Patents

Literature

170results about "Cap application using vaccuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for forming inflated containers

ActiveUS20060090421A1No sacrifice in production speedImprove sealingCapsPaper/cardboard articlesThin membraneEngineering

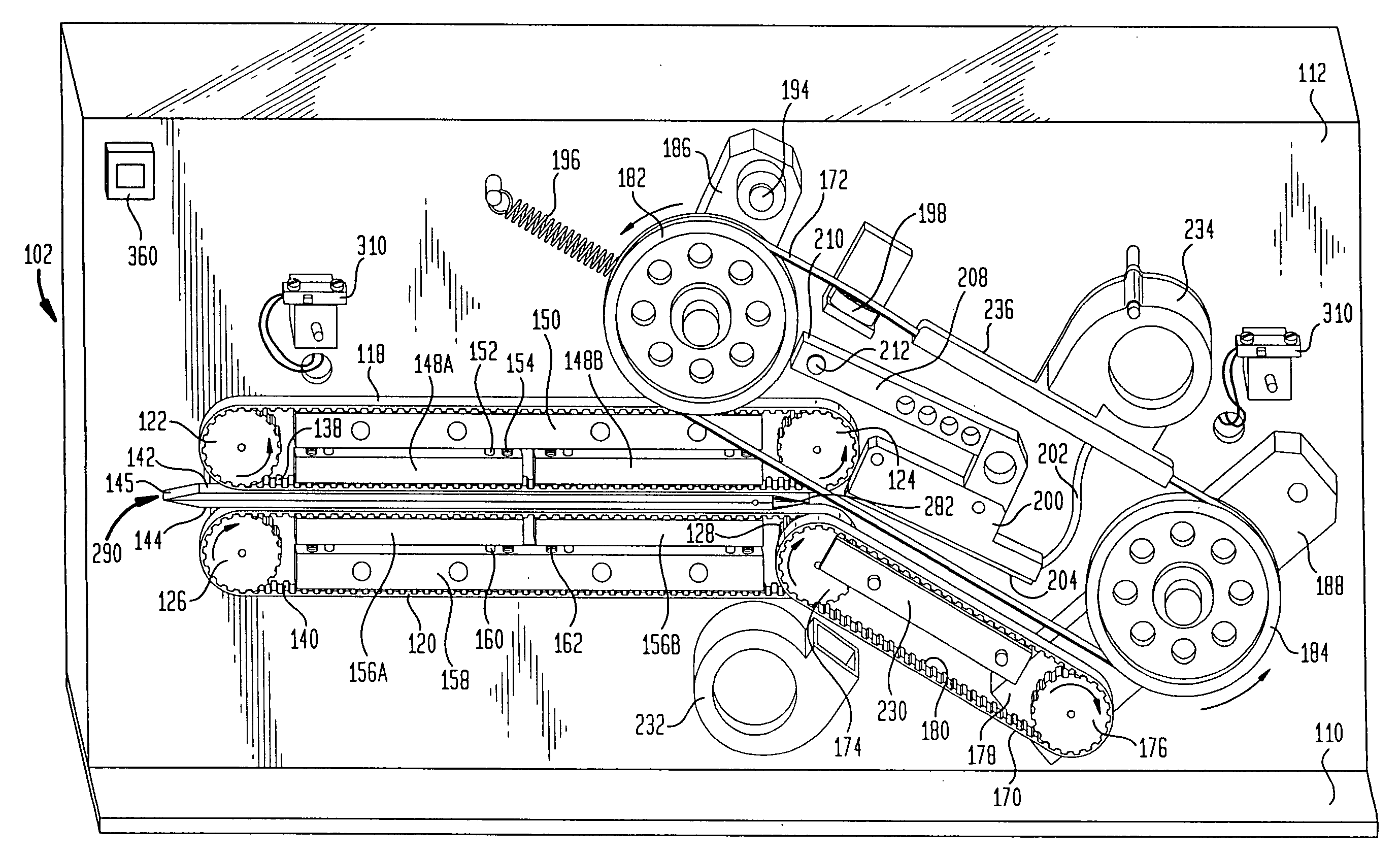

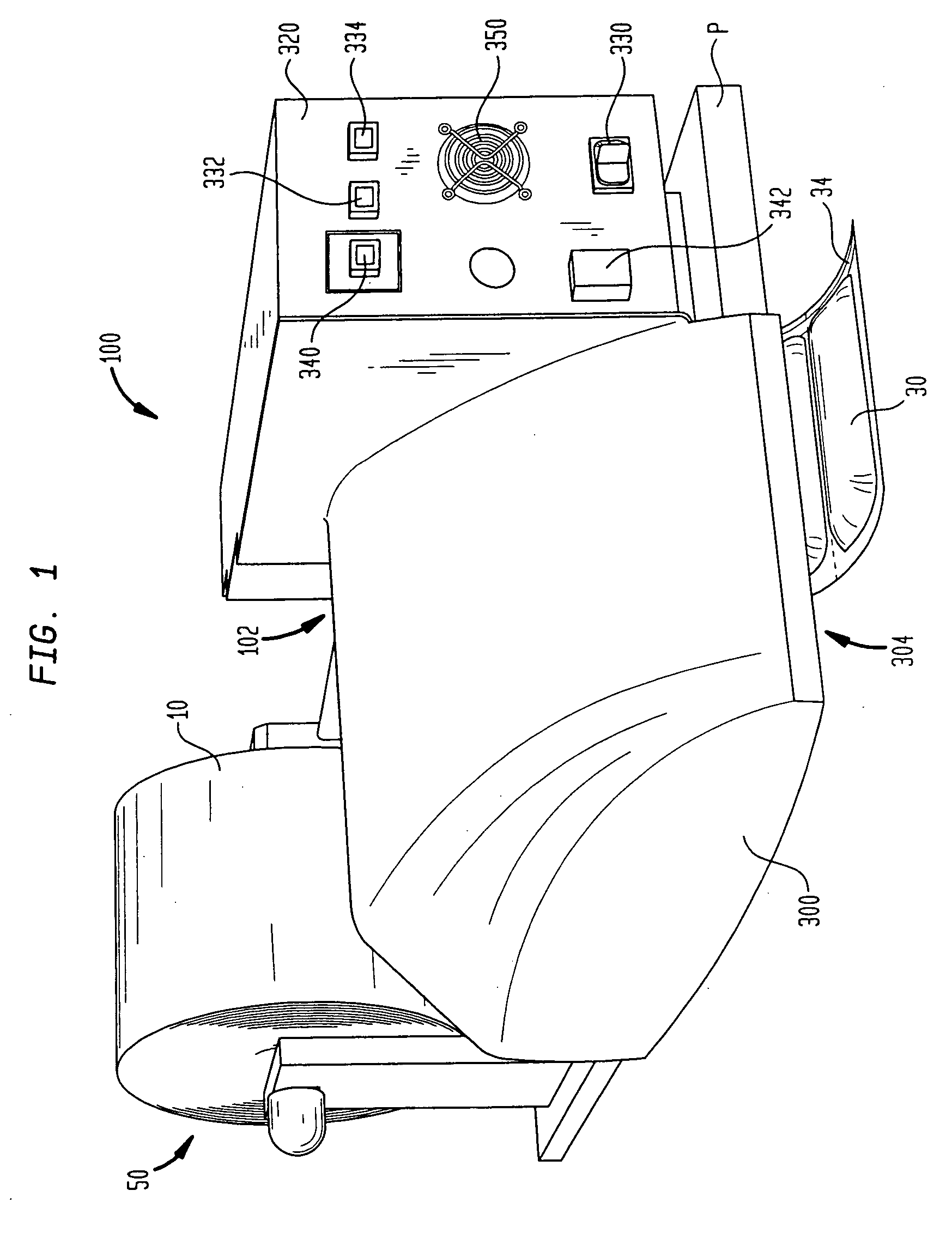

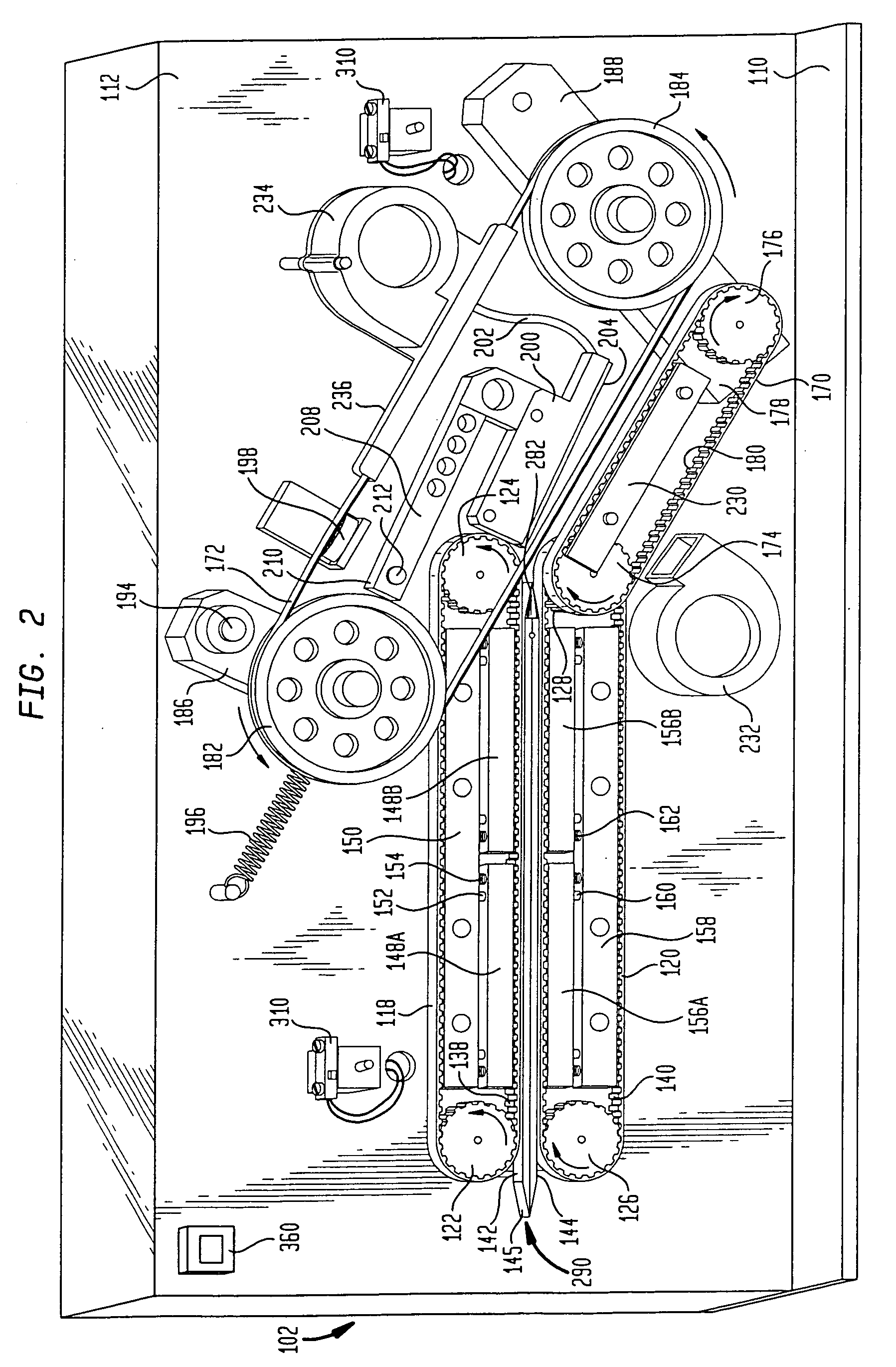

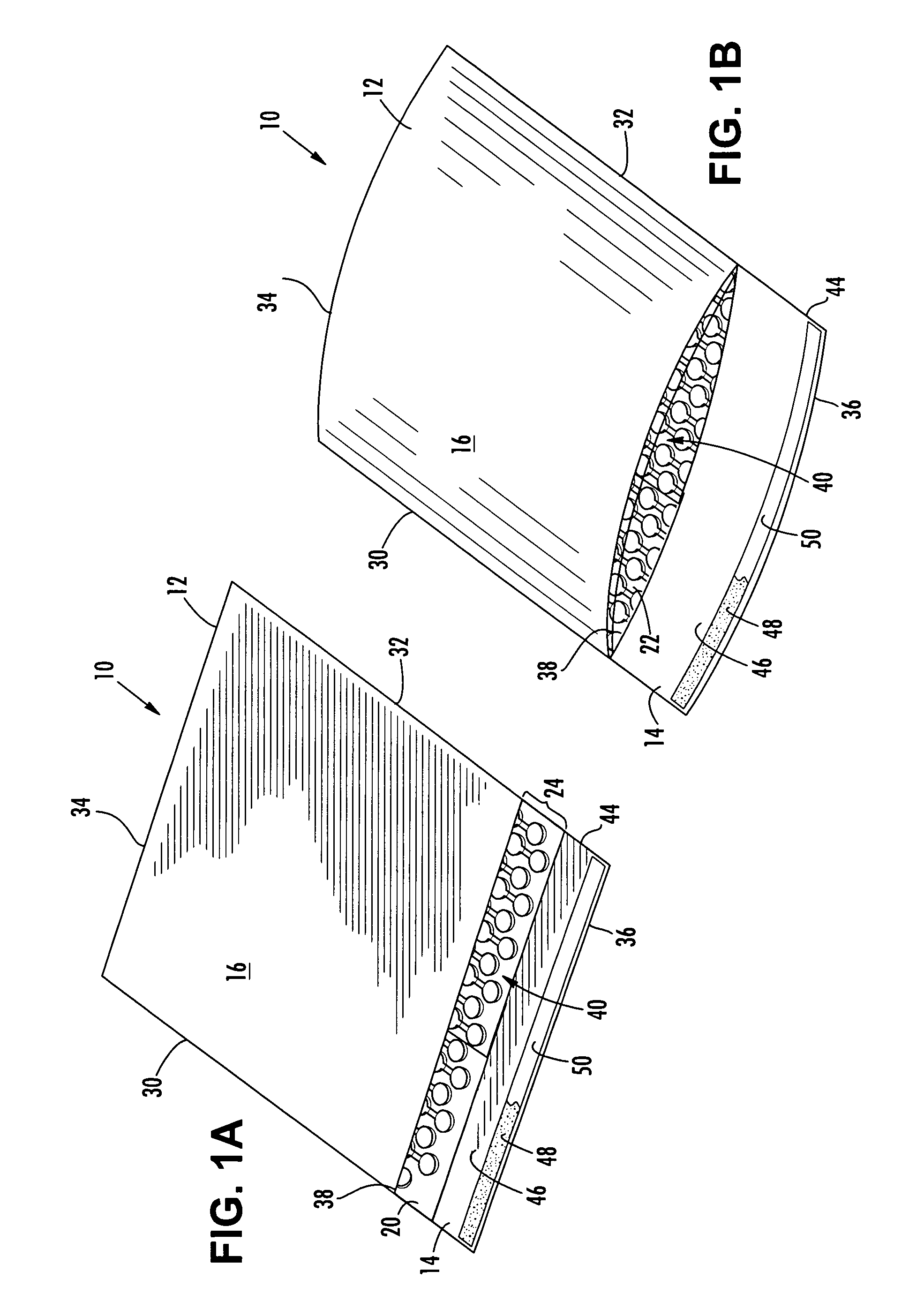

An apparatus for forming inflated containers from a film web having two juxtaposed film plies includes: a. a mechanism that conveys the film web along a path of travel; b. a first sealing device for producing one or more seals that bond the film plies together to form a container having at least one opening; c. an inflation assembly for inflating the container by directing a stream of gas into the opening thereof; and d. a second sealing device for sealing closed the opening of the inflated container.

Owner:SEALED AIR U S

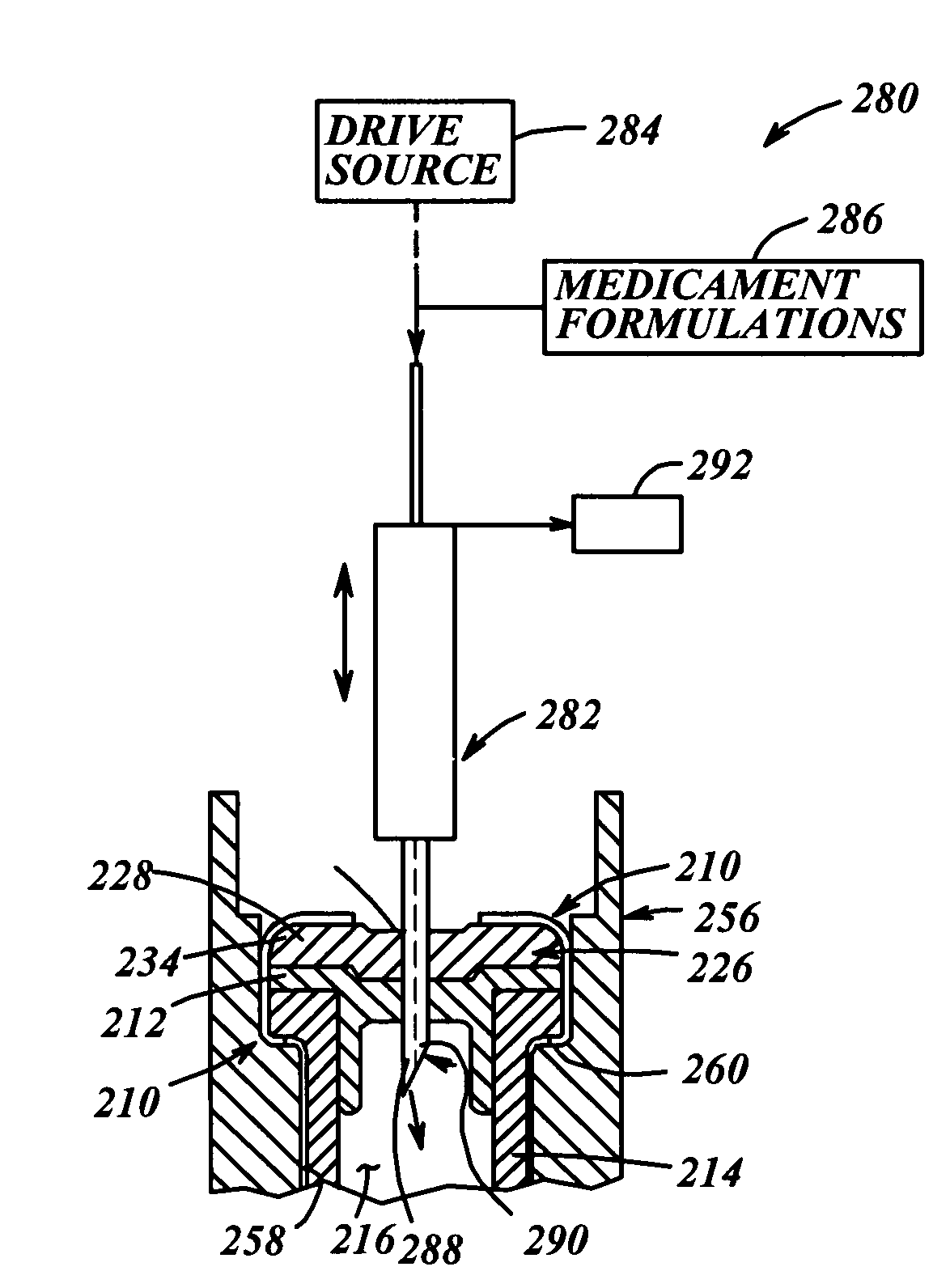

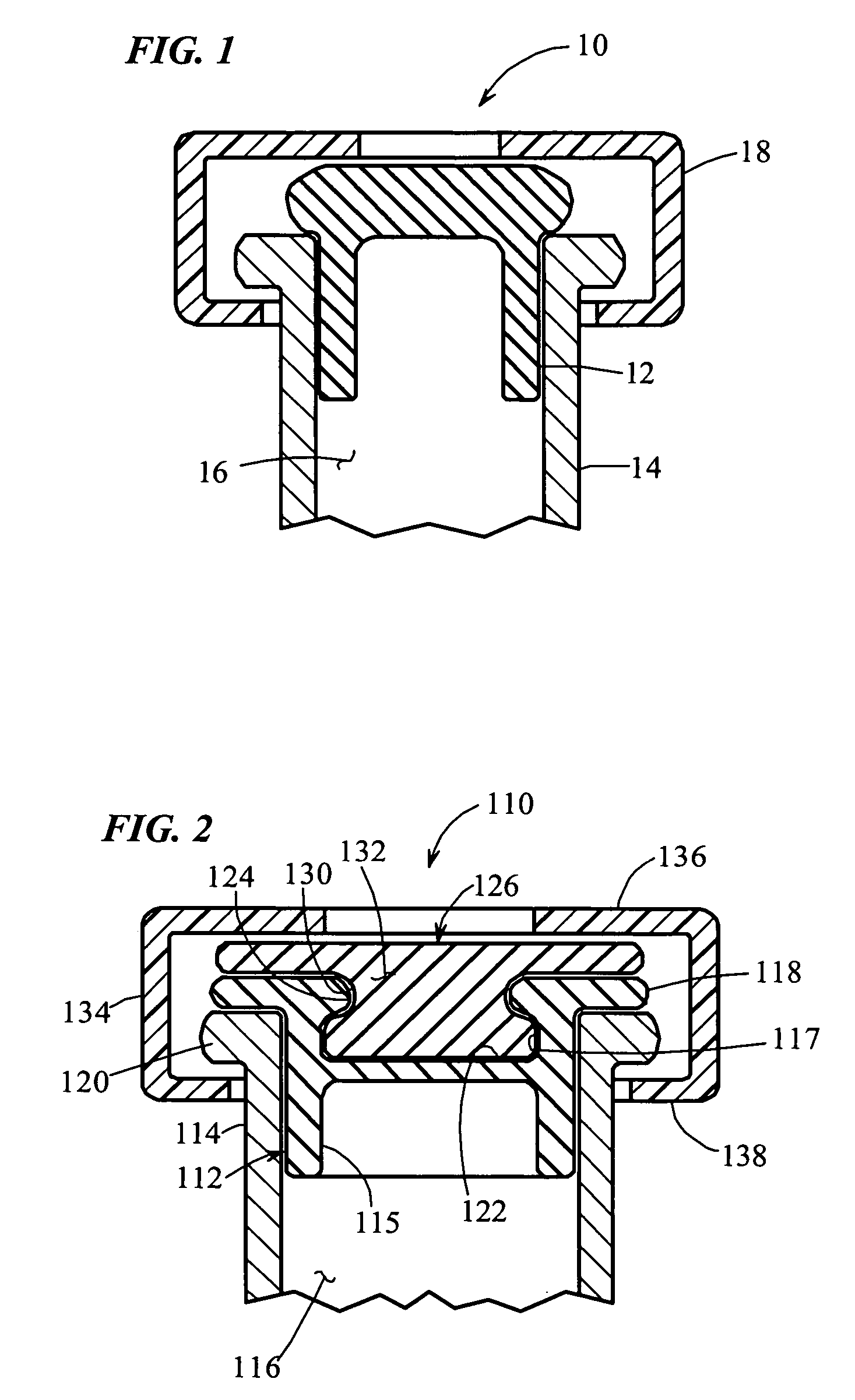

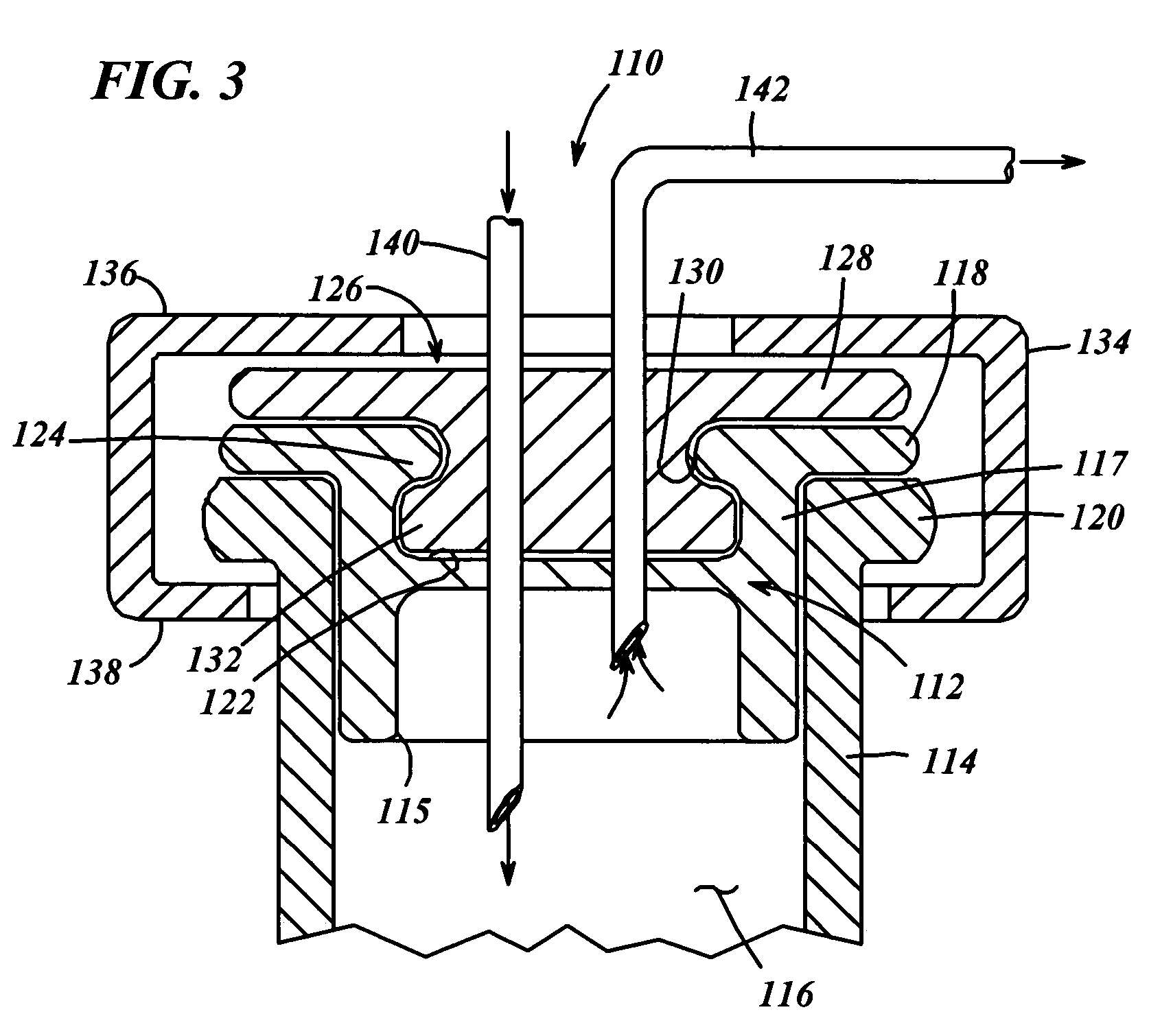

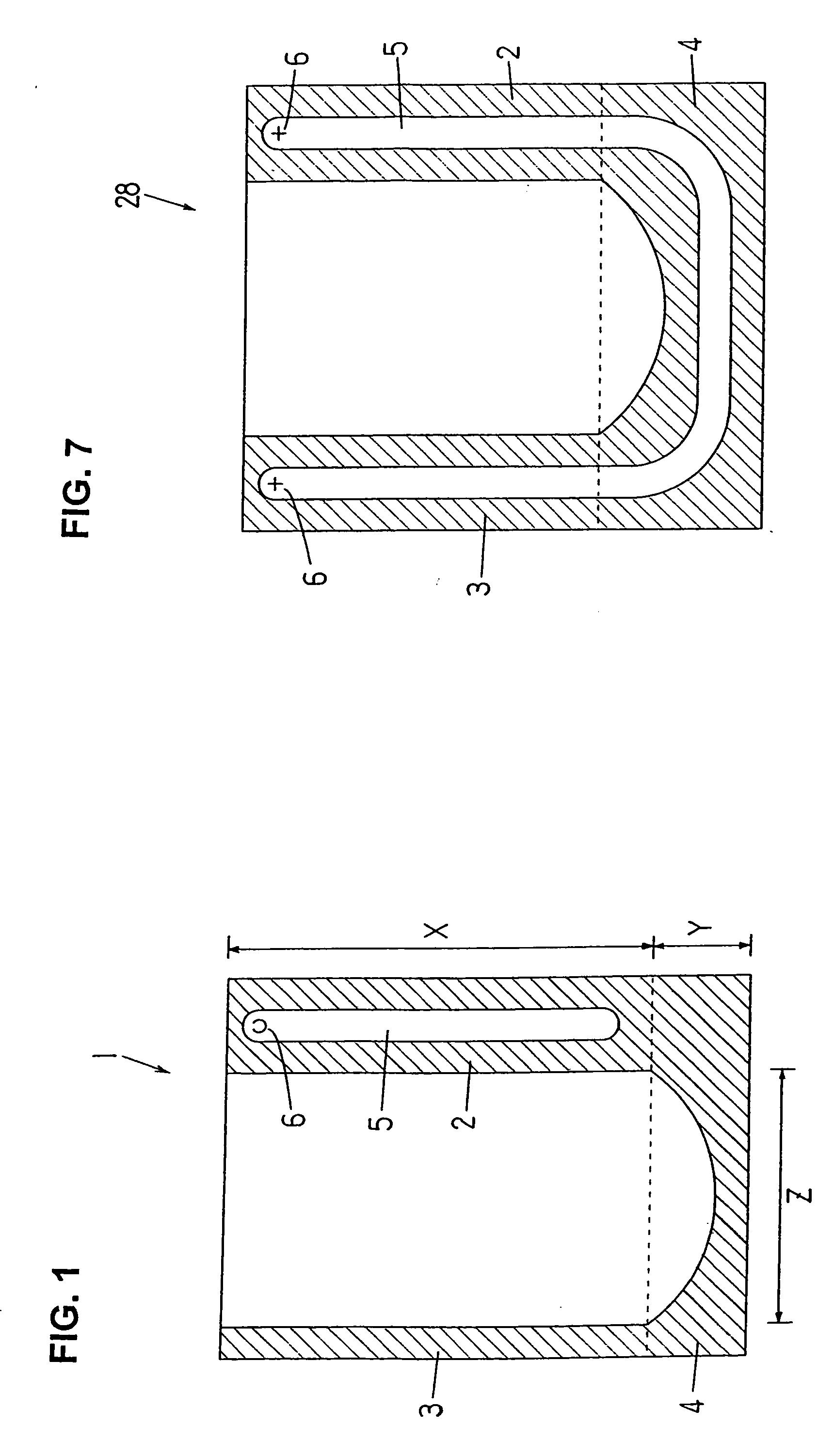

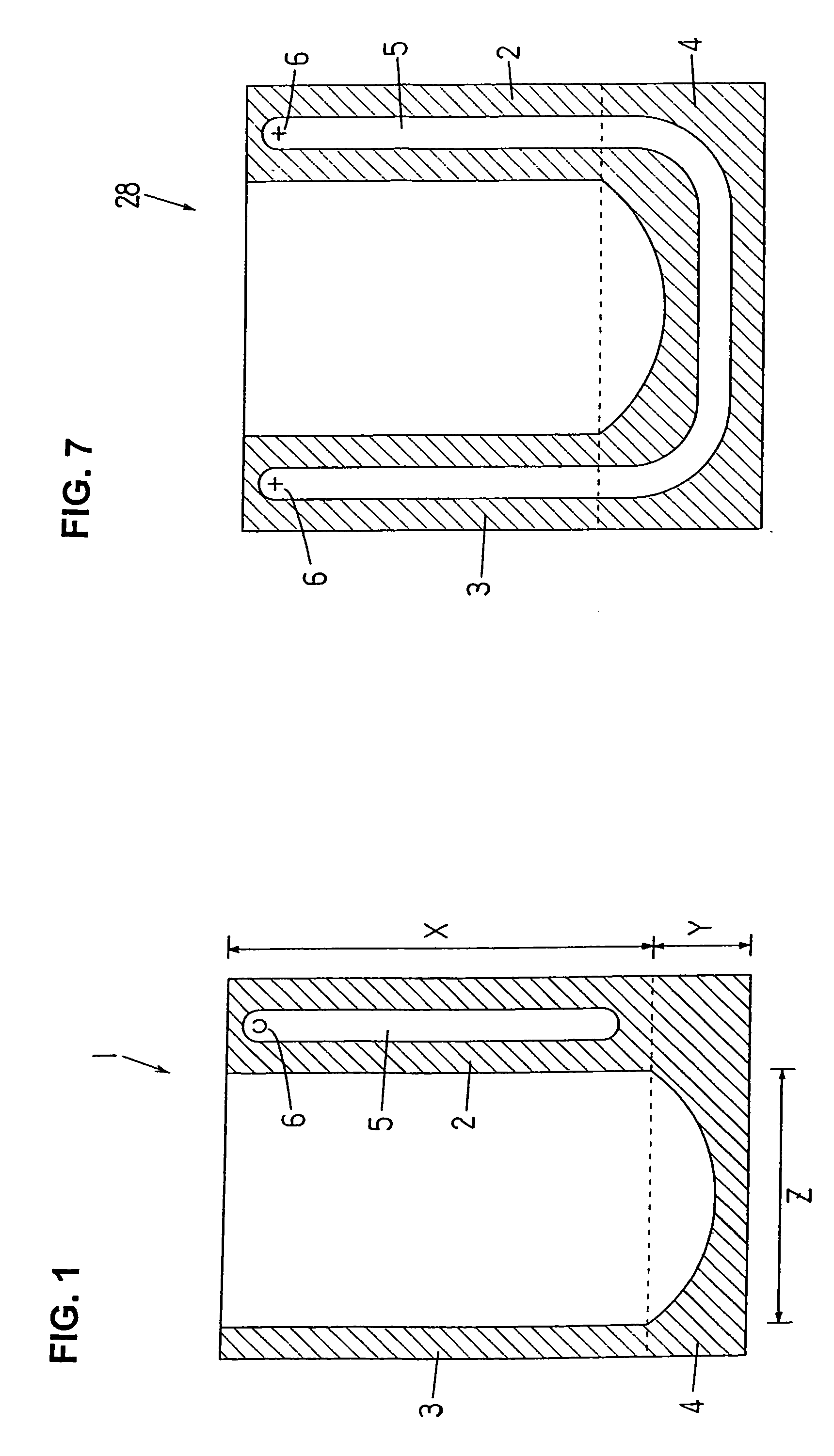

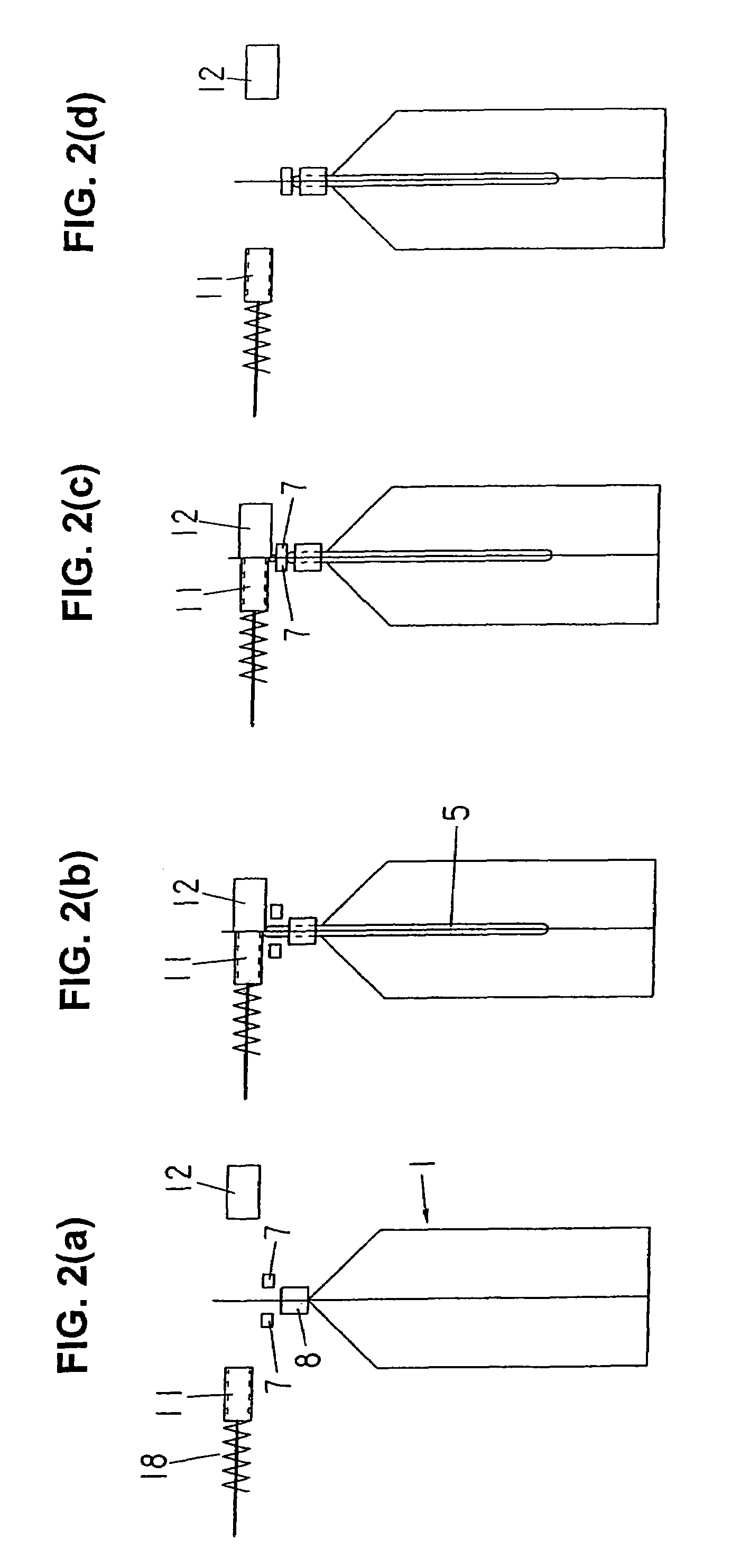

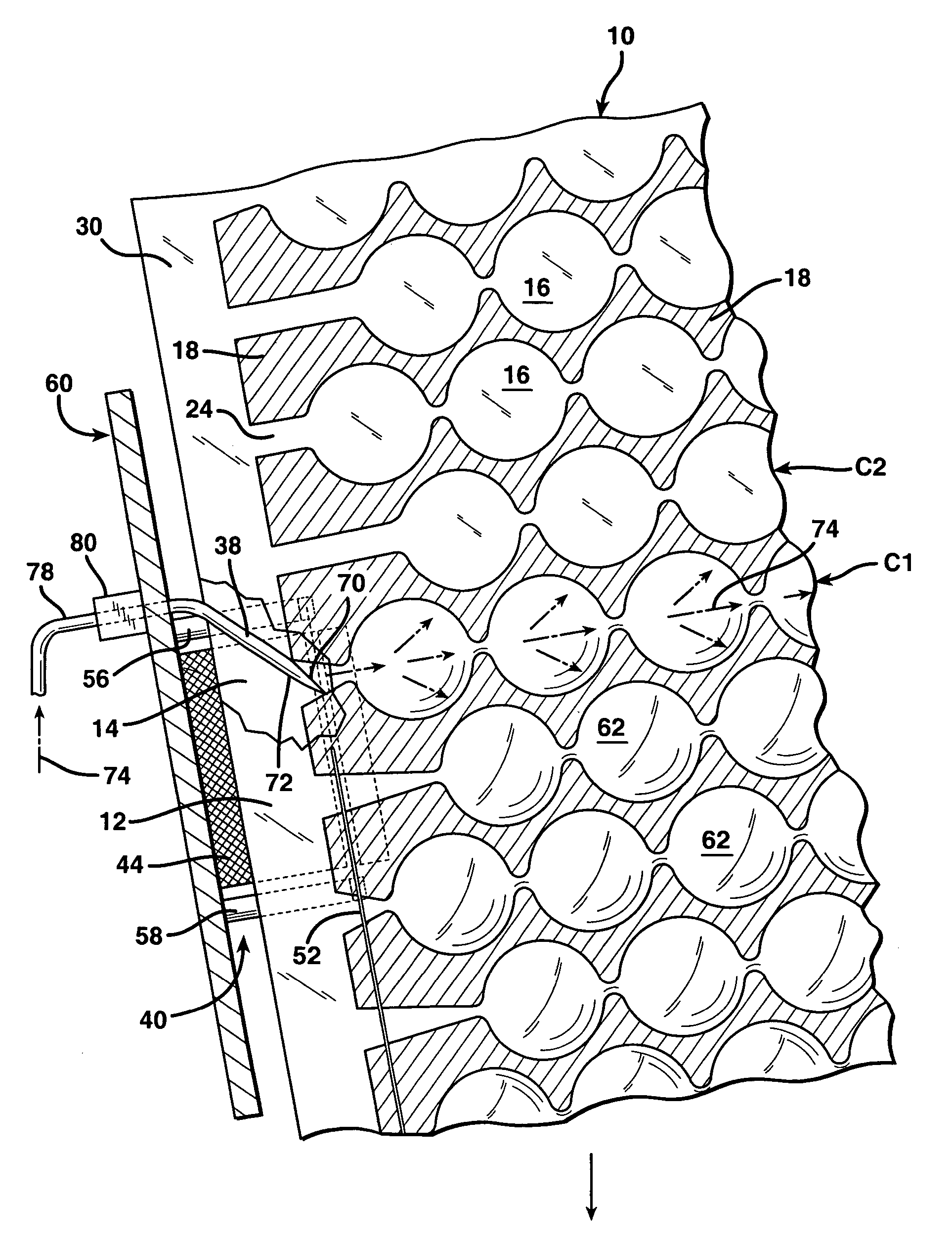

Medicament vial having a heat-sealable cap, and apparatus and method for filling the vial

InactiveUS7032631B2Stable environmentReduce frictionCapsCap application using vaccuumVialLow-density polyethylene

A resealable cap (110, 210) for a medicament vial (114, 214) has a base portion (112, 212) formed of vulcanized rubber or like material known for providing a stable environment for the medicament contained within the vial, and a resealable portion (126, 226) overlying the base portion. The resealable portion (126, 226) is made of low-density polyethylene or like material, and can be punctured by a needle or like injection member (140, 282) for dispensing medicament into the vial (114, 214). Prior to filling, the cap (110, 210) is assembled to the vial (114, 214) and the cap / vial assembly is sterilized. Then, a needle (140, 282) is inserted through the cap (110, 210) and medicament is introduced through the needle and into the vial. Upon withdrawal of the needle (140, 282), the penetrated region of the cap (248) is fused by laser (276) or direct heat sealing (264) to hermetically seal the needle hole (294) in the cap.

