmitted signals, mark the site for rescuers.

Owner:COURTNEY WILLIAM L

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

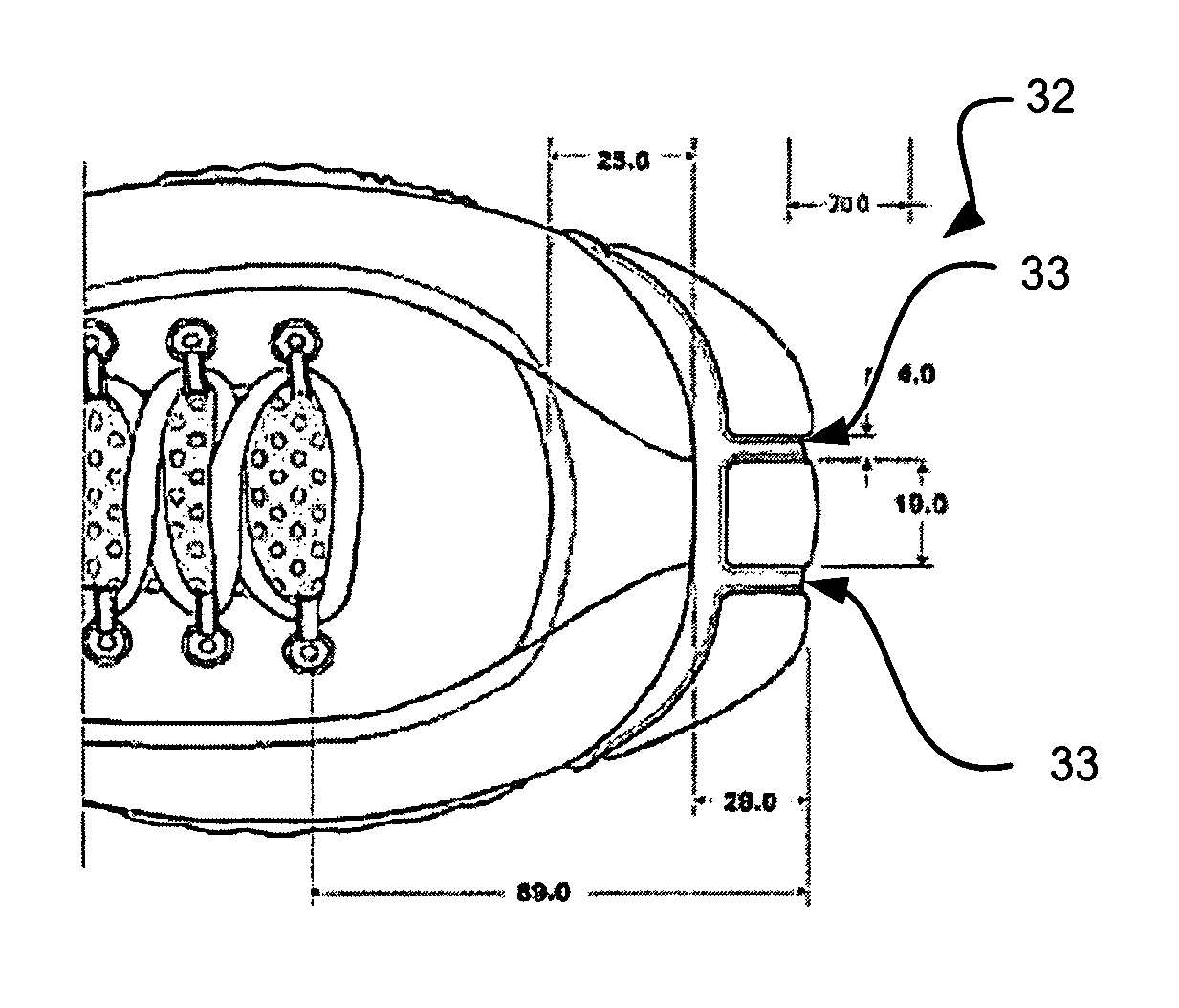

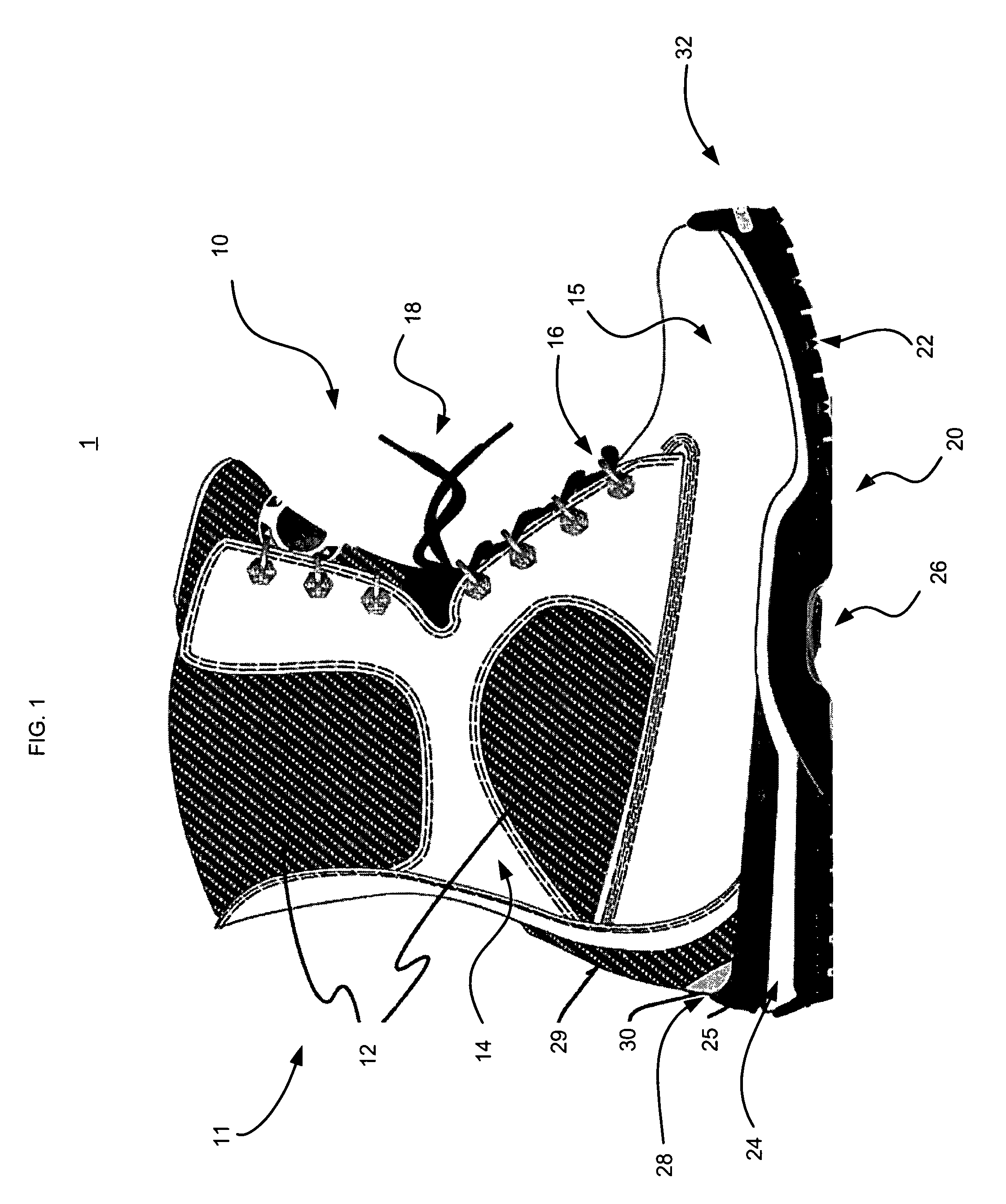

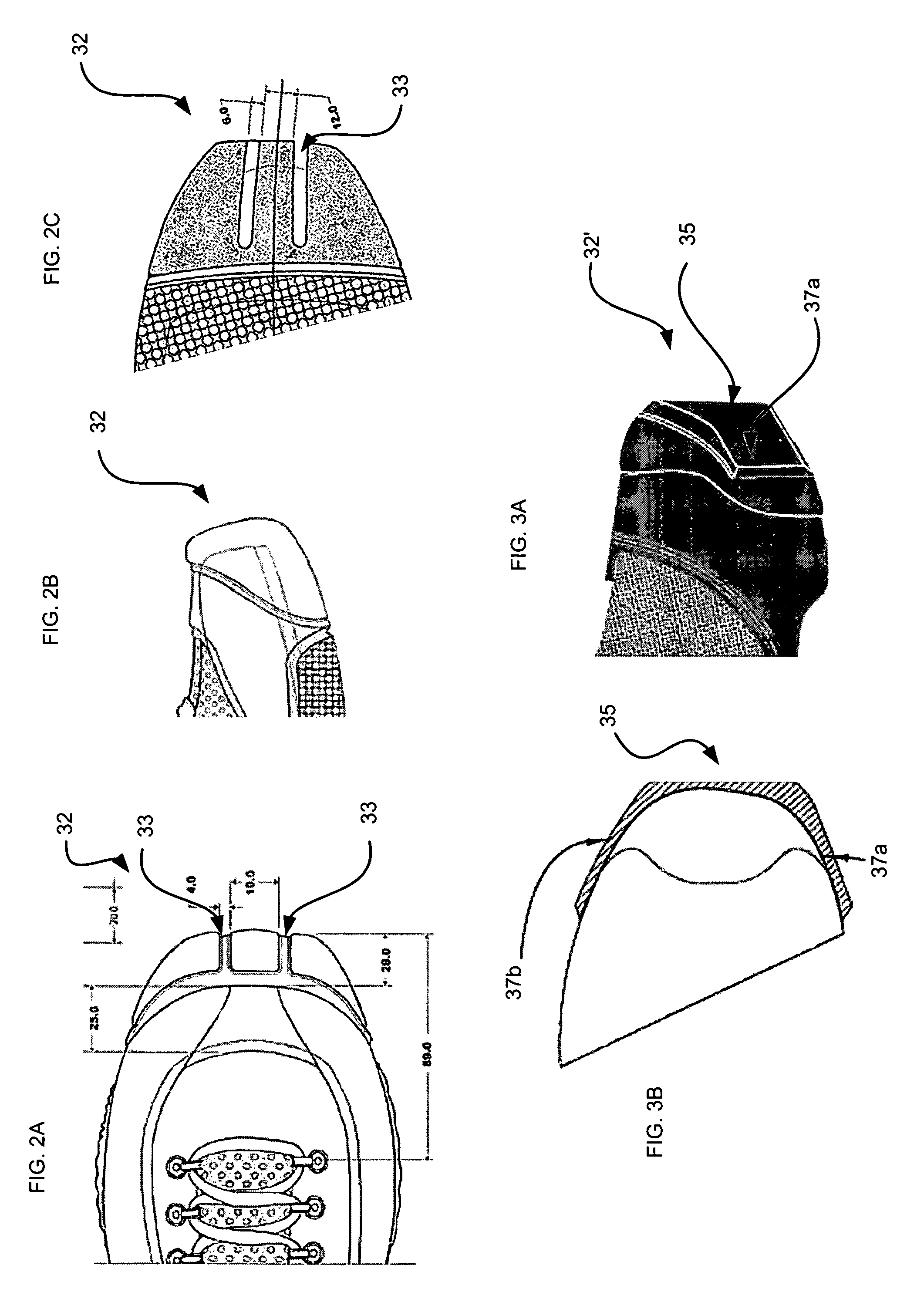

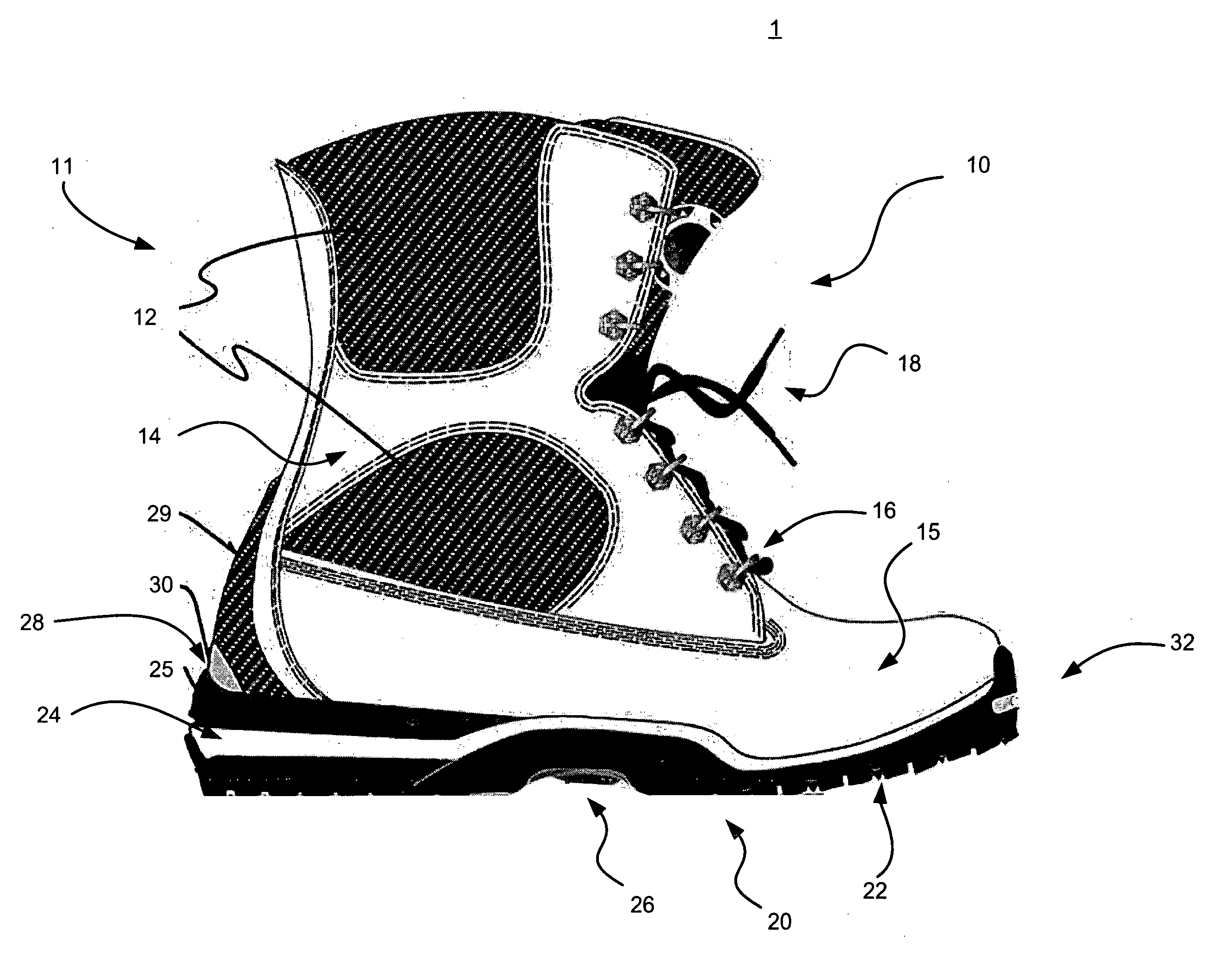

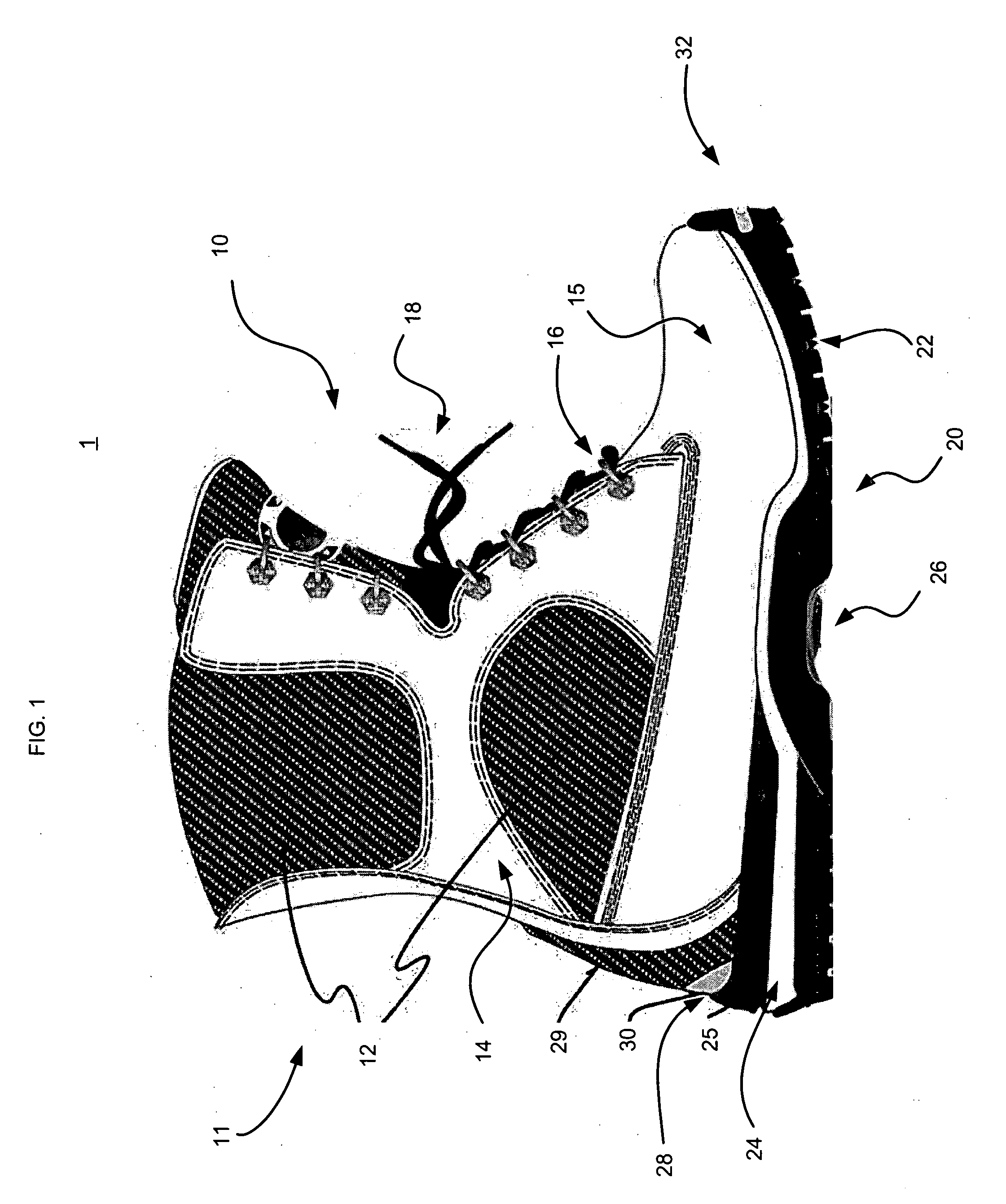

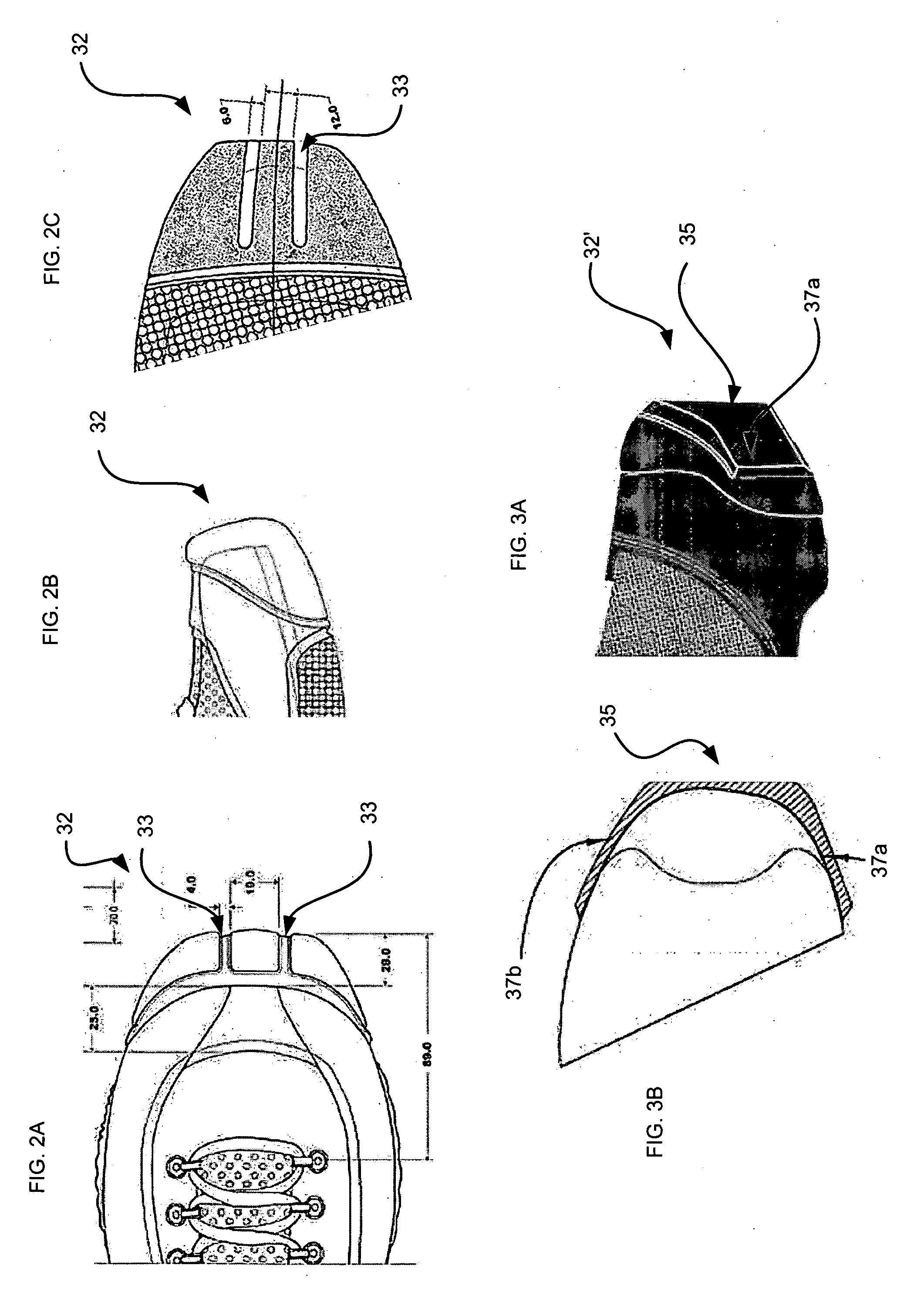

High performance boot

The present invention discloses various features and combinations thereof for use with articles of footwear such as boots. The boots are especially adapted for use on construction projects, and provide protection, support and comfort to the wearer. Numerous outsole configurations and styles are provided, which provide superior traction and a low center of gravity for enhanced balance. Different layers of materials provide puncture resistance, abrasion resistance, thermal insulation, waterproofing and other benefits. Protective and / or insulative plates may be utilized in the footwear for puncture protection or thermal insulation, for example. Shovel guards protect the wearer when using a tool, and toe tools permit the wearer to employ the boot as a tool of its own. Structural support cages chimney structures are also utilized for support and comfort.

