Patents

Literature

498results about How to "Easy to inflate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

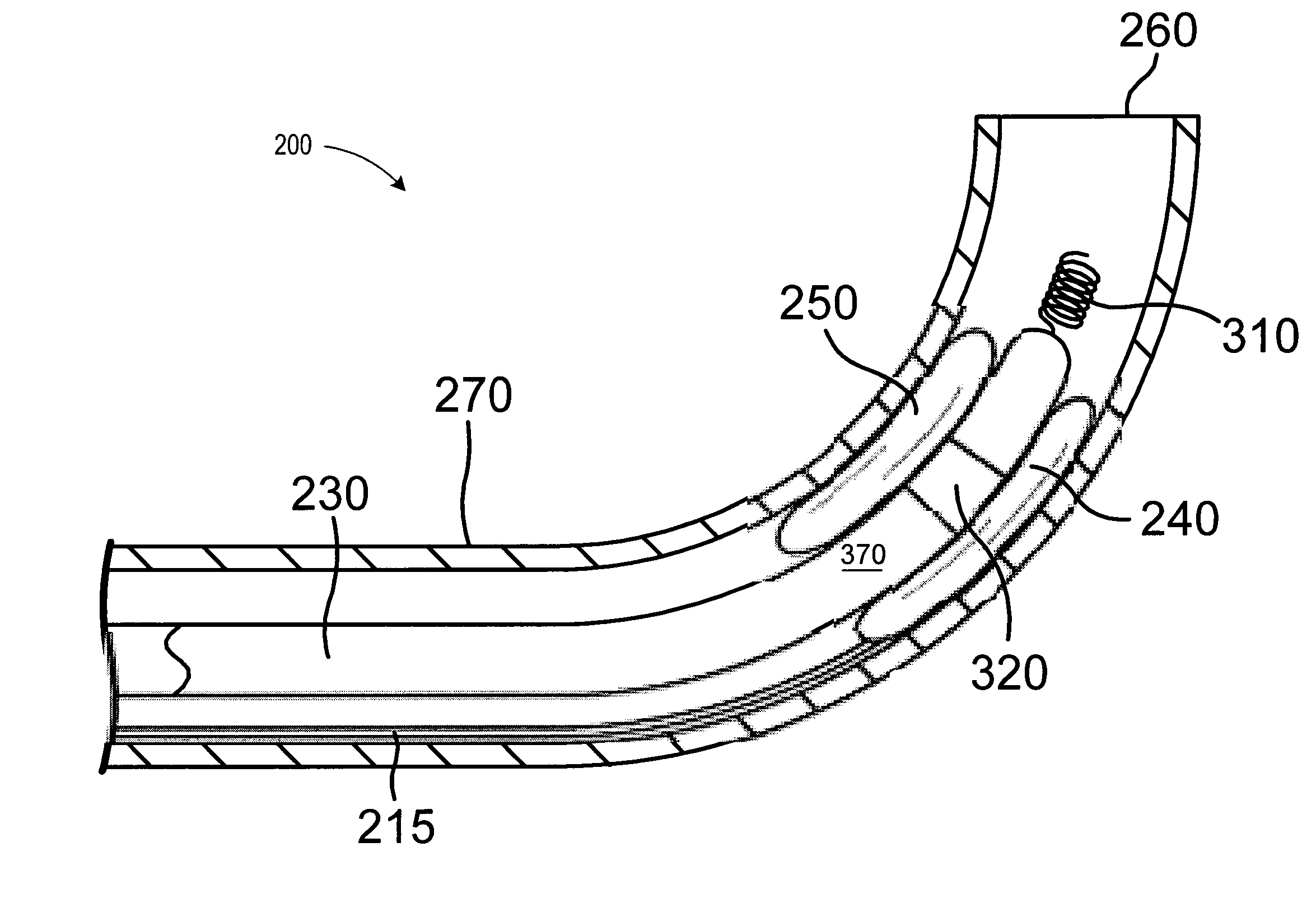

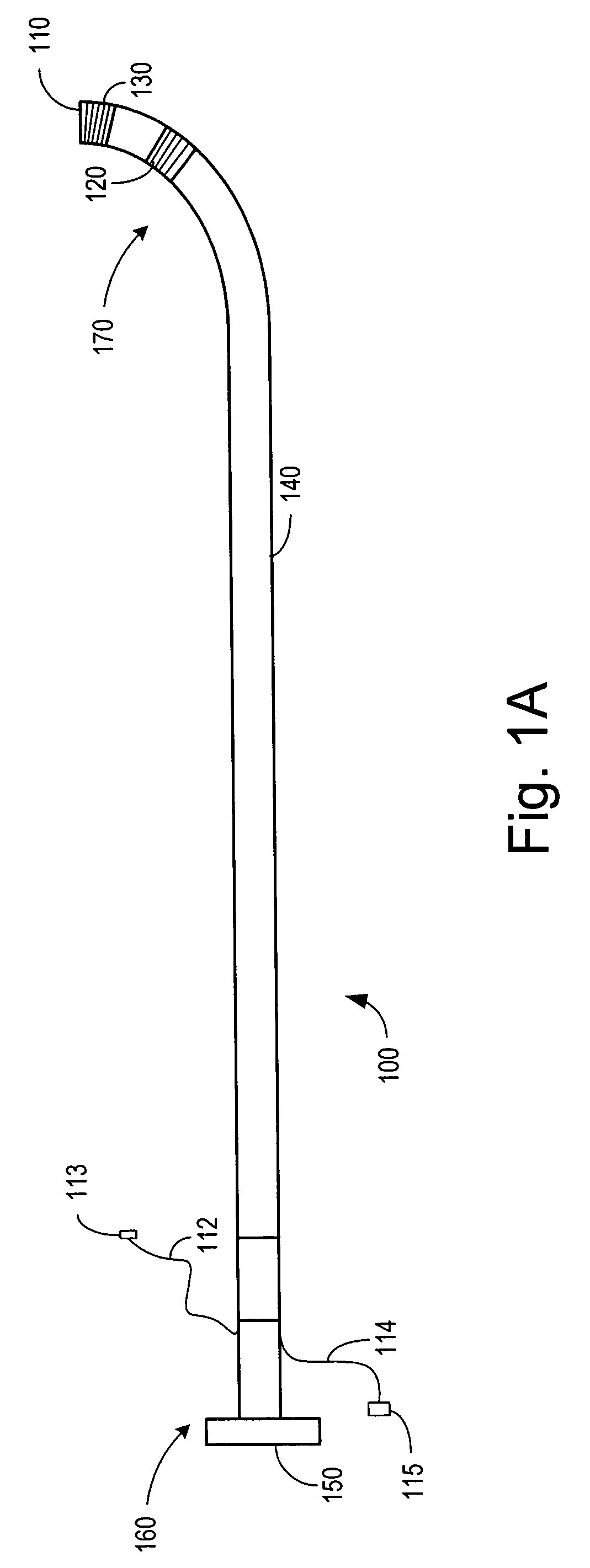

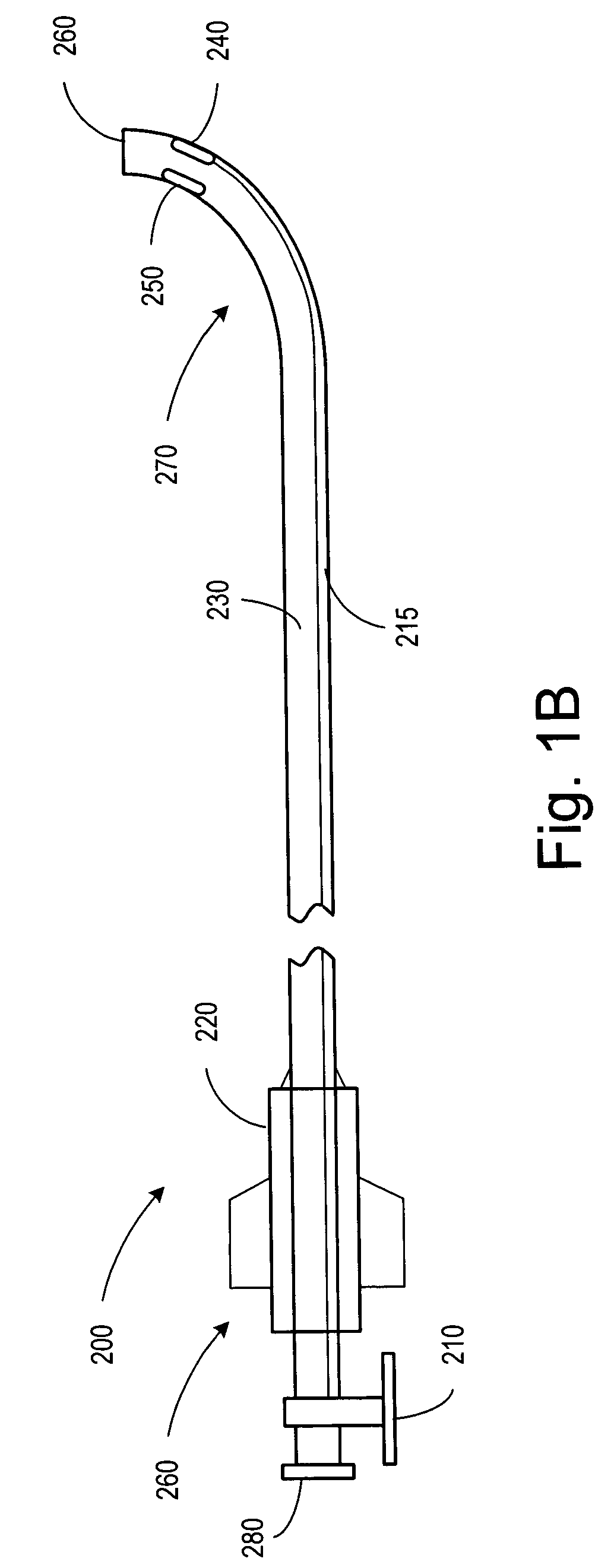

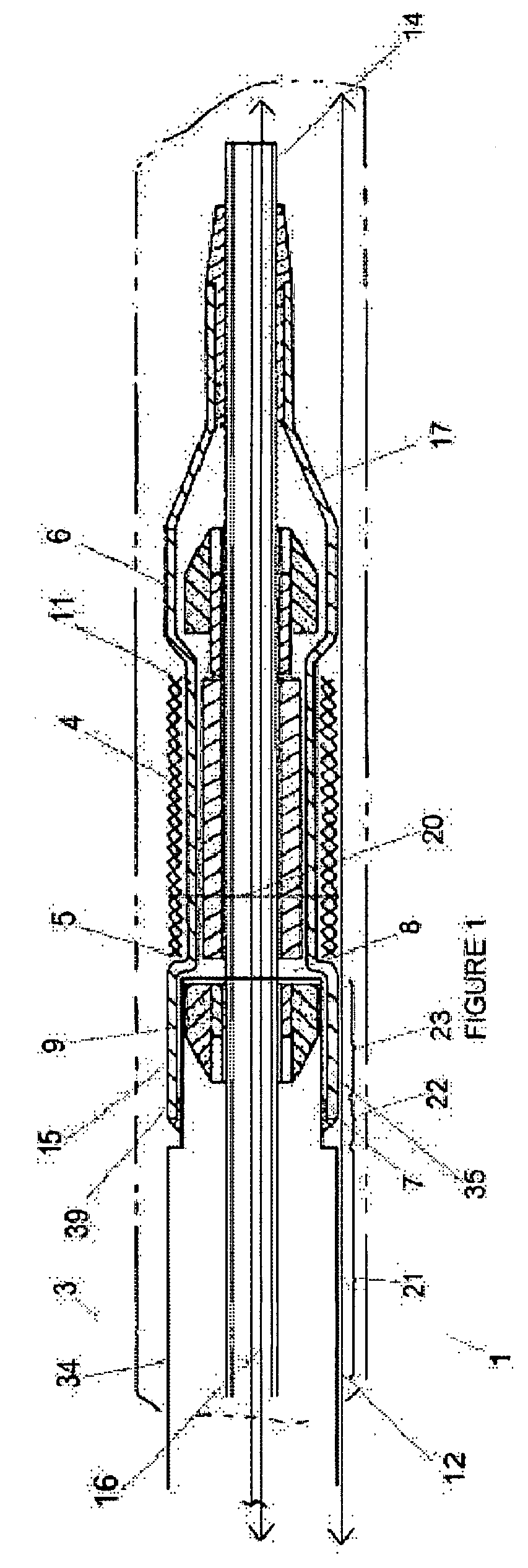

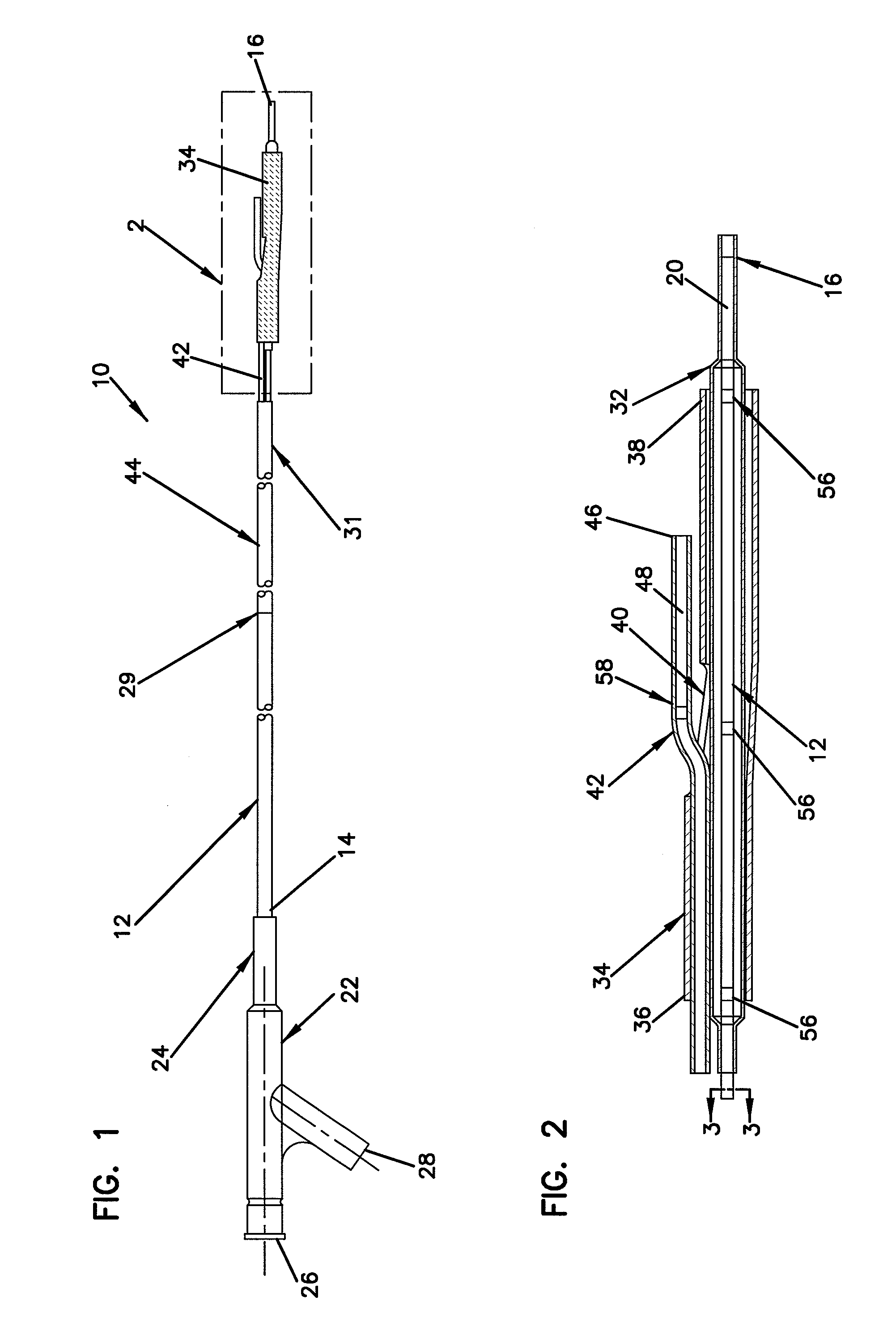

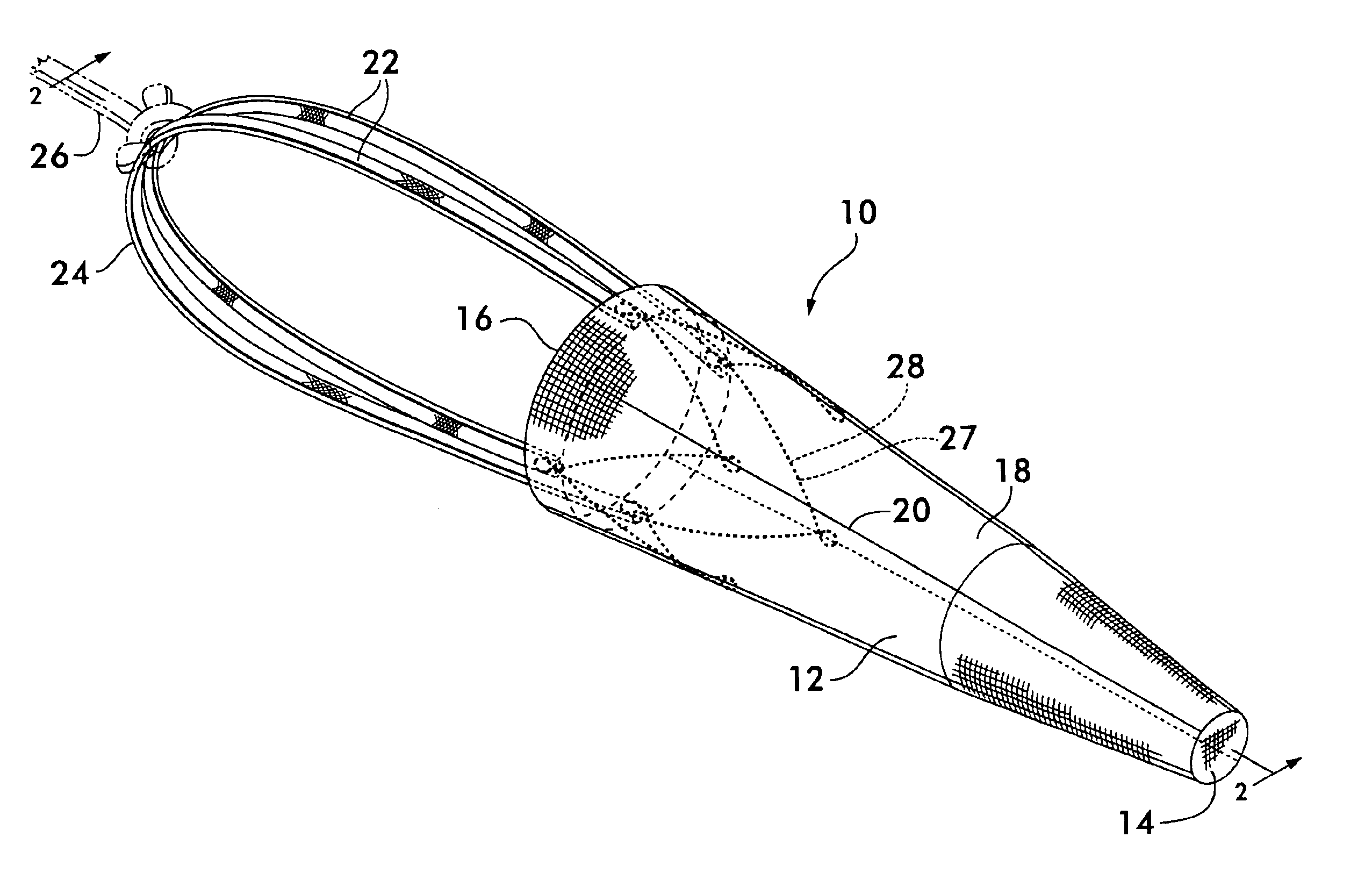

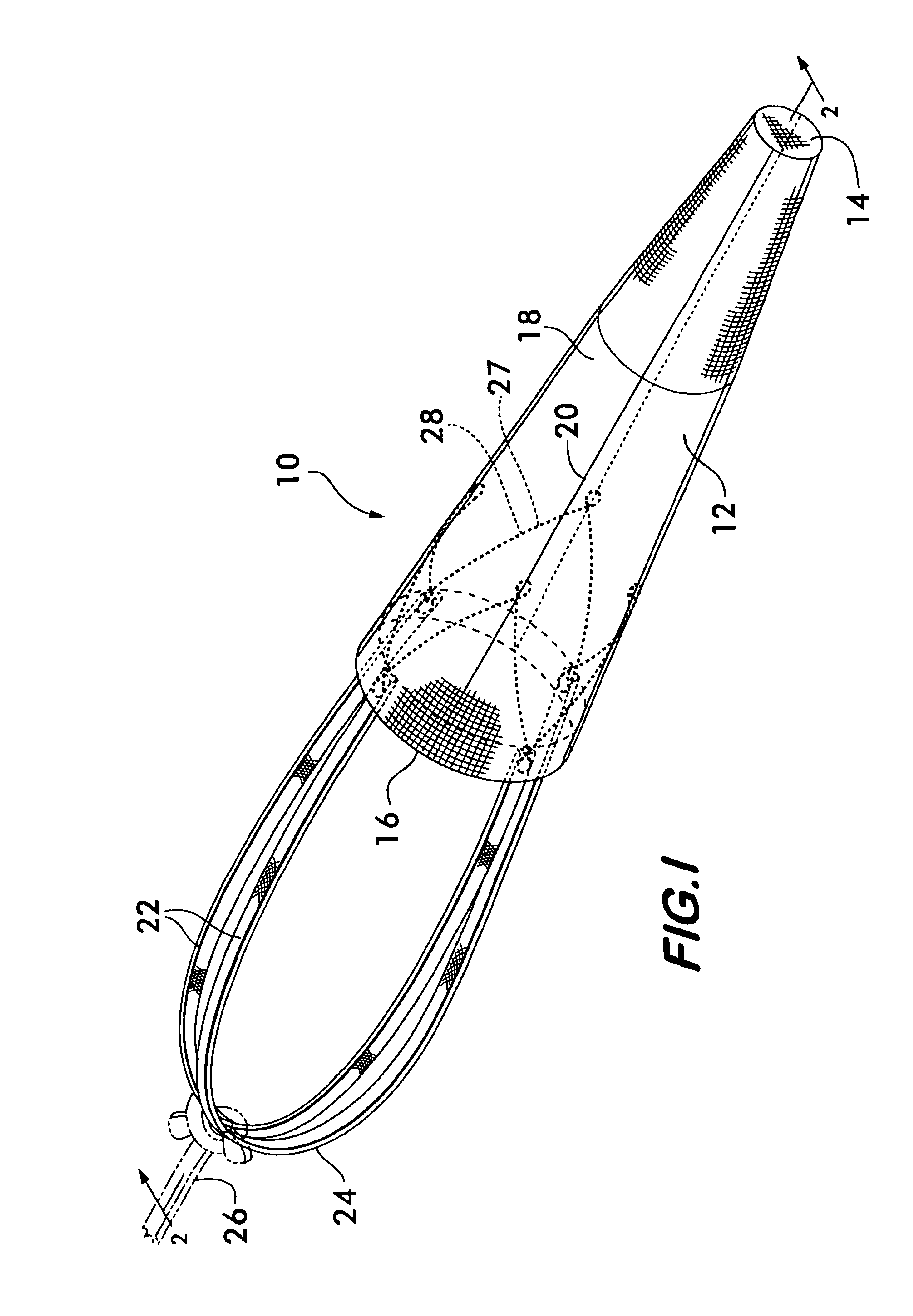

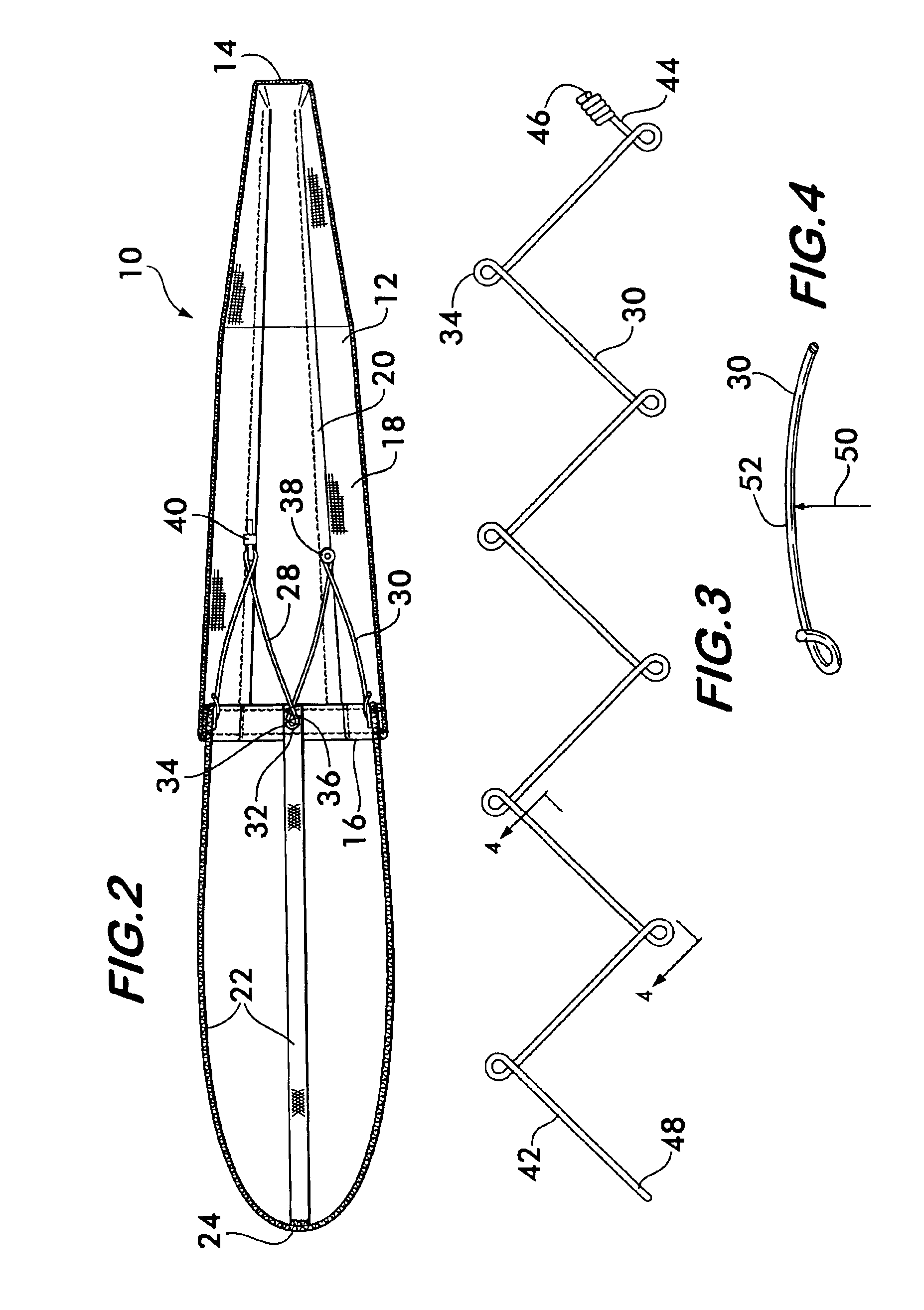

Catheter lead placement system and method

InactiveUS7035680B2Facilitate grasping and releasePrevent movementElectrocardiographyTransvascular endocardial electrodesBalloon catheterLead Placement

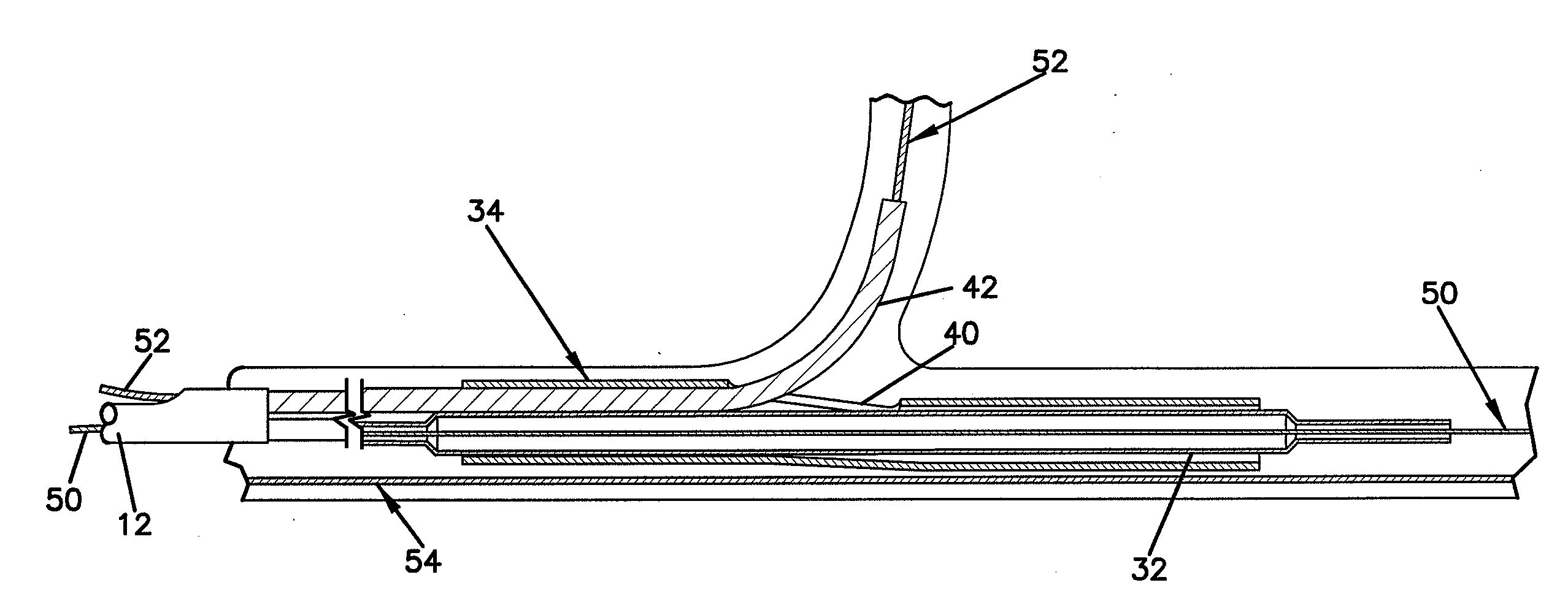

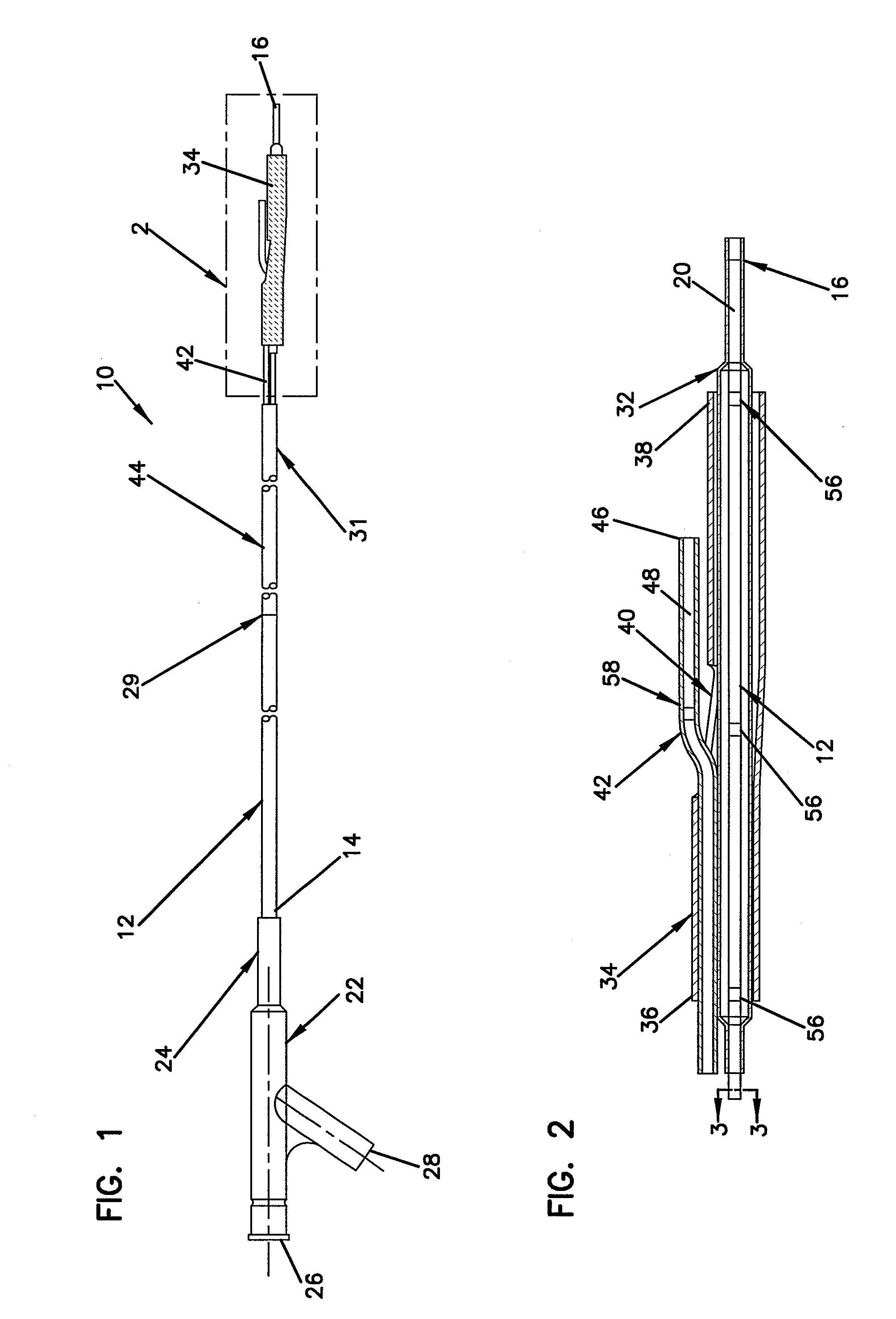

A catheter system includes a mapping catheter having an open lumen and a mapping arrangement provided at a distal end of the mapping catheter. A balloon catheter is movably disposed within the open lumen of the mapping catheter. The balloon catheter has an open lumen dimensioned to receive a lead. A balloon arrangement is provided at a distal end of the balloon catheter and inflatable with an inflation mechanism provided at a proximal end of the balloon catheter. The balloon arrangement is dimensioned to prevent movement of the lead upon inflation of the balloon arrangement, and to permit movement of the lead within the open lumen of the balloon catheter upon deflation of the balloon arrangement.

Owner:CARDIAC PACEMAKERS INC

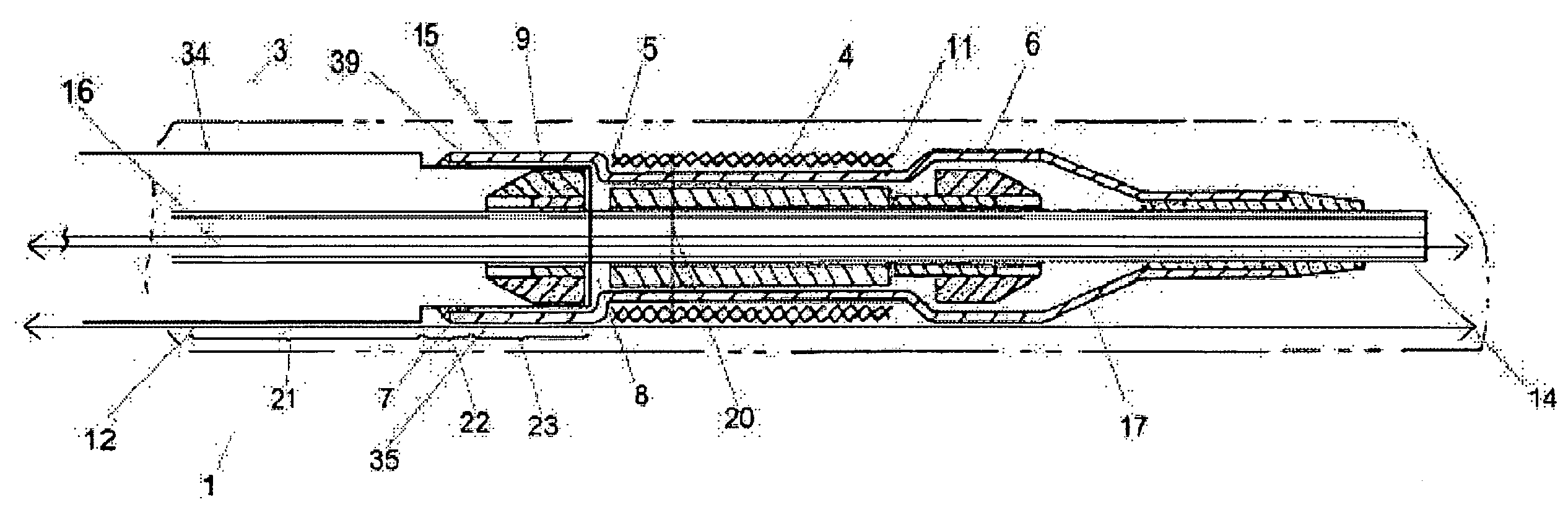

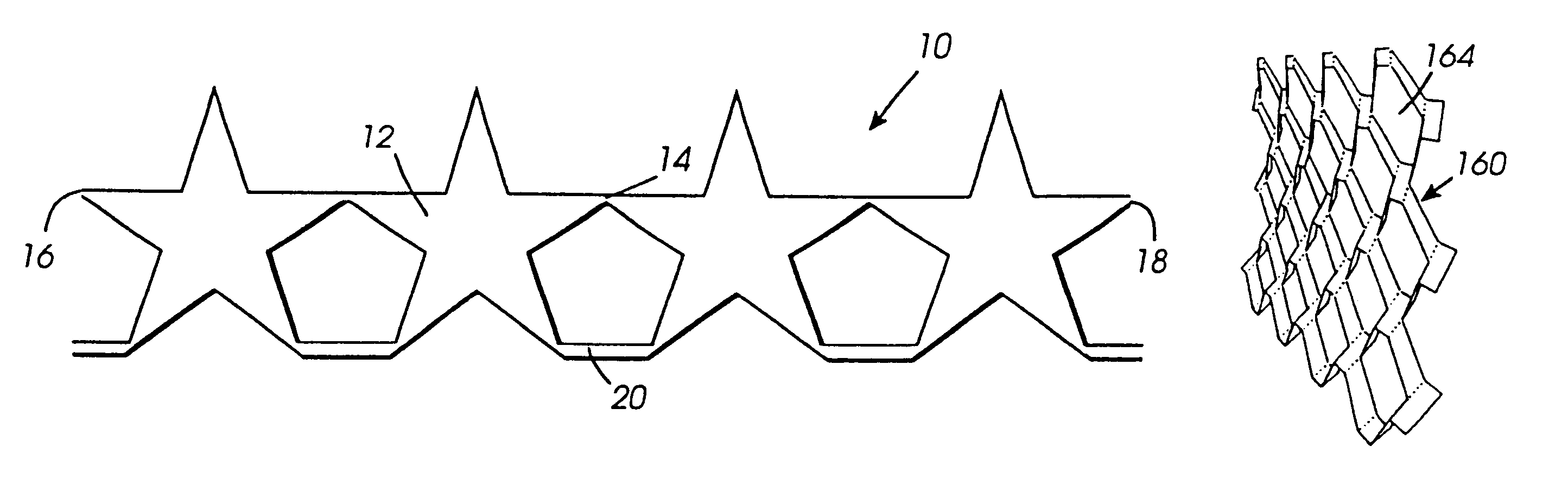

Semi rigid edge protection design for stent delivery system

A system to deliver or remove an inflation expandable stent in a body vessel. The system avoids causing damage or embolisms to a body vessel it is traversing by restraining the edges of the stent from scraping against the walls of the body vessel. The edges are restrained by balloon folds, compressive wedging, and angled reflective resistance. In addition the device can also inflate or deflate the balloon more efficiently.

