Patents

Literature

898results about "Preformed elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

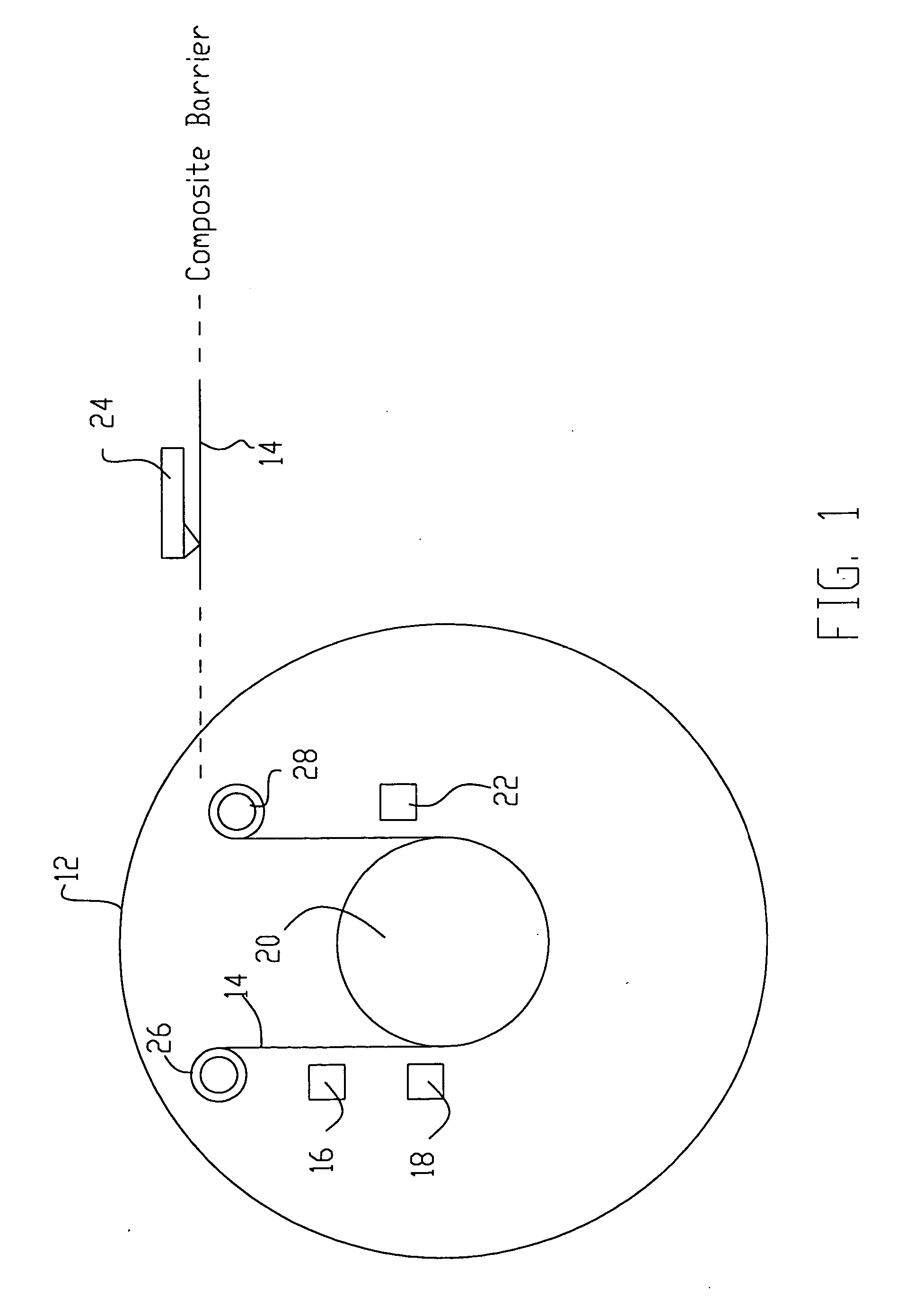

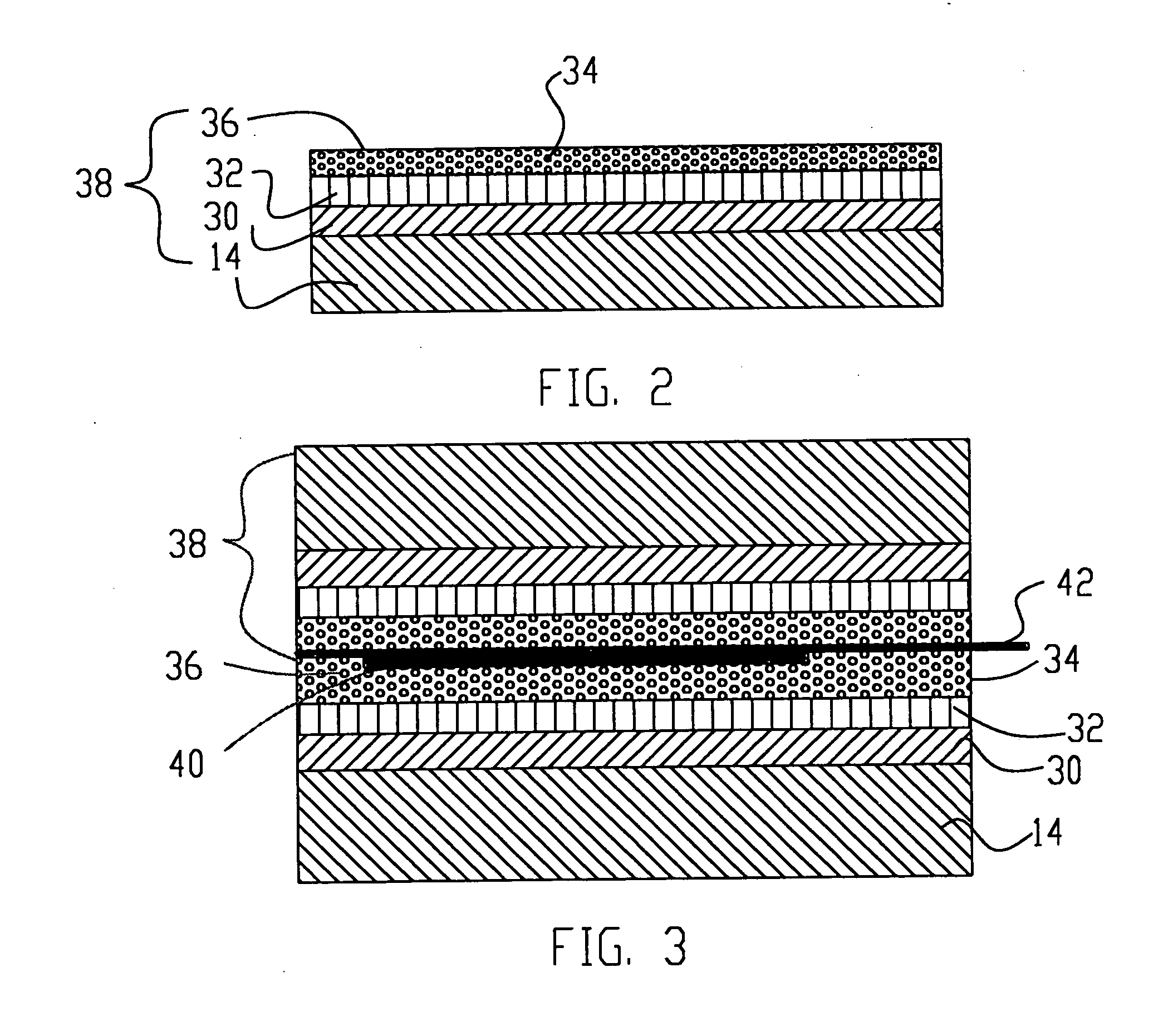

Composite modular barrier structures and packages

InactiveUS20050249901A1Improve barrier propertiesRemove moistureNanotechWrappersNanoparticleDesiccant

A composite multi-layer barrier is produced by first vapor depositing a barrier under vacuum over a substrate of interest and then depositing an additional barrier at atmospheric pressure in a preferably thermoplastic layer. The resulting multi-layer barrier is then used to coat an article of interest in a lamination process wherein the thermoplastic layer is fused onto itself and the surface of the article. The vacuum-deposited barrier may consists of a first leveling polymer layer followed by an inorganic barrier material sputtered over the leveling layer and of an additional polymeric layer flash evaporated, deposited, and cured under vacuum. The thermoplastic polymeric layer is then deposited by extrusion, drawdown or roll coating at atmospheric pressure. The resulting multi-layer barrier may be stacked using the thermoplastic layer as bonding agent. Nano-particles may be included in the thermoplastic layer to improve the barrier properties of the structure. A desiccant material may also be included or added as a separate layer.

