Technology device and method for preparing propylene by dehydrogenating propane or propane-enriched low carbon hydrocarbon

A process device and low-carbon hydrocarbon technology, which is applied in the field of propane or propane-rich low-carbon hydrocarbon dehydrogenation to propylene process devices, can solve the problems of unreported process devices and methods, and achieves low operating costs and labor intensity, and low operation cost. Stable, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

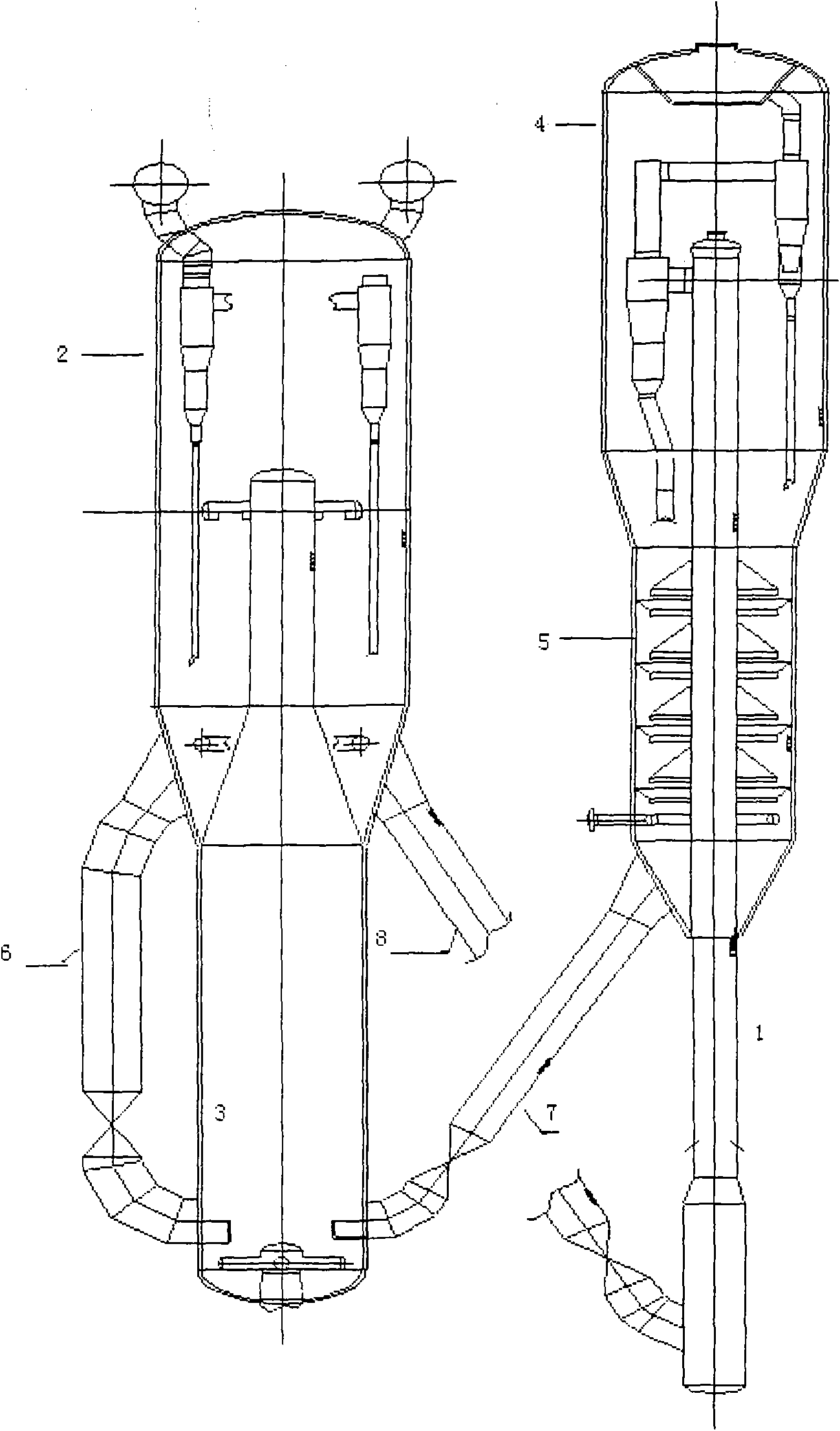

[0054] Example 1 is a reaction regeneration system diagram according to the parallel arrangement scheme of the inner riser of the process device of the present invention, see figure 1 , That is, the reaction settler and the regenerator are arranged side by side, and the regenerator adopts the type of coking tank. The raw material propane or low-carbon hydrocarbons rich in propane enters the raw material tank from outside the device, first is relieved by the pressure reducing valve, and then passes through the raw material gas-refrigerant water heat exchanger, the raw material gas-reaction product heat exchanger 23 and then enters the elevator The tube reactor 1 is in contact with the high-temperature regenerated catalyst for propane dehydrogenation reaction. The reaction gas and the waiting catalyst are rapidly separated by coarse rotation at the outlet of the riser, and then the catalyst fine powder carried by the cyclone separator is further removed and then leaves the settler...

