Patents

Literature

42results about How to "Keep vacuuming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

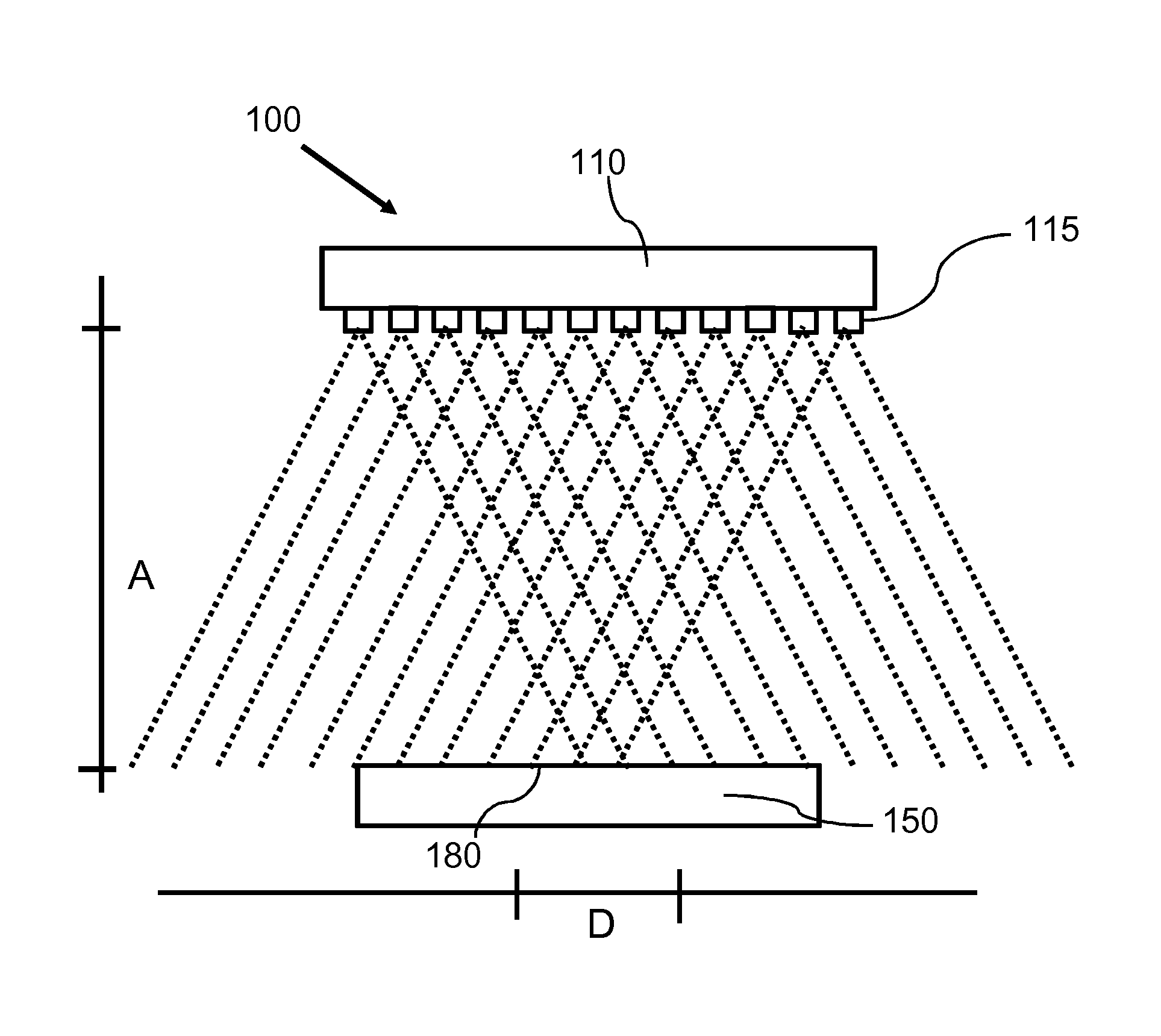

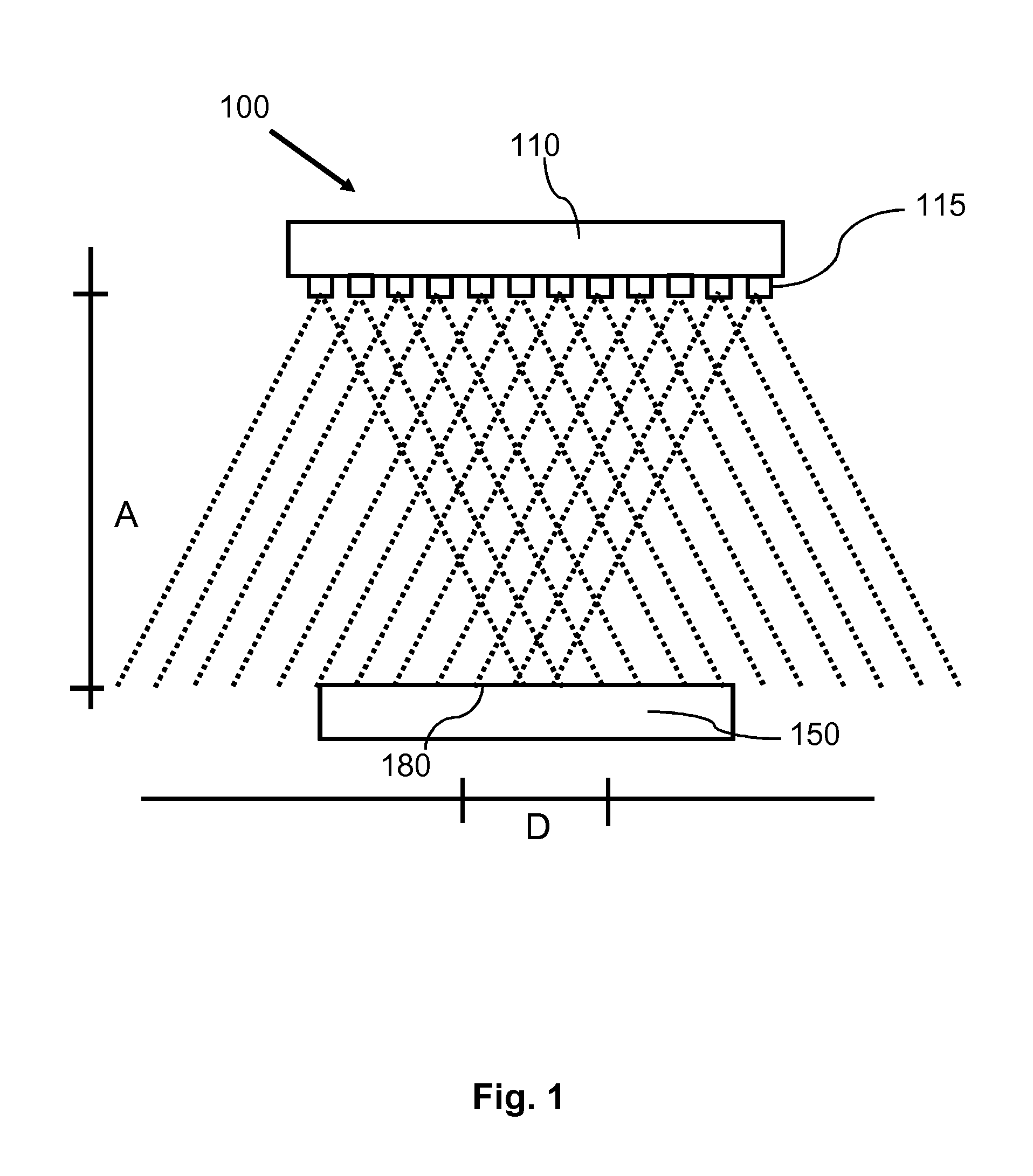

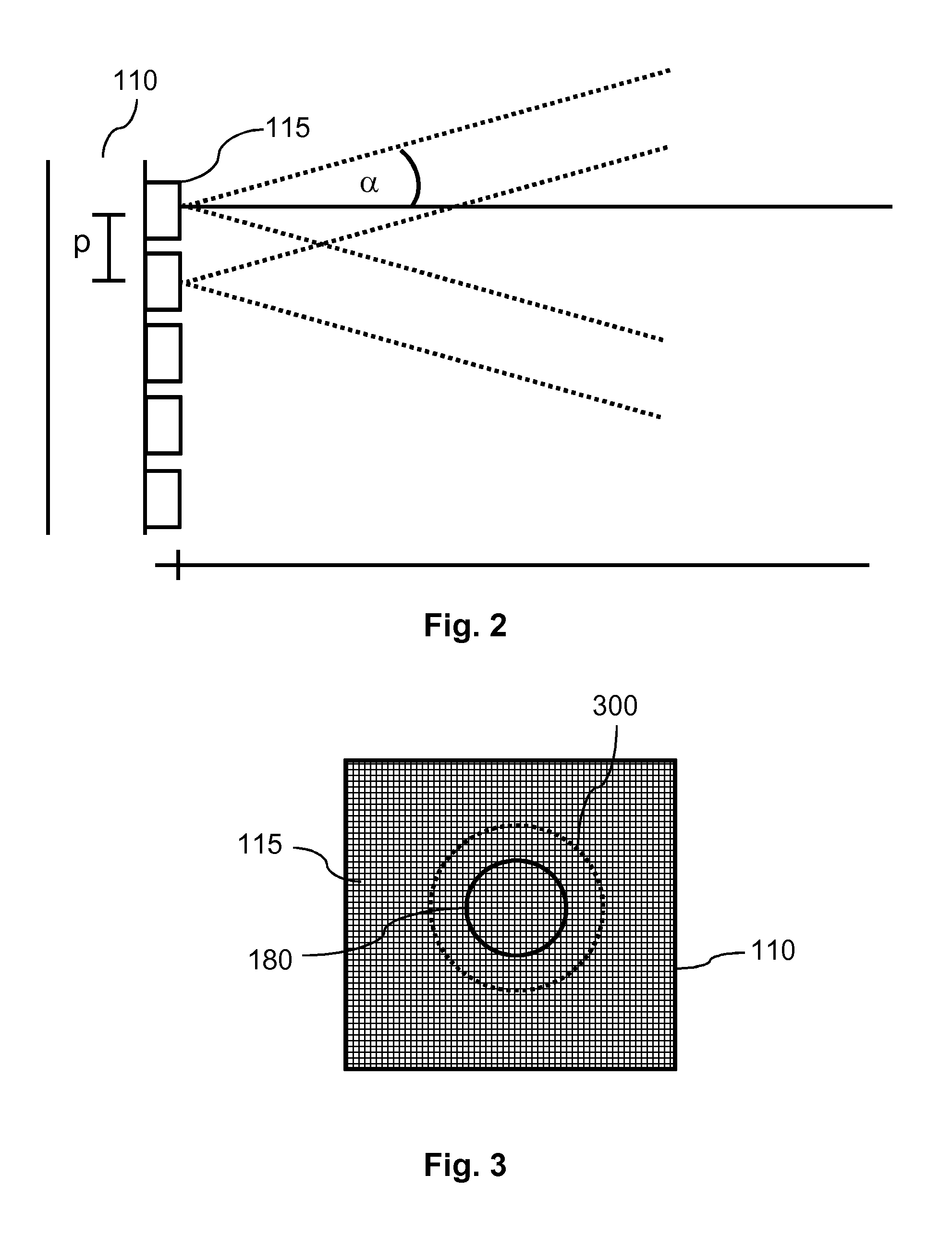

Heating system comprising semiconductor light sources

ActiveUS20160381732A1Improve homogeneityHeating system be improvedSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention describes a heating system (100) and a corresponding method of heating a heating surface (180) of an object (150, 950) to a processing temperature of at least 100° C., wherein the heating system (100) comprises semiconductor light sources (115), and wherein the heating system (100) is adapted to heat an area element of the heating surface (180) with at least 50 semiconductor light sources (115) at the same time. The heating system (100) may be part of a reactor for processing semiconductor structures. The light emitted by means of the semiconductor light sources (115) overlaps at the heating surface (180). Differences of the characteristic of one single semiconductor light source (115) may be blurred at the heating surface (180) such that a homogeneous temperature distribution across a processing surface of a, for example, wafer may be enabled.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

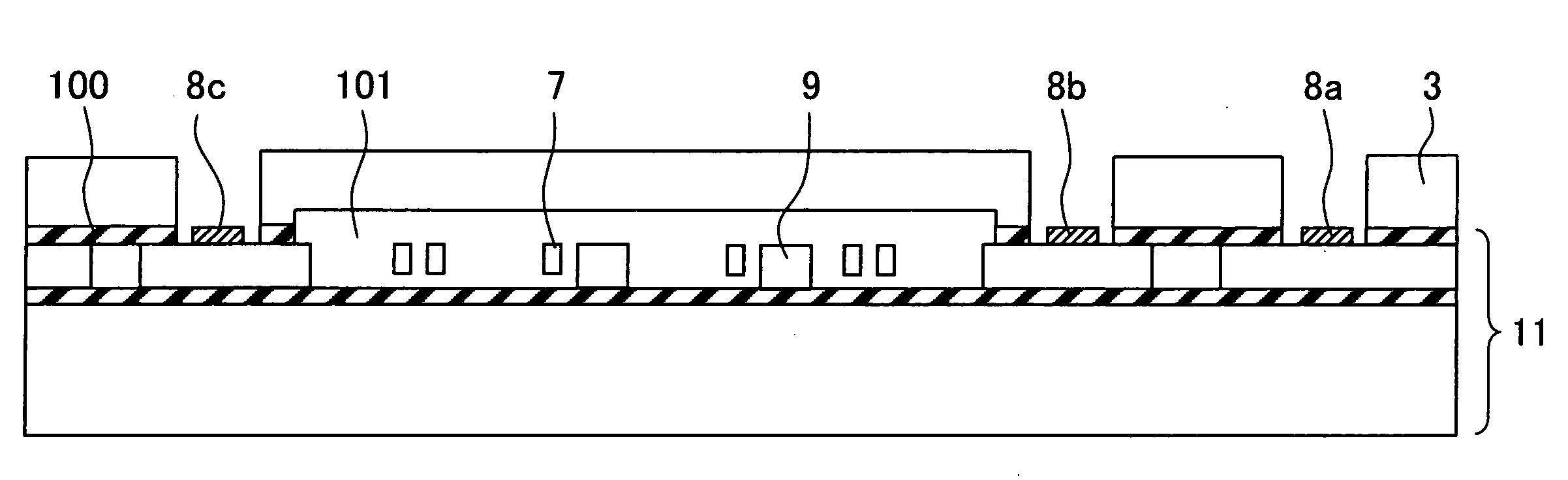

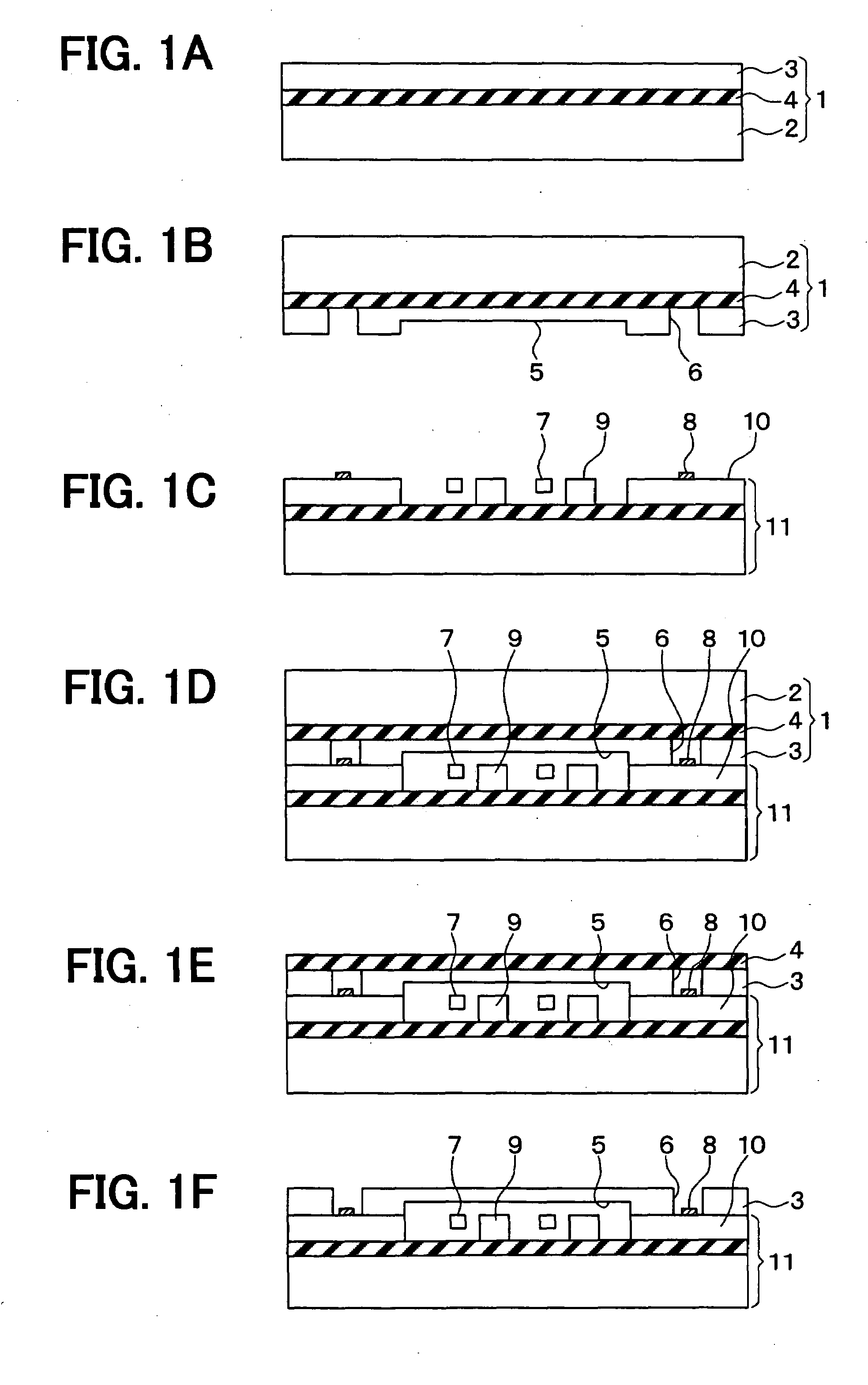

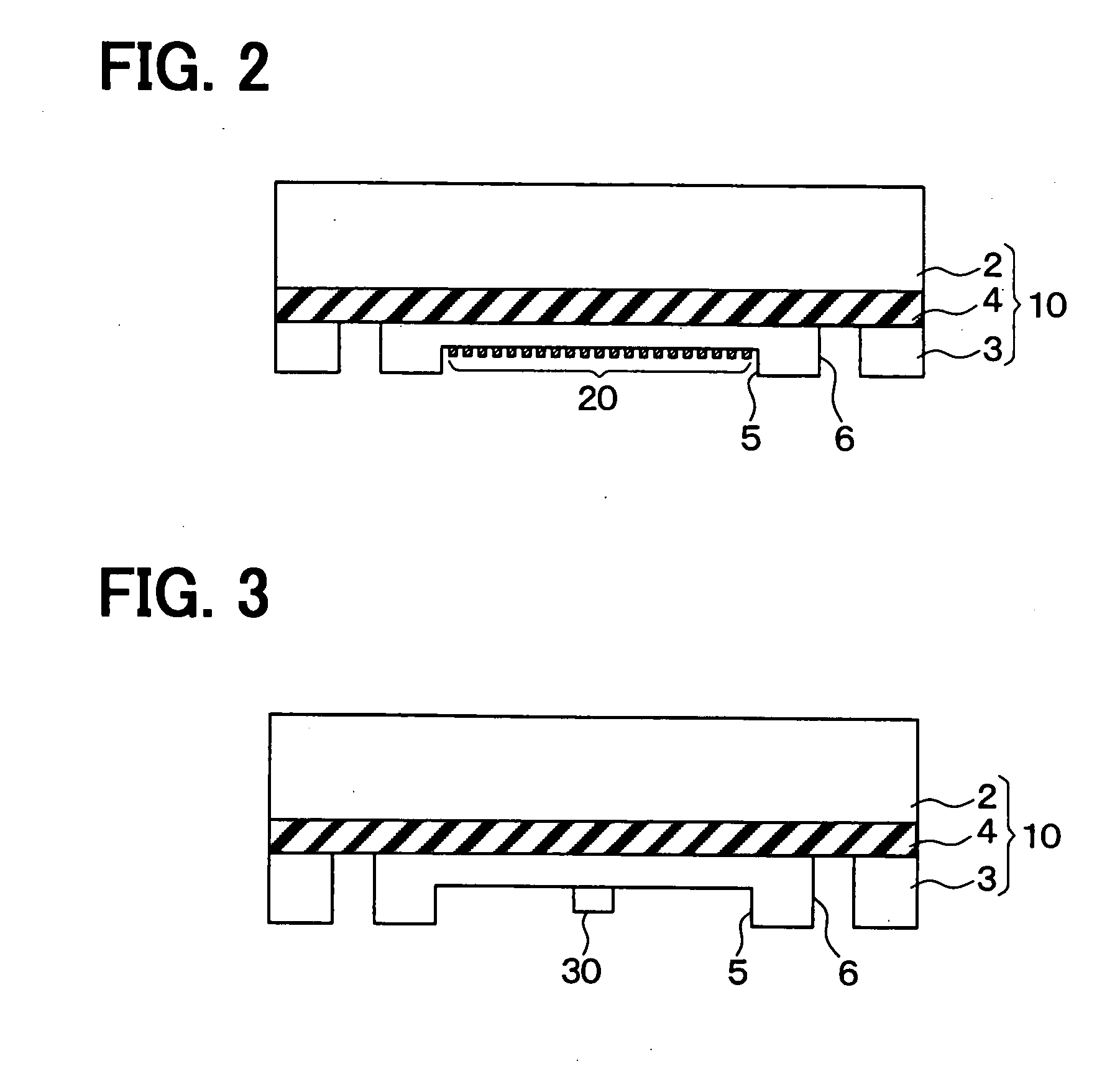

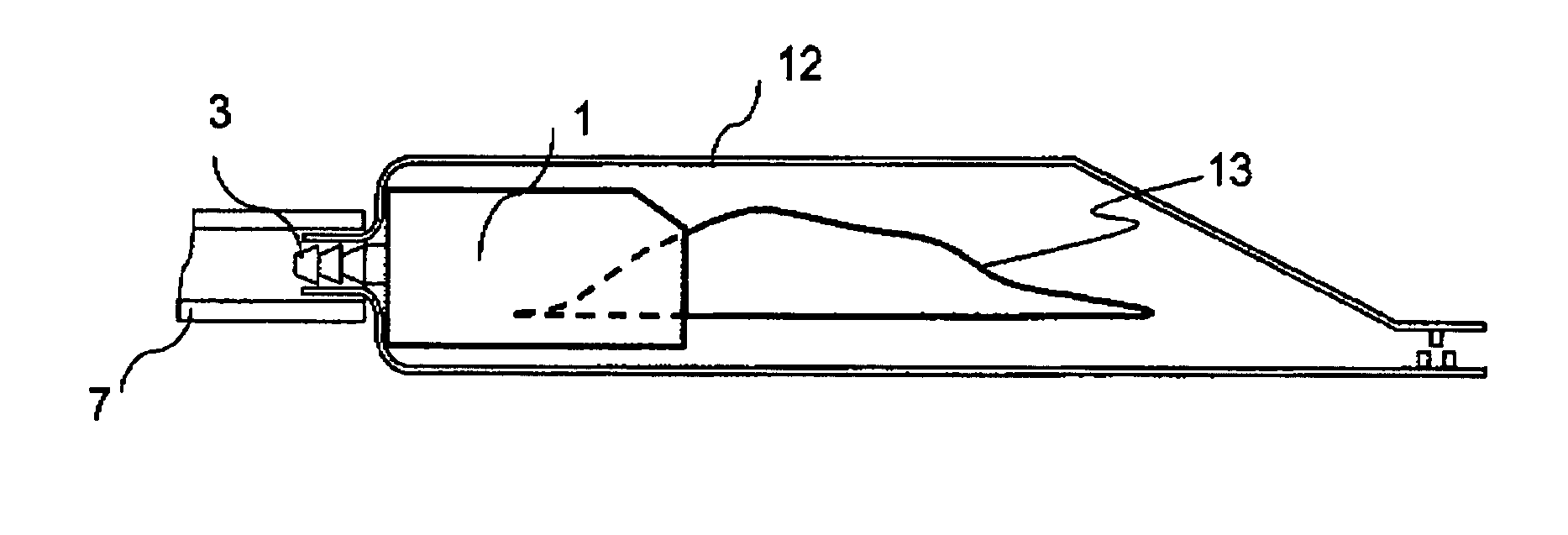

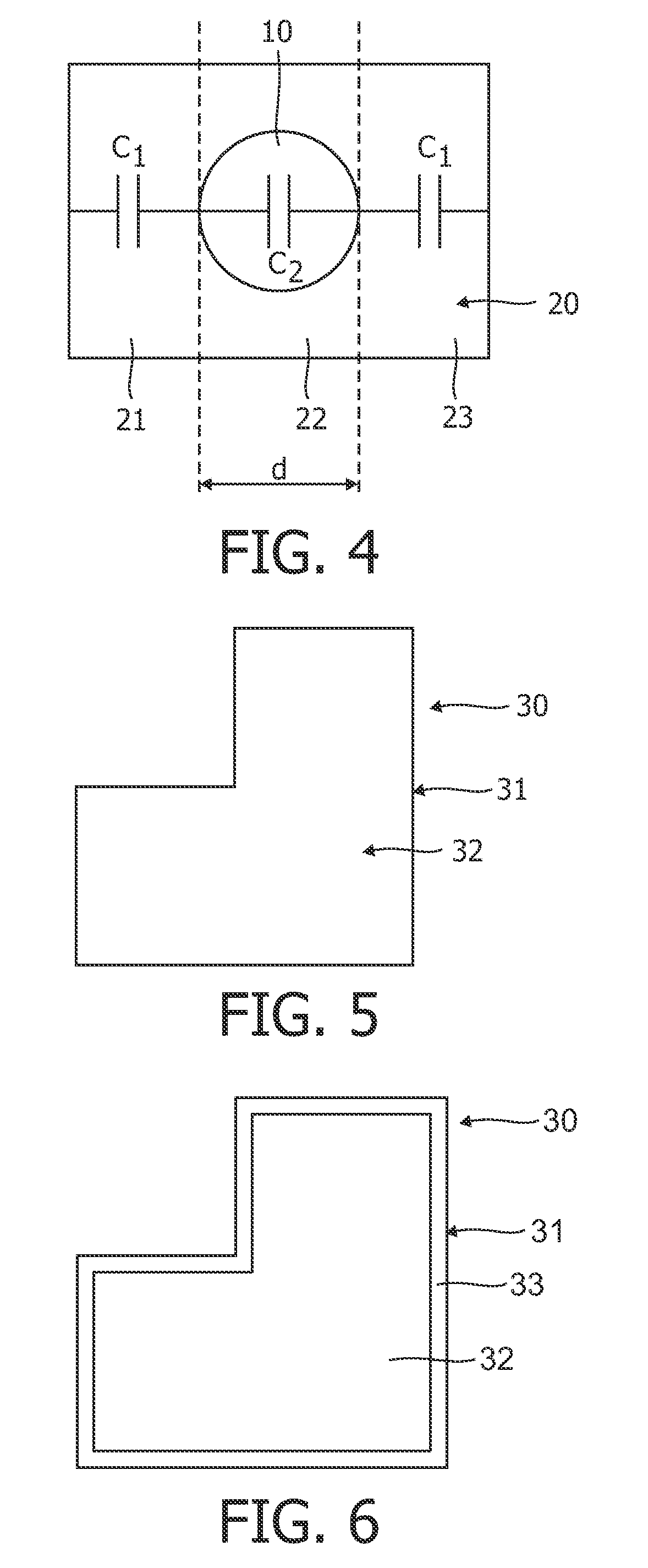

Physical quantity sensor and method for manufacturing the same

InactiveUS20080099862A1Reduce thicknessKeep vacuumingAcceleration measurement using interia forcesSemiconductor/solid-state device detailsEngineeringPhysical quantity

A method for manufacturing a physical quantity sensor includes: forming a sensor element in a first wafer; stacking a support substrate, a connection layer and a cap layer in this order so that a second wafer is prepared; bonding the cap layer of the second wafer to the first wafer in such a manner that the sensor element is disposed in a space between the first wafer and the second wafer; removing the support substrate and the connection layer from the second wafer; and dividing the first wafer together with the cap layer into a plurality of chips so that a plurality of physical quantity sensors is formed.

