Patents

Literature

360results about How to "Reduce operating labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

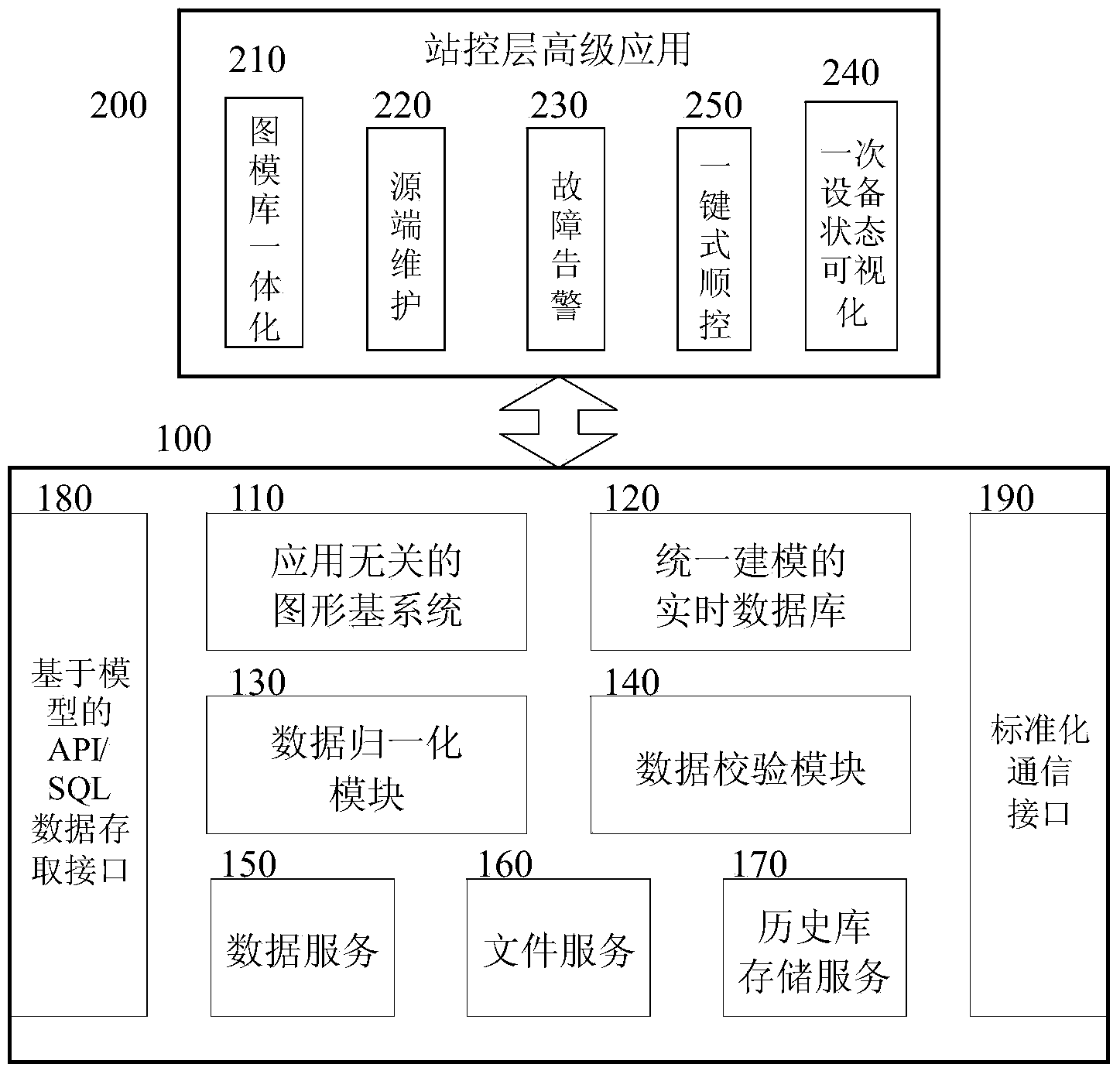

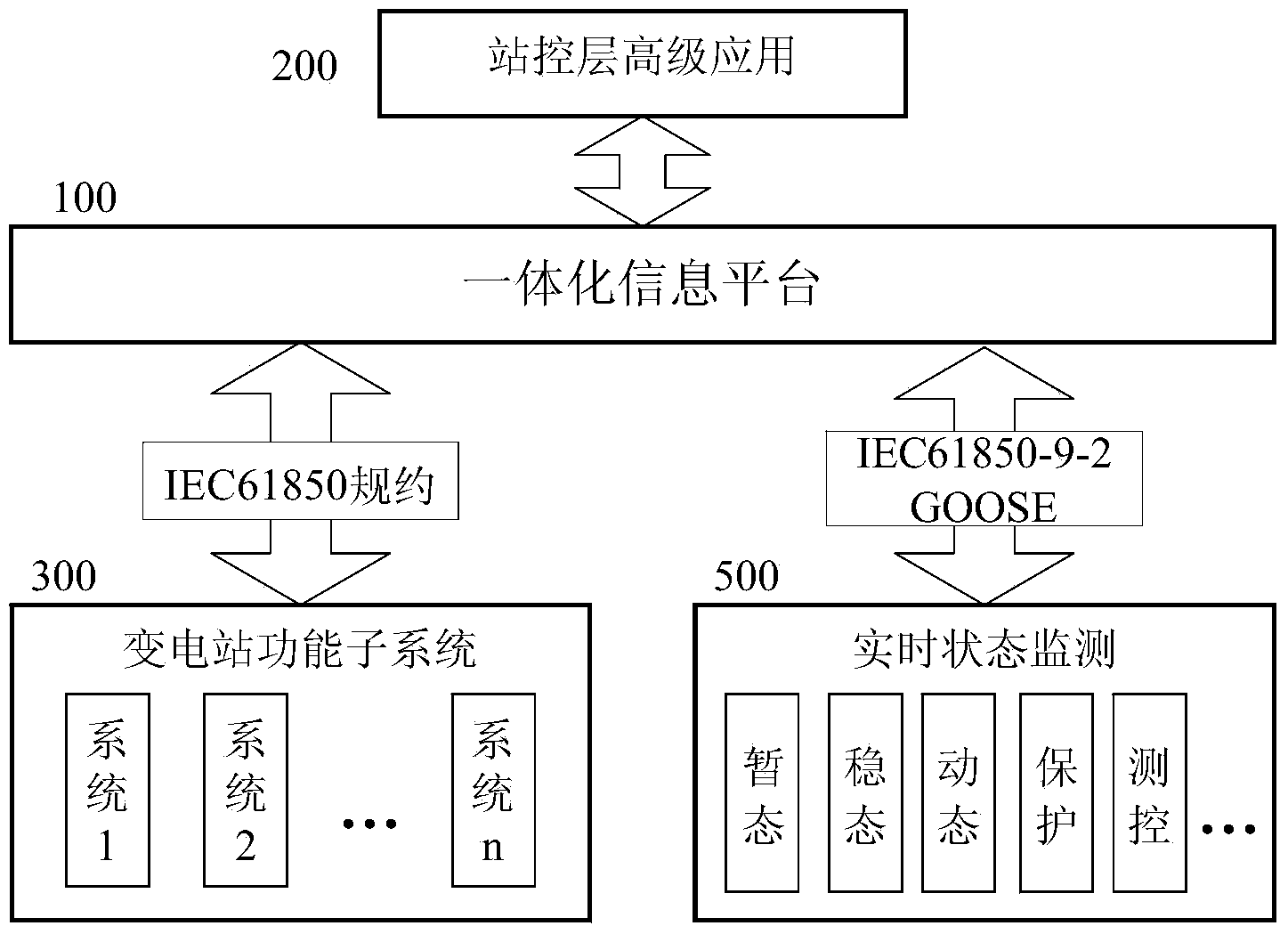

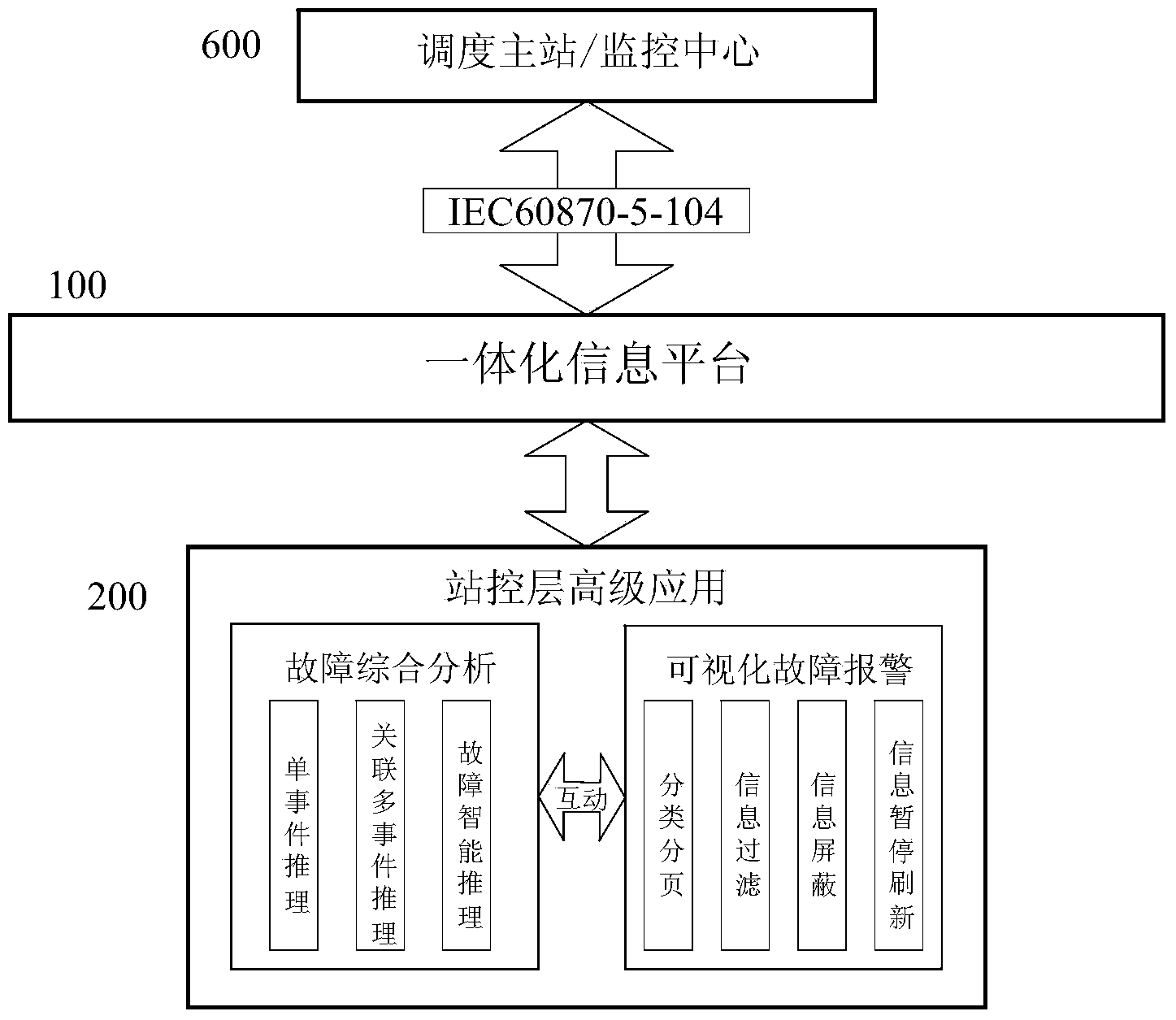

One-button type sequential control operation control method based on integrated information platform

InactiveCN103441570AReduce labor intensity and operation timeImprove operational efficiencyCircuit arrangementsPower gridControl switch

The invention relates to a control method for providing long-distance indication on conditions of a distribution network and controlling switch devices in the distribution network in a long-distance mode, in particular to a one-button type sequential control operation control method based on an integrated information platform. The one-button type sequential control operation control method based on the integrated information platform comprises the following steps that a sequential control model is built through the integrated information platform; a power grid monitoring center or a dispatch master station interacts with a video monitoring system or an intelligent patrol system in an intelligent substation through the integrated information platform, visualization operation of a control end is achieved, the control end interacts with the power grid monitoring center or the dispatch master station to achieve real-time monitoring on sequential control operations, and the whole sequential control operation process is controlled; network topology and operation rule data are obtained, and a sequential control operation task is generated automatically. As the control operation is programmed, selection, execution and calibration of operation tickets are finished automatically by an intelligent substation system, manual intervention is not needed, operation time is greatly shortened, labor intensity is greatly relieved, operation efficiency is improved, and the safe operation level of a power grid system is improved.

Owner:STATE GRID CORP OF CHINA +3

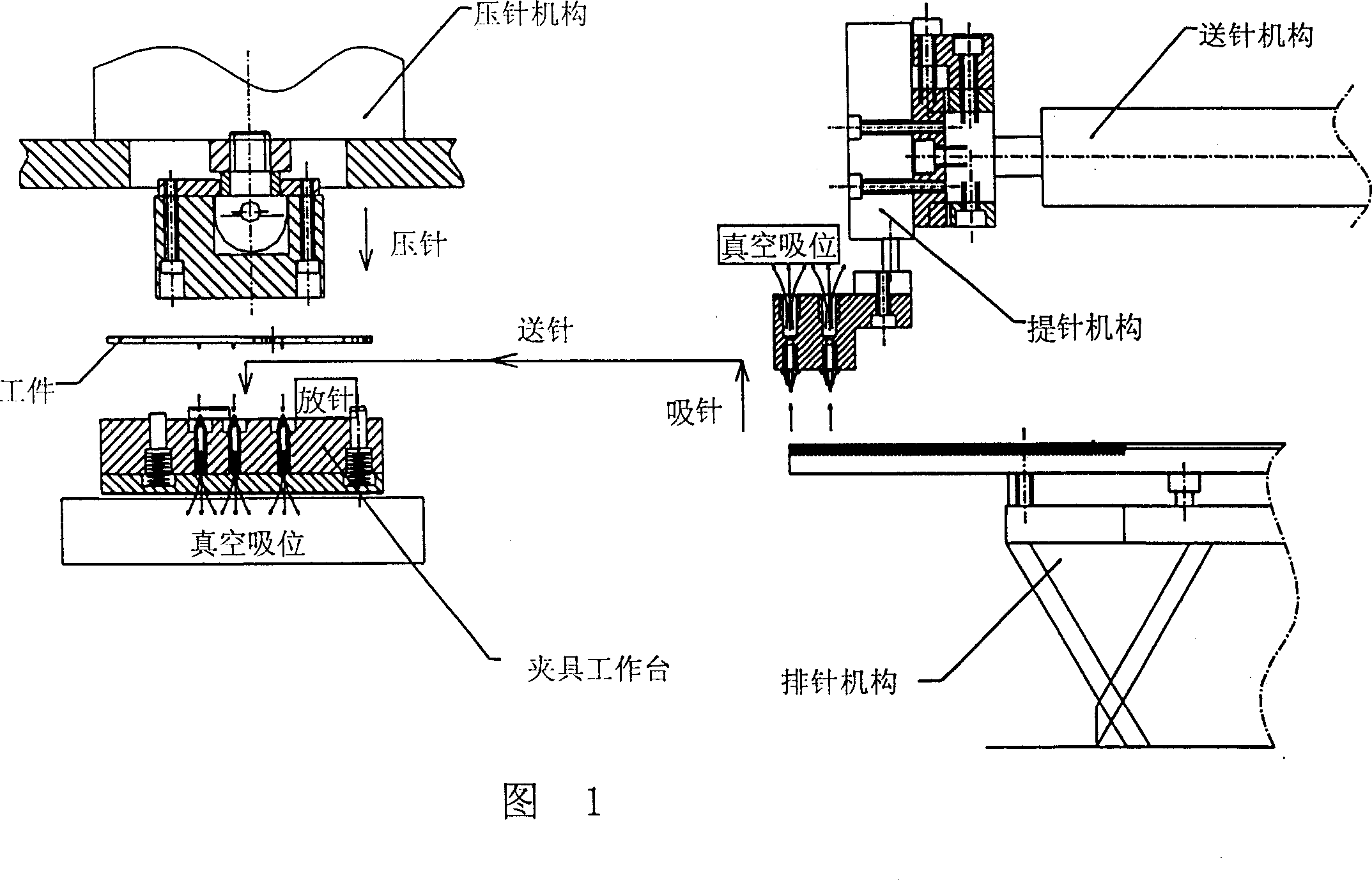

Automatic needle inserting machine

ActiveCN1945729ACompact structureReasonable structureRecord information storageRecord carrier contruction detailsFiberButt joint

This invention relates to an automatic pin-plug machine including an integral bearing basis and an electric control box loading a control device characterizing that the loading basis is set with a working stand, a pin-arranging device, a pin-feeding unit and a pressing unit, in which, a spare part test fiber head and an inducing switch are connected on the clamp working stand, a vacuum butt-joint piston is set at the front position of the working stand and connected on the vacuum generator, a vacuum absorption position is set at the bottom of the clamp base and connected with the vacuum butt joint piston by a vacuum cupule, which breaks through the traditional pin-plug way.

Owner:BELTON ELECTRONICS SHENZHEN

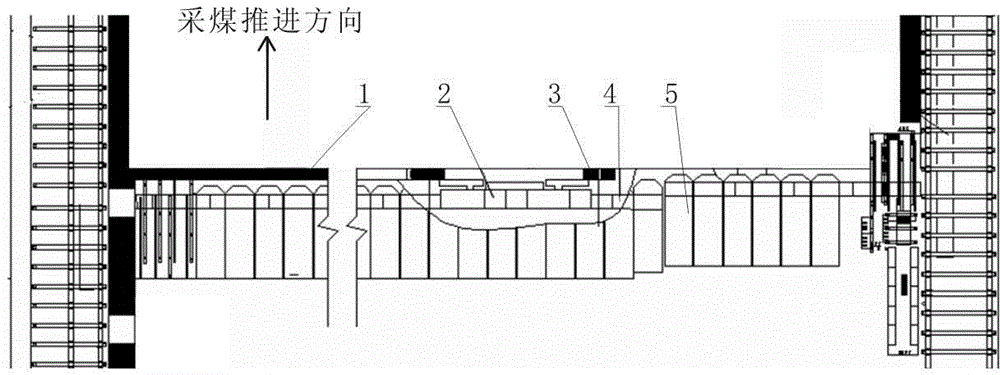

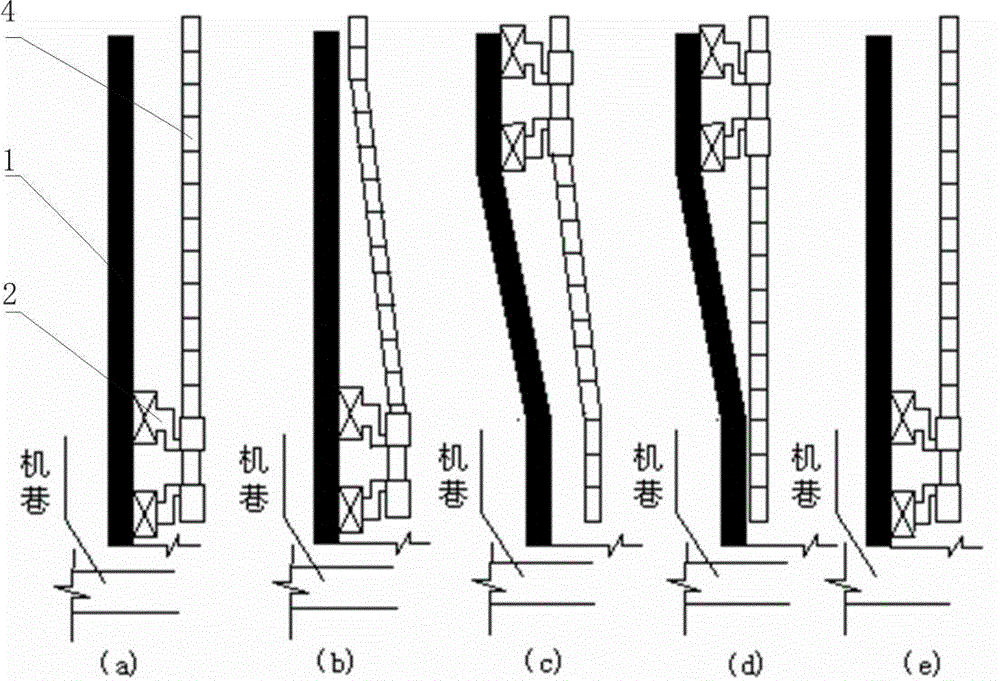

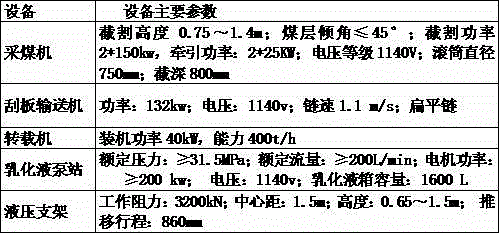

High-efficiency thin coal seam complete-set coal mining equipment and coal mining method

InactiveCN104912557ASolve the problem of mechanized comprehensive miningReduce engagementUnderground miningSurface miningProcess engineeringElectric traction

The invention relates to high-efficiency thin coal seam complete-set coal mining equipment and a coal mining method; a coal mining machine is an electric traction coal mining machine, and a machine body is hung out of a scraper conveyer. The coal mining method includes the steps: the equipment is arranged on a coal mining working face in a complete-set mode; the coal mining machine is moved to a position of an advanced notch for feeding, after feeding, the scraper conveyer is propelled by a transition way, and the coal mining machine goes forward to cut coal so as to complete feeding; after completion of feeding, the coal mining machine goes forward to cut the coal at a speed of 3-4 m per minute along a coal wall and allows the coal to be loaded to a middle groove of the scraper conveyer; after the coal mining machine walks, a hydraulic support is pushed to move; and pushing downspouting is carried out in the range of 10-15 m behind the hydraulic support propelled to move. The problem of extremely thin coal seam mechanization comprehensive mining is solved, all mining devices are mechanized, and the mining devices satisfy the problem of extremely low mining height space arrangement, the complete set of equipment is rational in layout, the coal mining steps are reasonably carried out, the production efficiency is improved, the worker participation degree is reduced, and the mining safety is improved.