Owner:BOSTON SCI SCIMED INC

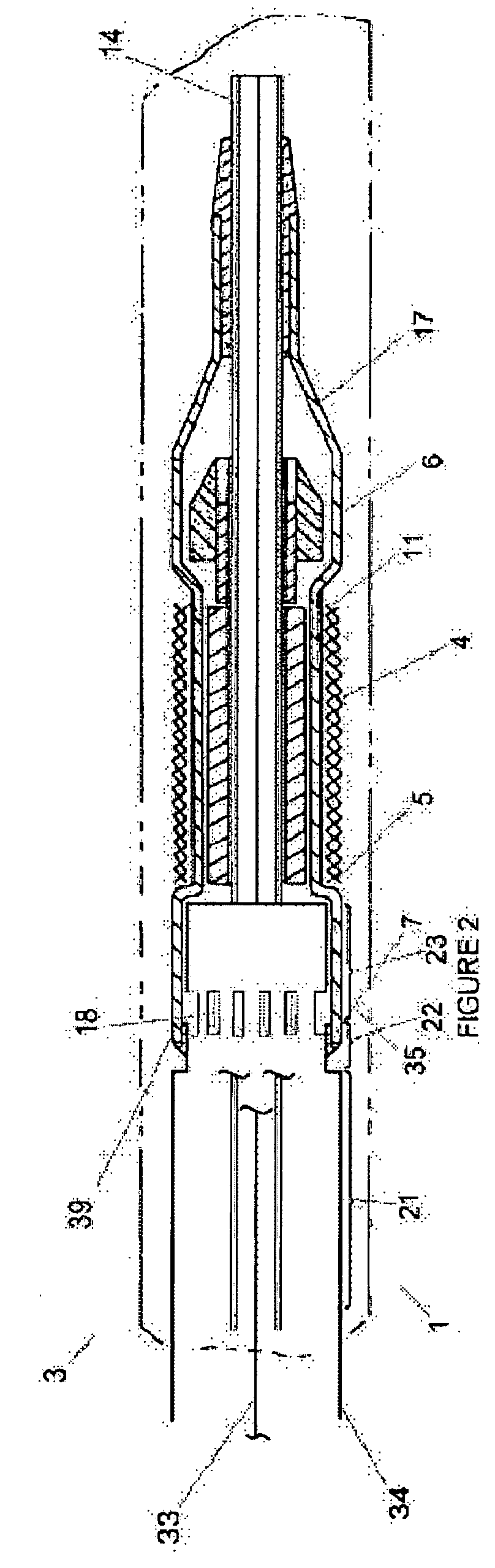

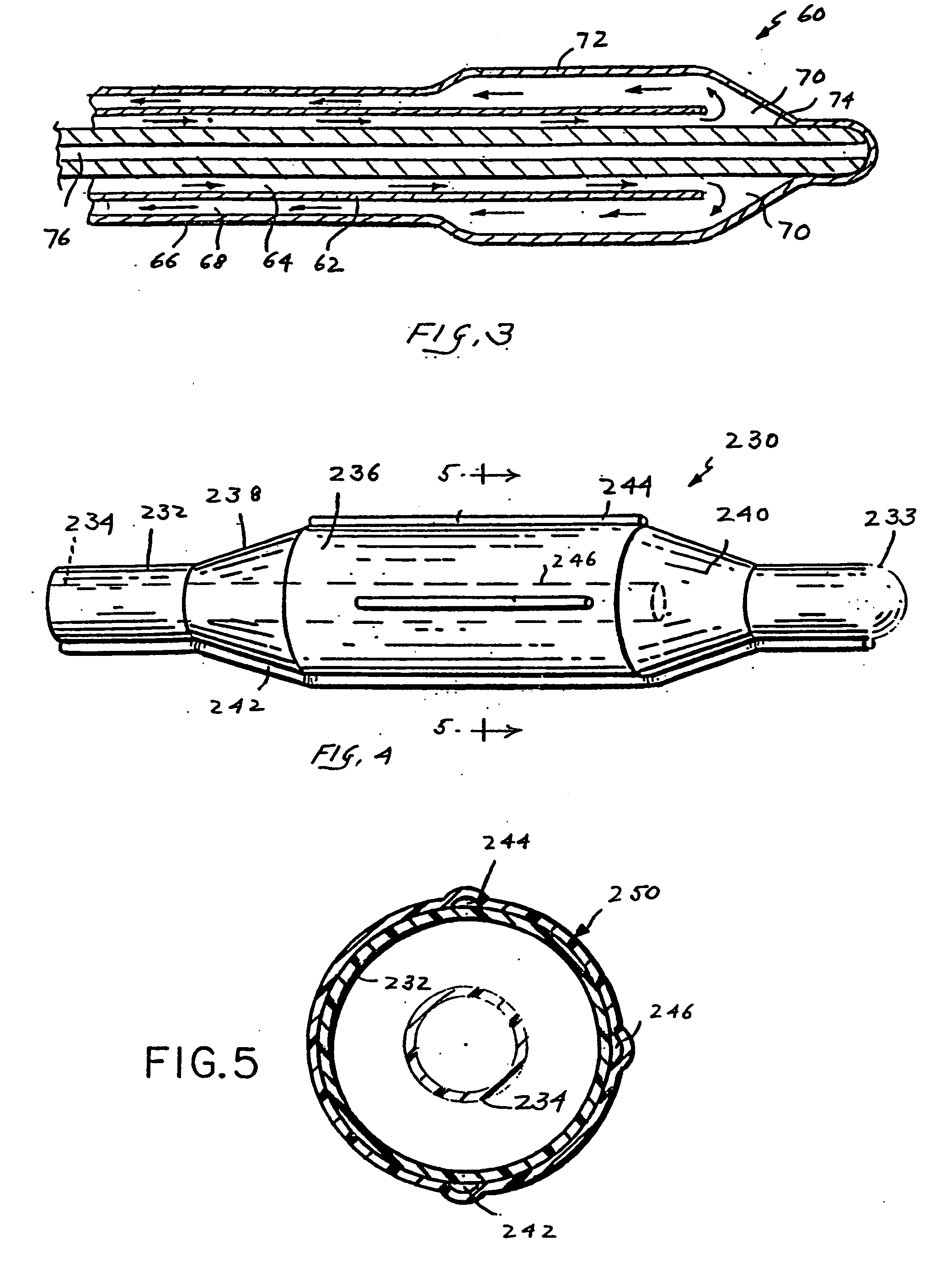

Heat transfer catheters and methods of making and using same

InactiveUS20050113893A1Easy to inflateHigh strengthStentsBalloon catheterThermal energyDistal portion

Heat transfer catheter apparatus and methods of making and using same are disclosed wherein a fluid connection is provided between the distal portions of two adjacent, thin-walled, high strength fluid lumens to define a closed loop fluid circulation system capable of controlled delivery of thermal energy to or withdrawal of thermal energy from remote internal body locations.

Owner:ZOLL CIRCULATION +2

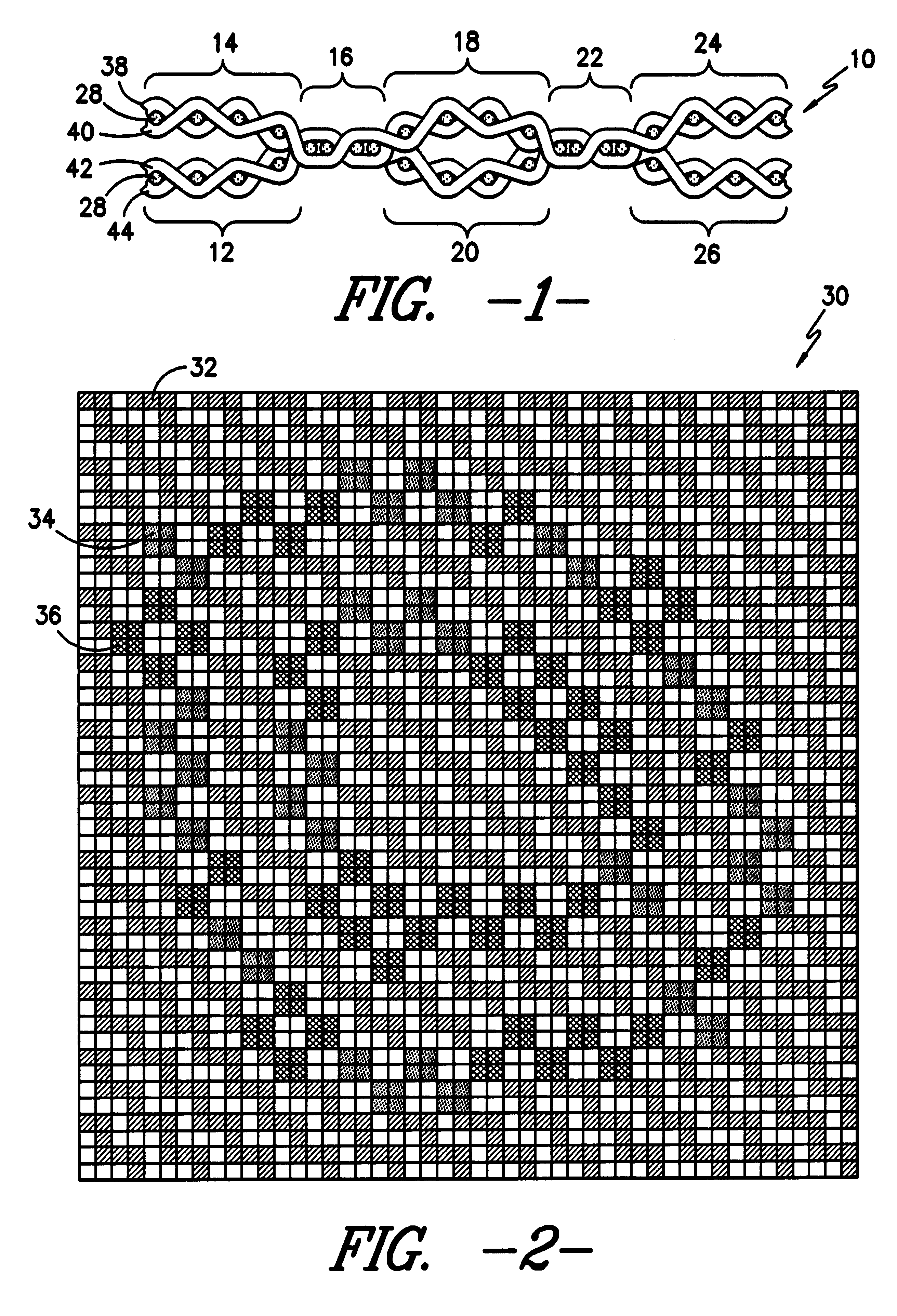

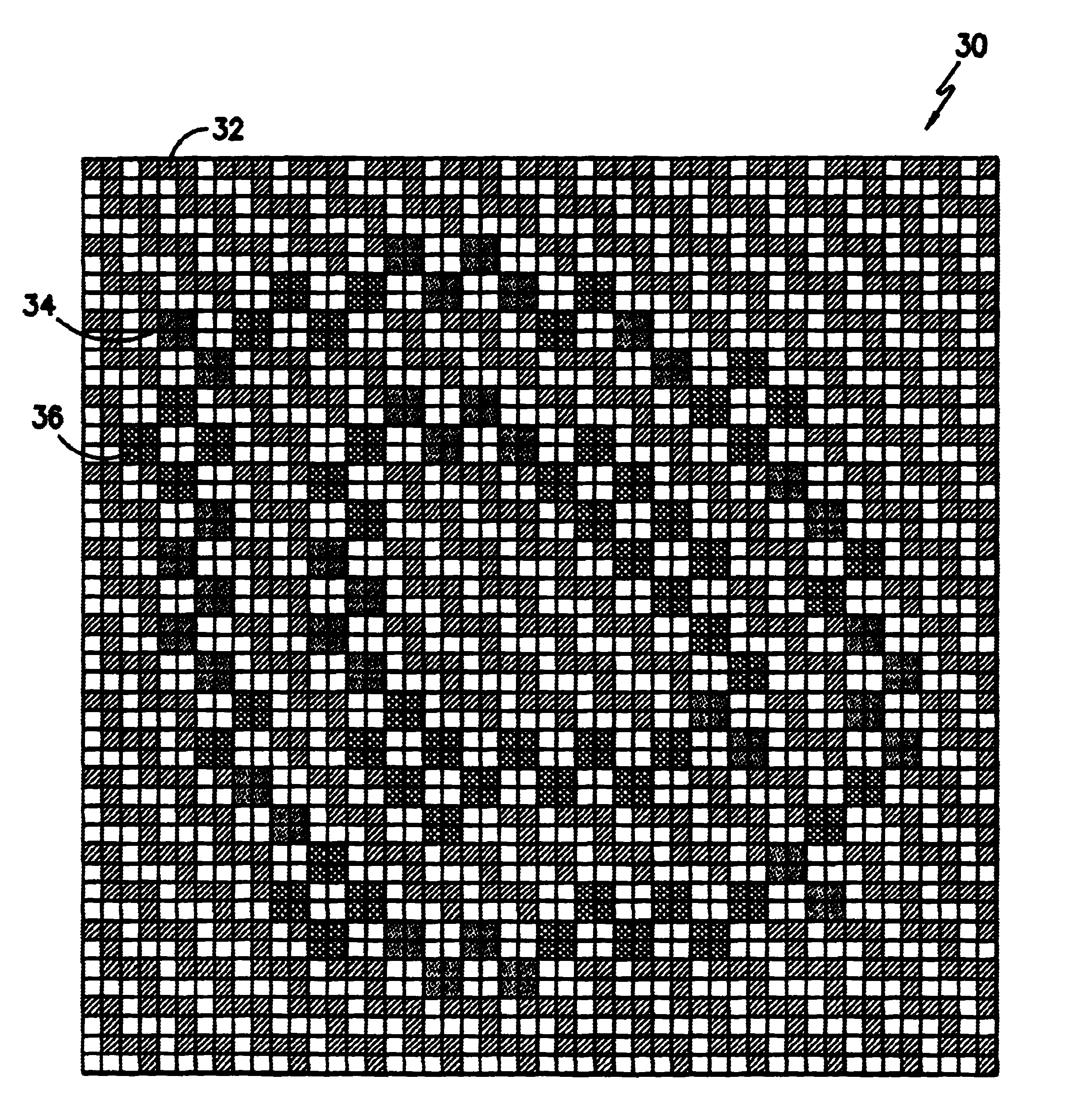

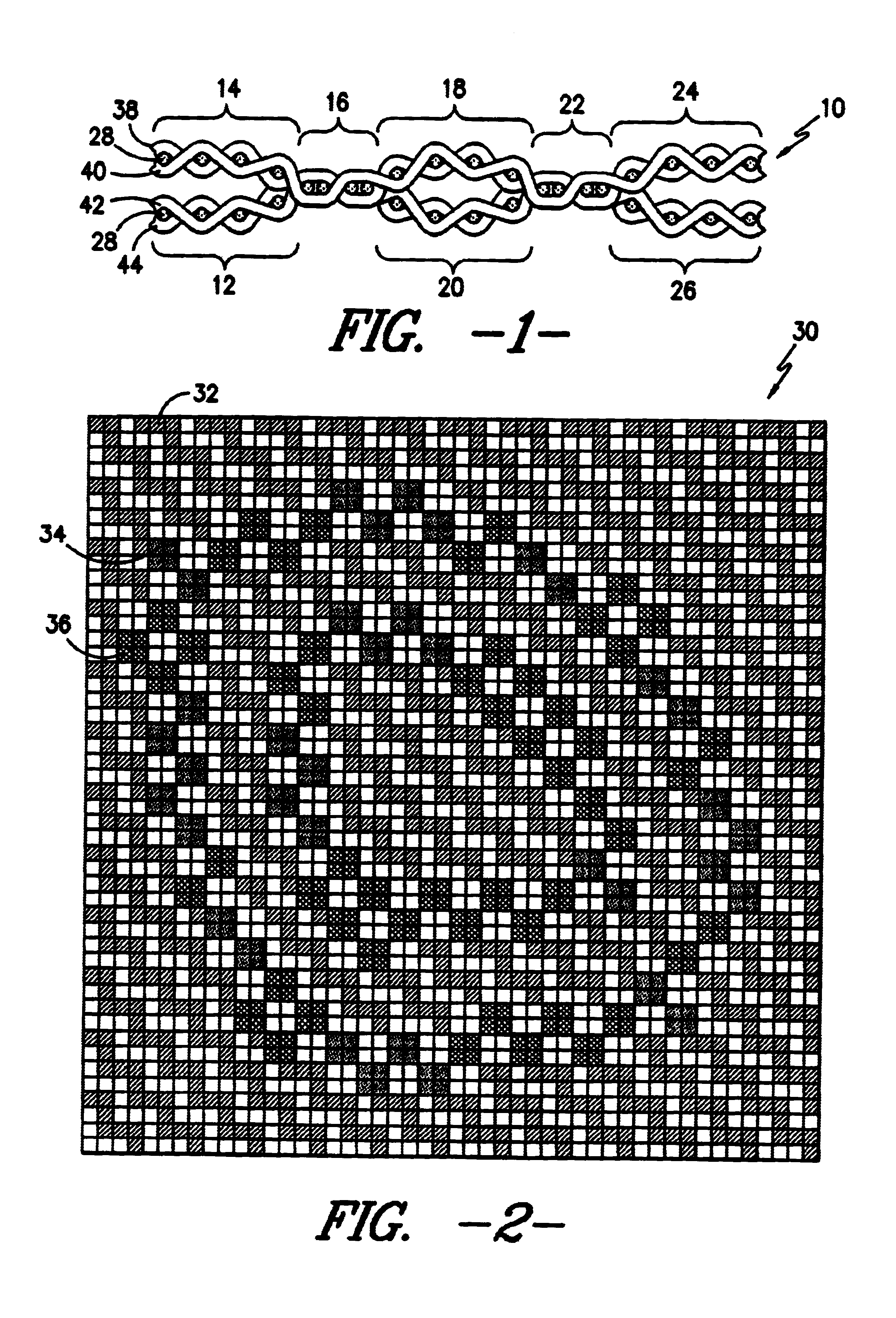

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6451715B2Keep for a long timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

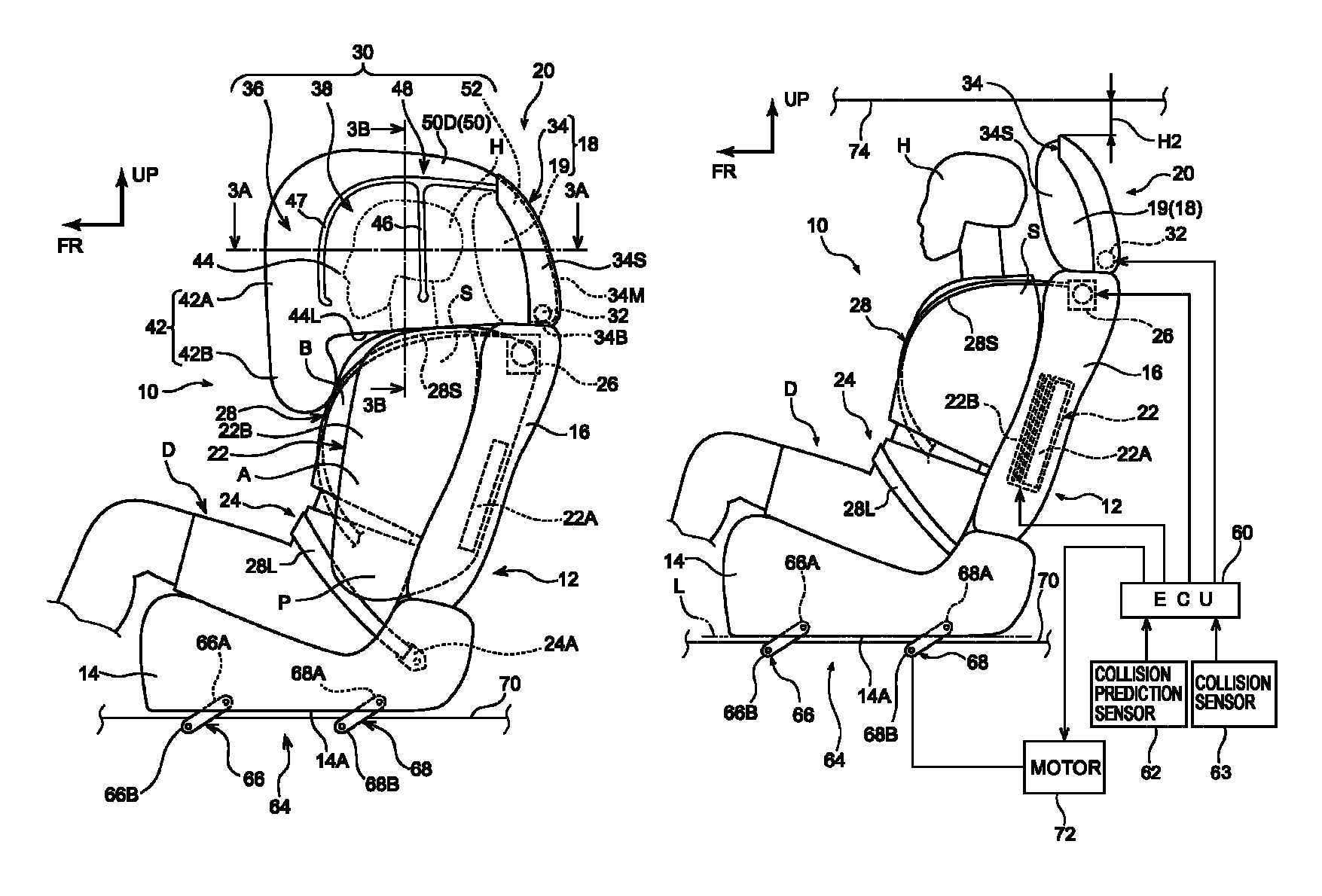

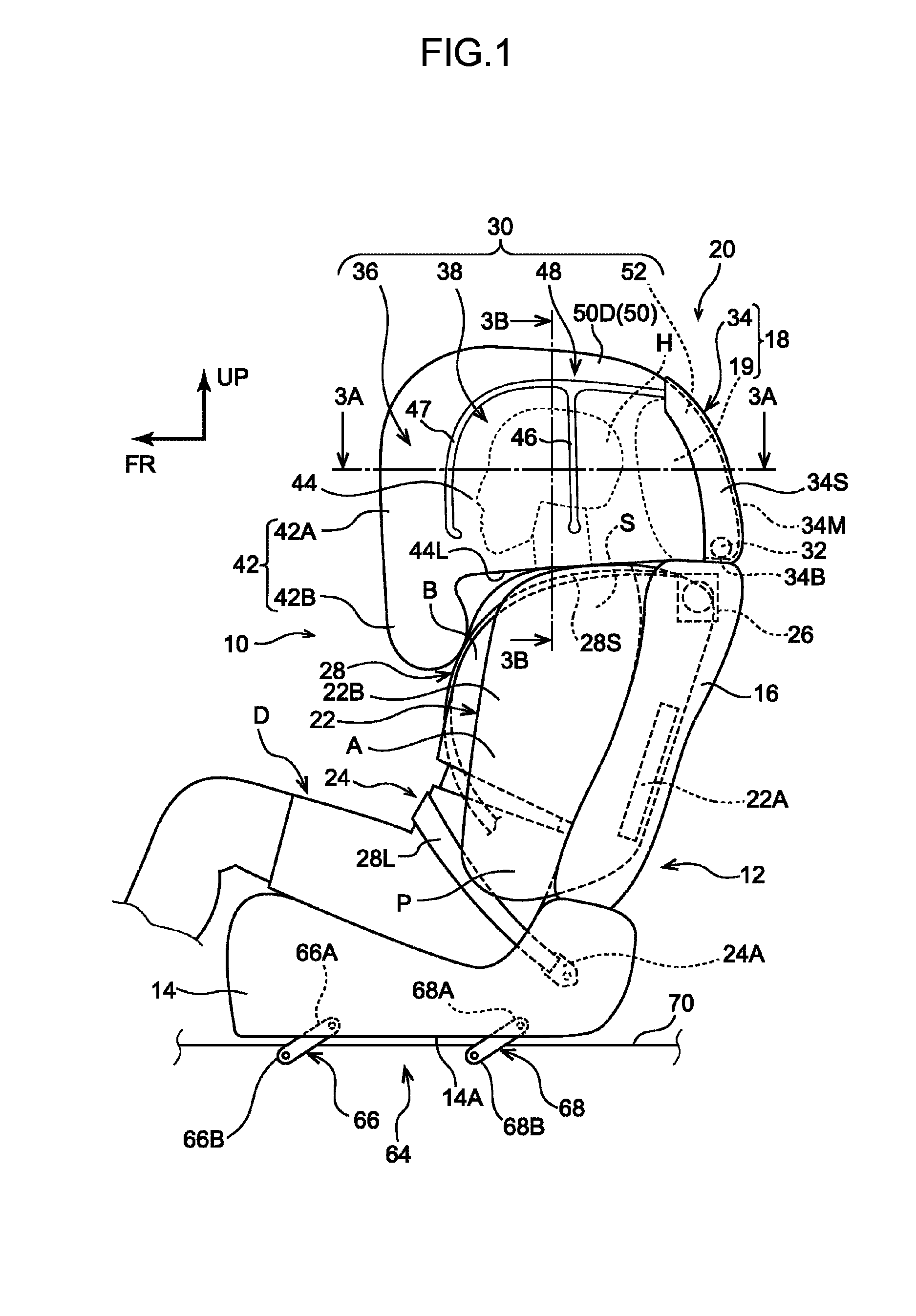

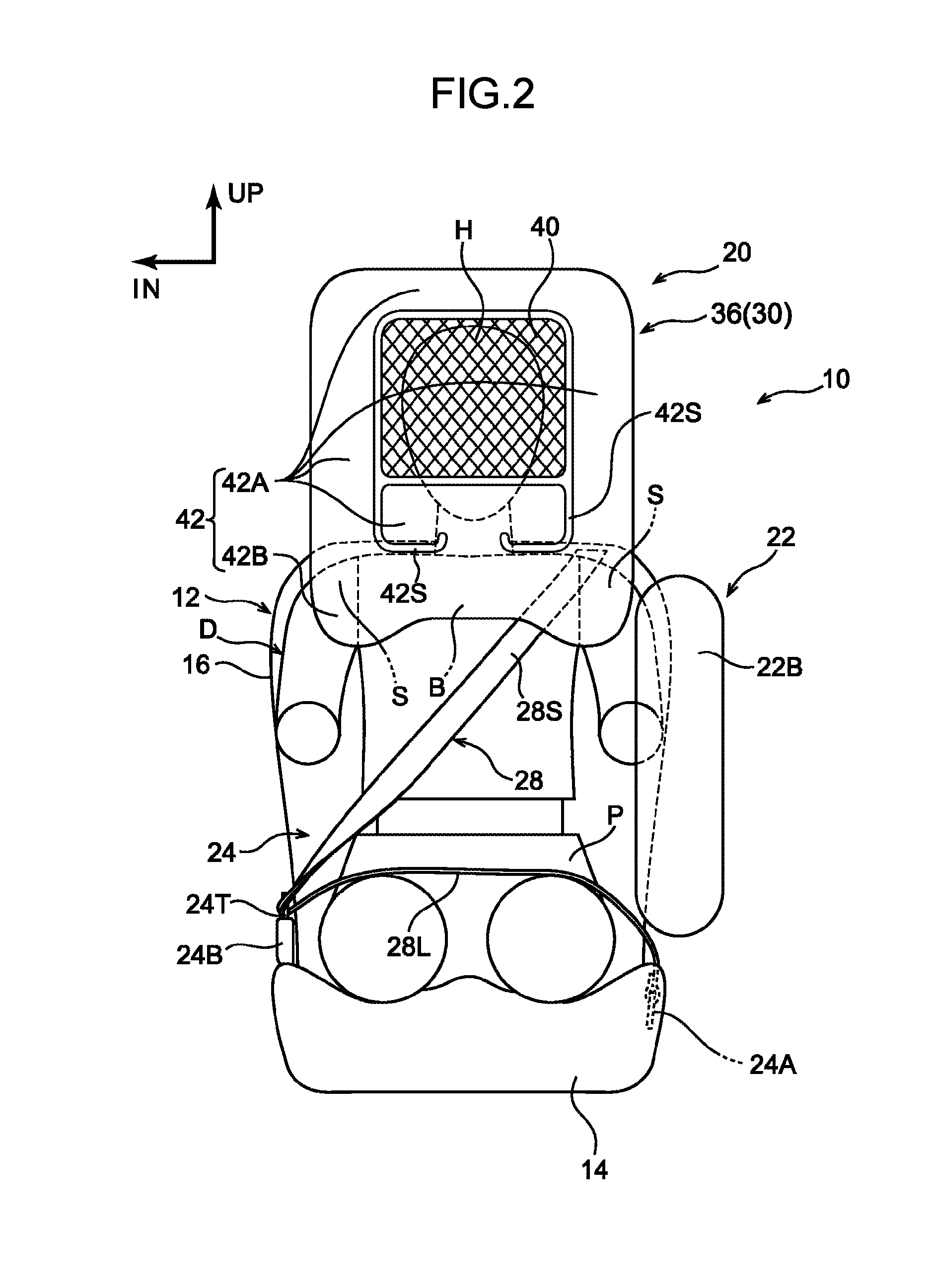

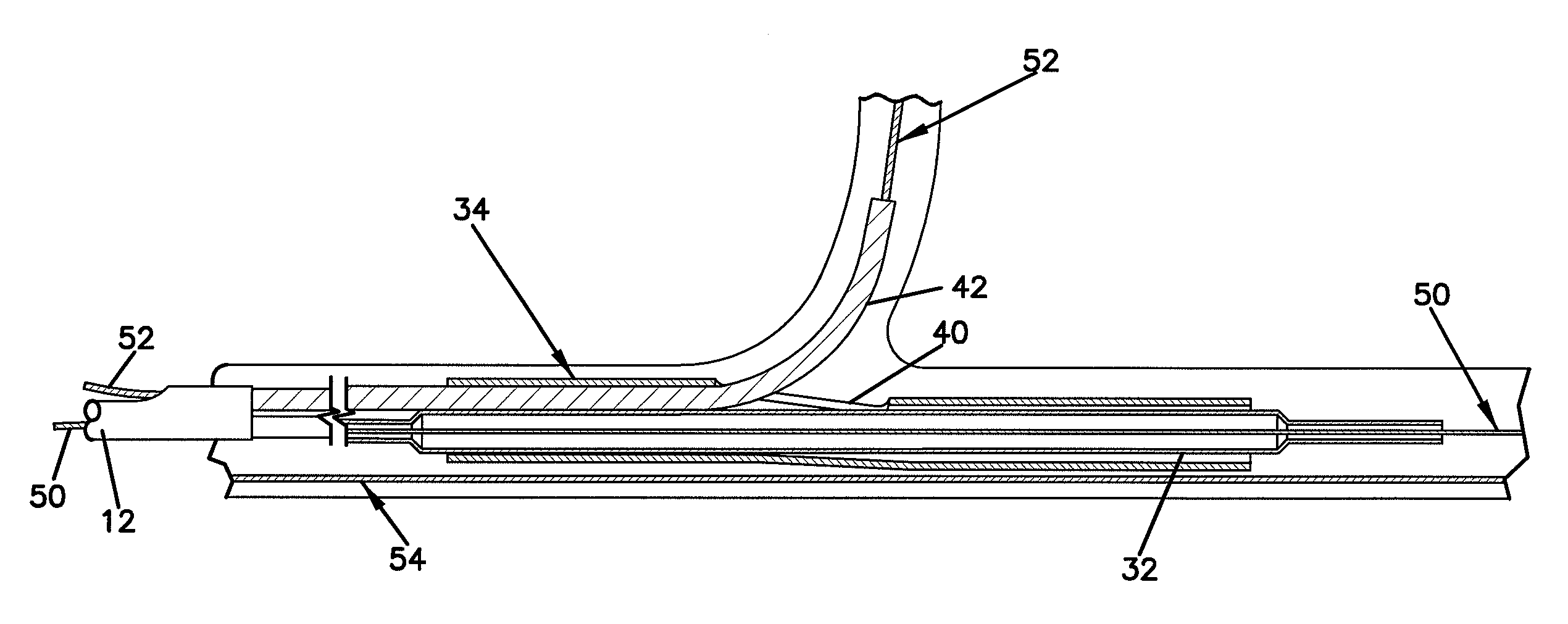

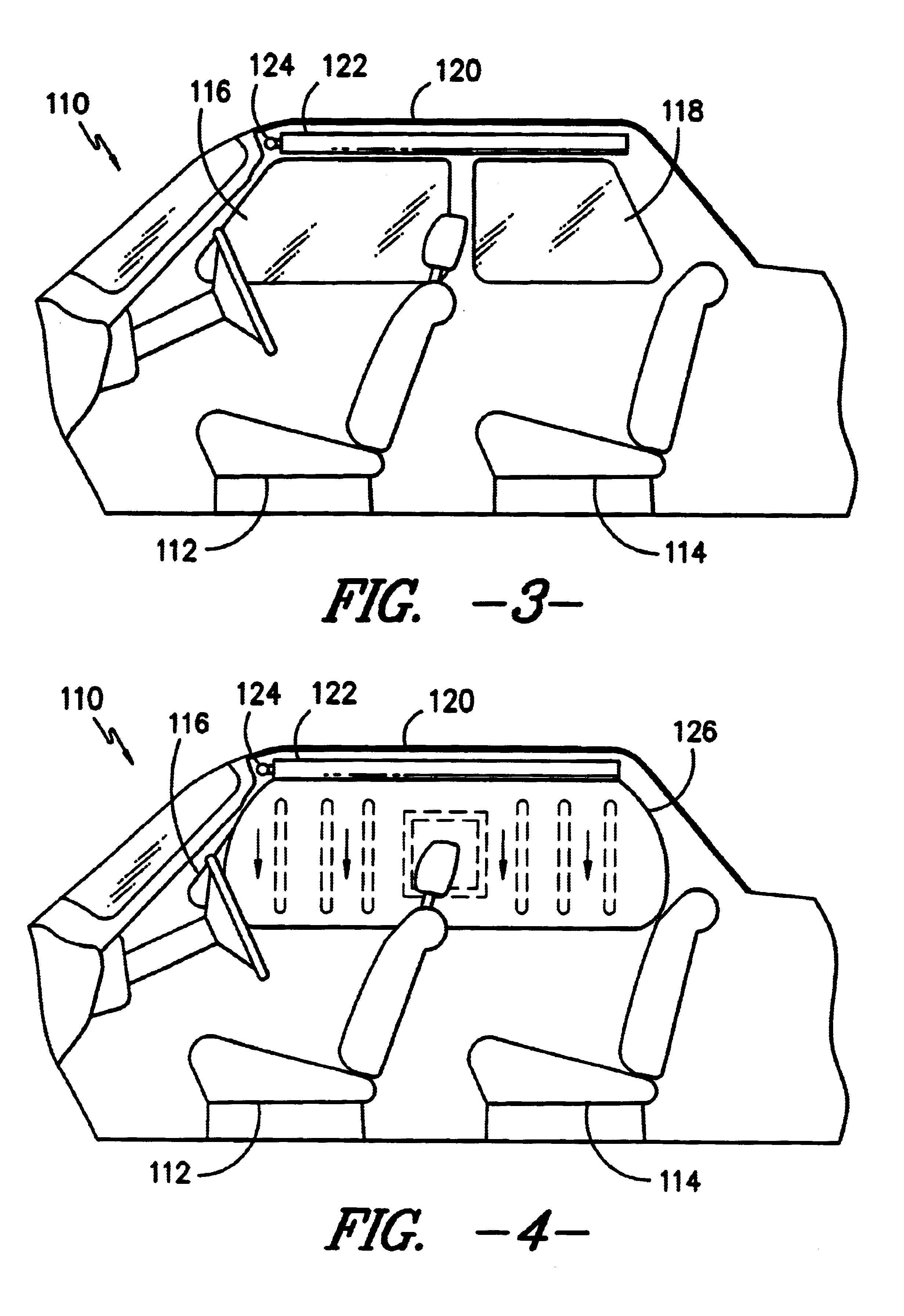

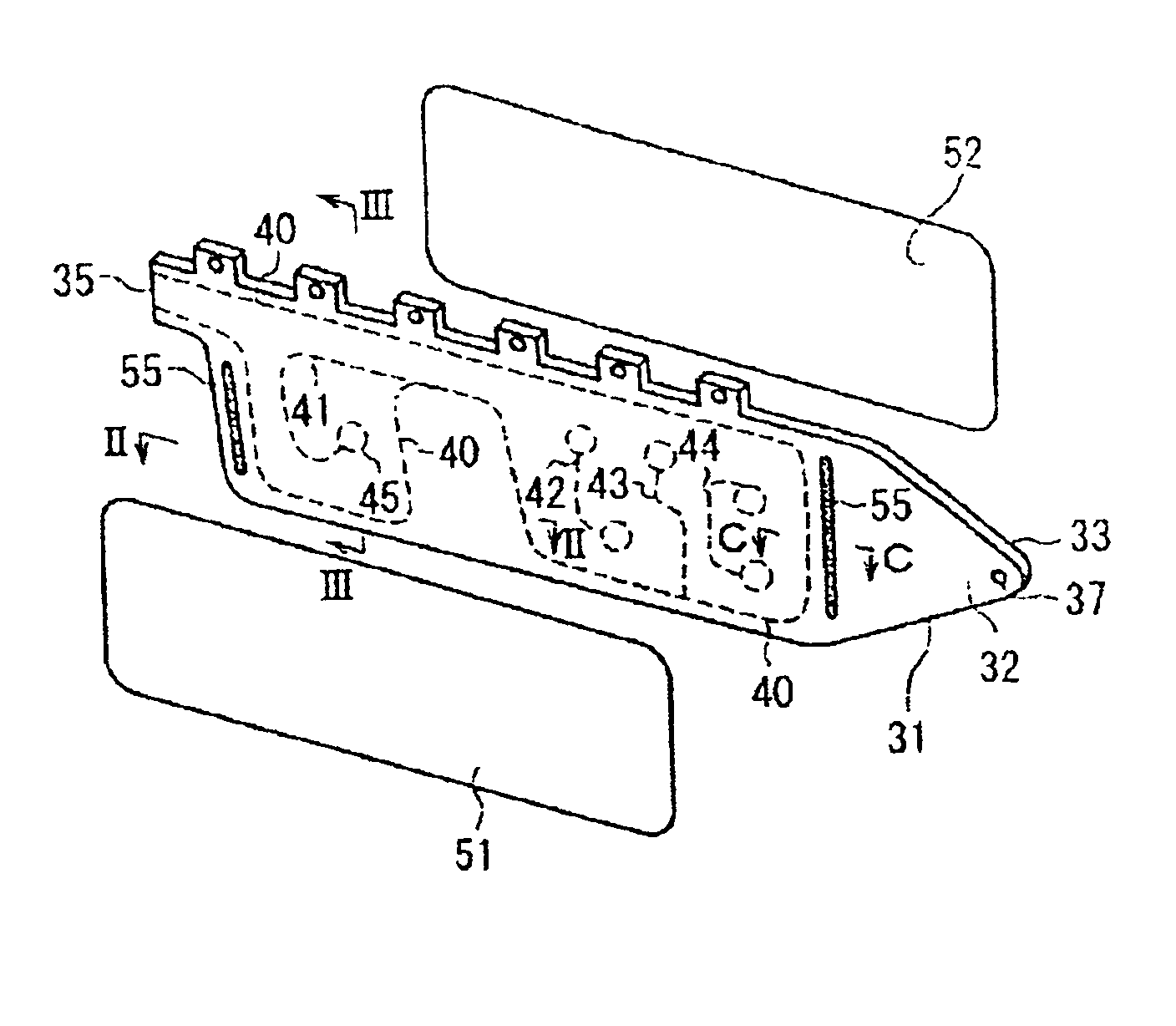

Occupant protection device

An occupant protection device is provided including (1) an airbag that covers the head of the occupant, and that has (i) a front deployment section that is housed in a headrest, and that is deployed at a seat forward direction with respect to the head of a seated occupant, and (ii) a pair of left and right lateral deployment sections that are inflated and deployed at seat sides with respect to the head of the seated occupant, (2) a lifting mechanism that raises and lowers the vehicle seat, and (3) a controller that uses the lifting mechanism to lower the vehicle seat to an airbag deployable height in cases in which a vehicle collision has been determined to be unavoidable and a height of the vehicle seat is higher than the airbag deployable height, and that inflates and deploys the airbag after lowering the vehicle seat.