Owner:SIGMA LAB OF ARIZONA

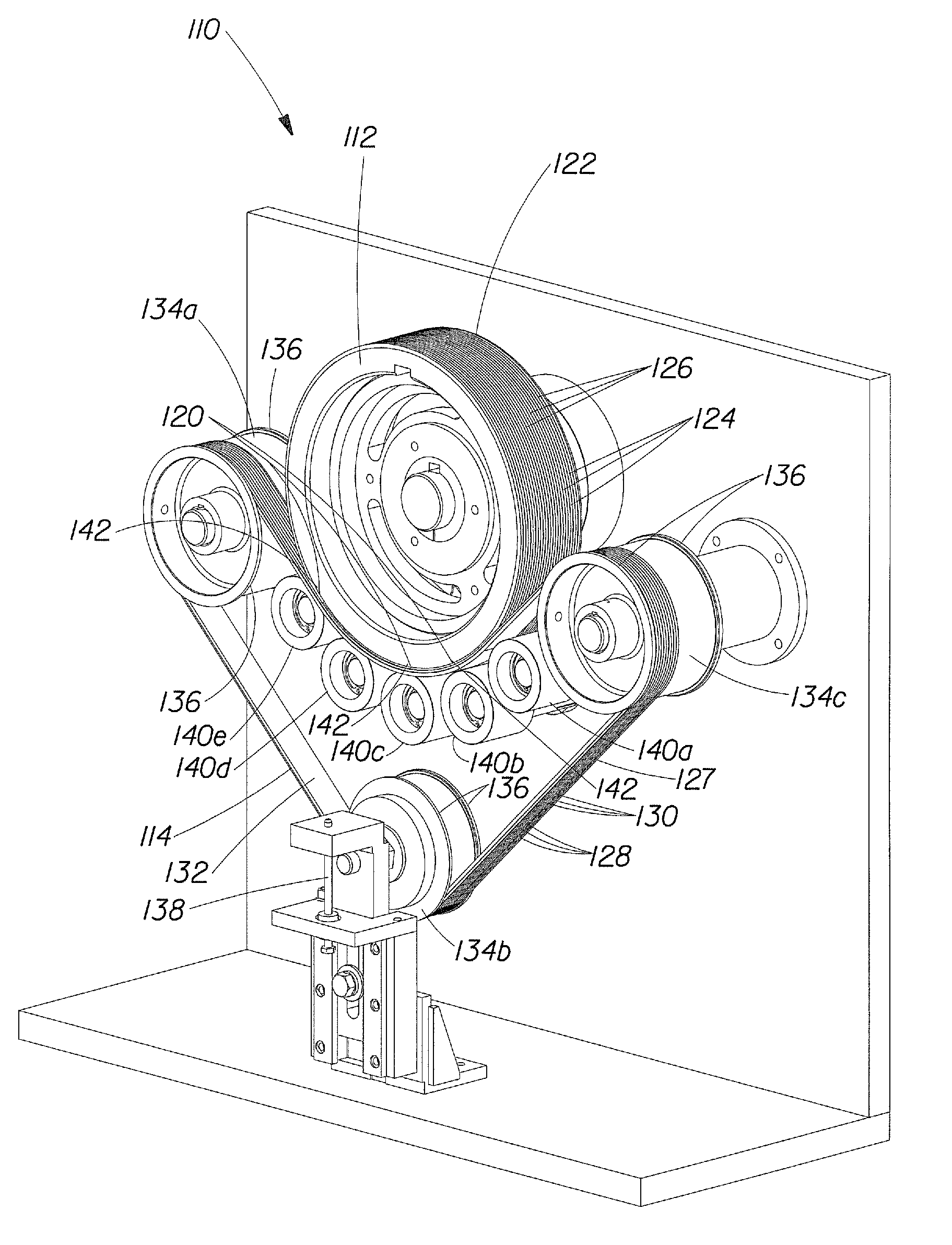

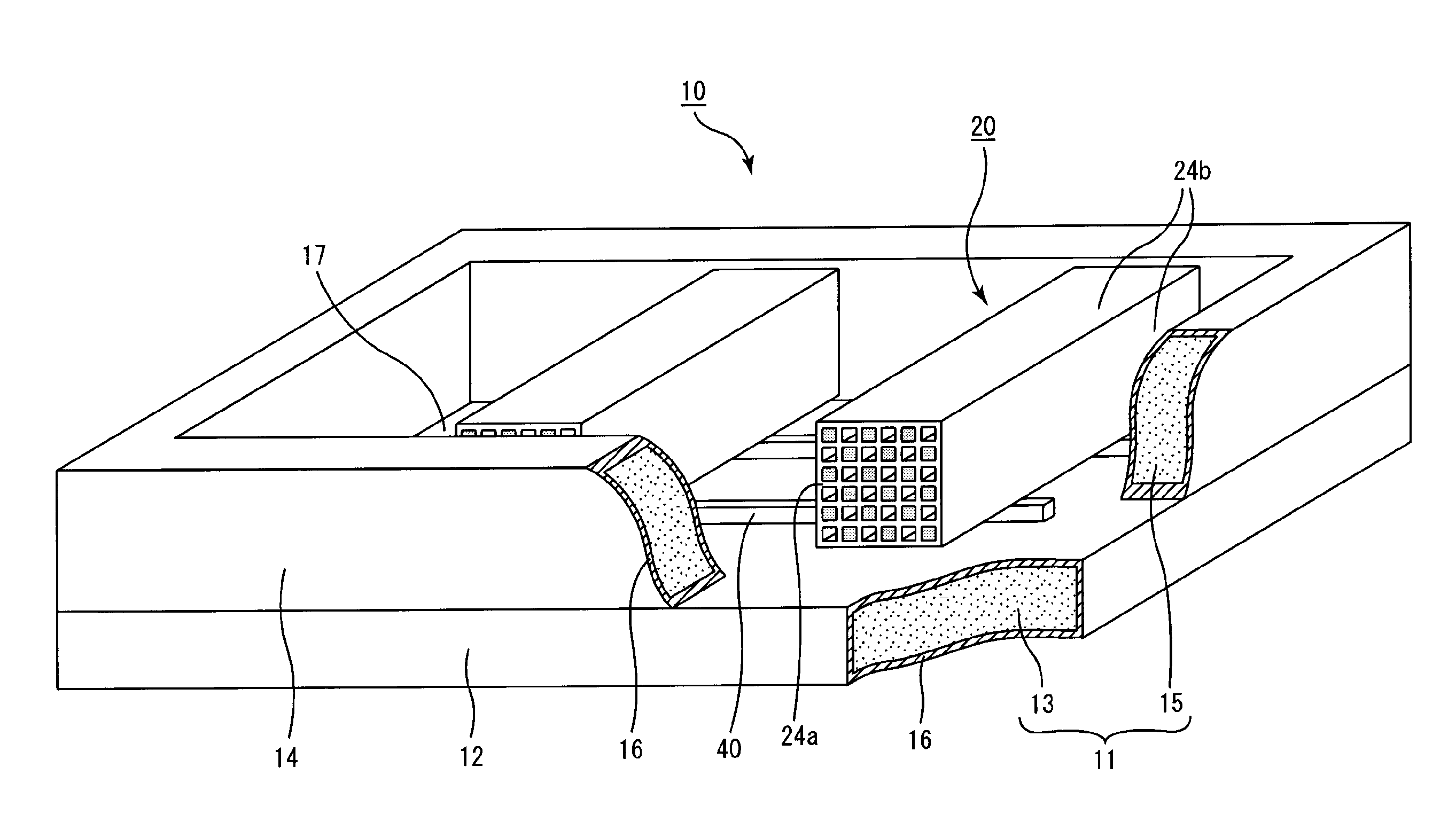

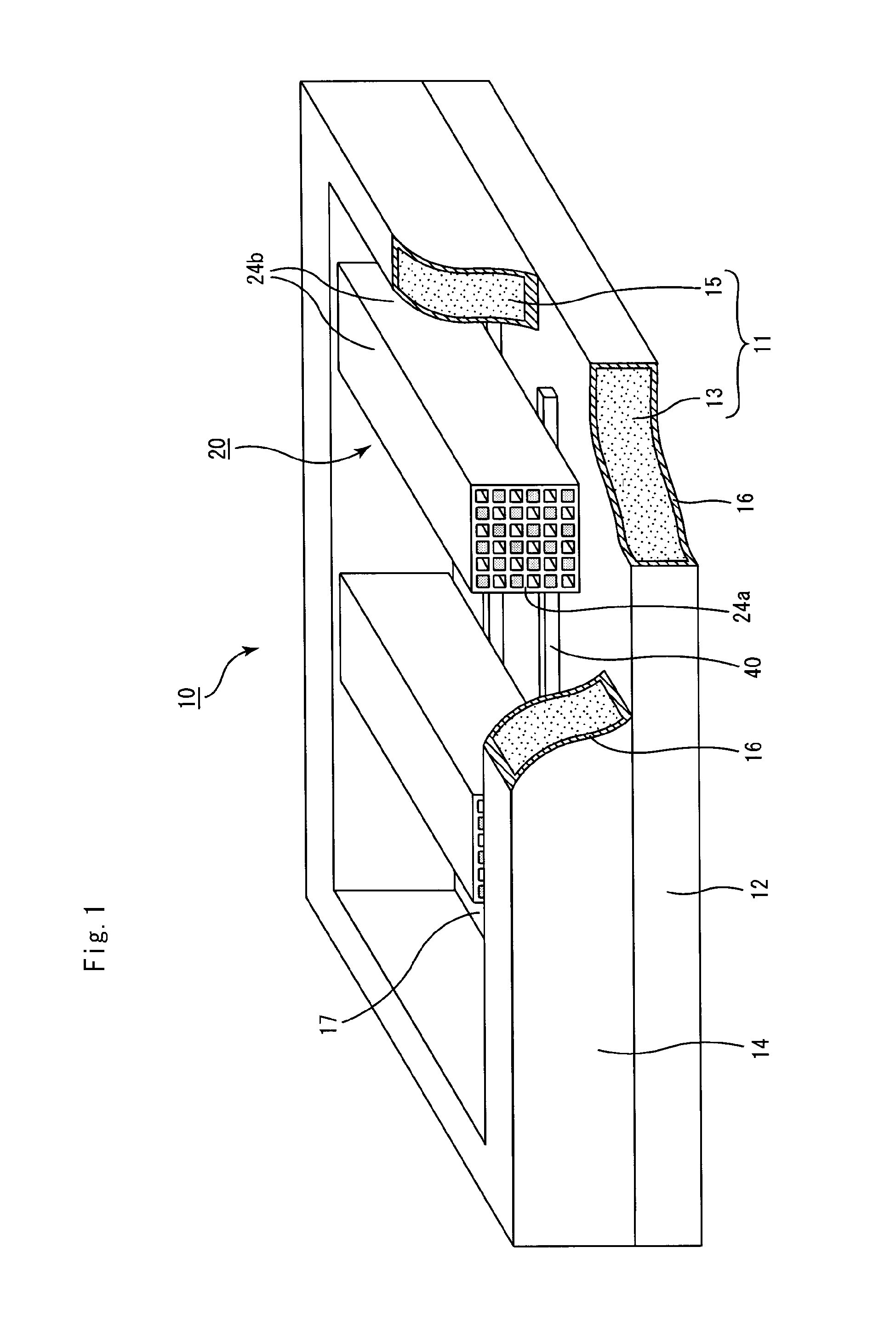

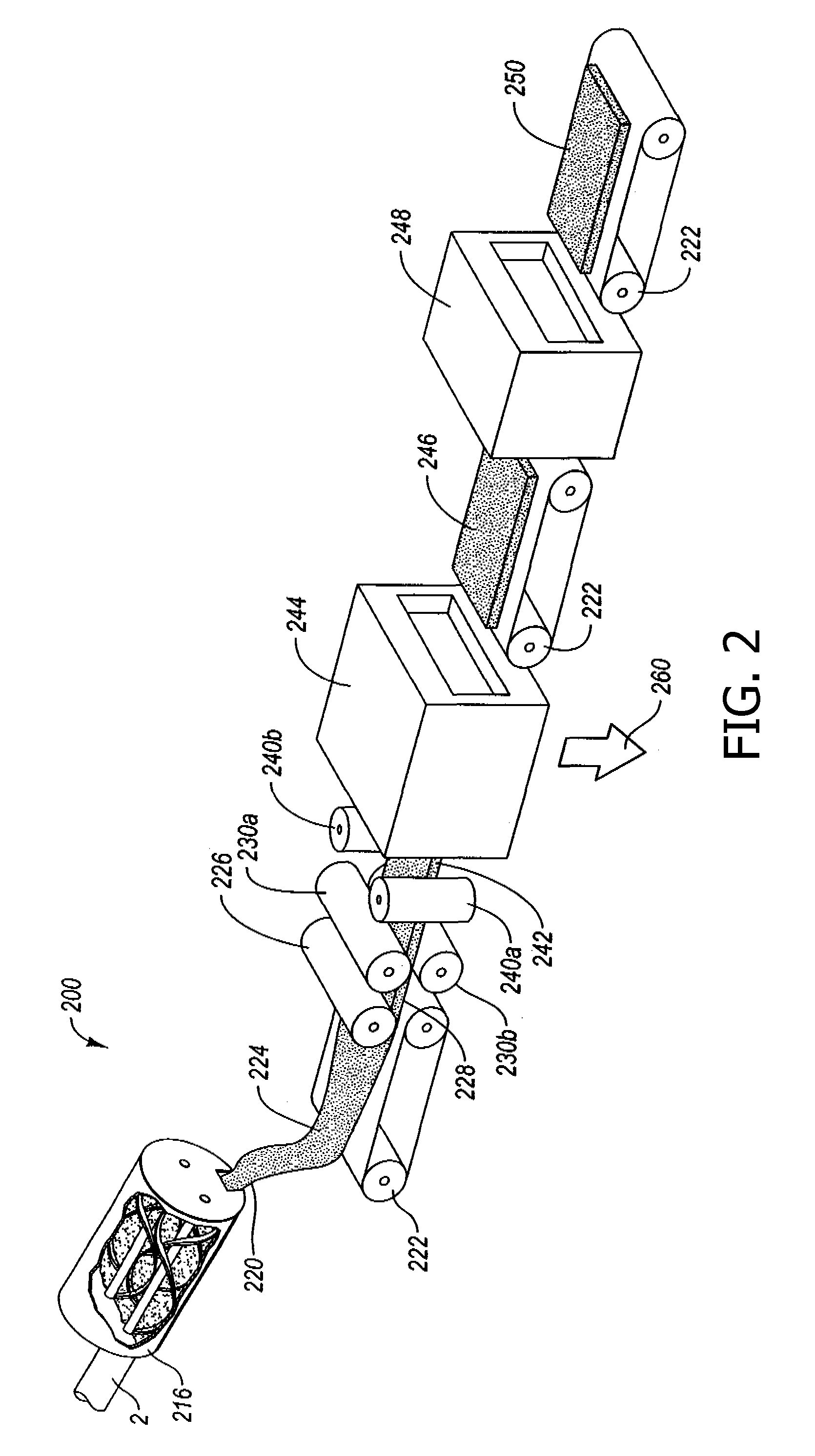

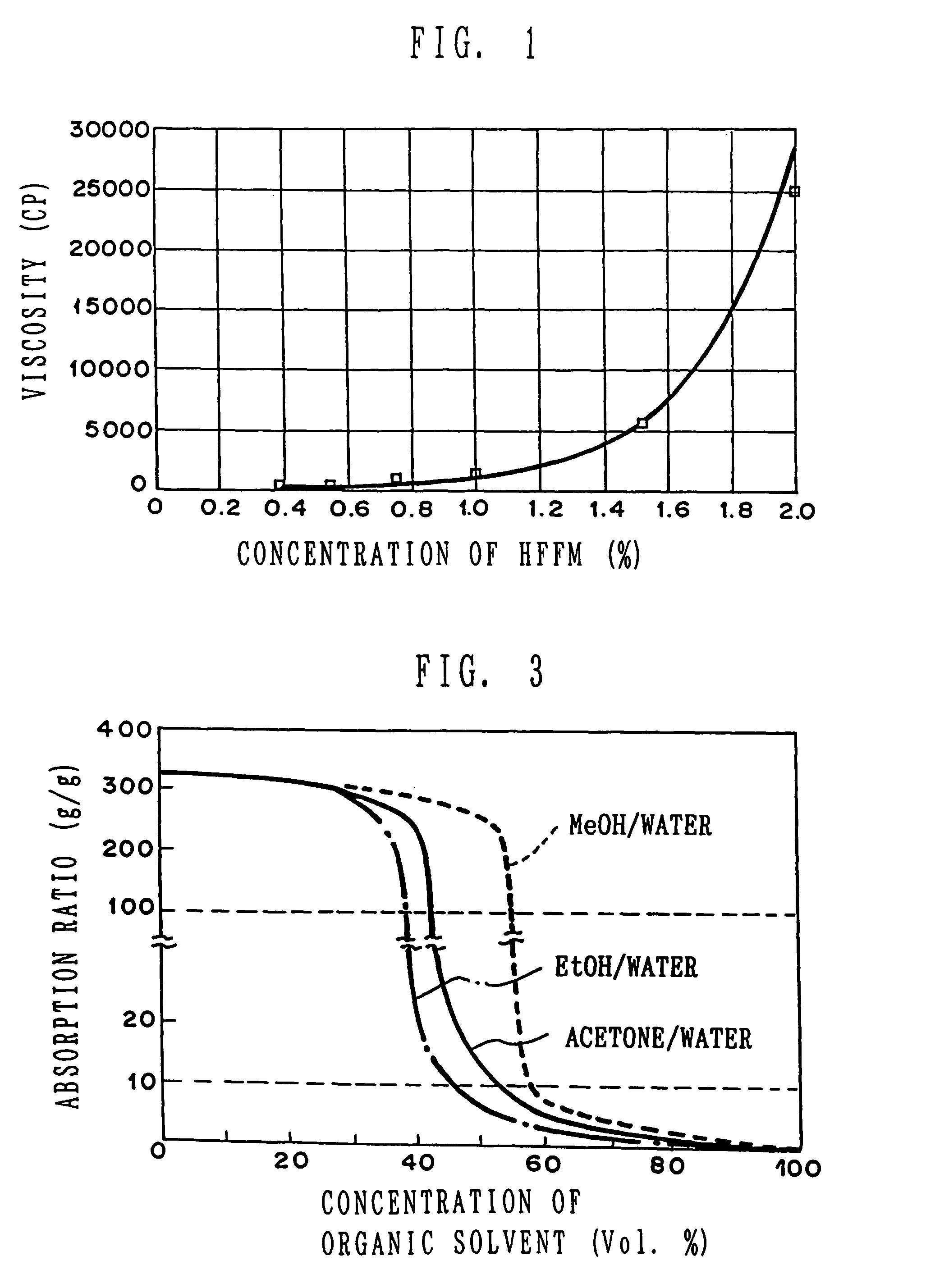

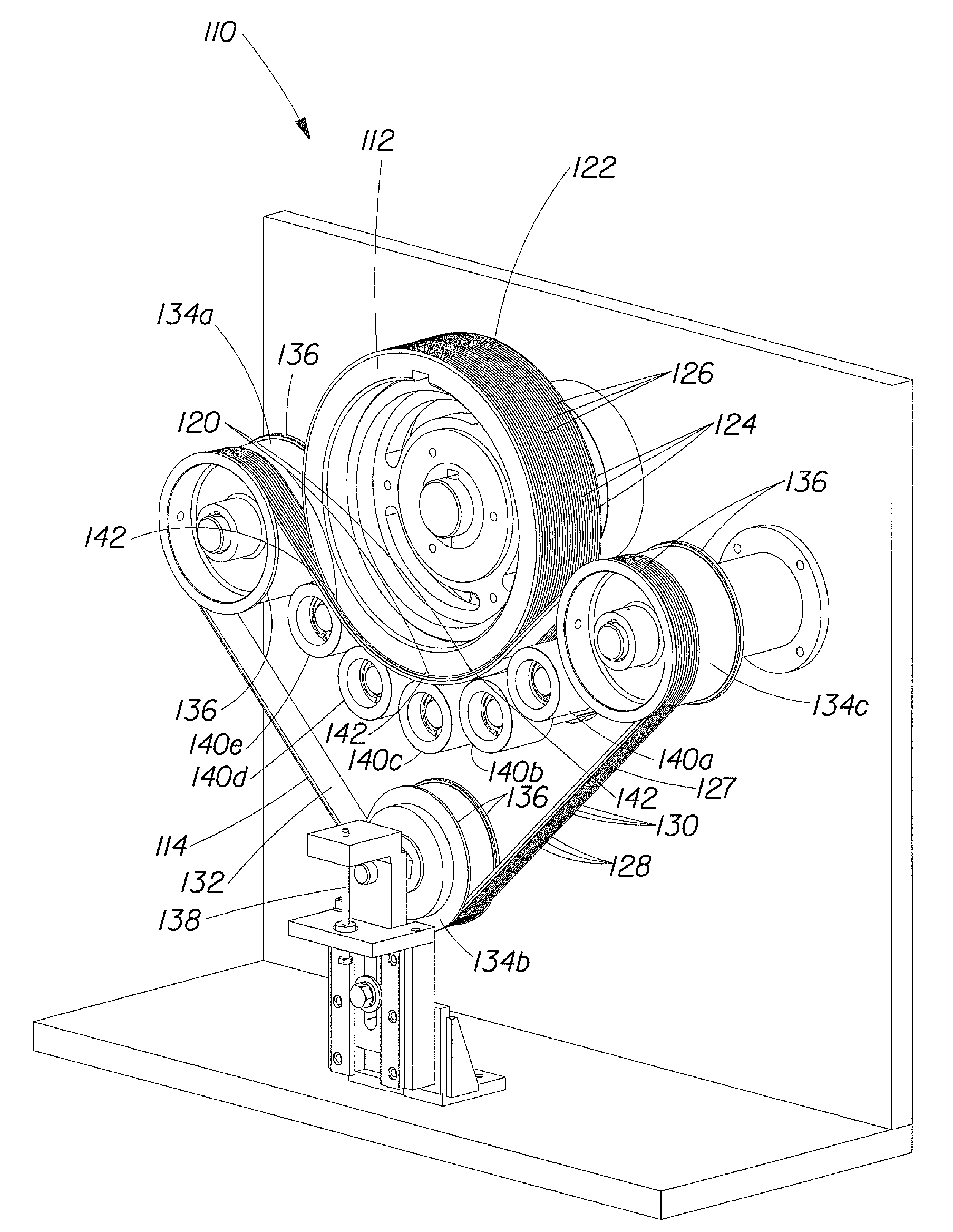

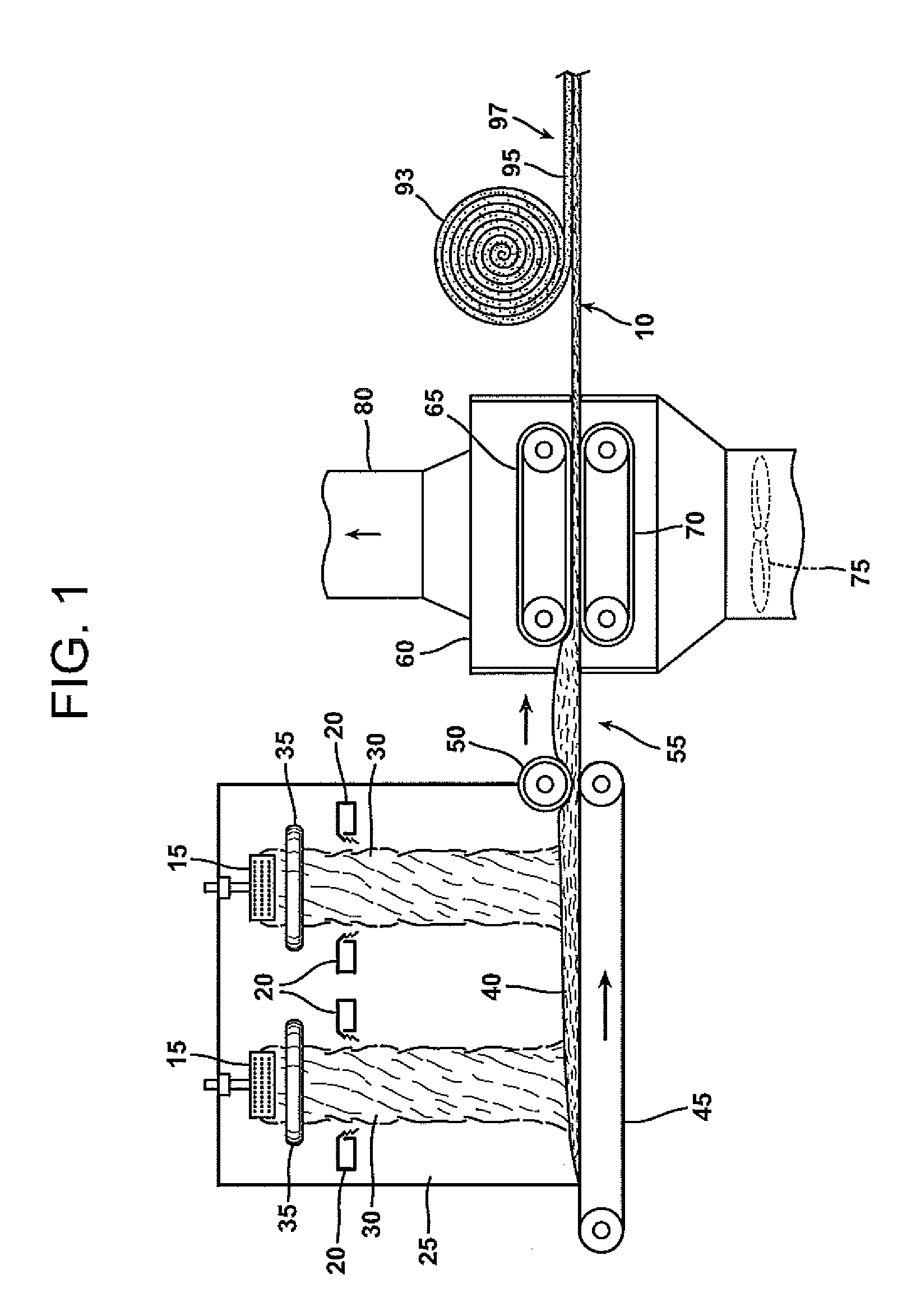

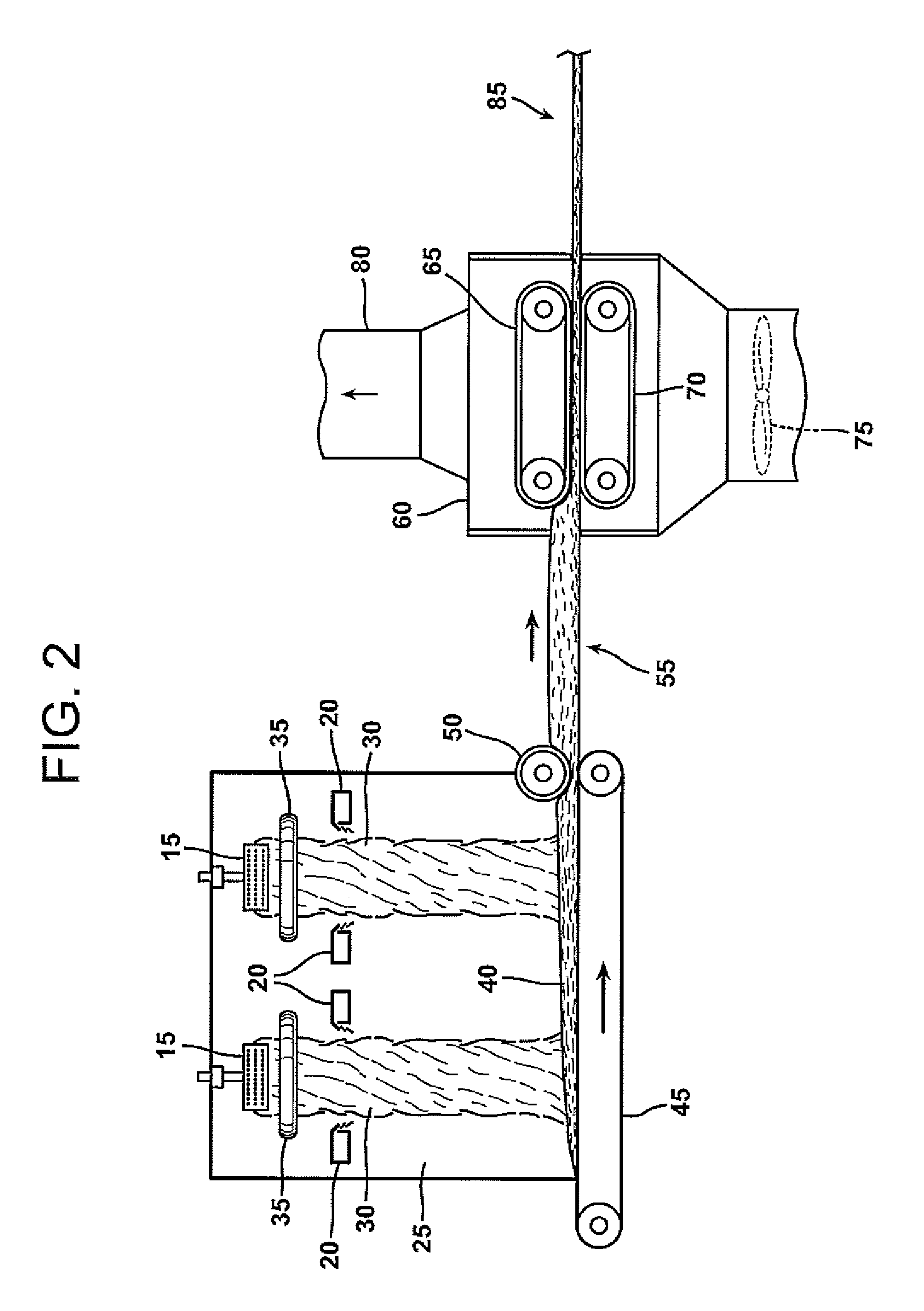

Method and Apparatus for Incrementally Stretching a Web

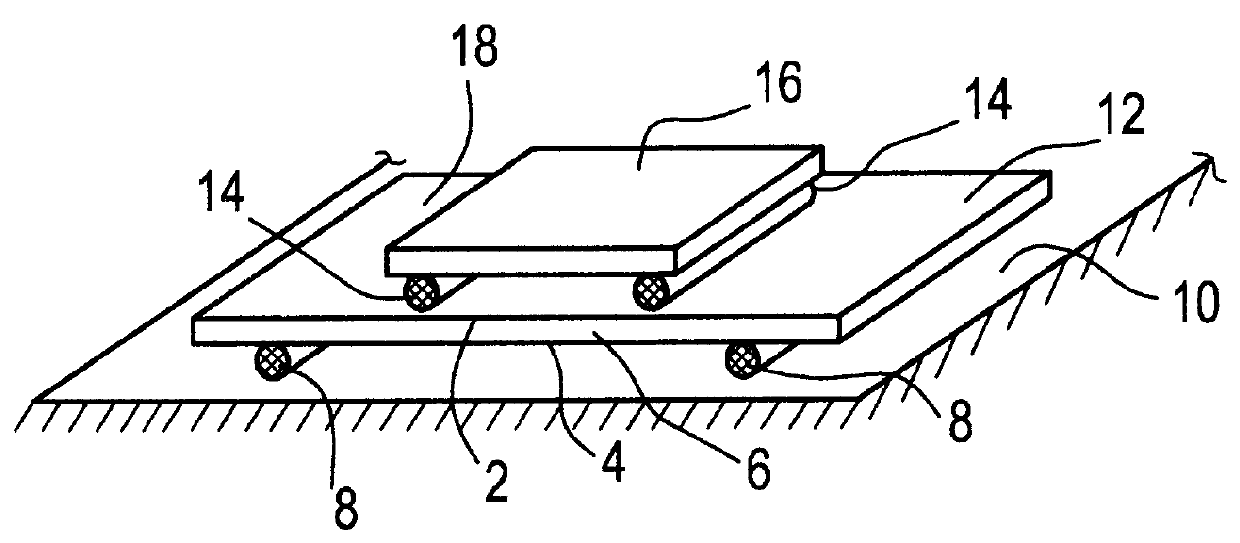

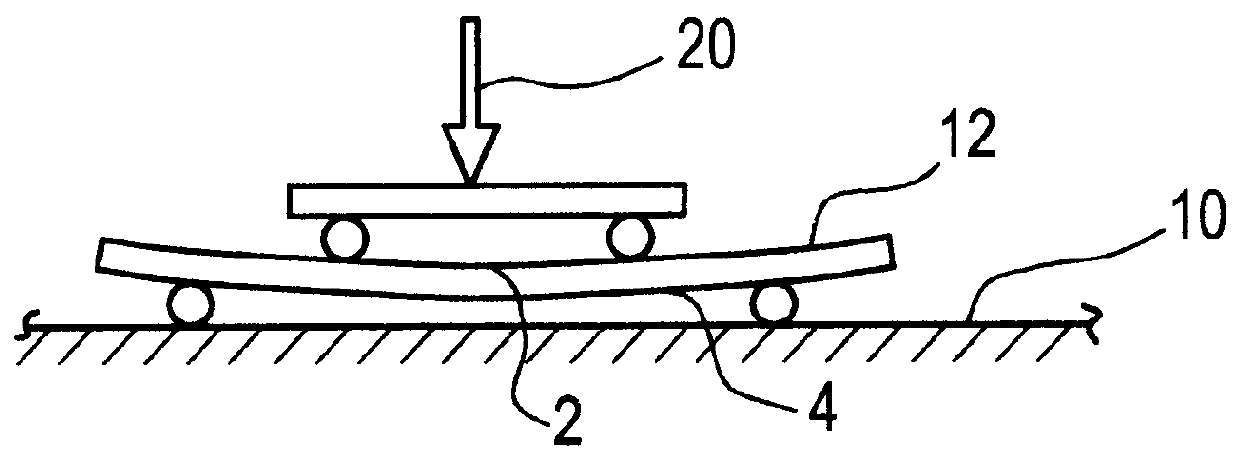

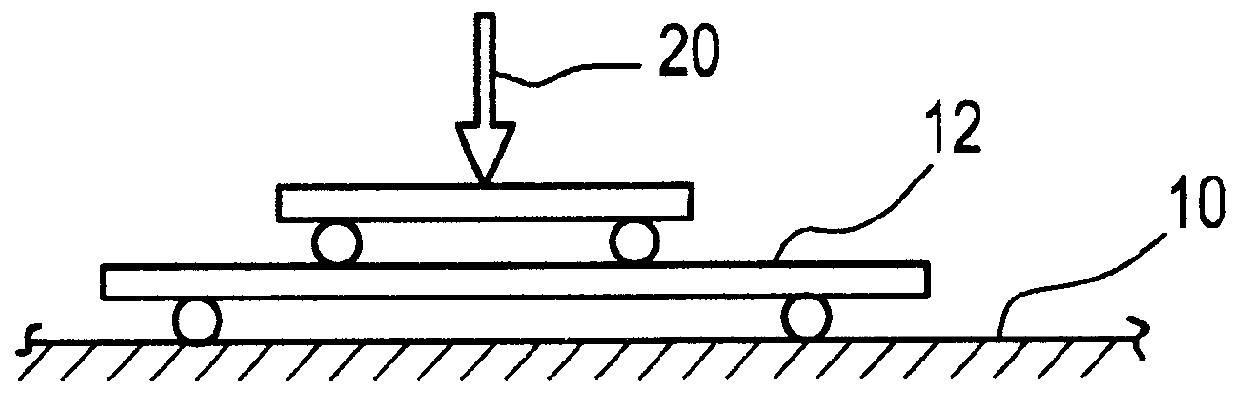

ActiveUS20080224351A1Increase path lengthIncrease line speedDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringBiological activation

A method and apparatus is provided which uses activation members for incrementally stretching a web at a low strain rate. The activation members include an activation belt and a single activation member wherein the activation belt and single activation member comprise a plurality of teeth and grooves that complement and engage one another at a depth of engagement in a deformation zone. The depth of engagement can be controlled to increase linearly over at least a portion of the deformation zone such that a web interposed between the activation belt and the single activation member in the deformation zone is incrementally stretched at a low rate of strain.

Owner:THE PROCTER & GAMBLE COMPANY

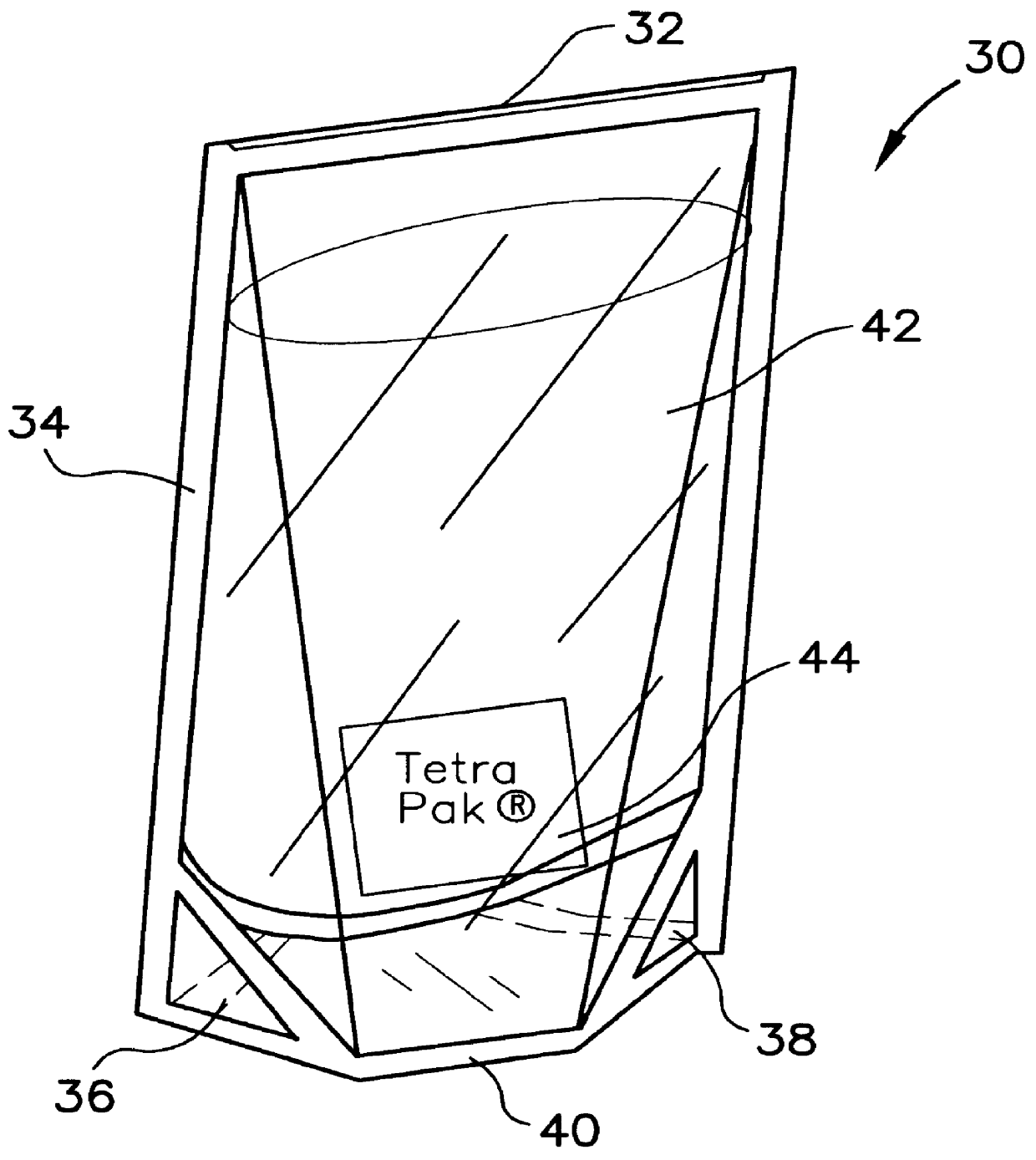

Polyolefin material integrated with nanophase particles

Owner:TETRA LAVAL HLDG & FINANCE SA

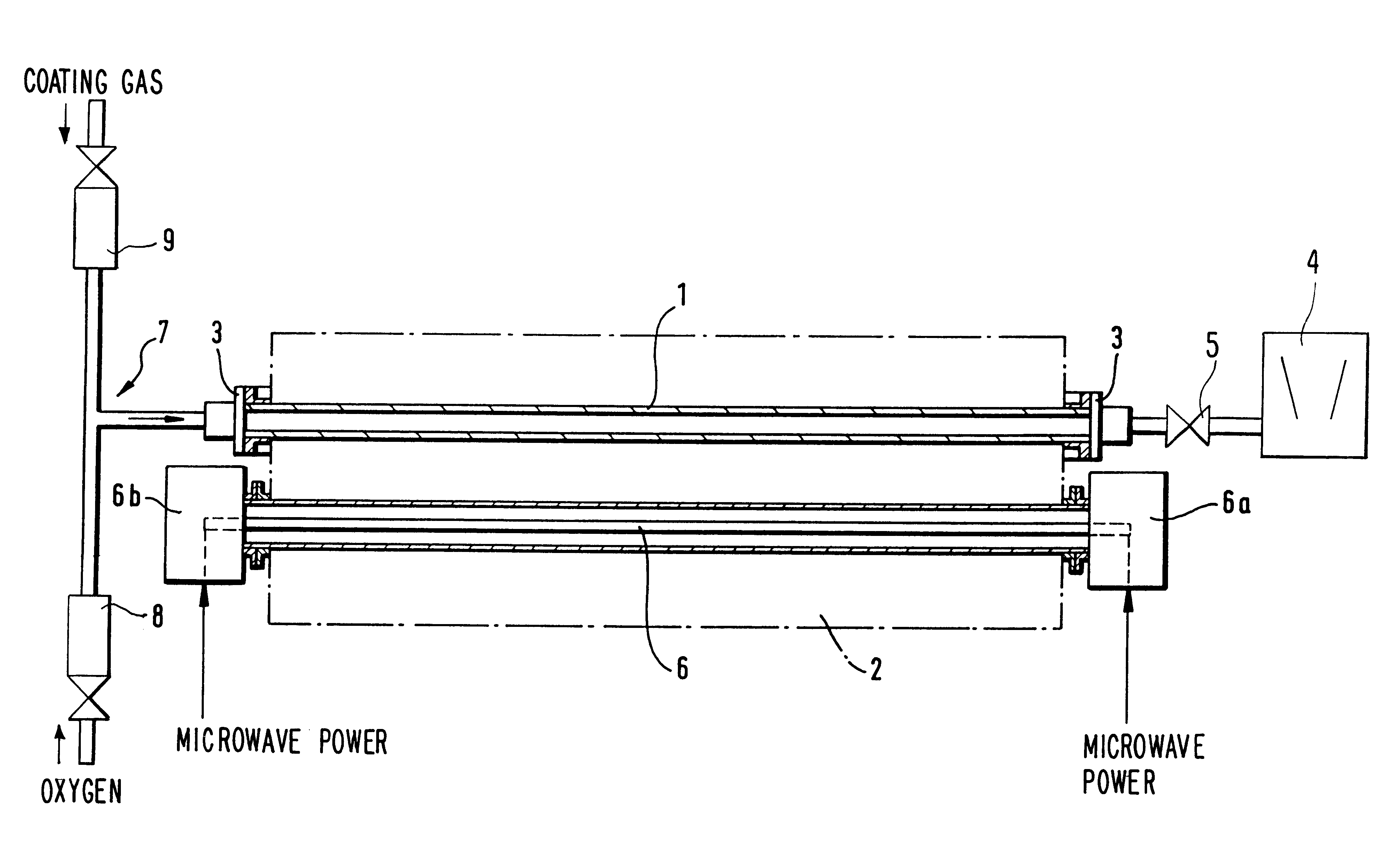

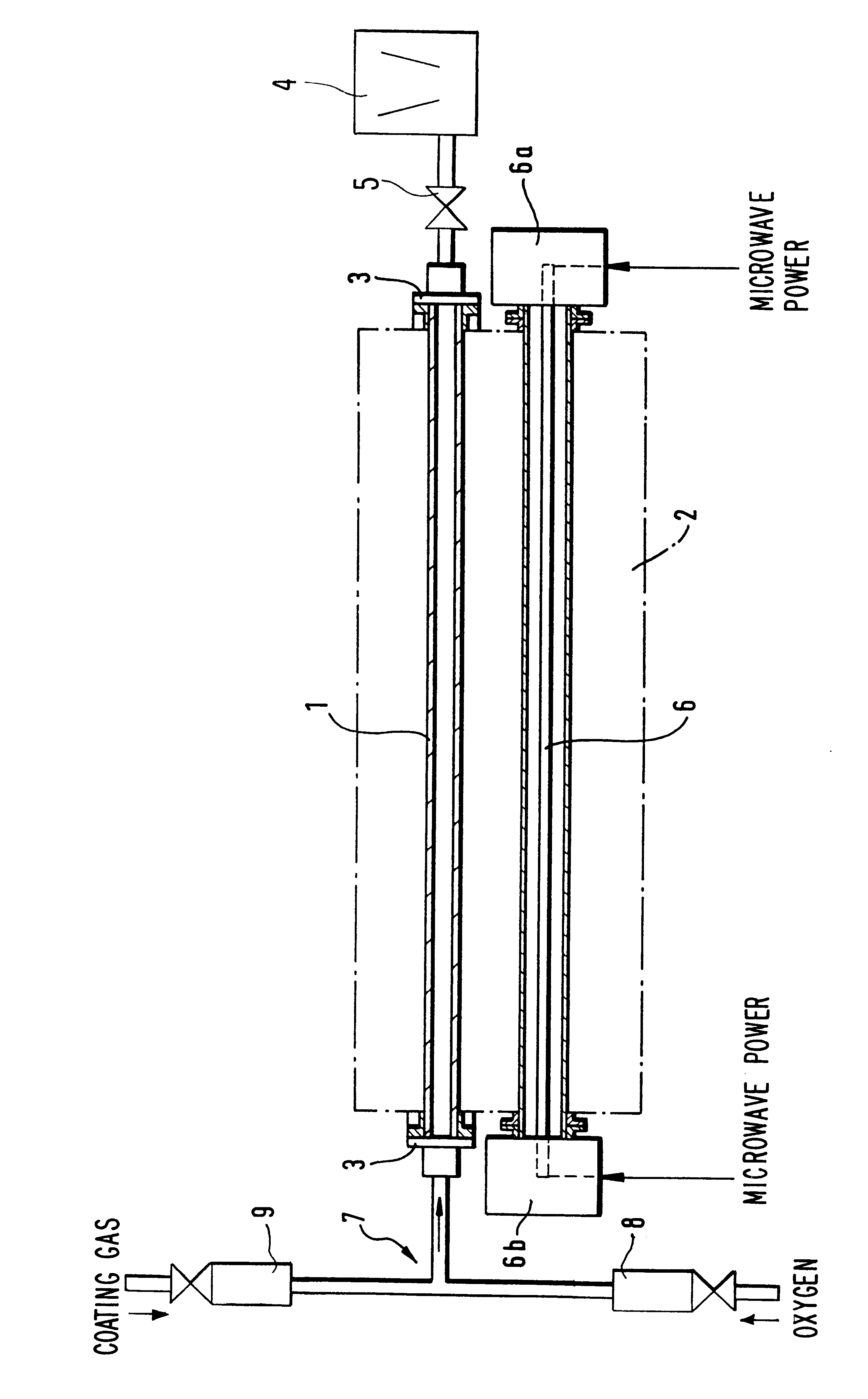

Method of making a hollow, interiorly coated glass body and a glass tube as a semi-finished product for forming the glass body

InactiveUS6200658B1Layered productsLiquid/solution decomposition chemical coatingVitreous BodiesWork in process

Numerous applications for hollow glass bodies made from low melting glass material require an increase in the chemical resistance of the interior surface of the glass body. In order to avoid a disadvantageous de-alkalizing process the hollow glass body must be provided with an interior coating in a comparatively expensive prior art process. In an improved process according to the invention a glass tube acting as a semifinished product from which the hollow glass body is made is provided with an interior coating of oxide material, preferably SiO2, Al2O3, TiO2 or mixtures thereof, having a predetermined coating thickness according to the required chemical resistance or working conditions for forming the glass body and then the hollow glass body is made from the glass tube. The coating is advantageously provided by means of a PICVD process.

Owner:SCHOTT AG

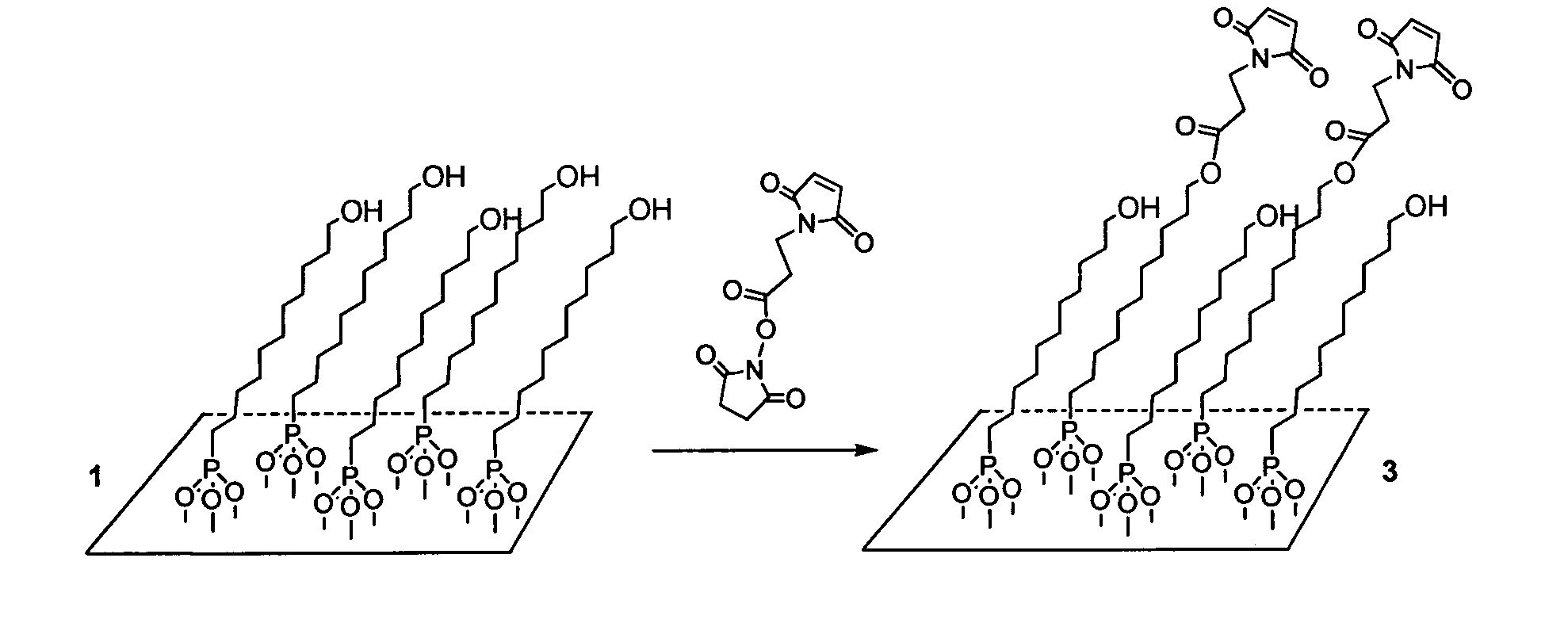

Devices with multiple surface functionality

InactiveUS20060194008A1Desirable surface propertyMaterial nanotechnologyLiquid surface applicatorsImplanted deviceP phosphate

Phosphorus-based coatings having a plurality of phosphate moieties, a plurality of phosphonate moieties, or both, covalently bonded to an oxide surface of an implantable substrate exhibiting one or more of the following characteristics: (a) the surface phosphorus-containing group density of the coated regions of the substrate is at least about 0.1 nmol / cm2; (b) the phosphorus-based coating has a thickness of less than about 10 nm; or (c) the surface phosphorus-containing group density of the coated regions of the substrate is equal to or greater than the surface hydroxyl group density of the oxide surface of the substrate. Implantable devices embodying the coated substrates are also disclosed.

Owner:PRINCETON UNIV

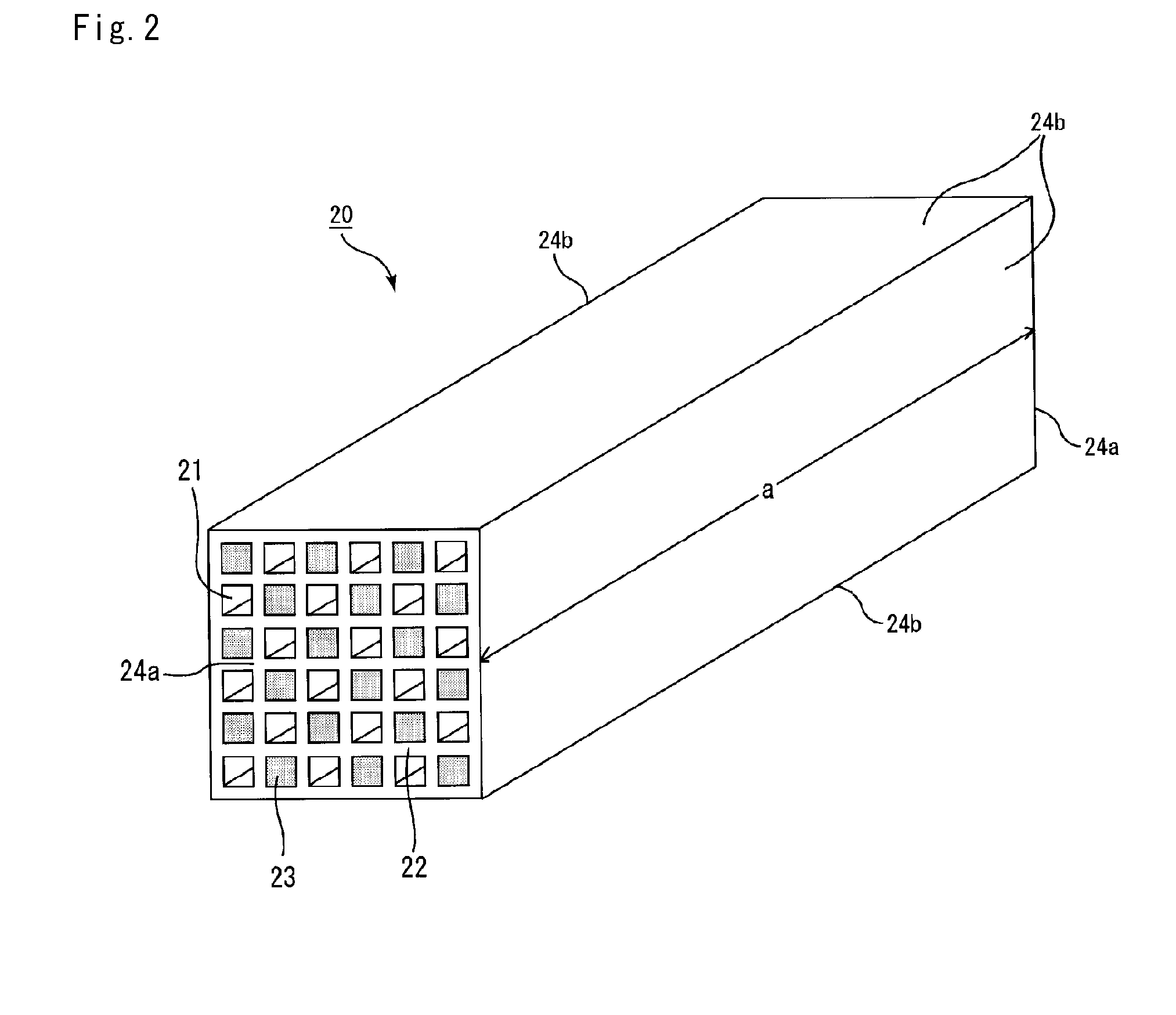

Firing jig and method for manufacturing honeycomb structure

InactiveUS20080305259A1Reduce yieldReduced strengthLayered productsCharge supportsHoneycomb structureSilicon carbide

A firing jig for a honeycomb molded body includes a housing body configured to place a pillar-shaped honeycomb molded body including silicon carbide as a main component with a side face of the honeycomb molded body facing down, and a coat layer formed on at least a placing face of the housing body configured to place the honeycomb molded body thereon. A main component of the coat layer is silicon carbide, the coat layer having an arithmetic average height Ra of about 10 μm or less obtained in conformity with JIS B 0601 (2001).

