Ice bag palletizer

a palletizer and ice bag technology, applied in the direction of conveyor parts, thin material handling, stacking articles, etc., can solve the problems of not offering a palletizing solution for automatically stacking bags of ice cubes, not addressing the problem of lifting and turning lumpy bags, shifting articles, etc., to achieve the effect of raising and lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

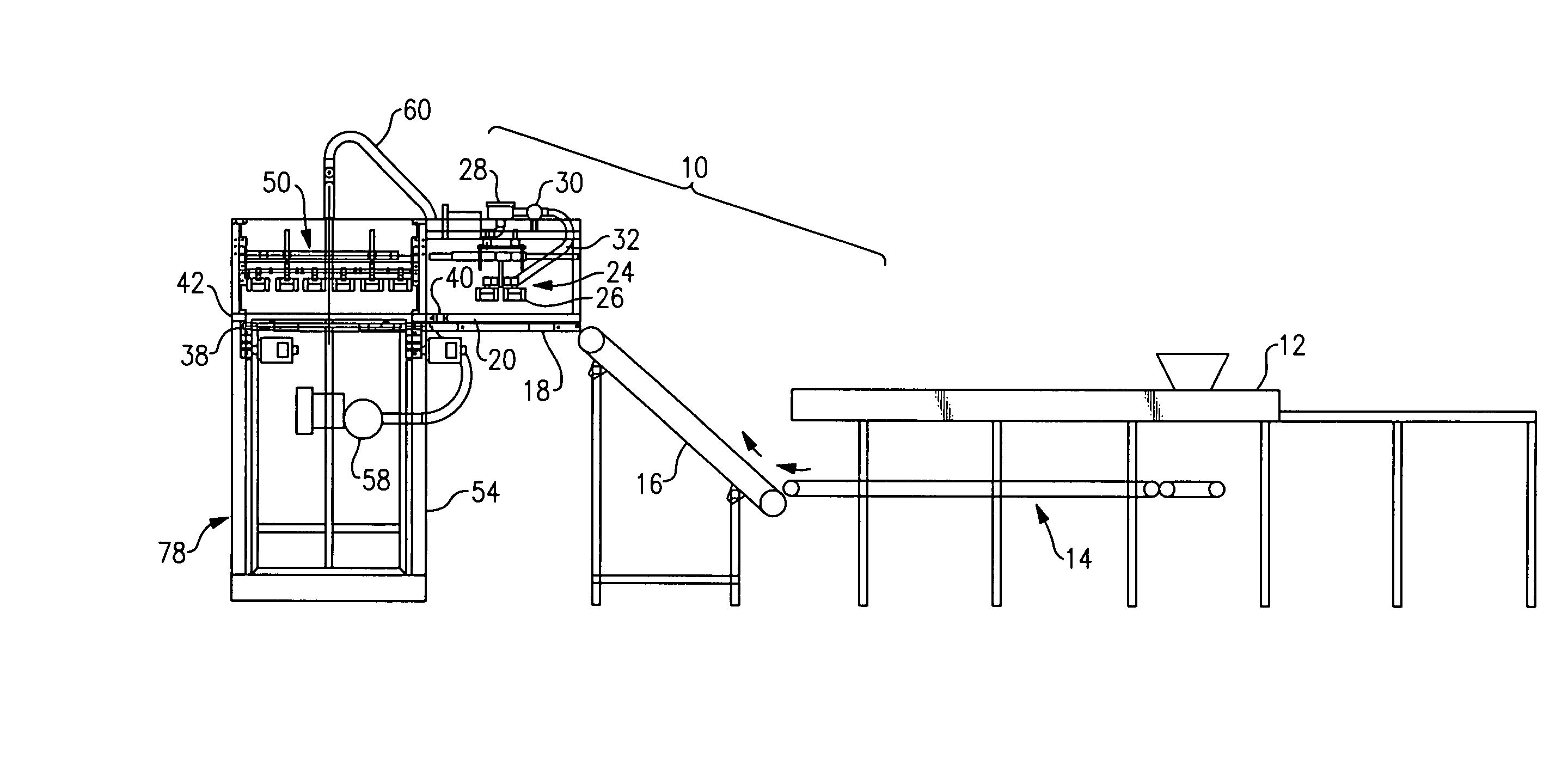

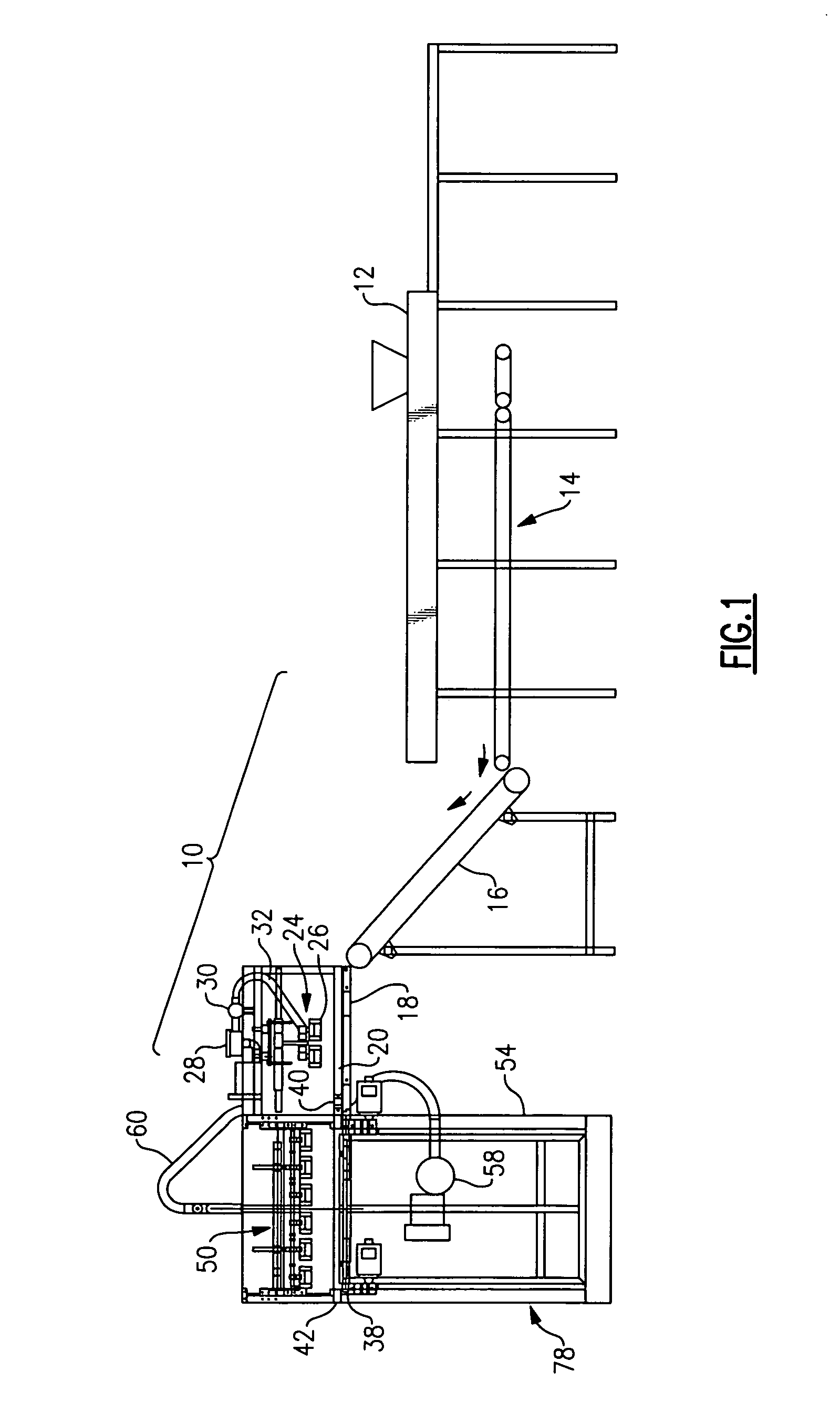

