Patents

Literature

54results about How to "Speed down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

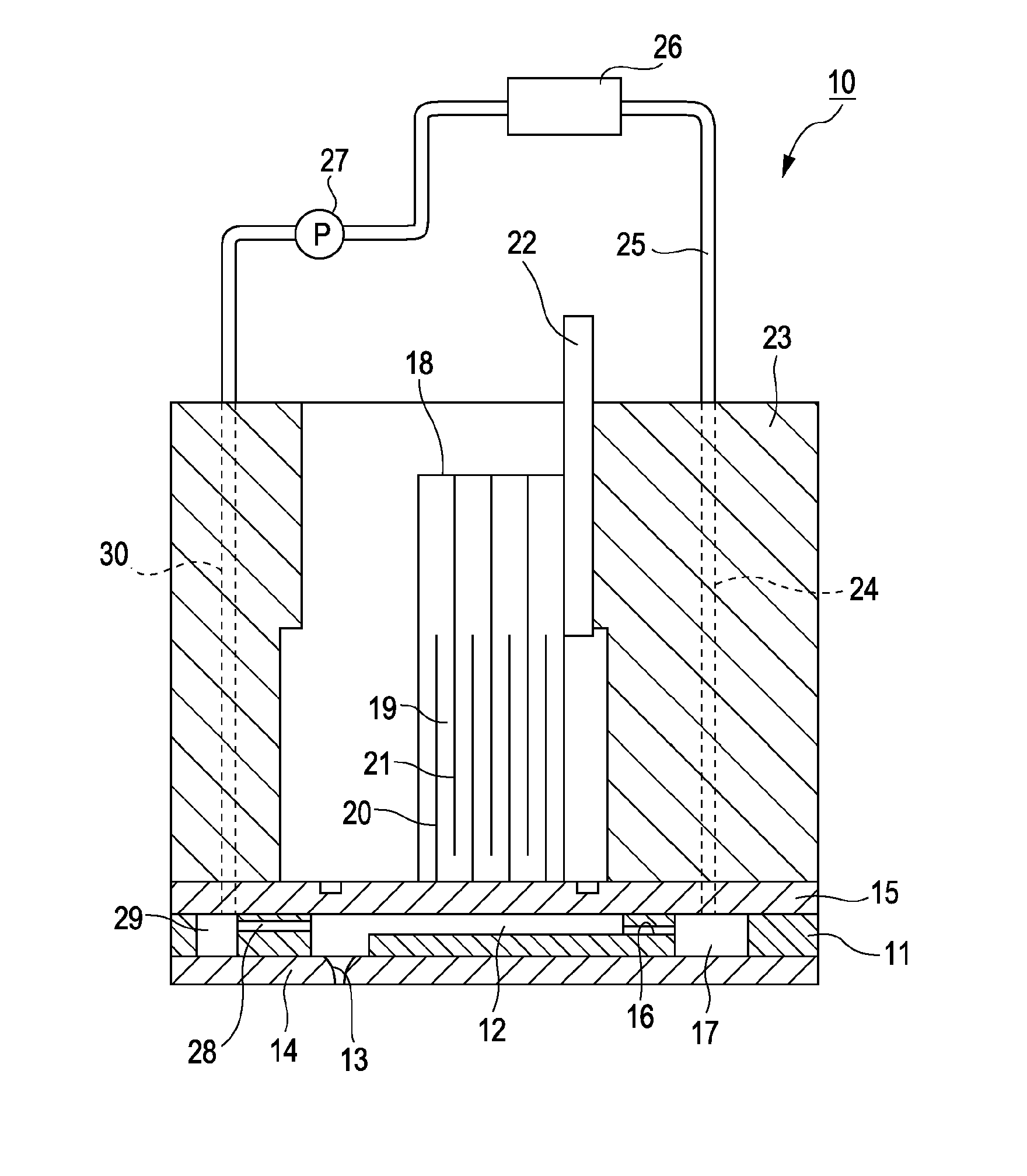

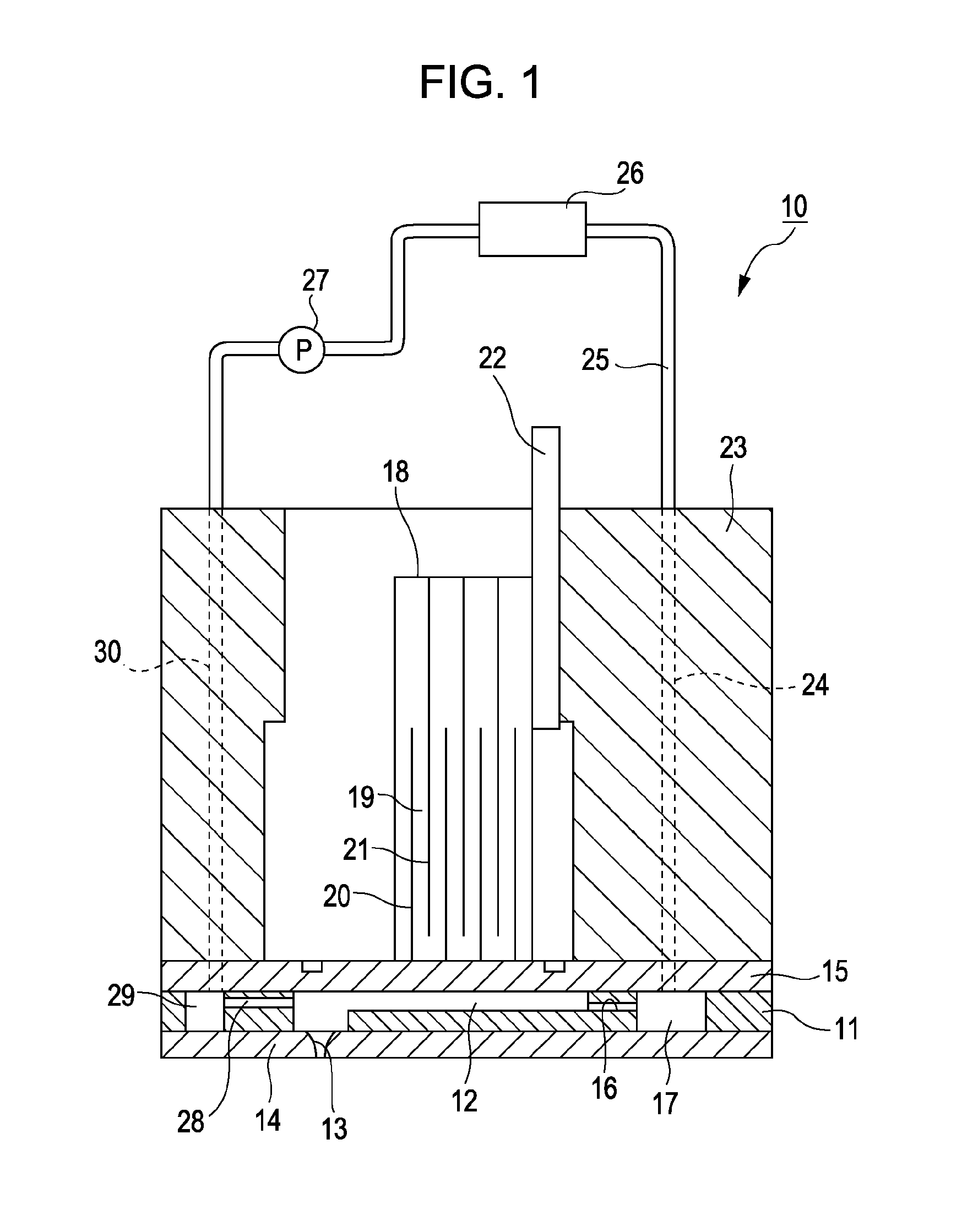

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20130233939A1Favorable ejection characteristicDeterioration of characteristicInking apparatusMovable spraying apparatusPressure generationEngineering

A ink jet type recording head which circulates ink between a first manifold and a second manifold via a pressure generation chamber is provided, the flow path member has a first and second bypass flow paths which connect the first and second manifolds, respectively in two locations of one end side and the other end side of a nozzle row on the outside of the nozzle row on which the nozzle openings are formed, and a relationship between a flow path resistance R of the first and second bypass flow paths, and a flow path resistance r of a flow path portion including the pressure generation chamber which connects the first and second manifolds is R<r / N (wherein, N is the number of all nozzle openings).

