Patents

Literature

183 results about "Sulfur electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

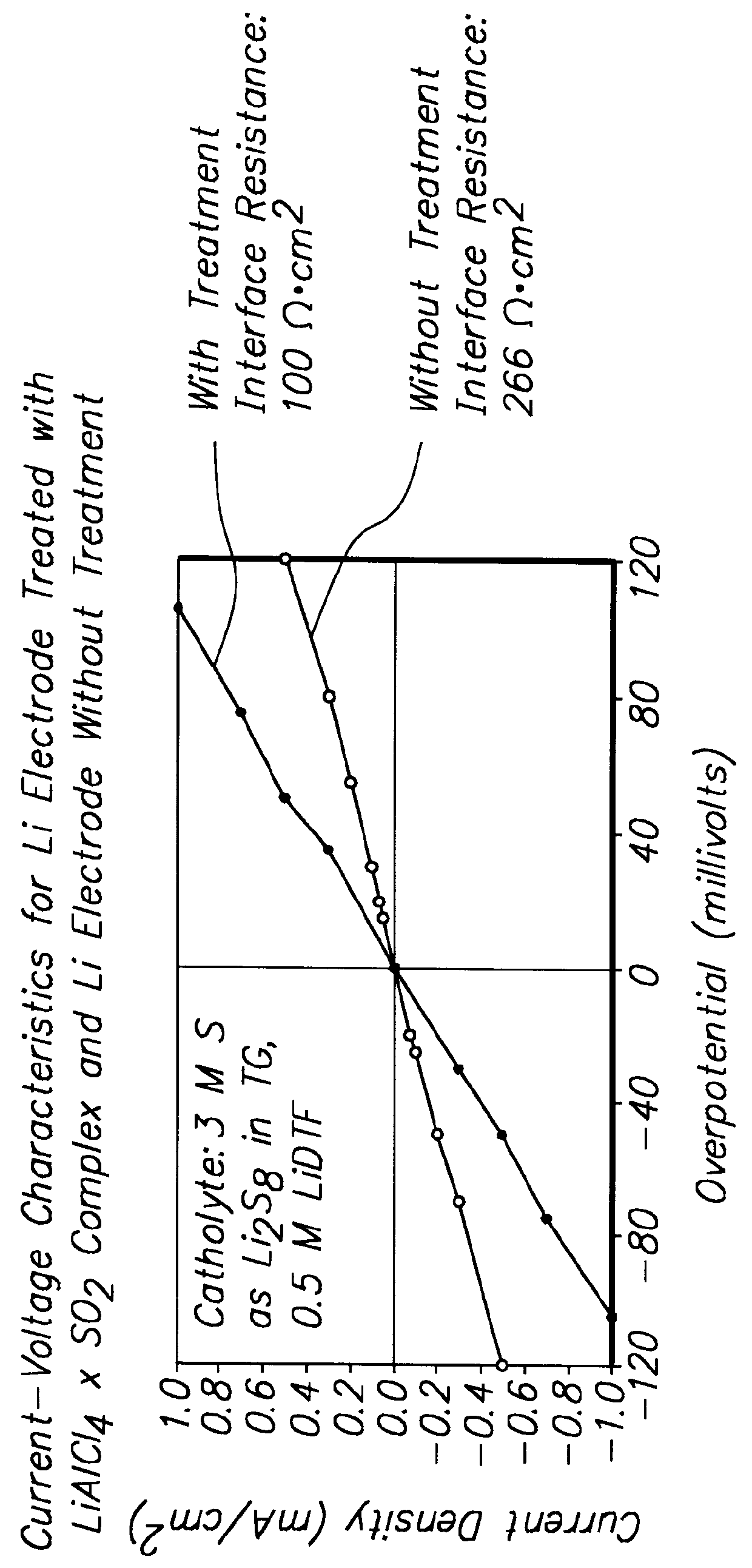

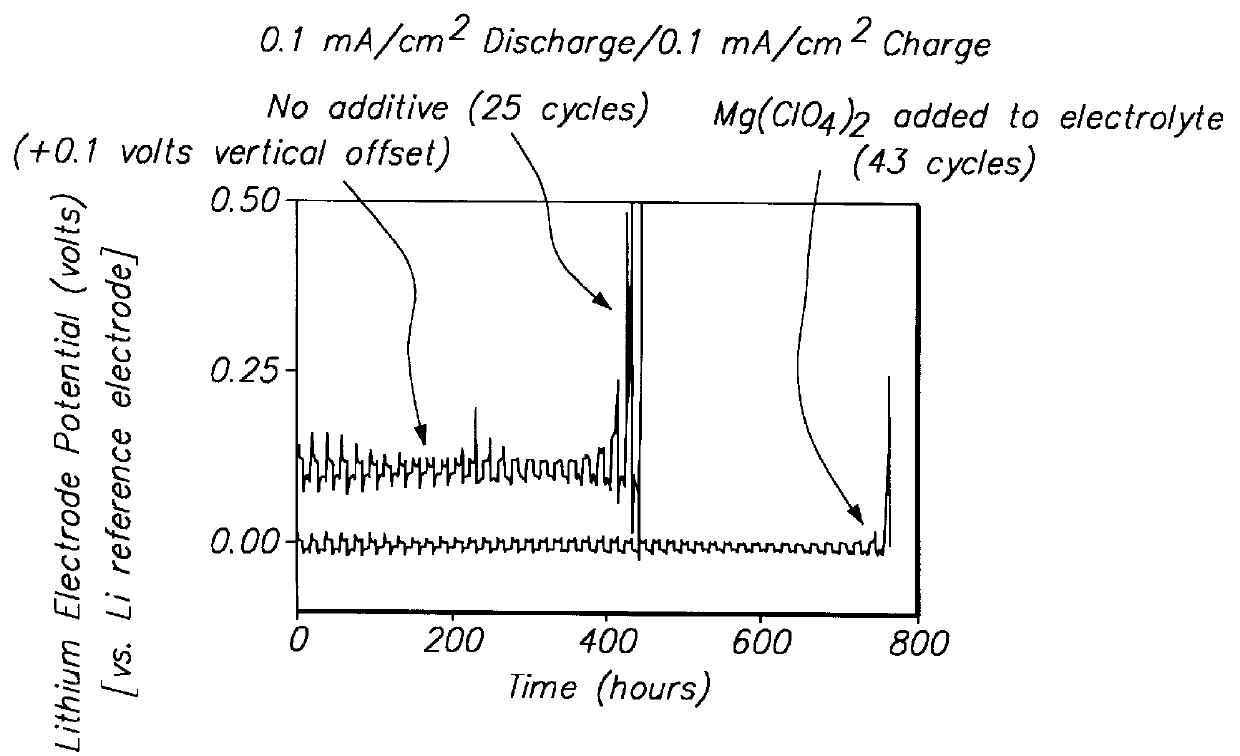

