Patents

Literature

983results about "Measurement of force applied to control members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

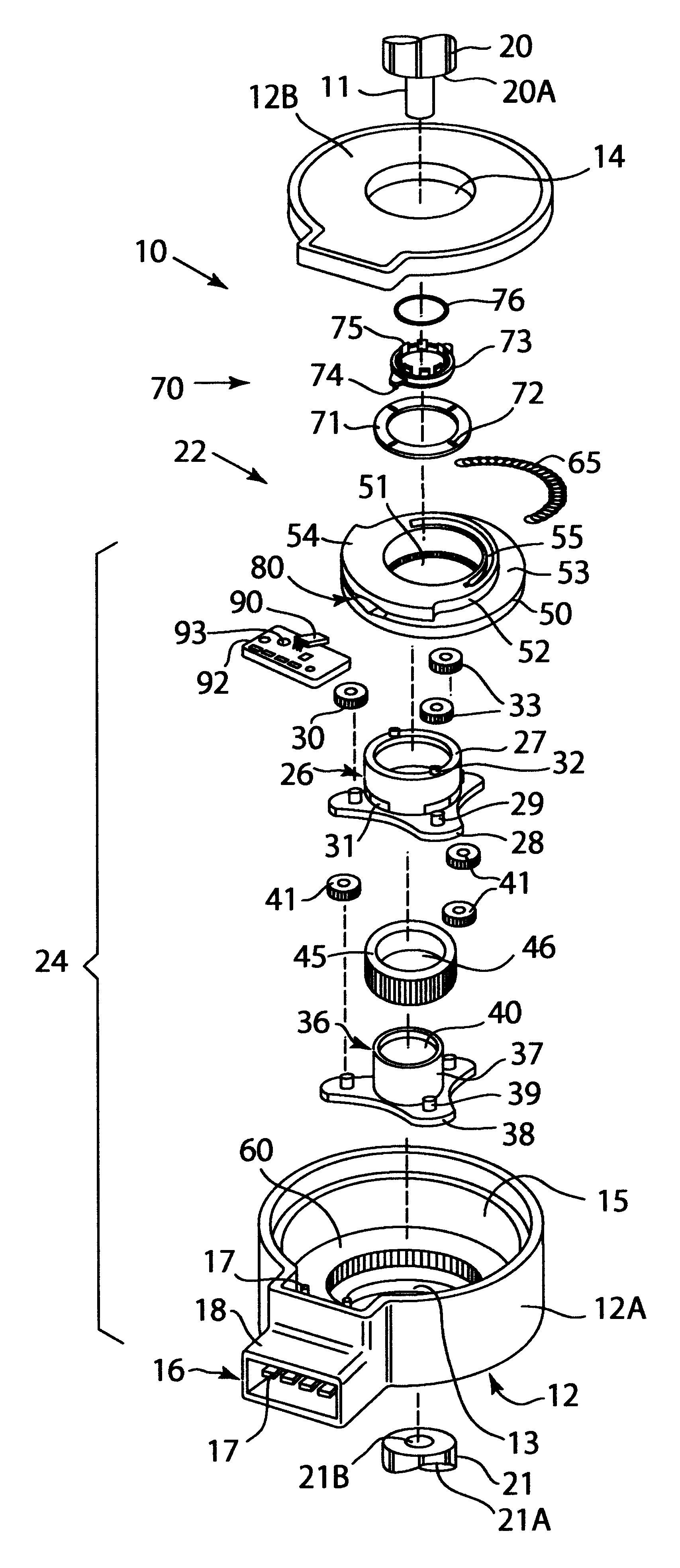

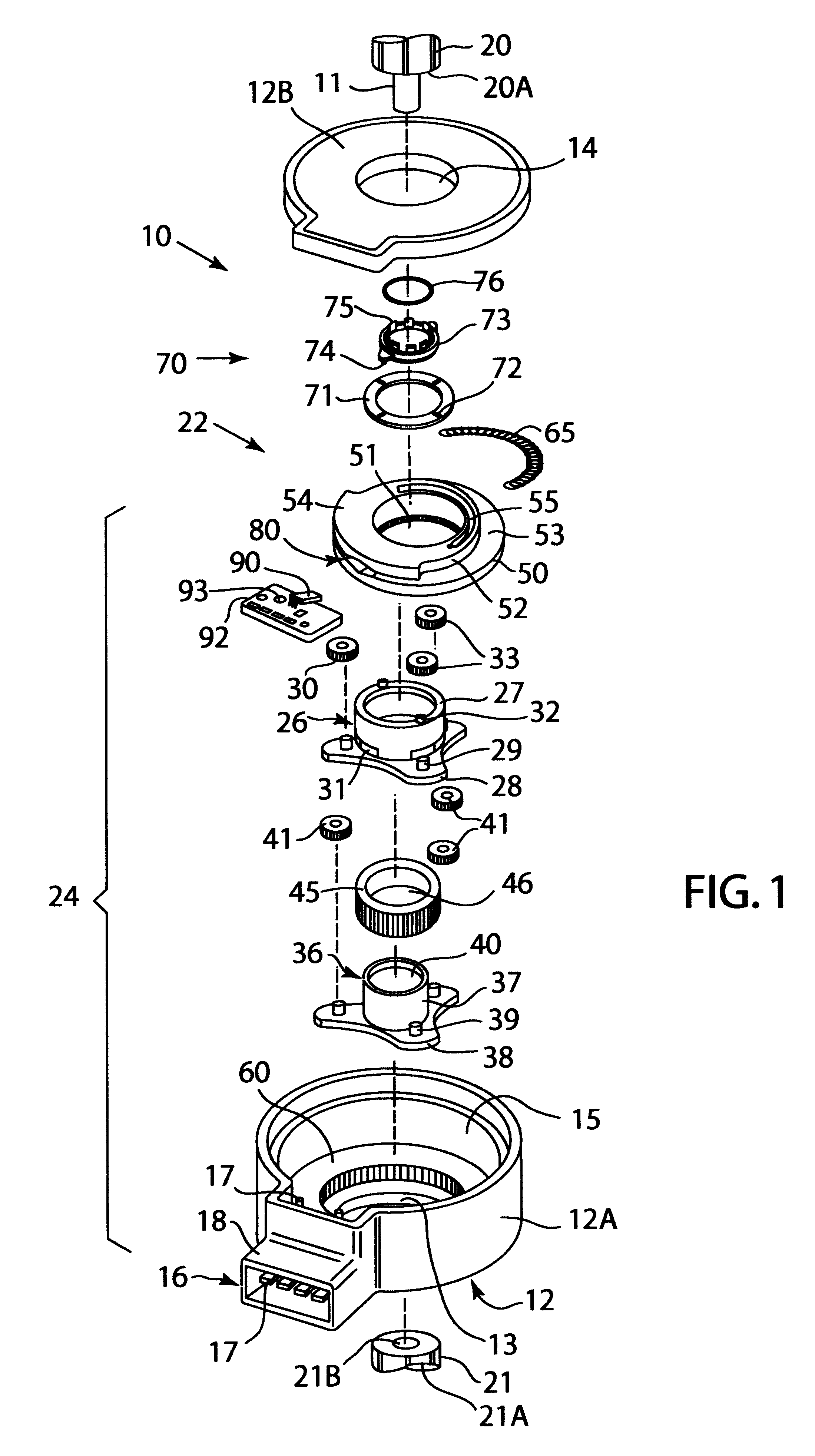

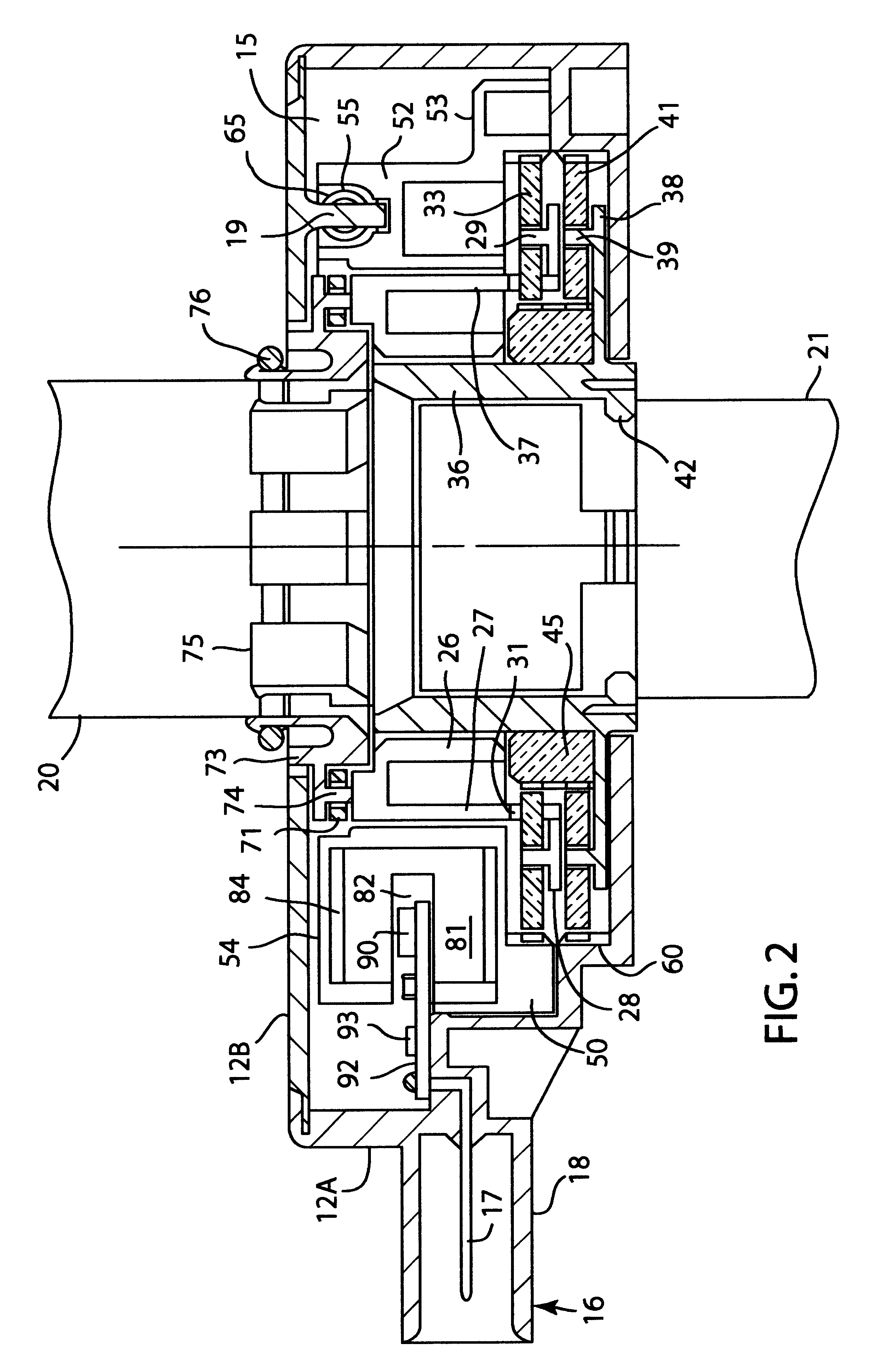

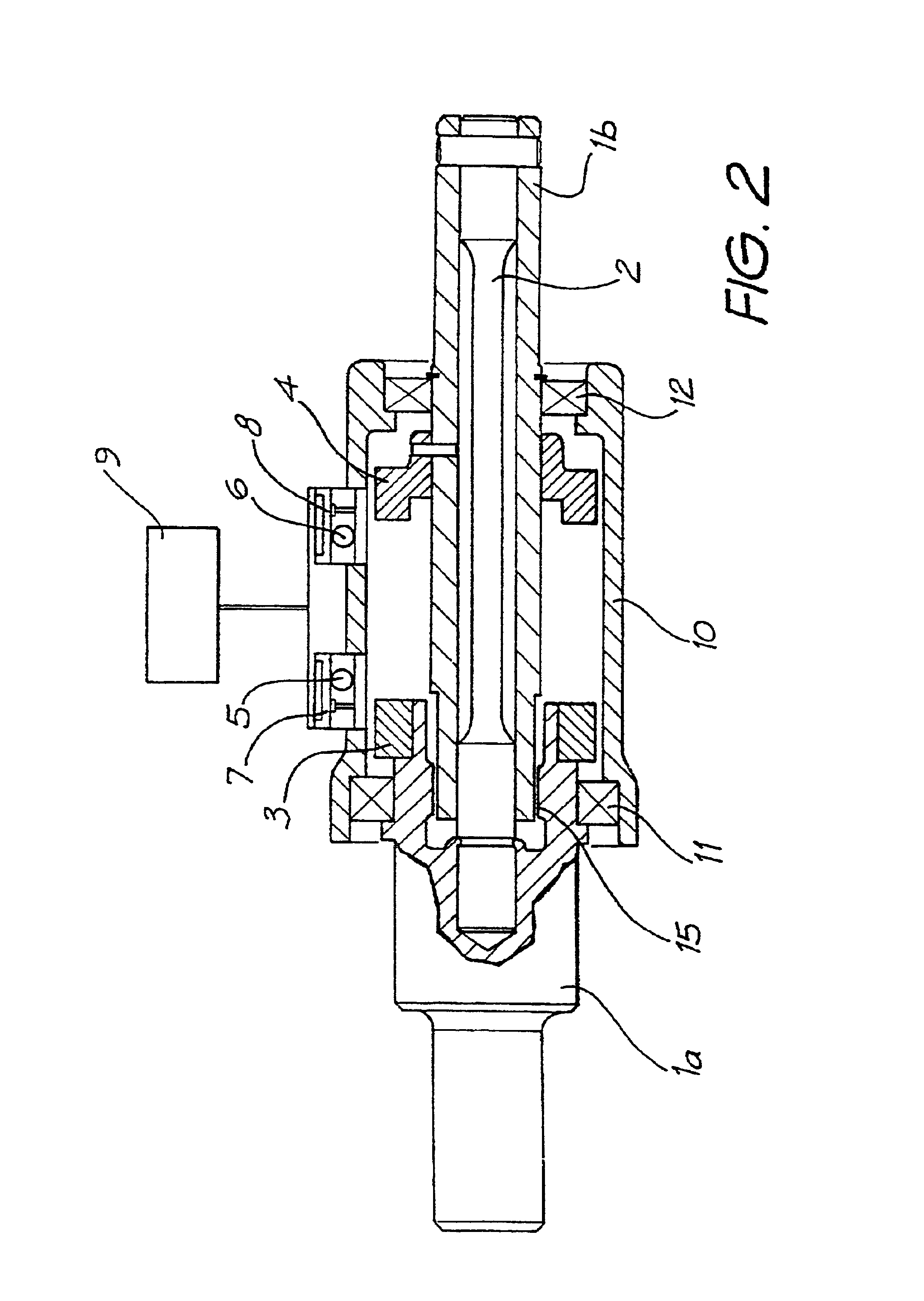

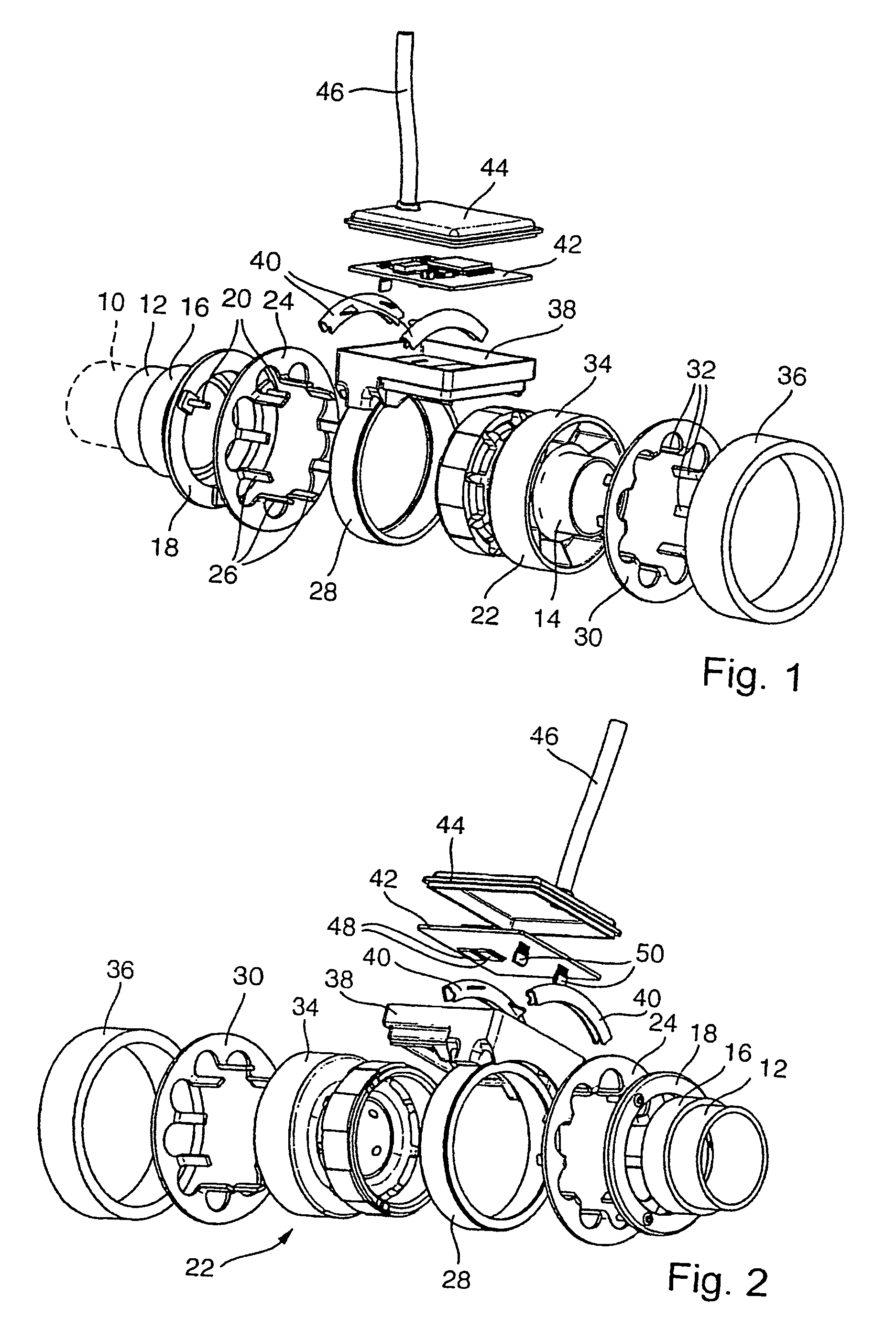

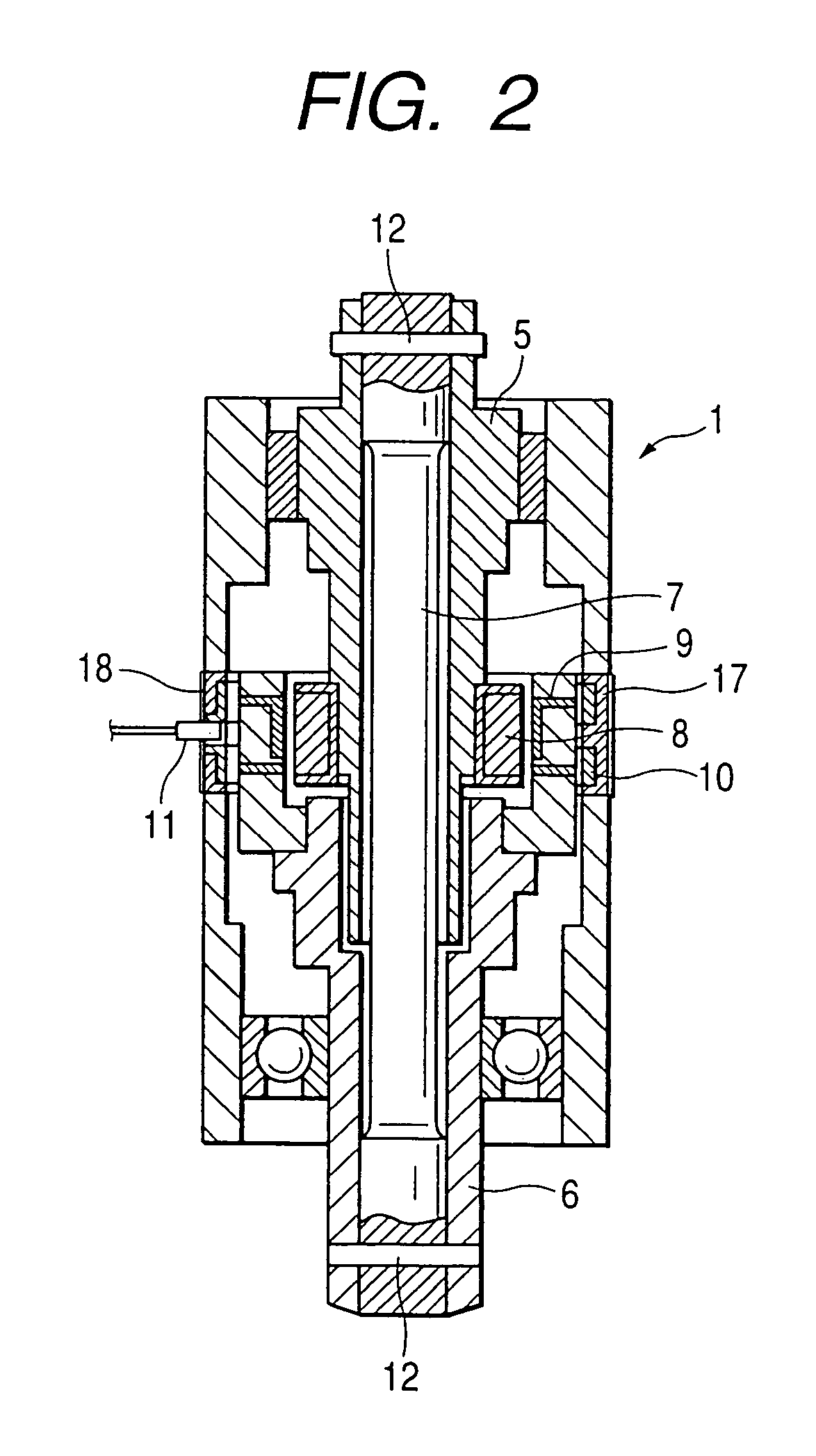

Non-contacting sensor for measuring relative displacement between two rotating shafts

A sensor for measuring the relative displacement between two rotating shafts. The sensor can sense a torque applied to the steering wheel of a vehicle. The sensor has a housing that has apertures at each end. The rotating shafts pass into the housing. A sensor assembly is located in the housing and connected to the shafts. The sensor assembly generates an electrical signal that is proportional to the relative rotational displacement between the shafts. An electrical connector is located in the housing and electrically connects with the sensor assembly. The sensor assembly has a planetary gear assembly that is connected to the shafts. A variable magnetic field generator is connected to the planetary gear assembly and moves proportional to the relative rotational displacement of the shafts. A magnetic field sensor is located adjacent the variable magnetic field generator and generates the electrical signal as the variable magnetic field generator moves.

Owner:CTS CORP ELKHART

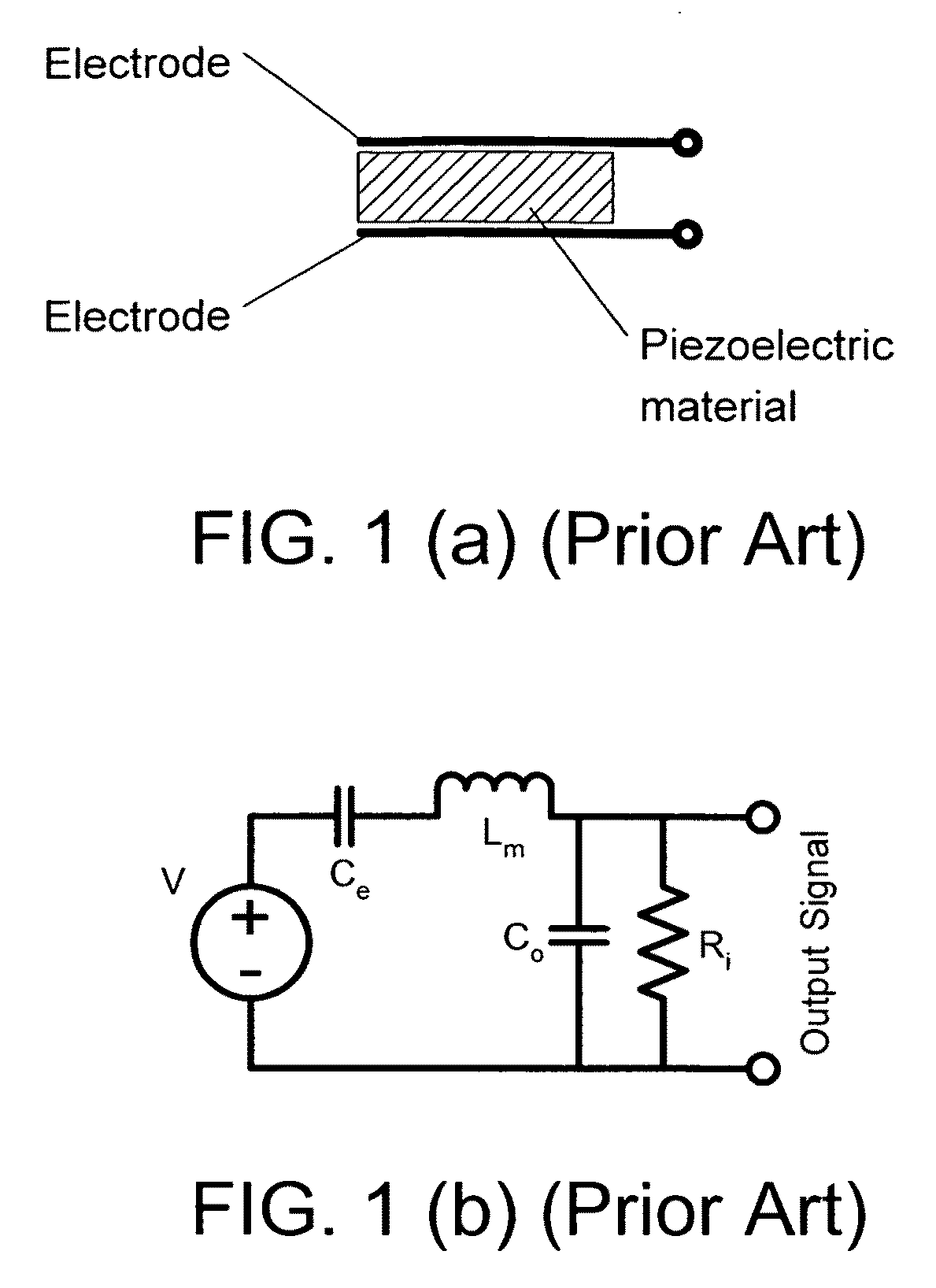

Capacitance type sensor and method for manufacturing same

InactiveUS6958614B2Reduce power consumptionReduce hysteresisResistance/reactance/impedenceFluid pressure measurement by electric/magnetic elementsCapacitanceEngineering

Owner:NITTA CORP

Sensor for sensing absolute angular position of a rotatable body

An angle sensor for sensing the absolute angular position of a rotatable body, such as a rotating shaft of an electric power steering system for an automobile, is disclosed.

Owner:BISHOP INNOVATION PTY LTD

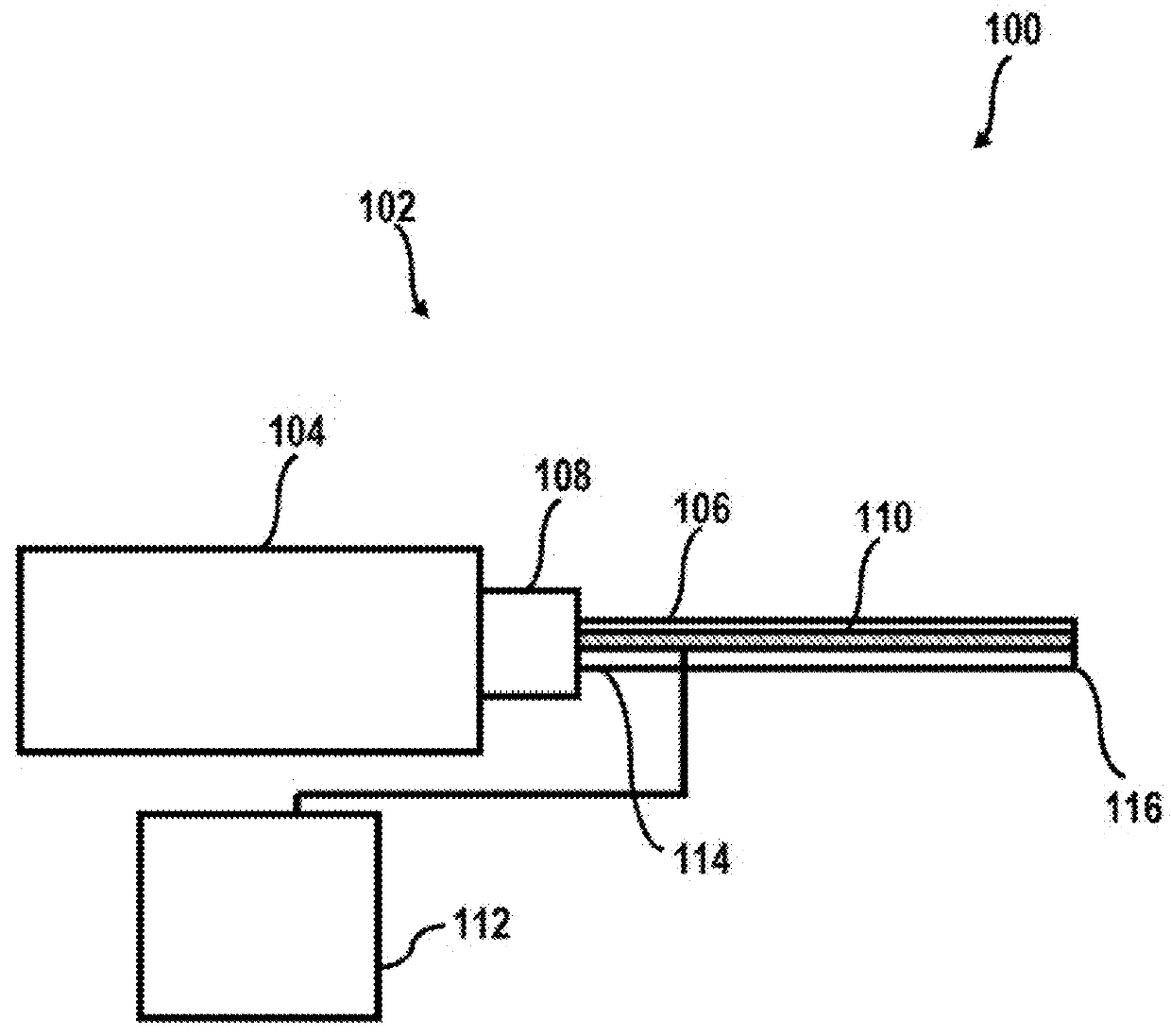

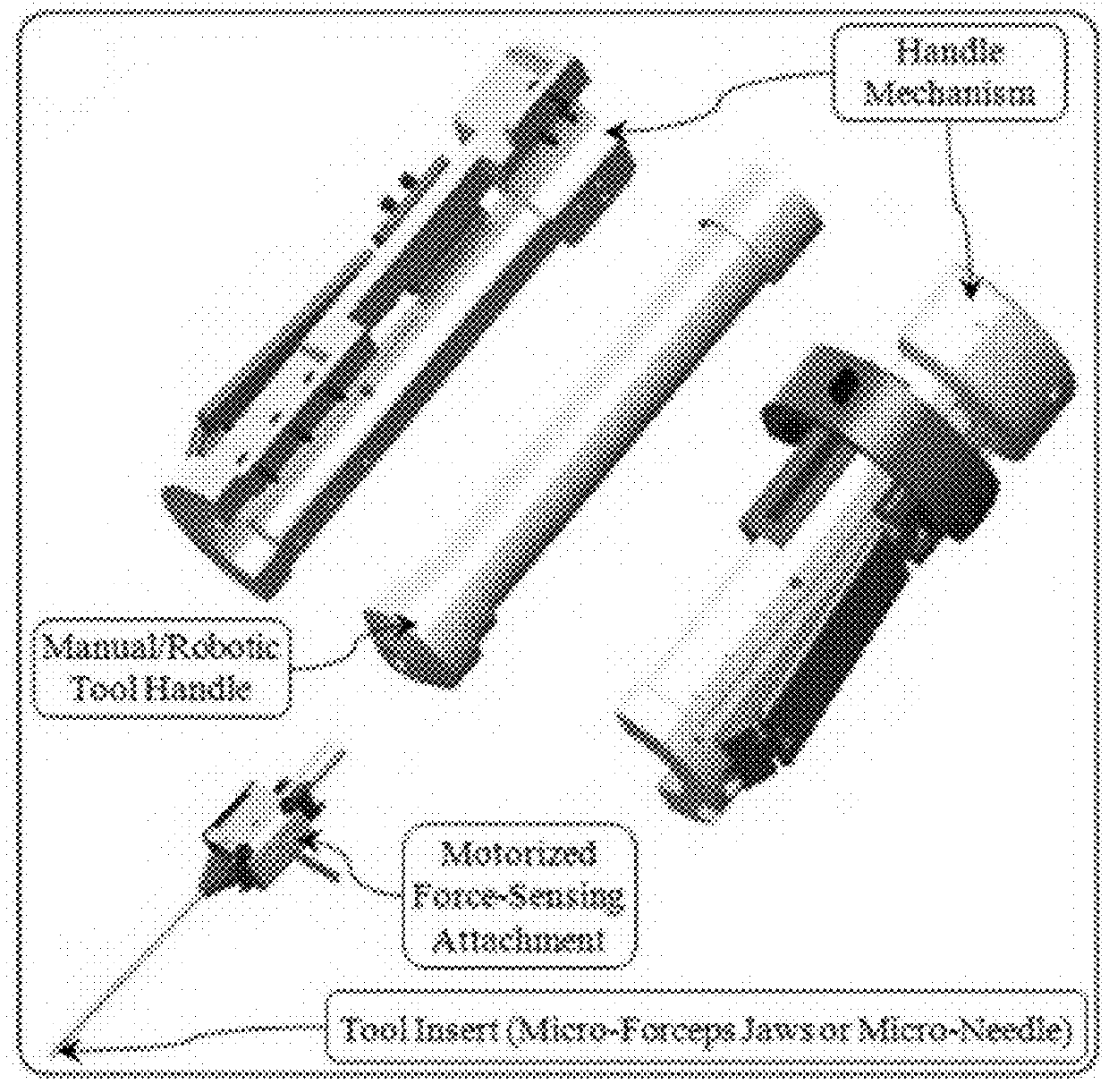

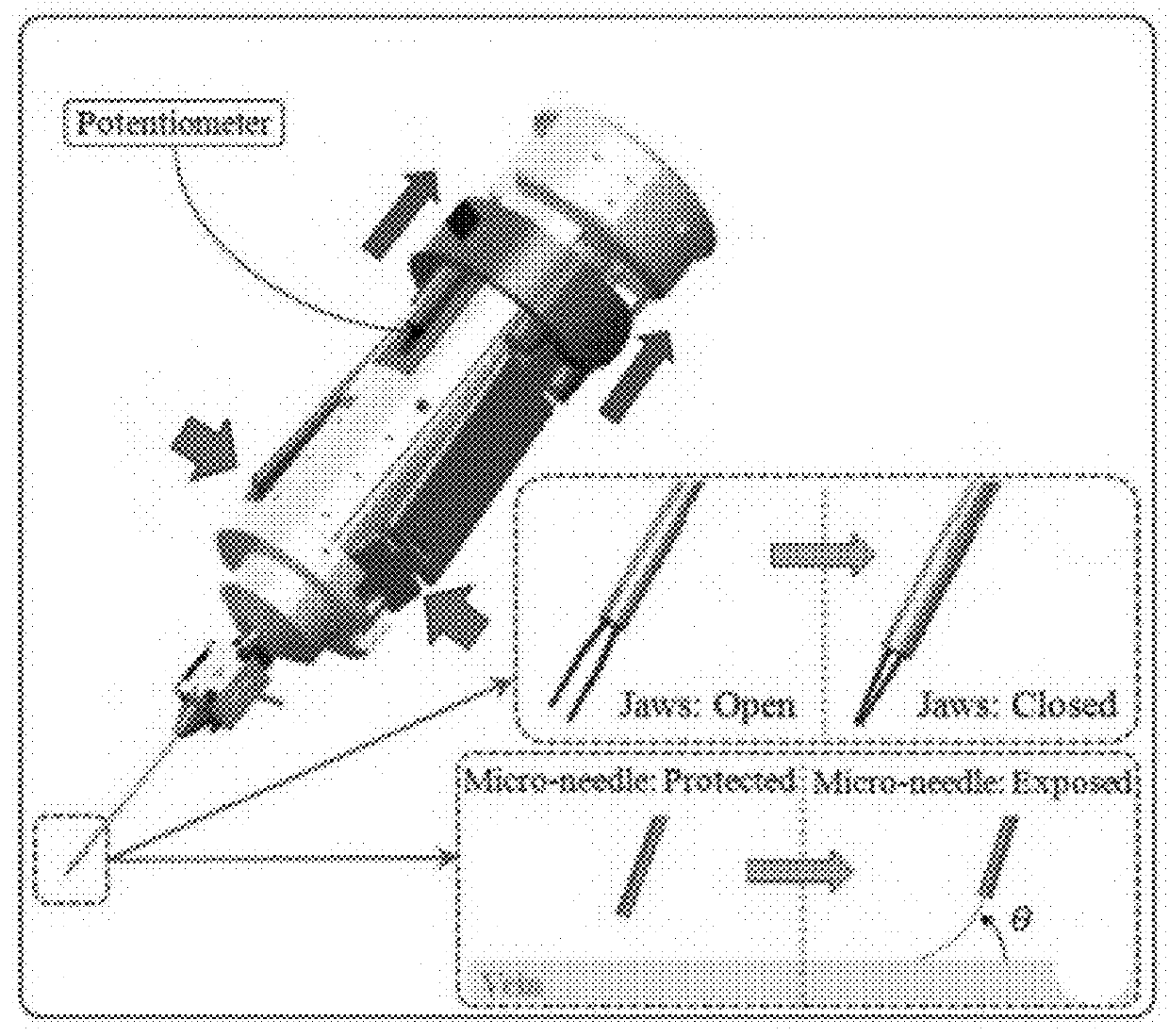

Micromanipulation systems and methods

A micromanipulation system includes a micromanipulator that includes a handpiece, and a micromanipulation tool that includes a tool shaft and is operatively connected to the handpiece. The micromanipulator further includes an actuator assembly connected to the micromanipulation tool to provide manual control of the micromanipulation tool, and a force sensing system comprising a force sensor attached to the tool shaft. The force sensing system is configured to provide an output signal that indicates a force imposed on the tool shaft. The micromanipulation system also includes a processor that is in communication with the force sensing system, and is configured to receive the output signal and compensate for forces due to actuation of the micromanipulation tool to determine a force due to interaction of the micromanipulation tool with a region of interest. The processor outputs an indication of at least one of a magnitude and a direction of the determined force.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