Owner:XIAOHEZUI COAL MINE OF SICHUAN COAL GRP DA ZHU CO

Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

ActiveCN105509062AGuaranteed incineration temperatureGuaranteed incineration efficiencyEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING UNIV OF TECH

Fluoride-contained wastewater treatment method and device

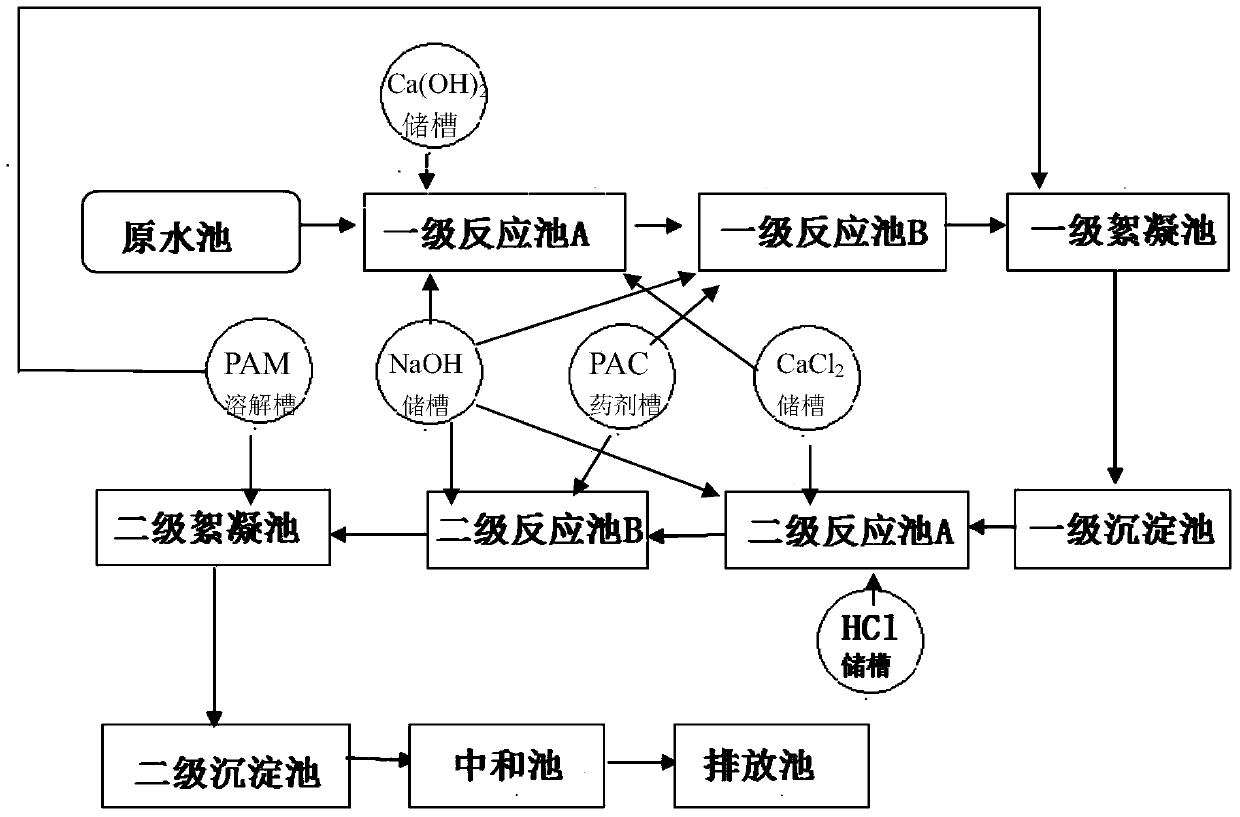

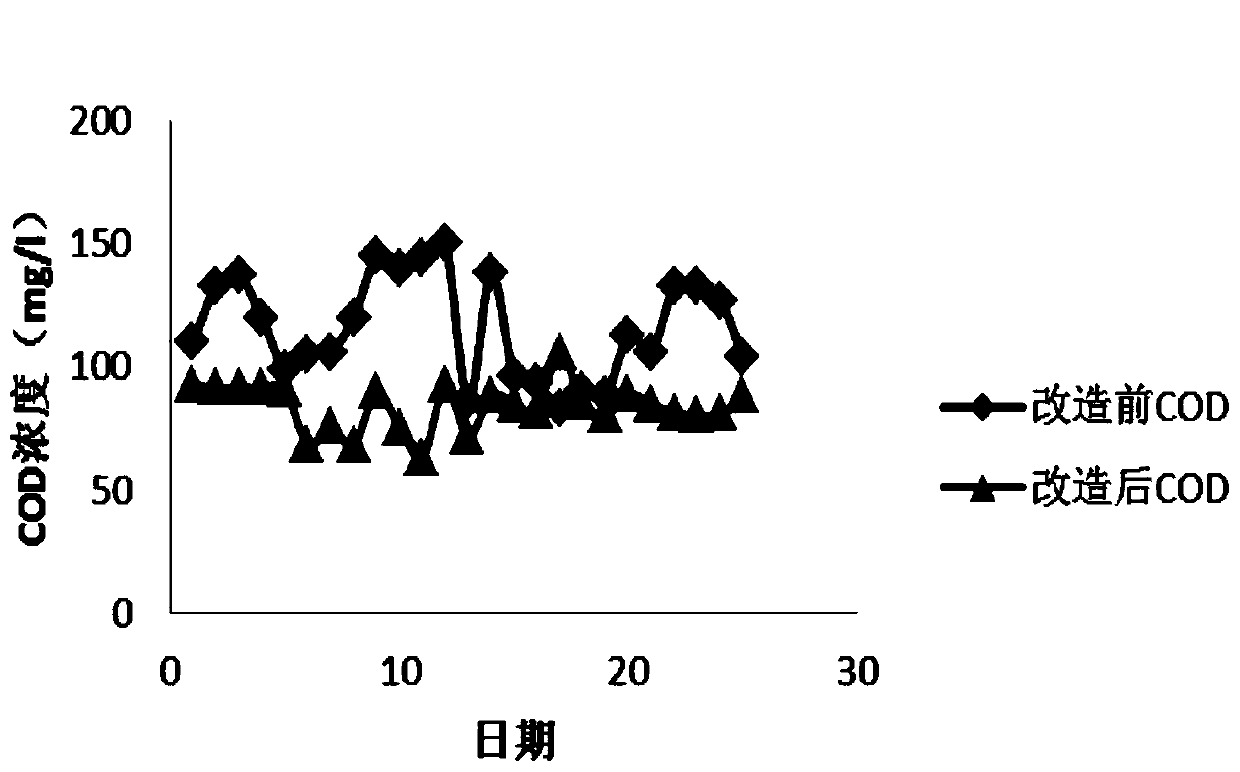

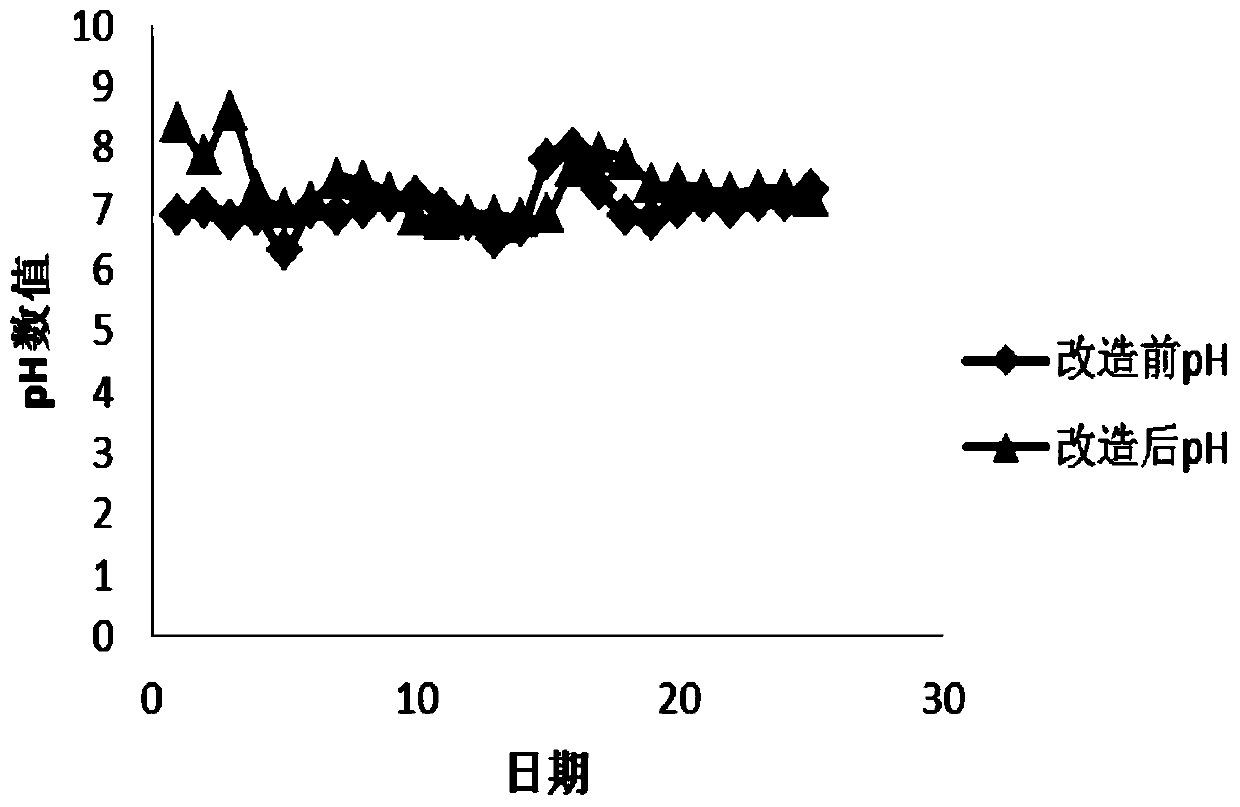

InactiveCN103991984AReduce dosageReduce processing costsWater contaminantsMultistage water/sewage treatmentIon contentWater quality

The invention discloses a fluoride-contained wastewater treatment method. Calcium hydroxide, sodium hydroxide and calcium chloride as well as sodium hydroxide and sodium chloride two-stage chemical precipitation reaction is adopted, meanwhile, PAM (Polyacrylamide) and PAC (Polyaluminum Chloride) flocculating settling is assisted, so that the fluorine concentration of effluent is greatly reduced; after fluoride-contained wastewater is treated by using the method, main pollution factors in the water are within the national normative standard range, and the fluorine ion content is reduced by about 3 times as comparison with the former fluorine ion content; the dosages of sodium hydroxide and calcium chloride and the wastewater treatment cost is greatly reduced. The invention also provides a fluoride-contained wastewater treatment device based on the treatment method. The fluoride-contained wastewater treatment method disclosed by the invention is simple and practical in process and capable of adapting to the changes of water quality and quantity and has a certain flexibility and adjustability; meanwhile, the treatment device is convenient to manage, operate and maintain.

Owner:HEFEI HAREON SOLAR TECH

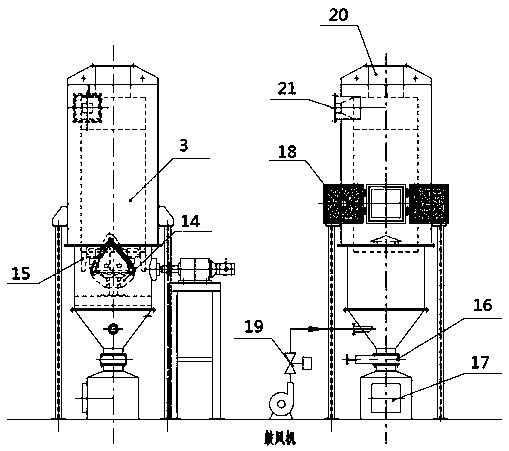

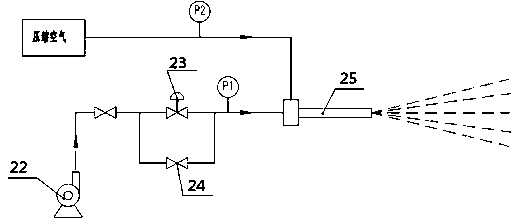

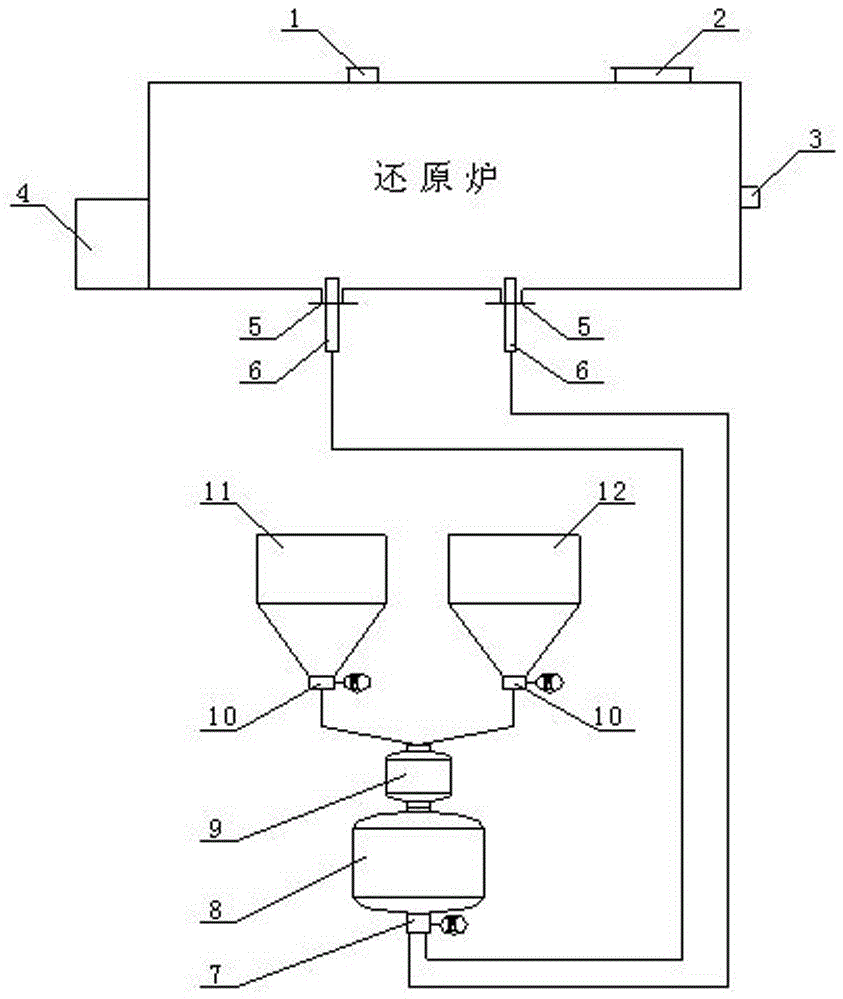

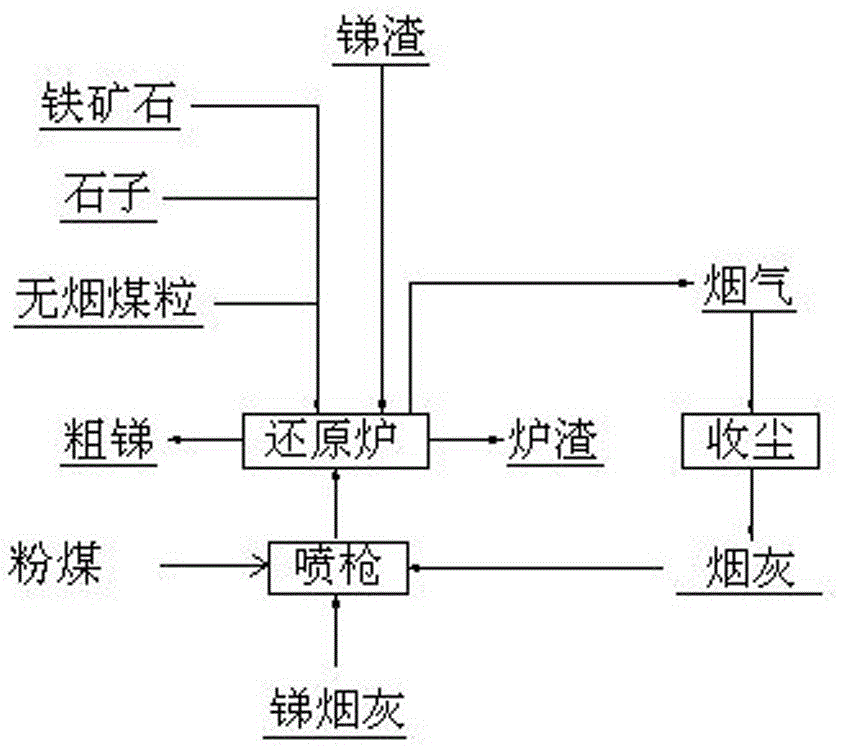

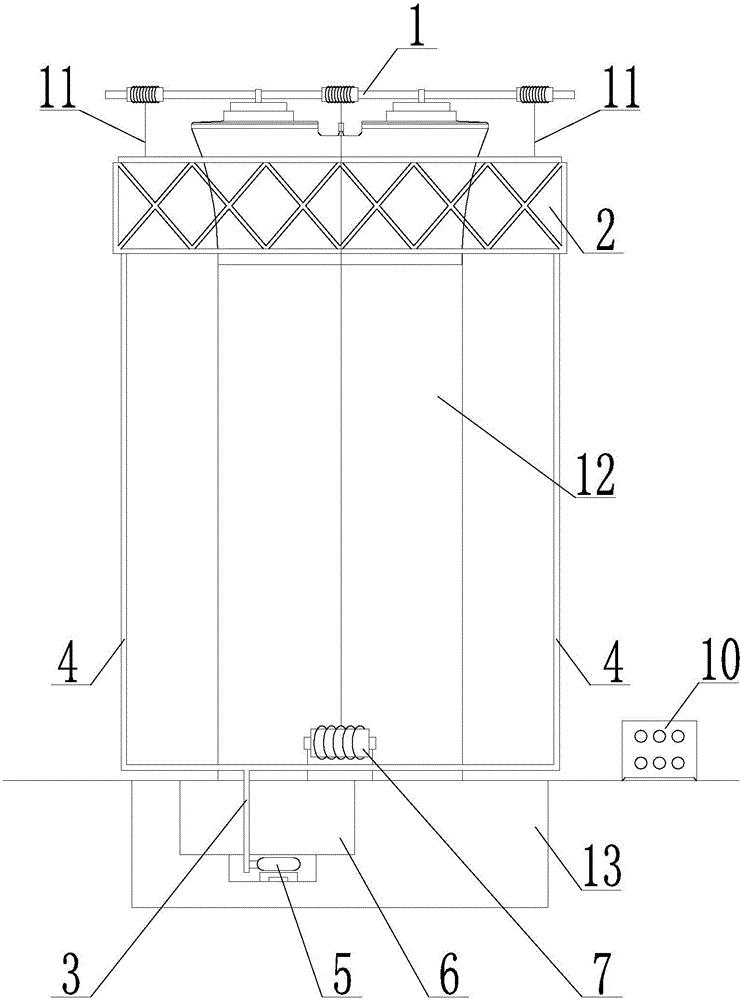

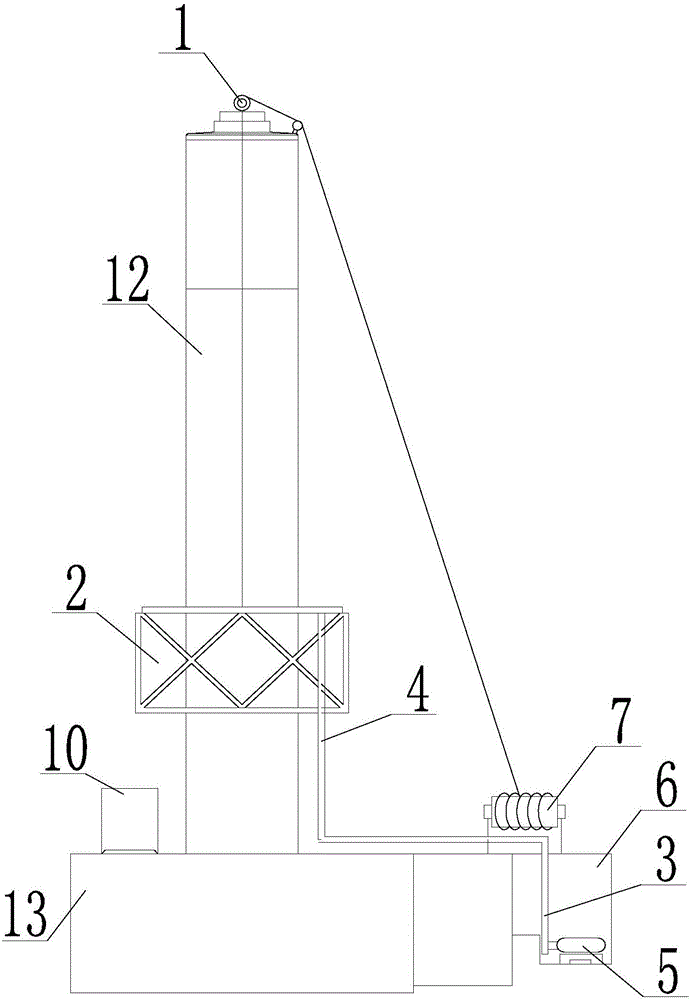

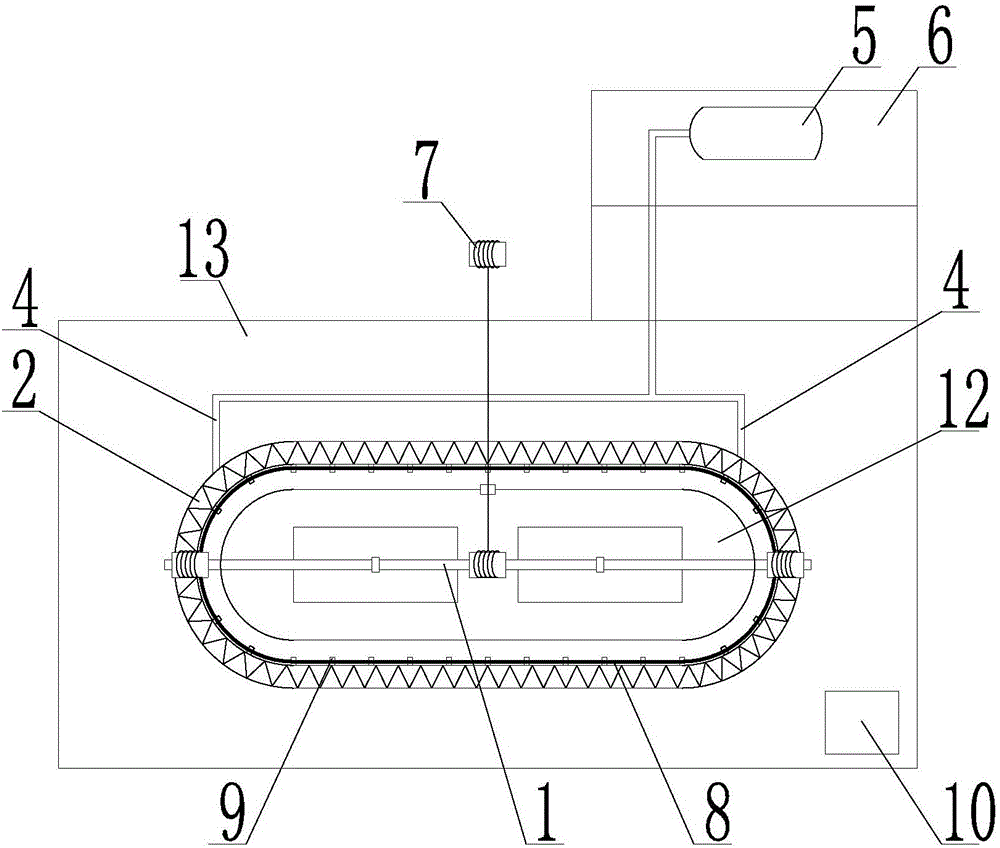

Device and process for directly reducing smelt antimony from antimony slag and antimony ash

InactiveCN105603197AImprove thermal efficiencyReduce soot rateProcess efficiency improvementIronstoneSlag

The invention relates to the non-ferrous metal metallurgy industry, in particular to a device and a process used for directly reducing smelt antimony from antimony slag and antimony ash and having the characteristics of short process, low energy consumption and high applicability. A reduction furnace comprises an antimony ash supply system, a powdered coal supply system and a flue gas dust collection system. The antimony slag is directly fed into the reduction furnace; iron ores, pebbles and anthracite particles are continuously supplied into the reduction furnace and serve as a slag former and a reducer at the same time; and the antimony ash, ash collected by the flue gas dust collection system and powdered coal as fuel are blown into the reduction furnace through a spray gun, so that materials in the reduction furnace are enabled to quickly produce a reduction reaction. The device and process are short in technological process, high in reduction degree, high in antimony direct recovery rate and low in energy consumption; and in addition, the environmental pollution is alleviated and the labor intensity is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

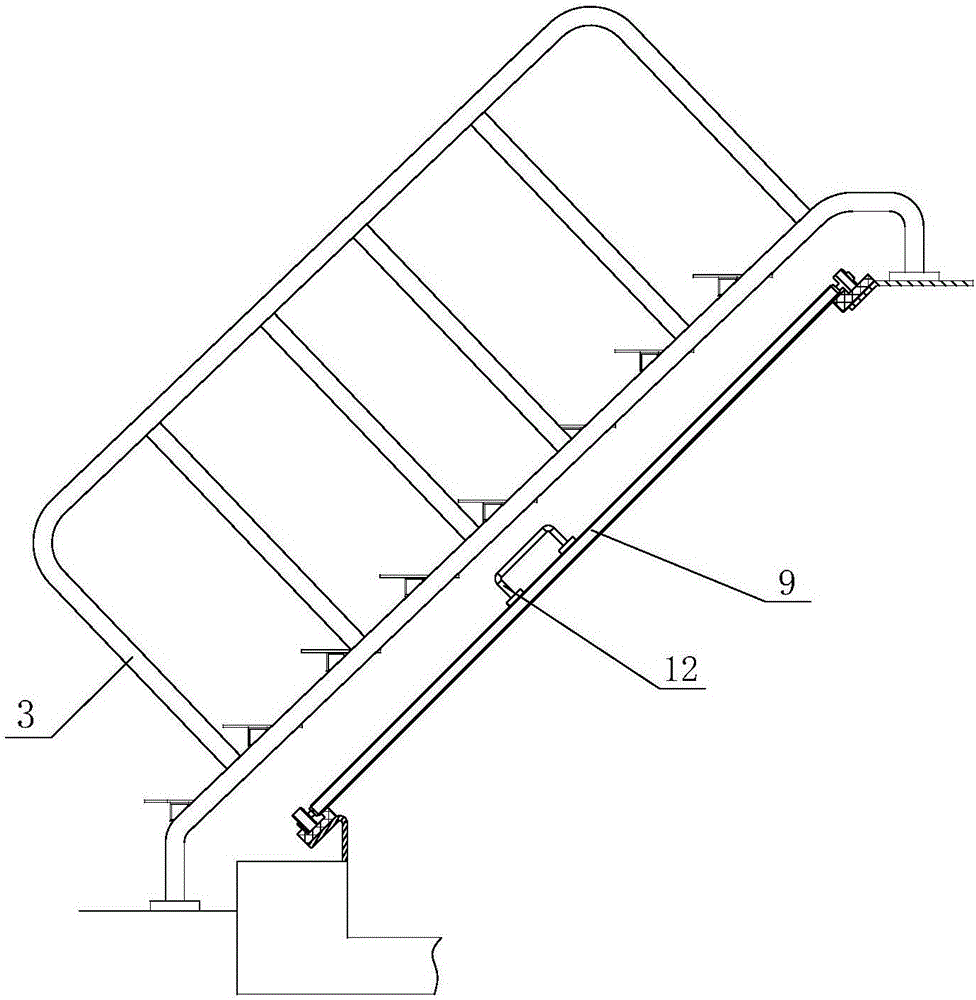

Automatic spraying curing device for concrete bridge pier and use method

InactiveCN106284095ASimple structureReasonable designBridge erection/assemblyWater pipeQuality standard

An automatic spraying curing device for a concrete bridge pier comprises a lifting system, a water supply system and a spraying system. The lifting system and the water supply system are started according to the set time. While a spraying curing frame is lifted, water pumped by a water pump is sequentially conveyed into a main water conveying pipe, a branch water conveying pipe and a spraying water pipe. Water spraying curing is carried out on the surface of the concrete bridge pier needing curing through water sprayed by sprayers. A winch is automatically reversed after the spraying curing frame is lifted to the top of the bridge pier, and the spraying curing frame descends to a bearing platform surface in continuous spraying. The automatic spraying curing device for the concrete bridge pier is simple in structure, reasonable in design, and convenient to use and operate. The problem that manual water spraying curing can not meet the spraying requirement, thereby causing cracks of the bridge per can be effectively solved, the engineering quality is improved, and the service life of the bridge pier is prolonged. A water curtain formed by sprayed water covering a pier body concrete curing surface is uniform, the omni-directional and full-wetting curing quality standards can be met, the curing effect is quite remarkable, and high pier high-altitude concrete curing is realized.

