Patents

Literature

258 results about "Peak pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

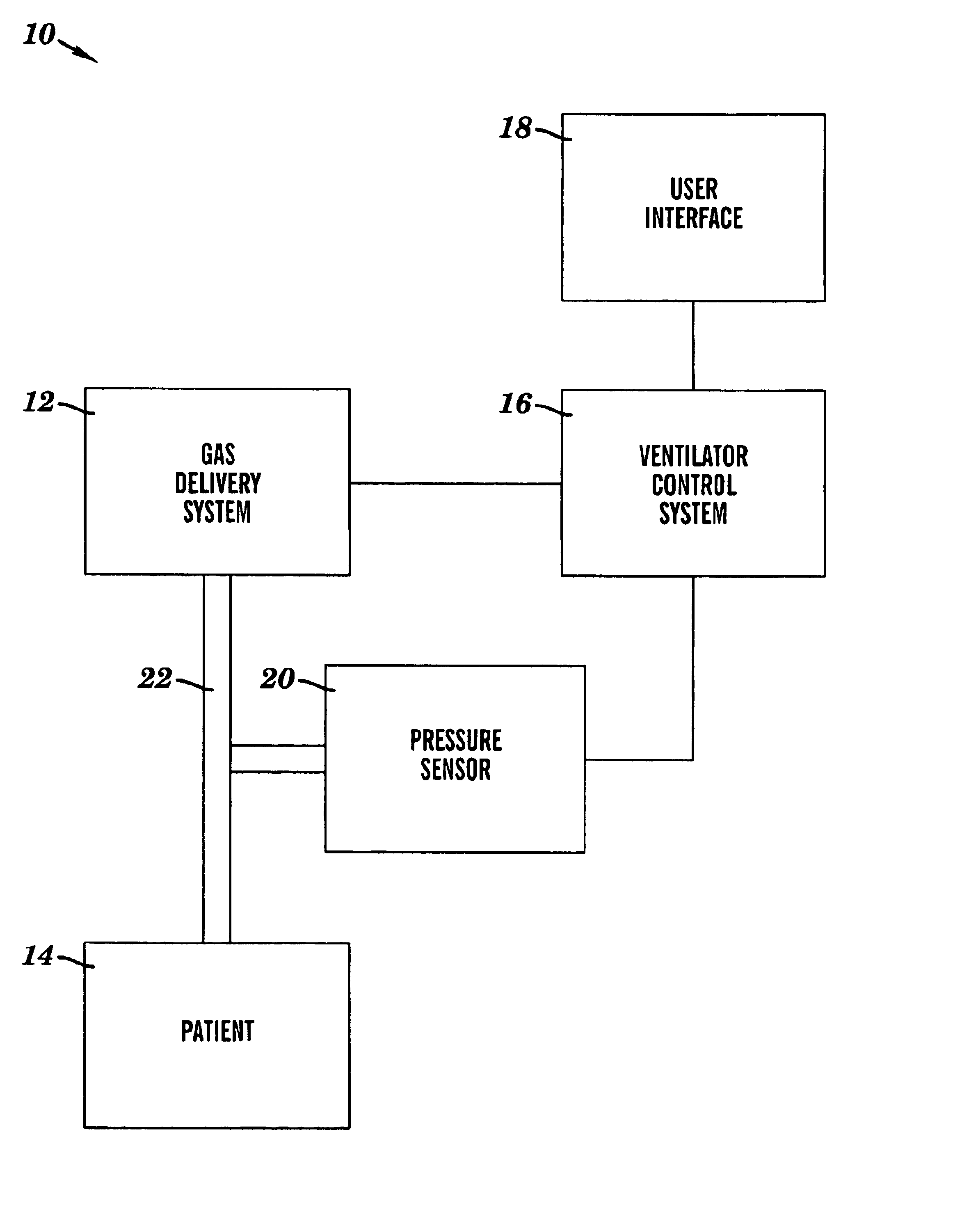

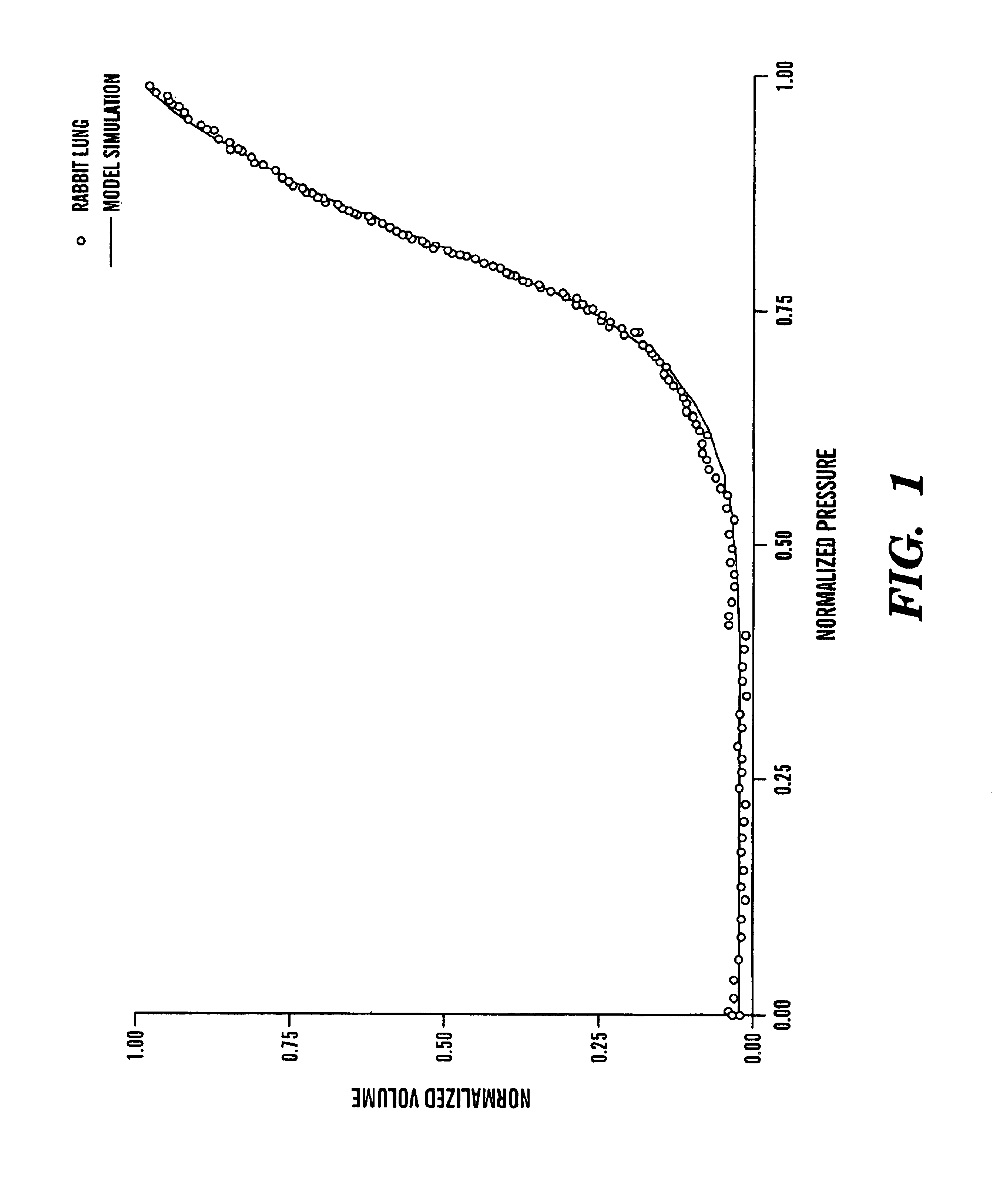

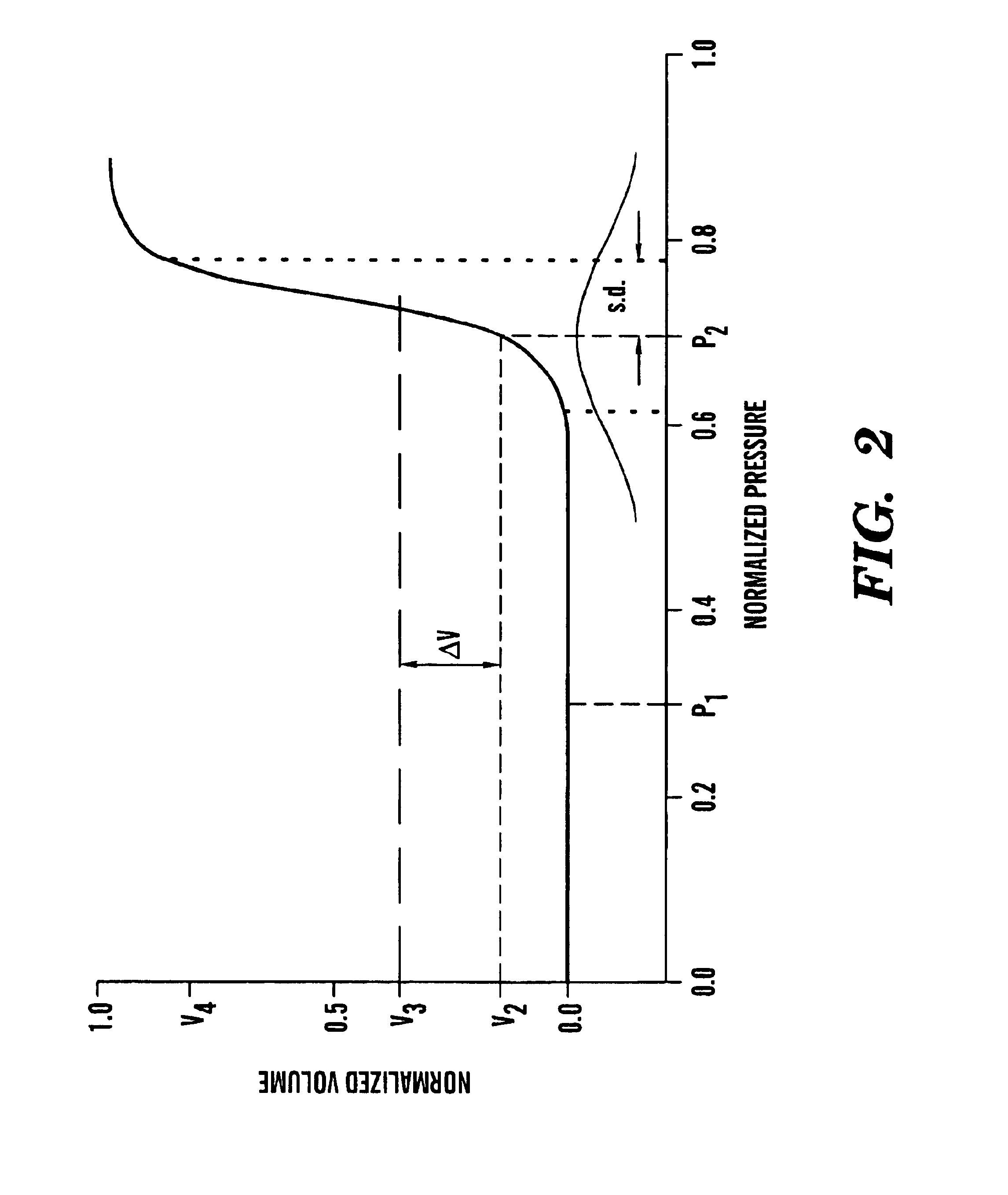

Variable peak pressure ventilation method and system

InactiveUS6907881B2Enhanced blood oxygenationImprove performanceRespiratorsOperating means/releasing devices for valvesBiological bodyPeak inspiratory pressure

A system and method for ventilating a lung in a living being by varying the peak inspiratory pressure. The peak inspiratory pressure may deviate about a mean that is chosen to correspond with a knee in a pressure-volume curve of the lung.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC +1

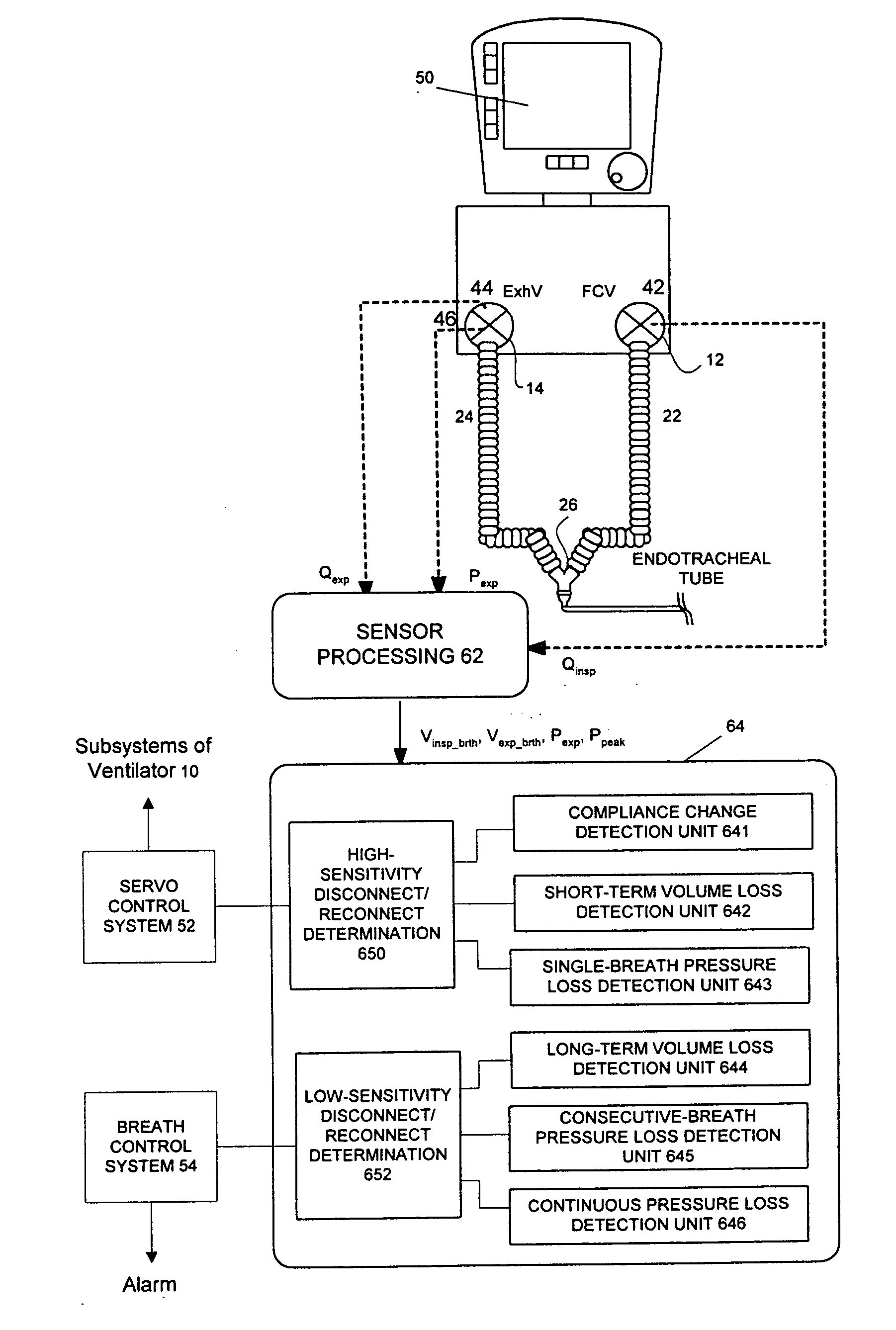

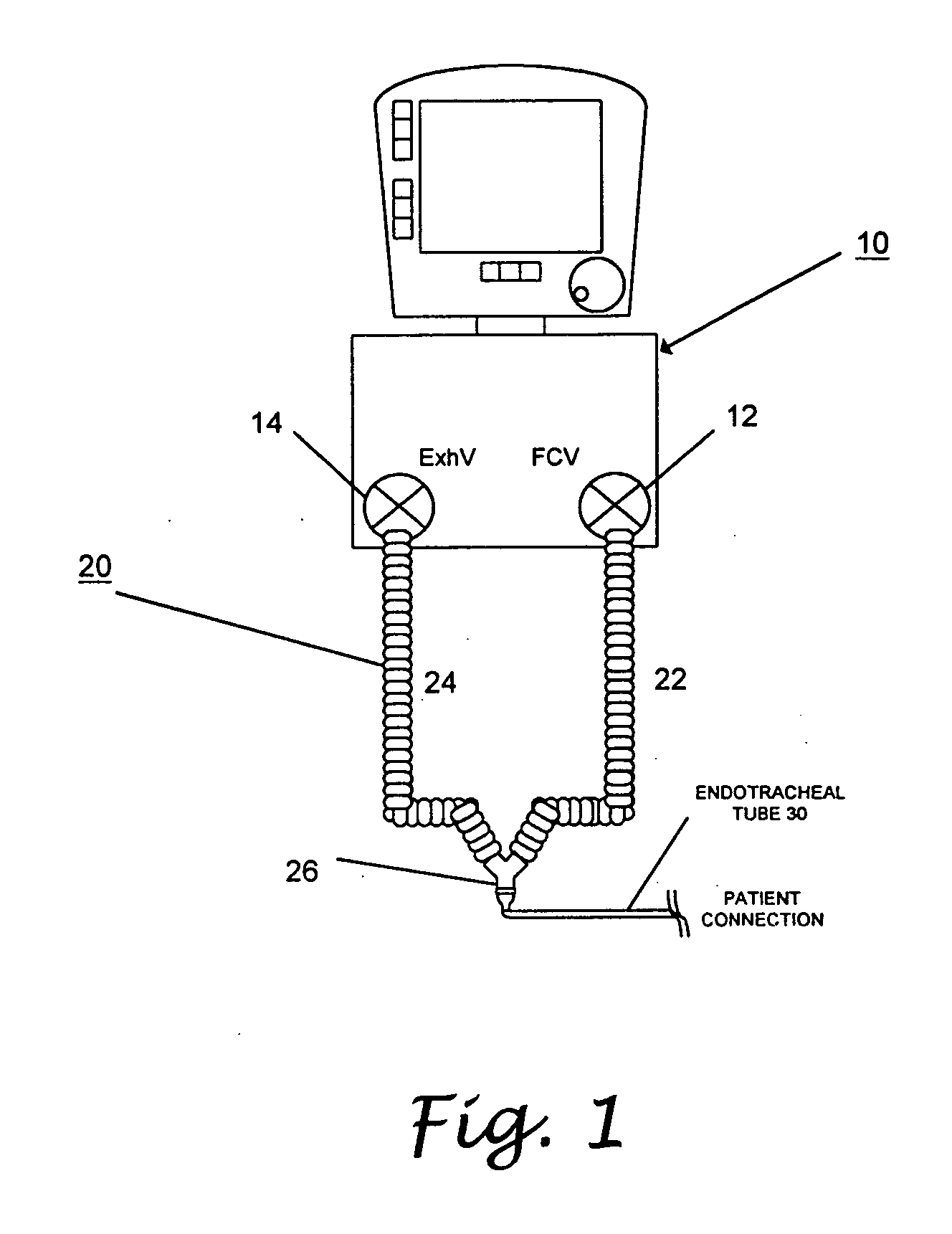

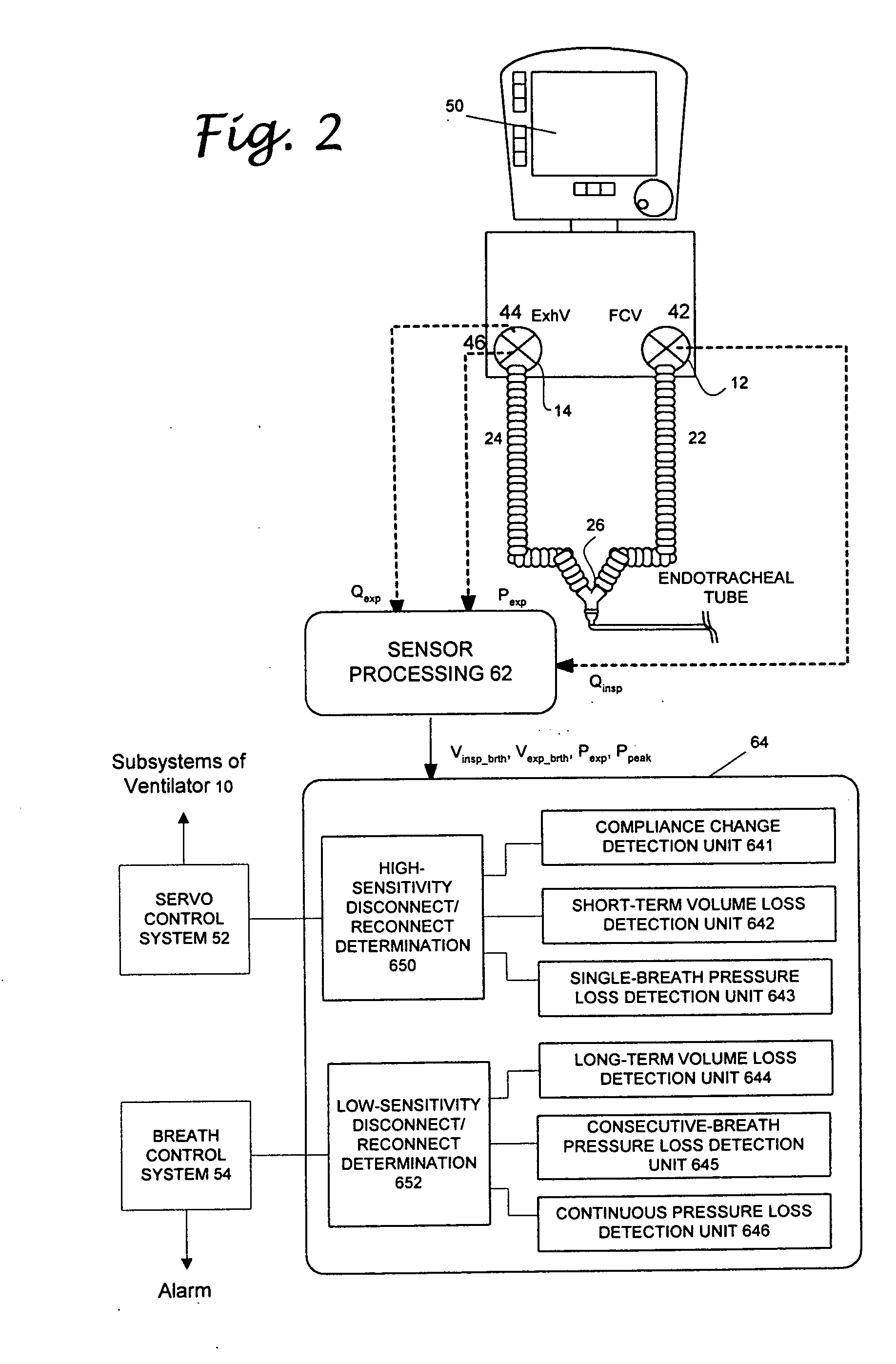

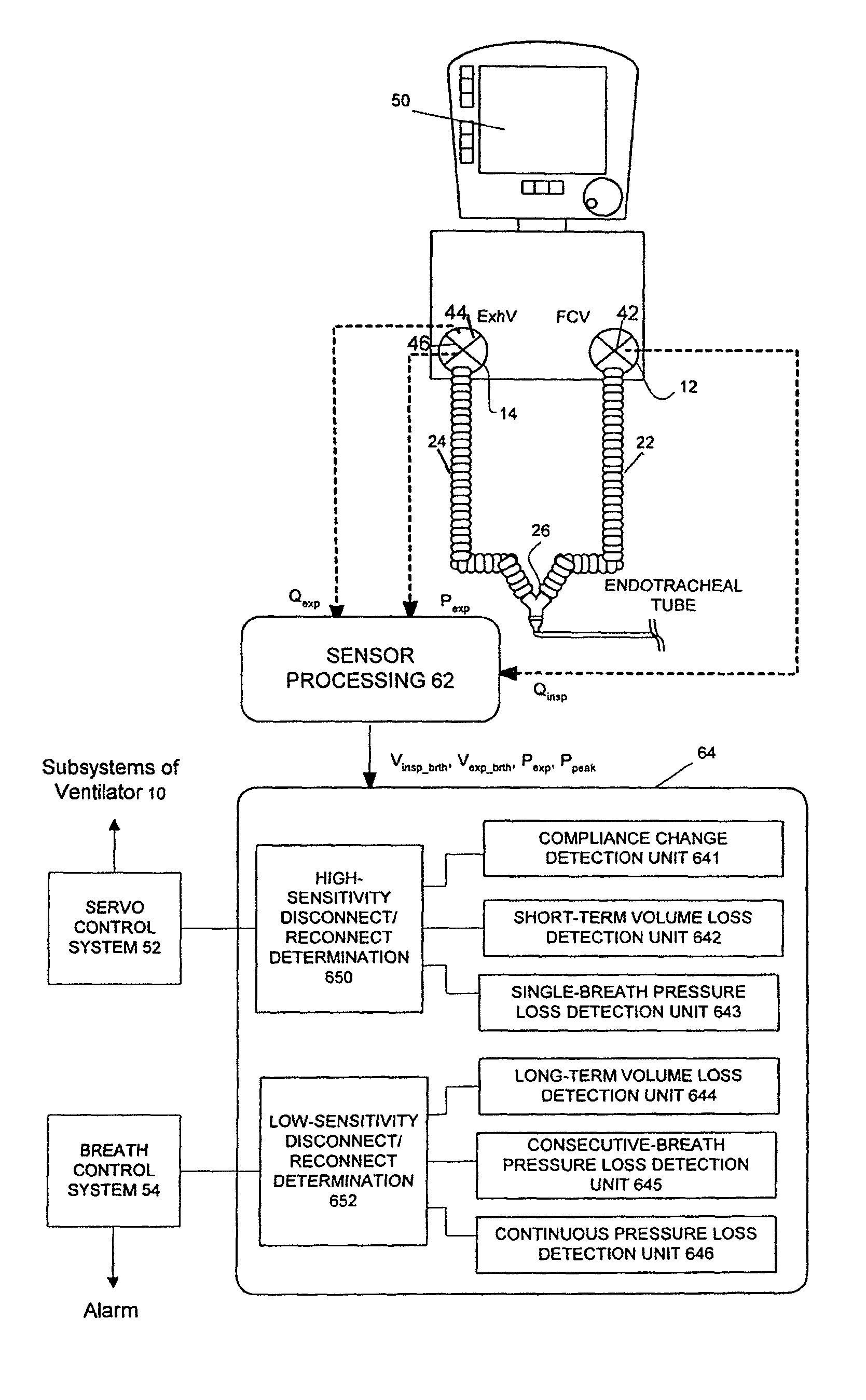

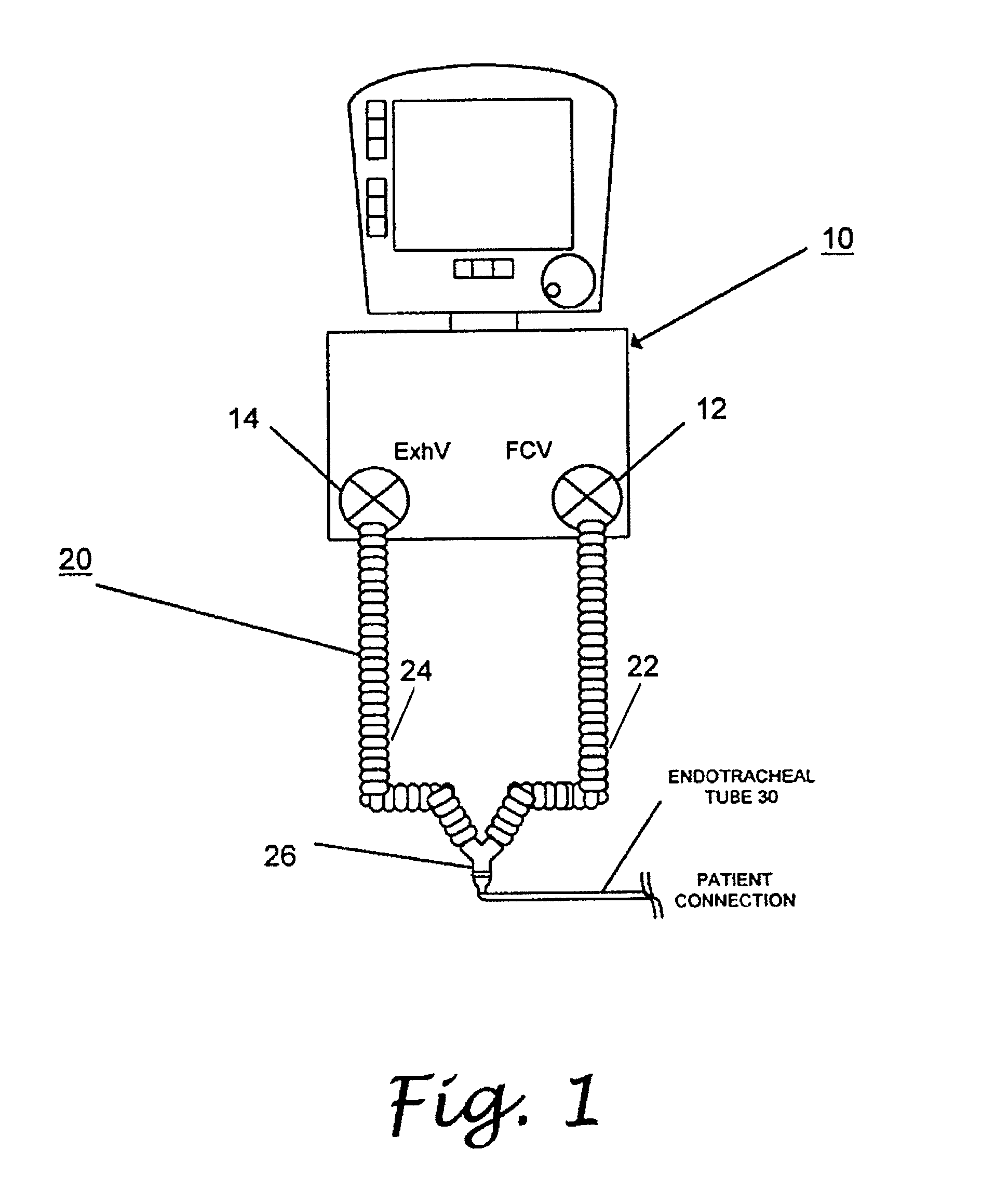

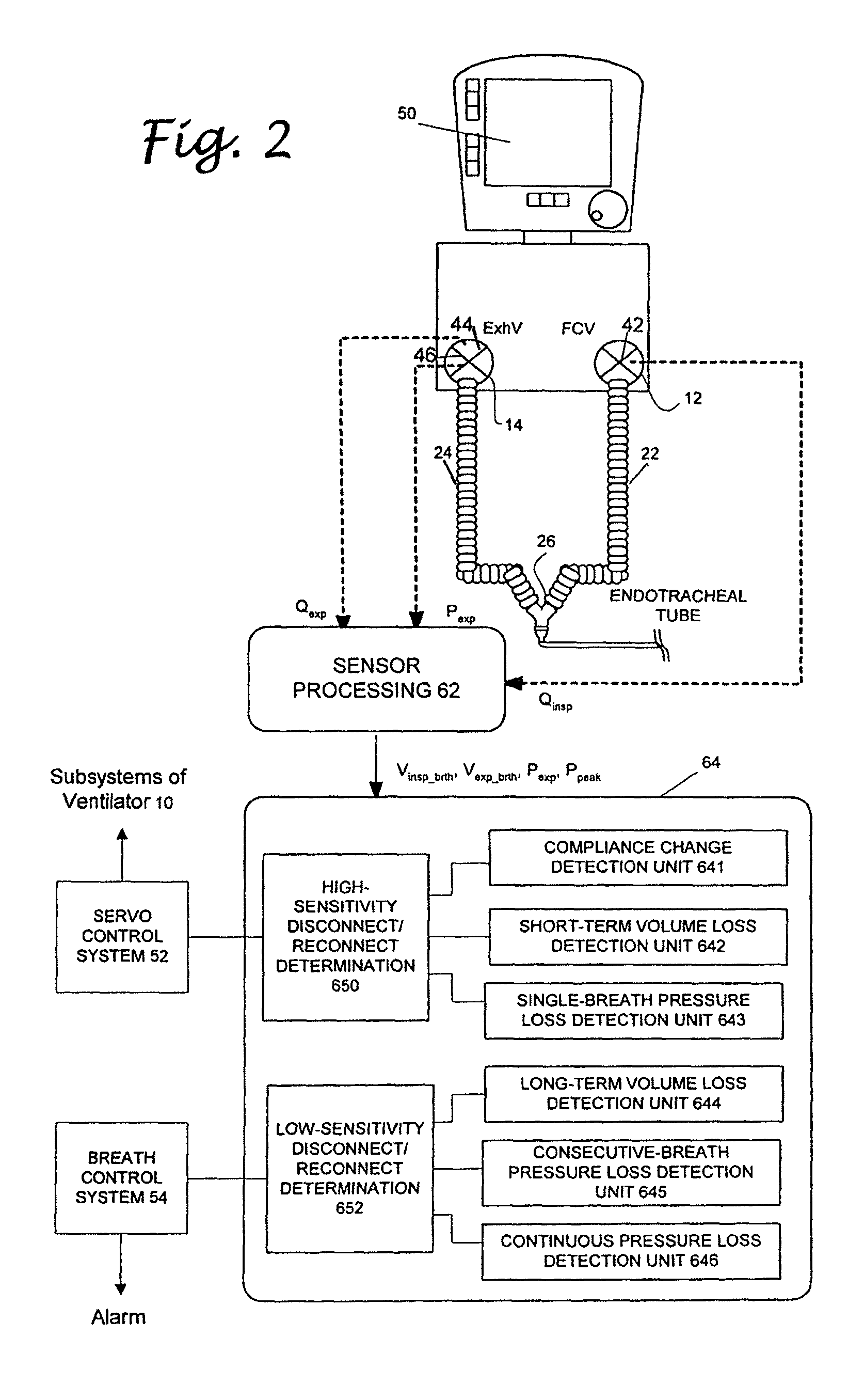

Patient circuit disconnect system for a ventilator and method of detecting patient circuit disconnect

ActiveUS20060086357A1Easy to adjustRespiratorsOperating means/releasing devices for valvesMedicinePeak value

A method of detecting disconnect of a patient circuit of a ventilation system, wherein a circuit disconnect is detected with a first sensitivity and a second sensitivity. The circuit disconnect detected with the first sensitivity is performed by detecting a volume loss for a minimum period of time, detecting a peak pressure loss for at least two consecutive breathing cycles or a minimum period of time, and detecting a pressure loss continuing for a predetermined period of time. The circuit disconnect detected with the second sensitivity is performed by detecting a volume loss for a single breathing cycle, detecting a pressure loss for a single breathing cycle, and detecting an increase of compliance. The first sensitivity is lower than the second sensitivity. Preferably, an alarm is activated when the circuit disconnect is detected with the first sensitivity, and subsystems of the ventilation system is informed of the circuit disconnect that has been detected with the second sensitivity.