Owner:IBIDEN CO LTD

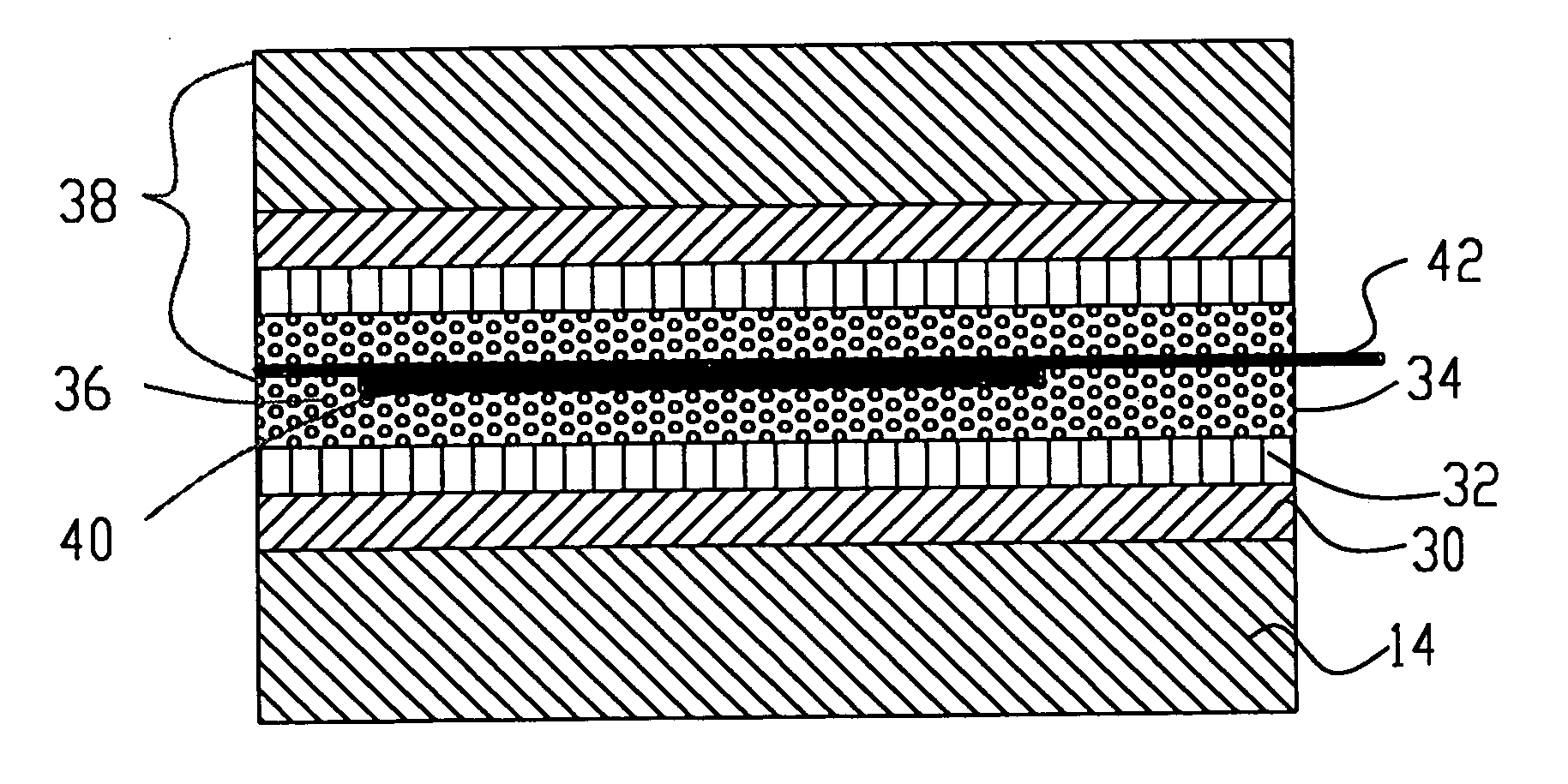

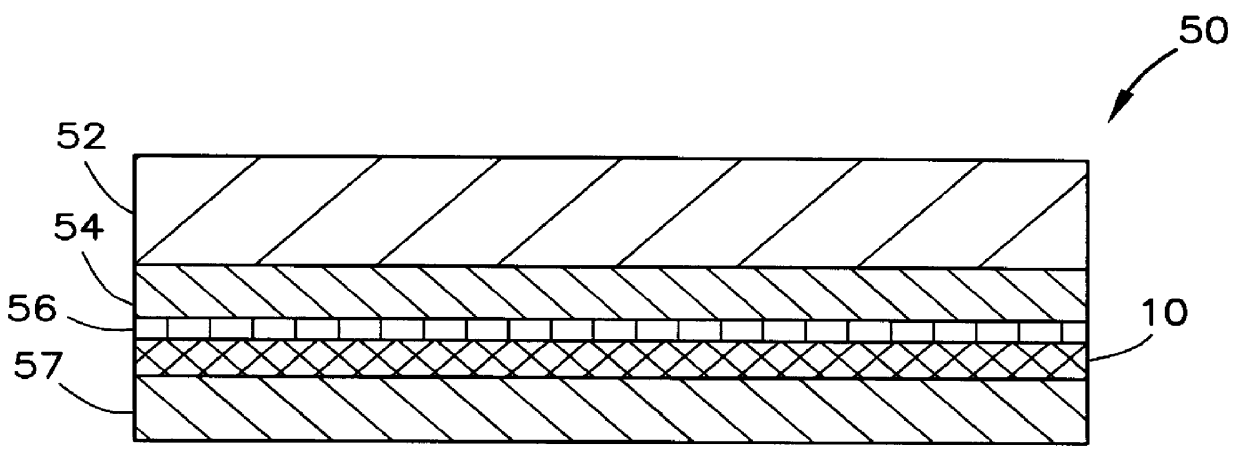

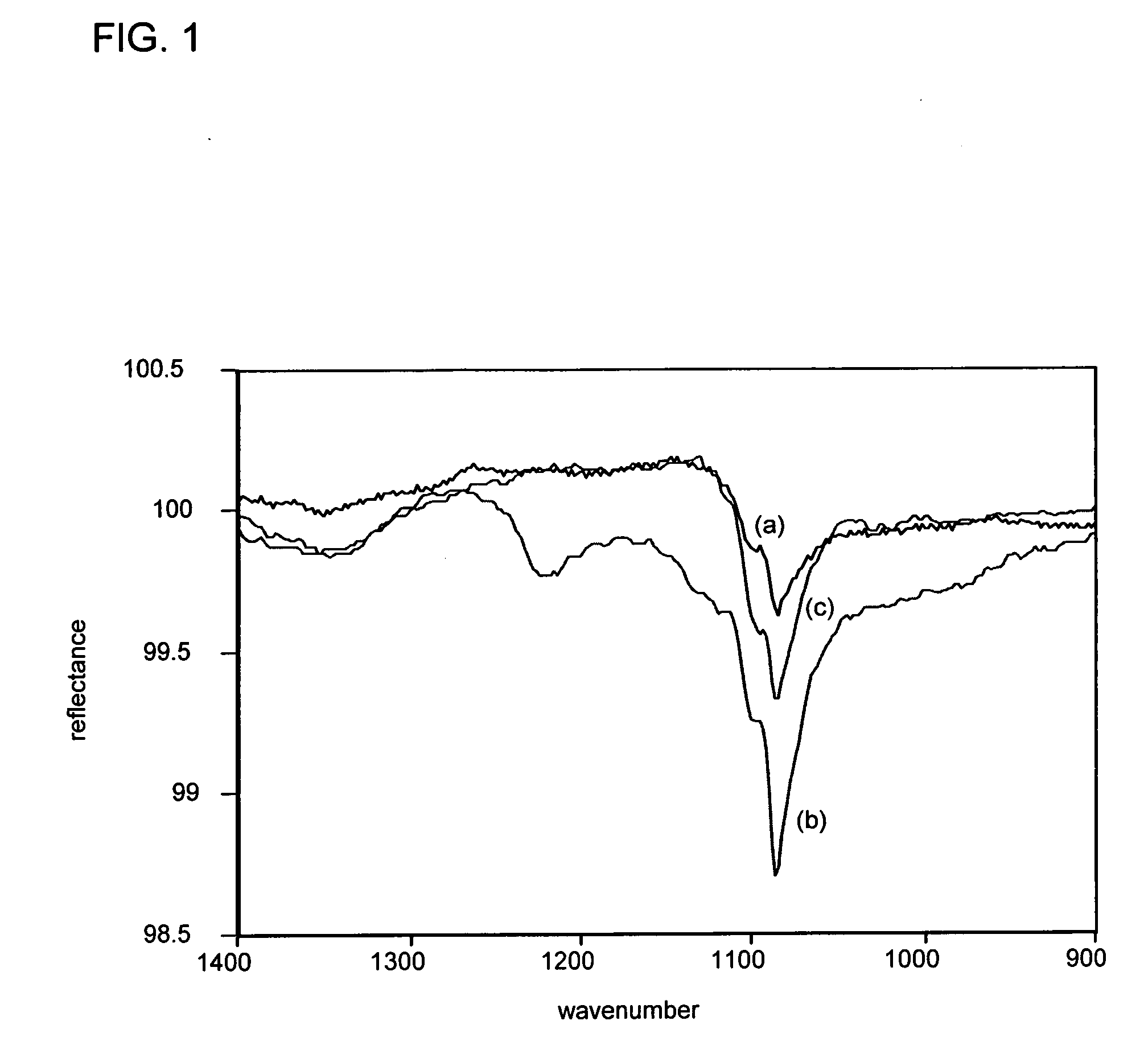

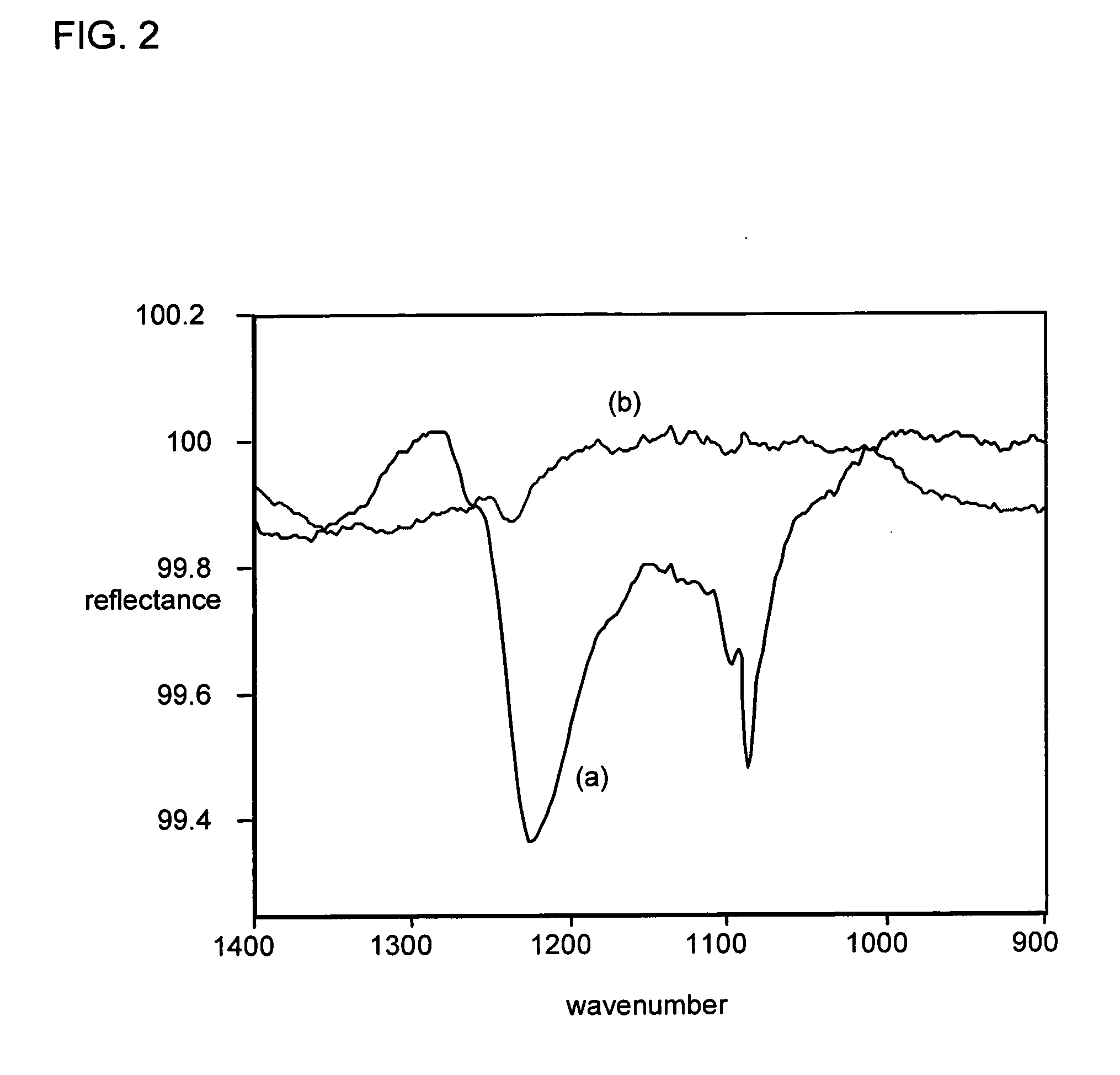

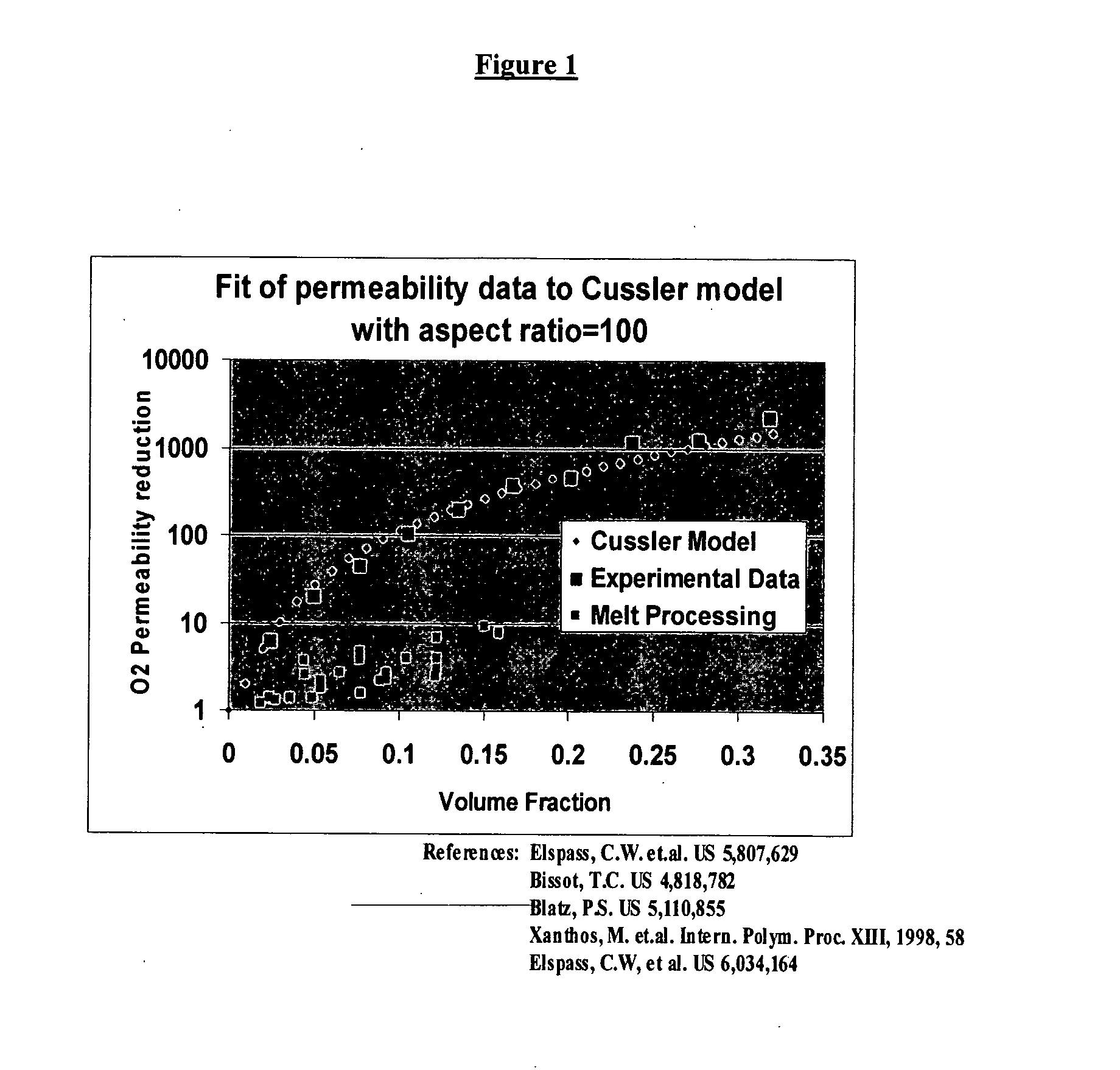

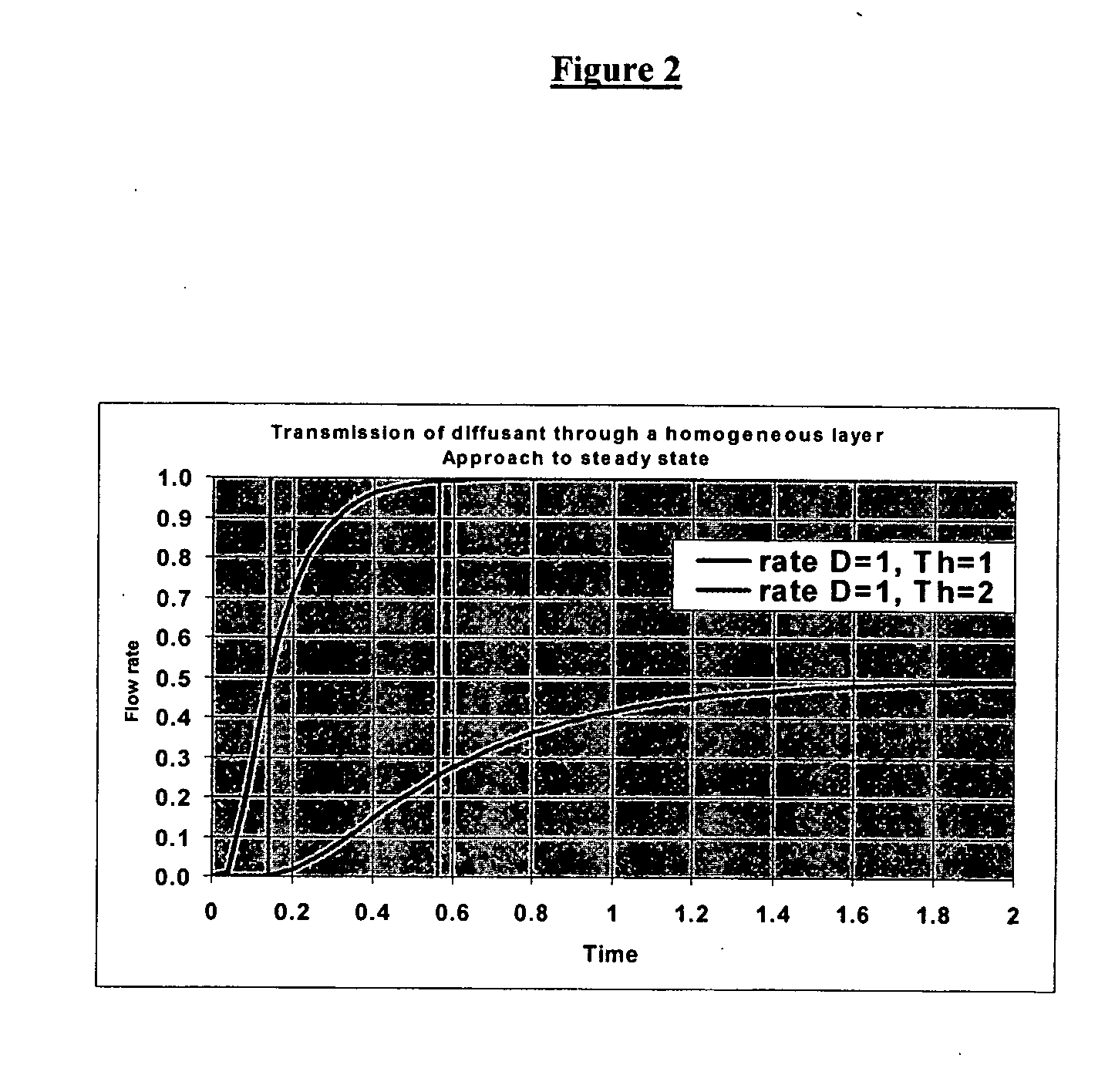

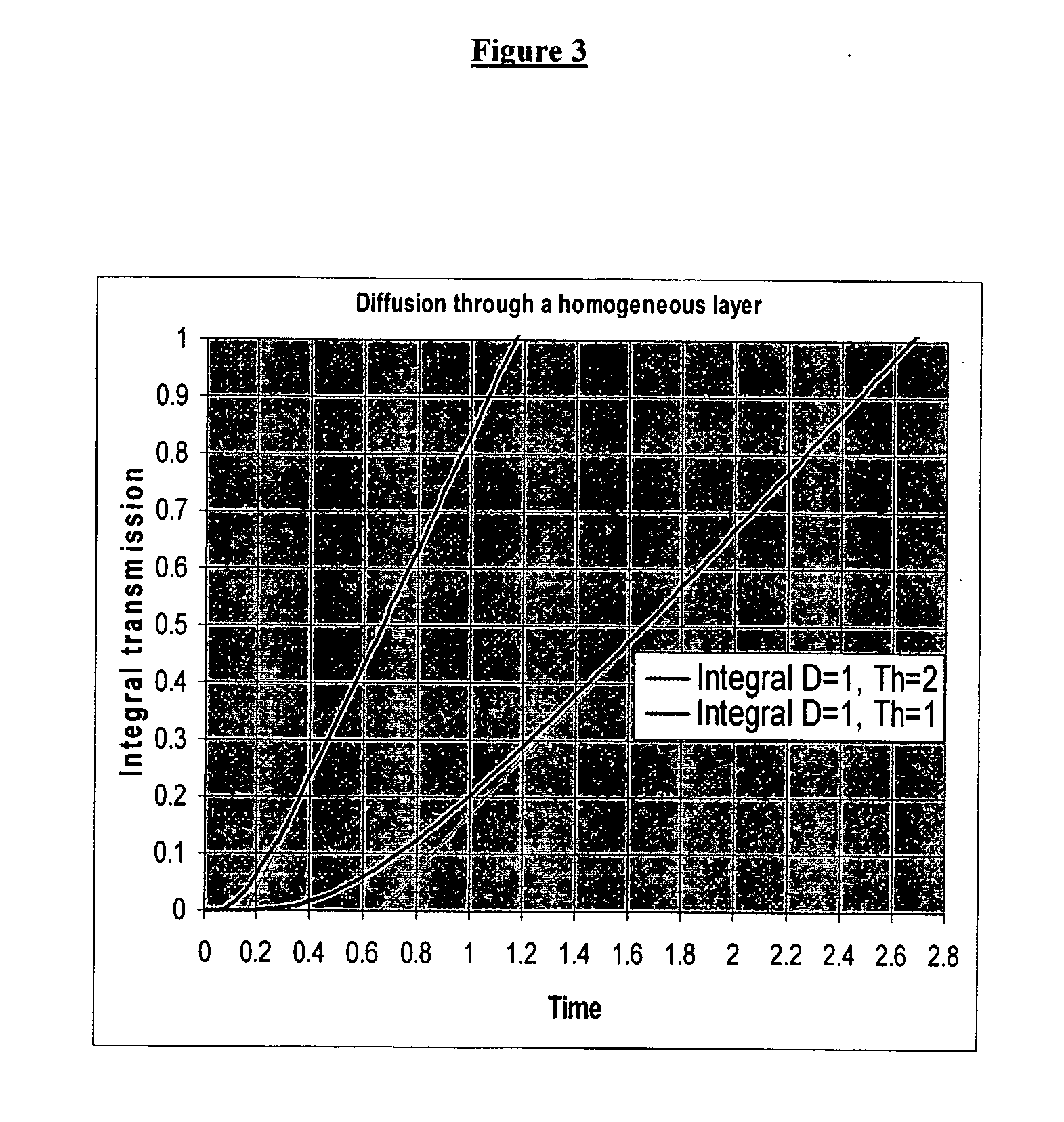

Multilayer nanocomposite barrier structures

InactiveUS20060110615A1Reduce penetrationInhibited DiffusionSynthetic resin layered productsDomestic containersElastomerNanometre

A multilayer barrier structure includes a plurality of relatively thin nanocomposite layers separated by one or more relatively thick intermediate layers selected from synthetic elastomers or non-elastomeric polymers. The composites exhibit remarkably long breakthrough and lag-times and are useful for packaging or protective apparel.

Owner:INMAT INC

Refrigerated display case having a transparent insulating glazing unit

ActiveUS20060005484A1Improve thermal performanceSeen clearly and easilyShow cabinetsEnvelopes/bags making machineryFrostEngineering

Owner:SAINT-GOBAIN GLASS FRANCE

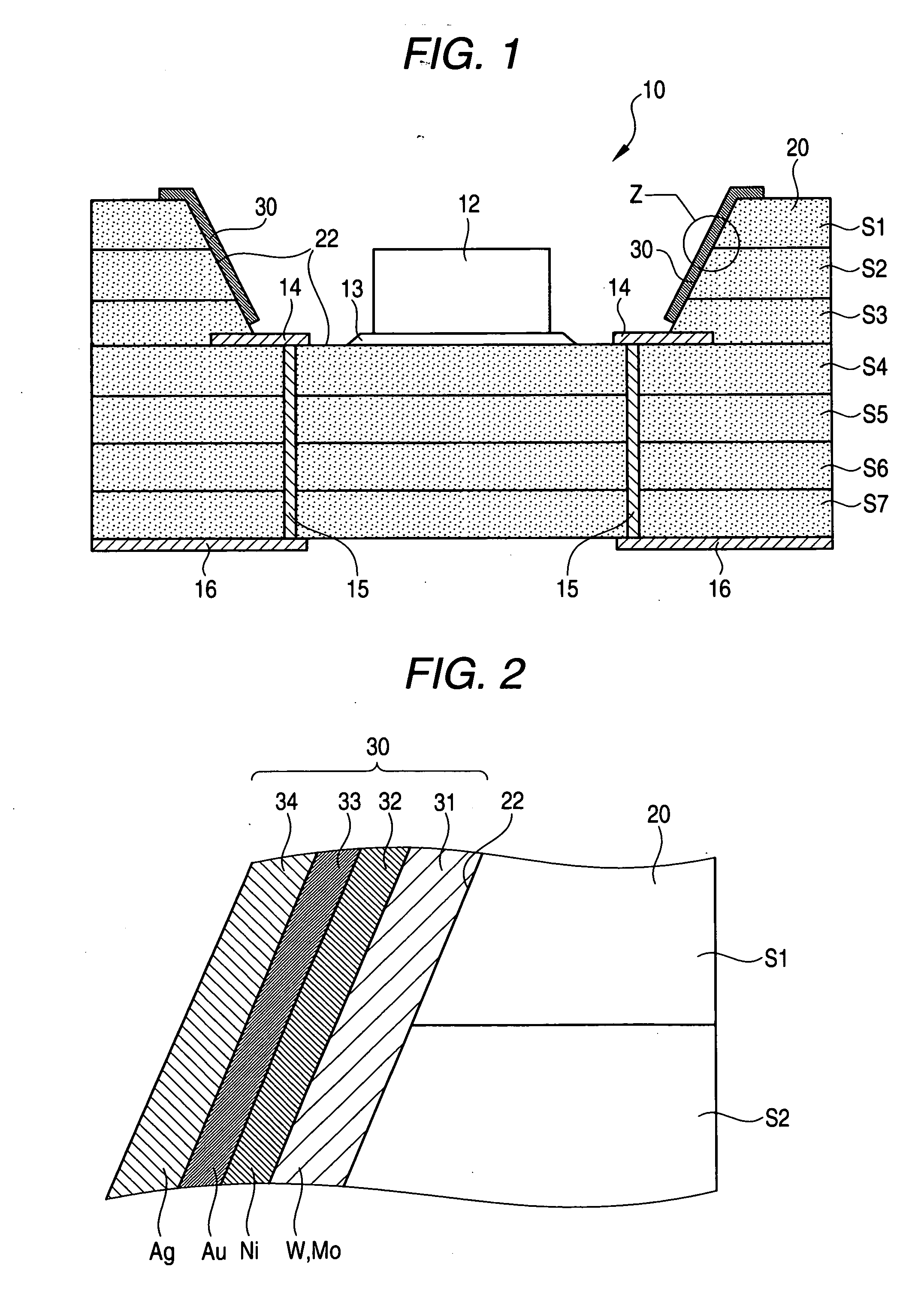

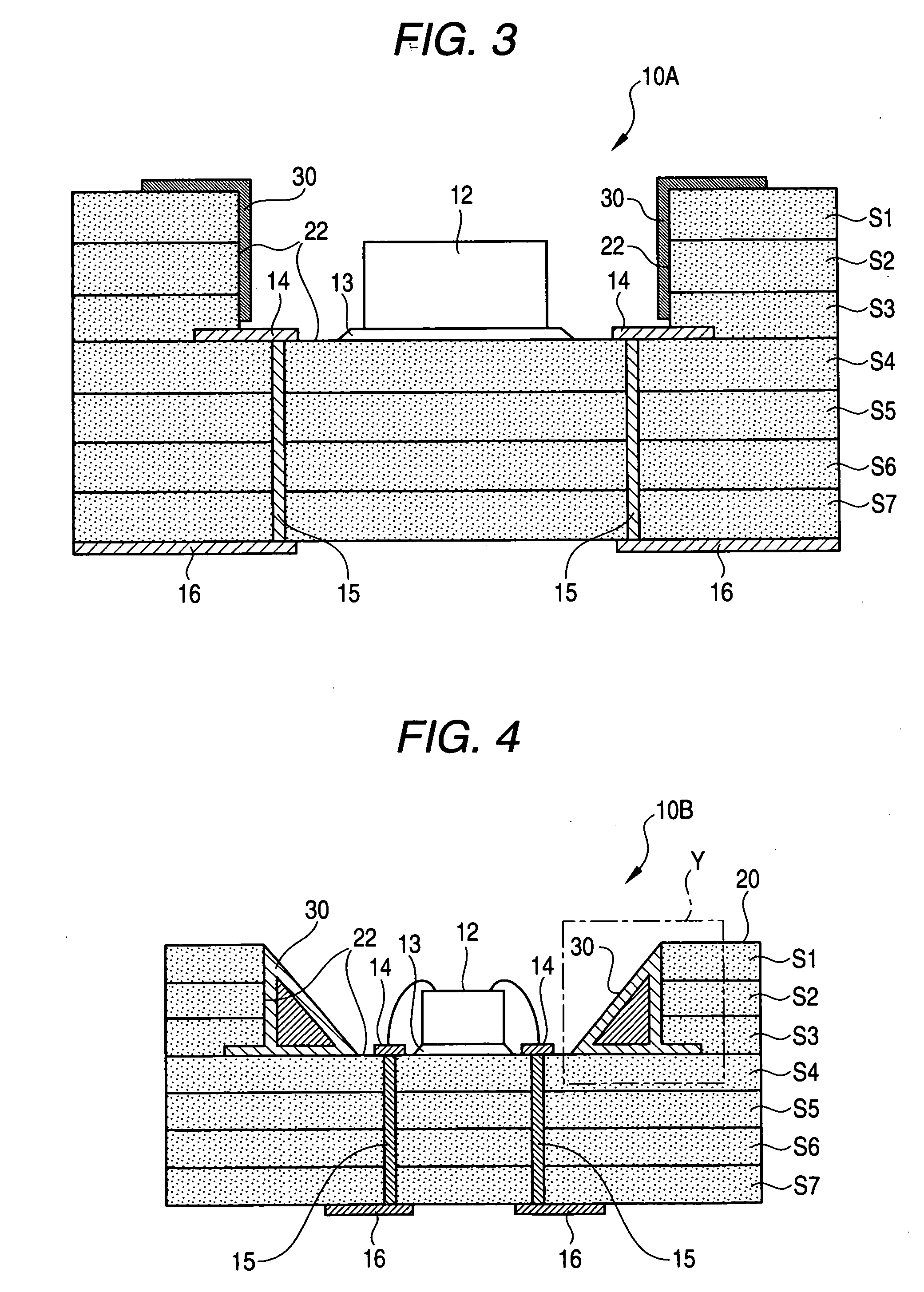

Ceramic substrate, ceramic package for housing light emitting element

InactiveUS20060147746A1Reduce smoothnessIncrease costExtrusion containersSolid-state devicesGold layerCeramic substrate

A ceramic substrate comprising a metallic layer on its surface, wherein said metallic layer includes: a silver layer containing silver; a gold layer containing gold; and a nickel layer containing nickel, in this order from an outermost layer of said metallic layer.

Owner:NGK SPARK PLUG CO LTD

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Highly absorbent composite compositions, absorbent sheets provided with the compositions, and process for producing the same

InactiveUS8268424B1Good dimensional stabilityEfficient designNon-fibrous pulp additionPreformed elementsFiberPolymer chemistry

A composite structure mainly composed of hydratable fine fibers in the form of microfibril and a water swellable solid body, the fine fibers being obtained from cellulose or a derivative thereof, and at least part of the surface of the solid body is covered with the fine fibers. The absorbent composite can be formed in various form of, for example, particle, pellet, sheet and the like, especially of a sheet type with a supporting sheet of a non-woven fabric. The present invention further provides a method of making the composite structure.

Owner:DSG INT LTD

Method and apparatus for incrementally stretching a web

ActiveUS8021591B2Easy to adjustIncrease path lengthDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