Owner:MEDINSTILL DEV

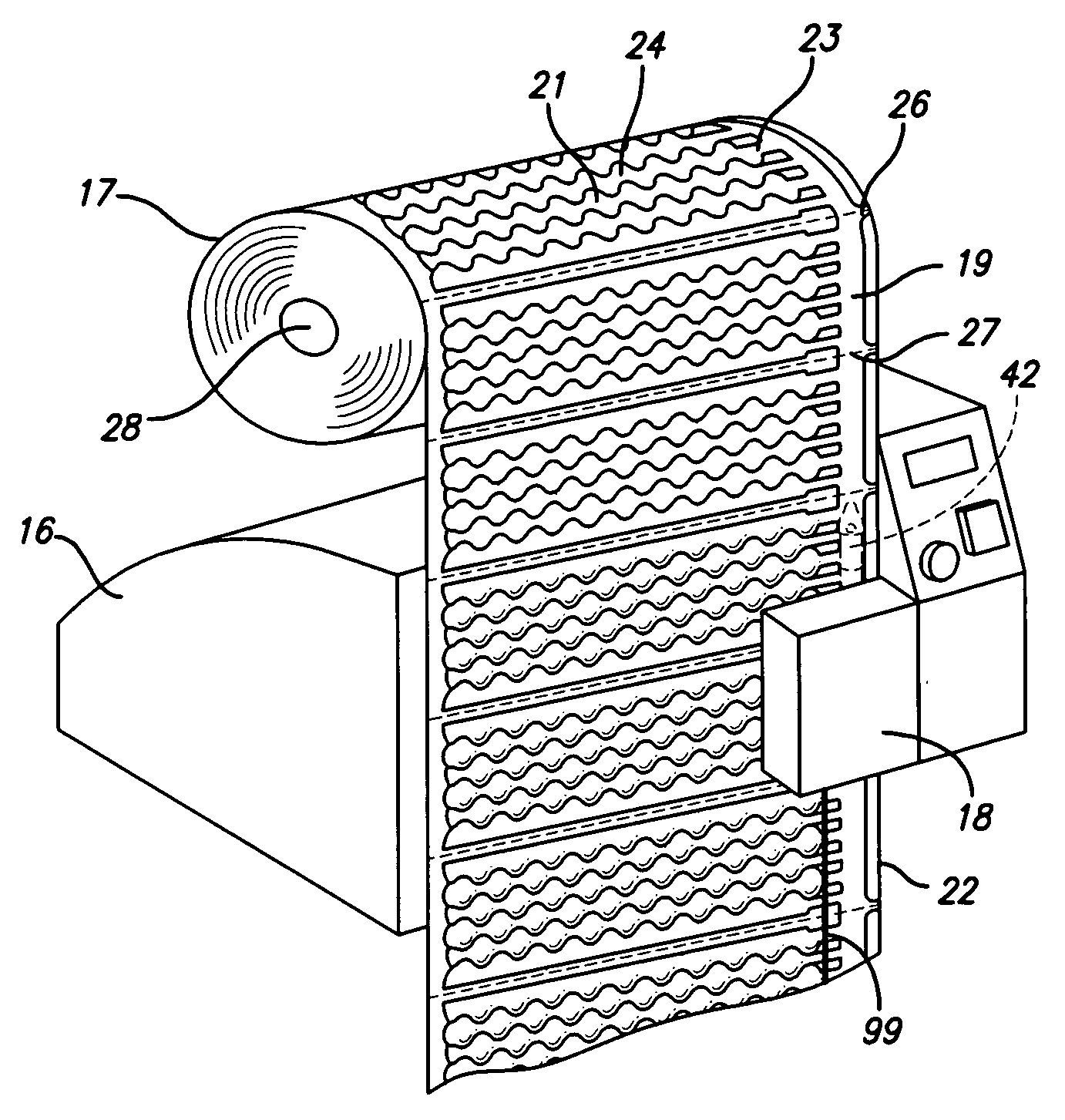

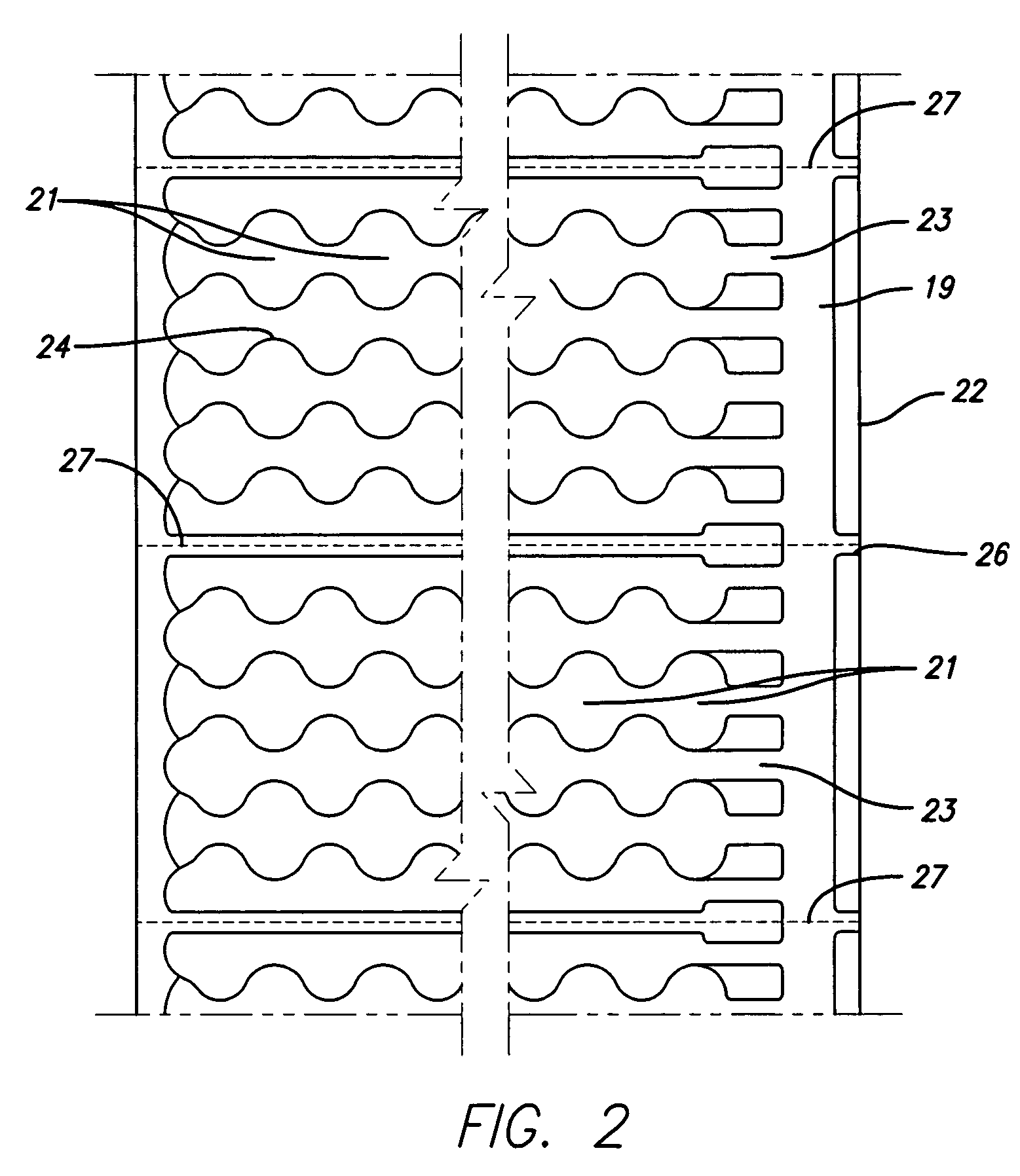

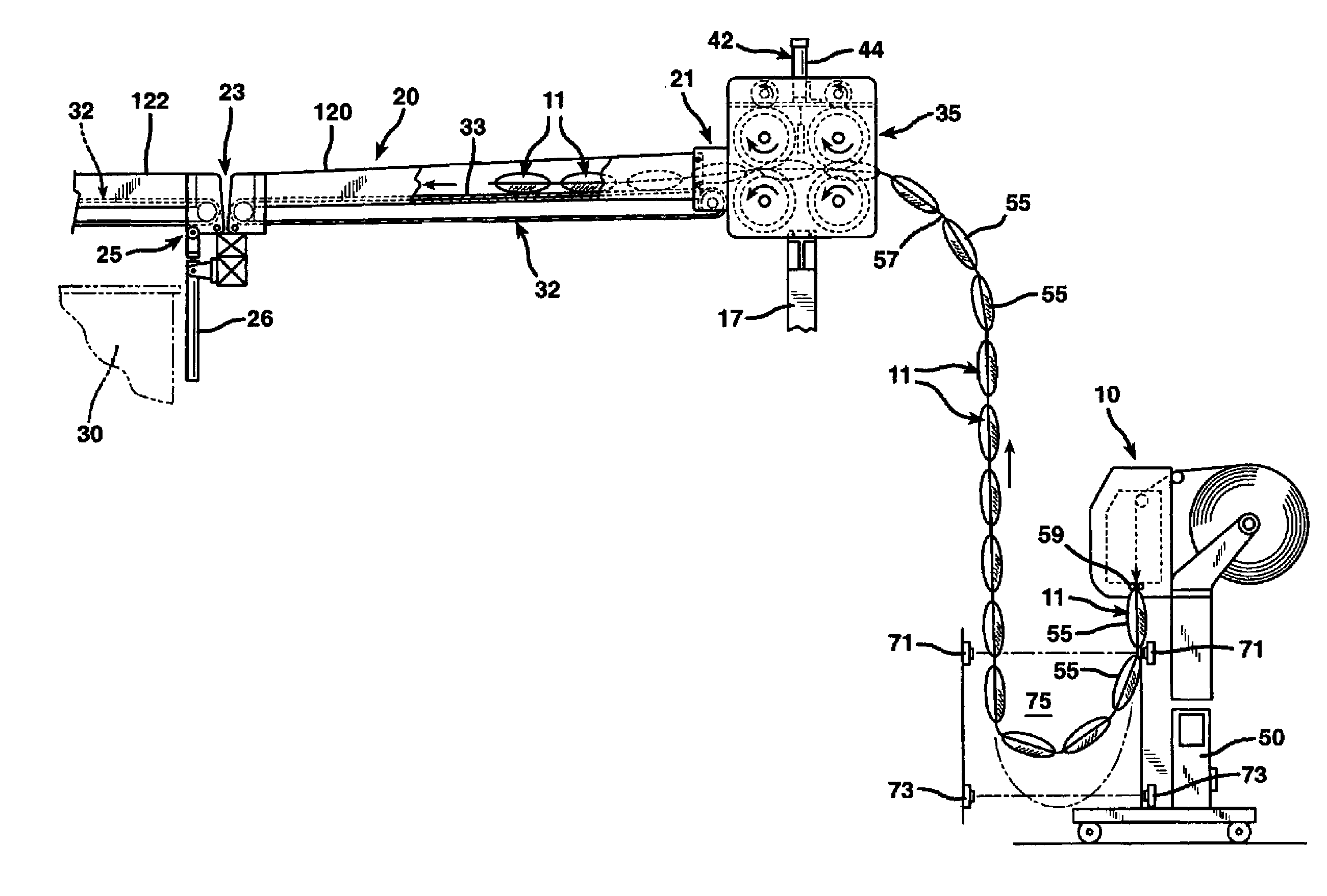

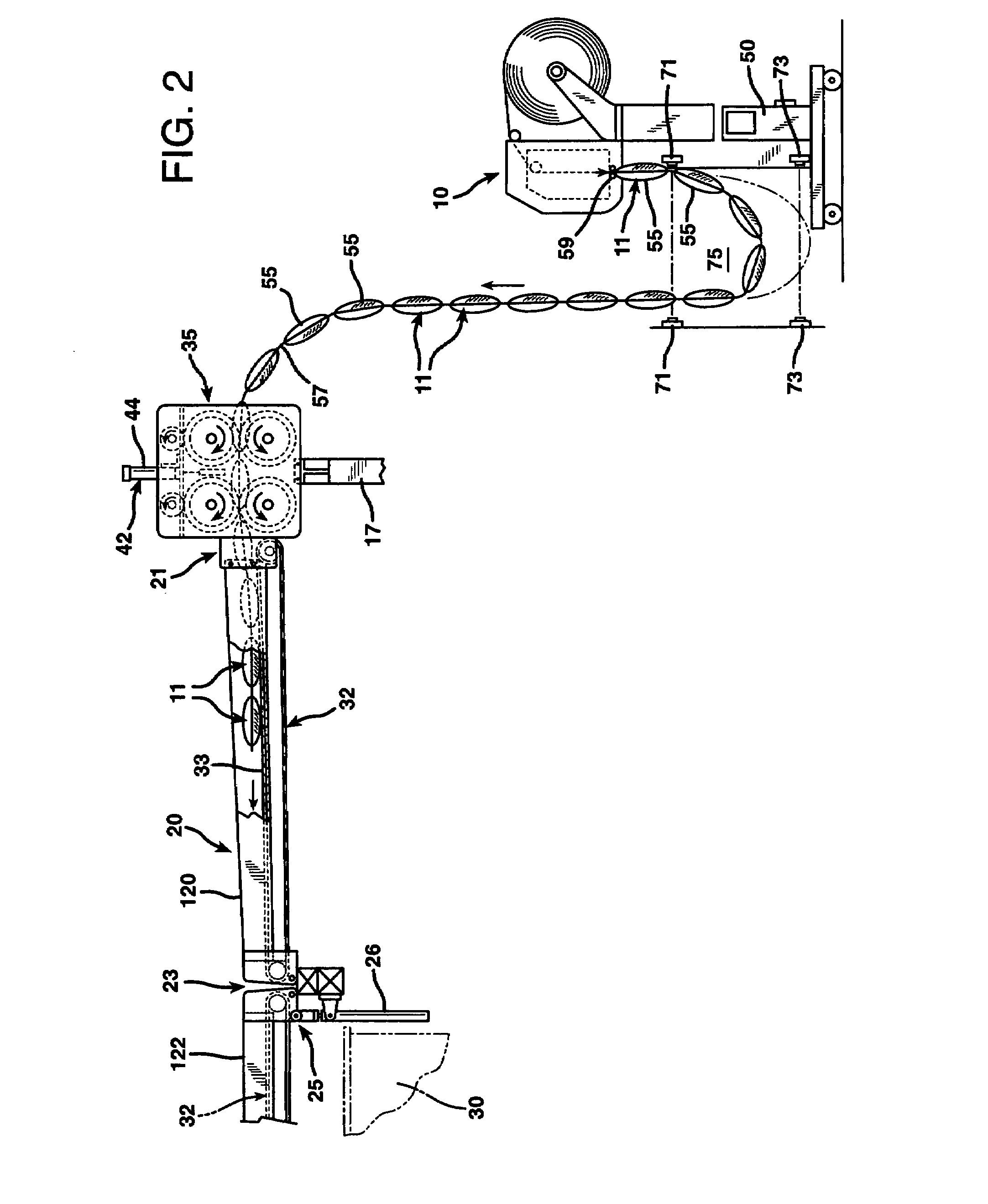

Machine for inflating and sealing an inflatable web

A machine for inflating and sealing an inflatable web comprising a series of pre-formed flexible containers, each of the pre-formed containers being capable of holding therein a quantity of gas and having an opening for receiving such gas.

Owner:SEALED AIR CORP

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

ActiveUS20070089377A1Automate processingEasy to operateCapsBag making operationsEngineeringPacking method

A method for sealing-in a gas in a gas filling compartment 5 of a bag having a cut-in 6 formed near the upper edge of the gas filling compartment. In the method, two edges of the bag with the contents inserted therein are gripped by grippers and suspended, the blow-in port of a gas (air) blow-in nozzle is brought to contact the cut-in, the back surface side of the bag is supported by a backing member, gas (air) is blown into the gas filling compartment, and the position below the cut-in is held from both sides of the bag by a gas cut-off grippers while the gas blow-in continues, so that the gas inside the gas filling compartment is not allowed to escape from the cut-in, and then the entire bag mouth, including the cut-in, is sealed.

Owner:TOYO JIDOKI CO LTD

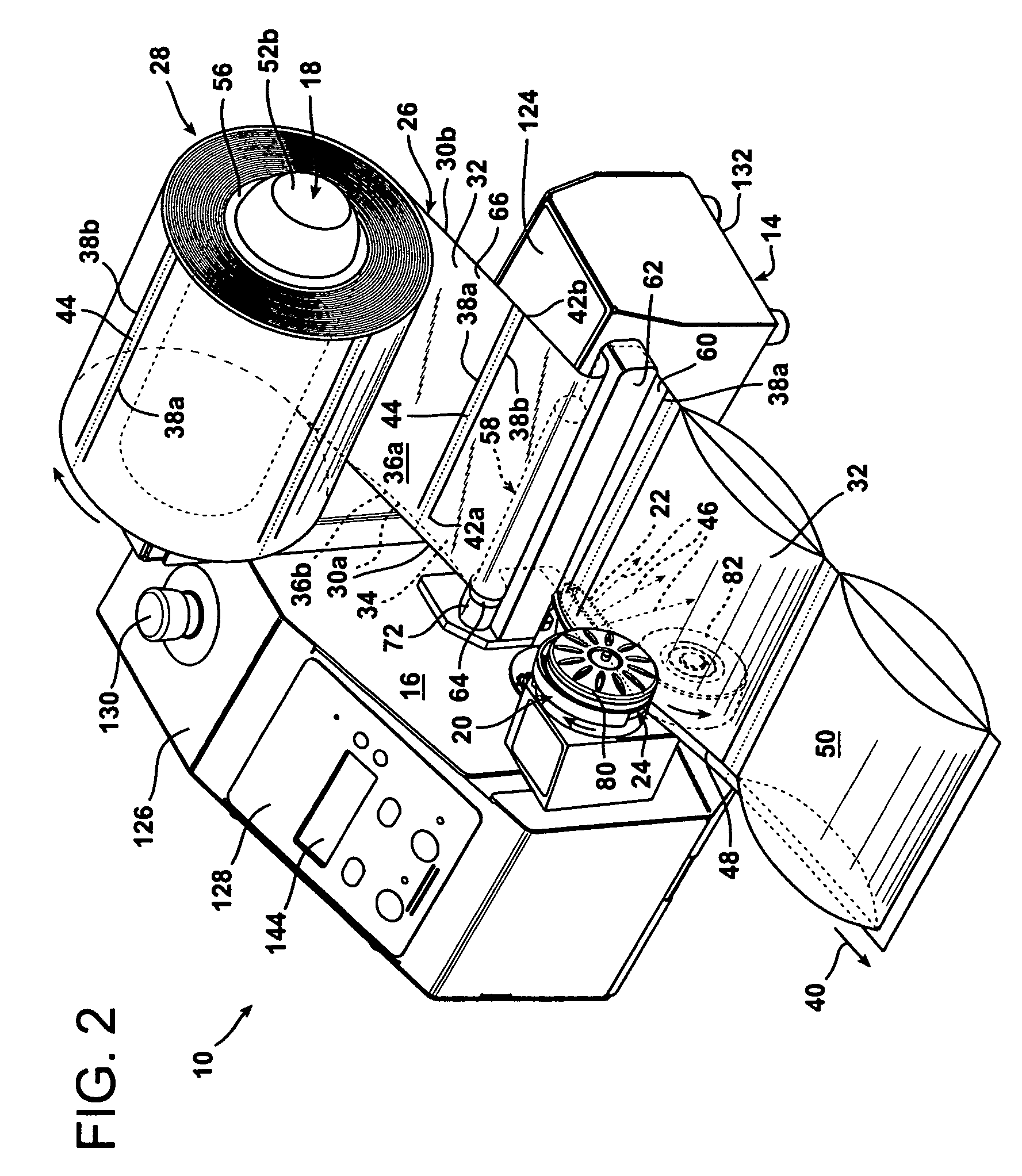

Method And Apparatus For Inflating And Sealing Packing Cushions Employing Film Recognition Controller

An apparatus for inflating and sealing packing cushions utilizes a controller adapted for acquiring information from preconfigured film material and automatically setting one or more operation parameters suitable for inflating and sealing the film. The controller can avoid or limit the need for user input, thus simplifying use of the apparatus.