Owner:BIRD PRODS

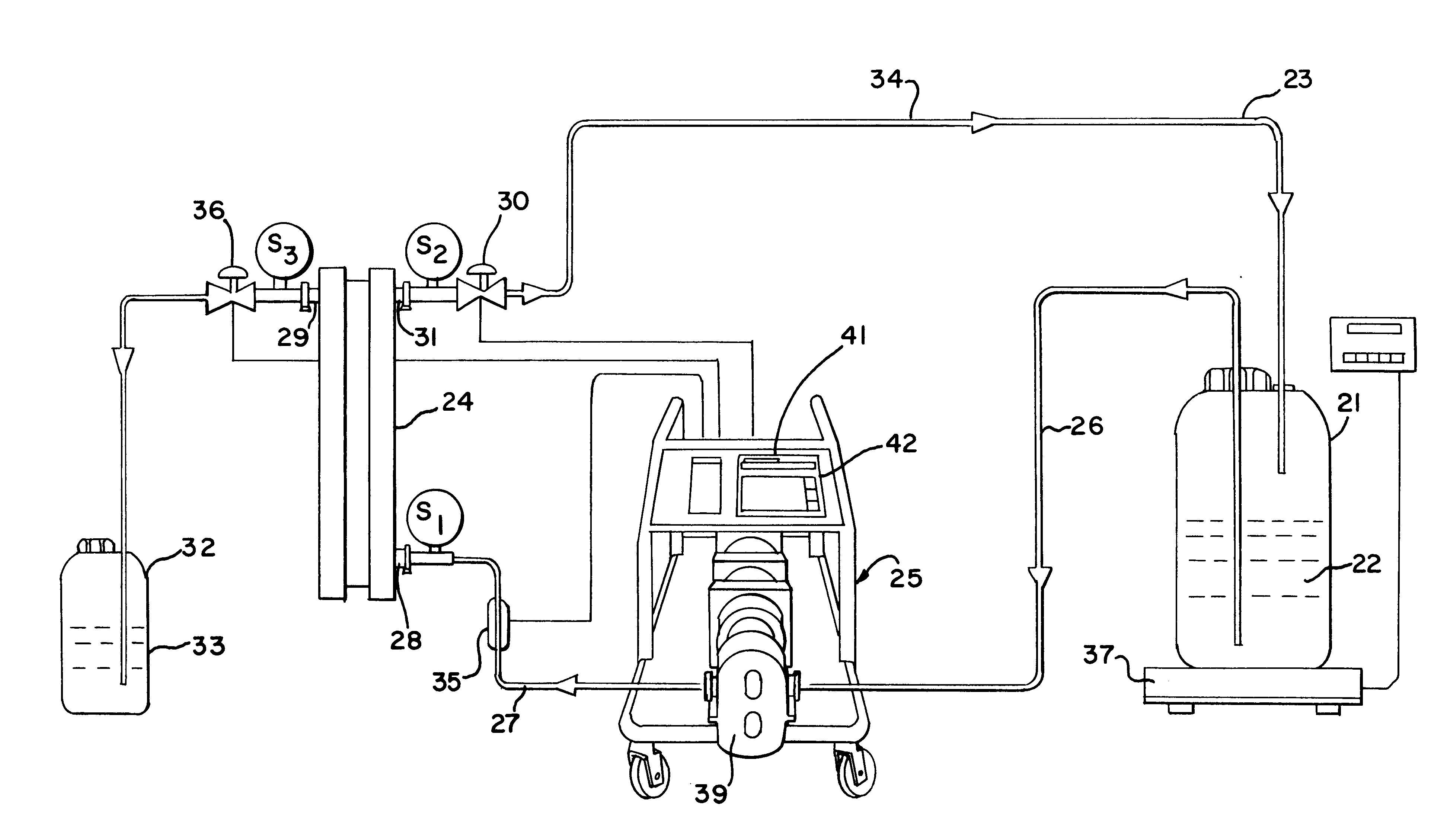

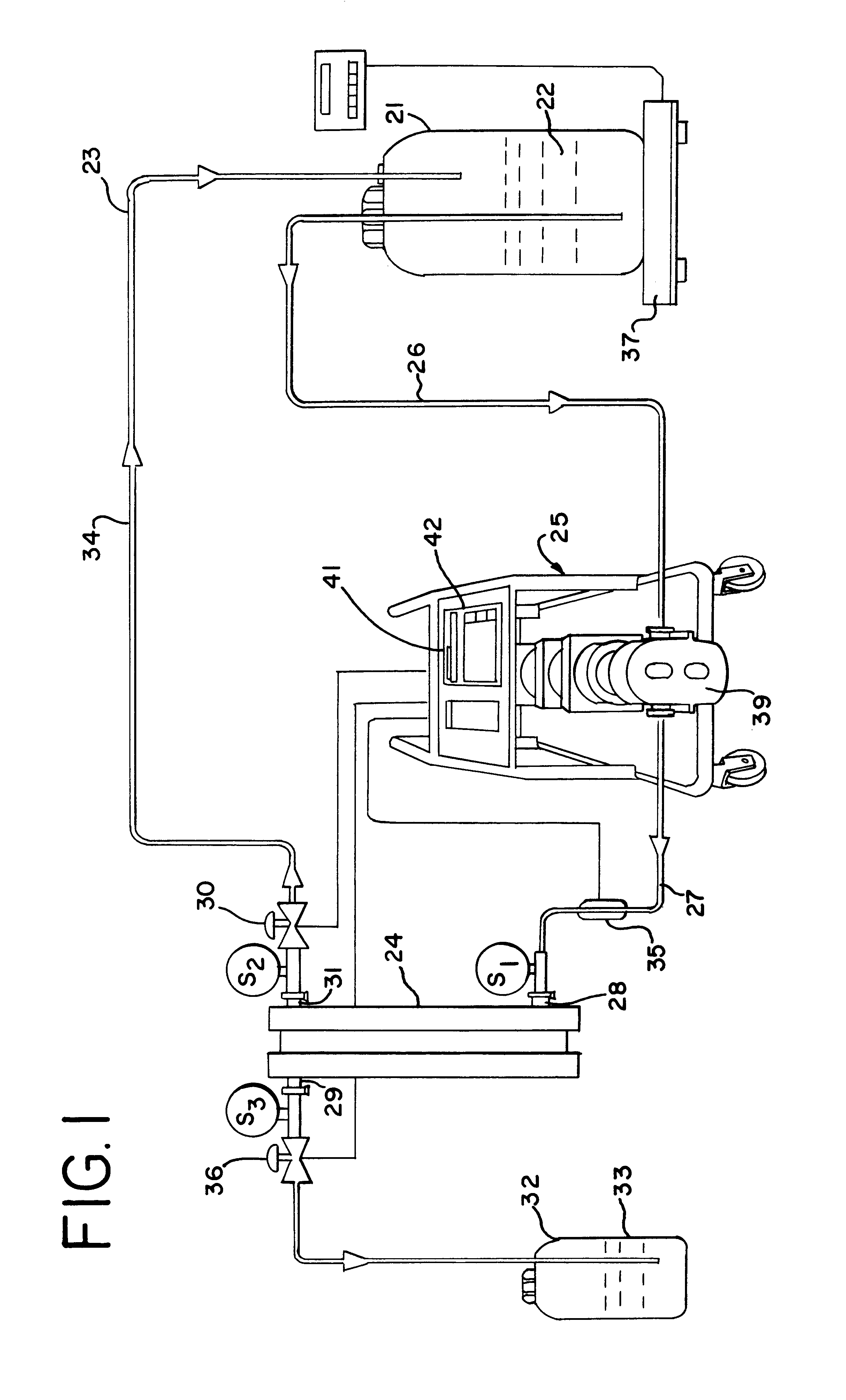

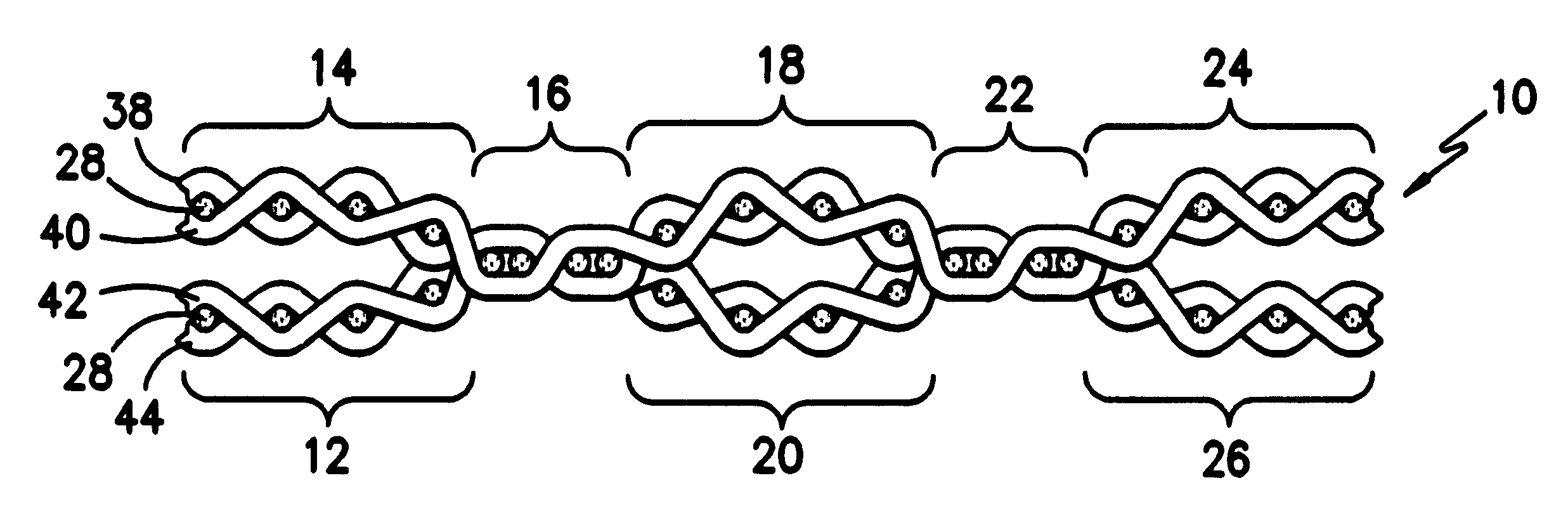

Enhancing filtration yields in tangential flow filtration

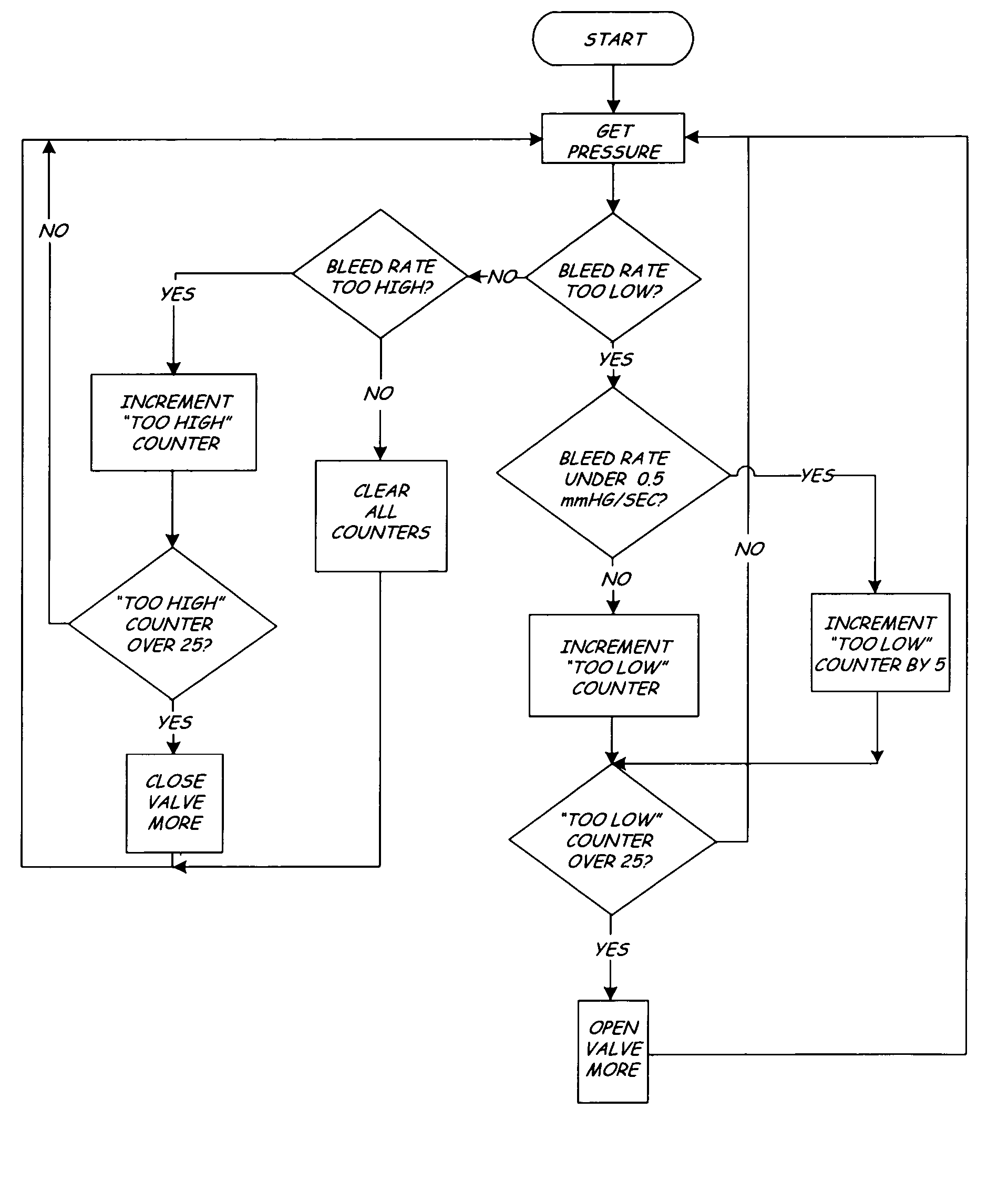

InactiveUS6350382B1High precision separationEasy to separateLiquid separation auxillary apparatusMembranesEngineeringPeak pressure

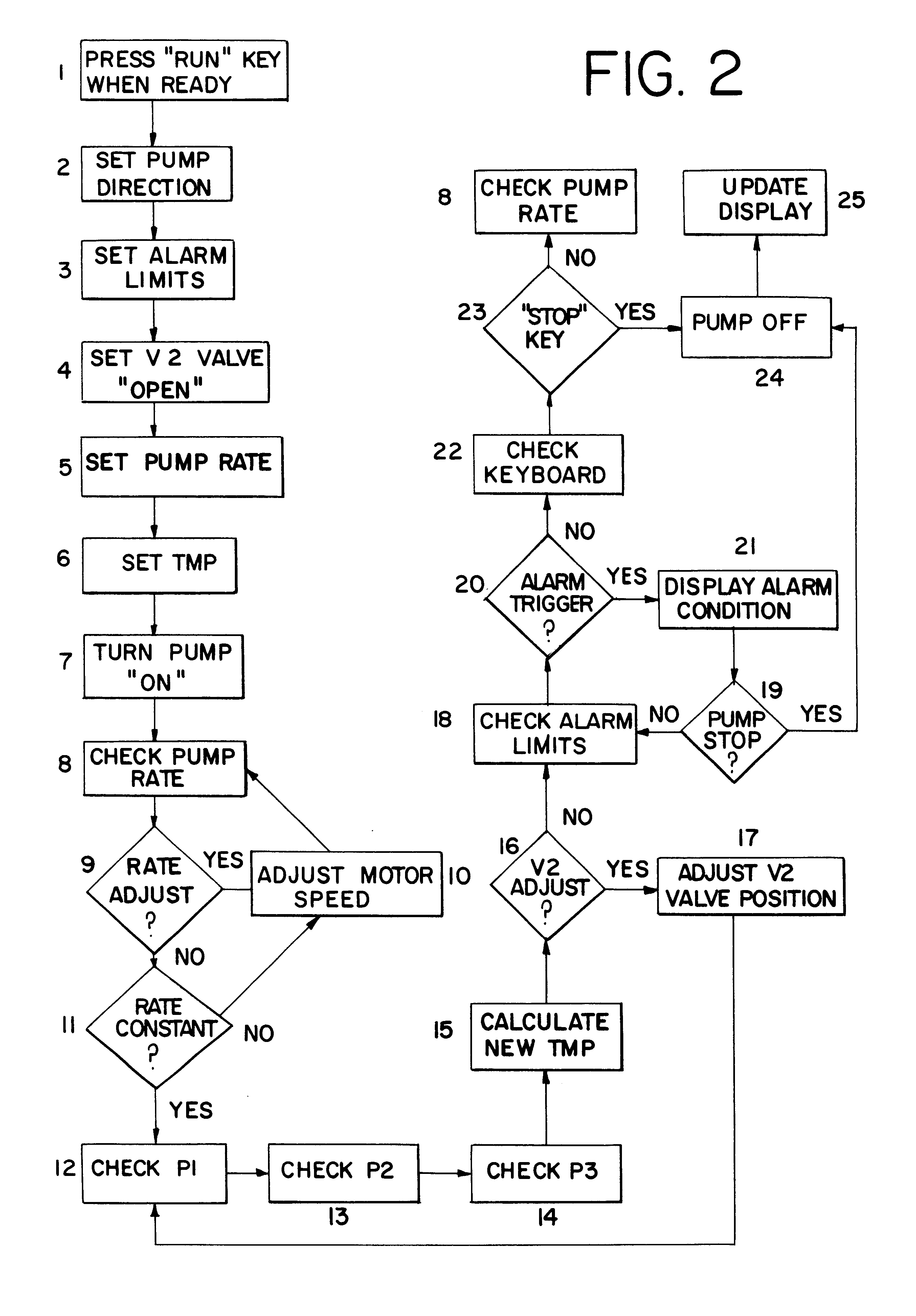

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained. Approaches also are described for determining optimal filtration conditions, including trans-membrane pressure and feed rate. Also described is a system and method for determining pressures in a pulsating system with enhanced accuracy by using a peak pressure mode.

Owner:PARKER INTANGIBLES LLC

Expandable product rate portable gas fractionalization system

ActiveUS7686870B1Improve pressure resistancePromote recoveryRespiratorsGas treatmentProduct gasEngineering

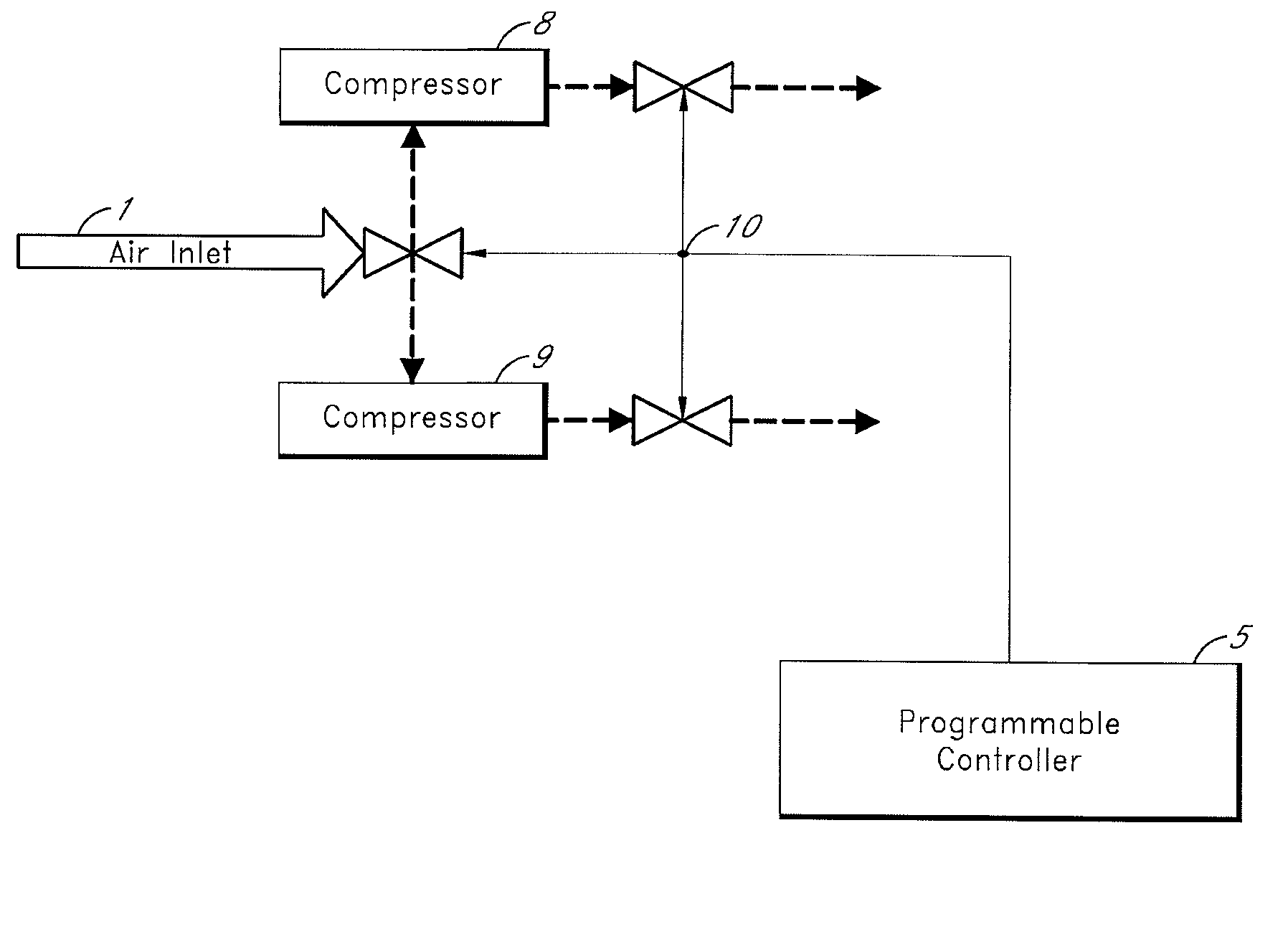

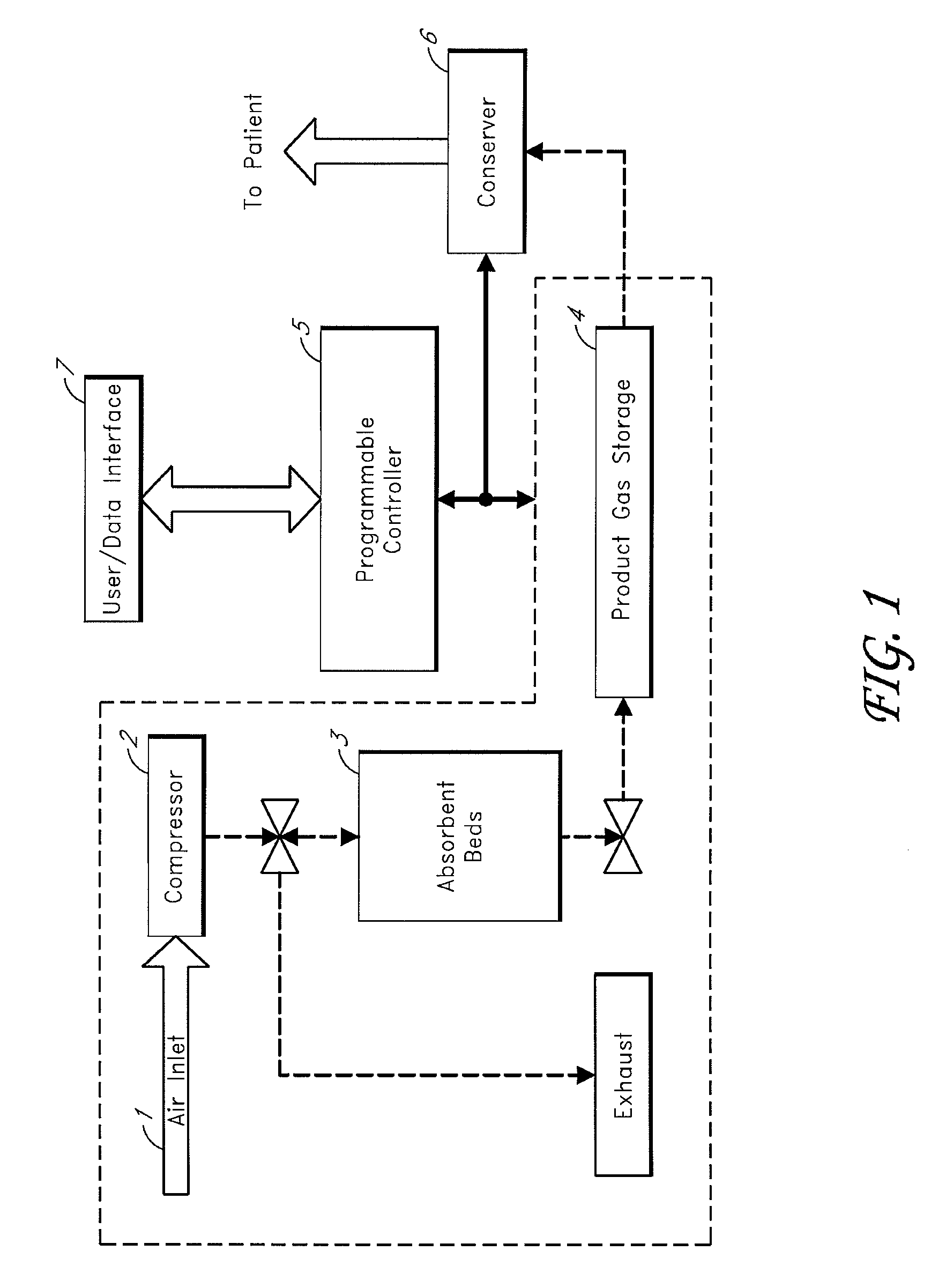

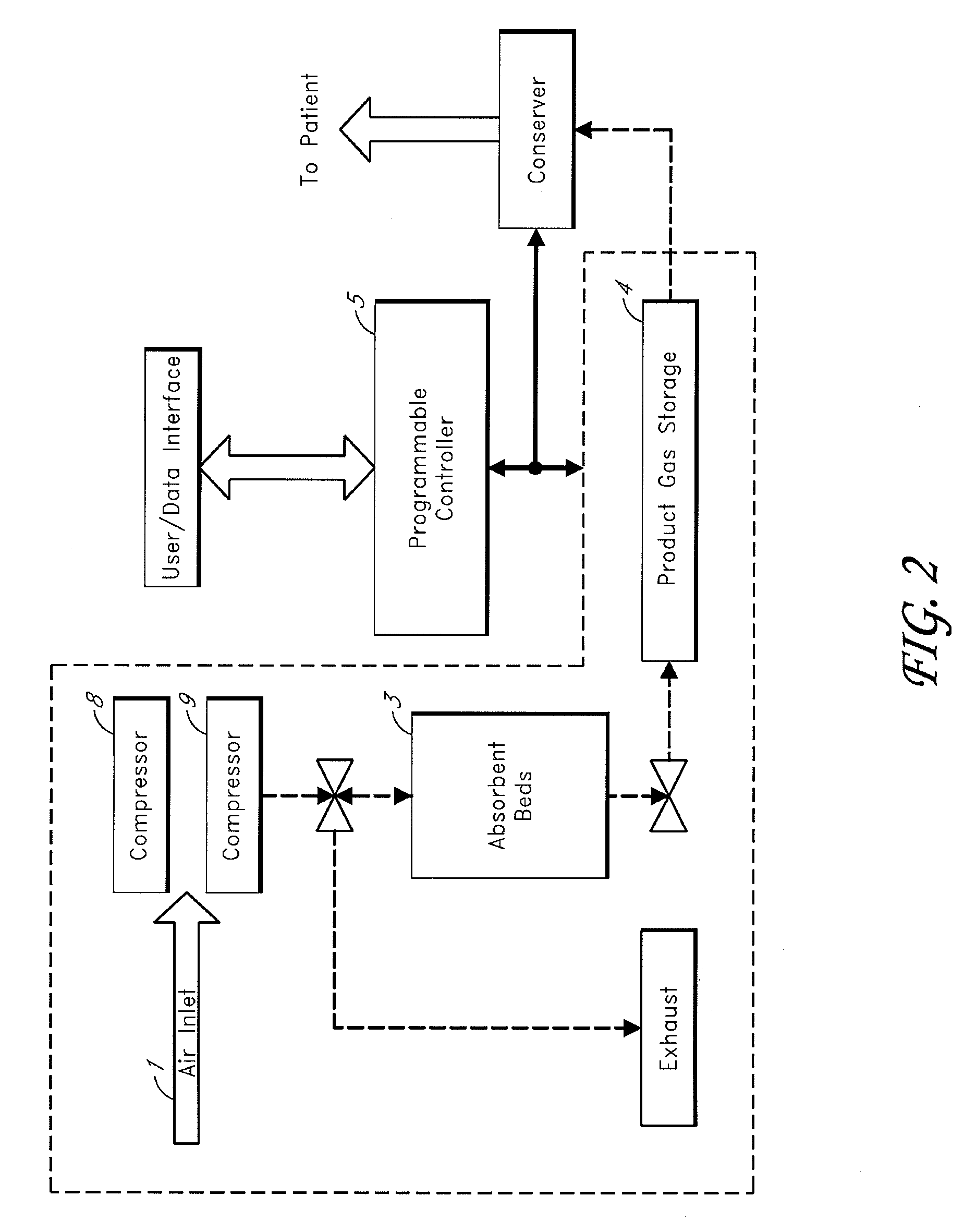

An oxygen concentrator system that includes or can be expanded to include more than one compressor is provided. The system utilizes a controller that is adapted to selectively activate or deactivate one or more of the compressors to optimize system performance and efficiency. Multiple compressors can be selected to operate at the same time, thereby enabling the system to operate at a higher peak pressure, increase the recovery of the PSA cycle, and expand the product rate. The additional compressors can also be removed when not in use so as to reduce weight of the system. In some implementations, the system housing reserves a certain amount of space for accommodating additional compressors and related components, which can be added to the system as after market parts. In other implementations, the additional compressor can be located external to the system.

Owner:INOGEN INC

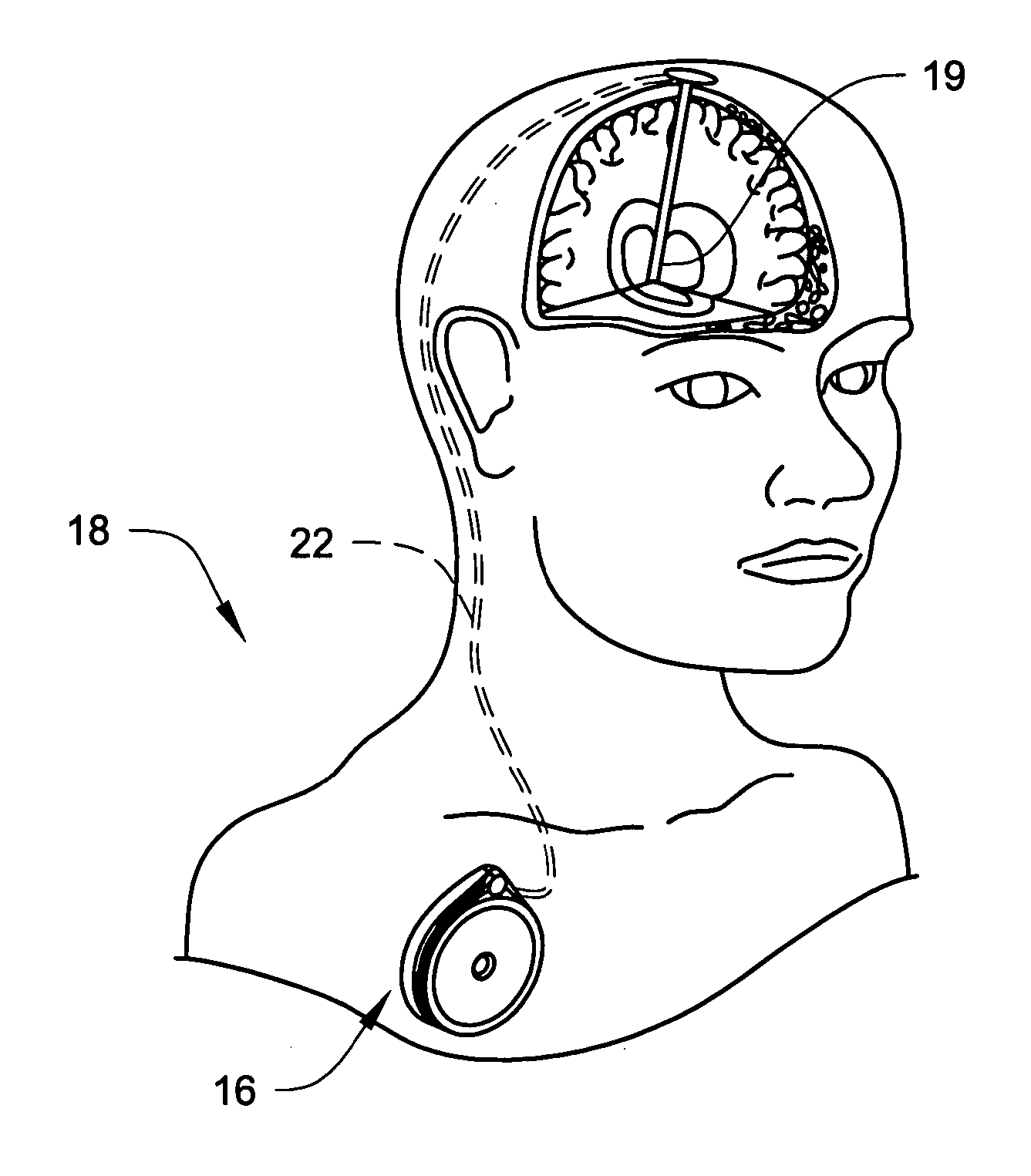

Implantable wireless sensor for in vivo pressure measurement and continuous output determination

InactiveUS20070282210A1Accurate pressure measurementCatheterDiagnostic recording/measuringLine sensorPeak value

A method and apparatus for determining cardiac parameters within the body of a patient includes a wireless sensor positioned in the patient's pulmonary artery. An external RF telemetry device communicates wirelessly with the sensor and interrogates the sensor to determine changes in pressure in the pulmonary artery over time. The peak pressure difference is determined. Then, assuming zero blood flow velocity at the time of valve opening and at the time of valve closing, a velocity-time function is determined. The velocity-time function is used to determine a velocity-time integral. The velocity-time integral is then used to determine cardiac stroke volume. The cardiac stroke volume is multiplied times the heartbeat rate to determine cardiac output. The cardiac output can be monitored over time to determine continuous cardiac output.