Owner:TOYOTA JIDOSHA KK

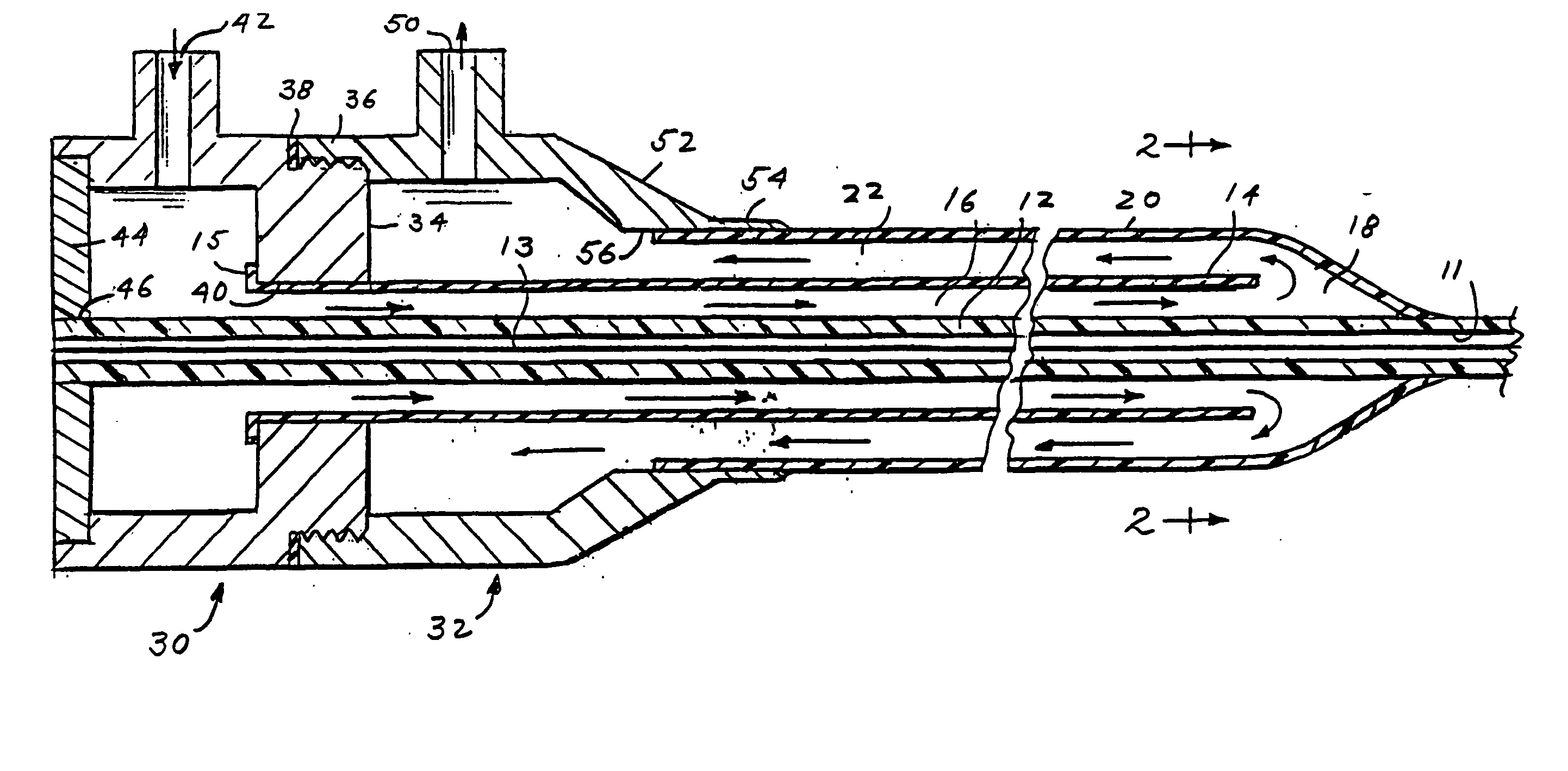

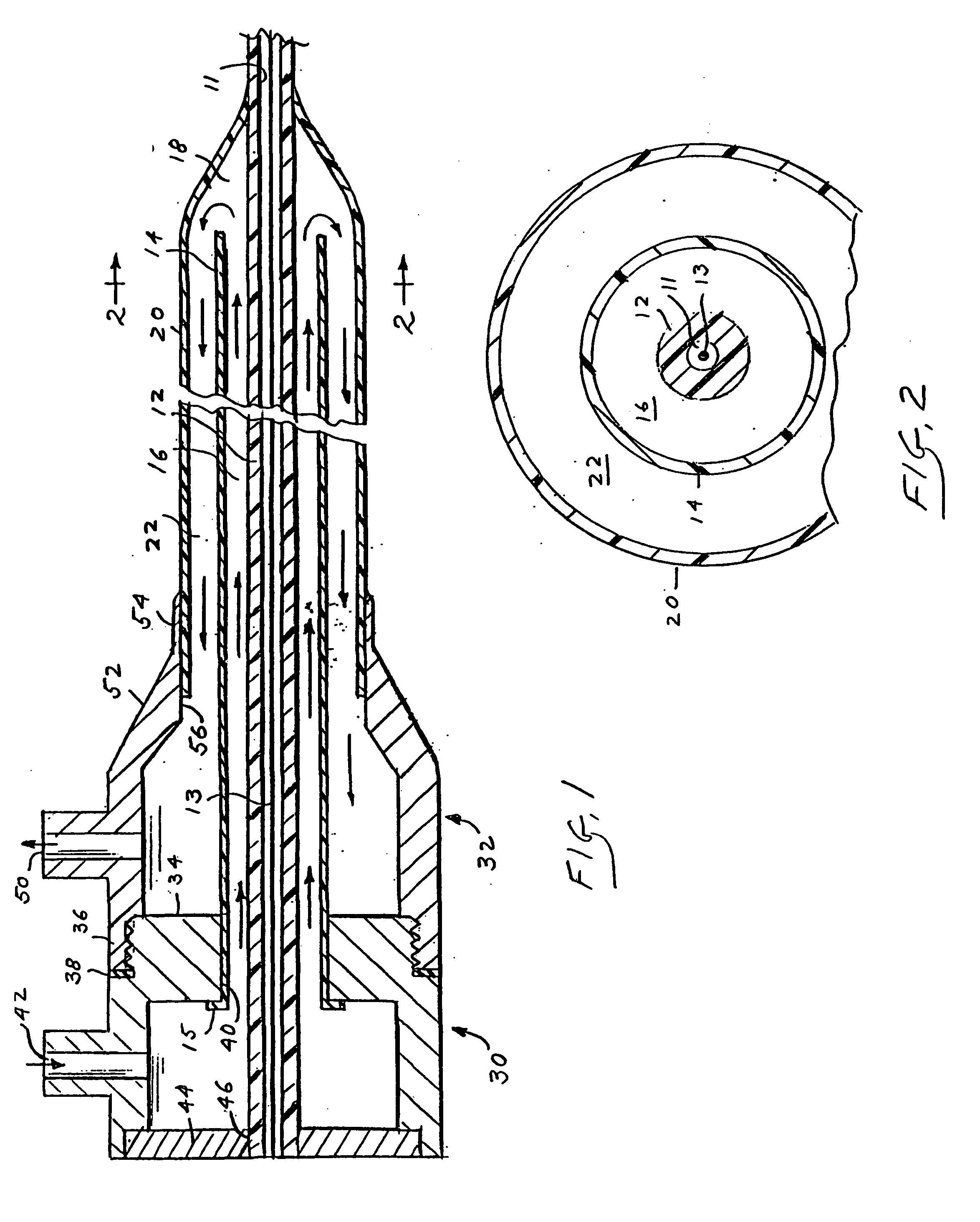

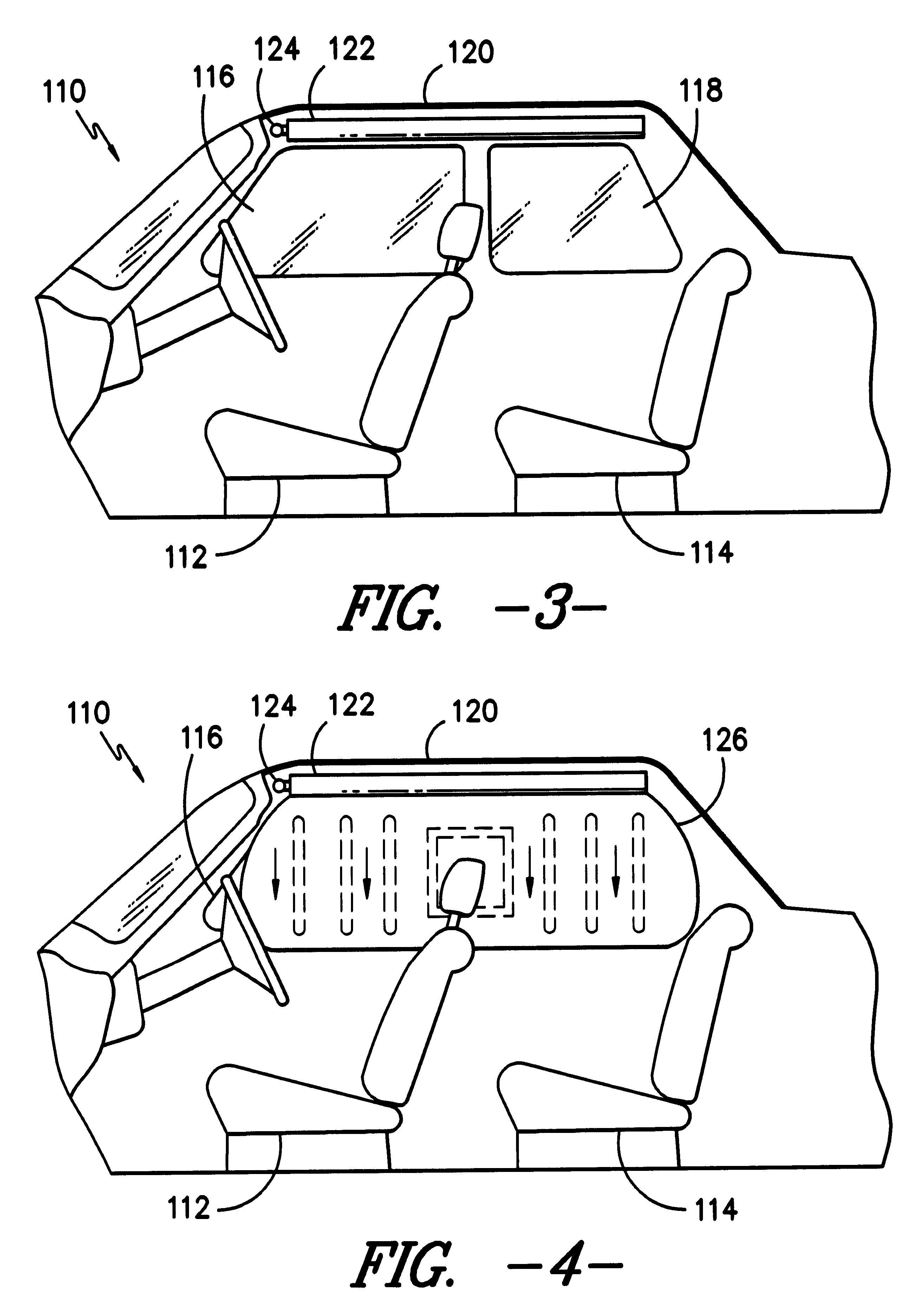

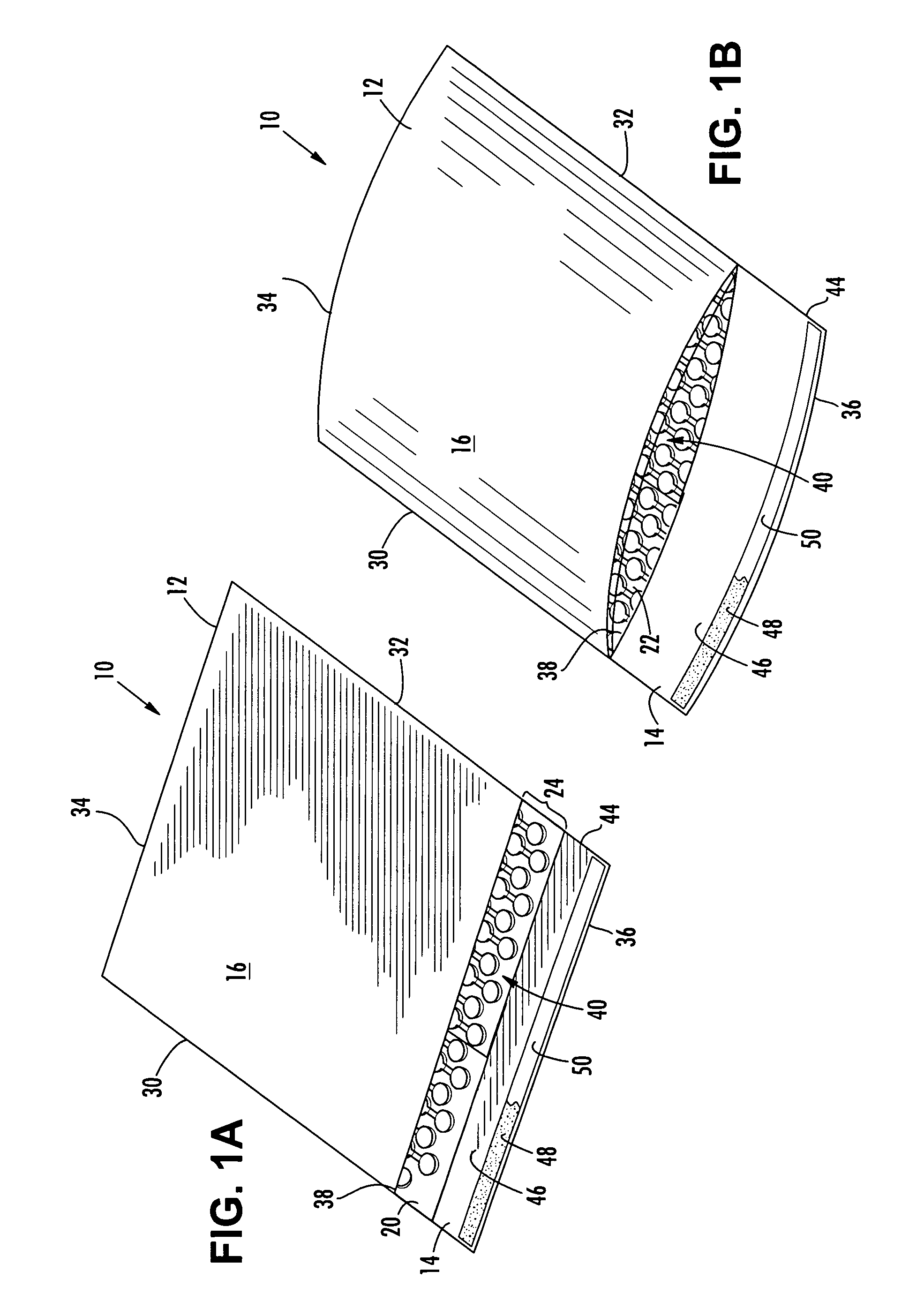

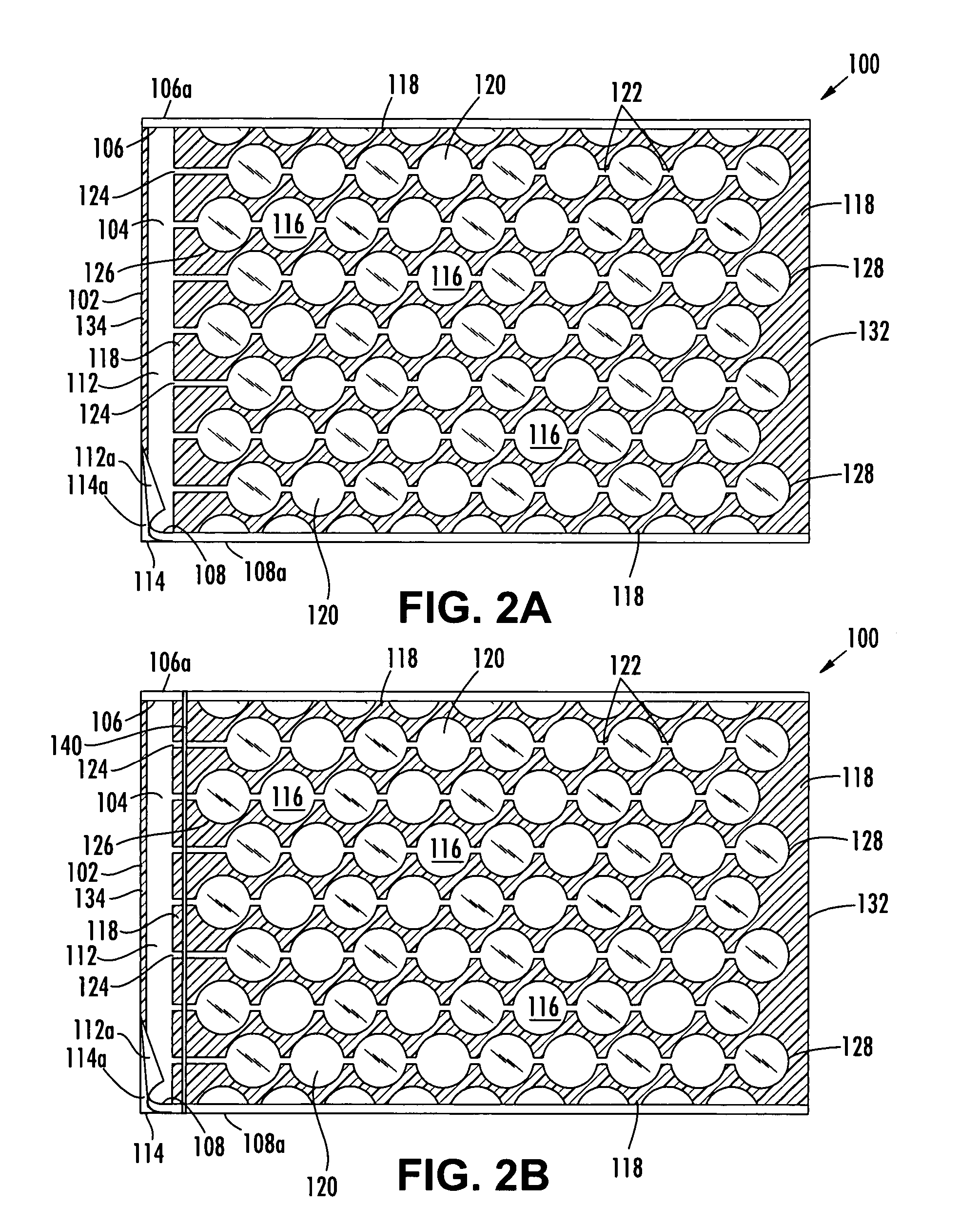

Short sleeve stent delivery catheter and methods

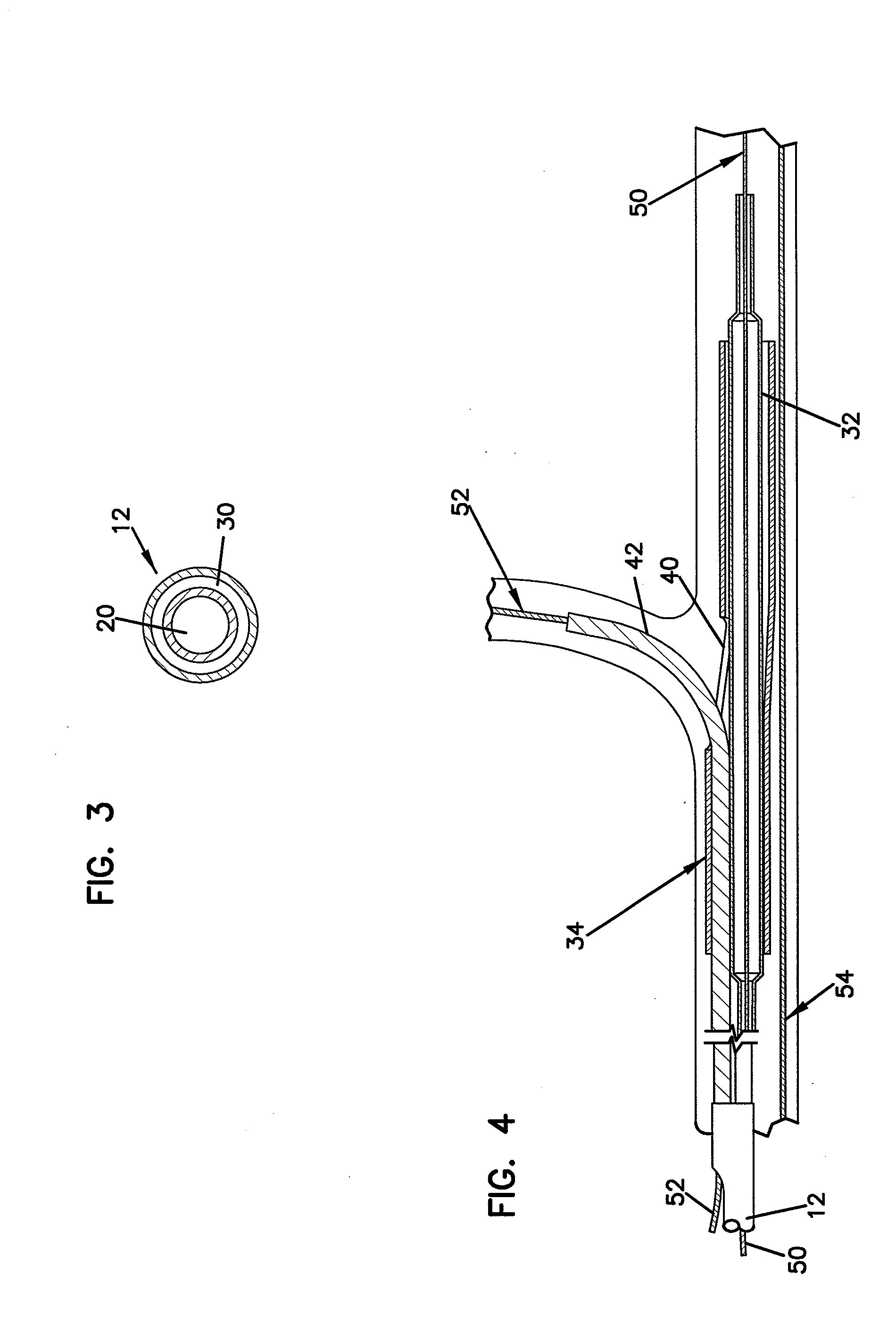

InactiveUS7387639B2Reduce decreaseFacilitate maneuveringStentsBalloon catheterInsertion stentCatheter

A stent delivery catheter comprises a catheter body having a proximal end, a distal end, and a guidewire lumen extending from the distal end to at least part way between the proximal end and the distal end. A balloon is disposed over the catheter body near the distal end, and a stent is positioned over the balloon. The stent has a proximal end, a distal end, and a side opening between the proximal end and the distal end. A side sheath is coupled to the catheter body and has a proximal end, a distal end, and a guidewire lumen extending between the proximal end and the distal end. The proximal end of the side sheath is located between the proximal end of the catheter body and the balloon, and the side sheath exits out of the side opening of the stent.

Owner:BOSTON SCI SCIMED INC

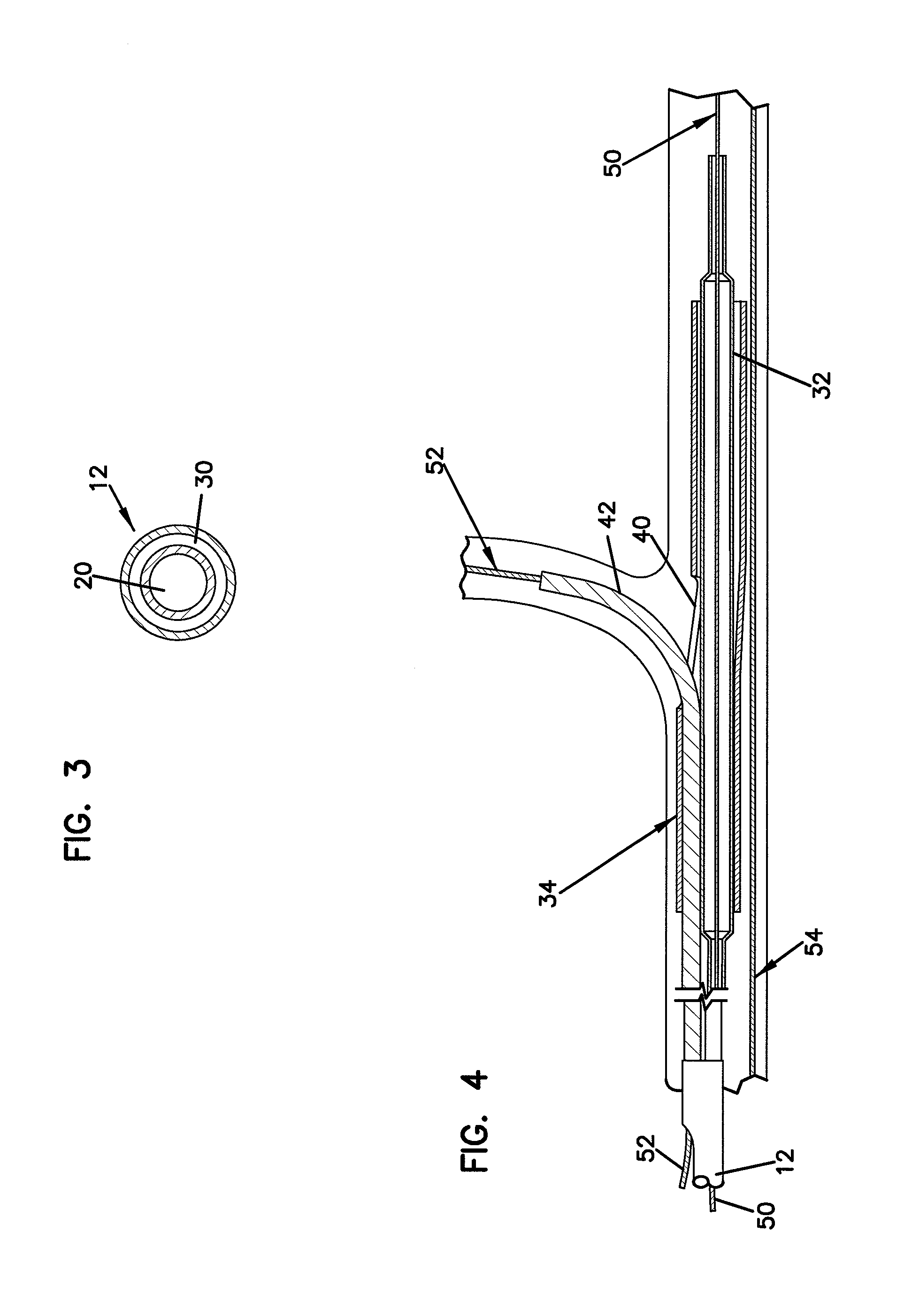

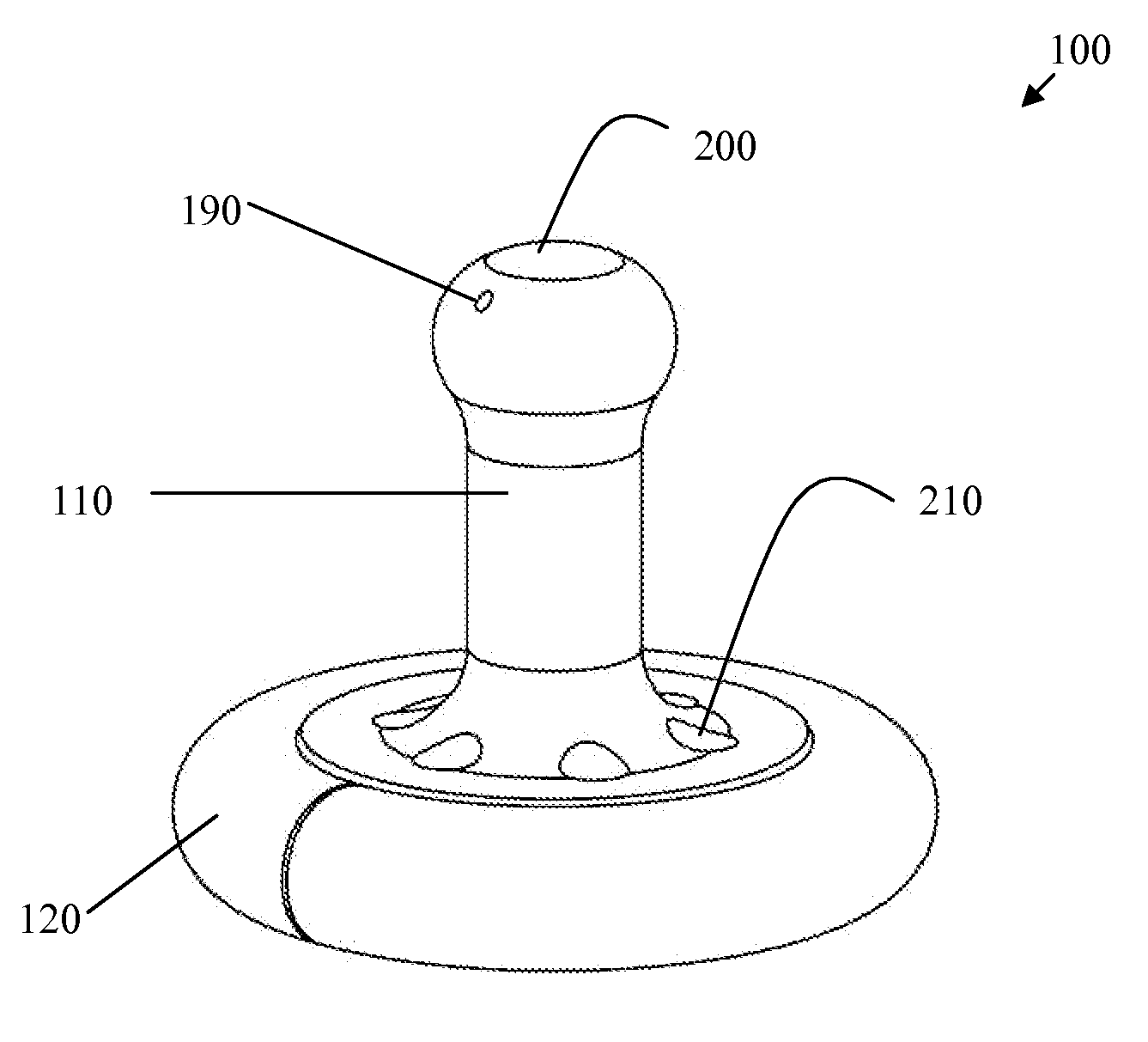

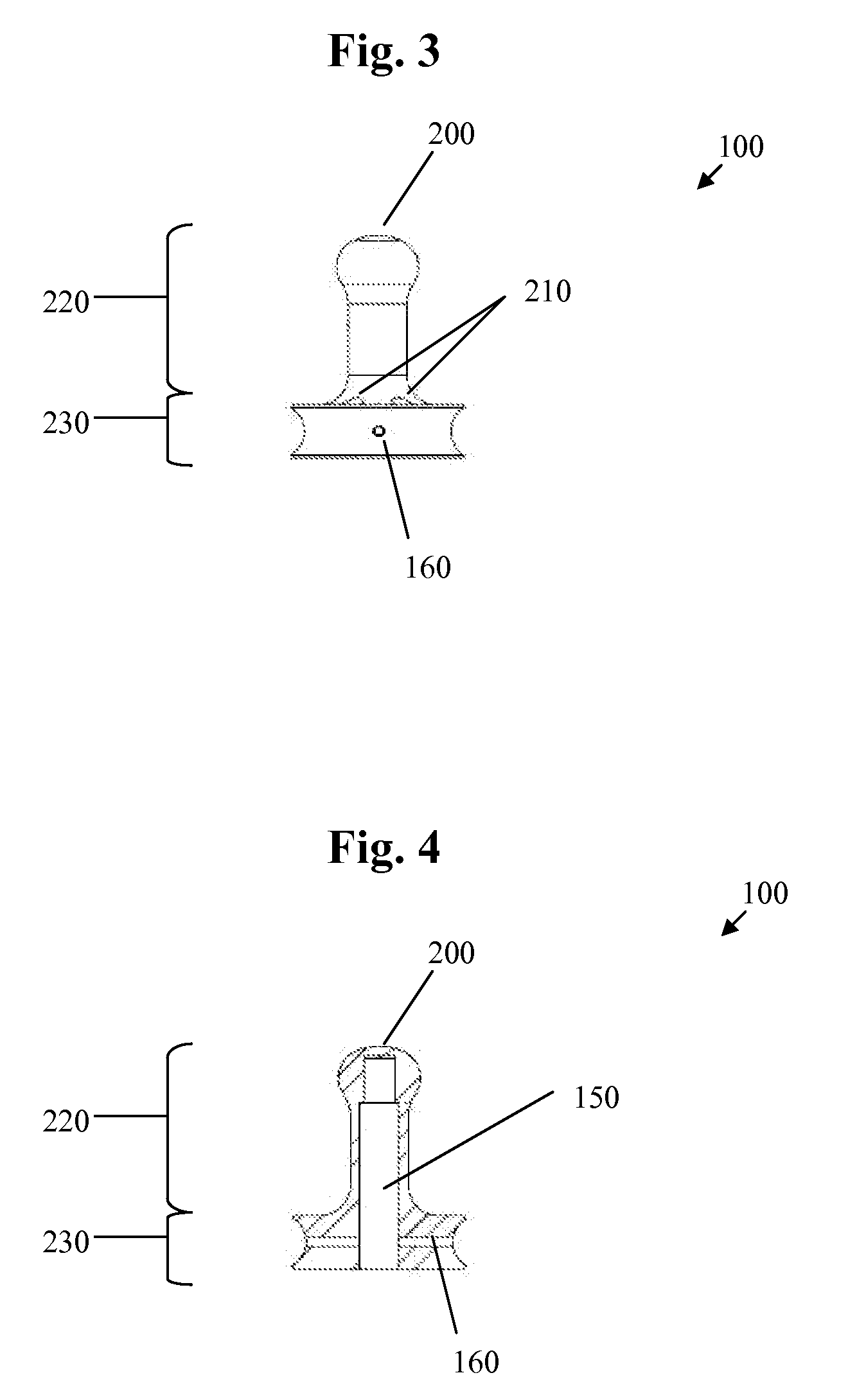

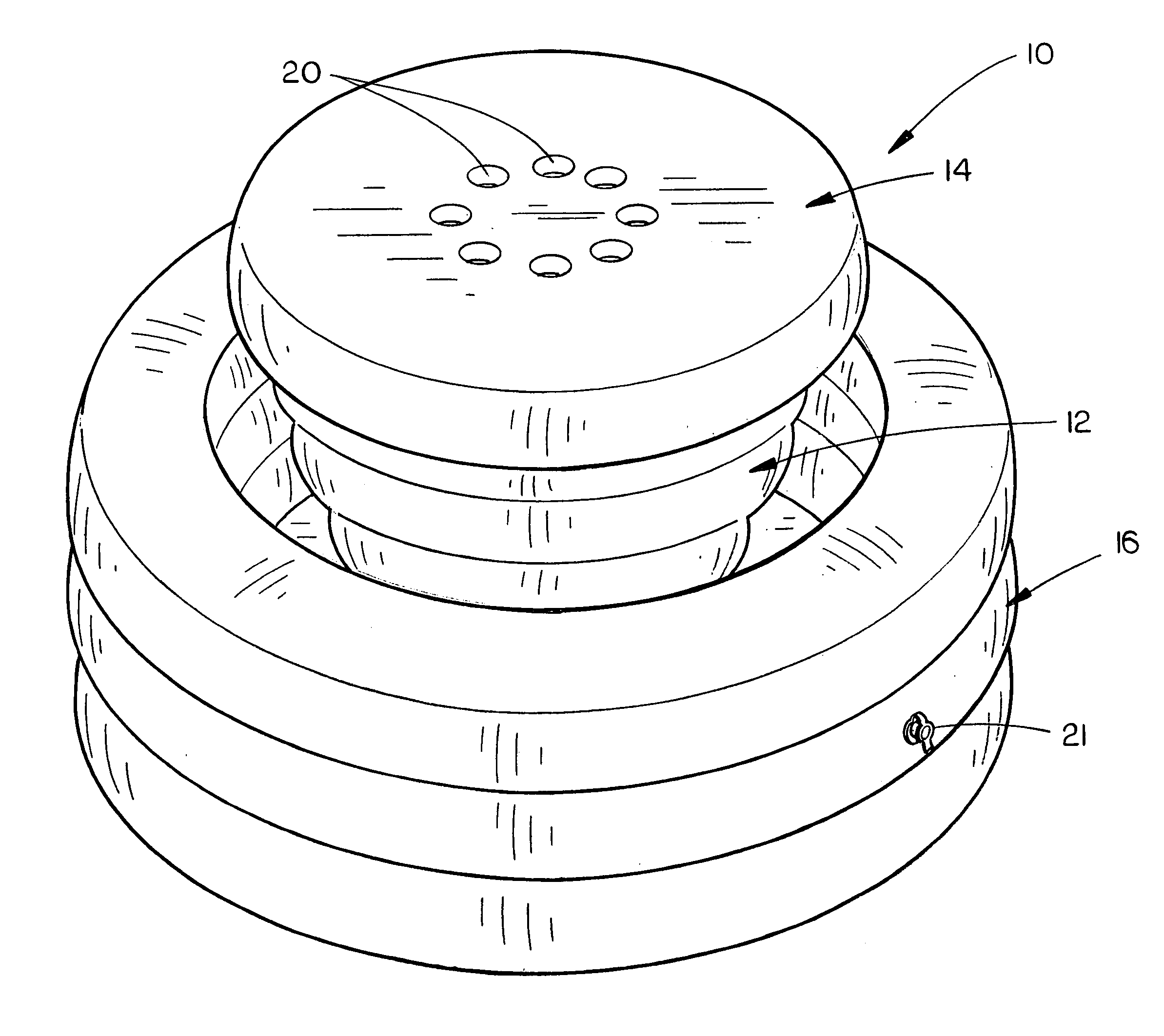

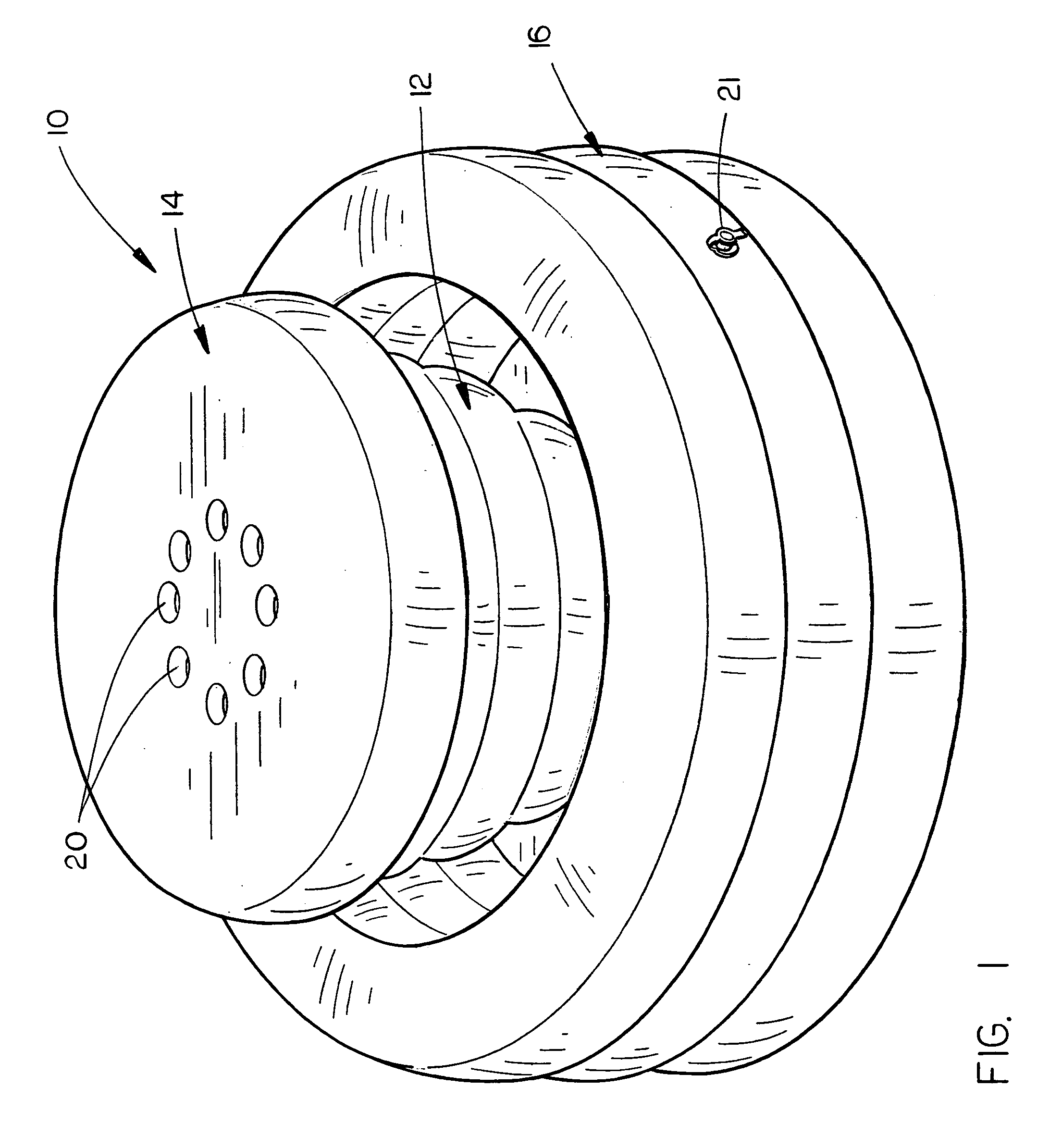

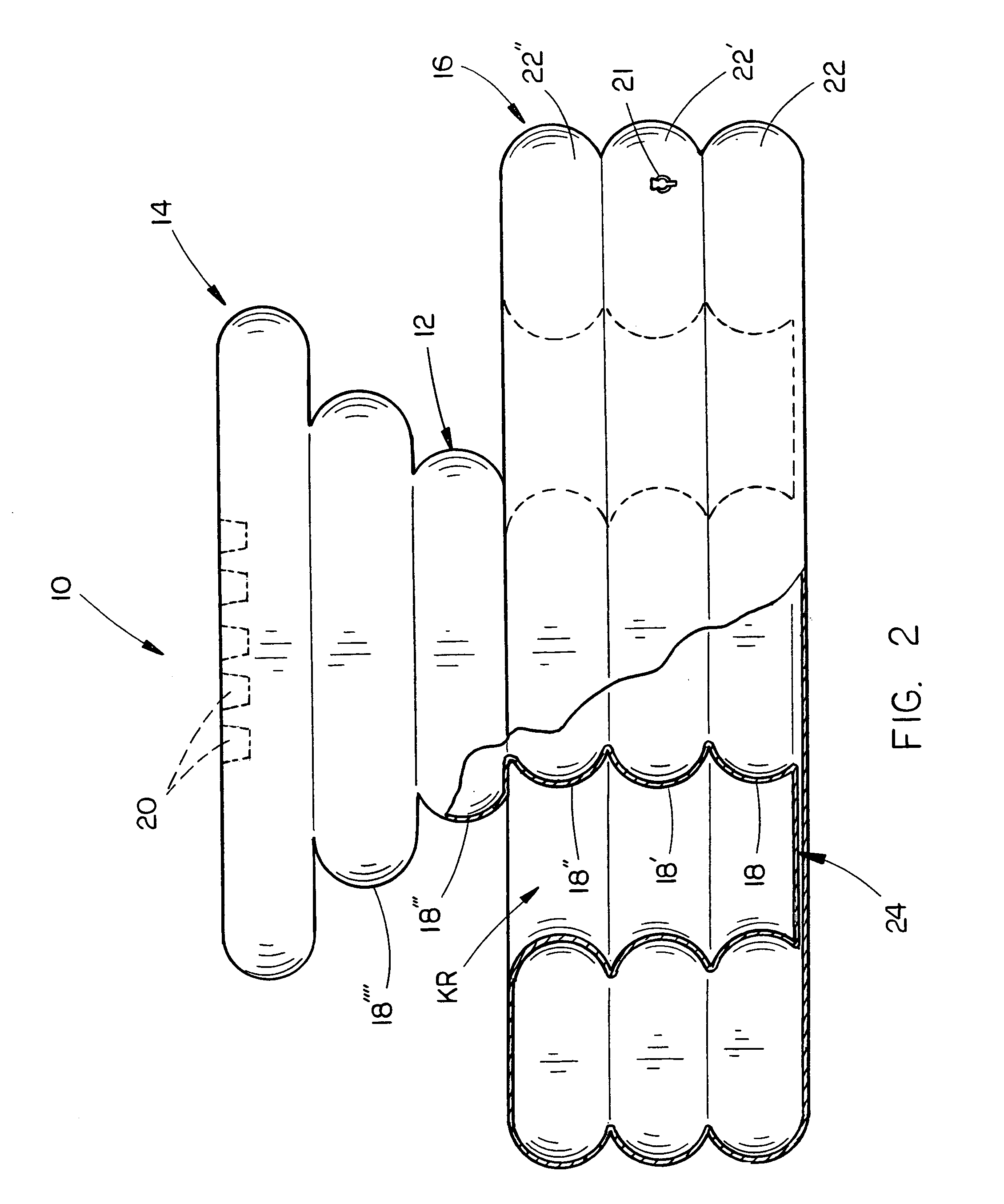

Pessary Device

InactiveUS20090216071A1Easy to inflateEasy to disassembleAnaesthesiaAnti-incontinence devicesUterusPessary

A pessary comprising a main stem and an inflatable bladder disposed about the proximal larger diameter section of the main stem. The main stem further comprises a distal smaller diameter portion having a cap at its distal tip and a check valve disposed there under. The check valve communicates with a central fluid passage that may extend into the proximal larger diameter section of the main stem. Secondary fluid passages connect the central fluid passage to the inflatable bladder volume disposed about the outer circumference of the proximal larger diameter section of the main stem. The main stem provides support to the pelvic structures and the inflatable bladder acts to hold the device in position. At least one void through the proximal larger diameter portion of the main stem allows bodily material to pass from the vagina through the pessary device thereby decreasing the amount of vaginal discharge.

