Patents

Literature

130results about How to "Guaranteed amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

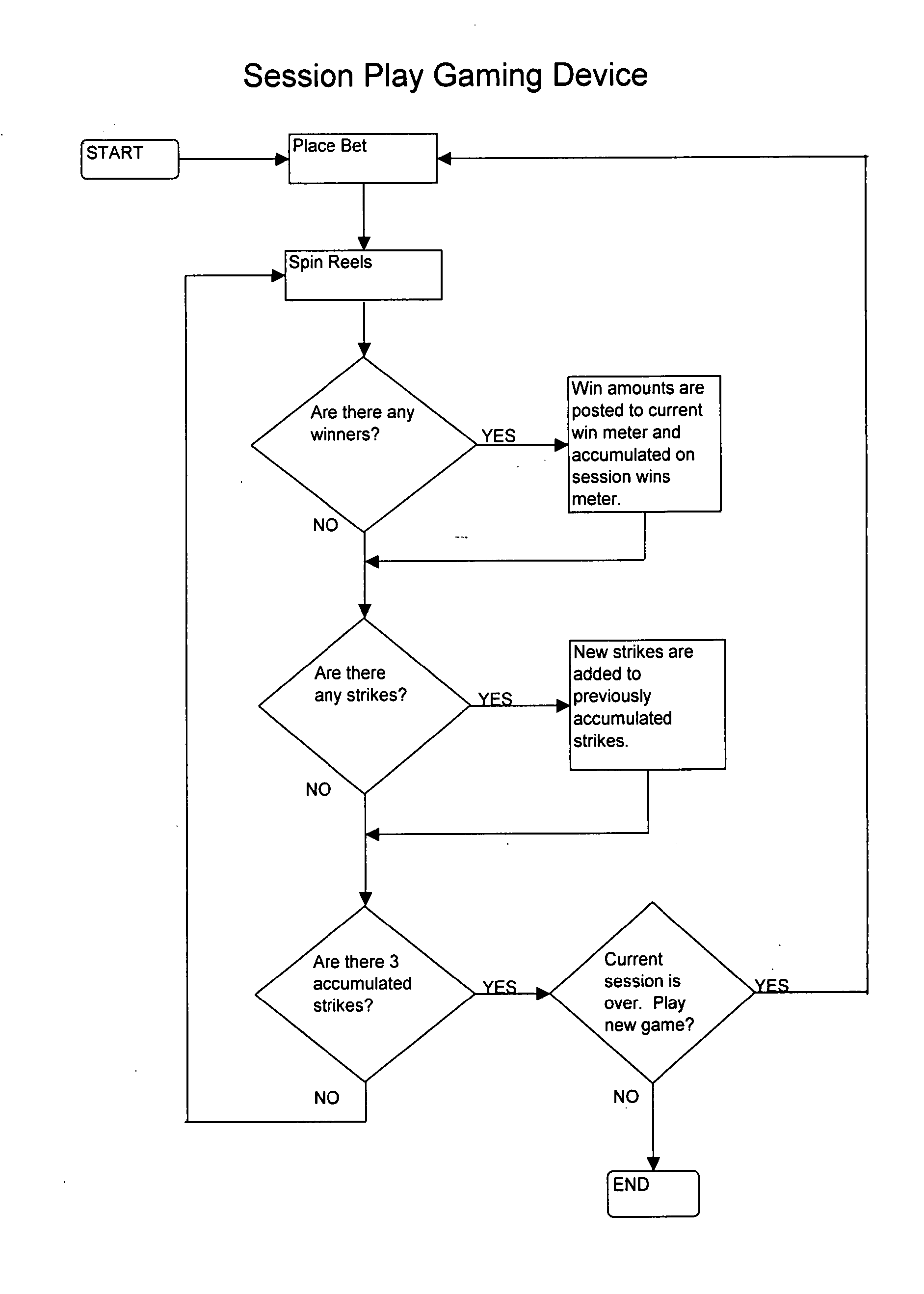

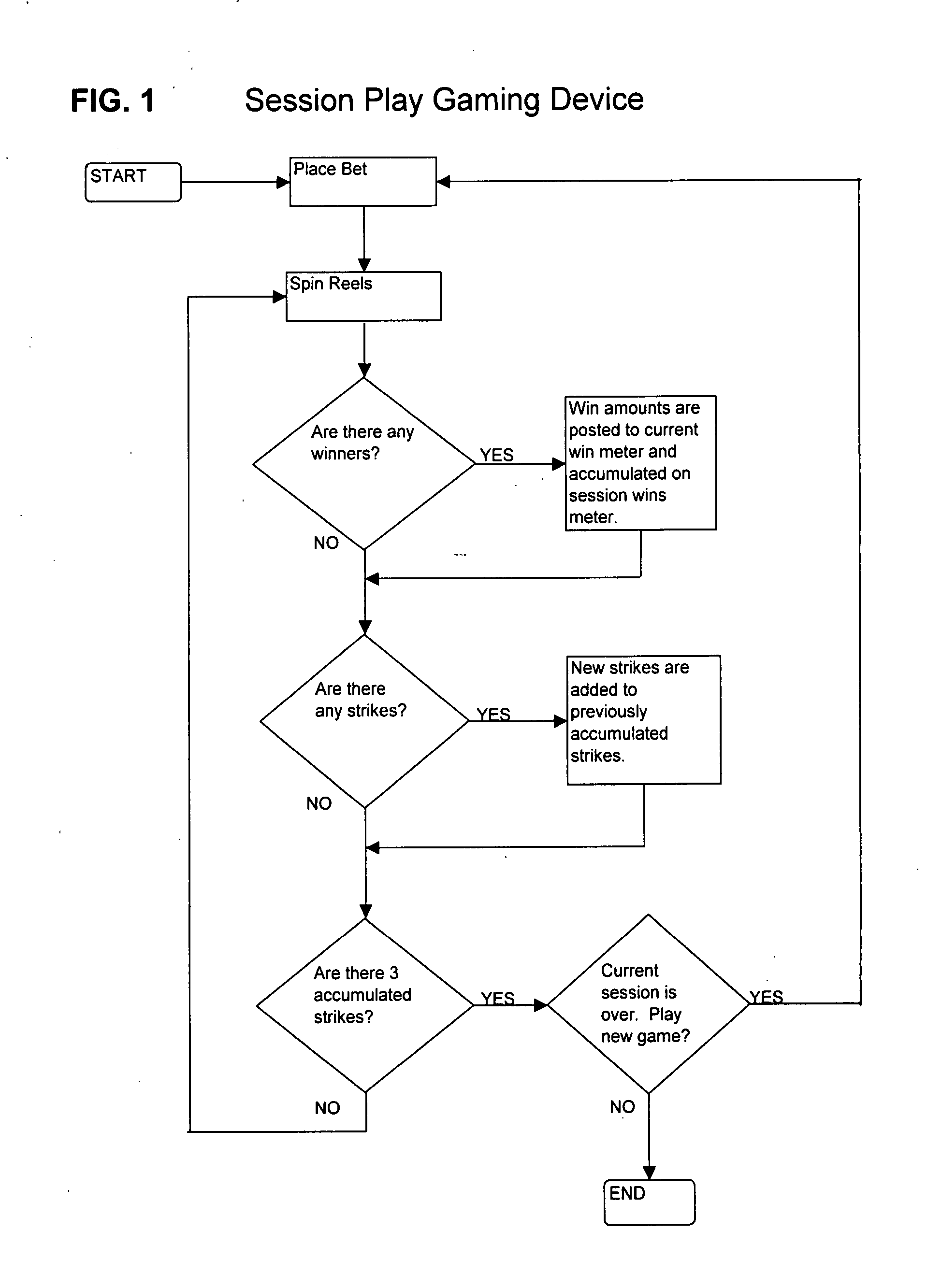

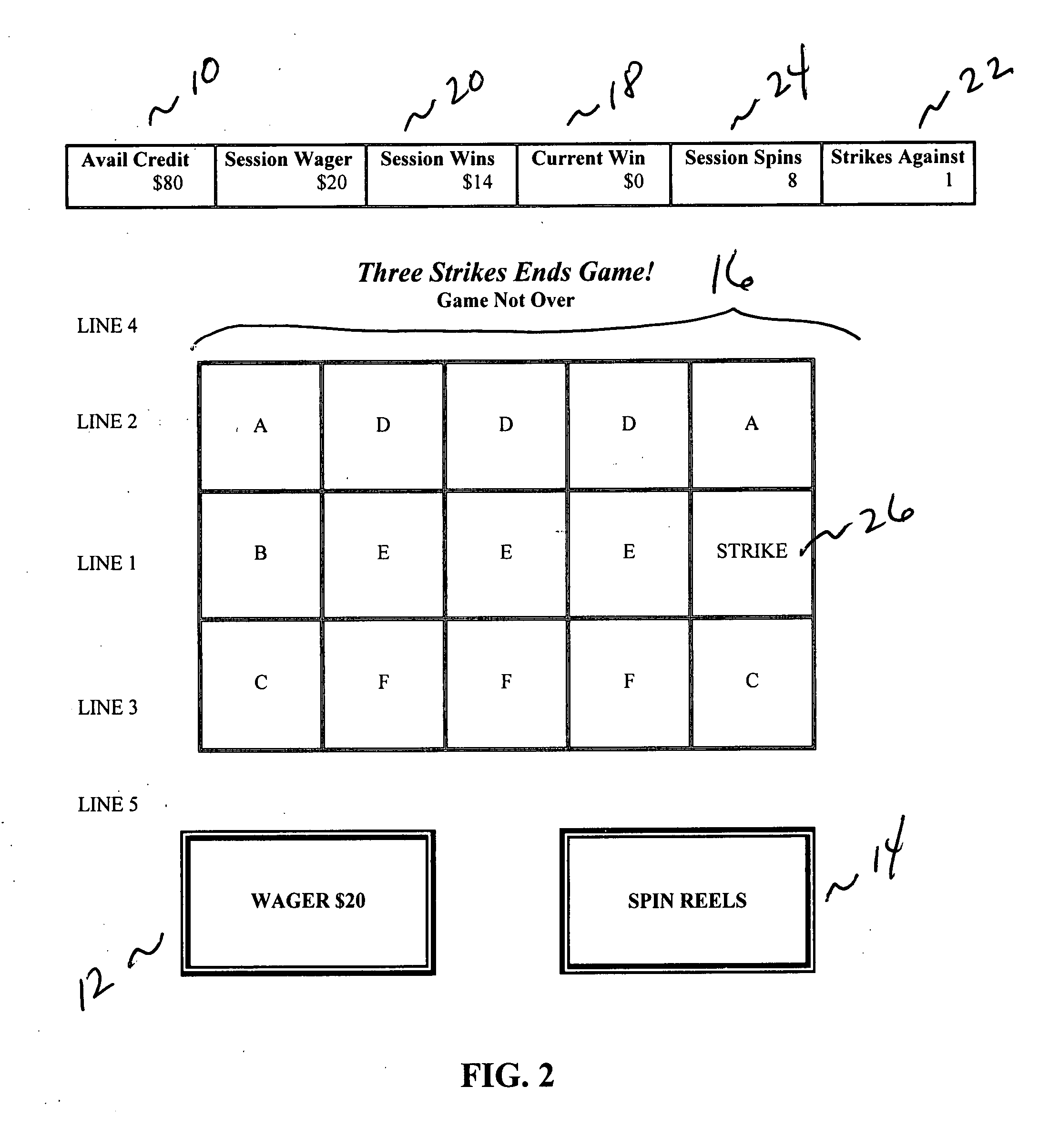

Method for gambling games of variable duration

InactiveUS20080064491A1Guaranteed amountOptimize timingApparatus for meter-controlled dispensingVideo gamesVariable numberEngineering

A method for wagering on a gaming device where players purchase a session as opposed to an individual game. Within a session, players have multiple winning opportunities and may be allowed to play a plurality of traditional games to maximize their returns. In one preferred embodiment, the session length is unknown at the time of wager and the game session is ended only when a predetermined or variable number of game termination symbols occur. In other embodiments players may decide the nature of their game terminating events. During a session players may also accumulate tools for use in subsequent game segments.

Owner:TAYLOR WILLIAM ARTHUR

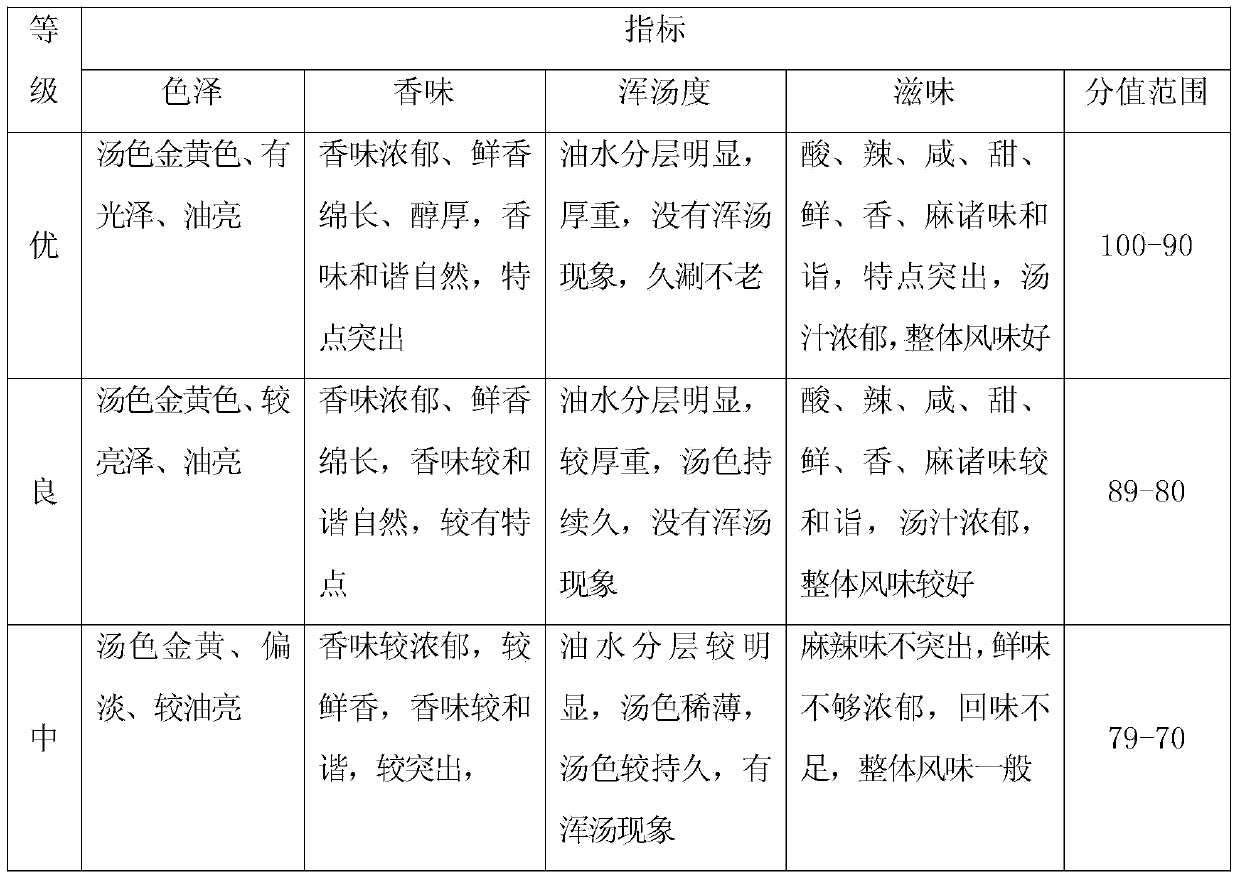

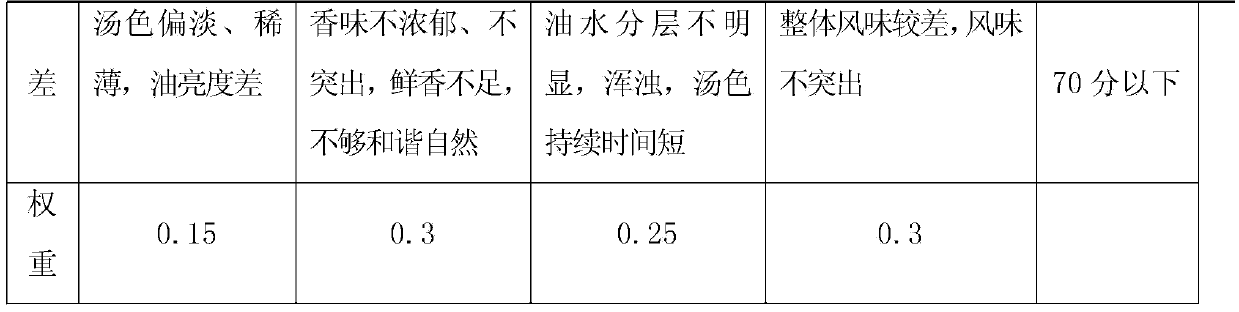

Golden soup hotpot condiment and preparation method thereof

ActiveCN103719791AFast and comprehensive intakeFull of nutritionLactobacillusFood preparationVegetable oilFood flavorings

The invention discloses a golden soup hotpot condiment and a preparation method thereof and belongs to the field of seasonings and condiments. The hotpot condiment consists of 12-18 parts of oil package, 1-3 parts of condiment package and 2-3 parts of nutrient package, wherein the main ingredient oil package comprises the following raw materials by weight: 1-10 parts of salt, 1-10 parts of garlic, 20-200 parts of edible vegetable oil, 0.1-2 parts of spice, 1-15 parts of ginger, 1-15 parts of white sugar, 1-10 parts of pepper, 5-20 parts of carrot chili sauce, 1-10 parts of pickle pulp, 1-5 parts of pickle fermentation liquor, 1-20 parts of goji juice, 1-10 parts of red date juice, 1-10 parts of edible mushroom enzymatic hydrolysate, 5-10 parts of pumpkin sauce and 1-20 parts of concentrated soup-stock. Through the adoption of biological fermentation and enzymolysis technologies, the operations of frying, thermally insulating and dipping are combined, so that the prepared hotpot condiment is balanced and comprehensive in nutrition, harmonious in flavors such as sour, pungency, saltness, sweetness, freshness, fragrance and spice, golden and attractive in color and outstanding in characteristics.