Owner:PREGIS INNOVATIVE PACKAGING

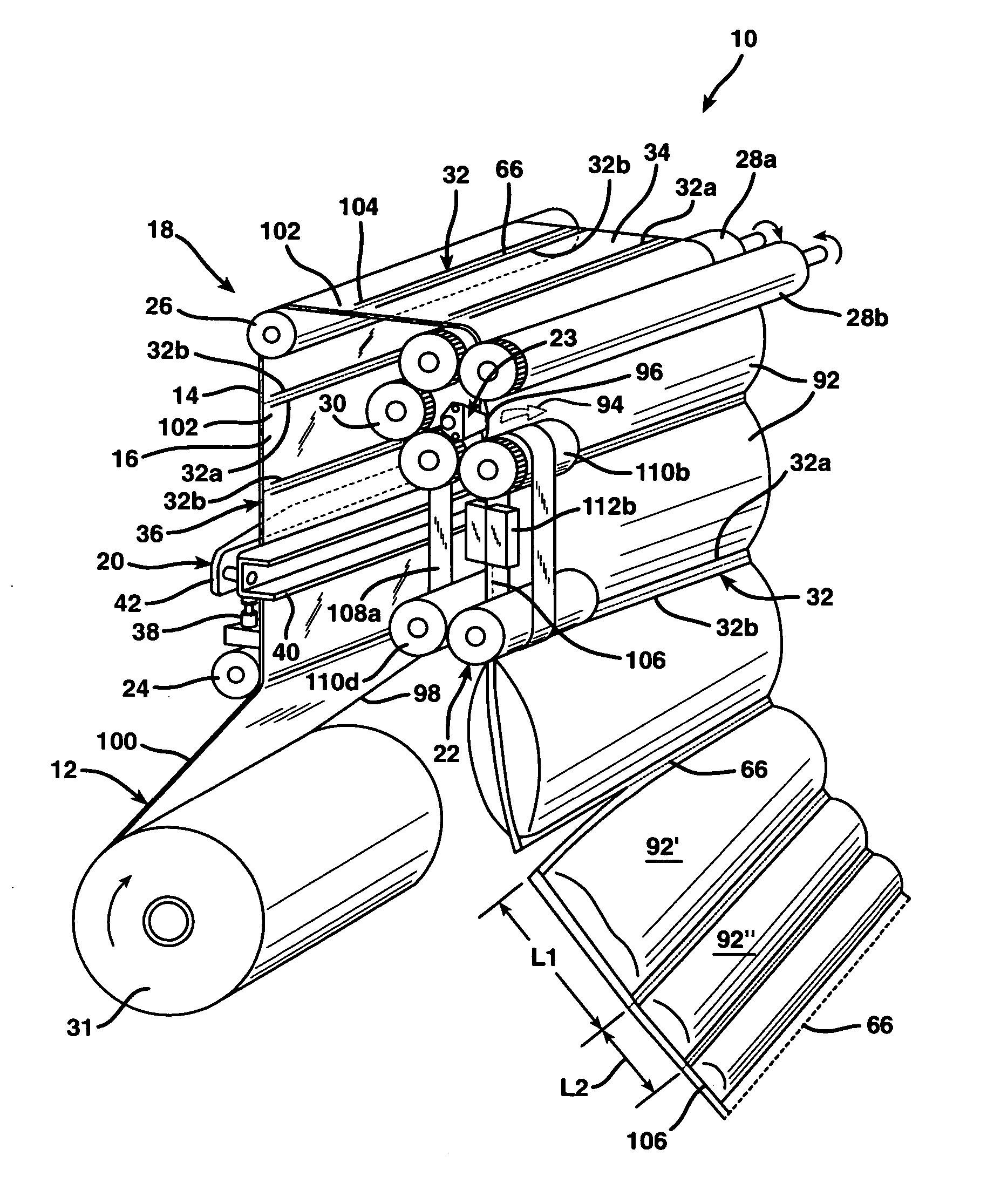

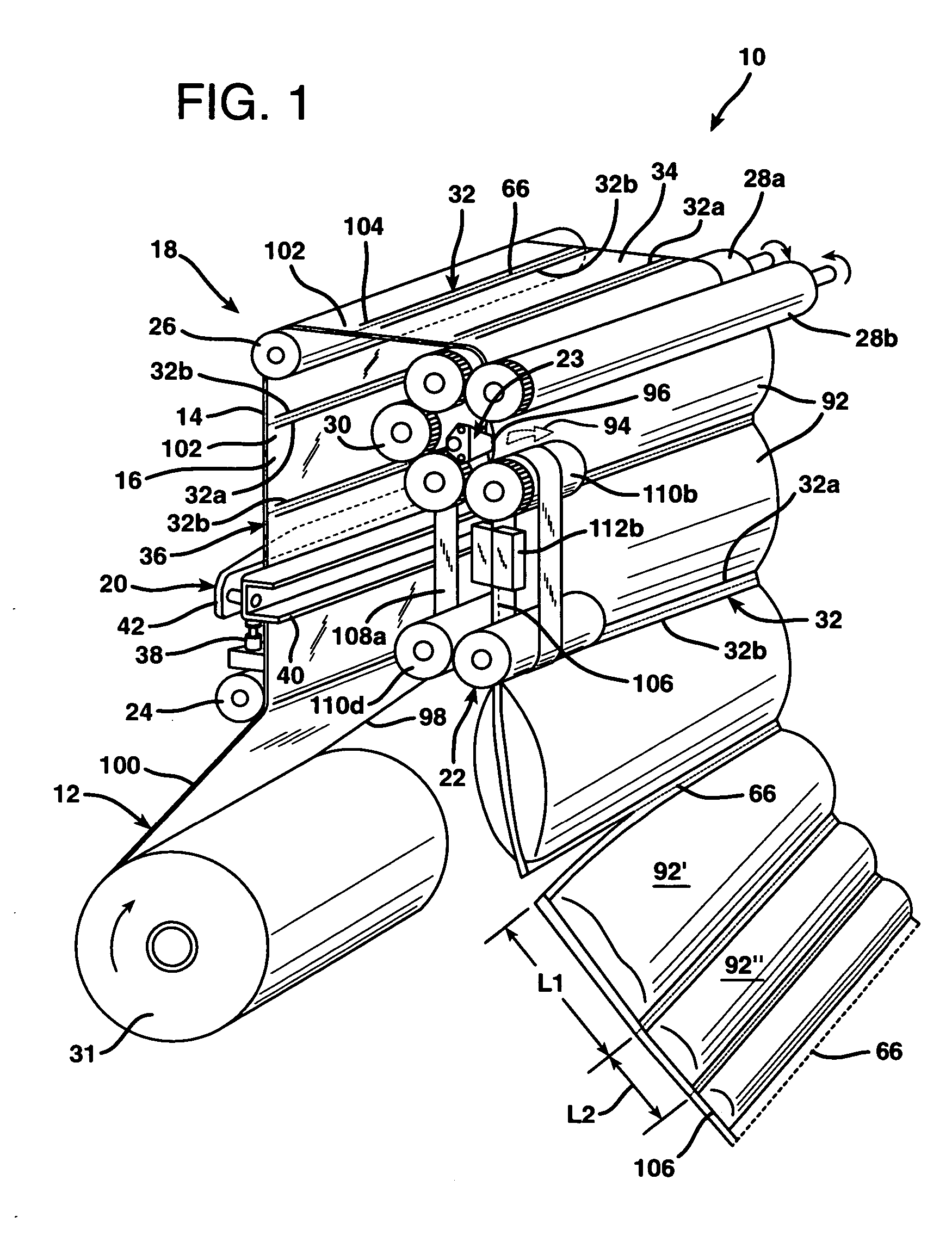

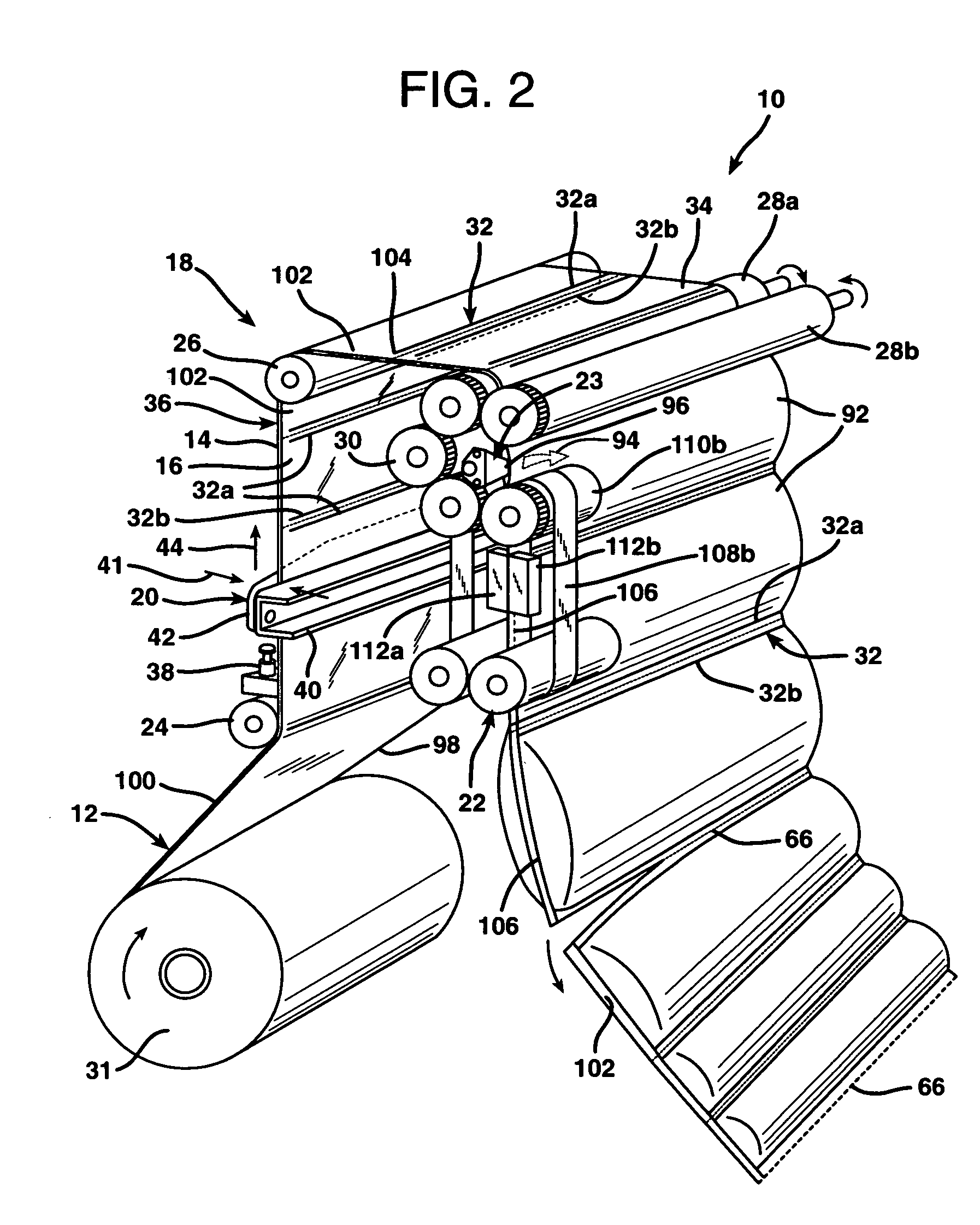

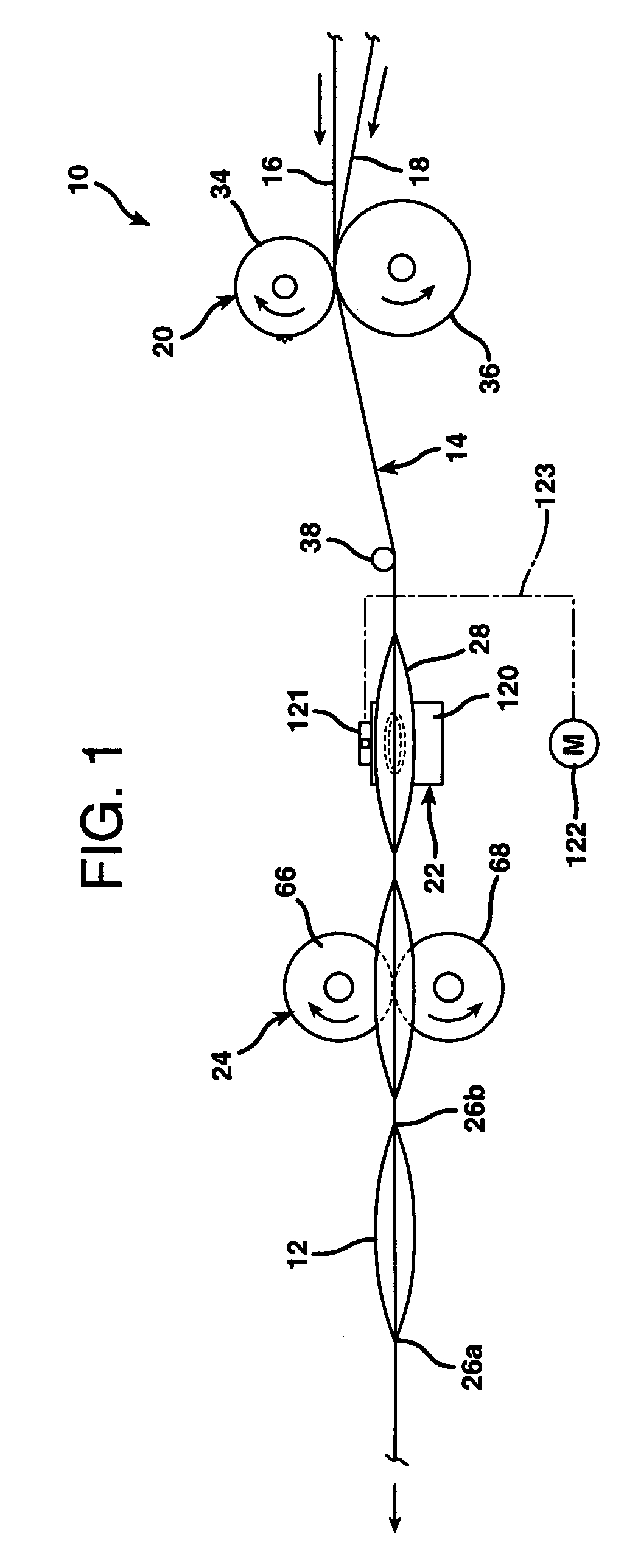

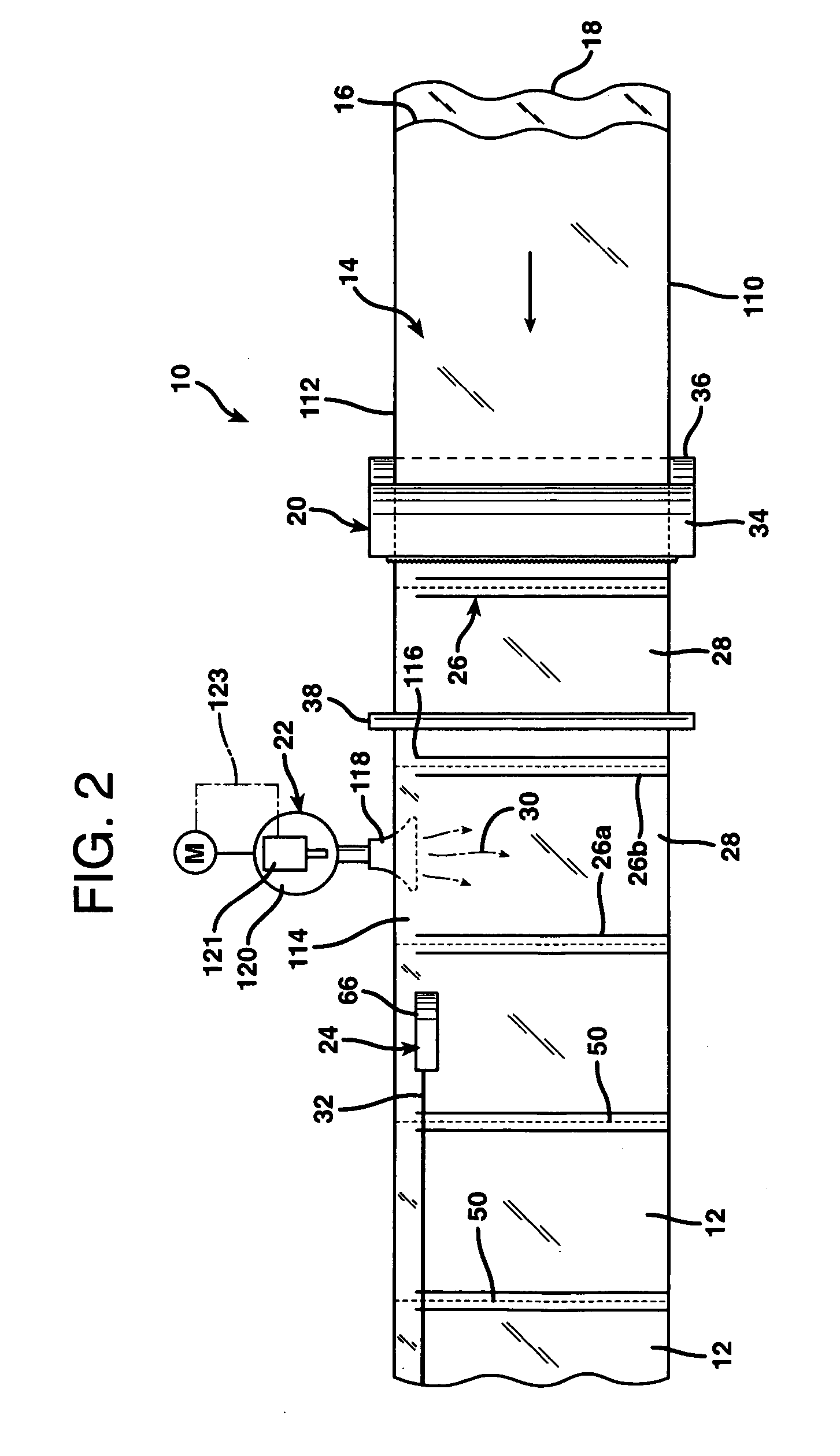

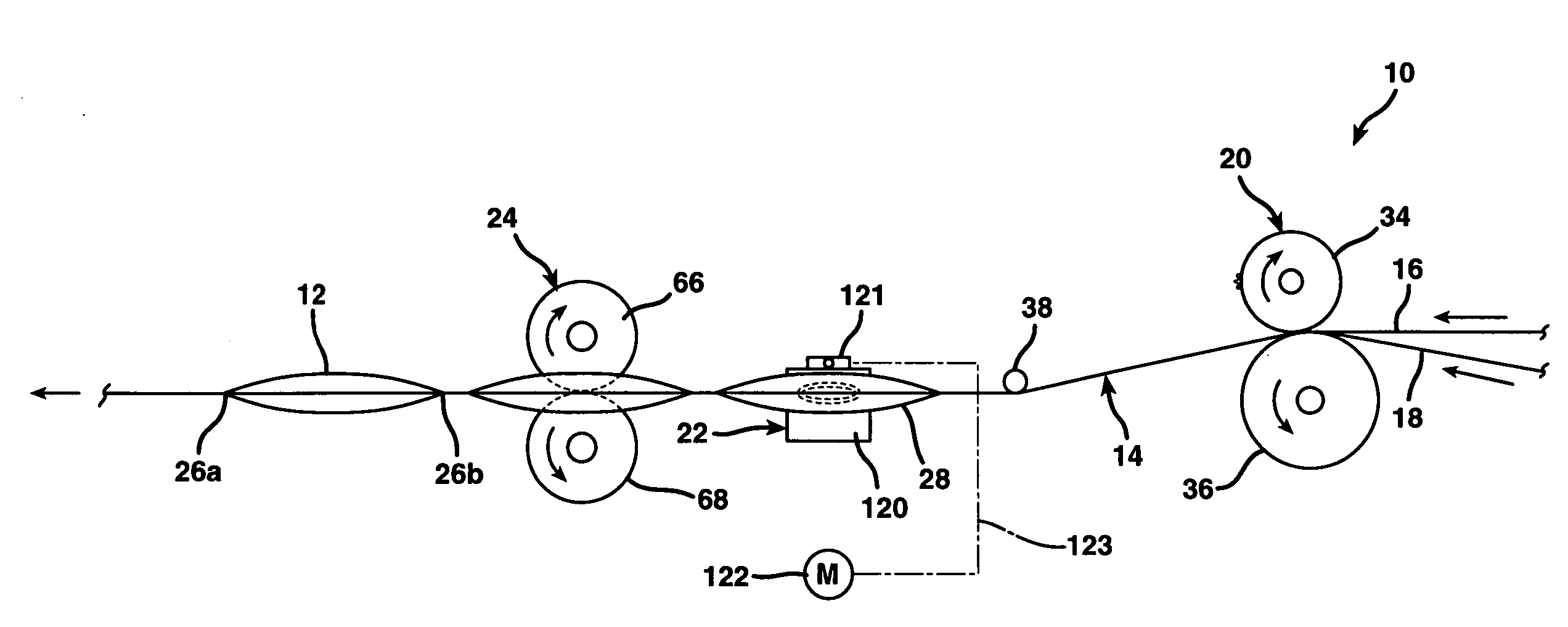

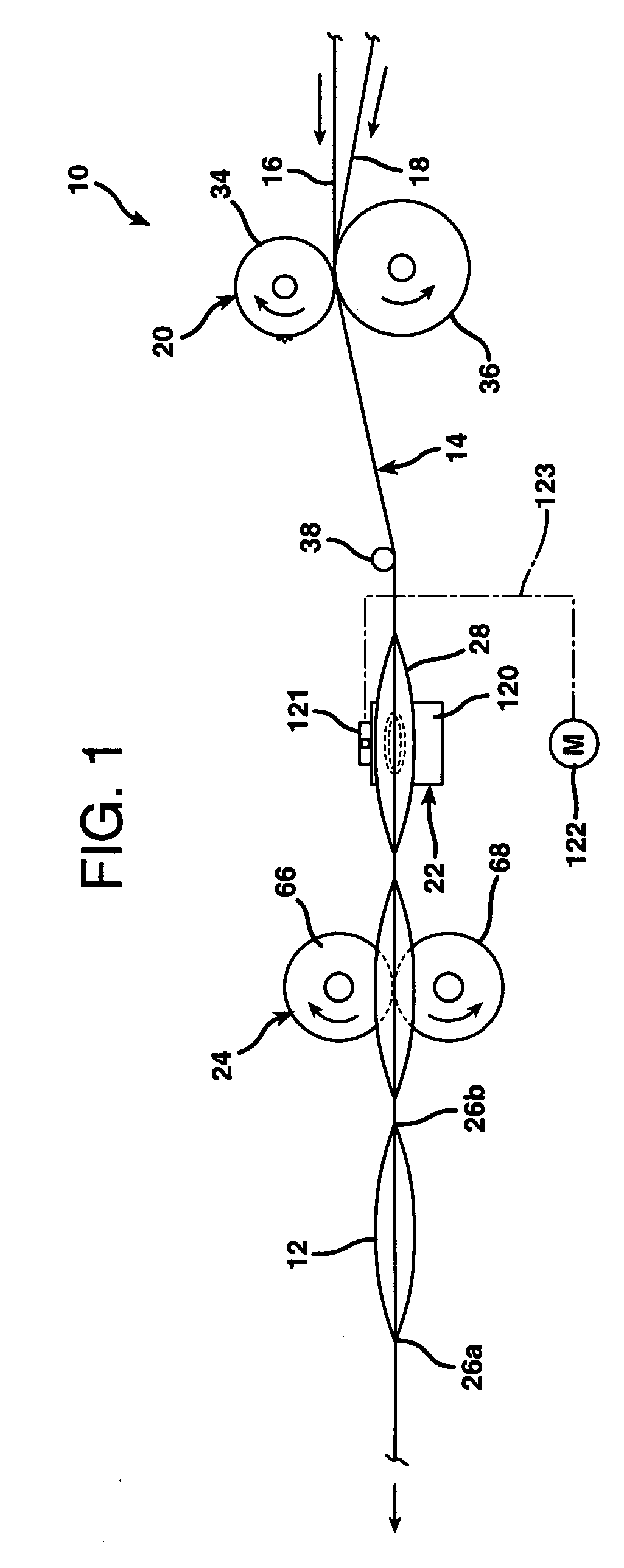

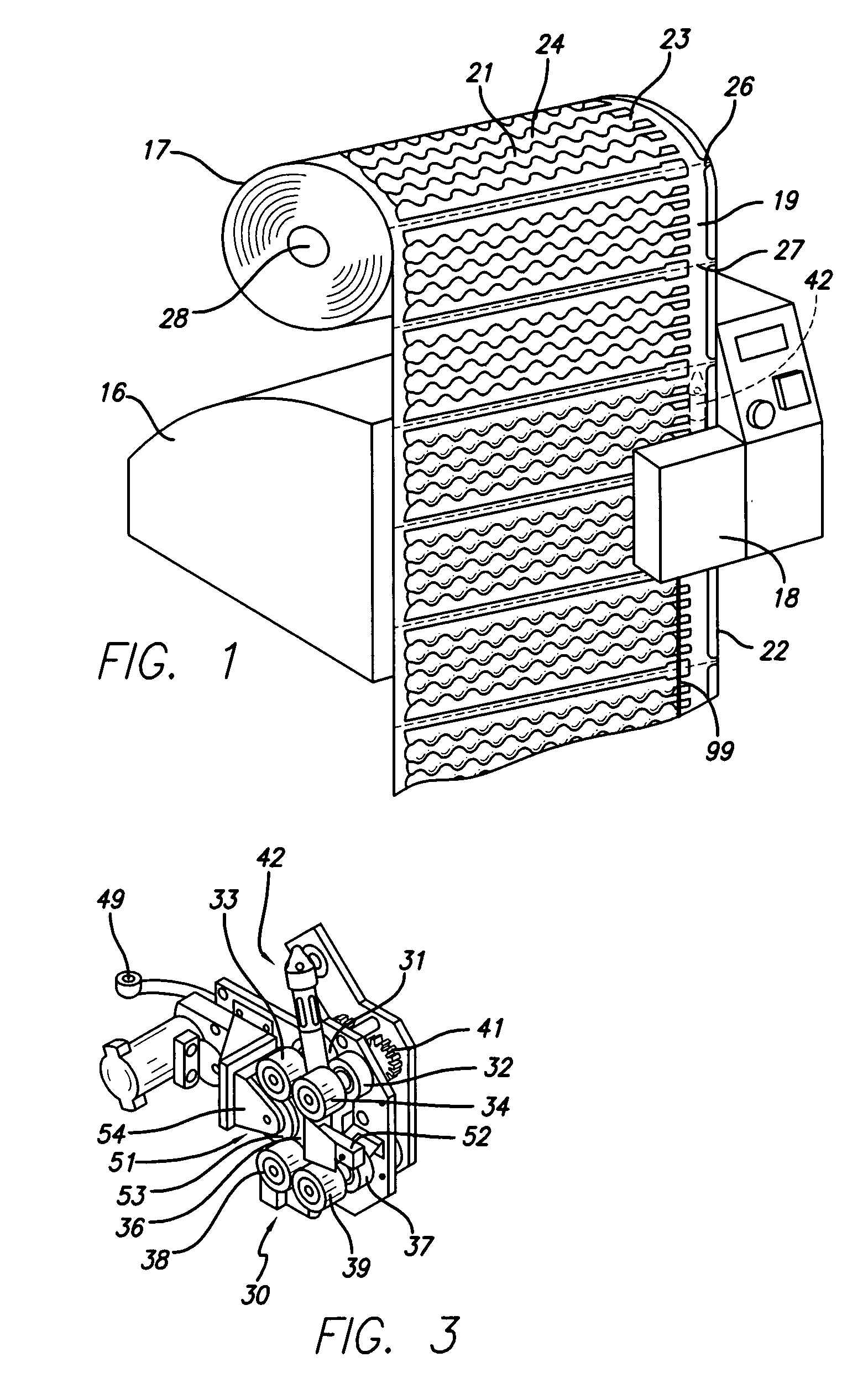

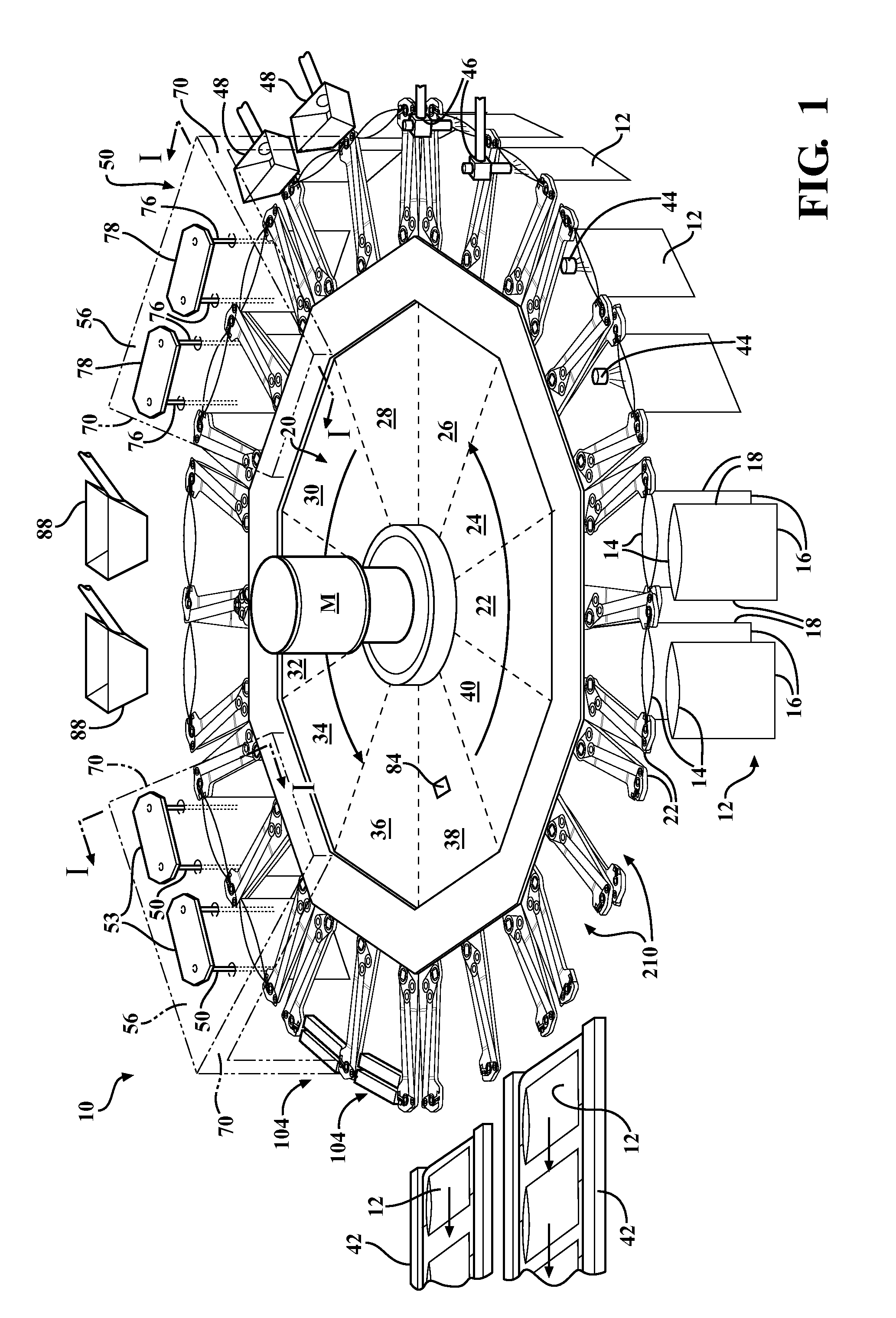

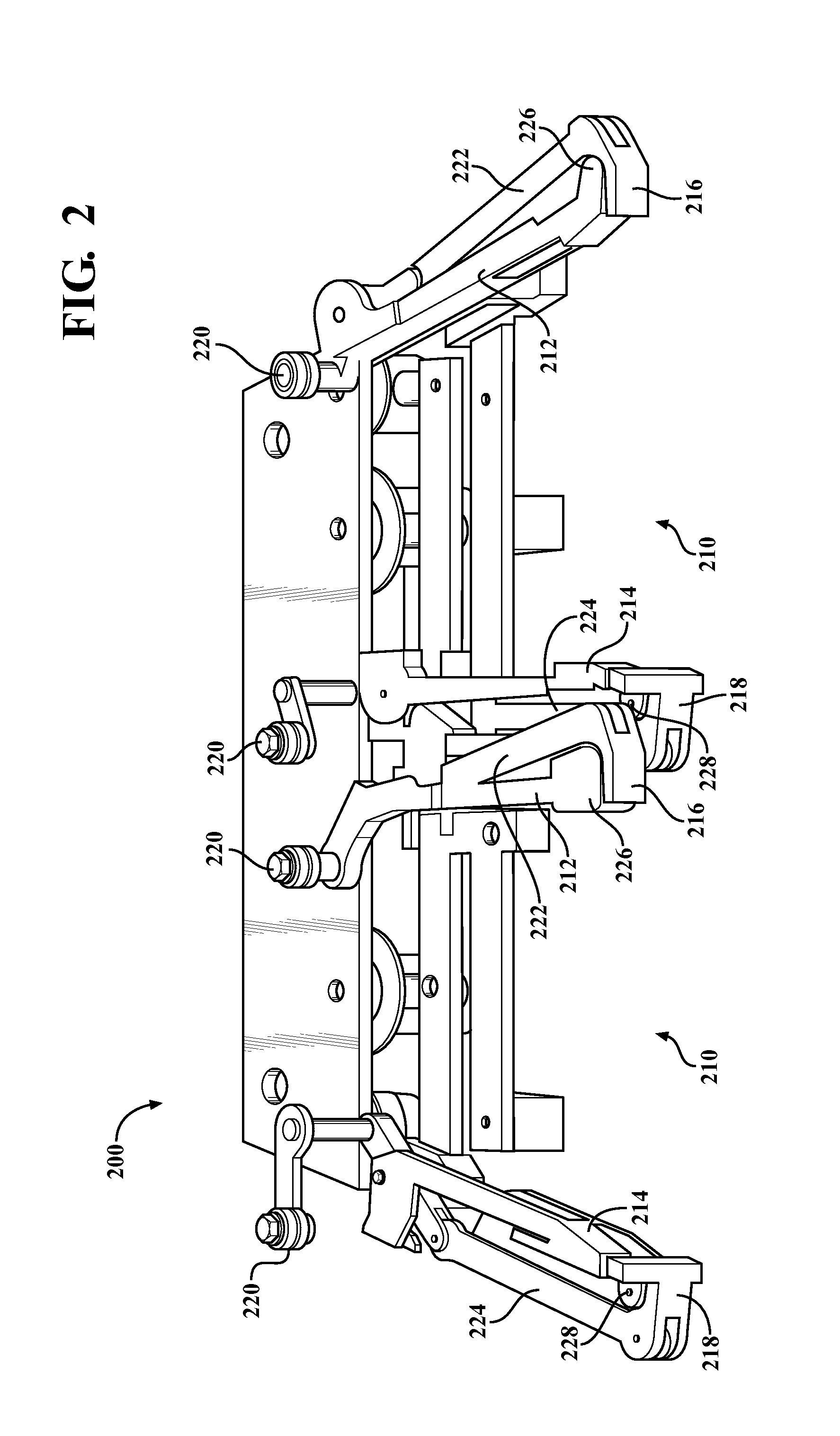

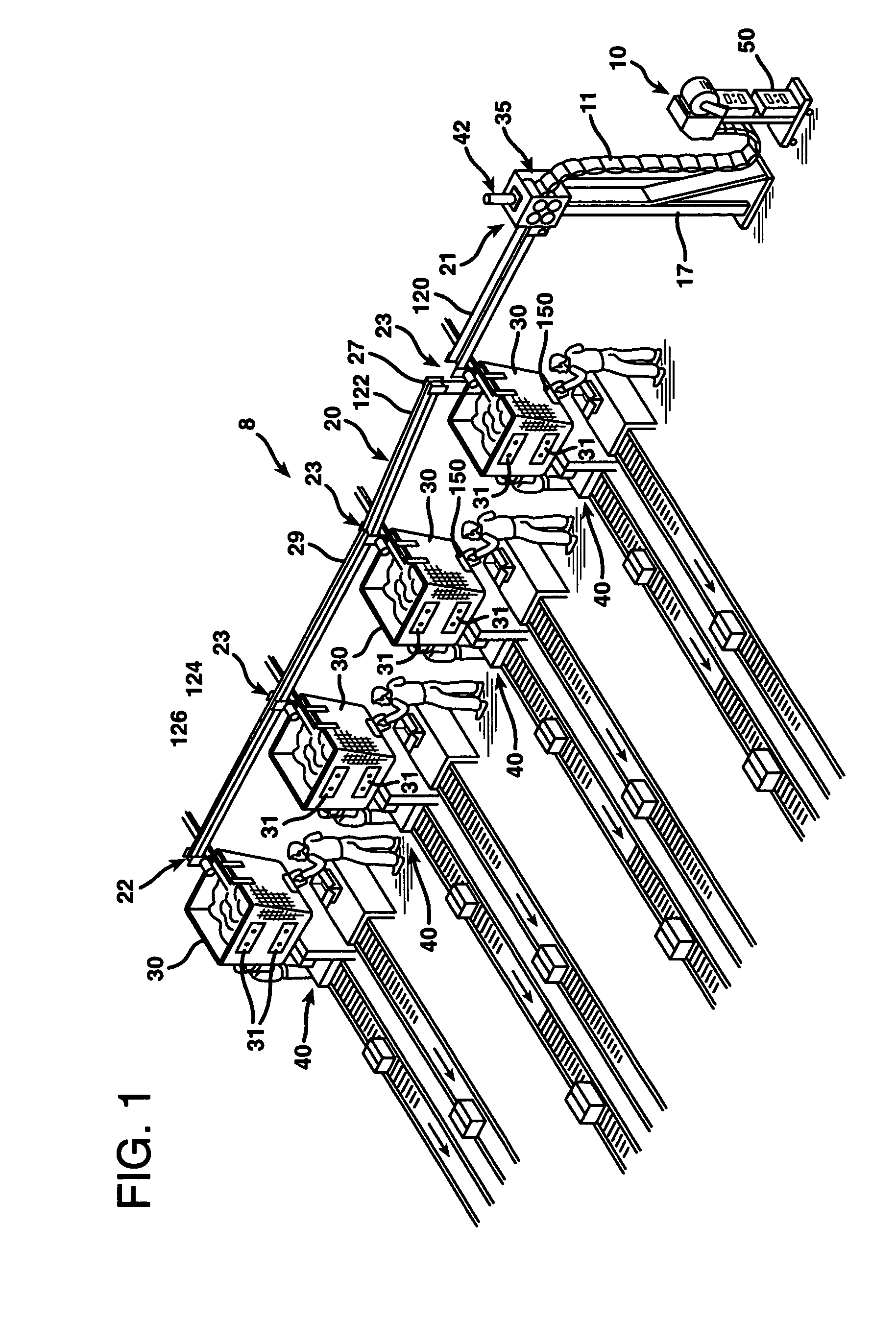

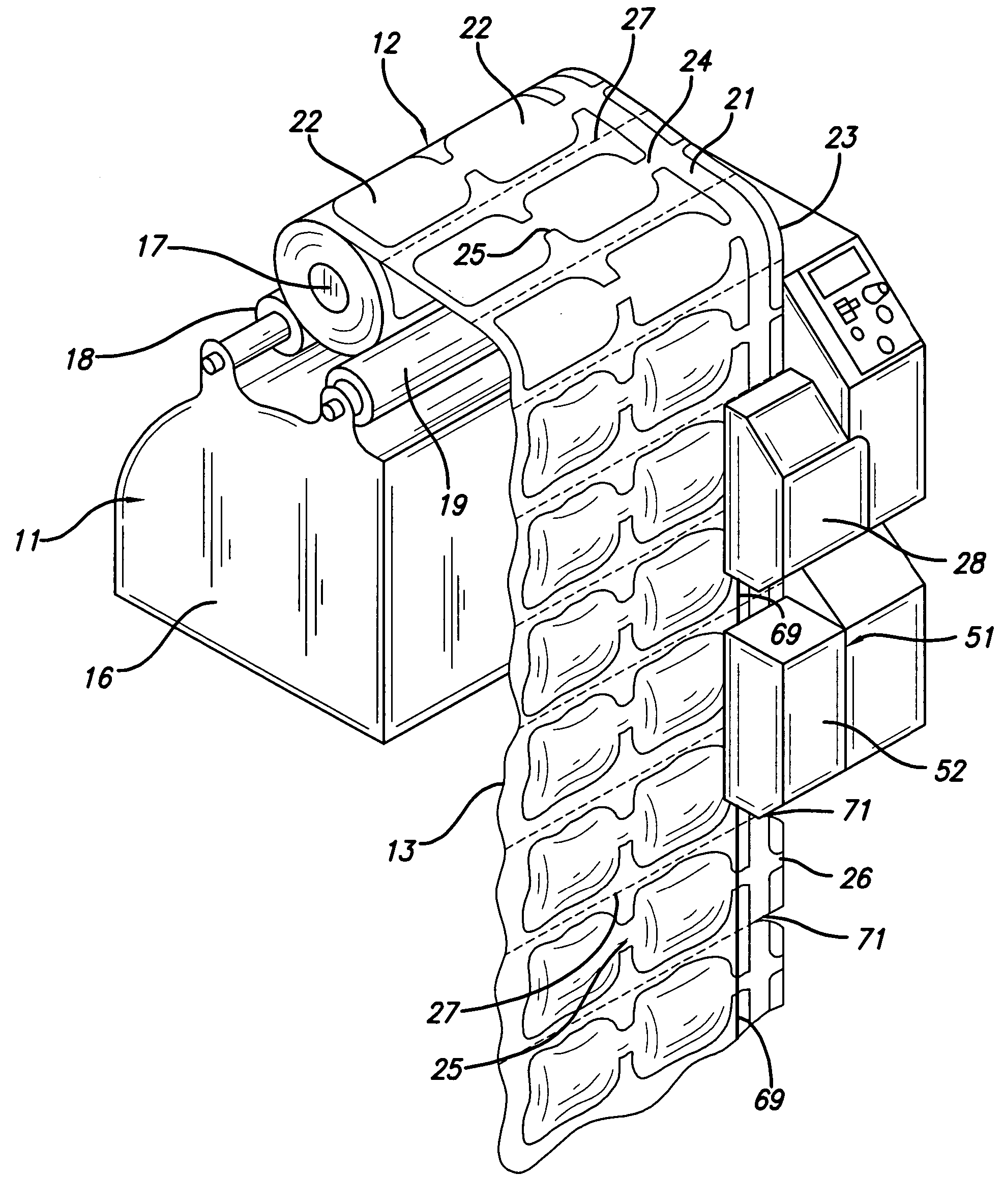

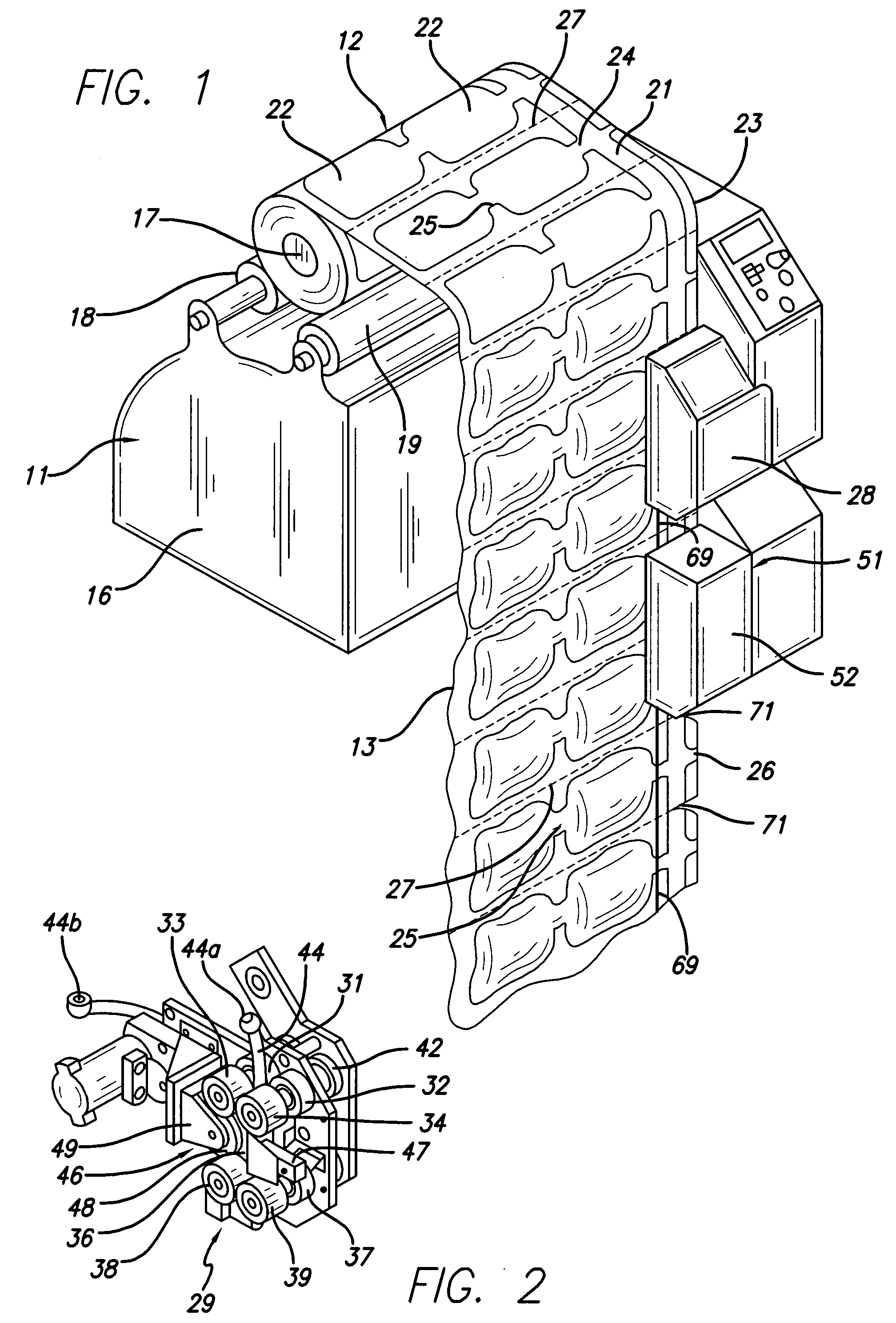

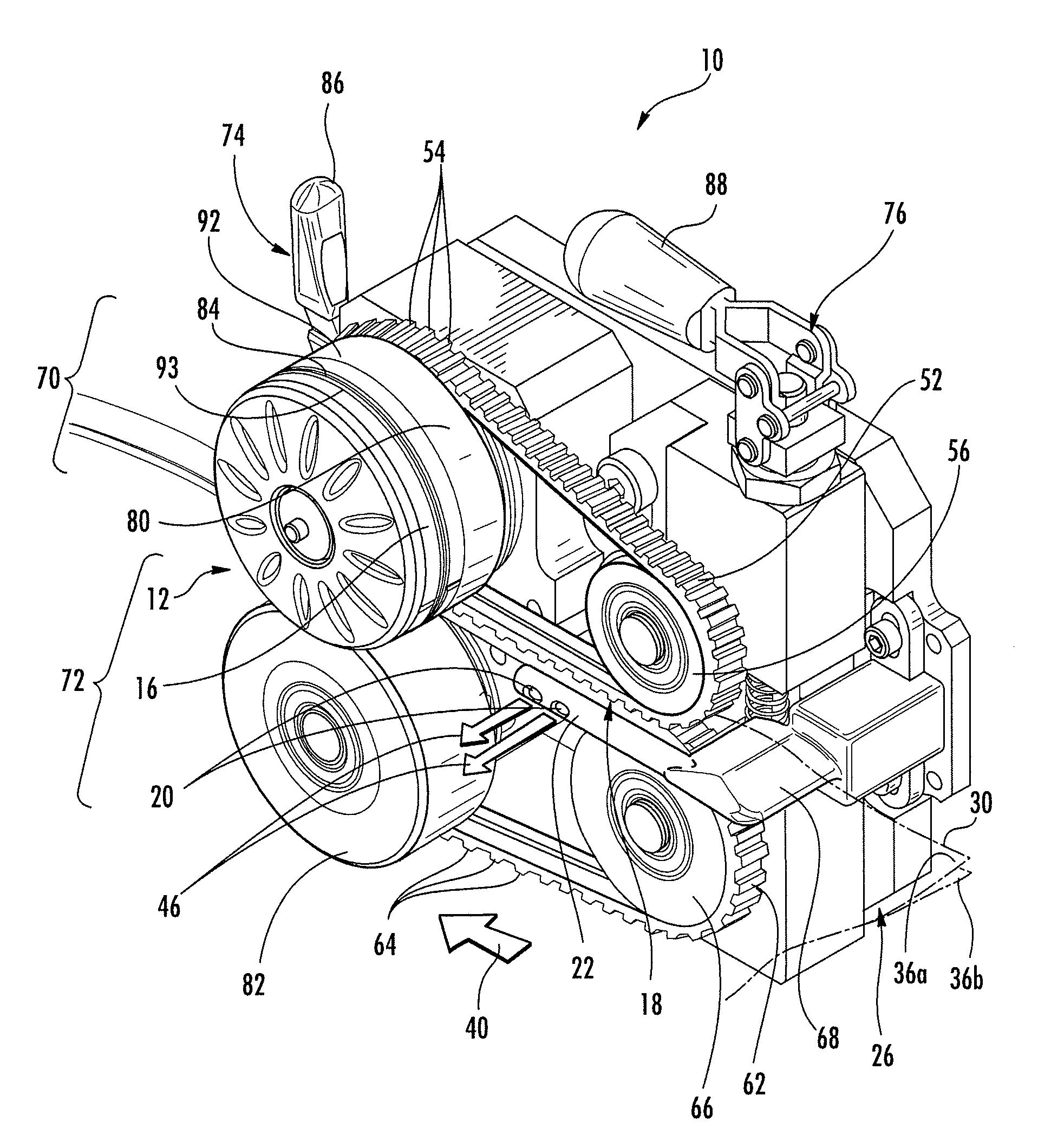

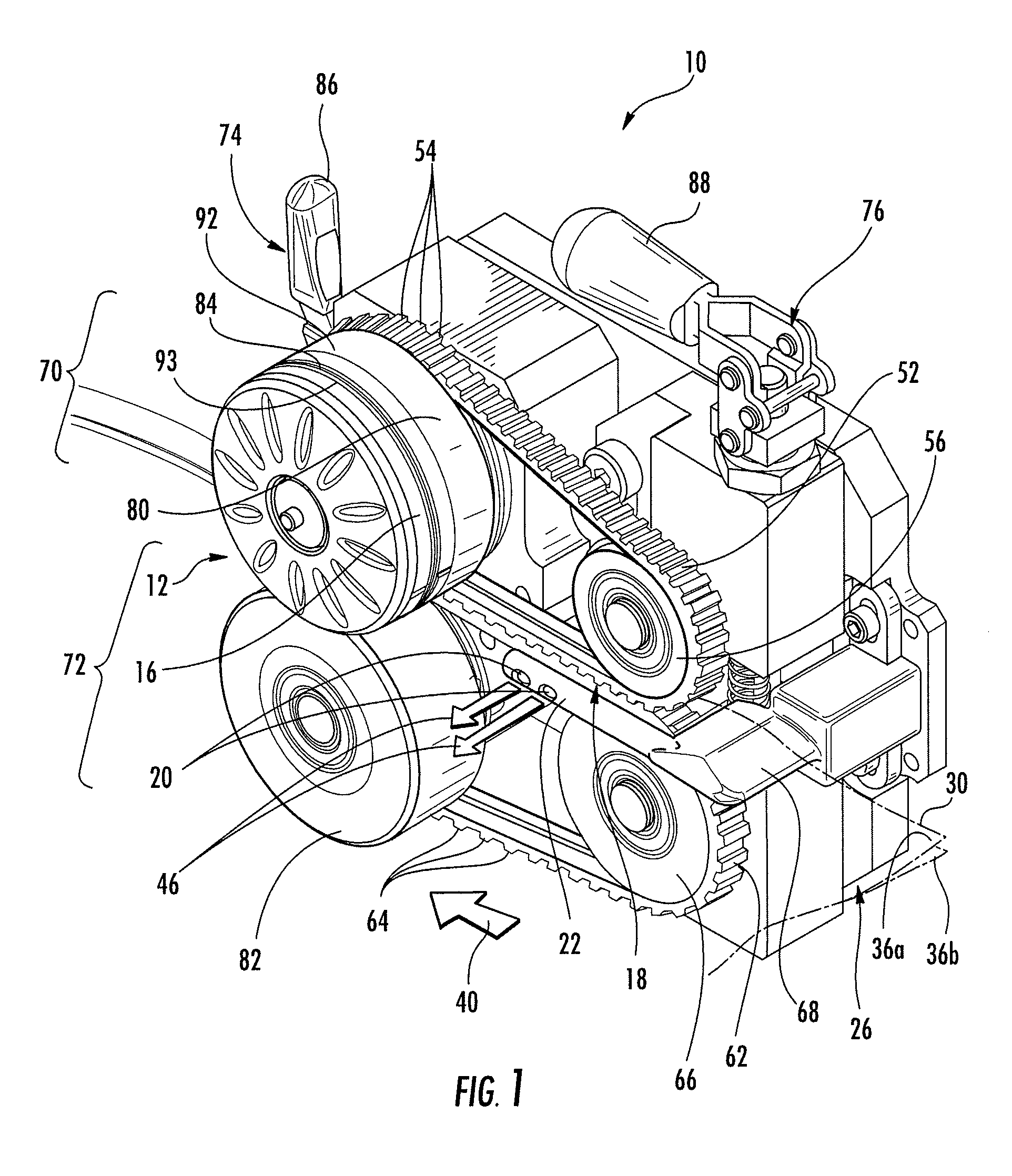

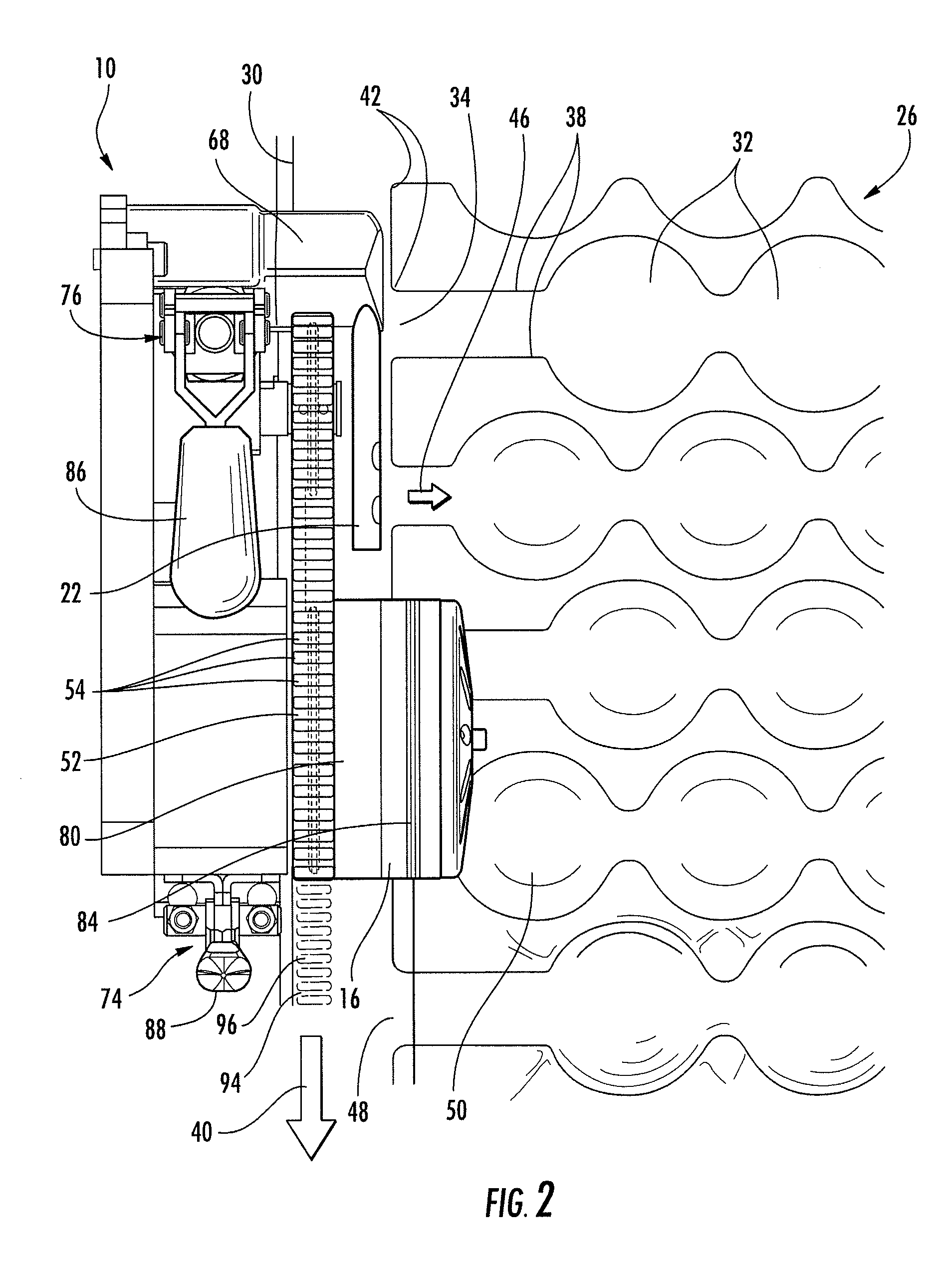

Apparatus and method for forming inflated articles

An apparatus for making inflated articles from a film web having two juxtaposed film plies. One version of the apparatus generally includes a first rotary sealing device for producing transverse seals that bond the film plies together, an inflation assembly for directing gas between the film plies, and a second rotary sealing device for producing a longitudinal seal between the film plies. The longitudinal seal intersects the transverse seals so that the gas is enclosed between the longitudinal seal, transverse seals, and film plies to thereby form an inflated article.

Owner:SEALED AIR U S

Apparatus and method for forming inflated articles

An apparatus for making inflated articles from a film web having two juxtaposed film plies. One version of the apparatus generally includes a first rotary sealing device for producing transverse seals that bond the film plies together, an inflation assembly for directing gas between the film plies, and a second rotary sealing device for producing a longitudinal seal between the film plies. The longitudinal seal intersects the transverse seals so that the gas is enclosed between the longitudinal seal, transverse seals, and film plies to thereby form an inflated article.

Owner:SEALED AIR U S

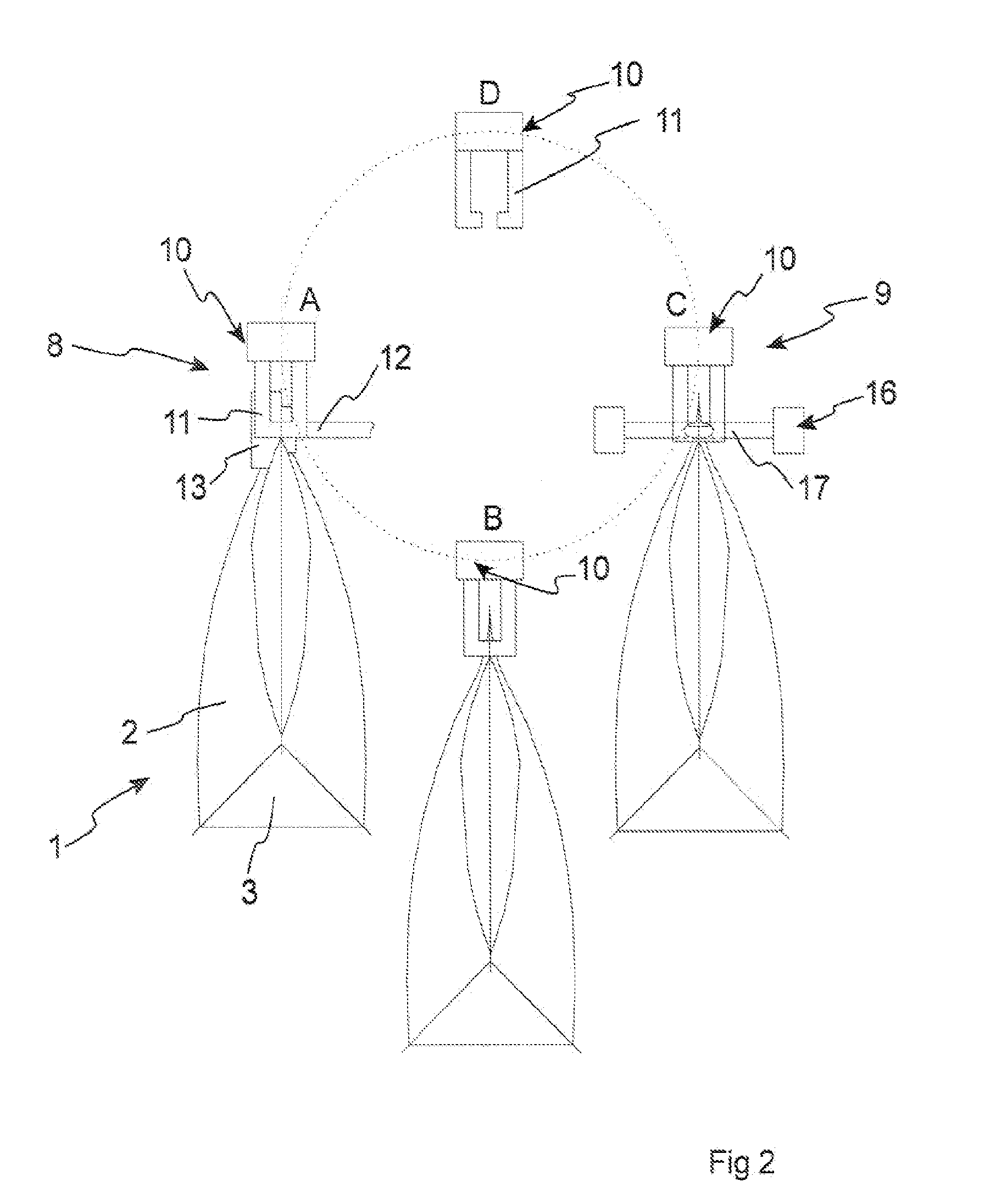

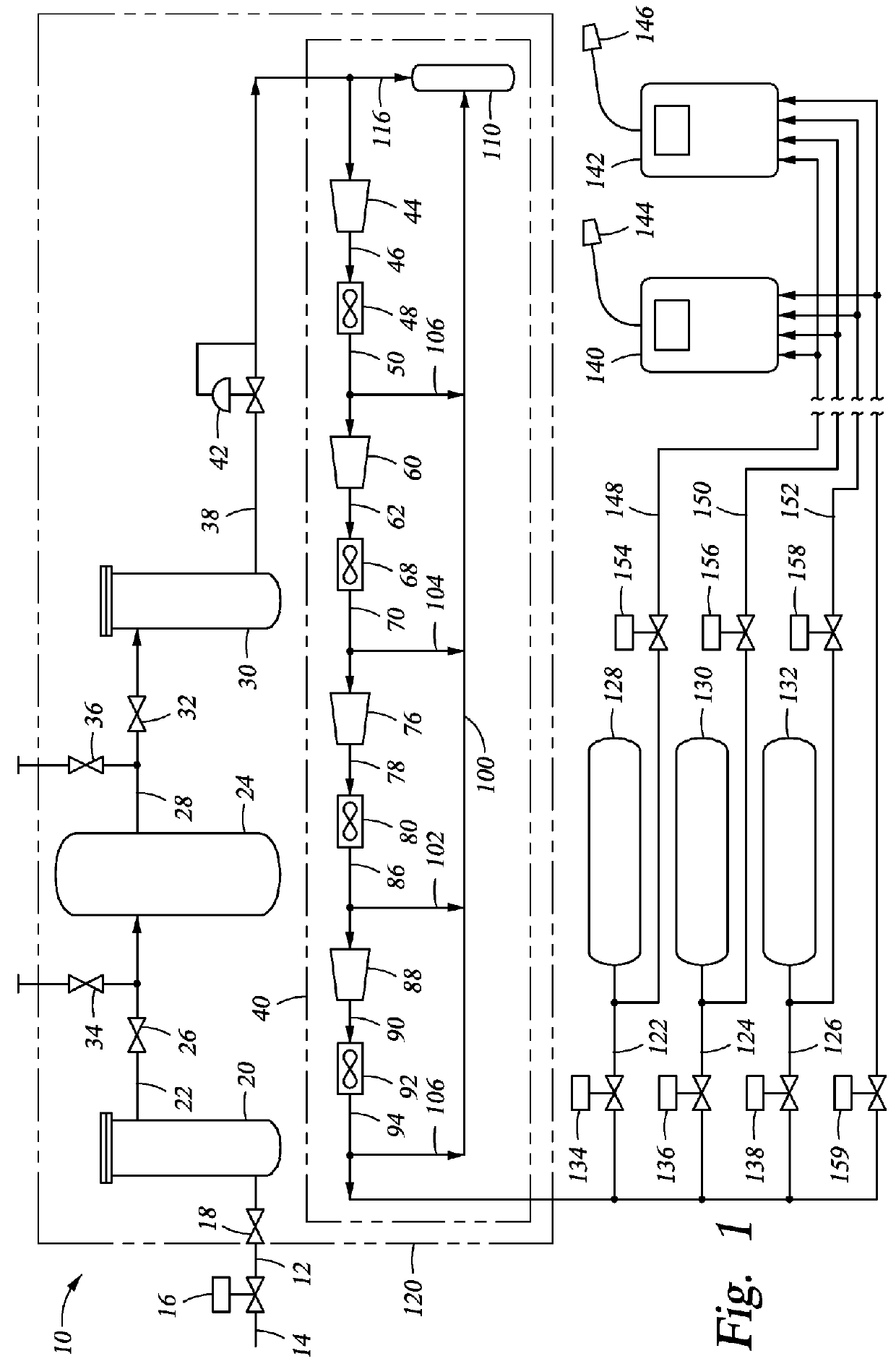

Method and System for Tank Refilling

ActiveUS20110259469A1Improve performanceLow costCapsCap application using vaccuumAnalytical equationsEngineering

