Patents

Literature

81 results about "Torsion element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsion element. [′tȯr·shən ‚el·ə·mənt] (mathematics) A torsion element of an Abelian group G is an element of G with finite period. A torsion element of a module M over an entire, principal ring R is an element x in M for which there exists an element a in R such that a ≠ 0 and ax = 0.

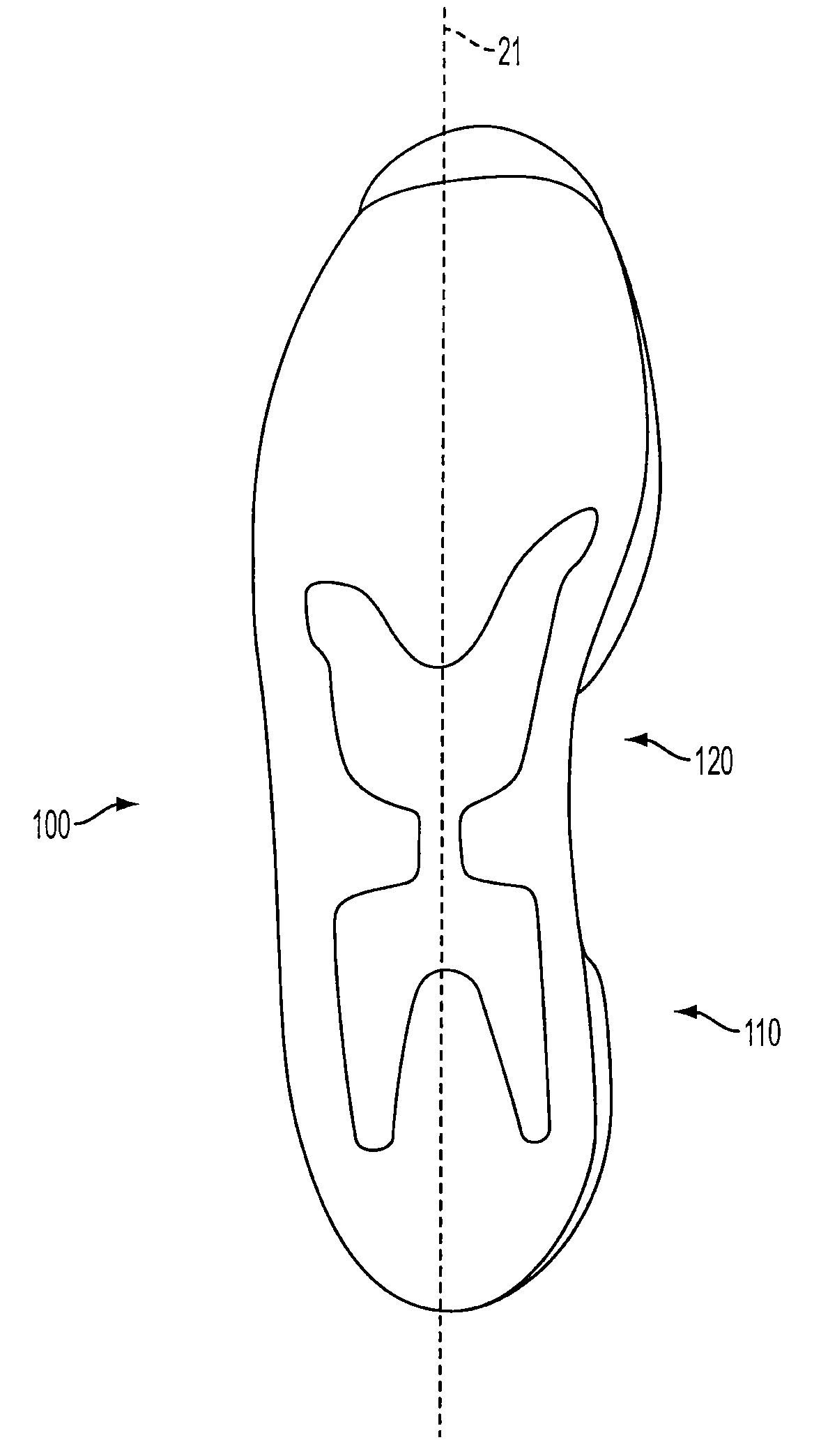

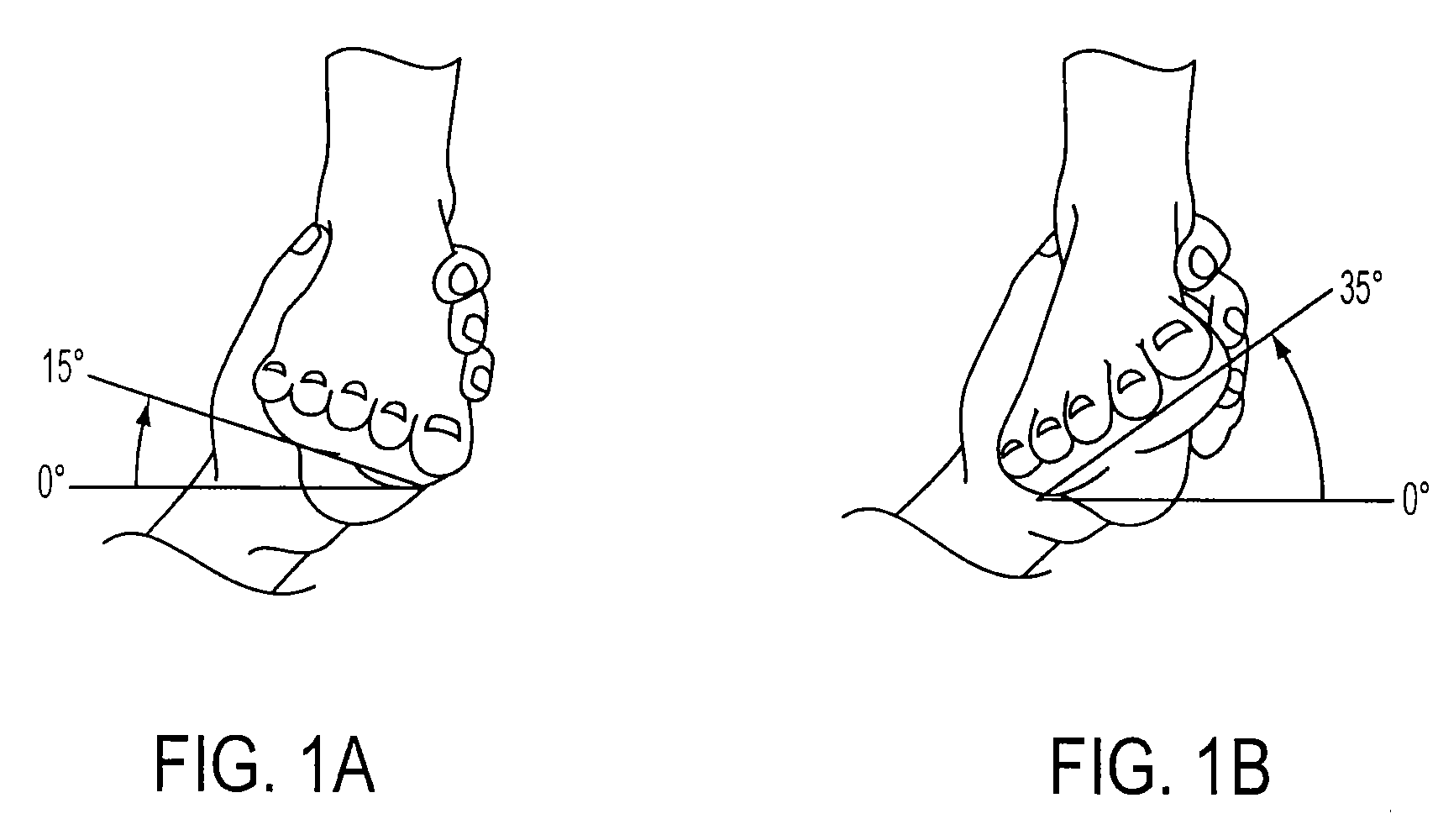

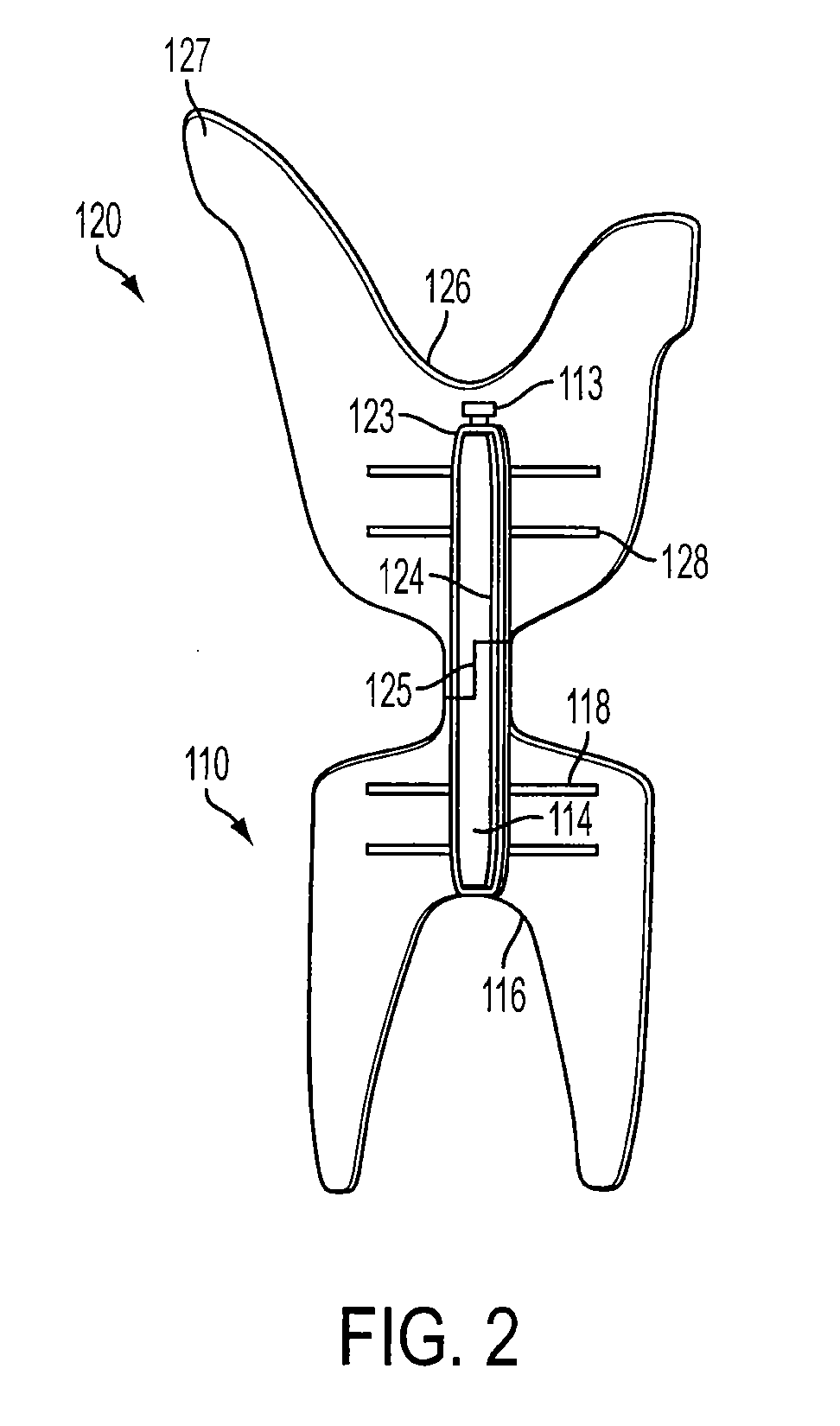

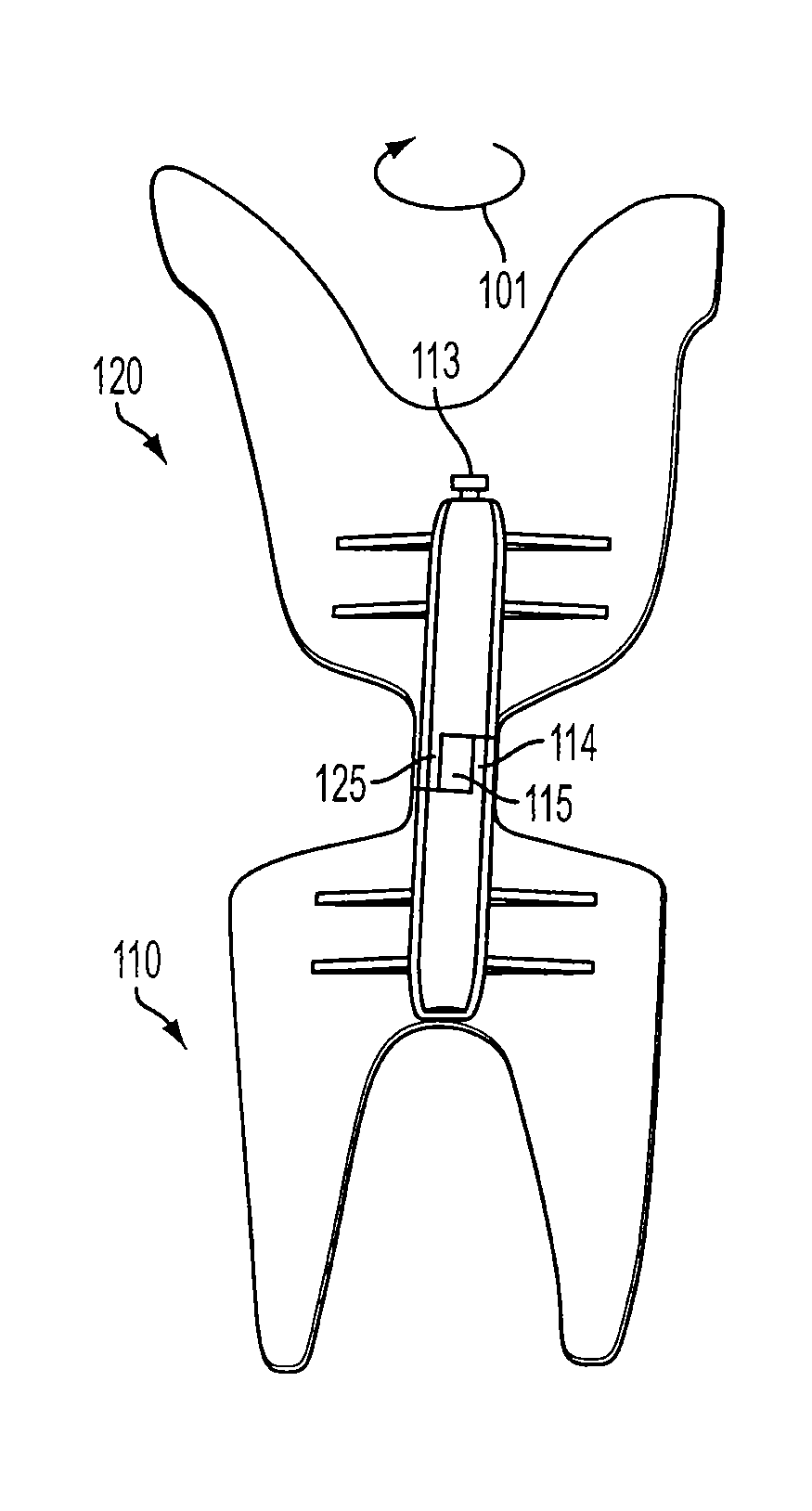

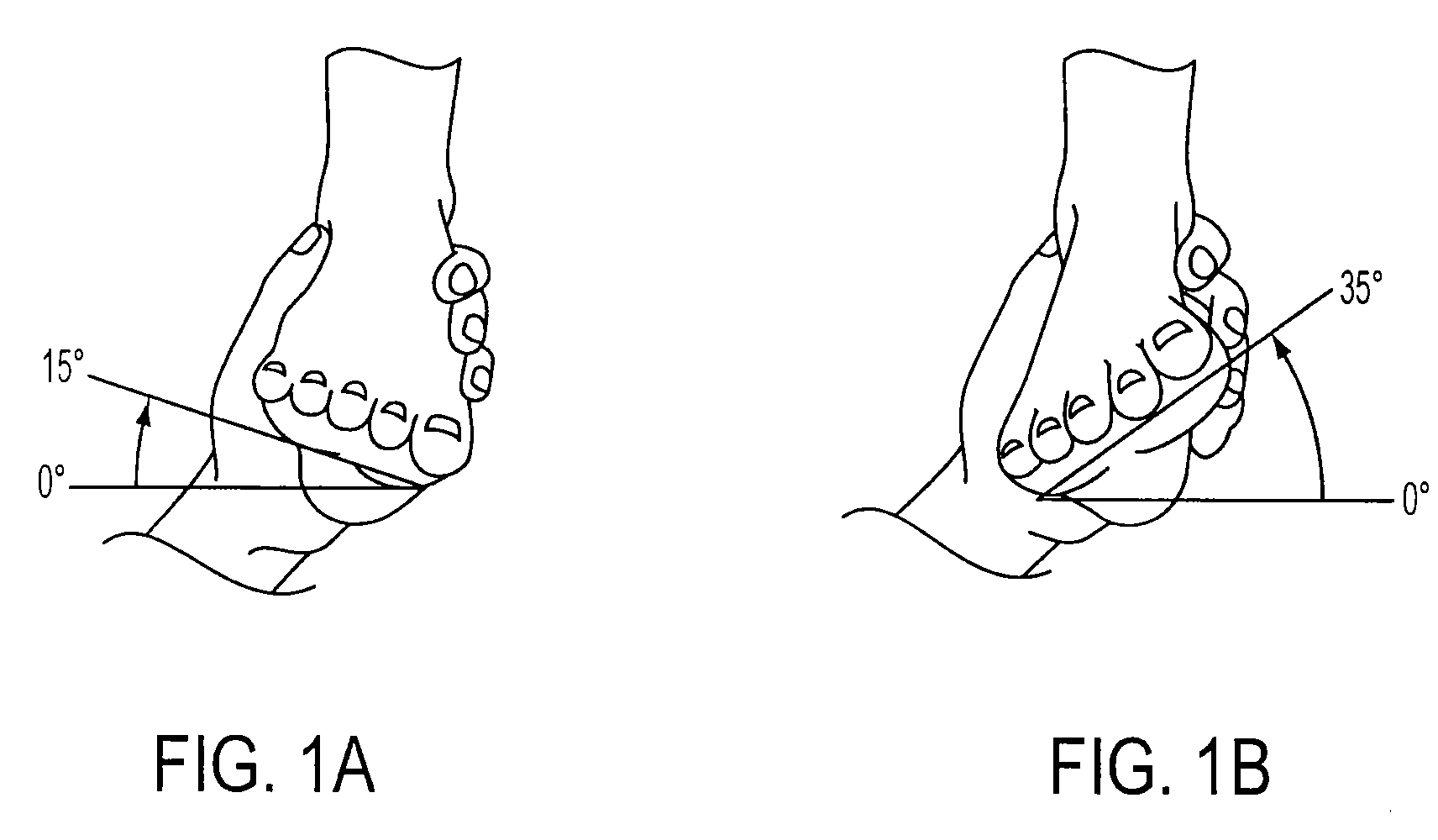

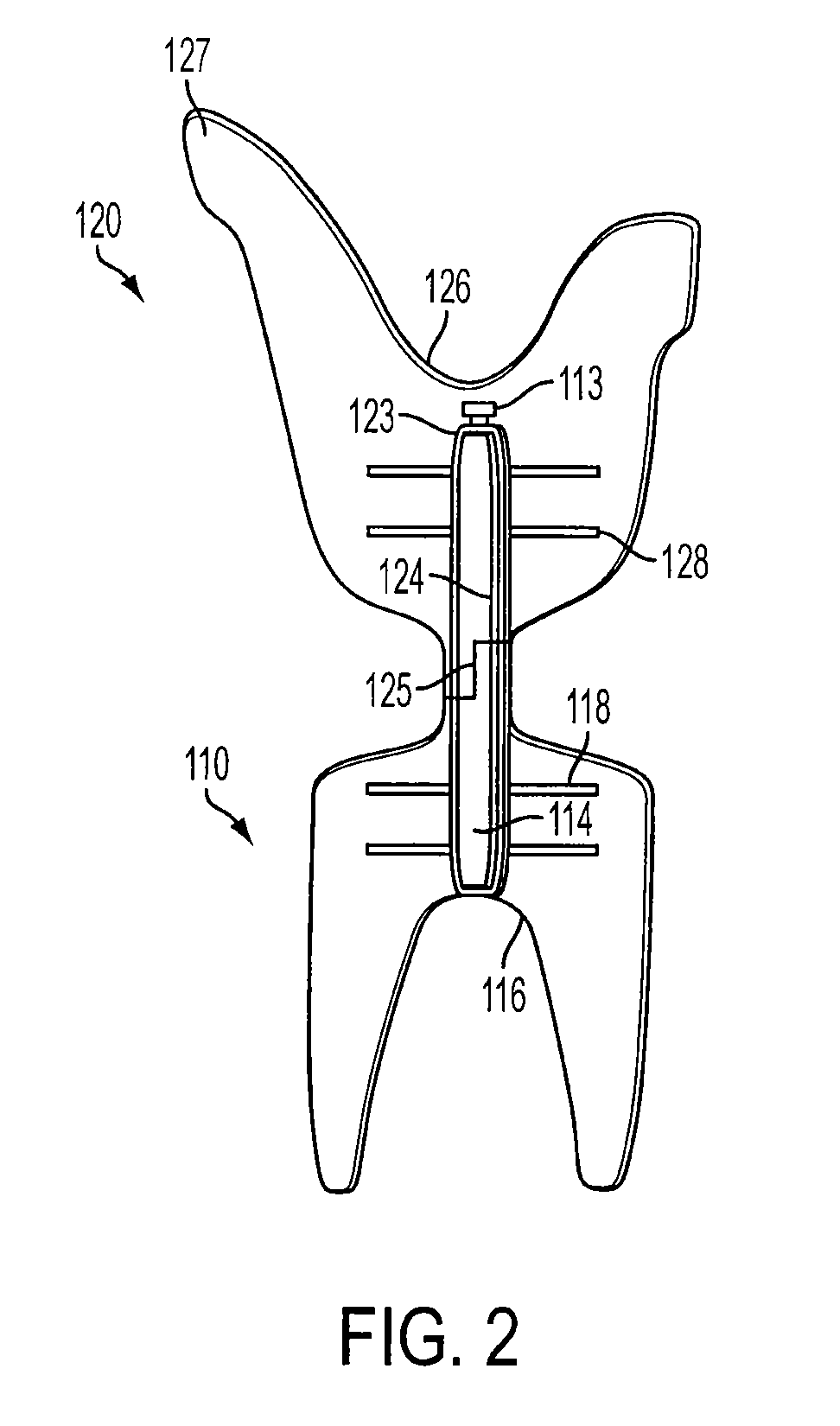

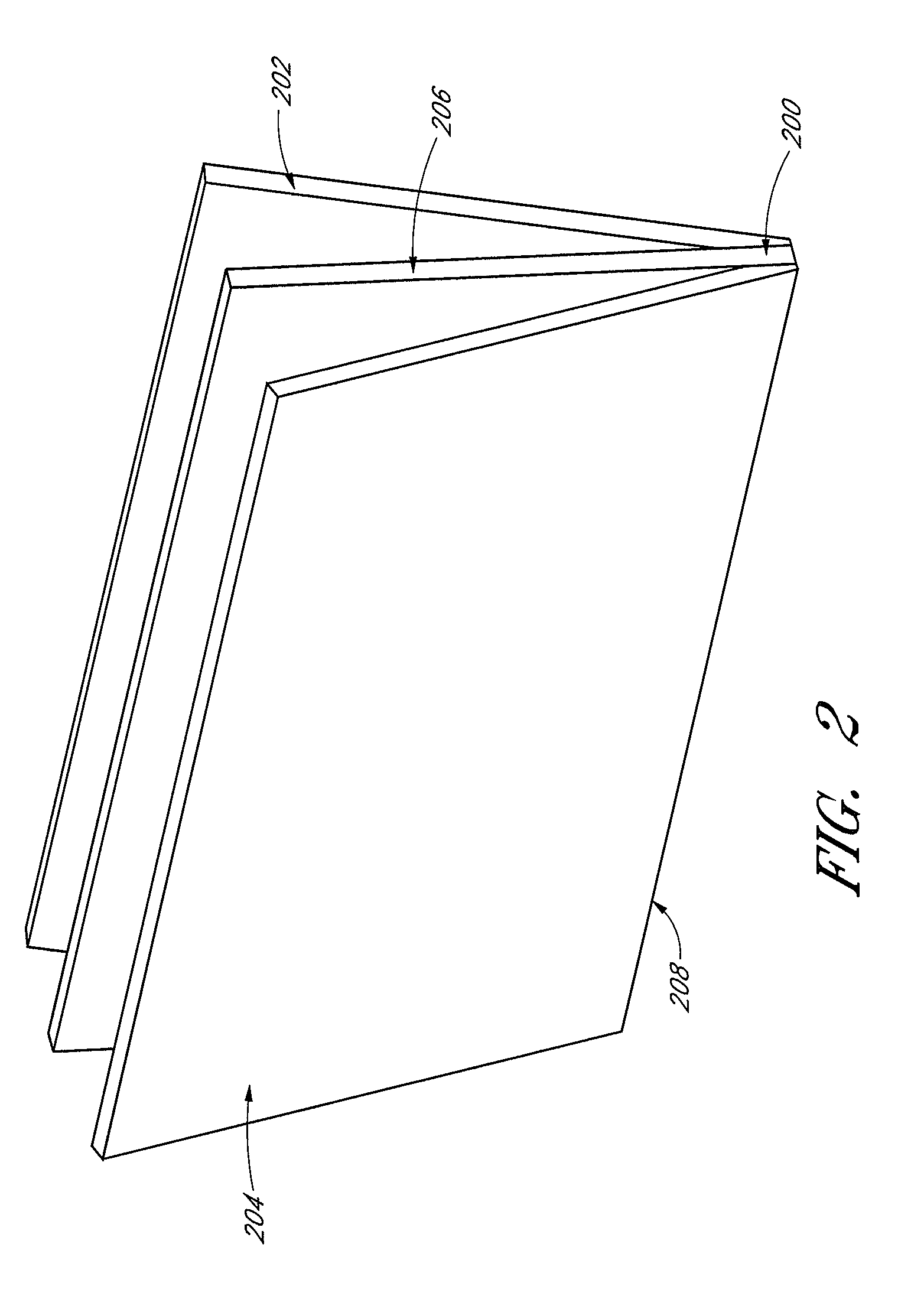

Torsion Control Devices and Related Articles of Footwear

ActiveUS20100122472A1Strong resistanceSolesNon-surgical orthopedic devicesEngineeringTorsion element

Torsion control devices for use in an article of footwear are disclosed. An article of footwear comprises: a sole having a forefoot portion and a rearfoot portion; and a torsion element disposed in the sole, wherein the torsion element allows the forefoot portion to rotate in a first direction relative to the rearfoot portion and restricts rotation of the forefoot portion relative to the rearfoot portion in a second direction.

Owner:ADIDAS

Torsion control devices and related articles of footwear

Torsion control devices for use in an article of footwear are disclosed. An article of footwear comprises: a sole having a forefoot portion and a rearfoot portion; and a torsion element disposed in the sole, wherein the torsion element allows the forefoot portion to rotate in a first direction relative to the rearfoot portion and restricts rotation of the forefoot portion relative to the rearfoot portion in a second direction.