Owner:DENSO CORP

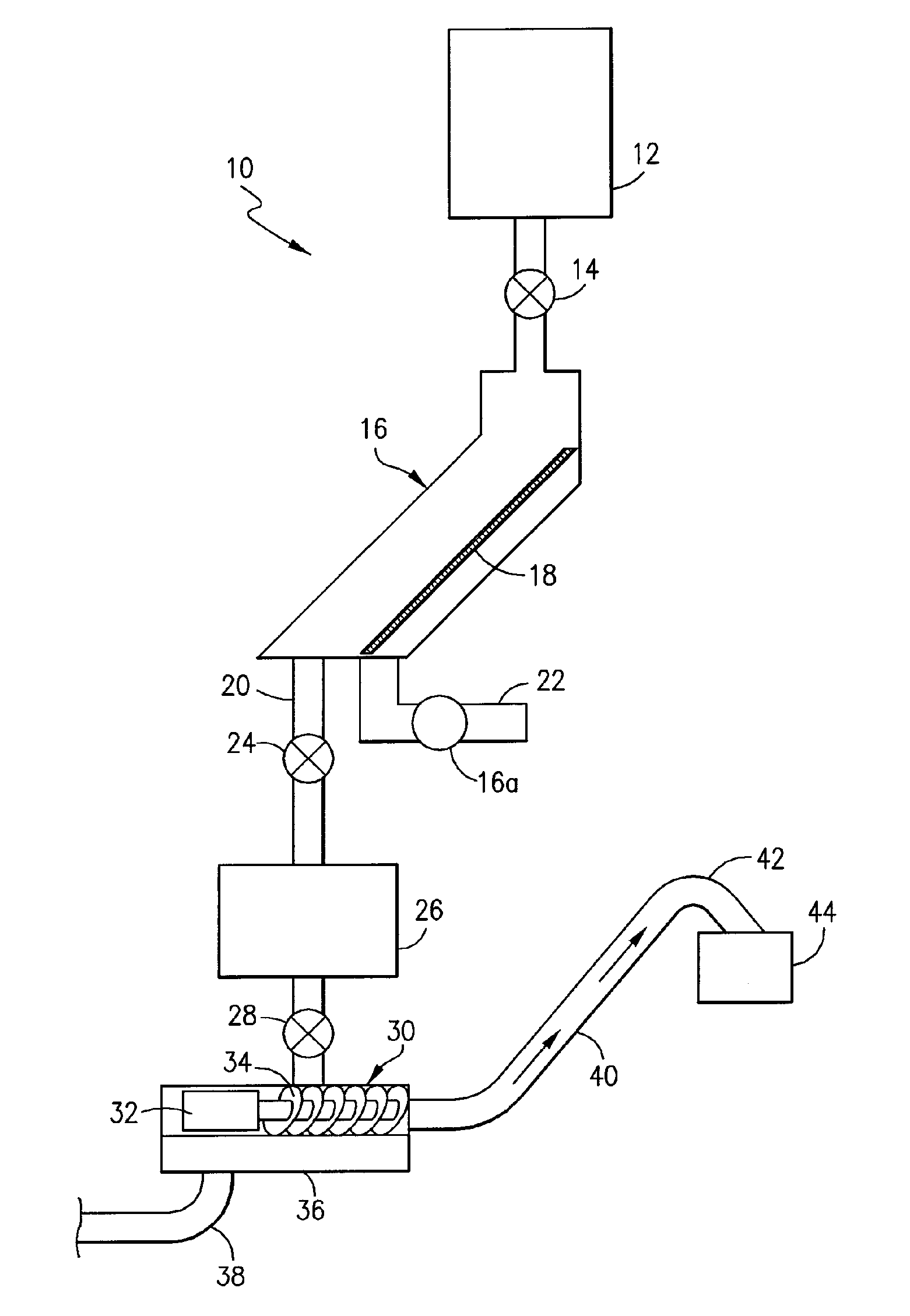

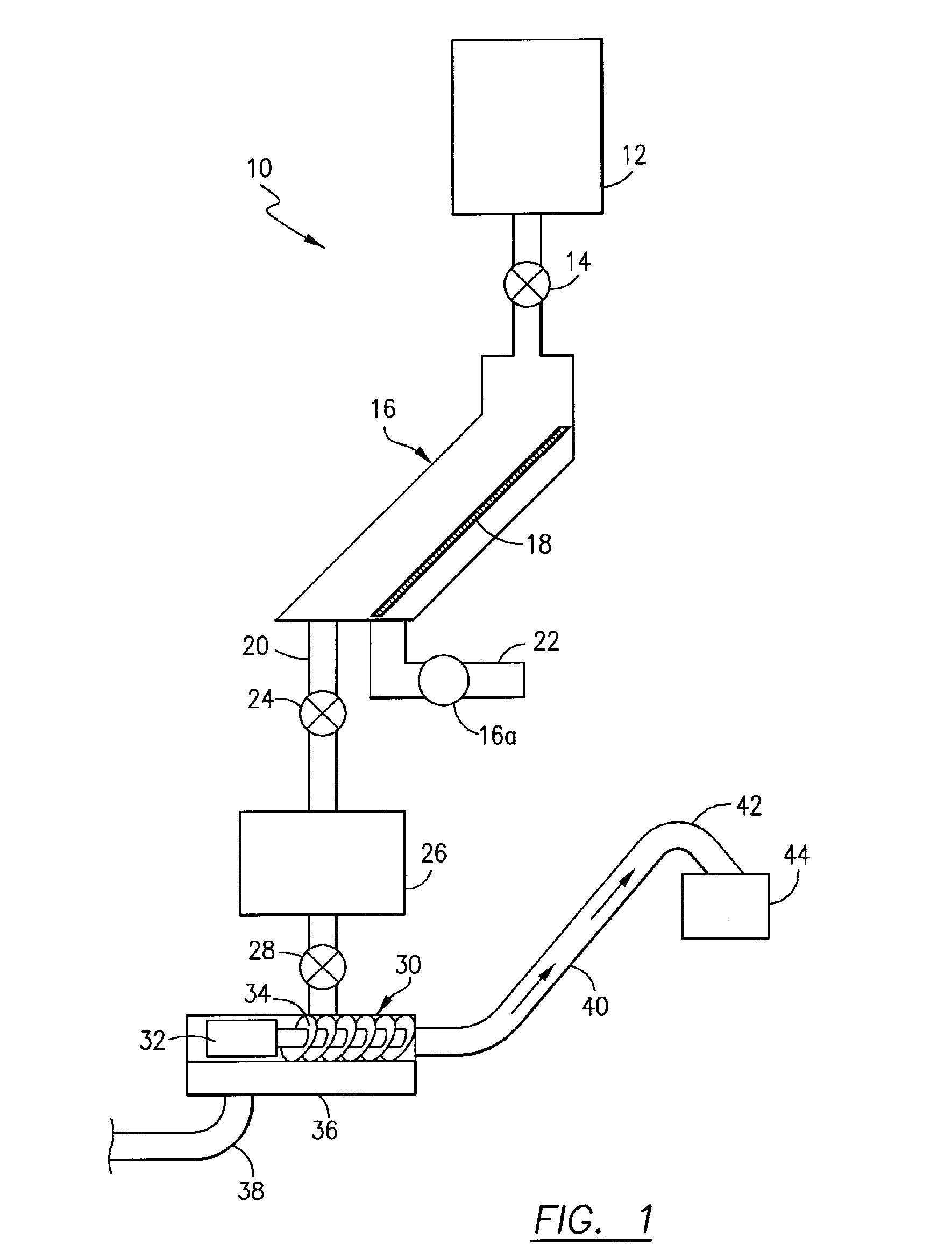

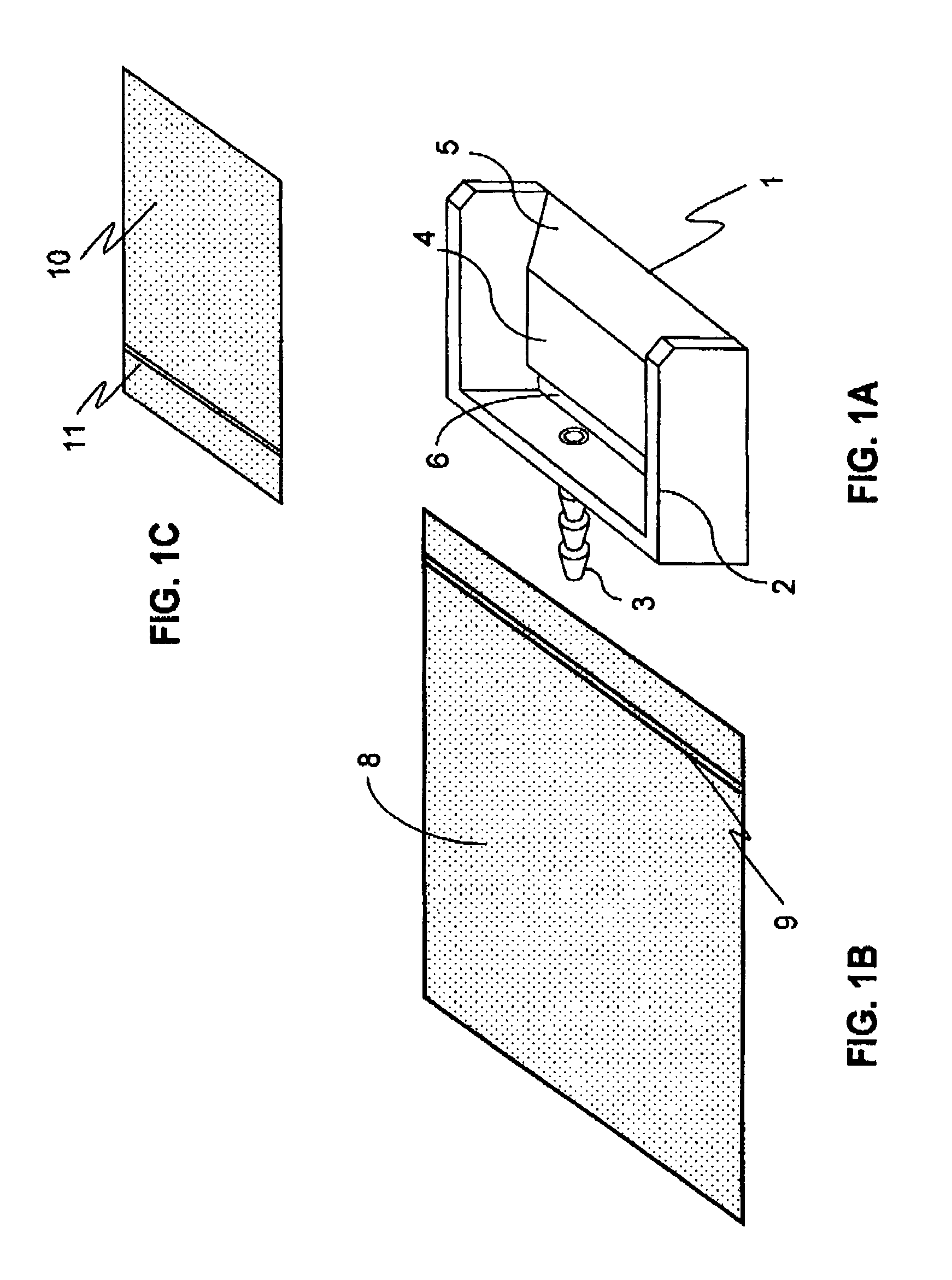

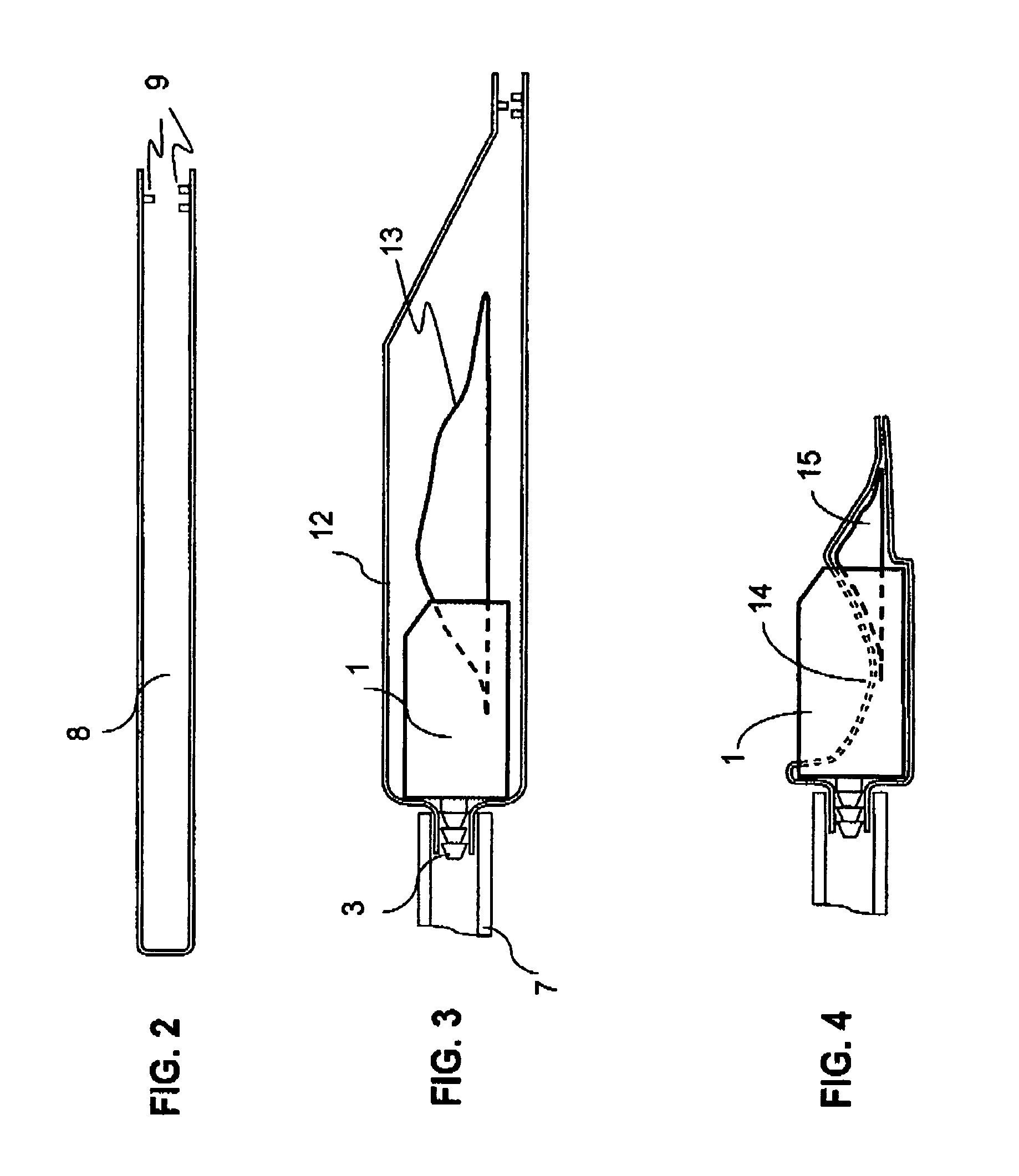

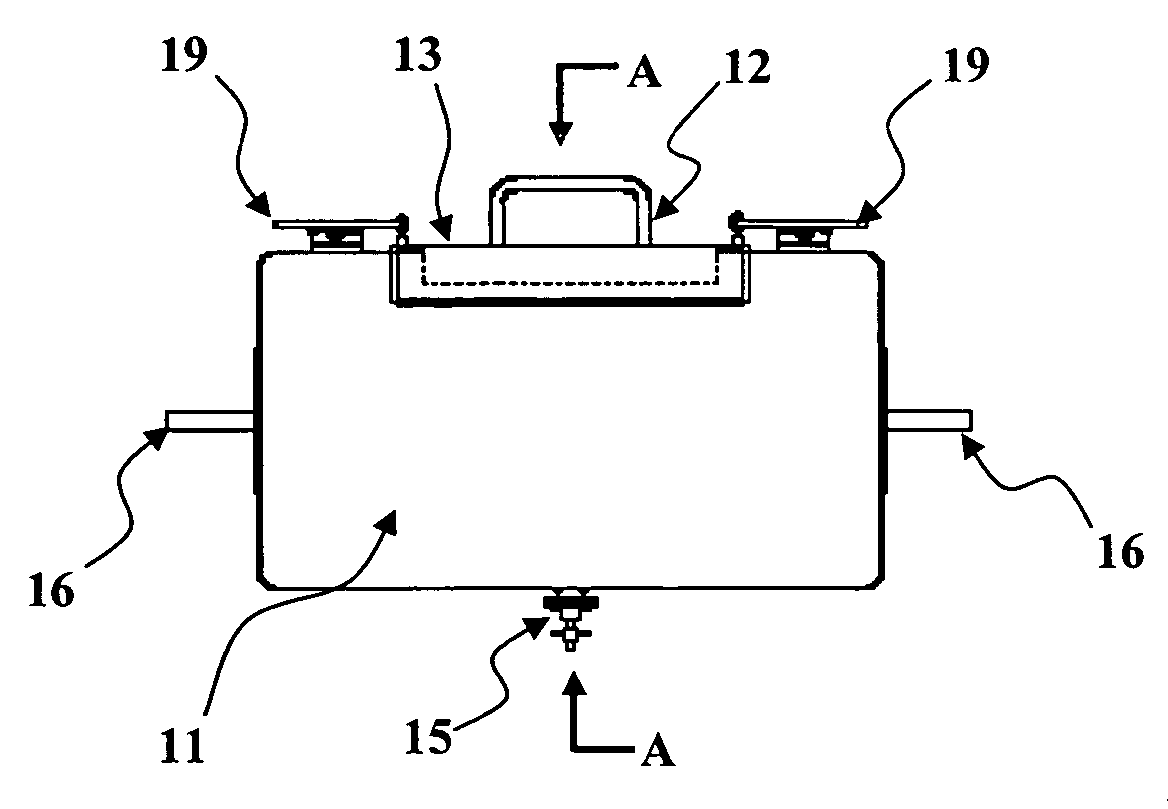

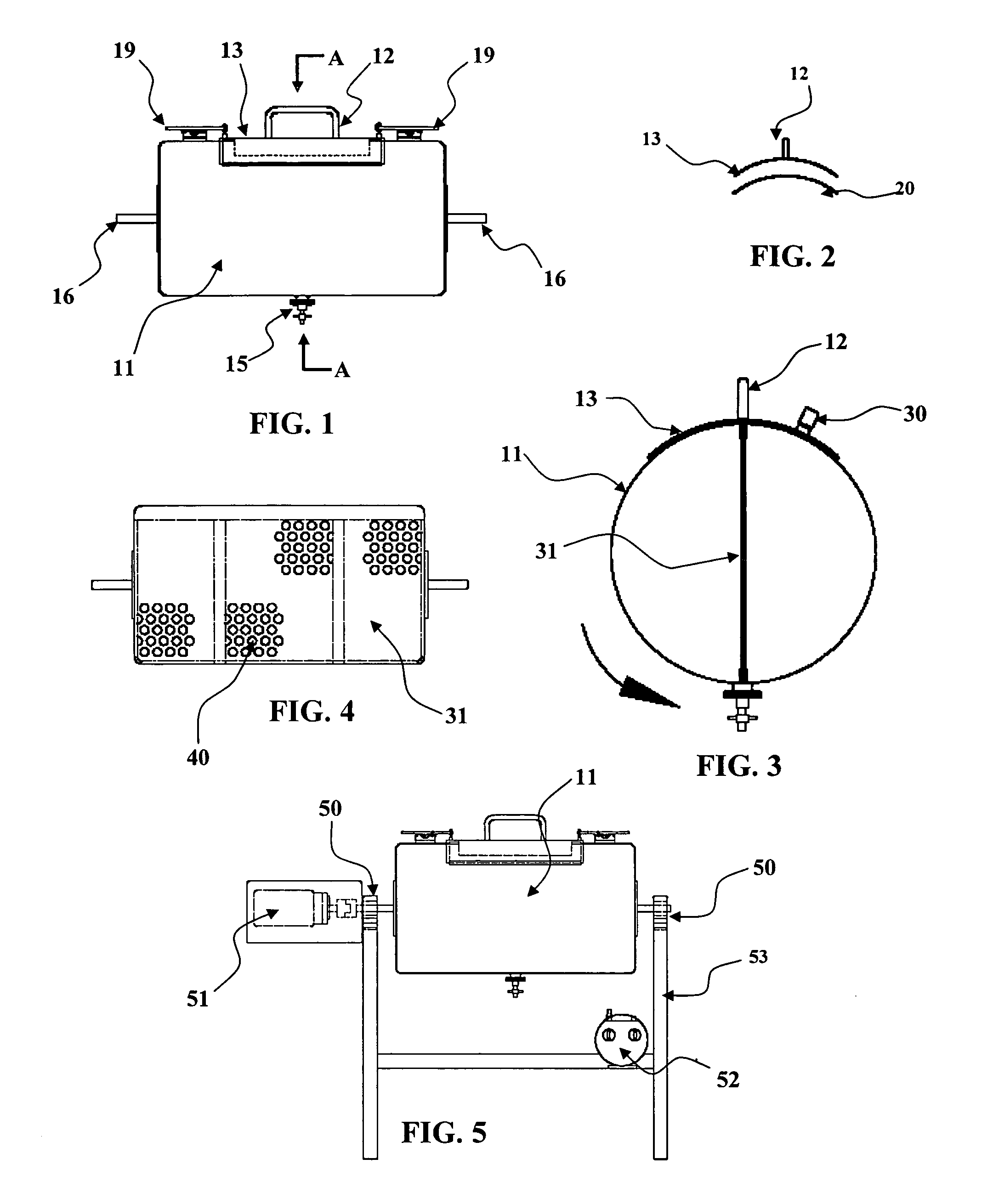

Shipboard human waste treatment for removing solids

InactiveUS7005077B1Easily storableEasy to storeAuxillariesBathroom accessoriesWaste treatmentEngineering

A method and system for separating human waste solids from liquid for a shipboard toilet system that allows for the separation of solid waste, compaction of the solid waste and storage of solid waste. Wastes are deposited into a shipboard toilet system that uses vacuum toilets to flush waste into a large, inclined solid waste separation tank. A vacuum pump is attached to the separation tank to maintain negative pressure within the tank and system and to move the separated liquid stream. The separation tank has a separating screen disposed across its entire width to retain solid wastes while allowing liquid to flow through. After separation from liquids, solid waste material is compacted and dewatered with a helical screw through an inclined tube, and packaged for later removal as landfill or burned in the ship incinerator.

Owner:BRENNER SAMUEL L +1

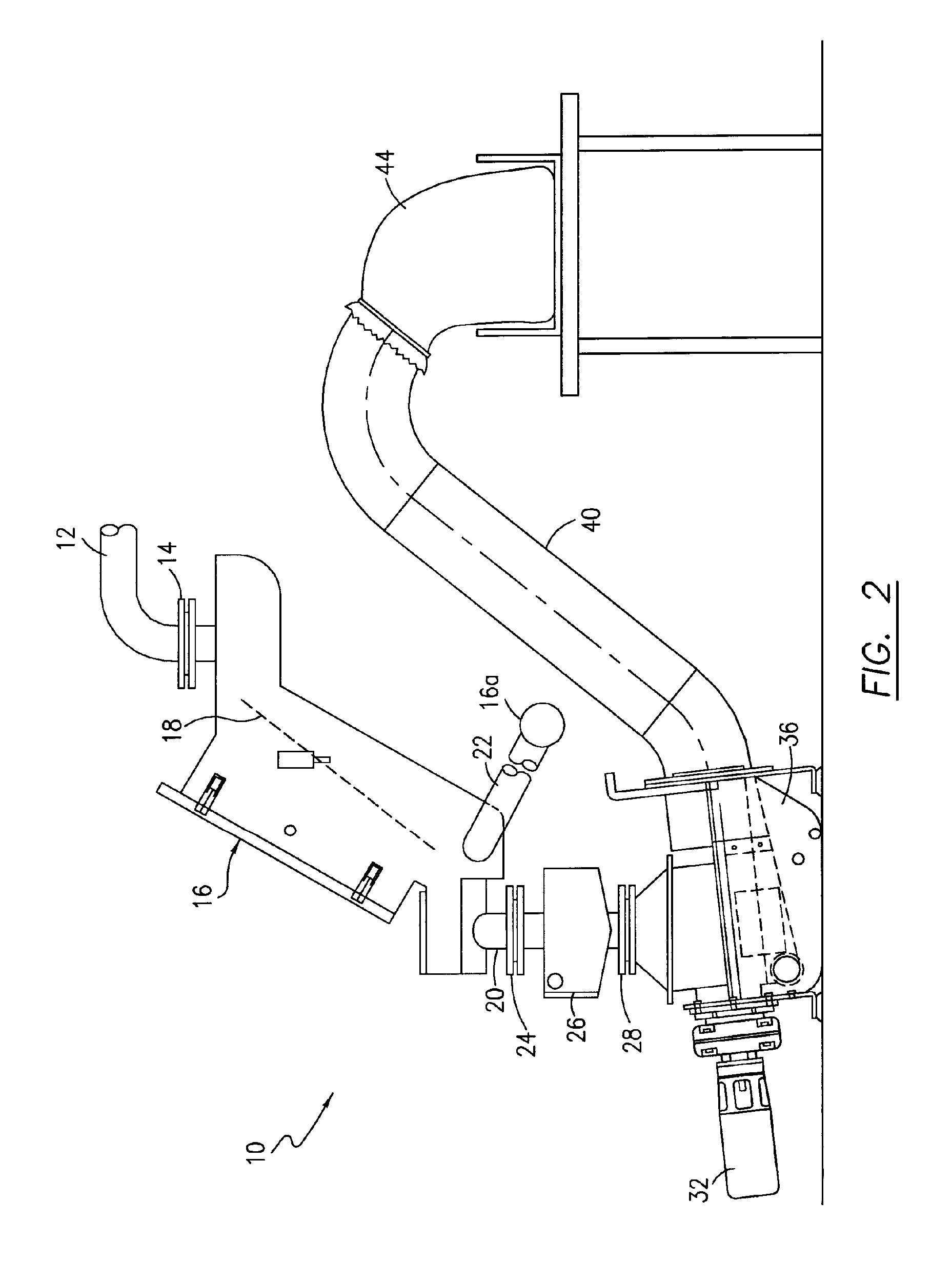

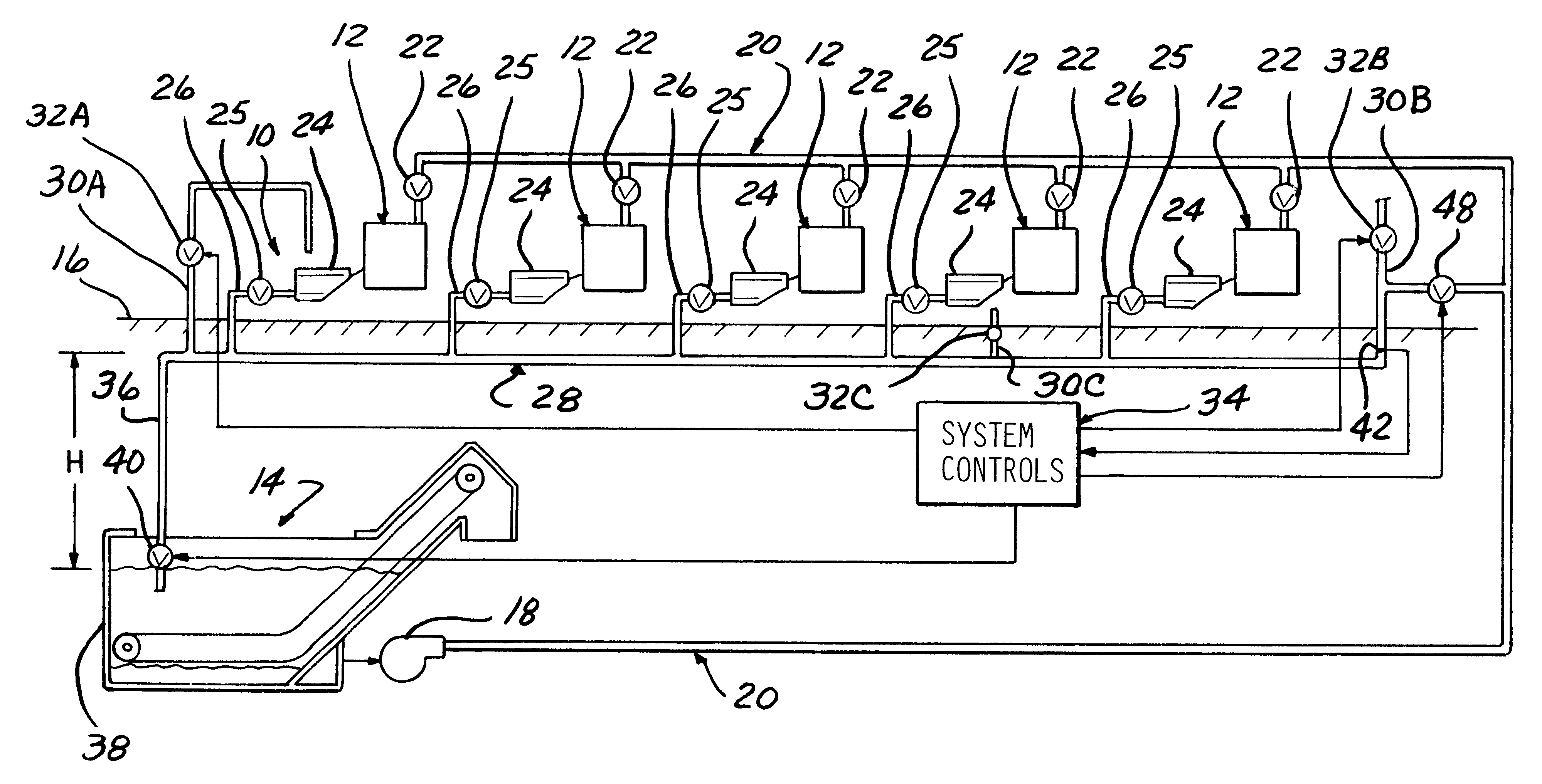

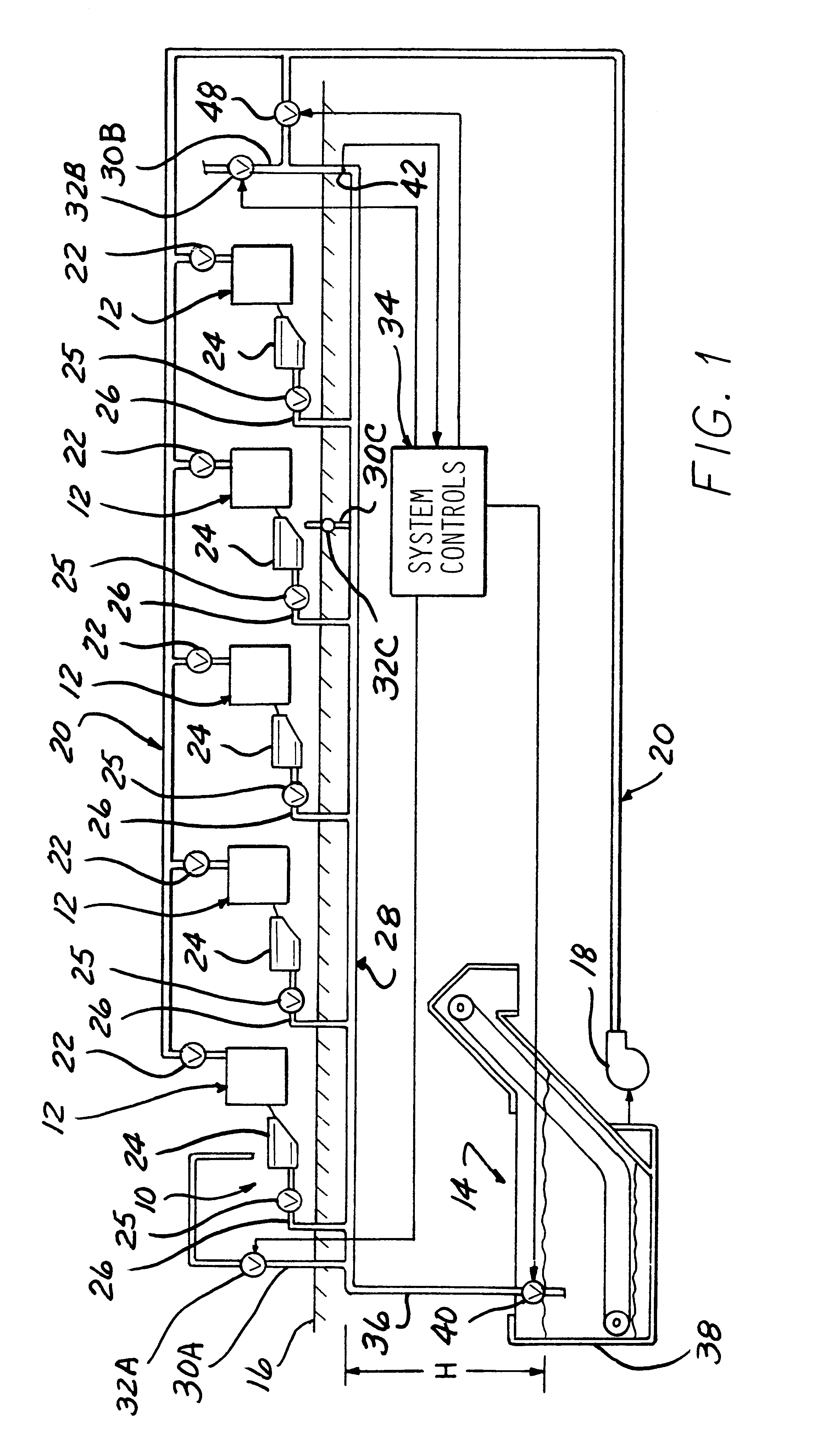

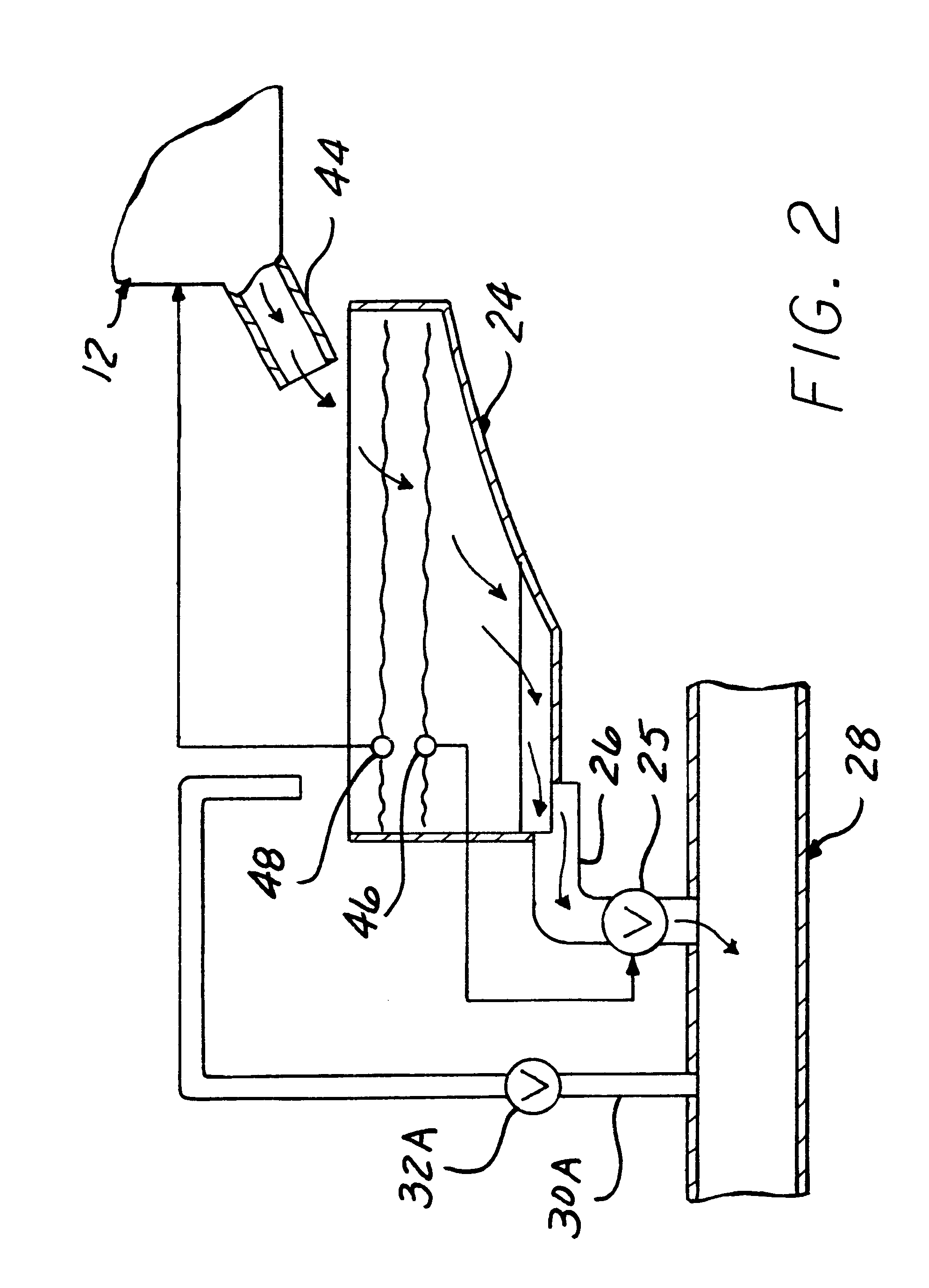

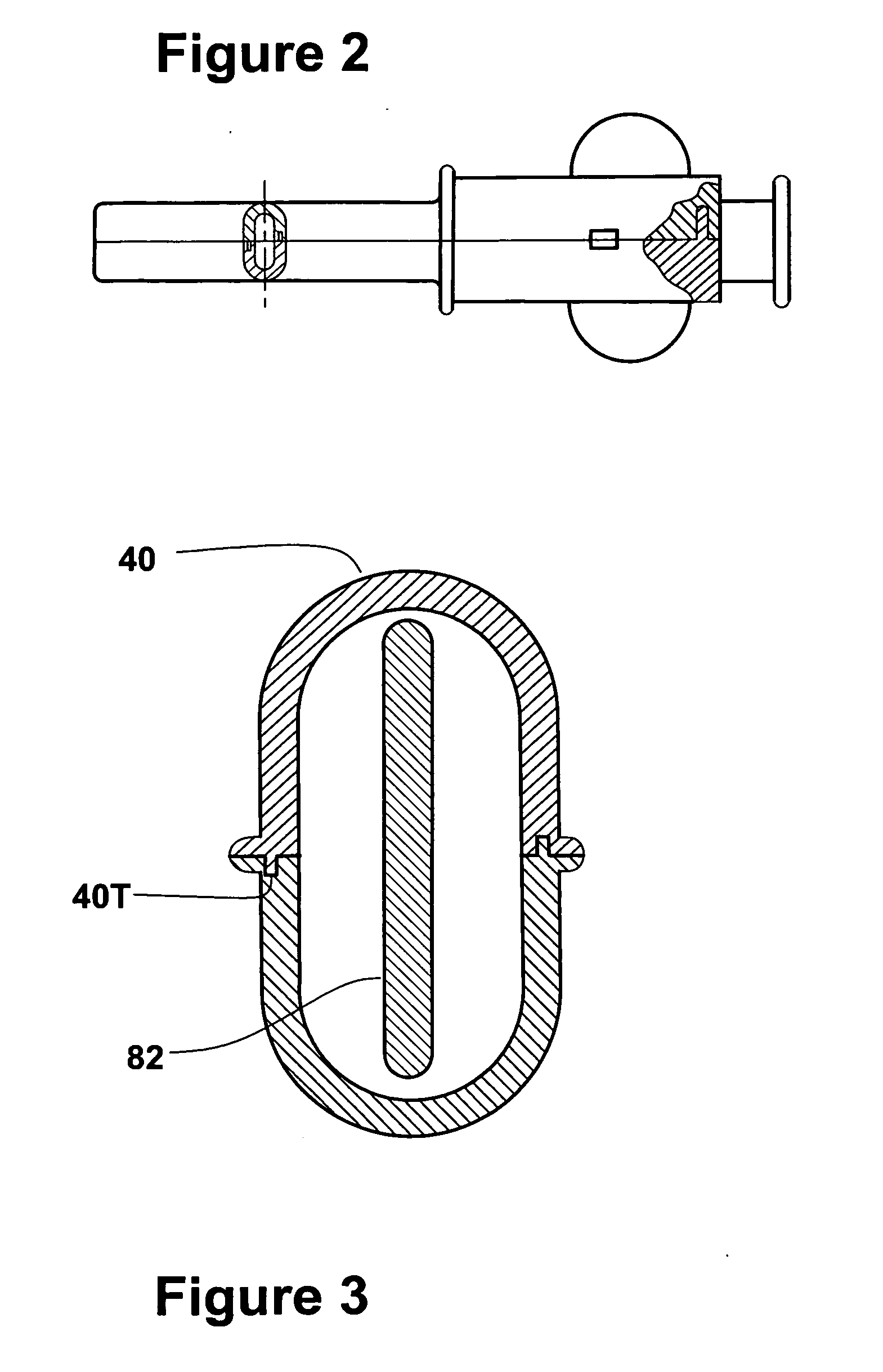

Vacuum flush assist system and process for handling machining cutting fluid

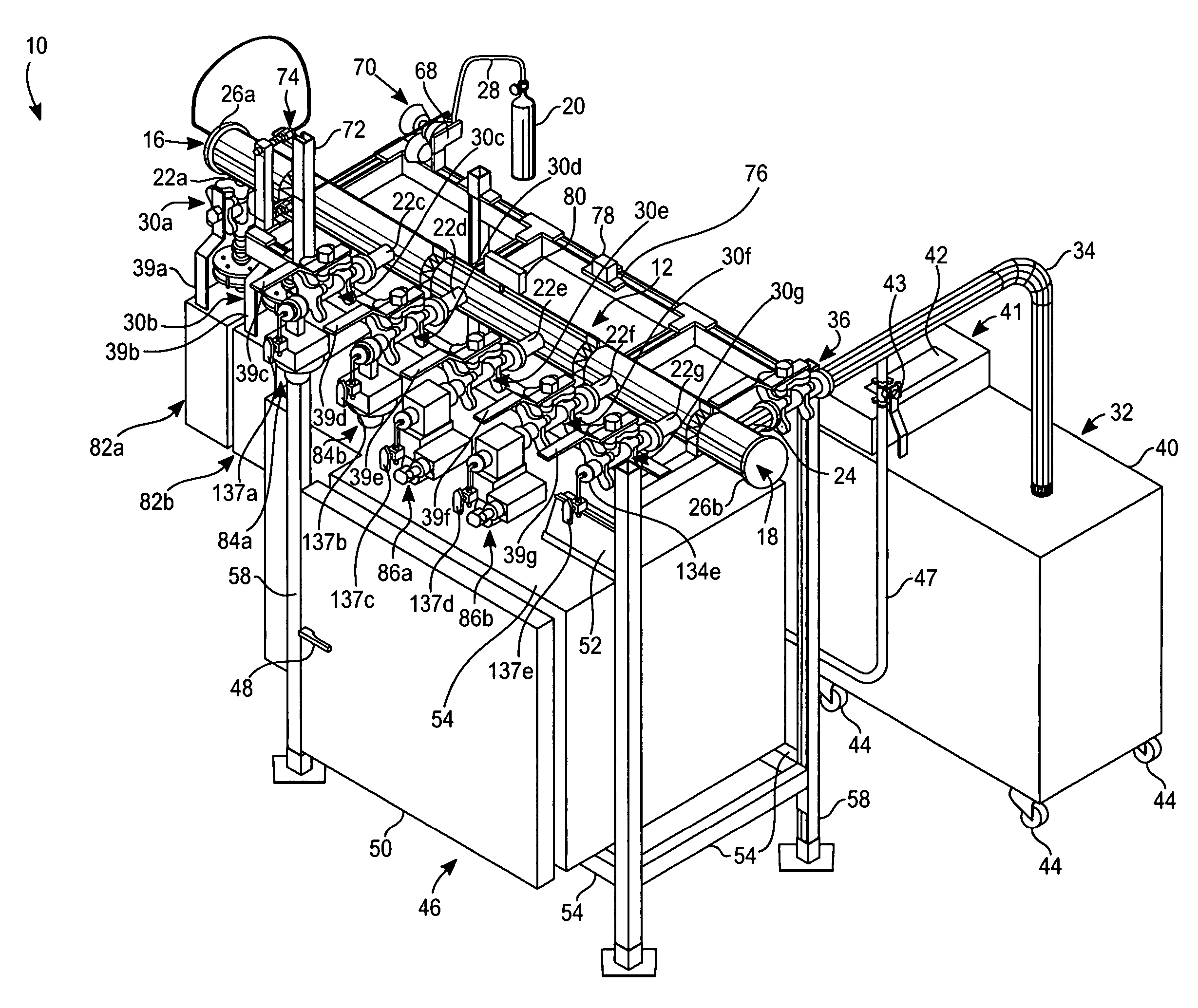

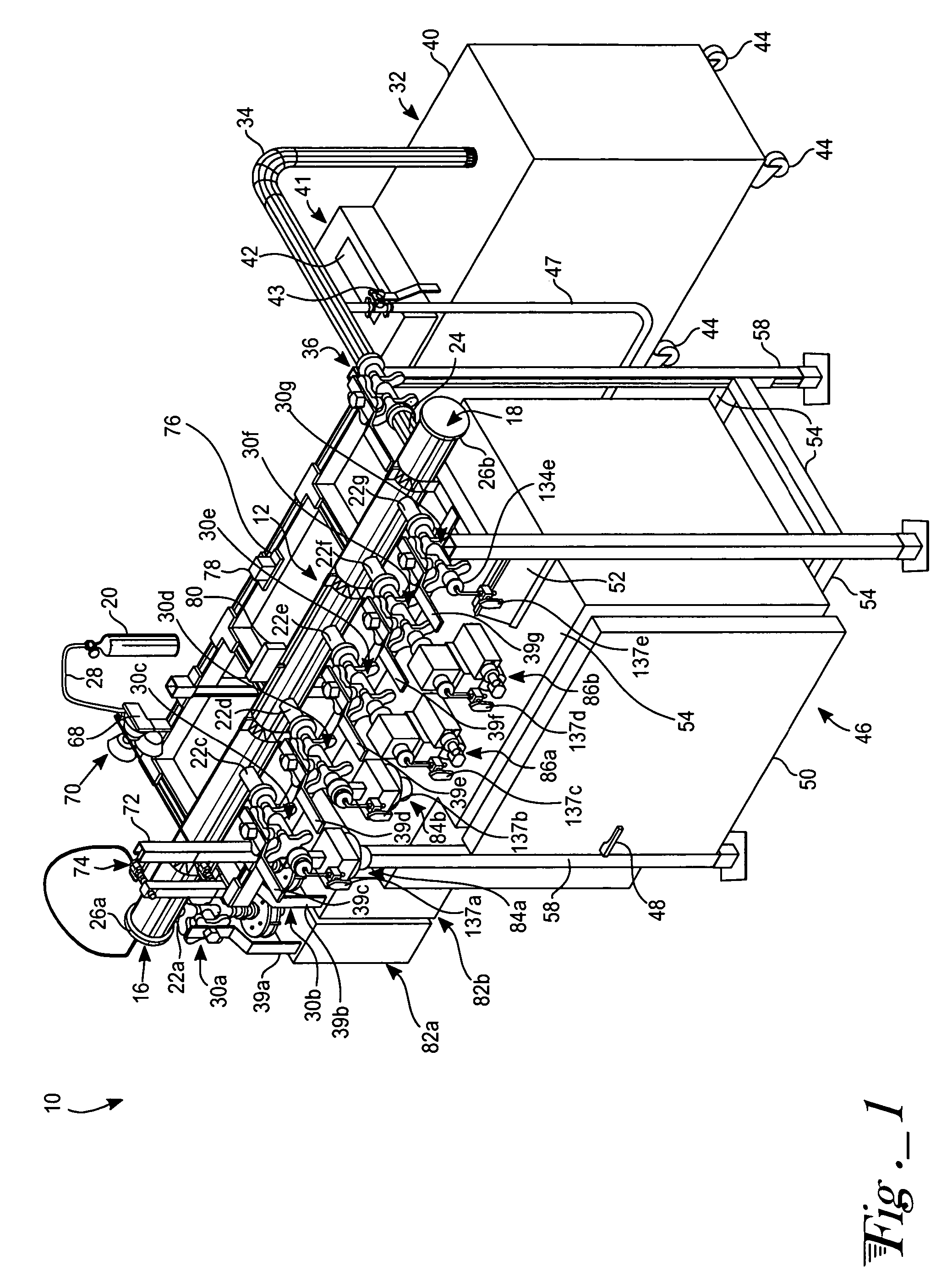

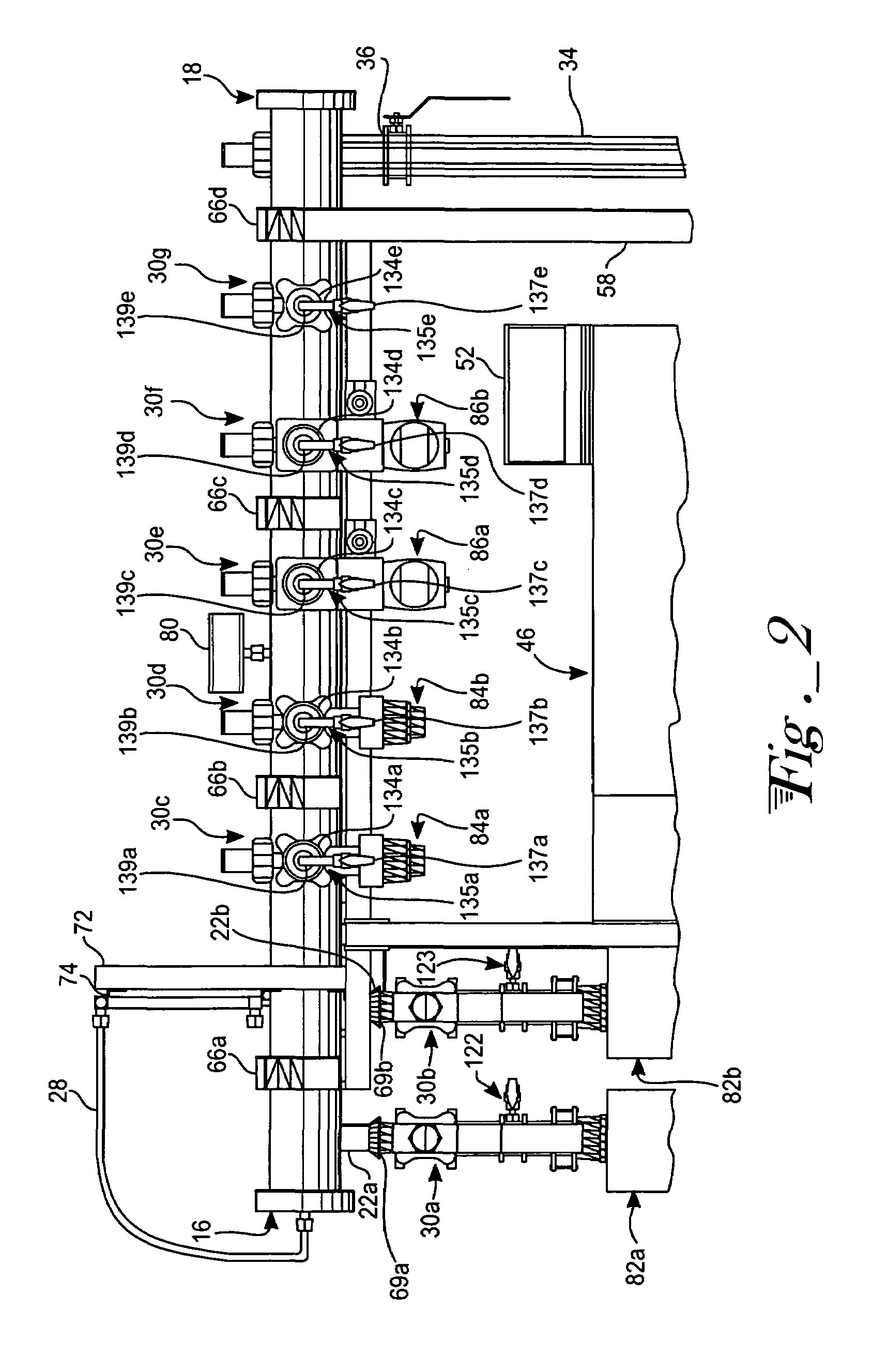

InactiveUS6508944B1Keep vacuumingIncrease flow rateLiquid separation auxillary apparatusWater/sewage treatmentVacuum assistedSwarf

A vacuum assist system and process for handling cutting fluid and chips collected from a series of machine tools includes a closed header pipe extending below a series of sumps associated with the machine tools, the sumps draining into the header pipe. The header pipe has a down leg extending vertically down to a filter tank which is opened periodically to drain the header pipe, developing a vacuum which assists the flow of liquid down the header pipe so as to insure a sufficient flow velocity in the header pipe to carry the collected chips out of the header pipe and into the filter tank with the cutting fluid.