Owner:CHINA RAILWAY 21ST BUREAU GROUP THE FOURTH ENG

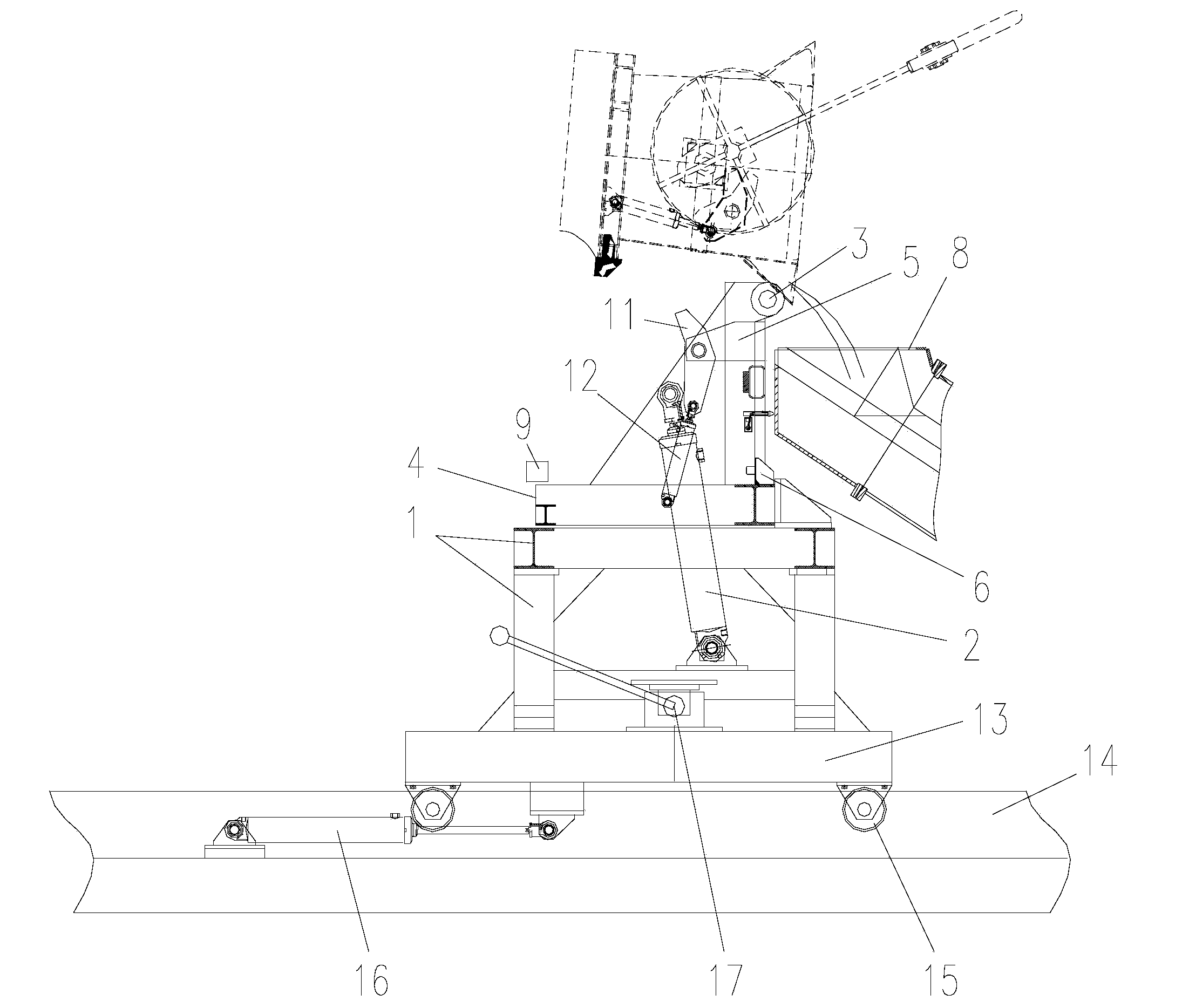

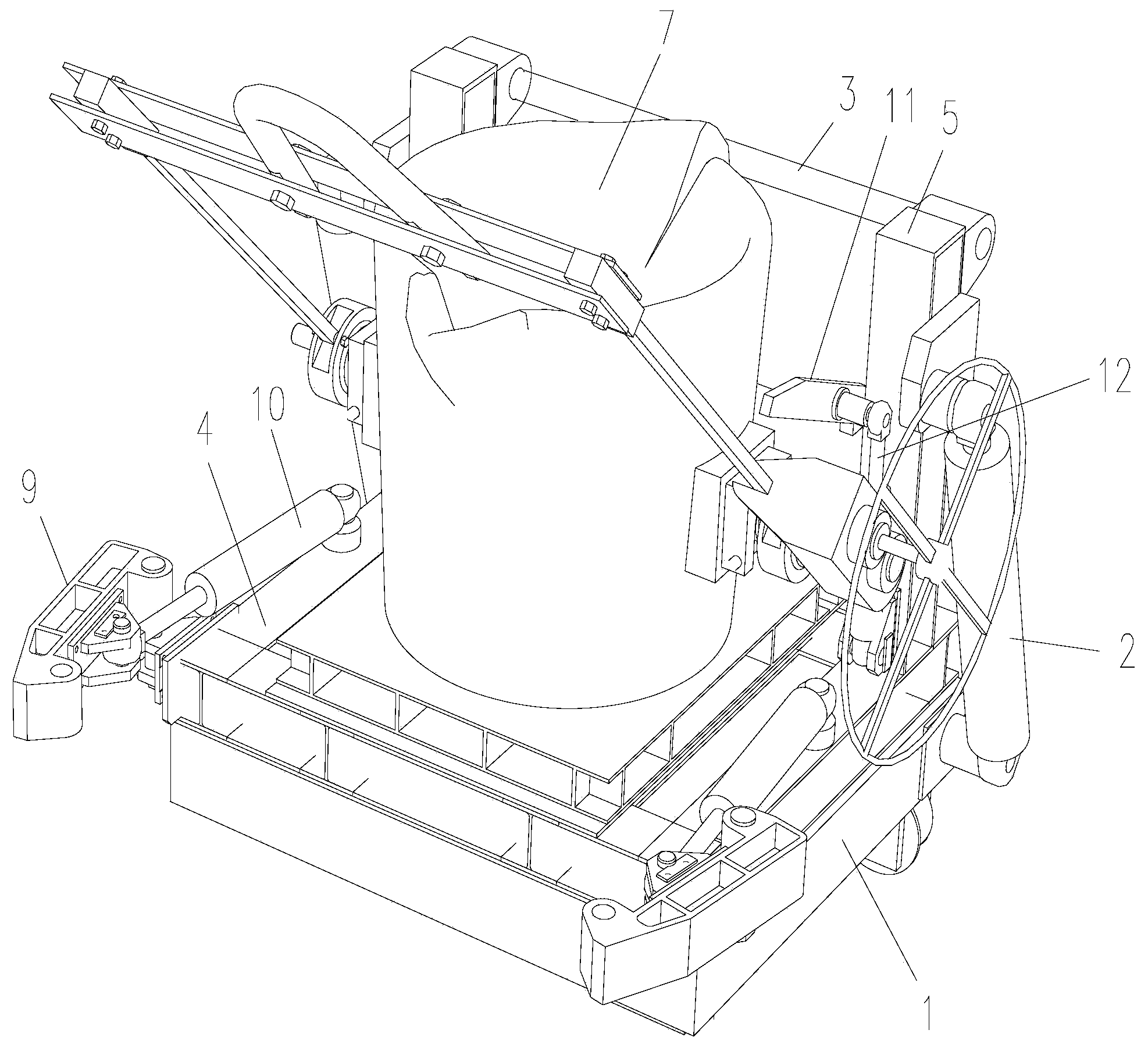

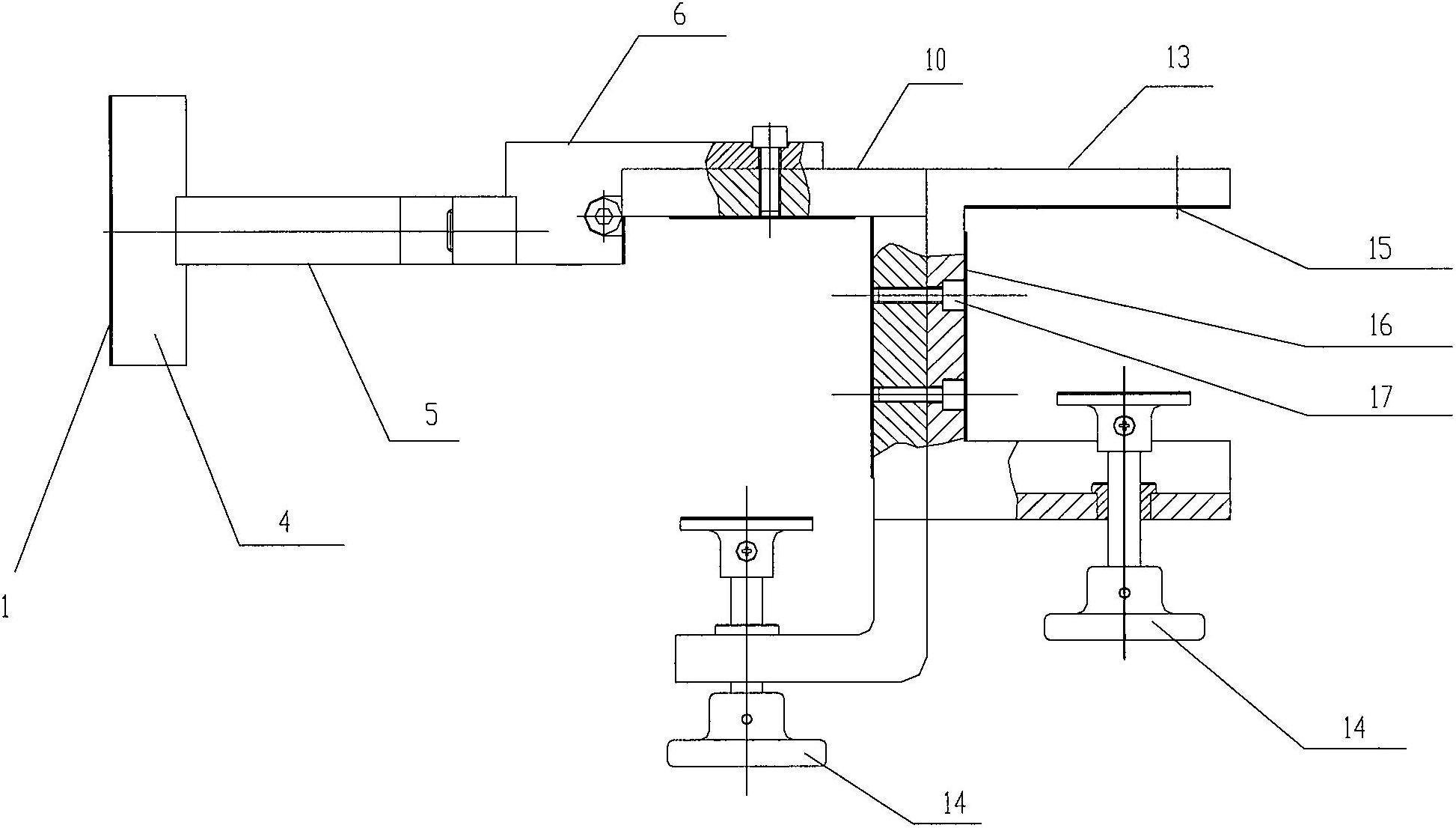

Ladle overturning and dumping machine

The invention discloses a ladle overturning and dumping machine. The ladle overturning and dumping machine comprises a work table, an overturning driving cylinder, an overturning center shaft, an overturning base which is placed on the work table, a shaft bracket which is fixed on the work table, and an overturning frame which is connected with the overturning center shaft and the overturning base, wherein one end of the overturning driving cylinder is hinged to the work table, and the other end of the overturning driving cylinder is hinged to the overturning frame; a ladle block, a horizontal compacting mechanism and a vertical compacting mechanism are arranged on the overturning base. The ladle overturning and dumping machine is used for dumping liquid iron of ladles, the ladles are reliable to fix, the dumping process is directly completed by the overturning driving cylinder, and working safety is high; at the same time, the processes of compacting, fixing and dumping the ladles are all automatically completed, the relative position of the ladles and a material receiving opening of an automatic casting machine can be adjusted, the labor intensity is small, and the production efficiency is high; furthermore, the ladles of national standard series do not need to be customized or changed to be used on the ladle overturning and dumping machine, so that the adaptability is good.