Owner:THE TIMBERLAND COMPANY

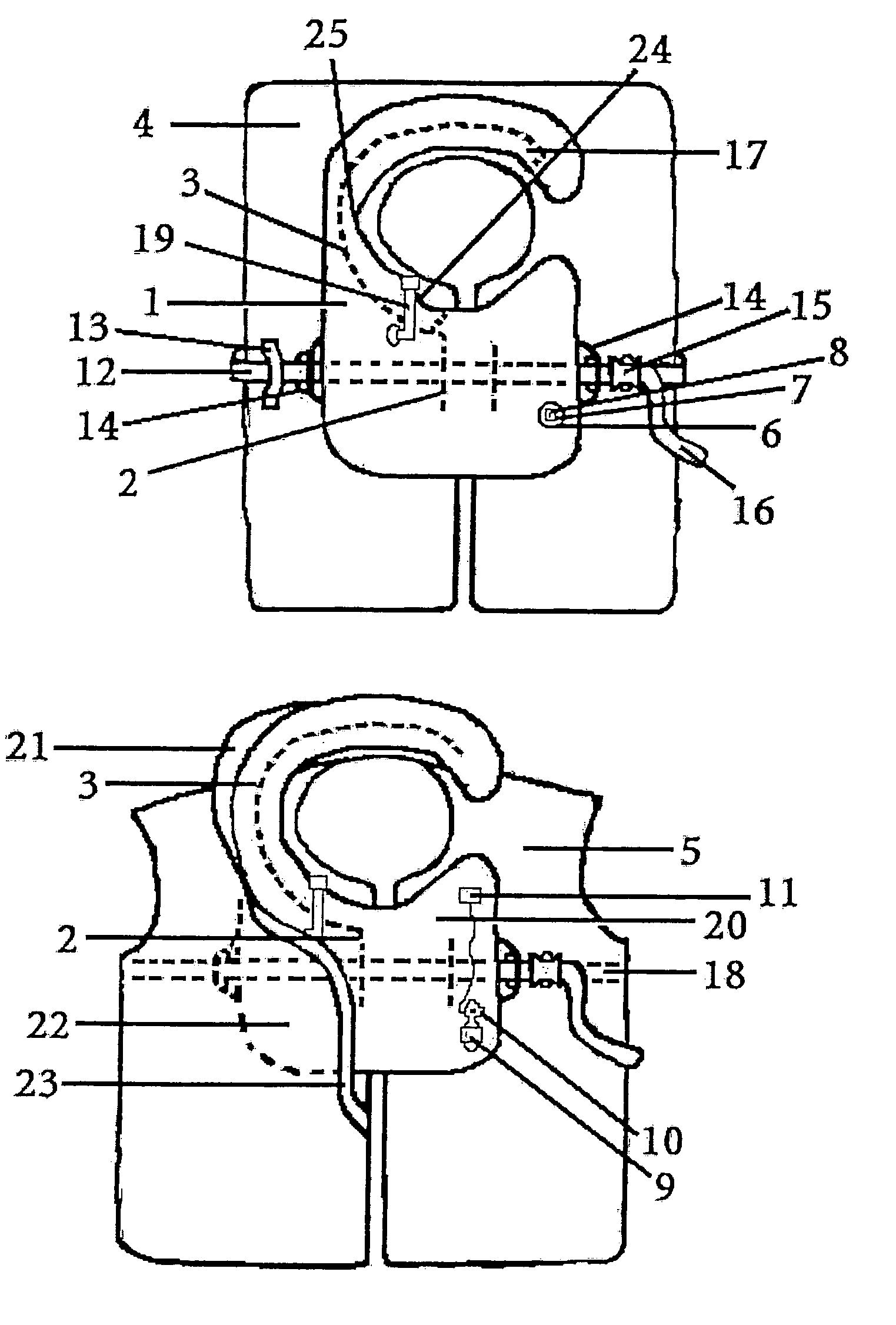

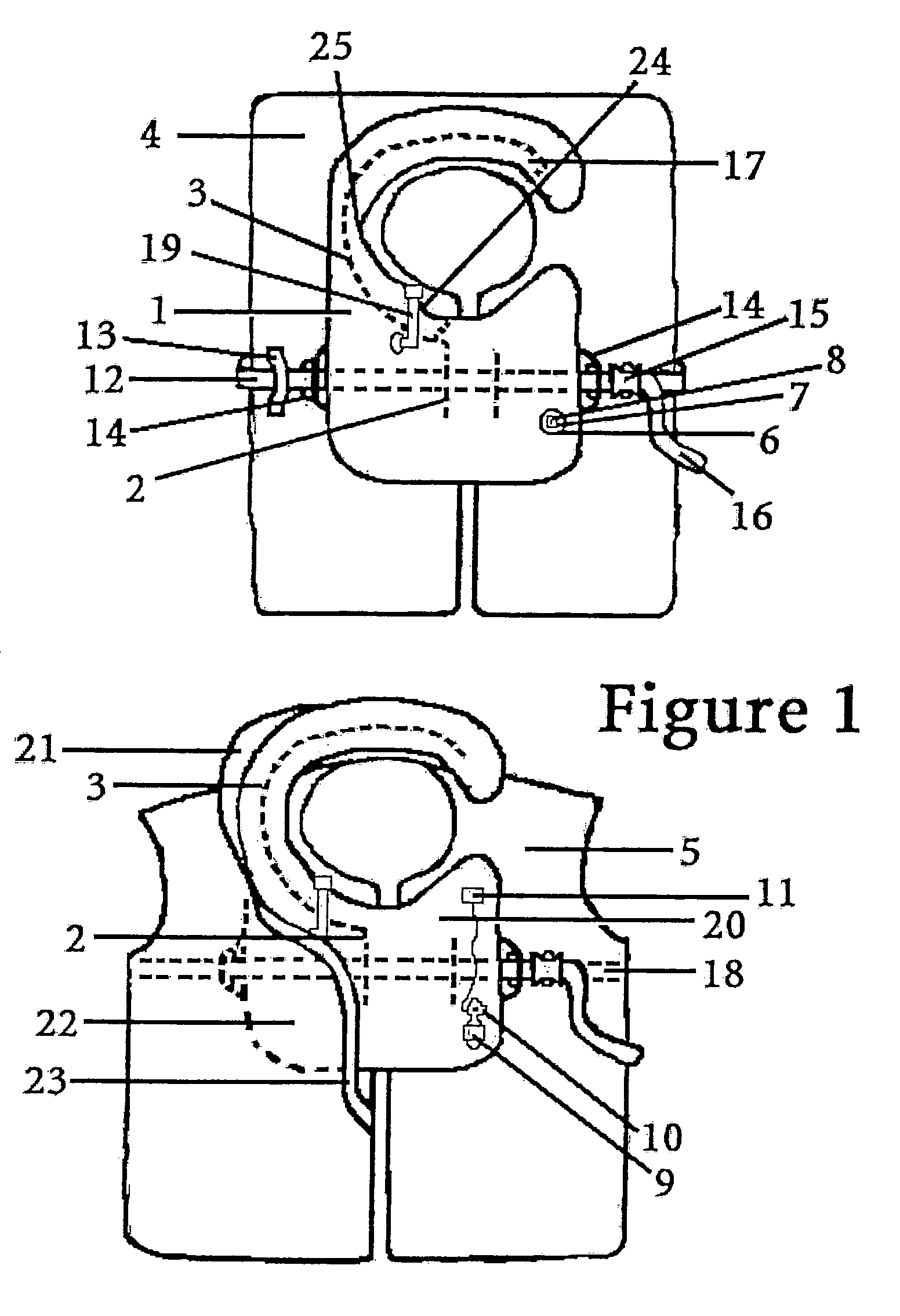

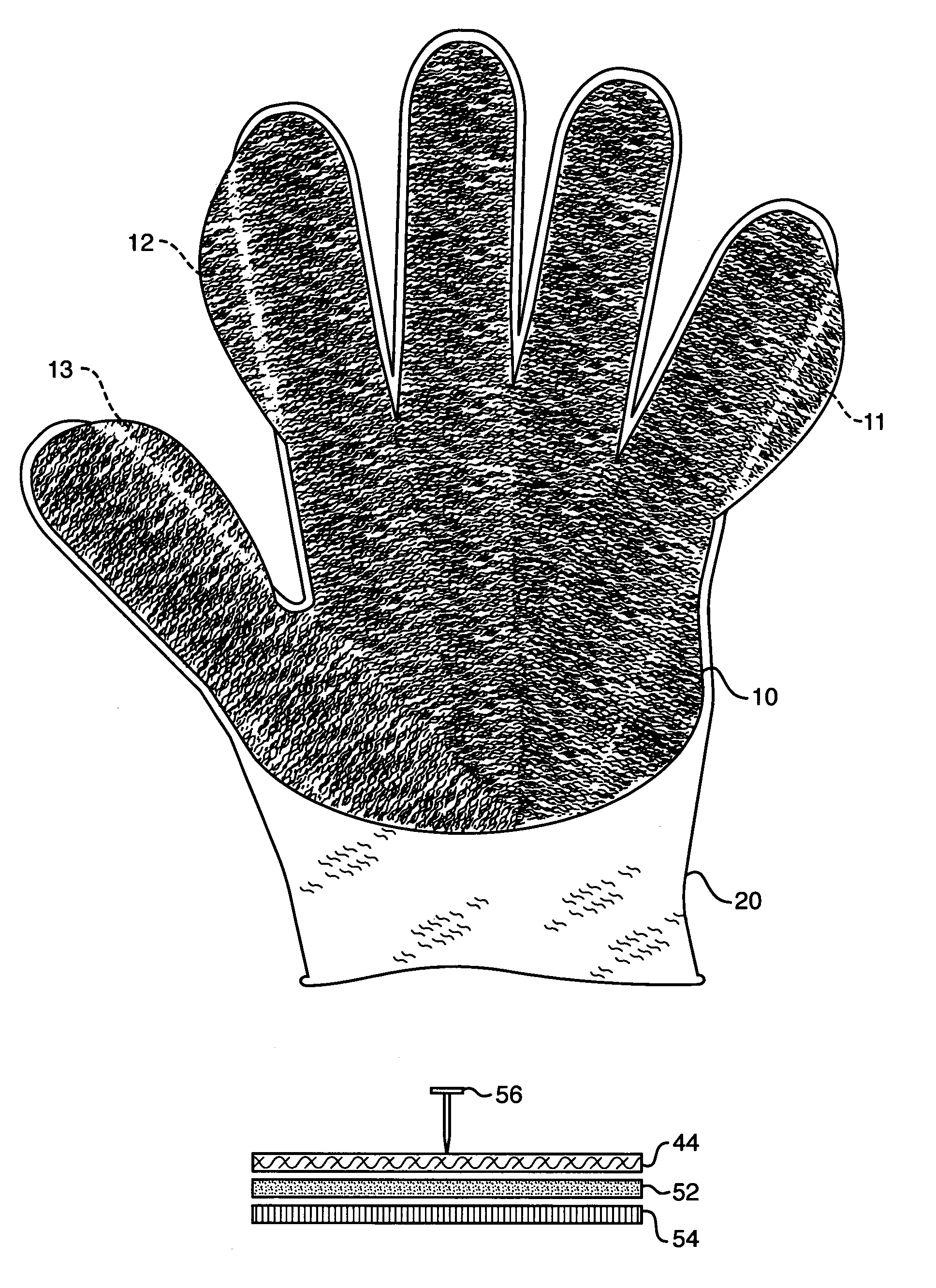

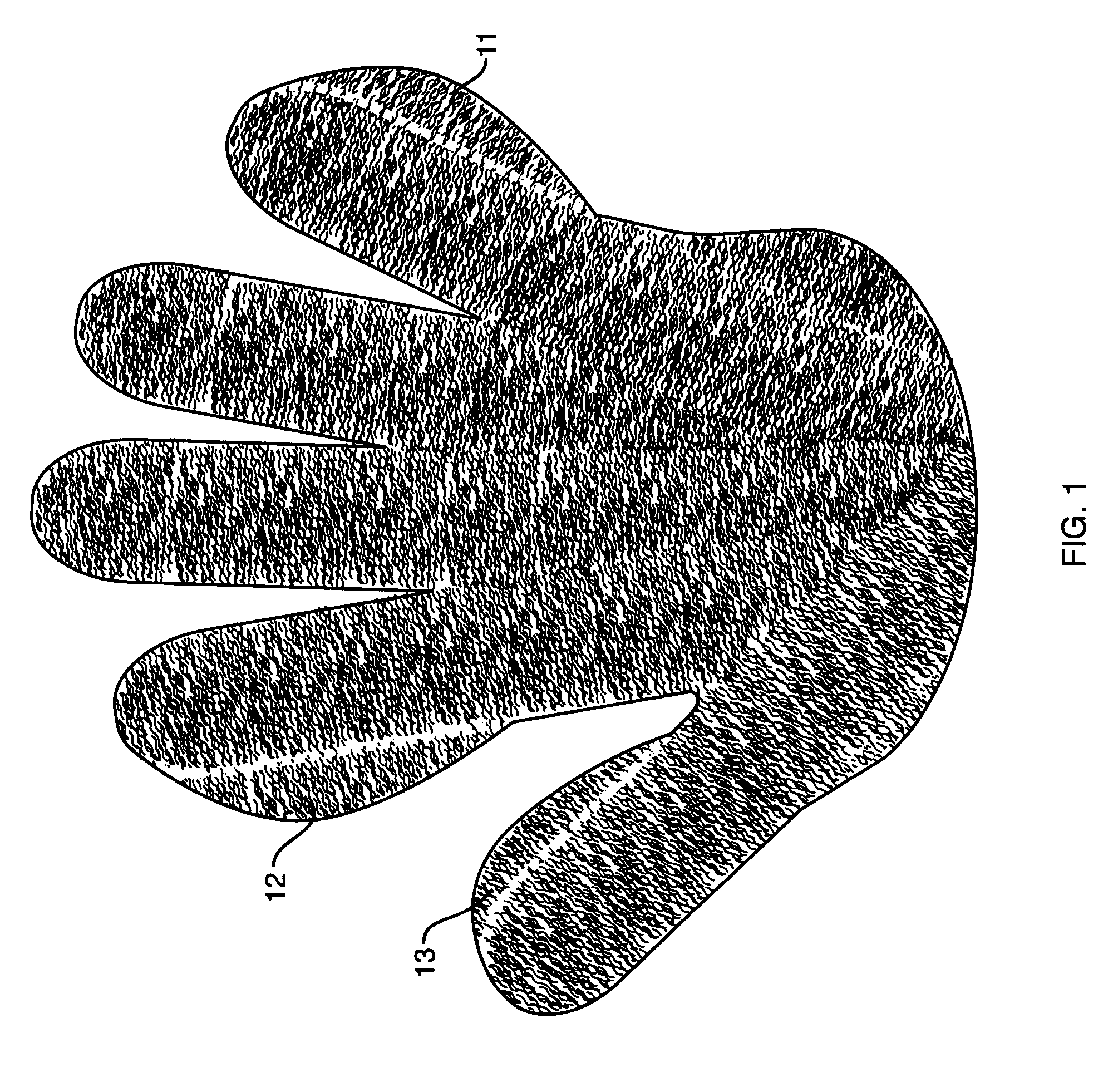

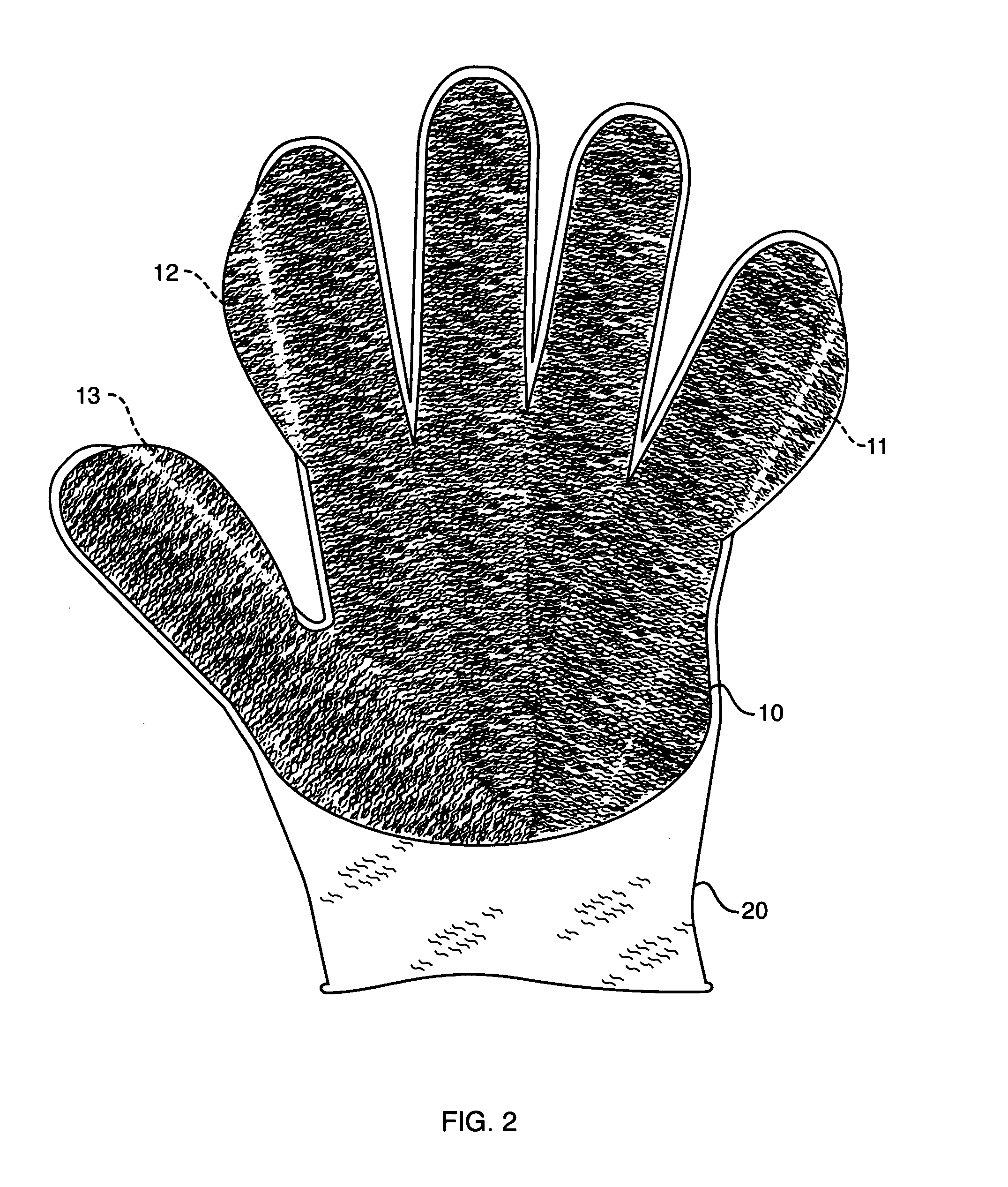

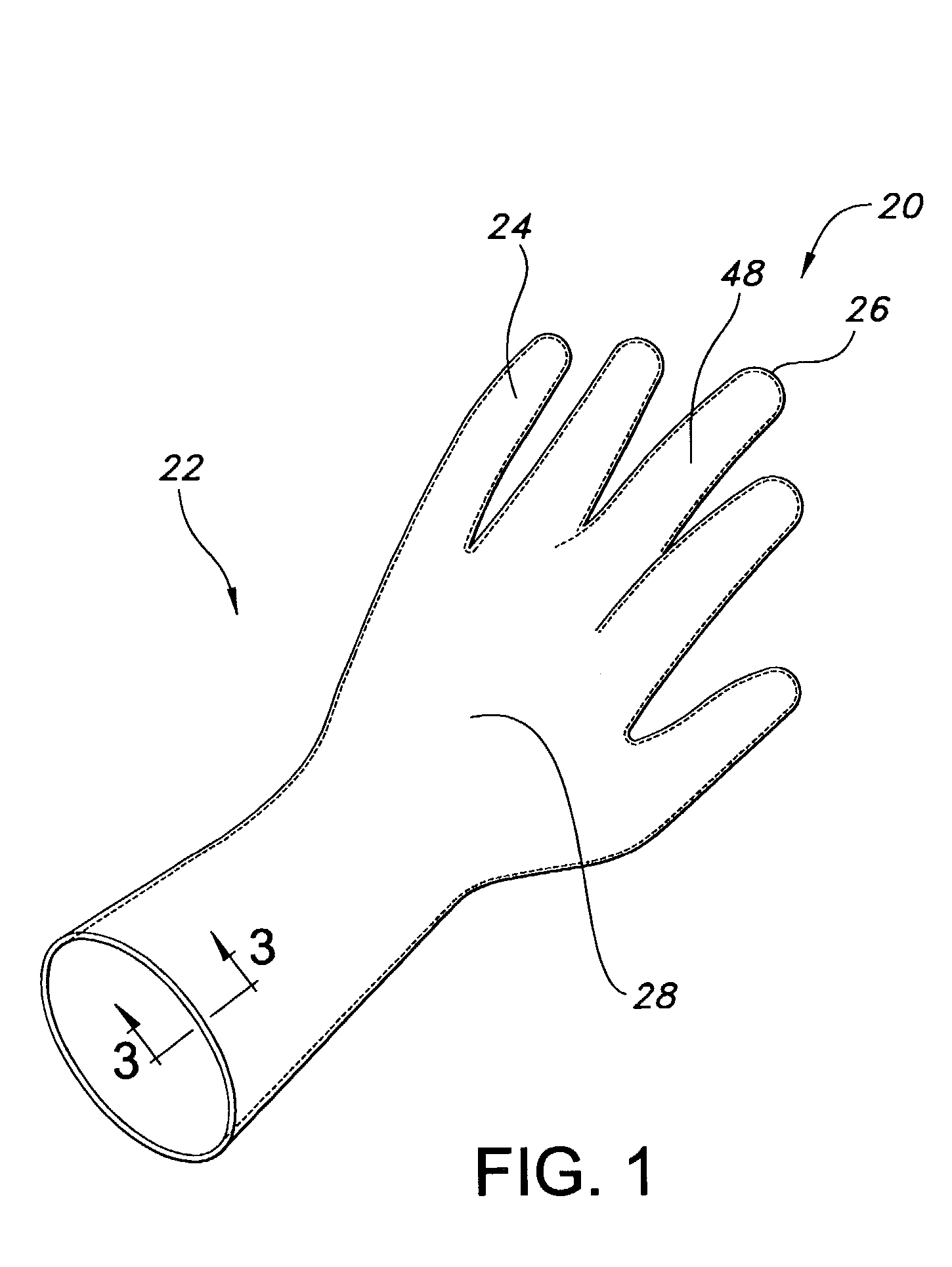

Protective garment and glove construction and method for making same

ActiveUS7007308B1High dexterityIncreasing overall composite puncture resistanceGlovesEye treatmentAdhesivePuncture resistance

A system of manufacturing to incorporate protective materials with high cut and puncture resistance into standard safety and apparel products including gloves, to create a highly effective and low cost system of producing safety garments while preserving the characteristics of the original garment. This includes attaching a cut and puncture resistant protective liner or multiple liners to the inside or outside of or within a garment such as a glove by means of adhesives or stitching. The liner may be a protective liner with cut resistance greater than 450 lbs per inch / thickness and / or puncture resistance greater than 50 lbs per inch / thickness depending on the application requirement for protection and dexterity.

Owner:WARWICK MILLS INC

Advanced body armor utilizing shear thickening fluids

InactiveUS20060234577A1High strengthNot impede fabric flexibilityWarp knittingCircular knitting machinesPuncture resistanceBody armor

An armor composite material has been invented which contains a fabric which has been impregnated with shear thickening fluid. This invention offers a ballistic resistant material that is more flexible and less bulky than comparable, conventional ballistic fabric. The material in the alternative can be puncture resistant. The invented material offers superior ballistic performance and / or puncture resistance compared to conventional ballistic fabric-based materials of equal thickness. The invented material can be applied to applications requiring armor that is compact and / or flexible, such as body armor, protective clothing and flexible protective devices and shields, and stab resistant clothing and devices.

Owner:UNIVERSITY OF DELAWARE

Child-resistant blister package

InactiveUS20050139505A1Small article dispensingSynthetic resin layered productsPackage designPuncture resistance