Owner:宁夏红山河食品股份有限公司

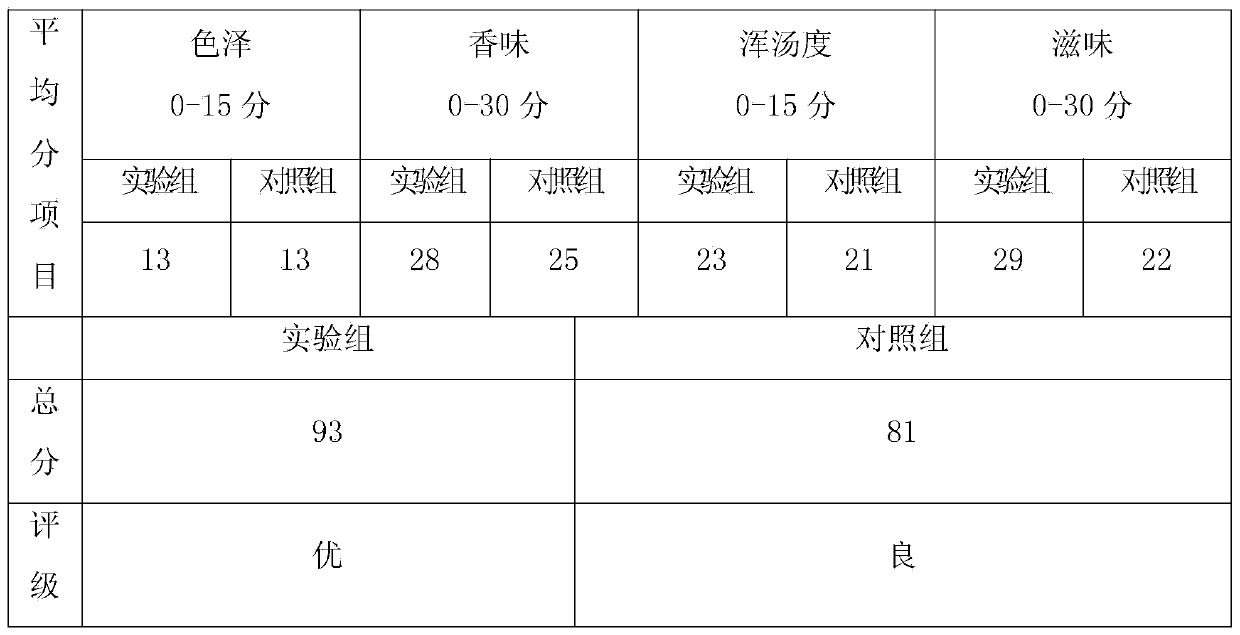

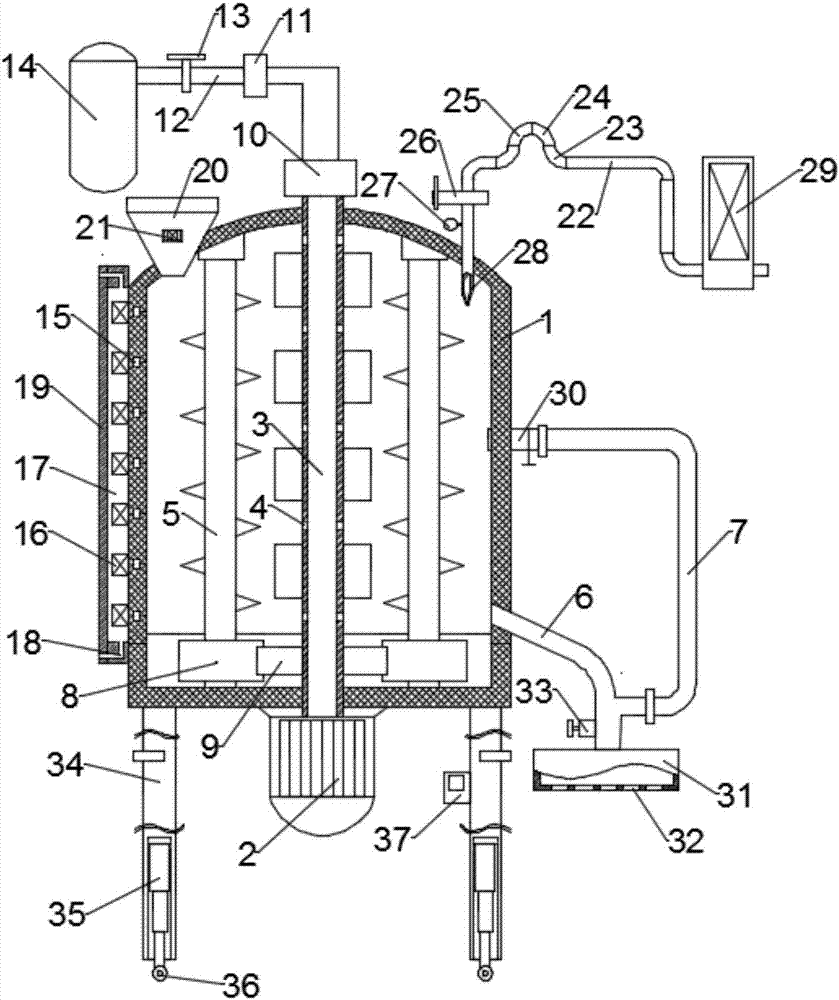

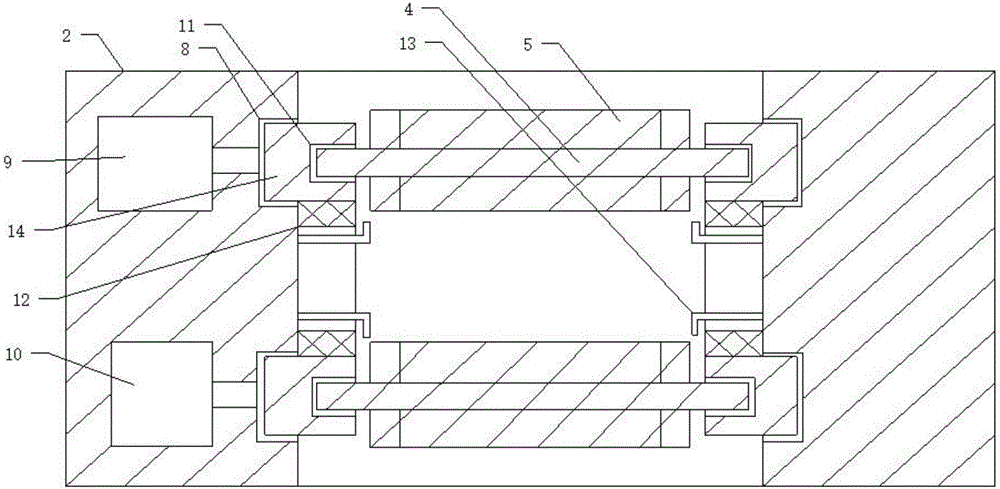

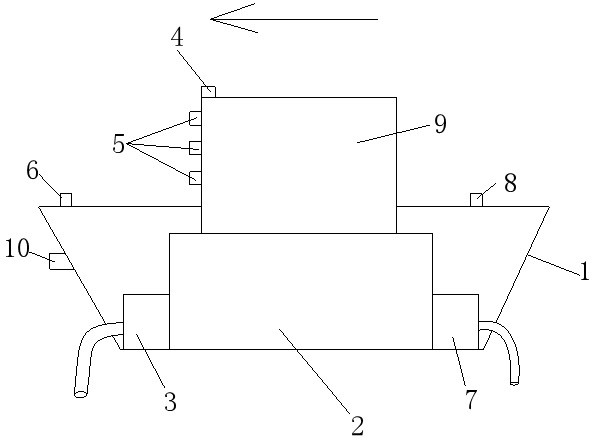

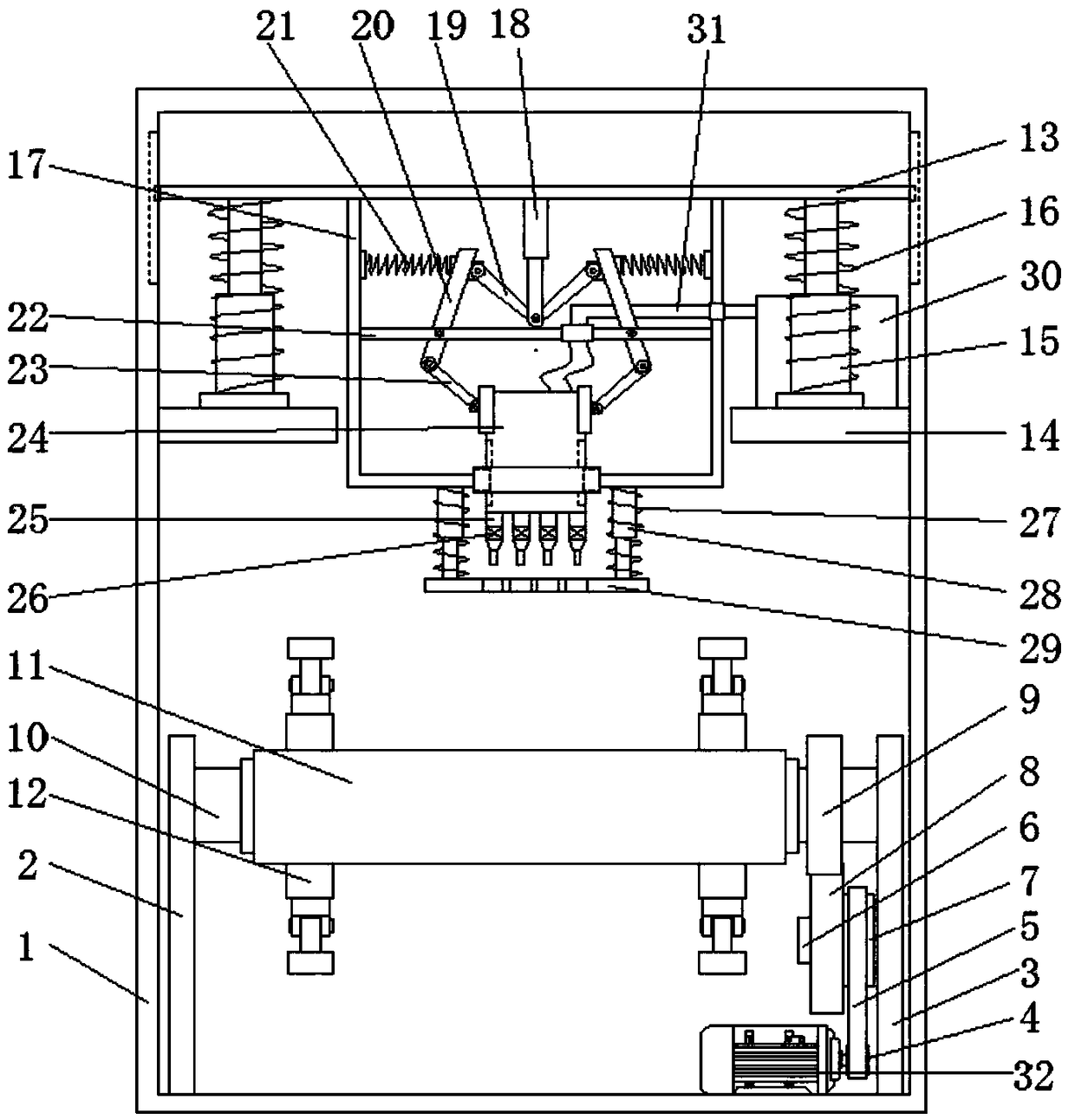

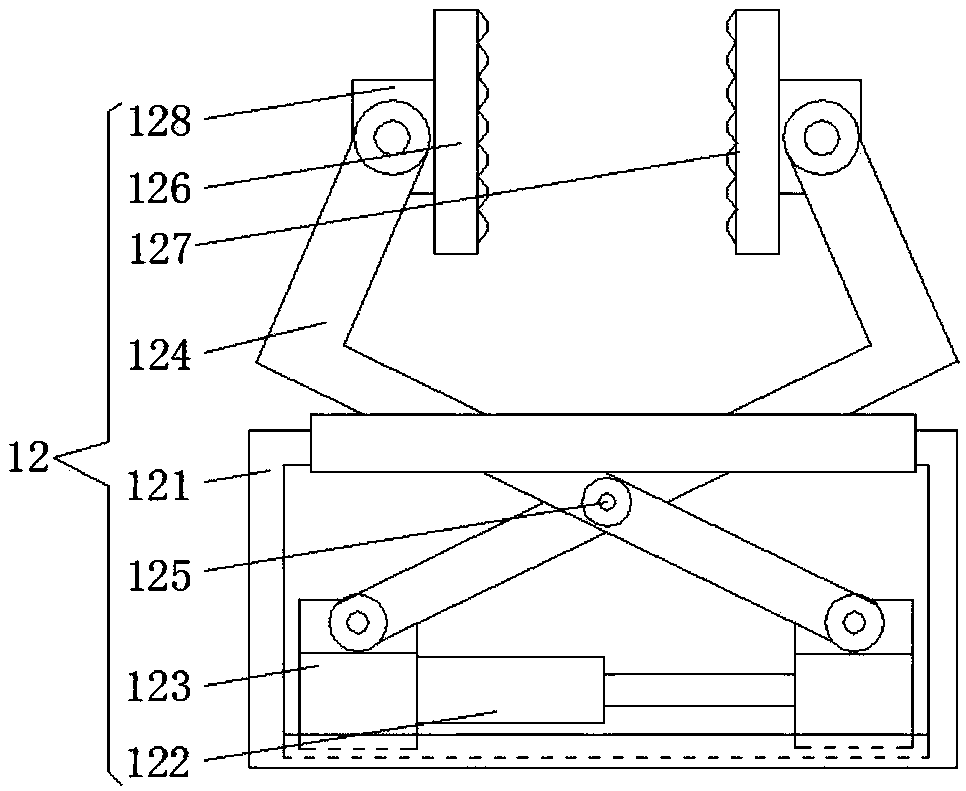

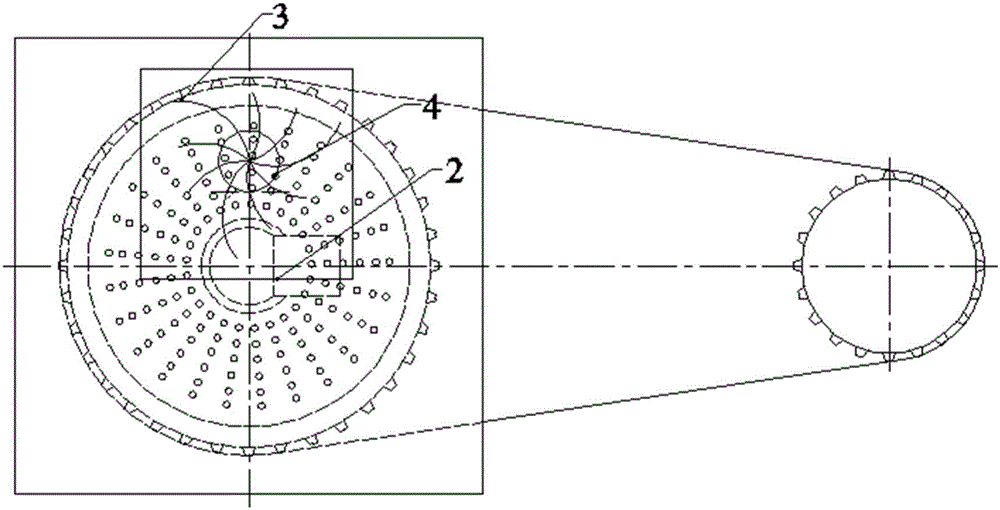

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

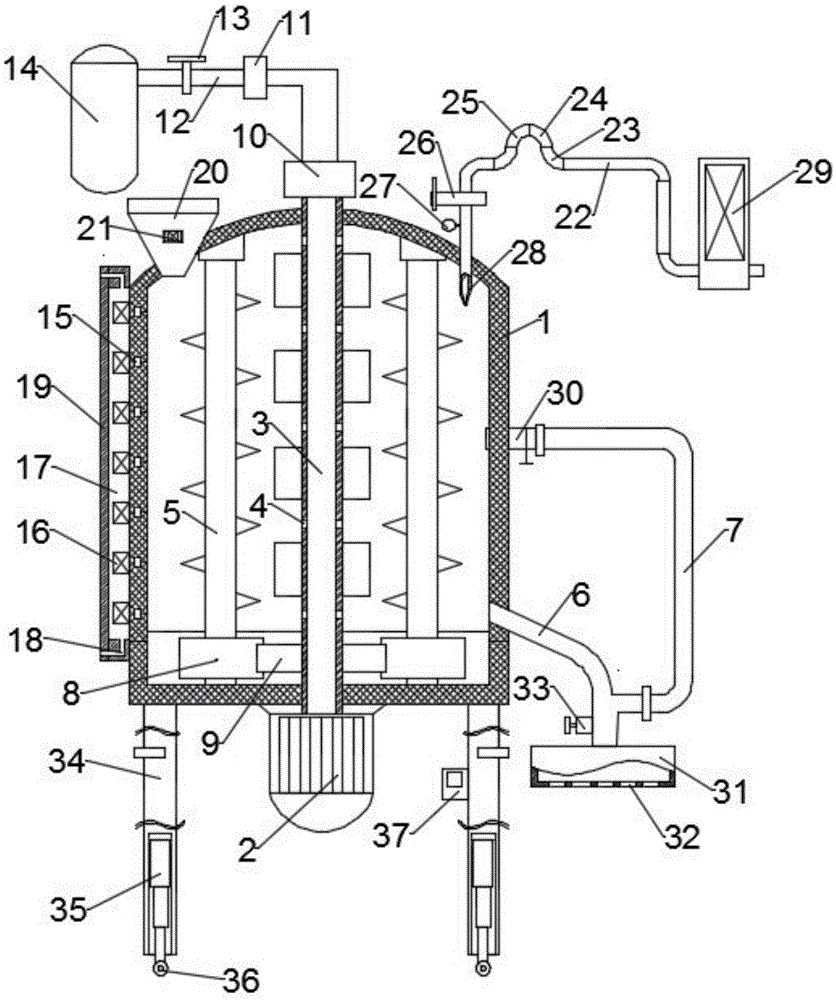

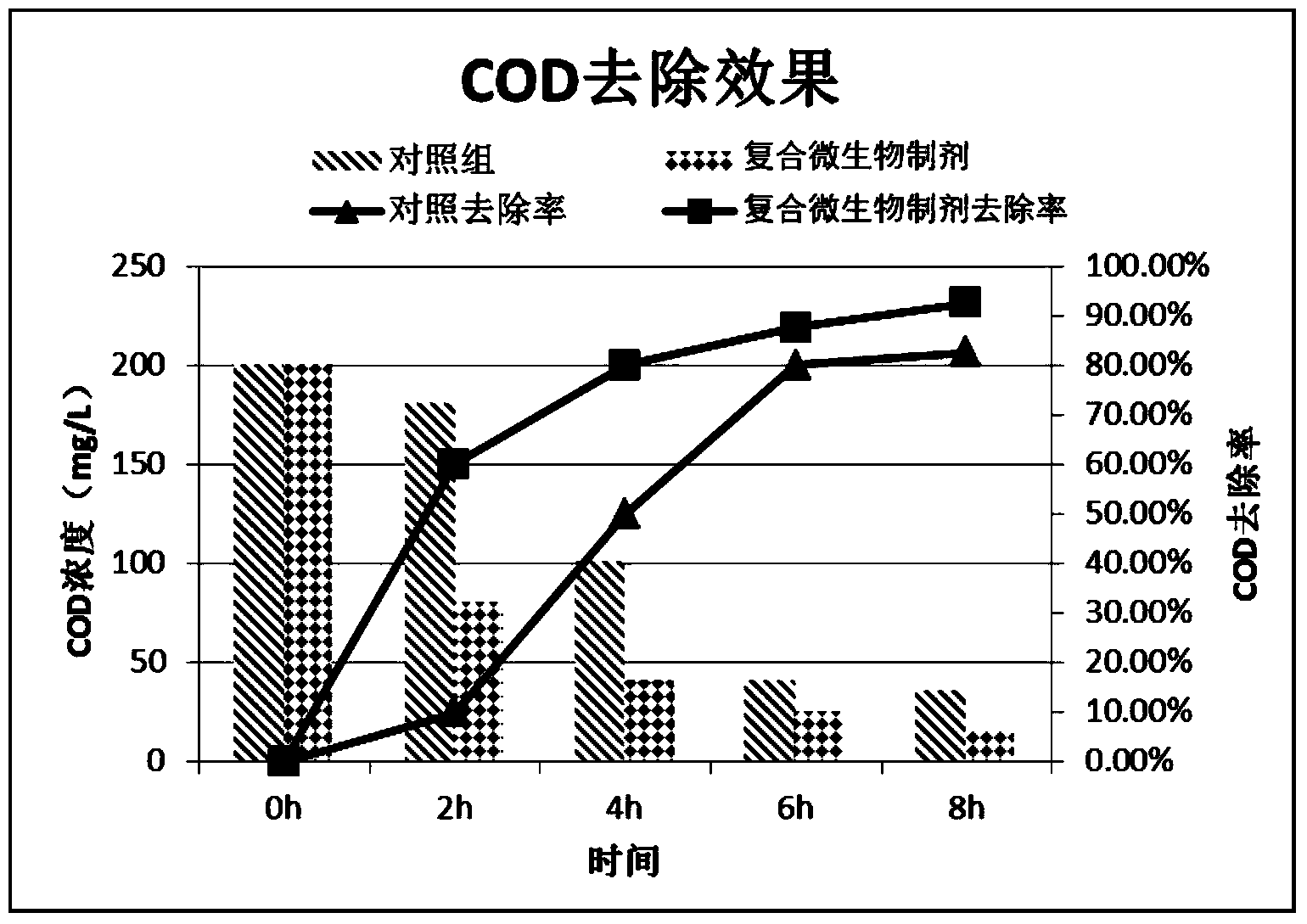

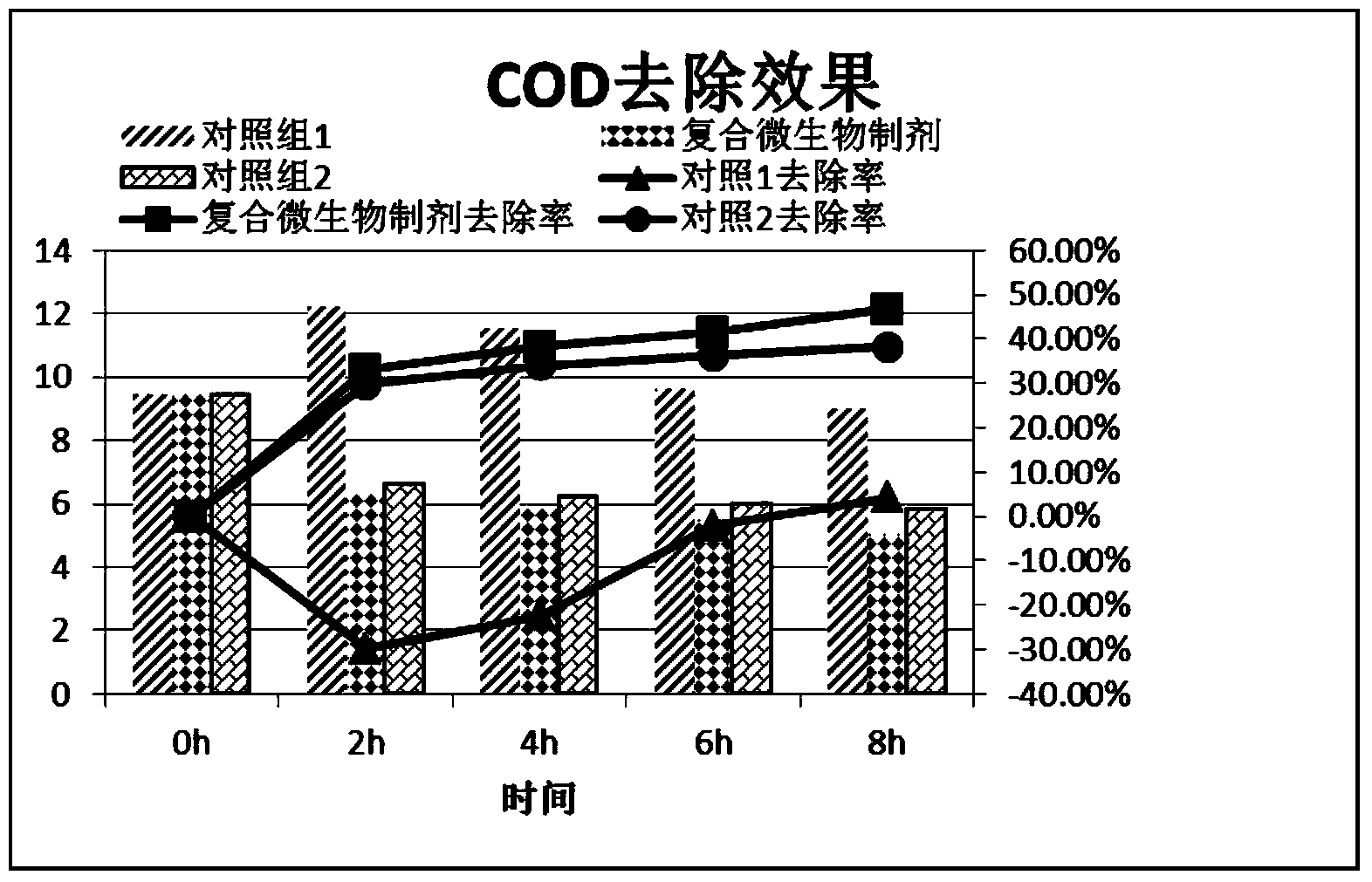

Composite microbial preparation for watershed bioremediation as well as preparation method and application thereof

ActiveCN103436519AStrong adsorption performanceImprove acid resistance and thermal stabilityMicroorganism based processesOn/in inorganic carrierChemistryMicrobiological growth

The invention relates to the field of bioremediation of rivers, and in particular relates to a composite microbial preparation for watershed bioremediation as well as a preparation method and application thereof. The microbial preparation comprises active ingredients including bacillus natto, candida utilis and rhodopseudomonas palustris which are mixed together in a volume fraction ratio of 1:1:1; the microbes for water treatment are combined with zeolite to prepare a comprehensive preparation for water treatment; the specific gravity of the obtained comprehensive preparation for water treatment is greater than that of water, so that the obtained comprehensive preparation for water treatment quickly sinks to the bottom of water and can not be washed away by water flow easily; the zeolite is used as a carrier for the microbes to grow, and can provide certain nutrition substances required by growth for the microbes while adsorbing pollutants, and the microbes attached to the zeolite perform decomposition and anabolism on the pollutants to ensure that the zeolite restores the adsorptive property, so that a virtuous cyclic process is formed. The microbial agent provided by the invention can adapt to fresh water and seawater environments at the same time, and has an effective bioremediation effect on watercourses of certain coastal cities, wherein the water quality of the watercourses has fresh water and seawater alternating conditions along with seasonal changes.

Owner:青岛水清木华环境工程有限公司

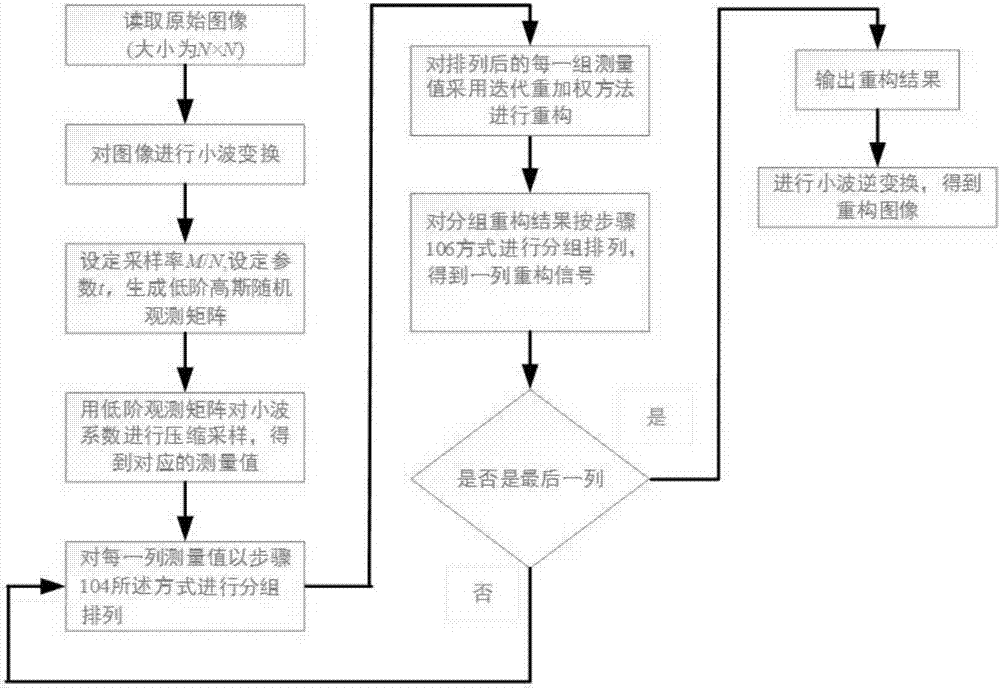

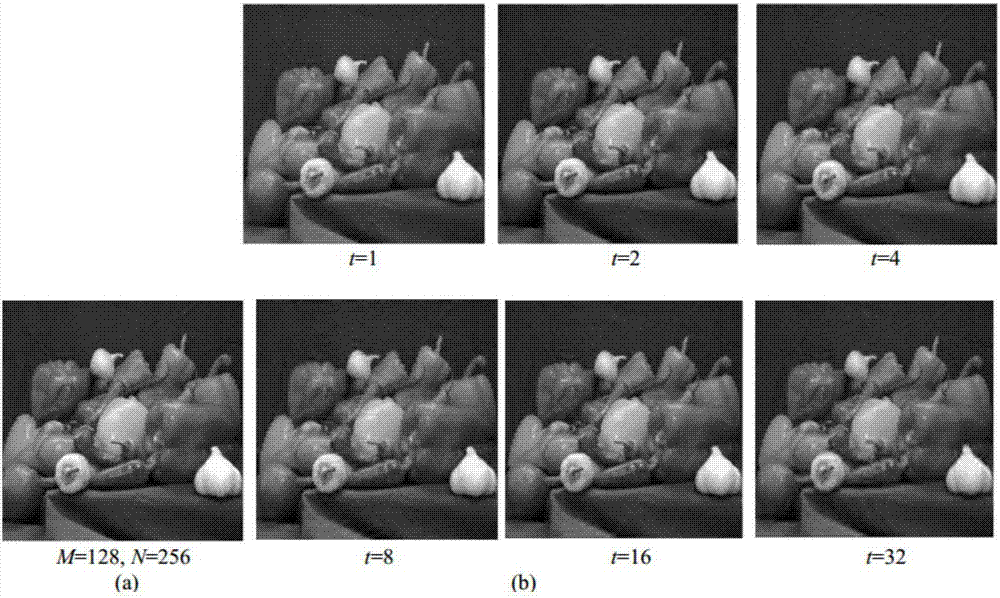

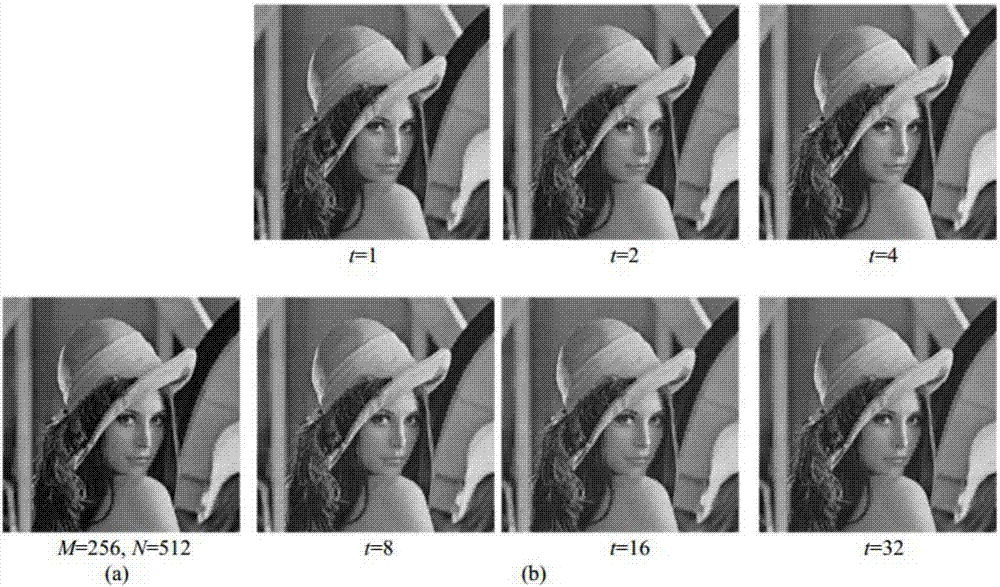

Rapid low-memory image compression perception method

ActiveCN107170019ASave storage spaceImprove real-time performanceCode conversionImage codingComputation complexityImaging processing

The invention discloses a rapid low-memory image compression perception method and belongs to the field of image processing. According to the invention, by use of a low-order random observation matrix, local sampling and blocking reconstruction are performed on an original signal, so the disadvantage that an observation matrix needs to occupy a lot of storage space and memory space in the traditional observation perception method is overcome, the disadvantage of poor timeliness of large-size image construction is overcome, storage space required by the random observation matrix is reduced, calculation complexity of the reconstruction is reduced and timeliness of the reconstruction is improved.