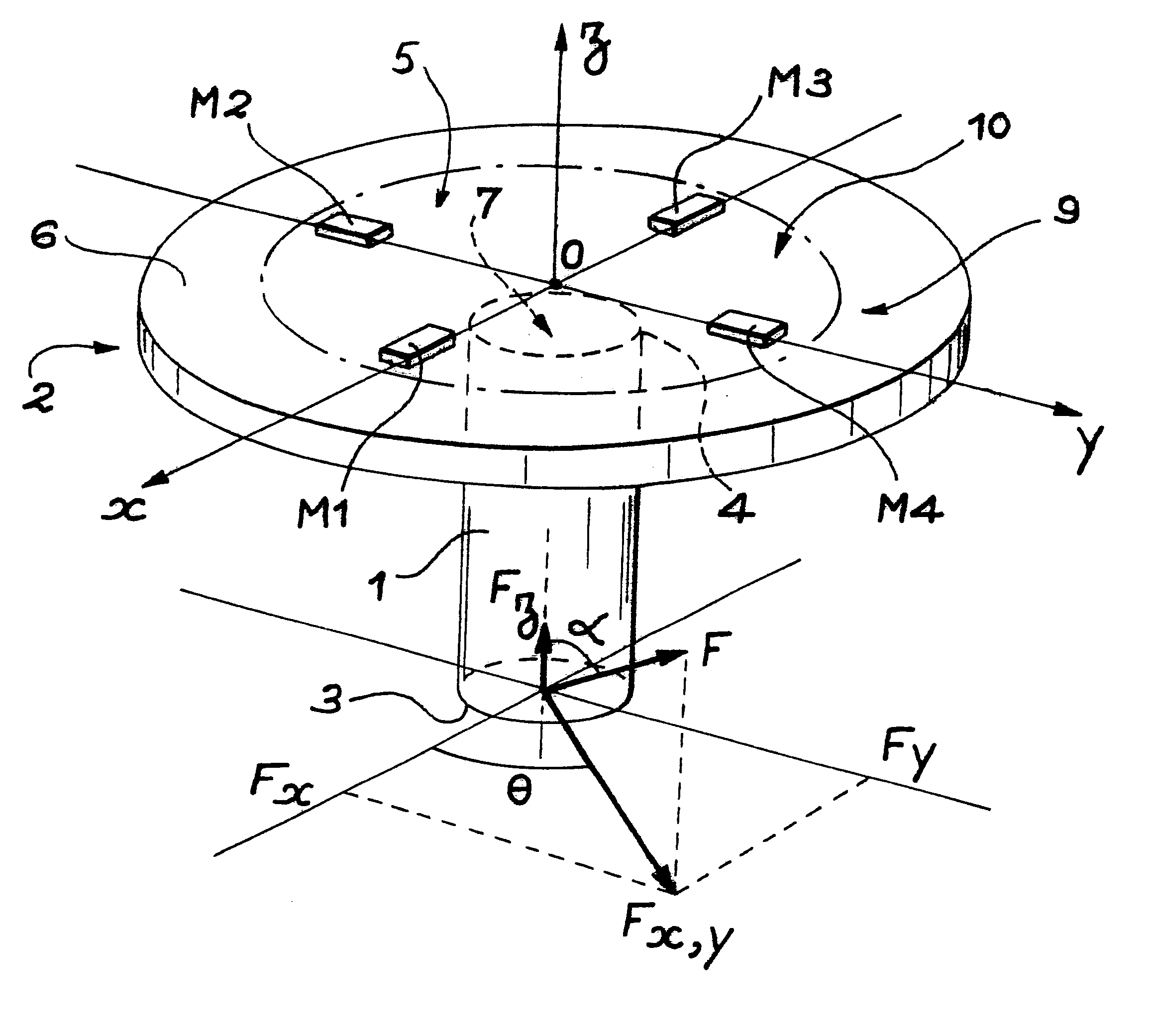

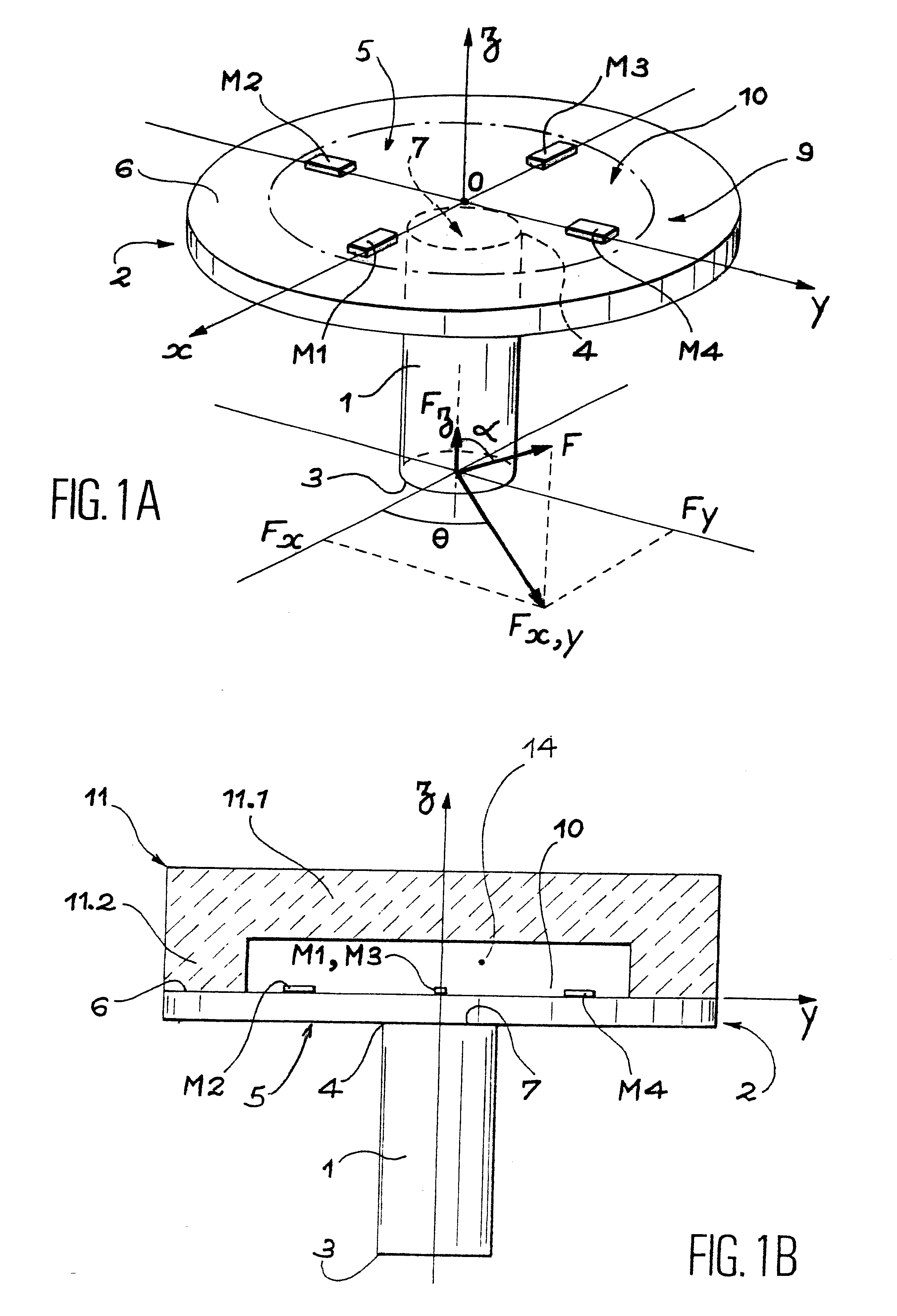

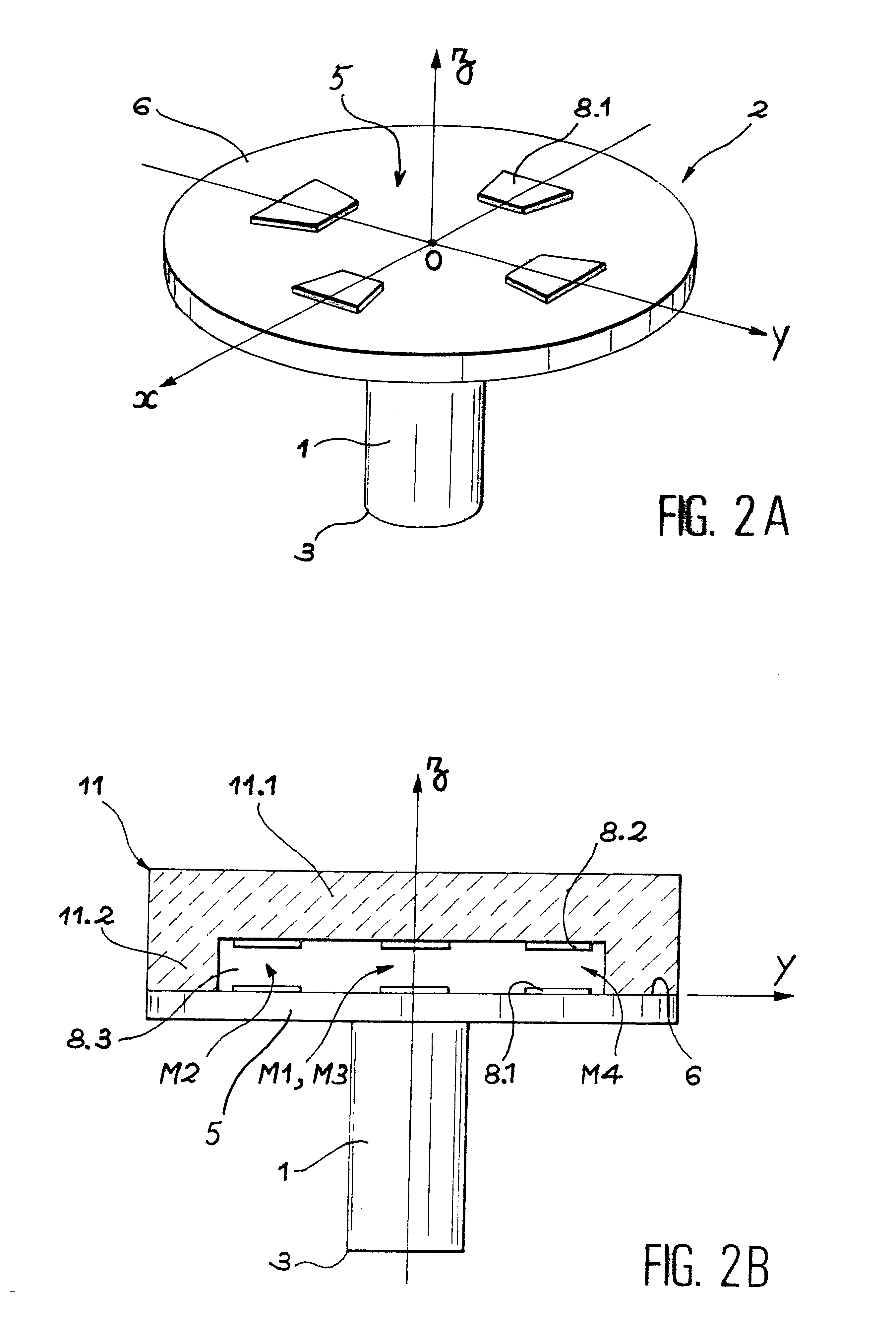

Tire comprising a measurement device

Owner:MICHELIN RECH & TECH SA

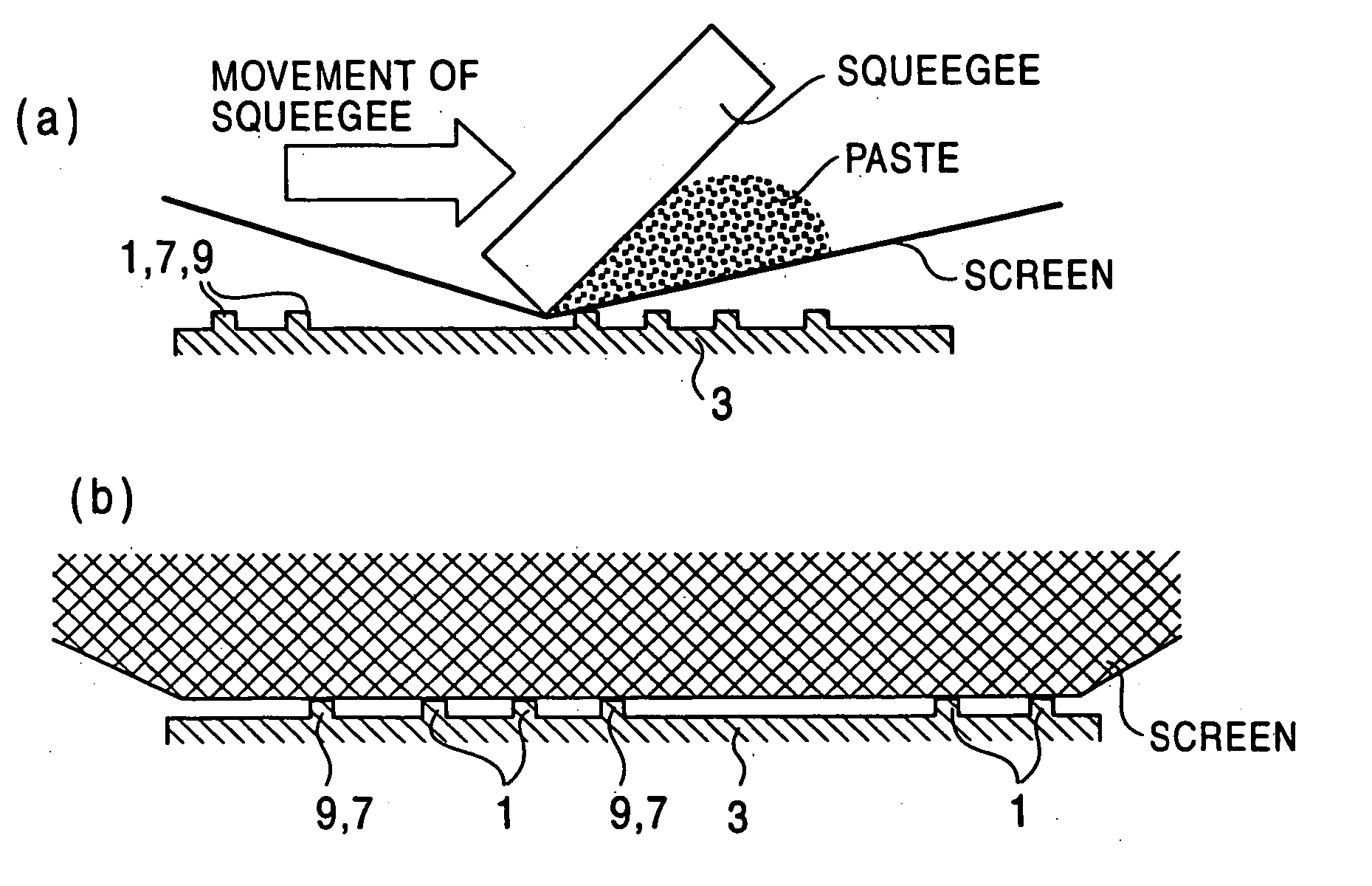

Resistor element, stress sensor, and method for manufacturing them

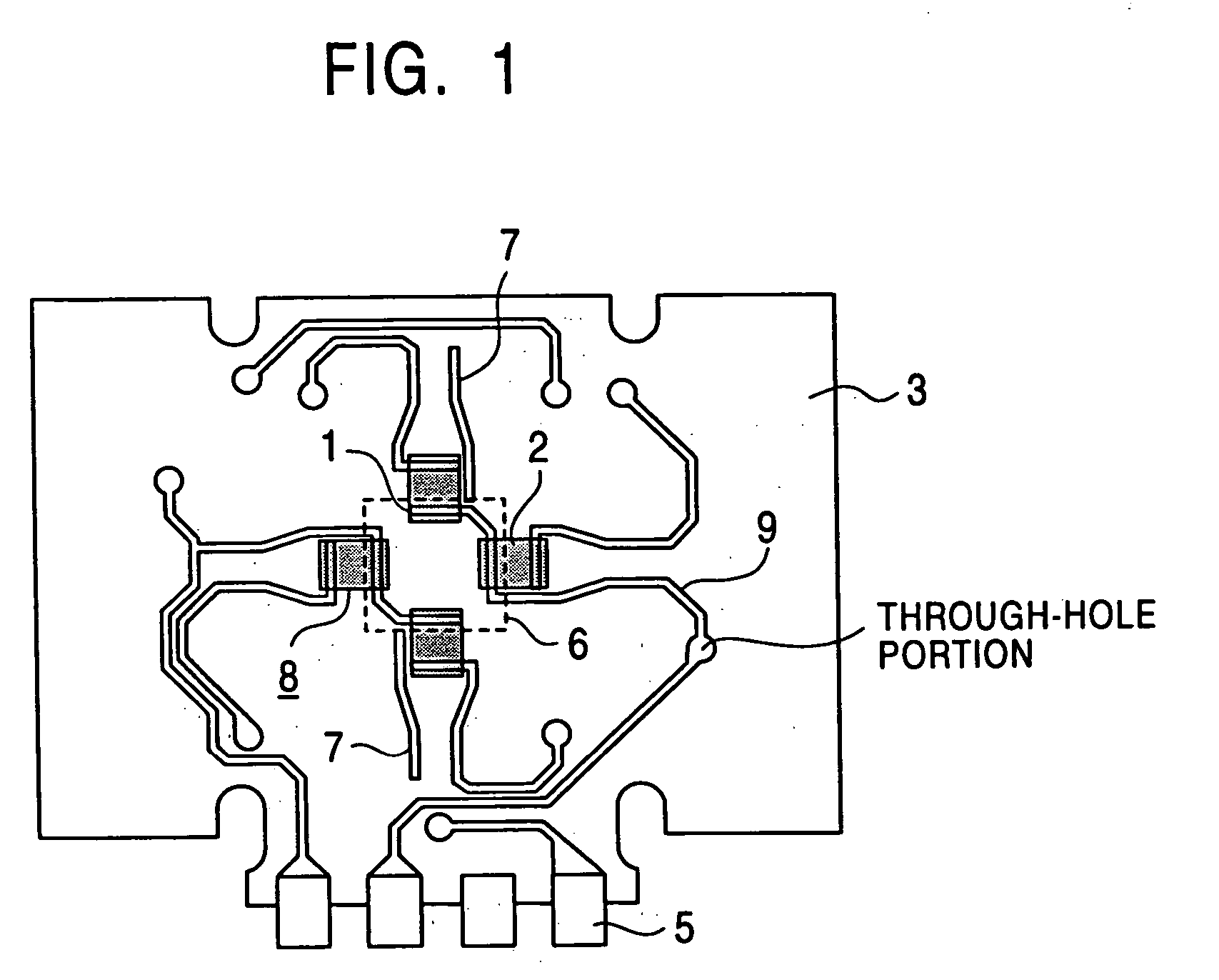

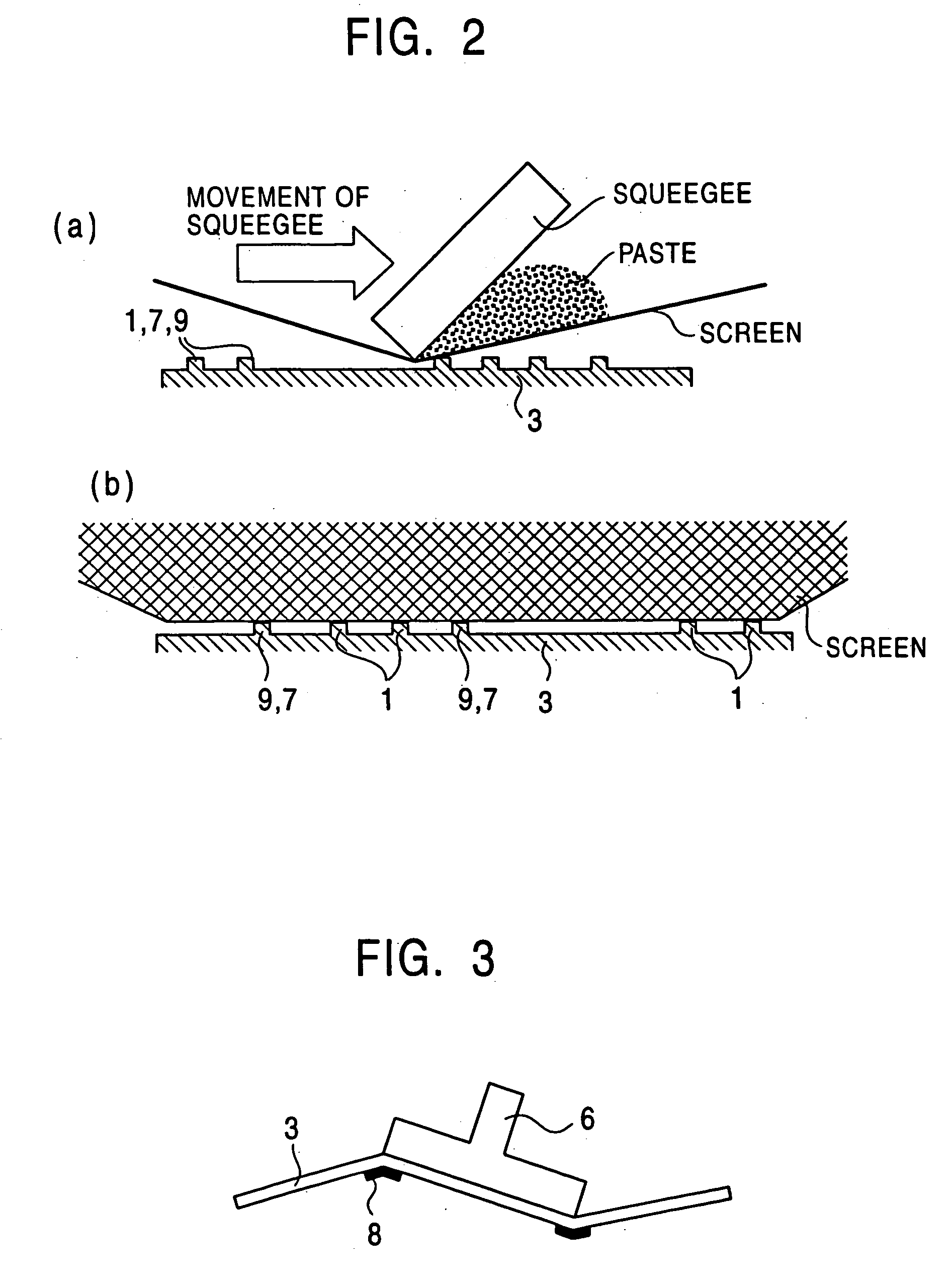

InactiveUS20060218779A1Easily and elastically changedPrinted circuit aspectsForce measurementElectrical resistance and conductanceScreen printing

A stress sensor in which the direction and magnitude of a stress being applied to a post bonded to or integrated with an insulating board can be grasped from variation in the resistance of resistor elements being stimulated by application of the stress while suppressing variation in the shape of each resistor. The resistor element comprises a resistor formed, by screen print, between a pair of electrodes for the resistor element, i.e. circuit pattern electrodes, arranged on the surface of the insulating board. The electrode is connected, through a conductor, with a board terminal part arranged at one end of the insulating board. The electrode and the conductor or a print accuracy adjusting member have a constant height from the surface of the insulating board. Arrangement of the conductor, electrode and print accuracy adjusting member is entirely identical or similar for the resistor elements in the vicinity thereof.