An improved child-resistant blister package is provided in which the lidding component includes a tear-resistant nonwoven layer and a barrier layer. The nonwoven layer can be a melt-spun continuous filament nonwoven web or a flash spun plexifilamentary sheet. The lidding component used in peel off-push through blister packages of the invention contains fewer layers and has improved puncture resistance compared to lidding components used in child-resistant packages known in the art. In addition, in peel off-push through and peel-open package designs of the present invention, the lidding peels more cleanly from the blister component compared to packages known in the art which have a tendency to tear during peeling.

Owner:EI DU PONT DE NEMOURS & CO

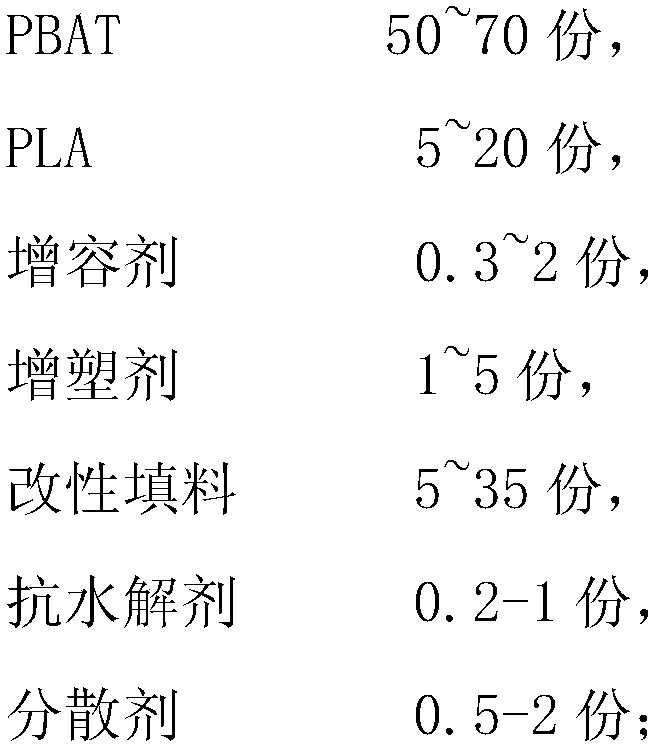

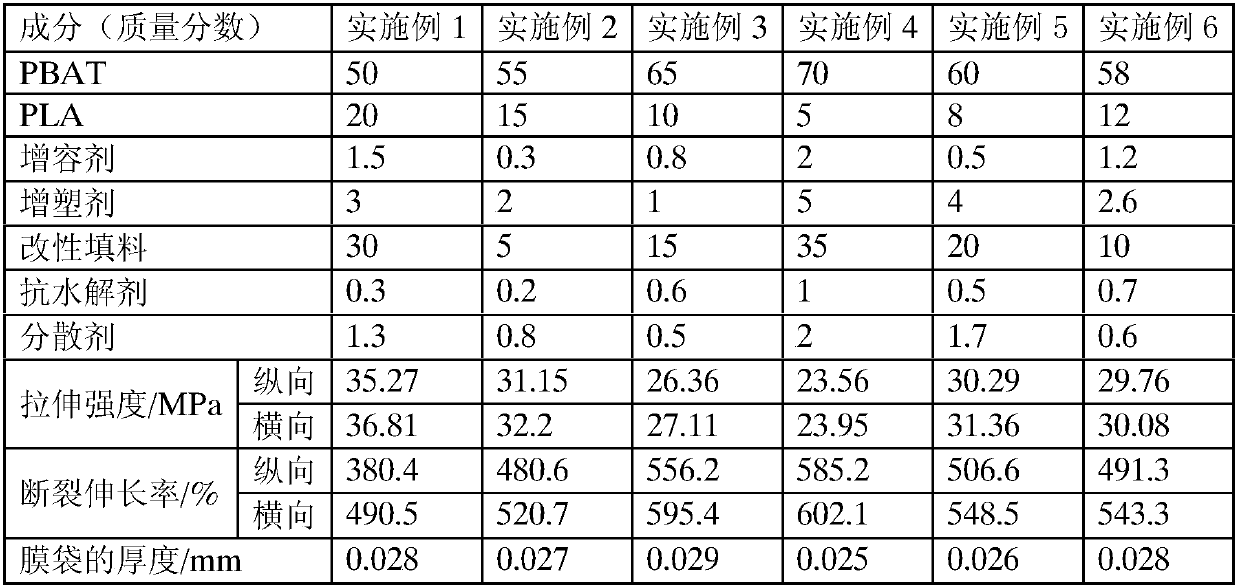

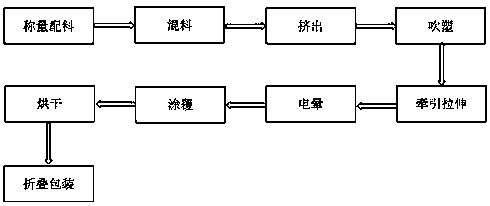

Completely-biodegradable film bag material and preparation method of film bag

The invention relates to a completely-biodegradable film bag material and a preparation method of a film bag. The completely-biodegradable film bag material is prepared from mixing the following raw materials in parts by weight: 50 to 70 parts of PBAT (poly-butylene adipate-co-terephthalate), 5 to 20 parts of PLA (poly-lactic acid), 0.3 to 2 parts of a compatilizer, 1 to 5 parts of a plasticizer,5 to 35 parts of modified filler, 0.2 to 1 part of an anti-hydrolysis agent, and 0.5 to 2 parts of a dispersant, wherein the modified filler is prepared by adding an inorganic filler or organic fillerinto a mixing machine, stirring, sequentially adding a surface modifying additive in the stirring process, and mixing. When the modified filler is added into the material, the property of the film bag product is not degraded; however, the production cost is greatly reduced. The completely-biodegradable film bag material and the preparation method of the film bag has the advantages that the production technology is simple; the forming stability, opening property, puncturing-resistant property, dispersing property of color master batch are good; the surface is smooth, and the completely-biodegradable film bag material can be used for producing shopping bags, rolling bags, express bags, garbage bags and the like.