Owner:ADIDAS

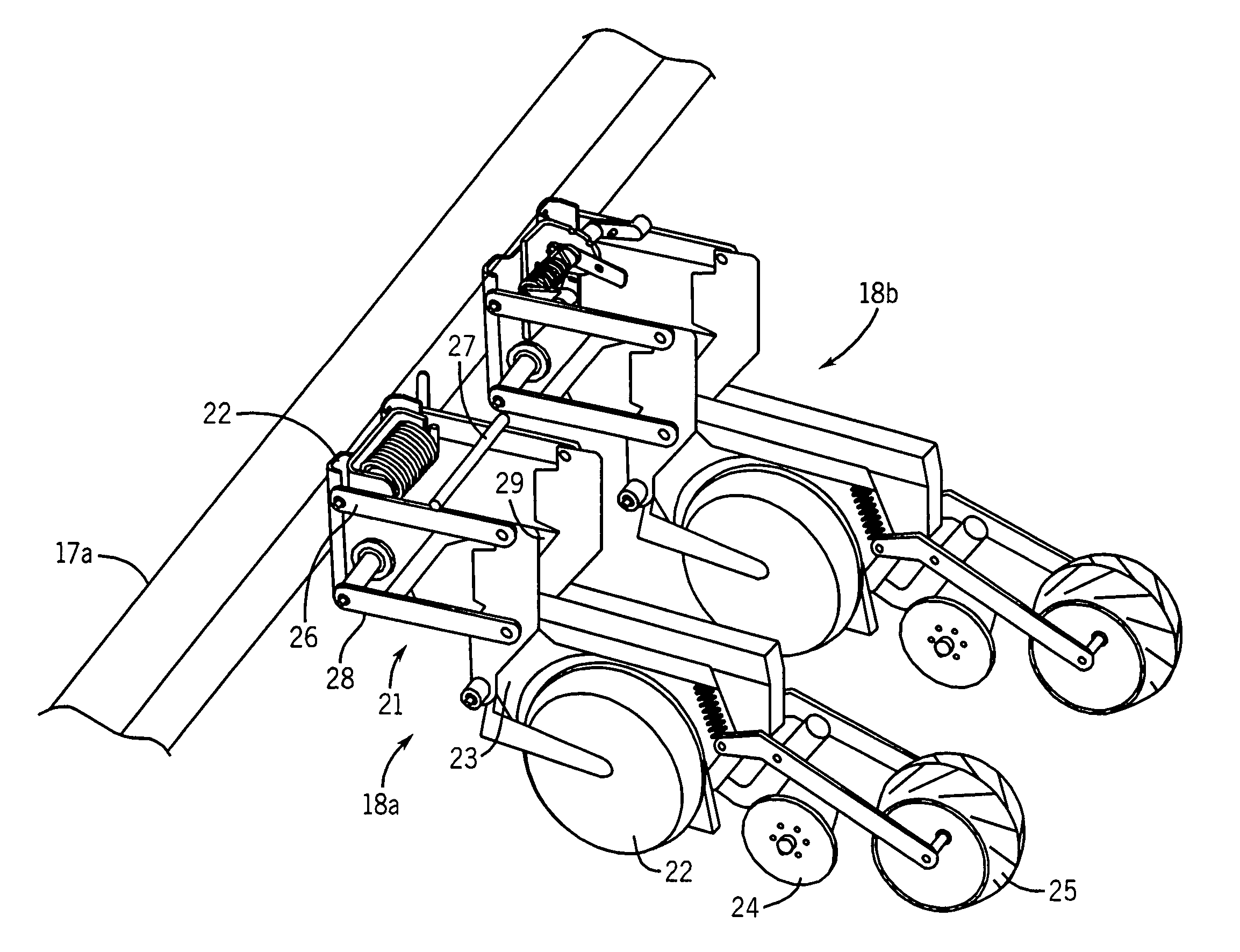

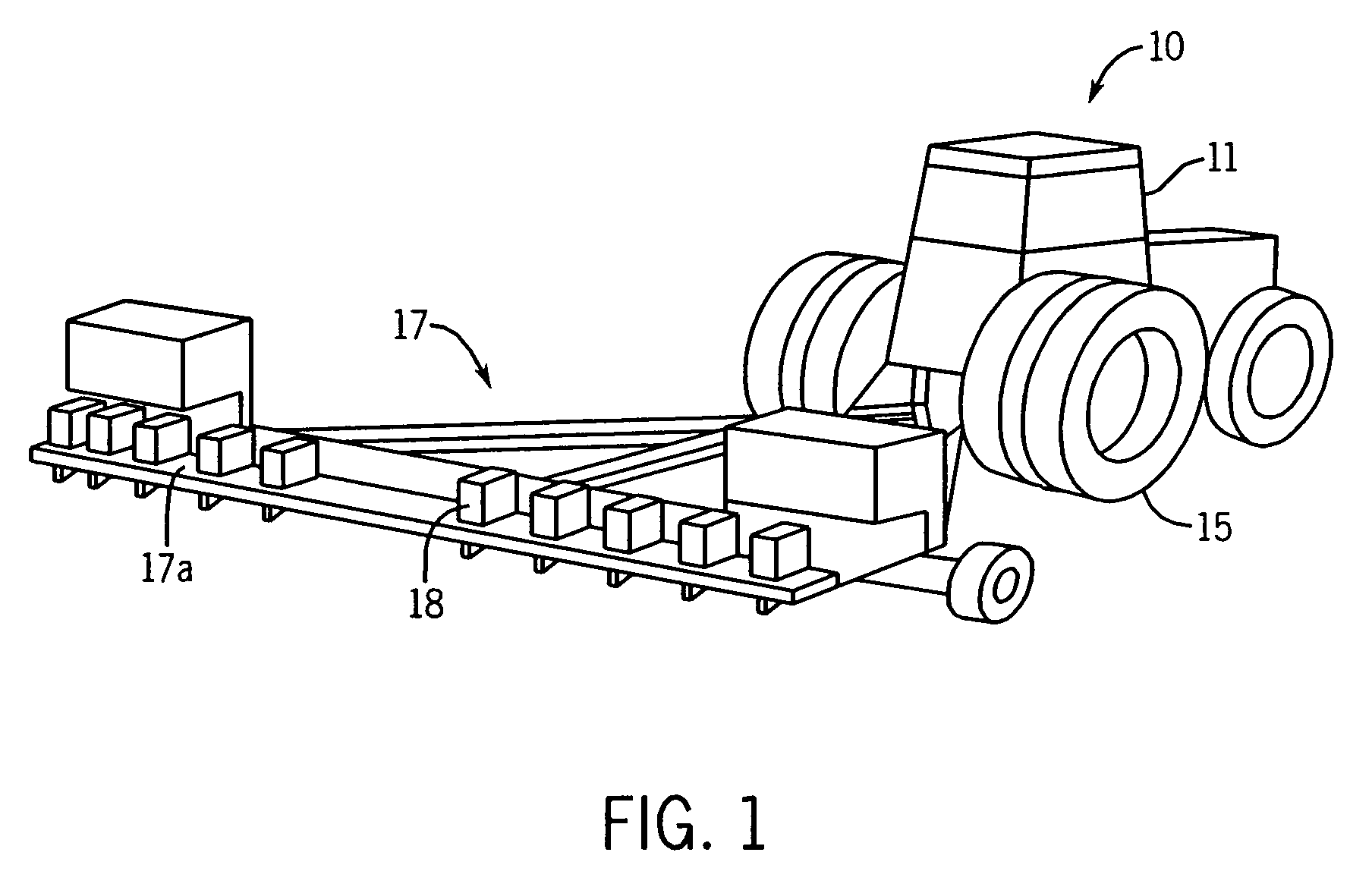

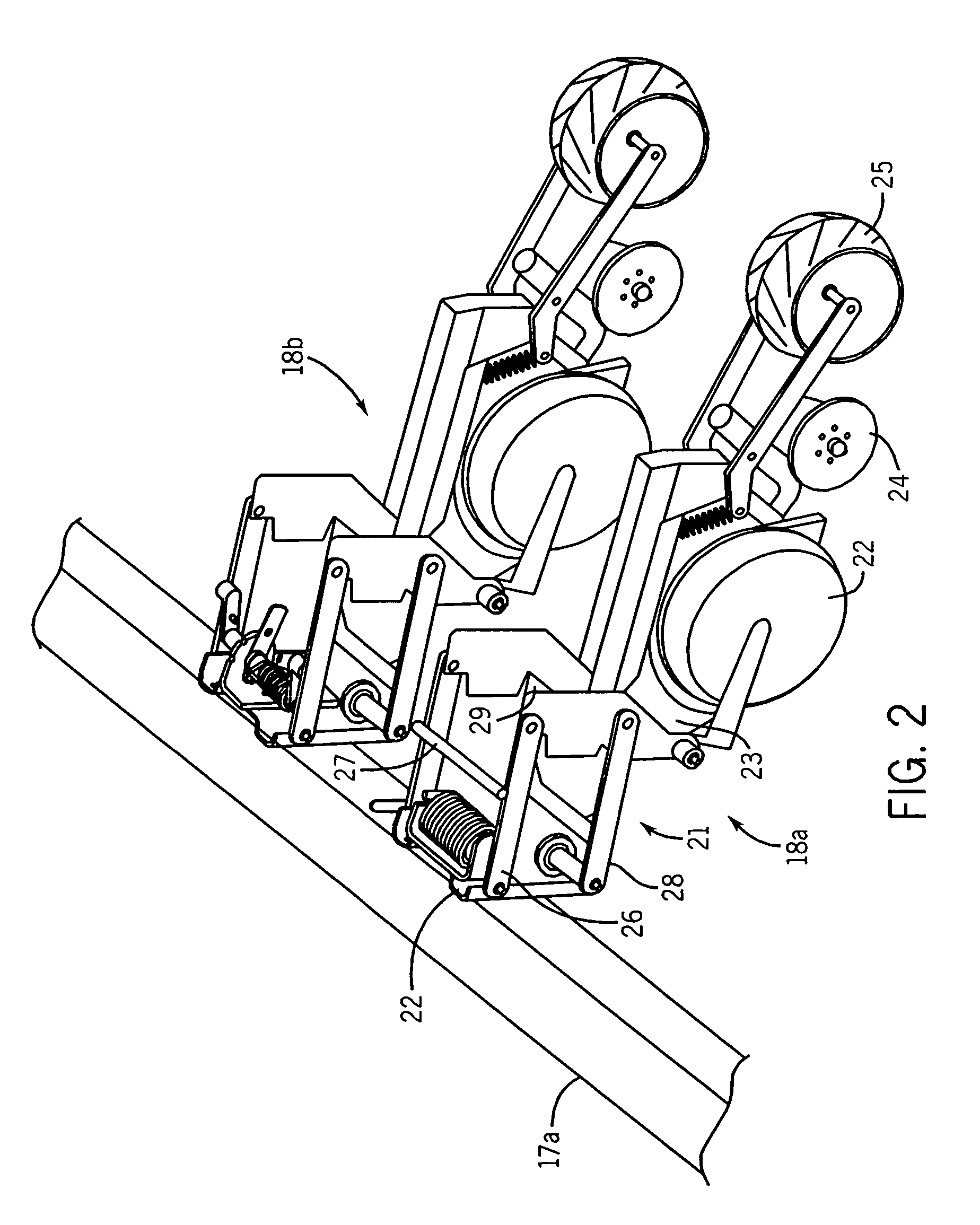

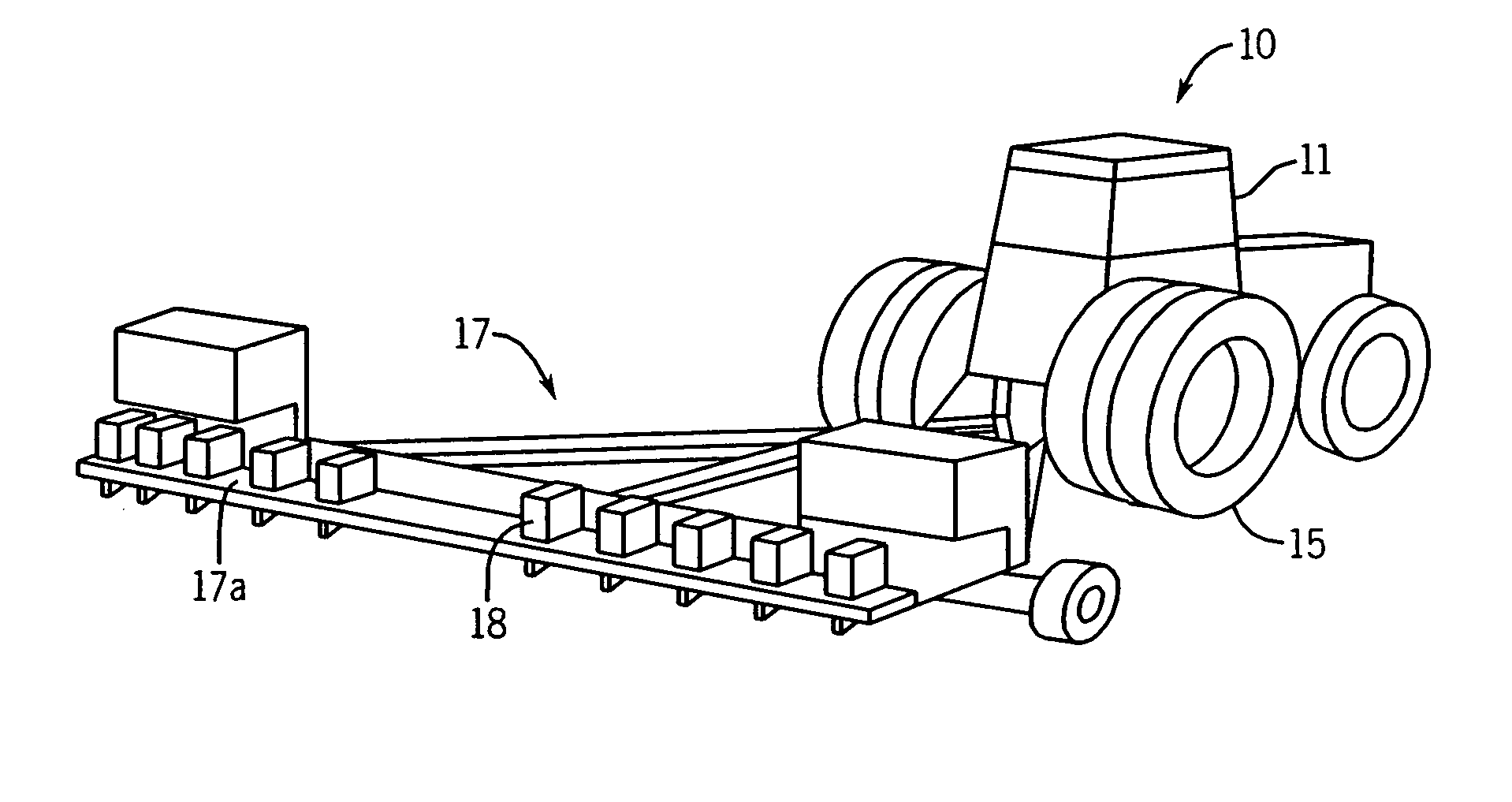

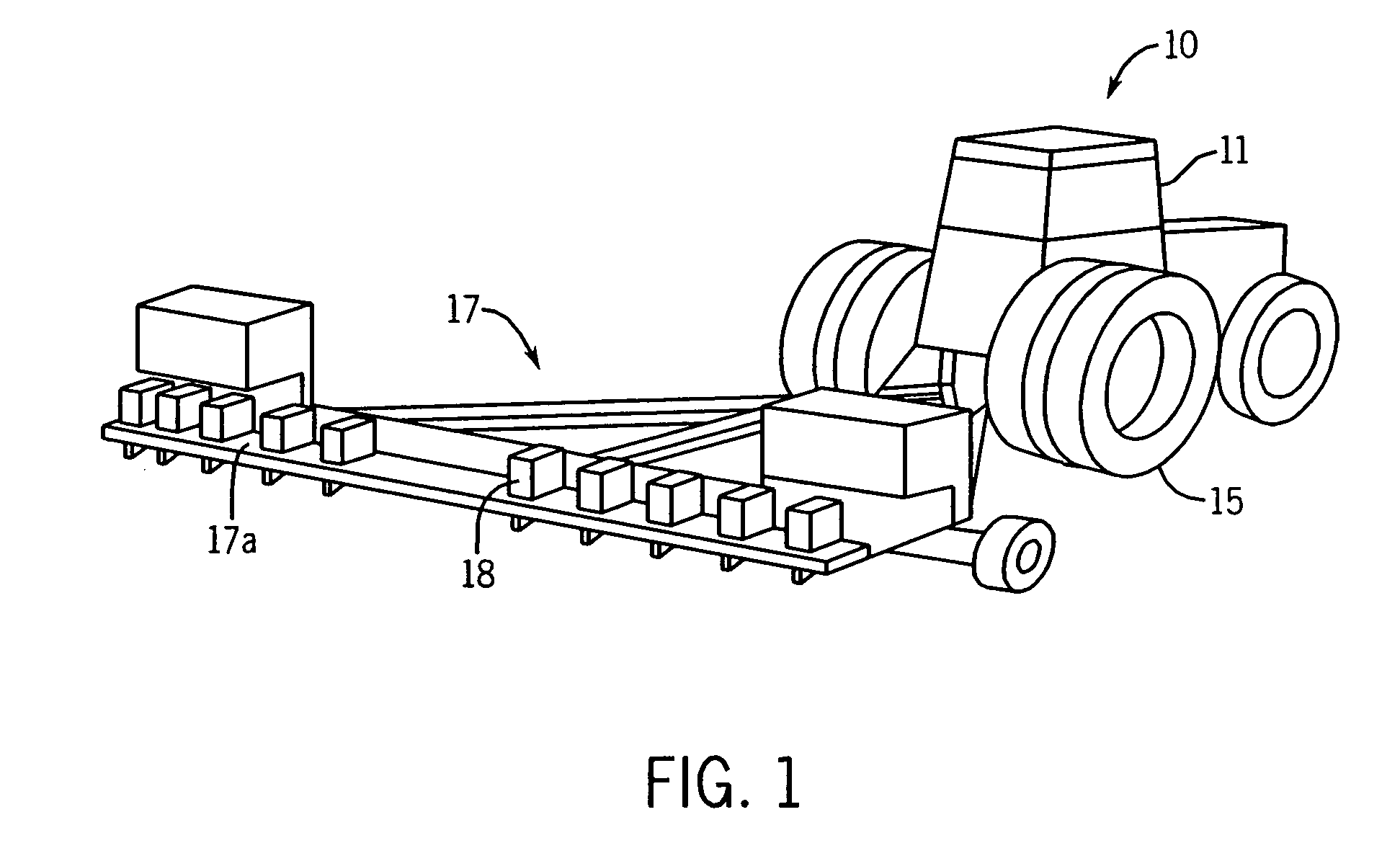

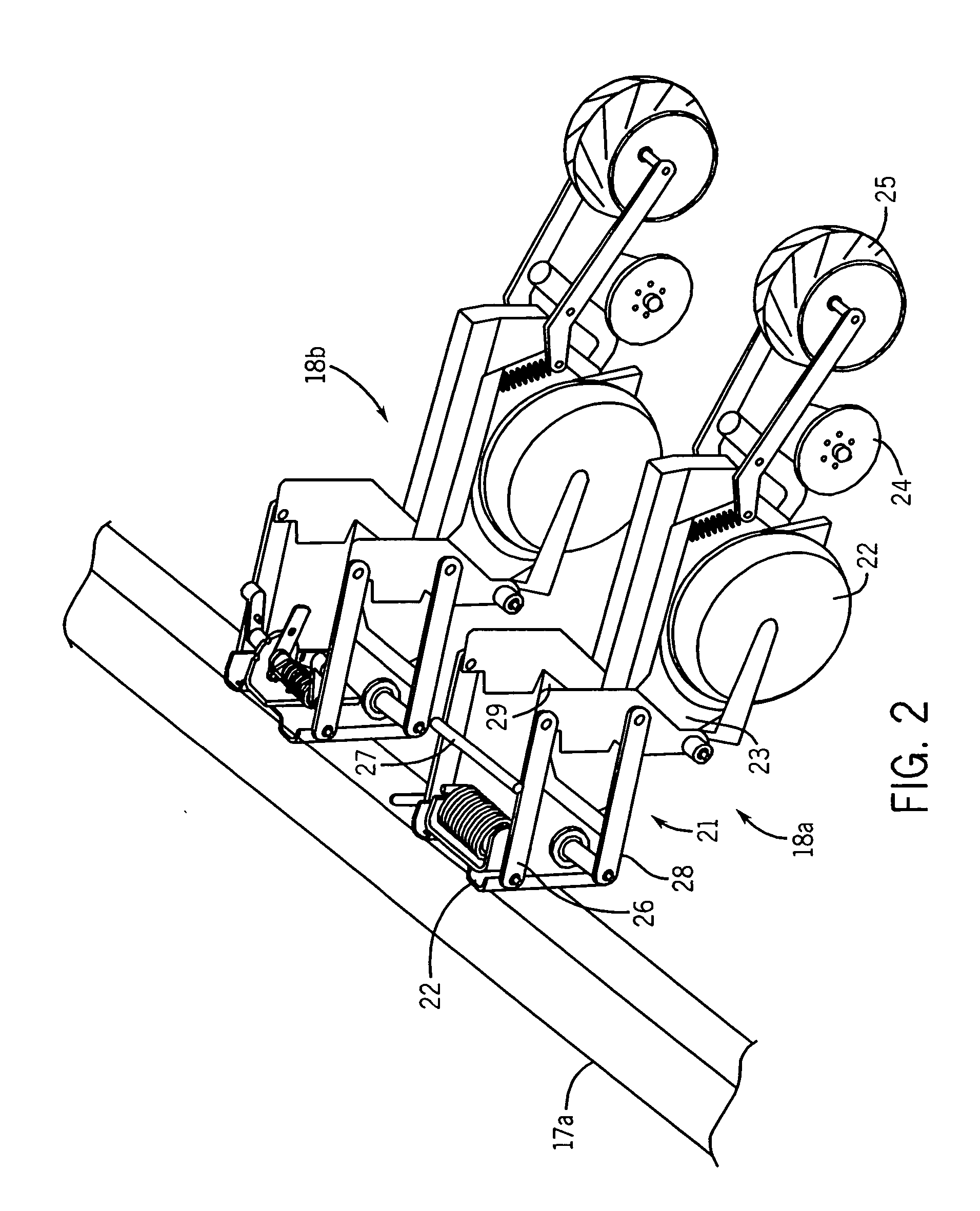

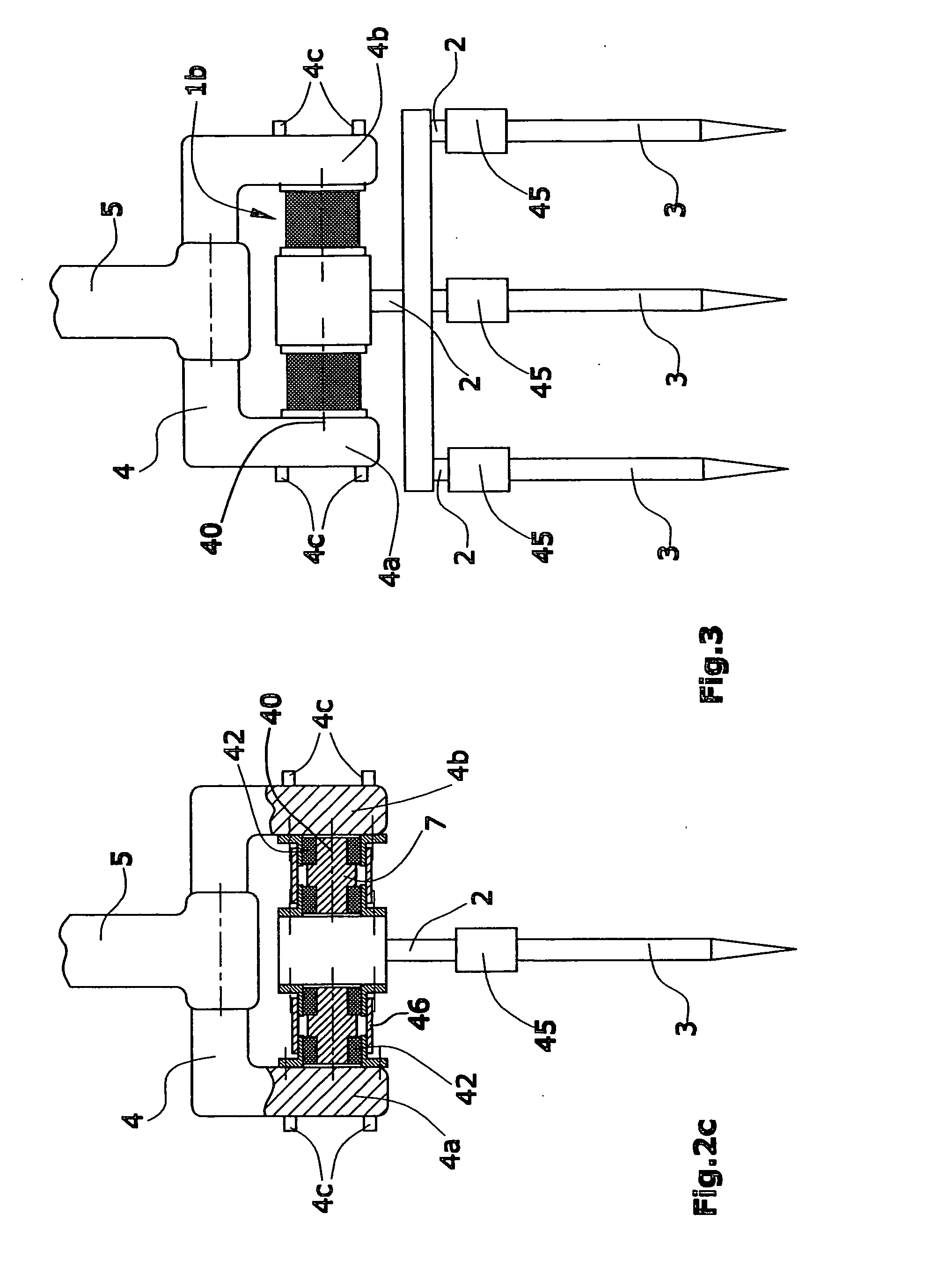

Row unit down pressure assembly

A down pressure assembly for incorporation into an agricultural implement to be pulled by a tractor (10) has an attachment frame (21) for attachment between a portion of the agricultural implement and at least two wheels (22) of a row unit (18) for traveling along the ground, the row unit (18) also having a tool (23) disposed between the two wheels (22) for engaging the ground, the down pressure assembly also having at least one torsion element (41, 50) disposed on the frame (21), with the torsion element (41, 50) having one fixed mounting to the frame (21) and one adjustable mounting to the frame (21), and the assembly further having an adjustment mechanism (37, 60) for varying the torsion of the torsion element (41, 50) at the adjustable mounting; and at least one down pressure member (36, 56, 57) for receiving a force from the torsion element to apply a downward force to the top members (26, 27) of the frame (21).

Owner:BLUE LEAF I P INC

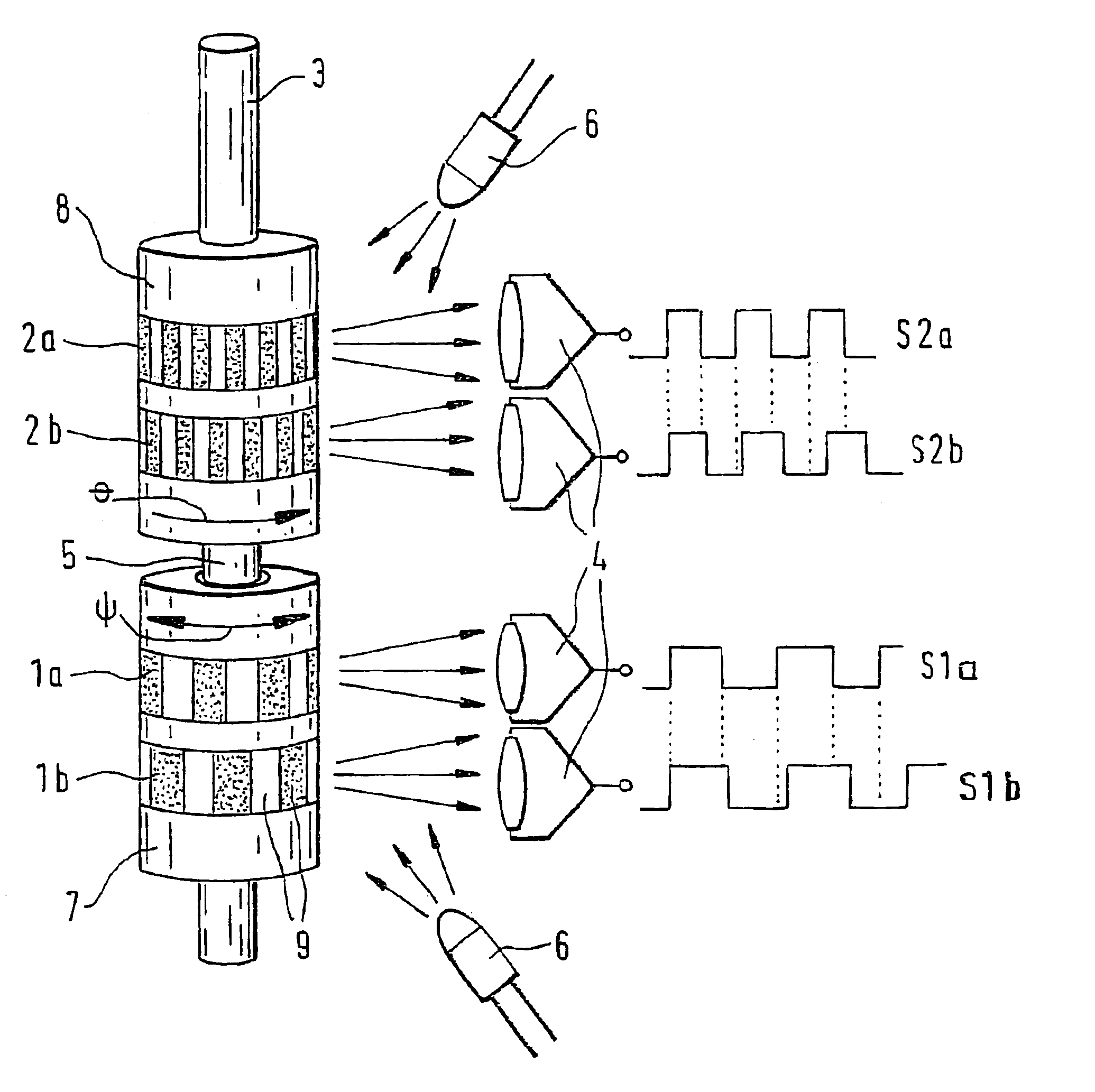

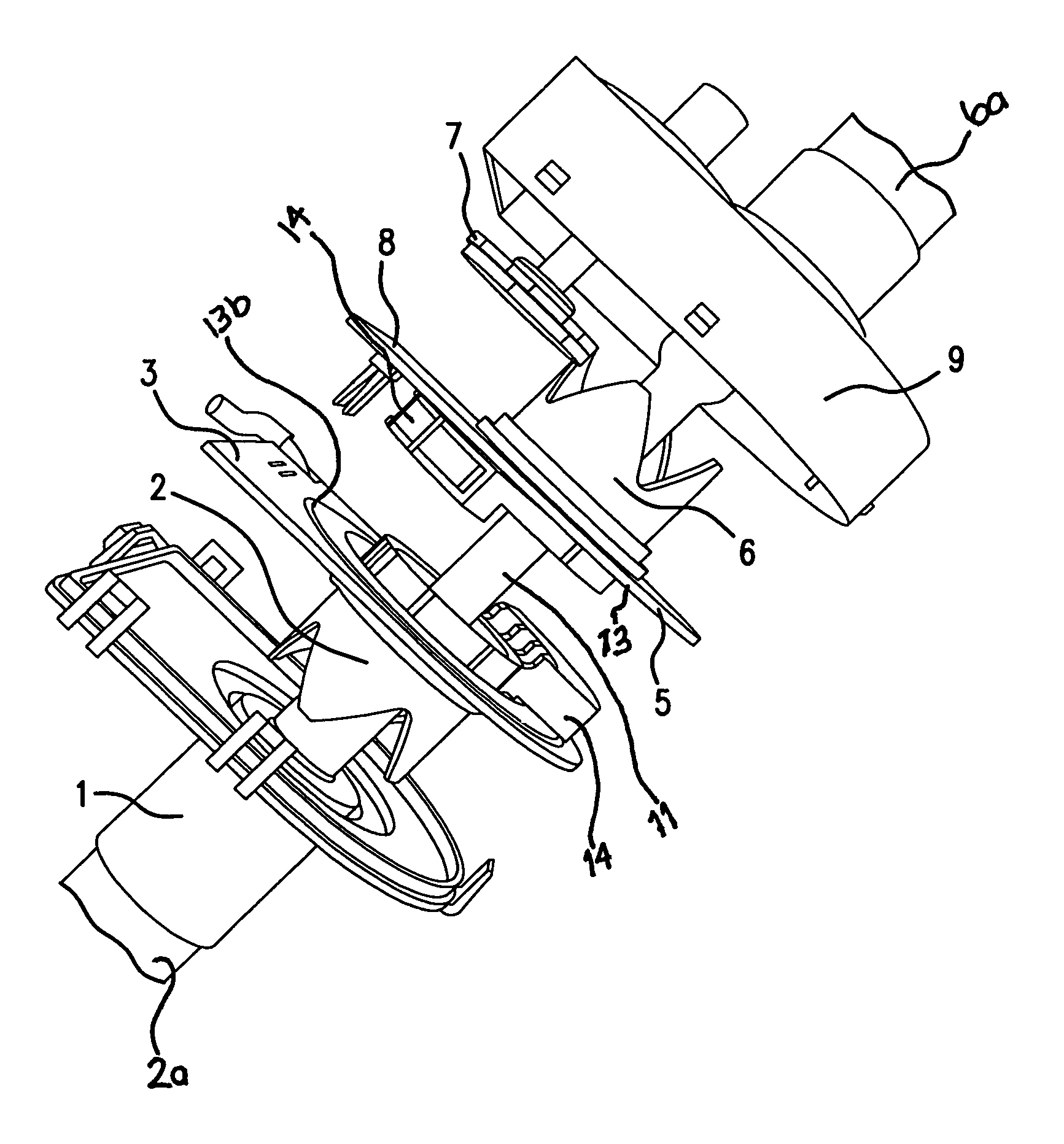

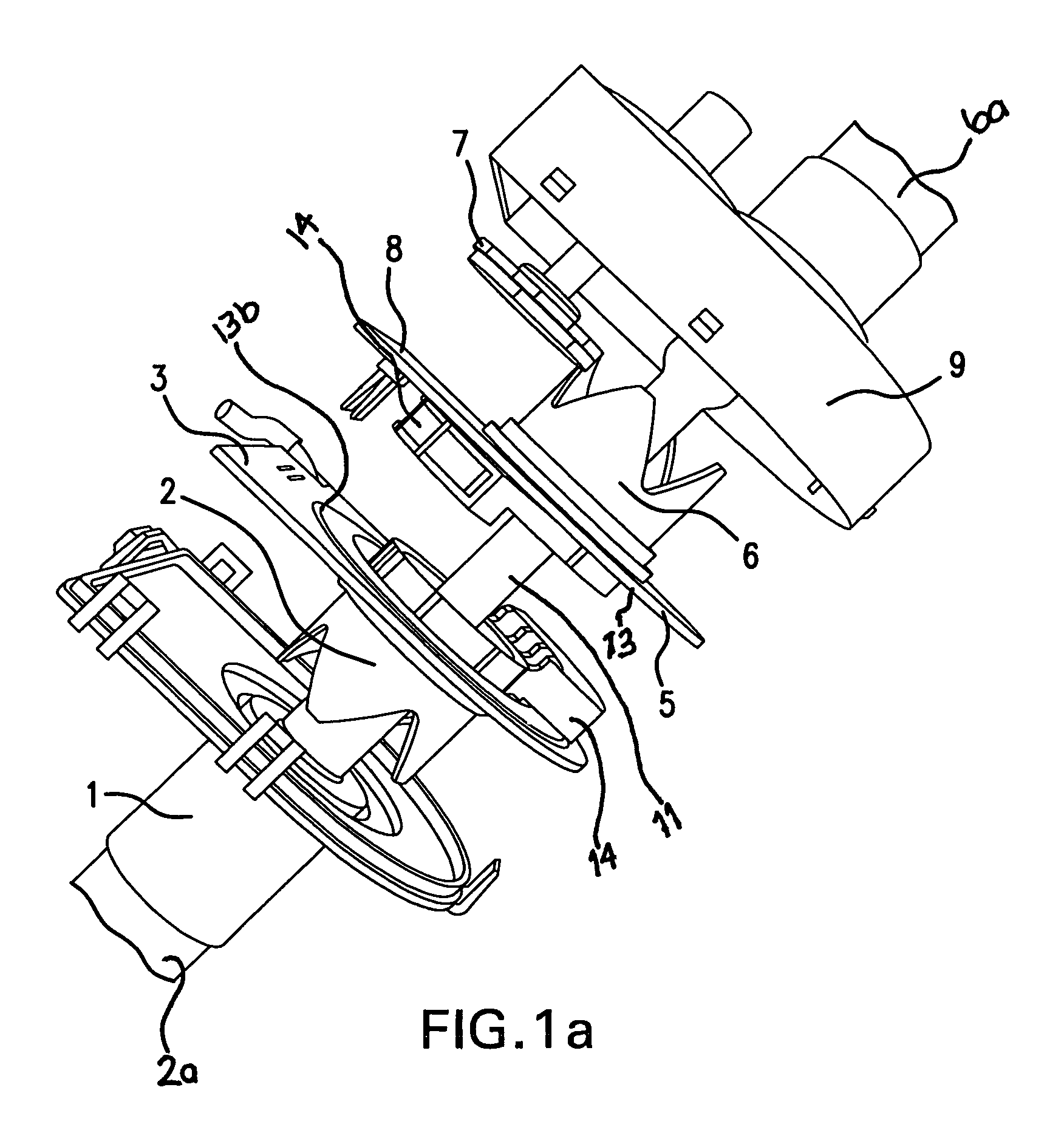

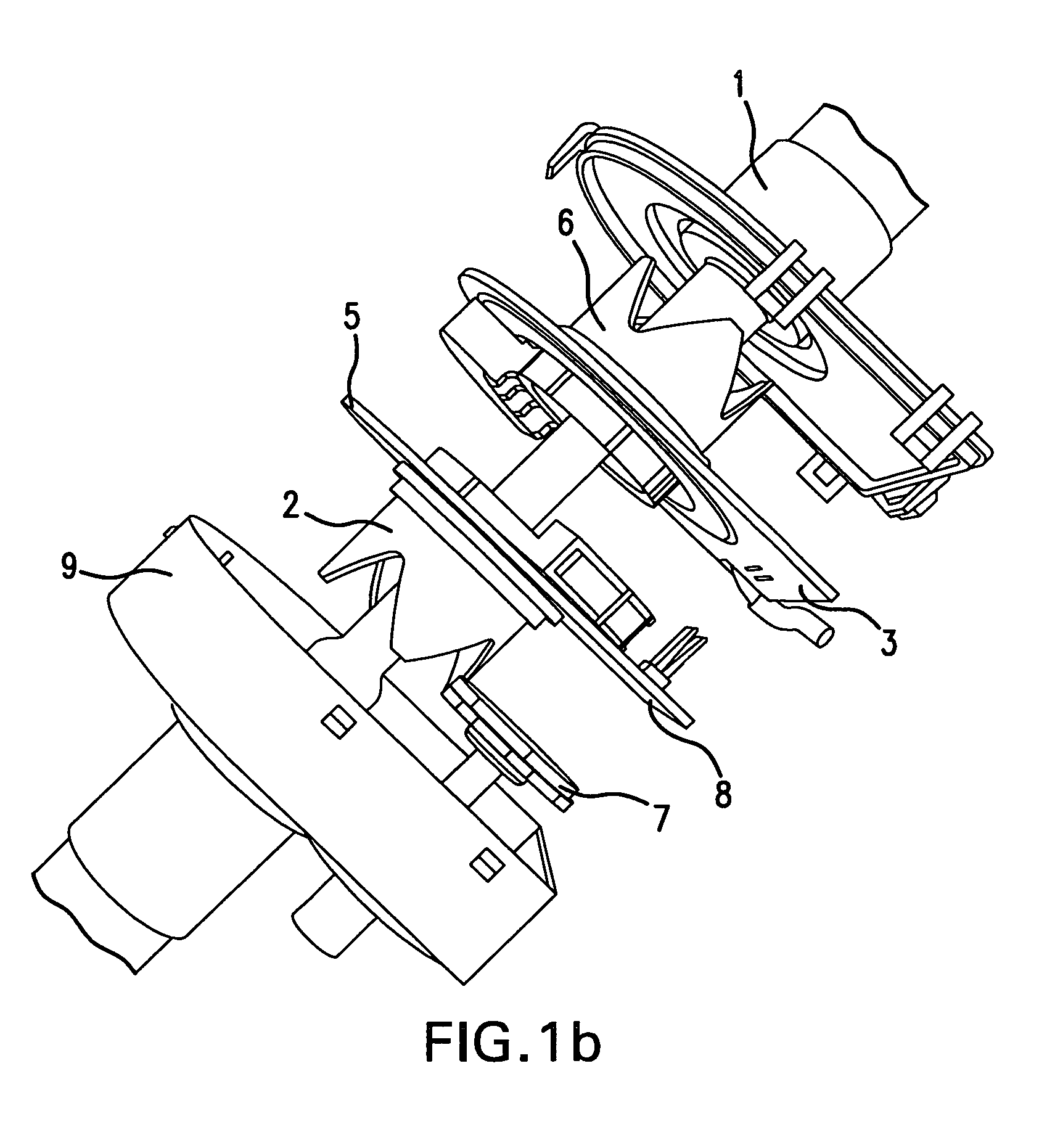

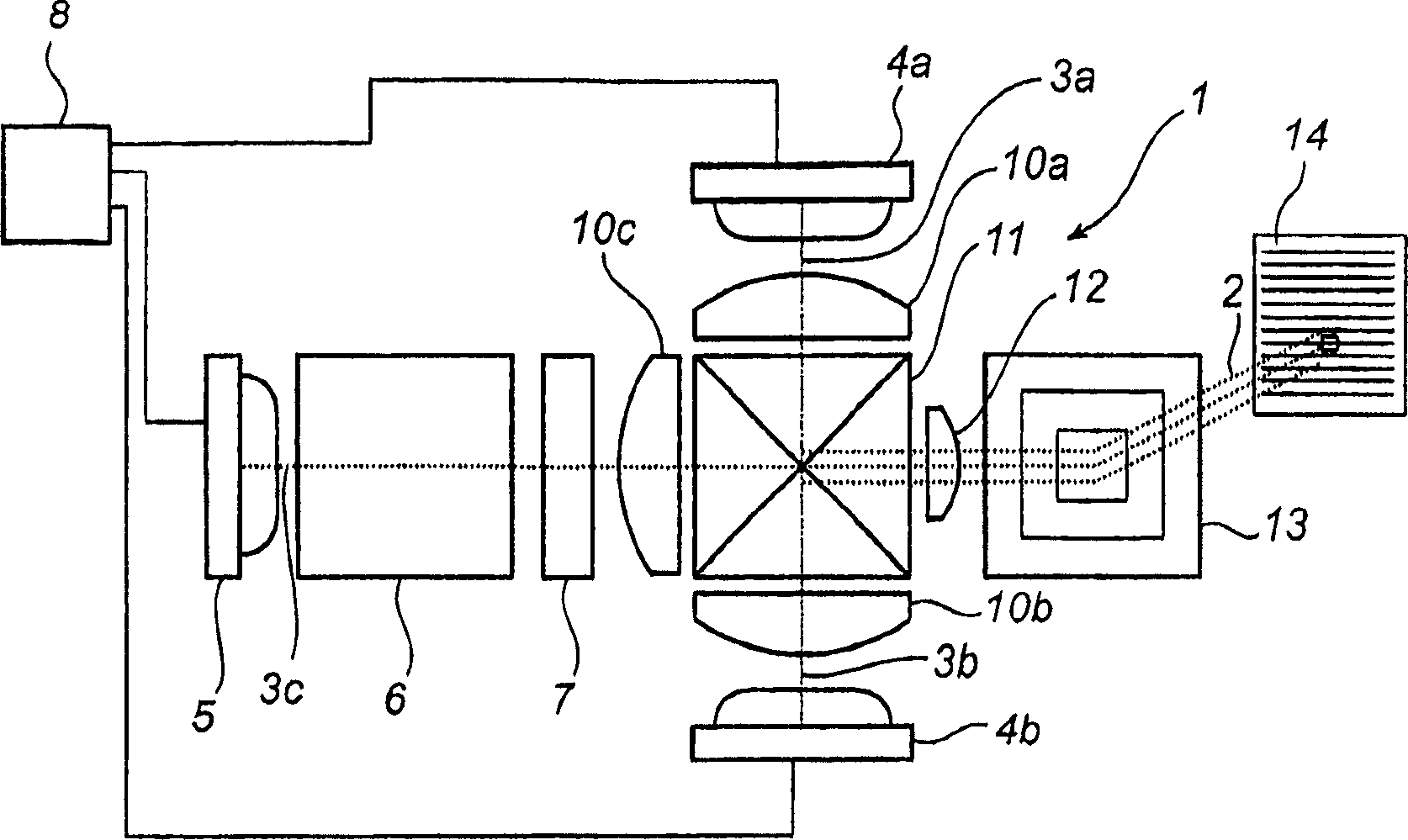

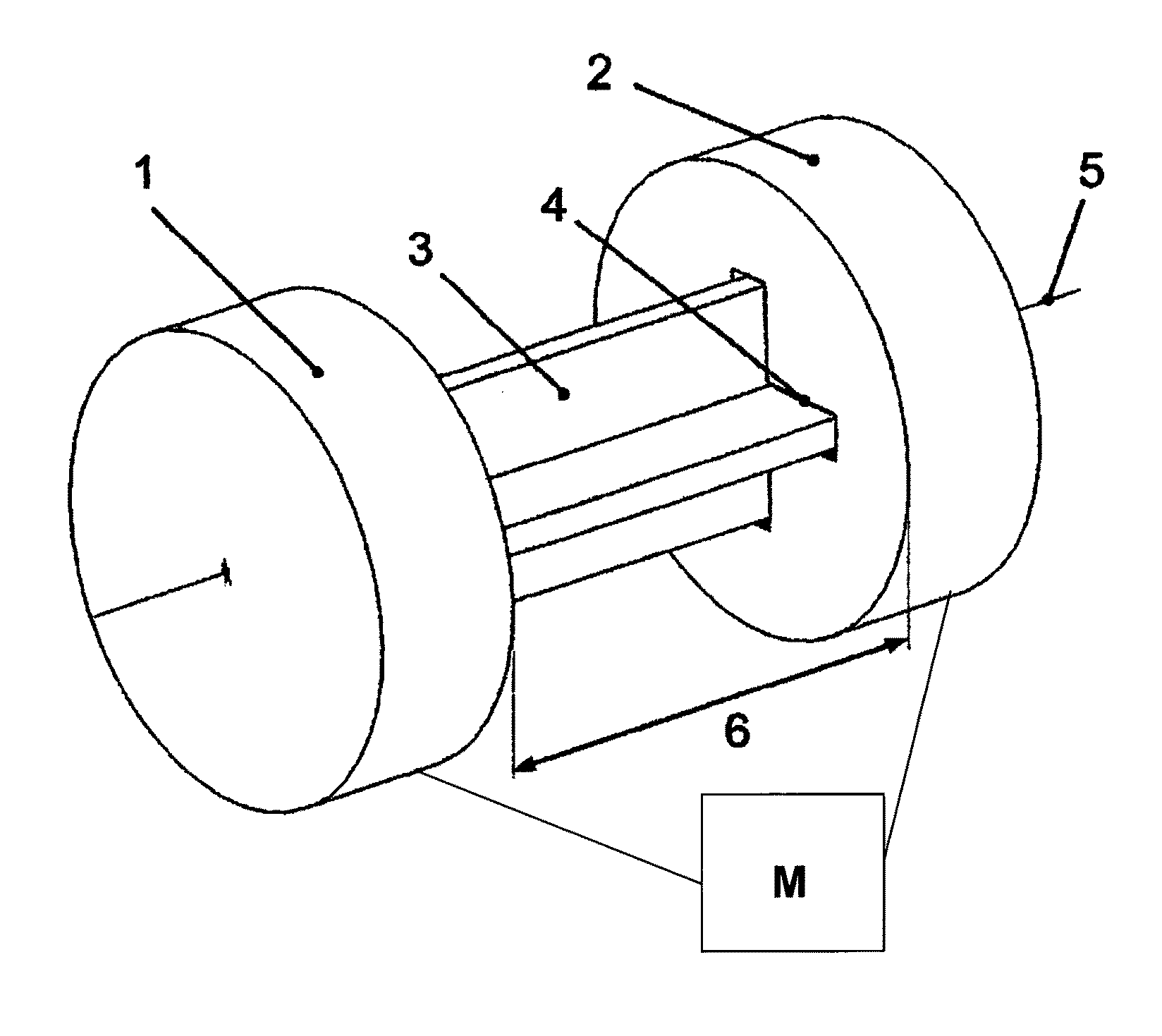

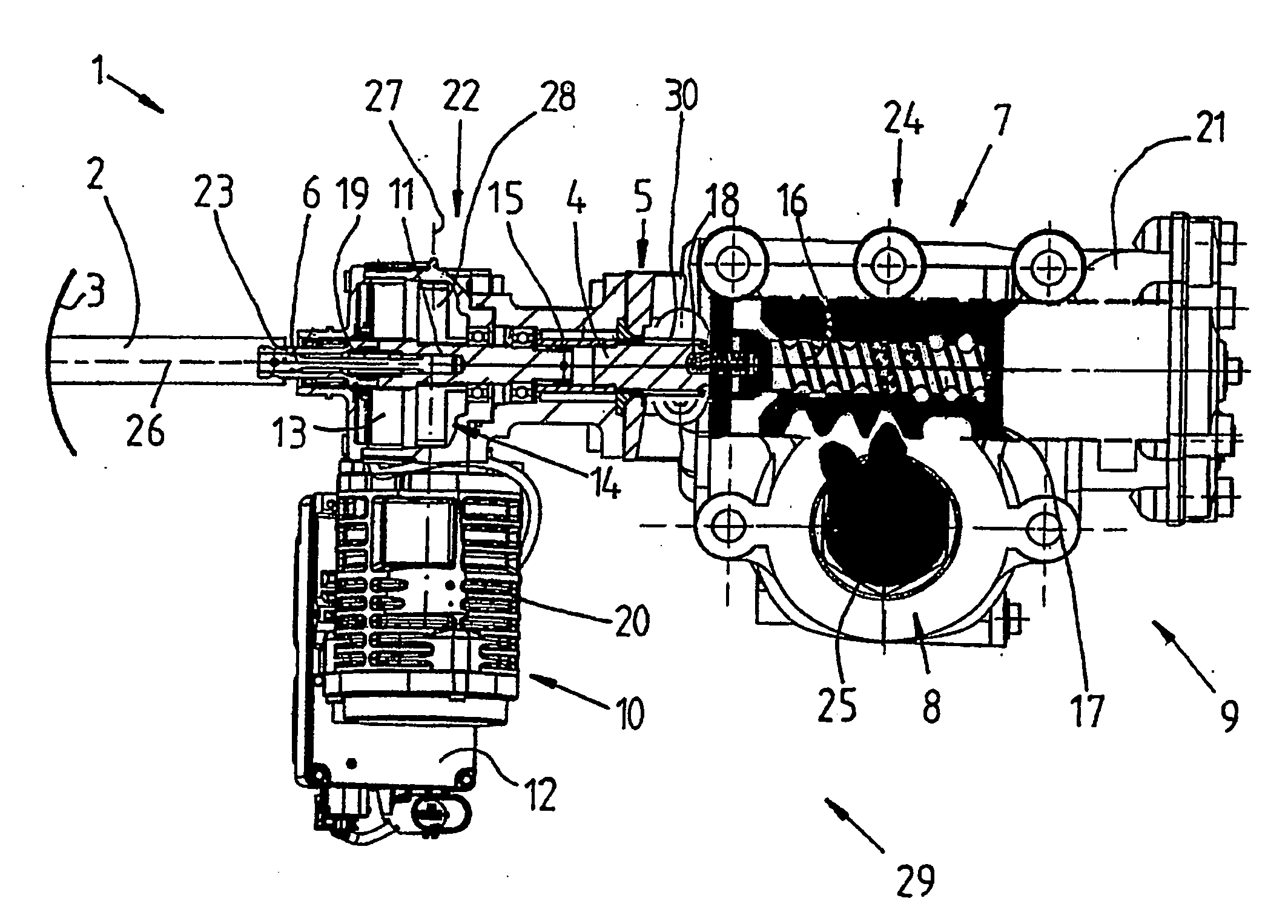

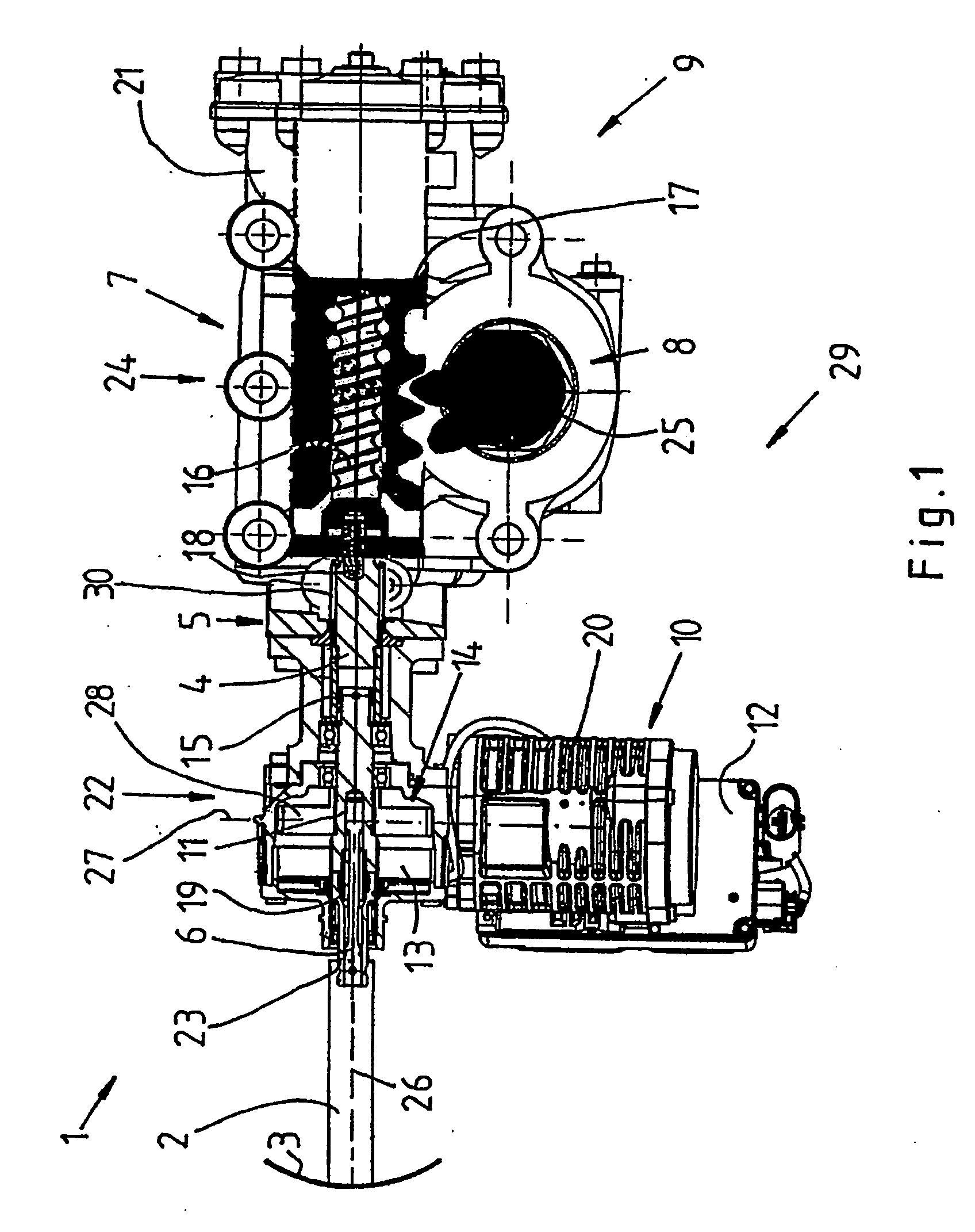

Device for measuring the angle and/or the angular velocity of a rotatable body and/or the torque acting upon said body

InactiveUS6935193B2High measurement accuracyExpand the measurement rangeSuspensionsDetection of fluid at leakage pointAngular velocityTorsion element

A device for measuring an angle and / or the torque acting on a rotatable body is proposed according to the invention, whereby the rotational angle is detected by means of magnetic or optical sensors. In particular, in a preferred exemplary embodiment, two devices (7, 8) are proposed, each of which comprises two optically readable code tracks. The two code tracks (1a, 1b or 2a, 2b) on one device (7 or 8) are similar in design and are offset in relation to each other, so that associated sensors (4) output a digital signal. The rotational angle is calculated based on the lag between the two digital signals. In a further embodiment it is provided that a torsion element (5) having a known torsional stiffness is situated between the two devices (7, 8). Torque transferred by the rotatable body (3) can also be calculated therefore from the angular difference of the two devices 7, 8. The device is used preferably in the steering axle of a motor vehicle.