Owner:CMCU ENG

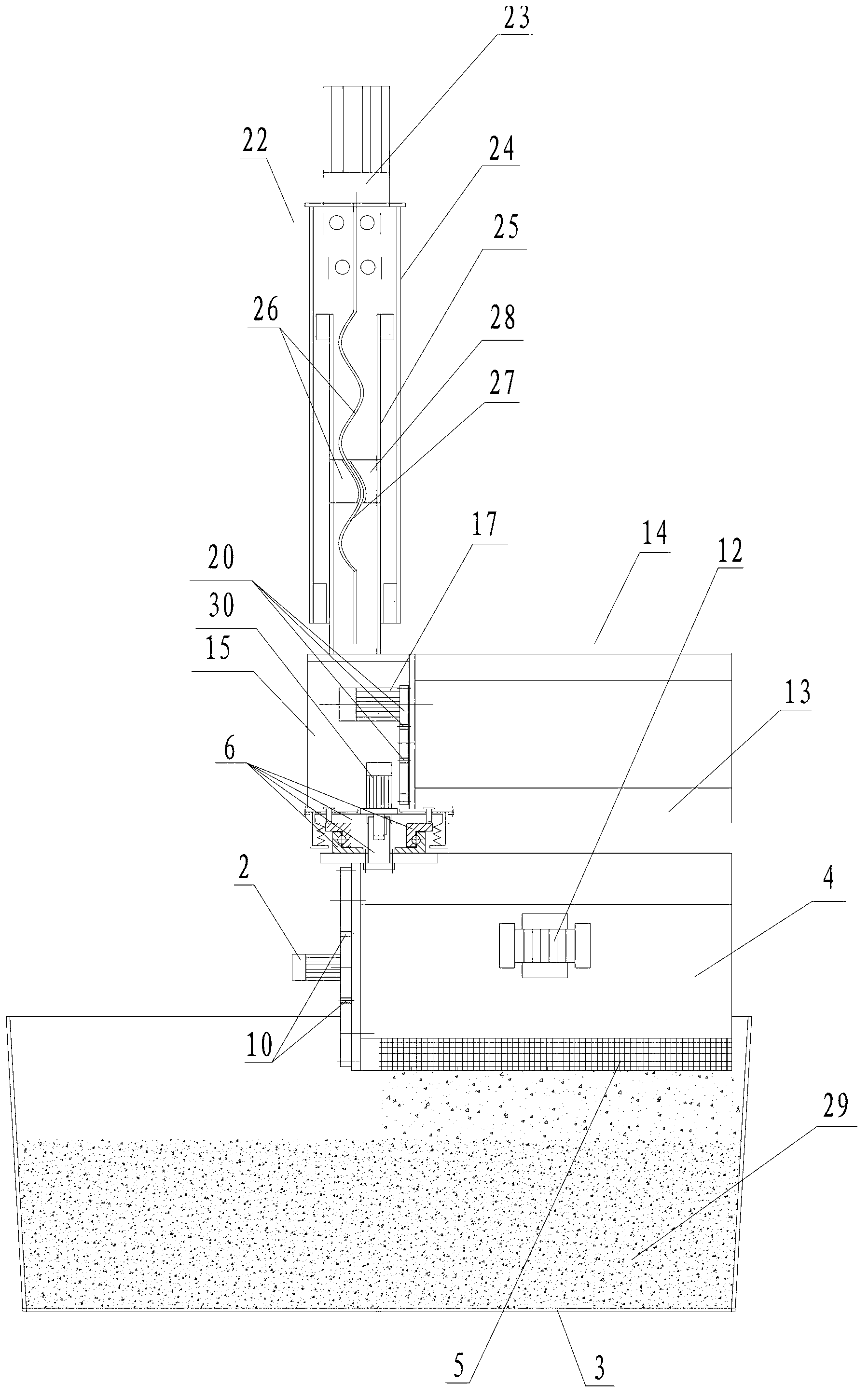

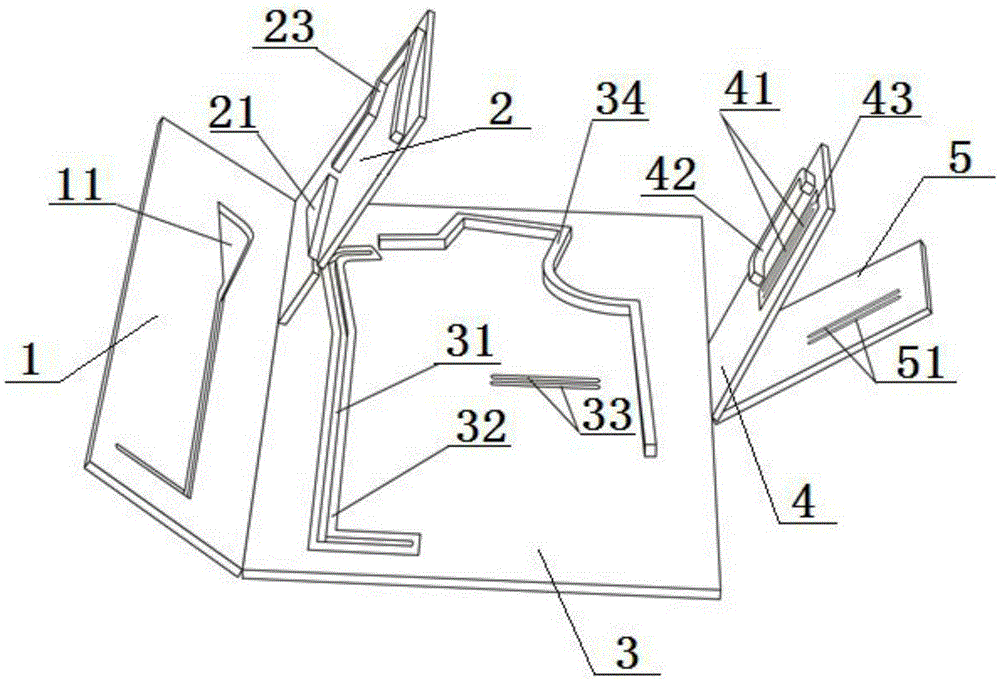

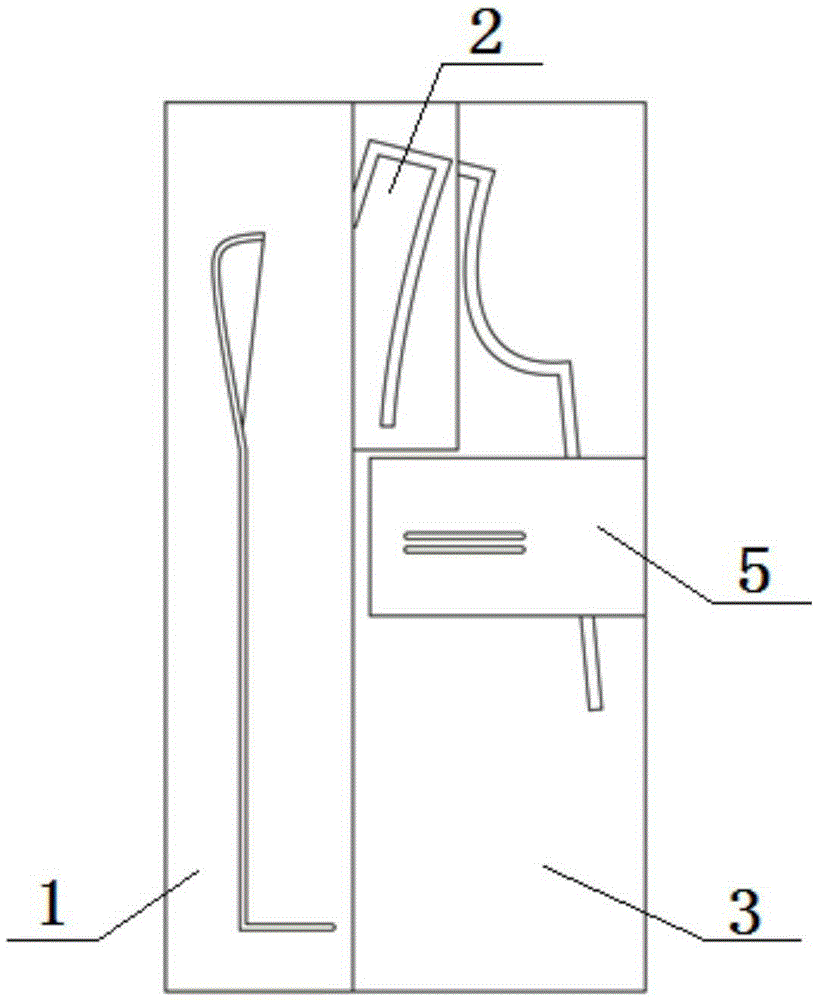

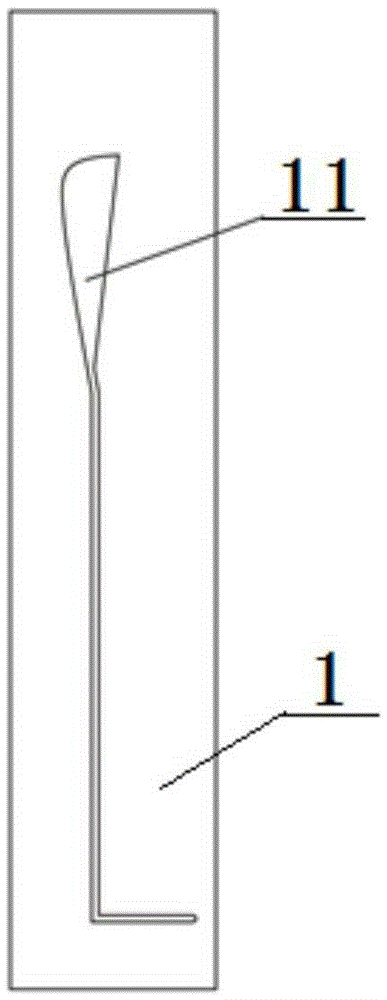

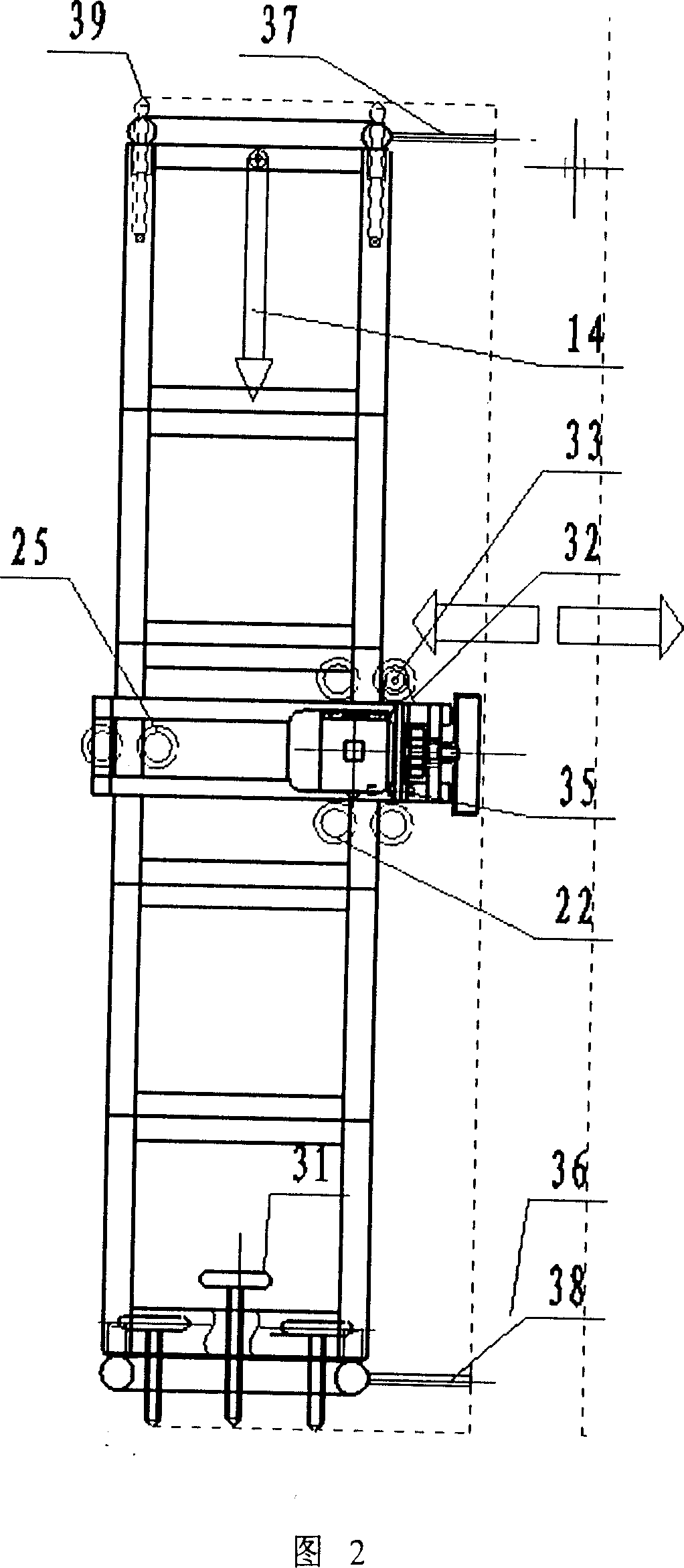

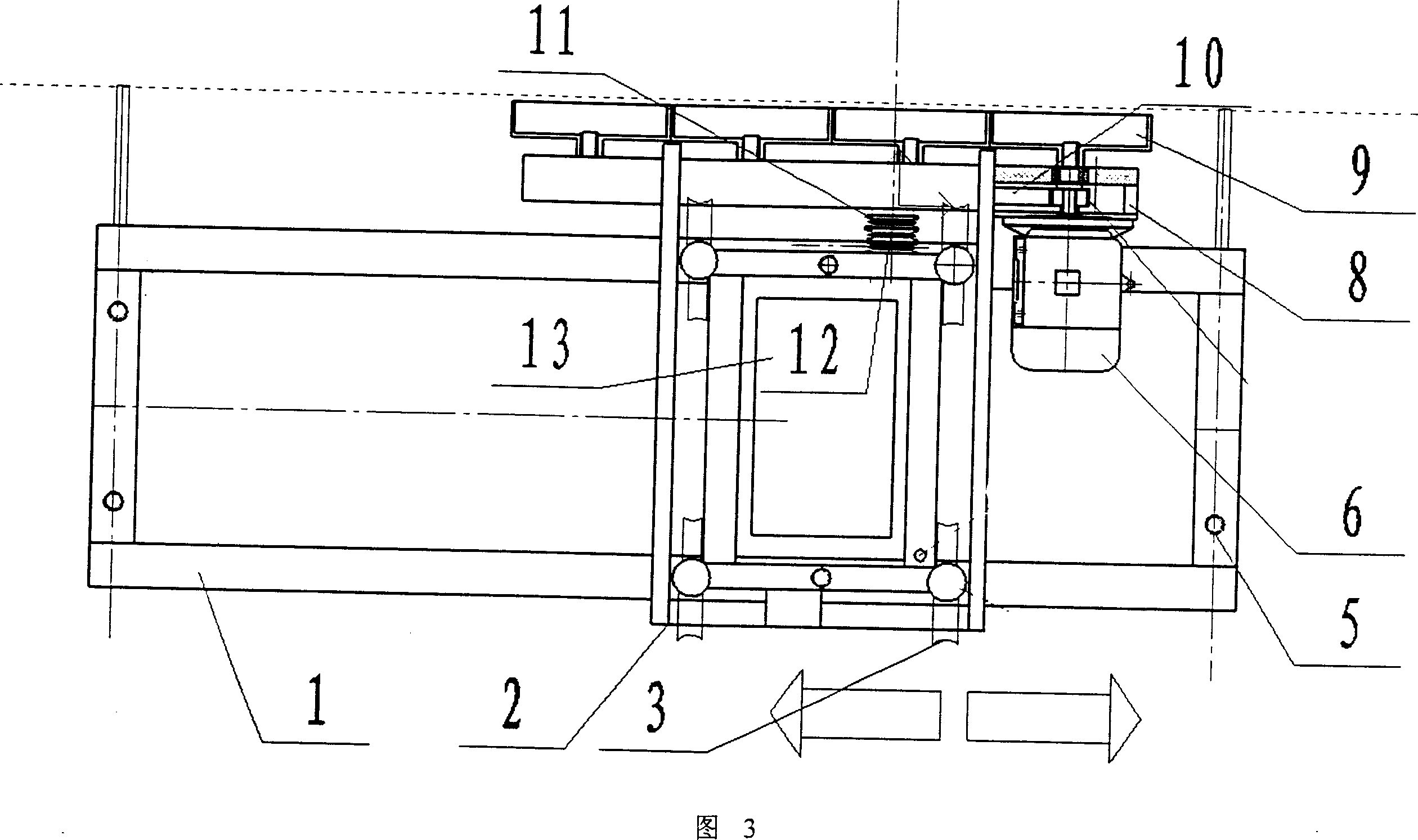

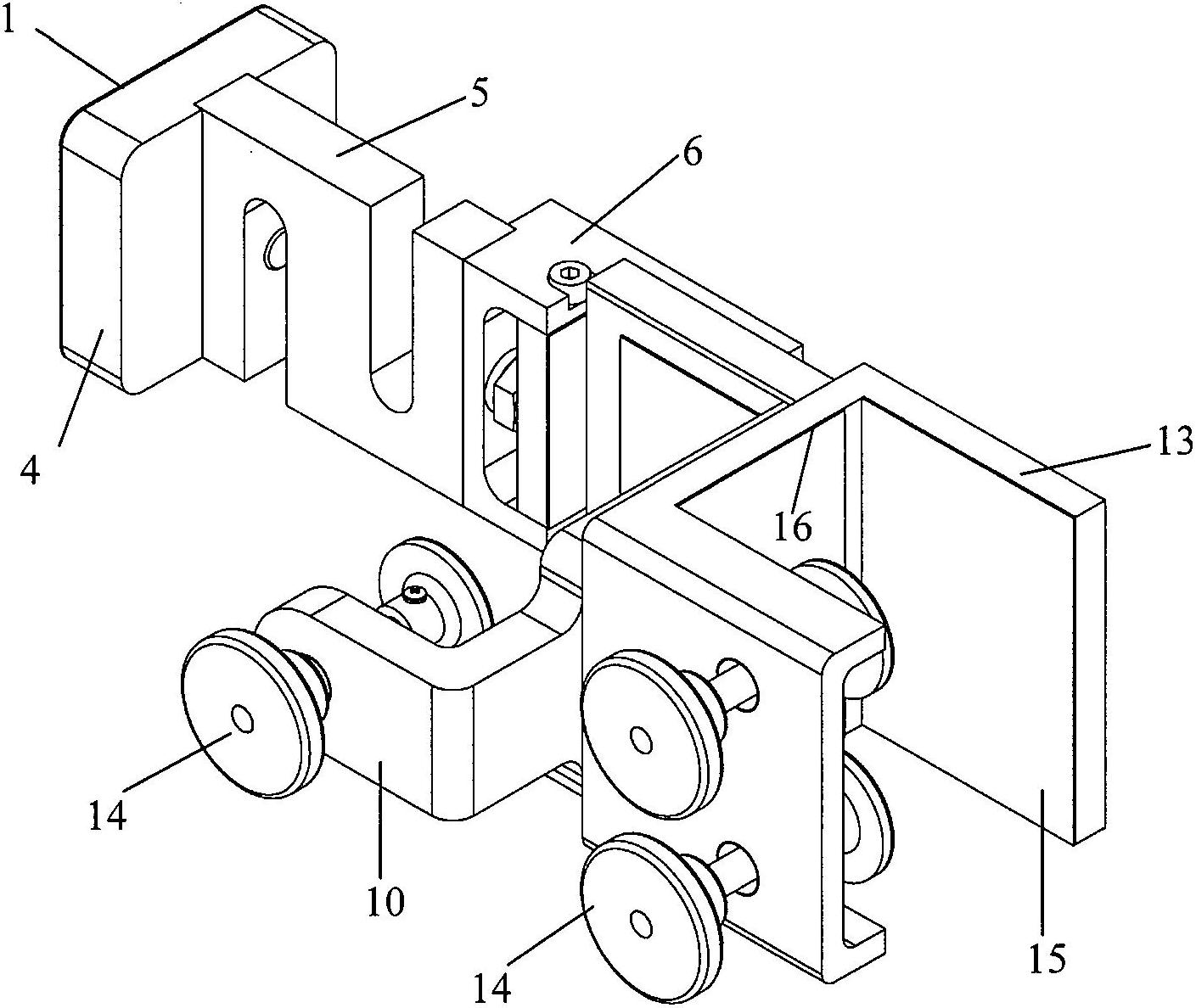

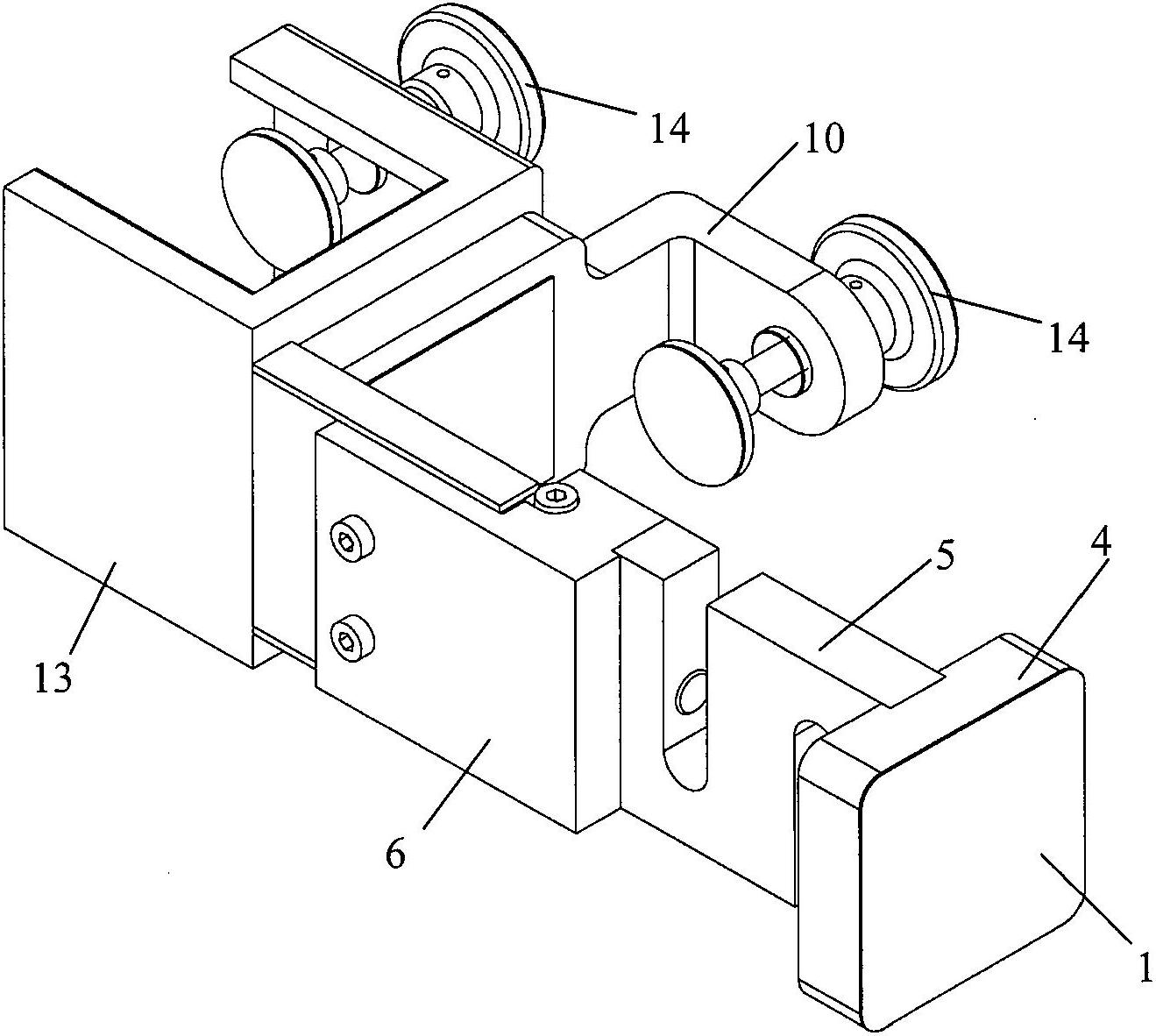

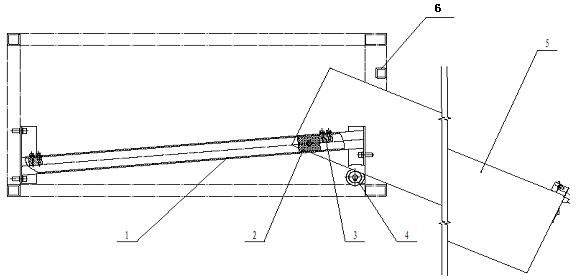

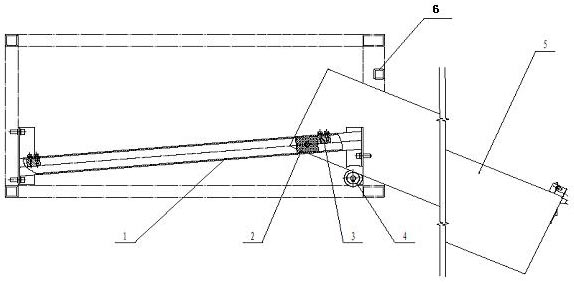

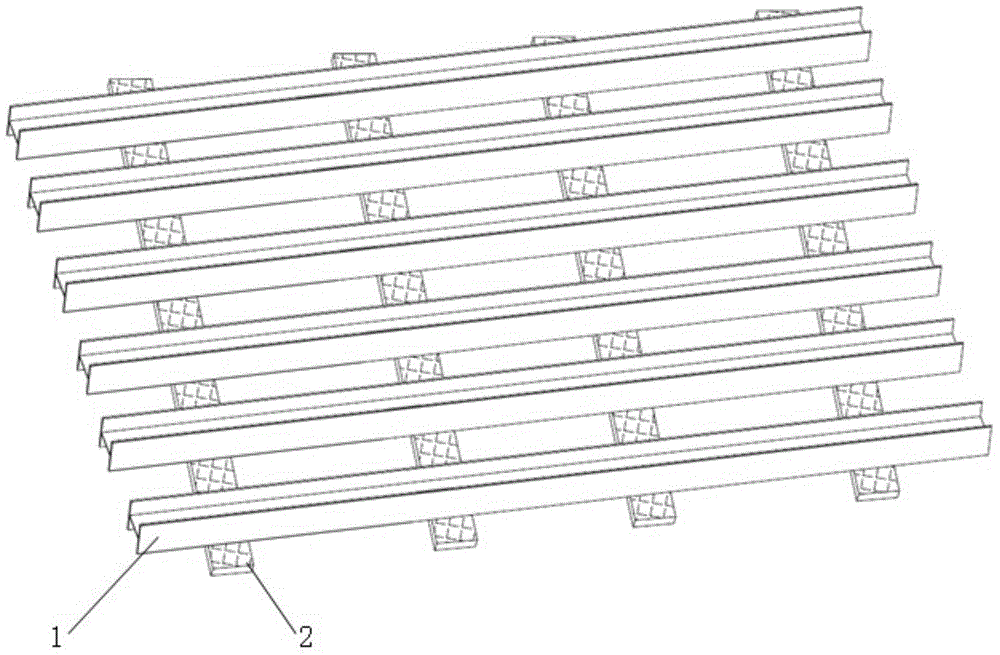

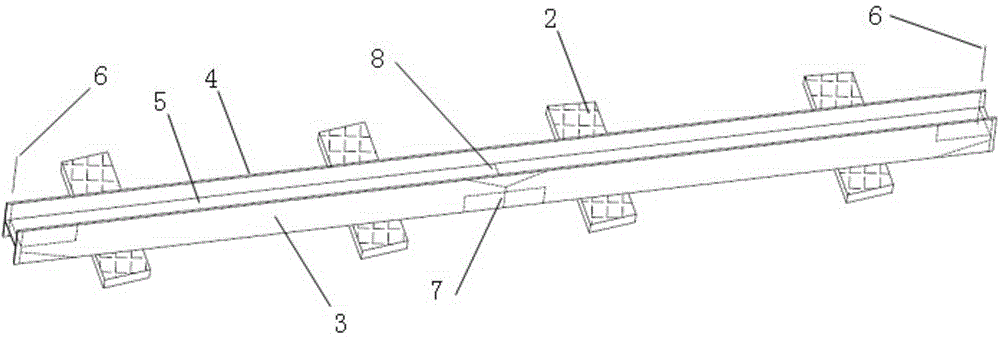

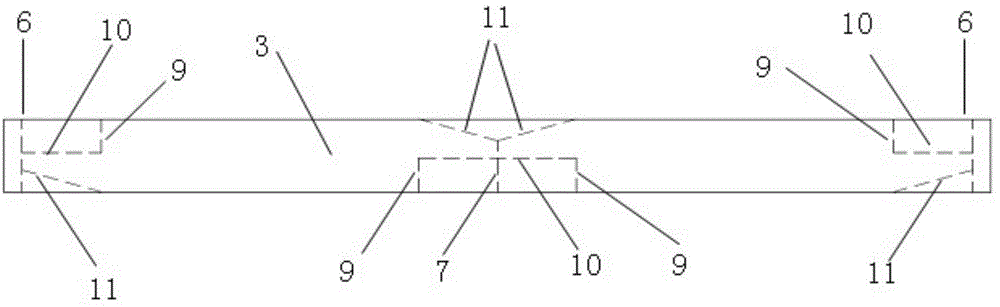

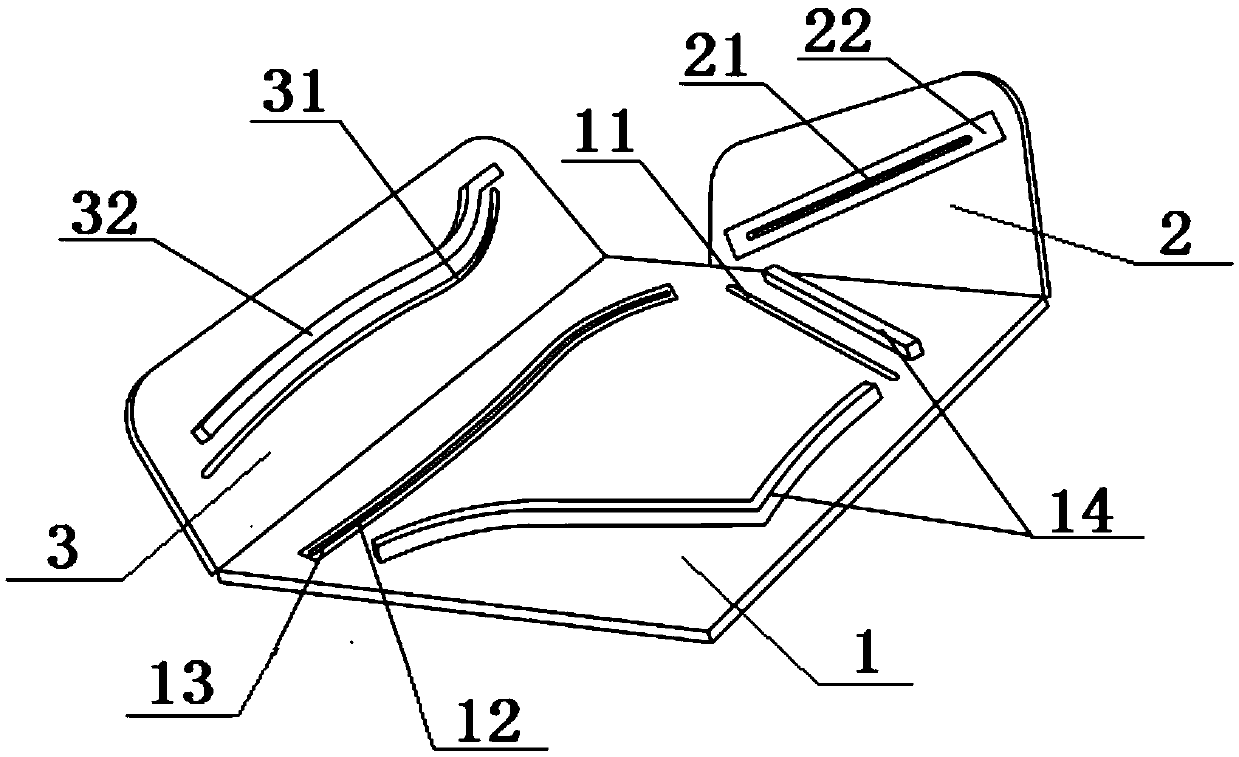

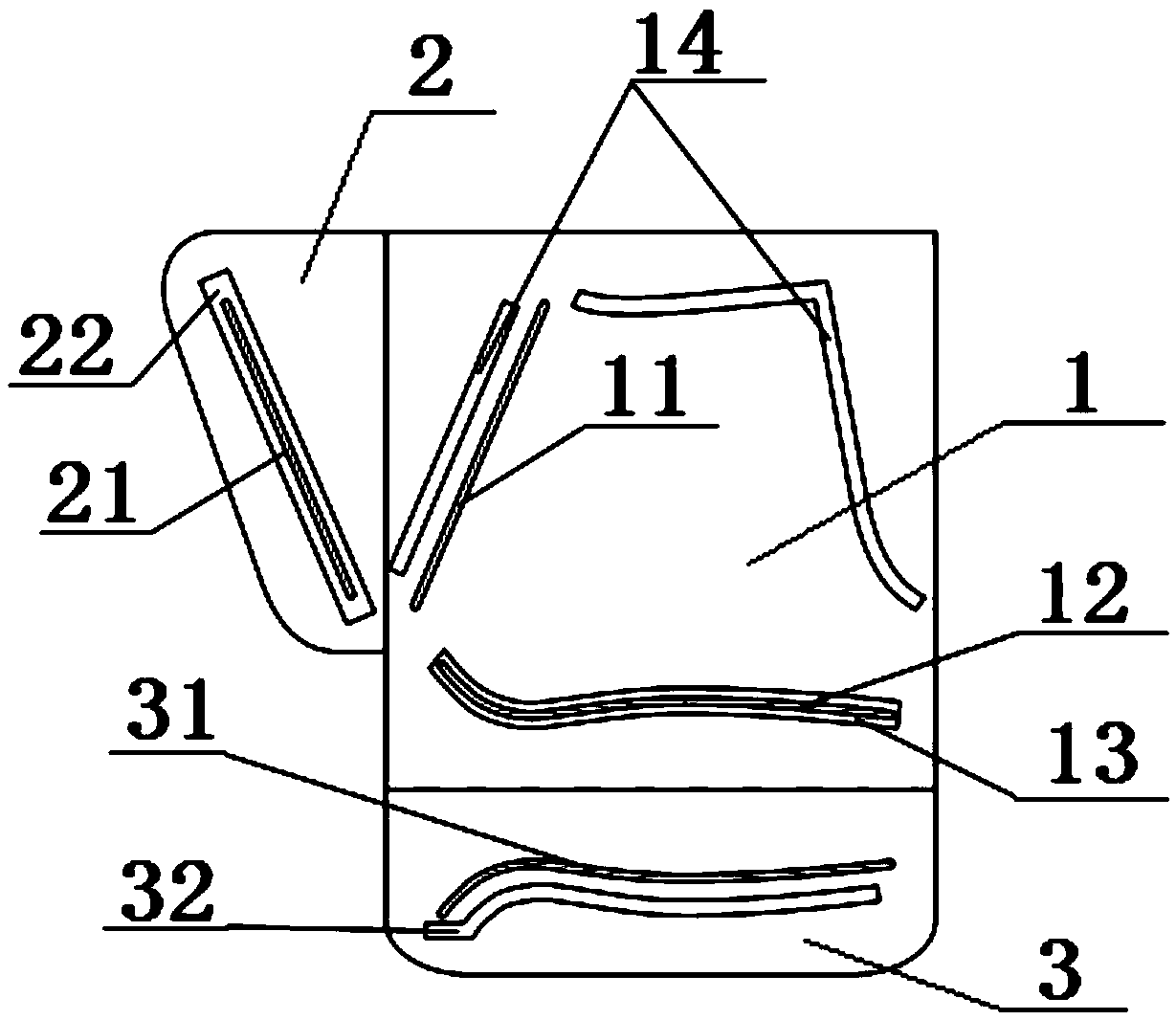

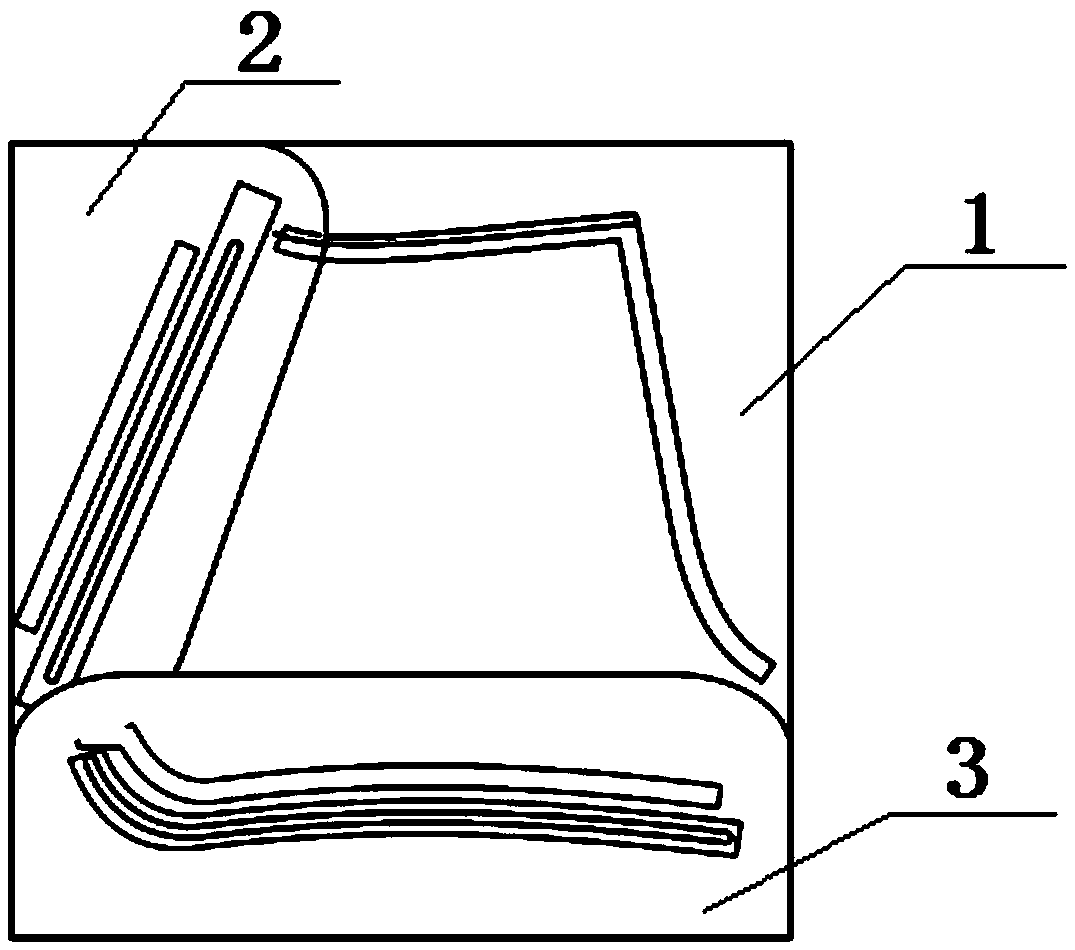

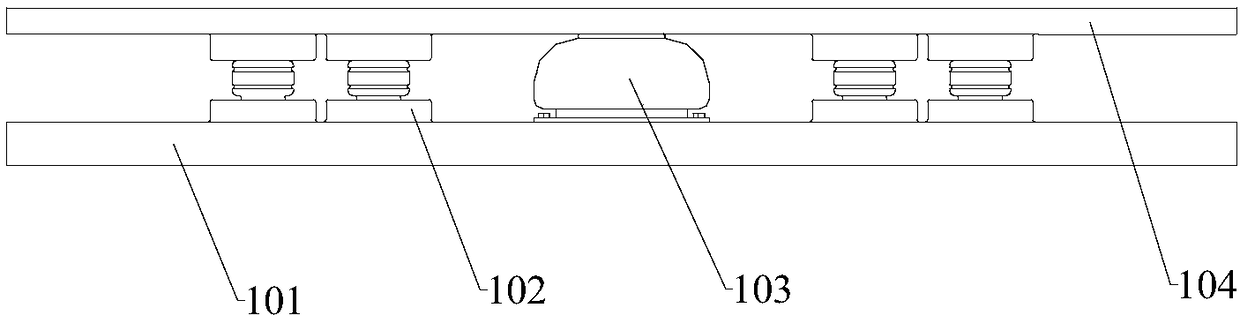

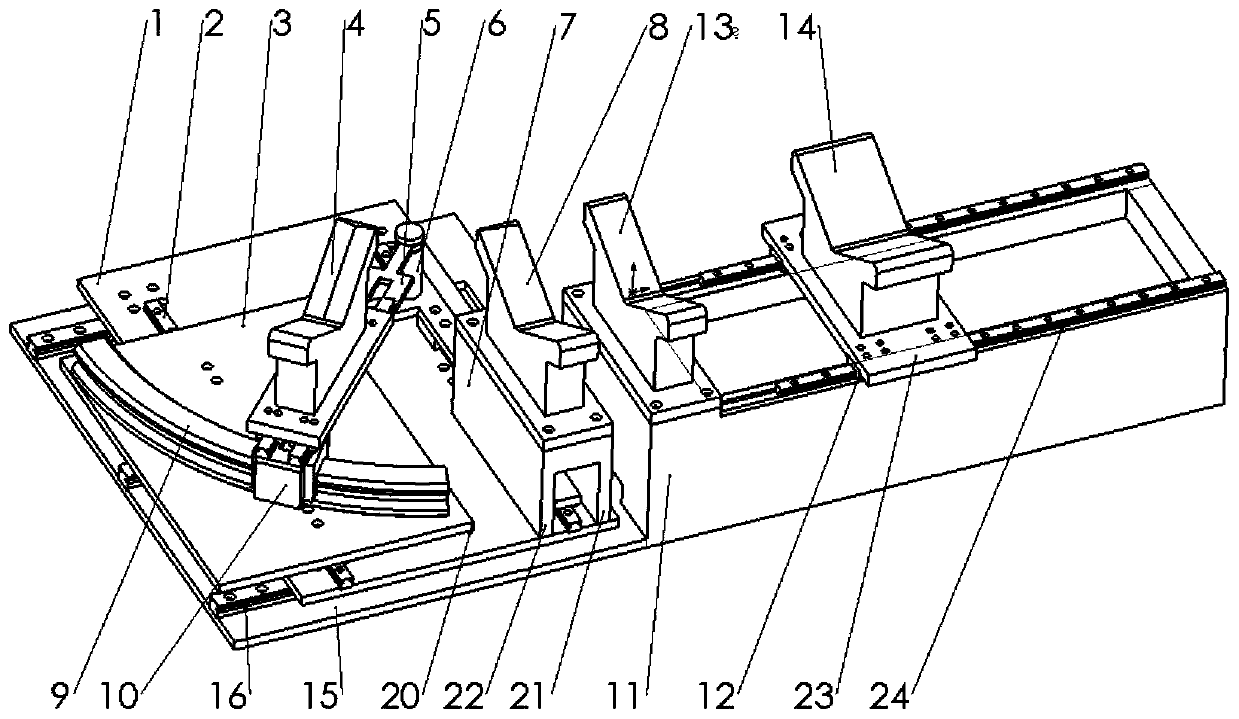

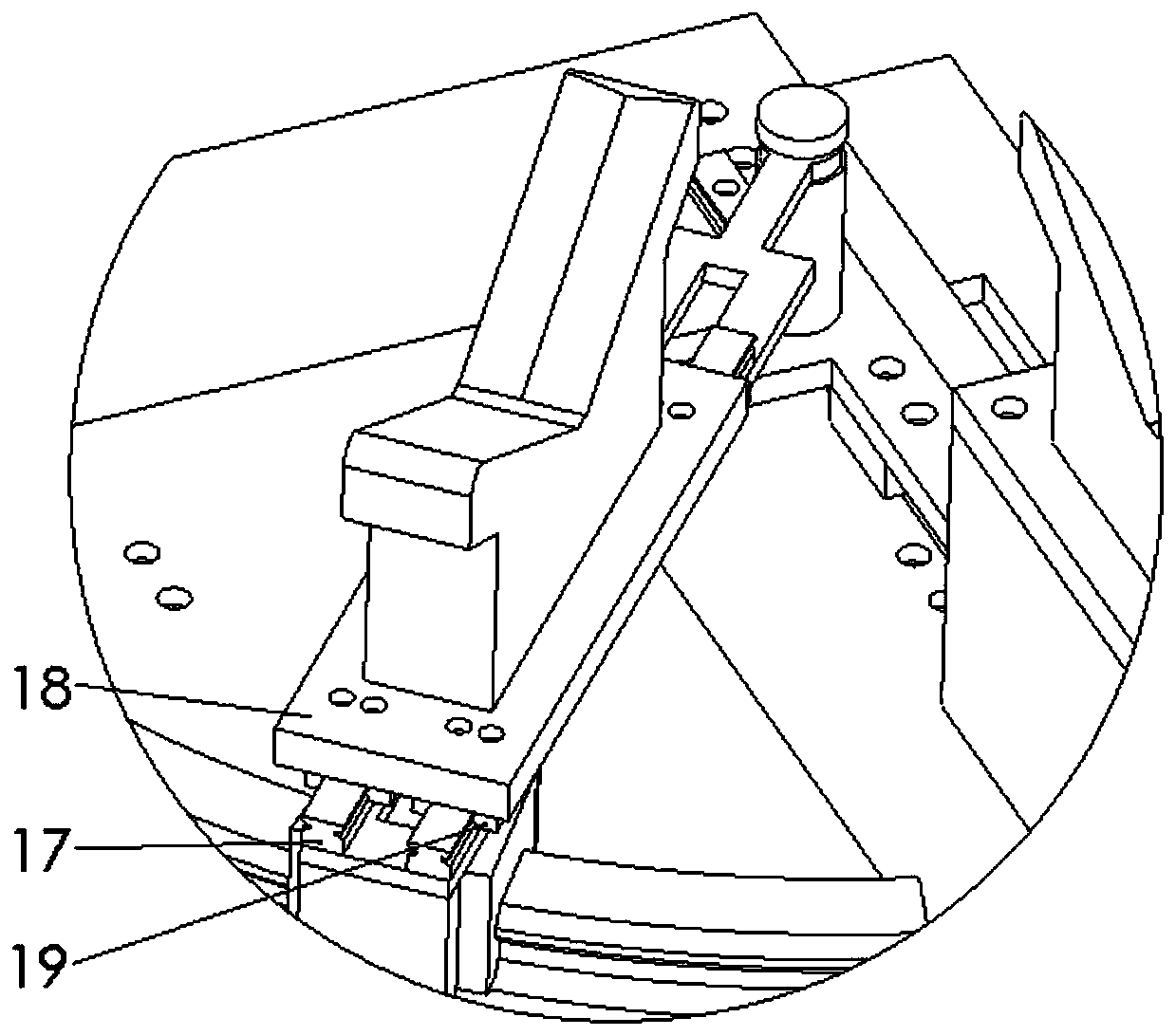

Distributor for loading fermented grains into steamers

ActiveCN103010771AReduce operating labor intensityReduce dependence on operating experienceLoading/unloadingEngineeringDistributor

The invention discloses a distributor for loading fermented grains into steamers, which belongs to the technical field of brewing production equipment. The distributor for loading fermented grains into steamers, which is provided by the invention, less depends on the operating experience of operators and can remarkably decrease the labor intensity of operators in the process of loading fermented grains into a steamer. The distributor comprises a conveying assembly, a conveying driving device and a distributing hopper; the length of the distributing hopper is matched with the radius of a steaming bucket; the bottom of the distributing hopper is provided with a screen, and the conveying assembly which is mounted along the length direction in the middle lower part of the distributing hopper is driven by the conveying driving device; the distributing hopper is provided with a pivot structure located on one end of the central part of the steaming bucket, and the distributing hopper is movably supported in the steaming bucket through the pivot structure. During distribution, the distributing hopper is turned around the pivot structure, the conveying assembly conveys the fermented grains in the middle upper part of the distributing hopper onto the screen on the bottom, and the fermented grains are evenly distributed into the steaming bucket via the screen.

Owner:WULIANGYE

Sewing fixture for sewing suit front part with flap pocket adding with welt to front facing

InactiveCN105350189AShort working hoursEasy to operateWork-feeding meansClothes making applicancesWaste productEngineering

Owner:盛楠

Machine tool for flattening wall space

The present invention relates to a wall surface trimmer. It includes a supporting frame which can be forwards and backwards, leftwards and rightwards and upwards and downwards moved, at least one cutting-tool and a feeding device. Said cutting-tool can adopt milling cutter or surface planer tool, and said supporting frame includes positioning mechanism, vertical lifting mechanism and horizontal moving mechanism. Said invention also provides its concrete operation method.

Owner:张旭东

Comprehensive testing device and method for rudder pedal force and angle in control cabin

ActiveCN102645299ASimple structureReduce the difficulty of operationMeasurement of force applied to control membersCombined testEngineering

The invention provides a testing device and a corresponding testing method for rudder pedal force and angle in a control cabin. The testing device comprises a testing fixture body which is installed at the upper part of a rudder pedal stand column. The testing fixture body comprises a first installation part which is used for installing a pedal force measurement instrument and a second installation part which is used for installing a pedal angle measurement instrument. The testing device additionally comprises a pedal, which is fixedly connected with the pedal force measurement instrument. By adopting a concept of integrated and modularized design and using one single fixture to integrate two different testing modules, the simultaneous accurate testing of rudder pedal force and angle data is realized; and compared with the traditional testing device and the traditional testing method, the testing device and the testing method provided by the invention can realize the synchronous measurement of force and angle parameters which cannot be realized by using general equipment, and is commonly suitable for the field practical situation of an assembly workshop.