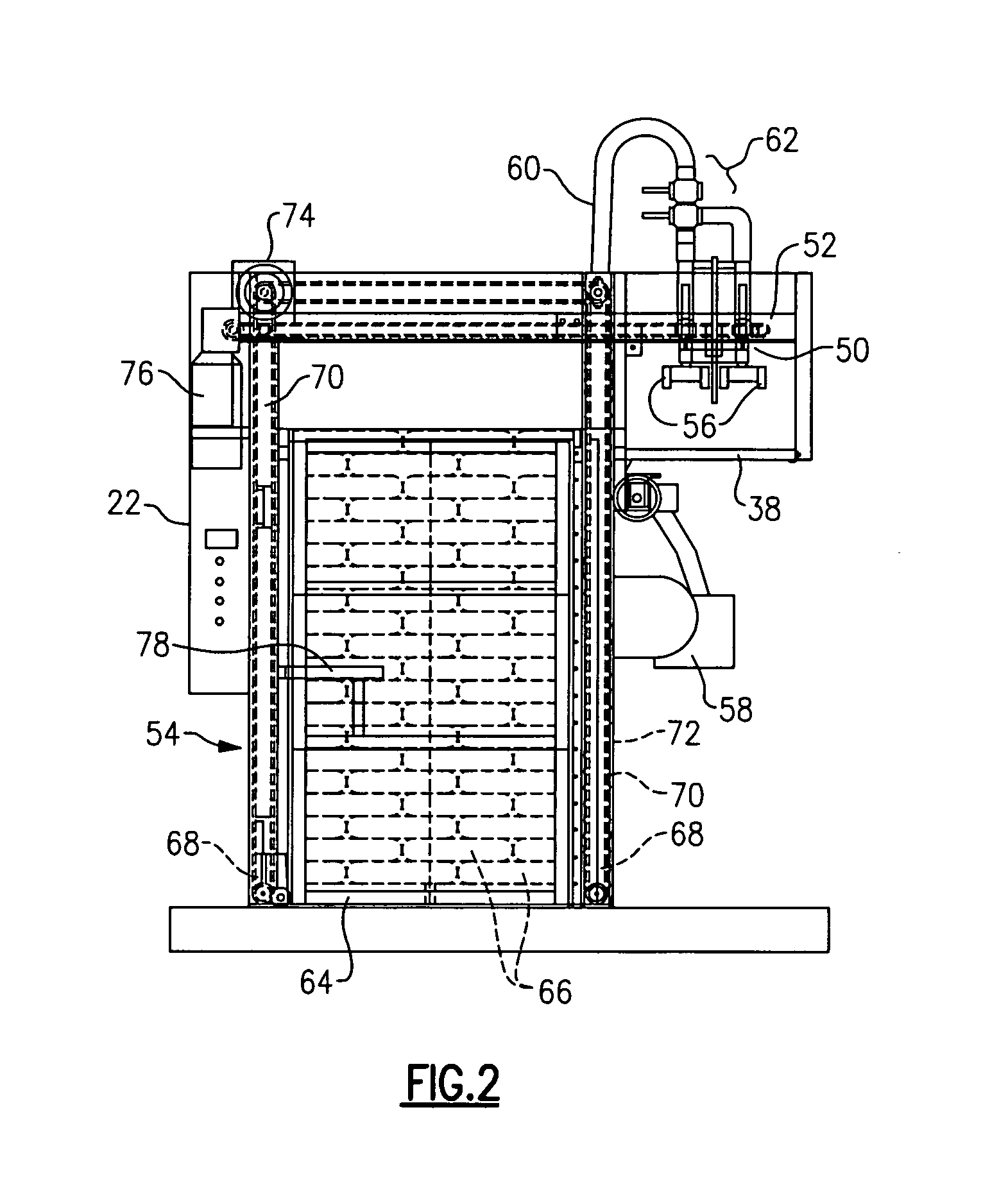

[0034]With reference now to the Drawing, and initially to FIGS. 1, 2 and 3, an ice bag palletizer arrangement 10 according to the present invention is shown adjacent an ice cube bagging machine 12, which here can be for example a Hamer ice packaging form fill and seal machine in any of various models. In FIG. 3, some of the structure is omitted. In this example, the ice cube bags and seals the ice cubes into polyethylene bags at a rate of about 40 bags per minute, with each bag being 7 to 8 pounds of ice and having length and width dimensions of about sixteen by nine inches. The bags of ice cubes drop down to a discharge conveyor 14 that carries the filled bags to an incline conveyor 16, which carries the bags up to an elevation of about six feet, to feed them to the ice palletizing arrangement 10.

[0035]An infeed conveyor 18 receives the ice cube bags, and is in the form of a low profile belt conveyor, 48 inches in length and 24 inches in width, with a belt formed of a polyurethane-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com