Owner:ROBERT BOSCH GMBH

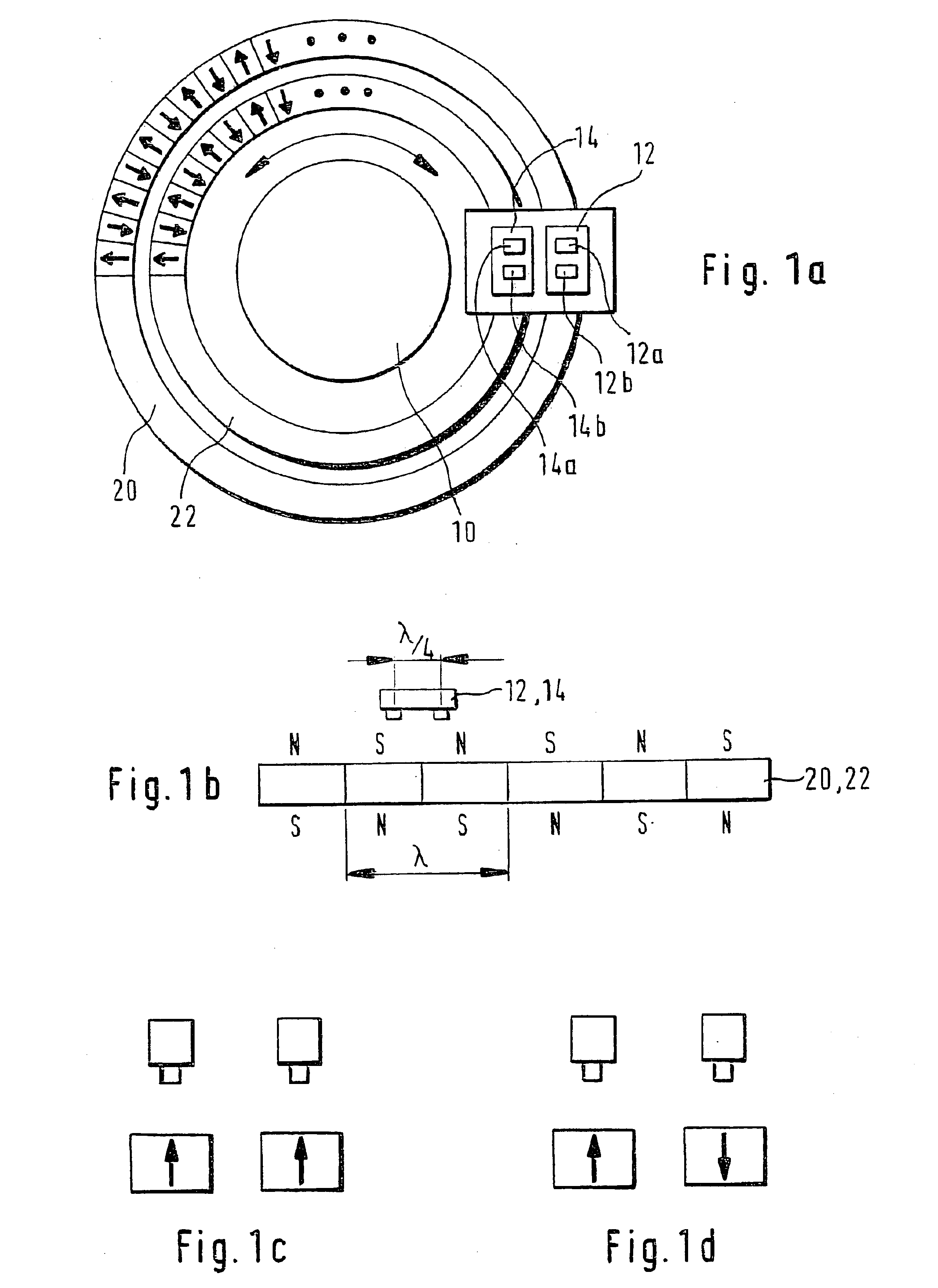

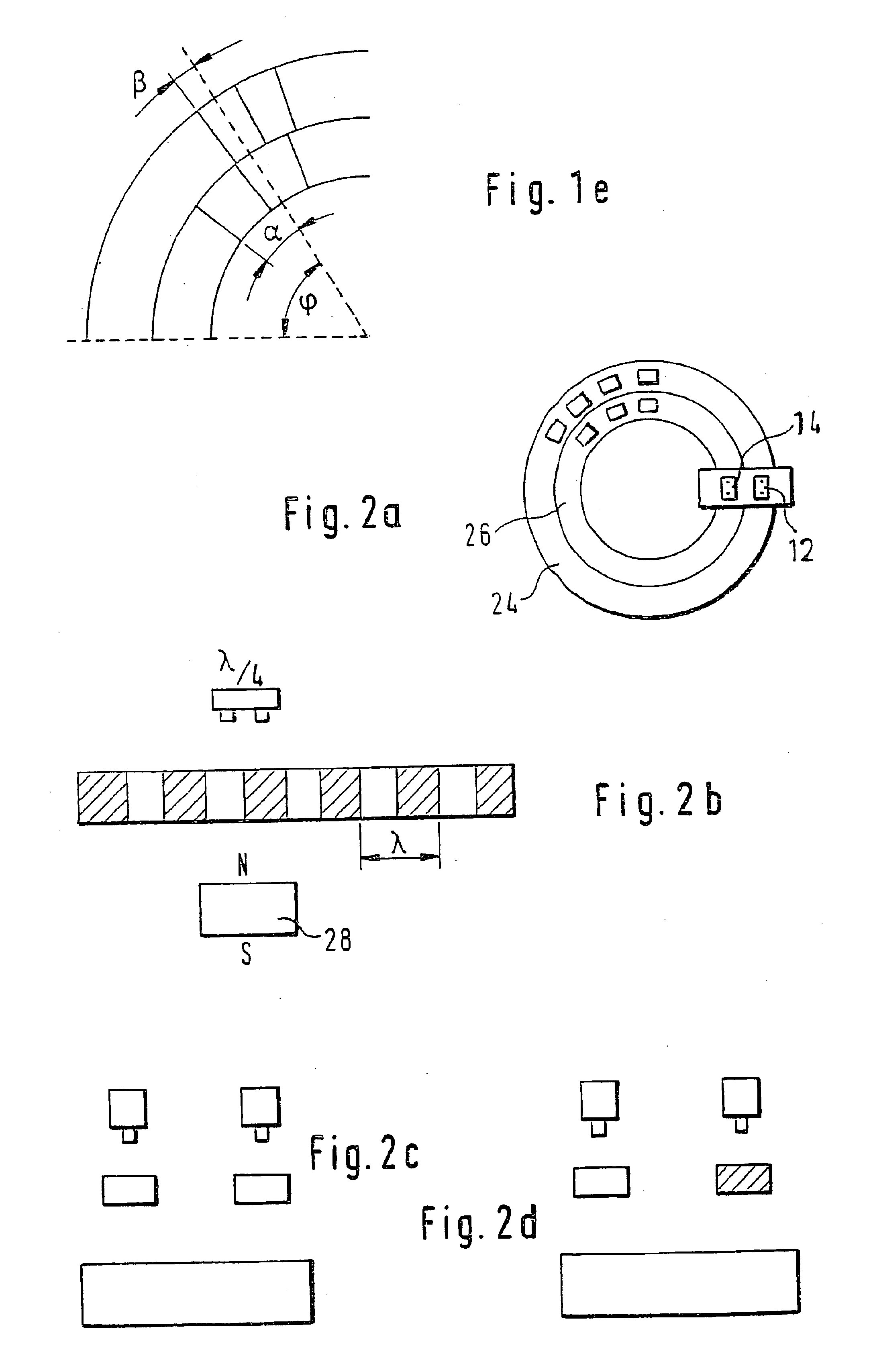

Combined steering angle and torque sensor

A combined steering angle and torque sensor that inductively and with eddy current damping generates two absolute angle measurement signals over an angle range of 360 degrees including a first damping rotor being disposed on an end of an input shaft of steering column divided by a torsion element; a second damping rotor being disposed on an end of an output shaft of the steering column; at least one carrier being fixed to a housing of the steering column and through which the steering column passes at a right angle, the at least one carrier being fitted with flat coils in a complete angle range; and at least one passive actuating element, without periodically repeated structures, being borne on each of said first and second damping rotors, the actuating elements being in two different locations of said angle range acting on the flat coils of the at least one carrier.

Owner:ZF FRIEDRICHSHAFEN AG

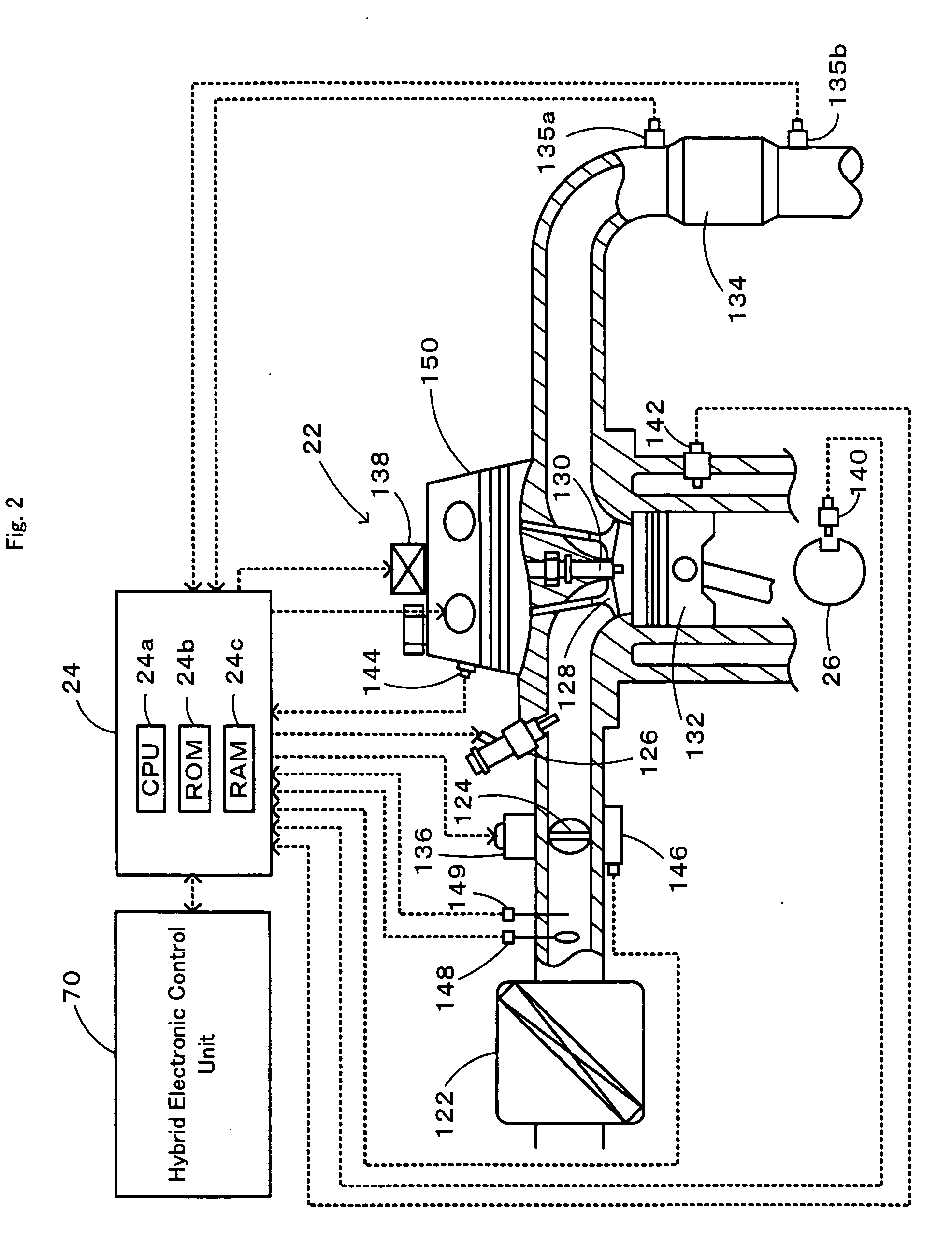

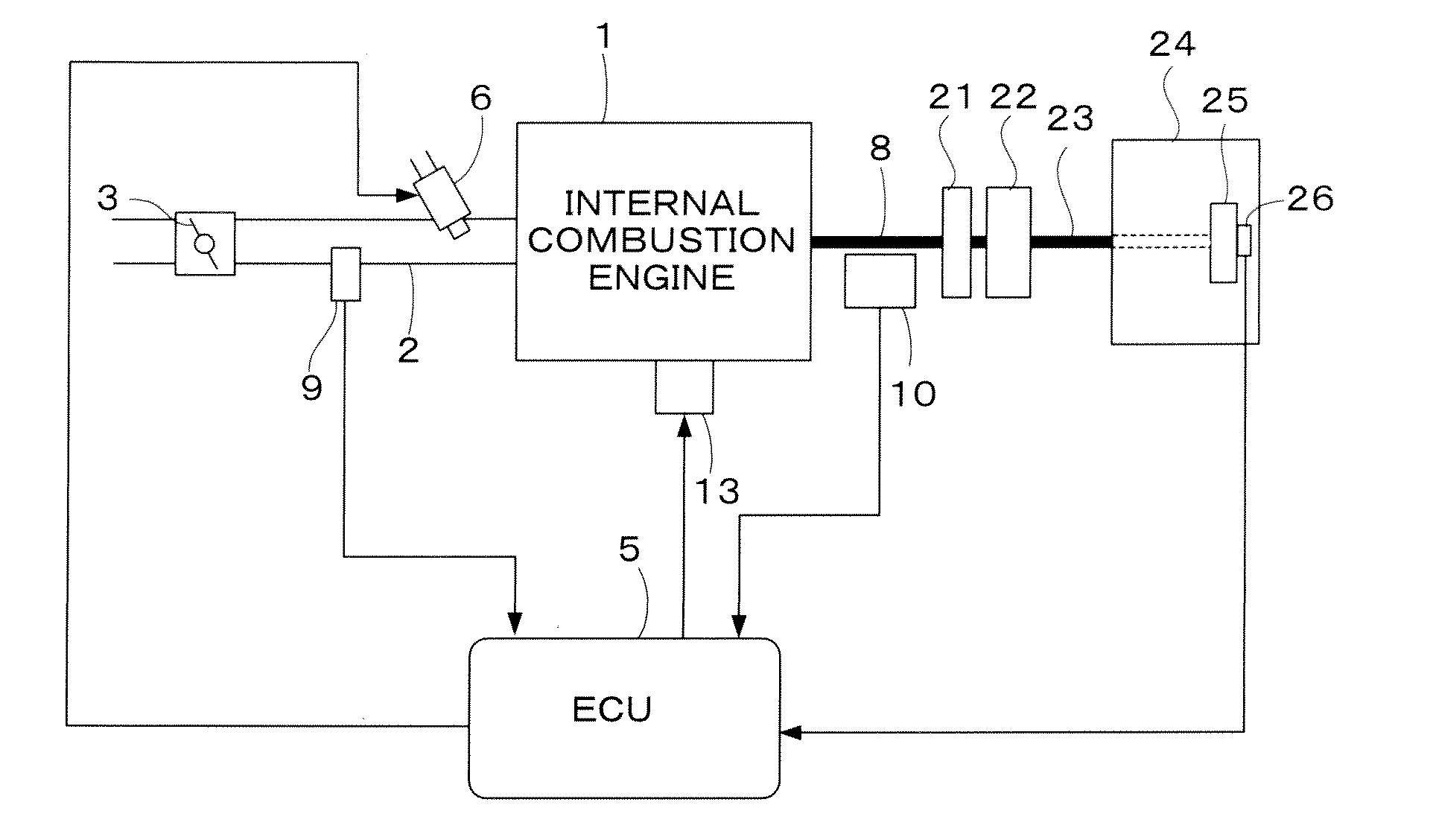

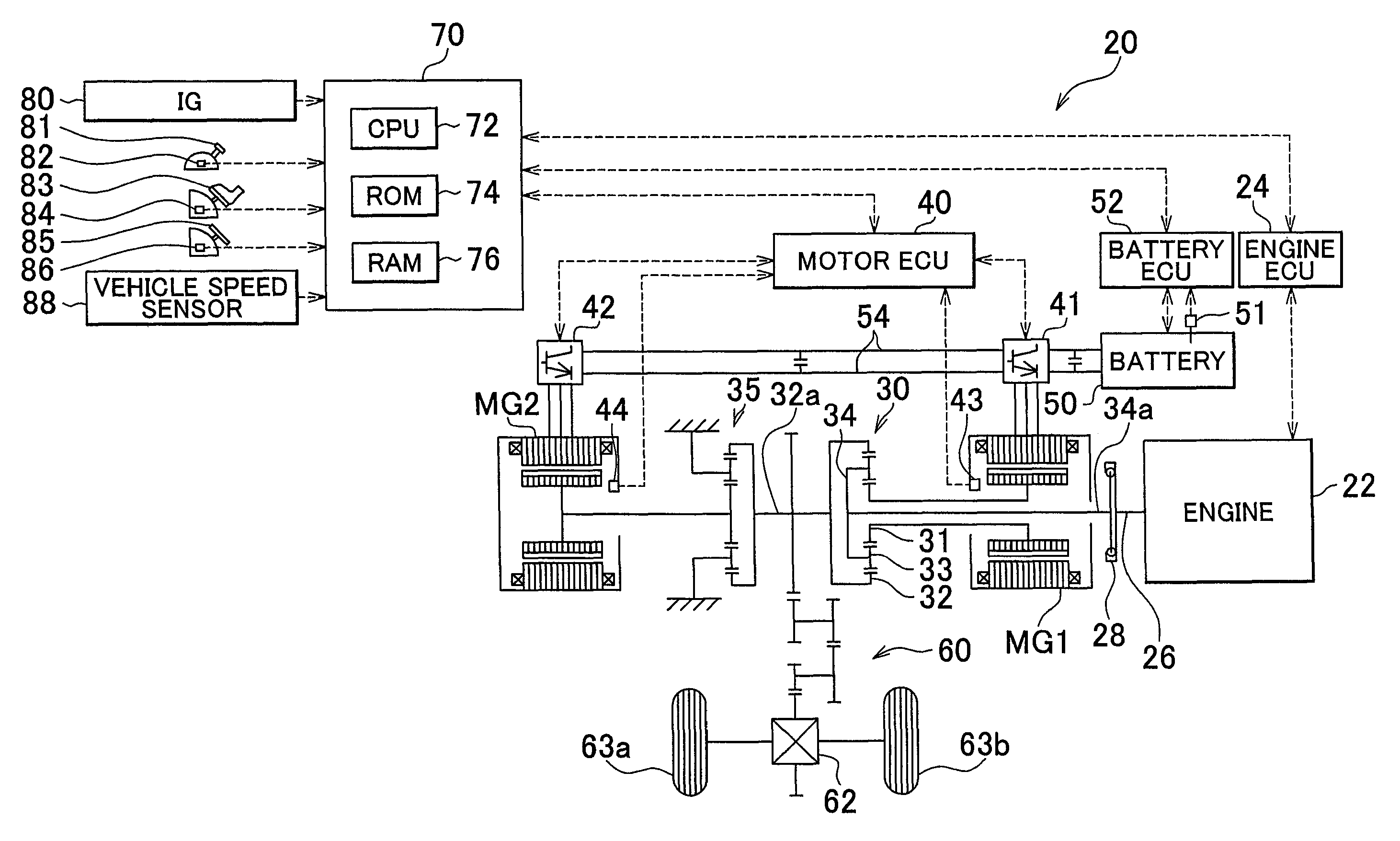

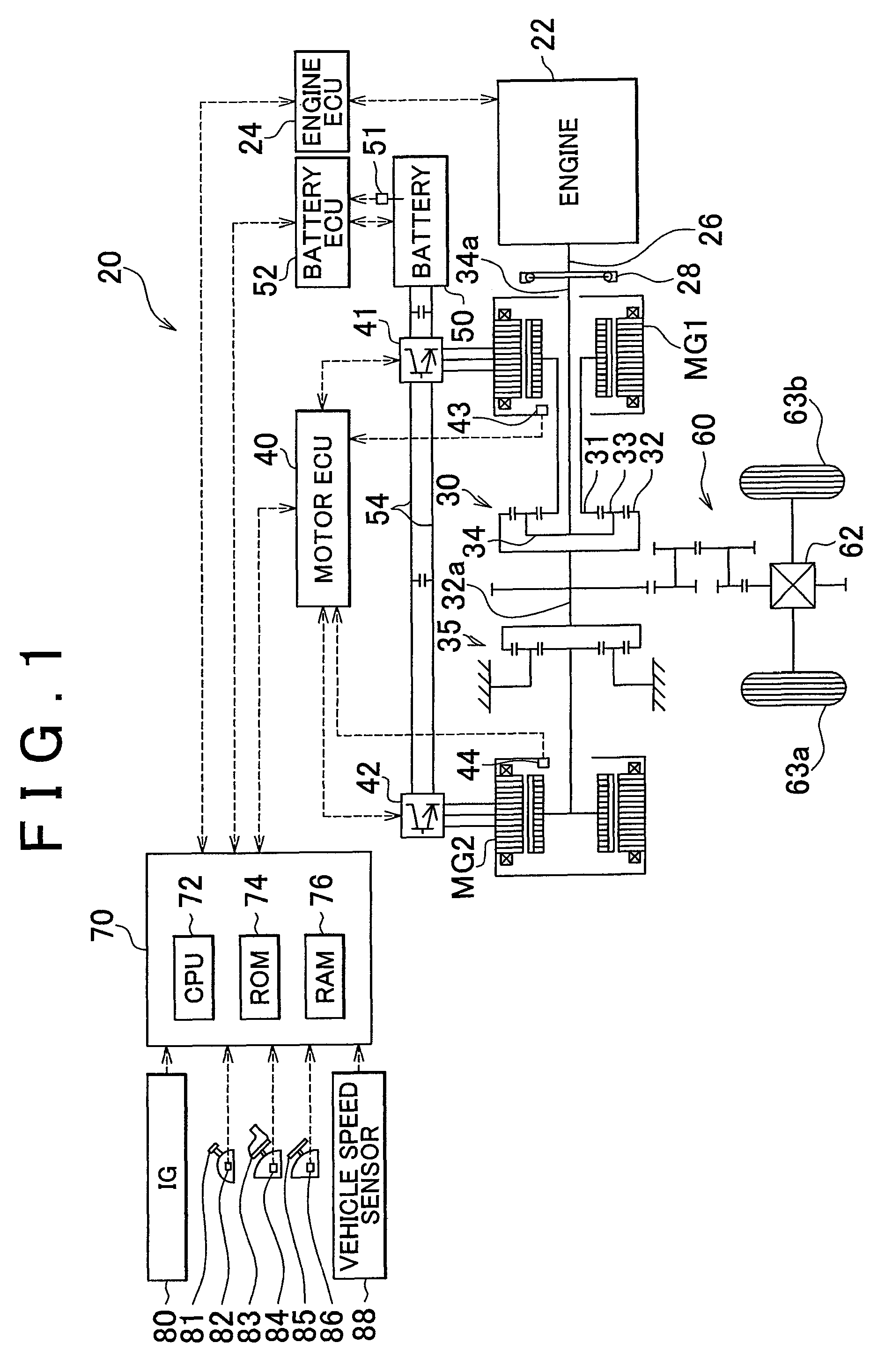

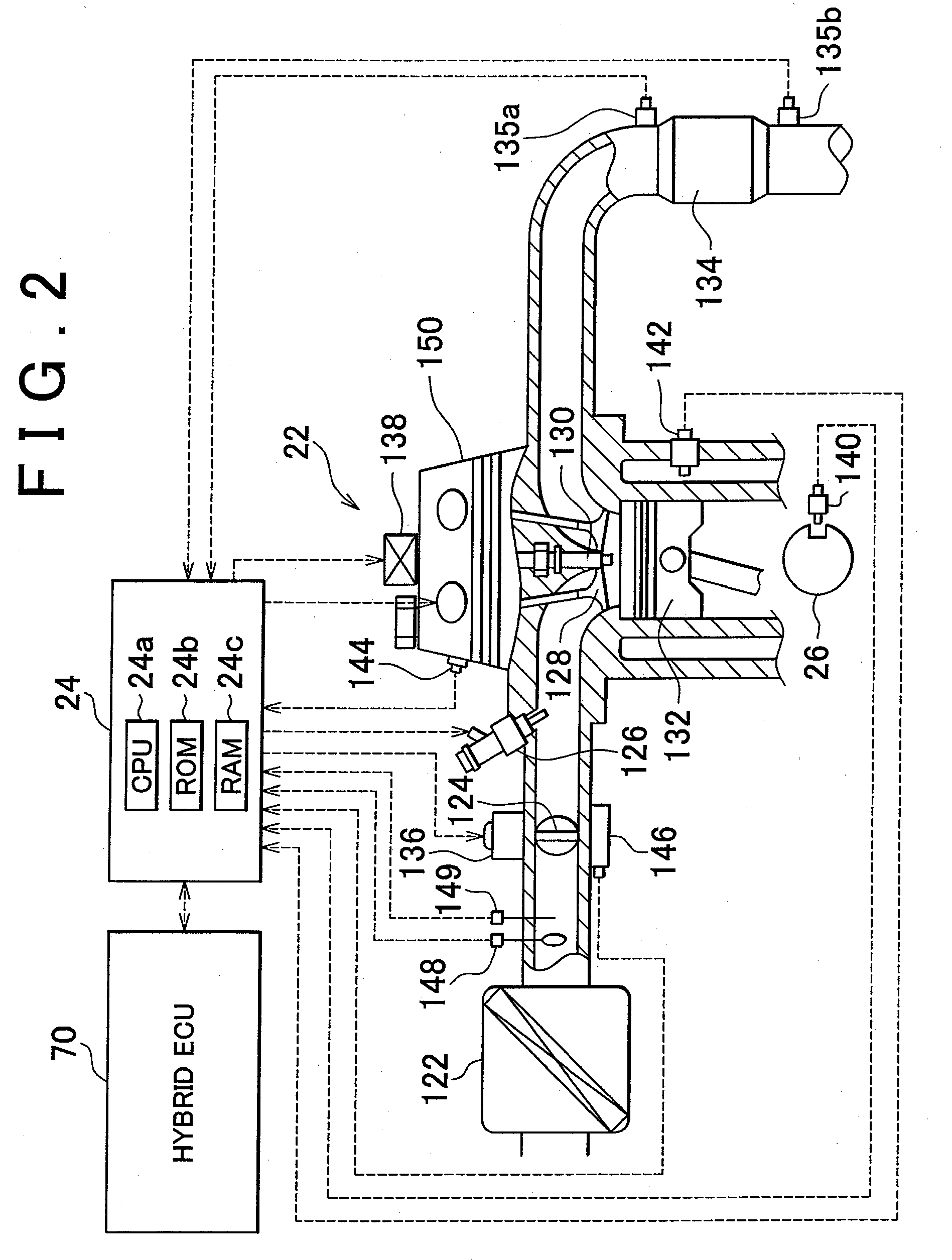

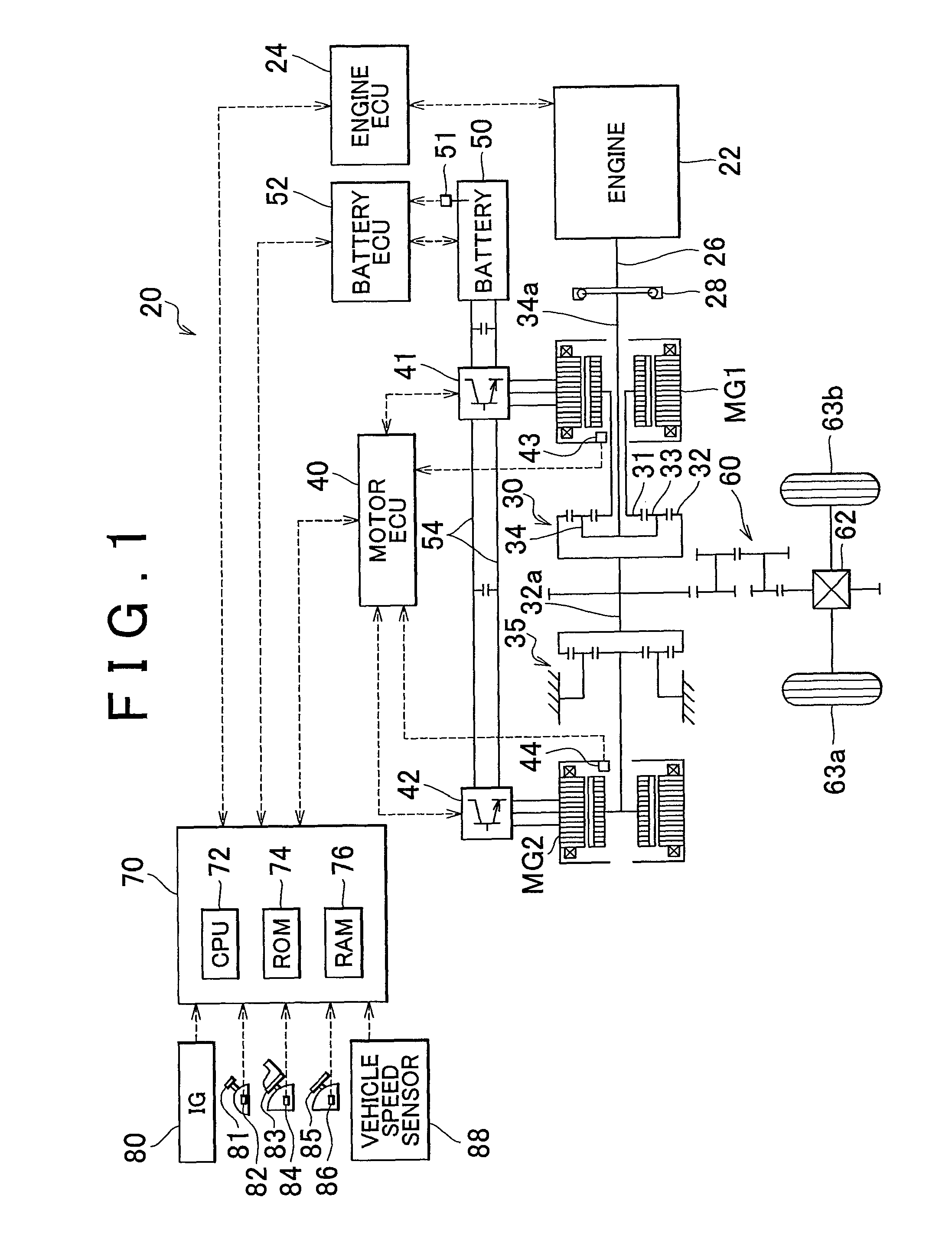

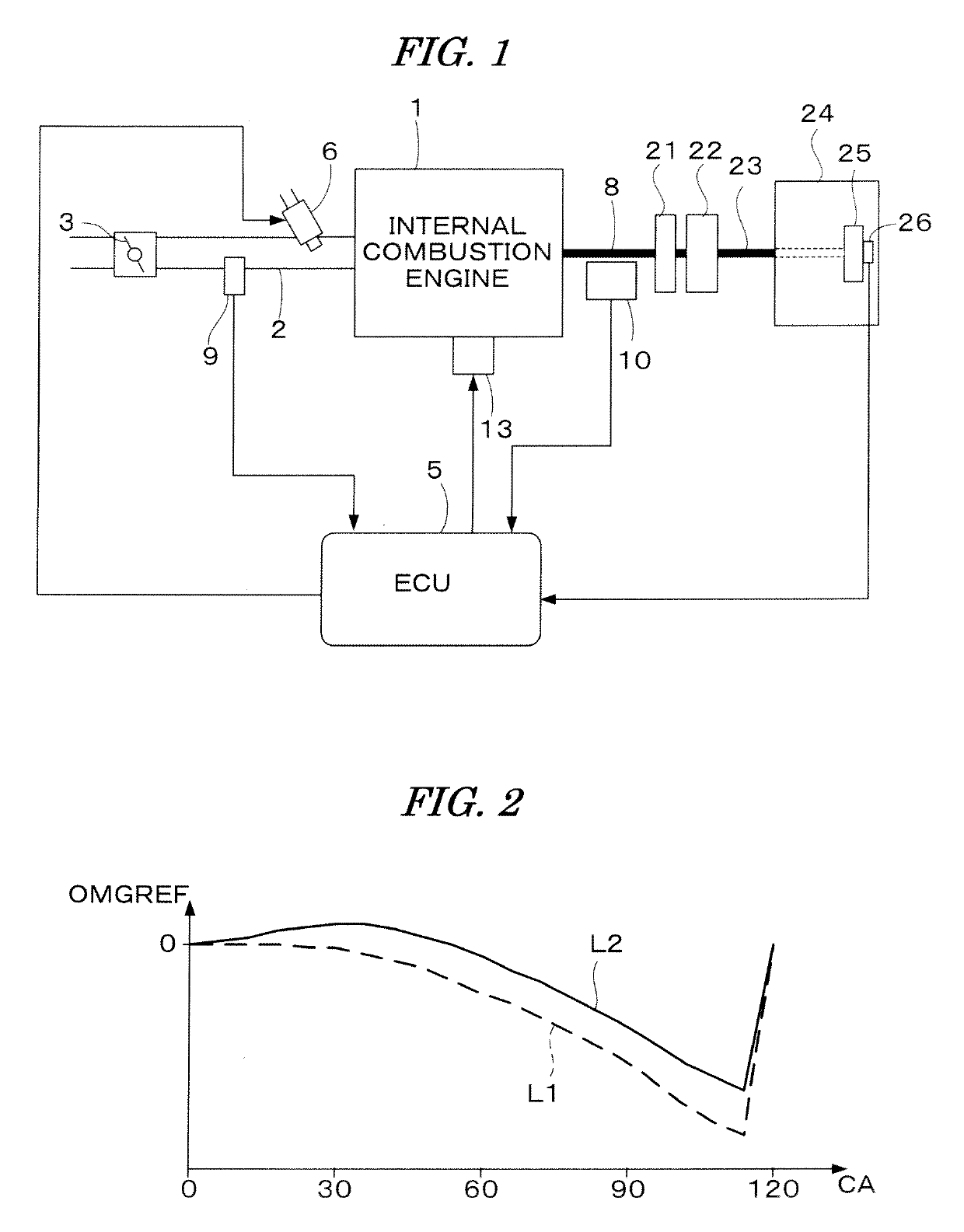

Engine Misfire Identification Device for Internal Combustion Engine, Vehicle Equipped With the Same and Method of Engine Misfire Identification

InactiveUS20100152991A1Improve accuracyReliable identificationAnalogue computers for vehiclesInternal-combustion engine testingExternal combustion engineResonance

An engine misfire is identified by ordinary engine misfire detection processing when the operating condition of an engine comprising a rotation speed Ne and a torque Te does not belong to a resonance region of a rear portion including a damper as a torsion element (S120), and an engine misfire is identified by resonance-region engine misfire detection processing, which is different from the ordinary engine misfire detection processing, when the operating condition of an engine belongs to a resonance region of a rear portion including a damper (S130). This enables an engine misfire to be identified more reliably and with good accuracy regardless of whether the operating condition of an engine belongs to a resonance region of a rear portion including a damper.