Embodiment 2

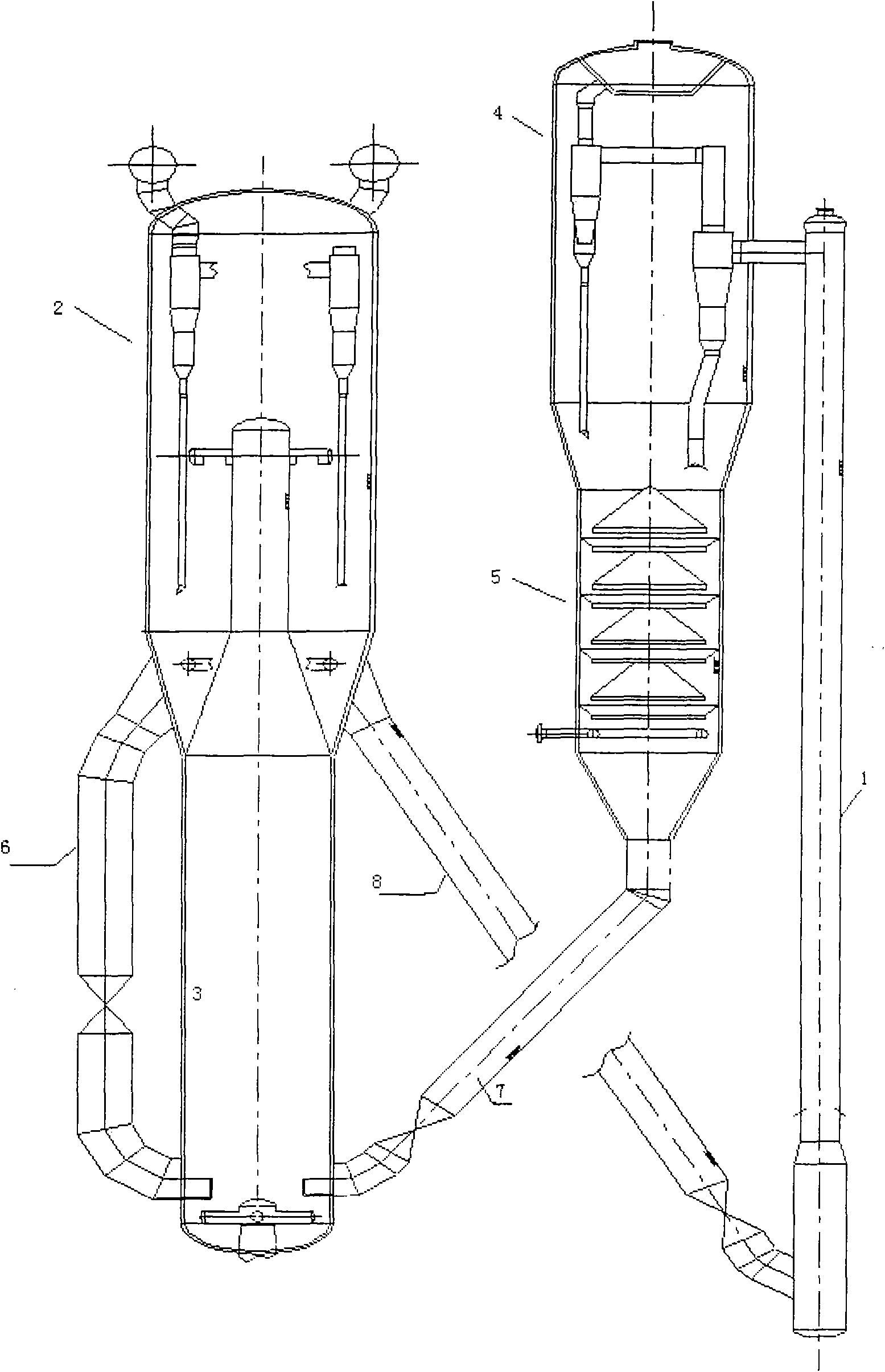

[0057] Example 2 is a reaction regeneration system diagram according to the parallel arrangement scheme of the outer riser of the process device of the present invention, see figure 2 , Except that the riser reactor is arranged externally, the other and the process flow are the same as in Example 1.