Owner:WUHAN HUALI BIOLOGY CO LTD

Stretch wrap films

InactiveUSRE38429E1Improve film propertiesEnhanced transverse direction tear propertySynthetic resin layered productsThin material handlingPolyolefinPuncture resistance

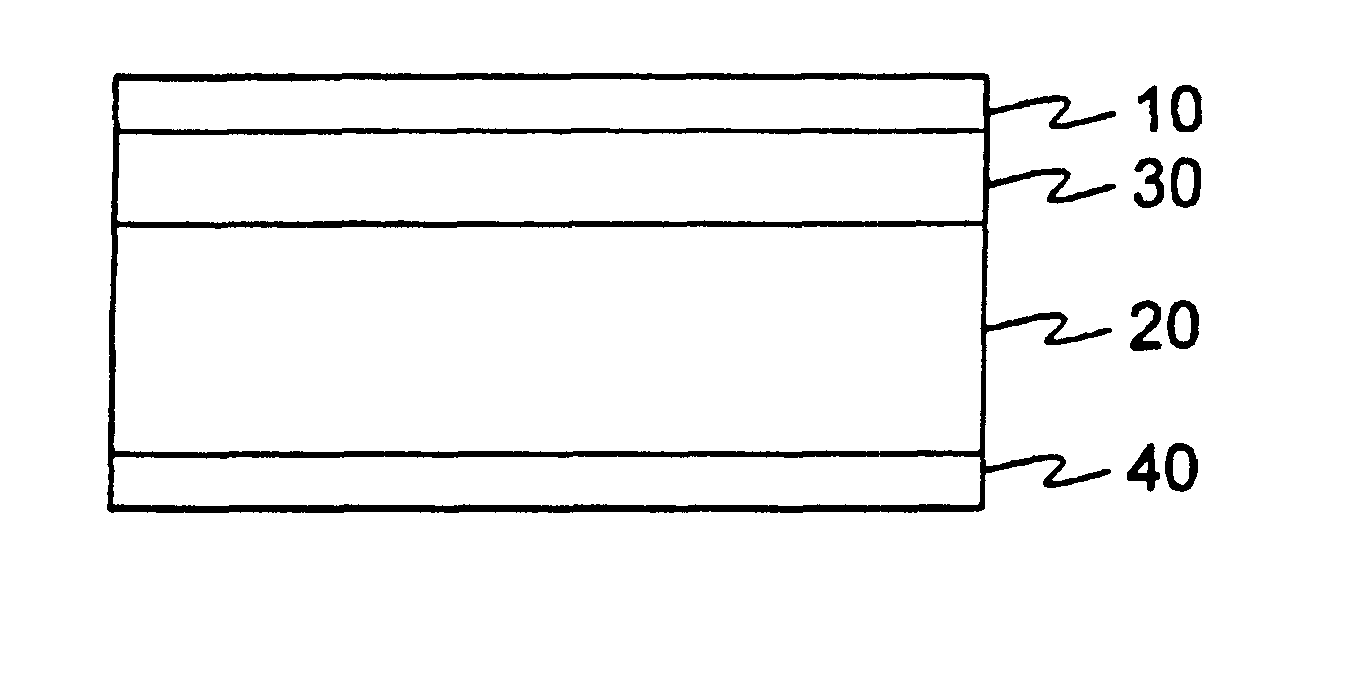

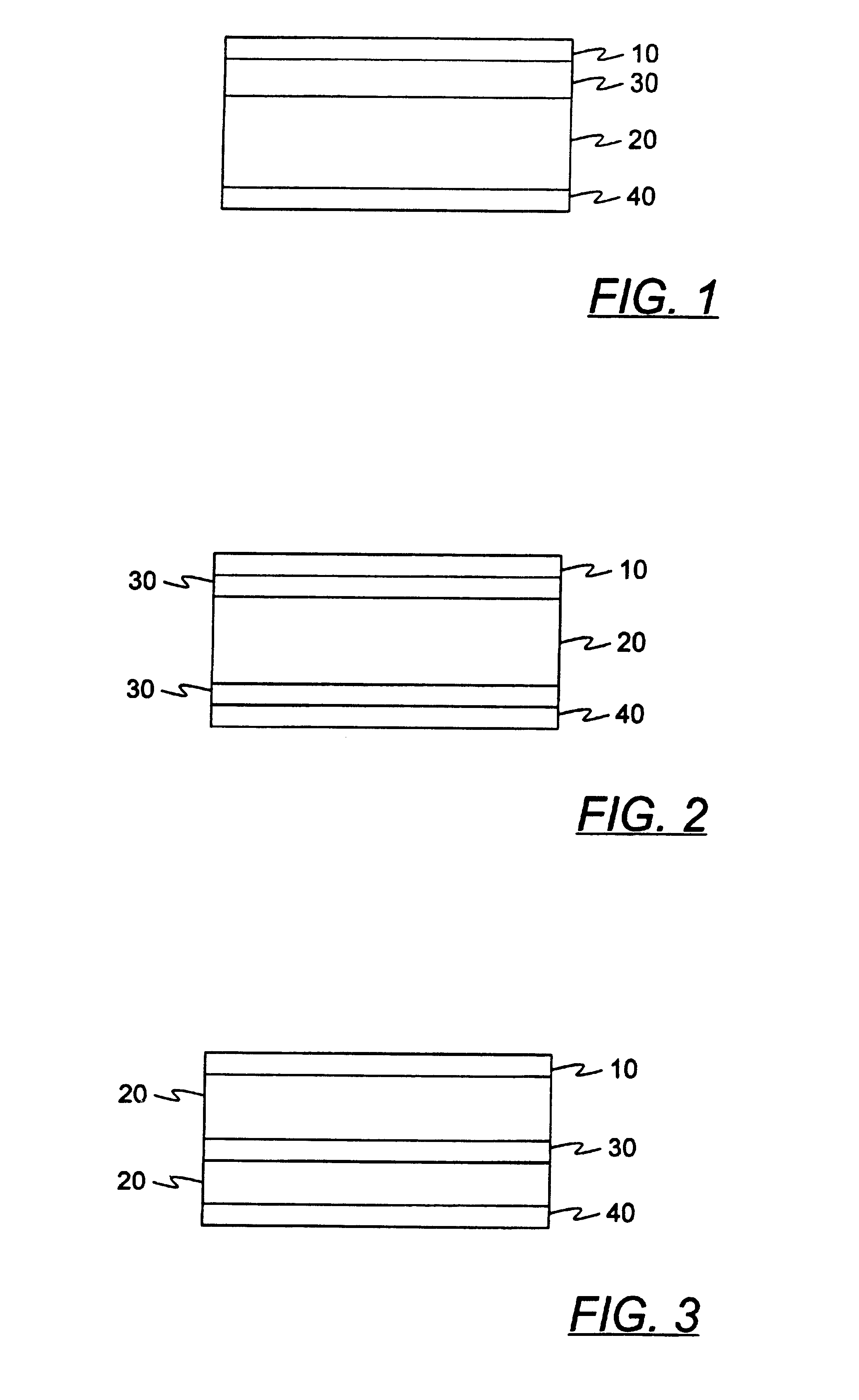

The present invention provides for improved polyolefin cling / slip stretch wrap films having superior load retention, elongation, tear resistance and puncture resistance properties and for the methods of using those stretch wrap films. The stretch wrap films are preferably constructed in a multilayer fashion having an outside cling layer, an outside slip layer, at least one inside puncture resistant layer comprising a metallocene-catalyzed polyethylene resin, and at least one inside transverse direction tear resistant layer.

Owner:BERRY PLASTICS CORP

Wear-resisting anti-slip mountaineering sole material and preparation method thereof

The invention discloses a wear-resisting anti-slip mountaineering sole material which is characterized by being prepared from the following components in percentage by mass: 25-30% of natural rubber, 10-20% of butadiene rubber, 20-25% of butadiene styrene rubber, 5-10% of an ethylene-vinyl acetate copolymer, 5-10% of a modified starch polymer, 1-3% of short fibers, 5-10% of carbon black, 5-10% of white carbon black (SiO2), 2-3% of stearic acid (SA), 3-5% of zinc oxide, 2-3% of tert-thio disilane (Si-69), 2-5% of sulfur (S), 1-3% of a filling agent, 0.5-0.8% of zinc stearate, 0.5-0.8% of diisopropylbenzene peroxide, 0.3-0.5% of azodicarbonamide, 2-3% of an active agent, 0.5-2.5% of a coupling agent, 0.8-1.0% of an accelerant and 1-2% of an anti-aging agent. The wear-resisting anti-slip mountaineering sole material is outstanding in water absorption property and moisture releasability; the prepared sole is low in hardness, good in flexibility and bending resistance, low in consumption, high in wear resistance and anti-tear property and good in elasticity and puncturing resistance; and the comfort and the security of mountaineering fitness exercise are improved; therefore, the wear-resisting anti-slip mountaineering sole material is wide in market application prospect.

Owner:朱伟萍

Polymer lithium ion battery core outer package forming material

InactiveCN102431239AImprove shielding effectNot easy to peel offSynthetic resin layered productsMetal layered productsHigh resistancePolyvinyl alcohol

The invention provides a polymer lithium ion battery core outer package forming material, and aims at providing a battery core outer package forming material with the advantages that the blocking performance is very high, the cold punching forming performance is good, and puncture resistance, electrolyte resistance stability and organic solvent and high-volatile substance resistance can be realized. An outer resistance layer lamination layer body is formed by at least one layer of heat resistance resin film: any one material from polyethylene glycol terephthalate (PET), biaxially oriented polyamide (BOPA) and polyethylene naphthalate (PEN) or coexistence of two materials from PET, BOPA and PEN through co-extrusion compounding, aluminum foils in a resistance permeation layer lamination body at least comprise 0.9 weight percent to 1.5 weight percent of Fe, a high-resistance layer lamination body comprises a base layer, a function layer and a hot sealing layer, the base layer is a co-polymer film formed by paired compounding or the combination of at least two kinds of film substrates in polystyrene (PP), chlorinated polypropylene (CPP), polyurethane (PE), PET, polyamide (PA) or metaxylylene diamine (MPE) elastic body polymer blends, polyvinyl dichloride (PVDC), ethylene vinyl silane (EVOH), PEN and transpeptidase (GT), and a high-resistance water-resistance modified polyvinyl acetate (PVA) coating film is respectively coated on the co-polymer film substrate. The polymer lithium ion battery core outer package forming material revolutionarily solves the electrolyte resistance stability problem.

