Patents

Literature

241results about How to "Same speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

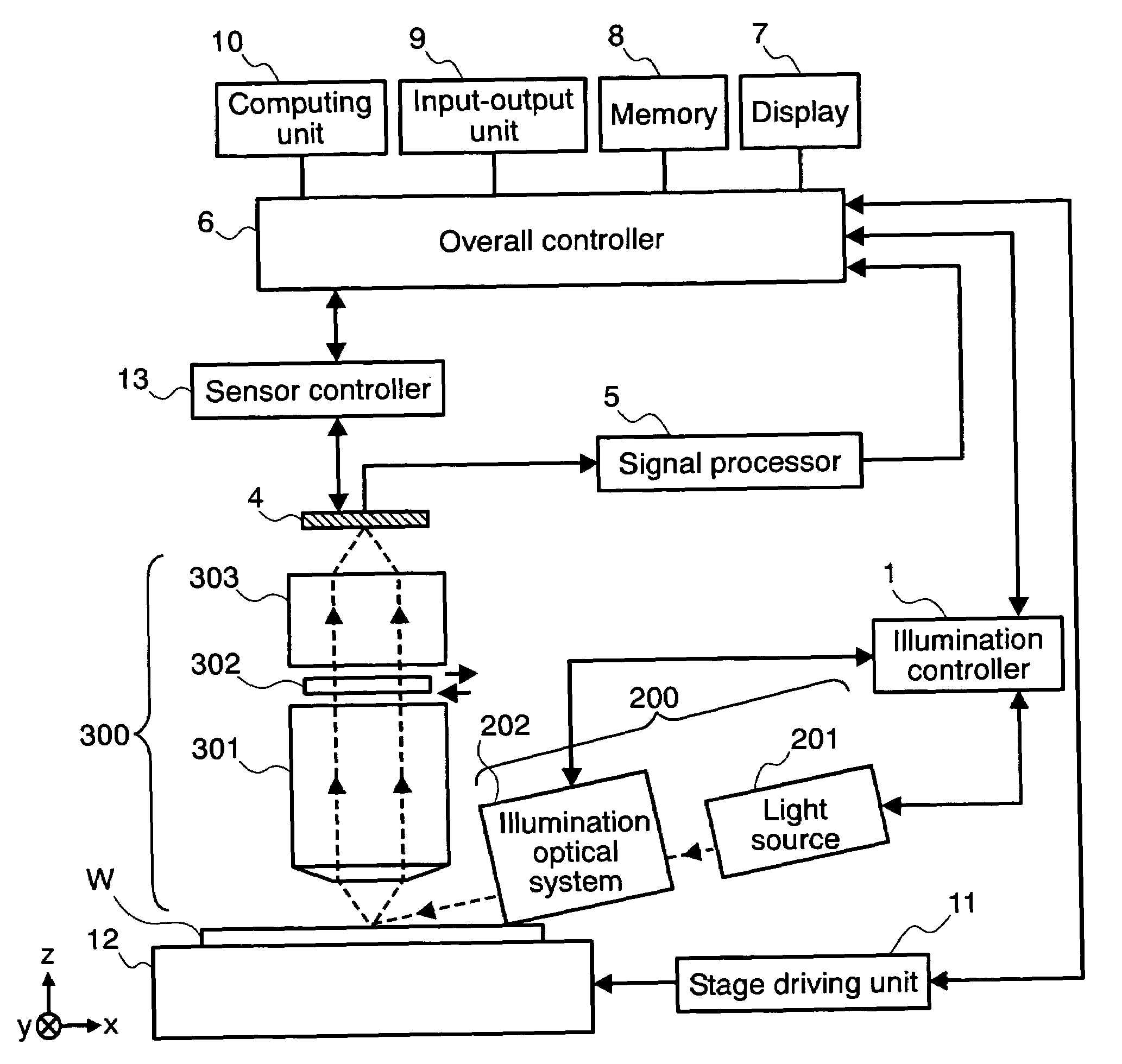

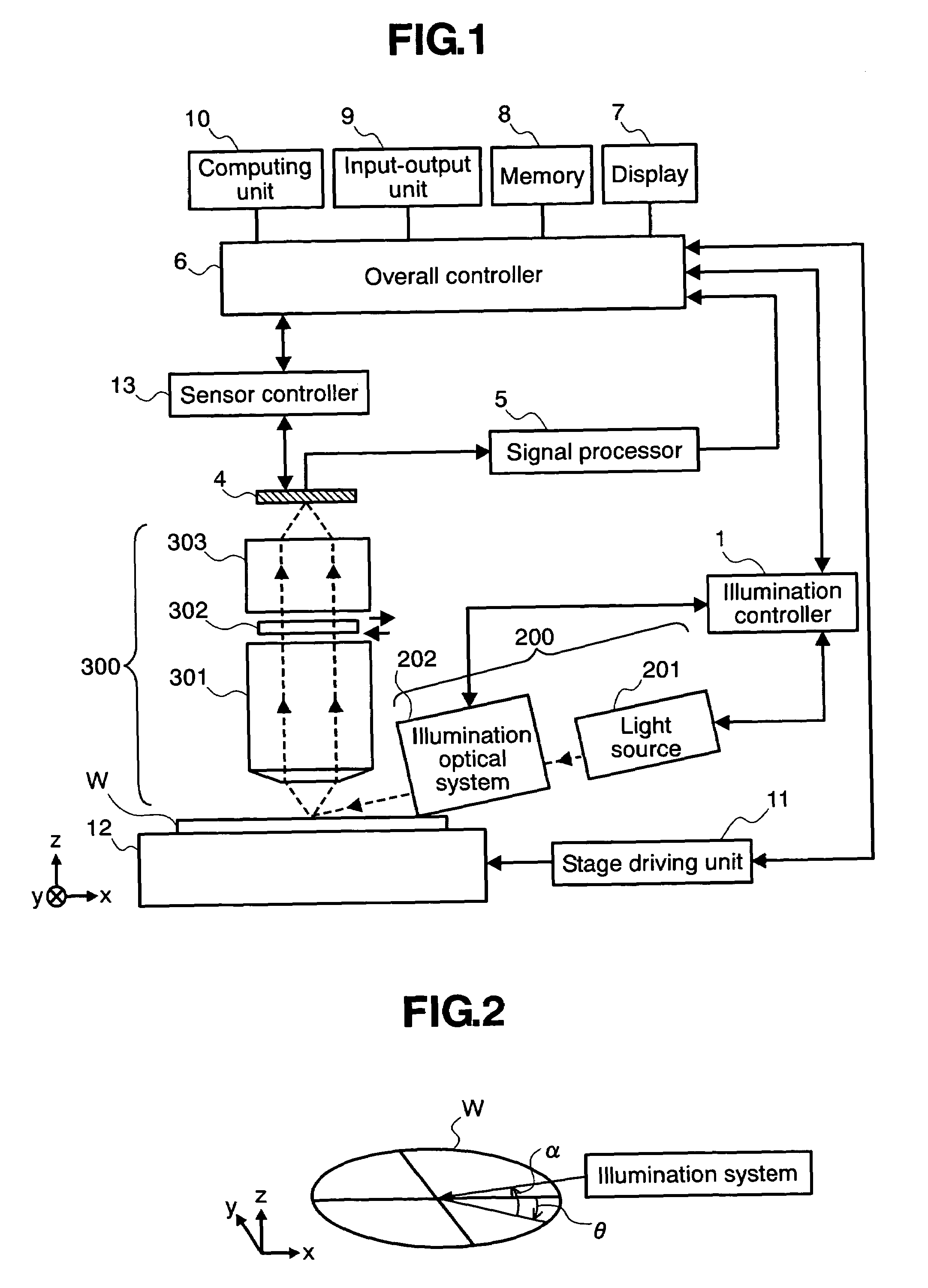

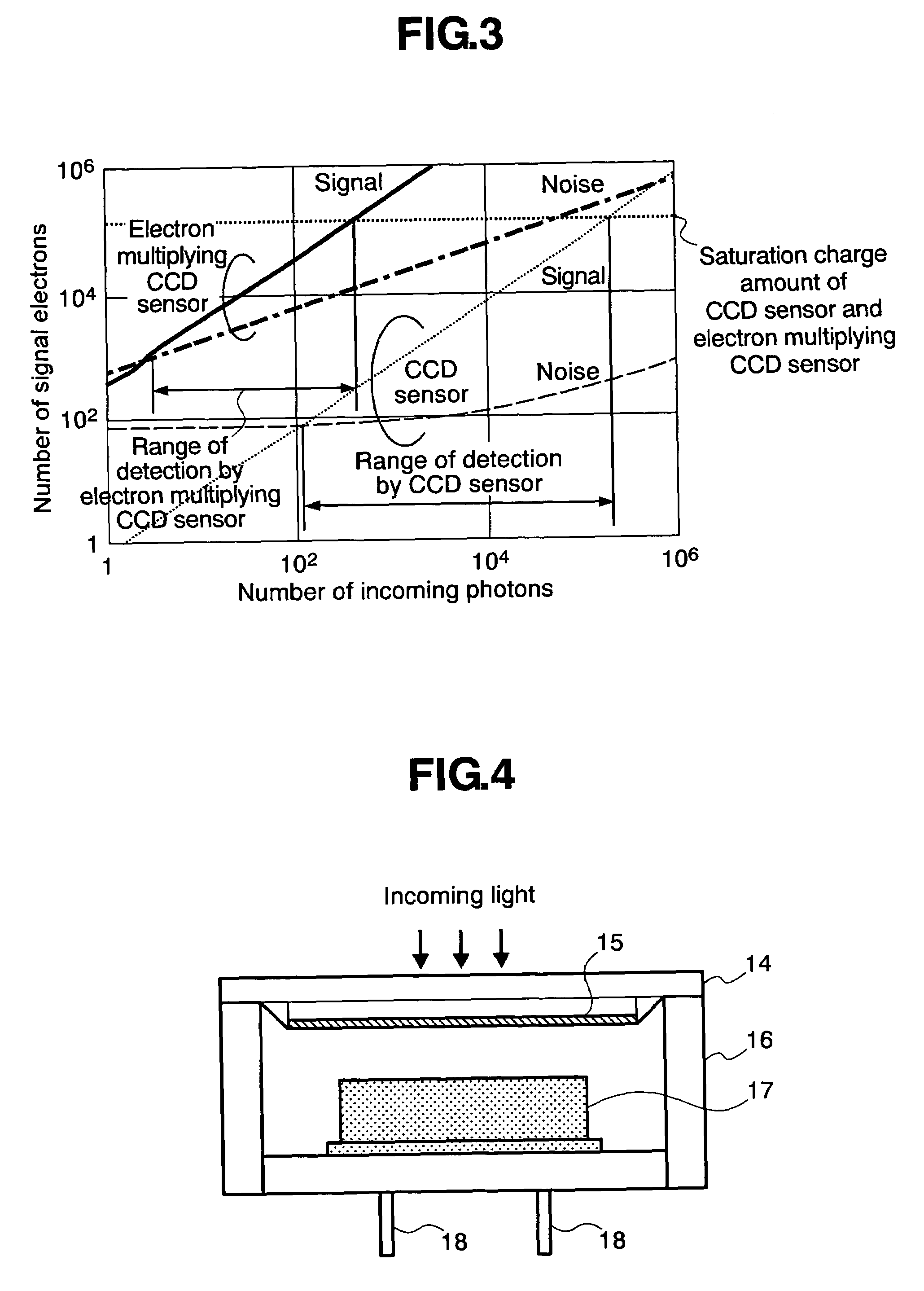

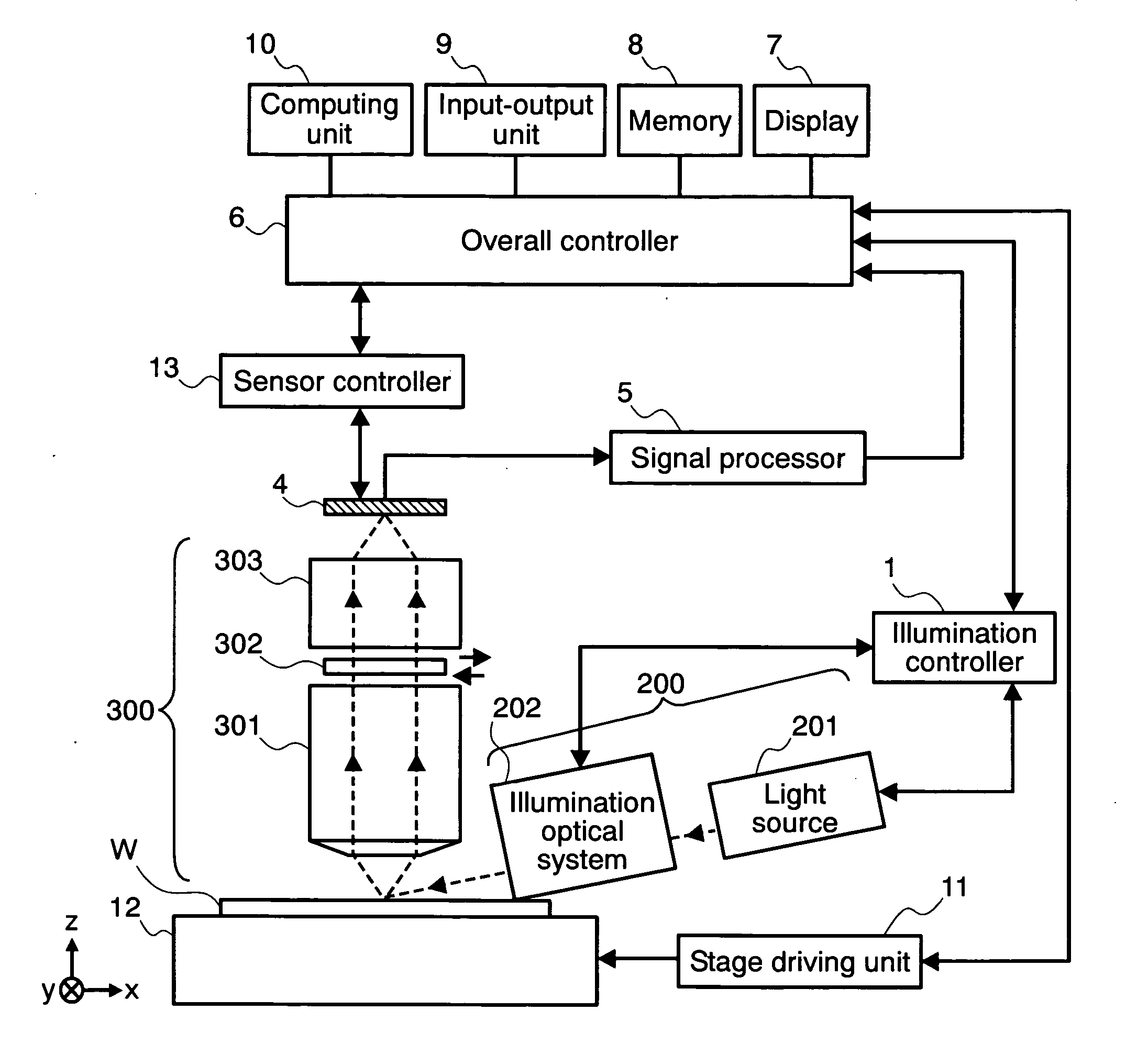

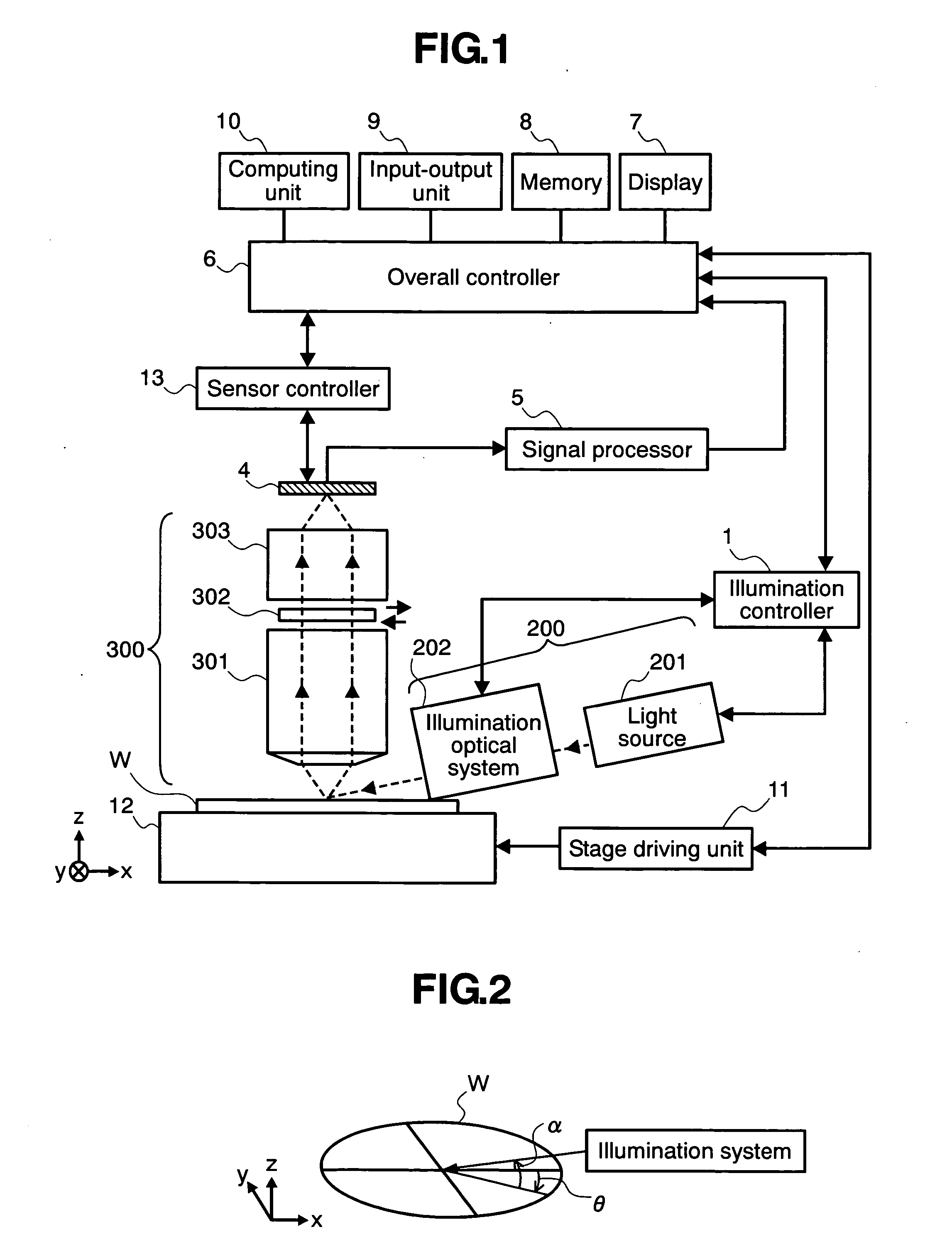

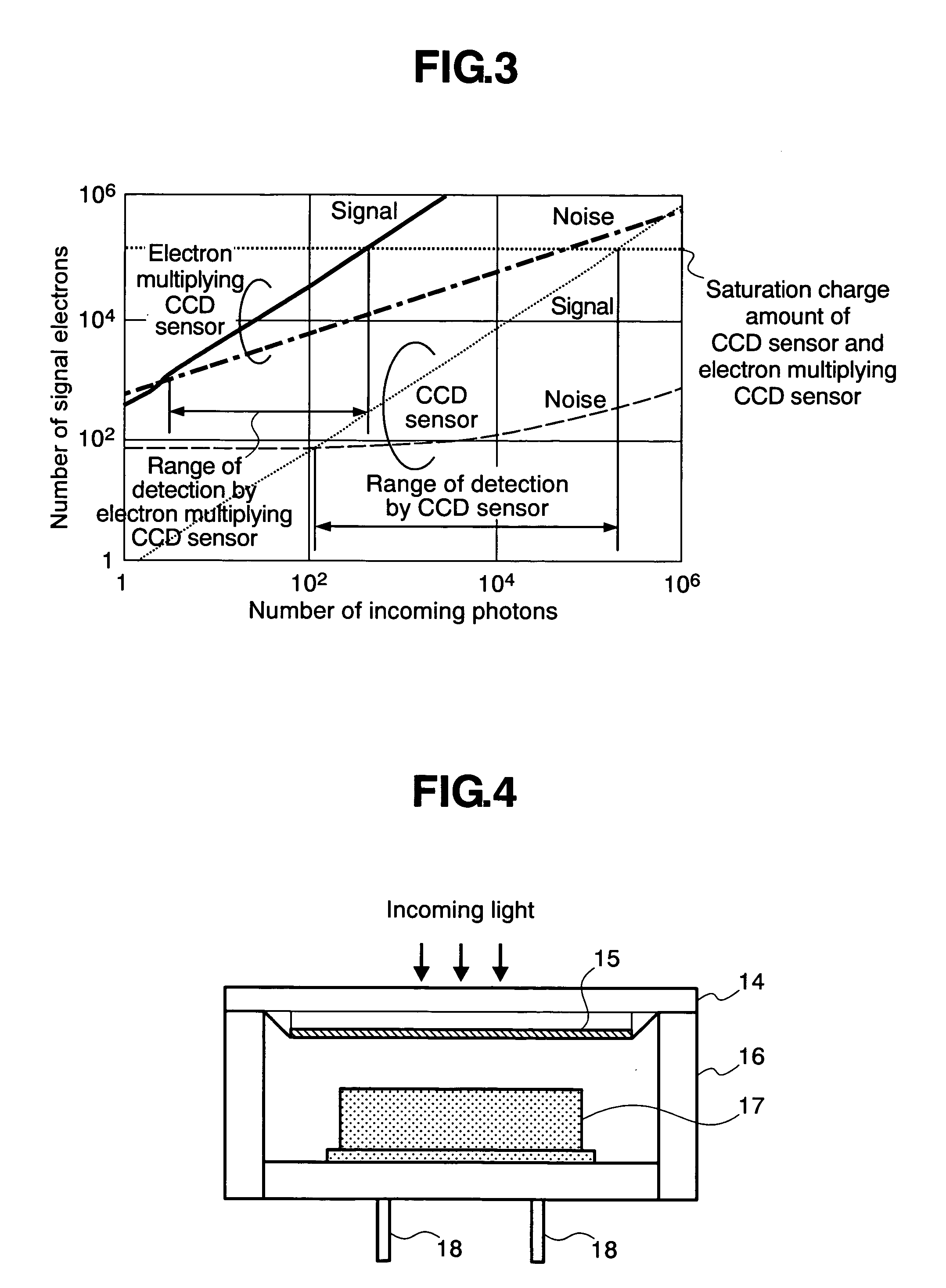

Method for inspecting pattern defect and device for realizing the same

InactiveUS7465935B2Sensitive highSame speedTelevision system detailsSemiconductor/solid-state device testing/measurementElectricityForeign matter

When using a CCD sensor as a photo-detector in a device for inspecting foreign matters and defects, it has a problem of causing electric noise while converting the signal charge, produced inside by photoelectric conversion, into voltage and reading it. Therefore, the weak detected signal obtained by detecting reflected and scattered light from small foreign matters and defects is buried in the electric noise, which has been an obstacle in detecting small foreign matters and defects. In order to solve the above problem, according to the present invention, an electron multiplying CCD sensor is used as a photo-detector. The electron multiplying CCD sensor is capable of enlarging signals brought about by inputted light relatively to the electric noise by multiplying the electrons produced through photoelectric conversion and reading them. Accordingly, compared to a conventional CCD sensor, it can detect weaker light and, therefore, smaller foreign matters and defects.

Owner:HITACHI HIGH-TECH CORP

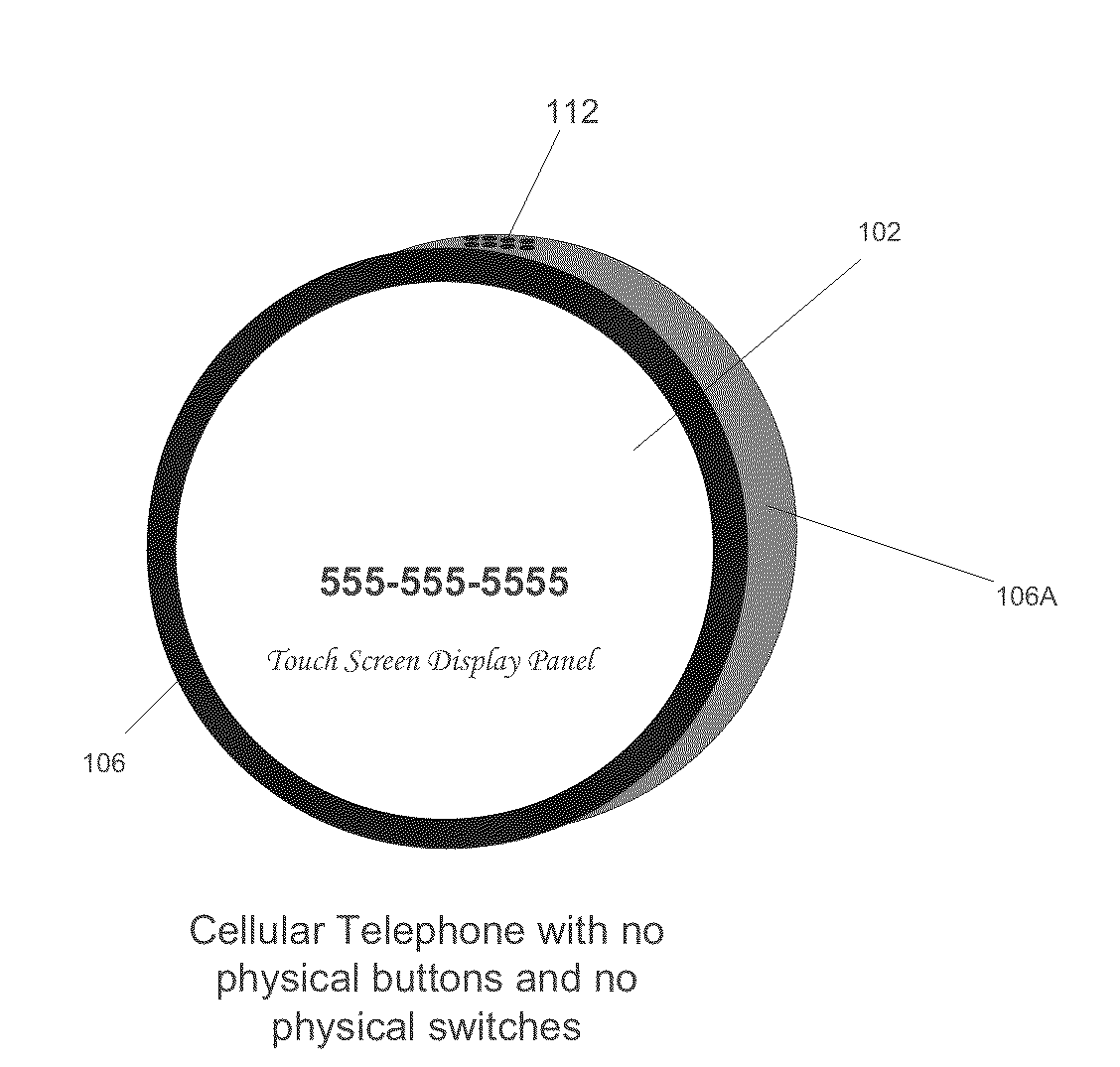

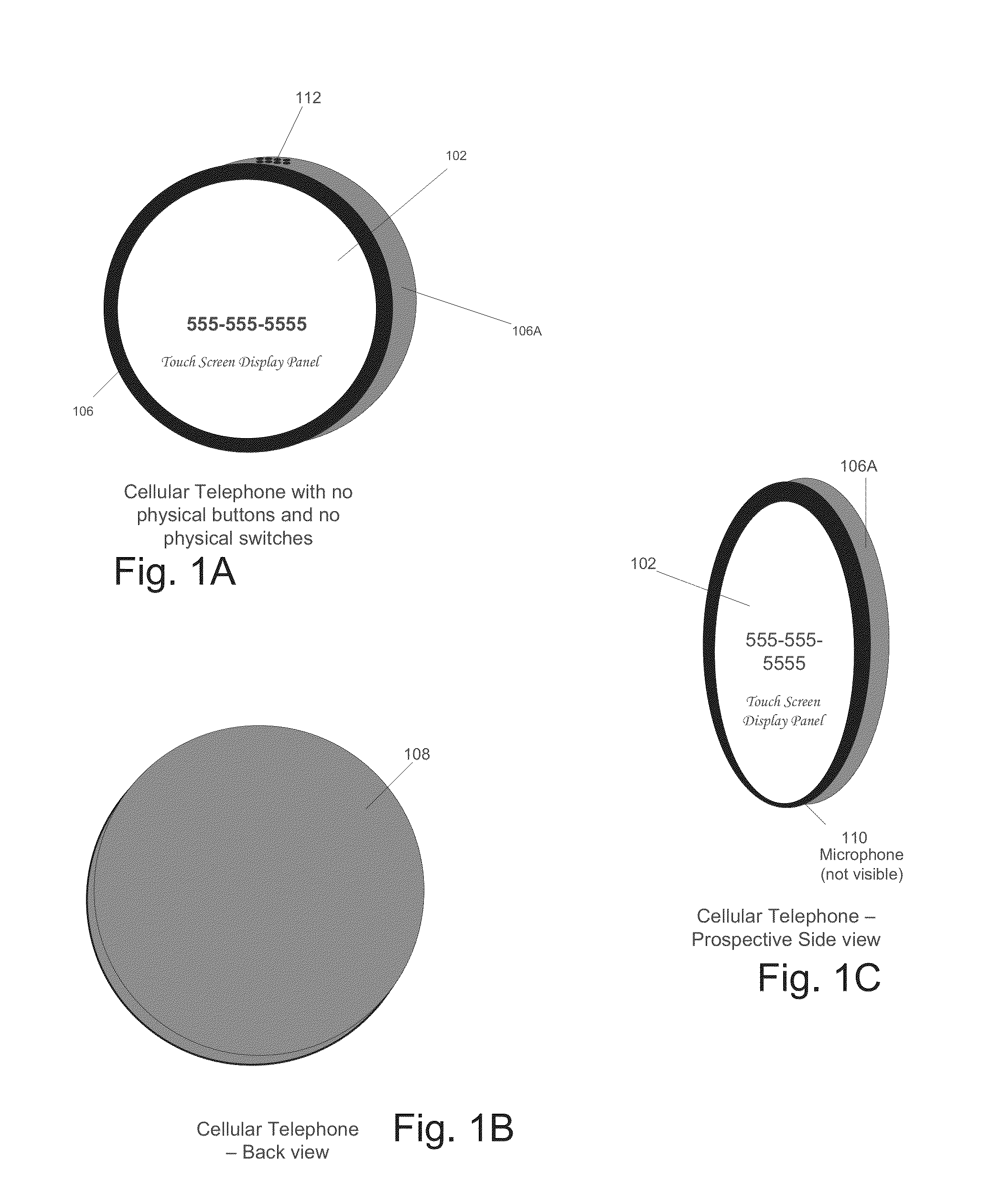

Mobile communication device

InactiveUS20140274216A1Easy to carrySame speedPower managementSpecial service for subscribersVirtual keyboardTouchscreen

Various embodiments of a cellular telephone are described, including embodiments having no external physical buttons and no external physical switches. In one embodiment, the device is small enough to fit in a small pocket yet has a touchscreen large enough for a smartphone-sized virtual keyboard. In one embodiment, the device automatically switches between various power modes configurations and can send at least one notification to a user when its battery needs charging. Each described embodiment of a cellular telephone can be used as a primary cellular device or a secondary cellular device, where the secondary cellular device can share the same cellular number as that of the primary cellular device.