Embodiment 3

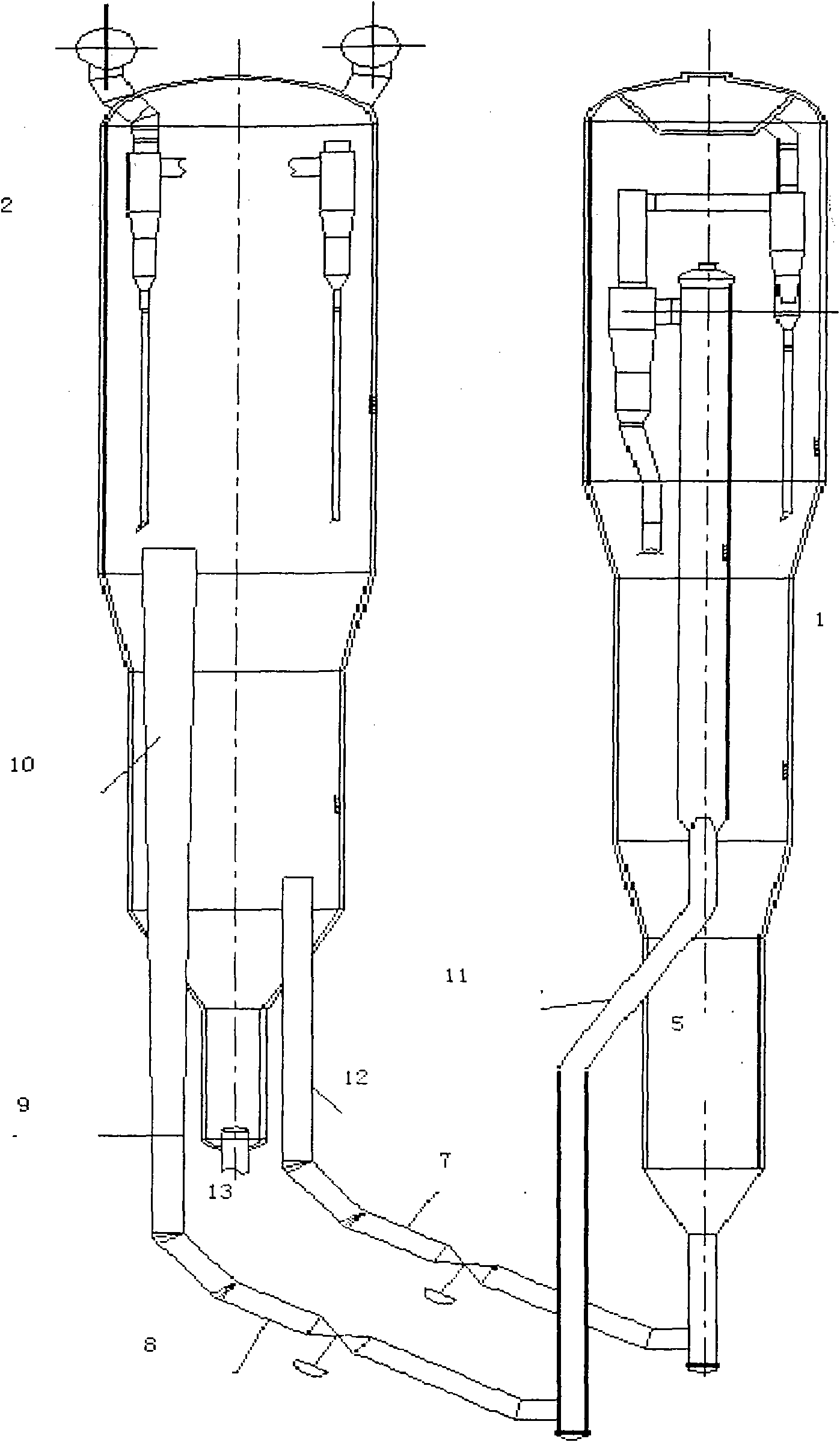

[0059] Example 3 is a diagram of the reaction regeneration system according to the parallel arrangement scheme of the inner riser of the process device of the present invention, see image 3 Except that the reaction settler and regenerator are arranged side by side at the same height and the riser reactor is arranged as a built-in type, the other and the process flow are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com