Child-resistant blister package

a blister package and child-resistant technology, applied in the field of blister packaging, can solve the problems of difficult peeling, poor puncture resistance of paper-film laminates and paper-film-foil laminates, and difficulty in initiating a new peeling,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

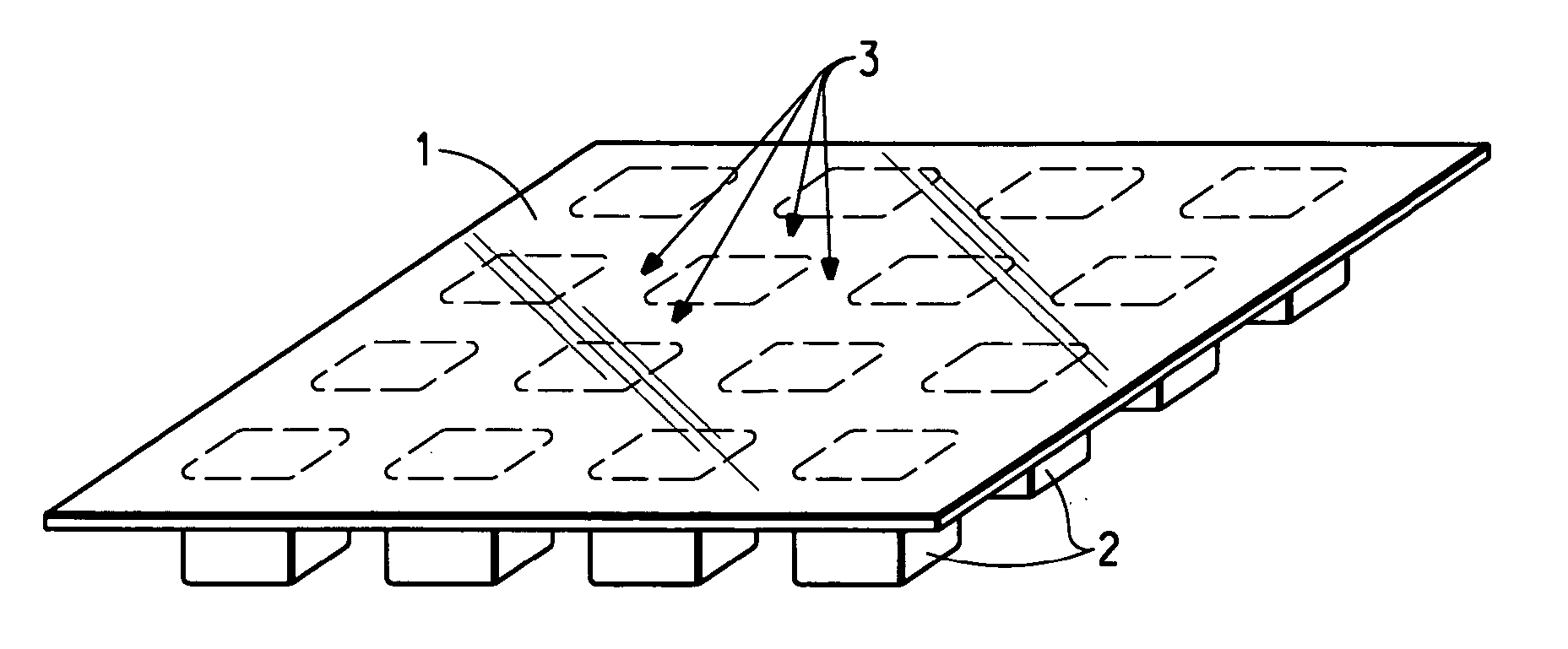

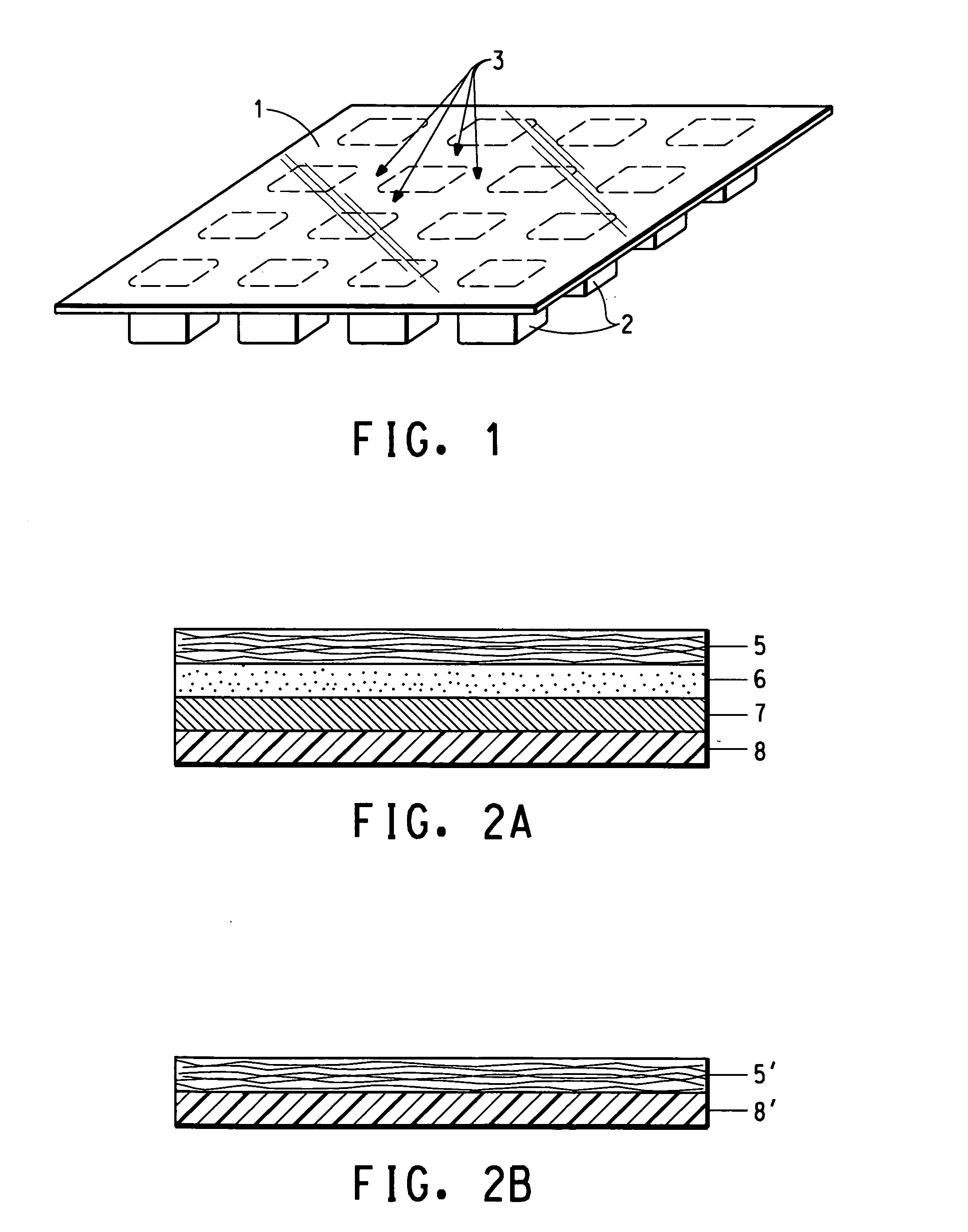

[0061] This example demonstrates preparation of a blister package comprising a lidding component according to FIG. 2a, wherein the nonwoven layer was a smooth-calendered full-surface bonded spunbond nonwoven web and the barrier layer in the lidding was a metal foil.

[0062] A spunbond bicomponent nonwoven web was prepared in which the fibers were continuous core / sheath fibers having a poly(ethylene terephthalate) (PET) core component and a co-polyester sheath component composed of 17 mole percent modified di-methyl isophthalate PET copolymer.