Owner:SIMPLE MATTERS

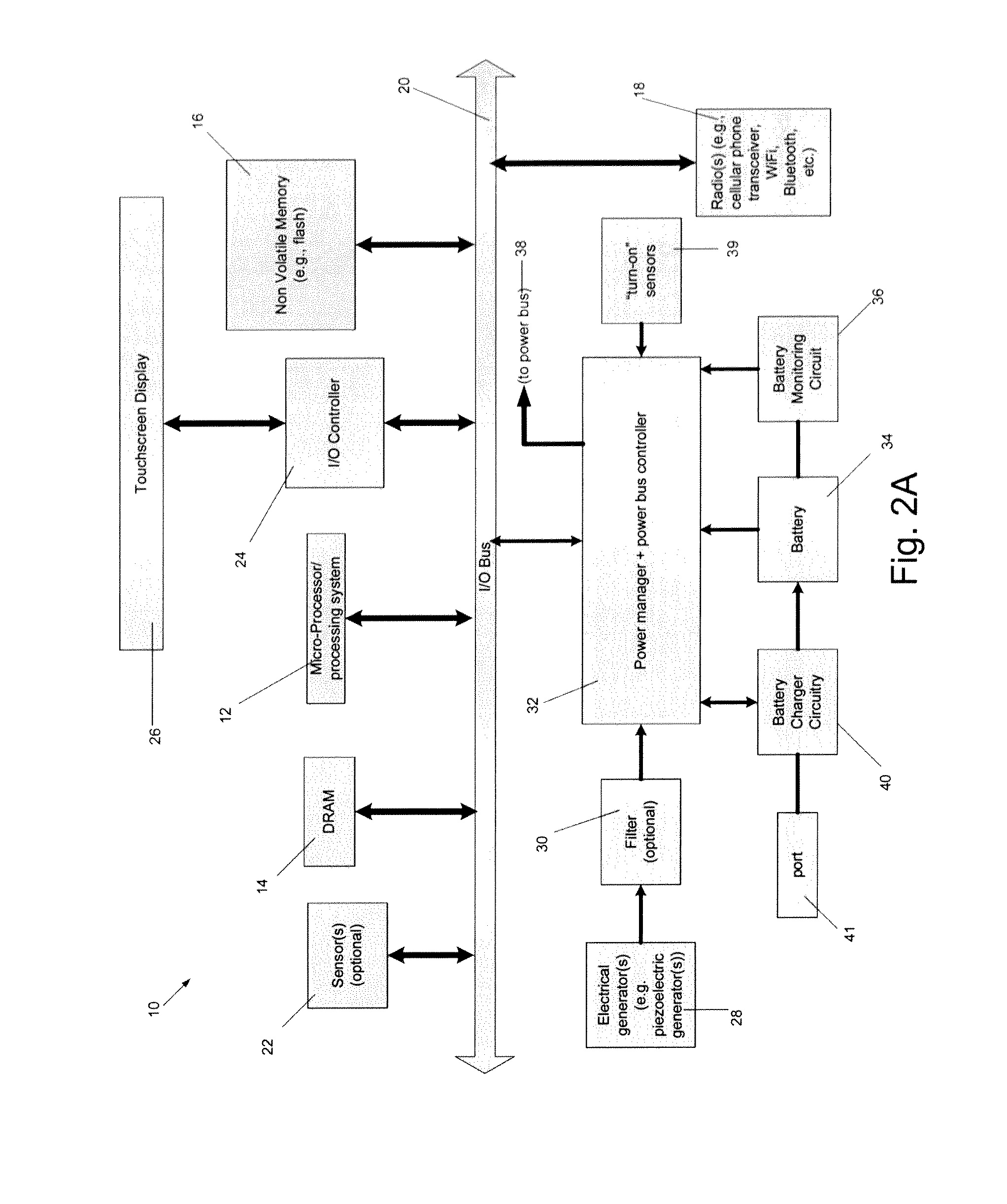

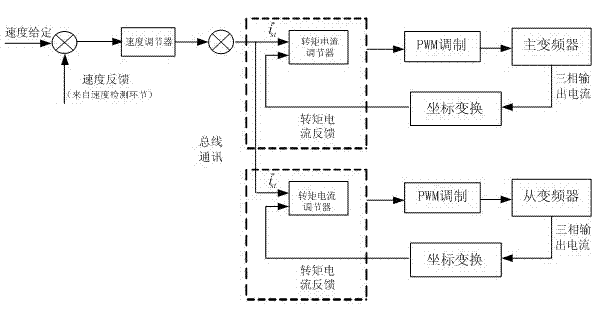

Multi-motor synchronous coordination control method

InactiveCN103501136ARealize parallel speed regulation operationRealize coordinated controlElectronic commutation motor controlVector control systemsMotor speedPulse control

The invention relates to a multi-motor synchronous coordination control method, which includes the following steps: acquiring the given value of torque current, acquiring exciting current and torque current feedback values, transmitting the given value of torque current, acquiring the current control quantity of each motor, controlling each motor with a pulse control signal and the like. Inverters are a master inverter and a slave inverter, the master inverter is a master motor inverter, and the slave inverter is a slave motor inverter; and master control and slave control are carried out between the inverters. By coordinatively controlling inverter control units, the method can ensure that a plurality of motors can operate in a synchronous state; a shared rotational speed loop is adopted in an algorithm to generate torque current tracked by each inverter, the value is transmitted via a CAN (Controller Area Network) bus, consequently, delay can be shortened, and thereby the coordinating performance and reliability of a system are enhanced; and the method not only ensures that the motors have the same rotational speed, but also ensures that load can be reasonably distributed between the motors.

Owner:中国船舶重工集团公司第七一二研究所

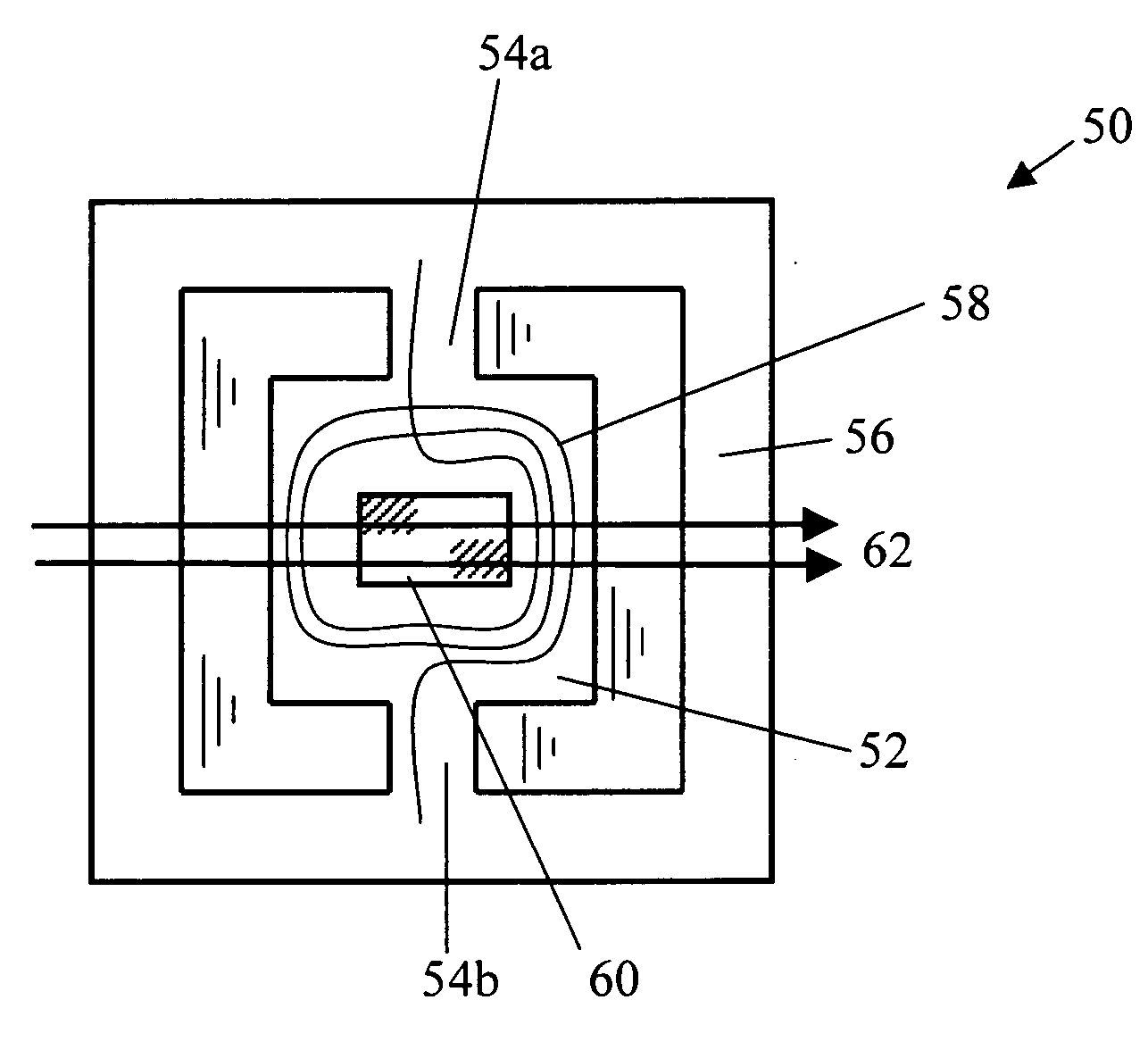

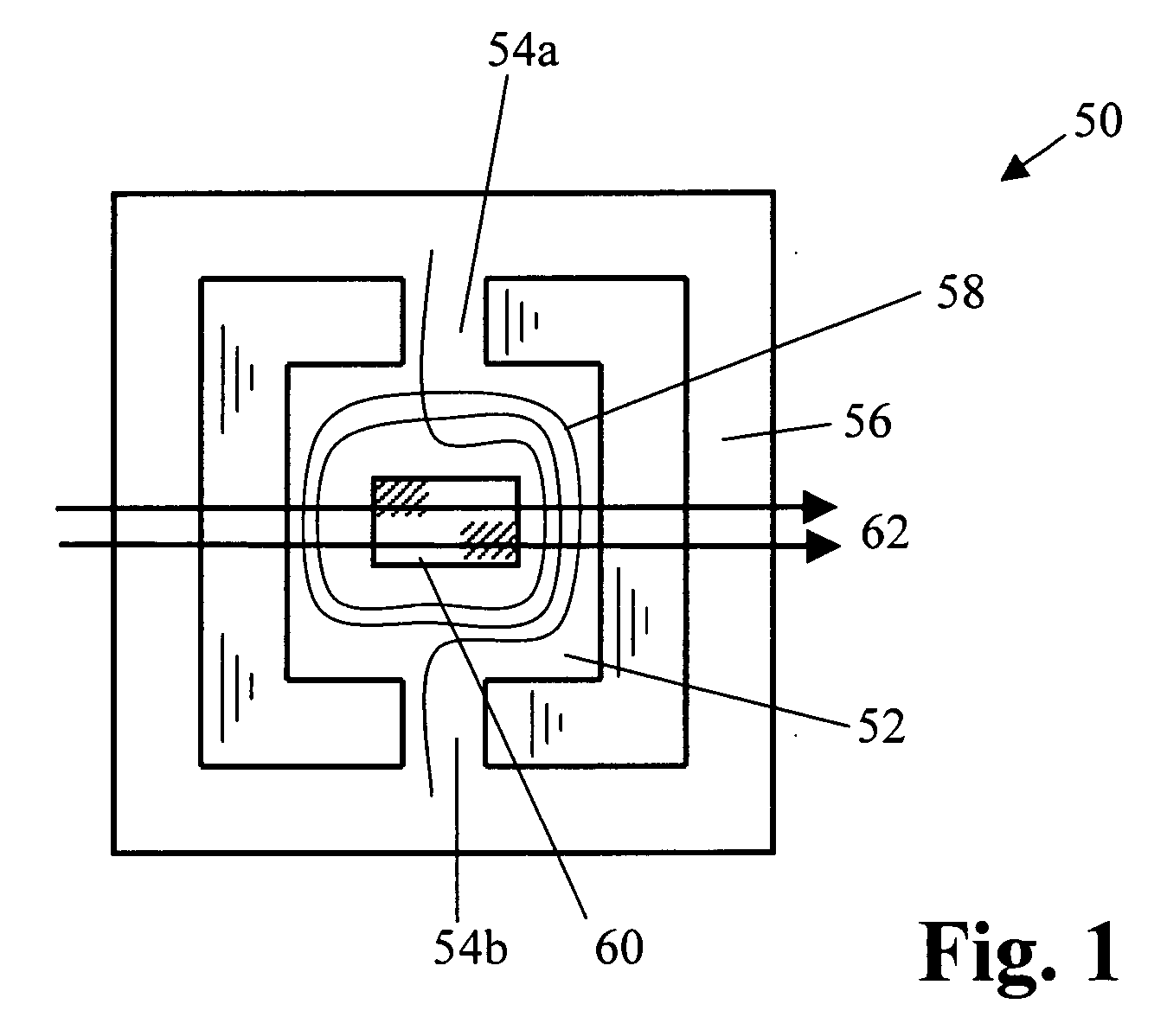

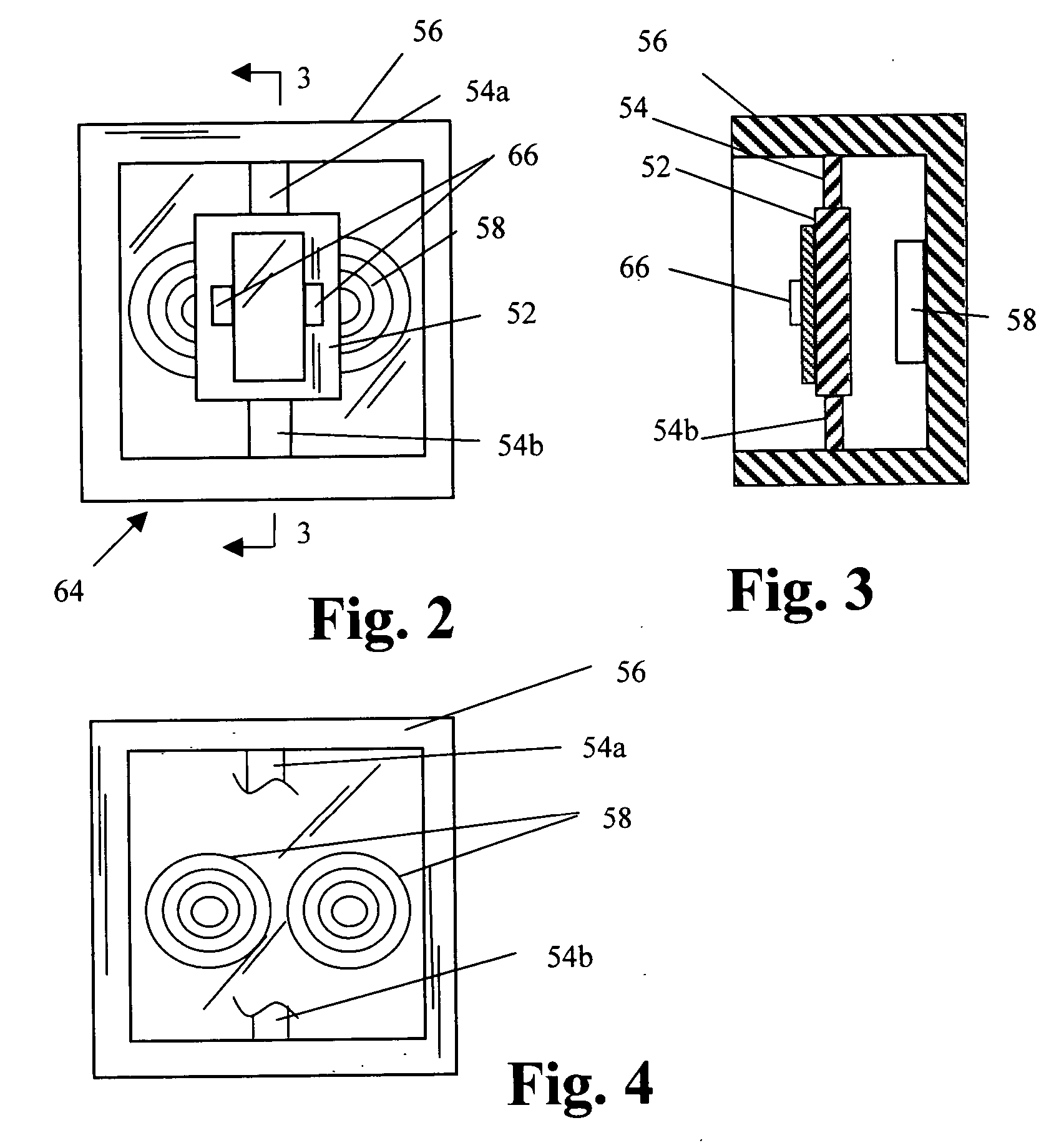

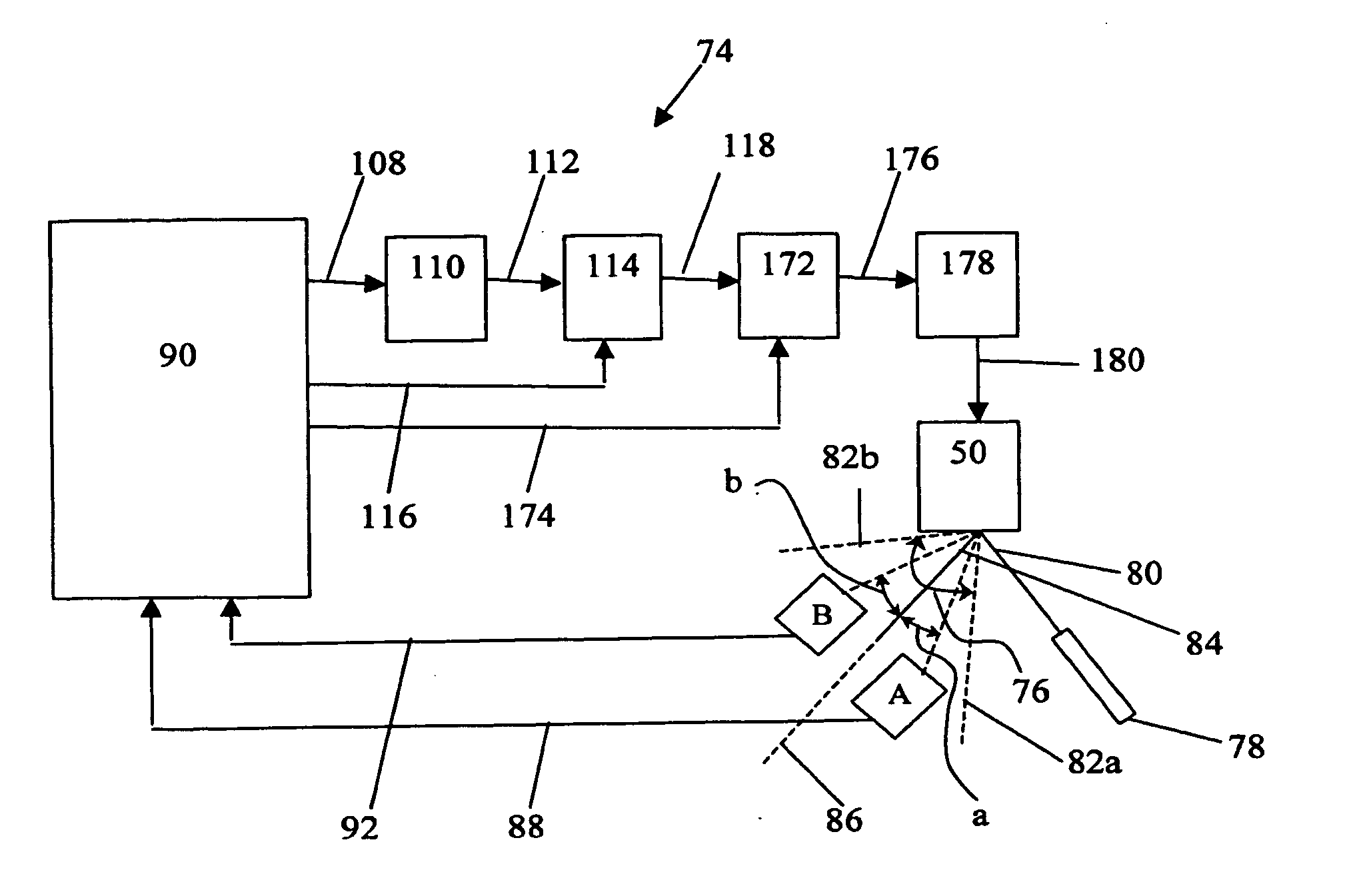

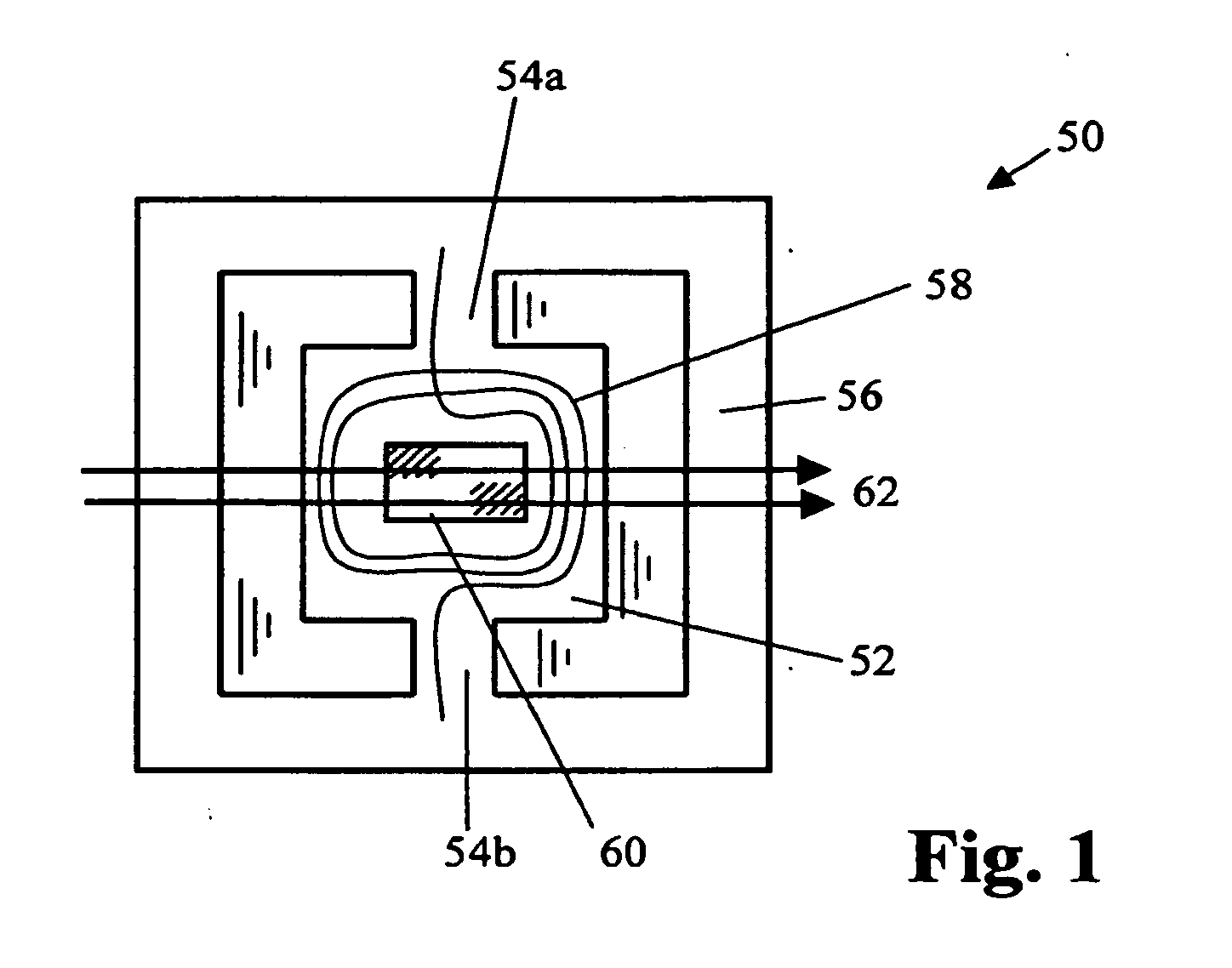

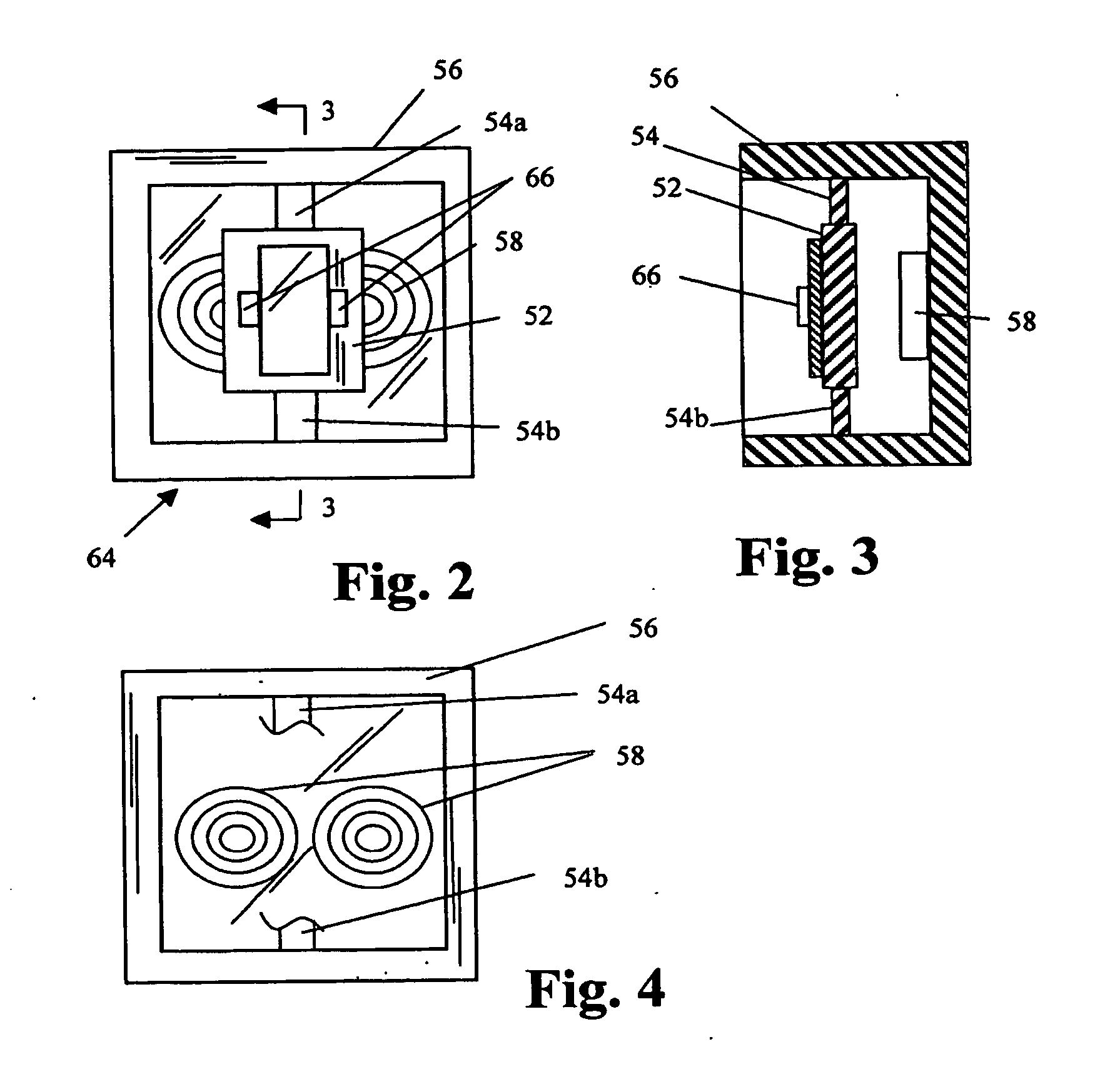

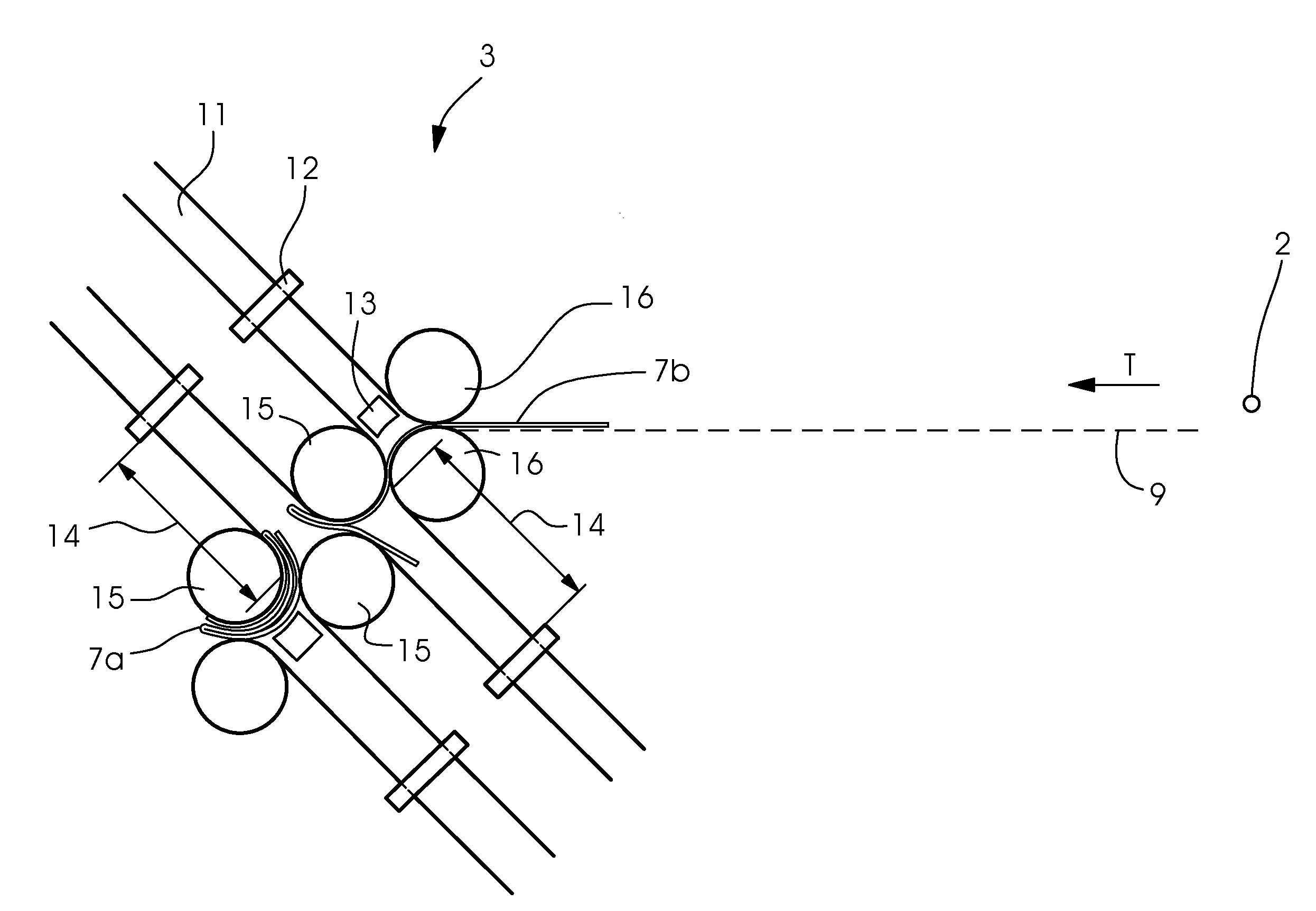

Resonant oscillating scanning device with multiple light sources

ActiveUS20050024701A1Improve throughputImprove efficiencyInking apparatusOther printing apparatusScan lineLight beam

An optical scanning system including a resonant oscillating device having a first magnetic field and a mirrored surface. The system includes first and second light sources for directing first and second beams of light to the mirrored surface of the resonant oscillating device to provide first and second reflected scan beams. The second reflected scan beam is offset a first distance from the first reflected scan beam. A second magnetic field is included for interacting with the first magnetic field to provide torque to the resonant oscillating device for scanning the first and second reflected scan beams across a surface to provide first and second scan lines on the surface substantially simultaneously as the resonant oscillating device oscillates under the influence of the first and second magnetic fields. The optical scanning system is effective to increase scan efficiency of the resonant oscillating device over that of a system using a single light source.