Owner:CARDIOMEMS

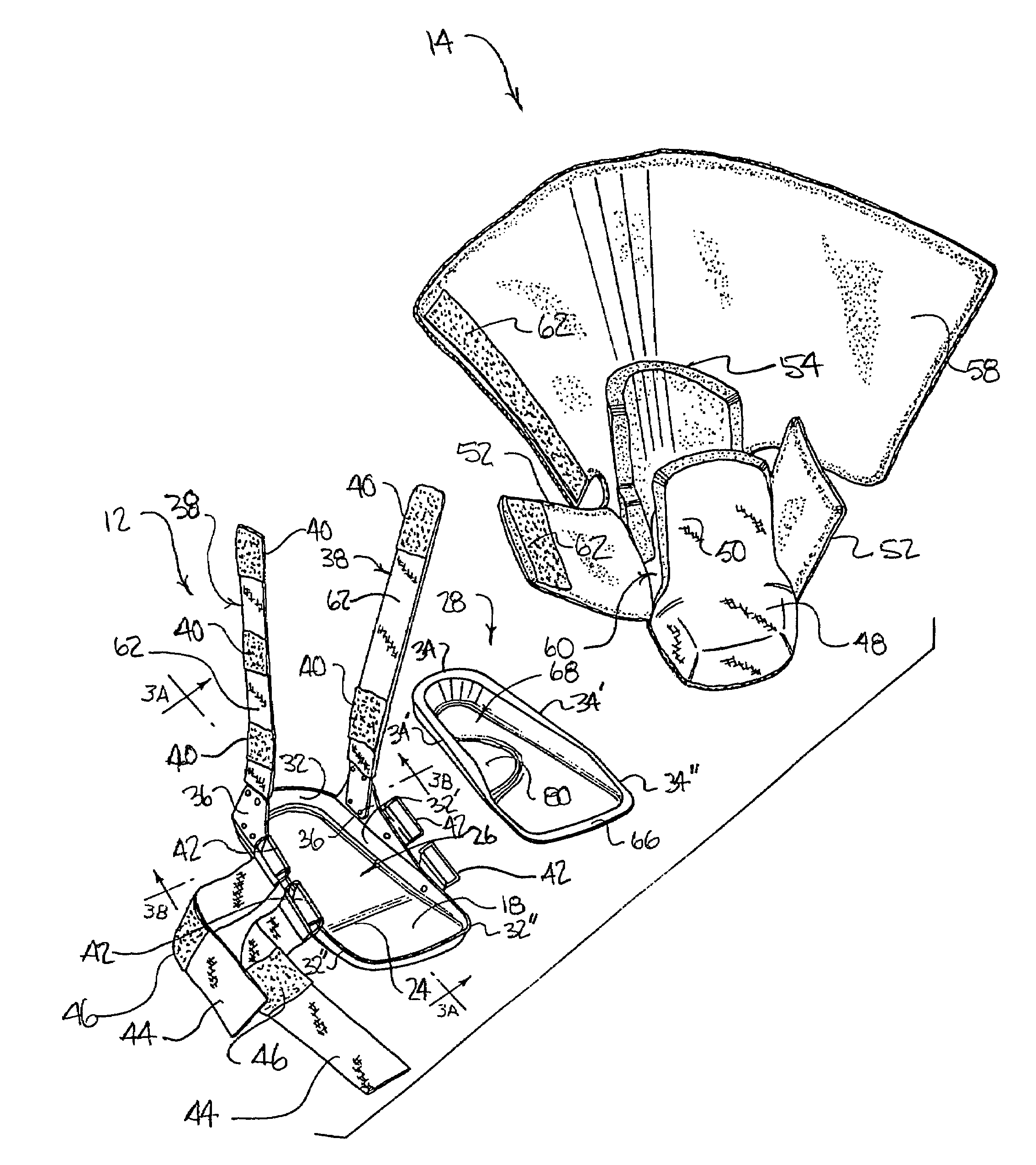

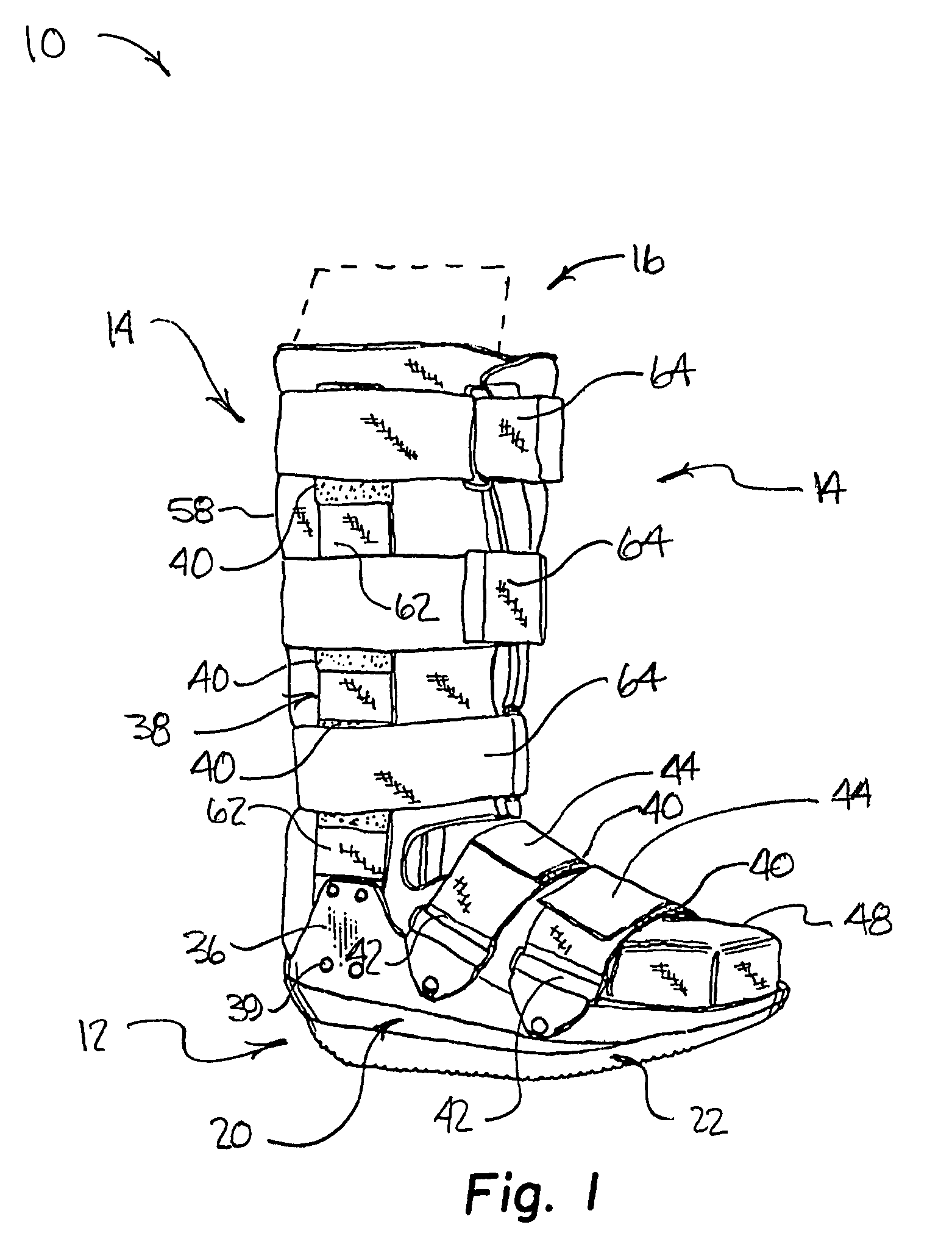

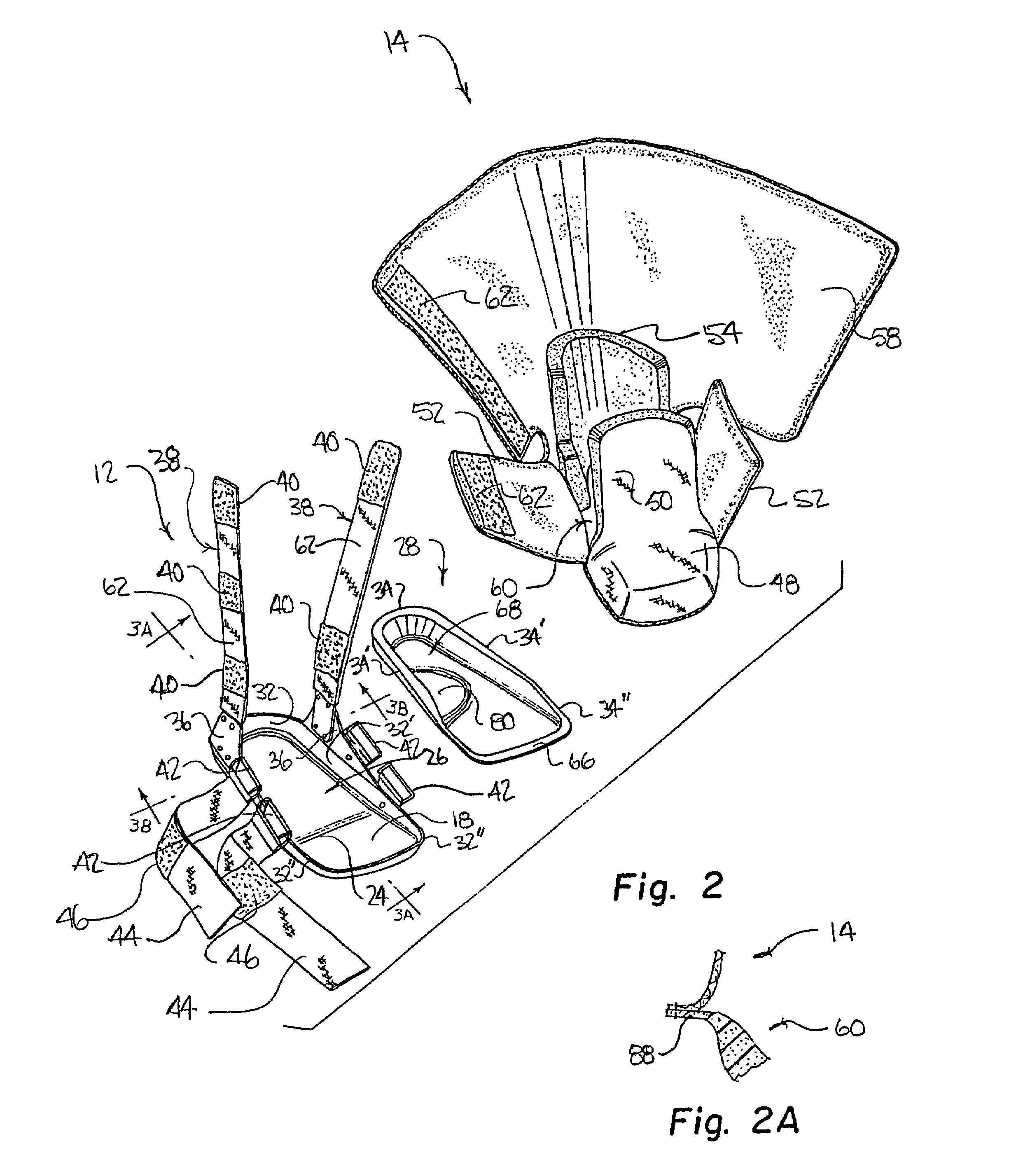

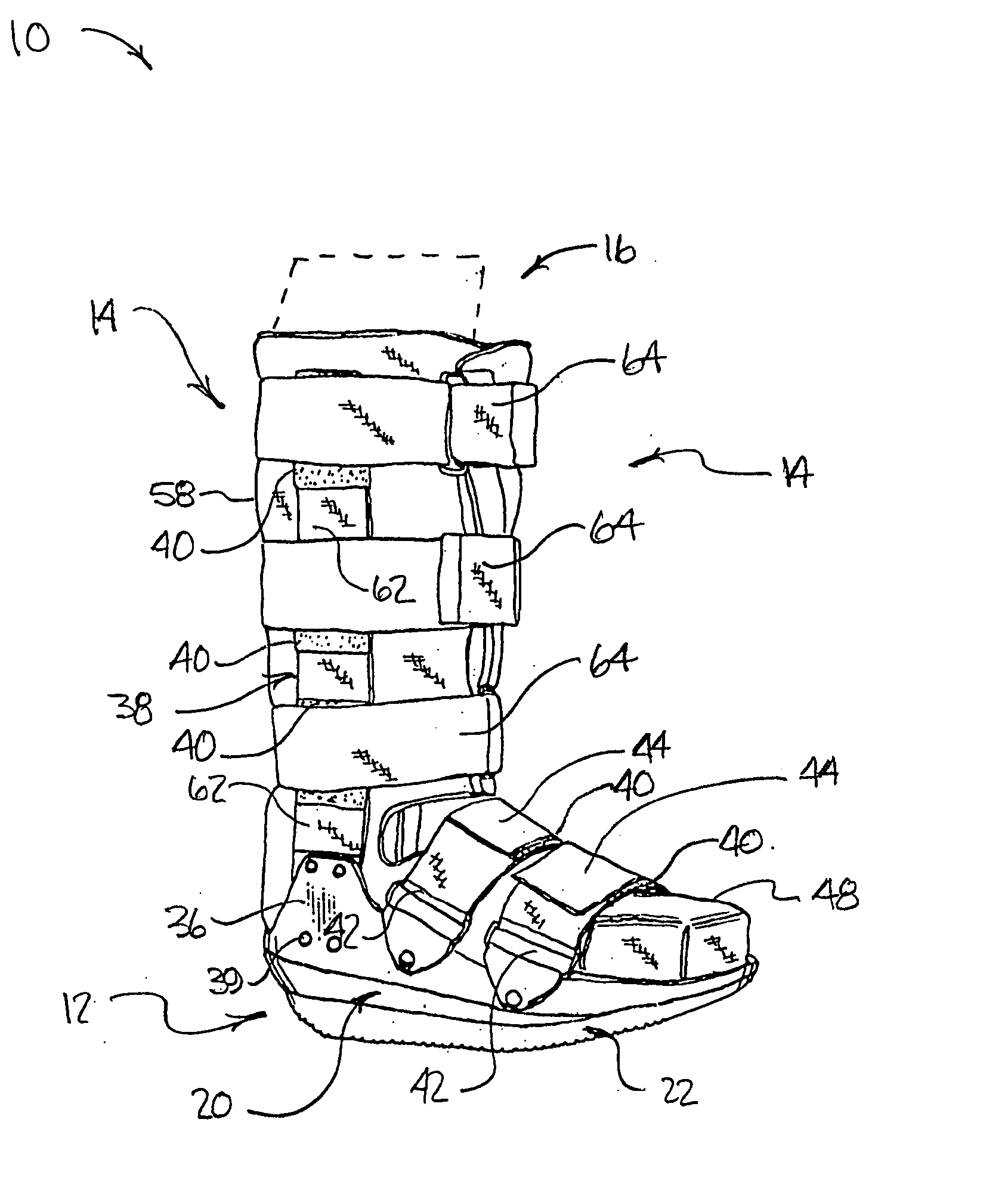

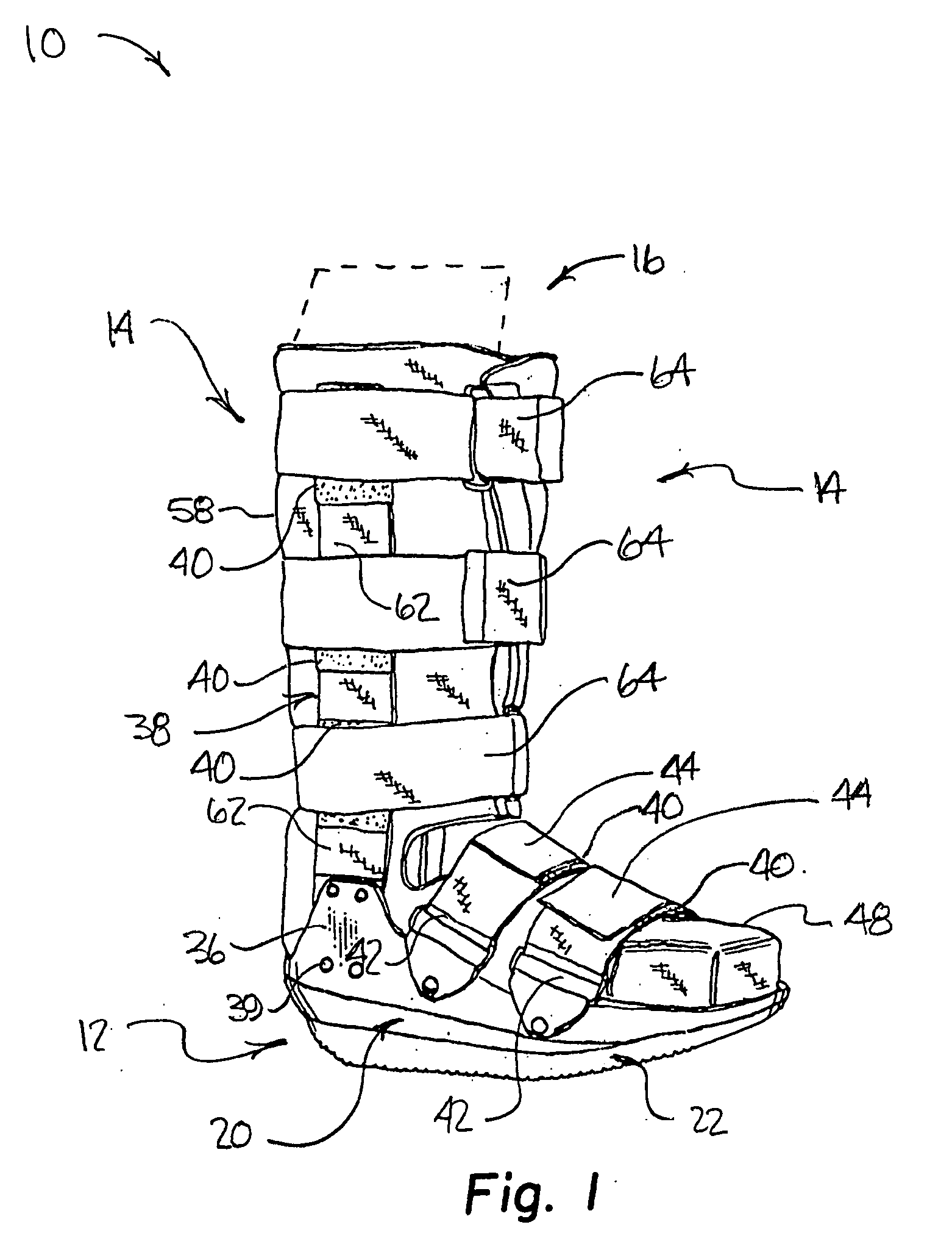

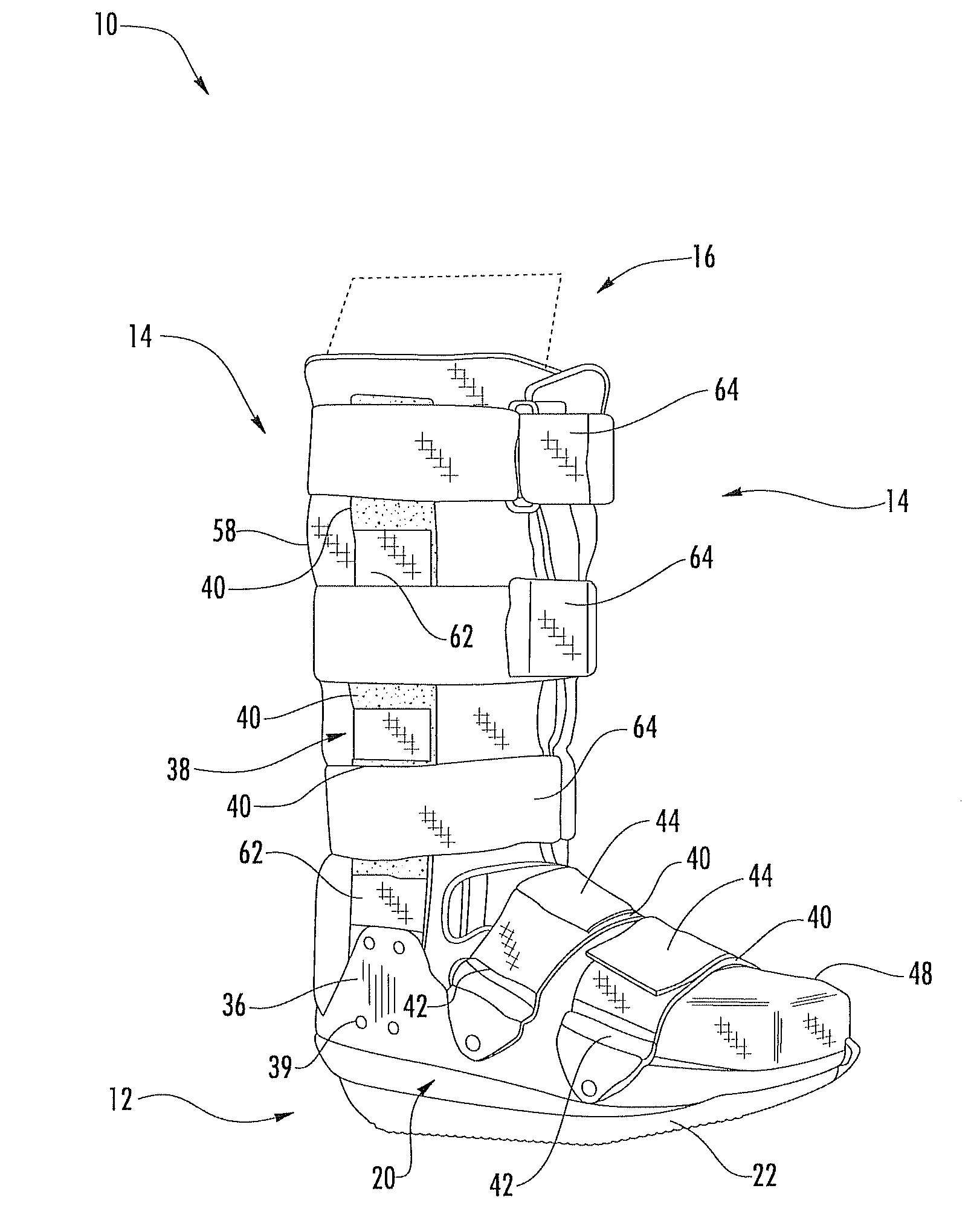

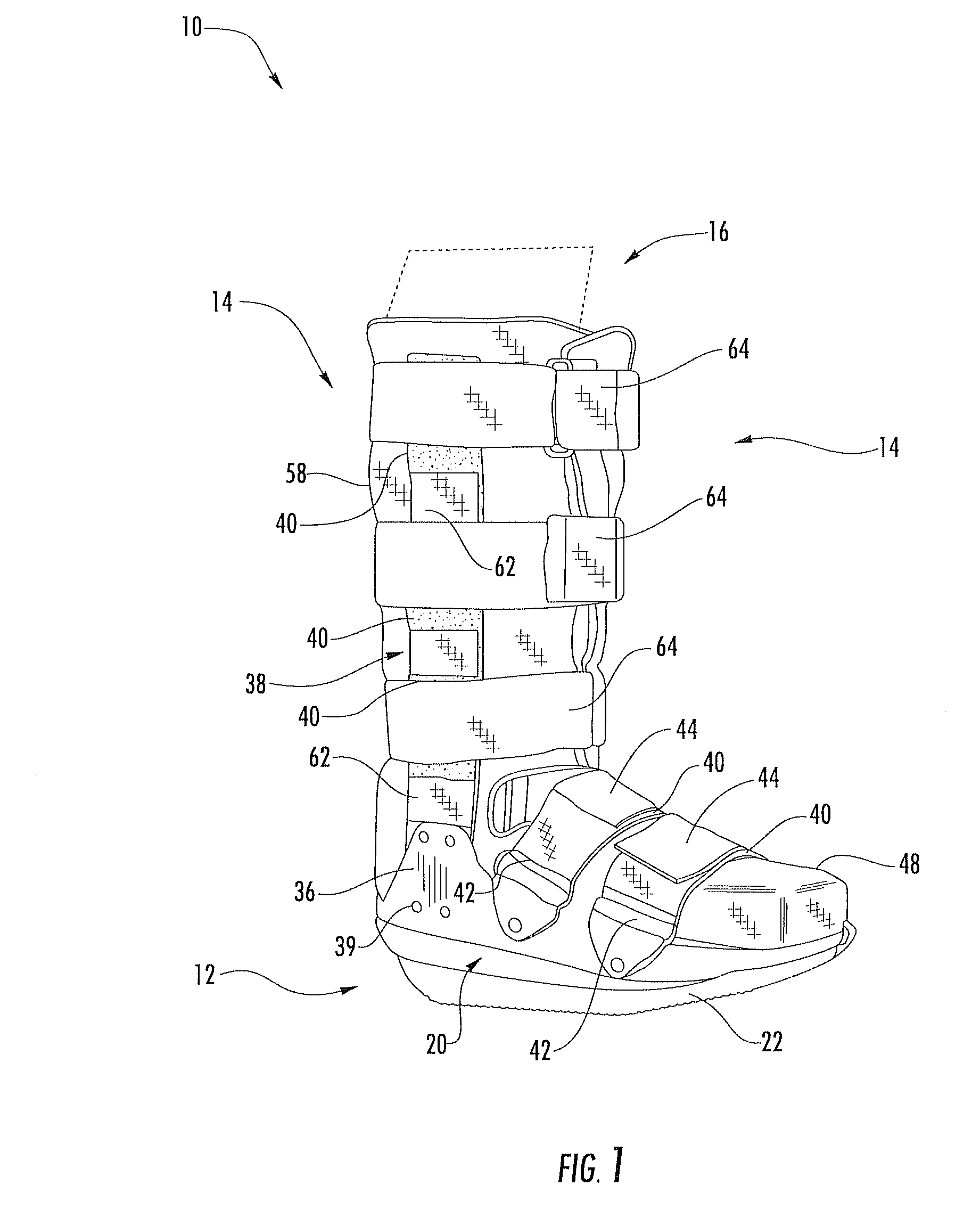

Walking boot for diabetic and other patients

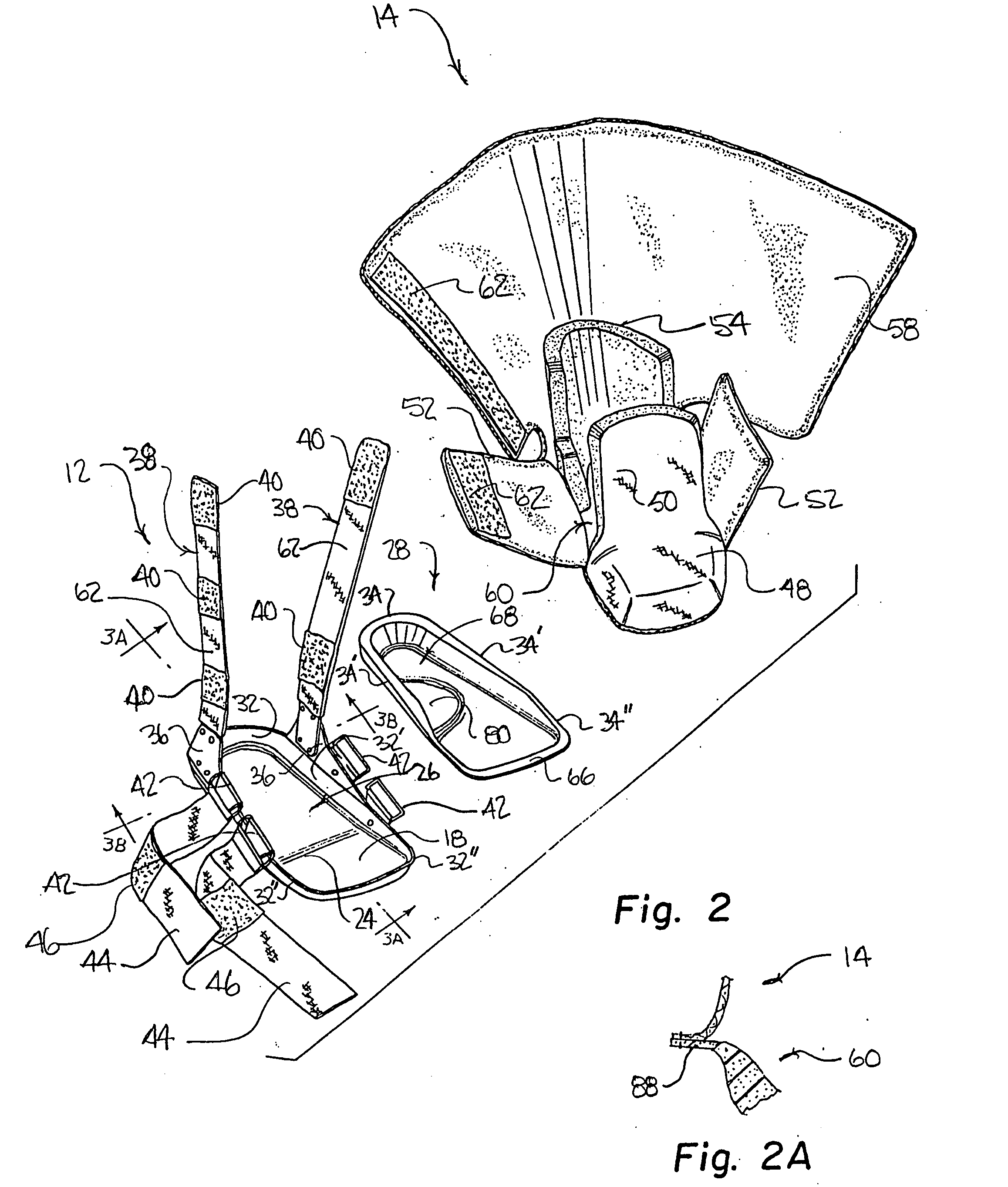

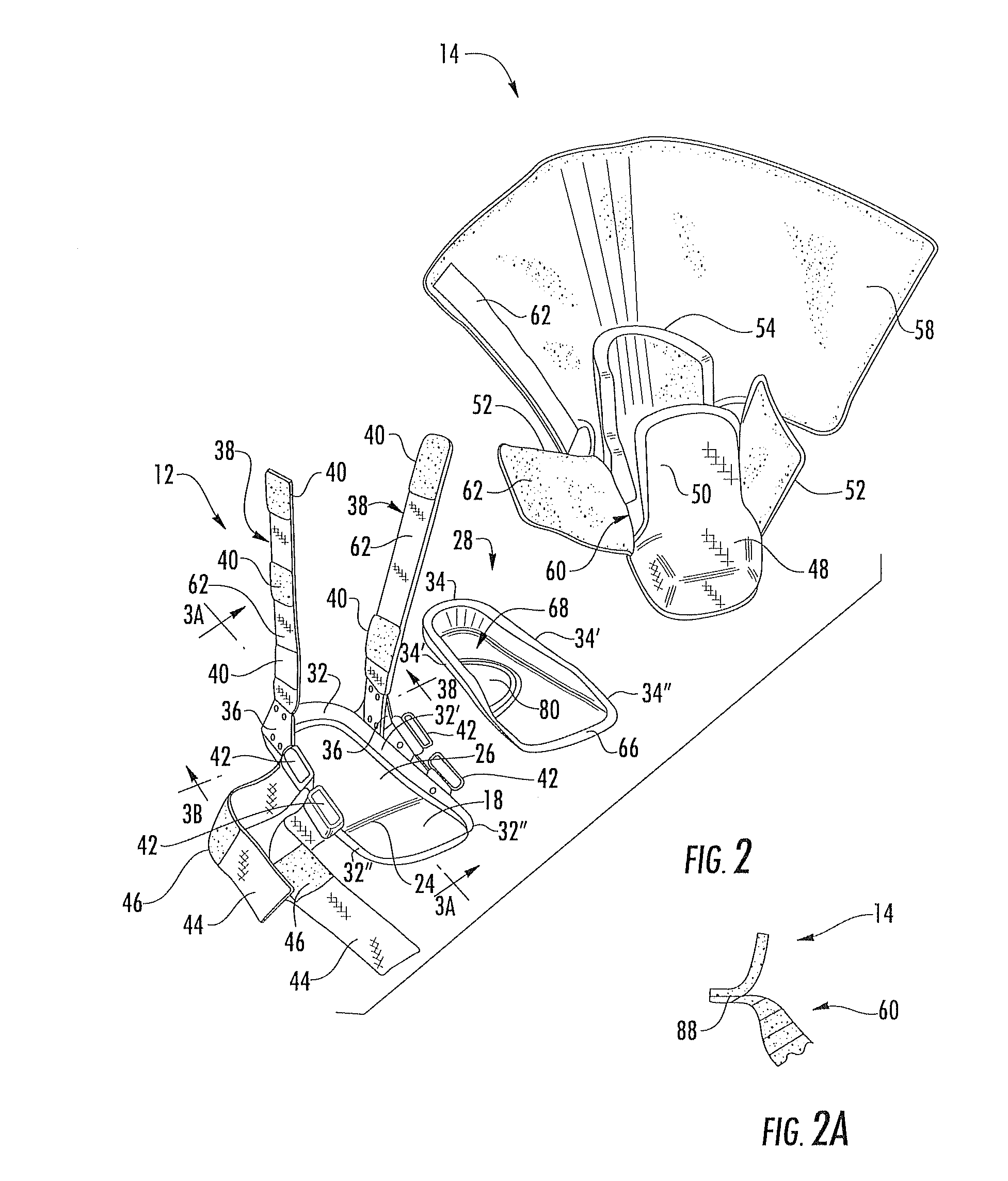

InactiveUS7418755B2Maximum peak pressureReduce pressureLastingNon-surgical orthopedic devicesDiabetic foot ulcerationPlantar surface

An orthopedic walking boot promotes rapid healing of diabetic foot ulcerations by lowering the maximum peak pressure imposed upon the foot. The walker has a hard unyielding shell which is designed for walking. The shell closely and rigidly supports a mid-sole in a foot-shaped bed. The mid-sole has a foot-shaped cavity with rounded sides adapted to form resilient support for the heel, arch and sides of a foot in addition to the bottom of a foot. A conformable inner-sole is adapted to fit over the foot-shaped cavity in the mid-sole and be compressed in response to foot pressure between the sides and bottom of the foot and the sides and bottom of the foot-shaped cavity in the mid-sole thereby compensating for small differences between the shape of the foot and the shape of the cavity. Weight applied to the foot is transferred to the walking shell by contact between the sides of the foot, arch, and heel and the arch, heel and sides of the foot-shaped cavity as well as the bottom of the cavity thereby decreasing the peak or maximum unit pressure on the plantar surface of the foot. A breathable bootie which wraps the foot and lower leg in a protective “cocoon” is preferably secured to the upper surface of the insole thereby preventing foreign materials from entering the foot cavity.

Owner:BREG

Walking boot for diabetic and other patients

InactiveUS20050172517A1Easy to walkGood walkabilityNon-surgical orthopedic devicesFootwearPlantar surfaceDiabetic patient

An orthopedic walking boot promotes rapid healing of diabetic foot ulcerations by lowering the maximum peak pressure imposed upon the foot. The walker has a hard unyielding shell which is designed for walking. The shell closely and rigidly supports a mid-sole in a foot-shaped bed. The mid-sole has a foot-shaped cavity with rounded sides adapted to form resilient support for the heel, arch and sides of a foot in addition to the bottom of a foot. A conformable inner-sole is adapted to fit over the foot-shaped cavity in the mid-sole and be compressed in response to foot pressure between the sides and bottom of the foot and the sides and bottom of the foot-shaped cavity in the mid-sole thereby compensating for small differences between the shape of the foot and the shape of the cavity. Weight applied to the foot is transferred to the walking shell by contact between the sides of the foot, arch, and heel and the arch, heel and sides of the foot-shaped cavity as well as the bottom of the cavity thereby decreasing the peak or maximum unit pressure on the plantar surface of the foot. A breathable bootie which wraps the foot and lower leg in a protective “cocoon” is preferably secured to the upper surface of the insole thereby preventing foreign materials from entering the foot cavity.

Owner:BREG

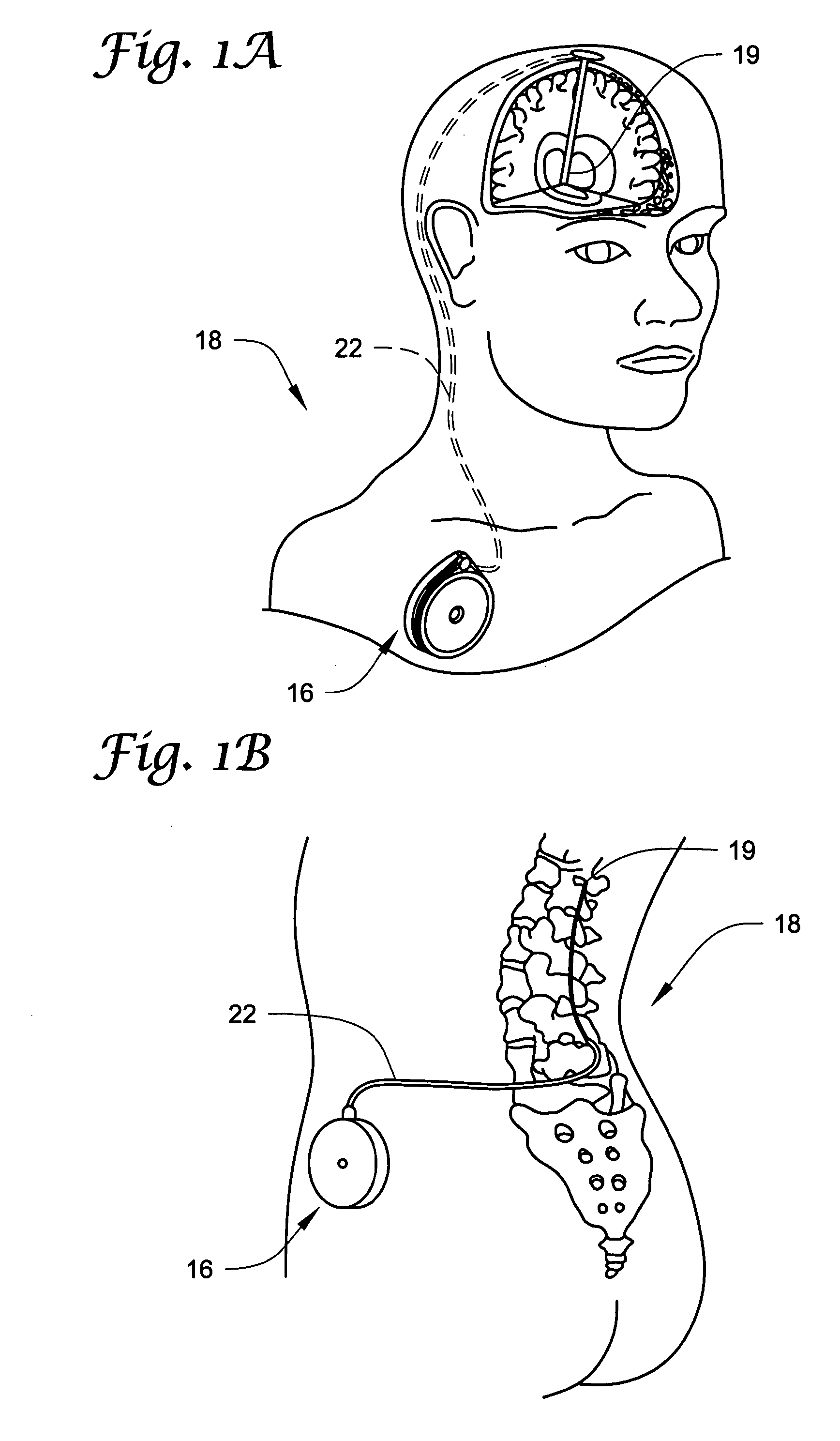

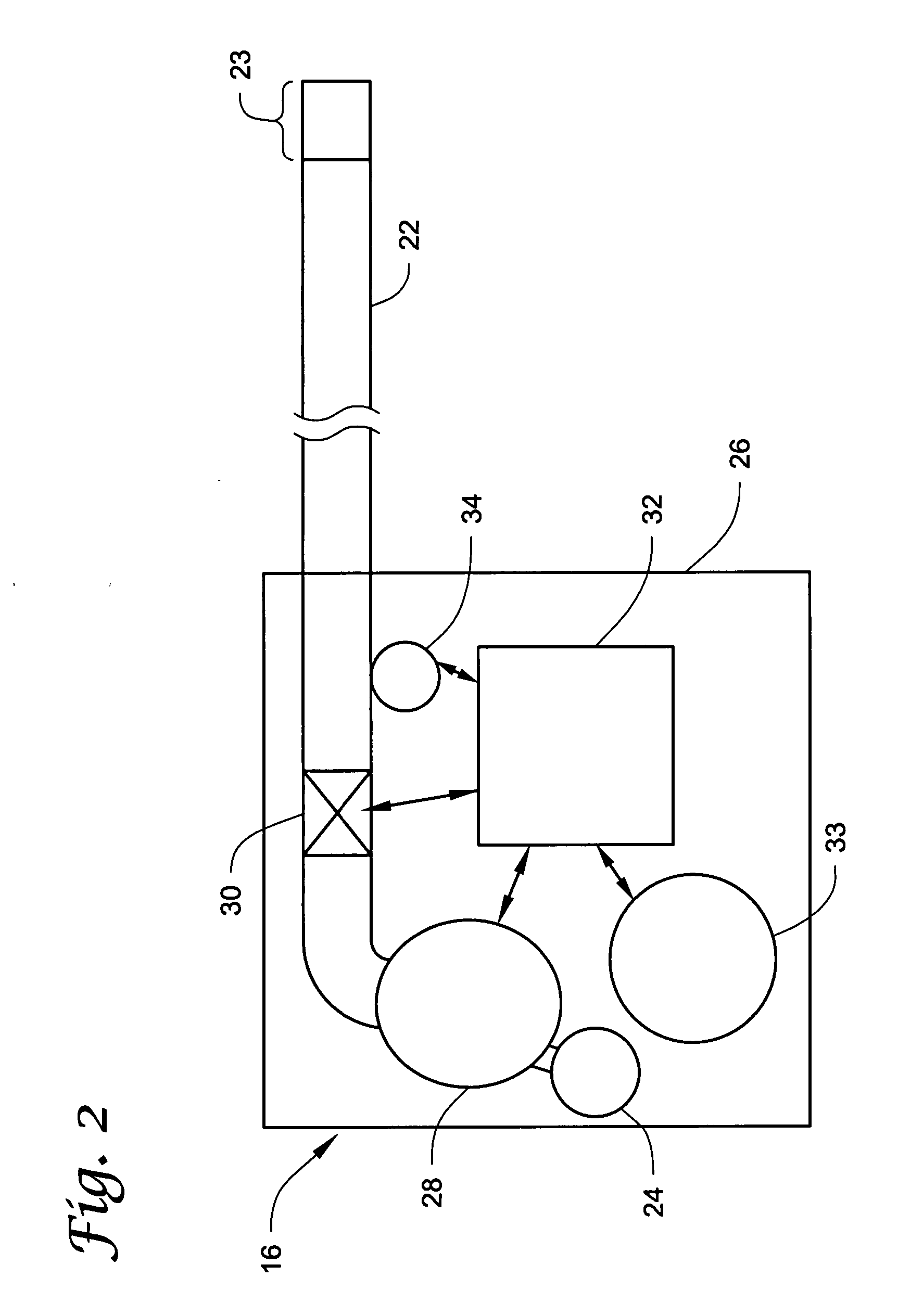

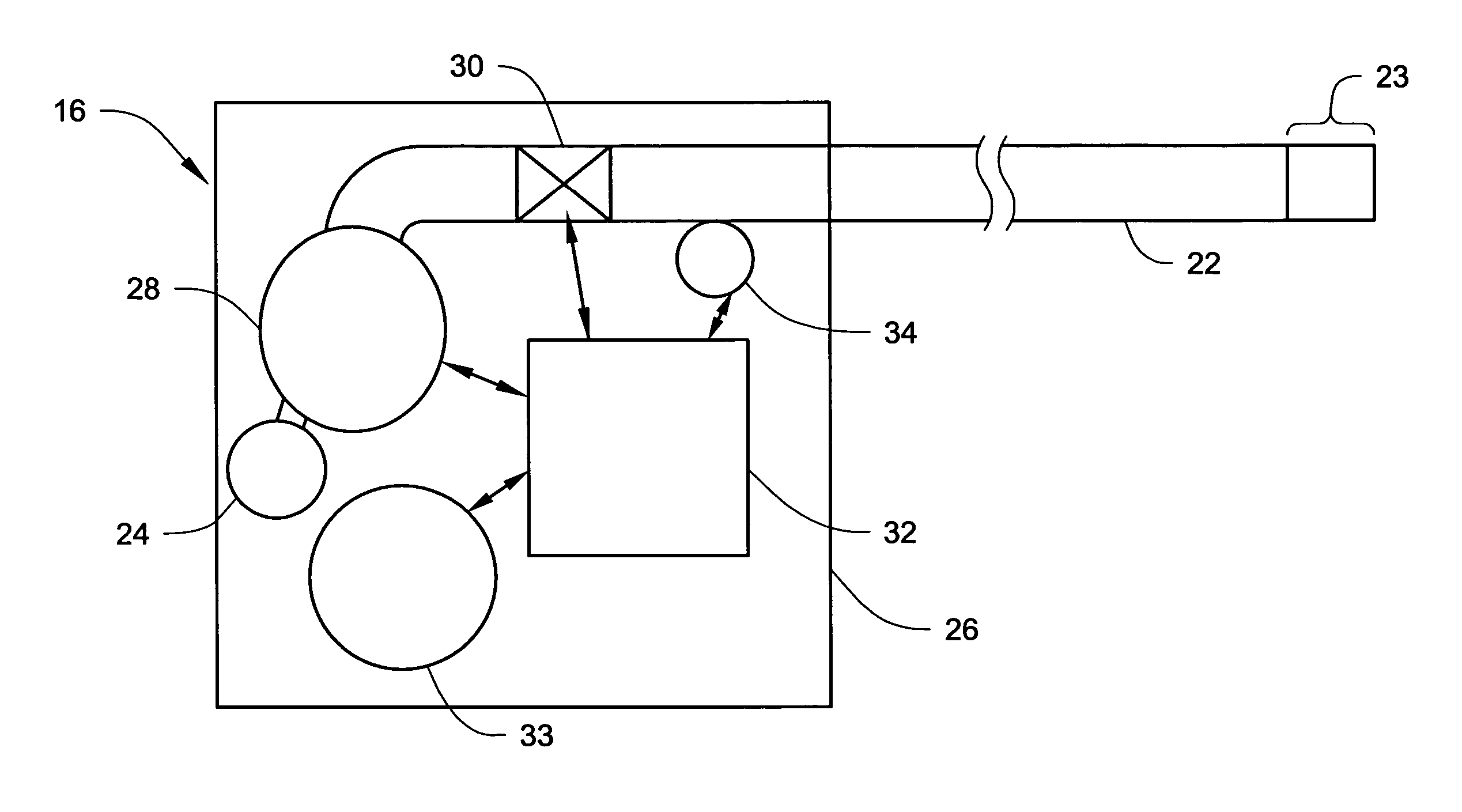

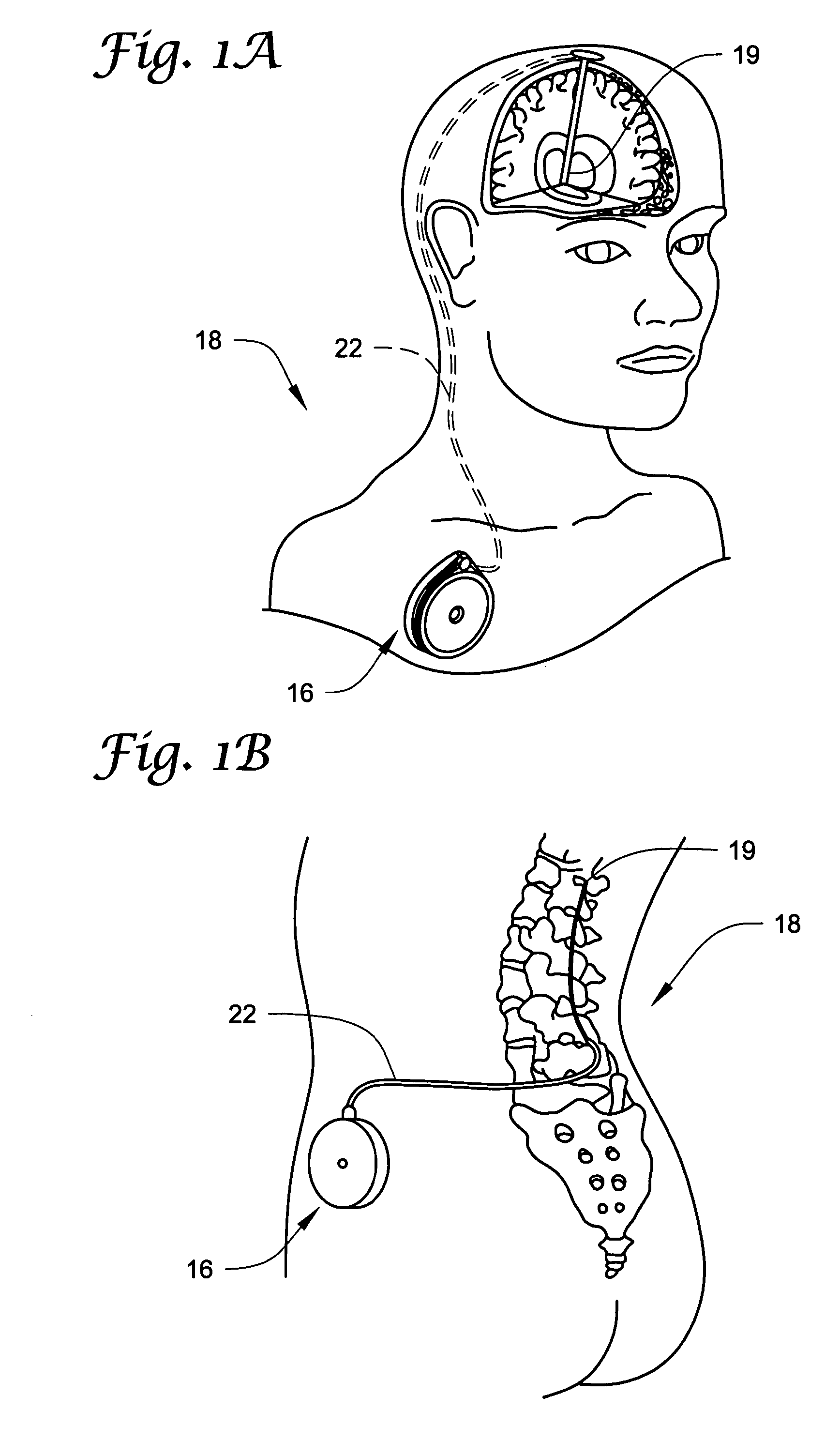

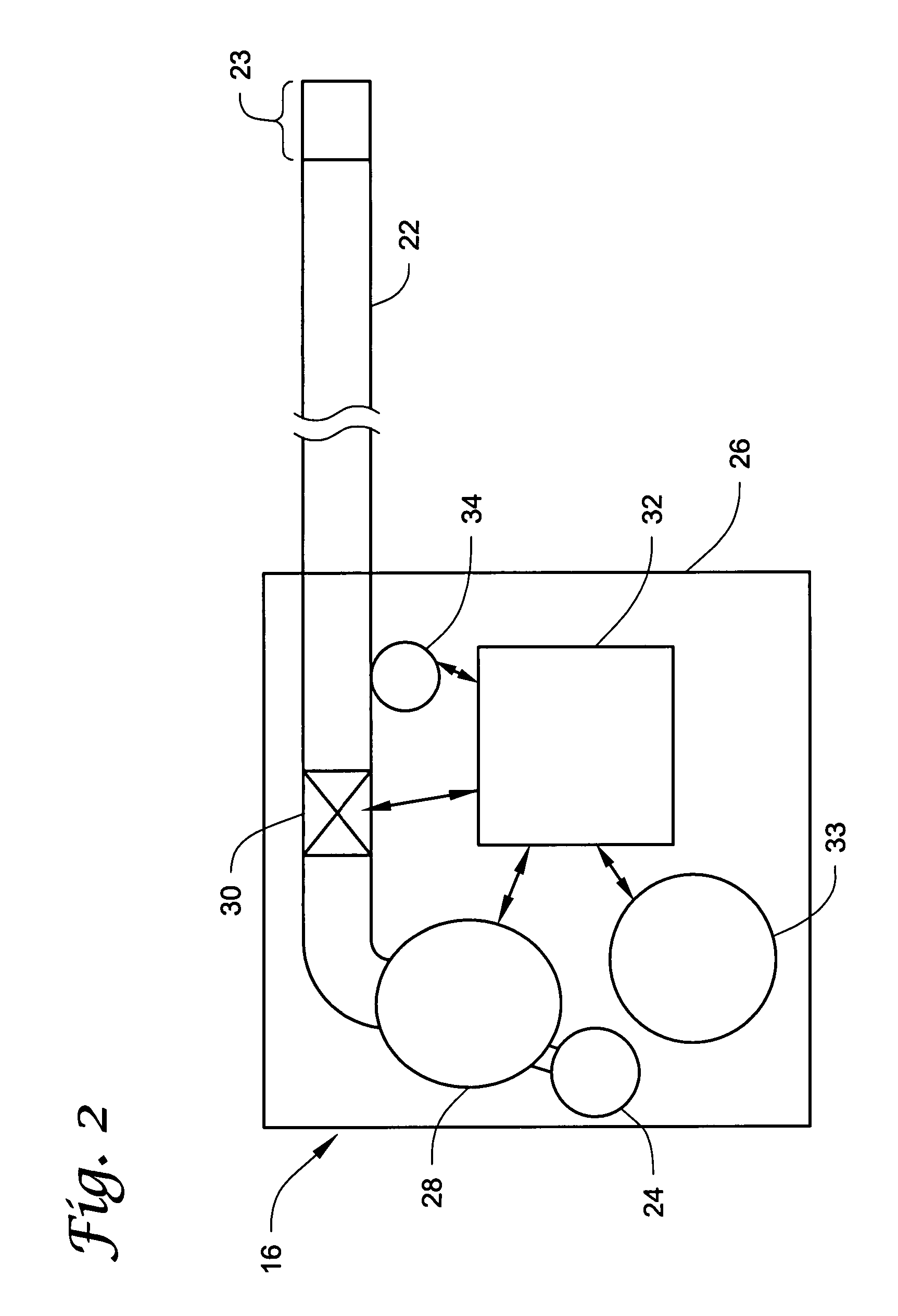

Systems and methods of identifying catheter malfunctions using pressure sensing

ActiveUS20070270782A1Complete understandingMedical devicesPharmaceutical delivery mechanismGas bubblePressure decay

Methods and systems for determining whether a catheter malfunction is present in a catheter by analyzing changes in the pressure of fluids being pumped through the delivery lumen of the catheter. The pressure changes that may be monitored may include, e.g., the peak pressure within the catheter and / or the pressure decay profile. The catheter malfunctions that may be determined using the methods and systems of the invention may include, e.g., leaks, blockages, the presence of gas bubbles, etc.