Owner:COMAC +1

Oblique-pulling drawer slide rail

InactiveCN102462223ASolve the problem of easy accessReduce the difficulty of operationVehicle componentsDrawersEngineeringMechanical engineering

The invention relates to an oblique-pulling drawer slide rail, and belongs to the field of special vehicles. The drawer slide rail is provided with a vehicle body frame, and is characterized in that: slide rails are symmetrically arranged on left and right sides in the vehicle body frame; the front end of each slide rail is acclivitous; a slide block is arranged on each slide rail and hinged with a drawer through a shaft; baffle blocks are fixedly arranged at the front end and rear end of each slide rail; and a guide wheel is fixedly arranged in the vehicle body frame below the front end of each slide rail. By the drawer slide rail, the problem that a high-position heavy drawer is inconvenient to take and put is solved, the operating difficulty and labor intensity of operating personnel are greatly reduced, and personal safety is better ensured.

Owner:WEIHAI YIHE SPECIAL EQUIP MFG CO LTD

Technology for machining two surfaces of infrared window piece

The invention relates to a technology for machining two surfaces of an infrared window piece, which performs the grinding with a two-surfaces grinding machine and performs the polishing with the two-surfaces grinding machine, wherein the grinding is firstly performed and the polishing is sequentially preformed. The technology comprises the following steps of: putting an infrared window piece in a loose pulley; primarily grinding on an iron-cast flat mould; fine grinding after the infrared window piece is detected to achieve the quality requirement, wherein the fine grinding is performed by a special flat disc; grinding with refined grinding materials, wherein the position is continually changed during grinding; putting the fine grinded infrared window piece on a polyurethane polishing disc to coarsely polish, so that the surface of the infrared window piece achieves the required precision; and fine polishing the eligible infrared window piece after coarse polishing with a polishing disc which is made from synthetic material of asphalt and rosin to guarantee the quality of the machined product through fine correction. The technology can improve the quality of the smooth finish of the infrared window piece, can improve the quality of the parallelism degree thereof, and can improve the machining efficiency thereof.

Owner:江苏南晶红外光学仪器有限公司

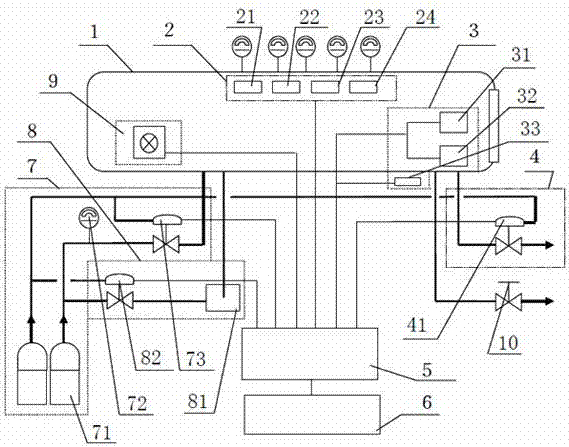

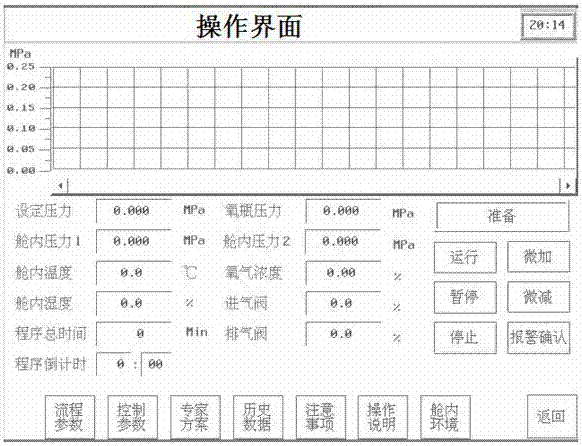

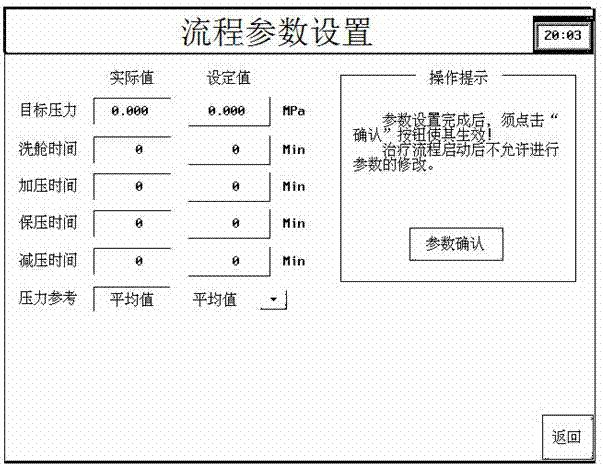

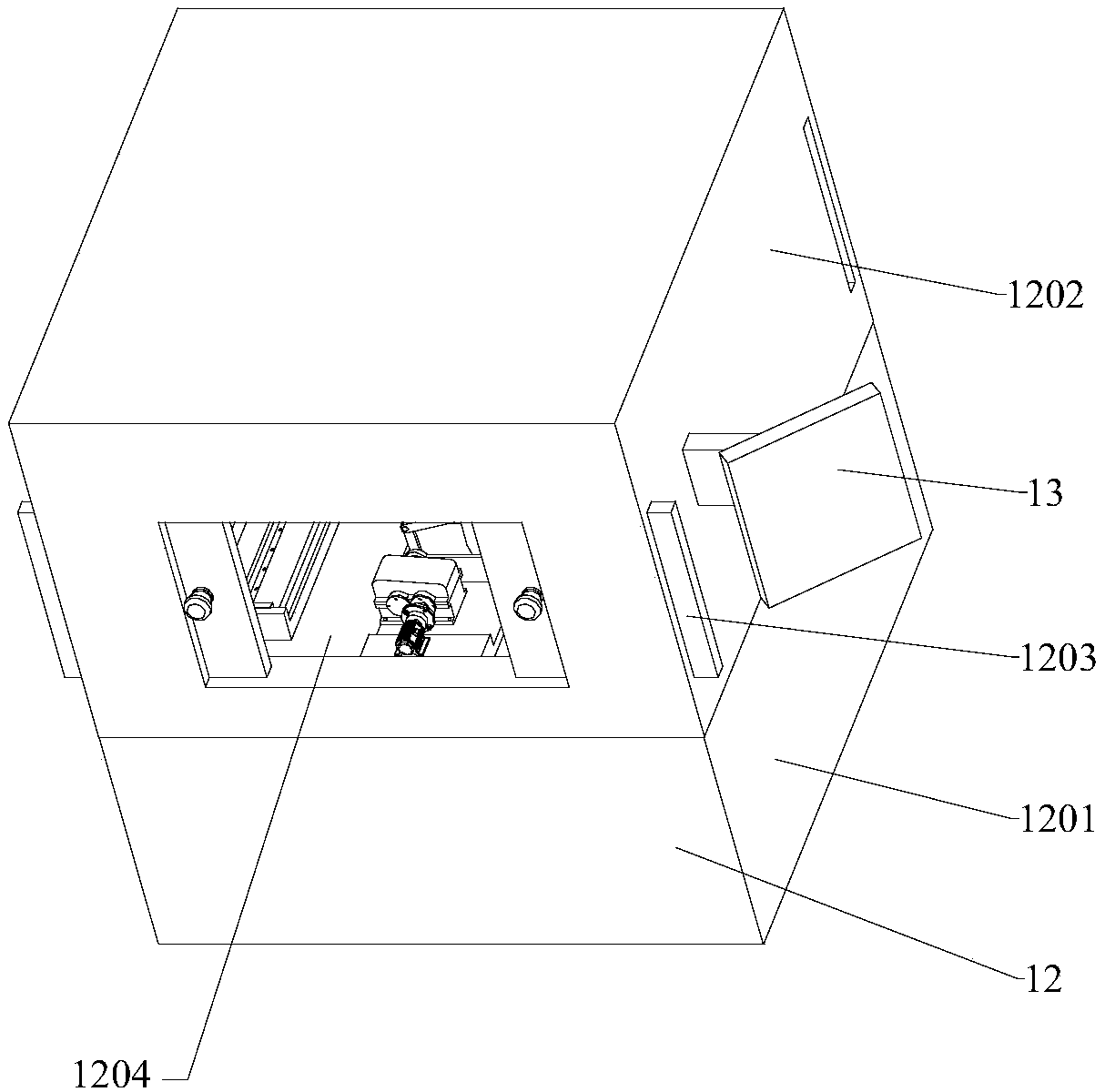

Novel medical oxygen pressure cabin realizing automatic control

PendingCN106955211APressure real-time monitoringReduce the difficulty of operationBreathing protectionTreatment roomsTemperature controlElectricity

The invention discloses a novel medicine oxygen pressure cabin realizing automatic control. The novel medicine oxygen pressure cabin comprises a cabin body, an oxygen supply system, an oxygen exhaust system, a detection system, an operation control and display platform, an electrical system, a control system and a humidifying system, wherein the control system is electrically connected with the oxygen supply system, the oxygen exhaust system, the detection system, the electrical system and the humidifying system and controls the oxygen supply system, the oxygen exhaust system and the humidifying system to perform oxygen supply, oxygen exhaust or humidifying operation on the cabin body through the operation control and display platform, so that cabin washing, pressure raising, pressure maintaining and pressure reduction can be performed on the cabin body during the whole treatment process. The medical oxygen pressure cabin is more intelligent and humanized and has the safety reaching a higher level by monitoring pressure, temperature and oxygen concentration in the cabin body and being matched with corresponding instruments for temperature adjustment, voice prompt and in-cabin monitoring as well as an alarm, the operation difficulty and the labor intensity of workers are reduced greatly, and the medical oxygen pressure cabin has the characteristics of being easy to operate, safe, reliable, flexible, available to a high variable phase and the like.