Owner:刘继福

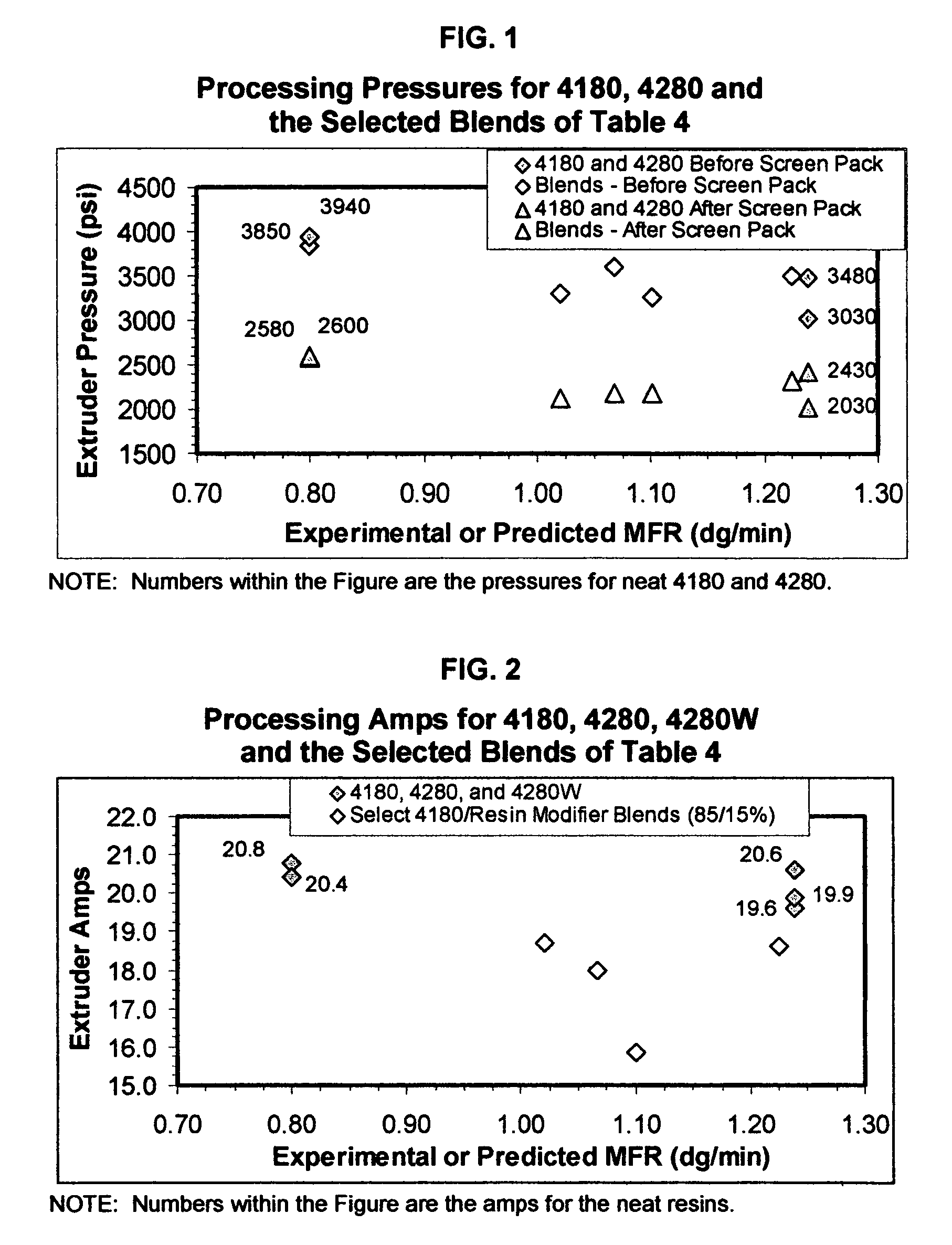

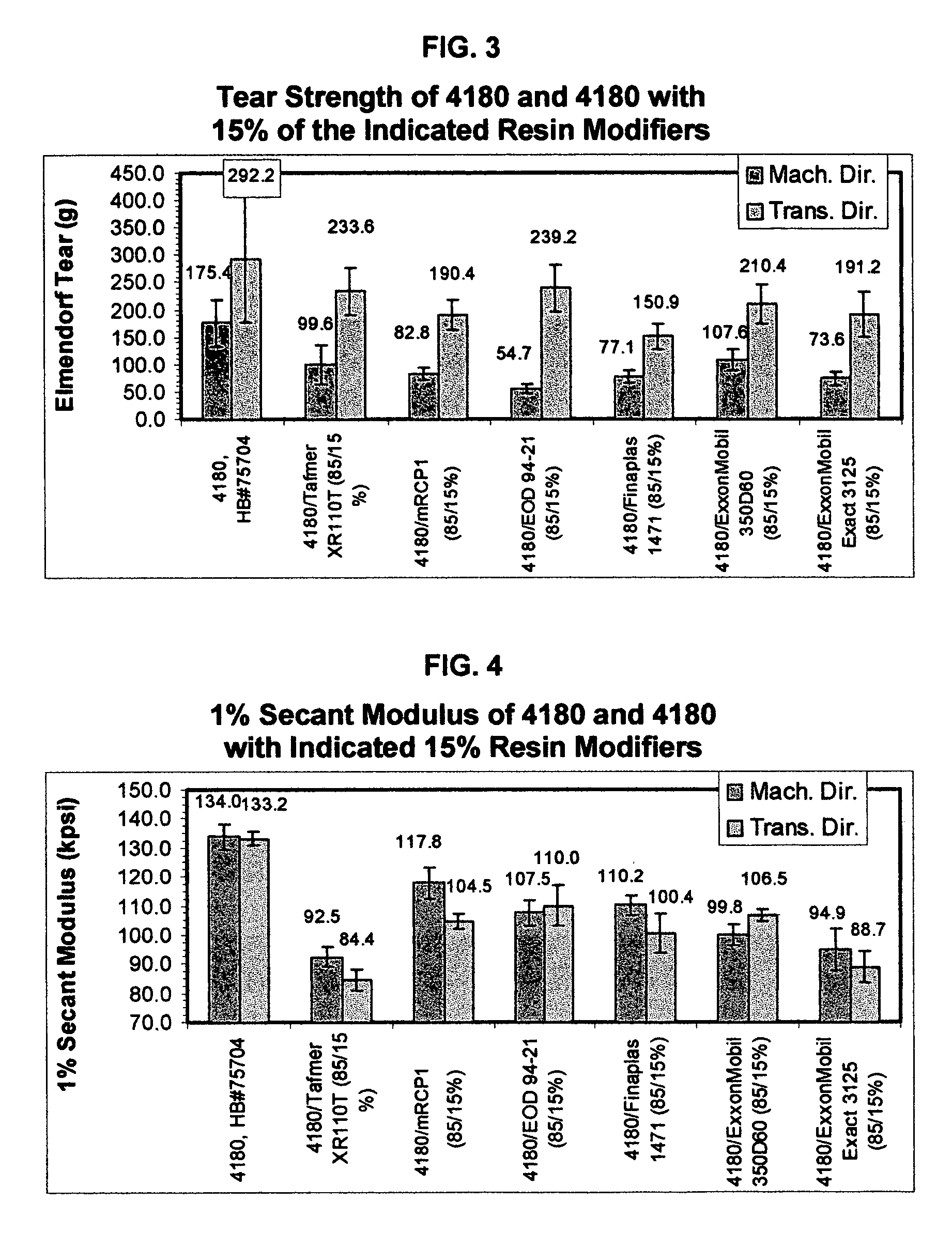

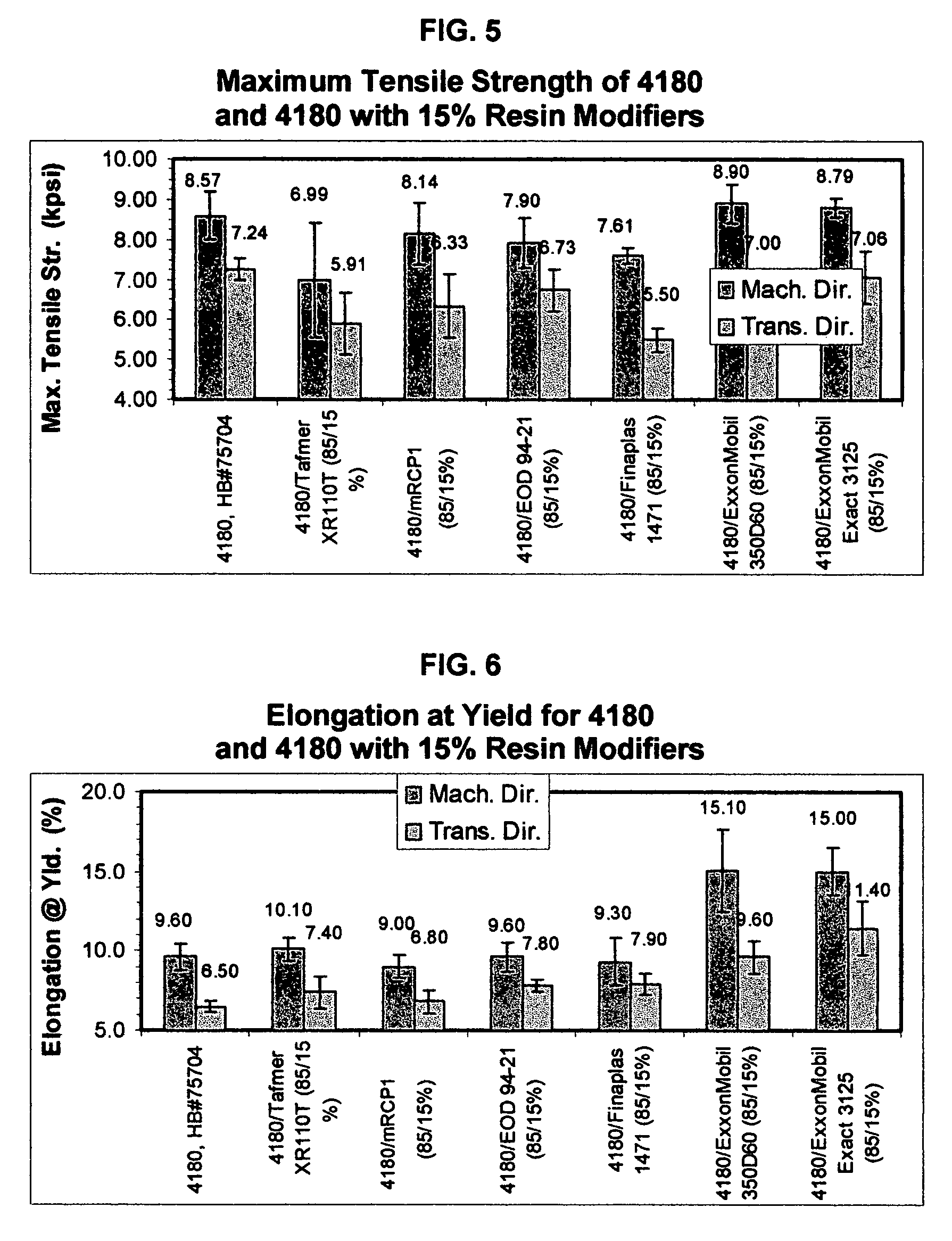

Blends of polypropylene impact copolymer with other polymers

It has been discovered that the properties of sheet or film materials of broad molecular weight distribution ethylene / propylene rubber impact-modified heterophasic copolymer (ICP) can be improved by blending the ICP with a second polyolefin. The second polyolefin may be a syndiotactic polypropylene (sPP), a random copolymer (RCP) of propylene and comonomer (e.g. ethylene and / or butene) made using a Ziegler-Natta or metallocene catalyst, medium density polyethylene (MDPE), linear low density polyethylene (LLDPE), or low crystalline copolymer of propylene / α-olefin. Improvements include, but are not necessarily limited to, reduced motor amps, lower secant modulus, increased dart drop strength, increased gloss, reduced haze, increased elongation to yield, elimination of stress whitening, improved puncture resistance, and decreased seal initiation temperature. This sheet of film materials may be co-extruded with other resins or laminated with other materials after extrusion.

Owner:FINA TECH

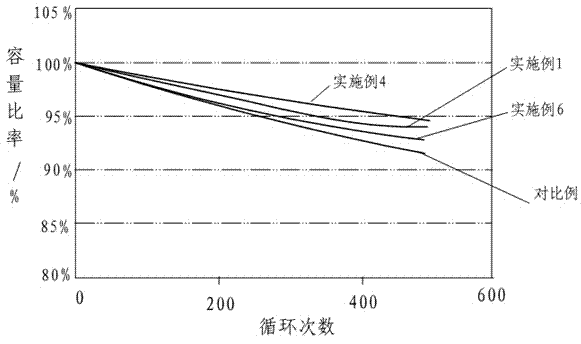

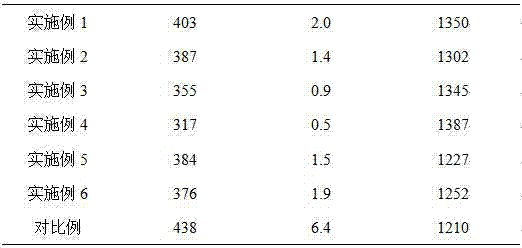

Composite lithium ion battery diaphragm and preparation method thereof

ActiveCN104269505AImprove uniformityGood dispersionCell component detailsPolymer adhesivePore distribution

The invention relates to a composite lithium ion battery diaphragm and a preparation method thereof. The composite lithium ion battery diaphragm comprises a base film and a coating (s) coated on the single side or the two sides of the base film; the coating is obtained by coating and drying slurry, the slurry contains 20-60 percent of a base material by weight percentage, and the balance is deionized water; the base material comprises the following substances in parts by weight: 0.2-4 parts of thickening agent, 0.2-3 parts of inorganic nanometer dispersing agent, 1-5 parts of polymer adhesive and 88-98 parts of nano alumina and nano barium sulfate, wherein the mass ratio of the nano alumina to the nano barium sulfate is 1: (1-10). The composite lithium ion battery diaphragm provided by the invention has the benefits that the coating uniformity is good, the bonding strength is high and the process is good; the abrasion of mechanical equipment can be reduced on the basis of ensuring uniform pore distribution, excellent air permeability and good foreign body puncture resistance, and continuous and stable mass production is facilitated.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

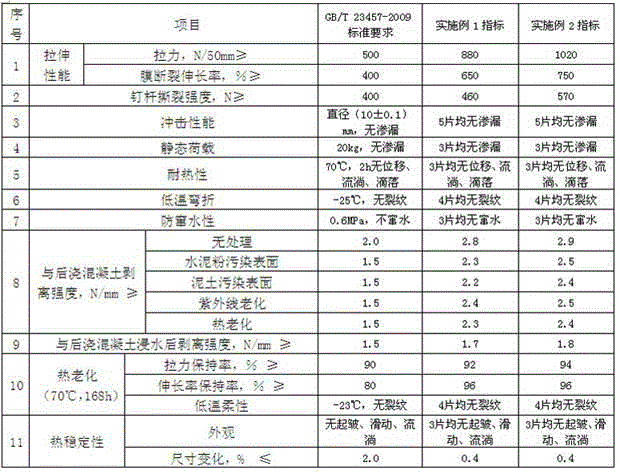

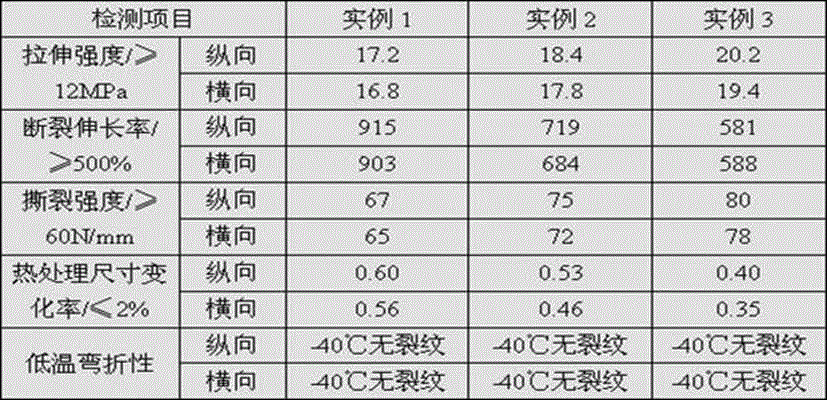

Preparation method of high-polymer self-adhesive waterproof roll

InactiveCN104059553AImprove water resistanceOvercoming technical deficienciesMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyesterSelf-healing

The invention relates to a preparation method of a high-polymer self-adhesive waterproof roll. The technical scheme is as follows: the preparation method comprises the steps of fully coating an SIS (Styrene-Isoprene-Styrene) hot melt pressure sensitive self-adhesive on a main plastic high-polymer waterproof layer by using a hot melt pressure sensitive adhesive coating machine to form an SIS hot melt pressure sensitive self-adhesive layer; then, coating an anti-adhesive isolating membrane on the pressure sensitive self-adhesive layer to prepare a high-polymer self-adhesive waterproof roll product, wherein the main plastic high-polymer waterproof layer is a high-density polyethylene cross laminated film or modified high-density polyethylene film; the anti-adhesive isolating membrane is a silicon oil coated polyurethane isolating membrane. The preparation method has the beneficial effects that firstly, the roll can be permanently and organically combined with the concrete of a structural layer due to the application of the SIS hot melt pressure sensitive self-adhesive, so that no hidden water breakthrough dangers in the intermediate process are caused, and the reliability of a waterproof layer is improved; secondly, the high-polymer self-adhesive waterproof roll is excellent in impact and puncture resistance and capable of bearing the impact of a construction load directly acting on the high-polymer self-adhesive waterproof roll; thirdly, the high-polymer self-adhesive waterproof roll is relatively strong in chemical corrosion resistance and favorable in resistance to alkaline water from concrete; fourthly, the SIS hot melt pressure sensitive self-adhesive is strong in self-healing property.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Tire tread glue formulation adapted for various pavement conditions

ActiveCN101319061AIncrease modulusImprove puncture resistanceSpecial tyresDispersityCrack resistance

The invention discloses a formula for tread rubber of a tire which is suitable for various pavement conditions. The formula is formed by adoption of natural rubber as a main material, cis-1, 4-polybutadiene rubber, intermediate and ultra abrasion resistant carbon black, high-dispersity white carbon black, a silane coupling agent, an anti-cracking resin and a heat stabilizer as main auxiliary materials, and zinc oxide, a stearic acid, a para-phenylene diamine anti-ageing agent, a ketoamine anti-ageing agent, insoluble sulfur, a sulfenamide type accelerator as auxiliary materials. The formula has the advantages that: the tread rubber is made to have the advantages of high tensile strength, high tear strength, high stress at definite elongation, good puncture resistance, low dynamic heat generation, good thermal stability, good abrasion resistance and good flexure and crack resistance. When the tread rubber is used for the tire, the tire is suitable for various pavement conditions, not only is suitable for highway pavements and high-speed conditions but also is suitable for off-highway conditions such as soil pavements, sand and stone pavements and so on, and has good abrasion resistance and long service life.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