Owner:MEDTRONIC INC

Patient circuit disconnect system for a ventilator and method of detecting patient circuit disconnect

ActiveUS7984712B2Easy to adjustRespiratorsRespiratory device testingType ventilatorIntensive care medicine

A method of detecting disconnect of a patient circuit of a ventilation system, wherein a circuit disconnect is detected with a first sensitivity and a second sensitivity. The circuit disconnect detected with the first sensitivity is performed by detecting a volume loss for a minimum period of time, detecting a peak pressure loss for at least two consecutive breathing cycles or a minimum period of time, and detecting a pressure loss continuing for a predetermined period of time. The circuit disconnect detected with the second sensitivity is performed by detecting a volume loss for a single breathing cycle, detecting a pressure loss for a single breathing cycle, and detecting an increase of compliance. The first sensitivity is lower than the second sensitivity. Preferably, an alarm is activated when the circuit disconnect is detected with the first sensitivity, and subsystems of the ventilation system is informed of the circuit disconnect that has been detected with the second sensitivity.

Owner:BIRD PRODS

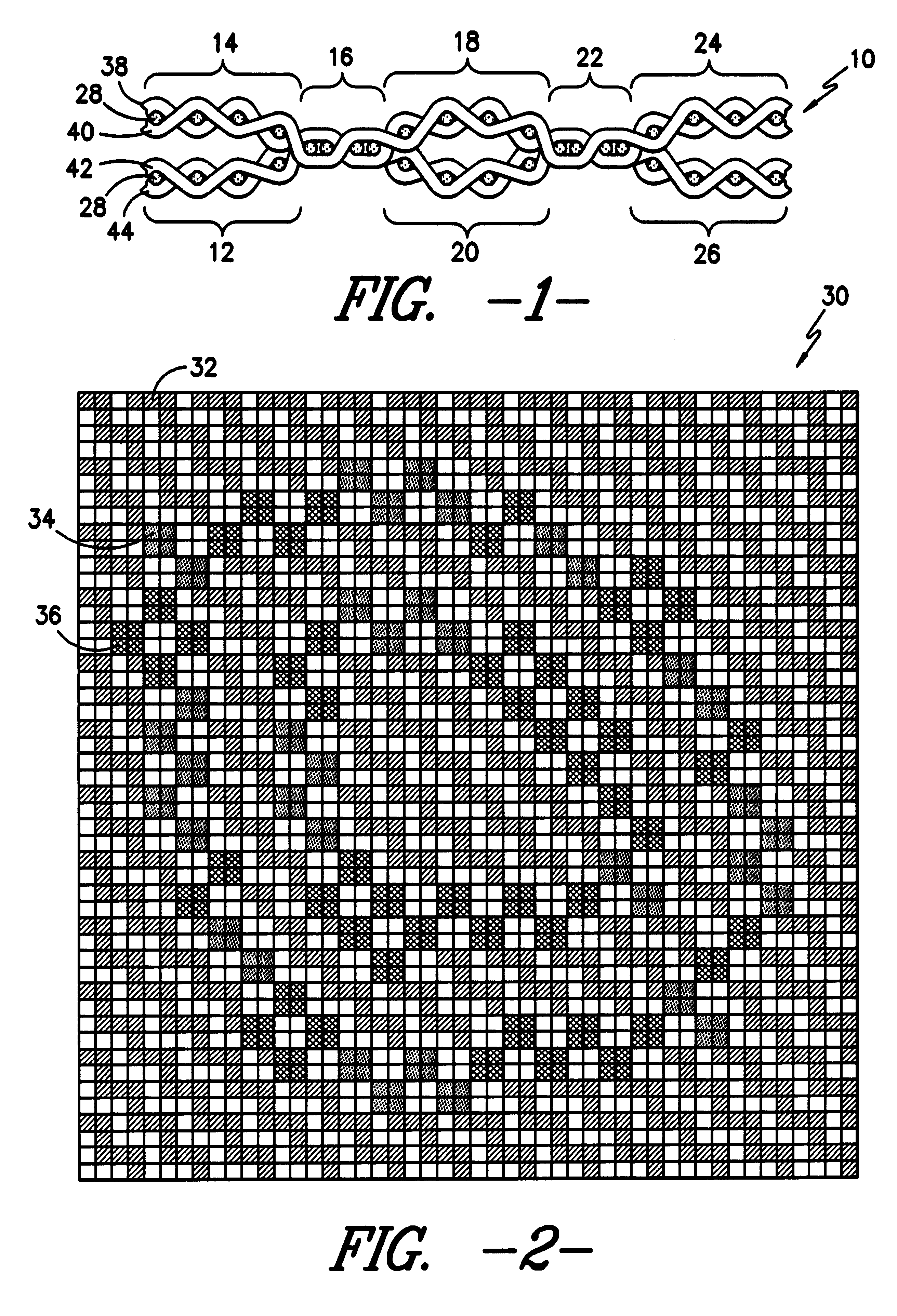

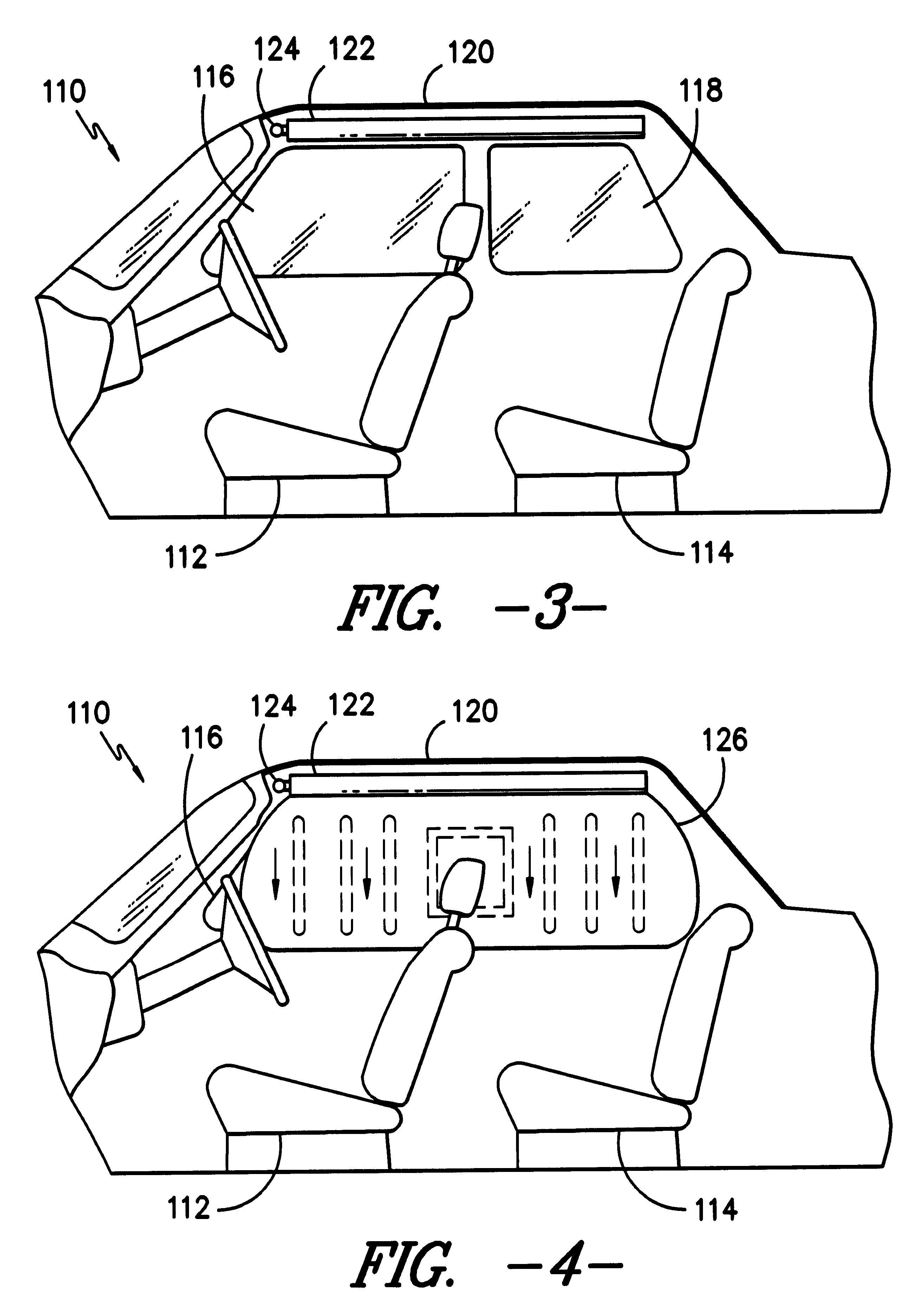

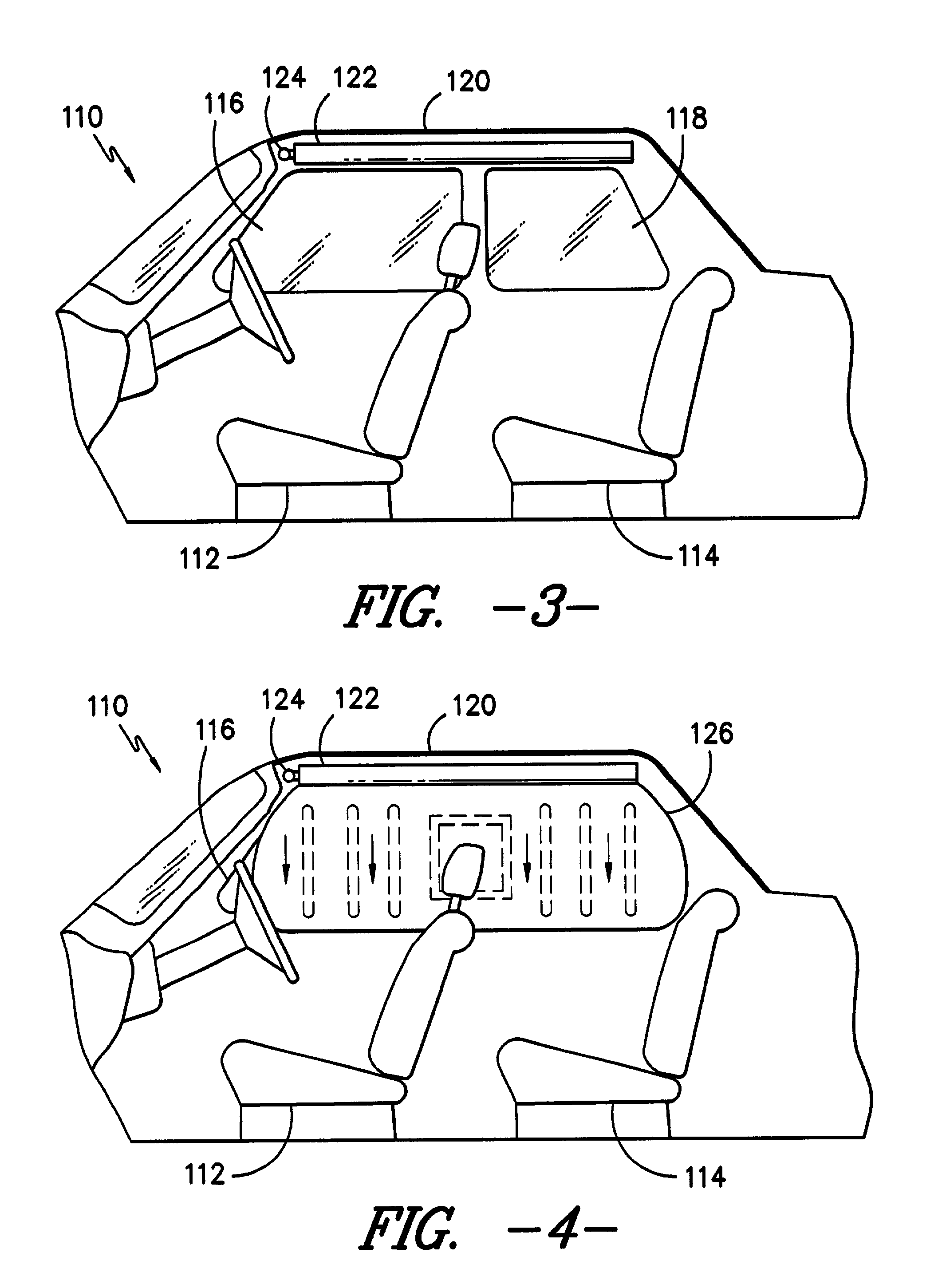

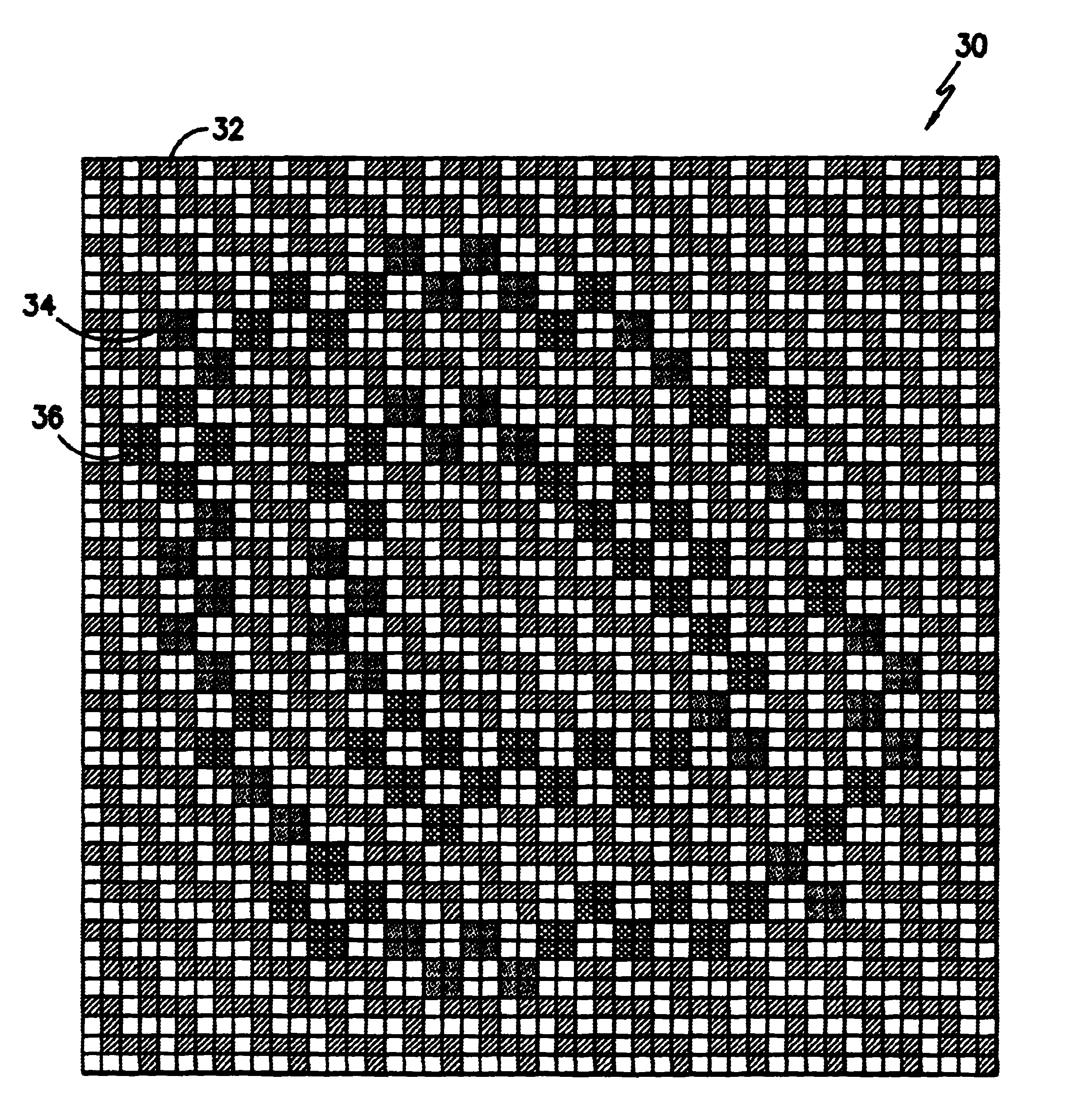

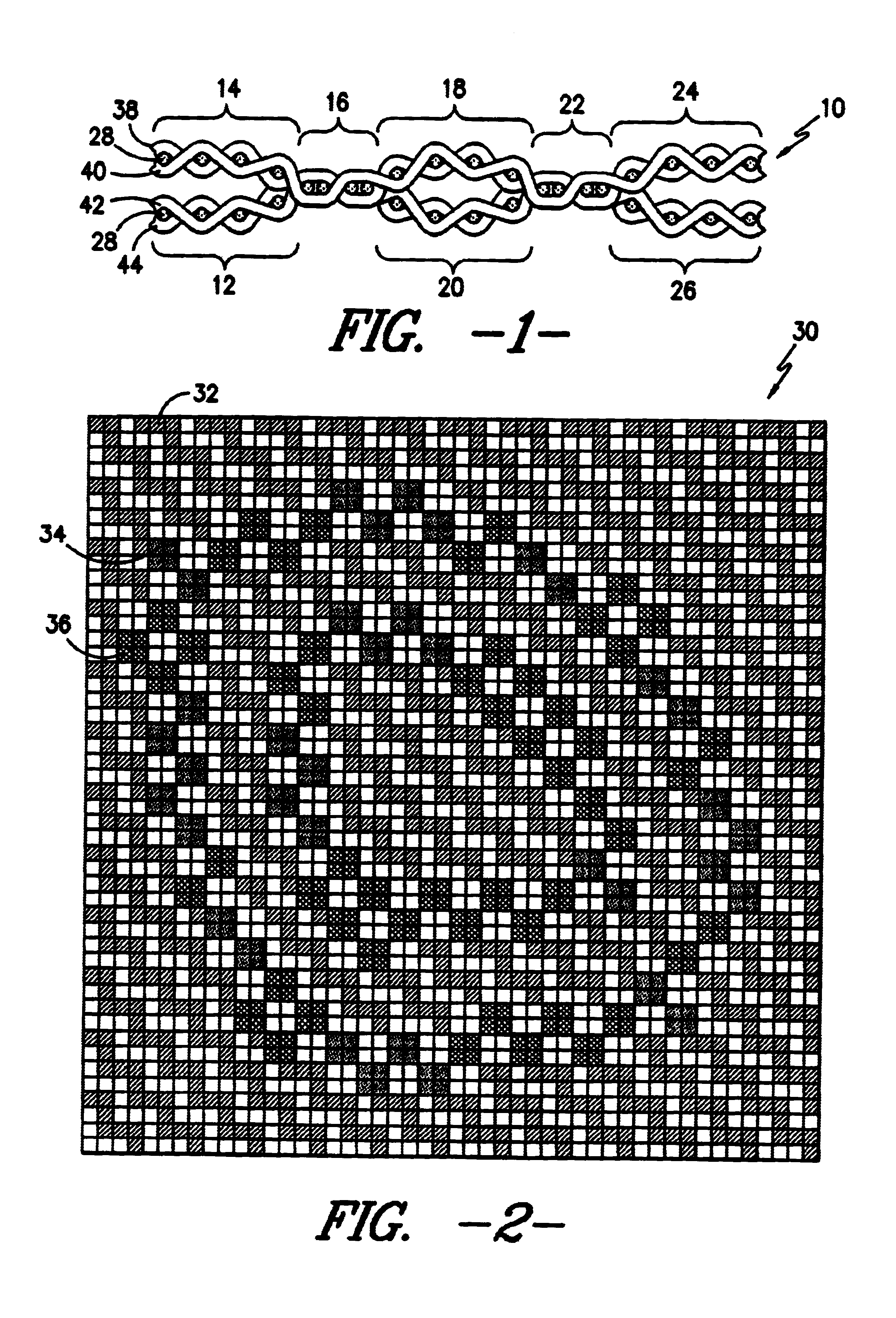

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6451715B2Keep for a long timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

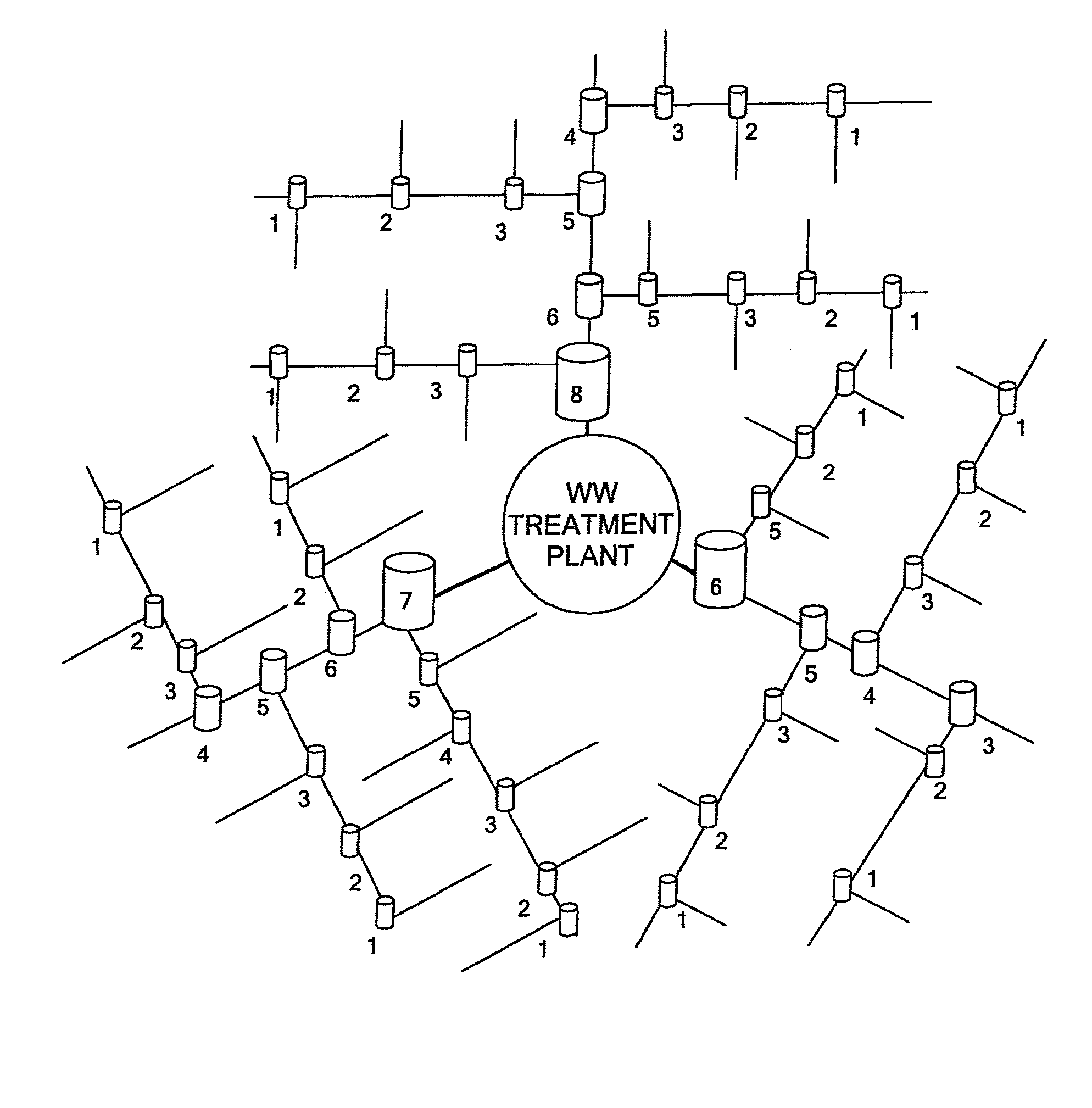

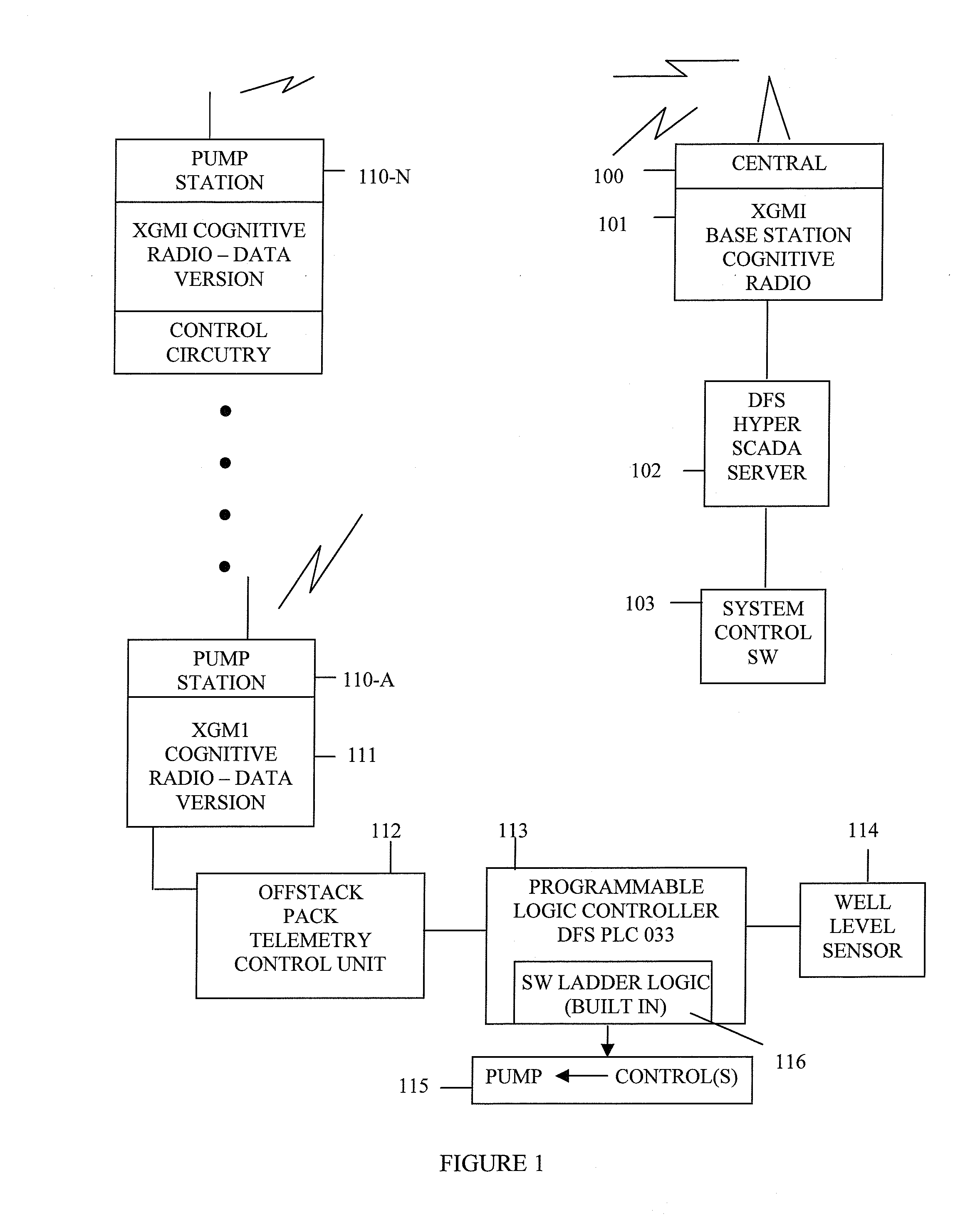

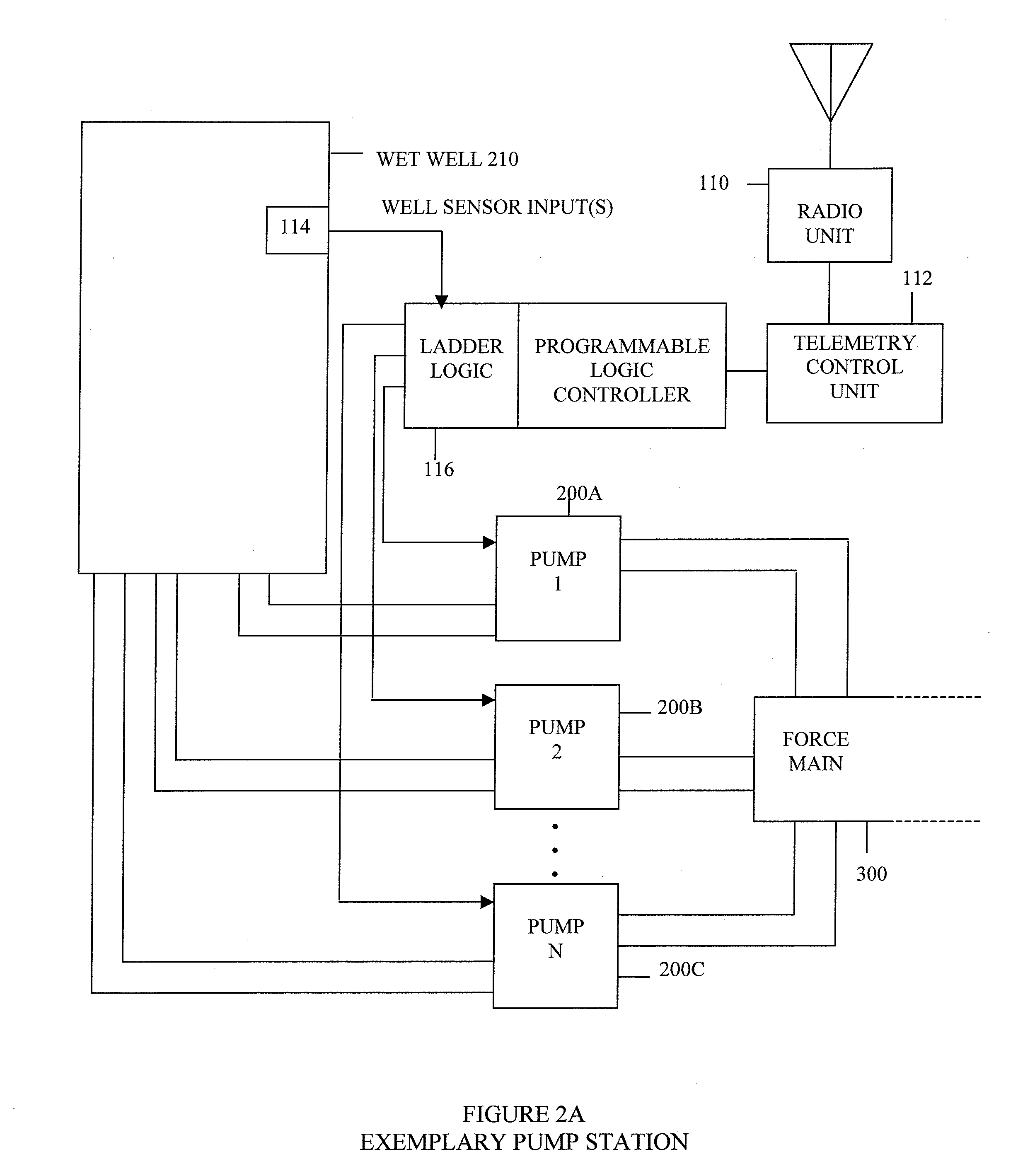

Wastewater collection flow management system and techniques

ActiveUS8594851B1Reduce maintenanceIncrease threshold level of activationFuel supply regulationLevel controlPeak valueEnergy expenditure

Reductions in energy consumption and maintenance requirements for operating a wastewater treatment plant are achieved by controlling the operation of pumps at pump stations along a force main in a systematic fashion. The operation of the pumps is controlled to manage the flow of wastewater along the force main to minimize energy consumption, to eliminate sediment, to manage peak pressures encountered by smaller pumps and to avoid septic conditions.

Owner:DATA FLOW SYST

Systems and methods of identifying catheter malfunctions using pressure sensing

Methods and systems for determining whether a catheter malfunction is present in a catheter by analyzing changes in the pressure of fluids being pumped through the delivery lumen of the catheter. The pressure changes that may be monitored may include, e.g., the peak pressure within the catheter and / or the pressure decay profile. The catheter malfunctions that may be determined using the methods and systems of the invention may include, e.g., leaks, blockages, the presence of gas bubbles, etc.

Owner:MEDTRONIC INC

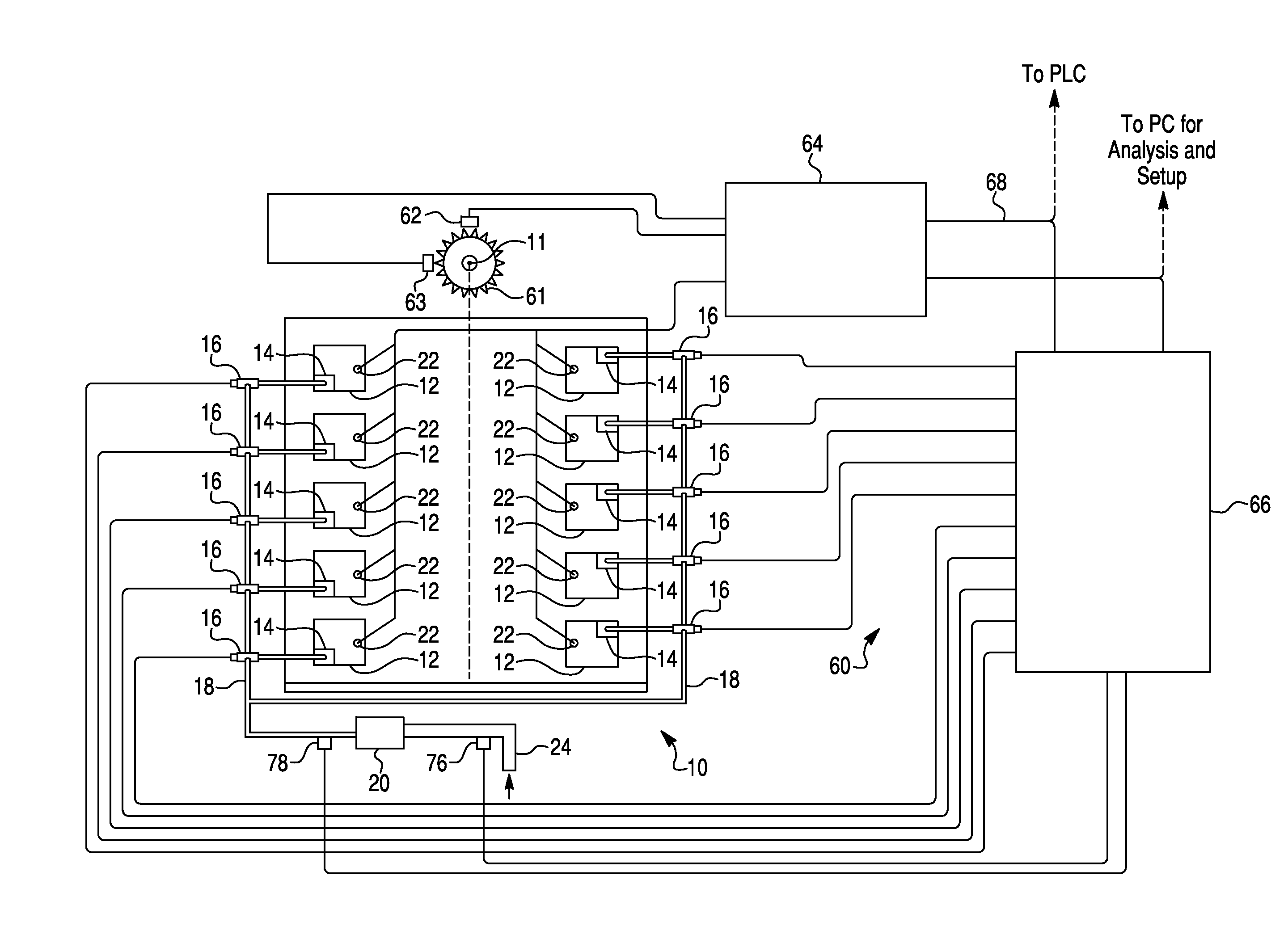

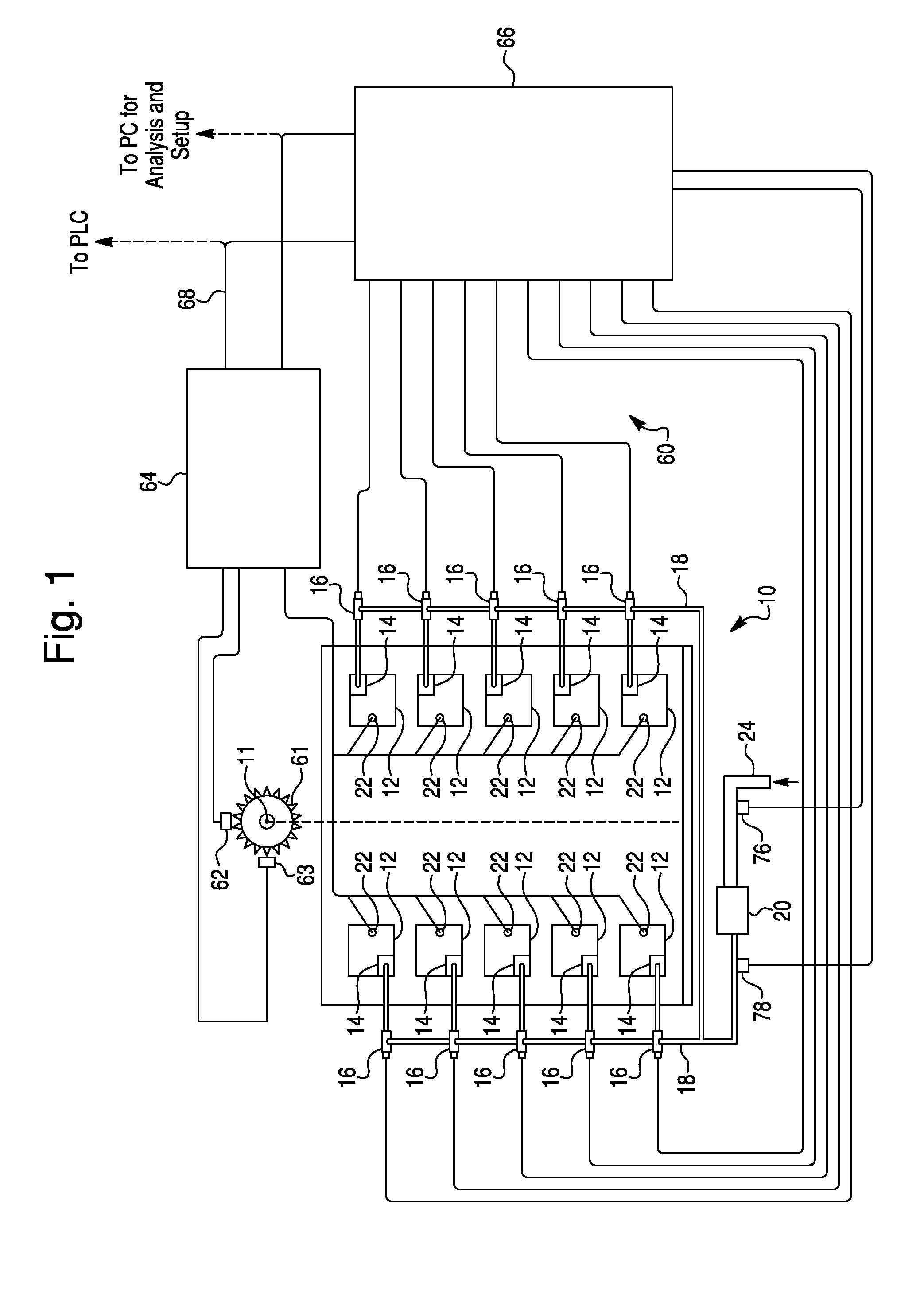

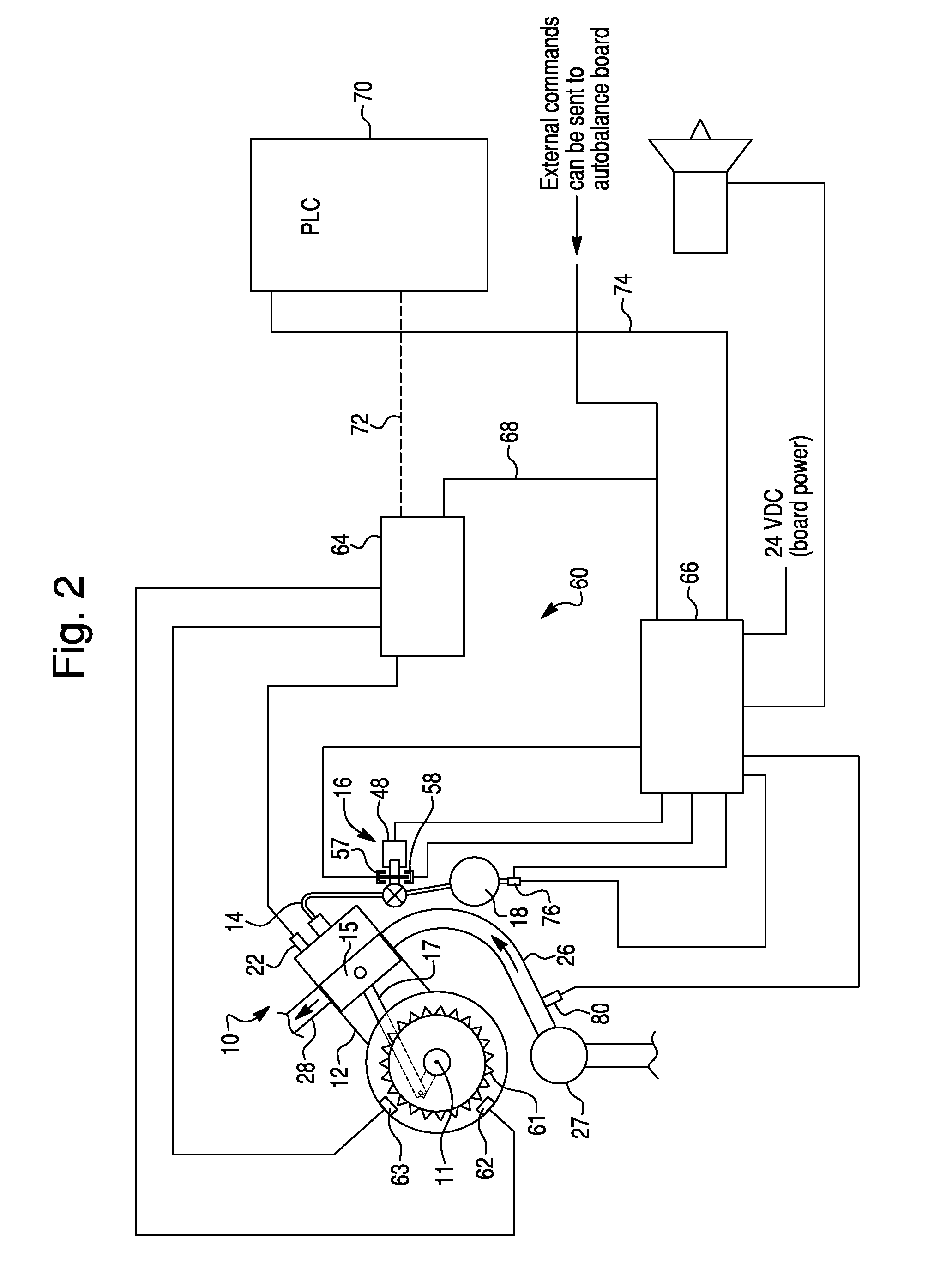

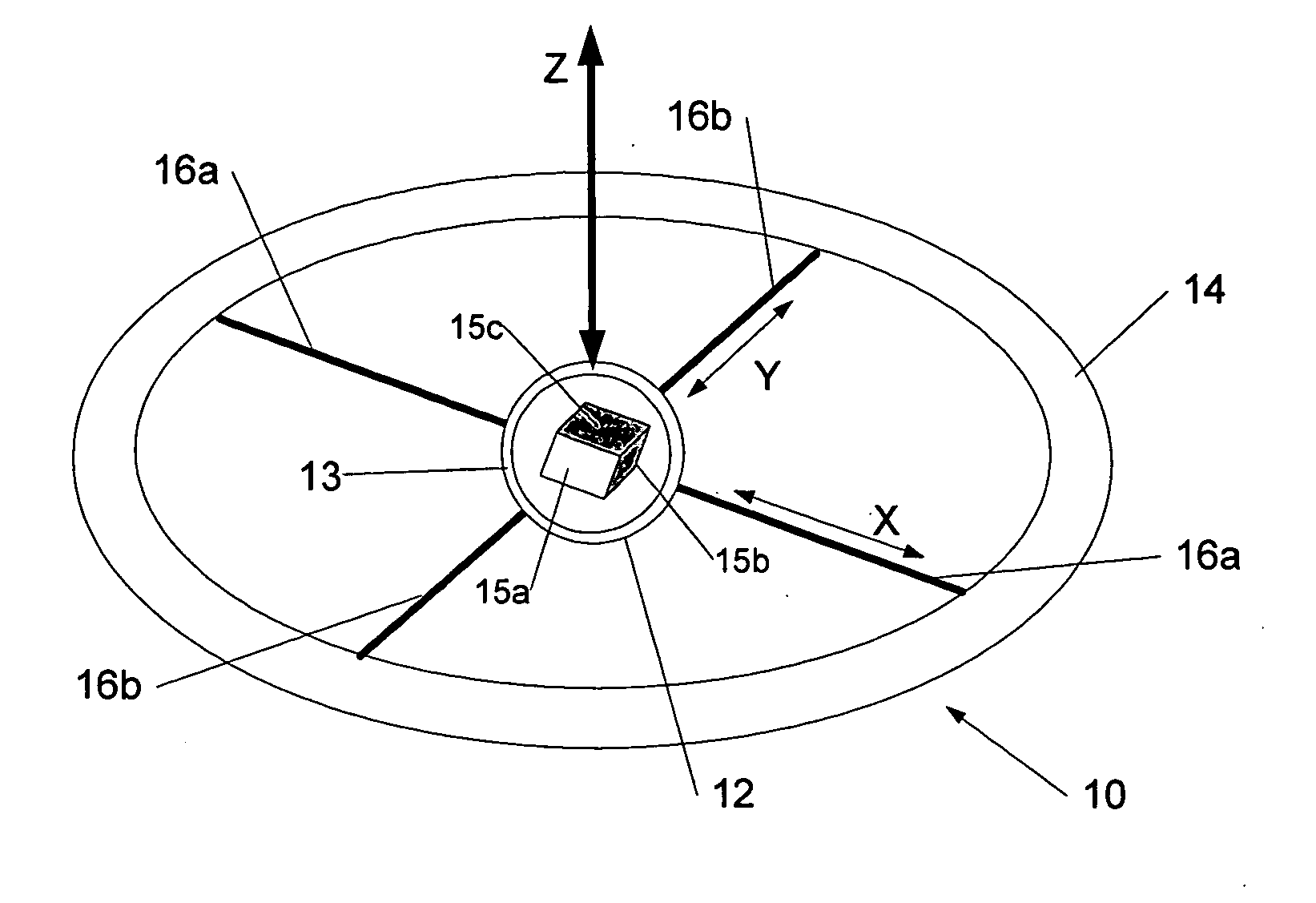

Method and apparatus for automatic pressure balancing of industrial large-bore internal combustion engines