Owner:FILTRA SYSTEMS COMPANY

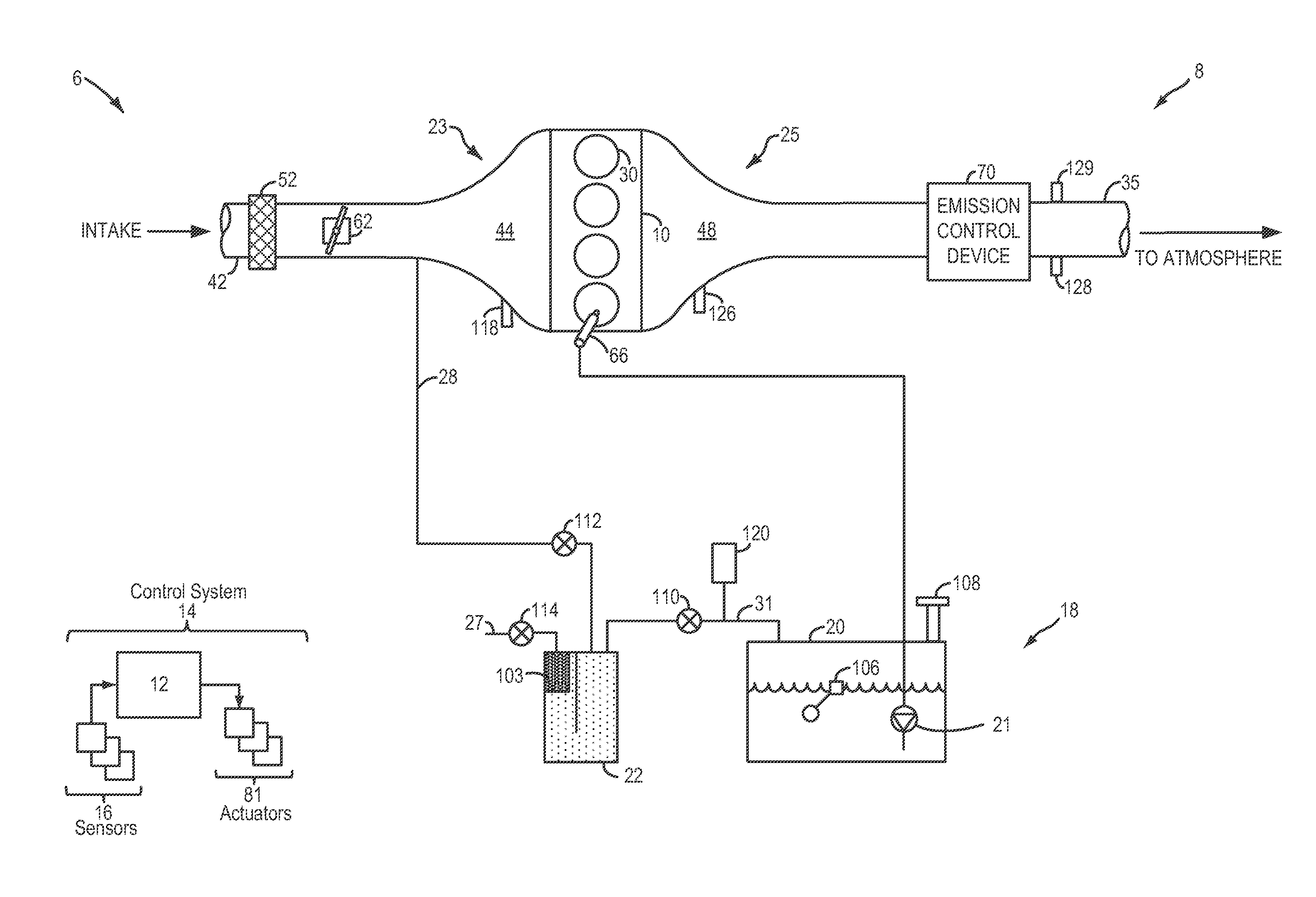

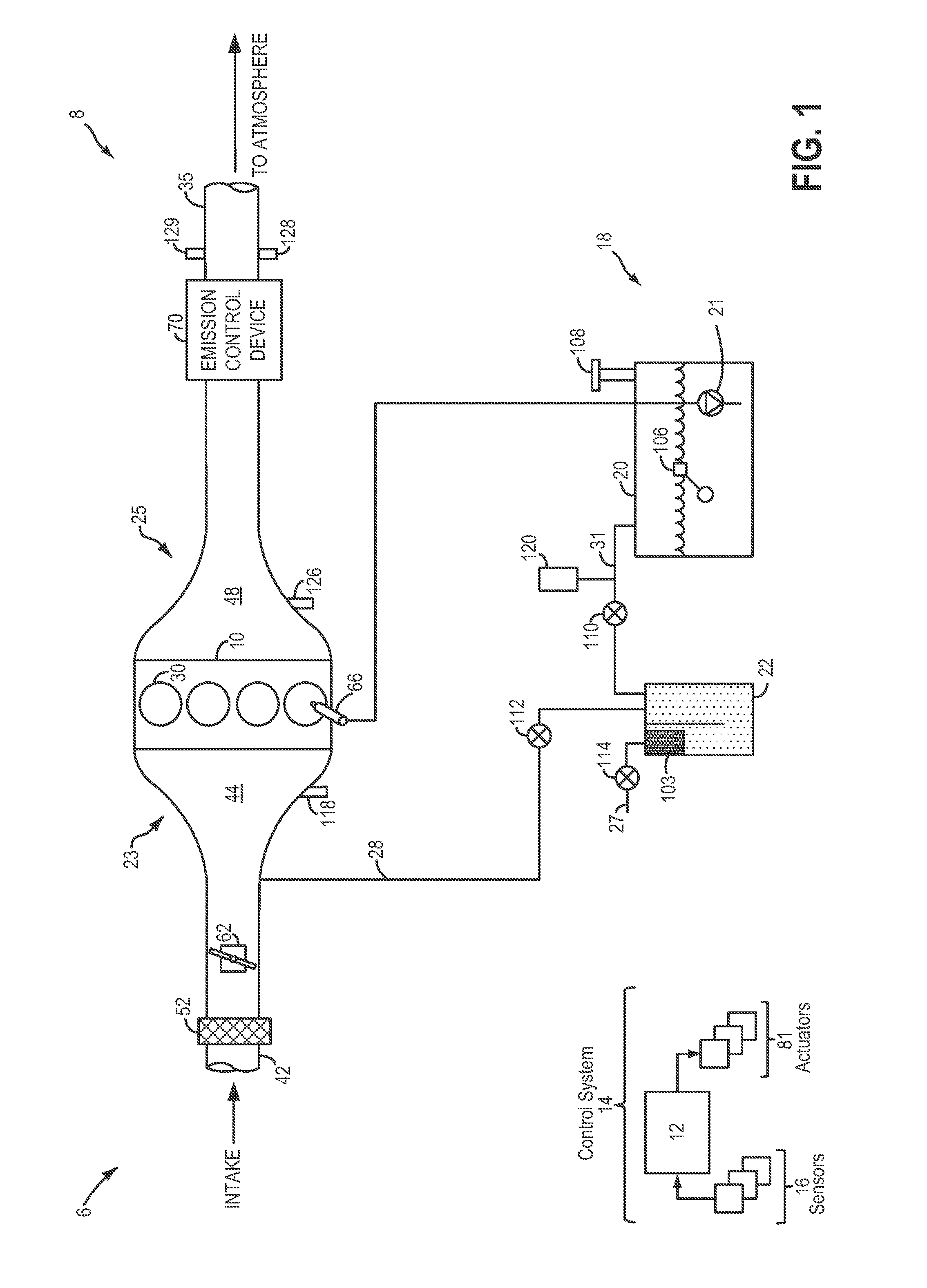

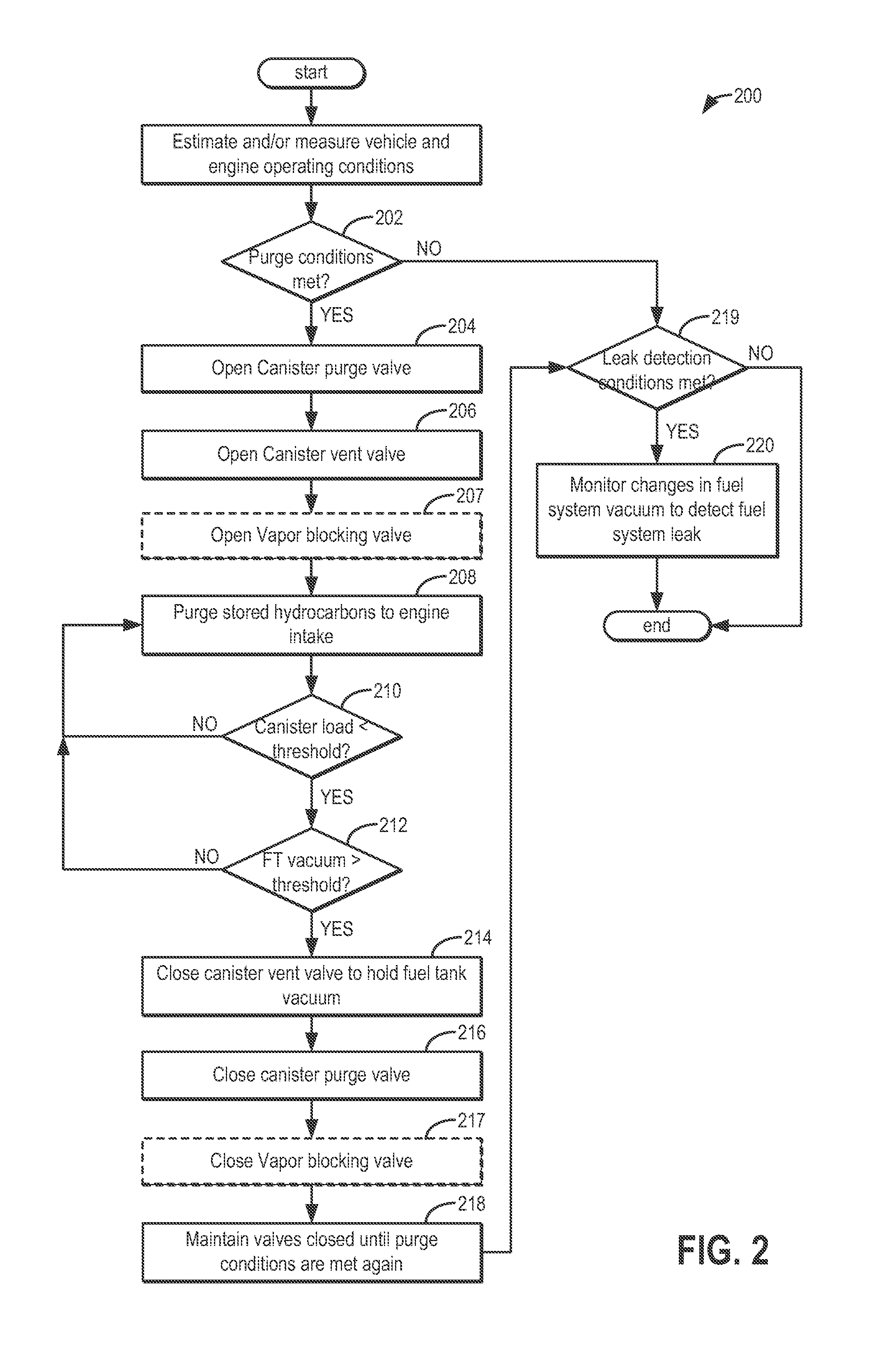

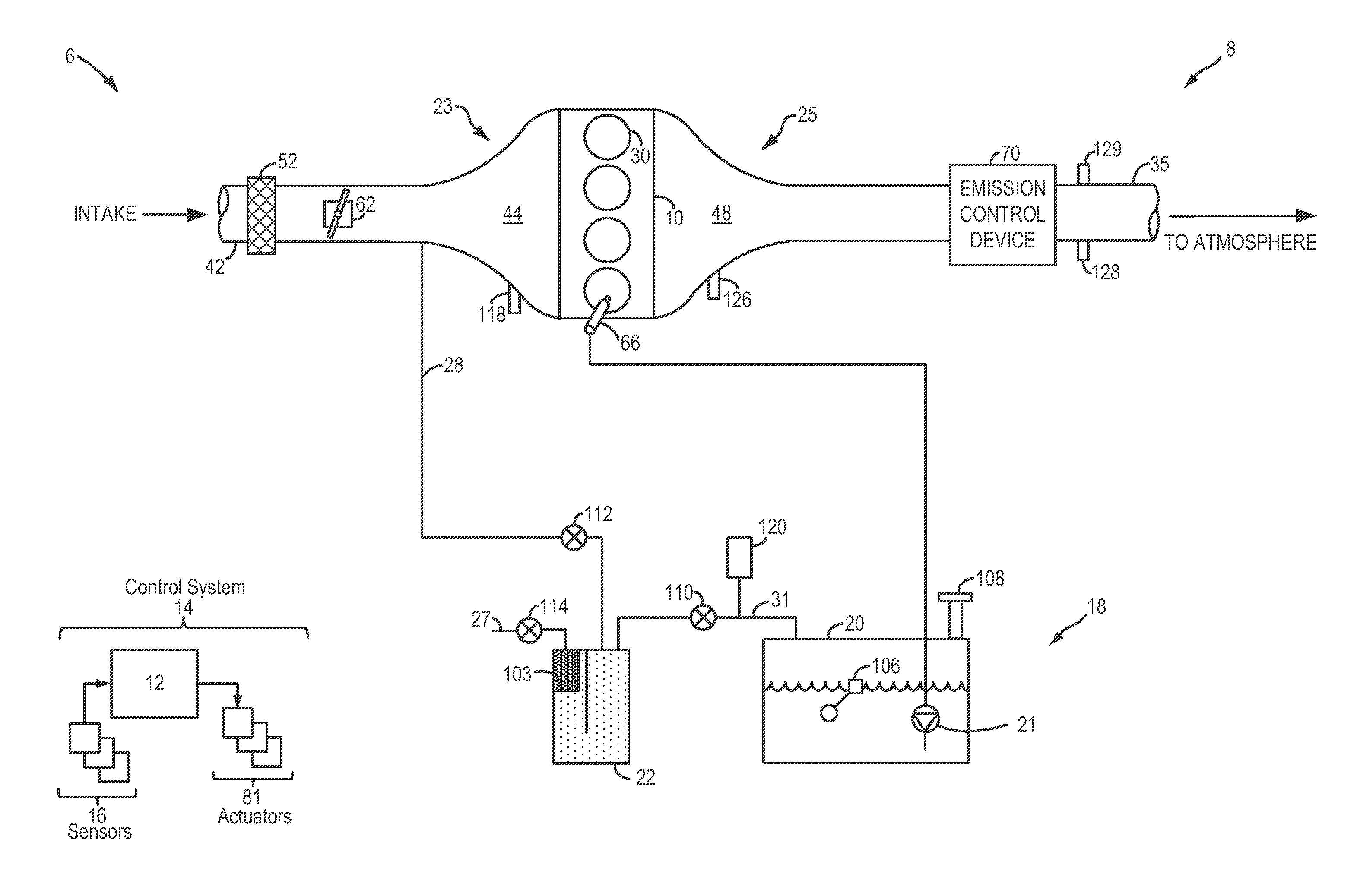

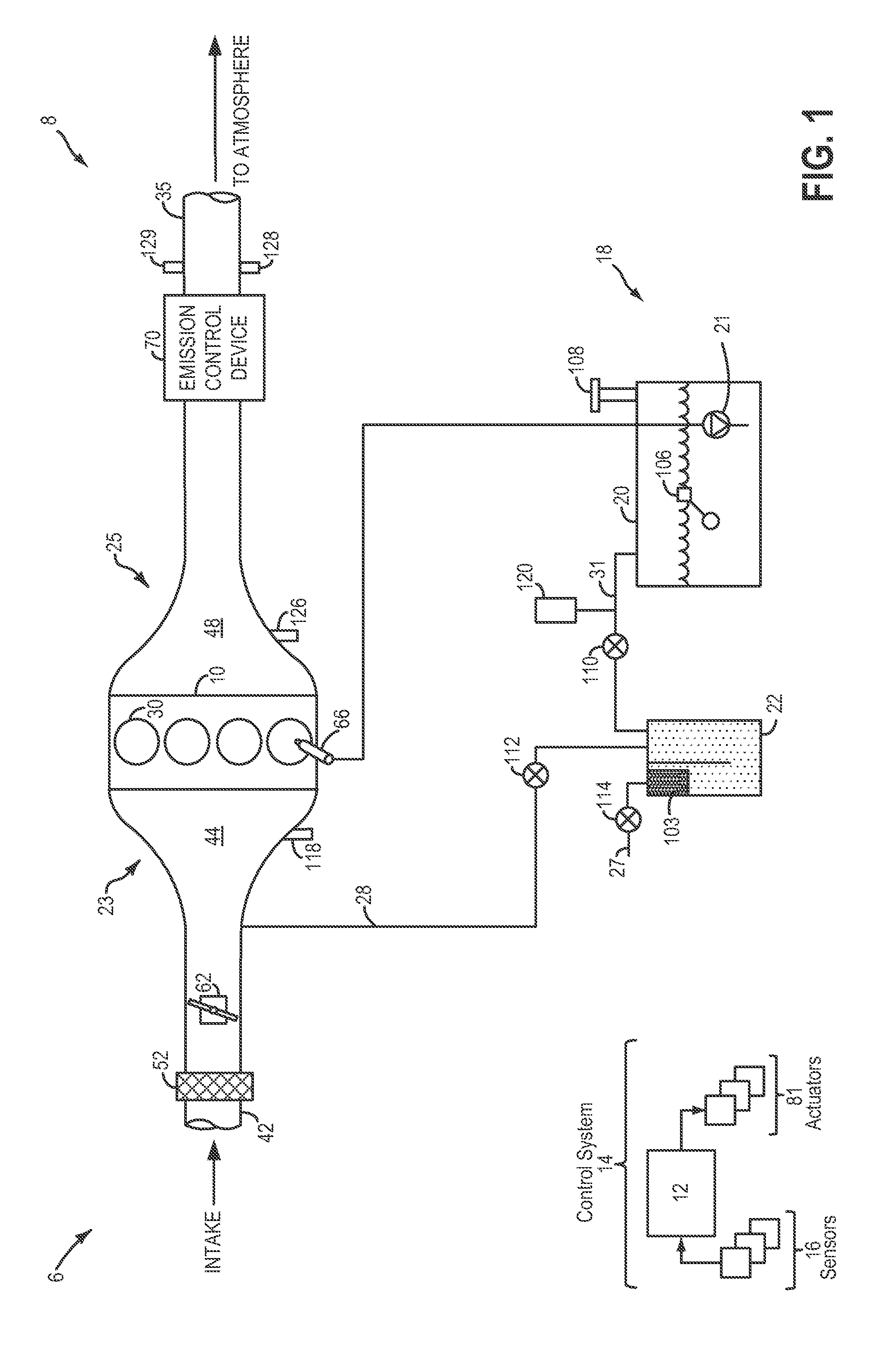

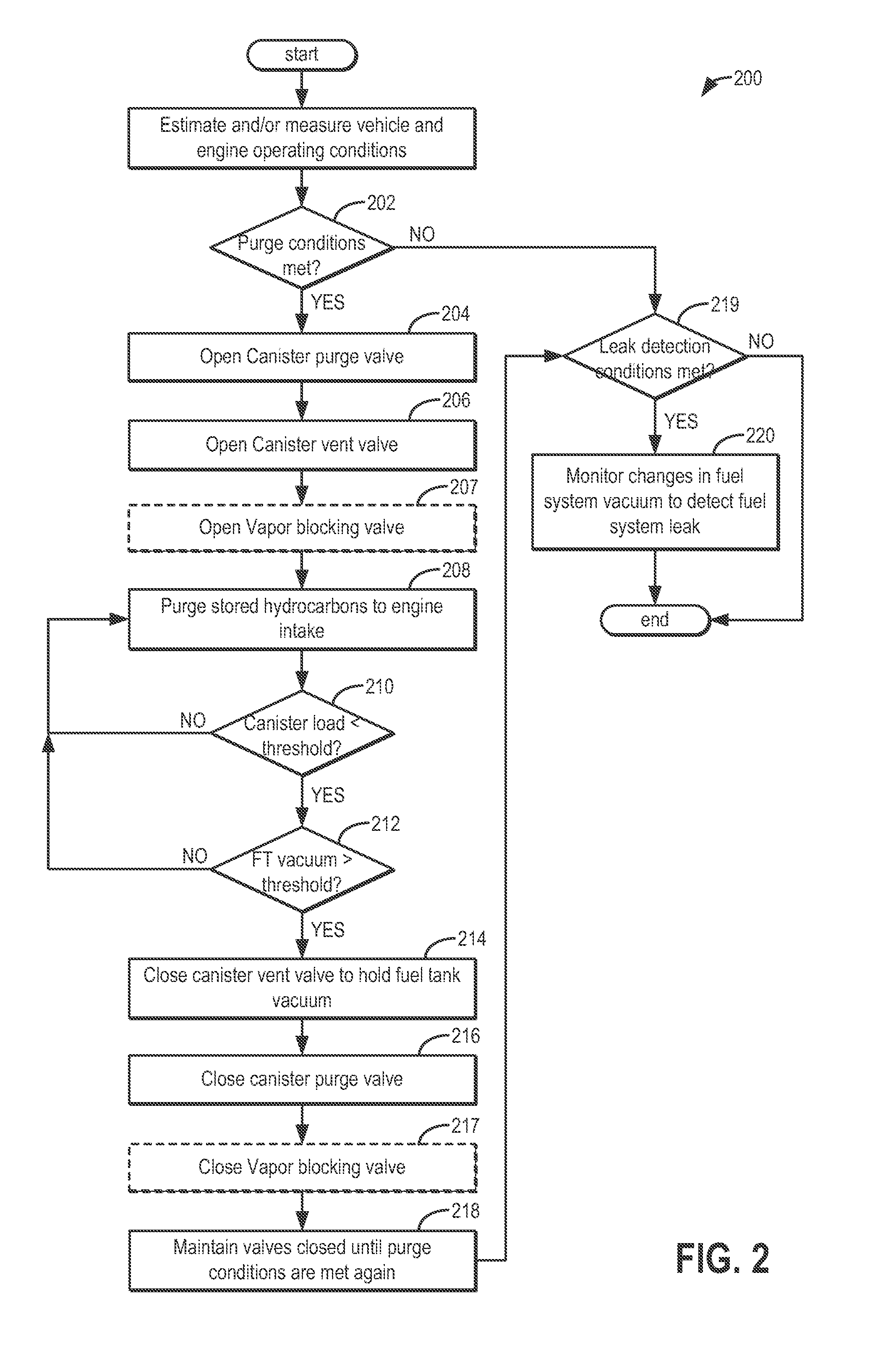

Method and system for fuel system control

ActiveUS20140026866A1Shorten operation timeFuel economyHybrid vehiclesElectrical controlFuel tankEngineering

Methods and systems are provided for controlling a fuel system in a hybrid vehicle. Before canister purging is stopped by closing a purge valve, a canister vent valve is closed to hold fuel tank vacuum. Then, during a subsequent canister purge, the purge valve is opened before opening the vent valve, allowing canister purge to initiate under fuel tank vacuum conditions.

Owner:FORD GLOBAL TECH LLC

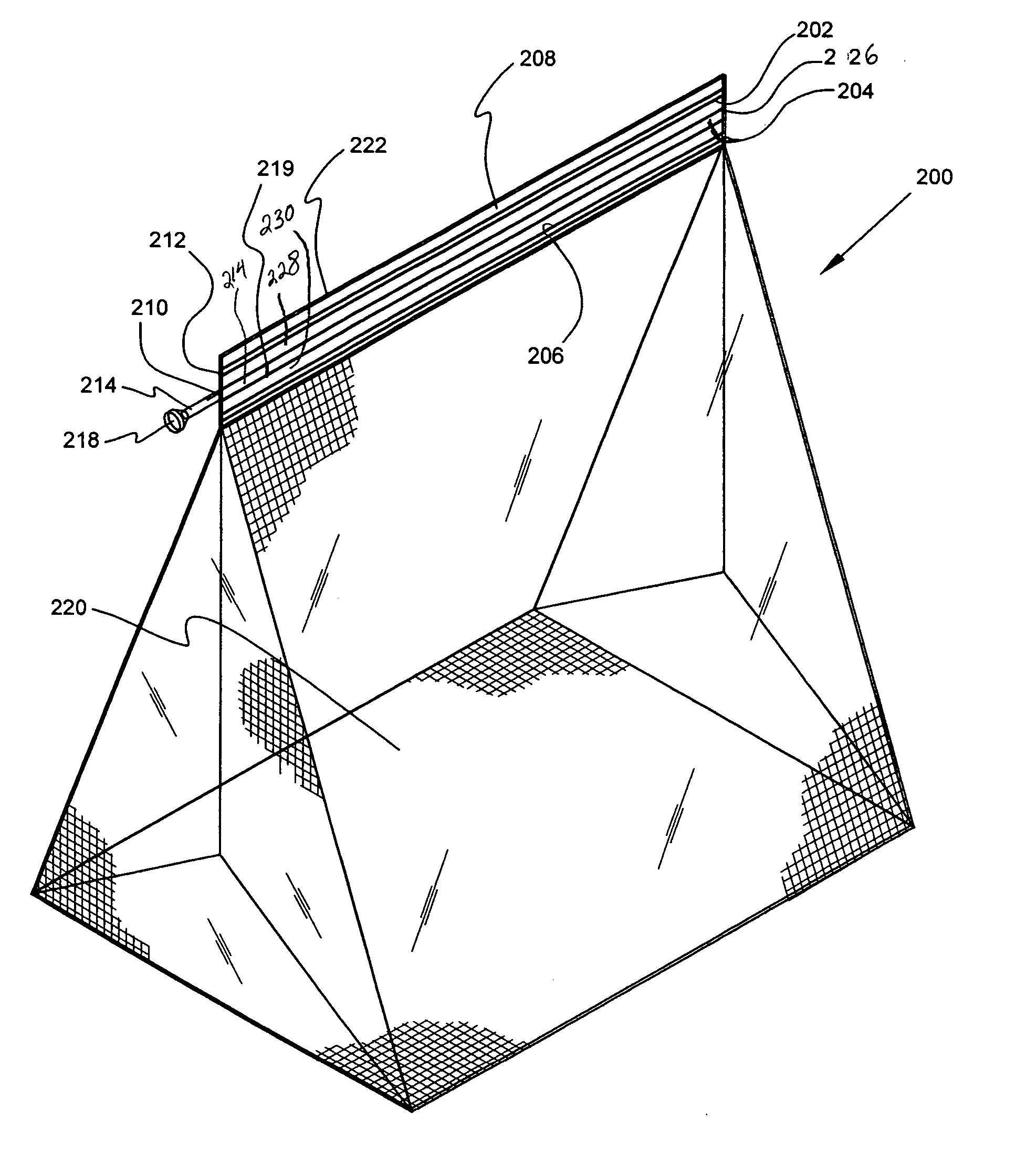

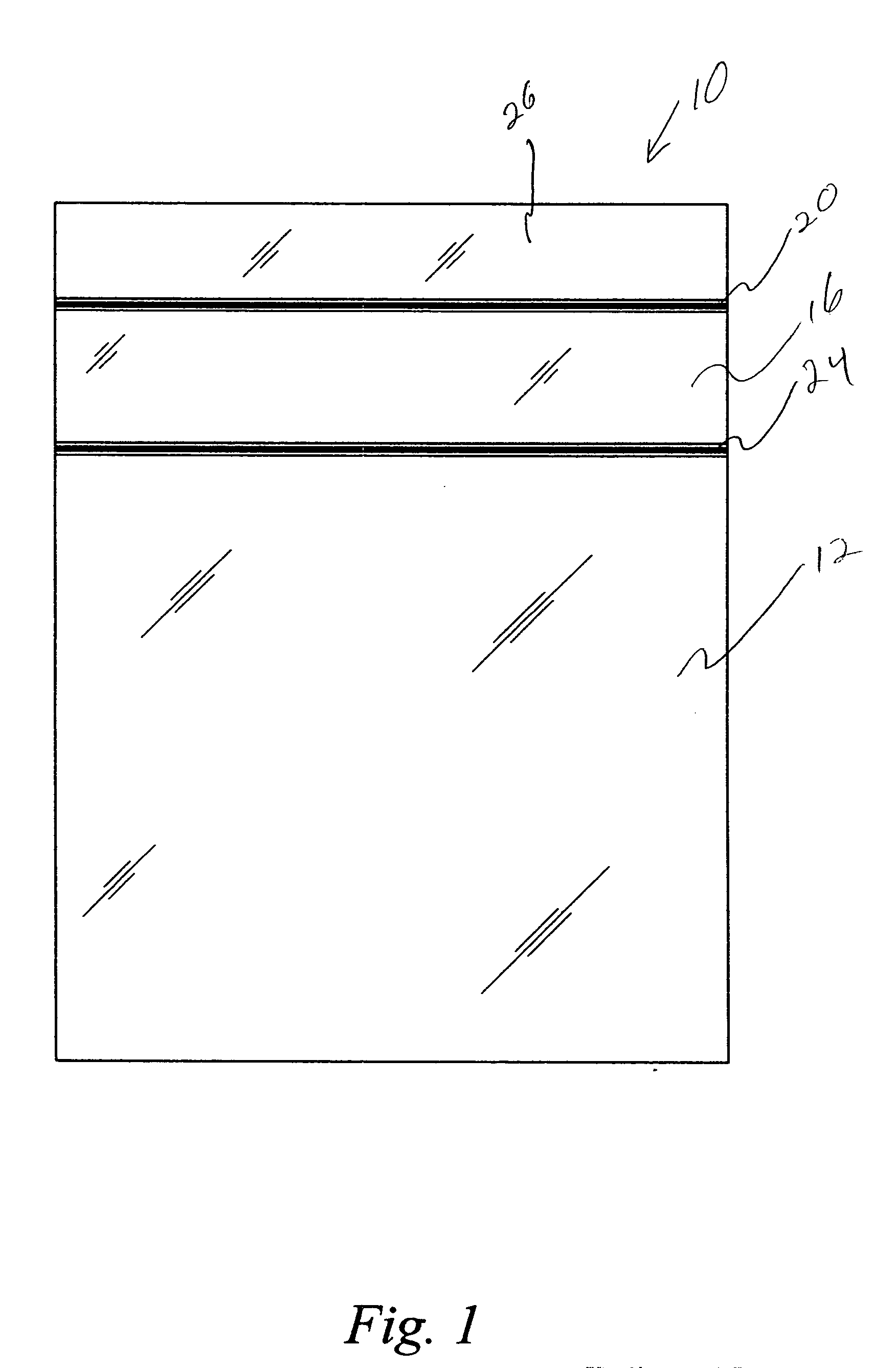

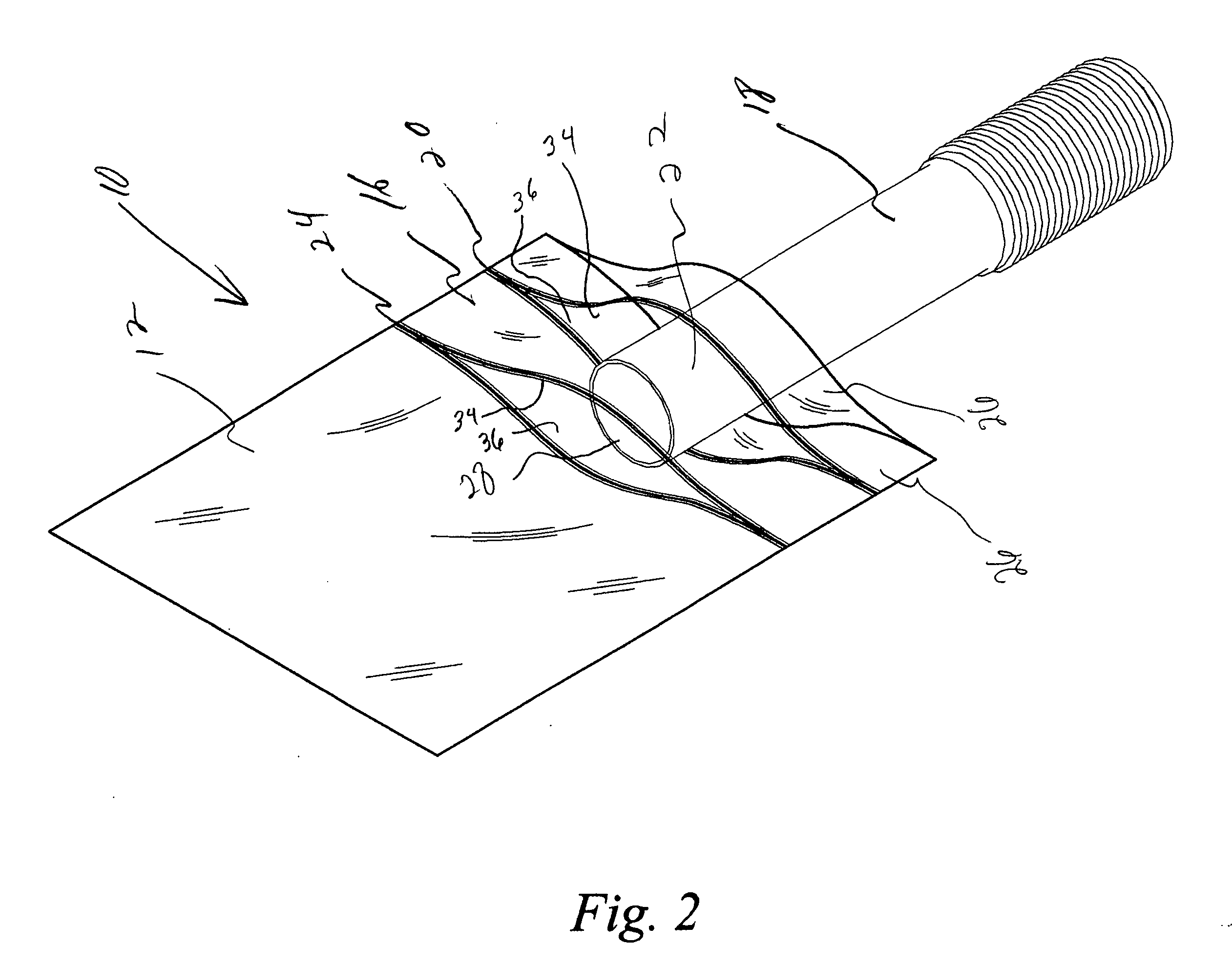

Enclosure for preserving perishable goods

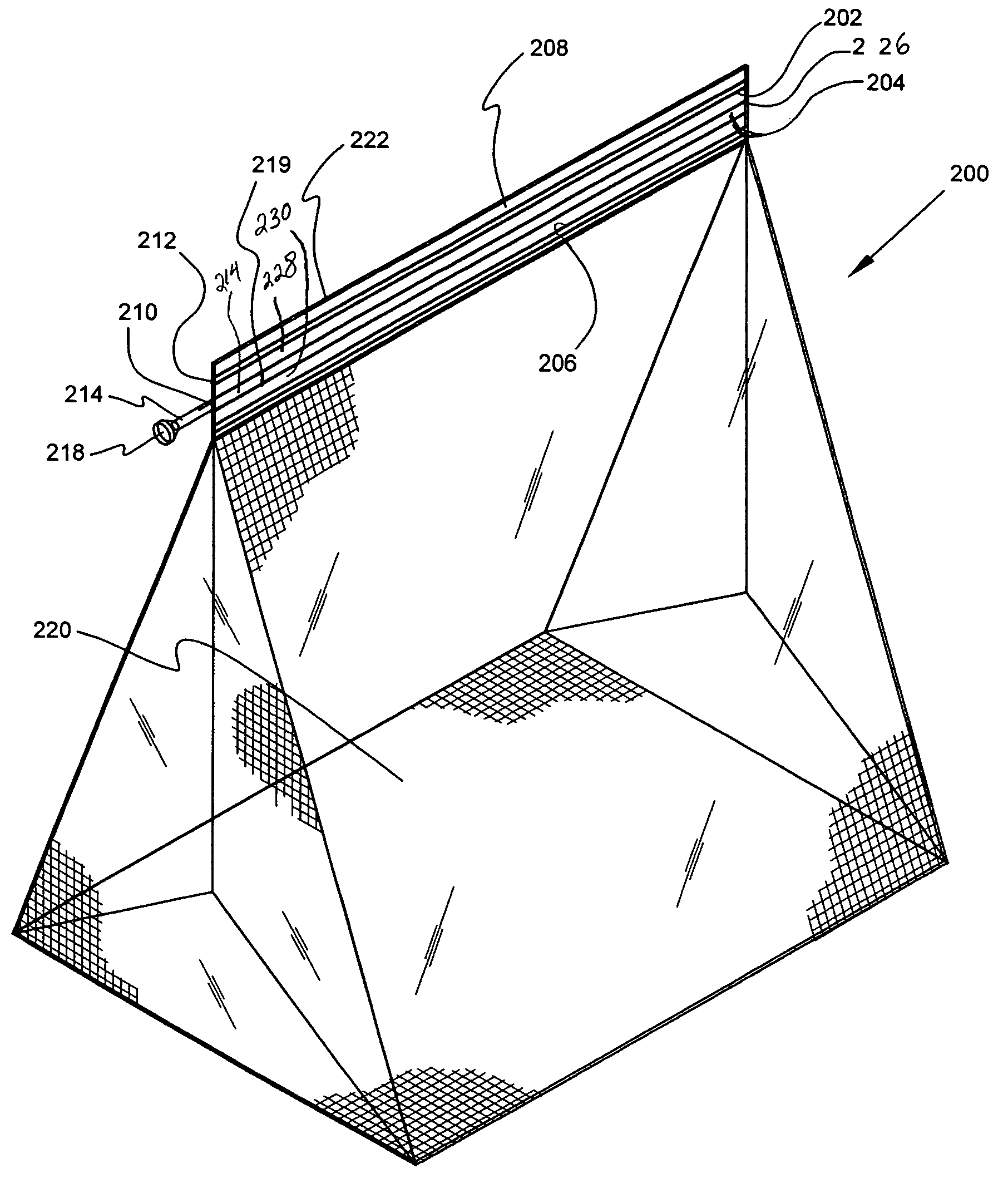

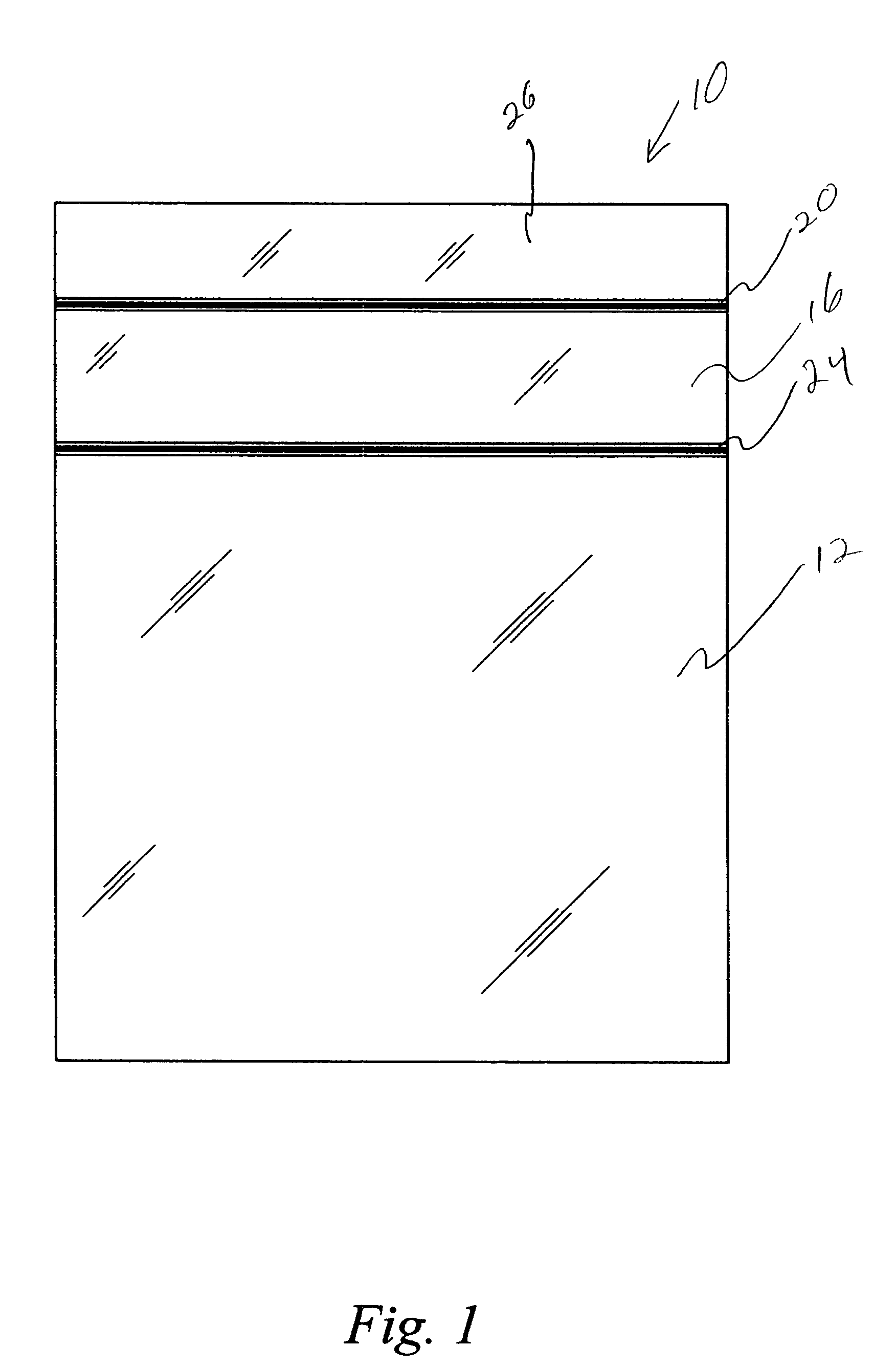

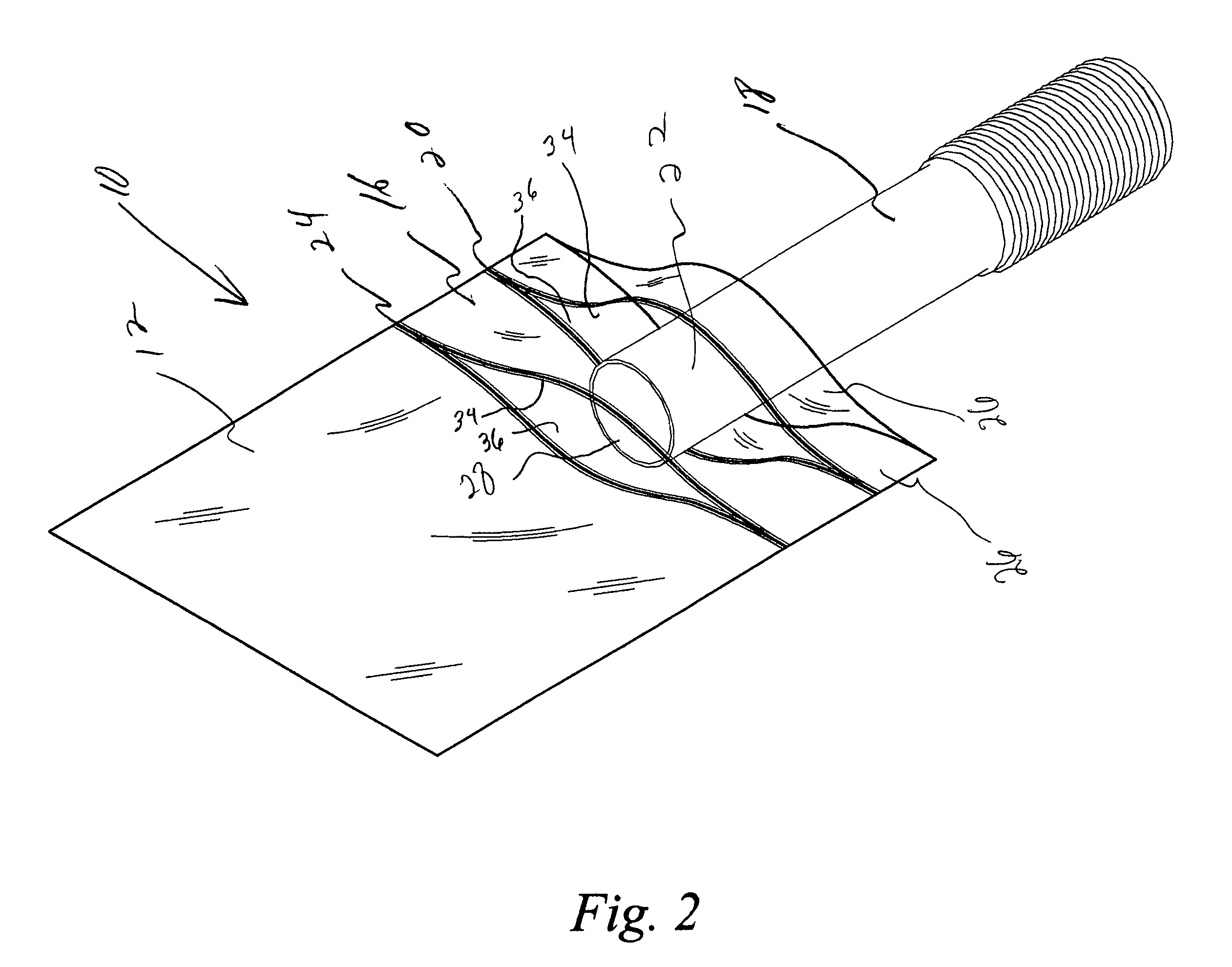

An enclosure 10 for preserving perishable goods 14 includes an inner portion 12 for removably receiving perishable goods 14, an outer portion 16 that removably receives a vacuum device 18 such as a vacuum cleaner which removes air from the enclosure 10 after the goods 14 have been inserted into the inner portion 12, a sealable outer seal 20 that provides an air tight boundary between the enclosure 10 and an end portion 22 of the vacuum device 18 to promote the removal of air from the enclosure 10, and a sealable inner seal 24 that provides an air tight boundary for the inner portion 12 and the goods 14 therein after the removal of air from the enclosure 10 and while the vacuum device 18 remains engaged with the outer seal 20; the vacuum device 18 being separated from the outer seal 20 after the removal of air from the inner portion 12 and the air tight sealing of the inner seal 24 whereby the perishable goods 14 are encased in a vacuum sealed inner portion 12 of the enclosure 10 to preserve the perishable goods 14 after the goods 14 are frozen. An alternative enclosure 200 includes an opening 222, a first locking seal 202 disposed relatively close and substantially parallel to the opening 222, a second locking seal 204 disposed adjacent and parallel to the first locking seal 202, a third locking seal 206 disposed adjacent and parallel to the second locking seal 204, and an aperture 210 disposed in a first side portion 212 of the enclosure 200 adjacent to the second locking seal 204 to enable an air evacuation tube to snugly insert through the first side portion 212 of the enclosure 200.