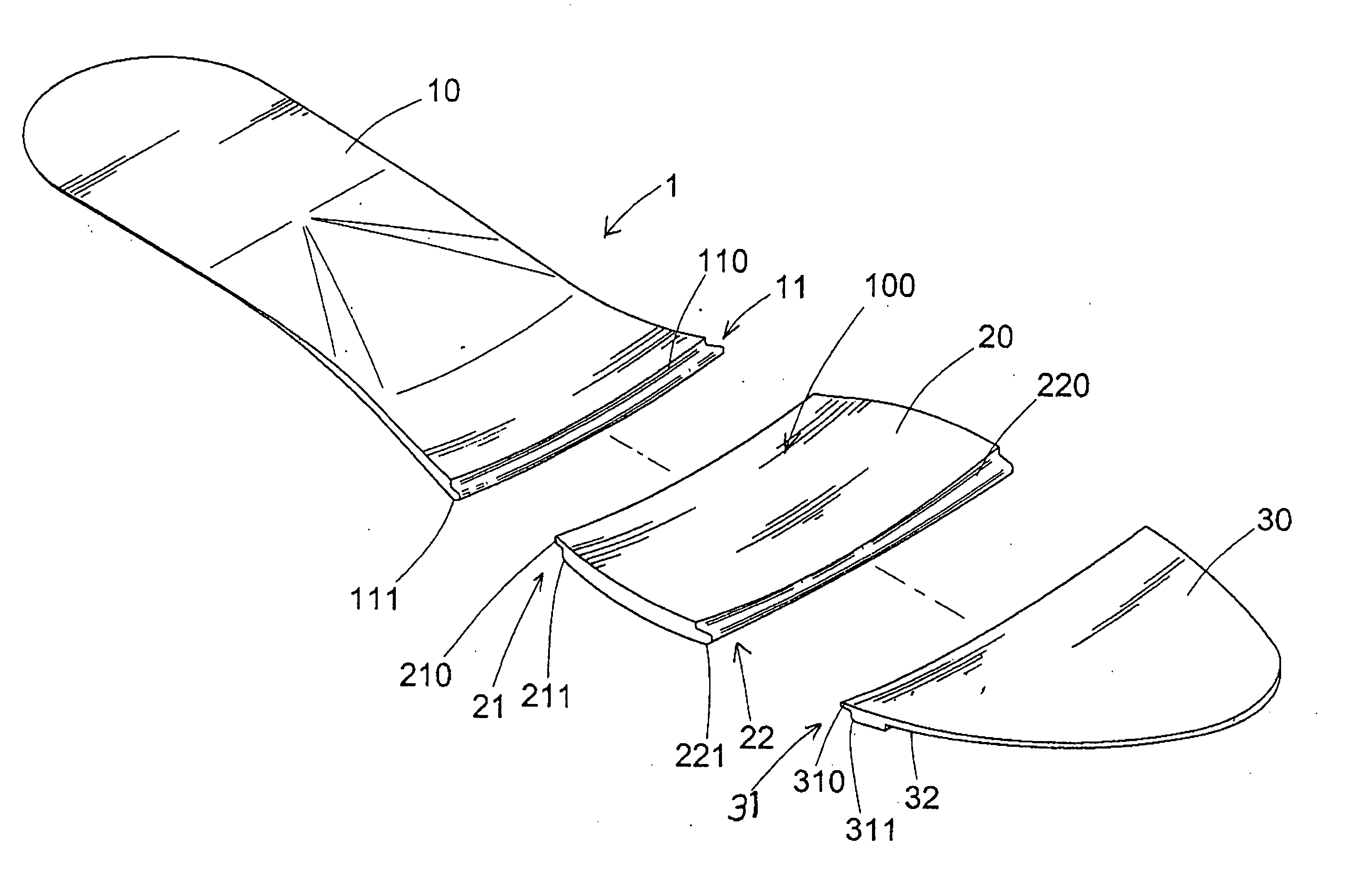

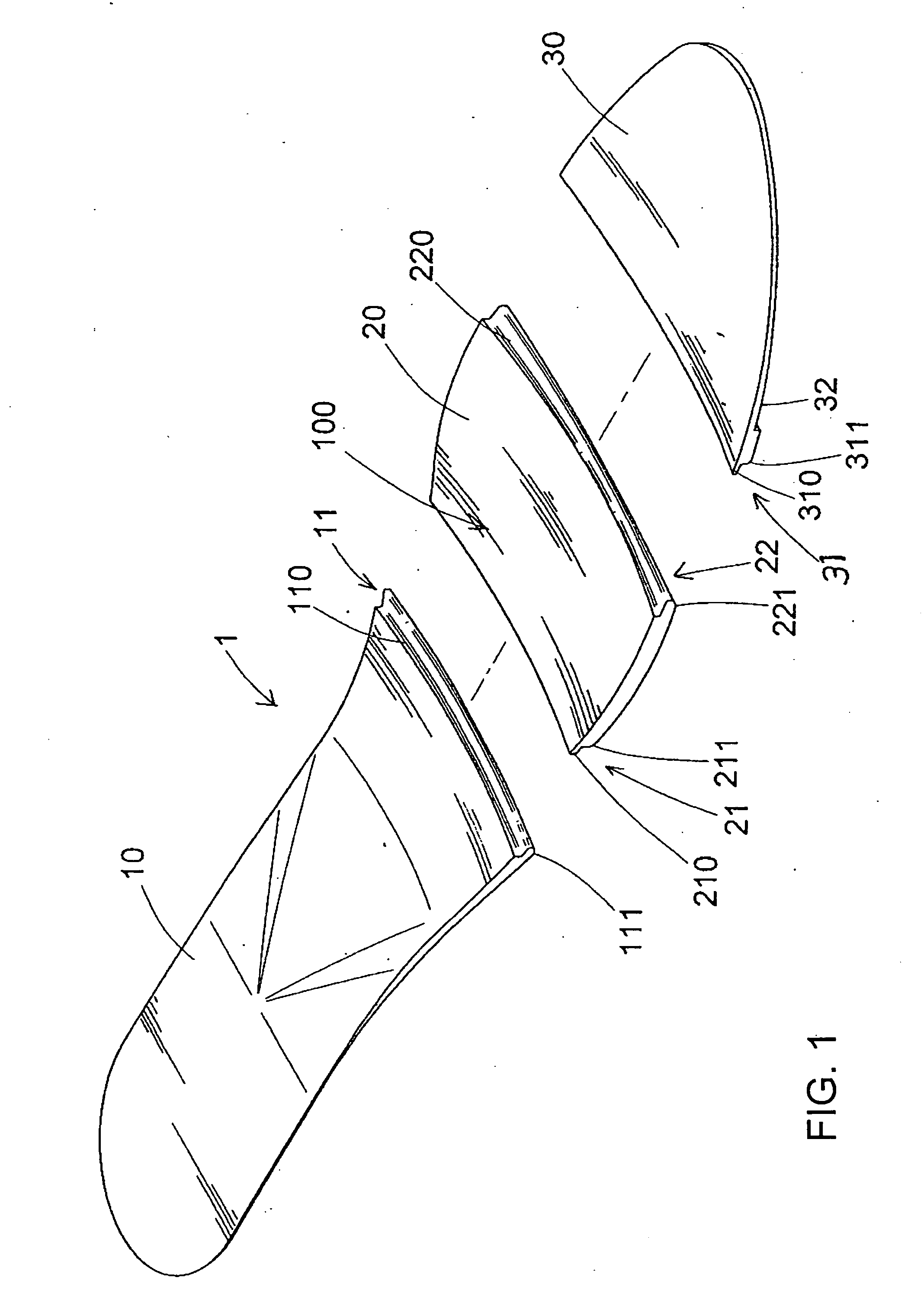

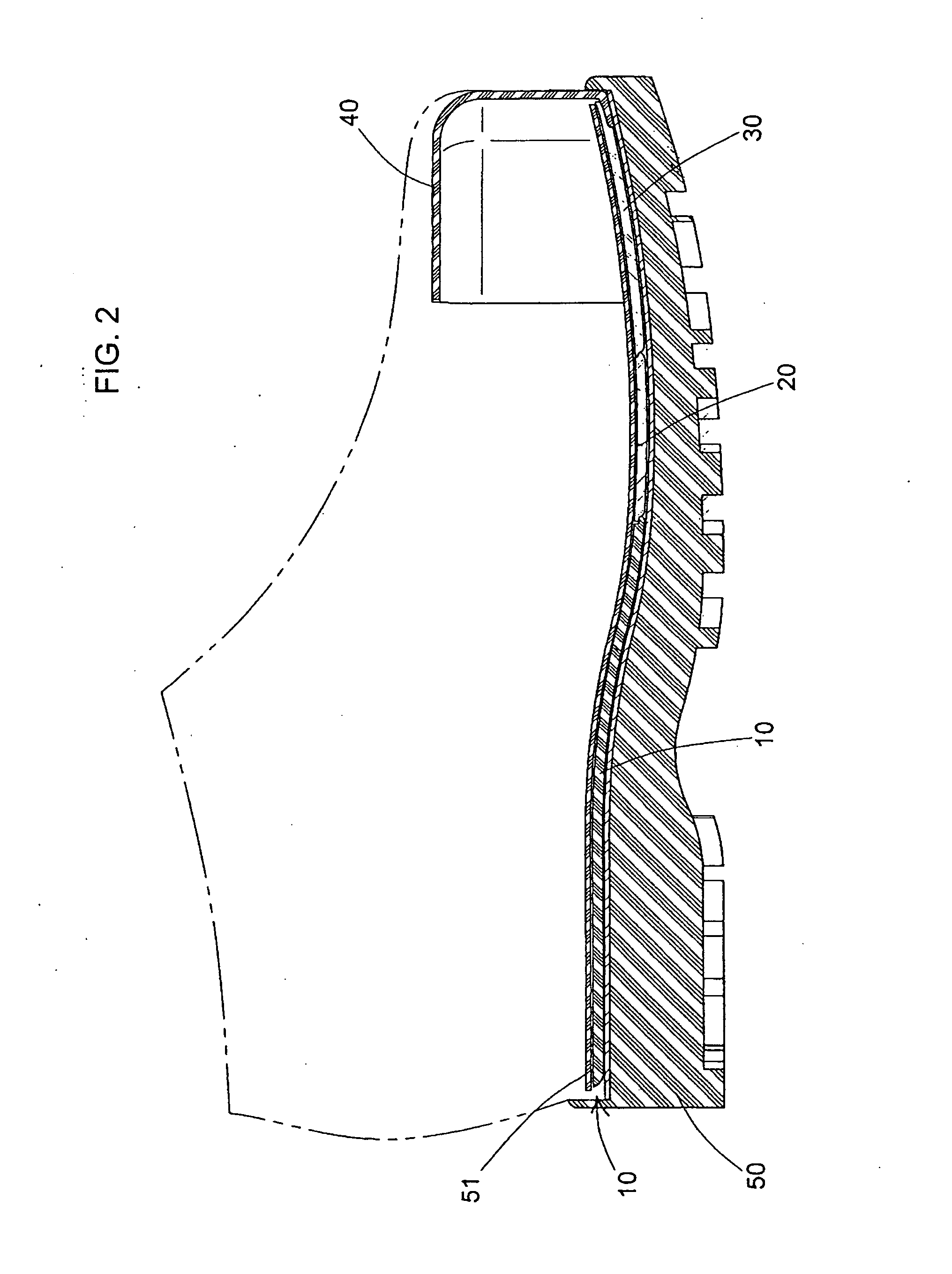

Composite plate

A protective sole plate for protective footwear having a number of sole plate bodies, optionally of an electrically and thermally insulating material, joined together with transverse hinged joint(s) whereby each sole plate body can rotate about the transverse hinge relative to other sole plate bodies thereby enabling flexing of the sole plate while maintaining puncture resistance.

Owner:LINEAR INT FOOTWEAR

Polyvinyl chloride article having improved durability

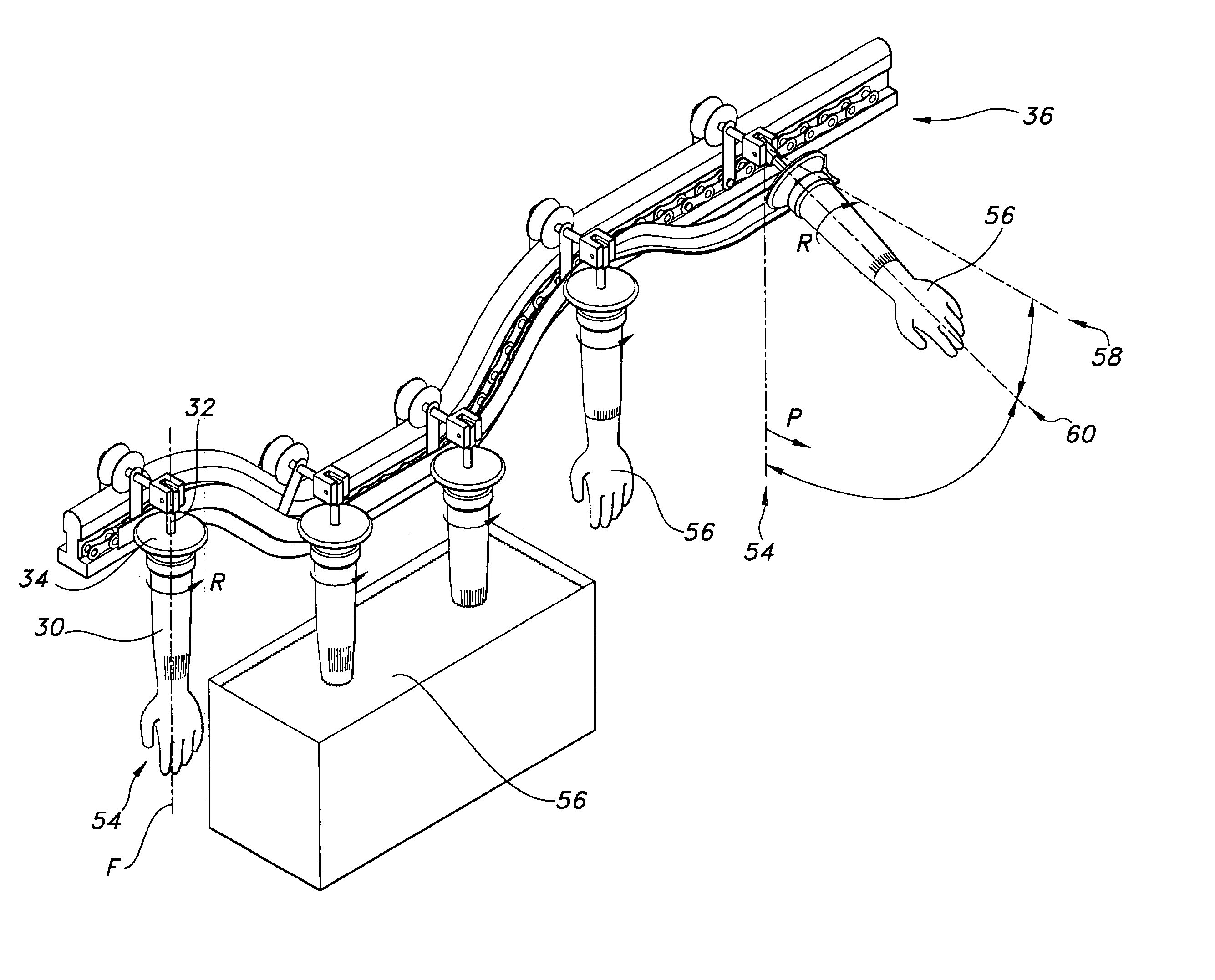

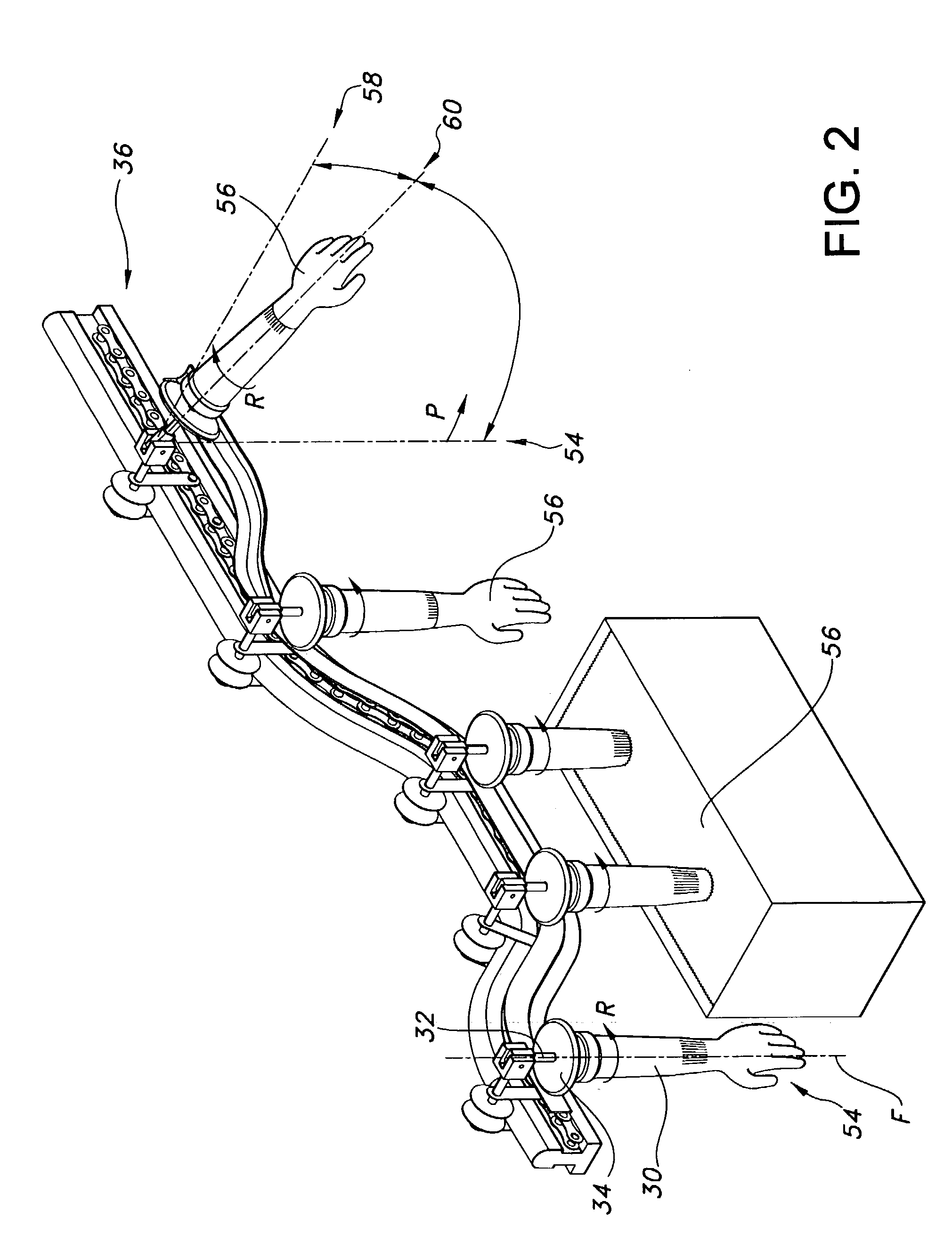

InactiveUS20050015846A1Improved fingertip puncture resistanceGlovesEye treatmentPolyvinyl chloridePuncture resistance

A method of forming a glove having improved fingertip puncture resistance is disclosed. The method includes providing a glove former, the former pivotably attached to a chain assembly, dipping the former into a plastisol in a first position, the position being substantially vertical, removing the former from the plastisol, pivoting the former to a second position, the second position forming an angle less than 90 degrees with respect to the first position, and maintaining the former at the second position until the plastisol forms a gel on the former.

Owner:KIMBERLY-CLARK WORLDWIDE INC

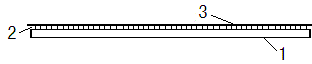

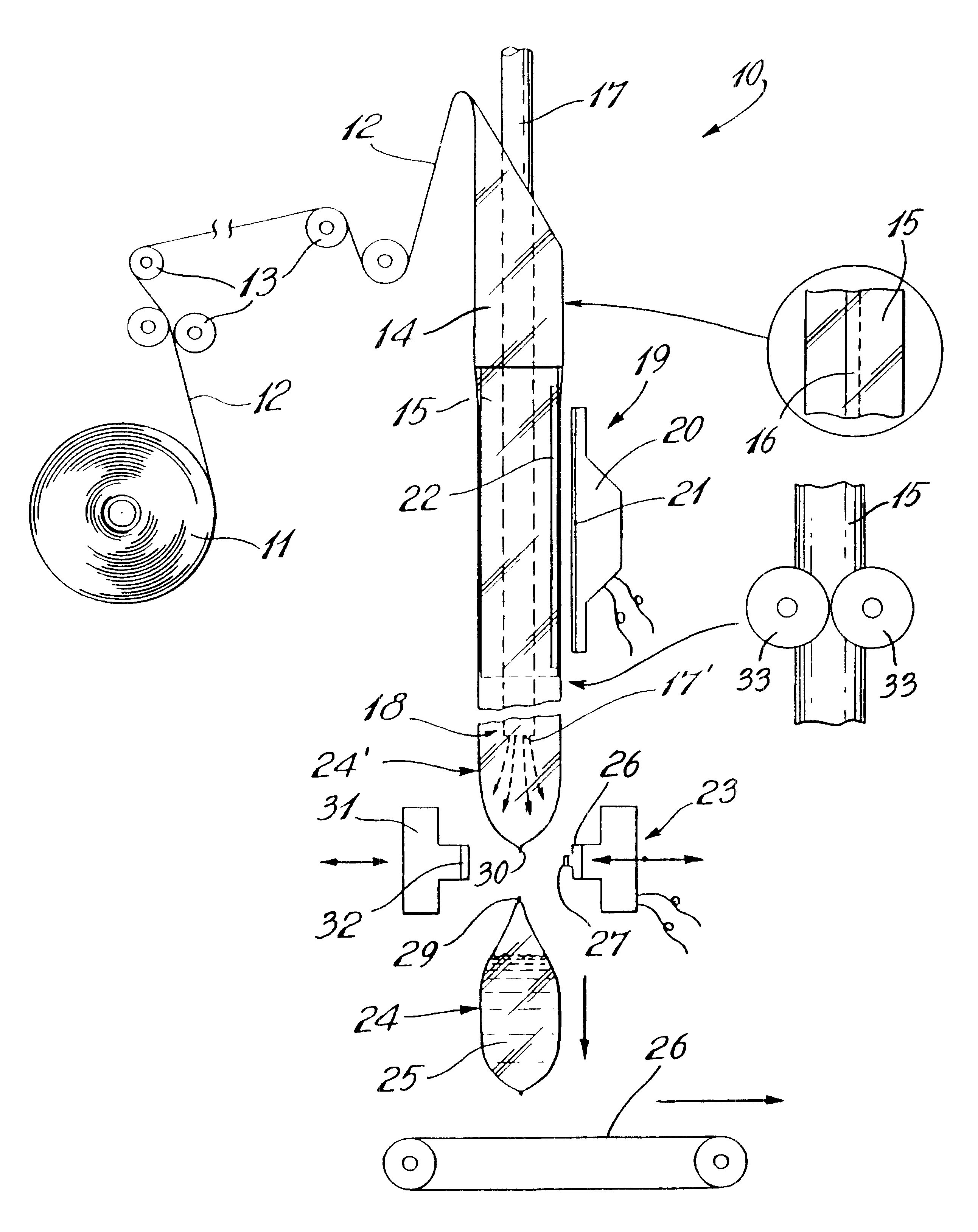

Use of a multilayer film in a high-speed pouch forming, sealing and filling machine, and method of operation