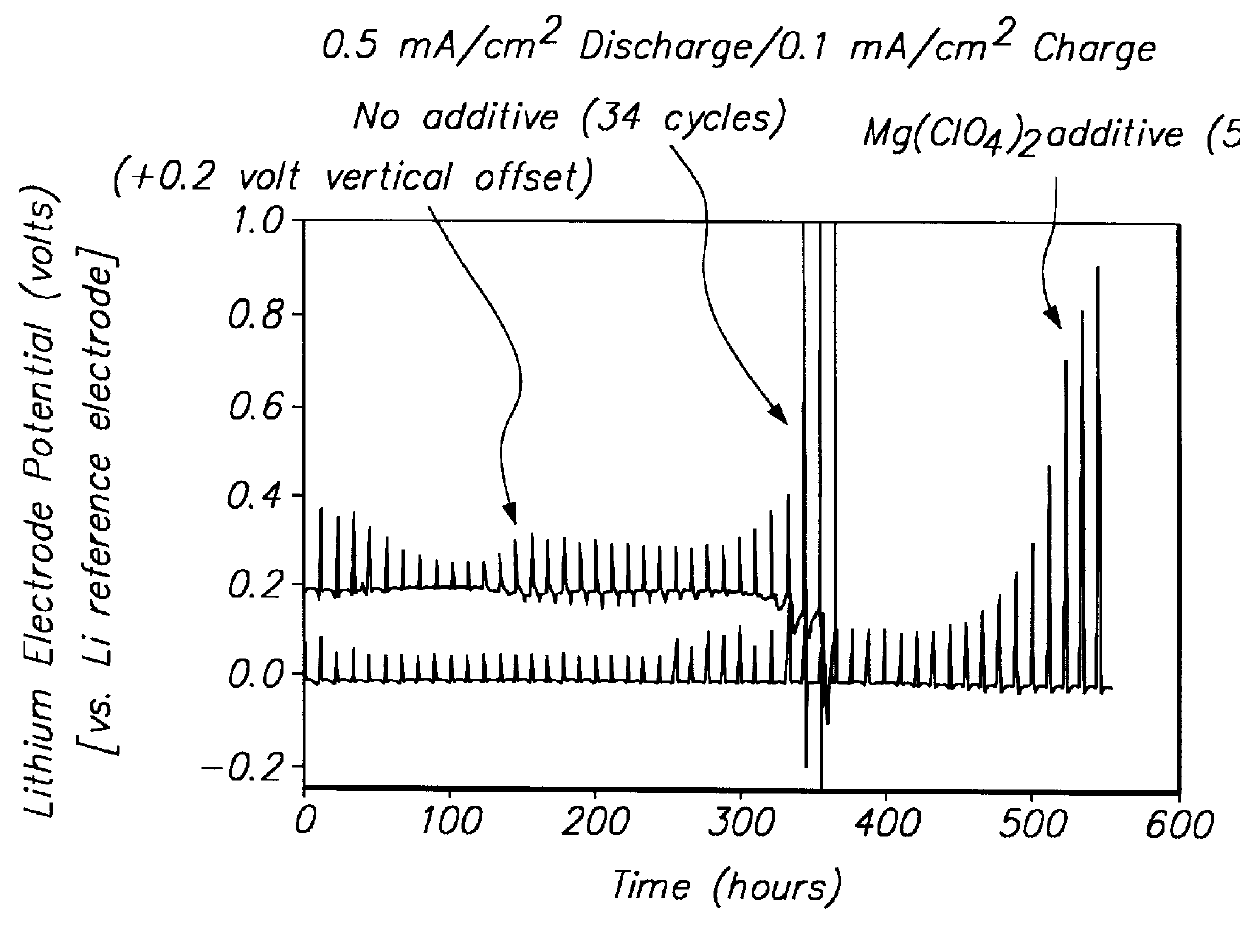

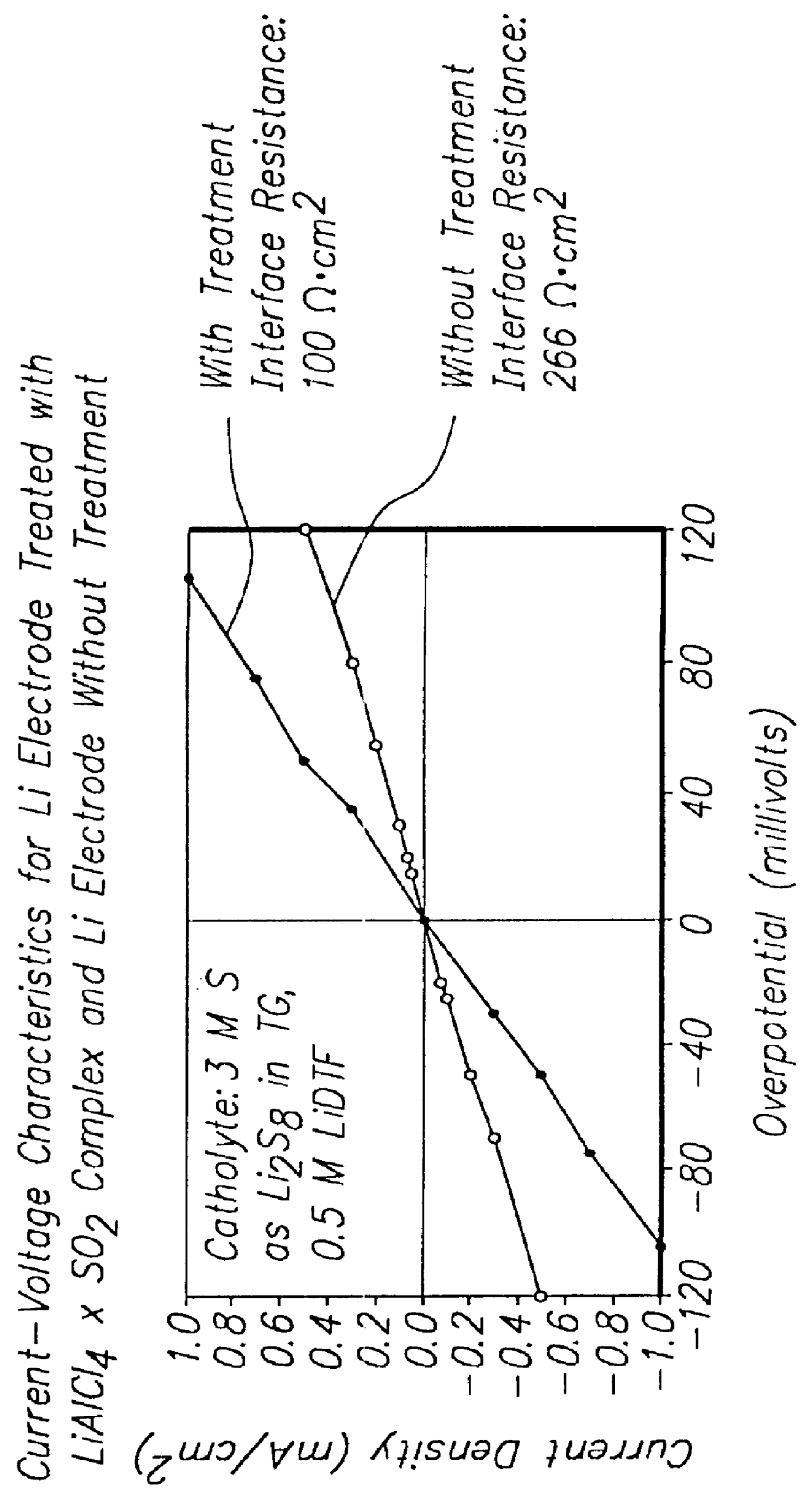

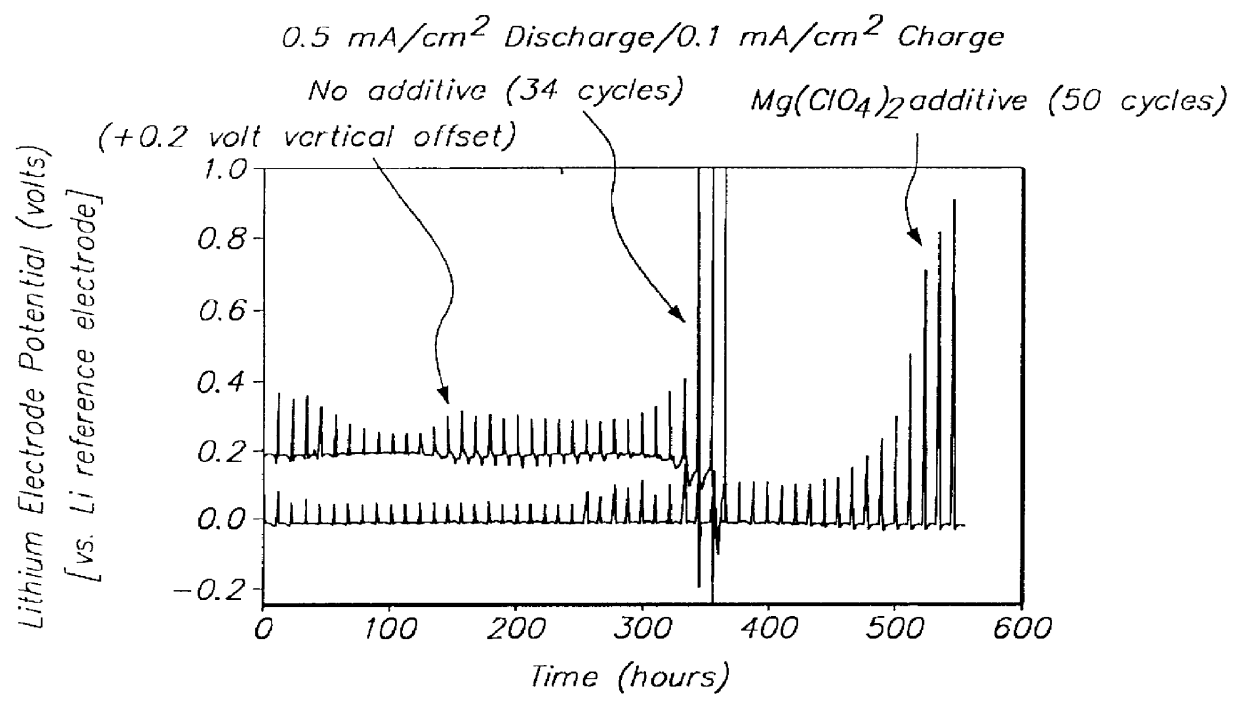

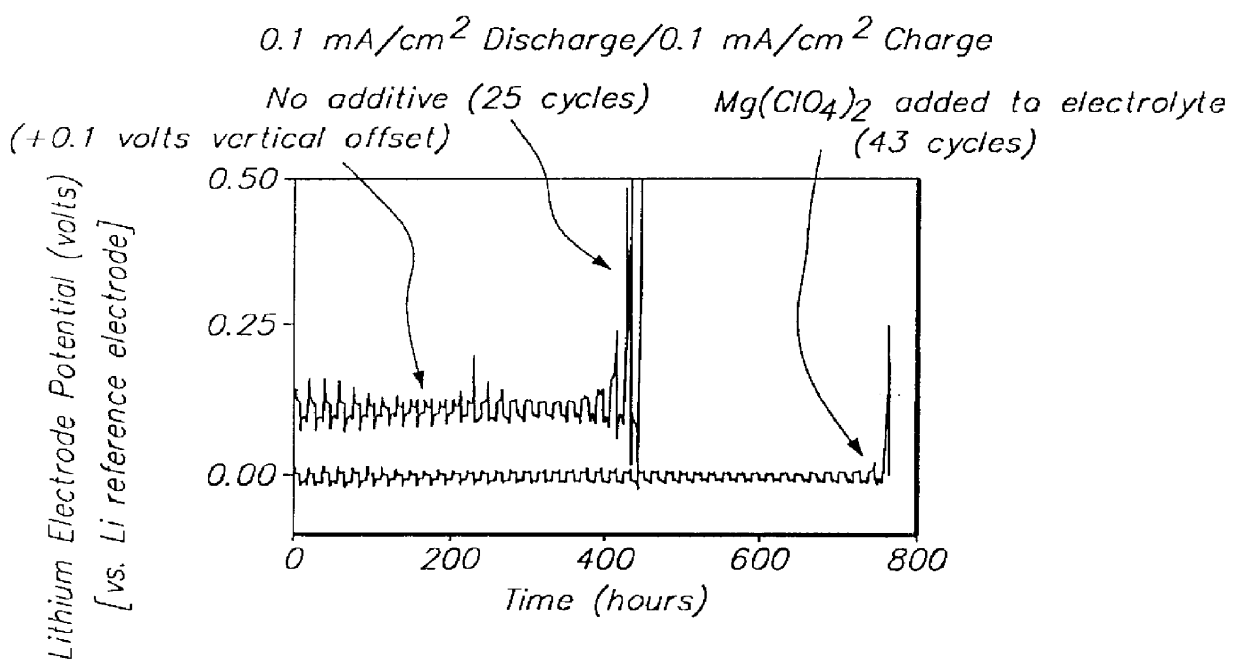

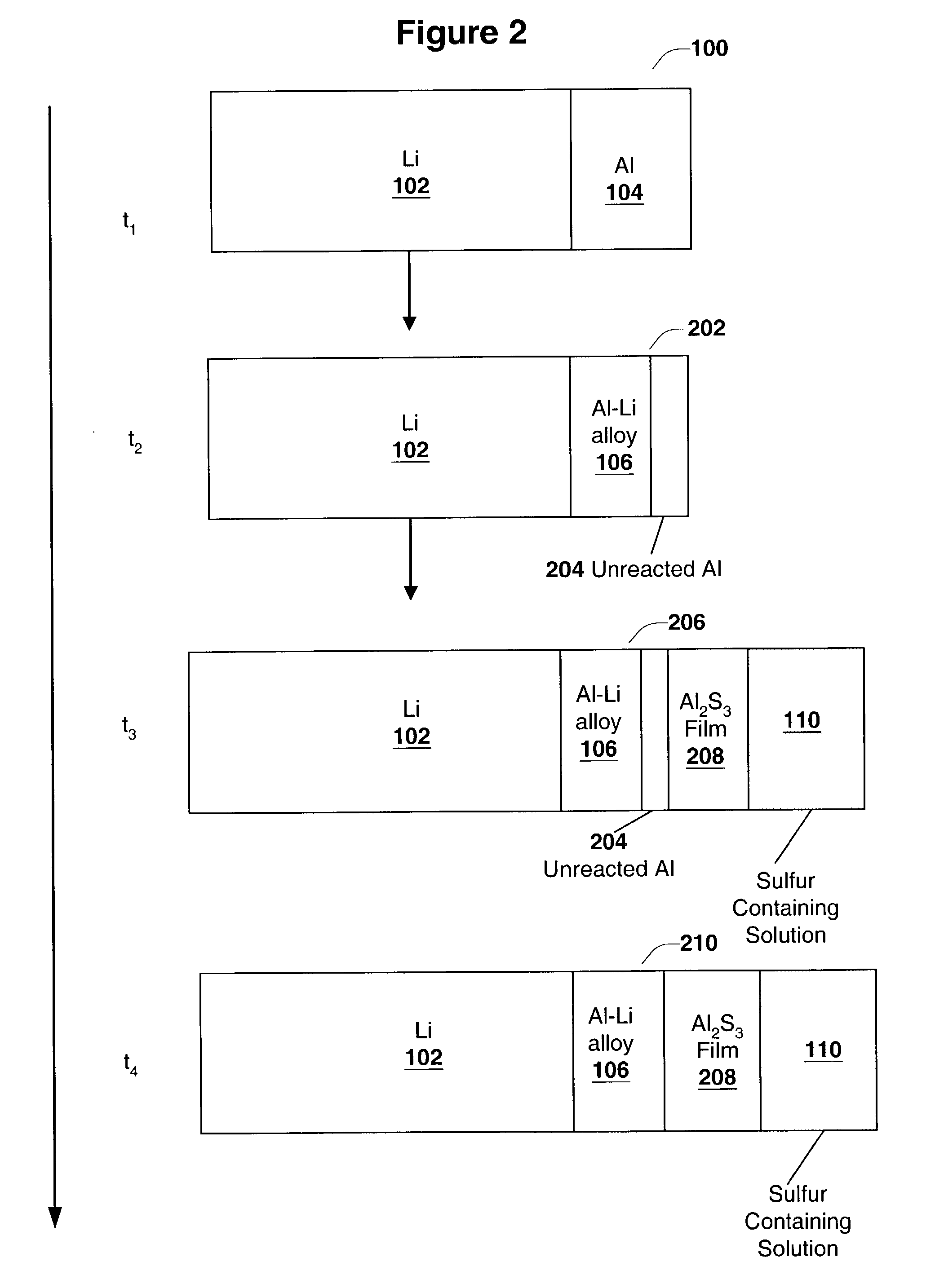

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Coated lithium electrodes

InactiveUS6955866B2Improve cycle lifeIncrease storageabilityCellsOrganic electrolyte cellsSulfur electrodePolysulfide