Owner:ELAN MICROELECTRONICS CORPORATION

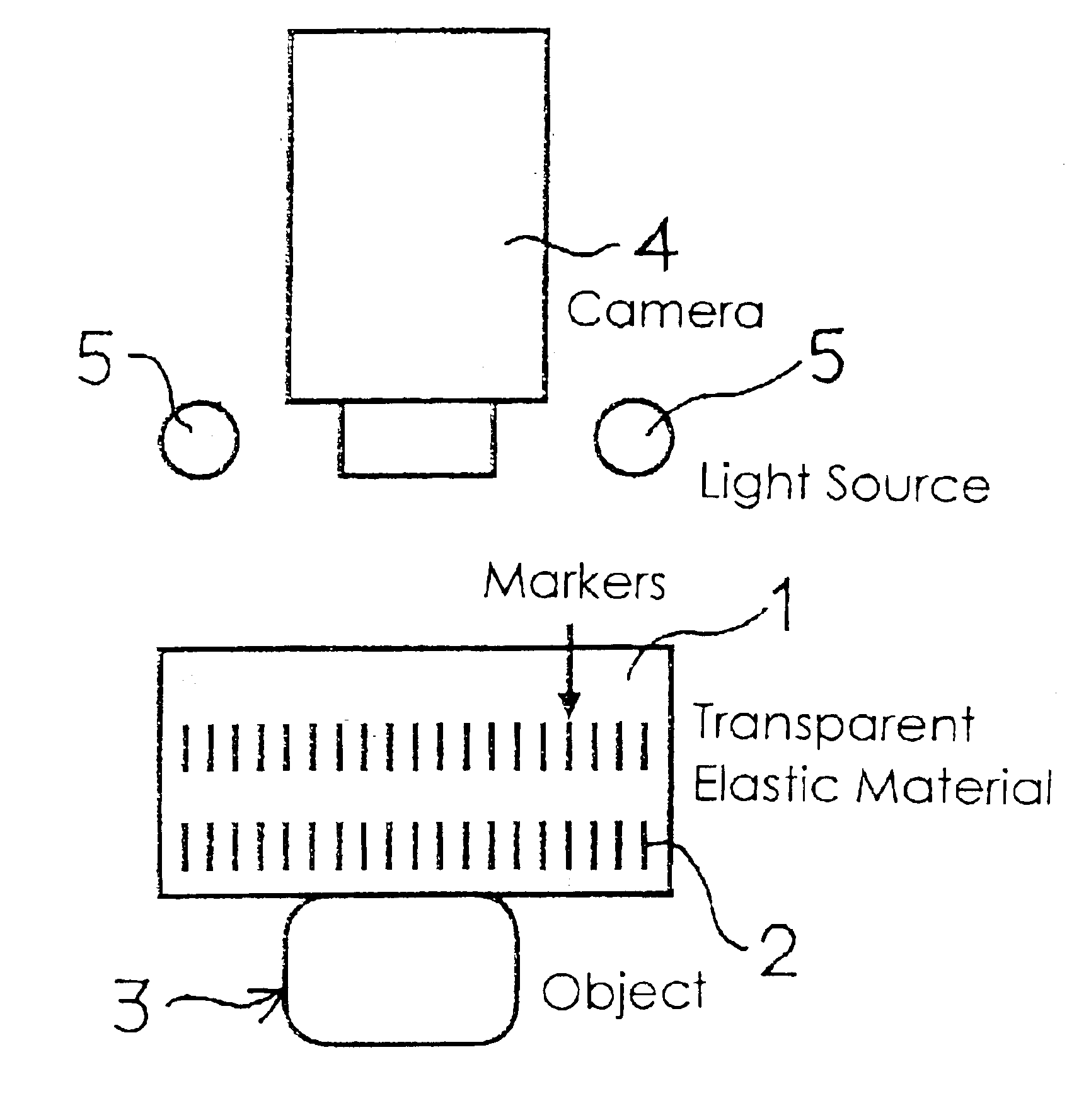

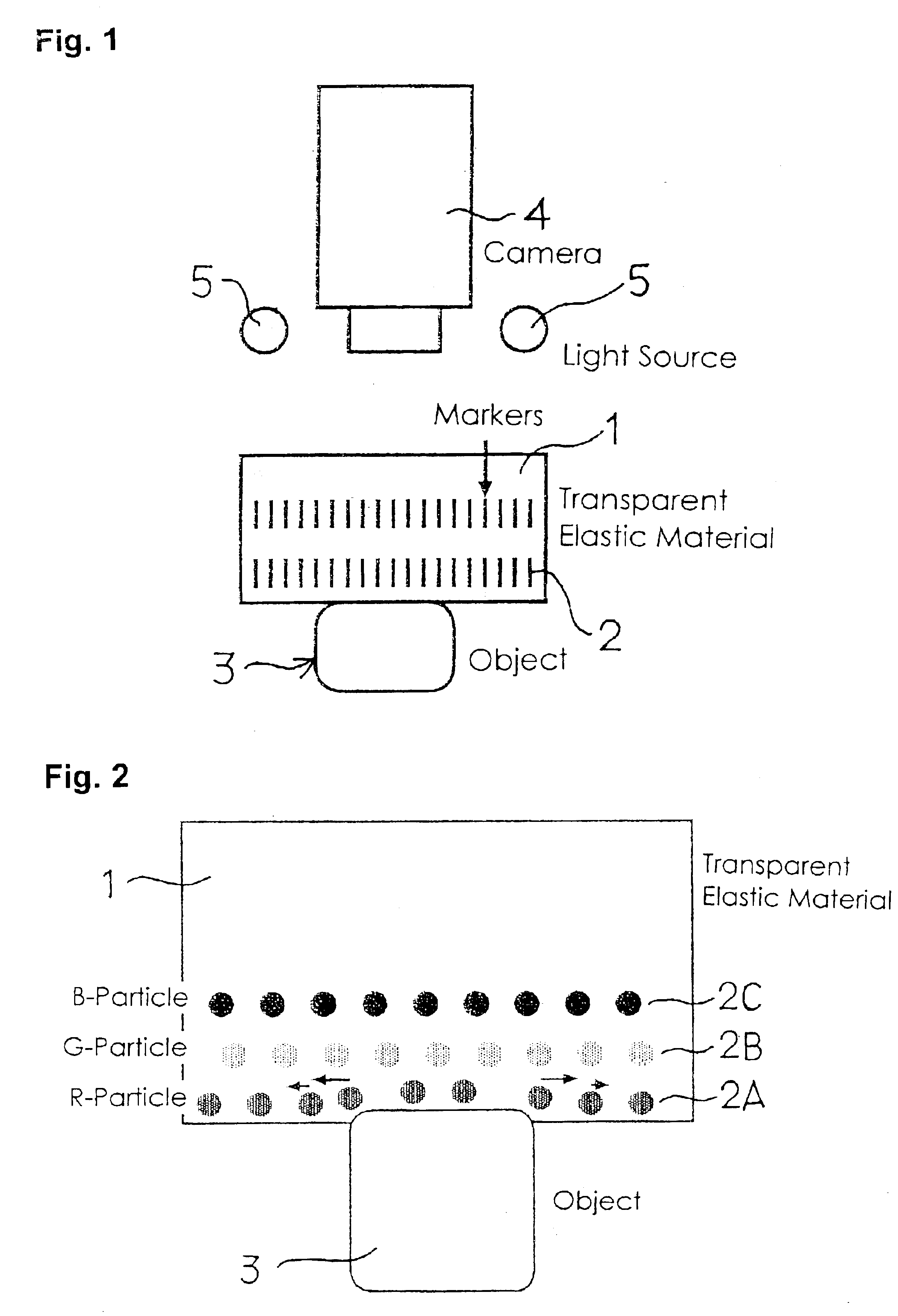

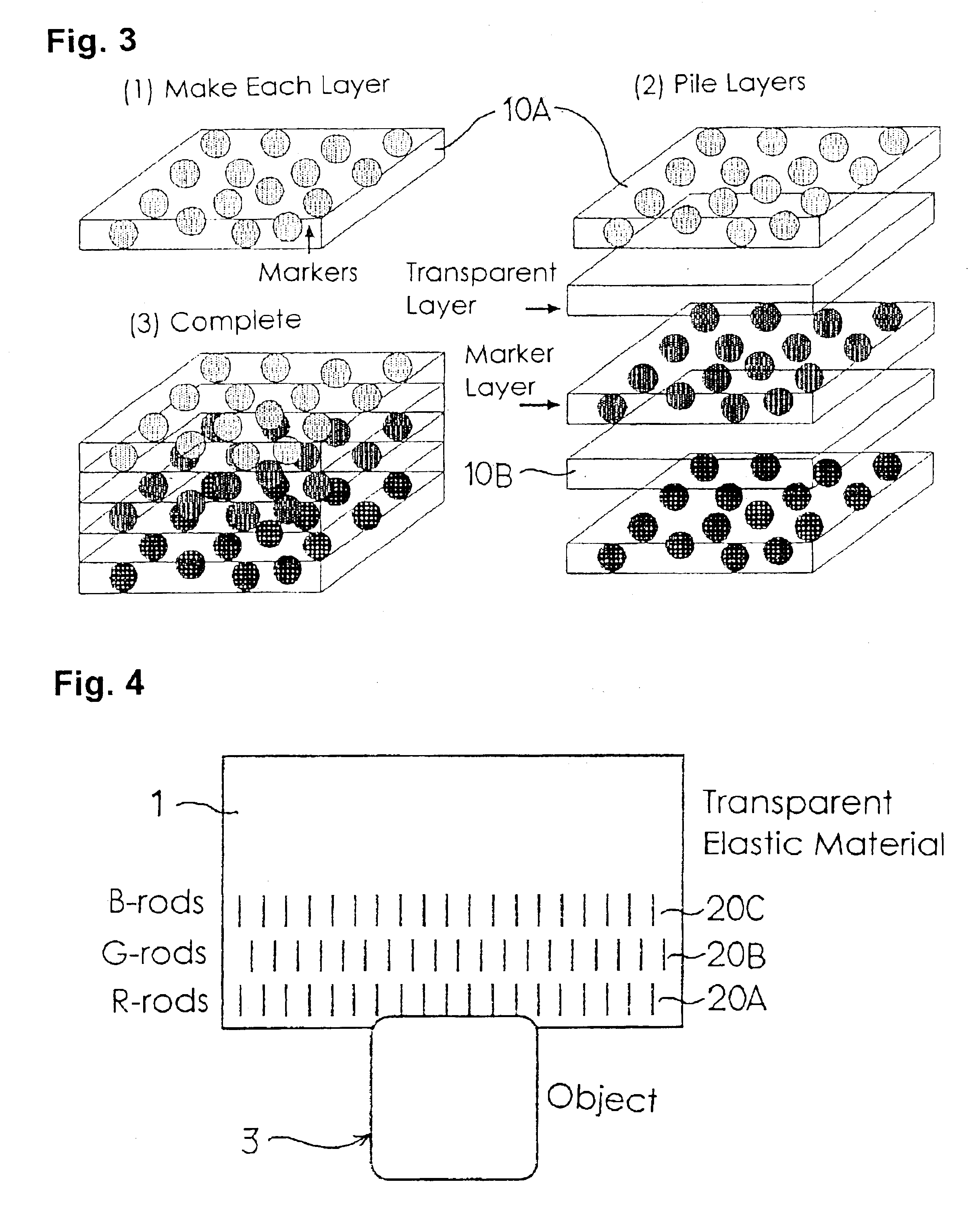

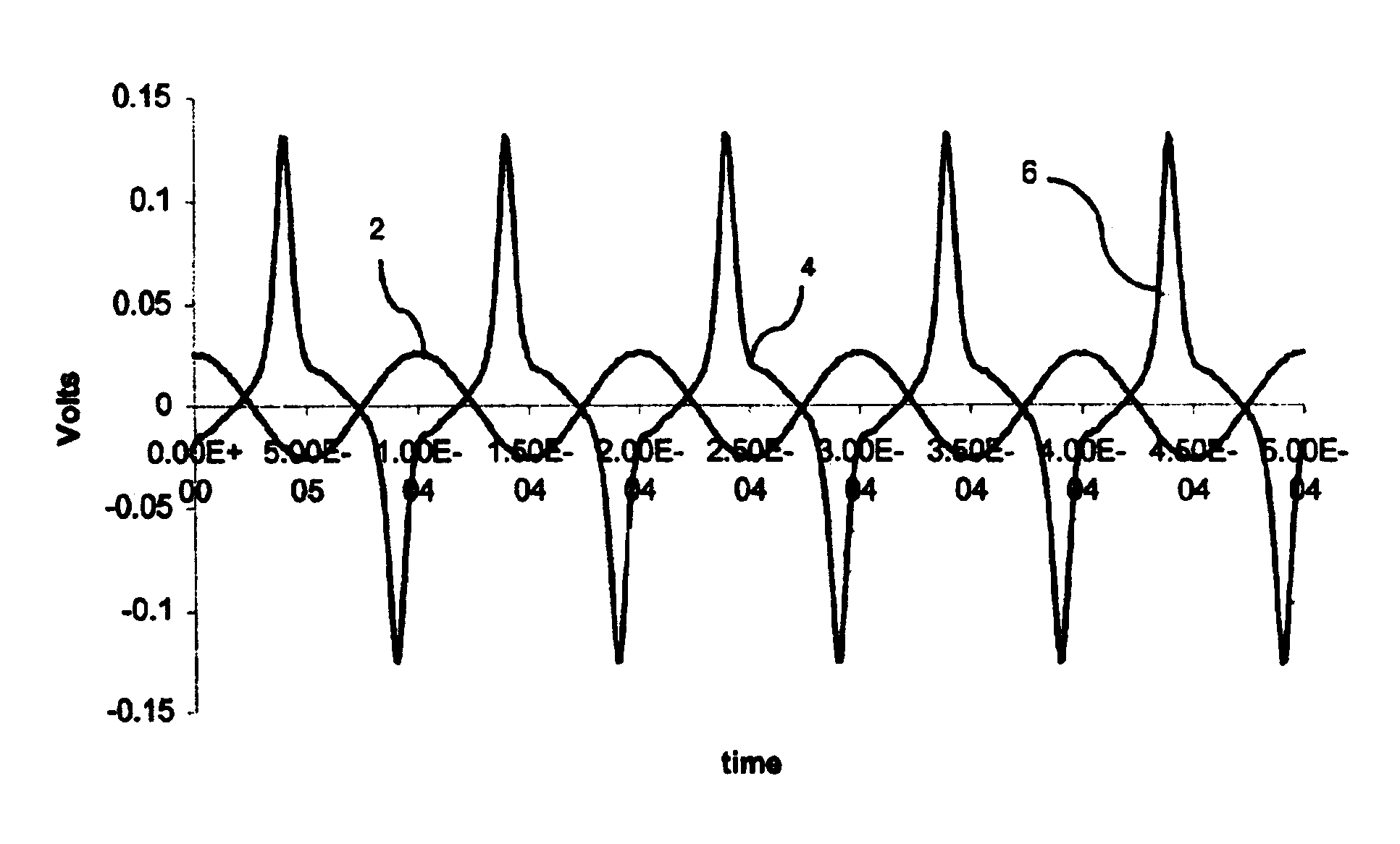

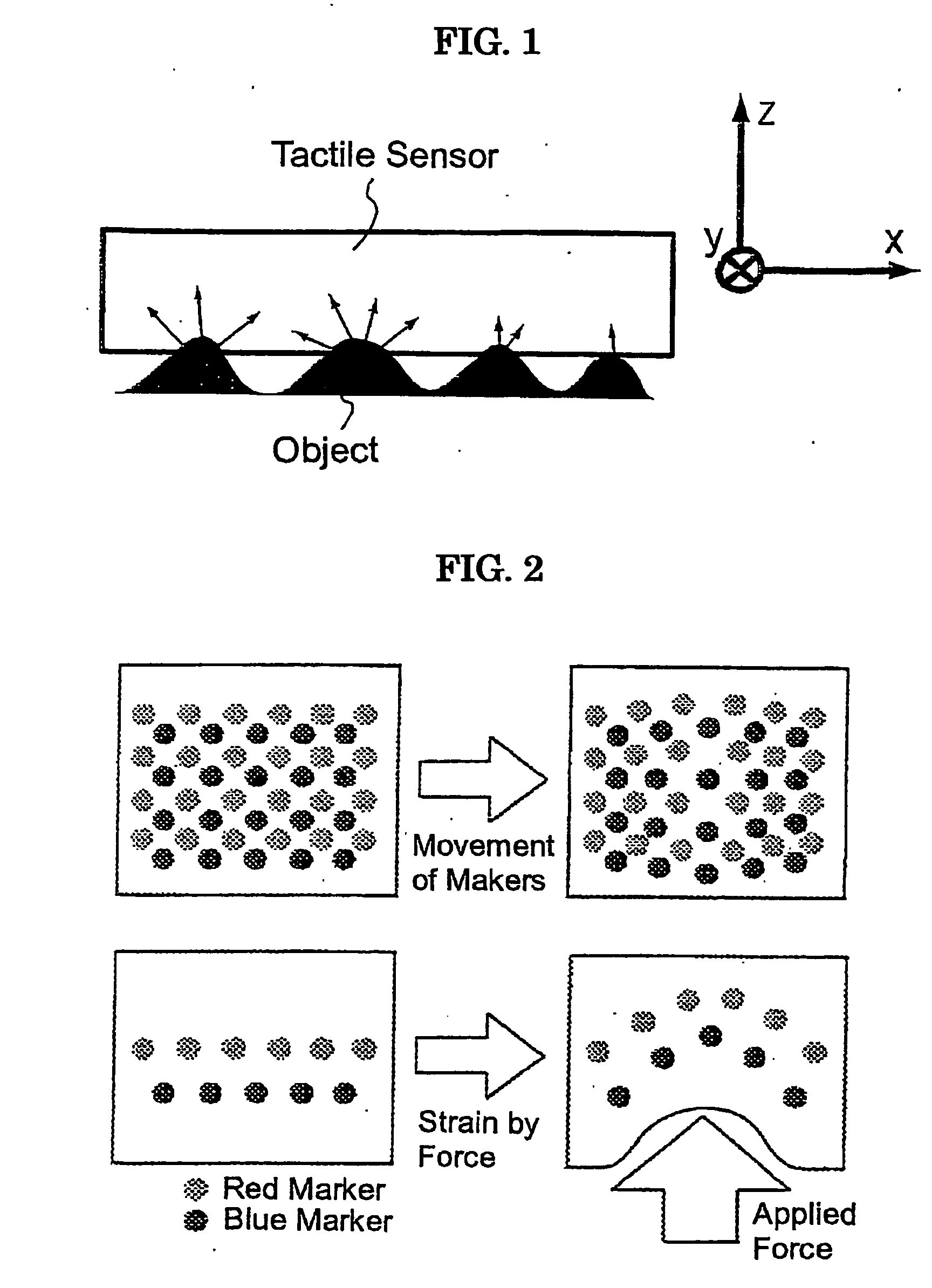

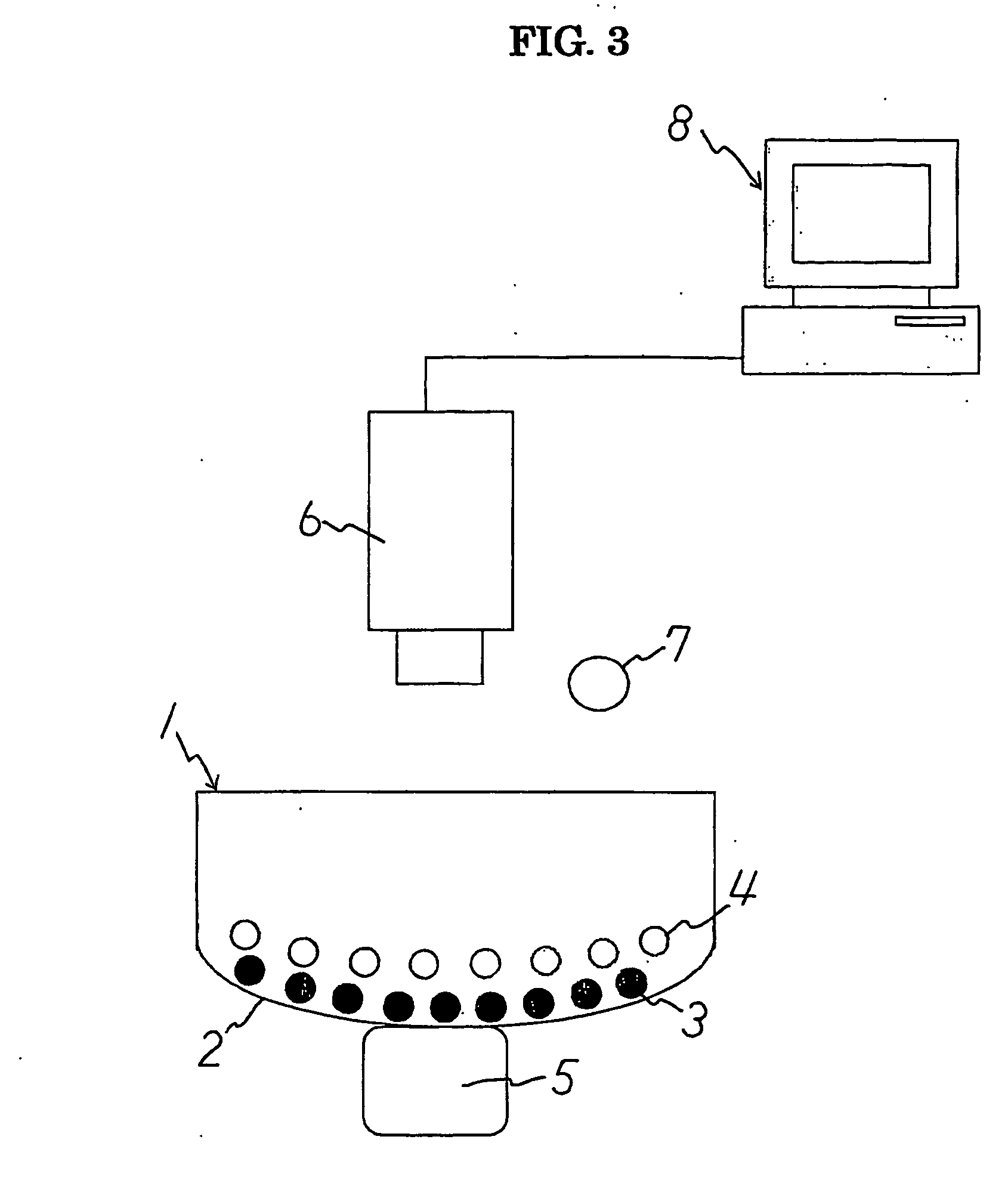

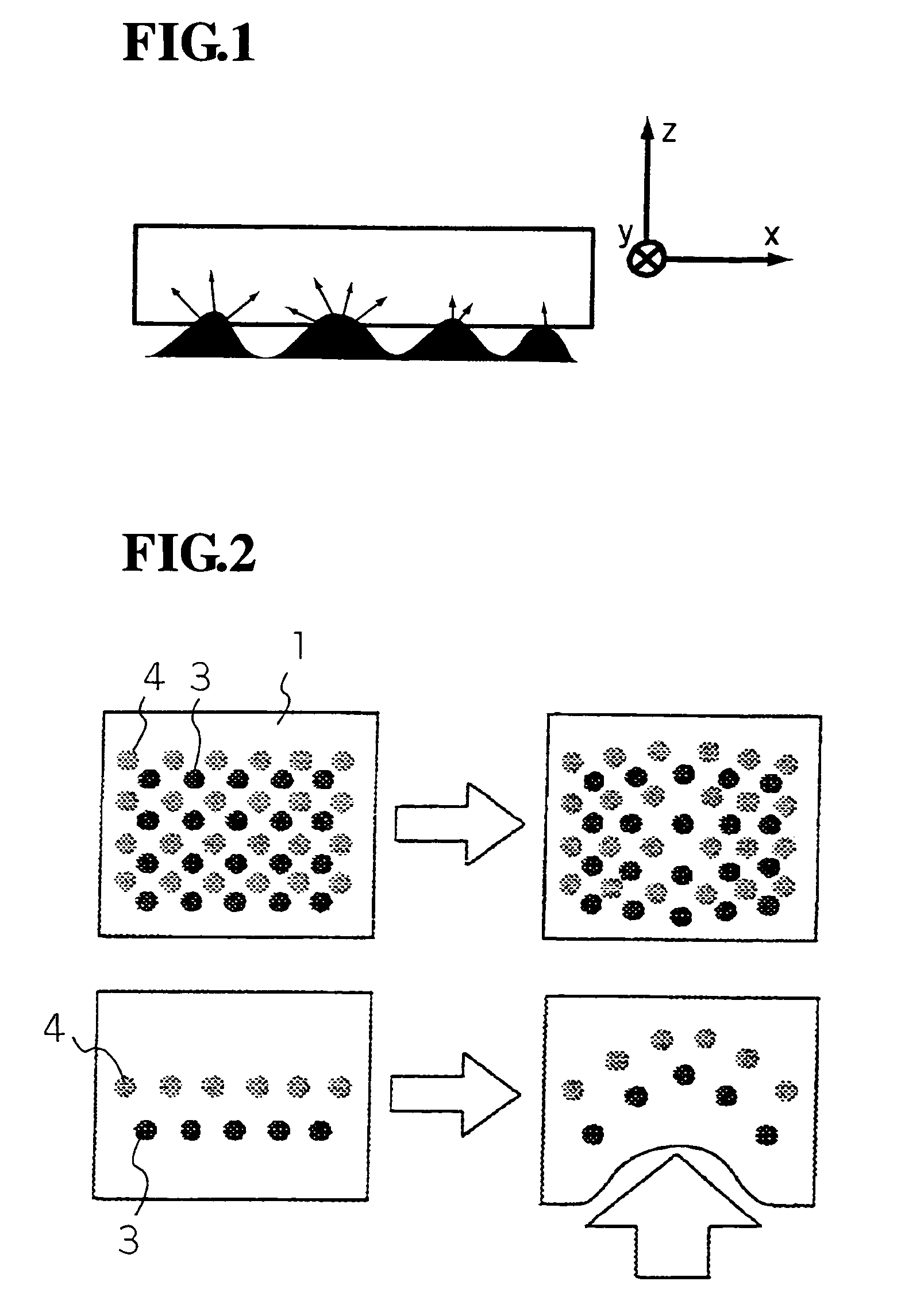

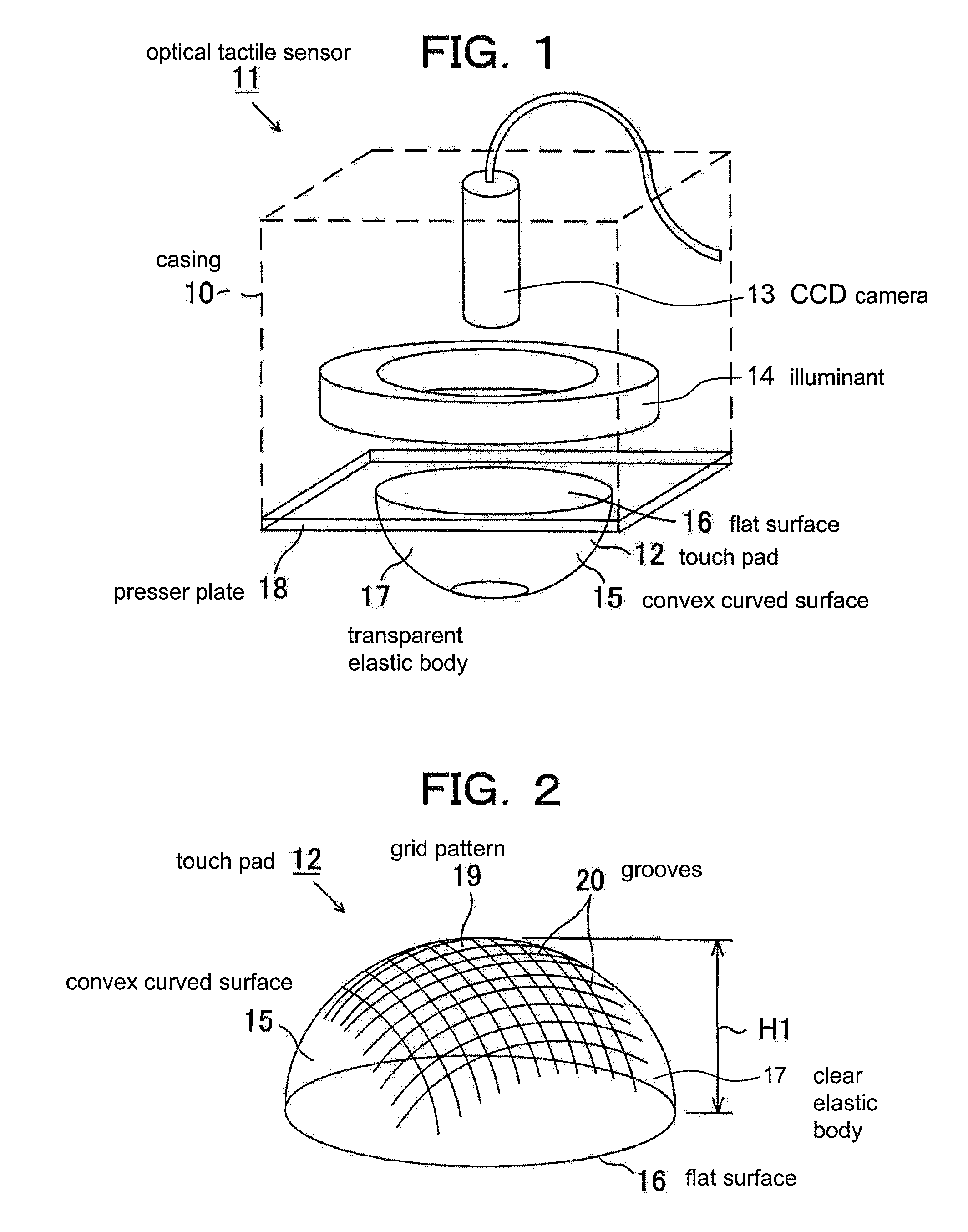

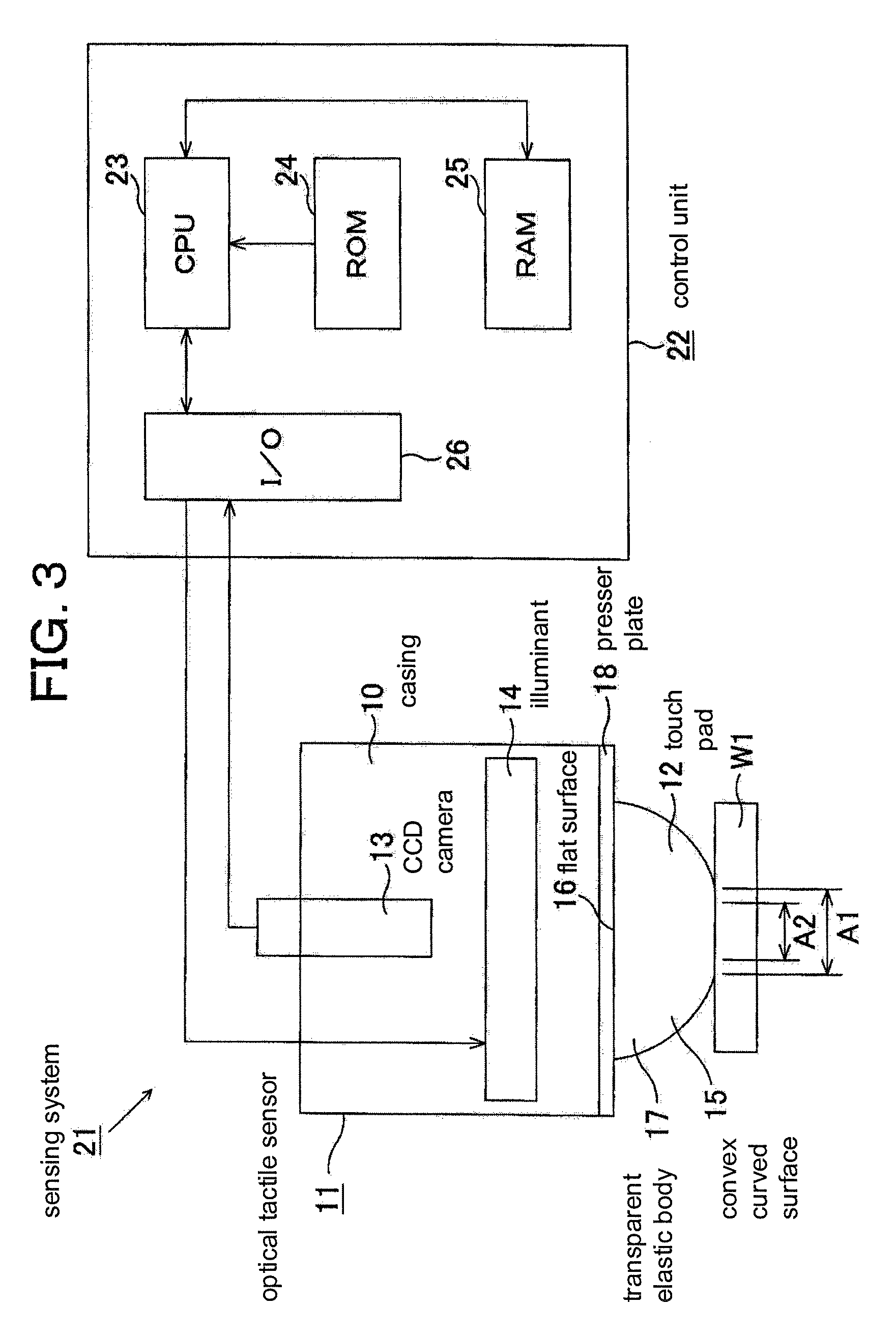

Optical tactile sensor having a transparent elastic tactile portion

The invention relates to a tactile sensor capable of obtaining information for a plurality of degrees of freedom at each point on a surface by introducing multi-channel sensing that uses color or optical spectrum to an optical tactile sensor. An optical tactile sensor is provided with a tactile section and imaging means, the tactile section comprising a transparent elastic body and a plurality of groups of markers provided inside the elastic body, each marker group being made up of a number of colored markers, with markers making up different marker groups having different colors for each group, and behavior of the colored markers when an object touches the elastic body being photographed by the imaging means. Preferably, the marker groups have mutually different spatial arrangements.

Owner:TOUDAITLO LTD

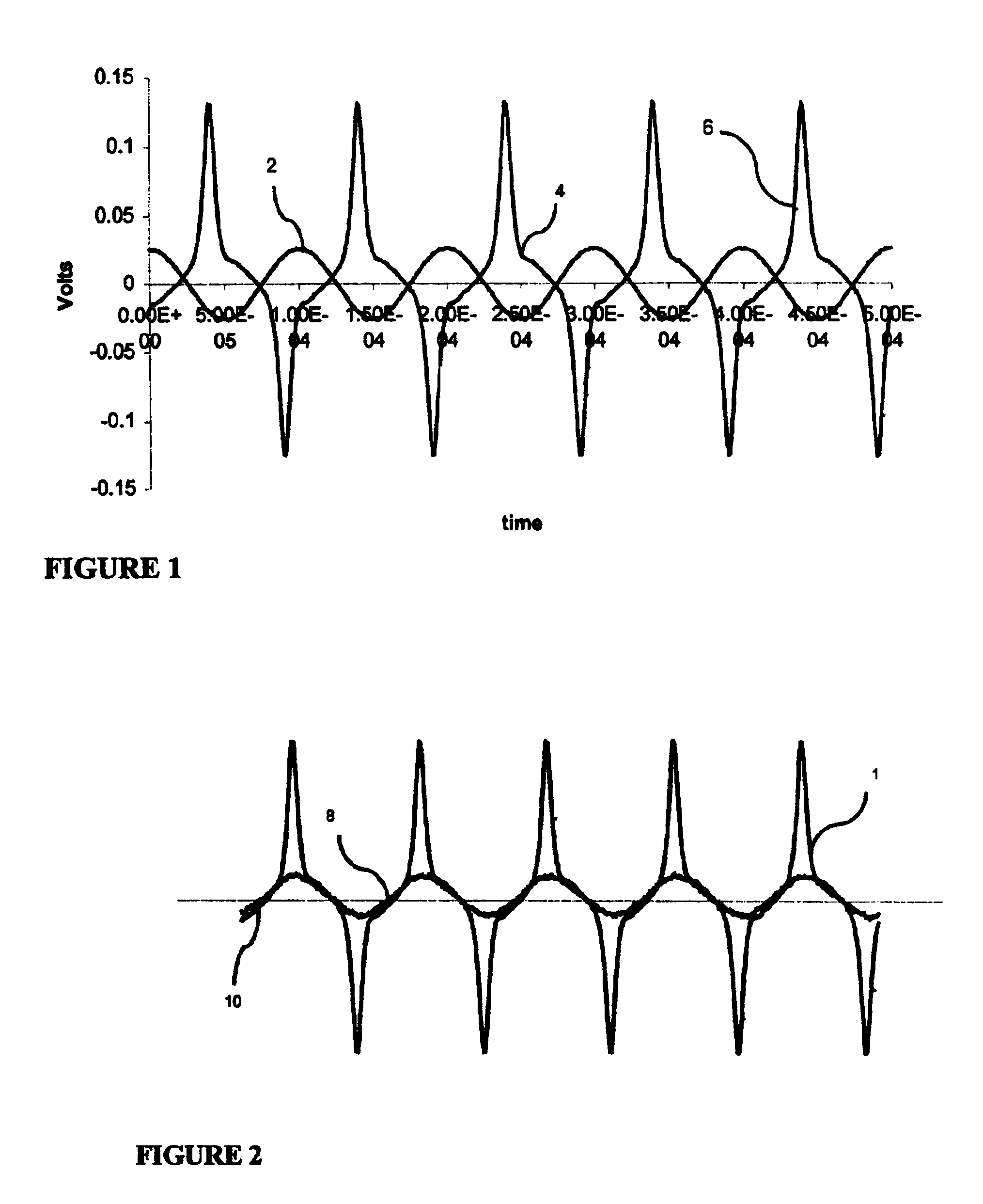

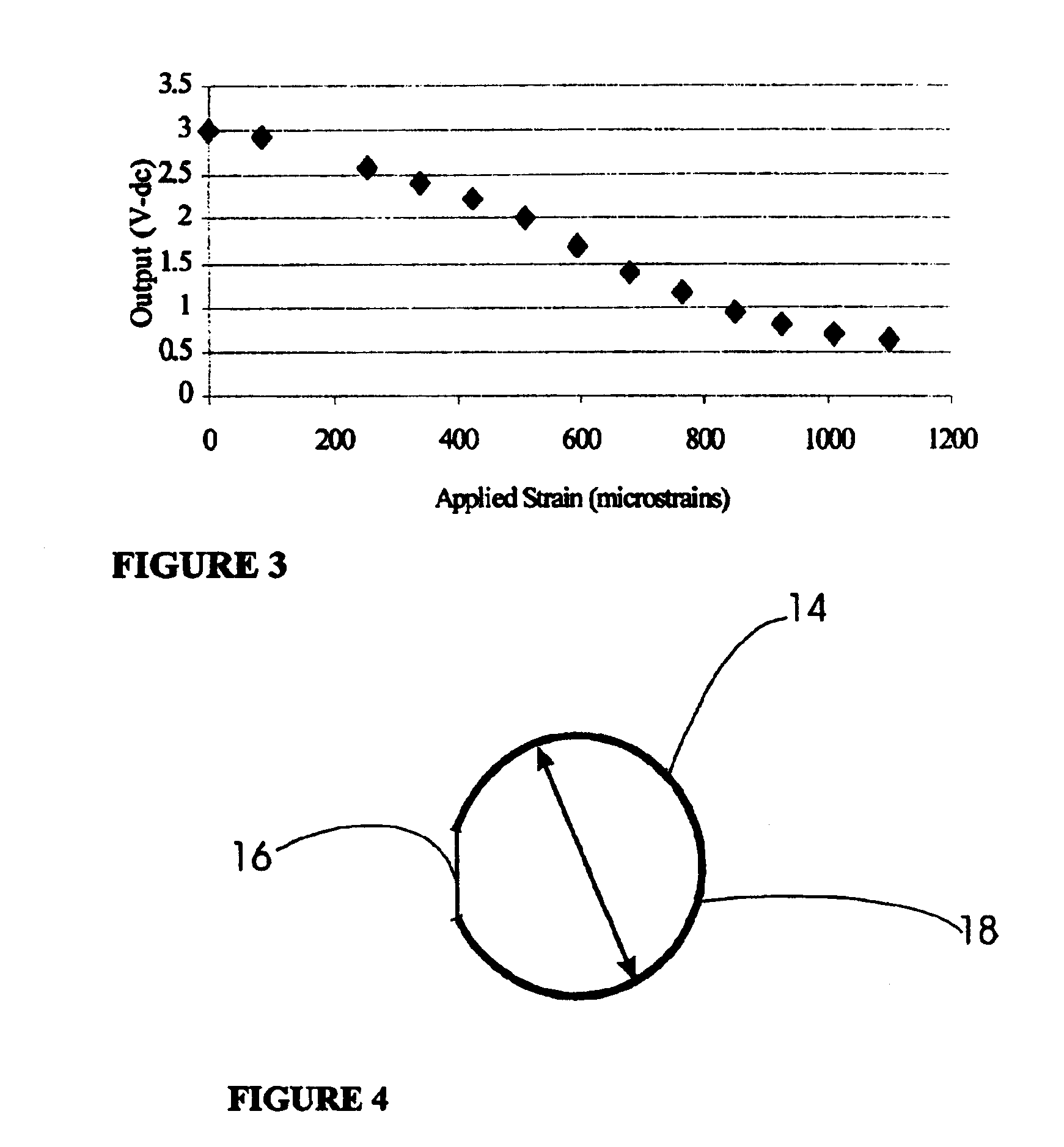

Inductively coupled stress/strain sensor

InactiveUS6912911B2Change relationshipForce measurement by measuring magnetic property varationWork measurementMagnetostrictionCouple stress

An improved method of sensing strain allows measurements of stress, torque, vibration and other loads imposed on a body without physical contact between the body / sensor and the monitoring equipment. An induction loop is at least partially comprised of a magnetostrictive material with a non-linear current-voltage relationship. An excitation device such as a coil is used to induce an AC response in the sensor. The non-linear response to the induced current is received by a sensing device such as a sensing coil, and the output thereof is filtered. The excitation device and sensing device are located in operative proximity to the sensor, but need not be in contact therewith, allowing easy measurement in small spaces, under harsh conditions, or of moving bodies such as drive shafts. The non-linear response of the sensor induces easily detectable harmonics of the base frequency of excitation. These harmonics may advantageously be measured as well.

Owner:SENSORTEX

Tire comprising a measurement device

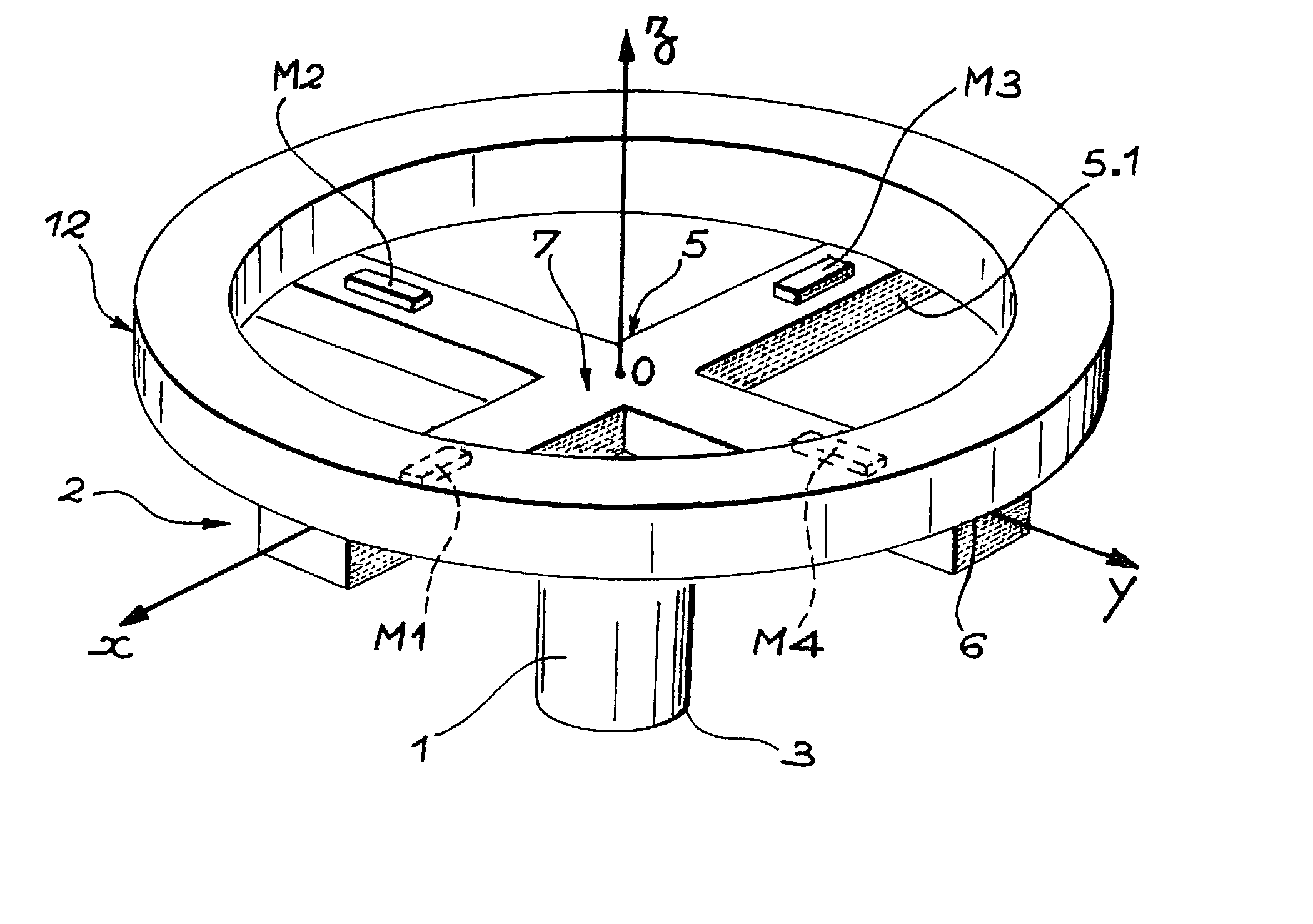

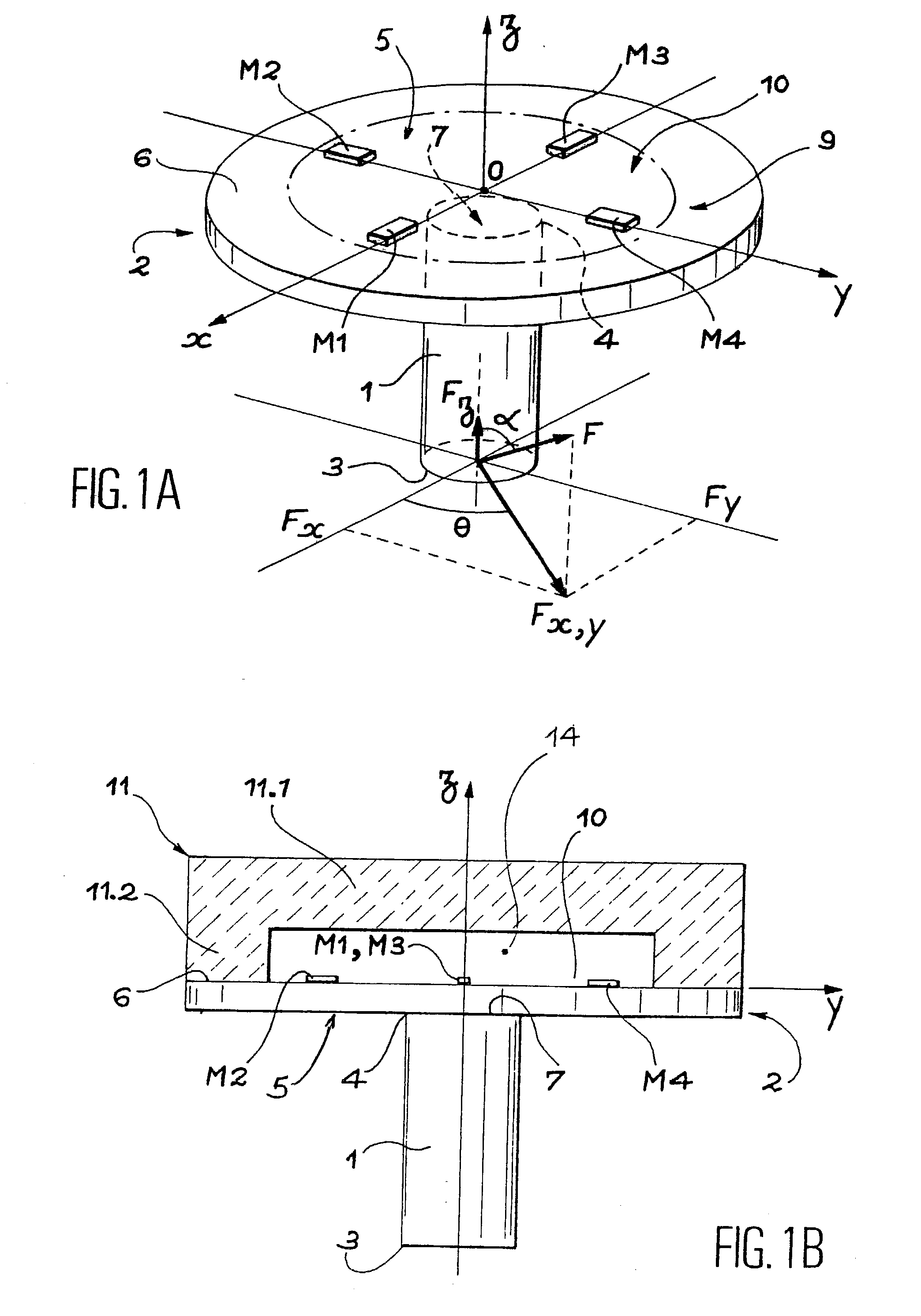

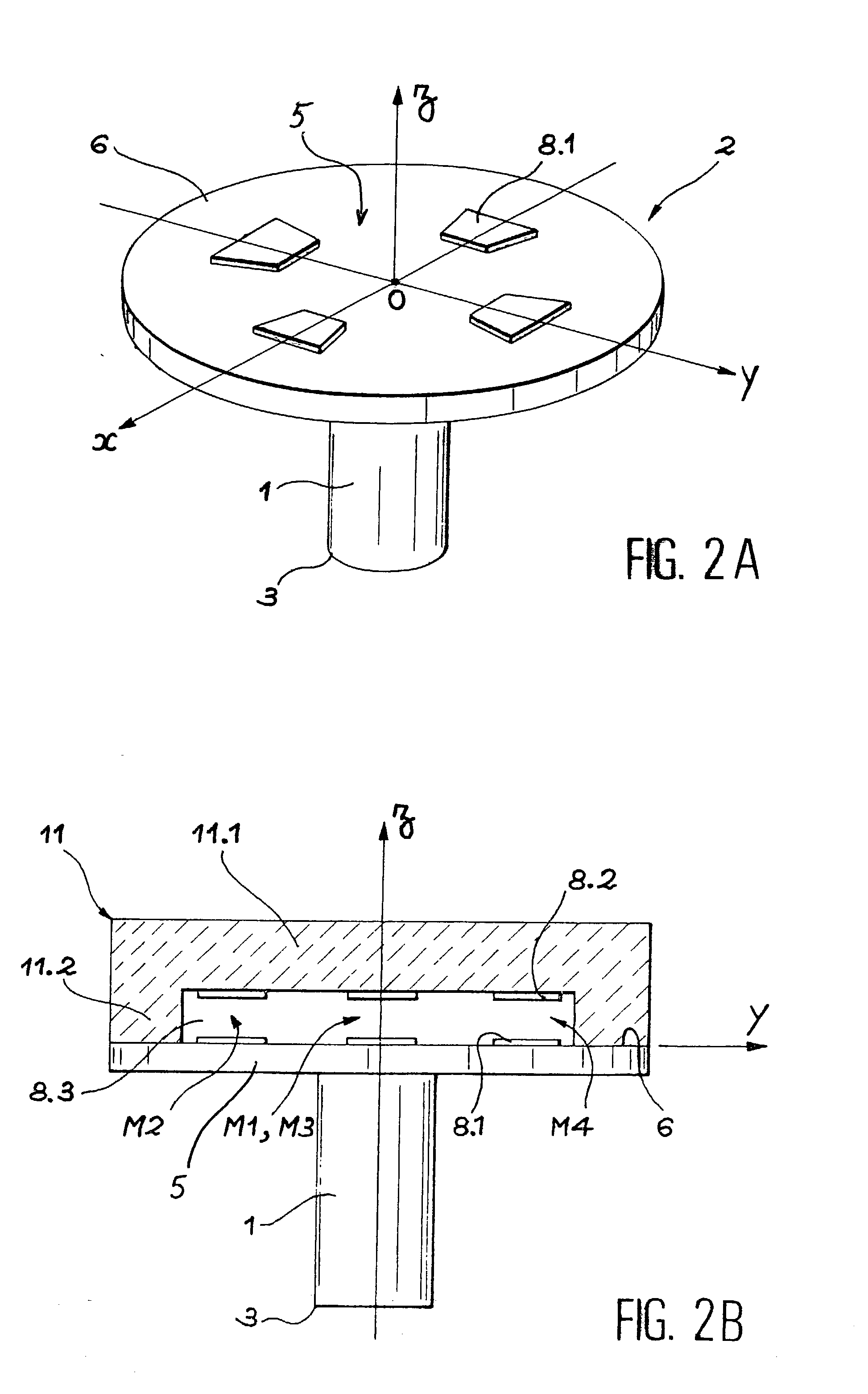

A tire includes a nail-type force sensor embedded, for example, in an isolated element such as a tread pattern block (T112). The sensor comprises a rigid shank (1) designed to be acted upon by the force to be determined and a head (2). The head (2) comprises an element attached to the shank (1) capable of being deformed when the shank is displaced. This deformable element carries means to measure the deformation and comprises anchoring points which have a position relative to the shank (1) at rest and which essentially maintain that position when the shank (1) is displaced.

Owner:MICHELIN RECH & TECH SA

Tactile sensor and gripping robot using the same

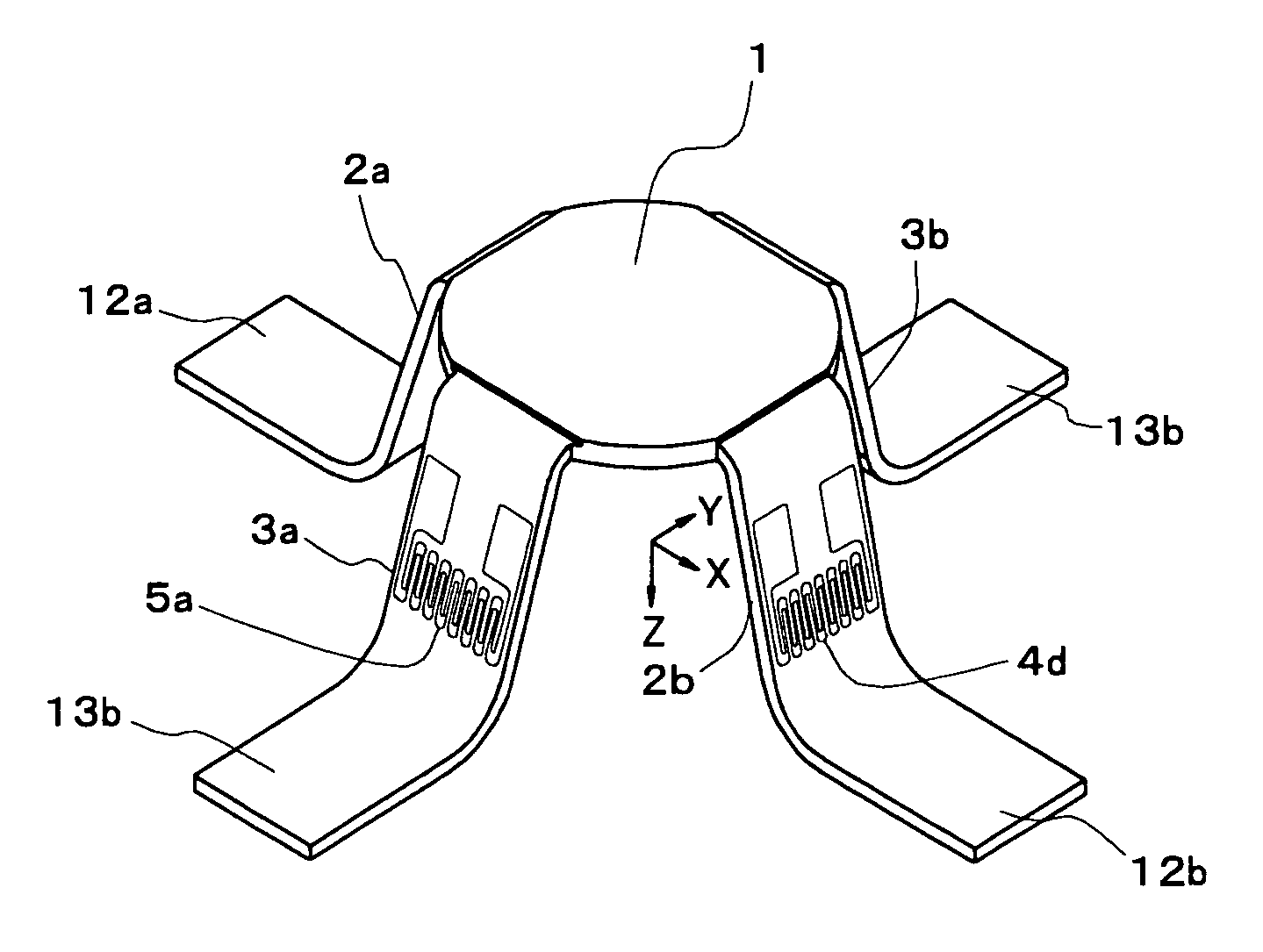

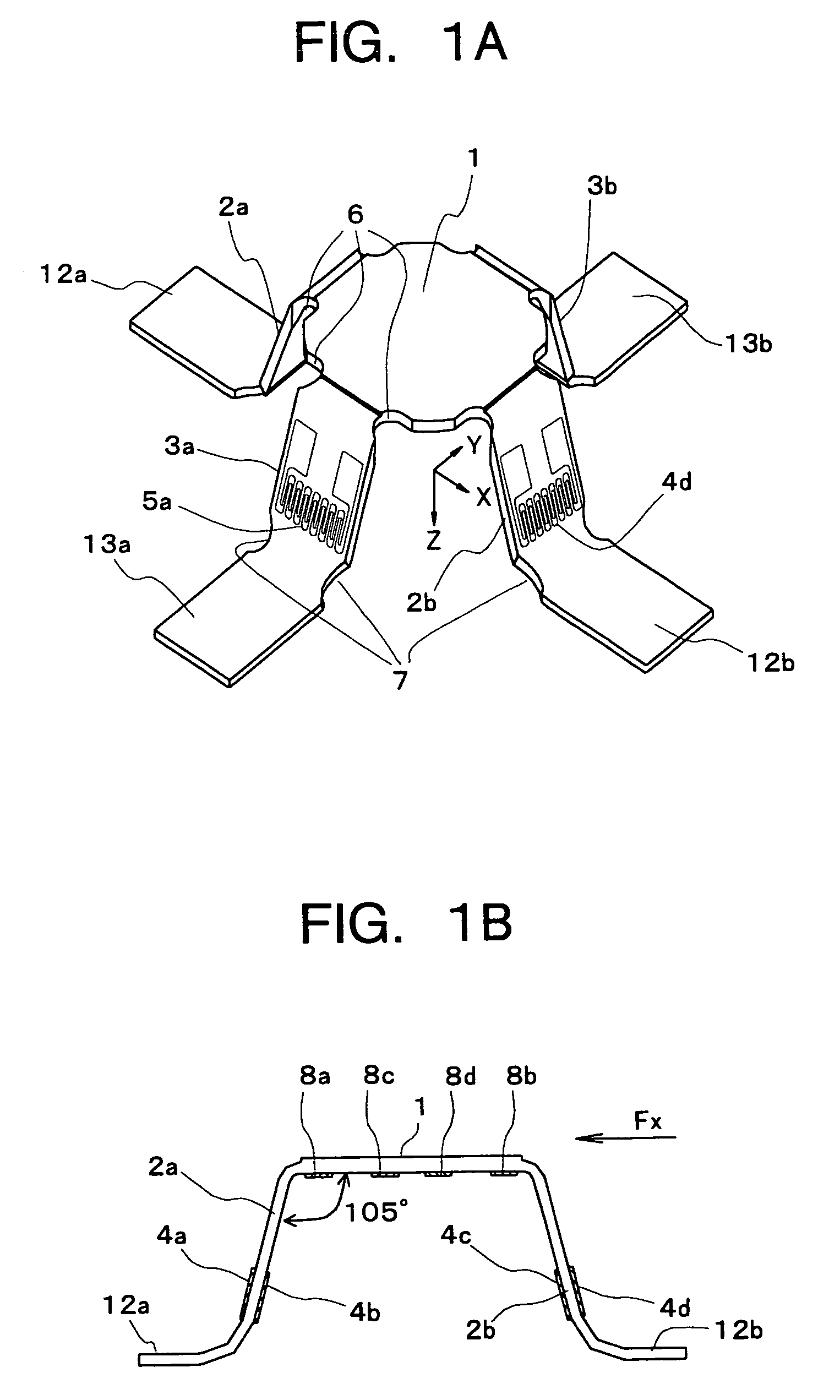

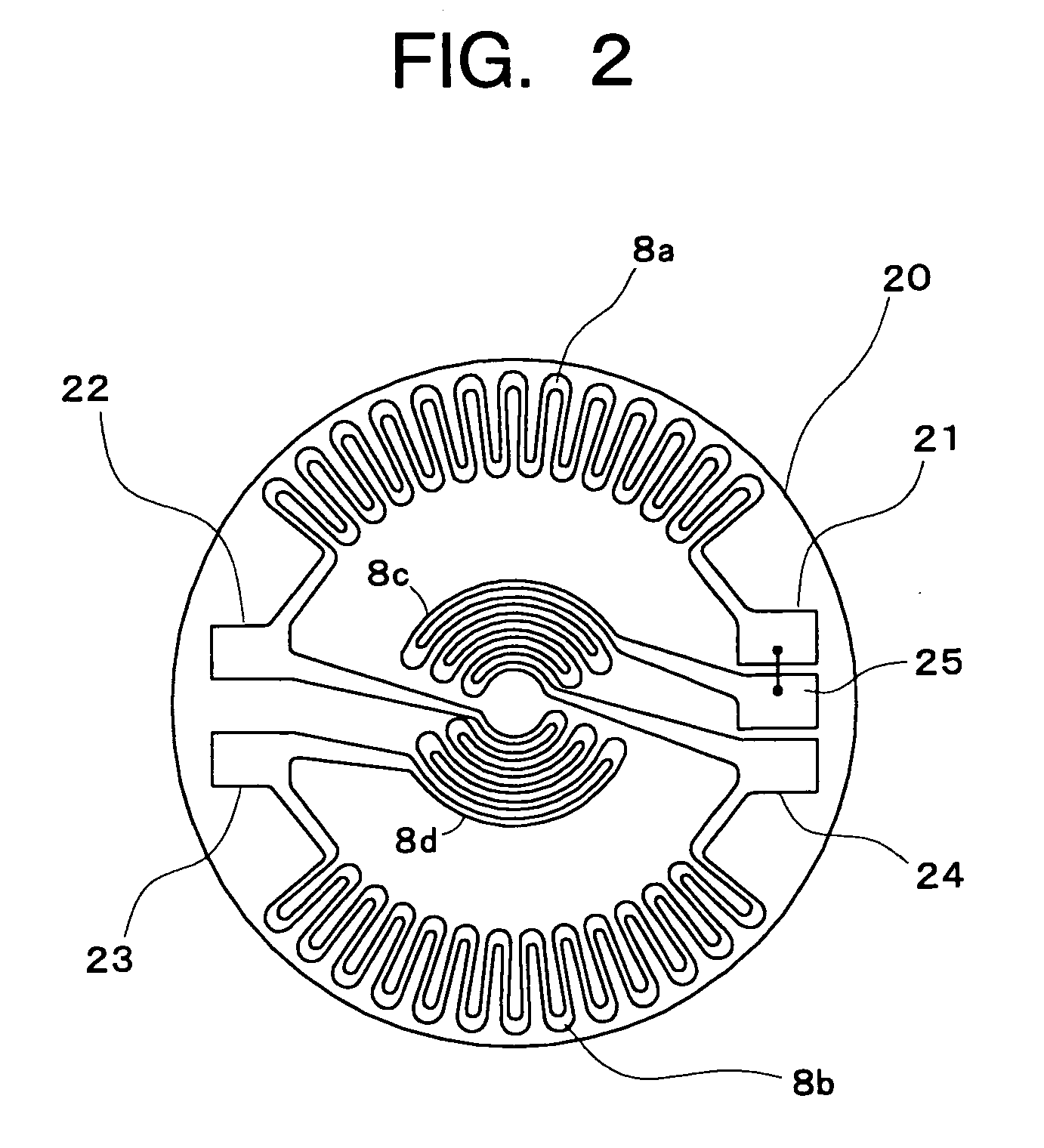

ActiveUS6886415B1Easy to bendImprove detection accuracyForce measurementMeasurement of force componentsContact pressureEngineering

Disclosed is a tactile sensor which includes: a disk-shaped first strain generating section; plate-shaped second to fifth strain generating sections each provided as an extension of the first strain generating section extended from one of four substantially equiangular peripheral edge portions of the first strain generating section, each of the second to fifth strain generating sections being structured to support the first strain generating section as a leg thereof; first to fourth foot sections extended at a side different from a first strain generating section side respectively from the second to fifth strain generating sections; a diaphragm type first strain gauge attached to a discoid surface of the first strain generating section; and second to fifth strain gauges attached respectively to planer surfaces of the second to fifth strain generating sections, and a gripping robot using the tactile sensor for detecting contact pressure.