InactiveUS6631605B1Improve methodImprove throughputSynthetic resin layered productsOther accessoriesPuncture resistanceEngineering

The multi-layer film structure having an inner sealing layer (<HIL><PDAT>36< / BOLD><PDAT>) which comprises metallocene resin, a core (<HIL><PDAT>38< / BOLD><PDAT>) which includes polypropylene copolymer and an outer layer (<HIL><PDAT>37< / BOLD><PDAT>) and wherein the multi-layer film structure has a thickness (X) within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.< / PTEXT>

Owner:GLOPAK INC

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

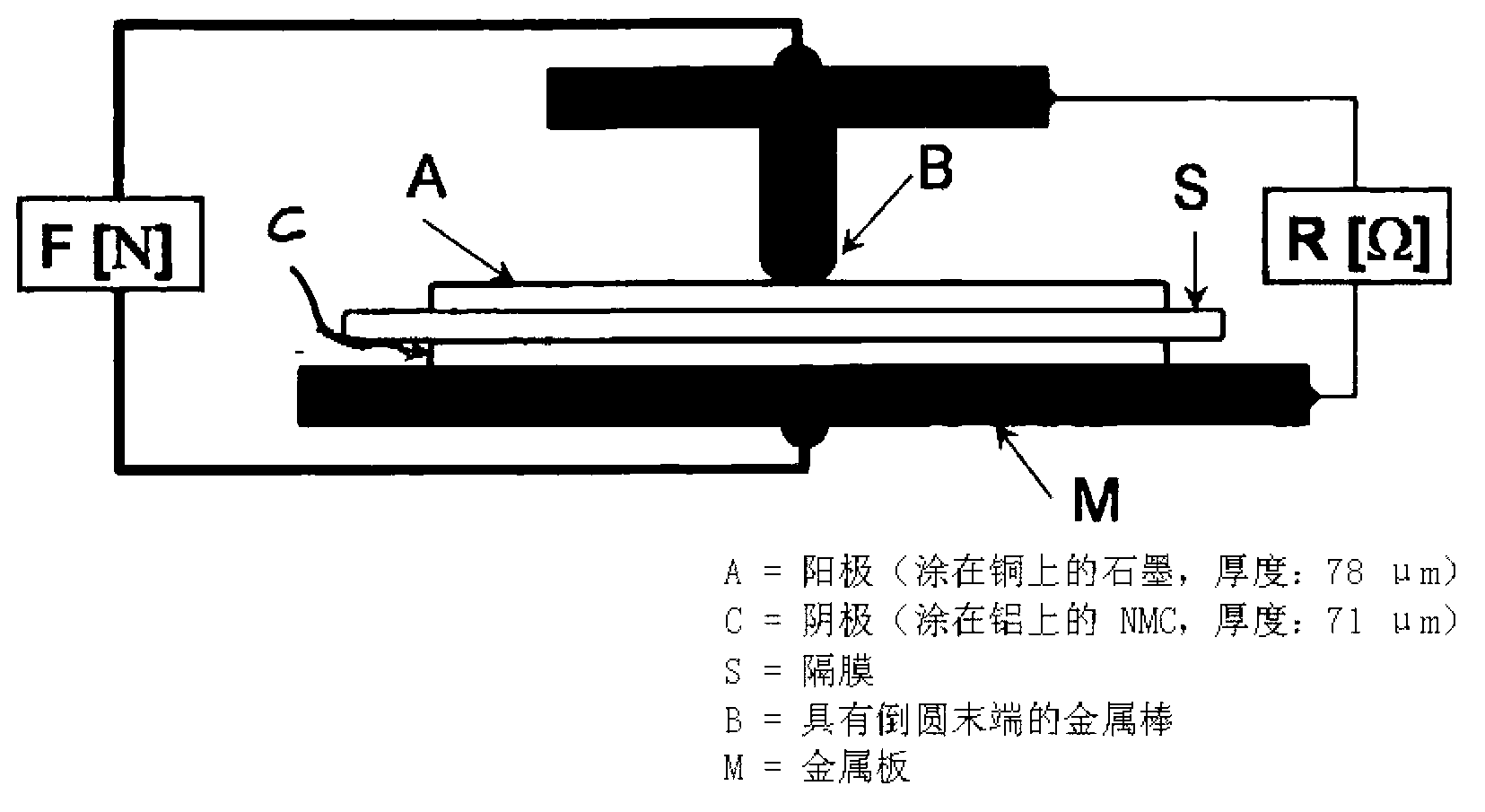

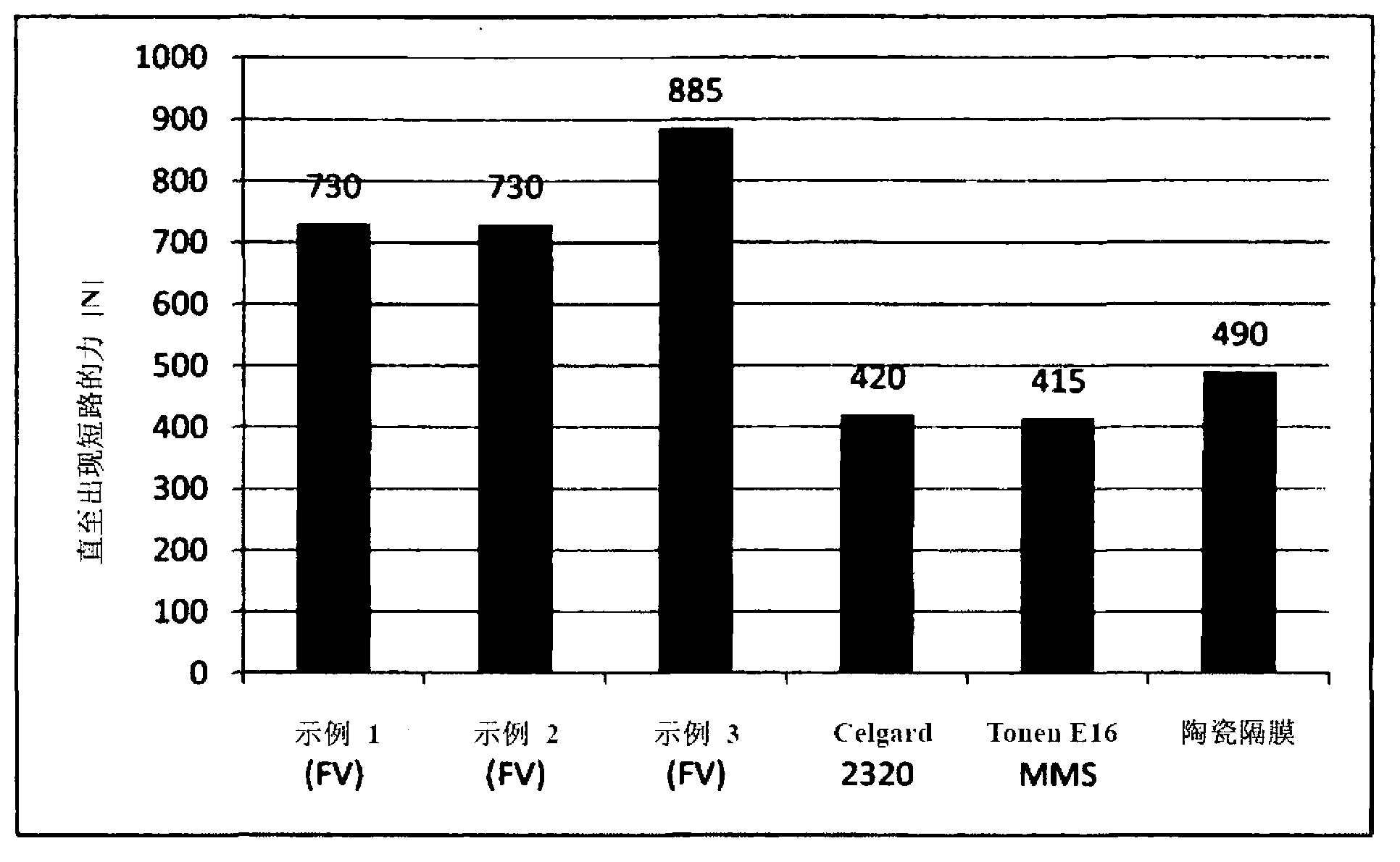

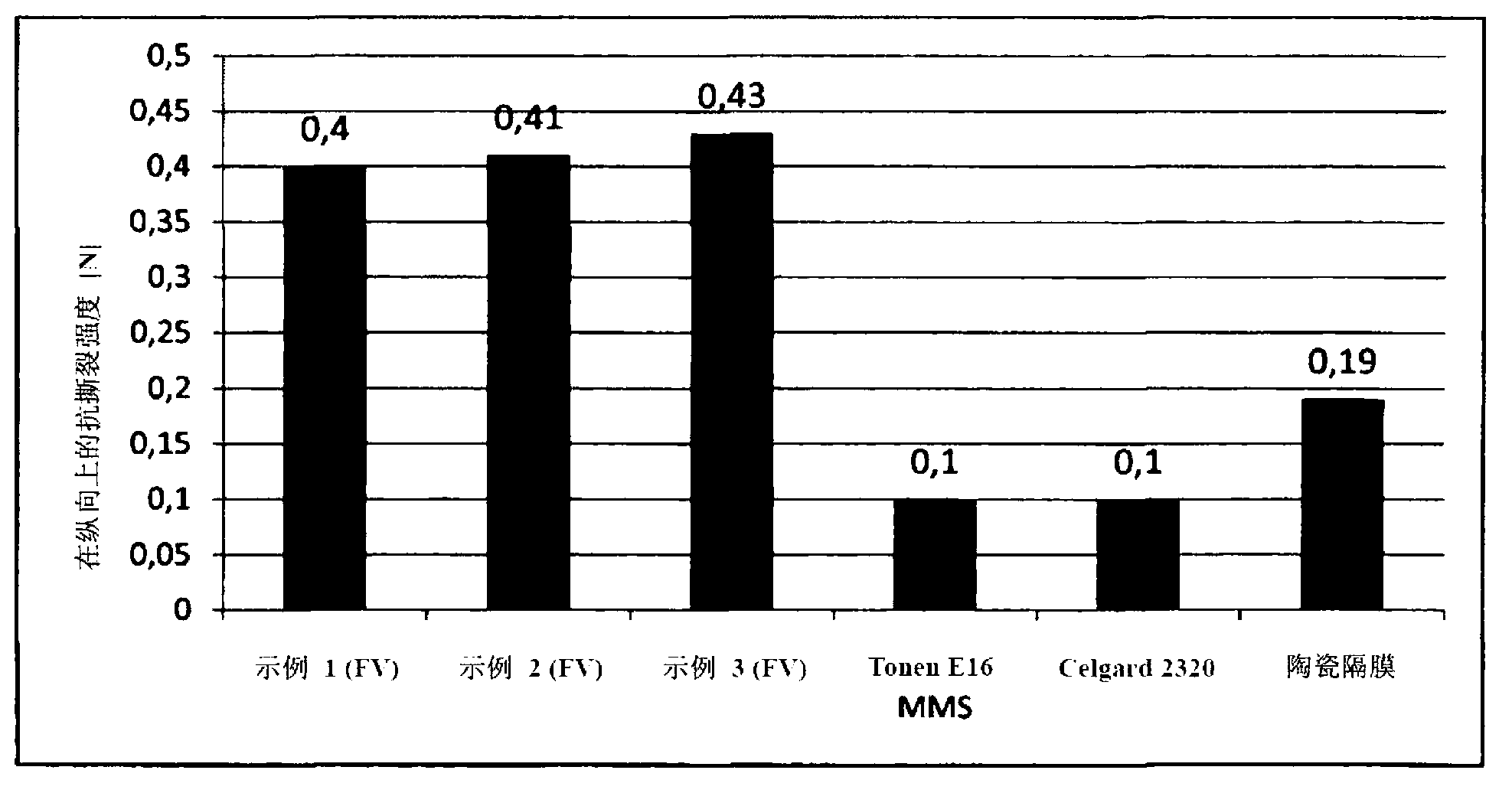

Separator with increased puncture resistance

InactiveCN103026530AExcellent mechanical propertiesImprove puncture strengthLi-accumulatorsCell component detailsPuncture resistanceMechanical stability

The invention relates to a separator with a main part which is made of nonwoven material, said main part being provided with a coating. The coating contains filler particles, cellulose, and flexible organic binder particles, said filler particles and flexible organic binder particles being connected to each other by the cellulose. The aim of the invention is to design and develop a separator such that said separator exhibits high permeability with increased mechanical stability. The separator is characterized in that the cellulose contains cellulose derivatives that have a chain length of at least 100 repeating units, preferably a chain length of at least 200 repeating units.