Owner:SEIKO EPSON CORP

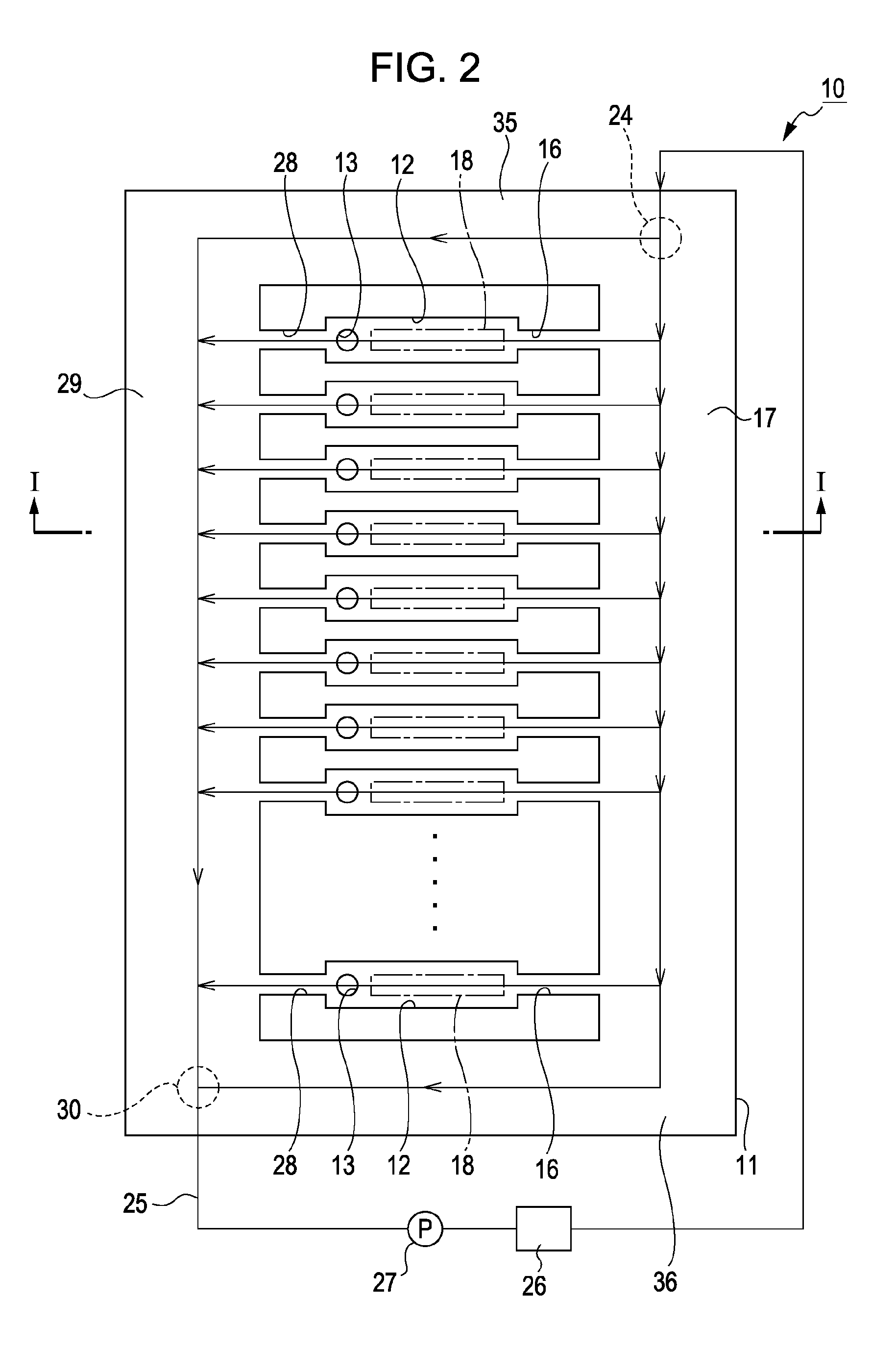

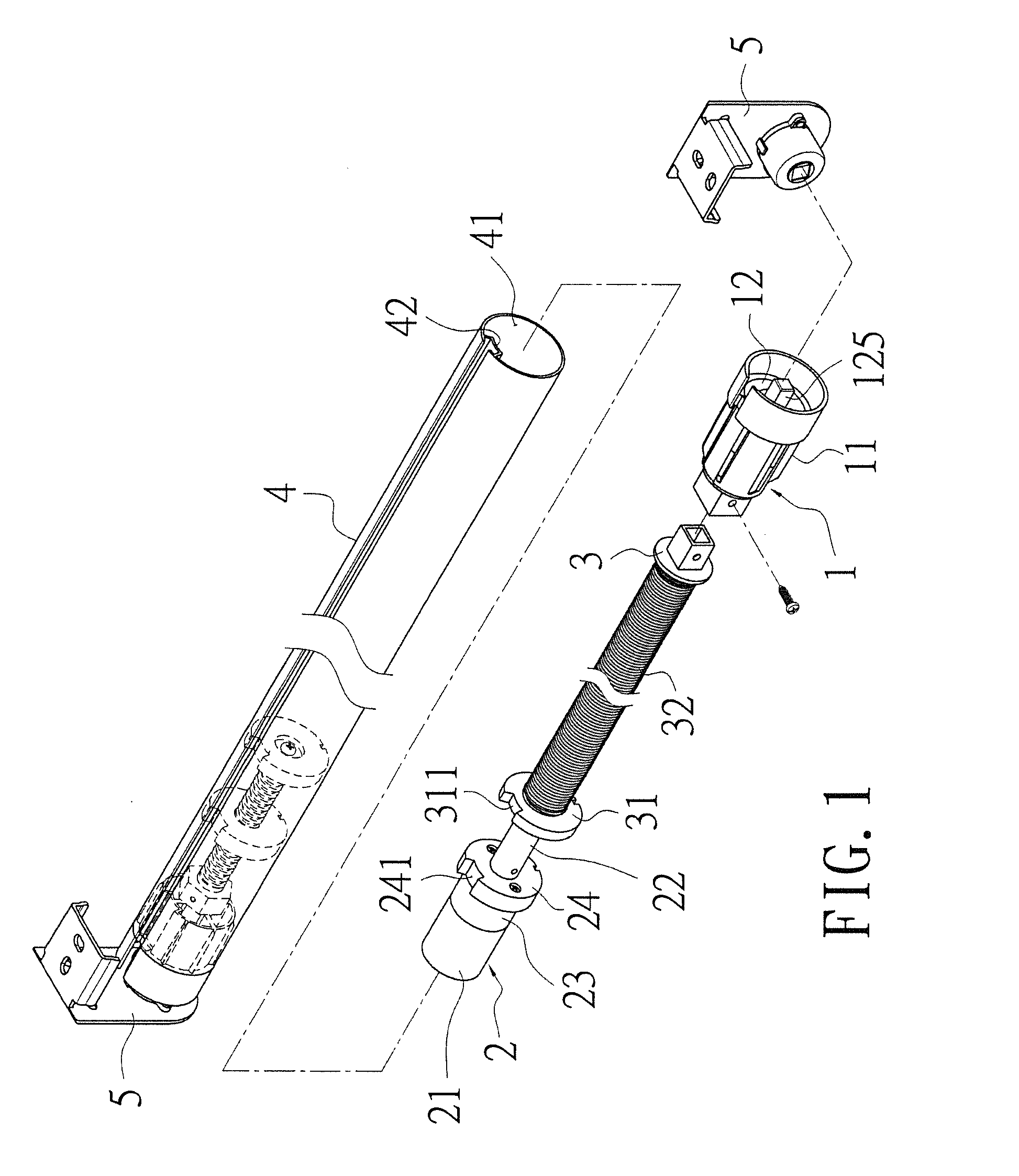

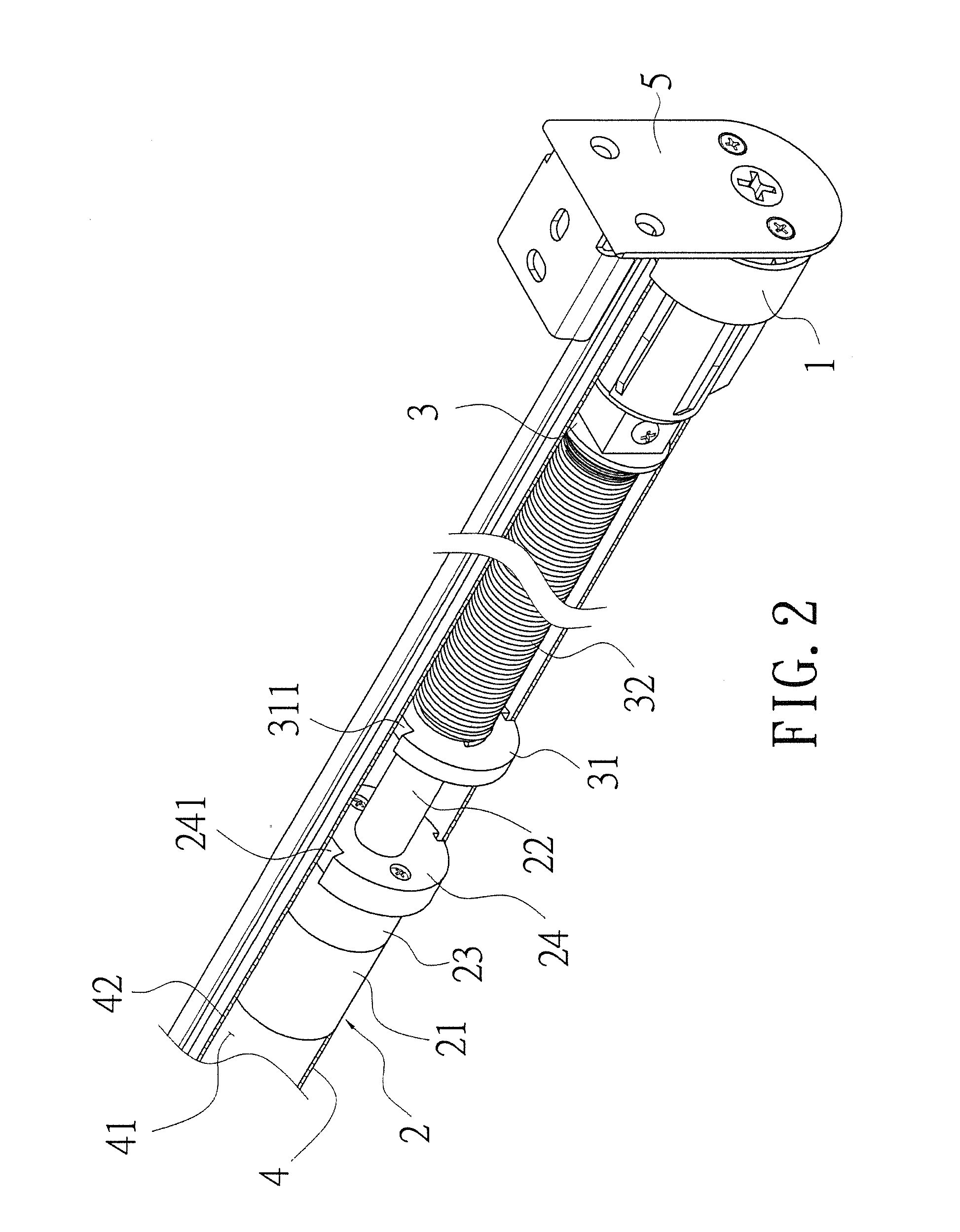

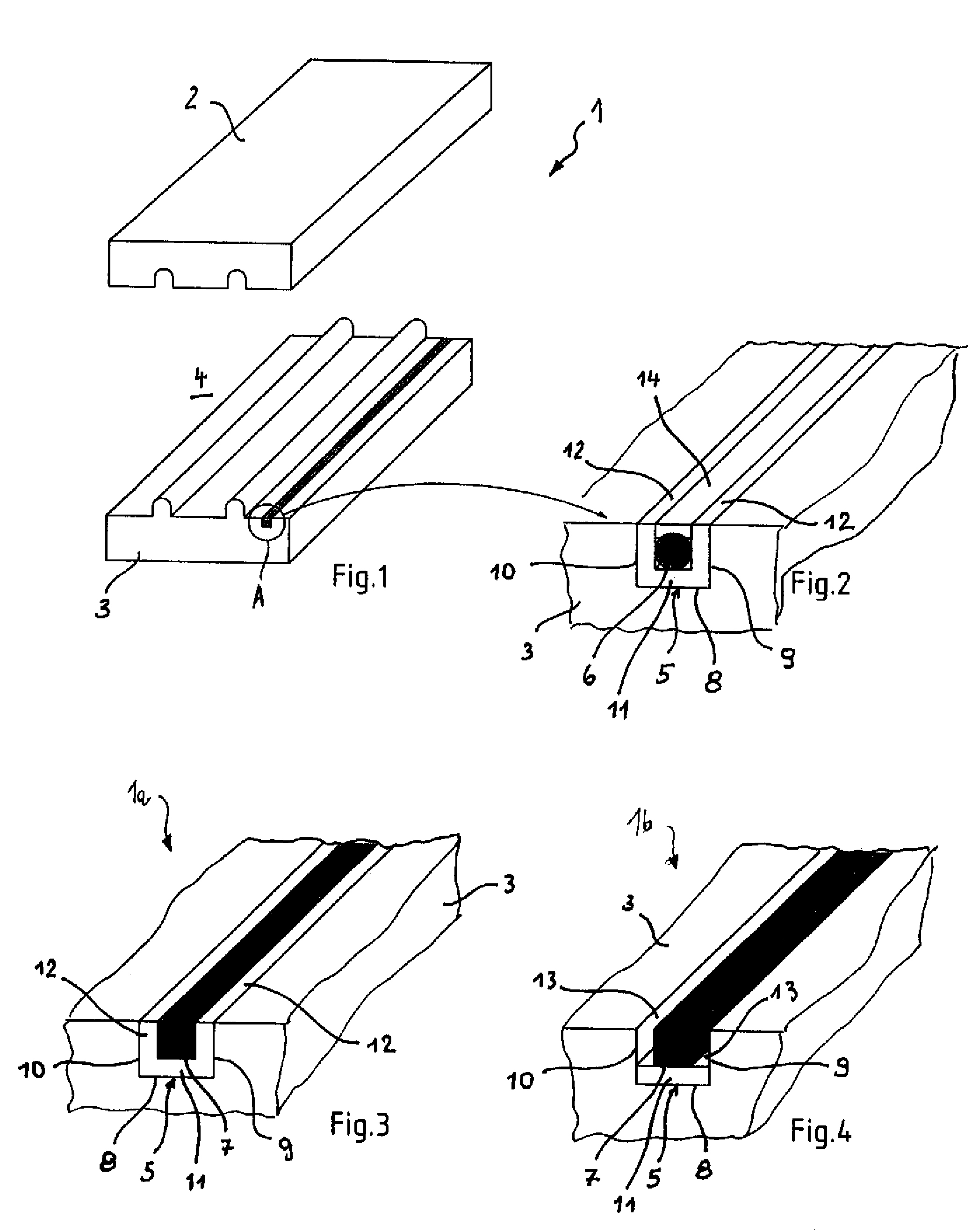

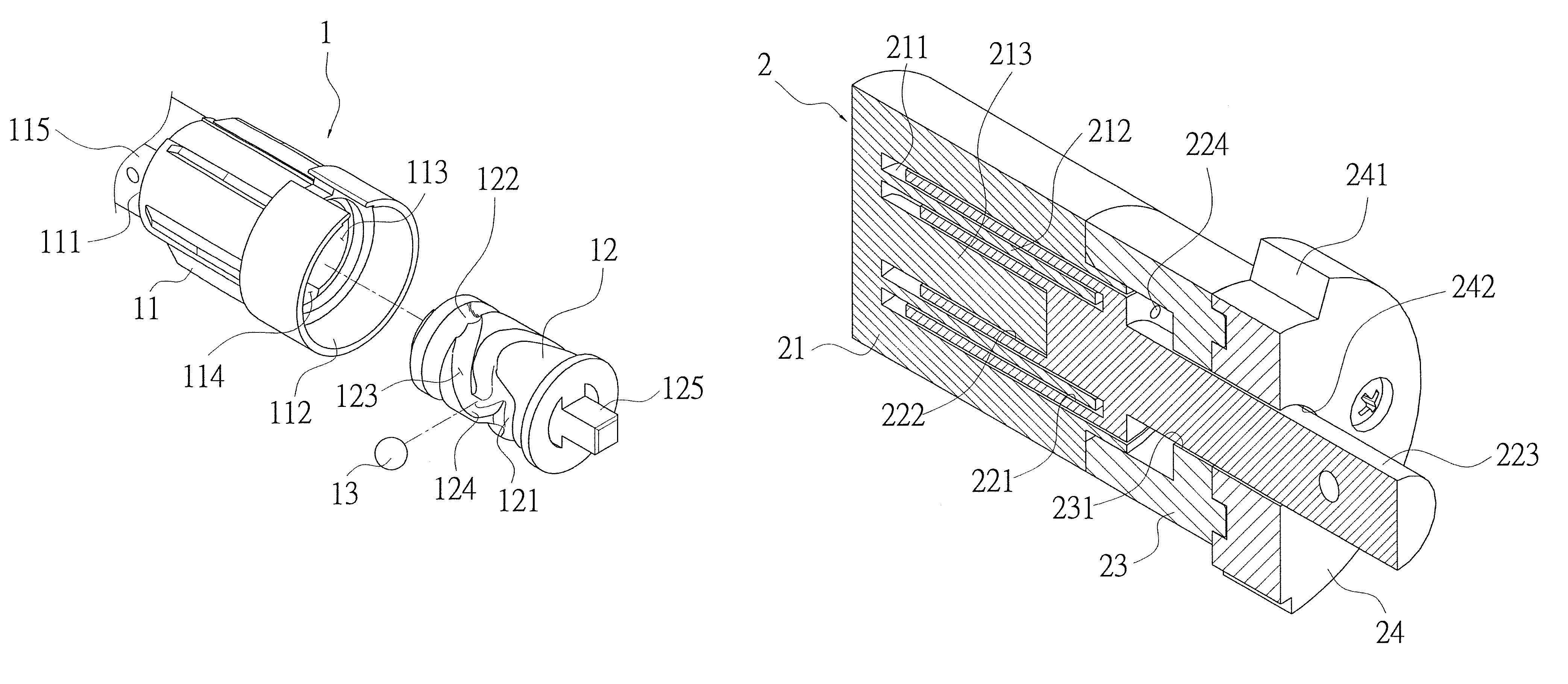

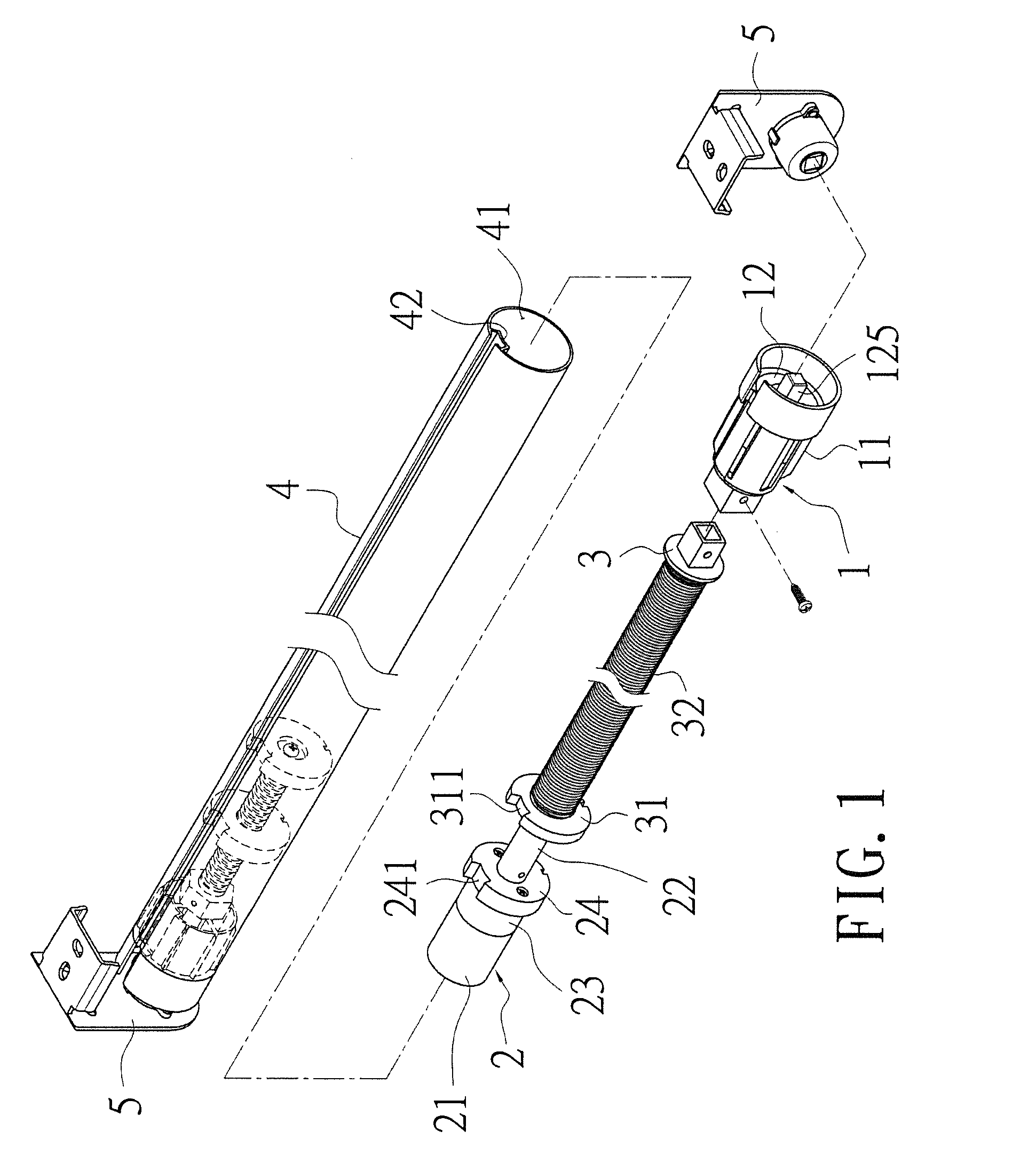

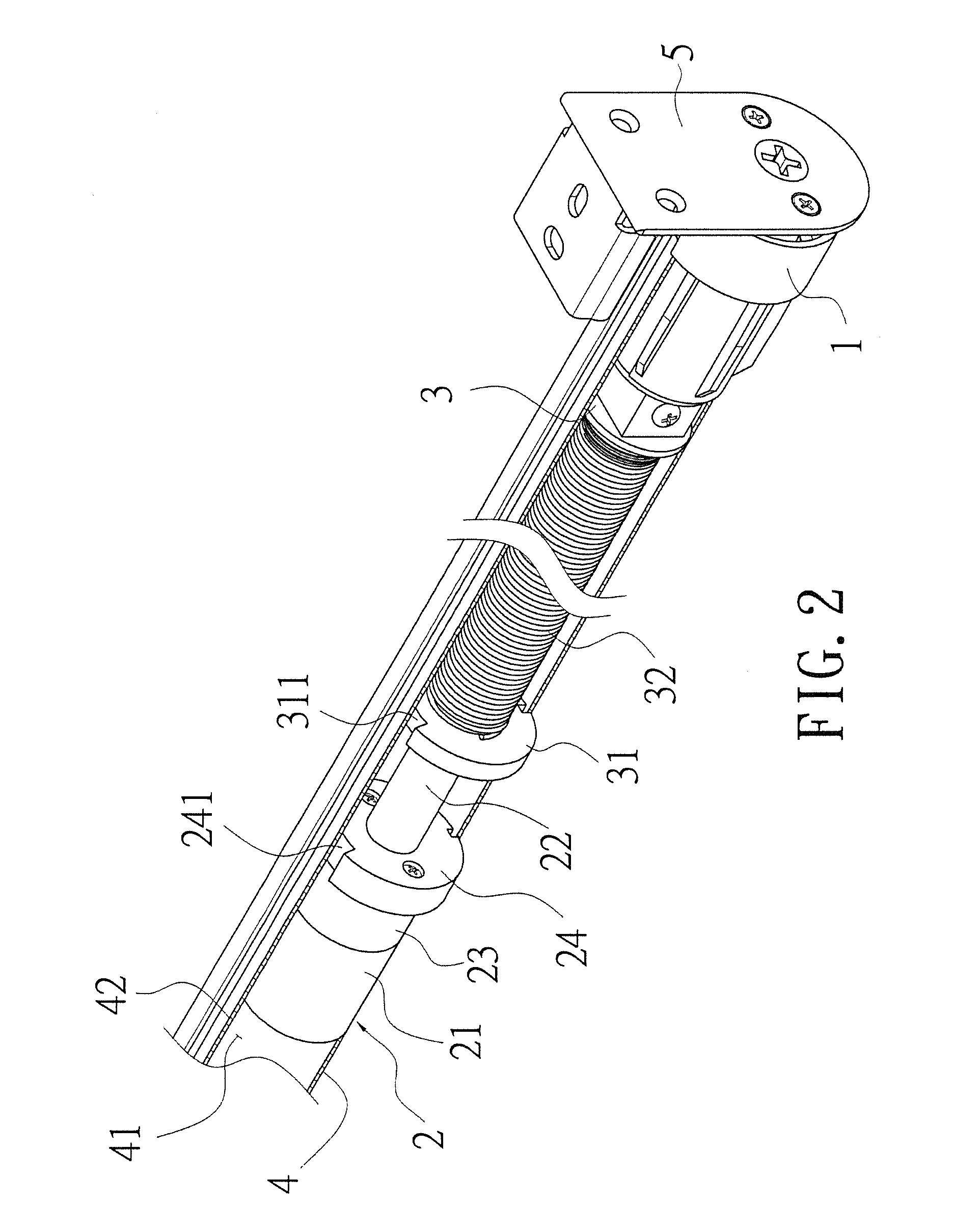

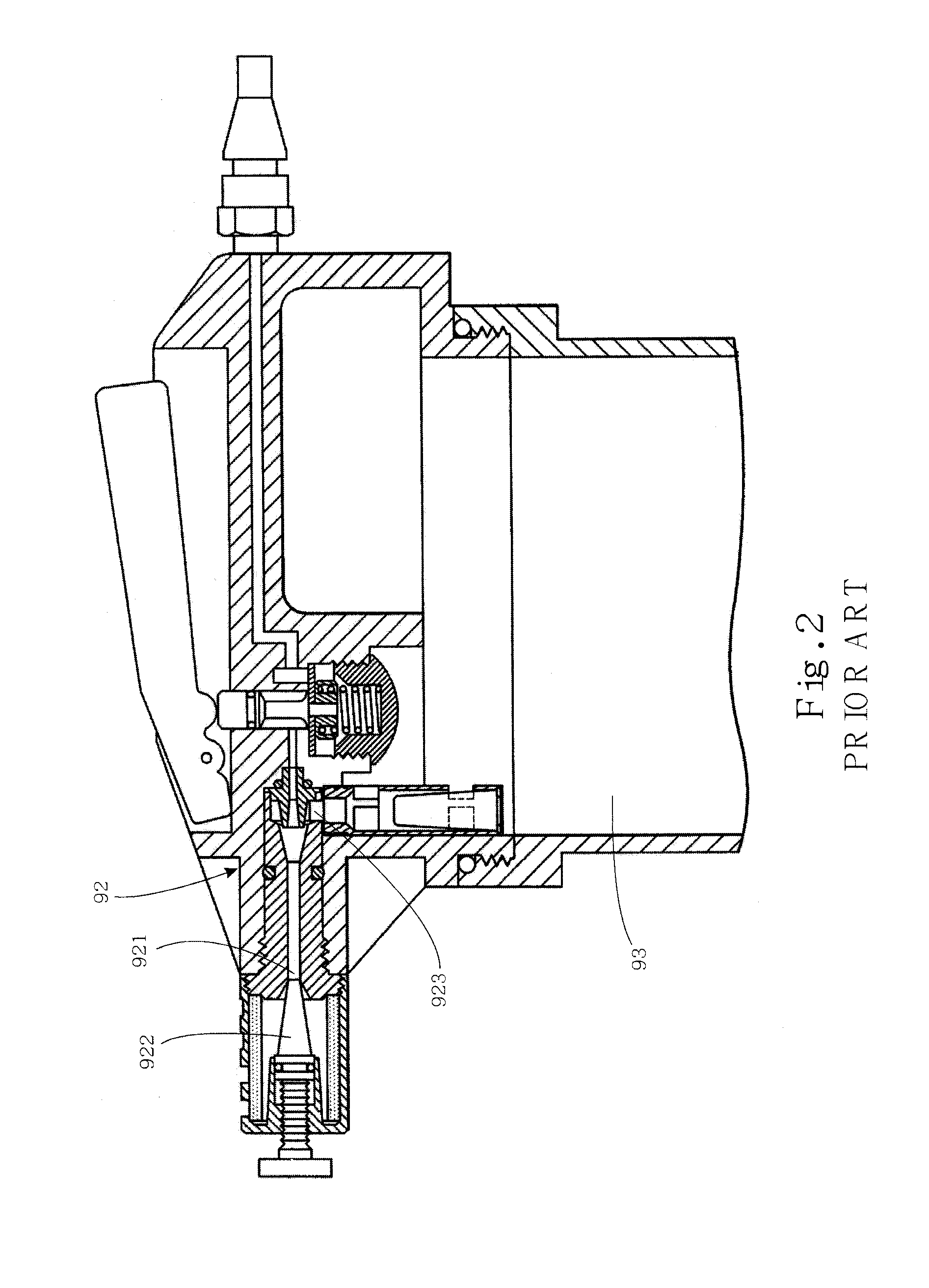

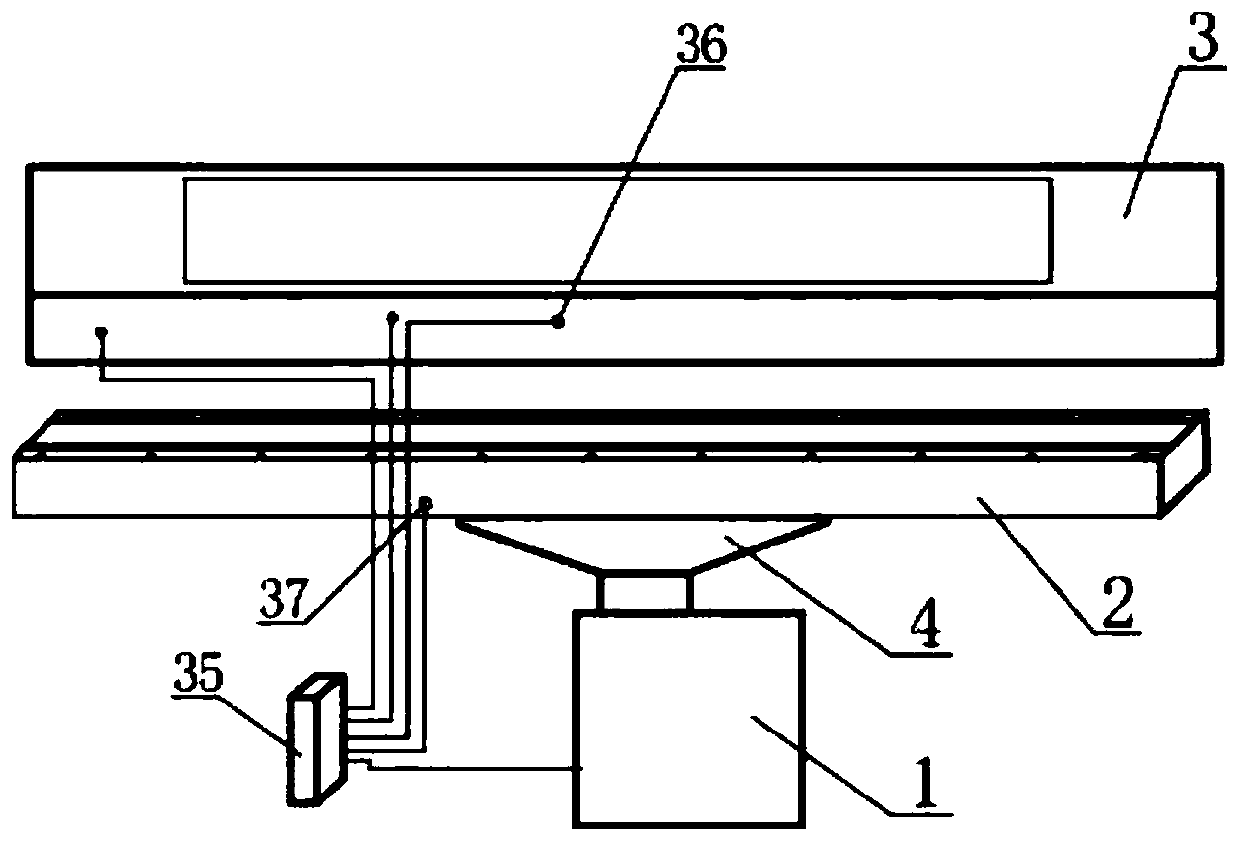

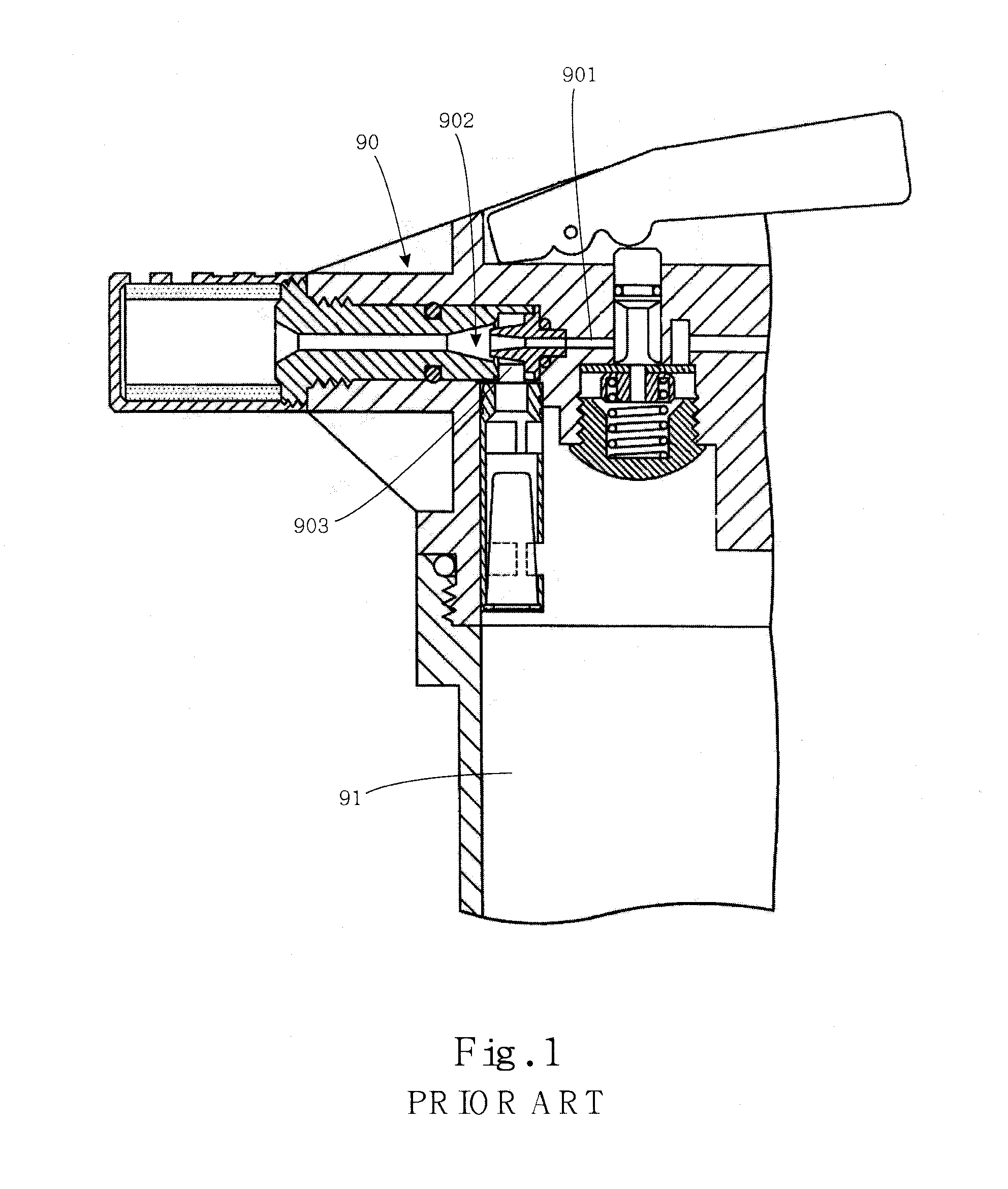

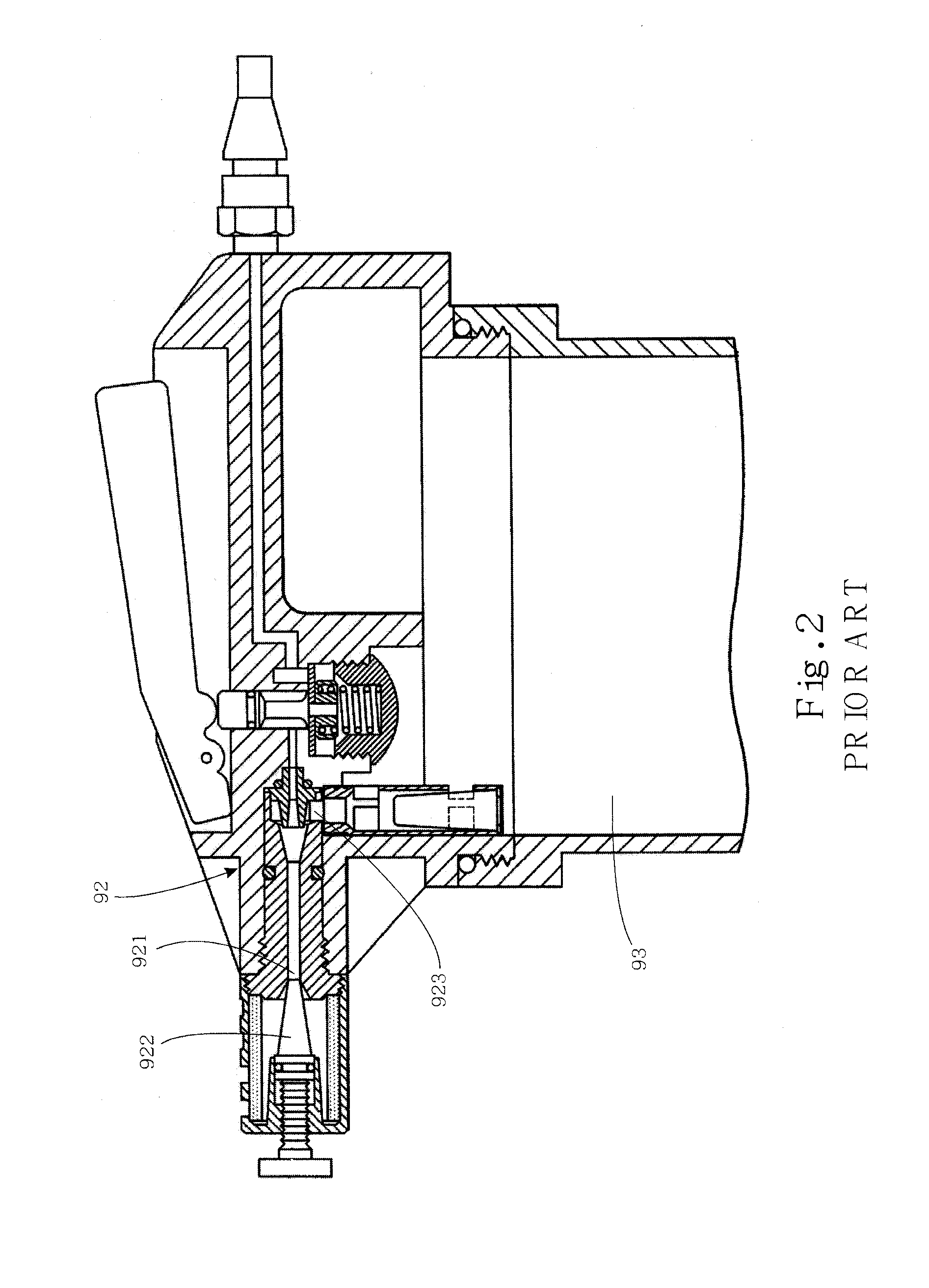

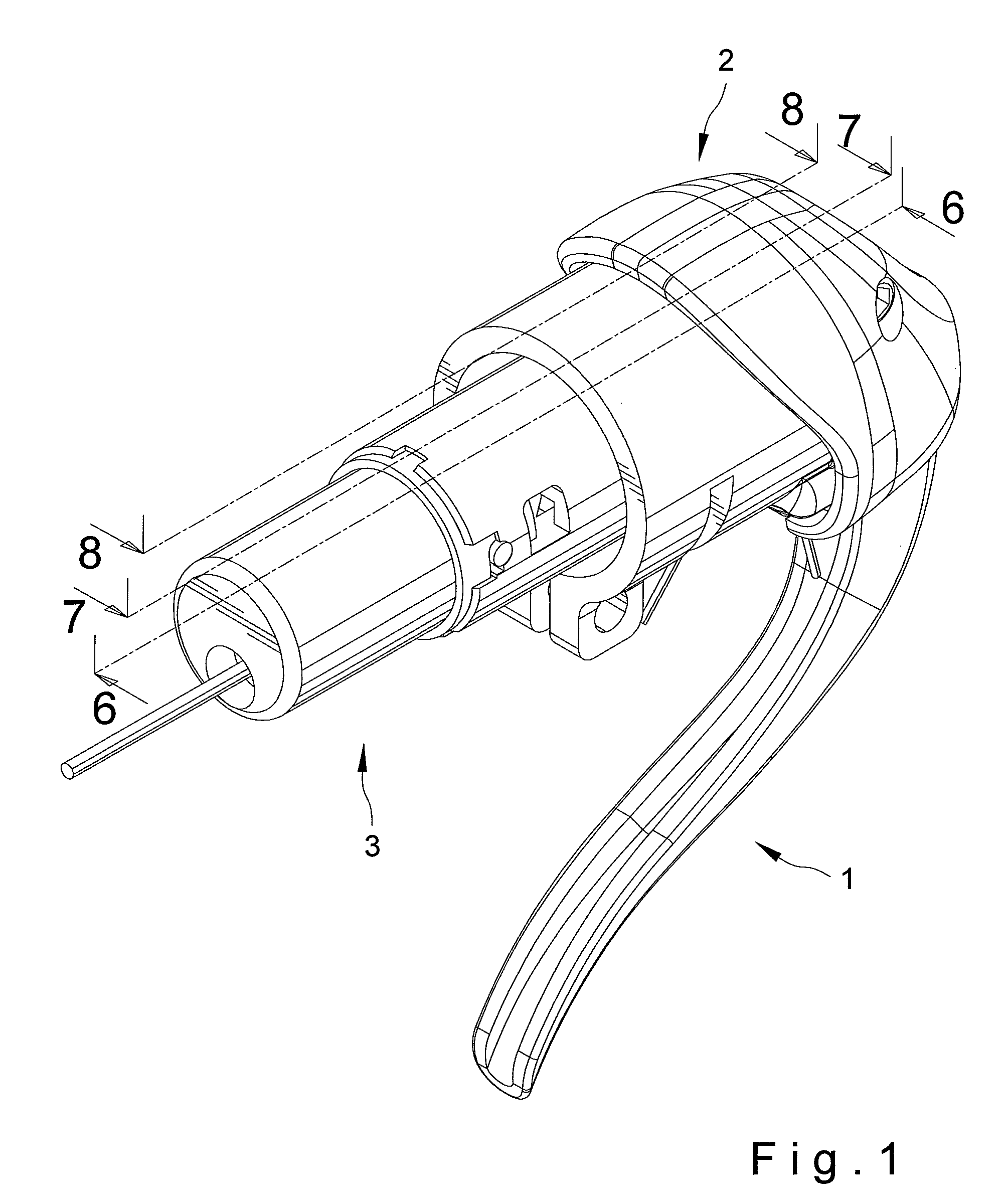

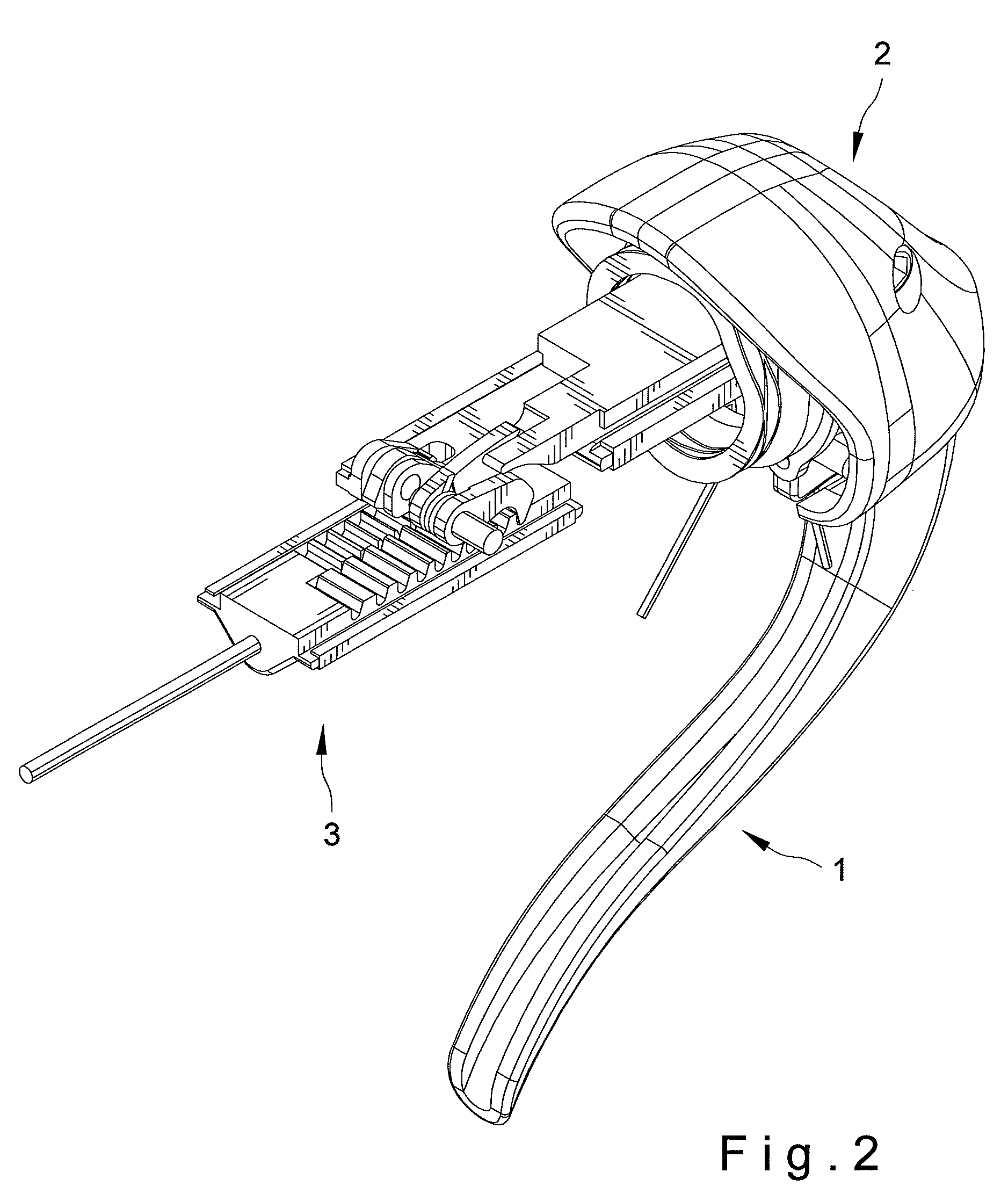

Curtain control device

InactiveUS20120266413A1Reduce speedSpeed downCurtain suspension devicesLight protection screensClassical mechanicsDamper

A curtain control device has a stroke setting device and a damper respectively assembled at both ends of a curtain spindle rod. A torsion element is further assembled on the curtain spindle rod. A curtain spindle sleeve is invaginated on the outside of the curtain spindle rod, the stroke setting device and the damper. The curtain spindle sleeve is assembled with the combination of the curtain spindle rod and the damper, and then a curtain fabric is assembled on the outside of the curtain spindle sleeve. In this manner, the opening range of the curtain fabric roll is controlled by the stoke setting device, and the roll-up speed of each part of the curtain fabric is slowed down by the damper so as to reduce effectively the noise produced by the quick actuation of each part and the defective rate.

Owner:UNI-SOLEIL ENT CO LTD

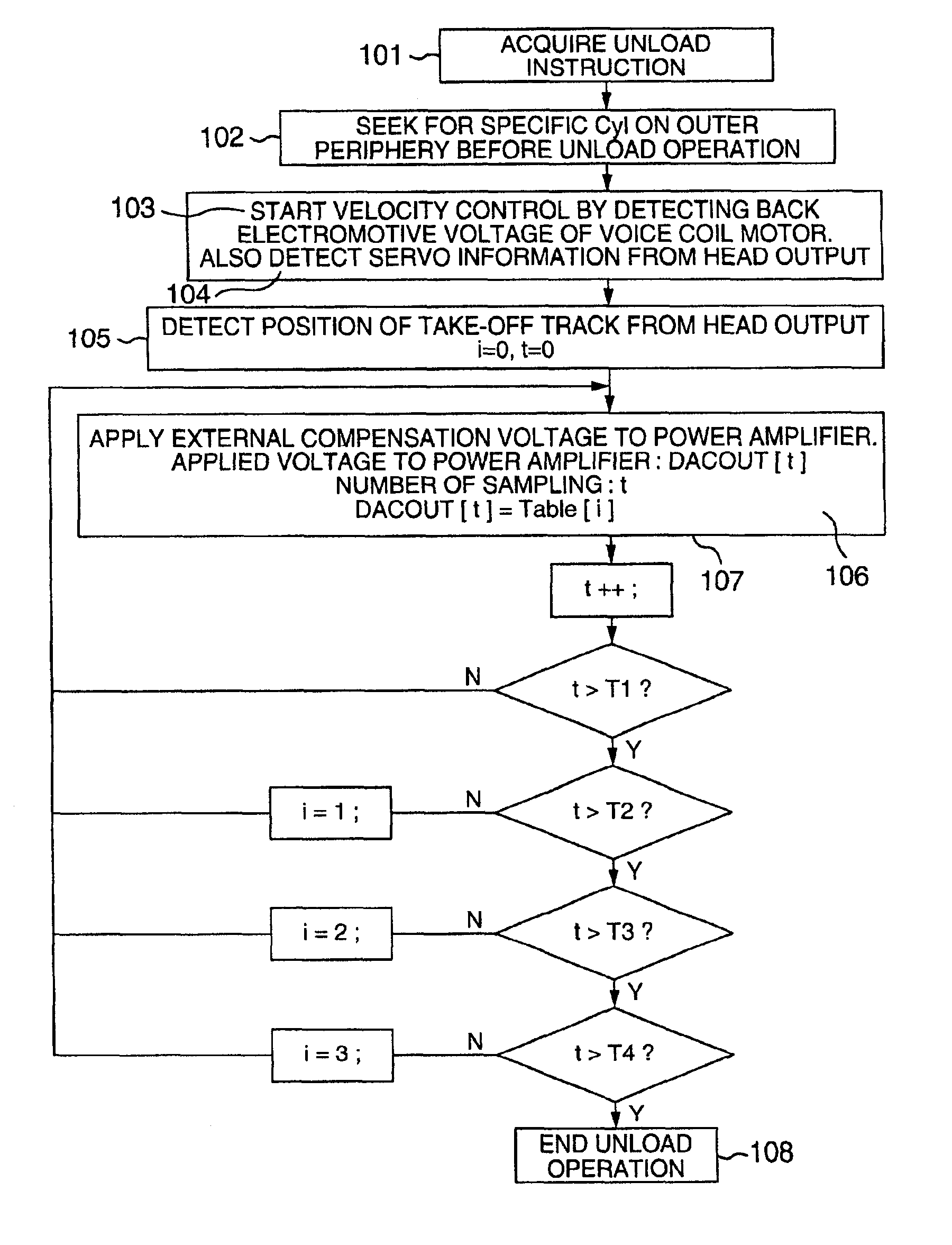

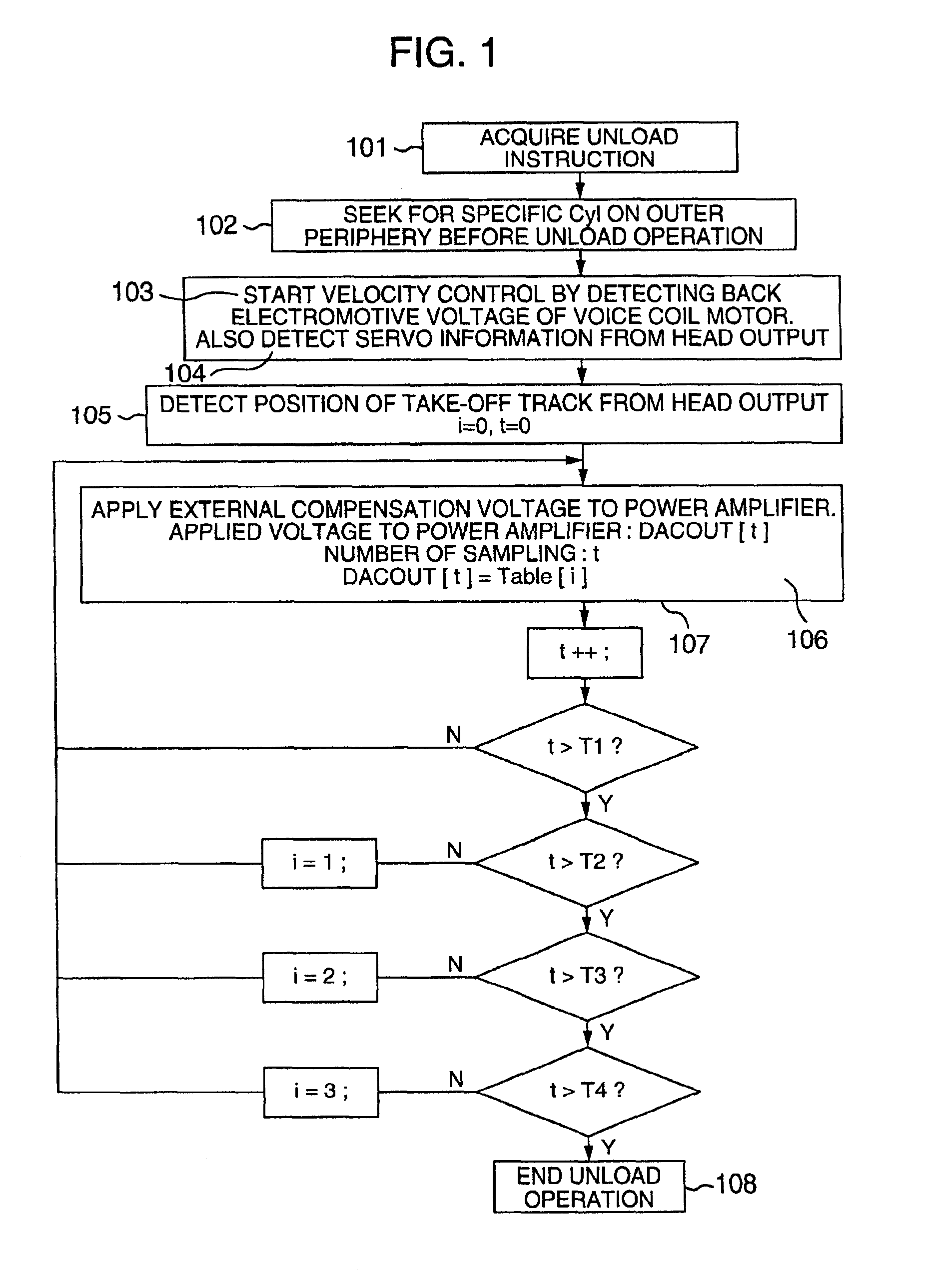

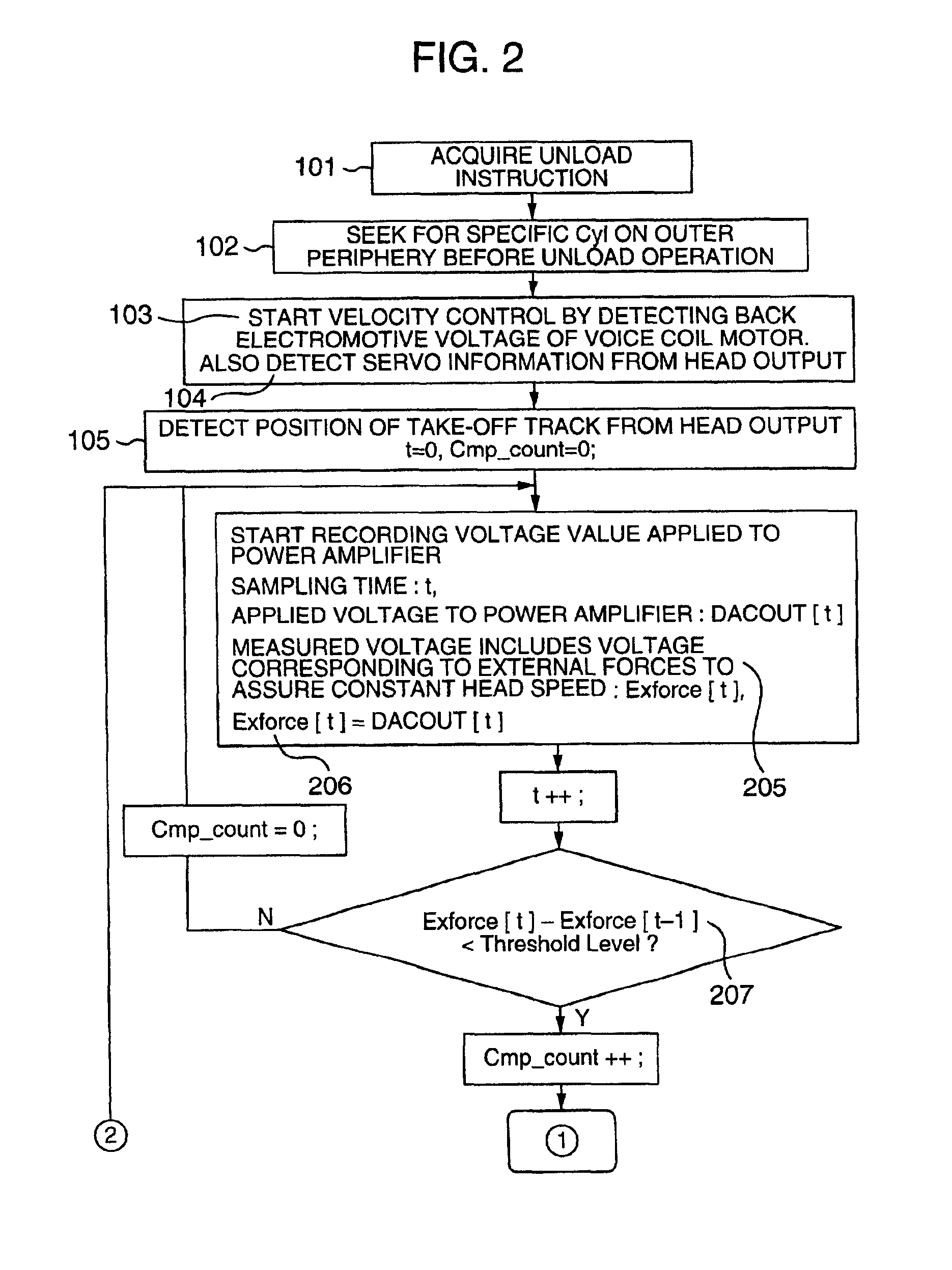

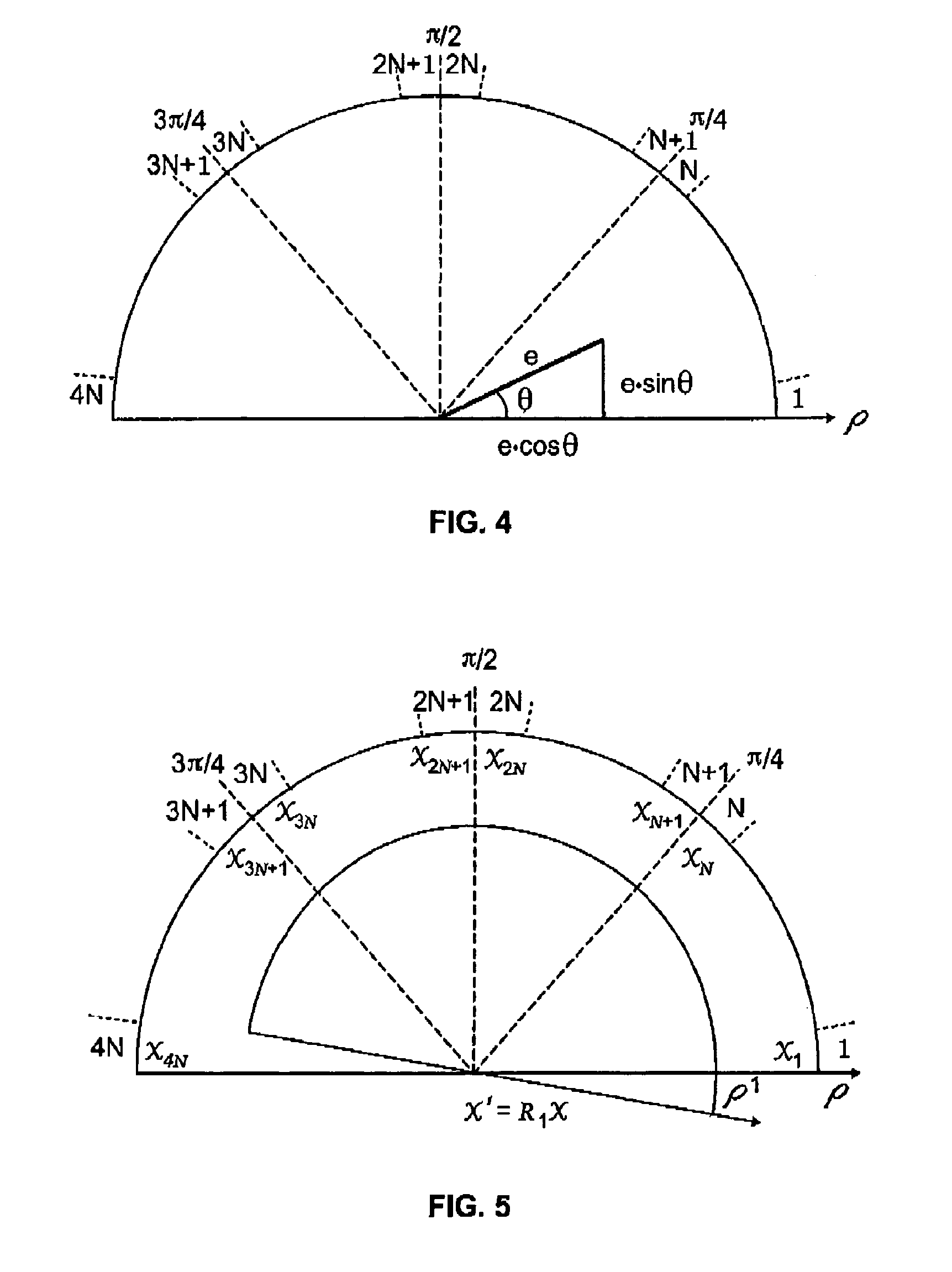

Load/unload method and a magnetic disk drive using the method

InactiveUS6920007B2Accurately controlEasy to controlDriving/moving recording headsRecord information storageMagnetic disksLanding zone

To control load / unload operation of a slider with magnetic head mounted thereon, by which the speed can always be controlled stably while avoiding the slowdown or temporary stop of an actuator during load / unload operation, a magnetic disk drive is configured using magnetic disk media with the servo information written therein beforehand up to the track located at a position corresponding to the landing zone for the load operation of the magnetic head (slider). The speed of the magnetic head (slider) withdrawn to the ramp is controlled at the unload operation. In the stage of initialization for controlling the speed of the load / unload operation, various parameters are recorded and updated to apply a voltage to power amplifier for compensating for the external forces caused by the friction mainly exerted between ramp and slider support members, with reference to the take-off track or the landing track specified in the landing zone.

