Lithium ion secondary battery, positive electrode material of battery, and preparation method of material

A technology for secondary batteries and cathode materials, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor cycle performance of lithium-sulfur batteries, low utilization rate of active materials, reduction of electrode active materials, etc., and achieve good cycle performance. , Excellent rate performance, inhibiting the effect of gradual decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a kind of preparation method of lithium ion secondary battery cathode material, comprises the following steps:

[0035] uniformly mixing the graphene oxide aqueous solution, surfactant, reducing agent and nano-sulfur powder, or uniformly mixing the graphene aqueous solution, surfactant and nano-sulfur powder to obtain a mixed solution;

[0036] The mixed solution is subjected to hydrothermal reaction to obtain the positive electrode material of the lithium ion secondary battery.

[0037] In the present invention, the aqueous solution of graphene oxide, surfactant, reducing agent and sulfur powder are firstly mixed uniformly, or the aqueous solution of graphene, surfactant and sulfur powder are uniformly mixed to obtain a mixed solution.

[0038] The present invention can use graphene oxide as raw material, and can also directly use graphene as raw material to prepare lithium ion secondary battery cathode material. If graphene oxide is use...

Embodiment 1

[0049] According to the mass ratio of graphene oxide:surfactant:reductant:sulfur powder=1:0.001:0.5:1, the graphene oxide aqueous solution with mass concentration of 10g / L was prepared. Add 0.01g Triton TX-100, 0.5g sodium borohydride and 1g nano-sulfur powder to 100mL of graphene oxide aqueous solution whose mass concentration is 10g / L, and ultrasonicate for 10 minutes to obtain a uniform mixed solution; Put it in a hydrothermal tank, and react in a blast drying oven at 100° C. for 8 hours to obtain a reaction product. Then the obtained reaction product is cleaned with deionized water, and dried under vacuum conditions to obtain the positive electrode material of the lithium ion secondary battery.

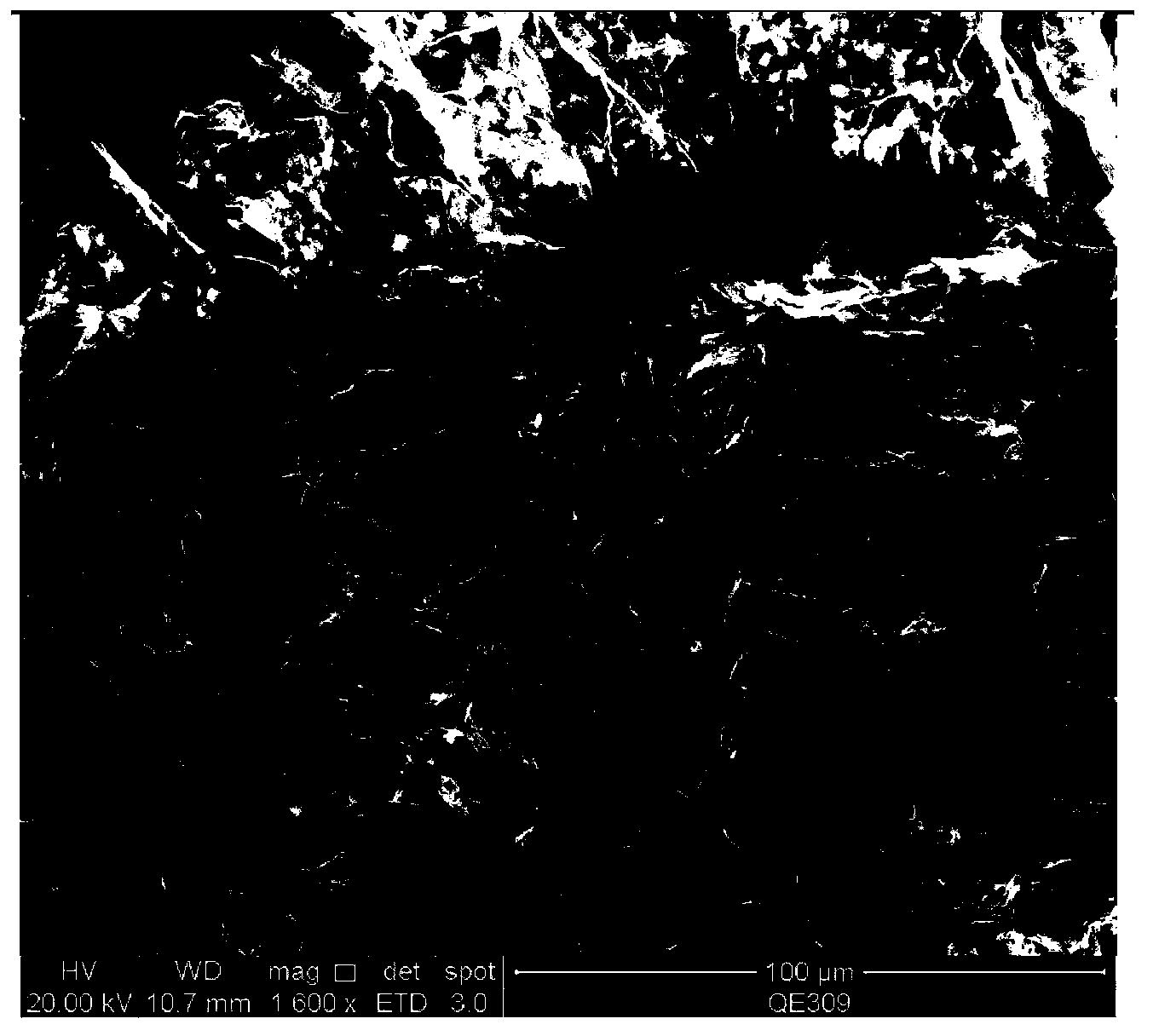

[0050] The present invention carries out scanning electron microscope scanning analysis to the obtained lithium ion secondary battery cathode material, has obtained its topography, the result is as follows figure 1 as shown, figure 1 For the embodiment of the present invention 1...