Owner:KOZAK BURTON

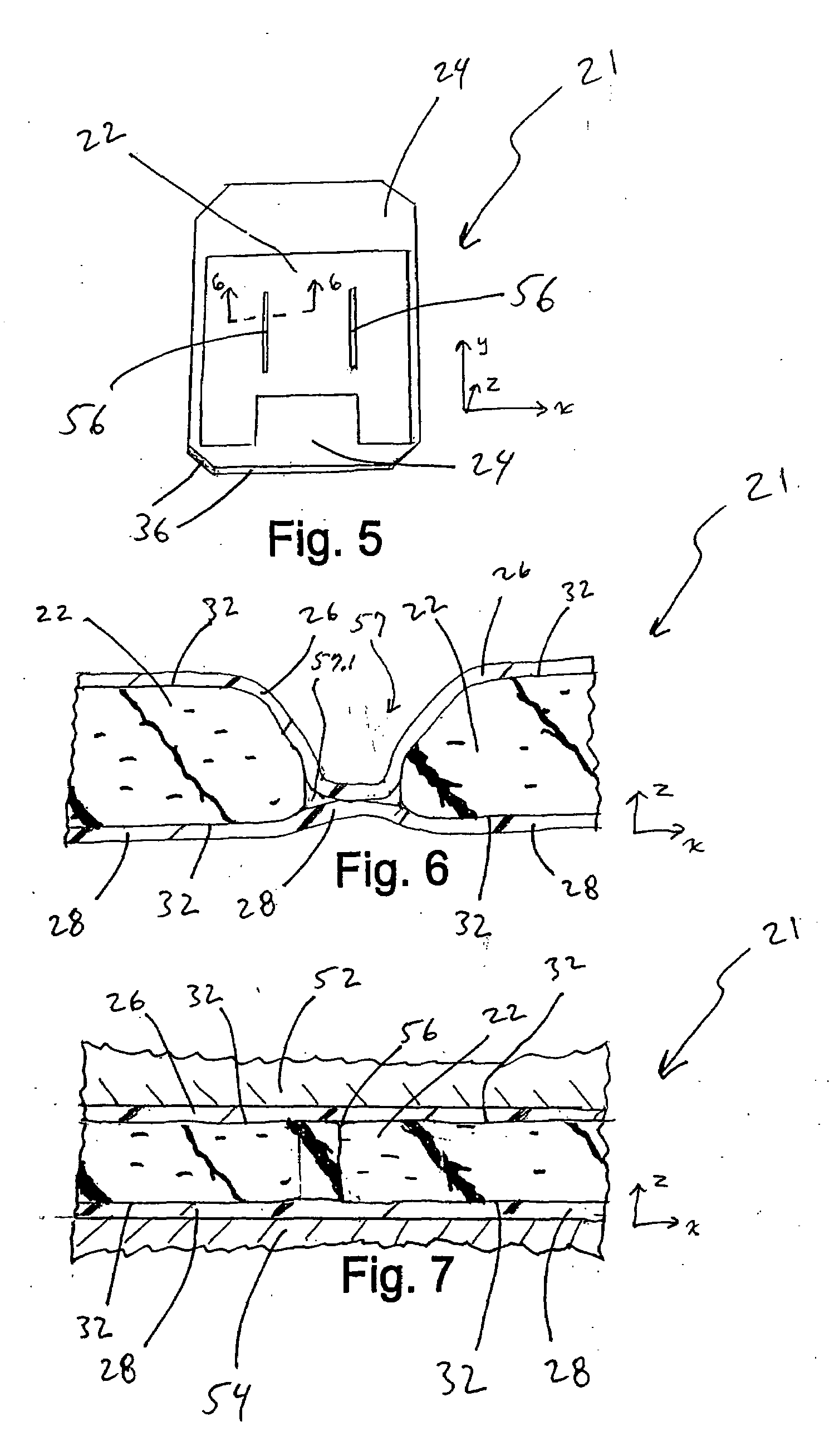

Aircraft side fairing

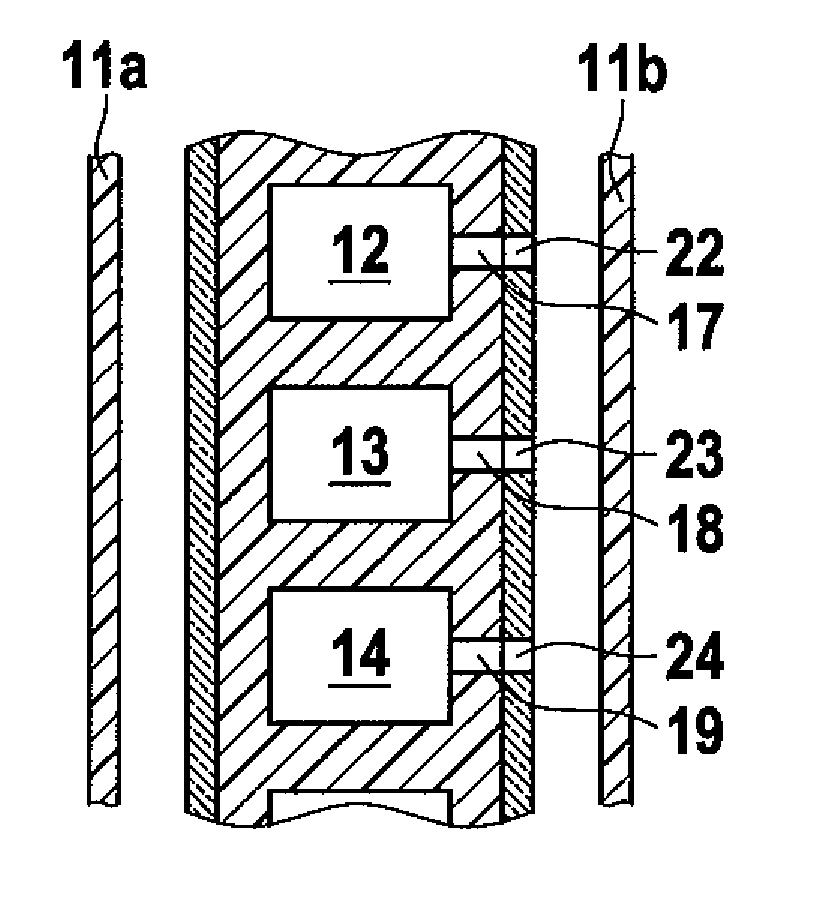

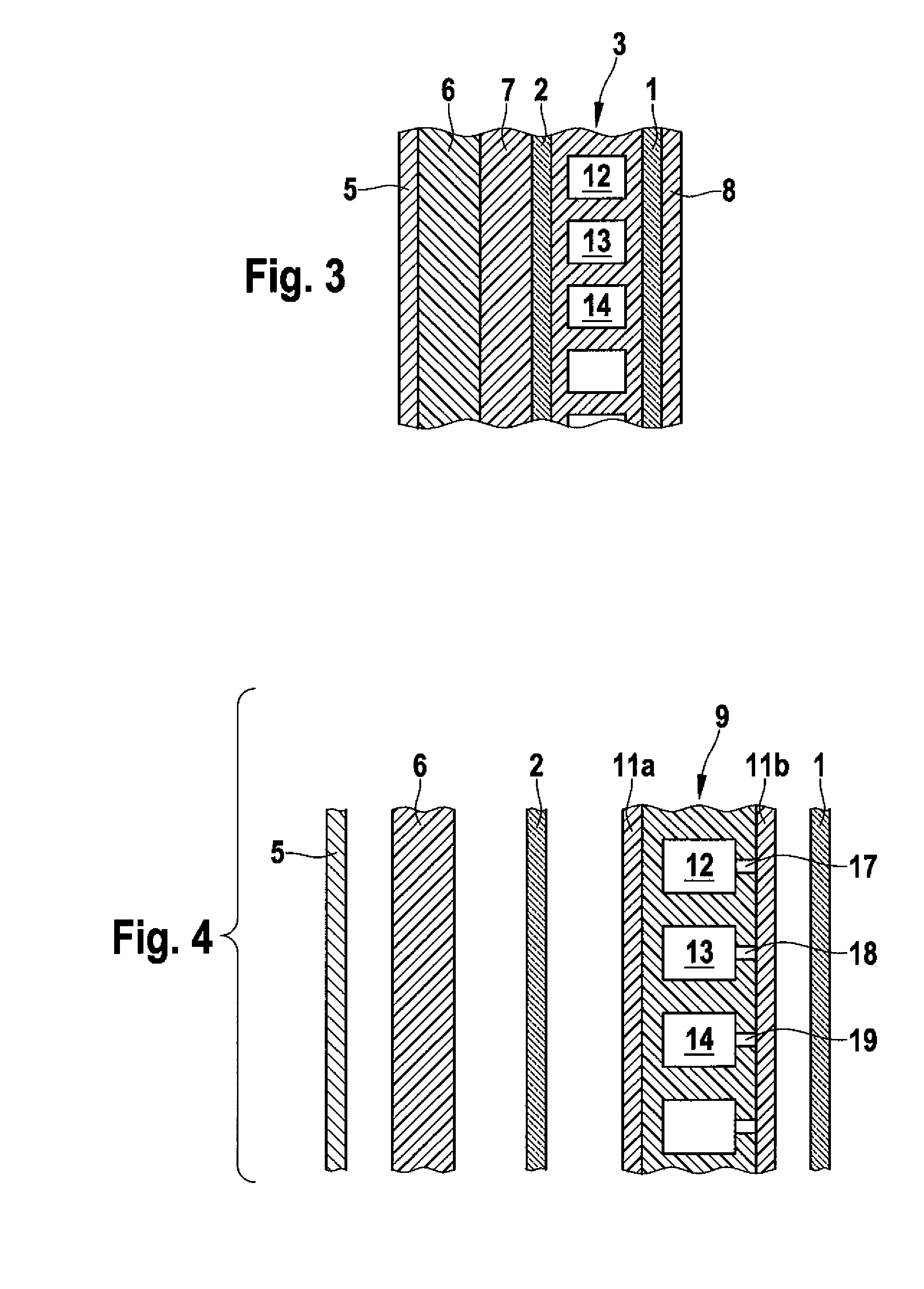

ActiveUS8490365B2Improve insulation performanceAvoid disadvantagesLayered productsWingsAirplaneWaste management

The invention relates to an aircraft side fairing, with a component (9) in the form of individual hollow chambers (12, 13, 14) which are arranged essentially in a preferably curved plane and are arranged between two cover layers (1, 2), wherein a gastight film which completely encases the component (9) with the hollow chambers (12, 13, 14) is provided and, after application of a vacuum to evacuate the hollow chambers (12, 13, 14), surrounds the component (9) with the hollow chambers in a gastight manner.

Owner:AIRBUS OPERATIONS GMBH

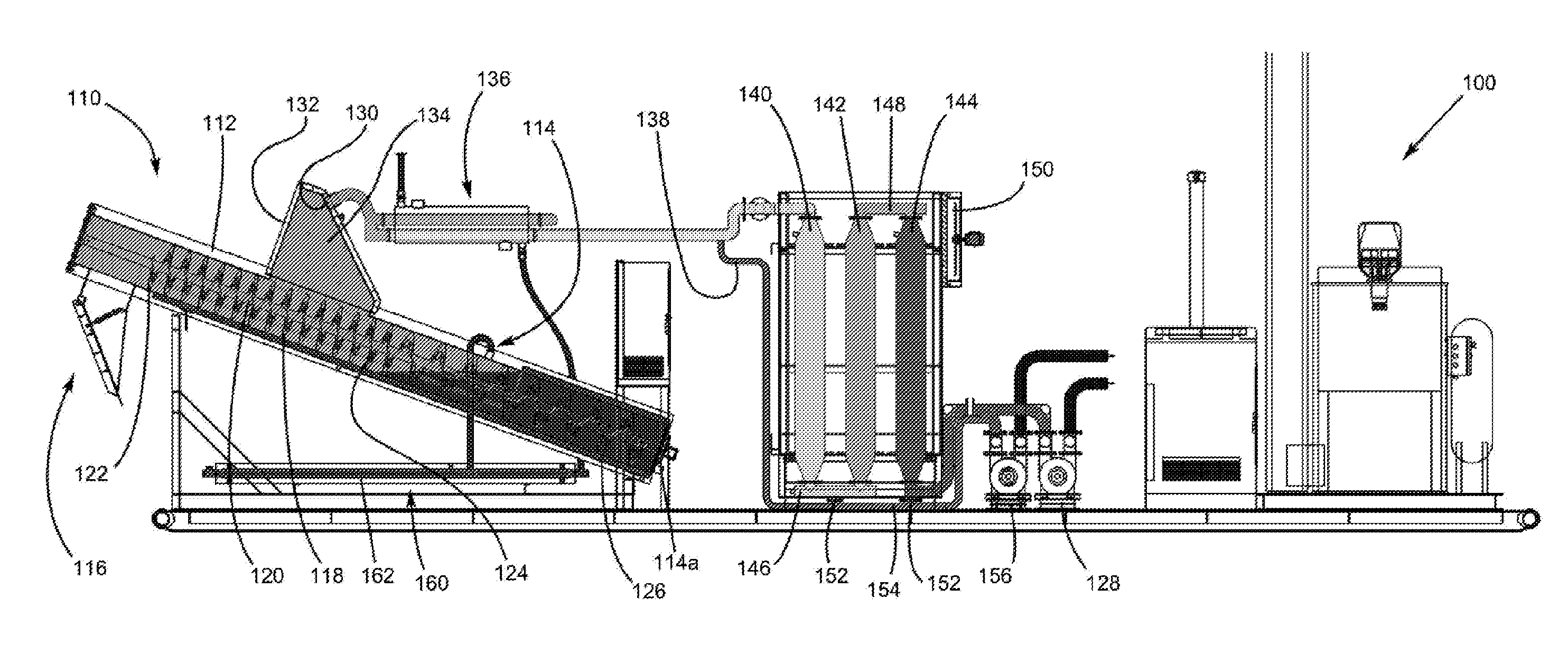

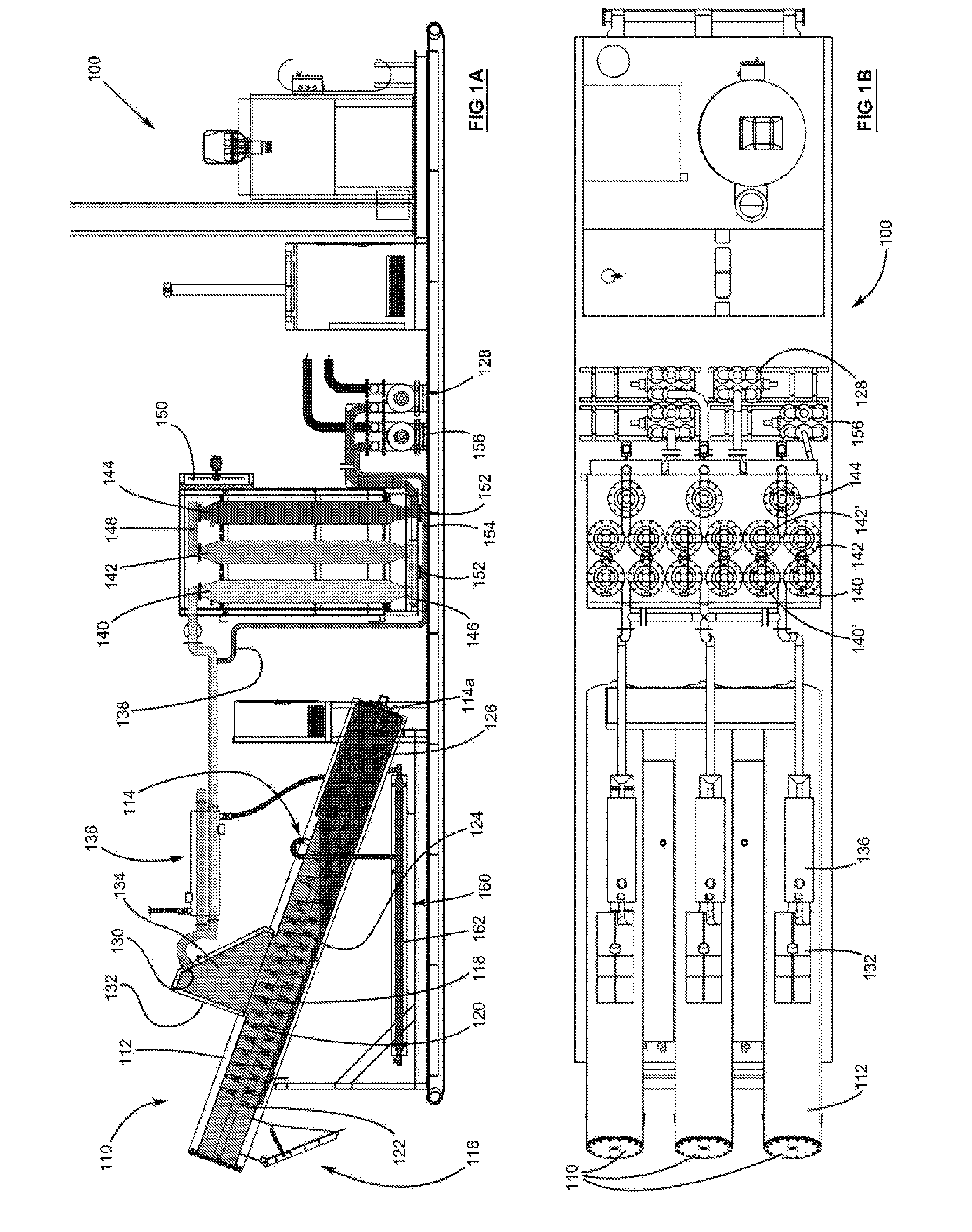

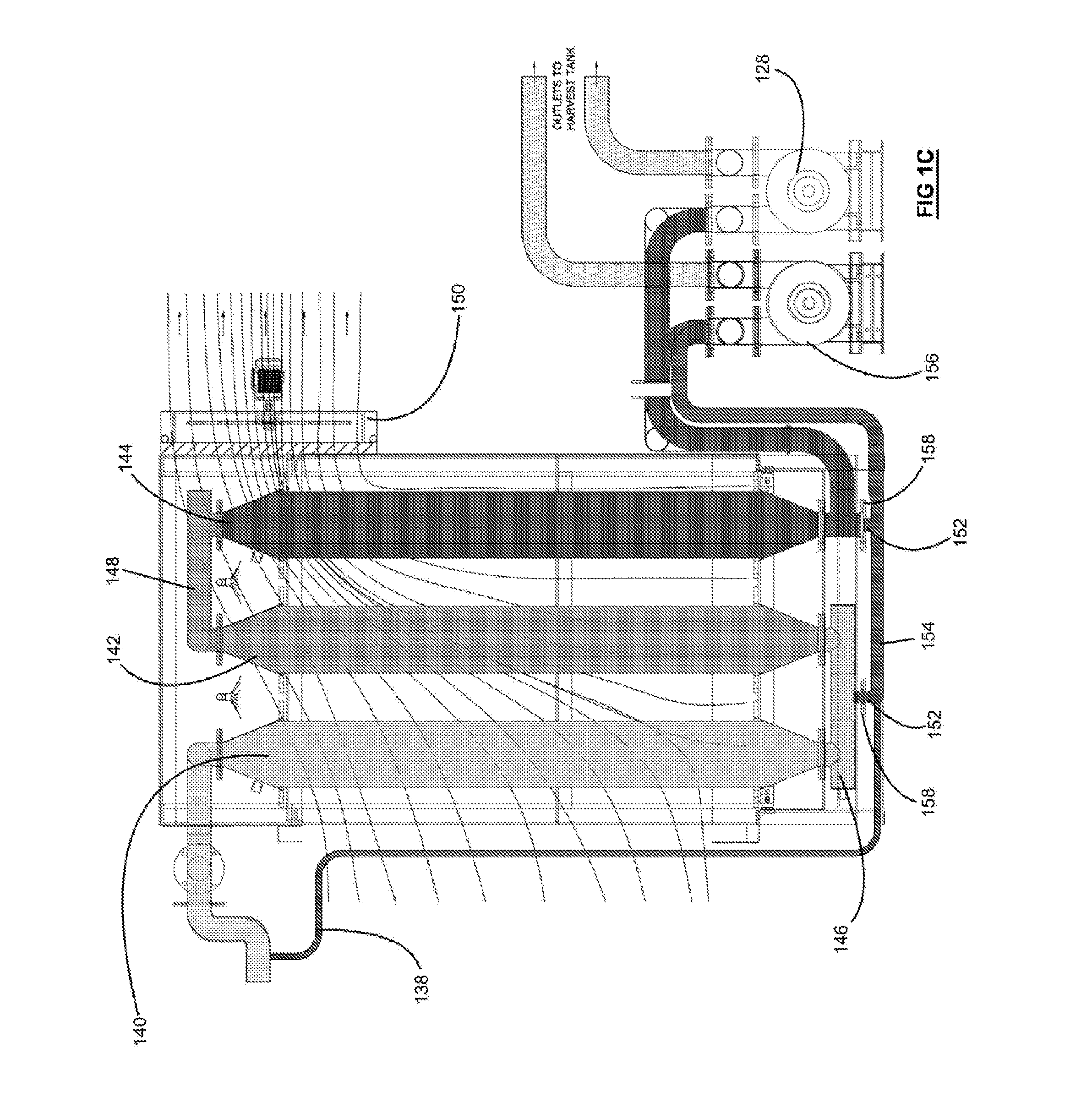

Process and apparatus for treating sludge

ActiveUS20160229728A1Lower the volumeLower energy requirementsWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeMoisture

An apparatus and process for removing moisture from sludge. The apparatus comprises a housing having an inlet and outlet for respective receipt and discharge of the sludge. A conveyor is located in the housing and is configured to transport the sludge from the inlet to the outlet. The apparatus further comprises a heater to heat the sludge to remove moisture therefrom whilst the sludge is being transported by the conveyor. The apparatus also comprises a vacuum pump arranged to extract air from the apparatus and, at the same time, to cause moisture removed from the sludge to flow therefrom together with the extracted air.

Owner:ALI JAK HLDG

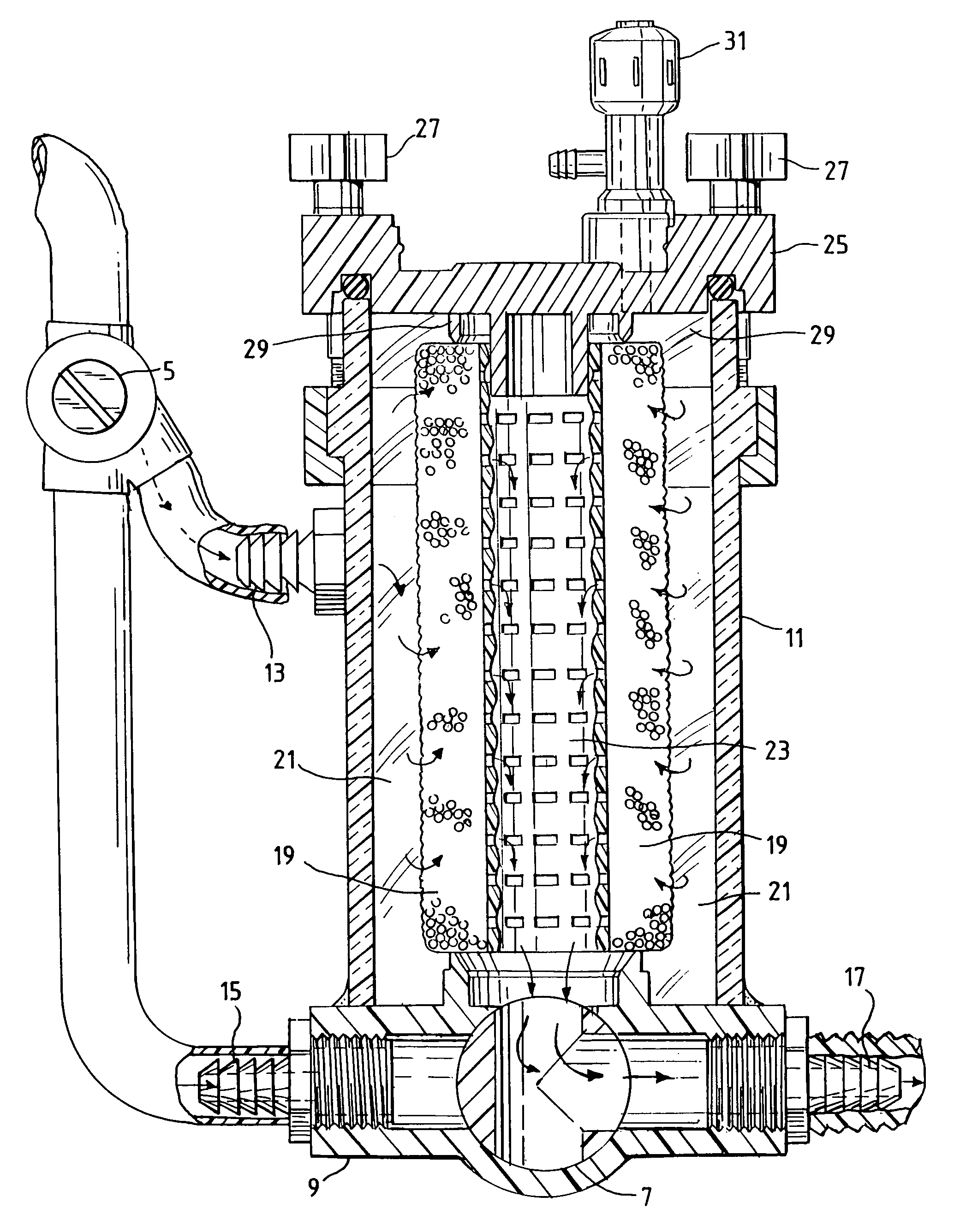

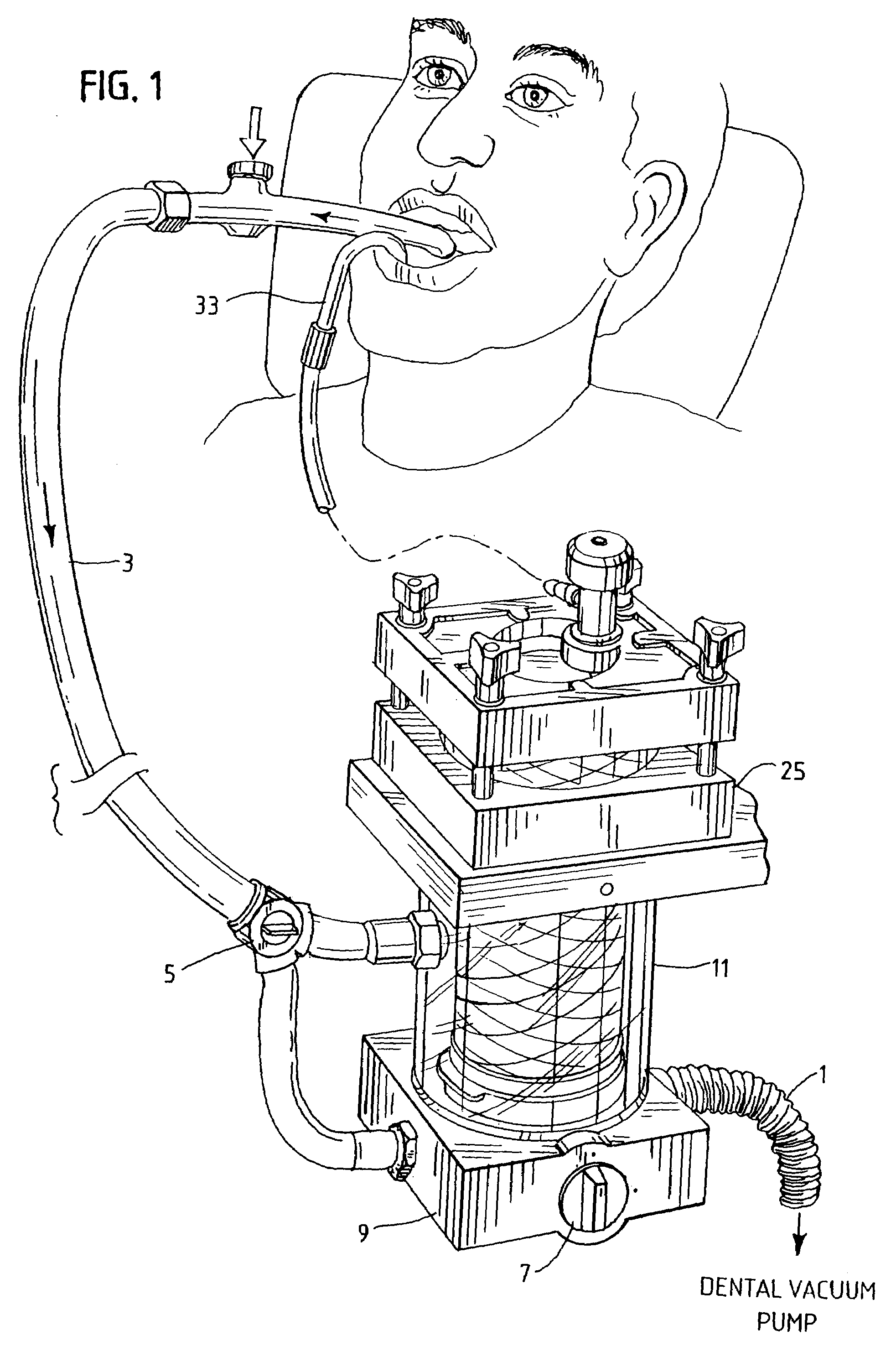

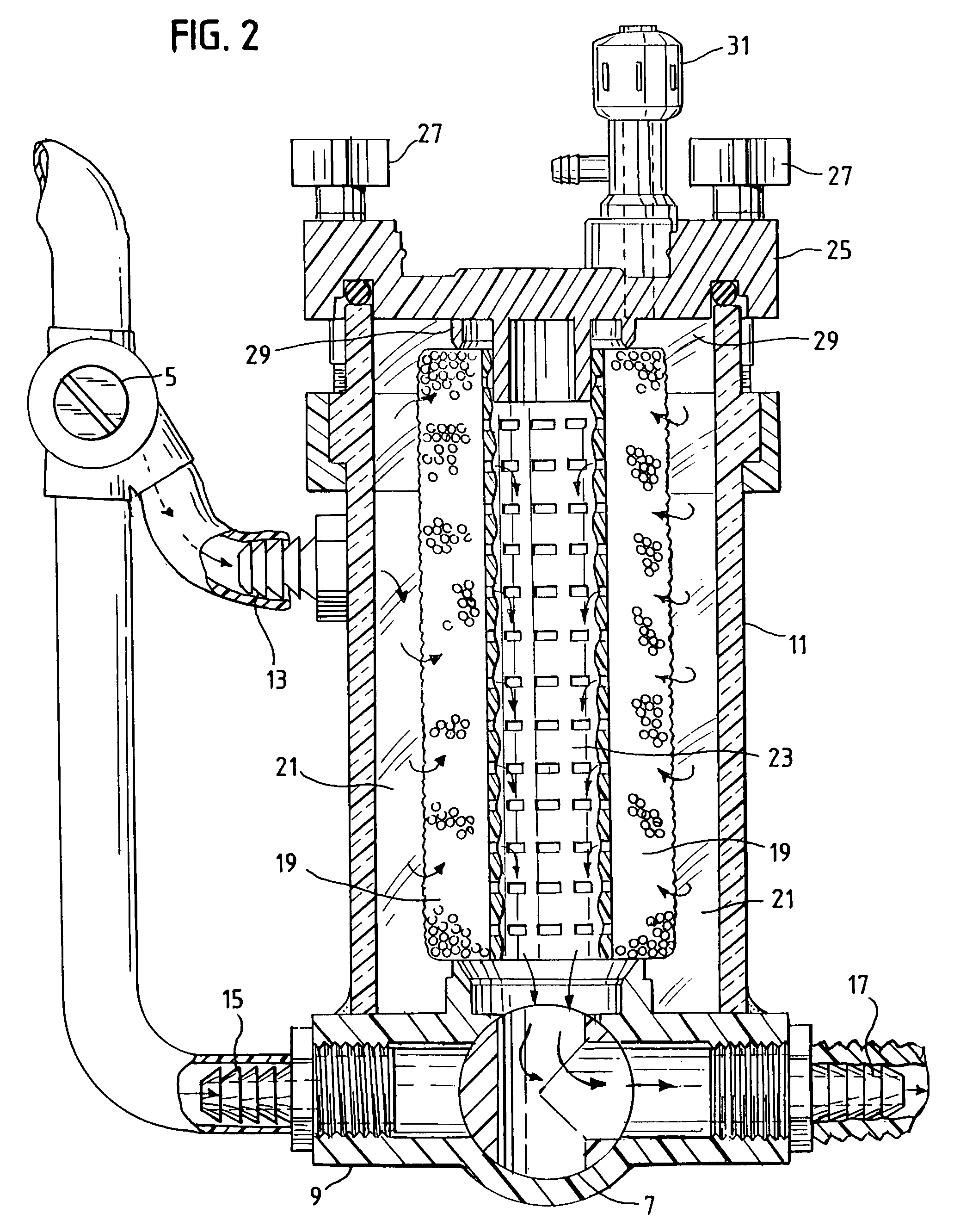

Method and apparatus for removing particulate metals from dental waste water

InactiveUS7182599B2Easy to replaceTransportation safetySettling tanks feed/dischargeIntravenous devicesWastewaterStopcock