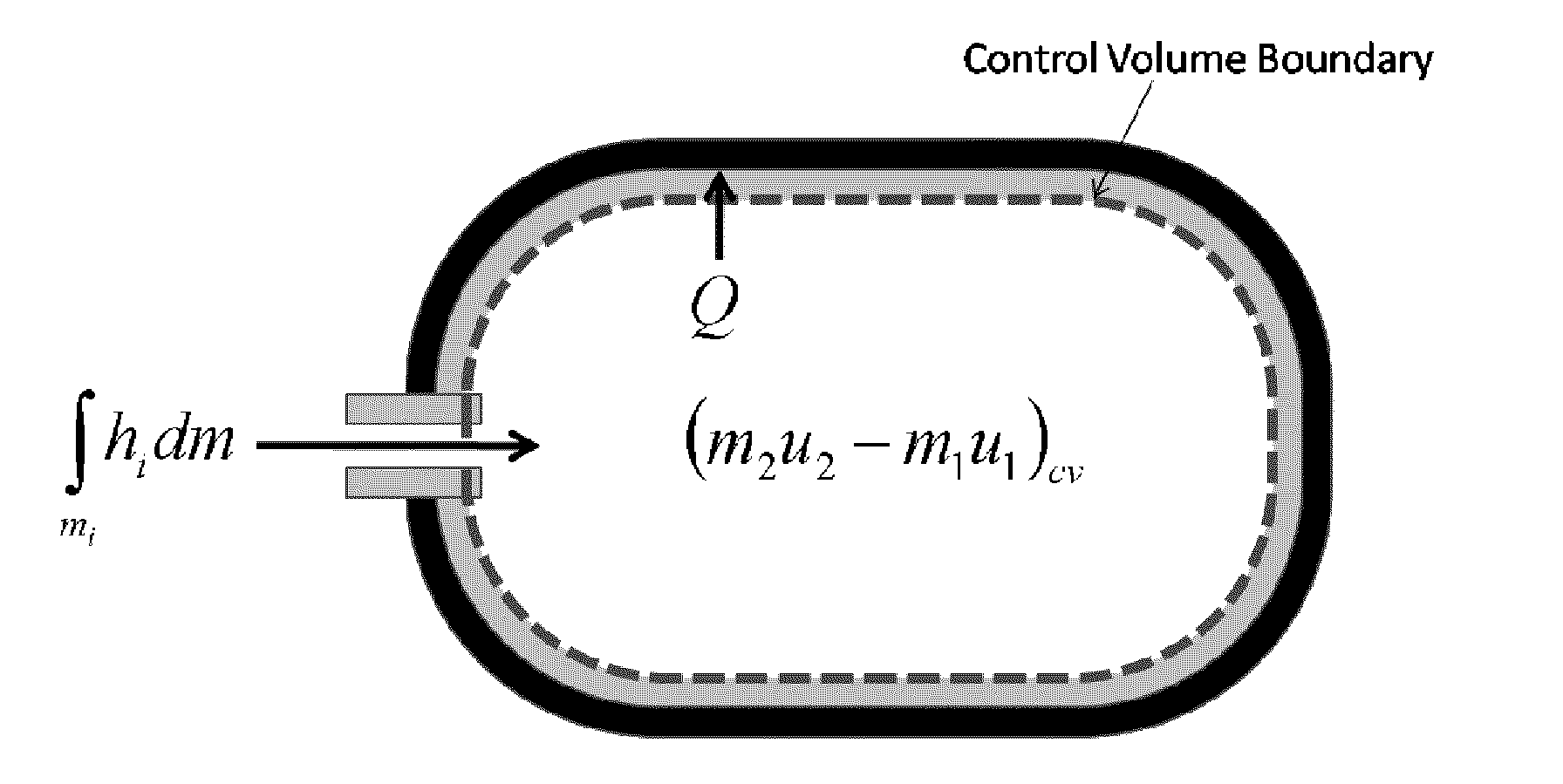

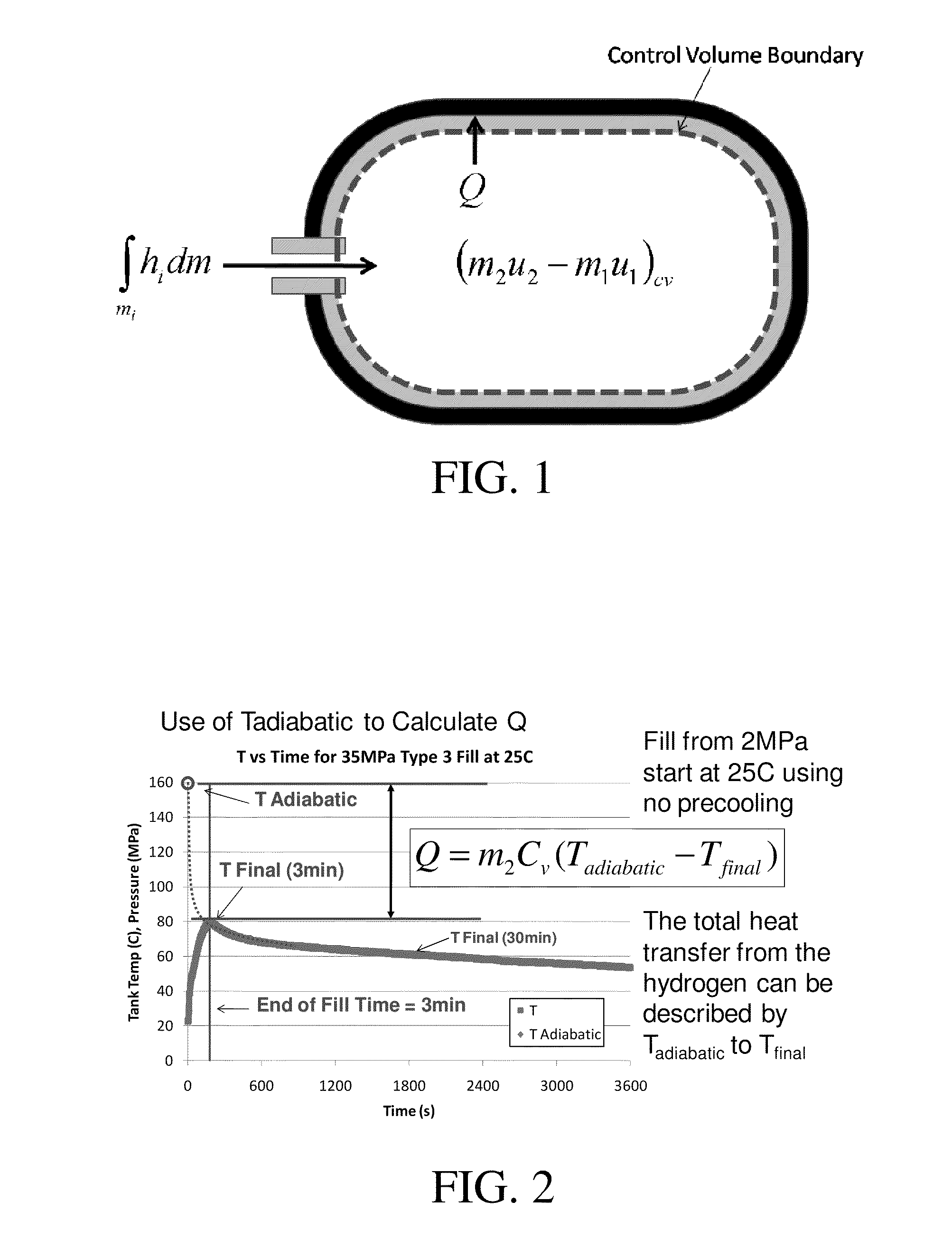

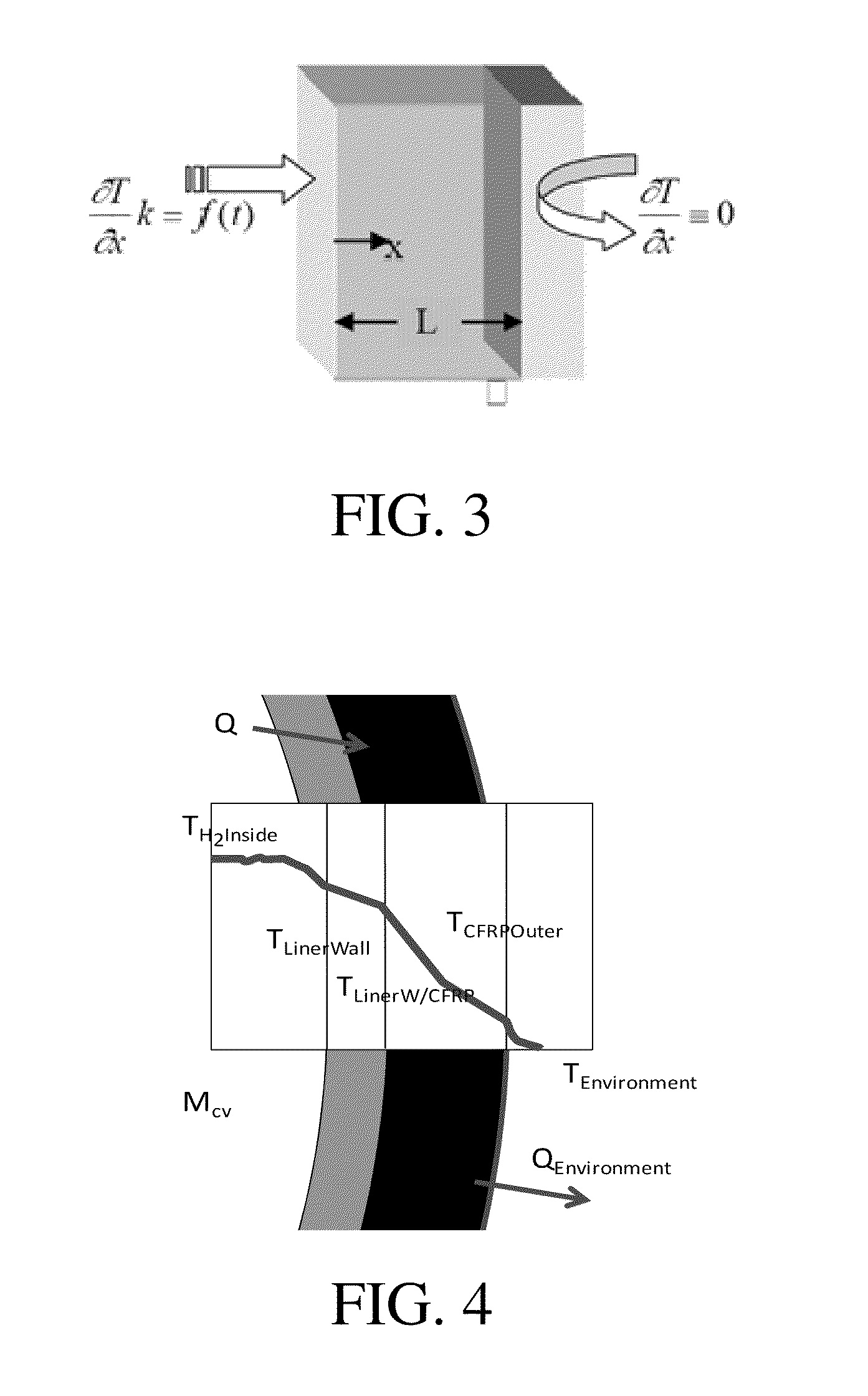

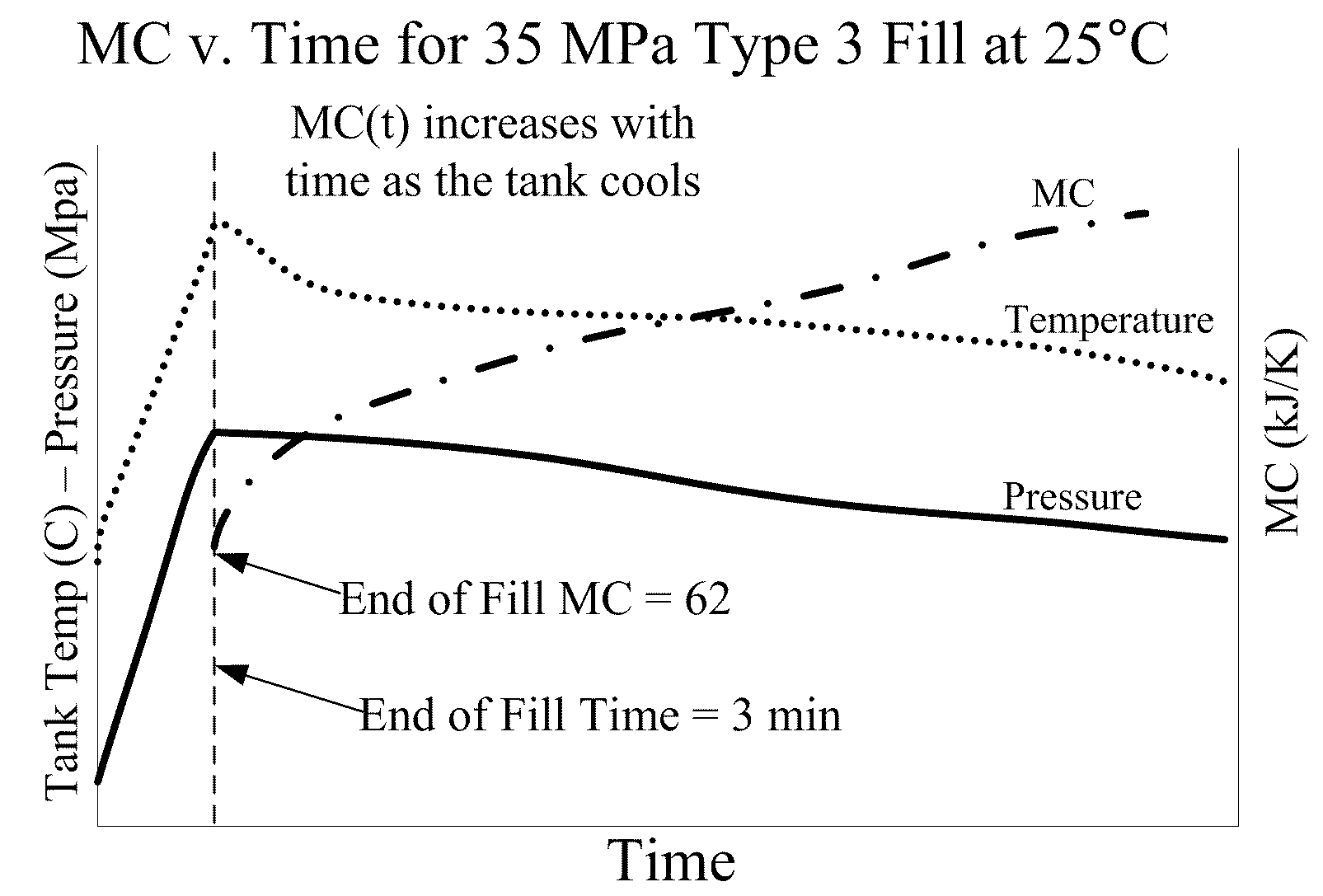

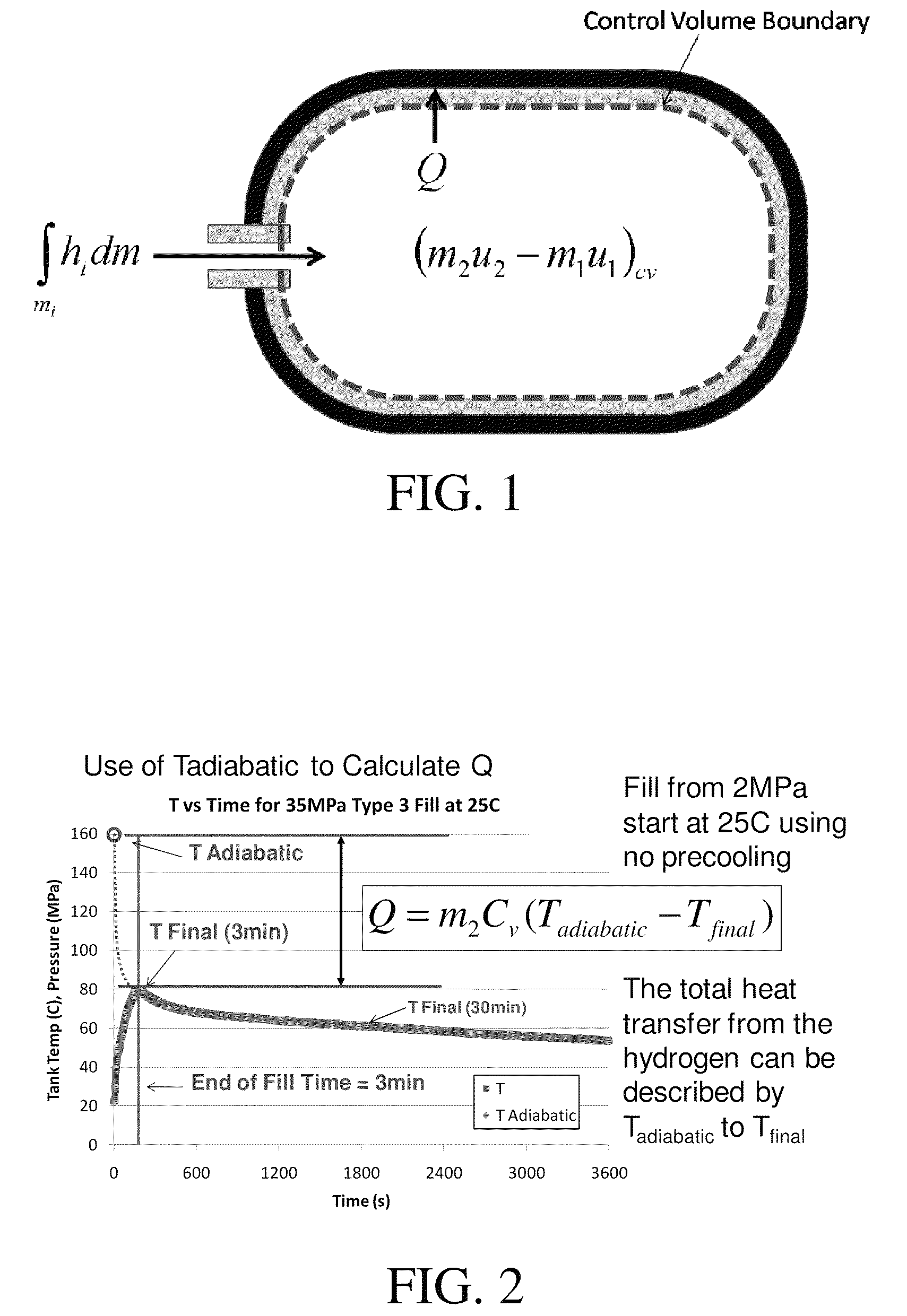

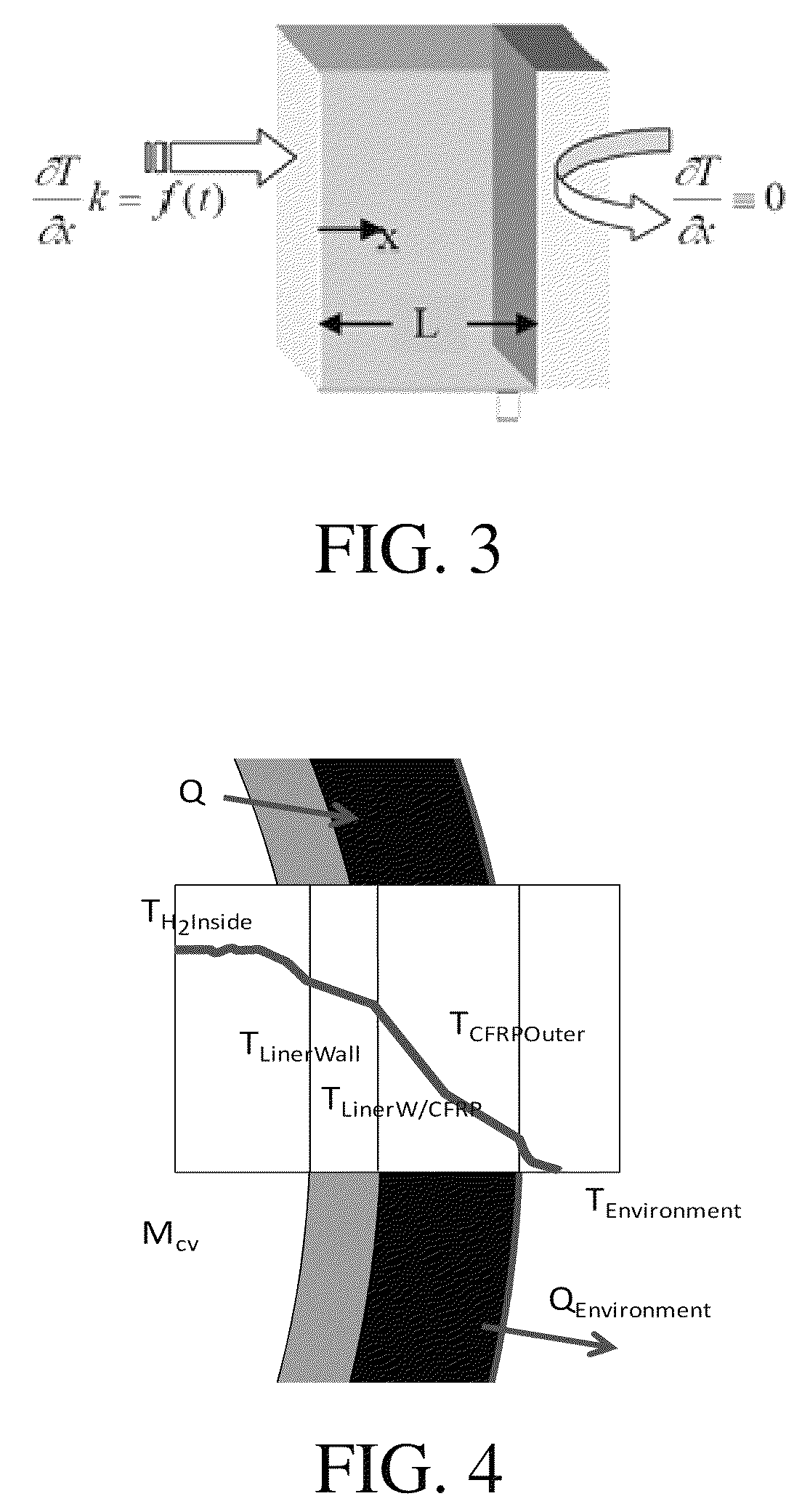

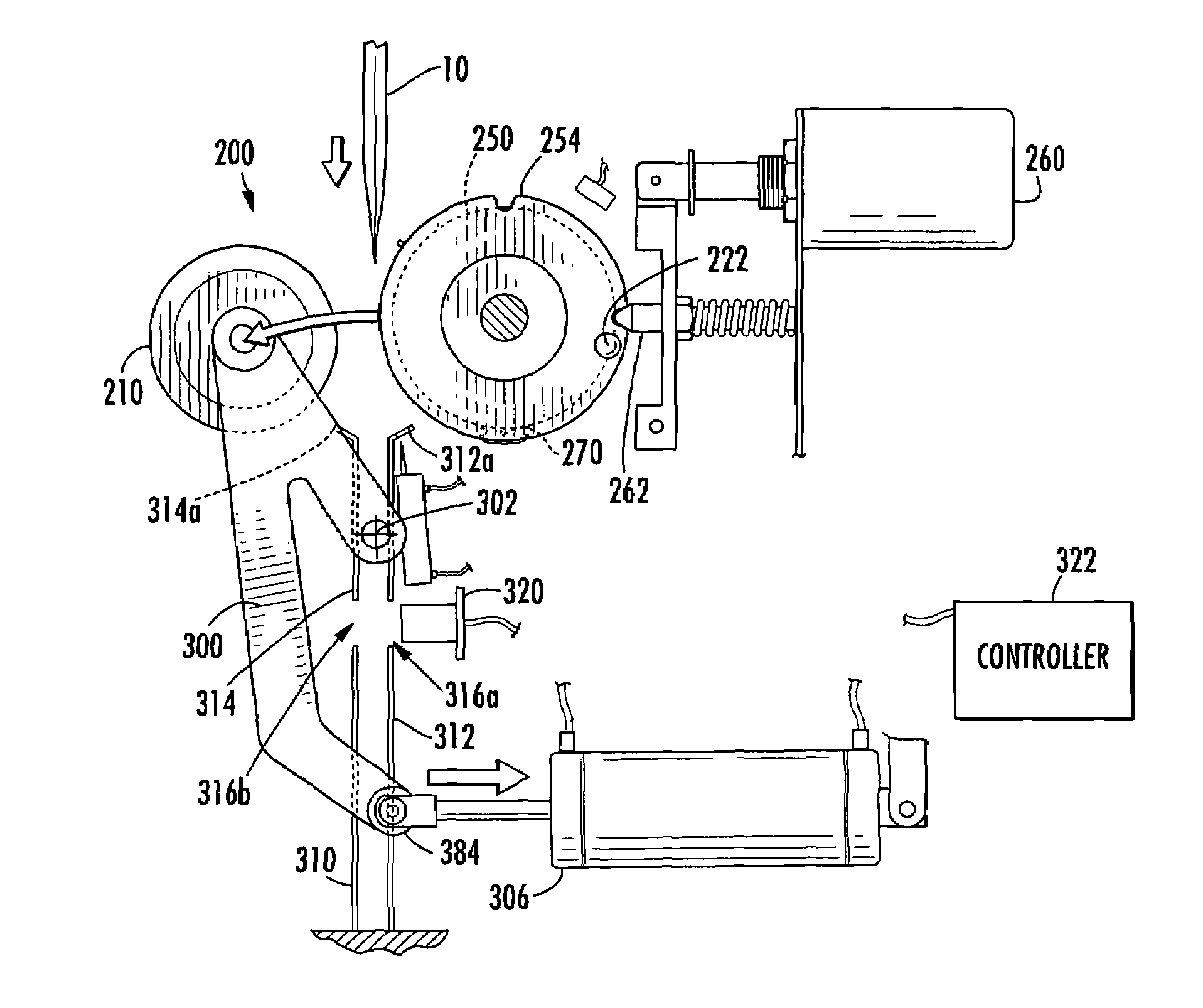

Disclosed is a simple, analytical method that can be utilized by hydrogen filling stations for directly and accurately calculating the end-of-fill temperature in a hydrogen tank that, in turn, allows for improvements in the fill quantity while tending to reduce refueling time. The calculations involve calculation of a composite heat capacity value, MC, from a set of thermodynamic parameters drawn from both the tank system receiving the gas and the station supplying the gas. These thermodynamic parameters are utilized in a series of simple analytical equations to define a multi-step process by which target fill times, final temperatures and final pressures can be determined. The parameters can be communicated to the station directly from the vehicle or retrieved from a database accessible by the station. Because the method is based on direct measurements of actual thermodynamic conditions and quantified thermodynamic behavior, significantly improved tank filling results can be achieved.