ActiveUS20100089364A1Minimize NOx emissionImprove performanceElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

A method and apparatus for providing automatic pressure balancing of an internal combustion engine. The engine includes cylinders, fuel injector valves provided to selectively deliver fuel directly into the cylinders, fuel-balancing valves each fluidly connected to the fuel injector valves for controlling the fuel delivered to the fuel injector valves and cylinder pressure sensors each mounted to one of the cylinders. The method comprises an automatic pressure balancing procedure including the steps of monitoring a cylinder pressure in each of the cylinders, determining a peak combustion pressure produced in each of the cylinders, calculating a mean peak pressure produced in all of the cylinders, calculating a pressure difference between the mean and the peak pressure and incrementally adjusting the fuel delivered by one of the fuel-balancing valves to the corresponding fuel injector valve mounted to the cylinder having the pressure difference larger than a predetermined pressure value.

Owner:DELAWARE CAPITAL FORMATION

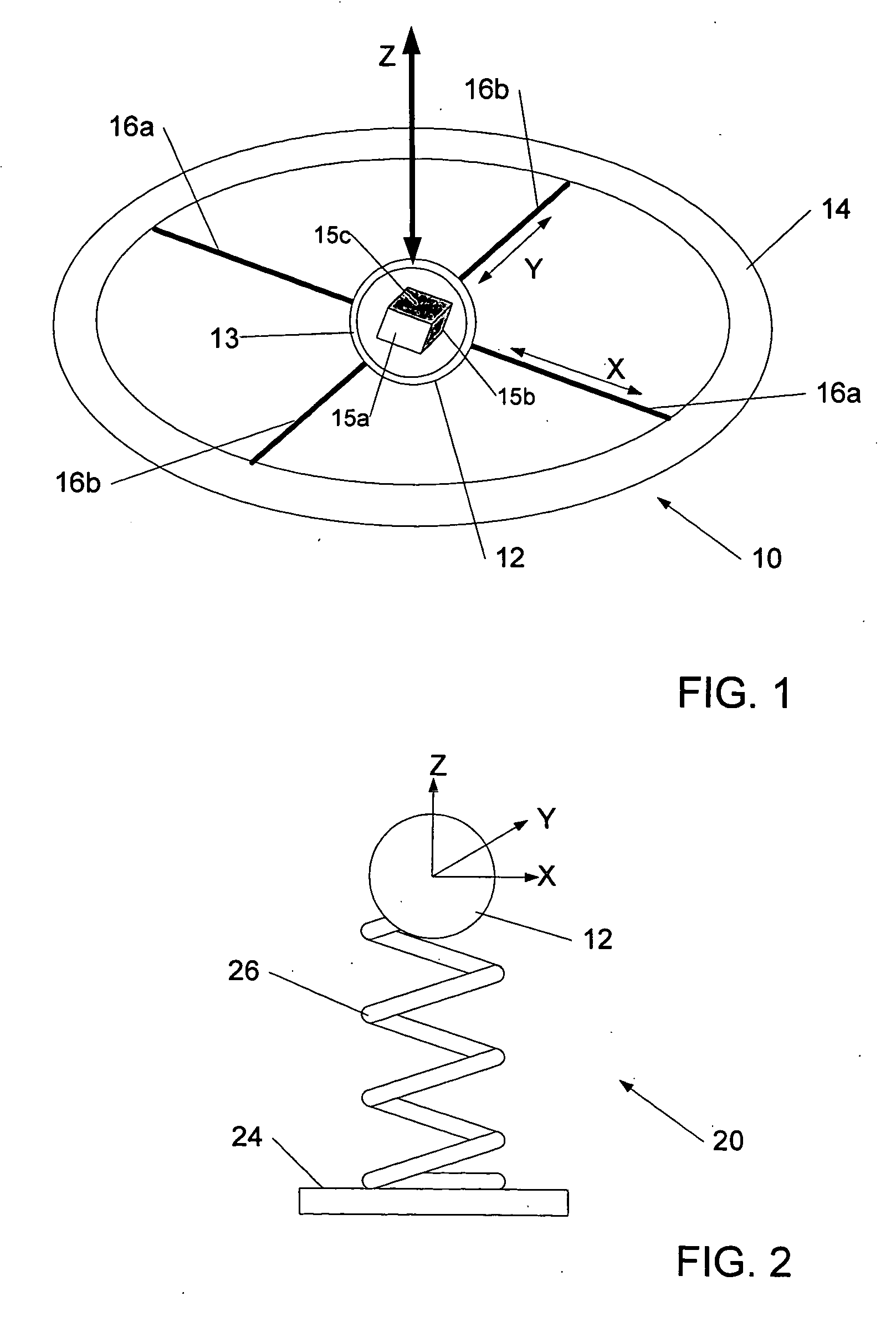

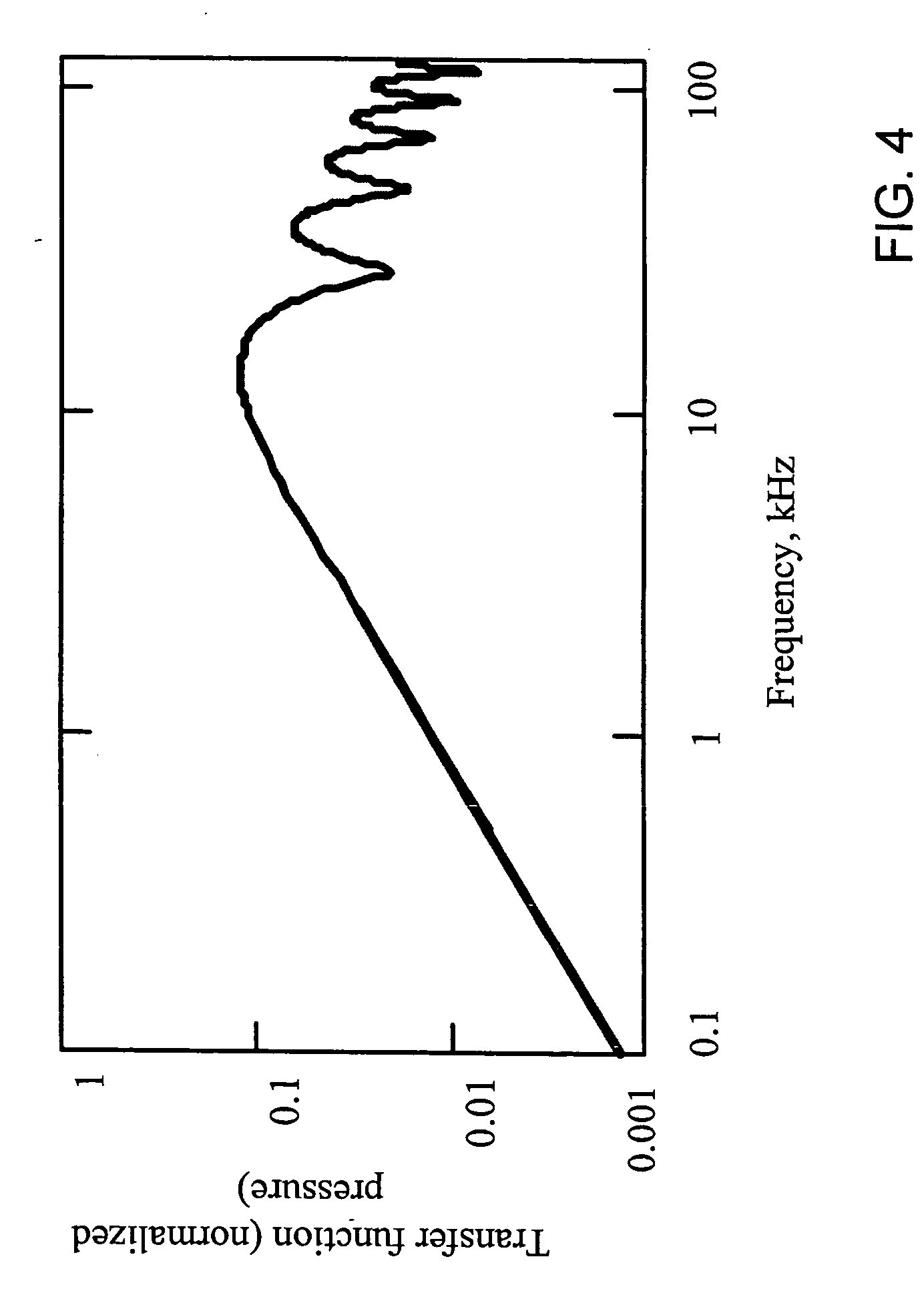

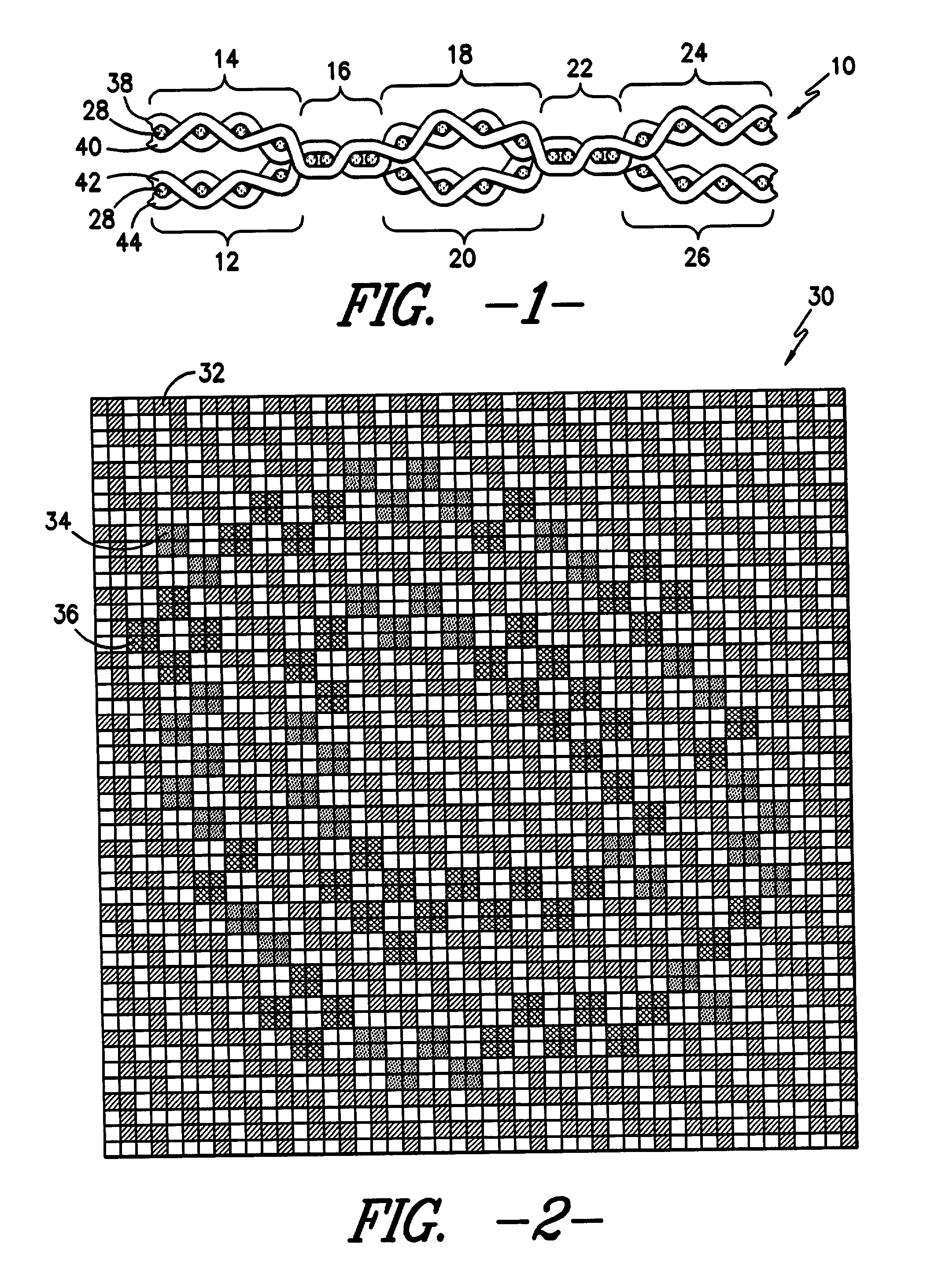

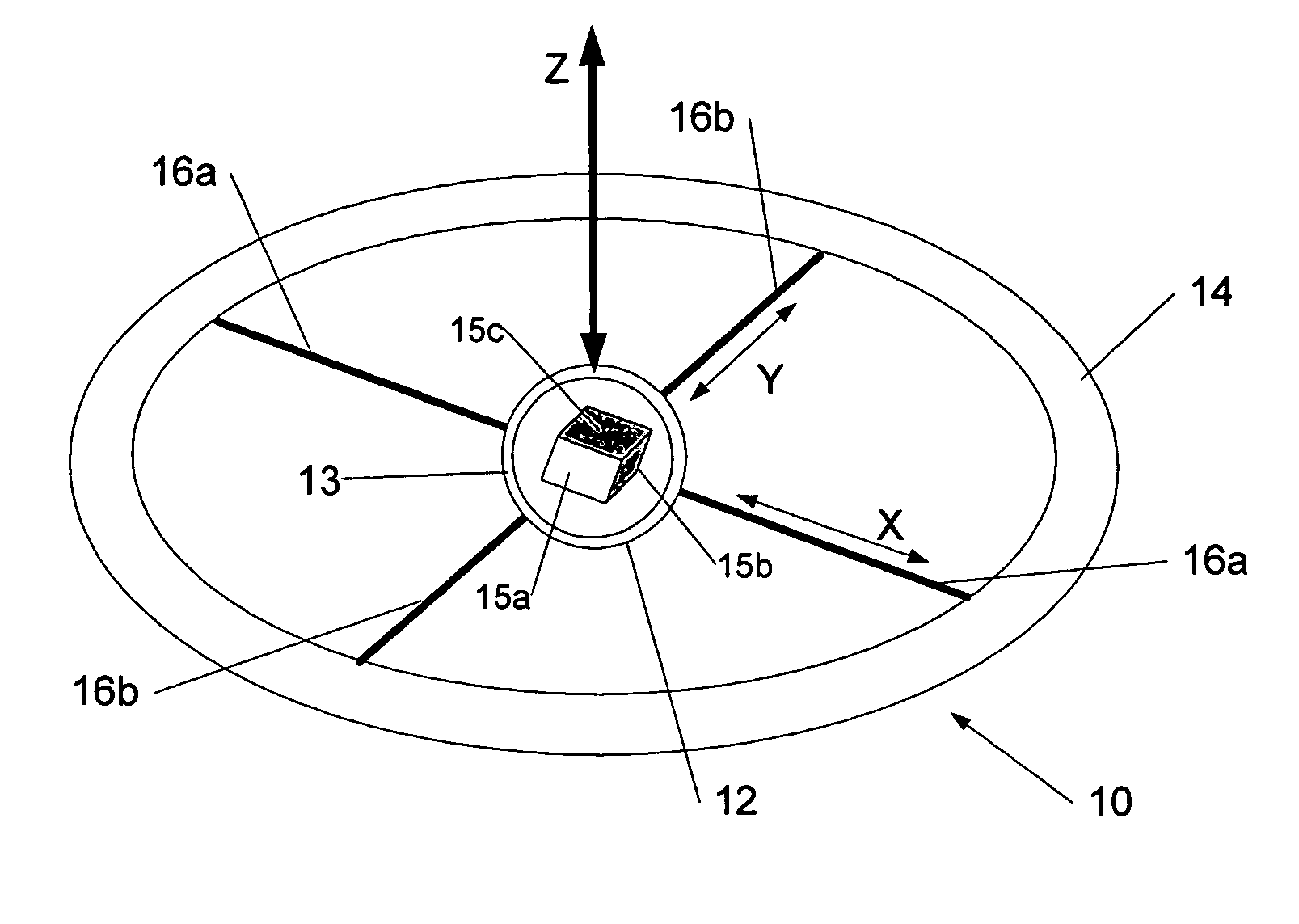

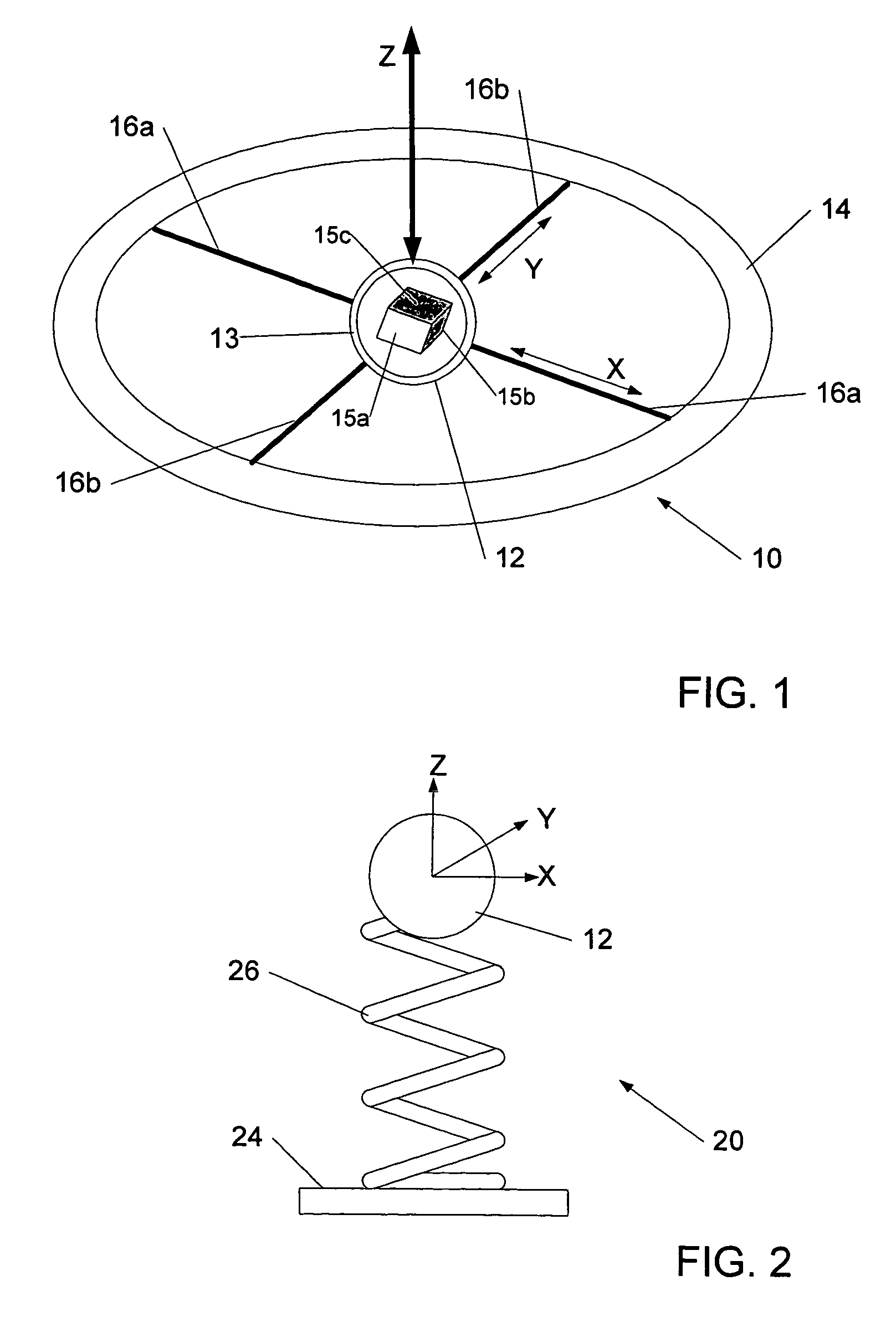

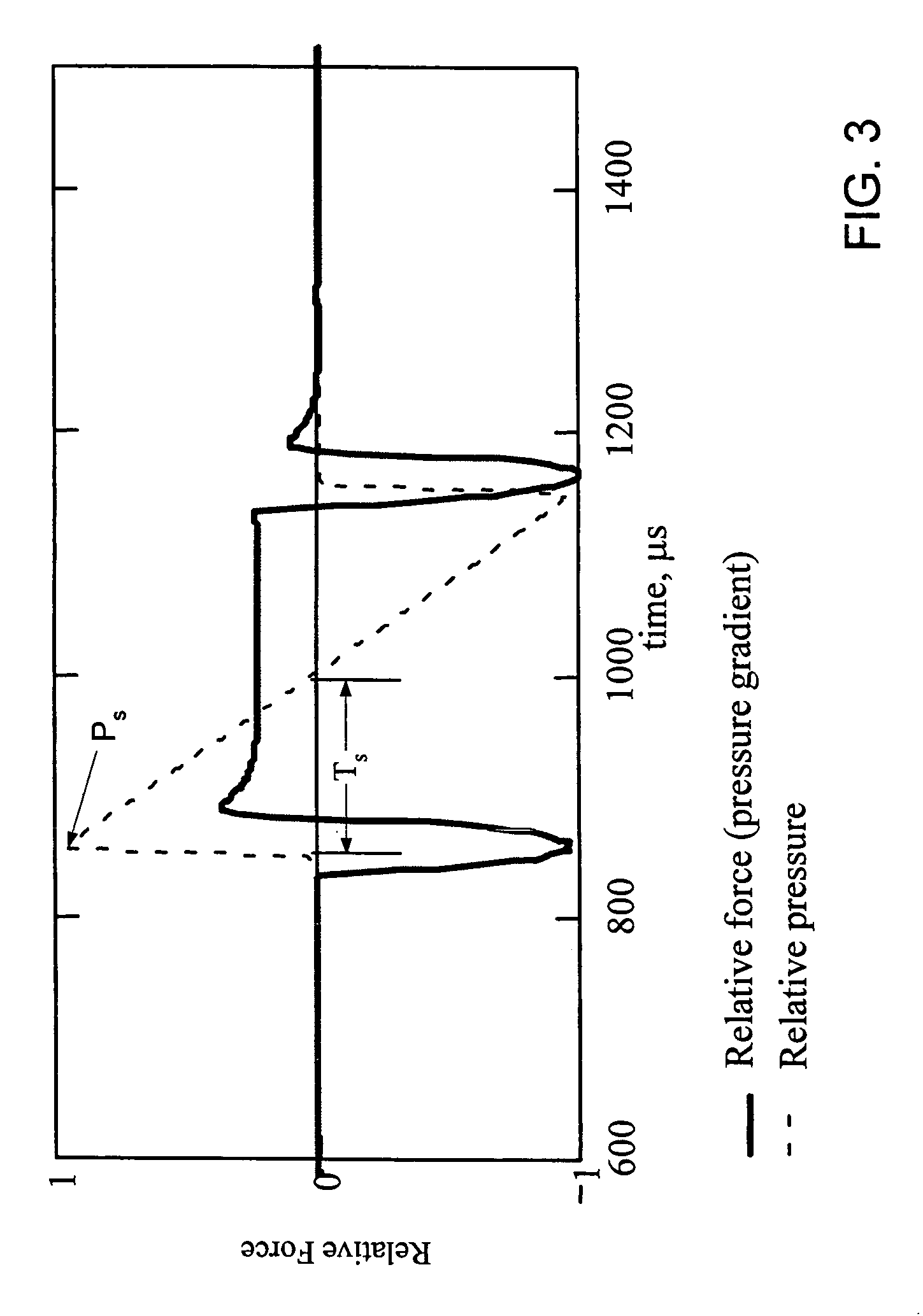

Compact shooter localization system and method

ActiveUS20060044941A1Material analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementAccelerometerLocalization system

Systems and methods for locating the shooter of supersonic projectiles are described. Muzzle blast signals are neither sought nor required. The system uses at least two sensors, with each sensor having a 3-axis accelerometer. The sensors are spaced apart at least 1 meter and have each a diameter of about one centimeter. The three accelerometer signals of each sensor represent pressure gradients and are processed to find the shockwave arrival angle unit vector, the shockwave arrival time instant and peak pressure. Noise signals seldom cause false detections with this sensing method because the sensors have maximum sensitivity at the high frequency characteristics of shockwaves, while their sensitivity to the low frequency characteristics of ambient noise is relatively low.

Owner:RAYTHEON BBN TECH CORP

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS20010005660A1Reduced packaging volumeLong leak-downEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

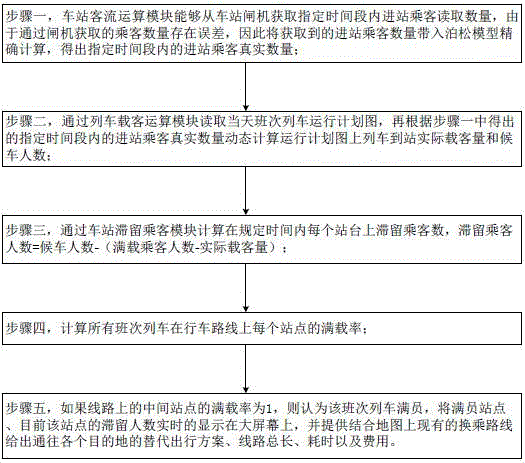

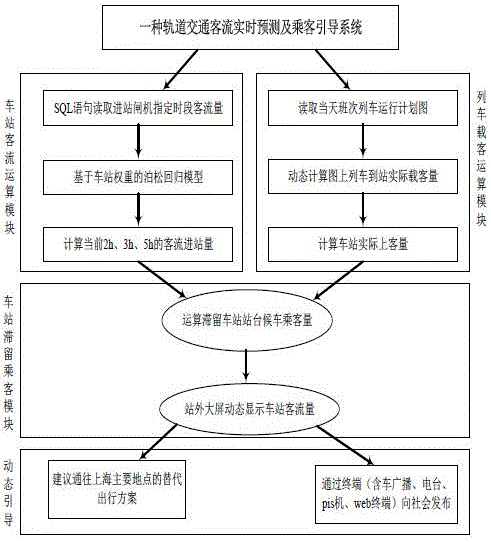

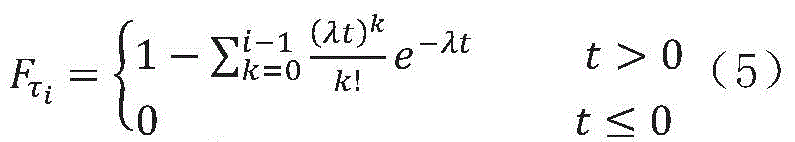

Real-time rail transit passenger flow prediction and passenger guiding system

The invention relates to the technical field of urban rail transit and transportation and provides a real-time rail transit passenger flow prediction and passenger guiding system.The real-time rail transit passenger flow prediction and passenger guiding system comprises a station passenger flow operation module for reading the number of passengers entering stations, substituting a Poisson model and performing accurate calculation to obtain the true number of passengers entering the stations, a train carried passenger operation module for reading an operation planning map of trains running on the same day and calculating the actual passenger capacity and the number of passengers waiting for the trains when the trains arrive at the stations, and a station stranded passenger operation module for calculating the number of stranded passengers at each station and calculating the load factor of each station of running routes of all trains, wherein if the load factors of middle stations of the routes are 1, it is indicated that the trains running along the routes are full, the stations at full strength and the number of stranded passengers at the current stations are displayed on a large screen in real time, and alternative trip plans leading to all destinations are provided.The real-time rail transit passenger flow prediction and passenger guiding system can predict stranded passenger flows at stations, takes preventive measures, avoids passenger stranding, reduces the peak pressure of rail transit and makes citizens' trips more convenient and safer.

Owner:SHANGHAI UNIV OF ENG SCI

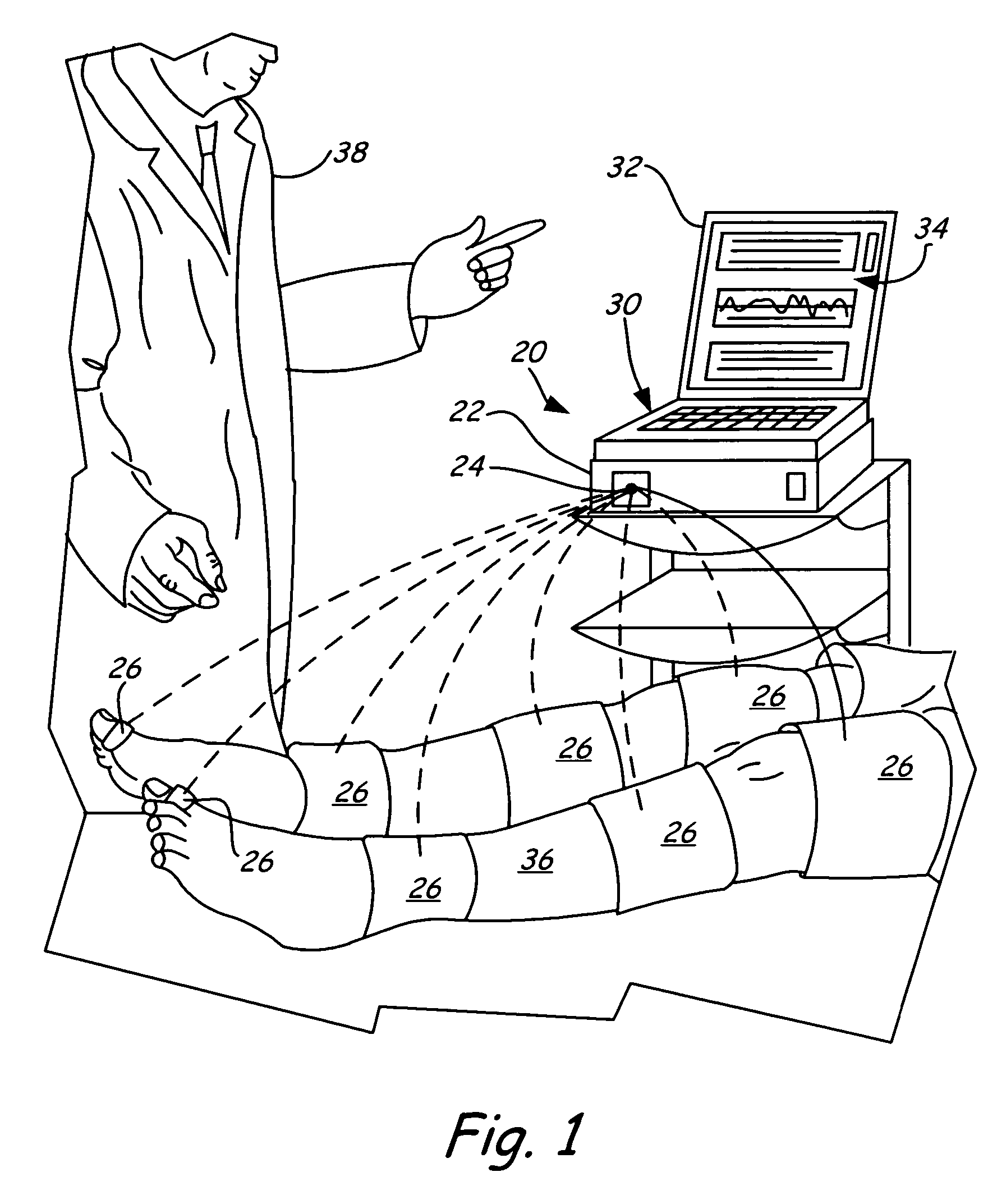

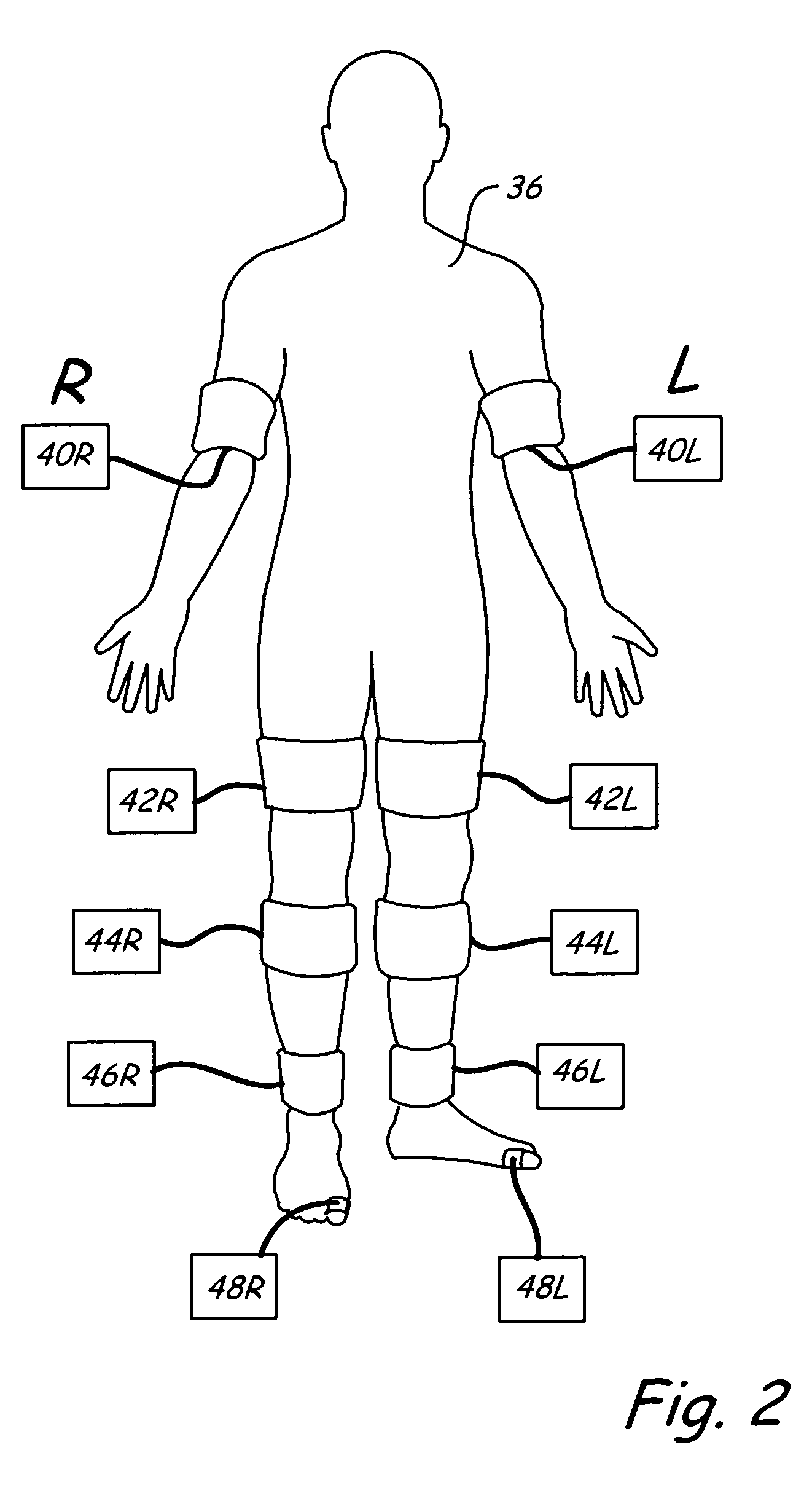

Vascular testing system

ActiveUS20060052714A1Desired locationReduce applicationsEvaluation of blood vesselsCatheterMedicinePeak value

A method of vascular testing includes inflating a cuff at a vascular location, controllably deflating the cuff, producing a pressure waveform while deflating the cuff, and producing an output representing a pressure at which blood flow returns, while deflating the cuff, based upon analysis of the pressure waveform. Further, a testing system for measuring vascular pressures according to the present invention includes a pressure applicator, a pressure sensor, and a diagnostic test unit. The pressure applicator is positionable along exterior portions of a human body for dynamically applying pressure to a desired vascular location. The pressure sensor is capable of detecting oscillations in a pressure at the pressure applicator. The testing system is capable of determining a peak pressure oscillation amplitude, and is also capable of determining, as a function of the peak pressure oscillation amplitude, a pressure of a return of flow at the desired vascular location as pressure applied to the desired vascular location by the pressure applicator is lessened.