Owner:PROCTER & GAMBLE CO

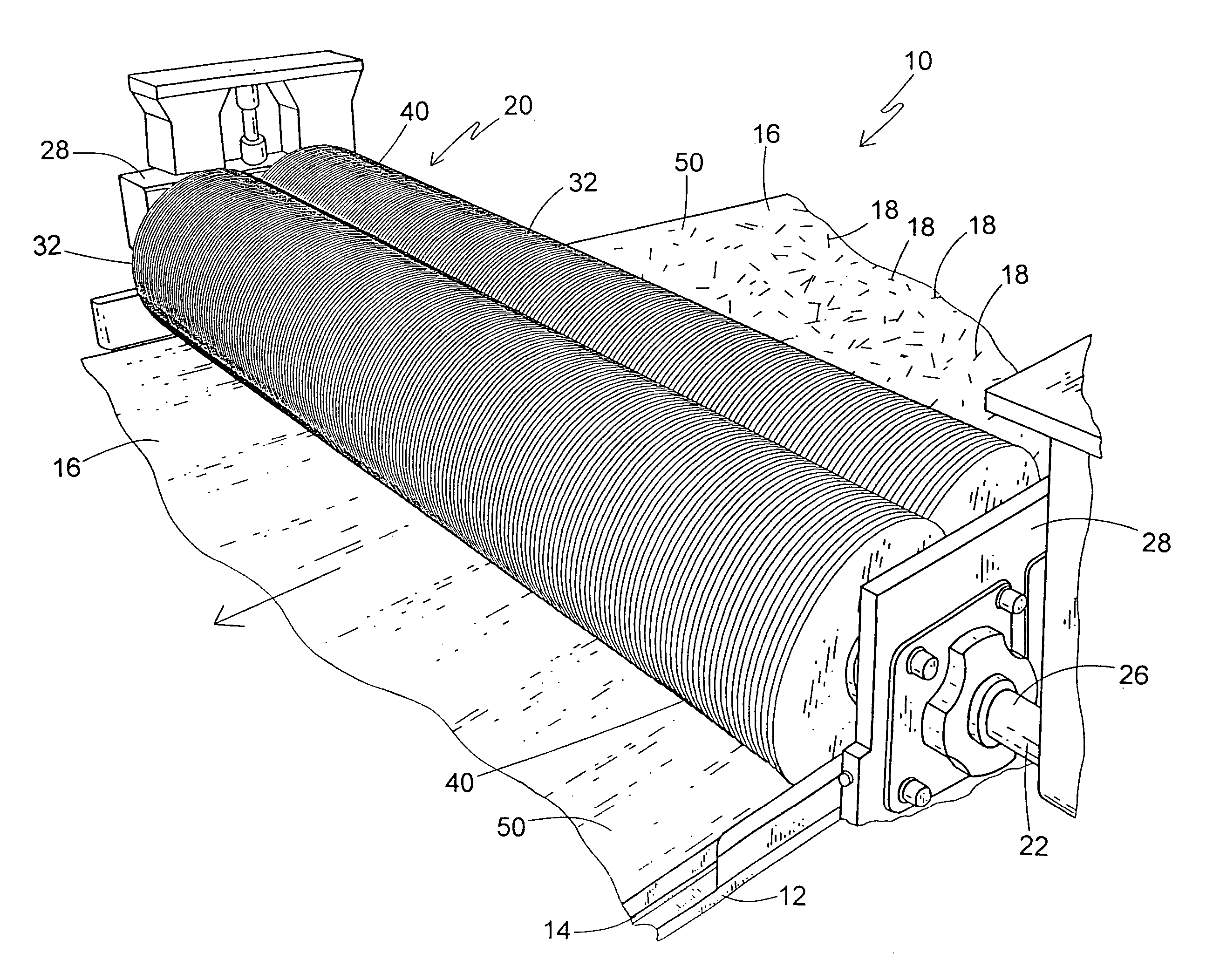

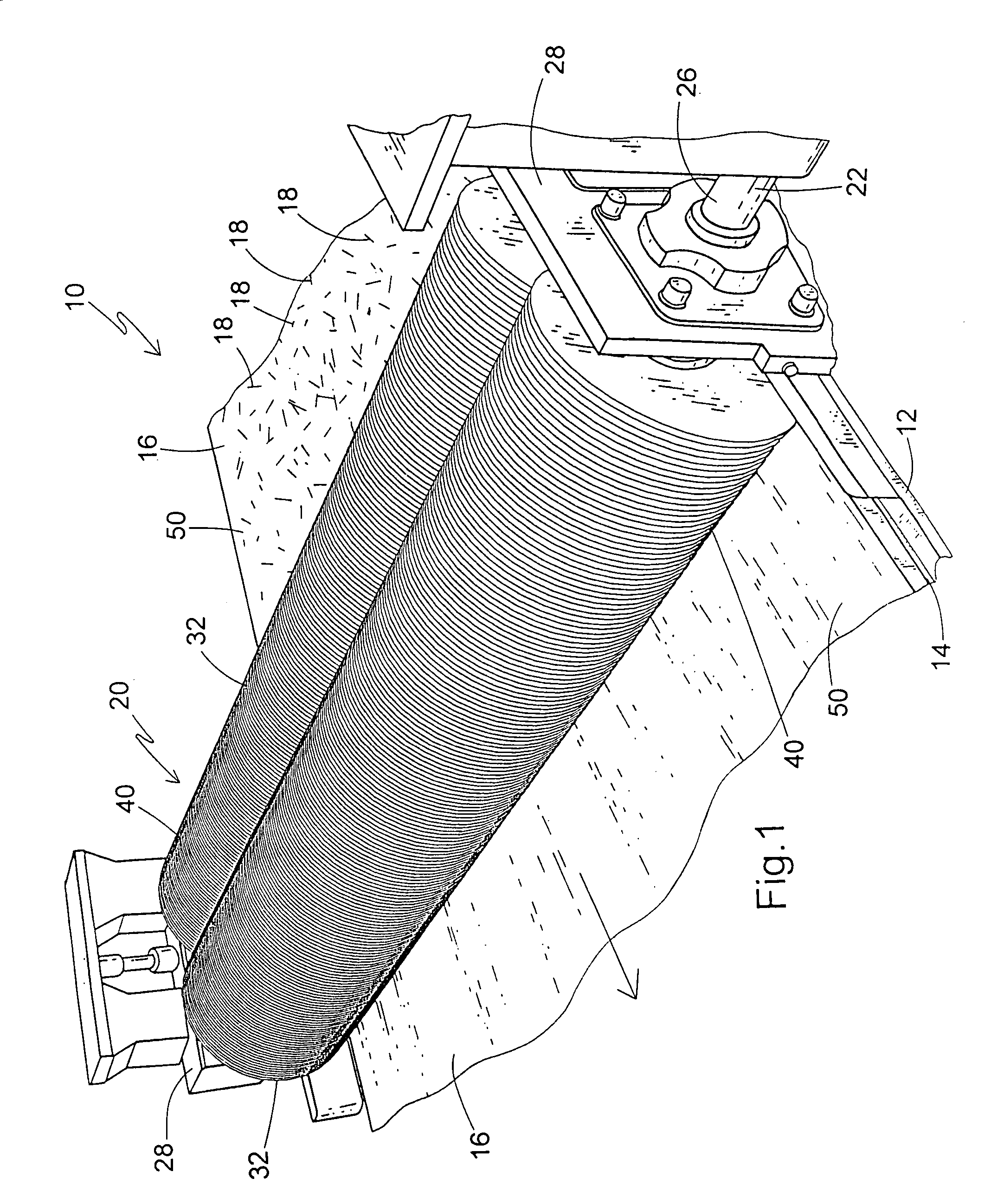

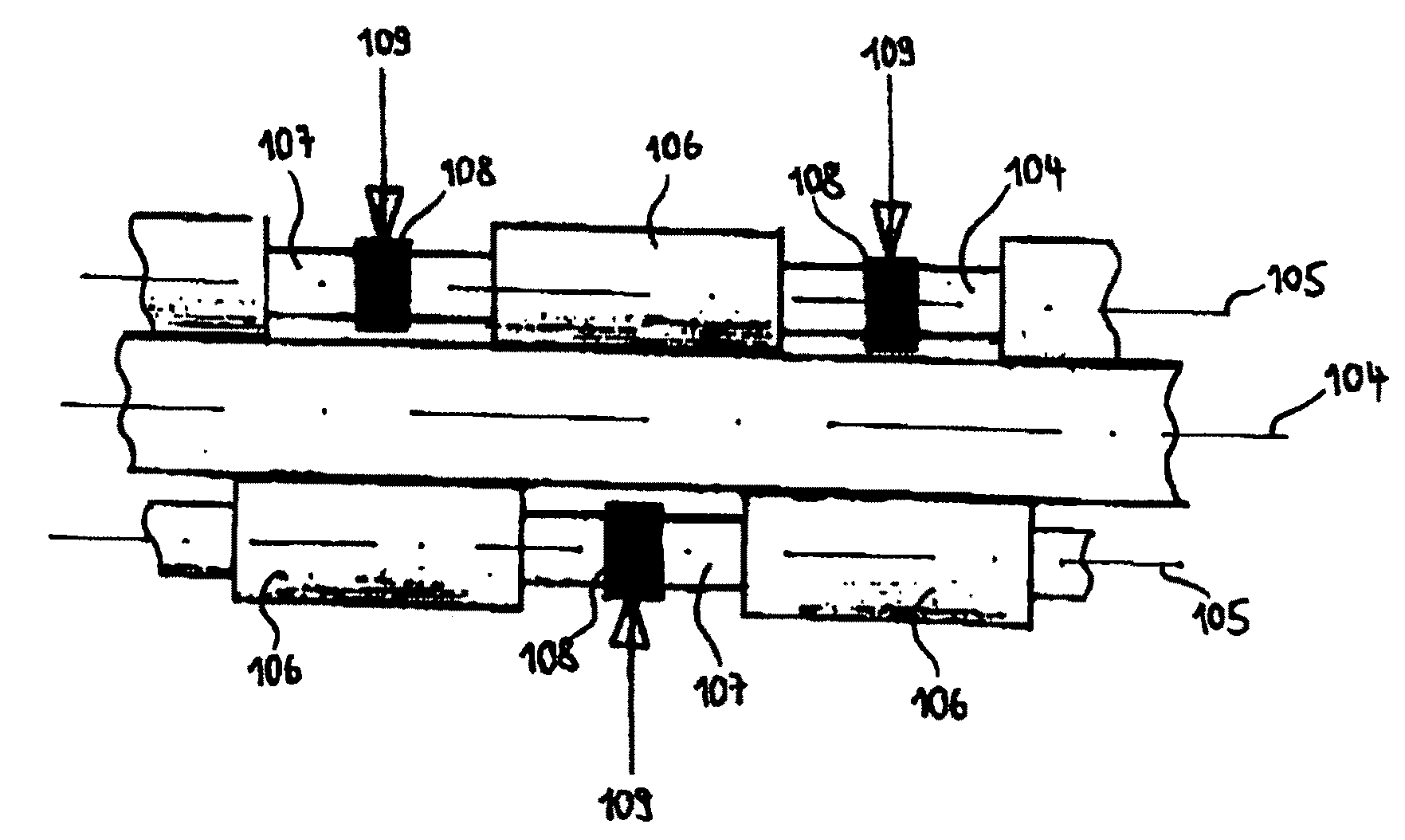

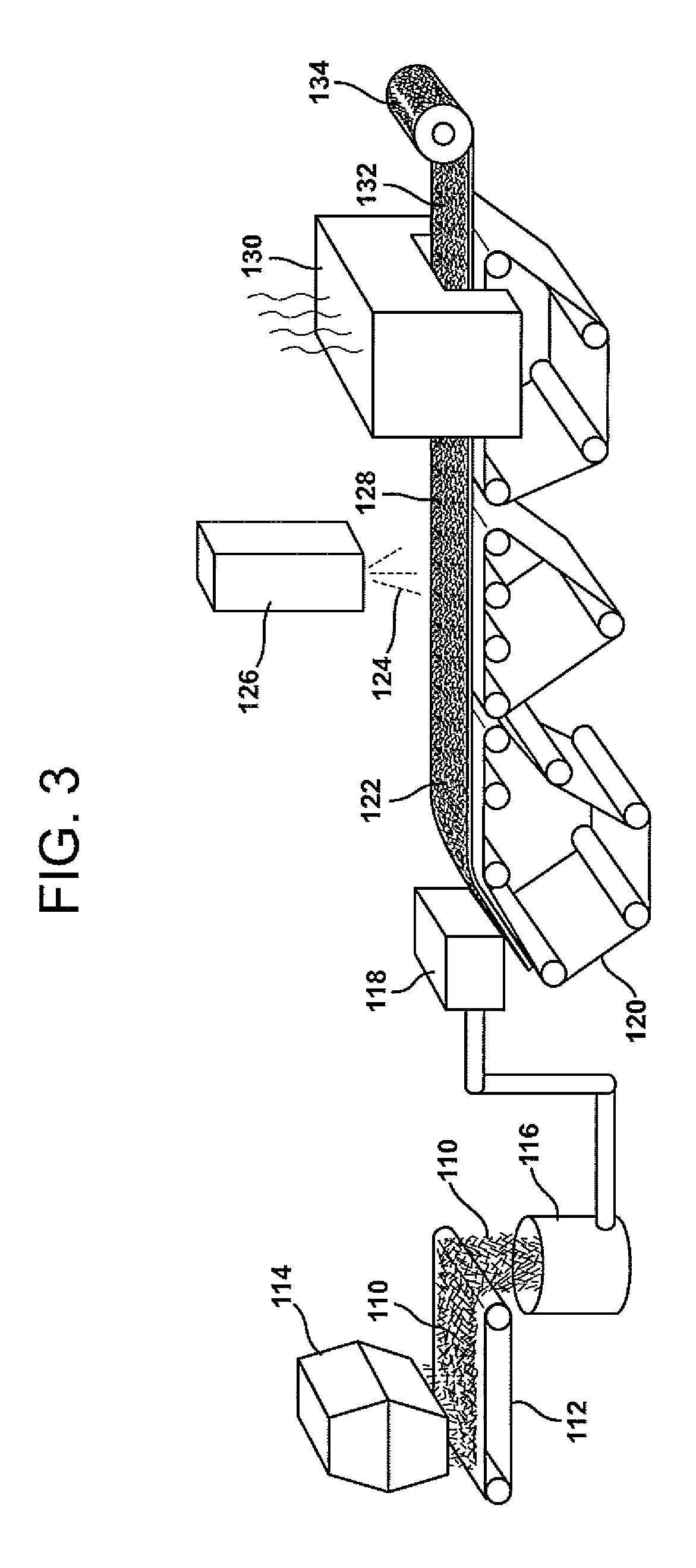

Embedment device for fiber-enhanced slurry

ActiveUS20050064055A1Reduces board line downtimePrevent buildupTransportation and packagingRotary stirring mixersFiberProduction line

An embedment device for use in a structural panel production line wherein a slurry is transported on a moving carrier relative to a support frame, and chopped fibers are deposited upon the slurry, includes a first elongate shaft secured to the support frame and having a first plurality of axially spaced disks, a second elongate shaft secured to the support frame and having a second plurality of axially spaced disks, the first shaft being disposed relative to the second shaft so that the disks intermesh with each other. The intermeshing relationship enhances embedment of the fibers into the slurry and also prevents clogging of the device by prematurely set slurry particles.

Owner:UNITED STATES GYPSUM CO

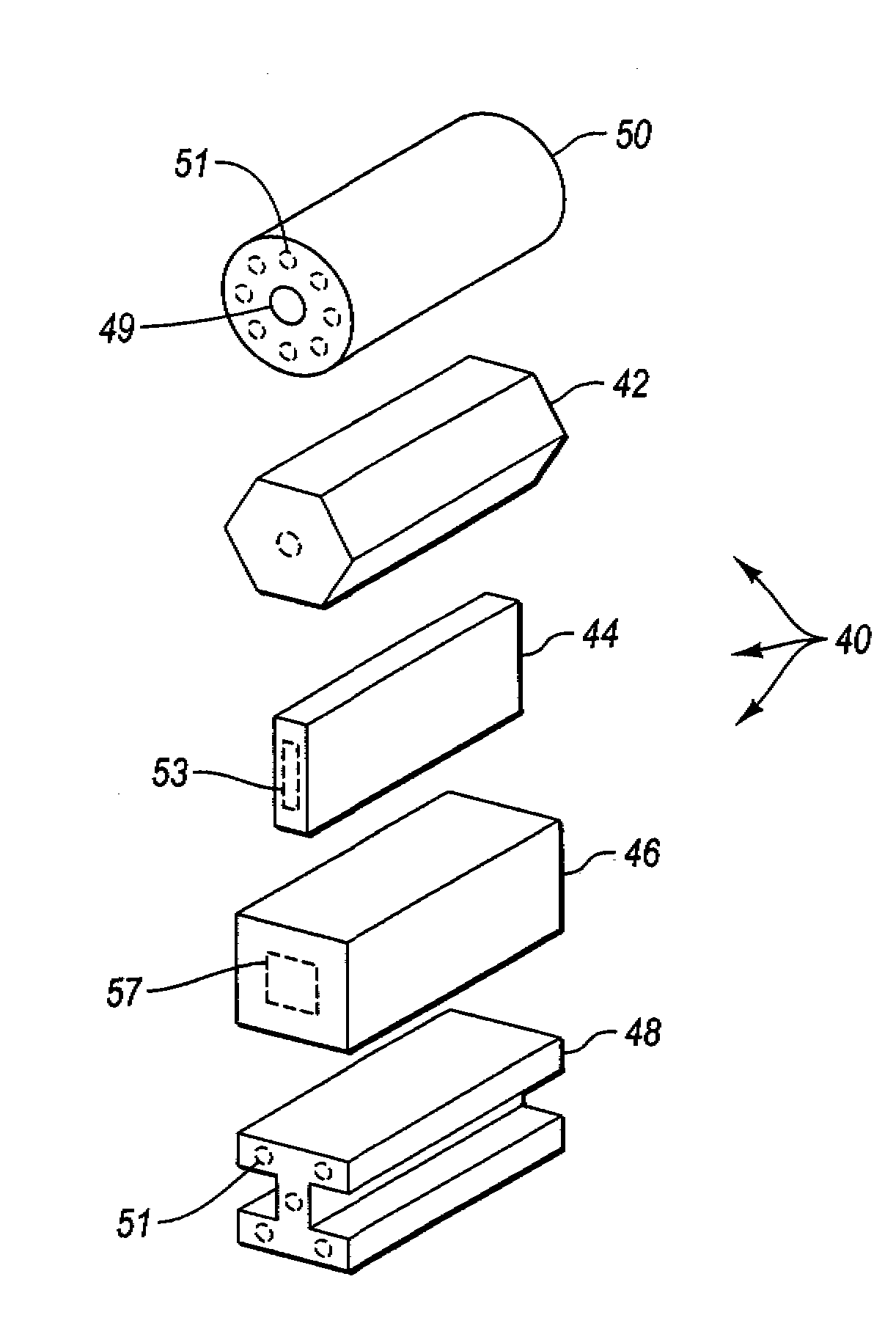

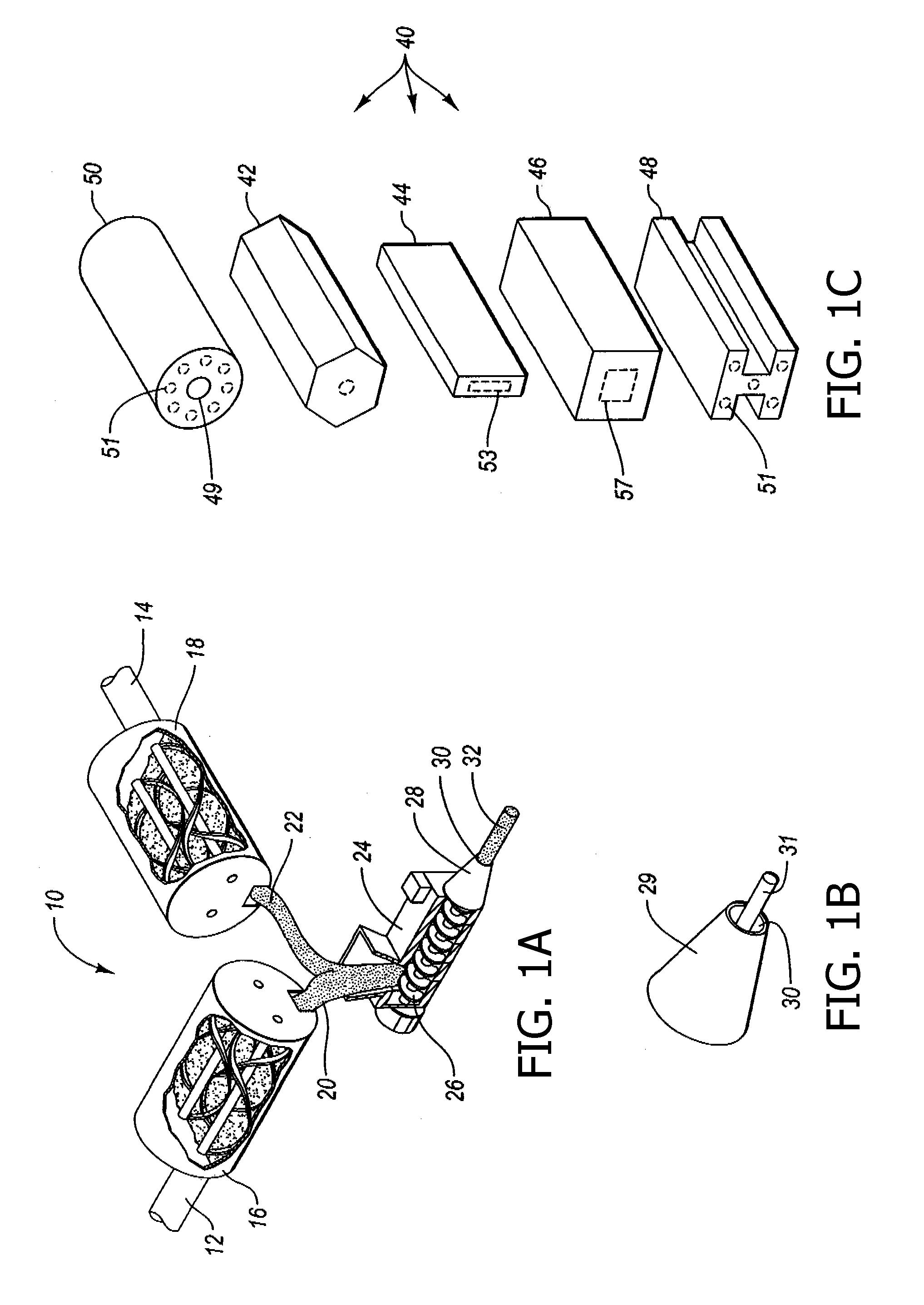

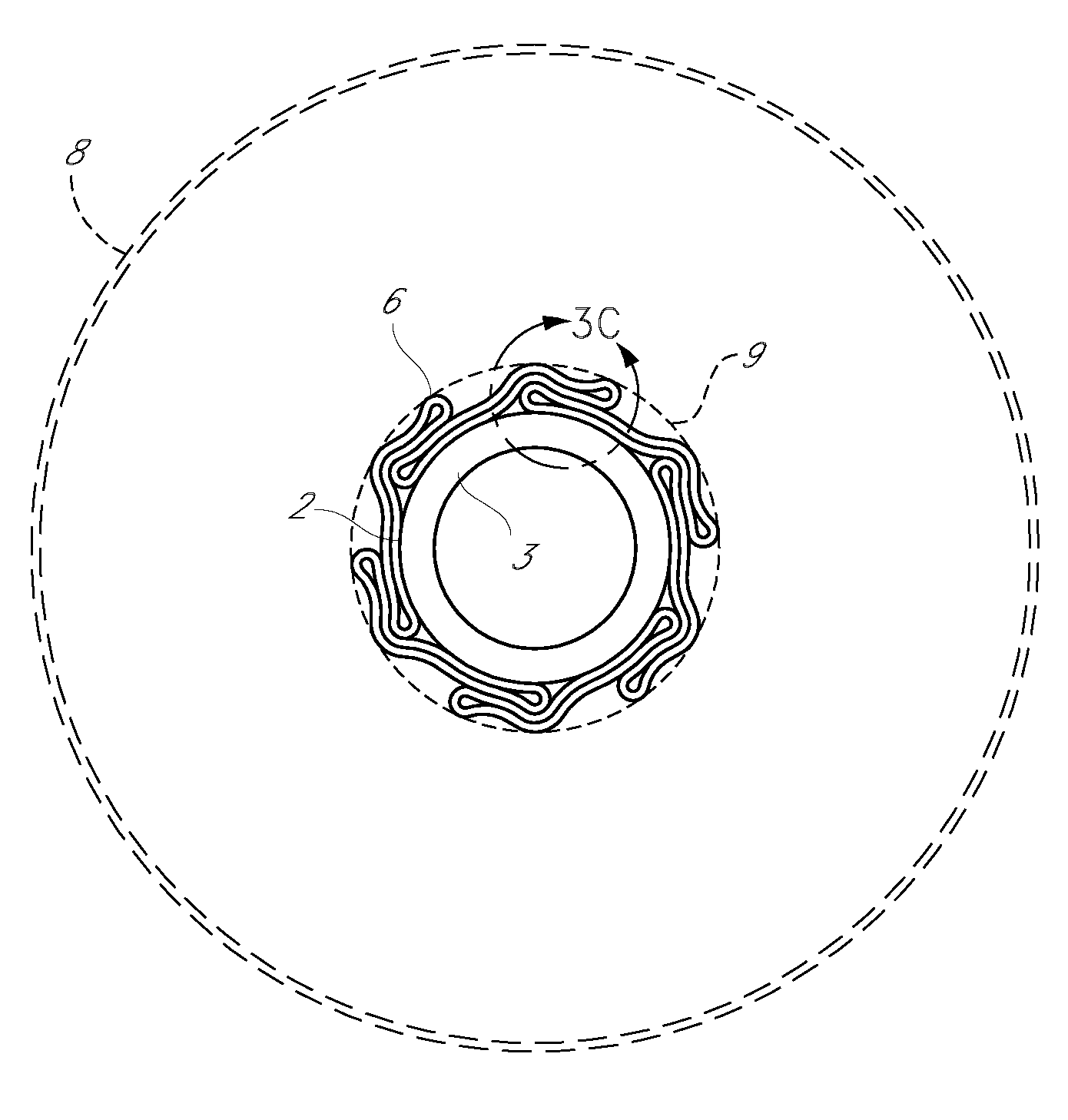

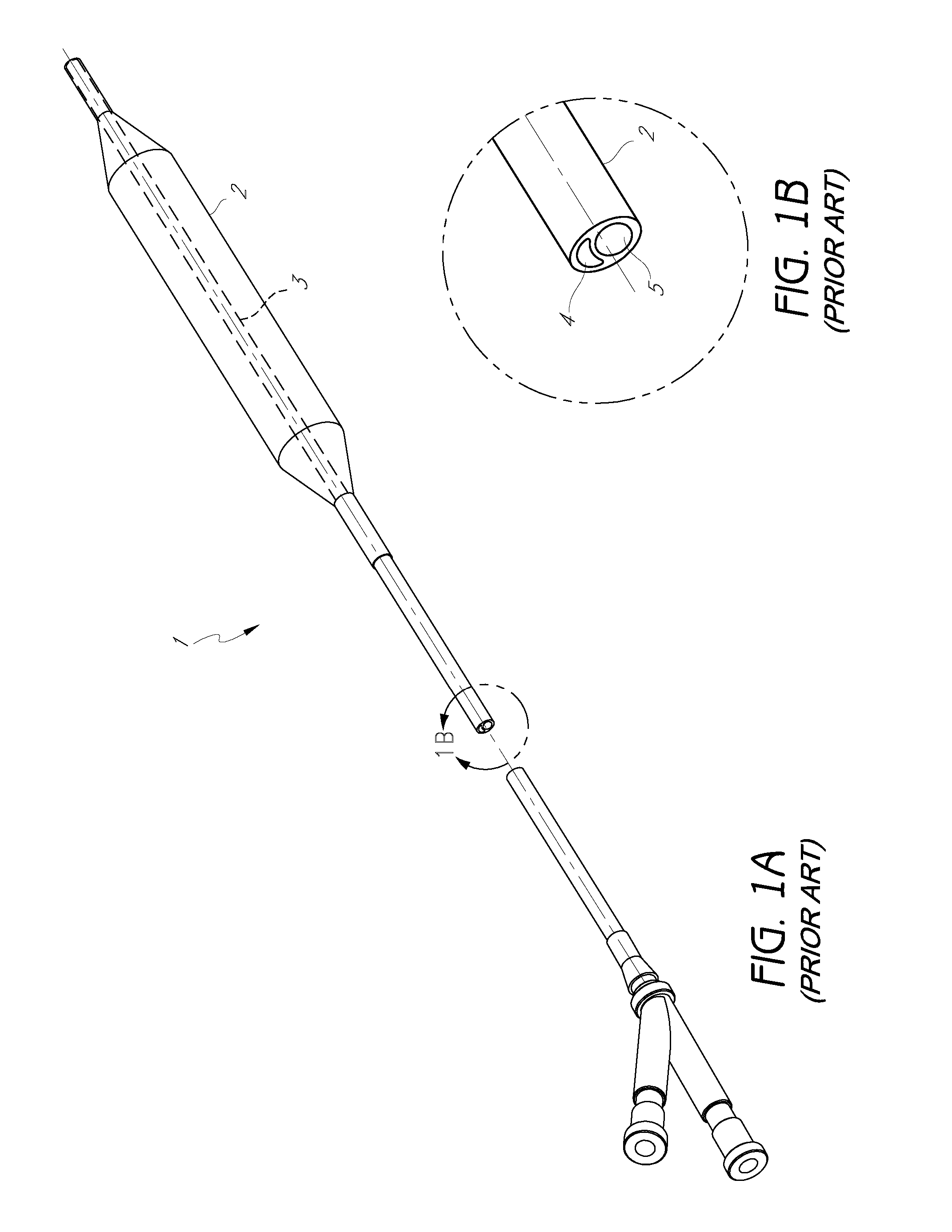

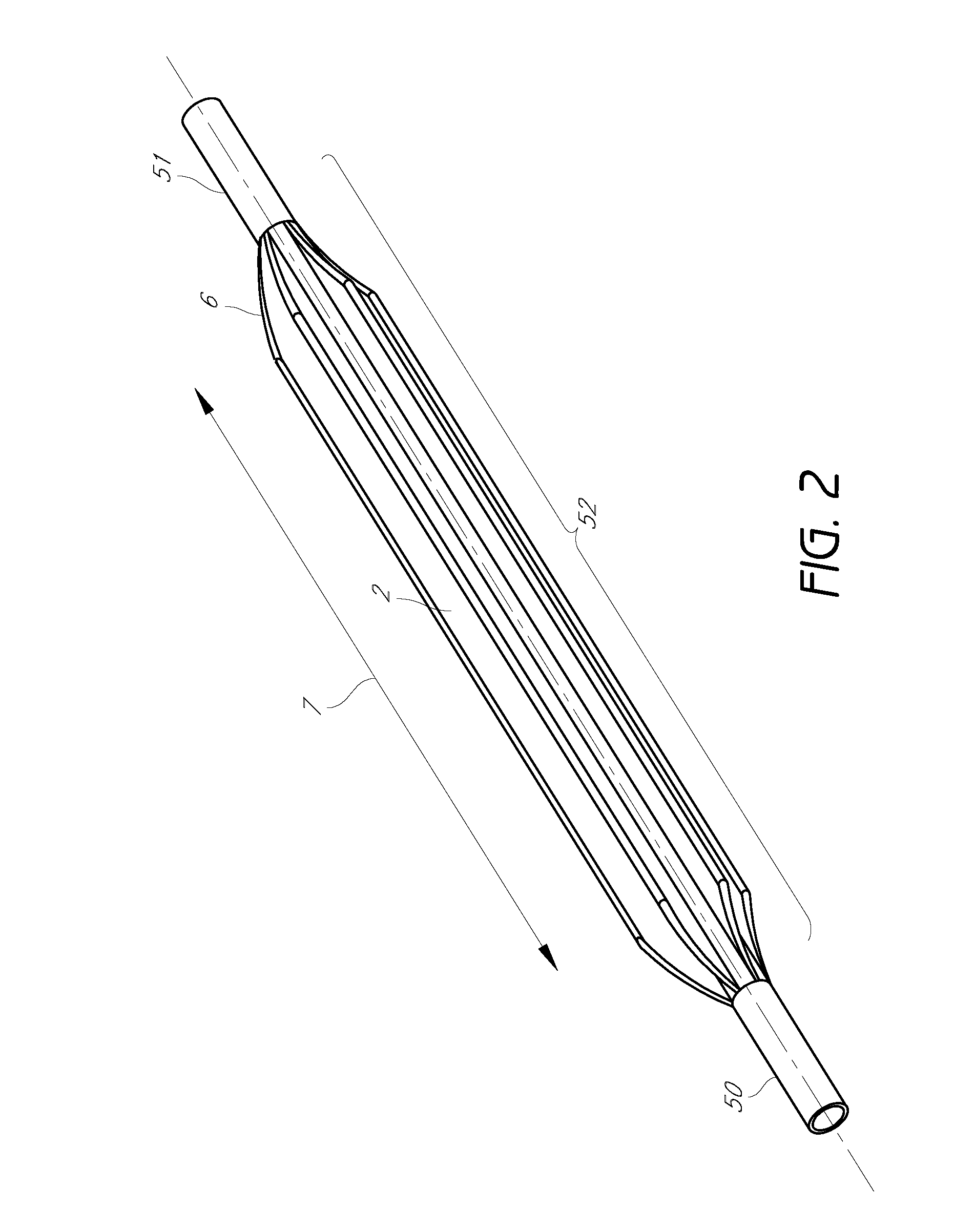

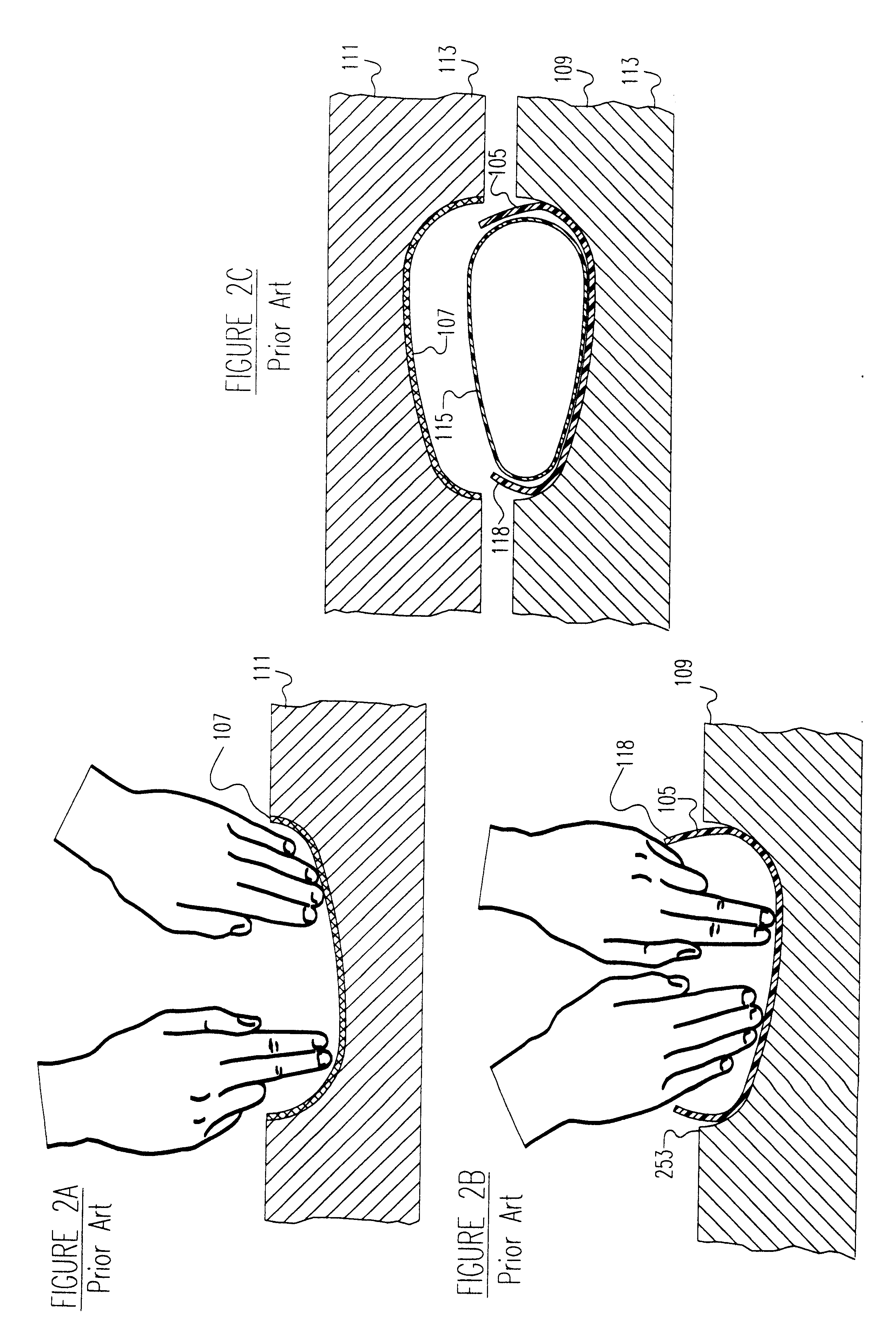

Multi-layer balloons for medical applications and methods for manufacturing the same

ActiveUS20070167973A1High pressure rating and toughnessExcellent folding propertiesBalloon catheterLayered productsEngineeringMechanical engineering

A multi-layered balloon is provided where each layer is formed such that each layer is made from tubing that optimizes the inner wall stretch thus providing maximum balloon strength. The high pressure, multi-layer balloon is provided with layers that allow for slipping, such that the balloon has a very high pressure rating and toughness, yet excellent folding characteristics. Methods for producing such multi-layer balloons using existing balloon forming equipment are also provided. The multi-layer balloons can have alternating structural and lubricating layers, or layers with low-friction surfaces. The multi-layer balloons are preferably manufactured using a variety of methods including nesting, co-extrusion, or a combination of nesting and co-extrusion. The multi-layer balloons have balloon layers having substantially similar, or the same, high degree of biaxial orientation of their polymer molecules such that each balloon layer of the multi-layer balloon will fail at approximately the same applied pressure.

Owner:CONFLUENT MEDICAL TECH INC

Strengthening flat glass by edge coating

InactiveUS6120908AMaximumHigh strengthCeramic layered productsGlass/slag layered productsFlat glassOptoelectronics

A method is described for strengthening or restoring strength to a flat brittle oxide substrate which includes the steps of coating the edges of the brittle oxide substrate with a strengthening composition without coating a significate portion of the flat surfaces. The strengthen brittle oxide substrate such as glass and a window containing as the window pane the edge strengthen glass are also provided.

Owner:ARKEMA INC

Angioplasty super balloon fabrication with composite materials

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Fluoropolymer Barrier Materials for Containers

A container having a barrier layer is provided. The container may be of thermoplastic and the barrier may inhibit materials from leaching from the thermoplastic material or from extraction of compounds from medicants by the thermoplastic. A process is also described that allows for molding thin barrier layers as container lines and for forming thermoplastic containers with barrier liners.

