Polishing method and device based on laser shock wave

A shock wave and laser technology, applied in the field of laser shock wave-based polishing technology, can solve the problems of low efficiency, long time-consuming chemical polishing and electrochemical polishing, etc., and achieve good laser controllability, improved fatigue performance and stress corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

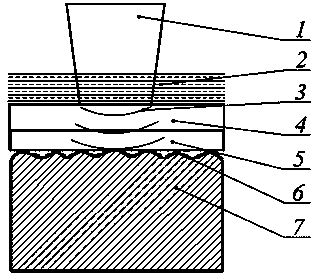

Embodiment 1

[0017] In this example, the pulse width of high-energy pulsed laser 1 is 10ns, the laser spot diameter is 3mm, and the power density is 1.5×10 9 GW / cm 2 , the peak pressure generated by the high-energy pulsed laser 1 is about 900 MPa; the constrained layer 2 is a flowing deionized water film with a thickness of about 1mm; the material of the rigid contact film 5 is 60Si 2 CrVA has a thickness of 50μm, a hardness of 700HV, and a dynamic yield strength of 2.8GPa; the metal workpiece 7 is made of LY2 aluminum alloy, with a hardness of 130HV and a dynamic yield strength of 2.8GPa. It is 460MPa, the Hugong Niu limit (HEL) is about 1GPa, and the initial surface roughness is 1.62μm.

[0018] By controlling the movement of the metal workpiece 7, the 10 mm × 10 mm area of the metal workpiece 7 is polished by high-energy pulsed laser 1 with a spot diameter of 3 mm for 5 laser shock wave polishing, and the measured average line roughness is 0.27 μm. The residual compressive stress o...

Embodiment 2

[0020] In this example, the pulse width of high-energy pulsed laser 1 is 20ns, the laser spot diameter is 3mm, and the power density is 1×10 9 GW / cm 2 , the peak pressure generated by the high-energy pulsed laser 1 is about 750MPa; the constrained layer 2 is a flowing deionized water film with a thickness of about 1mm; the material of the rigid contact film 5 is 60Si 2 CrVA has a thickness of 50μm, a hardness of 700HV, and a dynamic yield strength of 2.8GPa; the metal workpiece 7 is made of A304 stainless steel, with a hardness of 260HV and a dynamic yield strength of 2.8GPa. It is 580MPa, the Hugong Niu limit HEL is 800MPa, and the initial surface roughness is 2.35μm.

[0021] By controlling the movement of the metal workpiece 7, the 10 mm × 10 mm area of the metal workpiece 7 is polished by high-energy pulsed laser 1 with a spot diameter of 3 mm for 5 laser shock wave polishing, and the measured average line roughness is 0.22 μm. The residual compressive stress on the s...

Embodiment 3

[0023] In this example, the pulse width of high-energy pulsed laser 1 is 20ns, the laser spot diameter is 3mm, and the power density is 4×10 9 GW / cm 2 , the peak pressure generated by the high-energy pulsed laser 1 is about 2.5GPa; the constrained layer 2 is a flowing deionized water film with a thickness of about 1mm; the material of the rigid contact film 5 is 60Si 2 CrVA has a thickness of 100μm, a hardness of 700HV, and a dynamic yield strength of 2.8GPa; the metal workpiece 3 is made of Tc4 titanium alloy, with a hardness of 330HV and a dynamic yield strength of 2.8GPa. It is 1.5GPa, the Hugong Niu limit (HEL) is about 2.8GPa, and the initial surface roughness is 1.34μm.

[0024] By controlling the movement of the metal workpiece 7, the 10 mm × 10 mm area of the metal workpiece 7 is polished by high-energy pulsed laser 1 with a spot diameter of 3 mm for 5 laser shock wave polishing, and the measured average line roughness is 0.42 μm. The residual compressive stress o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com