Owner:ZIPPER RALPH

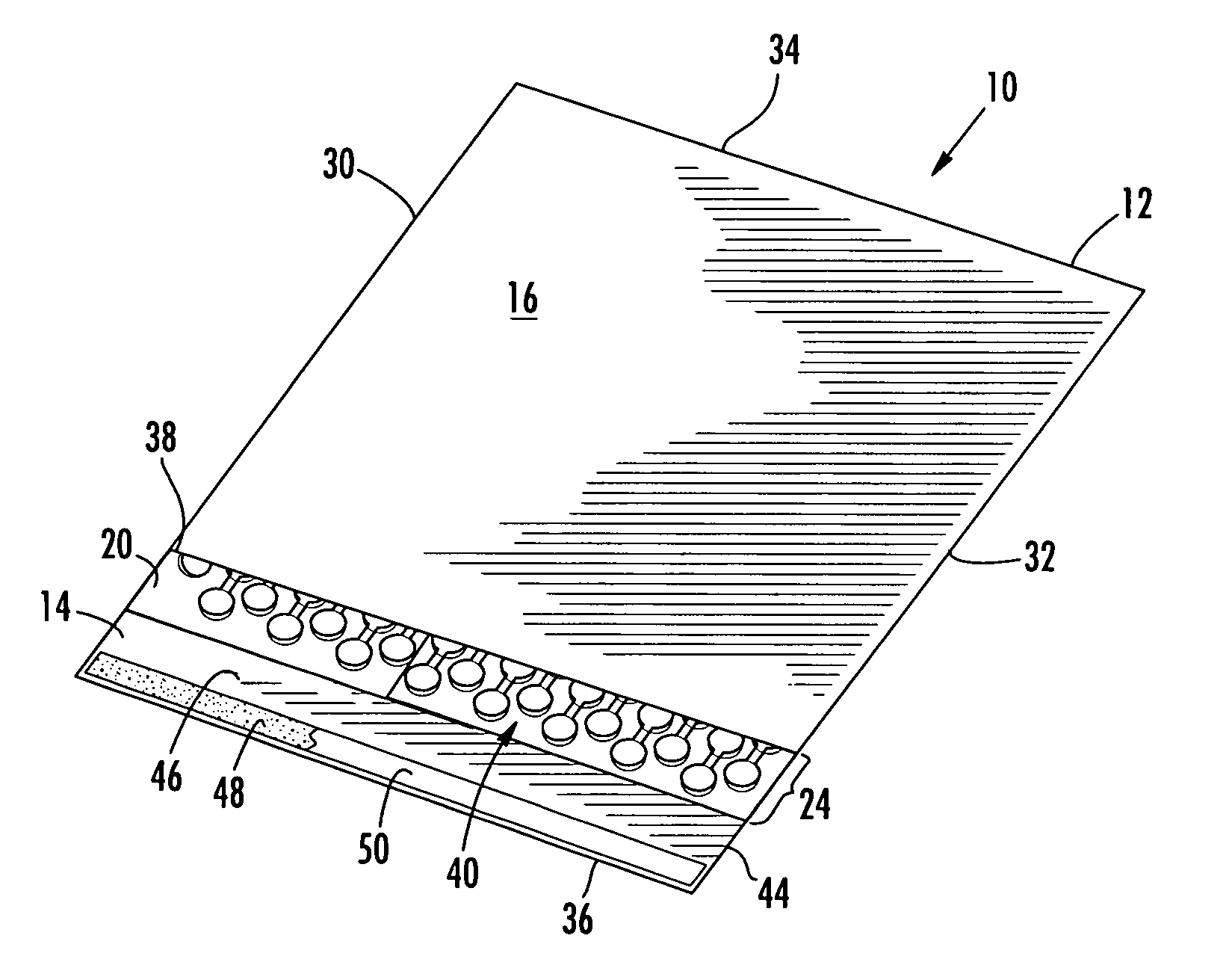

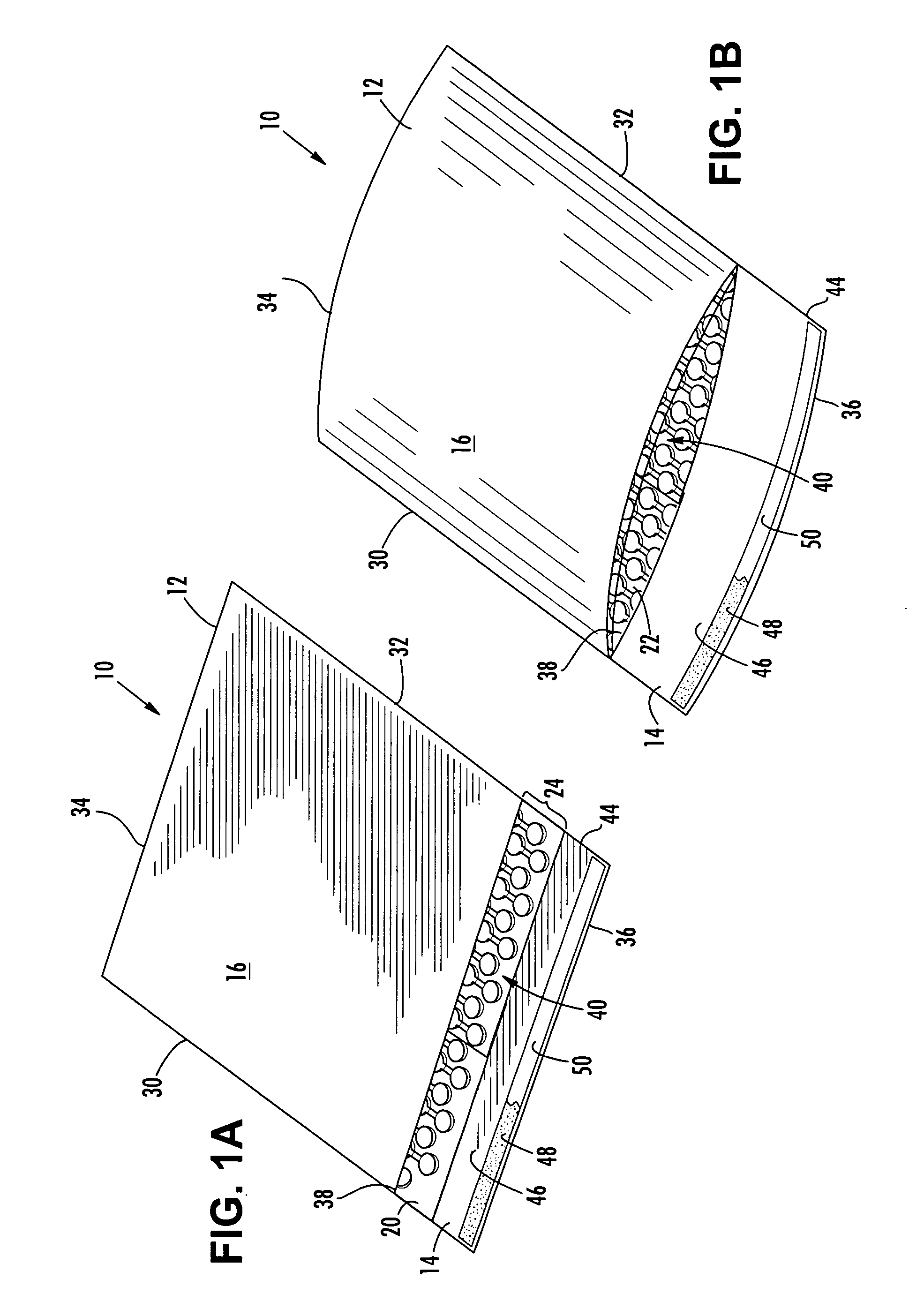

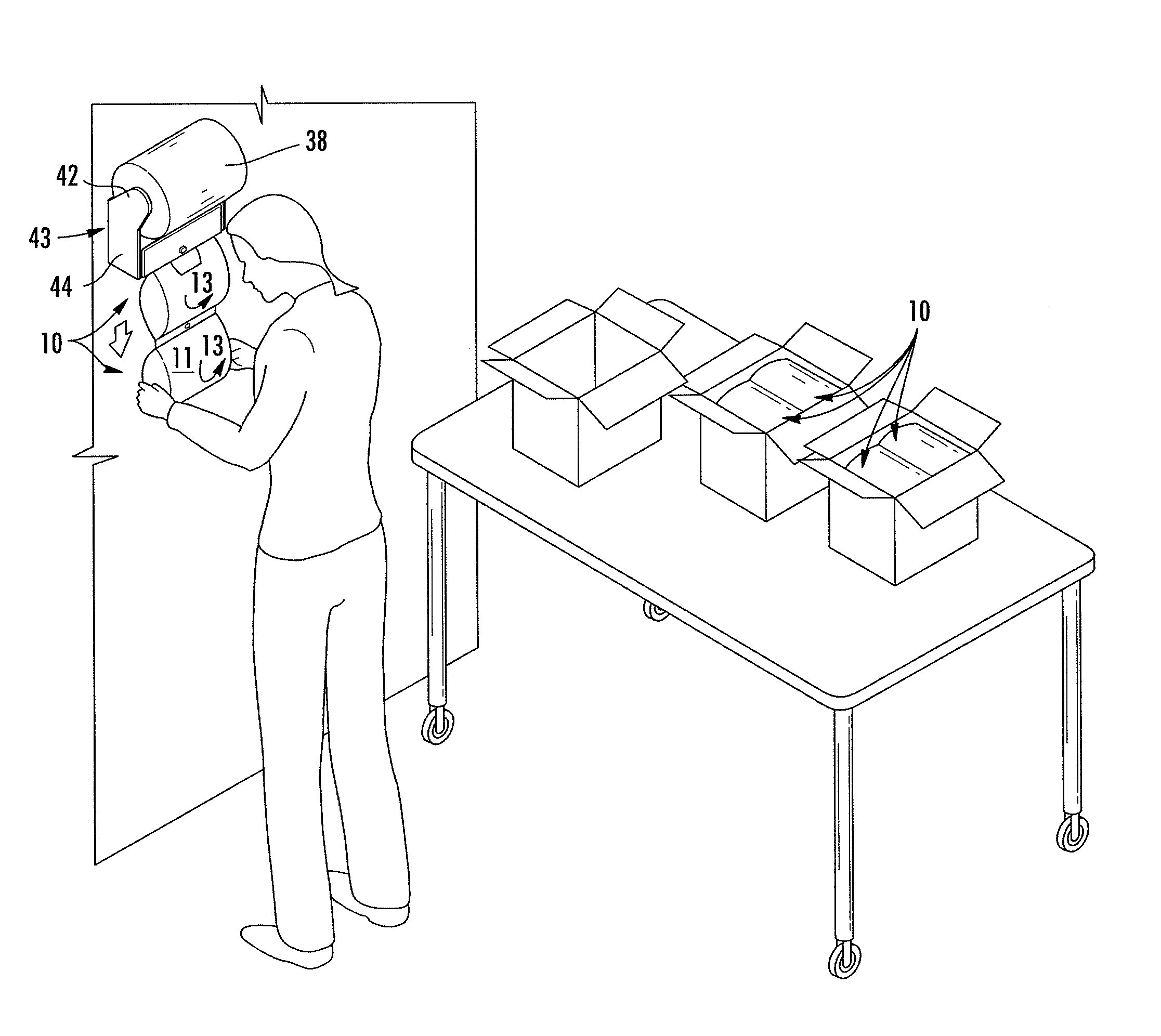

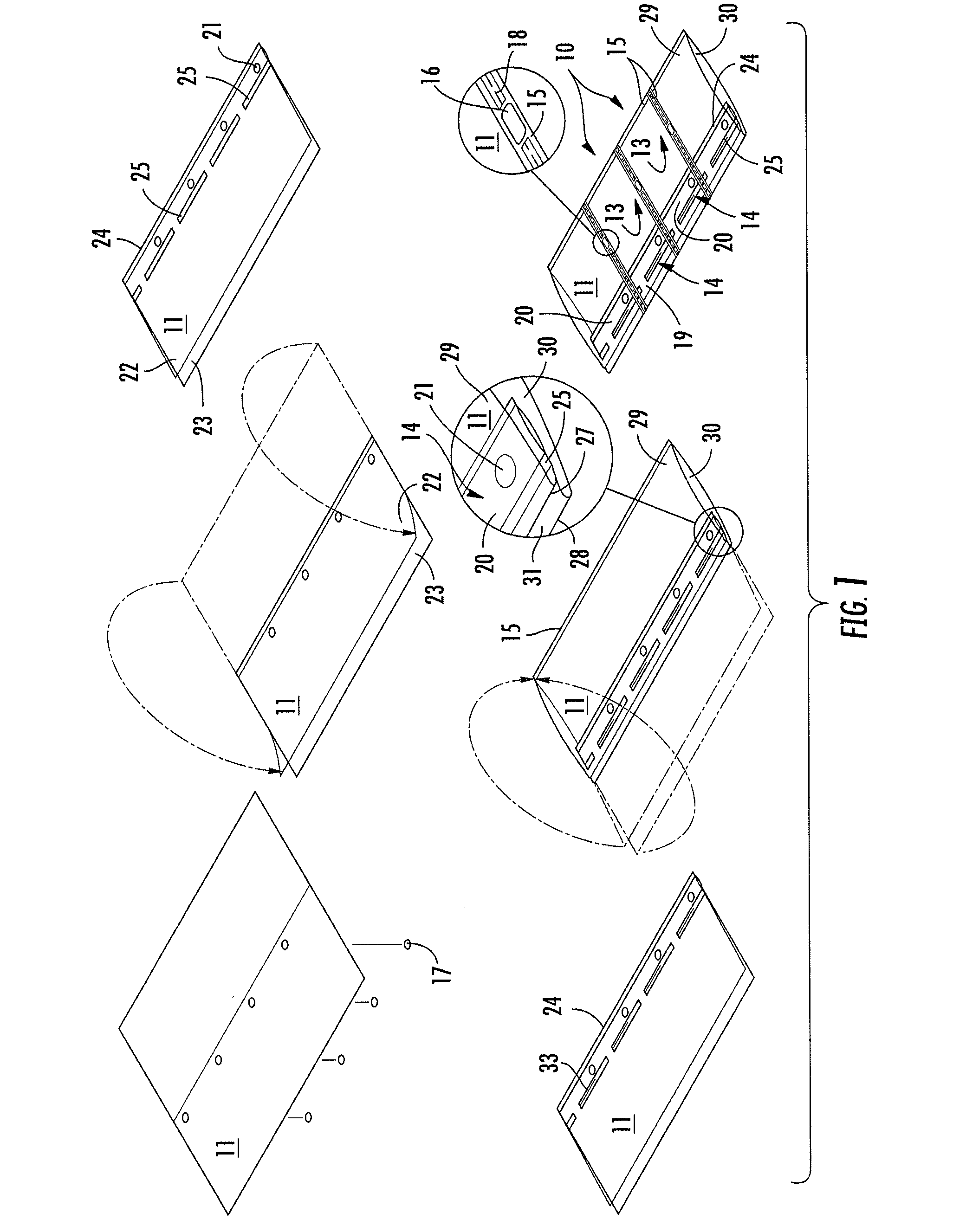

Inflatable mailer, apparatus and method for preparing the same

InactiveUS20060169753A1Save on transportation costReduce spaceEnvelopes/bags making machineryCapsEngineeringNozzle

The invention is an inflatable mailer having a liner that can be inflated at the point of use. The liner includes a series of inflatable chambers that are in fluid communication with a common channel. A controlled volume of gas is disposed in the liner. The gas is sufficient to inflate the common channel but is not sufficient to appreciably inflate the inflatable chambers. As a result, the inflatable mailer is in a relatively compact state. The invention includes an apparatus for inflating the mailer. The apparatus includes a nip for moving the controlled volume of gas into the common channel; an inflation nozzle adapted to pierce the inflated common channel and introduce a second portion of gas into the liner until the liner is inflated to a desired level; and a sealing device to seal the inflated liner.

Owner:SEALED AIR U S

Drogue having biased end opening

InactiveUS6932323B2Easy to inflateGood adhesionFilament handlingPropulsionEngineeringPneumatic pressure

A drogue for drawing an elongated item through a conduit is disclosed. The drogue includes a flexible bag having a closed end and an oppositely disposed end opening. Shroud lines attached to the bag at the end opening allow attachment of the drogue to the item. A biasing member, preferably in the form of a continuous loop of flexible, resilient interconnected wire legs, is attached to the bag and positioned proximate to the end opening. The loop engages the bag over a portion of its length and biases the end opening into an open configuration to prevent its collapse and loss of pneumatic pressure as it is propelled through the conduit.

Owner:FEDERAL MOGUL WORLD WIDE

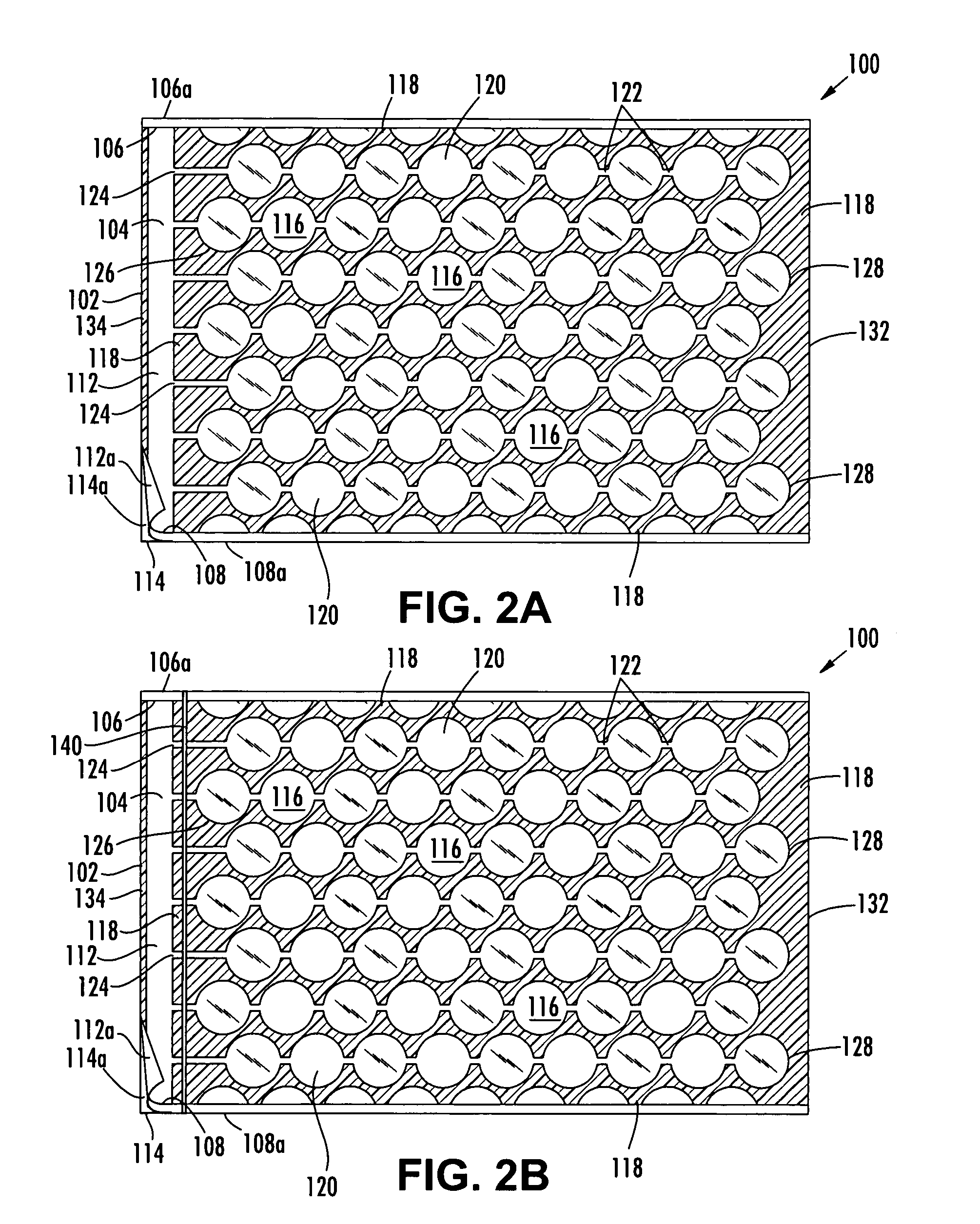

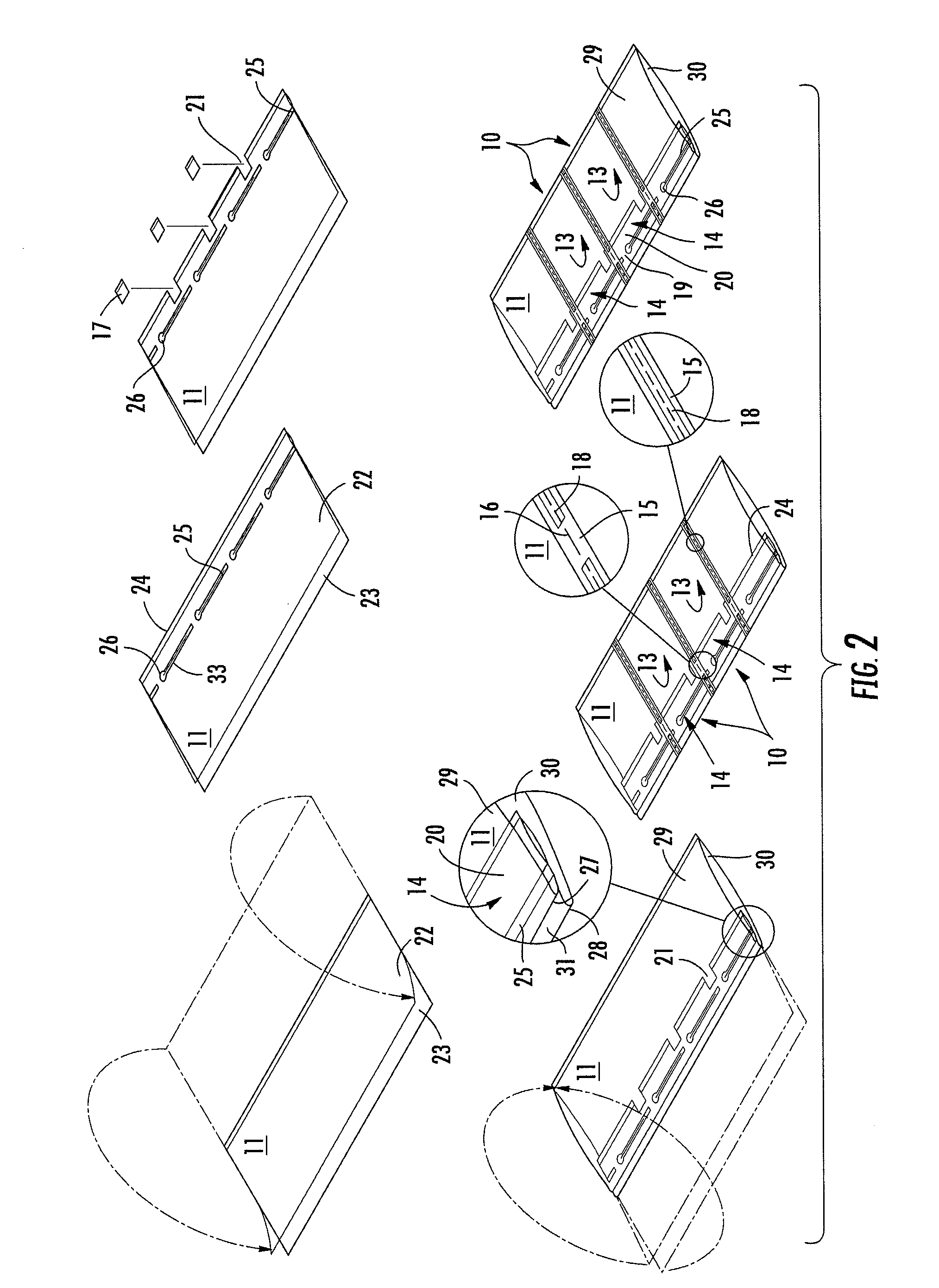

Inflatable Structure for Packaging and Associated Apparatus and Method

InactiveUS20100096290A1Easy to inflatePaper/cardboard articlesCheck valvesEngineeringMechanical engineering

An inflatable structure generally includes a valve formed between a pair of edge portions and an internal edge portion formed of a flexible film such that an enclosed chamber of the inflatable structure substantially envelops the internal edge portion. The valve and remainder of the inflatable structure can be formed from a single piece of flexible film using a method of manufacturing an inflatable structure from a continuous web of flexible film. A corresponding inflation device fills the inflatable structure with air and may do so without requiring heat sealing or contact between the inflatable structure and outlet of the inflation device. The inflation device may include a mechanical registration device which can engage an optional locator aperture in the inflatable structure such as to assist in temporarily locating the outlet of the source of pressurized air proximate to the valve in the inflatable structure.

Owner:SEALED AIR U S

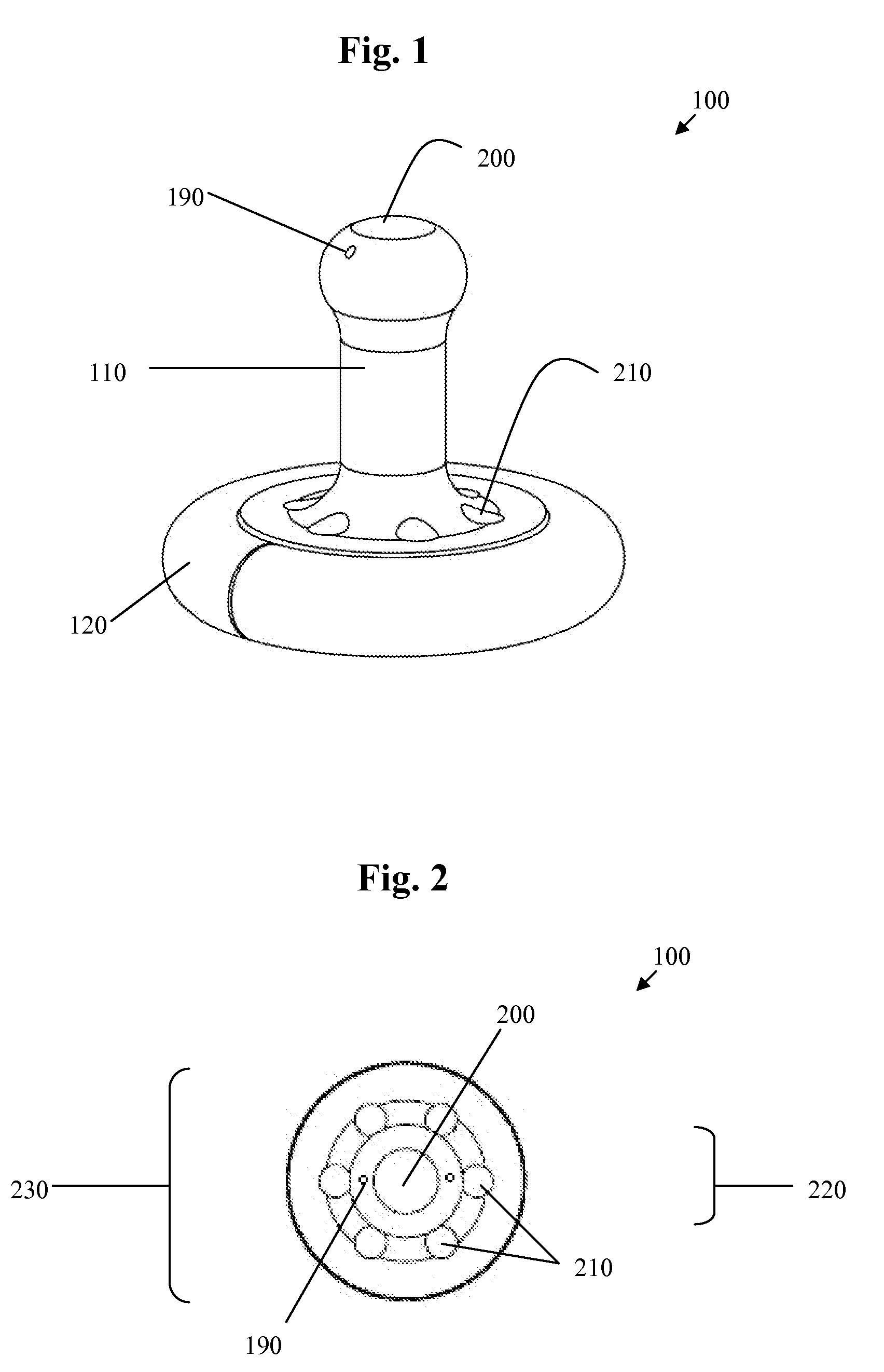

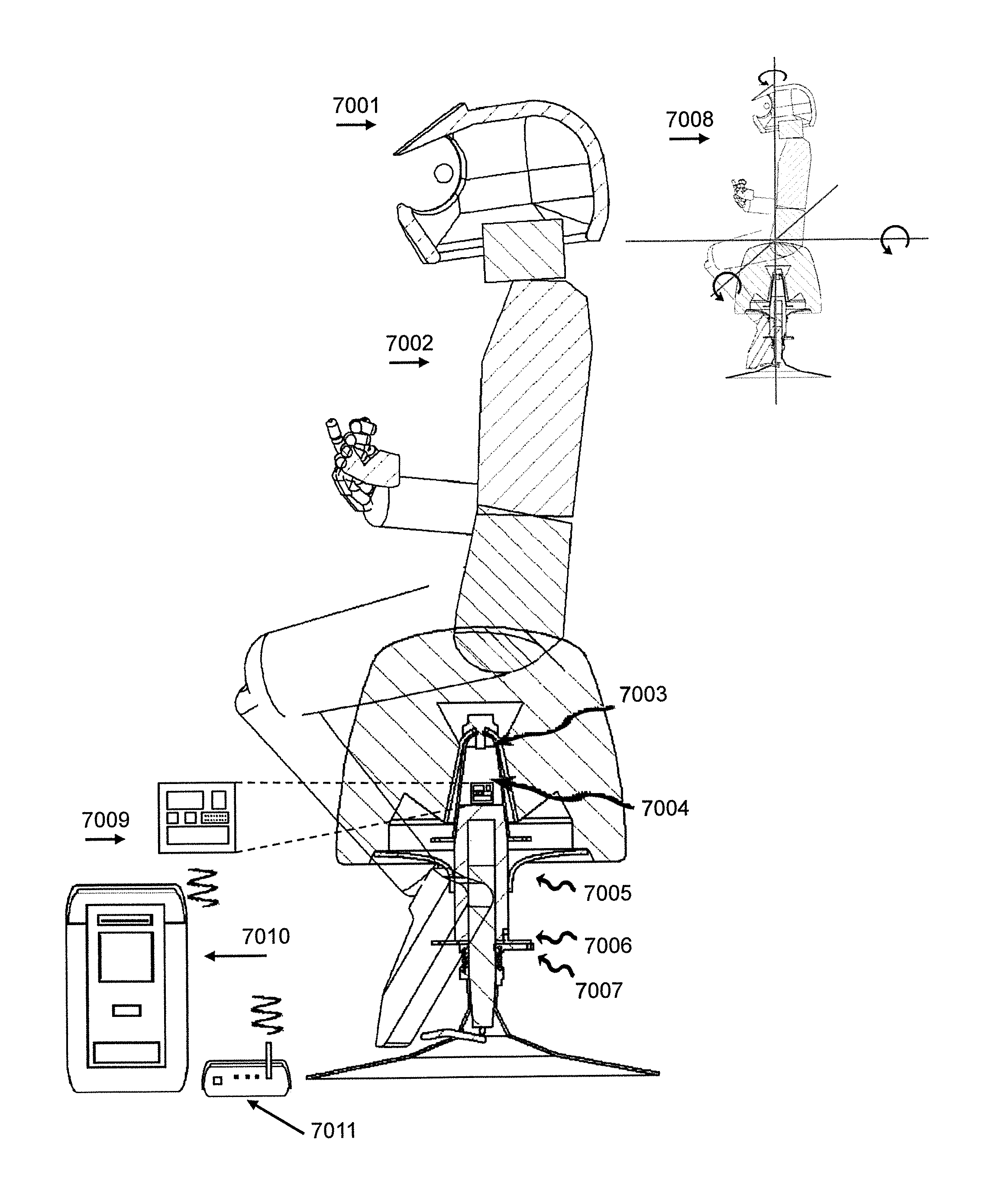

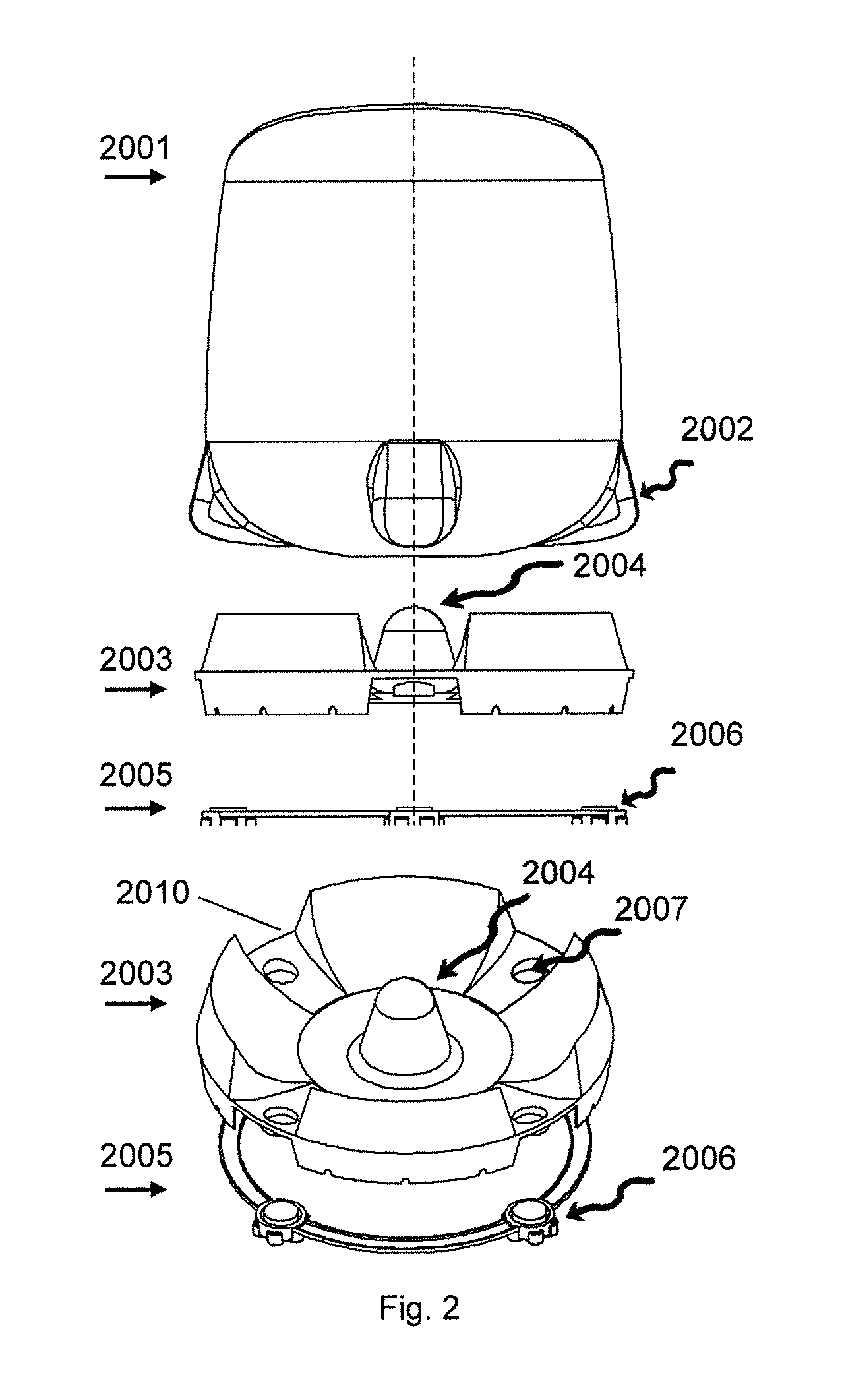

Motion control seat input device

PendingUS20160320862A1Lower the volumeImprove stabilityInput/output for user-computer interactionStoolsControl signalUser input

An input device for providing user input to a computing device includes a seat portion allowing a user to sit on the device. The input device further includes several positional sensors that detect changes in pitch, yaw and roll and convert those detected changes to a control signal for operating functions on a computing device and / or providing input to applications running on the computing device.

Owner:SCHRADIN AARON +1

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6701971B1Reduced packaging volumeLong leak-downLeno shedding mechanismPreformed elementsElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 7 seconds. All coatings, in particular elastomeric, non-silicon coatings, and coated airbags, meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

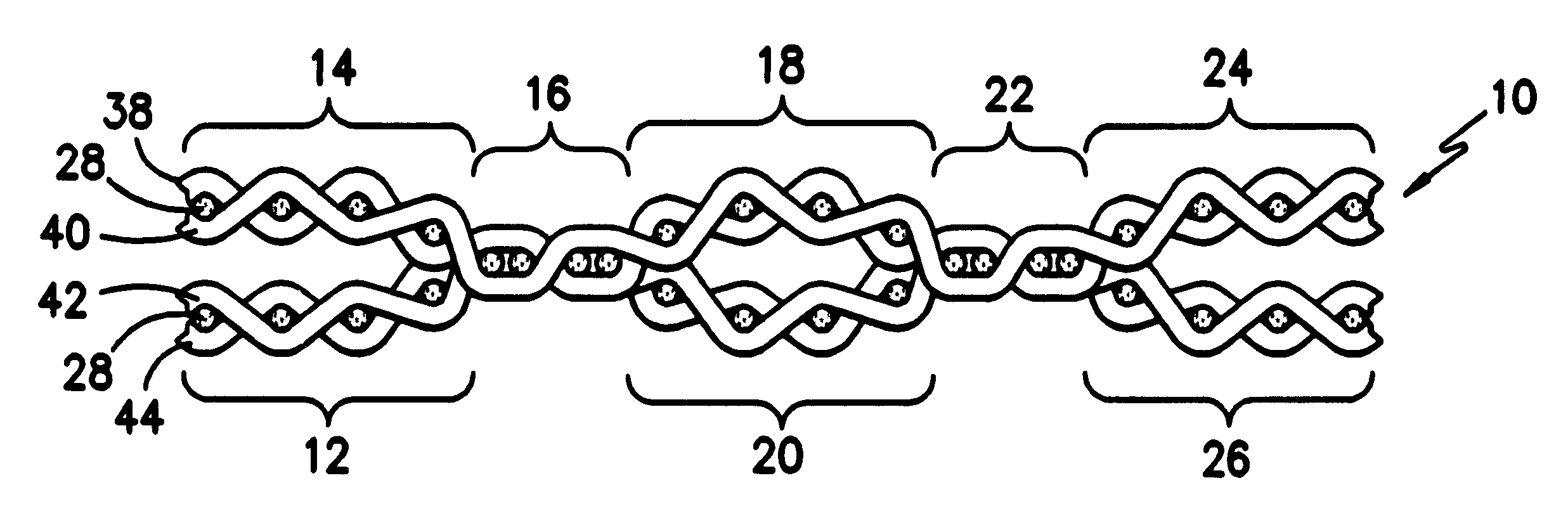

Cushion for protection of a vehicle occupant's head

InactiveUS6883826B2Easy to inflateEnergy absorbing amount is increasedPedestrian/occupant safety arrangementCushionYarn

A cushion for protecting a vehicle occupant's head. The cushion inflates and deploys smoothly and is configured so that gas leakage out of the cushion is reduced in order to maintain the inner pressure high for an extended period of time. The cushion includes a protective cushion element and outer shell fabrics superposed on both outer surfaces of the protective cushion element. The cushion element includes a cabin-side base fabric and a window-side base fabric that are sewn together by sewing yarns after being bonded to each other by adhesive. The outer shell fabrics are bonded to the protective cushion element by adhesives. When the protective cushion element is inflated, the outer shell fabrics are tightly stretched over the outer surfaces of the inflated protective cushion element so as to cover depressed portions of the base fabrics.

