Glass Articles with Improved Chemical and Mechanical Durability

a glass article and mechanical durability technology, applied in the field of glass articles, can solve the problems of reducing production yields, reducing the use of glass for many applications, and reducing the economic benefits of glass products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0090]Six exemplary inventive glass compositions (compositions A-F) were prepared. The specific compositions of each exemplary glass composition are reported below in Table 1. Multiple samples of each exemplary glass composition were produced. One set of samples of each composition was ion exchanged in a molten salt bath of 100% KNO3 at a temperature of 450° C. for at least 5 hours to induce a compressive layer in the surface of the sample. The compressive layer had a surface compressive stress of at least 500 MPa and a depth of layer of at least 45 μm.

[0091]The chemical durability of each exemplary glass composition was then determined utilizing the DIN 12116 standard, the ISO 695 standard, and the ISO 720 standard described above. Specifically, non-ion exchanged test samples of each exemplary glass composition were subjected to testing according to one of the DIN 12116 standard, the ISO 695 standard, or the ISO 720 standard to determine the acid resistance, the base resistance or ...

example 2

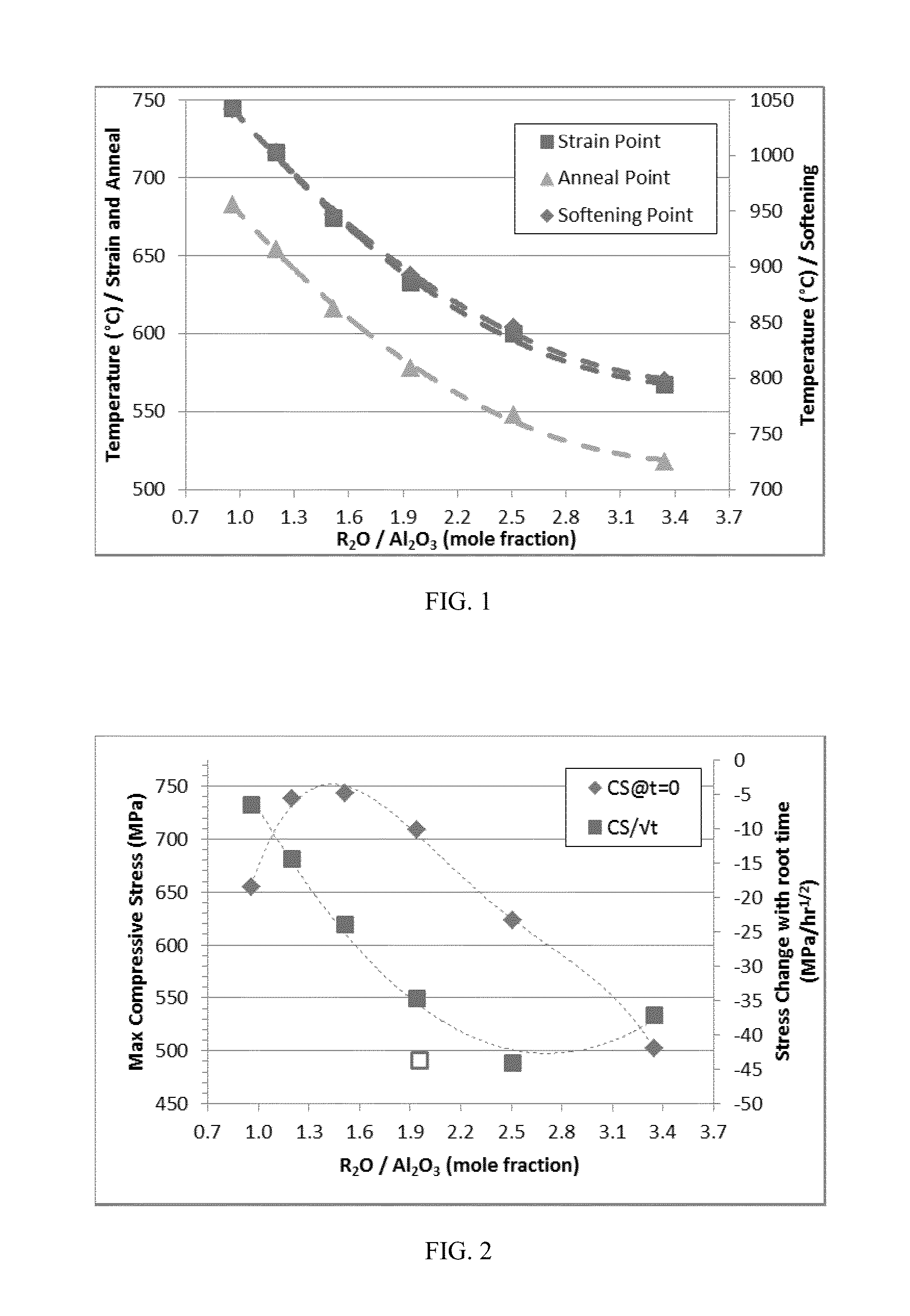

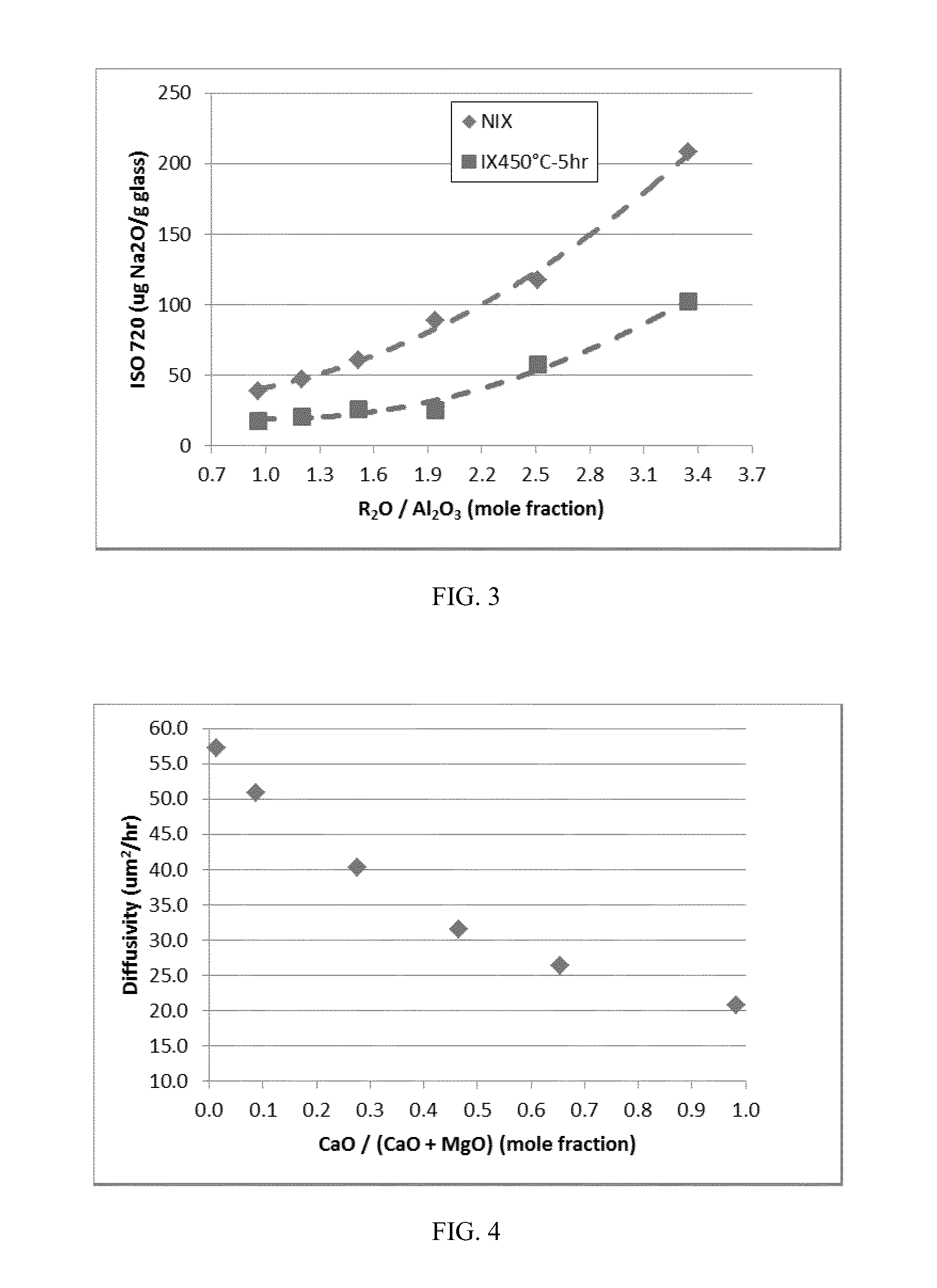

[0096]Three exemplary inventive glass compositions (compositions G-I) and three comparative glass compositions (compositions 1-3) were prepared. The ratio of alkali oxides to alumina (i.e., Y:X) was varied in each of the compositions in order to assess the effect of this ratio on various properties of the resultant glass melt and glass. The specific compositions of each of the exemplary inventive glass compositions and the comparative glass compositions are reported in Table 2. The strain point, anneal point, and softening point of melts formed from each of the glass compositions were determined and are reported in Table 2. In addition, the coefficient of thermal expansion (CTE), density, and stress optic coefficient (SOC) of the resultant glasses were also determined and are reported in Table 2. The hydrolytic resistance of glass samples formed from each exemplary inventive glass composition and each comparative glass composition was determined according to the ISO 720 Standard bot...