Owner:TOYOTA JIDOSHA KK

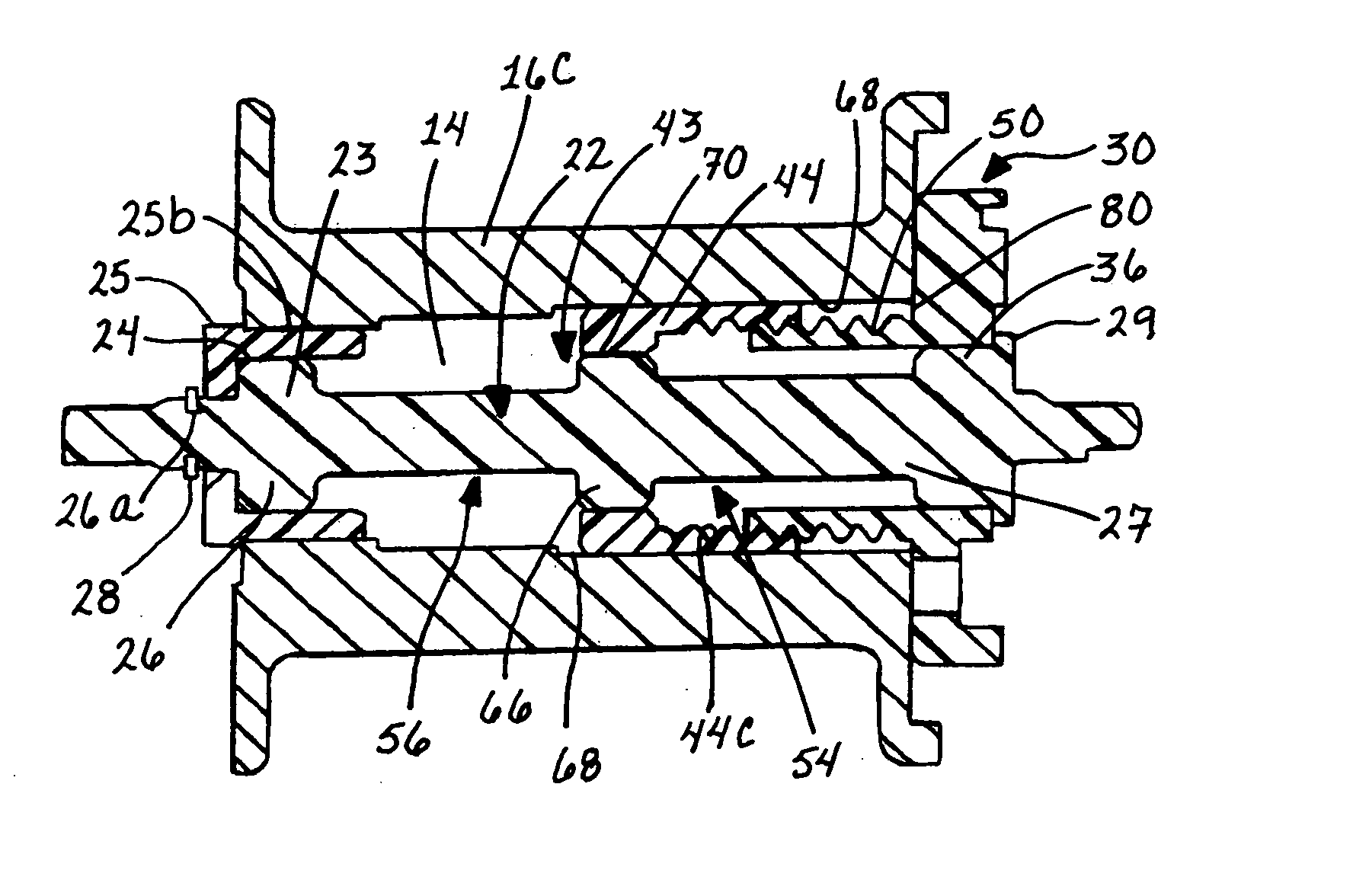

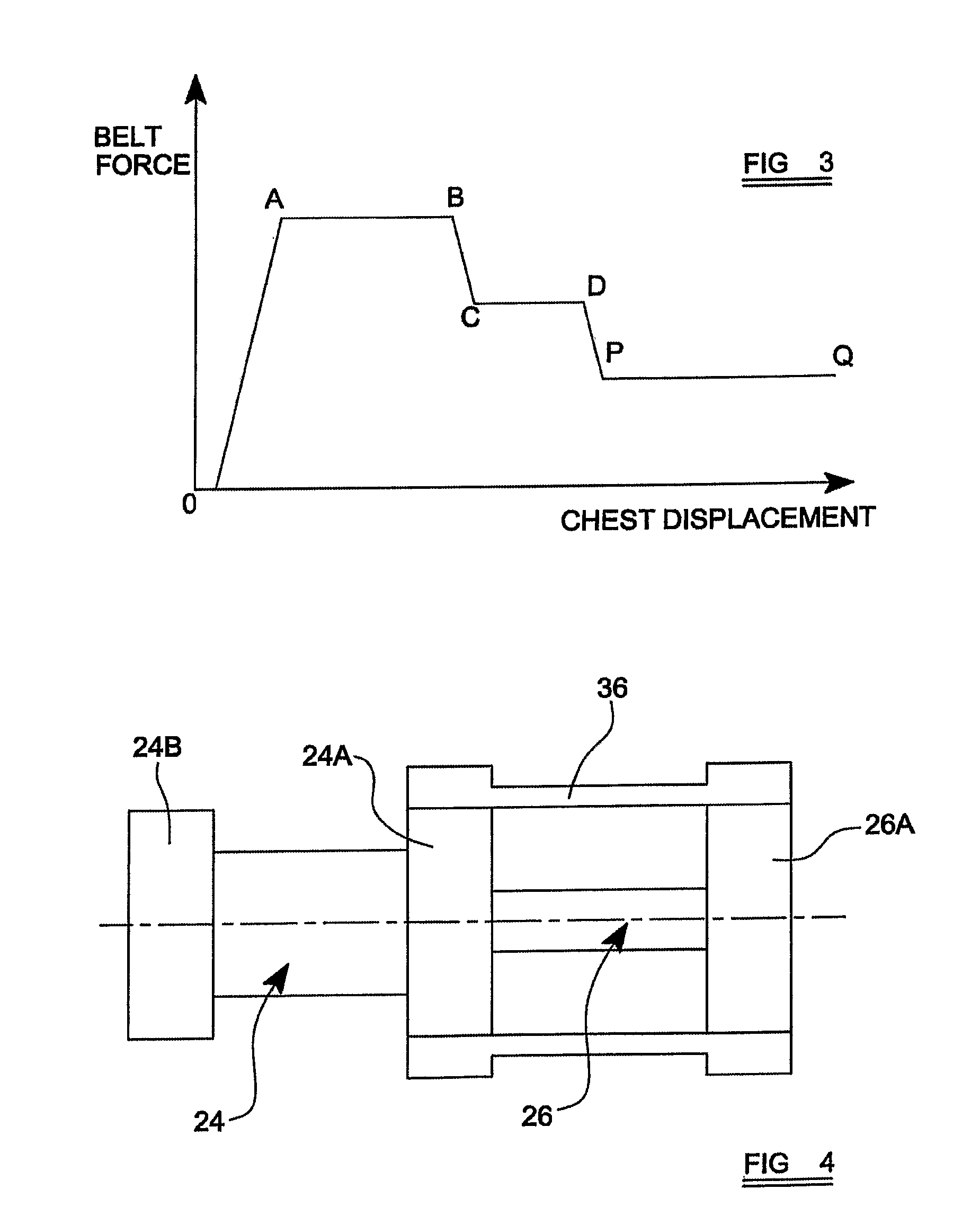

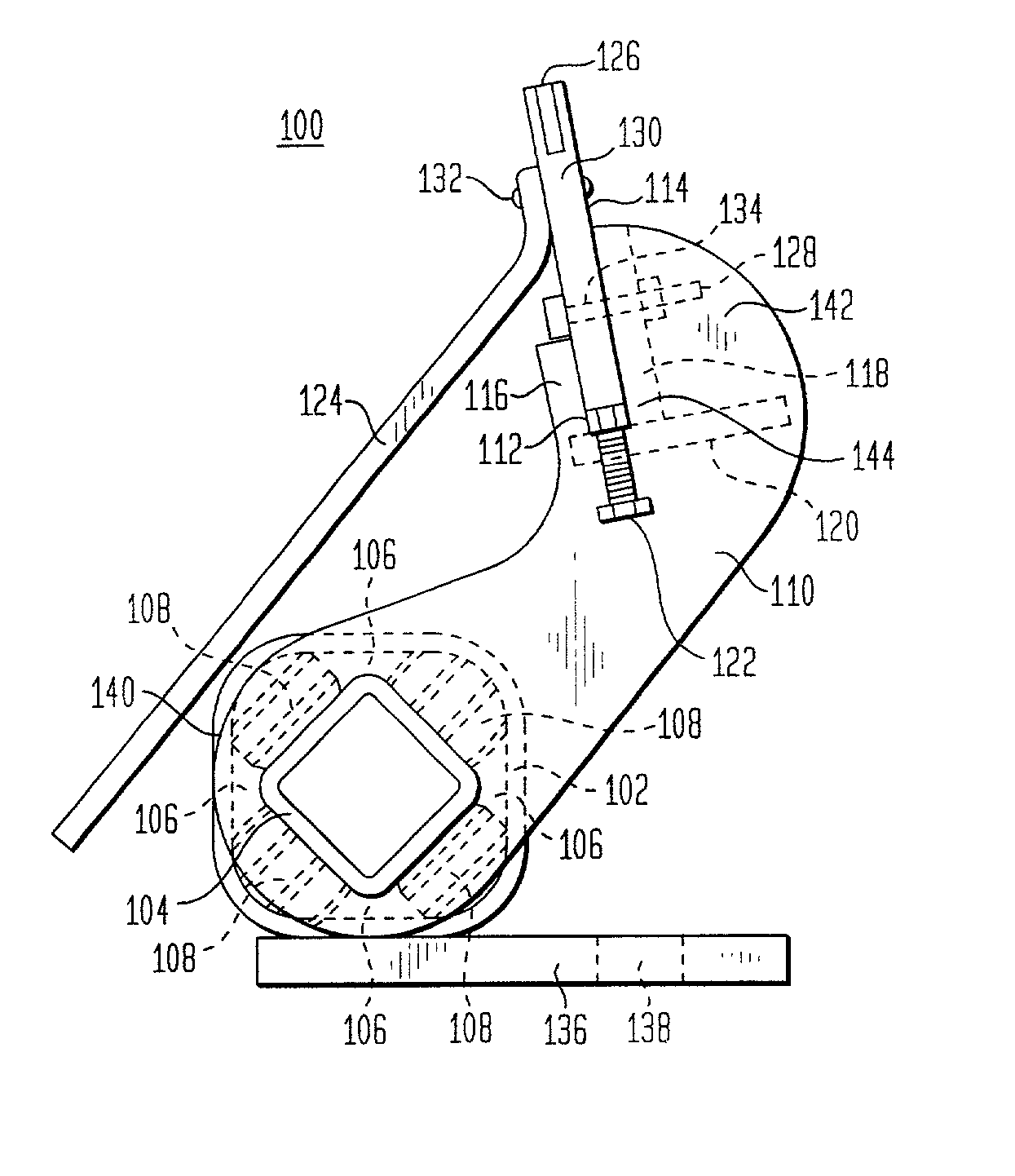

Retractor with multiple level load limiter

A multi-level energy absorption retractor is provided with a torsion type of energy absorption which is achieved automatically without the use of an independent sensing mechanism and an electrical control to start energy dissipation and / or to shift from one amount of energy absorption to another amount of energy absorption at the time of an accident. First and second torsion elements, preferably formed in a single torsion bar, are utilized with automatic twisting of the first torsion element for an initial predetermined amount of spool rotation and energy absorption and then automatically transitioning to twist the second torsion element for energy absorption at the second level. Preferably, a coupling device sequentially couples the first torsion element for energy absorption at the first level, and then, automatically after a predetermined amount of spool rotation couples the second torsion element for energy absorption at the second level.

Owner:TAKATA SEAT BELTS

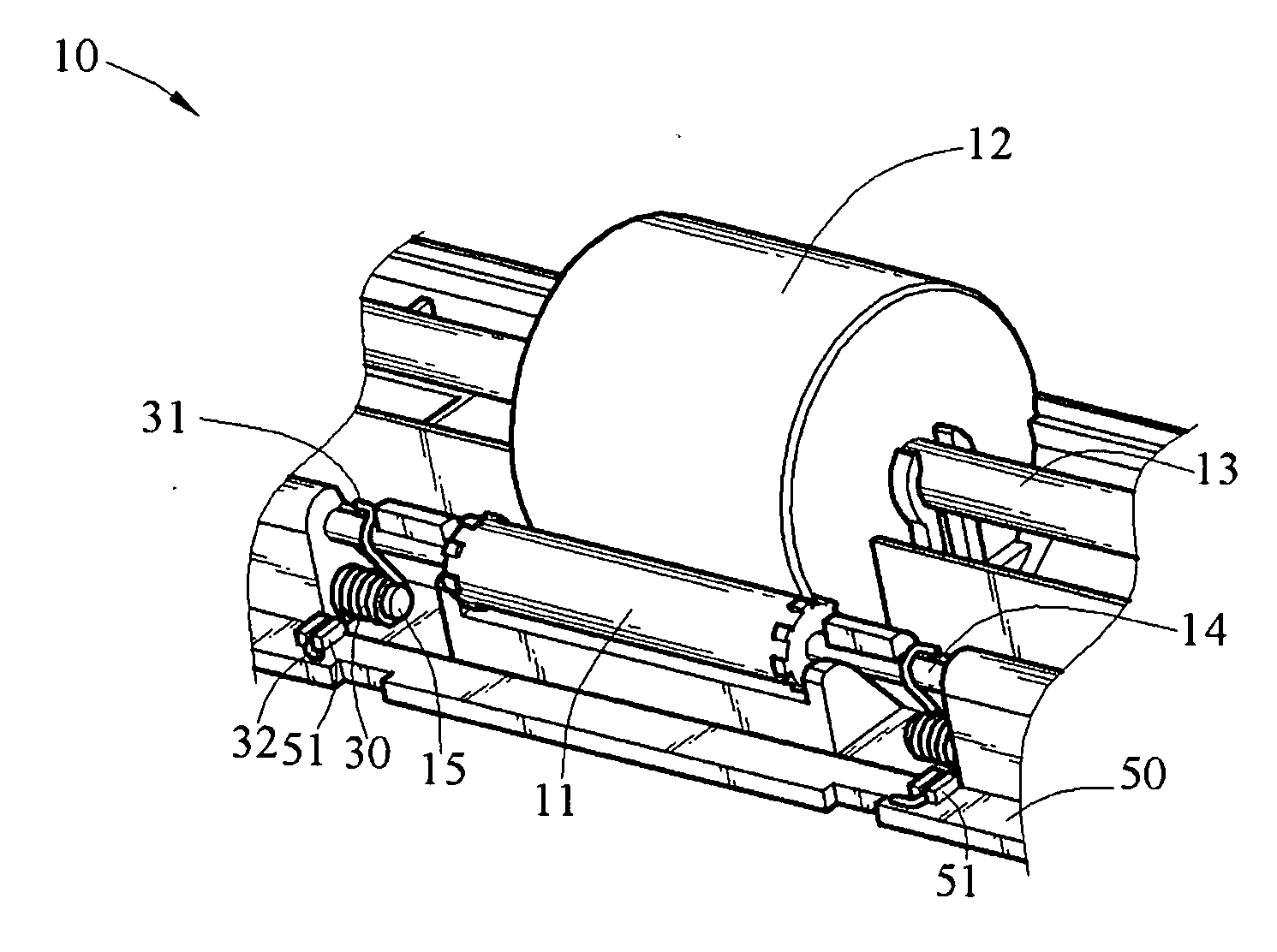

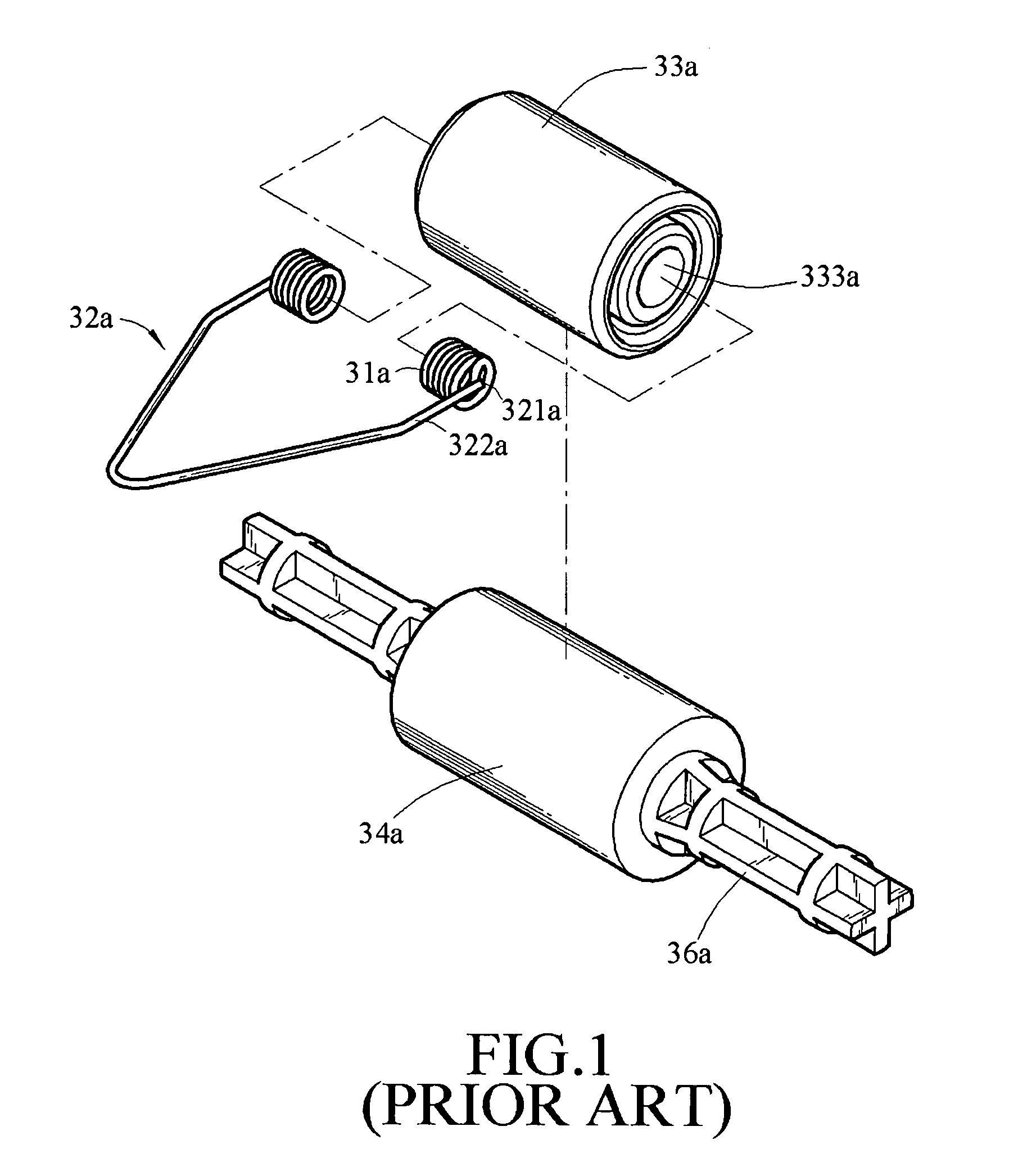

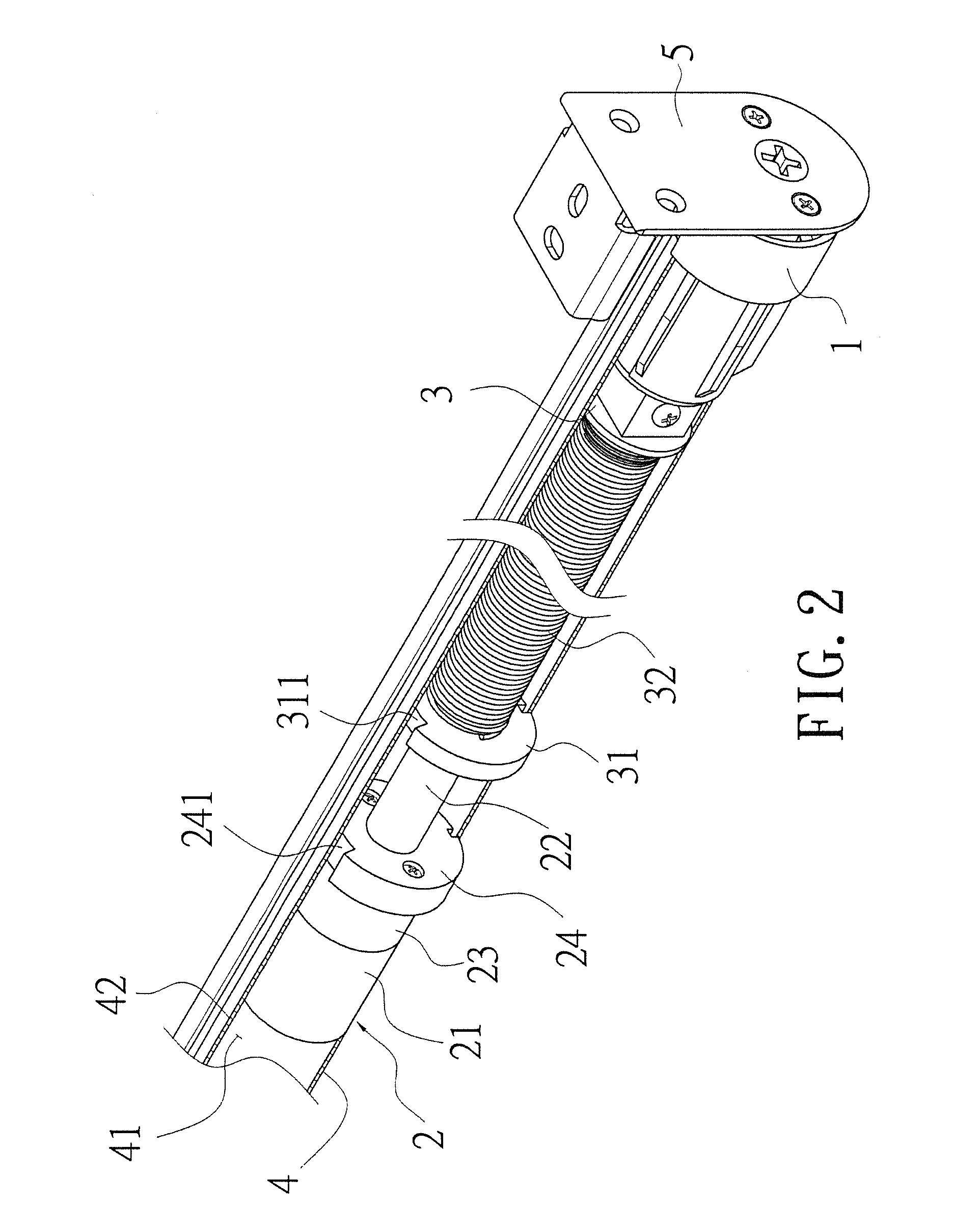

Paper feeding mechanism

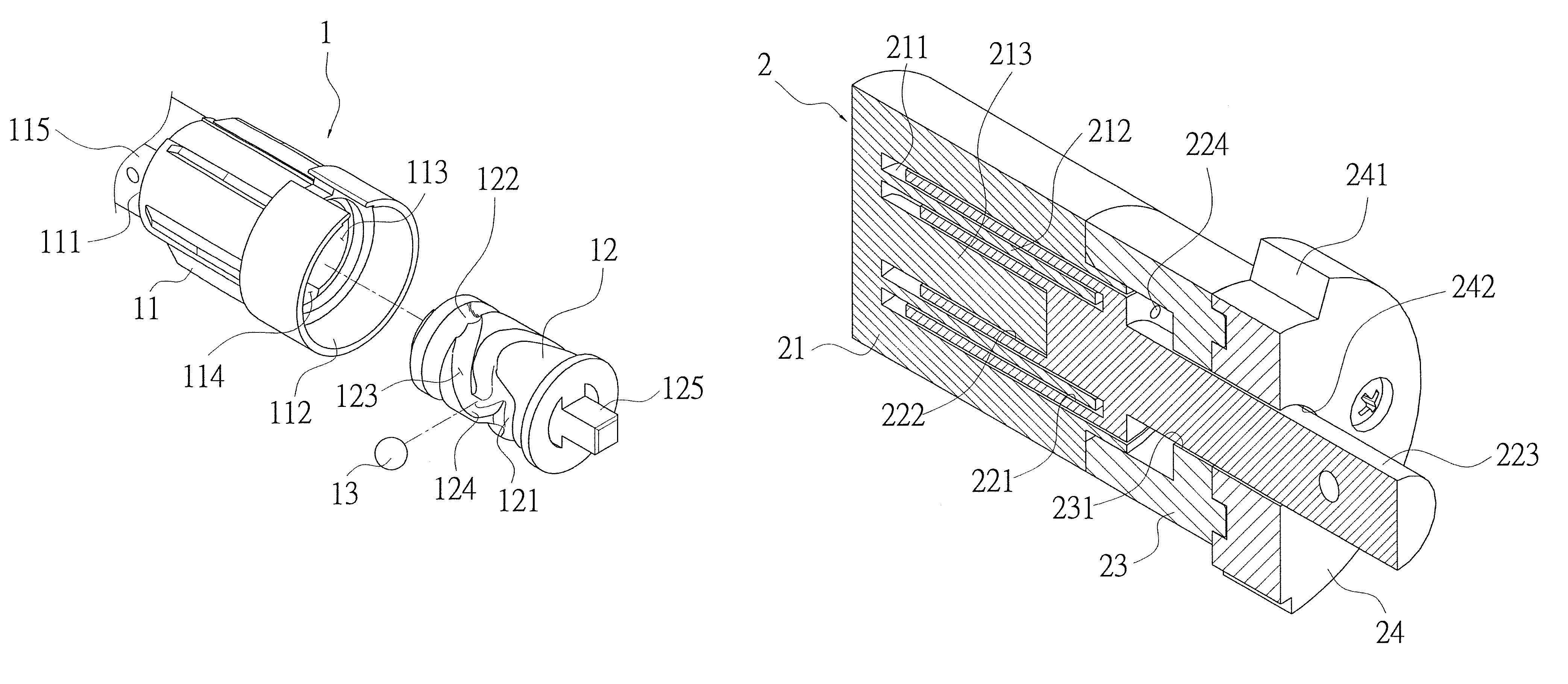

InactiveUS20080036141A1Lower the volumeEliminate ineffective component forceArticle feedersArticle separationTorsion elementNormal force

A paper feeding mechanism includes a base, a driven roller, an active roller, a shaft, and a plurality of torsion elements. The shaft is disposed on the base, and the torsion elements are coaxially connected to the shaft with a first and a second force arm pressing against the rotational axial position of the driven roller and the base respectively. The torsion elements provide a normal force to the driven roller, so that the driven roller may press against the active roller constantly.

Owner:LITE ON TECH CORP

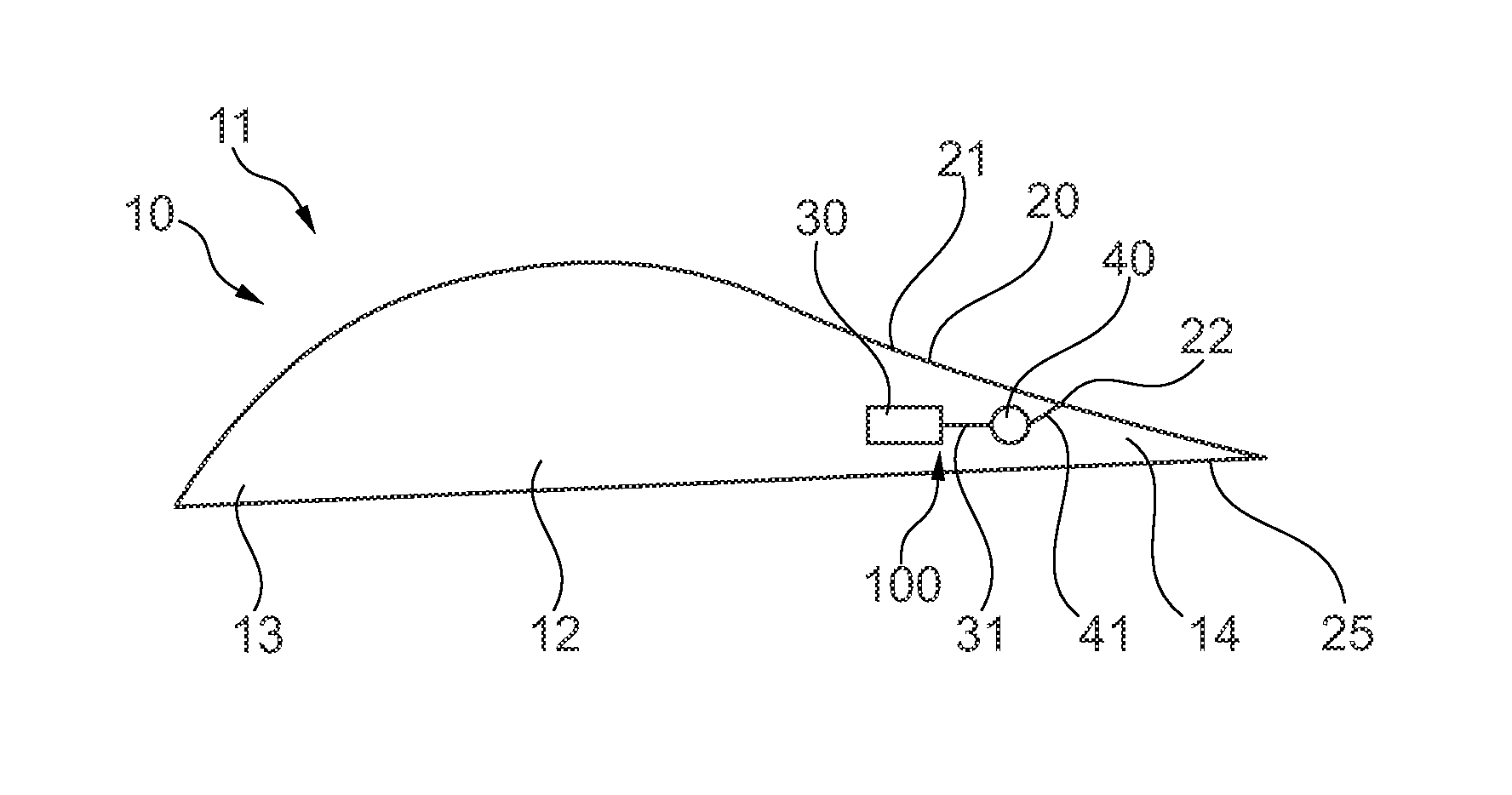

Row unit down pressure assembly

A down pressure assembly for incorporation into an agricultural implement (12) to be pulled by a tractor (10) has an attachment frame (21) for attachment between a portion of the agricultural implement and at least two wheels (22) of a row unit (18) for traveling along the ground, the row unit (18) also having a tool (23) disposed between the two wheels (22) for engaging the ground, the down pressure assembly also having at least one torsion element (41, 50) disposed on the frame (21), with the torsion element (41, 50) having one fixed mounting to the frame (21) and one adjustable mounting to the frame (21), and the assembly further having an adjustment mechanism (37, 60) for varying the torsion of the torsion element (41, 50) at the adjustable mounting; and at least one down pressure member (36, 56, 57) for receiving a force from the torsion element to apply a downward force to the top members (26, 27) of the frame (21).

Owner:BLUE LEAF I P INC

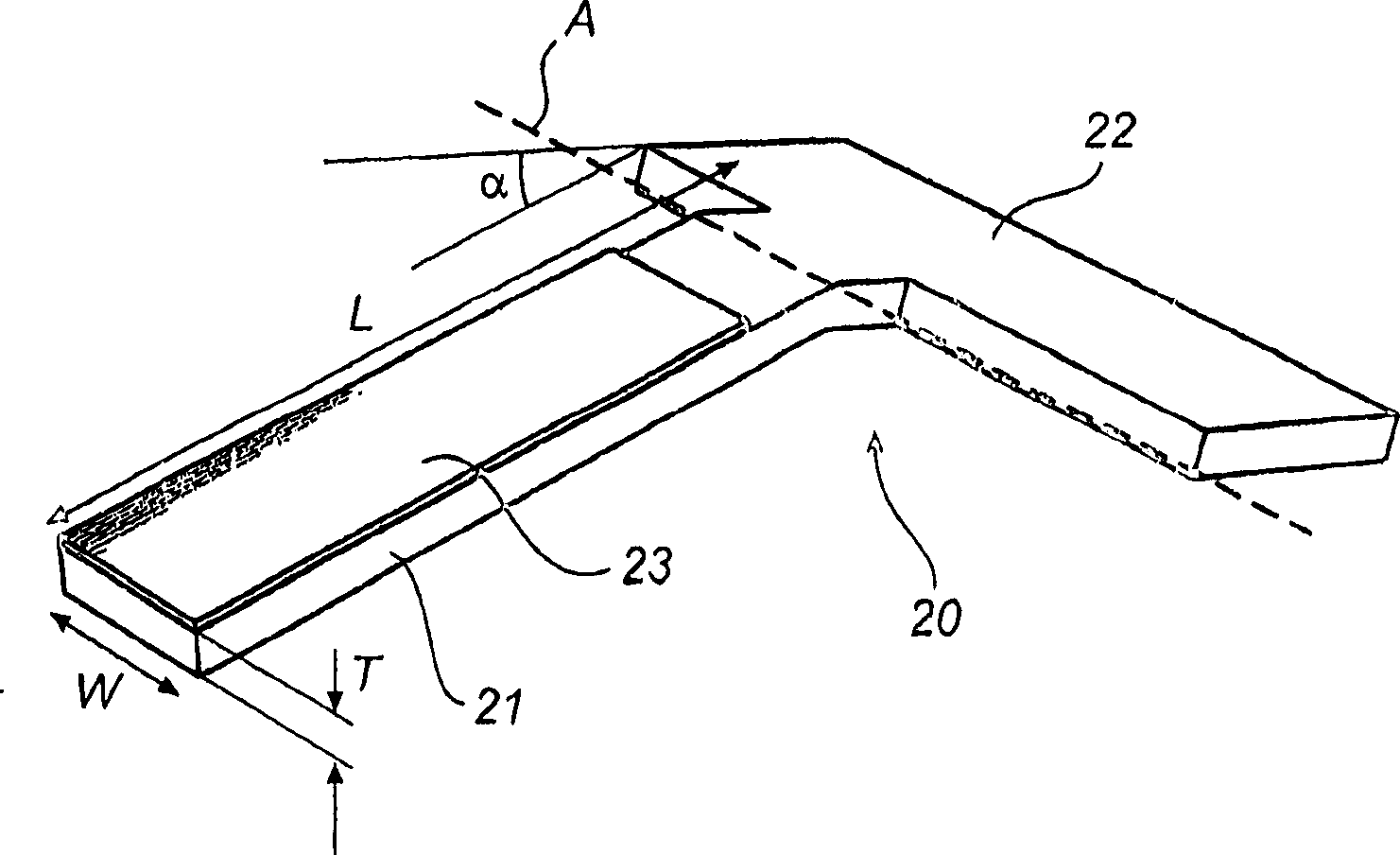

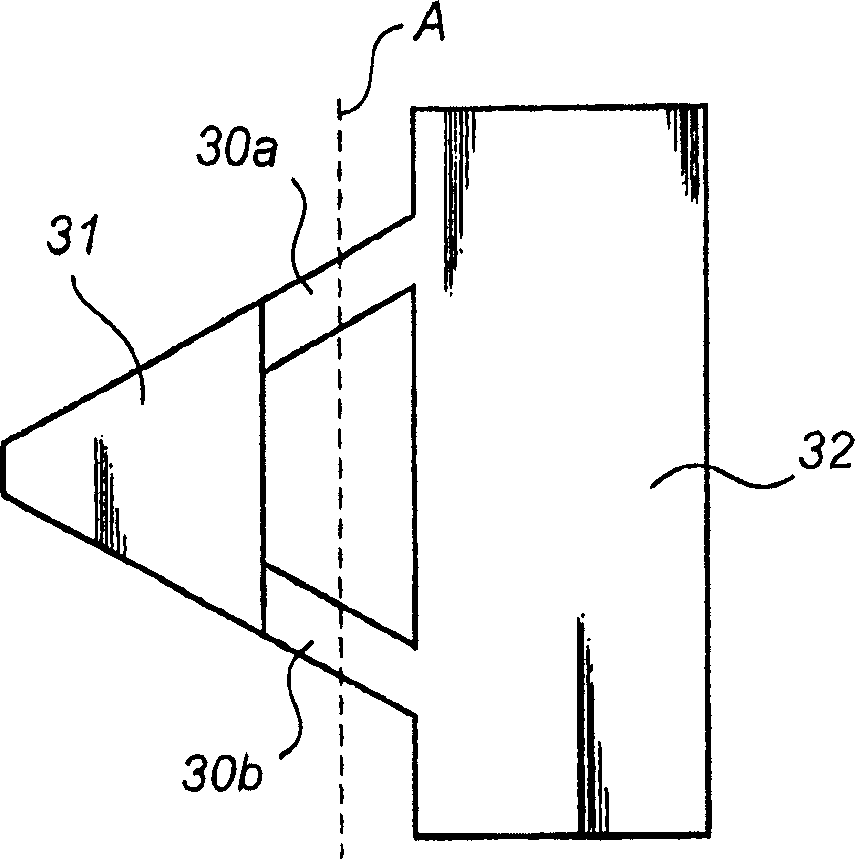

Laser beam scanner

A two dimensional scanning device, for use in a projecting display, comprising a surface (53) suspended by at least two torsion elements (55) defining a torsion axis (B), and a first actuator (60, 61) for pivoting said surface (53) around said torsion axis (B). The scanner further comprises a cantilever beam (51) having one end fixed in relation to said surface and an opposite end arranged to bend around a bending axis (A) non-parallel to said torsion axis (B). The cantilever beam (51) is provided with a reflective surface and a second actuator (58) is arranged to bring said cantilever beam to oscillate at its resonance frequency. The combination of a slow torsion scanner and a faster cantilever scanner 10 provides a two dimensional scanner capable of scanning a laser beam in a raster pattern to project an image.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