Owner:TOSHIBA ELECTRIC ENG +2

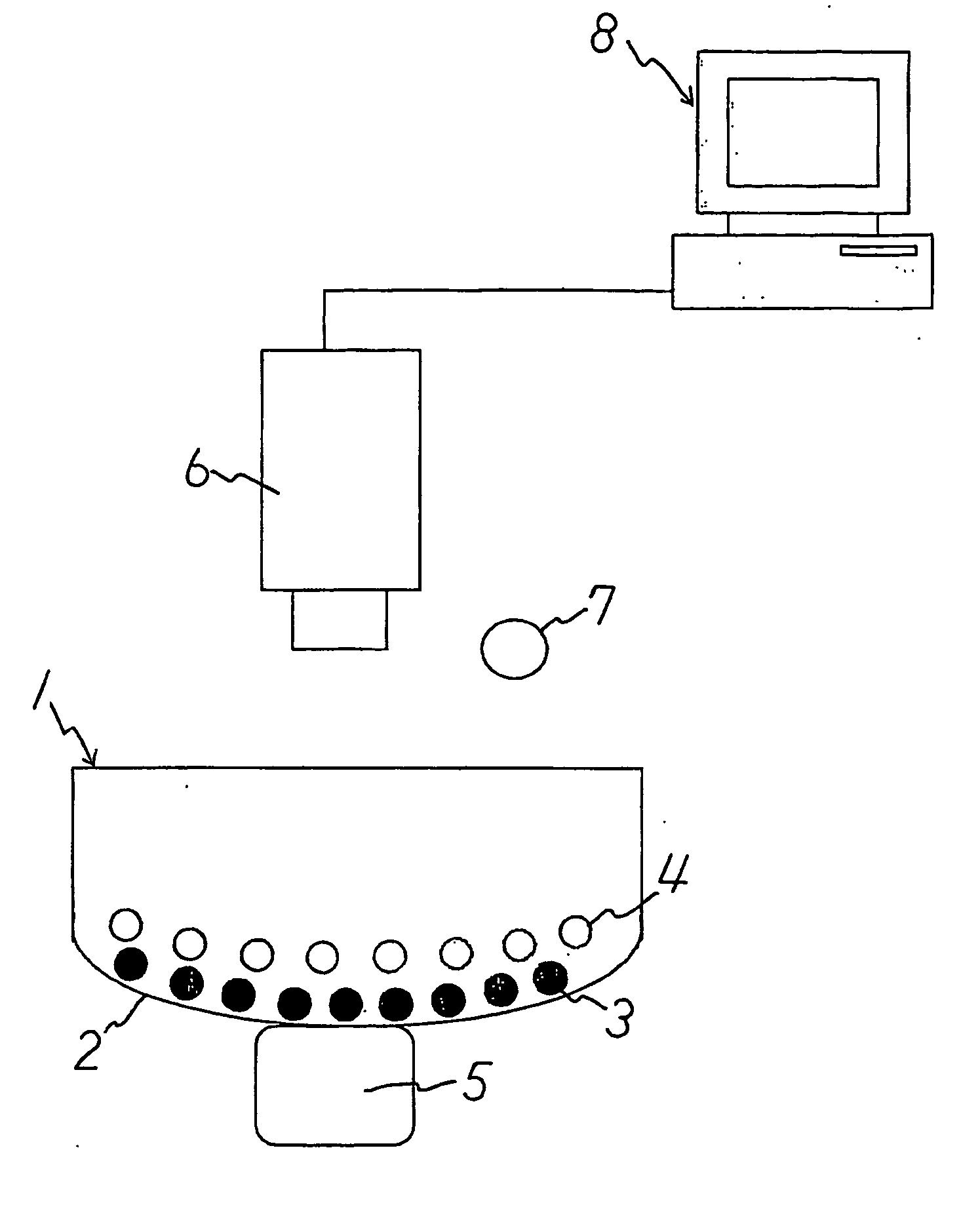

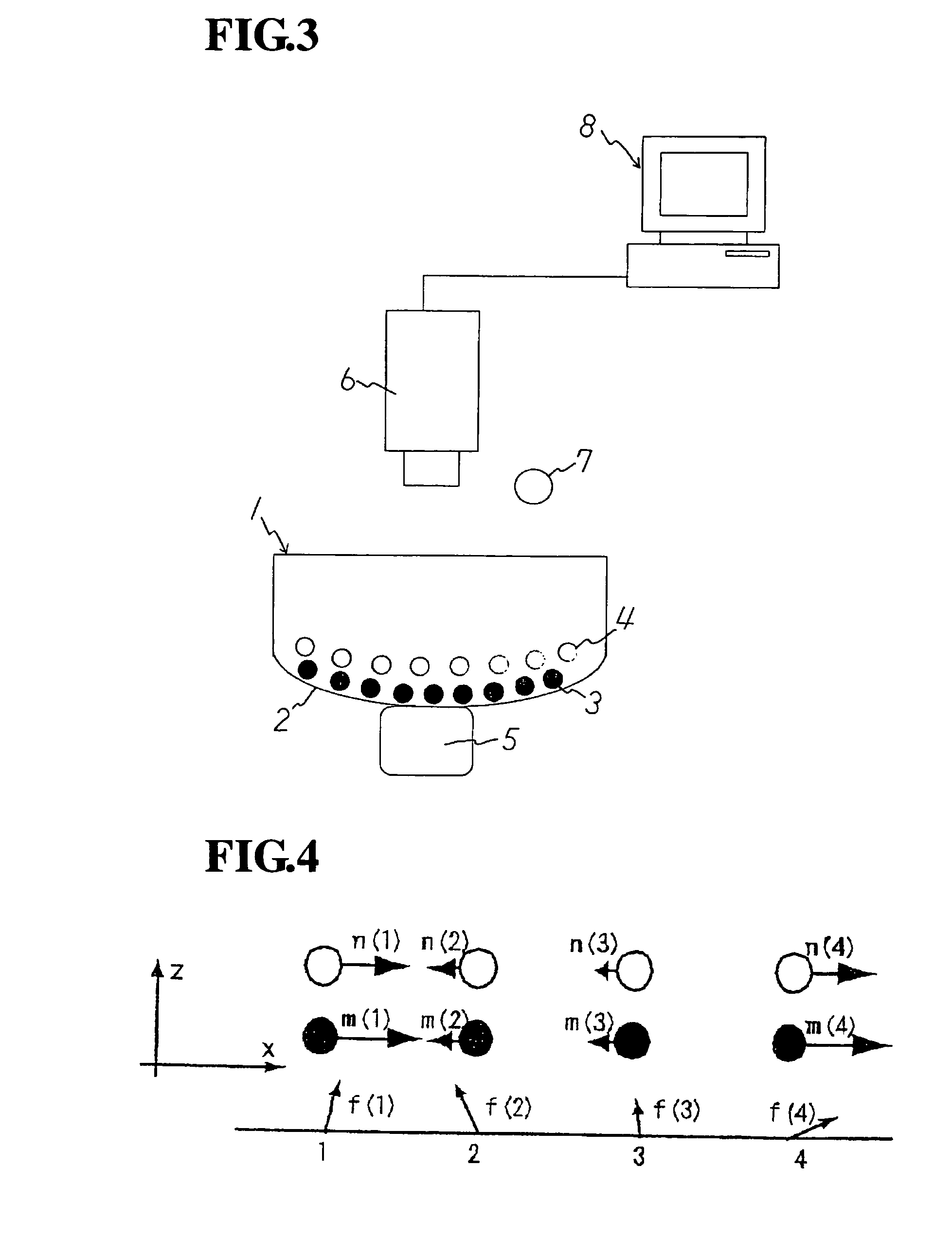

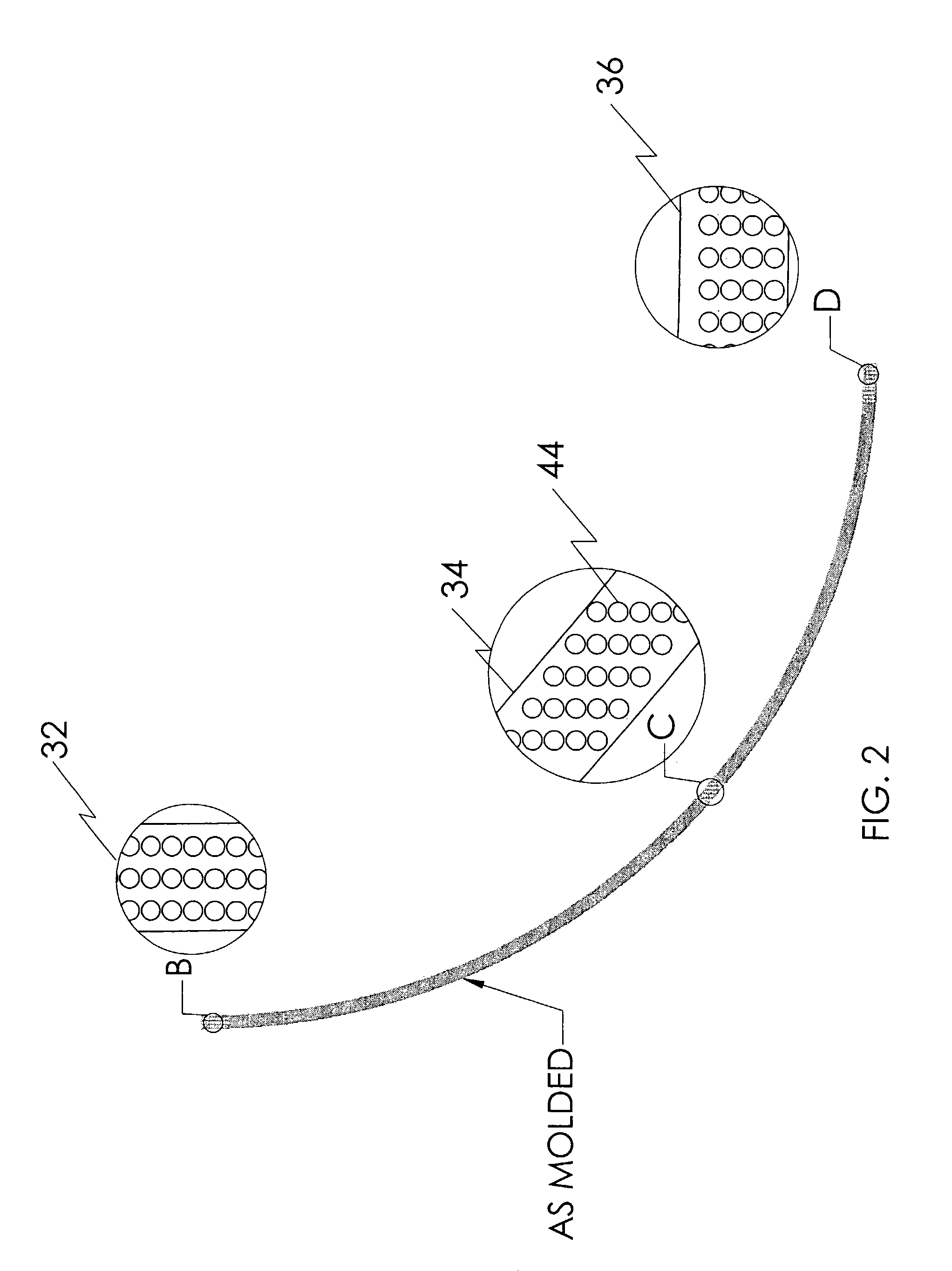

Optical tactile sensor and method of reconstructing force vector distribution using the sensor

InactiveUS20070040107A1Easy to processForce measurement by measuring optical property variationMaterial analysis by optical meansElastomerEngineering

The invention relates to a tactile sensor capable of obtaining information for a plurality of degrees of freedom at each point on a surface. An optical tactile sensor is provided with a sensing part and a photographing device, the sensing part comprising a transparent elastic body and a plurality of groups of markers provided inside the elastic body, each marker group being made up of a number of colored markers, with markers making up different marker groups having different colors for each group. The elastic body has an arbitrary curved surface. The behavior of the colored markers when an object touches the curved surface of the elastic body is obtained as image information of markers by photographing device. The sensor further comprises a force vector distribution reconstructing device for reconstructing forces applied to said surface from information as to the behavior of markers that is obtained from said image information of markers.

Owner:TOUDAITLO LTD

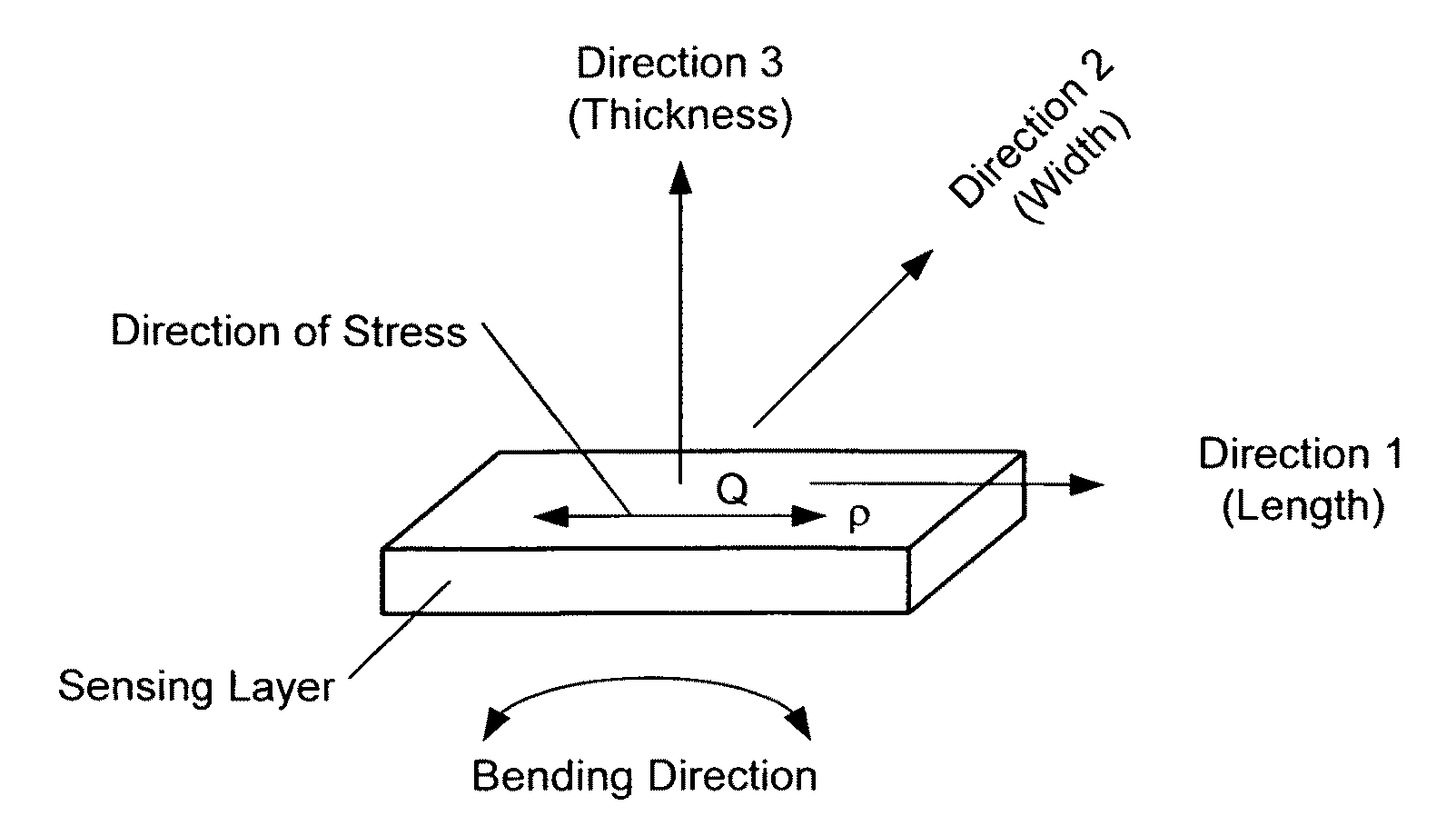

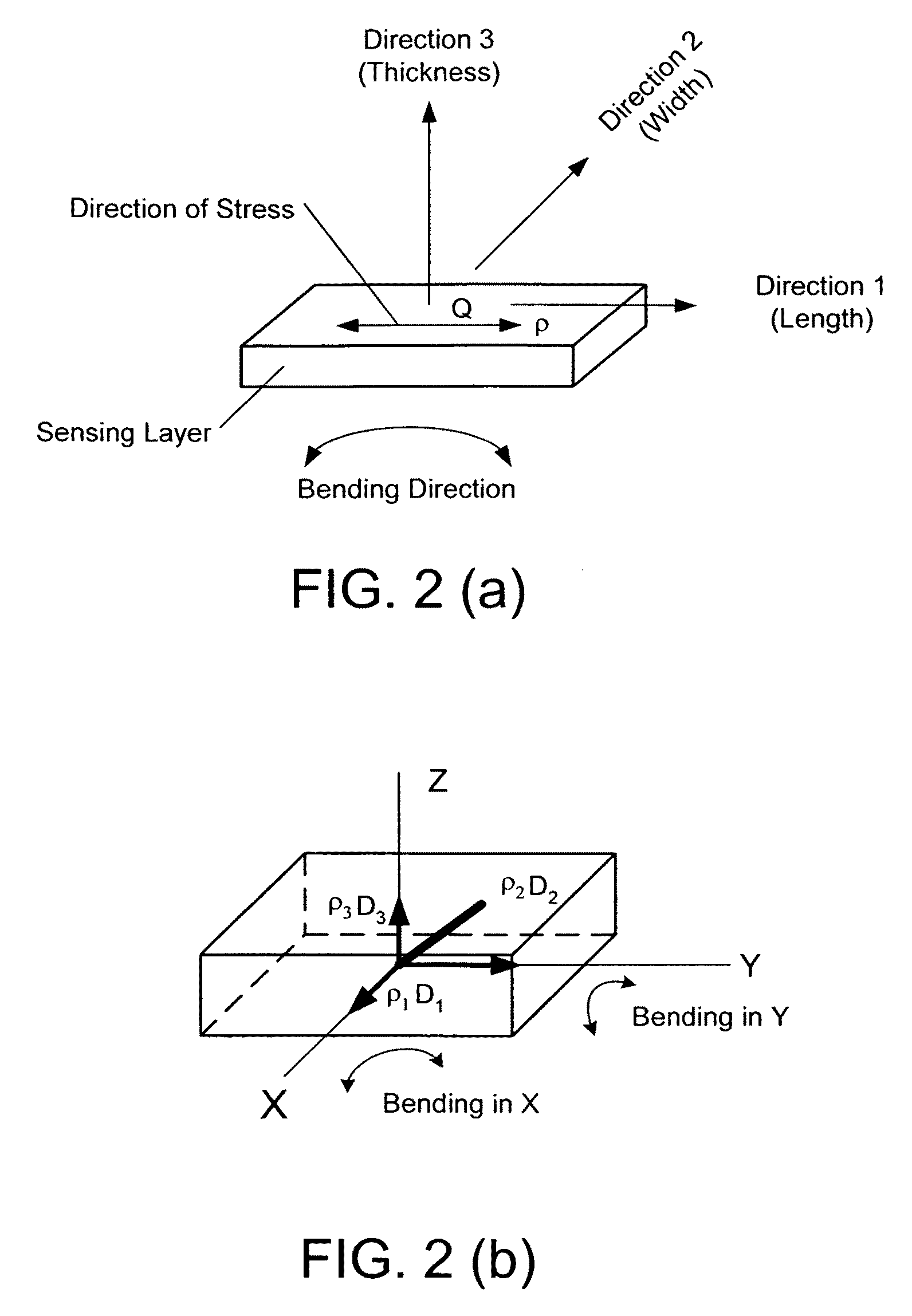

Flexural deformation sensing device and a user interface using the same

ActiveUS8132468B2Force measurement using piezo-electric devicesUsing electrical meansElectricityElectrical battery

Owner:RPX CORP

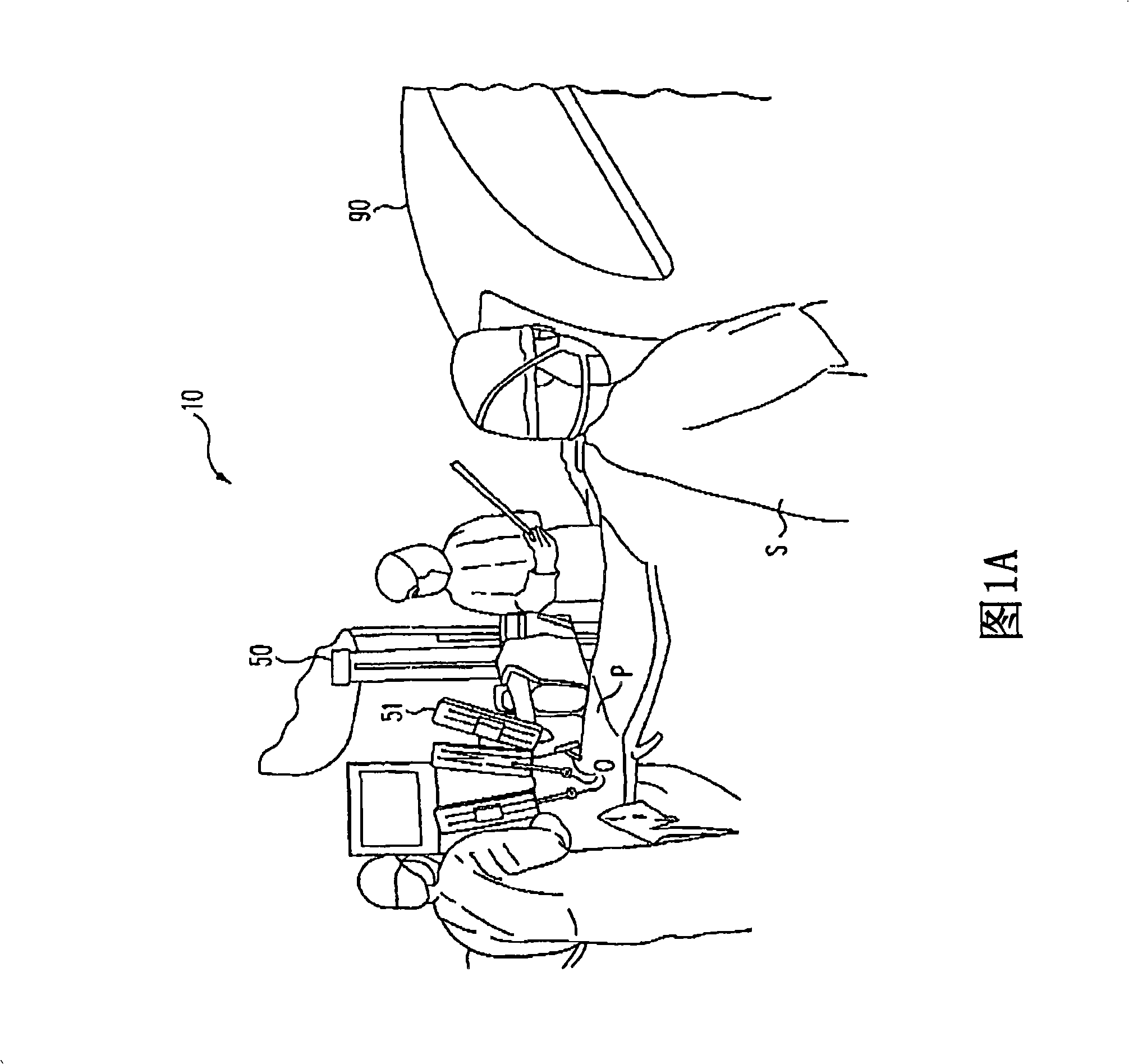

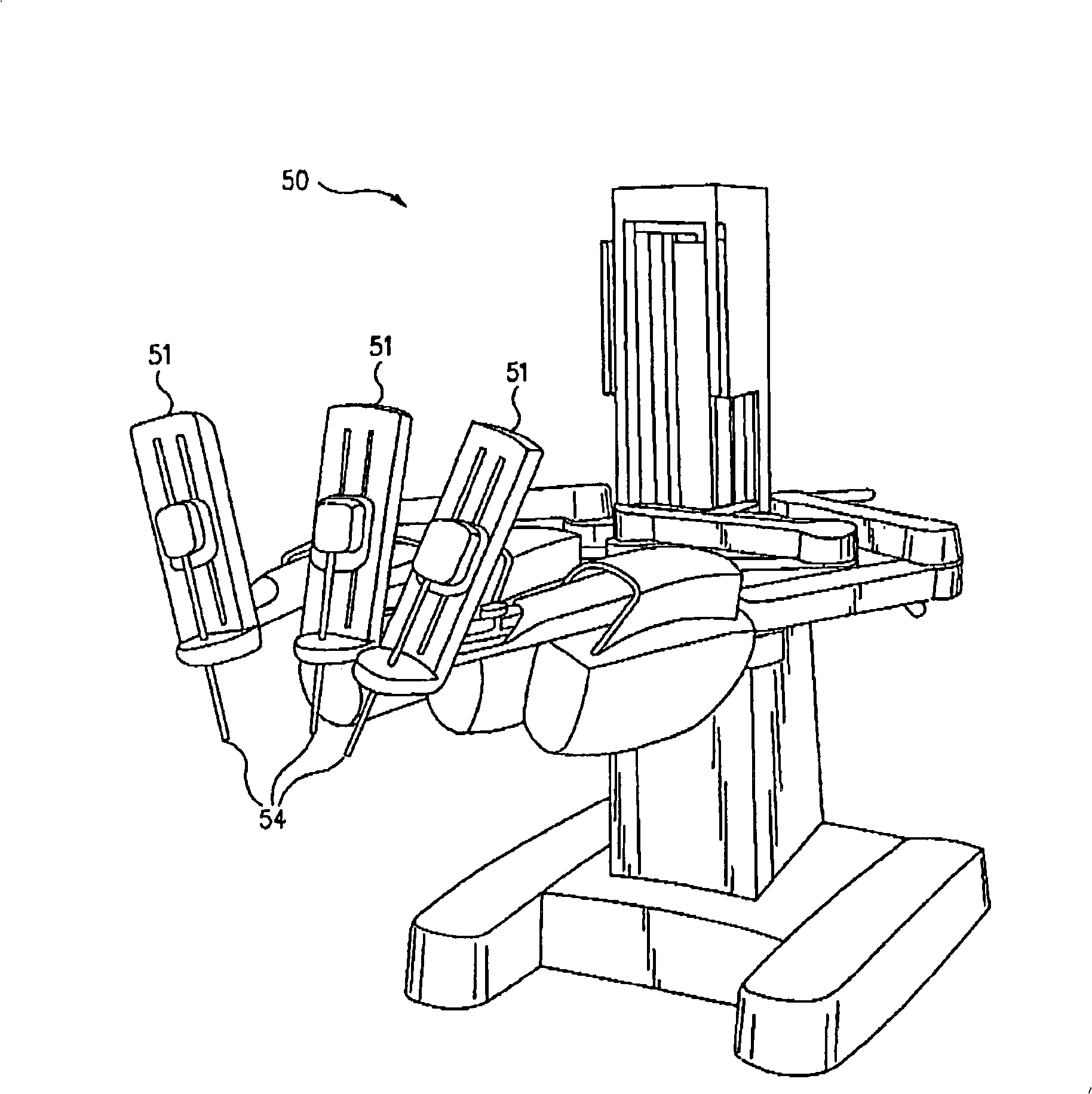

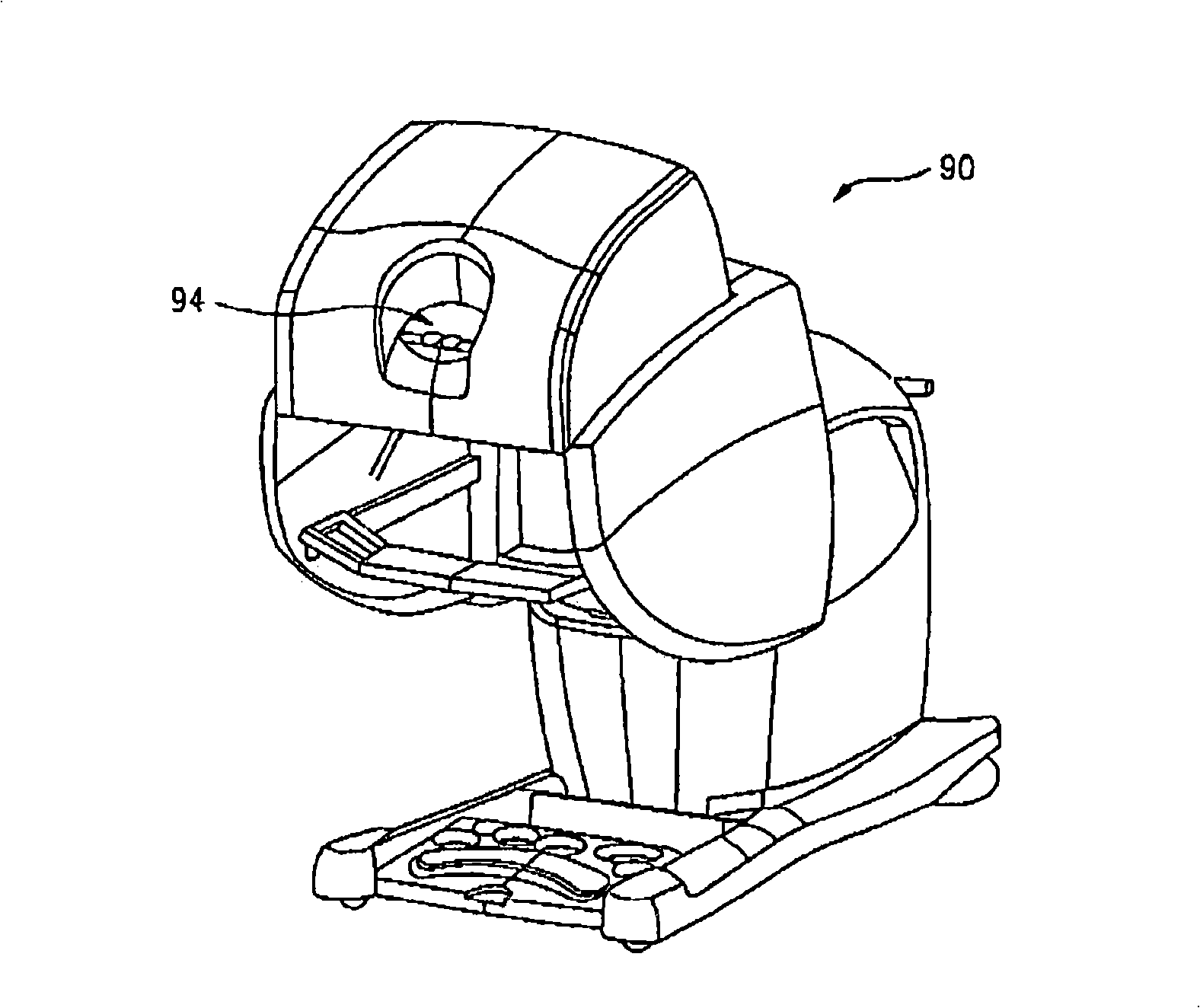

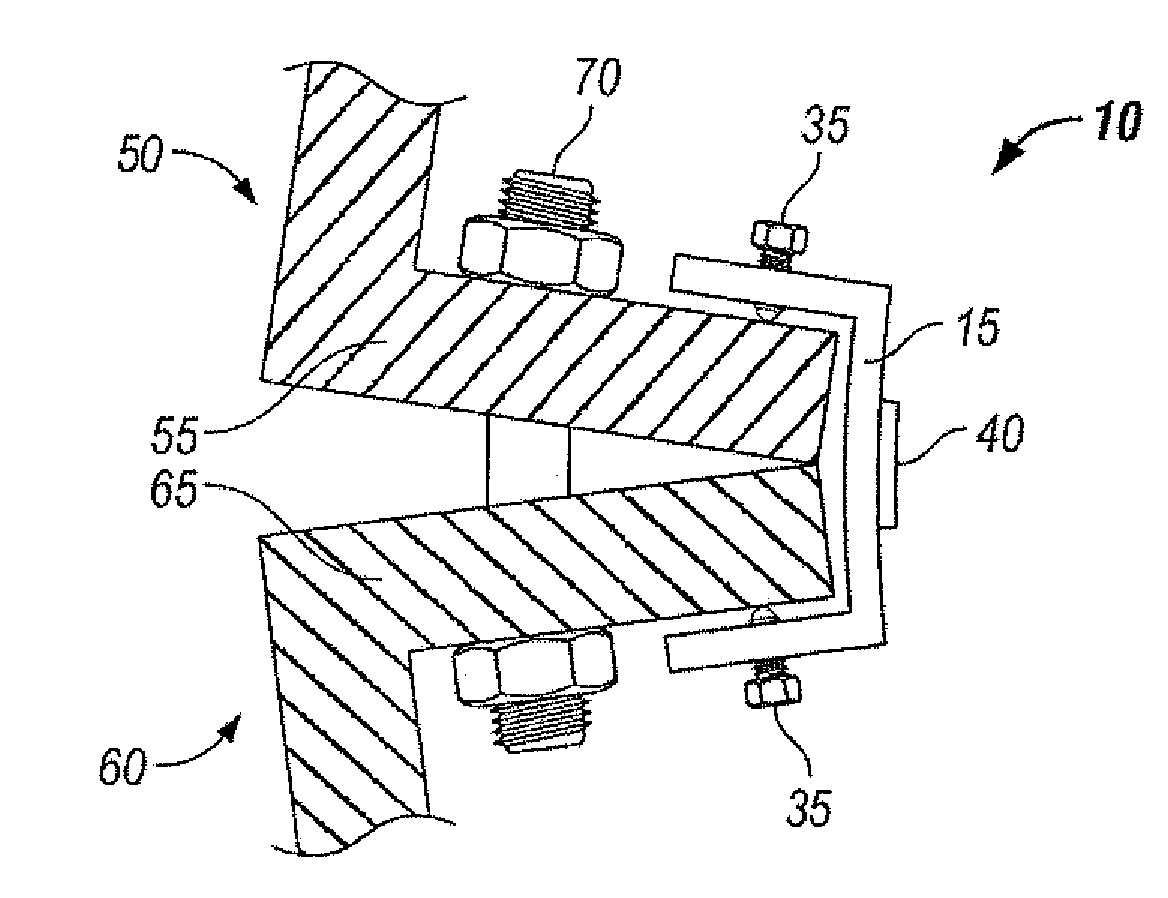

Force and torque sensing for surgical instruments

ActiveCN101340850AEliminates the problem of flexible wrist jointsComplete understandingMechanical apparatusStrain gaugeSteady state temperatureTeleoperated robot

An apparatus, system, and method for improving force and torque sensing and feedback to the surgeon performing a telerobotic surgery are provided. Groups of axially oriented strain gauges are positioned on a distal end of an instrument shaft proximate a moveable wrist of a robotic surgical instrument to sense forces and torques at the distal tip of the instrument. Advantageously, errors due to changes in the configuration of the tip or steady state temperature variations are eliminated. Other advantageous configurations and methods are disclosed.