Owner:NEOMAGIC +1

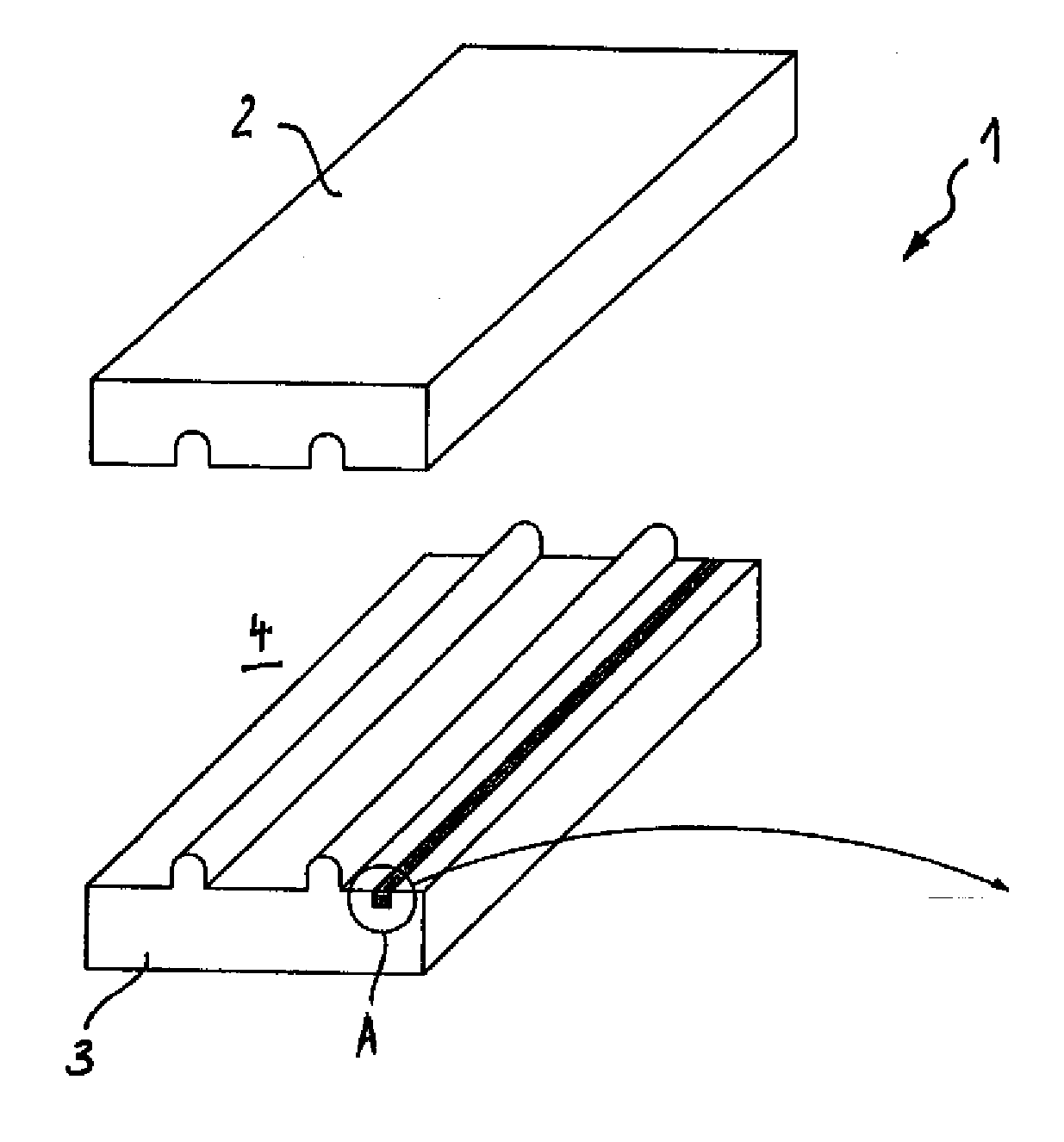

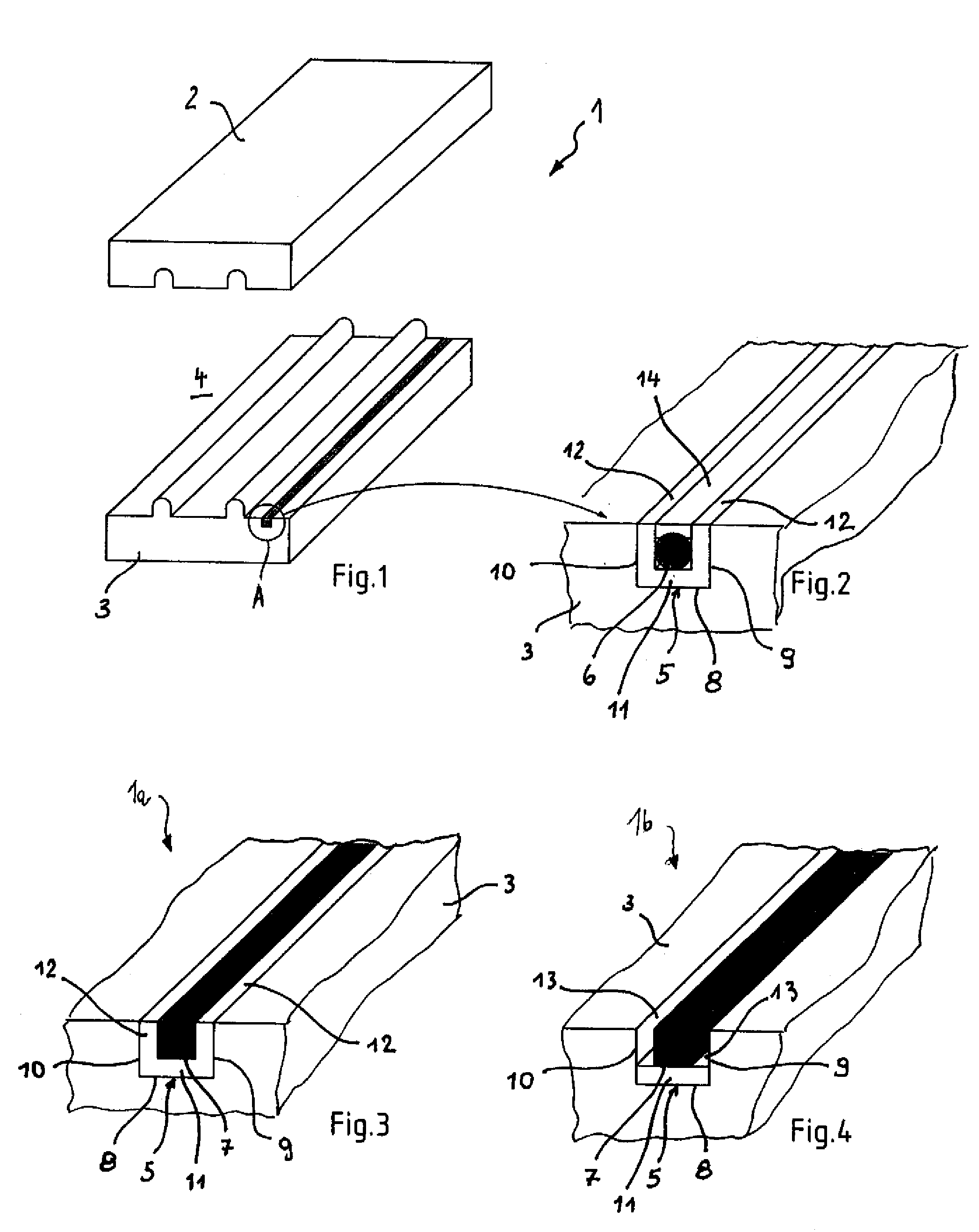

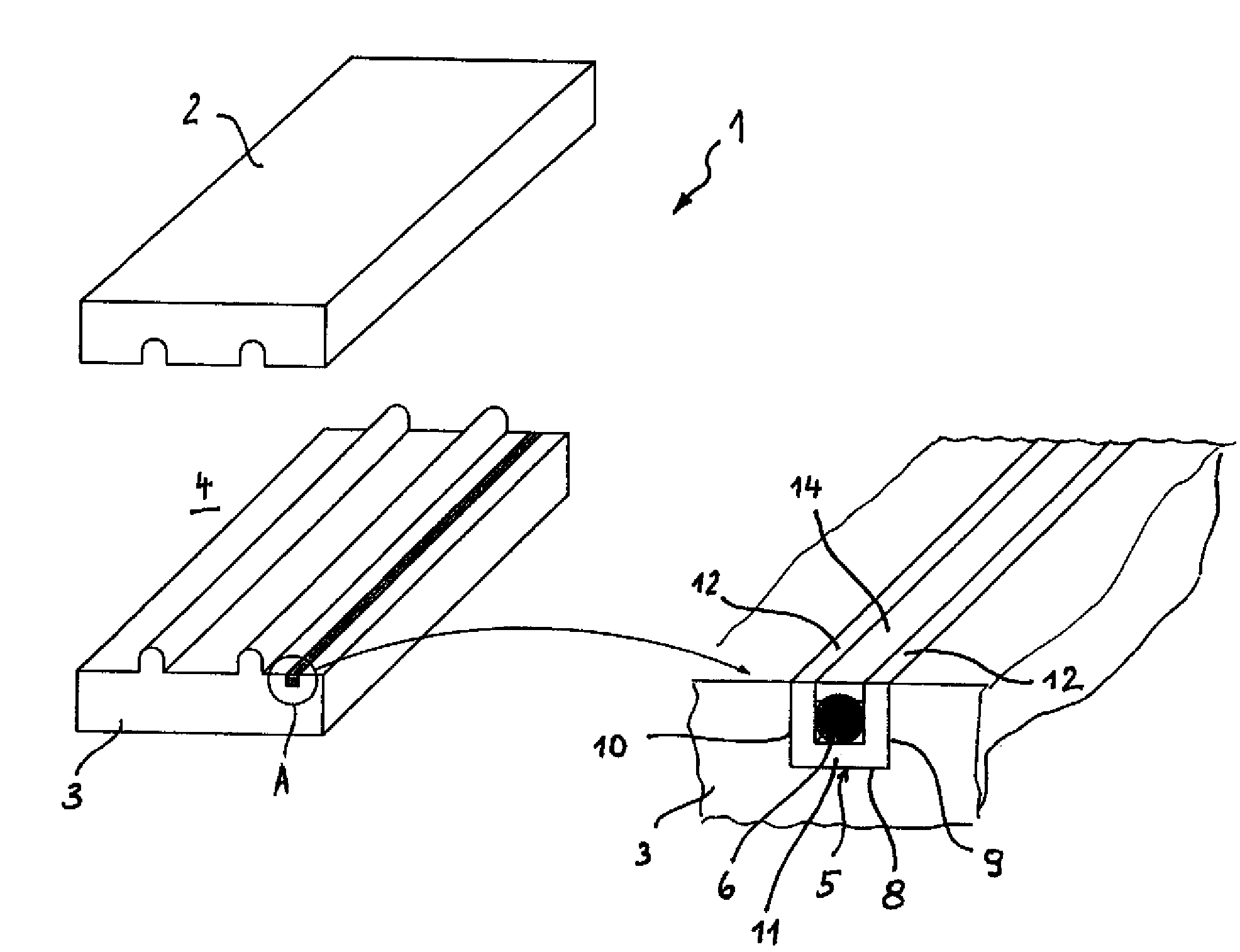

Apparatus for shaping metal sheets

InactiveUS20060230806A1Slow cool down speedSimple to executeShaping toolsPressesInsulation layerEngineering

Apparatus for shaping metal sheets including a shaping tool having an forming space for receiving a metal sheet. At least one heating element is disposed in a recess of the shaping tool for heating at least a portion of the metal sheet, whereby an insulation layer is provided to insulate the heating element from neighboring walls of the shaping tool.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Apparatus for shaping metal sheets

Apparatus for shaping metal sheets including a shaping tool having an forming space for receiving a metal sheet. At least one heating element is disposed in a recess of the shaping tool for heating at least a portion of the metal sheet, whereby an insulation layer is provided to insulate the heating element from neighboring walls of the shaping tool.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

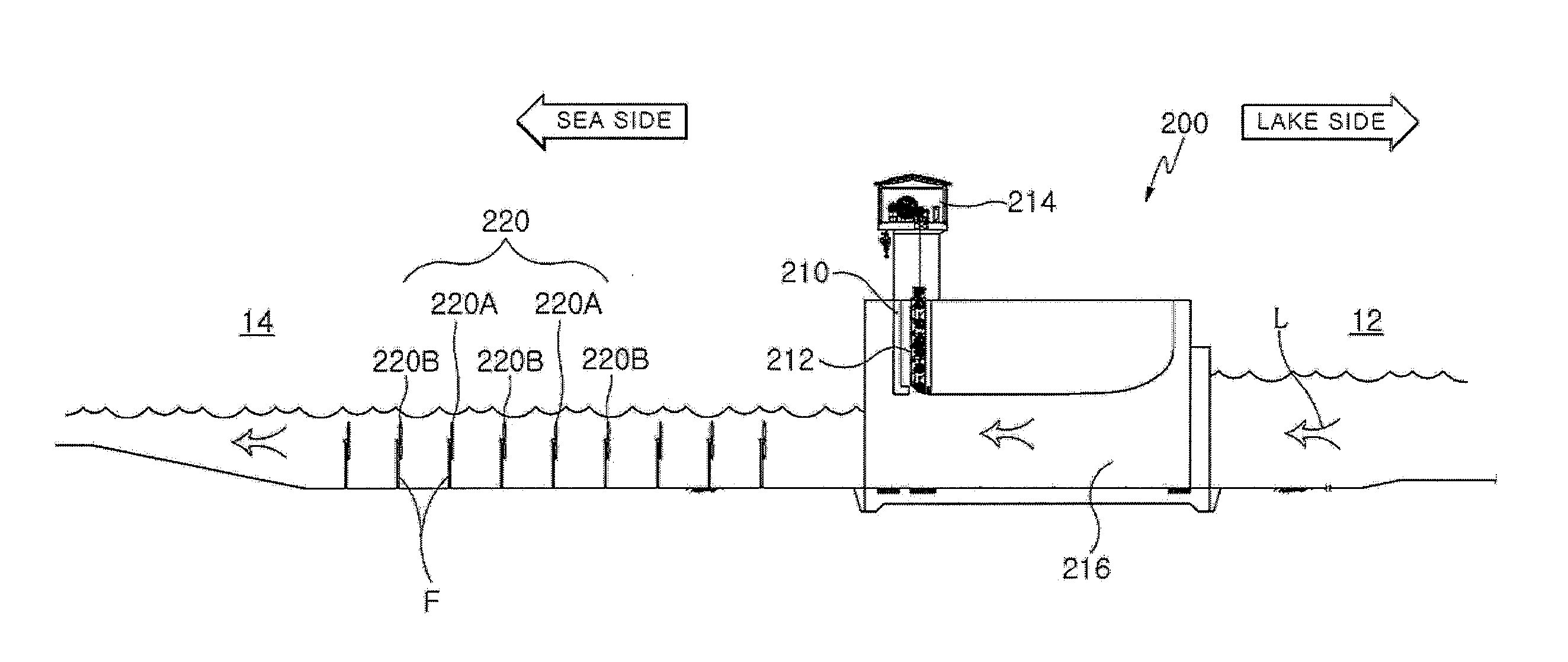

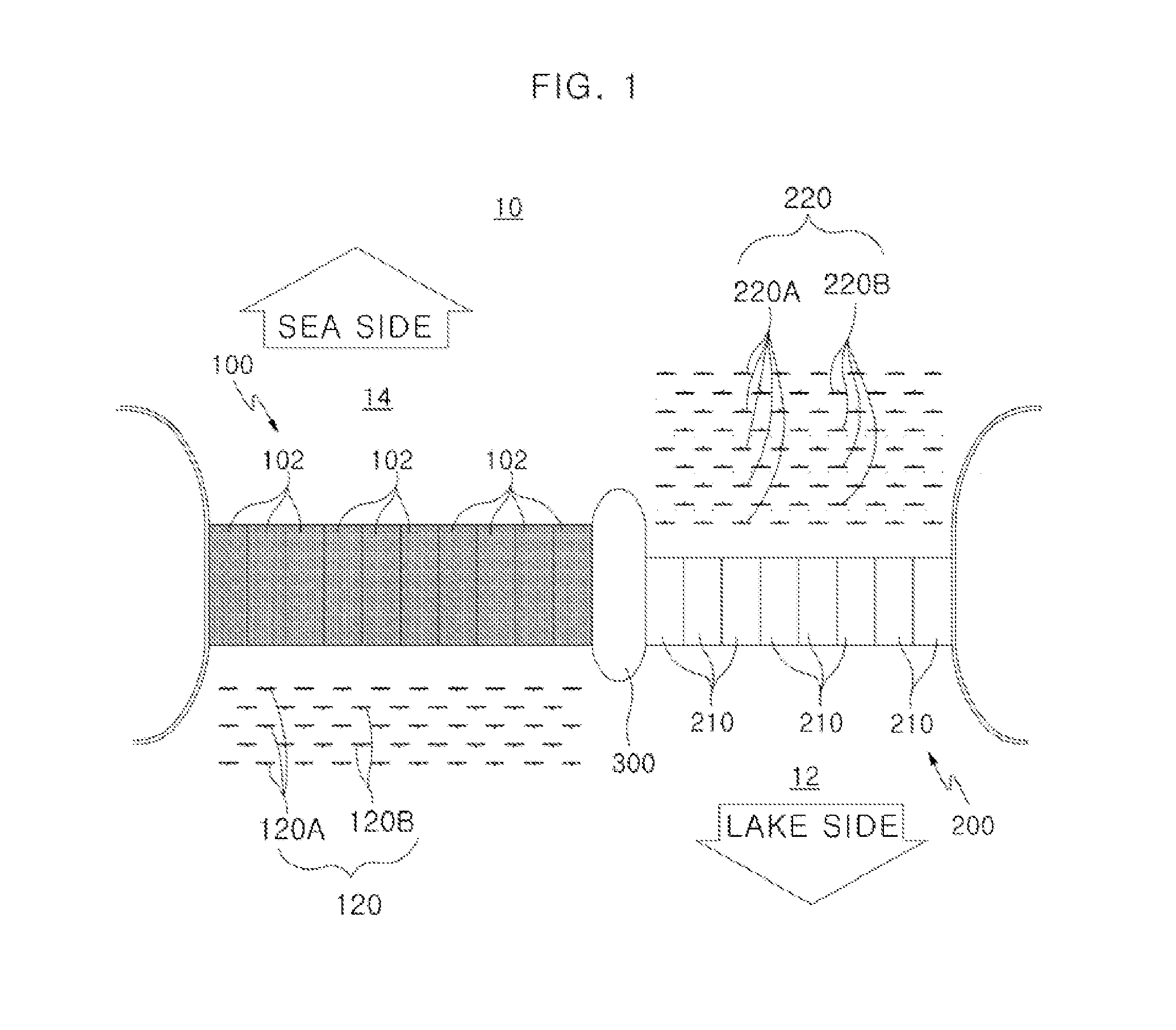

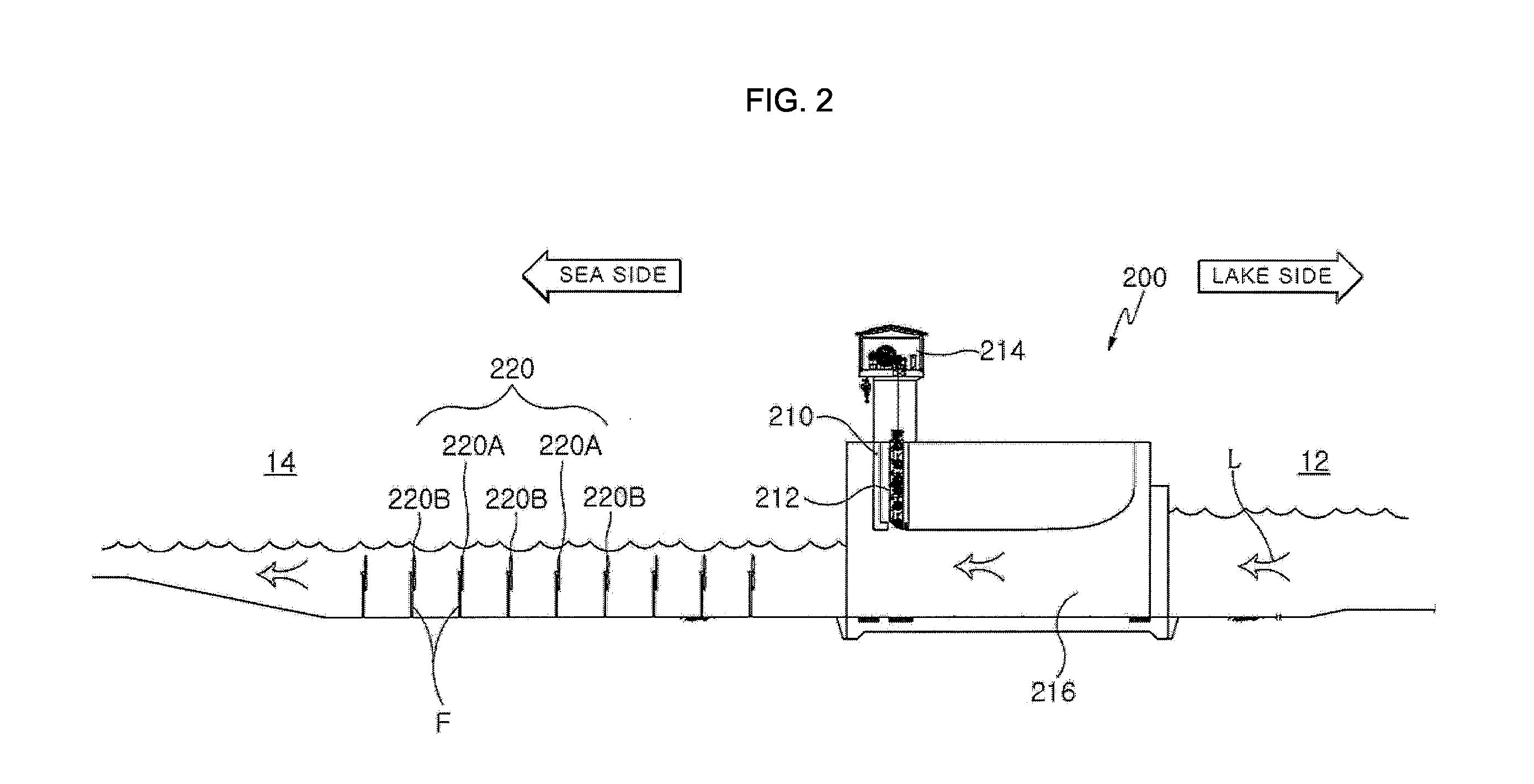

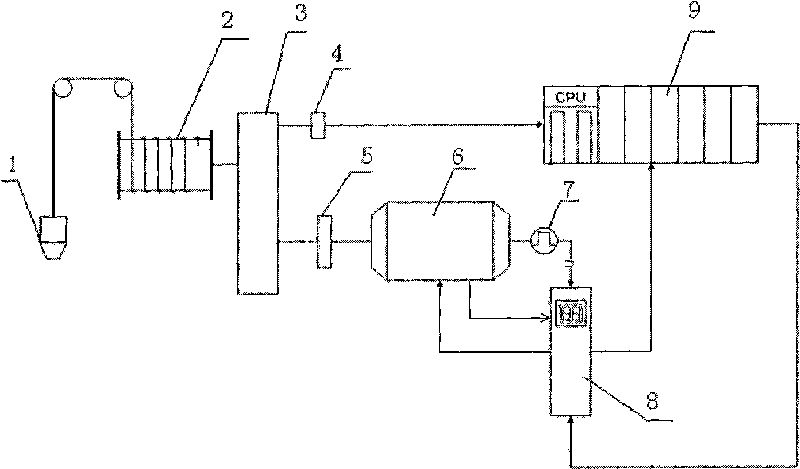

Integrated power system combining tidal power generation and ocean current power generation

InactiveUS20100289267A1Improve operating rateHigh utility valueMachines/enginesEngine componentsElectricityPower station

An integrated power system combining tidal power generation and ocean current power generation comprises: constructing barrages across the sea to make up a lake; installing turbine structures of a tidal power plant and sluice structures of a tidal power dam for generating electricity by using the potential energy difference between seawaters caused by tides and ebbs; forming an ocean current power park in a lake side by installing a plurality of ocean current generators, for generating electricity by using the flow of the seawater discharged through turbine generators, in a rear lake side of the turbine structures of the tidal power plant; and forming an ocean current power park in a sea side by installing ocean current generators, for generating electricity by using the seawater with the fast speed discharged into the sea through sluice gates, in a rear sea side of the sluice structures of the tidal power dam.

Owner:JANG KYUNG SOO +3

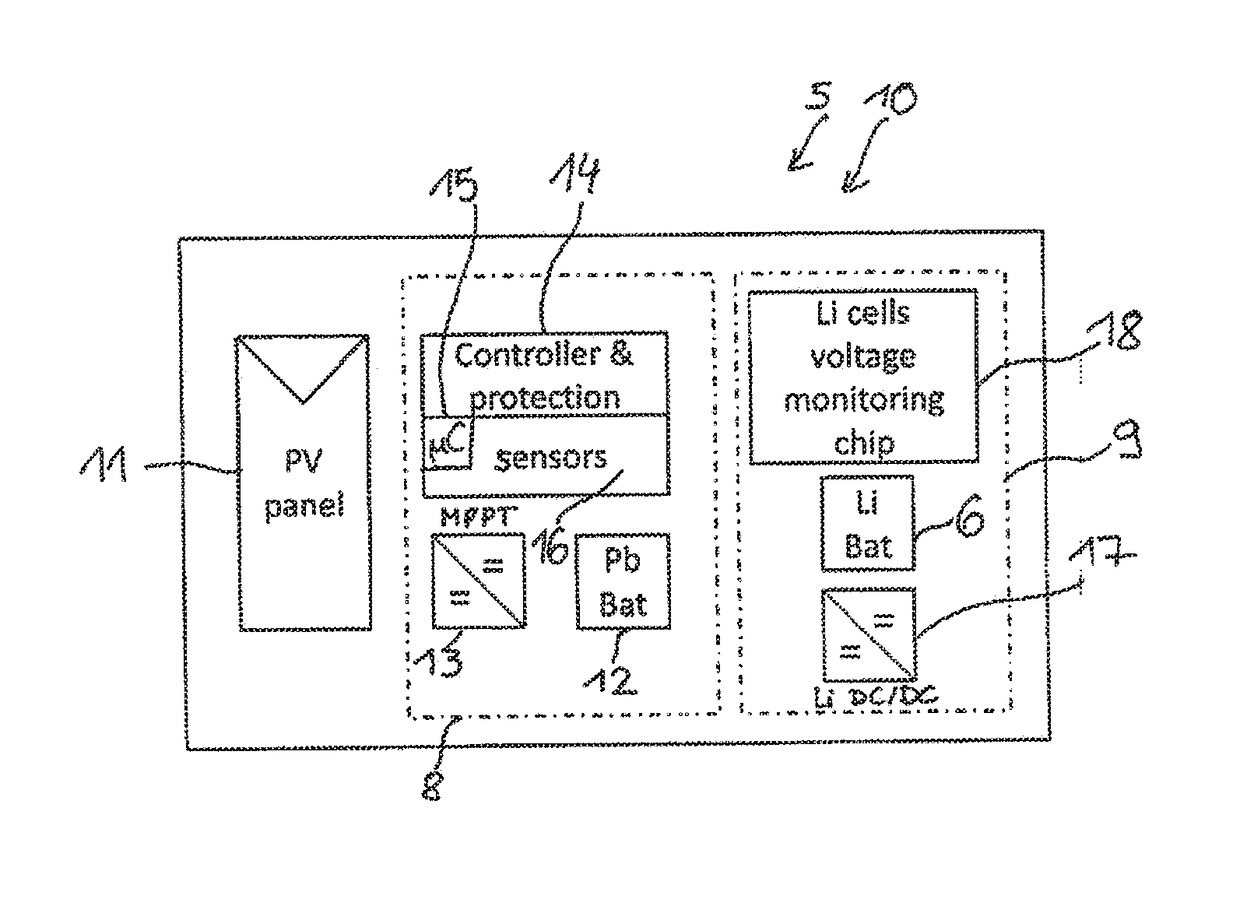

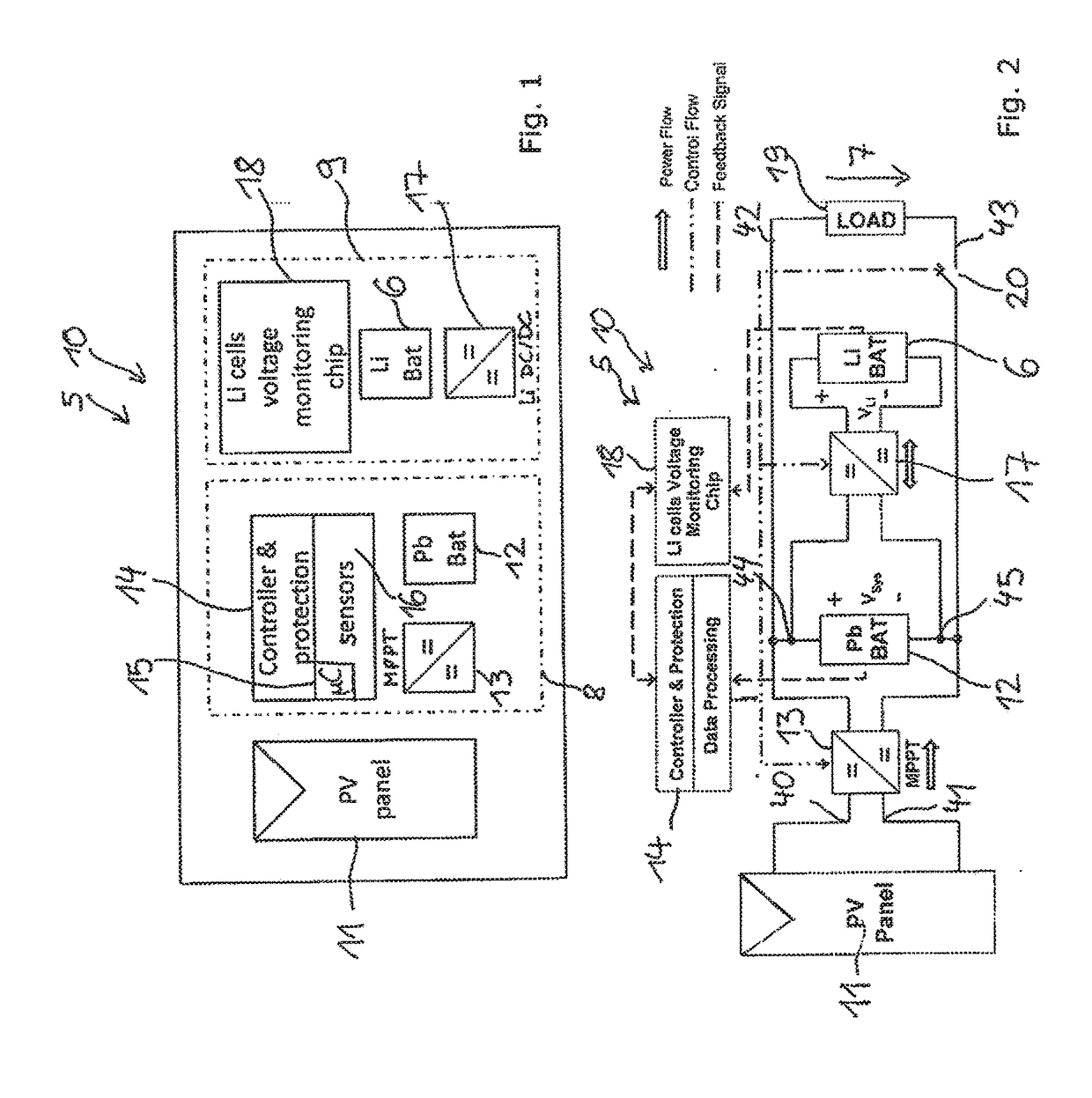

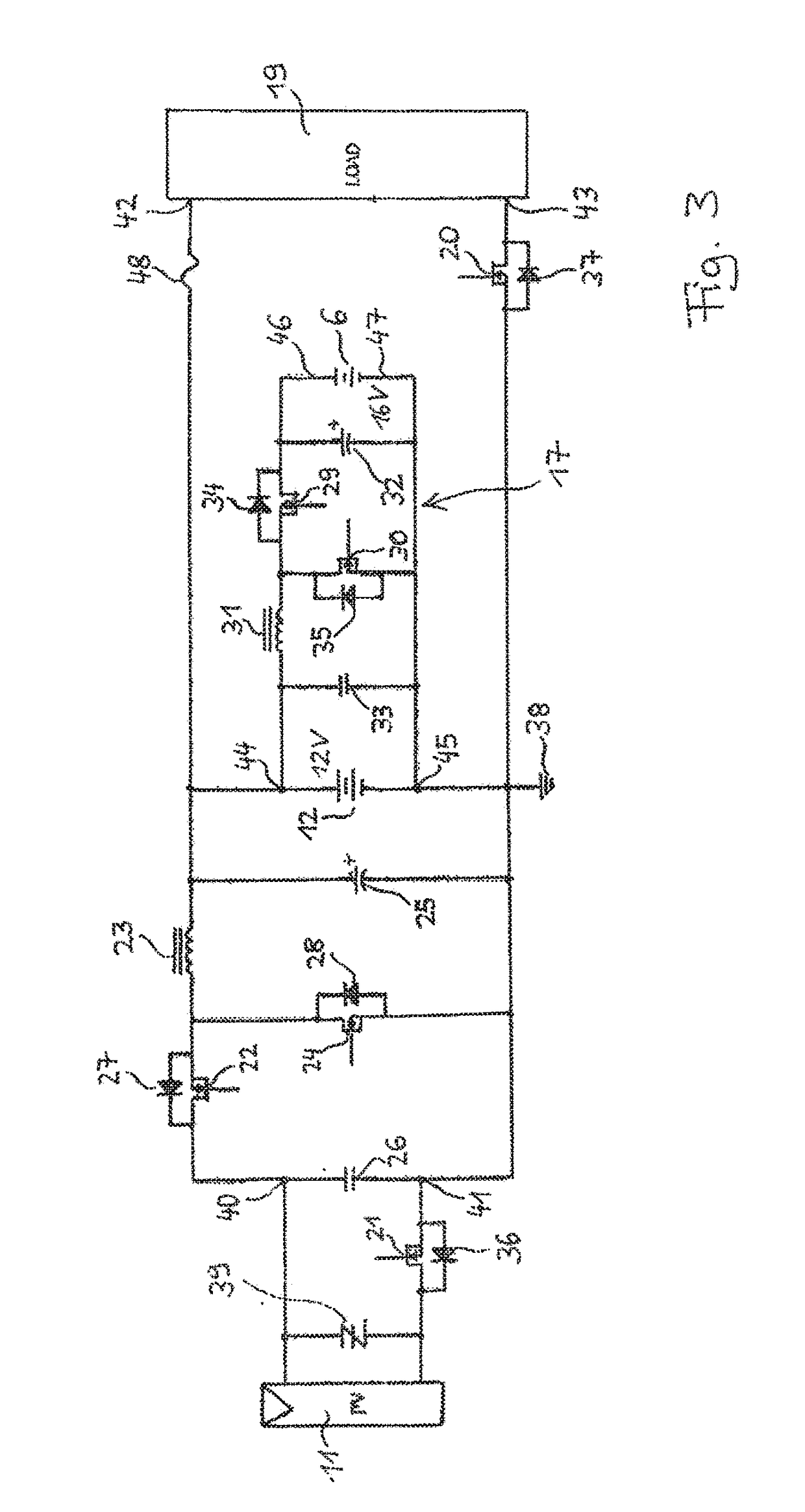

Topology and control strategy for hybrid storage systems

InactiveUS20170155274A1Speed downHigh cycle life performancePhotovoltaicsEnergy storageState of chargeCharge and discharge

A hybrid battery-charging device with input terminals for connecting a current source, first and second battery connections for connecting a lead-acid battery and a high-cycle chemical battery. A two-way DC / DC converter with first and second sets of terminals is connected with the second and first battery connections. A charge and discharge control system includes a controller unit, a control output for controlling the two-way DC / DC converter, and sensing inputs for sensing a charge state, an internal resistance of the lead-acid-battery and state of charge of the high-cycle chemical battery. The charge and discharge control system controls the two-way DC / DC converter such that the lead-acid battery is charged if its charge start is below a pre-determined threshold and that the high-cycle chemical battery is charged if its charge state is below a pre-determined threshold and if the state of charge of the lead-acid battery is above a pre-determined threshold.