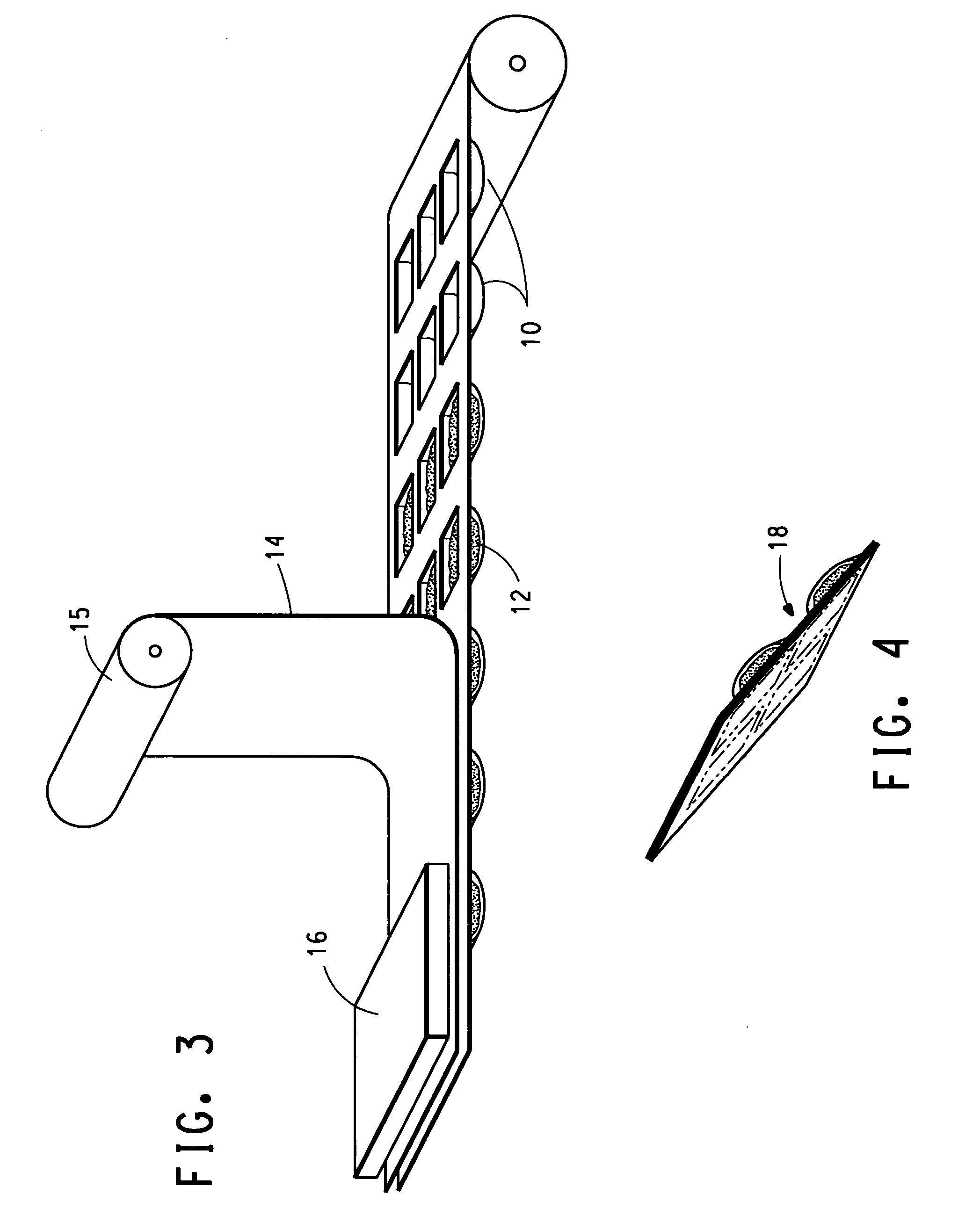

[0063] The thermally calendered bicomponent spunbond web was then laminated to a 0.93 mil (0.024 mm) thick soft-tempered aluminum foil obtained from Alcoa (Pittsburgh, Pa.) using Adcote 503 A / Cat F solvent-based poly(ethylene terephthalate)-based polyurethane permanent adhesive tie layer obtained from Rohm & Haas (Philadelphia, Pa.). An Inta-Roto dry-bond coater / laminator (Model ‘The Delaware’) was used to perform the lamination. The Adcote 503A...

example 2

[0067] This example demonstrates preparation of a lidding component comprising a flash spun plexifilamentary sheet and a metalized polyester film suitable for use in peel-open child-resistant blister packages.

[0068] A multi-layer laminated sheet was prepared using an extrusion lamination process with an Egan Coater / Laminator. First, a permanent adhesive tie layer was used to bond a layer of Tyvek® flash spun high density polyethylene sheet (Tyvek® 1073D, basis weight 74.6 g / m2, available from E.I. du Pont de Nemours and Company (Wilmington, Del.)) to a metalized poly(ethylene terephthalate) film (Mylar® 7100 metalized (aluminum) film having a thickness of 12 microns, available from DuPont-Teijin Films). The permanent adhesive tie layer was Nucrel® 1214 ethylene methyl acrylate resin. The Nucrel® 1214 resin was extruded between the nonwoven and film substrates by extruding onto the metalized side of the Mylar® polyester film at a thickness of 0.5 mil and subsequently contacting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com