Owner:COLLABORATIVE CARE DIAGNOSTICS

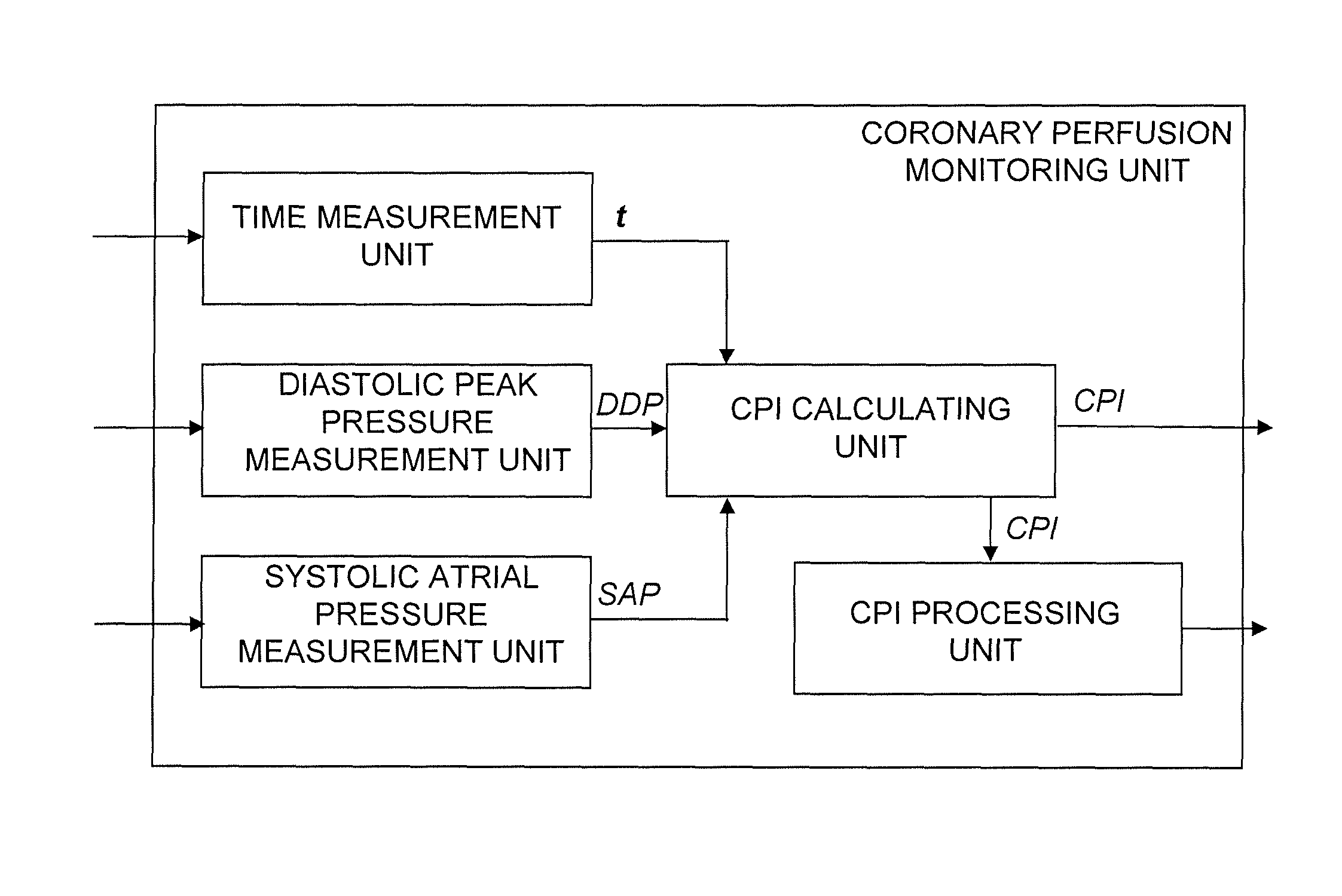

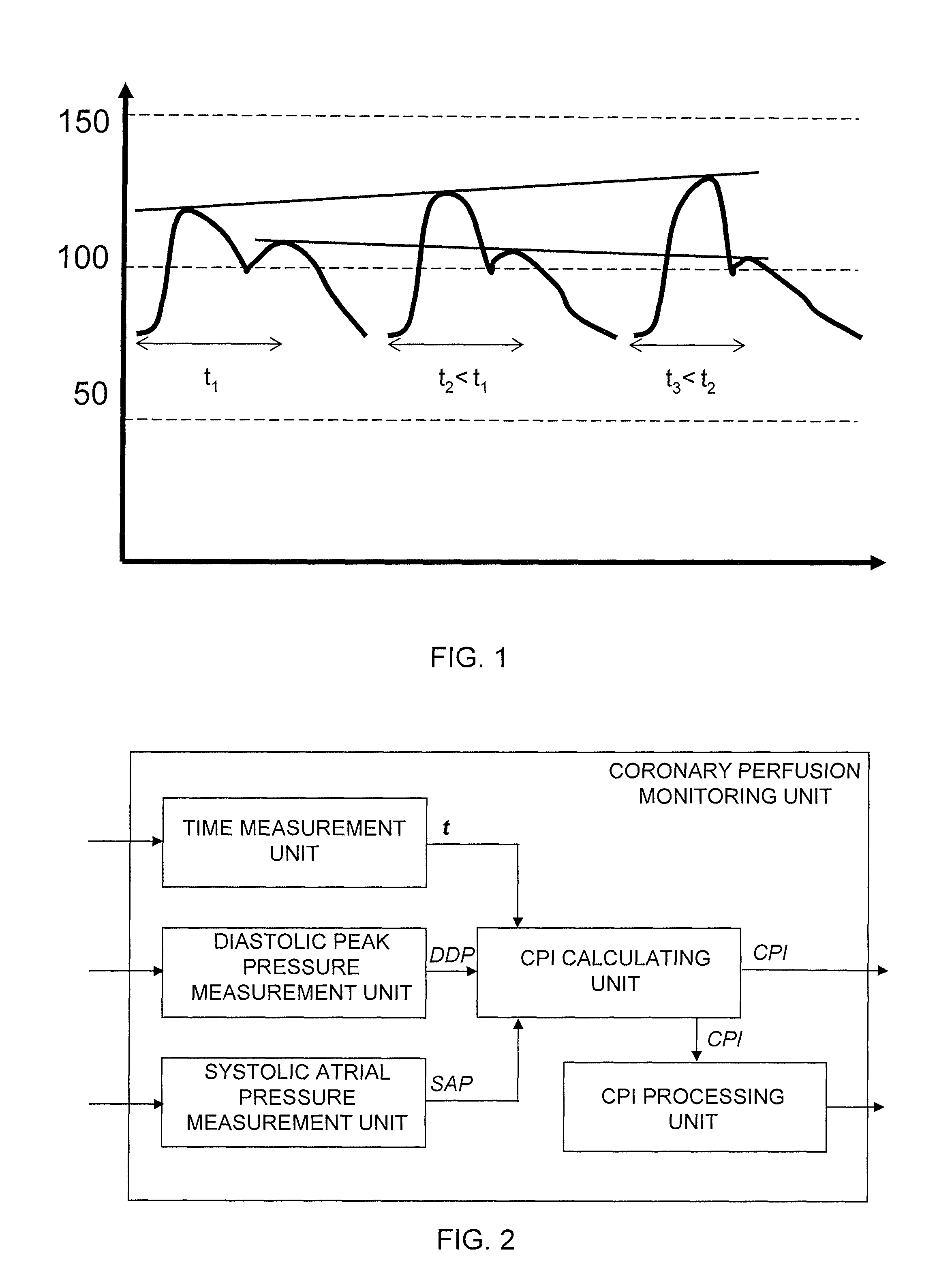

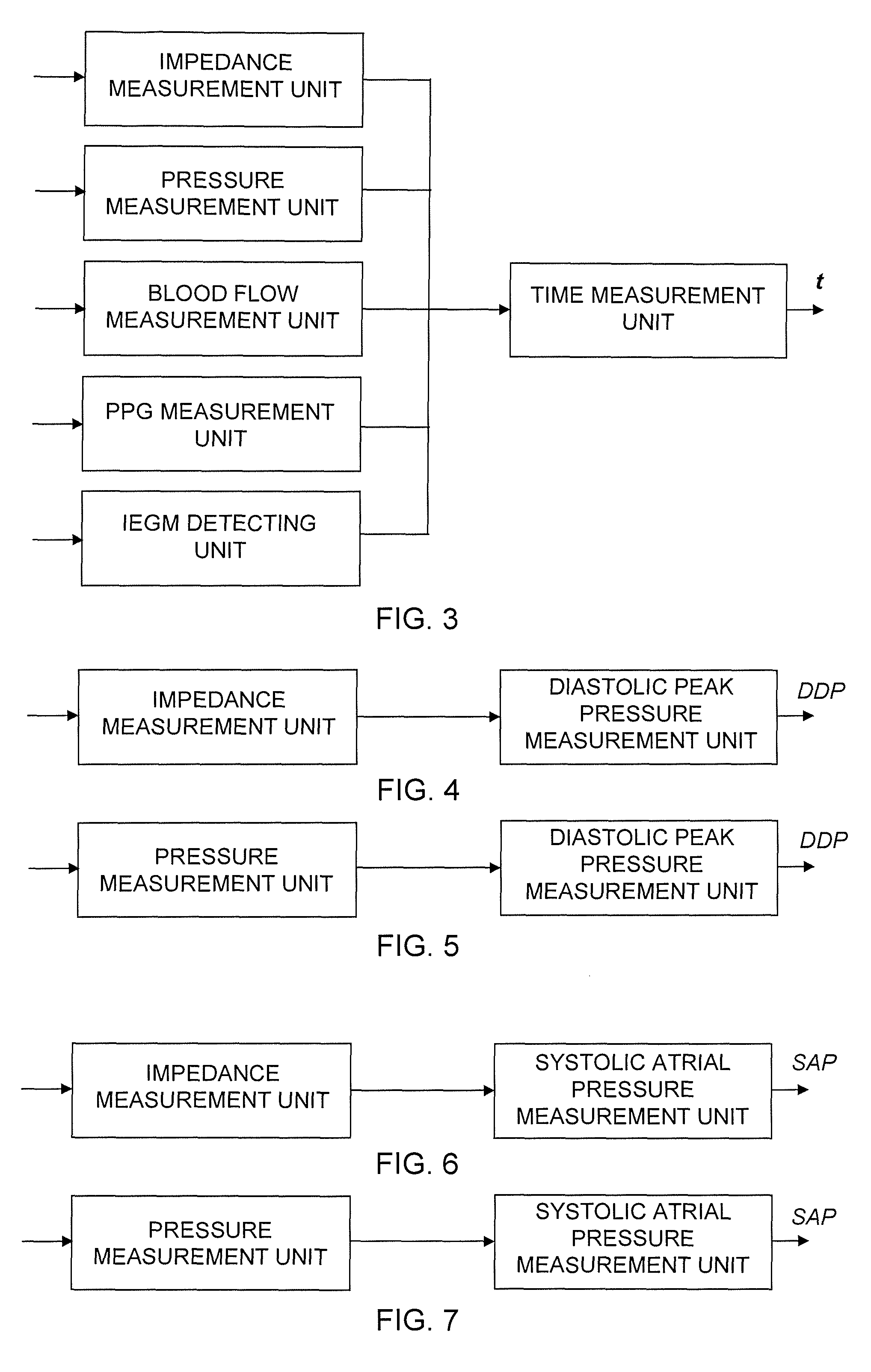

Implantable coronary perfusion monitoring device

An implantable coronary perfusion monitoring device for in-vivo determination of a coronary perfusion index (CPI) indicative of the coronary perfusion of a heart has a time measurement unit to determine a blood pressure reflection wave measure t indicating the timely position in the heart cycle of the maximum of a reflected blood pressure wave and in a time period starting at a preset point of time in systole and ending at a local maximum of blood pressure following aortic valve closure and, a diastolic peak pressure measurement unit adapted to determine a diastolic peak blood pressure measure DPP related to diastolic aortic peak pressure and a systolic arterial pressure measurement unit adapted to determine a systolic arterial blood pressure measure SAP related to systolic arterial pressure, and a coronary perfusion index calculating unit adapted to determine said coronary perfusion index CPI as (t·DPP) / SAP.

Owner:ST JUDE MEDICAL

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6701971B1Reduced packaging volumeLong leak-downLeno shedding mechanismPreformed elementsElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 7 seconds. All coatings, in particular elastomeric, non-silicon coatings, and coated airbags, meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

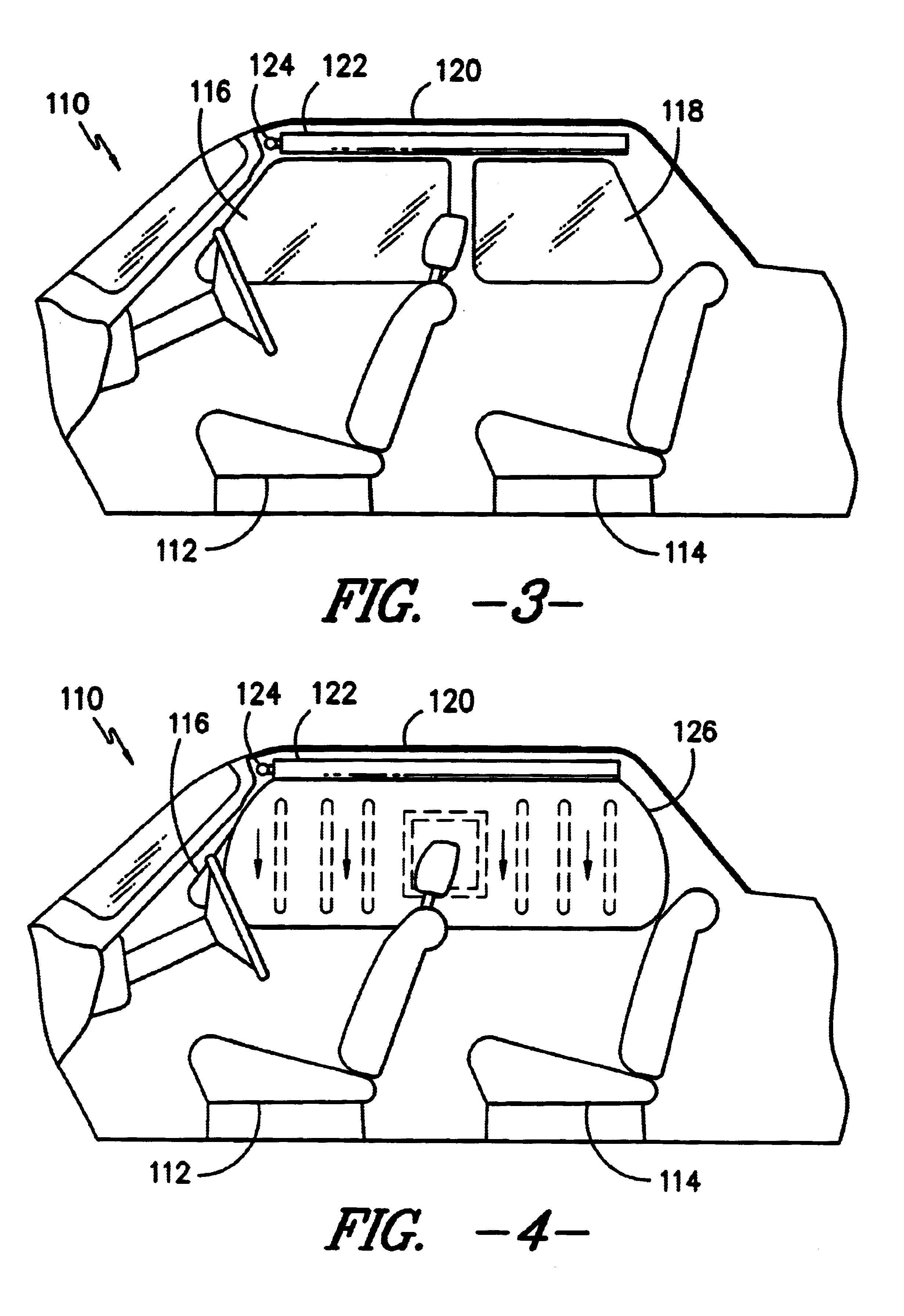

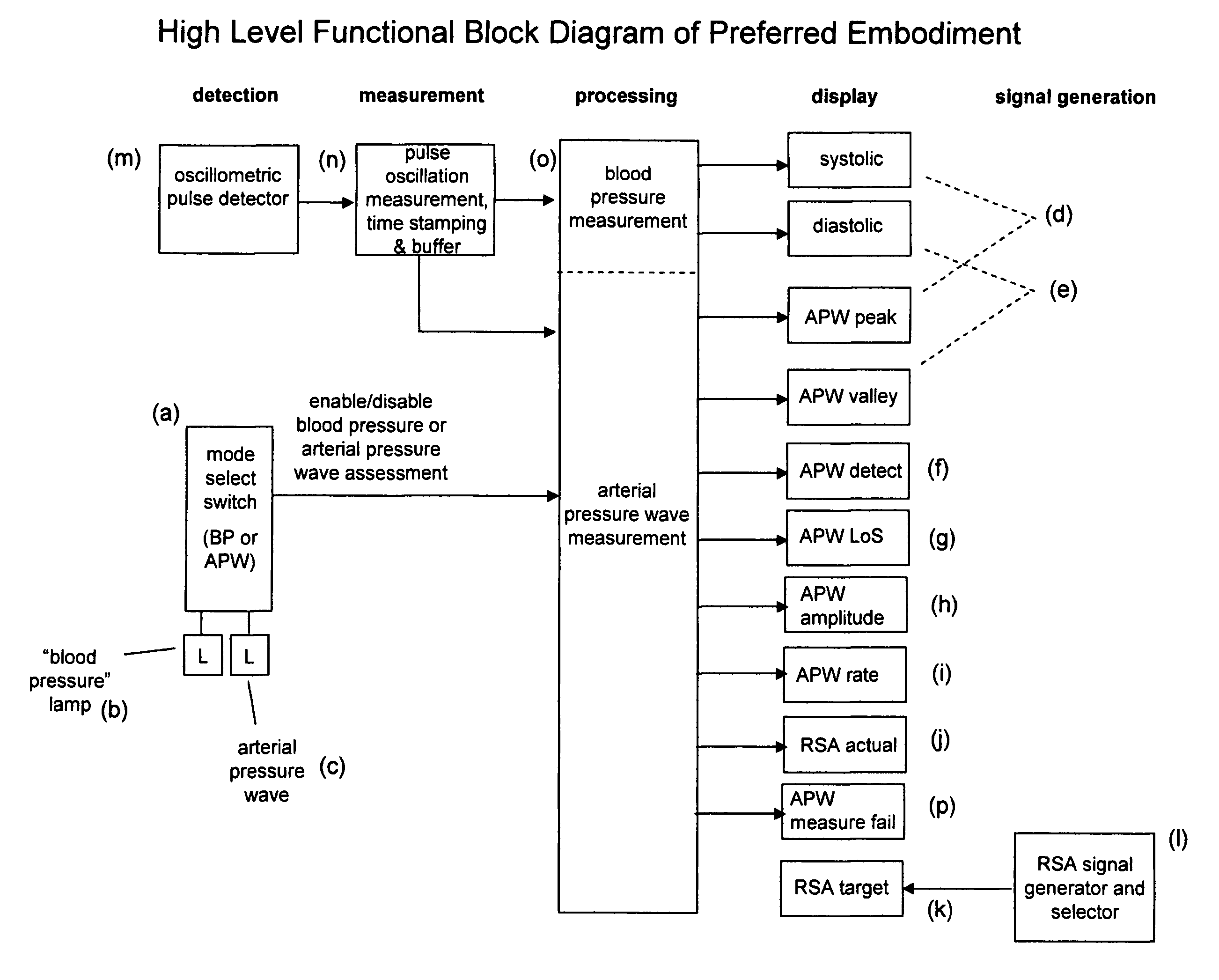

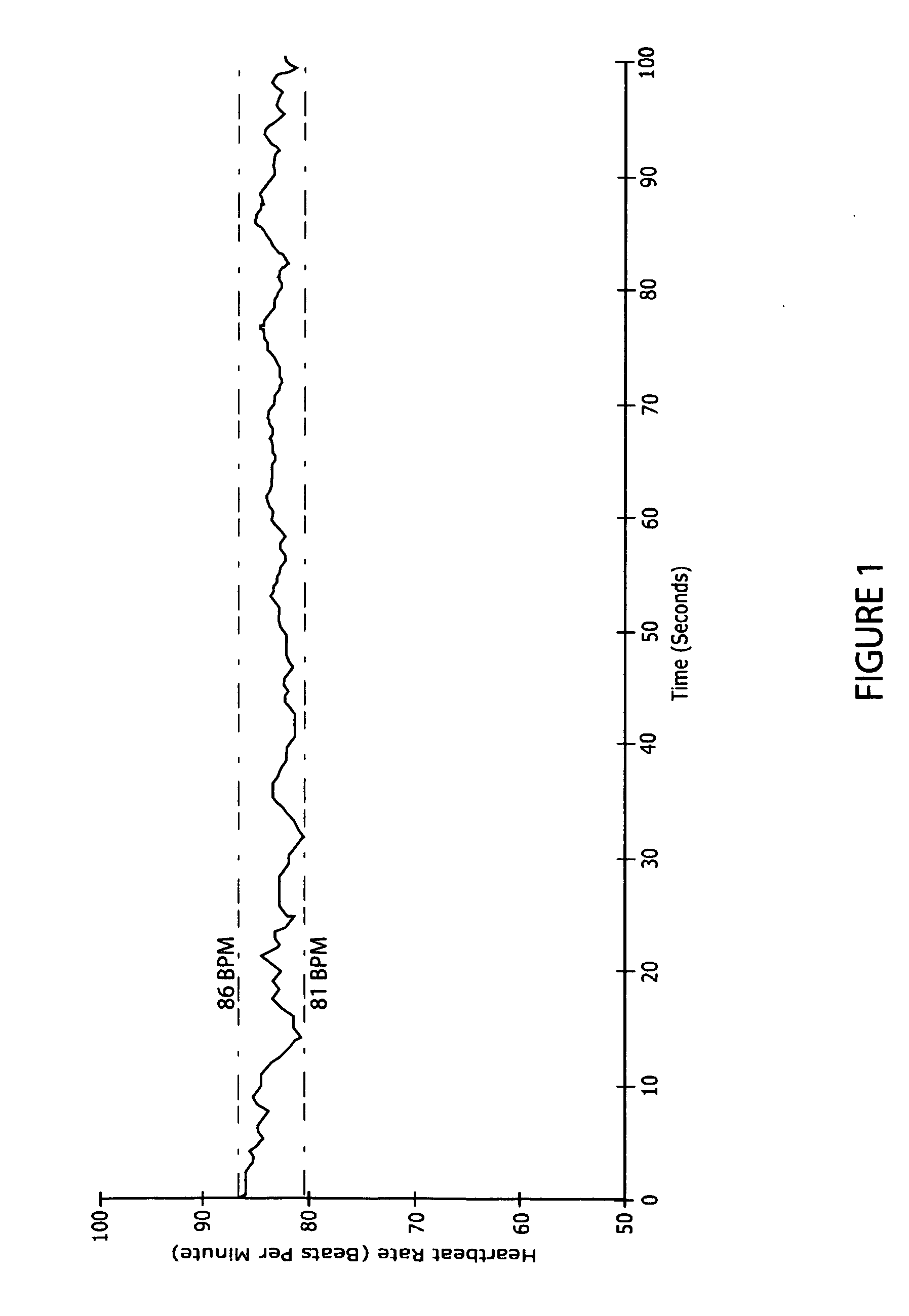

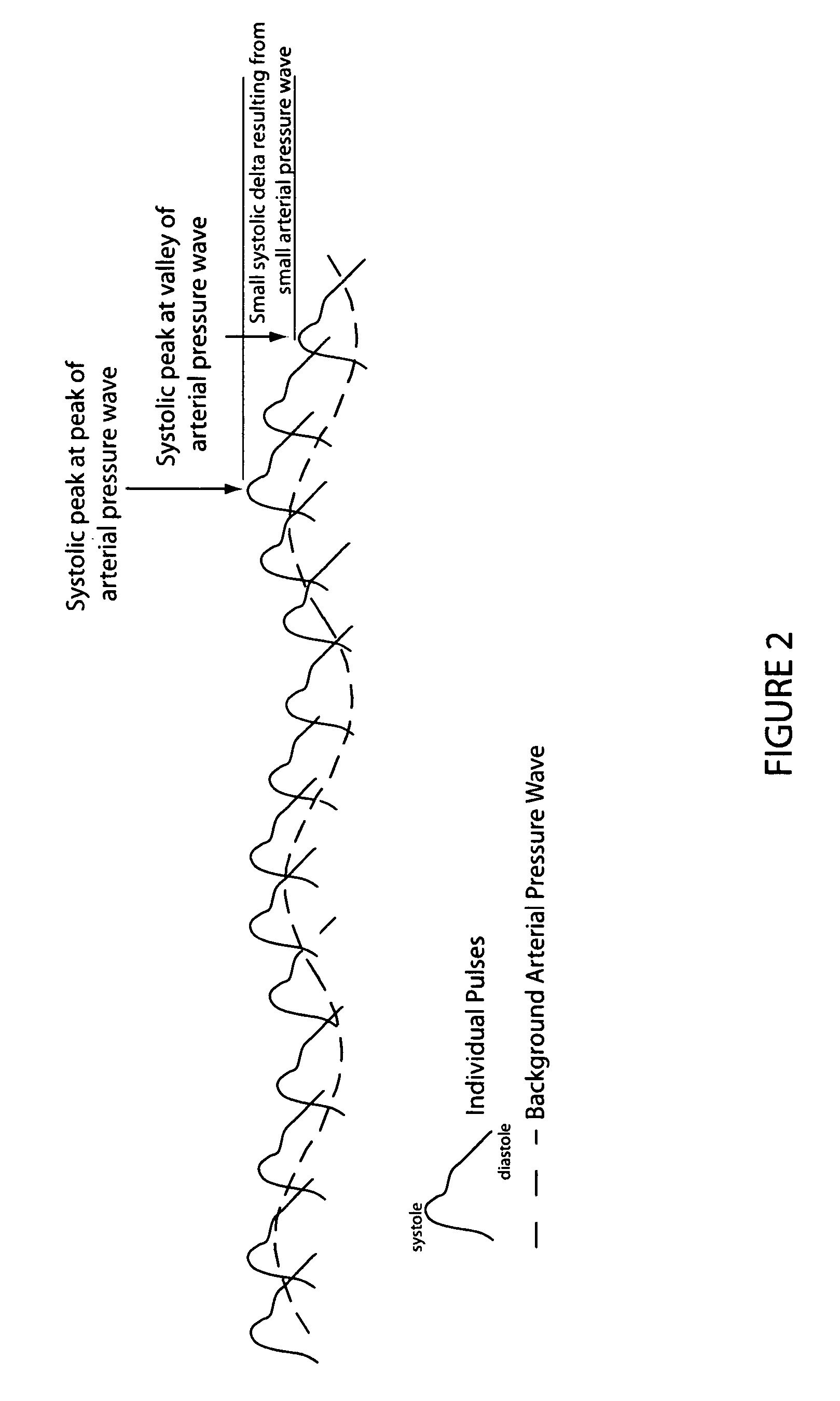

Method and system for assessing breathing effectiveness via assessment of the dynamic arterial pressure wave using the oscillometric measurement technique

The present invention specifies a method and system for assessing breathing effectiveness via dynamic assessment of respiratory sinus arrhythmia and the consequent arterial pressure wave using the oscillometric measurement technique. Arterial pressure wave peak pressure, valley pressure, amplitude, and rate are characterized and displayed for diagnostic and remedial purposes. The dynamic change in respiratory sinus arrhythmia and resultant arterial pressure wave is visually presented in real time as user biofeedback. A respiratory sinus arrhythmia generator generates varying frequencies to which the user synchronizes their breathing cycle for purposes of increasing arterial pressure wave amplitude with a consequent increase in breathing depth and decrease in breathing frequency. An instructive method in the application of the present invention is also specified.

Owner:COHERENCE

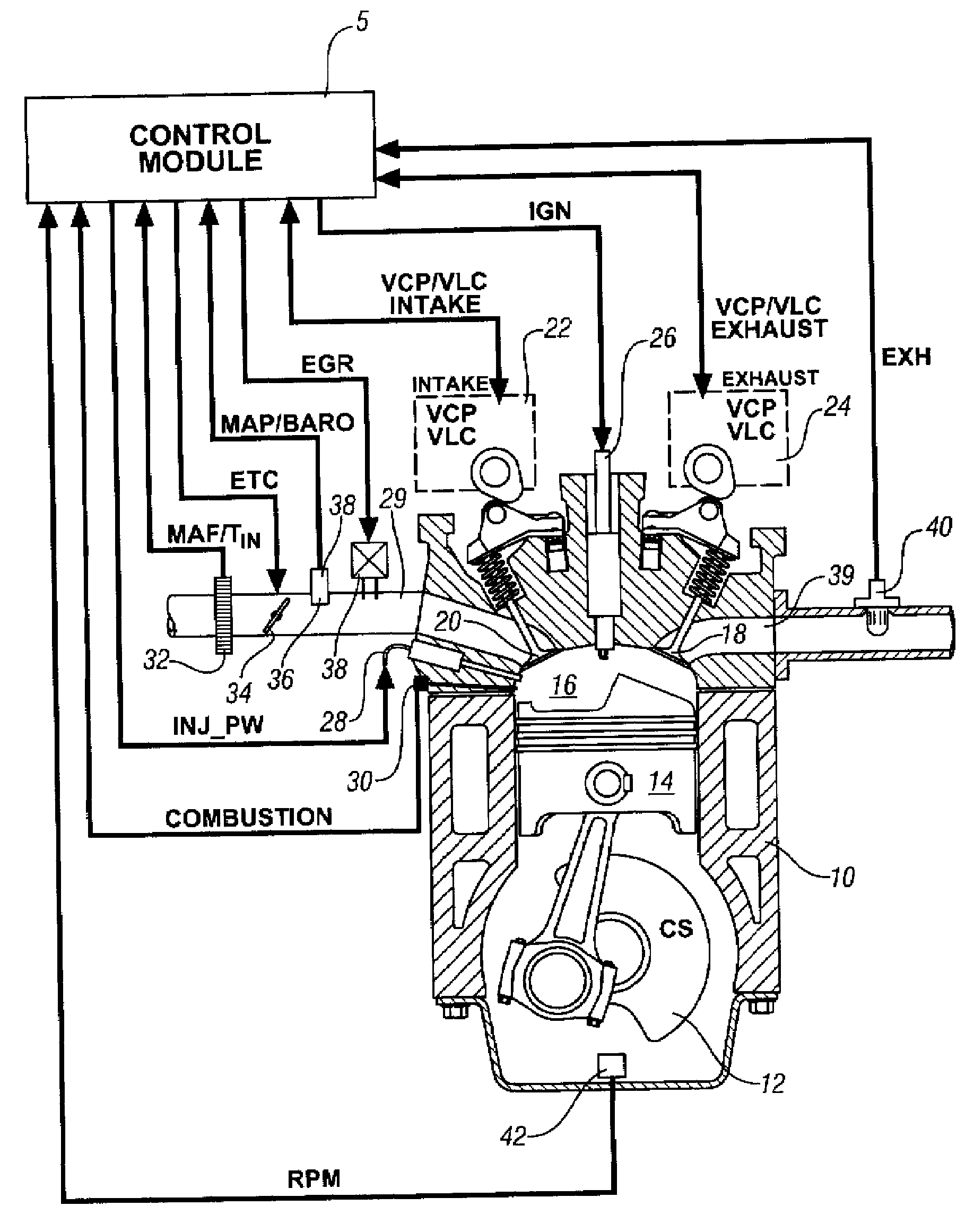

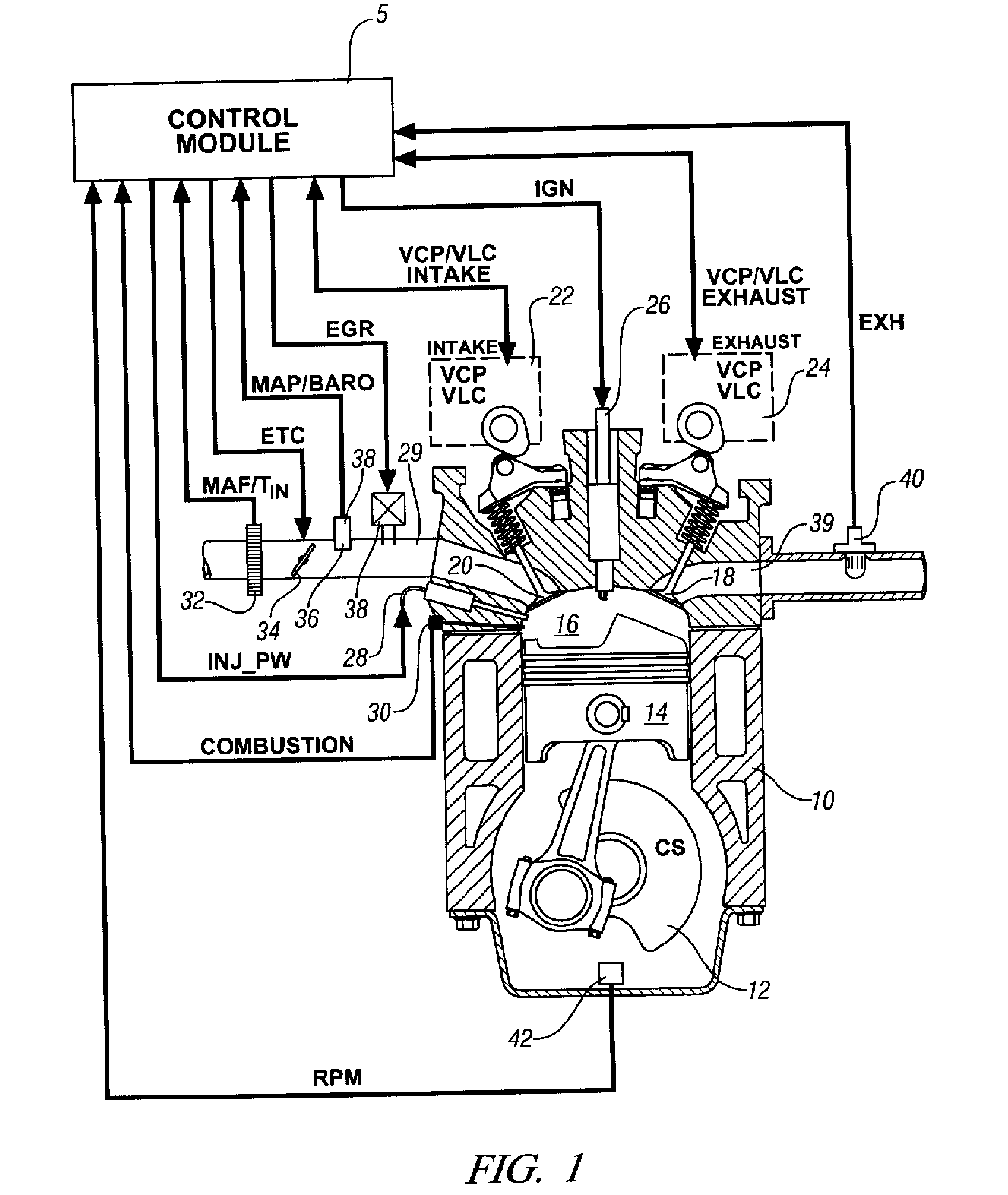

Method and apparatus for determining a combustion parameter for an internal combustion engine

There is provided a method to determine a combustion parameter for an internal combustion engine. The method comprises monitoring cylinder pressure and crank angle during a combustion cycle, and determining a peak cylinder pressure, a crank angle location of the peak cylinder pressure, and a cylinder pressure at a closing of an intake valve. A combustion parameter is calculated based upon the peak cylinder pressure, the cylinder pressure at the closing of the intake valve for the combustion cycle, the crank angle location of the peak cylinder pressure, the cylinder volume at the location of the peak cylinder pressure, and the cylinder volume at the closing of the intake valve for the combustion cycle. The combustion parameter correlates to an instantaneous heat release of a cylinder charge for the combustion cycle.