Owner:INTUITIVE SURGICAL OPERATIONS INC

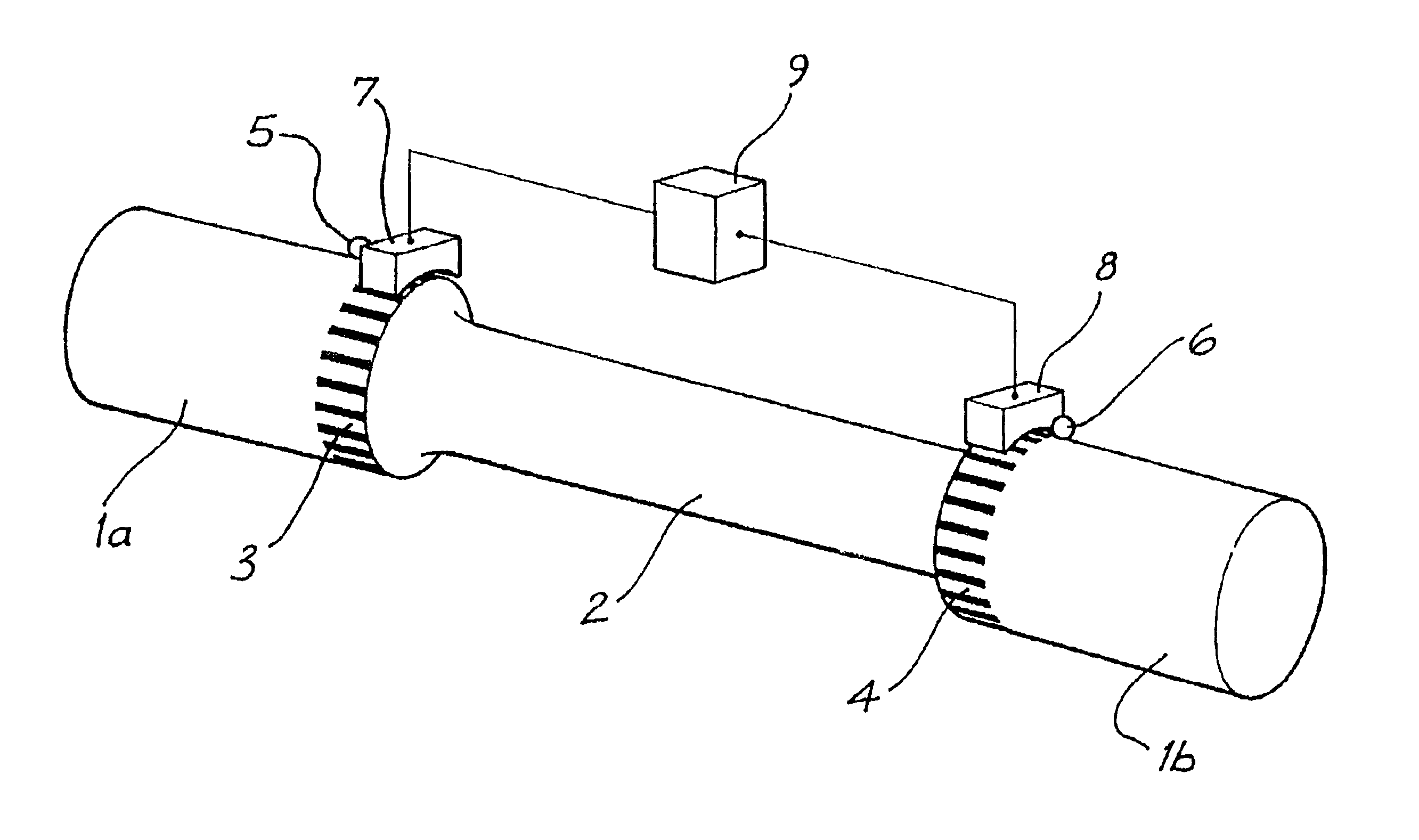

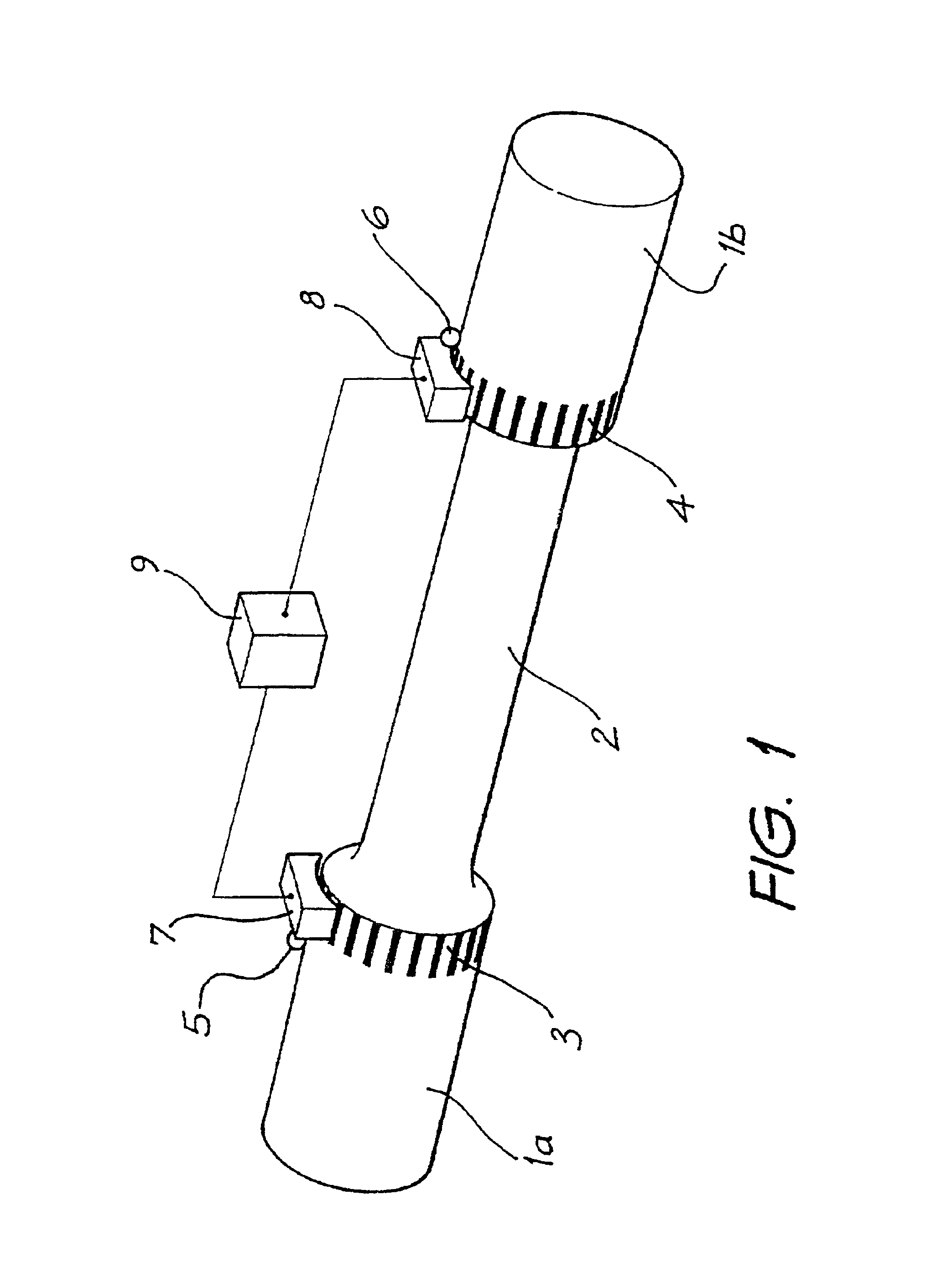

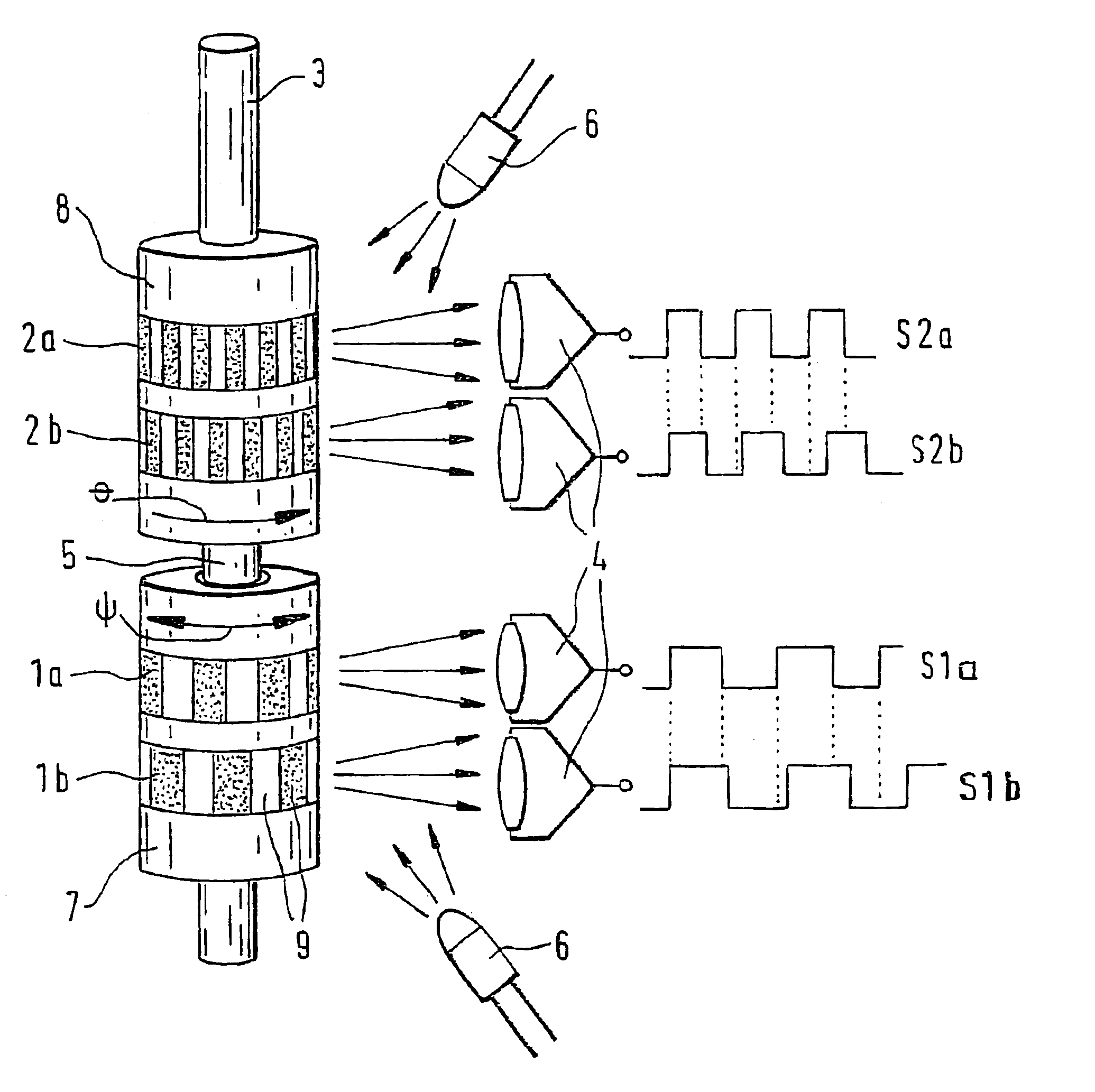

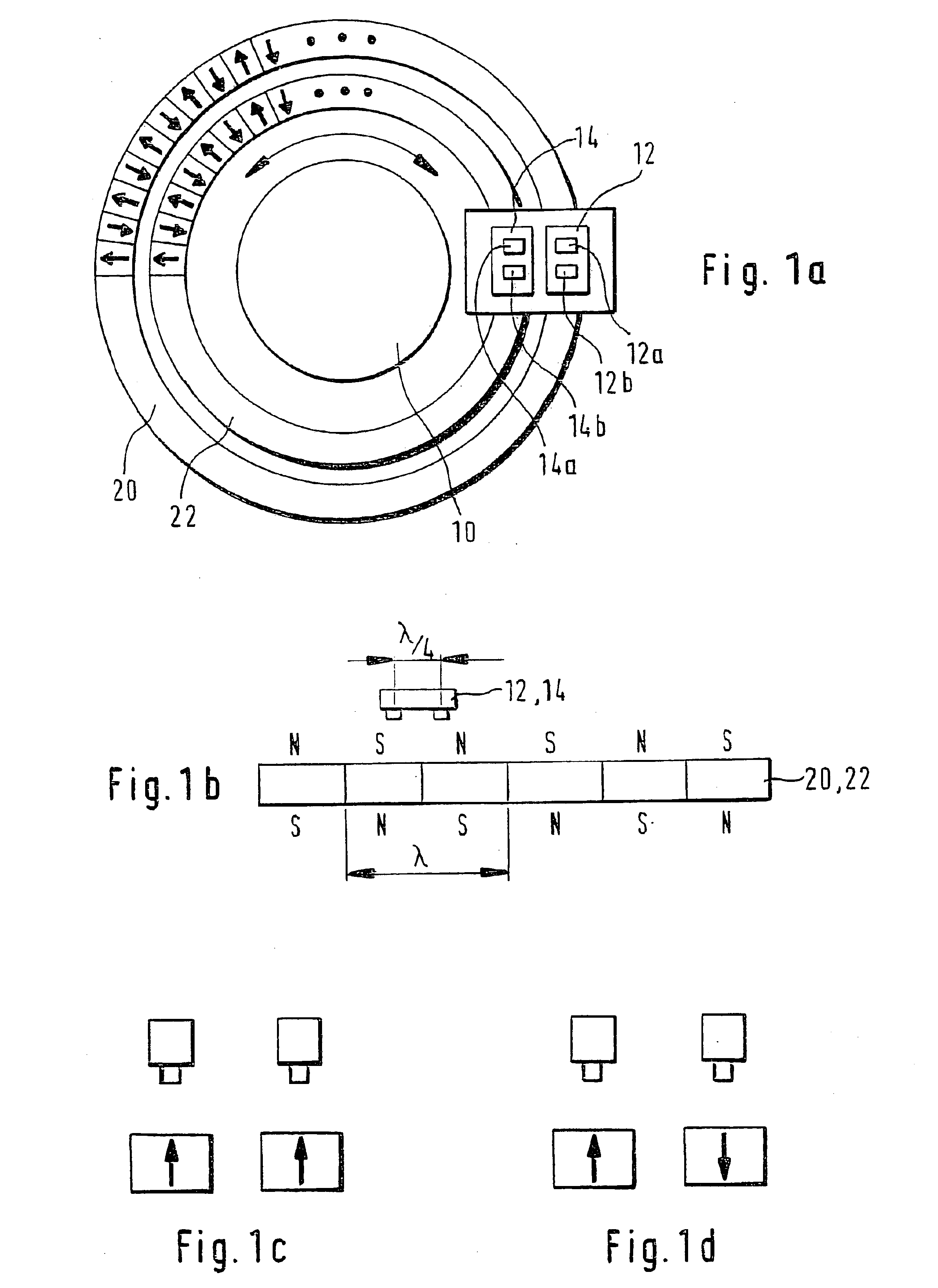

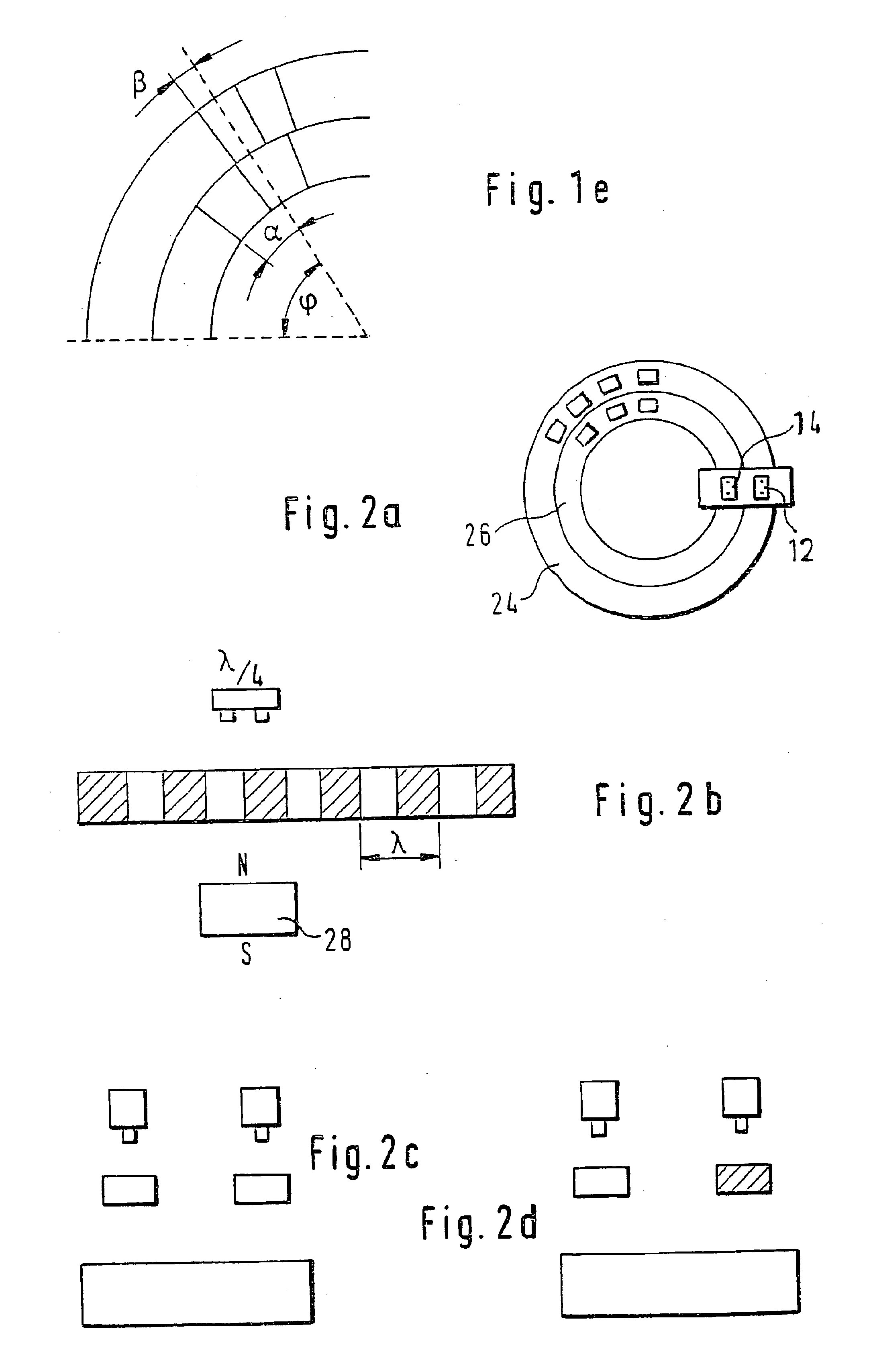

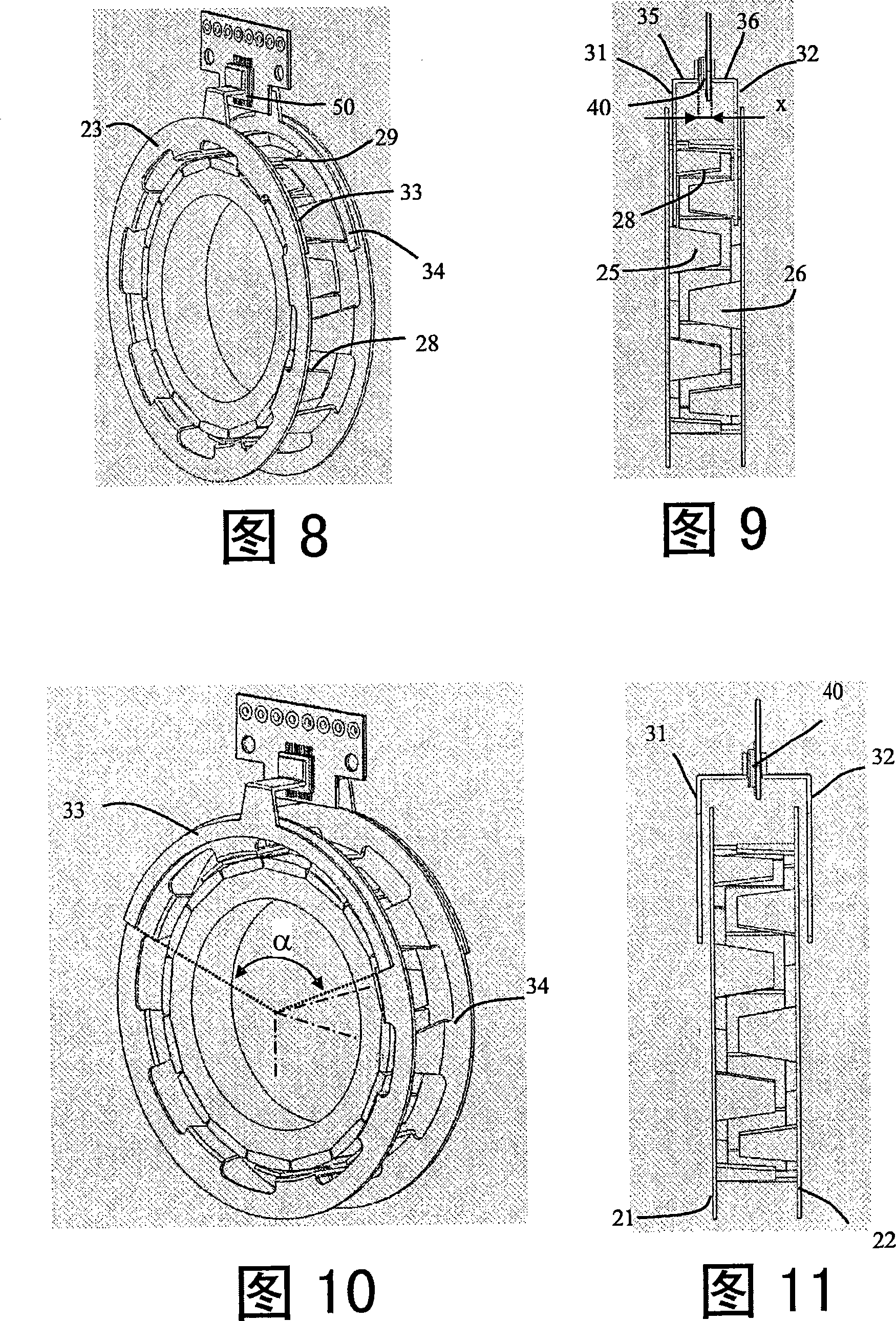

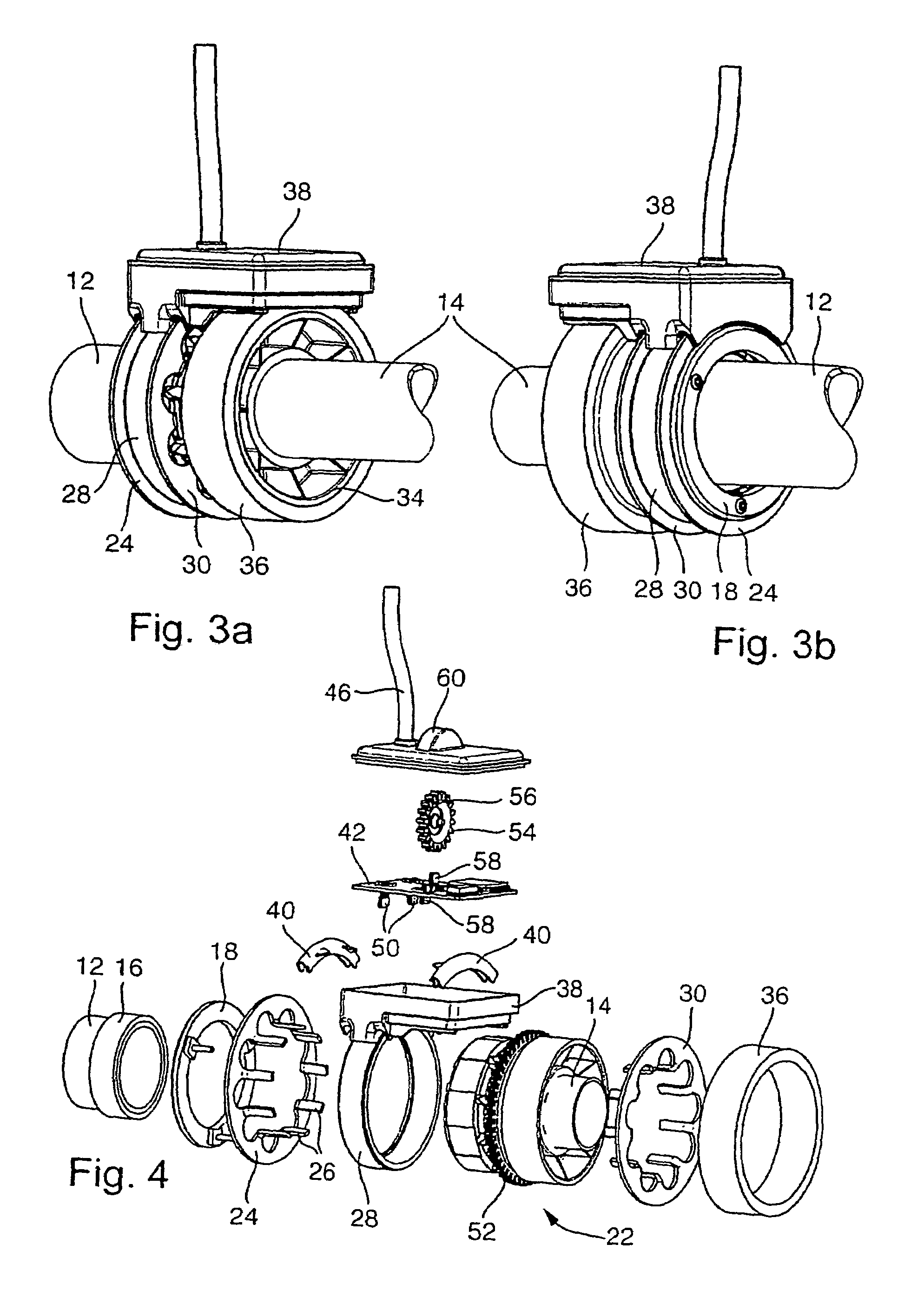

Device for measuring the angle and/or the angular velocity of a rotatable body and/or the torque acting upon said body

InactiveUS6935193B2High measurement accuracyExpand the measurement rangeSuspensionsDetection of fluid at leakage pointAngular velocityTorsion element

A device for measuring an angle and / or the torque acting on a rotatable body is proposed according to the invention, whereby the rotational angle is detected by means of magnetic or optical sensors. In particular, in a preferred exemplary embodiment, two devices (7, 8) are proposed, each of which comprises two optically readable code tracks. The two code tracks (1a, 1b or 2a, 2b) on one device (7 or 8) are similar in design and are offset in relation to each other, so that associated sensors (4) output a digital signal. The rotational angle is calculated based on the lag between the two digital signals. In a further embodiment it is provided that a torsion element (5) having a known torsional stiffness is situated between the two devices (7, 8). Torque transferred by the rotatable body (3) can also be calculated therefore from the angular difference of the two devices 7, 8. The device is used preferably in the steering axle of a motor vehicle.

Owner:ROBERT BOSCH GMBH

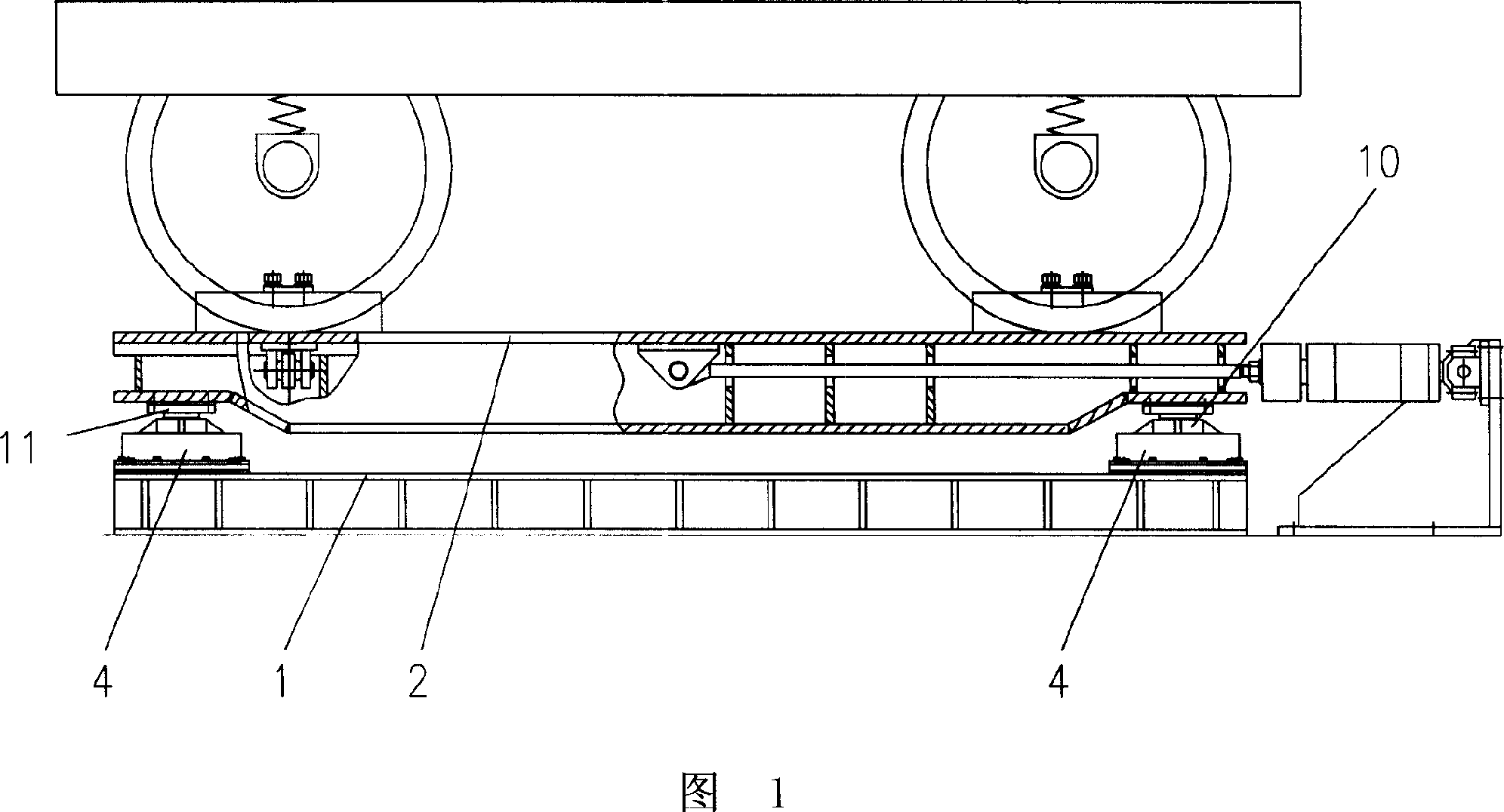

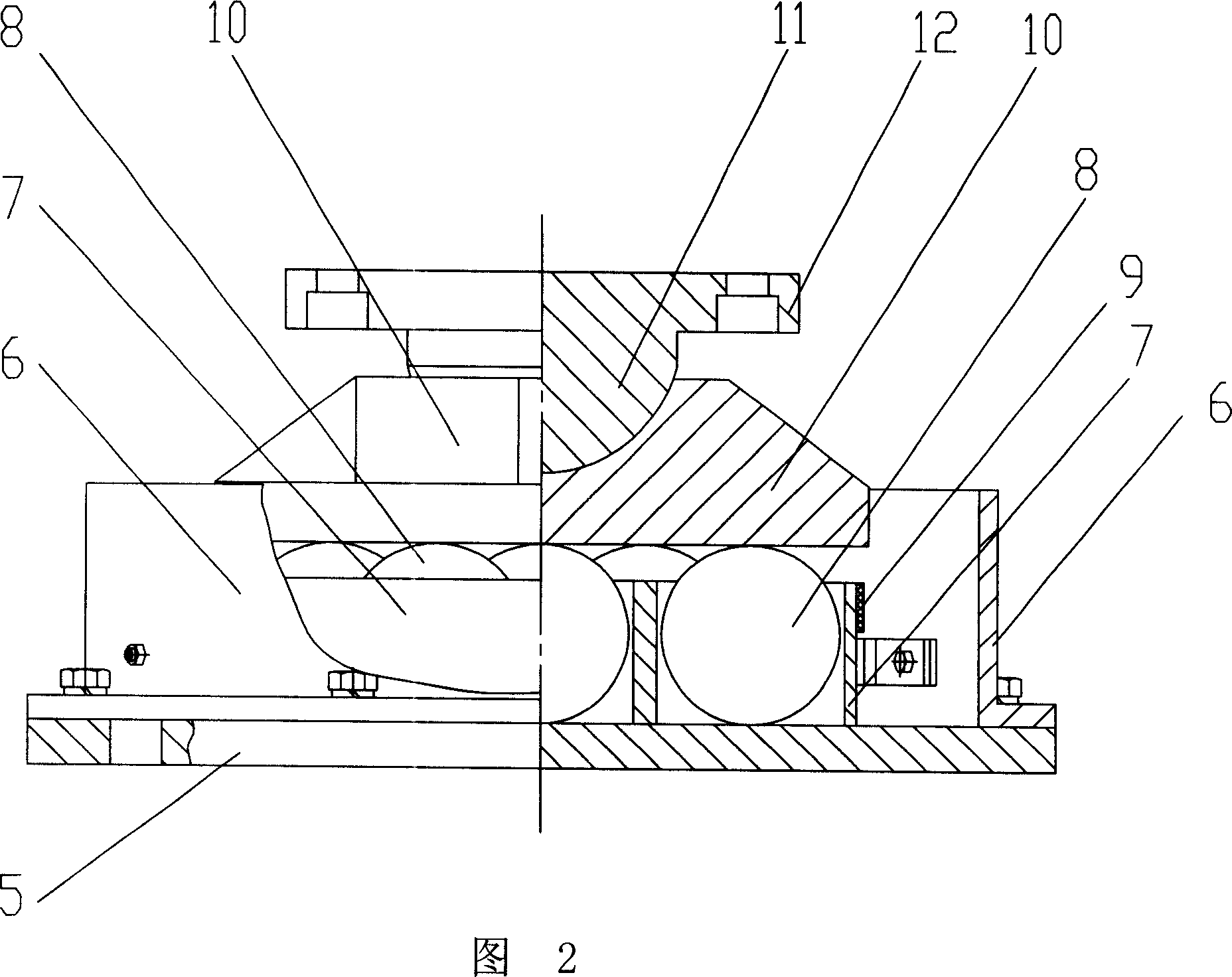

Rail vehicle truck parameter measuring table

InactiveCN1975365ASimple structureGuaranteed accuracyWork measurementMaterial strength using tensile/compressive forcesBogieSteel ball

This invention disclosed a testing plate used for car bogie. The base of the plate connects to the measuring platform via a fulcrum bearing; the fulcrum bearing can be described like this: a bearing plate was fixed to the base, a spacing ring was placed on the bearing plate, a steel ball holding frame was set in the spacing ring, steel ball was placed in the cavity of holding frame and the upper side of the ball was connected to the platform.

Owner:SOUTHWEST JIAOTONG UNIV

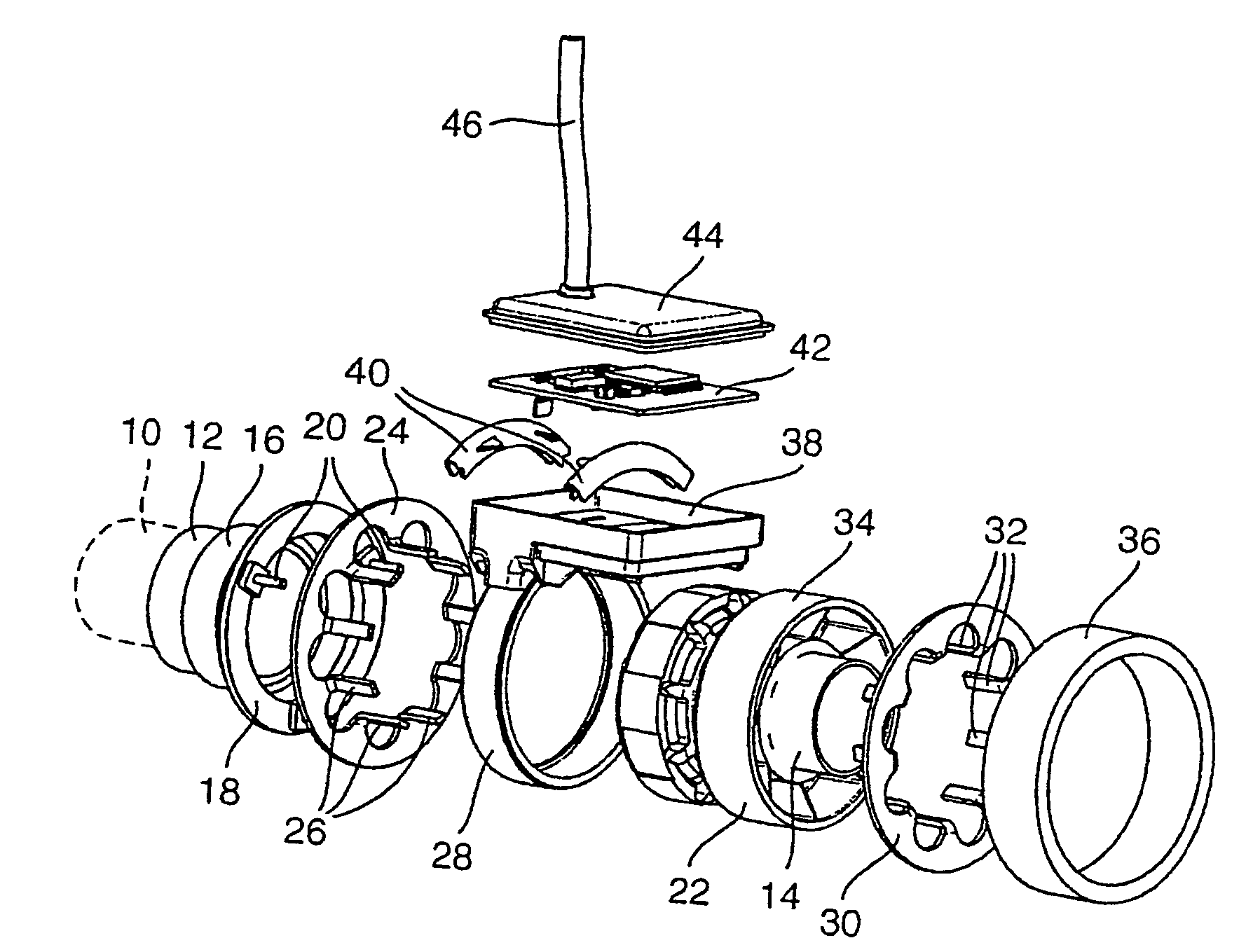

Position sensor which is intended, in particular, for measuring steering column torsion

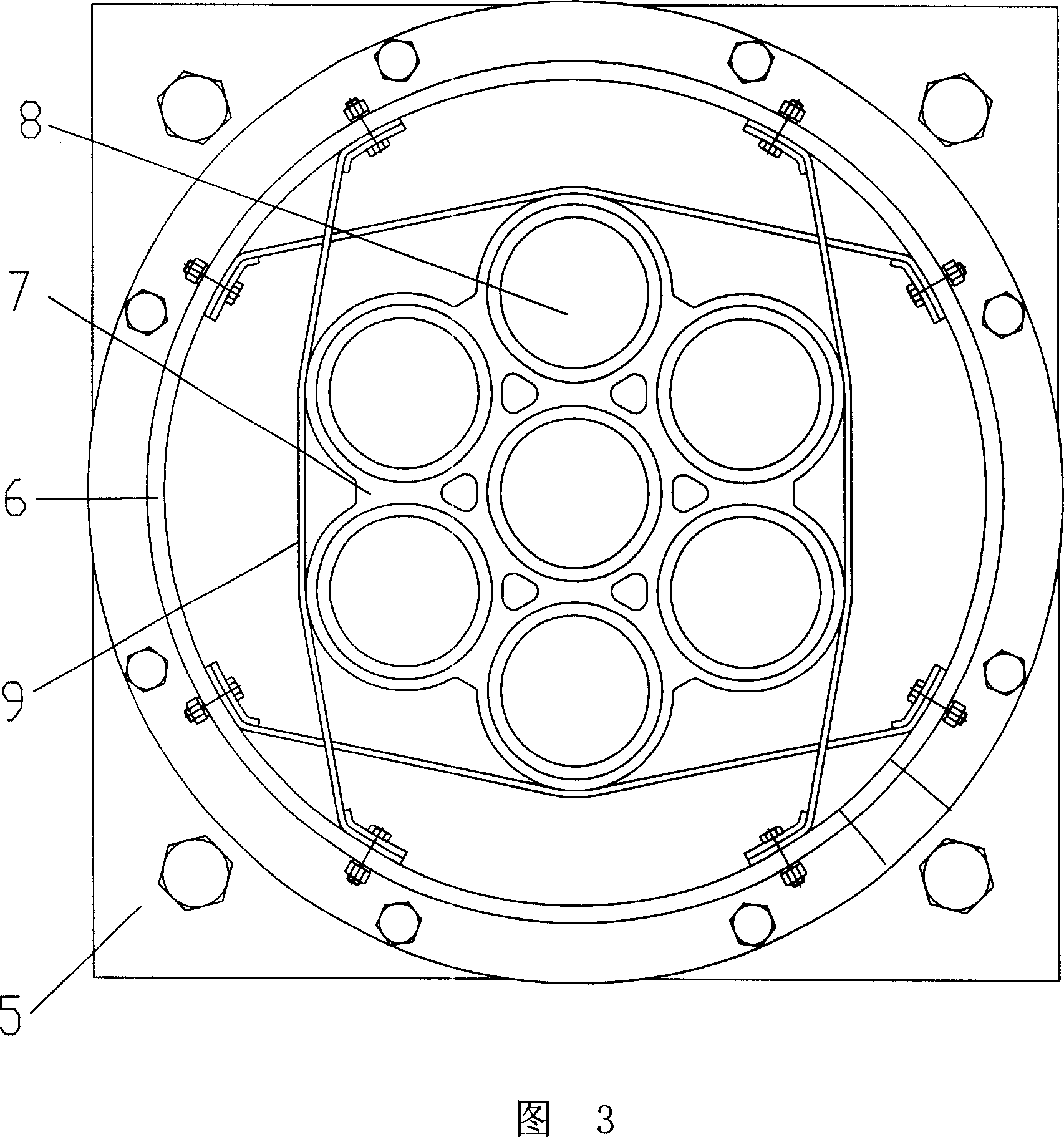

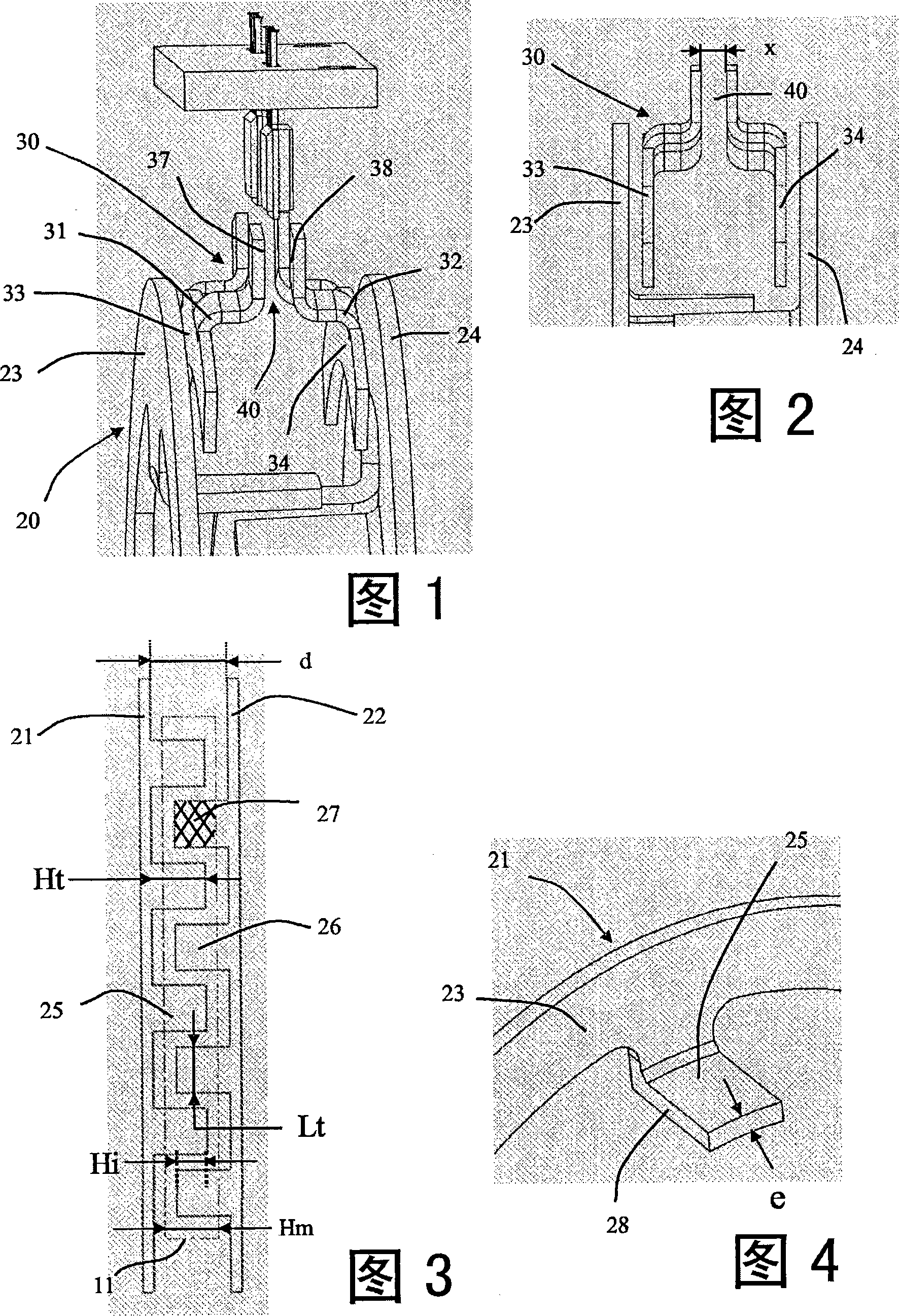

The invention relates to a position sensor which is intended, in particular, for detecting a steering column torsion. The invention consists of: a first magnetic rotor structure (10) comprising a plurality of radially-oriented magnets; a second stator structure comprising two rings (23, 24) which extend into axially-oriented overlapping teeth (25, 26); and a third fixed collector structure (30) comprising two flux-closing parts which define at least one air gap in which at least one magneto-sensitive element is placed. The invention is characterised in that the flux-closing parts and the stator rings (23, 24) define therebetween a constant collection surface that is independent of the relative radial position of the two structures.