Owner:ROBERT BOSCH GMBH

Curtain control device

InactiveUS8556204B2Speed downReduce noiseFilament handlingLight protection screensTorsion elementControl theory

A curtain control device has a stroke setting device and a damper respectively assembled at both ends of a curtain spindle rod. A torsion element is further assembled on the curtain spindle rod. A curtain spindle sleeve is invaginated on the outside of the curtain spindle rod, the stroke setting device and the damper. The curtain spindle sleeve is assembled with the combination of the curtain spindle rod and the damper, and then a curtain fabric is assembled on the outside of the curtain spindle sleeve. In this manner, the opening range of the curtain fabric roll is controlled by the stoke setting device, and the roll-up speed of each part of the curtain fabric is slowed down by the damper so as to reduce effectively the noise produced by the quick actuation of each part and the defective rate.

Owner:UNI-SOLEIL ENT CO LTD

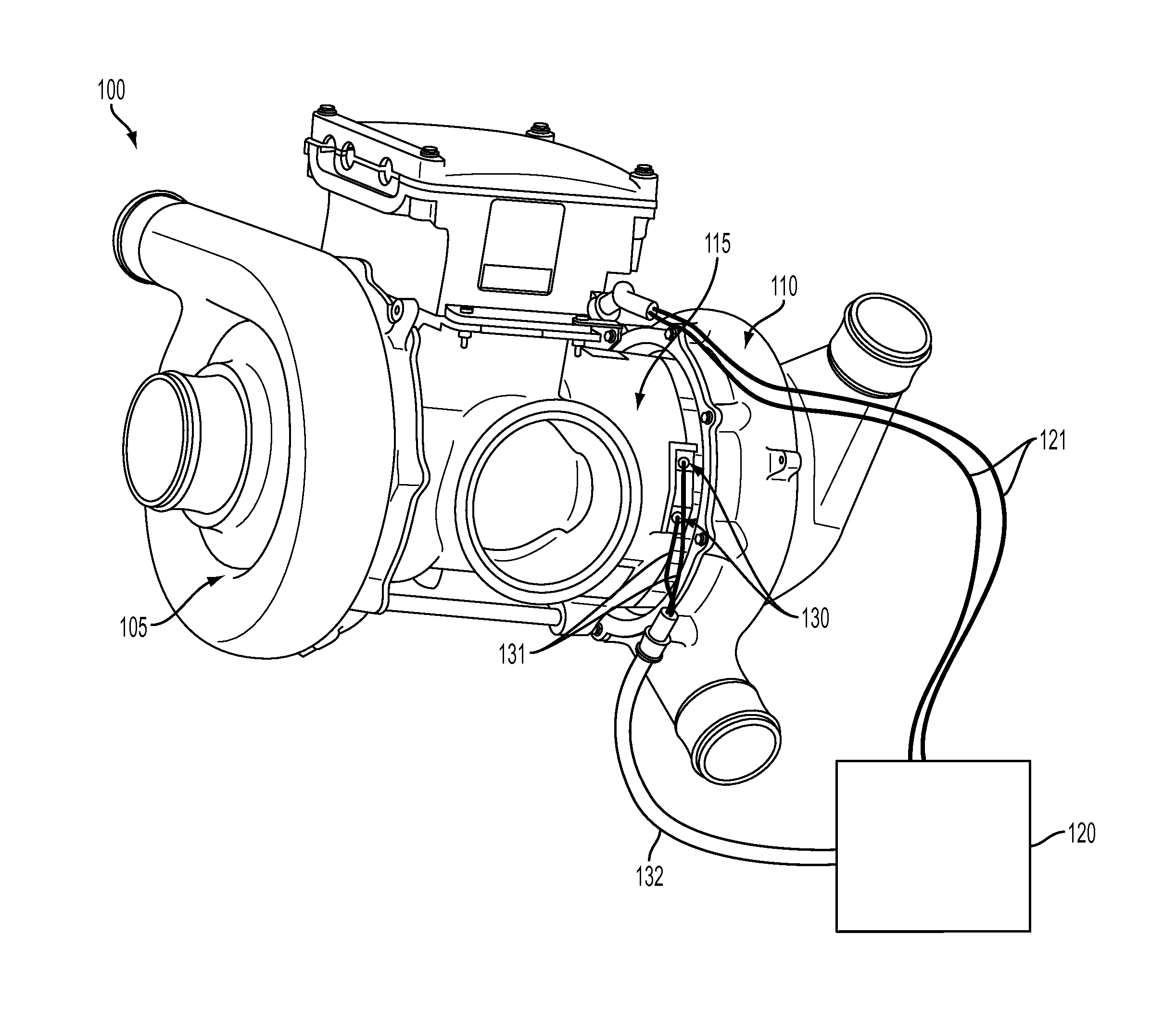

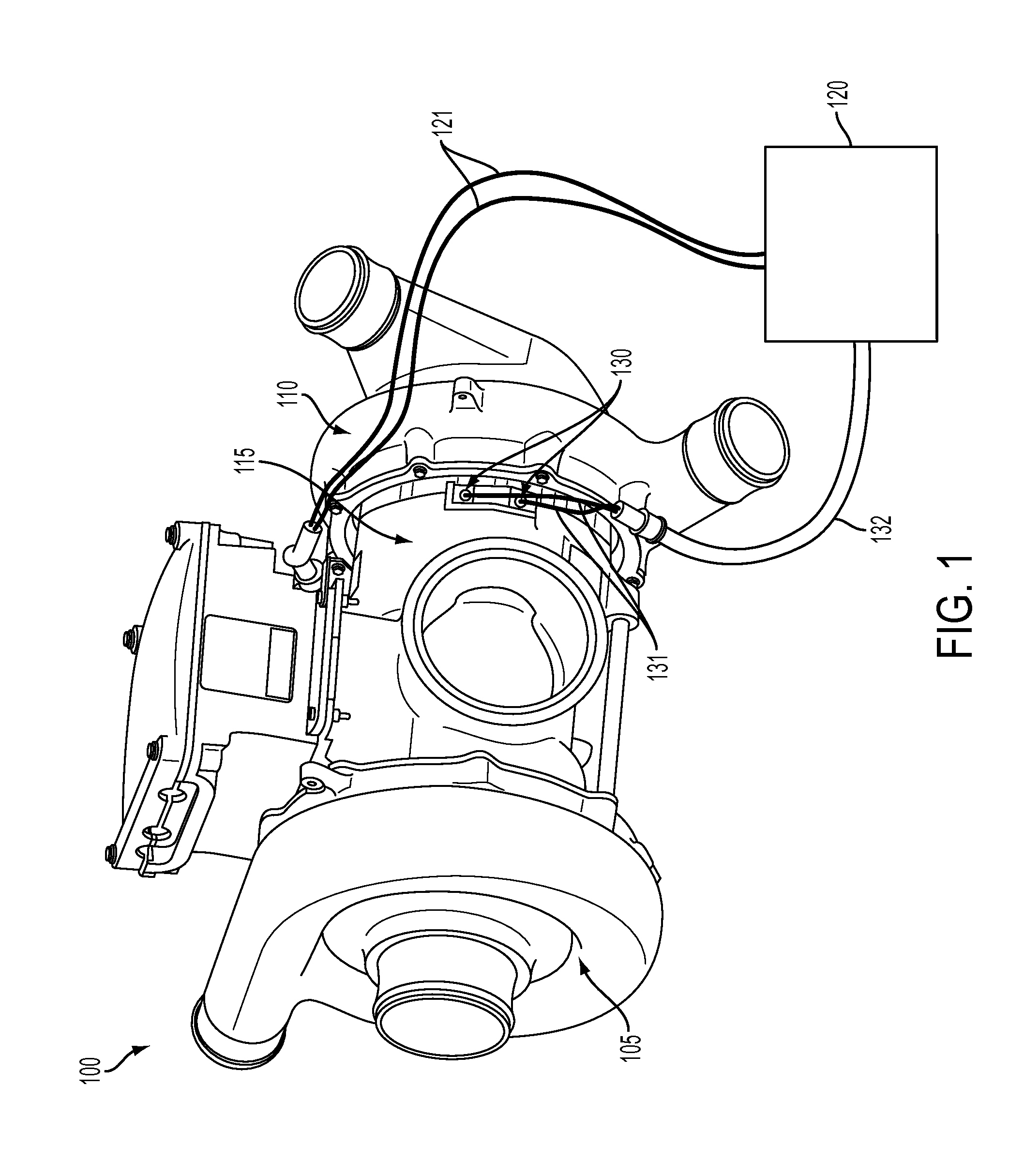

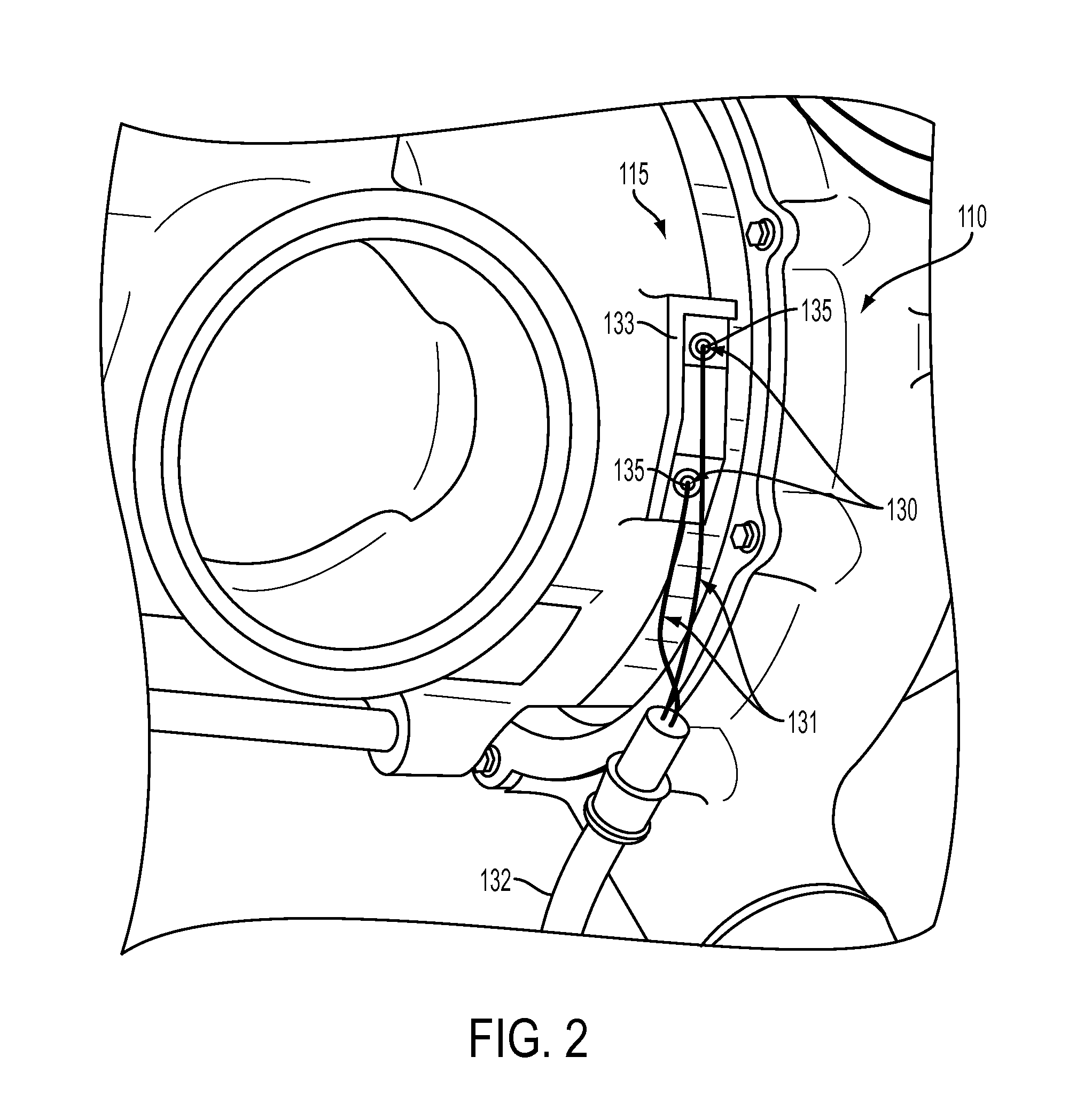

Motor housing thermal sensing

ActiveUS20130084193A1Speed downThermometer detailsTemperature measurement in motorsMotor driveElectric machine

A motor driven compressor apparatus includes a first stage compressor, a second stage compressor, an electric motor disposed between and coupled to the first stage compressor and the second stage compressor, thermal sensors disposed on the electric motor and configured to externally measure internal temperatures of the electric motor or internal bearings or components, and an external controller coupled to the electric motor and to the thermal sensors, and configured to at least one of slow down a speed of the electric motor and shut down the electric motor in response to at least one of an excess of a predetermined internal temperature and a rate of internal temperature change.

Owner:HAMILTON SUNDSTRAND CORP

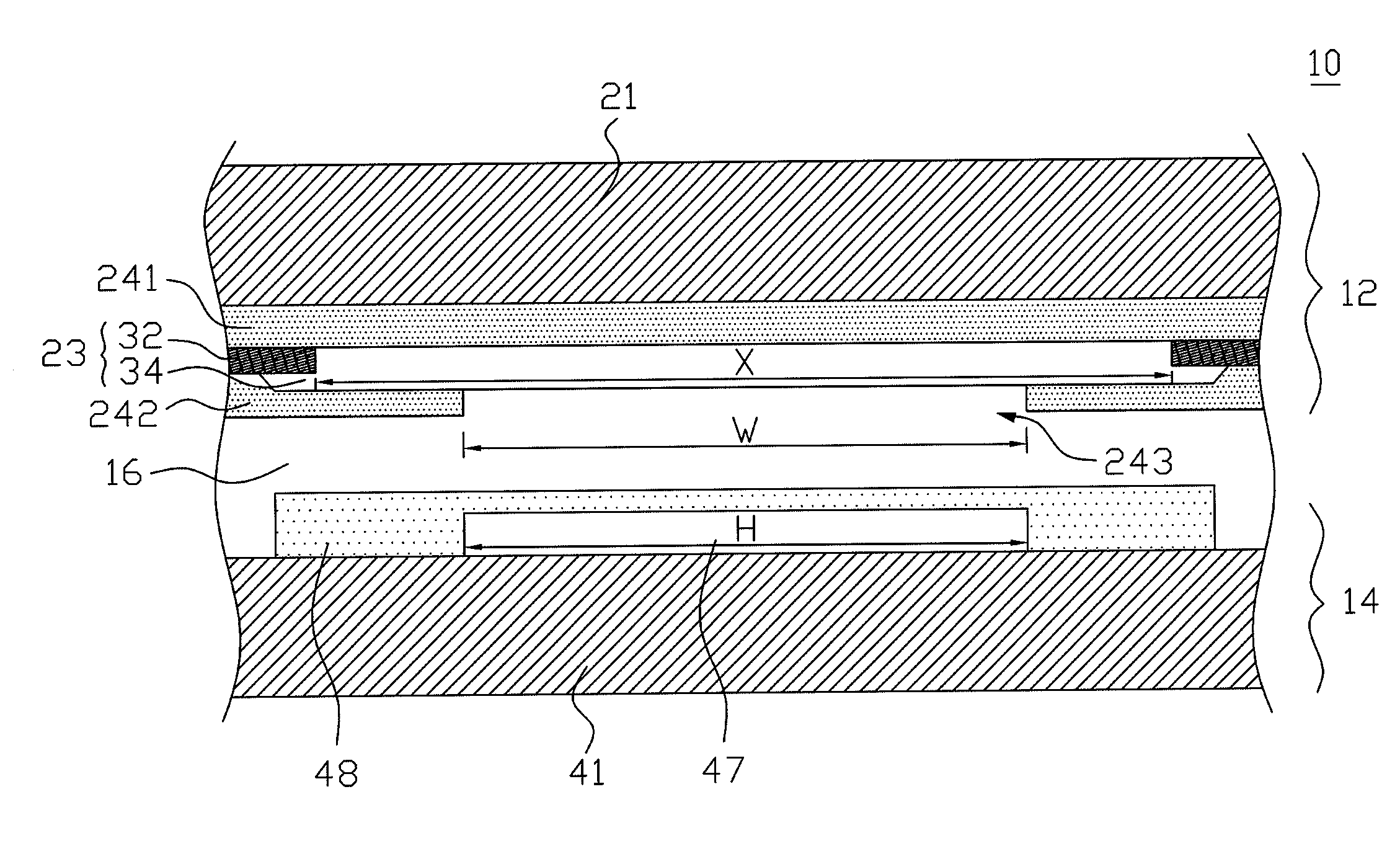

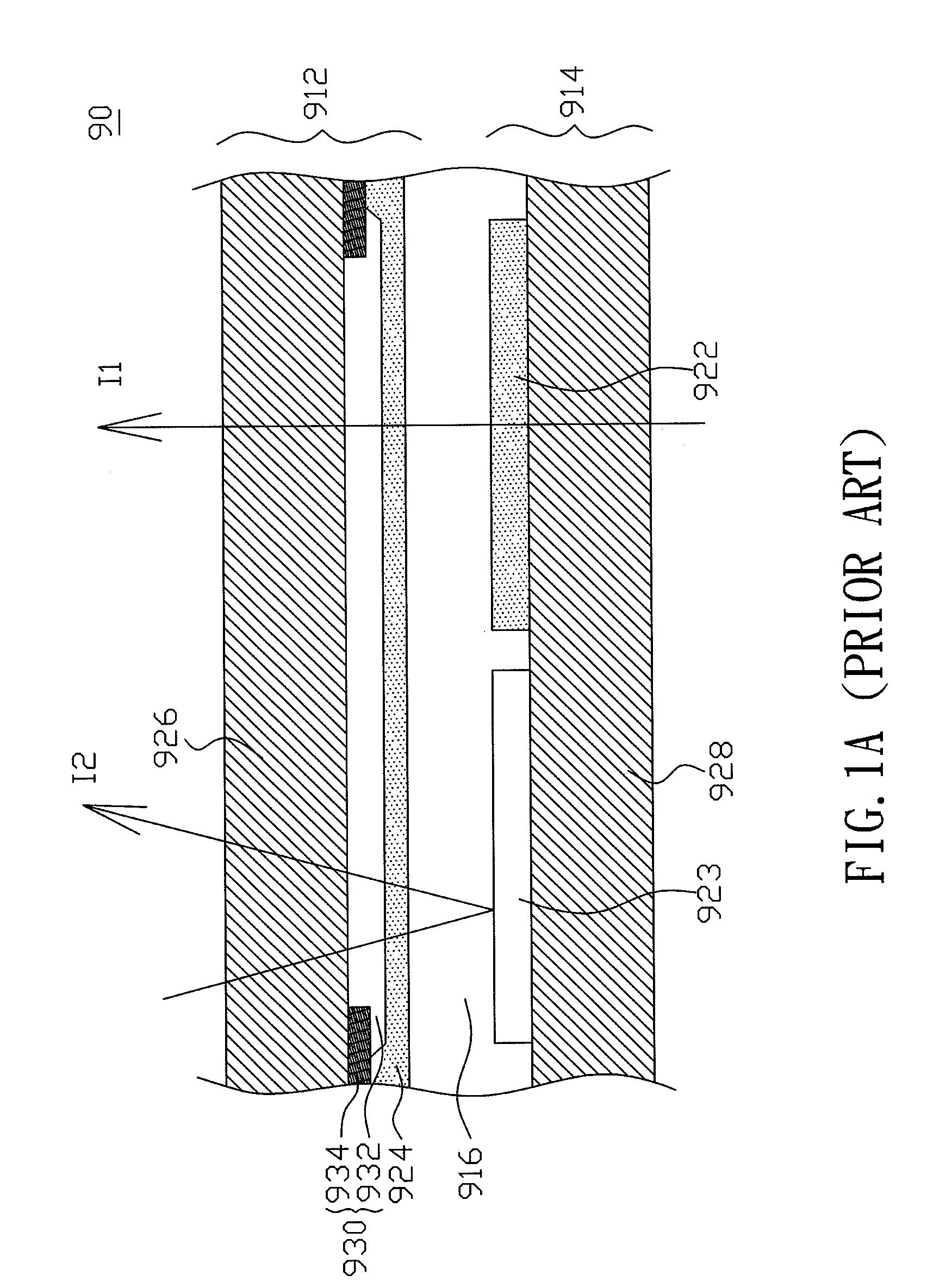

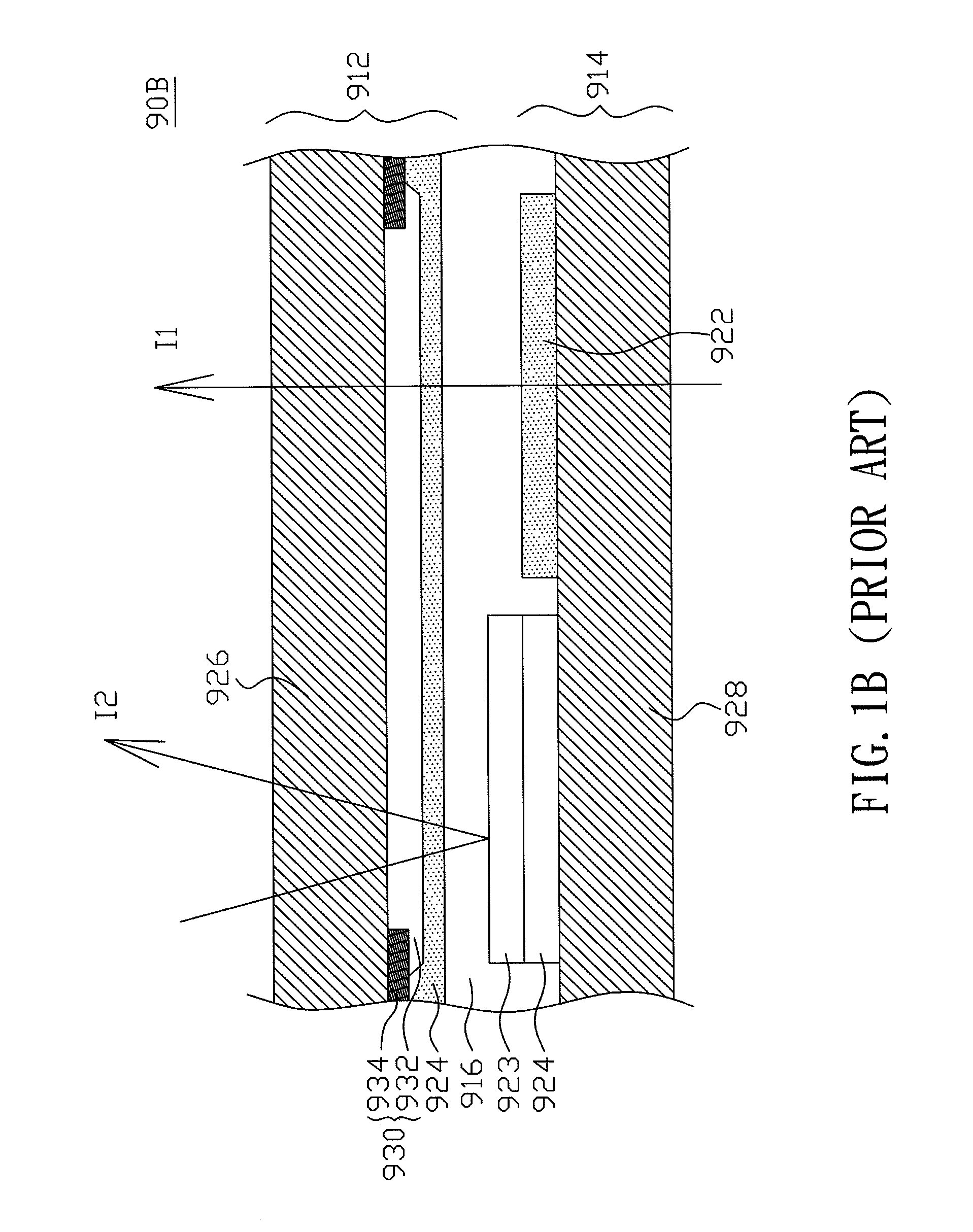

Transflective liquid crystal display

InactiveUS20110013126A1Reduce fadingImprove image qualityNon-linear opticsLiquid-crystal displayLiquid crystal

A transflective liquid crystal display is provided which includes a color-filter substrate, an active matrix substrate, and a liquid crystal layer interposed between them. The active matrix substrate includes a first transparent substrate and includes a plurality of switching devices, a plurality of transparent pixel electrodes and a plurality of reflective pixel electrodes formed on the first transparent substrate. The color-filter substrate includes a second transparent substrate, a first and second transparent conducting layers and a dielectric layer. The first transparent conducting layer is interposed between the second transparent substrate and the second transparent conducting layer, and the dielectric layer is interposed between the first and second transparent conducting layers. The second transparent conducting layer in each pixel area has at least one opening. The openings positionally correspond to the reflective pixel electrodes.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

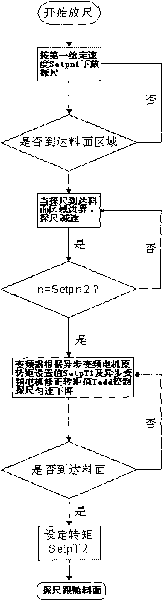

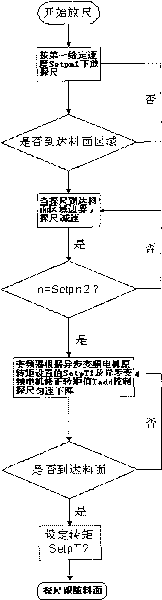

Trial rod inverse plummet resisting control method

InactiveCN101736110AControl the lowering speedSpeed downChecking devicesFrequency changerMotor drive

The invention relates to blast furnace top system, in particular to a trial rod inverse plummet resisting control method. The method sequentially comprises the following steps: firstly a rotary drum drives the trial rod to descend at constant first given speed; when the trial rod reaches charge level zone boundary, a PLC reads the signal by an absolute type encoder mounted on a reduction box, wherein the signal signals that the trial rod reaches the charge level zone boundary, then the PLC gives out an order to a frequency changer, after receiving the order, the frequency changer begins to control an asynchronous variable frequency motor to decelerate, the asynchronous variable frequency motor drives a gear reducer and the rotary drum to decelerate, and the rotary drum drives the trial rod to decelerate; when the trial rod decelerates to the second given speed, the PLC calculates according to the read data to obtain corrected torque of asynchronous variable frequency motor, then transmits the corrected torque of asynchronous variable frequency motor to the frequency changer, the frequency changer controls the trial rod to descend at constant speed according to the original torque set value and the corrected torque value of asynchronous variable frequency motor; and when the trial rod reaches charge level zone boundary, the asynchronous variable frequency motor converts output torque into rod holding torque under control of the frequency changer, and the trial rod acts along with the charge level.