Owner:HONDA MOTOR CO LTD

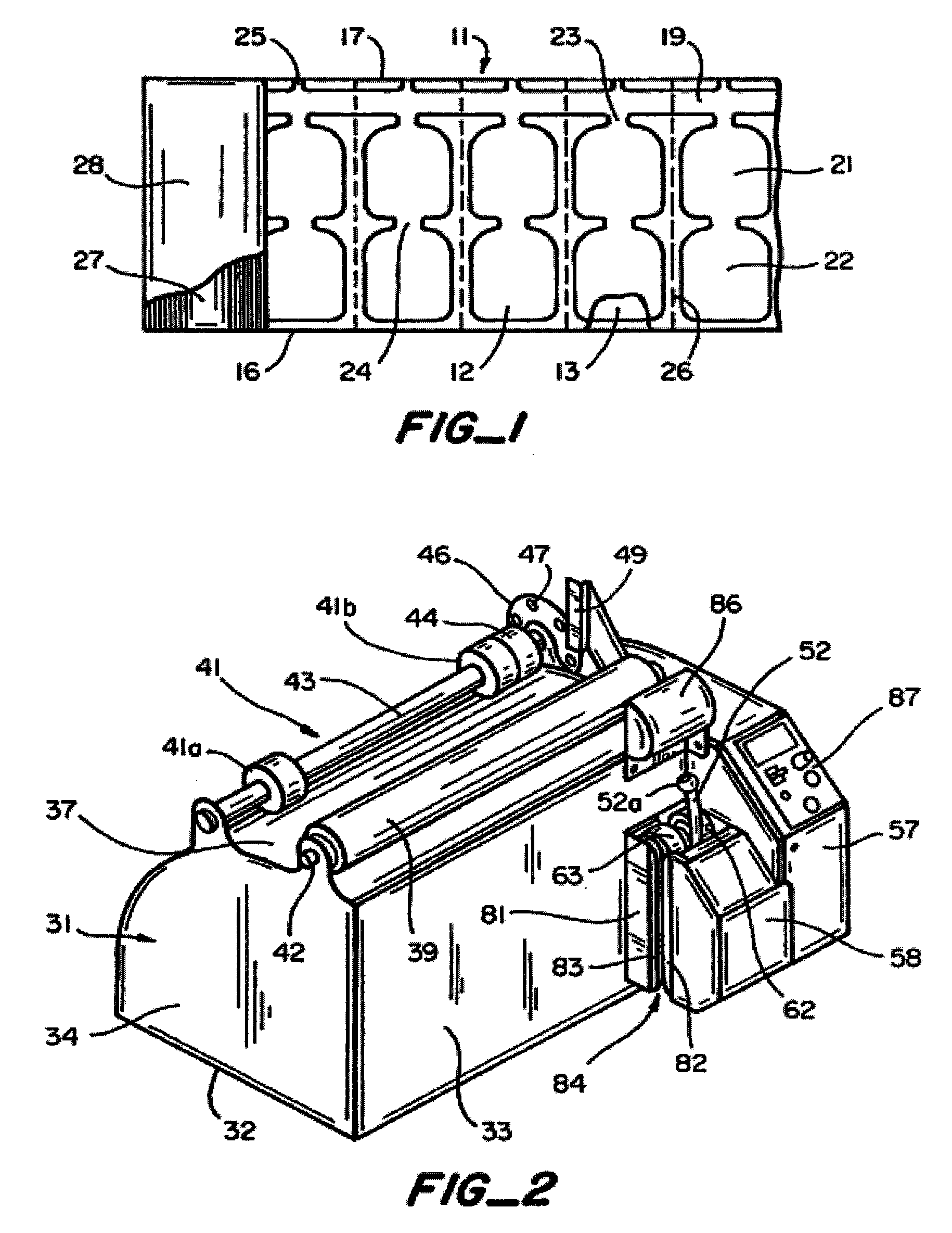

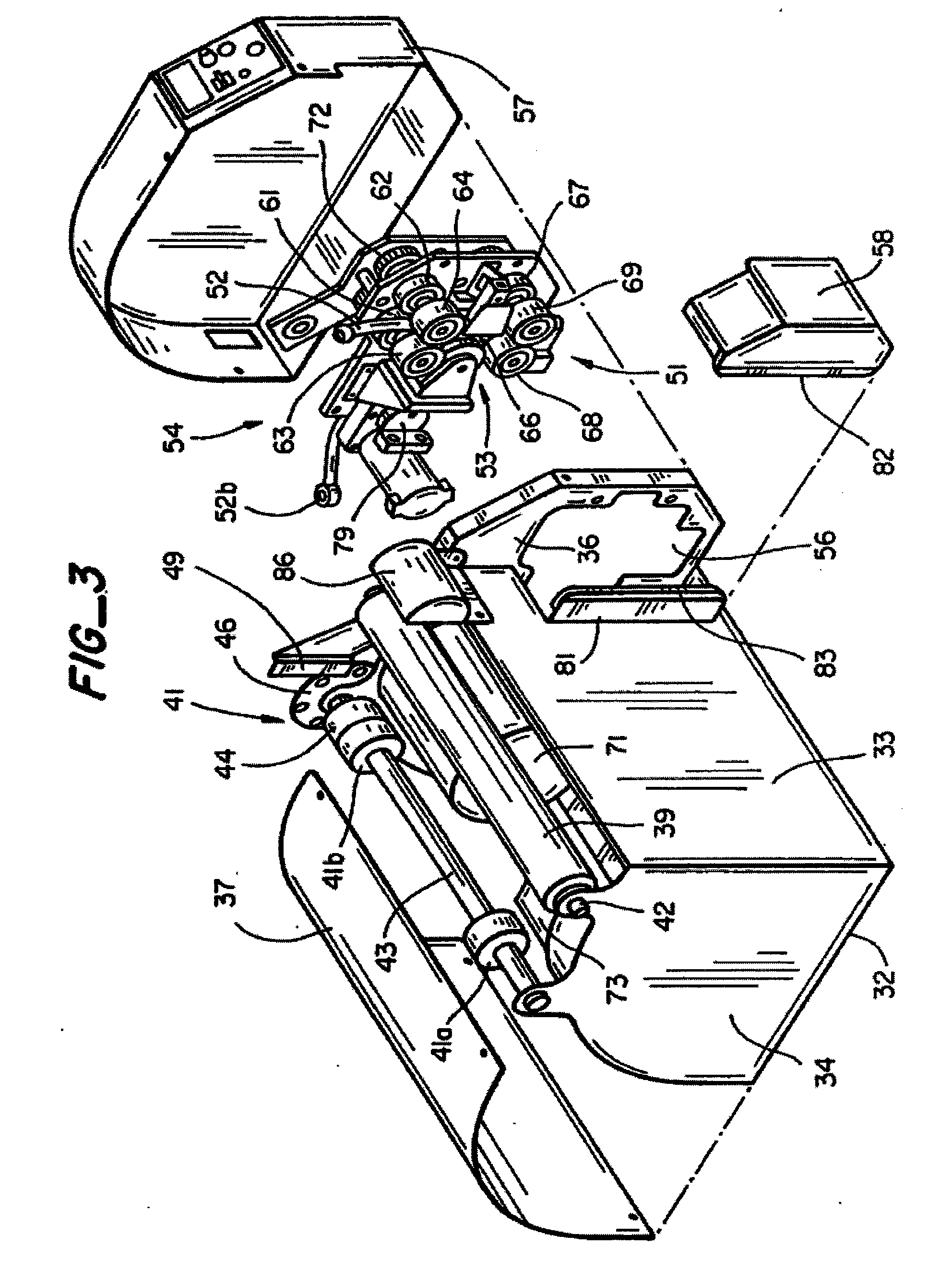

Machine for inflating and sealing air-filled cushioning materials

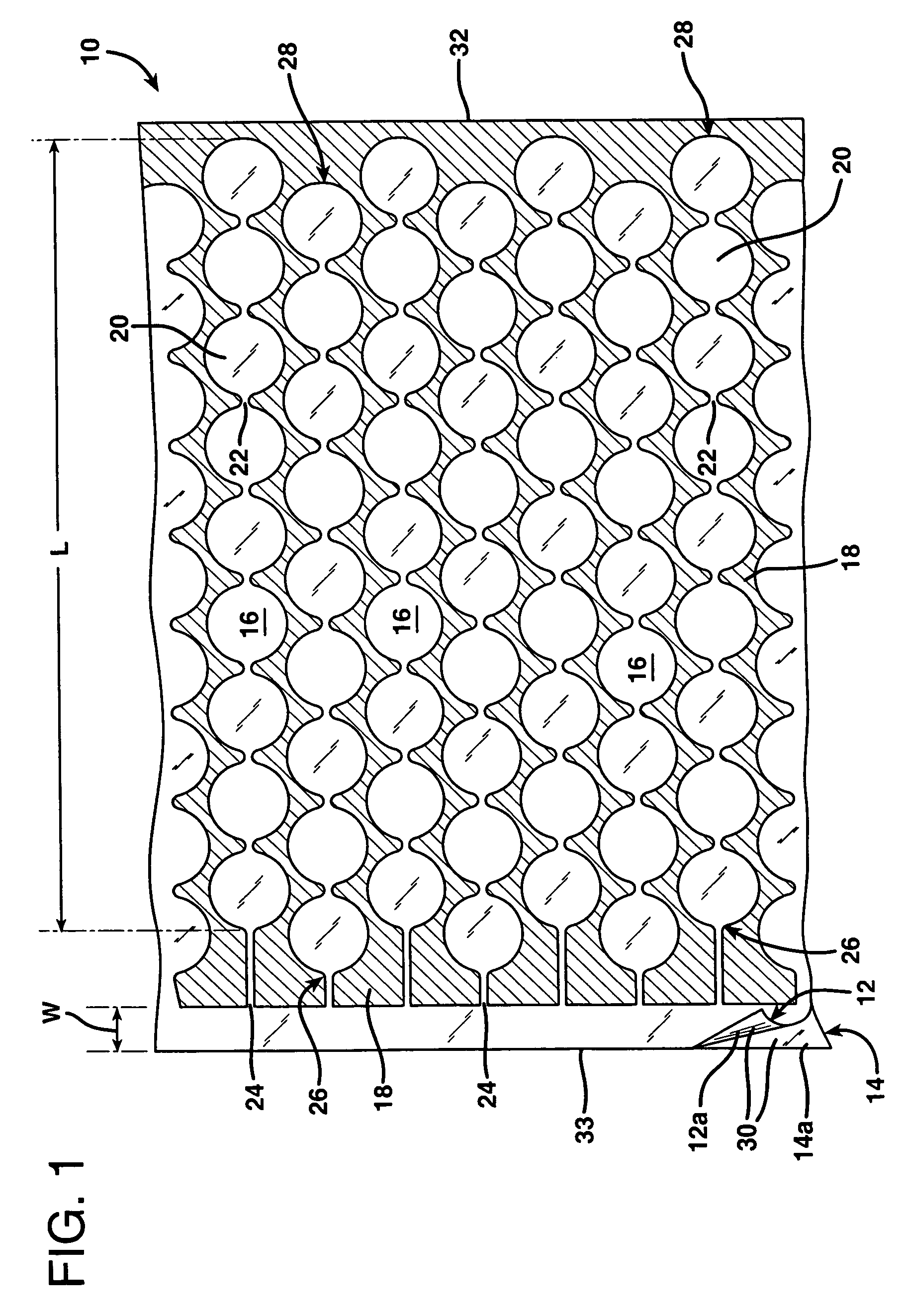

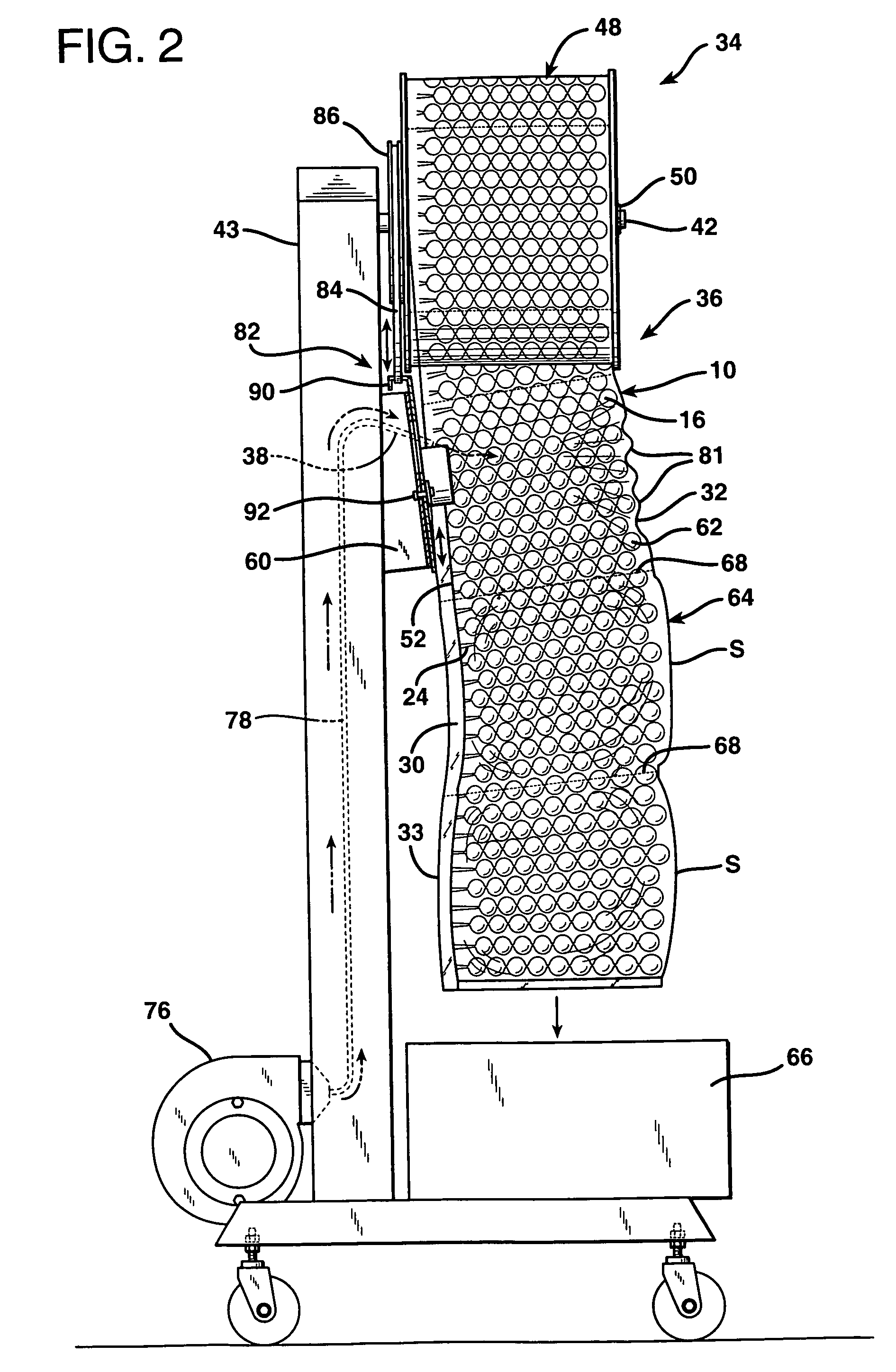

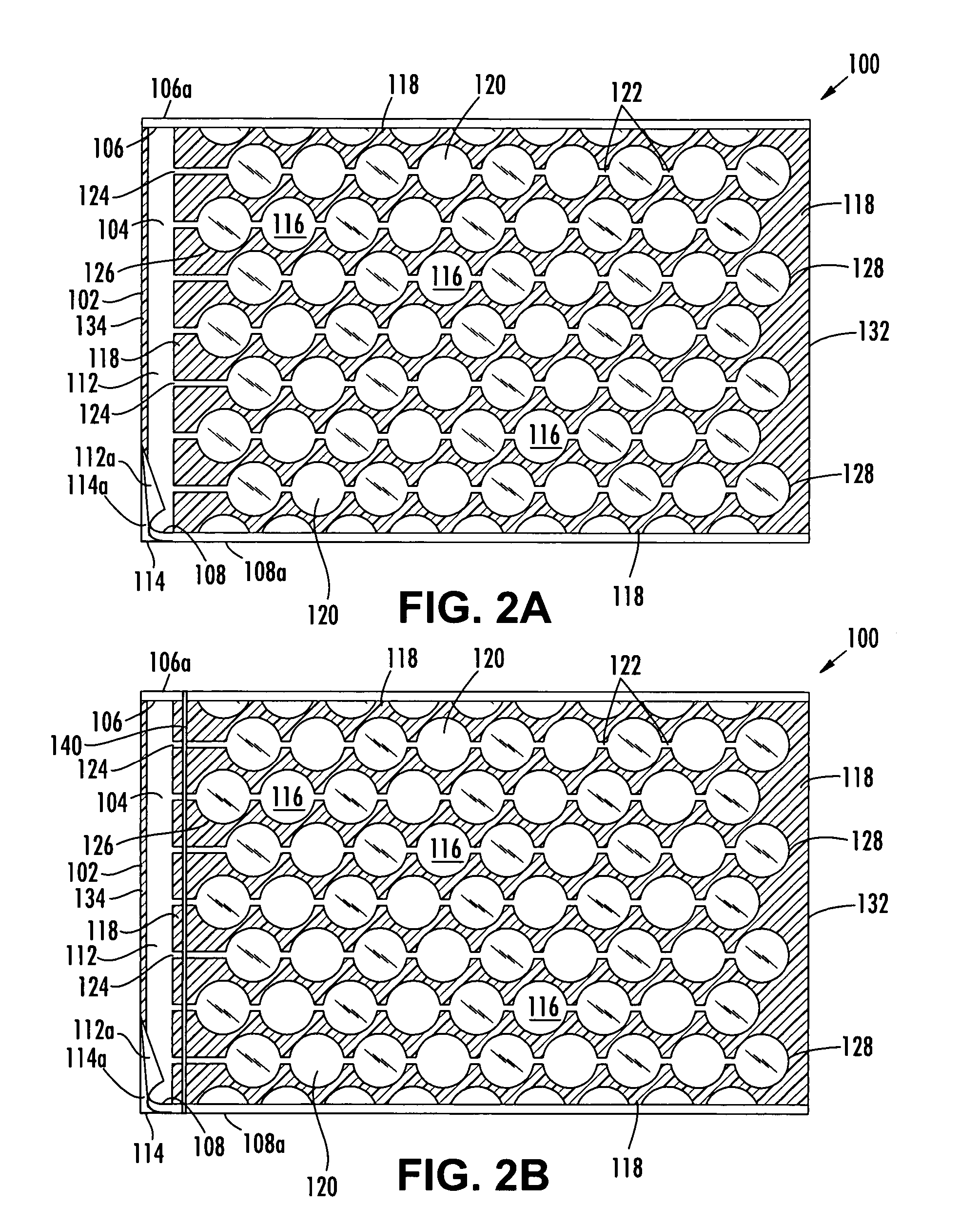

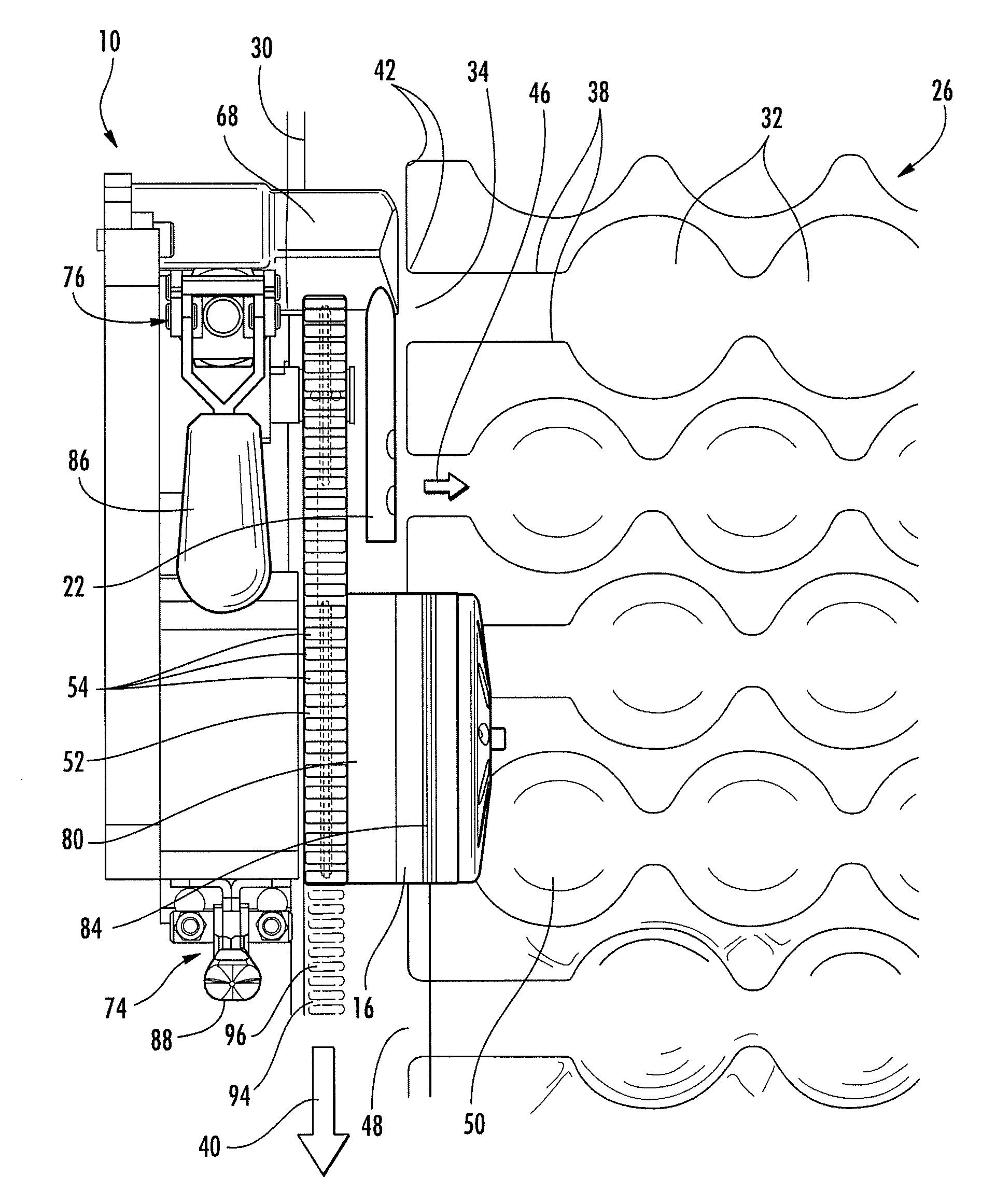

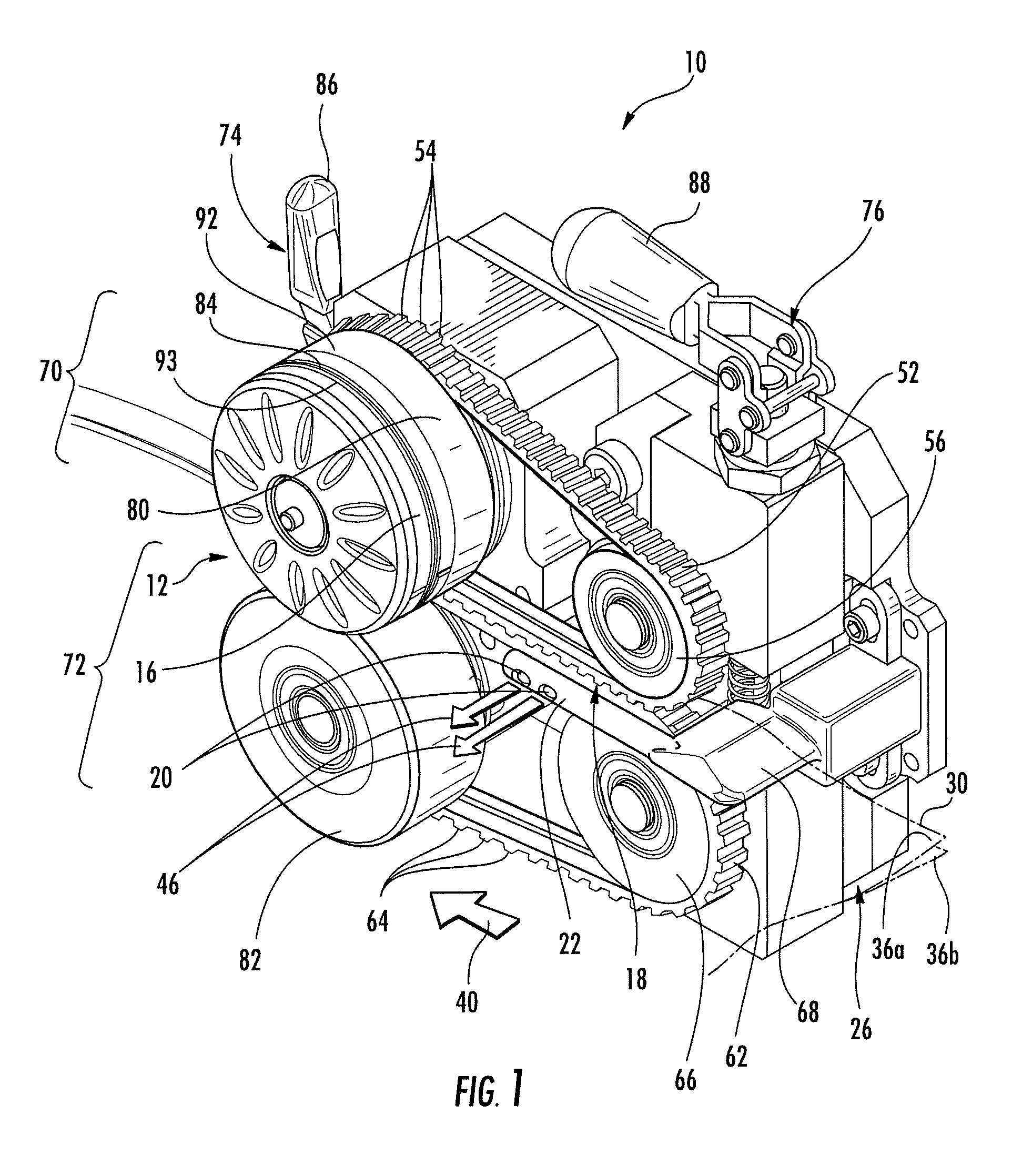

Machine for inflating and sealing a preconfigured cushioning material which is wound in a roll on a hollow cylindrical core and has superposed layers of plastic film sealed together to form rows of interconnected, inflatable cells, a longitudinally extending inflation channel near one edge of the material and inlet passageways interconnecting the inflation channel and the rows of cells. The machine includes a rotatively mounted roll support shaft having a fixed end and a free end, a hub mounted on the shaft near the fixed end for engagement with the core at the end of the roll near the inflation channel, a circumferentially expandable roll gripper at the free end of the shaft for locking engagement with the inner wall of the cylindrical core, means for drawing the material from the roll and feeding it along a predetermined path, an inflator having a conically tapered tip and a plurality of outlet openings adapted to be received in the inflation channel for injecting air into the cells as the material travels along the path, a nip roller, means for pressing the nip roller against the roll of film material to block the inflation channel and thereby limit the flow of air into the material on the roll, and means for sealing the inlet passageways to retain the air in the cells.

Owner:PREGIS INNOVATIVE PACKAGING

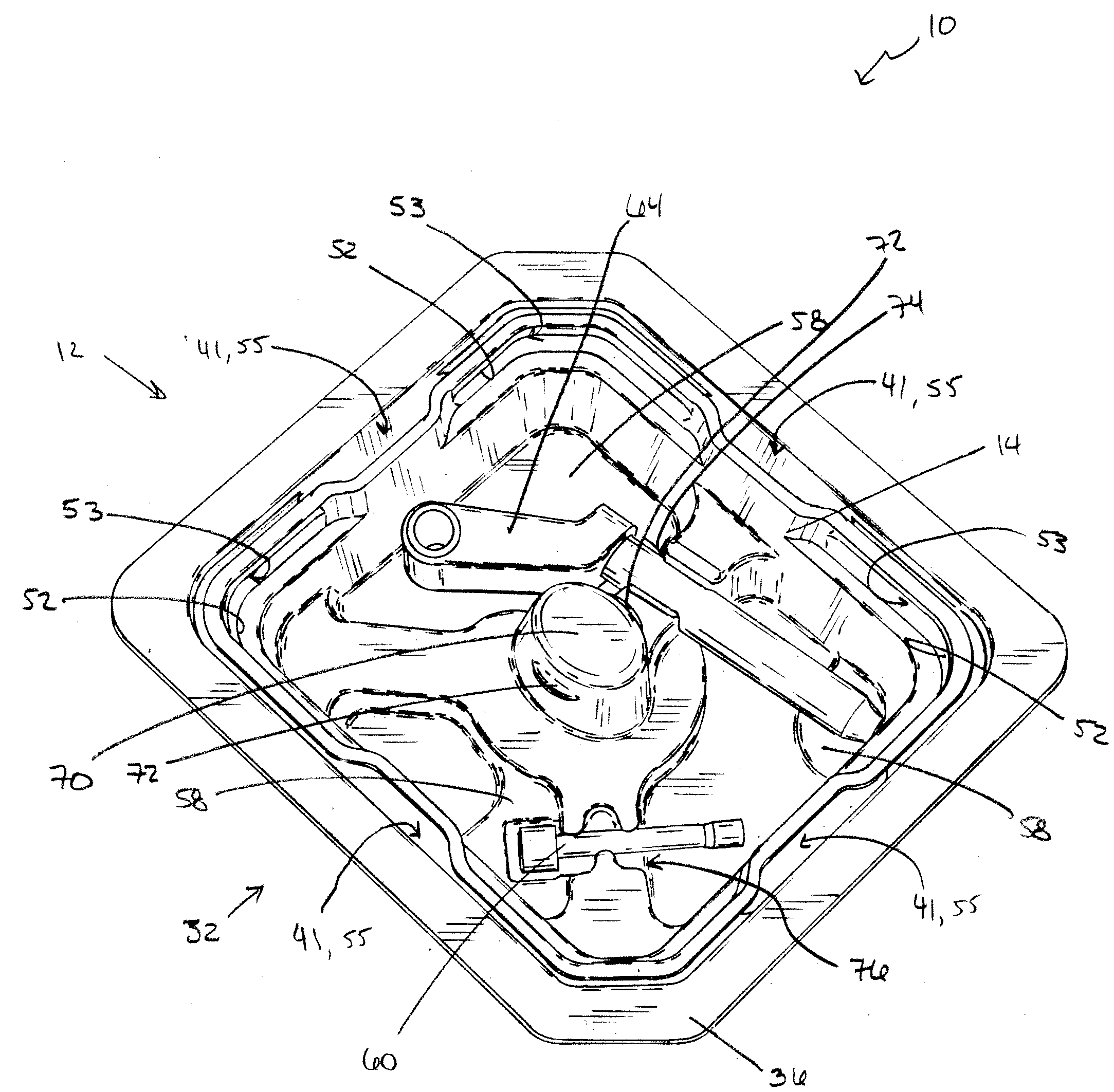

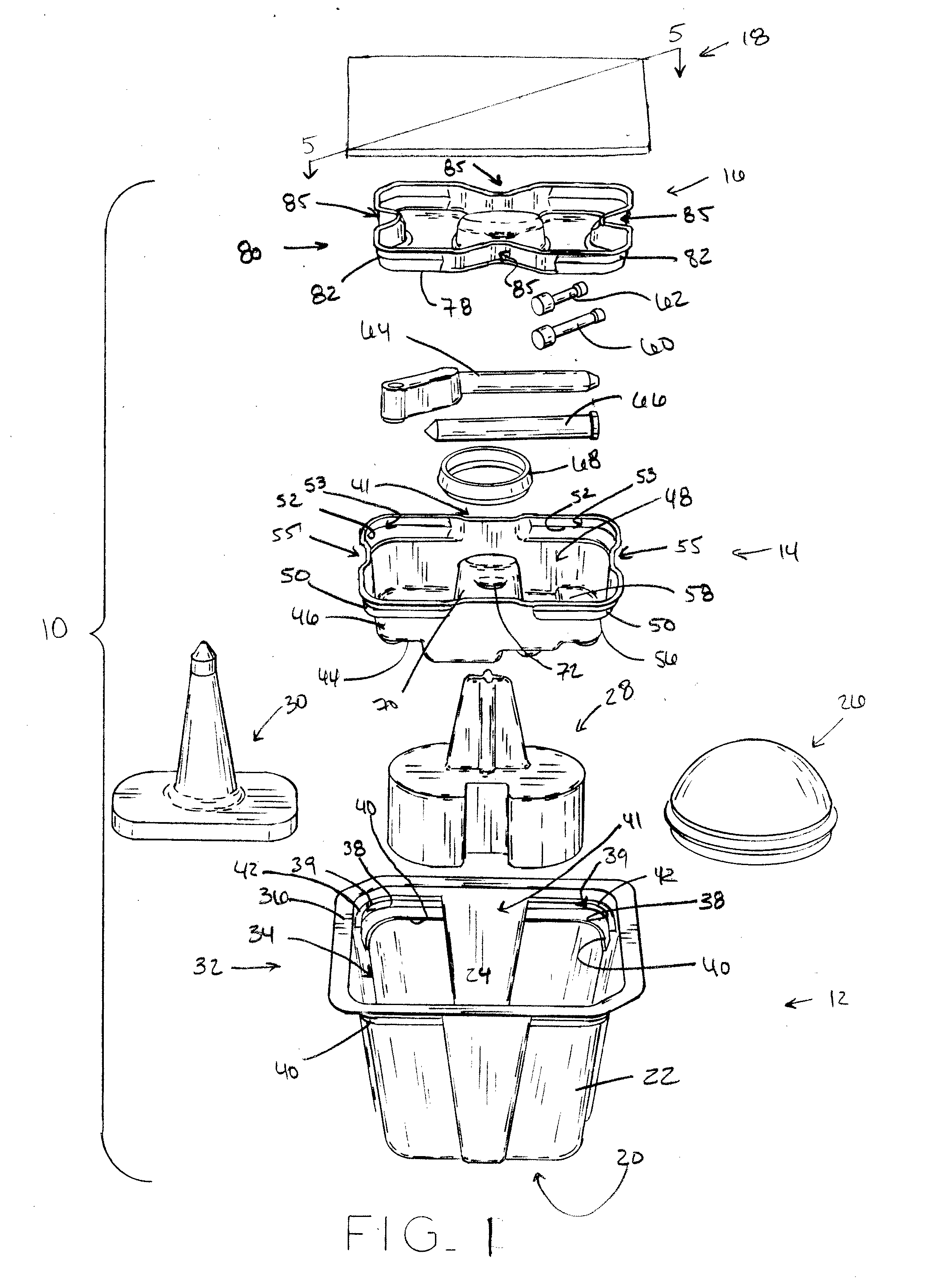

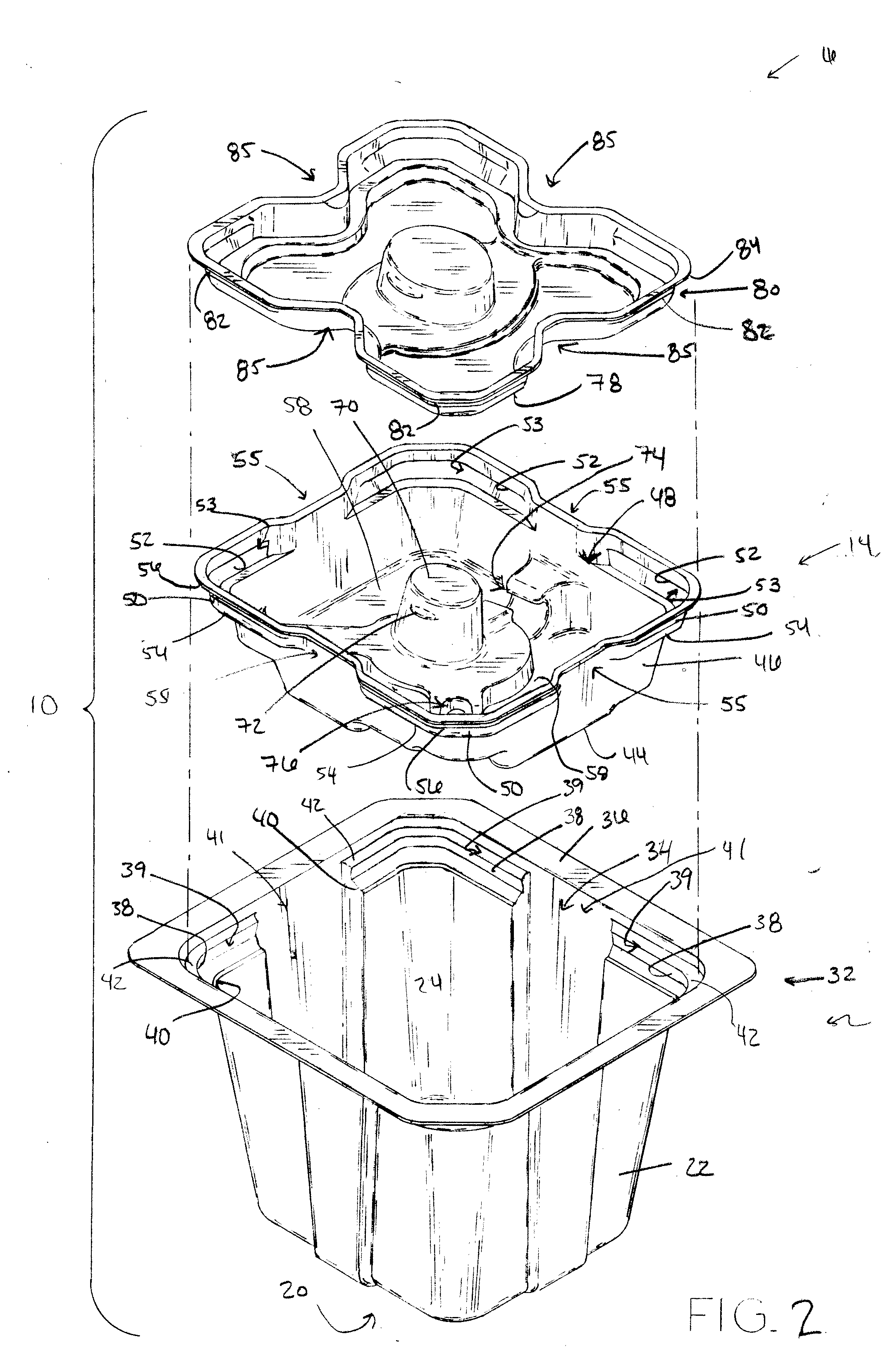

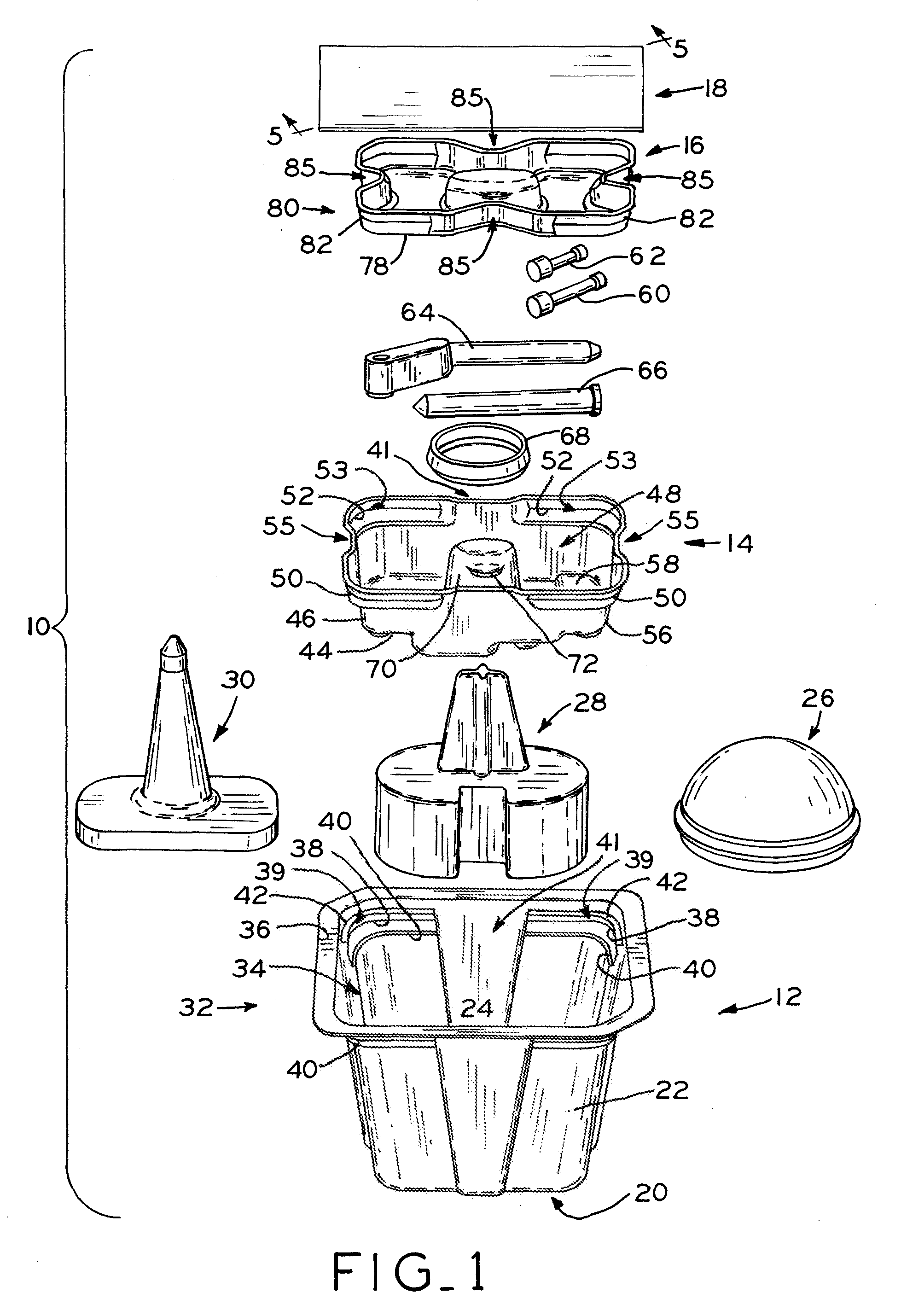

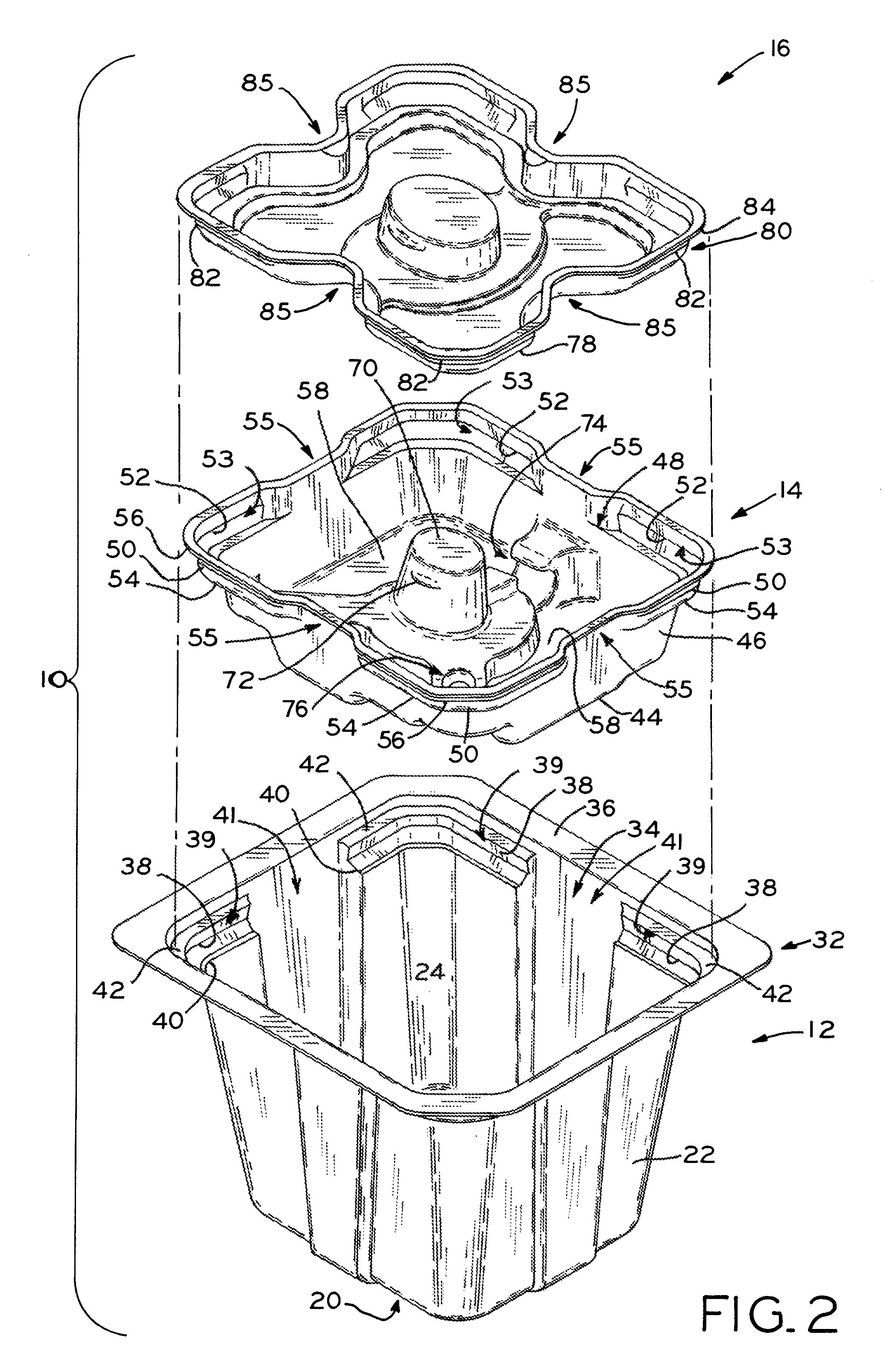

Method and apparatus for packaging medical devices

In one exemplary embodiment, the present invention provides a container system having an outer shell defining a cavity that is configured to receive a first medical device component therein. A support tray is sized for receipt within the outer shell of the container system and is supported above the first medical device component. In one exemplary embodiment, the support tray defines a second cavity that may receive a second medical device component. In addition, a retention tray may be positioned within the cavity of the support tray and supported above the second medical device component. The retention tray facilitates the retention of the support tray within the outer shell and also facilitates the retention of the first and second medical device components in their desired positions within the container system. Additionally, positioned to extend across an opening in the outer shell is a cover.

Owner:ZIMMER INC

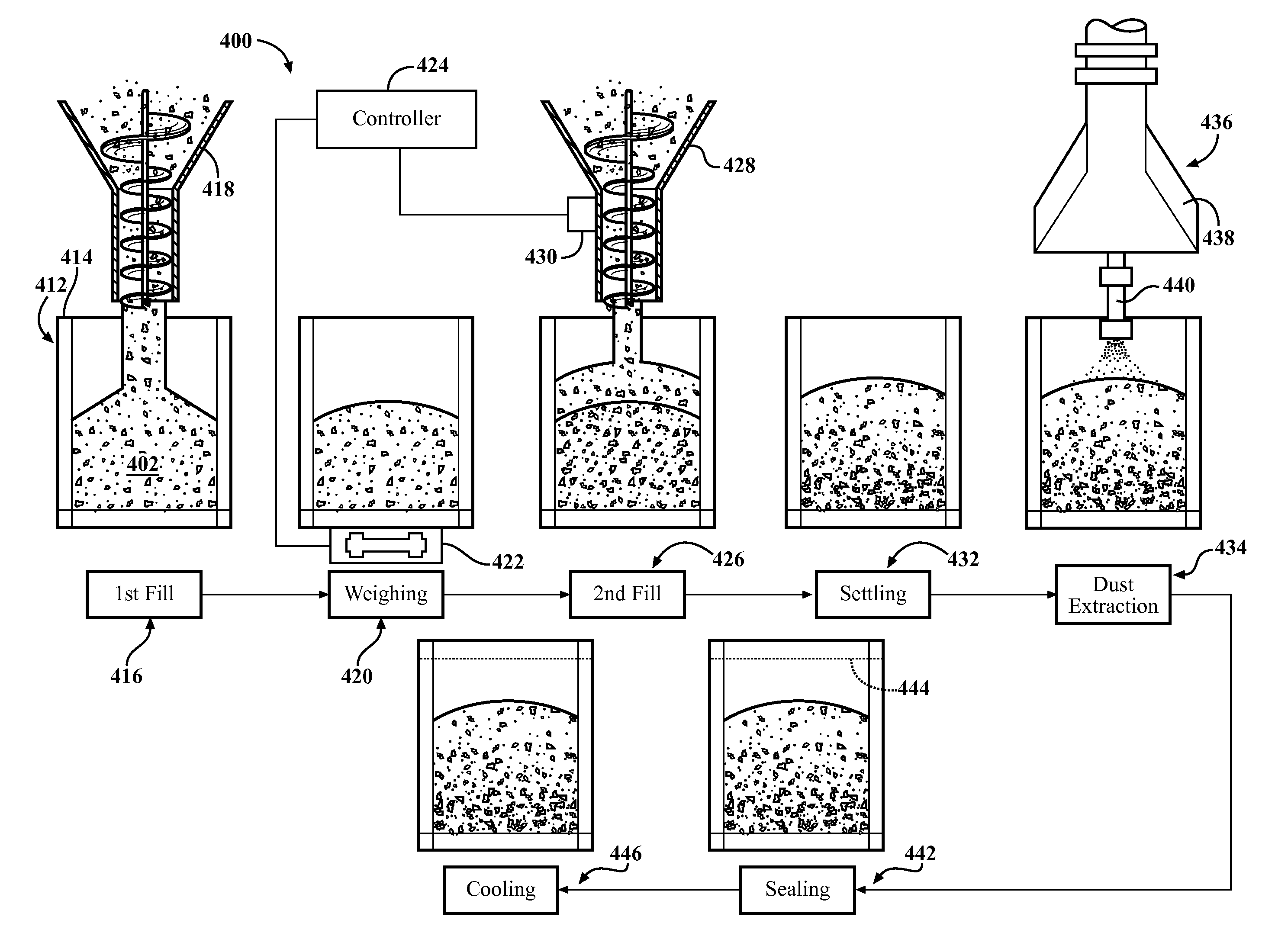

Method and apparatus for the two stage filling of flexible pouches

InactiveUS20120210675A1Accurately fills pouchIncrease in residual amountCapsCap application using vaccuumEngineeringMechanical engineering

The apparatus, for filling a flexible pouch having a bottom end, an opposite top end, and a pair of side edges extending between the bottom and top end, includes a filling station, a supply of compressed purging gas, and a gas purging station. The filling station includes a feeder that dispenses an amount of product into the pouch. The gas purge station is positioned subsequent to the filling station and includes a pair of gas lances. Each of the pair of gas lances have an outlet to discharge the purging gas into the pouch. The pair of gas lances being moveable between an inserted position and a withdrawn position. In the inserted position the pair of gas lances are disposed within the pouch a predetermined distance above the amount of product, and in the withdrawn position the pair of gas lances are provided above the top end of the pouch.

Owner:POUCH PAK INNOVATIONS +1

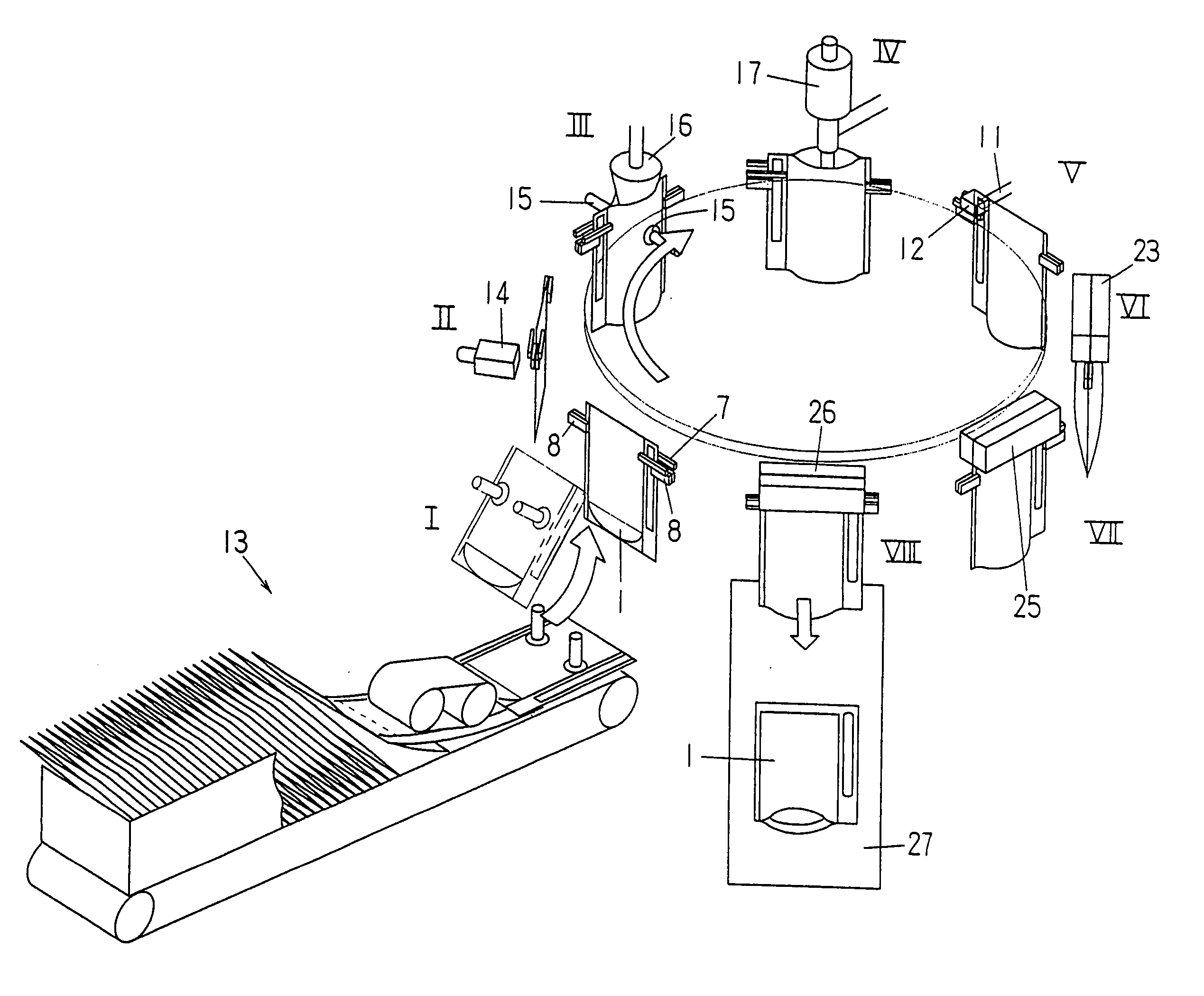

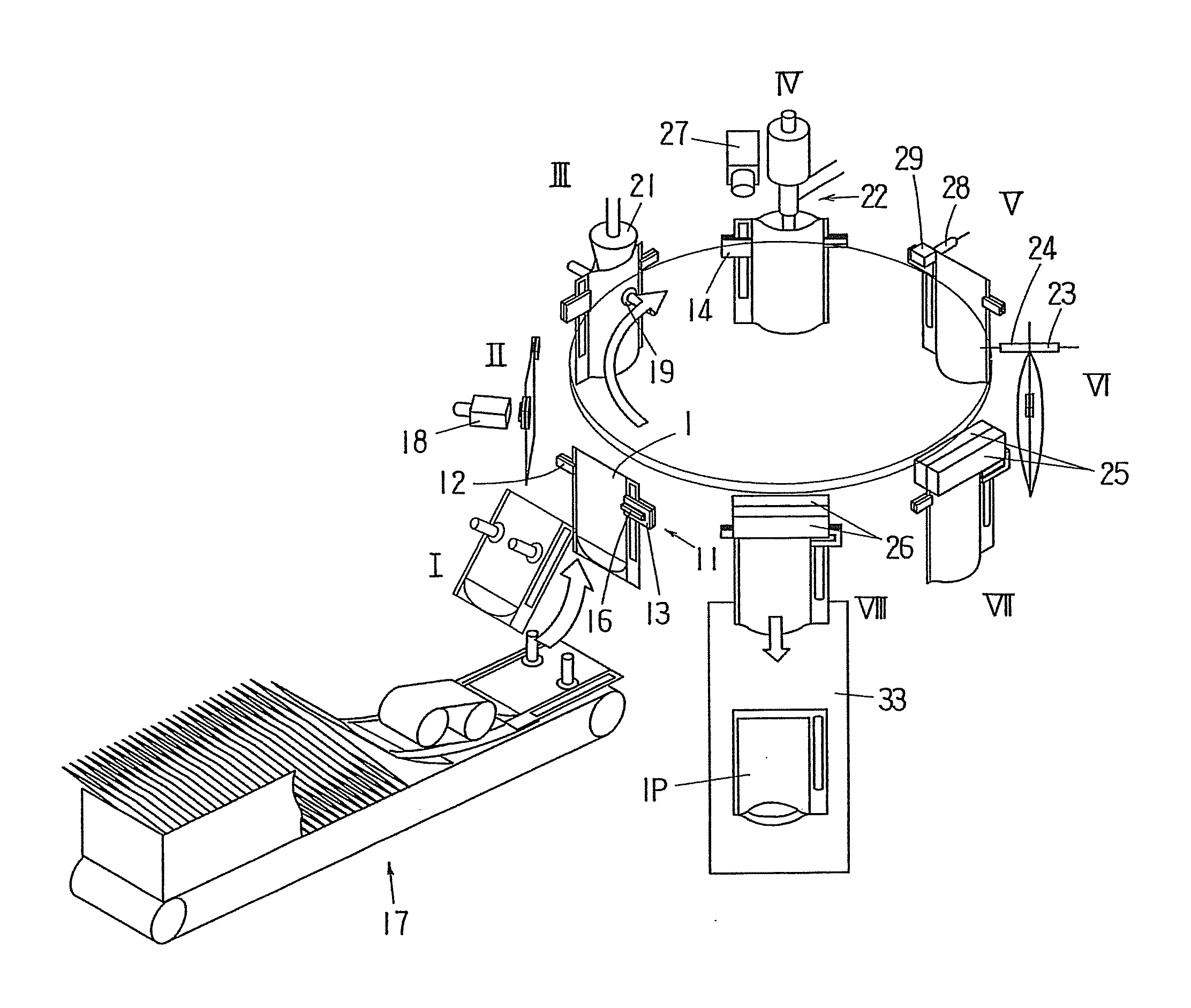

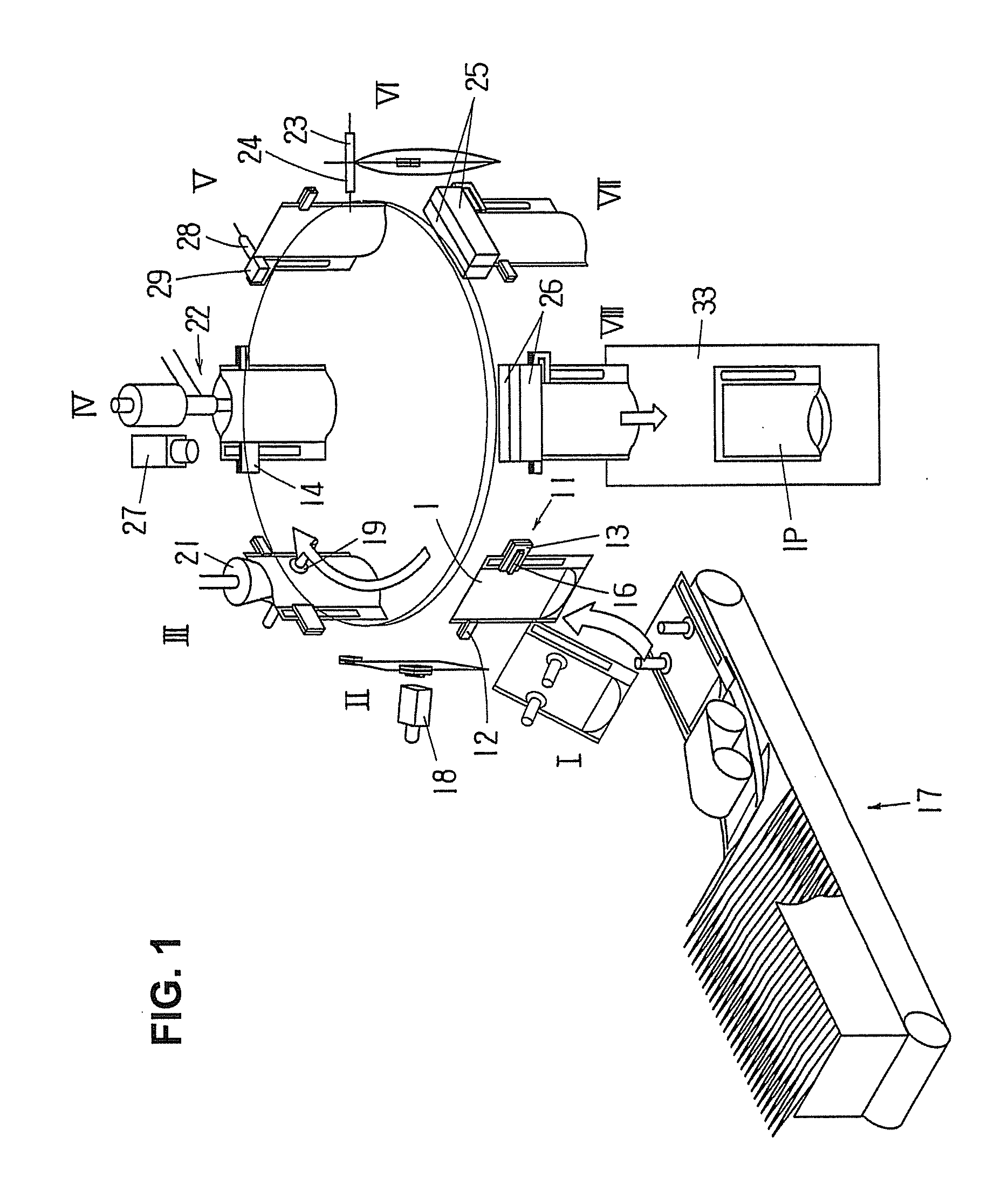

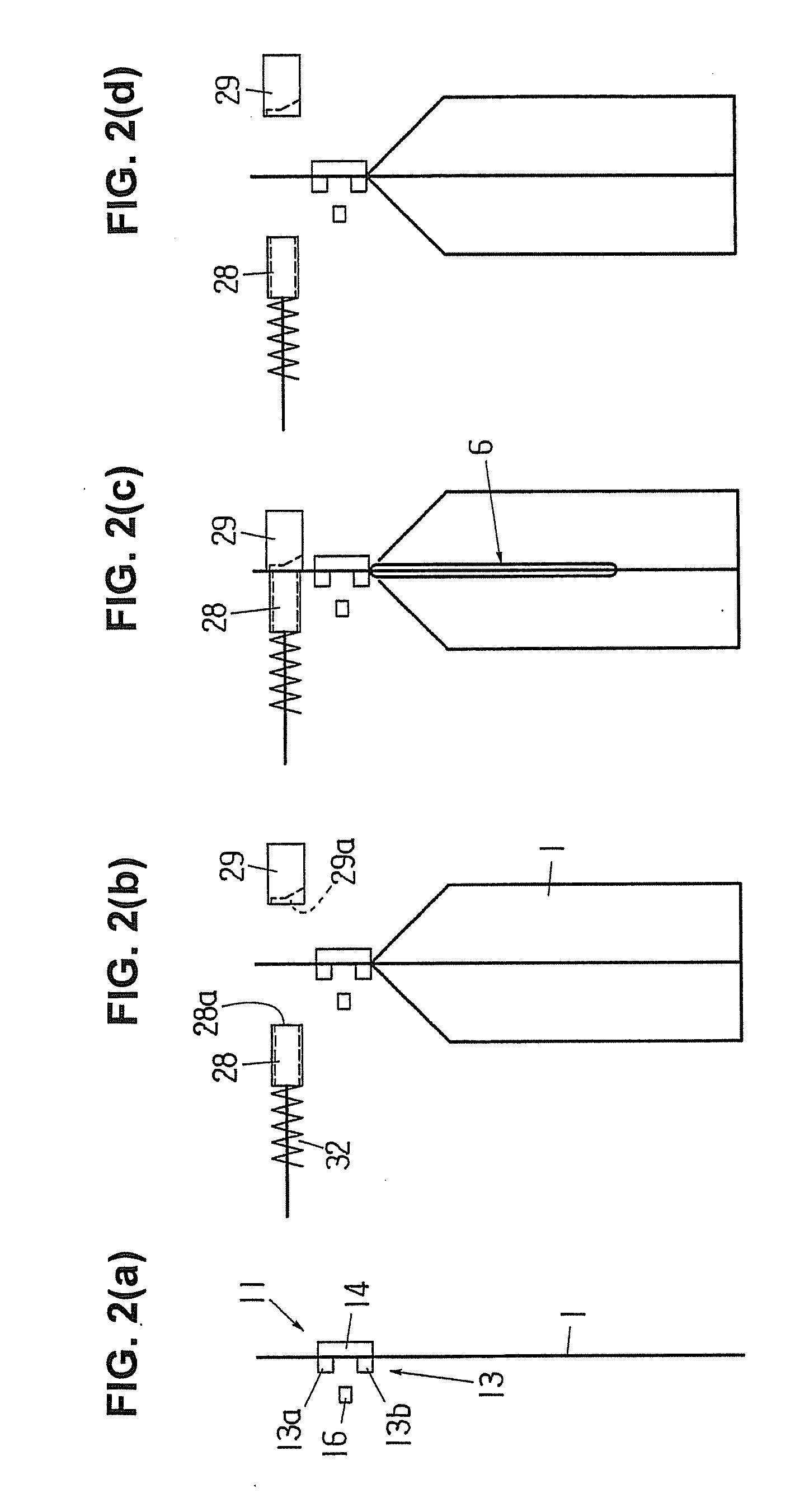

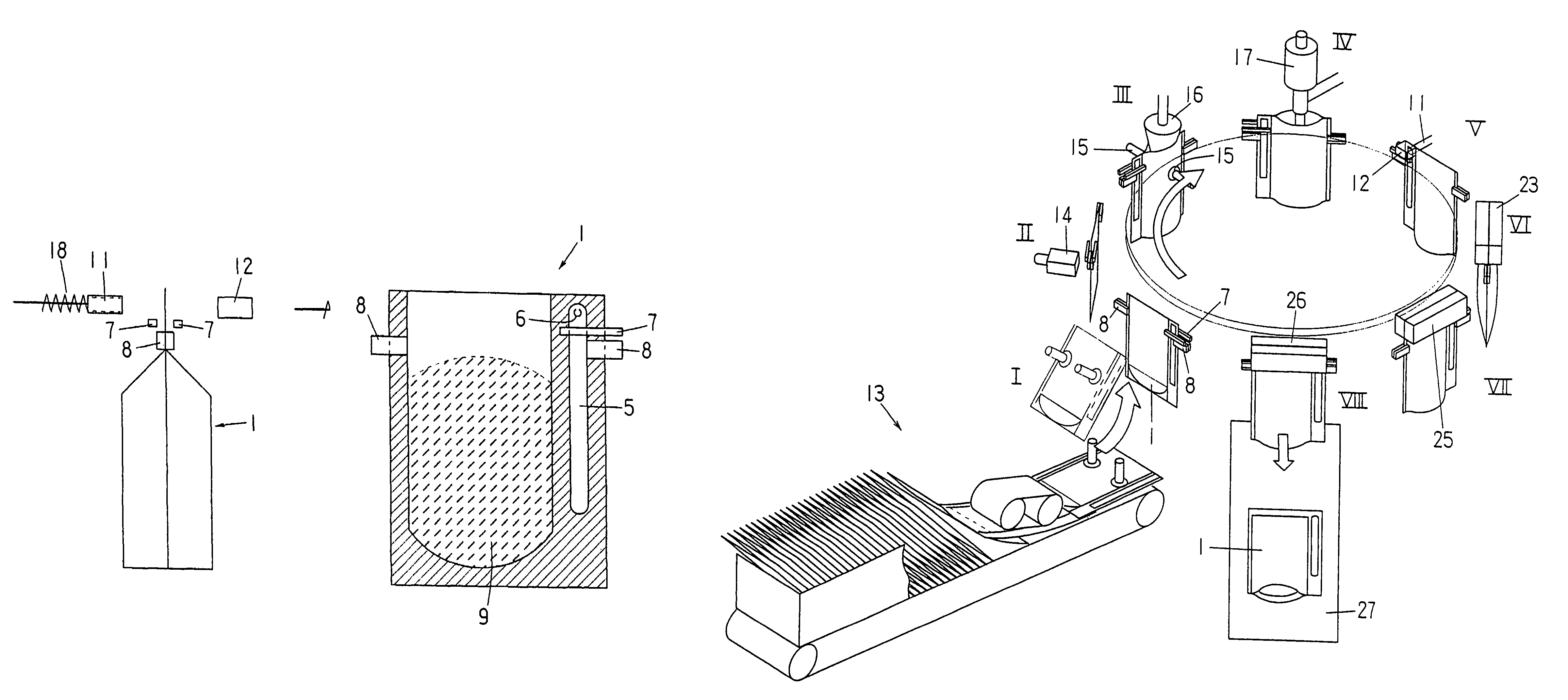

Gas Charging Method and Gas Charging Apparatus for Bag Equipped with Gas Compartment Portion