Owner:ZHEJIANG SHUREN UNIV

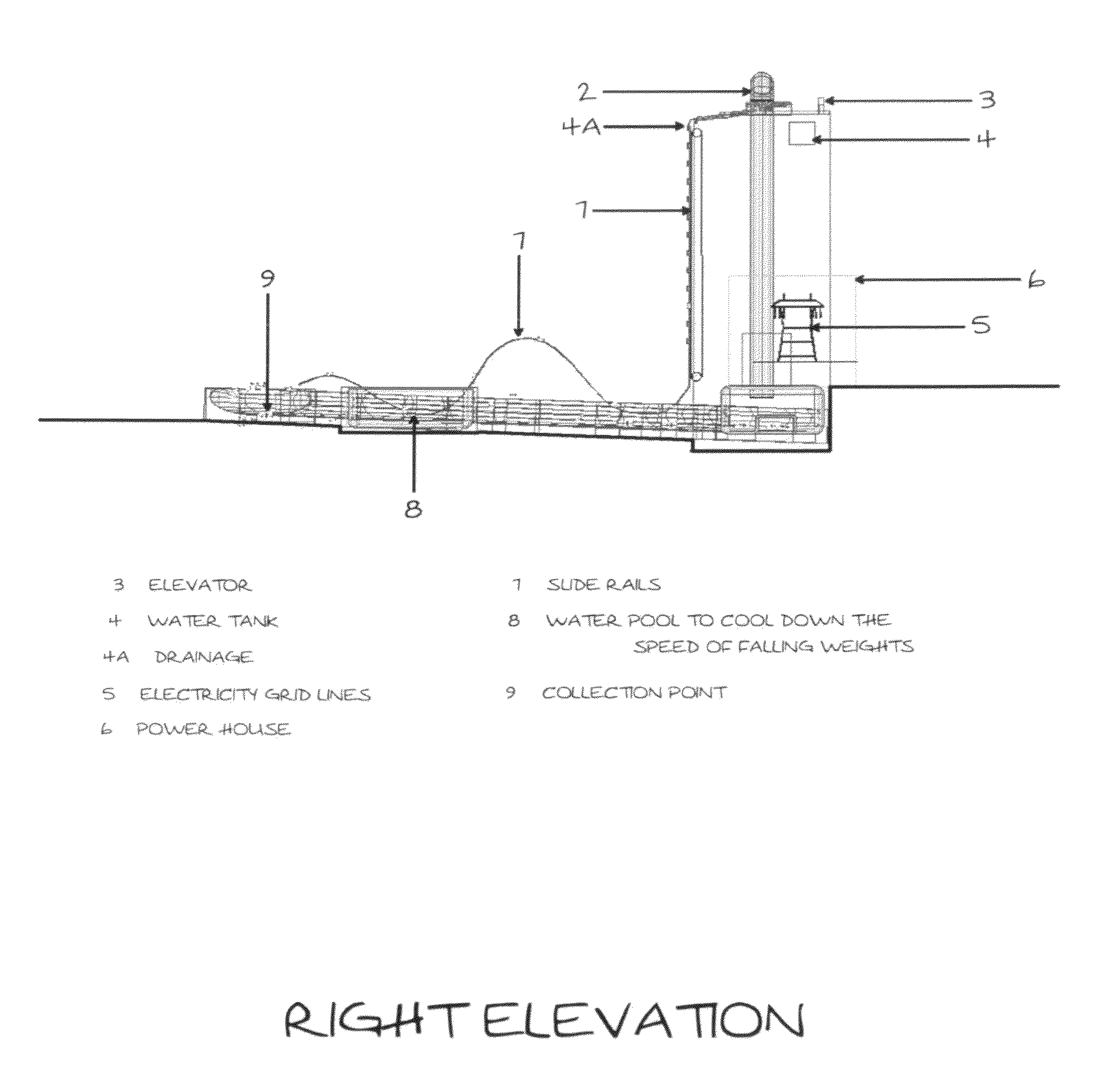

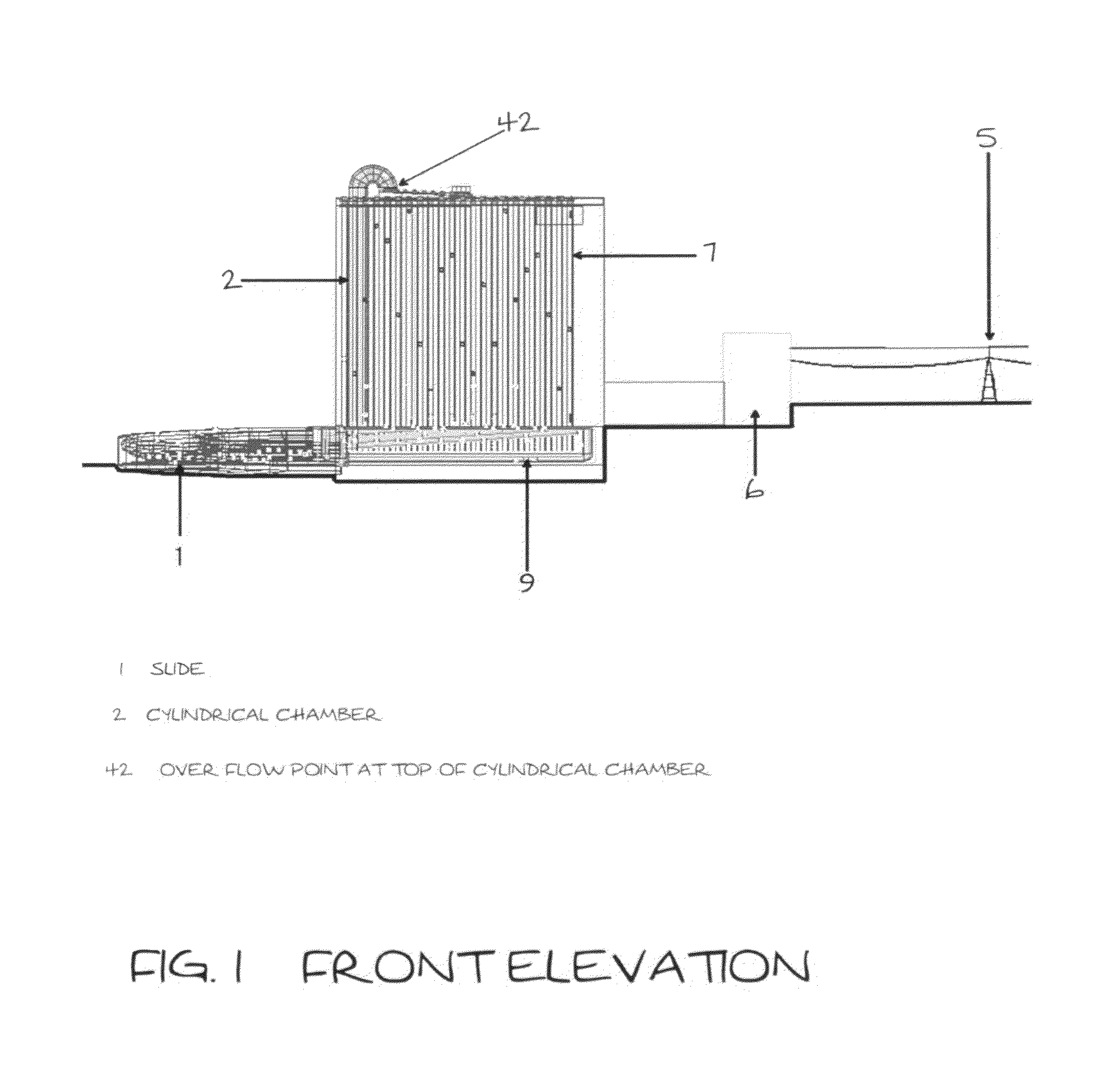

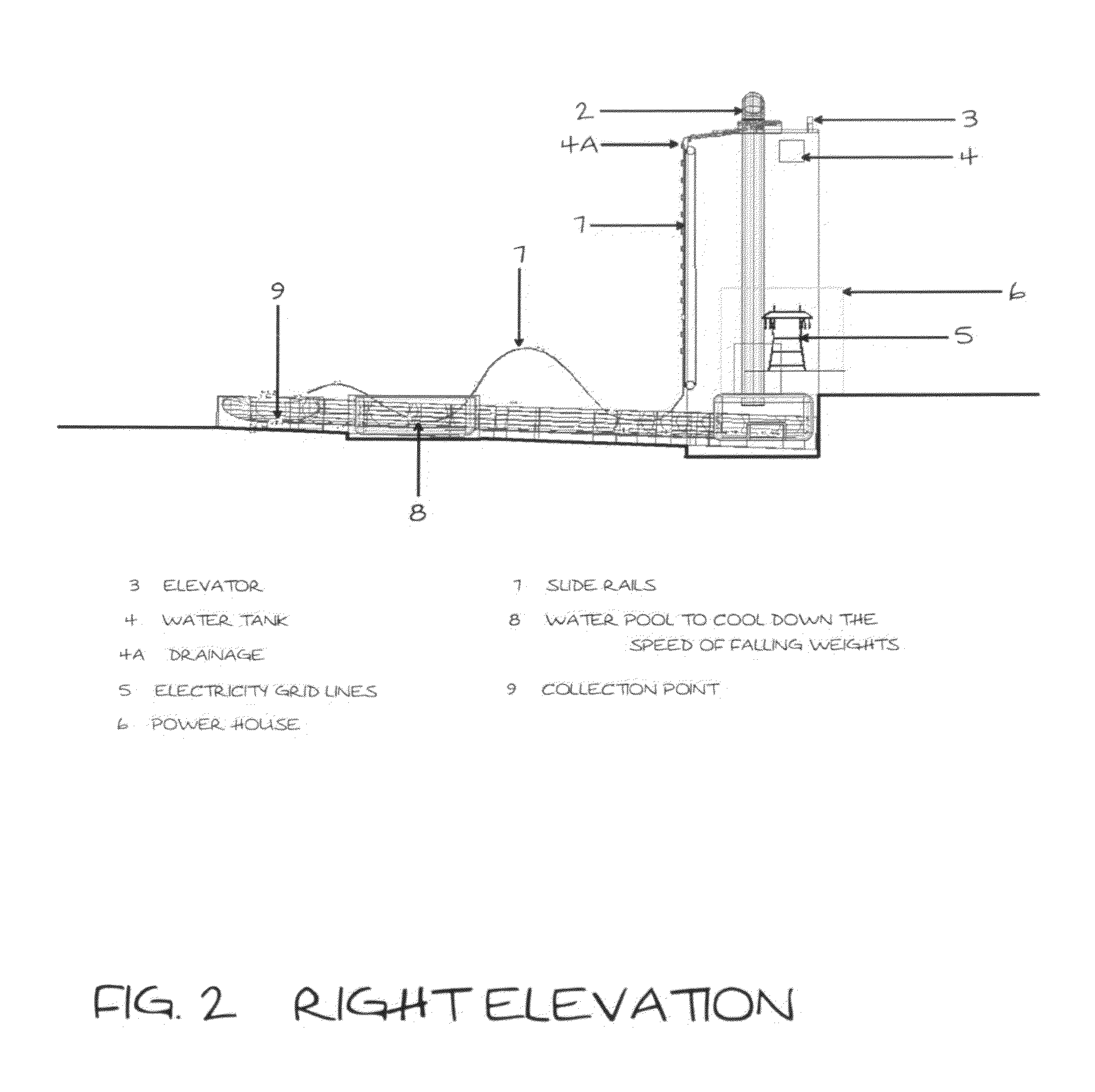

Gravity and Buoyancy Electricity Generation System

InactiveUS20120119508A1Generate clean environmentally friendly energyGravity and buoyancyHydro energy generationMachines/enginesProcess engineeringMechanical engineering

A method of generating electricity for mass production using the principles of gravity and buoyancy, that is:Abundant, Environmentally friendly, Clean, Controlled and manageable, Geographically applicable, Cheap and Reliable.

Owner:SPARKS USHIJIMA SHIRO CRESTO

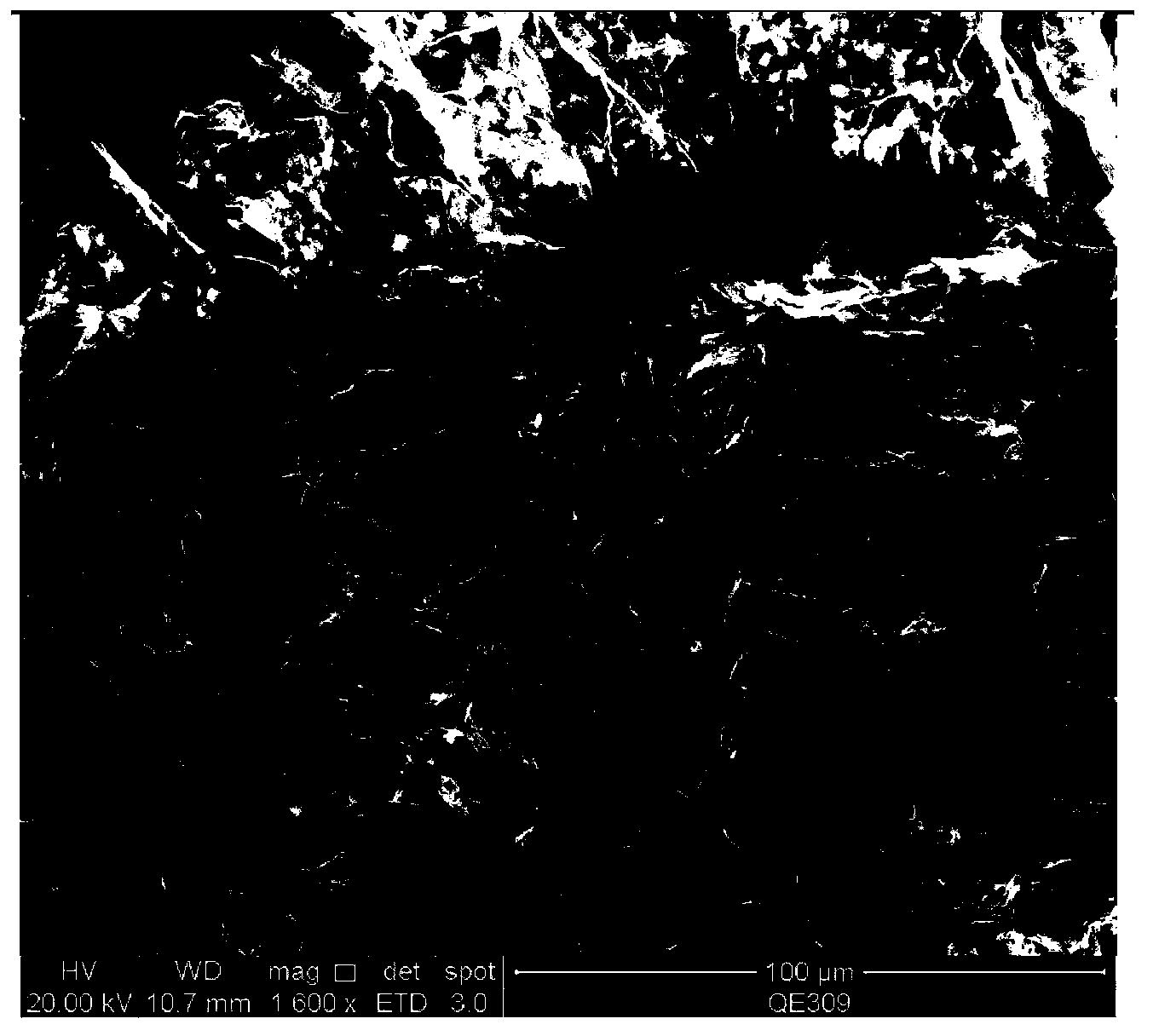

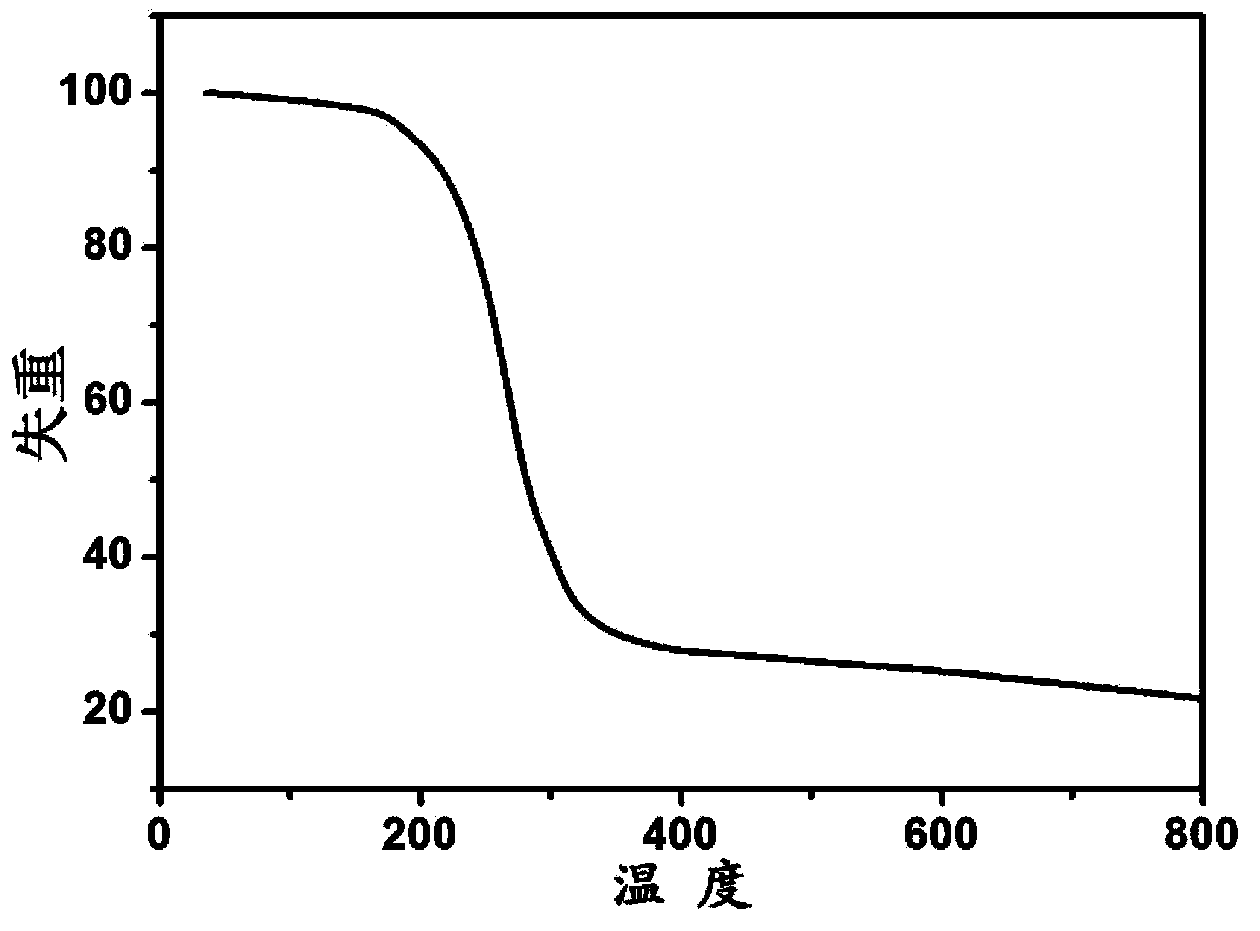

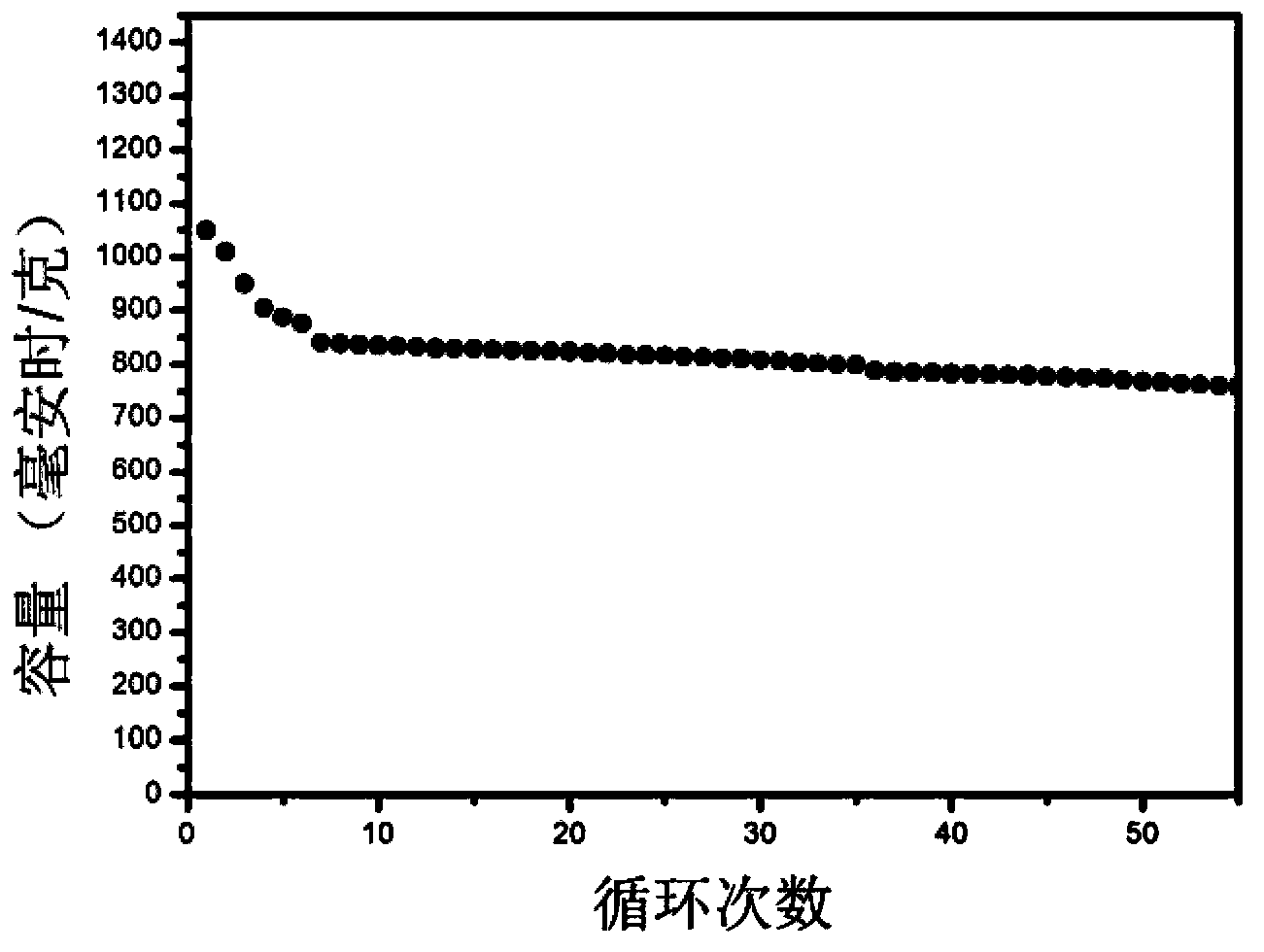

Lithium ion secondary battery, positive electrode material of battery, and preparation method of material

InactiveCN103682352AImprove electrochemical performanceElectrochemical Performance MitigationCell electrodesSecondary cellsElectric capacityDissolution

The invention provides a lithium ion secondary battery, a positive electrode material of the battery, and a preparation method of the material. The positive electrode material of the lithium ion secondary battery comprises graphene and nanometer sulfur particles which are loaded on the surface of the graphene. The graphene oxide or graphene, nanometer sulfur powder, a surface active agent and a reducing agent are adopted as raw materials, and after being mixed, the raw materials perform hydrothermal reaction to obtain the positive electrode material of the lithium ion secondary battery. The electronic conductivity of the positive electrode material is improved by virtue of the excellent conductivity of the graphene, and the dissolution of polysulfide ions can be alleviated through the unique two-dimensional structure of the graphene, so that the gradual attenuation of the electric capacity can be inhibited, and the cycling property of the battery can be improved. The experimental result shows that the primary discharging capacity of the positive electrode active material can reach 1100mAh / g under 0.1C, the capacity can be maintained at 800mAh / g after the battery is cycled for 50 times, the discharging capacity can be maintained at 450mAh / g under 2C, and the rate performance of the battery is excellent.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