Owner:WISDRI ENG & RES INC LTD

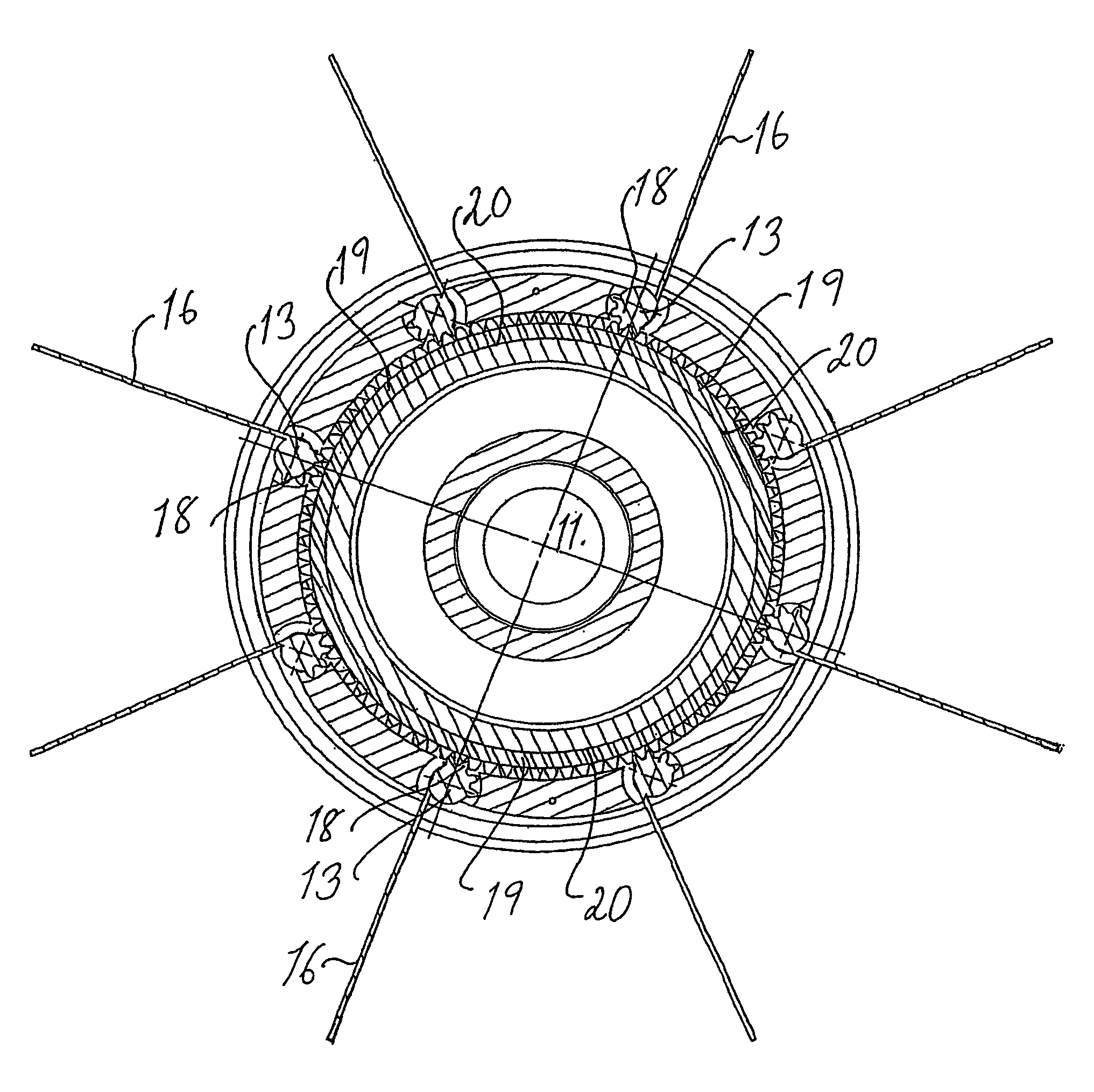

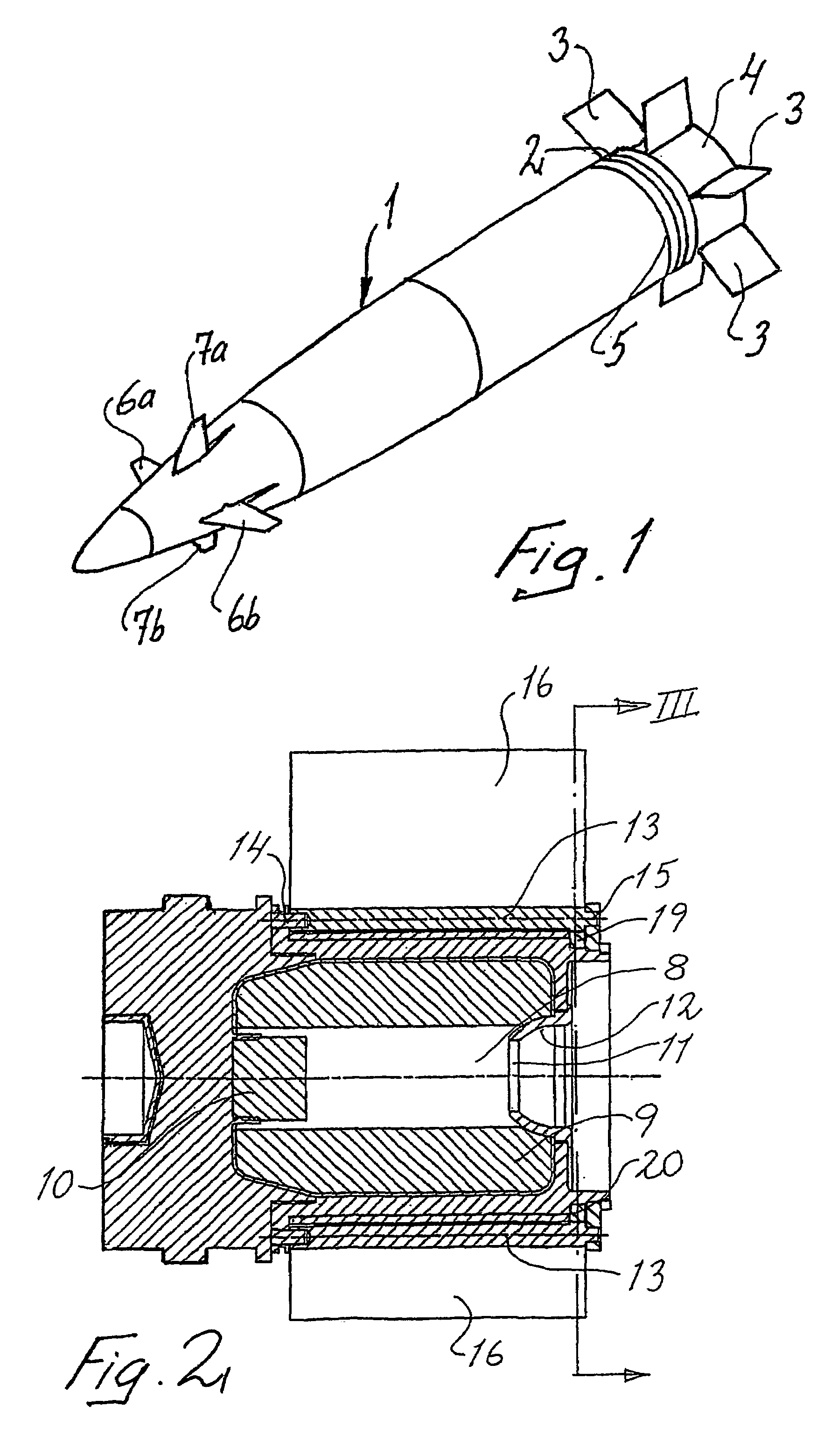

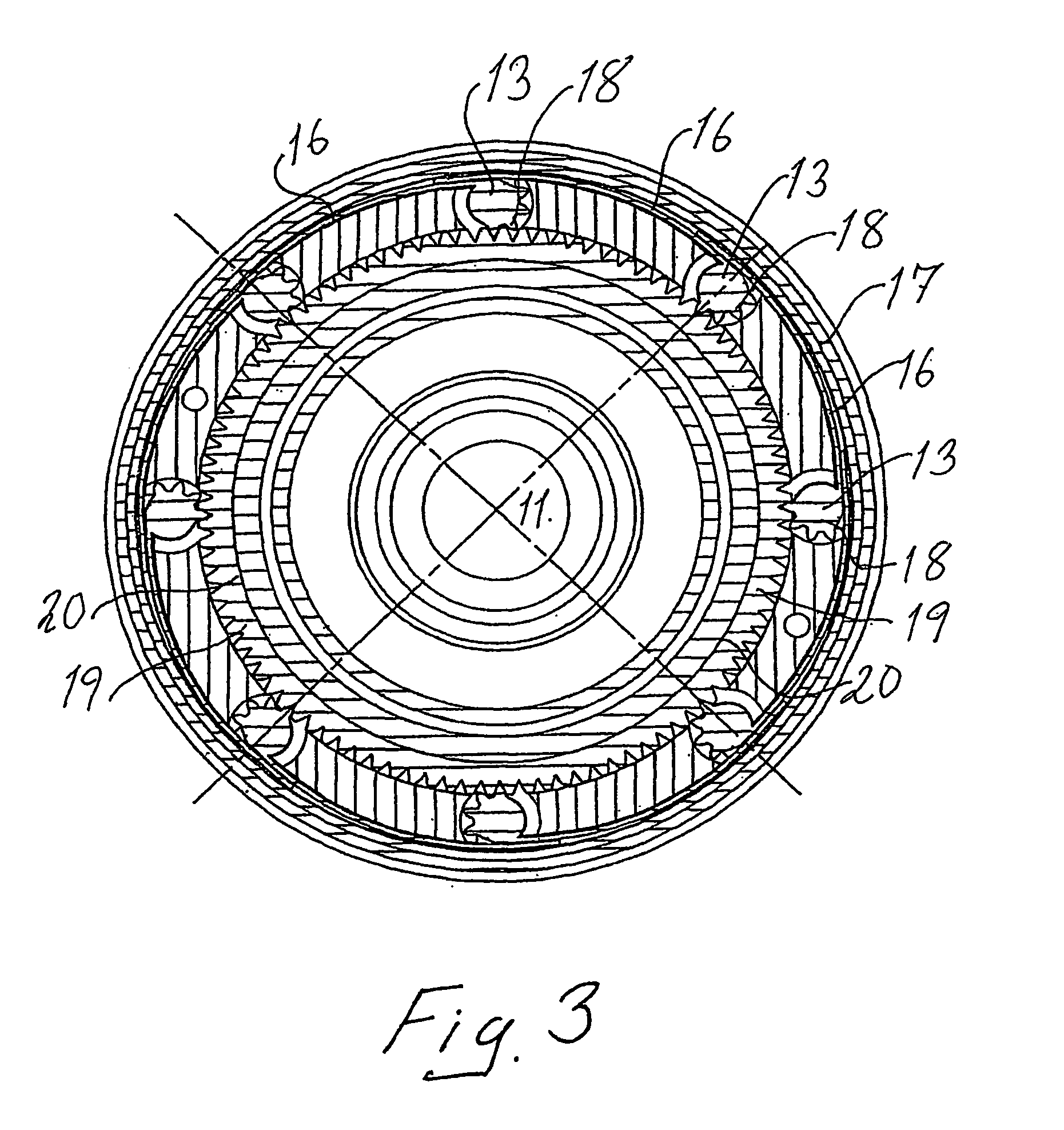

Method of synchronizing fin fold-out on a fin-stabilized artillery shell, and an artillery shell designed in accordance therewith

InactiveUS7104497B2Same speedReduce riskAmmunition projectilesSelf-propelled projectilesEngineeringMovement pattern

This disclosure relates to a method of limiting the yawing motion on the trajectory of an artillery shell during the firing phase using a sliding driving band and completely folded-in guide fins. The shell is converted as soon as possible outside the mouth of the barrel of the firing piece by fold-out of the guide fins into a fin-stabilized artillery shell. Any form of non-uniform fin fold-out is avoided by virtue of all the guide fins being interconnected to form a system which gives all the fins the same movement pattern and the same fold-out speed in each phase of fin fold-out. This disclosure also includes a shell in which synchronization of fin fold-out includes a rotatable control ring that is arranged around the axis of the shell and is connected to the rotation spindles of all the fins.

Owner:BAE SYST BOFORS

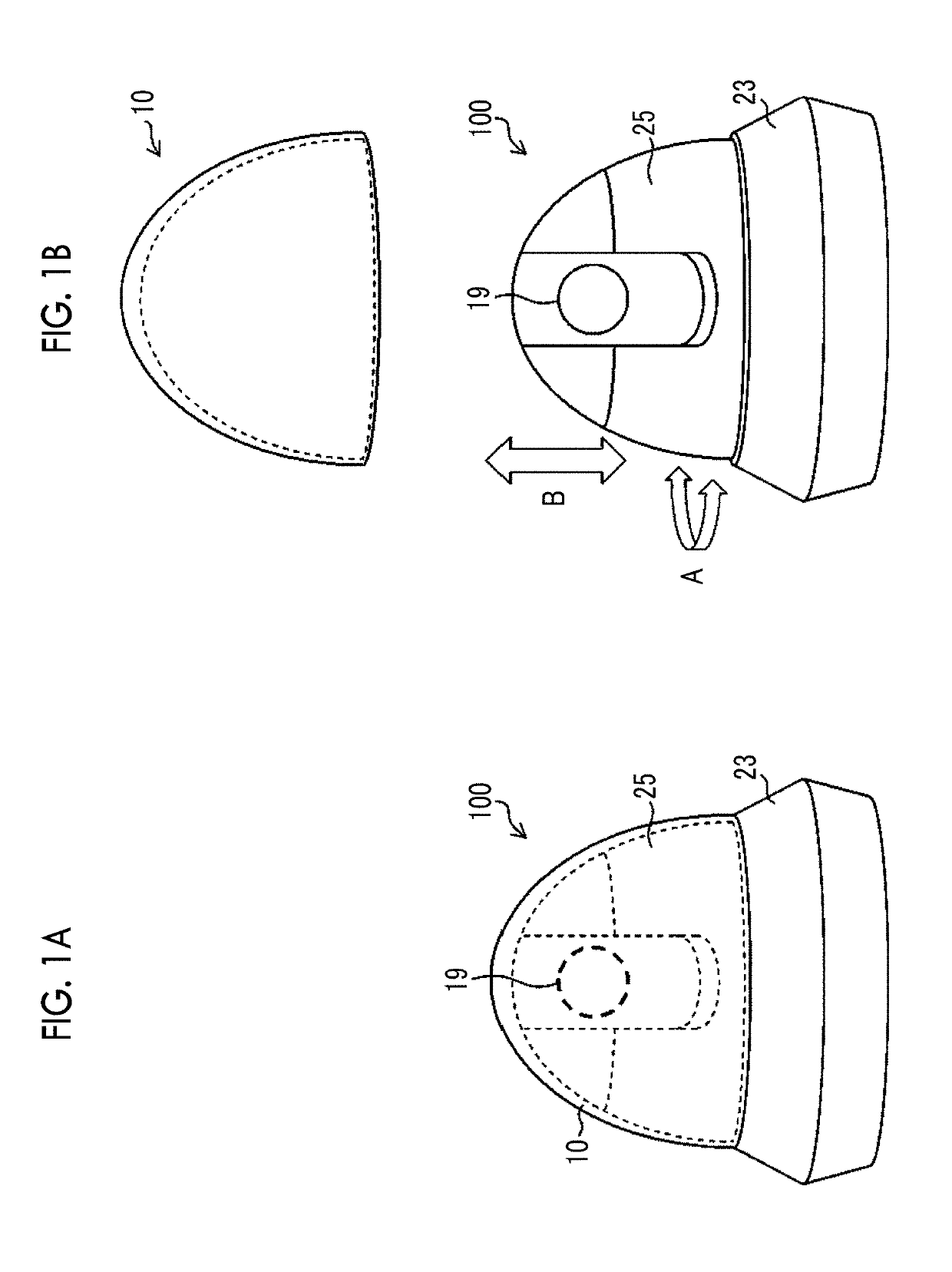

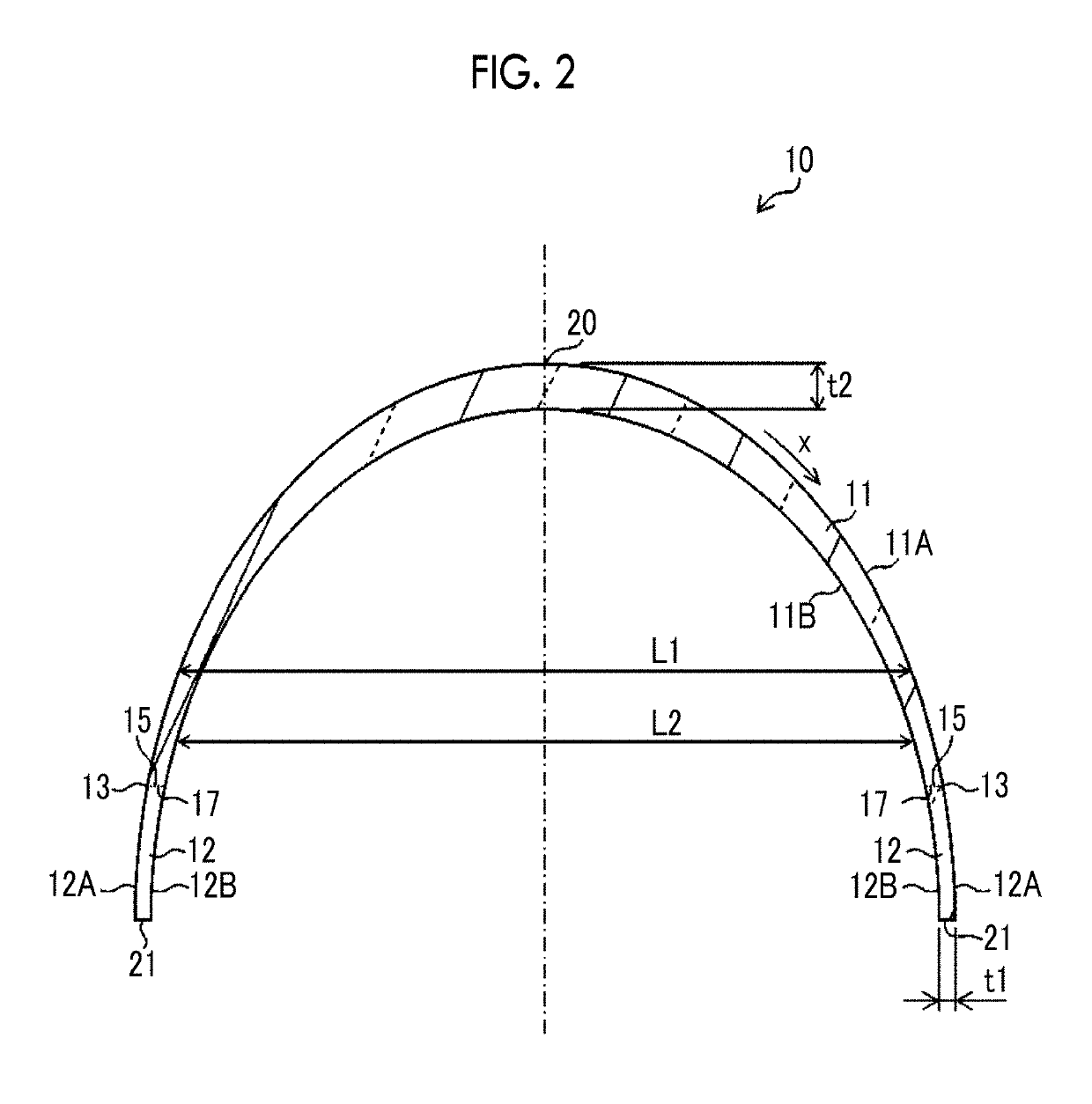

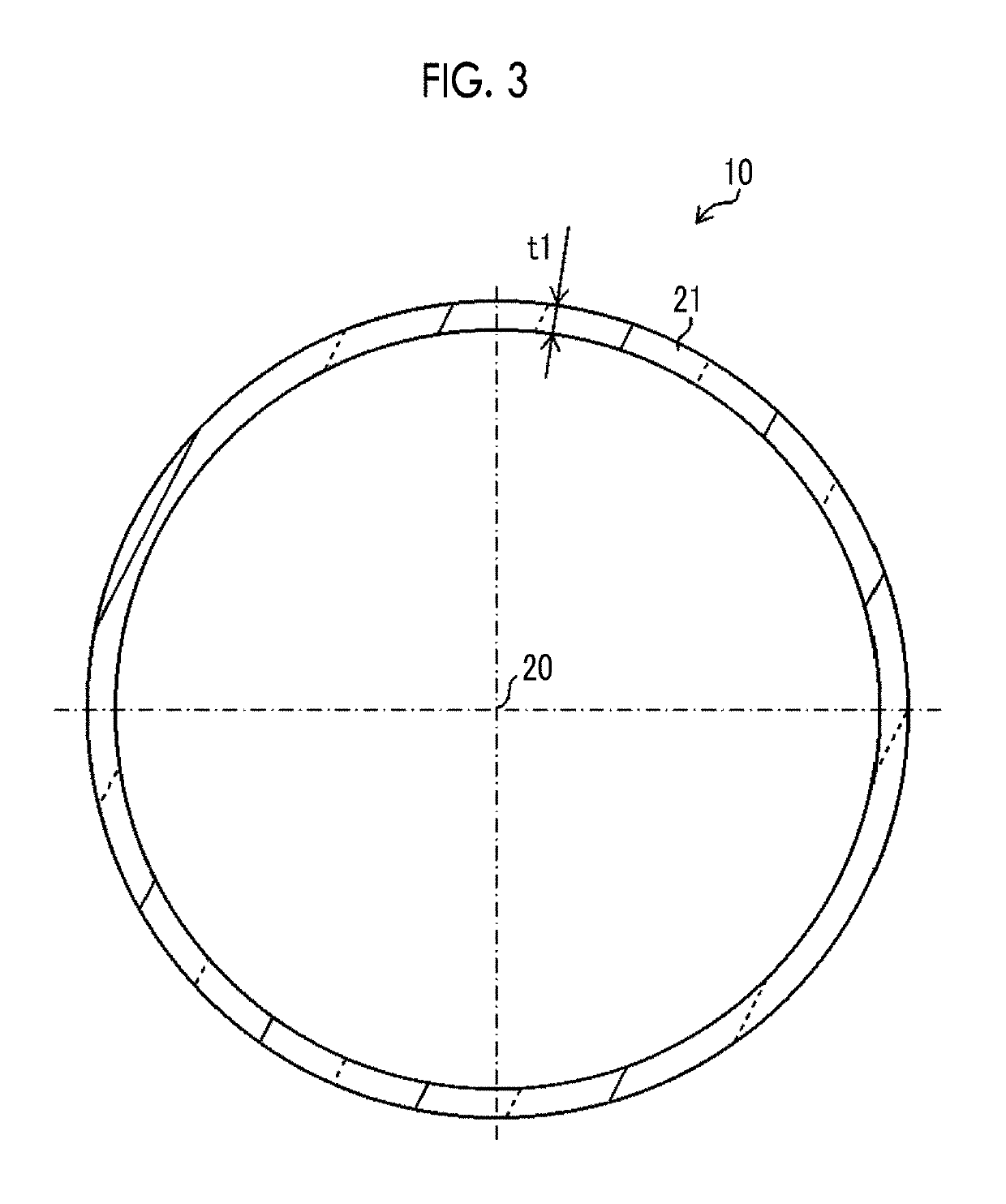

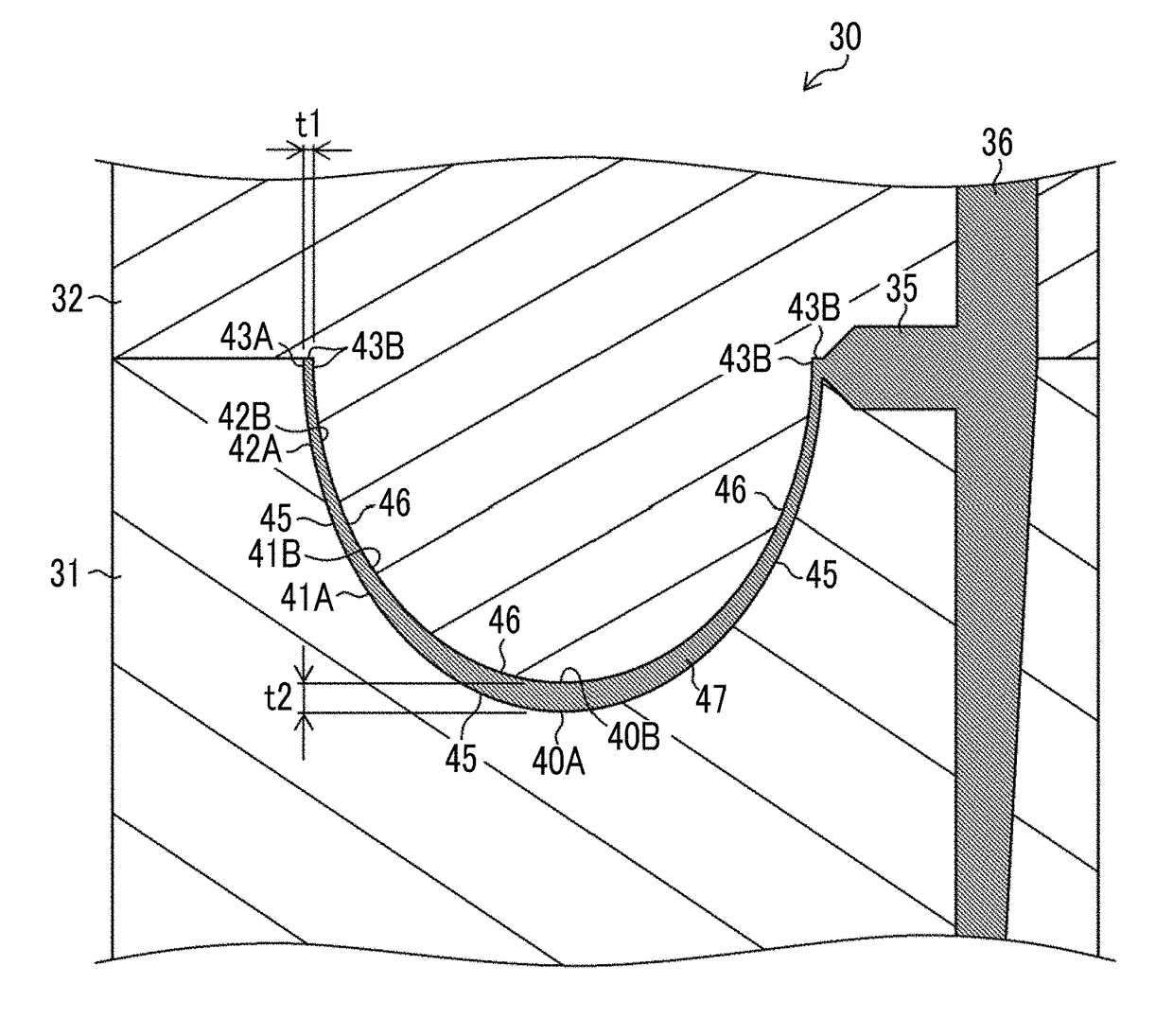

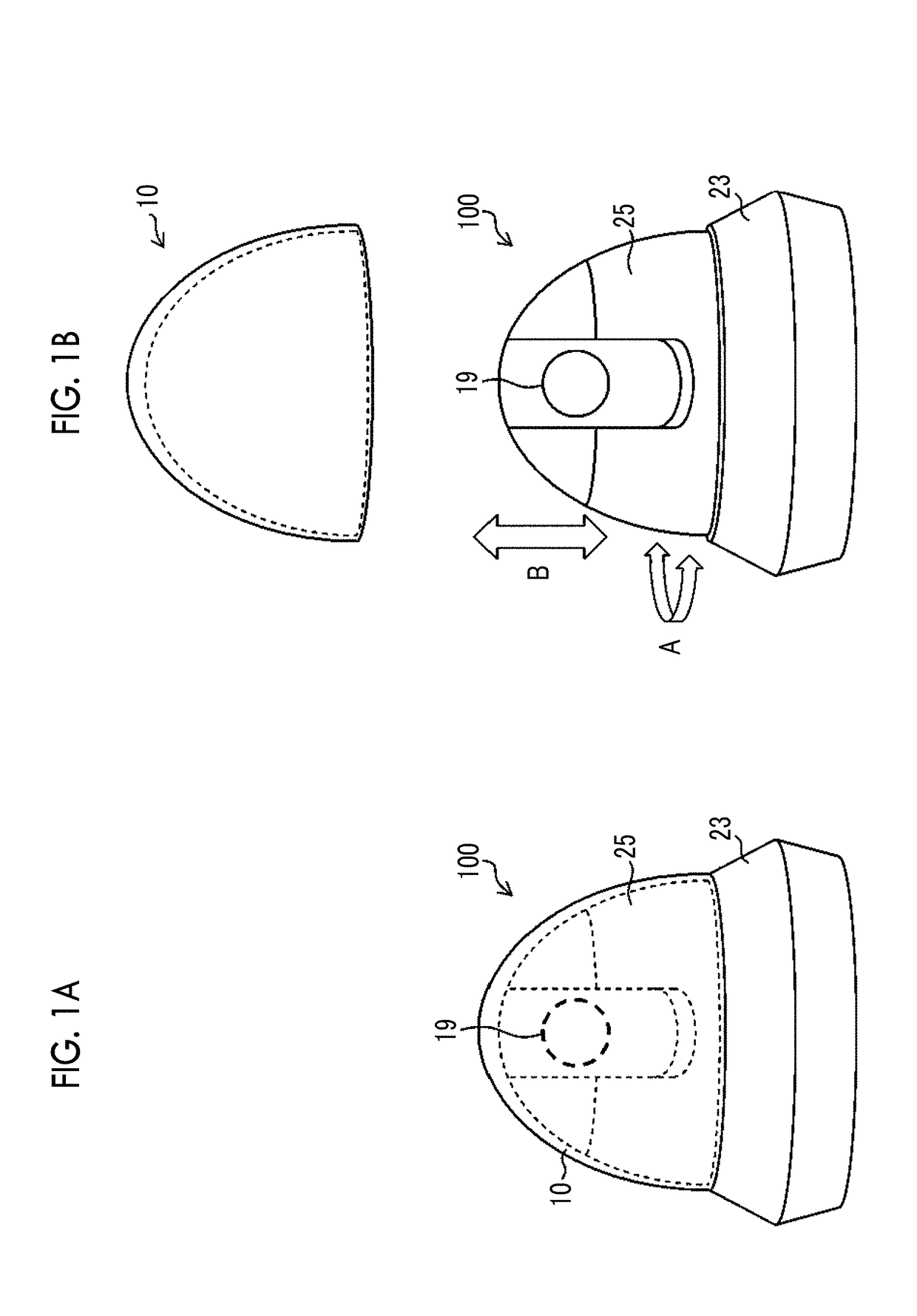

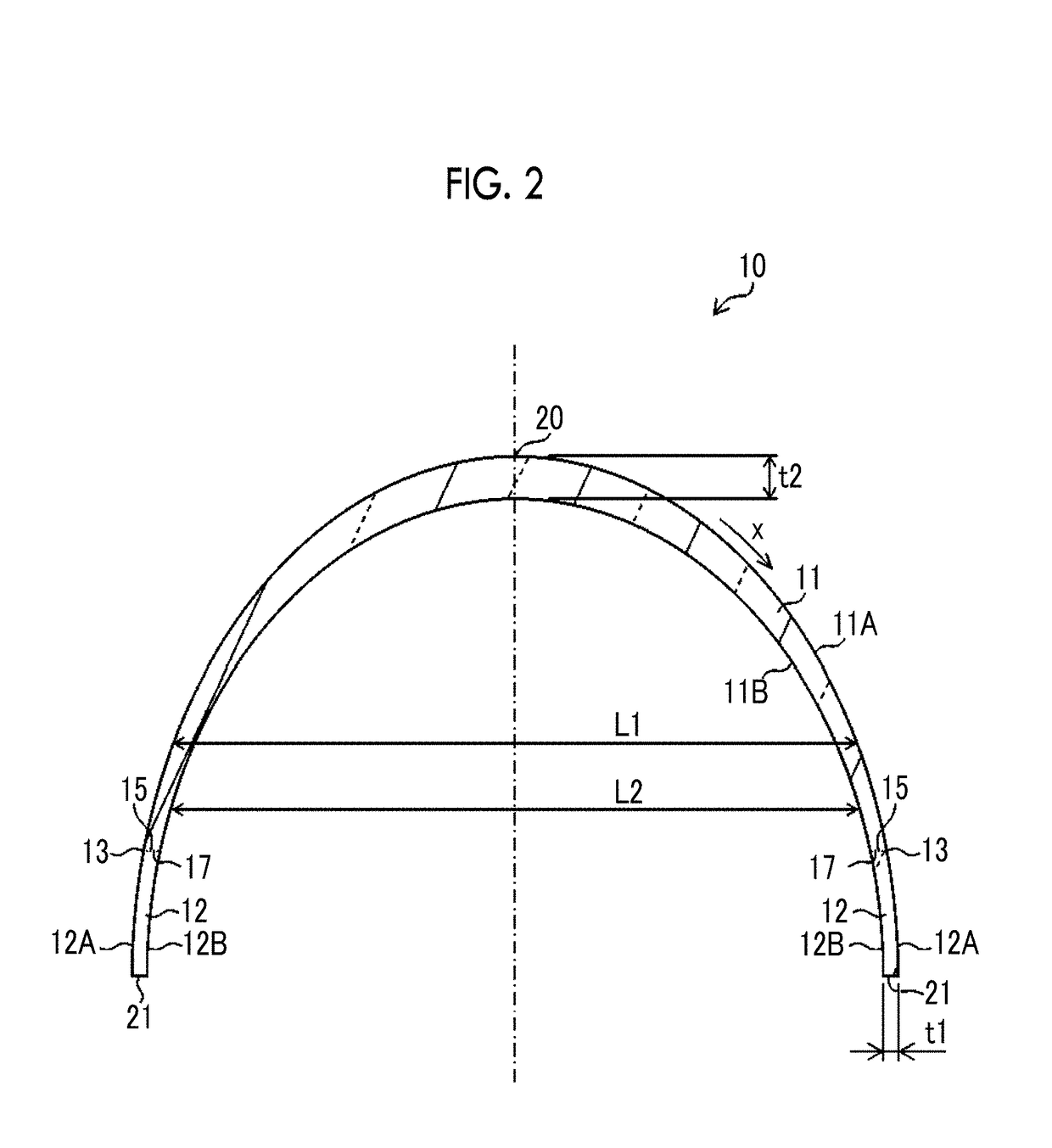

Dome cover, camera device, injection molding die, and injection molding method

ActiveUS10401715B2Suppress generationSpeed downTelevision system detailsColor television detailsStructural engineeringMechanical engineering

The invention provides a dome cover, a camera device, an injection molding die, and an injection molding method in which generation of a weldline is suppressed and deterioration of an acquired image is suppressed. In one aspect of the invention, a dome cover is a dome cover that covers a camera. The dome cover includes a curved section having a curved shape and a skirt section having a cylinder shape and has a top section at the curved section and an opening end section at the skirt section. The thickness of the dome cover is largest at the top section and smallest at the opening end section, and continuously decreases from the top section toward the opening end section. The inner diameter and the outer diameter of the dome cover continuously increase from the top section toward the opening end section.