InactiveUS20140250834A1Evenly filledWithout loss of productivityCapsCap application using vaccuumEngineeringElectrical and Electronics engineering

In a method and apparatus for charging a gas into a gas compartment portion (6) of a bag (1), after a pre-heating step which is performed in stop position (IV) so that the gas compartment portion of the bag is heated by a heated gas-blowing nozzle (27), a preliminary gas injection step for injecting gas into the gas compartment portion is performed by a gas blowing nozzle (28) and a receiving member (29) in stop position (V). Then, a gas filling step is carried out in stop position (VI) by gas injection nozzles (23, 24), and the incision (9) in the gas compartment portion is sealed in stop position (VII). In the following pre-heating step, the front and rear film sheets (7, 8) of the gas compartment portion are softened, and in the preliminary gas injection step, the film sheets are separated and their adhesion is eliminated.

Owner:TOYO JIDOKI CO LTD

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

Owner:TOYO JIDOKI CO LTD

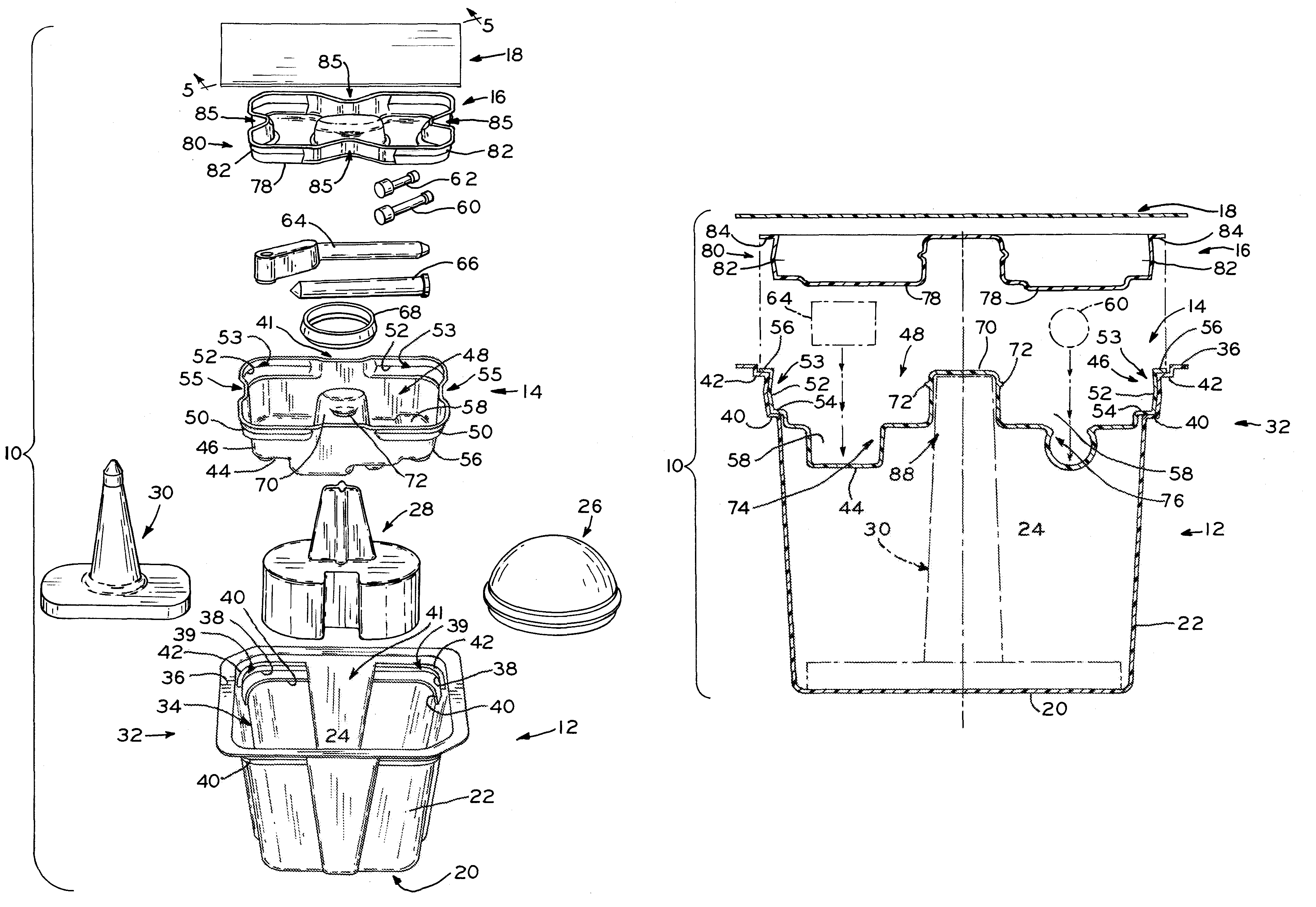

Method and apparatus for packaging medical devices

InactiveUS8006839B2Add supportKeep sterileCapsSurgical furnitureMedical deviceBiomedical engineering

In one exemplary embodiment, the present invention provides a container system having an outer shell defining a cavity that is configured to receive a first medical device component therein. A support tray is sized for receipt within the outer shell of the container system and is supported above the first medical device component. In one exemplary embodiment, the support tray defines a second cavity that may receive a second medical device component. In addition, a retention tray may be positioned within the cavity of the support tray and supported above the second medical device component. The retention tray facilitates the retention of the support tray within the outer shell and also facilitates the retention of the first and second medical device components in their desired positions within the container system. Additionally, positioned to extend across an opening in the outer shell is a cover.

Owner:ZIMMER INC

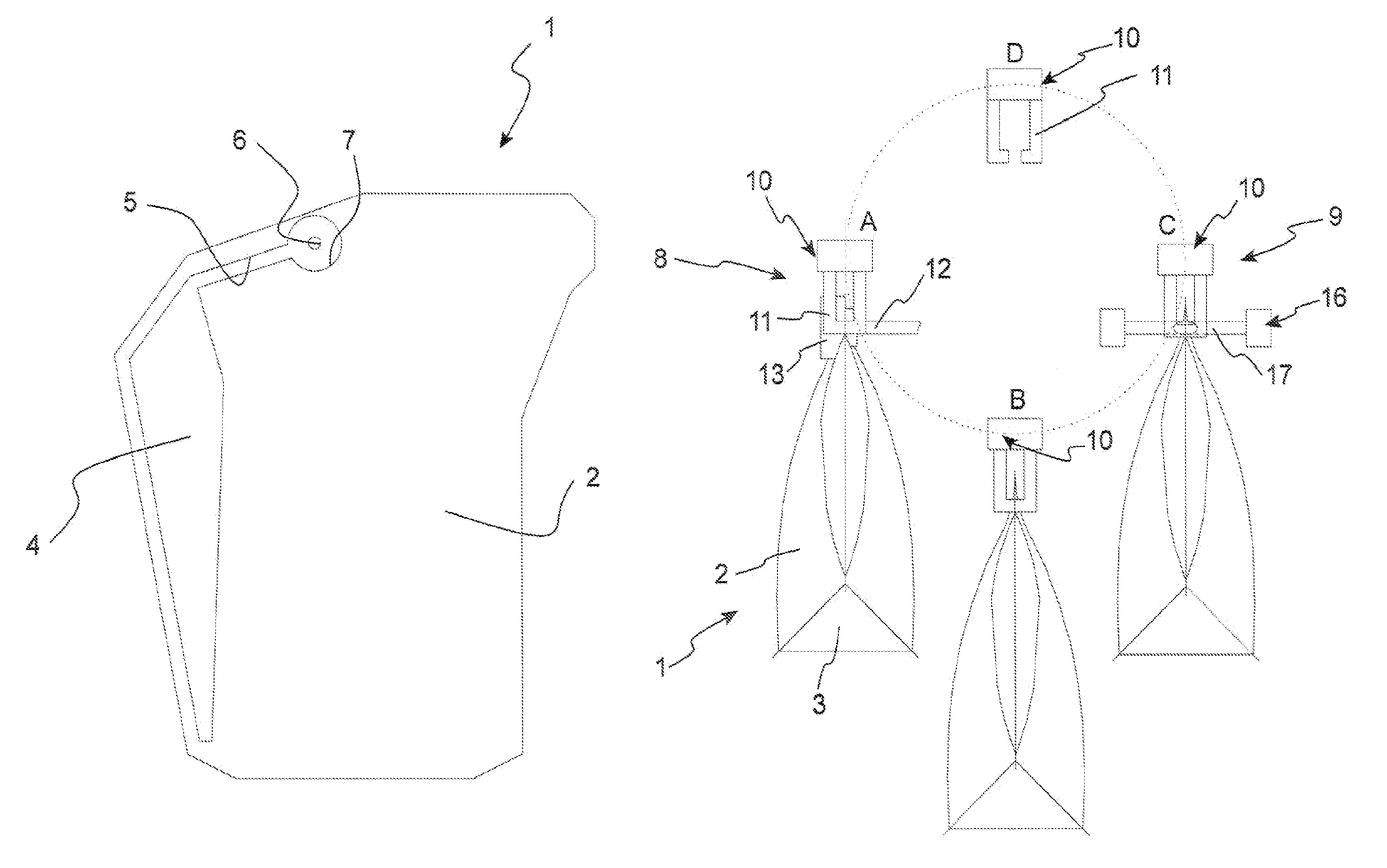

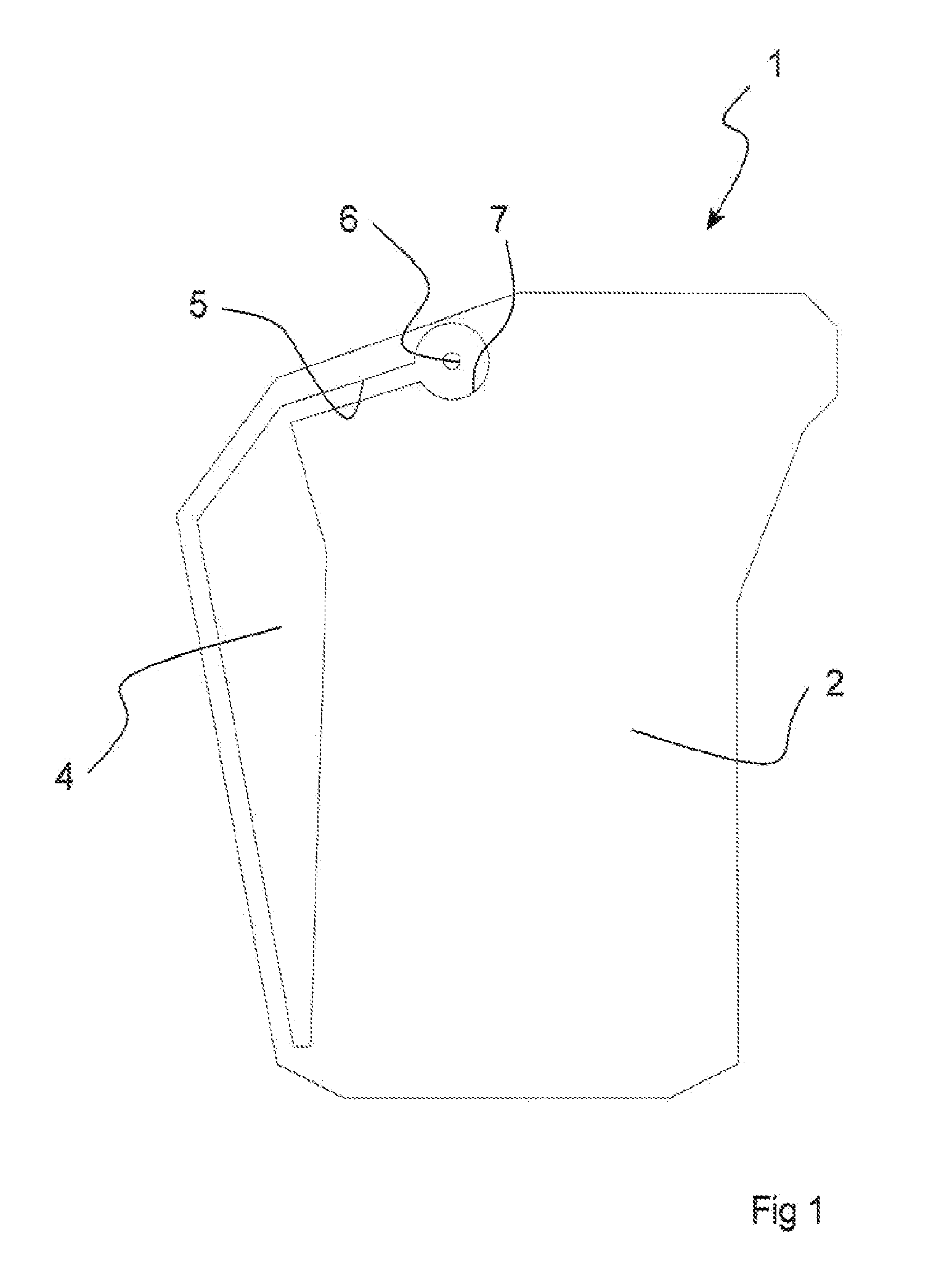

Method for gas filling of a handle portion of a container

ActiveUS8181428B2High-capacity productionIncrease speedEnvelopes/bags making machineryCapsEngineeringGas supply

A method for gas filling a handle portion of a container of a collapsible type. The handle portion being defined by two opposite side walls of the container and communicating, via a duct defined by the side walls, with an opening formed in one of the side walls. The method including the steps of supplying, at a gas filling station, a gas to the handle portion via the opening and the duct, blocking the duct by a squeezing action to retain the gas supplied to the handle portion, transporting the container to a sealing station while maintaining the squeezing action and, at said sealing station, sealing the duct while maintaining the squeezing action, so as to permanently enclose the gas in the handle portion. The disclosure further concerns a container of a collapsible type.

Owner:ECOLEAN

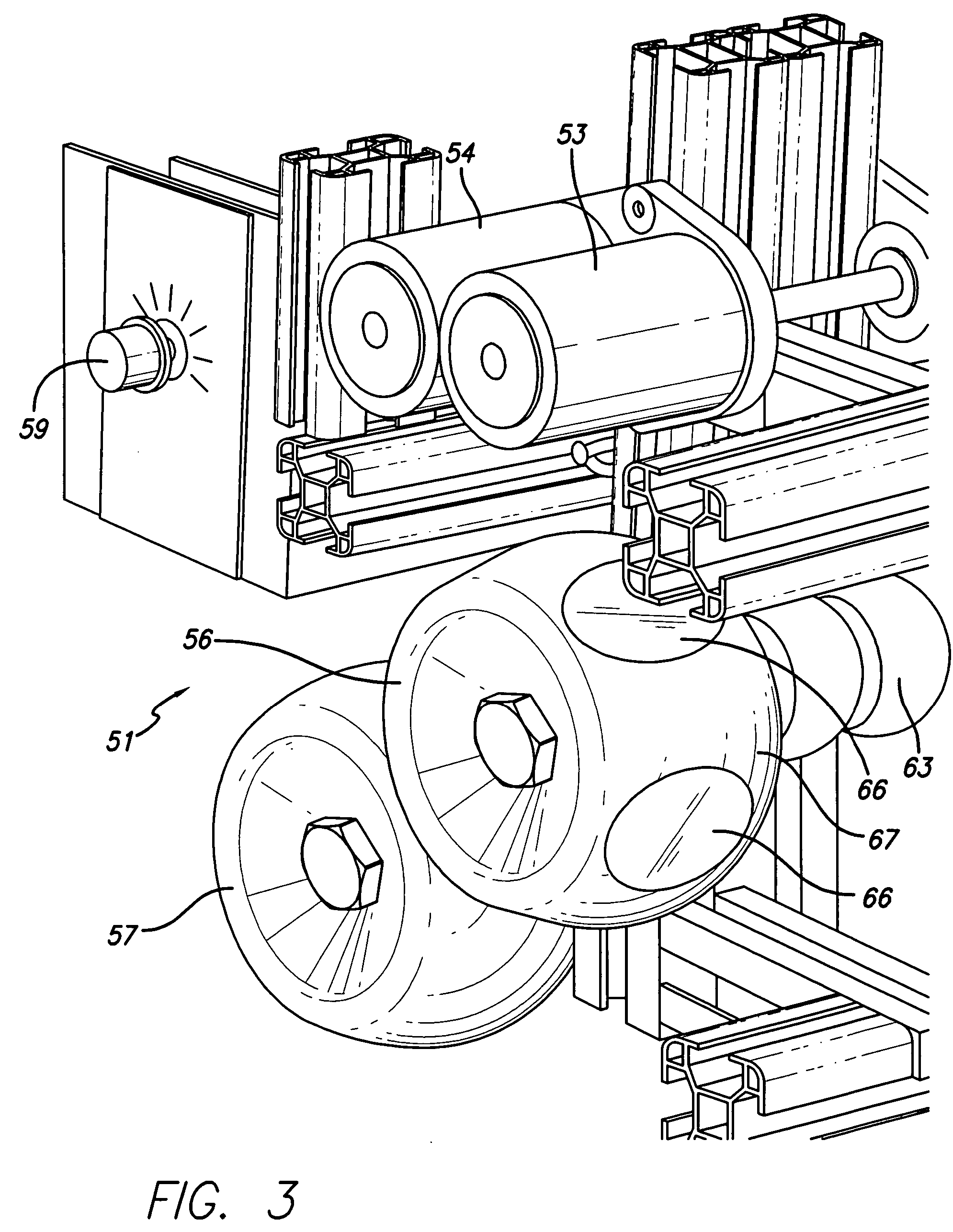

Packaging cushion delivery system

A system for conveying a string of packaging cushions includes a machine capable of manufacturing the string and a conveyor adapted to transport the string. The conveyor has an inlet end to receive the string and an outlet end to deliver the string of packaging cushions. The inlet end of the conveyor is higher than the cushion outlet elevation of the machine. At least one pair of rolls are adapted to lift the string of packaging cushions from the machine through the nip of the rolls to the conveyor inlet elevation.

Owner:SEALED AIR U S

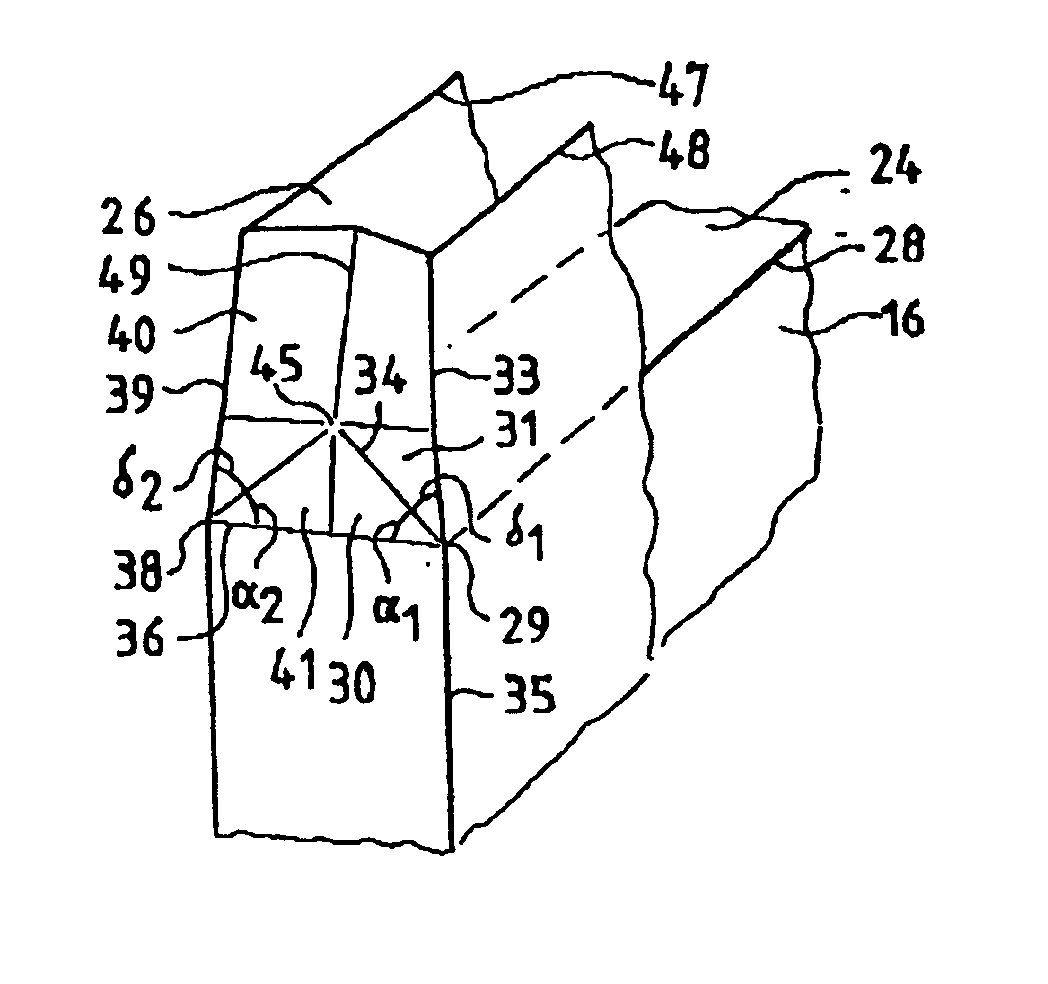

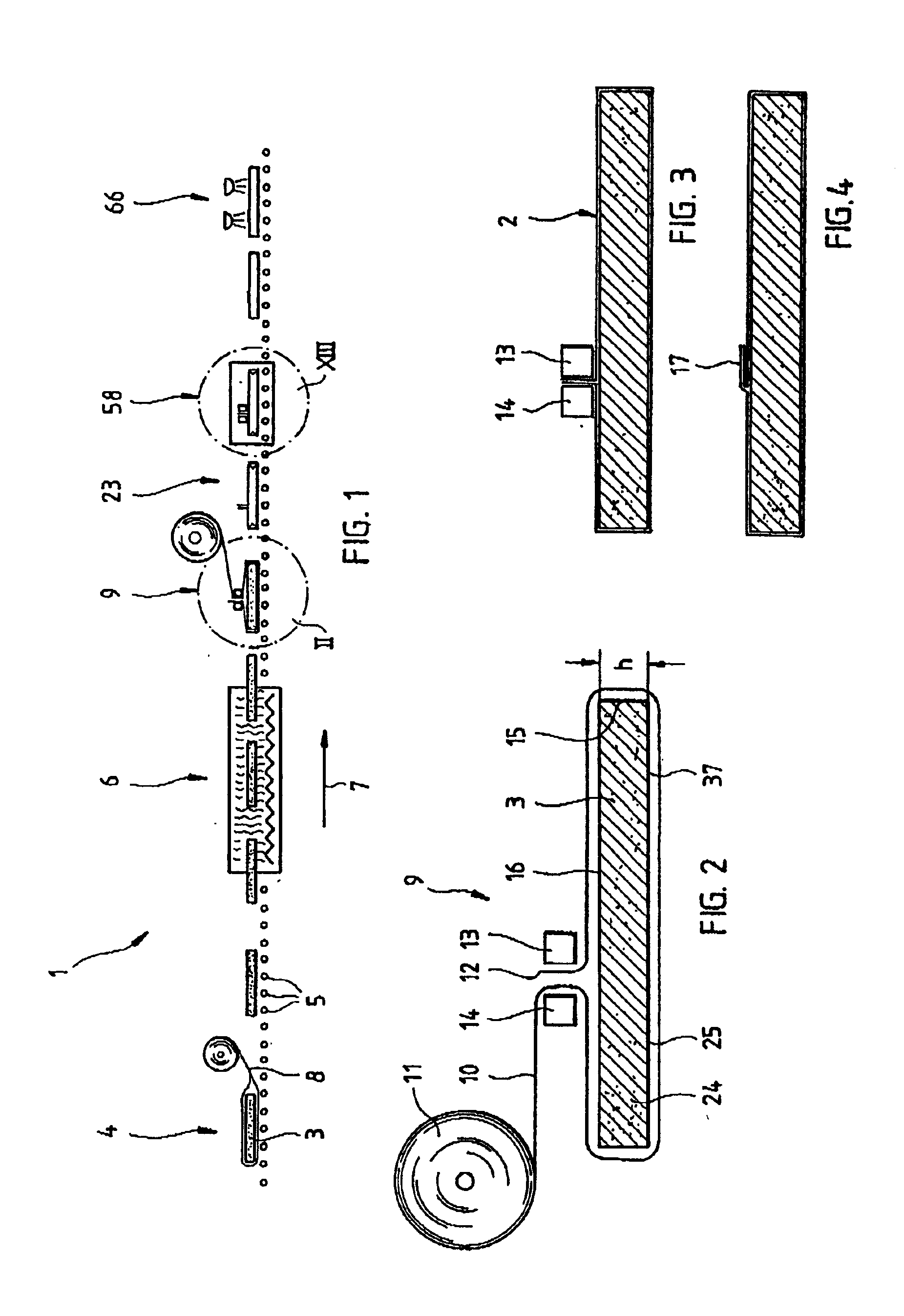

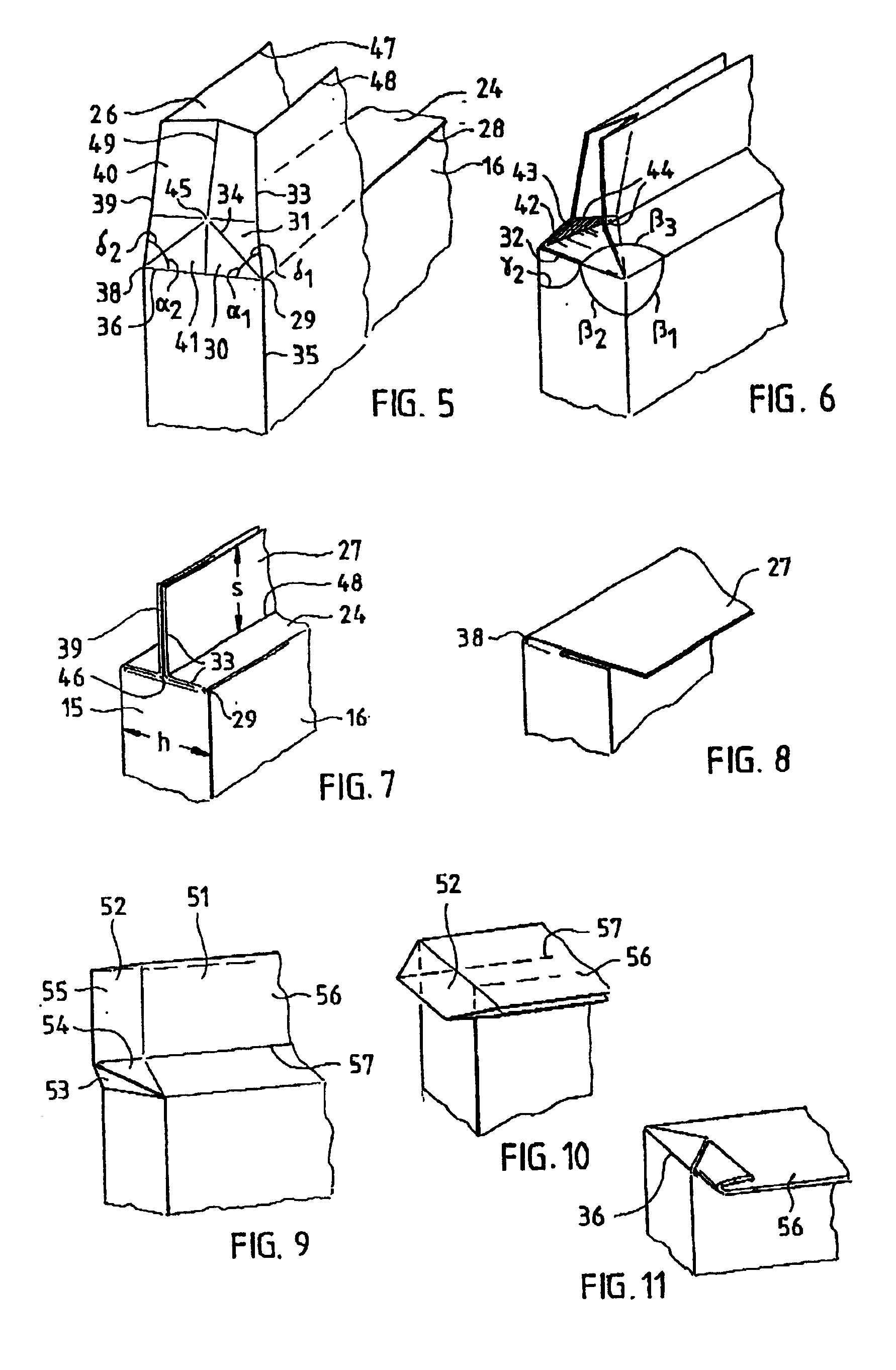

Foil-enveloped evacuated thermal insulation elements

The invention relates, on the one hand, to a prismatic, especially panel-formed thermal insulation element which is enveloped in a gas-tight foil and evacuated, whereby a stable core pre-formed from a porous material is completely enveloped in a single cut sheet of the gas-tight foil; as well as a manufacturing process for same comprising the following steps:a) Manufacture of a prismatic core corresponding to the desired form of the thermal insulation element from a porous material;b) Enveloping of the principal faces of this core with a single sheet of the gas-tight foil;c) At least partial welding together of the foil which is drawn tight around the core along the face of the core;d) Folding-in of the welded seam area of the foil against the face of the core;e) Stress-free folding-together of the areas of the cut sheet of gas-tight foil projecting beyond the core, covering and in flat contact with the end surface(s) of the core;f) Welding together of the folded-together areas of foil on at least one end face of the core;g) Evacuation of the enveloped core;h) Complete welding closed of all remaining openings in the foil under vacuum.

Owner:VA Q TEC AG

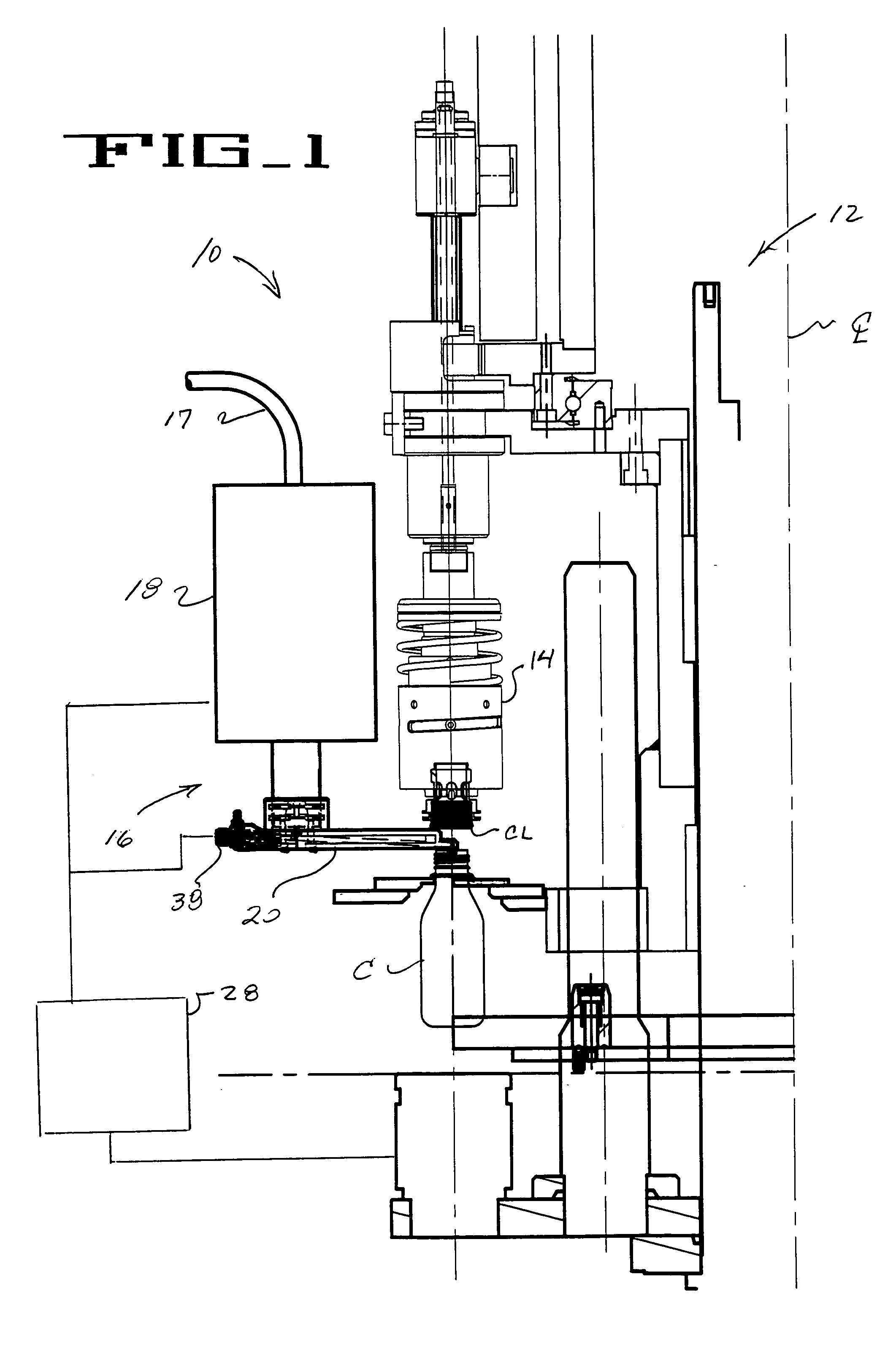

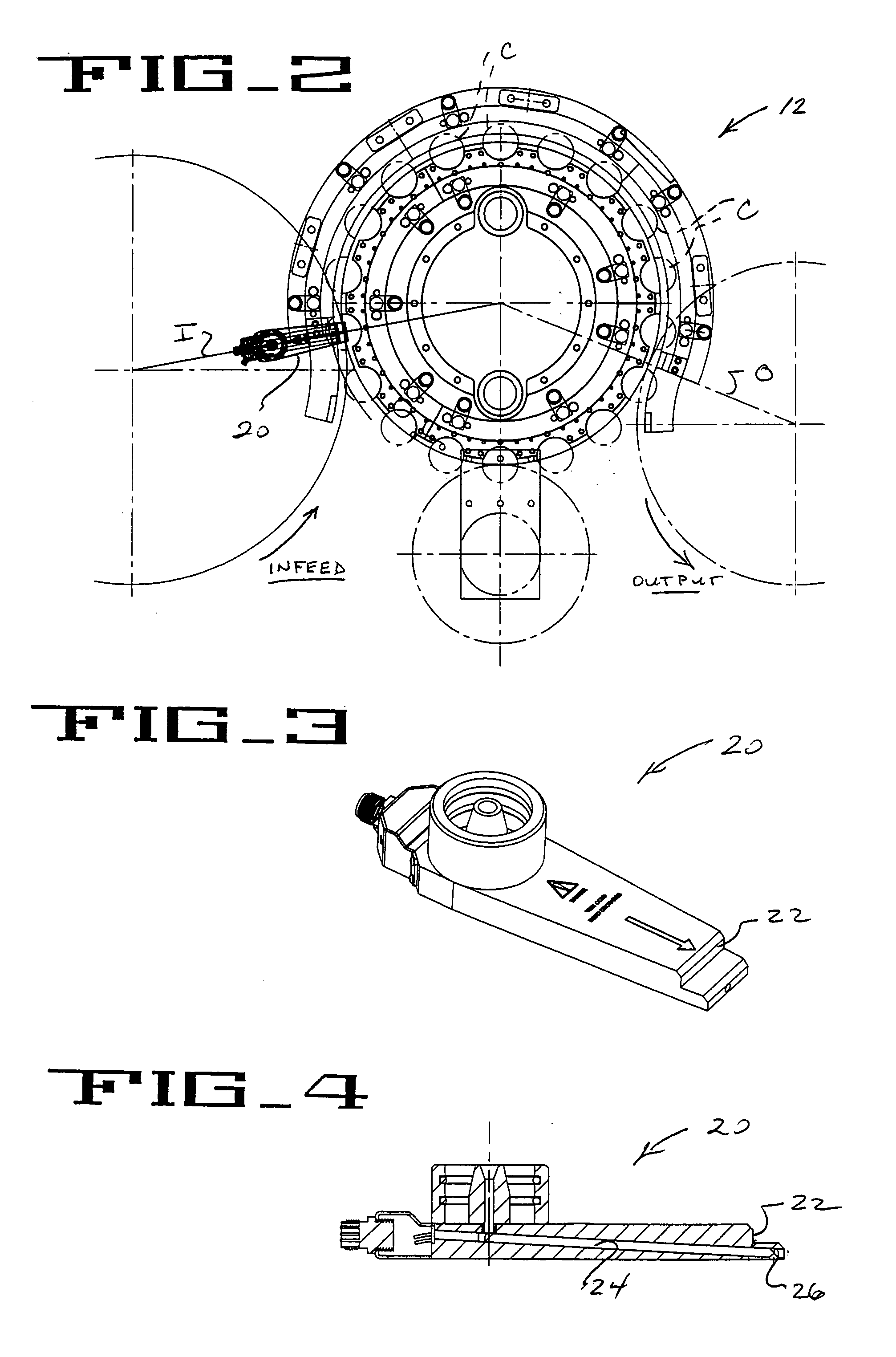

Capping and nitrogen dosing apparatus

InactiveUS20050028487A1Operation efficiency can be improvedFacilitate consistent operationCapsThreaded caps applicationNitrogenNitrogen gas

A capping and nitrogen dosing apparatus for containers includes a rotary capping machine which is configured to serially receive filled containers, and apply closures to respective ones of the containers. The present apparatus includes a dosing system for injecting an inert gas, typically nitrogen in liquid form, into the head space of each container to enhance the integrity and rigidity of the package, and to improve the freshness and flavor of the container's contents. Notably, the dosing system is configured to effect nitrogen injection close to or at the so-called transfer point of the capping machine, thus desirably abating nitrogen dissipation, and enhancing consistent and efficient product dosing.