Owner:WL GORE & ASSOC INC

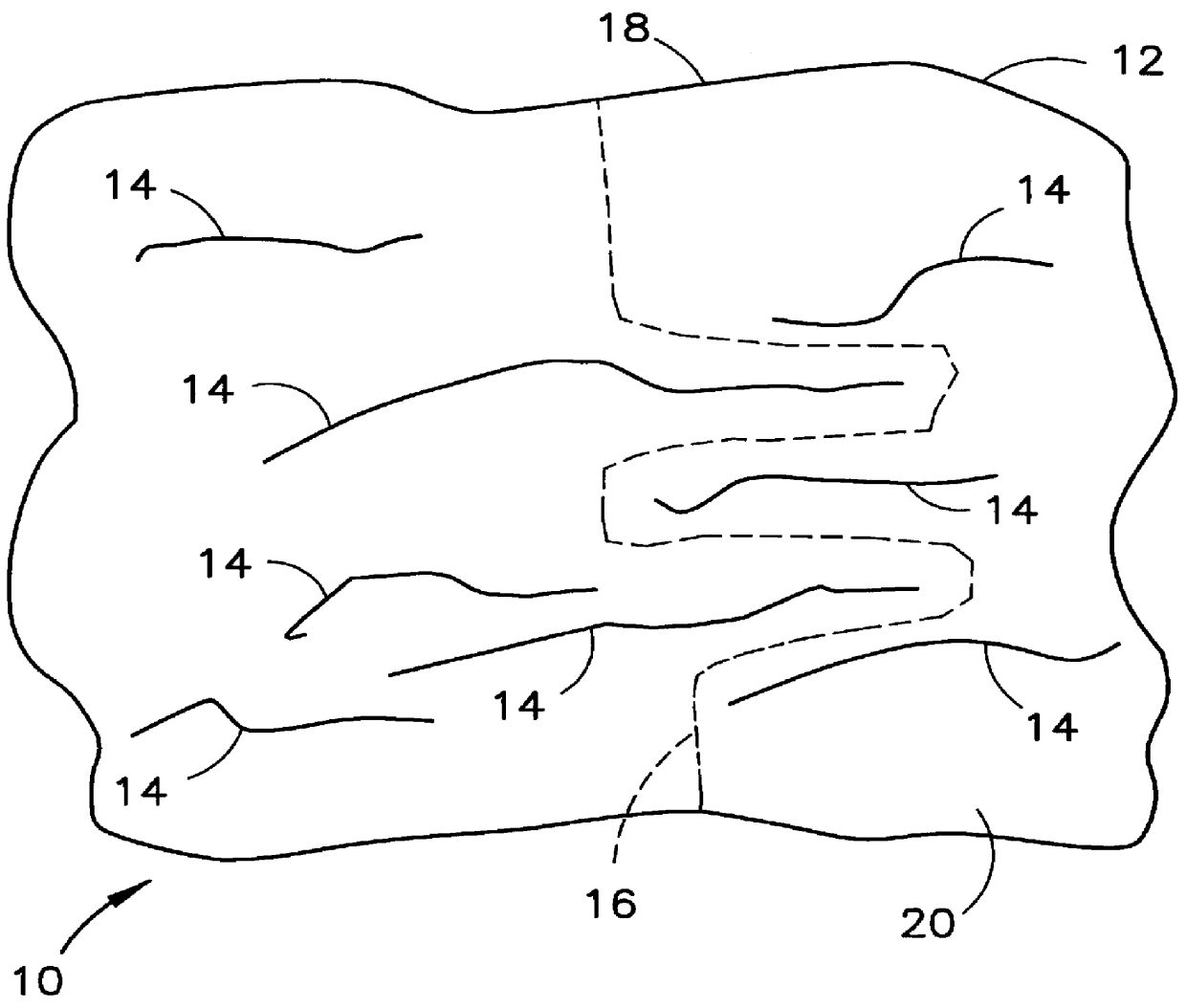

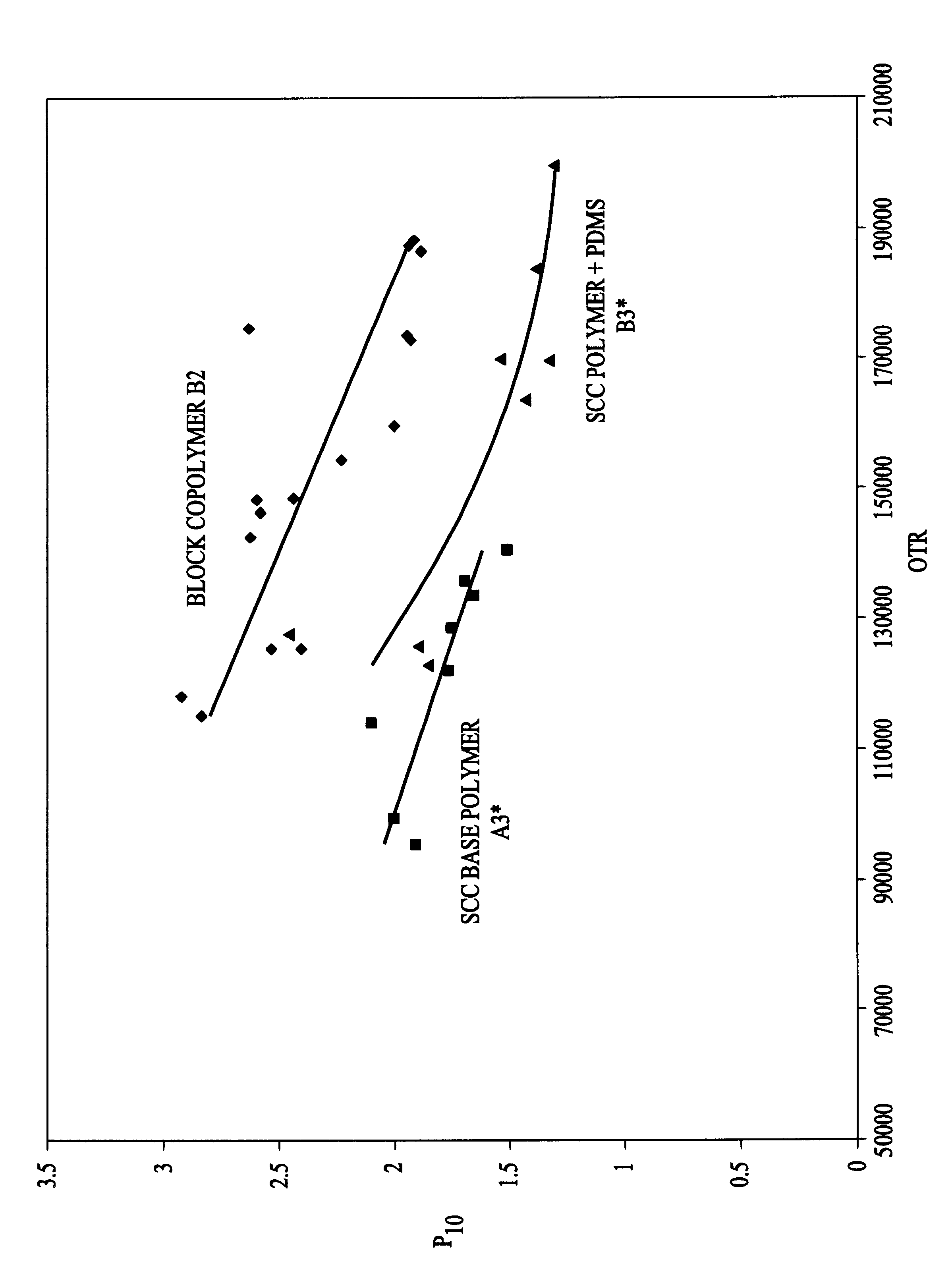

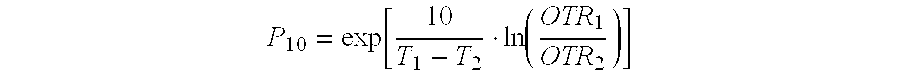

Packaging biological materials

InactiveUS6548132B1Reduction in tackUniform propertyWrappersPreformed elementsPolymer scienceBiological materials

Novel gas-permeable membranes which are particularly useful in the packaging of fresh cut fruit and vegetables, and other respiring biological materials. The membranes comprise a microporous film or other gas-permeable substrate and, coated on the substrate, a layer of a block copolymer having a heat of fusion of at least 5 J / g and containing polysiloxane polymeric blocks and crystalline polymeric blocks having a melting point of -5 to 40° C.

Owner:LANDEC

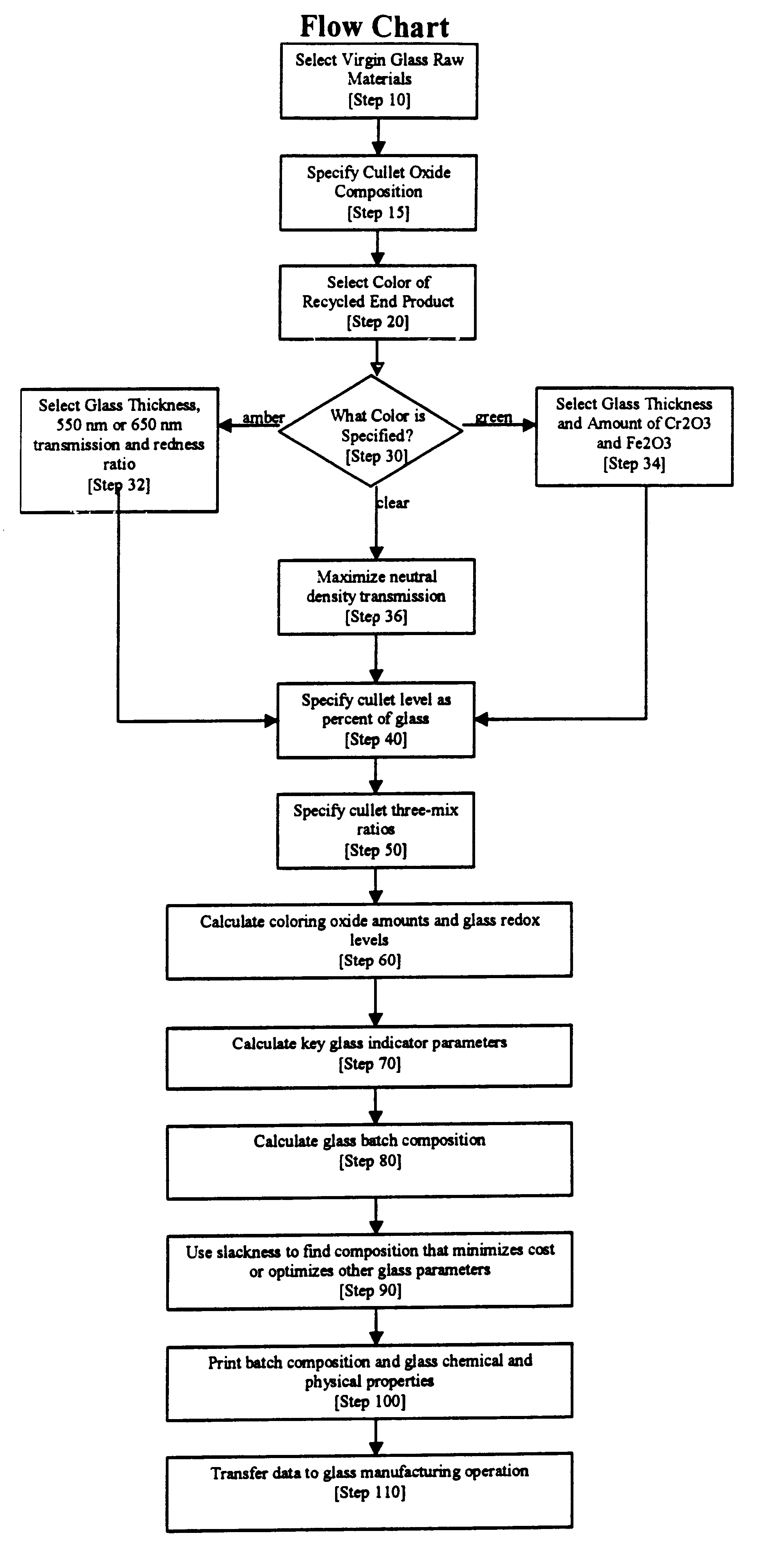

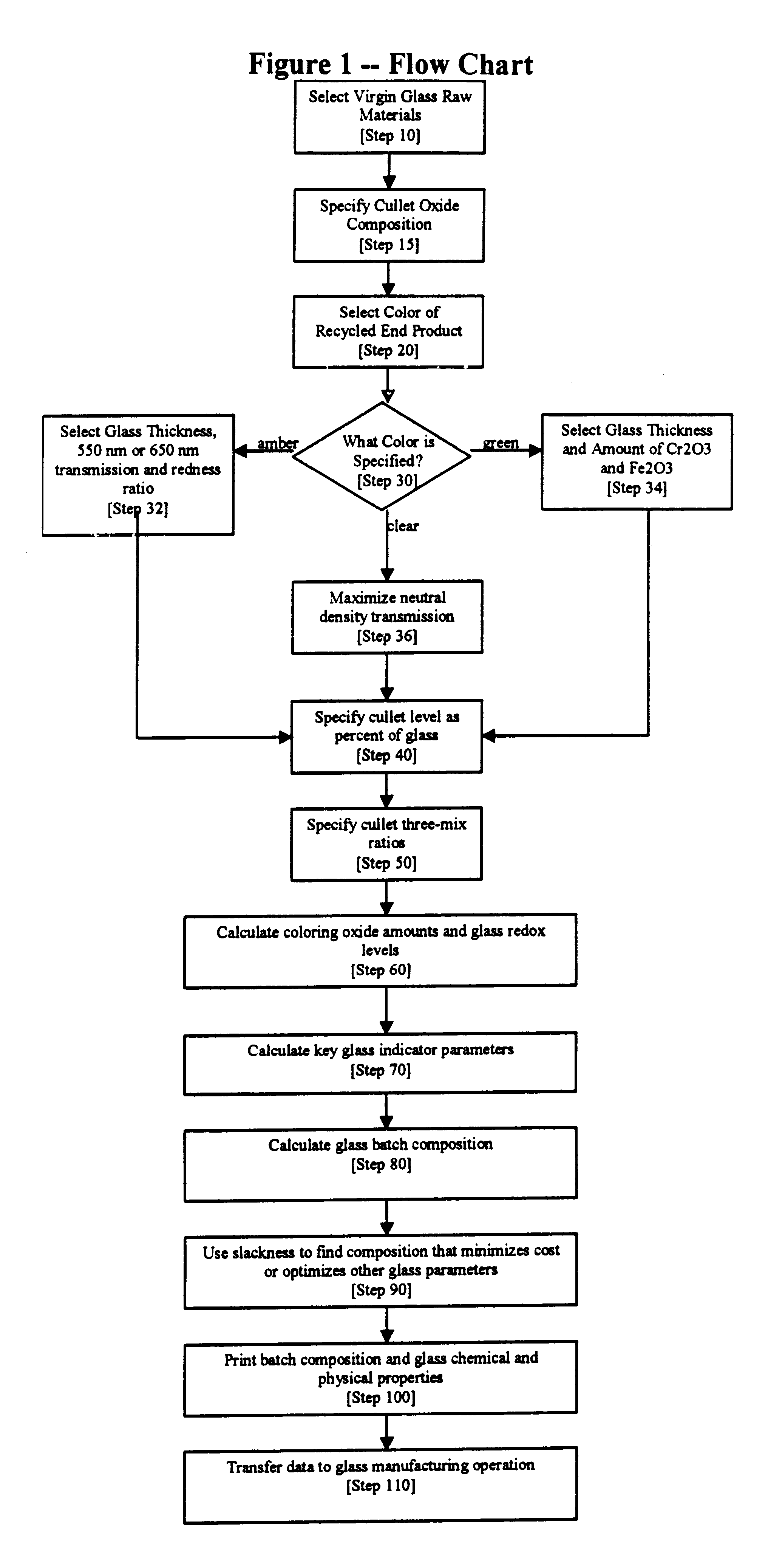

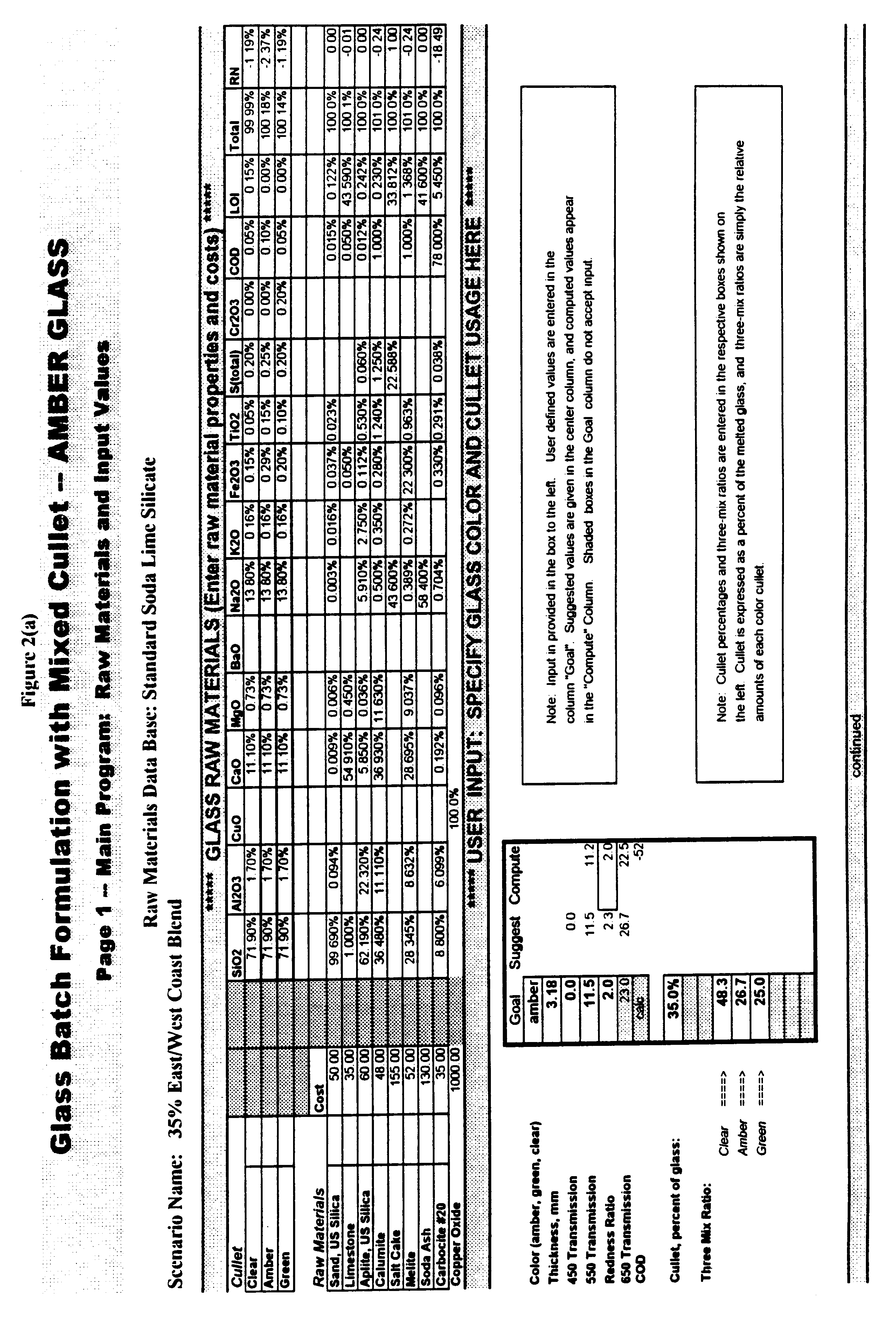

Method of recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6230521B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsOxidation-Reduction AgentBottle

An automated method for recycling mixed colored cutlet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

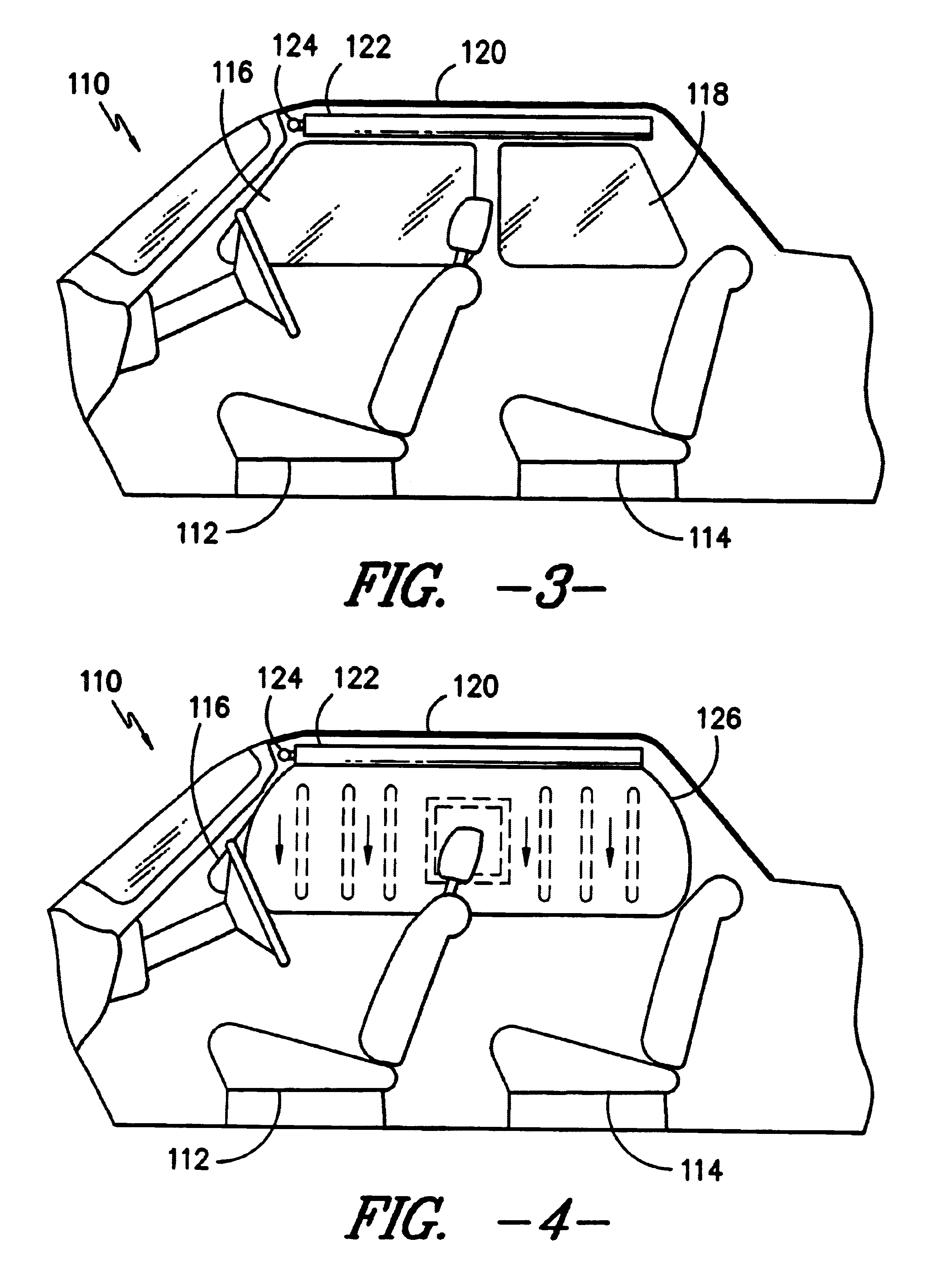

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6698458B1Beneficial and long-term low permeabilityExcellent long-term storage stabilityLeno shedding mechanismPreformed elementsNeopreneEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds wherein the film is present on the surface in an amount of at most 3.0 ounces per square yard of the fabric.