Owner:MOVING MAGNET TECH

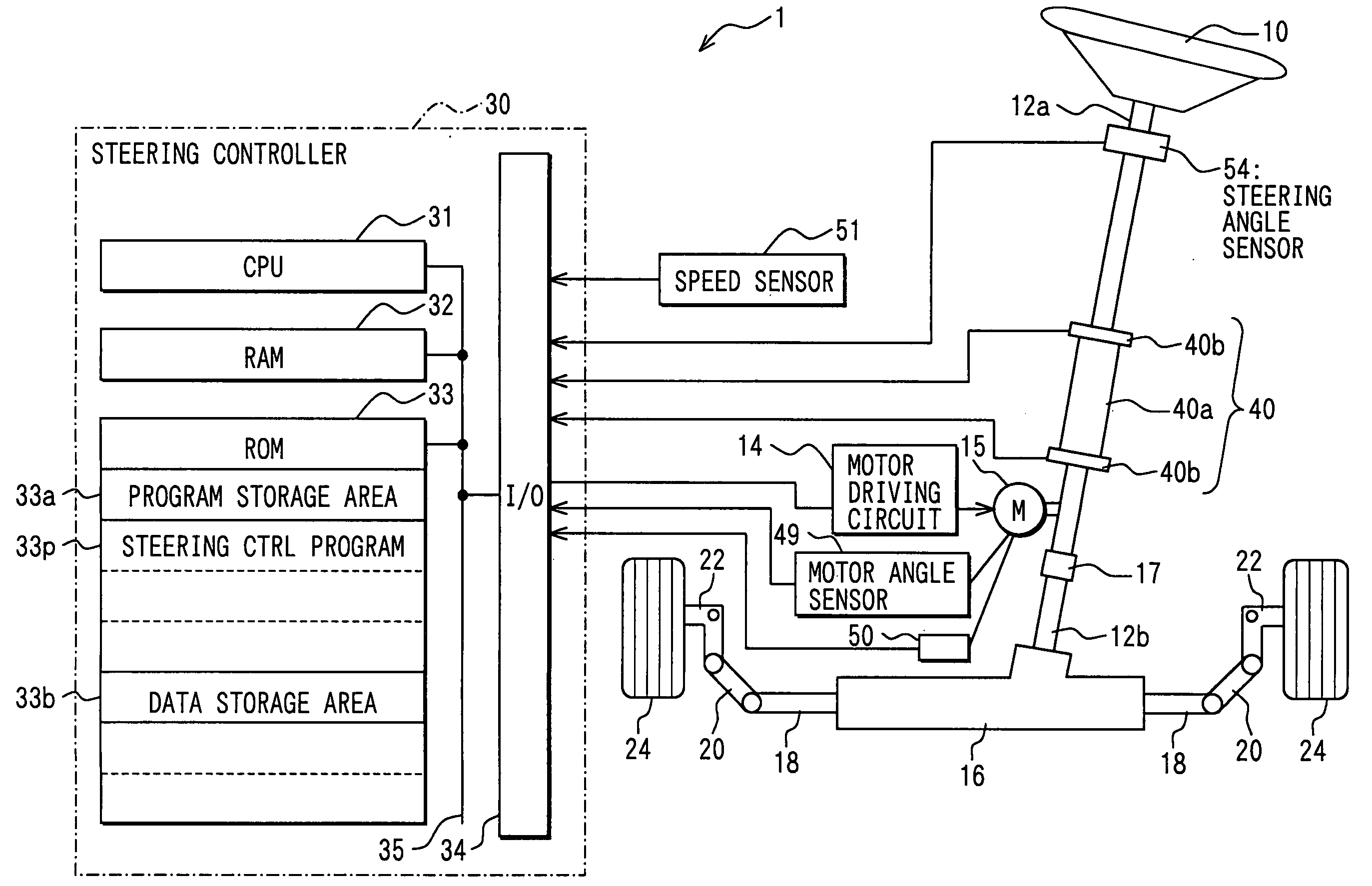

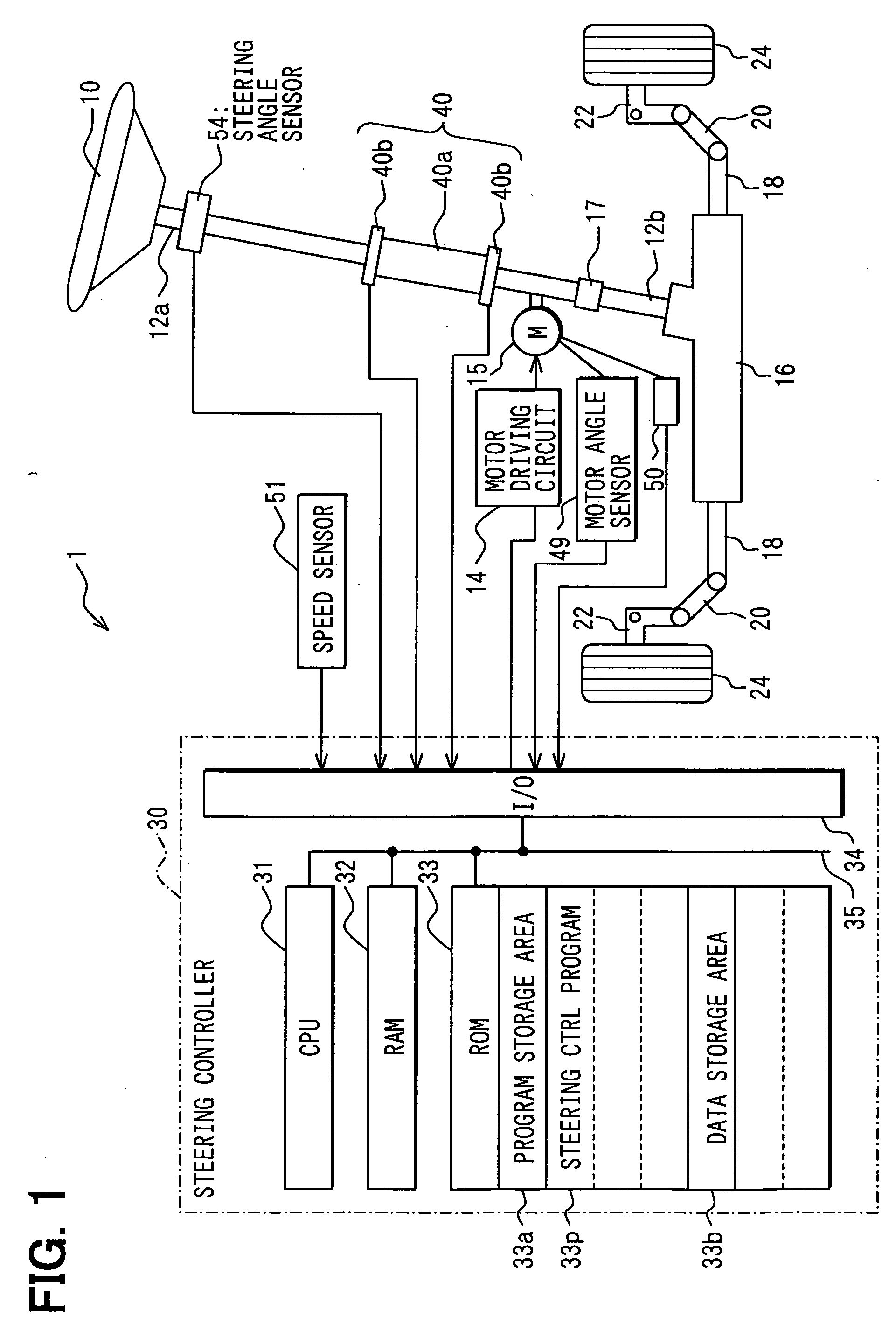

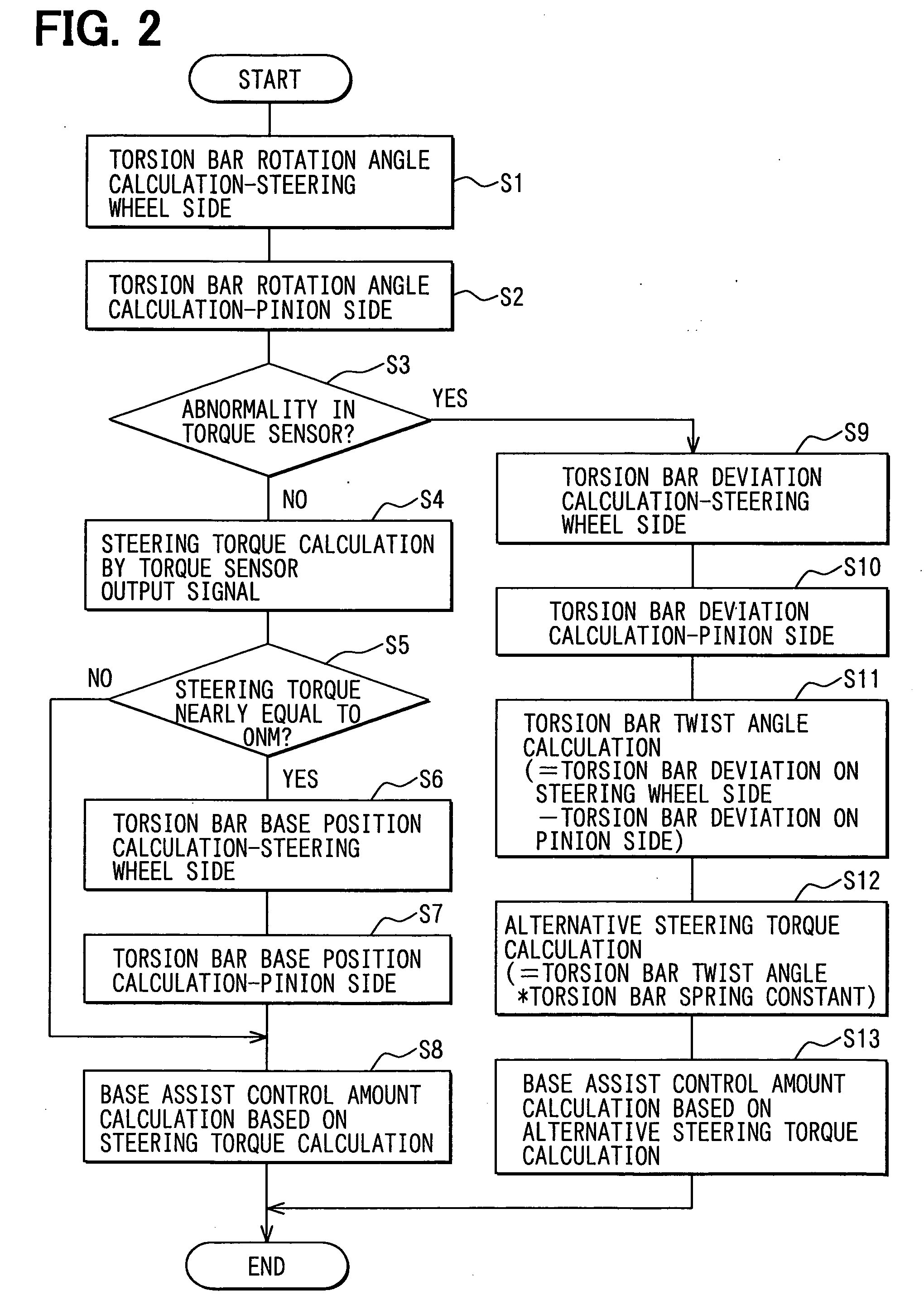

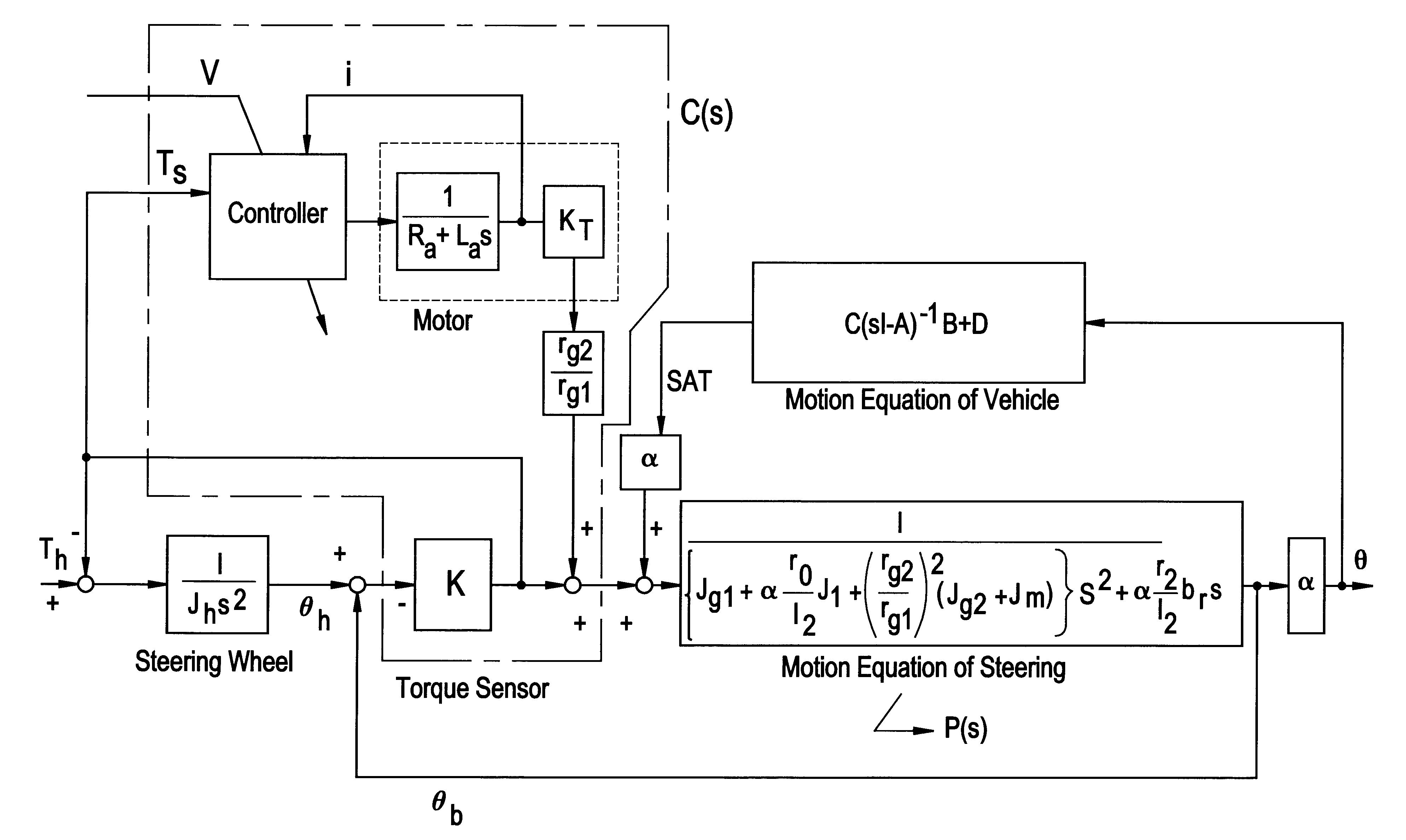

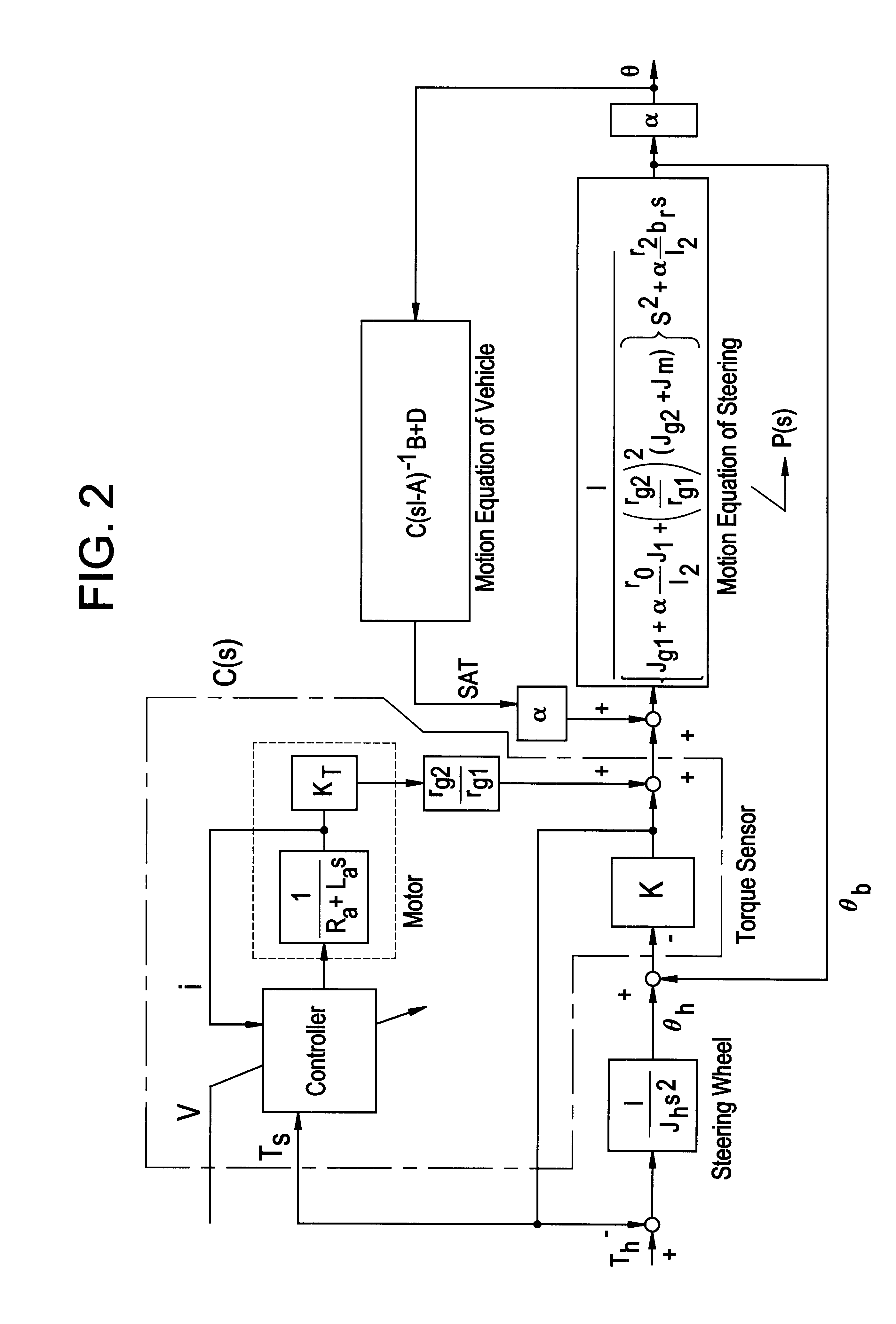

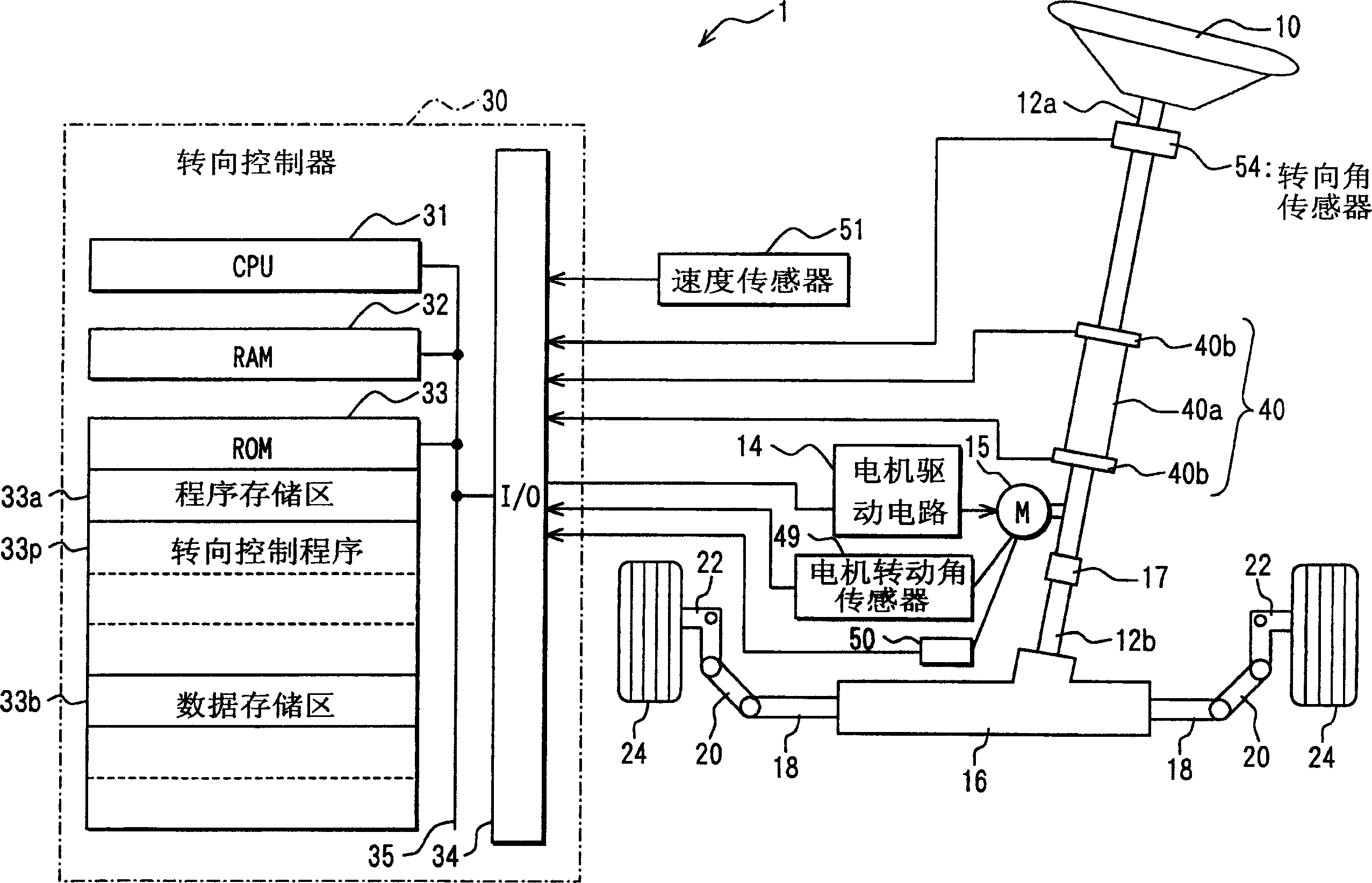

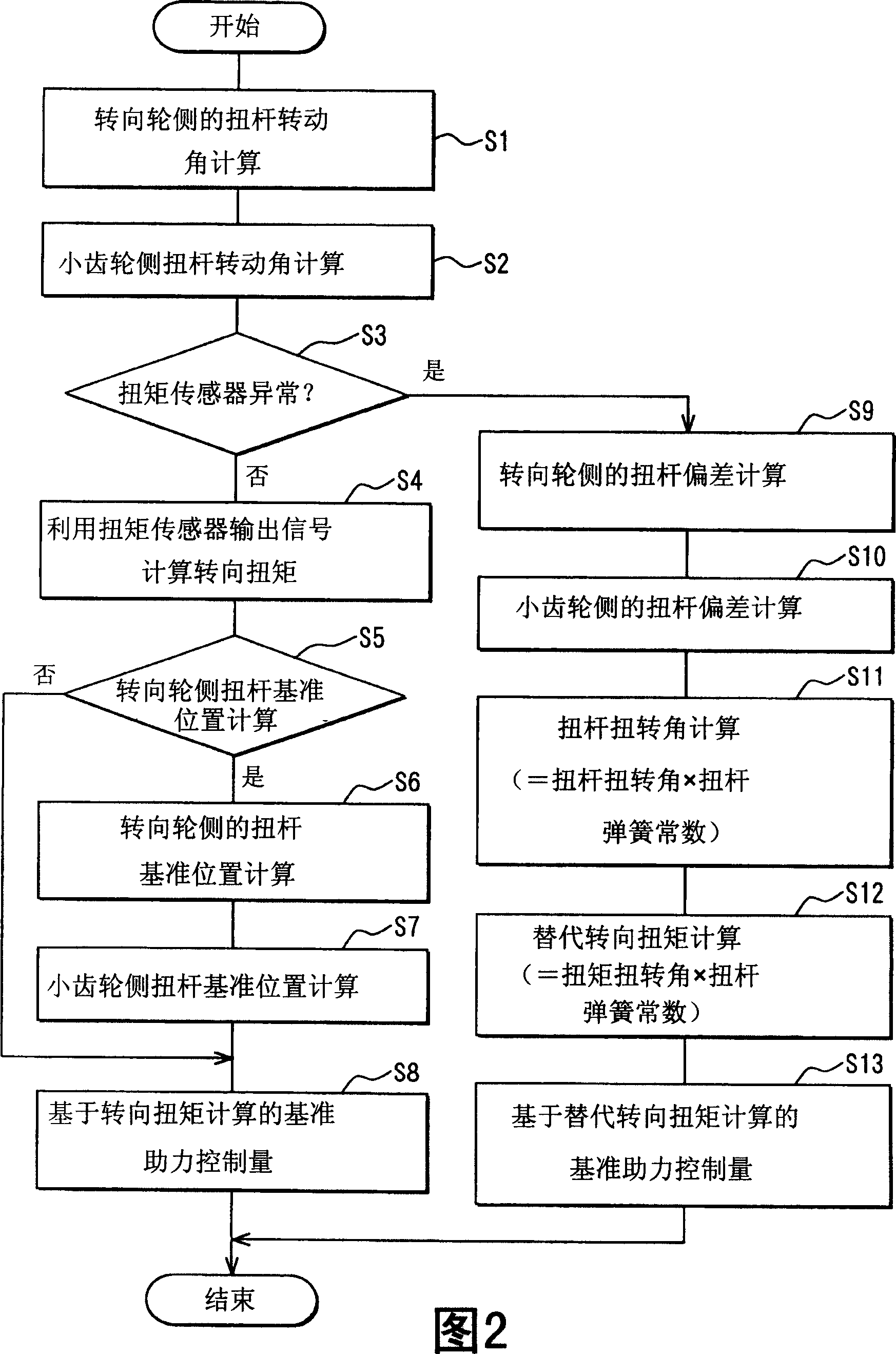

Electric power steering system and method having abnormality compensation function

InactiveUS20050171667A1Digital data processing detailsSteering initiationsElectric power steeringSteering wheel

A vehicle electric power steering system comprises a torque sensor including a torsion bar that detects a steering force applied to the steering wheel. A first rotation angle detection device detects a rotation angle of a steering shaft connected to the torsion bar, and a second rotation angle detection device detects a rotation angle of a pinion shaft connected to the torsion bar. A steering controller detects an abnormality in an output of the torque sensor. The steering controller detects the steering torque in place of the torque sensor based on the rotation angle of the steering shaft and the pinion shaft when an abnormality of the torque sensor is detected.

Owner:DENSO CORP

Device for determining a steering angle and a torque that is exerted on a steering shaft

ActiveUS7406884B2Simple designEasy maintenanceWork measurementTorque measurementSteering angleMagnetic loop

A device determines a torque that is exerted on a shaft, the shaft having a first shaft section and a second shaft section, the two shaft sections being rotatable in relation to one another. The device comprise a multi-pole magnetic ring and a stator support that is fixed to the second shaft section. Two stator elements are fixed to the stator support and each stator element has fingers that project in an axial or radial direction, are uniformly distributed at least over part of the circumference and are interspaced by gaps. The magnetic ring is situated between the fingers of one stator element and the fingers of the other stator element. A second magnetic ring is located on one of the two shaft sections and a magnetic sensor is mounted on one of the two shaft sections.

Owner:VALEO SCHALTER & SENSOREN

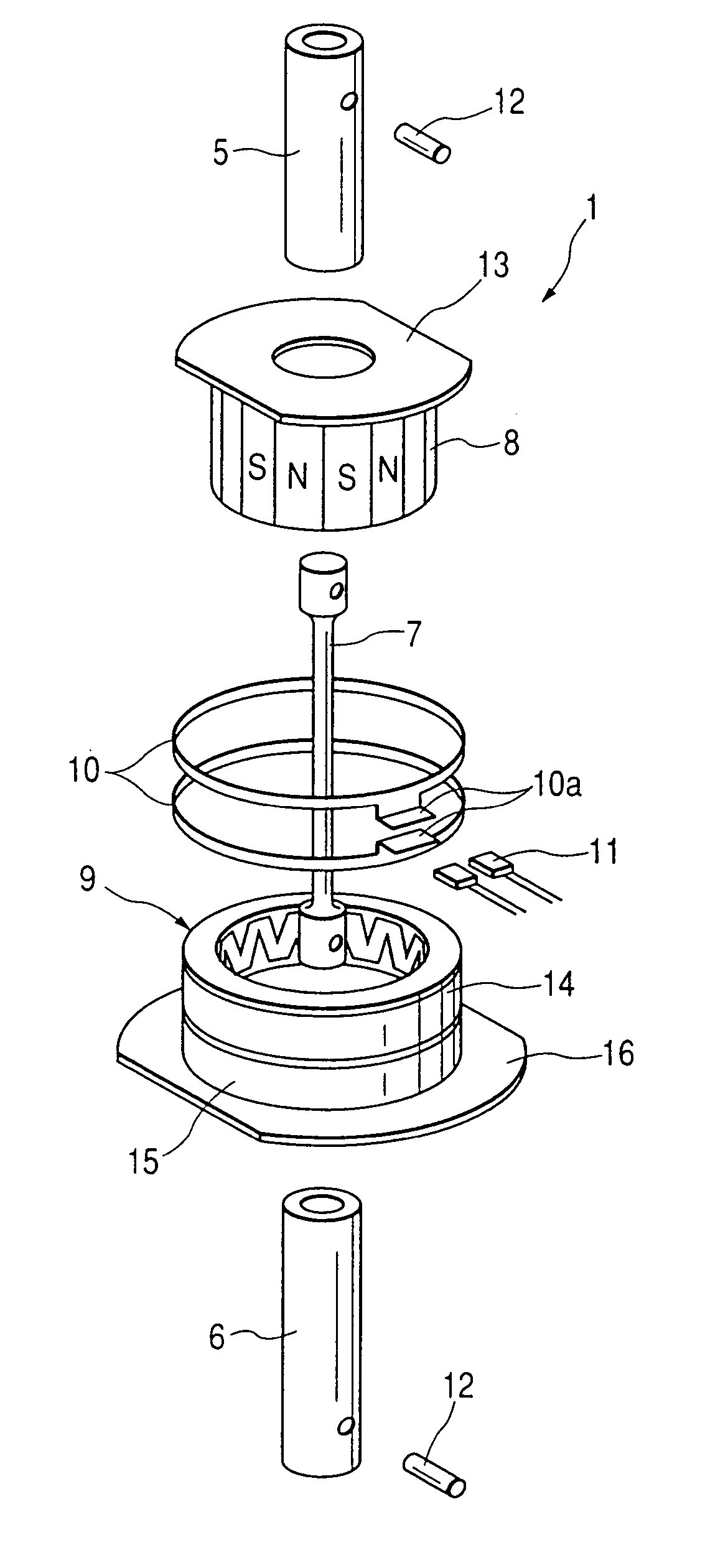

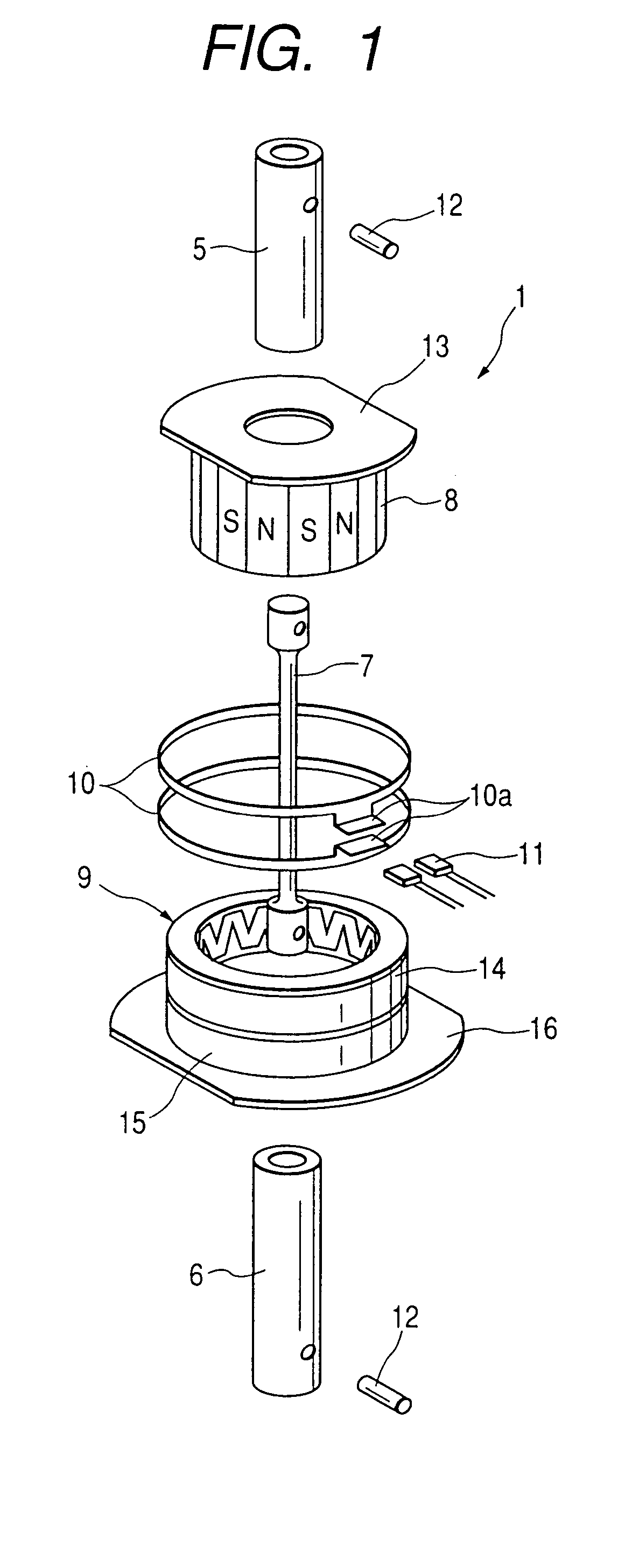

Torque sensor

InactiveUS7051602B2Effectively eliminate adverse influenceSimple configurationWork measurementTorque measurementEngineeringMagnetic shield

A first shaft and a second shaft are connected coaxially. A torsion bar converts a torque applied between two shafts into a torsion displacement. A multipolar magnet is fixed to the first shaft. One set of magnetic yokes is fixed to the second shaft and disposed in a magnetic field generated by the multipolar magnet. One set of flux collecting rings is disposed along an outer surface of the set of magnetic yokes and opposed to each other via an air gap in an axial direction. A magnetic sensor is provided for detecting the density of magnetic flux generated in the air gap. An outer cylindrical surface of the set of flux collecting rings is surrounded by a magnetic shield.

Owner:DENSO CORP +1

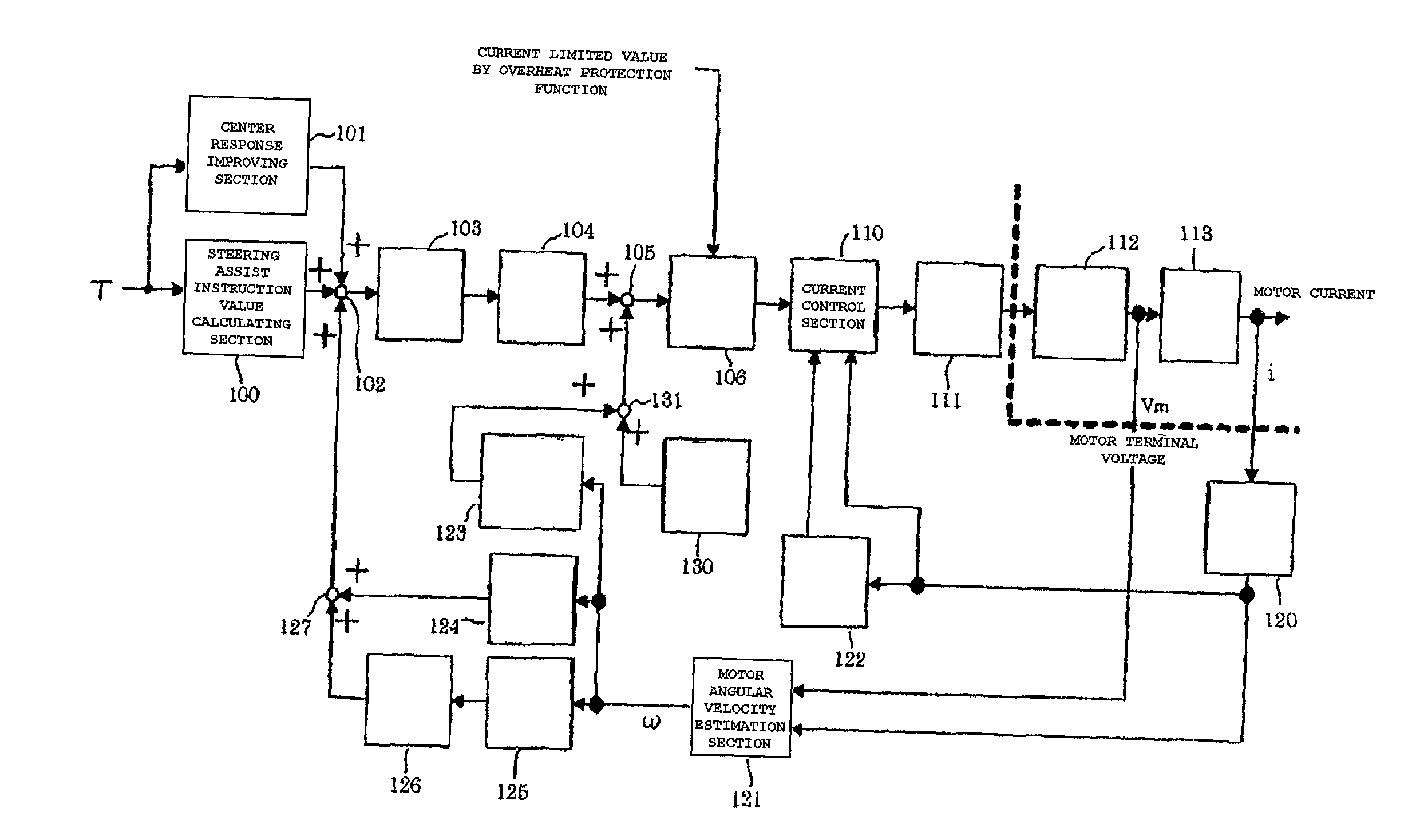

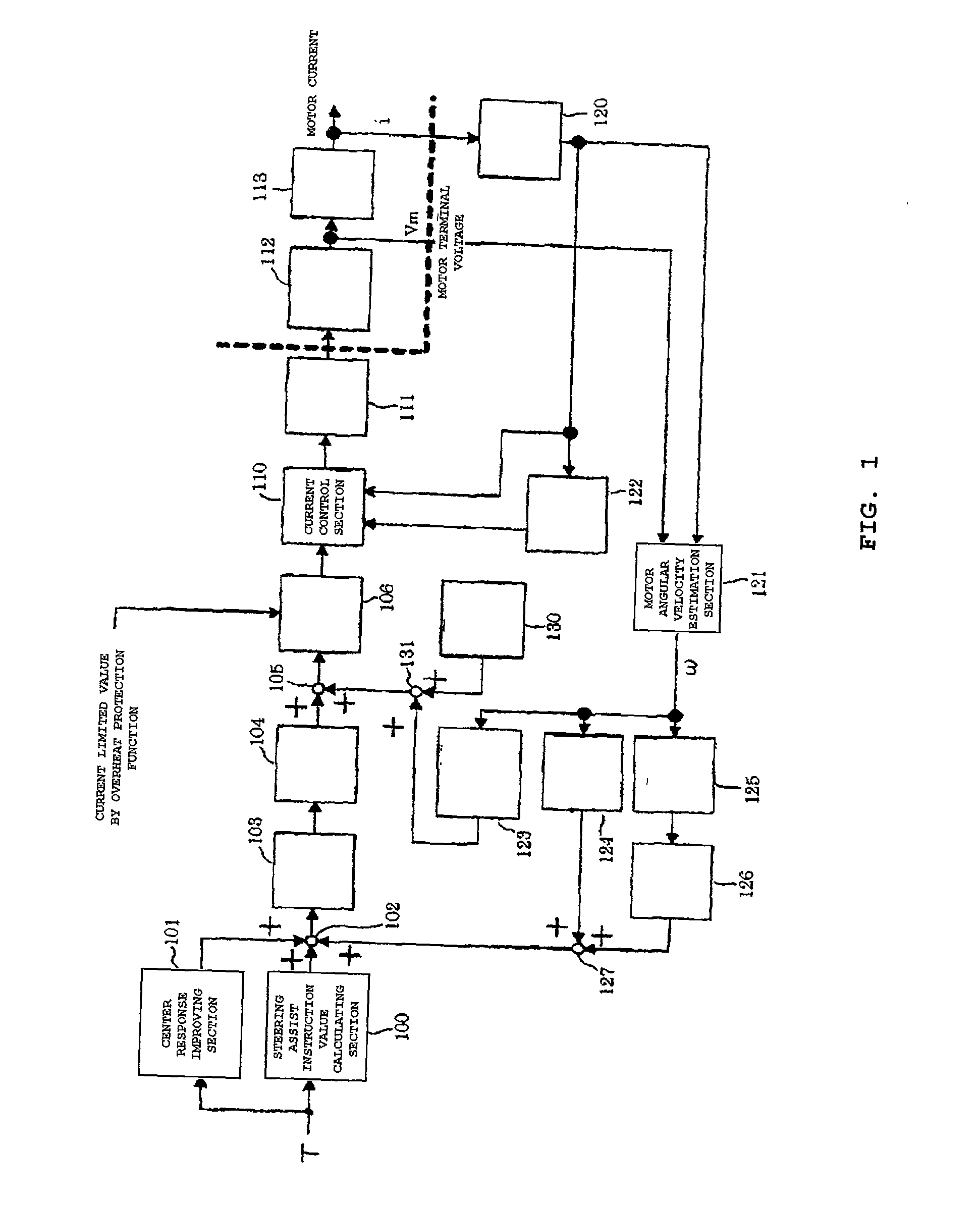

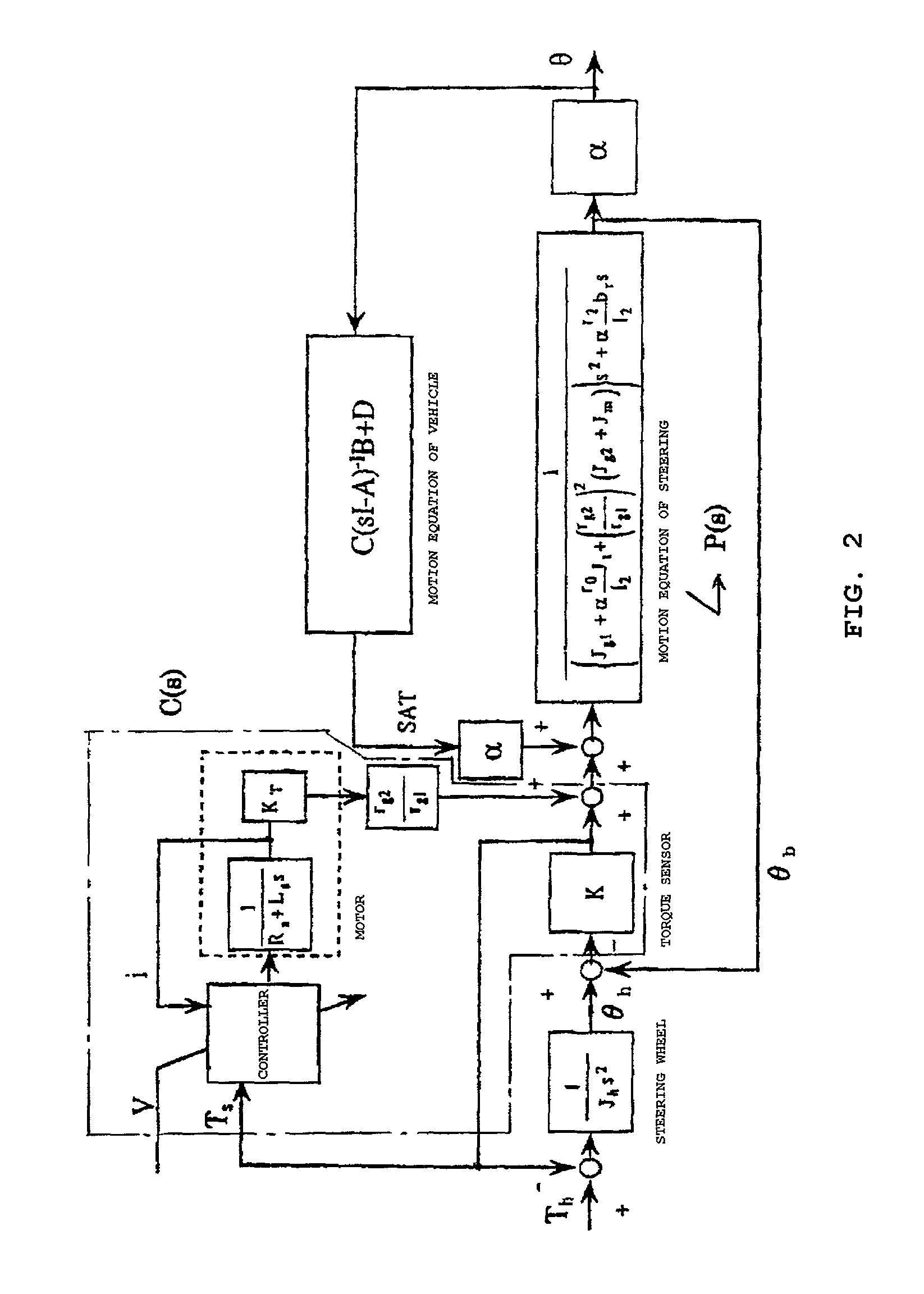

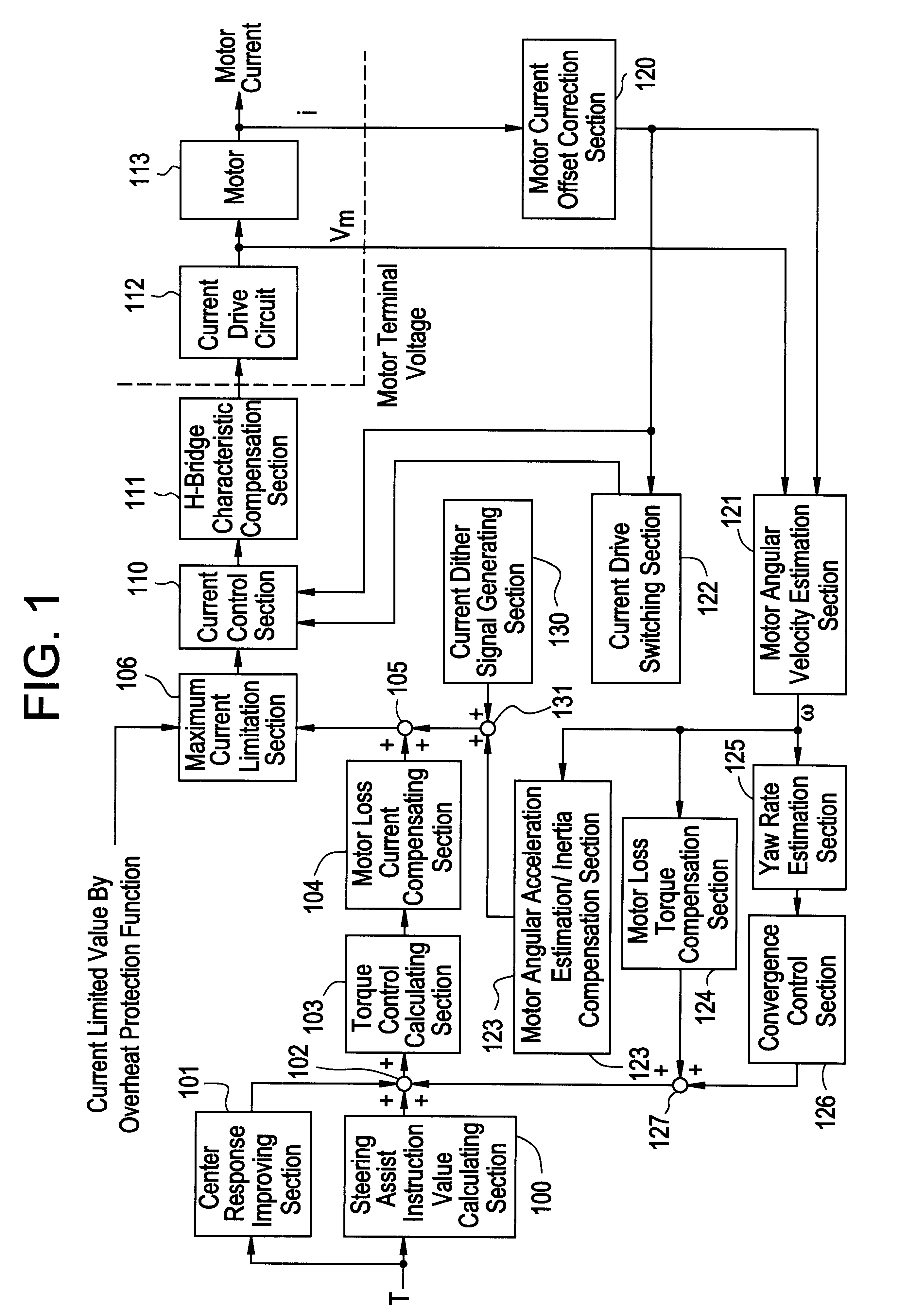

Control device for electric power steering apparatus

InactiveUS20020056587A1Efficient implementationDigital data processing detailsSteering initiationsElectric power steeringApproximation function

A control device for an electric power steering apparatus, which controls a motor based upon a steering assist instruction value calculated in a steering assist instruction calculating section based upon a steering torque generated in a steering shaft and a current control value calculated from a current value of the motor for applying a steering assist force to a steering mechanism, and has a gain curve of characteristics of the entire control system having the steering assist instruction value as its input, which at least partially possesses a gradient exceeding a predetermined value, and in this arrangement, the steering assist instruction value calculating unit is composed of an approximation functional expression in which at least one-step derived functions are continuous, and the steering assist instruction value is found through calculations based upon the approximation functional expression. It is possible to provide a control device which can achieve a continuous, pleasant sense of steering by providing the steering assist instruction value as a continuous function.