example 3

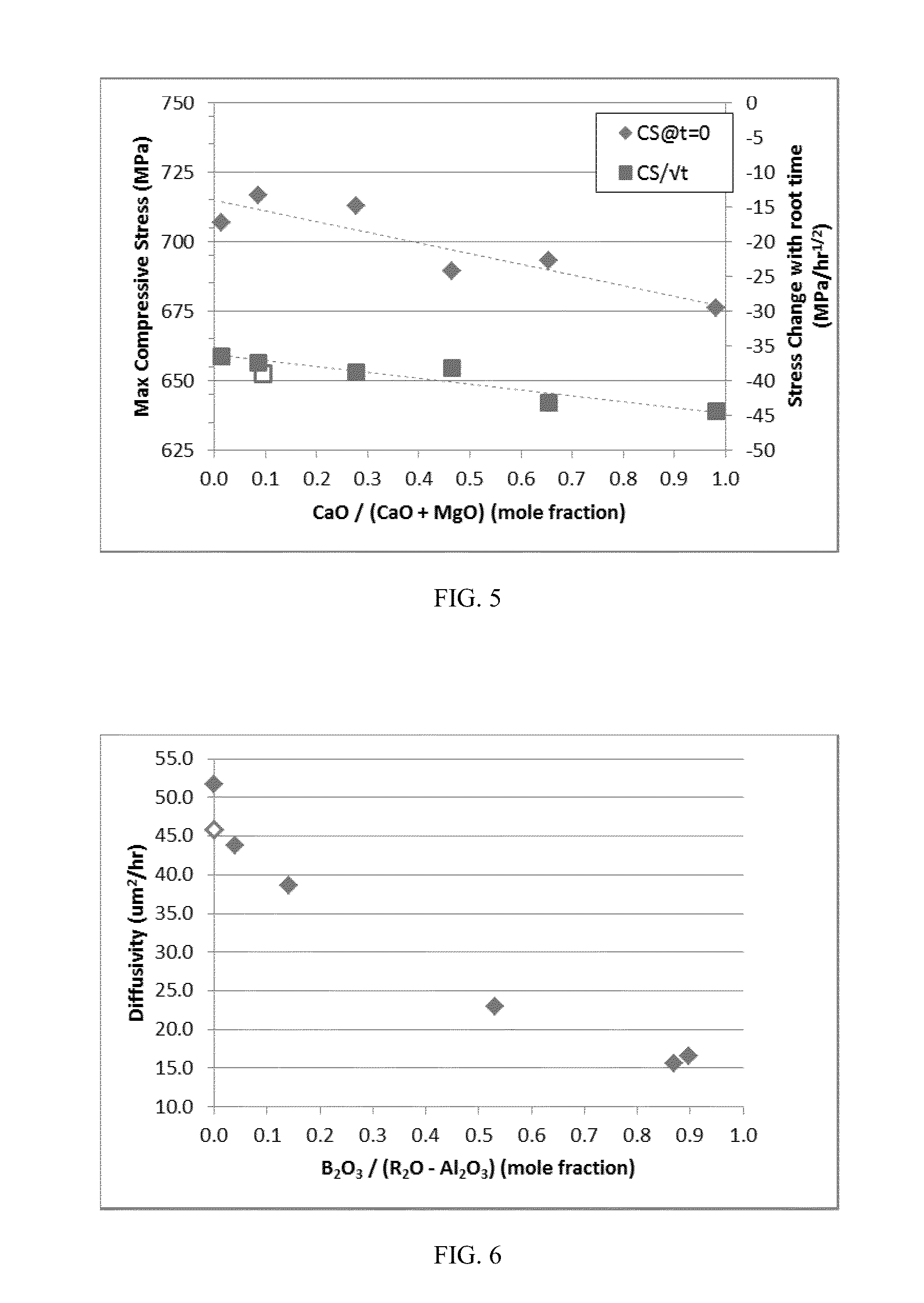

[0102]Three exemplary inventive glass compositions (compositions J-L) and three comparative glass compositions (compositions 4-6) were prepared. The concentration of MgO and CaO in the glass compositions was varied to produce both MgO-rich compositions (i.e., compositions J-L and 4) and CaO-rich compositions (i.e., compositions 5-6). The relative amounts of MgO and CaO were also varied such that the glass compositions had different values for the ratio (CaO / (CaO+MgO)). The specific compositions of each of the exemplary inventive glass compositions and the comparative glass compositions are reported below in Table 3. The properties of each composition were determined as described above with respect to Example 2.

TABLE 3Glass properties as function of CaO contentComposition Mole %JKL456SiO276.9977.1077.1077.0176.9777.12Al2O35.985.975.965.965.975.98Na2O11.3811.3311.3711.3811.4011.34K2O0.100.100.100.100.100.10MgO5.234.793.782.831.840.09CaO0.070.451.452.463.475.12SnO20.200.190.190.190.190...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com