Owner:LEXMARK INT INC

Method for inspecting pattern defect and device for realizing the same

InactiveUS20060163503A1Sensitive highHigh detection sensitivityTelevision system detailsSemiconductor/solid-state device testing/measurementForeign matterElectron multiplication

When using a CCD sensor as a photo-detector in a device for inspecting foreign matters and defects, it has a problem of causing electric noise while converting the signal charge, produced inside by photoelectric conversion, into voltage and reading it. Therefore, the weak detected signal obtained by detecting reflected and scattered light from small foreign matters and defects is buried in the electric noise, which has been an obstacle in detecting small foreign matters and defects. In order to solve the above problem, according to the present invention, an electron multiplying CCD sensor is used as a photo-detector. The electron multiplying CCD sensor is capable of enlarging signals brought about by inputted light relatively to the electric noise by multiplying the electrons produced through photoelectric conversion and reading them. Accordingly, compared to a conventional CCD sensor, it can detect weaker light and, therefore, smaller foreign matters and defects.

Owner:HITACHI HIGH-TECH CORP

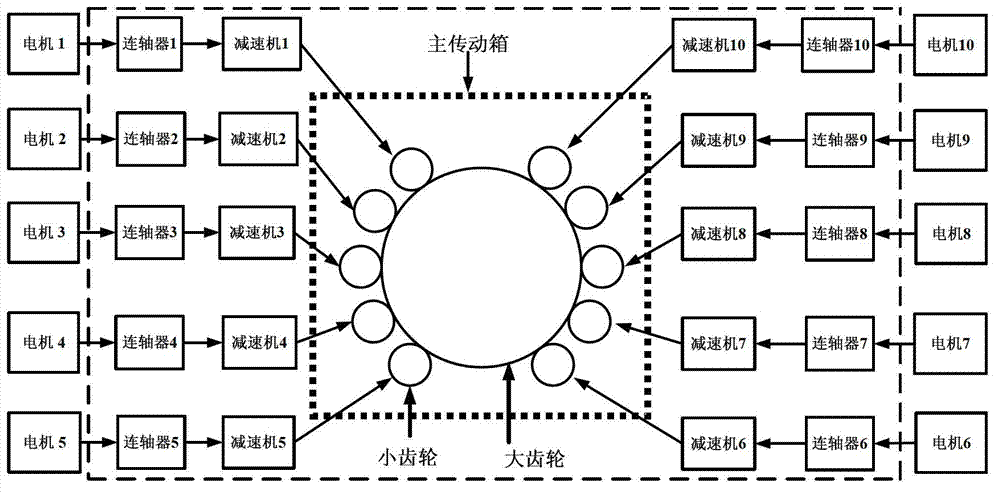

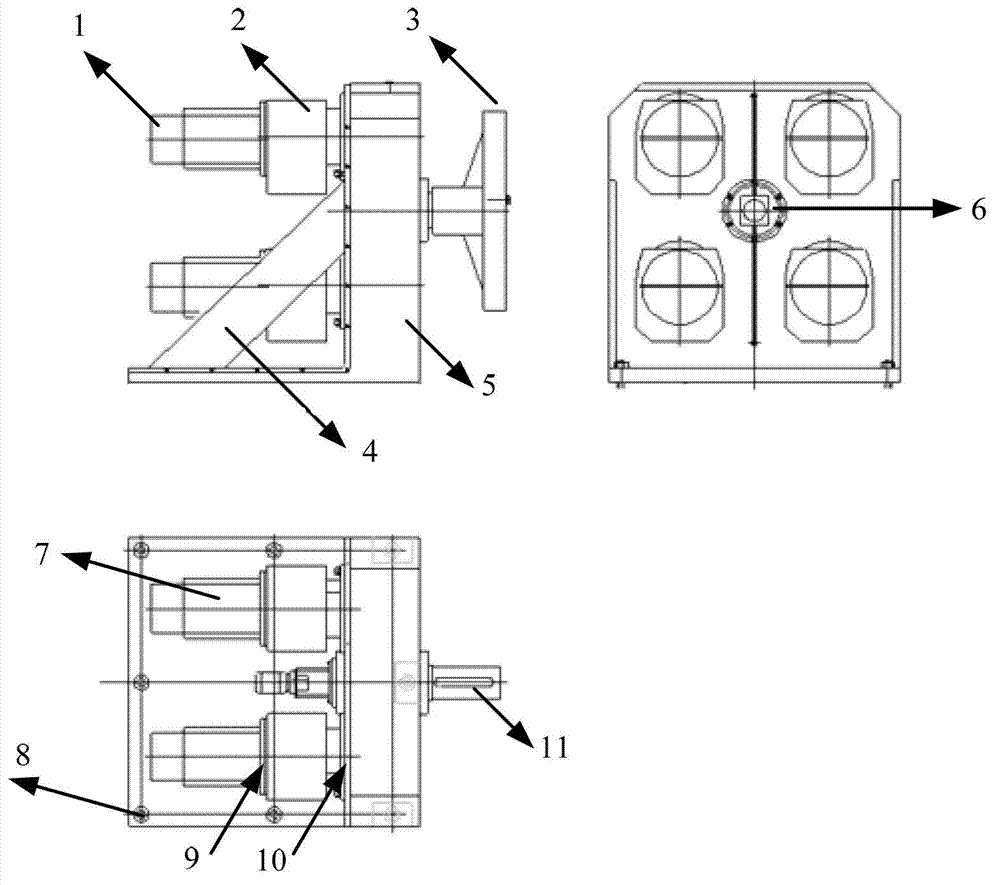

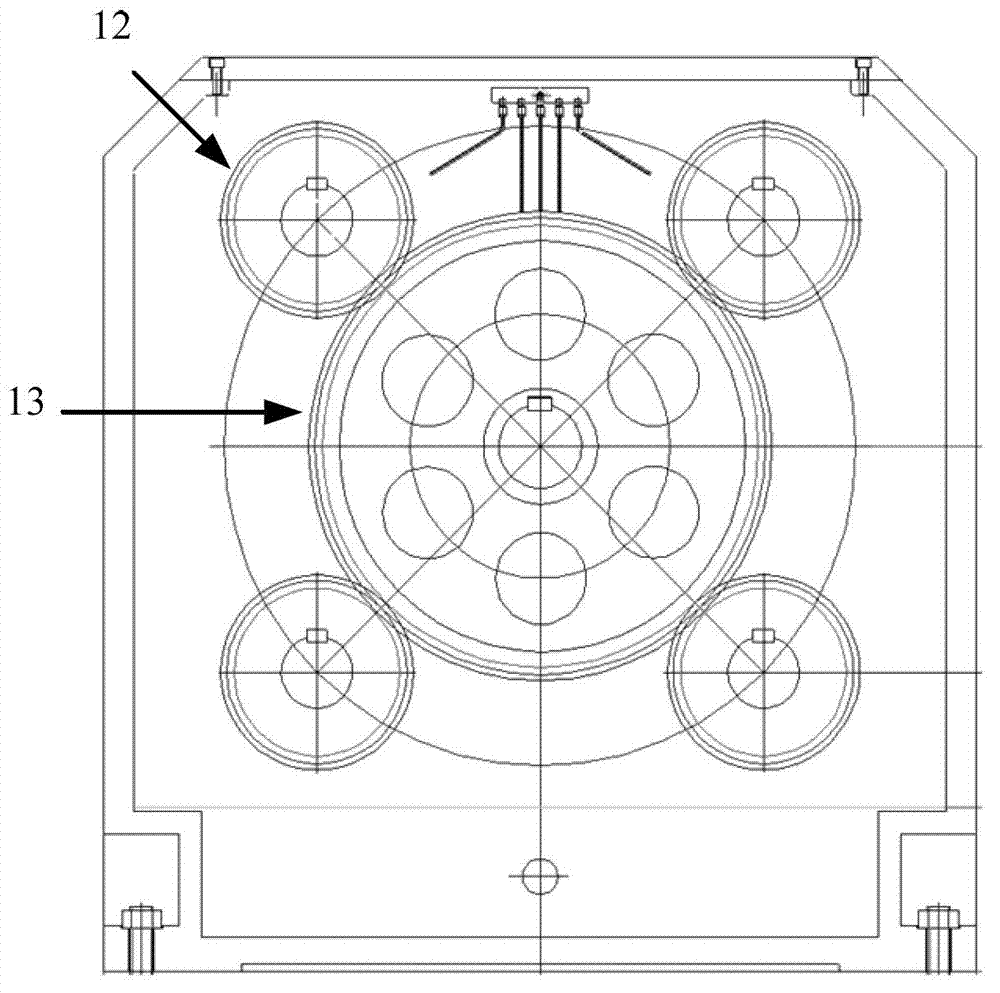

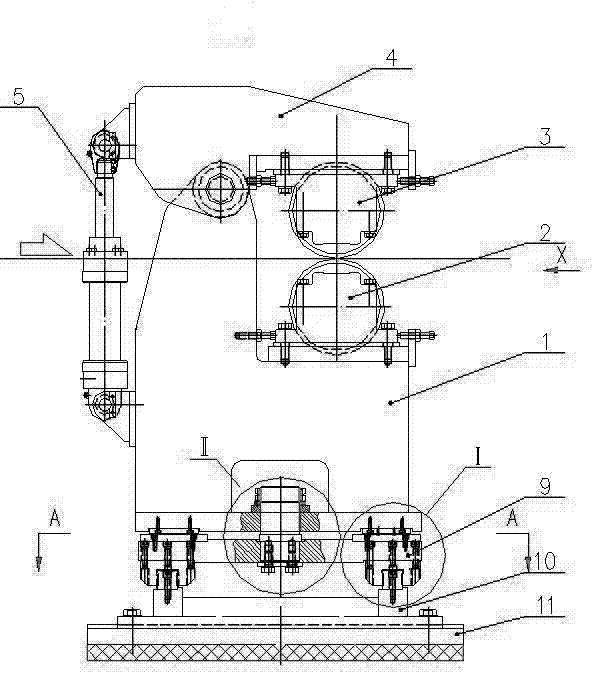

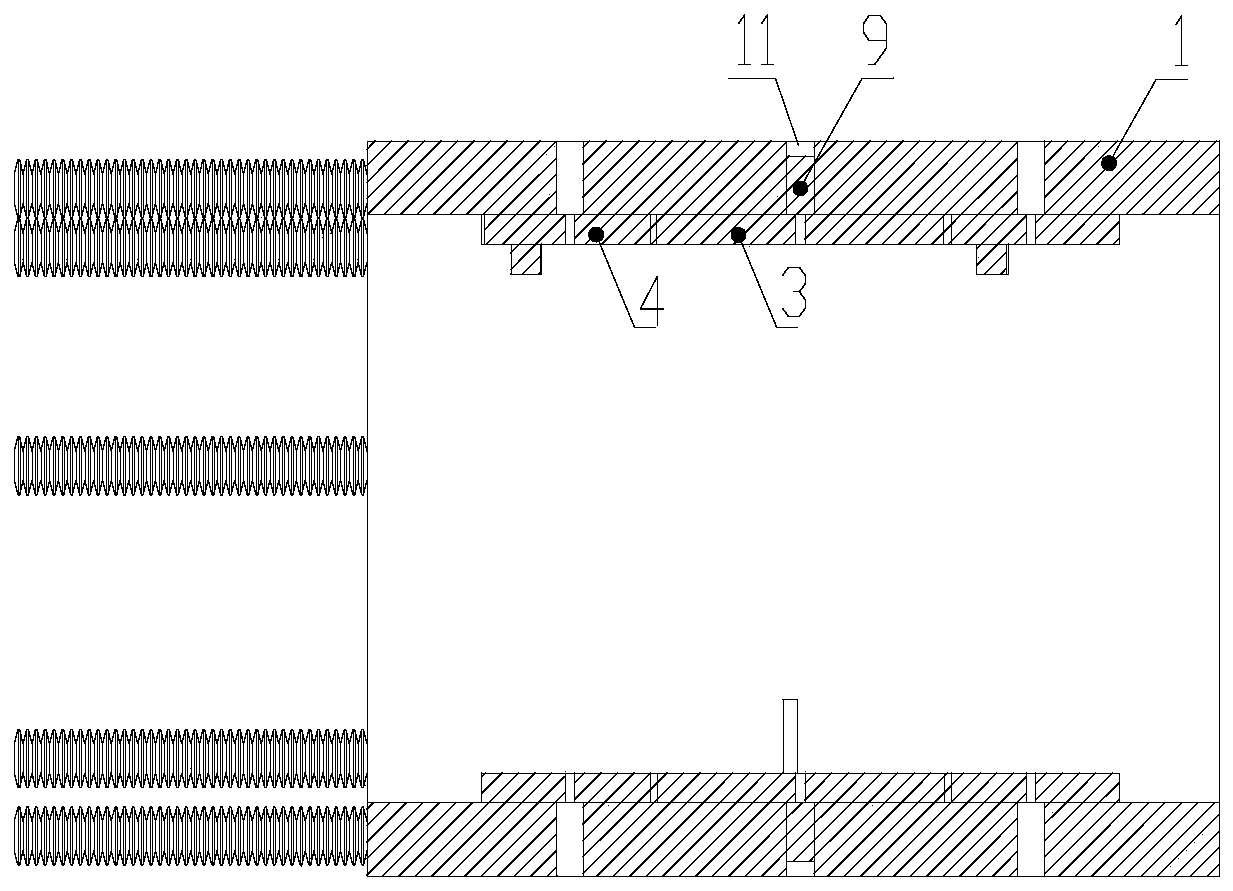

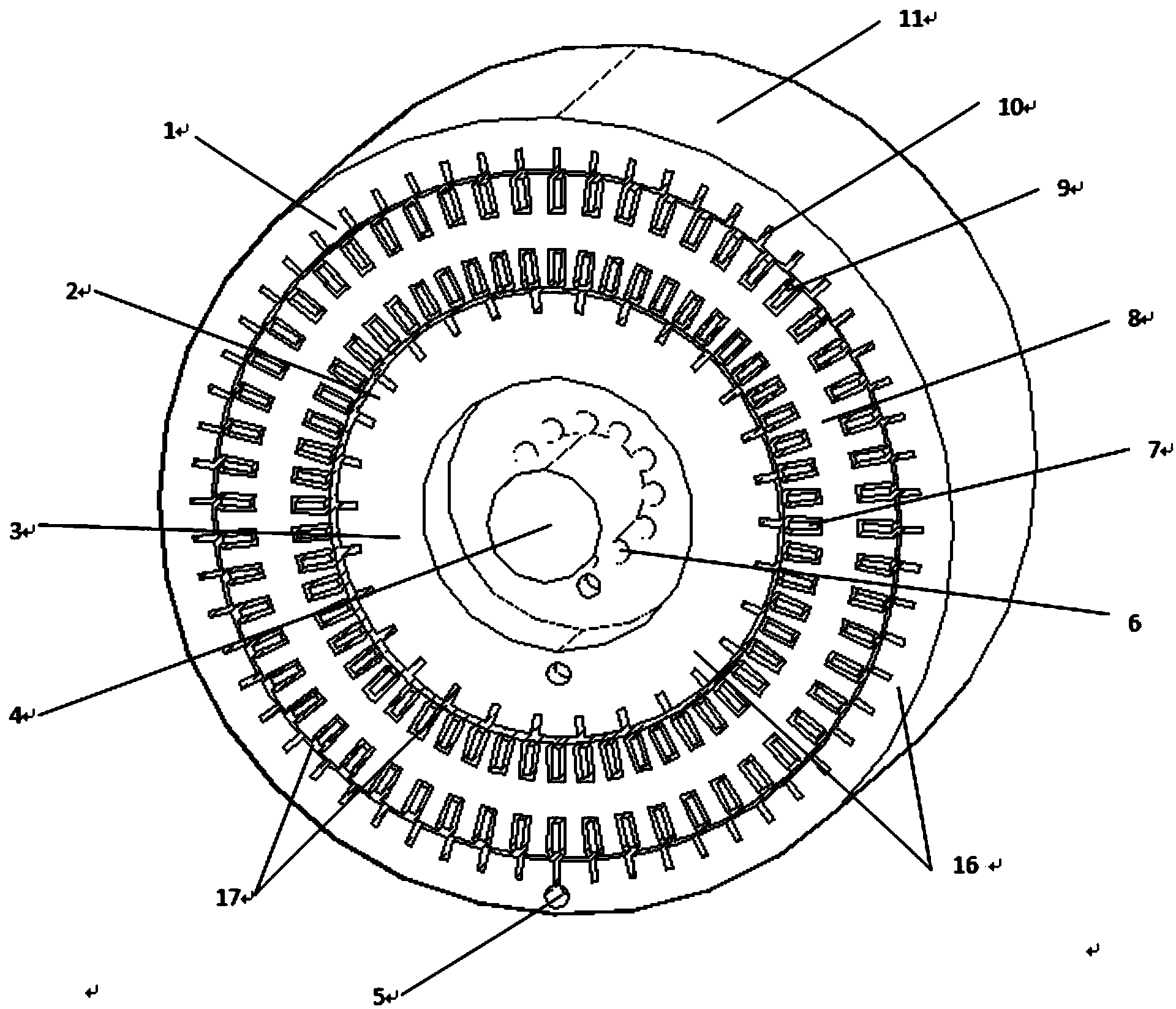

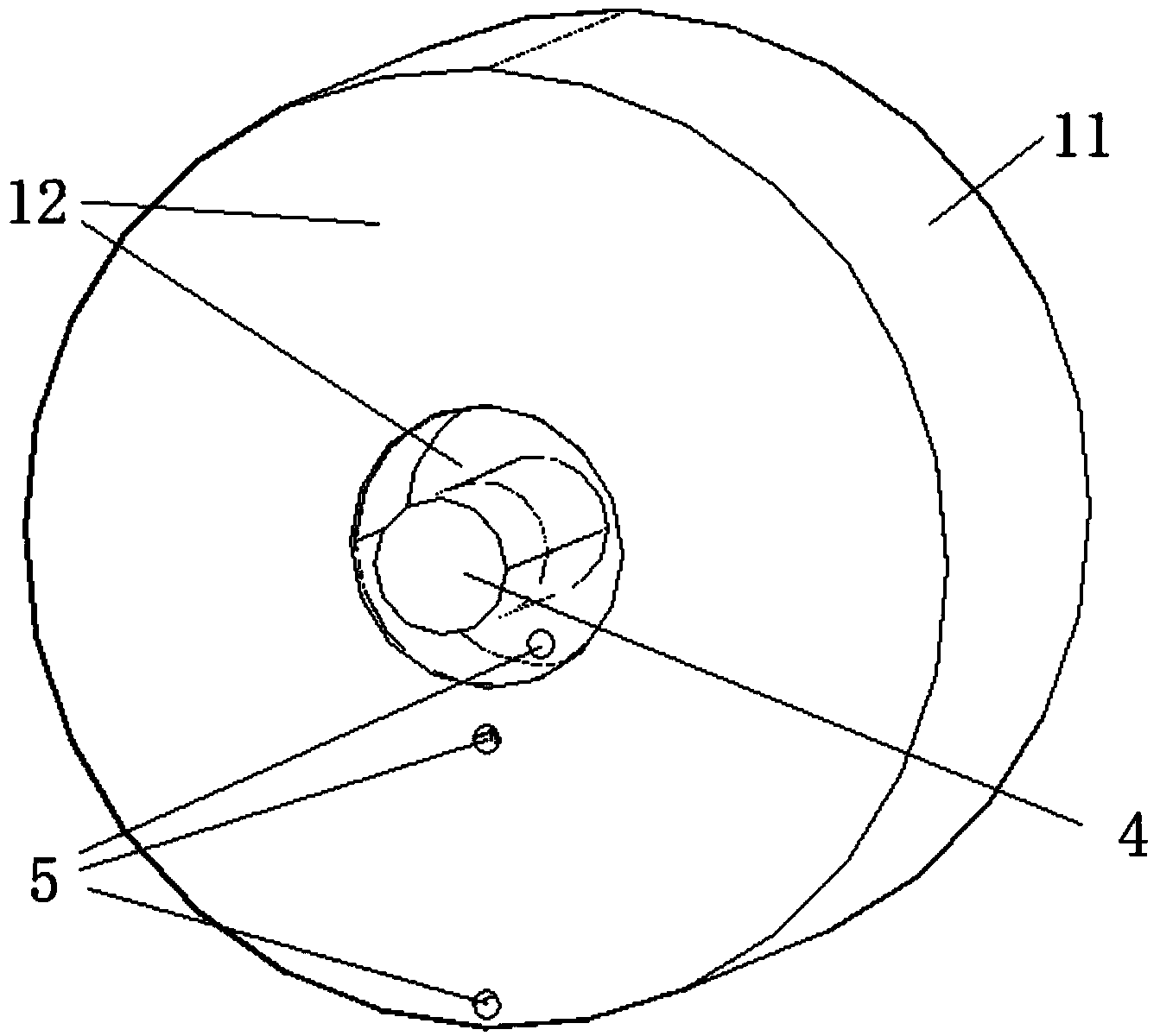

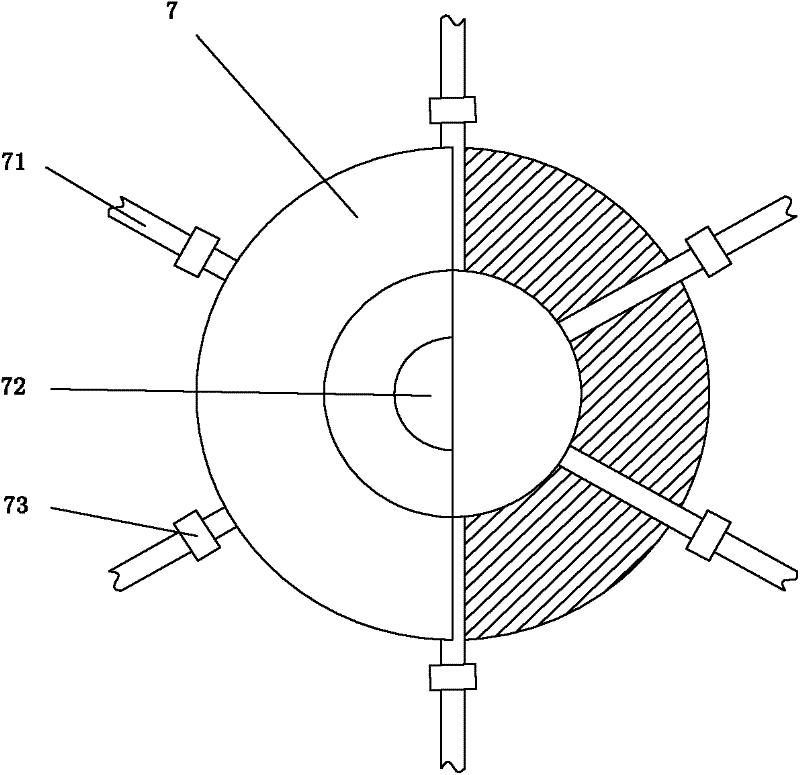

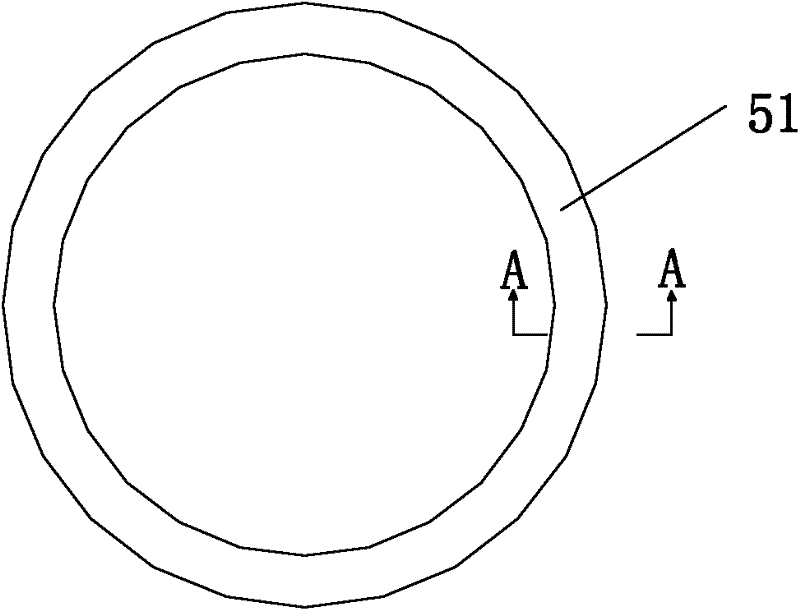

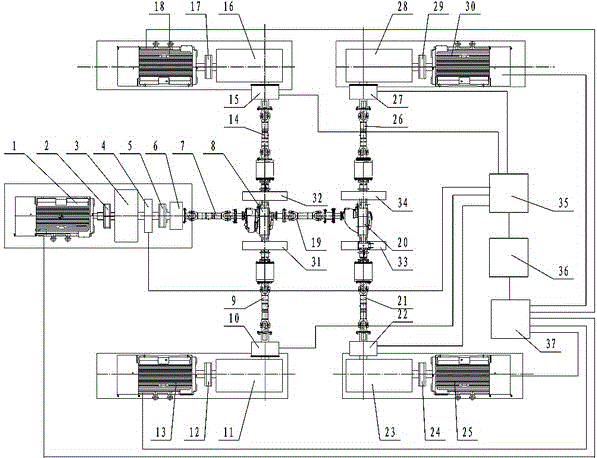

Cutter head driving device for shield tunneling machine and synchronous control method thereof

InactiveCN103016014ASolve fundamental problemsSolve the important technical problems of synchronous output operationMultiple dynamo-electric motors speed regulationTunnelsProportion integration differentiationLoop control

The invention relates to a cutter head driving device for a shield tunneling machine and a control method thereof. The driving device comprises a plurality of driving motors, a plurality of speed reducers, a main transmission box, a circular cutter head and a circulating oil pump. The synchronous control method for a cutter head of the shield tunneling machine comprises the following steps of: performing synchronous and parallel PID (Proportion Integration Differentiation) closed-loop control on the driving motors; keeping the reference input signals of the driving motors the same; computing the compensation signal of the output signal of each driving motor by adopting a synchronous error compensation method, and feeding back to the input end of a corresponding driving motor; and adding the compensation signals with a control signal output by an optimal PID controller, and inputting into a corresponding driving motor. Due to the adoption of the cutter head driving device and the synchronous control method, the technical problem of synchronous running of a plurality of motors of the cutter head of the shield tunneling machine is solved; the running synchronous performance and tracking performance of a cutter head driving system of the shield tunneling machine are improved; and the motors of the cutter head are enabled to have the same stable torque or speed, and dynamic performances among the driving motors of the cutter head of the shield tunneling machine can be kept the same.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

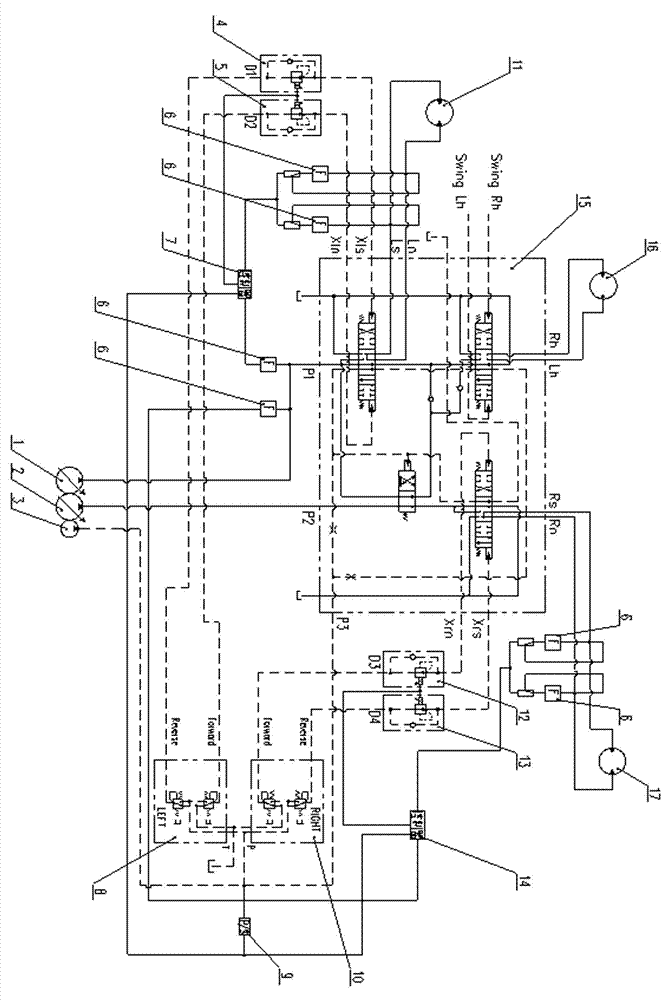

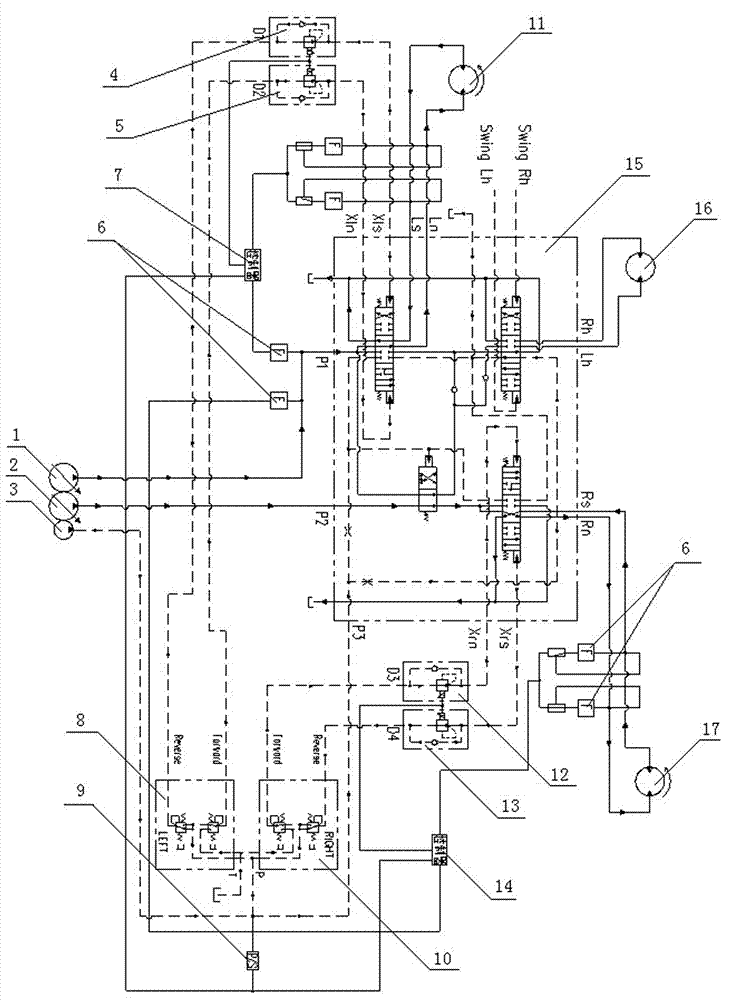

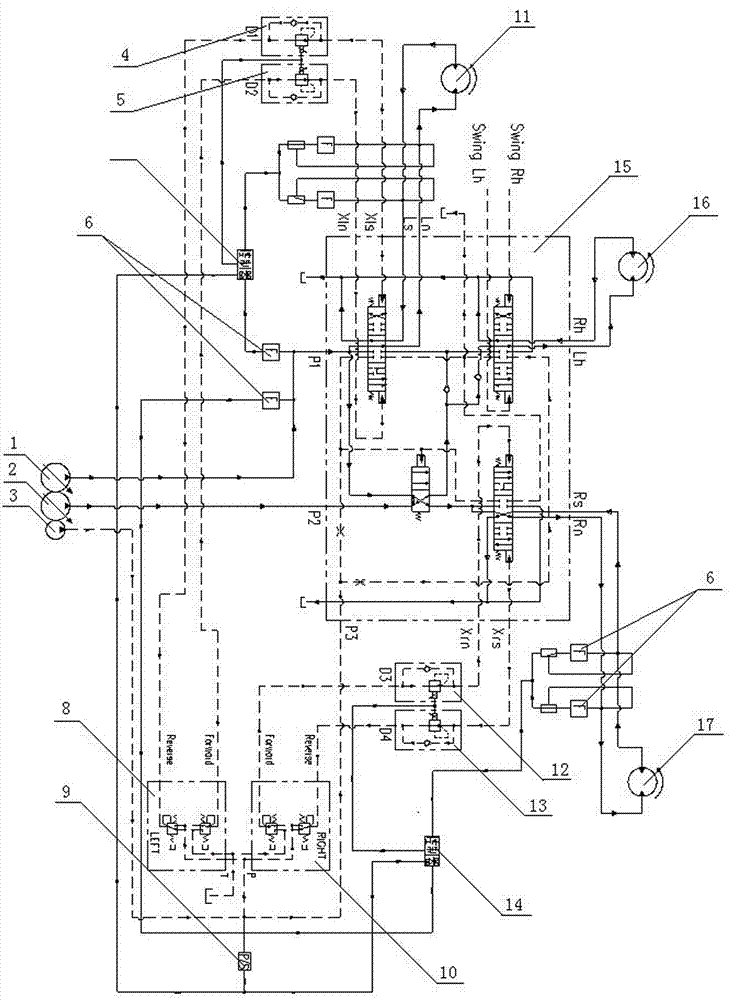

Device for improving linear running performance of excavator during compound action

ActiveCN102888873AAvoid wanderingImprove performance in straight walkingSoil-shifting machines/dredgersElectricityElectro hydraulic

The invention discloses a device for improving the linear running performance of an excavator during compound action and belongs to the technical field of excavators. According to the device, one-way electro-hydraulic proportional pressure valves are additionally arranged in a running control loop; flow sensors are additionally arranged in working loops of running motors, and switch-on and switch-off of signals of the flow sensors are controlled by a pressure valve; flow sensors are additionally arranged in a working loop in a region between a first main pump and a multiple-path valve group and electrically connected to running controllers respectively; and the running controllers compares and analyzes signals measured by the flow sensors, and output the compared and analyzed signals to control output pressure of the electro-hydraulic proportional pressure valves, the opening degrees of running control valve cores in the multiple-path valve group are regulated, and the amount of flow entering the running motor is changed, so that the rotation speeds of the running motors on two sides are equal. The device has the advantages that a running deviation phenomenon due to different loads borne by the two running motors on the two sides during combined action of the excavator is avoided, the linear running performance of the excavator is improved, and the construction safety is guaranteed.