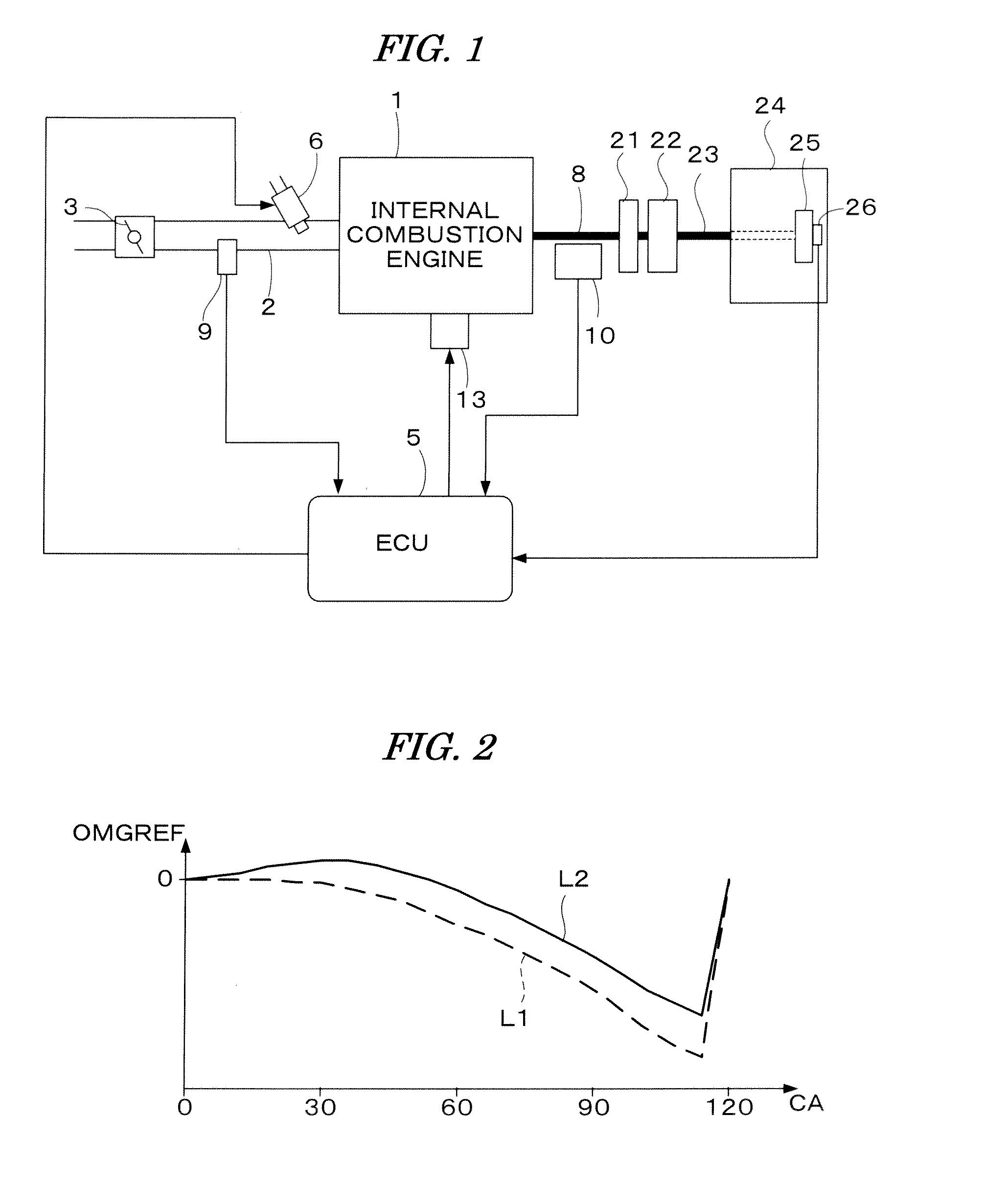

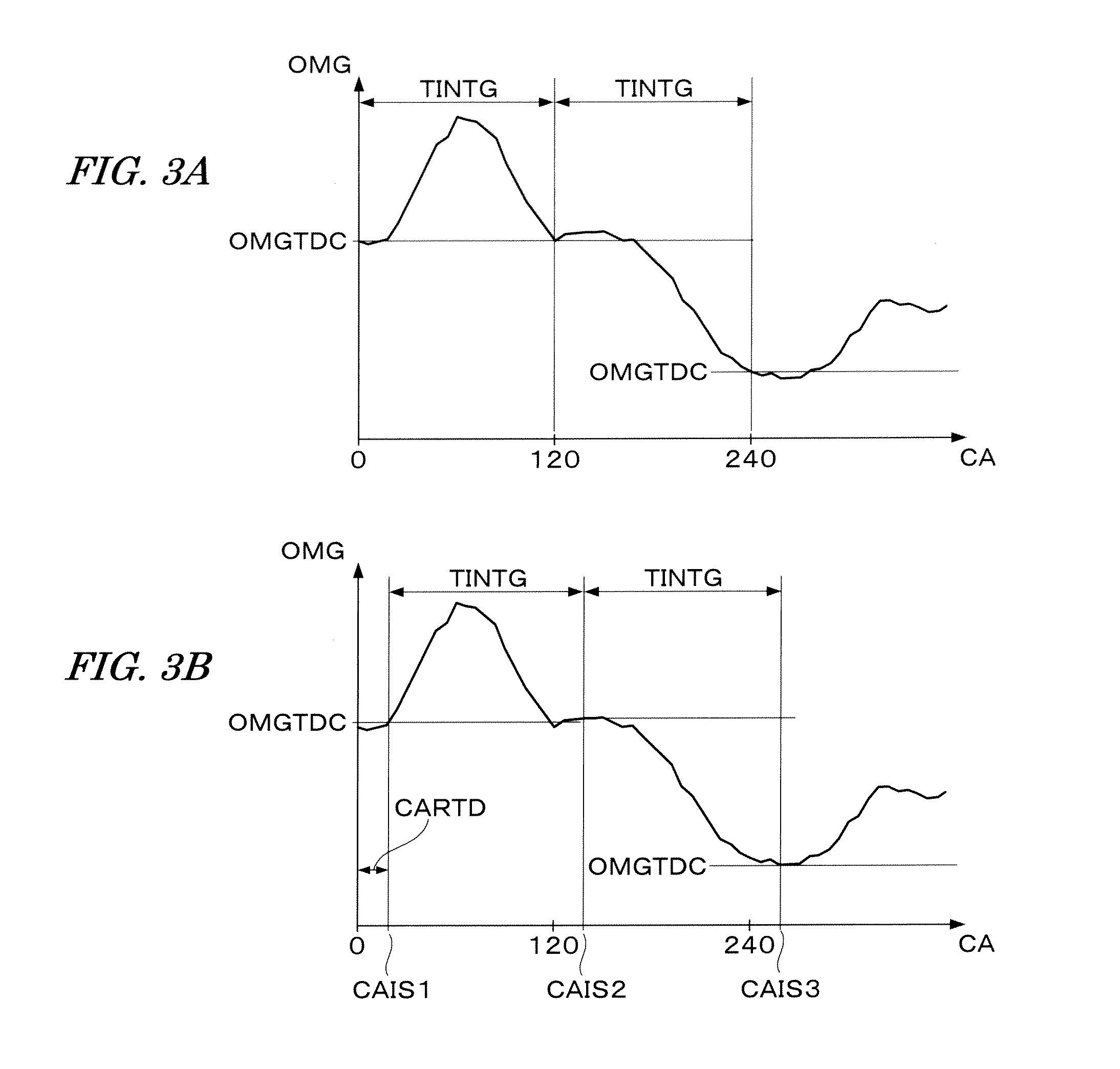

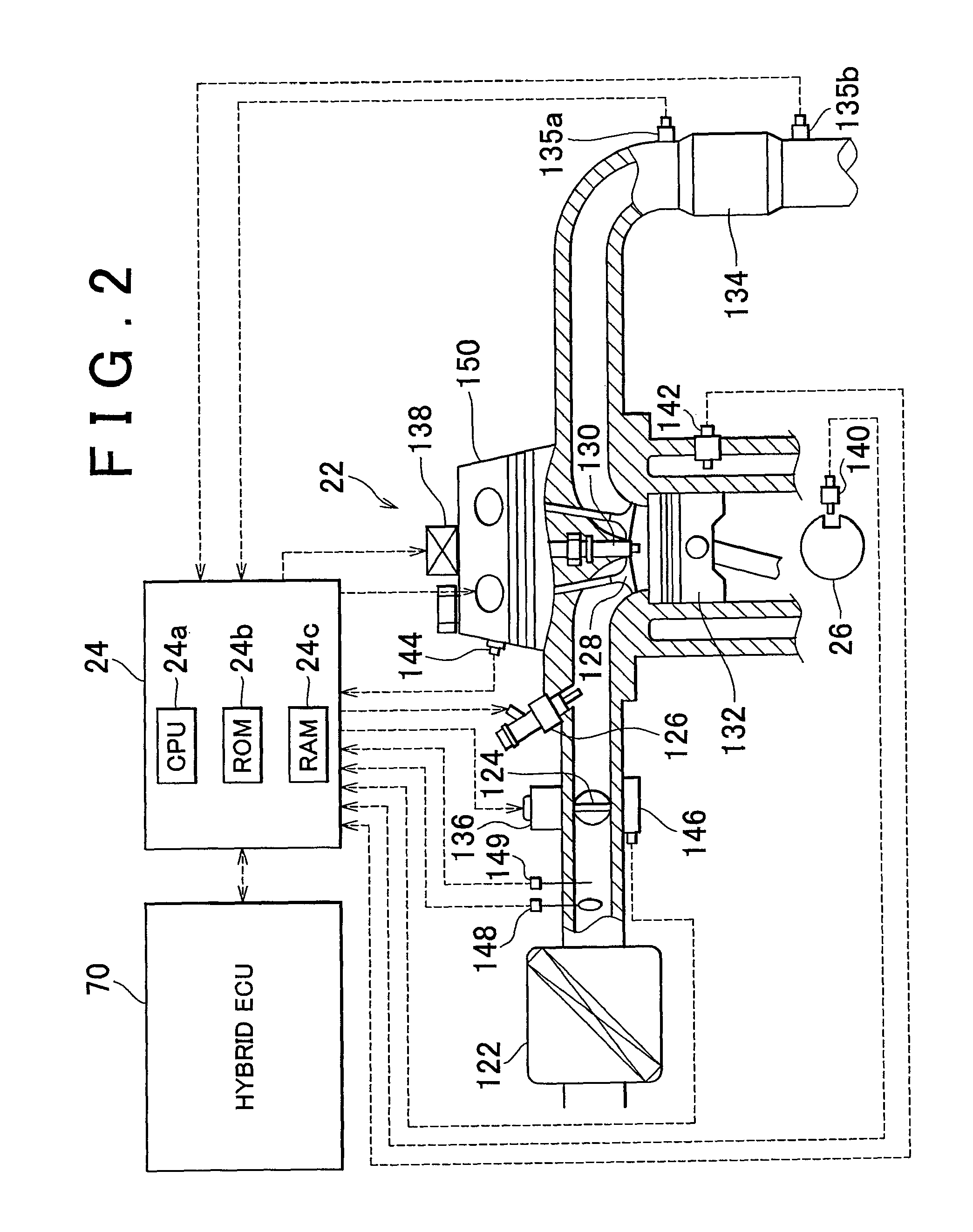

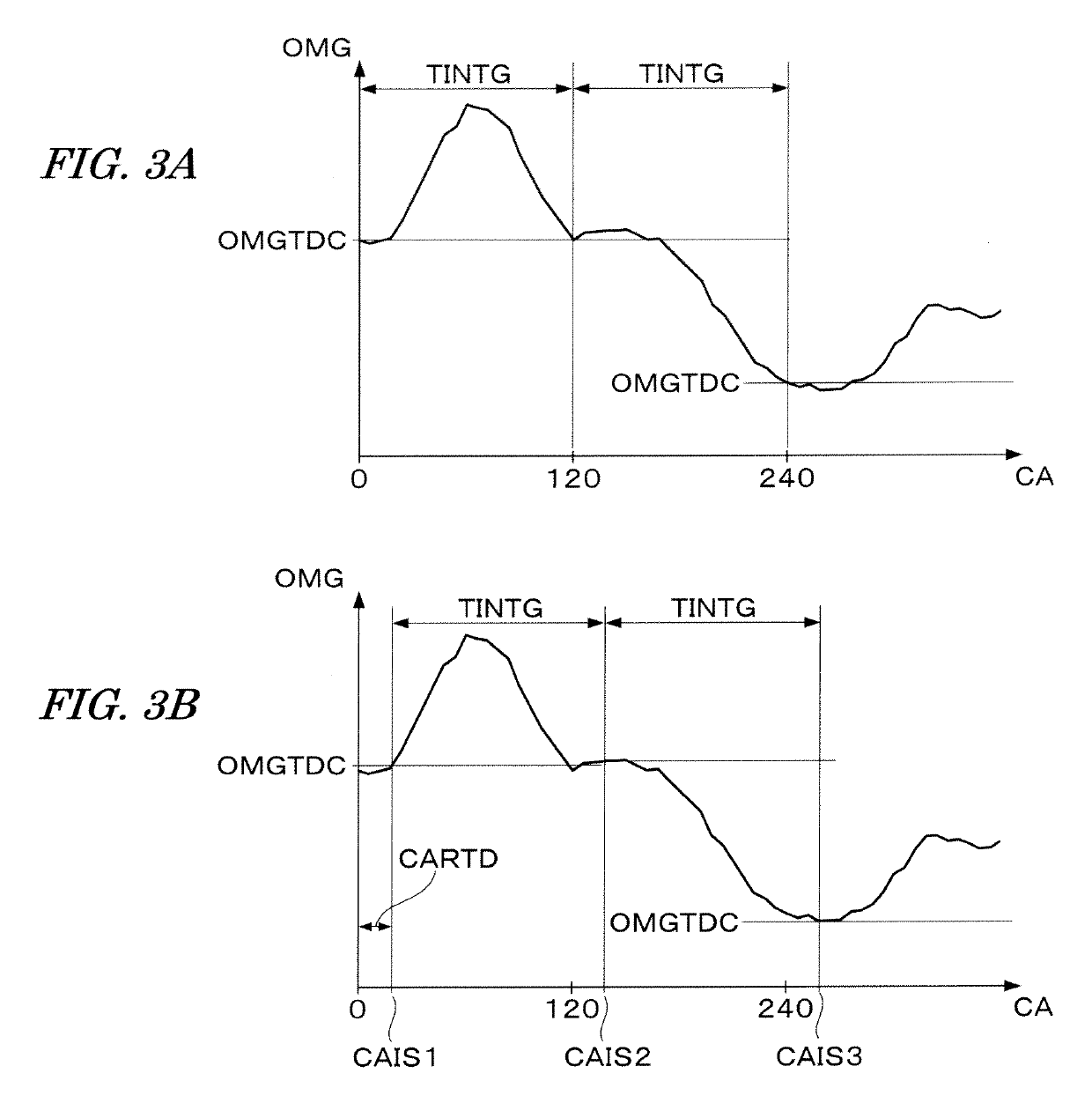

Misfire detecting apparatus for internal combustion engine

ActiveUS20120232774A1Ensure correct executionRaise the possibilityInternal-combustion engine testingElectrical controlExternal combustion engineInternal combustion engine

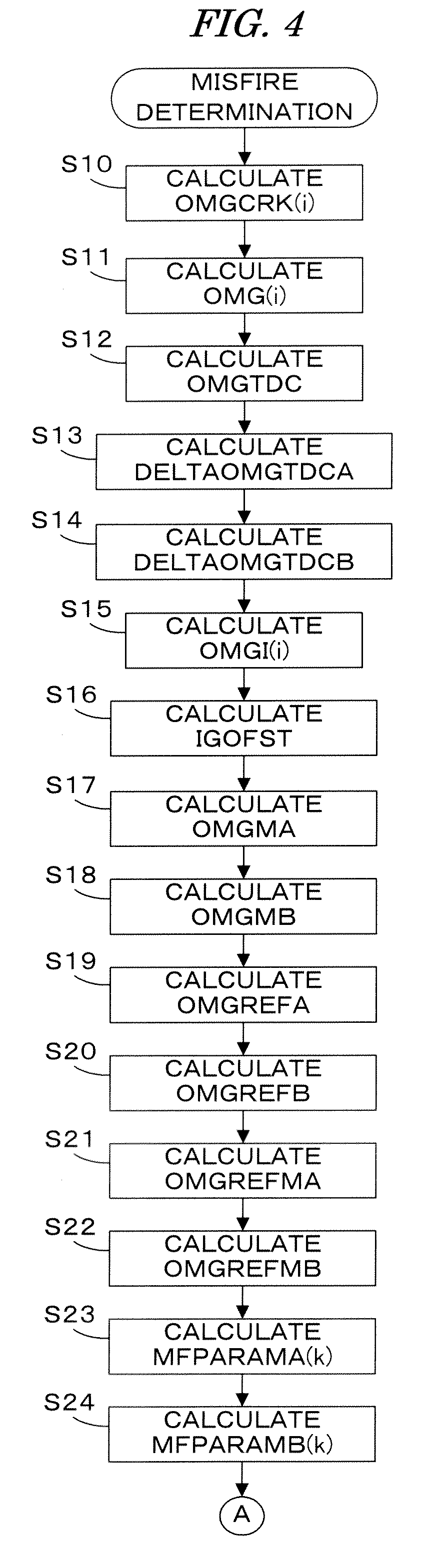

A misfire detecting apparatus for an internal combustion engine is provided. The engine has an output shaft connected via a torsion element to an input shaft of a transmission mechanism. A transmission rotational speed parameter indicative of a rotational speed of the input shaft is detected. A modified engine rotational speed parameter is calculated by modifying the detected engine rotational speed parameter based on the transmission rotational speed parameter, an engine rotation moment on the input side of the torsion element, and a transmission rotation moment on the output side of the torsion element. An average change amount of the modified rotational speed parameter, and an inertia speed changing component, are calculated. Further, a corrected rotational speed parameter is calculated by correcting the modified rotational speed parameter according to the average change amount and the inertia speed changing component. A relative speed parameter is calculated based on the corrected rotational speed parameter, and a determination parameter is calculated by integrating the relative speed parameter. The misfire determination is performed based on the determination parameter.

Owner:HONDA MOTOR CO LTD

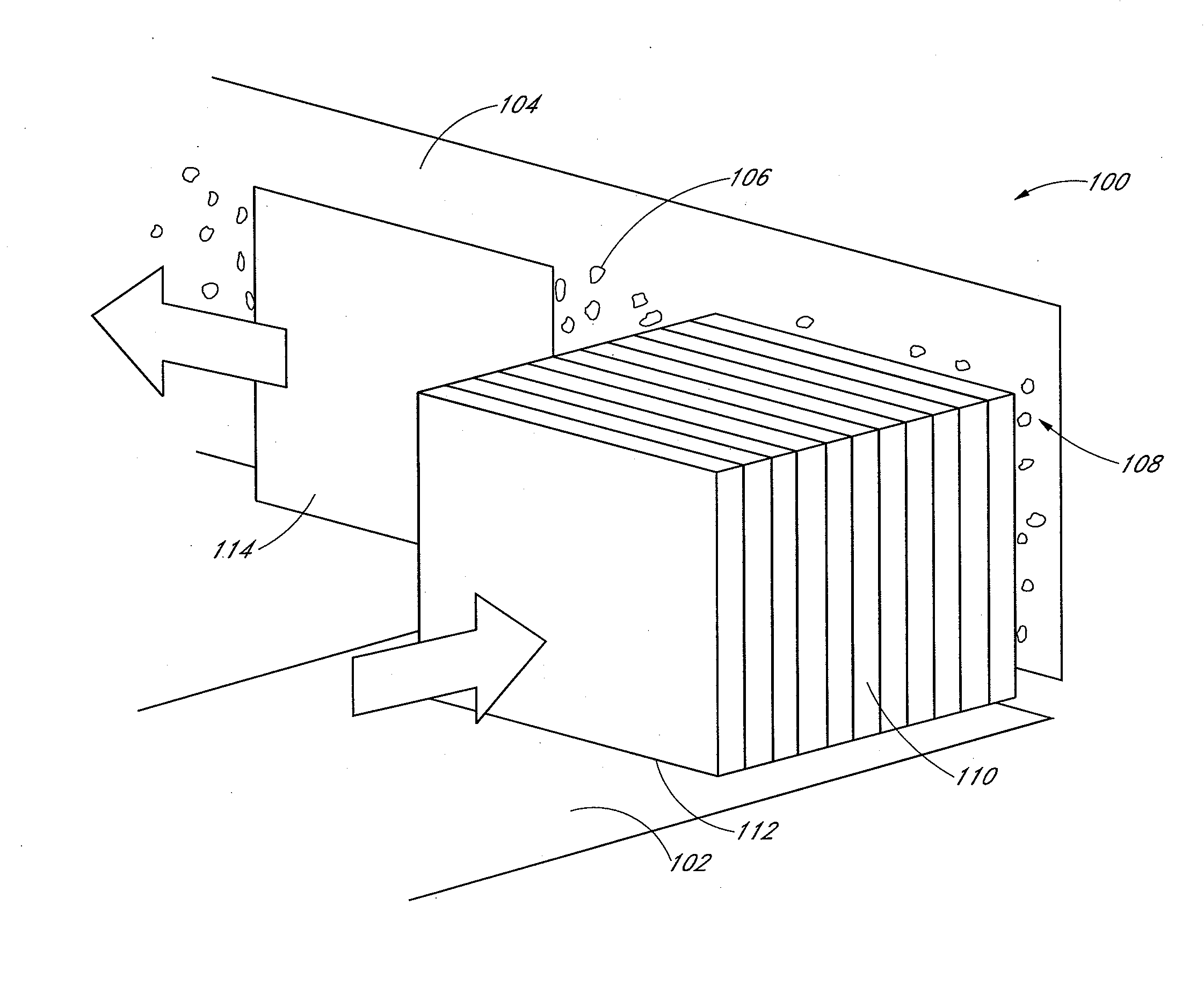

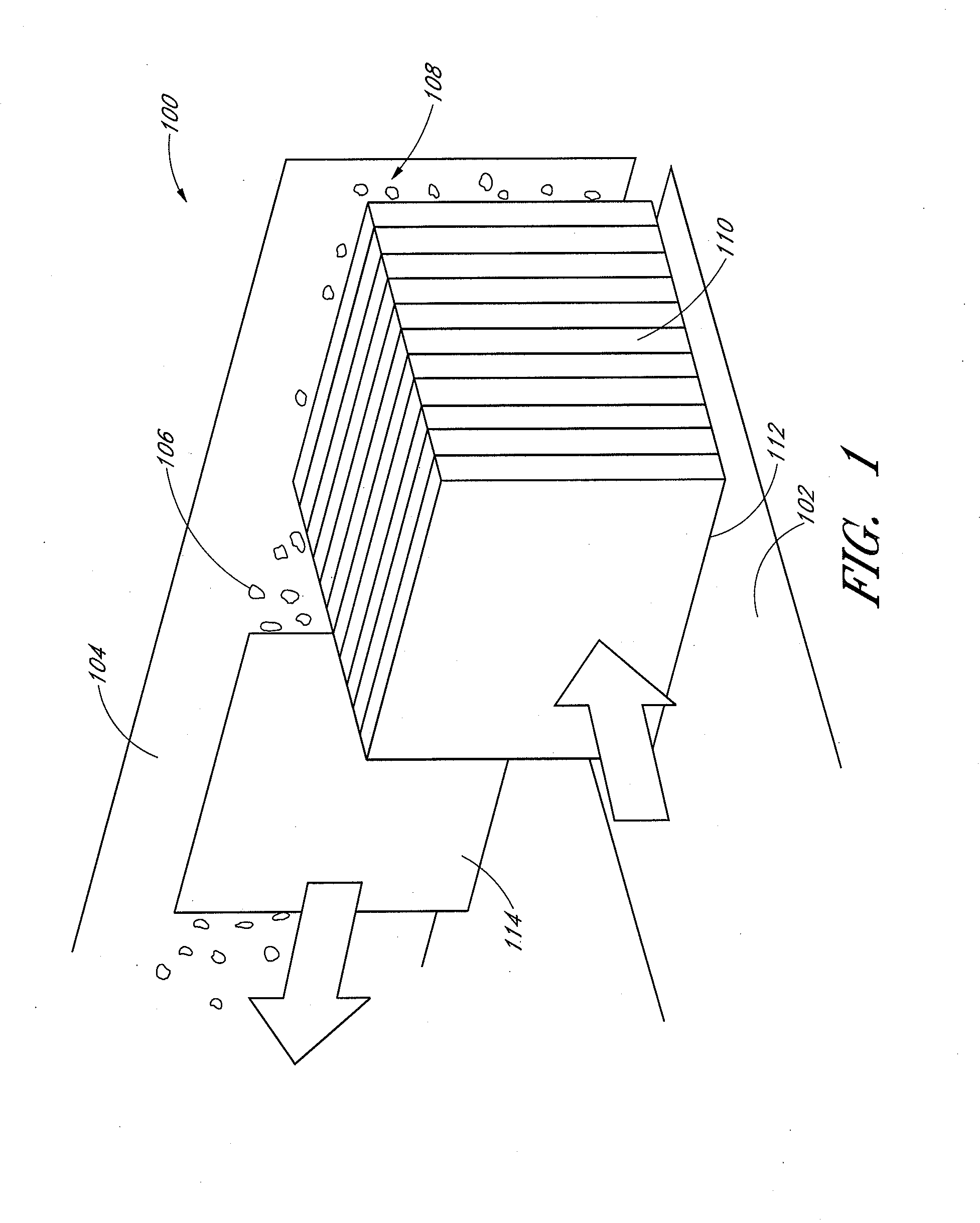

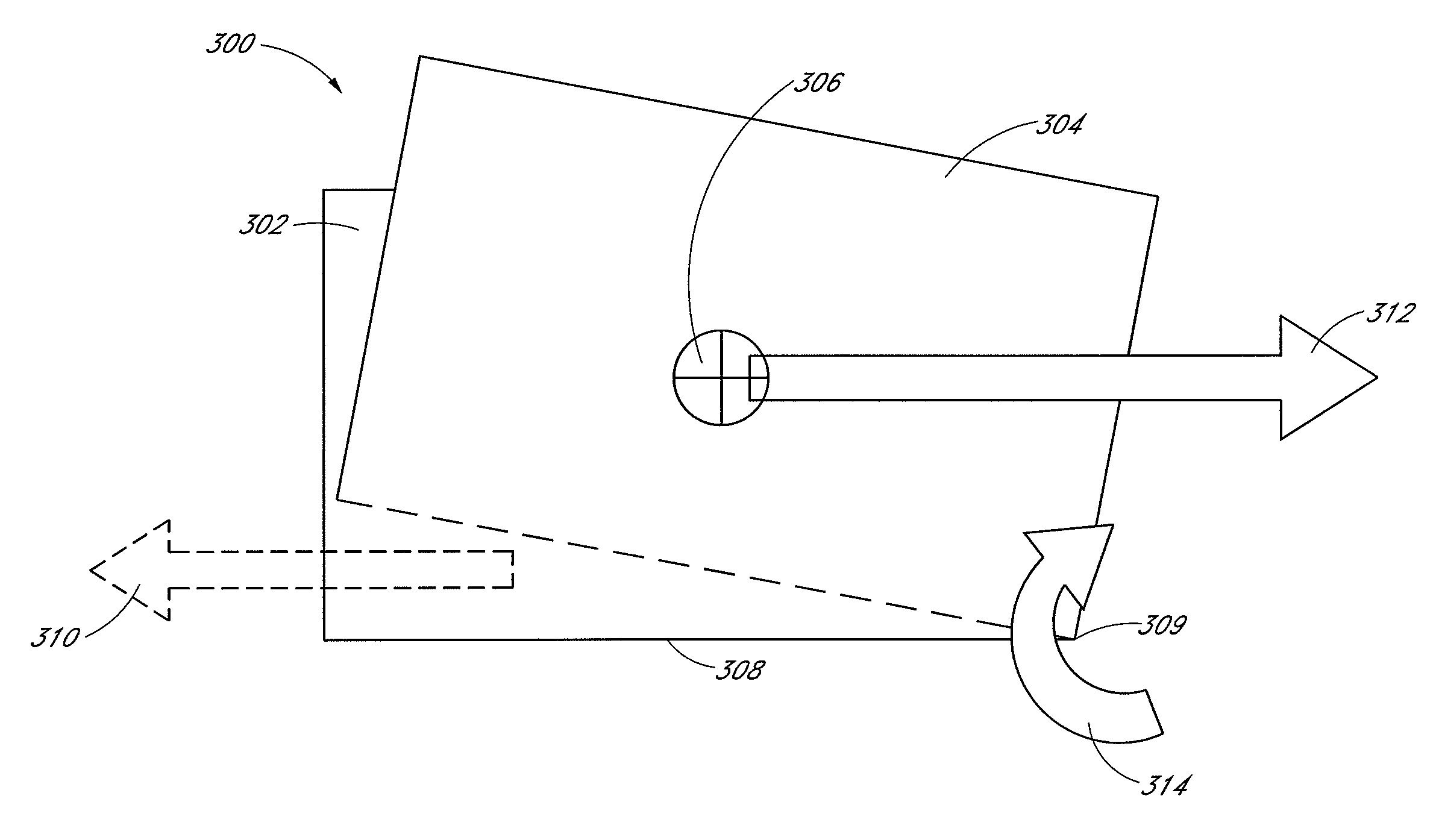

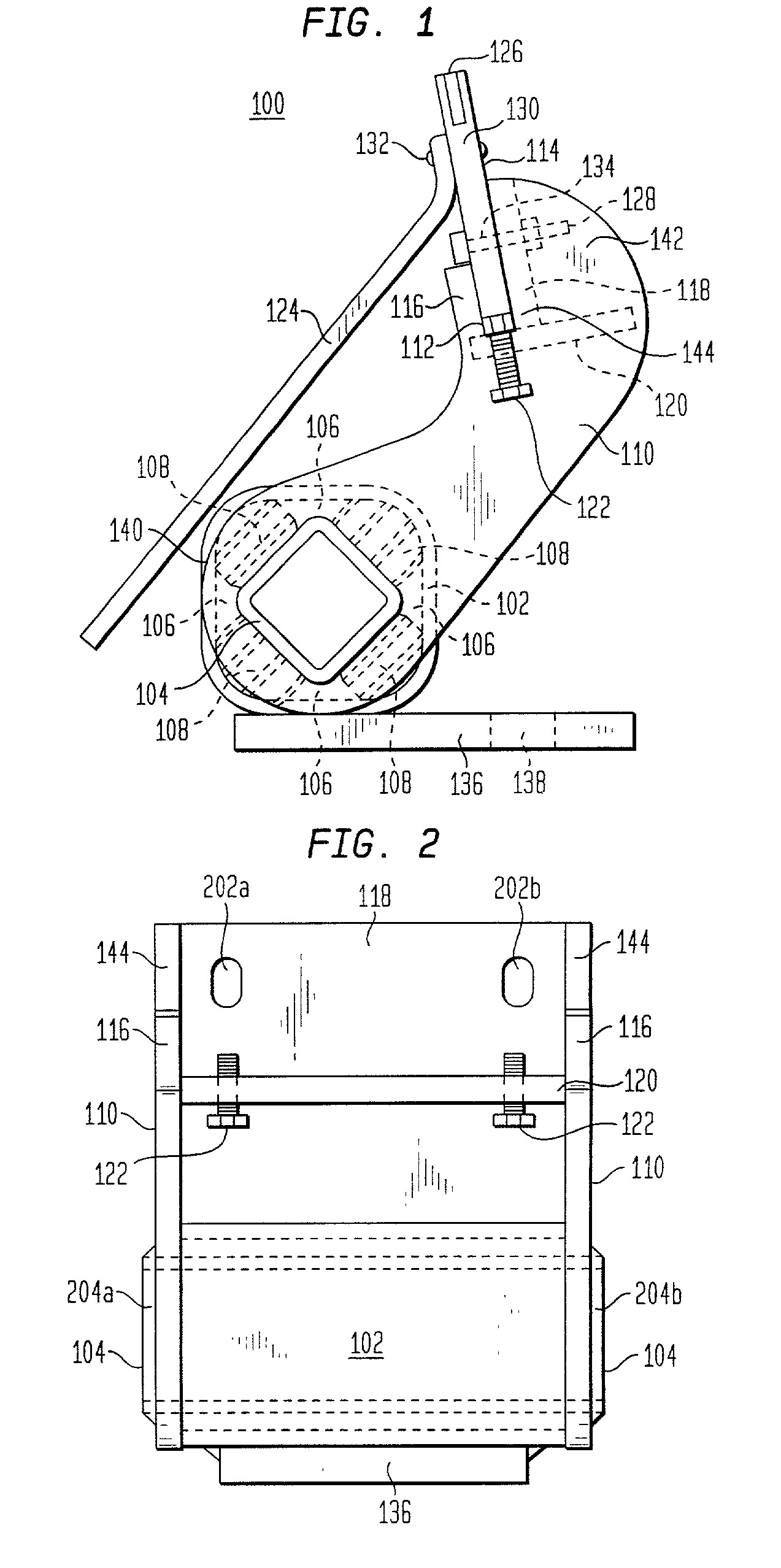

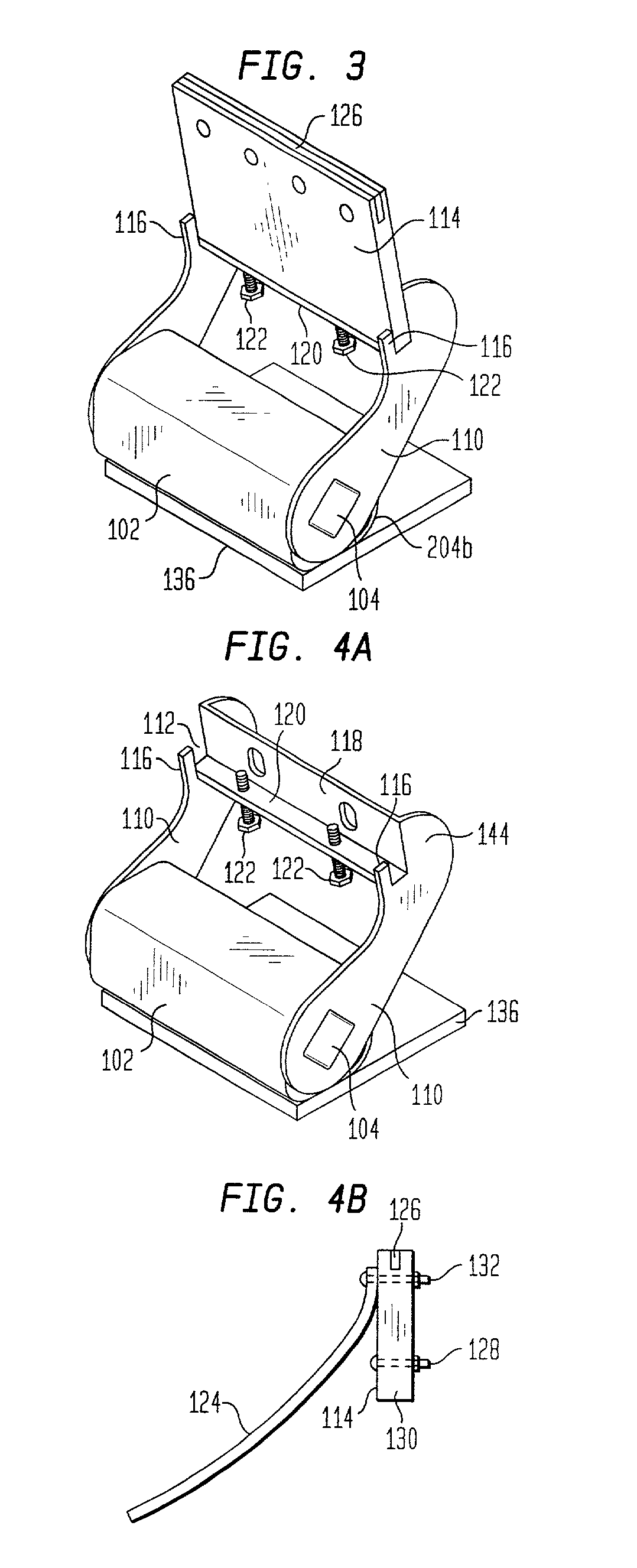

Anti-rotation device and method of use

ActiveUS20140271091A1Reduce rotationReduce the amount requiredConveyorsStacking articlesEngineeringTorsion element

A device for reducing rotation of an article during singulation of a stack of articles is disclosed. The device may include a torsion element, a rotatable member configured to rotate about an elongated axis of the torsion element between a first position and a second position, and a revolving member coupled to the rotatable member. An outer surface of the revolving member contacts a drive belt in the first position and an article in the second position. The torsion element exerts torque on the rotatable member when it moves from the first position towards the second position. The torque causes the outer surface of the revolving member to apply a frictional force to the article, thereby minimizing rotation of the article. Systems and methods of singulating articles are also disclosed.

Owner:US POSTAL SERVICE

Misfire determination device and method for internal combustion engine, and vehicle including misfire determination device

ActiveUS7707874B2Accurately determineReduce impactInternal-combustion engine testingResonanceInternal combustion engine

A misfire determination device for a multi-cylinder internal combustion engine, of which an output shaft is connected, through a torsion element, to a downstream shaft downstream of the torsion element, includes: an first portion for detecting an output shaft rotational speed that is the rotational speed of the output shaft; a second portion for detecting a downstream shaft rotational speed that is the rotational speed of the downstream shaft; a third portion that calculates a component caused by an influence of resonance due to torsion of the torsion element on the output shaft rotational speed, based on the acquired output shaft rotational speed and the acquired downstream shaft rotational speed; and a fourth portion for determining the occurrence of the misfire in the internal combustion engine based on a rotational speed that is obtained by subtracting the calculated component from the detected output shaft rotational speed.

Owner:TOYOTA JIDOSHA KK

Curtain control device

InactiveUS8556204B2Speed downReduce noiseFilament handlingLight protection screensTorsion elementControl theory

A curtain control device has a stroke setting device and a damper respectively assembled at both ends of a curtain spindle rod. A torsion element is further assembled on the curtain spindle rod. A curtain spindle sleeve is invaginated on the outside of the curtain spindle rod, the stroke setting device and the damper. The curtain spindle sleeve is assembled with the combination of the curtain spindle rod and the damper, and then a curtain fabric is assembled on the outside of the curtain spindle sleeve. In this manner, the opening range of the curtain fabric roll is controlled by the stoke setting device, and the roll-up speed of each part of the curtain fabric is slowed down by the damper so as to reduce effectively the noise produced by the quick actuation of each part and the defective rate.

Owner:UNI-SOLEIL ENT CO LTD

Anti-rotation device and method of use

ActiveUS9056738B2Reduce rotationReduce the amount requiredRegistering devicesArticle feedersEngineeringTorsion element

A device for reducing rotation of an article during singulation of a stack of articles is disclosed. The device may include a torsion element, a rotatable member configured to rotate about an elongated axis of the torsion element between a first position and a second position, and a revolving member coupled to the rotatable member. An outer surface of the revolving member contacts a drive belt in the first position and an article in the second position. The torsion element exerts torque on the rotatable member when it moves from the first position towards the second position. The torque causes the outer surface of the revolving member to apply a frictional force to the article, thereby minimizing rotation of the article. Systems and methods of singulating articles are also disclosed.

Owner:US POSTAL SERVICE

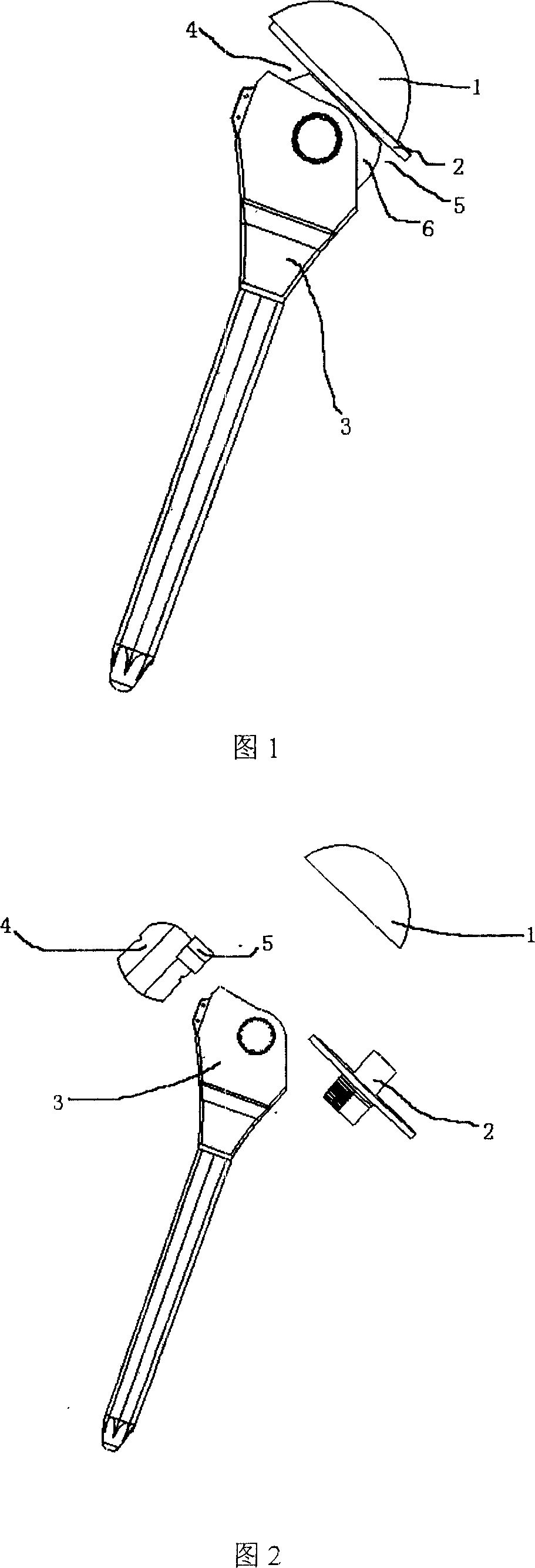

3-D shoulder joint prosthesis

InactiveCN101011299AGood individual adaptabilityLarge adjustment rangeJoint implantsShoulder jointsShoulder joint prosthesisEngineering

The invention relates to a novel three-dimension shoulder joint artificial prosthese, formed by a spherical cap element 1, a handle 3, an incline element (bar wedge 4 and arc block 6), and a torsion element (round plate 2 and cylinder block). The invention realizes the three-dimension design of shoulder joint, via tooth meshed, and uses incline element to realize the incline angle adjustment between 115 degrees and 140 degrees, and uses the torsion element to realize the torsion angle adjustment between -20 degree and +20 degrees, uses the eccentric design of spherical cap element 1 to meet the demand of eccentric distance of head of humerus, while the eccentric distances are 2.5mm, 3.5mm, and 4.0mm, uses the detachable arrangement of incline element and torsion element to confirm the repeatable adjustment of parameters. And the rod 9 of handle has plum blossom section to avoid the handle being rotated in the marrow. The invention is characterized in the large adjustment range of prosthese parameters with repeatable adjusting ability. The invention has simple structure, high reliability and simple operation.

Owner:彭晓东 +1

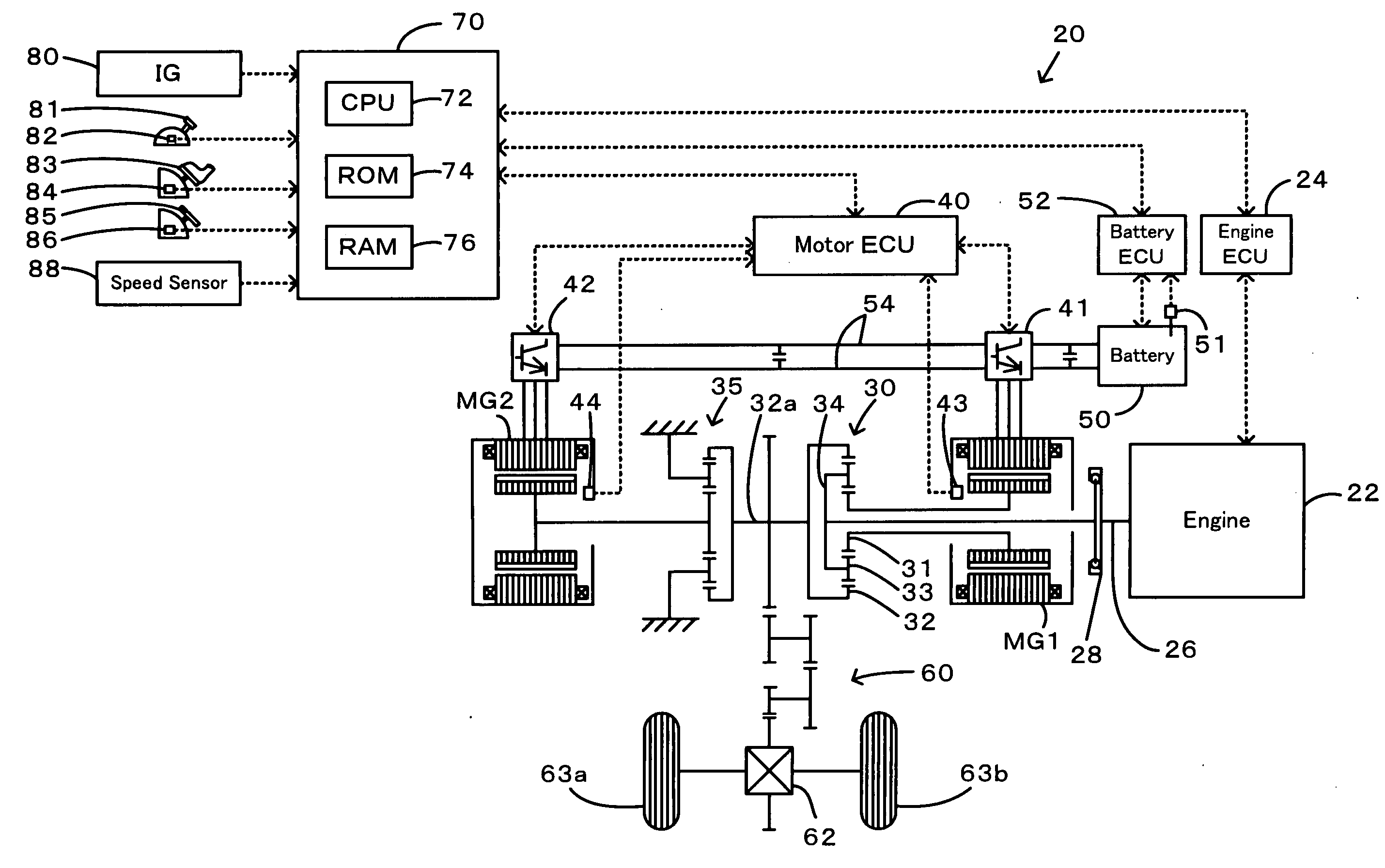

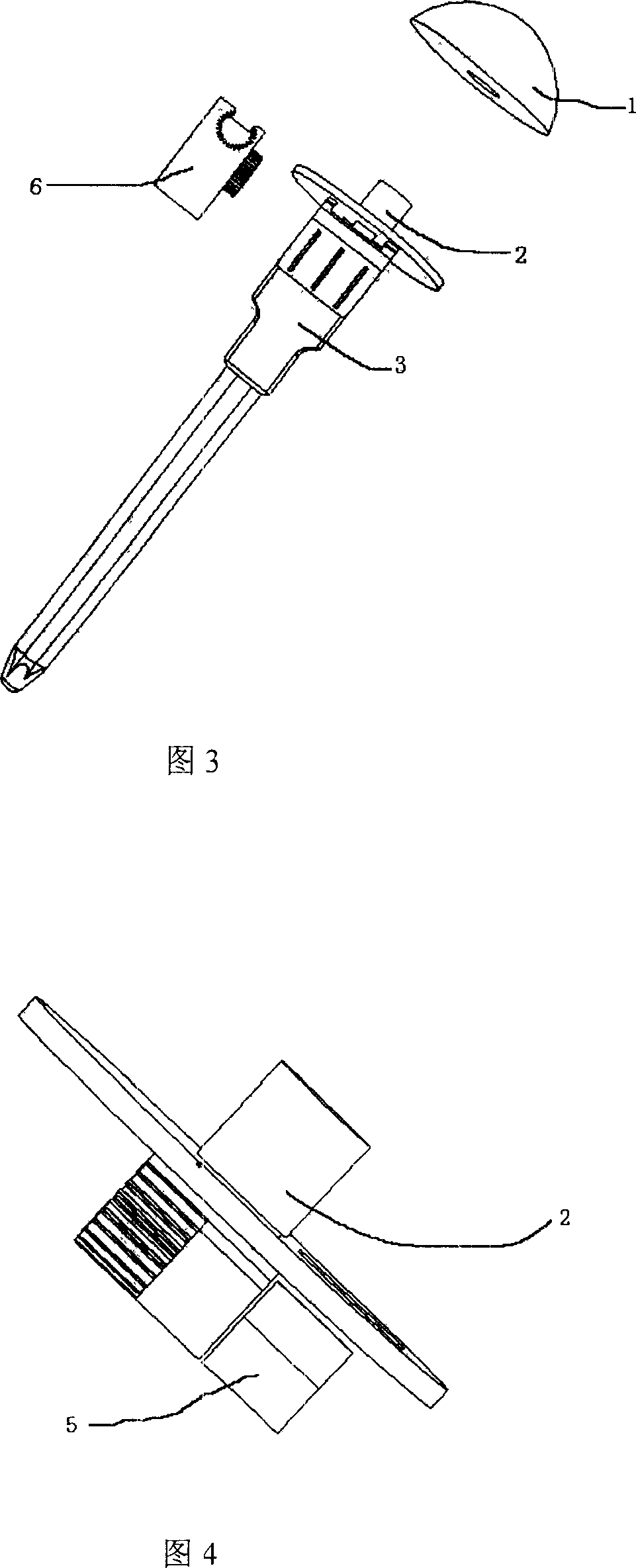

Misfire determination system and method for internal combustion engine, vehicle including misfire determination system for internal combustion engine, and system for and method of estimating rigidity of torsion element

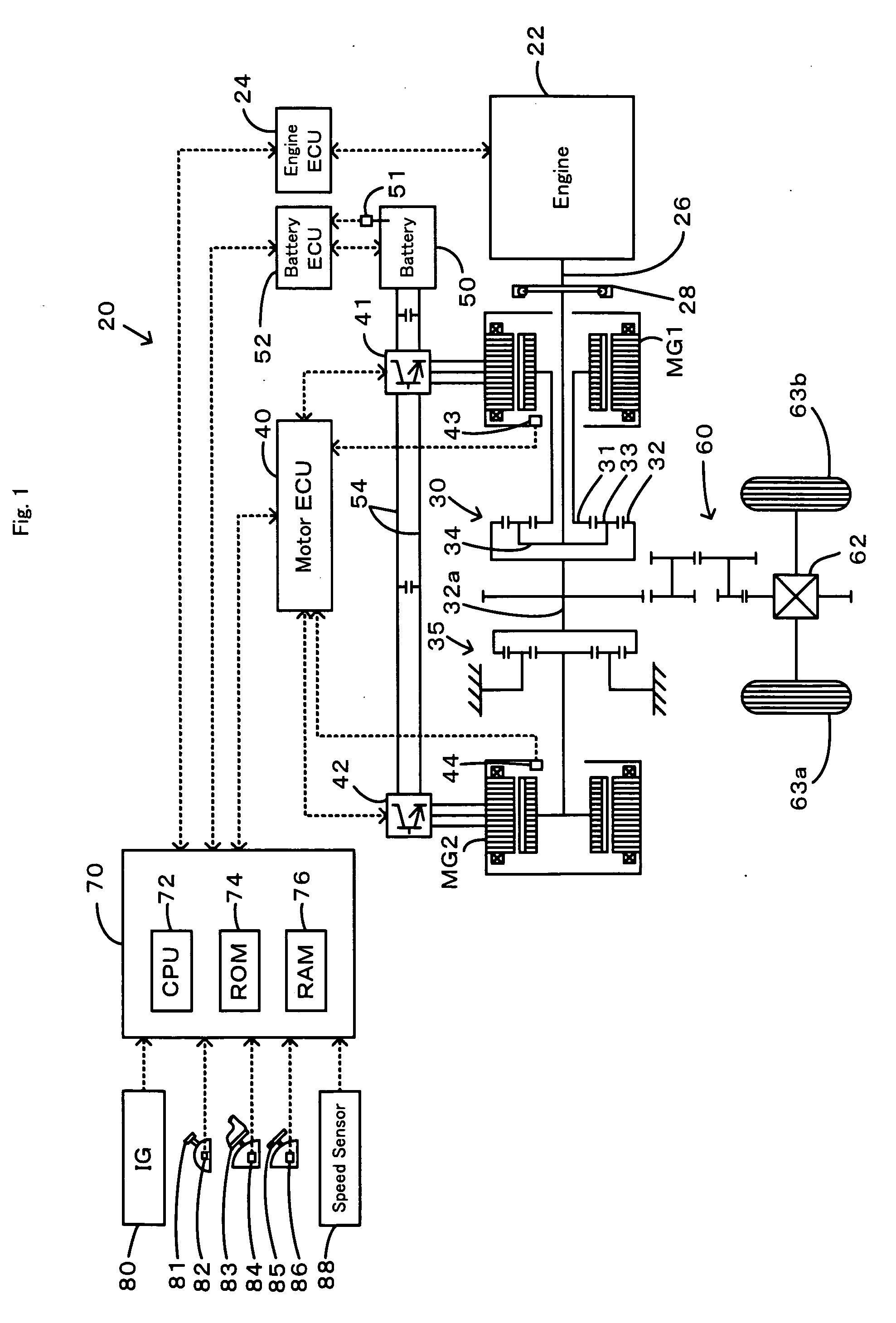

ActiveUS7712356B2Accurately determineAccurately estimate rigidityHybrid vehiclesInternal-combustion engine testingResonanceRotation velocity

An internal-combustion-engine misfire determination system includes: detection sections that detects the rotational speeds of the output shaft and the downstream shaft; a rigidity estimation section that performs a rigidity estimation process in which frequency components caused by a resonance due to torsion of the torsion element are extracted from the rotational speeds, and the rigidity of the torsion element is estimated based on a value obtained by comparing amplitudes of both of the extracted frequency components and on the detected output shaft rotational speed; a resonance influence component calculation section that calculates a resonance influence component caused by an influence of the resonance on the output shaft rotational speed; and a misfire determination section that determines the occurrence of the misfire in the internal combustion engine based on a rotational speed for determination that is obtained by subtracting the calculated resonance influence component from the output shaft rotational speed.