Owner:NSK LTD

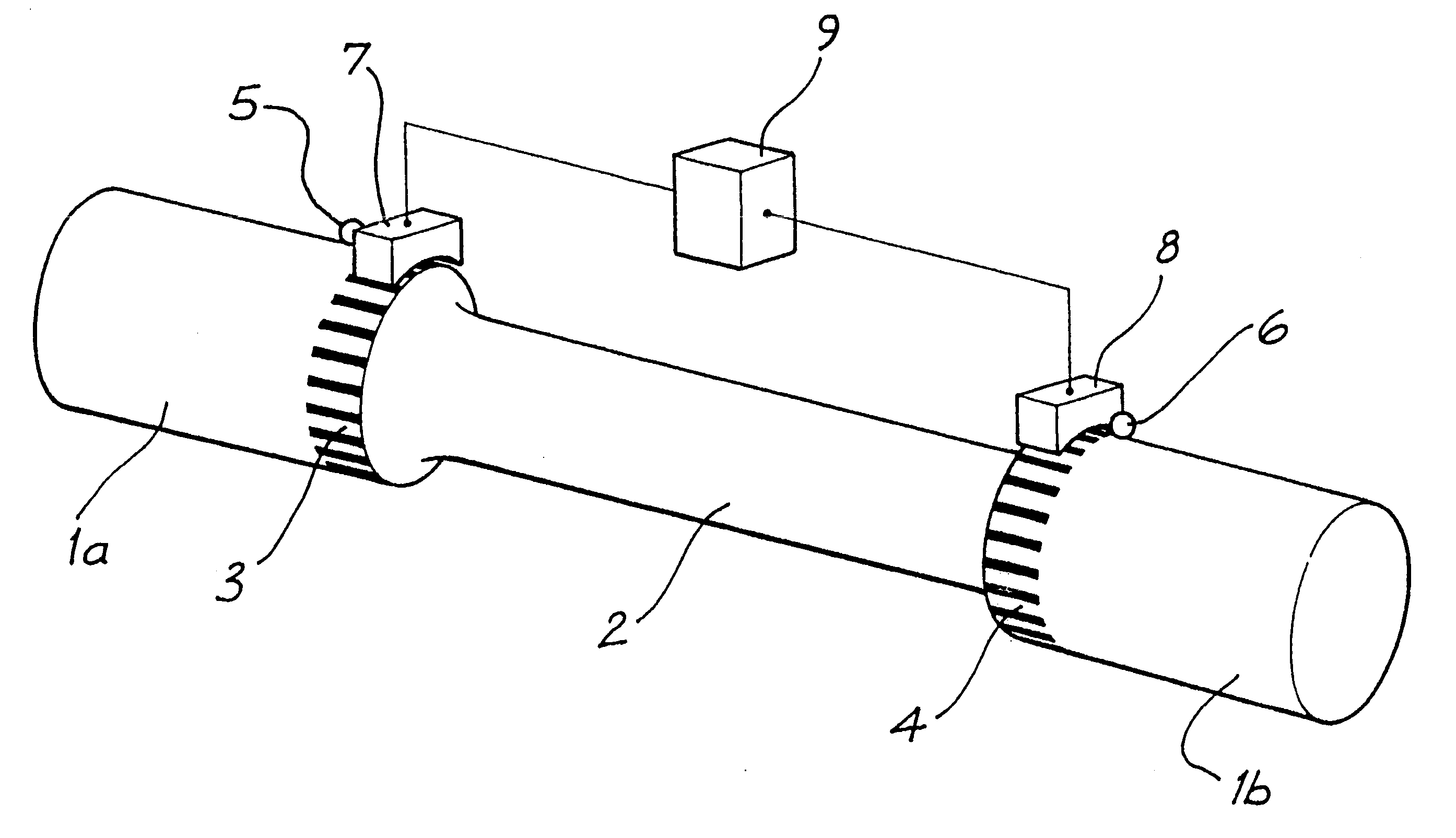

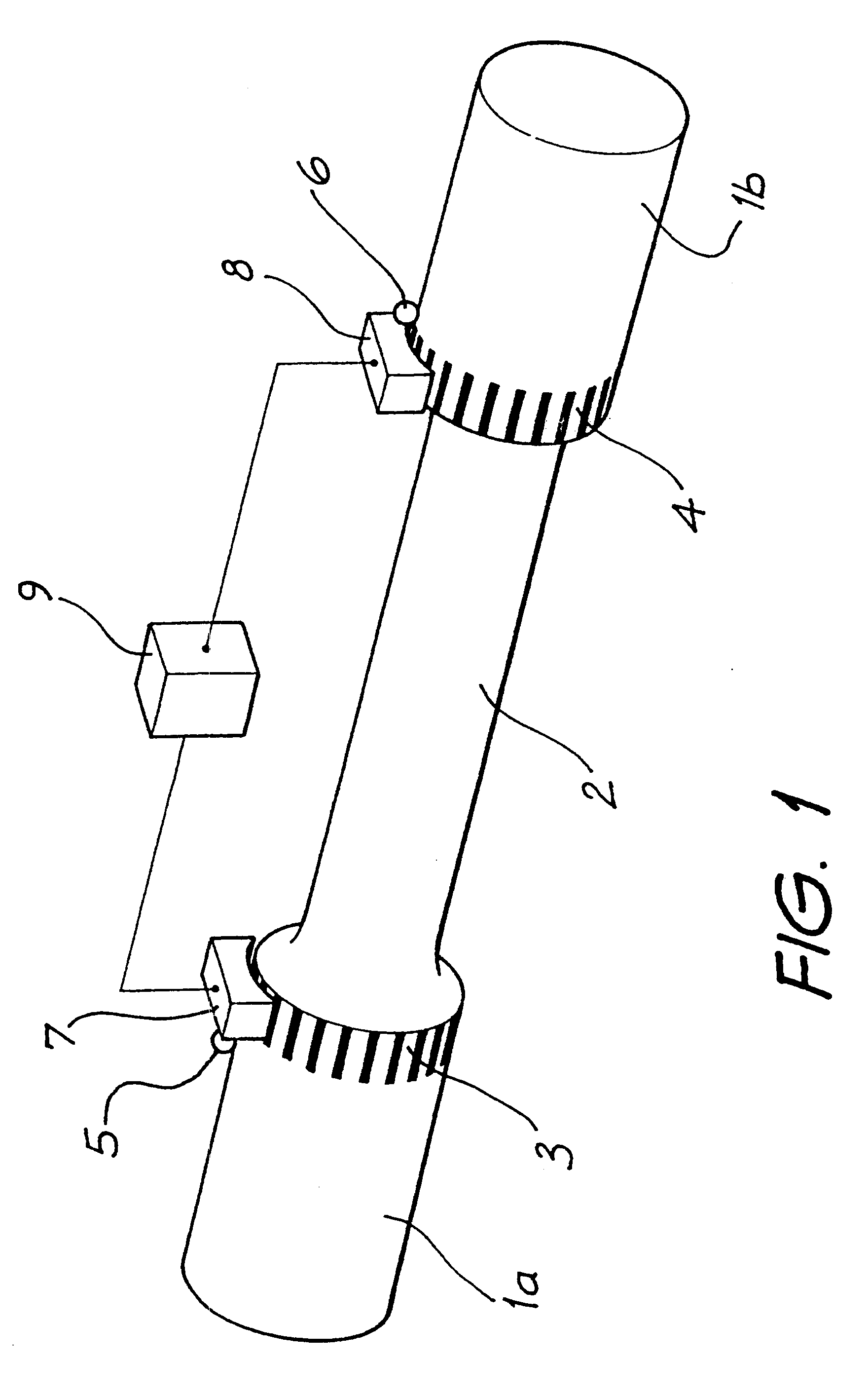

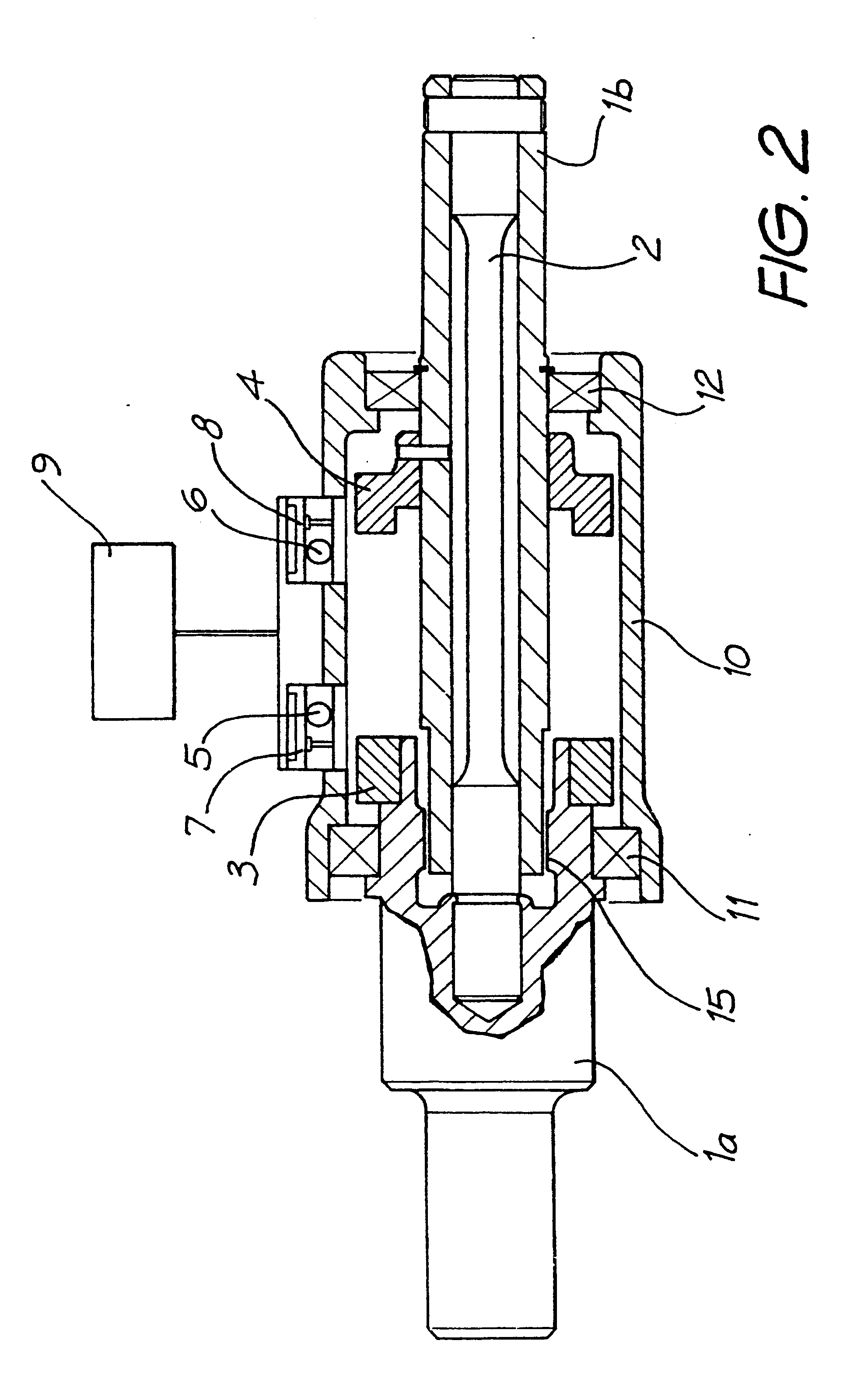

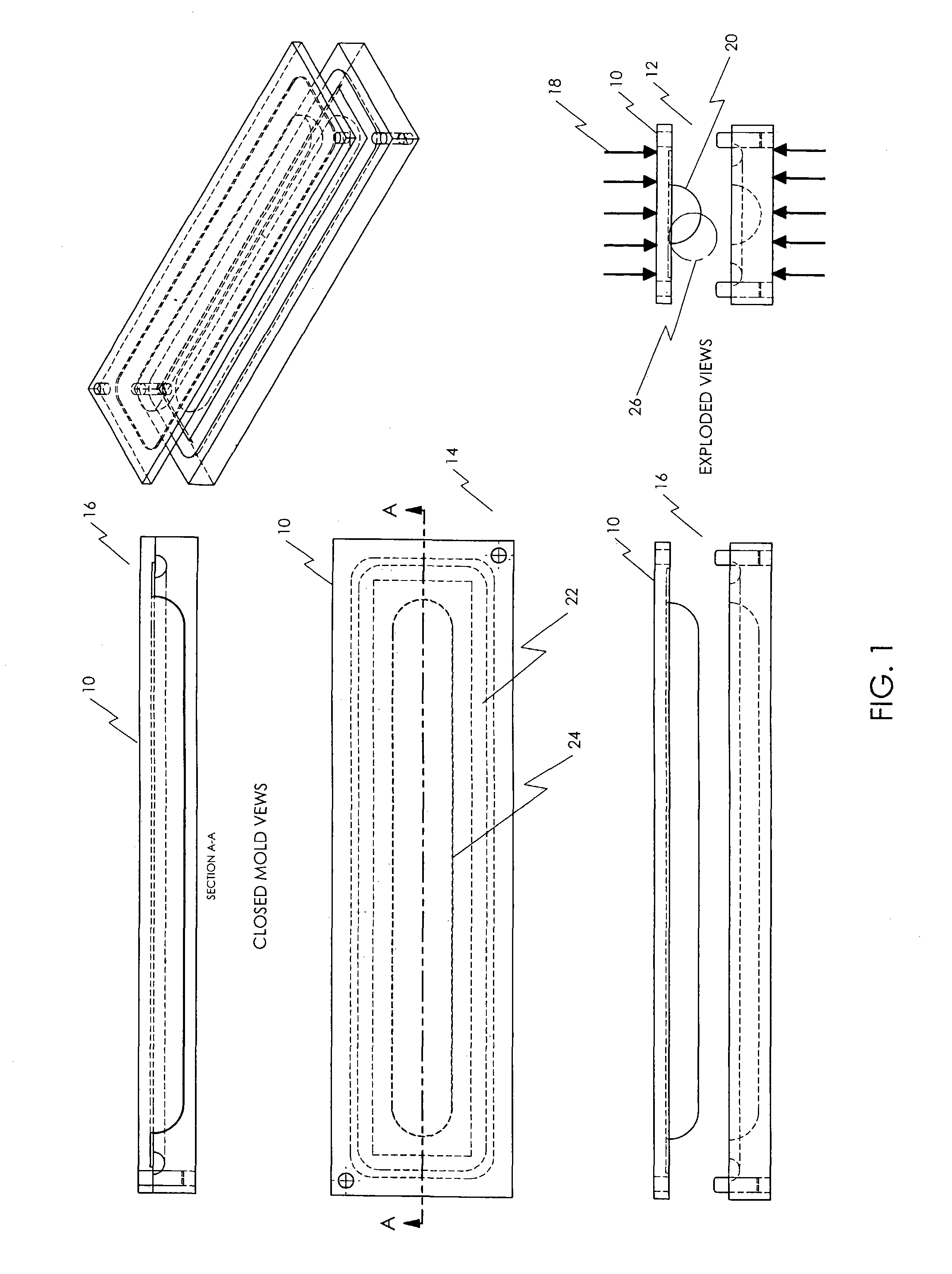

Torque transducer

A torque transducer having a rotating shaft with first and second substantially rigid torque input members connected by a torsionally compliant coupling that enables angular deflection of the first torque input member relative to the second torque input member as a function of the magnitude of the torque in the shaft. First and second grating elements are attached to or integral with first and second torque input members, respectively. The grating elements have surfaces with alternating regions of high and low reflectivity connected by a torsionally compliant coupling. The surfaces are illuminated by a source of electromagnetic radiation (EMR), which generates patterns on one or more arrays of detectors sensitive to the EMR. The disposition of the patterns is a function of torque applied to the shaft, and the output of the one or more arrays can be processed to produce a measure of the torque applied to the shaft.

Owner:BISHOP INNOVATION PTY LTD

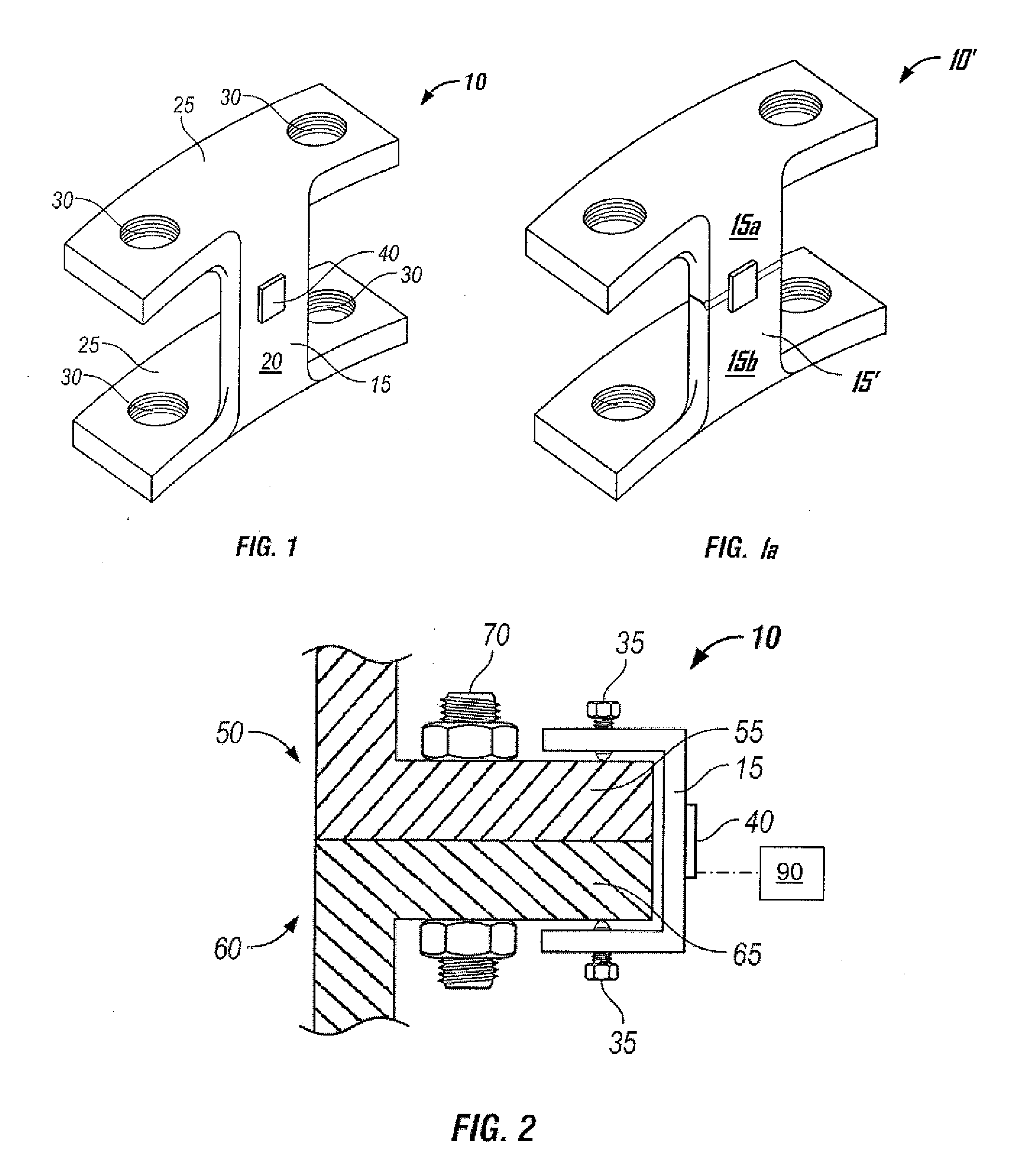

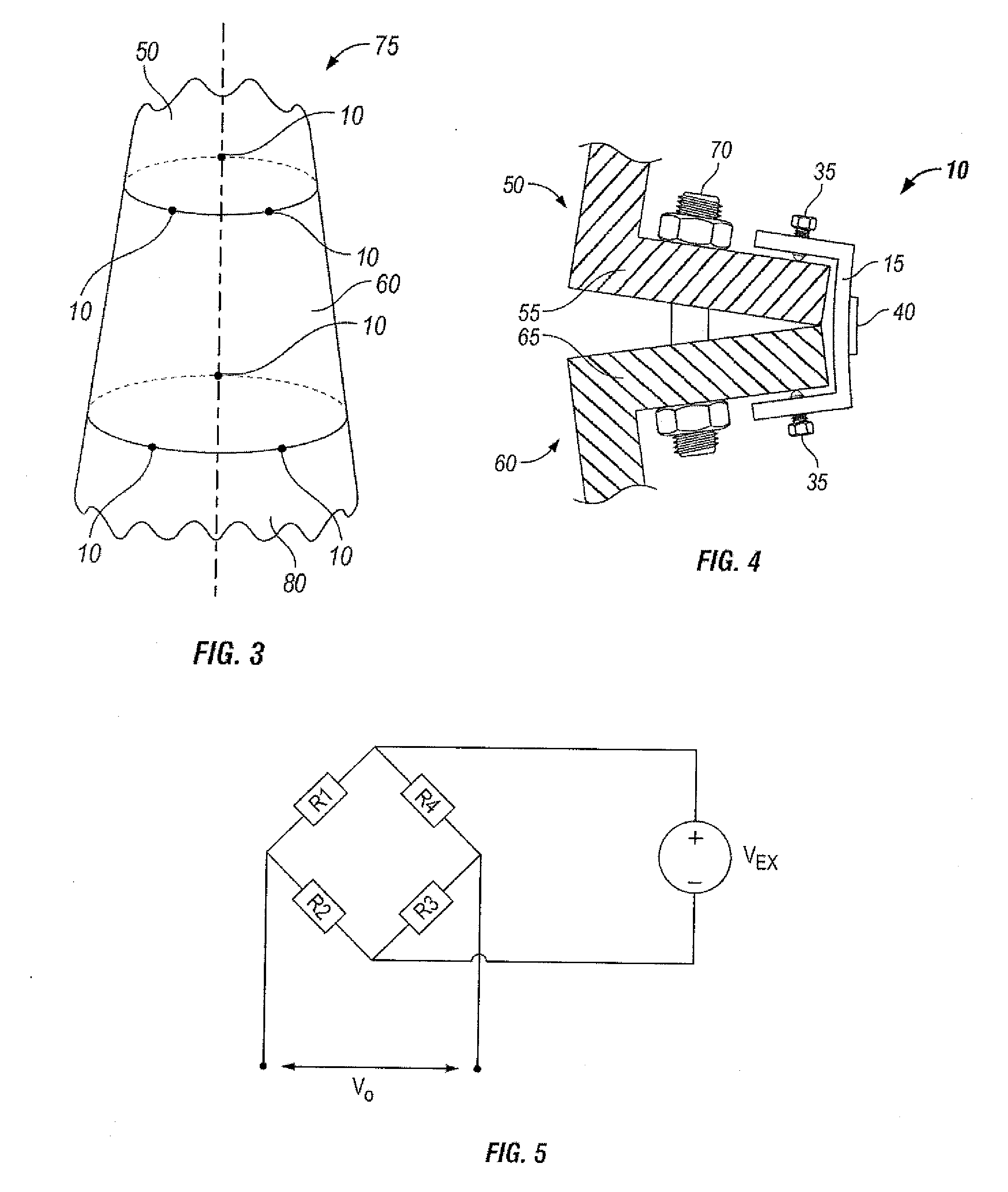

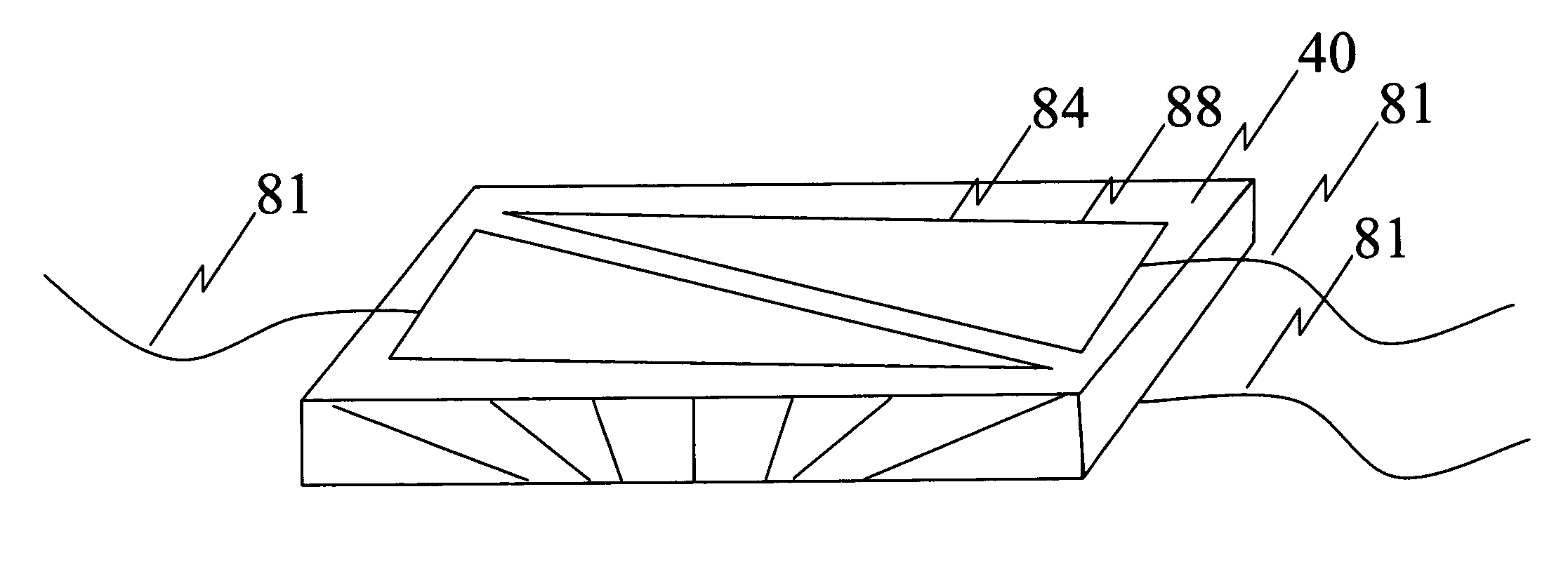

Wind Turbine Tower Monitoring Device

InactiveUS20100126115A1Non invasiveImprove installation speedEngine fuctionsForce measurementRelative motionTower

A wind turbine installation monitoring device, for detecting relative movement between two adjacent components of a wind turbine installation is provided. The device comprises a deformable member together with a securing device. The securing device is configured to enable the device to be connectable to a wind turbine installation, in use. The deformable member is located across an interface between the adjacent components of a wind turbine installation. Further, a detection device is provided and configured to detect deflection of the deformable member and thereby to detect relative movement between the two components.