Owner:CARL FREUDENBERG KG

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

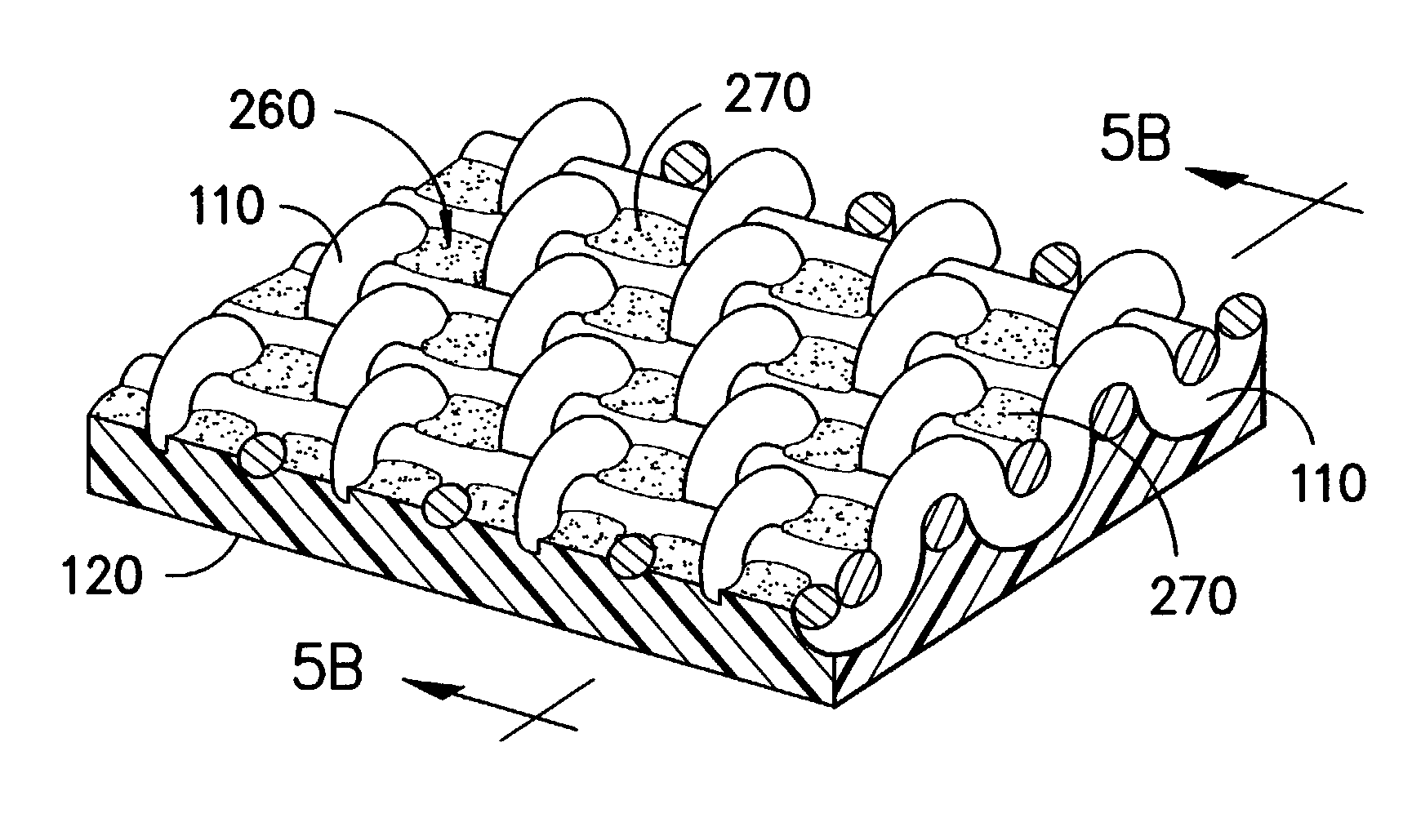

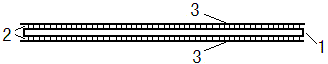

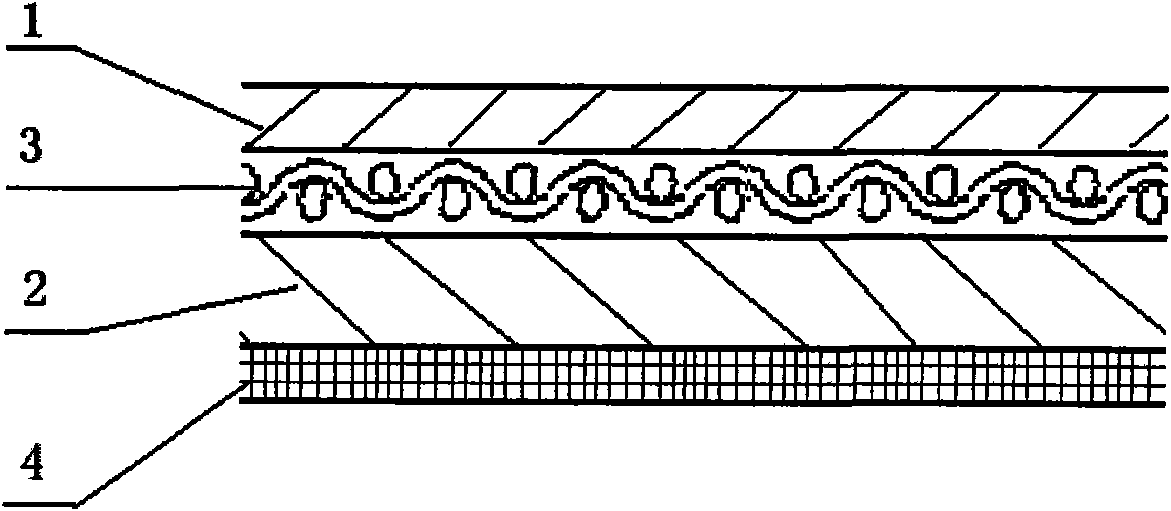

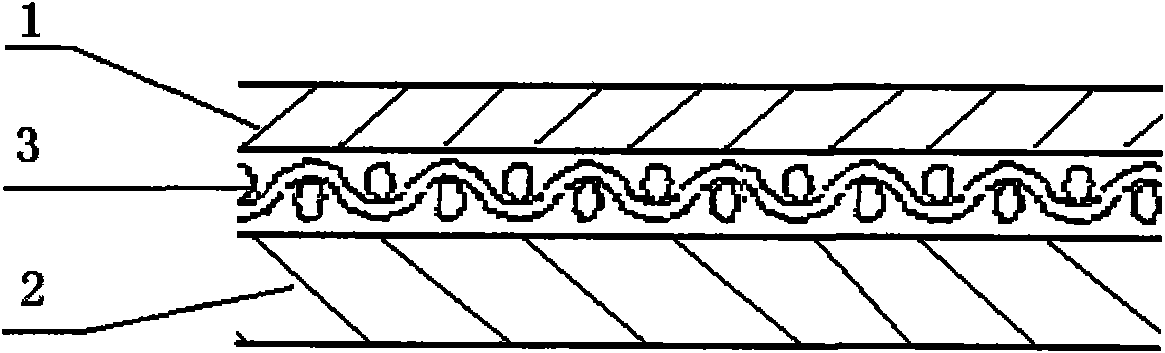

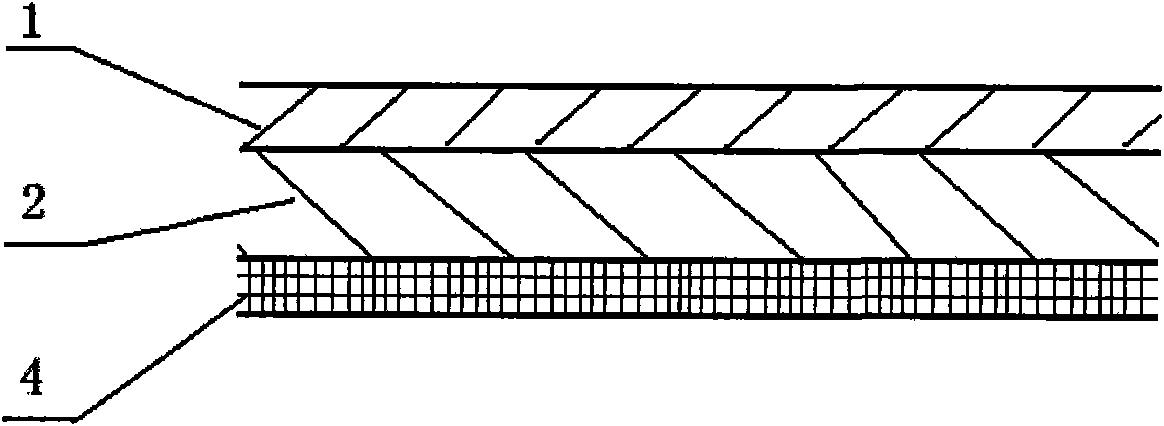

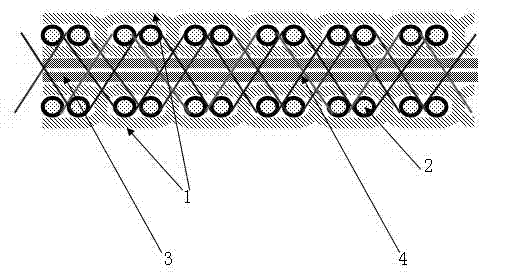

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

TPO waterproof coiled material and production process thereof

The invention provides a TPO waterproof coiled material comprising, by weight: 40-60 parts of POE, 15-35 parts of LDPE, 25-27 parts of lightweight calcium carbonate, 0.1-1.5 parts of an ultraviolet absorber, 0.1-0.5 parts of a main antioxidant, 0.2-0.8 parts of an auxiliary antioxidant 0.2-0.5 parts of stearic acid and 2.0-5.0 parts of titanium dioxide. With the process, the produced waterproof coiled material has the advantages of high strength, aging resistance, puncture resistance, high elongation, high deformation resistance, reliable fixing, good waterproof performance, moderate softness, high welding performance, and high welding strength. With the material, construction is convenient.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

High performance boot

The present invention discloses various features and combinations thereof for use with articles of footwear such as boots. The boots are especially adapted for use on construction projects, and provide protection, support and comfort to the wearer. Numerous outsole configurations and styles are provided, which provide superior traction and a low center of gravity for enhanced balance. Different layers of materials provide puncture resistance, abrasion resistance, thermal insulation, waterproofing and other benefits. Protective and / or insulative plates may be utilized in the footwear for puncture protection or thermal insulation, for example. Shovel guards protect the wearer when using a tool, and toe tools permit the wearer to employ the boot as a tool of its own. Structural support cages chimney structures are also utilized for support and comfort.

Owner:THE TIMBERLAND COMPANY

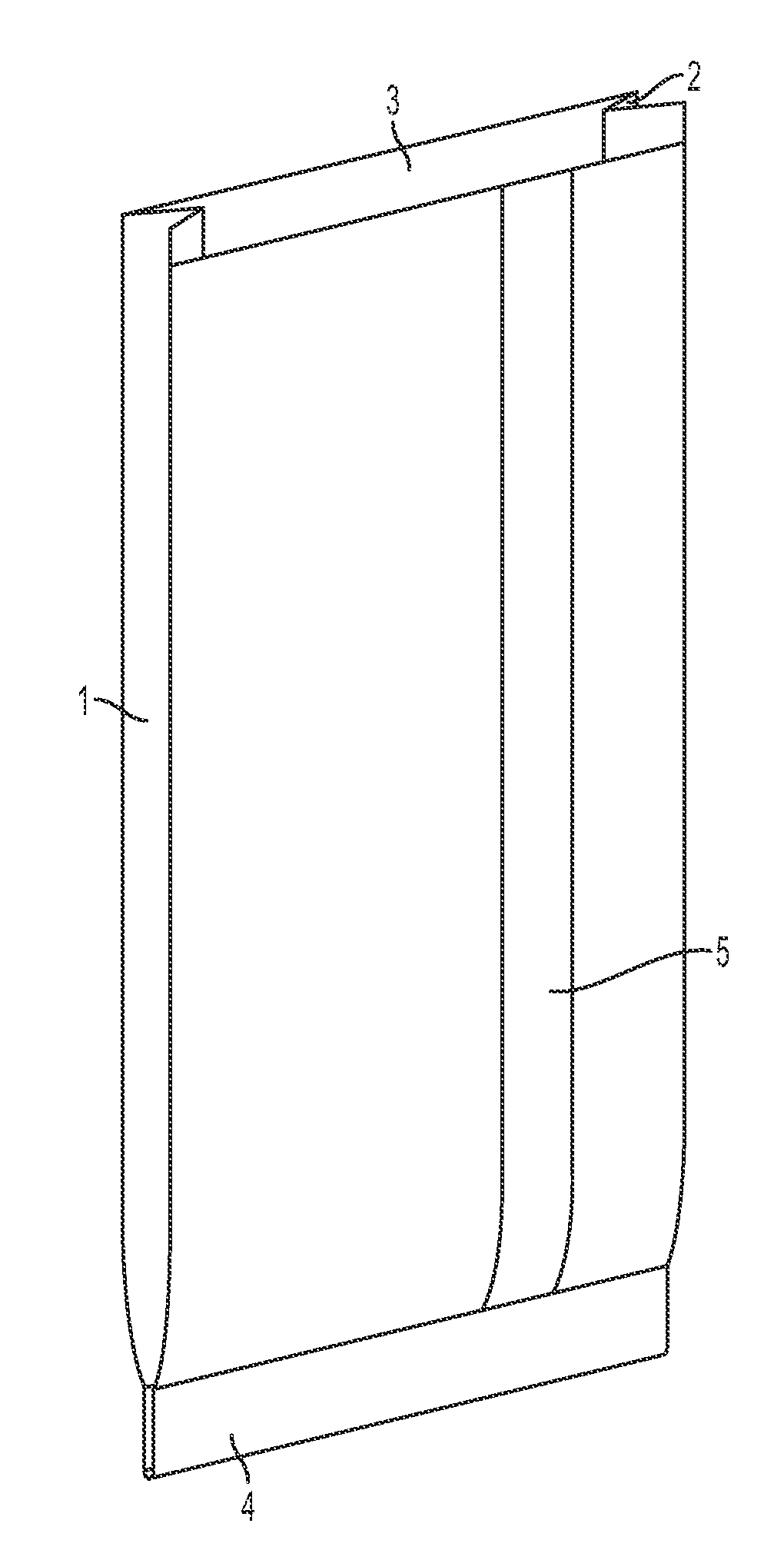

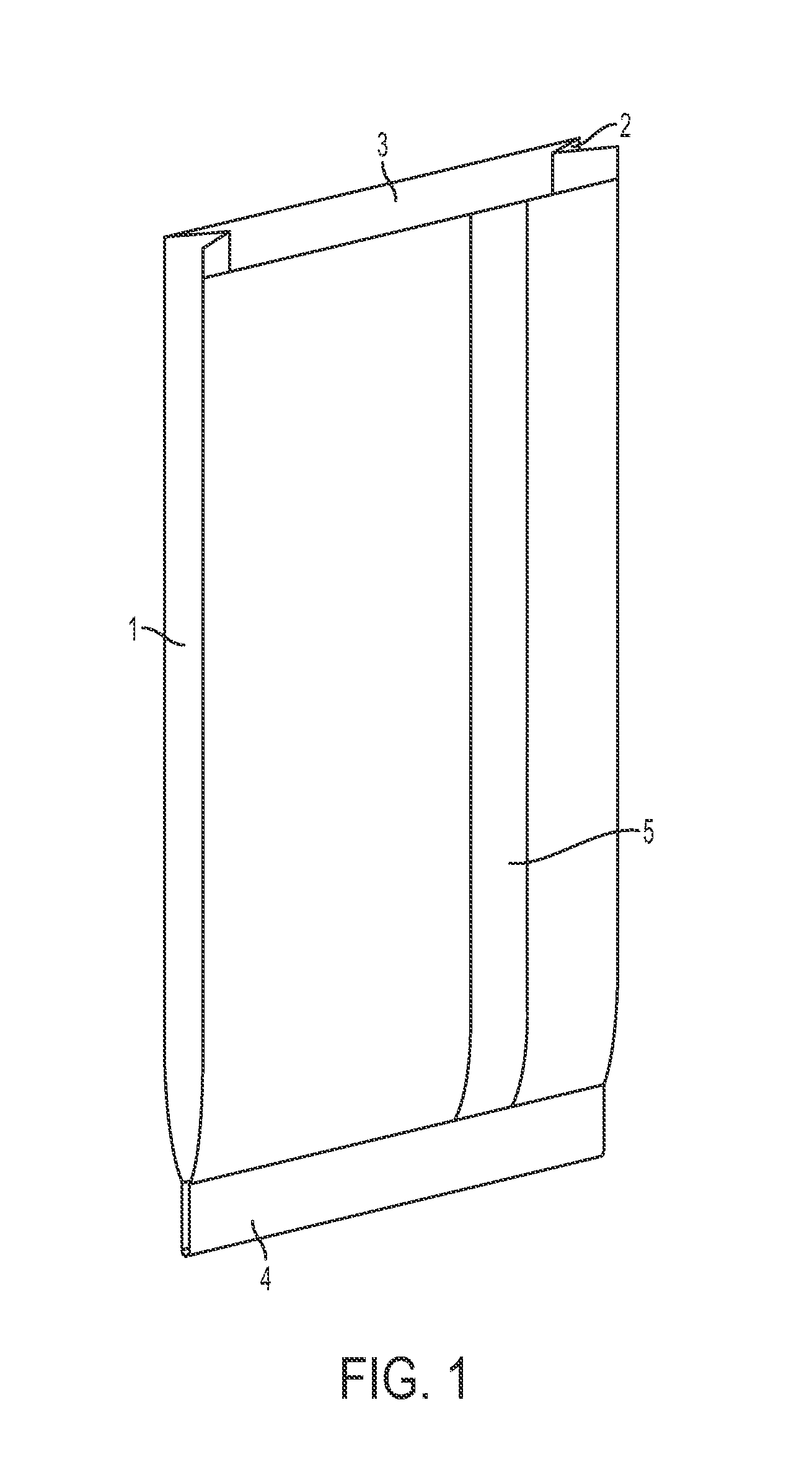

Laminate for packaging hygroscopic materials, pouches made therefrom, and method for manufacturing same

InactiveUS20120207954A1Good heat sealing performanceReduce water permeabilityBag making operationsFlexible containers manufacturePuncture resistancePolymer

The present invention provides a novel packaging laminate designed particularly for packaging highly hygroscopic, pelleted, flowable materials. It is a multilayer structure which incorporates a layer of heat-sealable polymeric material which has had a thin film of aluminum deposited onto it by vapour coating. This layer combined with a further effective barrier layer provides the low WVTR in the range required by such highly hygroscopic materials. This laminate can be used with additional structural layers of paper or plastic, to form bags that have the features of very low WVTR, excellent puncture resistance, and excellent heat sealability.

Owner:HOOD PACKAGING

Making method of vapor barrier film for vacuum heat insulating shield

The present invention relates to a making method of a vapor barrier film for a vacuum heat insulating shield, and a choke film of the vacuum heat insulating shield special for construction. The choke film not only satisfies the high choke performance needed by the vacuum heat insulating shield, but also has the advantages of puncture resistance, weather resistance, cracking resistance, easy hot sealing and good protective effect. The making method uses the following technical scheme: upper-layer material is fed to the topside flow way, and middle-layer material, lower-layer material, binder between the middle-layer material and the upper-layer material and binder between the middle-layer material and the lower-layer material are fed to each flow way of a module in turn; the upper-layer material is selected from PDVC, PS or PET, the middle-layer material is selected from PE, PVOH, PA, EVOH, EVA, PET or PP, and the lower-layer material is PE; a film bubble pipe is extruded through the module; the film bubble pipe is cooled; a clamping plate device in a shape of a character of 'ren' is leaded in to planish the film bubble pipe; and a single-layer flat film of 50 t 200 mum is made through a winder.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Three-layer co-extruded high-heat-preservation light-conversion PO film

ActiveCN108099326AHigh elongation at breakLow melting pointAgricultural articlesClimate change adaptationWater basedAgricultural engineering

The invention discloses a three-layer co-extruded high-heat-preservation light-conversion PO film, and belongs to the field of agricultural greenhouse films. According to the invention, on the basis of a previous product, ethylene-vinyl acetate copolymer (EVA) is added into metallocene polyethylene (mPE), a light-conversion master batch is added into a middle layer, the formulas of an outer layer,the middle layer and an inner layer are different, the formulas of the outer layer, the middle layer and the inner layer are mixed uniformly respectively, master batches are prepared by using a two-thread worm double-screw extruder, a three-layer film extrusion is formed through a co-extrusion die head to prepare a PO agricultural greenhouse film, and water-based dripping fog-eliminating coatingliquid is coated outside the PO film. The film is anti-aging and free of fog drops, and excellent in puncture resistance and has a service life of 3 years or more. After inspection and testing by an authoritative department, all quality and technical indexes reach or exceed a national standard, some of which are more than twice as good as the national standard. The PO film is good in light-conversion effect, has a light conversion rate reaching 13% or more, is very beneficial to the growth of crops and shortens the growth period of the crops at the same time.

Owner:HENAN YINFENG PLASTIC

Tyre

InactiveCN101450594AMaintain ice resistanceMaintain wet skid resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention discloses a tyre, which comprises (A) tread rubber, (B) tread basal rubber, (C) sidewall rubber, (D) rebate protective rubber, (E) carcass layer rubber, (F) lining layer rubber, (G) triangle rubber, (H) belted layer rubber, (I) air-tight layer rubber and (J) tyre bead steel wire rubber. The tyre components consist of rubber compositions, wherein the rubber compositions of the (A) tread rubber, the (B) tread basal rubber, the(C) sidewall rubber and the (D) rebate protective rubber adopt white carbon black and carbon black with high specific surface area as reinforcing fillers; and the rubber compositions of the (E) carcass layer rubber, the (F) lining layer rubber, the (G) triangle rubber, the (H) belted layer rubber, the (I) air-tight layer rubber and the (J) tyre bead steel wire rubber adopt white carbon black and carbon black with low specific surface area as reinforcing fillers. The tyre has the advantages of good puncture resistance and chunking resistance, low rolling resistance and heat generating performance, and greatly-reduced production cost. The full-steel giant engineering tyre is particularly suitable for an adverse road environment such as a large-scale mine yard.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com