Owner:NAVY UNITED STATES OF AMERICA AS REPRESENTED BY SEC OF THE

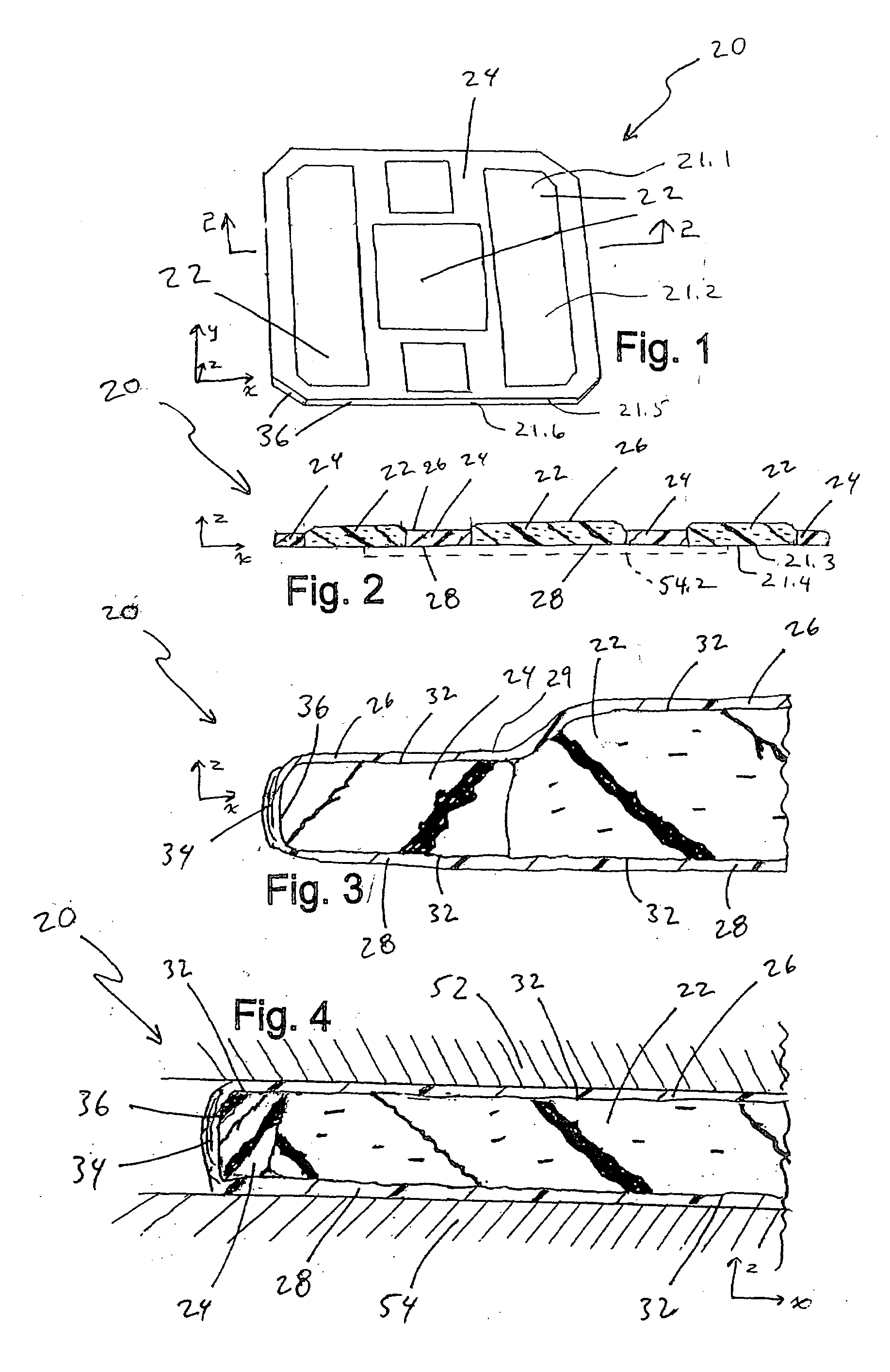

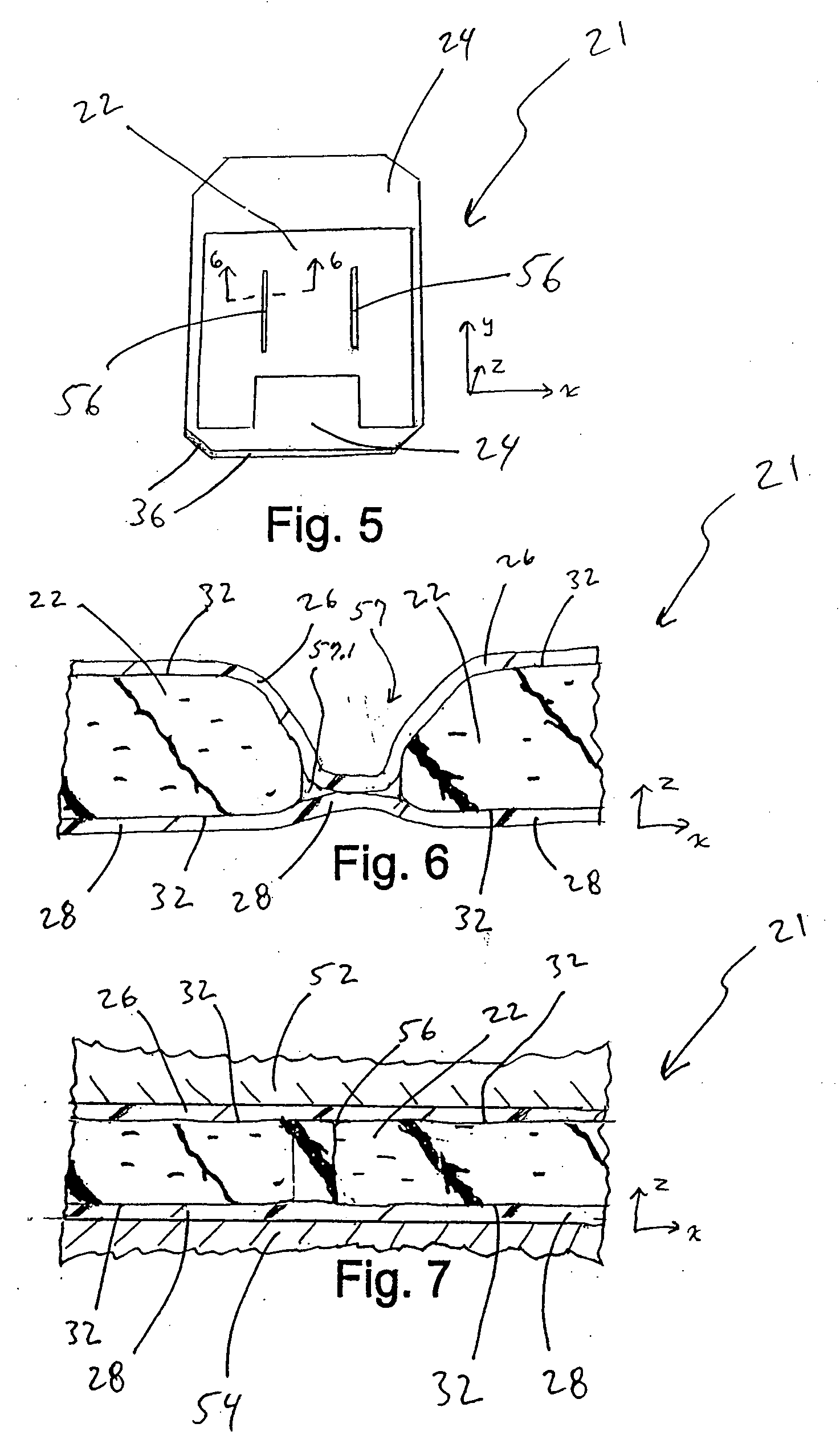

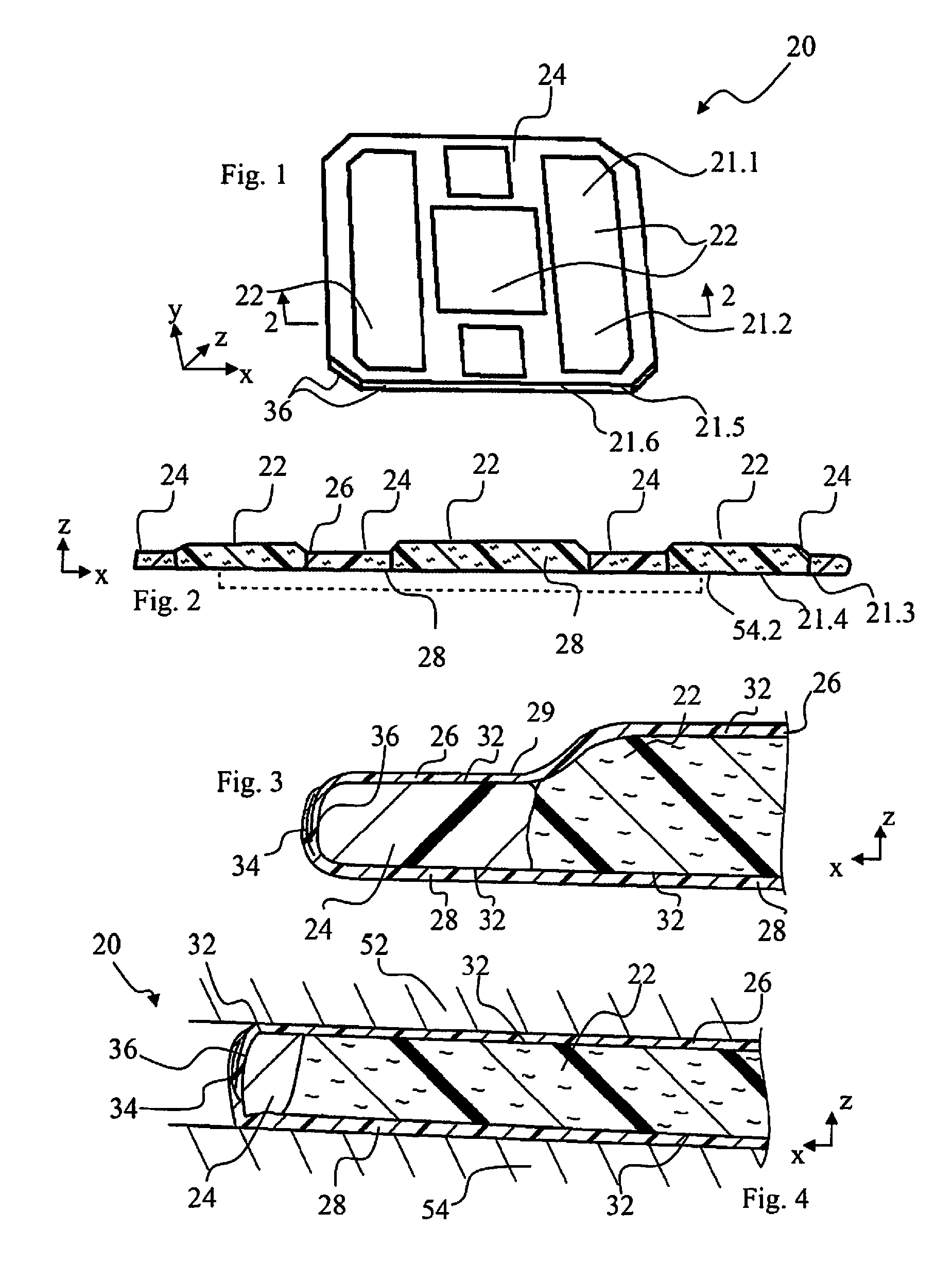

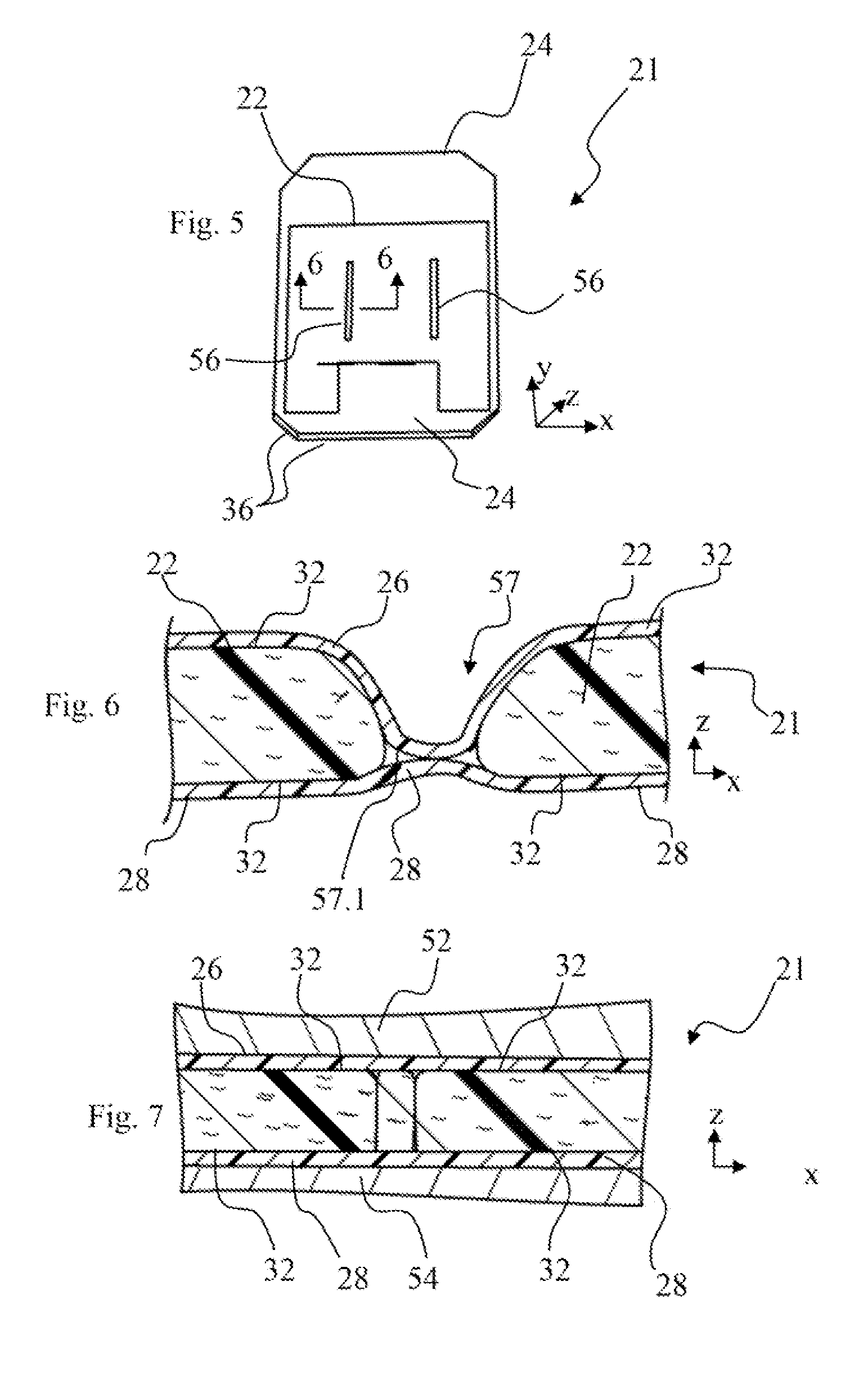

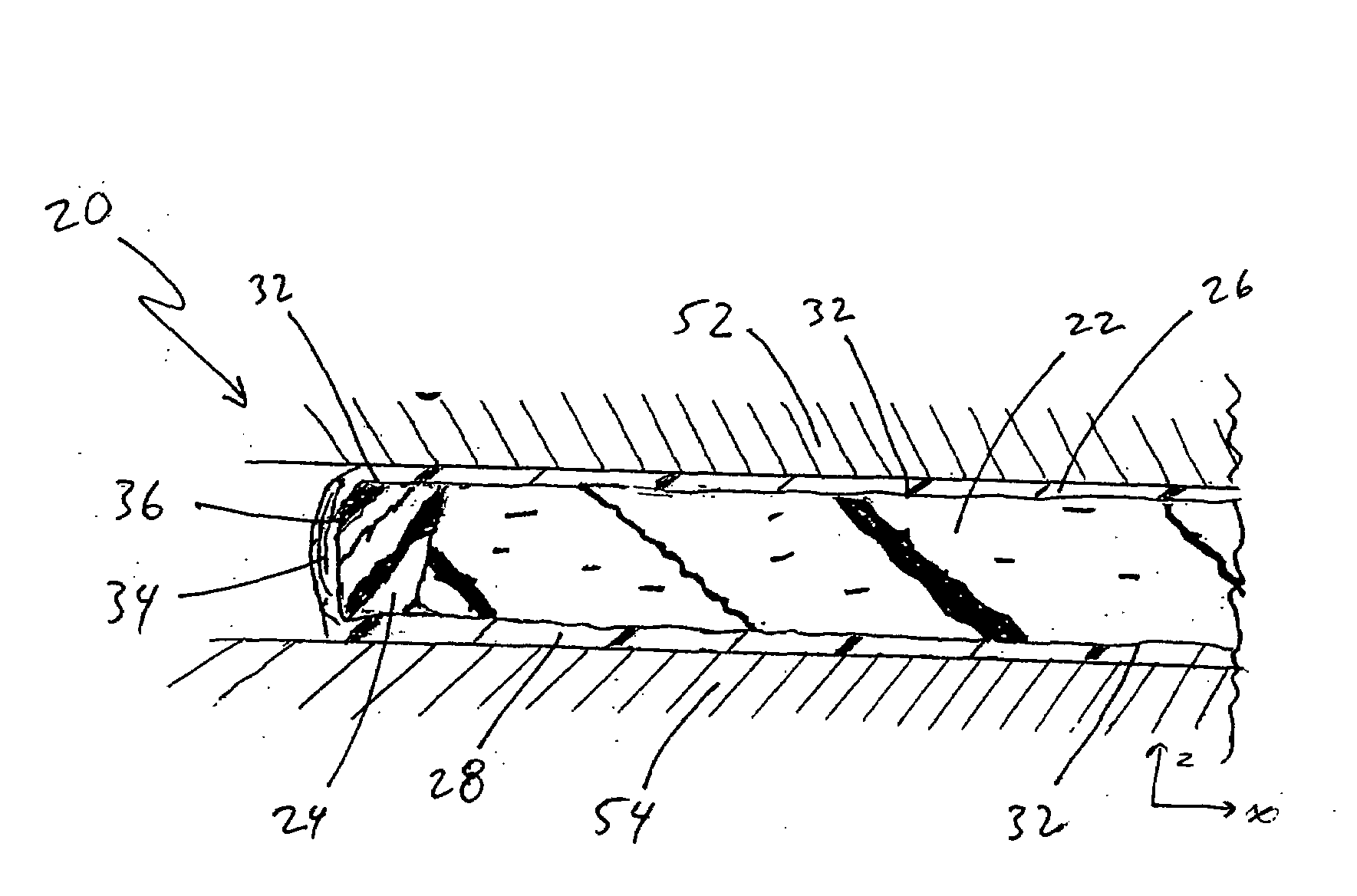

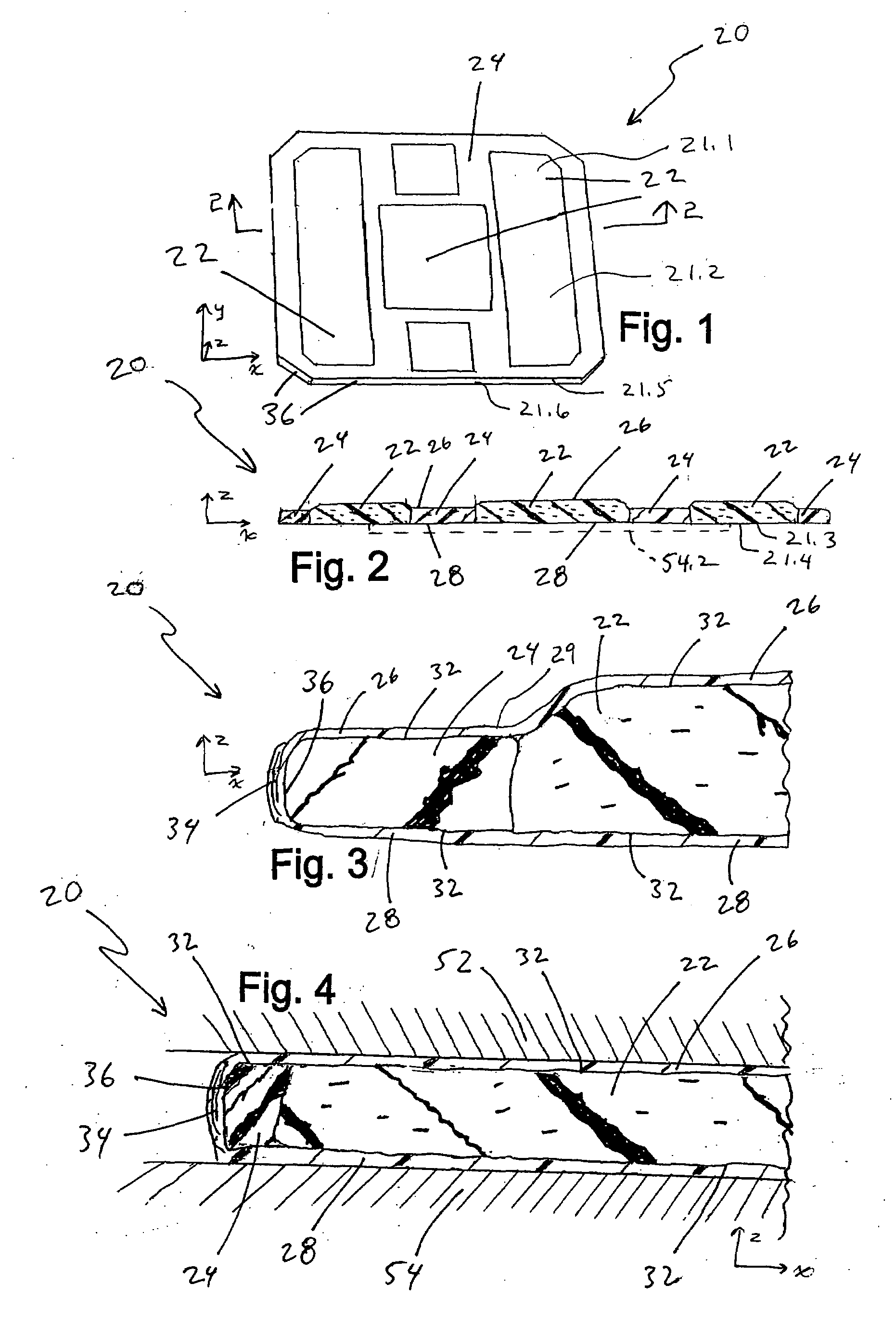

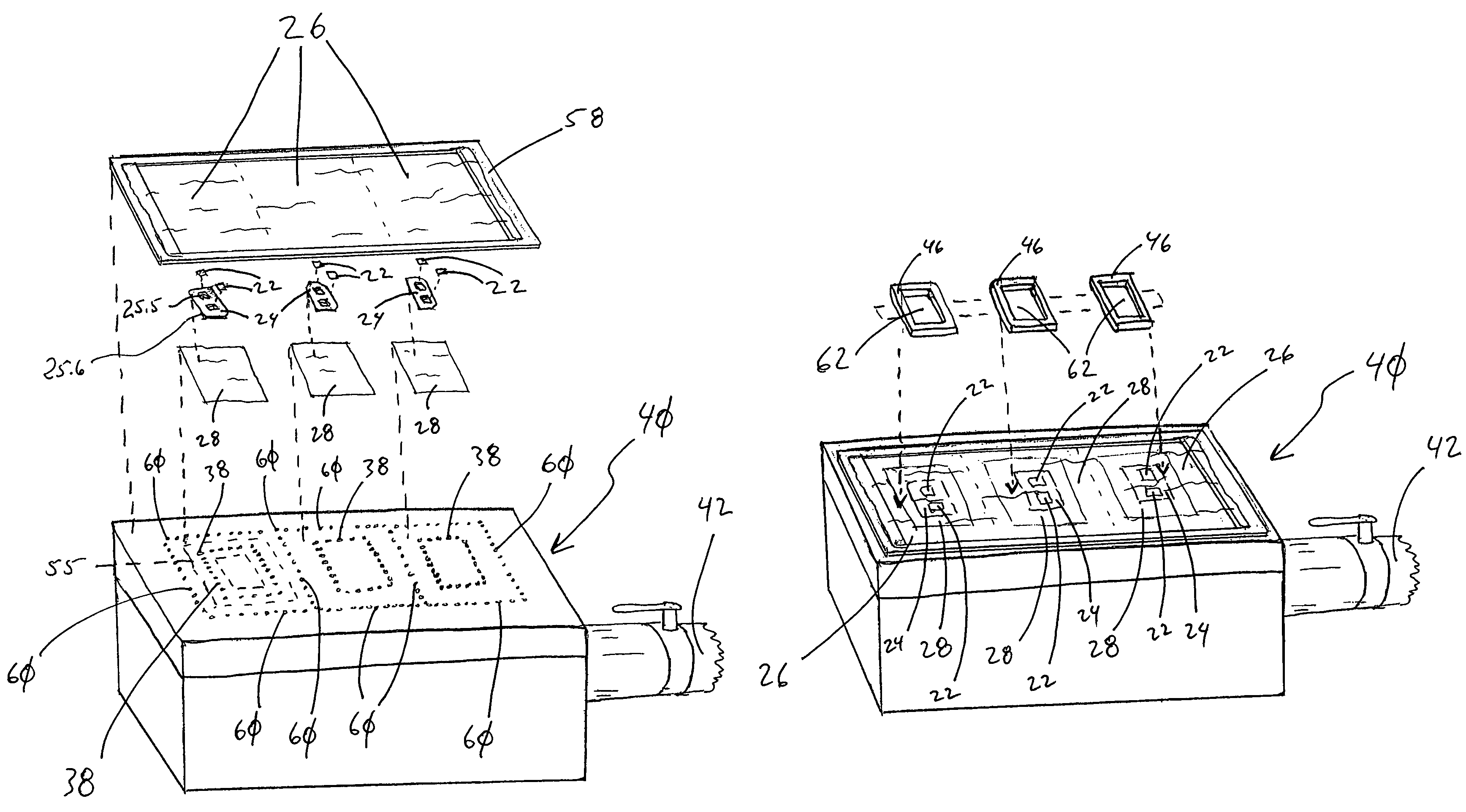

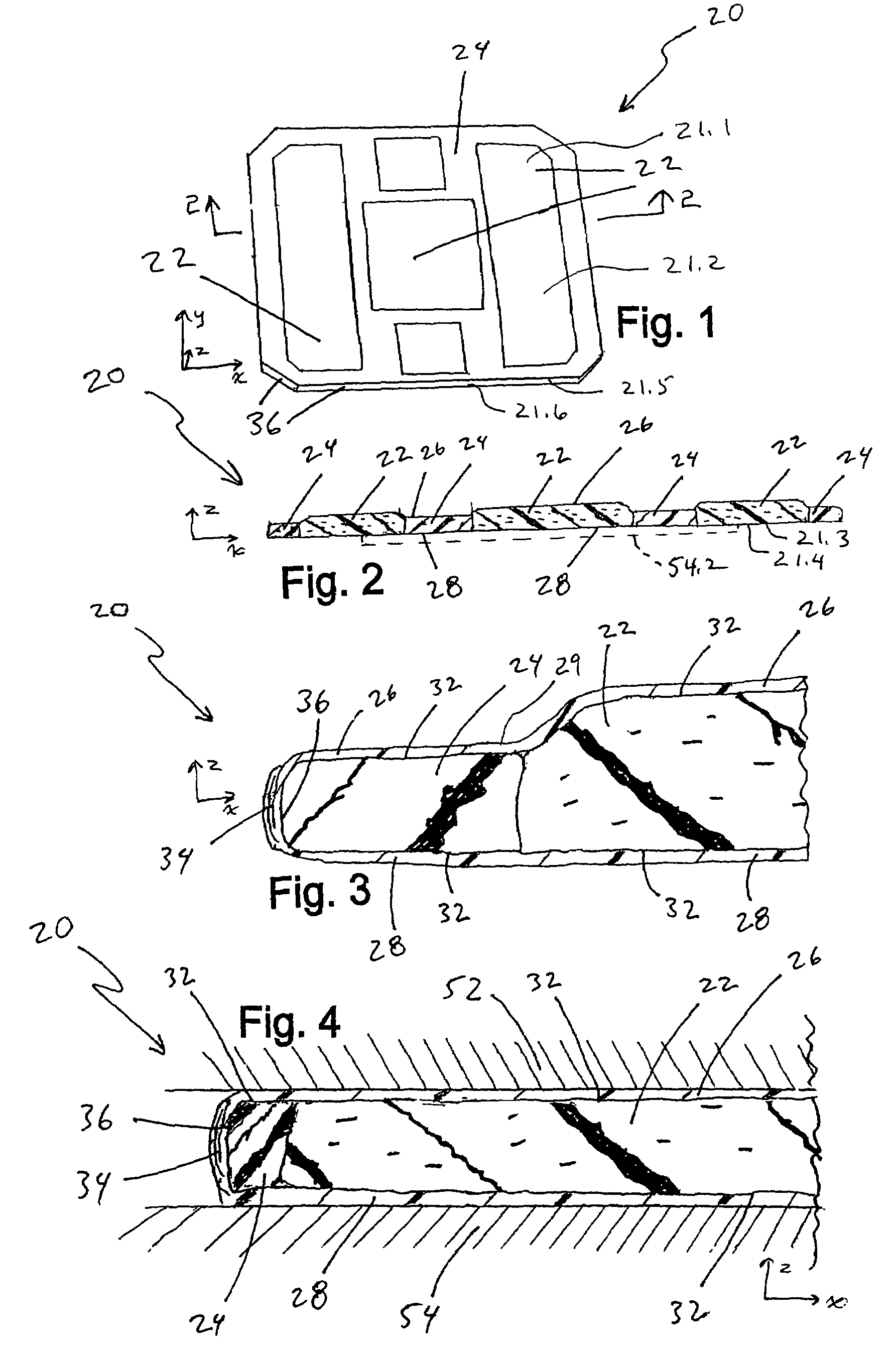

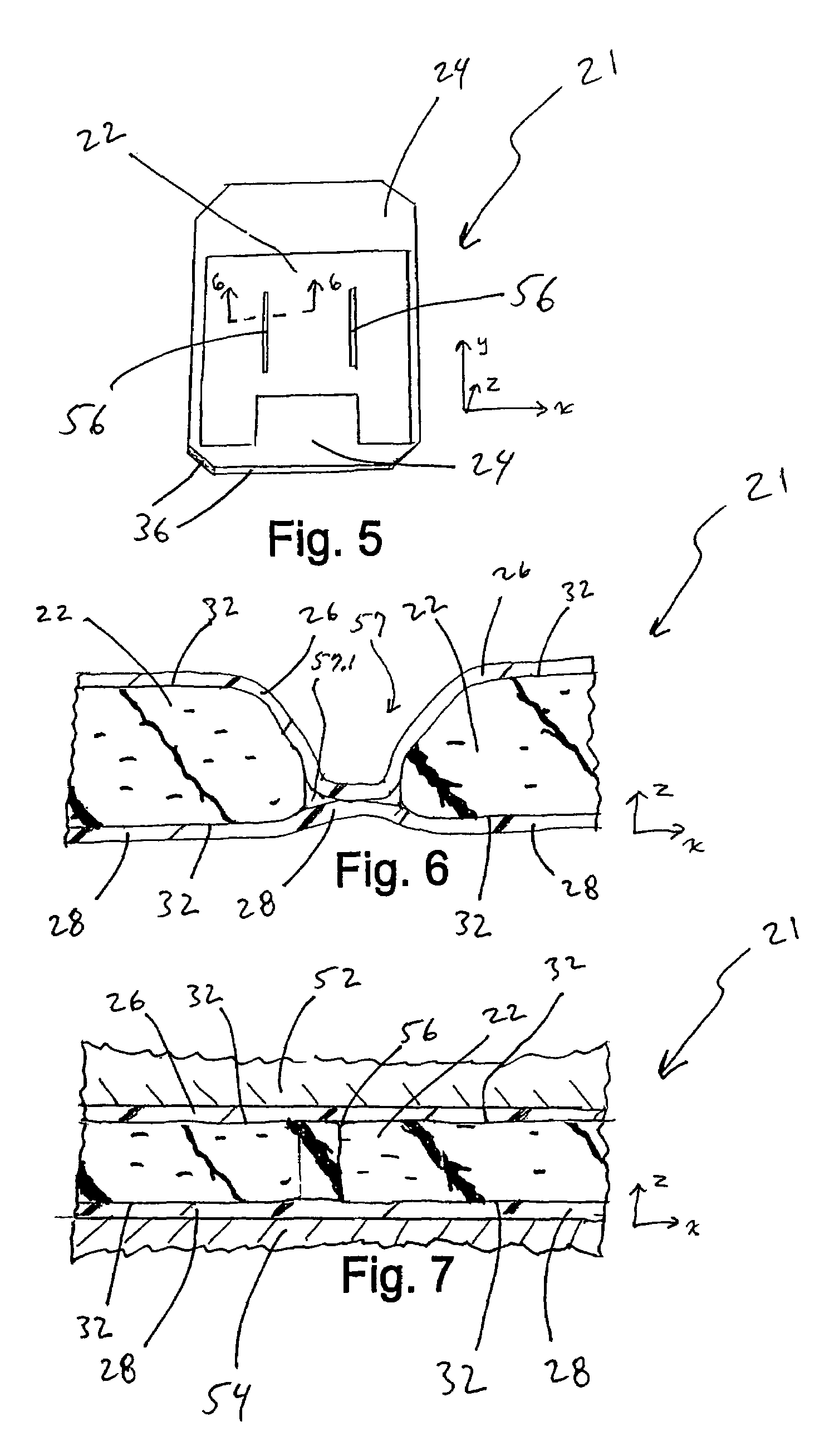

Sealed thermal interface component

ActiveUS20080190585A1Improve heat transfer characteristicsMinimize air gapSemiconductor/solid-state device detailsSolid-state devicesConductive materialsSilicone oil

A sealed thermal interface component minimizes or eliminates the exudation of fluids, such as silicone oils, while preserving the excellent thermal conductivity of silicon-based thermal pad materials and enhancing the conformability of the component. In an example embodiment, one or more thermal pads are formed of conformable thermal management material that may exude fluid under elevated temperatures or over time. Film encapsulates the thermal pad or pads, forming a sealed and partially evacuated thermal interface component. In one embodiment of the invention, the thermal pad or pads are formed of an elastomeric silicon-based thermally conductive material and the film is made of polyurethane.

Owner:LUNDELL MFG CORP

Device for removing a lodged mass

ActiveUS20120221010A1Increase chanceGood removal effectOral administration deviceSurgical pincettesVacuum pressureEngineering

A device for removing a mass lodged in a choking victim's throat comprises a manifold, piston, spool, and latch. The manifold has first, second, and third conduits in selective fluid communication with each other, with the second conduit terminating in an orifice in a mouthpiece. The spool, having a transverse orifice, may be disposed in the third conduit, slidable between a first position where the orifice permits fluid communication between the first and second conduits, and a second position where the spool blocks fluid communication. The piston is slidably disposed within the first conduit, and with the spool is in the second position, the latch is usable to secure the piston relative to the manifold at one or more discrete positions to create a measured amount of vacuum pressure in the first conduit. The vacuum pressure is transmitted to the mouthpiece by movement of the spool to said first position.

Owner:ODYSSEY GRP INT INC

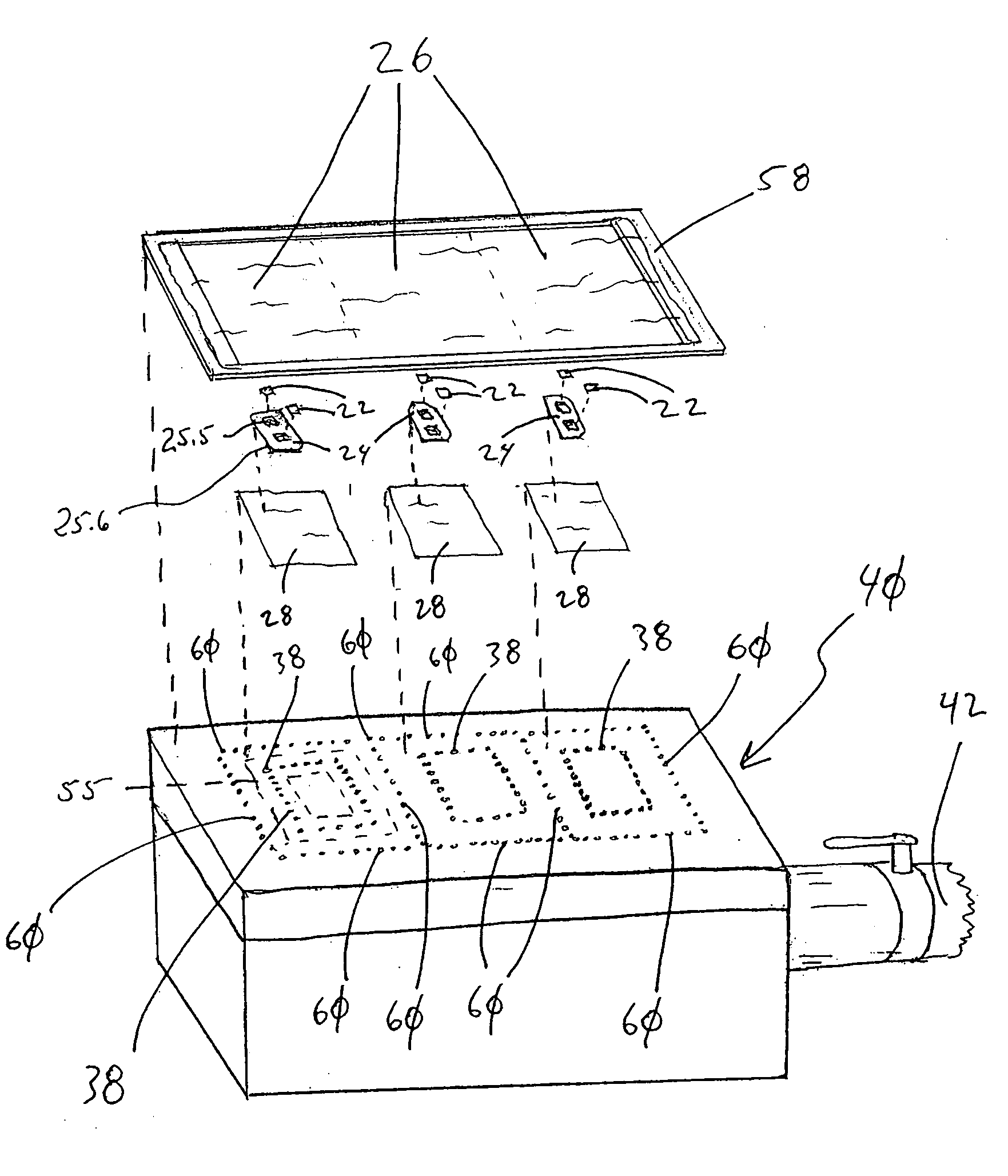

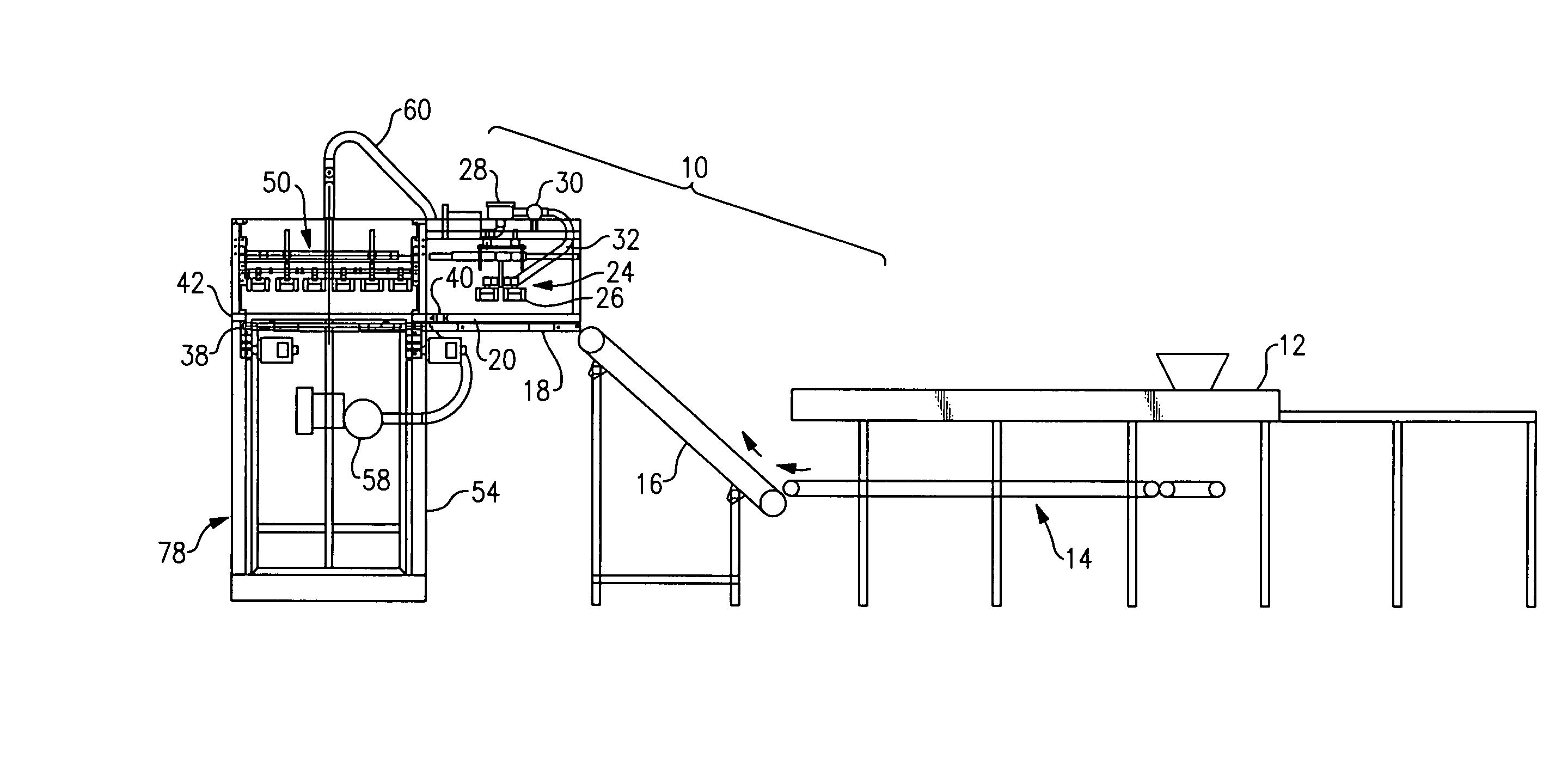

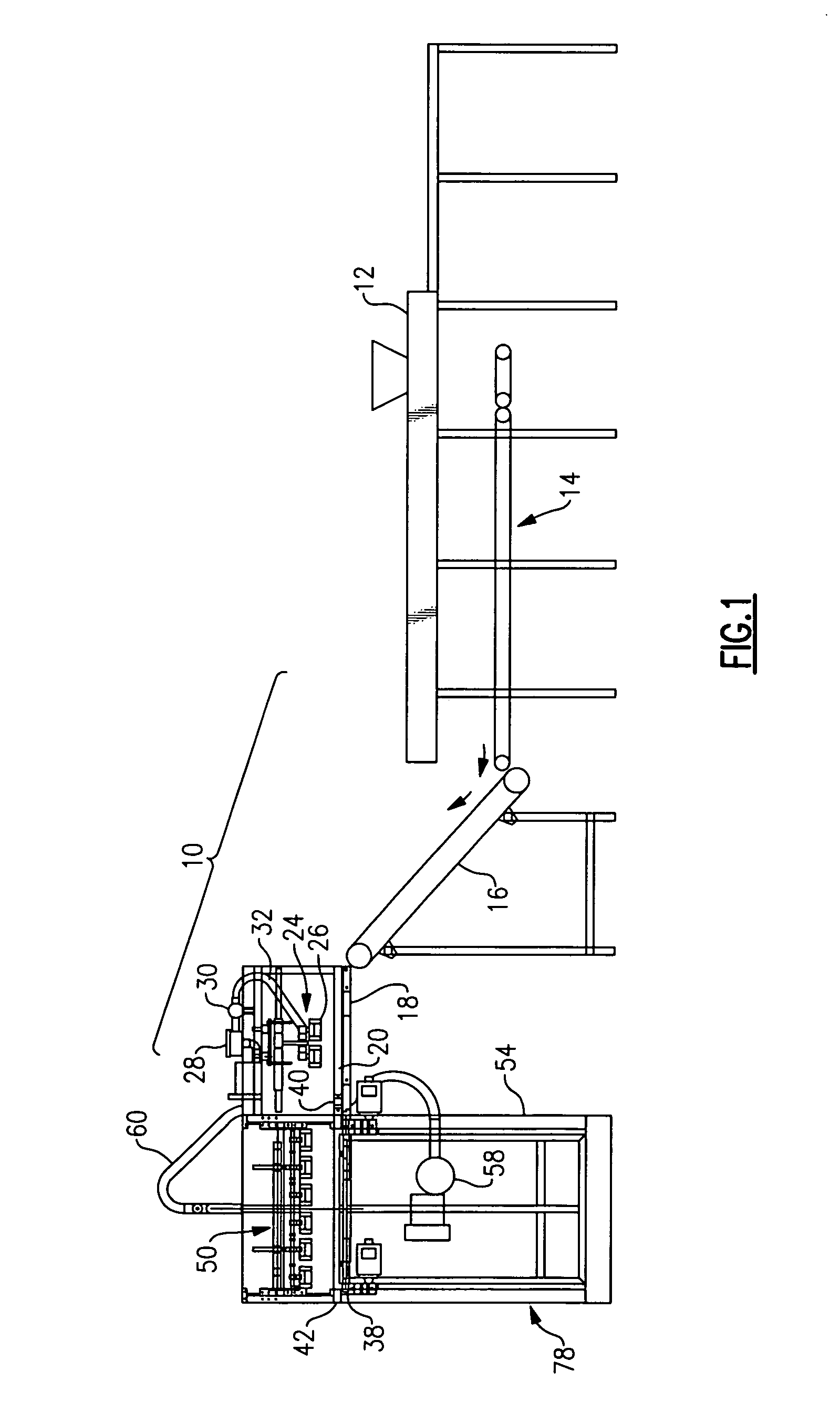

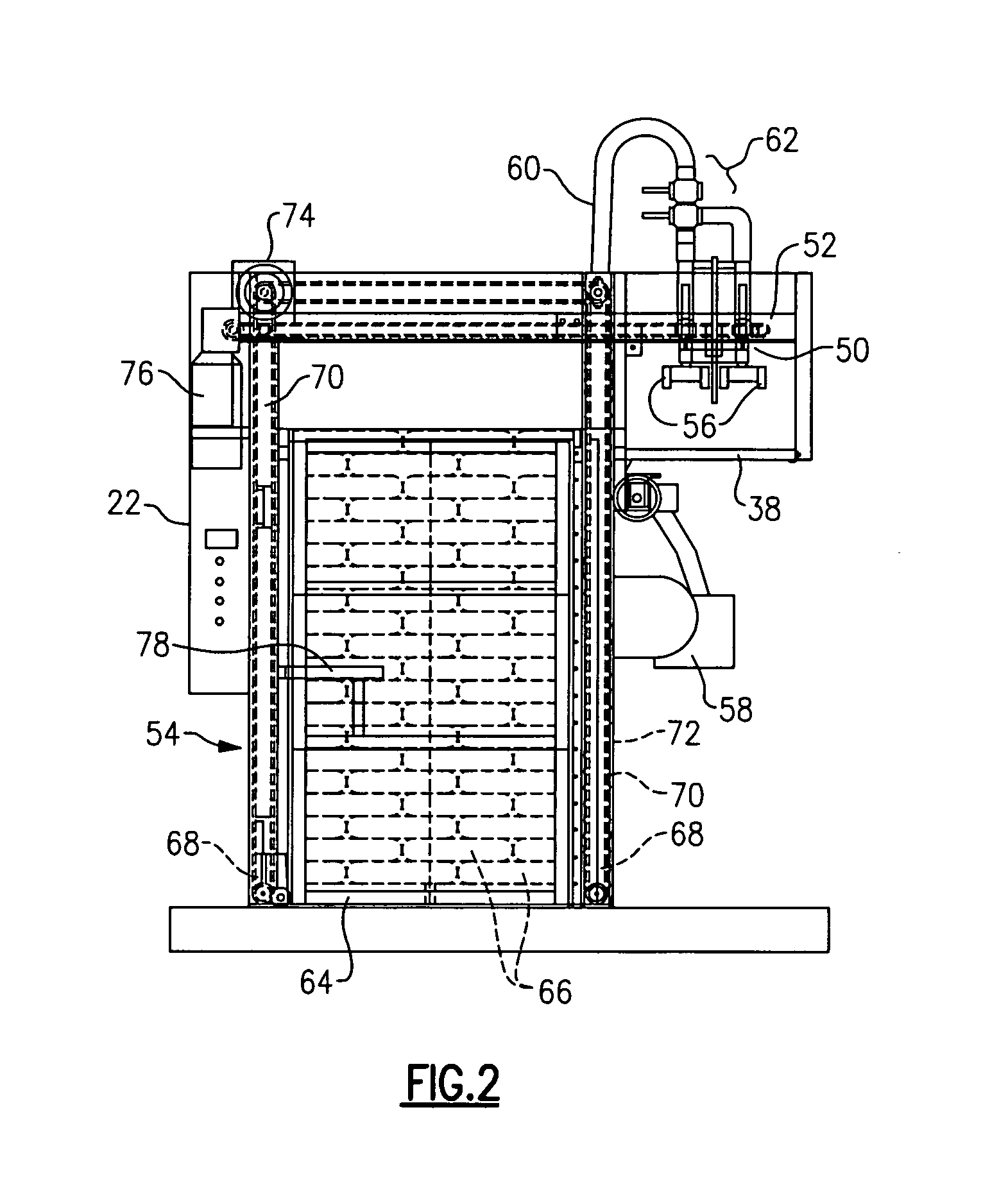

Ice bag palletizer

InactiveUS20080101911A1Raised and loweredKeep vacuumingStacking articlesConveyor partsStack machinePalletizer

An automatic pallet stacking machine for loading bags of ice cubes onto a pallet has a first infeed conveyor with a pick and turn device for orienting the bags, and a collating conveyor adjacent a pallet holder or pallet elevator where the bags are accumulated until a row of bags is formed. Then a gantry picks up the bags and places transports the row to the pallet. The pick and turn device and the gantry employ vacuum heads that have closed cell foam side walls to accommodate the lumpy and shifting nature of the bag contents. A programmable controller ensures that the bags rows are formed in appropriate patterns so that the bags in each tier interlock with the bags in the tier beneath.