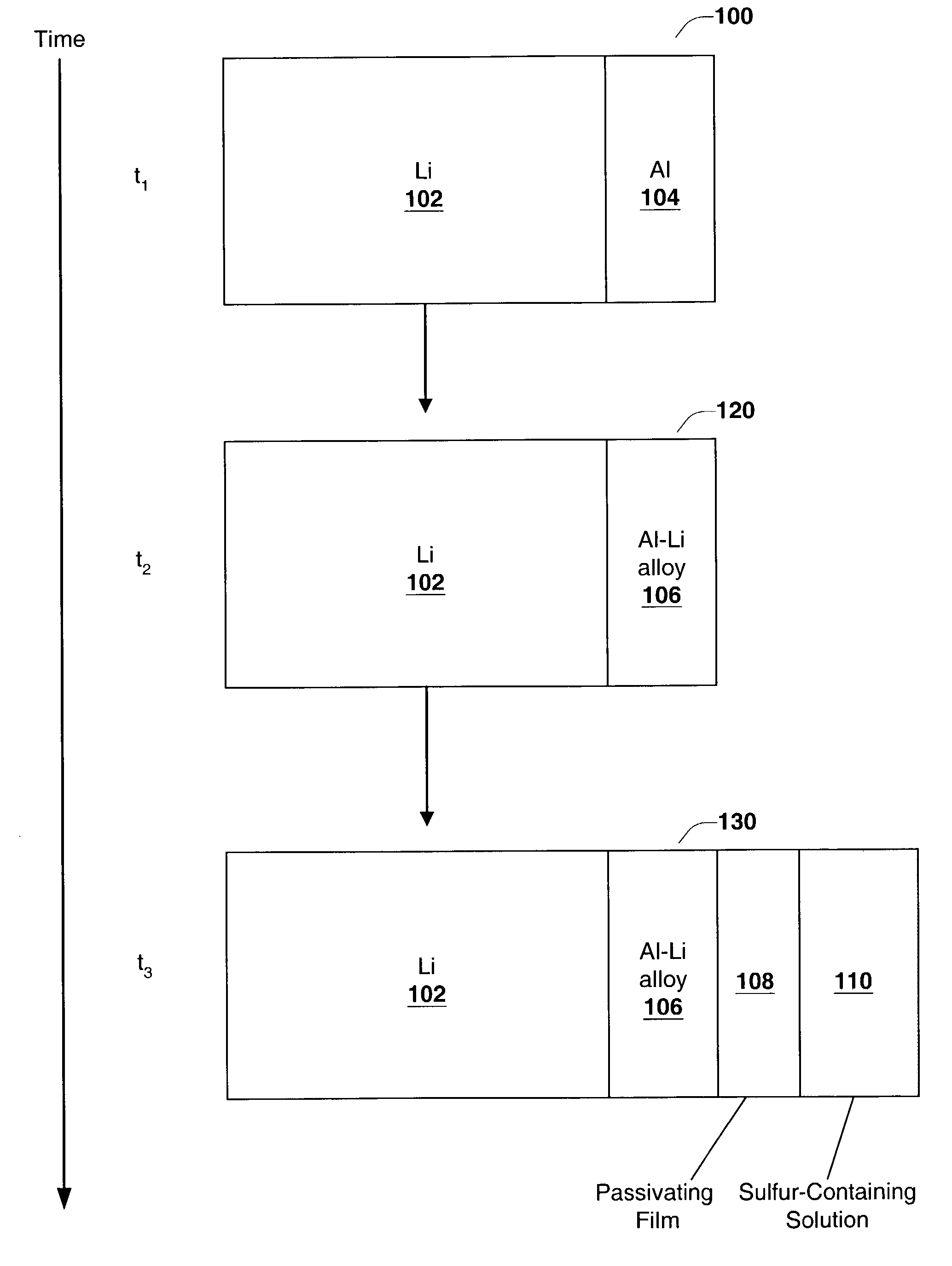

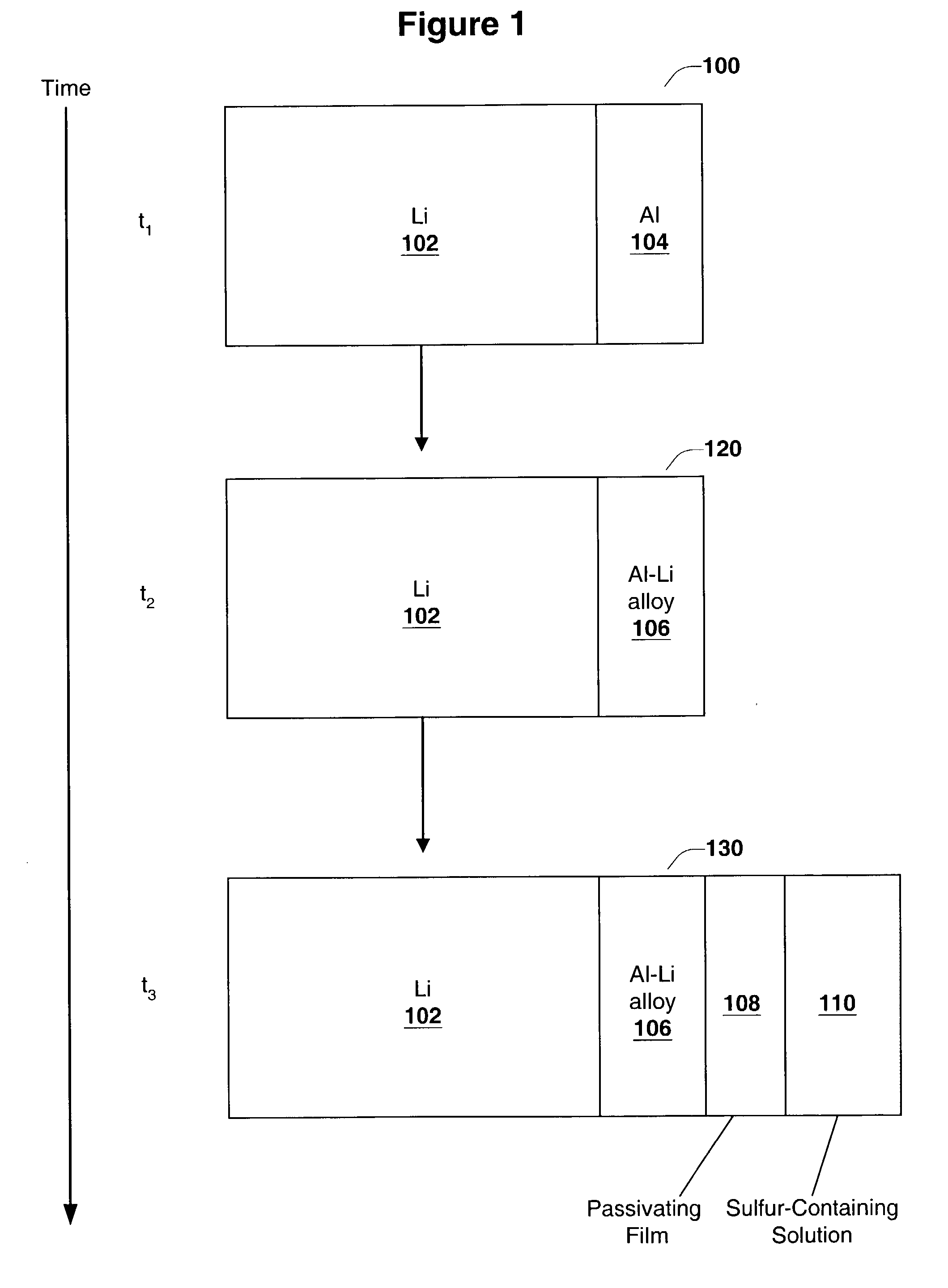

Batteries including a lithium anode stabilized with a metal-lithium alloy and battery cells comprising such anodes are provided. In one embodiment, an electrochemical cell having an anode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The anode includes a lithium core and a ternary alloy layer over the lithium core where the ternary alloy comprises lithium and two other metals. The ternary alloy layer is effective to increase cycle life and storageability of the electrochemical cell. In a more particular embodiment, the ternary alloy layer is comprised of lithium, copper and tin.

