Jar or Tin Lid

a lid and tin technology, applied in the field of lids, can solve the problems of high power force, inability to apply the required force for opening the lid and overcoming the vacuum force, and inability to solve the solution available to open the screw-lock mechanism of containers with tight lids altogether. , to achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

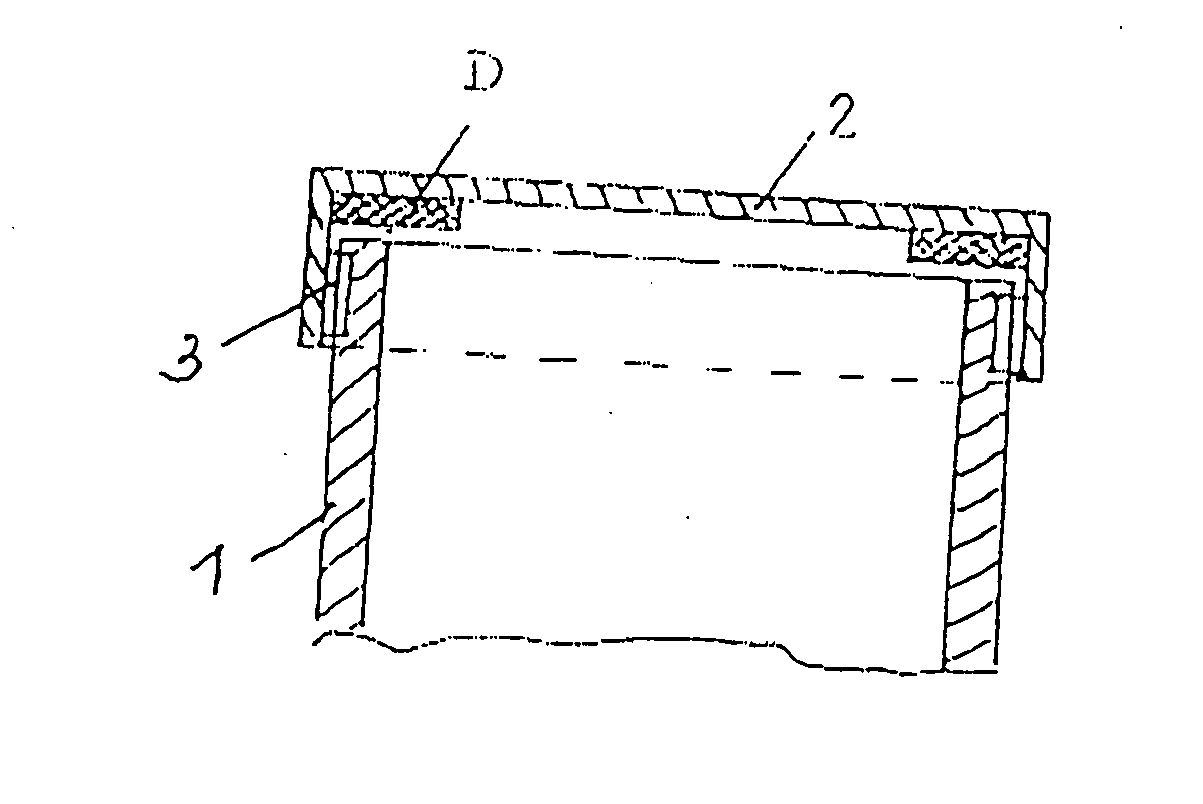

[0024]With a conventional embodiment of a jar 1 closed by a lid, in which food products are conserved by vacuum, a lid 2 is attached to the top side of the jar. The lid is screwed onto the top of the jar 1 at 3 and is locked by means of a screwing or twisting-off-closure. On the inner side of the lid a seal 4 is arranged at the peripheral edge of the bottom of the lid, which seal is in engagement with the top edge of the jar so that within the jar underpressure will be maintained for conserving the content. The seal 4 is a sealing ring firmly connected with the inner side of the lid. The diameter of the sealing ring corresponds with the inner diameter of the lid.