Owner:TAKATA CORPORATION

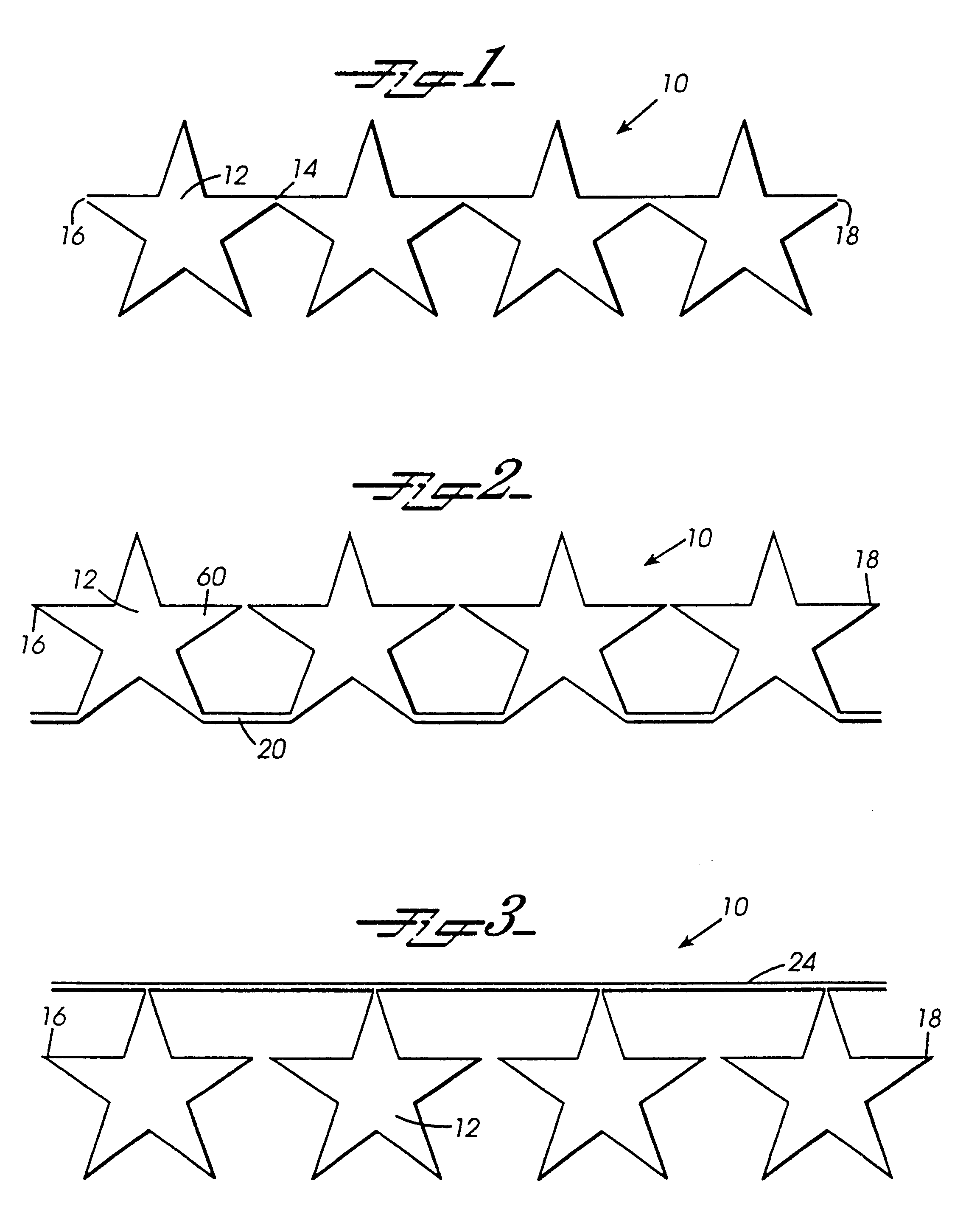

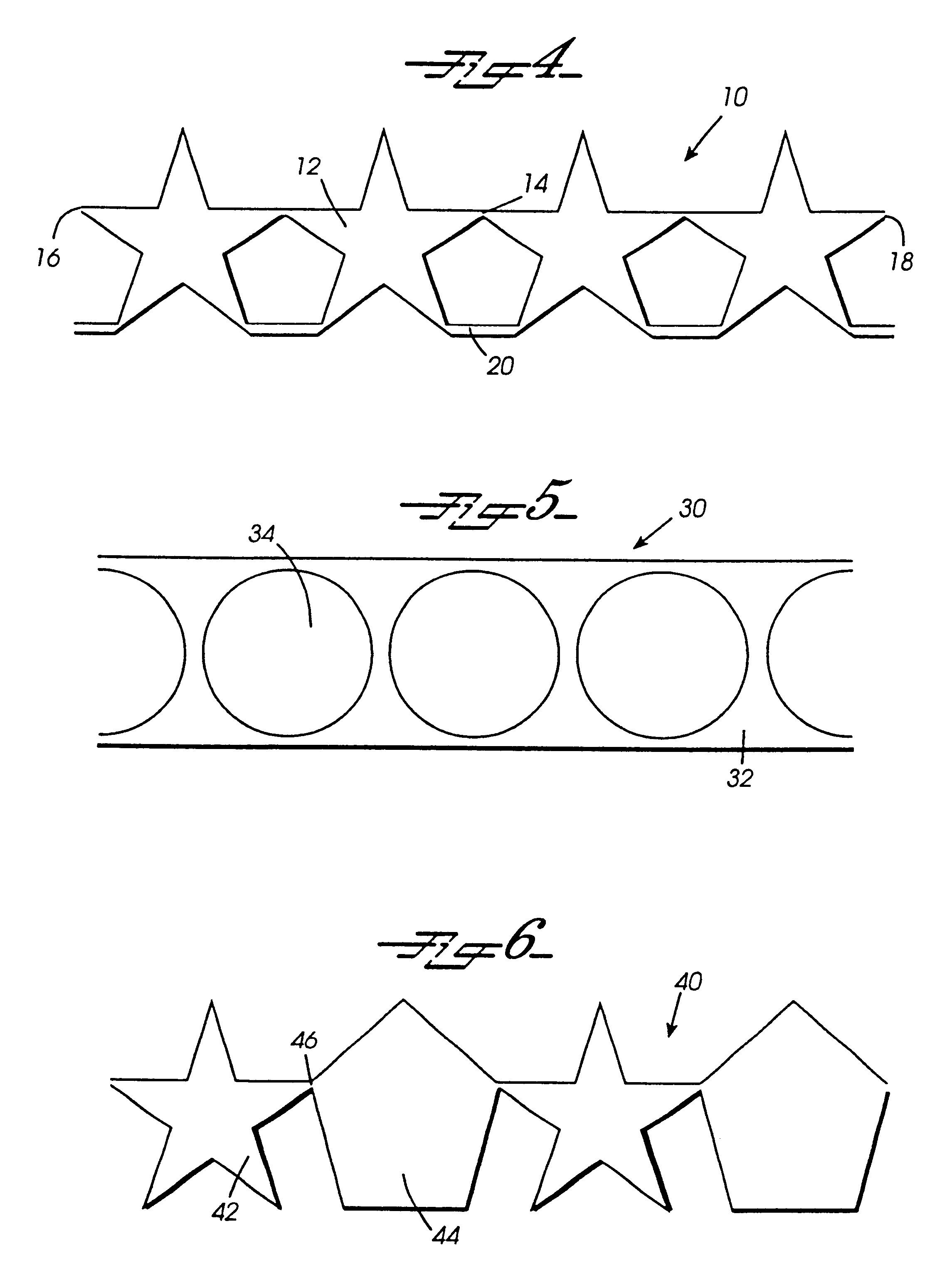

Balloon displays

A structural and / or decorative display is made by connecting inflatable balloon chambers into a network. The network of inflatable chambers may be generated as a balloon system comprised of at least two essentially identical balloonlets each of which has at least two openings and is in fluid communication with at least one other identical balloonlet. The set of inflatable chambers may be framed into a network by a matrix of apertures expanded from a sheet of material with a pattern of overlapping cuts. The network of inflatable chambers may be comprised of a balloon system of balloonlets framed by an overlapping cut expandable matrix.

Owner:ROUSE JR GRAHAM M

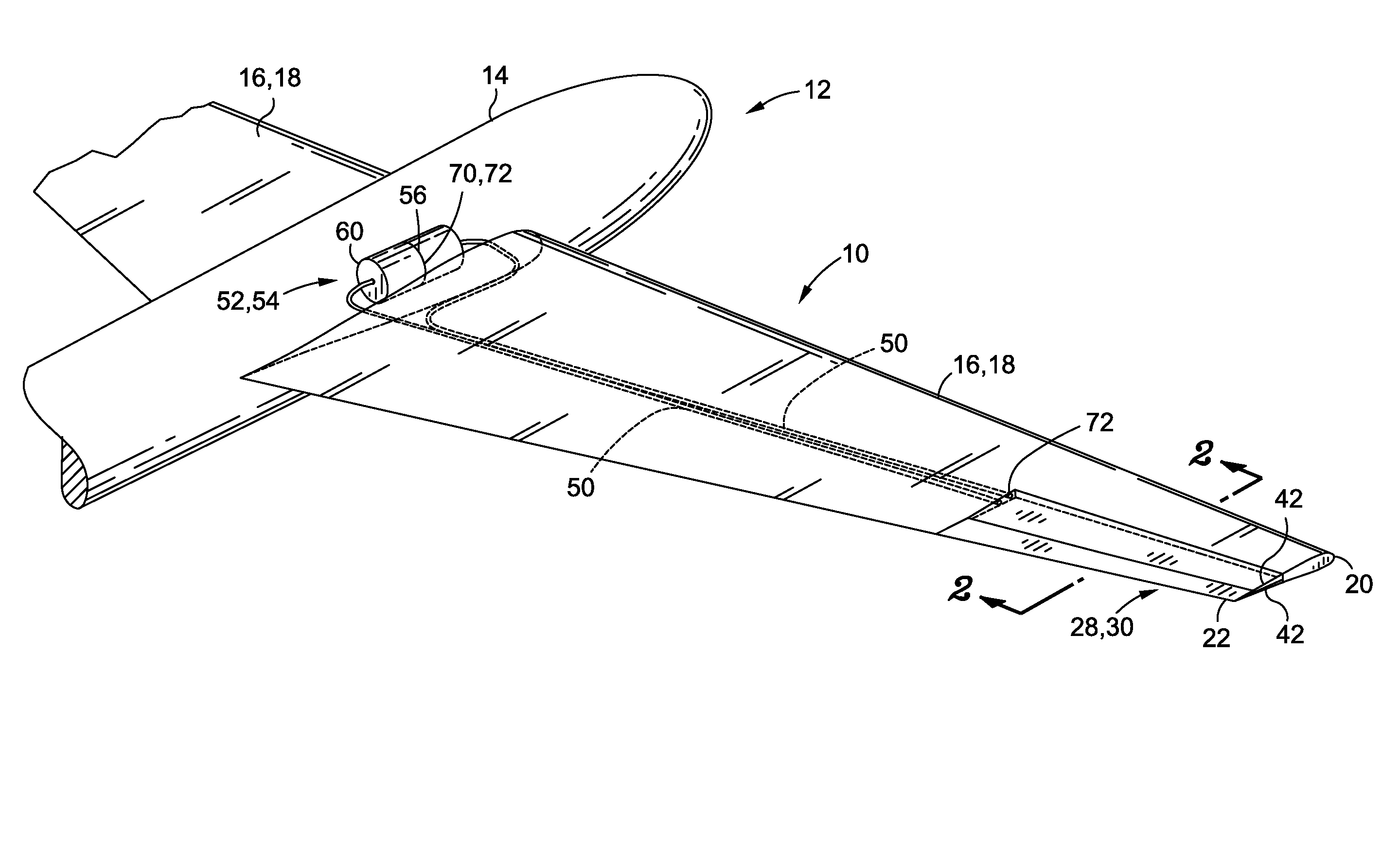

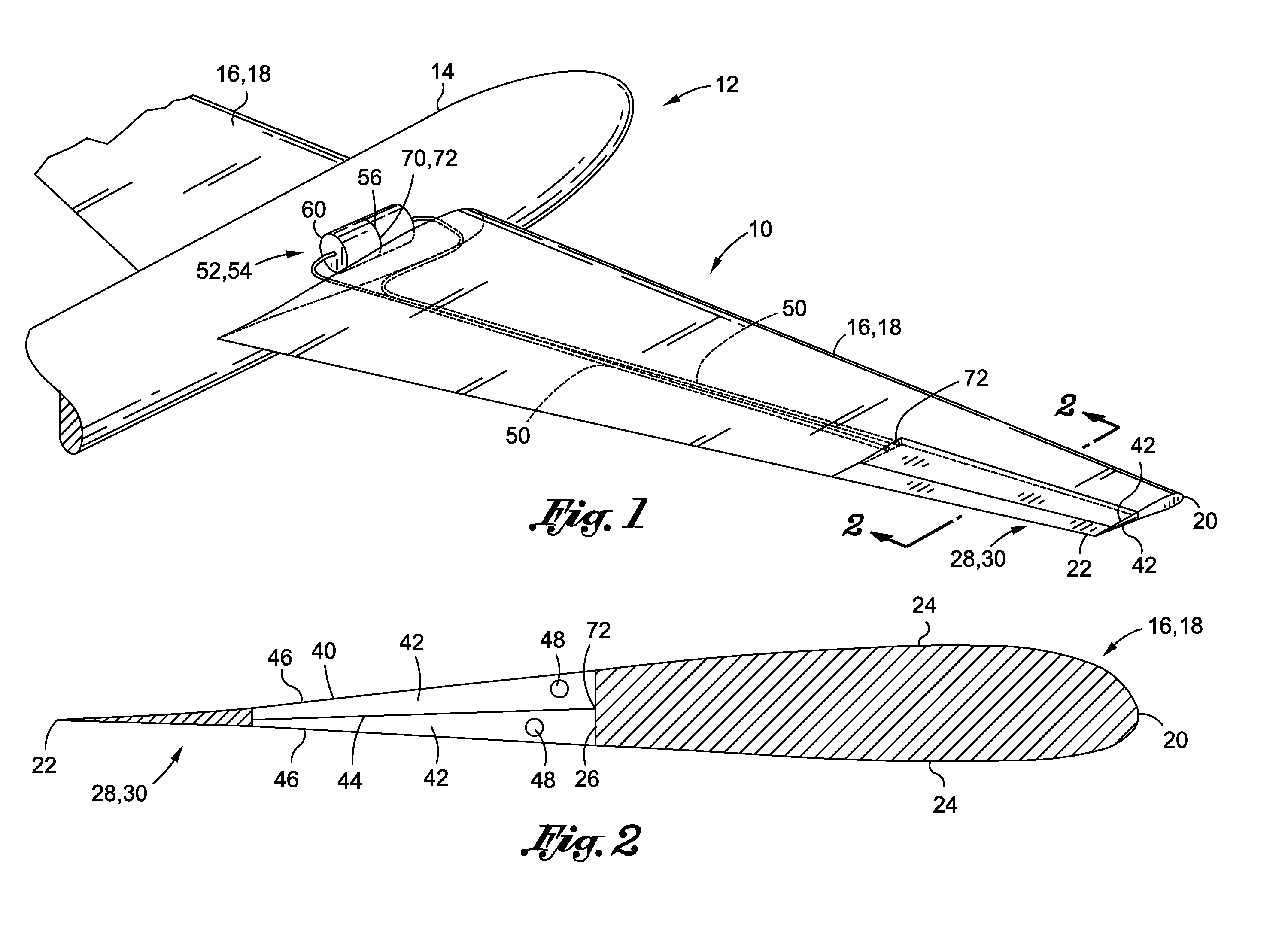

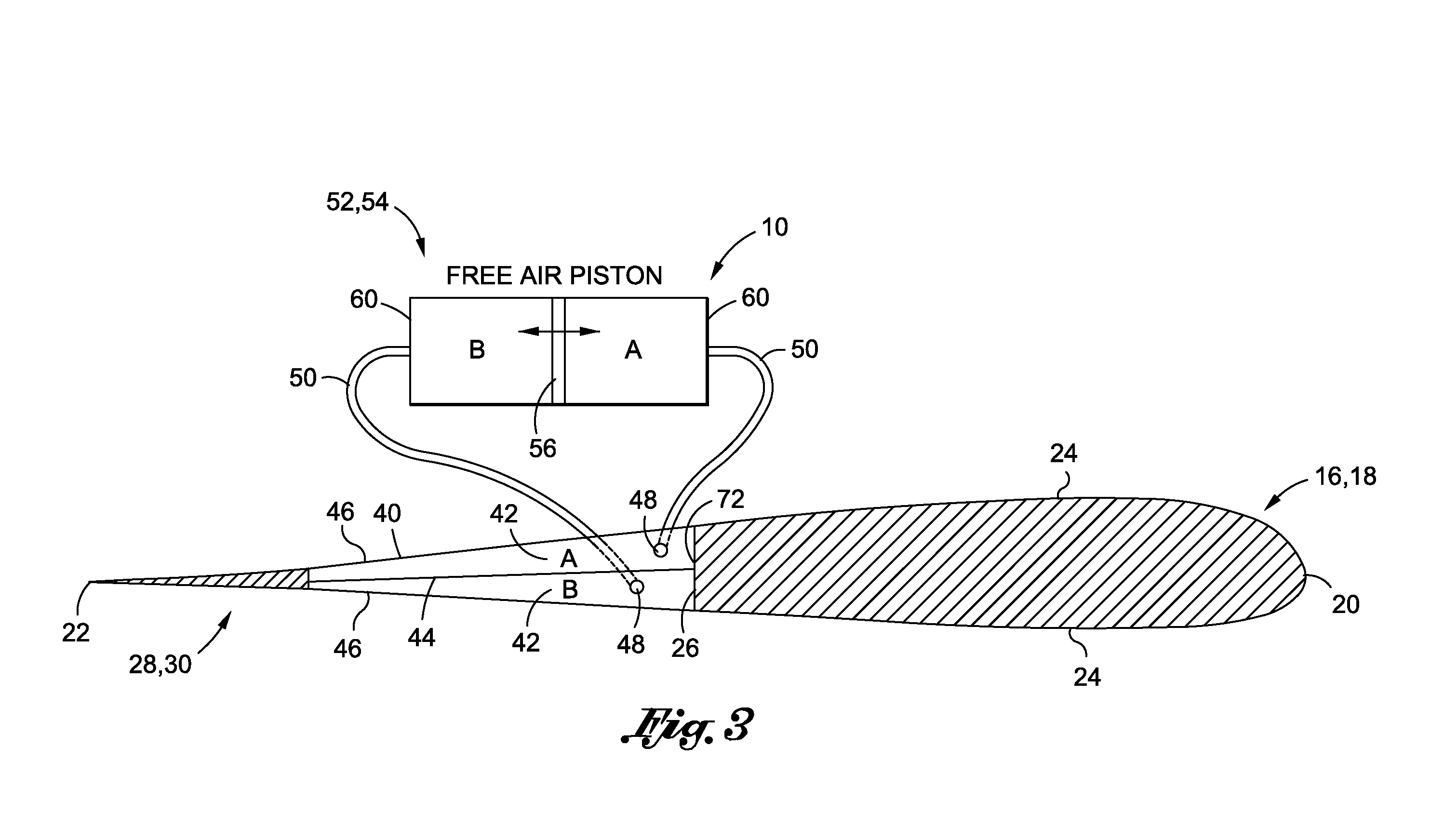

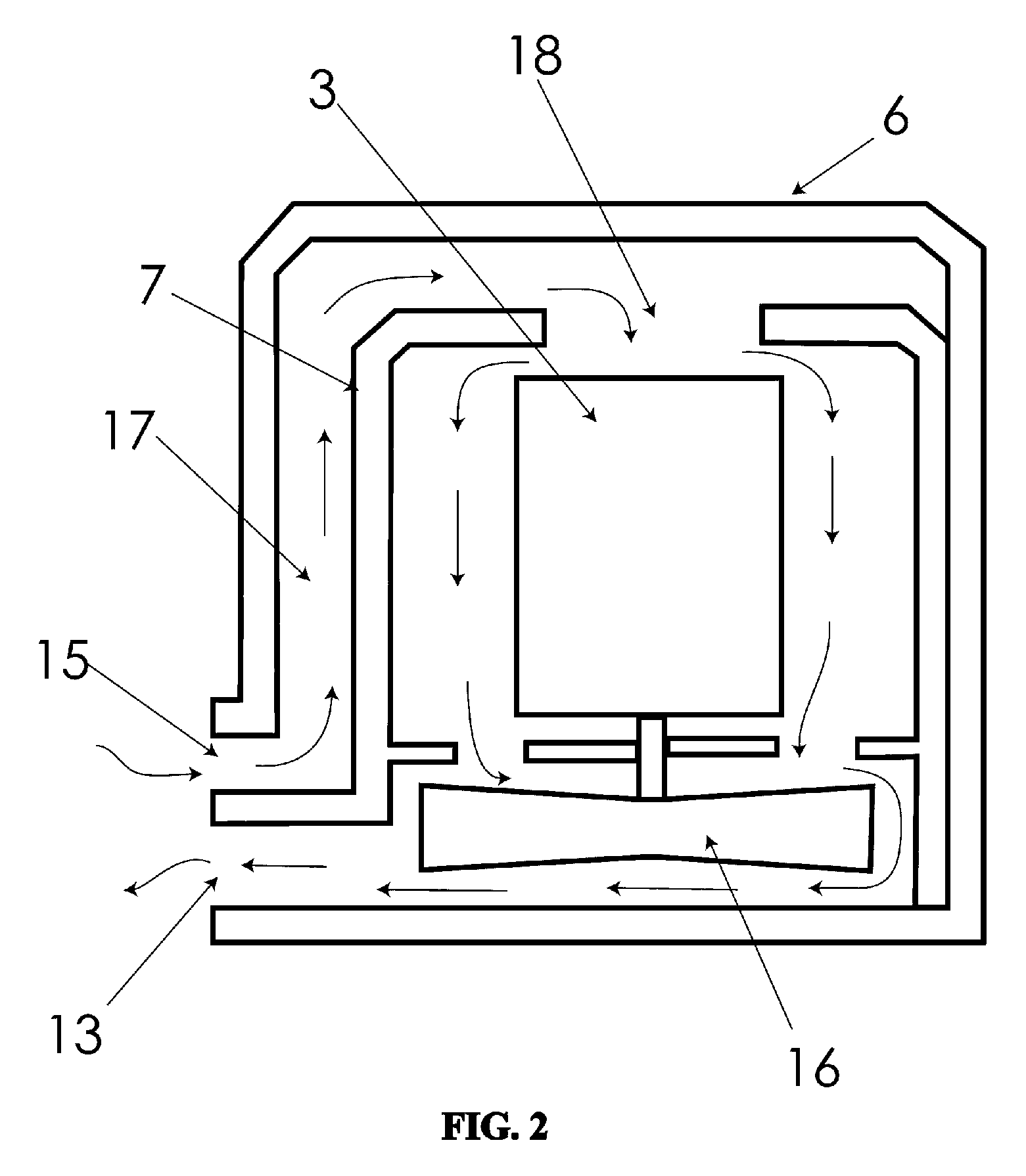

Pneumatic control system for aerodynamic surfaces

ActiveUS20090224108A1Facilitate upwardFacilitate downward actuationAircraft stabilisationWing adjustmentsDifferential pressureEngineering

A flight control system for an airfoil comprises a control surface, a chamber connecting the control surface to the airfoil, and a pneumatic mechanism fluidly connected to the chamber. The chamber may be comprised of at least two cells that may be fluidly separated by a membrane. The pneumatic mechanism is configured to provide differential pressure to the cells in order to alternately increase volume / pressure of the cells to cause deflection of the control surface. The cells may have a stretchable outer surface to allow for changes in the length of the outer surface in response to inflation / deflation of the cells. The outer surface of the cells may be substantially continuous with outer mold lines of the airfoil and of the control surface.

Owner:THE BOEING CO

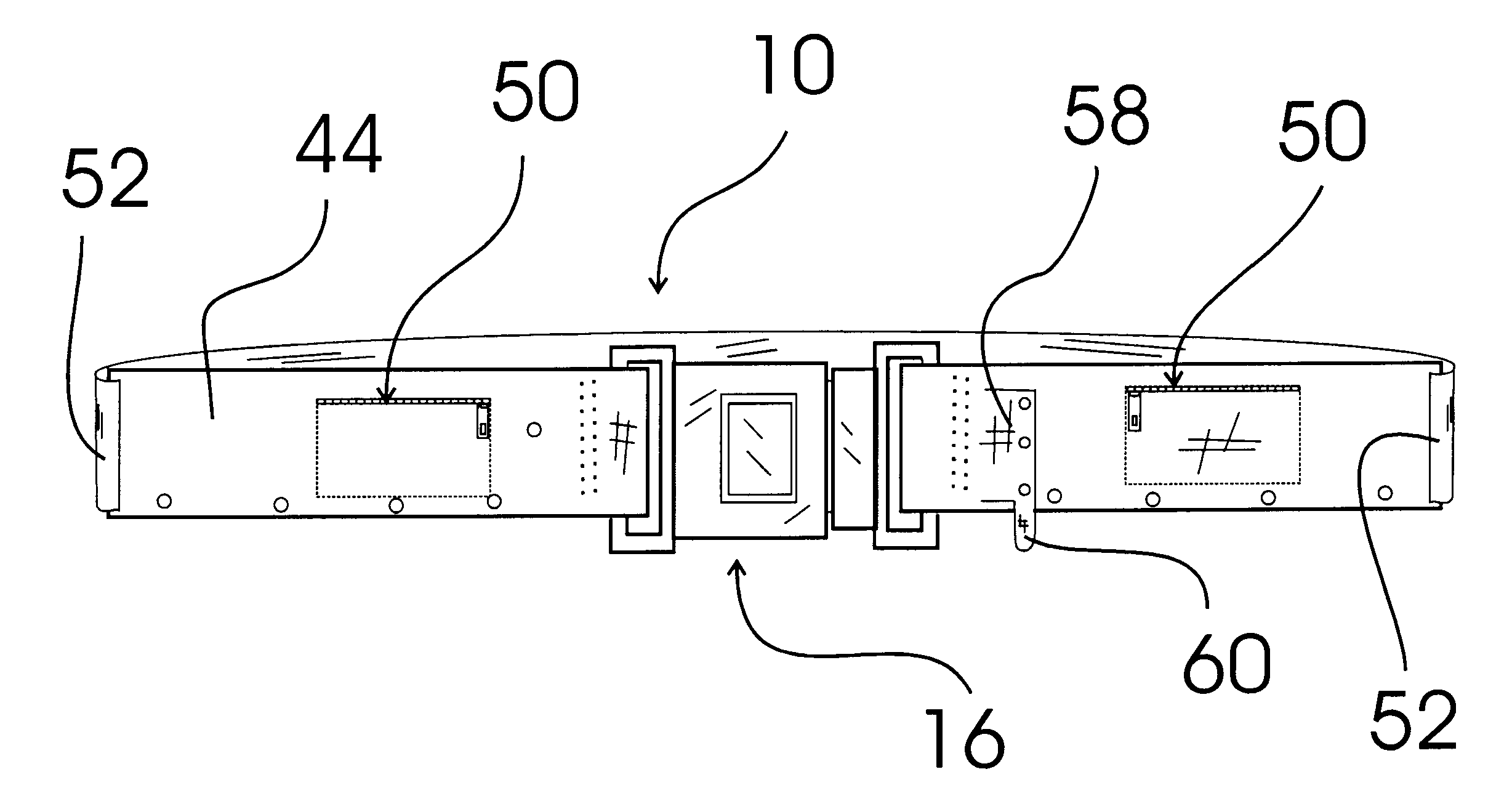

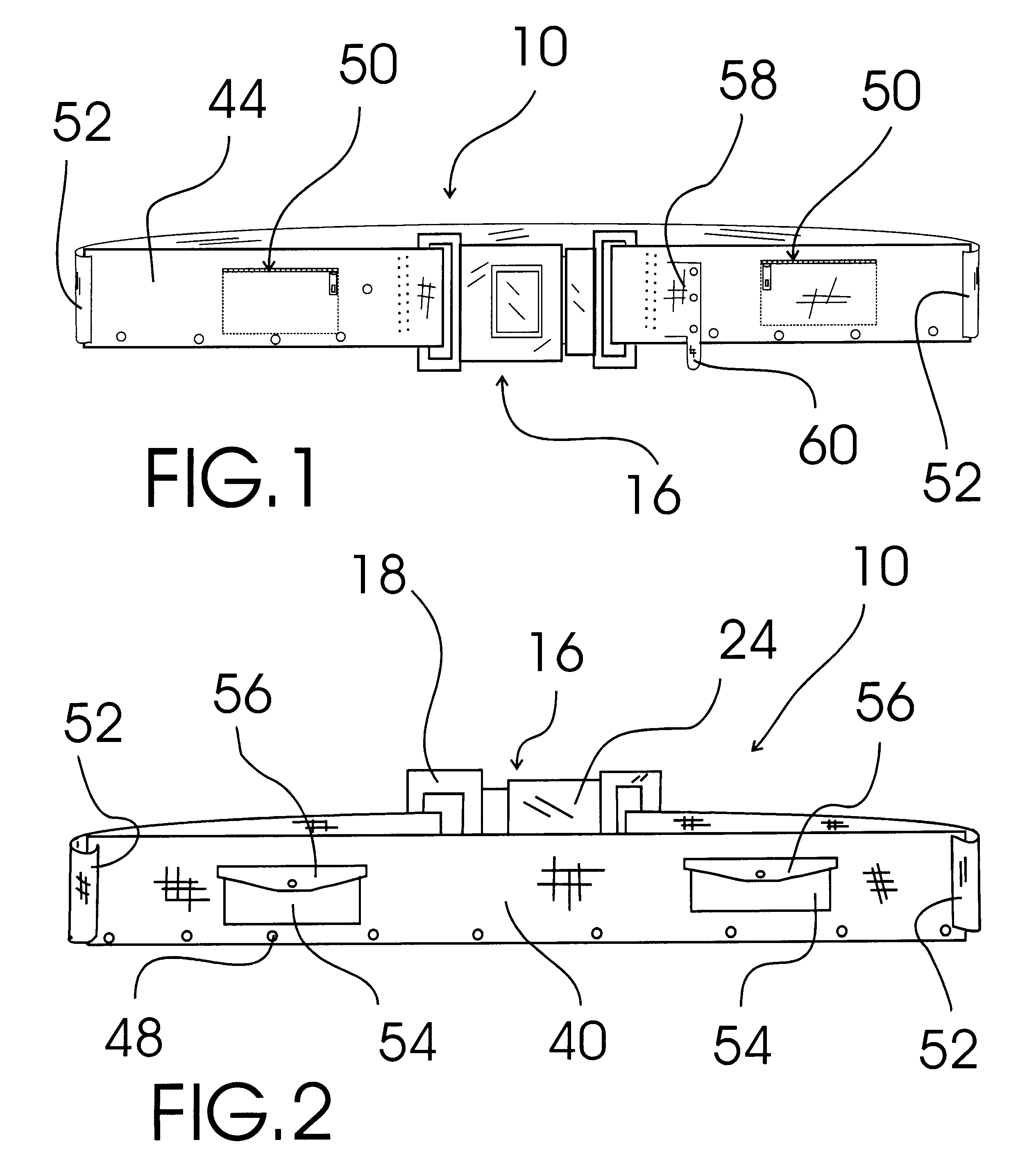

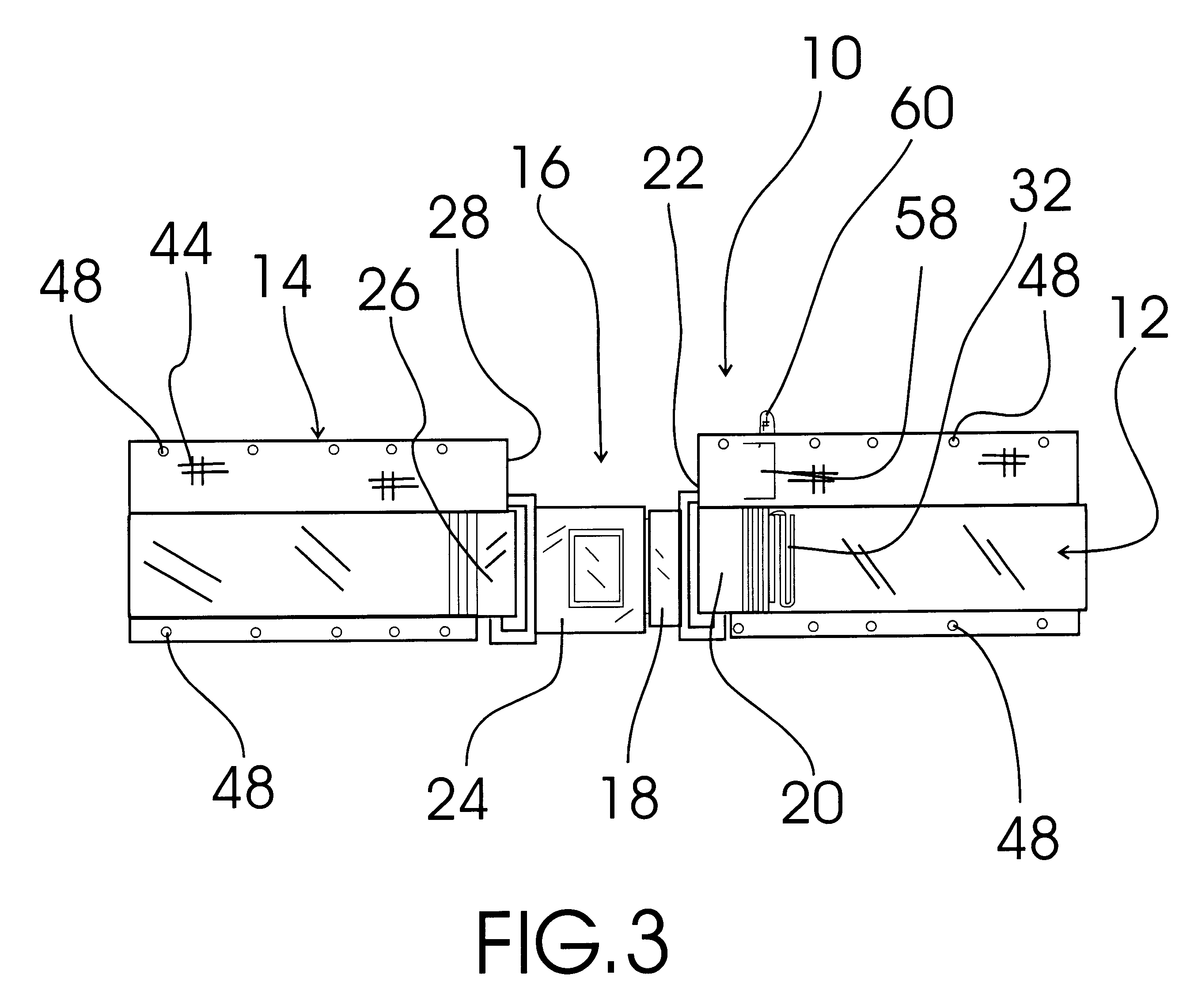

Water sport belt

InactiveUS6179677B1Easy to inflateImprove scalabilityLife-buoysOther accessoriesCredit cardEngineering

A water sport belt that includes an inflatable bladder that is be secured around the waist of a user to provide a flotation mechanism in an emergency. The inflatable bladder has a number of accordion fold sections that are inflated with an initial amount of air sufficient to provide buoyancy without the need for the user to blow with sufficient force to overcome the elastic walls of the bladder. The water sport belt also includes a water-tight compartment within which a user may safely position items to be kept safe and dry. A card holding structure is provided within the water-tight compartment to prevent damage to credit cards and the like by items such as coins and keys.