Owner:POLYPLUS BATTERY CO INC

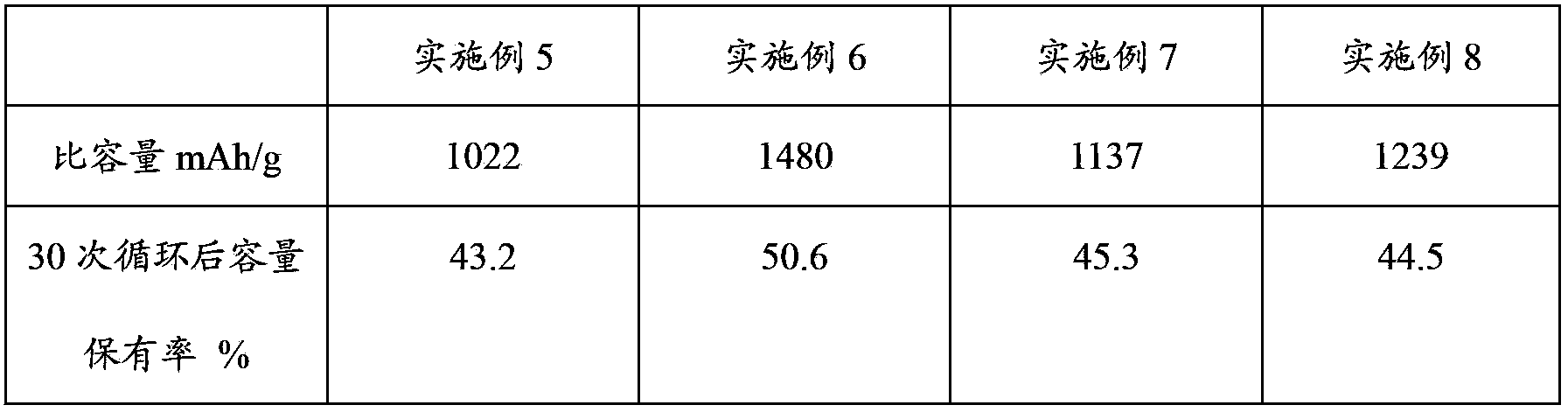

Preparation method for coating anode material of lithium battery

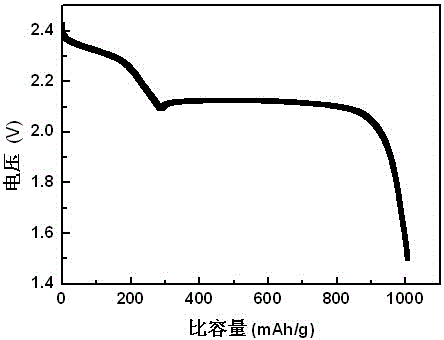

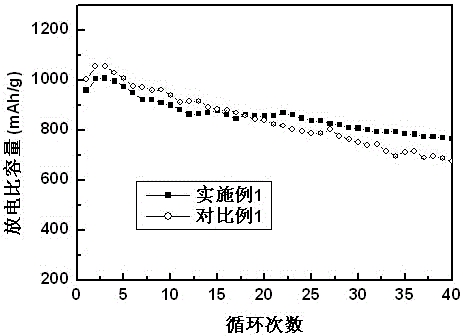

InactiveCN103579590AEasy and quick passImpede passingCell electrodesSecondary cellsSulfur electrodeLithium sulfur