Owner:FUJIFILM CORP

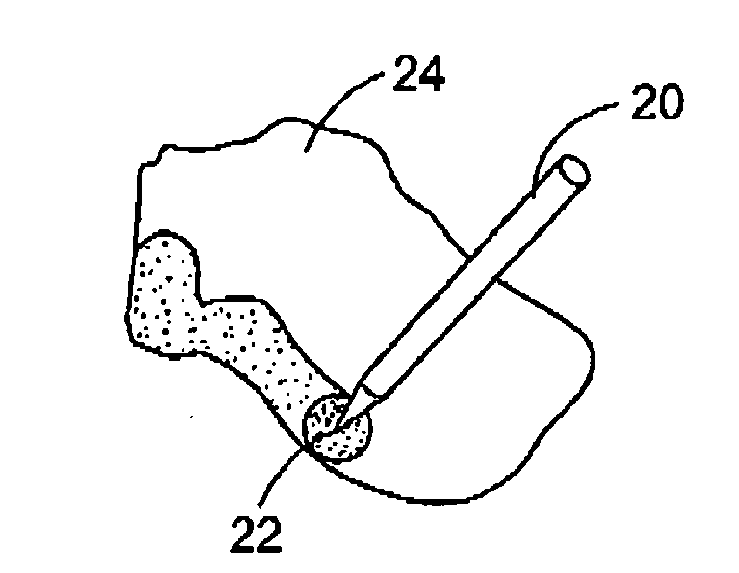

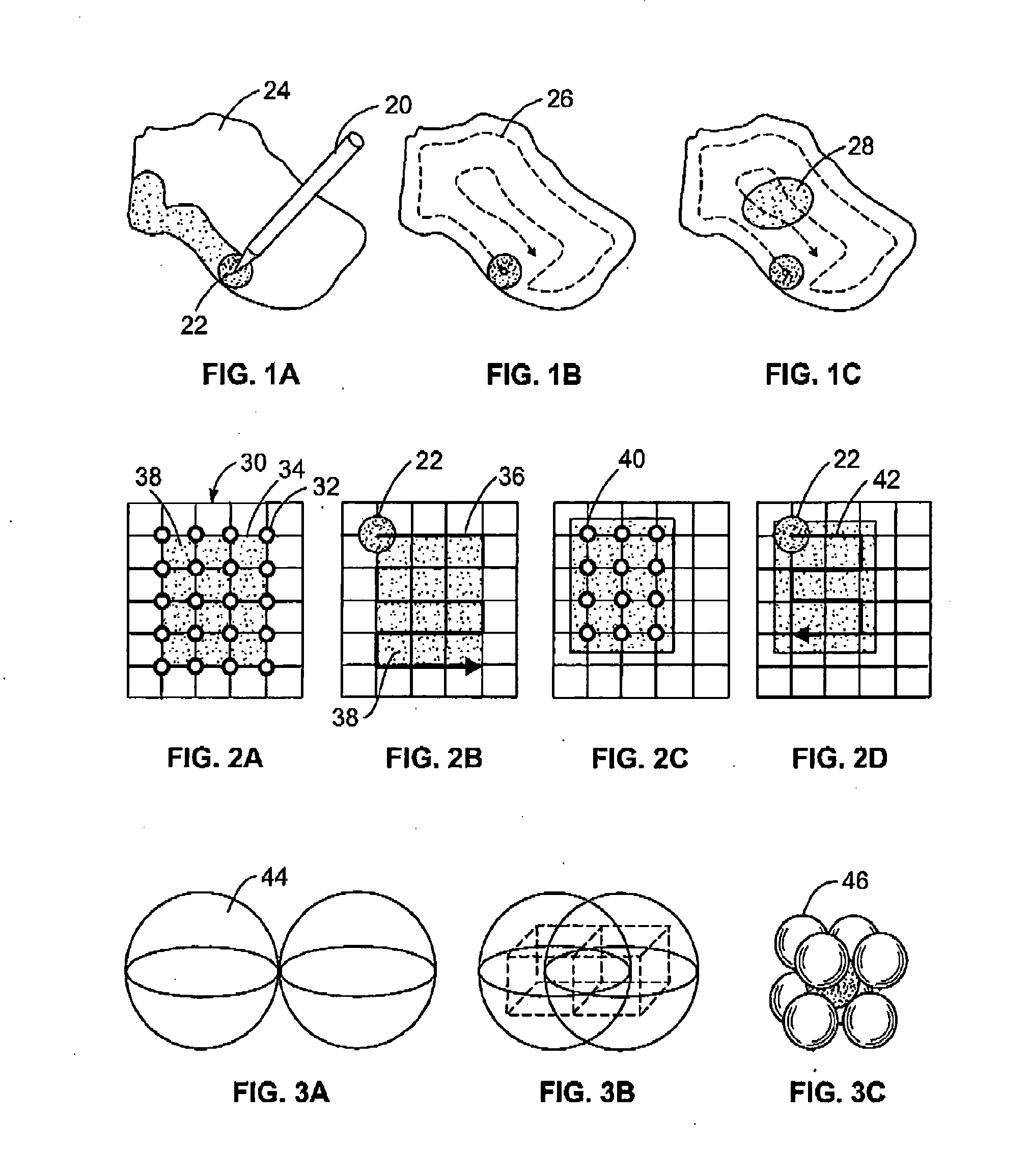

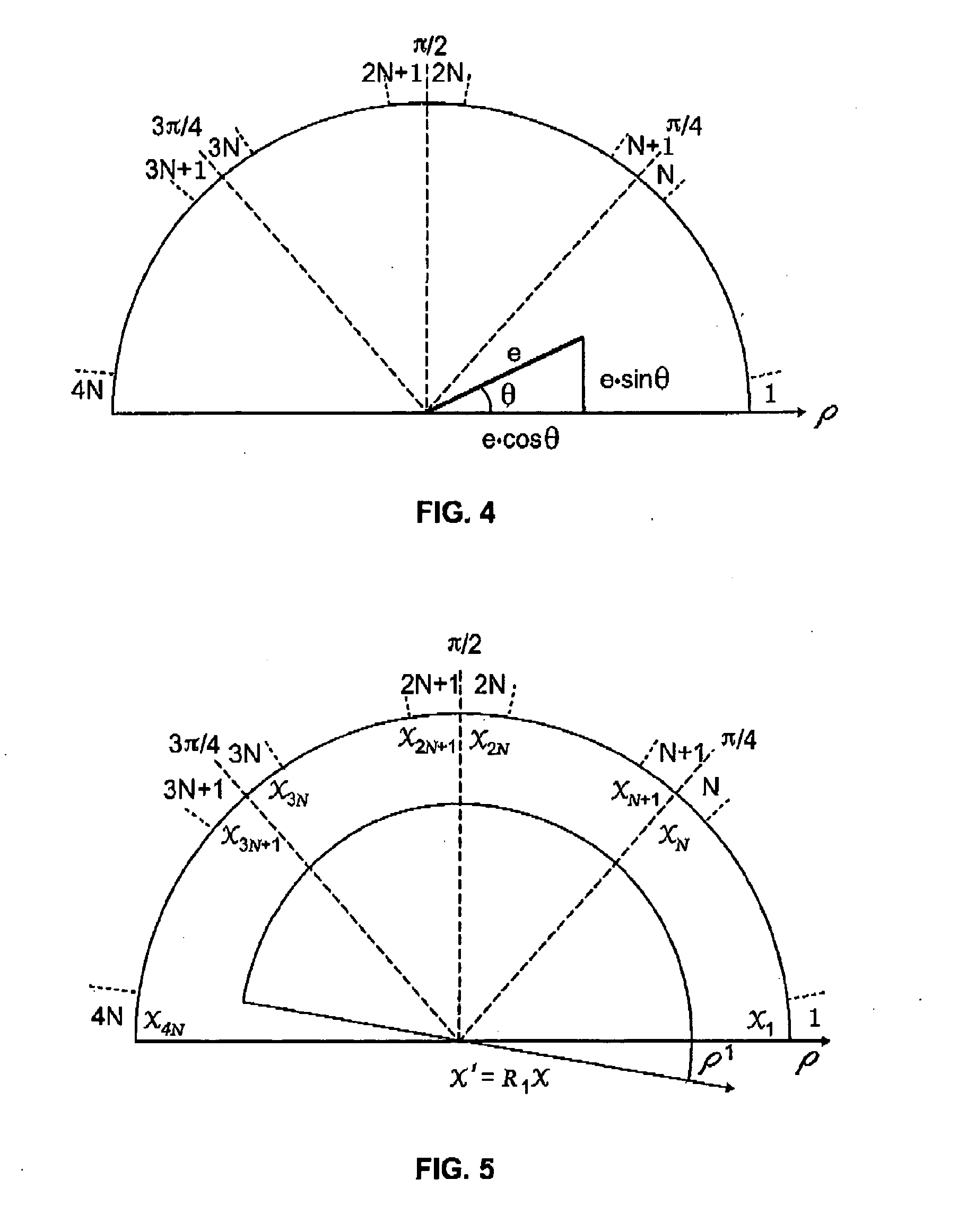

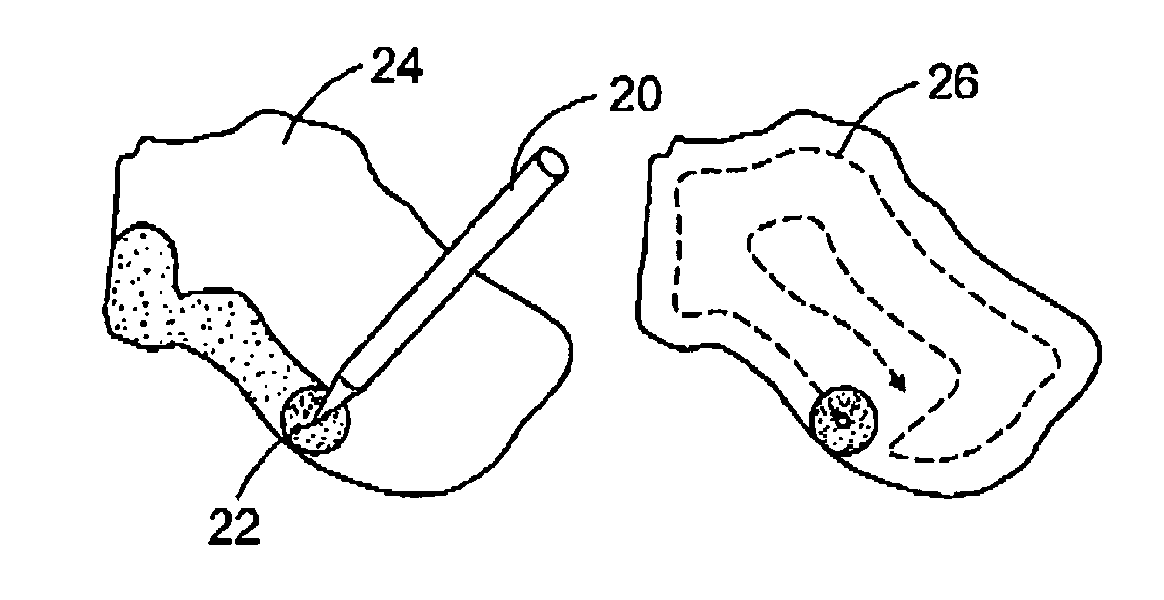

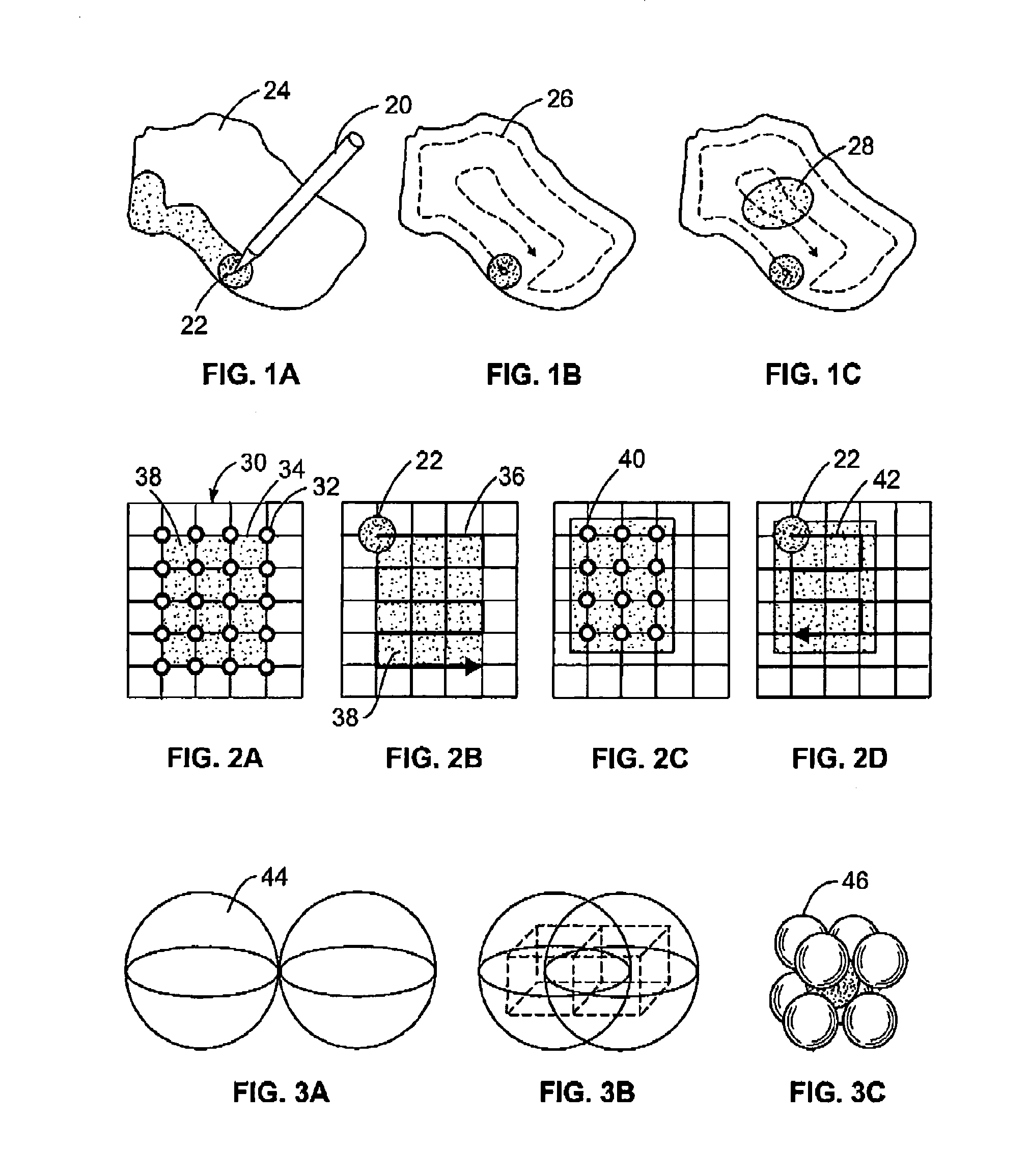

System and methods for using a dynamic gamma knife for radiosurgery

ActiveUS20110160513A1Reduced dose rateTreatment procedure is very comfortableDiagnosticsComputer-aided planning/modellingDose paintingHigh doses

The present invention is a method and system for developing a dynamic scheme for Gamma Knife radiosurgery based on the concept of “dose-painting” to take advantage of robotic patient positioning systems on the Gamma Knife C and Perfexion units. The spherical high dose volume created by the Gamma Knife unit will be viewed as a 3D spherical “paintbrush”, and treatment planning is reduced to finding the best route of this “paintbrush” to “paint” a 3D tumor volume. Under the dose-painting concept, Gamma Knife radiosurgery becomes dynamic, where the patient is moving continuously under the robotic positioning system.

Owner:RGT UNIV OF CALIFORNIA +1

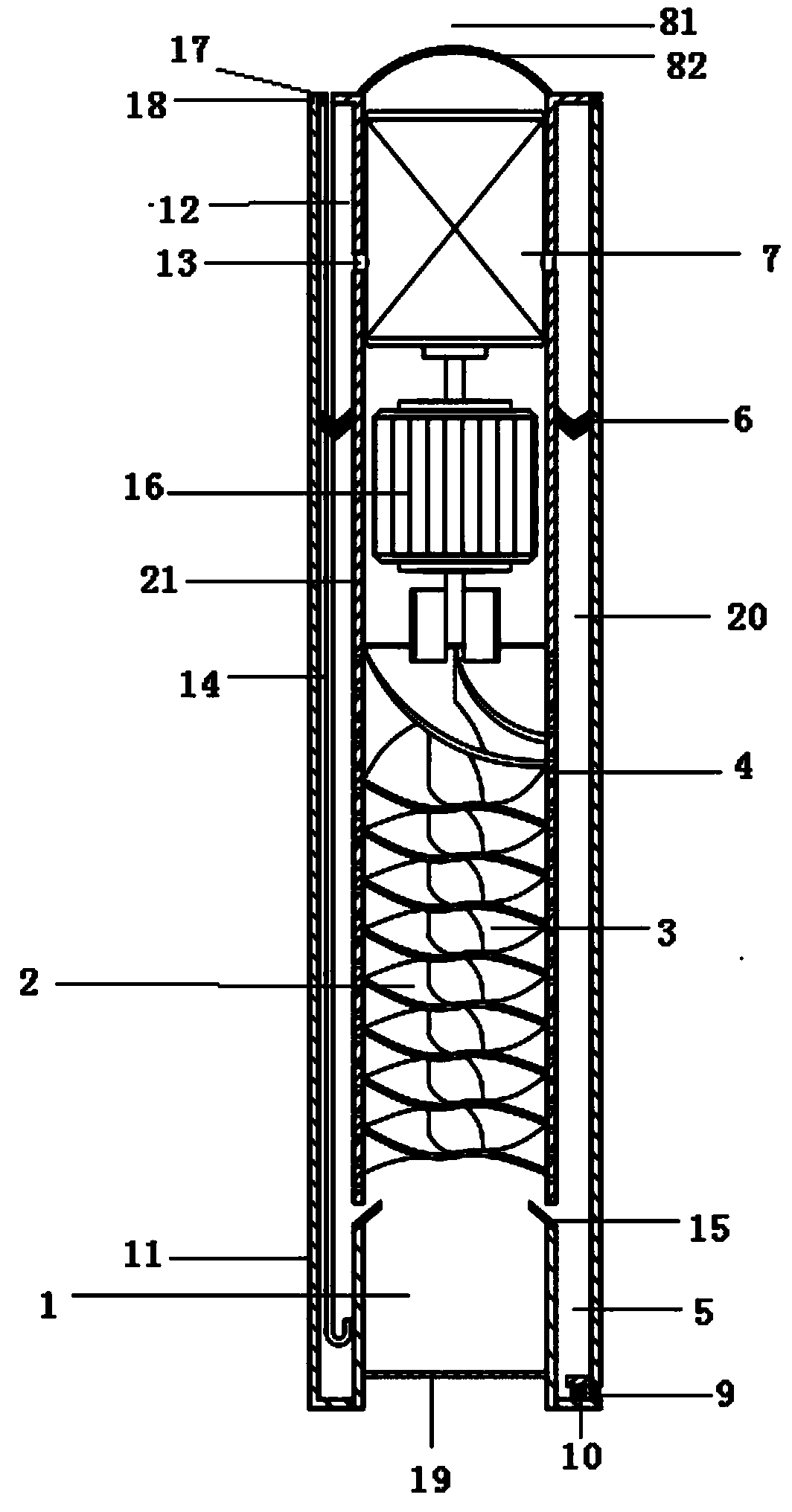

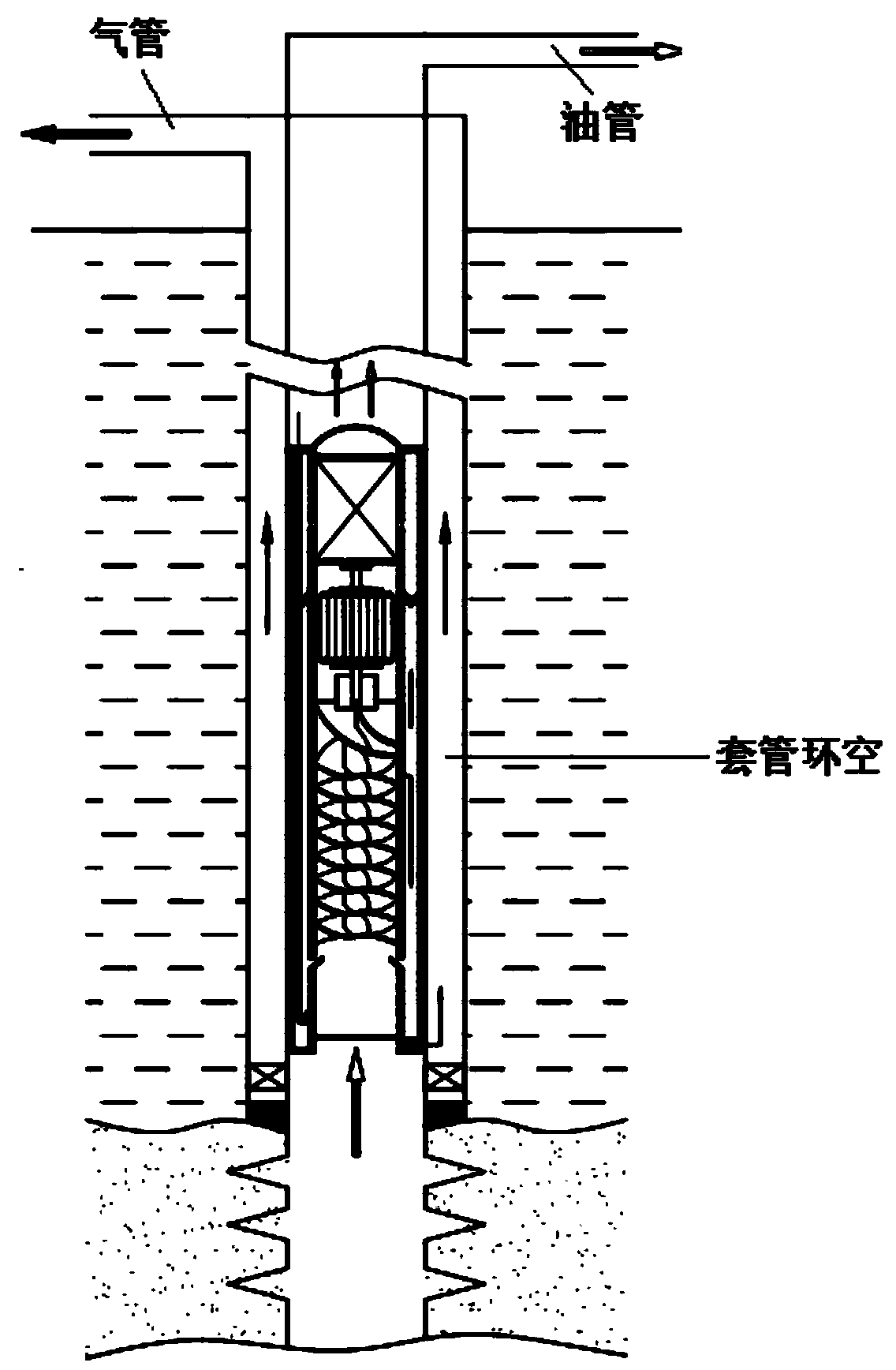

Well bottom gas-liquid separator

The invention provides a well bottom gas-liquid separator, which comprises a tubular part (21), a gas-liquid separation chamber (2), a through shaft motor (16) and a compressor (7), wherein a tube wall defining an air inlet (1) and an air outlet (81) is arranged around the tubular part (21), the air inlet (1) and the air outlet (81) have a certain axial distance, the gas-liquid separation chamber (2), the through shaft motor (16) and the compressor (7) are sequentially arranged in the tubular part (21) arranged between the air inlet and the air outlet on the same axial line, a liquid collecting convex plate (82) provided with a projected hole seals and covers the air outlet (81) formed in the top of the tubular part (21), a cavity formed between the tubular part (21) and an outer sleeve (11) forms a gravity separation part (20), the top of the gravity separation part (20) is sealed, an air inlet hole (13) is formed in a wall of the tubular part (21) corresponding to the compressor (7), a plurality of exhaust / liquid discharge holes (4) are formed in the tubular part (21) provided with the gas-liquid separation chamber (2) arranged in the middle part of the gravity separation part (20), a liquid collecting groove (5) is formed by a liquid blocking plate (15) and the outer sleeve (11) at the end, near the air inlet (1), of the gravity separation part (20), and a condensed liquid recovery pool (12) is positioned on the top of the gravity separation part (20).

Owner:SOUTHWEST PETROLEUM UNIV

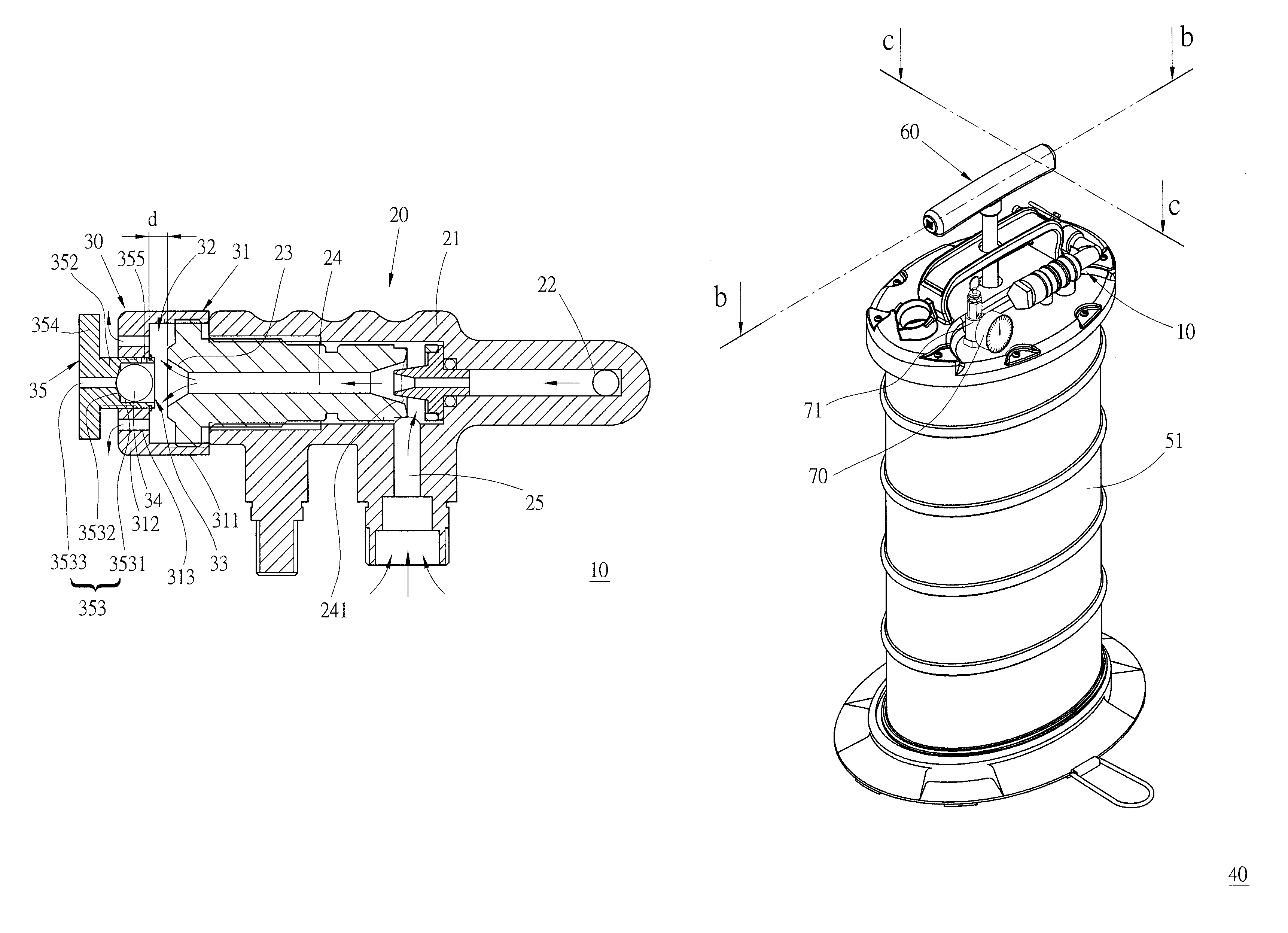

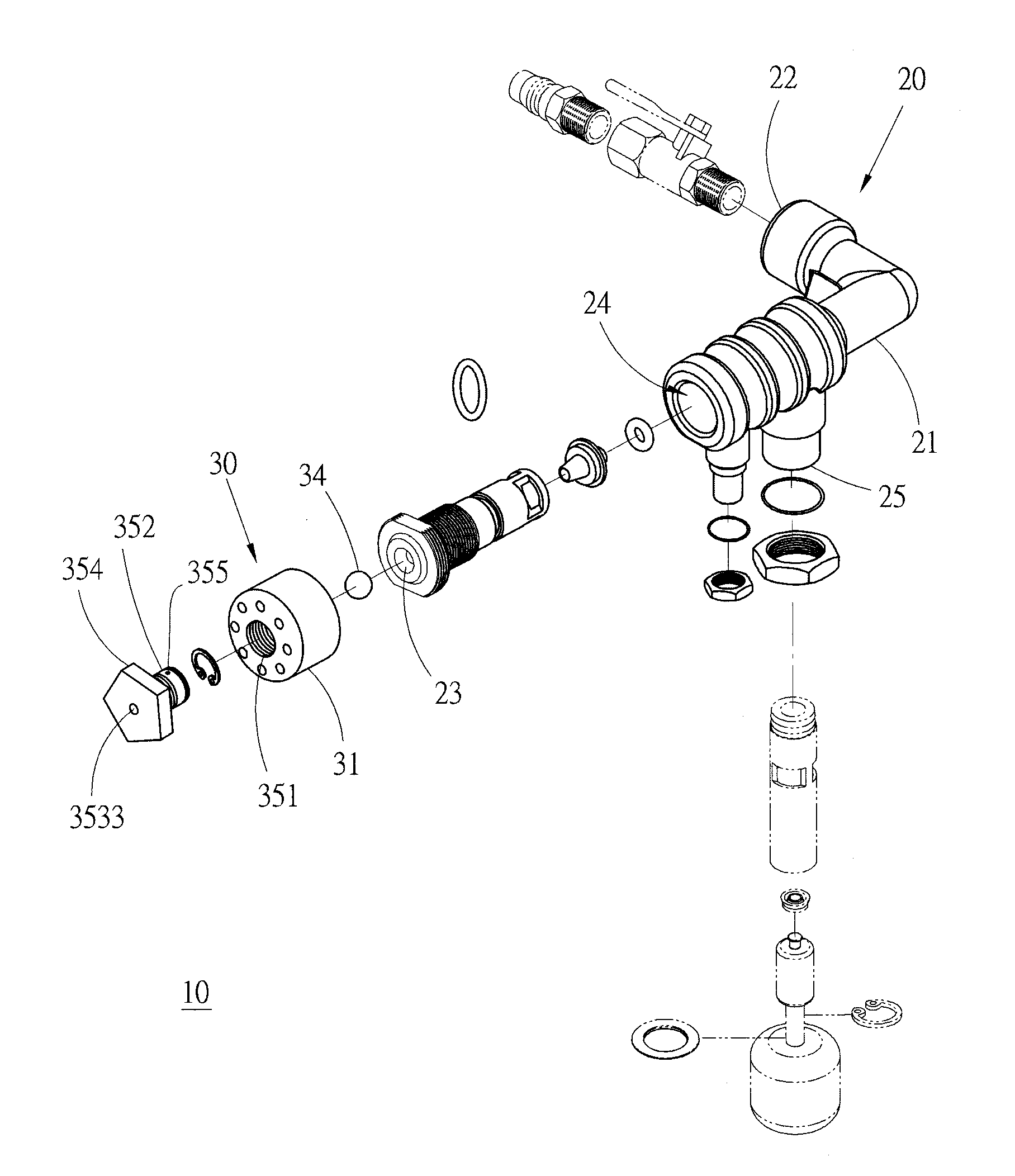

Venturi tube assembly and manual/pneumatic pump including the venturi tube assembly

A Venturi tube assembly includes: a Venturi tube having a body section with an inlet end, an outlet end and an internal flow passage between the inlet end and the outlet end, a pneumatic sucking passage outward extending from a low static pressure section of the internal flow passage to an outer circumference of the body section; and a blocking member having an exhaustion space for communicating the outlet end with the atmosphere, a blocking body movable between an unblocking position and a blocking position and a micro-section movable between a full open position and a micro-position. When positioned in the full open position, the exhaustion space fully communicates the outlet end with the atmosphere, whereby full amount of airflow is exhausted from the outlet end to the atmosphere. When positioned in the micro-position, only a micro-amount of airflow is exhausted from the outlet end to the atmosphere.

Owner:JEN SIAN IND

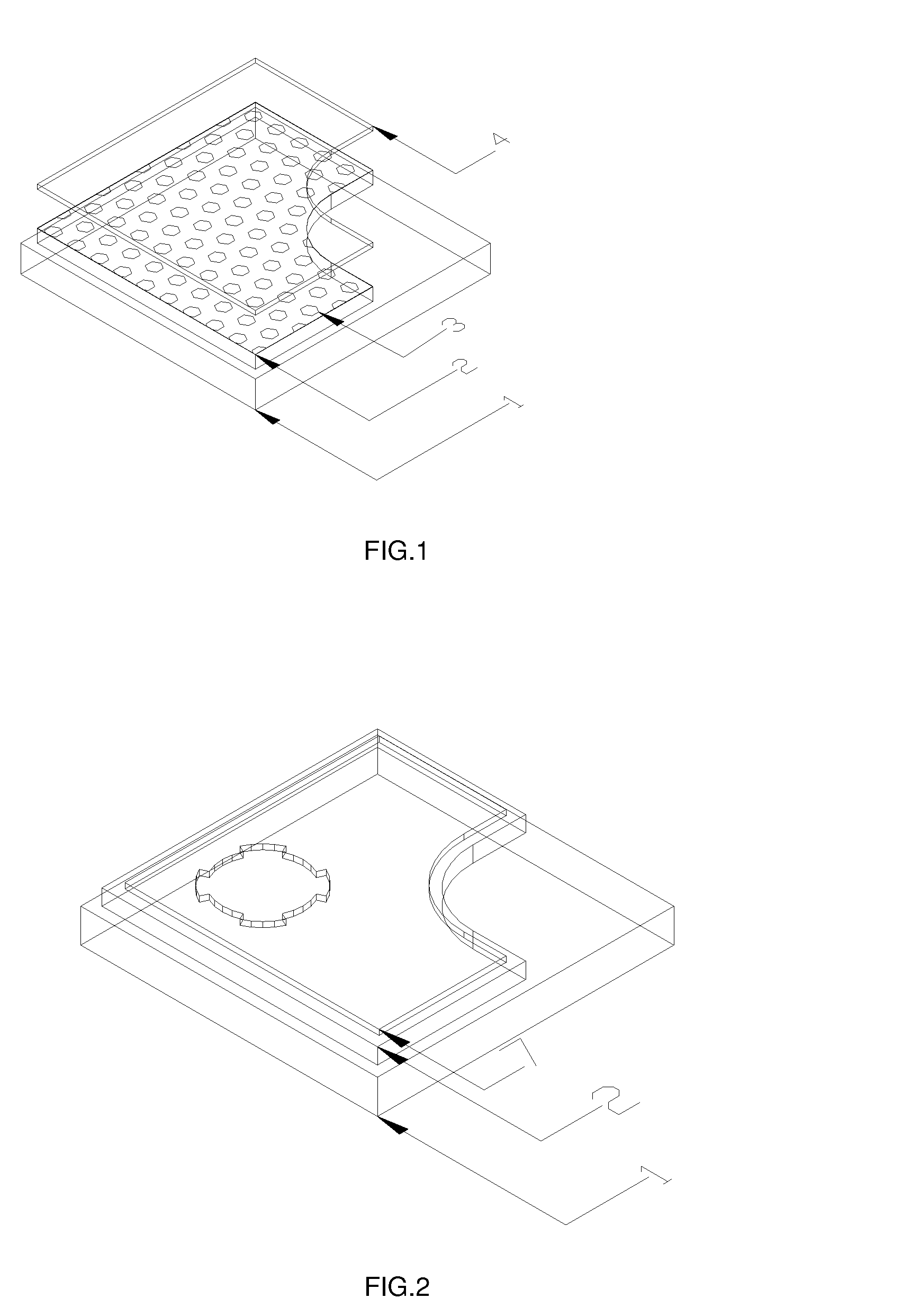

Multi-layer microporous membrane, battery separator and battery

InactiveUS8748028B2Improve balanceImprove electrochemical stabilitySemi-permeable membranesMembranesMolten stateHeat resistance

The invention relates to a particular multi-layer microporous membrane having a good balance of important properties, including excellent electrochemical stability and low heat shrinkage, while maintaining high permeability and heat resistance, with good mechanical strength, compression resistance and electrolytic solution absorption. Of particular importance when used as a battery separator, the present multi-layer microporous membrane exhibits excellent heat shrinkage, melt down temperature and thermal mechanical properties, i.e. low maximum shrinkage in the molten state. The multi-layer microporous membrane of the present invention is manufactured by layering, such as for example by coextrusion, one or more microporous membrane first layers and one or more microporous membrane second layers, such as on one or both sides of a first layer. The invention further relates to battery separators comprising the multi-layer microporous membrane and batteries utilizing the battery separators.