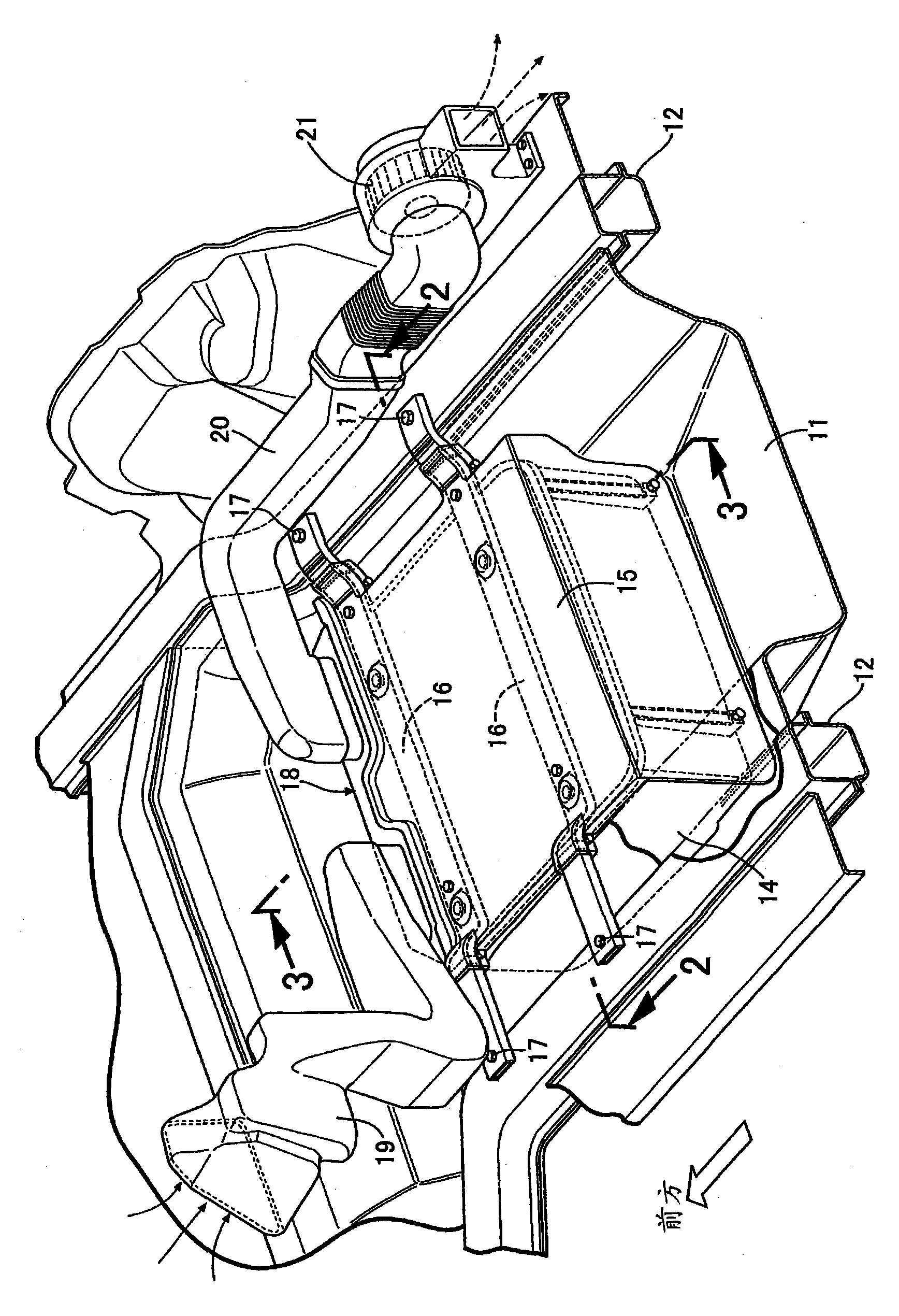

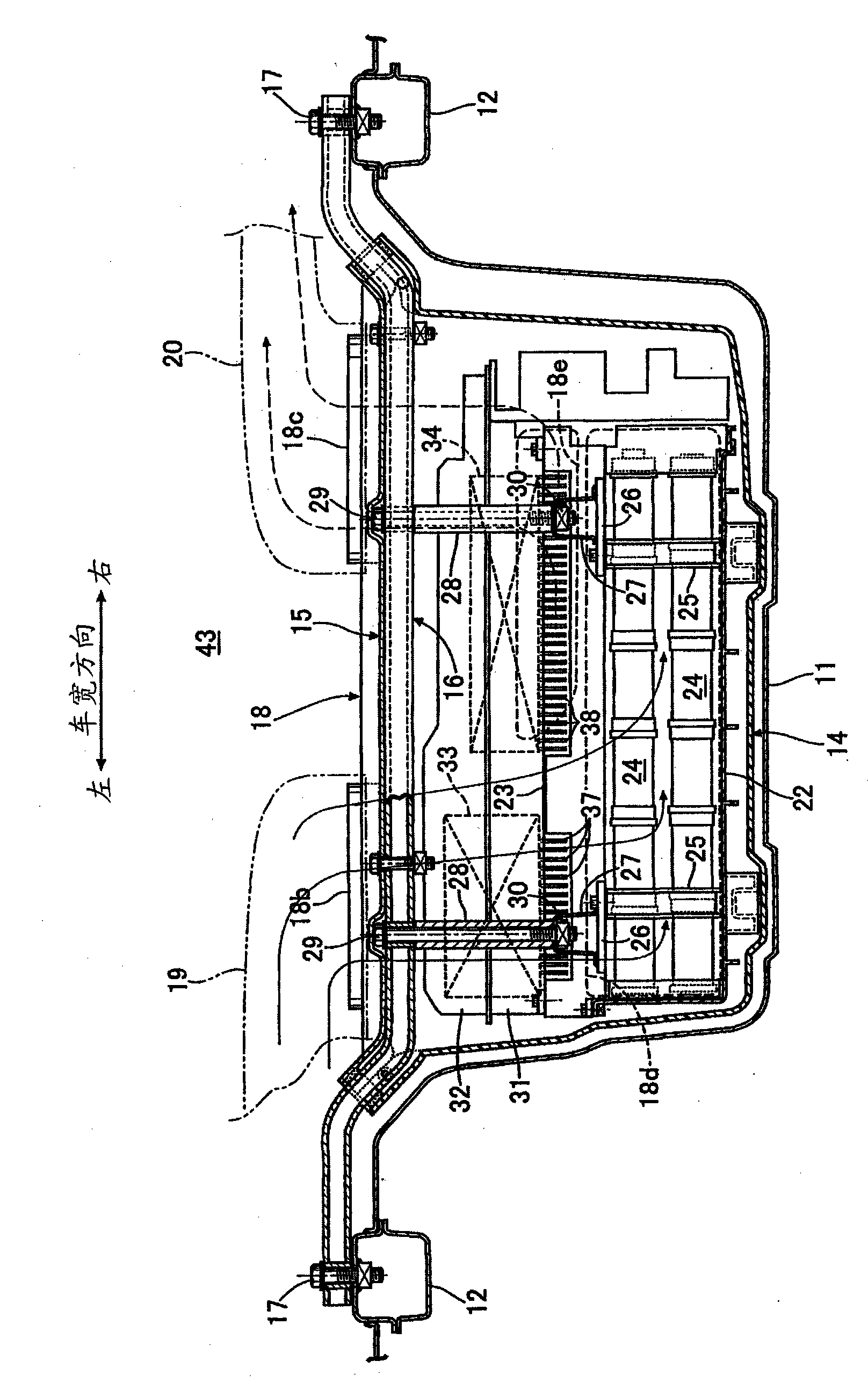

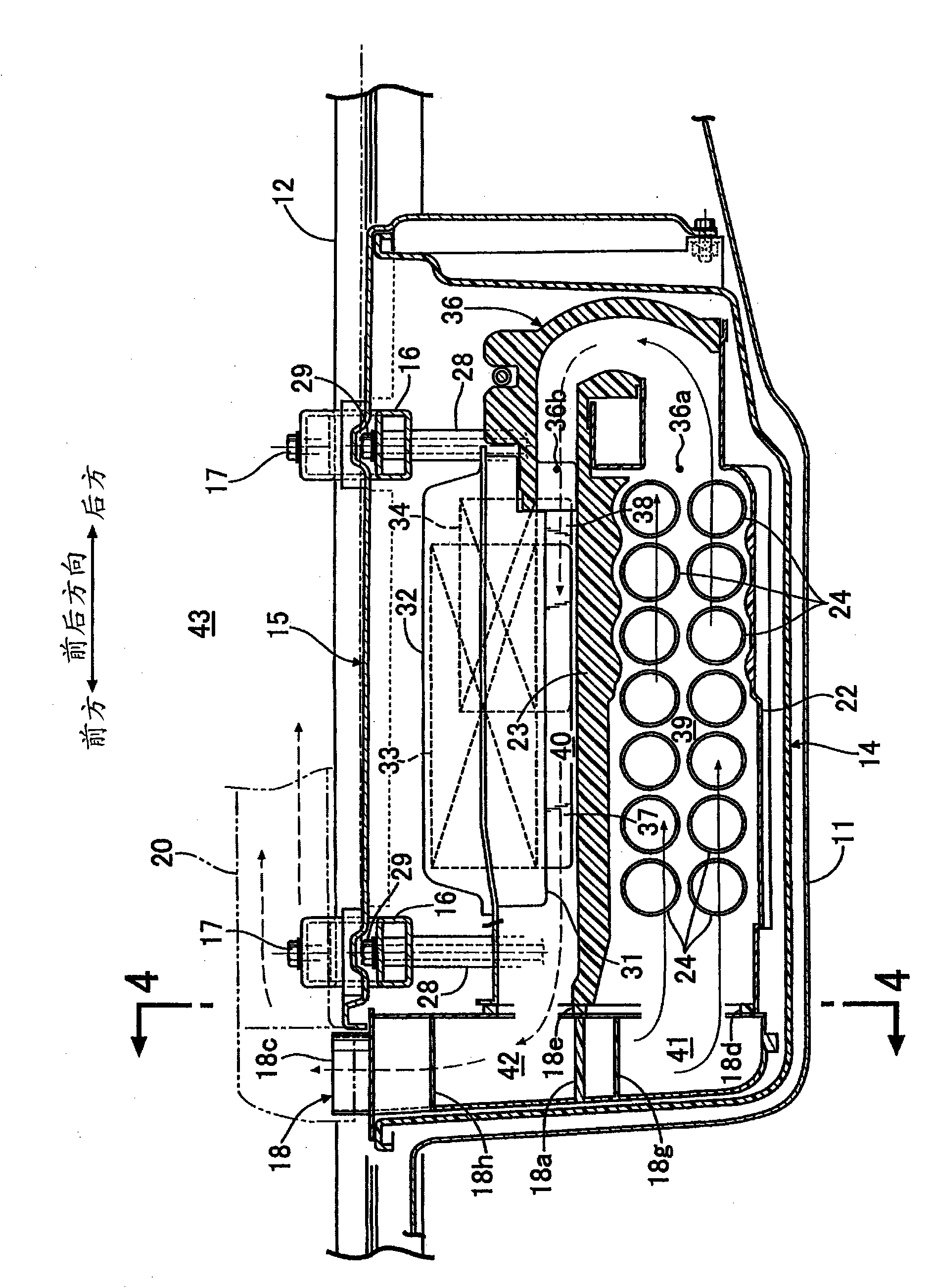

Electric power supply device

InactiveCN101925482AReduced durabilityFast heat releaseCell temperature controlElectric propulsion mountingElectrical batteryMiniaturization

An electric power supply device in which the inside of a waterproof case (14) is partitioned into a lower first cooling air flow path (39) and an upper second cooling air flow path (40), cooling air introduced from an intake air flow path (41) of a duct (18) and flowing through the lower first cooling air flow path (39) cools a battery module (24), and after that, the cooling air is introduced into the upper second cooling air flow path (40) by an intermediate duct (36) to cool high-voltage electrical components (33, 34). Air heated by the high-temperature electrical components (33, 34) aftera cooling fan is stopped is discharged from a discharge air flow path (42) of the duct (18) without contact with the battery module (24) located below the components. Further, because the intake air flow path (41) and the discharge air flow path (42) are provided integrally in the duct (18) which is provided on one end side of the waterproof case (14), the electric power supply device is more compact than in the case where the intake air flow path (41) and the discharge air flow path (42) are separately provided at opposite ends of the waterproof case (14).

Owner:HONDA MOTOR CO LTD

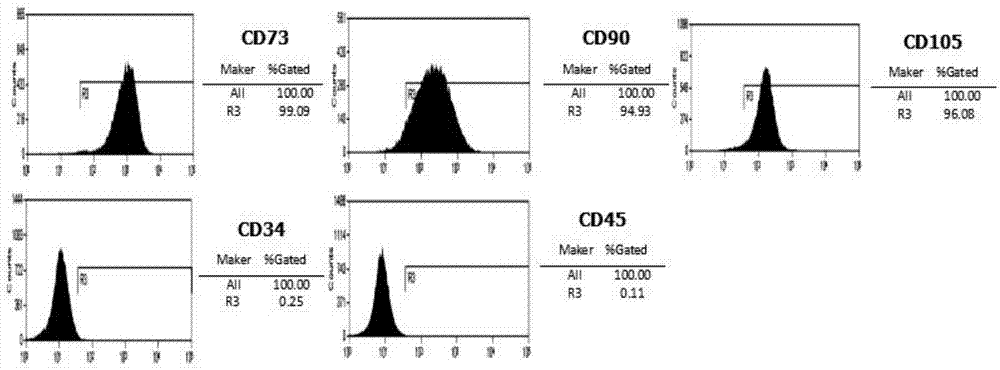

Preparation method and application of exosome derived from human olfactory mucosa mesenchymal stem cells

InactiveCN108004206AWon't hurtGuaranteed amountSkeletal/connective tissue cellsUnknown materialsOlfactory mucosaPolyethylene glycol

The invention provides a preparation method of an exosome derived from human olfactory mucosa mesenchymal stem cells, and belongs to the technical field of stem cells. When the fusion rate of P4-generation and / or P5-generation olfactory mucosa mesenchymal stem cells is 85% to 90%, a cultured object is subjected to first centrifugal separation, obtained first supernate is subjected to second centrifugal separation, obtained second supernate is subjected to third centrifugal separation, the obtained third supernate is filtered, the obtained filtrate is mixed with a polyethylene glycol solution,after standing and incubation for 8-10 hours, fourth centrifugal separation is conducted, the obtained fourth precipitate is washed by normal saline, and after fifth centrifugal separation, the obtained precipitate is the exosome. By adopting the method, a vesica of the exosome can not be damaged, the amount of the obtained exosome is ensured, and the obtained exosome can promote the proliferationof human-brain microvascular epithelial cells and improve the cell migration rate.

Owner:HUNAN NORMAL UNIVERSITY

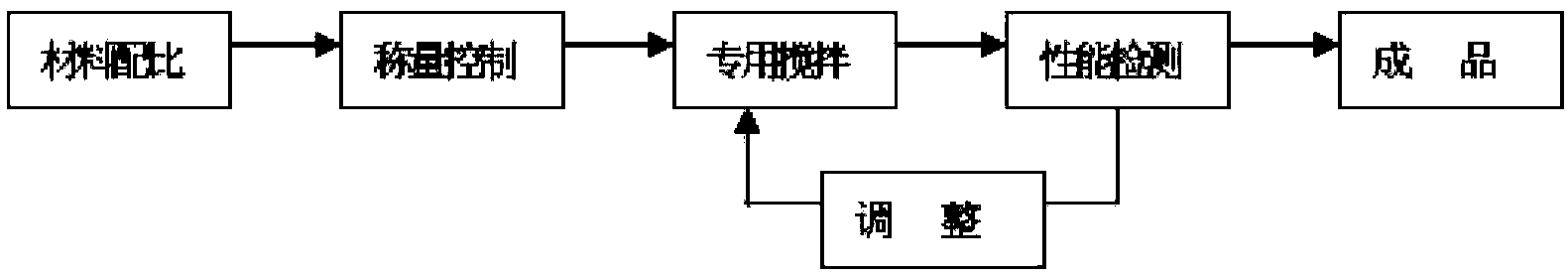

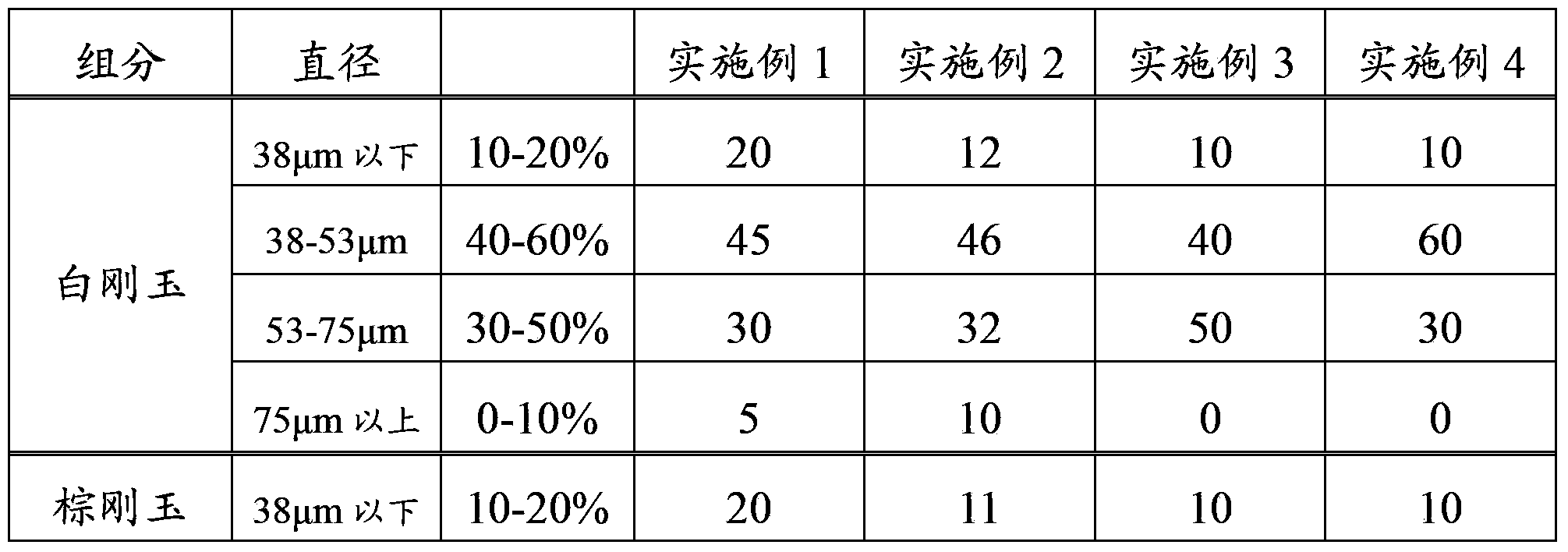

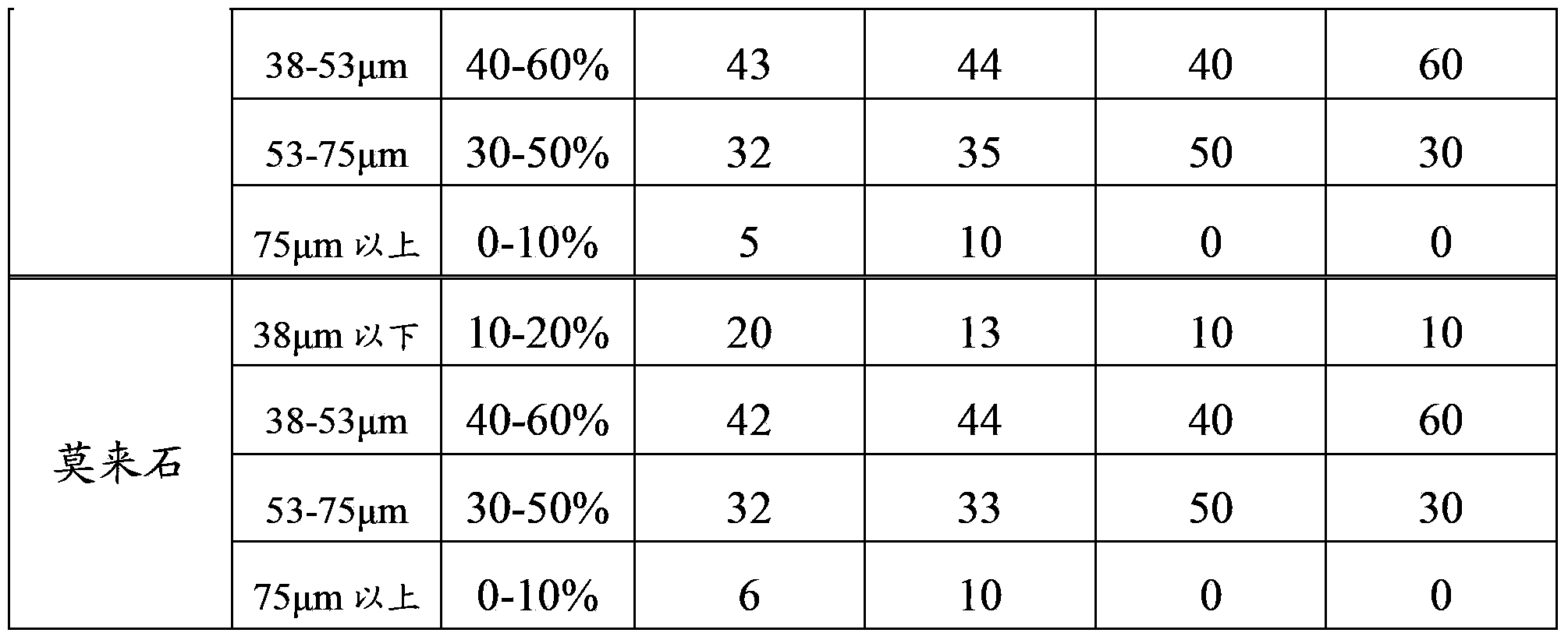

High-concentration alcohol-based paint used in cast steel

ActiveCN103406489AMaintain specific surface areaGuaranteed amountFoundry mouldsFoundry coresHigh concentrationAlcohol

The invention discloses high-concentration alcohol-based paint used in cast steel. The paint comprises 66-75% of refractory aggregates, 0.5-1.5% of a binder, 1.0-2.5% of a suspending agent, and 21-30% of isopropanol, wherein the refractory aggregates comprise 50-70% of white corundum, 20-40% of brown corundum, and 10-30% of mullite. The particle size distribution of the refractory aggregates is that: particles with diameters lower than 38mum accounts for 10-20%, particles with diameters of 38-53mum accounts for 40-60%, particles with diameters of 53-75mum accounts for 30-50%, and particles with diameters higher than 75mum accounts for 0-10%. According to the invention, the refractory aggregates with lower cost are intelligently selected for replacing a zircon powder aggregate, and characteristics of high refractory degree and surface fusion property are obtained as well. Also, the paint has large softening temperature zone. Through reasonable particle size selection and specific binder optimization, aggregate content is higher than 75%, such that excellent performance is obtained.

Owner:鑫工艺(上海)材料科技有限公司

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548AImproved particle morphology and molecular weight distributionImprove processing thermal stabilityChemistryPlasticizer

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products agingdue to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

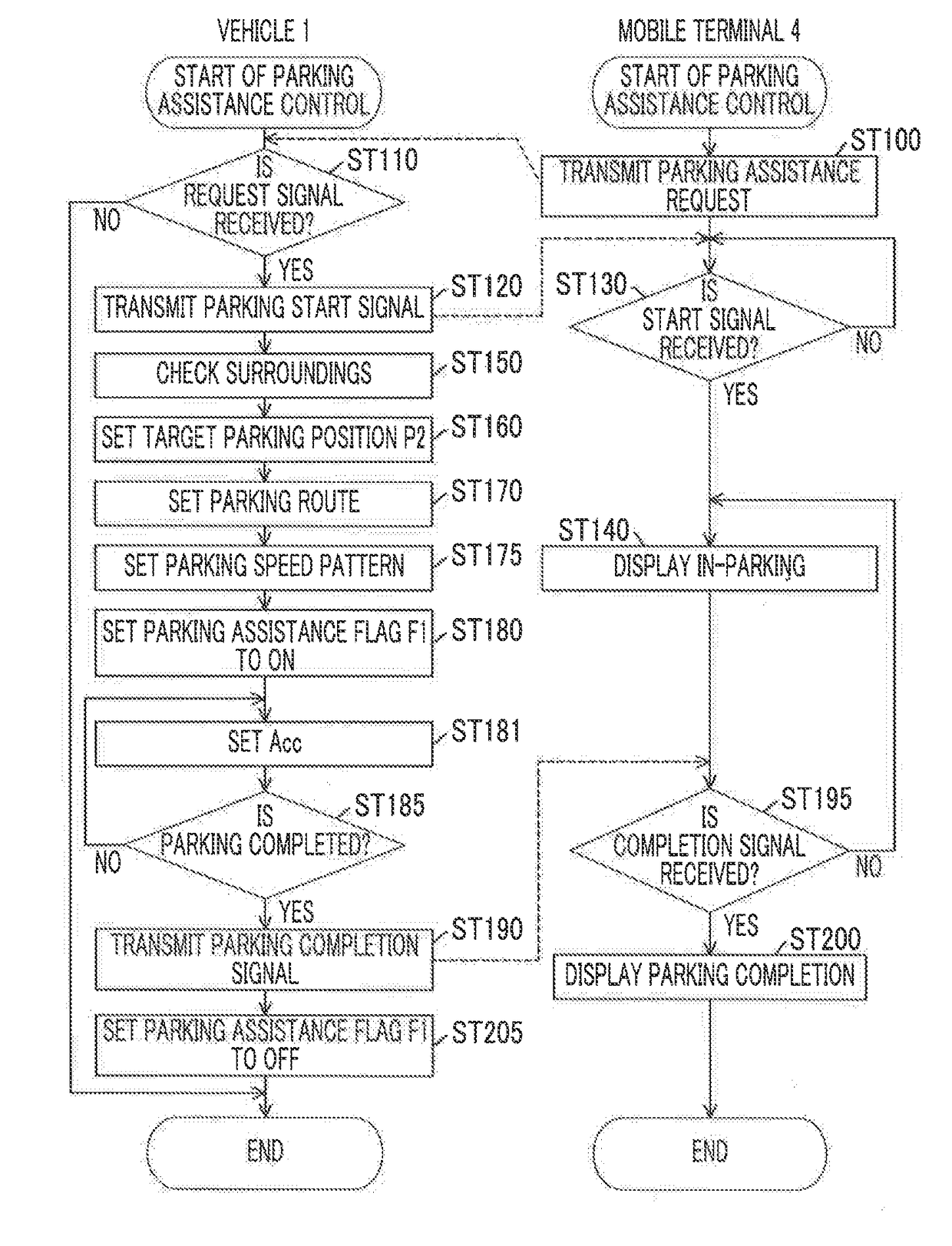

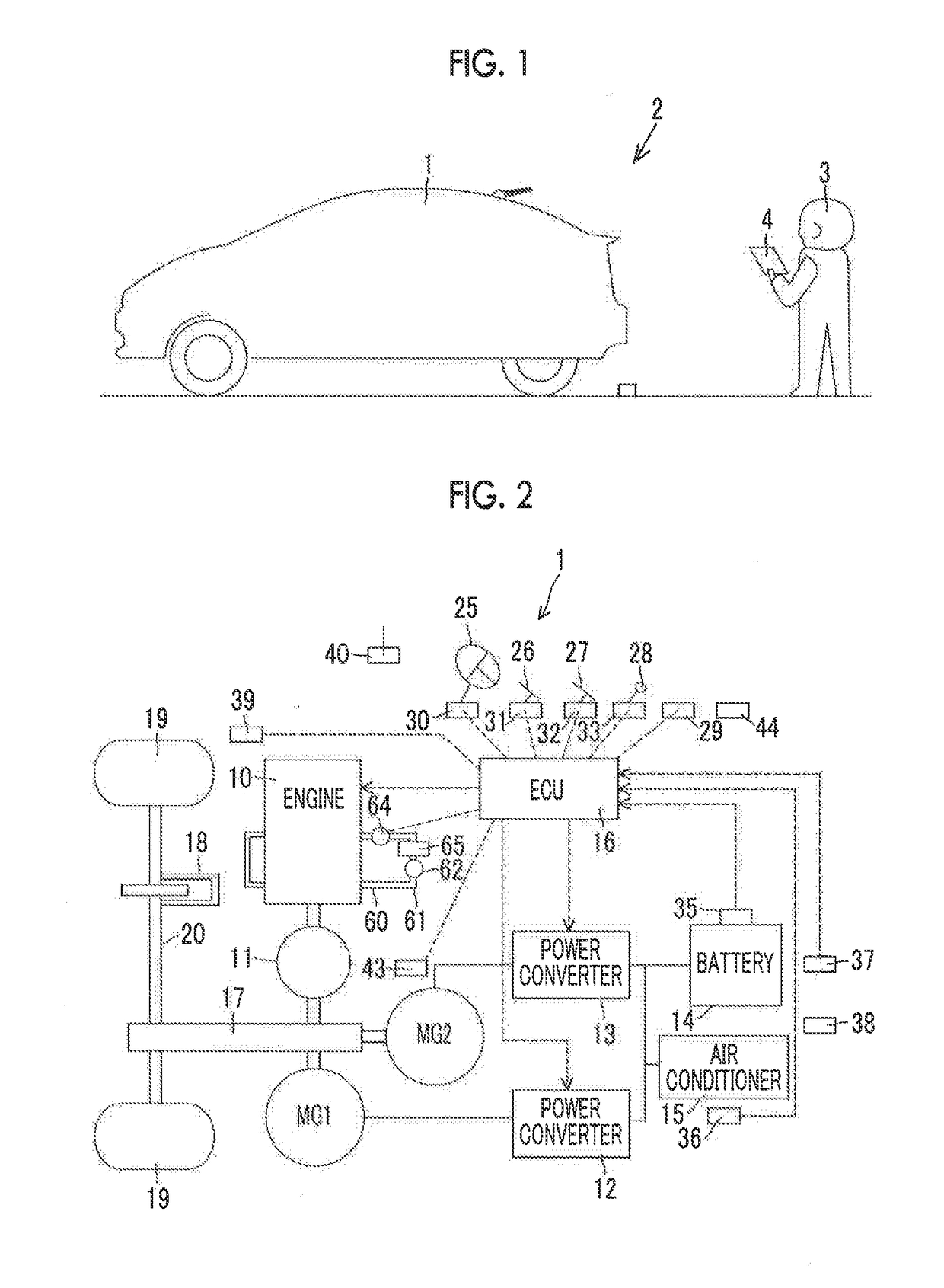

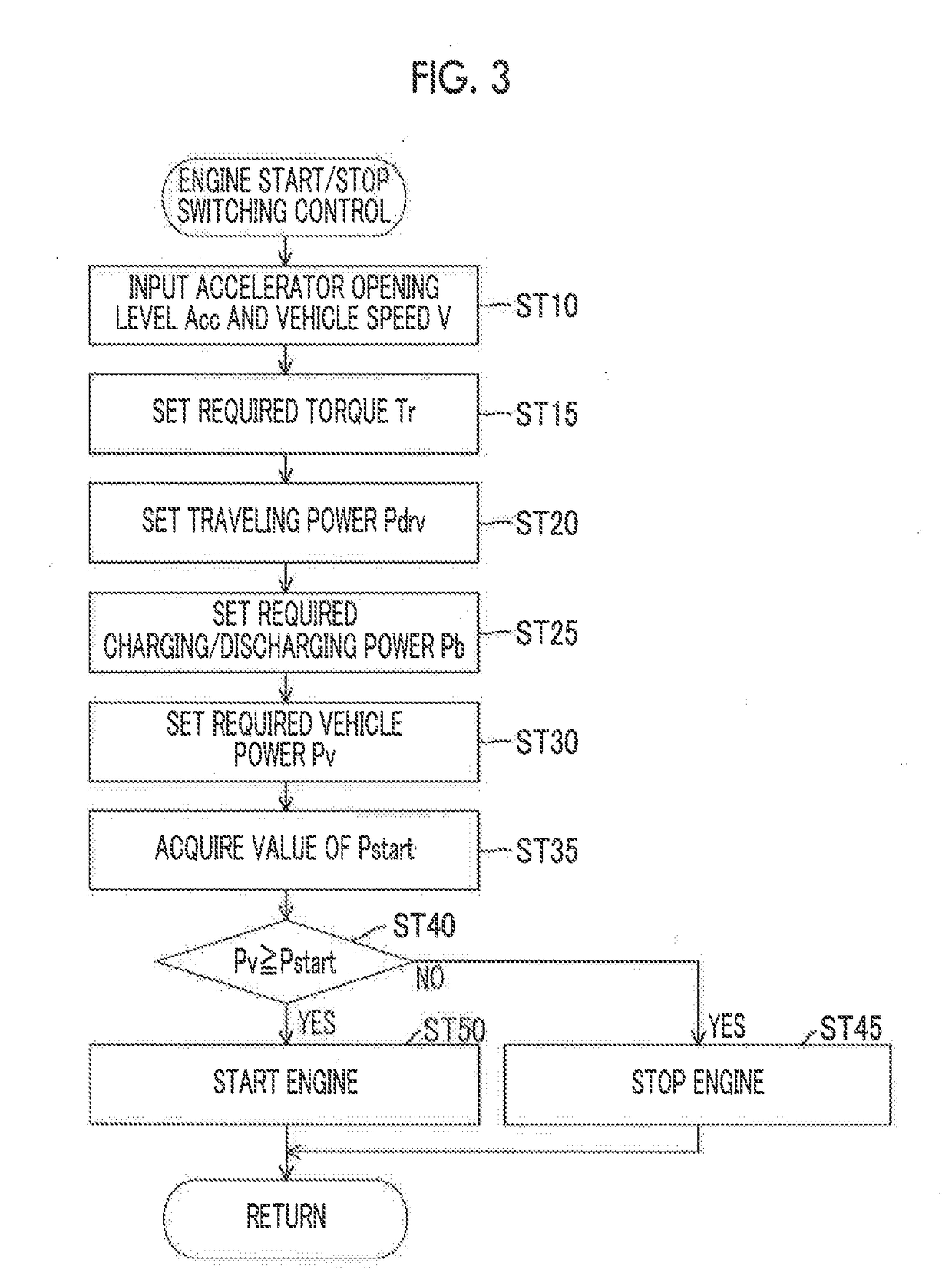

Hybrid vehicle and control method of hybrid vehicle

ActiveUS20170361837A1Guaranteed amountAvoid startingHybrid vehiclesInternal combustion piston enginesElectric machineHybrid vehicle

An electronic control unit of a hybrid vehicle is configured to determine whether or not parking operation of the hybrid vehicle is being performed. The electronic control unit is configured to control the engine and the rotary electric machine such that starting the engine when the parking operation of the hybrid vehicle is being performed is harder than starting the engine when the parking operation of the hybrid vehicle is not being performed.