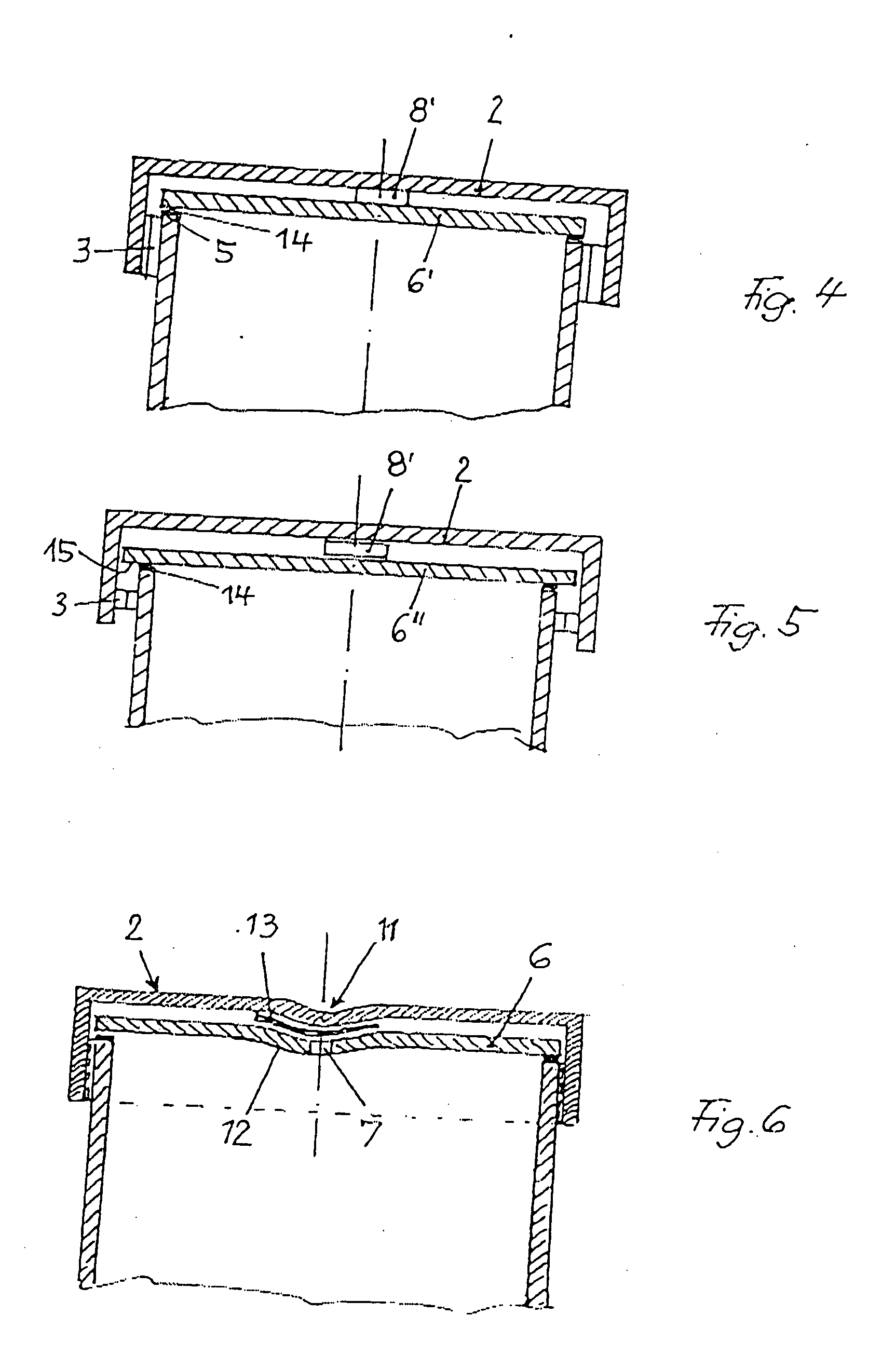

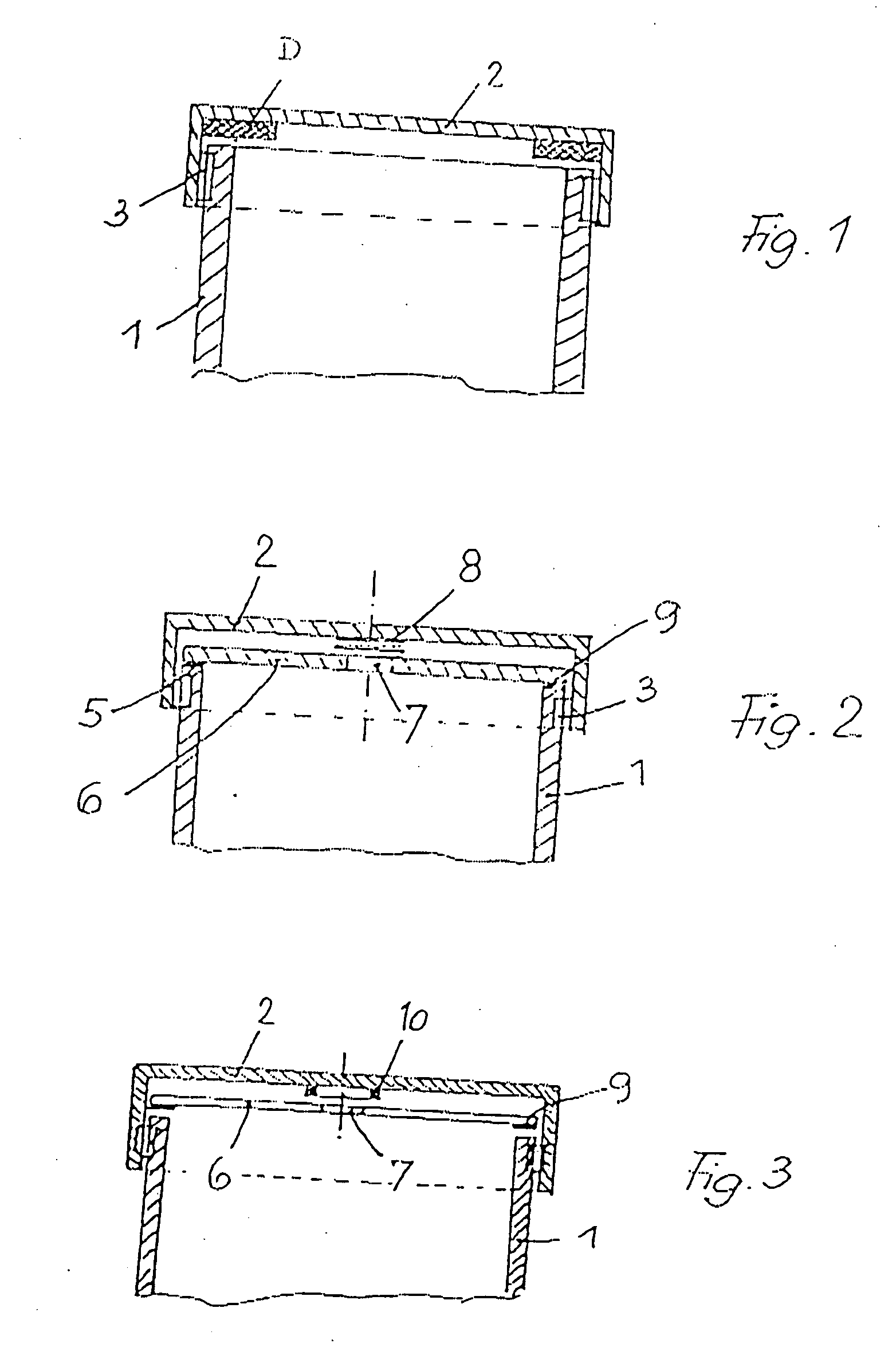

[0025]The arrangement according to FIG. 2, which is an embodiment of the lid system according to the invention, shows a plate 6 resting upon the top peripheral edge 5 of jar 1, which plate has a central opening 7 in engagement with a seal 8 firmly connected to the inner side of the lid, and shuts the opening 7 so that the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com