Owner:TORAY IND INC

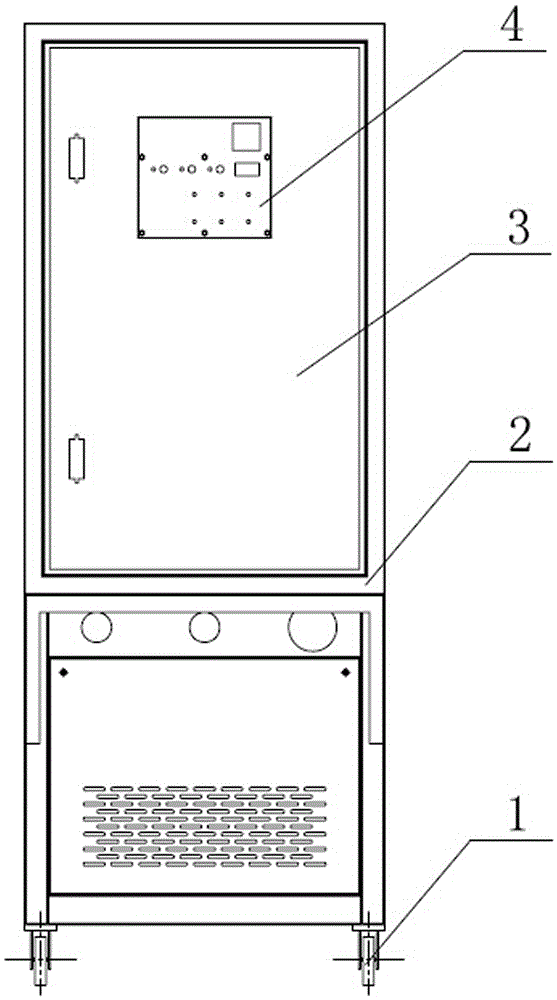

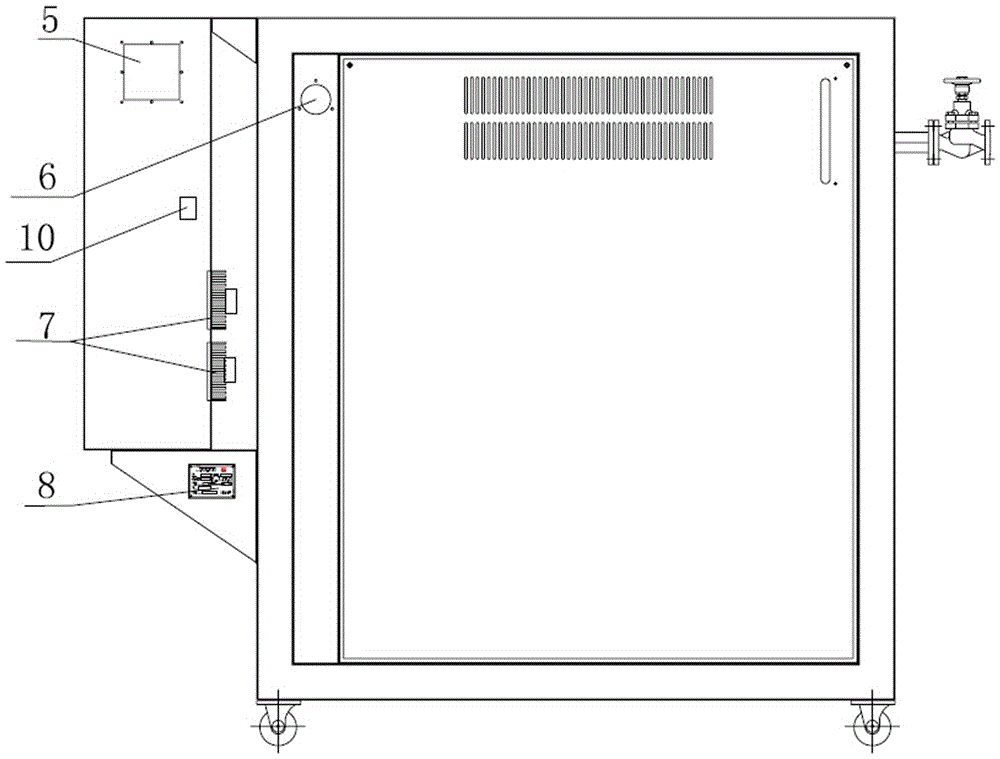

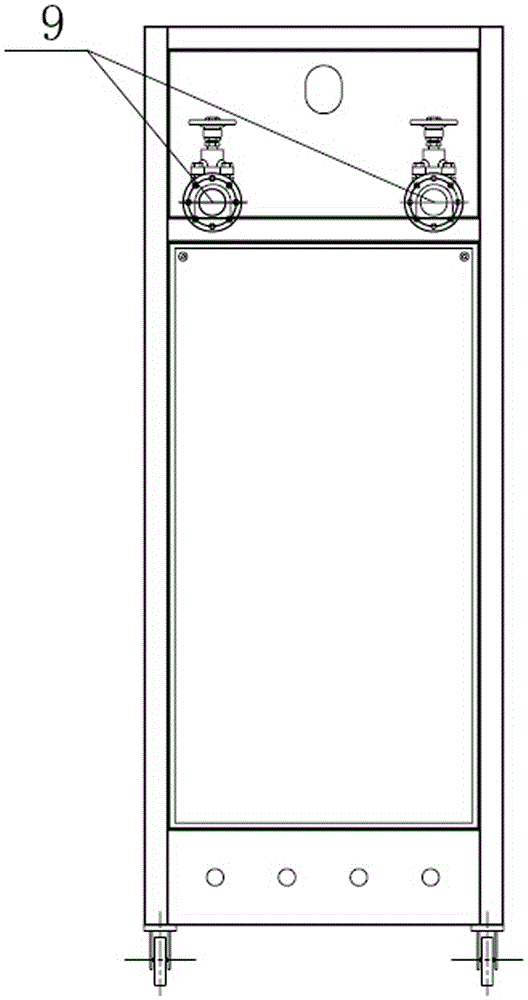

Temperature control equipment electric cabinet with external heat radiating device

ActiveCN105101760AAchieve constant temperature designImprove cooling effectCooling/ventilation/heating modificationsTemperature controlEngineering

The invention provides a temperature control equipment electric cabinet with an external heat radiating device. The temperature control equipment electric cabinet comprises a housing, a control panel which is fixed on the housing, heat radiating holes and a fan. The electric cabinet further comprises heat radiators. Each heat radiator comprises external heat radiating fins arranged at the back end of the housing, and heat radiating fans which are arranged on the heat radiating fins. According to the temperature control equipment electric cabinet with the external heat radiating device, heat is radiated through the heat radiating holes and the heat radiators simultaneously. Furthermore a heat radiating path is formed in and out the electric cabinet, thereby obtaining a better heat radiation effect. The heat radiators are furthermore connected with a temperature sensor in the electric control box. The rotating speed of the heat radiating fans can be adjusted according to the temperature in the cabinet, thereby realizing constant-temperature design of the electric cabinet. Furthermore the rotating speed of the heat radiating fans can be lowered for reducing energy consumption when the temperature in the electric cabinet is low.

Owner:深圳市奥兰特机械有限公司

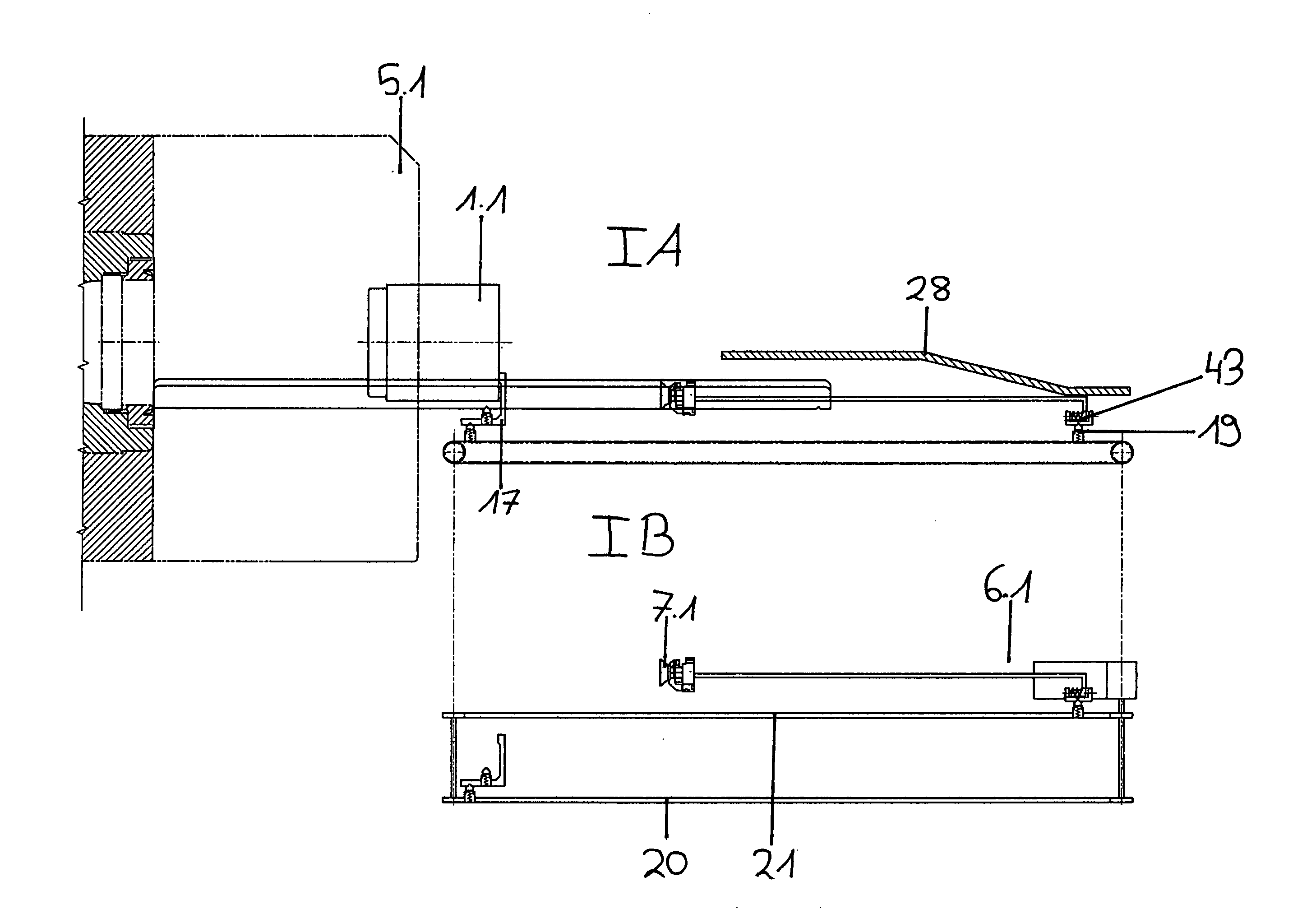

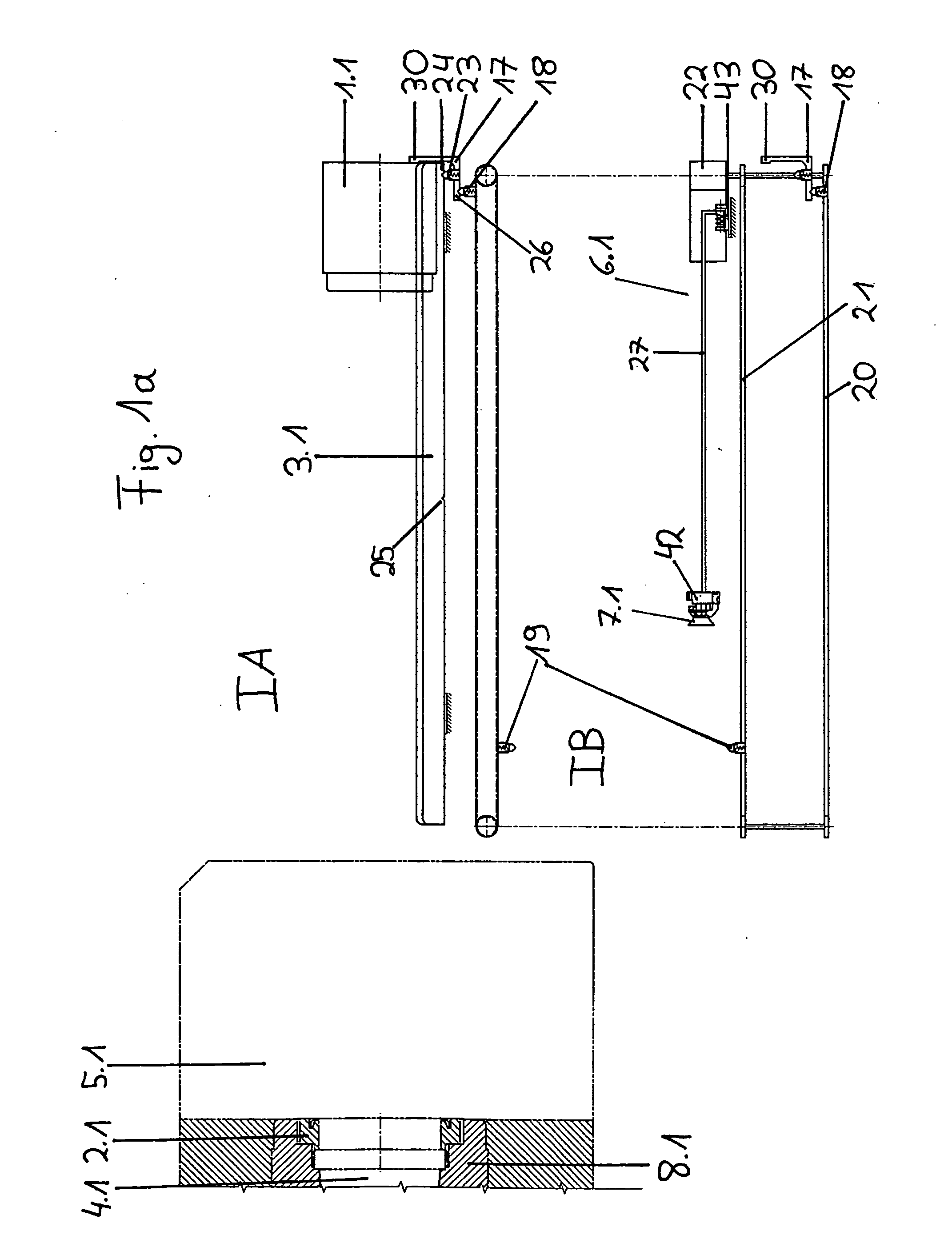

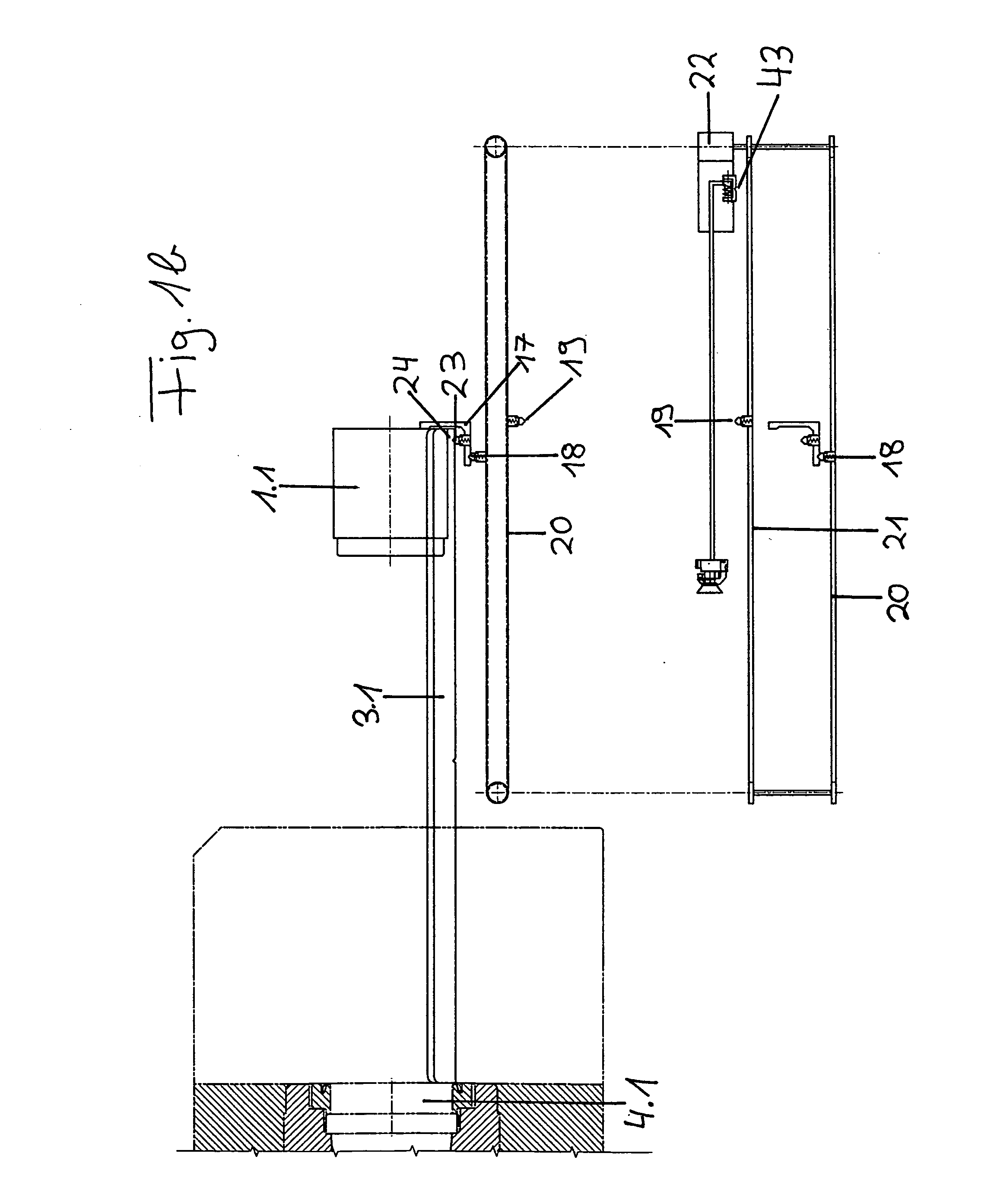

Propellant charge feed or supply means

InactiveUS20070113732A1Speed downCartridge extractorsAmmunition loadingINTRODUCTION devicePropellant

A propellant charge feed or supply system for automatic introduction of modular propellant charges into the weapon tube of a heavy weapon having a breech assembly and a propellant charge chamber in front of the breech assembly. An oblong propellant charge feed tray is pivotable into position behind the weapon tube such that propellant charges disposed on the propellant charge feed tray are disposed coaxial relative to the axis of the bore of the weapon tube. A providing device is adapted during a feed stroke to move the propellant feed tray into the breech assembly up to the propellant charge chamber. An introduction device is adapted during an introduction stroke to move the propellant charges from the feed tray into the propellant charge feed tray.

Owner:KRAUSS MAFFEI WEGMANN GMBH & CO KG

Method for Preparing High Shrinkage Rate PolytrimethyleneTerephthalate

ActiveUS20120316292A1Effectively arrangeSpeed downMonocomponent copolyesters artificial filamentChemistryPolymerization catalysts

A method for preparing high shrinkage PTT copolyester, comprising: adding starting raw materials into a reaction kettle and adding an esterification catalyst to carry out esterification reaction at 220° C.˜260° C. under 0.05˜0.30 MPa and completing the reaction when there being no water produced: adding polymerization catalyst into the reaction system and carrying out the polymerization reaction at 240° C.˜280°C. to get polytrimethylene terephthalate. The starting raw materials consists of 1,3-propylene glycol, terephtalic acid, a third monomer, a fourth monomer and a fifth monomer. The third monomer is selected from the group consisting of non-para aromatic dicarboxylic acid, 1,4-cyclohexane diformic acid and glutaric acid; The fourth monomer is selected from the group consisting of C3-C10 branched aliphatic dihydric alcohol, 1,4-cyclohexanedimethanol, diethylene glycol and triethyleneglycol; The fifth monomer is aliphatic polyalcohols which has carbon number between 3 and 10 and hydroxyl number per molecule is more than or equal to 3, or trimellitic anhydride, amount of the 1,3-propylene glycol, terephthalic acid, third monomer, fourth monomer and fifth monomer are such used in a molar ratio of carboxyl to hydroxyl is 1:1.16˜-1.85, wherein the amount of the third monomer used is 5%-10.5% of the total weight of the starting raw materials, the amount of the fourth monomer used is 0.05%-1.0% of the total weight of the starting raw materials, and the amount of the fifth monomer used is 50 ppm-600 ppm, based on the total weight of the starting raw materials. Polytrimethylene terephthalate prepared by the invention shows good spinning behaviour, of which the crystallization speed is noticeably lower than that of conventional polytrimethylene terephthalate, thus, fibers made of them has high boiling water shrinkage rate and ideal shrink property.

Owner:JIANGSU ZHONGLU TECH DEV

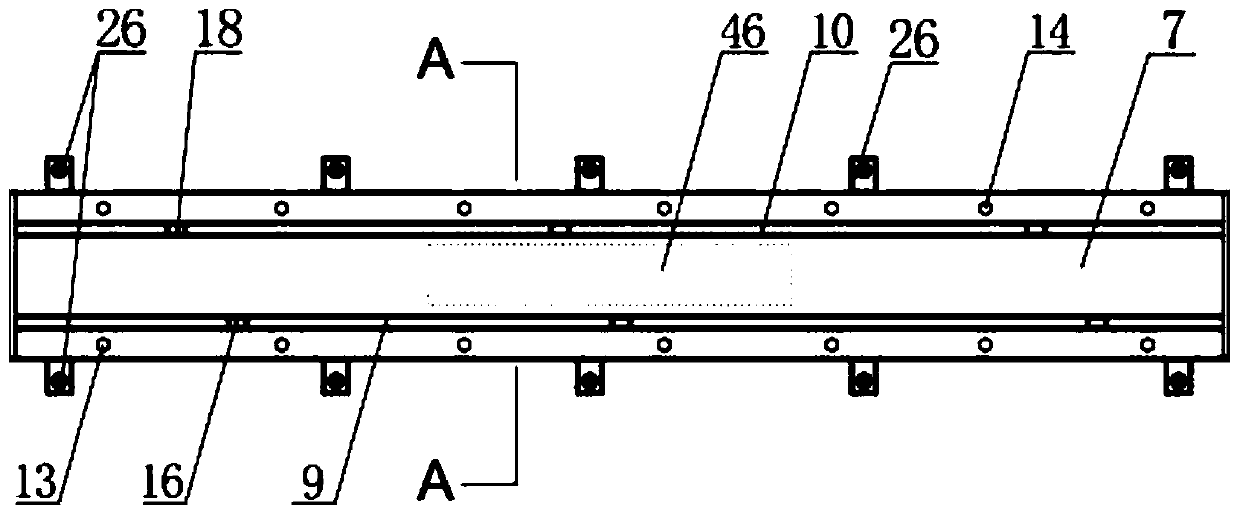

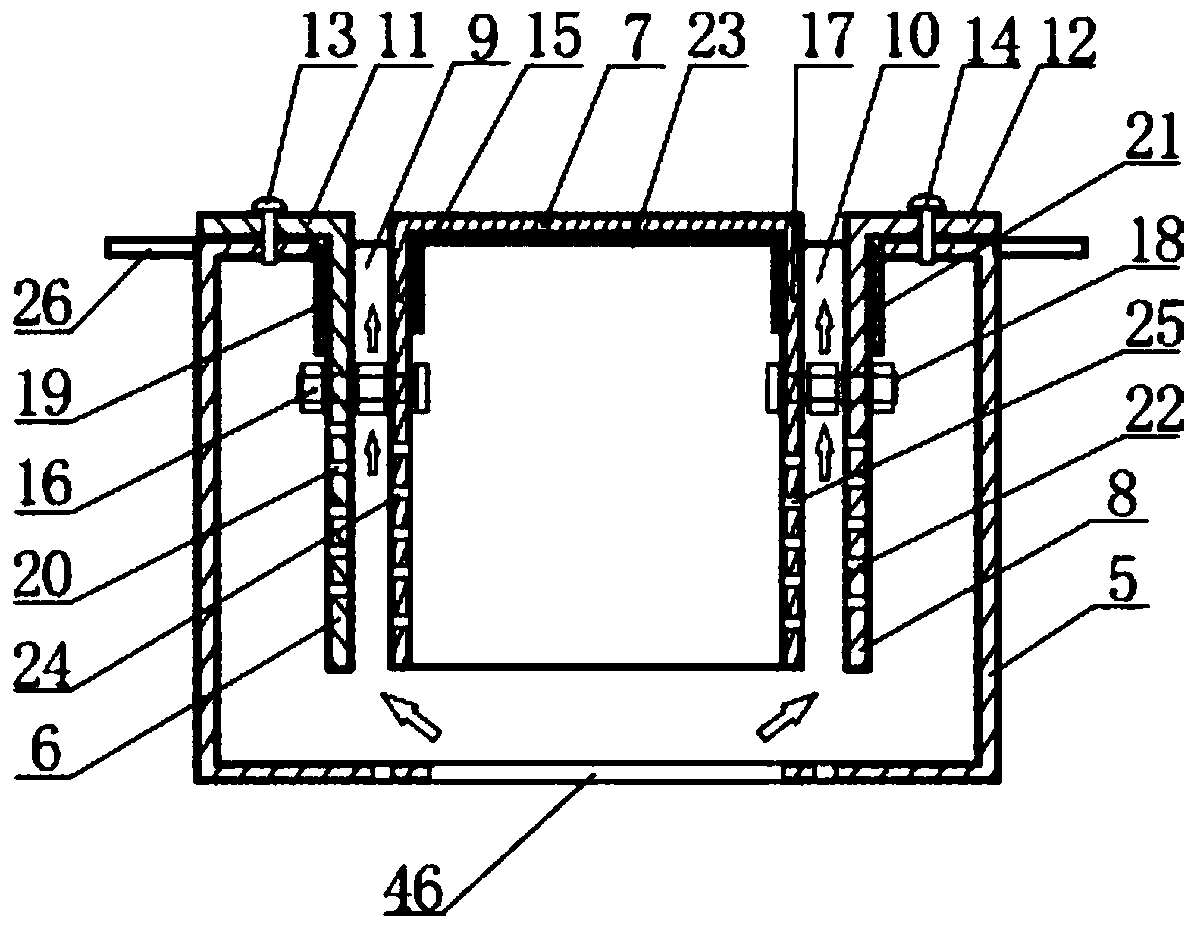

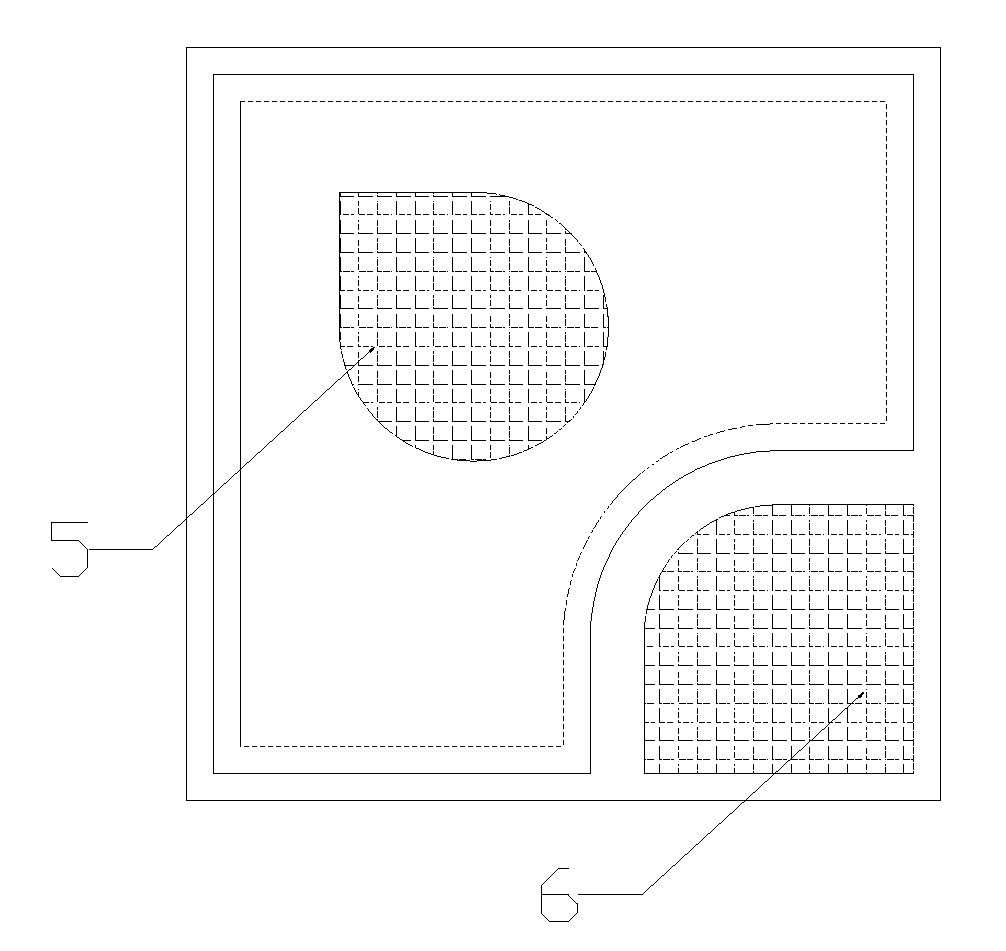

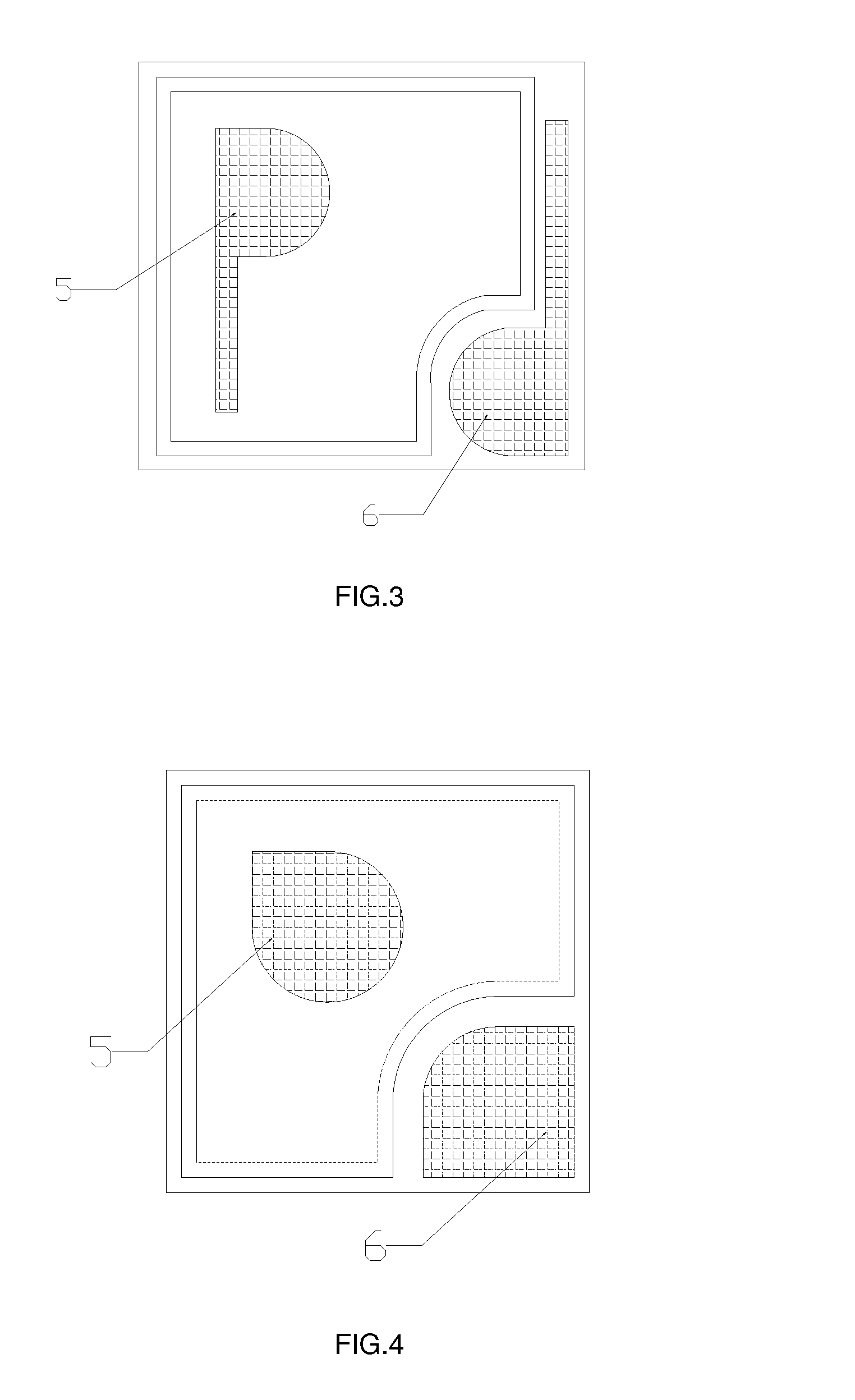

Parallel gap type air curtain isolating system

PendingCN111578437AEasy to filterWind powerMechanical apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a parallel gap type air curtain isolating system comprising an air supplying device, an air curtain device and an air collecting device. The air supplying device supplies air into the air curtain device. Air discharged by the air curtain device is blown to the air collecting device. The air curtain device comprises an outer groove, a longitudinal deflector A, a U-shaped deflector and a longitudinal deflector B. The groove bottom of the outer groove is provided with an air inlet. The longitudinal deflector A, the U-shaped deflector and the longitudinal deflector B are installed in the outer groove. The gap between the U-shaped deflector and the longitudinal deflector A is an air outlet A, and the gap between the U-shaped deflector and the longitudinal deflector B isan air outlet B. Because the air curtain device adopts the structure of two adjacent parallel gap type air outlets, a formed wind curtain is thicker than a single gap; the two wind curtains can be squeezed by the outside air and are gradually closer to each other and narrower, which is beneficial to filtering treatment of an air collector; the airflow inside the two wind curtains can disturb eachother and accelerate; and the air curtain device forms a complete wind curtain, and then a good air blocking effect is achieved.

Owner:广州市鑫湖能源科技有限公司

Method for producing gallium nitride light emitting diode wafer

InactiveUS20070254395A1Improve conductivityContact impedance is reducedSemiconductor/solid-state device manufacturingSemiconductor devicesContact impedanceGallium nitride

The present invention relates to a method for improving the performance of P-type ohmic contact of gallium nitride LED wafer. Magneto sputtering is used to spray nickel material in nano particles onto the surface of gallium nitride epitaxial layer. The thickness of nickel is between 1 nm to 100 nm. Following that, at least one layer of high work function metal film is deposited onto the surface of the nickel metal layer, and the ratio of the thickness of the nickel metal layer to that of high work function metal film is 1:0.5˜4. Zinc oxide may replace nickel metal layer and high work function metal film. The object of the present invention is to simultaneously reduce the contact impedance of P-type luminous zone and enhance the traverse of electric current, thereby attaining an eventual equilibrium of contact impedance and luminous efficiency and thus increasing the life span of the wafer. The present invention prescribes the thickness ratio for each contact metal layer, the conditions of thermal treatment and the unique design patterns for electrodes. Experiments prove that the present invention is able to control the decay of light intensity of gallium nitride LED in 1000 hours to less than 10% with good thermal stability and contact impedance being reduced to 2E-6 Ω-cm2.