Owner:DORNIER GARY P

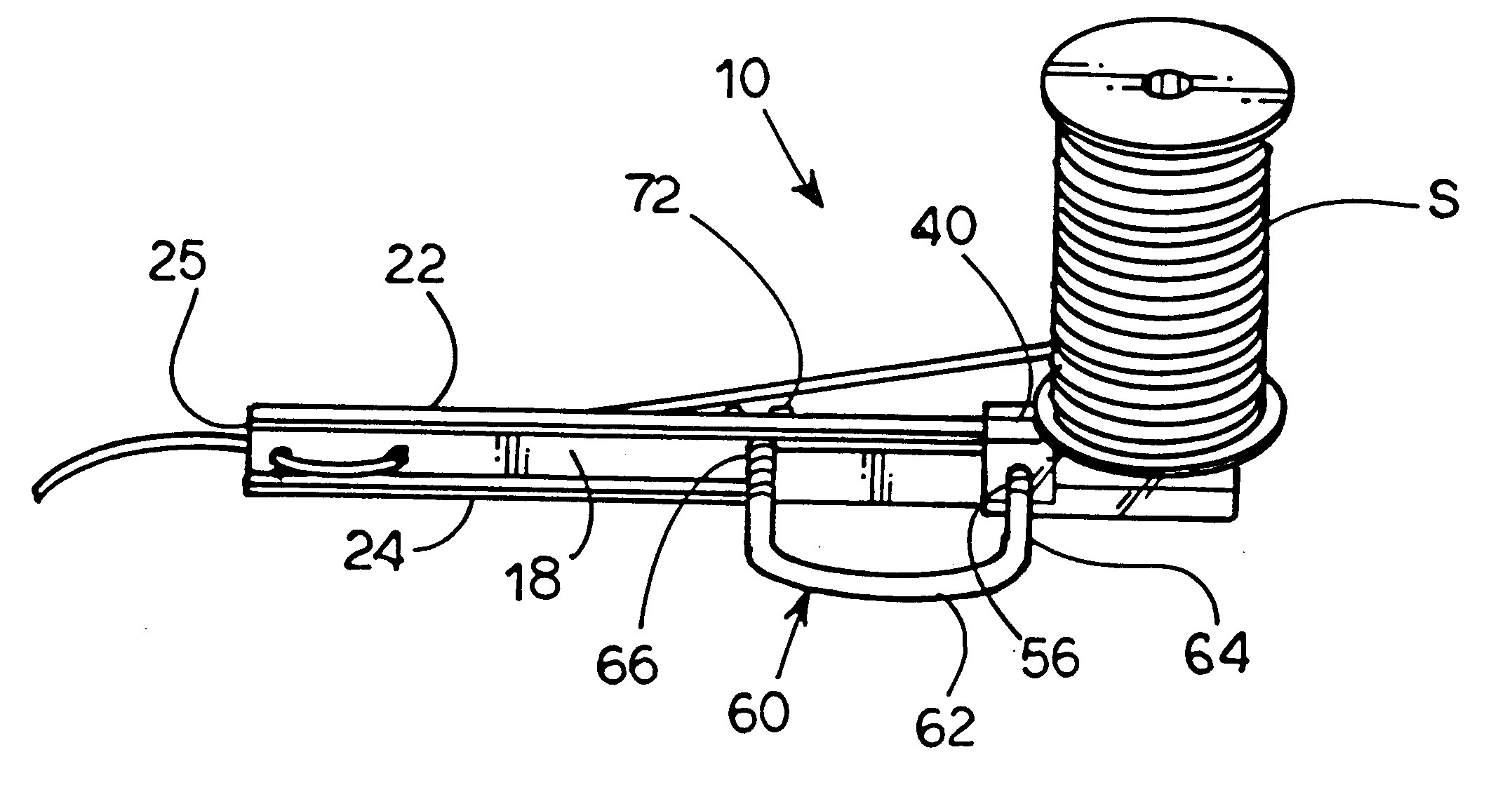

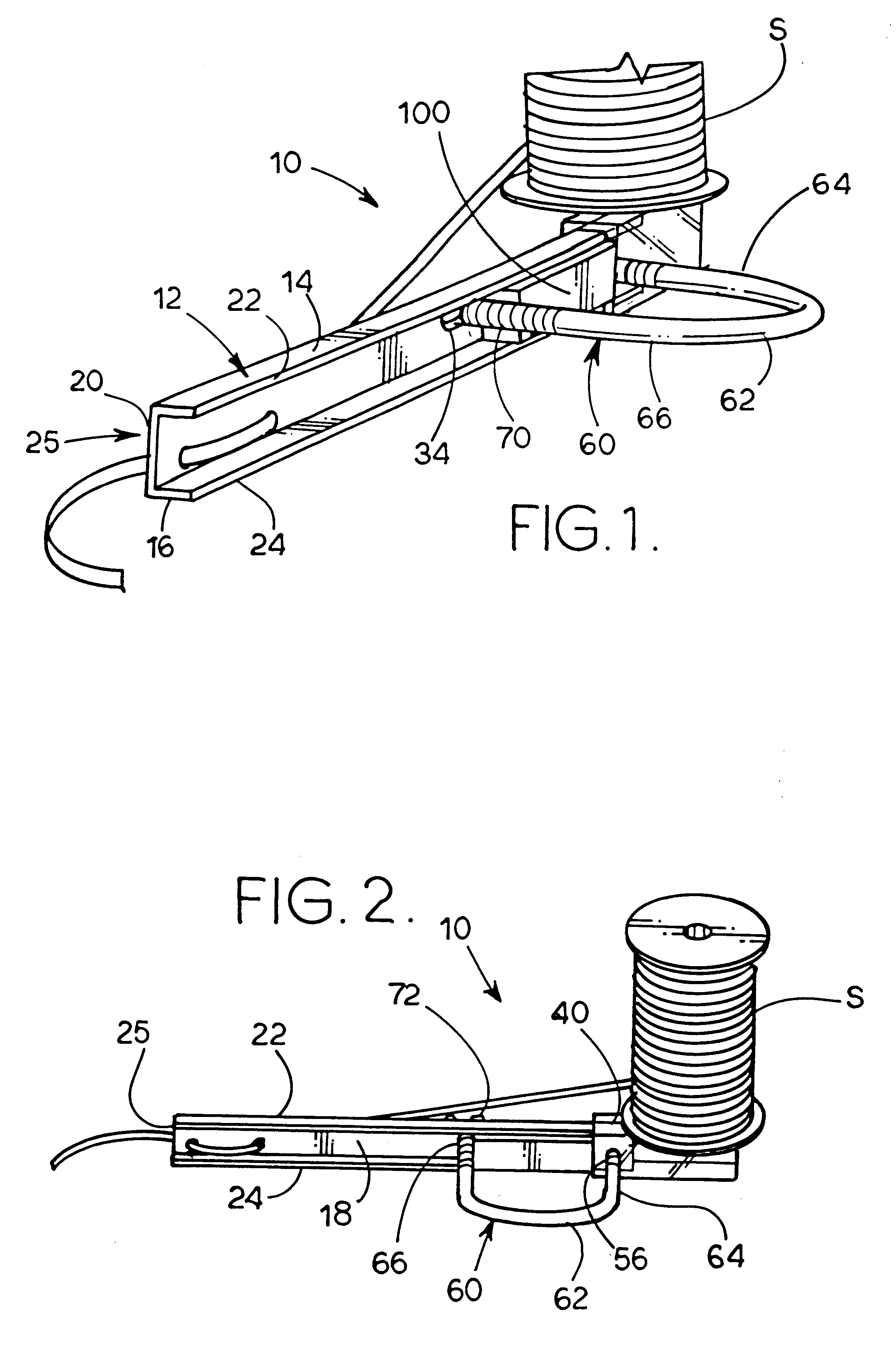

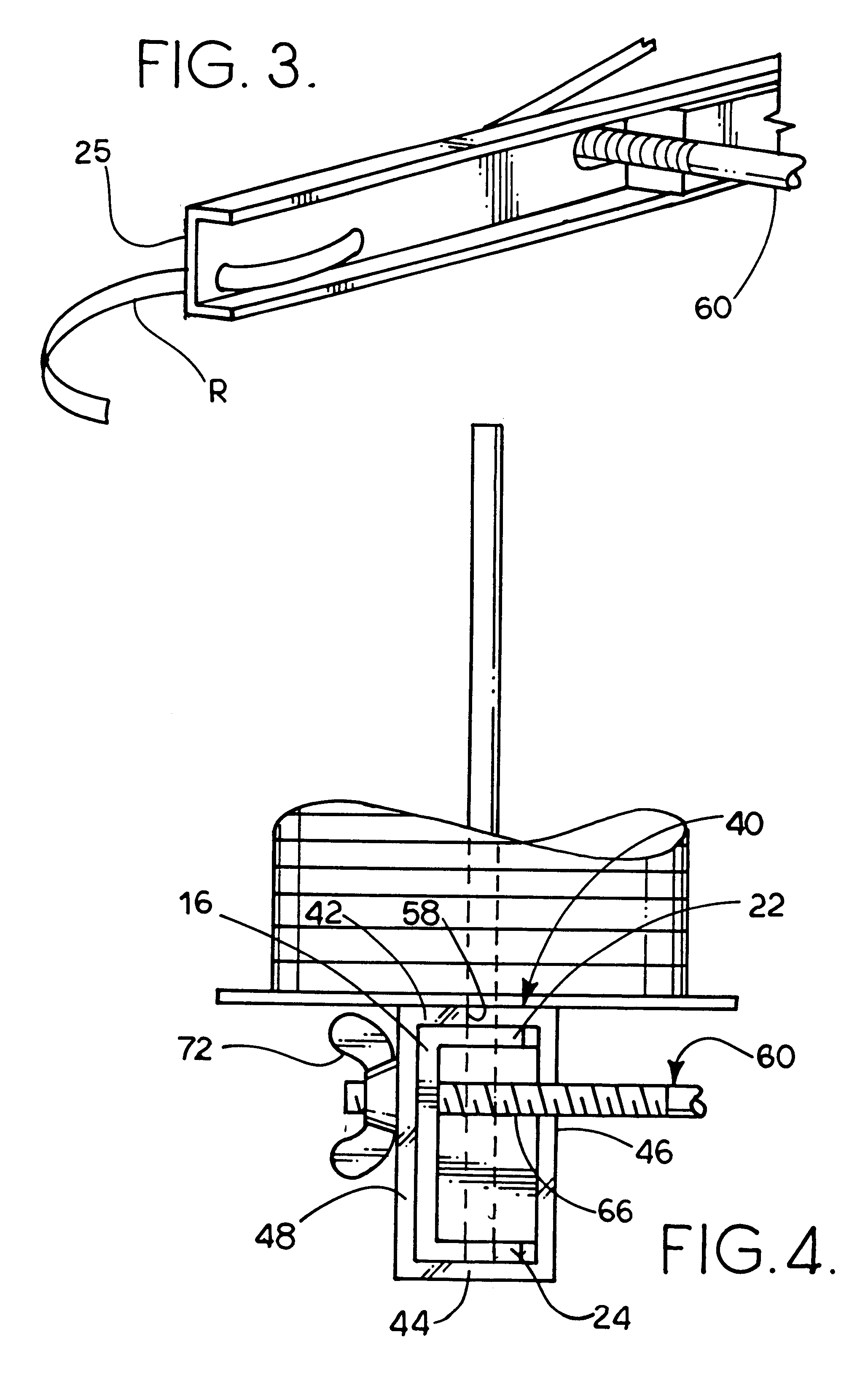

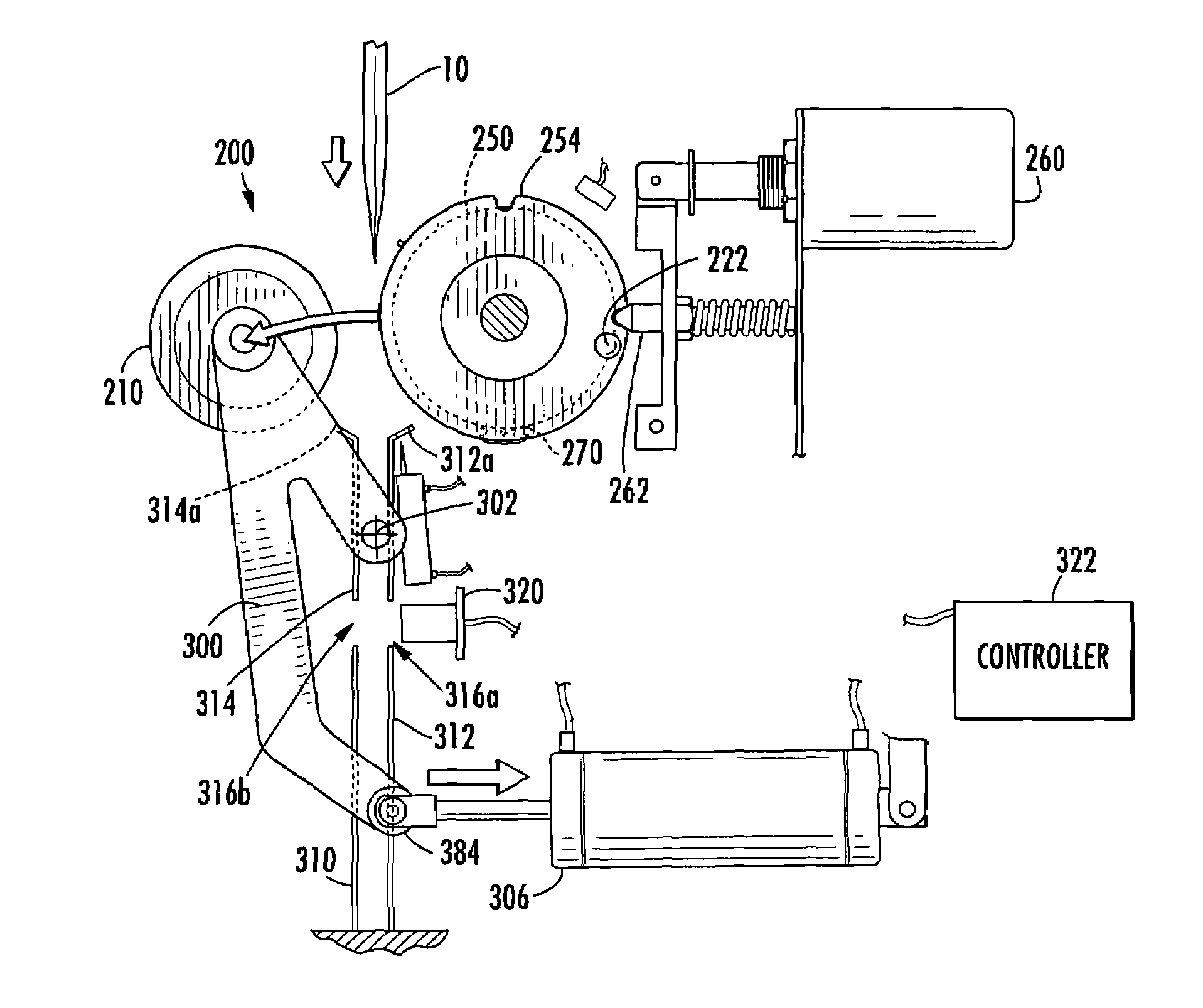

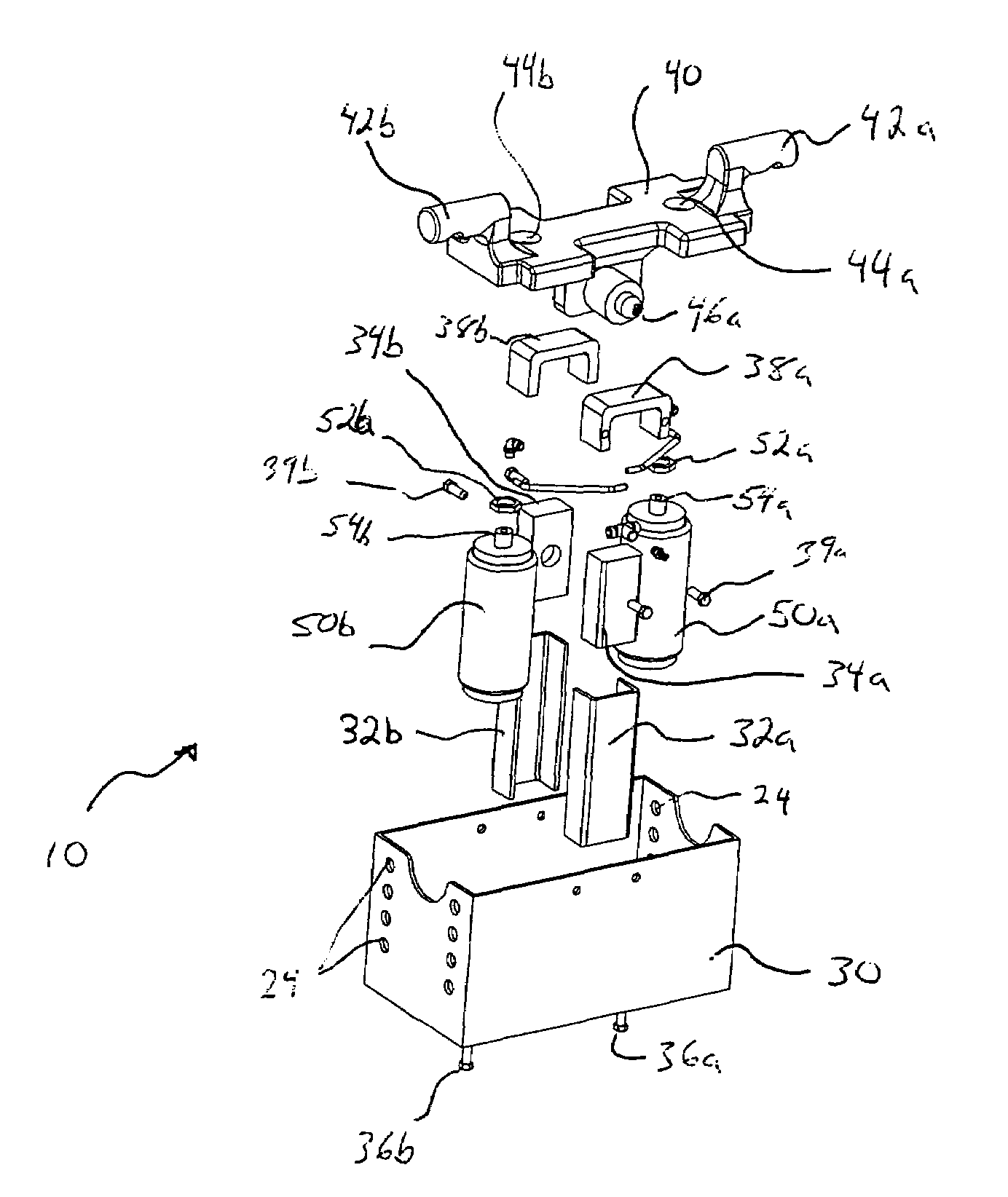

Unit for tying a balloon and securing a ribbon to the balloon

A unit is mounted directly on a tank of pressurized gas used to inflate a balloon and includes a supporting bracket having ribbon-accommodating holes defined through one end thereof and a support section on the other end. A ribbon supporting spool is rotatably mounted on the support section and ribbon drawn off the spool is threaded through the ribbon-accommodating holes to be captured in a knot formed in the neck of the balloon after that neck has been drawn around the supporting bracket and formed into a knot. A method of forming a knot in the balloon and capturing the ribbon therein is also disclosed.

Owner:CARLSON LELAND R

Inflatable mailer, apparatus and method for preparing the same

InactiveUS7621104B2Prevent escapeEasy to inflateEnvelopes/bags making machineryCapsEngineeringNozzle

Owner:SEALED AIR U S

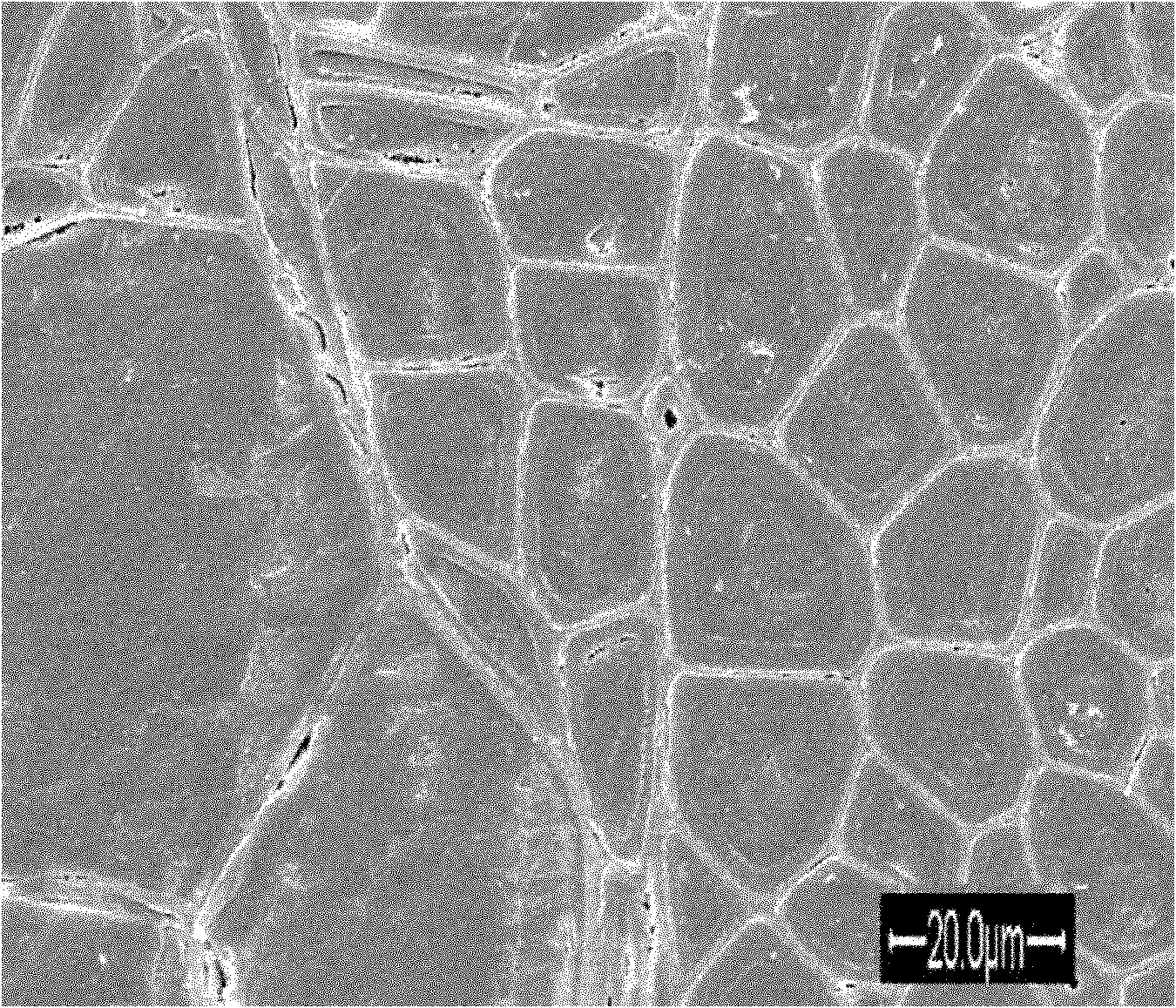

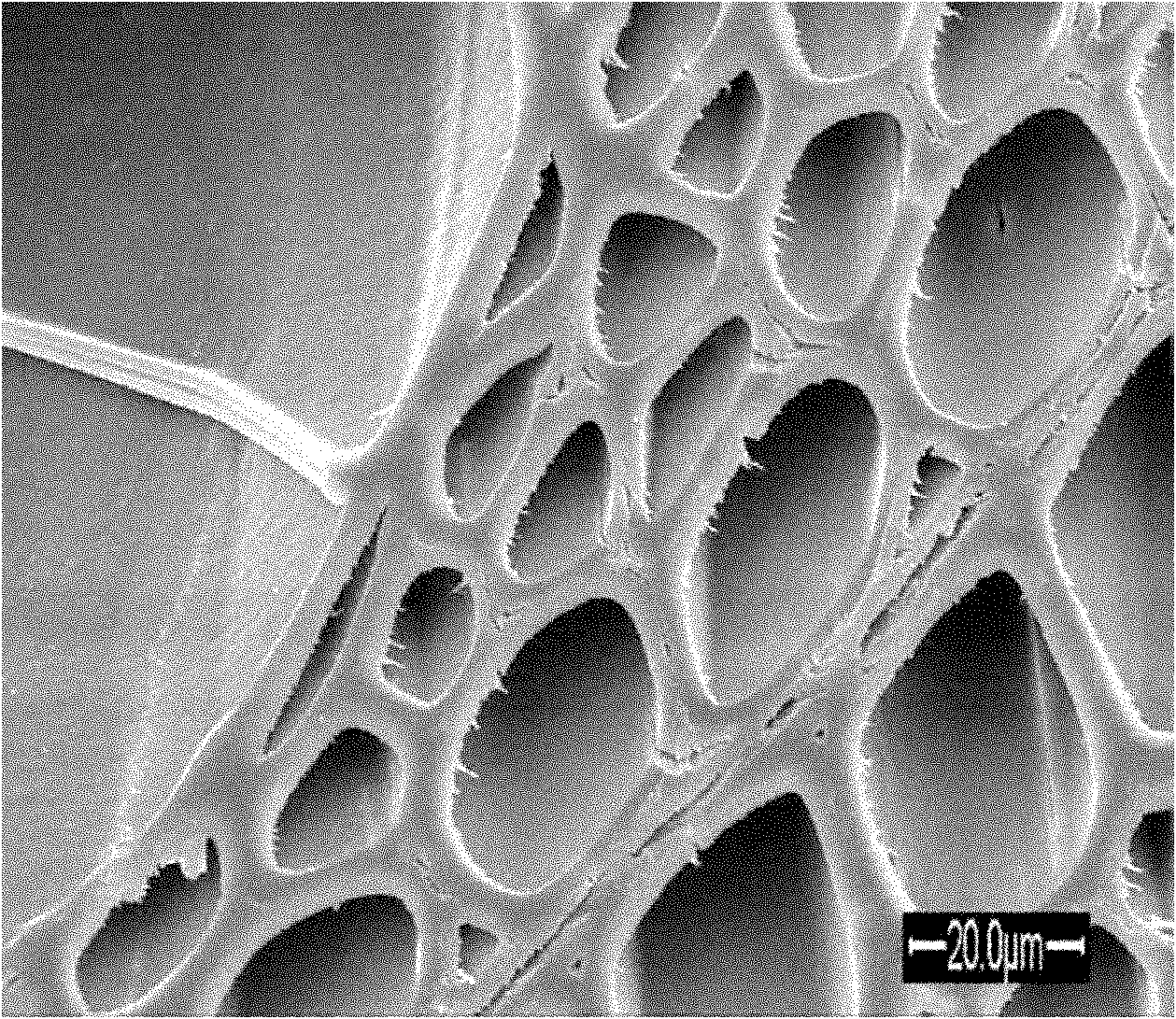

Method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities

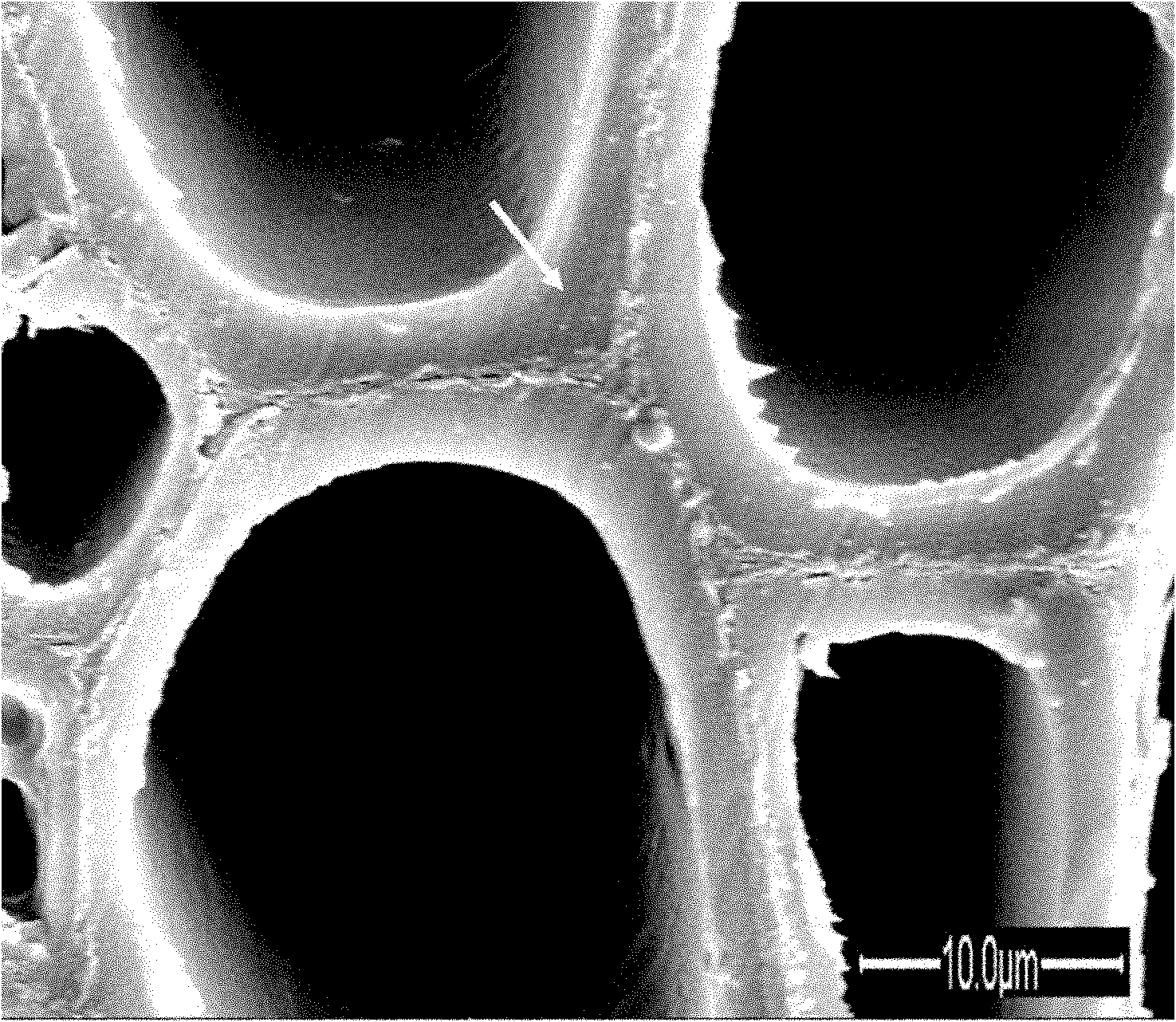

InactiveCN101954662AIncreased durabilityImprove mechanical propertiesPressure impregnationWood impregnation detailsCell cavityCell wall

The invention discloses a method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities, which relates to a wood modification method. The invention solves the problem of difficulty in simultaneously enhancing mechanical properties and durability of wood in the existing wood modification method. The method comprises the following steps: 1, preparing organic acid anhydride solution; 2, soaking the wood with the organic acid anhydride solution; 3, filling grafted wood cell walls with organic acid anhydride by heating; 4, preparing the organic polymerizable monomer solution; 5, soaking the wood with the organic polymerizable monomer solution; and 6, carrying out polymerization-filling on the wood cell cavities with the monomers by heating. Since organic function micromolecules firstly enter the wood cell walls, the method realizes filling and bonding and eliminates a great deal of hydroxyl groups in the cell walls, thereby enhancing wood durability; and the wood cell cavities are soaked by the organic polymerizable monomers to initiate the polymerization and realize the filling of the cell cavities, so that the wood has higher mechanical properties and durability.

Owner:NORTHEAST FORESTRY UNIVERSITY

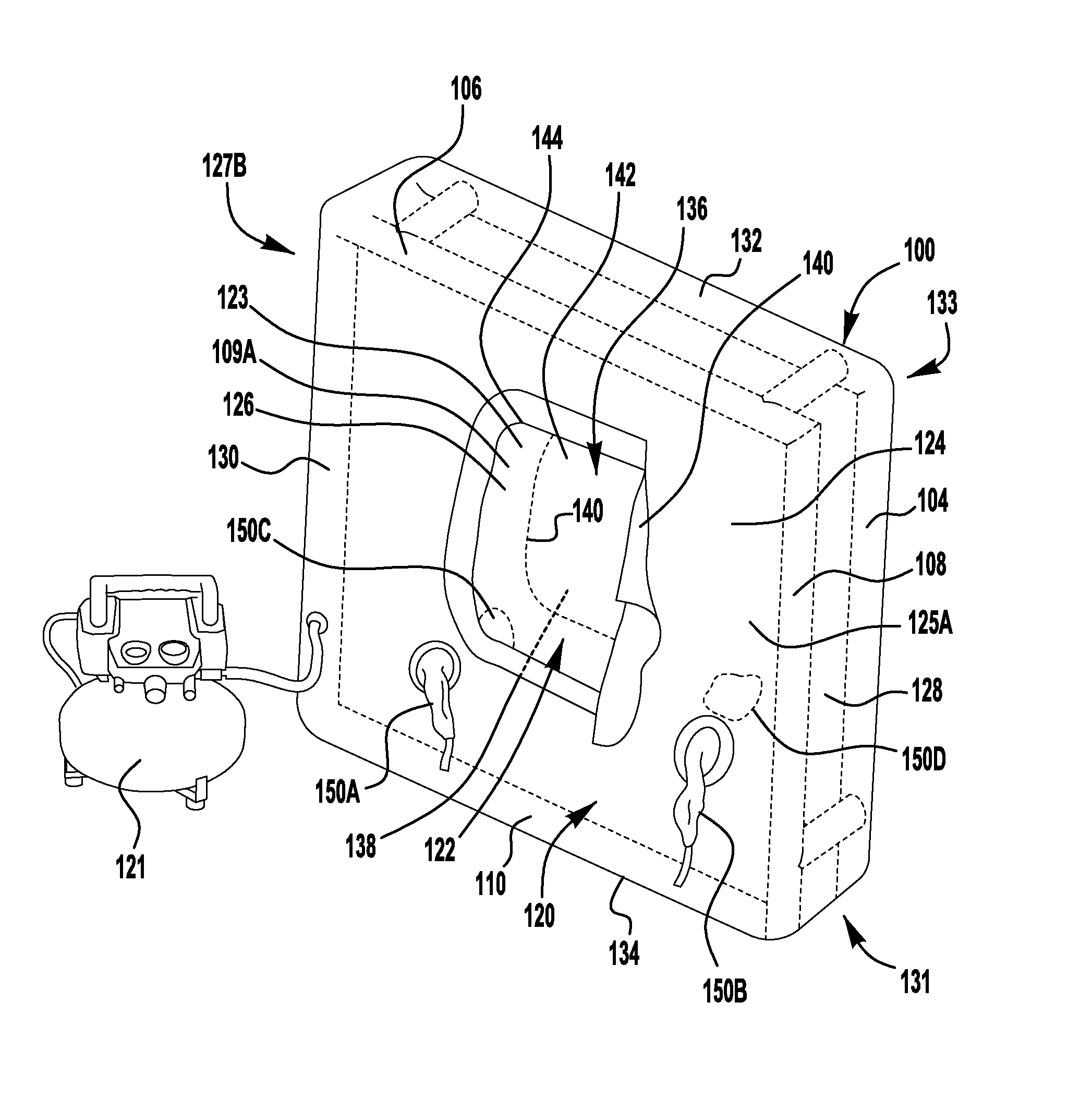

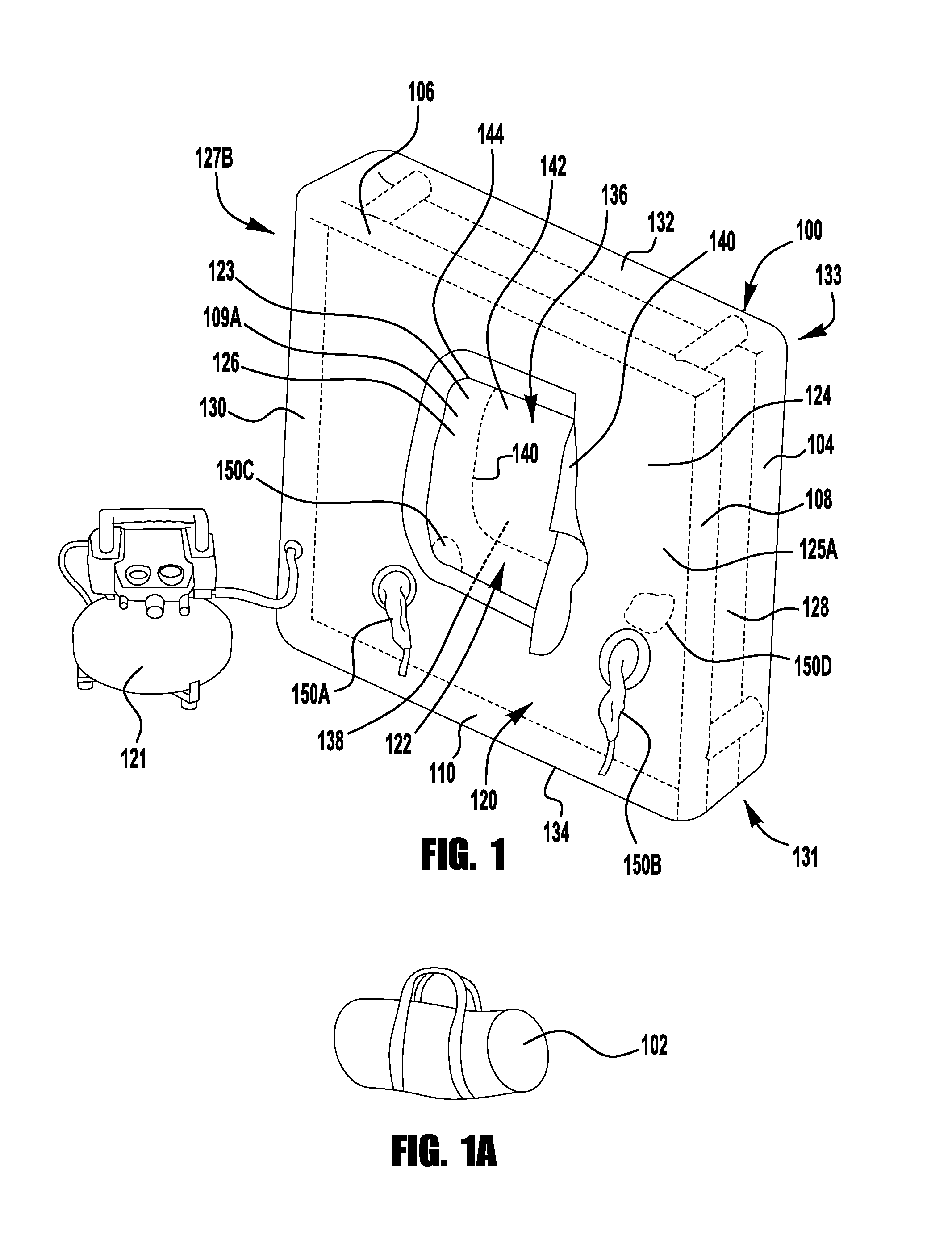

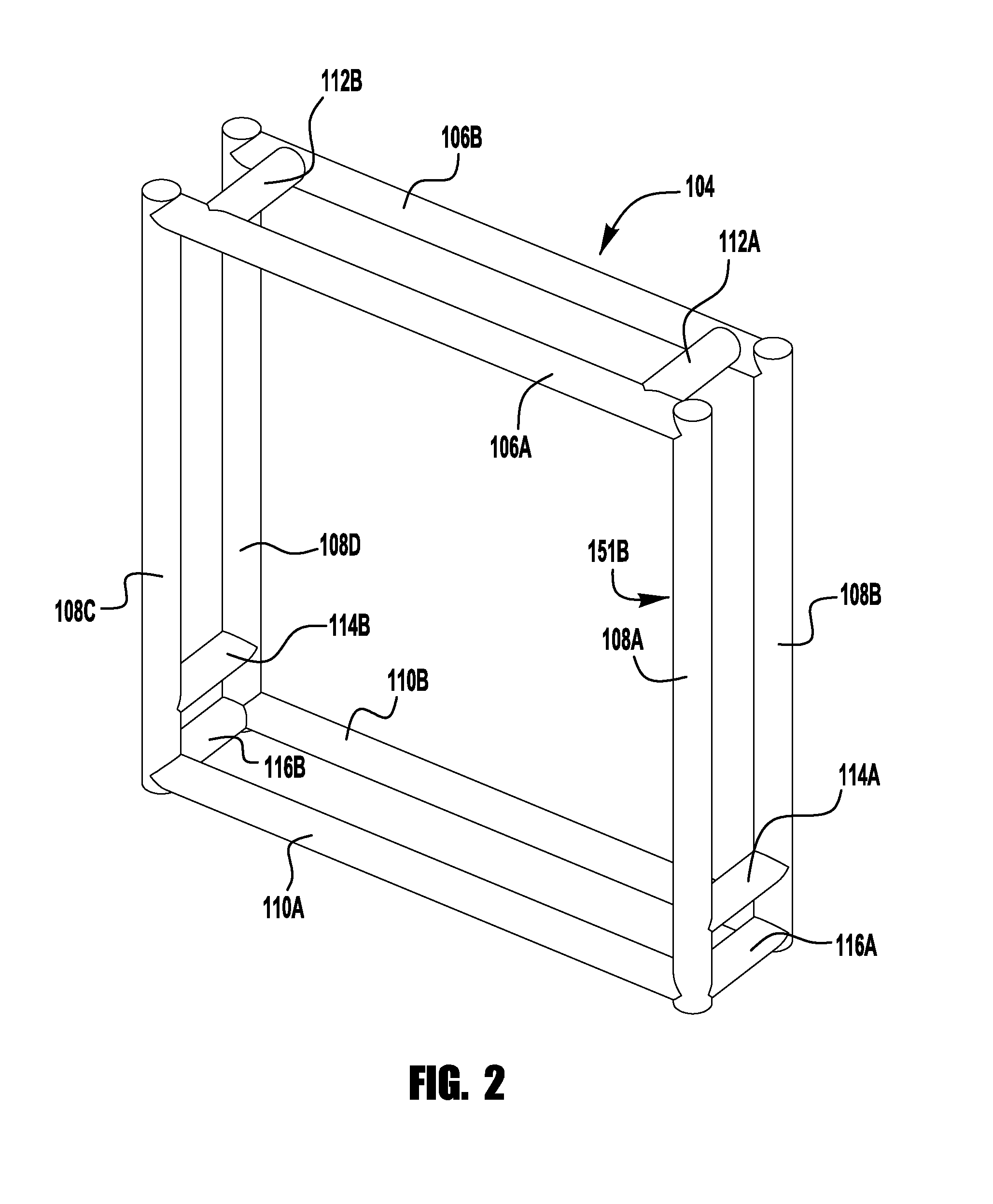

Portable inflatable protective partitioning system

An inflatable separation device and method of using the device to form a gas-impermeable barrier in a structural location such as a hallway. The device also provides a safe, effective passage across the barrier to form a concealed region for decontamination protocols. The inflatable separation device includes an inflatable support frame and a cover that envelops the support frame and forms an enclosed interior space when the support frame is inflated. An inflatable perimeter sealing bladder is disposed about the cover and adapted to form a seal between the cover and exterior surfaces of a structural space when the support frame and the sealing bladder are inflated.

Owner:UNITED STATES OF AMERICA

Inflatable picnic table

An inflatable picnic table which includes an integrally formed pedestal, tabletop and bench, all of which are inflatable, so that the picnic table may be stored in a deflated condition, taken to a picnic area, and inflated to provide a temporary and portable picnic table including a tabletop and bench.

Owner:HAGEDORN VANCE A

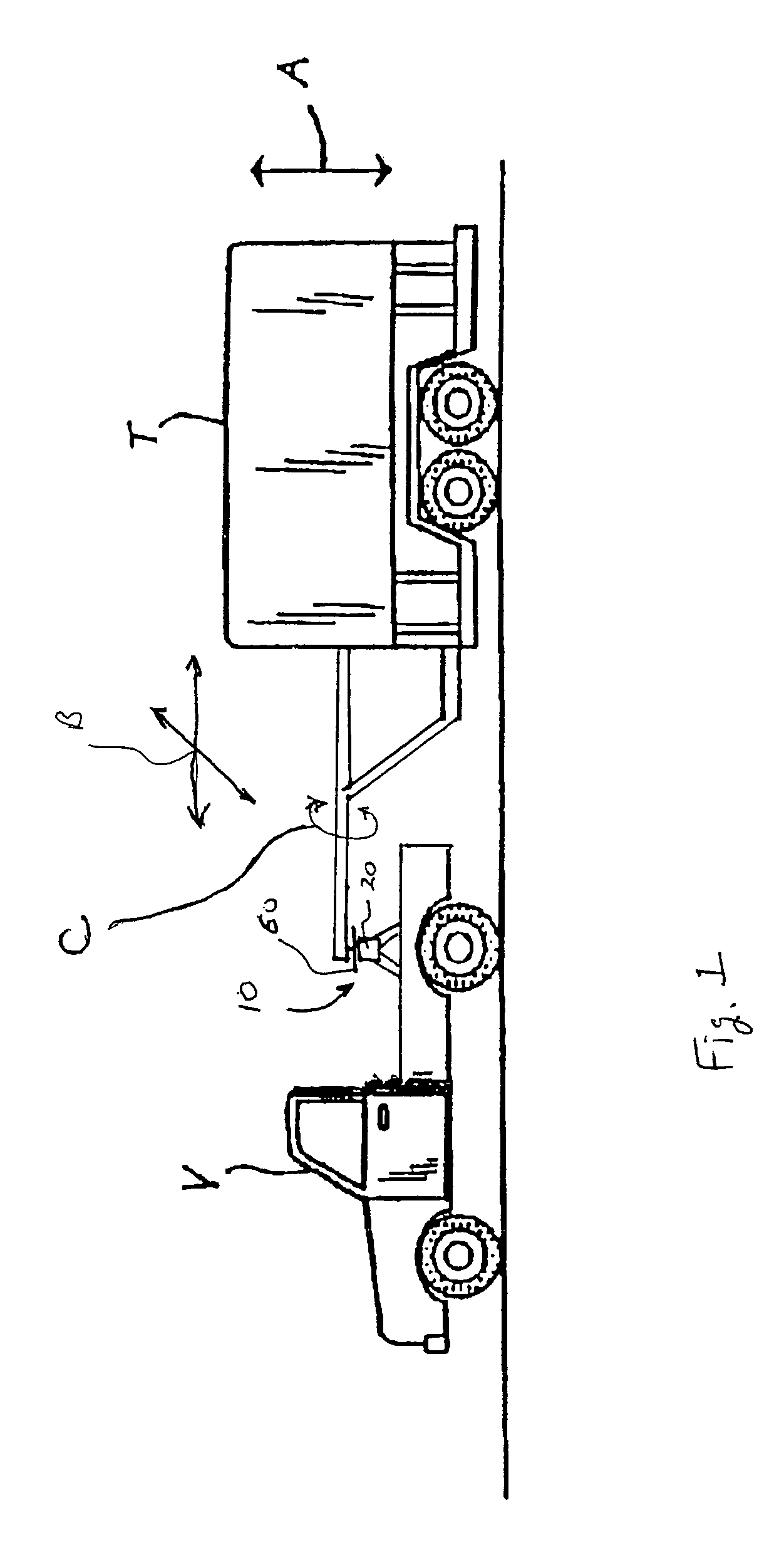

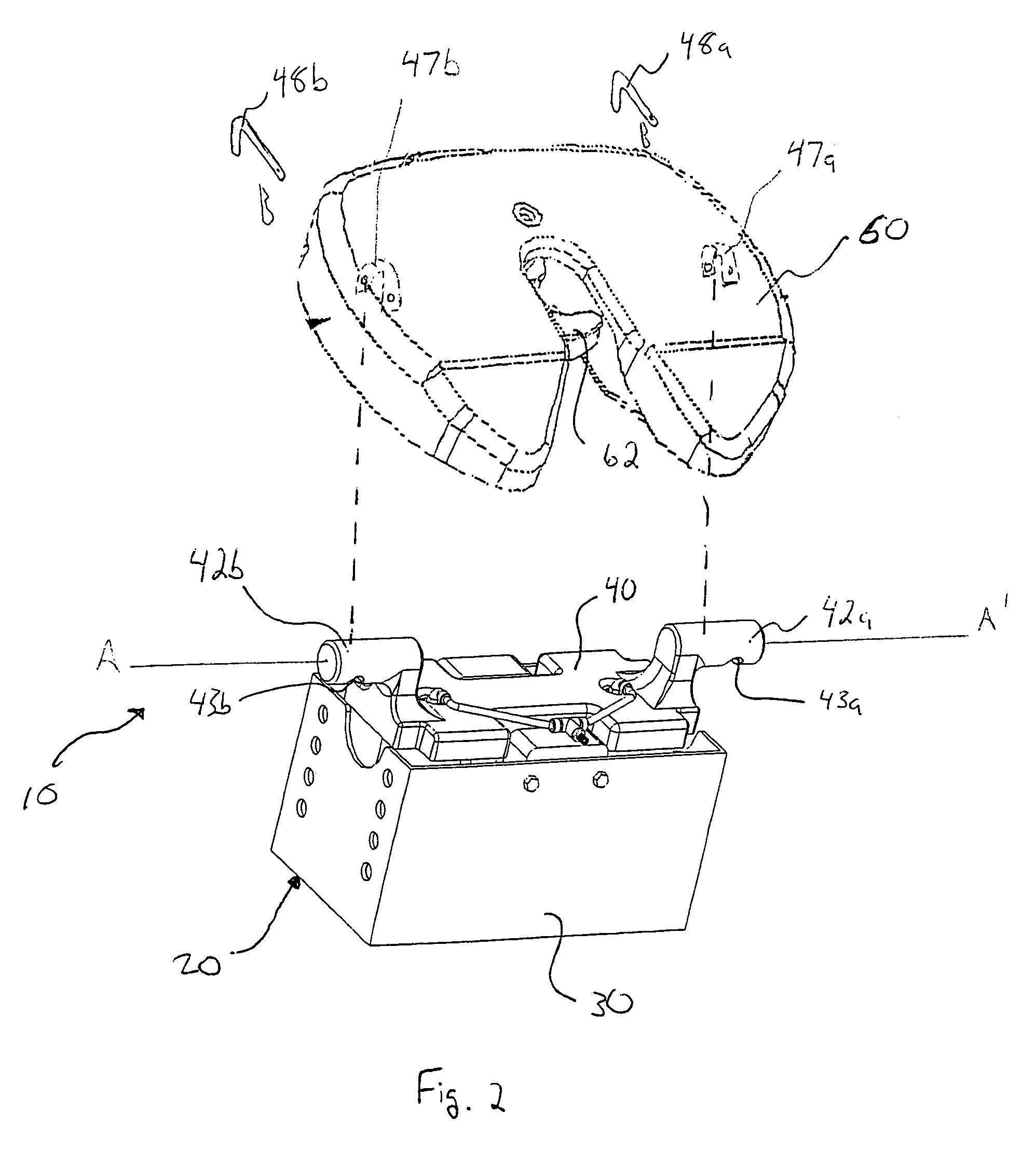

Vehicle hitch with multi-directional damping

InactiveUS7380810B1Avoid transmissionEasy to inflateTractor-trailer combinationsTowing devicesAir springEngineering

The present invention is directed to an adjustable trailer hitch that provides a suspended connection between a tow vehicle and an attached trailer. The hitch includes a support member that is adapted to be attached to a tow vehicle and a frame having first and second pivots for pivotally support a hitch plate, which is operative to connect to a trailer (e.g., engage a trailer pin). A first air spring has a first end fixedly connected to the support member and a second end fixedly connected to the frame. The air spring permits relative movement between the support member and the frame as well as transmitting towing forces therebetween. The air spring provides a pliable connection that at least partially mechanically isolates the trailer and the vehicle from each other. Instead of acting as a single unit, the vehicle and the trailer act at least partially independently of each other.