Owner:XCMG EXCAVATOR MACHINERY

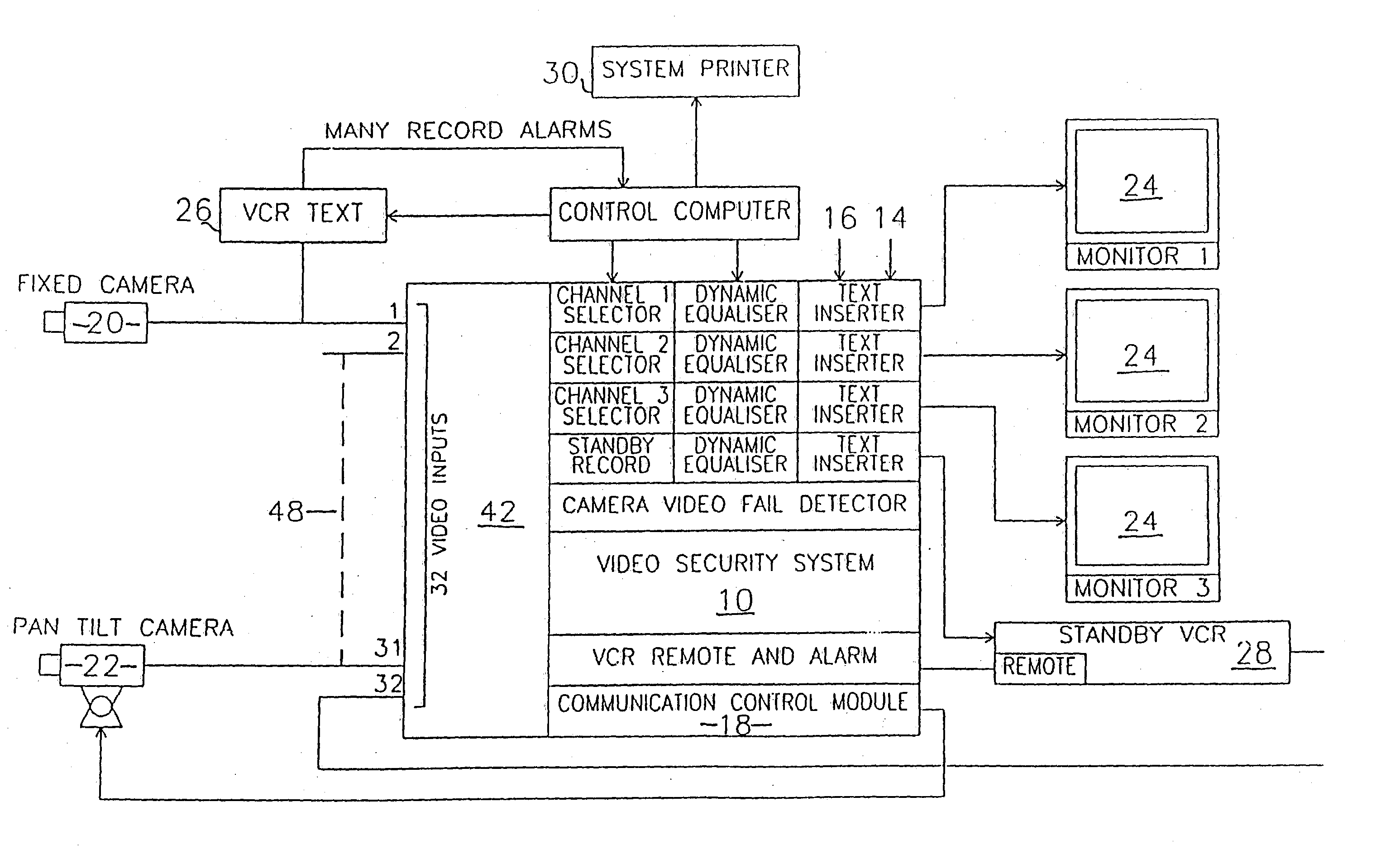

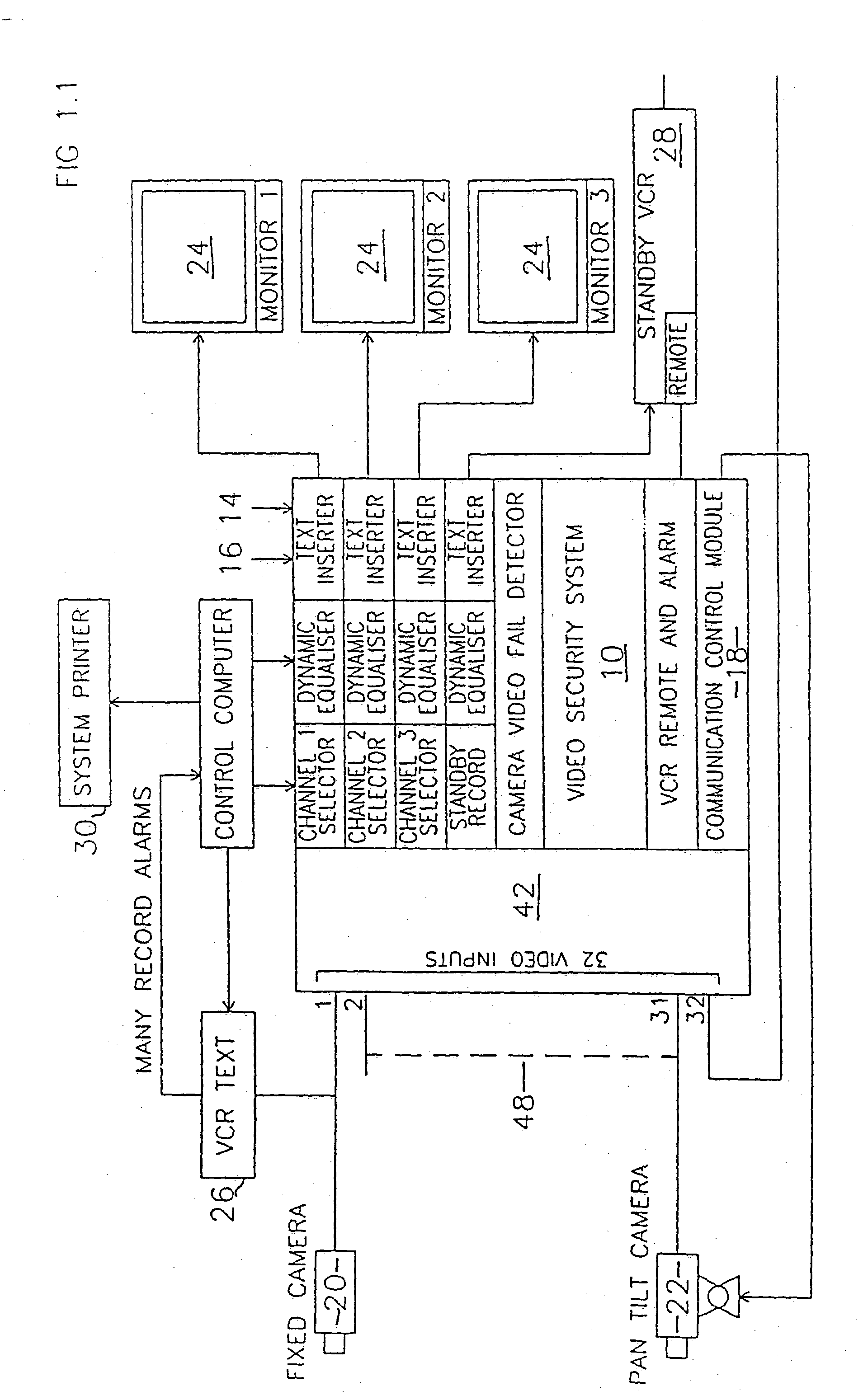

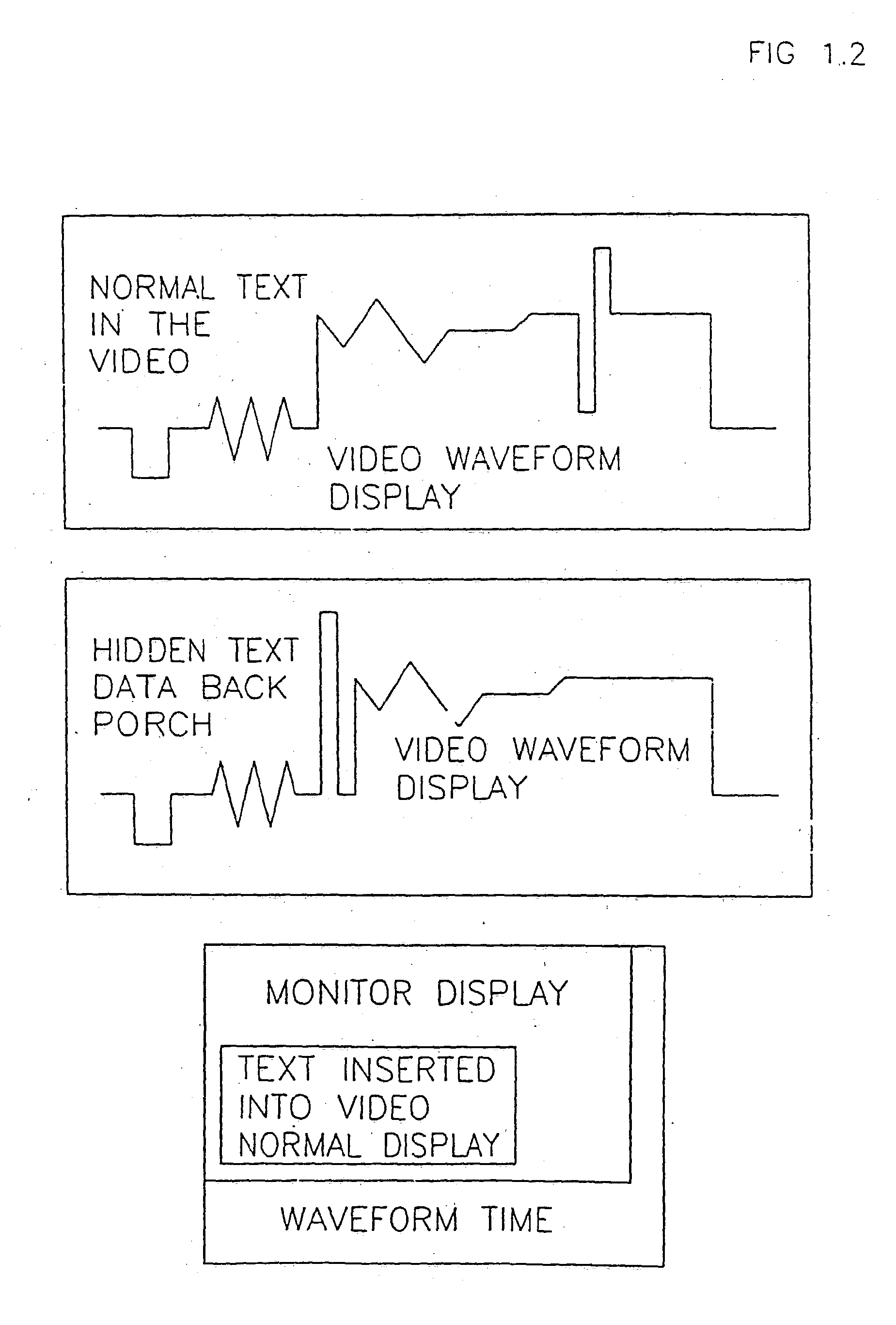

Video security system

InactiveUS20050086704A1Reduce the amount requiredImprove accuracyTelevision system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Equalization

The invention provides a video security system for monitoring a plurality of locations simultaneously. In one embodiment, the system includes a text insertion means connected between a video camera and monitor, a control means connected to the text insertion means, and a playback means operatively associated with the text insertion means and control means. Other embodiments include a video camera substitution system having a fixed video camera and a pan-tilt video camera and a video recorder substitution system having a plurality of alternate VRDs. In another embodiment, the system includes a programmable equalizer having a plurality of video input devices, a video output receiver, a switch connected between the input devices and receiver, a variable equalizer connected between the switch and receiver, and a controller storing line loss parameters for each input device, thereby providing equalization among a plurality of video cameras, monitors, and video signal recording devices.

Owner:RHODES SCOTT ANTHONY +1

Method for smearing wood wax oil on surface of wood product

InactiveCN103182725AIncrease exerciseIncrease oil intakeCoating impregnationCoatingsWaxEnvironmentally friendly

The invention relates to a method for smearing wood wax oil on the surface of a wood product, which comprises the following steps: 1, smoothening; 2, smearing the wood wax oil; 3, kneading a wax oil coating on the surface; 4, wiping floating oil; 5, drying; 6, repeating the steps 2-5 for one or two times; 7, polishing till the hand feeling is smooth; and 8, spraying polishing wax, polishing and entering a next assembly process. By using the method, the crack of the wood product can be effectively prevented, and the service life is prolonged; the operation is simple, and materials, labors and oil are saved; the wood wax oil is a green and environmentally-friendly coating and a low-carbon environmentally-friendly product; and by using the method, the wide application of the wood wax oil can be promoted, and an important significance on environment friendliness is realized.

Owner:张克广

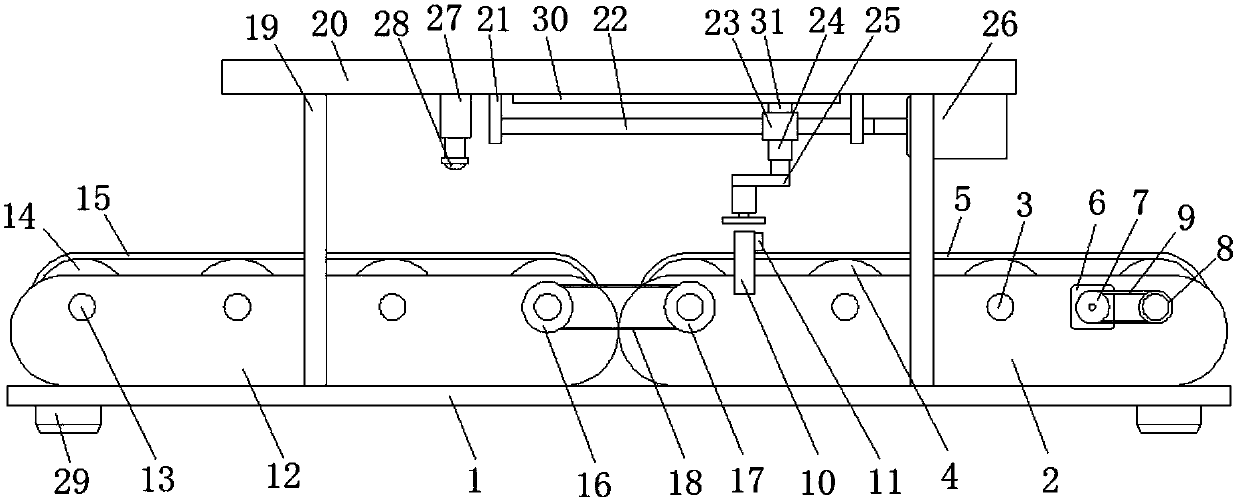

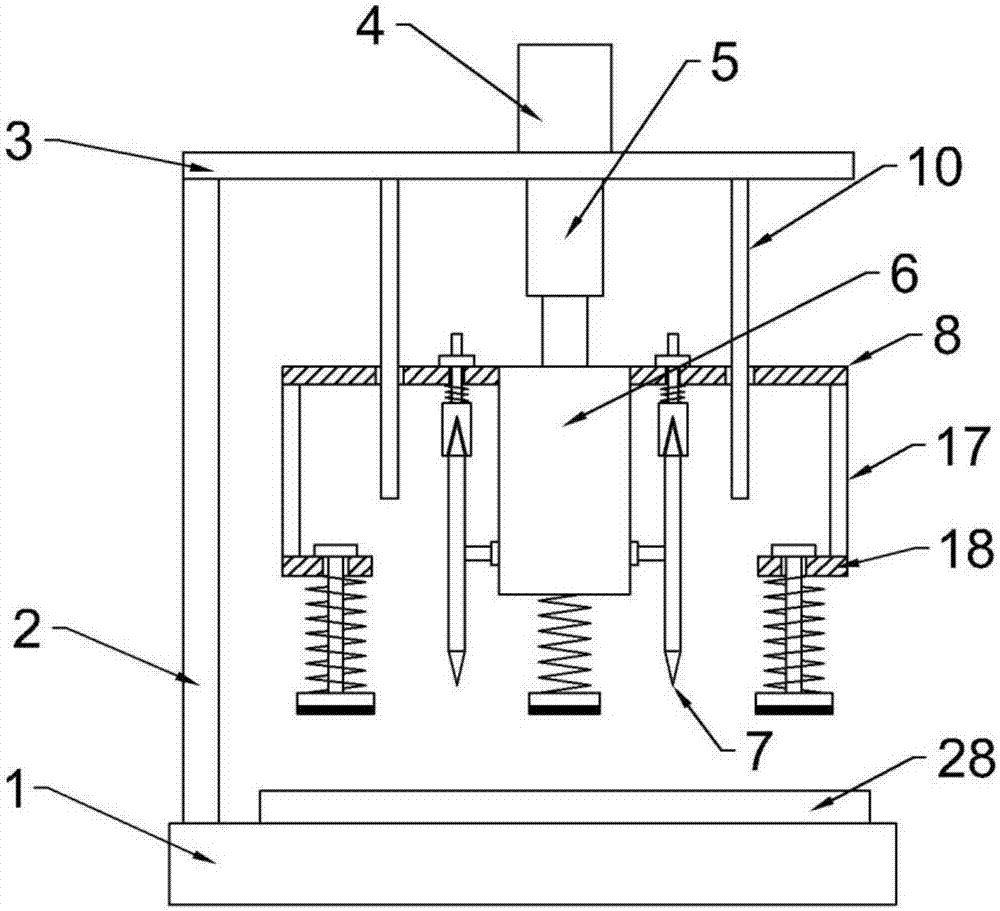

Metal powder composition detecting system

ActiveCN107738858ATo achieve the effect of missed detectionTo achieve the effect of clamping transferConveyorsControl devices for conveyorsLeak detectionElectrical and Electronics engineering

The invention discloses a metal powder composition detecting system. The metal powder composition detecting system comprises a base, wherein the upper surface of the base is fixedly connected with a first wallboard, the surface of the first wallboard is in inserted connection with first transmission shafts, the surface of each first transmission shaft is fixedly connected with a first conveying roller, the first conveying rollers are in transmission connection through a first caterpillar track, a first motor is fixedly installed on the surface of the first wallboard, and an output shaft of thefirst motor is fixedly connected with a first belt wheel. The first motor operates to drive the first caterpillar track and a second caterpillar track to run synchronously, the first caterpillar track transports a detecting box, the detecting check box stops when moving to touch a baffle, a pressure sensor is subjected to pressure induction, the first motor stops running immediately, a gripper jaw grips and moves the detecting box onto the second caterpillar track, meanwhile a second electric push rod drives a detecting probe to move downwards to detect metal compositions in the detecting box, and thus the effect of placing sample leak detection is realized.

Owner:义乌兰思体育用品有限公司

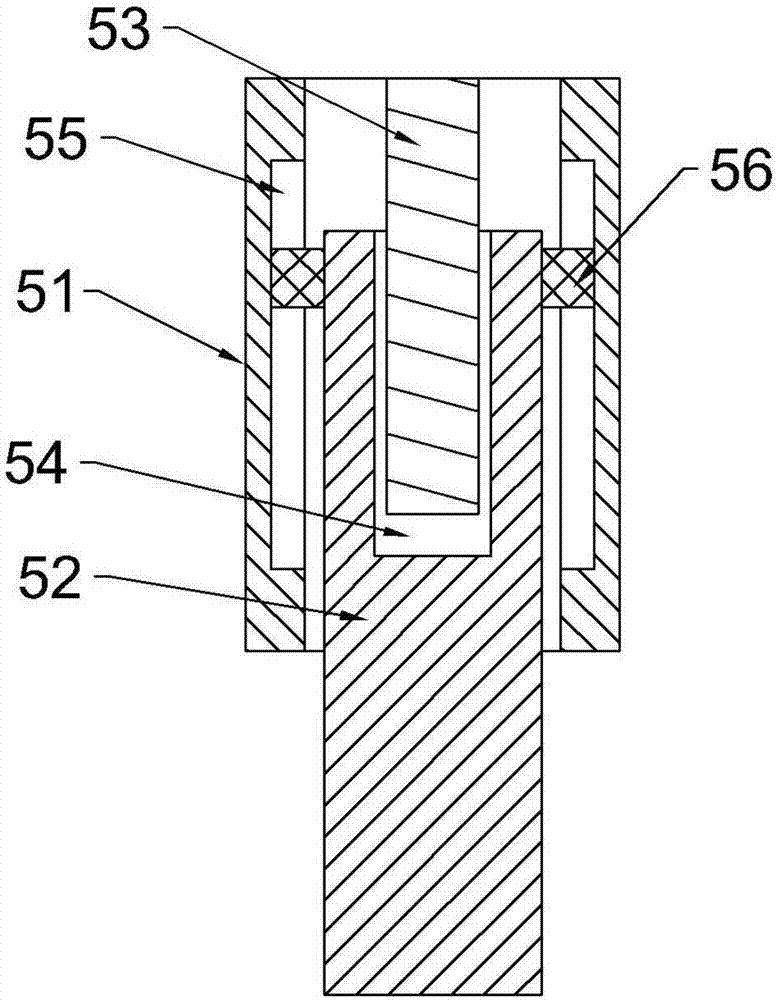

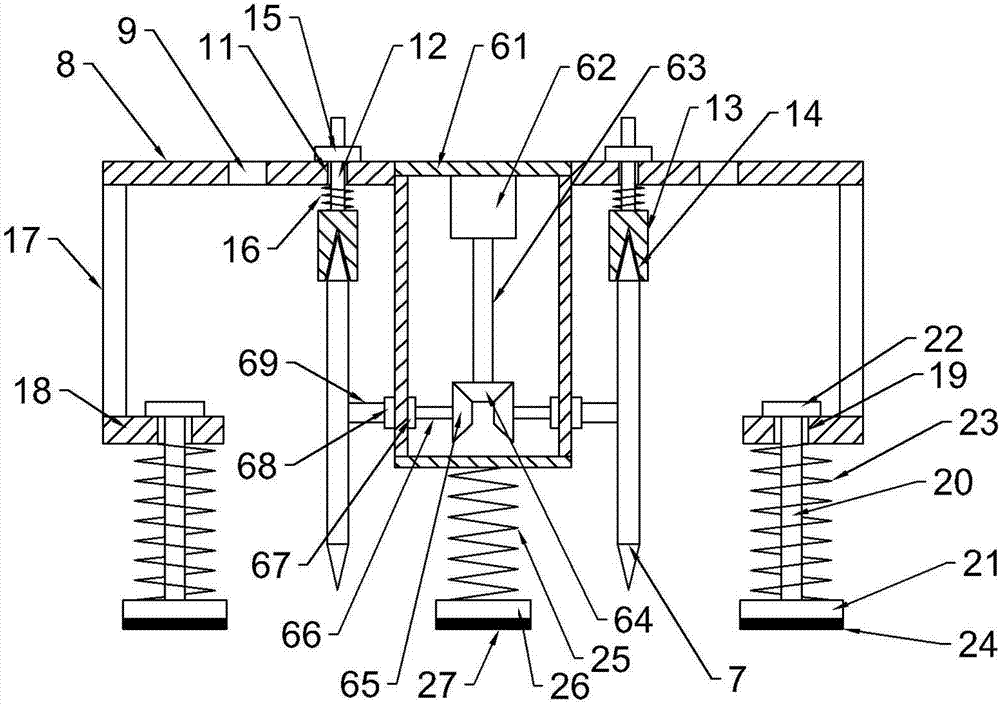

Double-cutter cutting device for packing plates

ActiveCN107876855ASame speedGuaranteed sharpMachine tool componentsShearing machinesDrive shaftCoupling

The invention discloses a double-cutter cutting device for packing plates. The double-cutter cutting device comprises a base, a supporting column, a transverse plate, a first motor, a feed mechanism,a cutting mechanism and an extension plate, and the cutting mechanism comprises a shell, a second motor, a driving shaft, a driving bevel gear, a driven bevel gear, a rotating shaft, a coupling and aconnecting shaft; cutting wheels are mounted at the end, away from the coupling, of the connecting shaft, and mounting holes are formed in the side, close to the shell, on the extension plate; threaded columns are arranged in the mounting holes, and friction blocks are mounted at the lower ends of the threaded columns; and a first spring is further arranged on each threaded column in a sleeving mode, and the first springs are located between the extension plate and the friction blocks. According to the double-cutter cutting device for the packing plates, single power is adopted to drive the double cutting wheels, the same rotational speed of the two cutting wheels can be achieved, neat cutting is ensured, by arranging the friction blocks, the cutting wheels can be grinded while being cut,so that the cutting wheels is ensured to be sharp, the plates can be pressed and fixed while feeding of the cutting mechanism is conducted by arranging pressing blocks, and a separate control fixtureis not required to be arranged.