Owner:GUIZHOU FENGLEI AVIATION ORDNANCE CO LTD

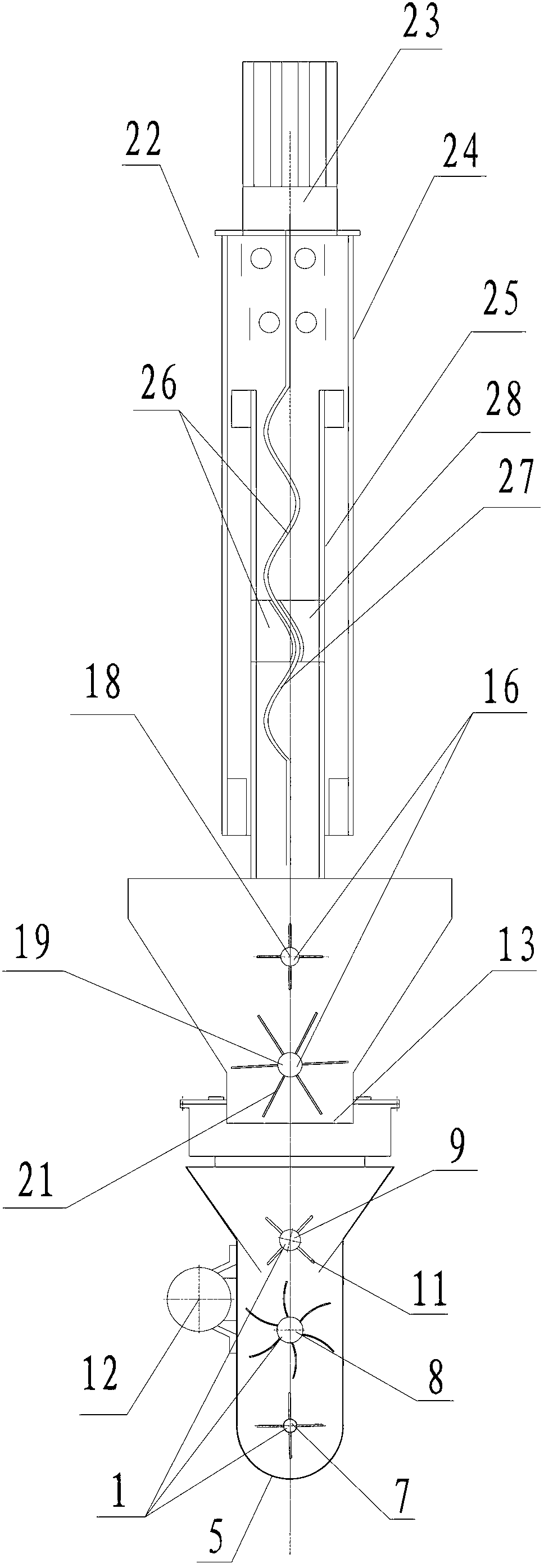

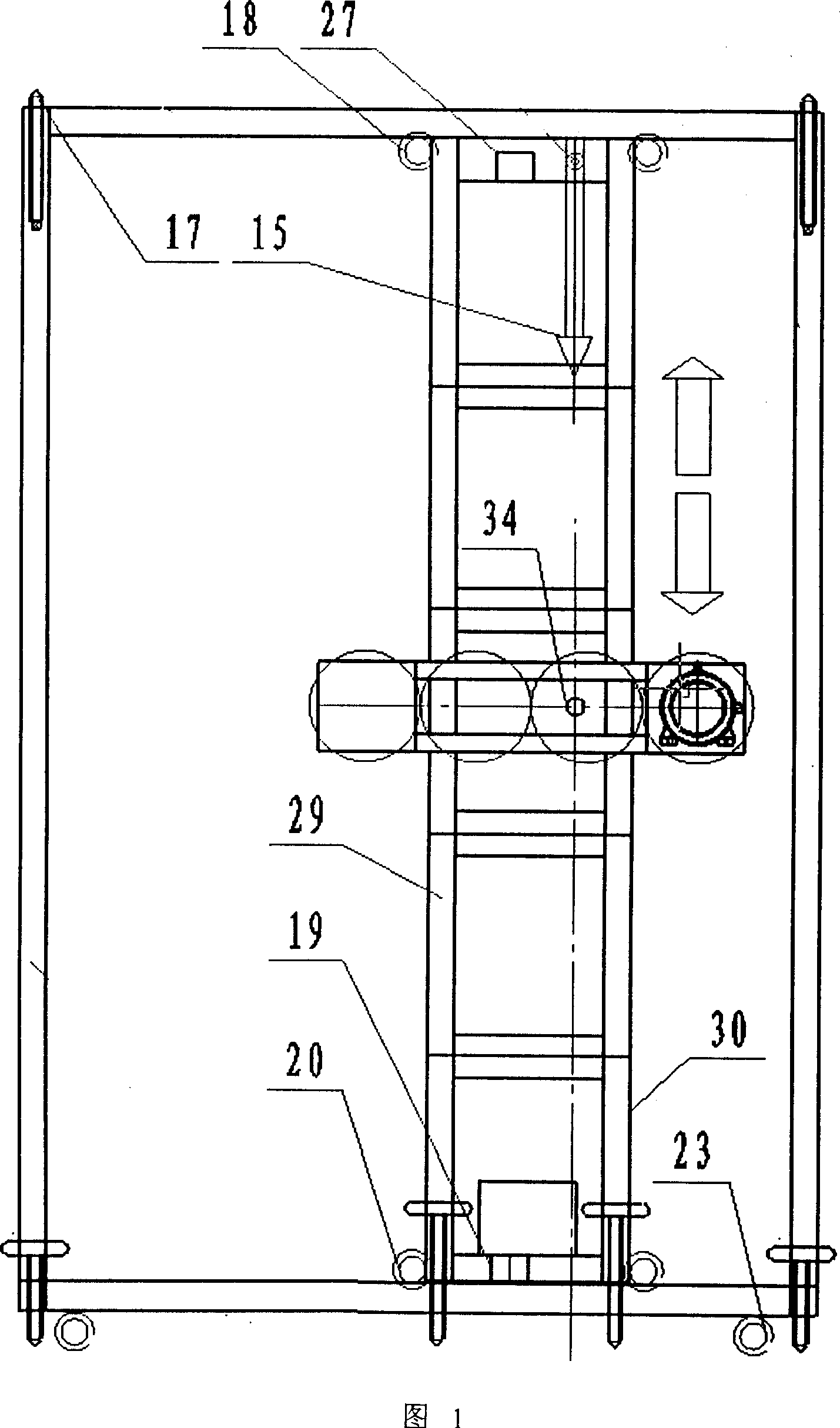

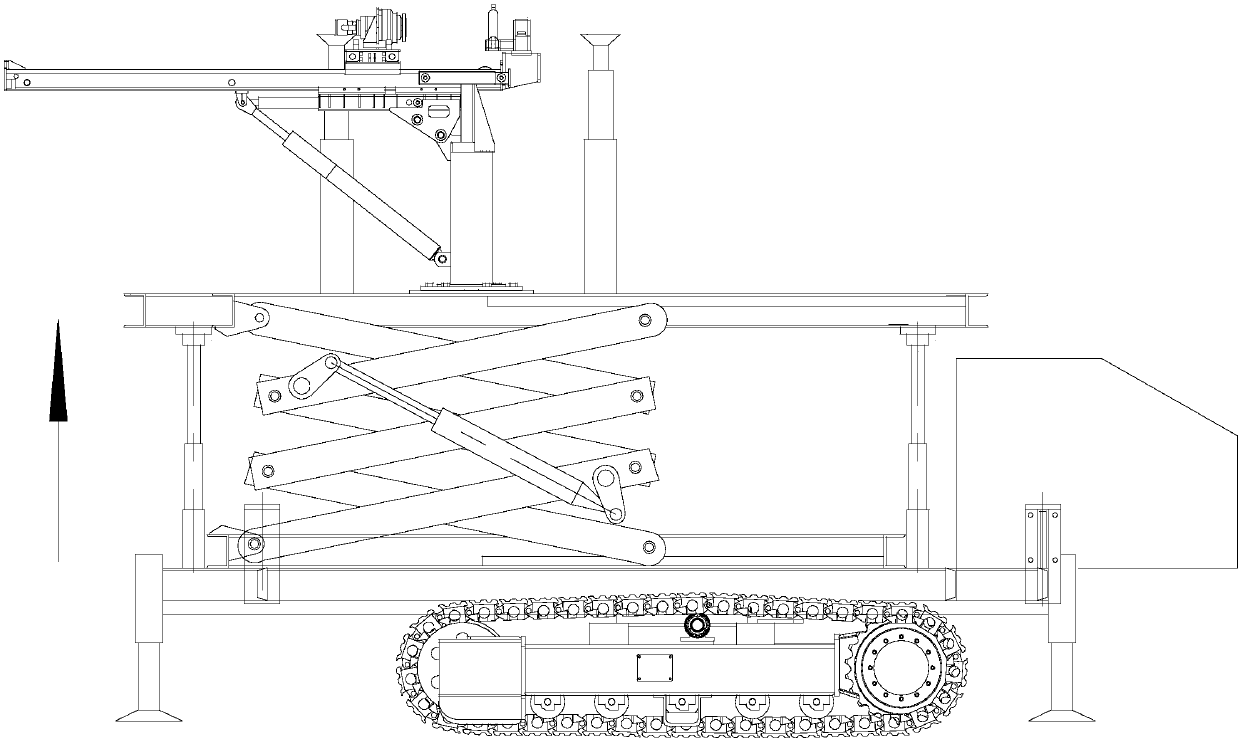

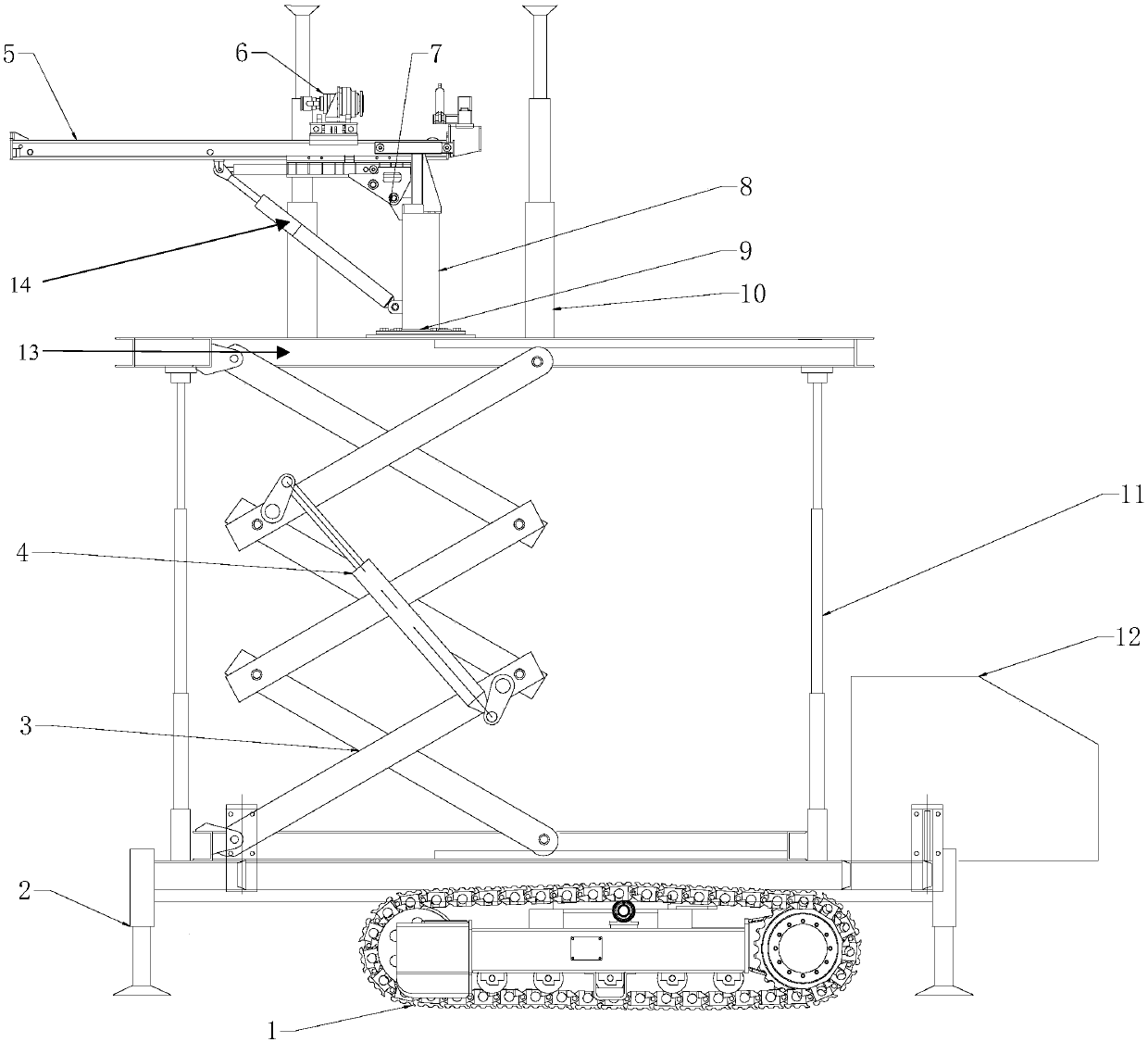

Track type lifting platform hydraulic drilling rig and working method thereof

InactiveCN108049809AEnsure stabilityRealize different functionsDerricks/mastsDirectional drillingSupporting systemPetroleum engineering

The invention relates to a track type lifting platform hydraulic drilling rig and a working method thereof, and belongs to the technical field of drilling rig equipment. The drilling rig comprises a power system, a hydraulic system, a travelling supporting system, a drilling-in system and an electrical system, and the power system provides power output for the whole drilling rig; the travelling supporting system comprises a base, the lower portion of the base is provided with a track, four supporting vertical columns are arranged around the base, and traveling and supporting are provided; theupper portion of the base is provided with a lifting platform, the upper portion of the lifting platform is provided with the drilling-in system, and the drilling-in system is used for providing drilling-in operation; the lifting platform is further provided with the hydraulic system which transmits hydraulic power for all oil cylinder assemblies; and the upper portion of the lifting platform is provided with a first supporting oil cylinder, and a second supporting oil cylinder is arranged between the lifting platform and the base. The track type lifting platform hydraulic drilling rig is small in whole machine size, the adjustable range of drilling hole azimuthal angles is large, the track type lifting platform hydraulic drilling rig adapts to the uneven ground and ground with the slope through a track traveling mechanism and a supporting mechanism, and tunnel hole drilling construction requirements can be well met.

Owner:SHANDONG UNIV

L-shaped notch of H-shaped steel and cutting technology of oblique notch

The invention provides an L-shaped notch of H-shaped steel and a cutting technology of an oblique notch. The technology comprises the following steps that first, the H-shaped steel is horizontally placed on a cup support, and cutting lines are marked on the front face and the back face of a flange slab of the H-shaped steel; second, cutting is conducted along the cutting line on the front face of the flange slab of the H-shaped steel; third, the H-shaped steel is erected; fourth, then cutting is conducted along the cutting line; fifth, a supporting rod is arranged on the cutting line on the front face of the flange slab, and cutting is conducted along the remaining cutting line under the assisting of the supporting rod; sixth, the H-shaped steel is overturned to enable the back face, which has not been cut, of the flange slab of the H-shaped steel to face upwards; seventh, the steps from the second to the fifth are executed again, and then cutting is conducted along the cutting line of the H-shaped steel until the entire H-shaped steel is cut to be a needed H-shaped steel finished product. According to the L-shaped notch of the H-shaped steel and the cutting technology of the oblique notch, the supporting rod is used as the support of a cutting gun so that the cutting gun can smoothly and precisely cut the H-shaped steel, and the cutting quality is guaranteed. Moreover, the operation difficulty of the H-shaped steel is greatly lowered, the potential safety hazards of safety production are avoided, and the production cost is lowered.

Owner:CHINA NAT OFFSHORE OIL CORP +2

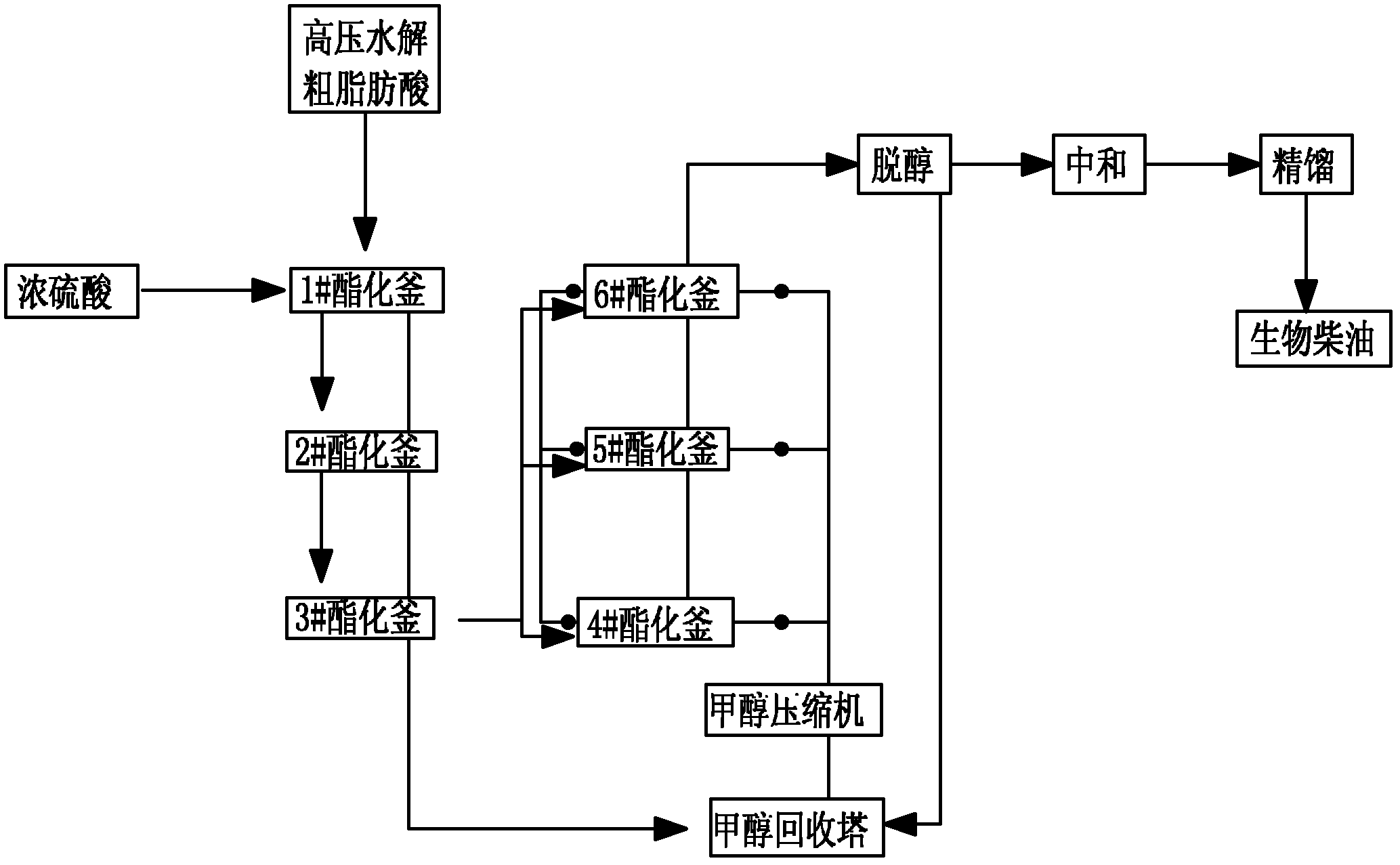

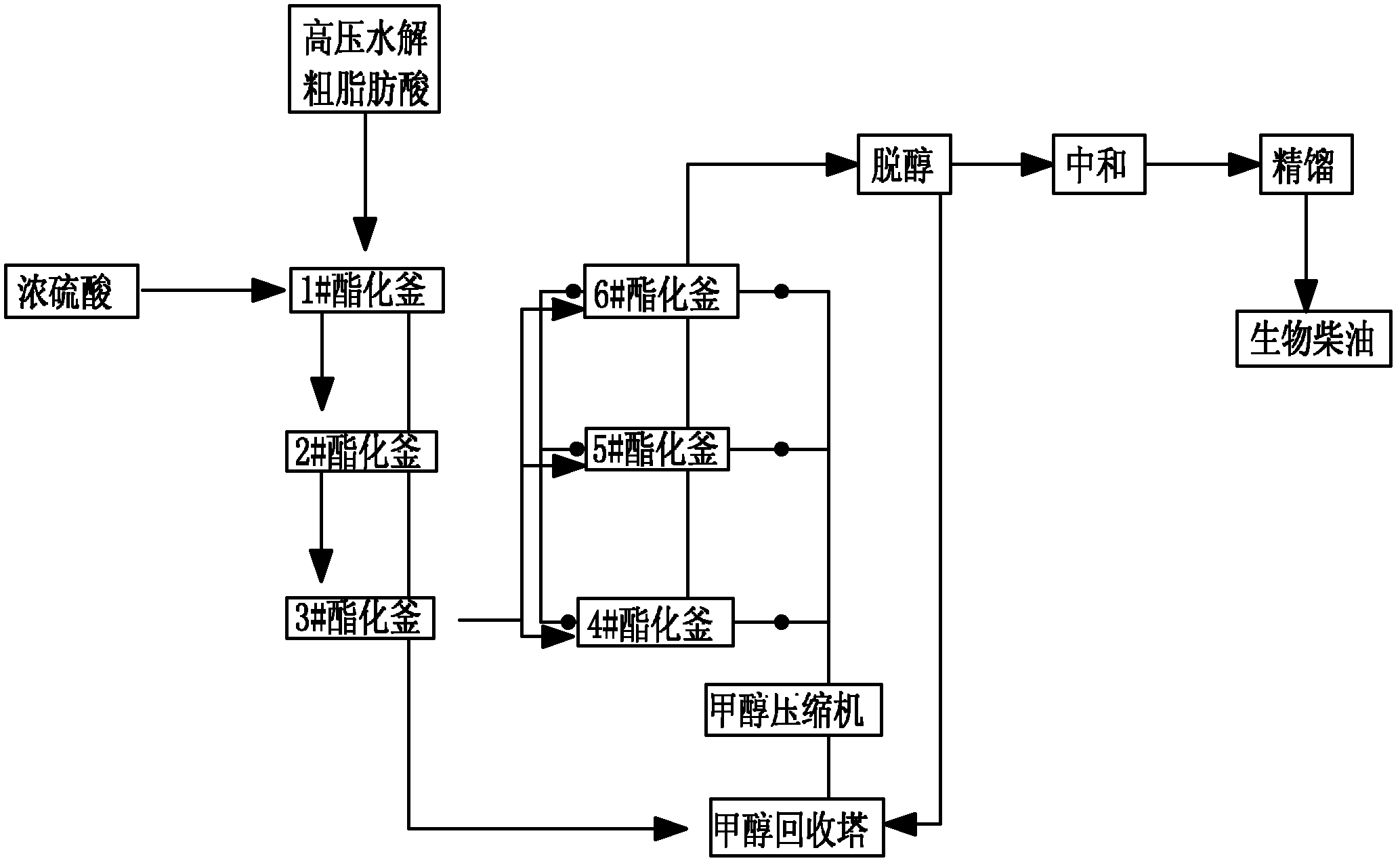

Continuous production method of biodiesel from waste oil/fat

InactiveCN102586027ARealize continuous operationIncrease profitFatty acid chemical modificationFatty acids production/refiningOil and greaseBiodiesel

The invention discloses a continuous production method of biodiesel from waste oil / fat. The method includes mixing waste oil / fat with water at volume ratio of (3-4):1, and hydrolyzing; naturally settling obtained crude fatty acid for 0.5-1.5 hr to remove water and impurities and collect dewatered fatty acid; injecting the dewatered fatty acid and concentrated sulfuric acid into esterification kettle, introducing compressed methanol gas, stepwise esterifying, and alternately removing alcohol after esterification to give crude ester; neutralizing the crude ester with sodium carbonate under stirring; and performing multi-stage distillation to give biodiesel. The method obviates mechanical vacuum distillation for water removal, reduces occurrence of reverse reaction, reduces investment of cooling equipment, improves utilization efficiency, lowers labor intensity, guarantees safe and stable production, and reduces sewage generation.

