Glasses and glass ceramics including a metal oxide concentration gradient

A concentration gradient and oxide technology, applied in the field of glass and glass ceramics containing a concentration gradient of metal oxides, can solve problems such as stress distribution of glass-based products that do not show thermal tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0195] Glass-ceramic substrates with nominal compositions as shown in Table 2 were provided. The glass-ceramic substrate has a thickness of 0.8 millimeters and includes a crystal phase combination including β-spodumene solid solution as a major crystal phase and one or more minor phases including rutile. The glass-ceramic substrate was impregnated with NaNO 3 and have a temperature of 485°C in a molten salt bath for 10 hours (condition A), 13 hours (condition B) or 24 hours (condition C), or immersed in a solution containing NaNO 3 and having a temperature of 430° C. in a molten salt bath for 2 hours (comparative condition D) to form a glass-ceramic article.

[0196] Table 2: Composition of the glass-ceramic substrate of Example 1 before chemical strengthening

[0197]

[0198] The stress distribution of the glass-ceramic article was measured by a microprobe and shown in Figure 5 middle. like Figure 5 As shown, when using a higher temperature bath (ie, conditions A-C...

Embodiment 2

[0200] By impregnating in the containing 100% NaNO 3 , and having multiple periods of time in a molten salt bath at about 430° C., to chemically strengthen glass substrates having the same composition as shown in Table 2 and a thickness of 0.8 mm, but with an amorphous structure (and no crystalline phase). The DO) and maximum CT values of the glass products were measured using a scattered light polarizer (scattered light polariscope, SCALP). like Figure 6 As shown, the DOC and maximum CT increase with prolonged impregnation or ion exchange. The maximum CT value was observed after immersing the glass for 16 hours.

[0201] The stress distribution of the glass article of Example 2 was measured using SCALP and is shown in Figure 7 middle. The upper portion of the x-axis representing positive stress values is the CT slice, and the lower portion of the x-axis representing negative stress values is the CS value. The stress distribution of the glass article chemically st...

Embodiment 3

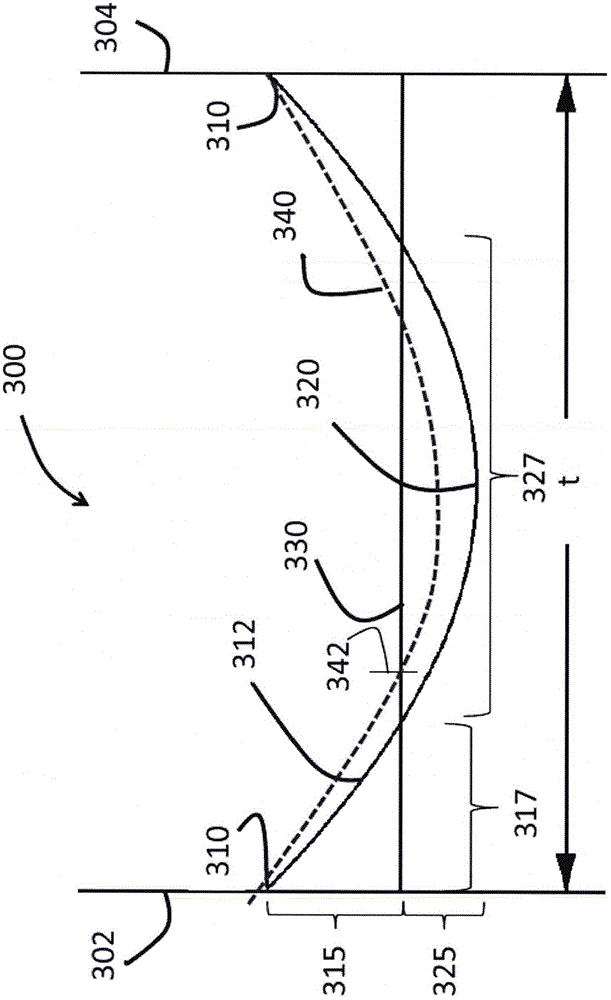

[0203] For comparison, by immersing in NaNO with a temperature of 350 °C 3 The glass-ceramic substrate of Example 1 and the glass substrate of Example 2, each having a thickness of about 0.8 mm, were chemically strengthened in a molten salt bath for 3.5 hours (Examples 3A and 3B, respectively). like Figure 8 The resulting stress distributions of the glass-ceramic and glass articles are shown to resemble an error function (erfc) or quasi-linear shape. Furthermore, the CS layer depth is less than the base ion exchange depth into the glass or glass ceramic (or the chemical ion exchange depth).

[0204] When by immersing it in NaNO with a temperature of 430C 3 When molten salt was used for 24 hours to chemically strengthen the glass ceramic substrate of Example 1 and the glass substrate of Example 2, both having a thickness of about 0.8 mm, as described herein (Examples 3C and 3D, respectively), the obtained Glass-based products present as Figure 9 The metal oxide concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com