Owner:AIR HITCH TECH

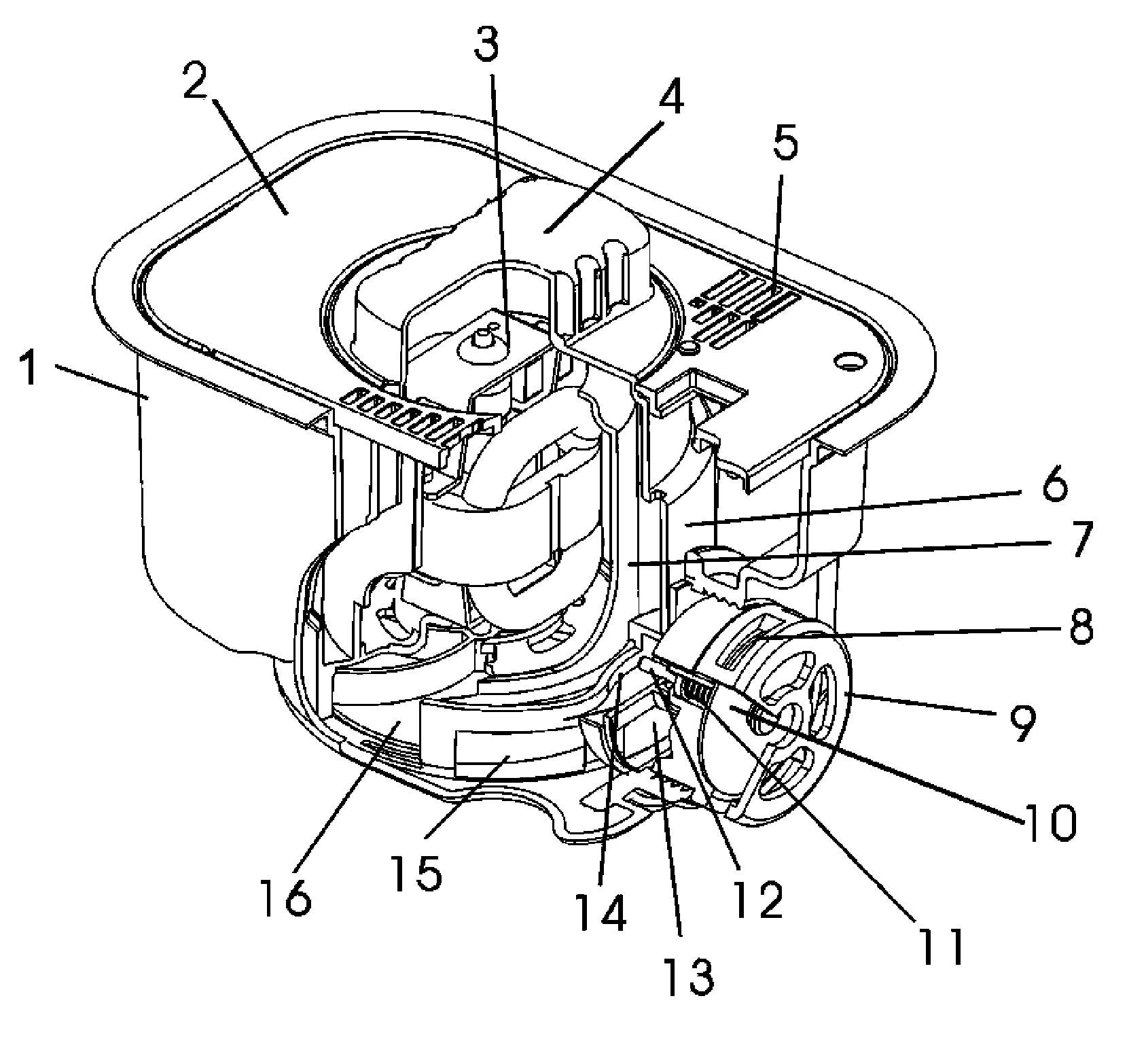

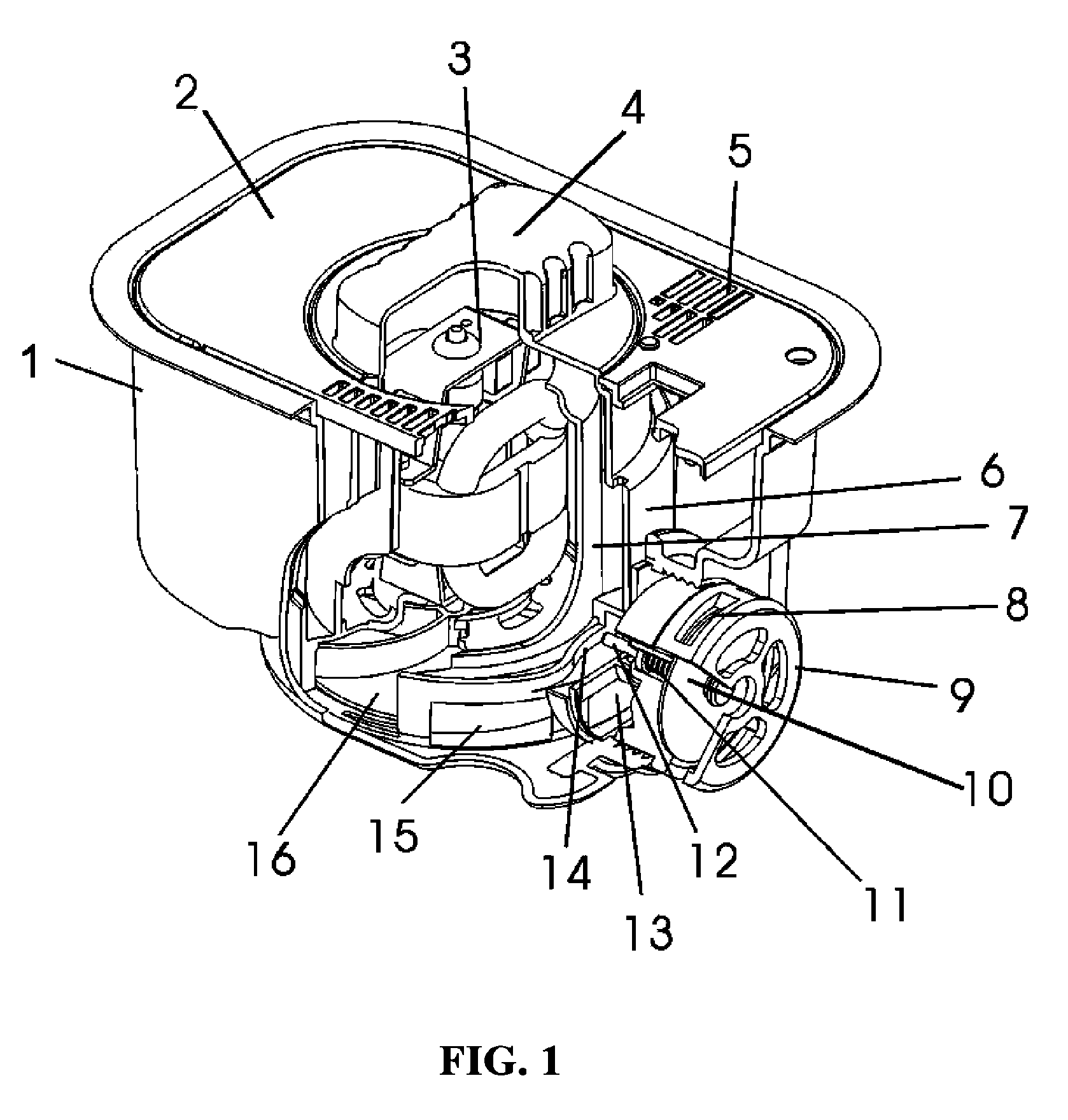

Adjustable Inflate and Deflate Air Pump

InactiveUS20060204361A1Easy to operatePump robustPump componentsRotary non-positive displacement pumpsPump chamberAir pump

The present invention provides an adjustable inflate and deflate air pump consisting of: a pump frame, a pump body, a motor, blades, an air input hole, an air output hole, and a valve. A pump compartment of the present invention consists of an air compartment and a motor compartment. The air compartment is built up by the pump protective shield and the motor protective shield. The air compartment is connected to the air input hole. The motor compartment is built up by the motor protective shield and is connected with the air output hole at its bottom. On the upper part of the pump is a swing knob which is connected to the pump body. On the lower part of the pump is a curved surface. During its working process, the motor is cooled by constant airflows through the motor compartment during both inflation and deflation. Thus, the difficult problem of the motor overheating and being damaged during inflation and deflation has been solved perfectly. It is therefore a new pump with promising prospects.

Owner:XIE SENYUAN

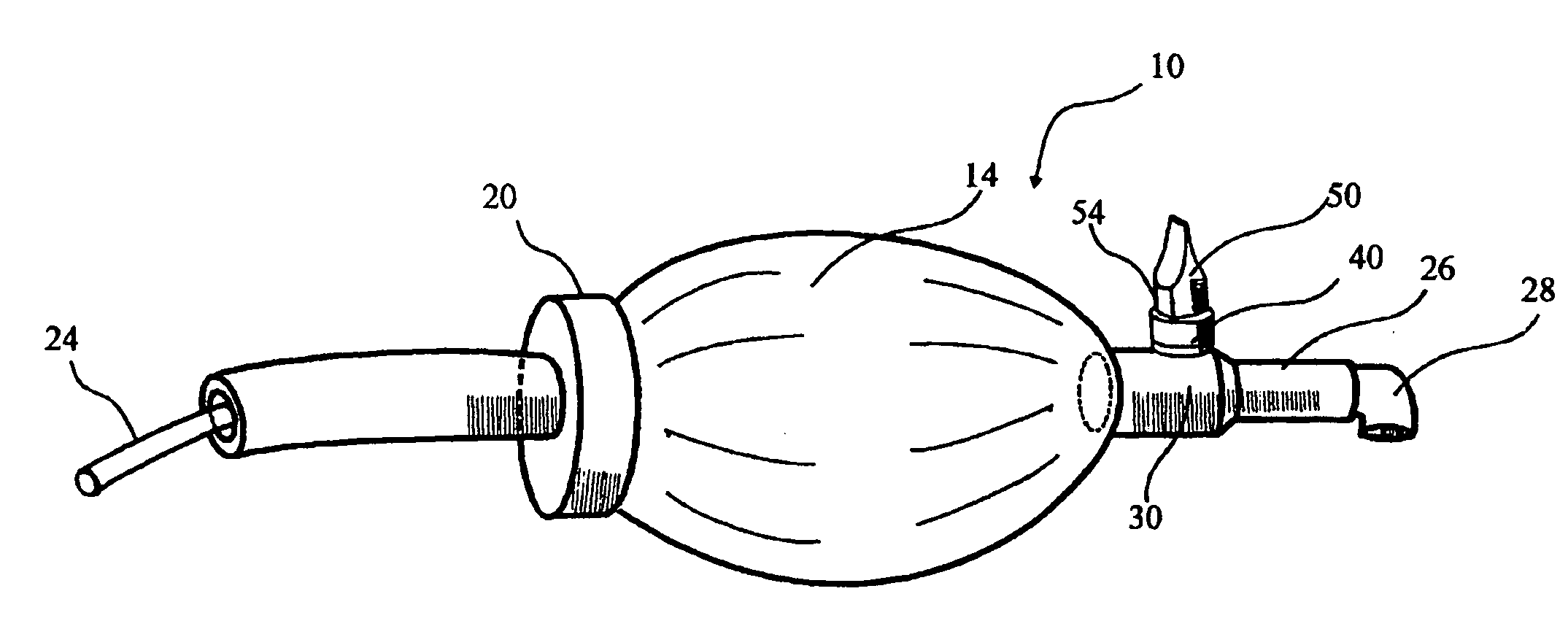

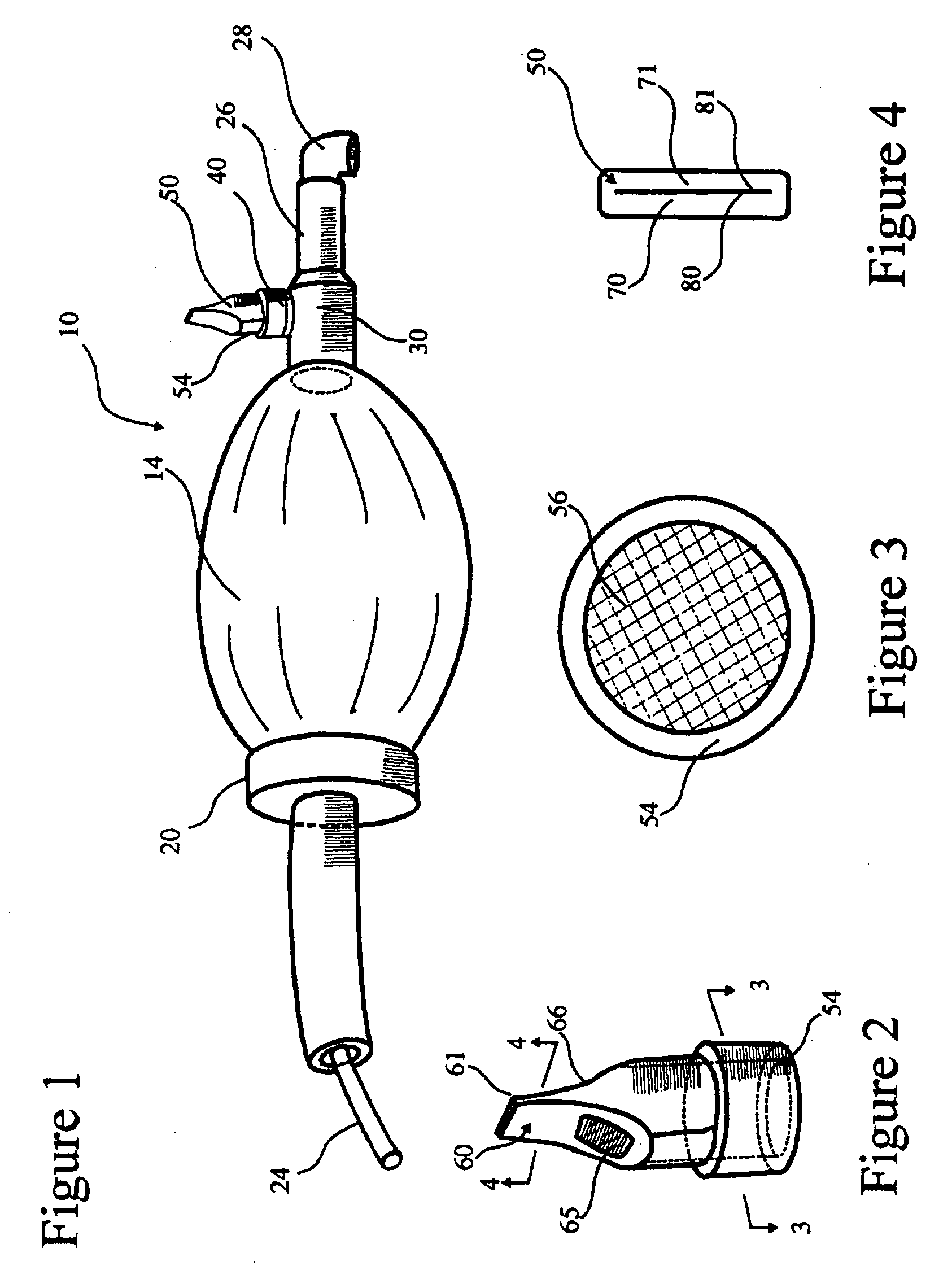

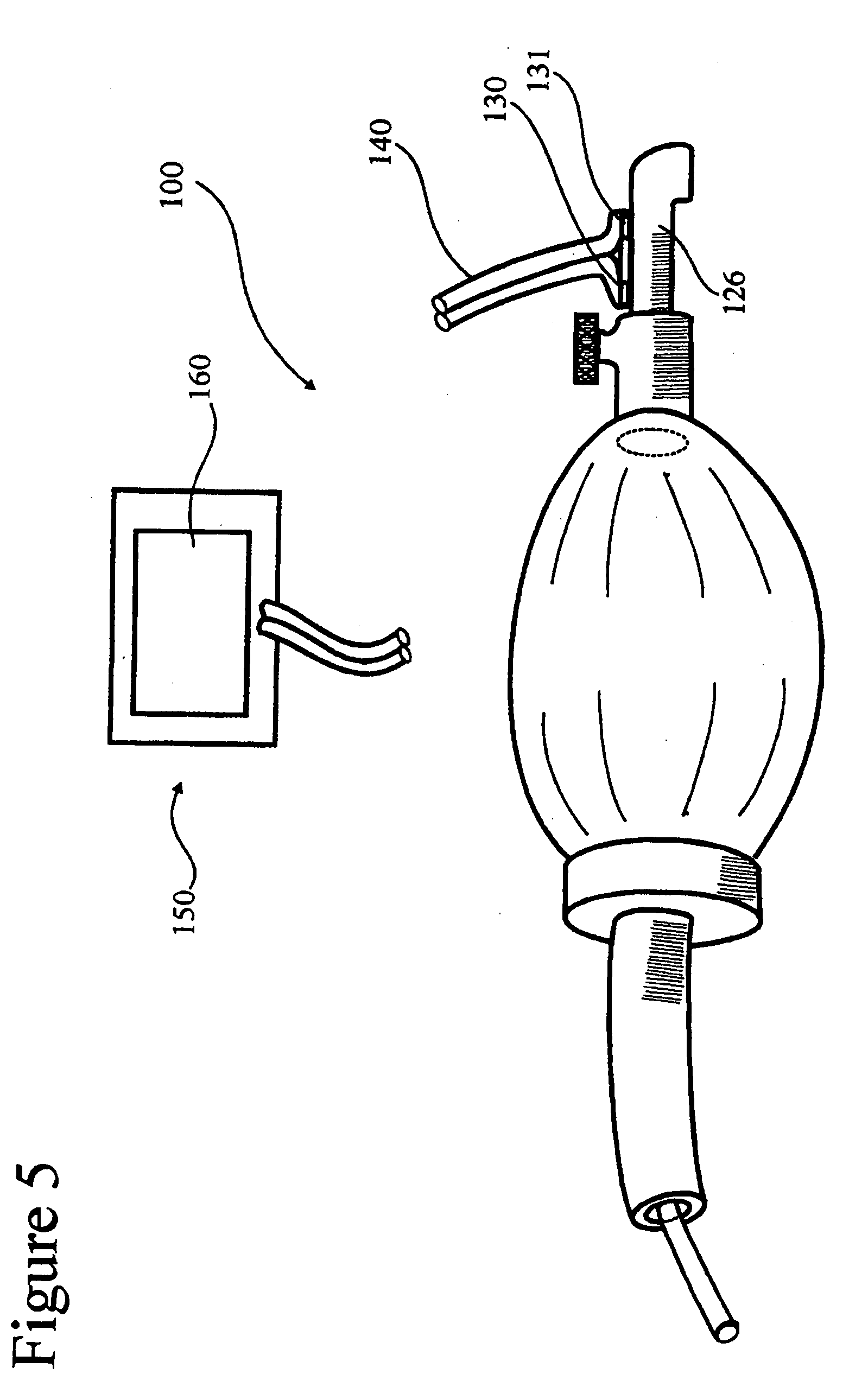

Apparatus and method for the simulation of the adverse cardiovascular effects of dynamic hyperinflation

InactiveUS20080305464A1Small sizeReduce probabilityEducational modelsGas exchangeCardiopulmonary resuscitation

A resuscitation system for the administration of cardiopulmonary resuscitation of asthma patients, and for teaching the cardiopulmonary resuscitation of asthma patients to simulate the cardiovascular and gas exchange effects of dynamic hyperinflation and to train healthcare workers to detect the adverse cardiovascular effects of dynamic hyperinflation.

Owner:LYNN LAWRENCE ALLAN

Multi-layer coating system for jacquard woven airbags

InactiveUS20060014456A1Reduce air permeabilityConvenient coatingEnvelopes/bags making machineryProtective equipmentMethacrylateEffective potential

Novel airbag coating compositions comprising at least two separate and distinct layers are provided. The first layer (base coat), being in contact with the airbag surface, comprises a composition of at least one coating material which may comprise up to 30% by parts of the total amount of material in the first layer of a silicone resin which provides excellent adhesion, excellent tensile strength, and overall lower cost than standard silicone airbag coating materials. The second layer, being a coating for the first layer, provides excellent reinforcement and blocking characteristics to permit effective potential long-term storage and optimum use upon the occurrence of a collision. Such a second layer (topcoat) is preferably a silicone material but may also be selected from the group consisting of homopolymer and coplymer resins based on ethylene, propylene, acrylates, methacrylates, vinyl esters, acrylic acid, methacrylic acid, polyurethanes, polyamides, and inorganic materials such as talc, silica, silicate, calcium carbonate, alumina, and the like. This two-layer system permits excellent strength and blocking properties to prevent undesired adhesion between portions of the target airbag when stored as well as to prevent seam combing at relatively low cost due to the materials and the relatively low amount required for the topcoat. An airbag fabric coated with this inventive two-layer system is also contemplated within this invention.

Owner:MILLIKEN & CO

Short sleeve stent delivery catheter and methods

InactiveUS20080255581A1Reduce traumaEasy to maneuverStentsBalloon catheterInsertion stentCatheter device

A stent delivery catheter comprises a catheter body having a proximal end, a distal end, and a guidewire lumen extending from the distal end to at least part way between the proximal end and the distal end. A balloon is disposed over the catheter body near the distal end, and a stent is positioned over the balloon. The stent has a proximal end, a distal end, and a side opening between the proximal end and the distal end. A side sheath is coupled to the catheter body and has a proximal end, a distal end, and a guidewire lumen extending between the proximal end and the distal end. The proximal end of the side sheath is located between the proximal end of the catheter body and the balloon, and the side sheath exits out of the side opening of the stent.

Owner:BOSTON SCI SCIMED INC

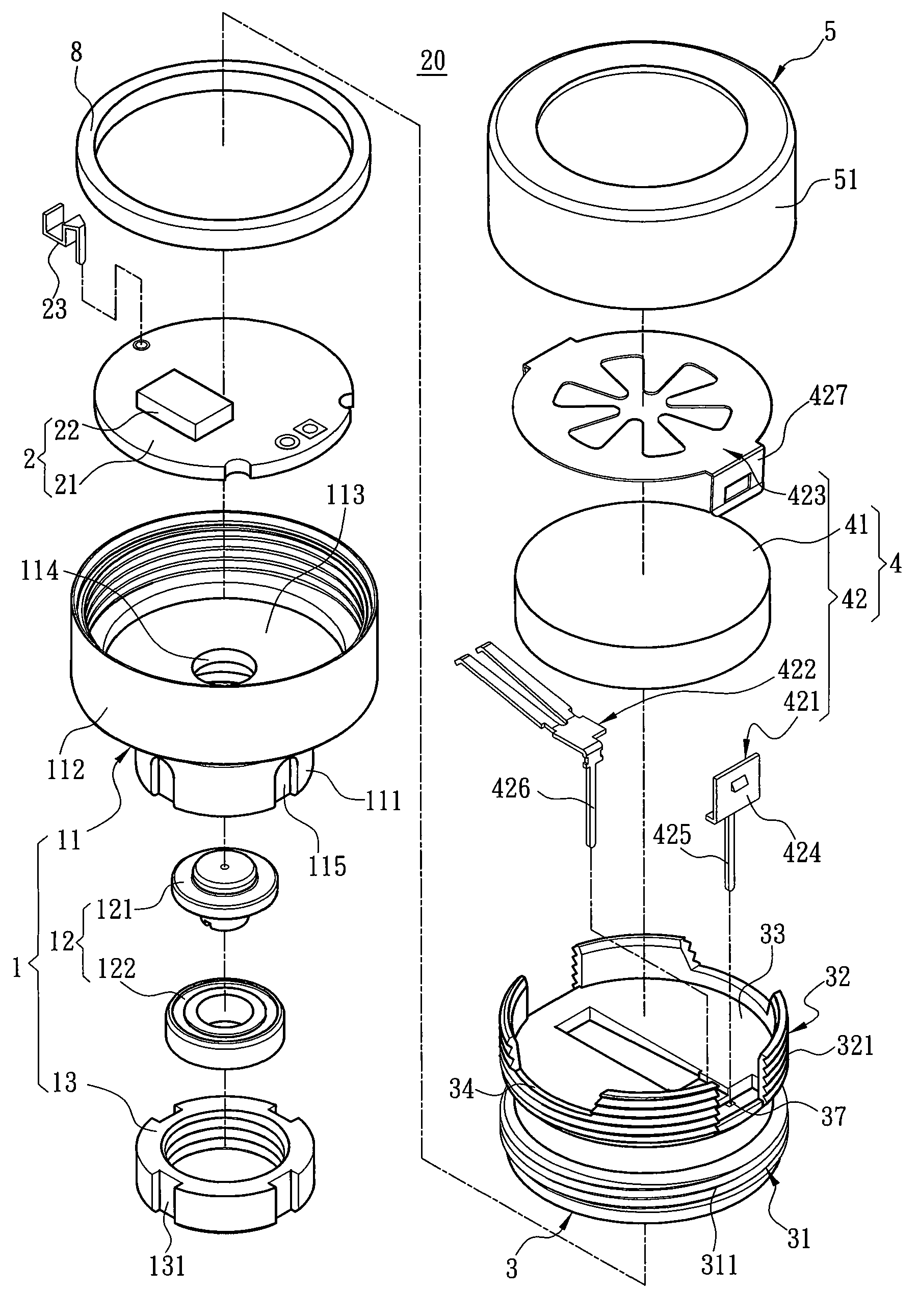

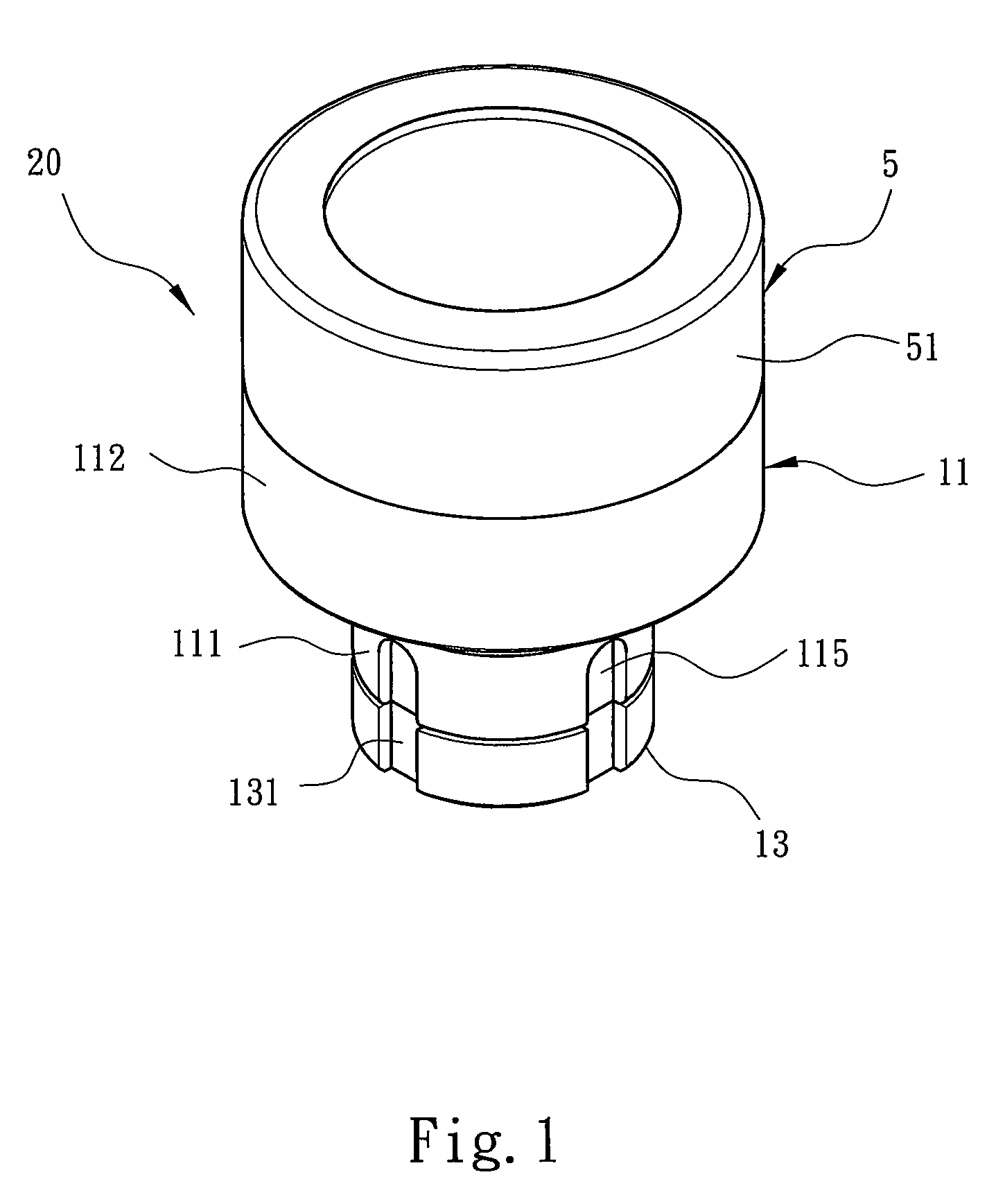

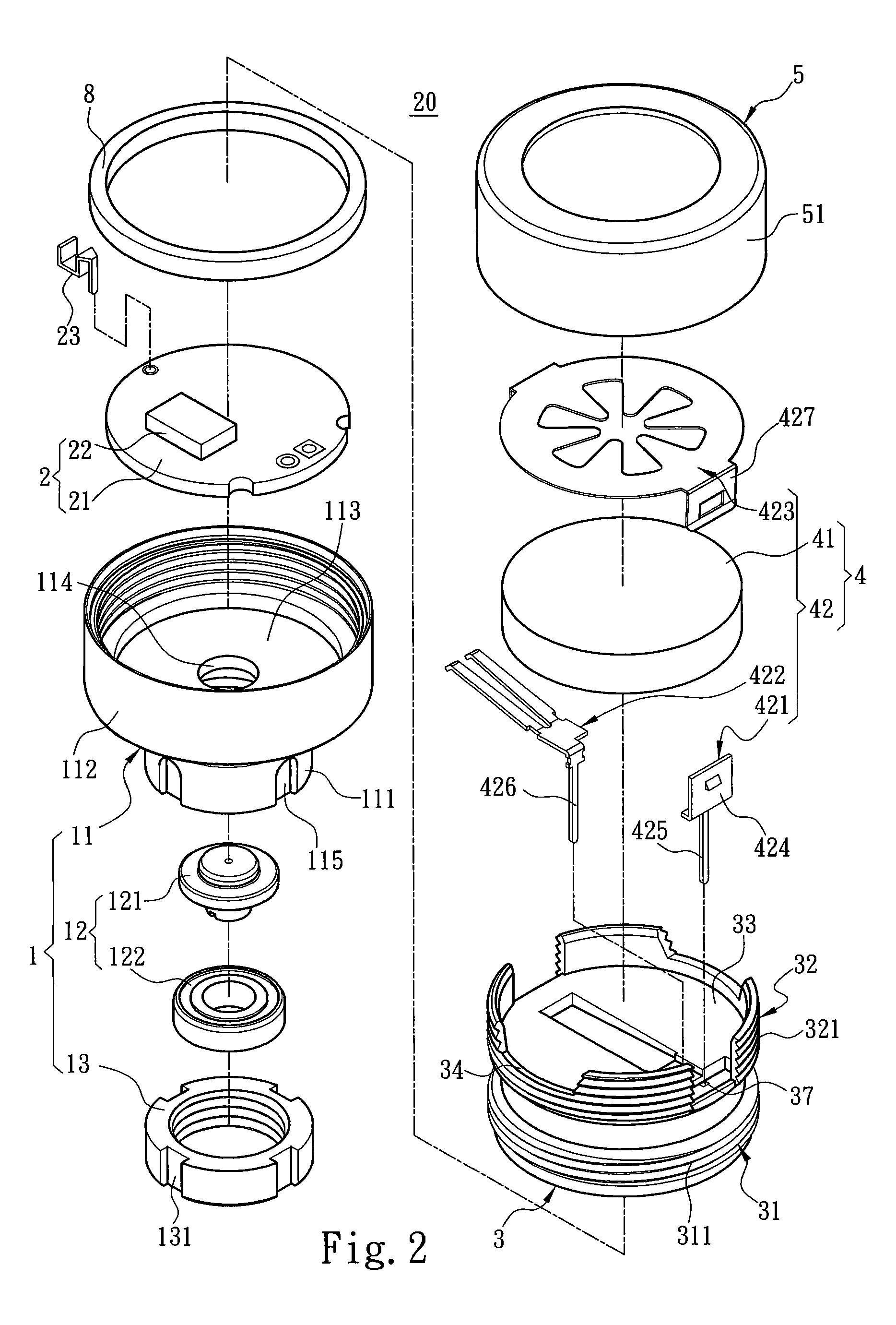

Tire pressure detector

InactiveUS7775097B1Improve poor airtightnessGuaranteed detection accuracyTyre measurementsEngineeringElectrical and Electronics engineering

A tire pressure detector, which is installed on an air tap of a wheel to detect the tire pressure, comprises an air-intake device, a bidirectional sleeve and a cap. The air-intake device includes an air-intake seat. The air-intake seat has an air-intake member and an engagement member. The air-intake seat is installed on the air tap via the air-intake member. The bidirectional sleeve has a first connection member and a second connection member, which are respectively formed on two sides of a separating member. The first connection member engages with the engagement member of the air-intake seat to form an air chamber accommodating a detection device detecting the tire pressure. The cap has a connection wall, which cooperates with the second connection member to form an accommodation space receiving a power source powering the detection device.