Owner:TOYOTA JIDOSHA KK

Peanut candy (crisp) and preparation method thereof

The invention discloses a peanut sugar (cake), which comprises the following raw materials based on weight proportion: 58-65 portions of groundnut kernels, 15-20 portions of chemical maltose, 12-17 portions of granulated sugar, and 3-10 portions of edible oil; through material preparing, peanut processing, sugar melting, screening, sugar boiling, cooked groundnut kernel pre-heating as well as stirring and forming, the peanut sugar (cake) is obtained. In the groundnut kernel pre-heating step, more groundnut kernels can be added into the sugar paste, and the content of the groundnut kernels accounts for more than half of the total peanut sugar (cake), so that the product tastes crisp and sweet but not greasy.

Owner:黄老五食品股份有限公司

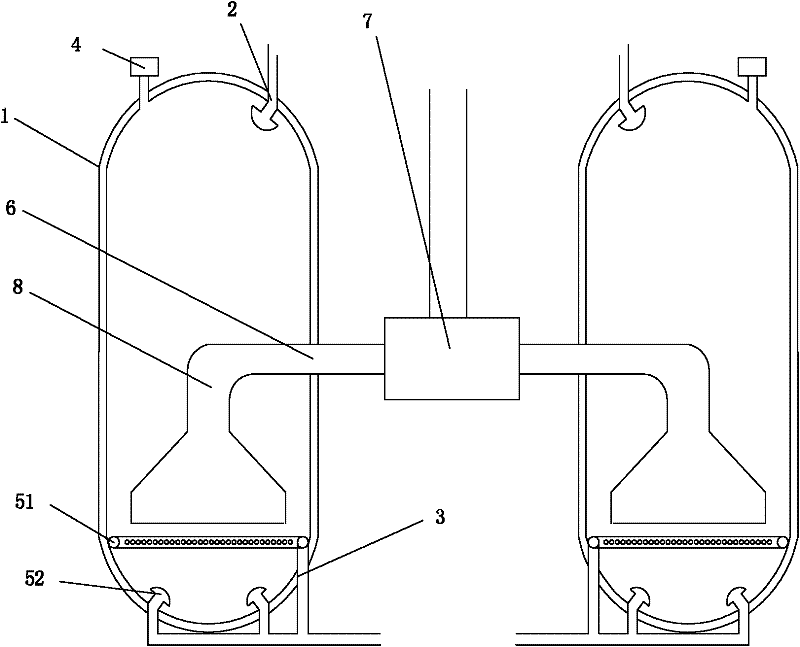

Parallel composite tank

The invention belongs to the field of fire-fighting fire extinguishing apparatus and especially relates to a parallel composite tank for fire extinguishing of large-scale equipment. The parallel composite tank comprises at least two powder storage tanks, which are for storing, atomizing and mixing dry powder and are in a same horizontal line; an upper air inlet and a lower air inlet are arranged on the top and the bottom of each powder storage tank; a pressure sensor for detecting pressure in each tank is arranged on the top of each powder storage tank; an atomizing device for loosening and atomizing the dry powder is arranged in each powder storage tank; the lower air inlet is connected with the atomizing device; a powder outlet is arranged on a side wall of each powder storage tank; and powder outlets of the at least two powder storage tanks are connected with a dry powder pipeline centralized controller through a connecting pipe. According to the invention, a plurality of powder storage tanks are connected through the dry powder pipeline controller, so as to start different numbers of powder storage tanks, according to fire behavior, to guarantee the amount of dry powder needed by fire extinguishing.

Owner:江苏中瑞电保智能装备有限公司

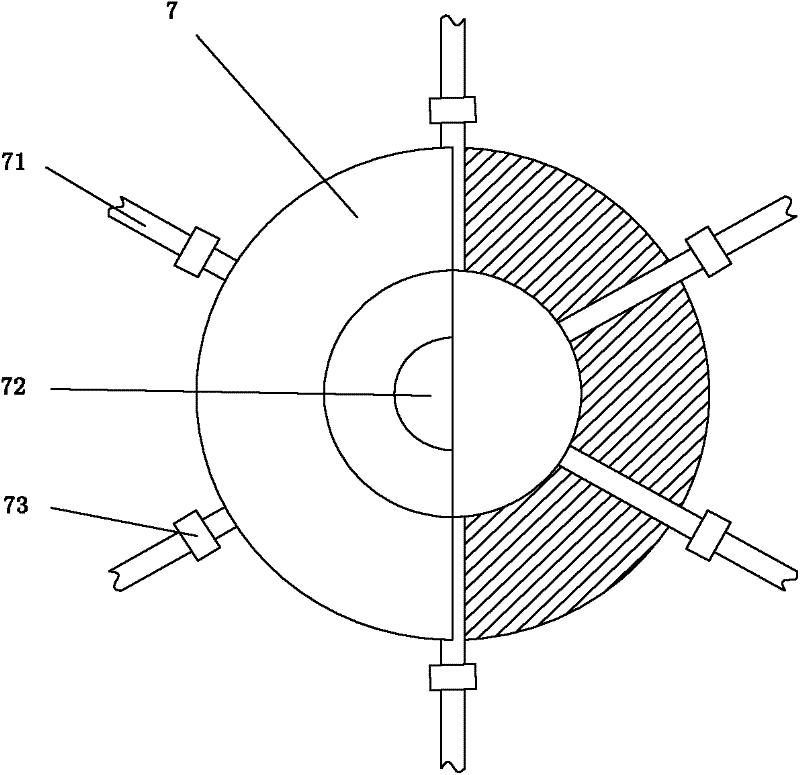

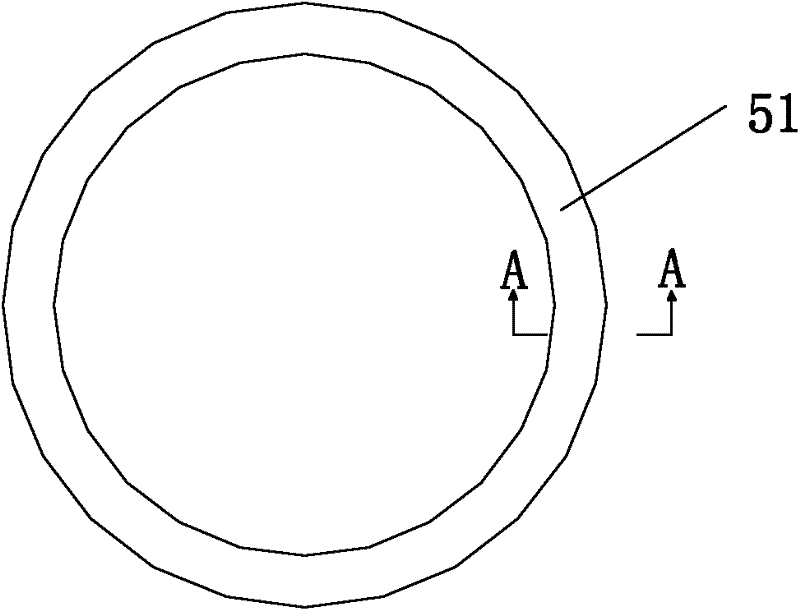

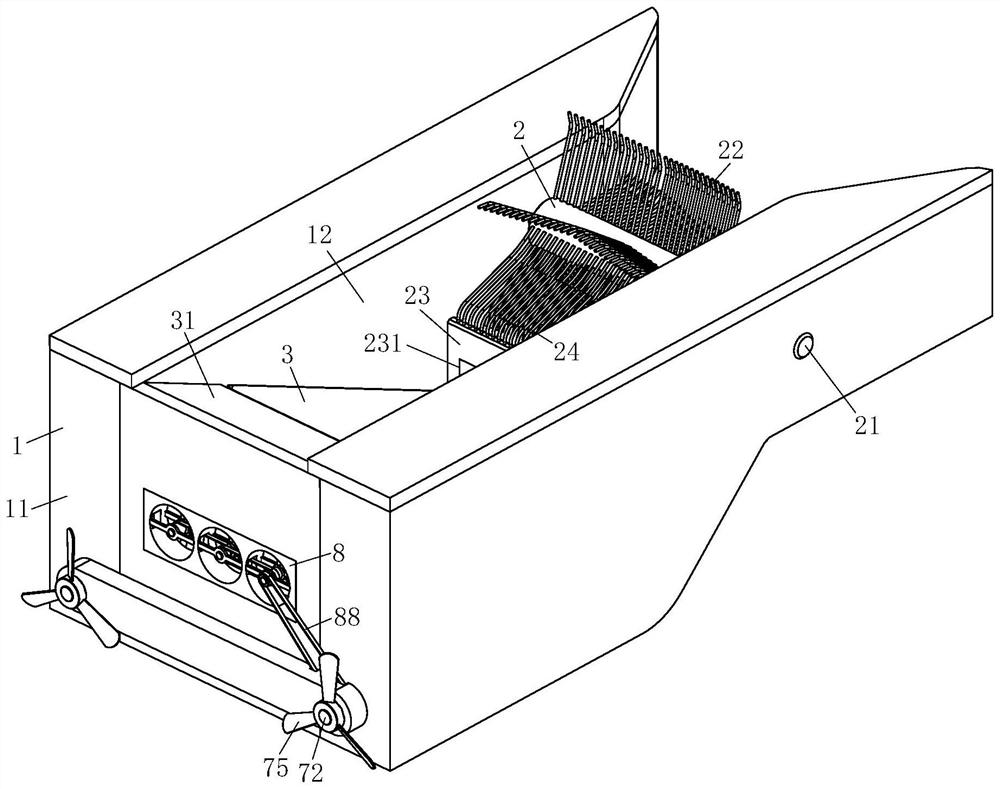

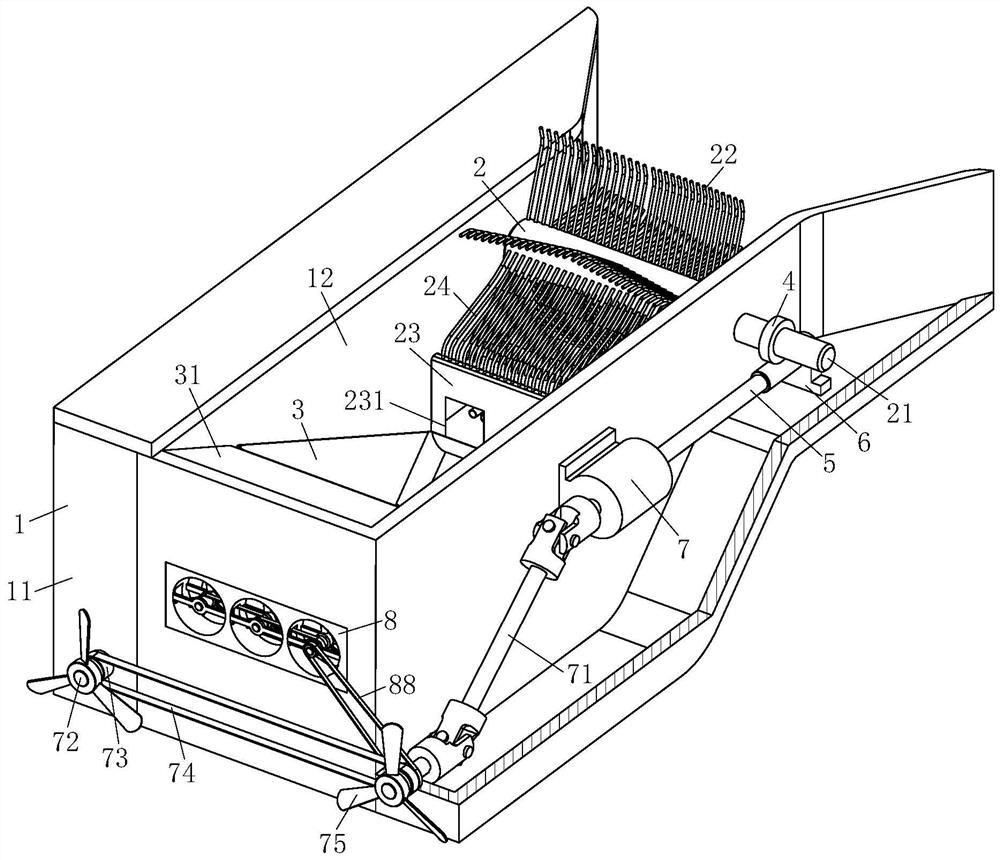

Automatic cleaning ship for marine floating garbage

ActiveCN111877293AGuaranteed service lifeExtended service lifeWater cleaningWaterborne vesselsDrive shaftElectric machinery

The invention belongs to the technical field of marine garbage cleaning, and particularly relates to an automatic cleaning ship for marine floating garbage. The automatic cleaning ship comprises a ship body, a garbage collecting roller, a first rotating shaft, a collecting and filtering net, a turbine, a worm shaft, a supporting seat, a double-head motor, a universal transmission shaft, a second rotating shaft, a first belt wheel, a first belt and a propeller. According to the automatic cleaning ship, the double-head motor drives the universal transmission shaft to rotate, then the second rotating shaft is driven to rotate, and further the propeller is driven to rotate, so that the garbage cleaning ship is pushed to move on the sea surface; meanwhile, the double-head motor drives the wormshaft to rotate, the turbine is in meshing transmission with the worm shaft, then the first rotating shaft is driven to rotate, and further the garbage collecting roller is driven to rotate; and meanwhile, a cylindrical rod rotates, the garbage floating on the sea surface is fished up by the rotating cylindrical rod and rotates along with the cylindrical rod, and when the cylindrical rod rotates over the highest point, the garbage slides down along the cylindrical rod and enters the collecting and filtering net in a garbage storage cavity, and the garbage floating on the sea surface is cleanedaccordingly.

Owner:CSIC SHANGHAI MARINE ENERGY SAVING TECH DEV CO LTD

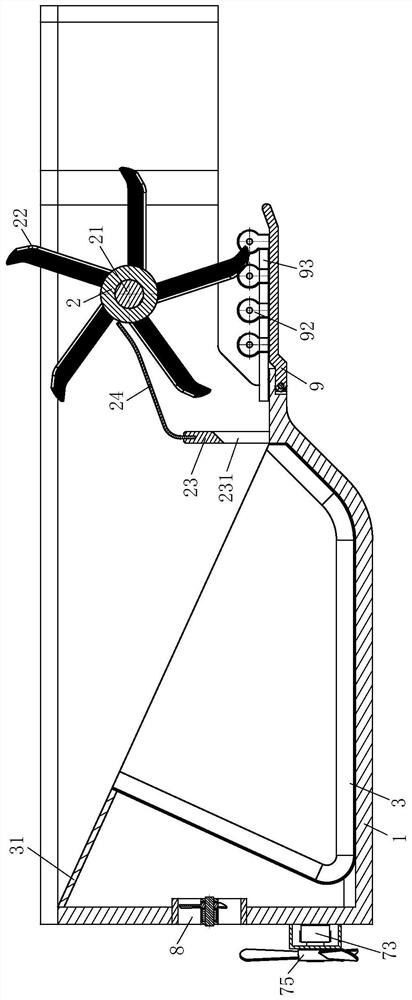

Temperature control type concrete stirring device

ActiveCN107297823AOvercome the problem of deviation in use effectImprove the uniformity of quality effectDischarging apparatusMixing operation control apparatusStopped workTemperature control

The invention discloses a temperature control type concrete stirring device, which comprises a stirring barrel body. A second driven gear is engaged with each of two sides of a first driving gear; the second driven gear is fixedly arranged on a driven driving shaft; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside the cavity; a first discharging pipe is arranged at the bottom of the right side wall of the stirring barrel body; the second discharging pipe is connected with an auxiliary material discharging hose; an additive guide-in device is also arranged on the top of the stirring barrel body; a horizontal section pipeline, a first bent head pipeline, a second bent head pipeline and a third bent head pipeline are arranged on a pipeline of a liquid agent control switch and an additive conveying pump. The temperature control type concrete stirring device can be used for performing temperature control on inside concrete; the automatic addition and quantitative addition of the water can be realized; the deflection problem due to different heights can be solved; the self remaining phenomenon cannot occur after the additive conveying pump stops working.

Owner:重庆拉瑞永固混凝土有限公司

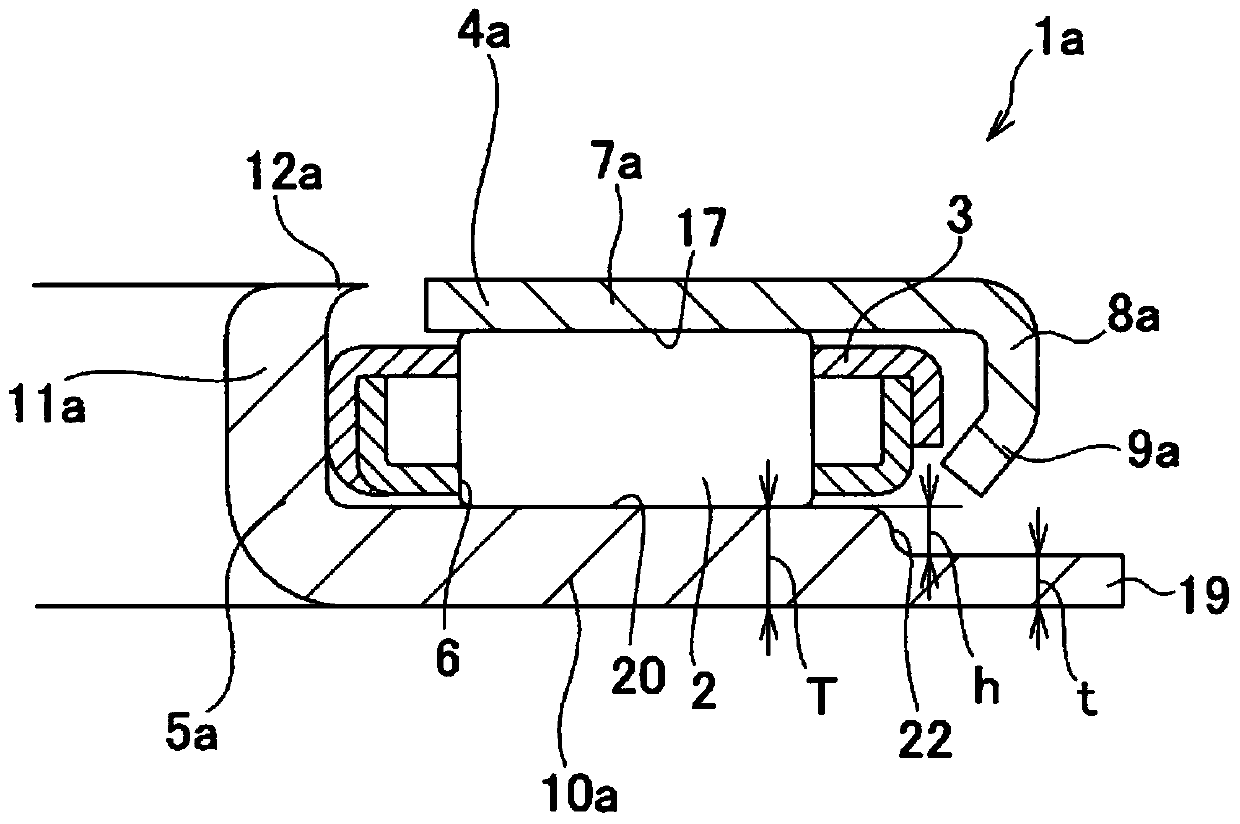

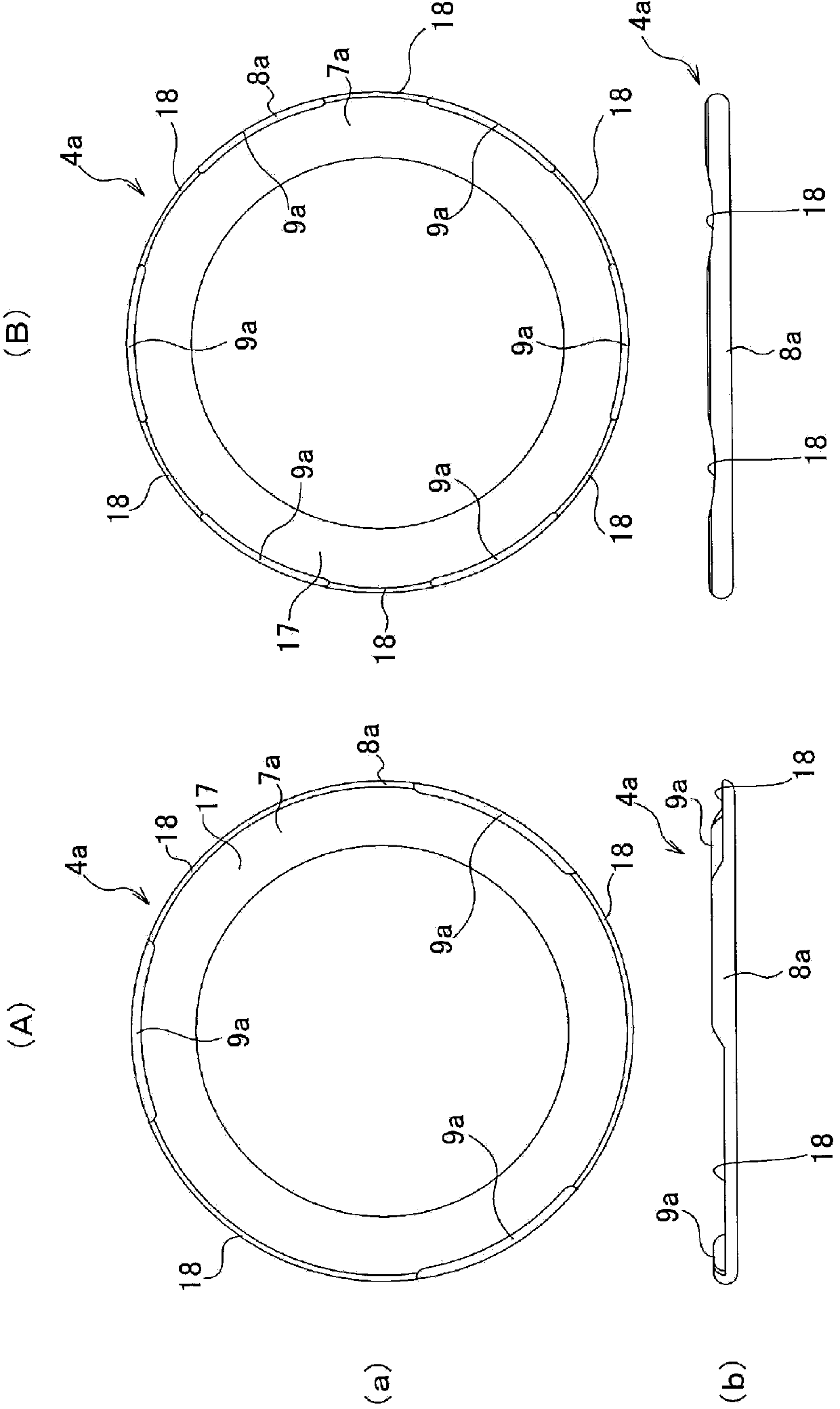

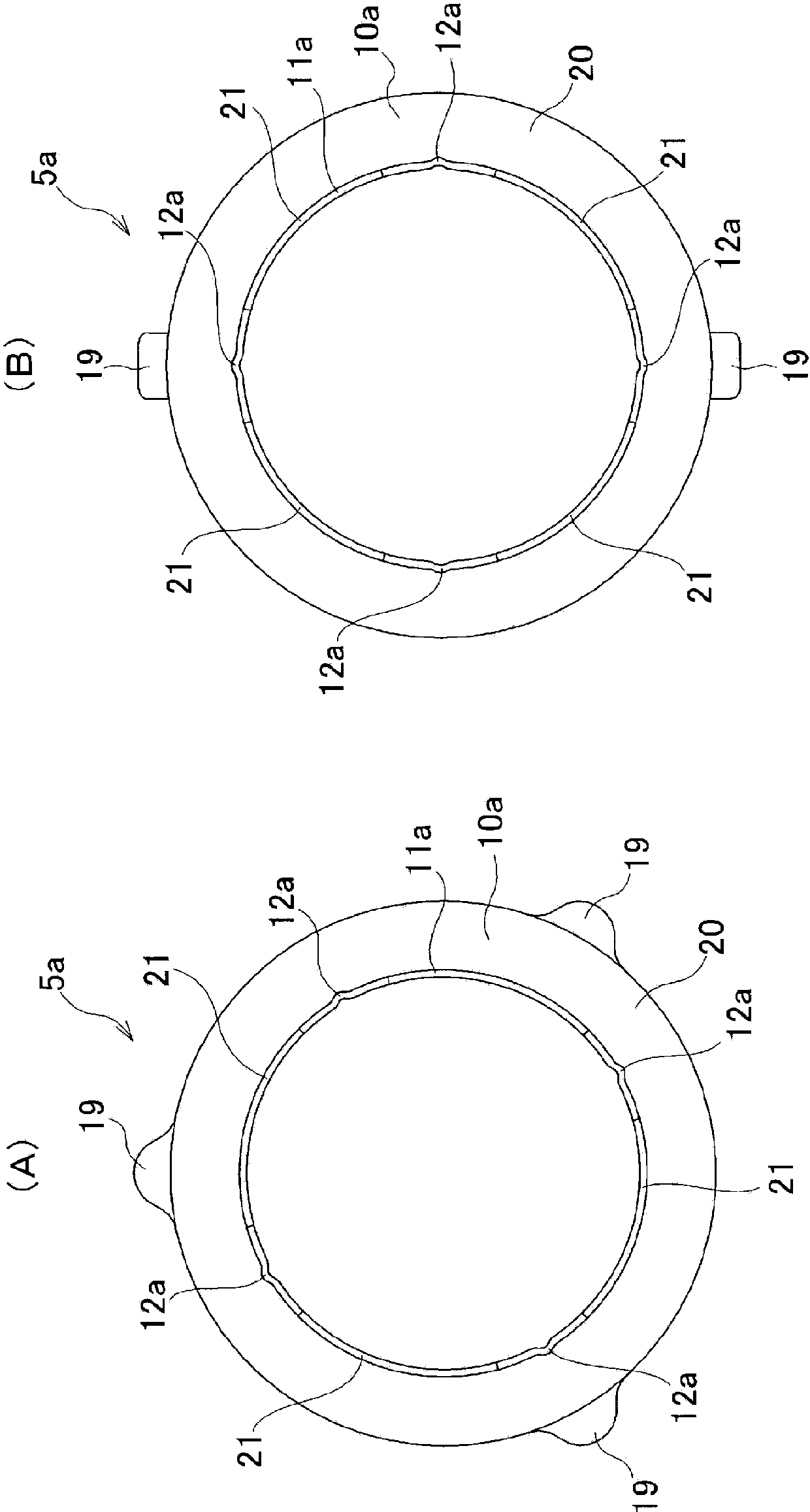

Thrust roller bearing with races

InactiveCN103635706APrevent separation functionExcellent handlingRoller bearingsShaftsLeading edgeFlange

The invention achieves a thrust roller bearing structure with races that can increase the permissible level of eccentricity of a pair of members that rotate relative to each other as well as increase the amount of lubricating oil that is circulated therein, while securing the function of preventing the separation of a cage (3), a first thrust race (4a) and a second thrust race (5a). The external diameter of the external diameter side flange (8a) formed on the outer margin of a first thrust race (4a) is 60 mm - 120 mm, the internal diameter of the internal diameter side flange (11a) formed on the inner margin of an internal diameter side flange (5a) is 40 mm - 80 mm, and the internal space is 1 mm - 2 mm. Therefore, the external diameter side catch (9a) is formed intermittently in the circumferential direction on the leading edge of the external diameter side flange (8a).

