Parallel composite tank

A composite tank and powder storage technology, which is applied in fire rescue and other directions, can solve the problems of dry powder limitation, uneven mixing of dry powder and gas, and the amount of dry powder cannot meet the fire extinguishing requirements, so as to overcome the delay of fire extinguishing timing and reduce the influence of gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

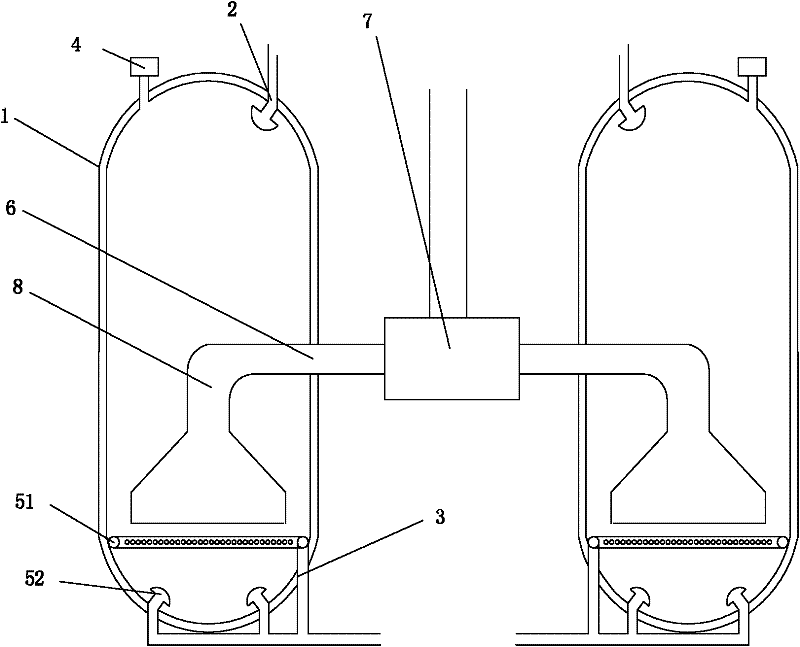

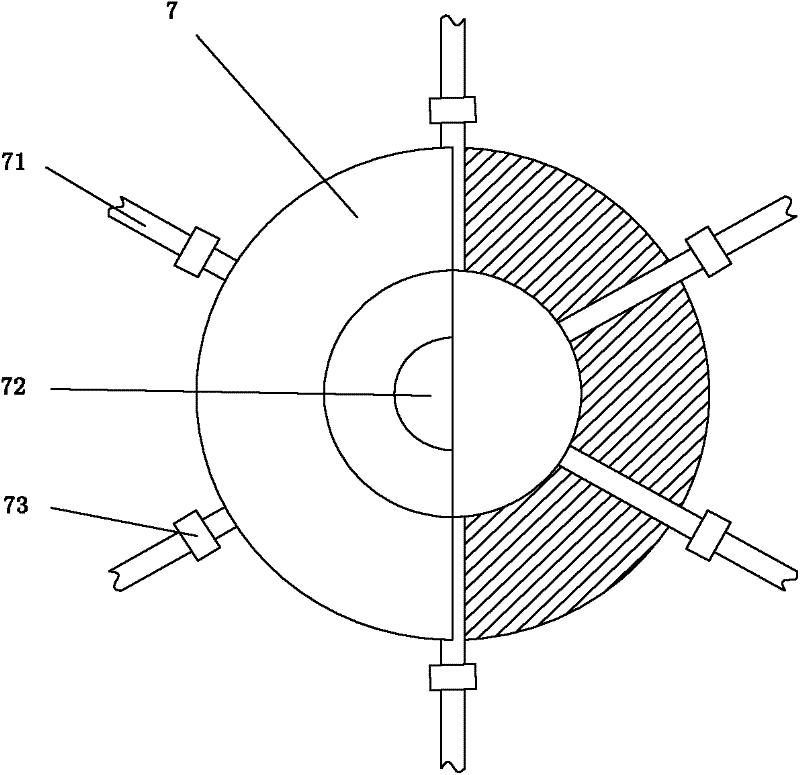

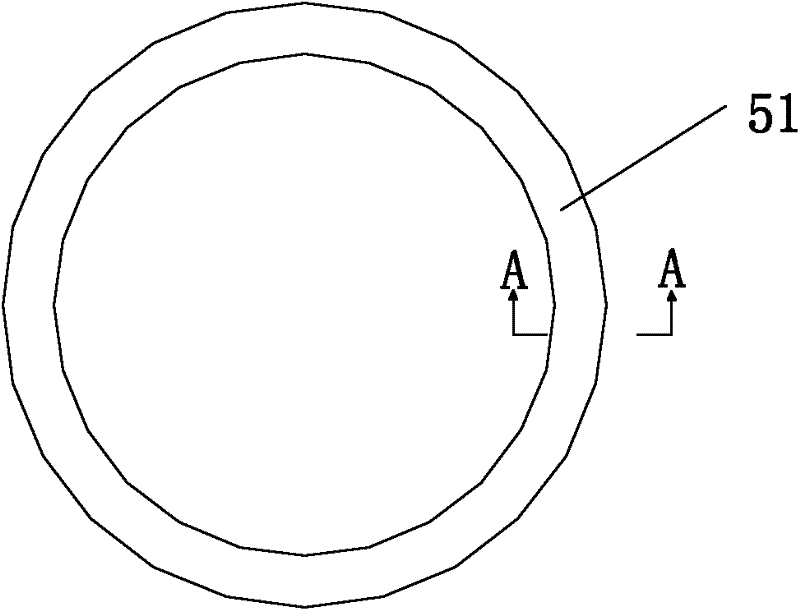

[0029] Such as Figure 1 to Figure 5 The parallel composite tank shown includes at least two powder storage tanks 1 for storing dry powder and capable of atomizing and mixing the dry powder in the tank. In this embodiment, two powder storage tanks are used for illustration. The two powder storage tanks 1 are arranged on the same horizontal line, which can reduce the influence of gravity on the dry powder airflow and ensure that the dry powder airflow output by the centralized controller of the dry powder pipeline is uniform. The top and bottom of the powder storage tanks An upper air inlet 2 and a lower air inlet 3 are provided. The top of the powder storage tank 1 is also provided with a pressure sensor 4 for detecting the pressure in the tank. The inside of the powder storage tank 1 is provided with a device for loosening and drying the dry powder. Atomized atomizing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com