Adsorbent for nuclear biochemical agent, and adsorption filter, protective clothing and manufacturing process for toxic substances

A technology of toxic substances and manufacturing processes, applied in nuclear engineering, other chemical processes, chemical instruments and methods, etc., can solve the problems of activated carbon shedding, loss of activated carbon, loss of breathability of fabrics, etc., to improve wearing comfort and improve adsorption performance. , to ensure the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

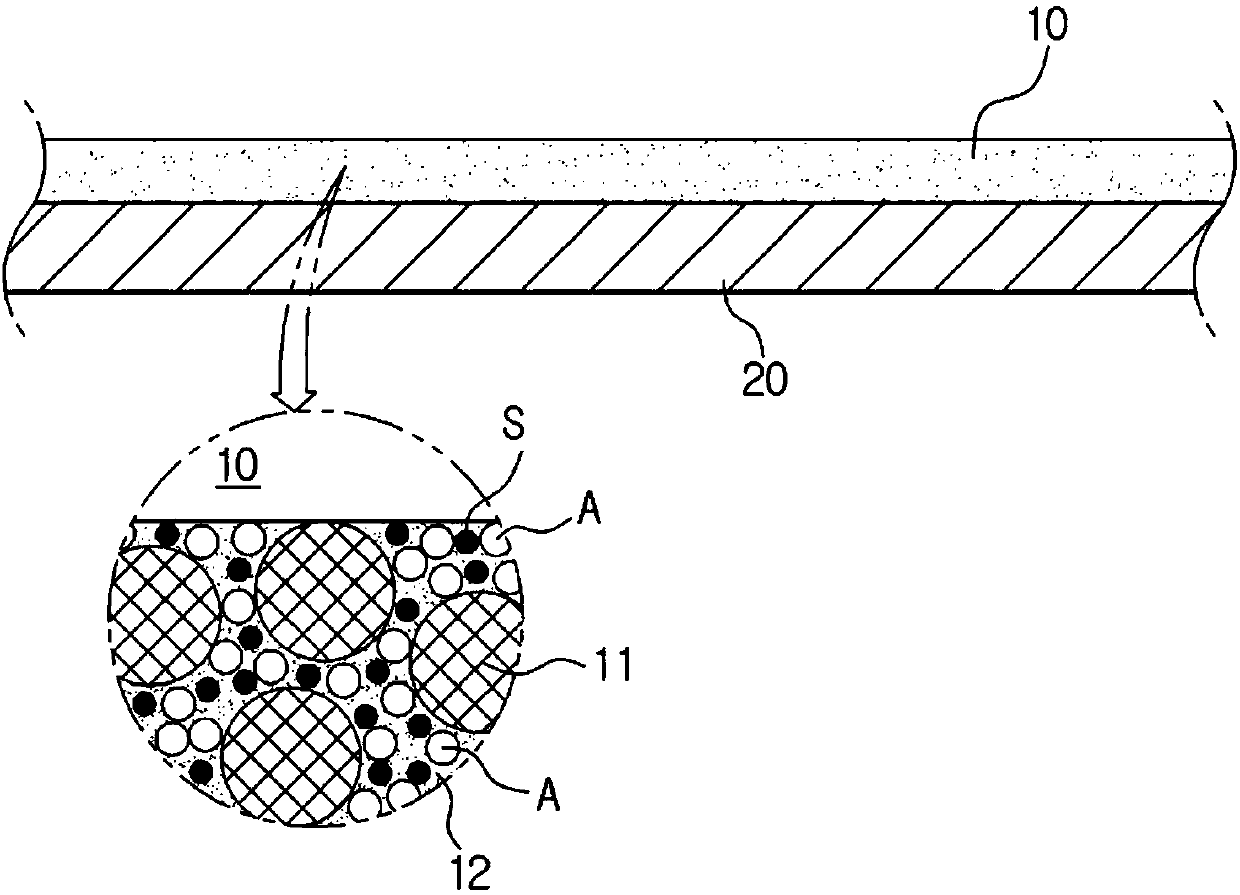

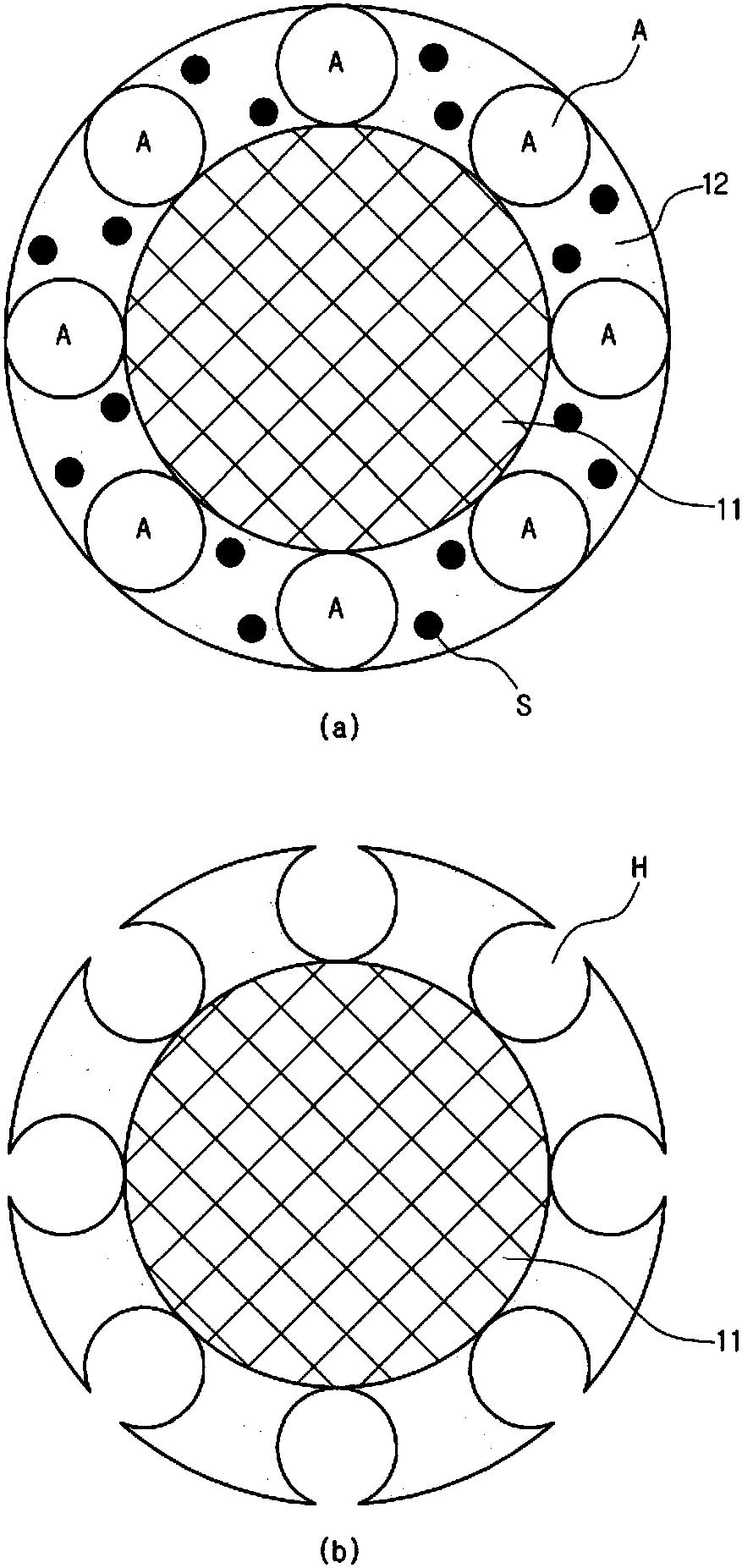

[0085] Such as figure 1 As shown, the adsorbent for nuclear, biological and chemical agents according to the embodiment of the present invention includes powdered activated carbon 11, matrix 12, solvent S and microparticle filler A.

[0086] The matrix 12 is a mixed activated carbon 11 and is composed of a gel or colloid of a thermosetting or thermoplastic material that hardens from a liquid state to a solid state, and after hardening provides a sheet-shaped adsorption layer described later. For example, the matrix 12 is also excellent in adhesion to fibers under low temperature hardening conditions, and has excellent adhesion to fibers, and imparts elasticity to the adsorption layer, and then environmental-friendly water-based polyurethane can be used alone to improve The durability of the adsorption filter, or according to other requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com