Owner:TOYOTA JIDOSHA KK

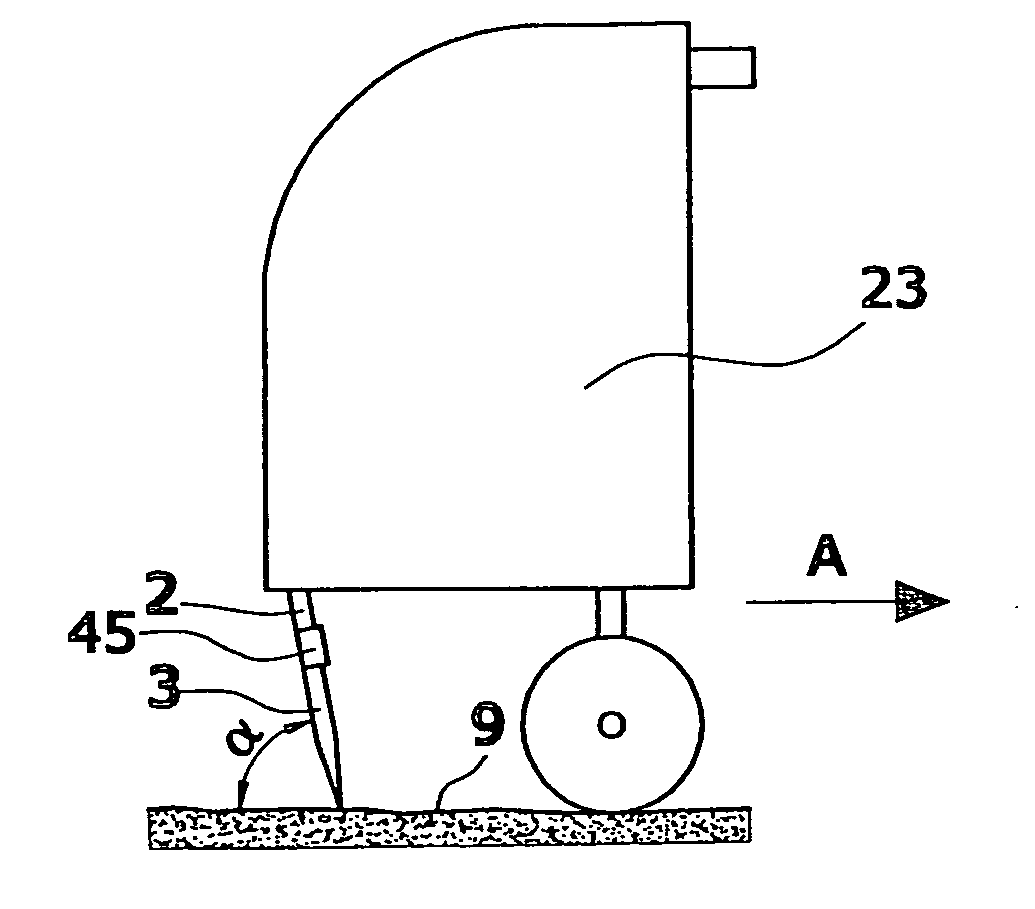

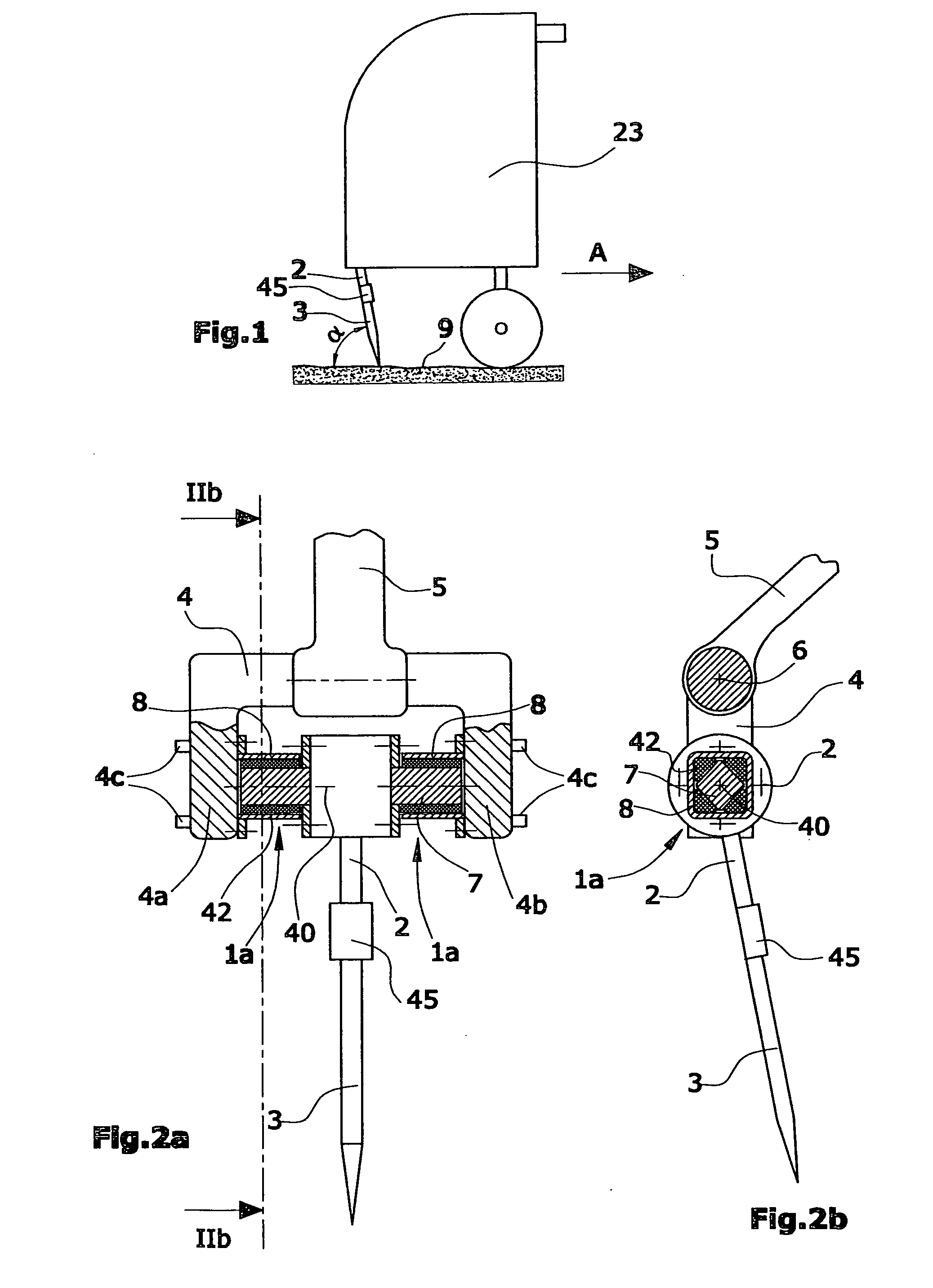

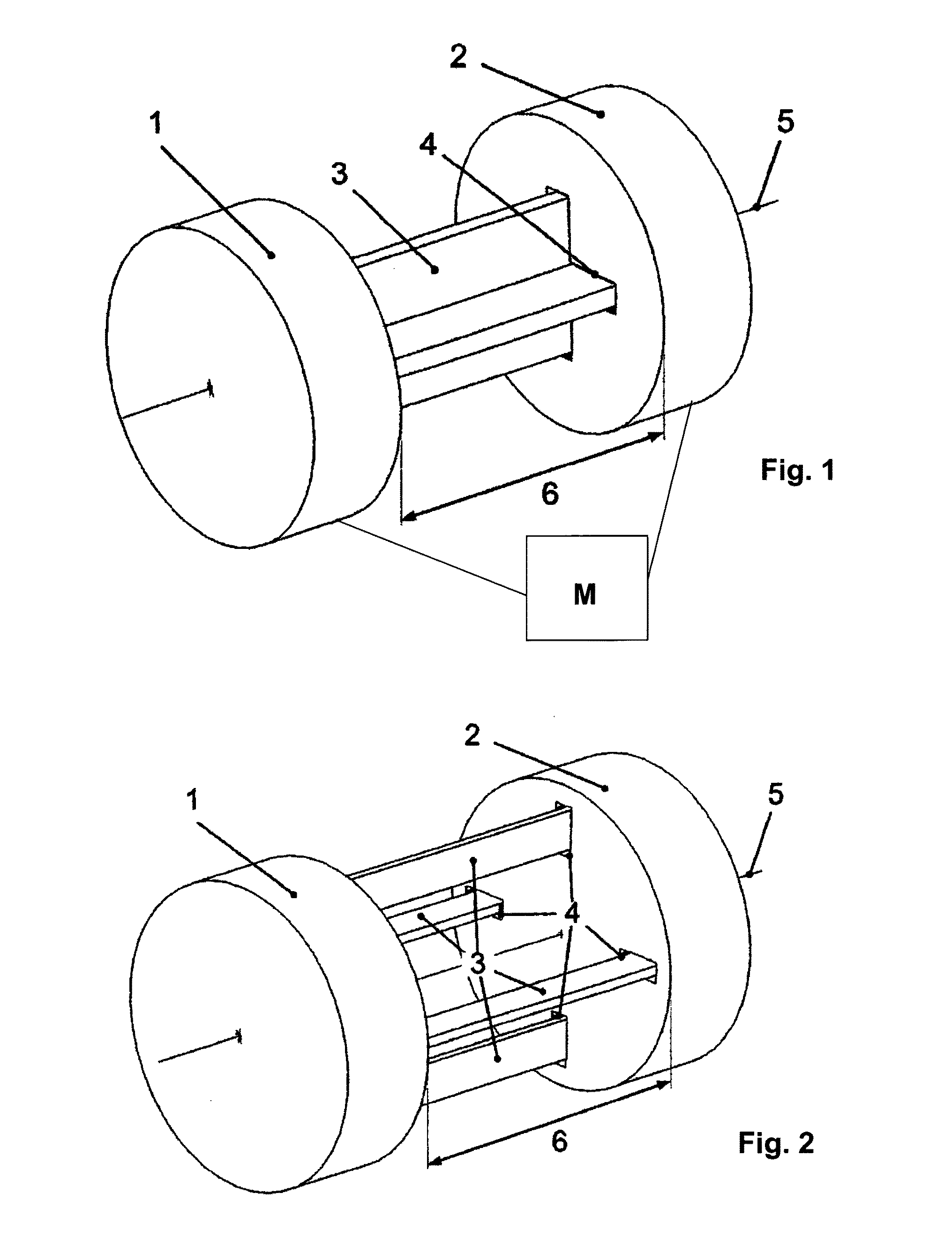

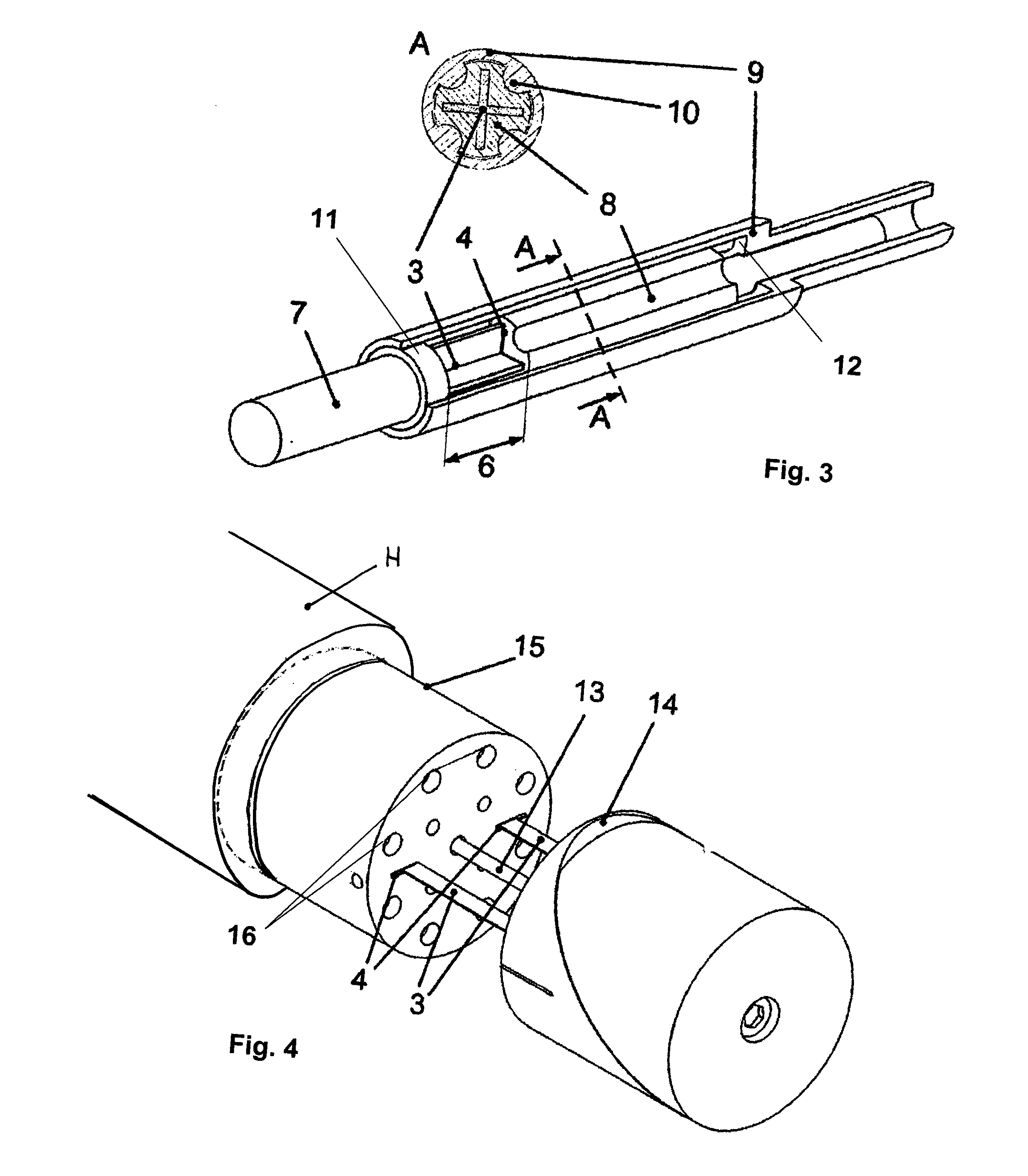

Soil working device

In a mobile soil working device comprising a machine frame (23), a drive for at least one penetration tool (3) adapted for up and down movement, the penetration tool (3) being adapted to be driven into the soil and to be pulled out again, a guide element (4) for at least one penetration tool (3), the guide element being guided movably at the machine frame (23), a tool holder (2) for the penetration tool (3), which is supported for pivotal movement about a first pivot axis (40) in the guide element (4) movable up and down by the drive, so as to allow a pivoting of the penetration tool (3) against a spring force while the tool is in the soil, it is provided that, between the tool holder (2) and the guide element (4), a torsion element (1a, 1b, 1c) is provided coaxially with the first pivot axis (40), which torsion element, under a force effect on the at least one penetration tool (3), allows the tool holder (2) to pivot relative to the guide element (4) and, when the force effect ceases, exerts a restoring moment on the tool holder (2) so that the penetration tool (3) pivots back to the home position after having been pulled from the soil.

Owner:REDEXIM HANDEL & EXPL MAATSCHAPPIJ BV

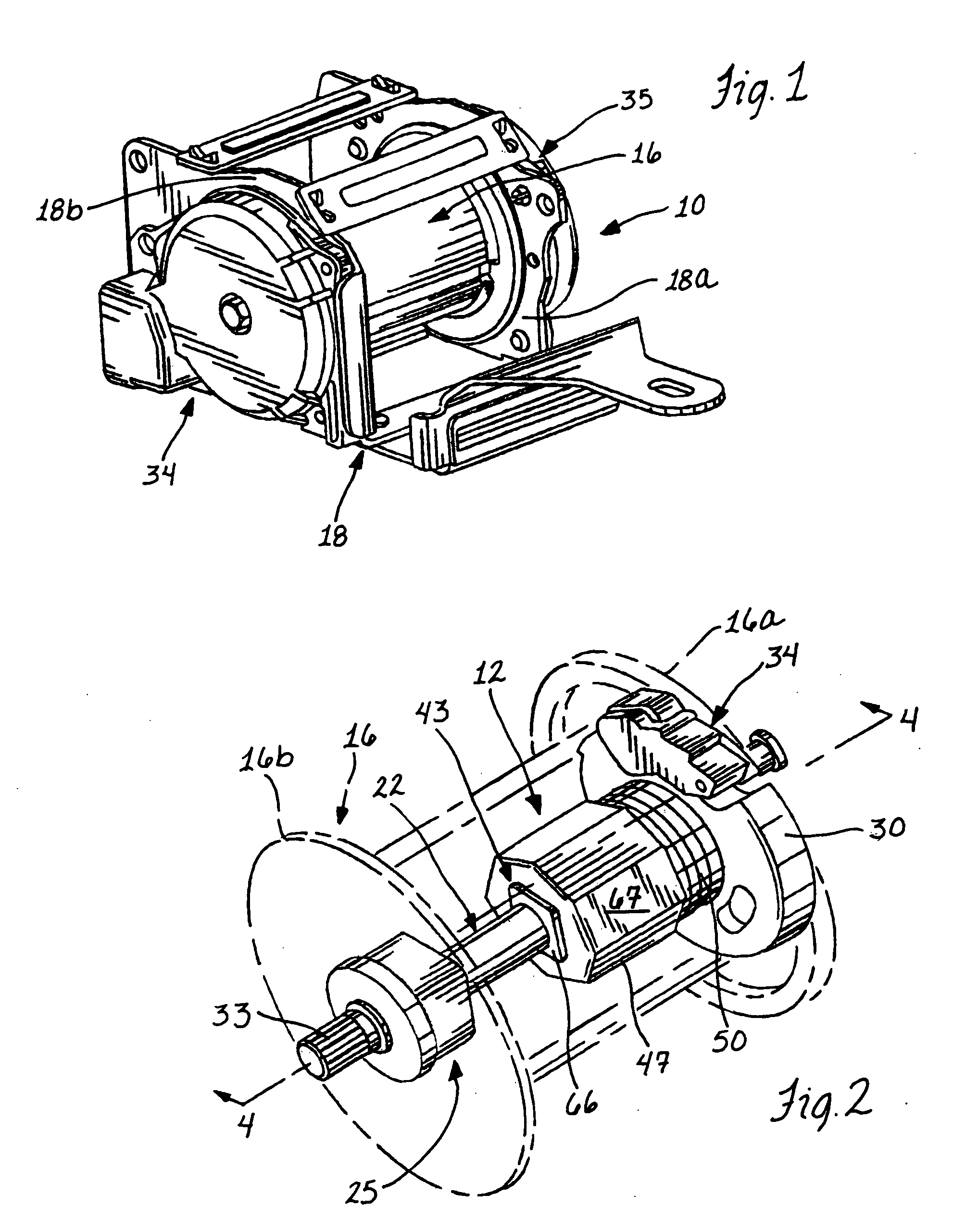

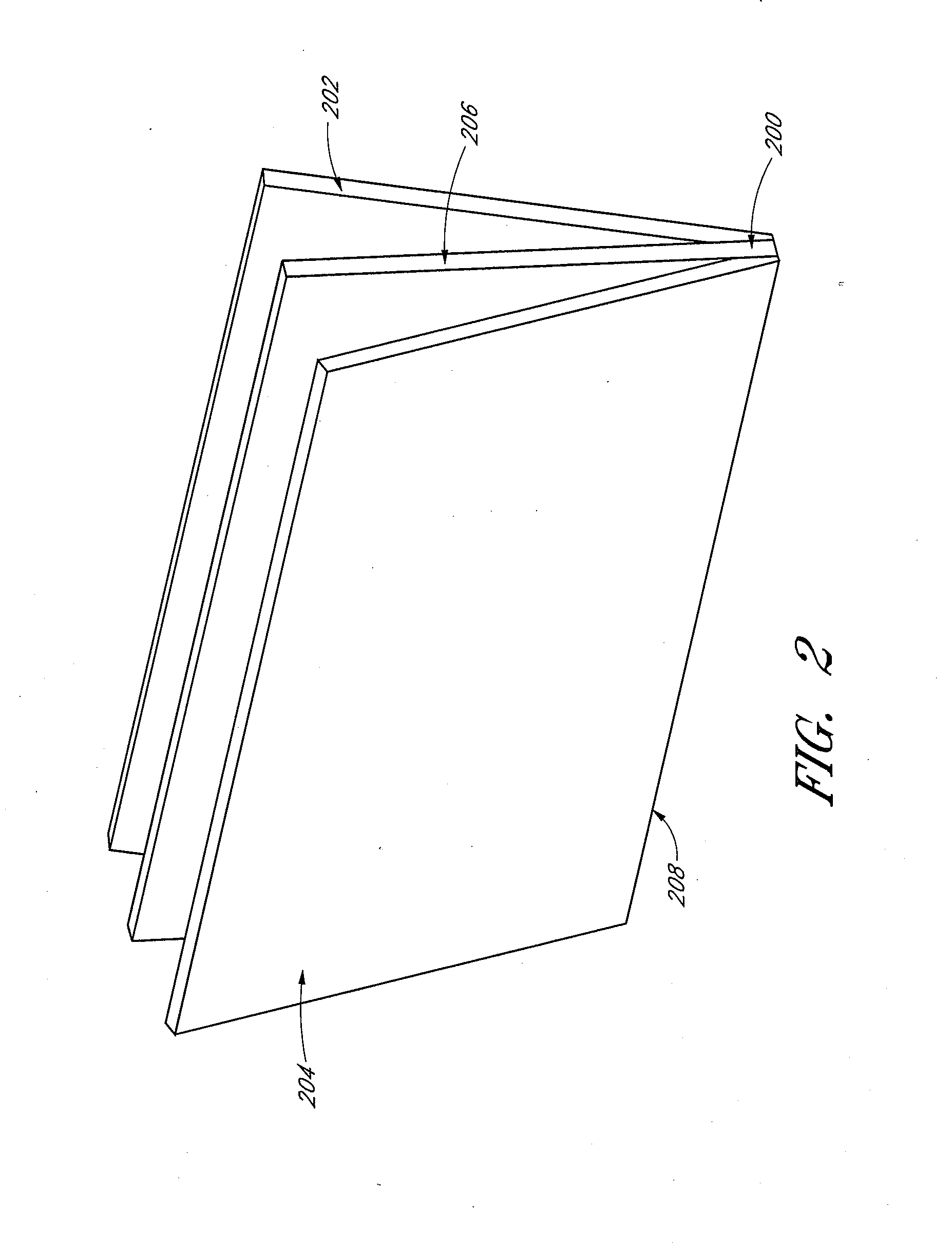

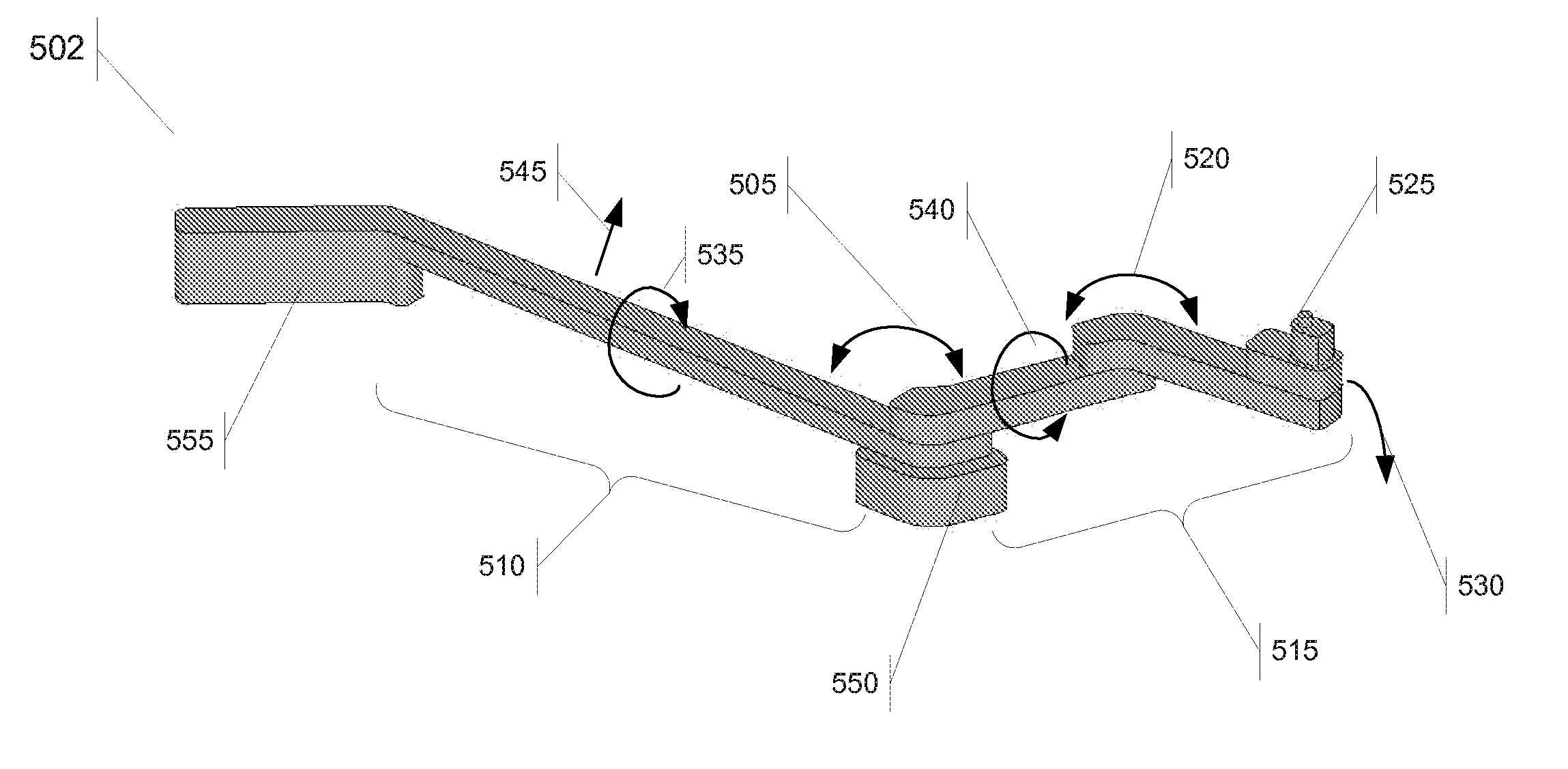

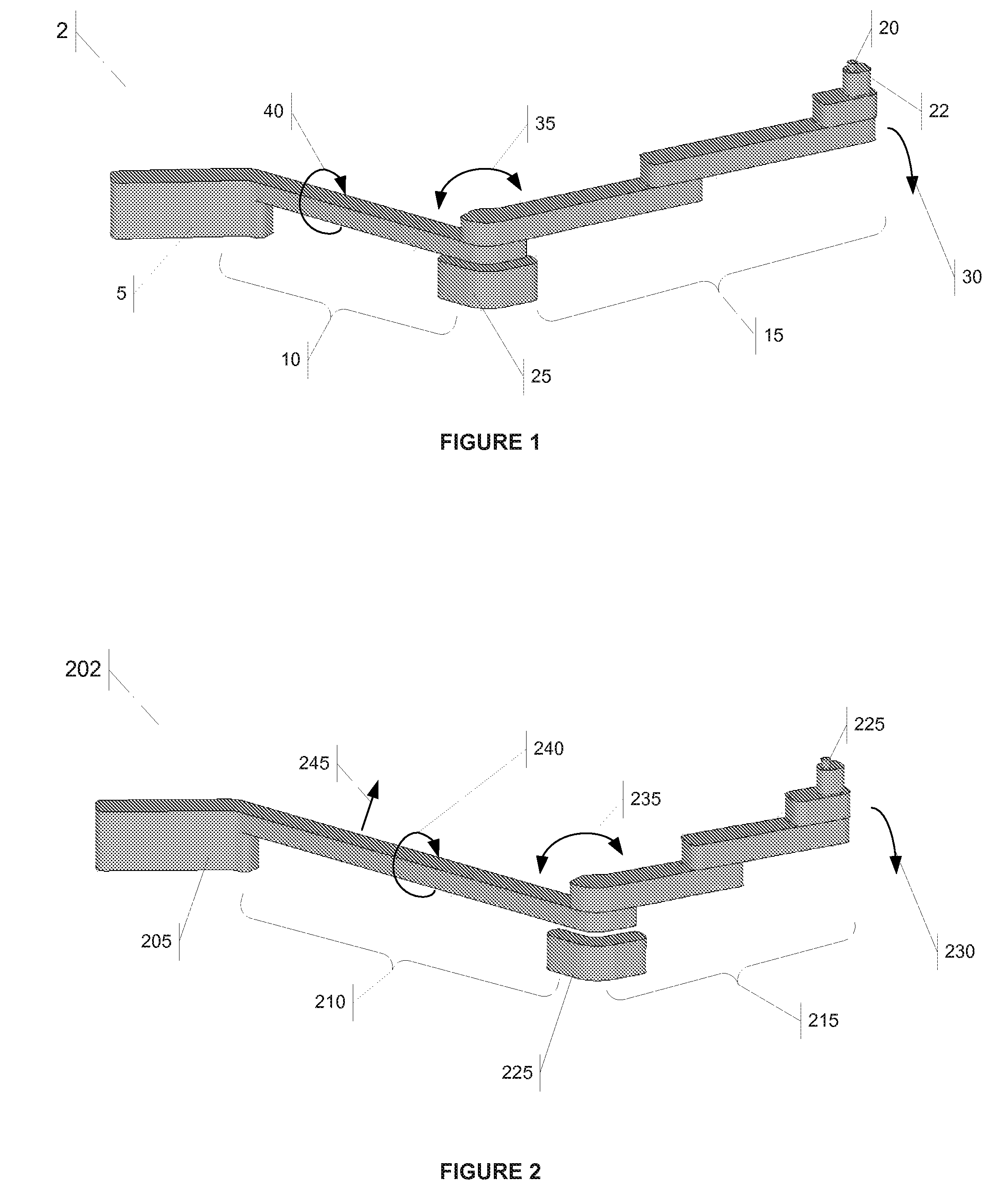

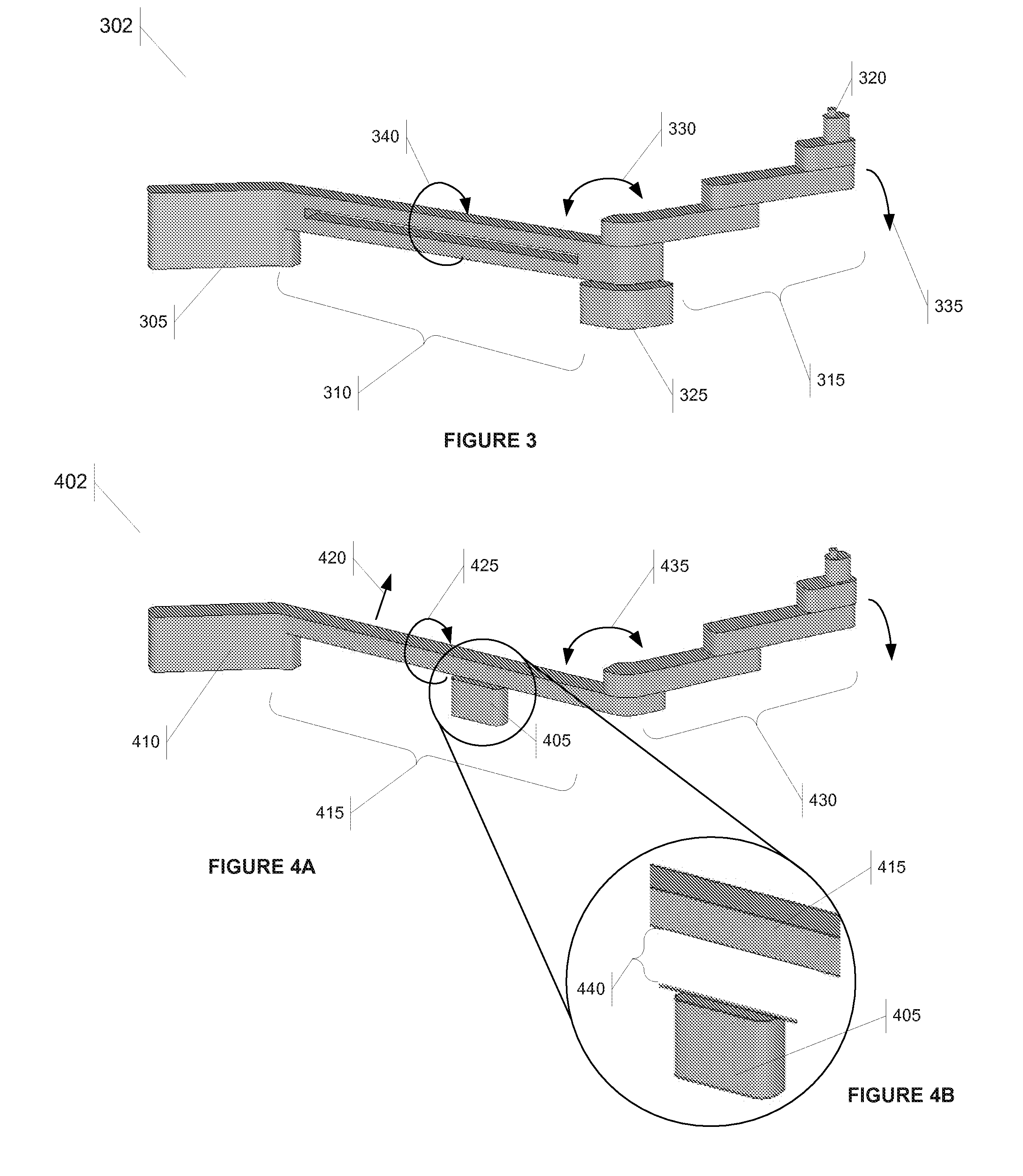

Hybrid probe for testing semiconductor devices

ActiveUS7589542B2Moment of inertia for the torsion and/or bending elements can be loweredAltering the energy absorption or distribution characteristicsSemiconductor/solid-state device testing/measurementManufacture of electrical instrumentsContact padEnergy absorption

A hybrid probe design is presented that includes a torsion element and a bending element. These elements allow the probe to store the displacement energy as torsion or as bending. The probe includes a base, a torsion element, a bending element, and a tip. The probe elastically deforms to absorb the displacement energy as the probe tip contacts the DUT contact pad. The bending element absorbs some of the displacement energy through bending. Because the torsion element and the bending element join at an angle, a portion of the displacement energy is transferred to the torsion element causing it to twist (torque). The torsion element can also bend to accommodate the storage of energy through torsion and bending. Adjusting the position of a pivot can alter the probe's energy absorption characteristics. One or more additional angular elements may be added to change the energy absorption characteristics of the probe.