Owner:CREDIT SUISSE SYDNEY BRANCH

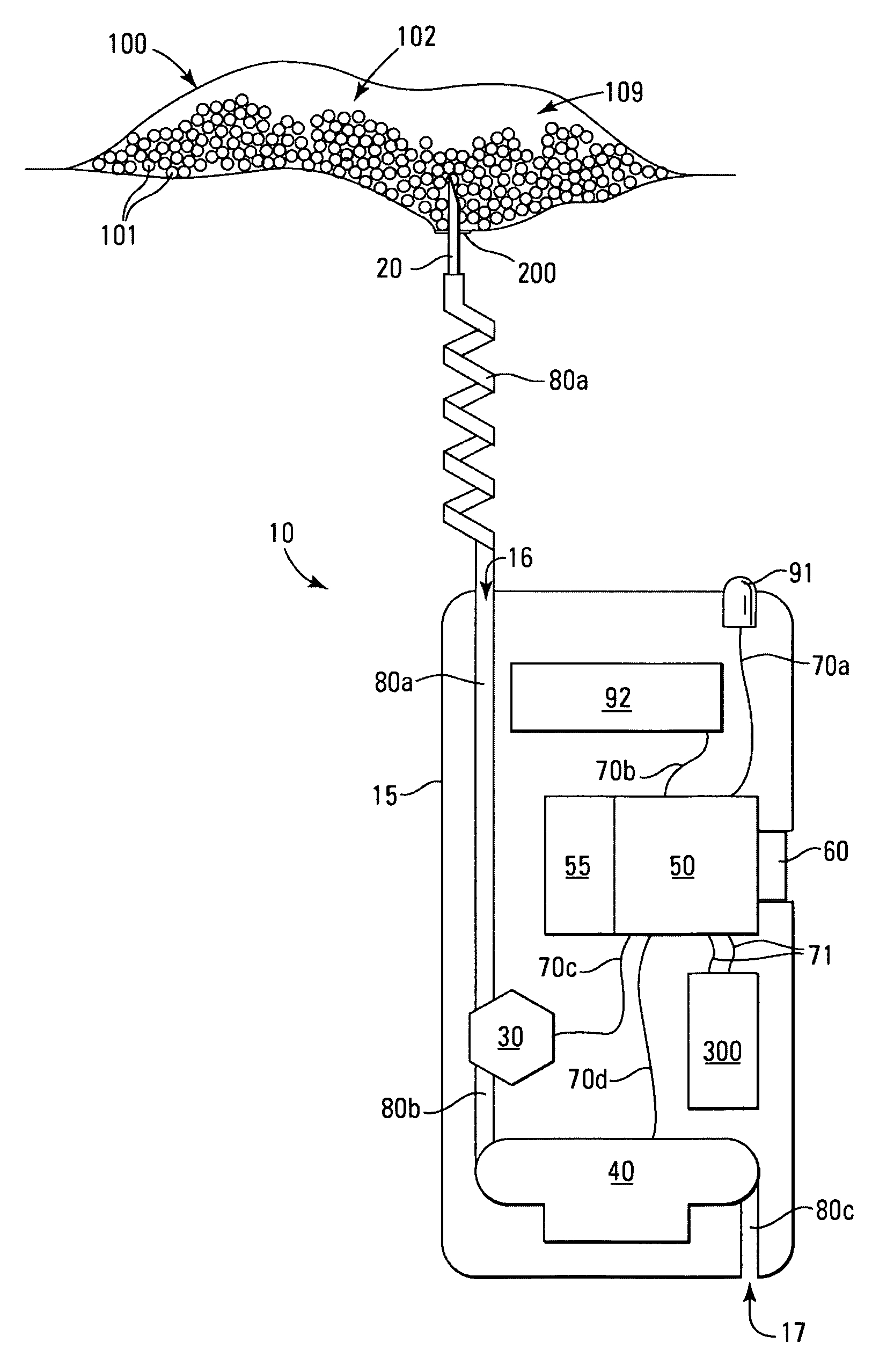

Instrument and method for measuring the volume of a hermetically sealed variable volume and pressure conforming container

An instrument and method for measuring the volume of a hermetically sealed, variable volume, pressure conforming container. The instrument includes a needle, a vacuum pump, a mass flow rate sensor and an integrator. The needle has a lumen operable for sealingly perforating a container and thereby placing the lumen of the needle in fluid communication with a retention chamber defined by the container. The vacuum pump evacuates the gaseous content from the retention chamber through the lumen defined by the needle and past a mass flow rate sensor for sensing mass flow rates pulled through the lumen and transmitting corresponding mass flow rate signals over time to the integrator. The integrator is programmed to integrate the received mass flow rate signals over time through achievement of an evacuated retention chamber to generate a total mass value, and calculate a volume from the total mass value employing the Ideal Gas Law.

Owner:MODERN CONTROLS

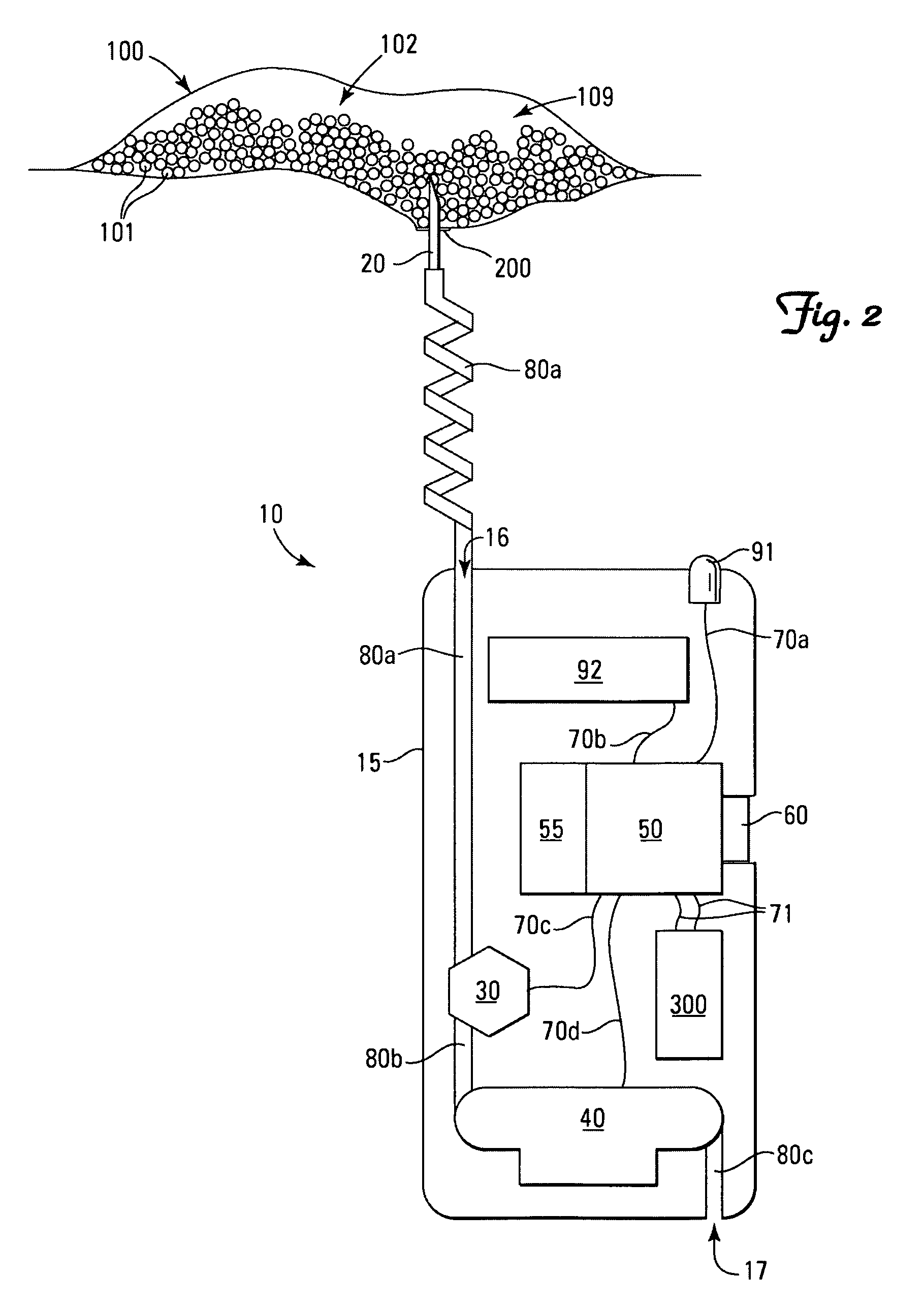

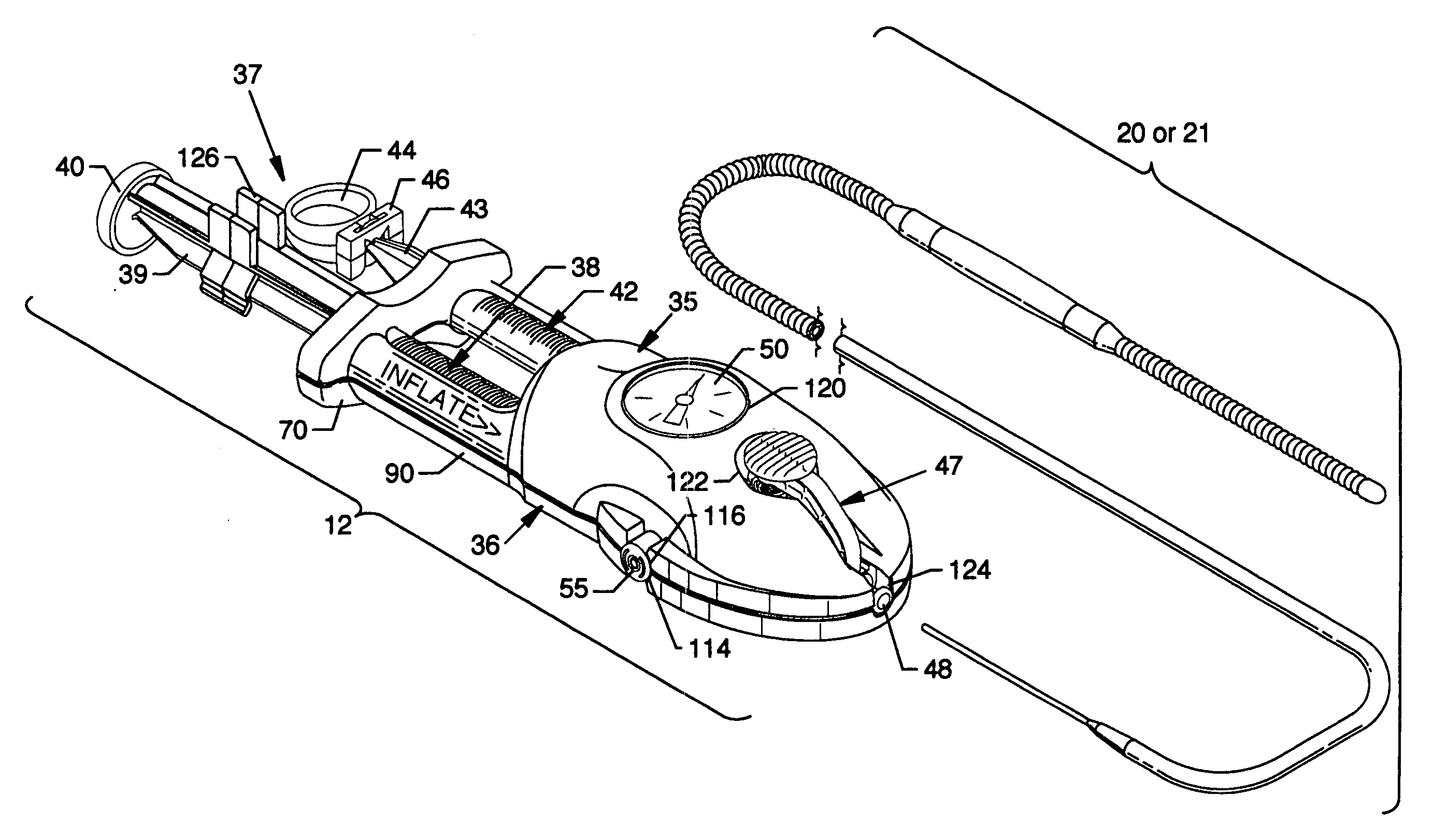

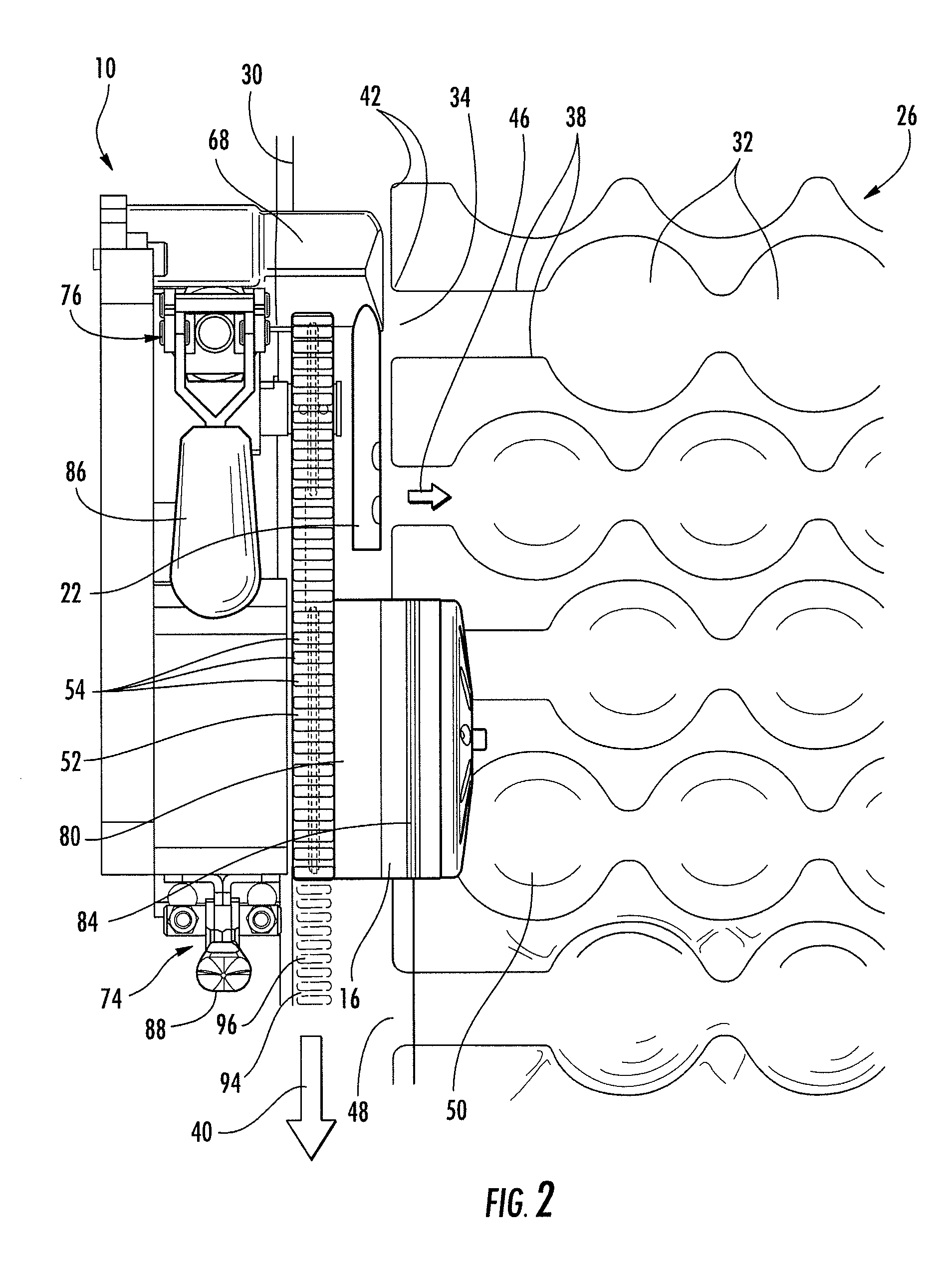

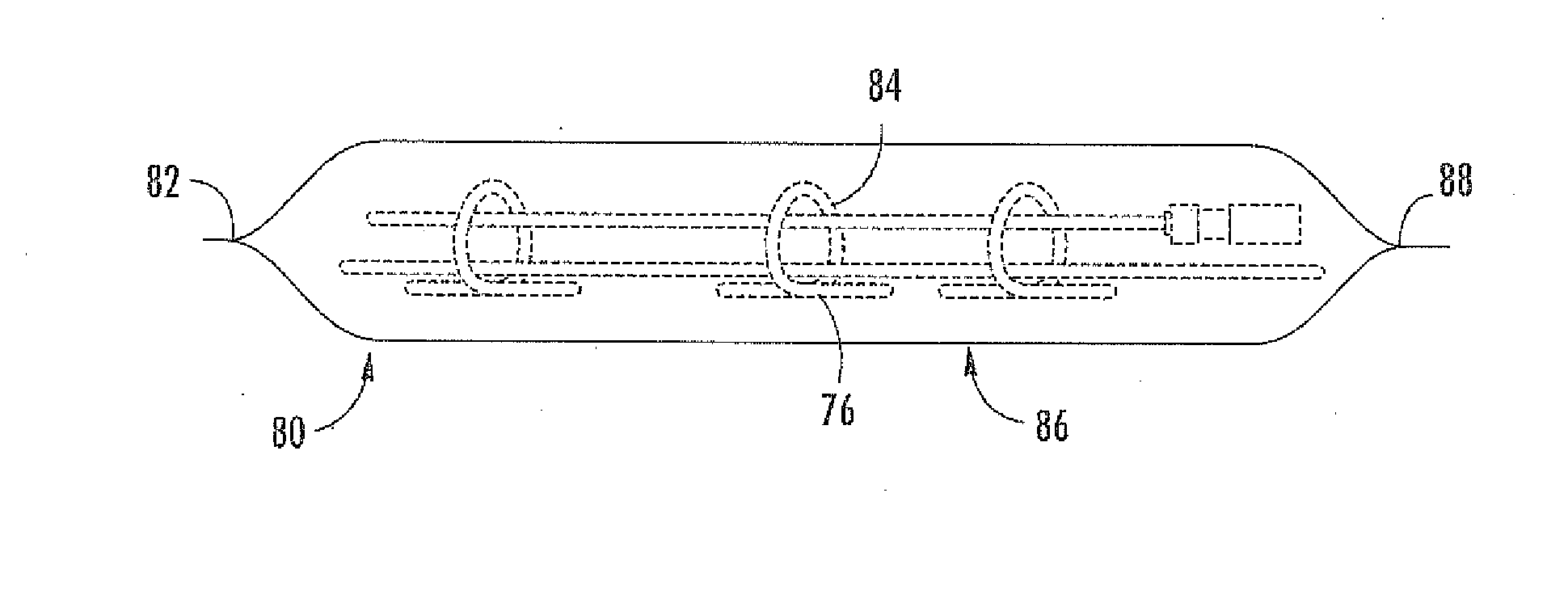

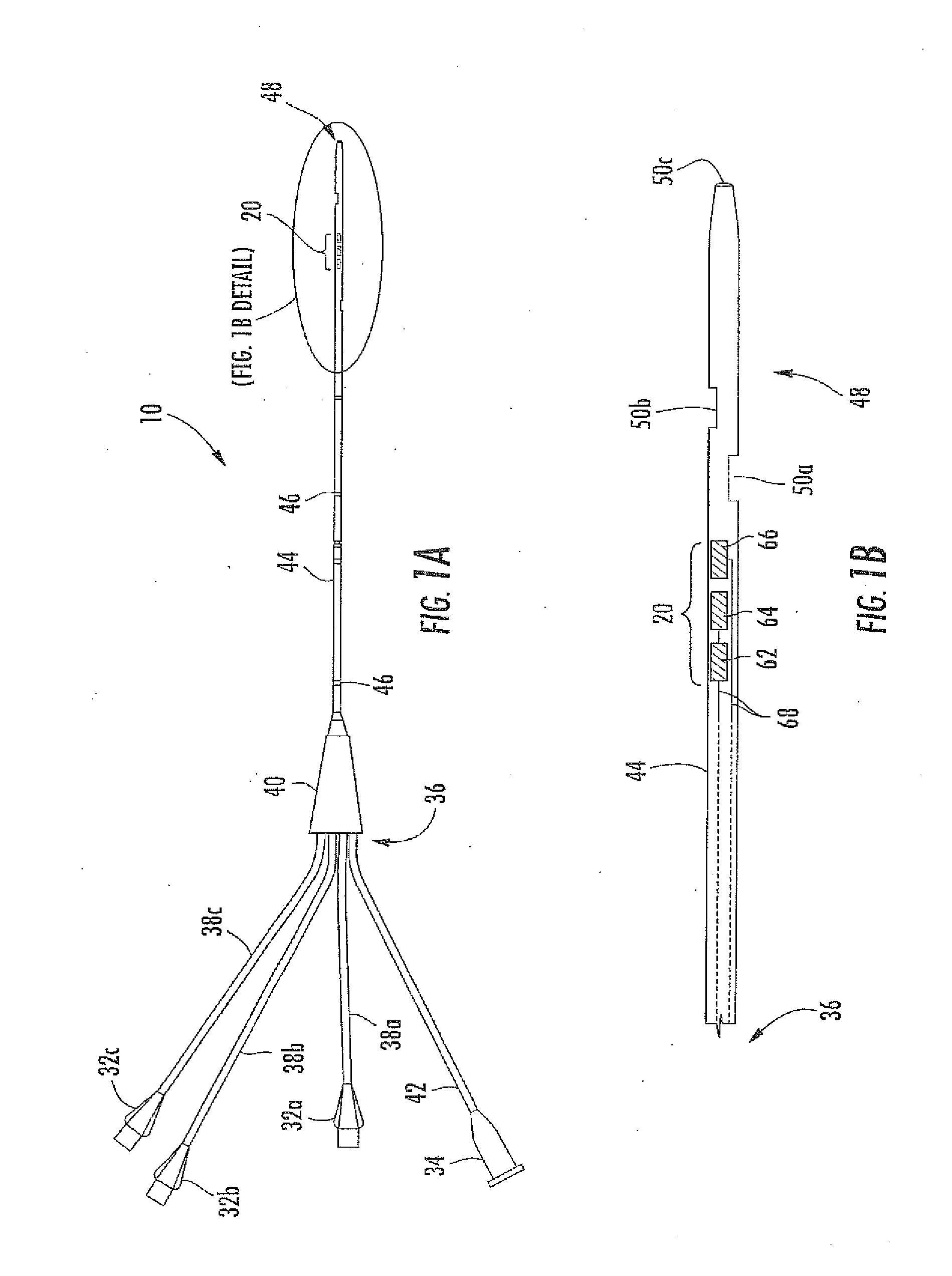

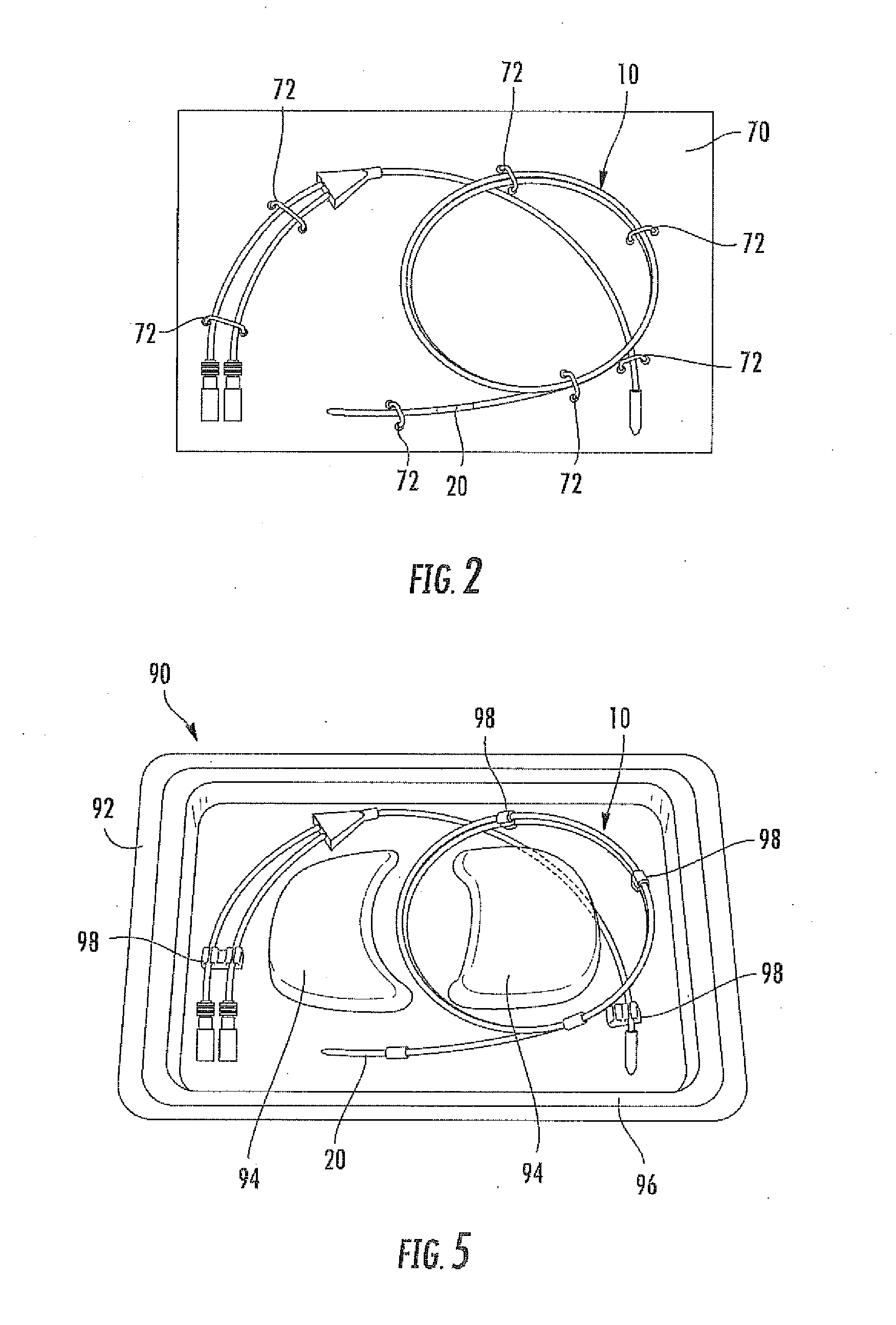

Occlusive guidewire system having an ergonomic handheld control mechanism prepackaged in a pressurized gaseous environment and a compatible prepackaged torqueable kink-resistant guidewire with distal occlusive balloon

An occlusive guidewire system having an ergonomic handheld control mechanism prepackaged in a pressurized gaseous environment and a compatible prepackaged torqueable kink-resistant guidewire with distal occlusive balloon. Convenient structure and overall mechanism for operation of a torqueable kink-resistant guidewire with a distal occlusive balloon, including evacuation and inflation control of the distal occlusive balloon, and sealing and severing of a crimpable inflation tube which is in communication with the occlusive balloon. Torqueable kink-resistant guidewires include centrally located structure which imparts robustness to the torqueable kink-resistant guidewires. An inflation lumen aligns within the torqueable kink-resistant guidewires for inflation of the occlusive balloon.

Owner:MEDRAD INC.

Apparatus for forming inflated packaging cushions

An inflation apparatus automatically inflates and seals a plurality of pockets preformed in a film web to form packaging cushions. As the film web is advanced, a stream of inflation gas is directed from an inflation port into each of the pockets. The steam of inflation gas is directed in a flow direction having a component in the direction of travel. A sealing mechanism is positioned as close as possible to the inflation port so that the opening of each pocket is almost entirely closed and sealed while the stream of inflation gas is directed into the pocket. As a result, it is possible to achieve more fully inflated packaging cushions on a consistent basis.

Owner:SEALED AIR U S

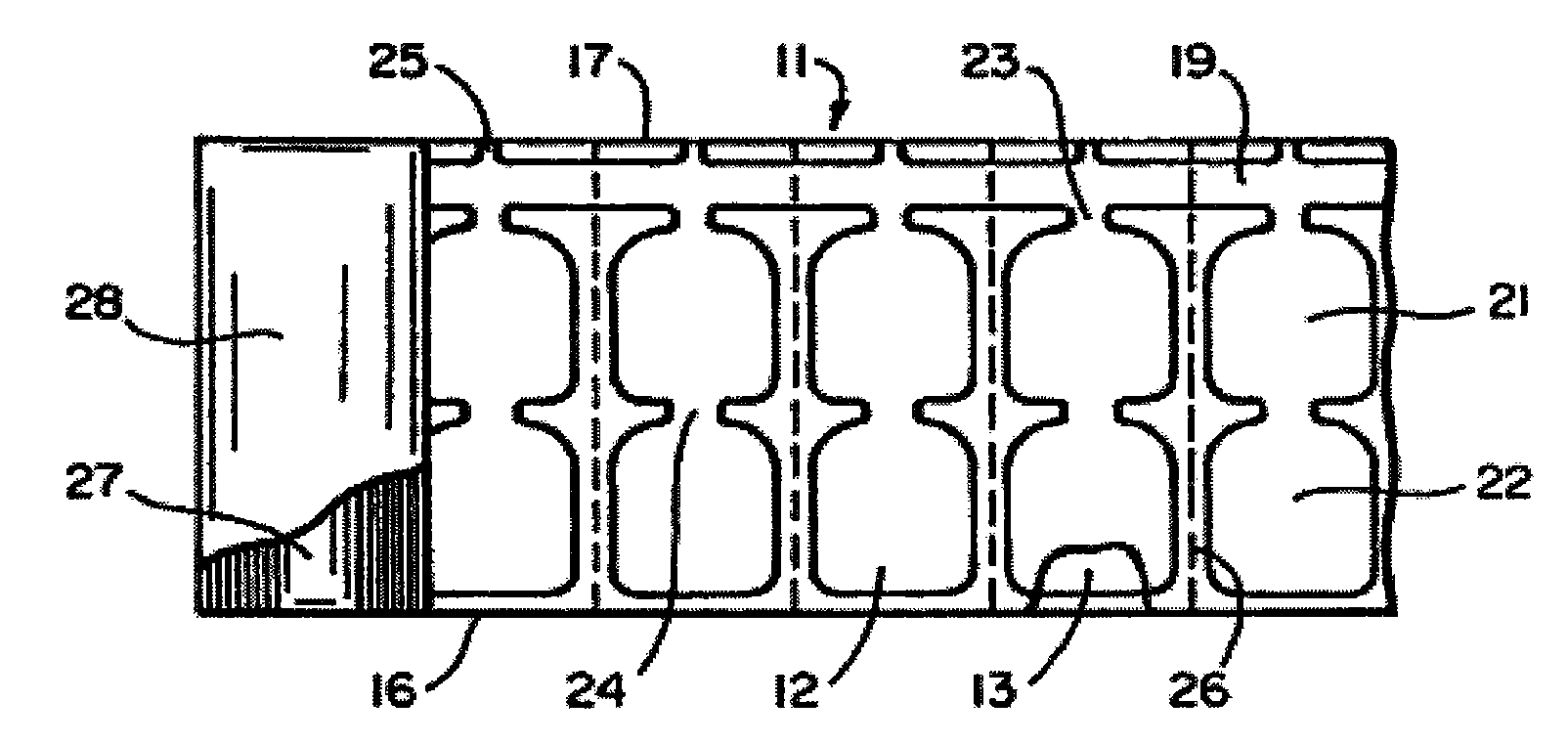

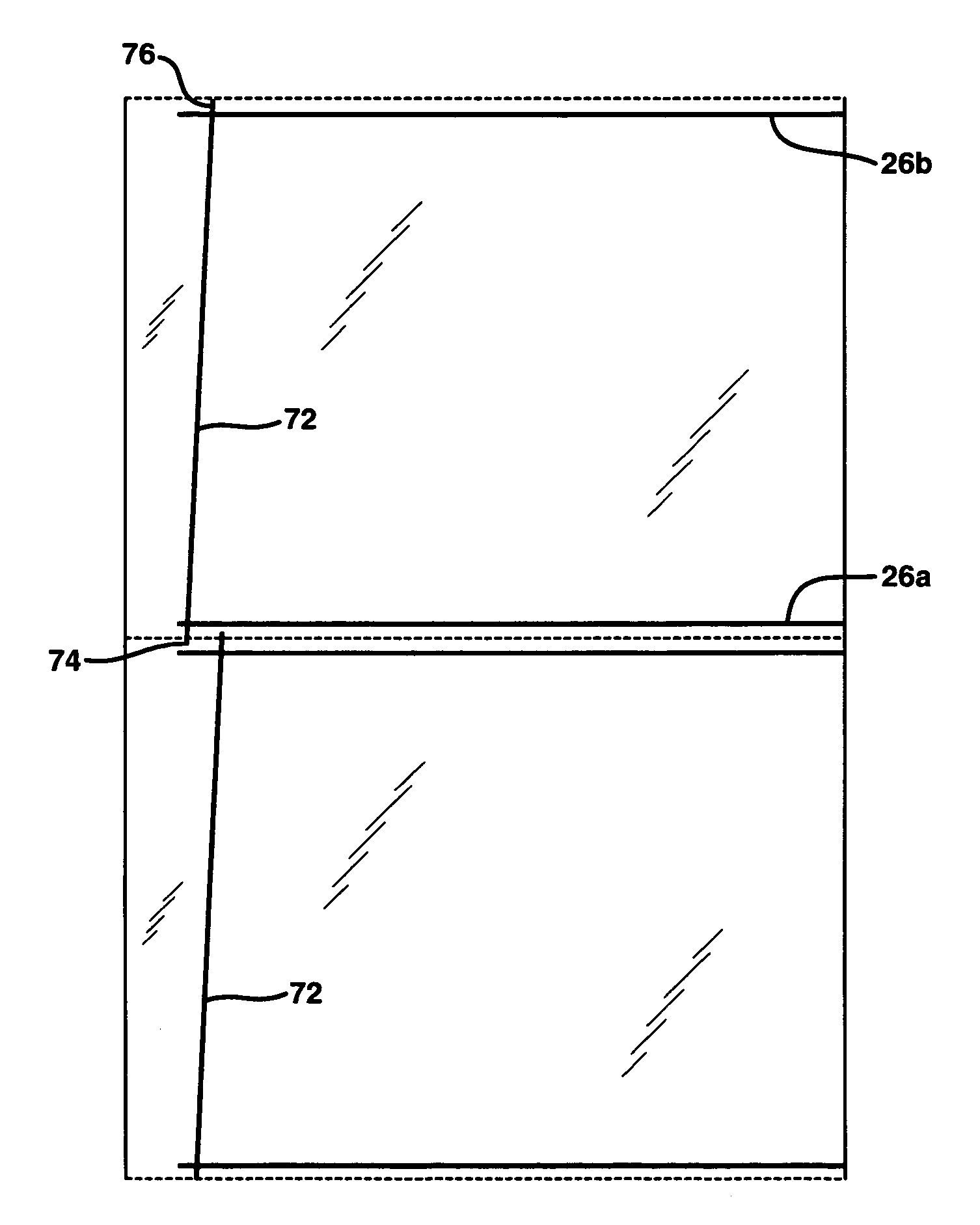

Apparatus and method for forming inflated chambers

An inflatable web, and method and apparatus for inflating the web, which generally includes two sheets having inner surfaces sealed to each other in a pattern defining a series of inflatable chambers of predetermined length, each of the chambers having at least one change in width over their length; an inflation port located at a proximal end of each chamber, the inflation ports being formed by intermittent seals between the sheets; and longitudinal flanges formed by a portion of each of the sheets that extend beyond the inflation ports and intermittent seals.

Owner:SEALED AIR CORP

Method and apparatus for pre-tearing strings of air-filled packing materials and the like

Owner:PREGIS INNOVATIVE PACKAGING

Machine for inflating and sealing an inflatable structure

ActiveUS20100251668A1Efficiently and quietly inflateFacilitate inflationCapsPaper/cardboard articlesEngineeringNozzle

A machine for inflating and sealing an inflatable structure having a longitudinal edge generally comprises a drive, an inflation nozzle, a sealing device, and a sheet engagement device. The machine may define an engaging assembly and an opposing assembly. The drive may be rotationally coupled to the sheet engagement device such that when the drive rotates, the engagement device also rotates. The sheet engagement device may comprise one or more engagement rollers which may have a plurality of teeth thereon. A first plurality of rollers and a second plurality of rollers comprising the engagement rollers may intermesh between a drive roller and a backing roller on the longitudinal edge of the inflatable structure. Thereby, the sheets of the inflatable structure may be engaged together and the length of the longitudinal edge may contract to facilitate inflation. The resulting inflated inflatable structure may comprise an embossed longitudinal edge.

Owner:SEALED AIR U S

Method and system for tank refilling

ActiveUS8783303B2Improve performanceLow costCapsCap application using vaccuumAnalytical equationsEngineering

Owner:HONDA MOTOR CO LTD

Inflatable mailer, apparatus and method for preparing the same

InactiveUS7621104B2Prevent escapeEasy to inflateEnvelopes/bags making machineryCapsEngineeringNozzle

Owner:SEALED AIR U S

Machine for inflating and sealing an inflatable structure

ActiveUS8991141B2Efficiently and quietly inflateFacilitate inflationCapsPaper/cardboard articlesNozzleSheet material

A machine for inflating and sealing an inflatable structure having a longitudinal edge generally comprises a drive, an inflation nozzle, a sealing device, and a sheet engagement device. The machine may define an engaging assembly and an opposing assembly. The drive may be rotationally coupled to the sheet engagement device such that when the drive rotates, the engagement device also rotates. The sheet engagement device may comprise one or more engagement rollers which may have a plurality of teeth thereon. A first plurality of rollers and a second plurality of rollers comprising the engagement rollers may intermesh between a drive roller and a backing roller on the longitudinal edge of the inflatable structure. Thereby, the sheets of the inflatable structure may be engaged together and the length of the longitudinal edge may contract to facilitate inflation. The resulting inflated inflatable structure may comprise an embossed longitudinal edge.

Owner:SEALED AIR U S

Method of Packaging and Package for Sensors

InactiveUS20100293892A1Avoid damageKeep sterileCapsCap application using vaccuumHermetic packagingEngineering

There are provided methods of packaging and packages that prevent damage of the package contents while maintaining sterility and that limit the negative effects of sterilization on sensors such as enzyme sensors. A method of packaging an enzyme sensor includes providing an enzyme sensor such as a glucose oxidase sensor in a gas impermeable package comprising one or more of oxygen and water, removing a significant portion of the oxygen and water present in the package, and sealing the package. The resulting package comprises the enzyme sensor in an atmosphere that is substantially free of oxygen and water. The package can also include a pressure indicator that indicates when the package has exceeded a predetermined pressure.