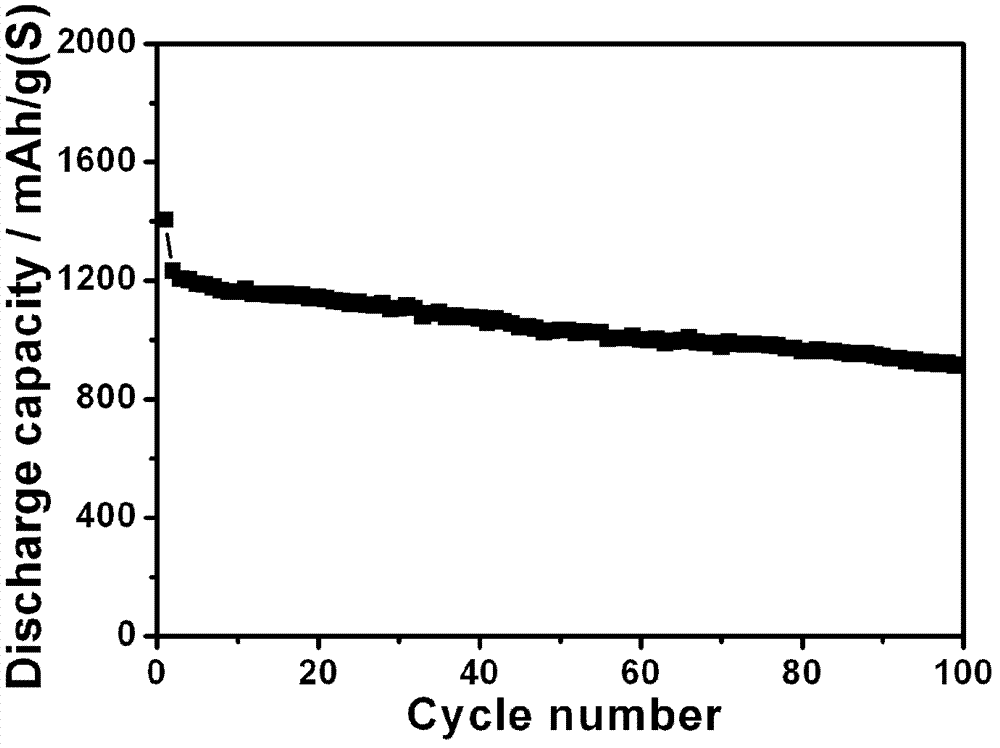

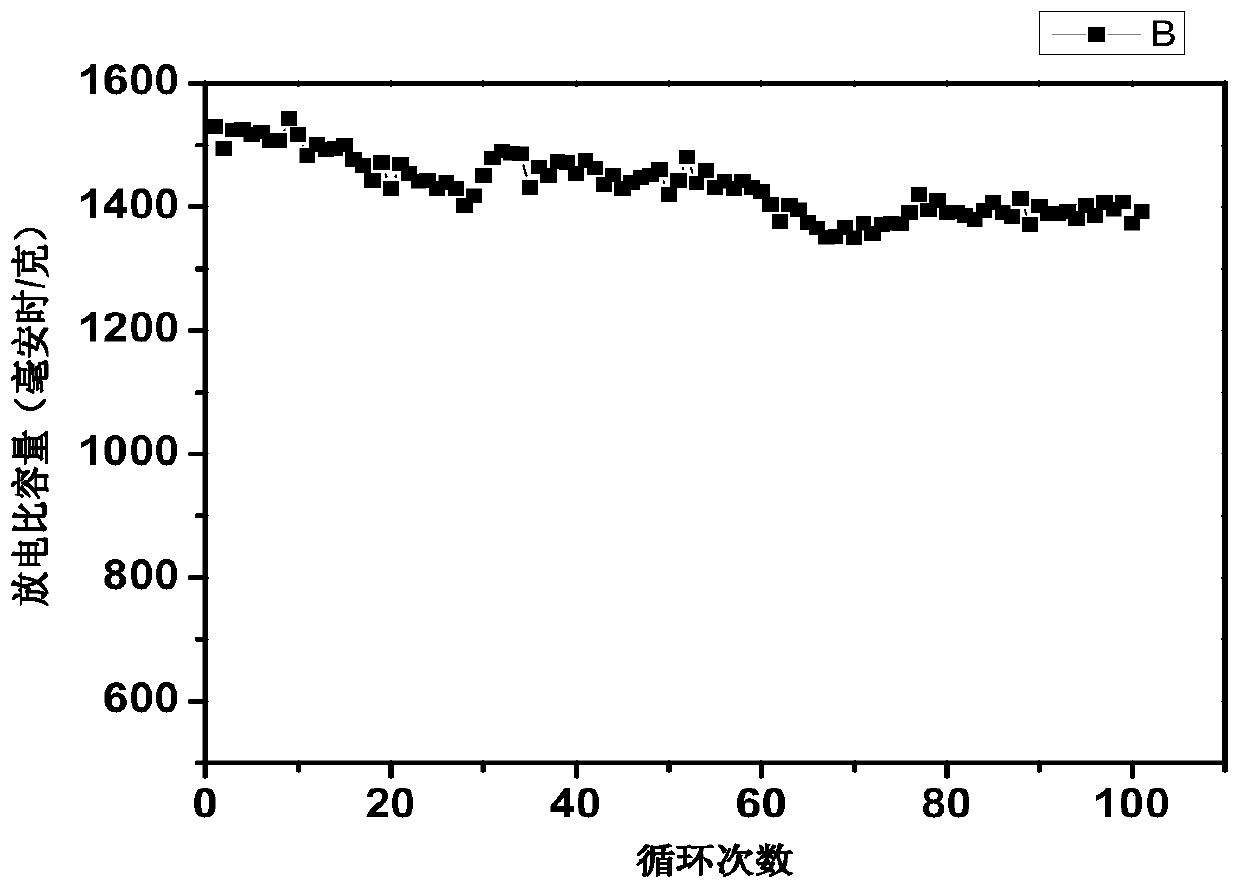

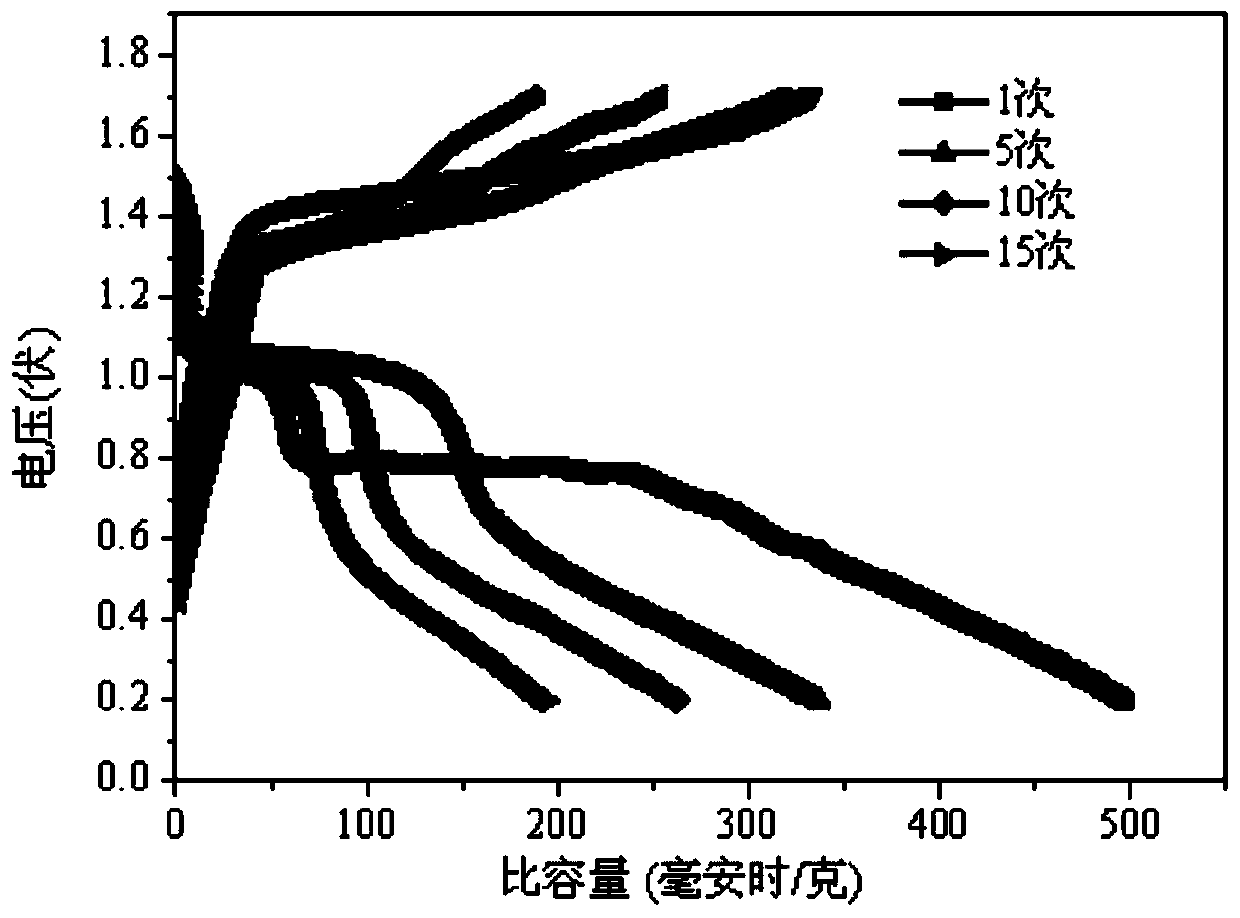

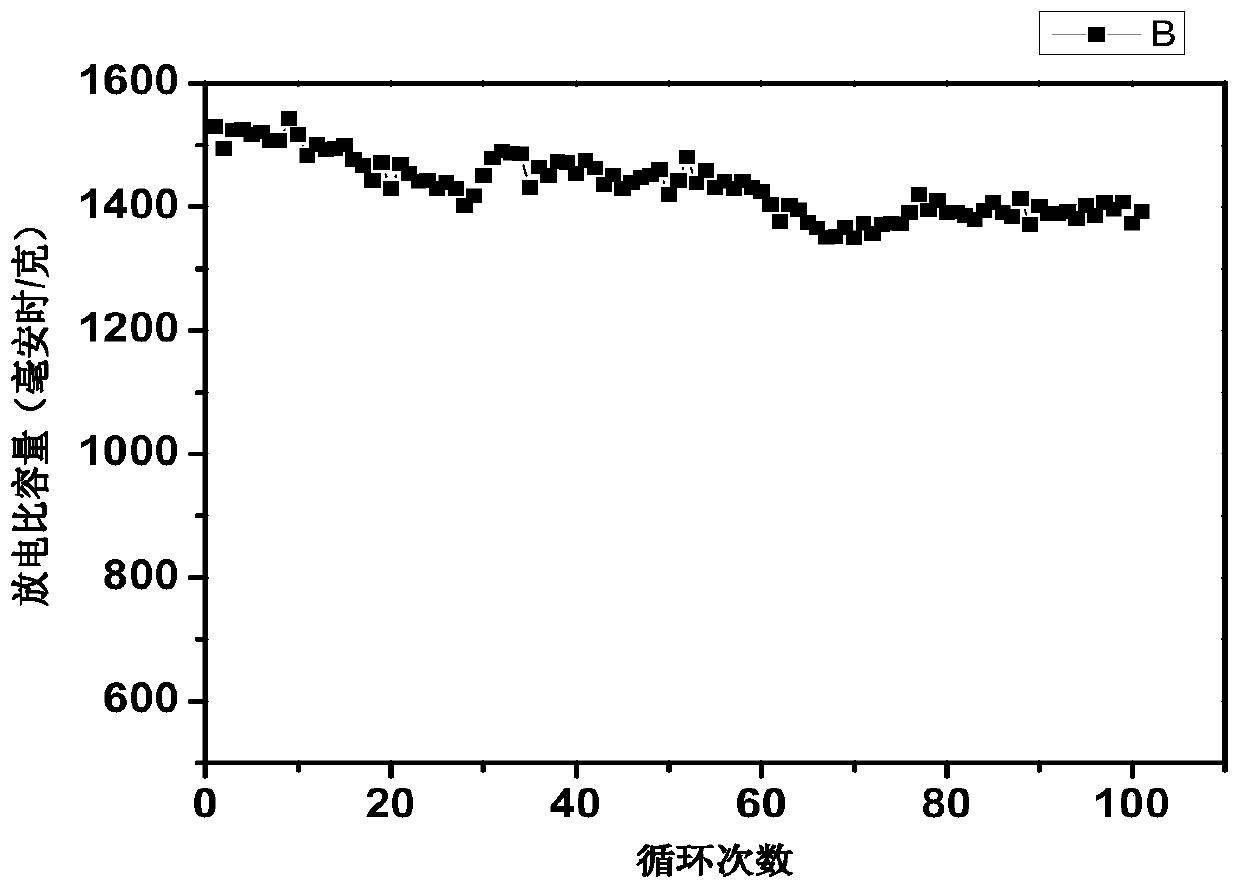

The invention provides a preparation method for a coating anode material of a lithium battery. The preparation method comprises the following specific steps: (1) weighing a coating material and monomer sulfur; weighing the coating material and the monomer sulfur according to a mass ratio, wherein the mass ratio of the coating material to the monomer sulfur ranges from 1:1 to 1:100; (2) preparing