Owner:MILLIKEN & CO

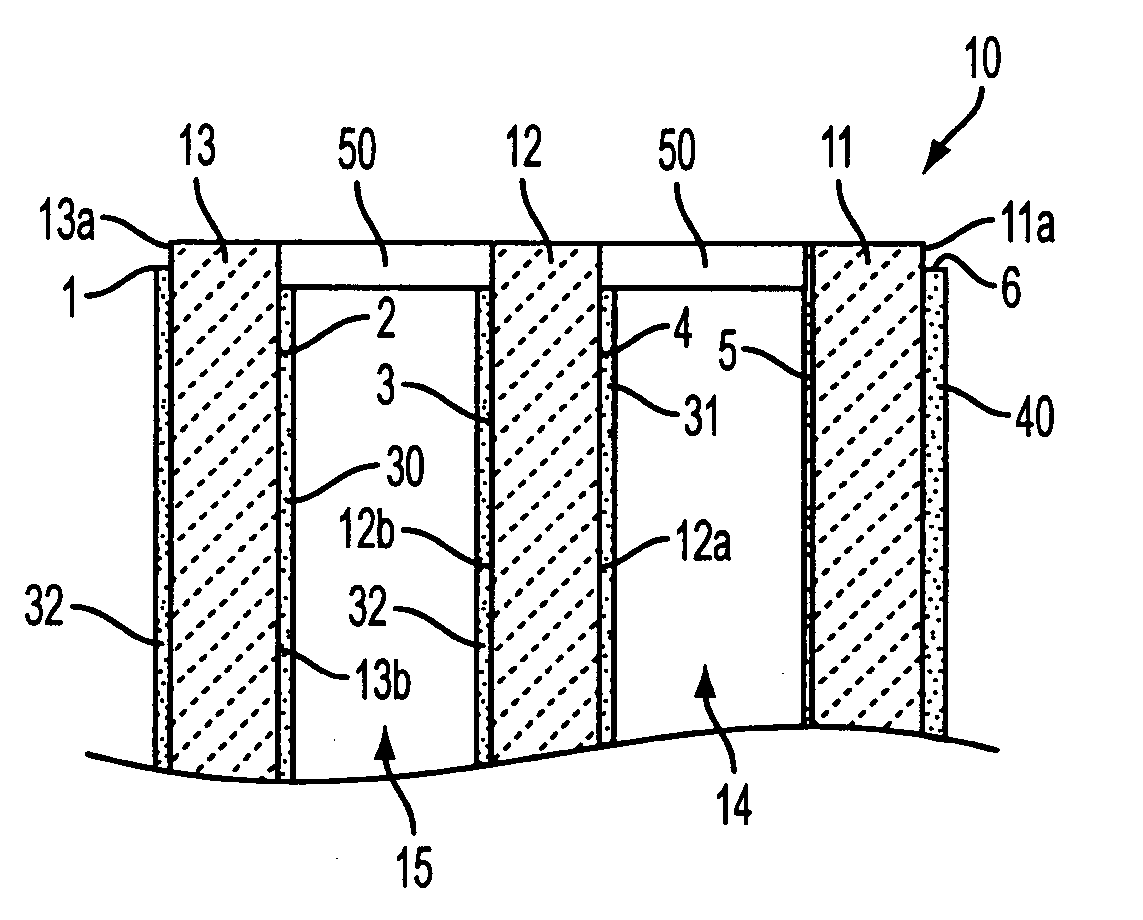

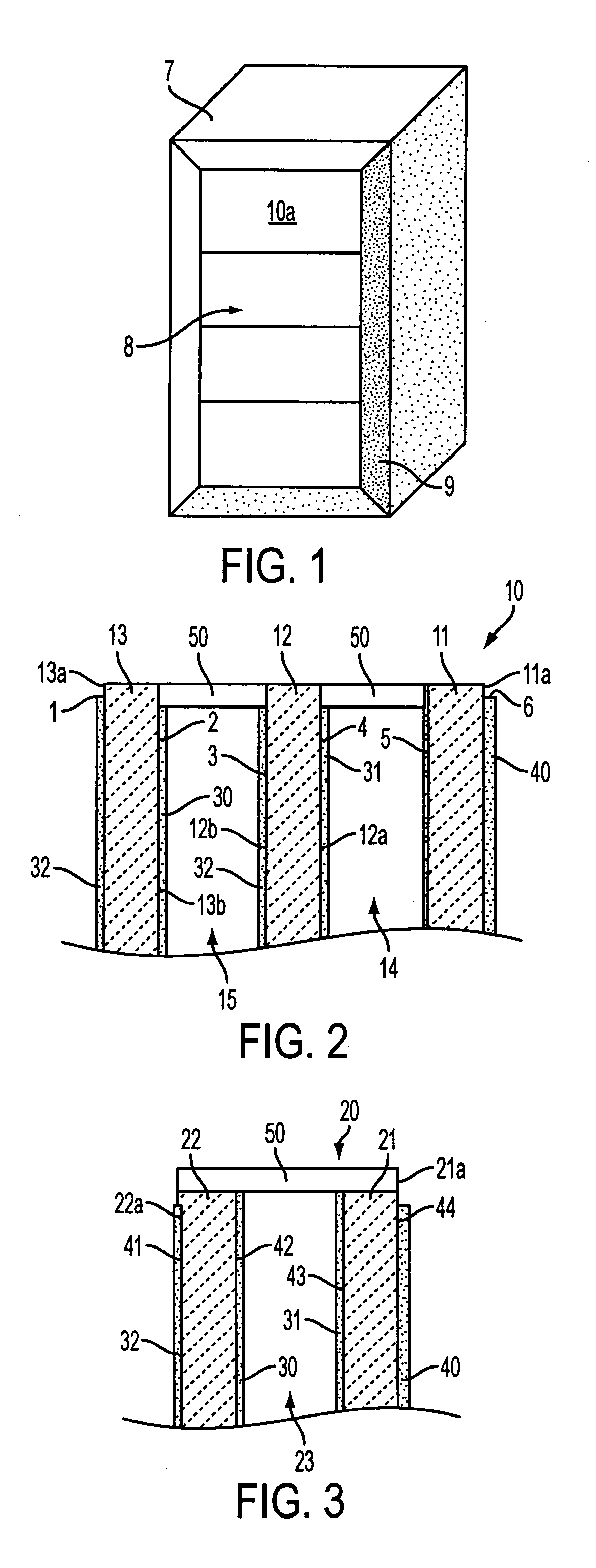

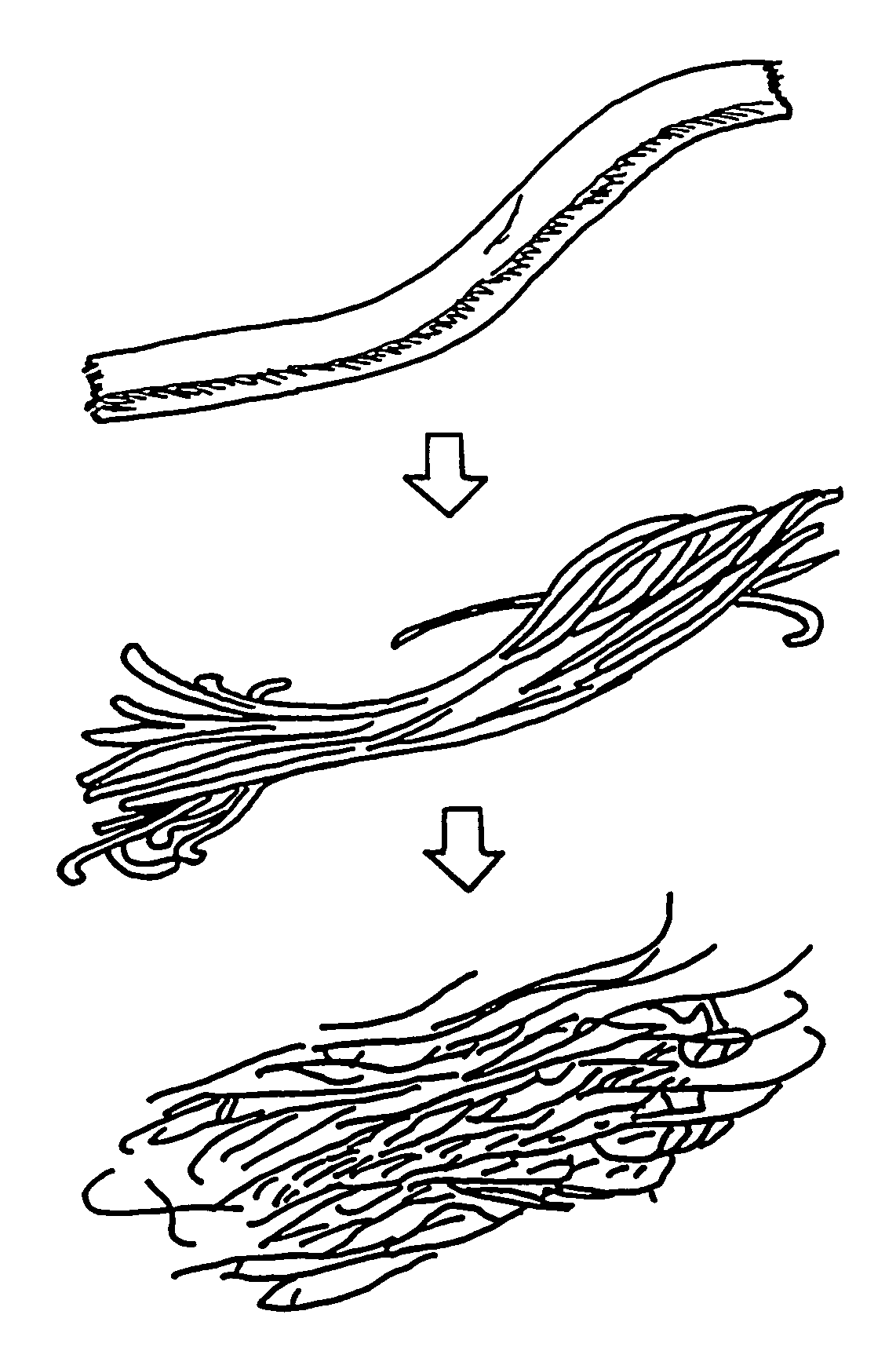

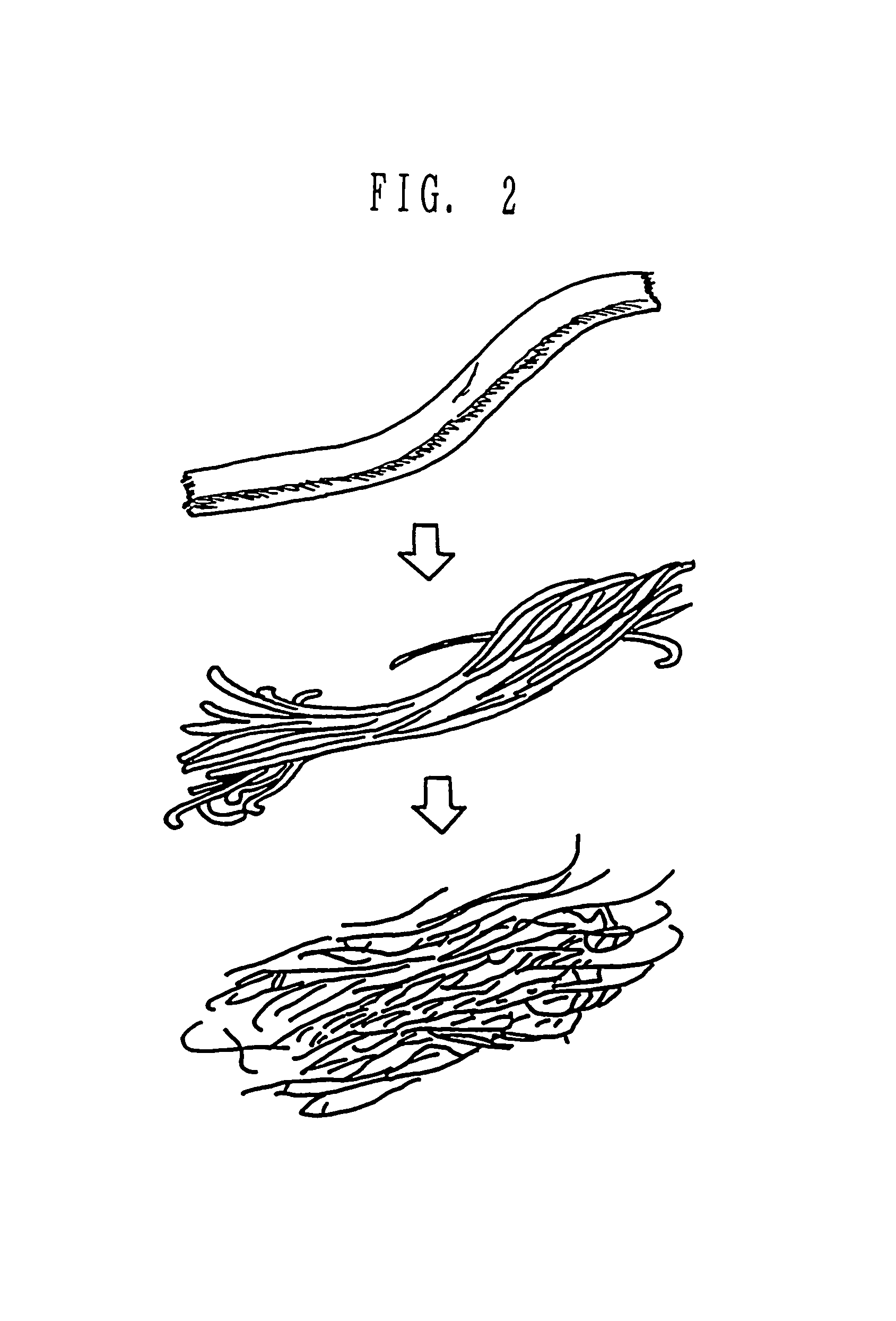

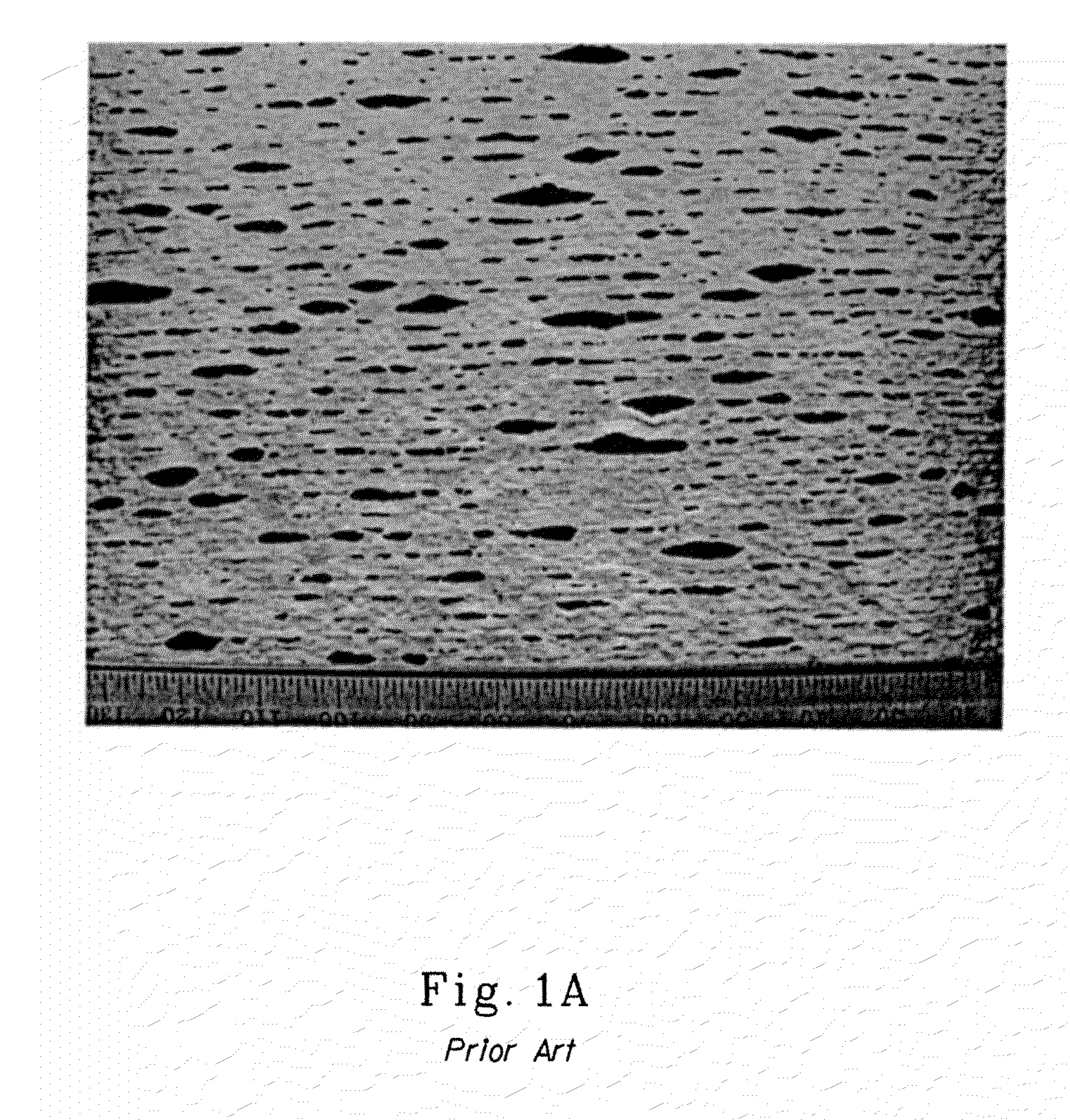

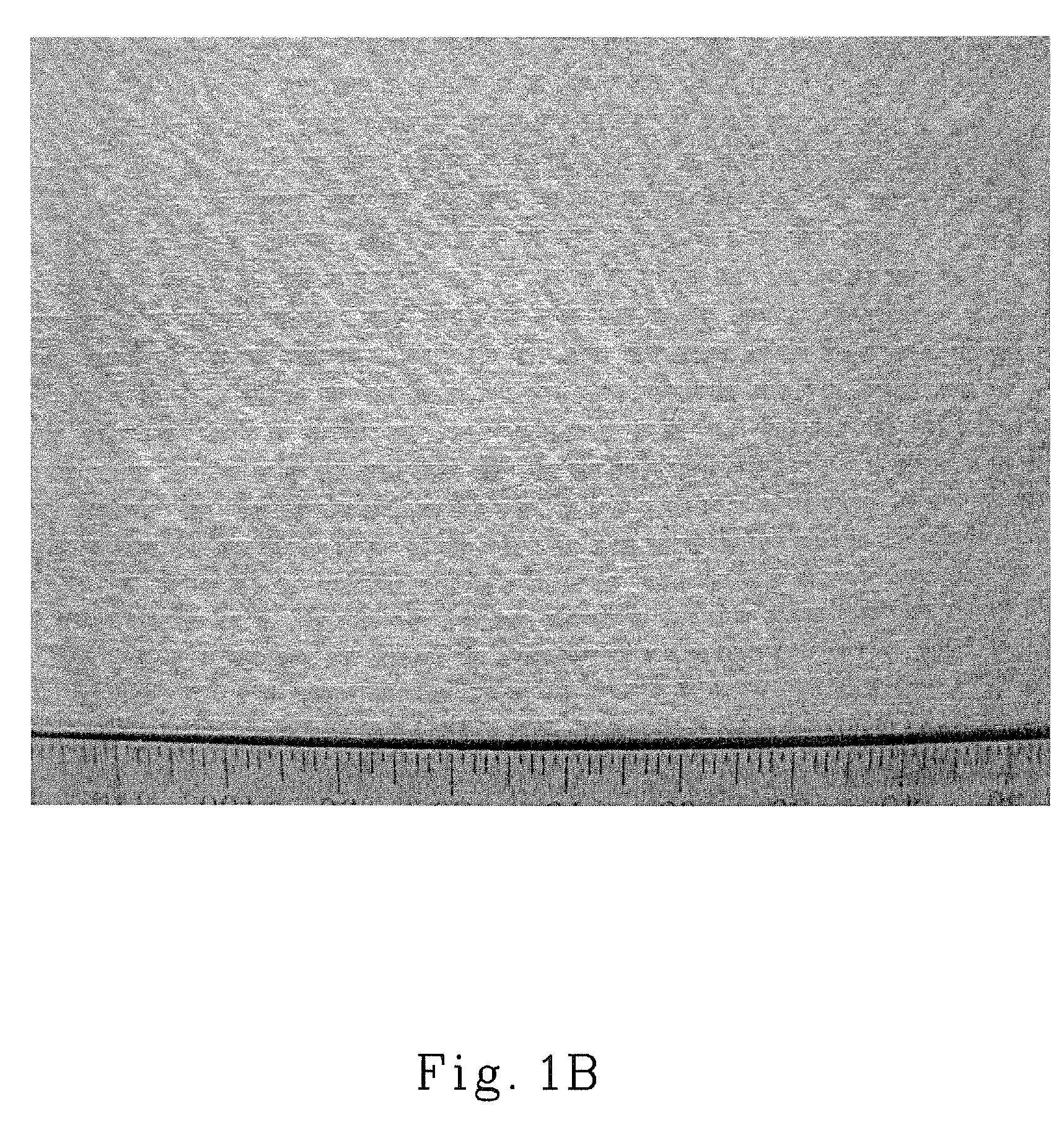

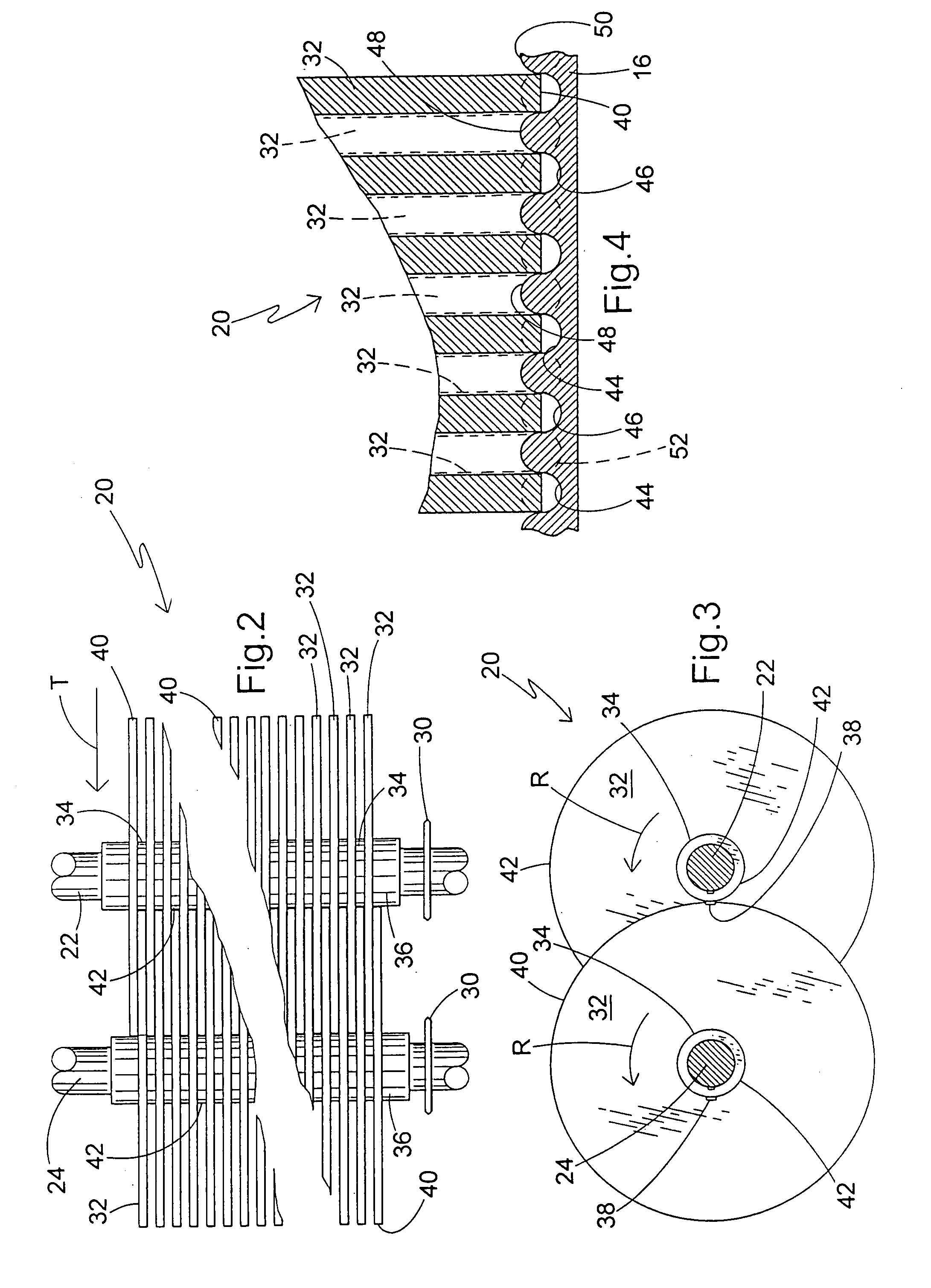

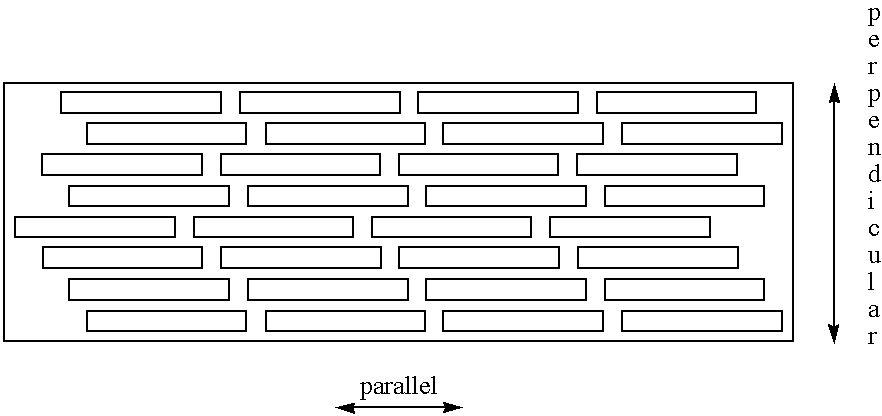

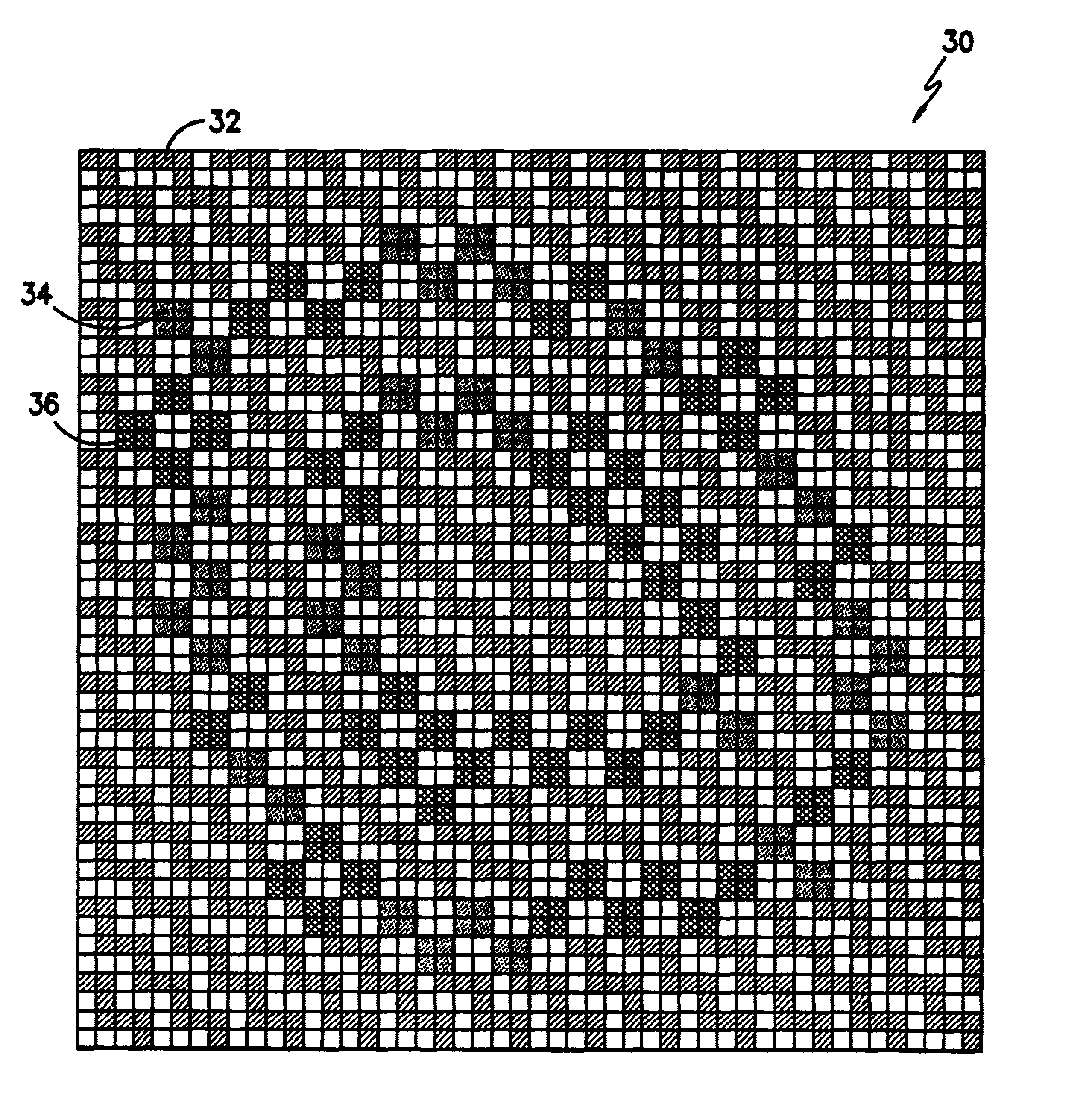

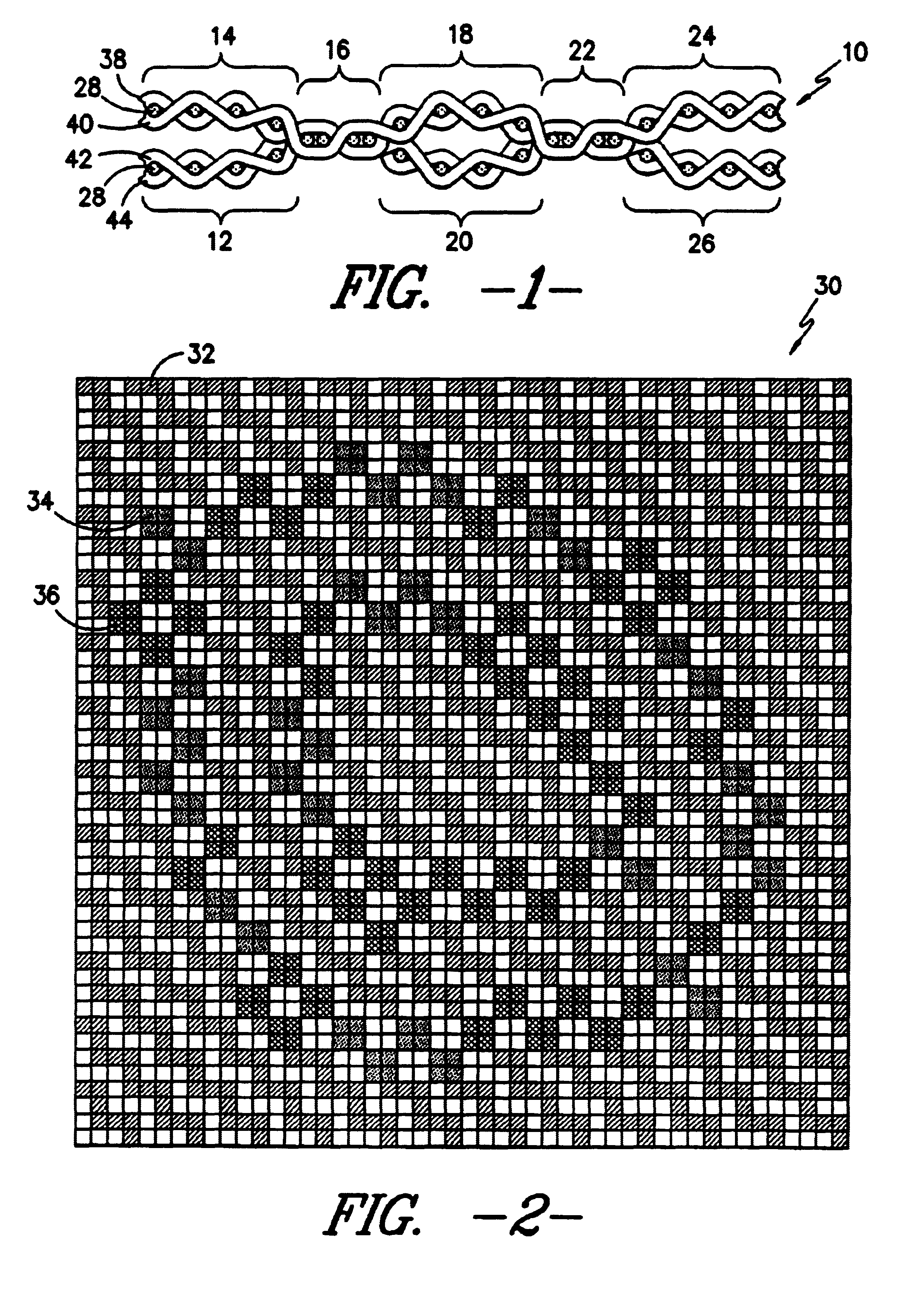

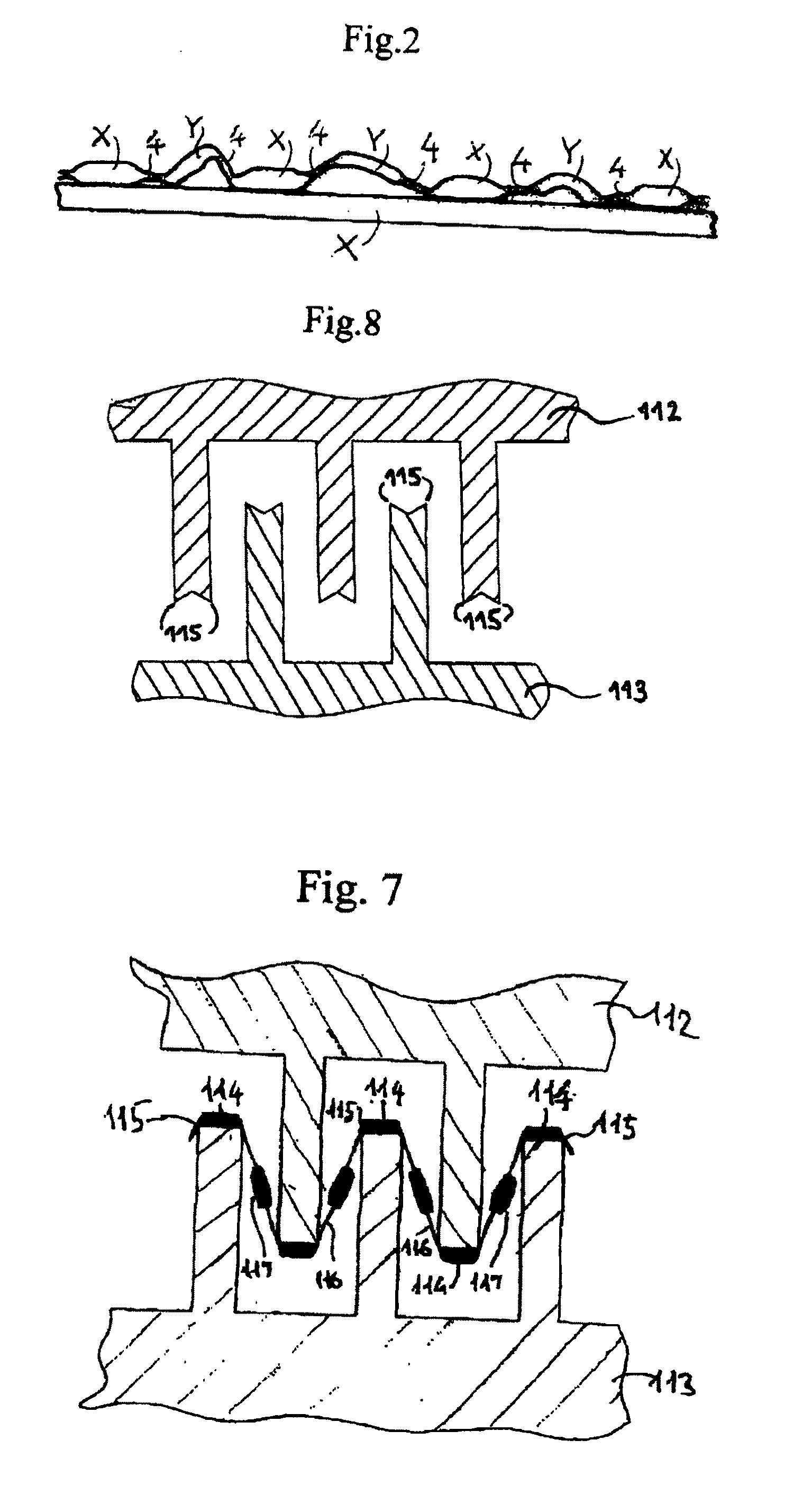

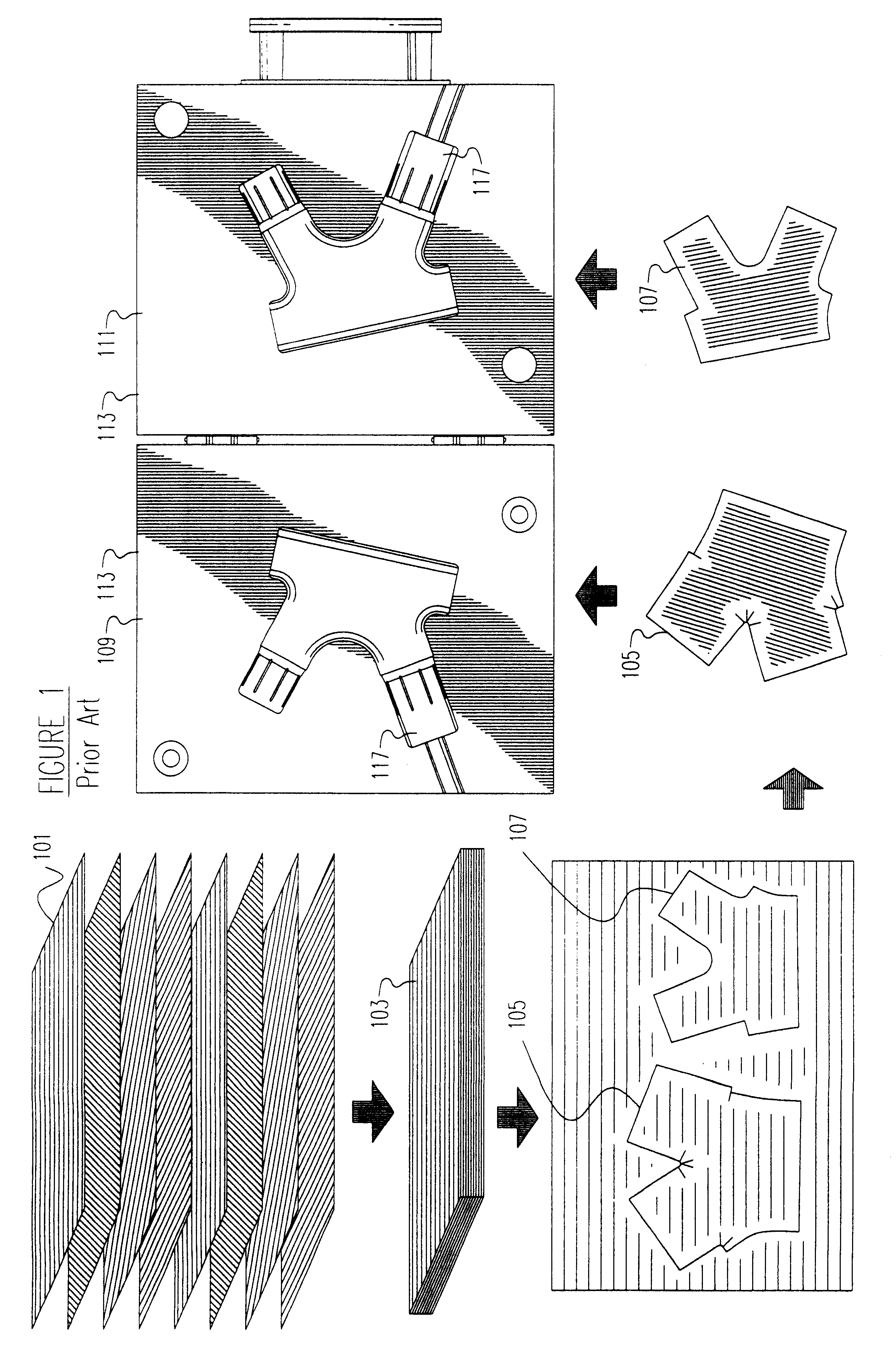

Crosslaminate of oriented films and methods and apparatus for manufacturing same

ActiveUS20090233041A1Improvement of tear propagation resistanceImprove aestheticsConfectioneryPress rollersEngineeringUltimate tensile strength

A crosslaminate is formed from two oriented plies of thermoplastic polymer material, arranged so that their orientation directions cross one another, the plies being heat sealed together. Each ply is semi-fibrillated, that is consist of linear thin regions of biaxially oriented material and thicker linear bosses between the thinner regions. The webs are sealed primarily through bonds formed at the intersection of the bosses (thicker regions). The array of bosses has a division less than 2 mm. The laminate has improved aesthetic and strength properties. A method for forming the crosslaminate involves segmental stretching of the material to form the thinner regions, and apparatus comprising intermeshing grooved stretching rollers having sharp-edged crests is described.

