Method for treating catalyst carrier, catalyst for hydrogenation of carbon dioxide to methanol, preparation method and application thereof

A technology of catalyst carrier and carbon dioxide, which is applied in the direction of catalyst carrier, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low selectivity and lower selectivity of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing a catalyst for hydrogenation of carbon dioxide described in the above technical proposal, comprising the following steps:

[0052] Mixing the active component precursor and water to obtain the active component precursor solution;

[0053] The carrier is immersed in the active component precursor solution to obtain a carrier for loading the active component; the carrier is obtained by processing a metal oxide through the treatment method described in the above technical scheme; the metal oxide includes TiO 2 , ZrO 2 or ZnO;

[0054] The carrier loaded with the active components is freeze-dried and calcined in sequence to obtain a catalyst for hydrogenation of carbon dioxide to produce methanol.

[0055] The invention mixes the active component precursor and water to obtain the active component precursor solution. In the present invention, the active component precursor is preferably a metal salt of the aforeme...

Embodiment 1

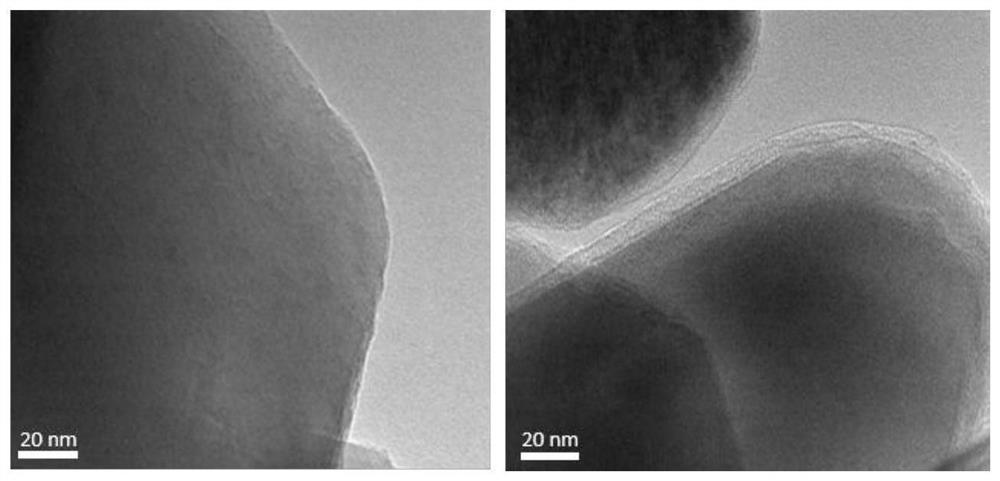

[0072] Weigh a certain amount of NaBH according to the mass ratio of 1:1 4 with rutile TiO 2 -R powder, grind for 30min, then put it into a tube furnace and bake it at 350℃ for 4h under the atmosphere of Ar gas, cool to room temperature, put it in water and let it stand for 4h, repeat centrifugation with water and ethanol several times, and freeze-dry in vacuum Machine dried under 20Pa vacuum for 24h, take out the carrier sample and mark it as TiO 2 -Rov with a specific surface area of 18m 2 / g;

[0073] 0.84g gold chlorate was mixed with deionized water for ultrasonic 20min to obtain an active component precursor solution with a concentration of 0.37g / mL; 1.6g of the TiO 2 -Rov is impregnated into the active component precursor solution, left to stand for 24 hours, dried in a vacuum freeze dryer at 20 Pa for 24 hours, and then placed in a tube furnace and calcined at 500 °C for 4 hours in an Ar gas atmosphere to obtain Au / TiO 2 -Rov Catalyst.

[0074] The Au / TiO obta...

Embodiment 2

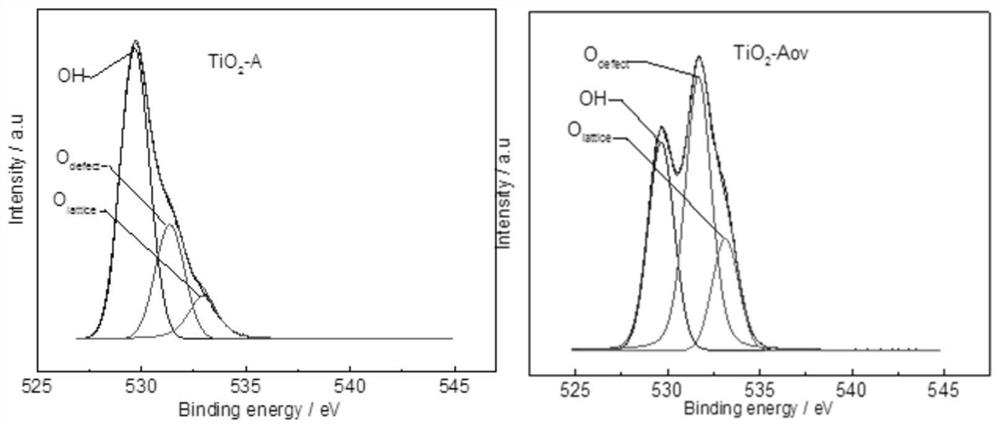

[0076] Weigh a certain amount of NaBH according to the mass ratio of 1:1 4 with anatase TiO 2 -A powder, grind for 30min, then put it into a tube furnace and roast at 350°C for 4h under the atmosphere of Ar gas, cool to room temperature, put it in water and let it stand for 4h, repeat centrifugation with water and ethanol several times, and freeze-dry in vacuum Machine dried under 20Pa vacuum for 24h, take out the carrier sample and mark it as TiO 2 -Aov with a specific surface area of 16m 2 / g;

[0077] 1.5g copper nitrate and deionized water were mixed and ultrasonicated for 20min to obtain an active component precursor solution with a concentration of 0.75g / mL; 1.6g of the TiO 2 - Aov is impregnated into the active component precursor solution, left to stand for 24 hours, dried with a vacuum freeze dryer at 20Pa vacuum for 24 hours, and then placed in a tube furnace and calcined at 500 ° C for 4 hours under an Ar gas atmosphere to obtain Cu / TiO 2 - Aov catalyst.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com