Owner:NSK LTD

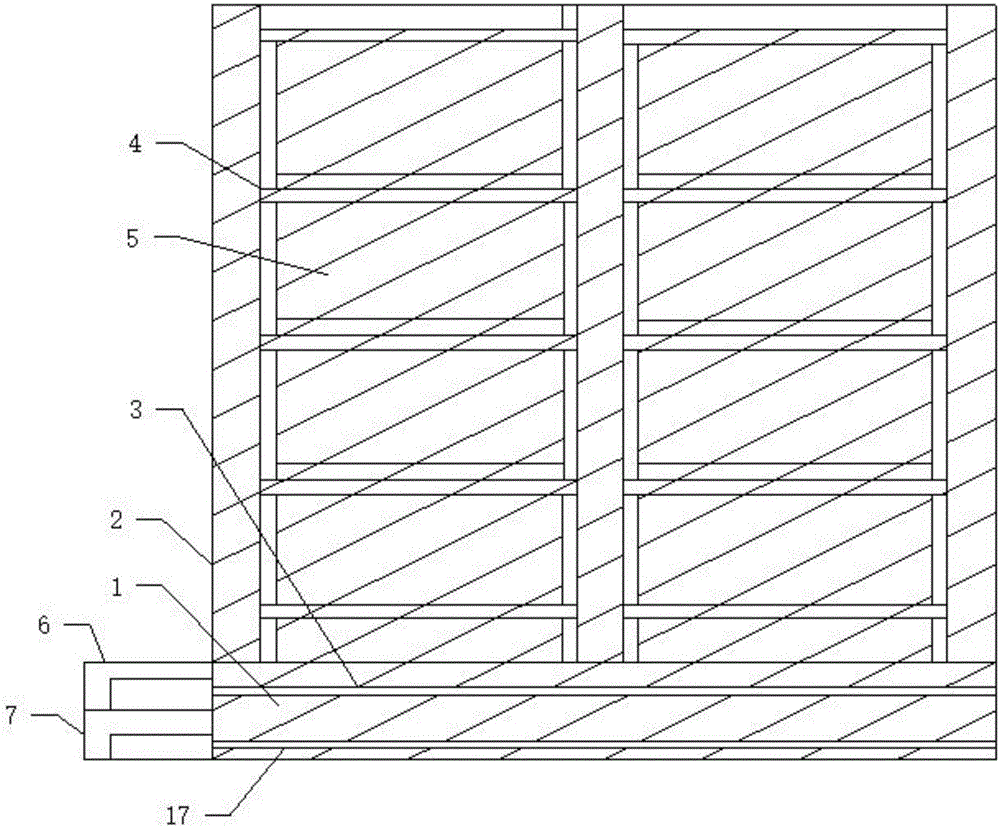

Environmental treatment automatic electric power station coal dust adsorption and cleaning protective wall

InactiveCN106836961AGuaranteed circulationEasy to install and disassembleCombination devicesFencingPower stationEngineering

The invention discloses an environmental treatment automatic electric power station coal dust adsorption and cleaning protective wall which comprises a base. The base is uniformly connected with a row of protective supporting rods. The two sides of the protective supporting rods are each provided with a rotary chain which is connected with a row of corresponding lifting blocks. A fixing rod is connected between every two adjacent lifting blocks and provided with a dustproof filter net which is provided with a filter plate. Each protective supporting rod is provided with a first inner cavity and a second inner cavity. The base is further provided with a dust collector and a water spraying pump which separately communicate with the first inner cavities and the second inner cavities. Dust on the dustproof filter nets can be collected through the dust collector, water can be drained through the water pump, and therefore the mount of the dust can be further decreased, and harm of the dust to the environment and the human body can be further avoided.

Owner:DATANG HEILONGJIANG POWER GENERATION +1

Automatic cruise type sewage treatment equipment for riverway

PendingCN112723446AGuaranteed uniformityGuaranteed treatment effectWater treatment parameter controlMeasurement devicesStormwaterSewage treatment

The invention discloses automatic cruise type sewage treatment equipment for a riverway. The equipment is used for monitoring water flow information of the riverway in real time so as to adjust the moving speed of a moving ship body on the water surface in real time and adjust the amount of a medicament put into a riverway water body in real time, and thus the proper amount of the medicament put into the riverway water body is ensured, and the sewage treatment effect is ensured. A first height-limiting obstacle detection mechanism is arranged to obtain height-limiting obstacle information in front of the moving direction of a moving ship body in real time in the cruising process, and the height of the whole sewage treatment equipment placed on the water surface of a riverway is adjusted in real time according to the height-limiting obstacle information so as to prevent the sewage treatment equipment from colliding with a height-limiting obstacle to be damaged; before the sewage treatment equipment is started for cruising, whether rain falls in the current environment or not is detected through the raindrop sensor, fed chemicals are prevented from being washed away by the rain, and the sewage treatment effect is guaranteed; by adjusting the position of the sewage treatment equipment in the riverway in real time, the uniformity of chemicals fed into the riverway is ensured.

Owner:FOSHAN YUHUANG ECOLOGICAL ENVIRONMENT TECH

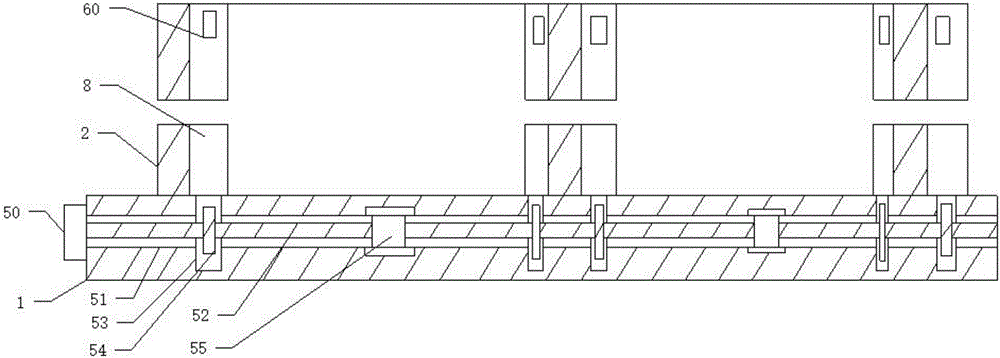

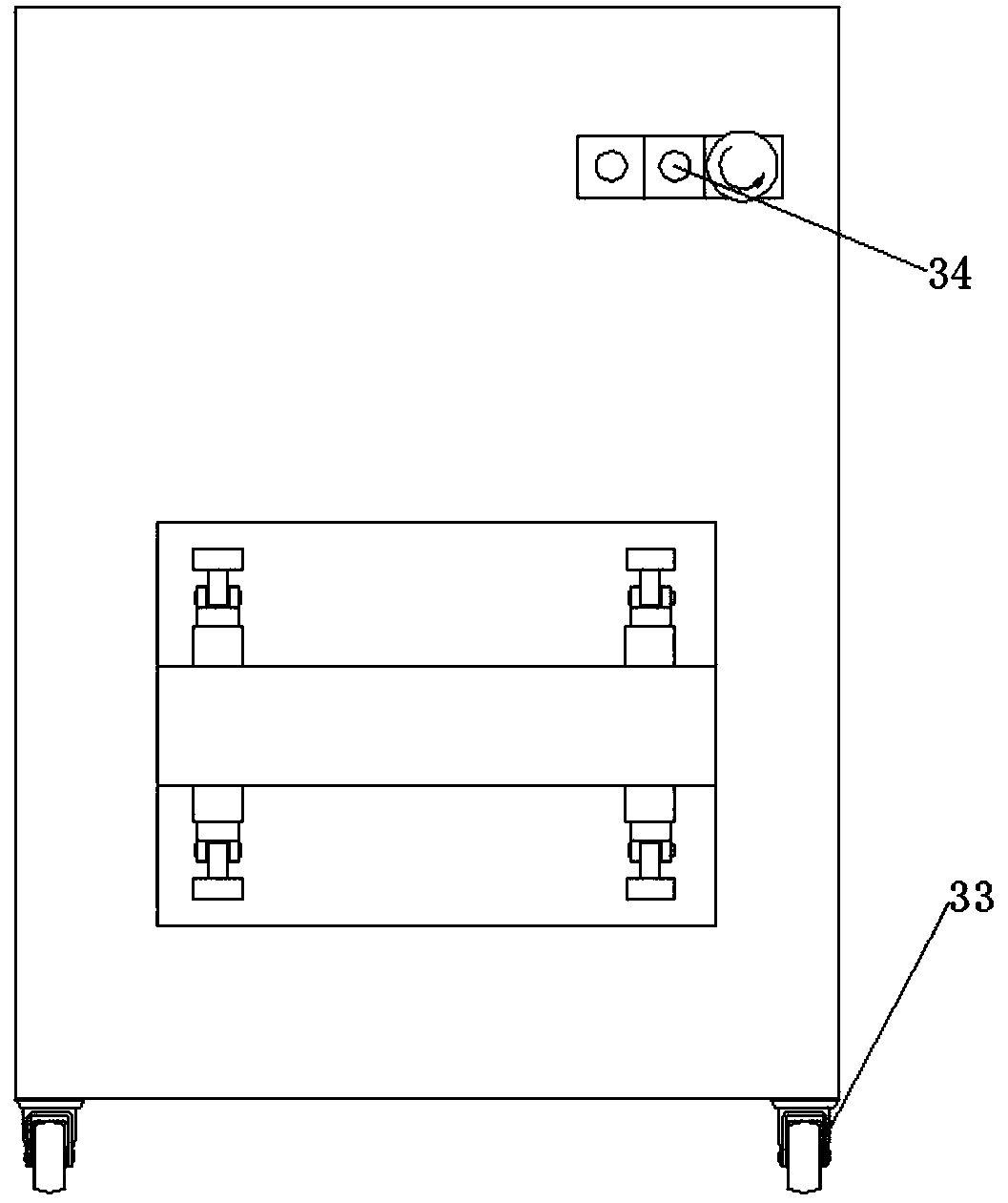

Automatic ink injecting device of ink cartridge of printer

InactiveCN108357214ARealize automatic feedingImprove loading and unloading timesPrintingGear driveGear wheel

The invention discloses an automatic ink injecting device for an ink cartridge of a printer, and relates to the technical field of office supplies. The automatic ink injecting device comprises a box body; a motor is fixedly connected to the inner wall of the bottom surface of the box body; an output shaft end of the motor is in transmission connection with a roller through a belt and gears; the surface of the roller is in transmission connection with a conveying belt; clamping devices are fixedly connected to the surface of the conveying belt; a sliding plate is connected between the two opposite sides of the inner wall of the box body in a sliding mode; an automatic ink injecting device body is fixedly connected to the bottom of the sliding plate; an ink supply device is fixedly connectedto the top of a fixing plate on the inner side of the box body and communicates with injection heads through an ink pipe. According to the automatic ink injecting device for the ink cartridge of theprinter, automatic injecting for the ink cartridge can be realized, the ink cartridge can be automatically clamped and fixed on the conveying belt, the mounting and dismounting time can be shortened,through the cooperation of the conveying belt, automatic ink injecting can be realized, the ink injecting amount can be guaranteed, the ink injecting time can be shortened, the working efficiency canbe improved, and the labor intensity can be lowered.

Owner:合肥市硕理机电科技有限公司

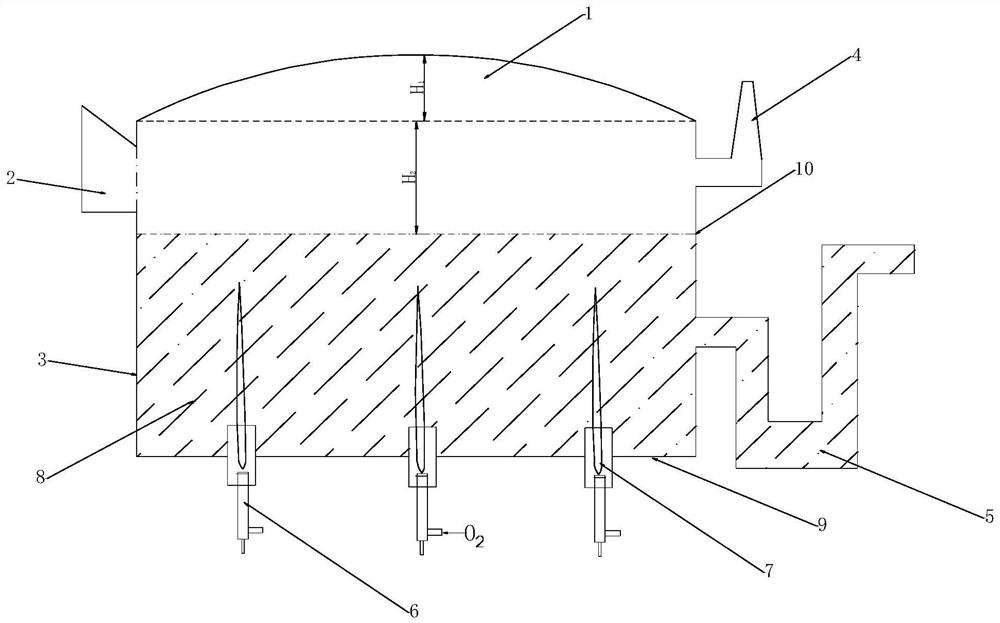

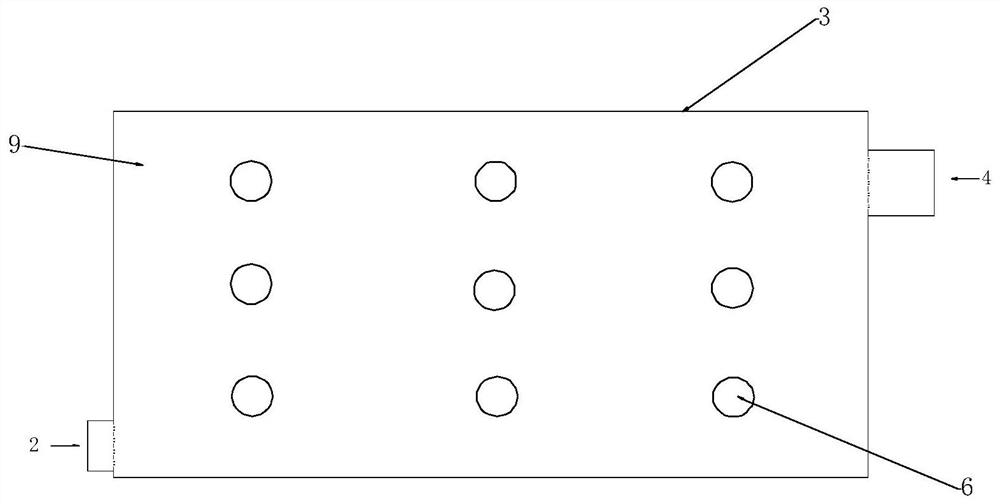

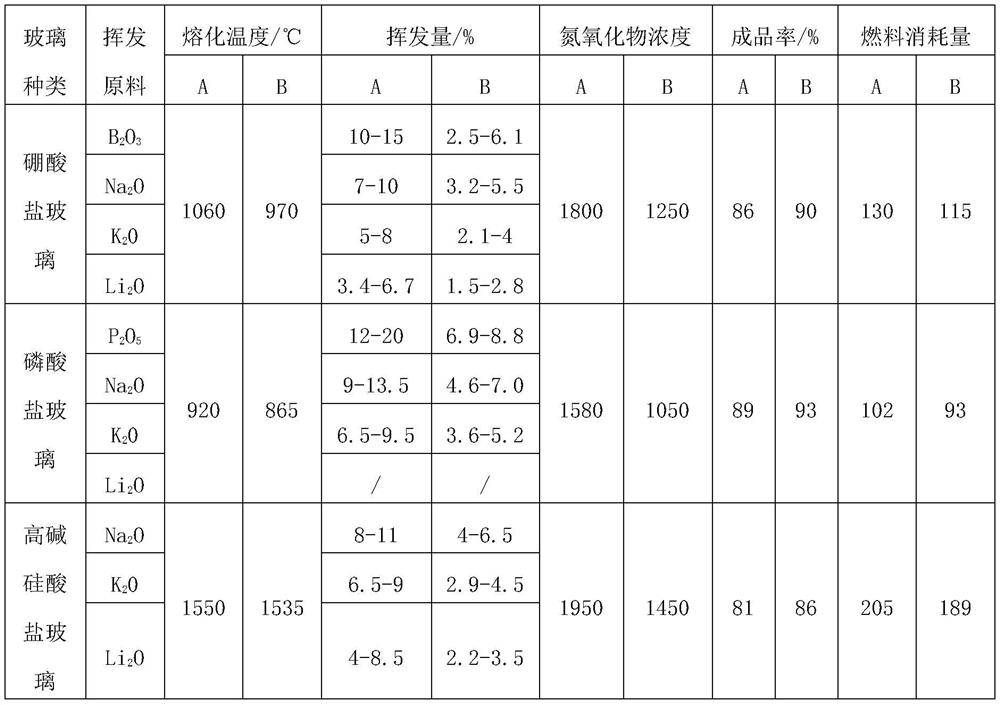

Heating method of glass batch

ActiveCN111995226AReduce the temperatureReduce manufacturing costGlass furnace apparatusGlass productionMelting tankKiln

The invention discloses a heating method of a glass batch. In the process of heating and melting the glass batch, a glass kiln is used for heating and melting the glass batch into molten glass, wherein the glass kiln comprises a kiln side wall, a melting tank and a crown which is positioned above the melting tank and forms the top of the glass kiln, and a plurality of combustion spray guns are arranged at the bottom of the melting tank; and fuel in a combustion spray gun at the bottom of the melting tank is controlled to combust, and vertically upward flame is sprayed to heat and melt the glass batch into molten glass. The flame directly heats the glass batch in the glass batch, so that the volatilization amount of the volatile raw material can be reduced, and the content of each element in the finally formed glass product is ensured to be within a design range. Combustion products are generated in the glass batch, so that clarification of molten glass is facilitated; and the additionamount of a clarifying agent can be reduced, or even the clarifying agent is not added, so that the preparation cost of the glass can be reduced on the premise that the melting clarification quality of the molten glass is guaranteed.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

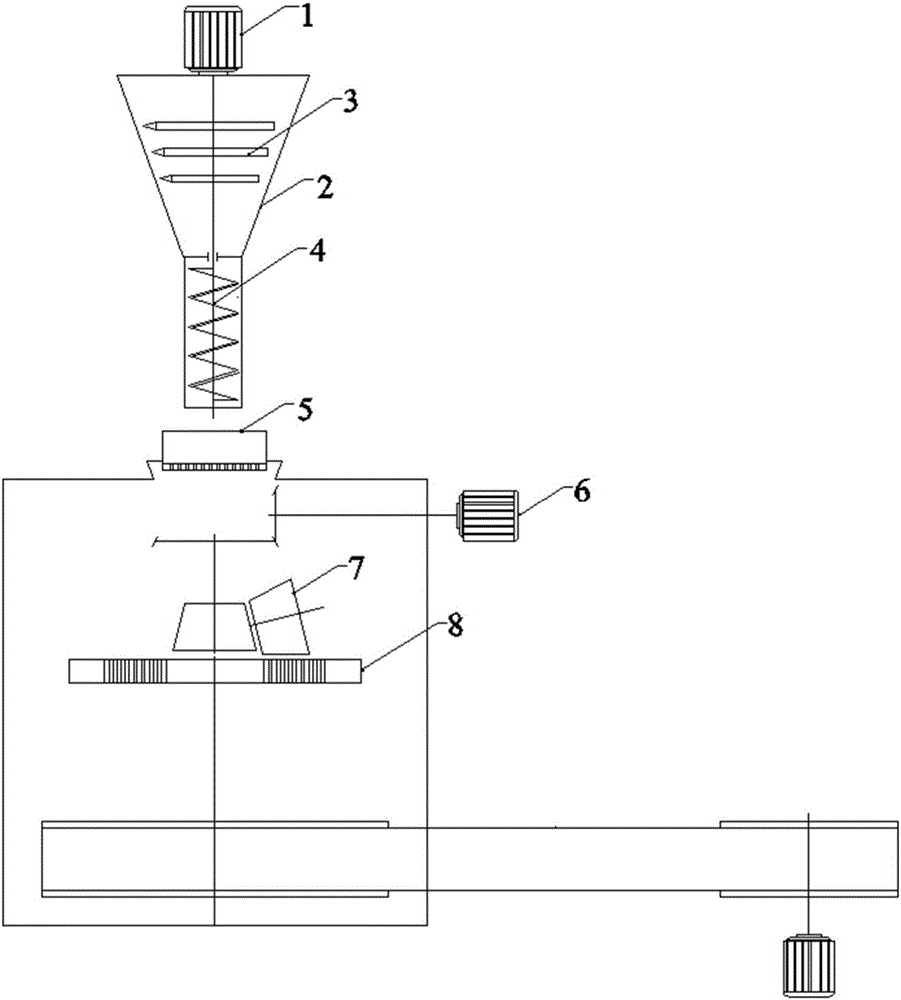

Feeding device used for granulator

InactiveCN106552550AAvoid accumulationAvoid material jamsBiofuelsSolid fuelsEngineeringVolumetric Mass Density

The invention discloses a feeding device used for a granulator. The feeding device used for the granulator comprises a grading material stirring mechanism, a helical feeding shaft controlling feeding quantity and a vibration screen enabling feeding to be uniform. When a motor 1 rotates, the grading material stirring mechanism and the helical feeding shaft are driven to rotate. The quantity of material falling onto a template is controlled by controlling the rotating speed of the helical feeding shaft. The vibration screen with a certain aperture is added between a helical feeding port and the template, and the vibration screen vibrates in a rotating mode and then enables the material to disperse on the template evenly. Compared with the prior art, the feeding device used for the granulator has the following advantages that by means of helical drive, the feeding quantity can be controlled conveniently and fast according to the need of production, so that the phenomena of overloading and material blocking are avoided and the possible problem that the motor is damaged is avoided; through the vibration screen, the material falling onto the template is dispersed evenly, the contact area of the material is increased, and the yield of granulator is increased; and meanwhile, the density of forming particles is uniform because of the uniform distribution of the material and the quality is controlled effectively.

Owner:邢献军

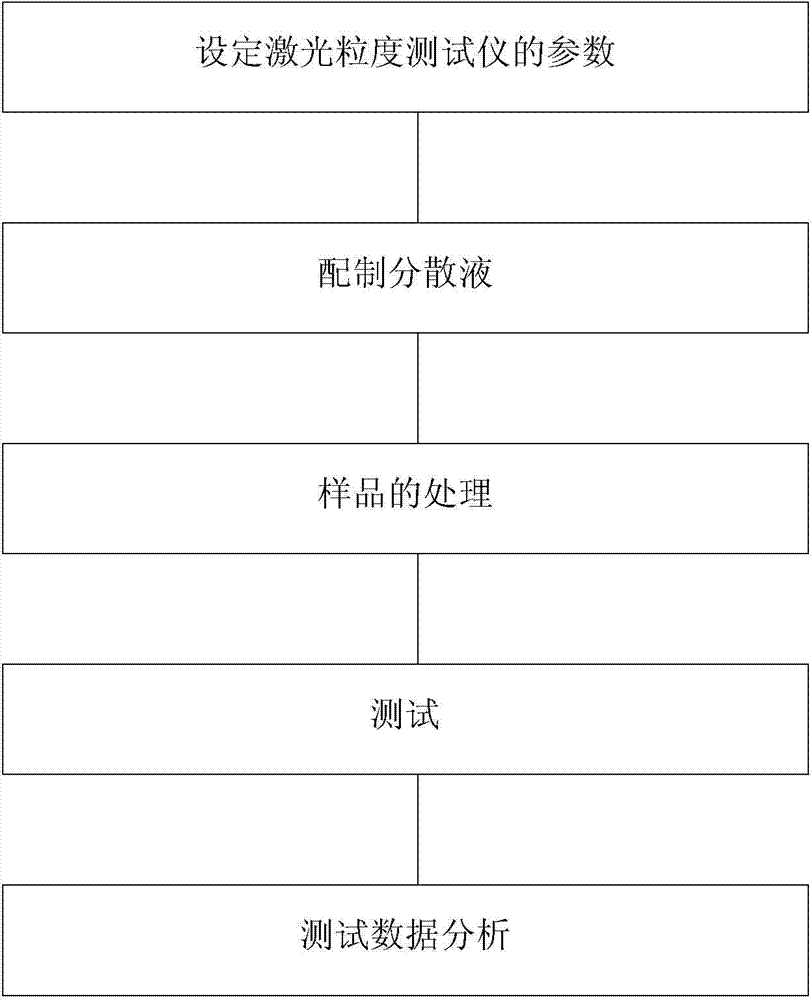

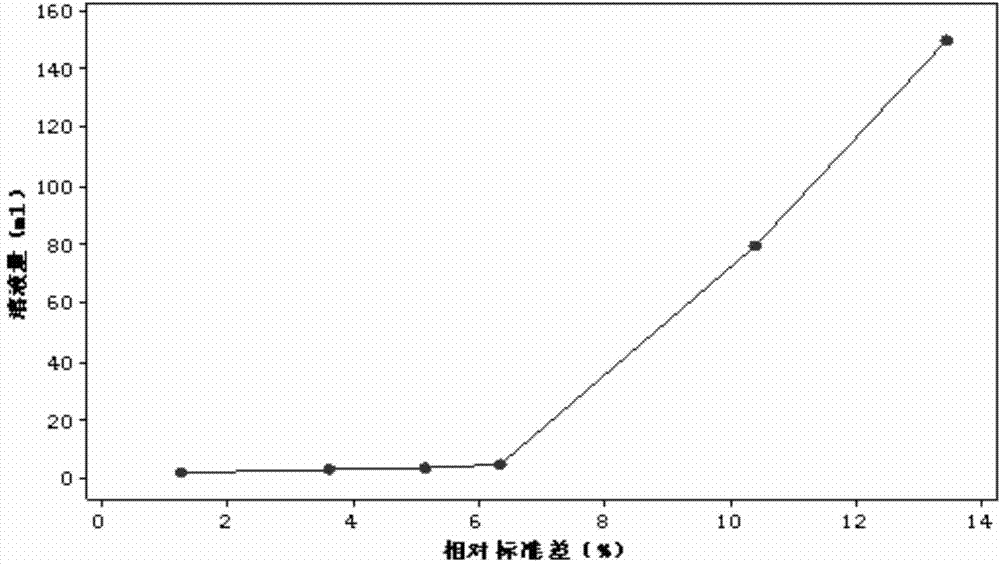

Method for testing granularity of 12-14 mu m ammonium perchlorate

InactiveCN103792167AGuaranteed amountGuaranteed stabilityParticle size analysisAcetic acidButyl acetate