Owner:宣城大天新材料科技股份有限公司

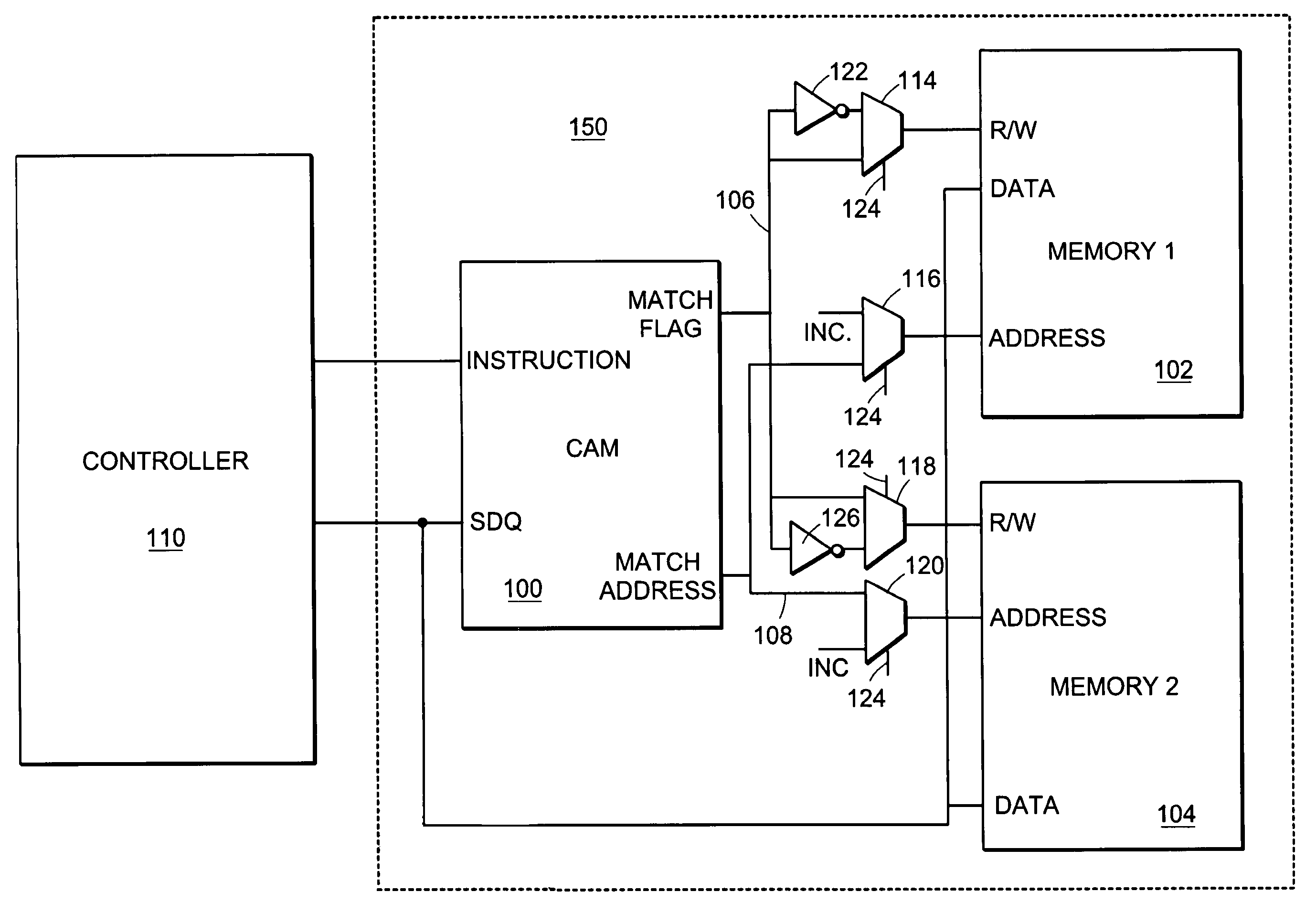

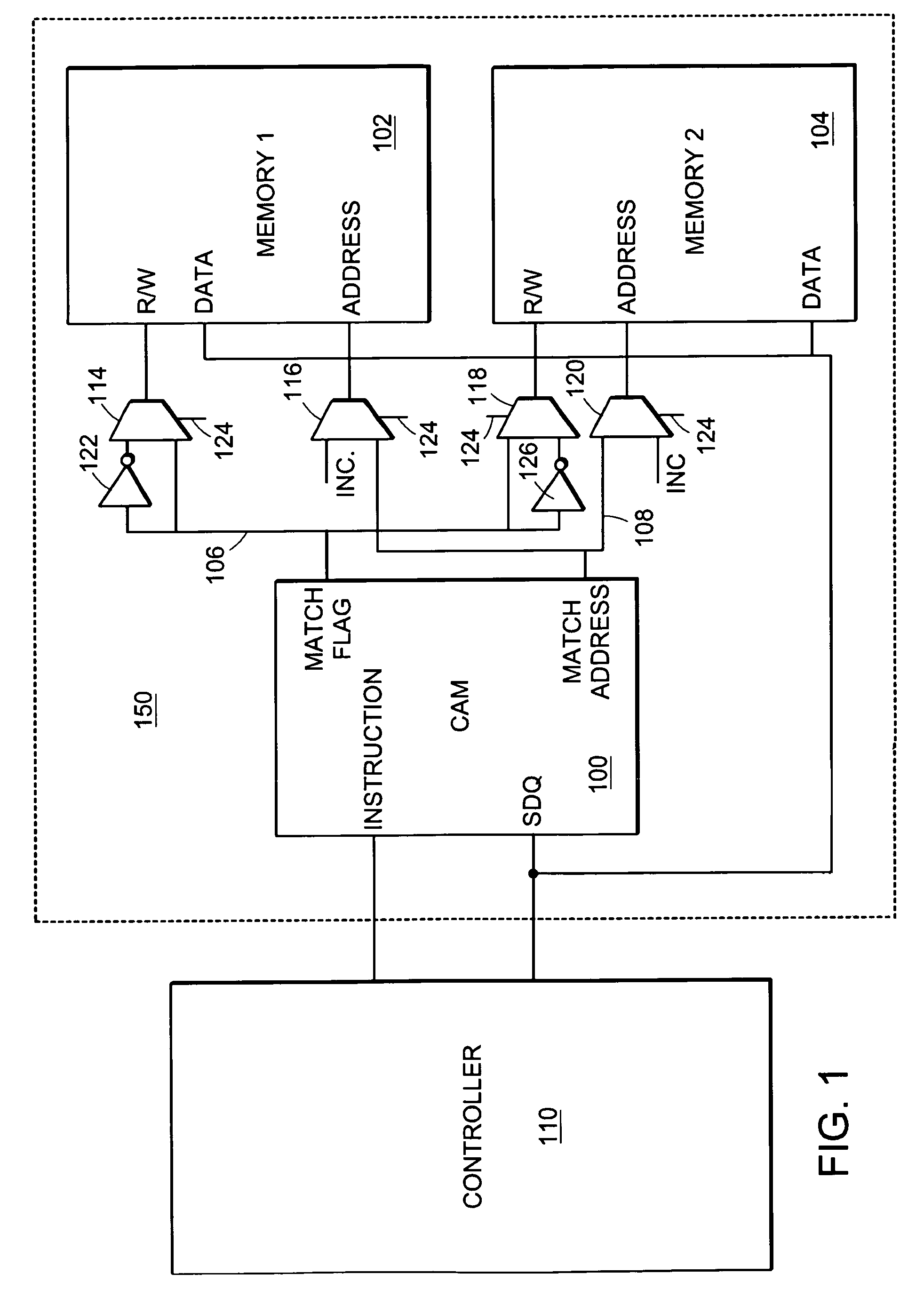

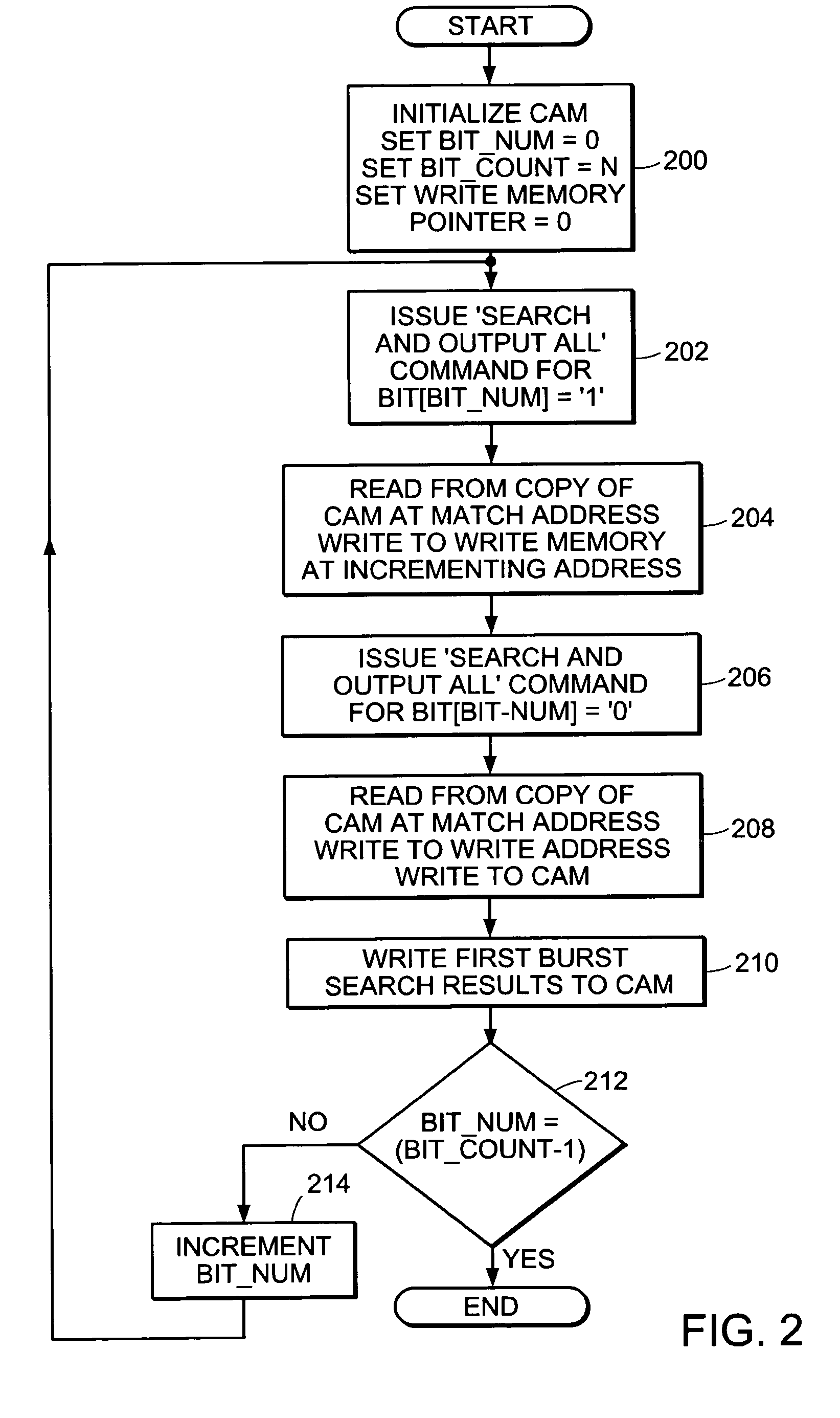

Sorting method and apparatus using a CAM

ActiveUS6990552B2Same speedSame performanceData processing applicationsDigital storageTheoretical computer scienceClassification methods

Method and apparatus using a Content Addressable Memory for sorting a plurality of data items is presented. The data items to be sorted are stored in the Content Addressable Memory. A plurality of bit-by-bit burst searches are performed on the contents of the Content Addressable Memory with all other bits in the search key masked. The number of burst searches is proportional to the total number of bits in the data items to be sorted. The search is deterministic dependent on the number of bits in each data item on which a sort is performed and on the number of data items to be sorted.

Owner:MOSAID TECH

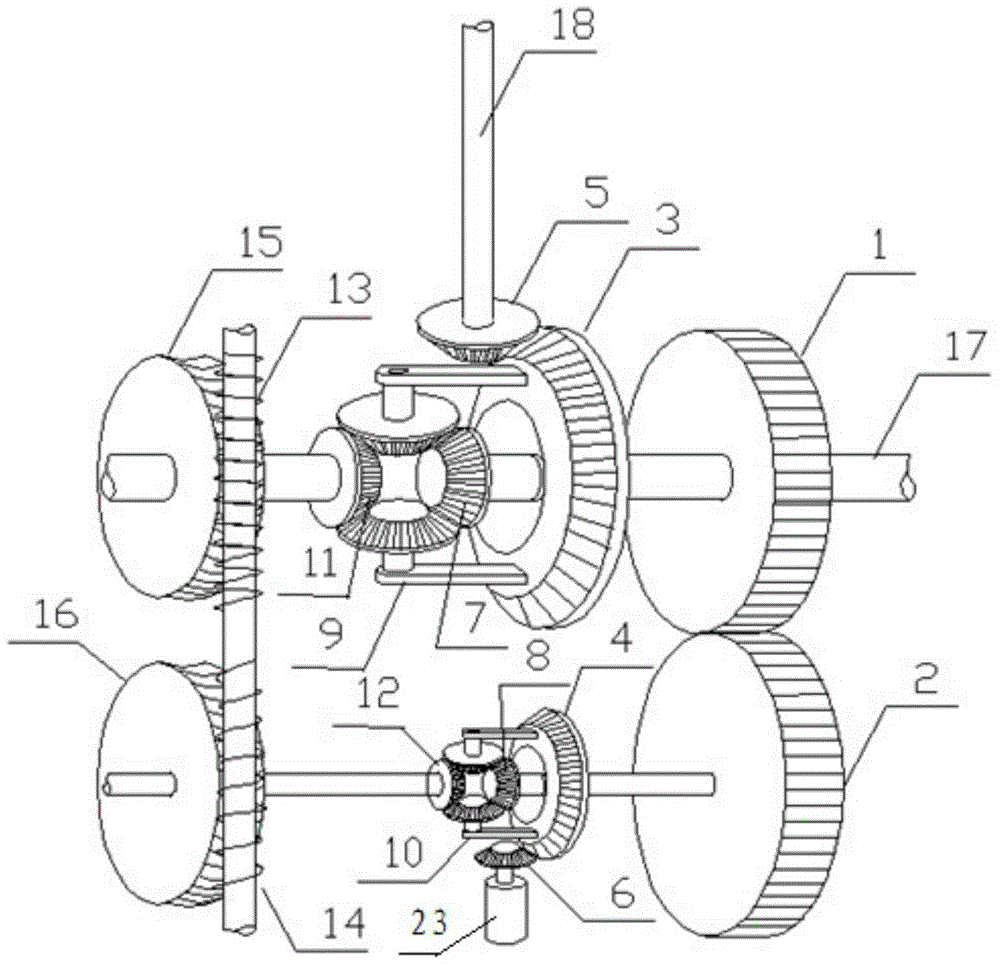

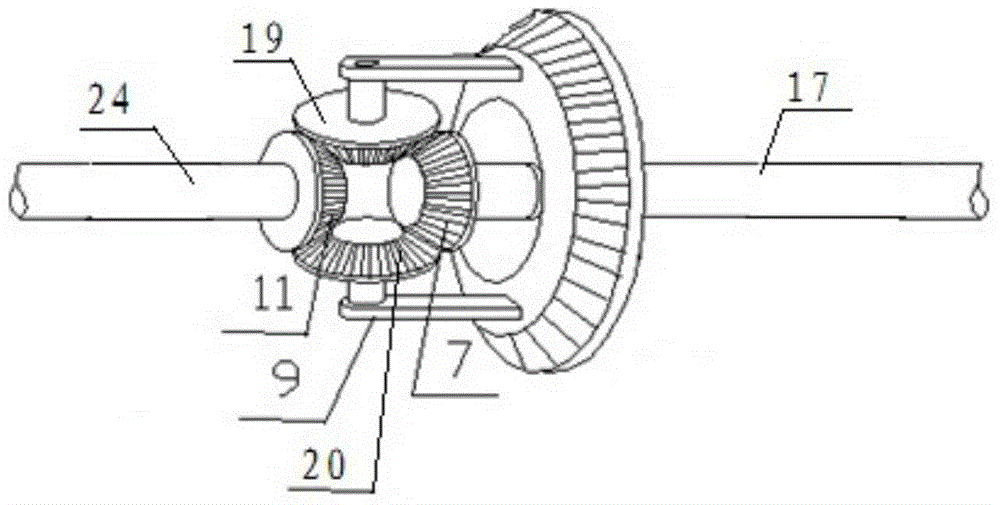

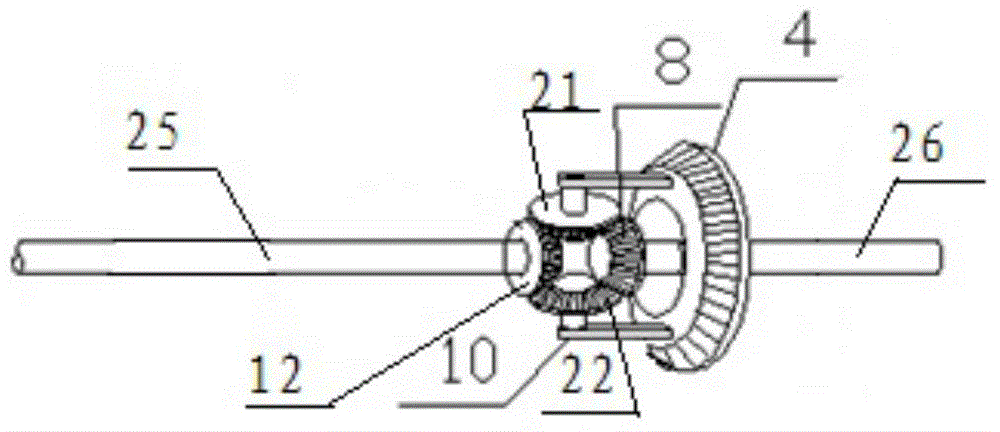

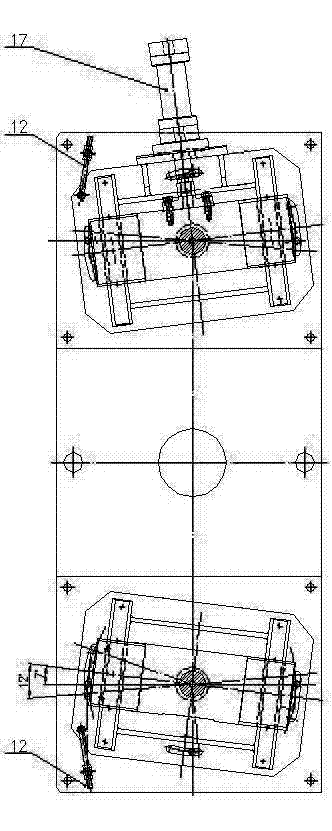

Constant-speed transmission device used for power generation of wind turbine and fuel engine

The invention discloses a constant-speed transmission device used for power generation of a wind turbine and a fuel engine. The constant-speed transmission device comprises a main differential mechanism, a deputy differential mechanism, a first turbine worm reducer with a self-locking function, a second turbine worm reducer without the self-locking function, and a driving gear and a driven feat which are meshed with each other, and a synchronous motor; by utilizing a differential speed adjustment principle of the differential mechanisms, a first sun gear of the main differential mechanism is connected with an engine revolving shaft under variable working conditions to form a driving wheel, and the rotation speed of a second sun gear is adjusted to achieve a constant planet carrier speed transmission by the self-locking function of the first turbine worm reducer, and the rotation speed of the self-locking turbine worm reducer is limited by the deputy differential mechanism and a second turbine worm reducer without the self-locking function, the rotation speed of the second sun gear and a fourth sun gear of the main and deputy differential mechanisms is changed along with the rotation speed of the engine due to the constant speed of the synchronous motor, and the output of the main differential mechanism is the same as the rotation speed of the synchronous motor so that an aim of constant speed transmission is achieved.

Owner:PETROCHINA CO LTD

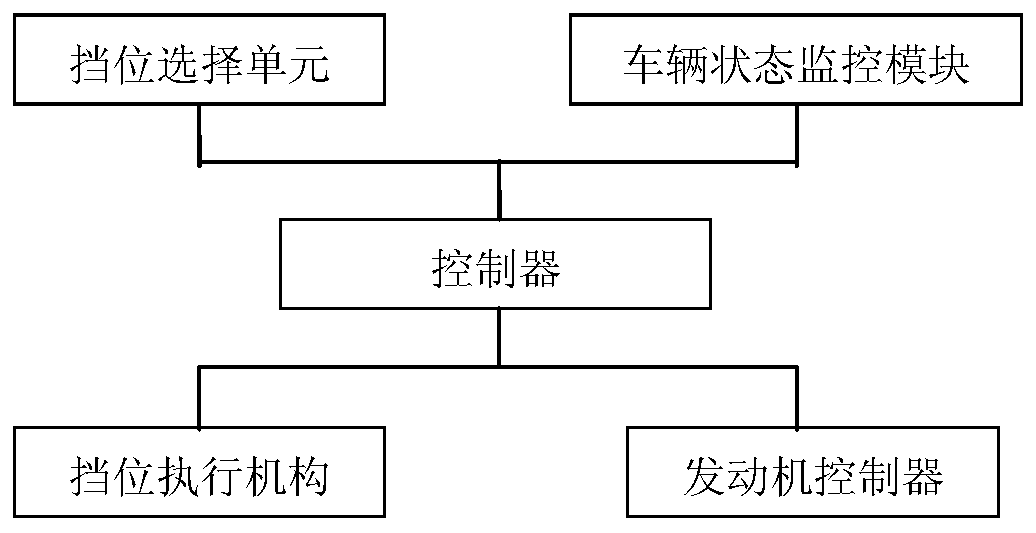

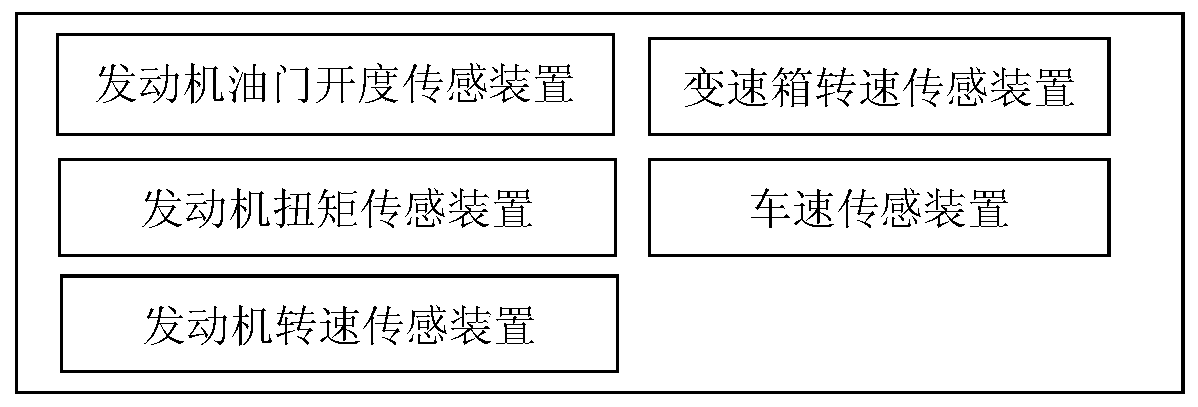

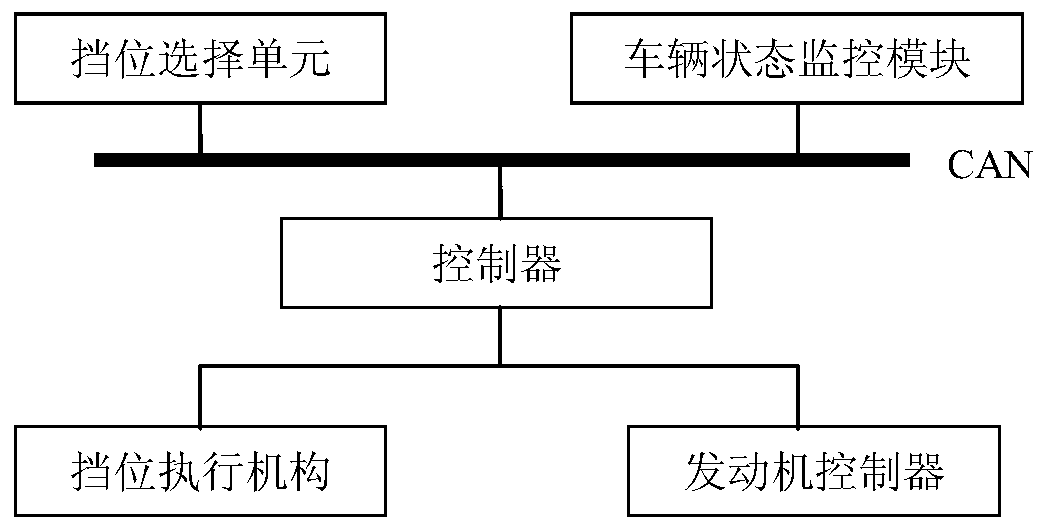

Loader gear and speed automatic control system and control method

The invention discloses a loader gear and speed automatic control system and control method. The loader gear and speed automatic control system is characterized in that a gearbox gear input request signal is monitored through a gear selection unit; an engine throttle opening, an engine torque, an engine rotating speed, a gearbox rotating speed and a vehicle speed signal are collected through a vehicle state monitoring module; a controller controls the vehicle state monitoring module to monitor the current state of a vehicle and compares with a preset condition, controls a gear actuator to be switched between a first gear and a current gear n according to a comparison result, or sends a rotating speed reduction control command to an engine controller to adjust the engine rotating speed so as to make the vehicle speeds of a n+1 gear consistent with the n gear while controlling a gear shift actuator to rise to the n+1 gear from the current gear n. The loader gear and speed automatic control system disclosed by the invention solves the problem that the vehicle speed, gear and engine of a loader are optimally matched under driving working conditions with different shovel loading distance, and achieves the best power performance under the short-distance operation working conditions and the best economy under the long-distance operation working conditions.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

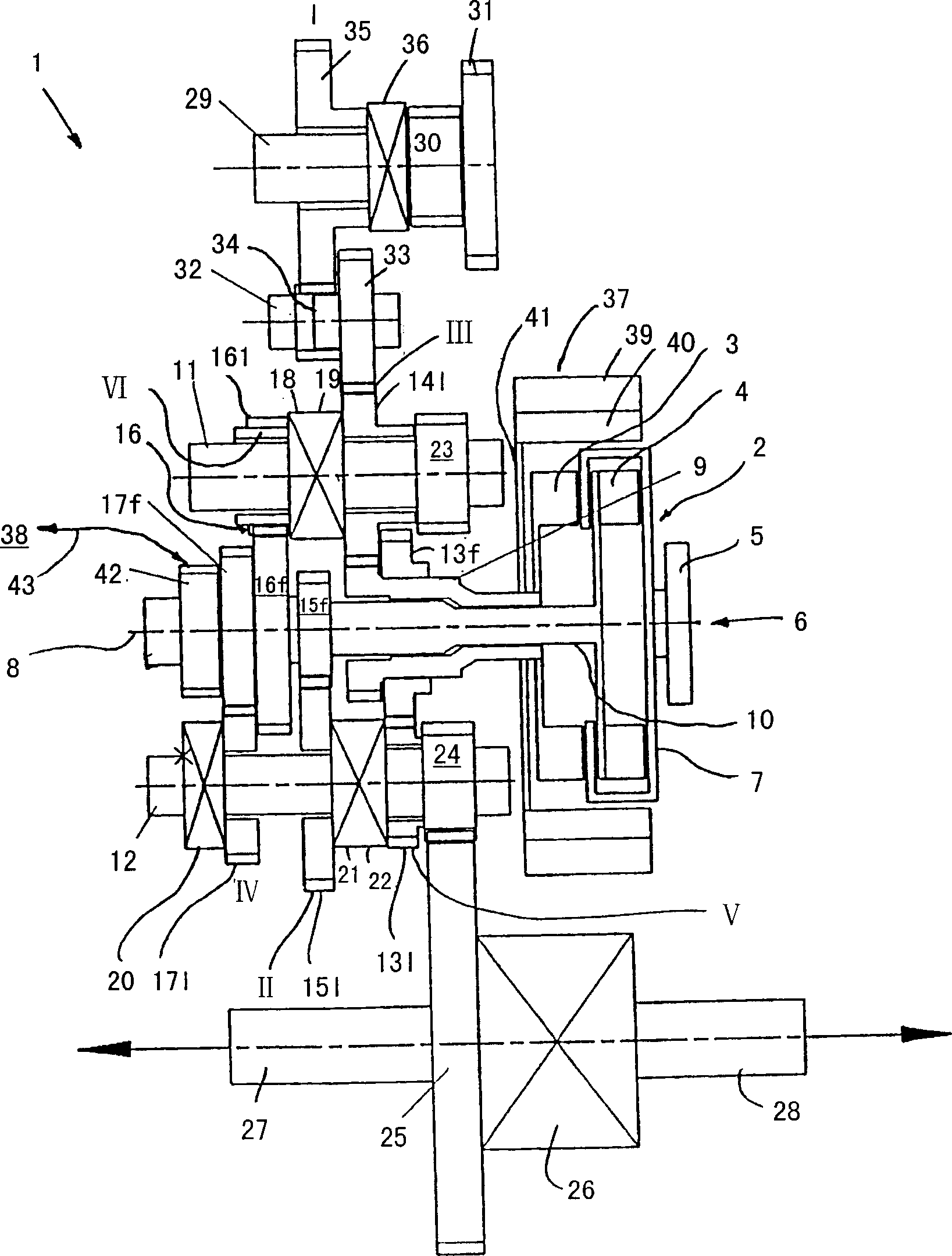

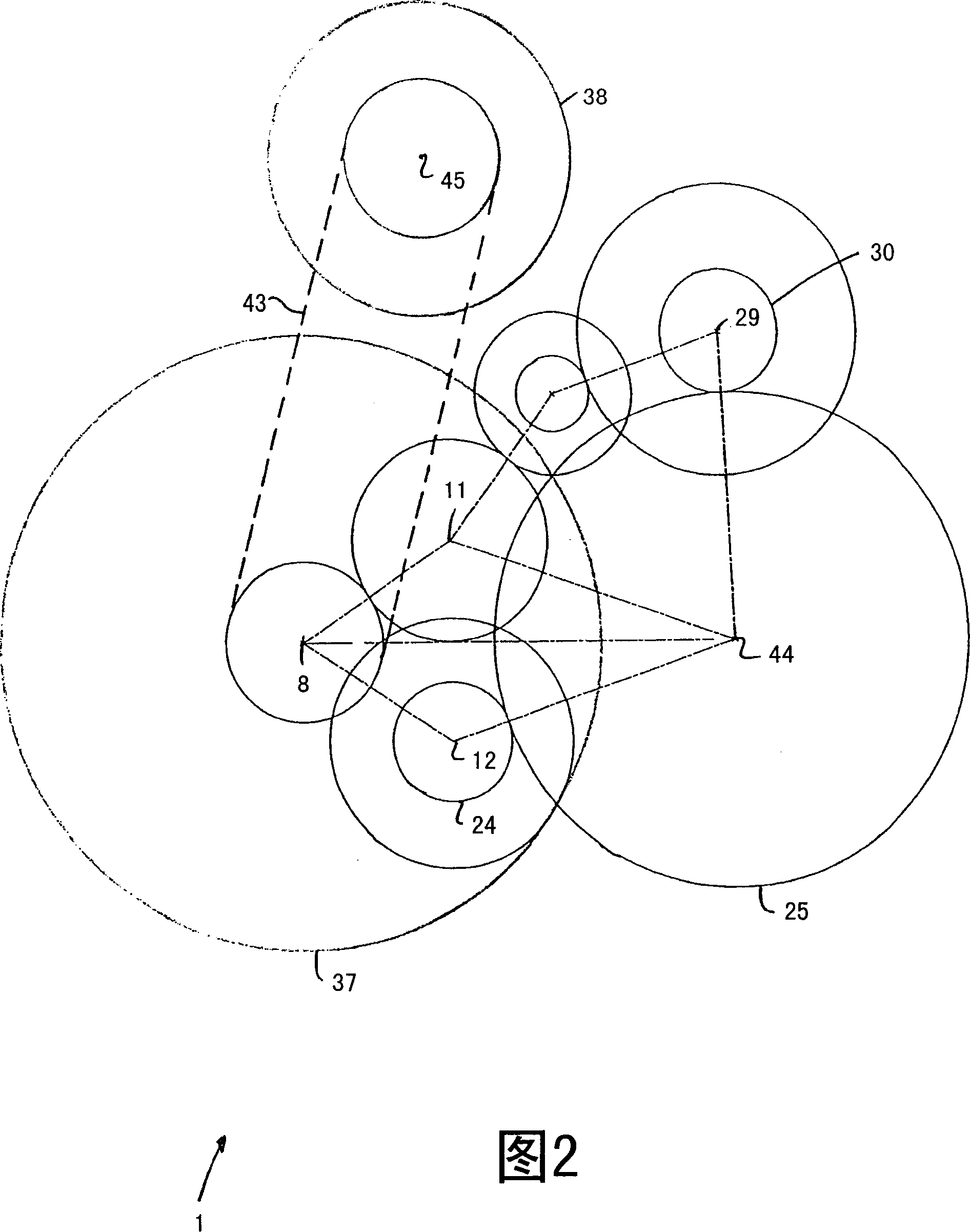

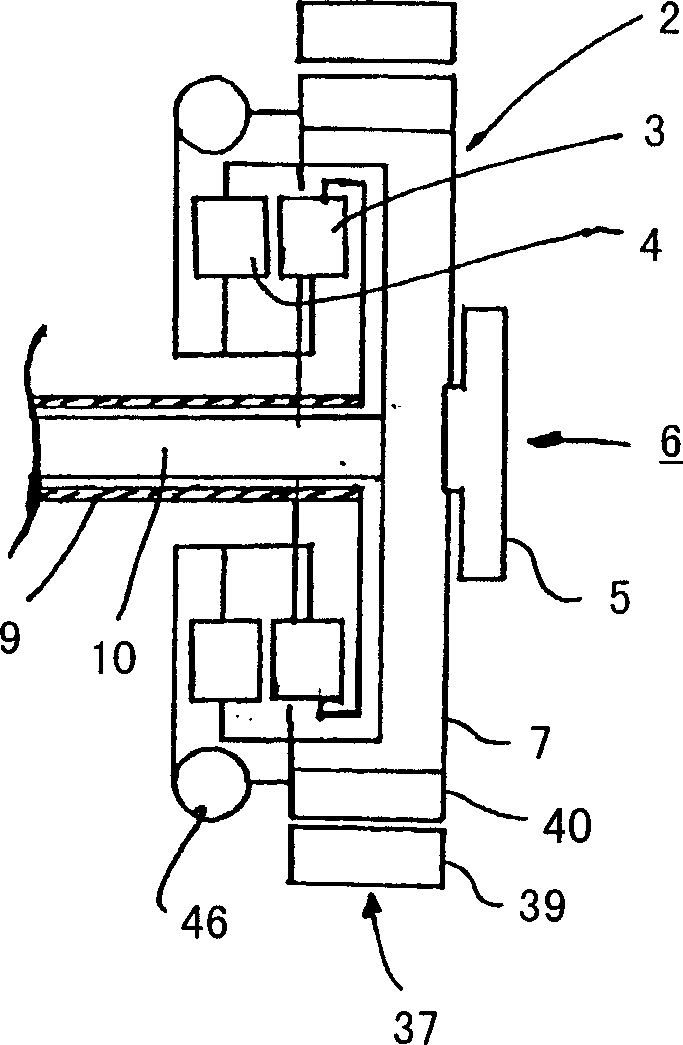

Double clutch transmission

InactiveCN1854561AShort axial structural lengthAxial structural length has no effectHybrid vehiclesToothed gearingsRotational axisDrive shaft

A twin-clutch transmission, in particular for a motor vehicle, with a twin-clutch arrangement comprising: a first clutch; a second clutch; a first input shaft; a second input shaft; at least one output shaft; a number of engageable gearwheel pairs for connecting the input shafts to the at least one output shaft; a first drive unit; and a second drive unit having a drive shaft rotatable around a rotational axis. The clutches having a common rotational axis connect the first and second input shafts to an engine. A serial and / or parallel hybrid mode of the twin-clutch transmission can be established by means of the first and second drive units. The first drive unit is arranged coaxially with the first and second clutches and surrounds the clutches in the radial direction. The drive shaft of the second drive unit and the clutches have different rotational axes.