Owner:VESTAS WIND SYST AS

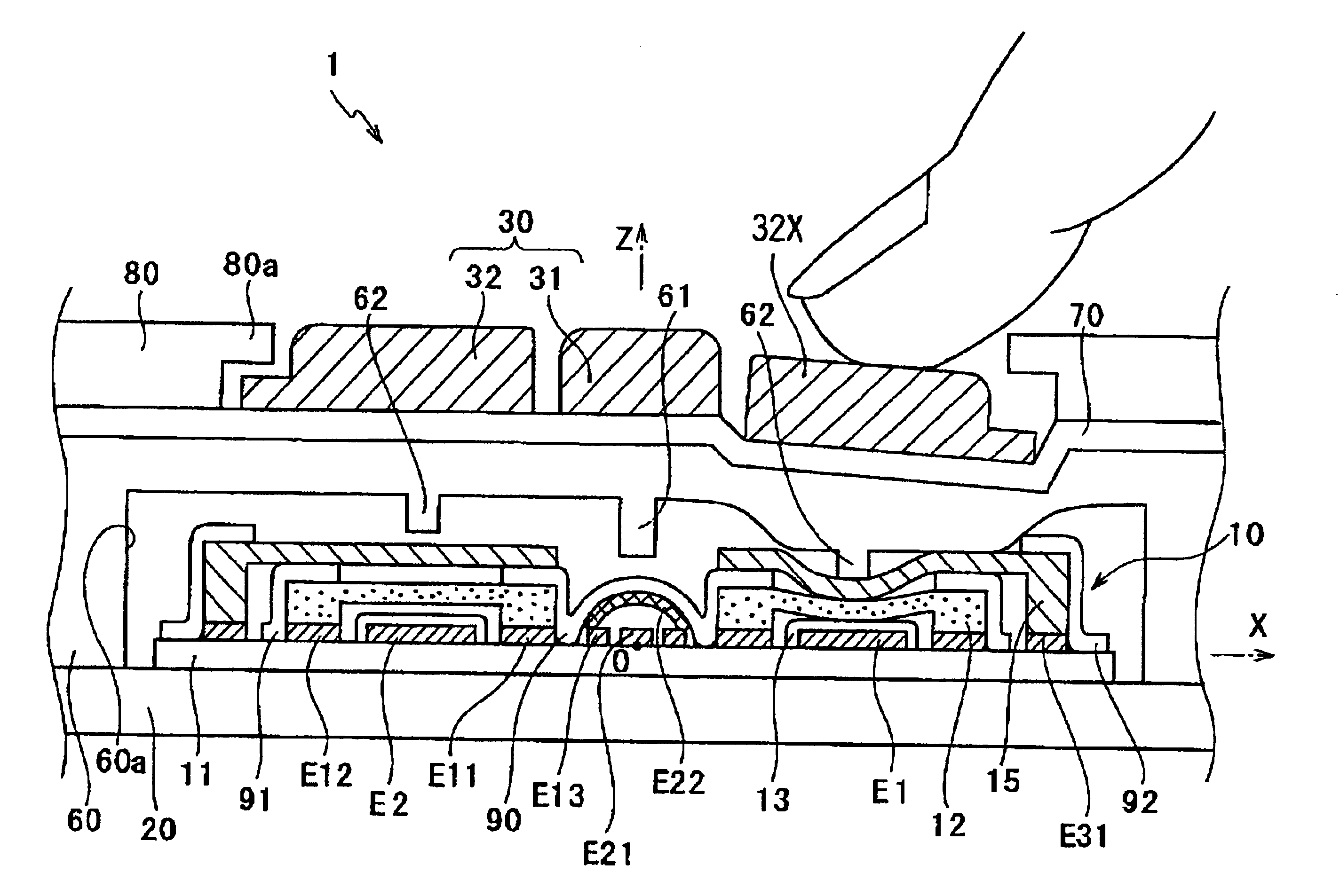

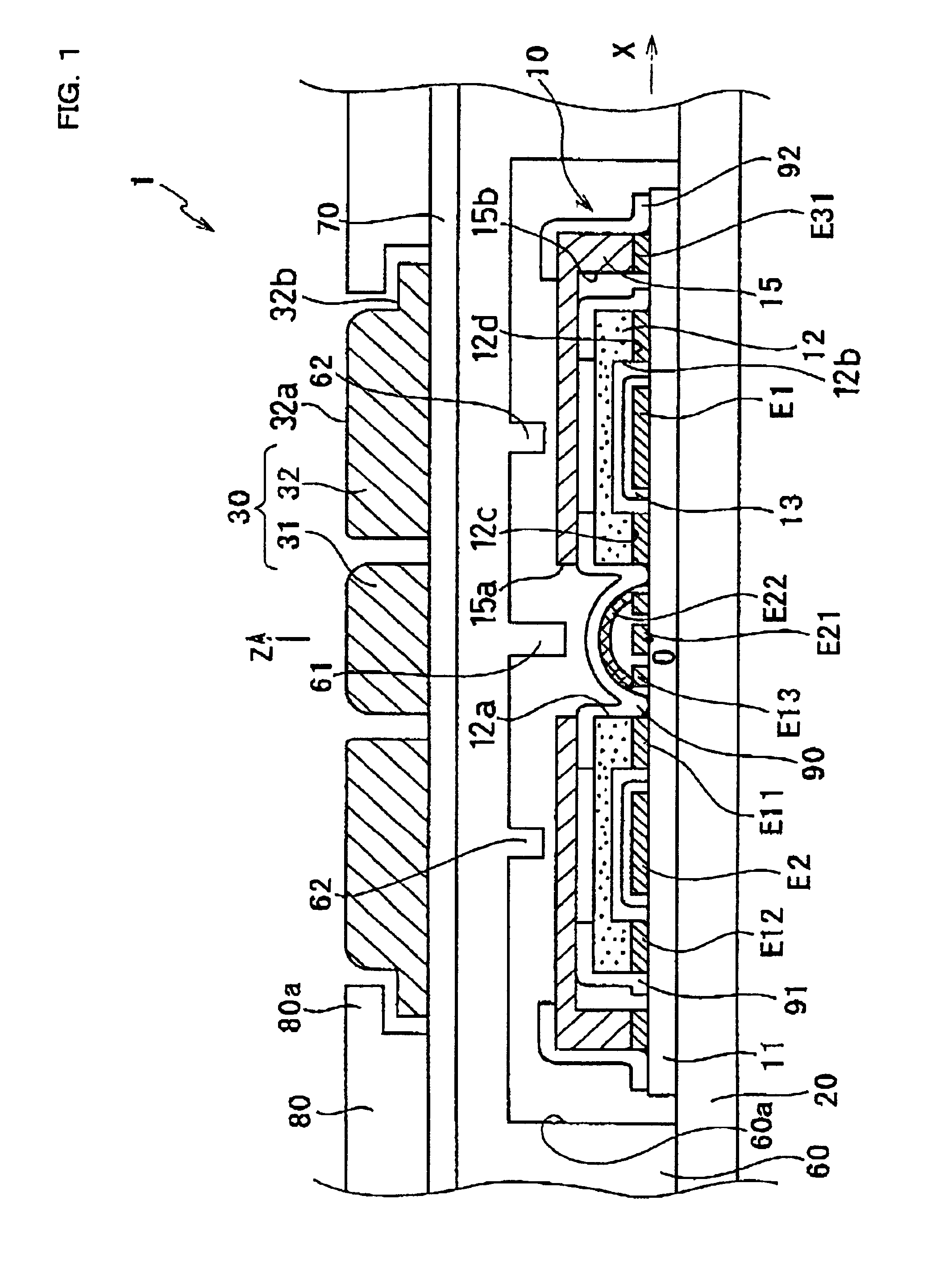

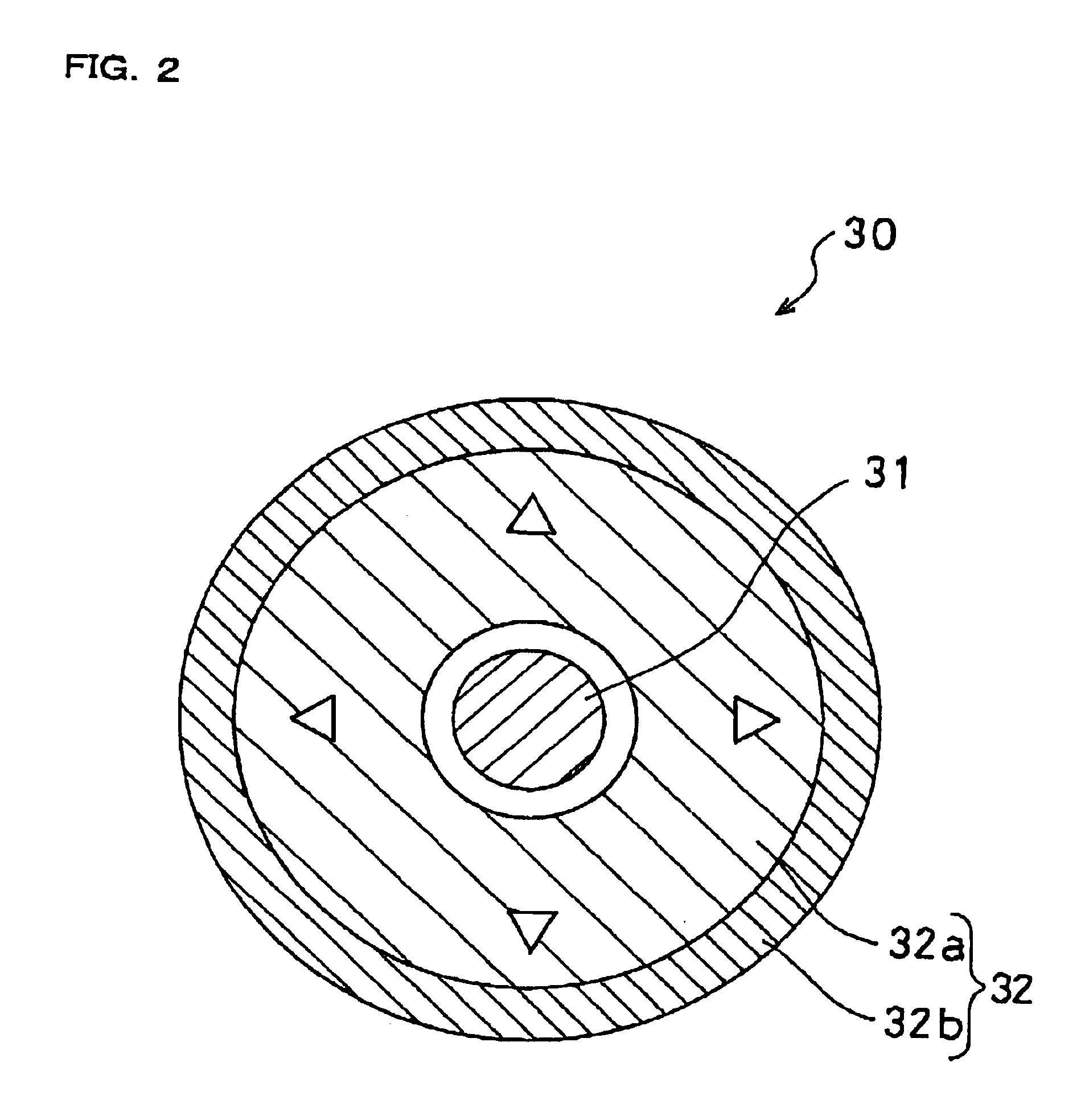

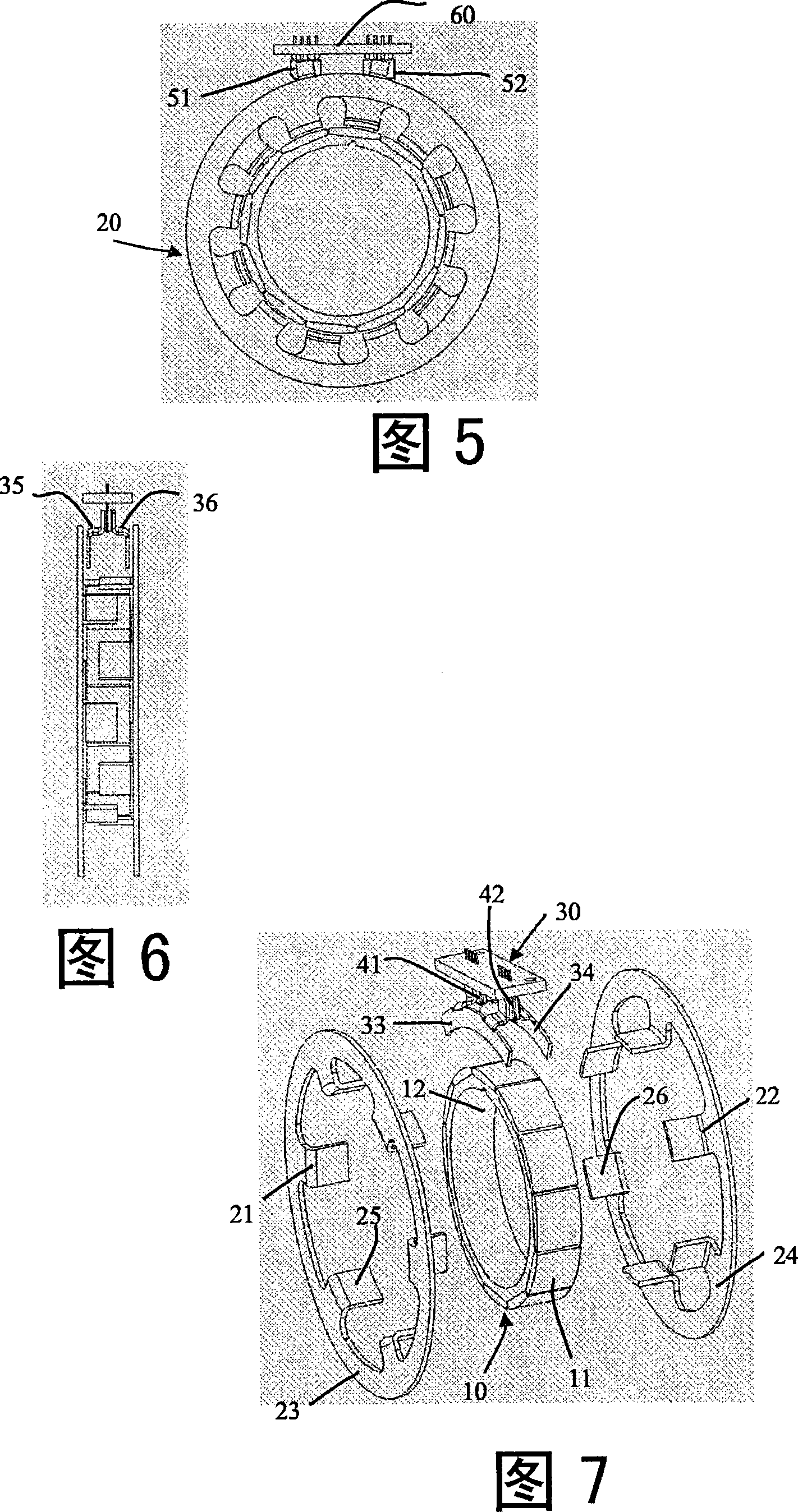

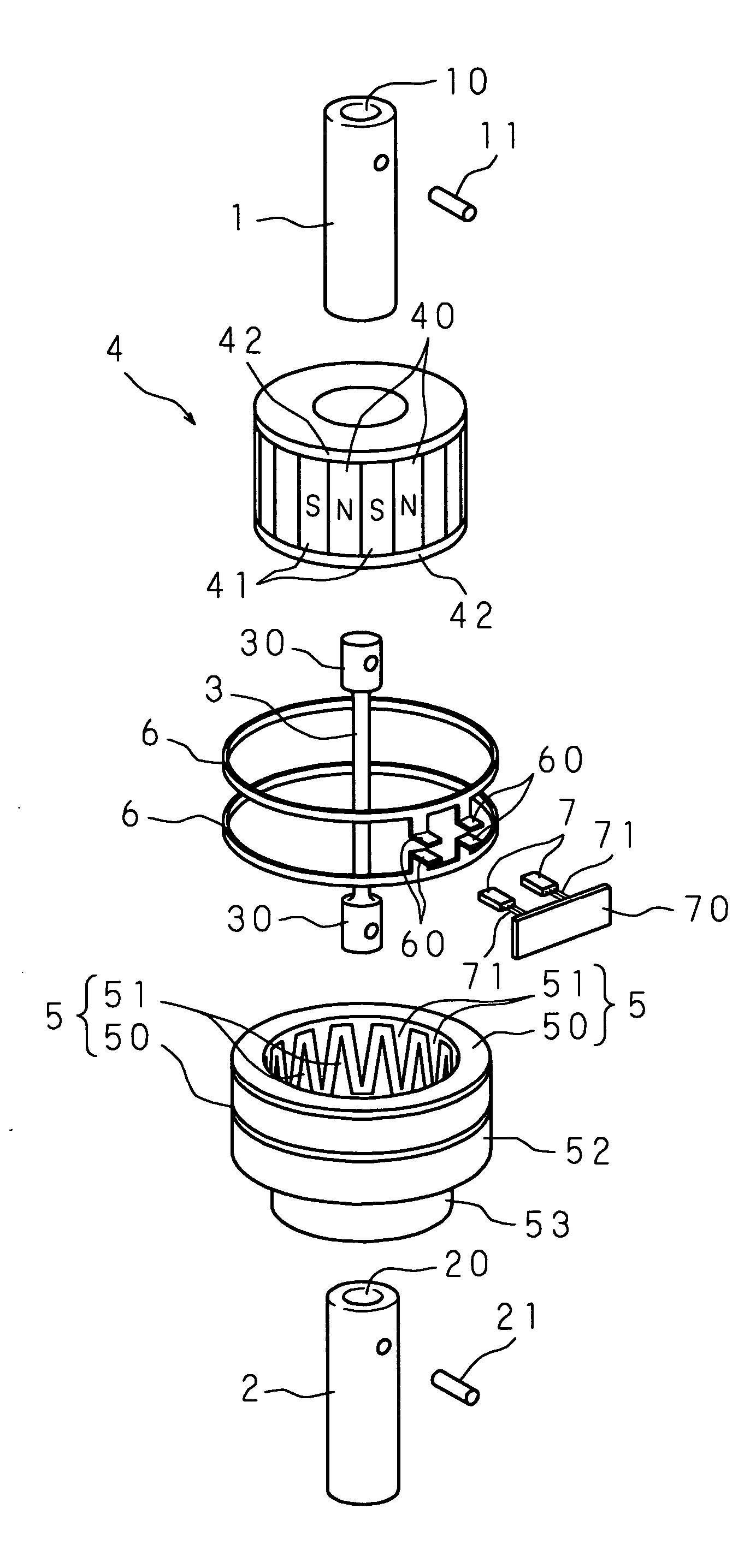

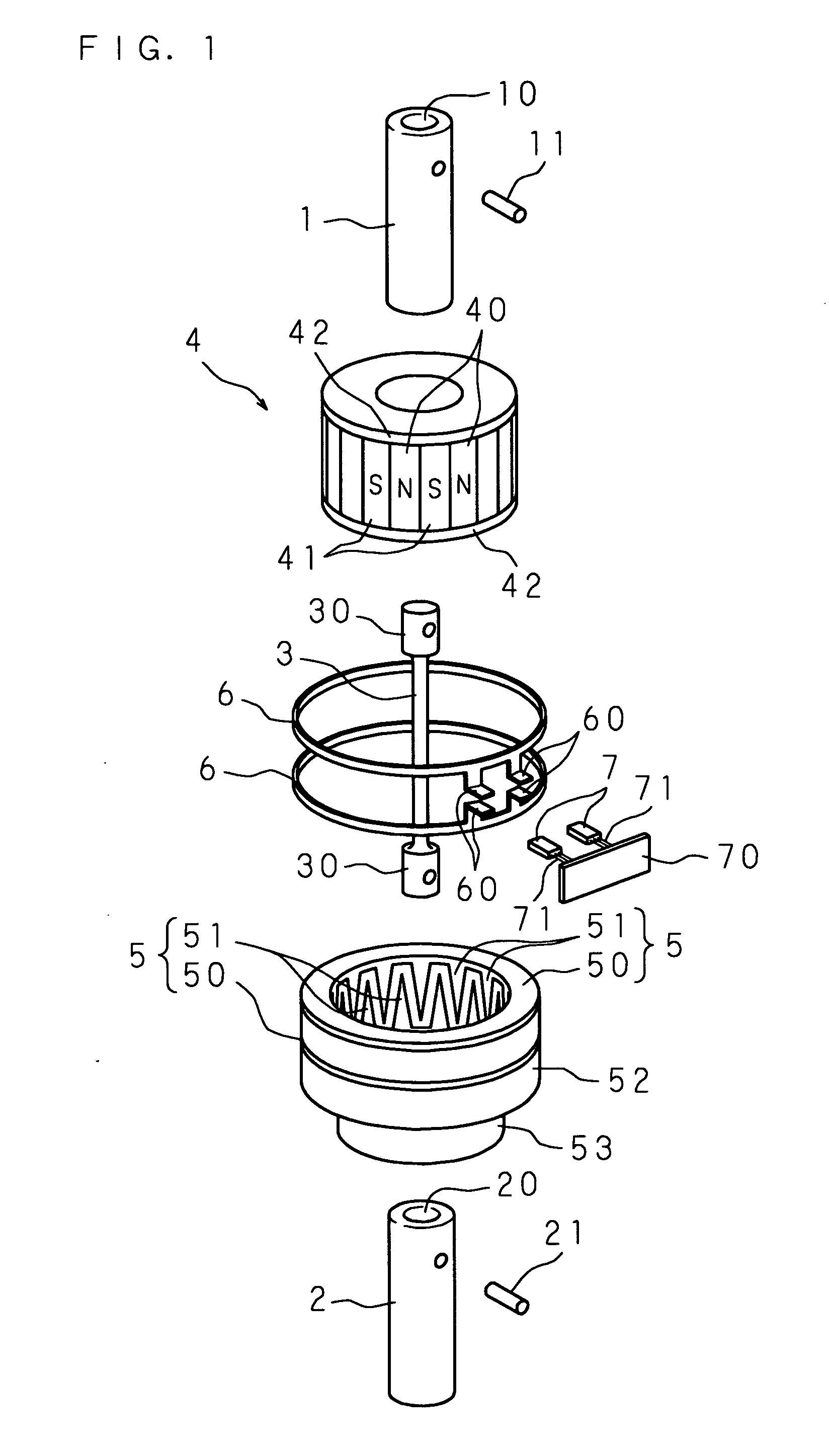

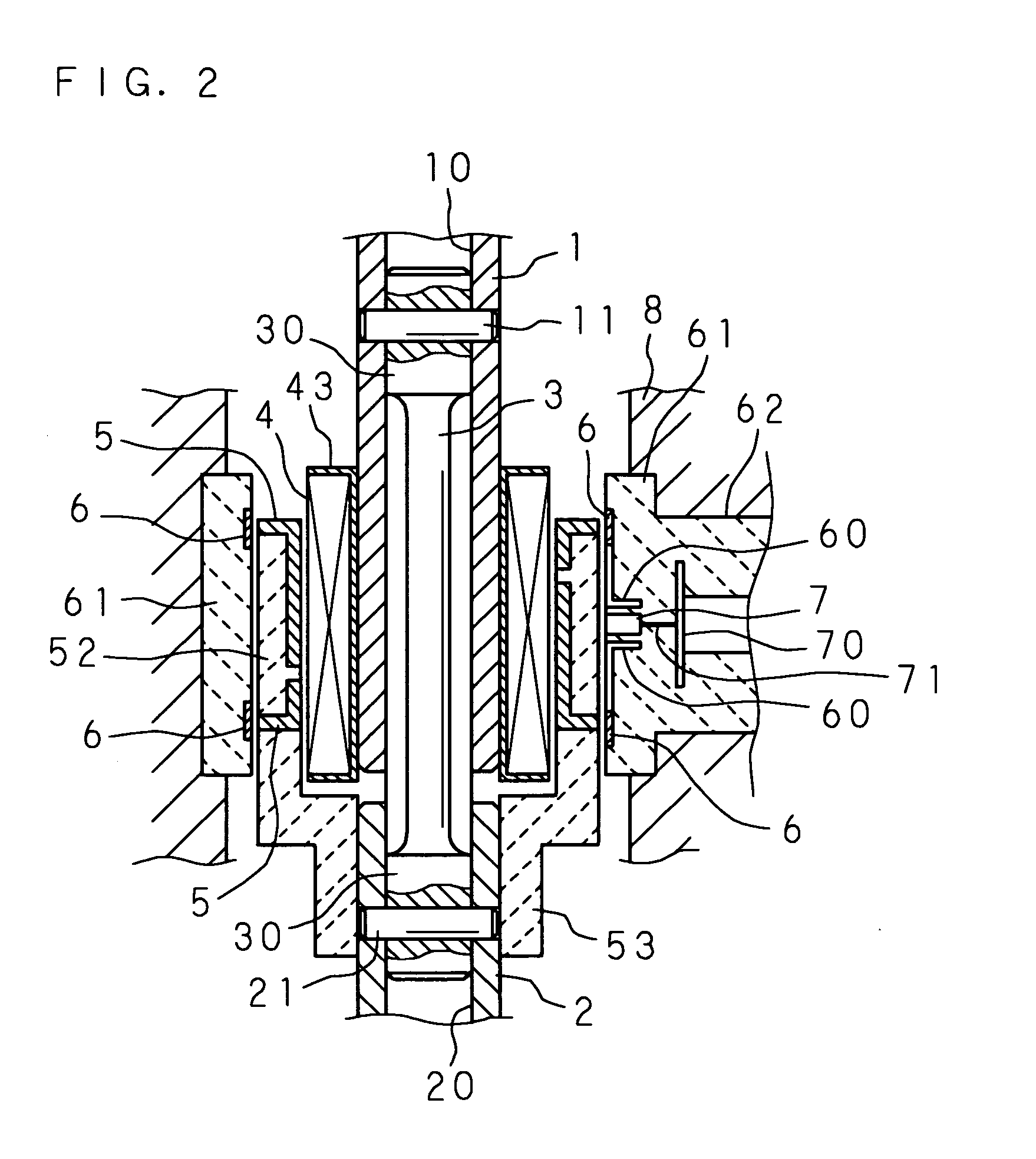

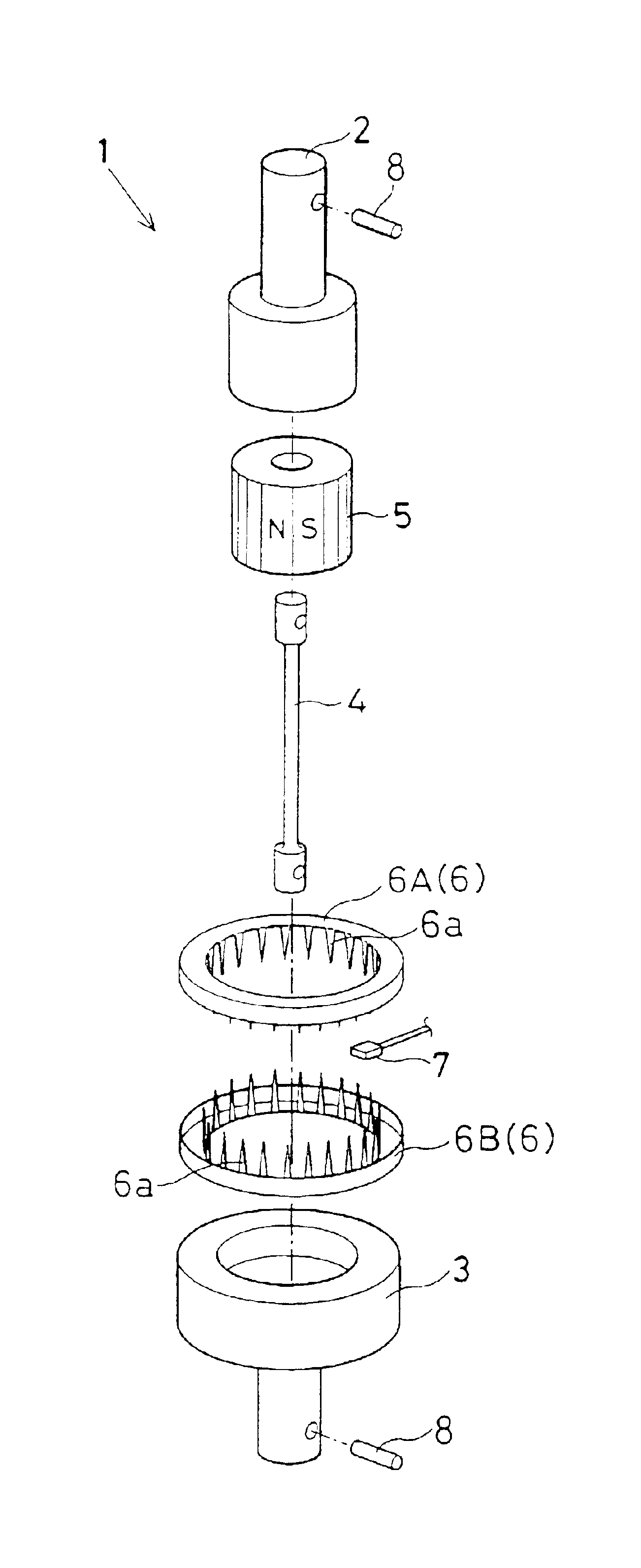

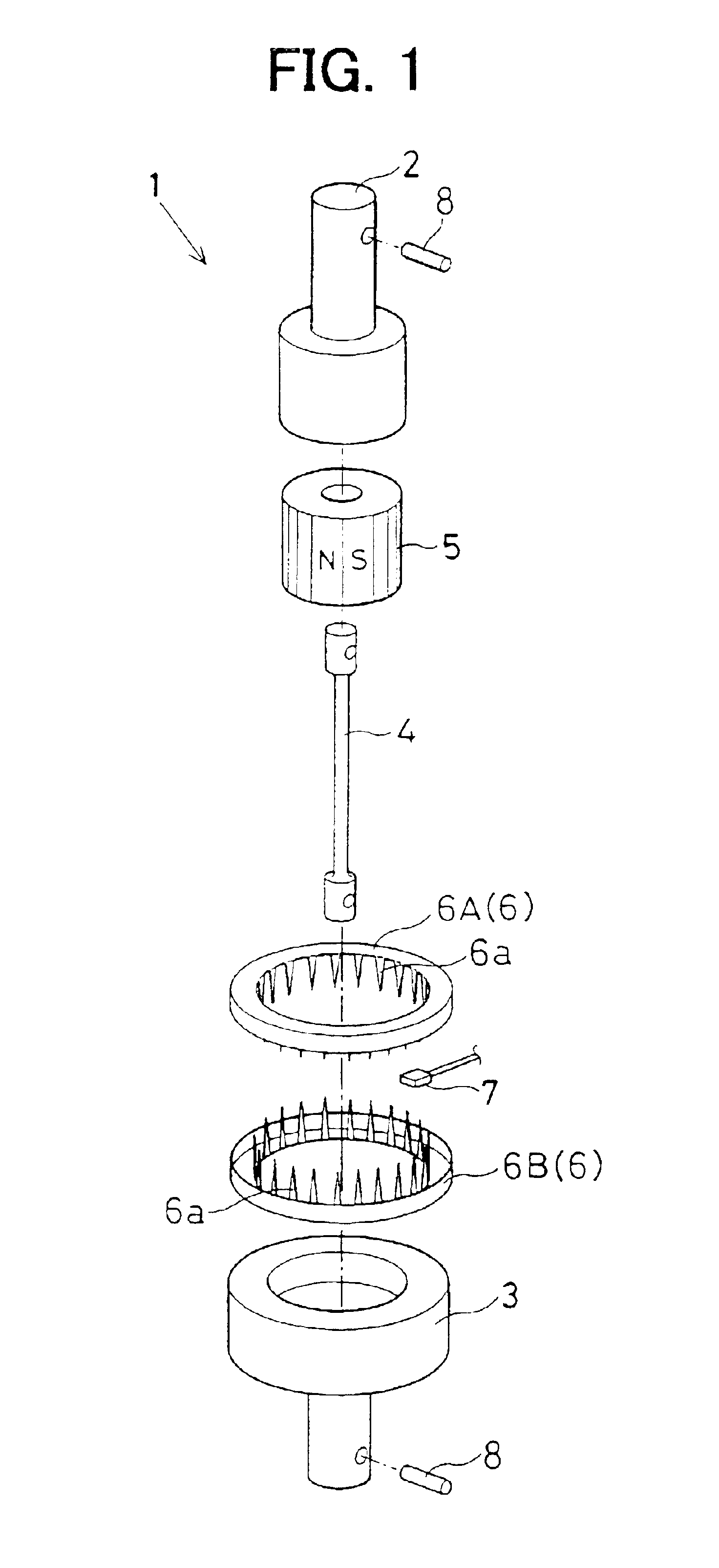

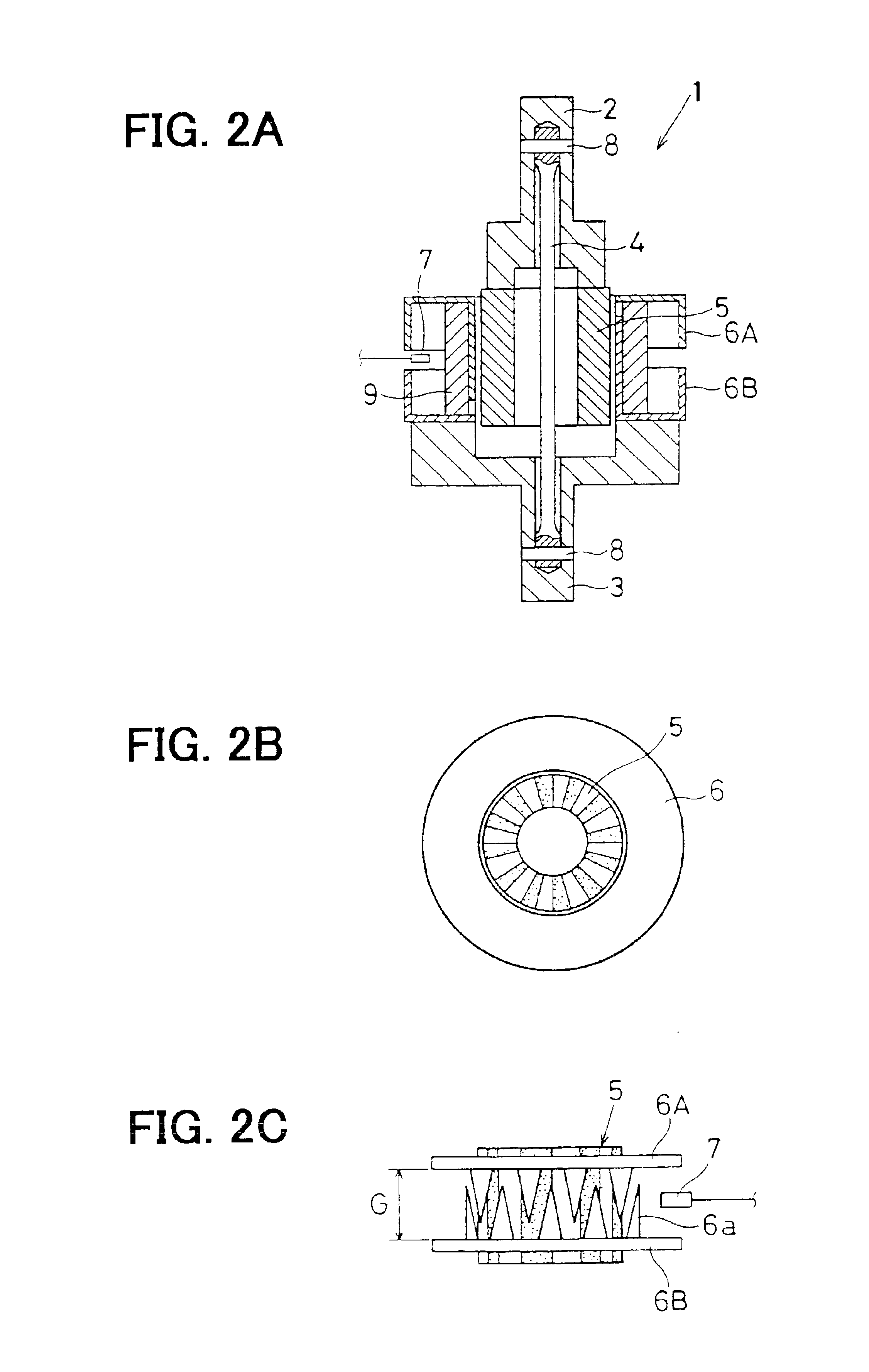

Torque Detecting Apparatus

InactiveUS20080028870A1Work measurementAutomatic steering controlElectrical and Electronics engineeringEngineering

A torque detecting apparatus is provided which is capable of easily positioning a magnetic sensor in relation to a corresponding pair of magnetism collecting projections and thus improving the detection accuracy of the magnetic sensor without increasing the number of assembling and processing steps. A pair of magnetism collecting projections 60 and 60 of each magnetism collecting ring 6 are arranged to extend not in their respective radial directions but substantially in parallel to each other while two magnetic sensors 7 and 7 are mounted to a circuit board 70 and inserted along the direction of projection of the magnetism collecting projections 60 and 60 into the air gaps respectively between the two magnetism collecting projection 60 and 60 of one magnetism collecting ring 6 and the two magnetism collecting projection 60 and 60 of the other magnetism collecting ring 6.

Owner:JTEKT CORP +1

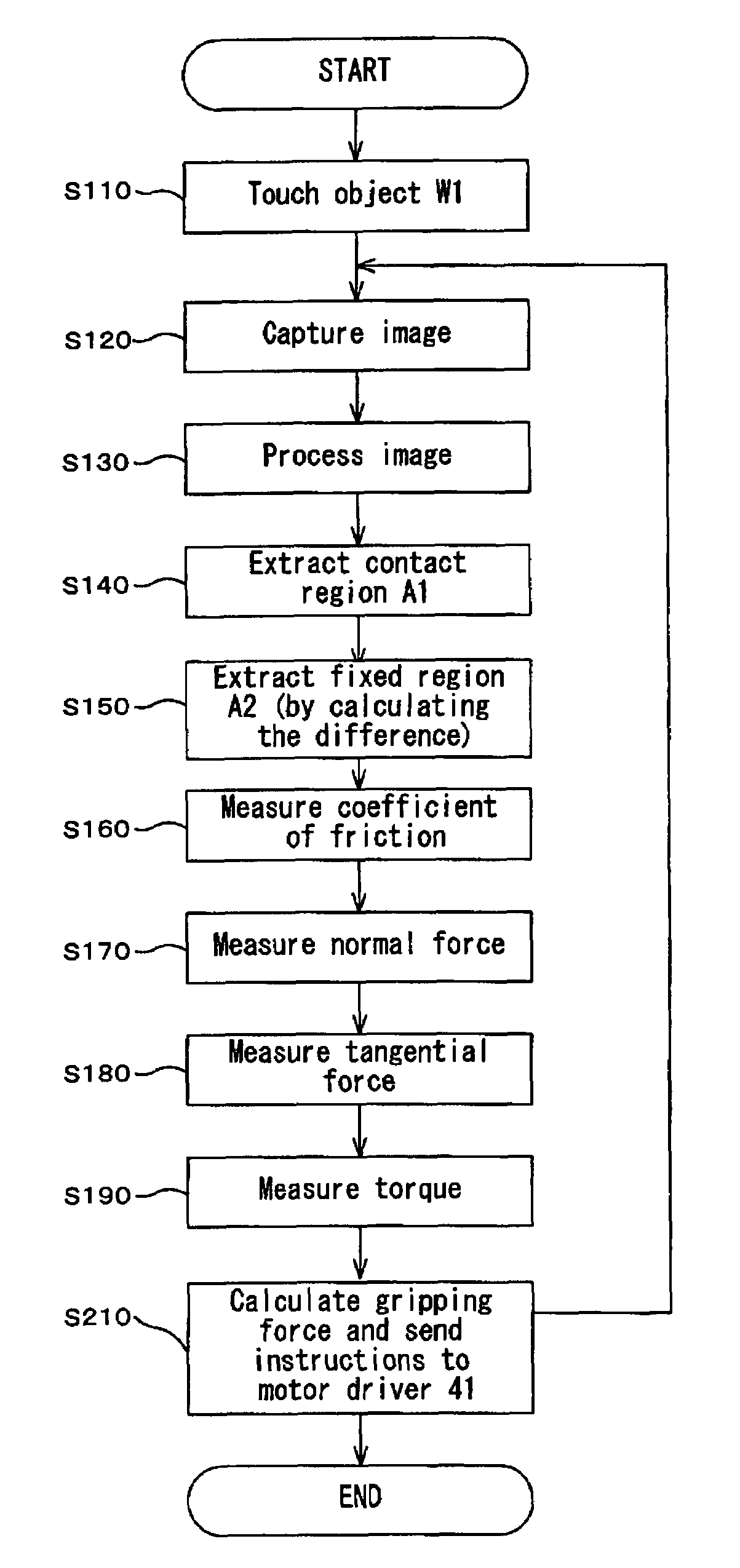

Force vector reconstruction method using optical tactile sensor

InactiveUS7460964B2Reduce the amount of calculationSmall sizeInflated body pressure measurementForce measurement by permanent gauge deformationReconstruction methodTactile sensor

The invention relates to a technique for reducing computation time for force vector calculation. A force vector reconstruction method that uses an optical tactile sensor, comprises a step for obtaining a marker image by taking an image of behavior of colored markers when an object contacts a contact surface of an elastic body, a step of obtaining information relating to the marker behavior from the marker image, the information being more than the number of force vectors to be obtained, and a step of obtaining force vectors as outputs by inputting information relating to the obtained marker behavior to a transfer function. The step of obtaining force vectors comprises calculating force vectors using only information relating to behavior of markers neighboring region A1 of a position A where it is desired to obtain force vectors.

Owner:TOUDAITLO LTD

Sensor for measuring shear forces

Owner:GREAT LAKES NEUROTECH

Torque sensor and electric power steering system having same

InactiveUS6880411B2Low number of componentsImprove reliabilitySteering linkagesWork measurementElectric power steeringElectric power system

Owner:NIPPON SOKEN +1

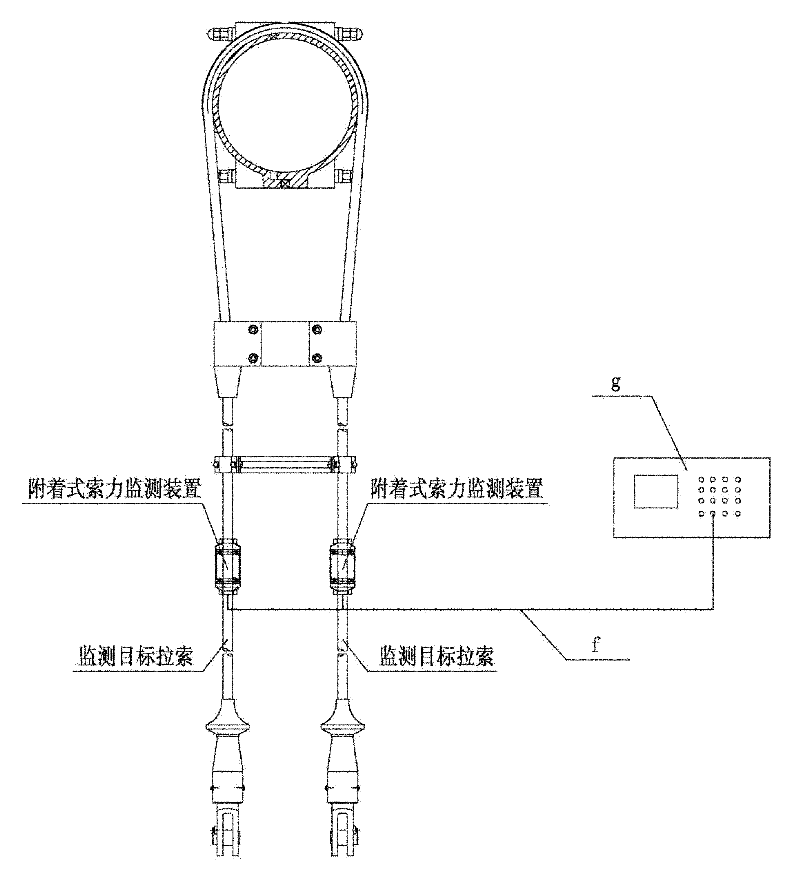

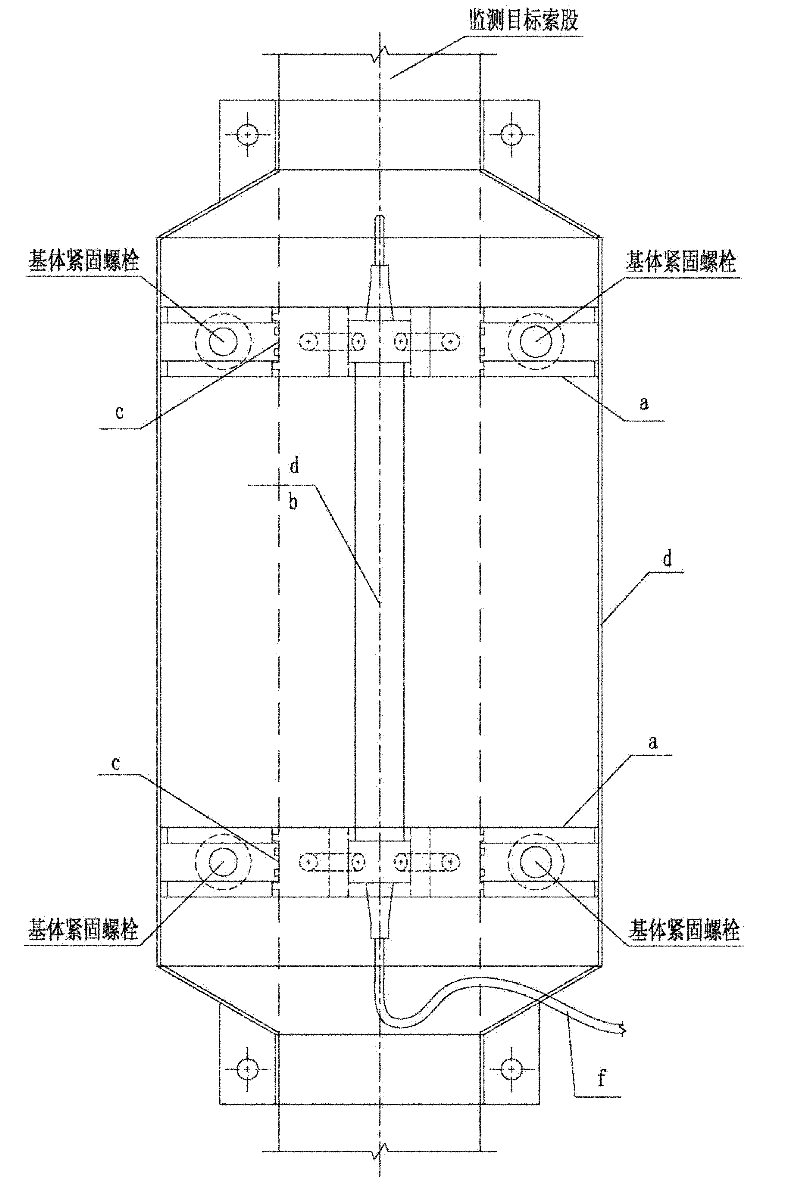

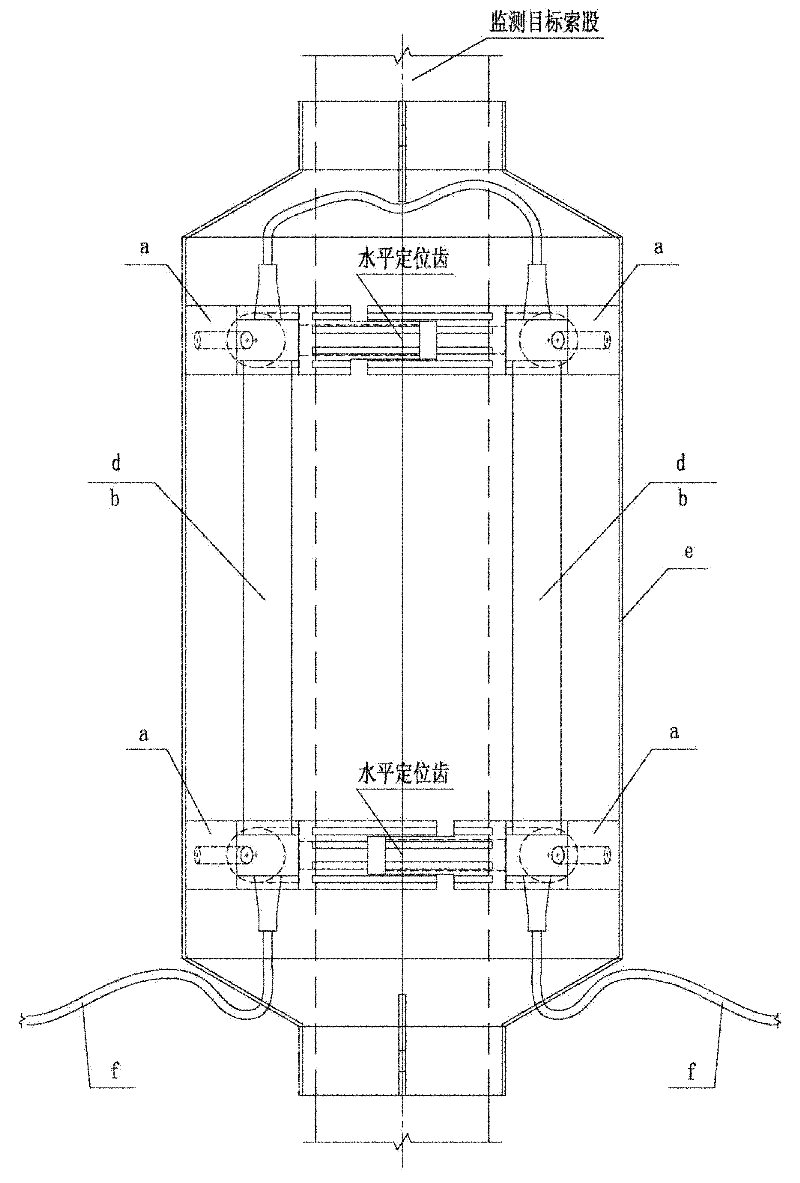

Cable force monitoring device for attached-type stay cable

ActiveCN102162760AImprove connection strengthFree from mechanical damageNon-electrical signal transmission systemsUsing optical meansFiberFiber gratings

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Control device for electric power steering apparatus

InactiveUS6681165B2Steering initiationsDigital data processing detailsElectric power steeringApproximation function

A control device which: controls a motor based upon a steering assist instruction value calculated in a steering assist command operating section based upon a steering torque generated in a steering shaft and a current control value calculated from a current value of the motor for applying a steering assist force to a steering mechanism; and at least partially possesses a gradient when a gain curve of characteristics of an entire control system having the steering assist command value as its input exceeds a predetermined value. The steering assist command value operating section is composed of an approximation functional expression in which a one-step derived function is continuous, and the steering assist command value is obtained by calculations based upon the approximation functional expression.

Owner:NSK LTD

Electric power steering system and method having abnormality compensation function

A vehicle electric power steering system comprises a torque sensor including a torsion bar that detects a steering force applied to the steering wheel. A first rotation angle detection device detects a rotation angle of a steering shaft connected to the torsion bar, and a second rotation angle detection device detects a rotation angle of a pinion shaft connected to the torsion bar. A steering controller detects an abnormality in an output of the torque sensor. The steering controller detects the steering torque in place of the torque sensor based on the rotation angle of the steering shaft and the pinion shaft when an abnormality of the torque sensor is detected.

Owner:DENSO CORP

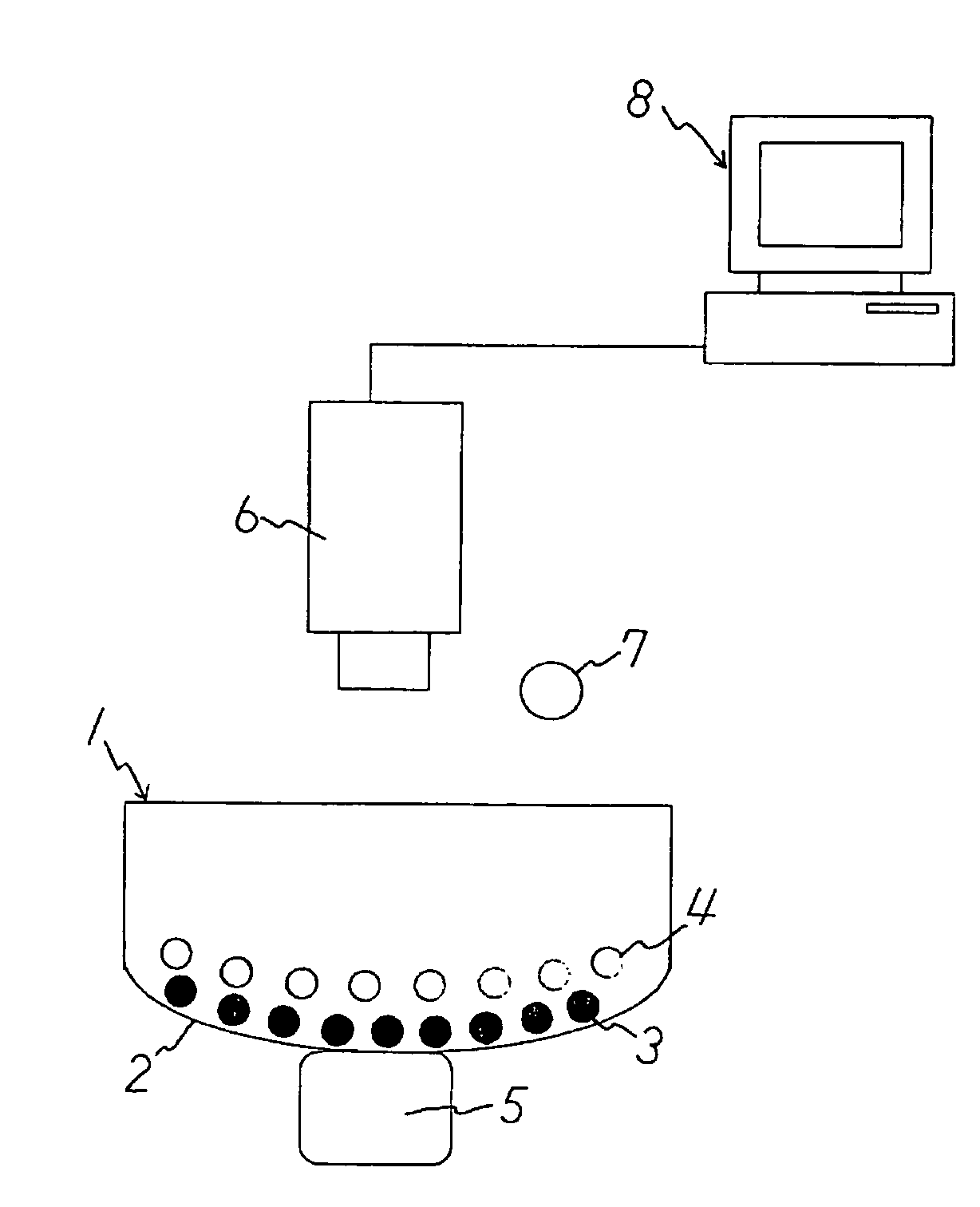

Control of object operating force, object gripping force and robot hands

ActiveUS7707001B2Small and simple structureA large amountForce measurementMeasurement arrangements for variableGrip forceRobot hand

An optical tactile sensor has a touch pad and a CCD camera for imaging behavior of the touch pad. A CPU processes image information from the CCD camera, extracts information on the size, shape, and center of gravity of a contact region, and extracts information on the size of a fixation region. The CPU obtains a normal force from the size of the contact region, obtains a tangential force from the shape of the contact region and the center of gravity of the contact region, and obtains a friction coefficient from the ratio of the size of the fixation region to the size of the contact region.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

Popular searches

Magnetic field measurement using galvano-magnetic devices Galvano-magnetic hall-effect devices Electrical steering Measurement of force applied to control members Electric switches Power supply for data processing Tension measurement Stringed rackets Indication of measured values Input/output processes for data processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com