Embodiment 2

[0053] The lithium-ion secondary battery cathode material obtained in Example 1 is mixed uniformly in nitrogen methyl pyrrolidone in a ratio of 80:10:10 by mass ratio with conductive agent Super P and binder polyvinylidene fluoride, and will obtain The mixed solution was coated on an aluminum foil with a coating thickness of 30 μm, and the aluminum foil coated with the mixed solution was dried at 80° C. to obtain a positive electrode sheet. Lithium sheet was used as the negative electrode, the microporous polypropylene film was used as the diaphragm, and LiN(CF) with a molar concentration of 1mol / L 3 SO 2 ) 2 The non-aqueous solution (the solvent is a mixed solvent of equal volumes of 1,3-dioxolane and dipropyl carbonate) is used as the electrolyte, which is assembled with the obtained positive electrode sheet to obtain a lithium ion secondary battery.

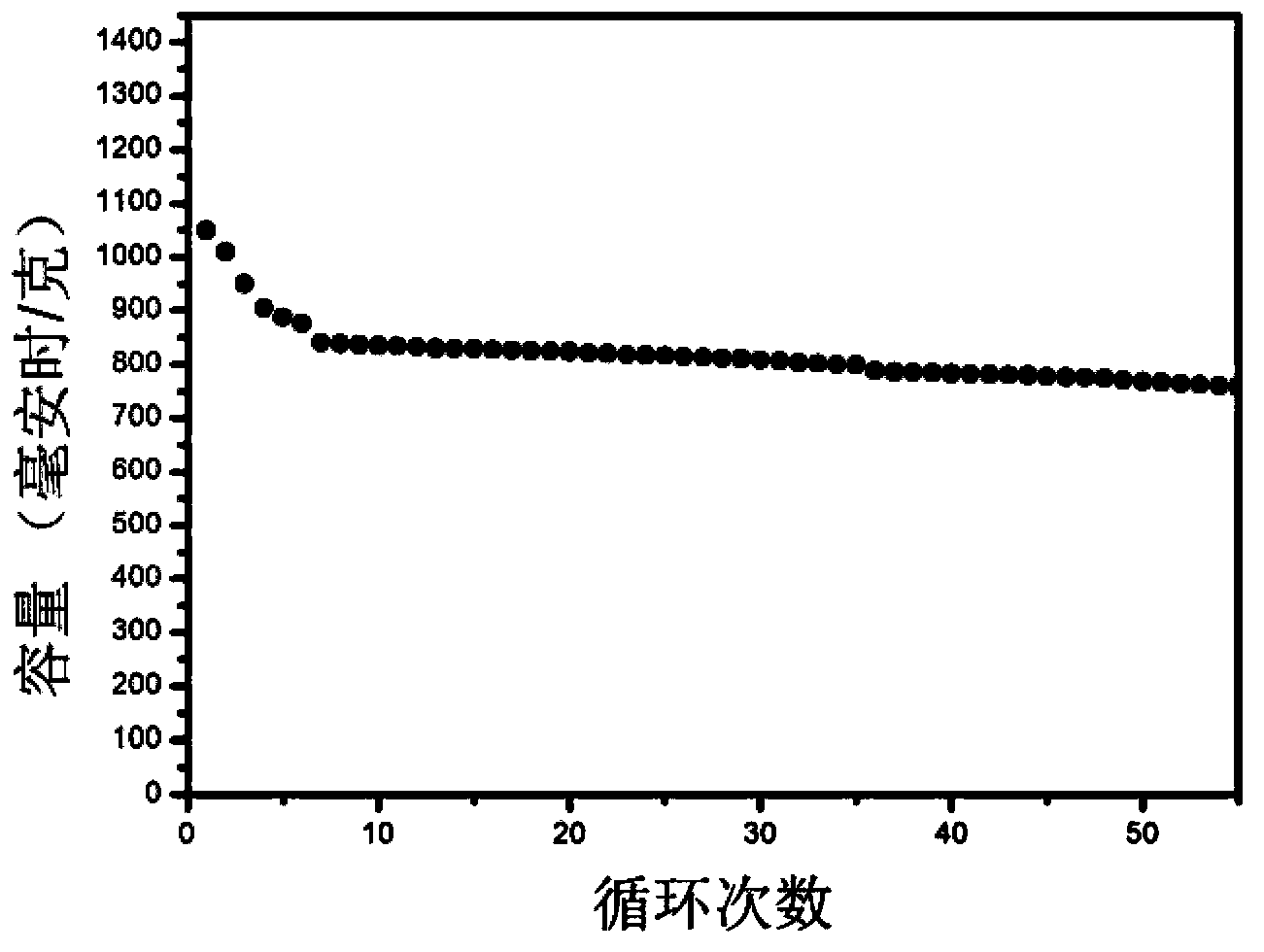

[0054] The present invention has investigated the charging and discharging situation of the lithium-ion secondary battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com