Owner:GETRAG FORD TRANSMISSIONS GMBH

Resonant oscillating scanning device with multiple light sources

InactiveUS20050185235A1Improve throughputImprove efficiencyBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansScan lineLight beam

Owner:LEXMARK INT INC

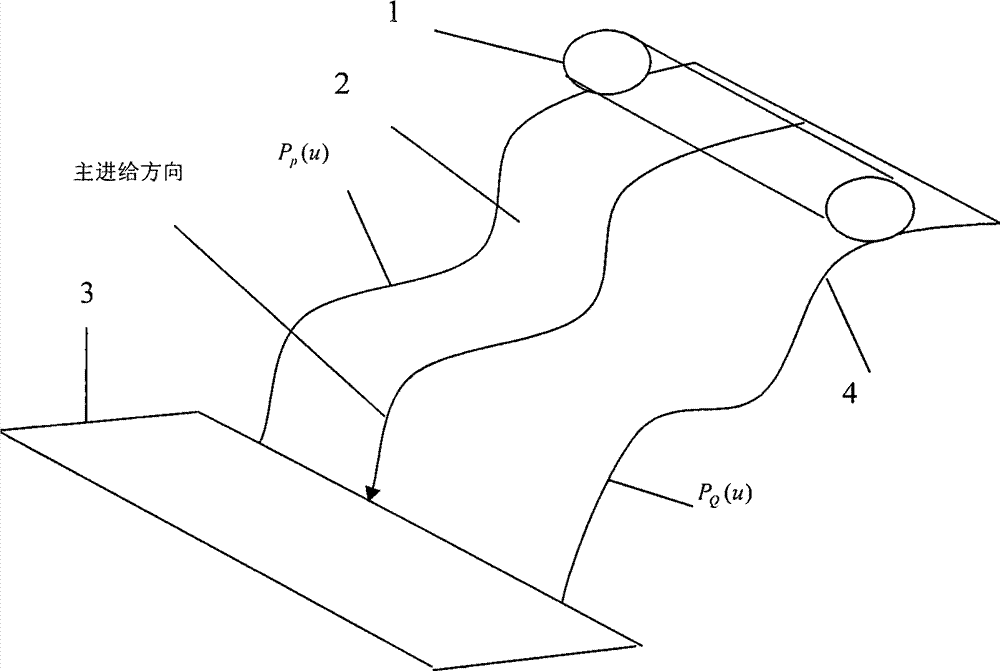

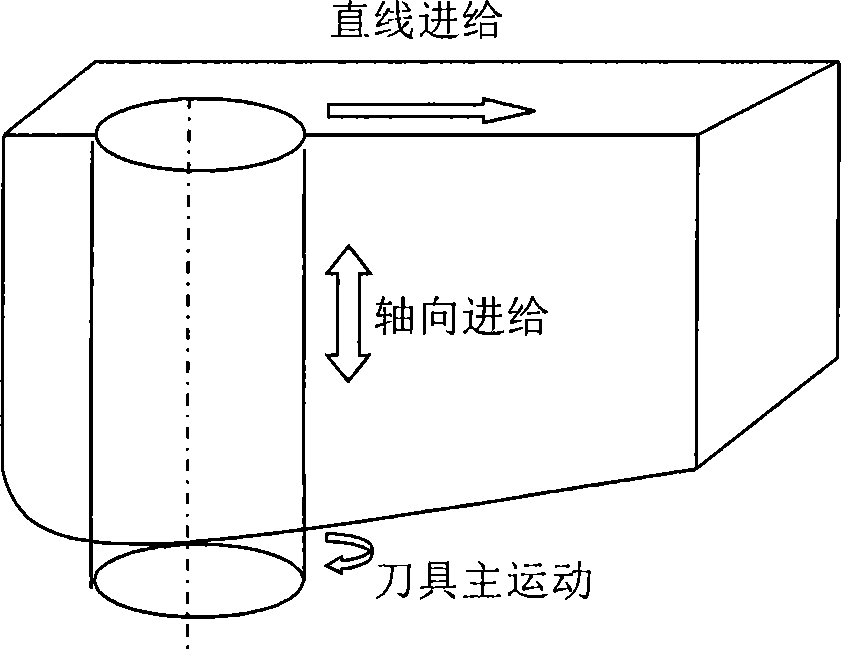

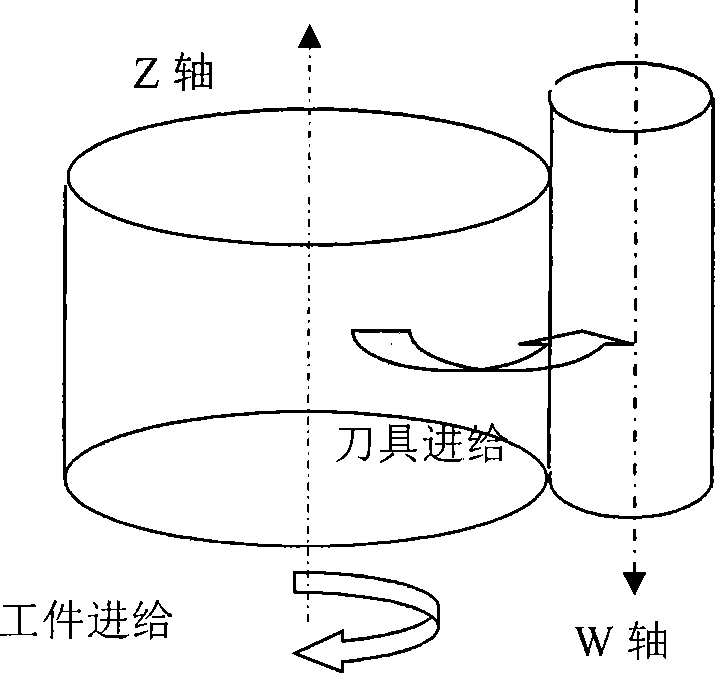

Efficient and direct curved surface numerical control machining method

The invention relates to an efficient and direct curved surface numerical control machining method. Feature ruled surface interpolation is used as the minimal interpolation unit to replace a traditional point location and curve interpolation method to be used as a basic interpolation unit method. On a numerically-controlled machine tool where the swing, rotation and turning radius adjustment of a tool can be achieved, a circumferential cutting edge of a cylindrical milling cutter is used for machining workpieces, and accordingly the ruled surfaces such as a plane, a cylindrical surface, a conical surface and a spiral surface can be formed directly. A ruled surface interpolation instruction is used as a basic machining instruction, and efficient numerical control machining of the feature ruled surfaces with curved boundaries can be achieved under a numerical control interpolation code. The feature ruled surfaces are used as basic units, so that other curved surfaces are fitted, and machining is completed on the numerically-controlled machine tool where a composite surface machining instruction can be achieved. The numerical control machining method can be used in the numerical control finish machining fields of machines for numerical control milling finish machining, finish machining, numerical control turn-milling machining, numerical control electrolytic machining, numerical control electrosparking and the like.

Owner:XIAN TECH UNIV

Method for massively purifying trimethylaluminum crude product

ActiveCN109569002AImprove uniformityGood practical valueGroup 3/13 element organic compoundsFractional distillationGas phaseBoiling point

The invention discloses a method for massively purifying a trimethylaluminum crude product. The method comprises the following steps: through inert gas exchange of a microchannel rectifying tower, enabling the trimethylaluminum crude product to be transferred to a rectifying kettle; after transferring a material, closing a feeding valve, and rectifying, wherein a rectifying pressure is 0.02-0.1 MPa, and a rectifying temperature is 80-128 DEG C; collecting the distillated material of which a boiling point is 125-127 DEG C by using a condenser, to obtain a high-purity trimethylaluminum product.In the microchannel rectifying tower, a plurality of microchannel rectifying columns is fixed as a rectifying column beam through a beam concentrating device. A heating jacket is installed outside themicrochannel rectifying tower. A gas phase feeding port is connected below the microchannel rectifying tower, and a gas phase discharging port and a backflow liquid pipe are connected above the microchannel rectifying tower. The lower end of the backflow liquid pipe is connected with a gear-type flow distributor. The method is capable of, through improving a structure of the rectifying tower, guaranteeing an efficient distillation separation feature of a microchannel structure, and optimizing homogeneity of pipe body gas-liquid distribution, thereby realizing a large-scale efficient purification technology for trimethylaluminum in production.

Owner:江西石华精细化工科技协同创新有限公司

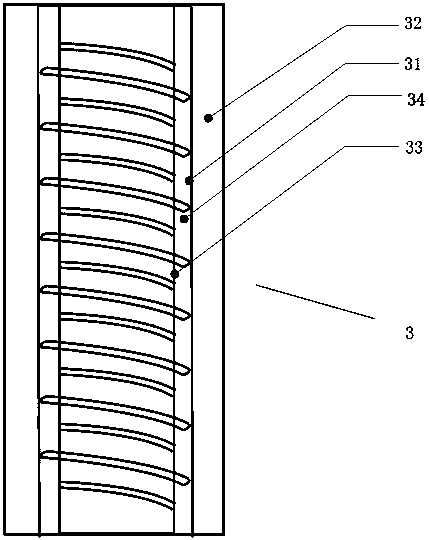

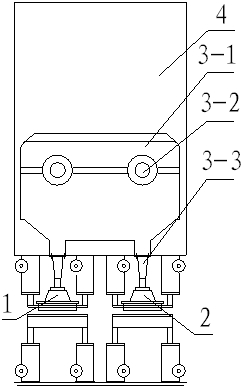

Horizontal type corrective pinch device

InactiveCN103084416AQuick correctionImprove deviationGuiding/positioning/aligning arrangementsHydraulic cylinderStrip steel

The invention provides a horizontal type corrective pinch device which is used in strip steel processing line. The horizontal type corrective pinch device comprises a base, a fixing frame, a motor, a compression roller frame, a compression roller and a pinch roll, wherein the fixing frame is connected with the base and can rotatably adjust the angle. A guide rail and a moving frame are installed on the fixing frame, wherein the moving frame can move on the guide rail, a compression roller frame drive hydraulic cylinder is installed on the side surface of the moving frame, the compression roller frame is connected with the moving frame in a hinged mode and connected with the compression roller frame drive hydraulic cylinder, the compression roller frame can be driven by the hydraulic cylinder to revolve around the hinge point, the pinch roll is installed on the moving frame, and the position of the pinch roll rightly faces the compression roller which is in the compression roller frame. The horizontal type corrective pinch device can effectively overcome the defect of deviation in the operation of strip steels, ensure the safety of rolling equipment of the strip steels and meet the quality requirement of products.

Owner:WISDRI ENG & RES INC LTD

Self-opening velocity type hydraulic energy absorption and consumption device

ActiveCN105951581AReduce frictionReduce the impact of navigationBridge structural detailsEnergy absorptionHanging basket

The invention discloses a self-opening velocity type hydraulic energy absorption and consumption device. The self-opening velocity type hydraulic energy absorption and consumption device mainly comprises a steel box girder and a hanging basket, wherein the hanging basket is arranged in a square concave hole at the bottom of the steel box girder; the hanging basket comprises a hanging basket bottom plate and peripheral side walls; the hanging basket bottom plate is provided with a plurality of water through holes; a cover plate is hinged above the water through holes; one rope is connected with each of four corners at the upper part of the hanging basket; after the four ropes are bound together, the four ropes are connected with a hanging rope; the other end of the hanging rope is wound on one side of a rotary barrel; the rotary barrel is fixedly arranged on a top plate of the steel box girder; a pressing device and a friction sheet are mounted above the rotary barrel; a horizontal supporting plate is arranged at each of four corners of the bottom of the square concave hole; a vertical baffle is arranged on each horizontal supporting plate; the vertical baffles are connected with a side plate at the bottom of the square concave hole through limiting springs; and the four corners of the hanging basket bottom plate are supported on the four horizontal supporting plates at the bottom of the square concave hole through round balls. An energy consumption device can be automatically opened when a bridge starts to vibrate, and the vibration of the bridge is inhibited through hydraulic energy consumption.

Owner:HUNAN UNIV OF SCI & TECH

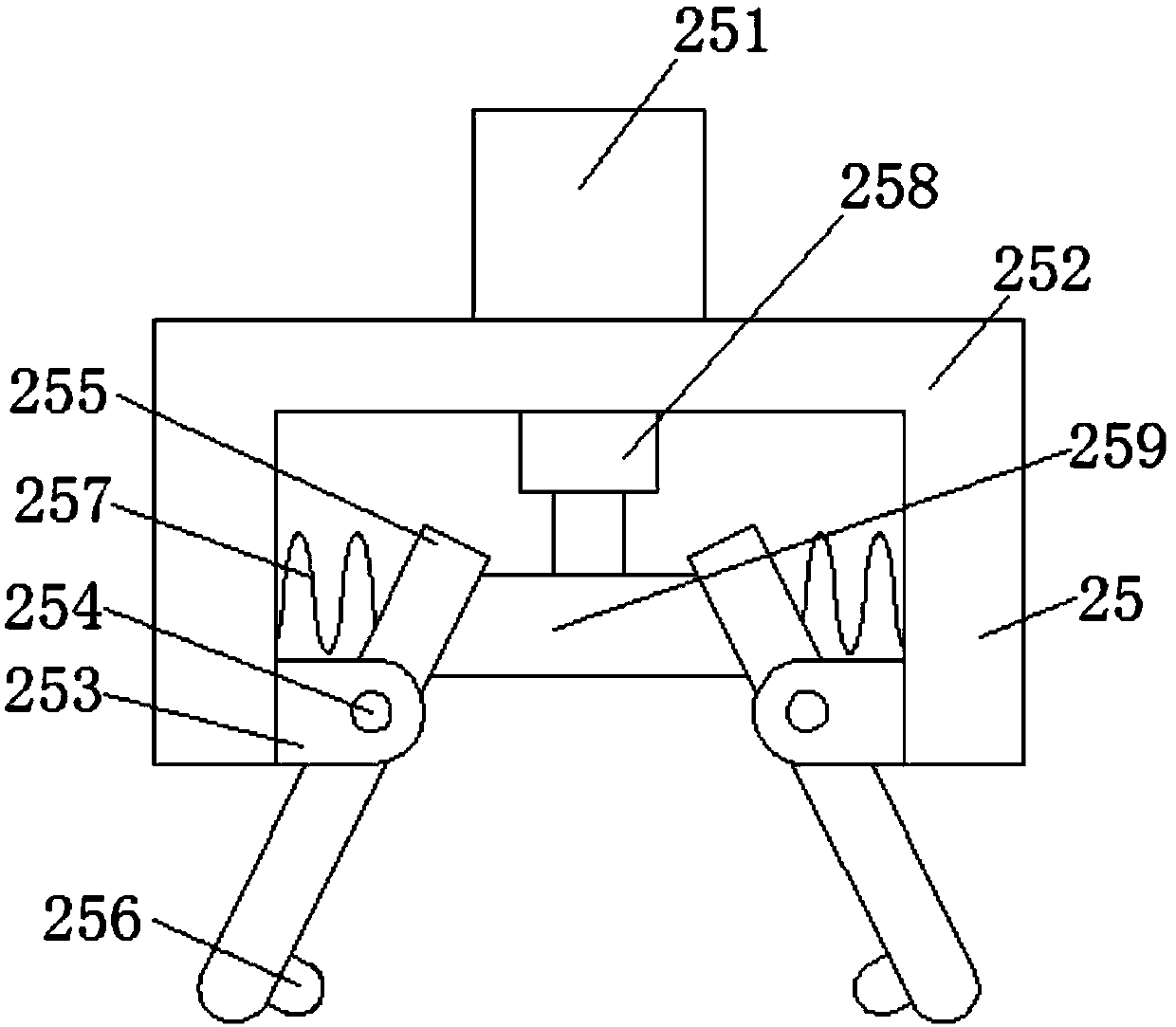

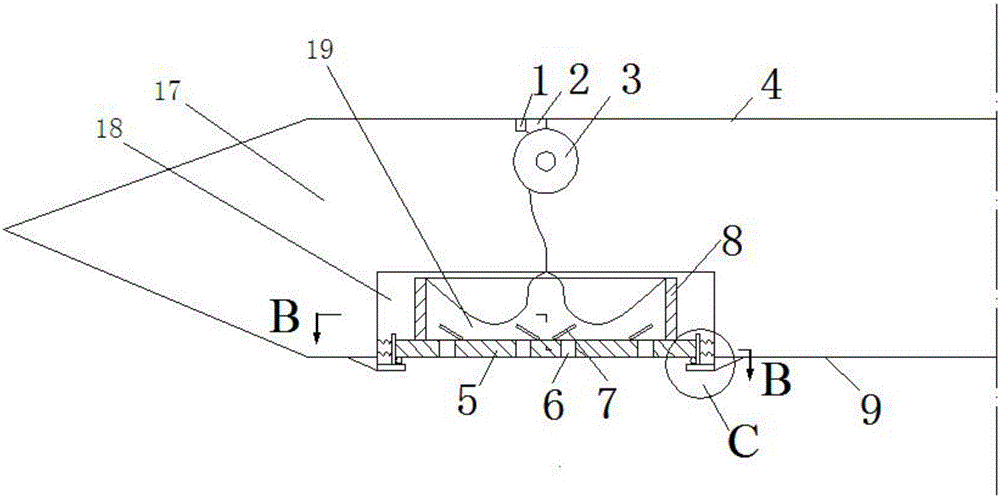

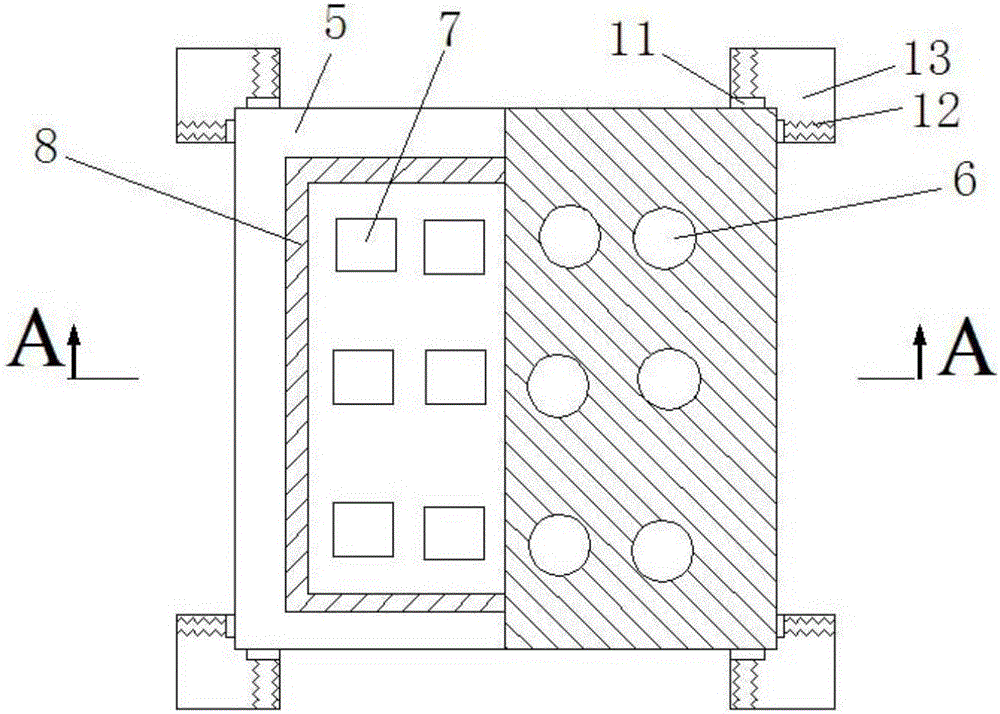

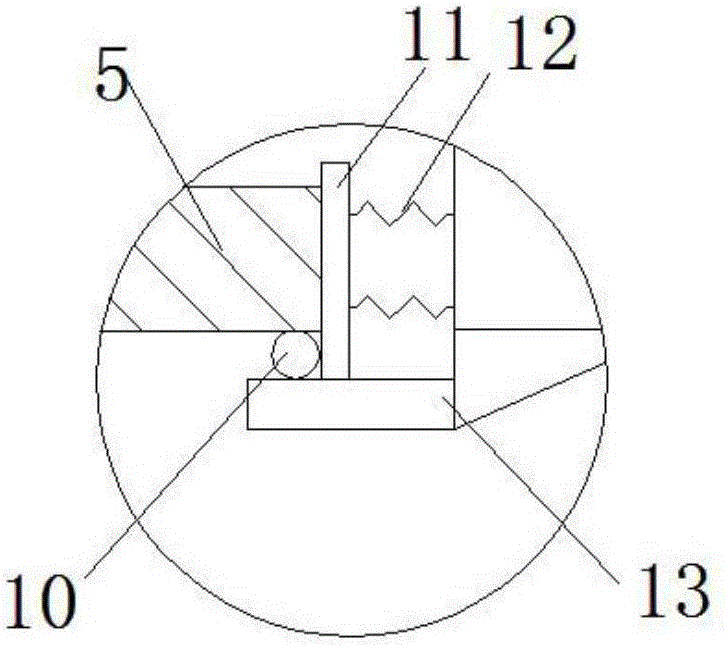

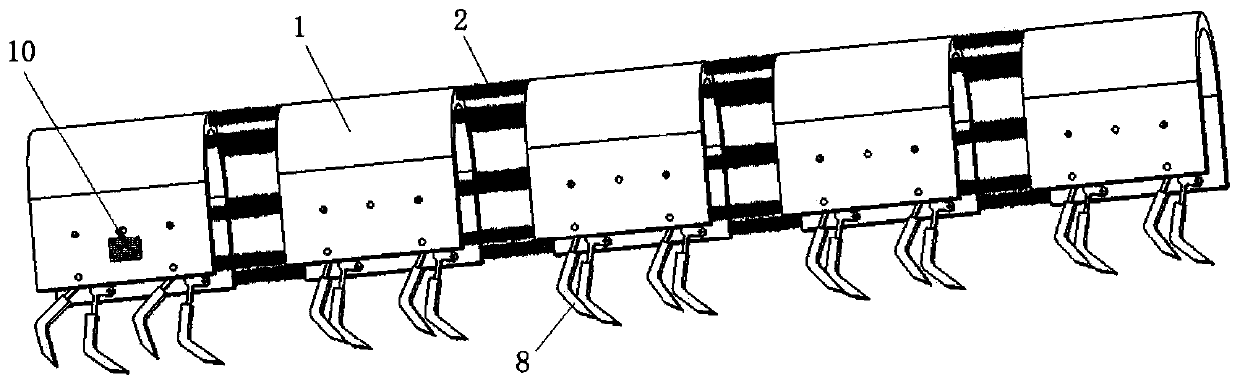

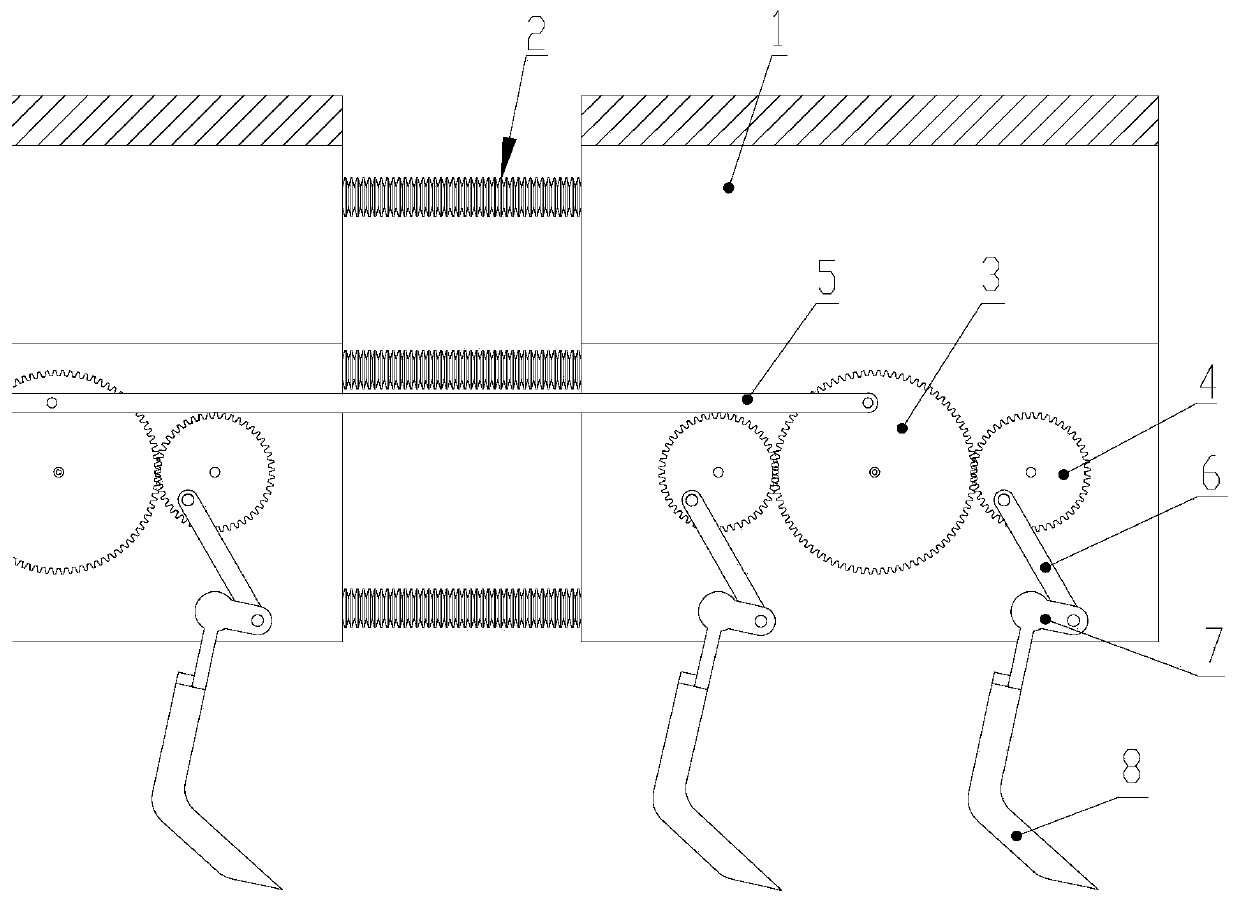

Bionic mantis shrimp underwater rowing device based on motor driving

PendingCN111137421ASimple controlFlexible movementPropulsion power plantsPropulsive elements of non-rotary typeElectric machineryRowing

The invention relates to the field of robots. The invention aims to provide a bionic mantis shrimp underwater rowing device based on motor driving, the bionic mantis shrimp underwater rowing device simulates paddling action of mantis shrimps in water, motor driving and a mantis shrimp bionic structure are combined, underwater rowing sensitivity of the device can be greatly improved, and the bionicmantis shrimp underwater rowing device has the advantages of being simple in structure and flexible in movement. According to the technical scheme, the bionic mantis shrimp underwater rowing device based on motor driving is characterized by comprising a main body frame, a transmission assembly, a rowing assembly and a driving assembly, wherein the main body frame comprises a plurality of shells which are parallel to one another and are linearly arranged in the front-back direction, and a plurality of connecting columns for fixedly connecting the adjacent shells; the left side and the right side of the inner wall of each shell are symmetrically provided with one group of transmission assemblies. The transmission assembly comprises a large gear driven by the driving assembly and two small gears which are rotatably positioned on the inner wall of the shell, arranged on the front side and the rear side of the large gear respectively and in meshing transmission with the large gear.