Owner:FORMFACTOR INC

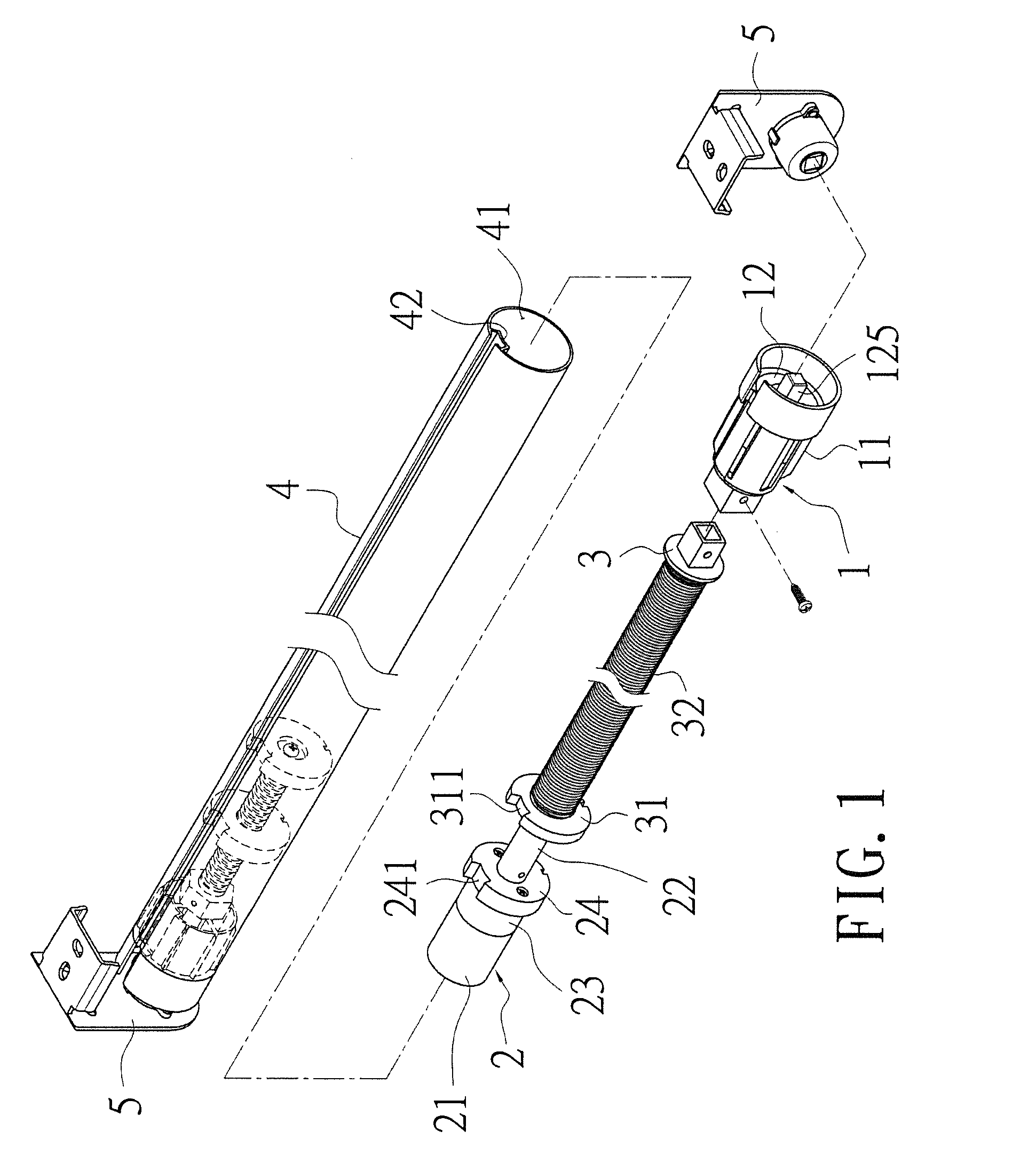

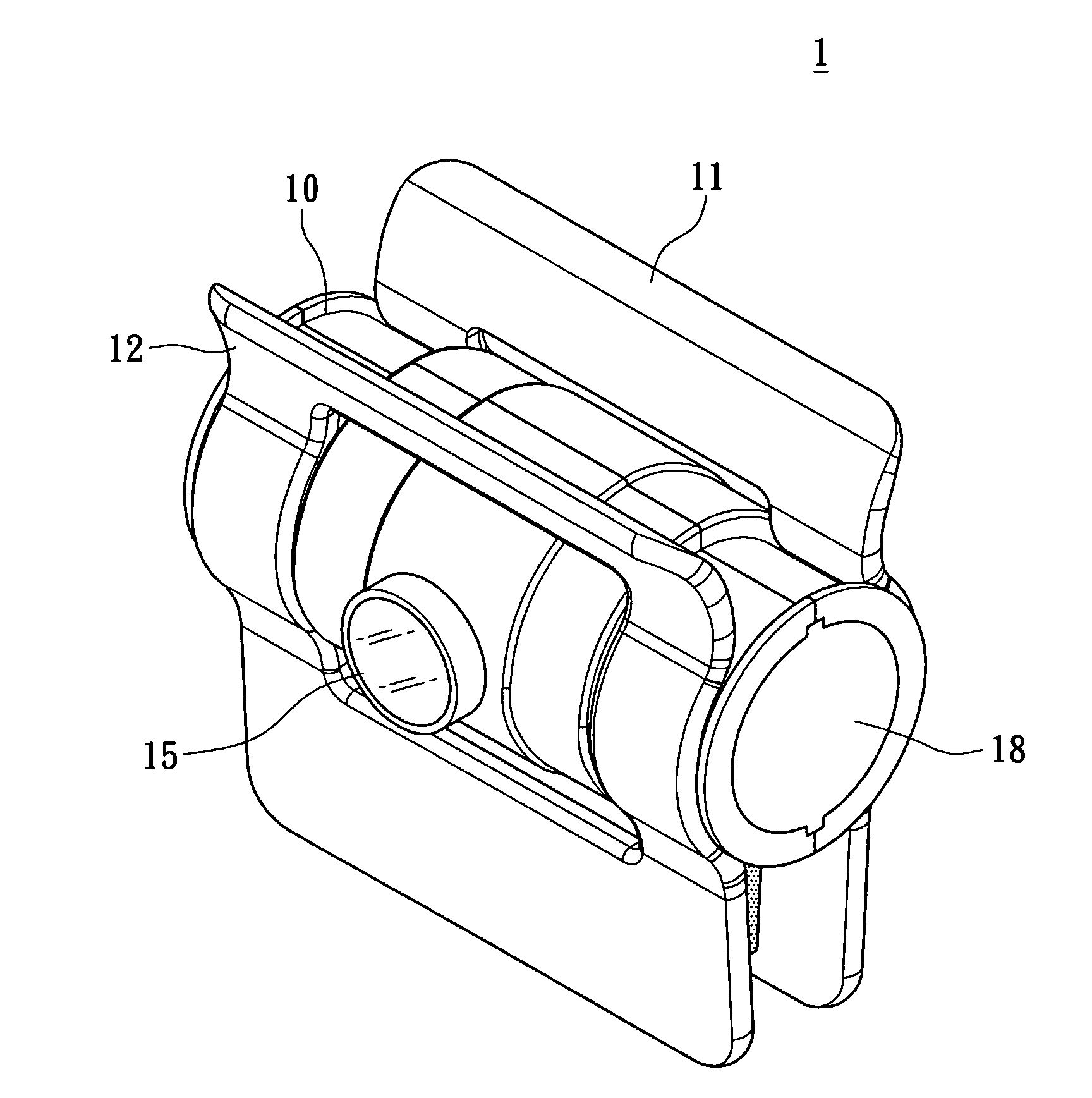

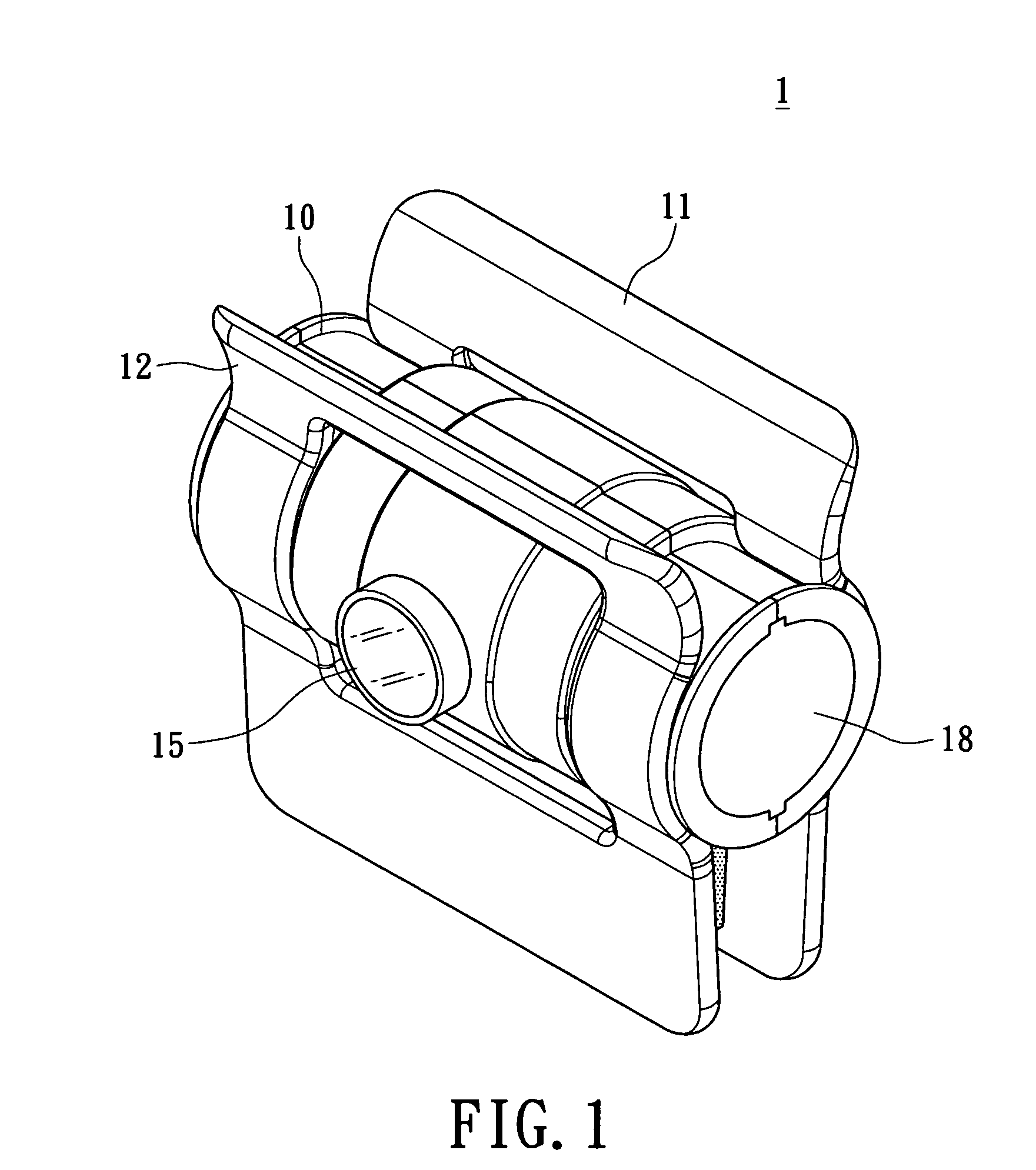

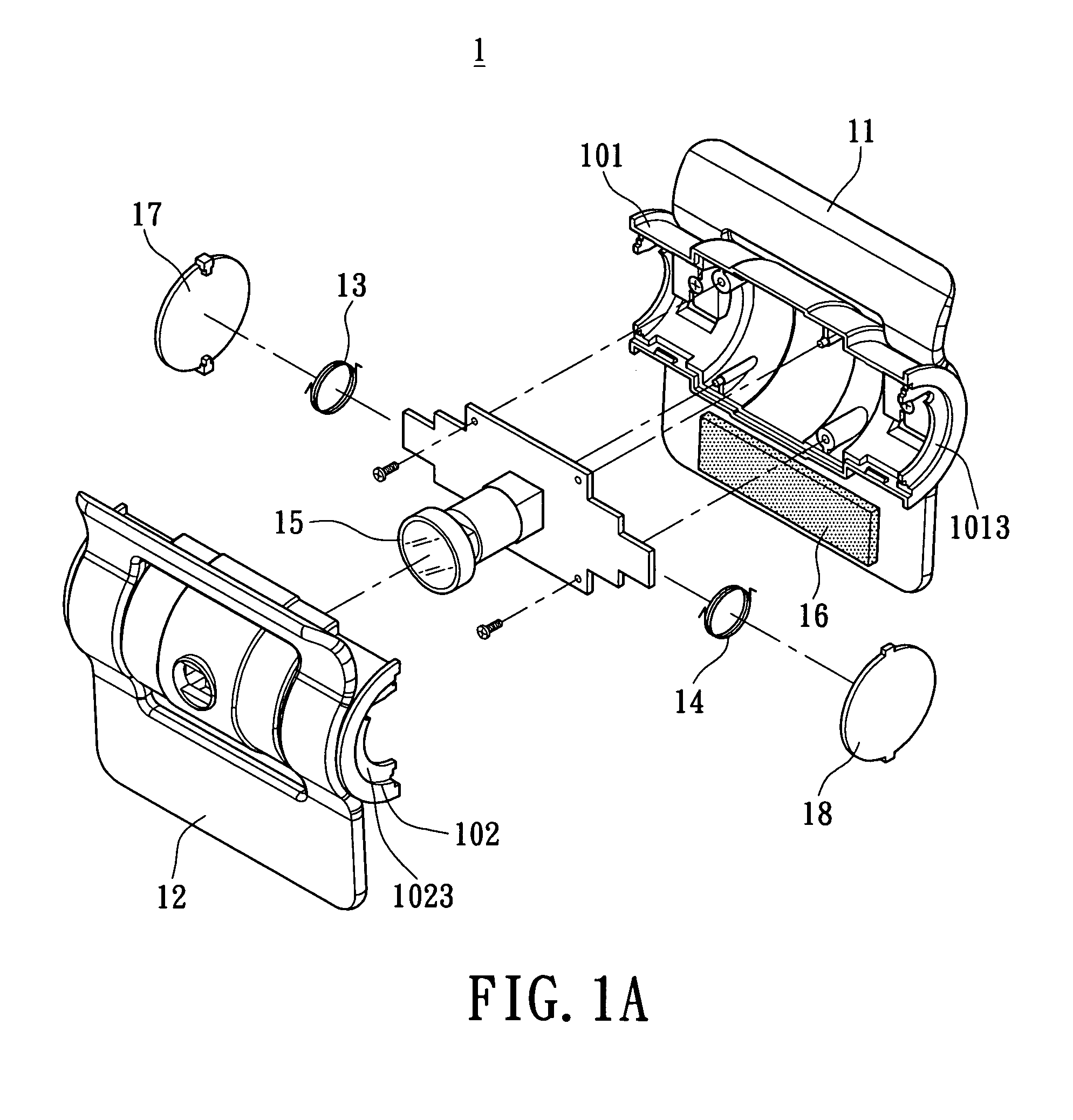

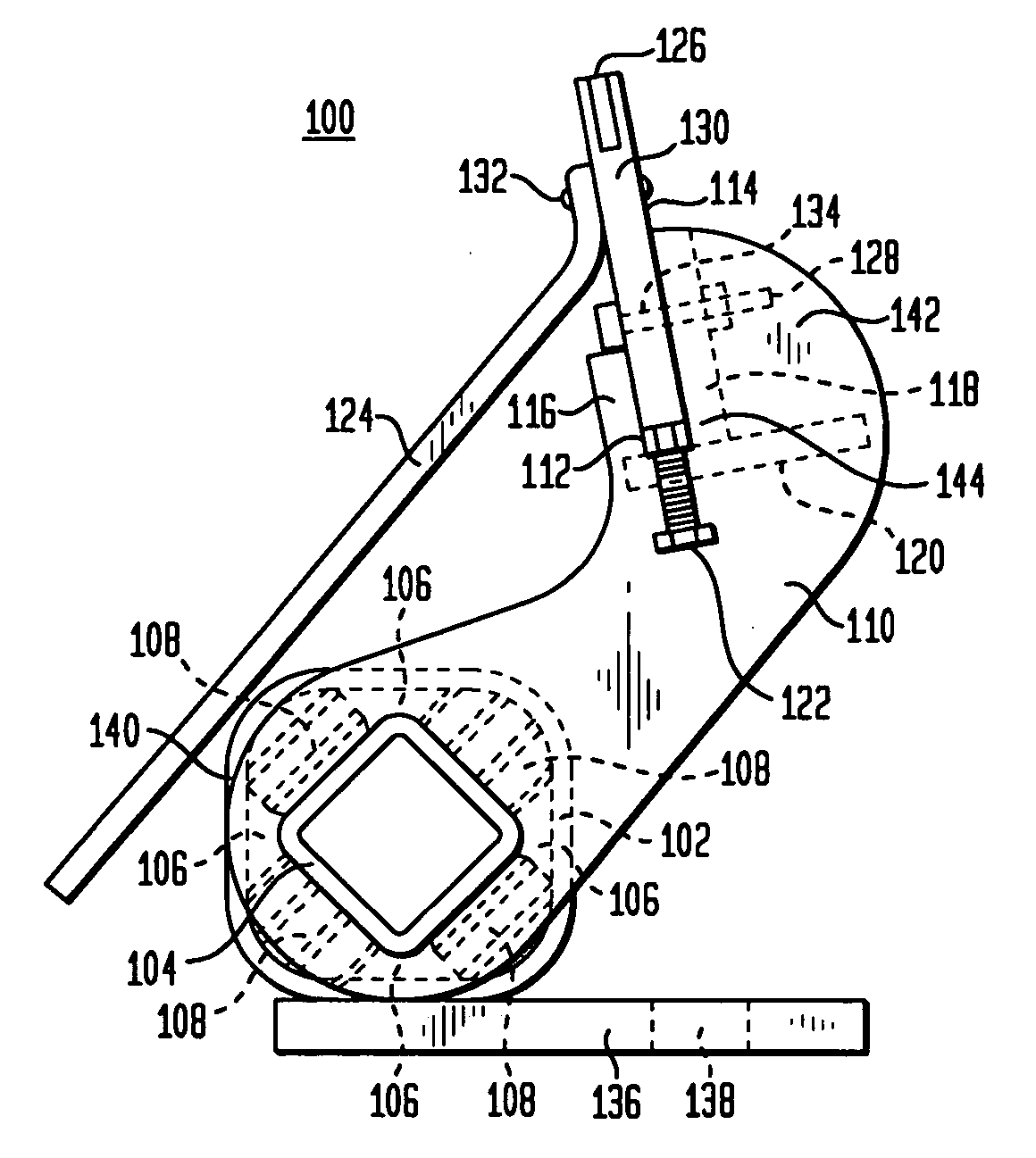

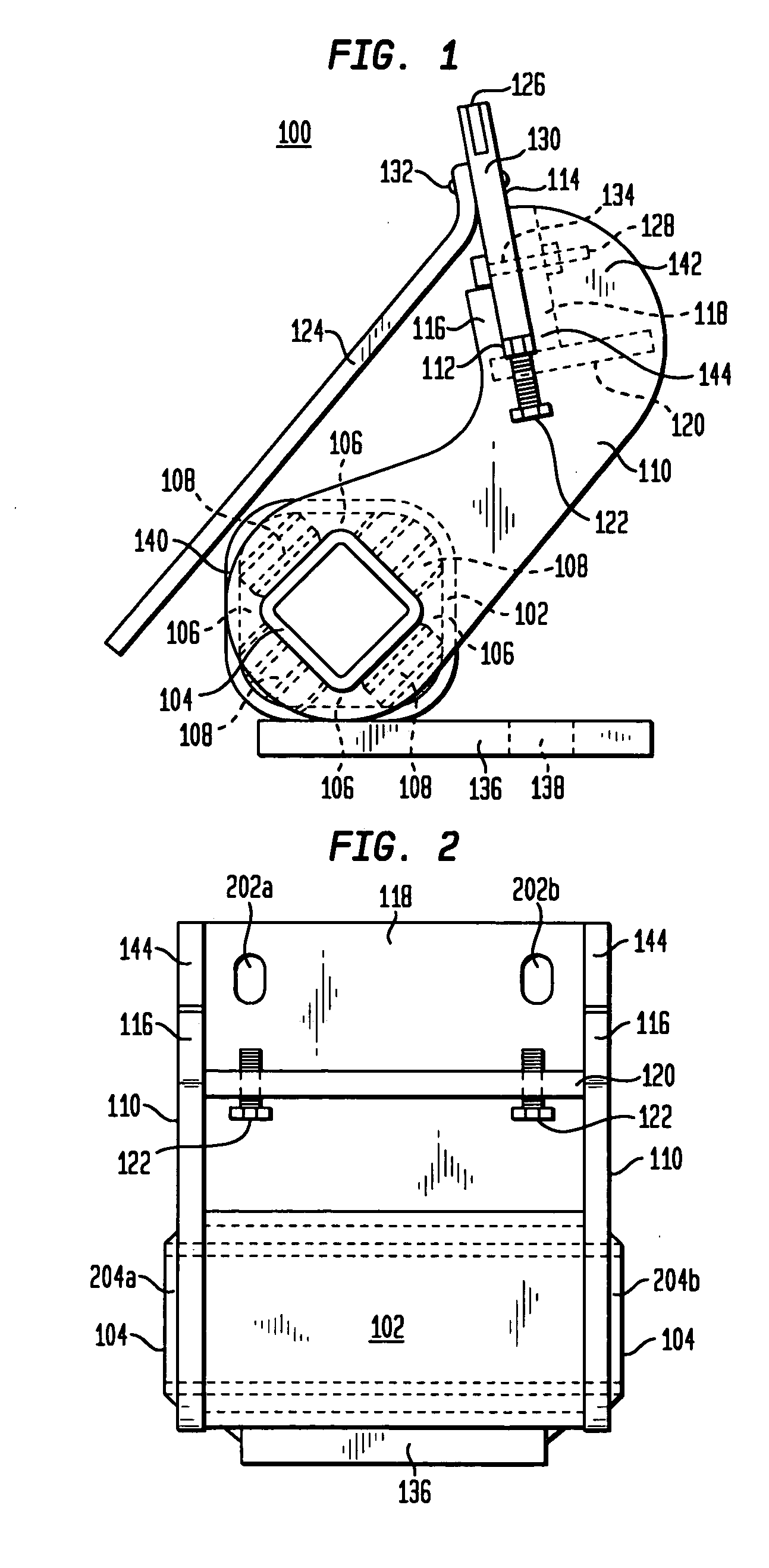

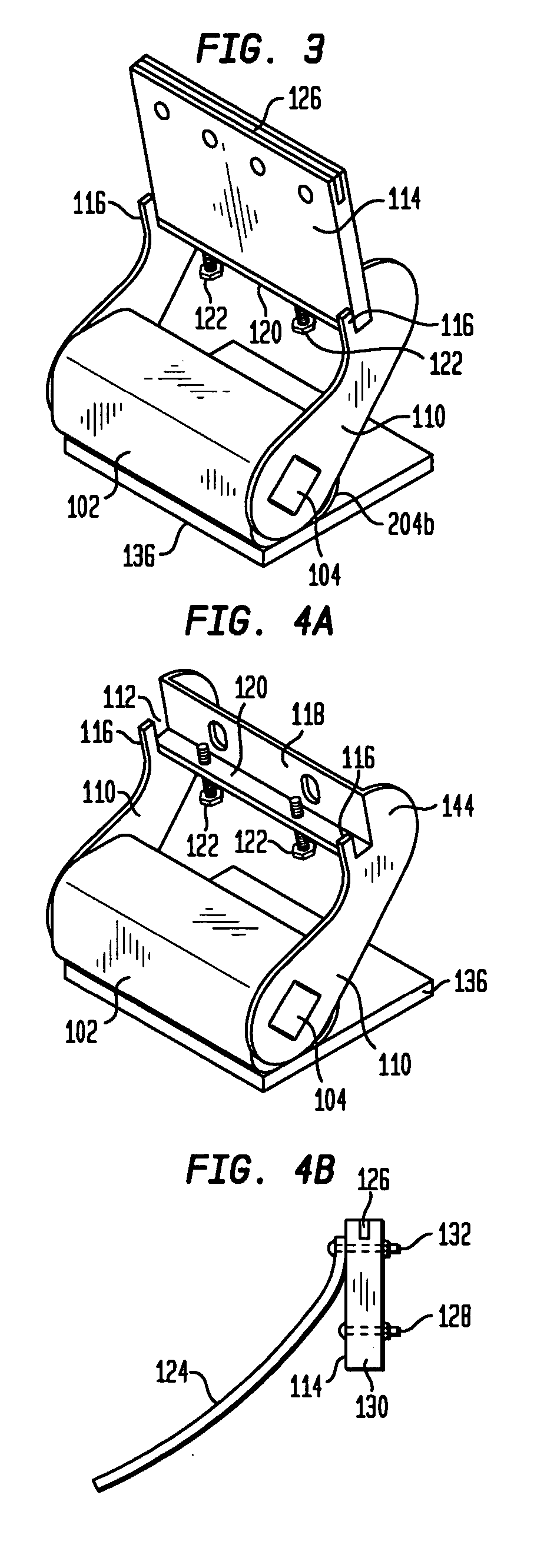

Webcam module having a clamping device

ActiveUS8054378B2Guaranteed effective sizeEffective volumeTelevision system detailsColor television detailsComputer moduleEngineering

A webcam module having a clamping device includes a body portion, a first sliding unit, a second sliding unit, a first torsion element and a second torsion element. The first sliding unit and the second sliding unit are provided on the body portion. The first sliding unit is able to slide by means of the cooperation between the sliding block and the guiding though-groove. The torsion elements are used to generate a force for clamping an article. Via the above arrangement, a user can turn a first turning portion of the first sliding unit and a second turning portion of the second sliding unit, thereby opening a first clip and a second clip to a predetermined angle. The torsion elements allow the first clip and the second clip to be clamped at a predetermined position.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

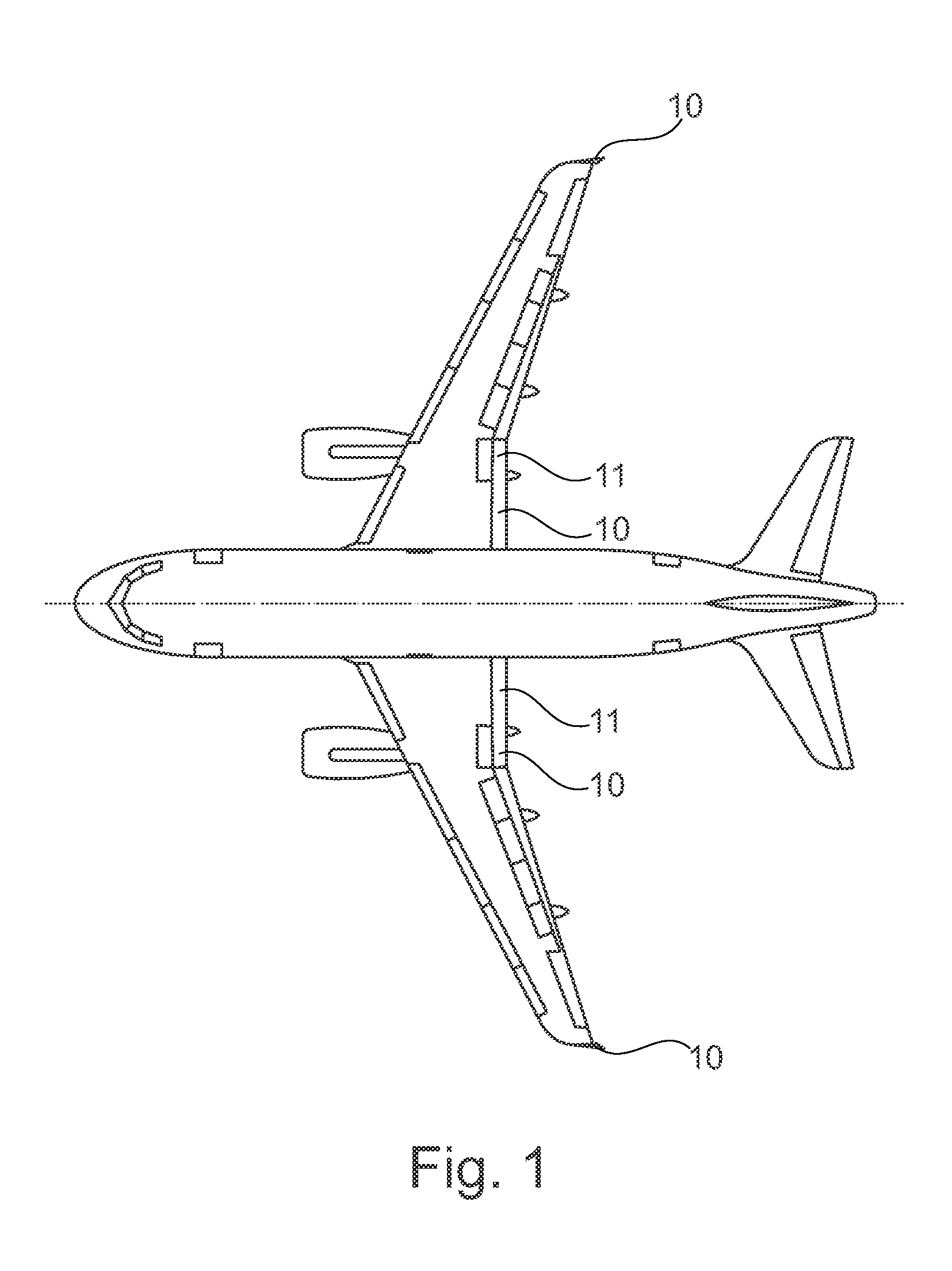

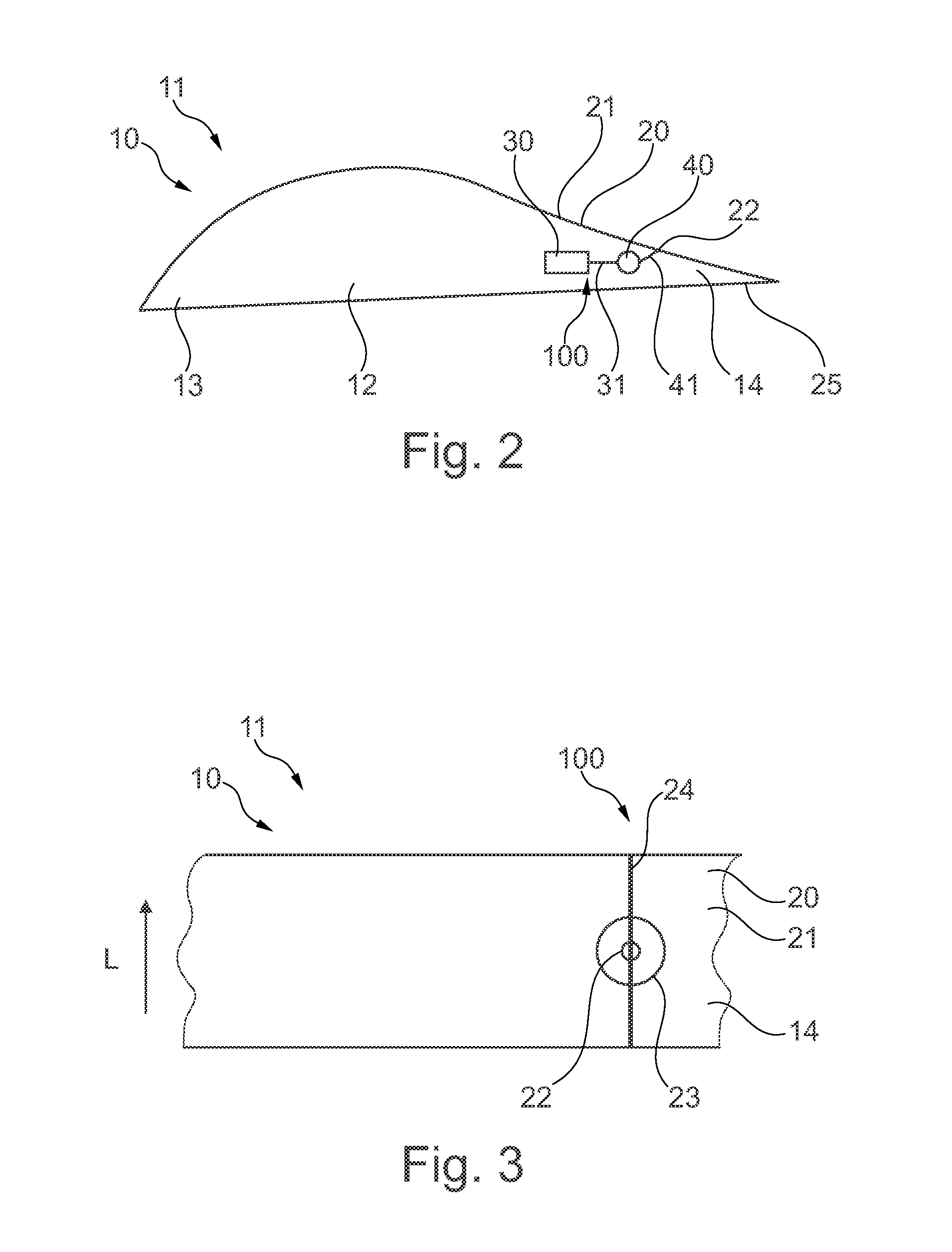

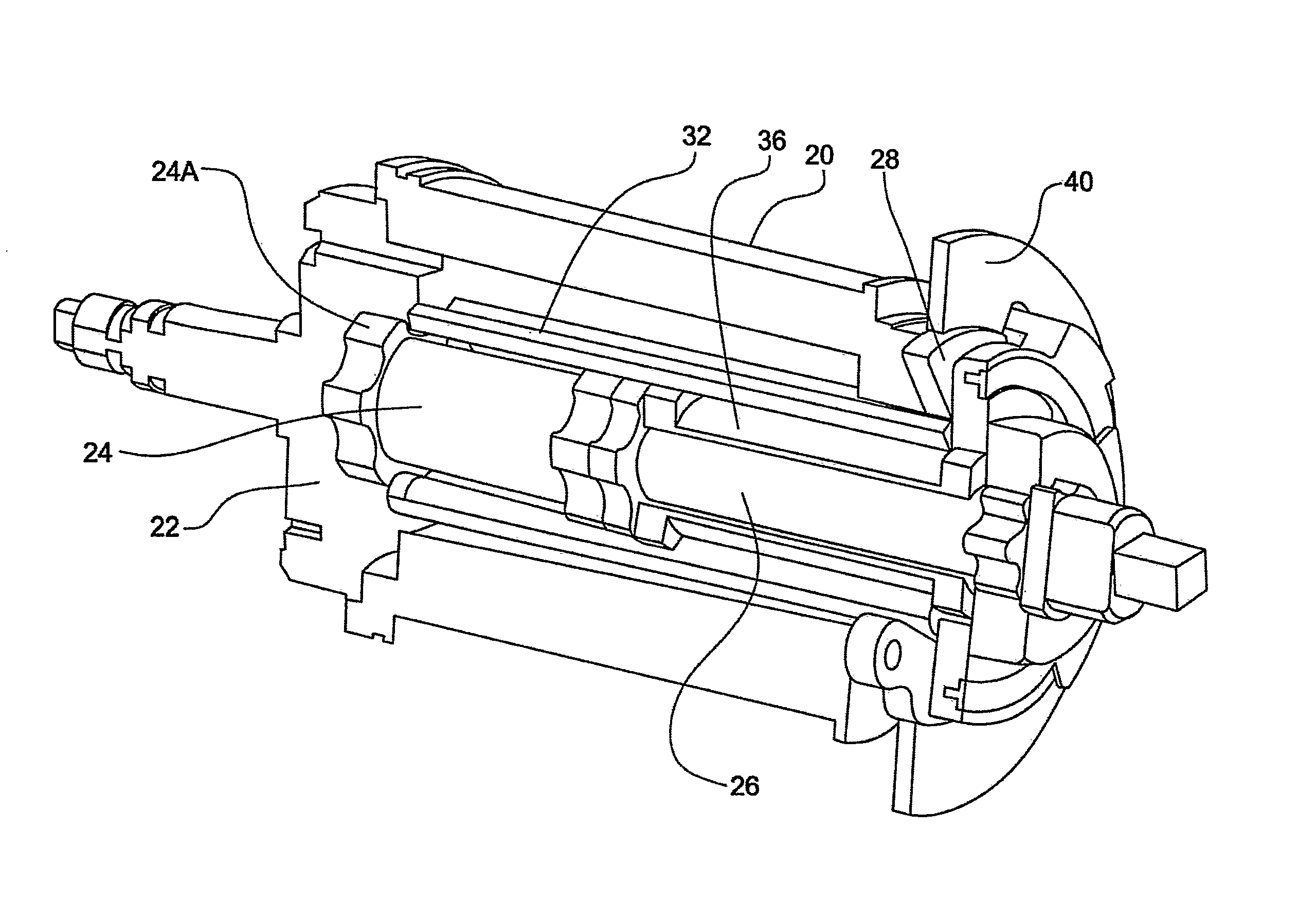

Morphing trailing edge device for an airfoil

A morphing trailing edge device for an airfoil includes a skin member, an actuator, and a torsion element. The skin member is configured to extend on a surface of a trailing edge region of an airfoil and includes a load introduction point within a reinforced area. The skin member further includes a stiffening member arranged essentially perpendicular to the load introduction point, wherein the load introduction point, the reinforced area and the stiffening member are integrated into the skin member. The actuator is configured to drive the torsion element with an actuation load. The torsion element is configured to translate the actuation load to the load introduction point, so that the actuation load morphs the trailing edge region up- or downwardly relative to a horizontal plane. A morphing airfoil for an aircraft, an aircraft with a morphing airfoil and a method for manufacturing a morphing airfoil are also described.

Owner:AIRBUS OPERATIONS GMBH

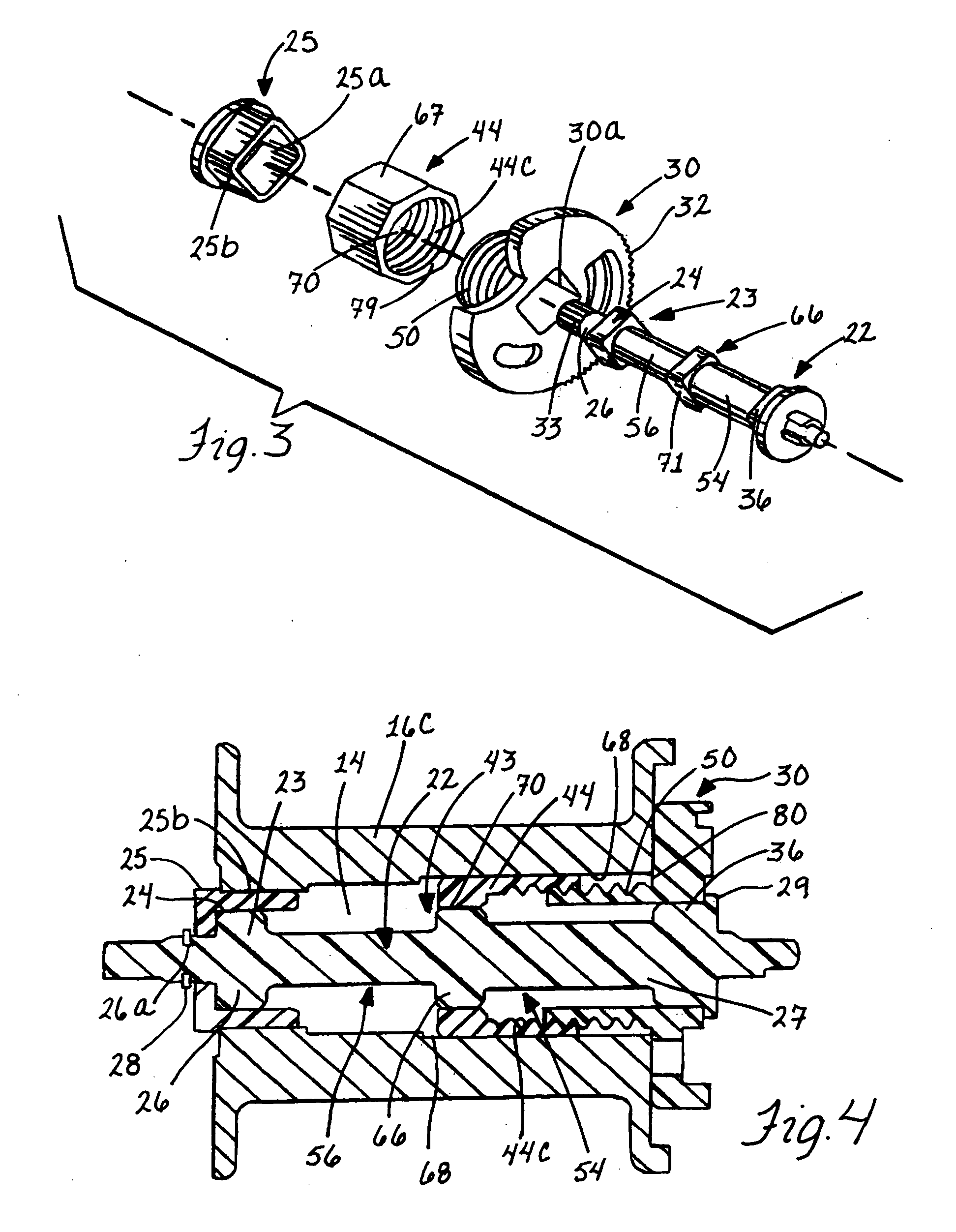

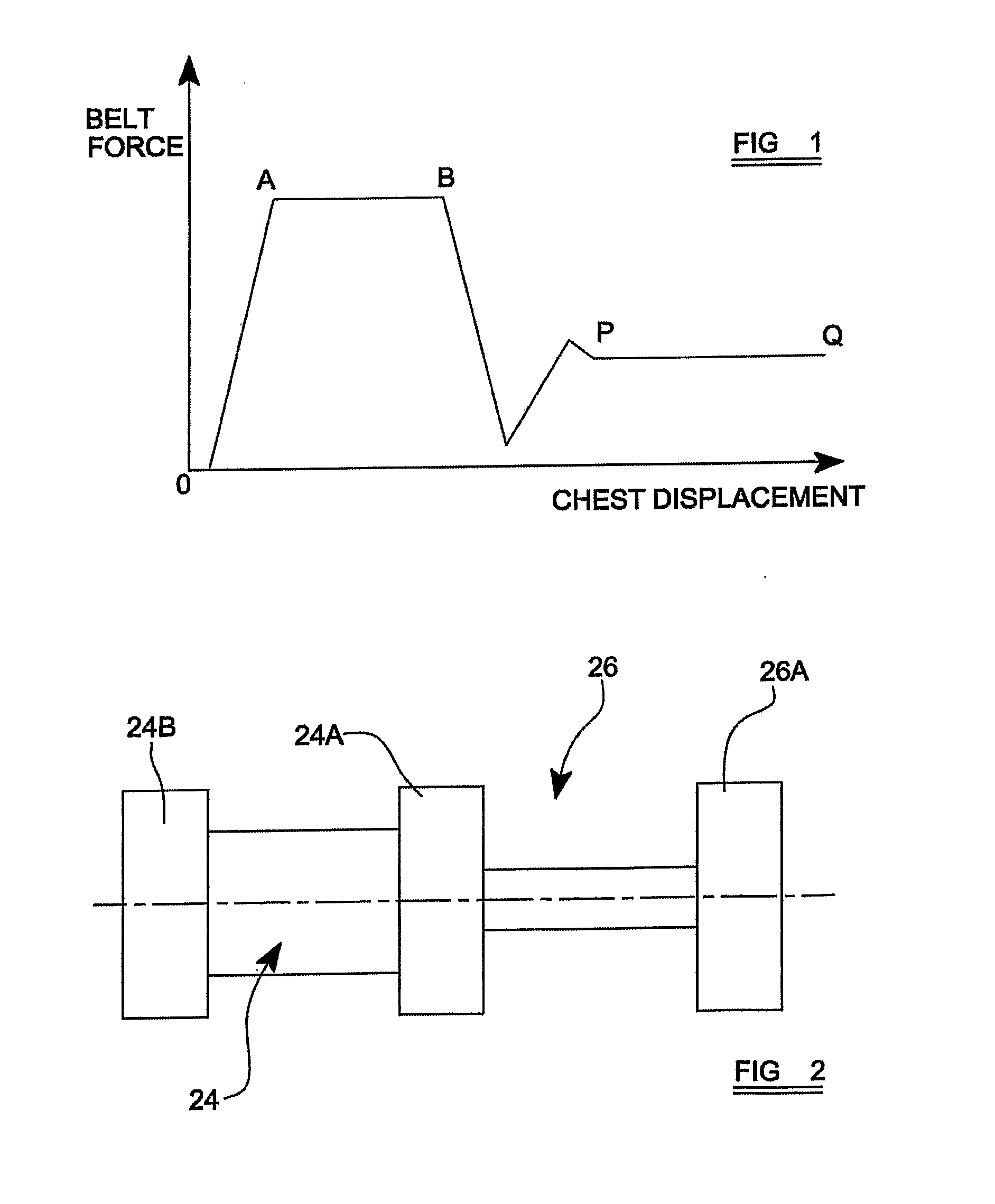

Adaptive Load Limiting Seat Belt Retractor

A safety seat belt arrangement comprises a retractor or spool assembly including a spool (20), carrying the seat belt, rotatable in a frame (18) unless blocked by a blocking mechanism (25), the spool assembly including a head member (22) cooperating with the blocking mechanism. A load limiting torsion bar assembly within the spool and acting between the head member and the spool includes a high level torsion bar portion (24), a low level torsion bar portion (26) and an intermediate torsion element in the form of a torsion pipe (36) fixed at its ends with respect to the ends of the torsion bar portion (26). A torque tube (32) initially provides a direct drive connection between the outer end of the spool (20) and the outer end (24A) of the high level torsion bar portion, so that, in a frontal impact situation, in which the blocking mechanism blocks rotation of the head member, the torque applied to the spool by the belt tension is transferred to the head member principally via the high level torsion bar (24), limiting the belt tension to a relatively high level, until the torque tube is disconnected from the outer end of the spool in a changeover operation effected by a changeover mechanism (28, 40, 42) after which the belt tension is limited by twisting of the bar portion (26) and the torsion pipe (36) together, until the torsion pipe breaks, leaving rotation of the spool restrained only by twisting of the low level torsion bar part (26).