The invention relates to a method for testing granularity of 12-14 mu m ammonium perchlorate. The method comprises the following steps: respectively adding 2-5ml of dispersion liquids consisting of butyl acetate and lecithin in ammonium perchlorate samples, thus respectively obtaining pasty ammonium perchlorate samples, wherein the adding amounts of the dispersion liquids are different; and testing each ammonium perchlorate sample for 3-5 times, and respectively obtaining test data of the rest ammonium perchlorate samples. According to the method disclosed by the invention, under fixed dispersion time, complete dispersion of the samples under ultrasonication is guaranteed, the uniformity in sample treatment is realized, the method is simple and easy to learn, the artificial errors are reduced, the accuracy and reproducibility of test results are greatly improved, the range of multiple test results for the same sample is reduced to below 0.5 mu m for 2 mu m, and meanwhile, the method can be suitable for properly guiding production.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

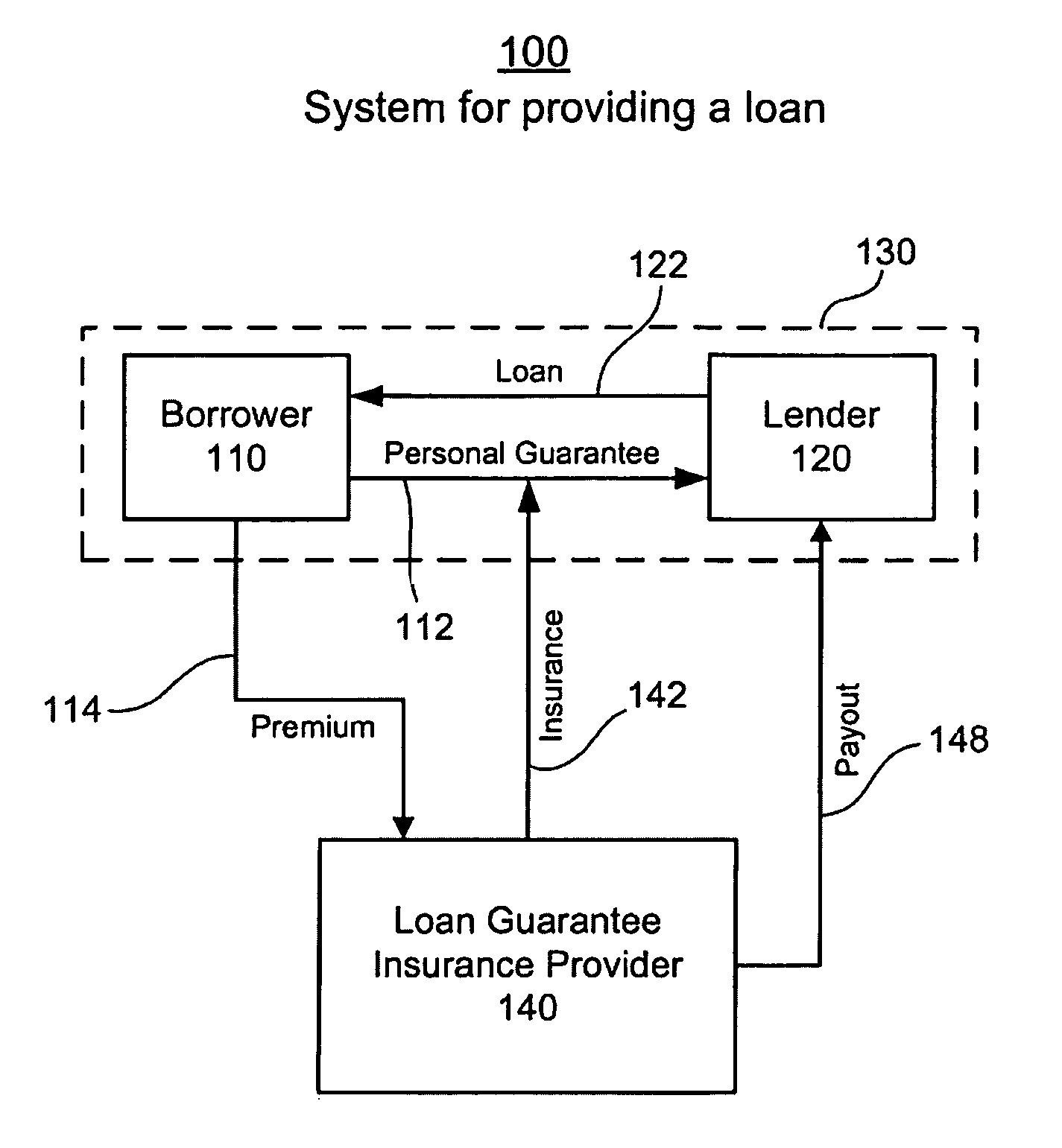

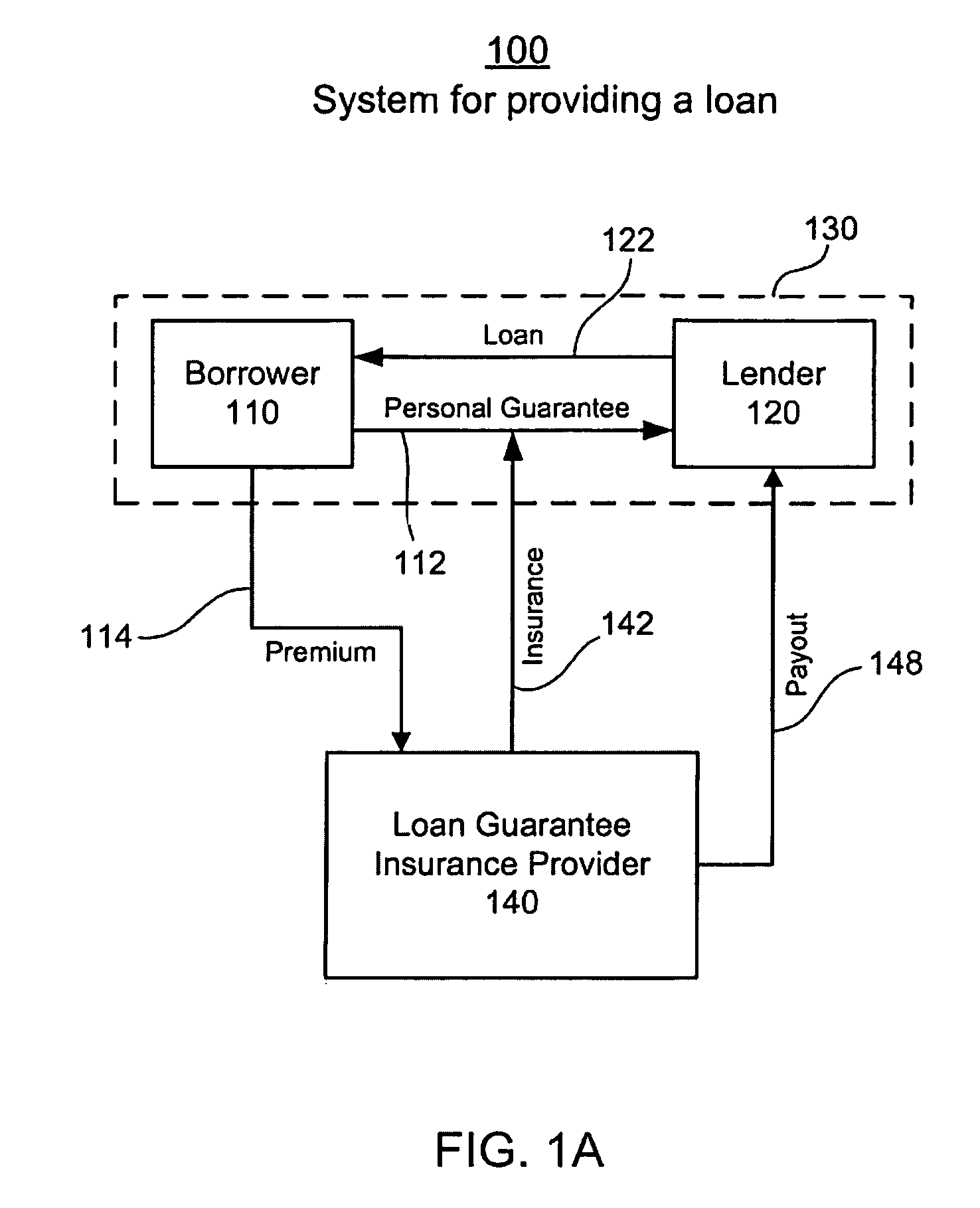

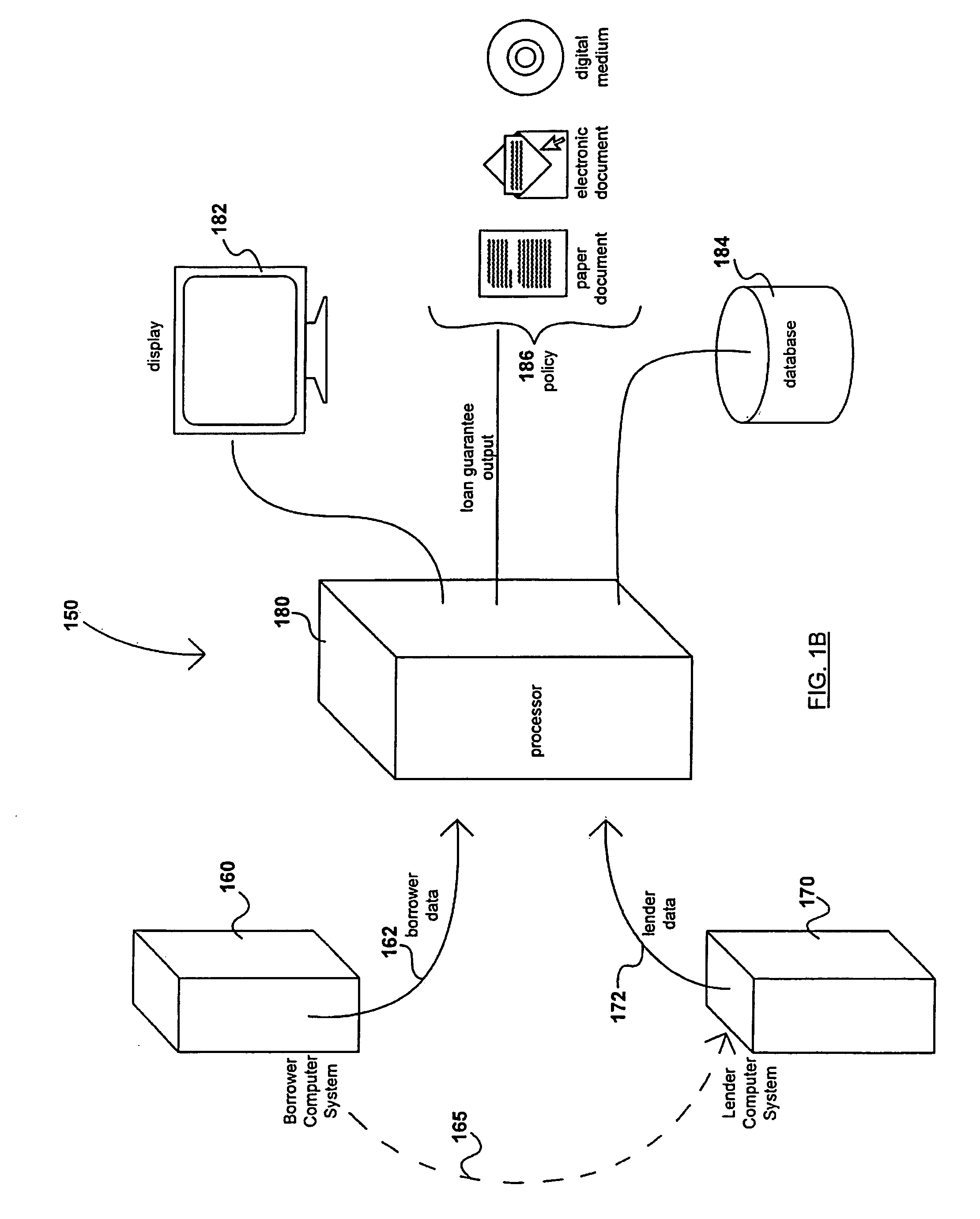

System and method for loan guarantee insurance

ActiveUS8548829B1Personal guarantee amount required of the borrower can be reduced or eliminatedGuaranteed amountFinanceThird partyPayment

Loan guarantee or surety insurance processes and systems for use in a commercial loan arrangement between a borrower and a lender, in which the borrower is typically required to provide to the lender a personal guarantee of some or all of the amount of the commercial loan to obtain the loan, wherein loan guarantee insurance of an insured amount is calculated and provided, in exchange for payment of premiums, by a loan guarantee insurance provider or similar third party in order to replace some or all of the personal guarantee amount required of the borrower. The terms of the loan guarantee insurance is calculated and based on information about the commercial loan, the underlying project, the borrower, and other underwriting criteria.

Owner:EICHENBLATT DAVID

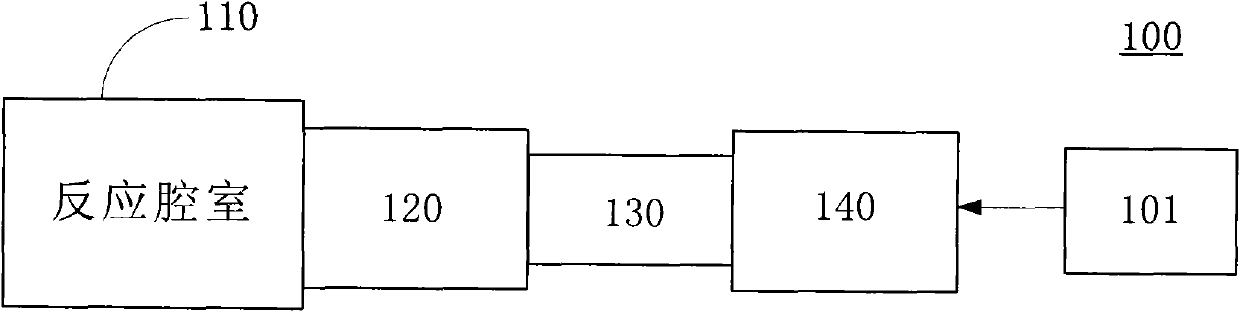

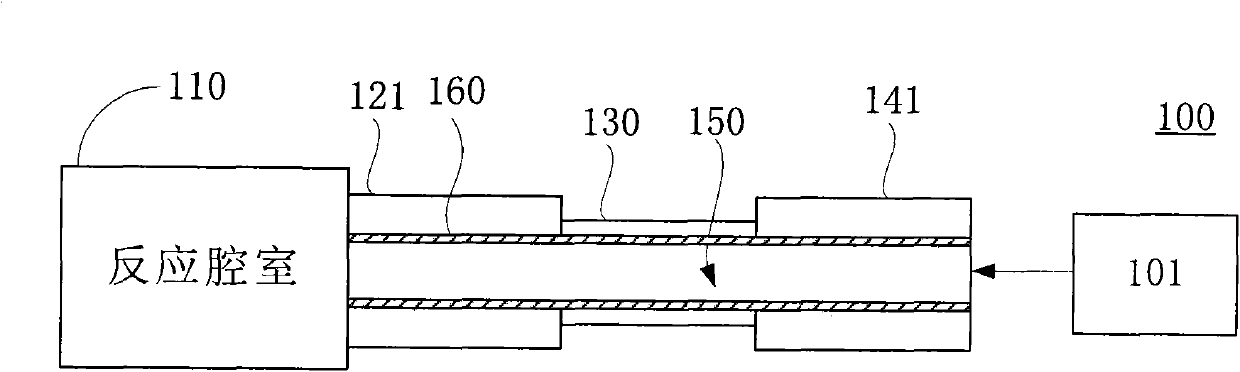

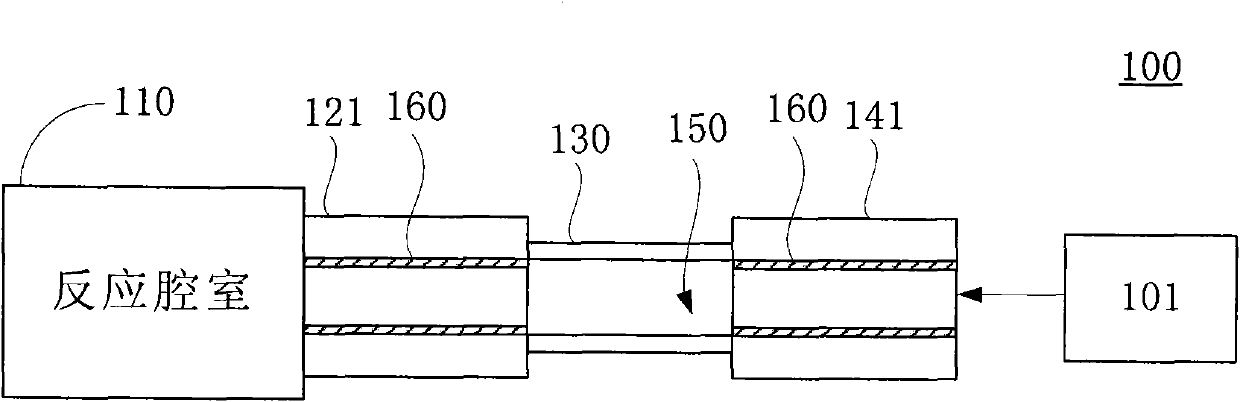

Chemical vapor deposition equipment and cooling tank thereof

InactiveCN102002686AGuaranteed amountImprove cleanlinessChemical vapor deposition coatingRemote plasmaEngineering

The invention provides chemical vapor deposition equipment and a cooling tank thereof. The chemical vapor deposition equipment comprises a reaction chamber, at least one clean gas channel connected between the reaction chamber and a remote plasma source, and an anti-fluorinated material layer formed in the clean air channel. The clean gas channel can be formed in the tank body of the cooling tank. The invention can ensure the cleanliness inside the reaction chamber.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

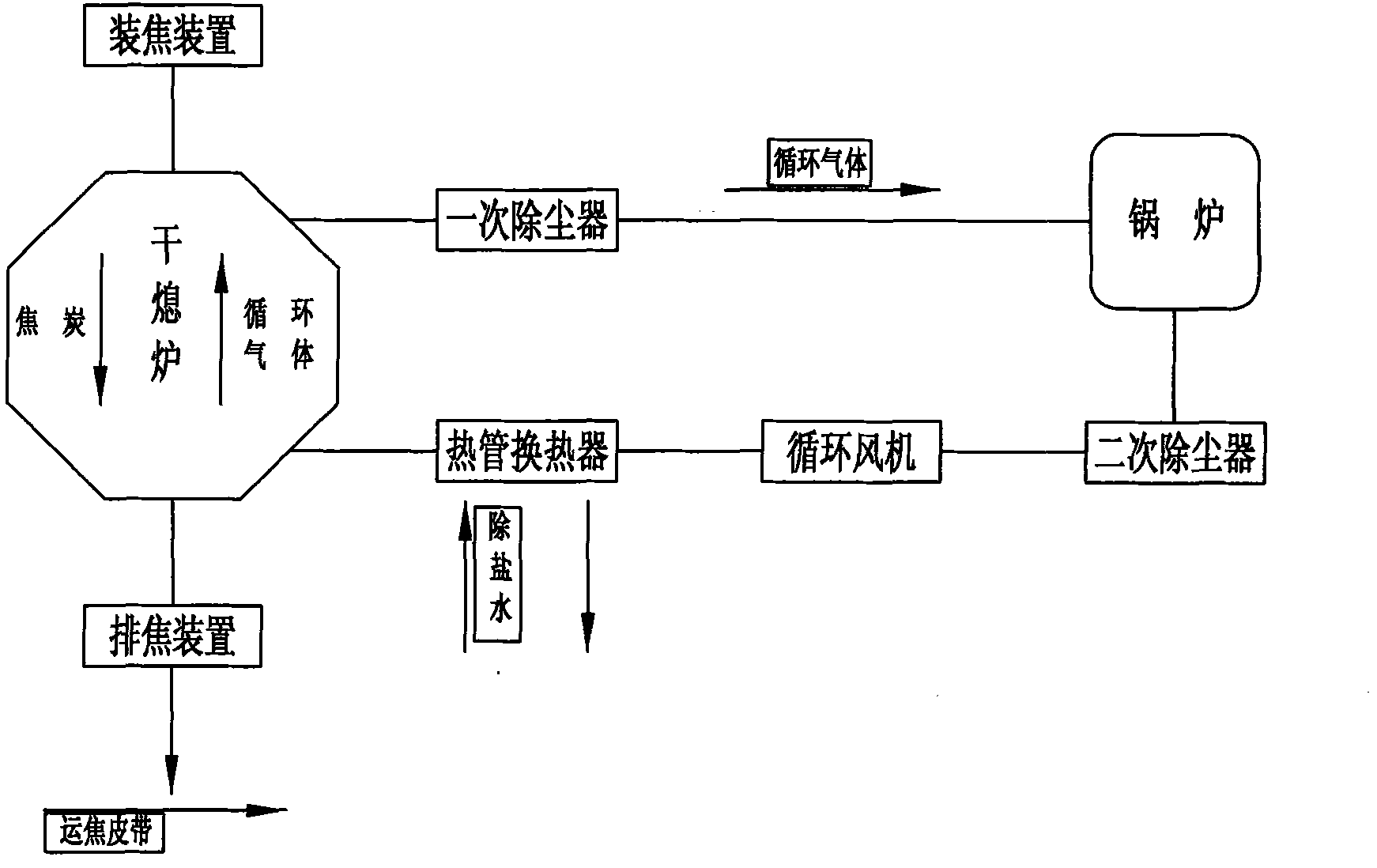

Method for keeping stable coke dry quenching gas circulation system after pipe explosion of heat pipe exchanger and device thereof

The invention relates to a relative technology of a coke dry quenching process and discloses a method for keeping a stable coke dry quenching gas circulation system after pipe explosion of a heat pipe exchanger and a device thereof. The device comprises the heat pipe exchanger. A water inlet pipe and a water outlet pipe are connected to the heat pipe exchanger, a water pipe is in short connection between the water inlet pipe of the heat pipe exchanger and the water outlet pipe of the heat pipe exchanger, and a valve is arranged on the short connected water pipe. After pipe explosion of the heat pipe exchanger occurs, the heat pipe exchanger is in short circuit through the short connected water pipe, and water of a pipeline in the heat pipe exchanger can be avoided entering the whole coke dry quenching gas circulation system, thereby recovering the coke dry quenching gas circulation system to be in a normal state, keeping the stable system, efficiently preventing an explosive accident from occuring and conveniently maintaining the heat pipe exchanger. The method has the advantages of convenient maintenance, convenient and suitable operation and ensures the dry quenching ratio and the steam productivity without delaying production.