Owner:ZHEJIANG SCI-TECH UNIV

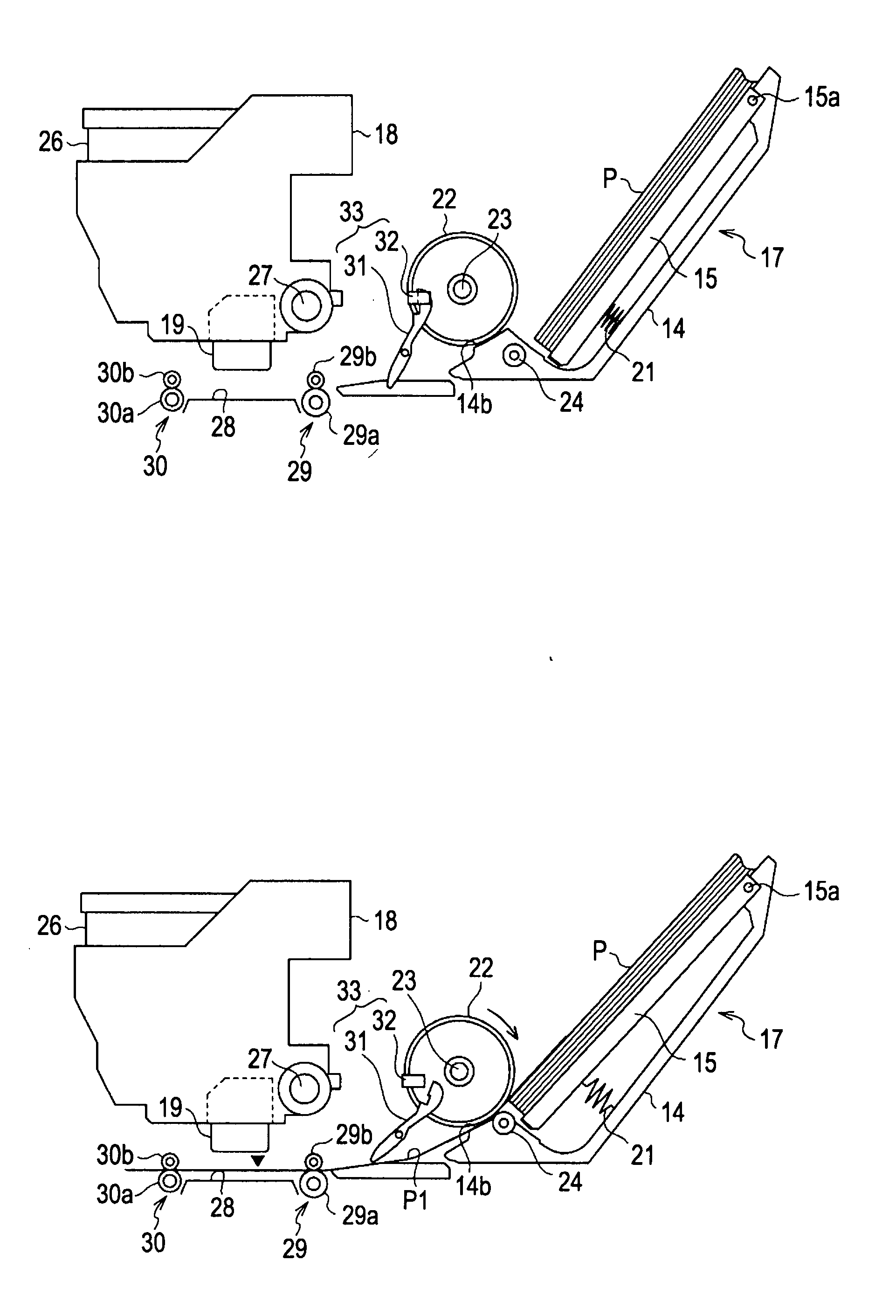

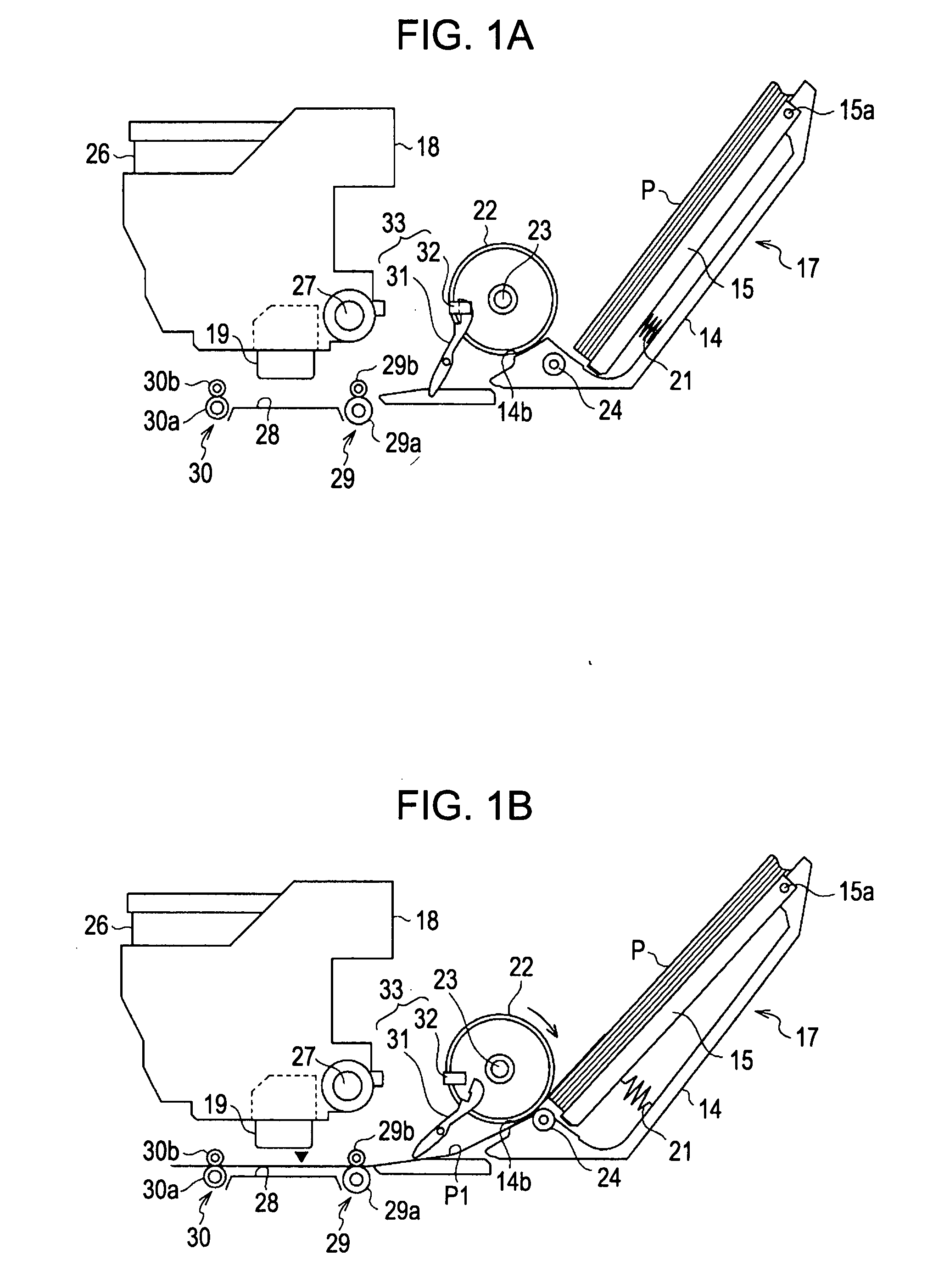

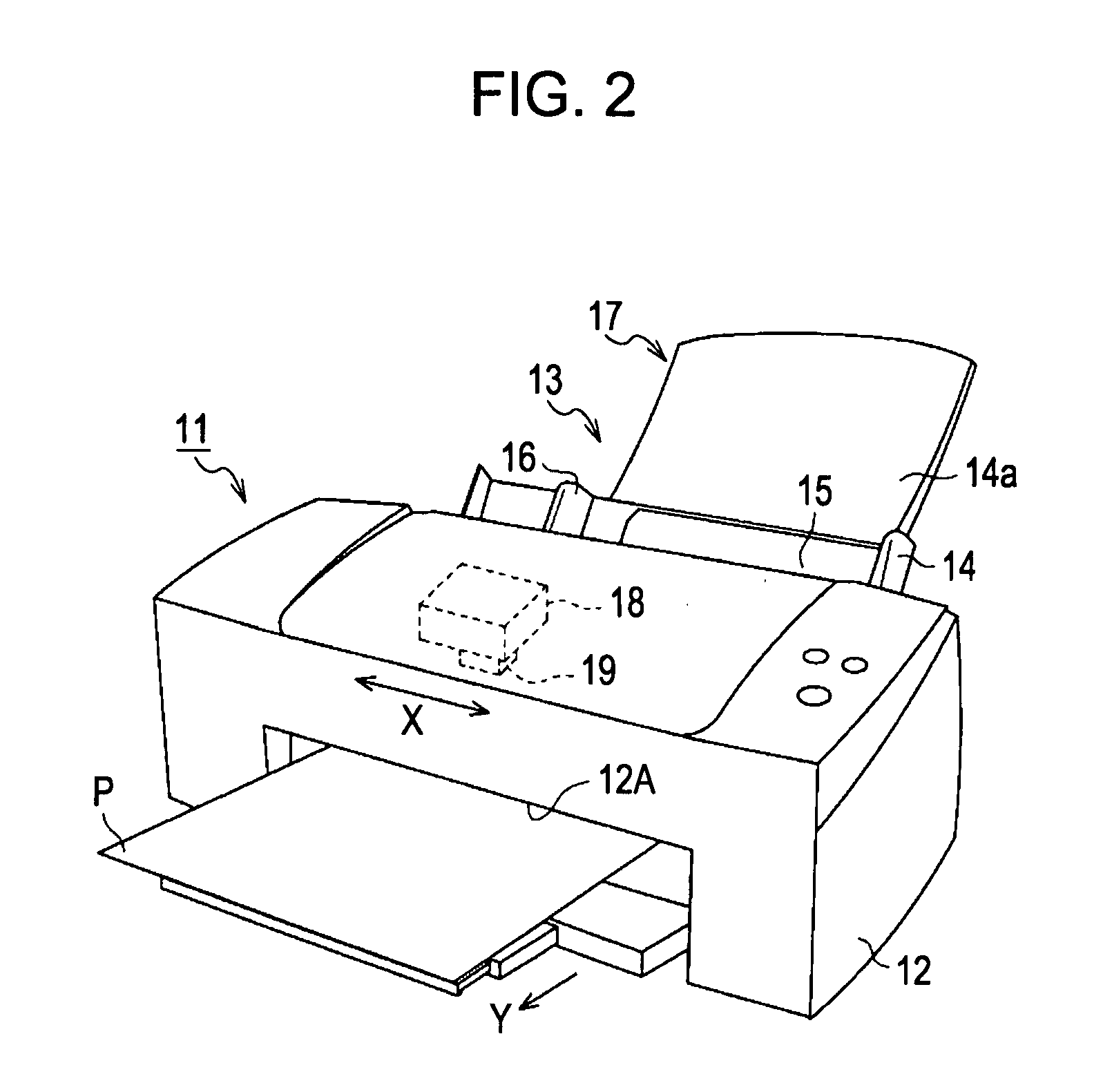

Recording apparatus and medium transporting method

ActiveUS20080063449A1Improve throughputExcessive loosenessFunction indicatorsElectrographic process apparatusControl theory

Owner:SEIKO EPSON CORP

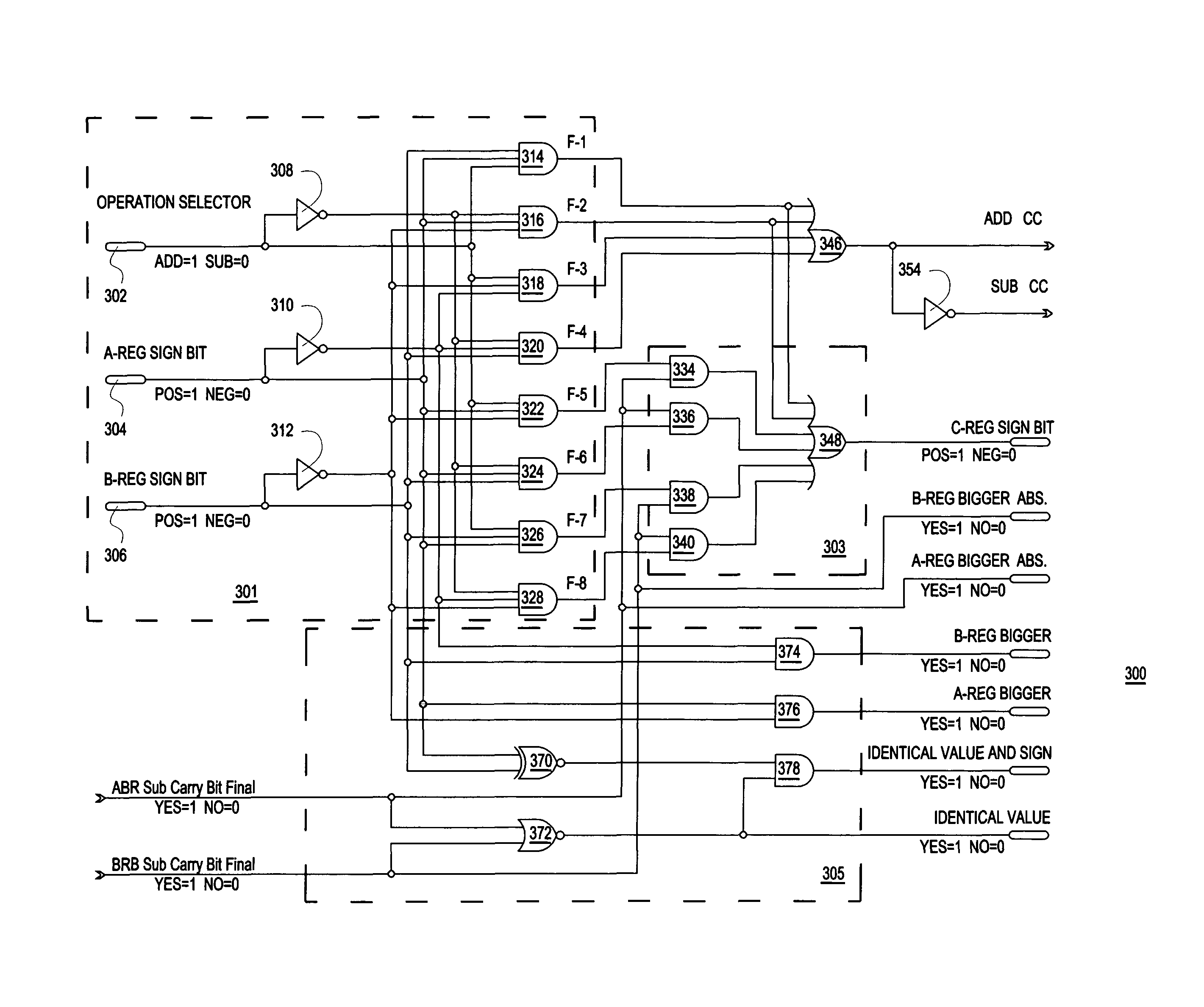

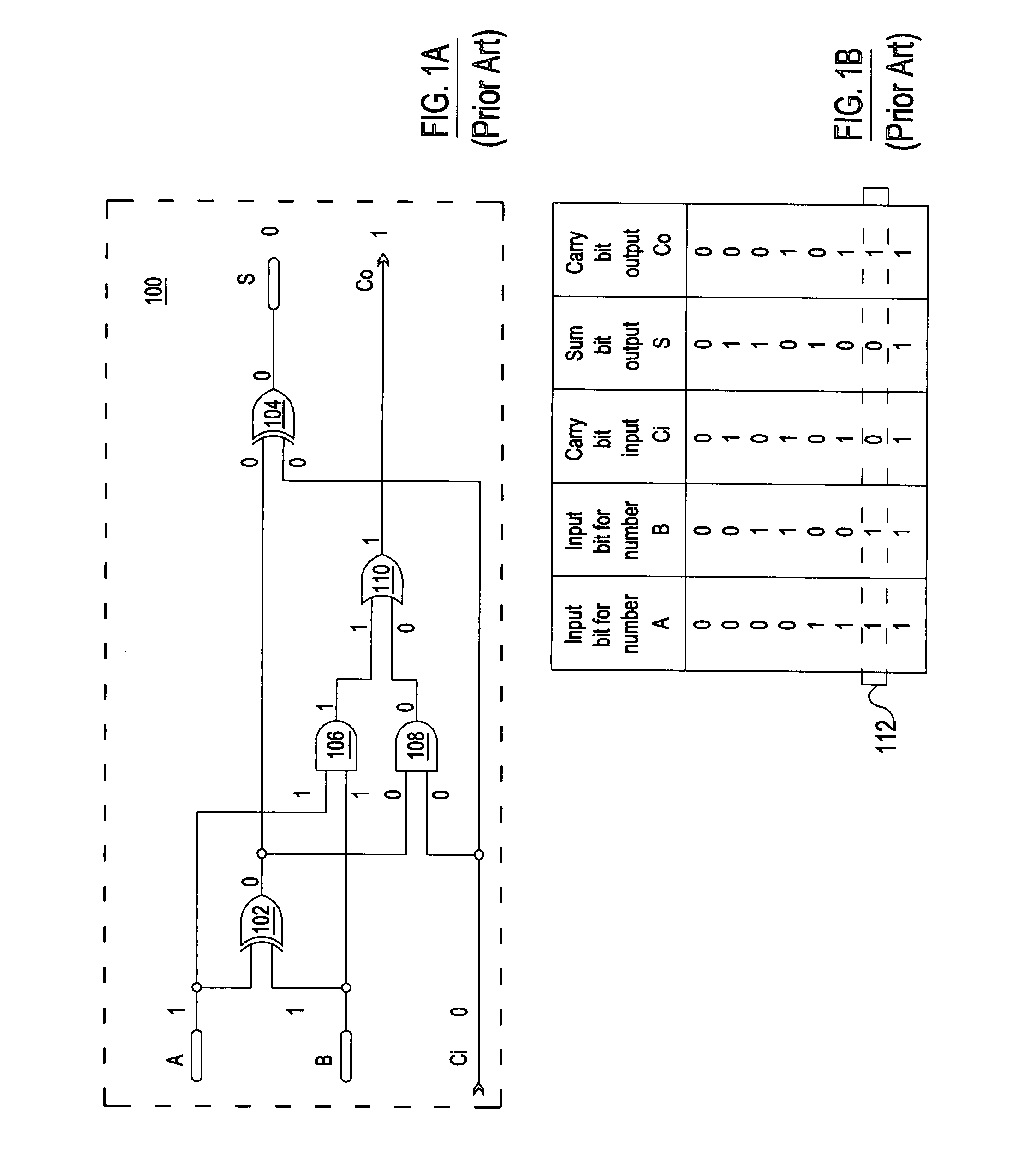

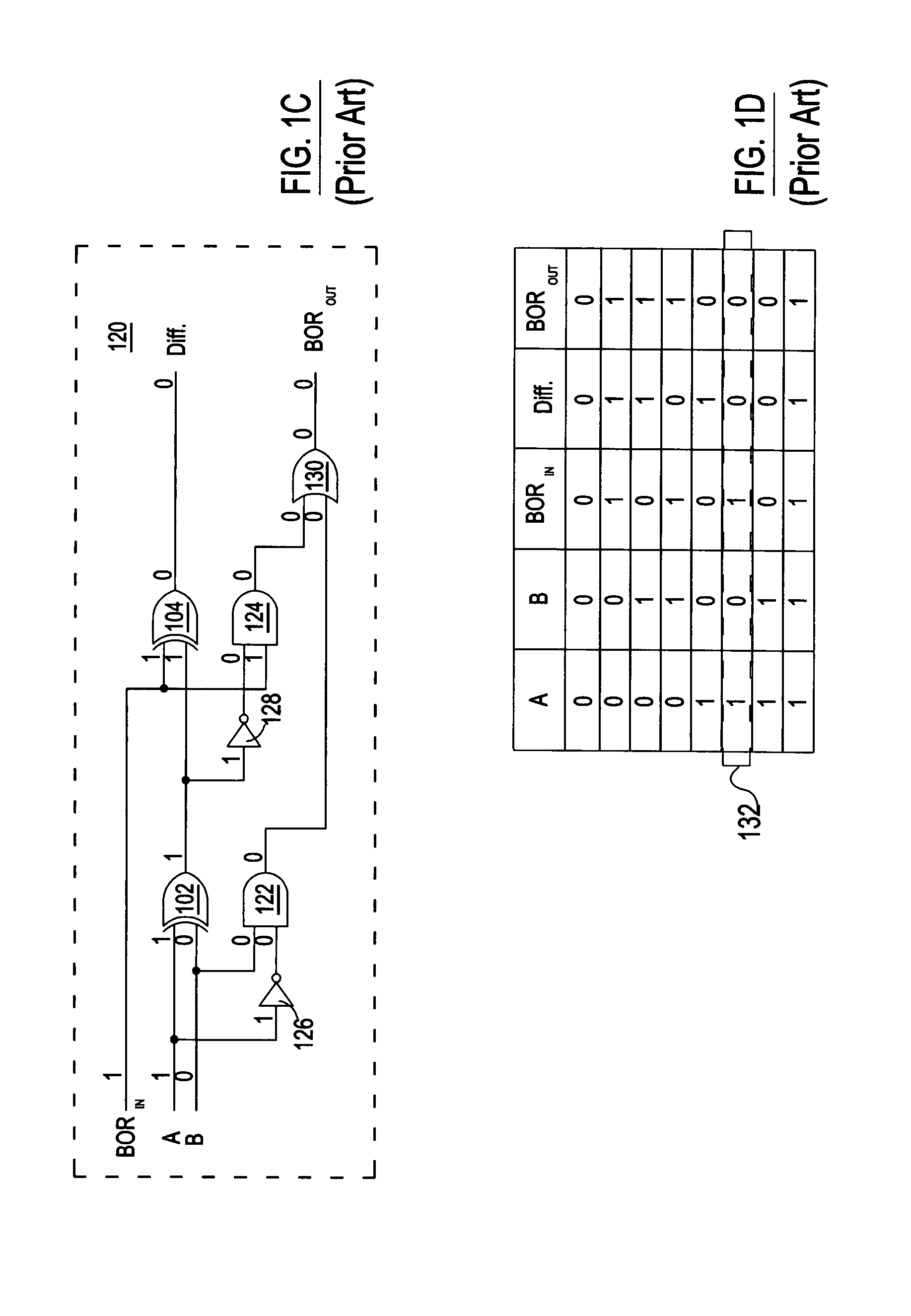

One step binary summarizer

InactiveUS7991820B1Eliminate needEliminate utilizationComputation using non-contact making devicesProcessor registerOperand

The ONE STEP BINARY SUMMARIZER is a digital logic circuit. It is used for summarizing two binary numbers. It contains one Function Generator Module and one or more SUMMARIZER Units. For subtraction it is subtracting Register “A” from Register “B” and Register “B” from Register “A”. The two subtraction and one addition operations are executed simultaneously. The Function Generator Module determines the actual correct operation, (addition or subtraction) and selects the correct results for the resultant operand. The circuit utilizes the subtraction-by-carry method; therefore the subtraction operation does not require any presorting, complementary operations, iterative additions, temporary storage, and multiple instruction sets, etc. The logic-flow is similar, the operational speed is identical for the addition and subtraction operations; and therefore, it is a true Time Symmetrical circuit. It is independent from the initial operation selection, the signs and magnitudes of the input operands.

Owner:SOHAY LESLIE IMRE

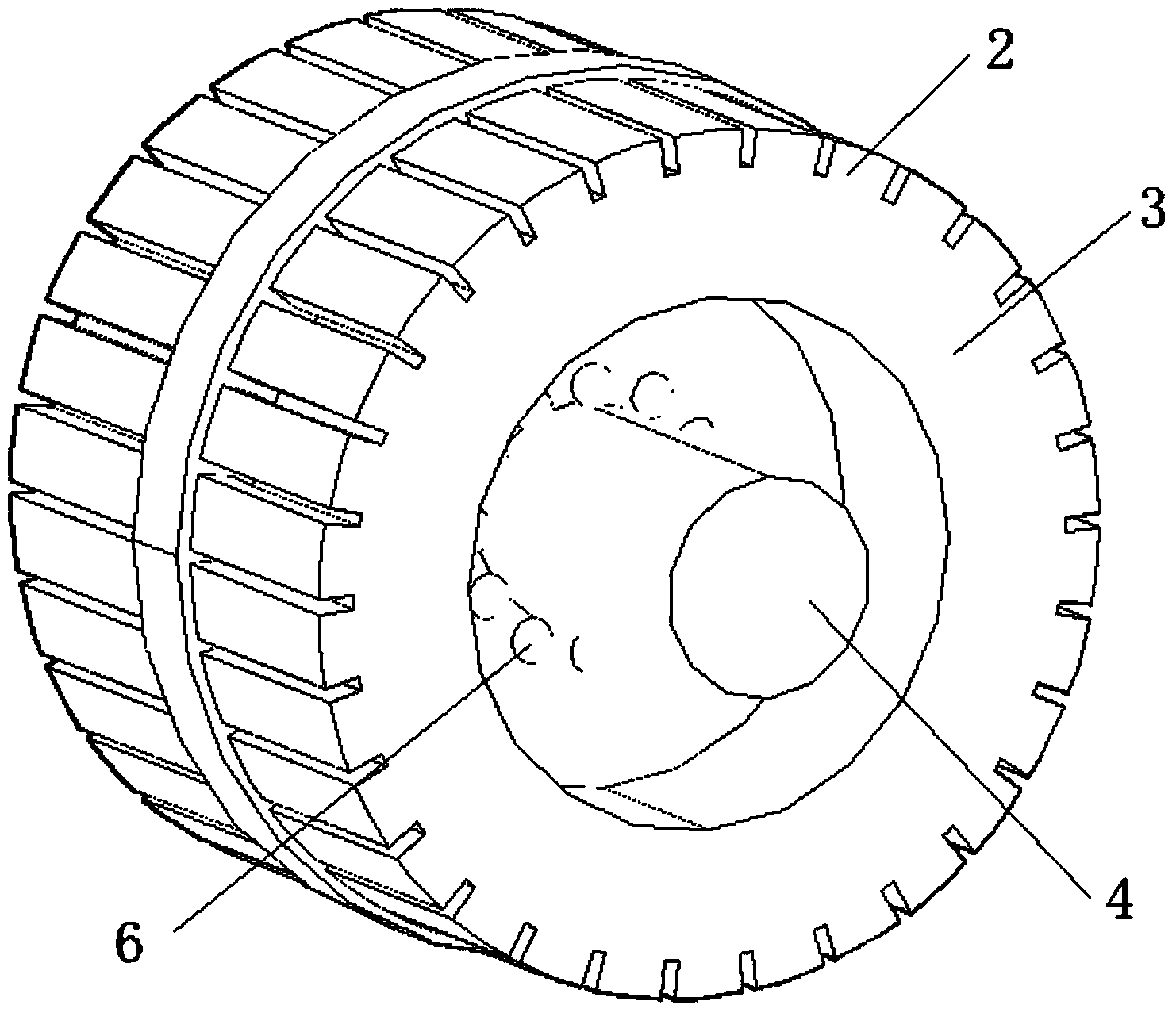

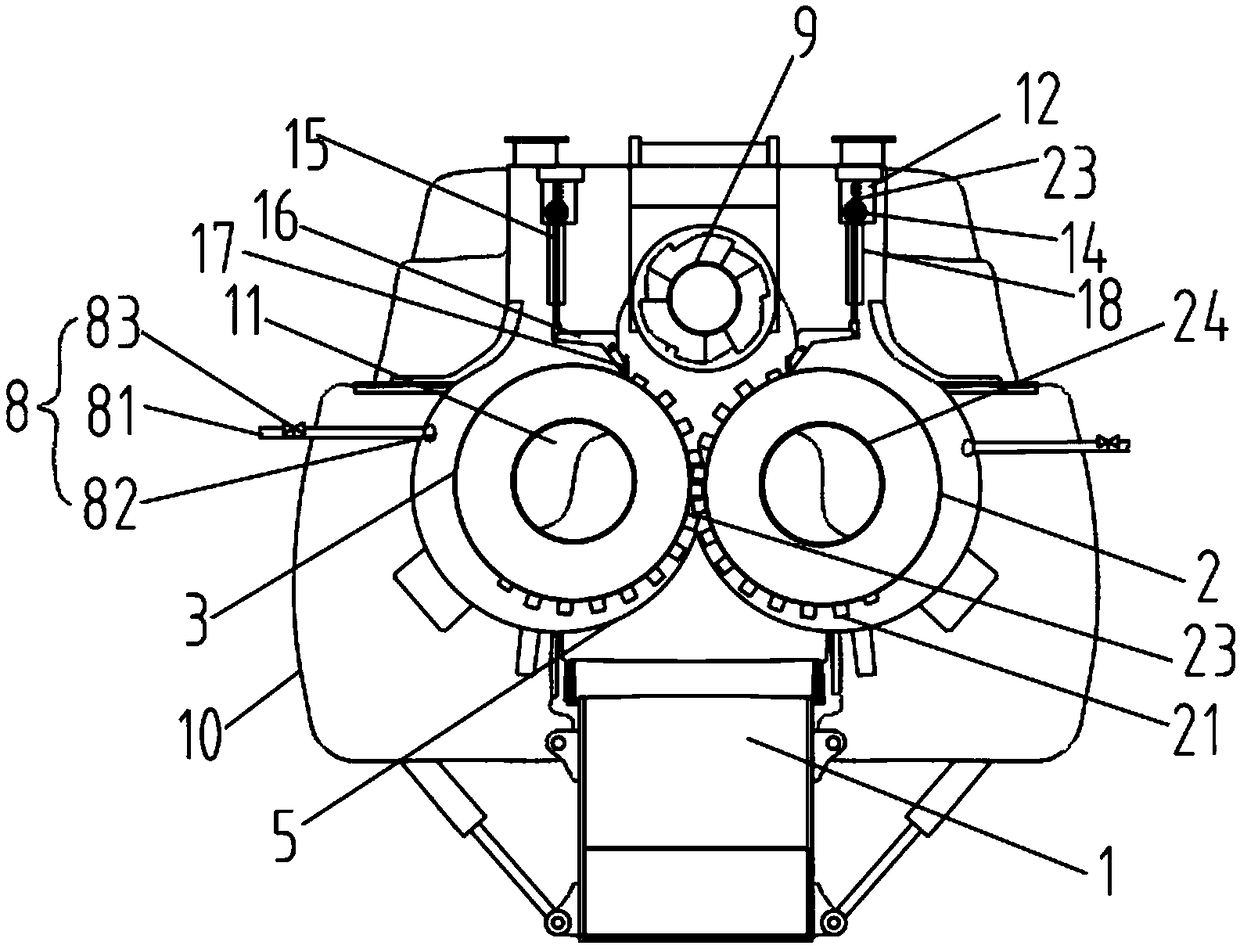

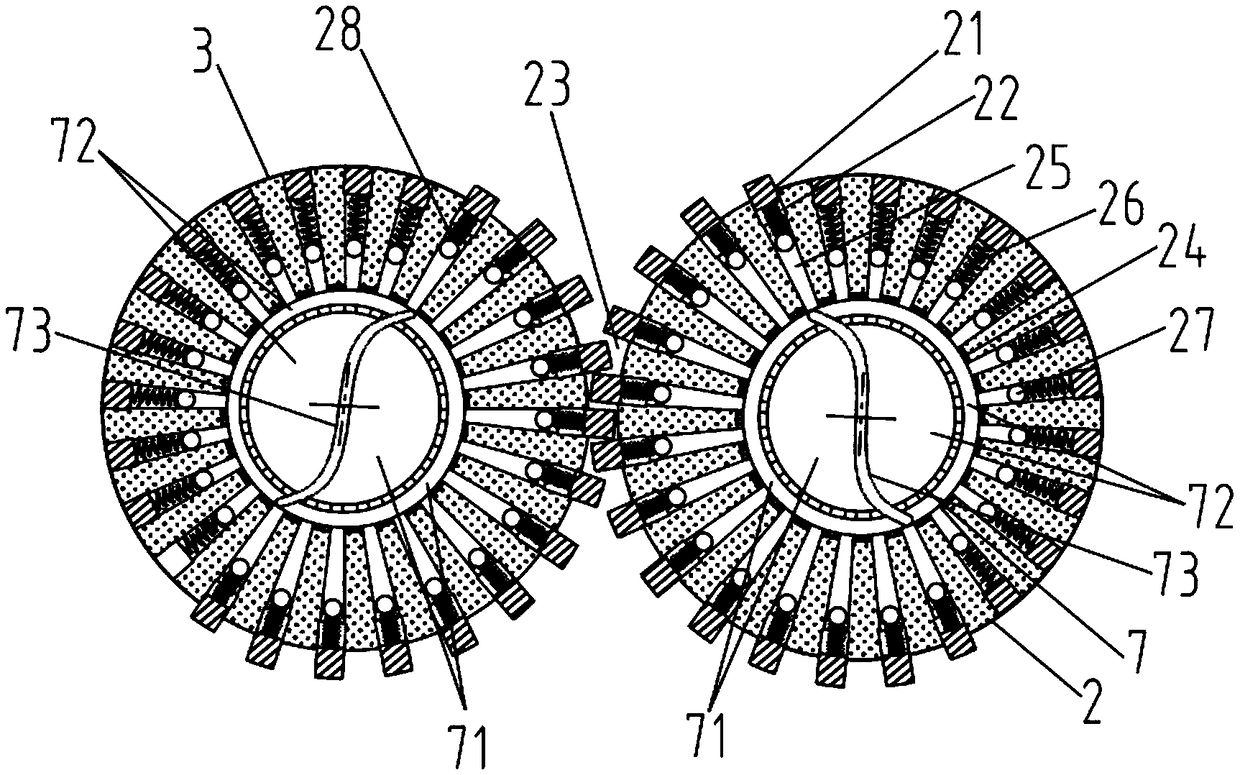

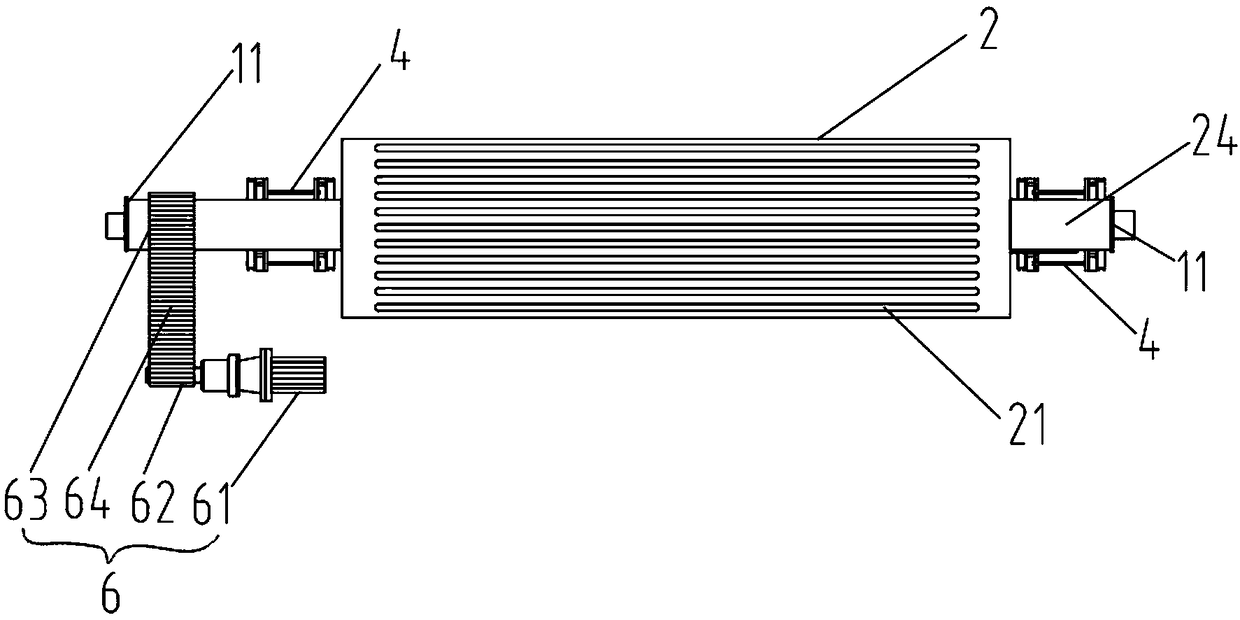

A birotor wheel hub electric automobile motor

InactiveCN103647378ALarge output torqueSame speedMagnetic circuit rotating partsElectric machinesElectricityEngineering