Owner:HULCHANSKI RICHARD

System, apparatus and method for contaminant reduction in semiconductor device fabrication equipment components

ActiveUS7044147B2Avoid enteringKeep vacuumingPlug valvesDomestic plumbingMoistureBiomedical engineering

Owner:ATMEL CORP

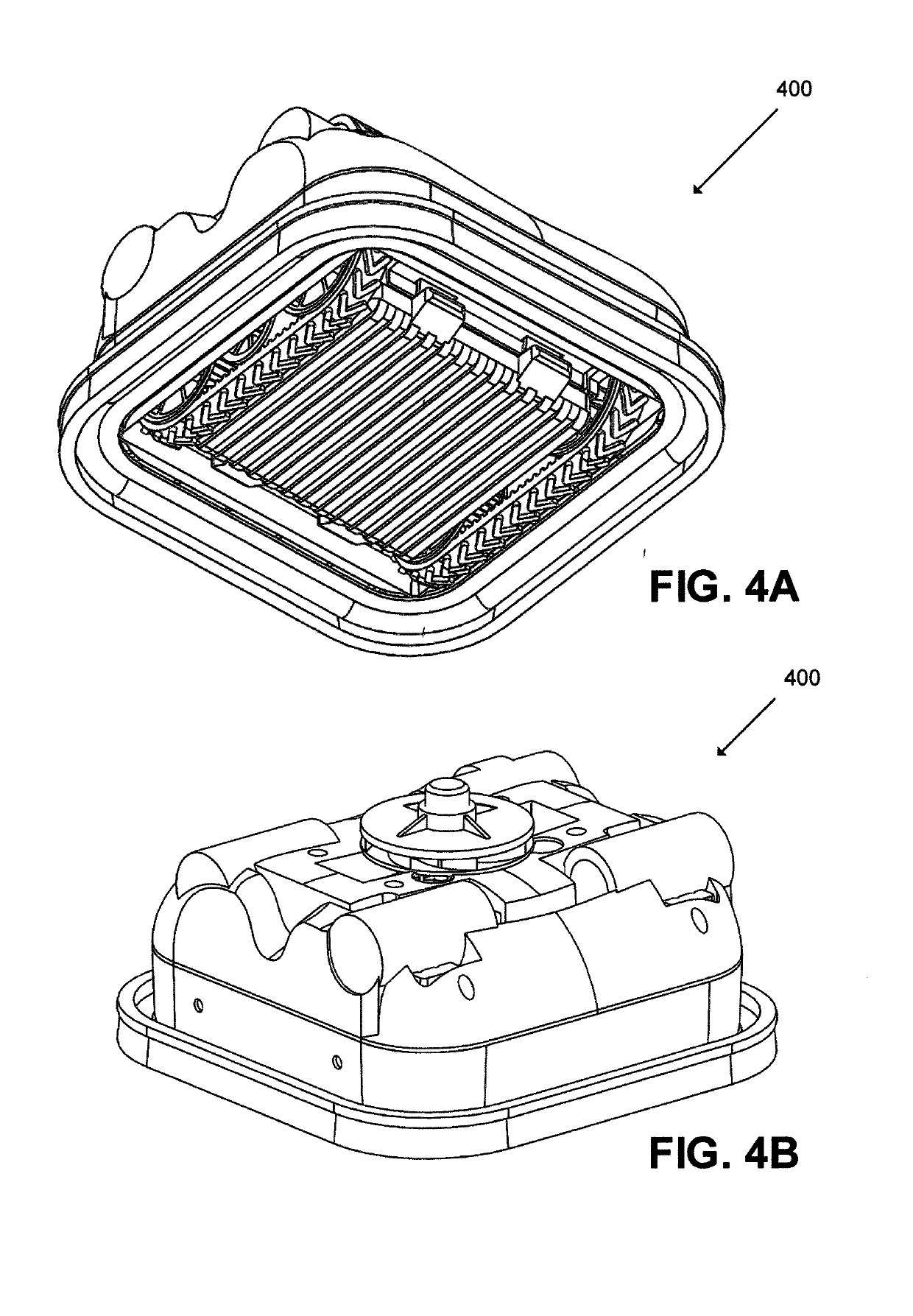

Sealed thermal interface component

ActiveUS8448693B2Eliminating of minimizingImprove heat transfer characteristicsSemiconductor/solid-state device detailsSolid-state devicesConductive materialsSilicone oil

A sealed thermal interface component minimizes or eliminates the exudation of fluids, such as silicone oils, while preserving the excellent thermal conductivity of silicon-based thermal pad materials and enhancing the conformability of the component. In an example embodiment, one or more thermal pads are formed of conformable thermal management material that may exude fluid under elevated temperatures or over time. Film encapsulates the thermal pad or pads, forming a sealed and partially evacuated thermal interface component. In one embodiment of the invention, the thermal pad or pads are formed of an elastomeric silicon-based thermally conductive material and the film is made of polyurethane.

Owner:LUNDELL MFG CORP

Sealed thermal interface component

ActiveUS20080190584A1Excellent thermal transfer characteristicSimple encapsulationSemiconductor/solid-state device detailsSolid-state devicesSilicone resinThermal conductivity

A sealed thermal interface component minimizes or eliminates the exudation of fluids, such as silicone oils, while preserving the excellent thermal conductivity of silicon-based thermal pad materials and enhancing the conformability of the component. In preferred embodiments, a foam frame surrounds a plurality of thermal pad portions formed of conformable thermal management material that may exude fluid under elevated temperatures or over time. Film encapsulates the foam-framed thermal pad portions, forming a sealed and partially evacuated thermal interface component. In one embodiment of the invention, the thermal pads are formed of an elastomeric matrix material containing silicone, the foam frame is made of urethane, and the film is made of polyurethane.

Owner:LUNDELL MFG CORP

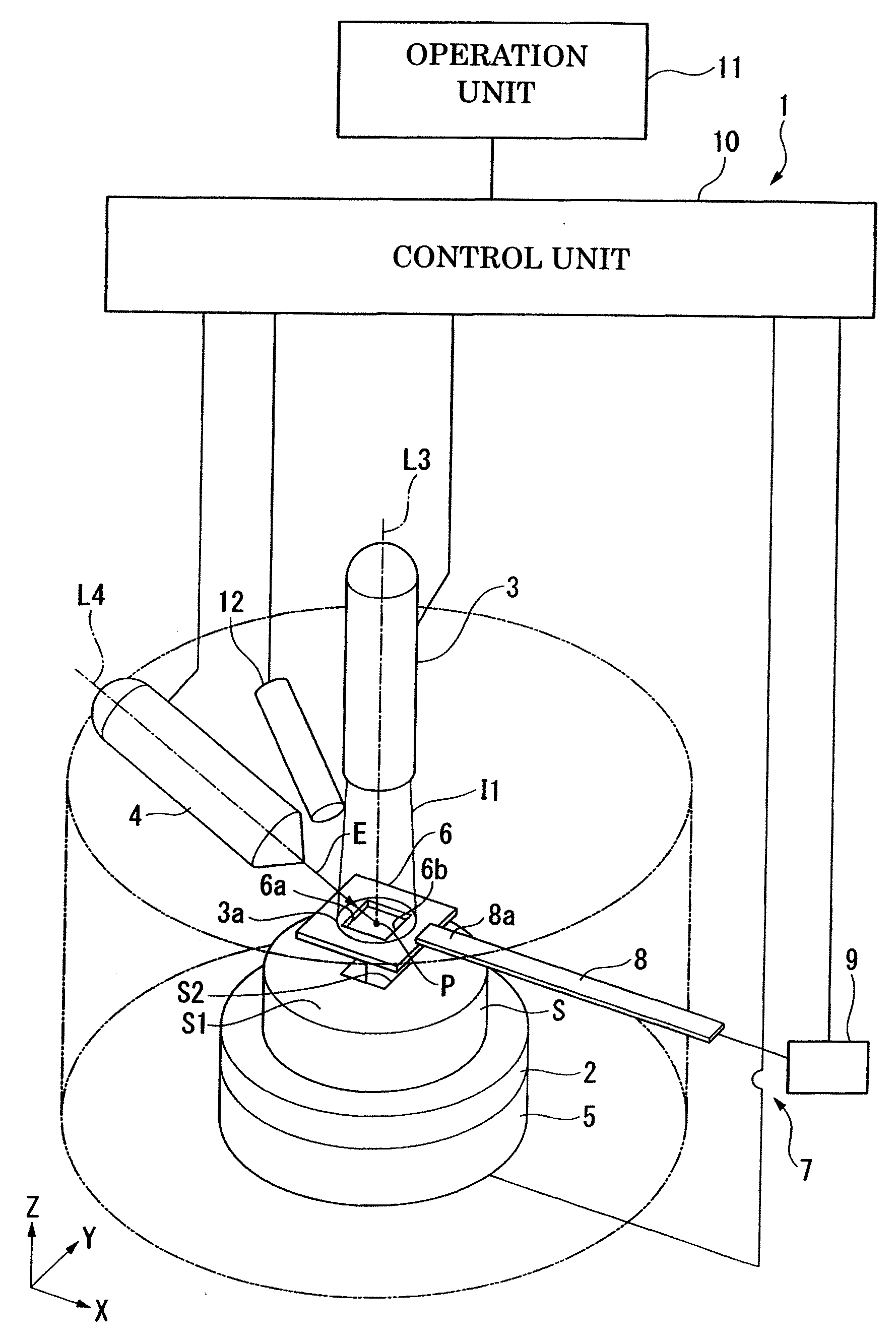

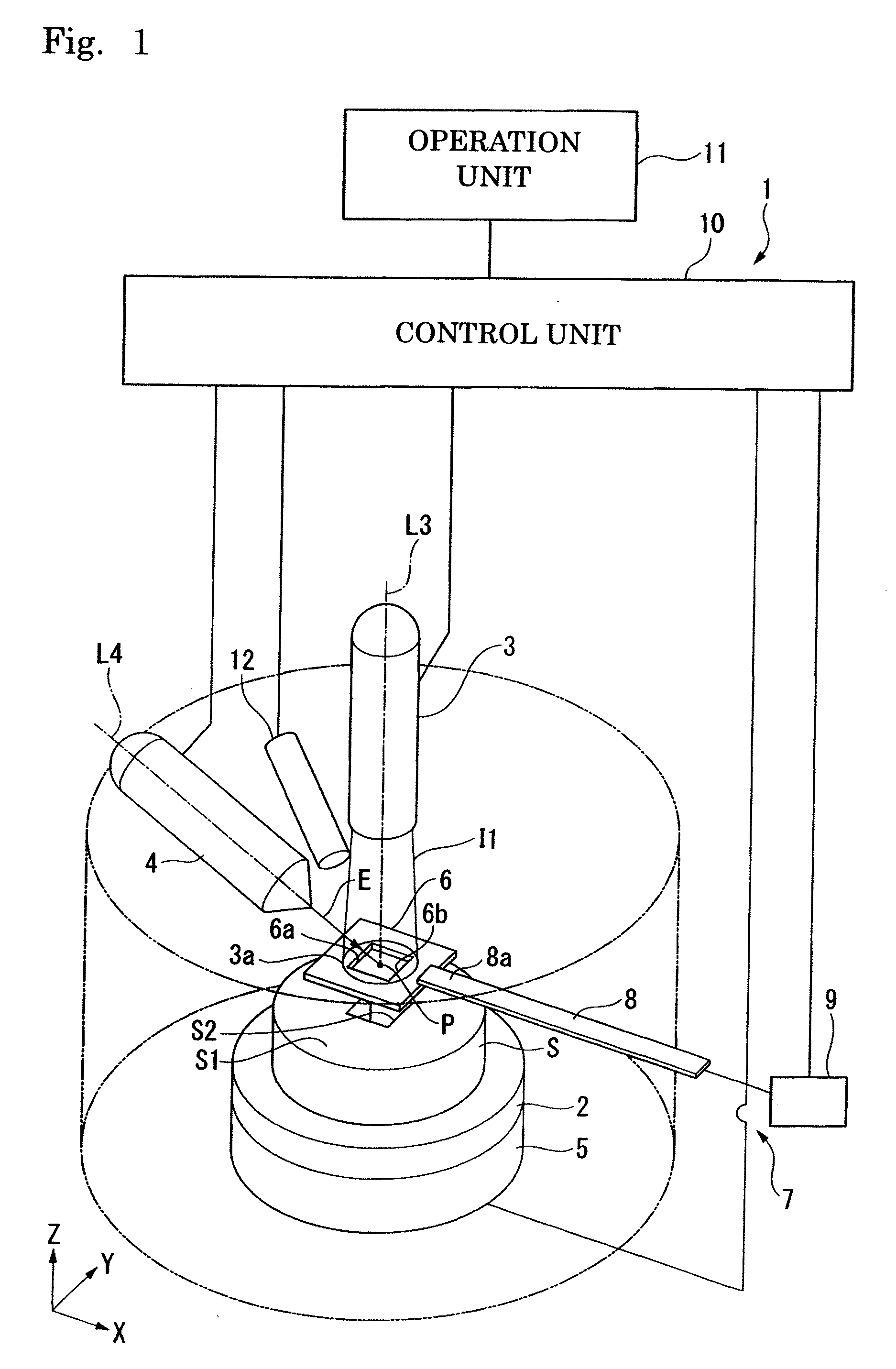

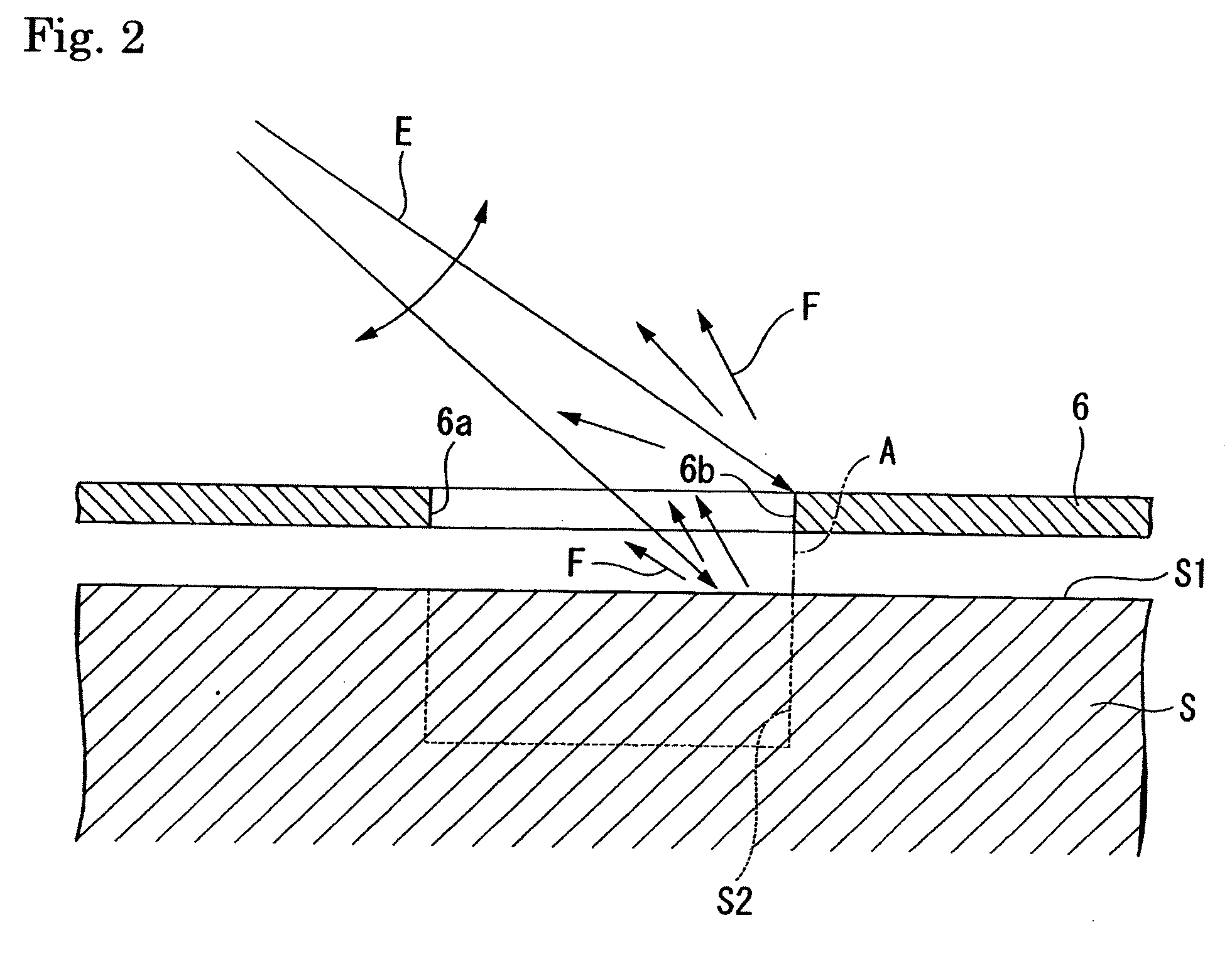

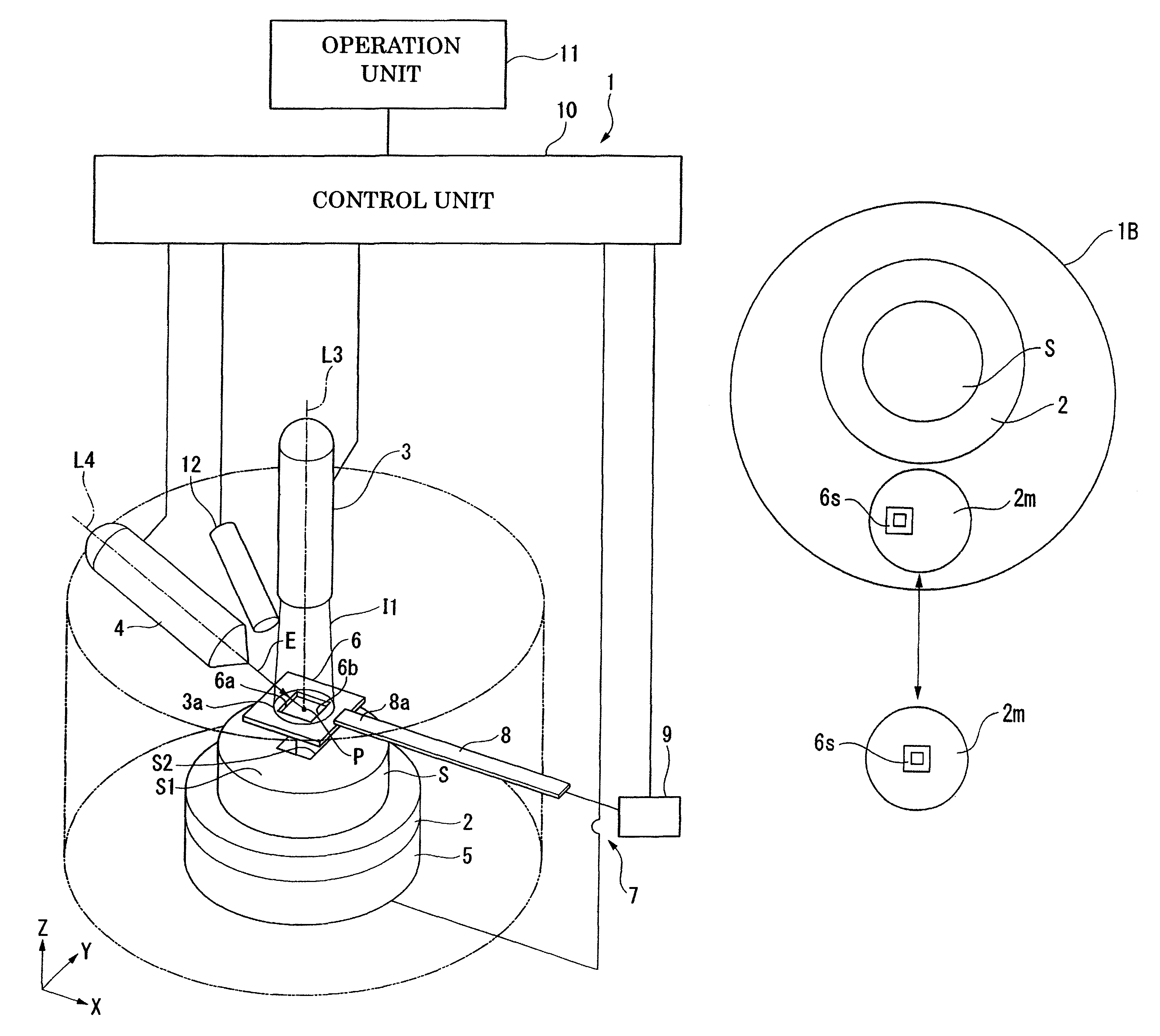

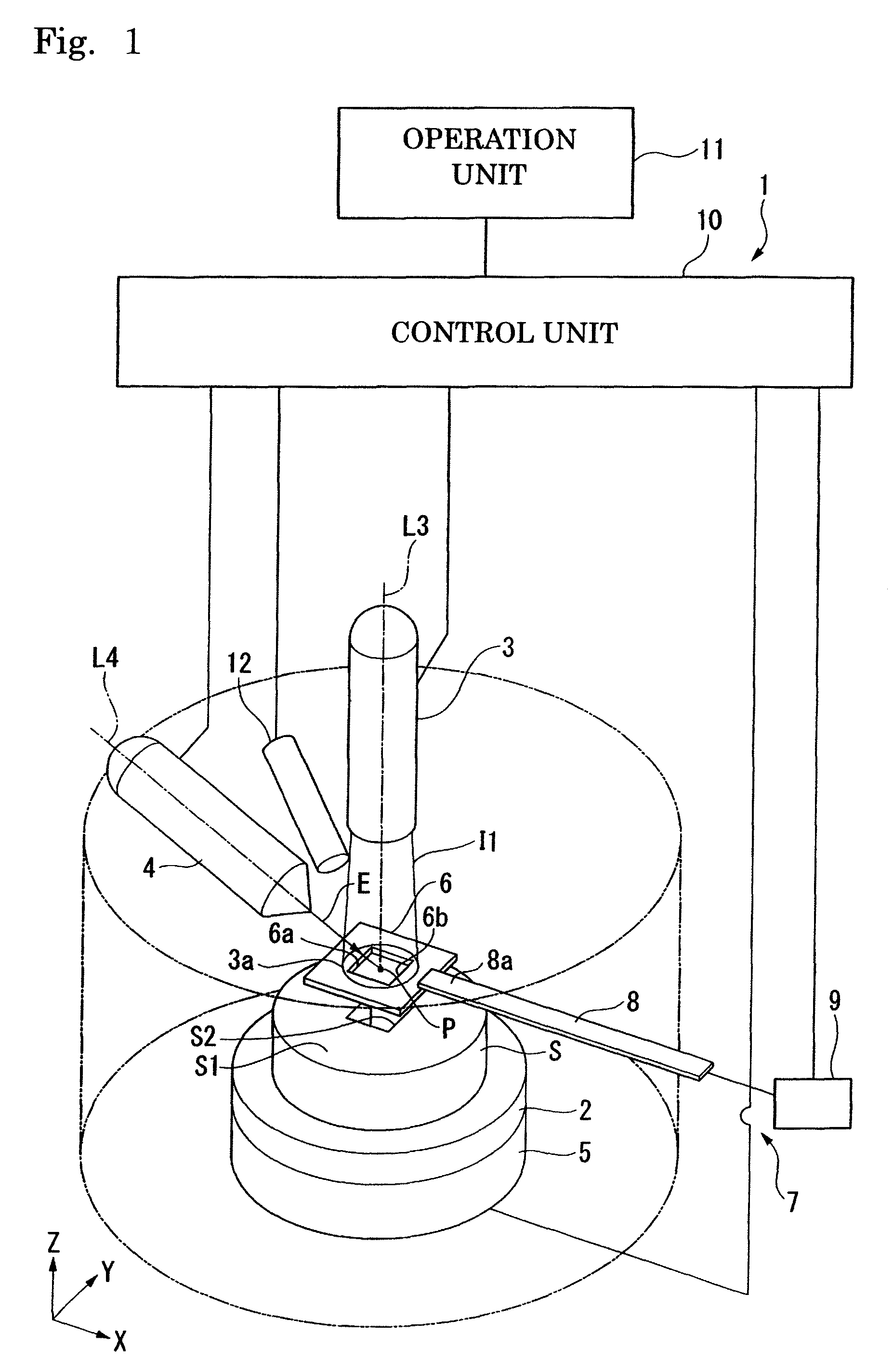

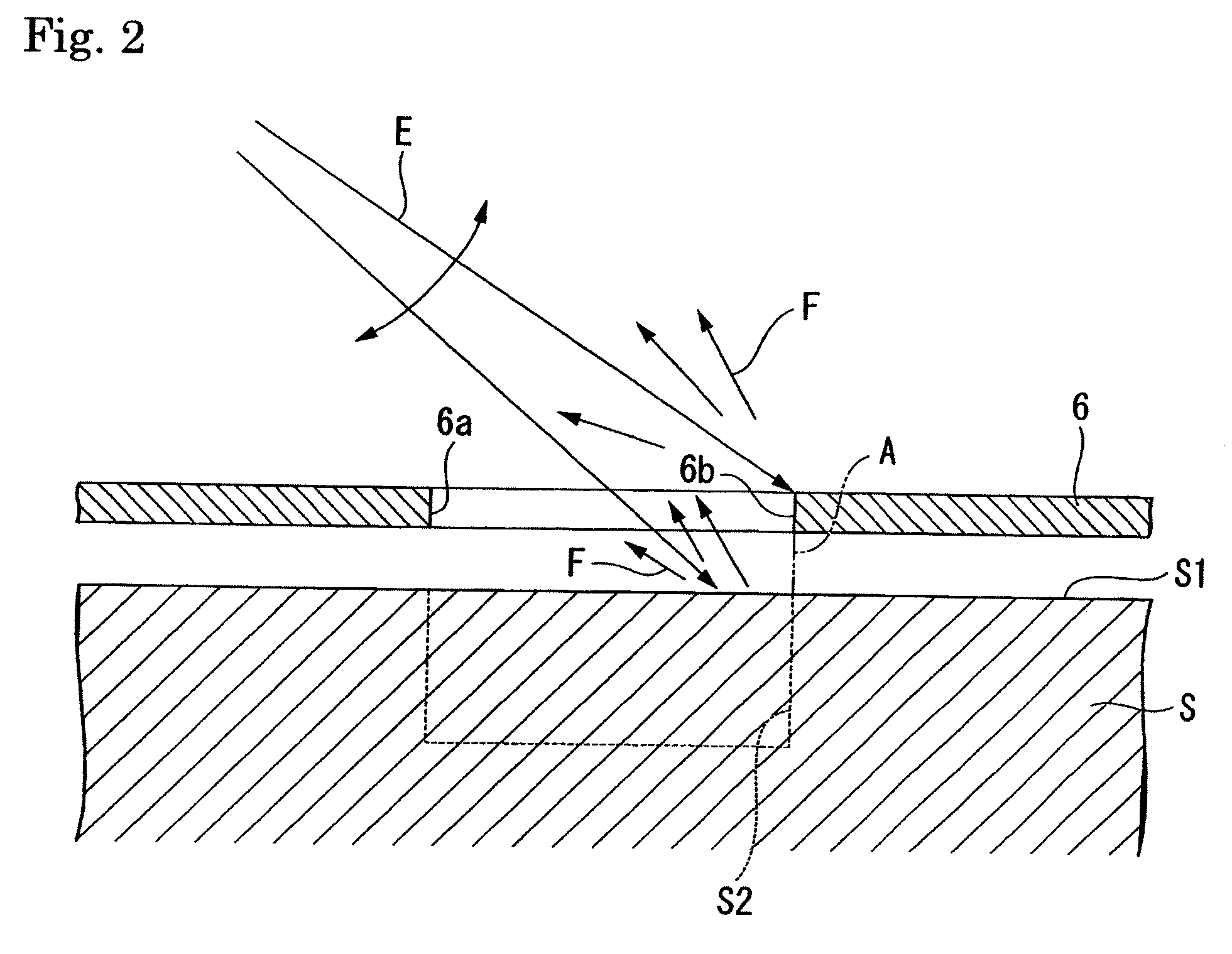

Apparatus for working and observing samples and method of working and observing cross sections

ActiveUS20080224198A1Effectively etchedPrecise positioningTransistorMaterial analysis using wave/particle radiationIrradiationFocused beams

The apparatus for working and observing samples comprises a sample plate on which a sample is to be placed; a first ion beam lens barrel capable of irradiating a first ion beam over a whole predetermined irradiation range at one time; a mask that can be arranged between the sample plate and the first ion beam lens barrel, and shields part of the first ion beam; mask-moving means capable of moving the mask; a charged particle beam lens barrel capable of scanning a focused beam of charged particles in the range irradiated with the first ion beam; and detection means capable of detecting a secondarily generated substance.