Owner:GM GLOBAL TECH OPERATIONS LLC

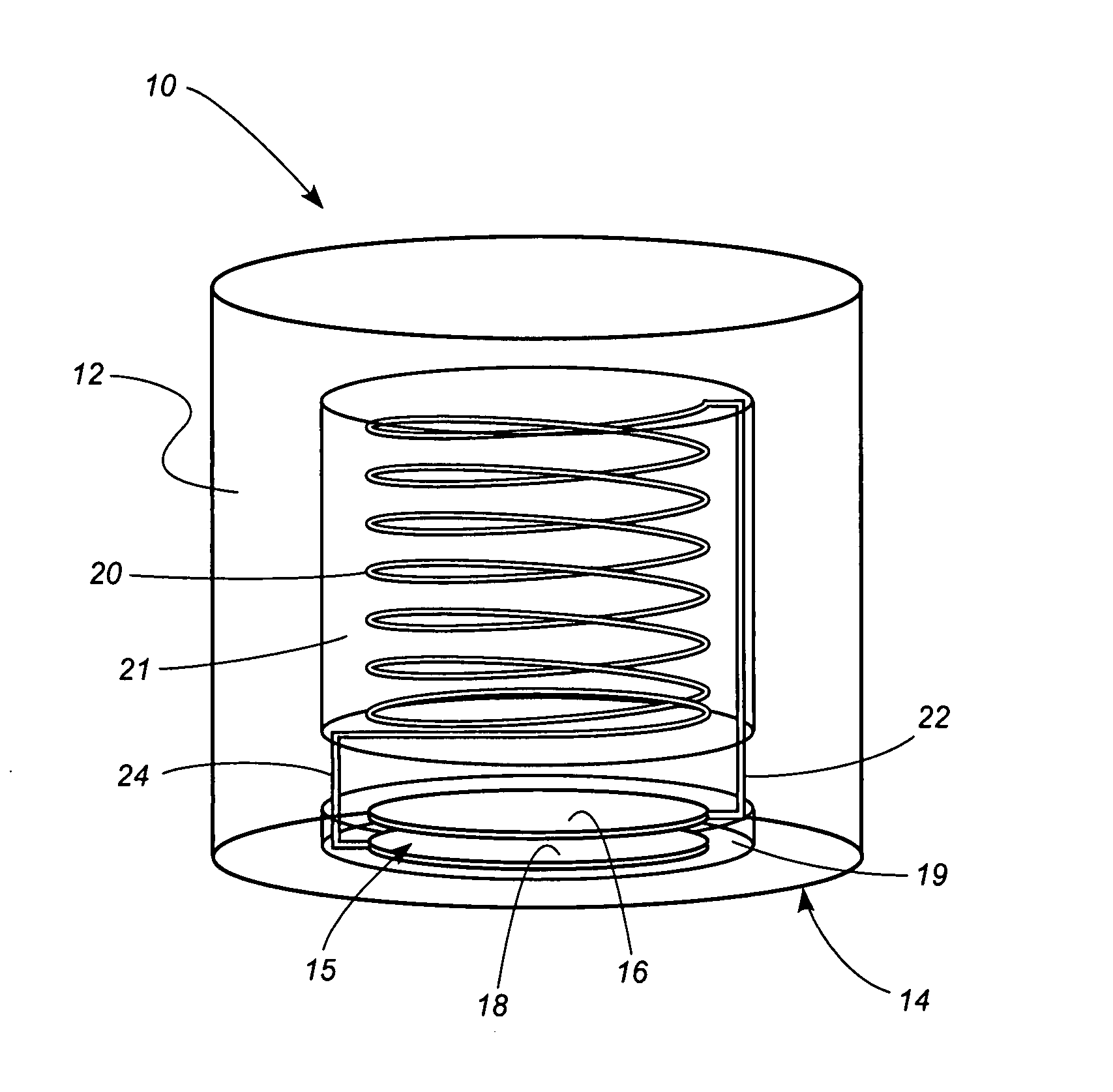

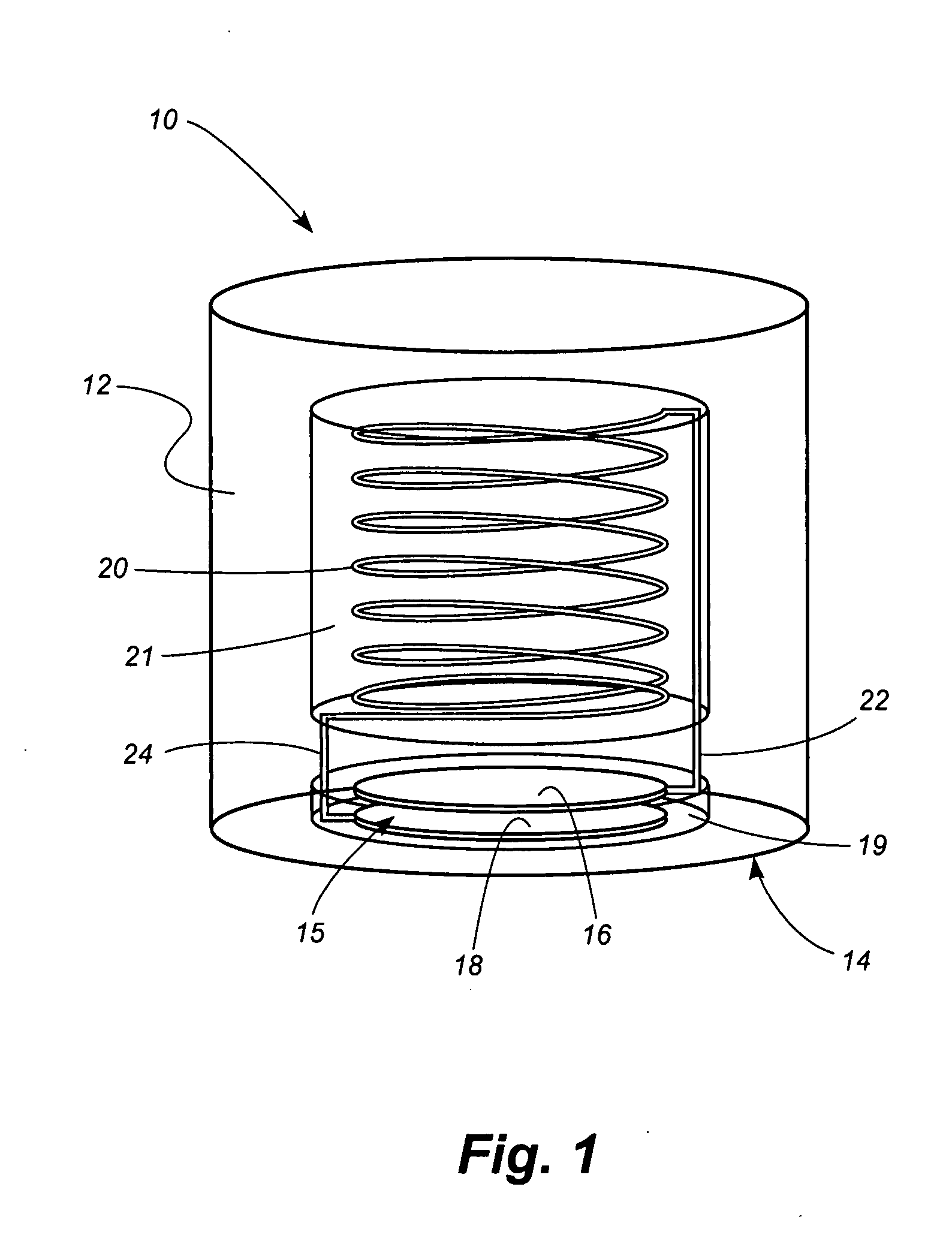

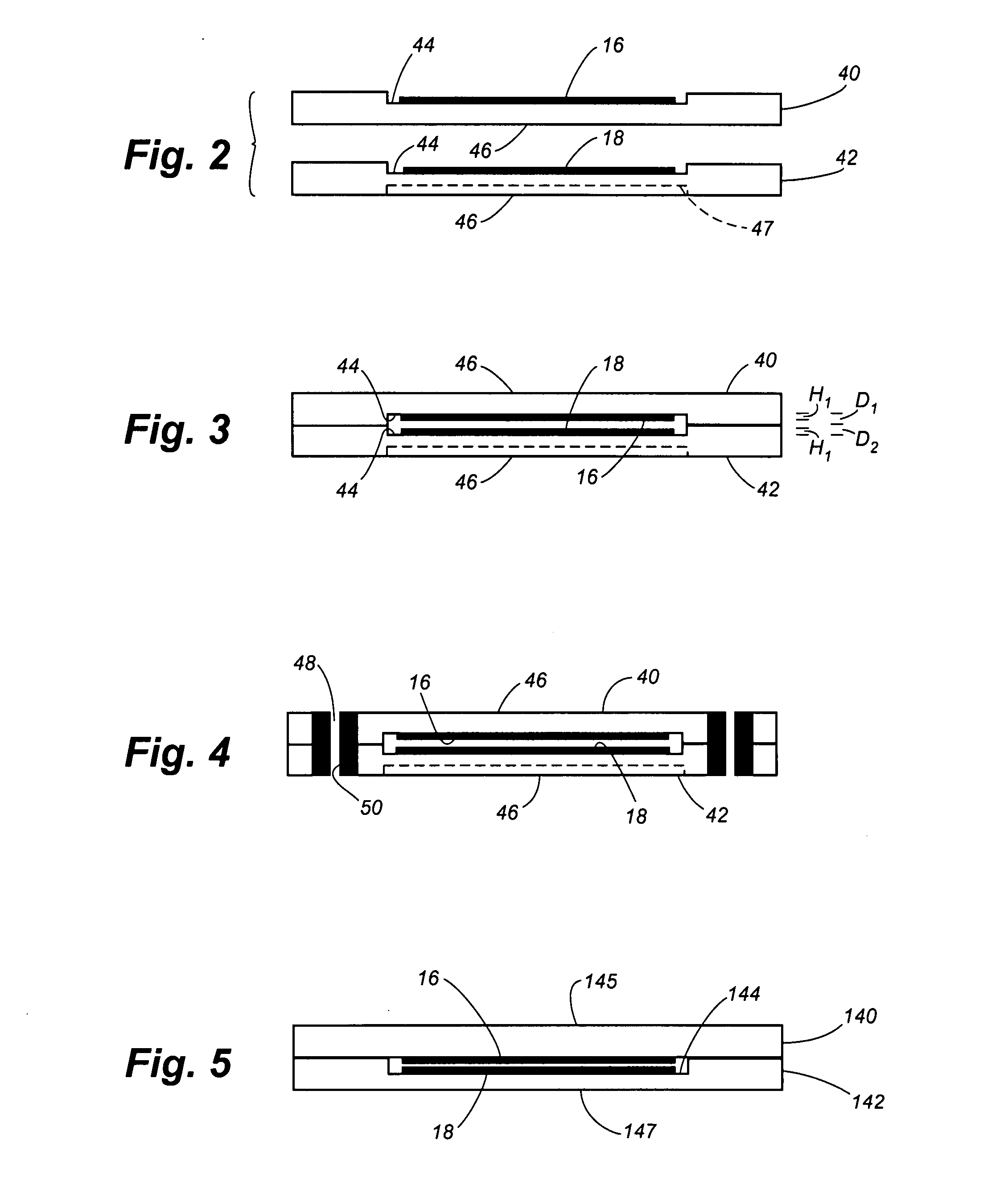

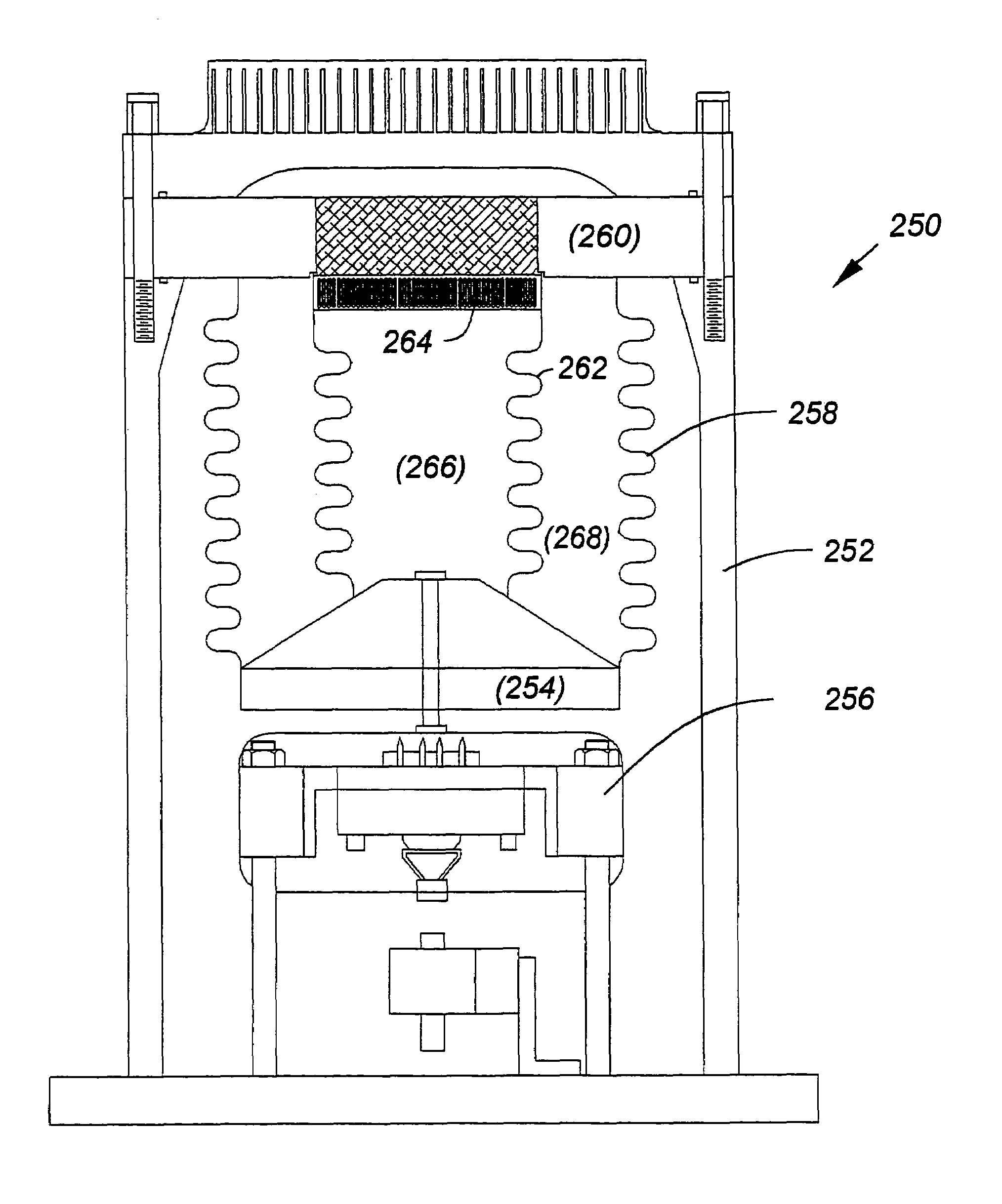

Thermoacoustic device

A thermocoustic device includes a housing with a thermal core supported in the housing and having a first and a second surface. The thermal core includes a first heat exchanger defining the first surface of the thermal core and a second heat exchanger defining the second surface of the thermal core. A main chamber is in fluid communication with the first surface of the thermal core and a secondary multiplier chamber is in fluid communication with the second surface of the thermal core. A working volume of a gaseous working fluid fills the main chamber, the multiplier chamber, and the thermal core at a pressure. An equilibrium pressure is defined as the pressure of the working volume of gaseous working fluids with the thermoacoustic device is in a non-operating mode. The main chamber includes a first oscillating member that is operable when the thermoacoustic device is in an operating mode to oscillate such that the pressure in both the main chamber and in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A main pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the main chamber. The secondary multiplier chamber includes a second oscillating member that is operable when the thermoacoustic device is in the operating mode to oscillate such that the pressure in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A multiplier pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the multiplier chamber. The first and second oscillating members oscillate at substantially the same frequency and such that the pressure oscillations in the main chamber and the multiplier chamber are substantially in phase with each other. The multiplier pressure amplitude is greater than the main pressure amplitude.

Owner:PENN STATE RES FOUND

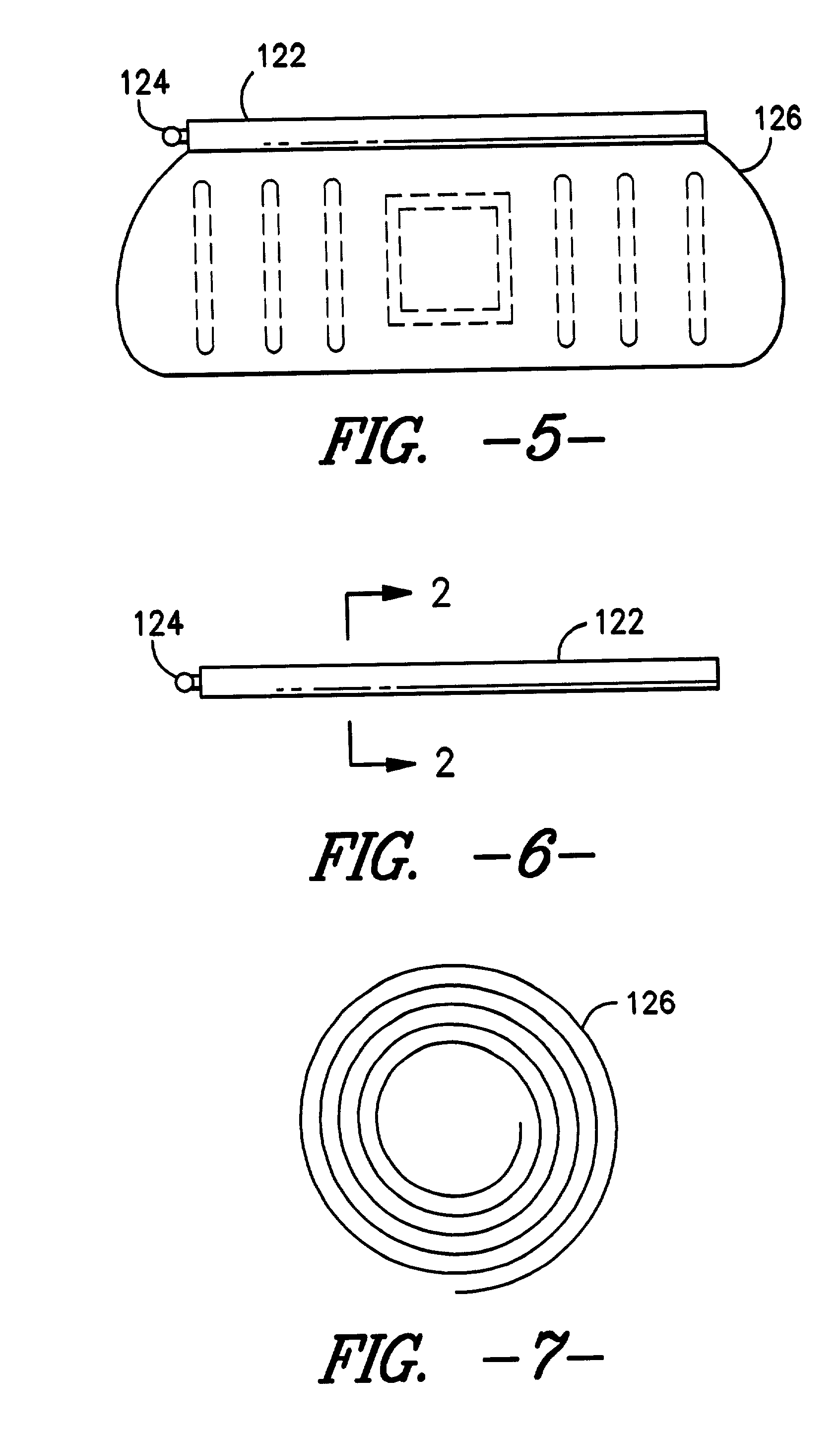

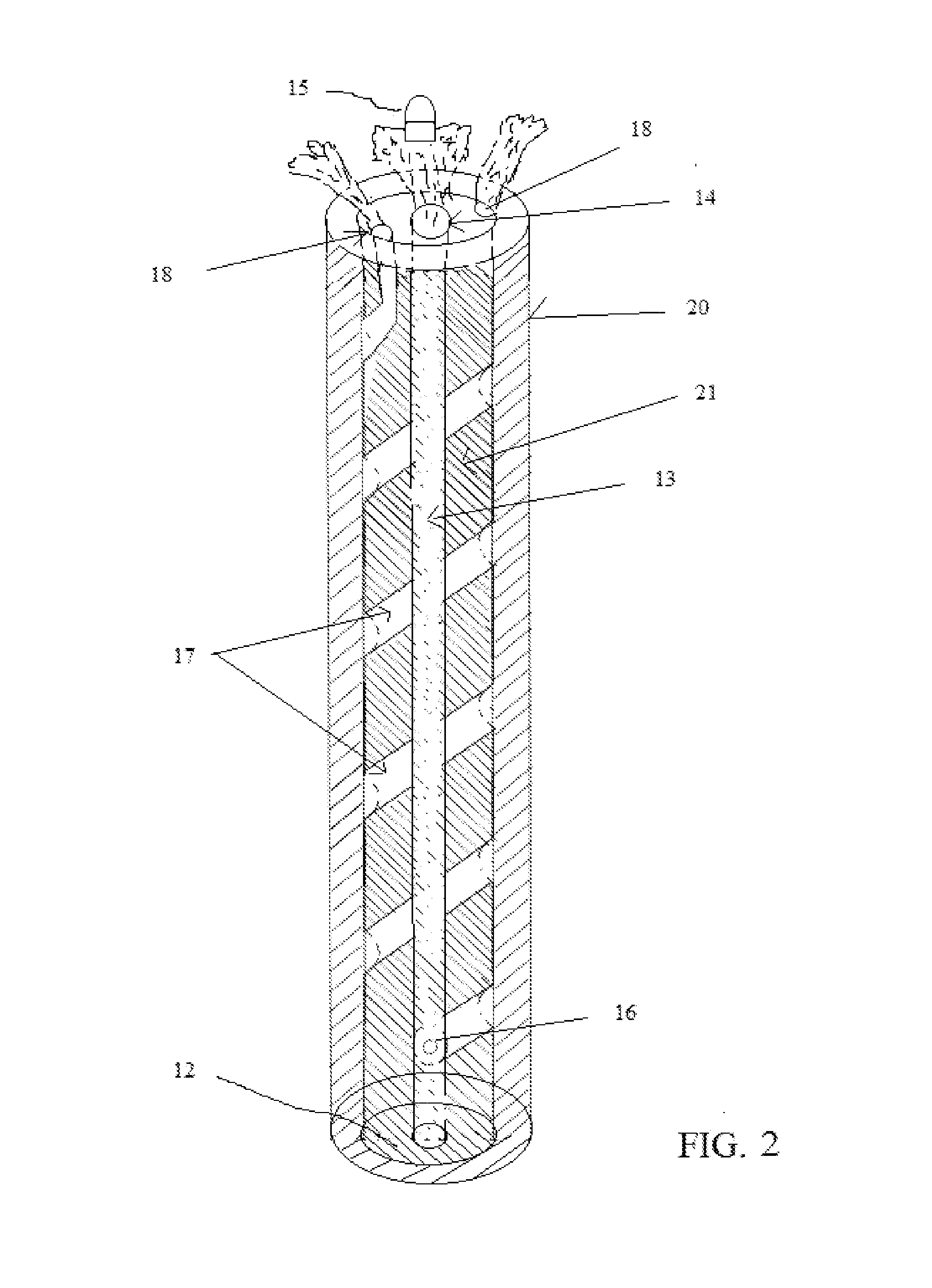

Suppressor For Firearm

A firearm noise and recoil suppressor having a plurality of ported channels in fluid contact with the barrel to redirect some of the firing gasses for the purpose of distributing the firing propellant gasses out the discharge end of the firearm. The channels redirect part of the propellent gasses to exit the barrel at times other than when the main projectile discharge occurs thus reducing peak pressure, thus reducing noise and recoil. The channels are contained within the tubular device, being in fluid communication with the projectile passageway through ports that regulate the amount of gas flow. The channels direct gasses to exit the device through apertures at the projectile exit end of the device in at an angle of between parallel to the projectile to up to perpendicularly.

Owner:BUTLER DAVID LARRY

Compact shooter localization system and method

ActiveUS7292501B2Material analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementAccelerometerLocalization system

Owner:RAYTHEON BBN TECH CORP

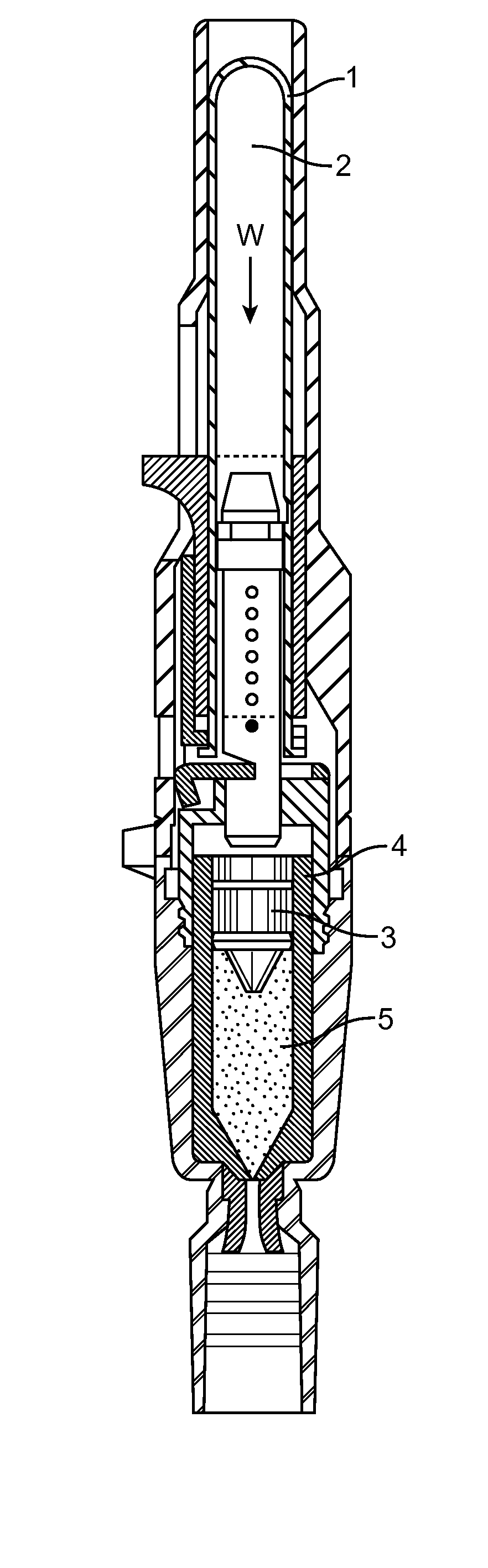

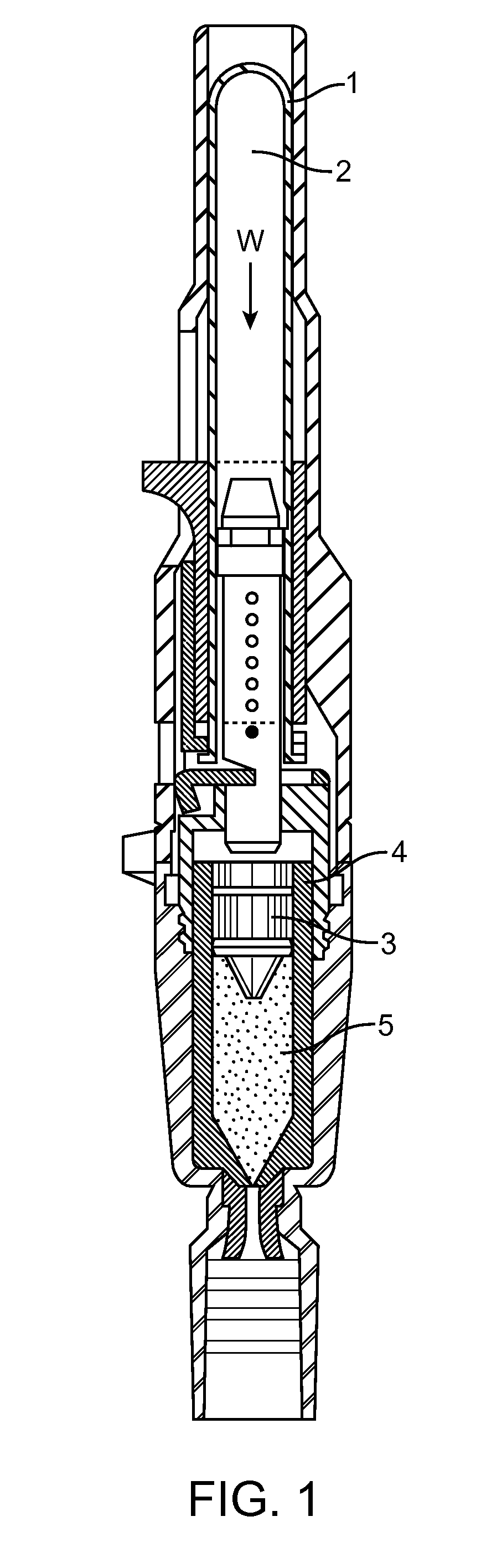

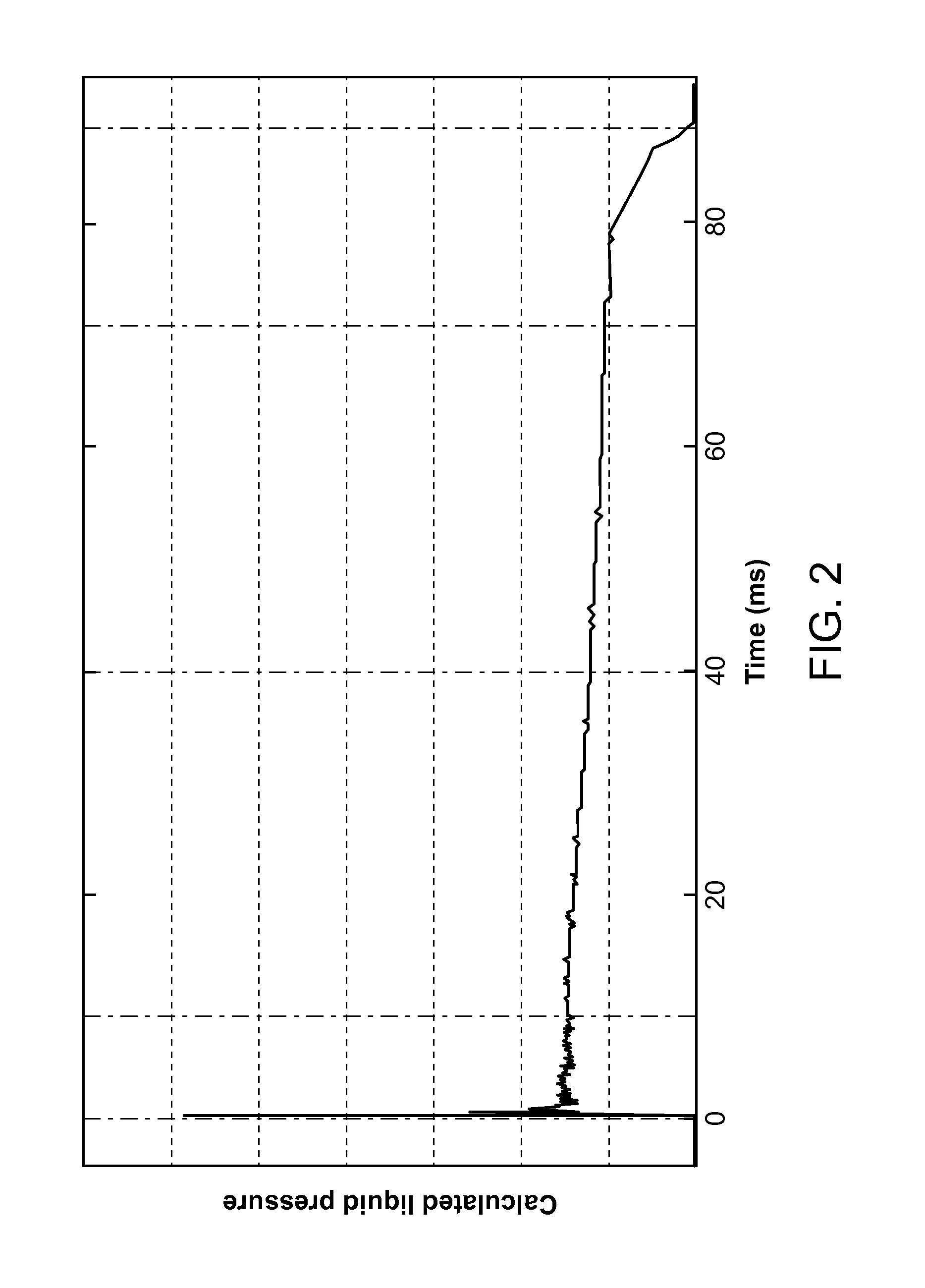

Needle-free injectors and design parameters thereof that optimize injection performance

InactiveUS8734384B2Patient compliance is goodImprove efficacyOrganic active ingredientsJet injection syringesNeedle Free InjectionNeedle free

A needle free injector system and a method for delivering a formulation using this system are disclosed. The method comprises actuating a needle free injector to pressurize a liquid formulation and force the formulation through an orifice in a skin puncture phase followed by injection of the formulation during a delivery phase. The skin puncture phase is defined by a pressure profile vs. time curve after actuation which has a main pressure peak with a maximum pressure. The delivery phase occurs at a lower pressure than the maximum pressure of the main peak pressure. The device may have one or more orifices and pressurizing the formulation during the puncture phase and delivery phase to extrude the formulation through each orifice is structured so as to improve characteristics of needle free delivery.

Owner:ZOGENIX INC

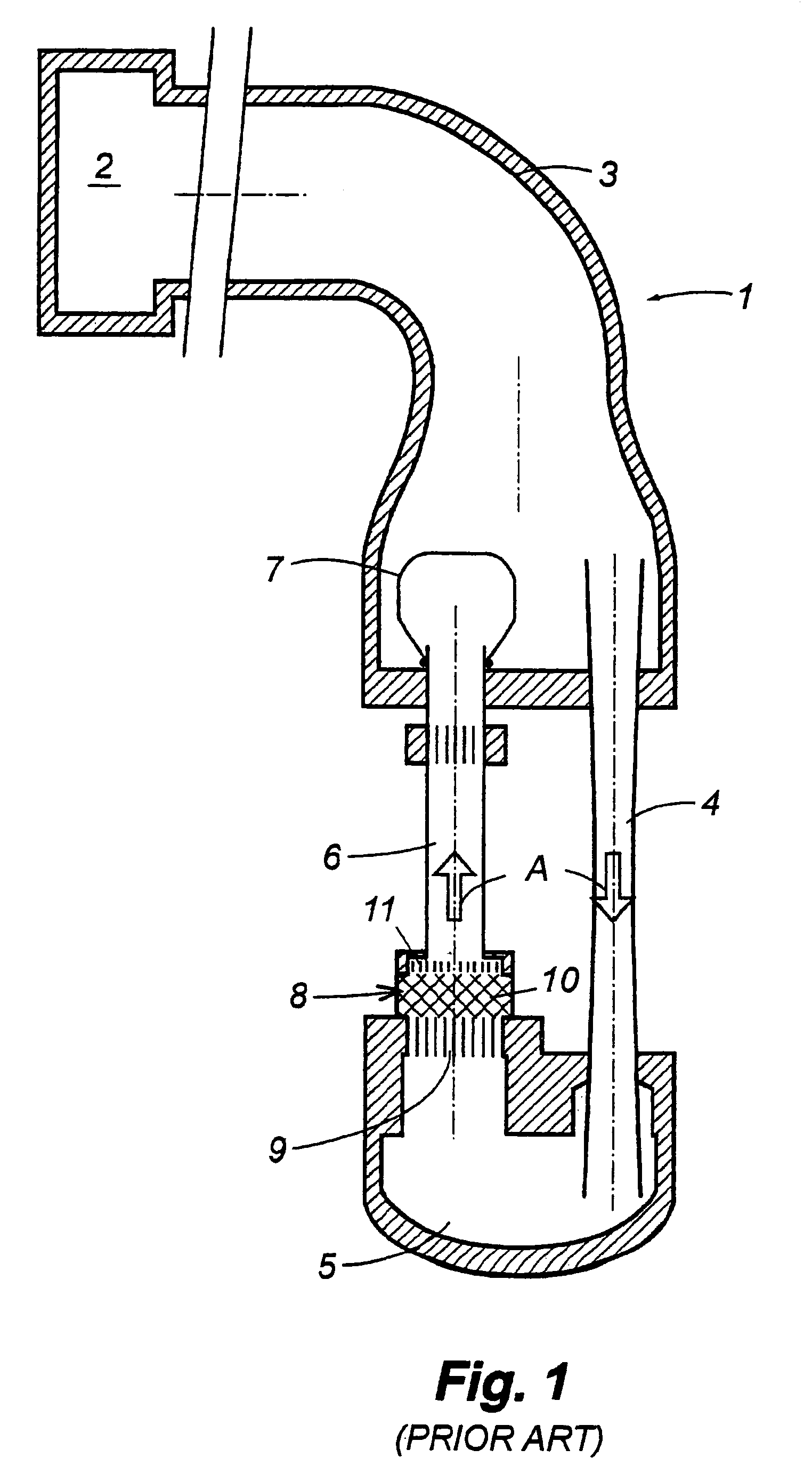

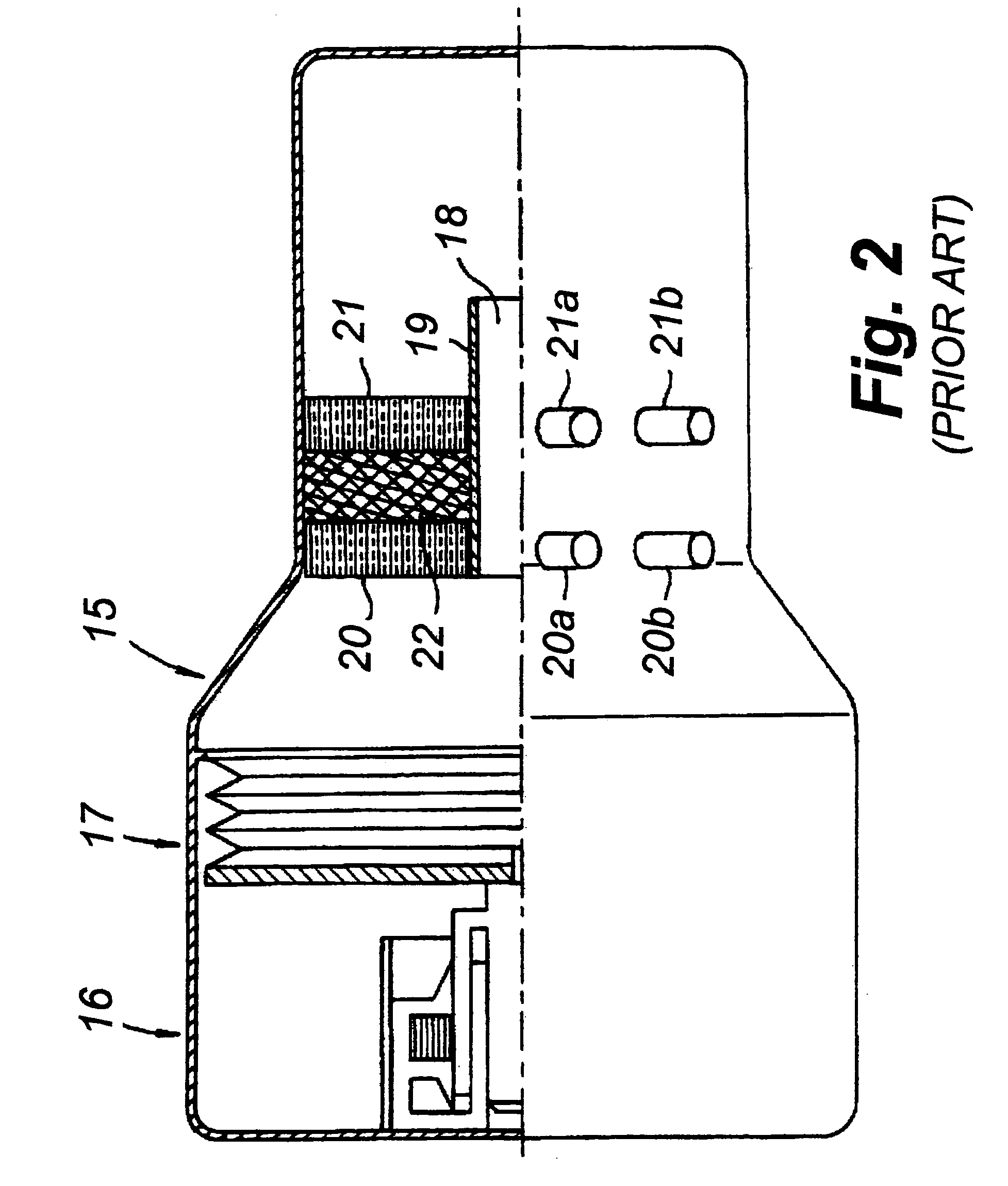

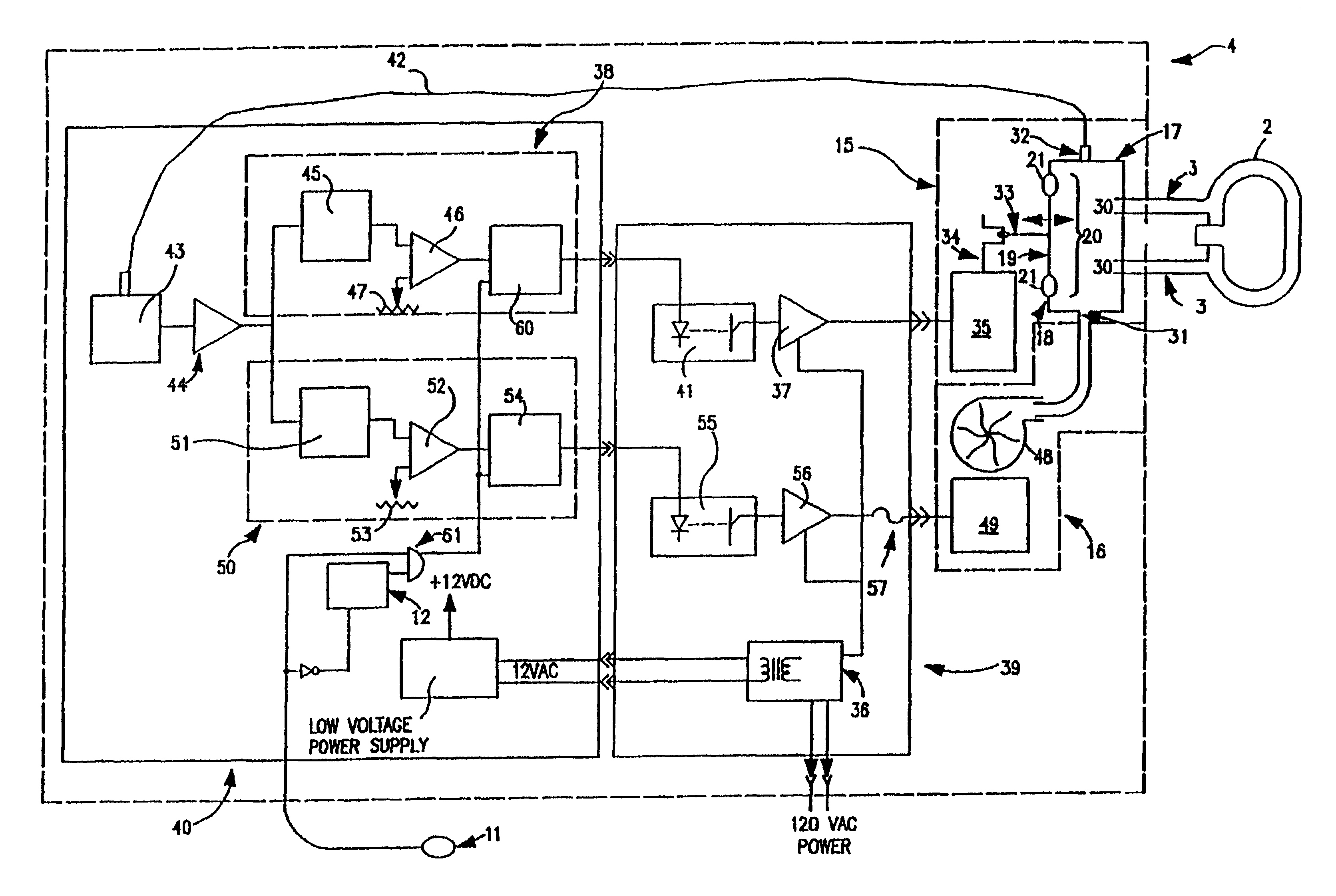

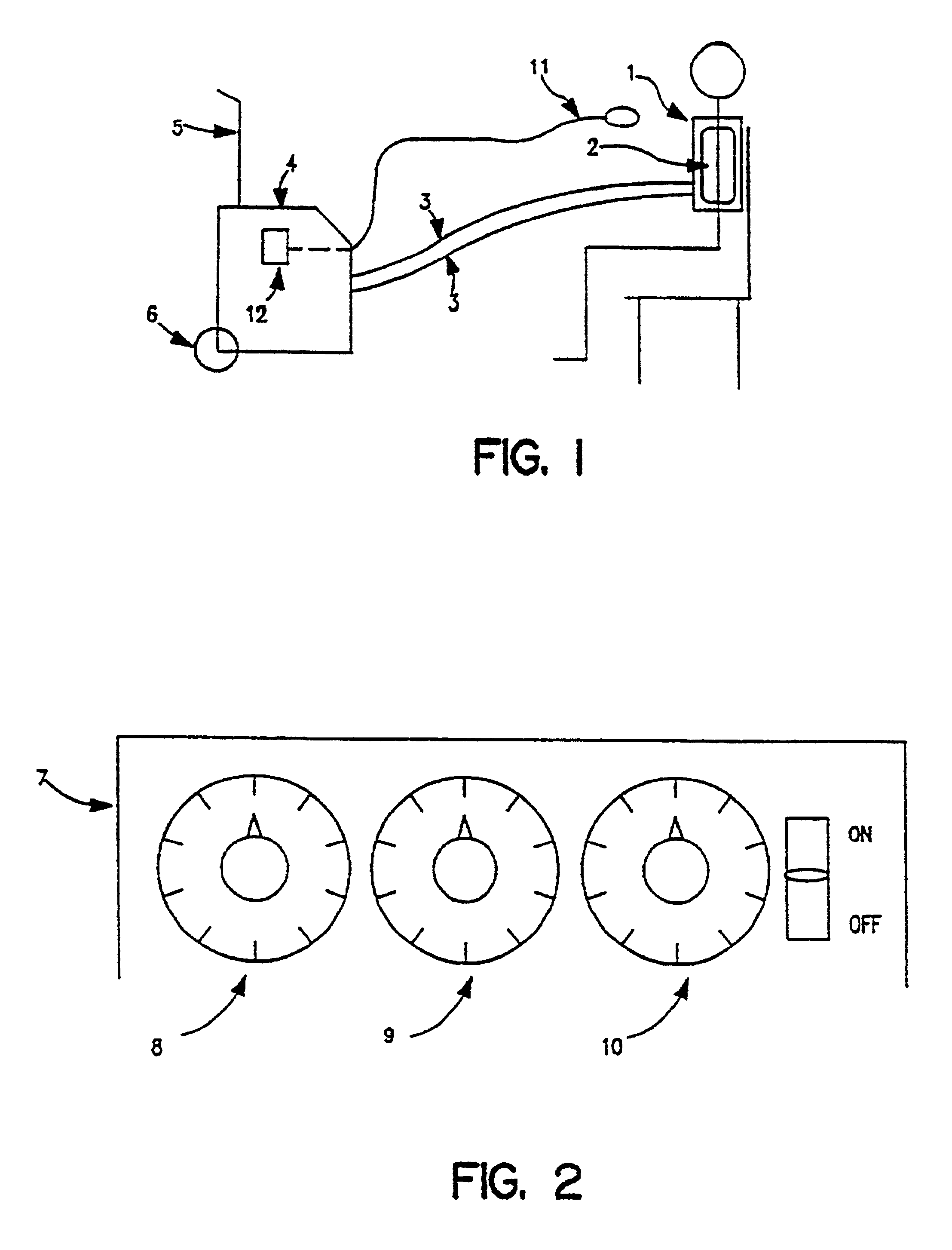

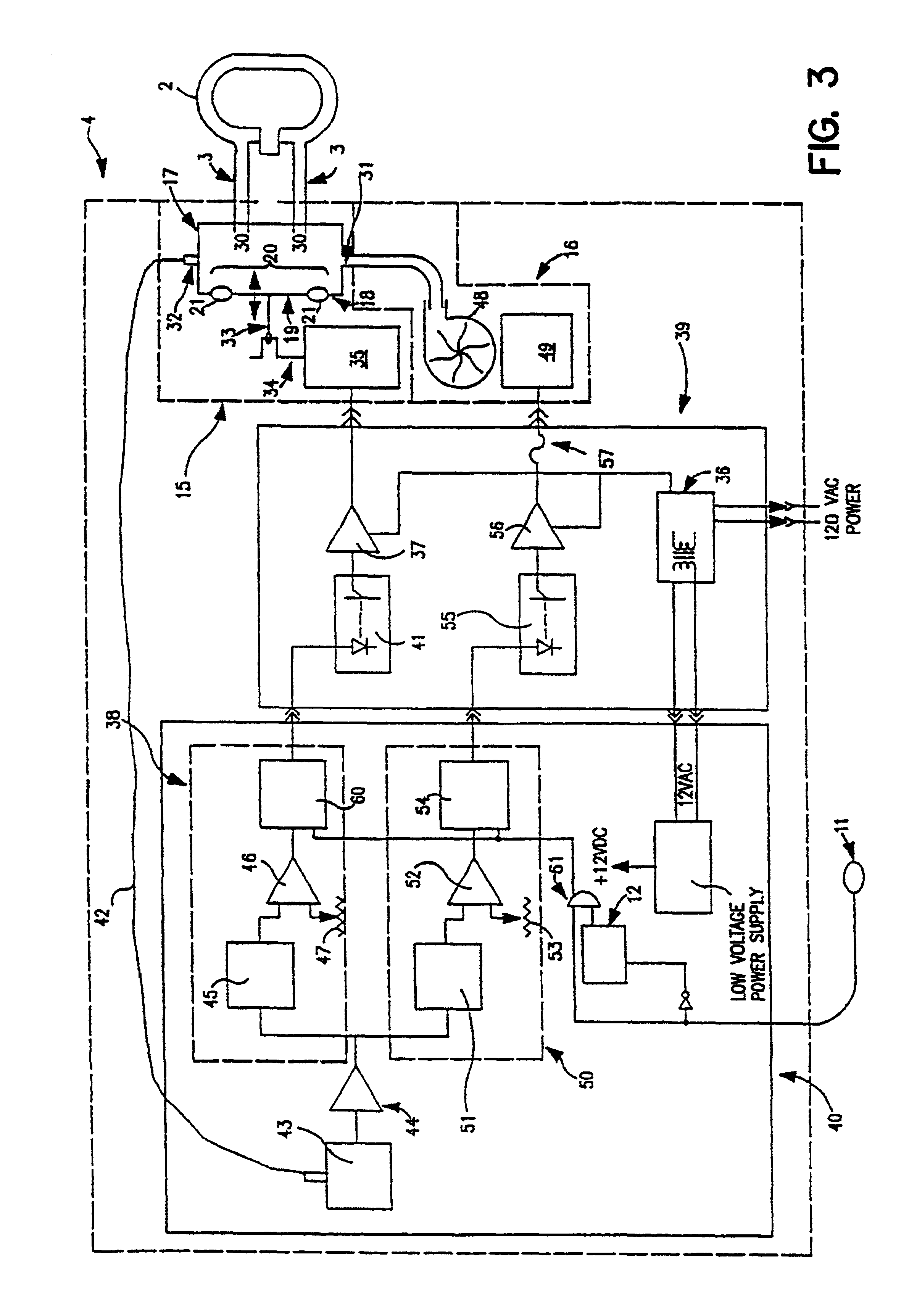

Oscillatory chest compression device

InactiveUSRE40814E1Preventing unsafe conditionAvoid adjustmentElectrotherapyPneumatic massageCompression devicePeak value