Owner:SUNG JUNG MINUTE IND

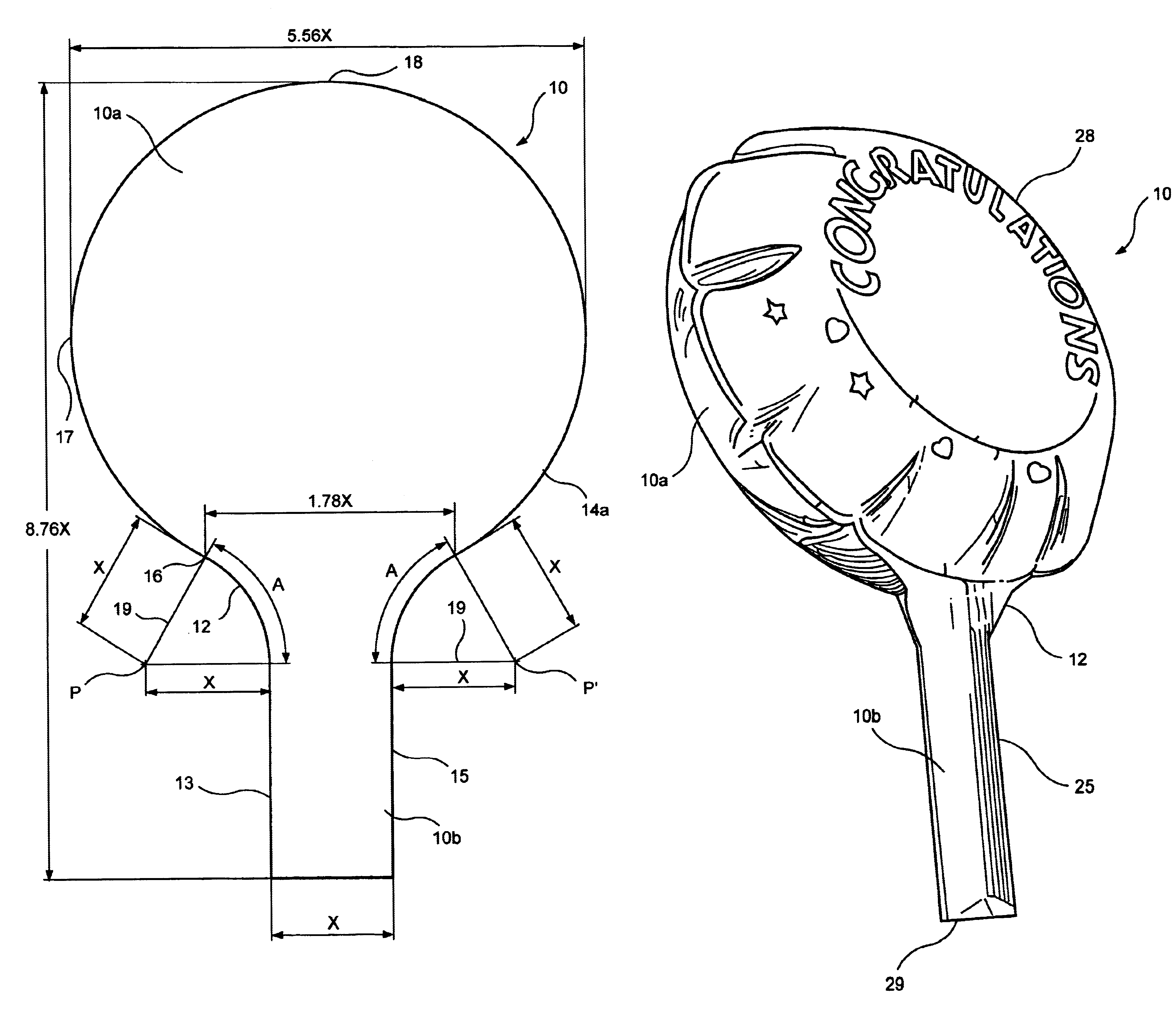

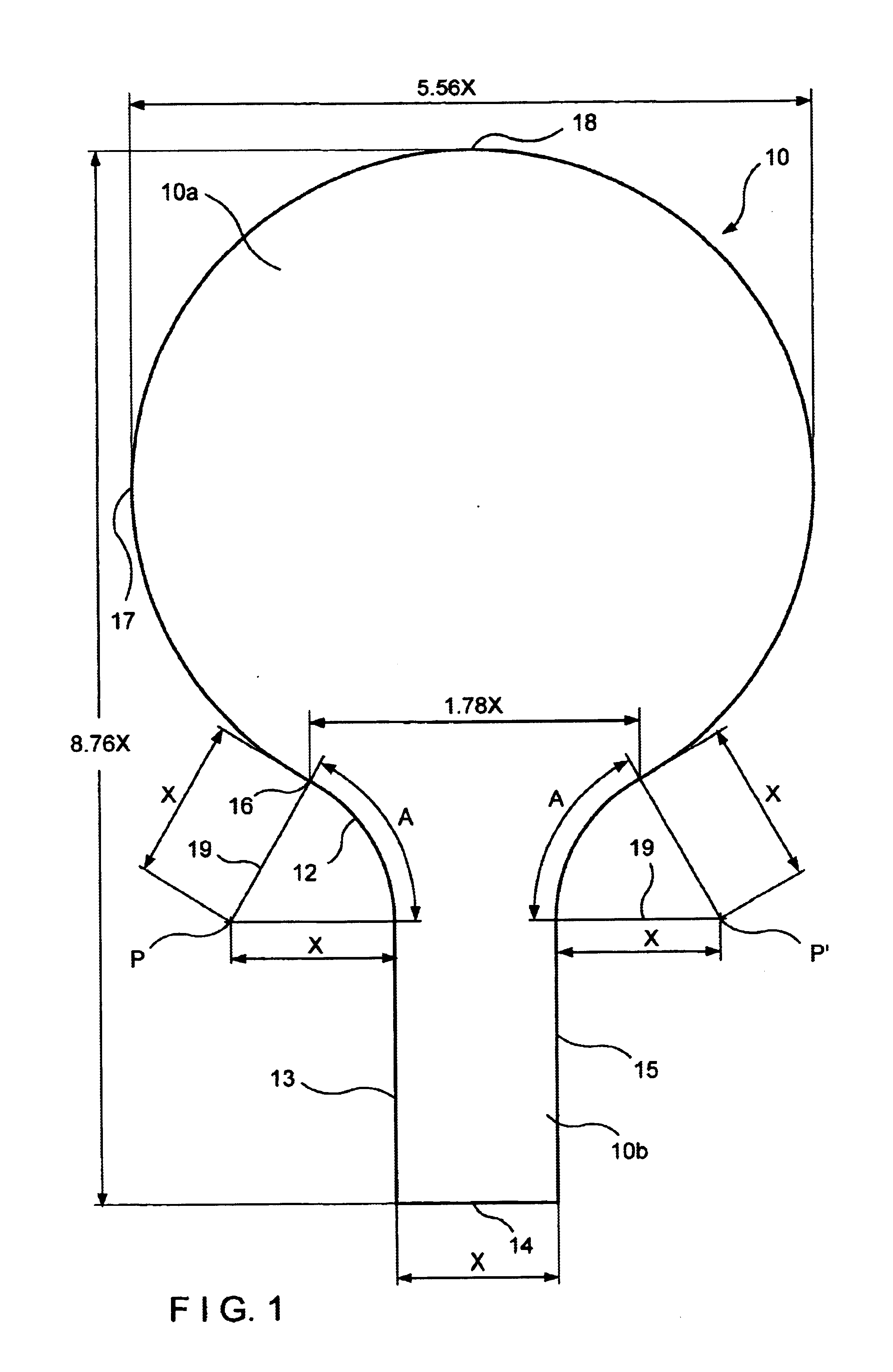

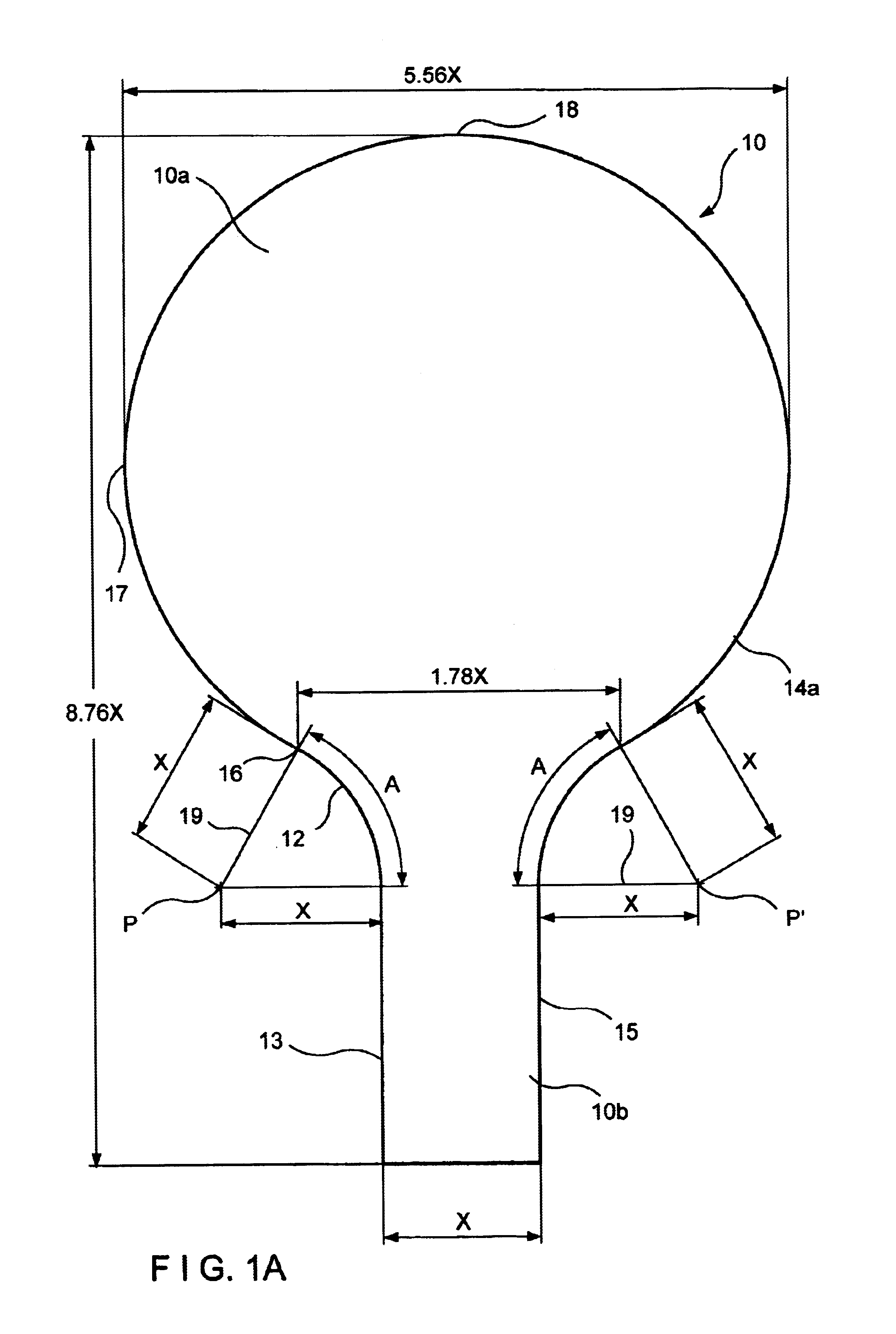

Toy balloon with integral inflatable handle

A balloon has an inflatable main body with a flexible extension. The extension is connected to the main body in such a manner that, when they are inflated, the extension forms a semirigid handle. The balloon therefore requires no separate holder. The balloon can be deflated for storage or shipment and reinflated when desirable or necessary.

Owner:EPSTEIN MARC I

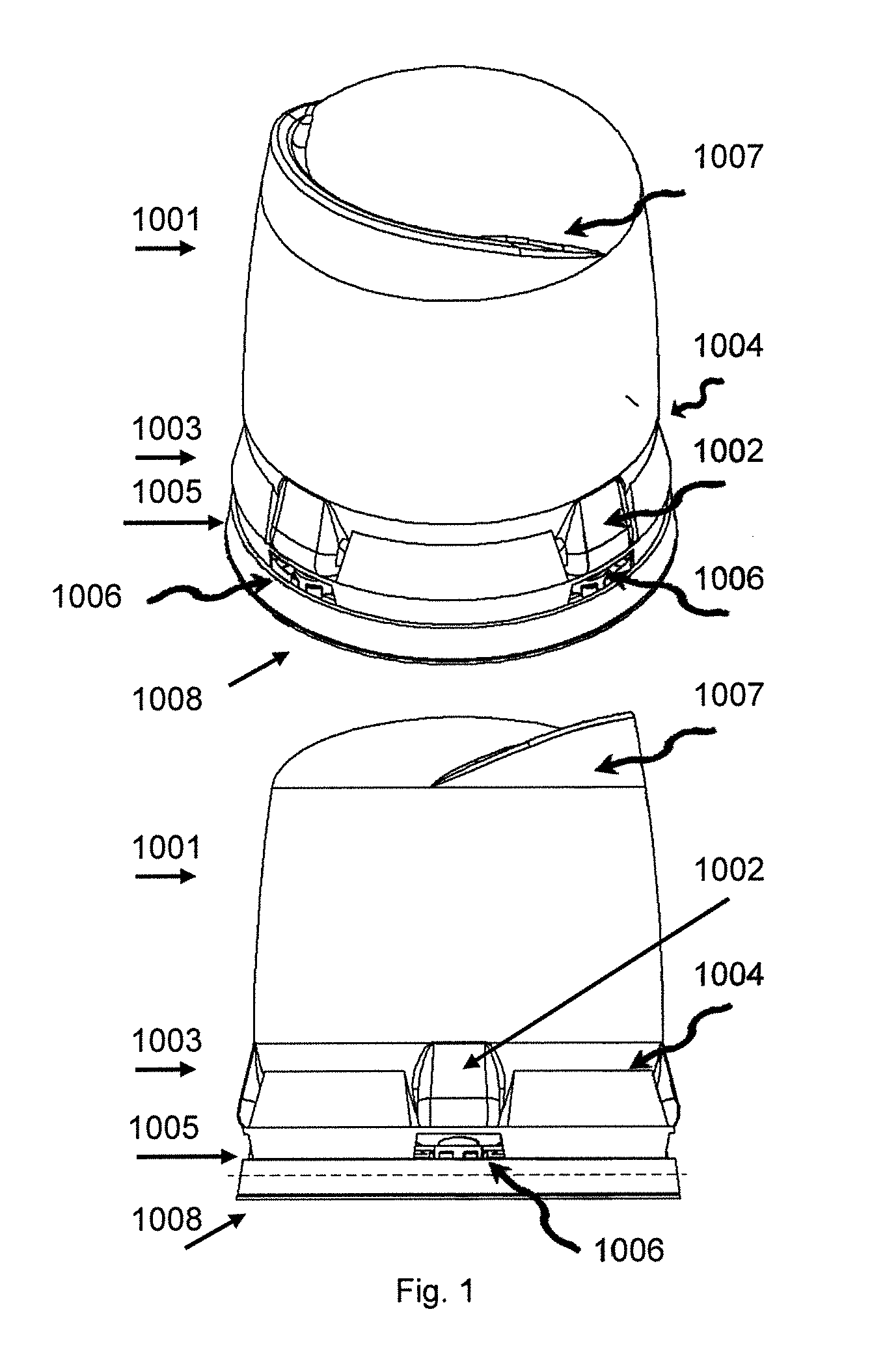

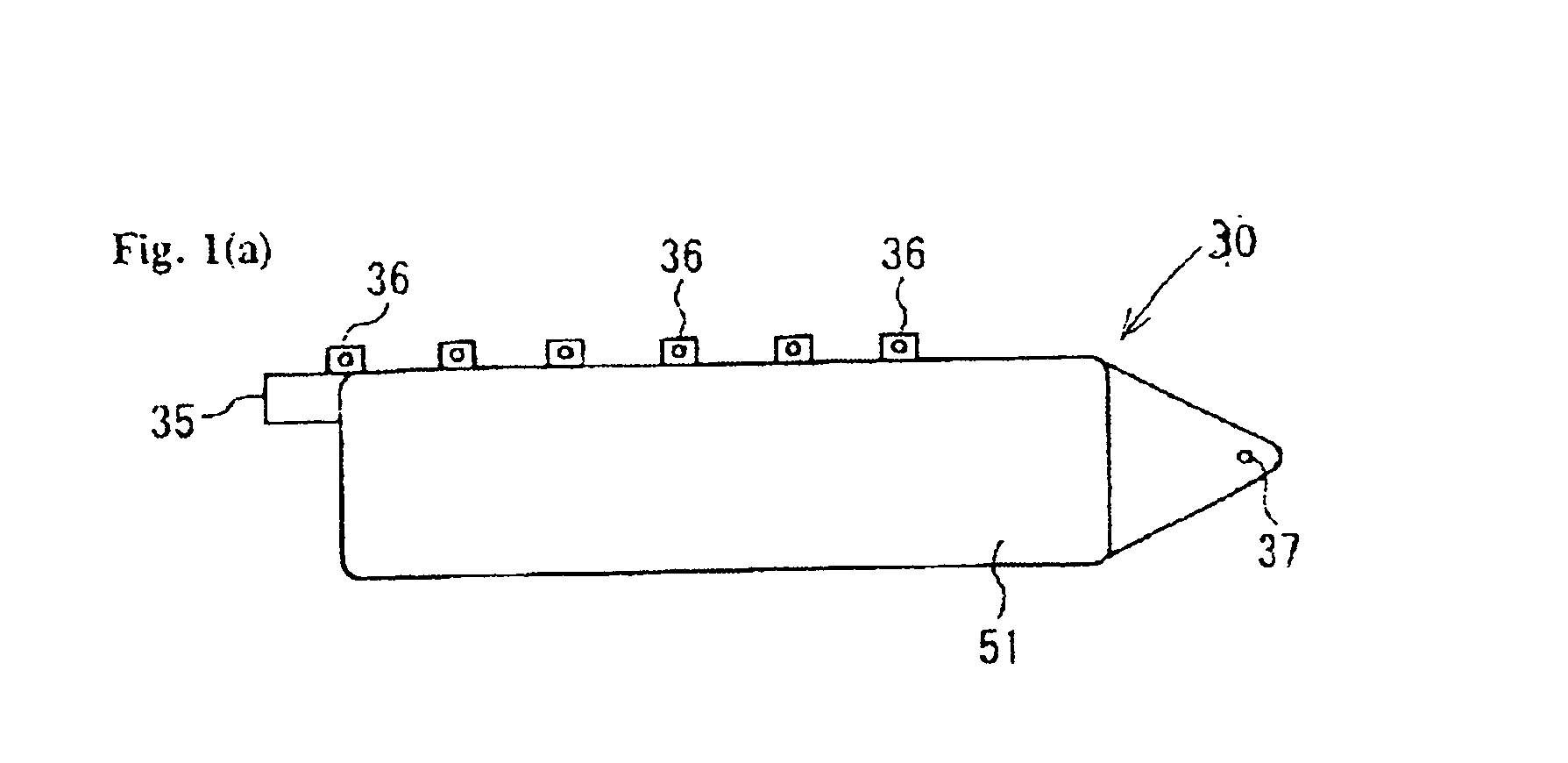

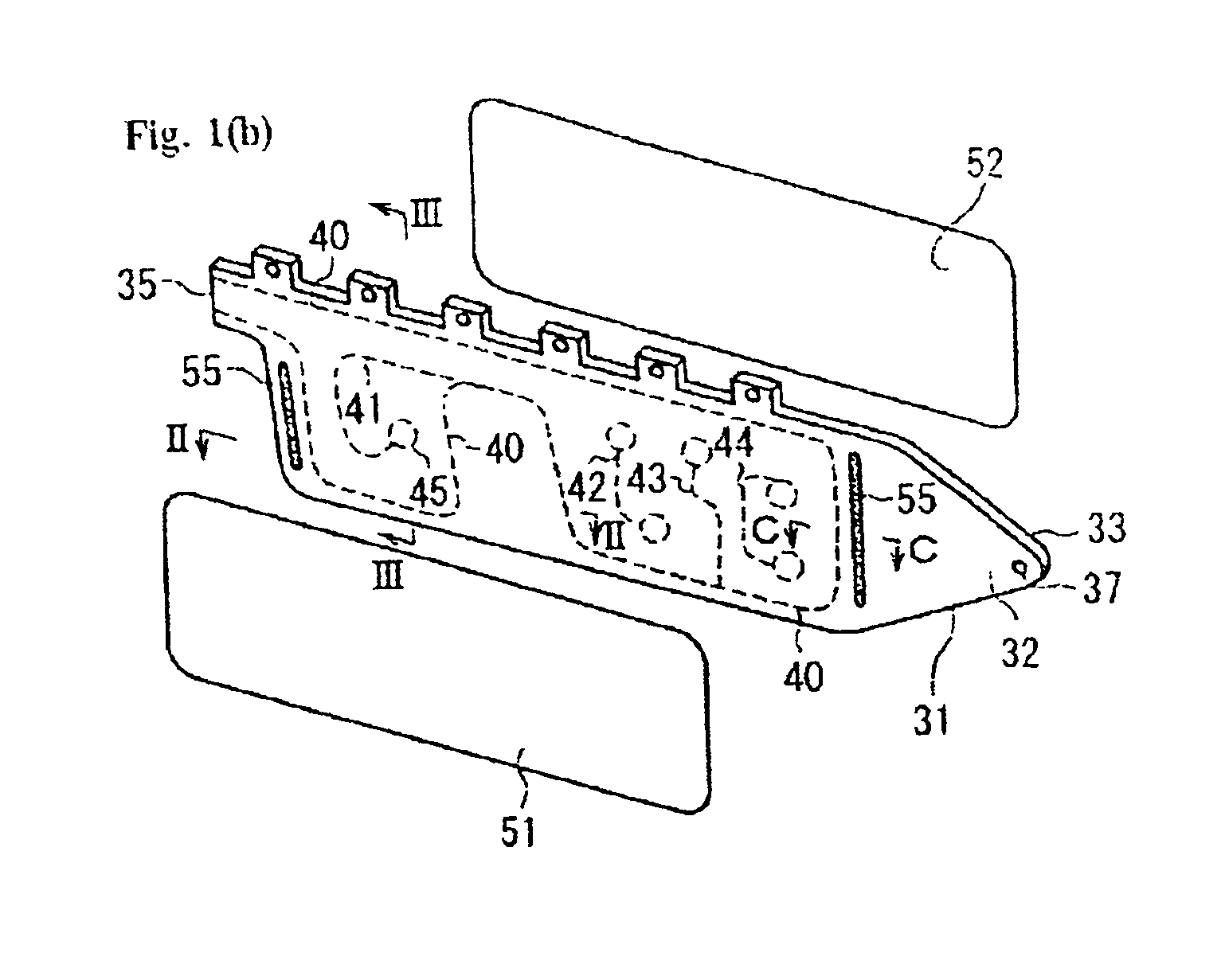

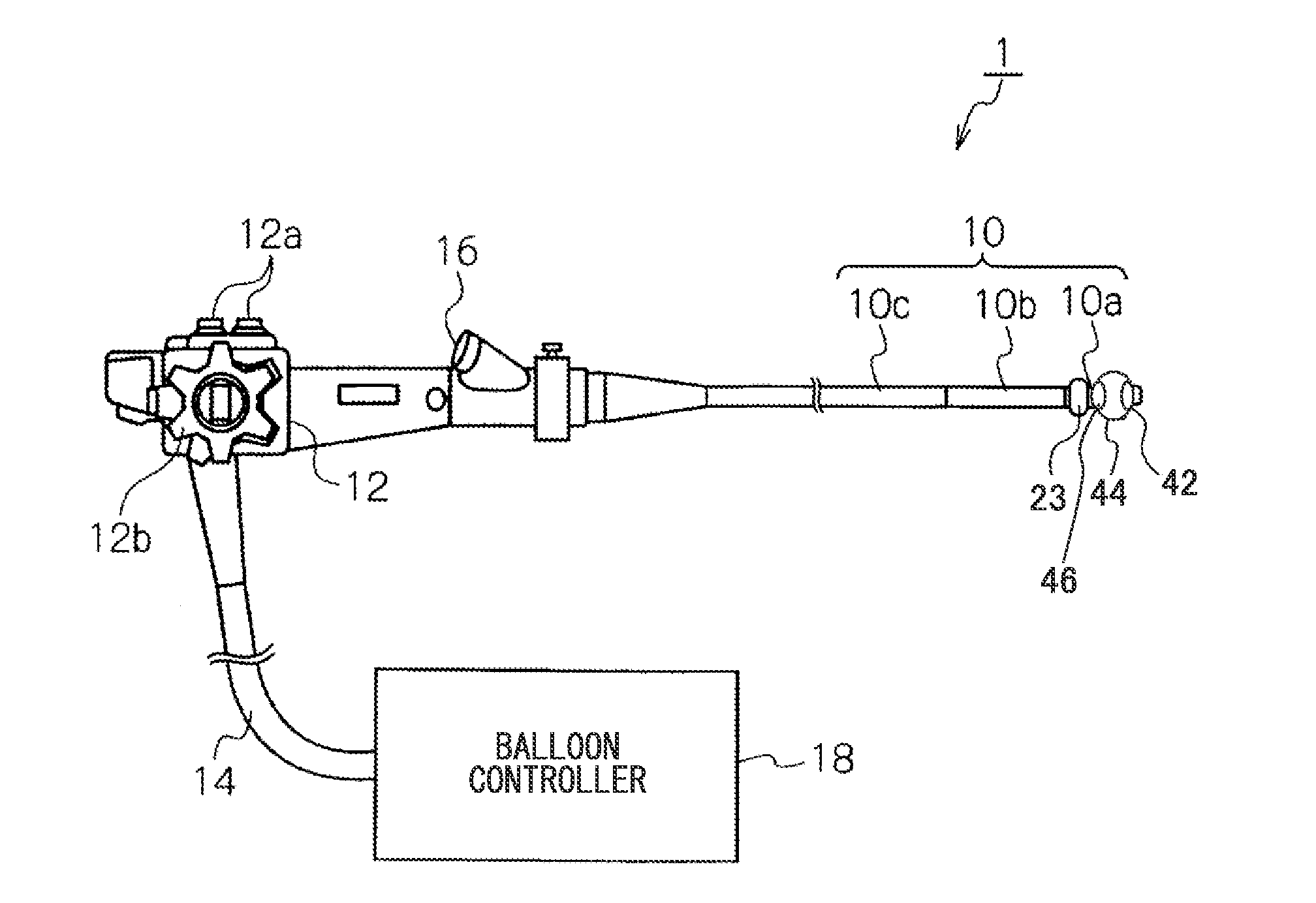

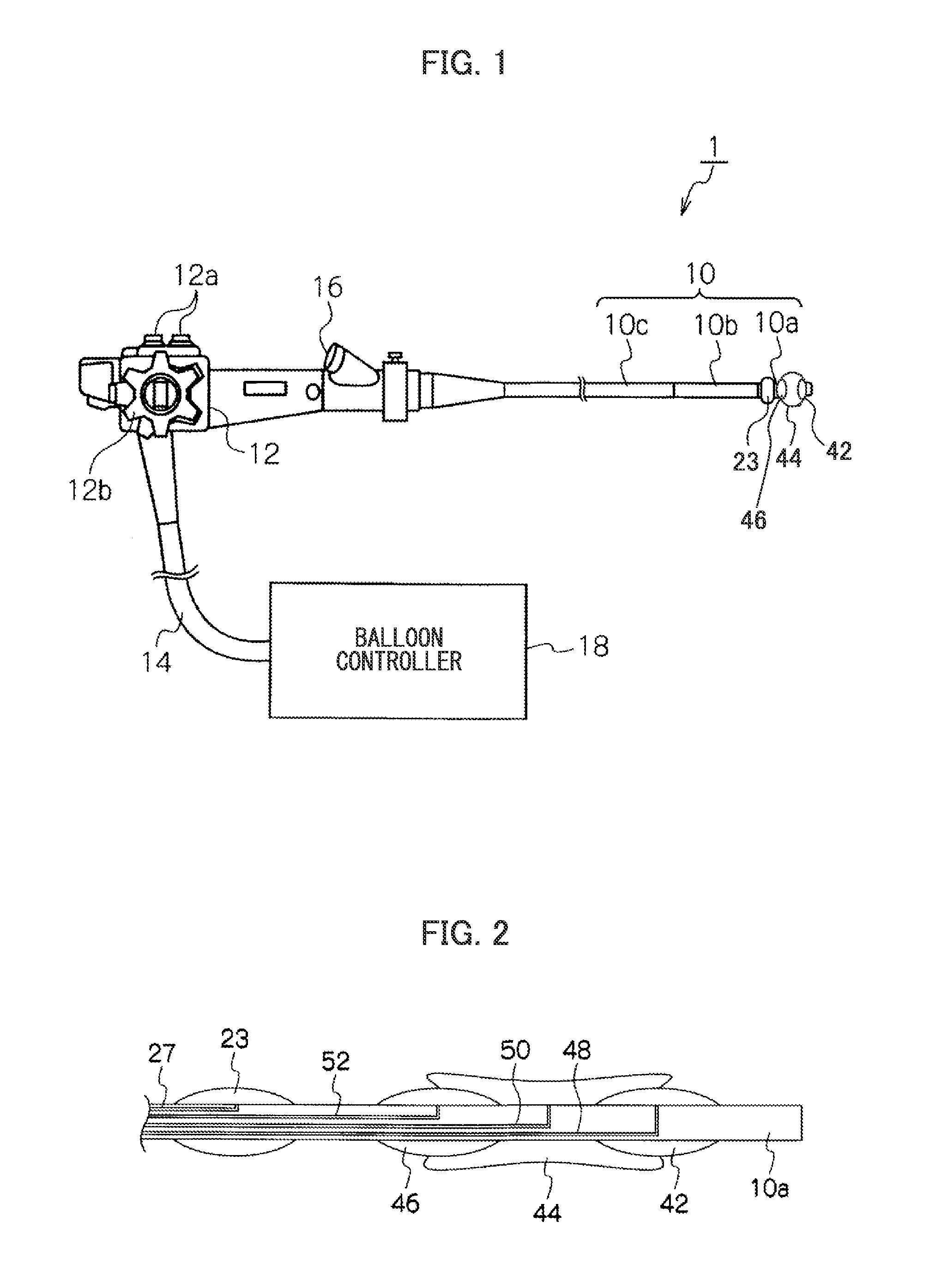

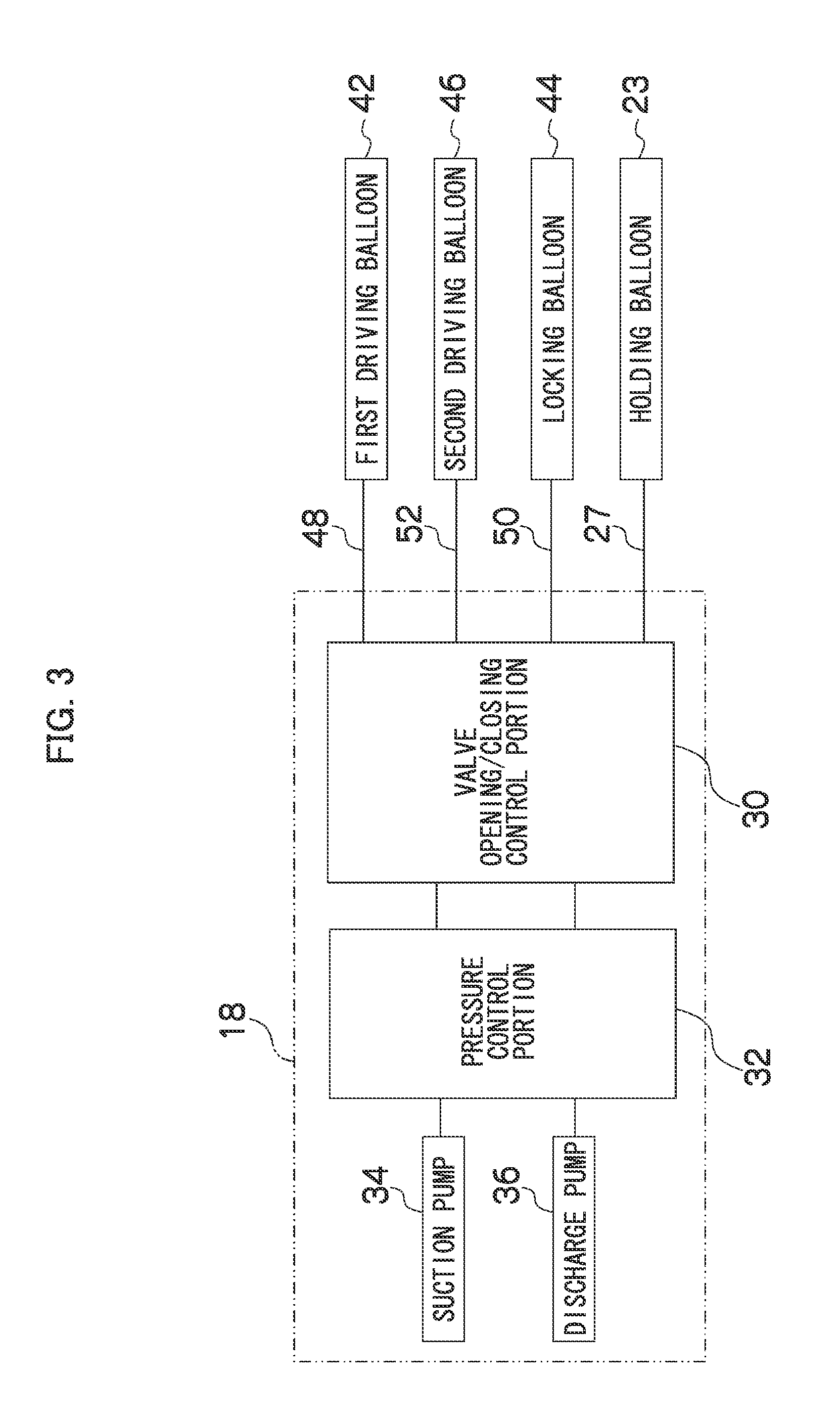

Medical fixed balloon, actuator for intraductal moving body, and endoscope

InactiveUS20110190583A1Reliable and sufficient body-cavity fixing forceExclude influenceSurgeryEndoscopesCatheterActuator

A medical fixed balloon disposed in an insertion portion to be inserted into a body cavity so as to fix the insertion portion to the inside of the body cavity, comprising:an inflation membrane inflated by supplying a fluid into an inside of the inflation membrane and whose outer peripheral surface is brought into contact with an inner wall of the body cavity, the inflation membrane having regions extended with a predetermined extension rate and having a plurality of low extension regions of a lower extension rate than the predetermined extension rate, formed on a line segment from a base end to a distal end along an insertion axis of the insertion portion.

Owner:FUJIFILM CORP

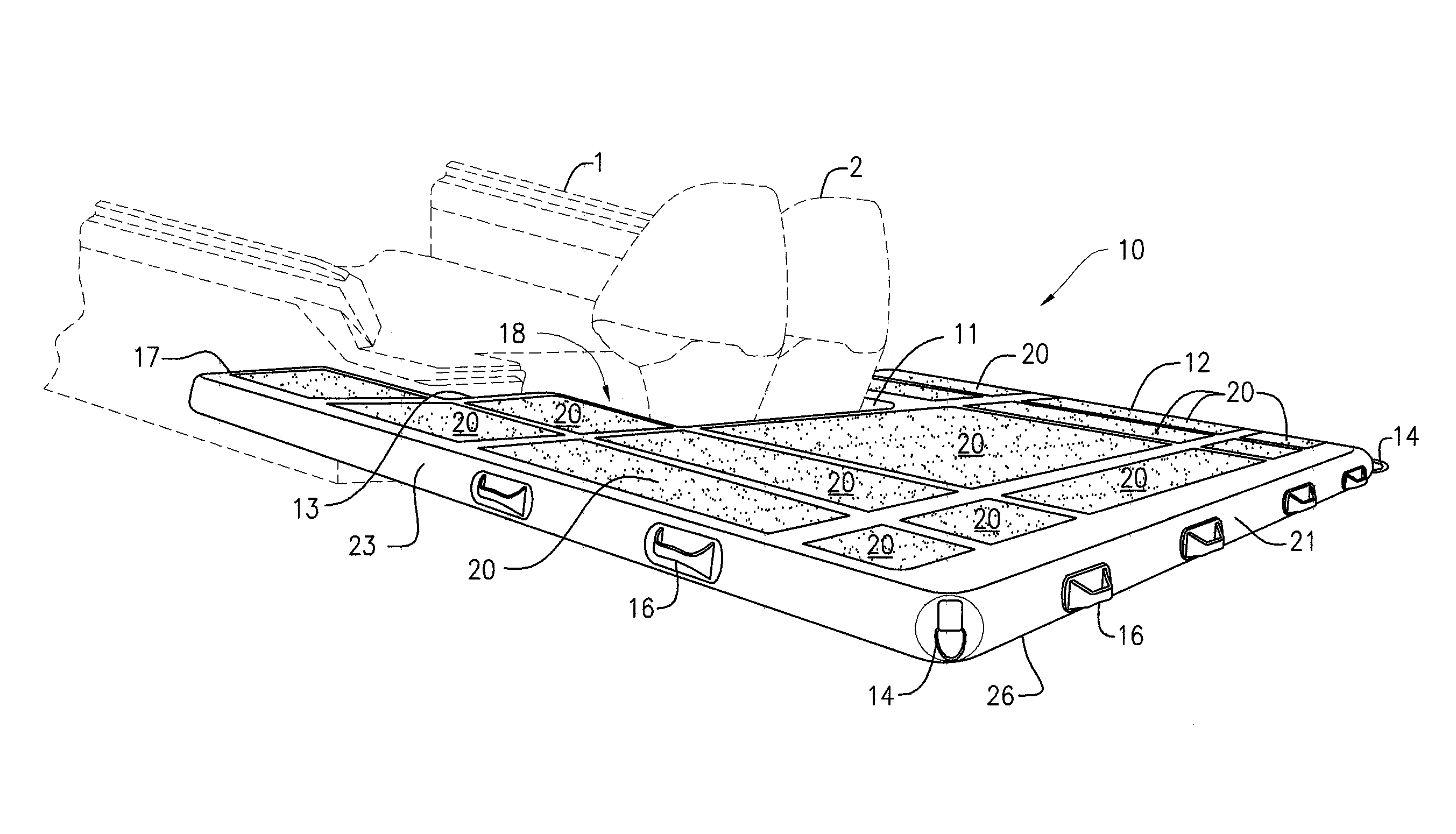

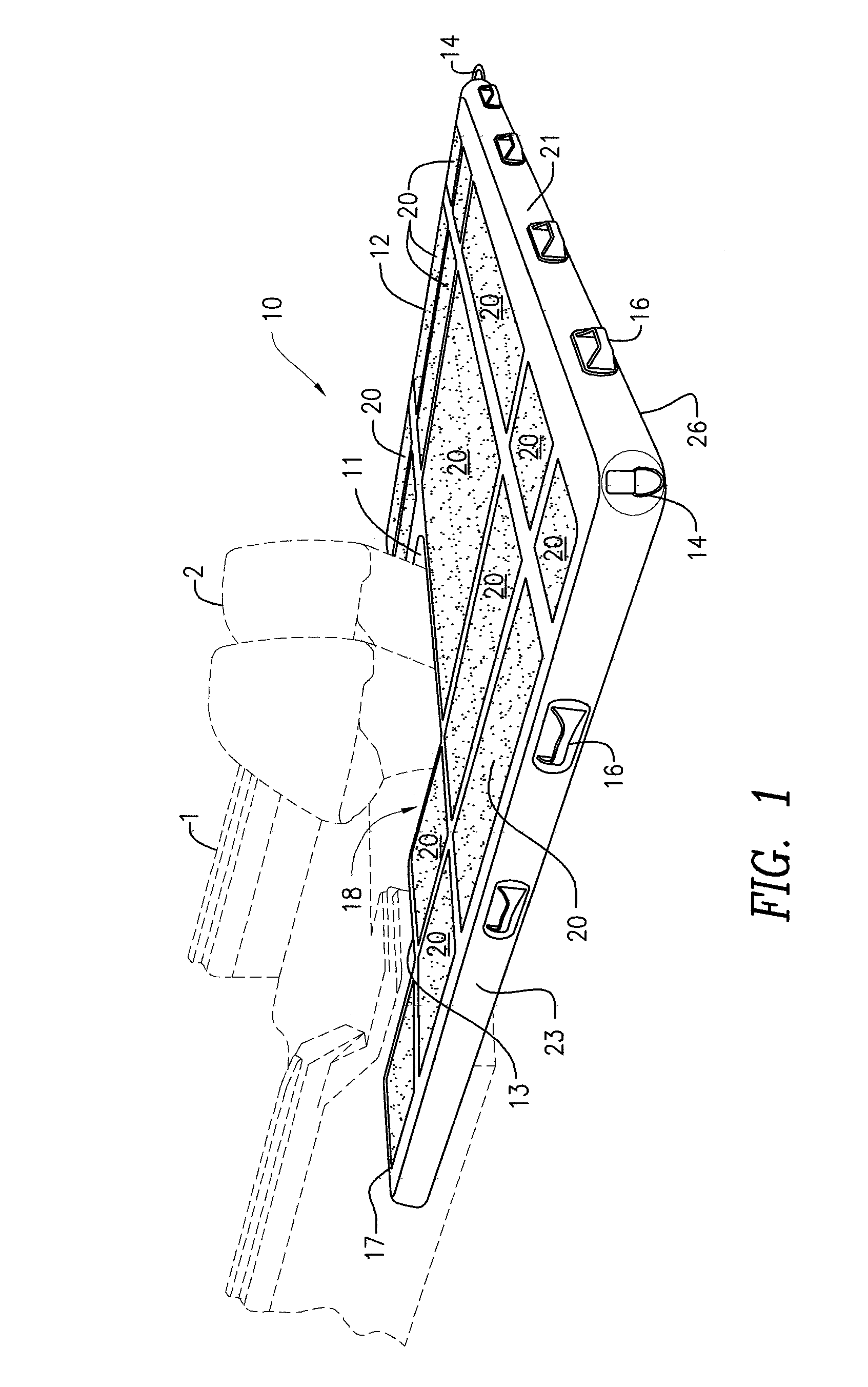

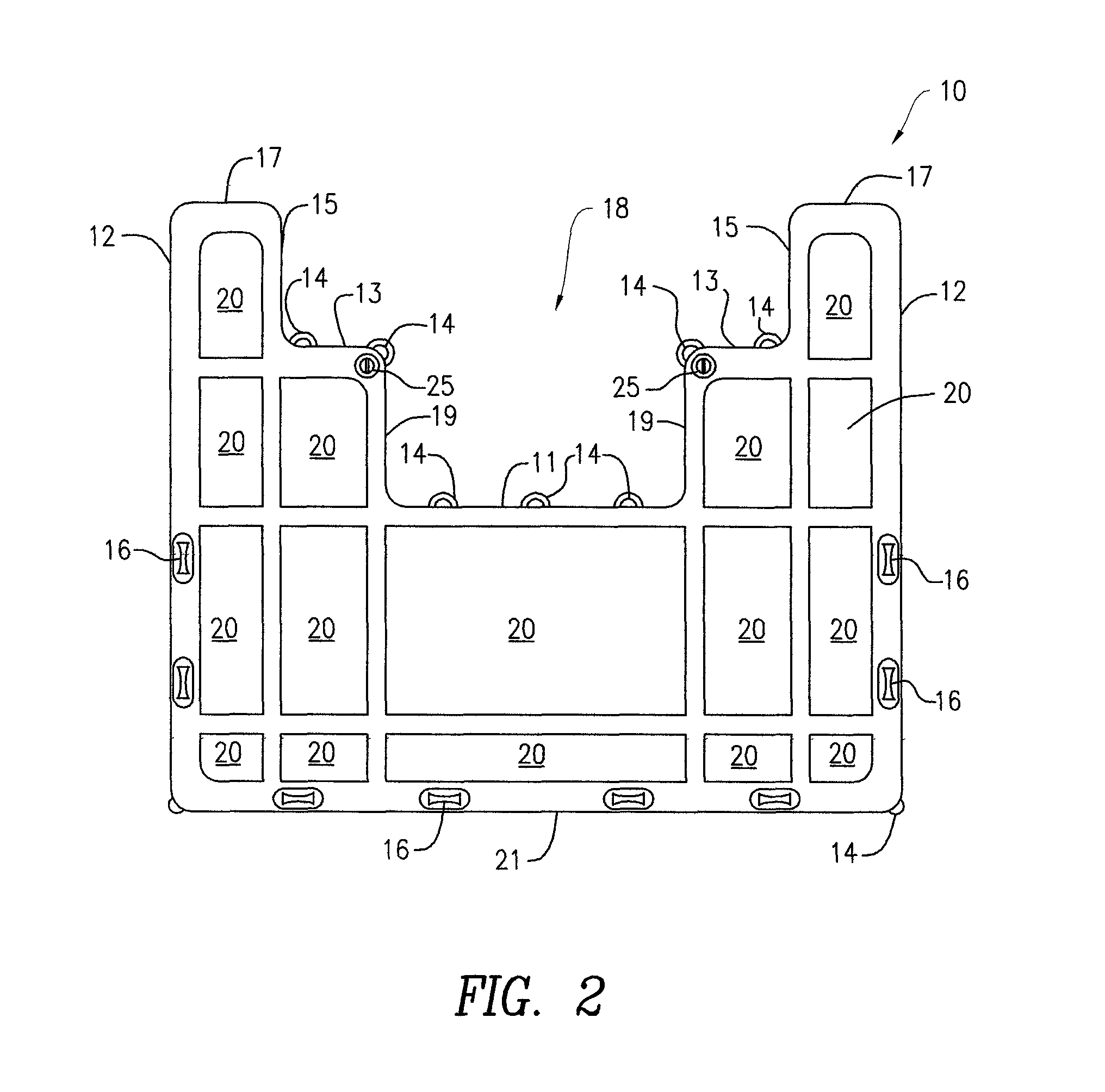

Inflatable boat transom platform device

ActiveUS9278731B1Flexible and soft propertyEasy to inflateCargo handling apparatusNon-magnetic metal hullsPolyesterFiber

An inflatable boat platform floatation device having a “T” or “U” shaped opening in the front surface that receives the motor(s) and wraps around the motor(s) and sides of a boat allowing the front surface to engage the transom and side surfaces forming the opening at the front surface to engage the sides of the boat near the stern such that the platform rests against the boat in a manner that shields the propeller(s) from ropes, debris, hands and feet while providing a platform for the passengers outside the boat. The platform has top and bottom surfaces that are connected by stitched polyester fibers (“SPF”) which hold the surfaces together and determine the platform's thickness when inflated and keep the surfaces uniform and rigid when the platform is inflated. The upper surface includes at least one ethylene vinyl acetate (EVA) pad. The platform further includes a plurality of handles, at least one inflation and deflation valve and a plurality of D-rings for securing the platform to a boat and tethering other platforms or tethering other watercraft to the platform.

Owner:CANELA RAMON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com