Owner:HITACHI HIGH TECH SCI CORP

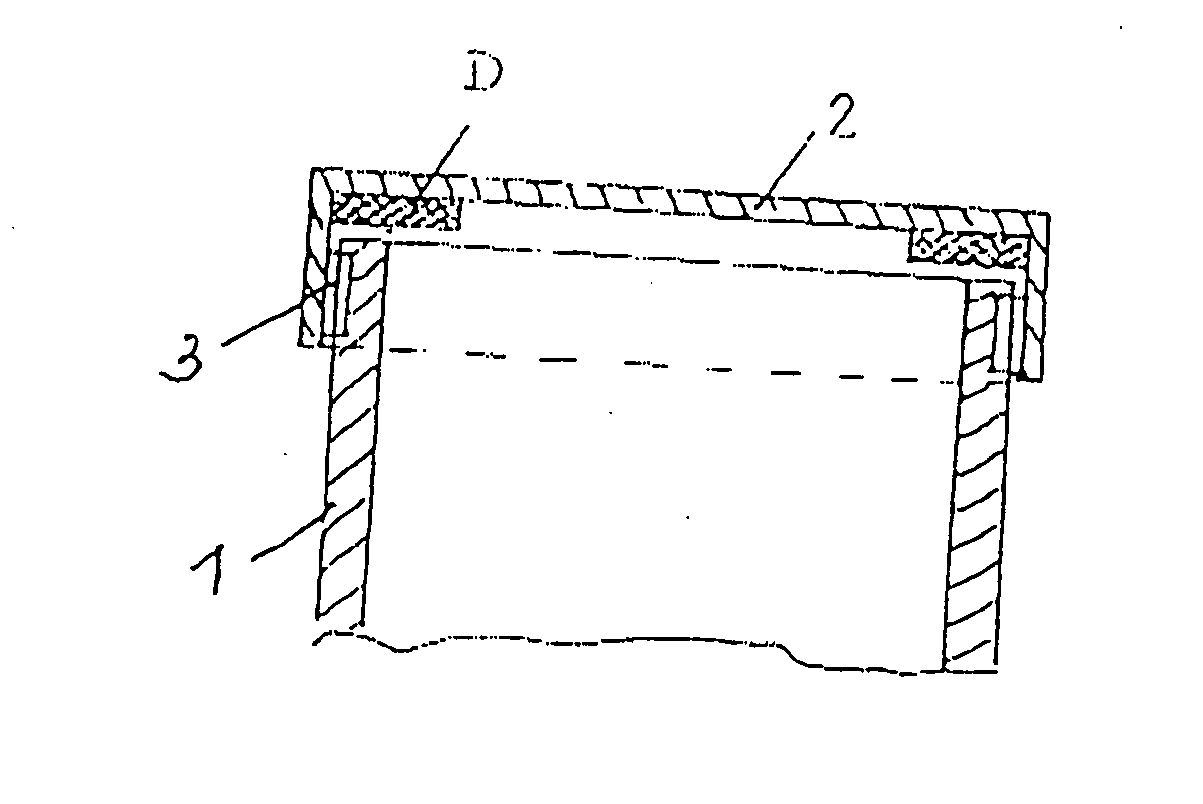

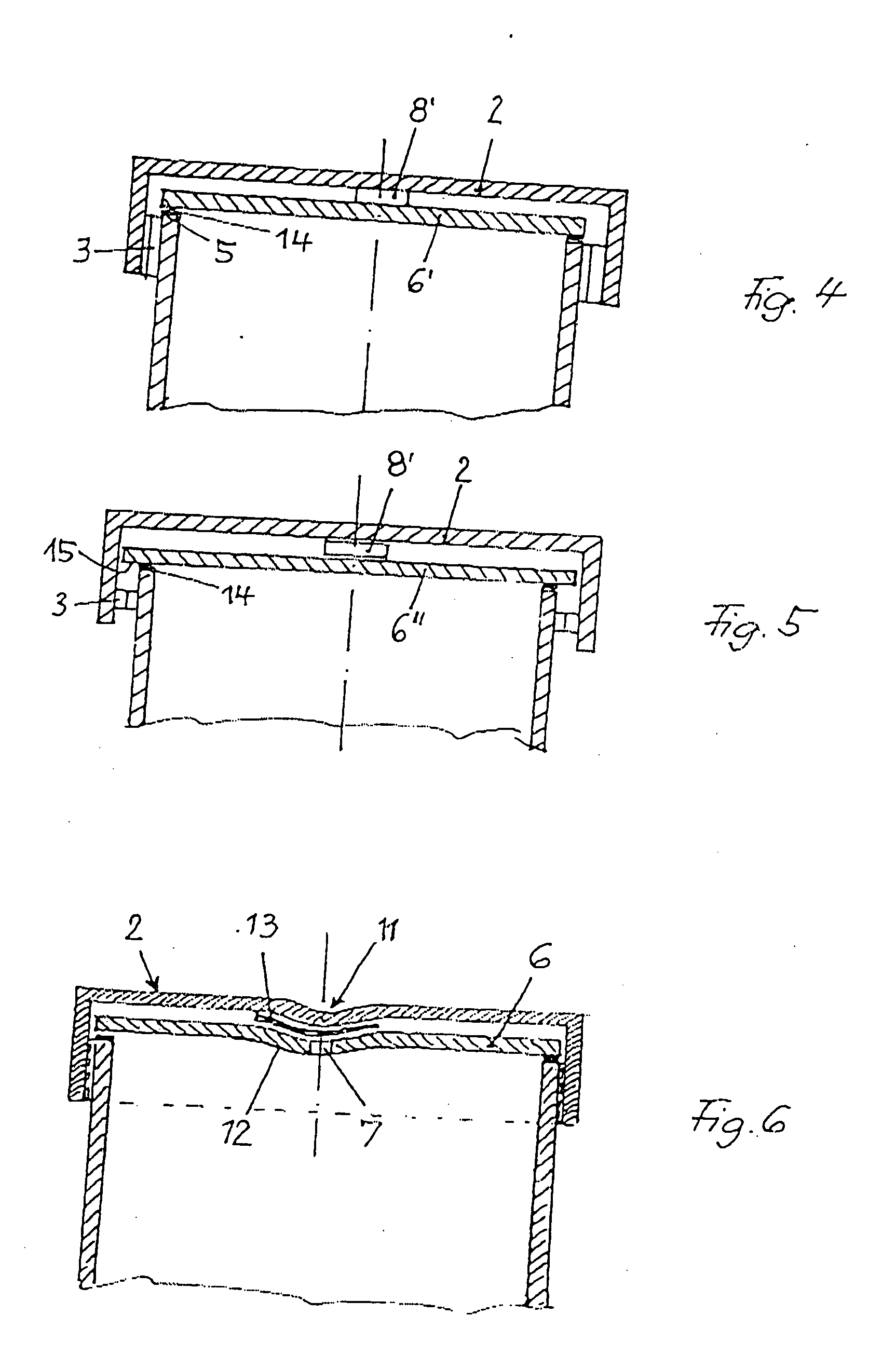

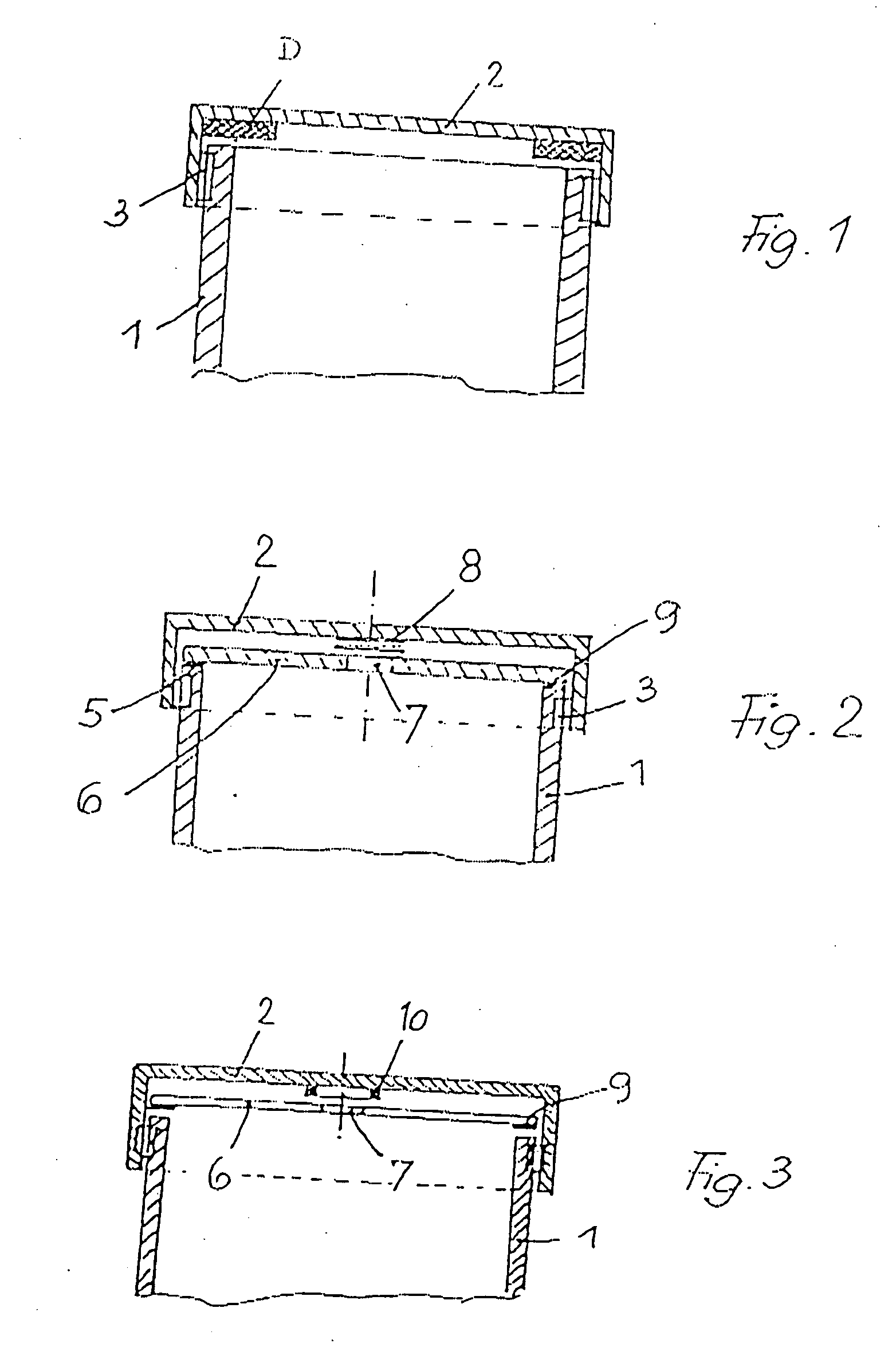

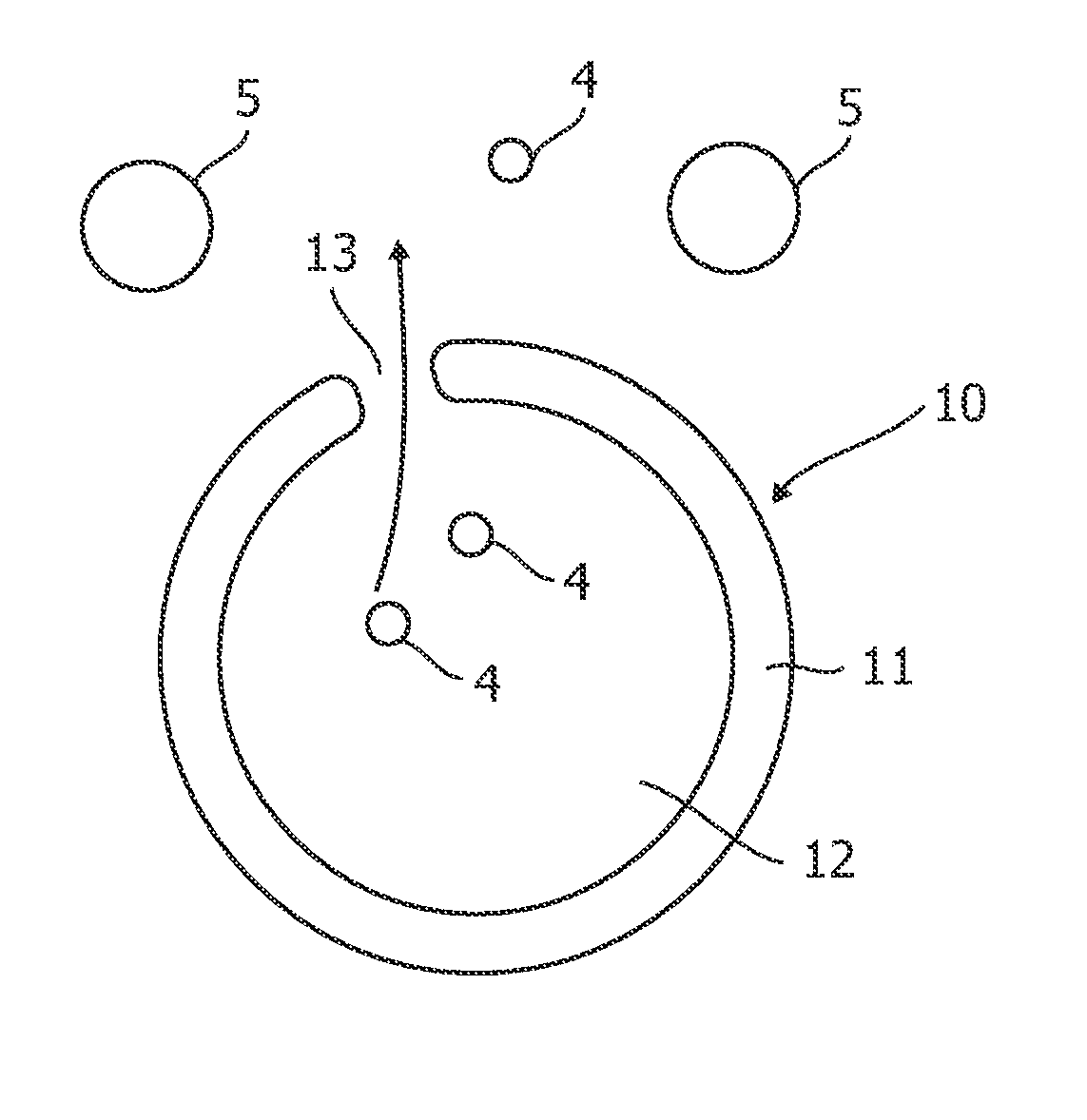

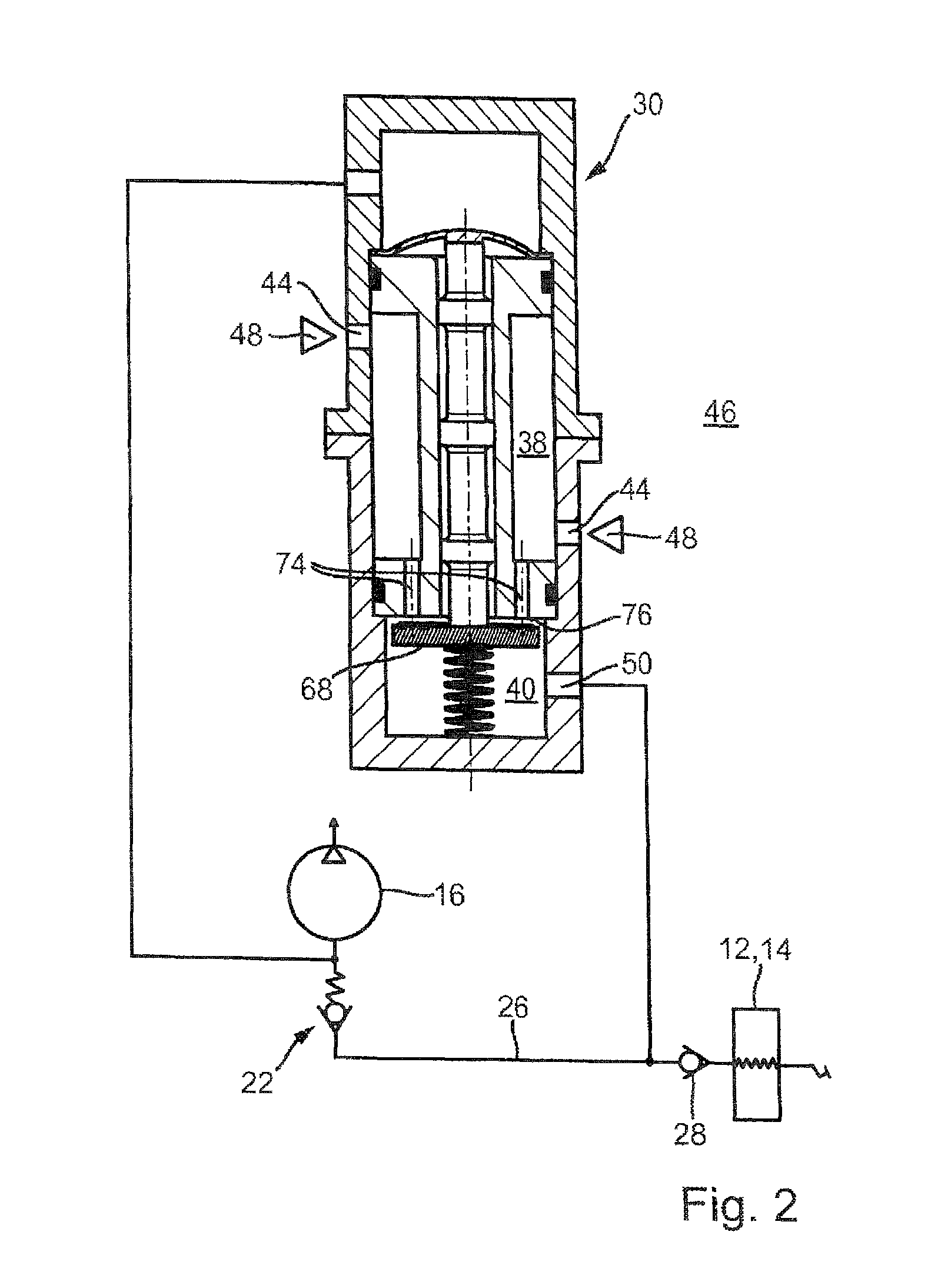

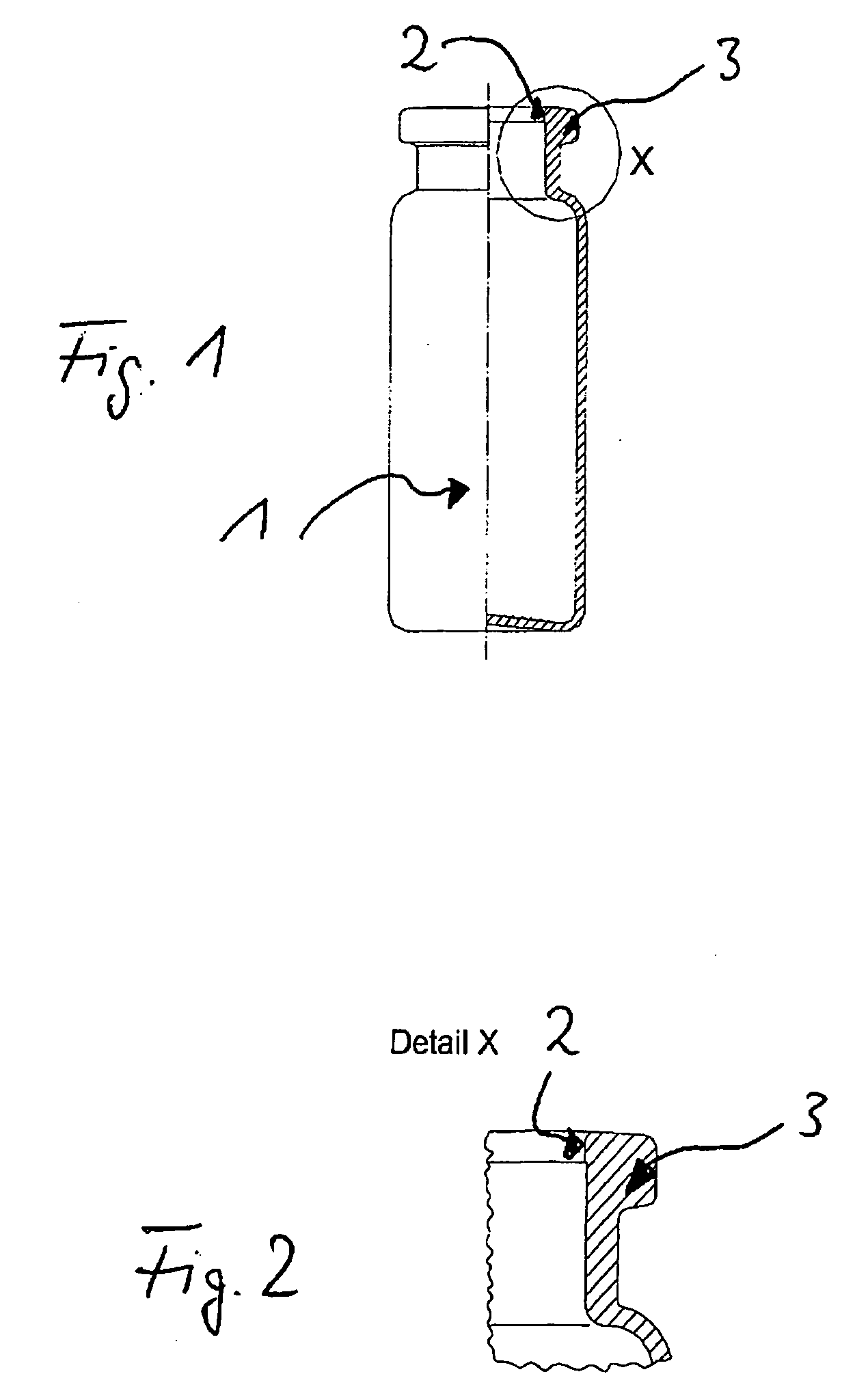

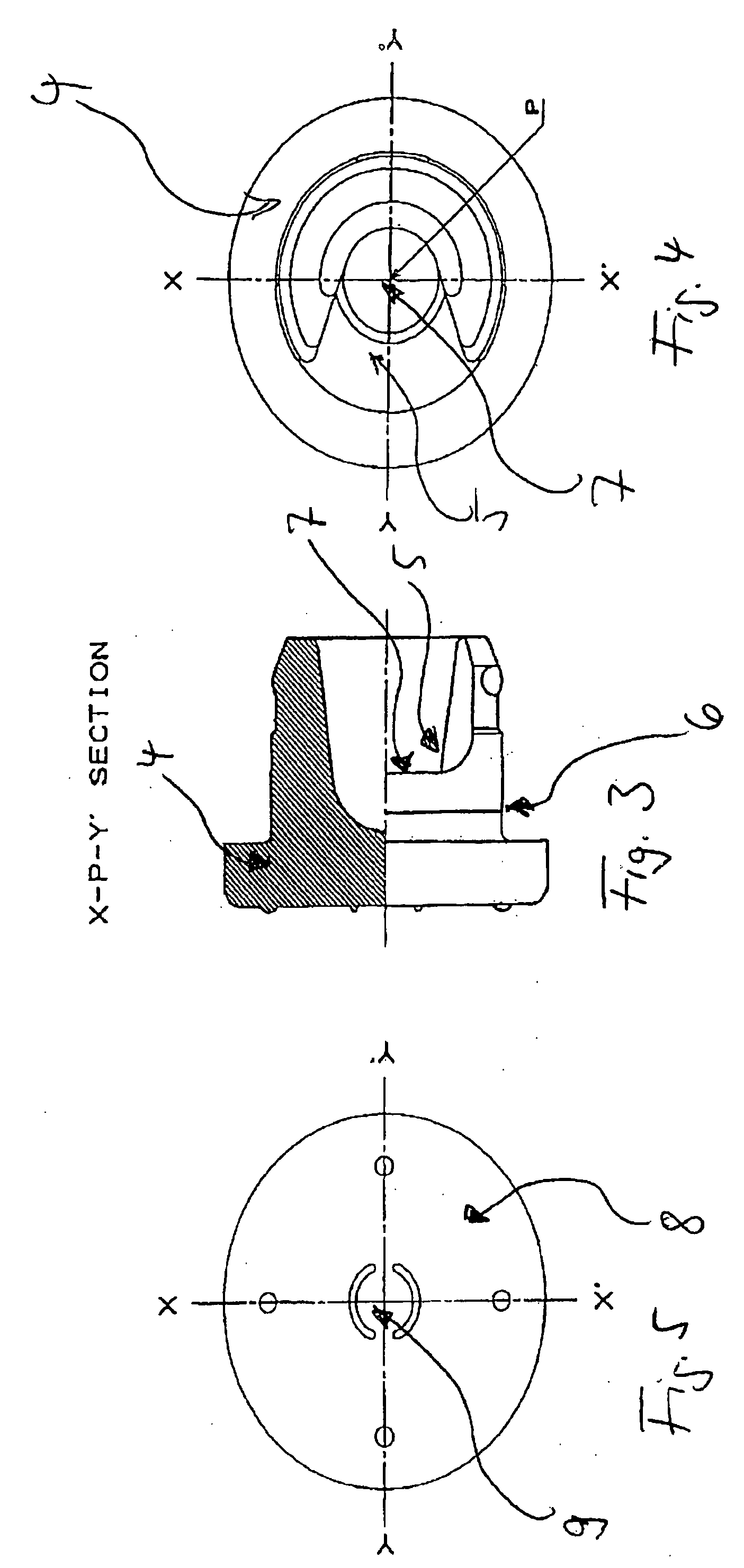

Jar or Tin Lid

The invention relates to a lid for jars or tins having a screw-lock or twist-lock mechanism for sealing the content of the jar or tin in an air-tight manner. The lid is made up of a rubber or plastic seal between the inside of the lid and the upper peripheral edge of the jar or tin. The lid has a discoid plate having a continuous opening or alternatively-no opening is inserted between the lid and the upper edge of the jar or tin. The peripheral edge representing the upper edge of the jar or tin is configured to form a tight seal with the discoid plate when the jar or tin is closed. The opening of the plate is associated with a seal facing the inside of the lid and blocking air from penetrating the opening.

Owner:ANTON DUSEL +3

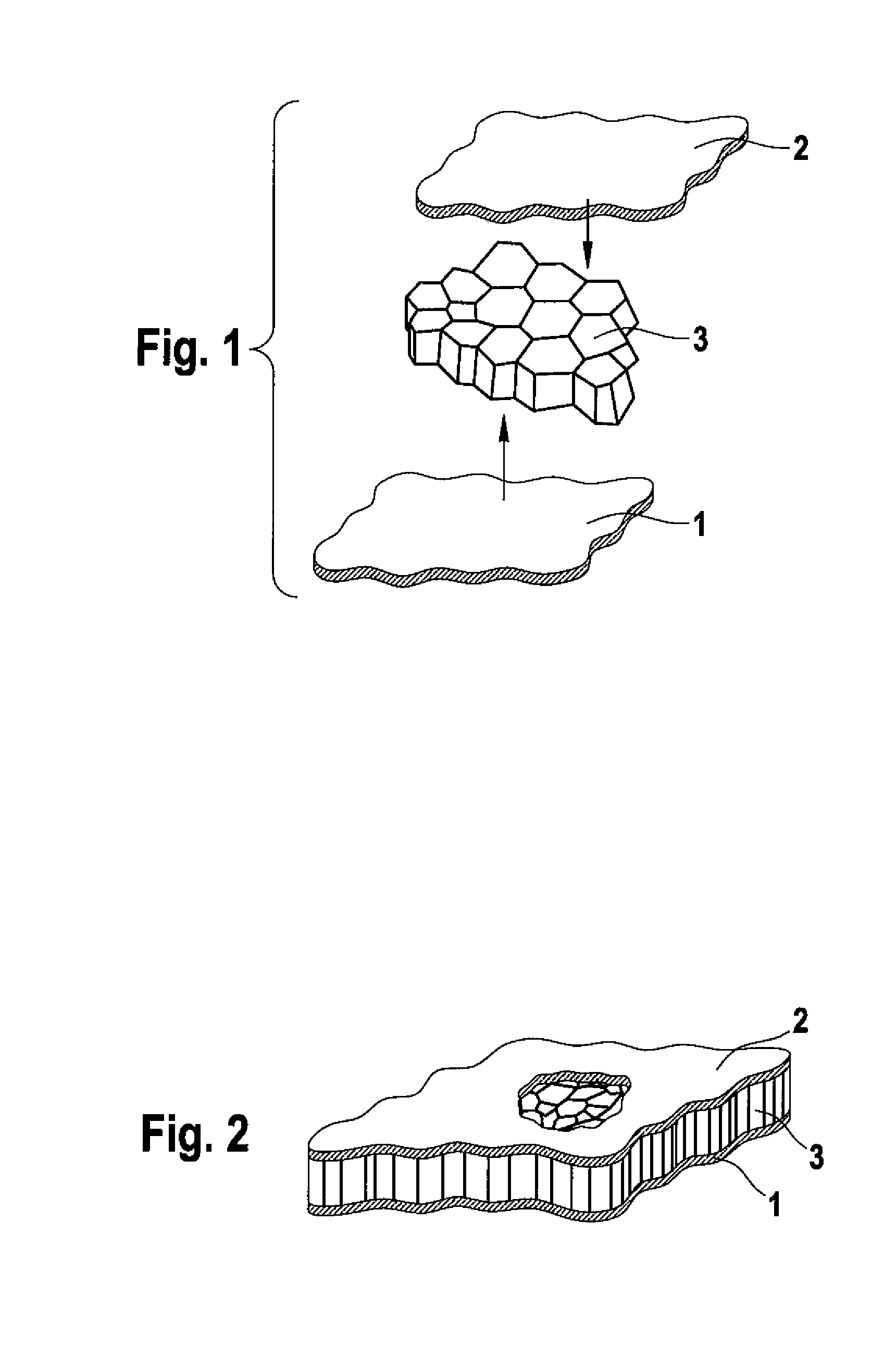

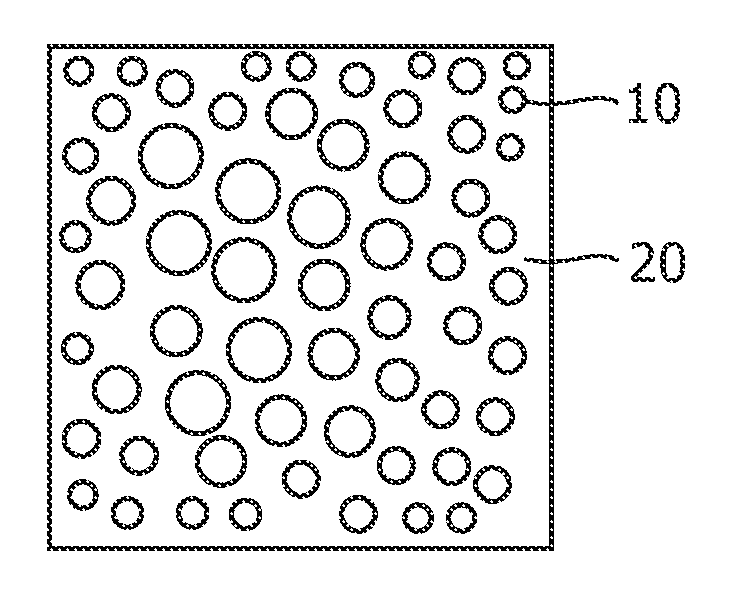

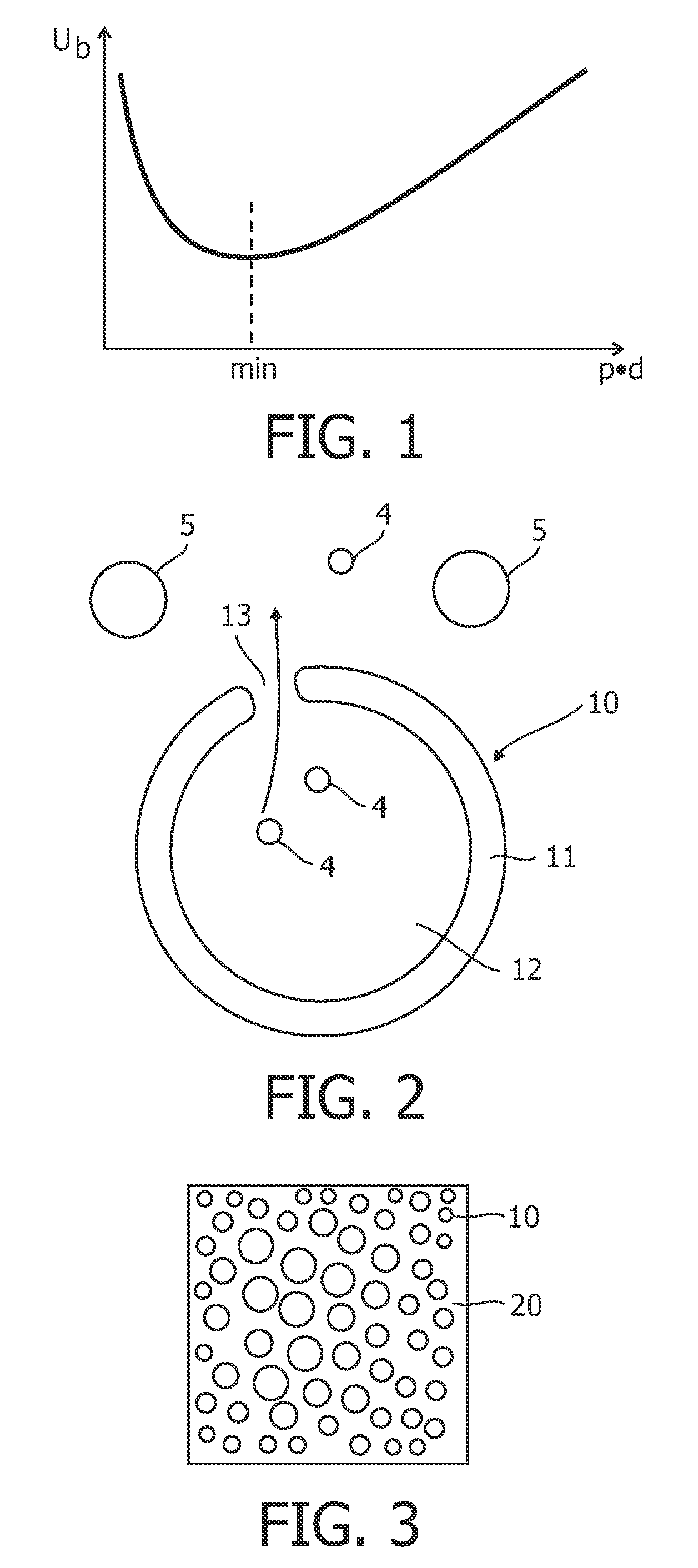

Insulator material and method for manufacturing thereof

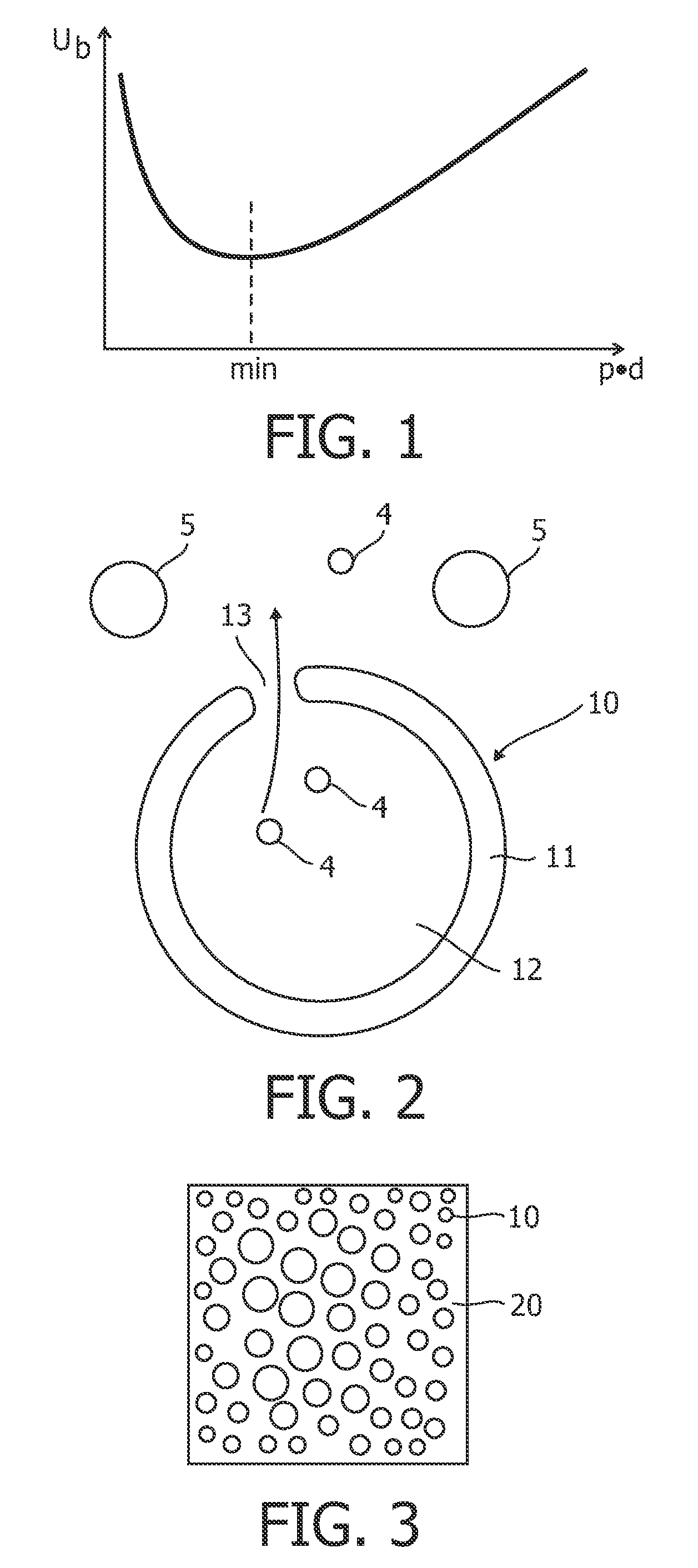

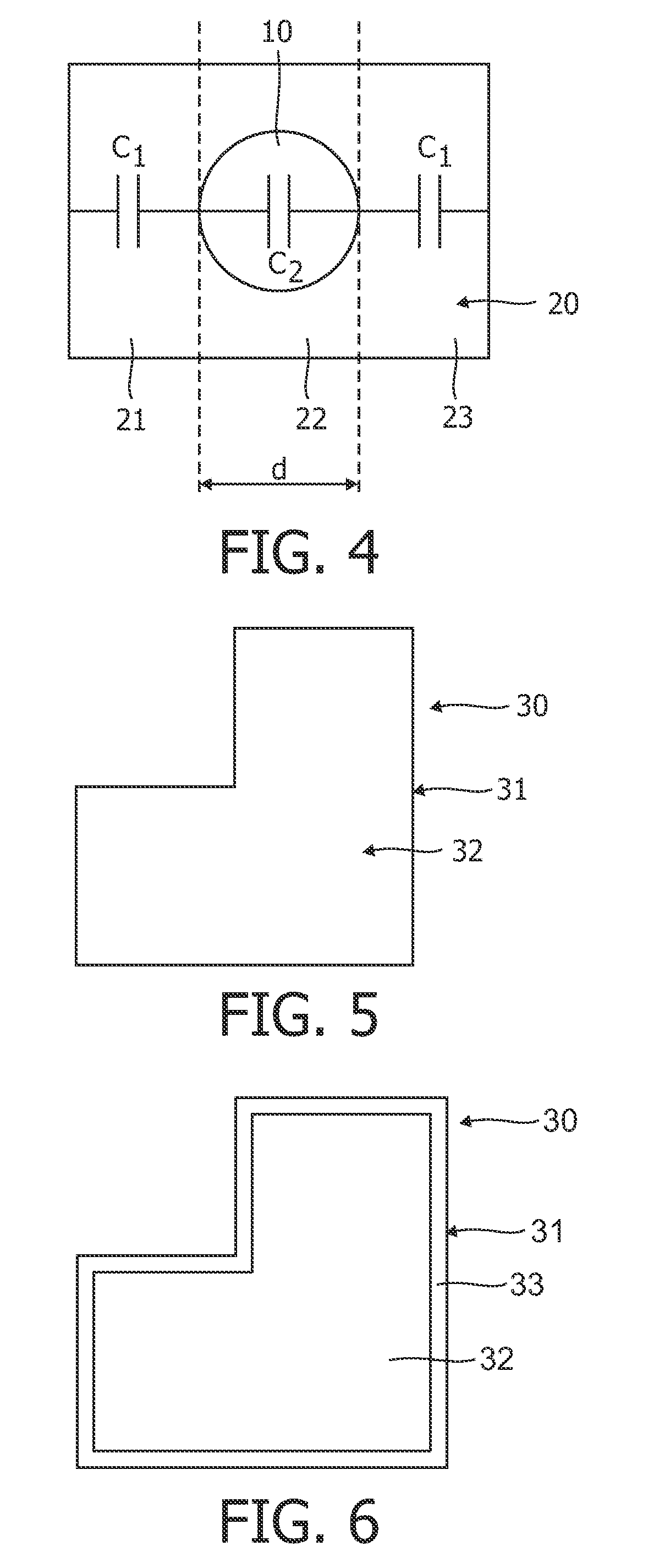

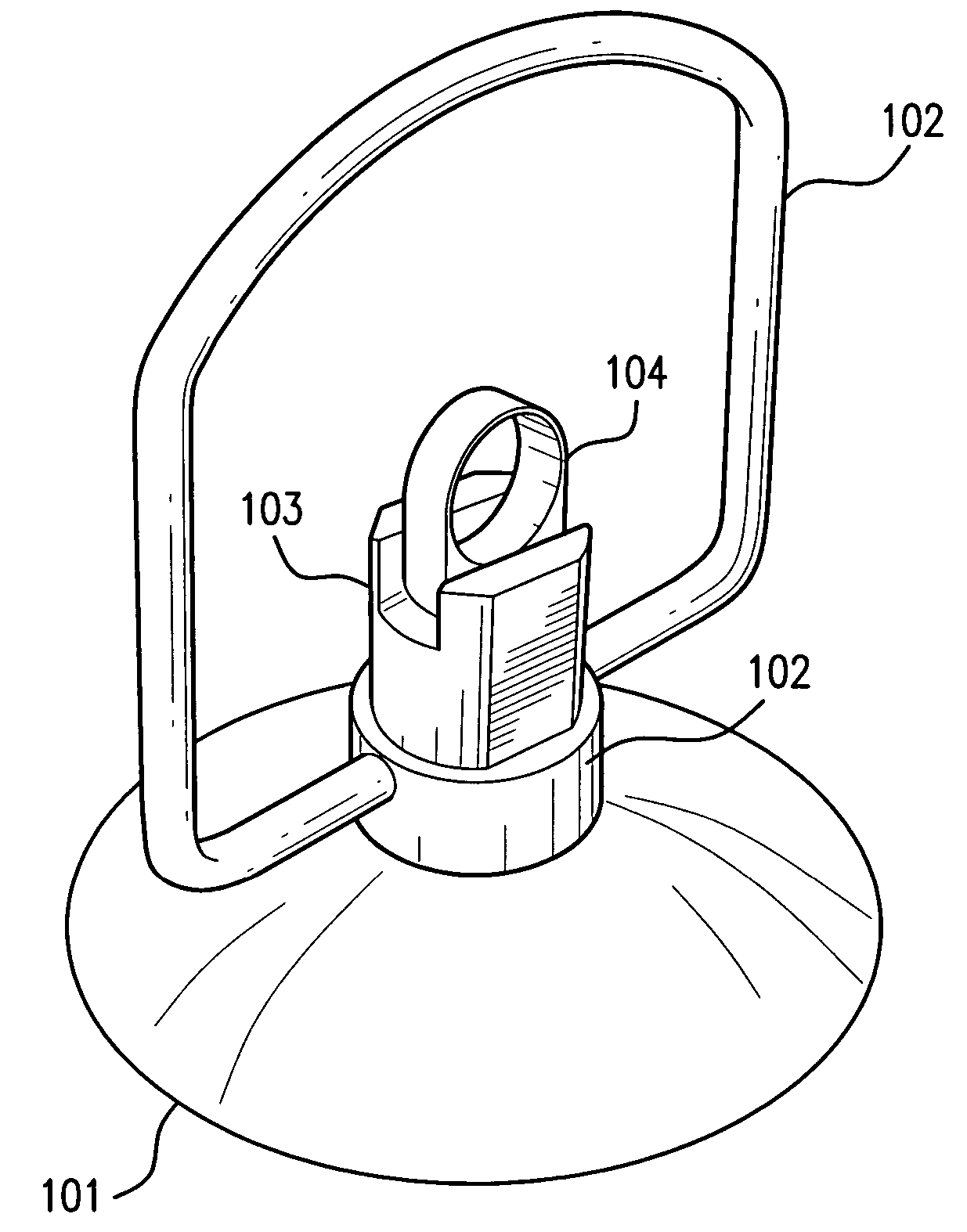

InactiveUS8343603B2Avoid enteringKeep vacuumingGlass/slag layered productsWood layered productsEngineeringBreakdown voltage

Vacuum filled hollow alveoles embedded in an insulation material in order to arrive at a light weight insulation material using the high breakdown voltage of evacuated cavities, i.e. alveoles at a vacuum lower than the minimum of the Paschen law. Pressurized hollow alveoles embedded in an insulation material in order to arrive at a light weight insulation material using the high breakdown voltage of pressurized cavities, i.e. alveoles at a pressure higher than the minimum of the Paschen law.

Owner:KONINK PHILIPS ELECTRONICS NV

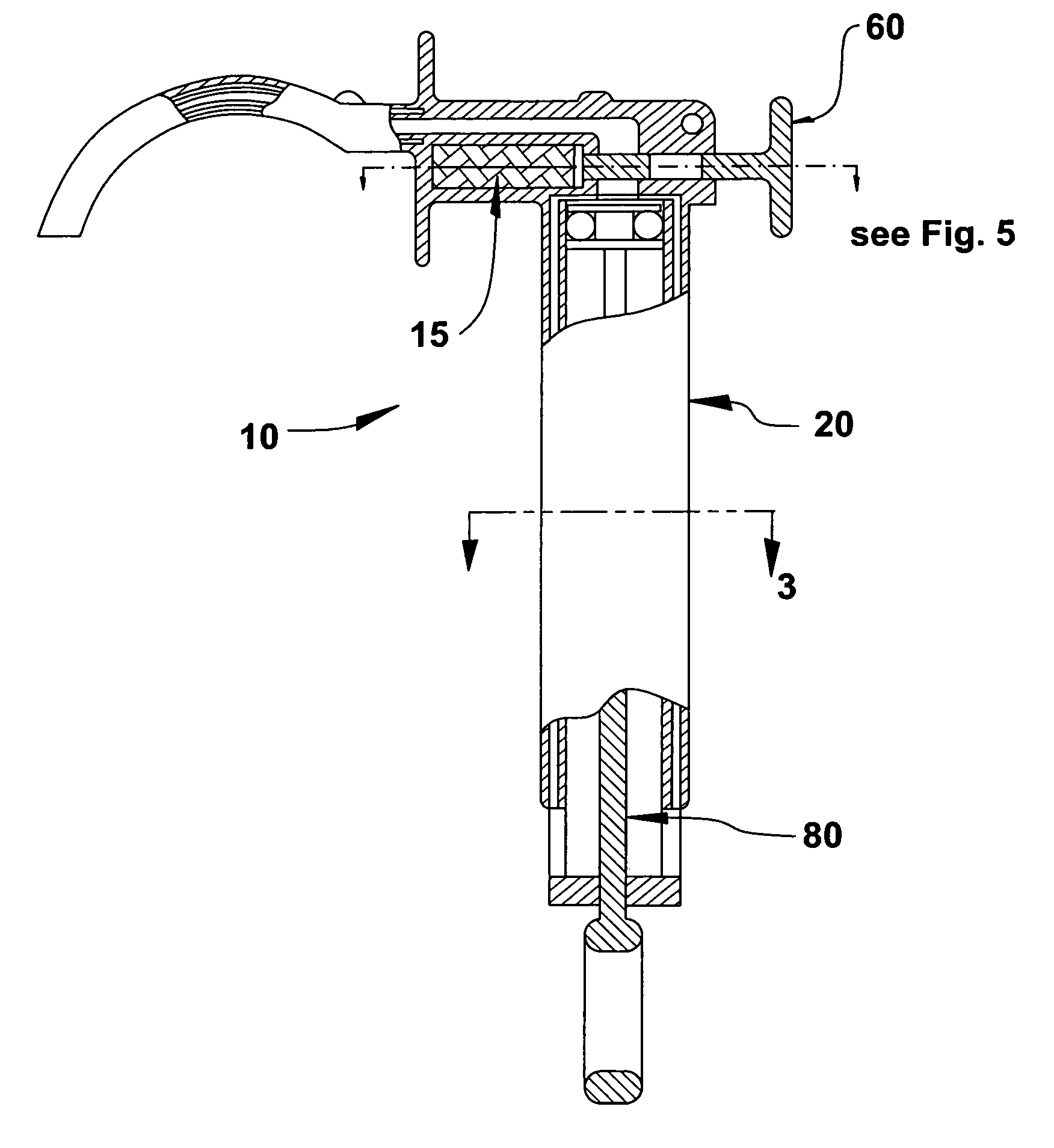

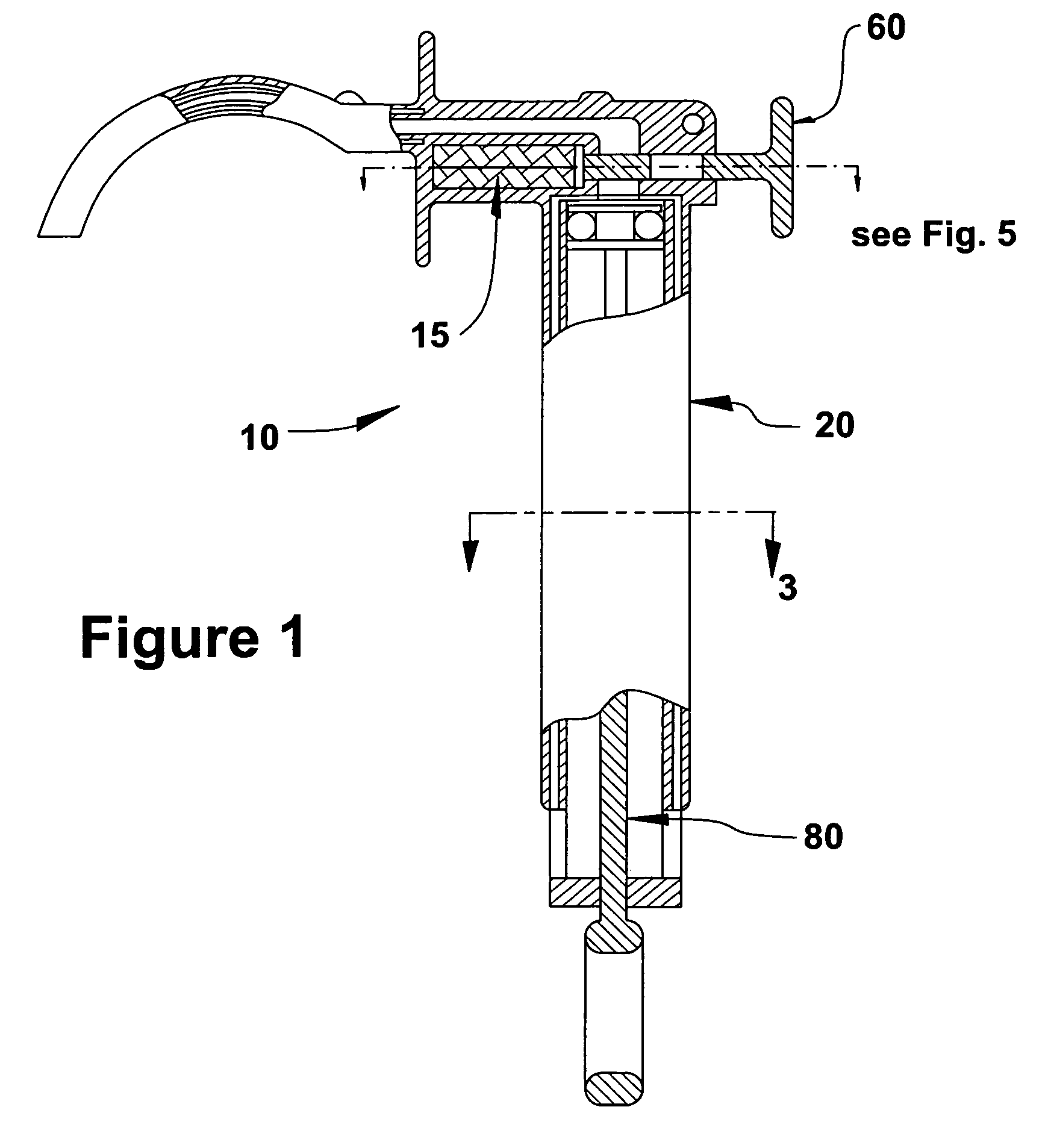

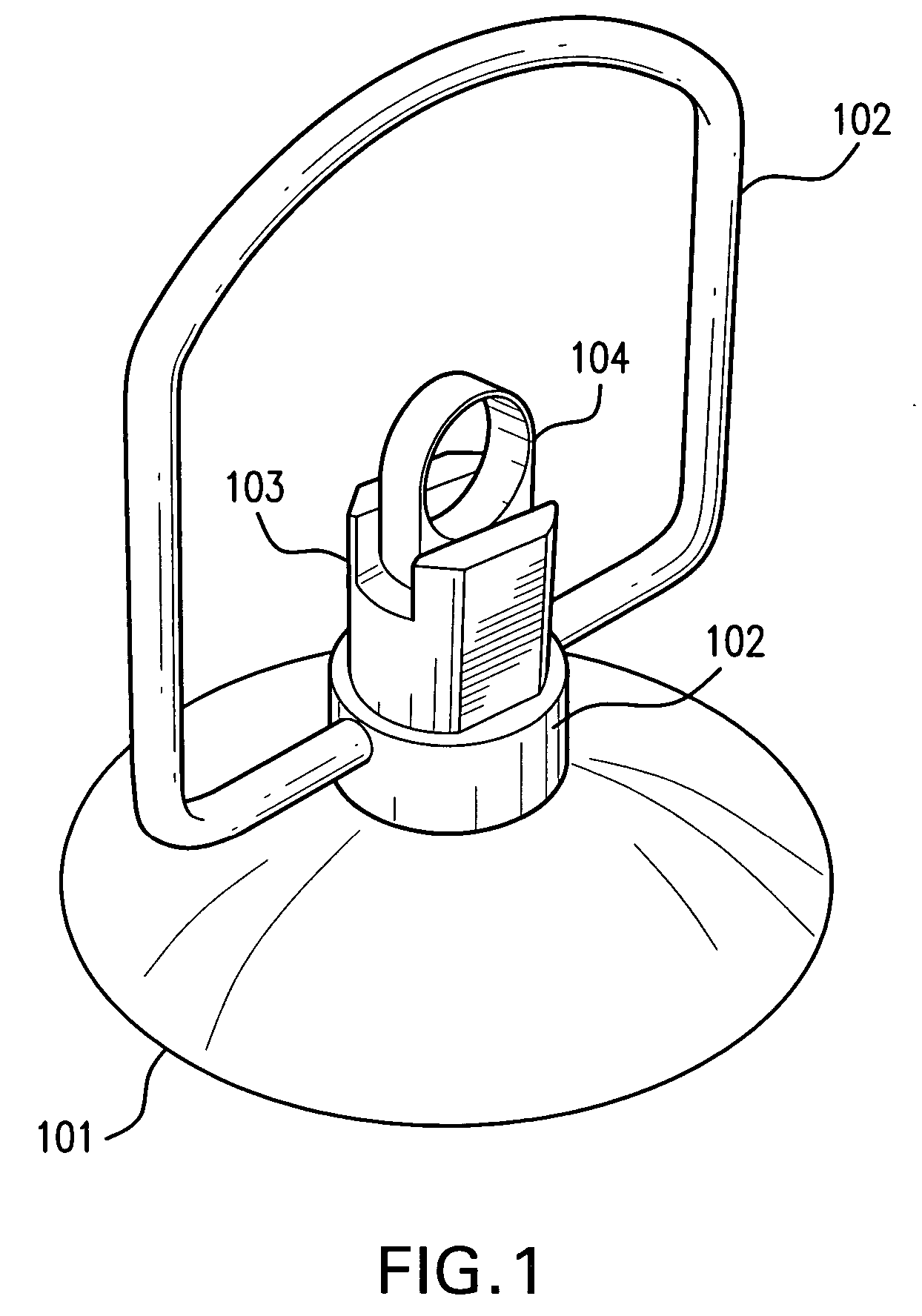

Autoclavable vacuum lifter

The present invention relates to an apparatus that aids in the transportation of objects having at least one side with a smooth, flat surface. The vacuum lifter is autoclavable and washable by disinfectants routinely used to maintain aseptic compliance in industries such as the pharmaceutical and food industries. In addition the vacuum lifter of the present invention includes a check valve assembly that can be optionally maintained in the open position during the autoclave or disinfection operation.