An oscillatory chest compression device includes an oscillatory air flow generator and a positive air flow generator. A first feedback system controls the oscillation rate of the oscillatory air flow generator, and a second feedback system controls the peak pressure created by the positive air flow generator.

Owner:HILL ROM SERVICES

Walking boot for diabetic and other patients

InactiveUS20090043234A1Maximum peak pressureReduce pressureNon-surgical orthopedic devicesFootwearPlantar surfaceDiabetic patient

An orthopedic walking boot promotes rapid healing of diabetic foot ulcerations by lowering the maximum peak pressure imposed upon the foot. The walker has a hard unyielding shell which is designed for walking. The shell closely and rigidly supports a mid-sole in a foot-shaped bed. The mid-sole has a foot-shaped cavity with rounded sides adapted to form resilient support for the heel, arch and sides of a foot in addition to the bottom of a foot. A conformable inner-sole is adapted to fit over the foot-shaped cavity in the mid-sole and be compressed in response to foot pressure between the sides and bottom of the foot and the sides and bottom of the foot-shaped cavity in the mid-sole thereby compensating for small differences between the shape of the foot and the shape of the cavity. Weight applied to the foot is transferred to the walking shell by contact between the sides of the foot, arch, and heel and the arch, heel and sides of the foot-shaped cavity as well as the bottom of the cavity thereby decreasing the peak or maximum unit pressure on the plantar surface of the foot. A breathable bootie which wraps the foot and lower leg in a protective “cocoon” is preferably secured to the upper surface of the insole thereby preventing foreign materials from entering the foot cavity.

Owner:BREG

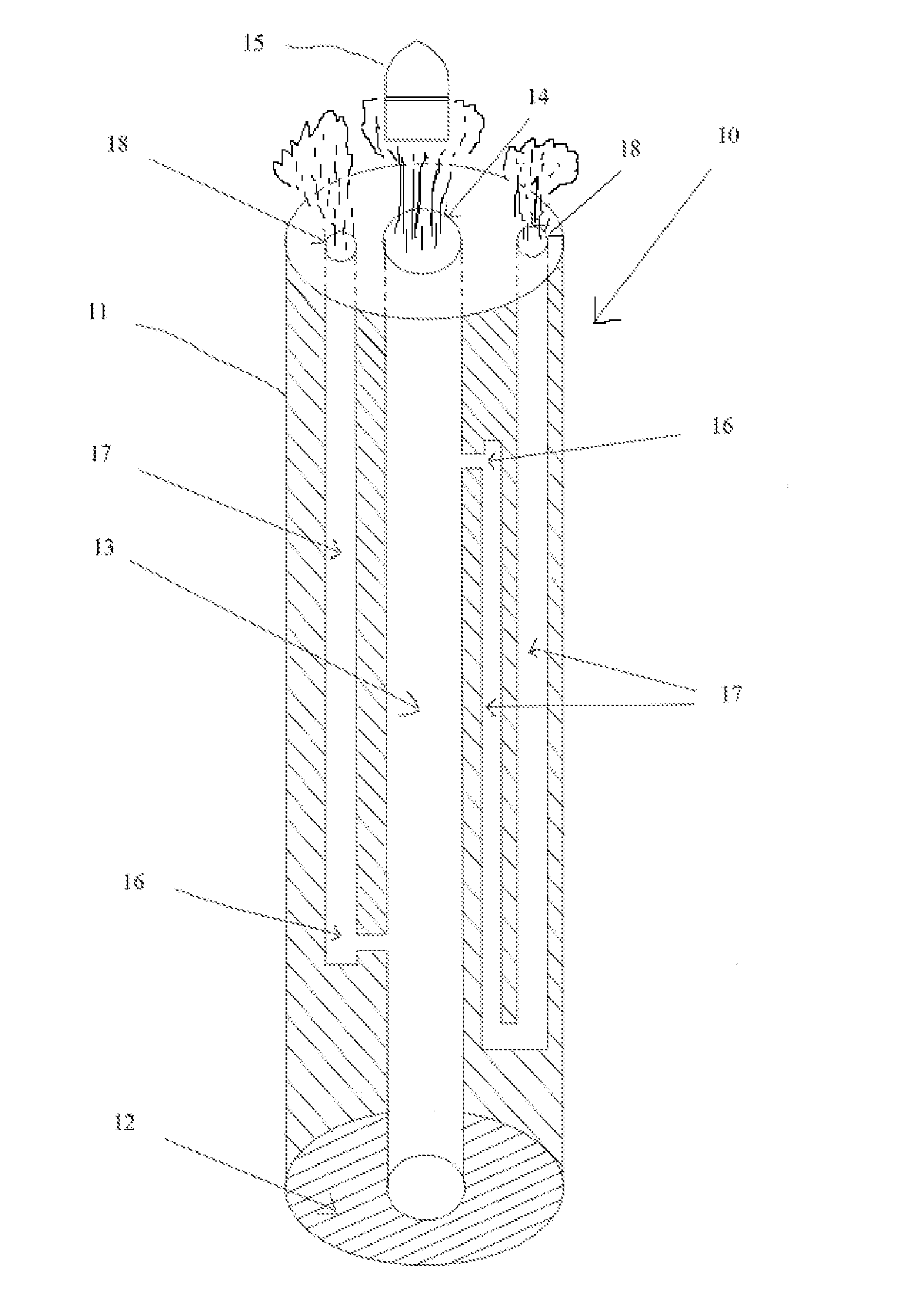

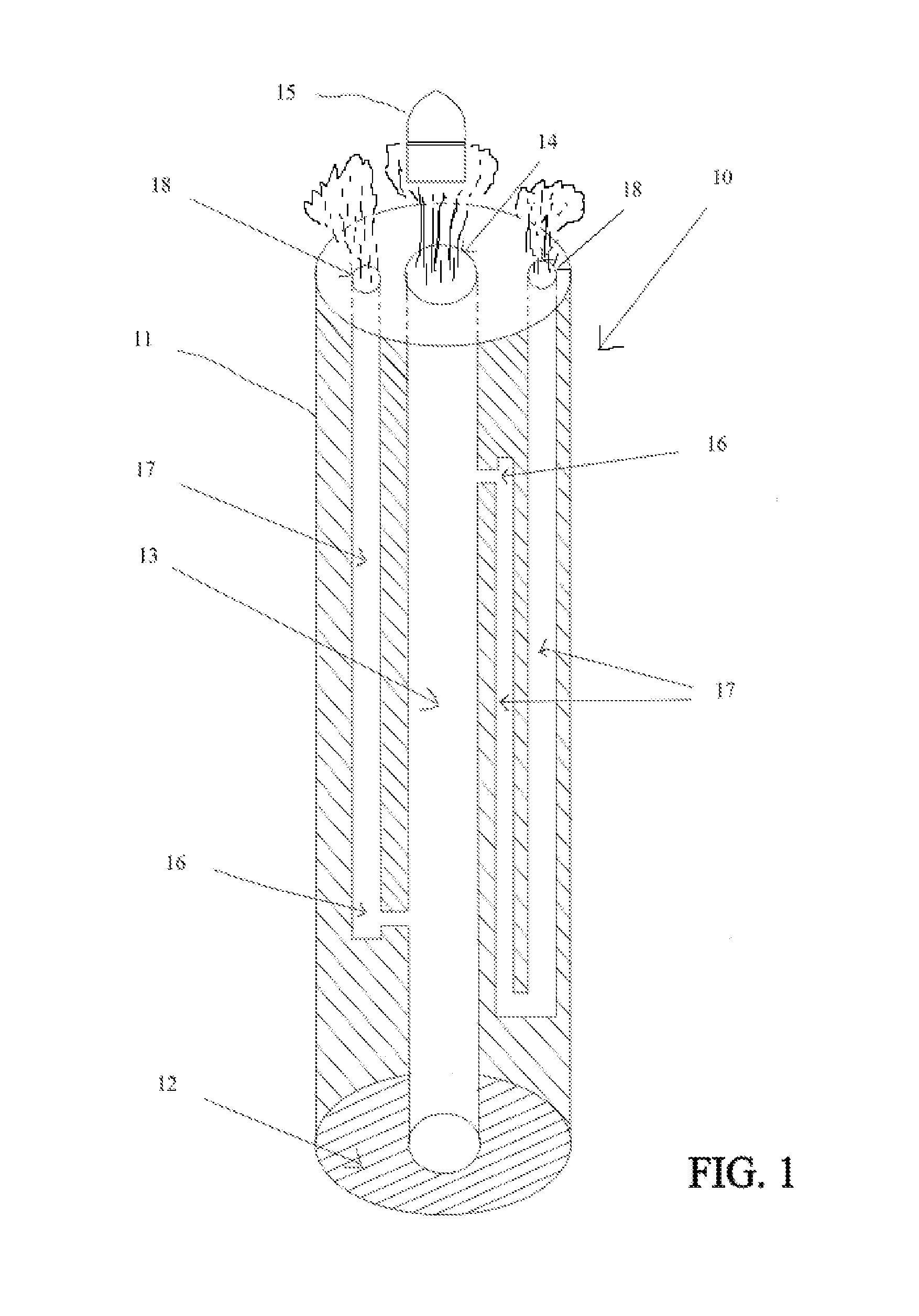

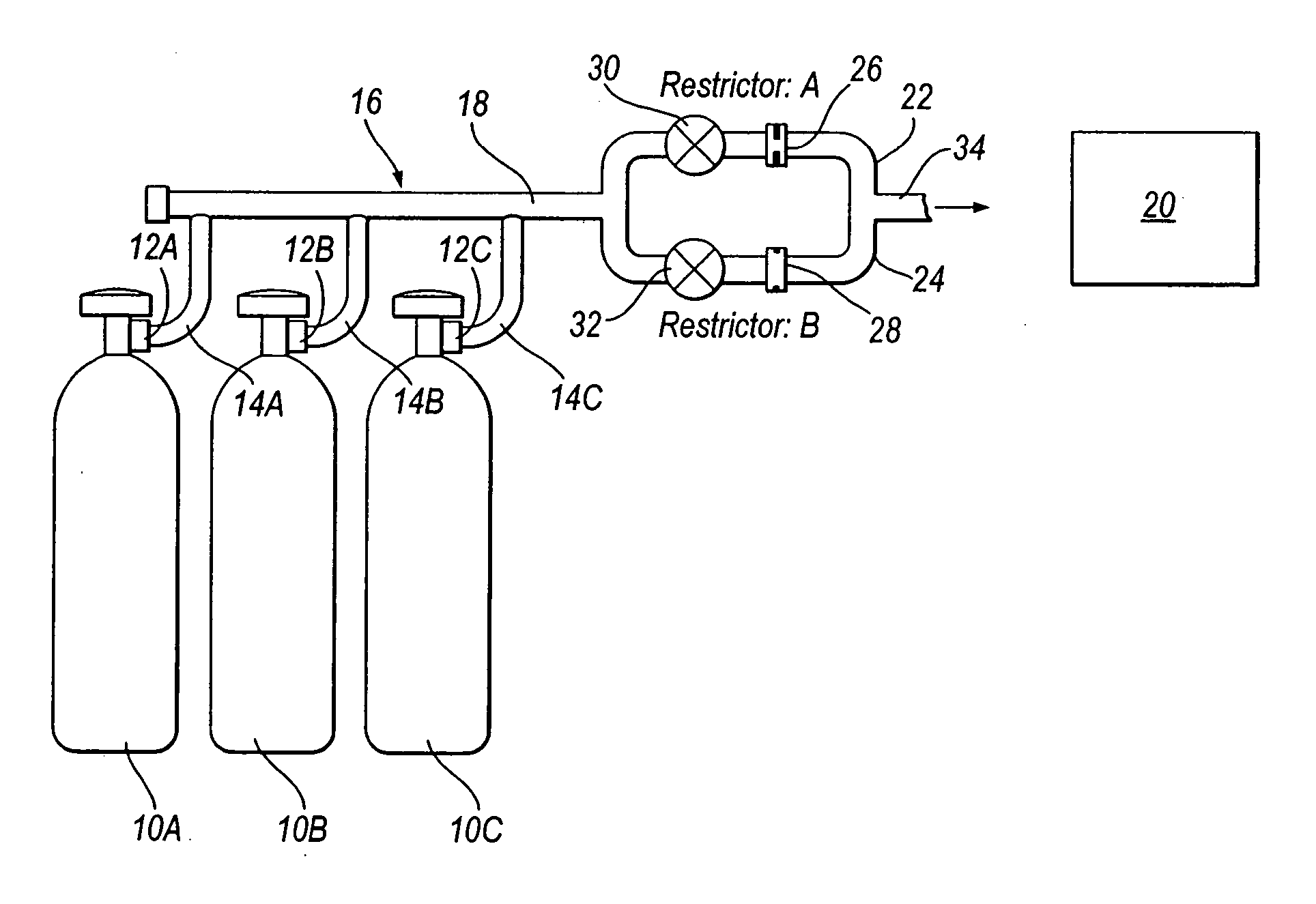

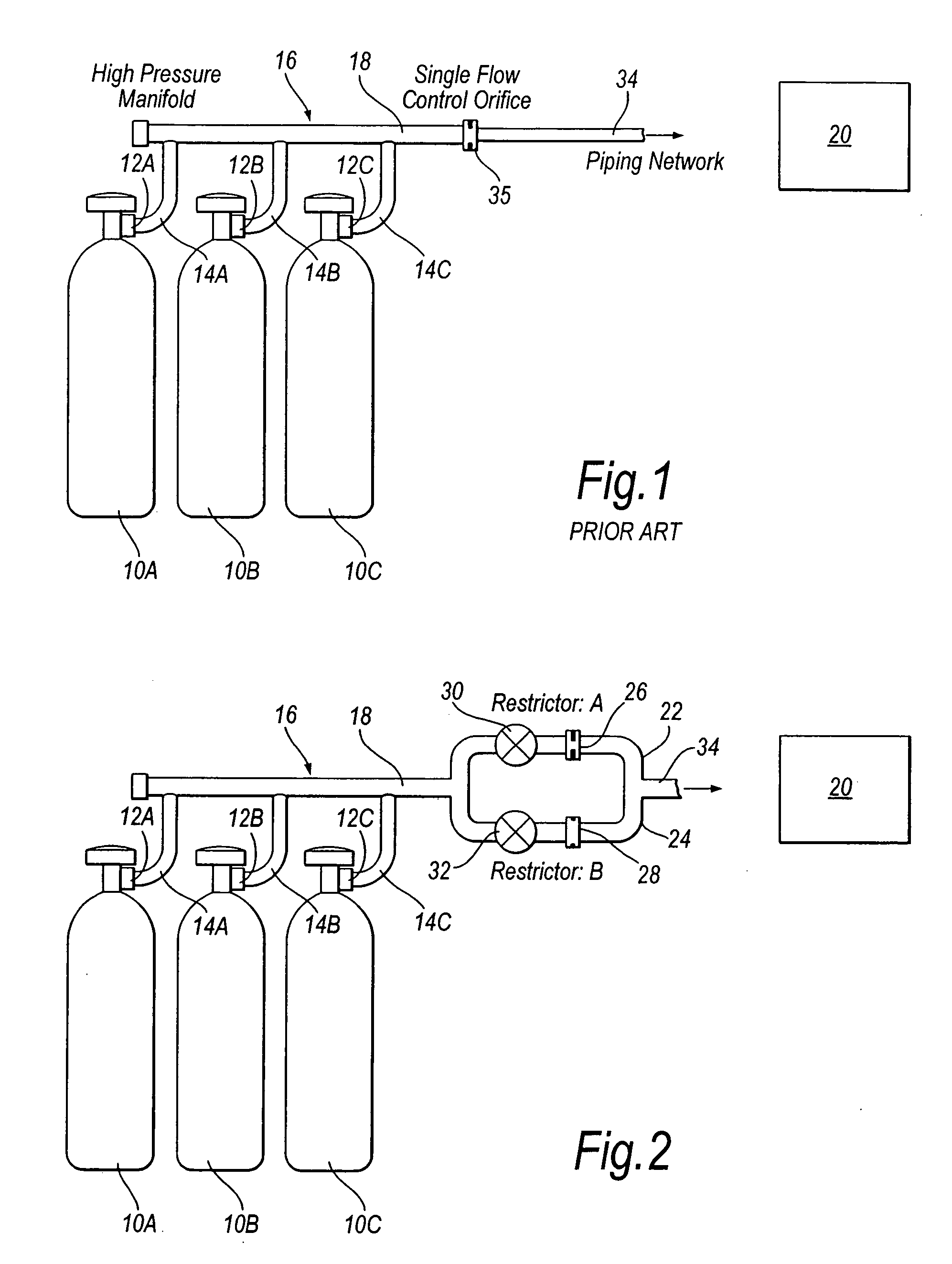

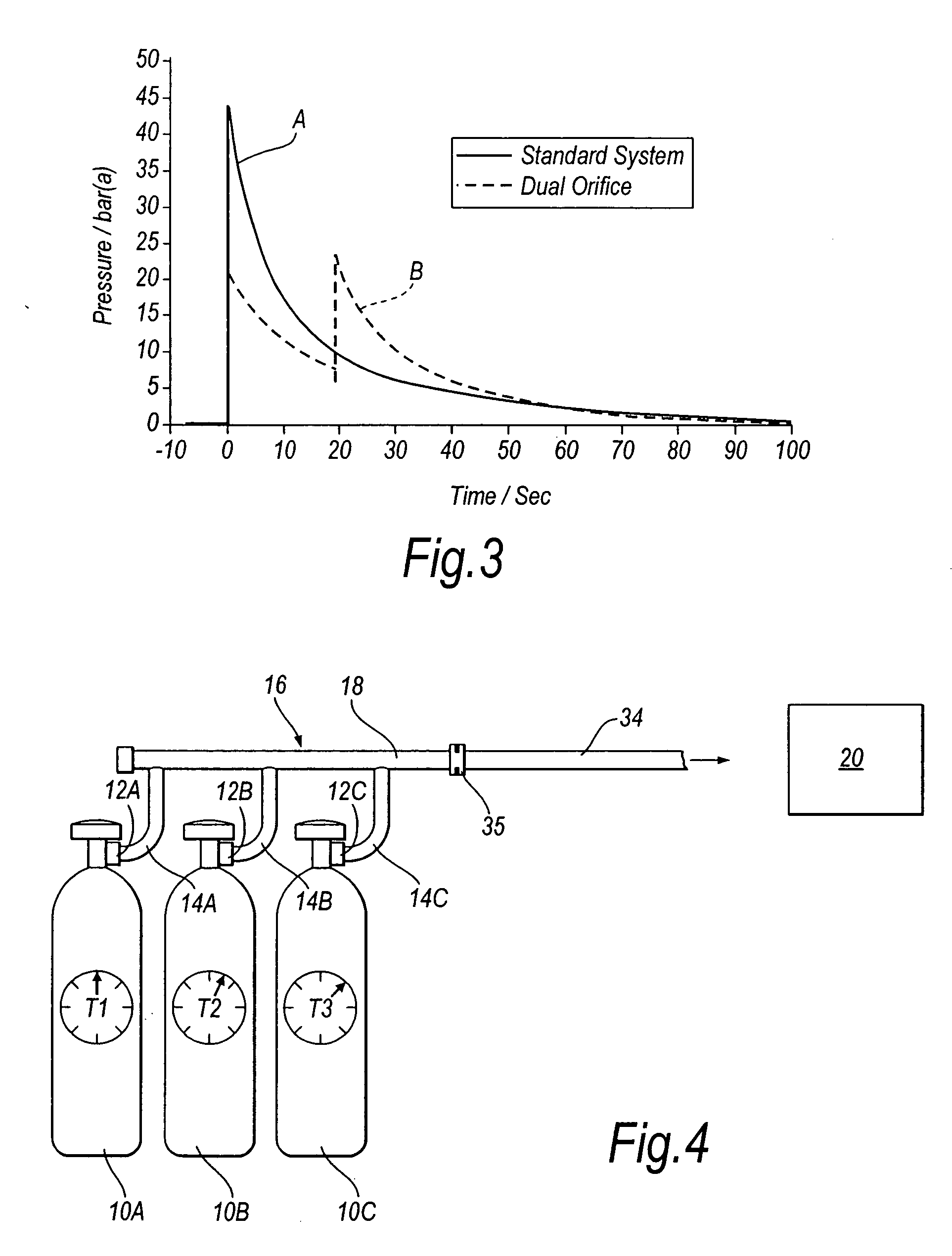

Fire suppression system

ActiveUS20070034387A1Reduce pressureReduce peak pressureFire rescueBoring toolsEngineeringGas supply

A system for discharging inert gas for extinguishing or suppressing a fire is disclosed. A fluid discharge control arrangement is positioned in a fluid flow path between a pressurised gas supply 10A,10B,10C and the target fire suppression zone 20. The fluid discharge control arrangement reduces the pressure in the fluid flow path downstream thereof. This may allow the downstream pipework to be selected to withstand a lower pressure than in a conventional system in which the fluid discharge control device was not provided, thereby reducing costs. The fluid discharge control device may comprise a first valve 30 and first restrictor 26 in the first flow path 22 and a second valve 32 and a second restrictor 28 provided in the second flow path 24. Fluid from the containers 10A,10B,10C flows initially through flow path 24 and restrictor 26. Subsequently flow path 22 may be closed by optional valve 30, and flow path 24 is opened by valve 32. Fluid flow then passes through restrictor 28. This reduces the peak pressure in the downstream pipework 34. In another embodiment the discharge of inert gas from the containers 10A,10B and 10C is staggered to reduce the peak pressure in pipeline 34. A further embodiment provides a restrictor in the inlet 14A,14B,14C from each of the containers 10A,10B,10C to the manifold 16, thereby also reducing the peak pressure in the pipeline 34.

Owner:KIDDE IP HLDG

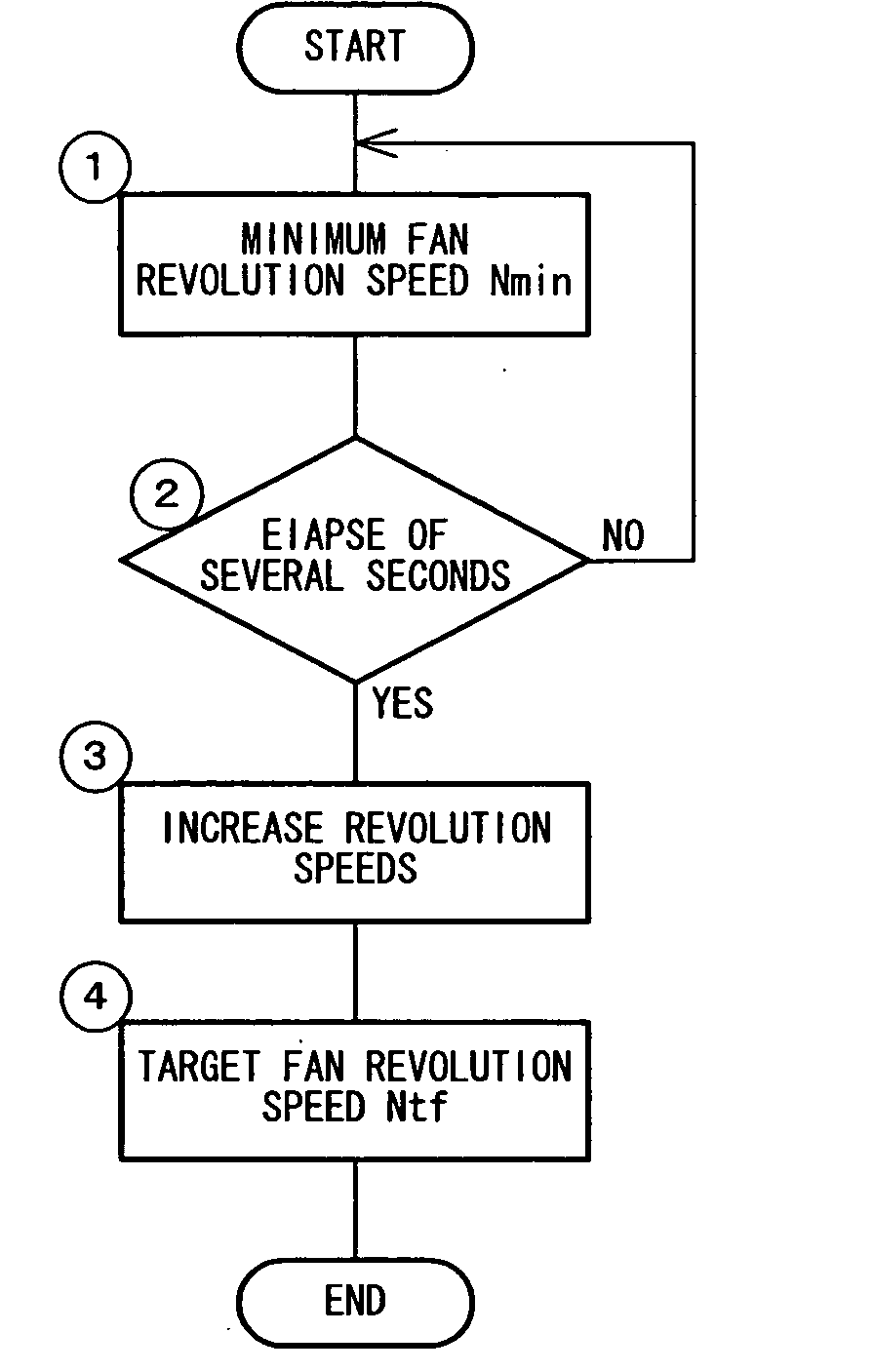

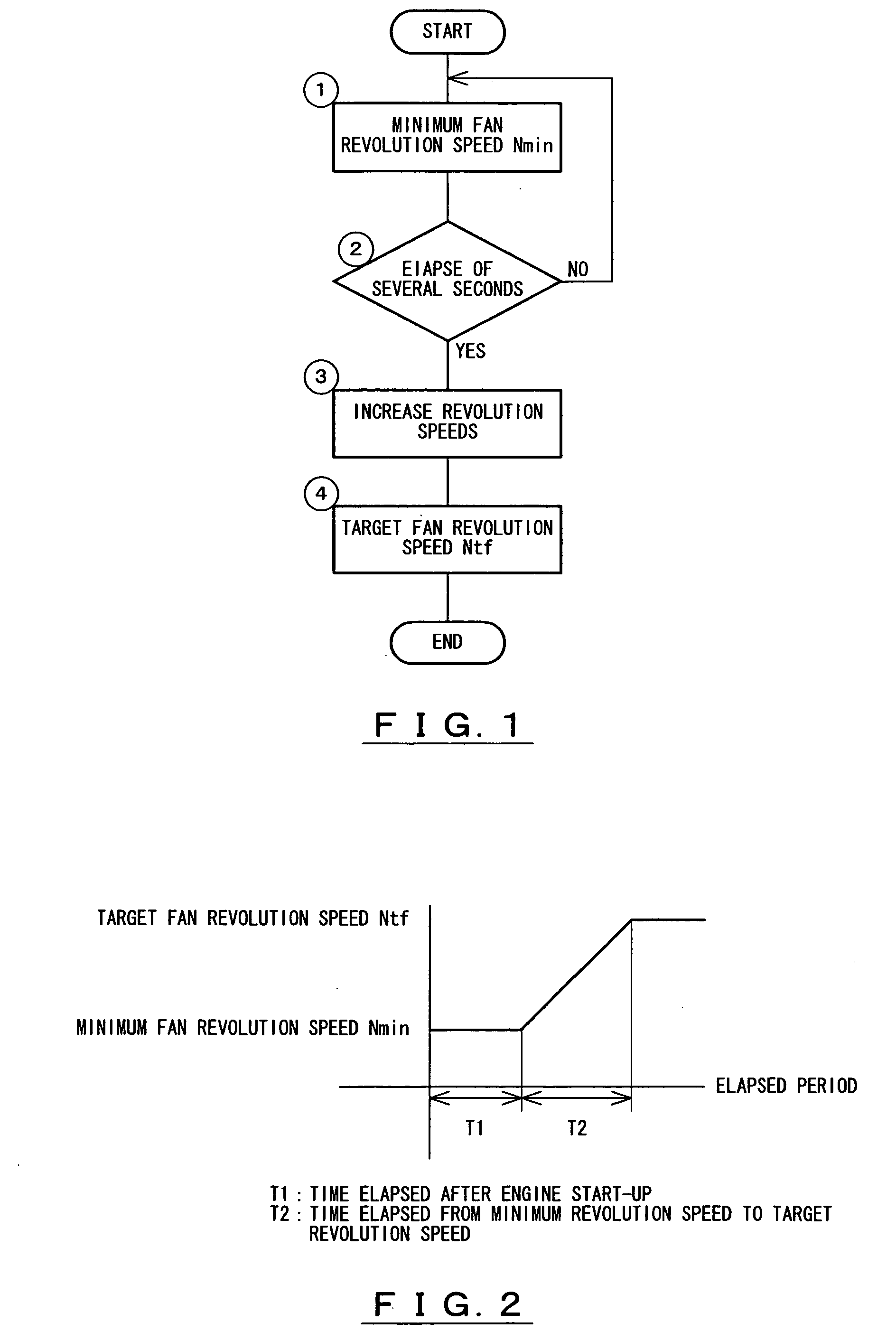

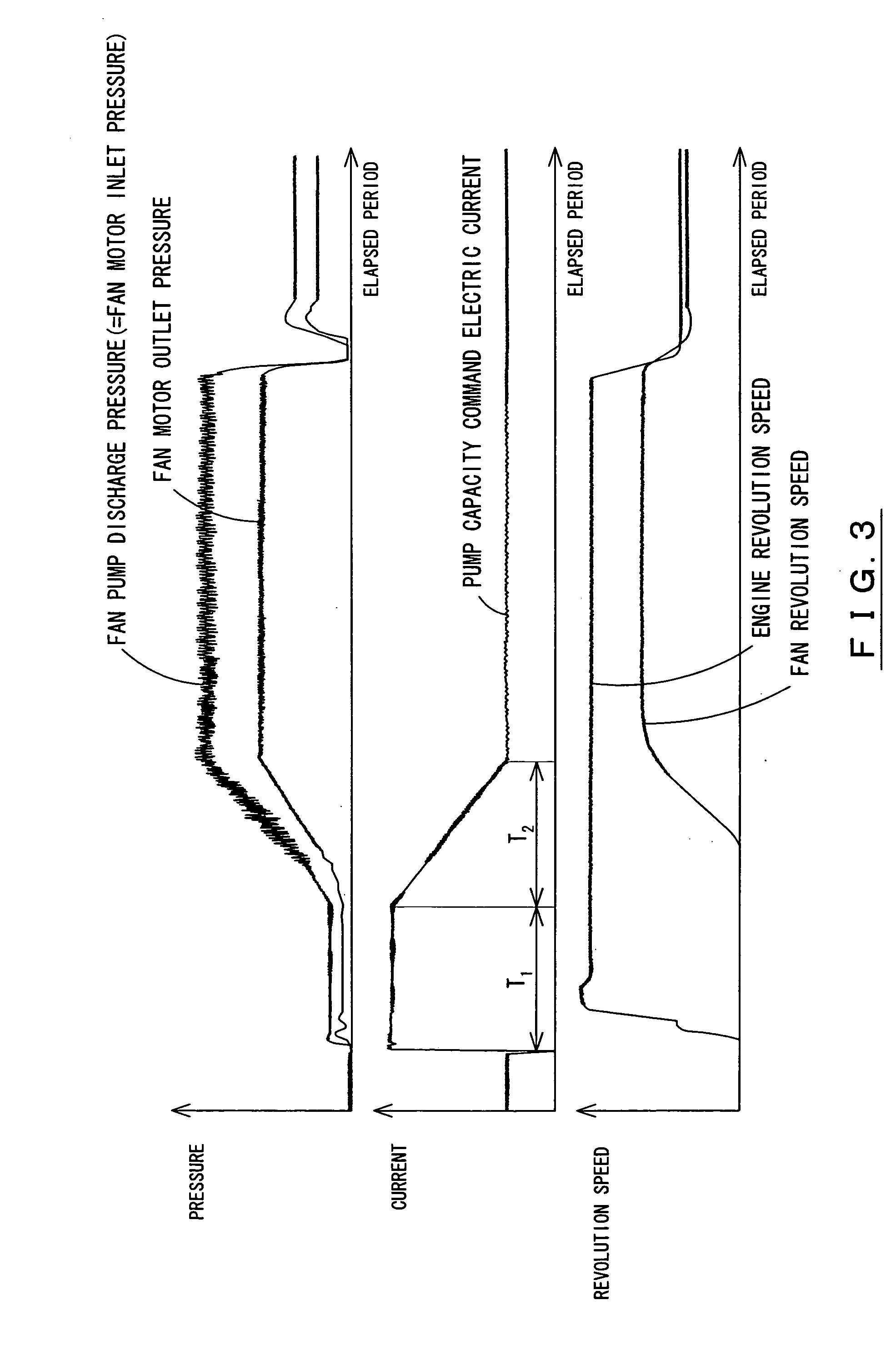

Fan revolution speed control method

InactiveUS20050254959A1Reduce the burden onPreventing generation of peak pressureCoolant flow controlRotary clutchesHydraulic fluidControl theory

The invention is a fan revolution control method for controlling a pump-motor system, by controlling the fan revolution speed of a cooling fan adapted to be rotated by a fan motor to cool cooling target fluids. The pump-motor system drives the fan motor by a hydraulic fluid fed from a fan pump driven by an engine. The pump-motor system is controlled so the fan revolution speed starts from the minimum fan revolution speed when the engine is started up; the minimum fan revolution speed is maintained for at least several seconds; after the elapse of several seconds, the fan revolution speed is gradually increased from the minimum fan revolution speed. The fan revolution speed reaches a target fan revolution speed over a period of at least several seconds. The method prevents generation of peak pressure or pressure hunting.

Owner:CATEPILLAR SARL

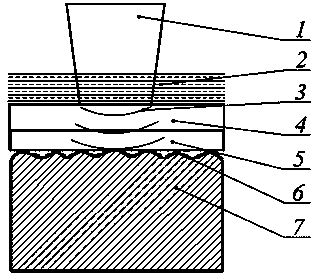

Polishing method and device based on laser shock wave

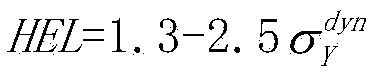

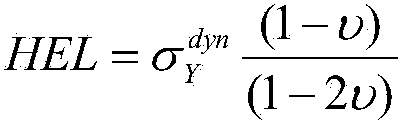

The invention discloses a polishing method and device based on a laser shock wave, a structure for implementing the method comprises high energy pulse laser, a constraint layer, the laser shock wave, an absorption layer, a rigid contact film, a micro bump and a metal workpiece. The working principle is that the absorption layer generates plasma explosion under the irradiation of the high energy pulse laser, the plasma explosion generates a high-pressure shock wave under the constraint action of the constraint layer, the micro bump can be taken as an uniaxial stress state under the action of the shock wave, and the surface of the metal workpiece can be taken as an uniaxial strain state under the action of the shock wave. At the uniaxial stress state, when shock wave peak pressure is greater than the dynamic yield strength of material, the material generates plastic deformation, at the uniaxial strain state, when the shock wave peak pressure is greater than the HEL (Hugoniot Elastic Limit) of the material, the material generates plastic deformation; through controlling the power density of the high energy pulse laser, the shock wave peak pressure is between delta <dyn>Y and HEL of metal, the micro bump can be ironed by the rigid contact film, and macroscopical plastic deformation is not generated on the surface of the metal, so that a polishing effect is realized. The polishing method and device can be applied to polishing processing on the surface of the metal.

Owner:江苏羿昇智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com