Owner:THE GLAD PROD CO

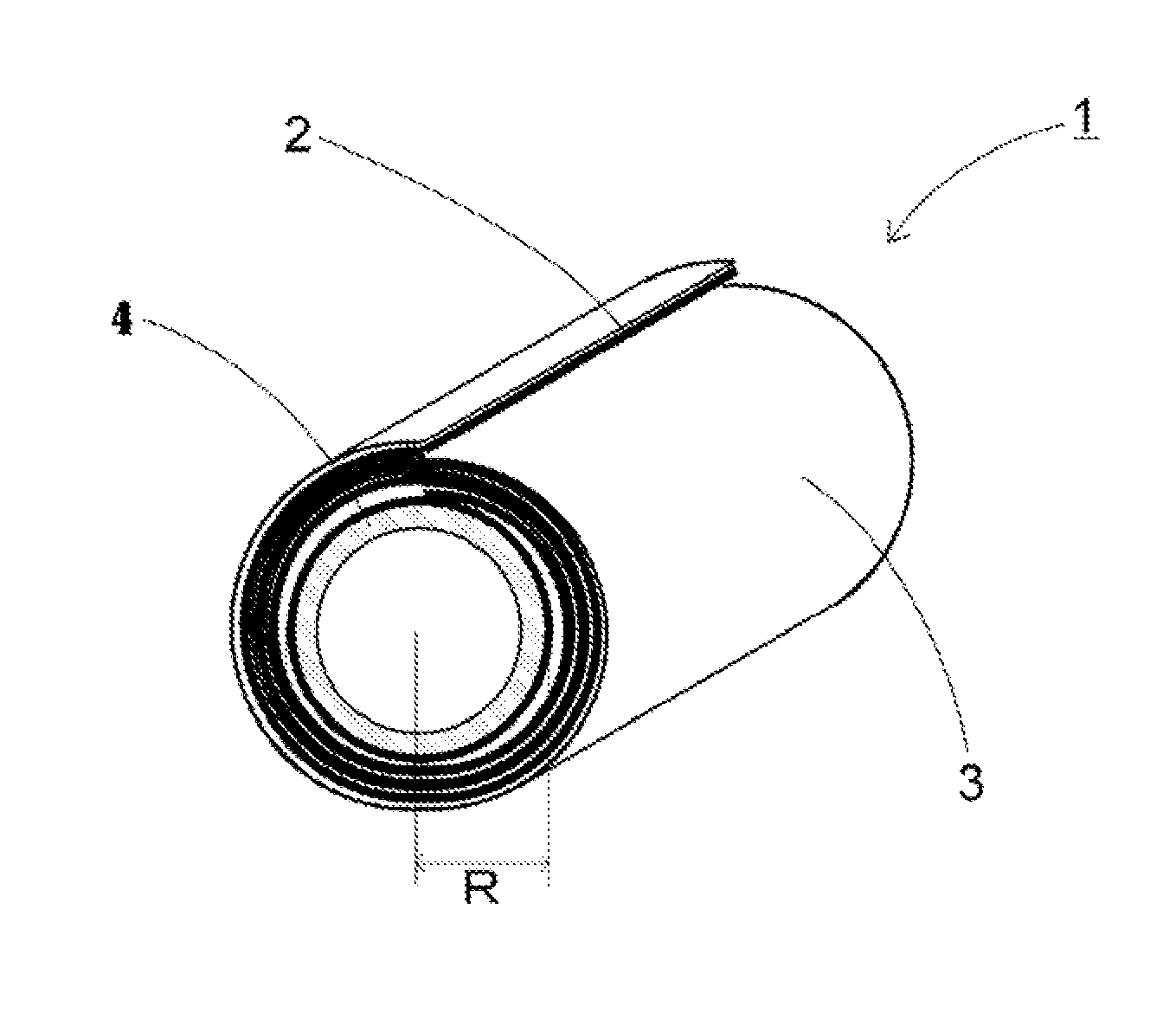

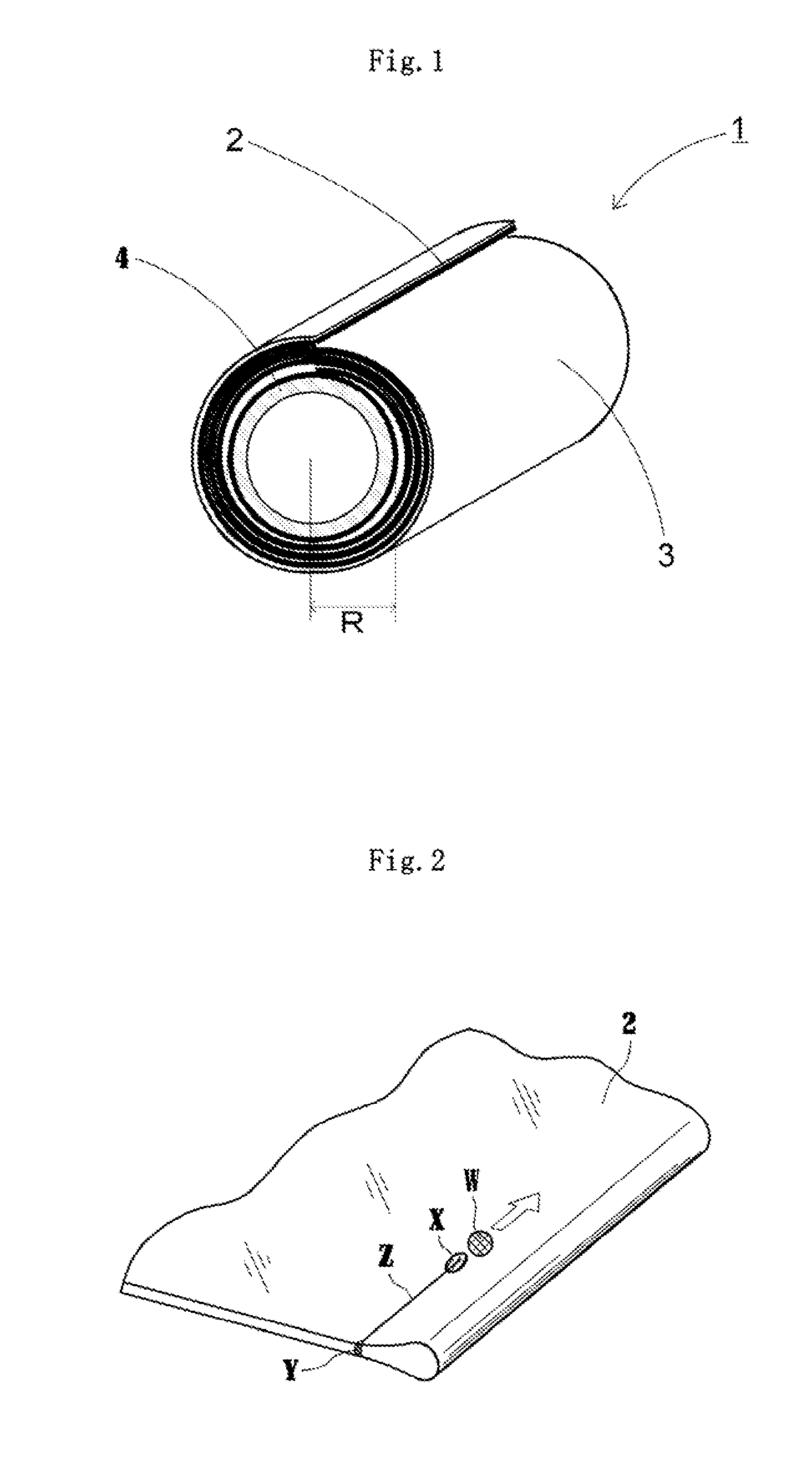

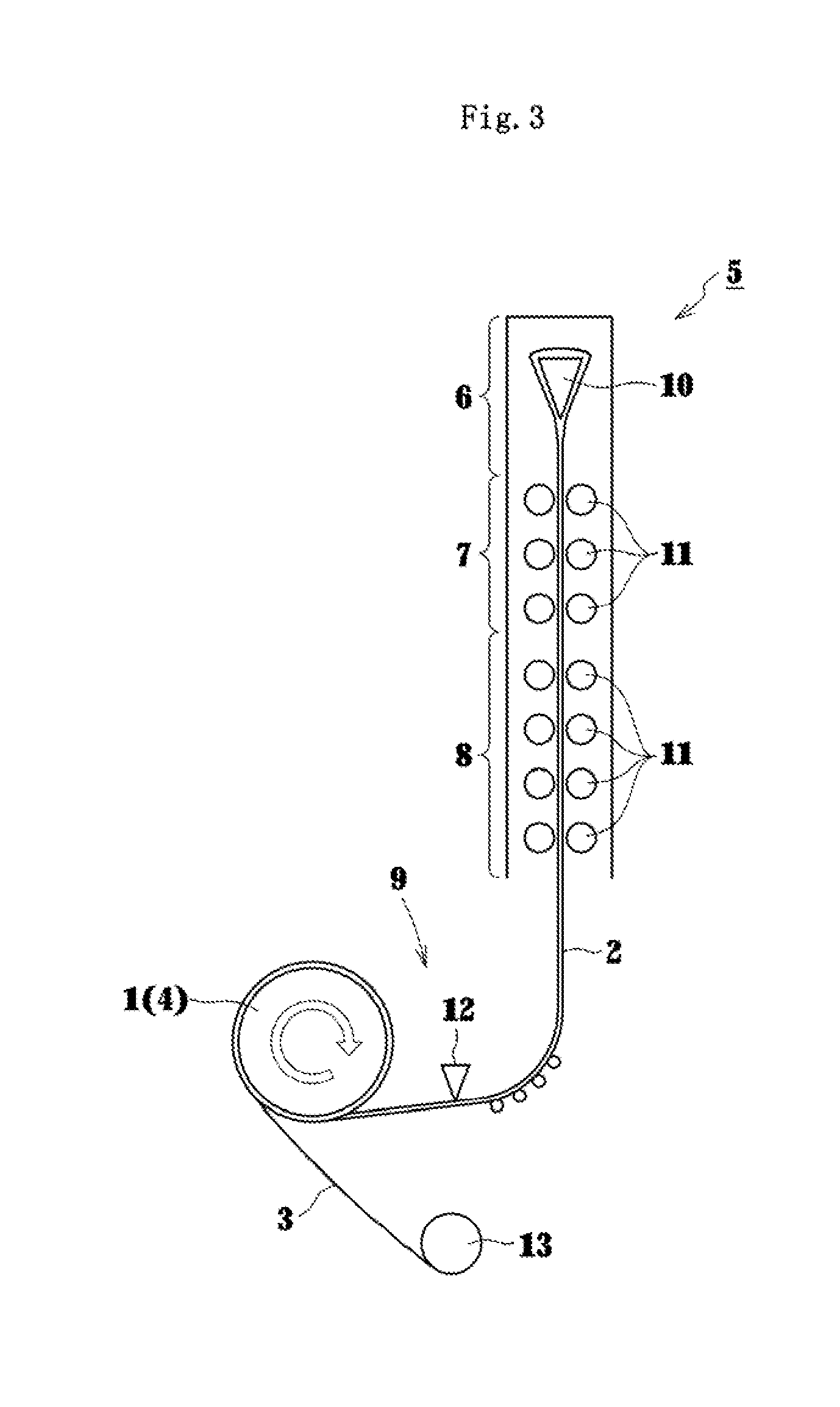

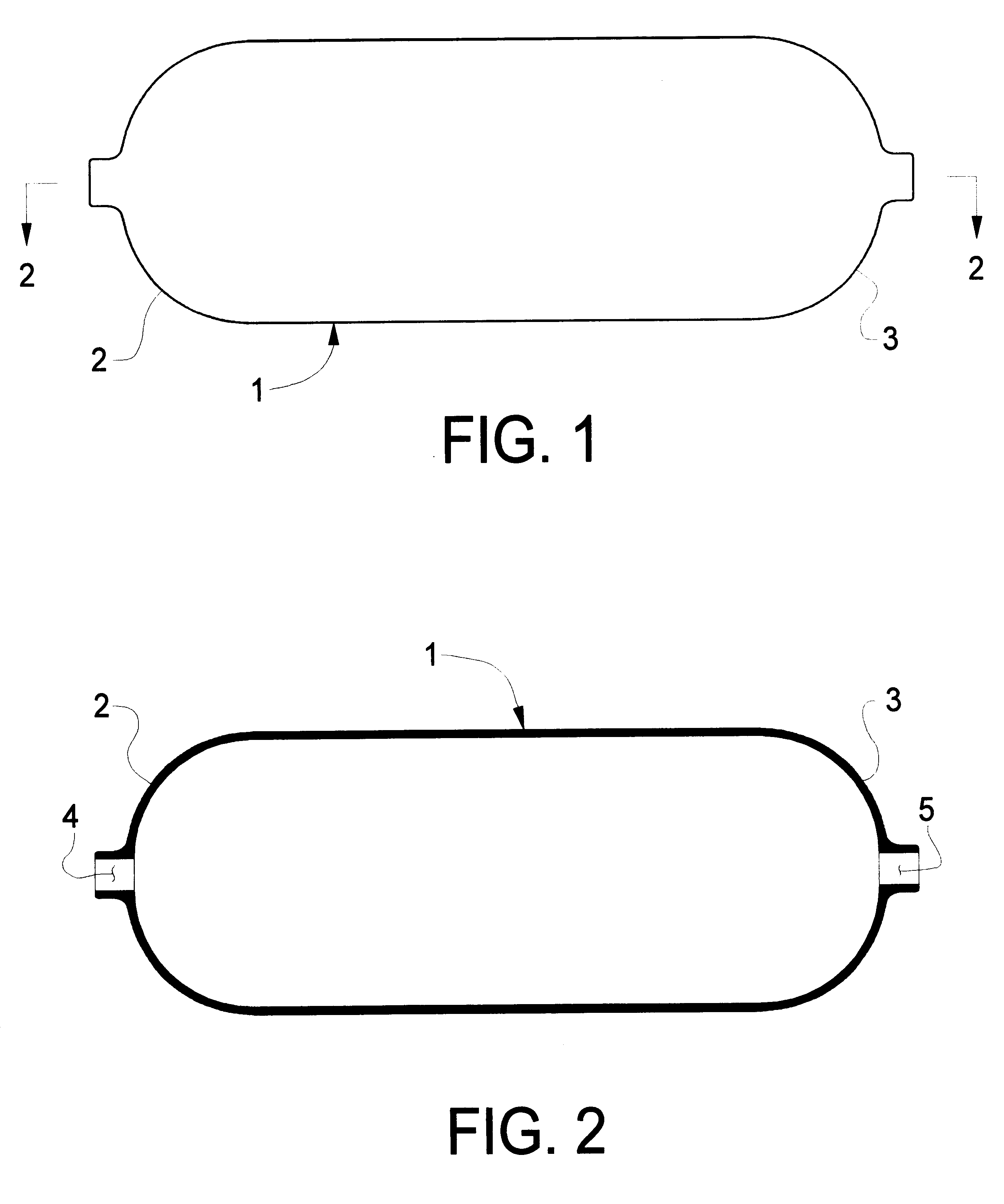

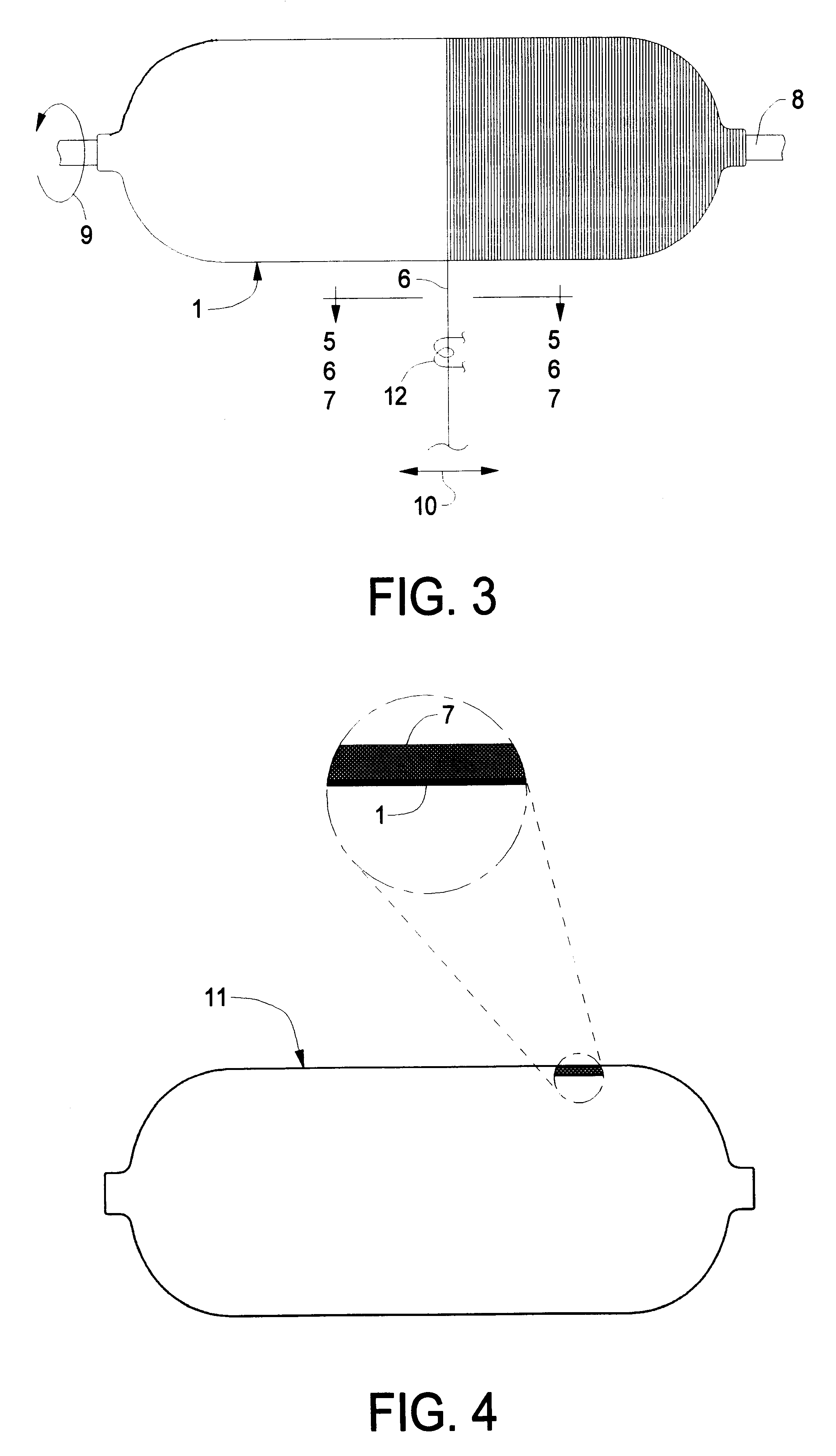

Glass roll and process for producing glass roll

ActiveUS20110200812A1Suppress situationReliable manufacturingShaft and bearingsGlass drawing apparatus3 point bendingFlexural strength

Provided is a glass roll formed by winding a glass film into a roll, in which a minimum winding radius of the glass film is optimized. Thus, the glass film is reliably prevented from breaking due to static fatigue, and is able to be stored for long periods. A glass roll (1), which is formed by winding a glass film (2) into a roll, has a configuration in which the glass film has a minimum winding radius (R) satisfying the following relation: R≧(T / 2)[(2.3 / σ)×E−1], where σ represents flexural strength of the glass film (2) obtained by a 3-point bending test, T represents a thickness of the glass film, and E represents a Young's modulus of the glass film.

Owner:NIPPON ELECTRIC GLASS CO LTD

Insulative products having bio-based binders

InactiveUS20110223364A1Readily availableLow costStarch adhesivesStarch derivtive adhesivesFiberWater soluble polysaccharides

Fibrous insulation products have an aqueous binder composition that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

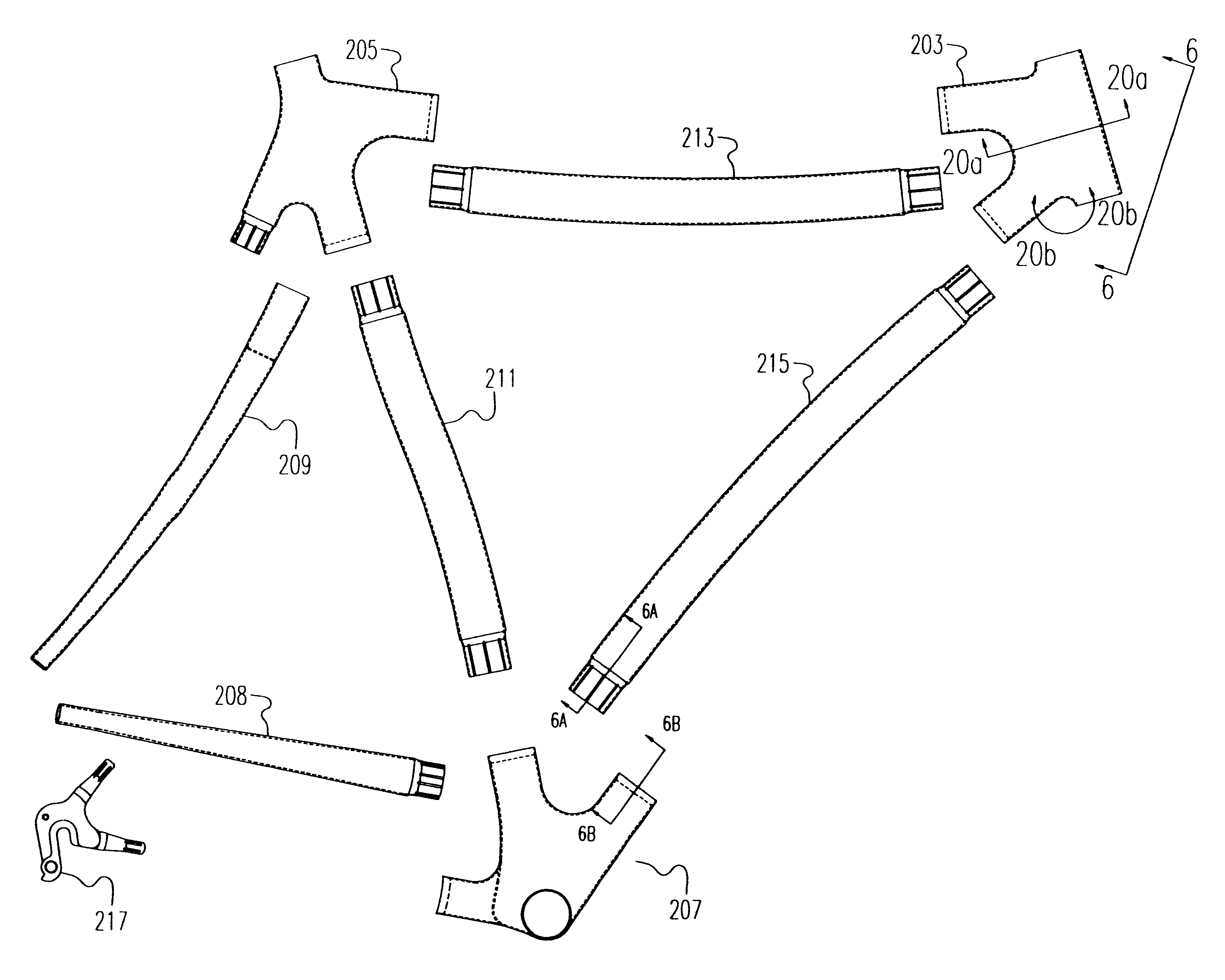

Composite bicycle frame and method of construction thereof

InactiveUS6340509B1Avoiding extra weightInhibition strengthPassenger cyclesChildren cyclesFiberVehicle frame

Bicycle frame components without laps made by a method comprising;shaping a fluid-removable core in the general form of the component,placing a flexible inflatable bladder around the core,wrapping over the assembly of core and bladder at least one ply of fiber impregnated with a curable resin, forming a cured part by inflating the bladder while the assembly of core, bladder, and impregnated fiber is in a mold to force the plies against the inner surfaces of the mold, such that compaction of the fiber against the mold is predominantly from the bladder inflation and not from the core, and heating to cure the resin to form a cured part, removing the bladder and the fluid-removable core from the interior of the cured part by disintegrating the fluid-removable core with a fluid sufficient to allow removal of the core and the bladder.

Owner:RADIUS ENG

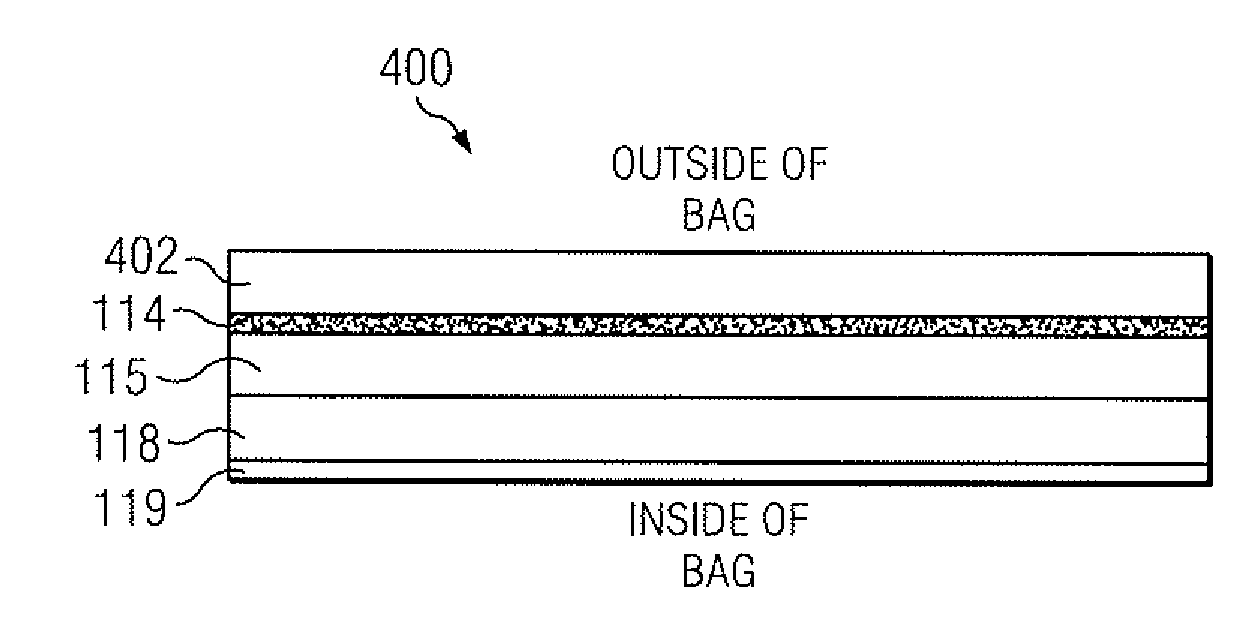

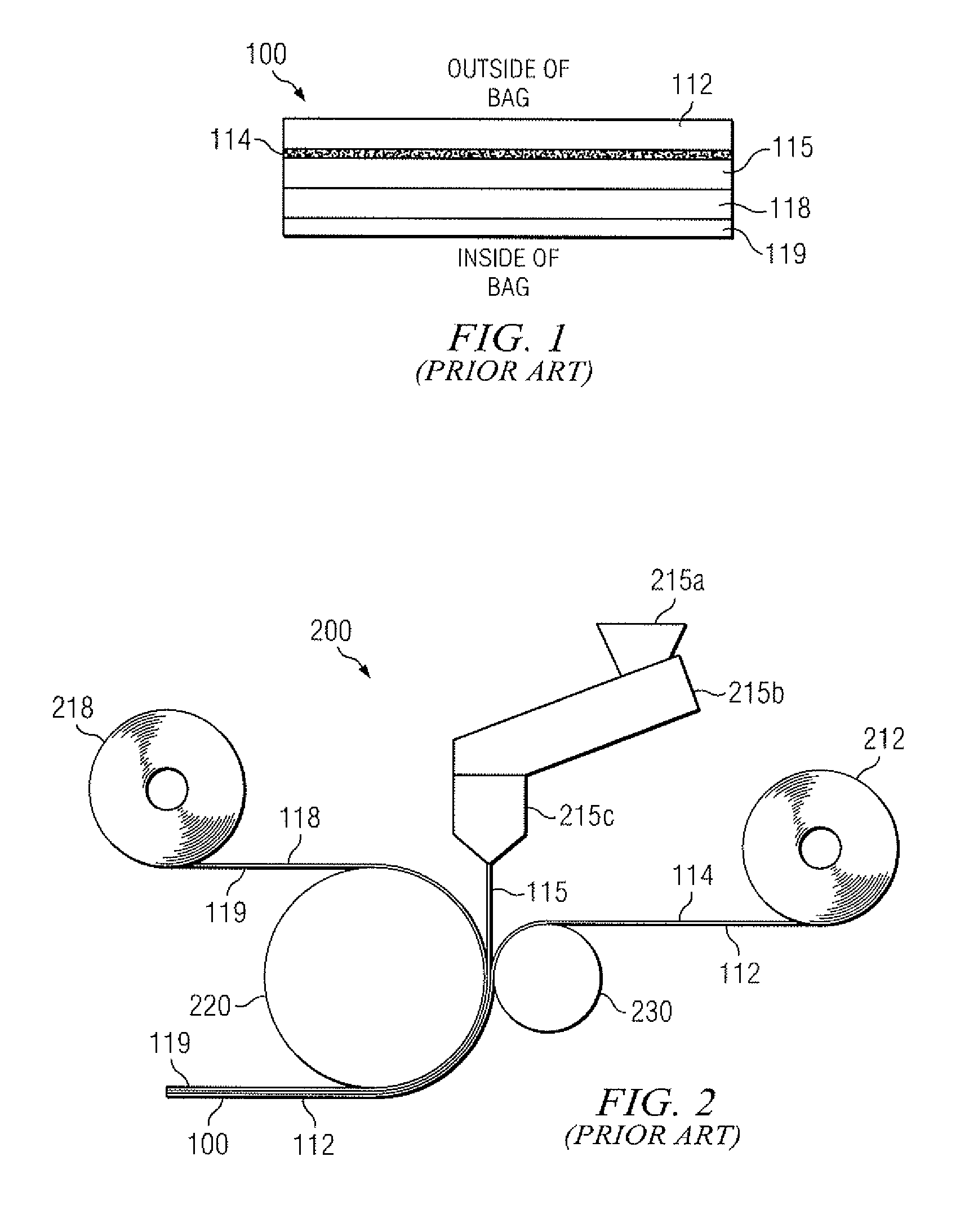

Environmentally-Friendly Multi-Layer Flexible Film Having Barrier Properties

A multi-layer film with barrier properties having one or more layers made from a bio-based film is disclosed. In one aspect, the print web comprises a bio-based film. The bio-based film can comprises polylactide or polyhydroxy-alkanoate. Unlike prior art petroleum-based films, the bio-based film of the present invention is made from a renewable resource and is biodegradable.