Owner:AUTOLIV DEV AB

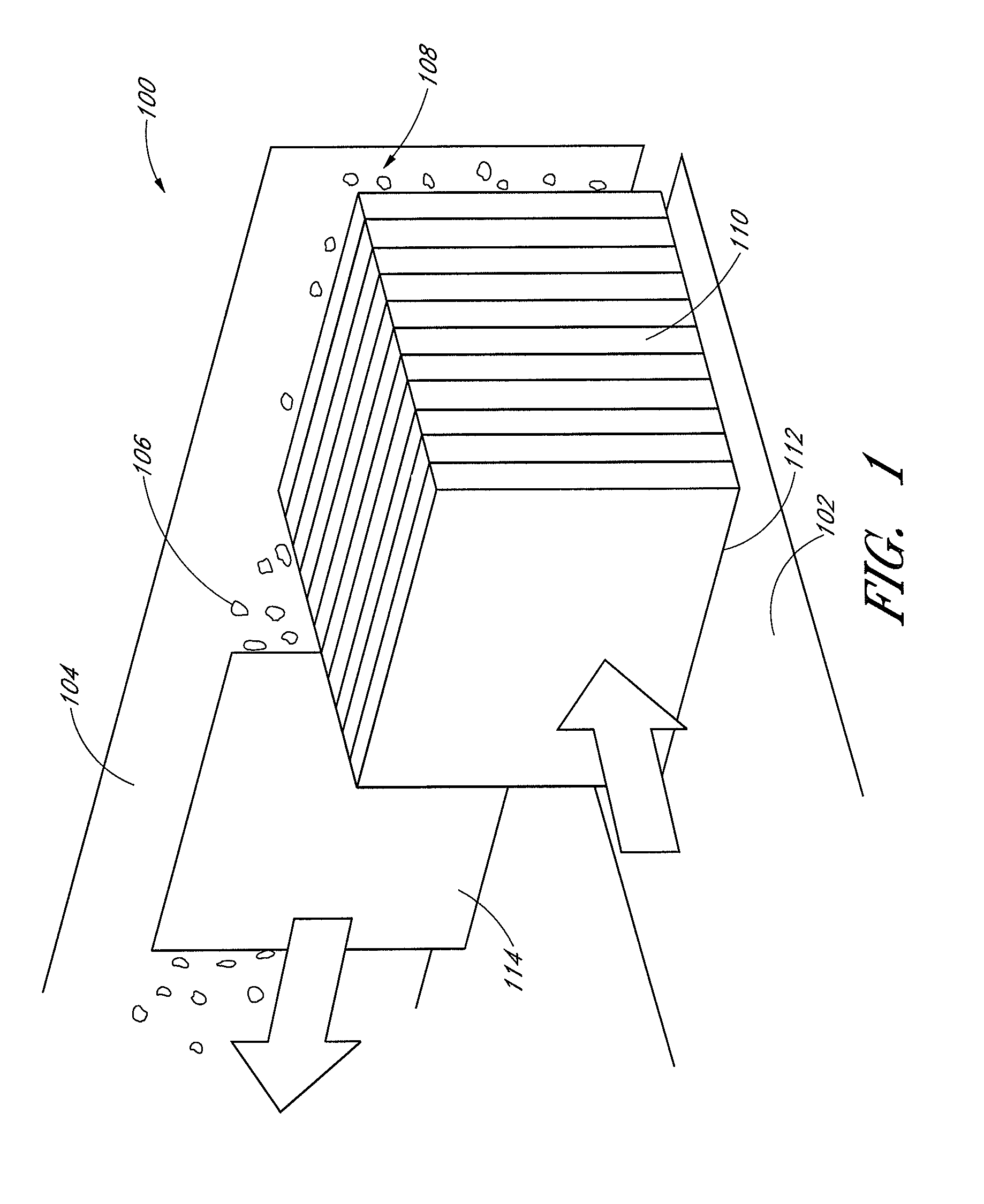

Conveyor belt cleaning system

A conveyor belt cleaning system being a torsion blade holder assembly having a mounting sub-assembly and a blade support sub-assembly. The mounting sub-assembly has a first hollow member and a second member situated at least partially therein with torsion elements in the plurality of spaces or cavities between the first hollow member and the second member. The blade support sub-assembly, in which a scraper blade is secured, is attached to the second member such that when the scraper blade meets resistance while scraping the surface of a conveyor belt, the torsion elements are compressed and the blade support sub-assembly with the scraper blade rotates away from the conveyor belt. The blade support sub-assembly includes notched receiving members for receiving the scraper blade, a face plate extending between the notched receiving members approximately parallel to the scraper blade such that at least a portion of the scraper blade rests flush against the face plate when the scraper blade is situated in the notched receiving members, a horizontal blade stabilizer approximately perpendicular to and extending beneath the face plate, and a means for vertically adjusting the scraper blade within the notched receiving members. The means for vertically adjusting is one or more adjustable lock bolts extending upward through the horizontal blade stabilizer for adjusting the scraper blade up and down within the notched receiving members. The torsion blade holder assembly optionally includes a shield and a means for spraying a liquid on the conveyor belt.

Owner:MARTIN ENG

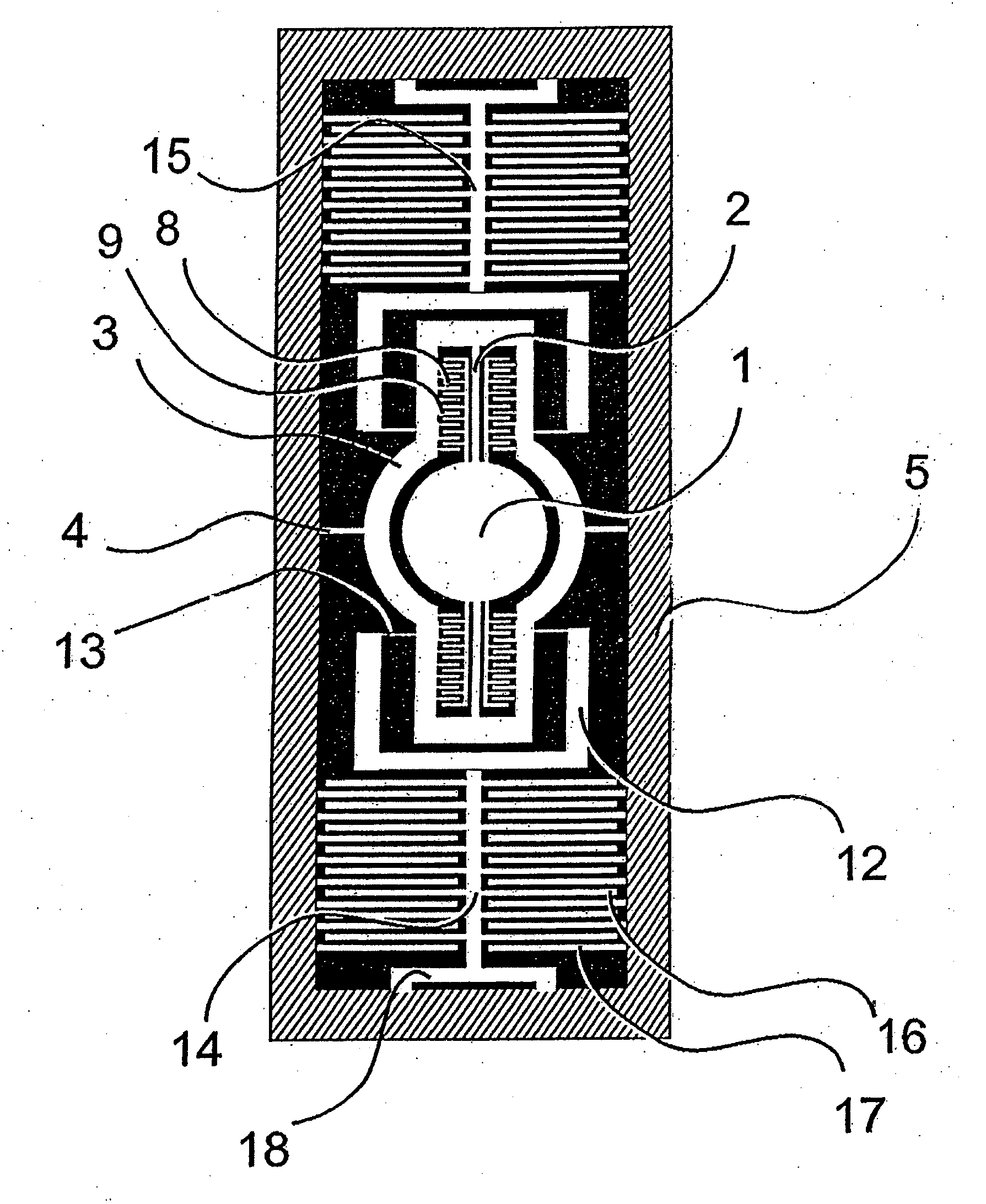

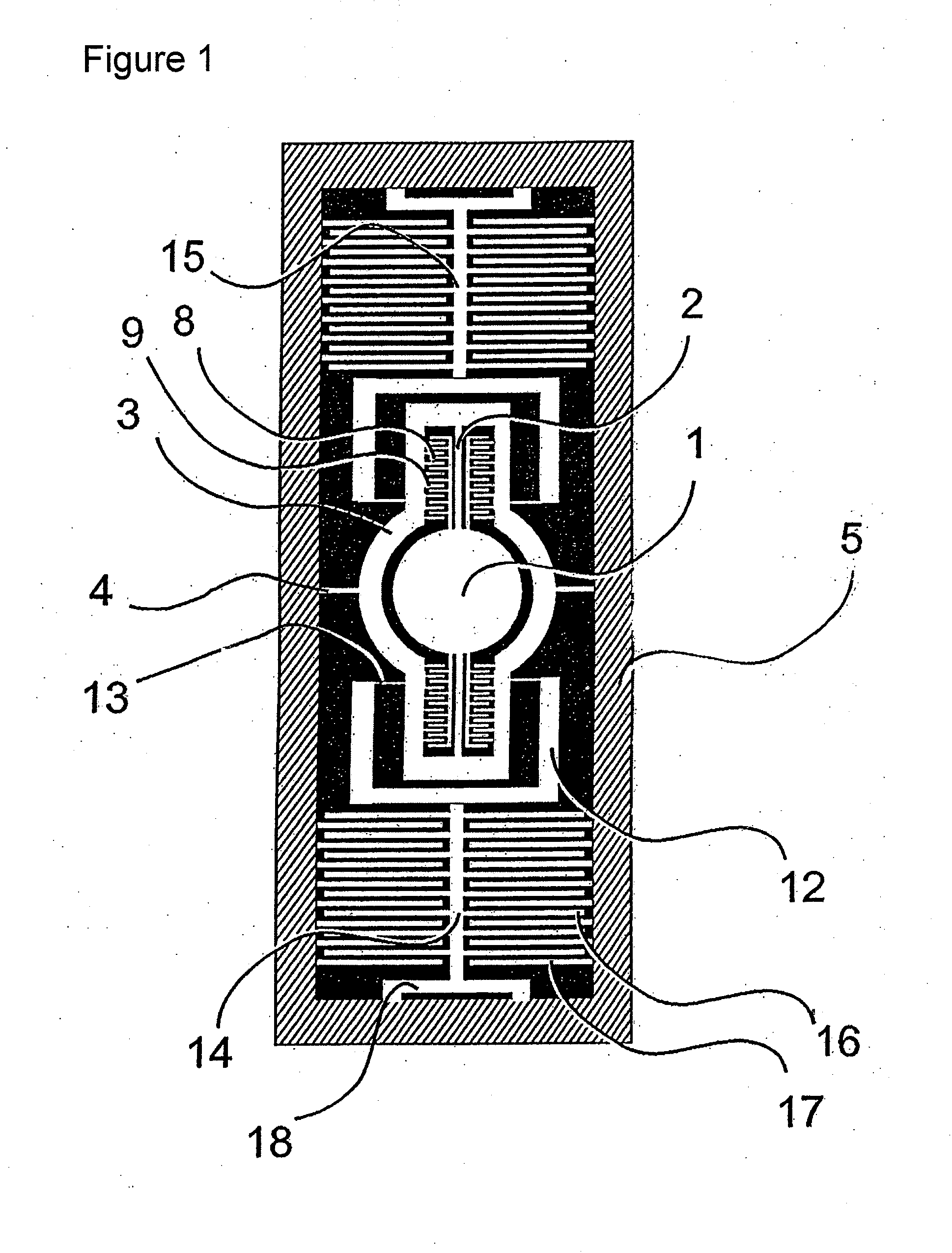

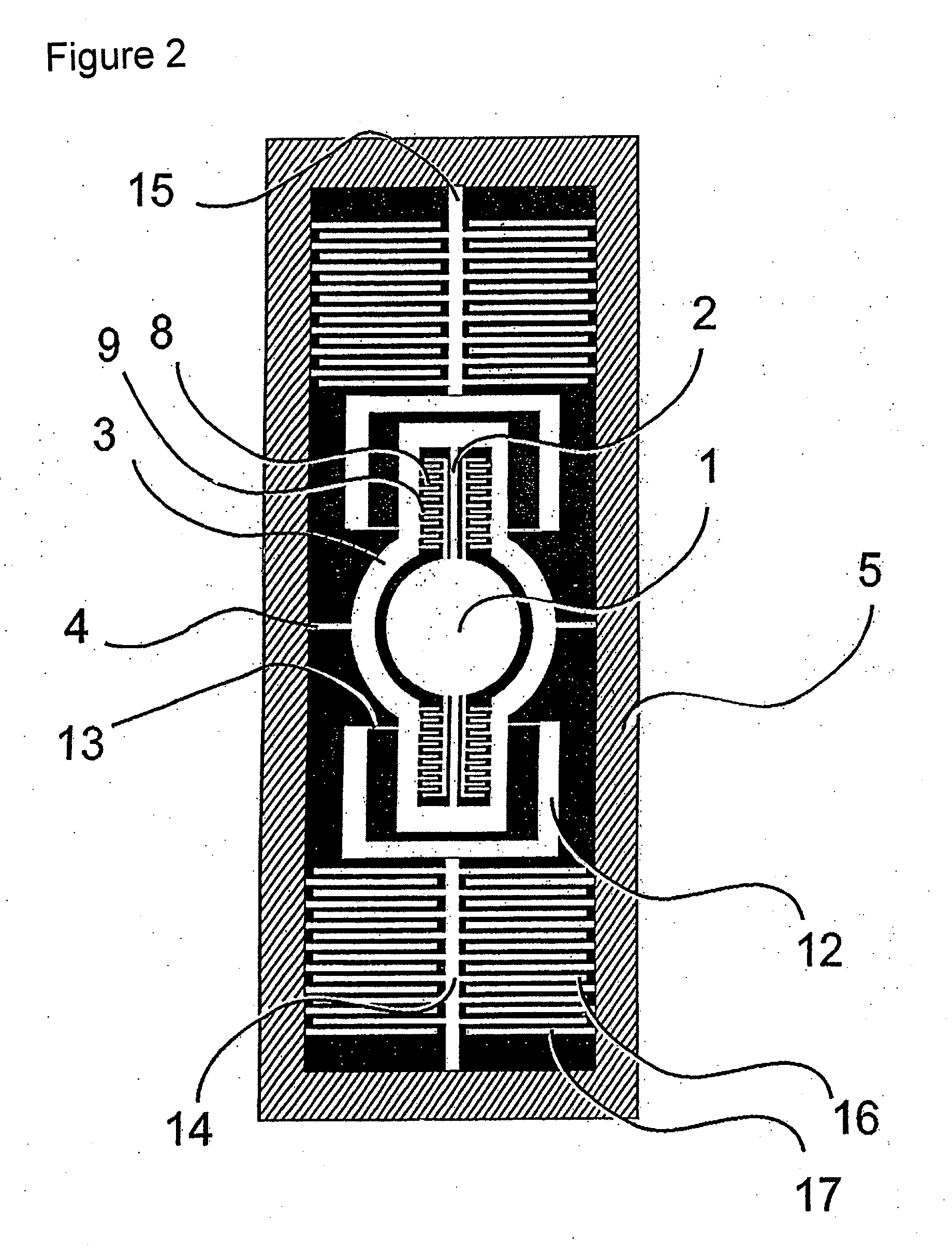

Electrostatic comb-drive micromechanical actuator

ActiveUS20120075685A1Simple hermetically sealed wafer level packagingIncrease the lengthElectrostatic generators/motorsOptical elementsComb driveEngineering

The invention relates to a micromechanical actuator, especially a micro-mirror scanner, comprising an actuator unit in an outer frame which unit is suspended in the outer frame via two torsion elements, and electrostatic tilt drives from intermeshing first and second comb-type electrodes which are off-set from each other vertically. The first electrodes are rigidly connected to the outer frame and the second electrodes to the outer frame via an outer connecting element and to the actuator unit via an inner connecting element. The inner connecting element has a spring which extends in parallel to the outer tilting axis, which is connected to the same in a section of the actuator unit close the outer tilting axis, and which is designed and arranged to be rigid in the vertical direction and flexible at a right angle to the vertical direction. The micromechanical actuator according to the invention allows the use in a micro-mirror scanner whose slow axis is non-resonantly driven with excursions of >+ / −7°, lateral mirror sizes having dimensions of 1 mm and more and a resonant frequency of >1 kHz and can be integrated even into flat mobile phones.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Shaft arrangement and method for relaying torques acting around a rotational axis

ActiveUS20150159700A1Continuous changeStable changeRotating vibration suppressionYielding couplingRotational axisTorsion element

A shaft arrangement is disclosed for transmitting torques acting around a rotational axis, with a variably adjustable torsional stiffness acting around the rotational axis and a method for varying the torsional stiffness of a shaft arrangement. The invention includes a first shaft section, having at least one torsion element secured thereto which is not damaged by torque and is axially fixed manner, which is mounted to be dimensionally stable transverse to the rotational axis, a second shaft section spaced axially apart from the first shaft section, to which the at least one torsion element is secured which is not rotatable but is axially movable and that a means for operatively interacts or can be made to operatively interact with the second shaft section for axially moving the second shaft section in relation to the first shaft section and in relation to the at least one torsion element.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Misfire detecting apparatus for internal combustion engine

ActiveUS10378468B2Ensure correct executionRaise the possibilityInternal-combustion engine testingElectrical controlExternal combustion engineInternal combustion engine

A misfire detecting apparatus for an internal combustion engine is provided. The engine has an output shaft connected via a torsion element to an input shaft of a transmission mechanism. A transmission rotational speed parameter indicative of a rotational speed of the input shaft is detected. A modified engine rotational speed parameter is calculated by modifying the detected engine rotational speed parameter based on the transmission rotational speed parameter, an engine rotation moment on the input side of the torsion element, and a transmission rotation moment on the output side of the torsion element. An average change amount of the modified rotational speed parameter, and an inertia speed changing component, are calculated. Further, a corrected rotational speed parameter is calculated by correcting the modified rotational speed parameter according to the average change amount and the inertia speed changing component. A relative speed parameter is calculated based on the corrected rotational speed parameter, and a determination parameter is calculated by integrating the relative speed parameter. The misfire determination is performed based on the determination parameter.

Owner:HONDA MOTOR CO LTD

Conveyor belt cleaning system

A conveyor belt cleaning system being a torsion blade holder assembly having a mounting sub-assembly and a blade support sub-assembly. The mounting sub-assembly has a first hollow member and a second member situated at least partially therein with torsion elements in the plurality of spaces or cavities between the first hollow member and the second member. The blade support sub-assembly, in which a scraper blade is secured, is attached to the second member such that when the scraper blade meets resistance while scraping the surface of a conveyor belt, the torsion elements are compressed and the blade support sub-assembly with the scraper blade rotates away from the conveyor belt. The blade support sub-assembly includes notched receiving members for receiving the scraper blade, a face plate extending between the notched receiving members approximately parallel to the scraper blade such that at least a portion of the scraper blade rests flush against the face plate when the scraper blade is situated in the notched receiving members, a horizontal blade stabilizer approximately perpendicular to and extending beneath the face plate, and a means for vertically adjusting the scraper blade within the notched receiving members. The means for vertically adjusting is one or more adjustable lock bolts extending upward through the horizontal blade stabilizer for adjusting the scraper blade up and down within the notched receiving members. The torsion blade holder assembly optionally includes a shield and a means for spraying a liquid on the conveyor belt.

Owner:MARTIN ENG

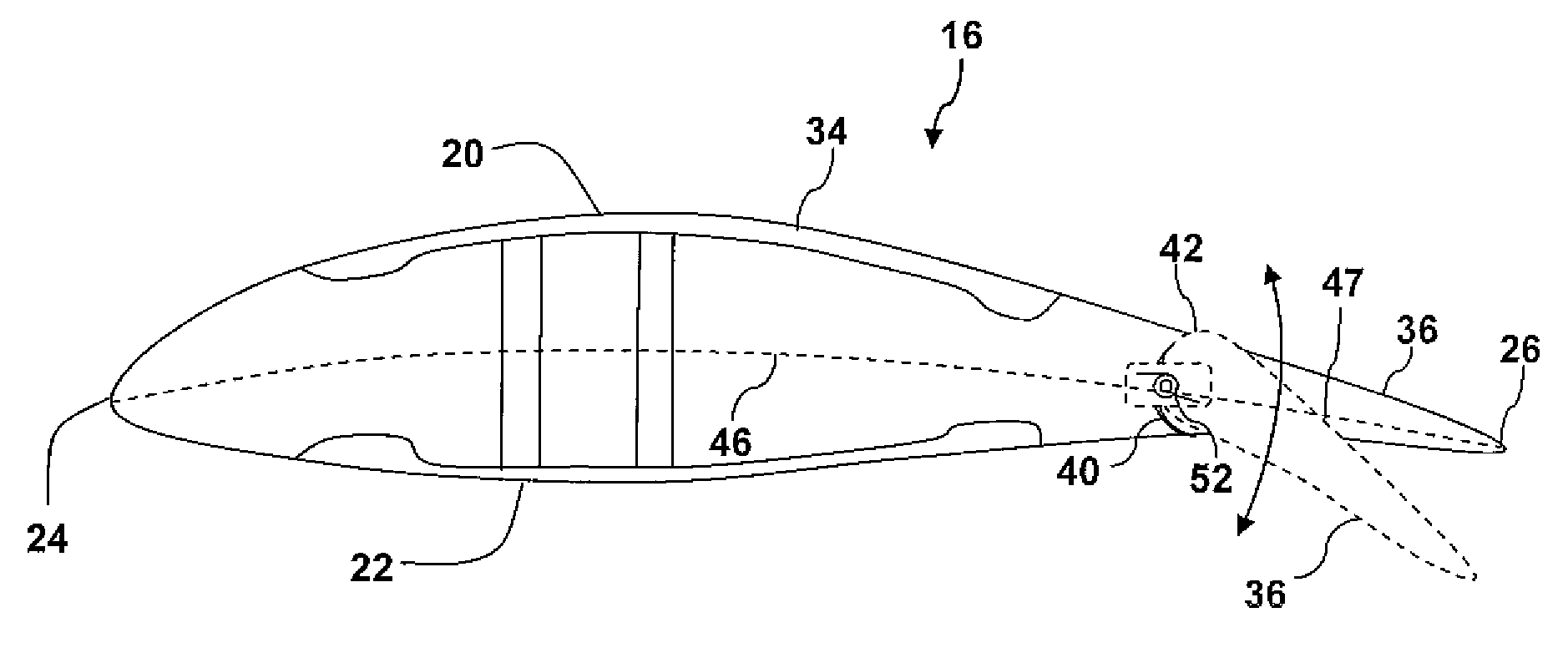

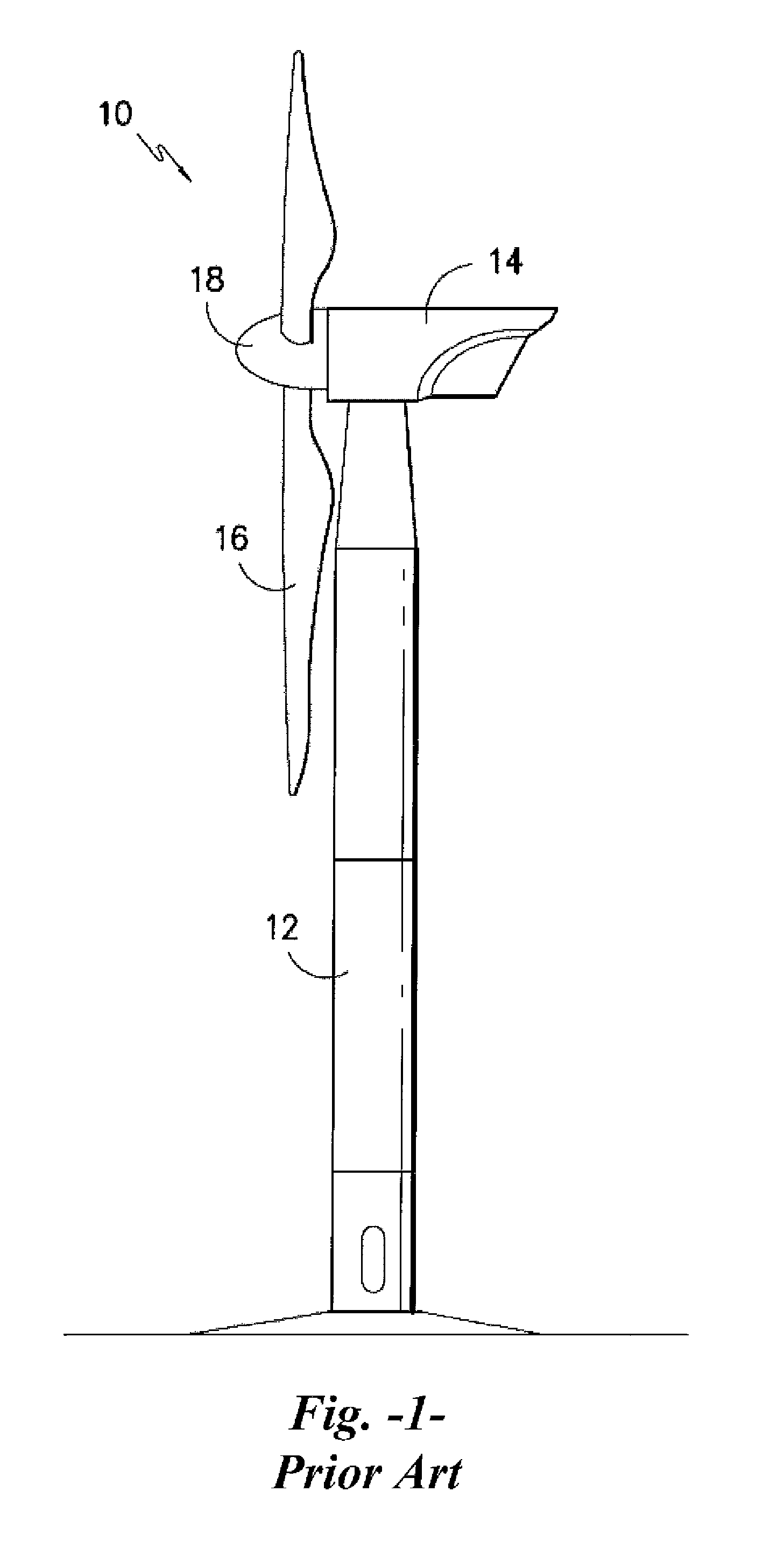

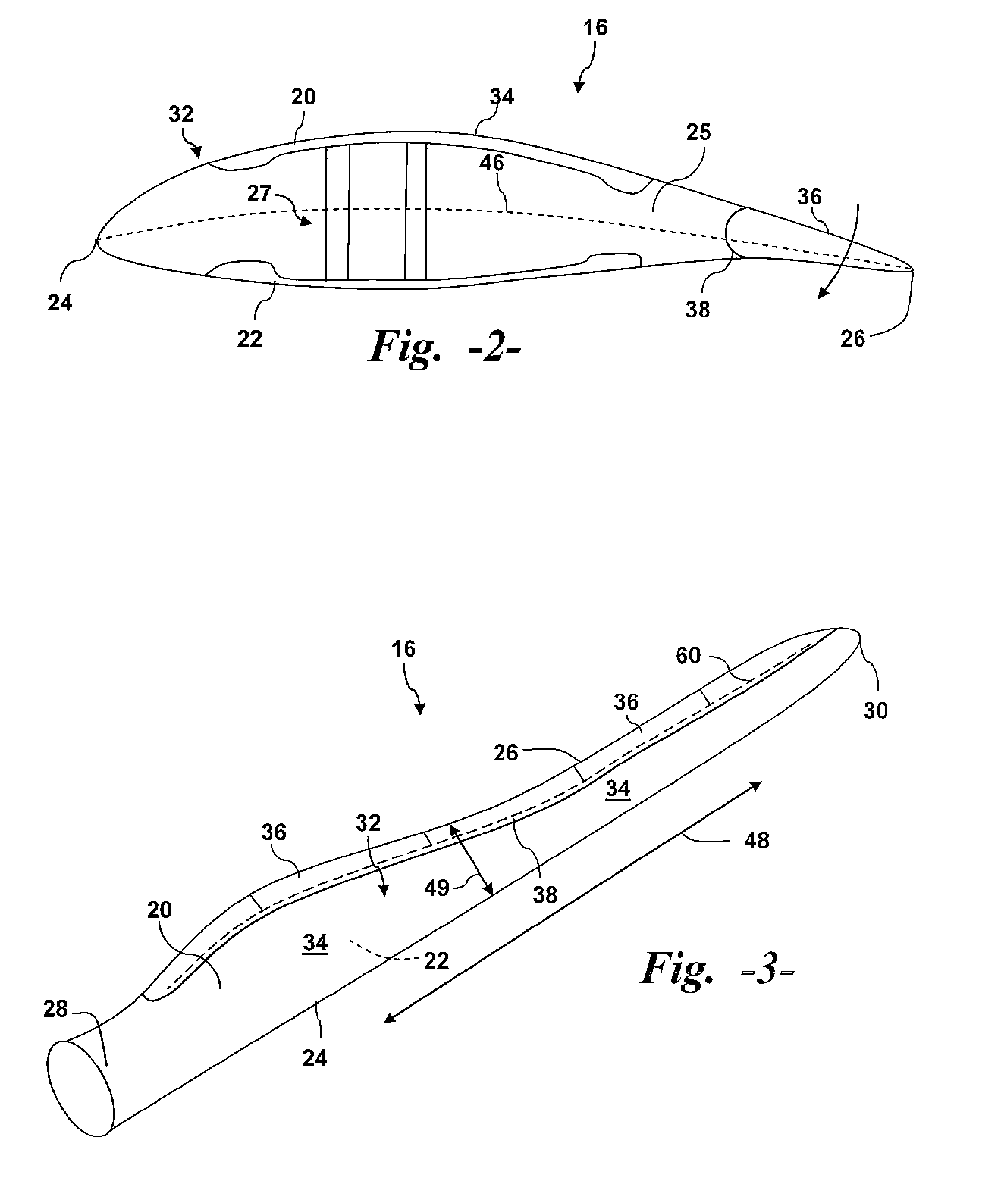

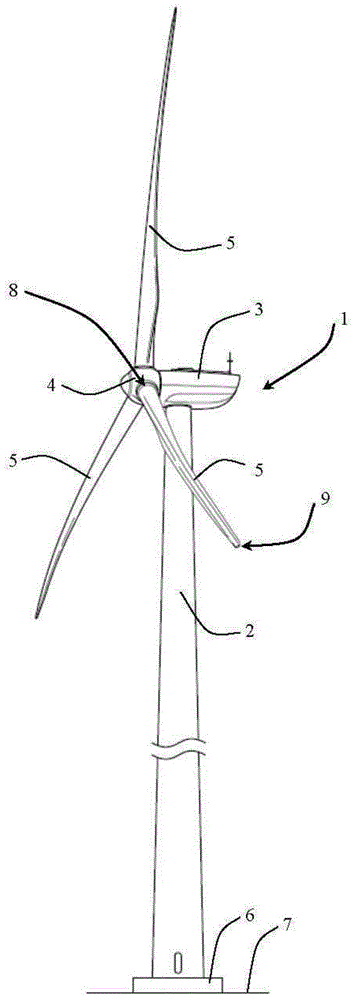

Wind turbine rotor blade with passively modified trailing edge component

A wind turbine rotor blade includes a root portion and an airfoil portion extending from the root portion and defined by a leading edge and a trailing edge. The airfoil portion further includes a main foil section and a trailing edge section that is pivotally connected to the main foil section along a span-wise extending hinge line. A passive torsion element is coupled between the main foil section and the trailing edge section. The torsion element is biased to a neutral position wherein the trailing edge section is pivoted chord-wise to a low wind speed position relative to the main foil section. The trailing edge section is self-actuating from the low wind speed position to an increased wind speed position relative to the main foil section as a function of the biasing force of the torsion element and wind speed over the airfoil section.

Owner:GENERAL ELECTRIC CO

Steering system for a vehicle

InactiveUS20070163833A1Fail safeTracking is possibleFluid steeringElectrical steeringSpool valveTorsion element

A steering system for a vehicle, e.g., a hydraulically assisted power-steering system for a motor vehicle, includes a steering spindle that connects a steering handle on its one end to a rotary slide valve or rotary pistons of a steering valve via a first torsion element. The steering system has a hydraulic servomotor for actuating an output member of a steering gear, a flow of pressurized media into working chambers of the hydraulic servomotor being controlled by the steering valve. The steering system additionally has an electric servomotor for actuating the output member. In order to provide a steering system, whose hydraulic servomotor is assisted, during operation, both mechanically by a steering handle and by an electric servomotor and is fail-safe, it is provided that the electric servomotor and the steering spindle act upon a common rotating member between the first torsion element and the rotary slide valve or rotary piston.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

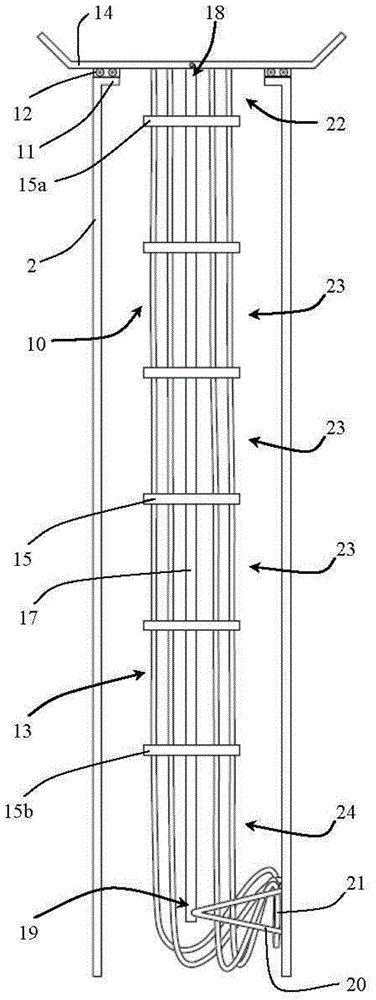

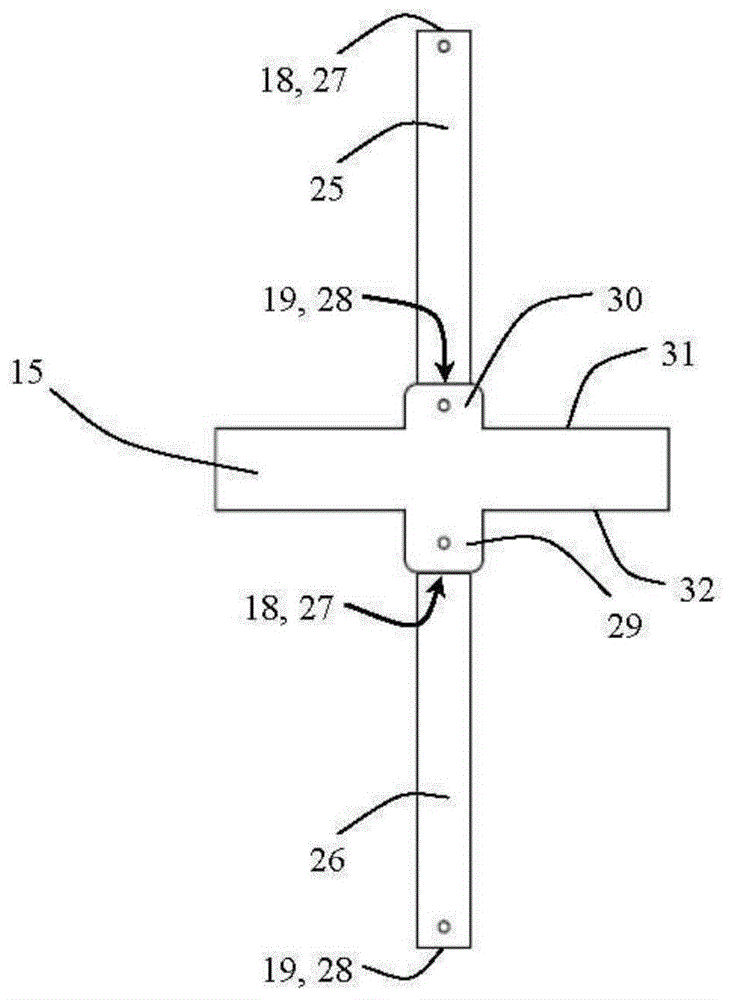

System for twisting cables in wind turbine tower

The present invention relates to a wind turbine having a wind turbine tower with a nacelle provided on the top to which a rotor hub with one or more wind turbine blades is rotatably mounted. A cable twisting system is arranged inside the wind turbine tower and suspended from the bottom of the nacelle. The cable twisting system comprises a number of cable spacing plates coupled to a suspension element where a number of guiding means guide the electrical cables from the nacelle to the bottom of the wind turbine tower. The suspension element is a torsion element having a first end capable of twisting relative to a second end when torque is applied to the first end. This allows the individual cable spacing plates to be rotated in a more uniform manner along the length of the system when the nacelle is yawing. It also allows the upwards movement of the cable spacing plates caused by the torque applied by nacelle to start at the uppermost cable spacing plate.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com