Owner:CHAVDA KISHOR N +1

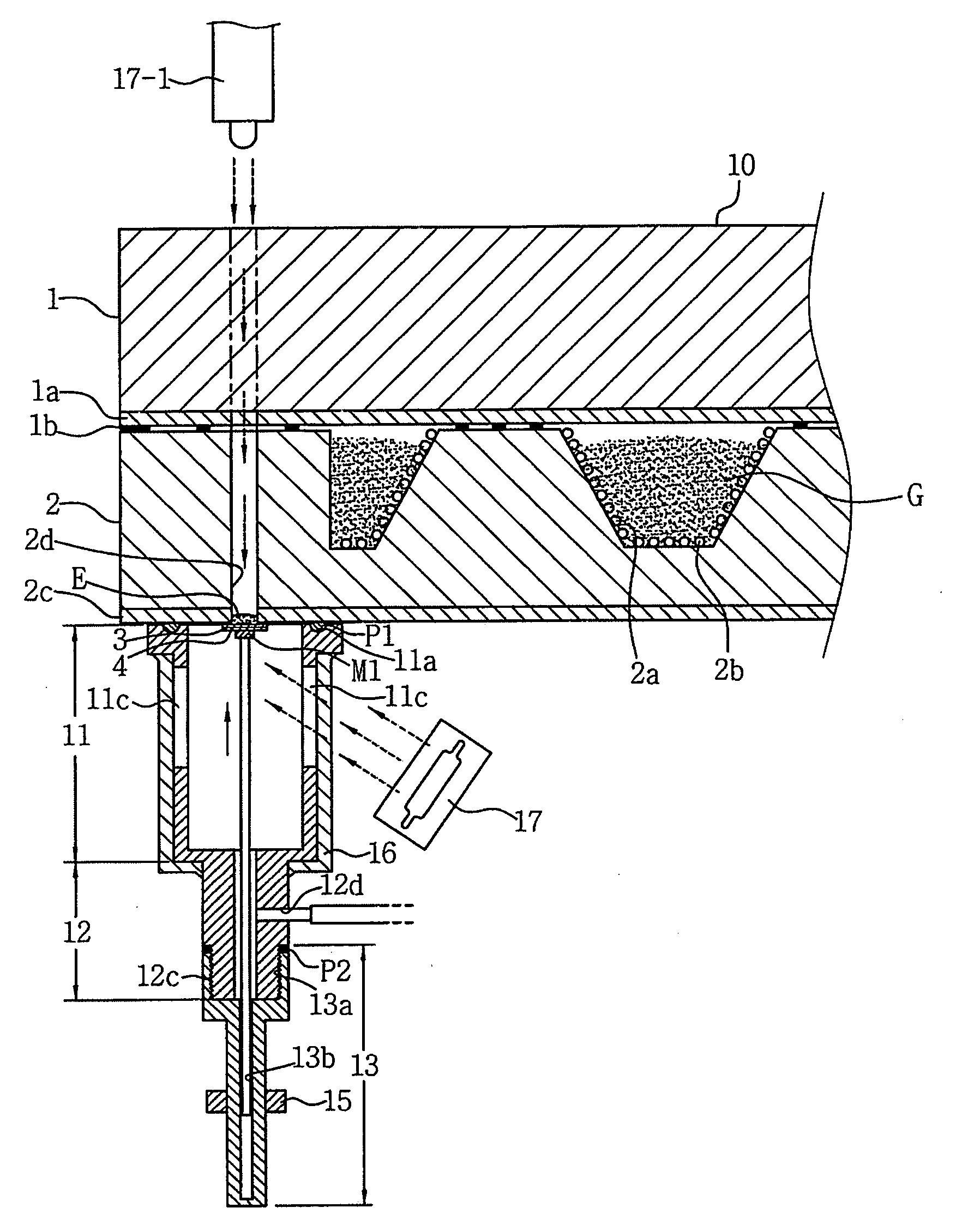

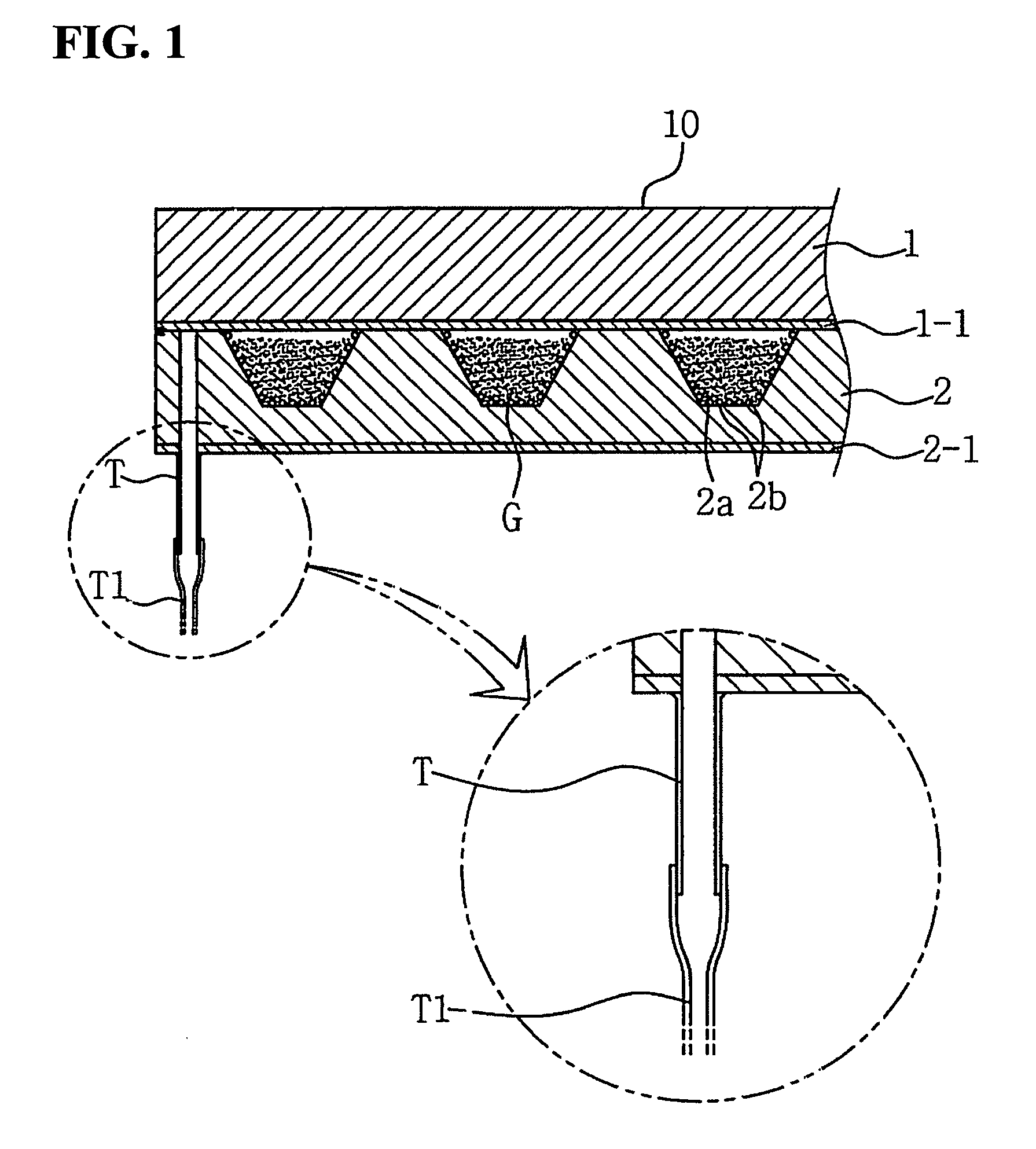

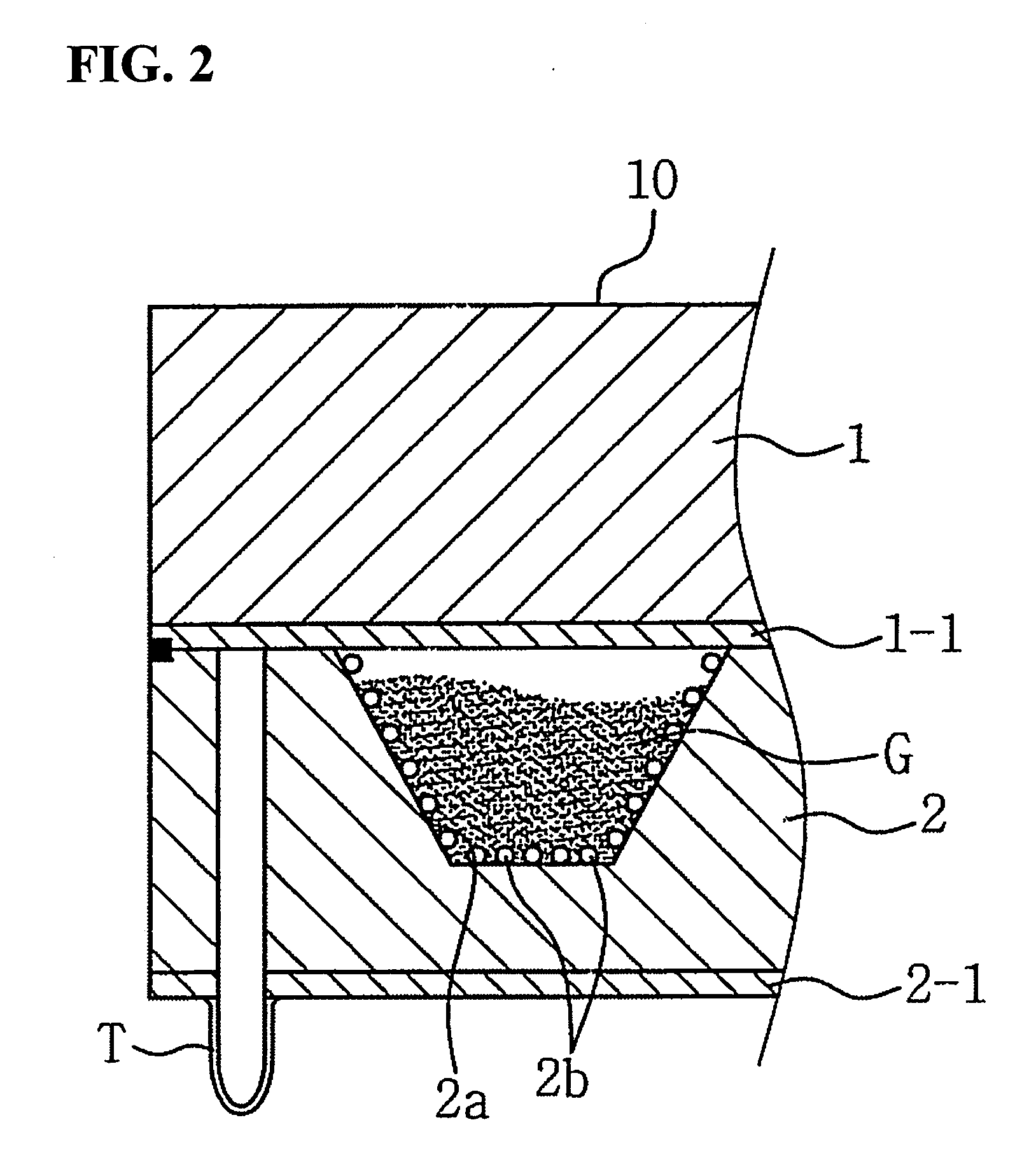

Plasma display panel without injection tip, and method of manufacturing the same

InactiveUS20050191928A1Reduce thicknessAvoid damageDischarge tube luminescnet screensLamp detailsEngineeringFree space

The present invention provides a plasma display panel without any injection tip and a method of manufacturing the same. The plasma display panel without any injection tip has a structure capable of directly injecting gas for electric discharge into the plasma display panel through an injection hole of a lower glass substrate using a vacuum apparatus while manufacturing the plasma display panel, thus sealing the plasma display panel in the vacuum. Therefore, the plasma display panel without any injection tip reduces a thickness thereof, thus reducing a space required to install the plasma display panel. Furthermore, the plasma display panel without any injection tip avoids damages, caused by an injection tip of conventional plasma display panels, during a process of transporting or installing the plasma display panel.

Owner:JANG DUK YOUN

Enclosure for preserving perishable goods

An enclosure for preserving perishable goods includes an inner portion for removably receiving perishable goods, an outer portion that removably receives a vacuum device such as a vacuum cleaner which removes air from the enclosure after the goods have been inserted into the inner portion, a sealable outer seal that provides an air tight boundary between the enclosure and an end portion of the vacuum device to promote the removal of air from the enclosure, and a sealable inner seal that provides an air tight boundary for the inner portion and the goods therein after the removal of air from the enclosure and while the vacuum device remains engaged with the outer seal; the vacuum device being separated from the outer seal after the removal of air from the inner portion and the air tight sealing of the inner seal whereby the perishable goods are encased in a vacuum sealed inner portion of the enclosure to preserve the perishable goods after the goods are frozen. An alternative enclosure includes an opening, a first locking seal disposed relatively close and substantially parallel to the opening, a second locking seal disposed adjacent and parallel to the first locking seal, a third locking seal disposed adjacent and parallel to the second locking seal, and an aperture disposed in a first side portion of the enclosure adjacent to the second locking seal to enable an air evacuation tube to snugly insert through the first side portion of the enclosure.

Owner:KOZAK BURTON

Method and apparatus for evacuating re-sealable bags

InactiveUS7818948B2Quickly and inexpensively exhausting airKeep vacuumingCapsCap application using vaccuumVacuum packVacuum chamber

The present invention is a method and apparatus for quickly, reliably, and inexpensively evacuating air from ordinary re-sealable plastic bags without employing special adapters to interface with vacuum pumps. The system consists of a vacuum pump, an outer re-sealable plastic bag that acts as a flexible vacuum chamber, a vacuum tray that fits inside the outer plastic bag and prevents the outer bag from collapsing onto the vacuum port. Users operate the system by inserting the re-sealable bag to be evacuated inside the outer plastic bag until the seal of the inner bag is in the proper sealing position inside the vacuum tray. The user then seals the outer bag, turns on the vacuum pump and allows the vacuum process to run to completion, during which the re-sealable inner bag is automatically sealed by the device. The user then opens the outer plastic bag and removes the vacuum-packed inner bag.

Owner:CANNON THOMAS CALVIN

Apparatus for working and observing samples and method of working and observing cross sections

ActiveUS7755044B2Effectively etchedPrecise positioningTransistorMaterial analysis using wave/particle radiationIrradiationFocused beams

The apparatus for working and observing samples comprises a sample plate on which a sample is to be placed; a first ion beam lens barrel capable of irradiating a first ion beam over a whole predetermined irradiation range at one time; a mask that can be arranged between the sample plate and the first ion beam lens barrel, and shields part of the first ion beam; mask-moving means capable of moving the mask; a charged particle beam lens barrel capable of scanning a focused beam of charged particles in the range irradiated with the first ion beam; and detection means capable of detecting a secondarily generated substance.

Owner:HITACHI HIGH TECH SCI CORP

Method of assembling a sealed thermal interface

ActiveUS7954236B2Minimizes and eliminates exudationImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesElastomerSilicone oil

A sealed thermal interface component minimizes or eliminates the exudation of fluids, such as silicone oils, while preserving the excellent thermal conductivity of silicon-based thermal pad materials and enhancing the conformability of the component. In preferred embodiments, a foam frame surrounds a plurality of thermal pad portions formed of conformable thermal management material that may exude fluid under elevated temperatures or over time. Film encapsulates the foam-framed thermal pad portions, forming a sealed and partially evacuated thermal interface component. In one embodiment of the invention, the thermal pads are formed of an elastomeric matrix material containing silicone, the foam frame is made of urethane, and the film is made of polyurethane.

Owner:LUNDELL MFG CORP

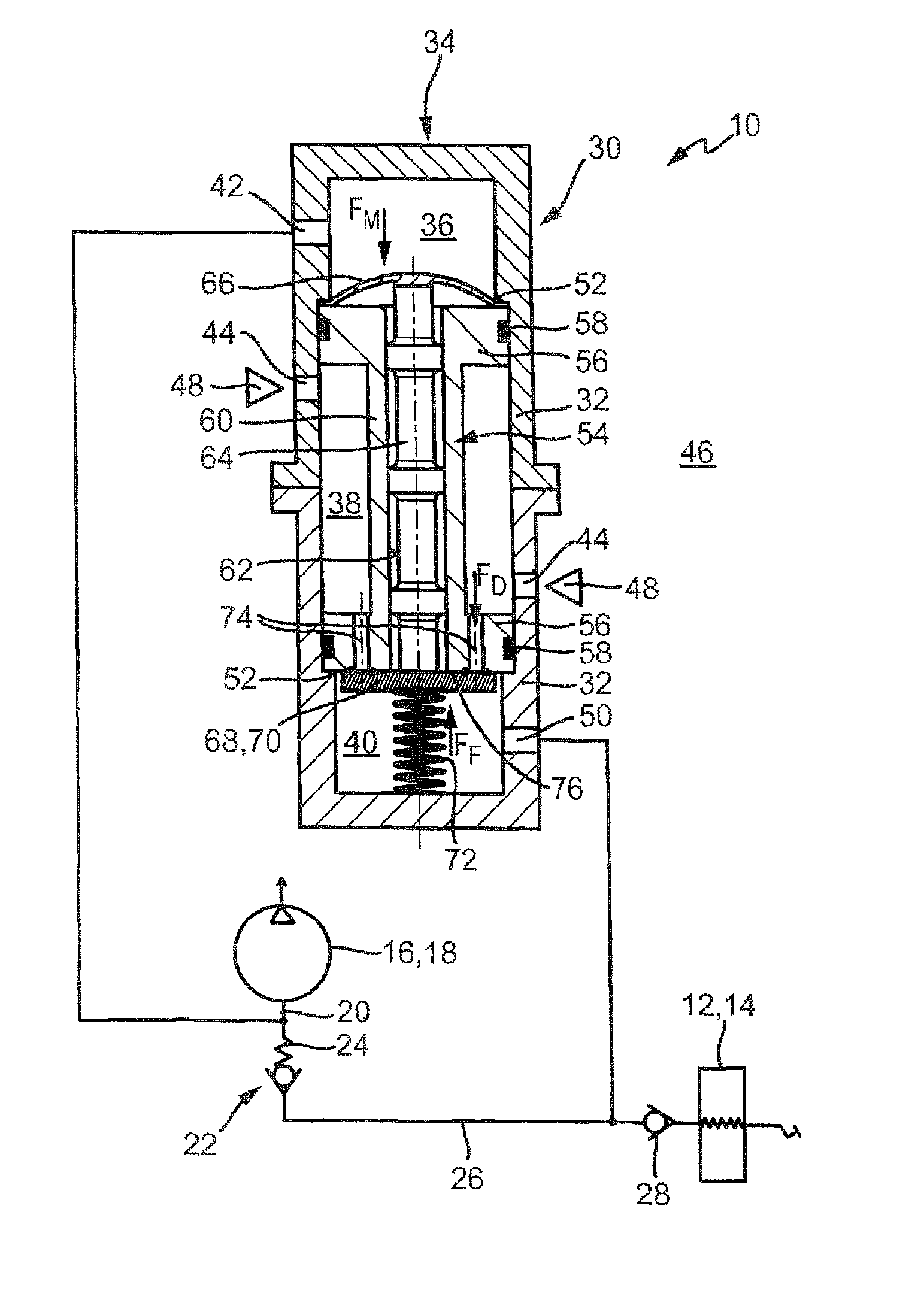

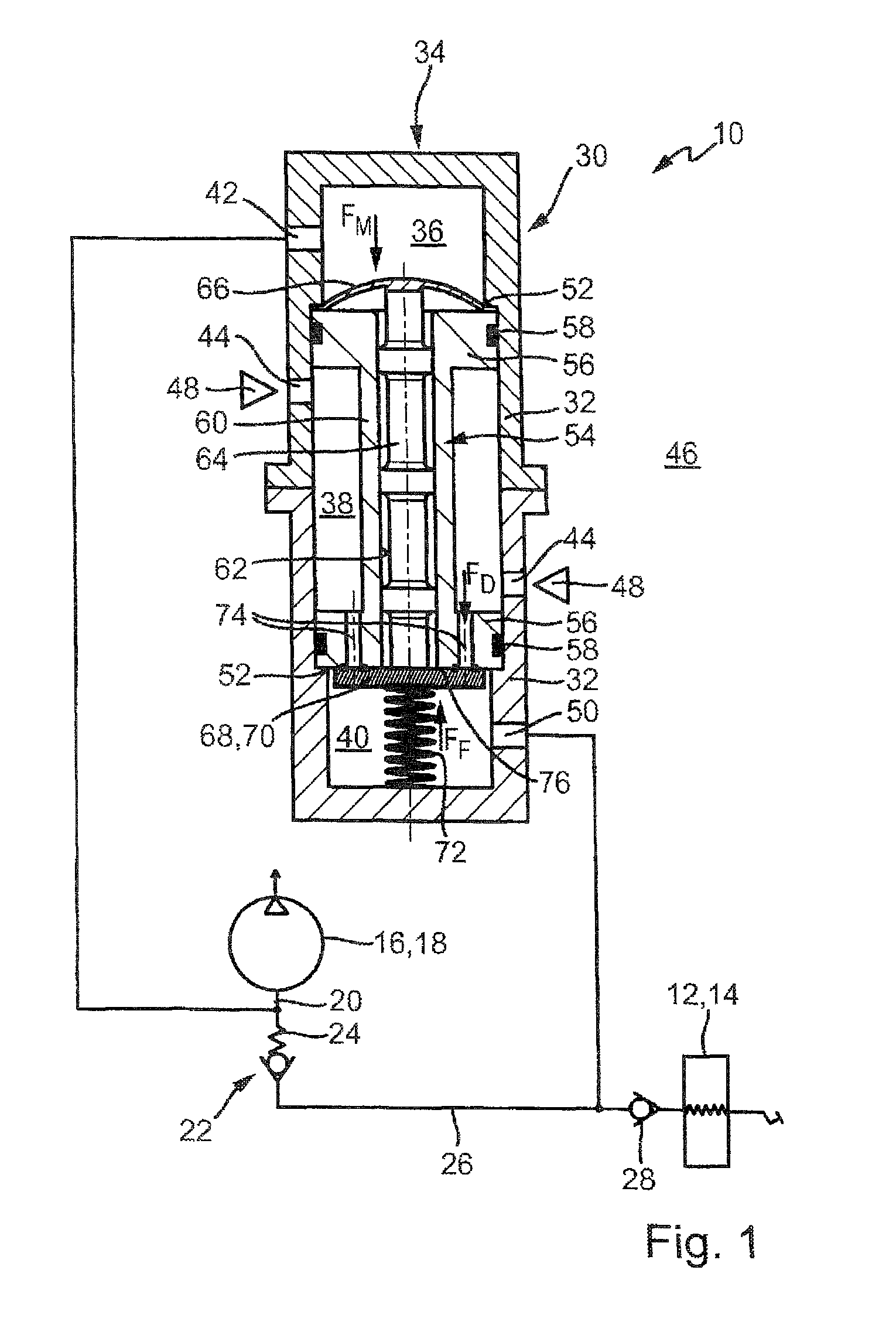

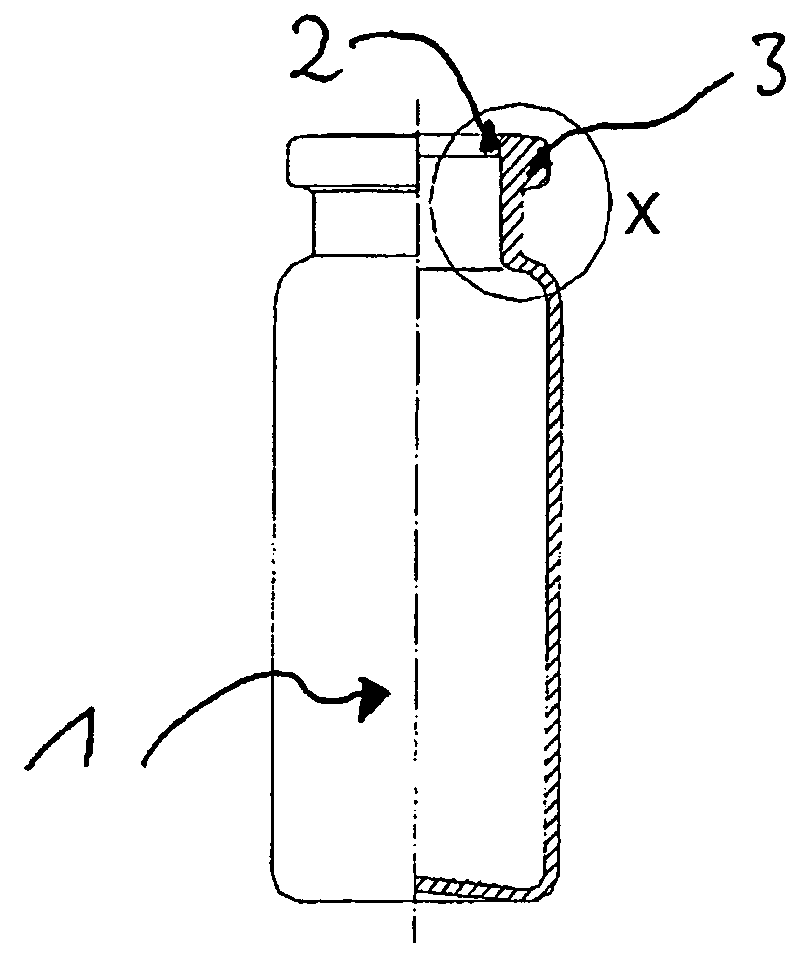

Device for producing and providing a vacuum, and ventilation valve

ActiveUS8973604B2Efficiency of pump is limitedKeep vacuumingBraking action transmissionCheck valvesCheck valveEngineering

The invention relates to a device for producing and providing a vacuum for a vacuum consumer, having a vacuum source, having a suction valve, having a non-return valve arranged between the vacuum consumer and the suction valve, and having a ventilation valve, the control inlet of which ventilation valve is connected to the suction port of the vacuum source, the output of which ventilation valve opens out between the control valve and the non-return valve, and the input of which ventilation valve is open to the environment.

Owner:JOMA POLYTEC

Pharmaceutical Product For Injection

The present invention is related to a pharmaceutical product for injection comprising a container including a closure suitable for preparations for injection, the container containing an acid labile proton pump inhibitor, a salt thereof, a solvate of the acid labile proton pump inhibitor or a salt thereof, wherein the container and closure are made of material which essentially does not release zinc ions.

Owner:NYCOMED GMBH

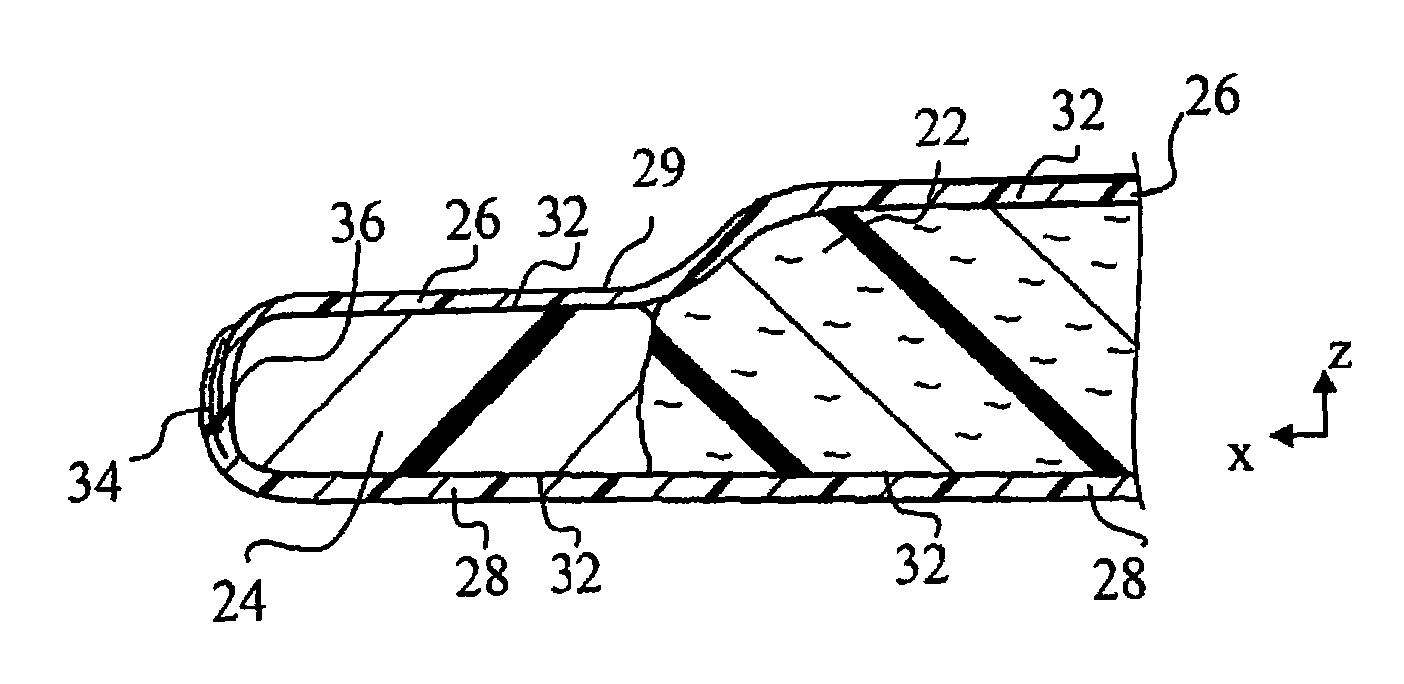

Machine for processing animal hides

InactiveUS20070283504A1Effective applicationAggressive and efficient applicationTanning treatmentPre-tanning chemical treatmentProcess engineeringAnimal hide

A machine and method for processing animal hides with a vessel to hold animal hides, processing animal hides in a closed container held under vacuum, rotating a container allowing for the repeated emersion of the animal hides, paddles within the container which move a hide through a tanning solution, paddles within the container aligned to minimize the damage to the hides by abrasion, a process of tanning using a vacuum which eliminates the need for heating the tanning solution, and a process of tanning using a vacuum which reduces the time necessary to prepare animal hides. A preferred embodiment includes a vessel made of materials resistant to the corrosive action of the tanning solution.

Owner:WEGNER RONALD EUGENE

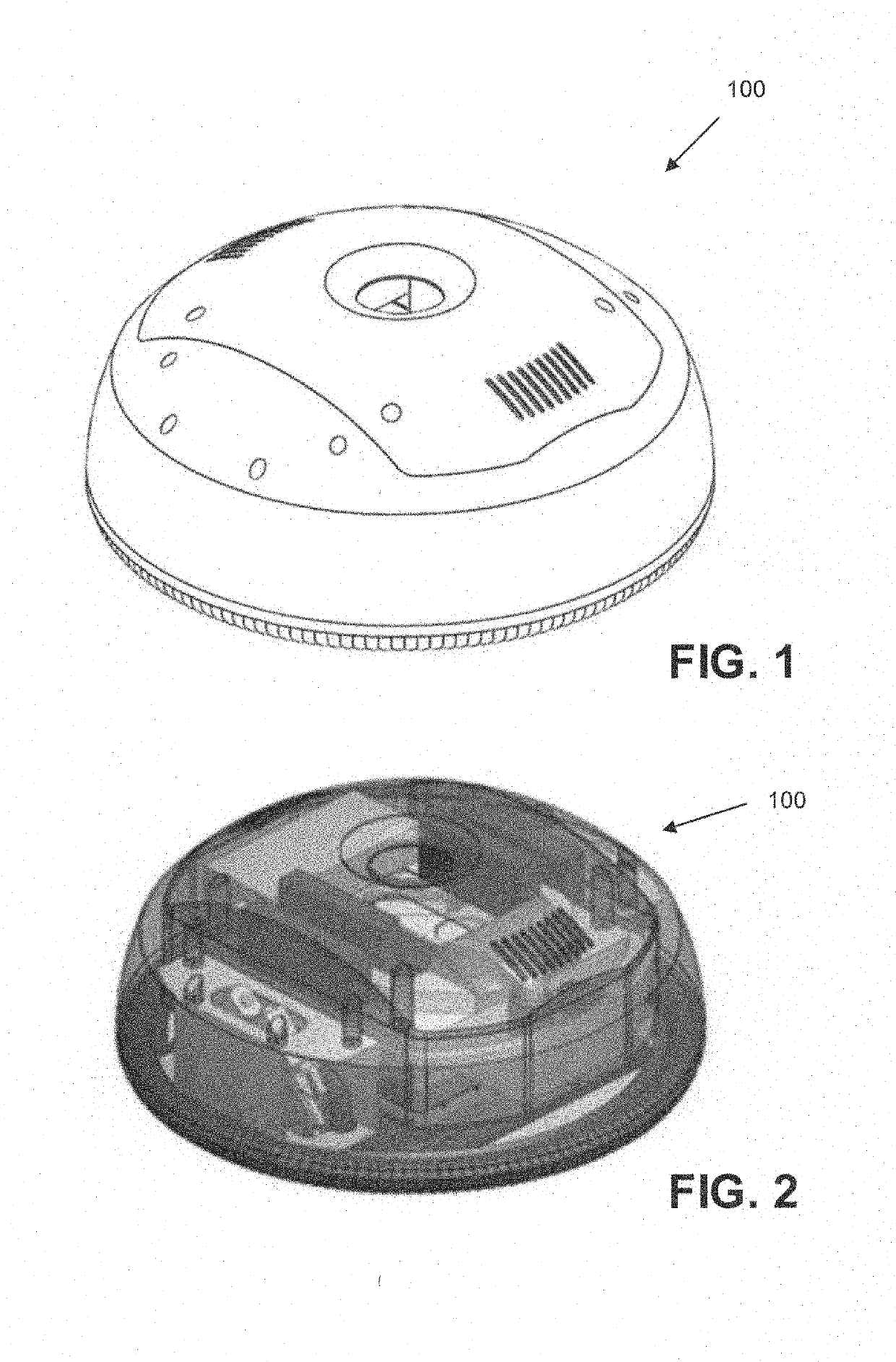

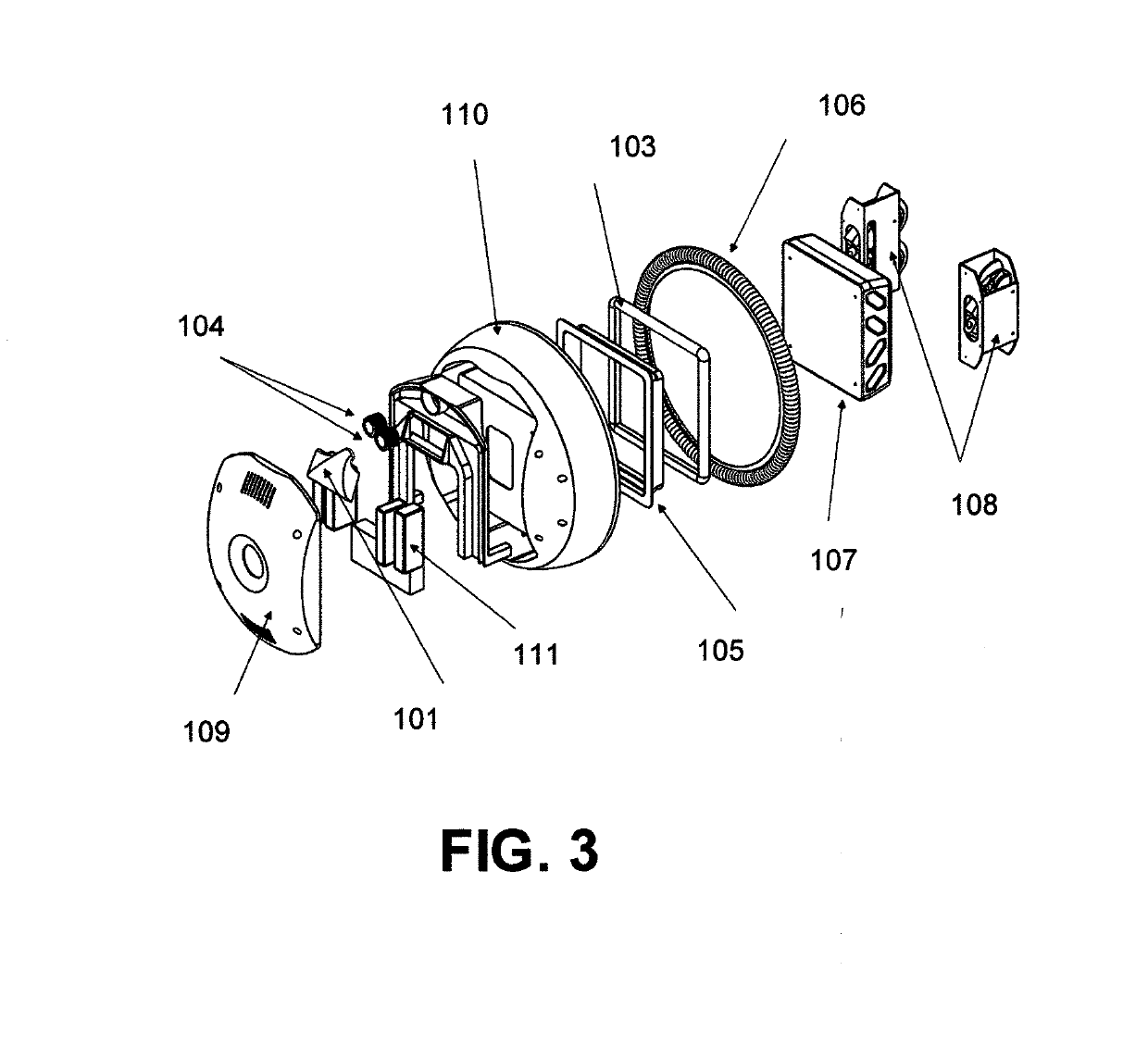

Robotic device for providing vertical mobility

ActiveUS20190337579A1Reliable vacuum chamberKeep vacuumingCarpet cleanersFloor cleanersEngineeringCentral compartment

A robotic device for providing vertical mobility has a payload is disposed inside a central compartment and supported by a skid. The skid can move up and down through latch and hook pairs to keep intimate contact with the surface and cross over bumps. The apparatus uses a flexible seal to create a reliable vacuum chamber. The flexible seal comprises a foam ring inside fabric pocket. A plurality of rod and spring strips are configured to apply a downward force to the flexible seal to conform with surface curvatures. The fabric pocket fills in the gaps or seams to maintain a vacuum. The air flows inside a manifold and passes through a filter to avoid debris from damaging the vacuum motor assembly.

Owner:INNOVBOT +1

Method and system for fuel system control

ActiveUS9027533B2Shorten operation timeFuel economyHybrid vehiclesElectrical controlFuel tankHybrid vehicle

Methods and systems are provided for controlling a fuel system in a hybrid vehicle. Before canister purging is stopped by closing a purge valve, a canister vent valve is closed to hold fuel tank vacuum. Then, during a subsequent canister purge, the purge valve is opened before opening the vent valve, allowing canister purge to initiate under fuel tank vacuum conditions.

Owner:FORD GLOBAL TECH LLC

Insulator material and method for manufacturing thereof

InactiveUS20100139951A1Breakdown strength can be keptHigh dielectric strengthGlass/slag layered productsWood layered productsStructural engineeringMechanical engineering

Vacuum filled hollow alveoles embedded in an insulation material in order to arrive at a light weight insulation material using the high breakdown voltage of evacuated cavities, i.e. alveoles at a vacuum lower than the minimum of the Paschen law. Pressurized hollow alveoles embedded in an insulation material in order to arrive at a light weight insulation material using the high breakdown voltage of pressurized cavities, i.e. alveoles at a pressure higher than the minimum of the Paschen law.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com