Owner:FRITO LAY NORTH AMERICA INC

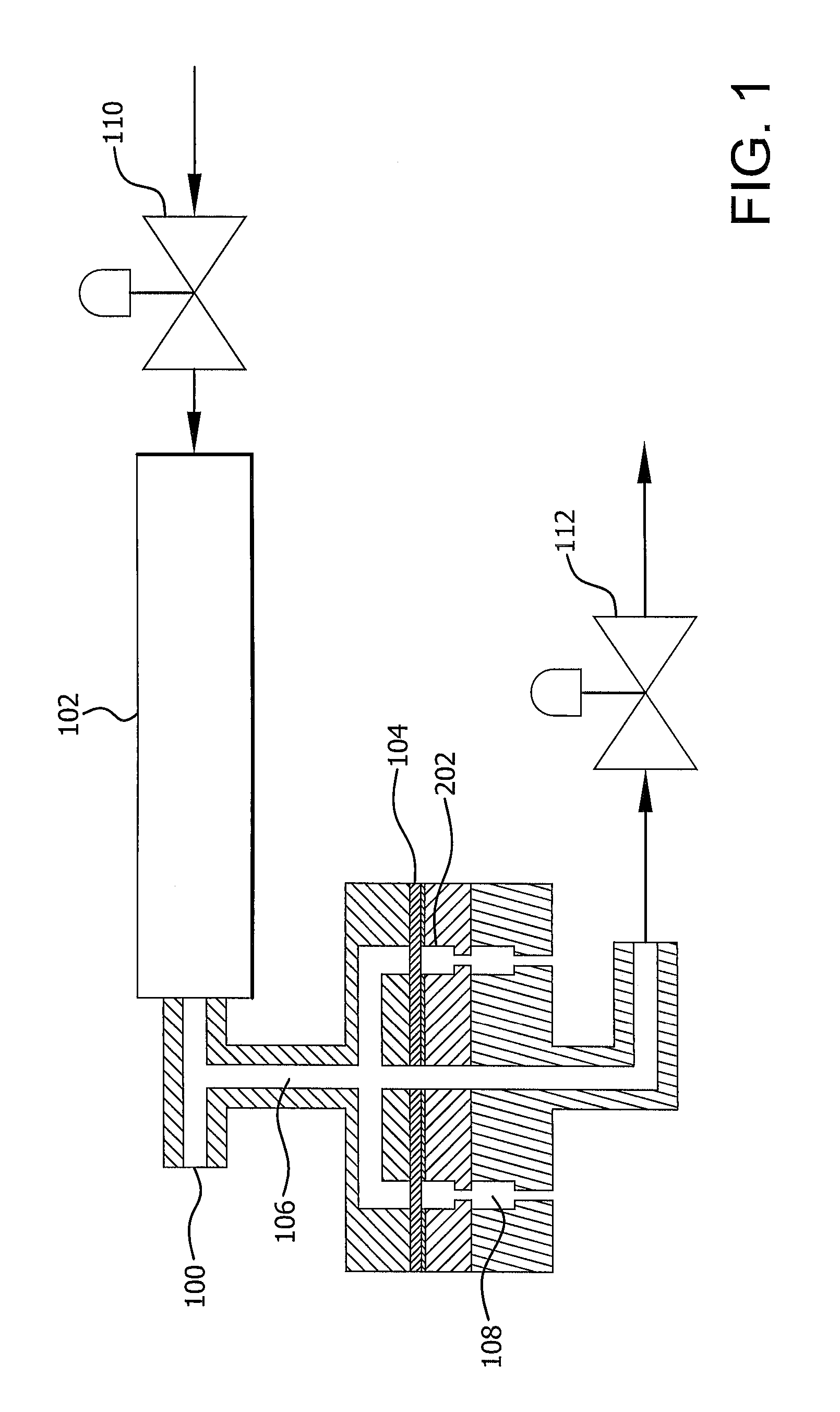

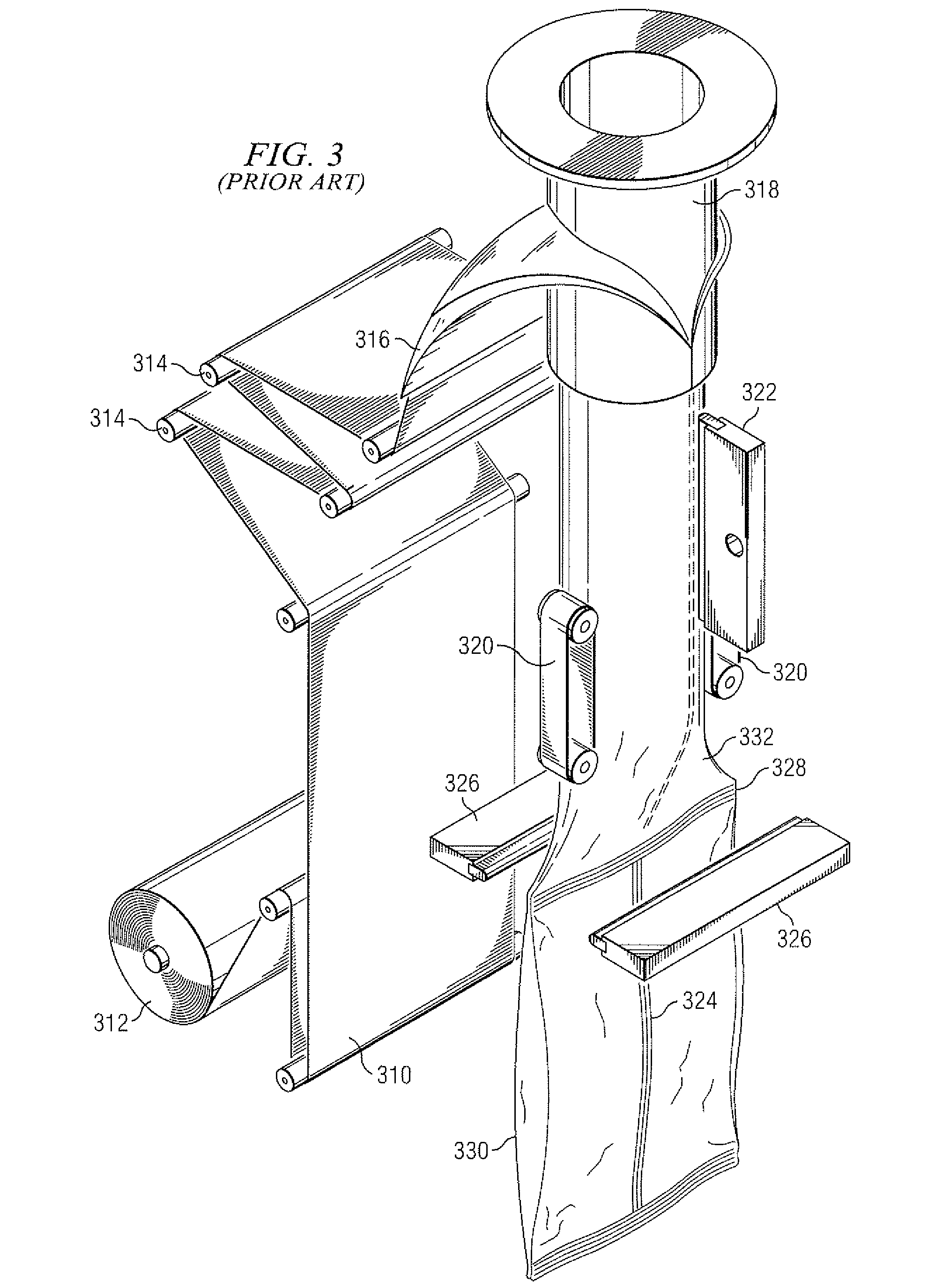

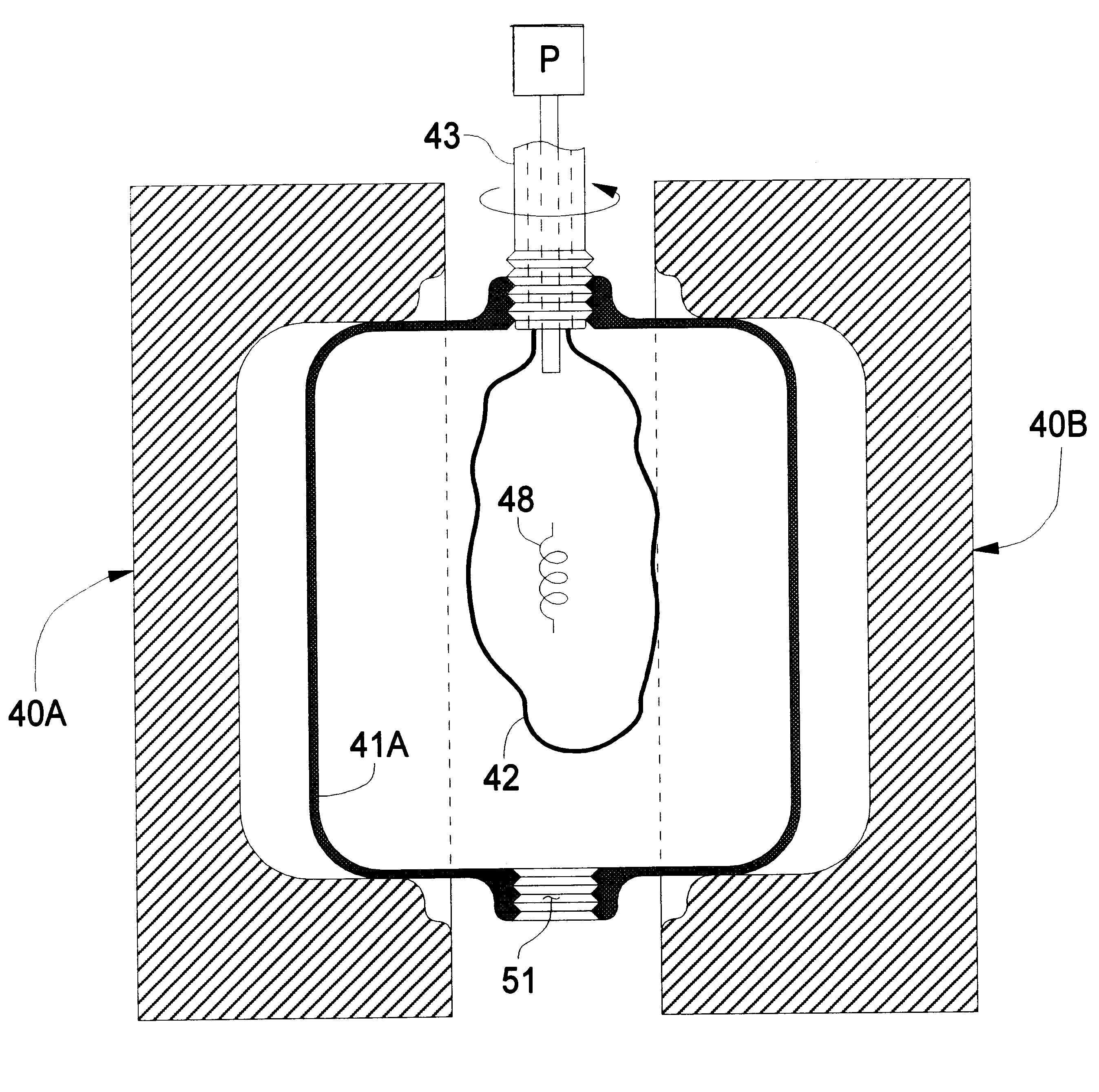

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

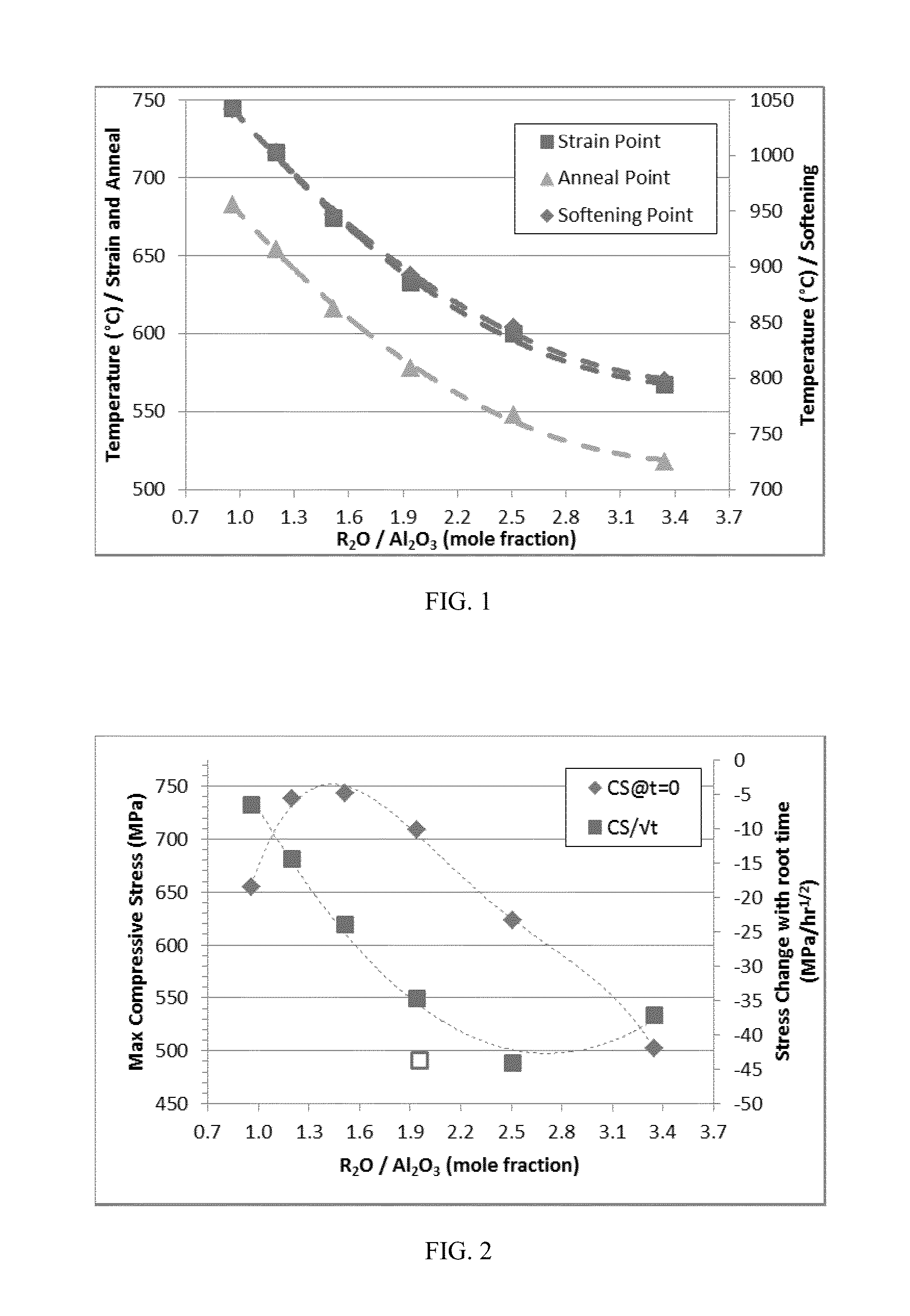

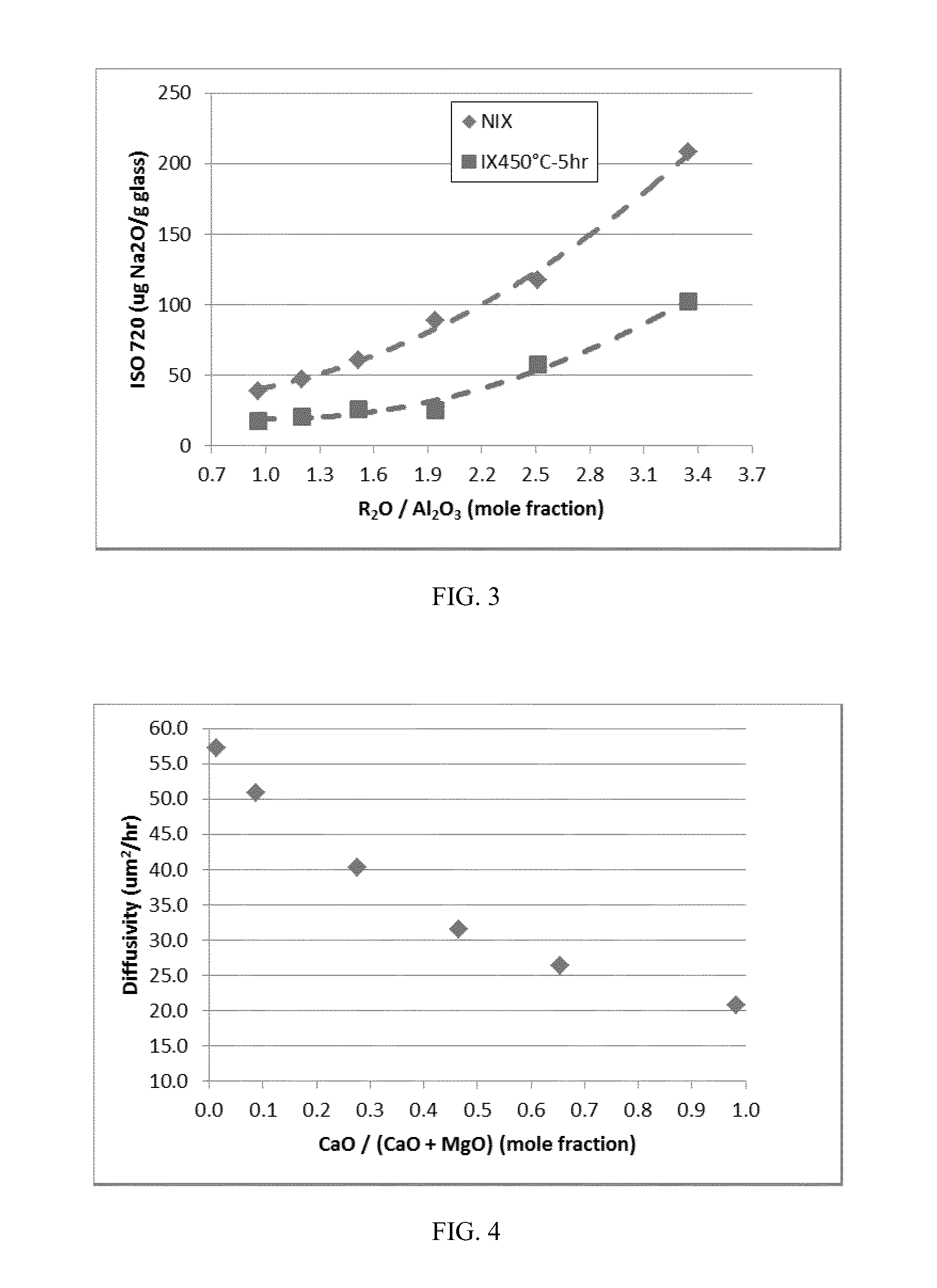

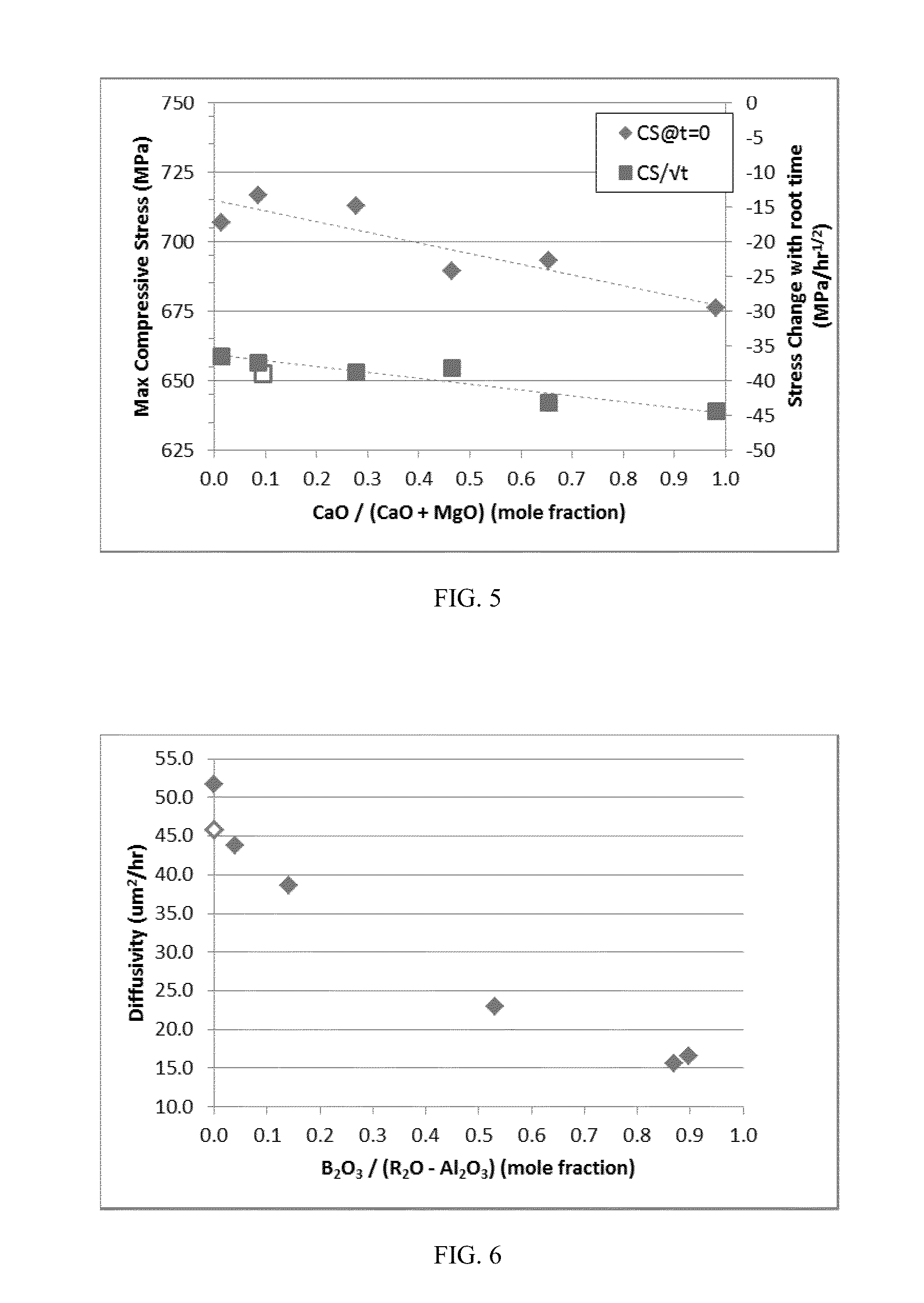

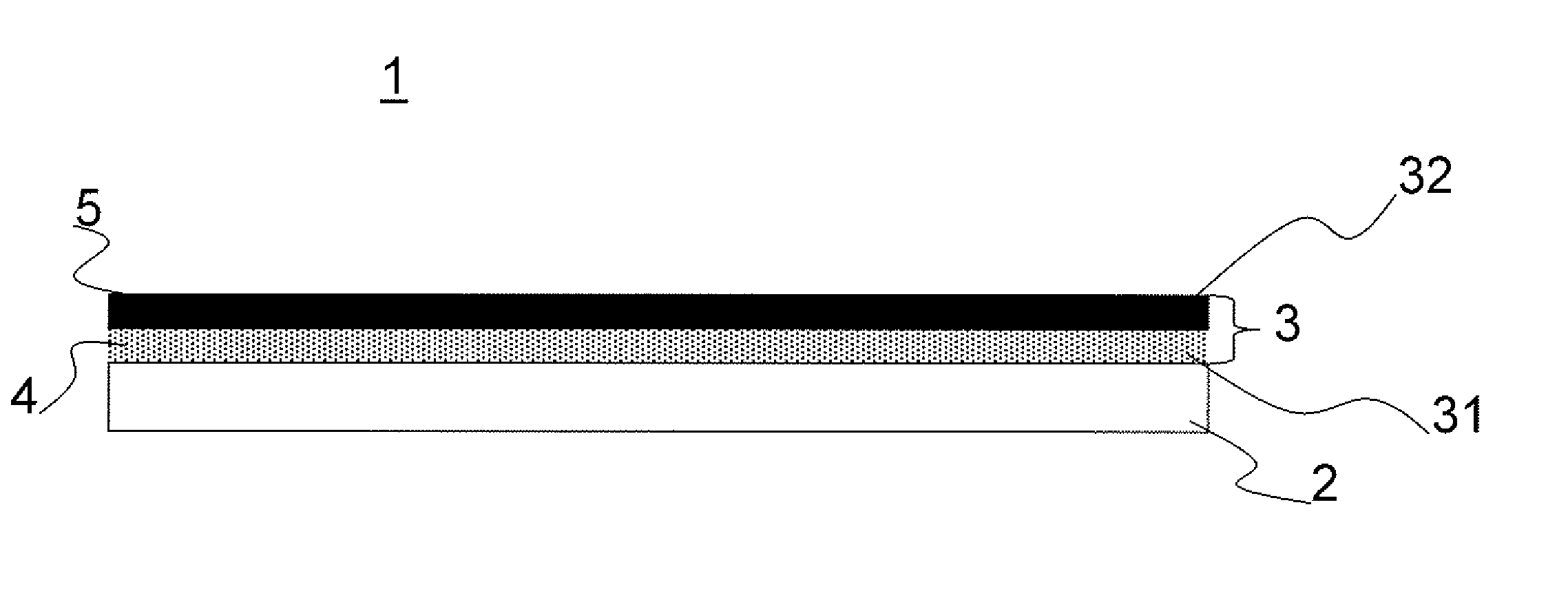

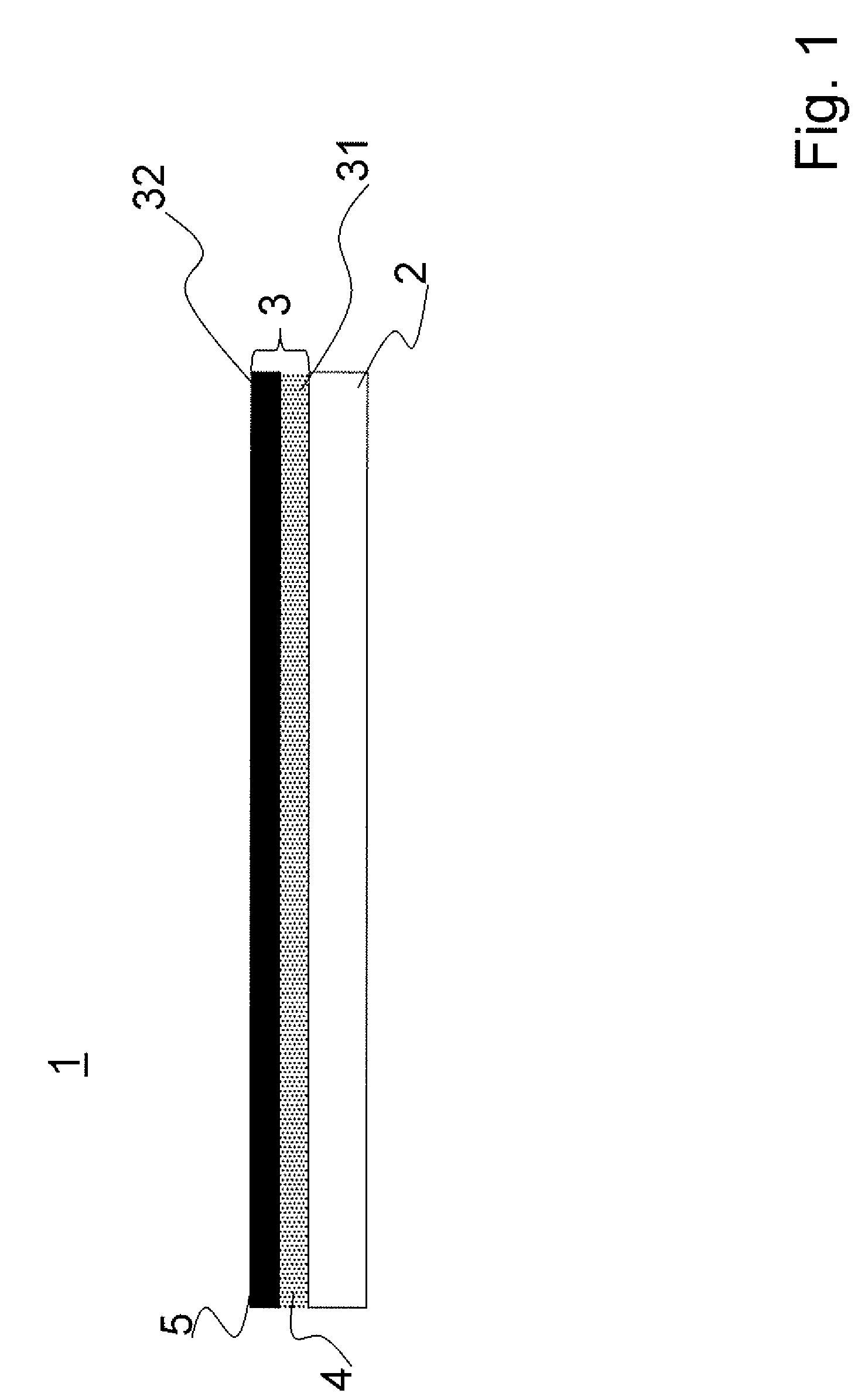

Glass Articles with Improved Chemical and Mechanical Durability

InactiveUS20130101764A1Pharmaceutical containersMedical packagingAlkali metal oxideAlkaline earth oxides

A glass article may formed from a glass composition that may include from about 70 mol. % to about 78 mol. % SiO2, from about 3 mol. % to about 13 mol. % alkaline earth oxide, X mol. % Al2O3, and Y mol. % alkali oxide. The alkali oxide may include Na2O in an amount greater than or equal to about 9 mol. % and less than or equal to about 15 mol. %. The ratio of Y:X may be greater than 1. The glass article may be free of boron and compounds of boron. The glass article may have a compressive stress layer with a compressive stress greater than or equal to about 250 MPa and depth of layer greater than or equal to about 25 μm. The glass article may have at least a type HGA2 hydrolytic resistance according to the ISO 720 standard.

Owner:CORNING INC

Methods and compositions for coating pipe

InactiveUS20040191439A1Improve stabilityHigh strengthSolid waste managementPretreated surfacesUltimate tensile strengthMechanical property

The present invention includes cement compositions and methods for using such cement compositions to coat pipe surfaces, particularly usefull for providing protection from hostile conditions that may otherwise lead to corrosion of the pipe surface. These cement compositions have improved mechanical properties including tensile strength, elasticity, and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

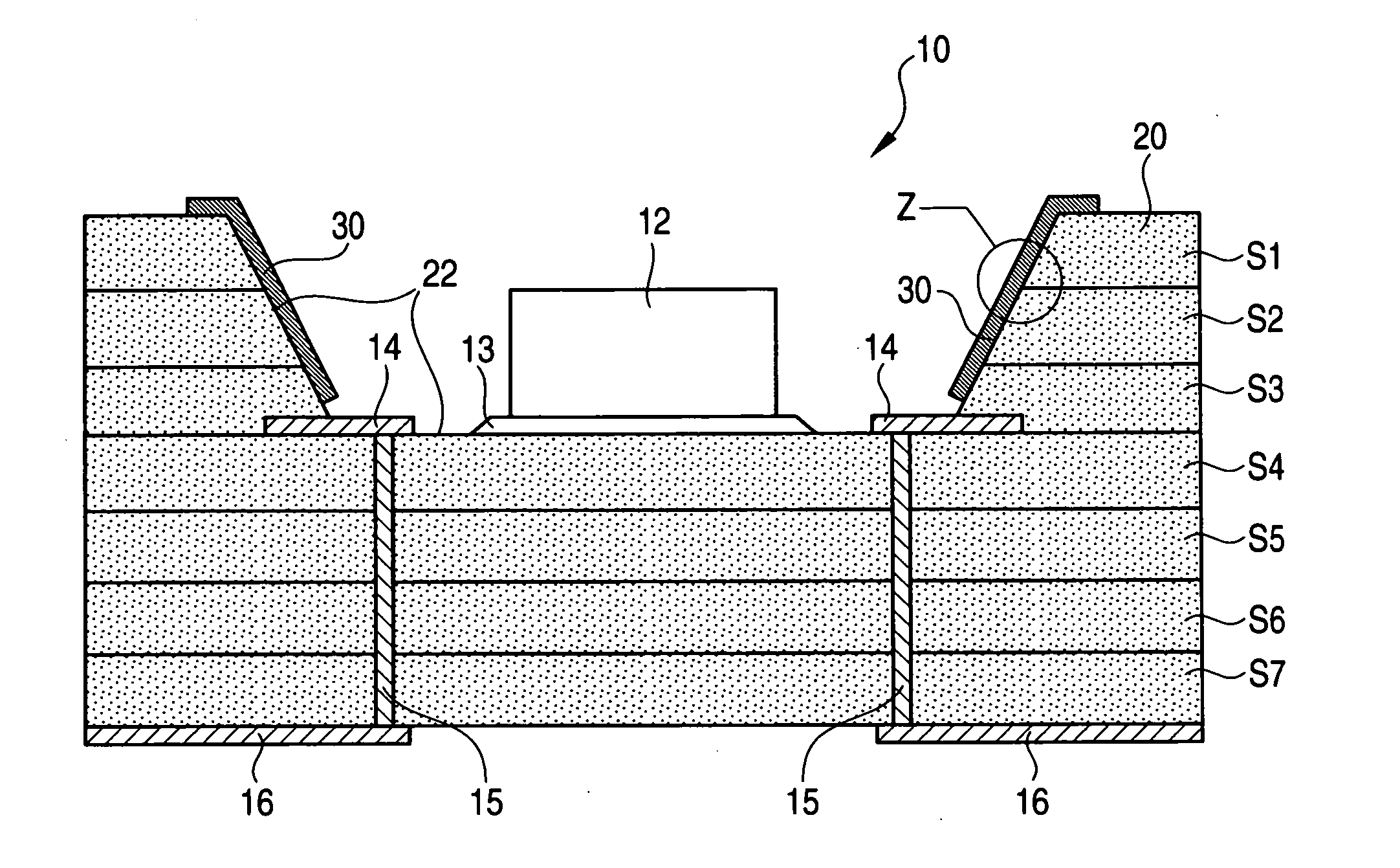

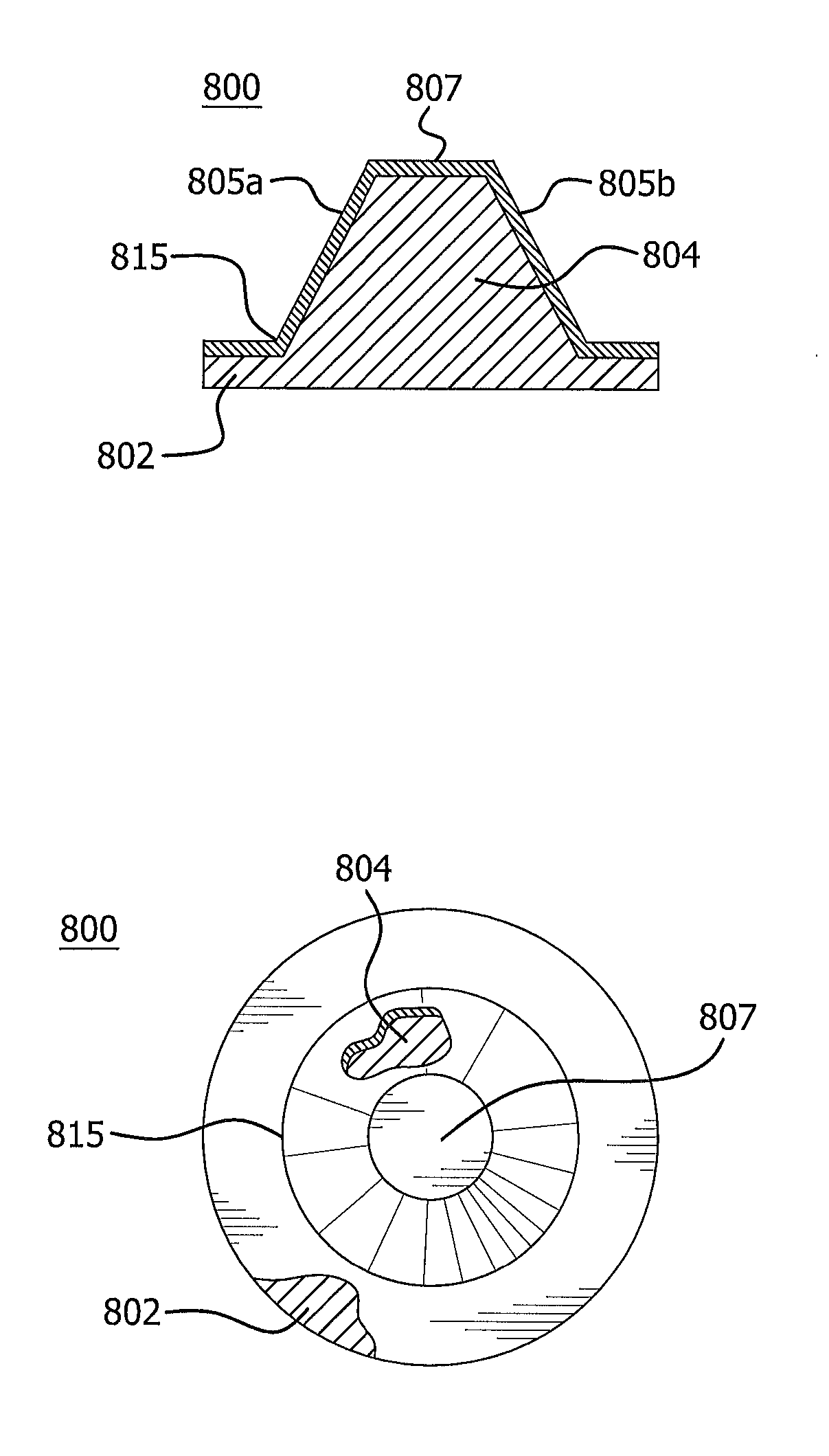

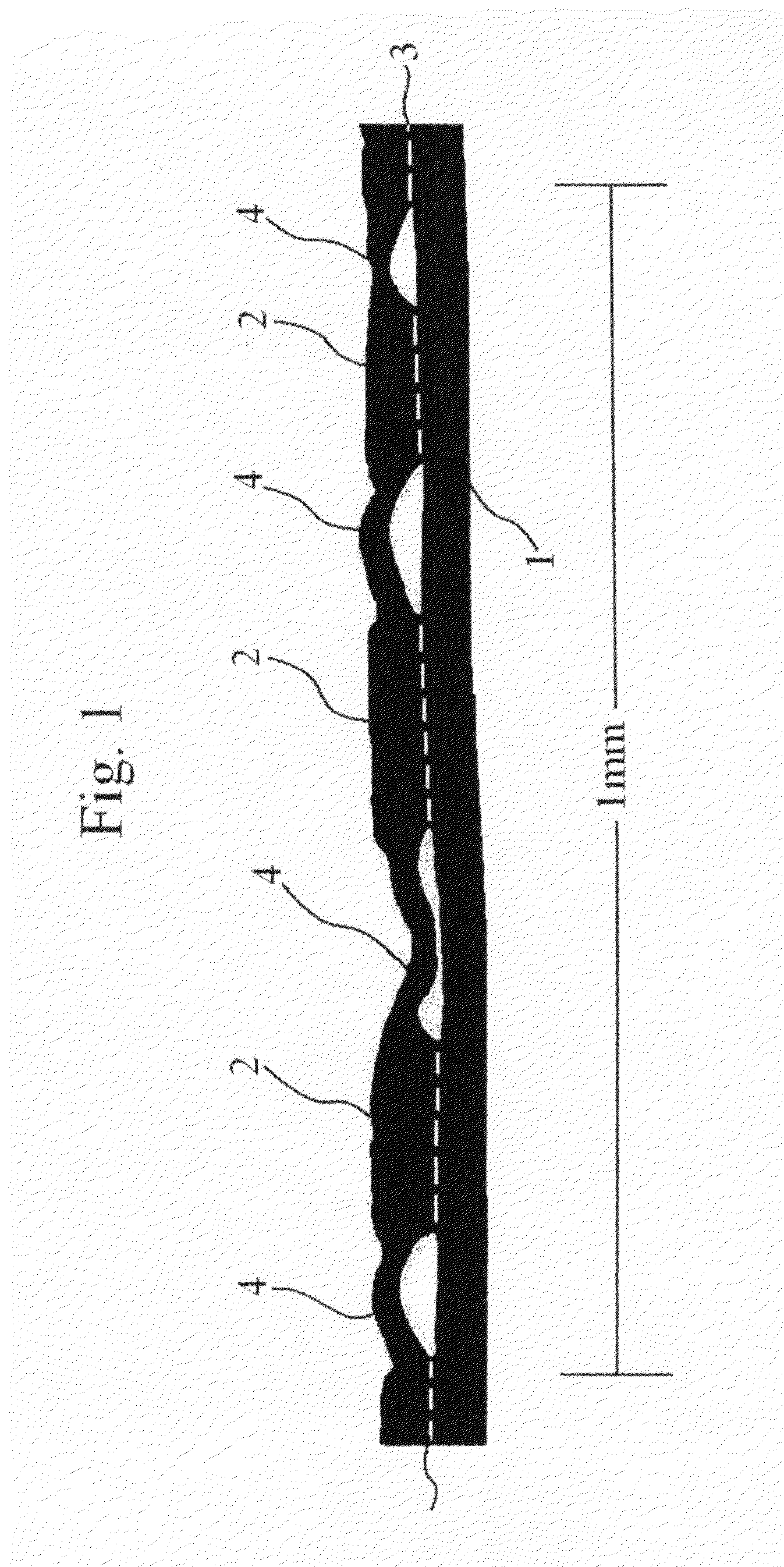

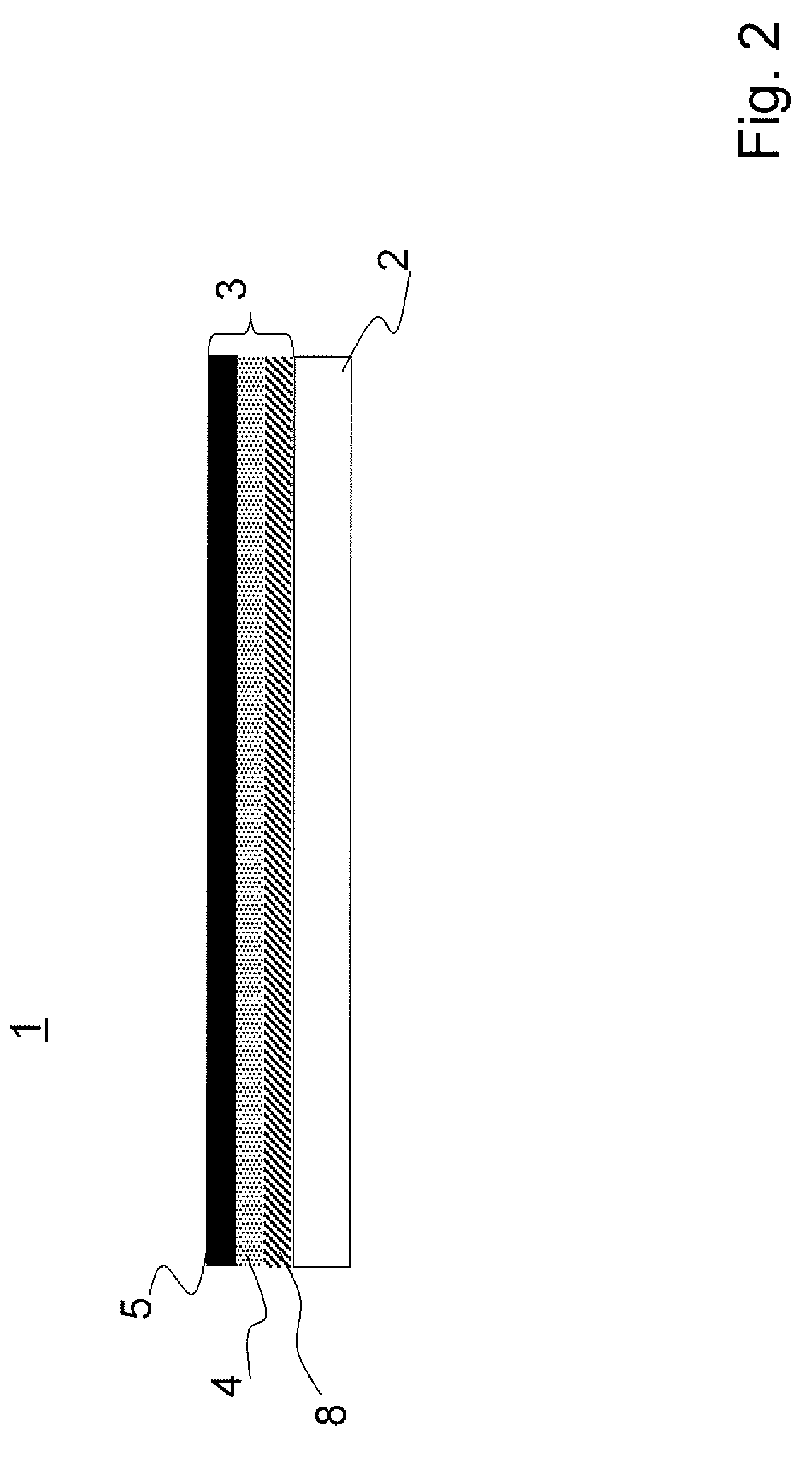

PICVD coating for plastic containers

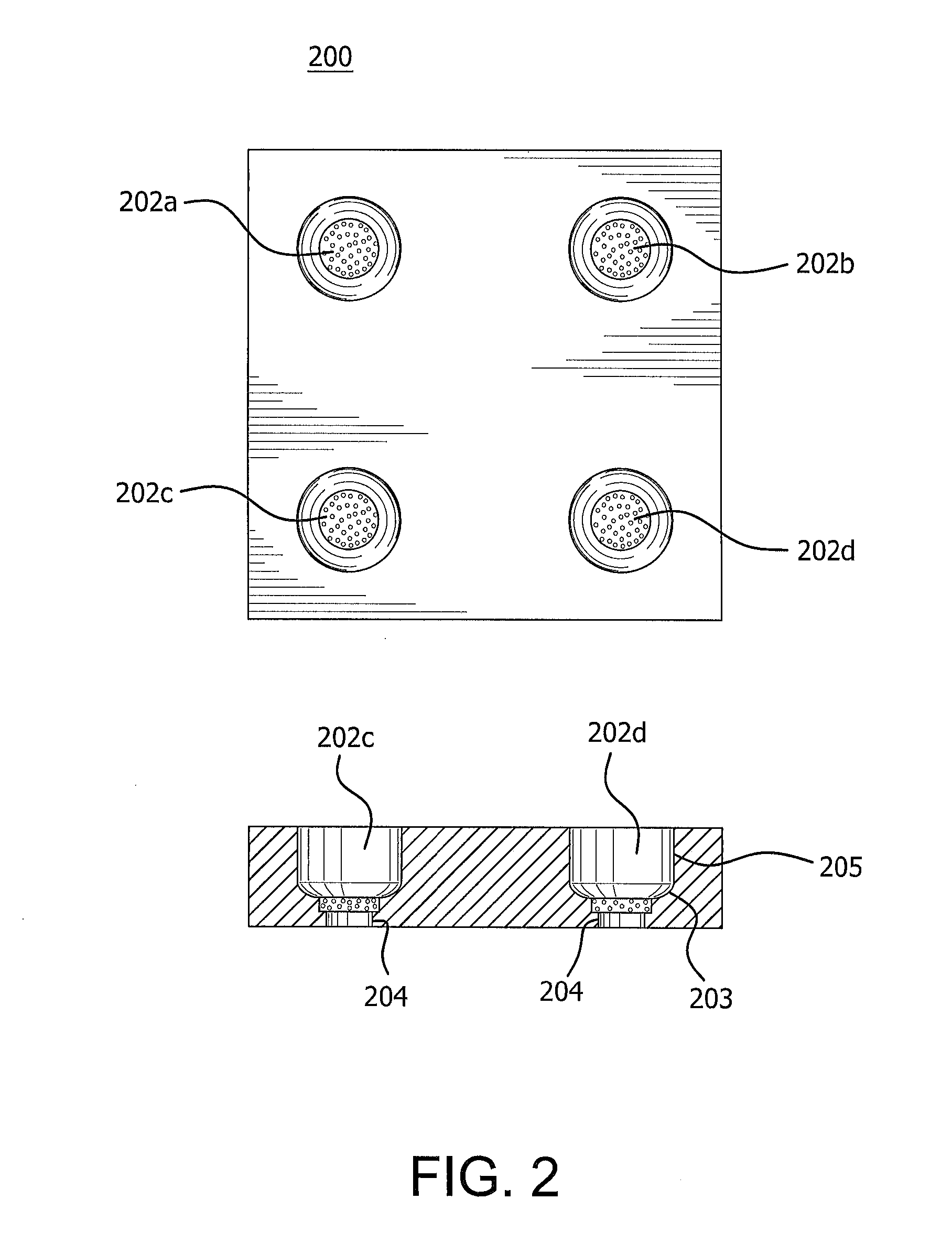

ActiveUS8067070B2Efficient compressionSynthetic resin layered productsPreformed elementsOptoelectronicsCoating

The invention relates to a composite material (1), to containers made therefrom and to a method for producing the composite material (1), which comprises a substrate (2) and a coating (3) on the substrate (2), wherein the coating (3) provides at least a first region (31) facing the substrate (2) and at least a second region (32) facing away the substrate (2), and wherein the first region (31) comprises a barrier layer (4) and the second region (32) a passivation layer (5).

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com