High-concentration alcohol-based paint used in cast steel

A high-density, alcohol-based technology, applied in the direction of coating, casting mold, casting mold composition, etc., can solve the problems of not very specific regulations, high material cost expenditure, etc., and achieve the effect of ensuring stability and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0016] A high-density alcohol-based coating for cast steel, comprising 66-75% of refractory aggregate, 0.5-1.5% of binder, 1.0-2.5% of suspending agent, and 21-30% of isopropanol;

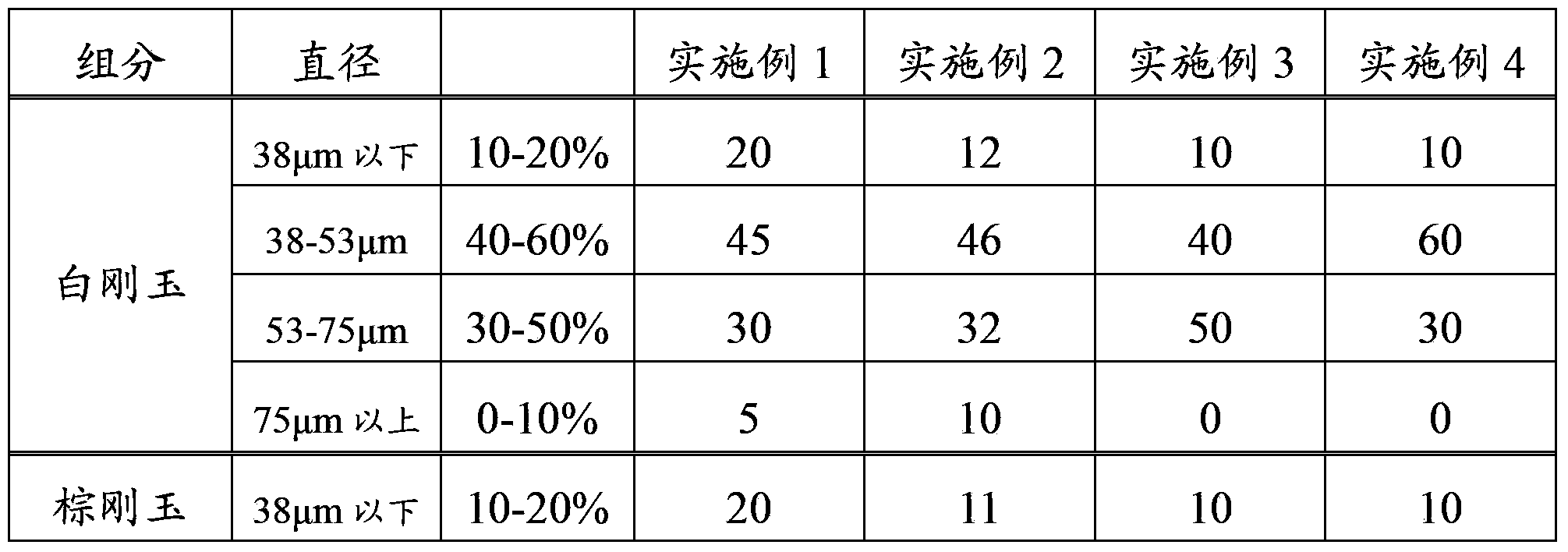

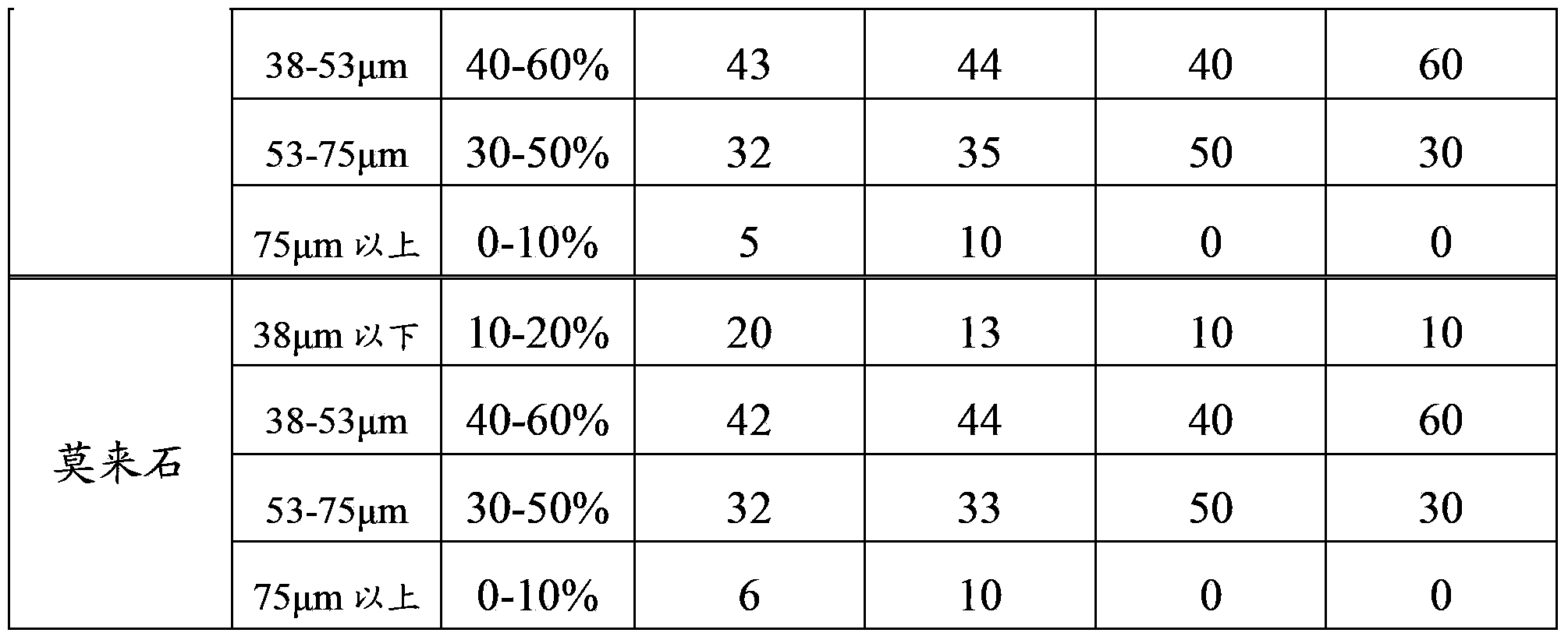