Owner:PODIUM PHOTONICS GUANGZHOU

Method for modifying the flavor profile of a plant protein preparation

ActiveUS20100092654A1Process economyStrong flavorProtein composition from vegetable seedsVegetable proteins working-upFlavorWater soluble

A method for modifying the flavor profile of a plant protein preparation, especially a protein preparation from a leguminous plant. The protein preparation is brought into contact with water-soluble carbohydrates in an aqueous solution before being added to a food product, the contact advantageously influencing the flavor profile of protein preparations from leguminous plant, so that the preparations can be used in foodstuffs without essentially changing the flavor thereof.

Owner:PROLUPIN GMBH

Venturi tube assembly and manual/pneumatic pump including the venturi tube assembly

A Venturi tube assembly includes: a Venturi tube having a body section with an inlet end, an outlet end and an internal flow passage between the inlet end and the outlet end, a pneumatic sucking passage outward extending from a low static pressure section of the internal flow passage to an outer circumference of the body section; and a blocking member having an exhaustion space for communicating the outlet end with the atmosphere, a blocking body movable between an unblocking position and a blocking position and a micro-section movable between a full open position and a micro-position. When positioned in the full open position, the exhaustion space fully communicates the outlet end with the atmosphere, whereby full amount of airflow is exhausted from the outlet end to the atmosphere. When positioned in the micro-position, only a micro-amount of airflow is exhausted from the outlet end to the atmosphere.

Owner:JEN SIAN IND

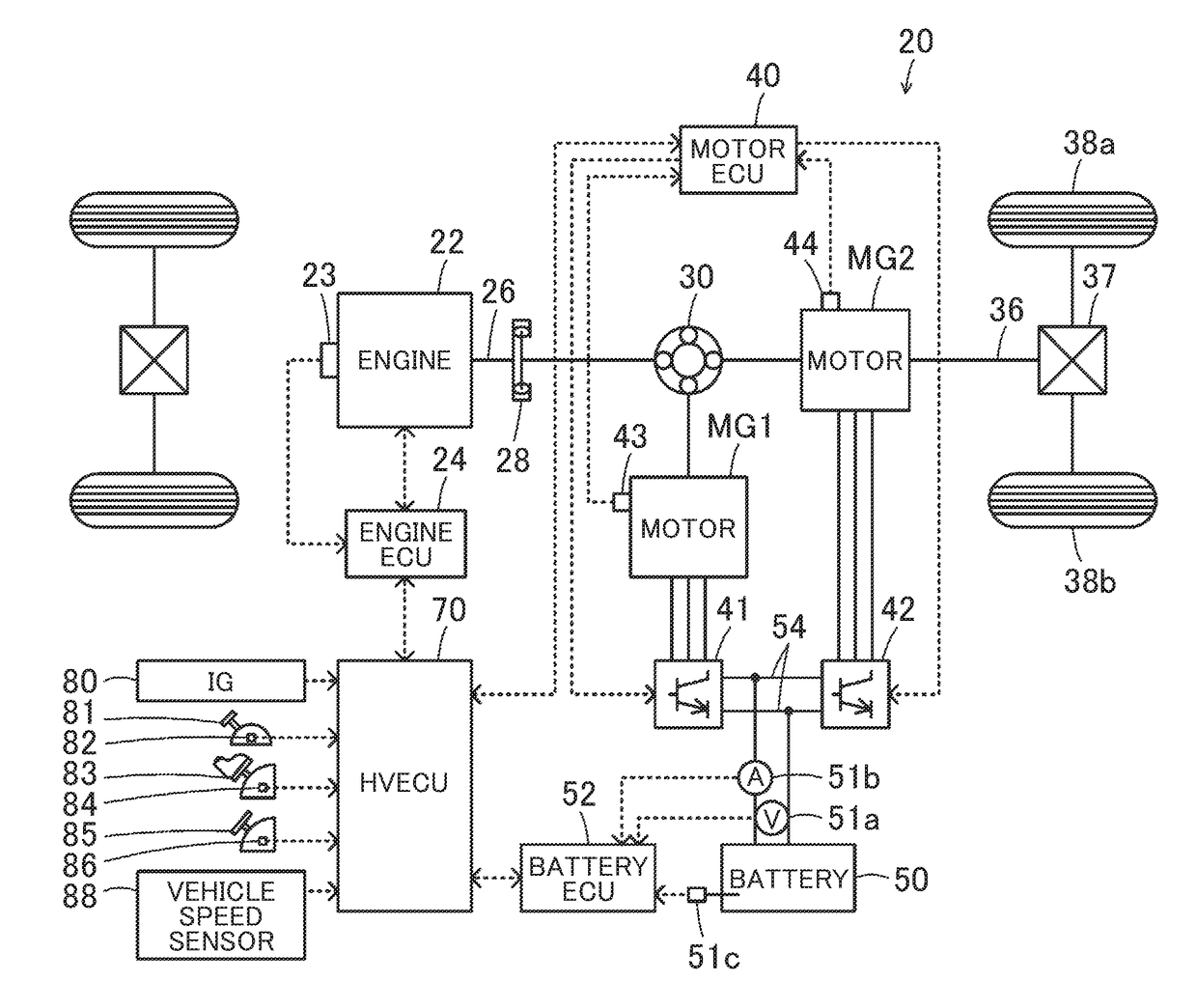

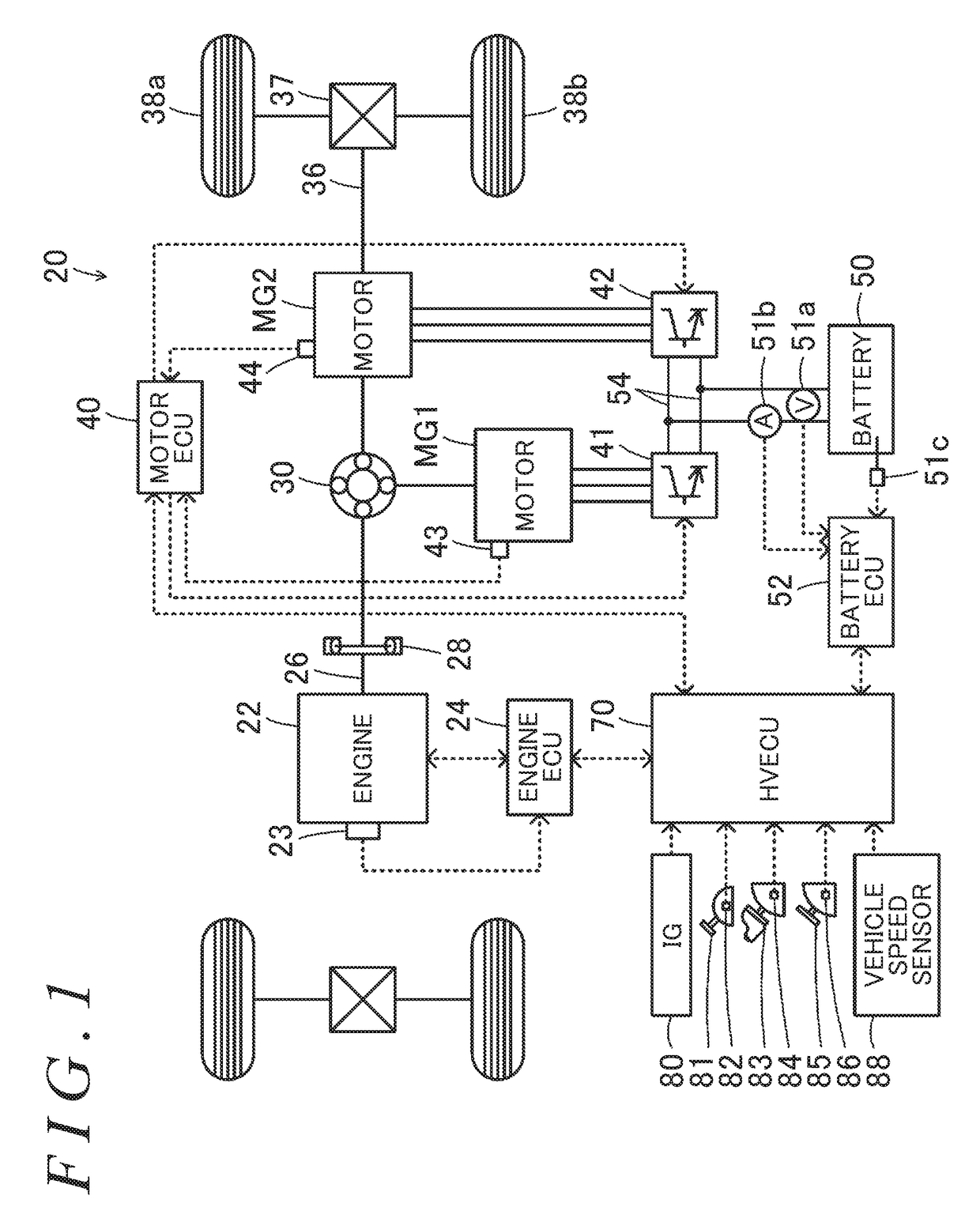

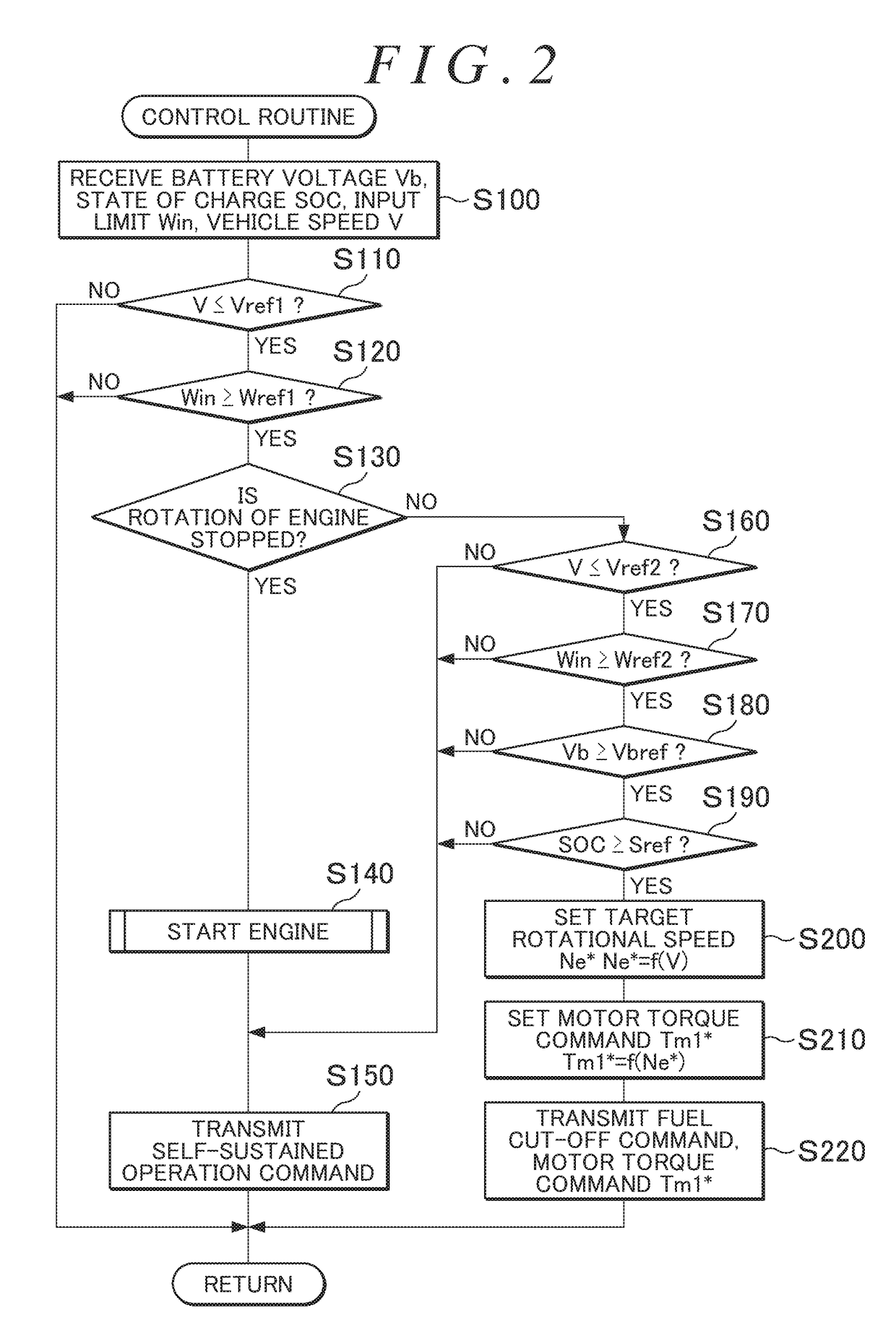

Hybrid vehicle

ActiveUS9919695B2Keep for a long timeImprove powerHybrid vehiclesGas pressure propulsion mountingHybrid electrical vehicleControl theory

In a hybrid vehicle, an electronic control unit is configured to: control an engine such that the engine is started and a self-sustained operation is performed in a case where i) torque for forward traveling is output from a second motor, ii) sliding down of the vehicle is tentatively detected before the sliding down is detected, and iii) permissible charge electric power is equal to or smaller than first prescribed electric power and rotation of the engine is in a stopped state; and execute drive control such that fuel injection is stopped and the engine is driven by a first motor at a rotational speed larger than that before the sliding down is detected in a case where i) the sliding down is detected thereafter and ii) the permissible charge electric power is equal to or smaller than second prescribed electric power.

Owner:TOYOTA JIDOSHA KK

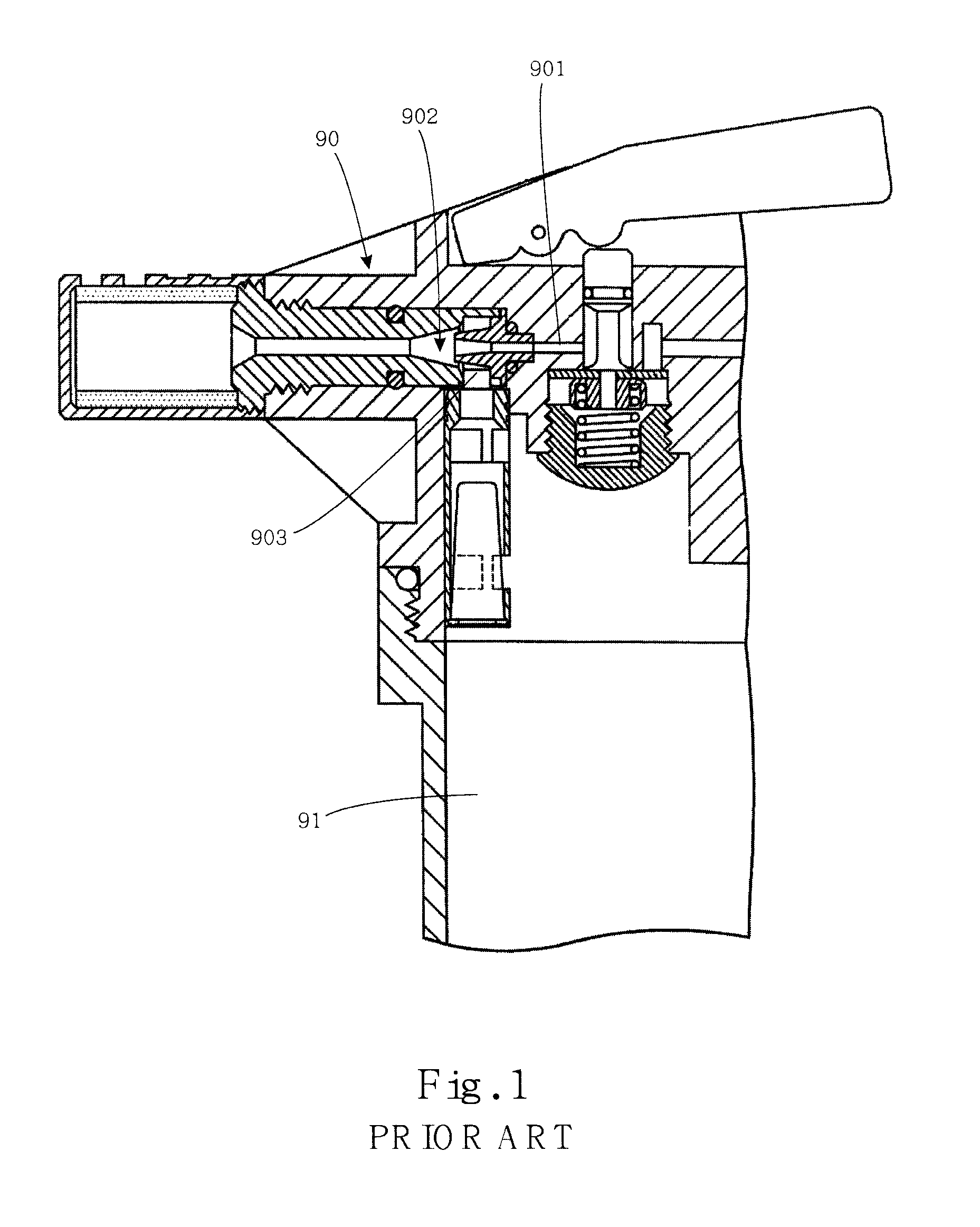

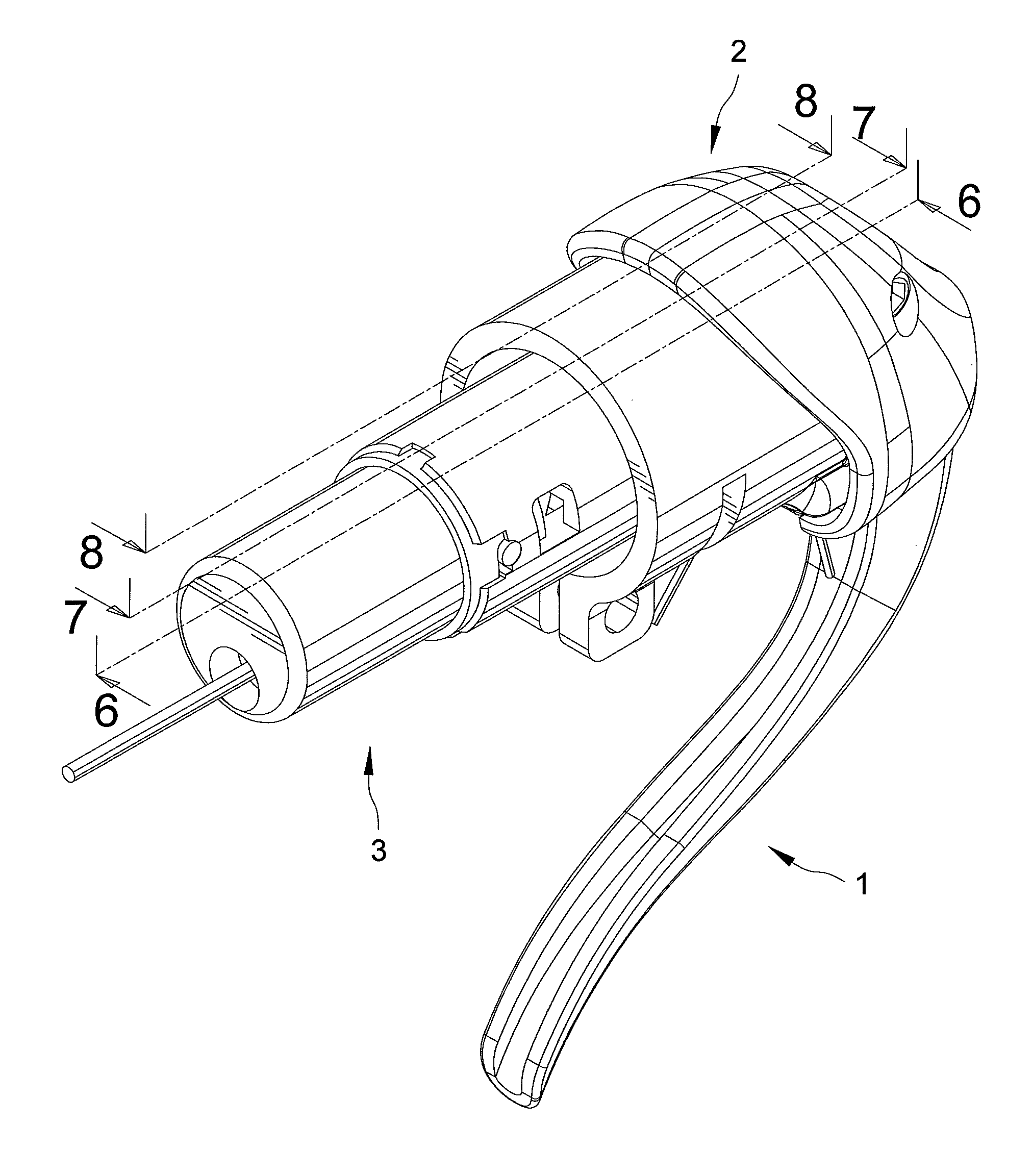

Shift control device for bicycle

InactiveUS8033198B2Easy to operateSpeed downCycle control systemsShaft for linear movementEngineeringElectrical and Electronics engineering

A shift control device includes a shift-up control apparatus, a shift-down control apparatus and a transmission control assembly. The shift-up control apparatus includes an operable shift-up controller, a first link member connected with the shift-up controller and a first pawl pivotally mounted on the first link member. The shift-down control apparatus includes an operable shift-down controller and a second link member connected with the shift-down controller. The second link member includes first and second actuating members. The transmission control assembly includes a locking member, a housing assembly and first and second pawls. The locking member is moveable in the housing at various positions for various bicycle speed transmissions and includes first and second engaging sections. The first engaging section is selectively engaged by the first pawl of the shift-up control apparatus and the second engaging section is selectively engaged by the first and second pawls of the transmission control assembly.

Owner:TIEN HSIN INDS

System and methods for using a dynamic scheme for radiosurgery

ActiveUS8654923B2Reduced dose rateTreatment procedure is very comfortableDiagnosticsComputer-aided planning/modellingDose paintingHigh doses

The present invention is a method and system for developing a dynamic scheme for Gamma Knife radiosurgery based on the concept of “dose-painting” to take advantage of robotic patient positioning systems on the Gamma Knife C and Perfexion units. The spherical high dose volume created by the Gamma Knife unit will be viewed as a 3D spherical “paintbrush”, and treatment planning is reduced to finding the best route of this “paintbrush” to “paint” a 3D tumor volume. Under the dose-painting concept, Gamma Knife radiosurgery becomes dynamic, where the patient is moving continuously under the robotic positioning system.

Owner:RGT UNIV OF CALIFORNIA +1

Dome cover, camera device, injection molding die, and injection molding method

ActiveUS20180017851A1Suppress generationSpeed downCamera filtersDomestic articlesCurve shapeEngineering

The invention provides a dome cover, a camera device, an injection molding die, and an injection molding method in which generation of a weldline is suppressed and deterioration of an acquired image is suppressed. In one aspect of the invention, a dome cover is a dome cover that covers a camera. The dome cover includes a curved section having a curved shape and a skirt section having a cylinder shape and has a top section at the curved section and an opening end section at the skirt section. The thickness of the dome cover is largest at the top section and smallest at the opening end section, and continuously decreases from the top section toward the opening end section. The inner diameter and the outer diameter of the dome cover continuously increase from the top section toward the opening end section.

Owner:FUJIFILM CORP

Multi-layer microporous membrane, battery separator and battery

ActiveUS8323821B2Improve balanceImprove electrochemical stabilityMembranesSemi-permeable membranesMolten stateHeat resistance

Owner:TORAY IND INC

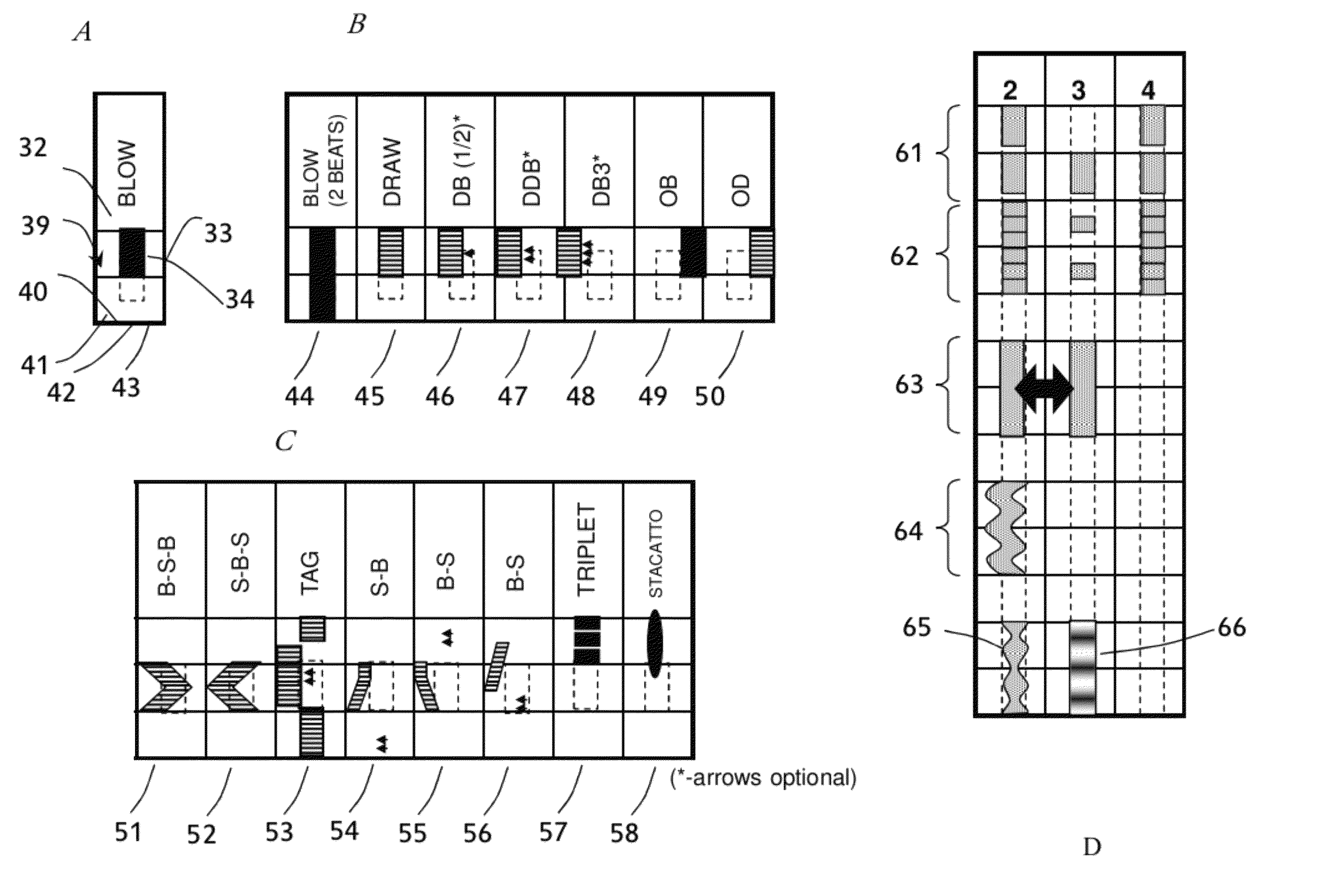

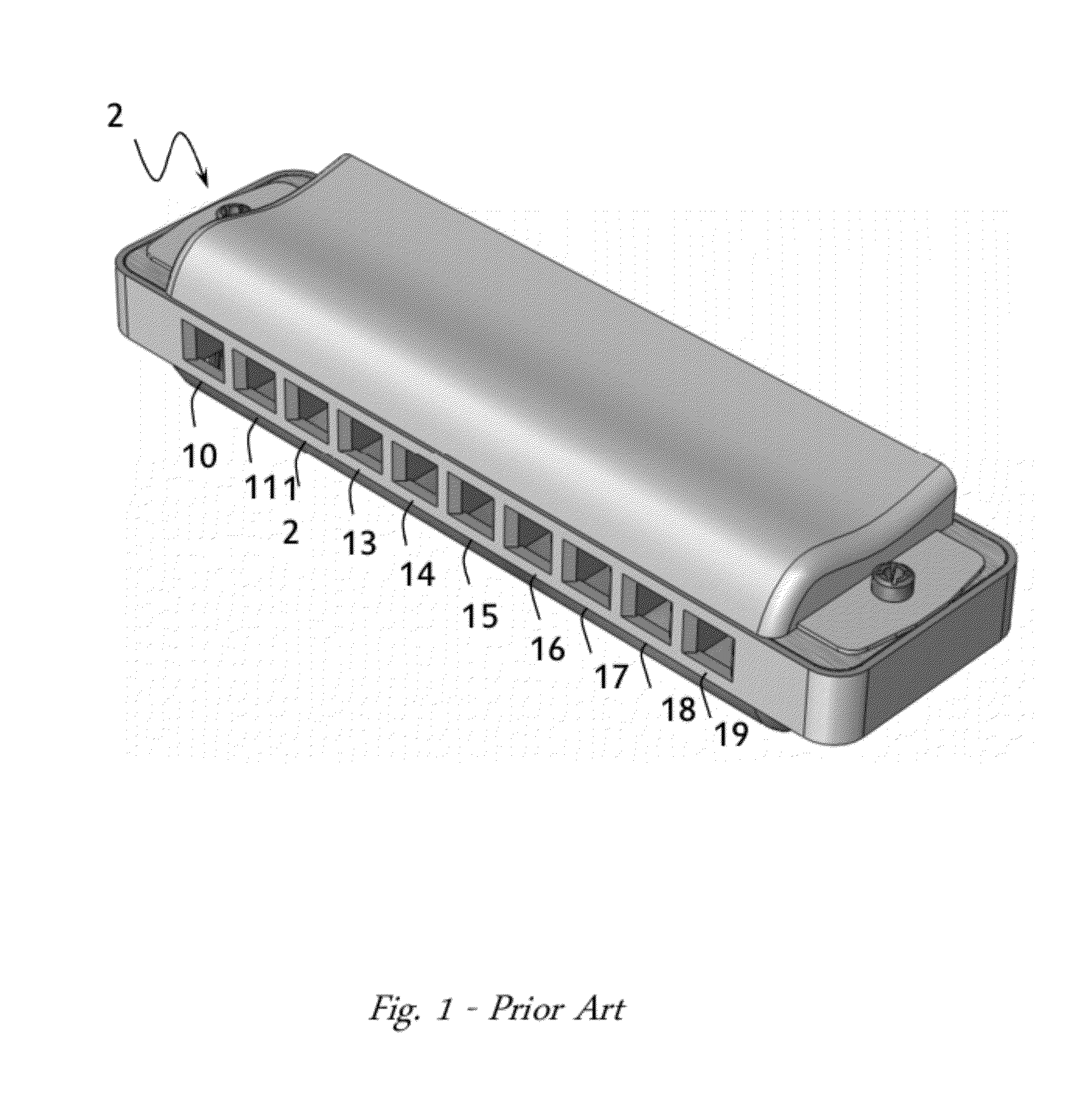

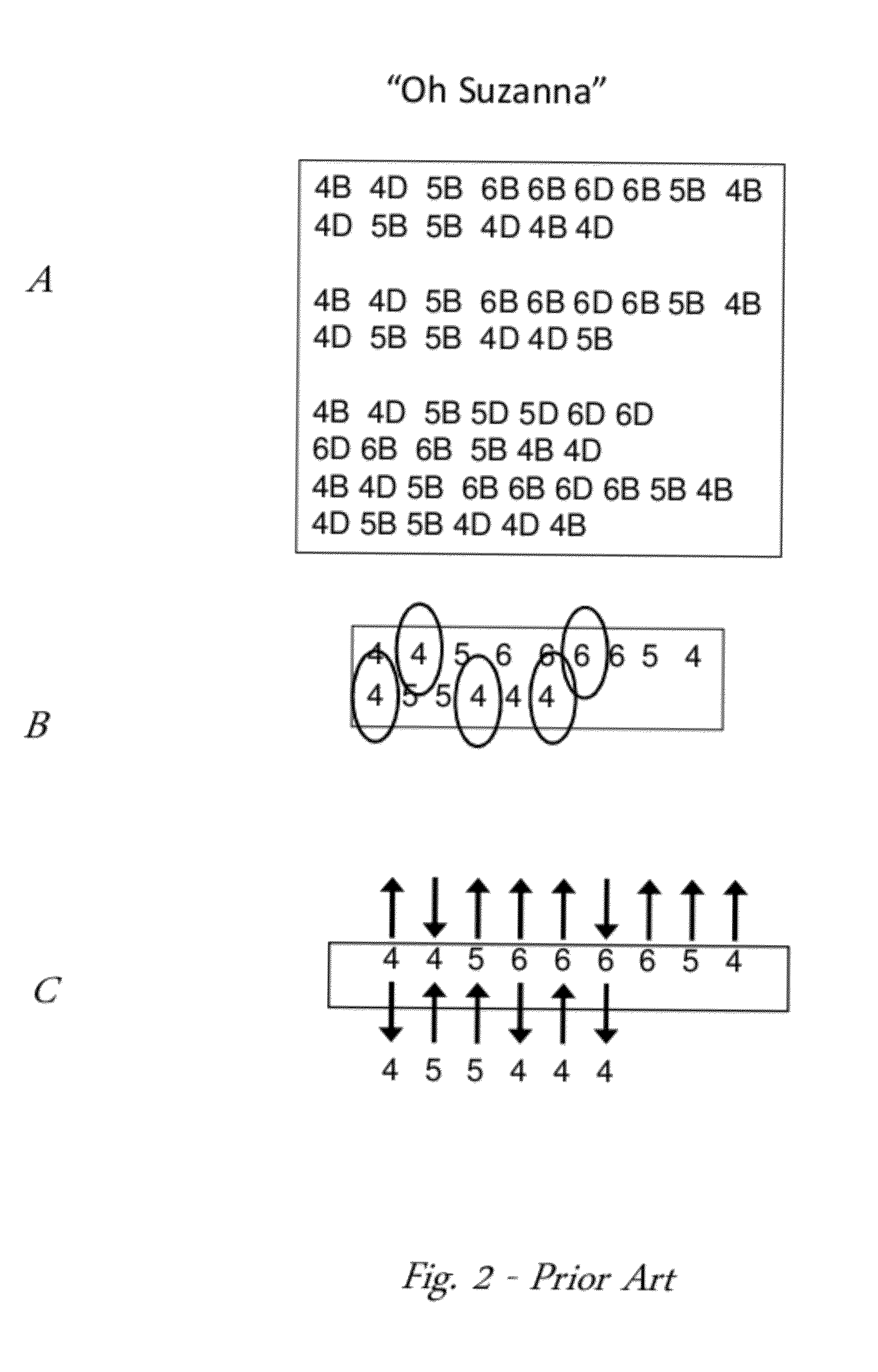

Musical notation and method of teaching same

The invention provides an apparatus and method for notating music for a harmonica. The apparatus incorporates a vertical staff in which vertical lines or tracks represent individual notes, the length of which represents duration of the note, and the horizontal location represents the physical location of the corresponding hole in a harmonica. The invention provides a rapid means of learning to play a harmonica and, for experienced players, provides a means for sight reading a new piece of music. The invention further provides ways of representing the dynamics of both pitch and loudness and a convenient way to manually transcribe musical selection for archival purposes.

Owner:ANTAKAMATICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com