Owner:NANJING IRON & STEEL CO LTD

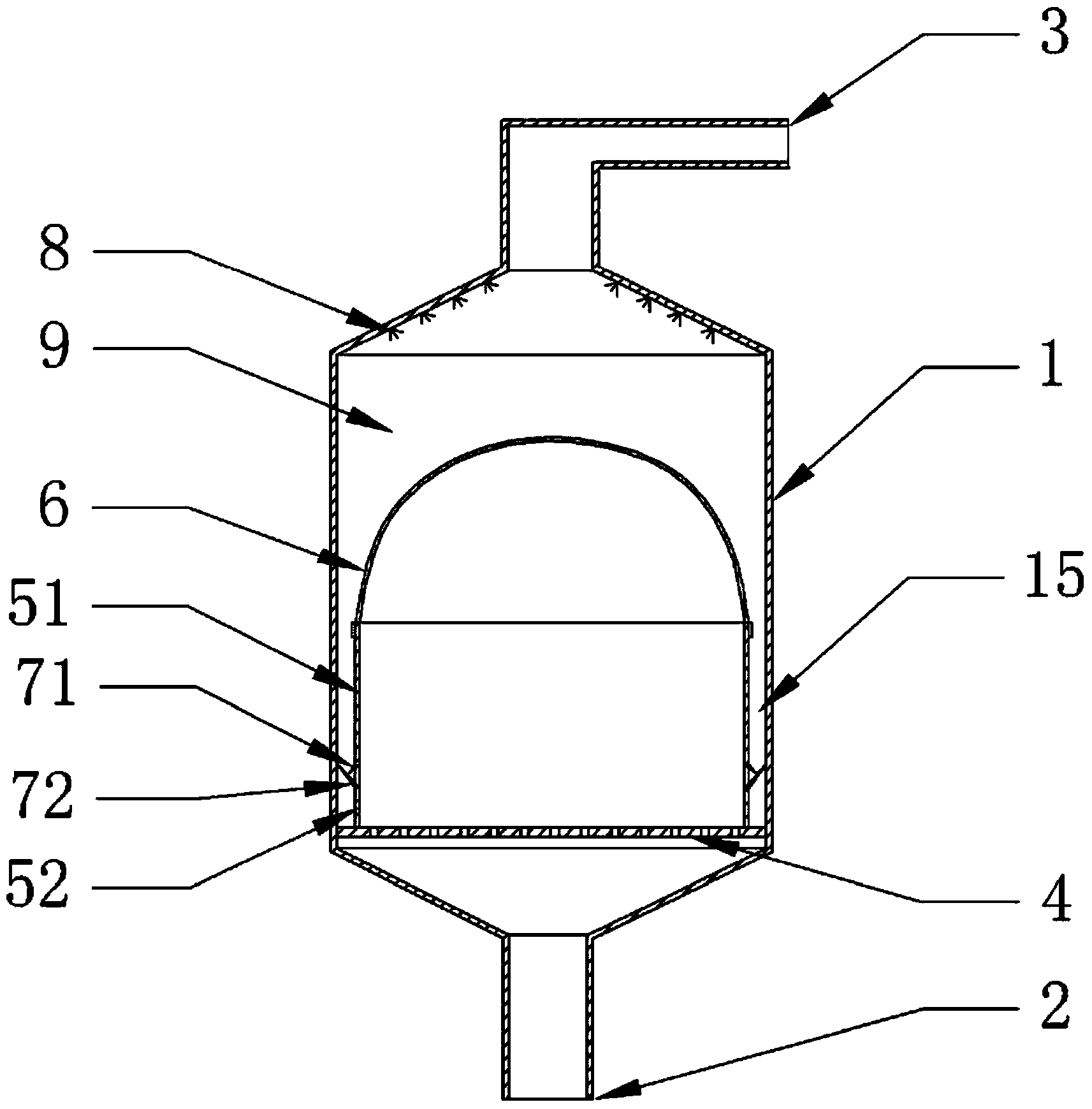

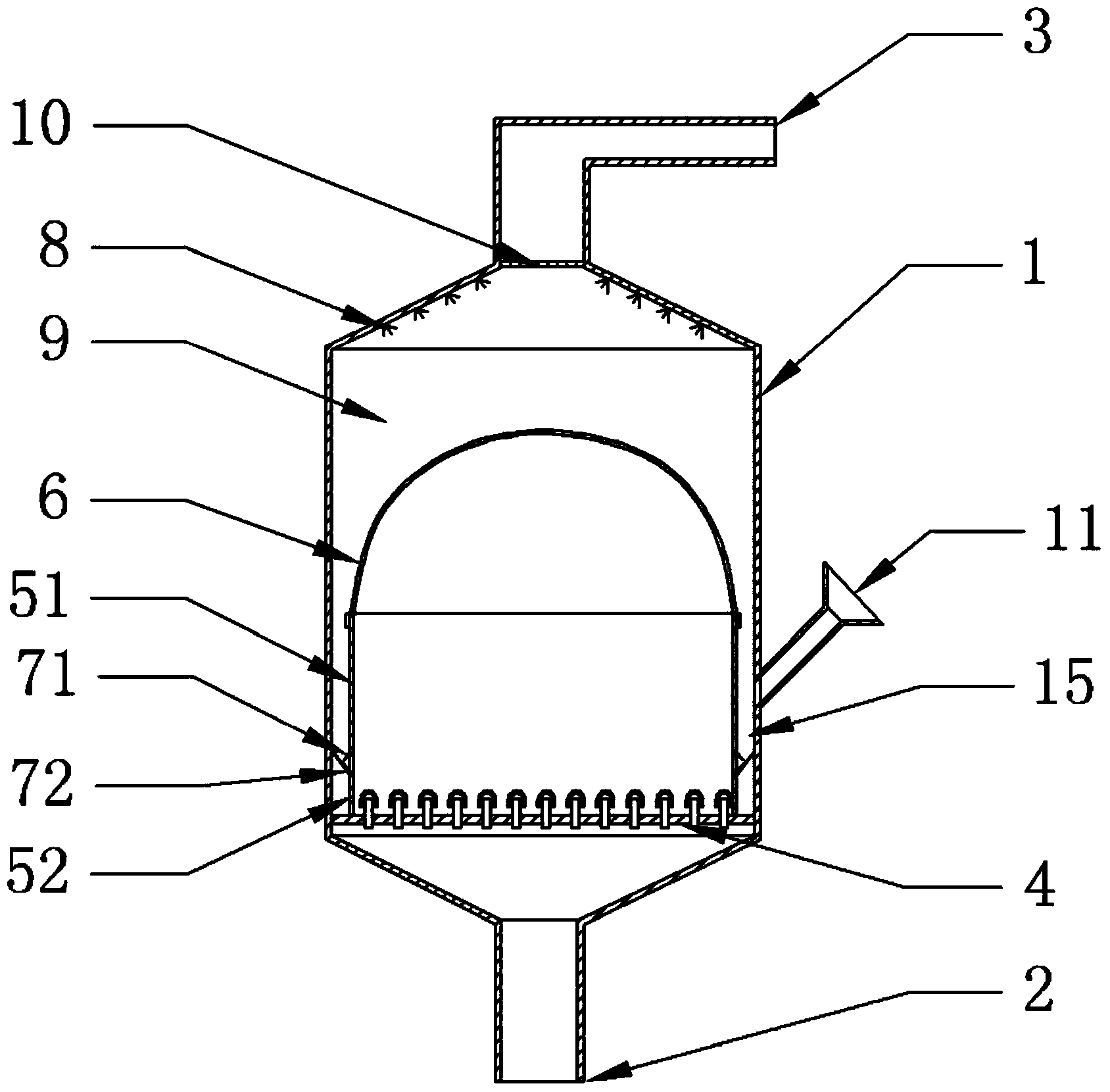

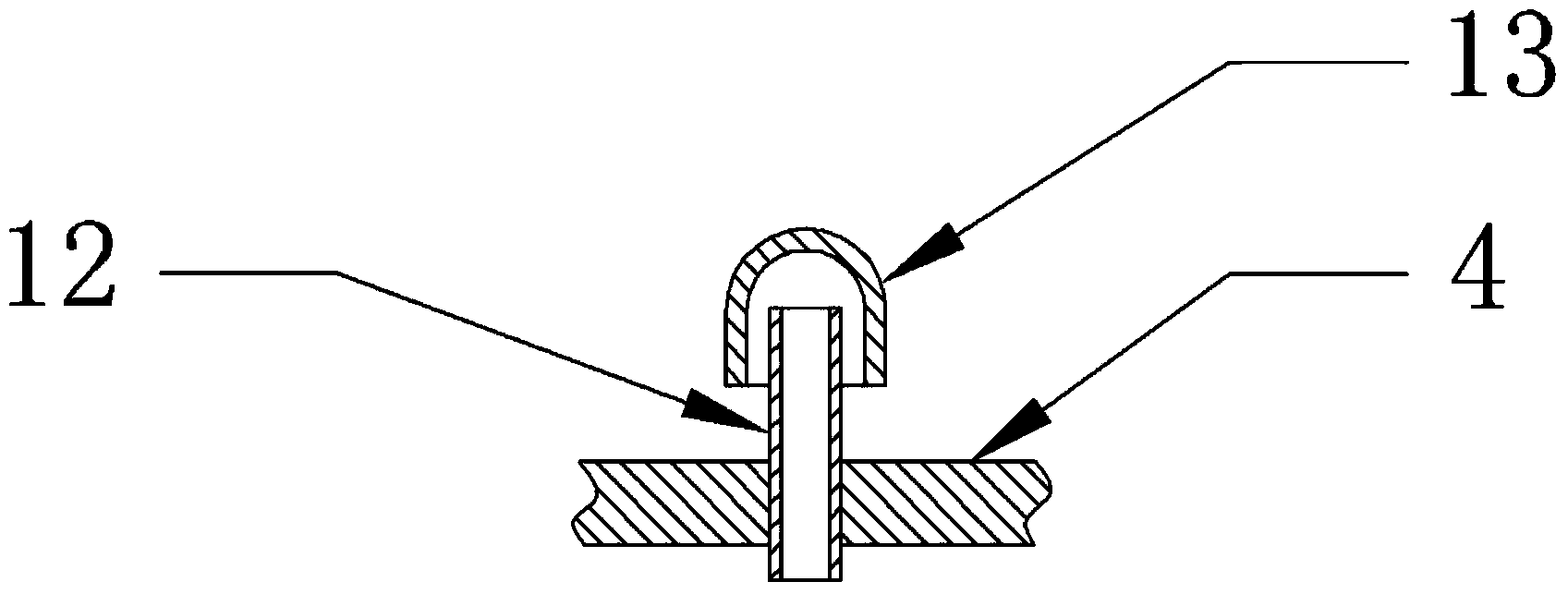

Catalytic reduction type de-nitrification reactor of circulating fluidized bed

InactiveCN103432905AReduce in quantitySolve the problem of easy detachment from the fluidized bedDispersed particle separationChemical/physical processesFluidized bedFlue gas

The invention discloses a catalytic reduction type de-nitrification reactor of a circulating fluidized bed. The catalytic reduction type de-nitrification reactor comprises a reactor housing with a reactor inner cavity, wherein the bottom and the top of the reactor housing are respectively provided with an inlet flue and an outlet flue; the lower part of the reactor inner cavity is provided with an air distribution plate with air distribution holes; a filtering container is arranged above the air distribution plate in the reactor inner cavity and is used for intercepting a catalyst; the periphery and the top of the filtering container are sealed; the lower part of the filtering container is provided with a downward opening; the container wall of the filtering container is provided with filtering holes; a material returning channel in which the catalyst drops is remained between the external surface of the container wall of the filtering container and the inner wall of the reactor inner cavity; material returning openings connected with the material returning channel are formed between an opening edge of an opening of the filtering container and the air distribution plate or formed in the container wall of the lower part of the filtering container. Through the de-nitrification reactor disclosed by the invention, the amount of the catalyst removed from the fluidized bed along with flue gas is greatly reduced, the catalyst can react in the de-nitrification reactor all the time, and the utilization rate of the catalyst is effectively increased.

Owner:HENAN UNIV OF SCI & TECH

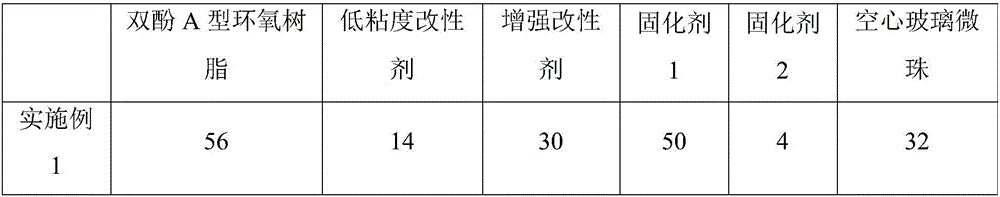

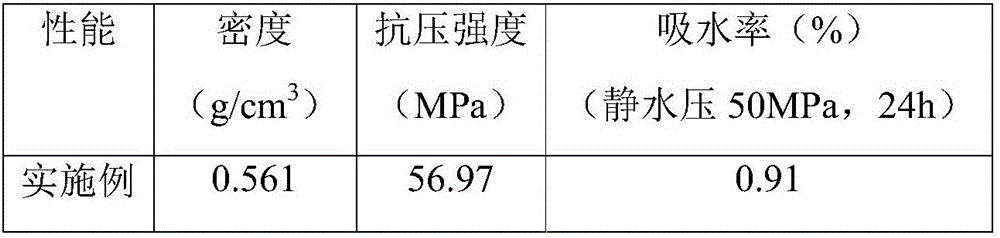

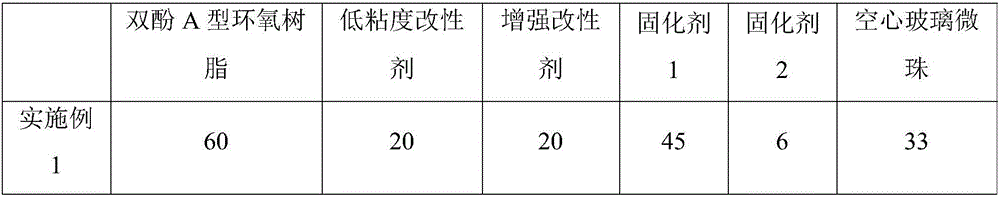

Light pressure-resistant buoyancy material for deep submergence vehicle and preparation method of buoyancy material

The invention provides a light pressure-resistant buoyancy material for a deep submergence vehicle and a preparation method of the buoyancy material. The buoyancy material is prepared from, in parts by mass, 50-60 parts of bisphenol-A epoxy resin, 20-40 parts of a reinforced modifier, 10-20 parts of a low-viscosity modifier, 40-60 parts of a first curing agent, 2-8 parts of a second curing agent and 30-40 parts of hollow glass beads, wherein the reinforced modifier is hexahydrophthalic diglycidyl ester, the low-viscosity modifier is neopentyl glycol diglycidyl ether, the first curing agent is a liquid-state organic acid anhydride curing agent, and the second curing agent is a liquid-state imidazole curing agent. The prepared light pressure-resistant buoyancy material for the deep submergence vehicle has the density of 0.50-0.57 g / cm<3>, the compression strength reaching 40-60 MPa and the isostatic hydrostatic pressure water absorption rate smaller than 1% and can meet requirements of the deep sea submergence vehicle at 3,000-5,000 m underwater.

Owner:HARBIN ENG UNIV

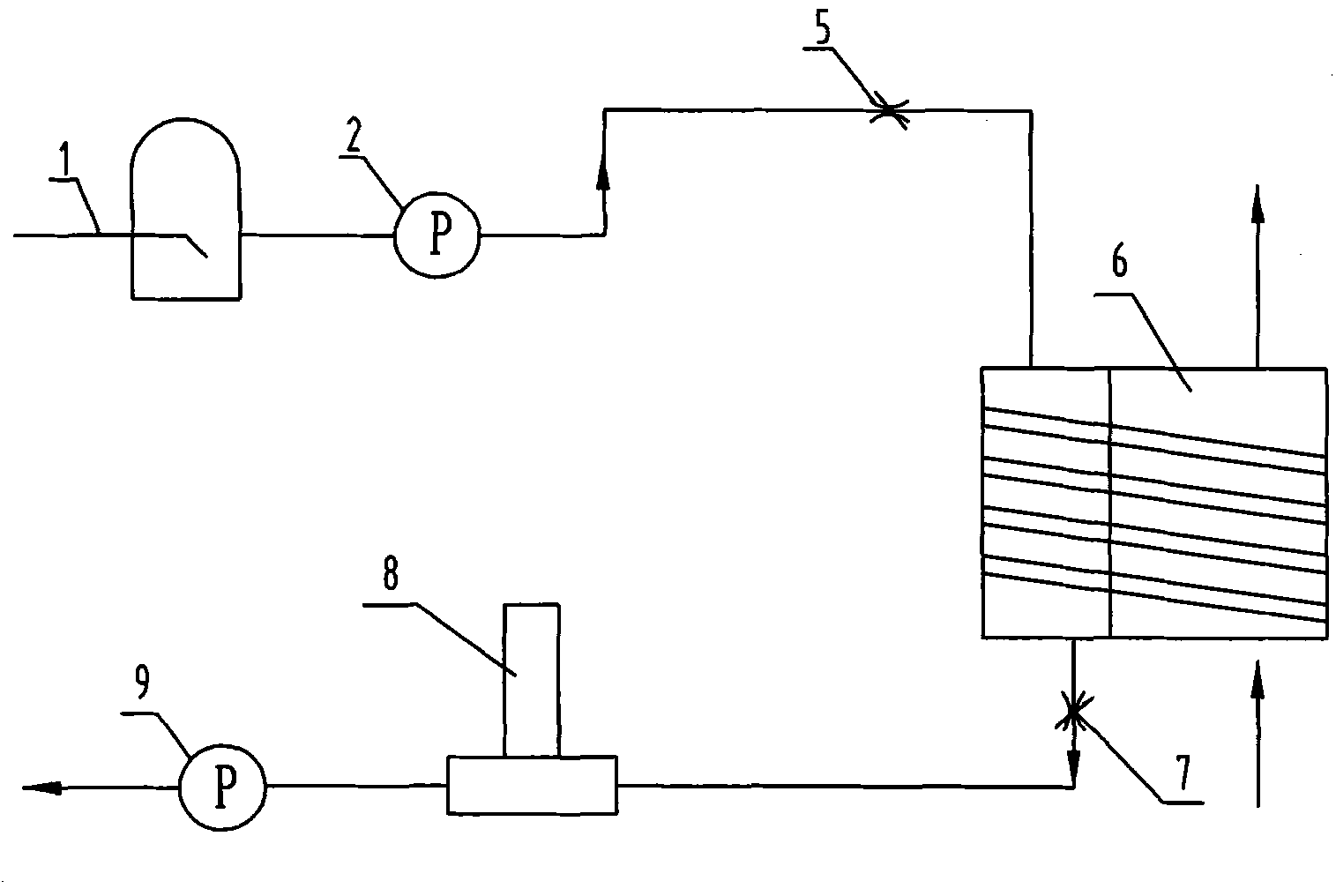

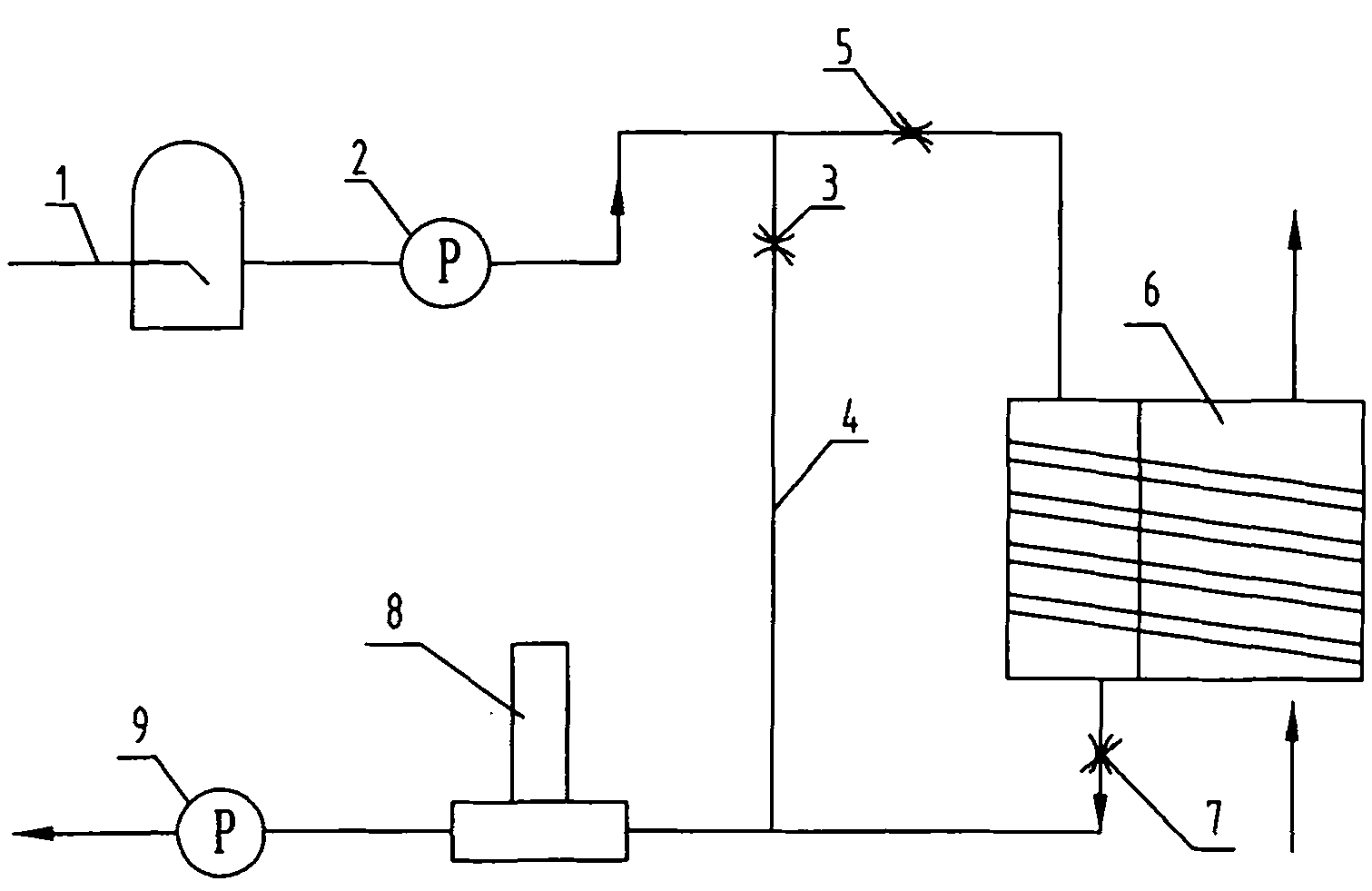

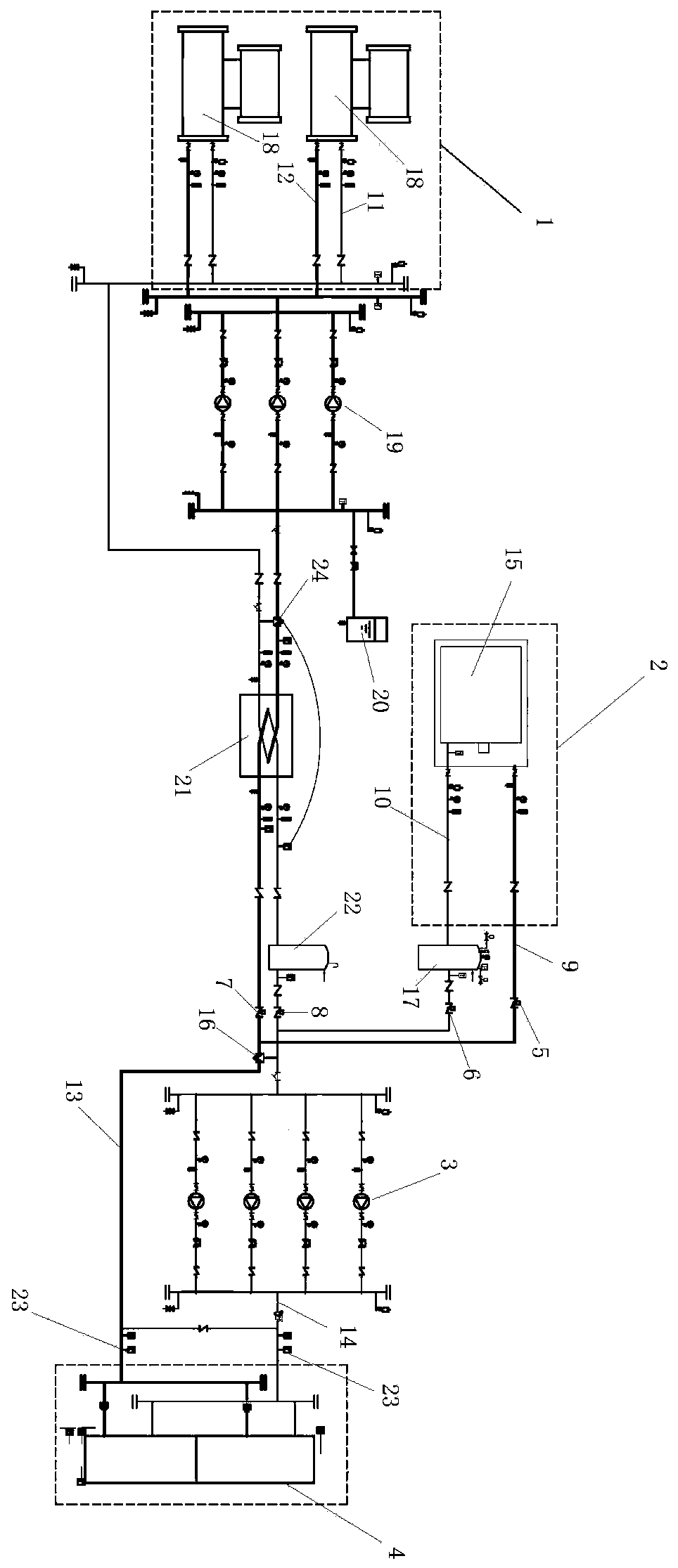

Wind tunnel heat exchange system

The invention provides a wind tunnel heat exchange system. The system comprises a heating system, a refrigerating system, a water supply pump and a wind tunnel heat exchanger, a first electric valve and a second electric valve are respectively arranged on a hot liquid supply pipeline and a hot liquid return pipeline of the heating system; a third electric valve and a fourth electric valve are respectively arranged on a cold liquid supply pipeline and a cold liquid return pipeline of the refrigerating system; the hot liquid supply pipeline and the cold liquid supply pipeline are intersected toform a liquid supply pipeline which is connected with a liquid inlet of the wind tunnel heat exchanger; the hot liquid return pipeline and the cold liquid return pipeline intersect to form a liquid return pipeline to be connected with a water outlet of the wind tunnel heat exchanger, the liquid supply pipeline is connected with the liquid return pipeline through the electric three-way valve, the water supply pump is arranged on the liquid return pipeline, the water-water heat exchanger is arranged between the cold liquid supply pipeline and the liquid return pipeline, and the normal pressure storage tank is arranged on the liquid return pipeline. The system has the beneficial effects that PID adjustment can be carried out according to the temperature detected by the sensor, and the liquidsupply temperature and precision of the heat exchanger of the test hall meet the target requirements.

Owner:JIANGSU YONGSHENG AIR CONDITIONER

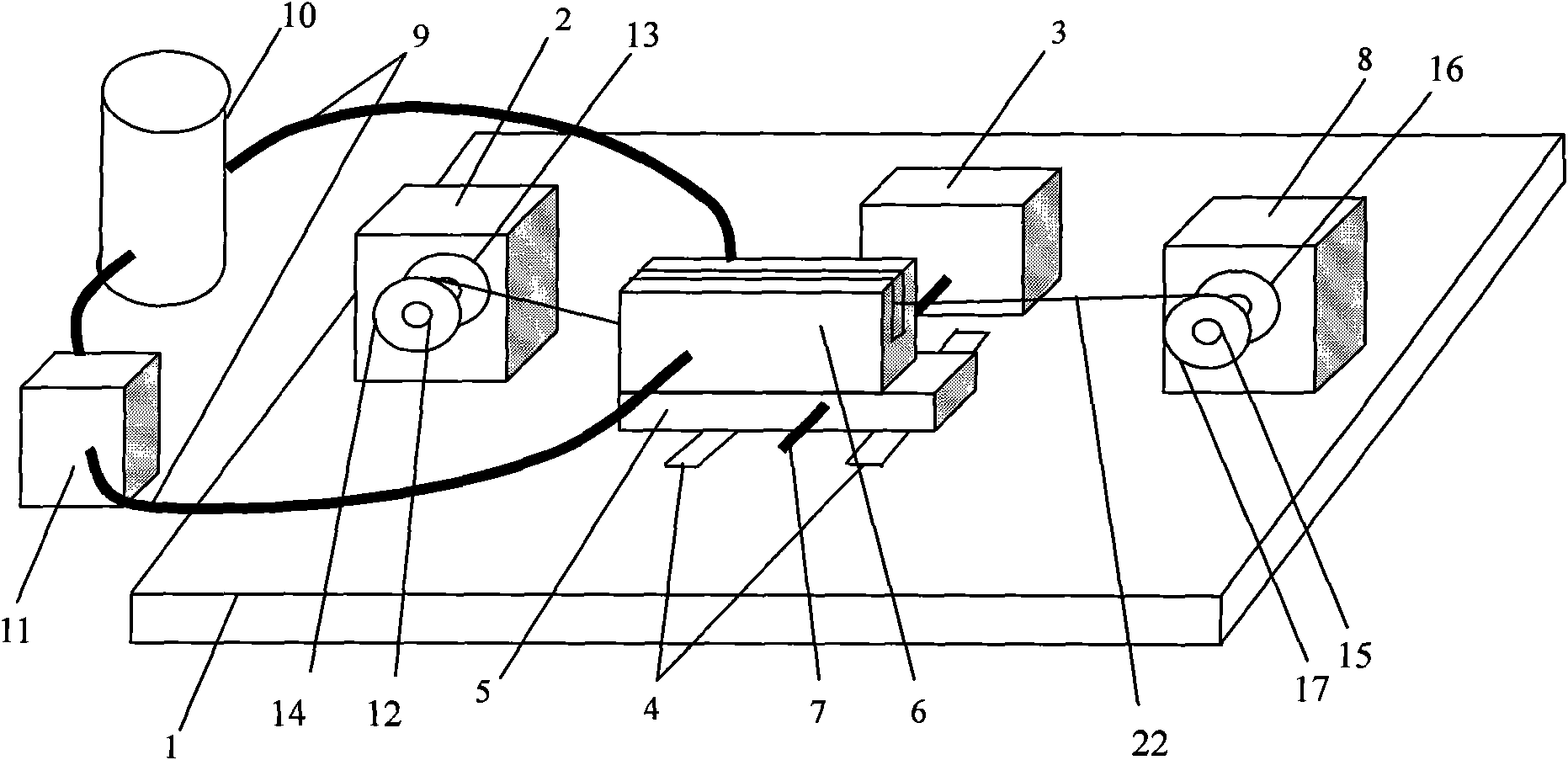

Device for continuously removing optical fiber coating and winding bare fiber

InactiveCN101561278AGuaranteed amountContinuous dissolutionCladded optical fibreSagnac effect gyrometersElectric machineBare fiber

The invention discloses a device for continuously removing an optical fiber coating and winding a bare fiber for an optical fiber gyro. A first motor, a second motor, a parallel guide and a third motor are arranged on a base in turn; the parallel guide is provided with a sliding block and a solution chamber; the solution chamber is connected with a liquid pump through two liquid conduits and a fluid container; the front lateral surface of the first motor is provided with a first rotating shaft, and the first rotating shaft is driven to rotate by the first motor and is provided with a first baffle and a preparation ring; the front lateral surface of the second motor is provided with a second rotating shaft with threads, wherein the second rotating shaft is driven to rotate by the second motor and passes through the middle part of the sliding block, and the solution chamber is internally provided with two pulleys and solution; and the front lateral surface of the third motor is provided with a third rotating shaft which is driven to rotate by the third motor and is provided with a second baffle and an annual shelf to be winded. The device is used for continuously removing the optical fiber coating and winding the bare fiber into an optical-fiber ring.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com