[0017] Wherein, the refractory aggregate includes 50-70% of white corundum, 20-40% of brown corundum and 10-30% of mullite; -20%, 40-60% for diameters between 38-53μm, 30-50% for diameters between 53-75μm, and 0-10% for diameters above 75μm;

[0018] Described binding agent is made up of polymerized rosin and maleic rosin, and its weight ratio is 1:2;

[0019] Described suspending agent is organic bentonite,

[0020] The ratios of the above components are listed as percentages by weight.

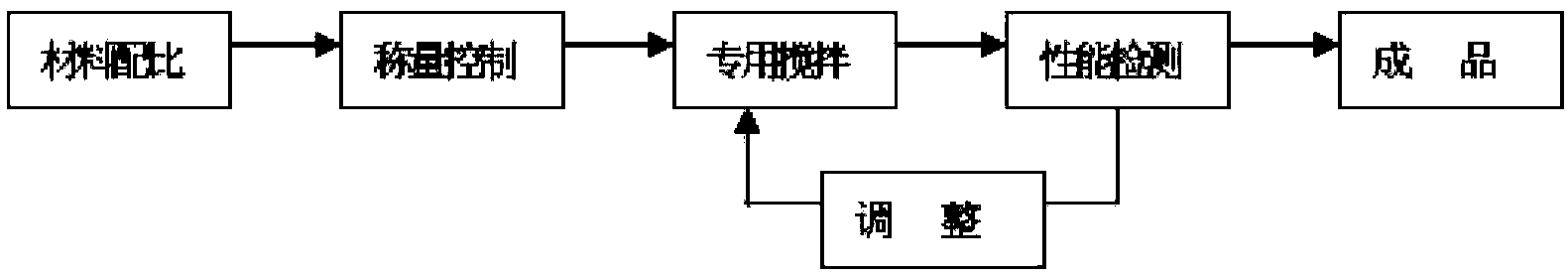

[0021] then follow figure 1 The production process shown produces the finished coating of the invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com