Provided is a birotor wheel hub electric automobile motor comprising an external rotor, internal rotors, a stator and a bearing. The internal rotors are arranged in a symmetrical mode. The symmetrical internal rotors are connected with a stator axle through the bearing. The internal and external surfaces of the stator are of double-face grooving structures. Coil windings which are distributed symmetrically are embeded in the double-face grooving structures arranged on the stator. The coil windings are separately connected with corresponding ECUs, and are separately controlled by the ECUs. Each ECU is connected with a main ECU of each wheel of a vehicle system. The coil windings are electrically connected with a power supply. The beneficial effects of the present invention are that: problems of burnout due to overheating of the wheel hub motor is solved through alternative working of an appropriate number of independent motors, so that the utility life of the motor is prolonged; since the coil windings in the stator are distributed in the symmetrical mode, when the birotor wheel hub electric automobile motor of the invention works, the symmetrical distribution of the coil windings enables a stress applied to the motors in a symmetrical direction to be offset, so that friction of the axle and the bearing is reduced, and the usage life is prolonged.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Method and machine for folding sheets

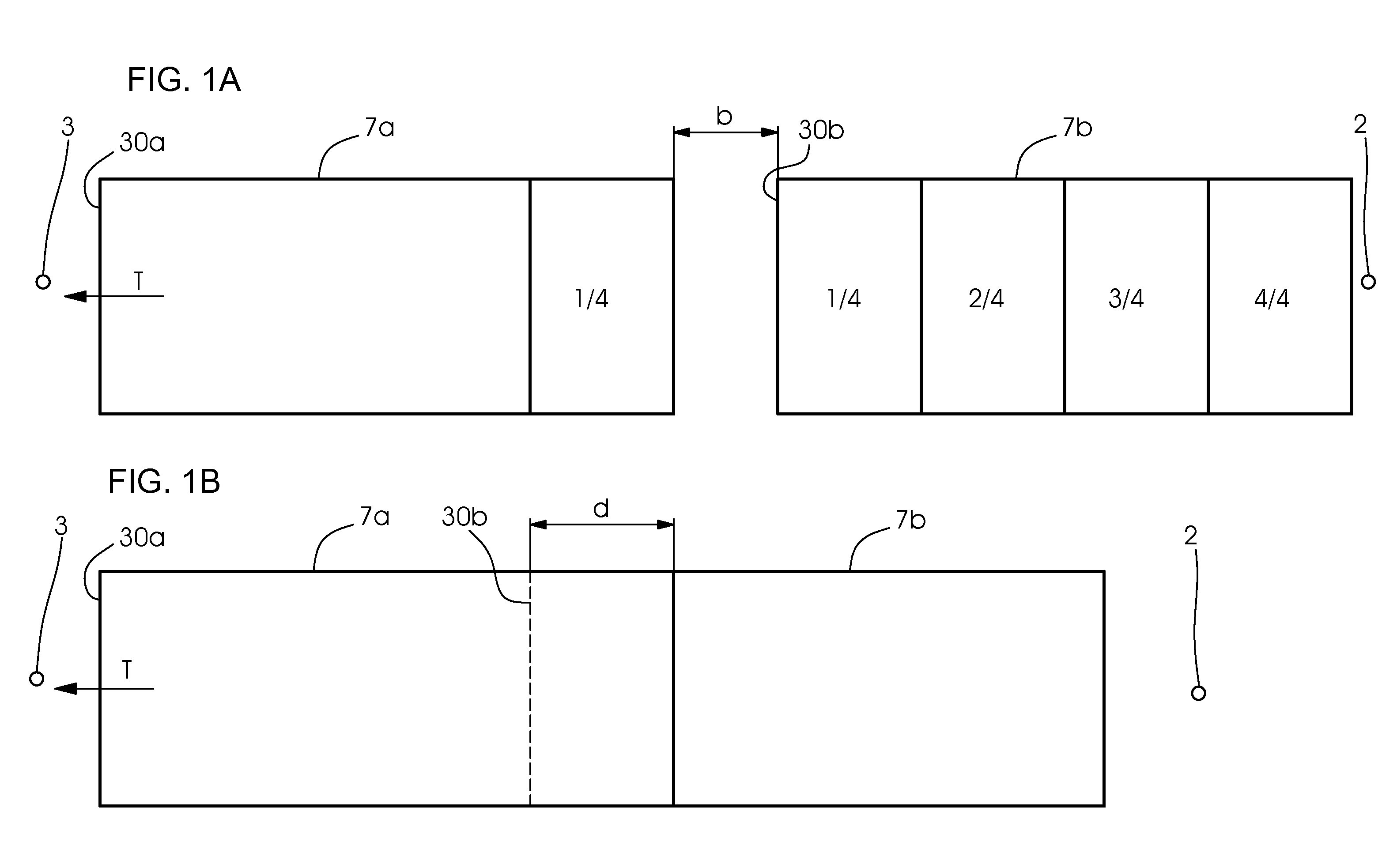

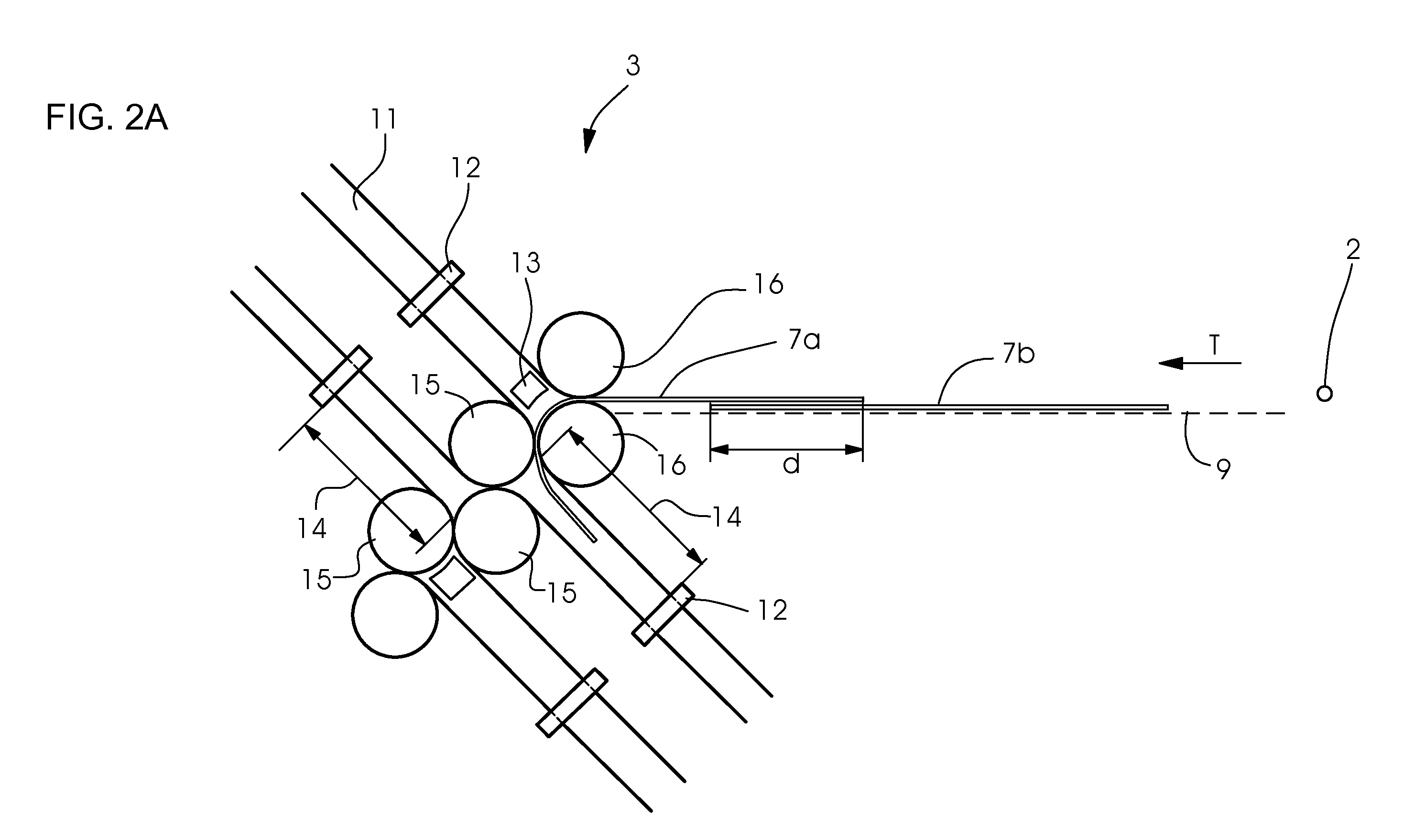

ActiveUS20100075821A1Same qualitySame speedMechanical working/deformationFolding thin materialsCardboardSheet material

A folding machine and a method of folding sheets of paper, board and the like with underlapping, include at least a first folding station with folding units and an imbricated feeder for feeding sheets to the first folding station, over an aligning table, in a first transporting direction. The imbricated feeder has a device for separating the sheets and a suction configuration which can be adjusted in and counter to the first transporting direction and is intended for the underlapping transfer of sheets from a sheet stack of the imbricated feeder to the aligning table.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

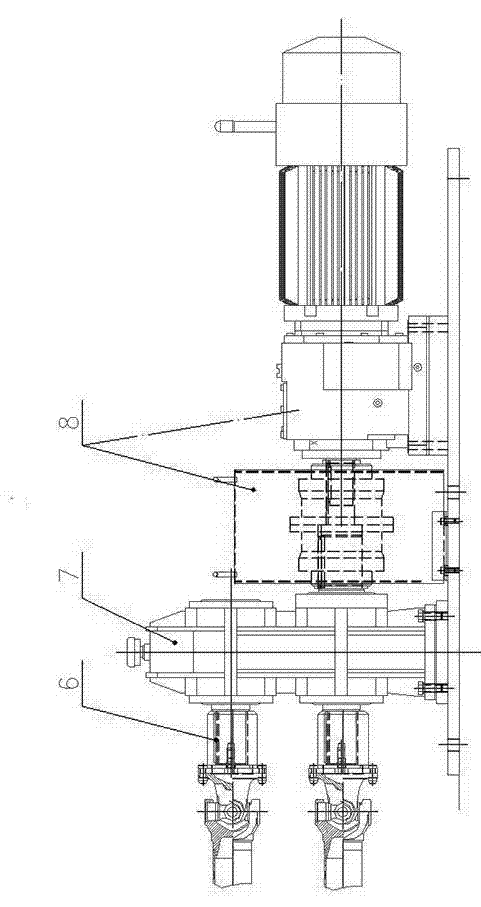

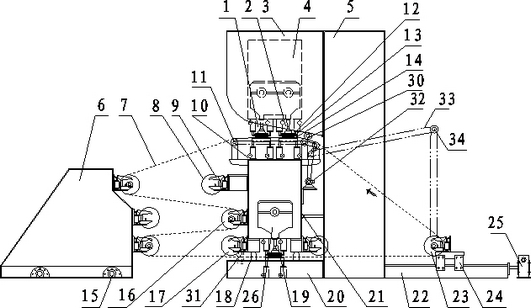

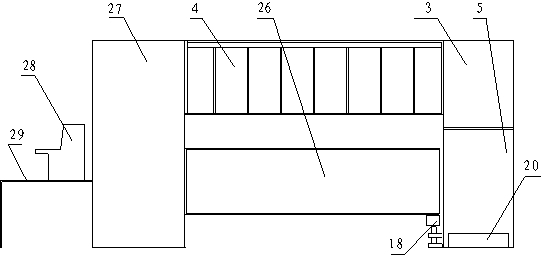

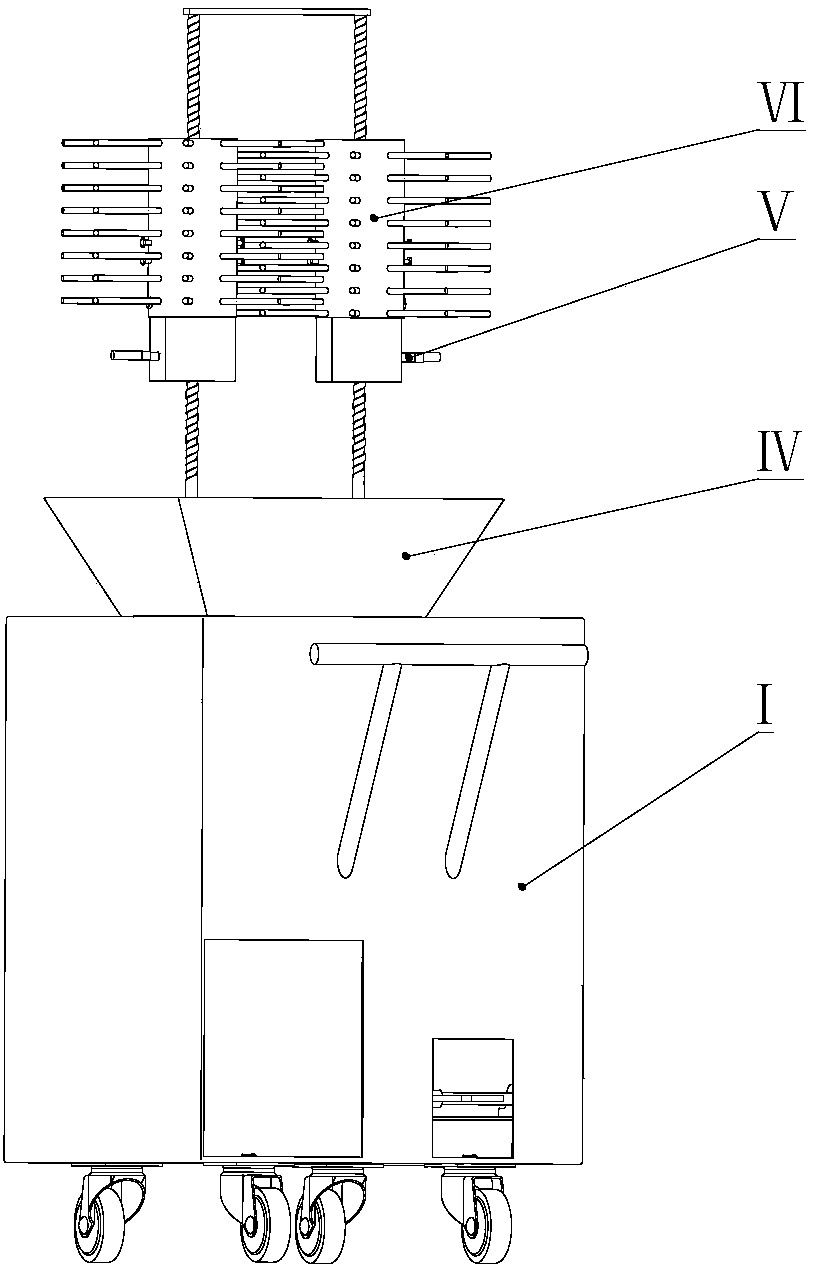

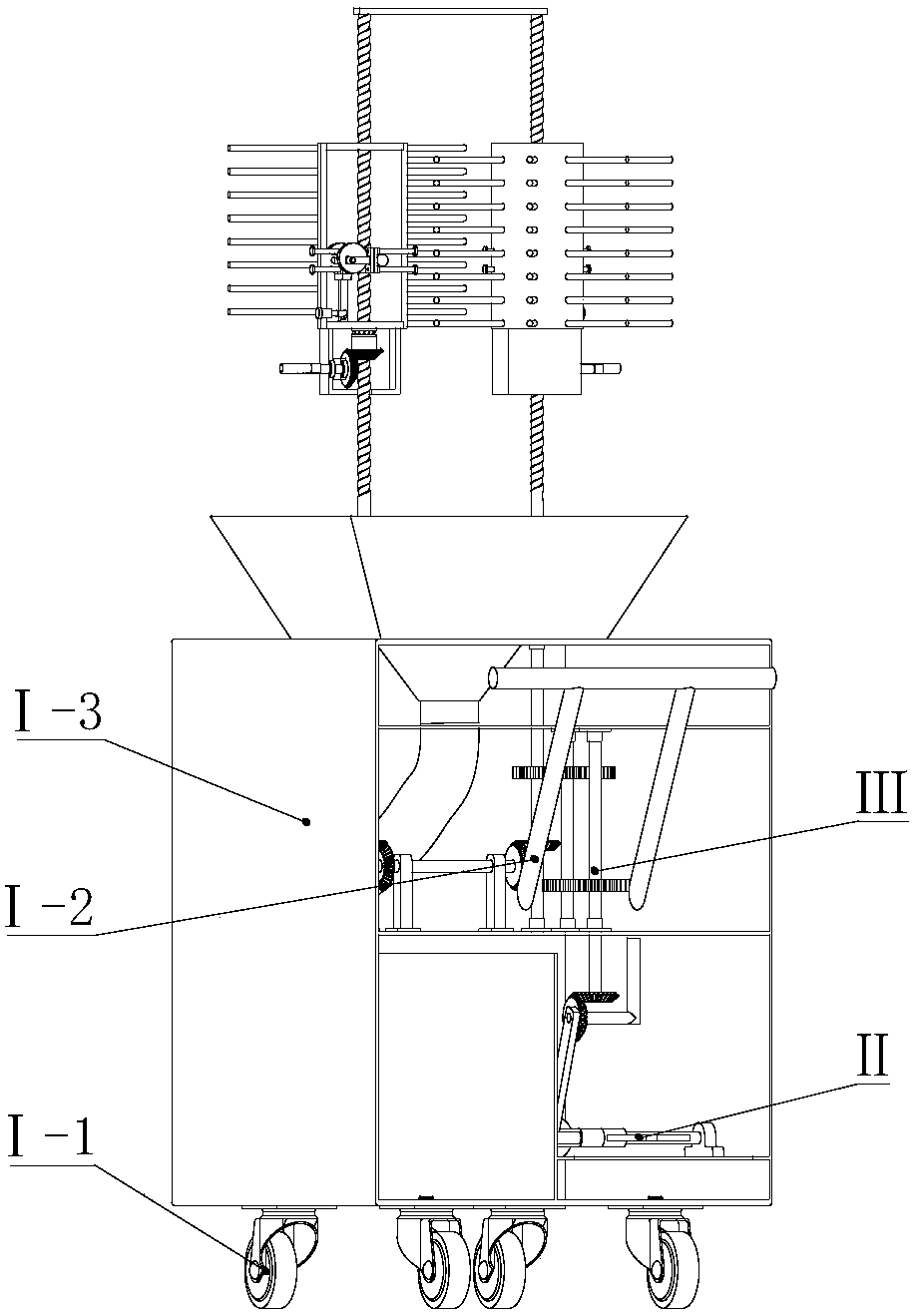

High-speed broad-width paper-making felt needling device

The invention relates to a high-speed broad-width paper-making felt needling device, which belongs to the paper-making felt needling device. The needling device comprises two main supports, a traveling vehicle is arranged in front of the main supports, a tension device is connected behind the main supports, a main beam is connected between the upper ends of the two main supports, a suspension beam is connected below the main beam, the operation end of the suspension beam is fixed on the support on the operation side, and a top beam is connected on the bottom end at the cloth end below the suspension beam; an electrical operation table is connected on the outer side of the main support on the operation side through an operation frame; a dragging bed is connected at the upper end of the suspension beam; and a third needling device is connected on the suspension beam, a pressure roller and a guide roller are connected on two sides of the upper end of the suspension beam, the pressure rollers are connected on the two sides of the lower end of the suspension beam, a stepping motor is connected on one side of the suspension beam, and a transmission pin shaft is arranged behind the main supports. The high-speed broad-width paper-making felt needling device has the advantages of improving performances of the device, monitoring the whole working conditions, timely reporting faults of the device, reducing the labor intensity of workers, improving working efficiency, enabling the device to operate stably and realizing smaller vibration and low power consumption.

Owner:徐州工业用呢厂

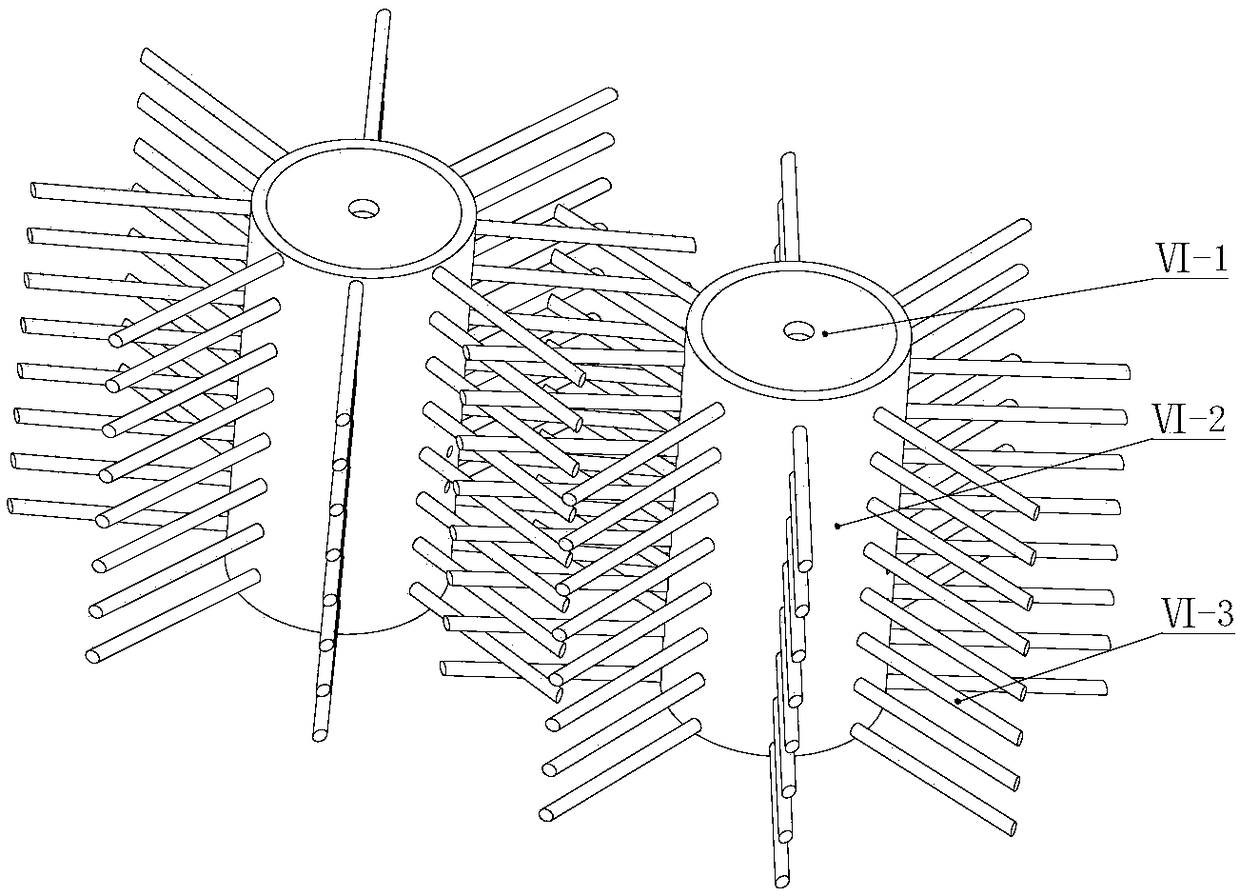

Roller-type auxiliary artificial winter jujube picking device and lifting lock mechanism

The invention discloses a roller-type auxiliary artificial winter jujube picking device and lifting lock mechanism, which solves the problems that the prior art that the winter jujube picking processis easy to damage and the common manual picking is too complicated in prior and has the beneficial effects of high picking efficiency and low winter jujube damage, and the scheme is as follows: a roller-type auxiliary artificial winter jujube picking device, roller-type picking device comprises at least two rotating rollers, wherein the roller picking mechanism comprises at least two rotating rollers, the two adjacent rotating rollers are arranged at intervals, the relative rotation direction of two adjacent rotating rollers are opposite, and a plurality of comb teeth rods are arranged in thecircumferential direction of each rotating roller, and in the rotating process of the rotating roller, the comb teeth of the two adjacent rotating rollers can be crossed and staggered so as to form acrack for separating the fruit and the fruit stem, the crack is smaller than or equal to the diameter of the fruit, the branches and leaves with the fruits are fed into the crossed regions of the adjacent two rotating rollers under the driving of the comb teeth rod, so as to separate the fruit and the fruit stem through the comb tooth rod.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

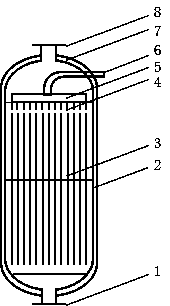

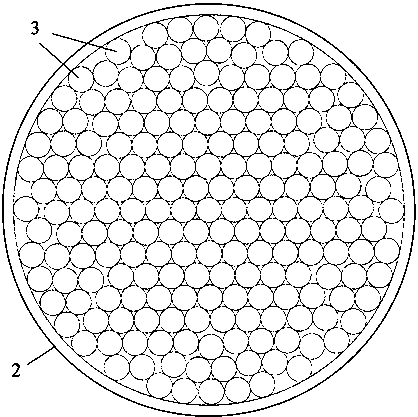

High-efficiency pulp filter-pressing and dehydrating equipment

ActiveCN109487611APerfect filter press dehydration effectPrevent backflowPulp de-wateringPulp and paper industryMechanical equipment

The invention discloses high-efficiency pulp filter-pressing and dehydrating equipment, and relates to the technical field of paper-making mechanical equipment. The equipment comprises a base, two pressing rollers, a spiral conveying mechanism and a frame shell arranged on two sides of the base, wherein a stock tank supporting plate and a driving mechanism driving the two pressing rollers to rotate are arranged on the base; and extruding bumps are uniformly distributed on the circumference of the two pressing rollers, and accommodating grooves for accommodating extruding bumps and power components which are used for driving the extruding bumps to extend out or retract along the accommodating grooves are arranged on inner sides of the two pressing rollers correspondingly. By implementing the technical scheme, the pulp carrying performance of the two pressing rollers can be effectively improved, pulp in an extruding area can be meshed and extruded with each other by utilizing the extruding bumps, the pulp discharge concentration can be 46 percent or more, and the filter-pressing and dehydrating effect of pulp can be effectively improved.

Owner:SICHUAN QIANWEI FENGSHENG PAPER LLC

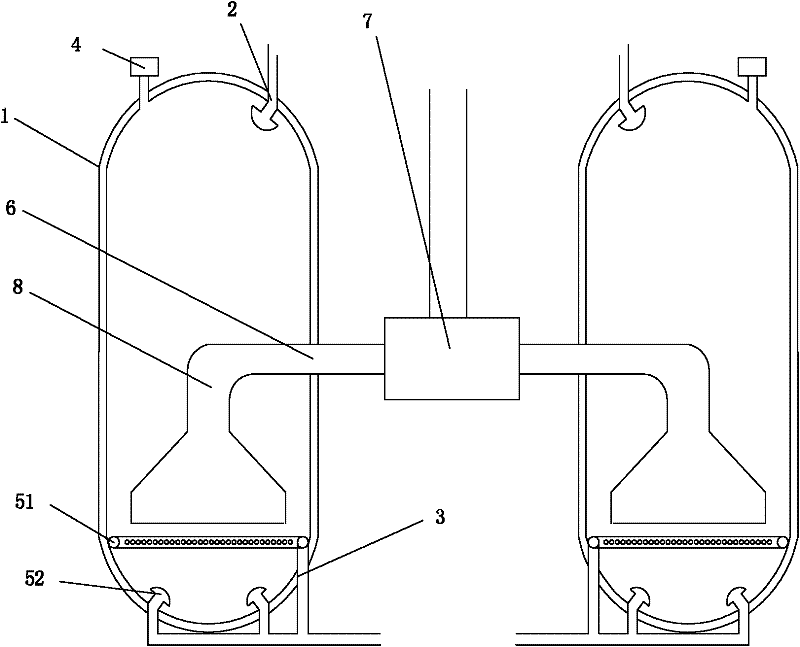

Parallel composite tank

The invention belongs to the field of fire-fighting fire extinguishing apparatus and especially relates to a parallel composite tank for fire extinguishing of large-scale equipment. The parallel composite tank comprises at least two powder storage tanks, which are for storing, atomizing and mixing dry powder and are in a same horizontal line; an upper air inlet and a lower air inlet are arranged on the top and the bottom of each powder storage tank; a pressure sensor for detecting pressure in each tank is arranged on the top of each powder storage tank; an atomizing device for loosening and atomizing the dry powder is arranged in each powder storage tank; the lower air inlet is connected with the atomizing device; a powder outlet is arranged on a side wall of each powder storage tank; and powder outlets of the at least two powder storage tanks are connected with a dry powder pipeline centralized controller through a connecting pipe. According to the invention, a plurality of powder storage tanks are connected through the dry powder pipeline controller, so as to start different numbers of powder storage tanks, according to fire behavior, to guarantee the amount of dry powder needed by fire extinguishing.

Owner:江苏中瑞电保智能装备有限公司

Automobile double-drive-axle tester

An automobile double-drive-axle tester comprises a support device, a driving mechanism and a loading mechanism; the support device is used to fix a to-be-tested middle axle of an automobile and a to-be-tested rear axle, connected to the to-be-tested middle axle of the automobile; the driving mechanism is connected with the input end of the to-be-tested middle axle, and comprises a driving motor, an input shaft coupling, an input reduction box and an input transmission shaft connected successively, and an output shaft of the input reduction box is provided with an input torque and rotation speed sensor; and the loading mechanism is connected with two output ends of the to-be-tested middle axle and two output ends of the to-be-tested rear axle, and comprises a a loading motor, a shaft coupling, a gear case and a transmission shaft connected successively, and an output shaft of the gear case is provided with an output torque and rotation speed sensor. The middle and rear axles are tested in a lined way simply, the middle and rear axle assembly can be examined by simulating the whole automobile condition, the speed difference between the middle and rear axles can be tested by simulating the whole automobile condition, and the tester also has advantages of simple structure, compact layout and high reliability.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com