Owner:EDWARDS LIFESCIENCES CORP

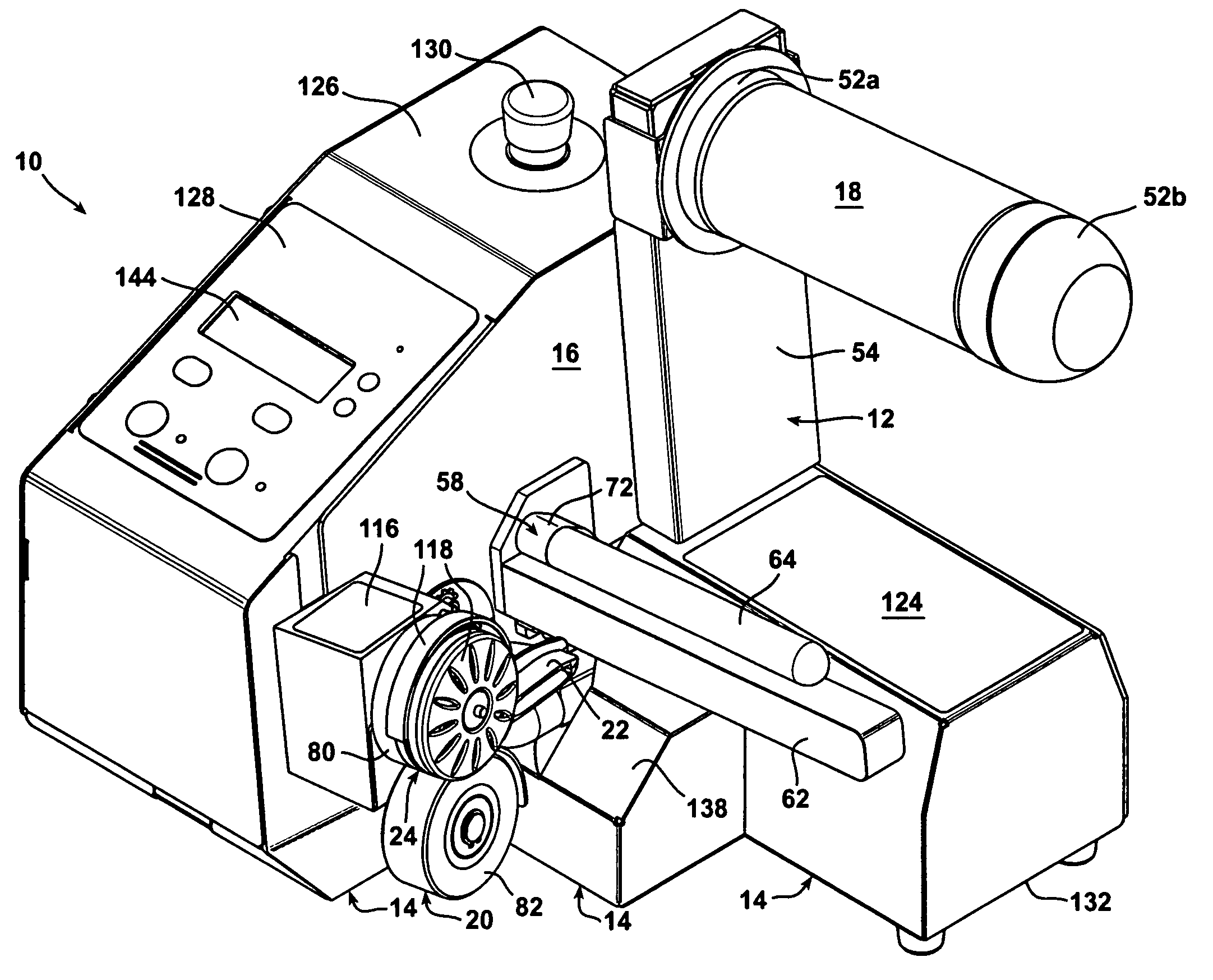

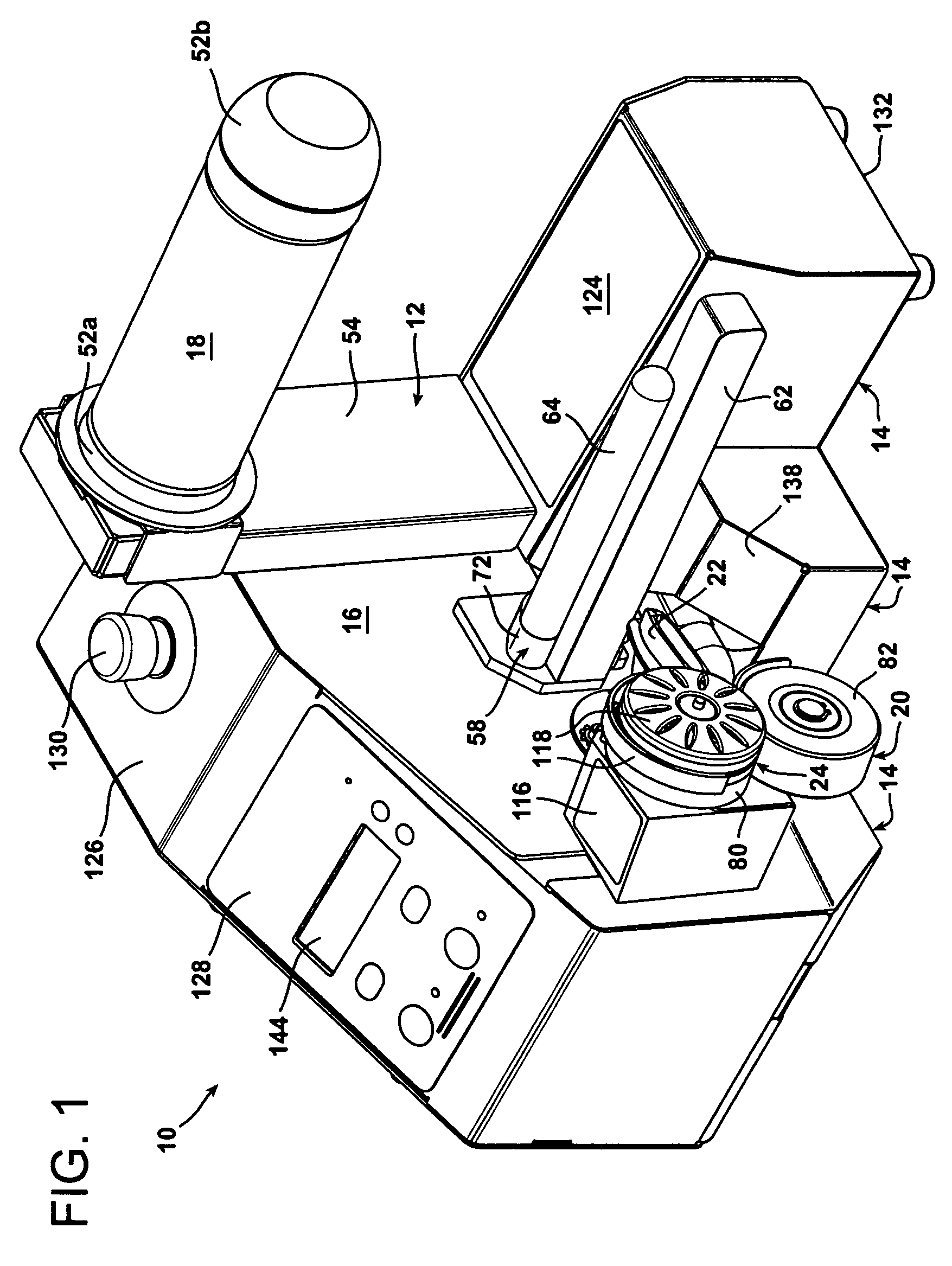

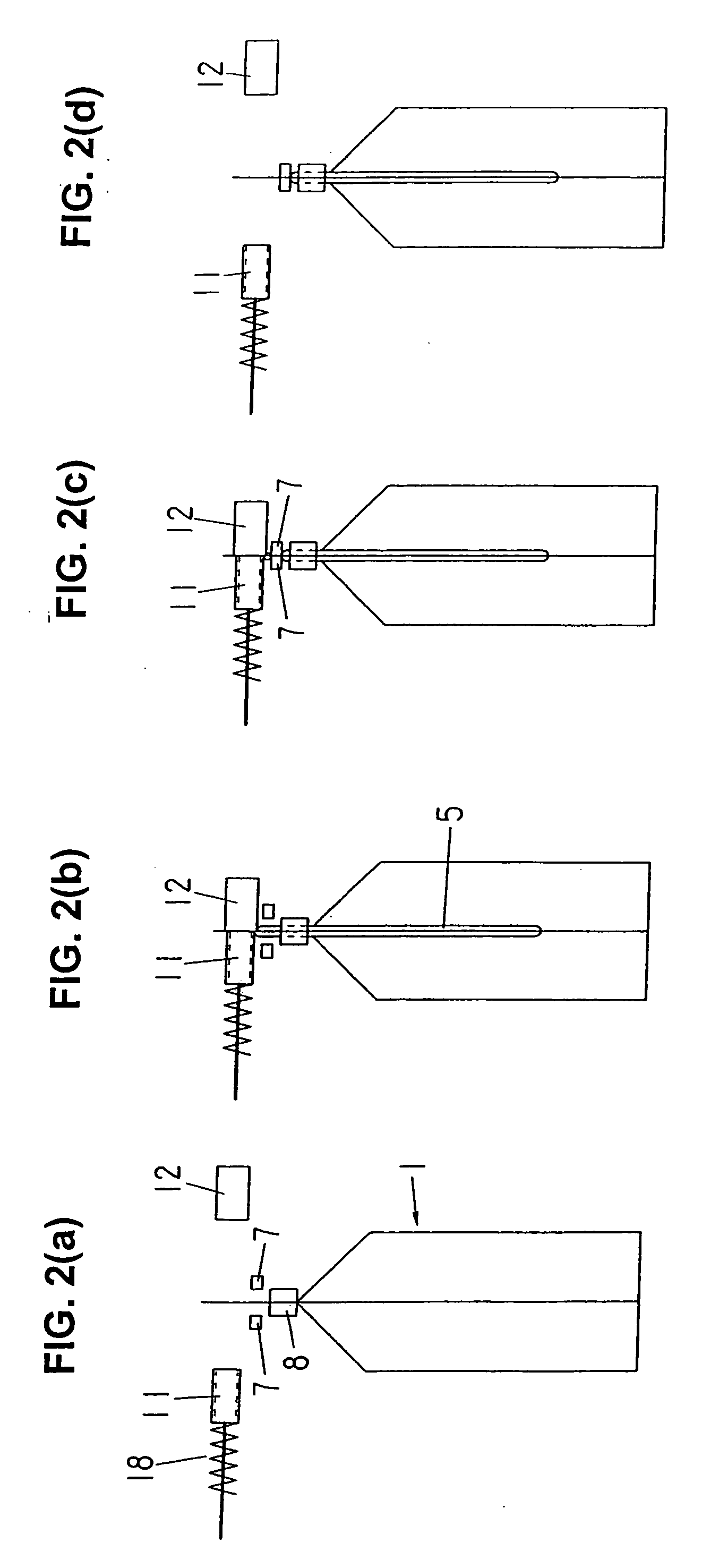

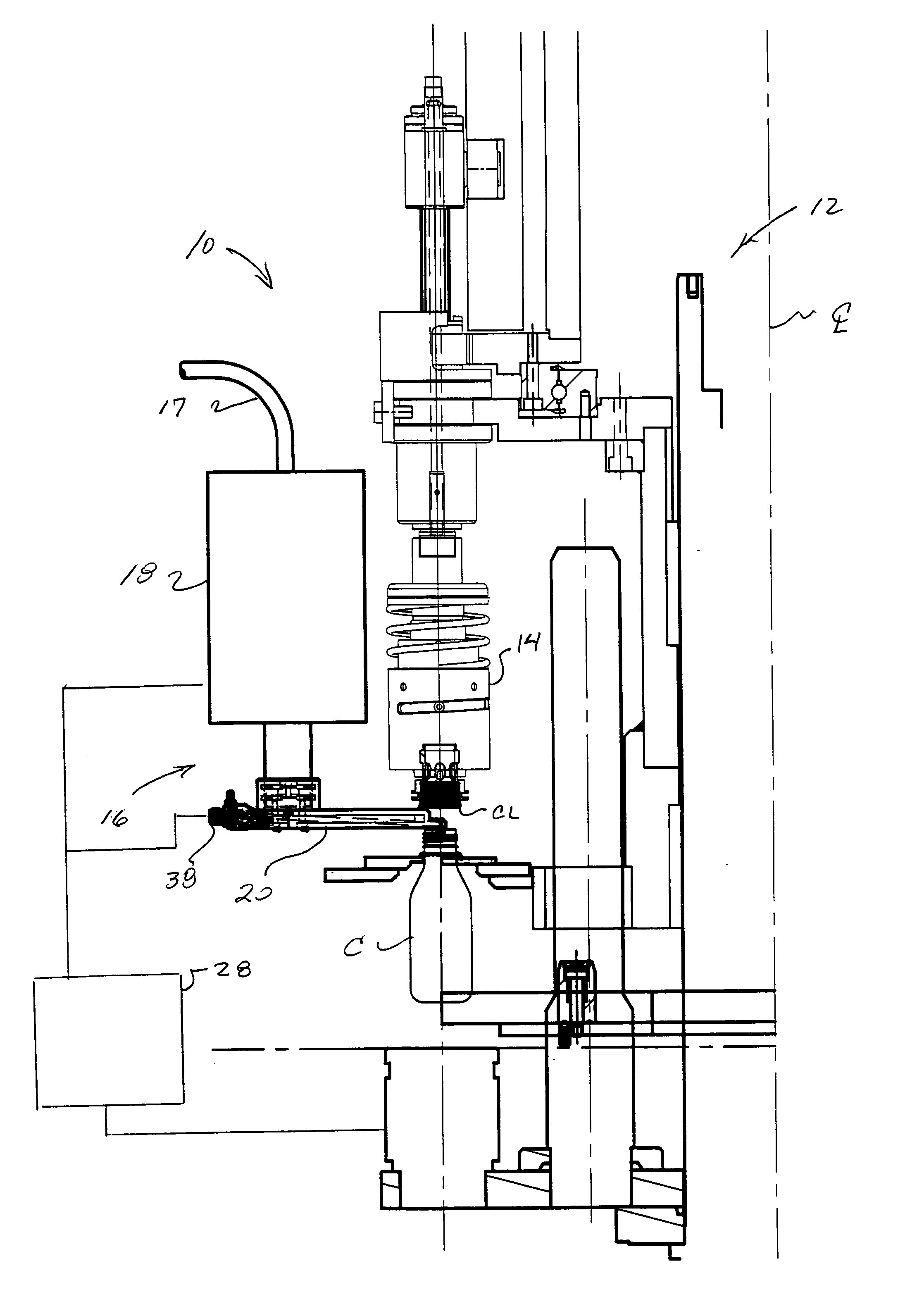

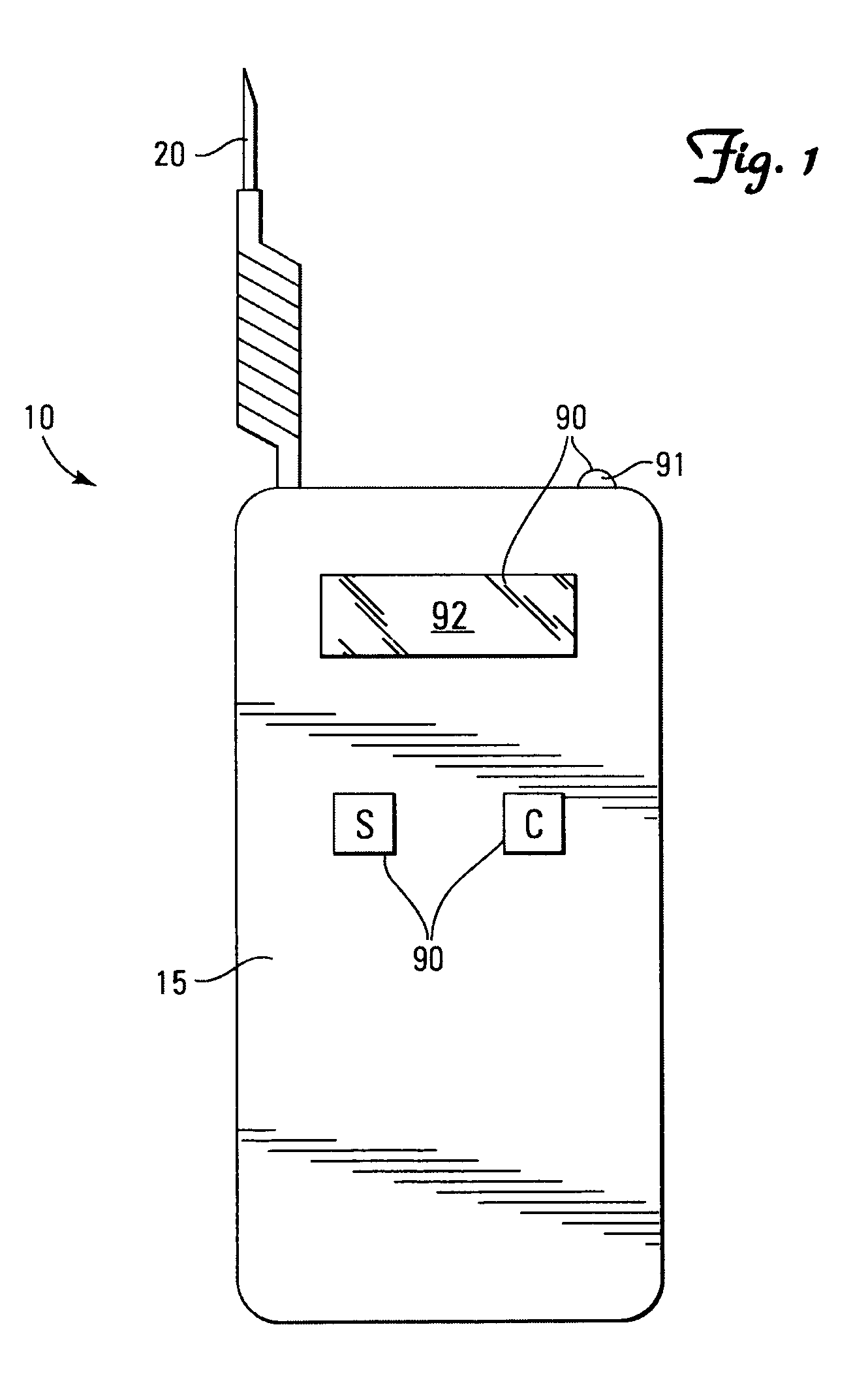

Method and Apparatus for Sterilization

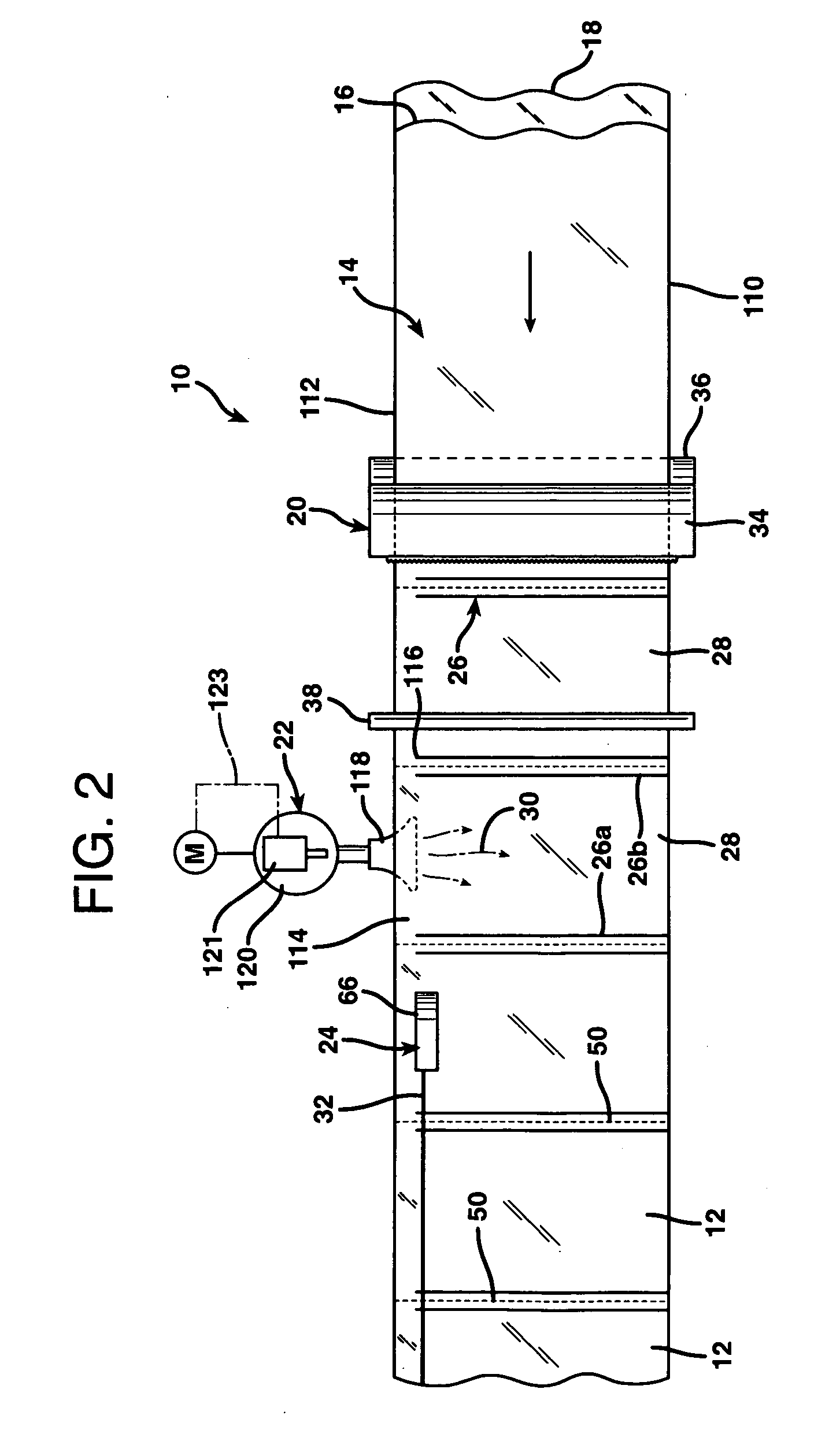

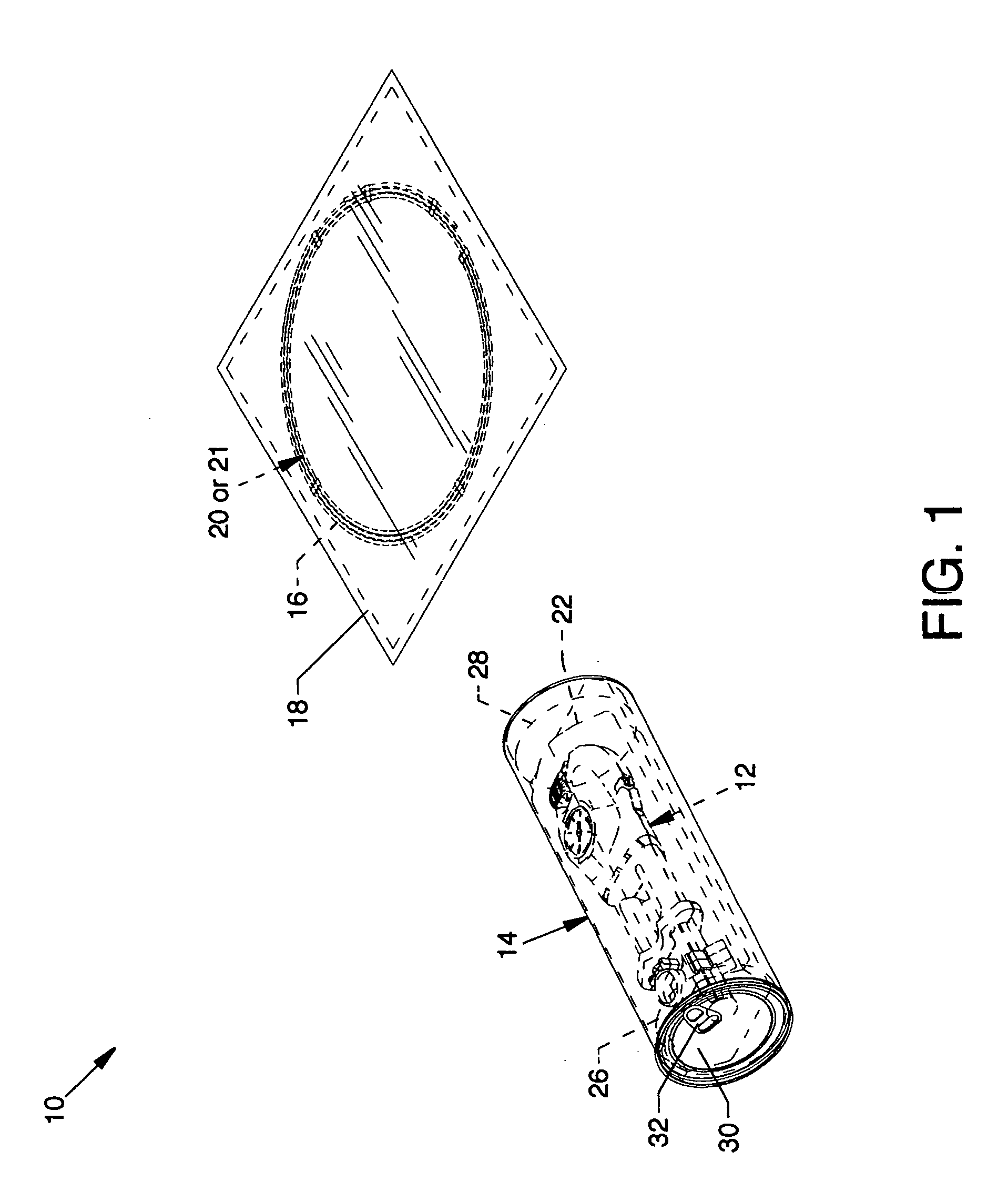

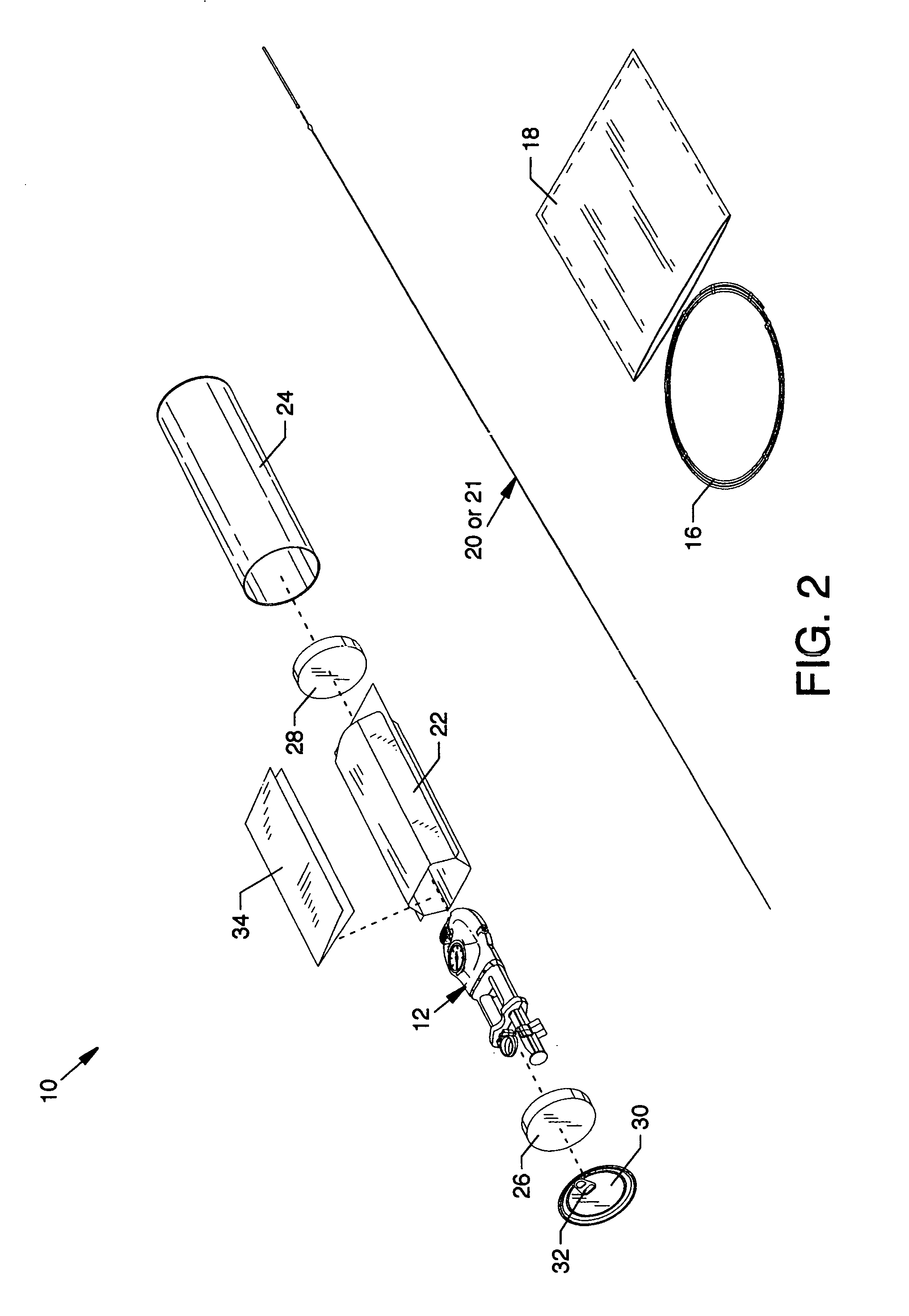

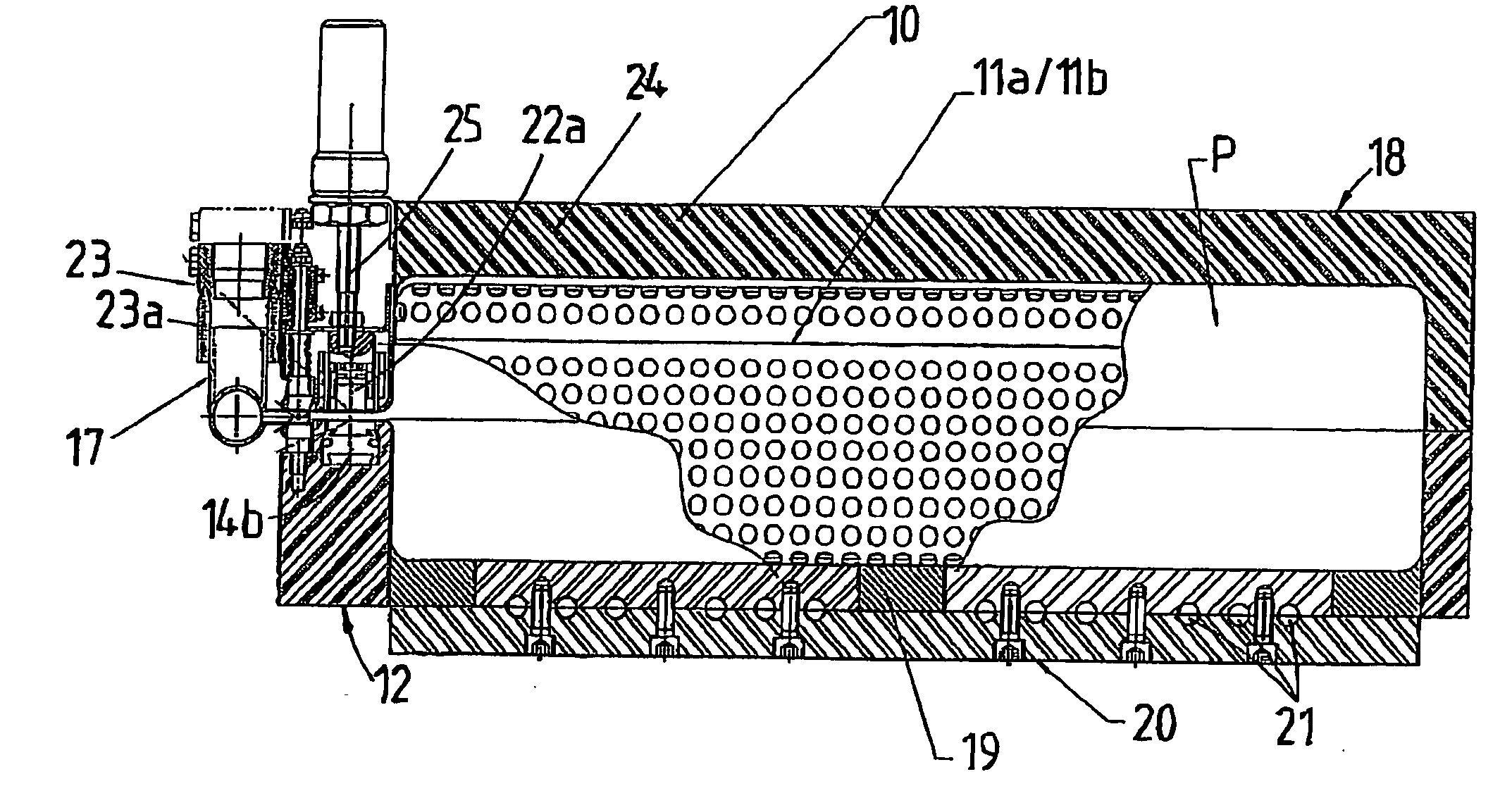

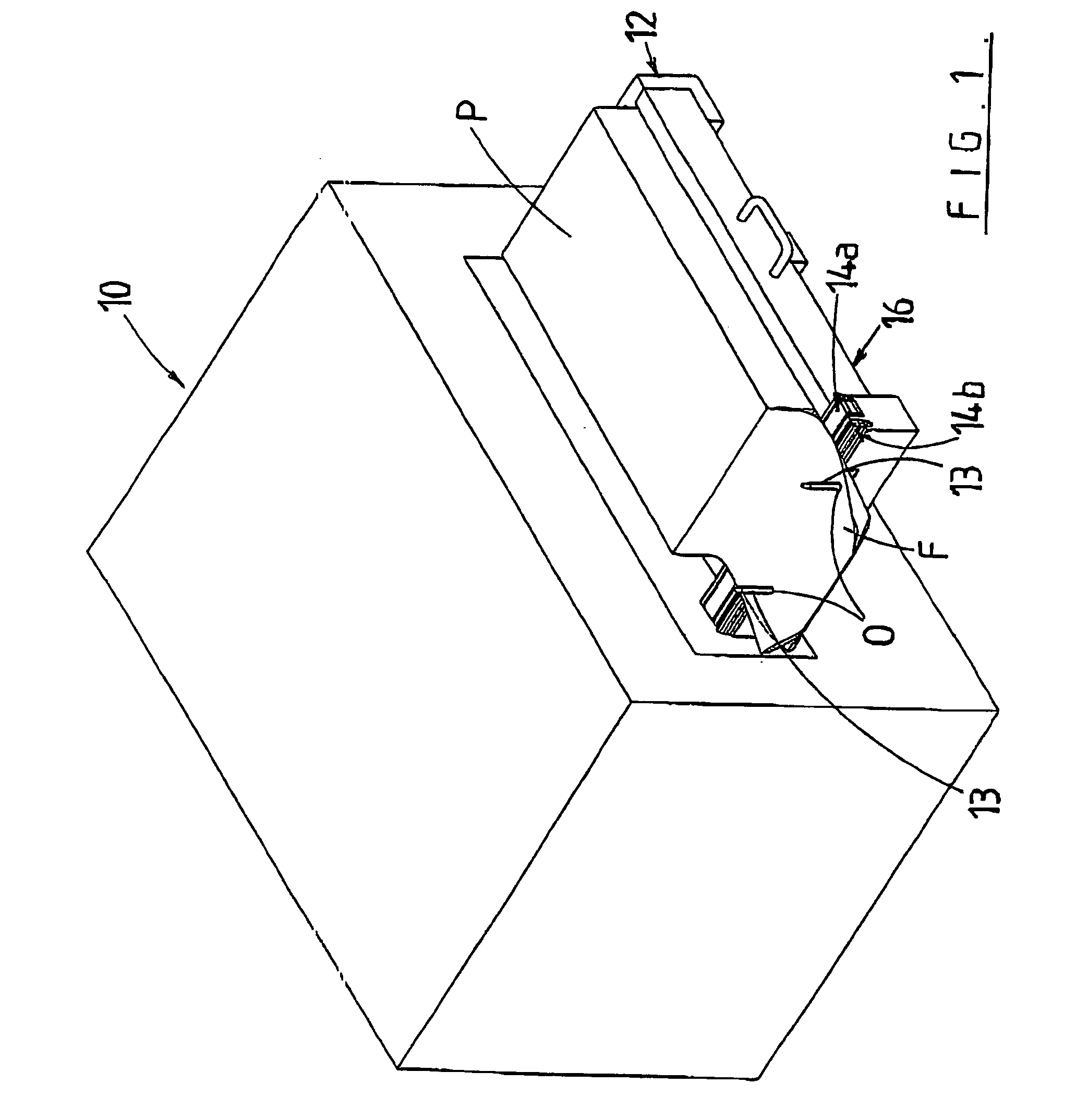

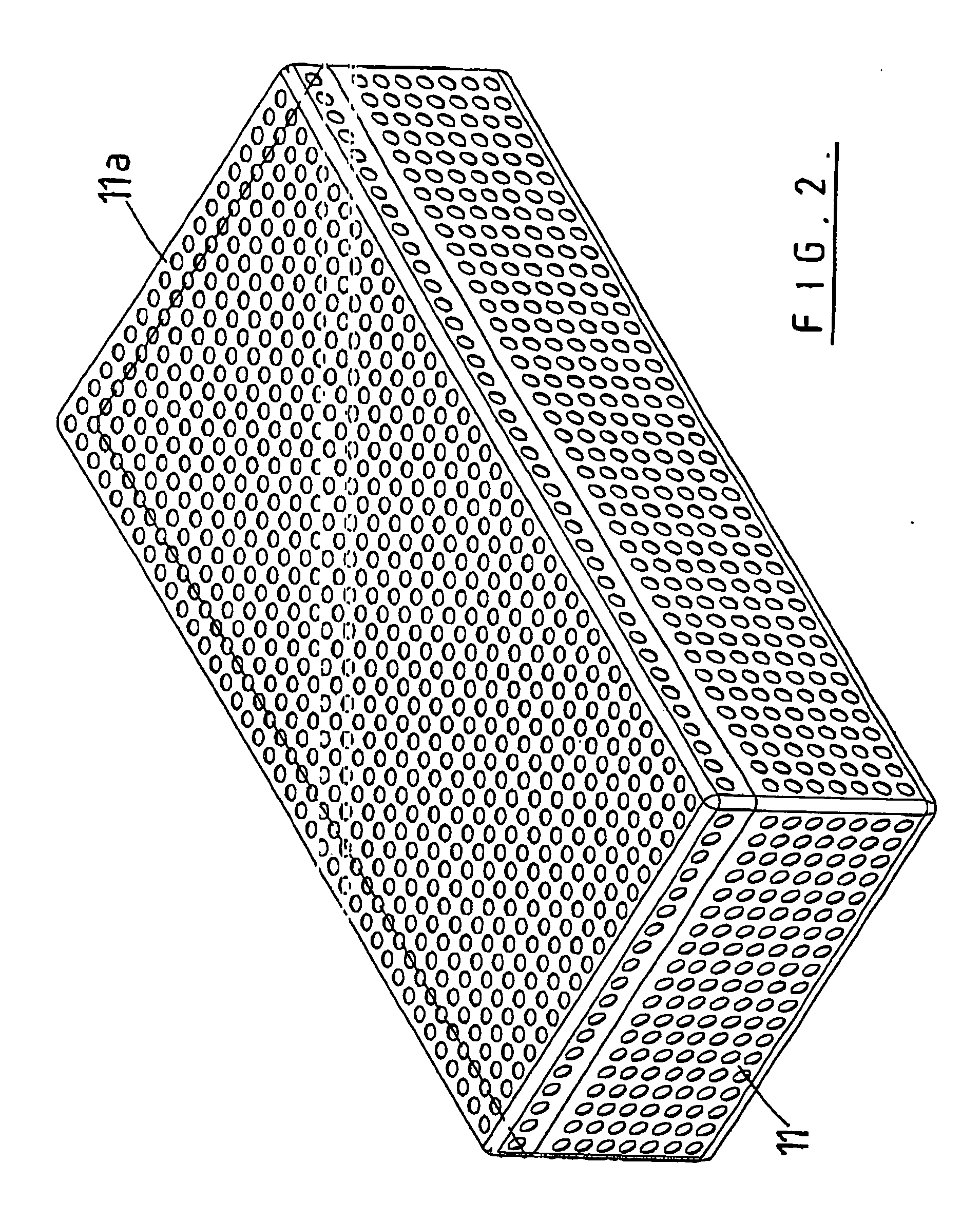

ActiveUS20090217626A1Service degradationImprove processing efficiencyCapsCap application using vaccuumMechanical engineeringSnorkel diving

A method and apparatus for sterilization in which items to be sterilized are placed in an impervious sealable package and the sterilization process is carried out within the package. The apparatus (10) includes a cabinet (18) in which a package (P) preferably with a carrier (11) located within, can be positioned. A snorkel (17) is inserted into the package (P) and via connector (23) vacuum, pressure and sterilant can be applied to the interior of the package (P). A sealing arrangement (14b, 22b) can seal the package closed after the sterilization process has been completed.

Owner:MERCER TECH

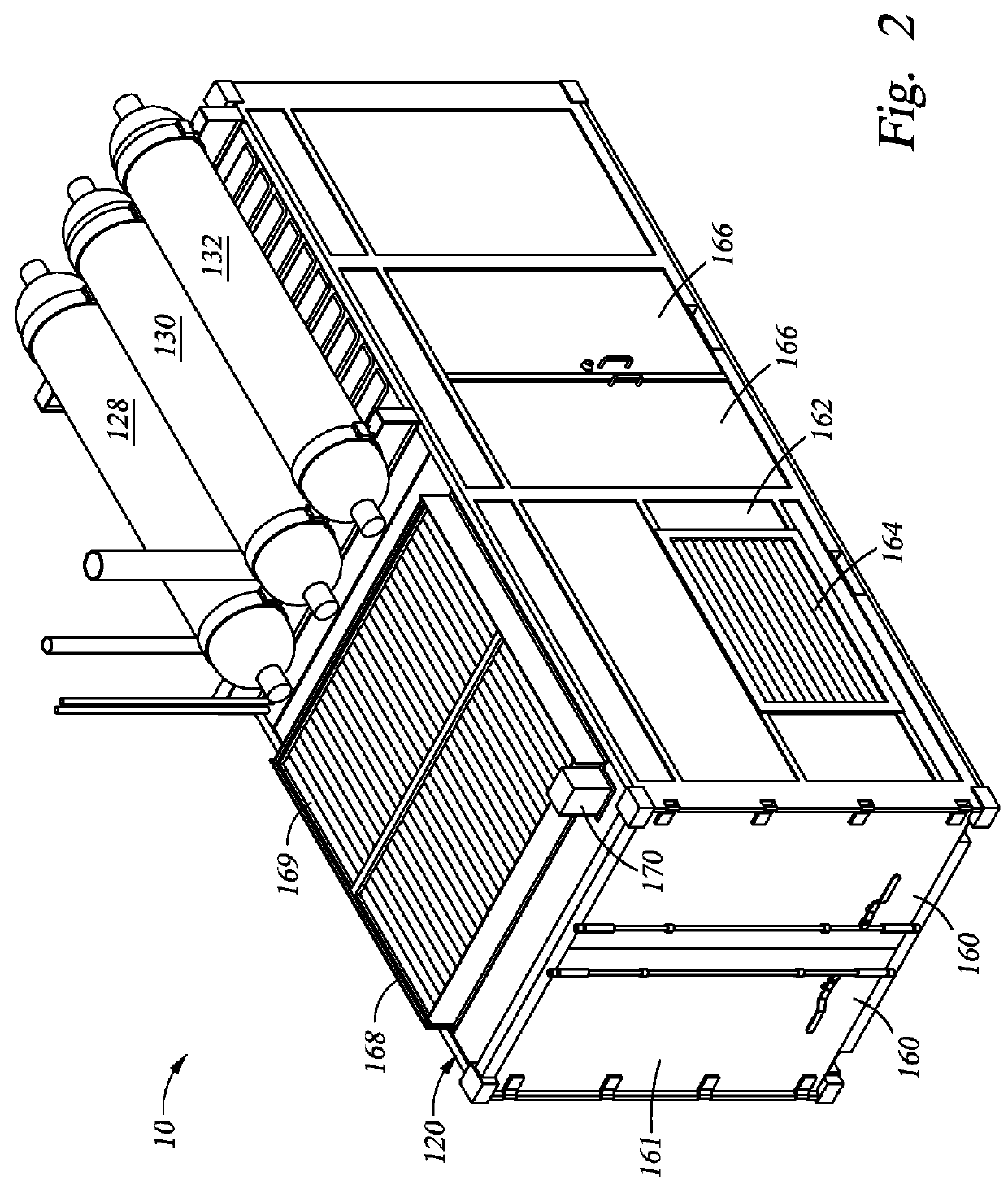

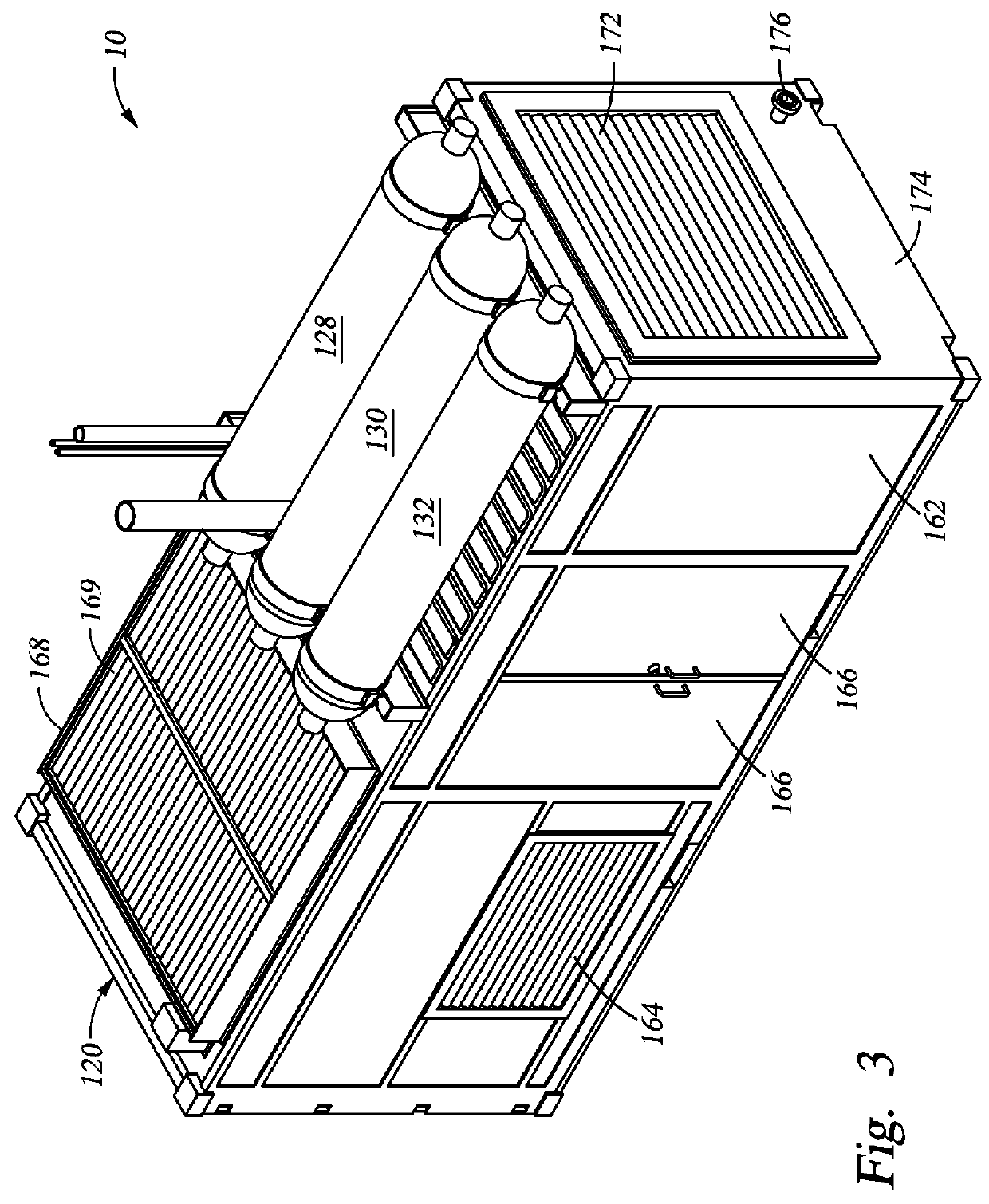

Modular compressed natural gas system

A compression system is disposed in a container and shipped to a location having a supply of natural gas. The compression system connects to the natural gas supply, compresses gas from the supply, and provides compressed gas to a consumer. The container, which can be a standardized ISO shipping container, is fitted with removable vents at designated locations. Strategic positioning of compression system components in combination with the removable vents allows for ready access to the compression system for repair and maintenance.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com