Owner:潍坊大明生物科技有限公司

Method for refining hydroxyethylcellulose

InactiveCN102492044AFacilitate continuous passageGreat operating flexibilityProduction lineInorganic acids

The invention belongs to the technical field of production methods for hydroxyethylcellulose and particularly relates to a method for refining the hydroxyethylcellulose. The invention aims to solve the technical problem that a method for refining the hydroxyethylcellulose is required to be provided, the method is simple and convenient in technologies, and an obtained product has high quality. The method for refining the hydroxyethylcellulose comprises the following steps of: neutralizing, crosslinking, washing, filtering, drying and crushing, wherein a neutralizer used in the neutralizing step is inorganic acid. By changing the variety of the neutralizer, the continuous production can be performed by the method for refining the hydroxyethylcellulose, the whiteness and free-running property of the product obtained through processing are high, and the stability of the product is higher. In addition, a production line is continuous, so that the production efficiency of the production line is greatly improved, the operating labor intensity of workers is reduced, the essential safety of the production line is improved, and the consumption of energy sources and raw materials is reduced.

Owner:LUZHOU NORTH CHEM IND

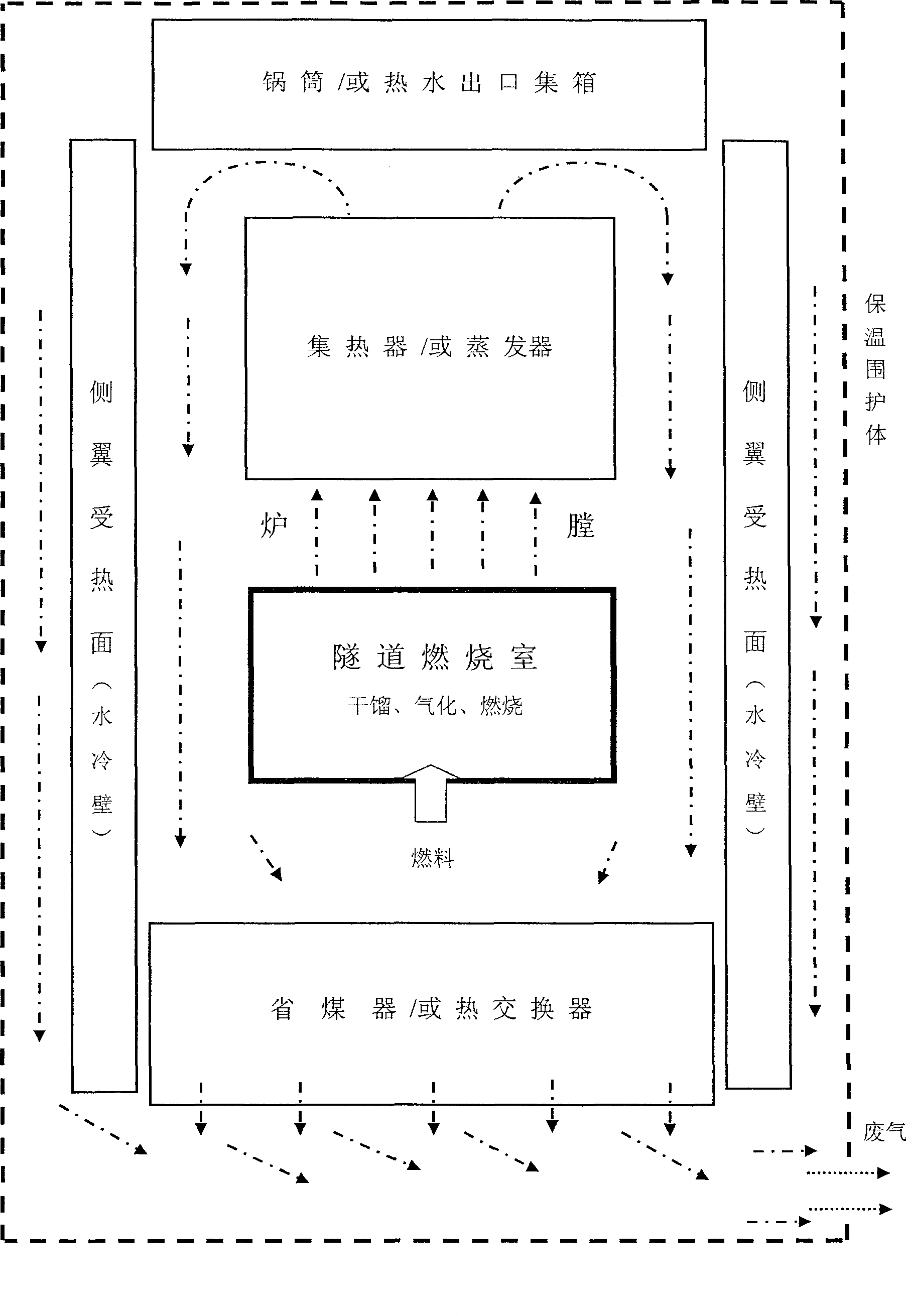

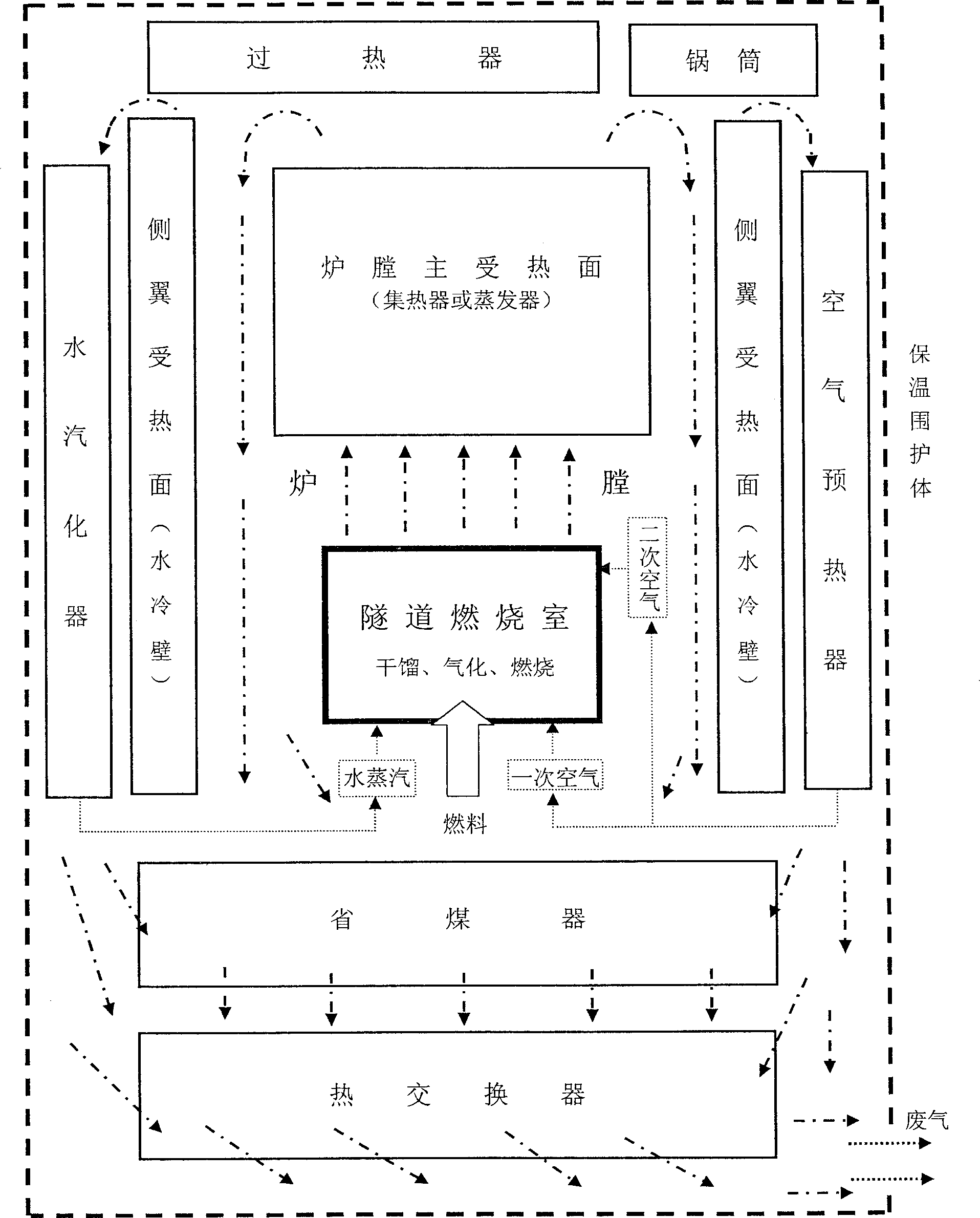

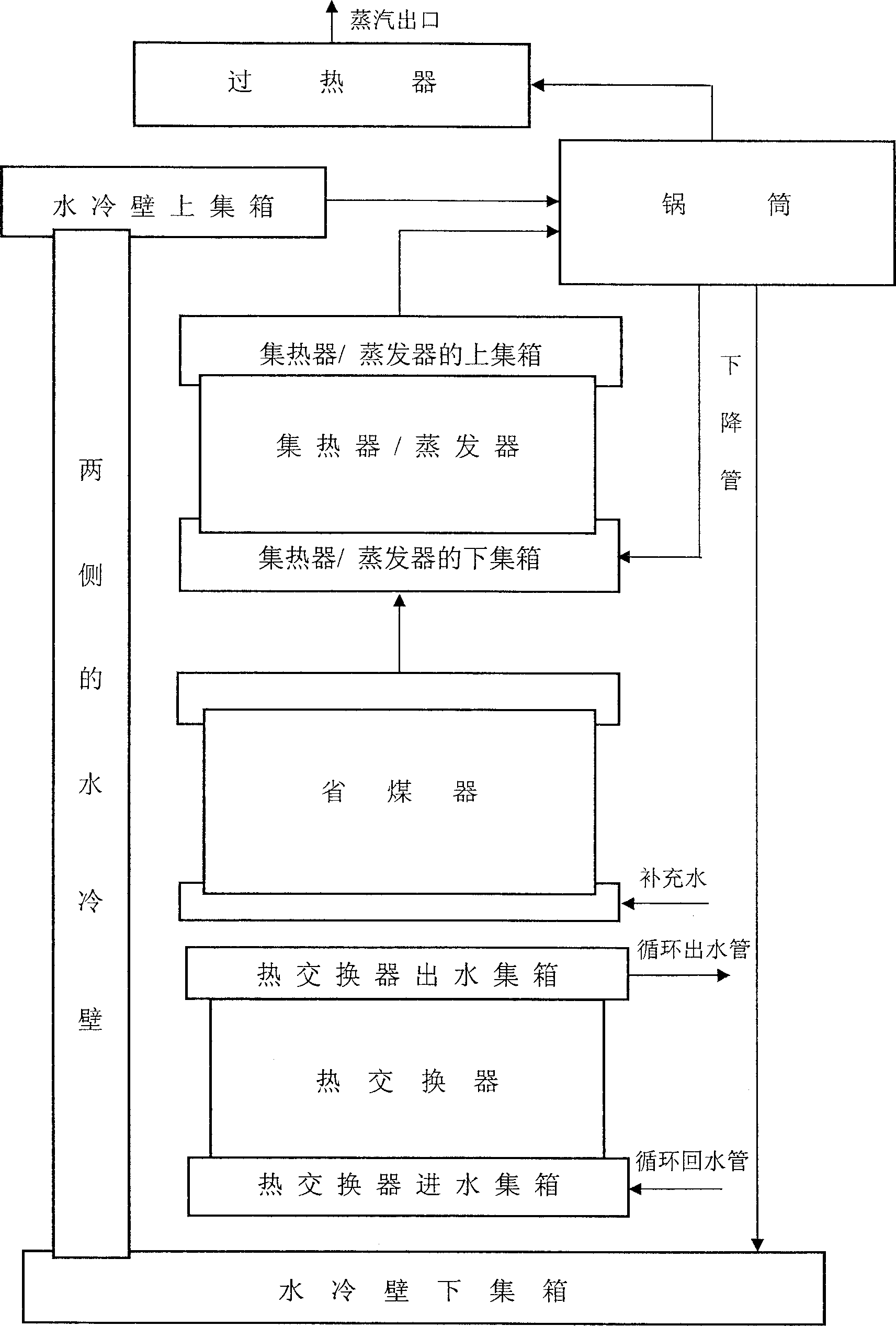

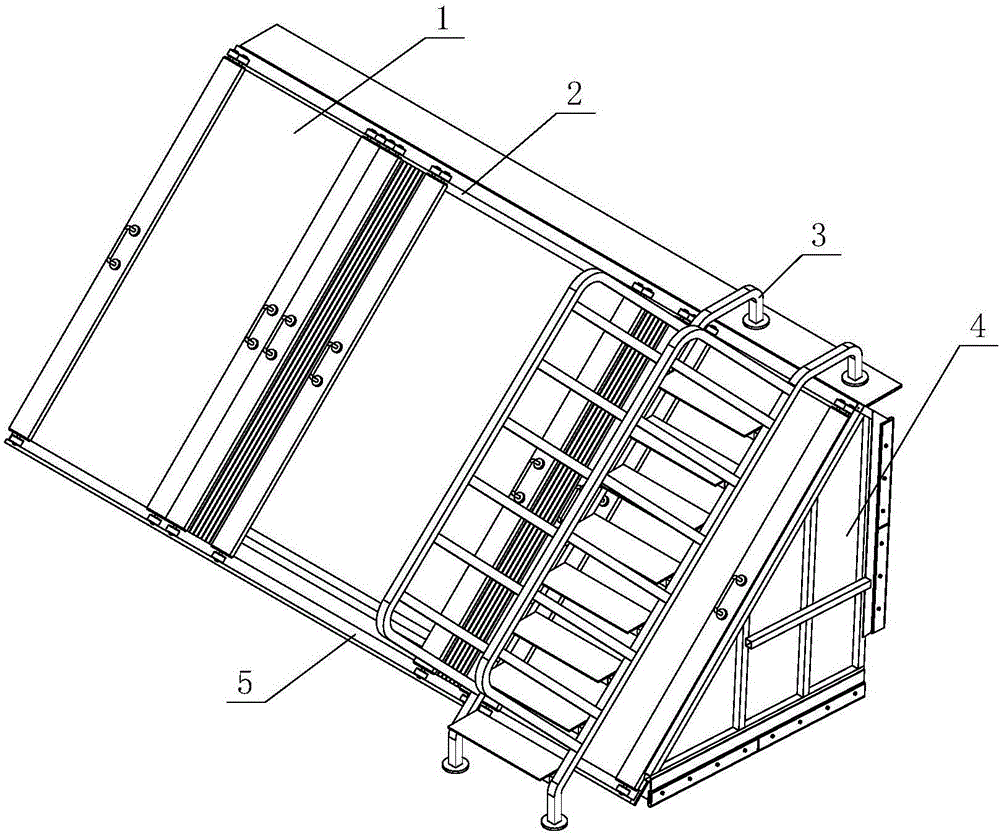

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

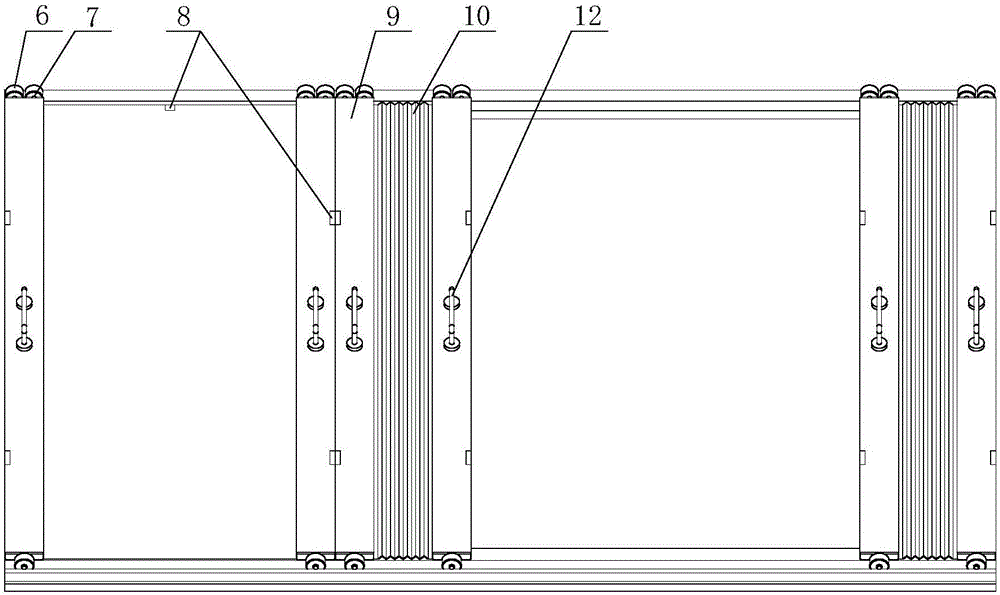

Folding-fan-type cell cover plate of aluminum electrolytic cell

The invention discloses a folding-fan-type cell cover plate of an aluminum electrolytic cell. The cell cover plate comprises a corner cell cover, a ladder stand, an upper track, a lower track and a large face cell cover. The corner cell cover is arranged at the end of the electrolytic cell. The ladder stand is arranged on the side end, close to a flue, of the electrolytic cell. The upper track is located on the cell edge of the upper portion of the electrolytic cell. The lower track is located on the cell edge of the lower portion of the electrolytic cell and parallel to the upper track. The large face cell cover is arranged on the electrolytic cell and slides along the upper track and the lower track. The large face cell cover comprises multiple pairs of aluminum square tubes, each pair of the aluminum square tubes is of a folding-fan structure, and every two adjacent pairs of the aluminum square tubes are connected through strong magnets. Fixing shafts are fixed at the ends of the aluminum square tubes, rollers are mounted on the fixing shaft, and the large face cell cover moves on the upper track and the lower track through the roller. The heat preservation sealing and the tread function are separated, and the cell cover plate further has the advantages of lightweight, low cost, low operation labor intensity, good heat insulation effect and excellent airtight performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

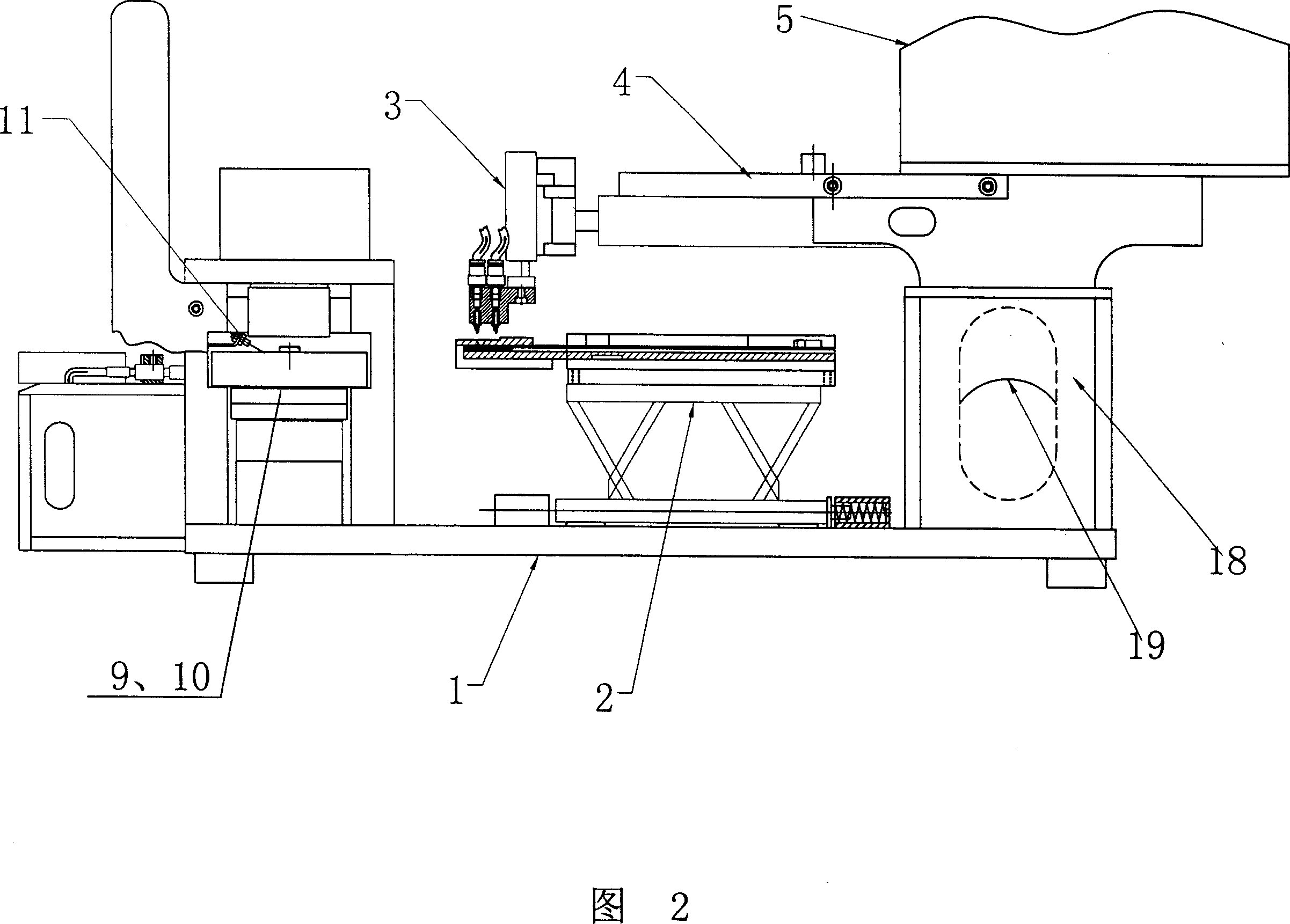

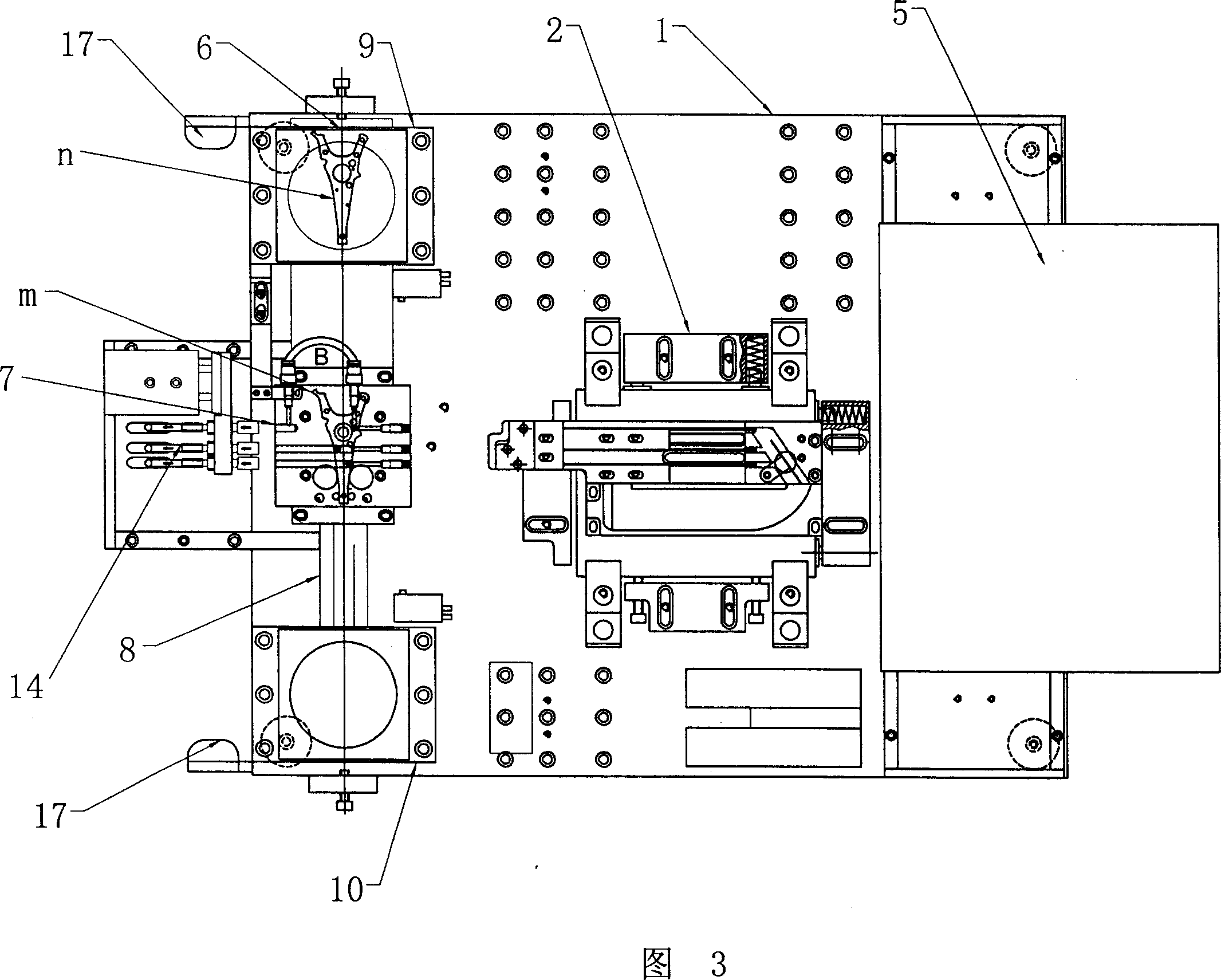

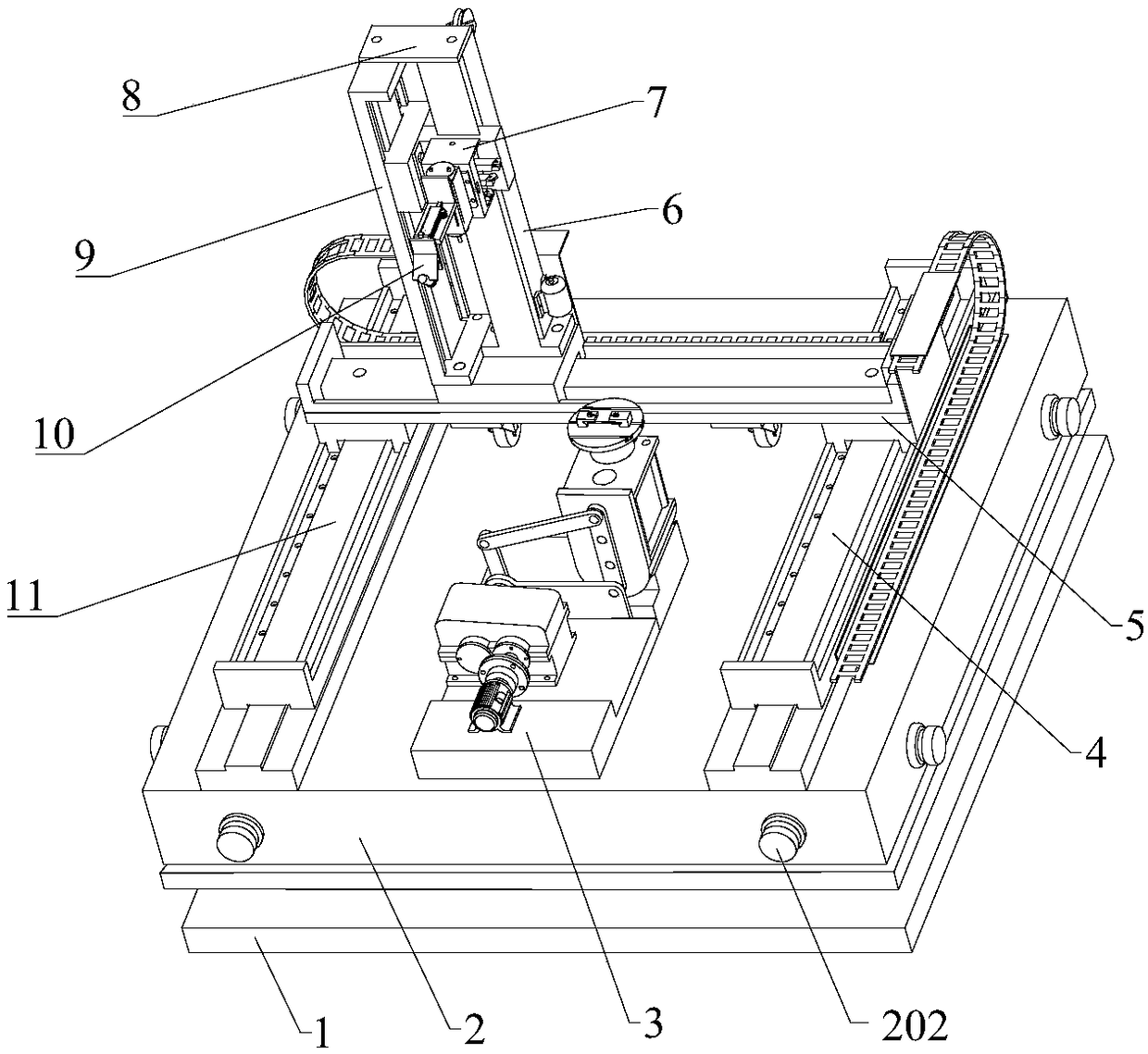

Table top five-freedom-degree microminiature combined machining machine tool

ActiveCN108145535AMiniaturizationTo achieve ultra-high precision requirementsMetal working apparatusMicro devicesControl system

The invention discloses a table top five-freedom-degree microminiature combined machining machine tool. The table top five-freedom-degree microminiature combined machining machine tool comprises a workpiece rotating module, a tool module, a control system, an X-direction driving module, a Y-direction driving module and a Z-direction driving module. The workpiece rotating module comprises a swinging workbench, a clamping device and a rotation driving device, wherein the rotation driving device is used for driving the swinging workbench to swing. The clamping device comprises a turning clamp and / or a milling clamp. The milling clamp is fixed through the turning clamp. The tool module comprises a turning tool rest and multiple turning tools, wherein the multiple turning tools are arranged onthe turning tool rest. The turning tools move to the clamping device under the synergistic effect of the X-direction driving module, the Y-direction driving module and the Z-direction driving module,so that machining of a to-be-machined workpiece on the clamping device is achieved. By means of the table top five-freedom-degree microminiature combined machining machine tool, the redundant productivity or idle functions of the machine tool can be reduced conveniently; the manufacturing energy consumption and cost are lowered; machining quality of micro devices is improved; and the systematization, integration and intelligentization progress of product manufacturing is accelerated.

Owner:SHANDONG UNIV OF SCI & TECH

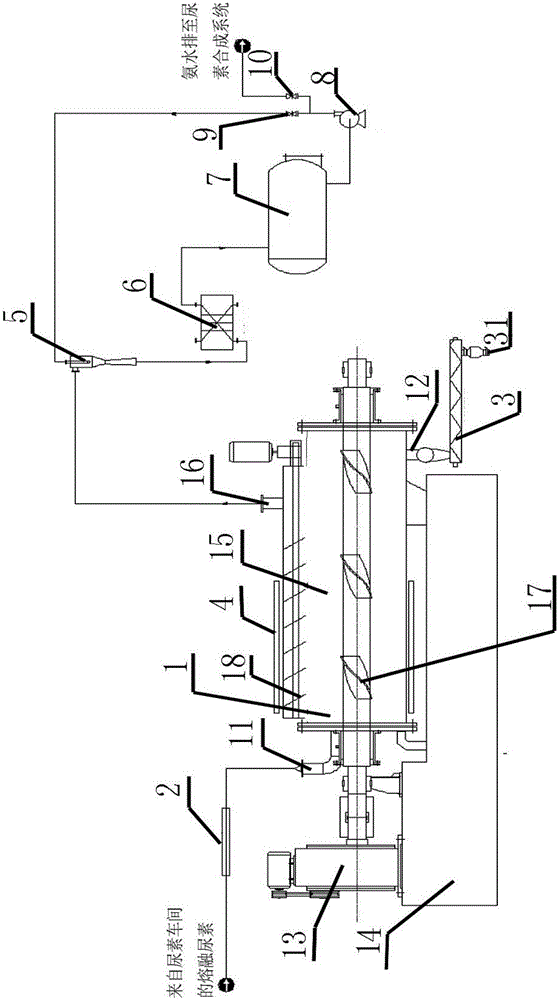

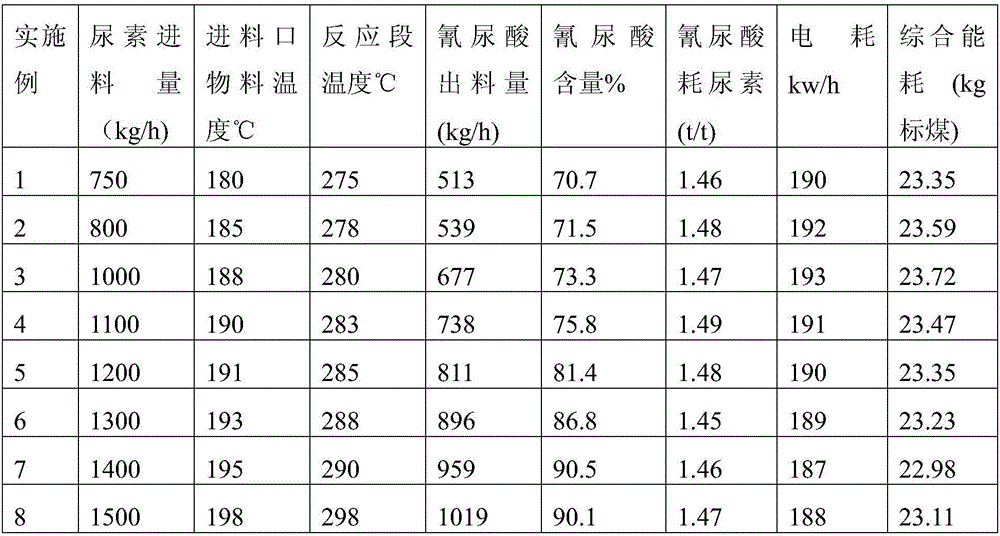

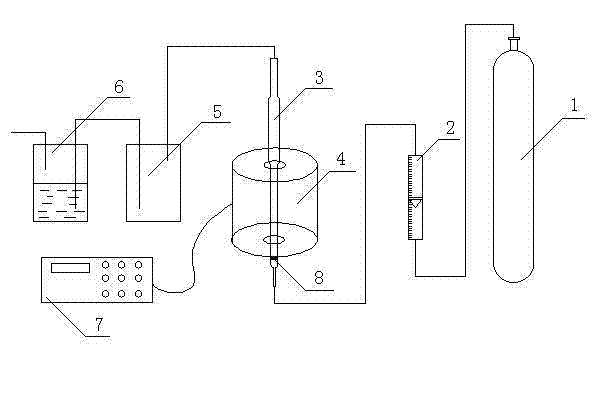

System and method for preparing crude cyanuric acid continuously by using urea

ActiveCN106008383AReduced granulation processReduce the heating and melting process of urea particlesOrganic chemistryTemperature controlWorking environment

The invention discloses a system and method for preparing crude cyanuric acid continuously by using urea. The system comprises: a differential stirring reactor for receiving urea melt and for deaminating it to produce crude cyanuric acid; a heating device disposed outside a reaction barrel of the differential stirring reactor and used for heating the reaction barrel; an ammonia recycling device connected with a gas outlet of the differential stirring reactor and used for recycling ammonia as a material for urea synthesis. The system and method enable continuous feeding, automated temperature control and automated discharging, rarely cause equipment blockage and blocking, reduce operation intensity of workers and improve work environment, optimize an operation process, and provide an organic integrity of human, machinery, material, process and environment.

Owner:河北冀衡集团有限公司

Method for removing free carbon in micro-silica fume by fluidized bed method

The invention discloses a method for removing free carbon in micro-silica fume by a fluidized bed method. The method comprises the steps of: taking and putting a certain quantity of micro-silica fume material into a fluidized bed reactor, and leading in reaction atmosphere to react under an optimal fluidized state so as to remove the free carbon in the micro-silica fume. According to the method for removing the free carbon in the micro-silica fume by the fluidized bed method, the free carbon in the micro-silica fume can be effectively removed; the content range of the free carbon in the micro-silica fume is 2-5% (mass fraction), and the content of the free carbon in the processed micro-silica fume is smaller than 0.05% (mass fraction), thereby improving the use value of the micro-silica fume. A continuous operation of purification operation of the micro-silica fume can be achieved; the carbon removing process is simple in operation and the method has a great market prospect.

Owner:铁生年

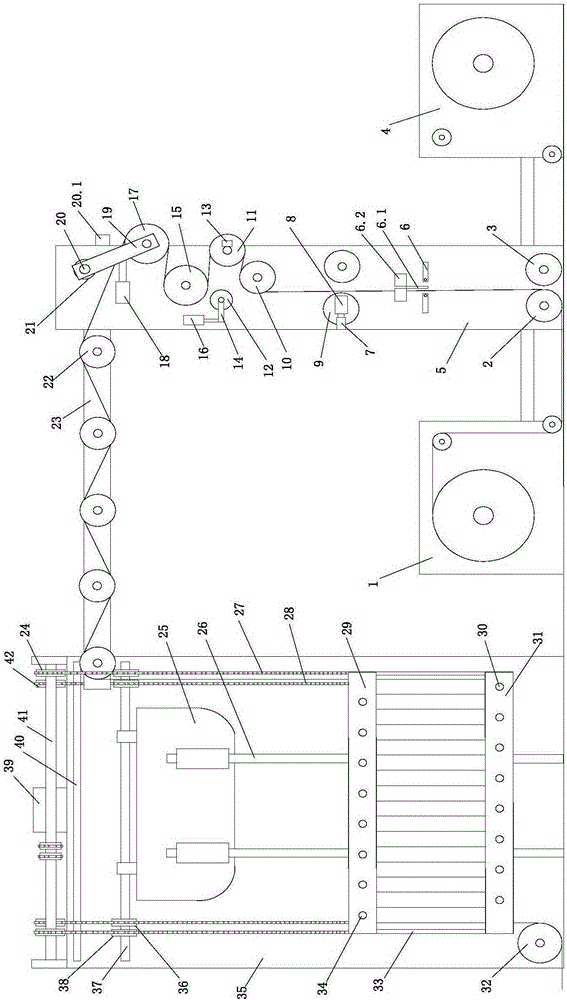

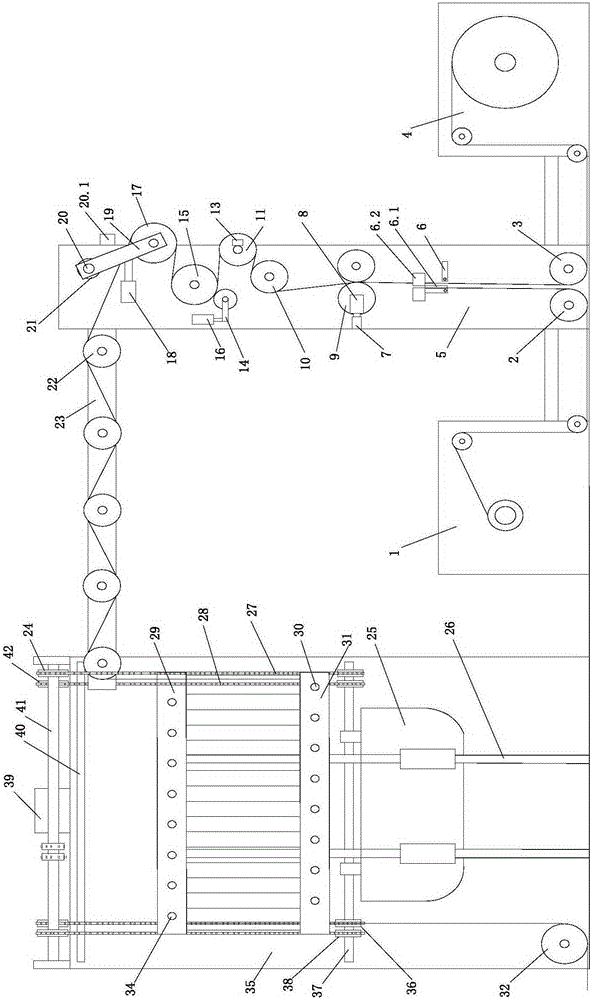

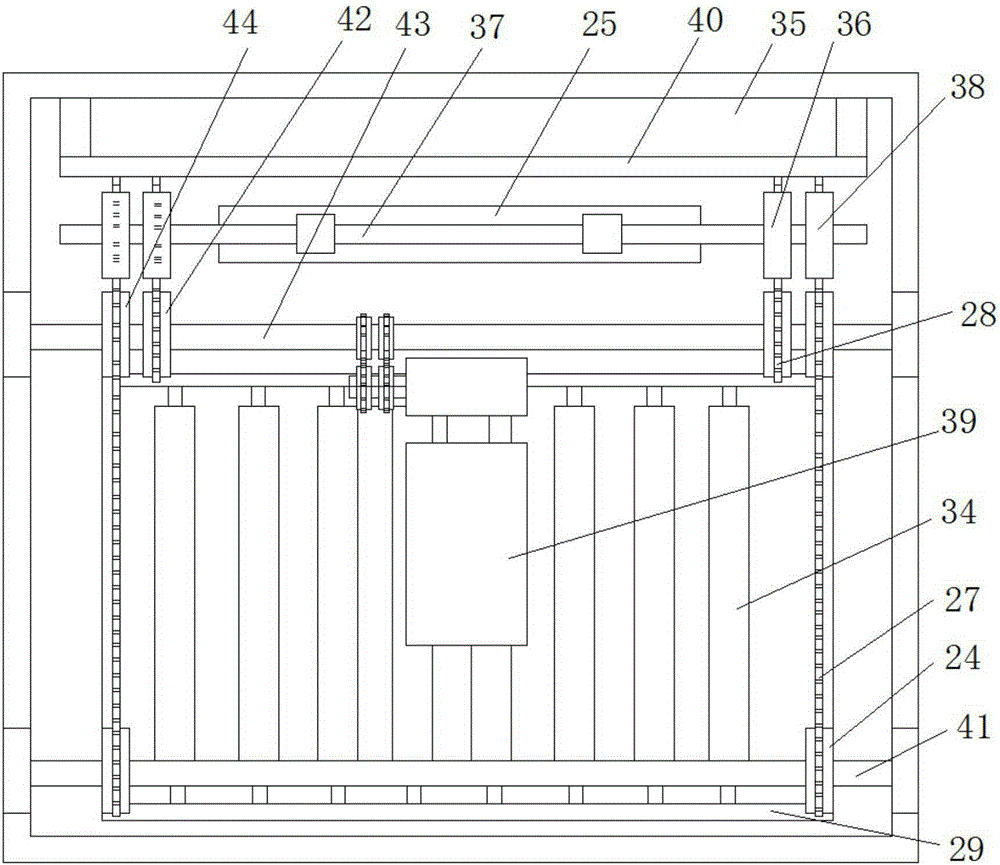

Continuous web feeding system

The invention relates to a continuous production machining system, in particular to a continuous web feeding system. The continuous web feeding system comprises a first web feeding machine, a second web feeding machine, a web cutting device, a web receiving device, a web storage roller pair and a web storage box; the web storage roller pair vertically shifts in the web storage box to store and release webs to be printed; in the process of storing the webs to be printed by the web storage roller pair, the web cutting device and the web receiving device finish web changing work of the web to be printed on the first web feeding machine and the web to be printed on the second web feeding machine, so that the function of continuously feeding webs without halt is achieved, the production efficiency is improved, energy loss is reduced, and then the production cost is reduced.

Owner:CHONGQING HONGJIN PRINTING

Auxiliary device for ship pipeline welding centering and method

ActiveCN110842460AReduce operating labor intensityImprove alignment efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringStraight tube

The invention discloses an auxiliary device for ship pipeline welding centering, and belongs to the technical field of pipeline welding equipment. The auxiliary device comprises a bent pipe part and astraight pipe part, wherein a first V-shaped support block and a second V-shaped support block are arranged at the bent pipe part in the pipeline direction; a third V-shaped support block and a fourth V-shaped support block are arranged at the straight pipe part in the pipeline direction, and are arranged oppositely at the equal height; the fourth V-shaped support block slides in the pipeline direction on a base. The invention also discloses a centering method for the straight pipe and the bent pipe by the auxiliary device for ship pipeline welding centering. The distance and angle between the four V-shaped support blocks are adjusted, so that straight pipes with certain length and bent pipes with different bending radii and bending angles can be centered and positioned. The auxiliary device has the advantages of low operation labor intensity, high centering efficiency and easy-to-control centering precision, and facilitates subsequent welding operation for operators.

Owner:ZHEJIANG UNIV +1

Anhydrous environment-friendly taphole clay

InactiveCN107285750APromote environmental protectionSmall midline rate of changeBlast furnace componentsBlast furnace detailsModified carbonSlag

The invention discloses anhydrous environment-friendly taphole clay which comprises the following components in parts by weight: 8-20 parts of a waste skateboard material of not more than 5mm, 5-10 parts of high-alumina bauxite of 3-5mm, 10-20 parts of coke of not more than 3mm, 8-12 parts of black corundum of not more than 1mm, 10-15 parts of silicon carbide of not more than 1mm, 4-8 parts of kyanite powder, 8-12 parts of Guangxi mud, 5-8 parts of asphalt powder, 4-7 parts of graphite powder, 5-10 parts of silicon carbide powder, 2-5 parts of silicon nitride powder, 0.3-0.6 part of aluminum ashes and 12-16 parts of ethylene glycol-modified carbon-containing resin. The anhydrous environment-friendly taphole clay has the advantages of being good in environmental protection property, small in linear change rate in using process, stable in volume, free of a fracture taphole, easy to open, high in slag resistance, relatively small in operation intensity, high in adaptability to blast furnace condition, is especially suitable for a relatively large blast furnace, can play a key role in maintenance of the depth of the taphole.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Abrasive polishing method of automobile die

InactiveCN106944899AReduce manufacturing costSimple polishing operationGrinding machinesFiberGrinding wheel

The invention provides an abrasive polishing method of an automobile die. The abrasive polishing method comprises the following steps: S1, before polishing, first inspecting machining traces left on the surface of a die main body; S2, carrying out rough polishing on the surface of the die by using diamond fiber oilstone with a 320-mesh grain size to remove knife marks and burrs on the surface of the die; S3, sequentially carrying out semi-precise polishing by using 500-mesh, 700-mesh, 900-mesh, 1100-mesh and 1300-mesh abrasive paper to remove machining textures on the surface of the die, using 100% pure cotton to absorb alcohol and wipe the surface of the die main body before changing one different model of abrasive paper, and checking polishing conditions; and S4, coating a polishing abrasive wheel with a 35000-mesh abrasive paste, and carrying out mirror surface precise polishing on the surface of the die, wherein under the condition of not considering geometrical precision, only steps S3-S4 are executed; and otherwise, steps S1-S4 are executed. According to the polishing method of an automobile lamp die, the polishing operating process is simple, the operation labor intensity is low, the polishing period is greatly shortened, the production cost of the die is reduced, the surface of the die manufactured by the method is smooth, and the precision is high.

Owner:LIUZHOU TONGWEI MACHINERY

Ramee degumming process

InactiveCN101012575AEasy to separateLoose separationFibre treatment to obtain bast fibreOxalateBoiling process

The invention relates to a degumming technology for ramie, comprising unpacking and untying braches, loading cage, boiling, softening, bleaching and washing by acid, supplying oil, deoiling and drying. The boiling process is that the original fiber is put into the mixed solution, of which the weight is nine to twelve times of the weight of original fiber; the pressure is maintained in 0.1-0.2MPa and the maintaining time is for 1-1.5 hours. The mixed solution comprises sodium hydroxide, oxidant, oxalate and scouring agent. Thereinto, the content of sodium hydroxide is 5-8g / l, the content of oxidant is 5-10g / l, the content of oxalate is 3-8g / l and the content of scouring agent is 3-5g / l. By adopting the degumming technology for ramie, the scouring time for ramie is decreased, the manufacturing efficiency is improved, the circumstance pollution is decreased and the quality of ramie after degumming is improved.

Owner:CHONGQING FULING KINGLONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com