a dispersion solution of the sulfur: dissolving the monomer sulfur into a sodium polyacrylate water solution with the mass percentage of 2%-10% at a room temperature to obtain the dispersion solution of the sulfur; (3) preparing a dispersion solution of the coating material: dissolving the coating material into a surfactant water solution at 20-45 DEG C to obtain the dispersion solution of the coating material; and (4) preparing the coating anode material of the lithium battery. According to the preparation method for the coating anode material of the lithium battery, self discharge of the battery is reduced effectively and the stability of the structure in a charging / discharging process of a sulfur electrode is kept; a sulfur active material prepared by the preparation method is used as a lithium-sulfur secondary battery anode material and the prepared lithium material has a high specific discharge capacity and a good circulating performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

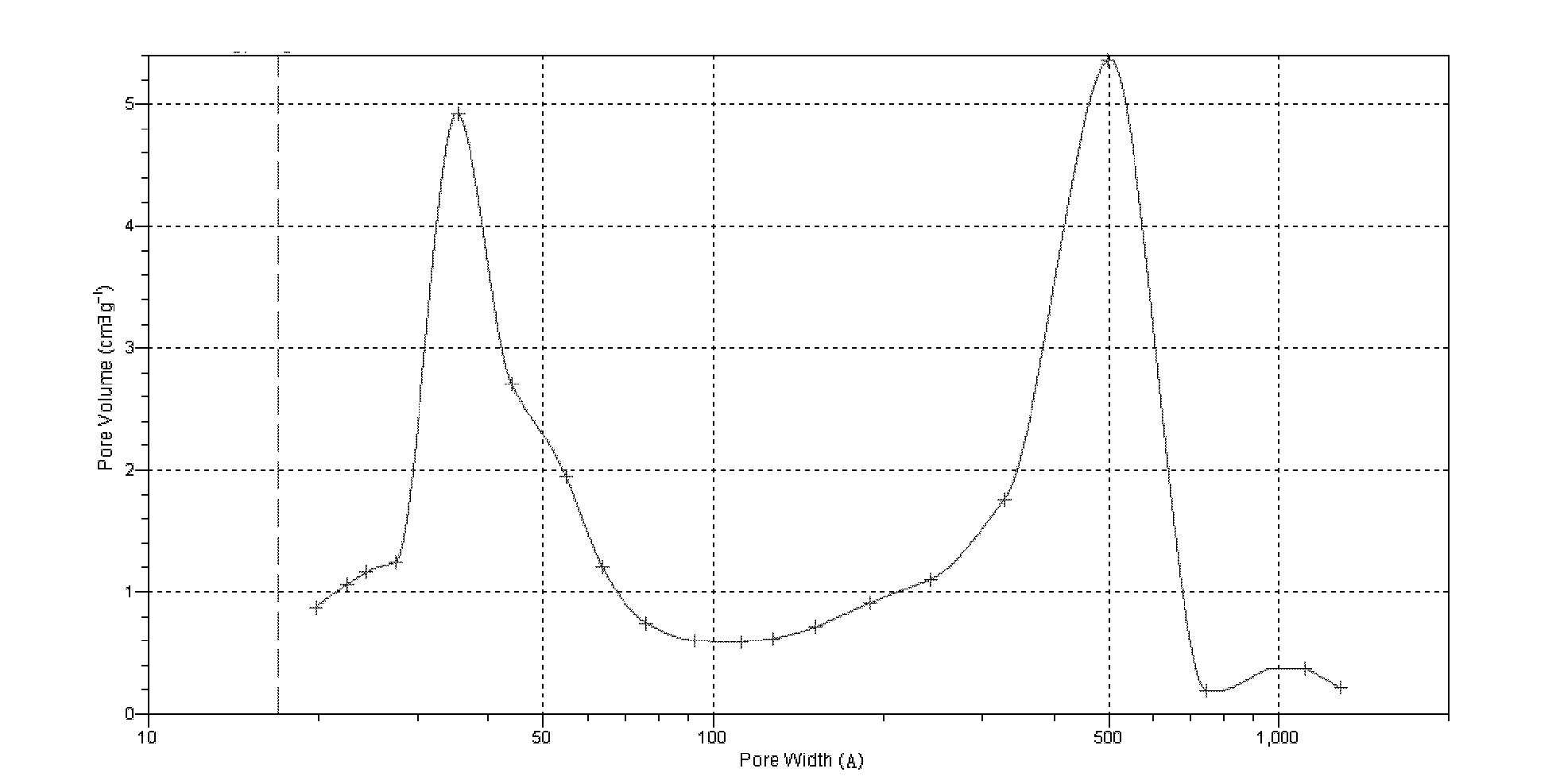

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

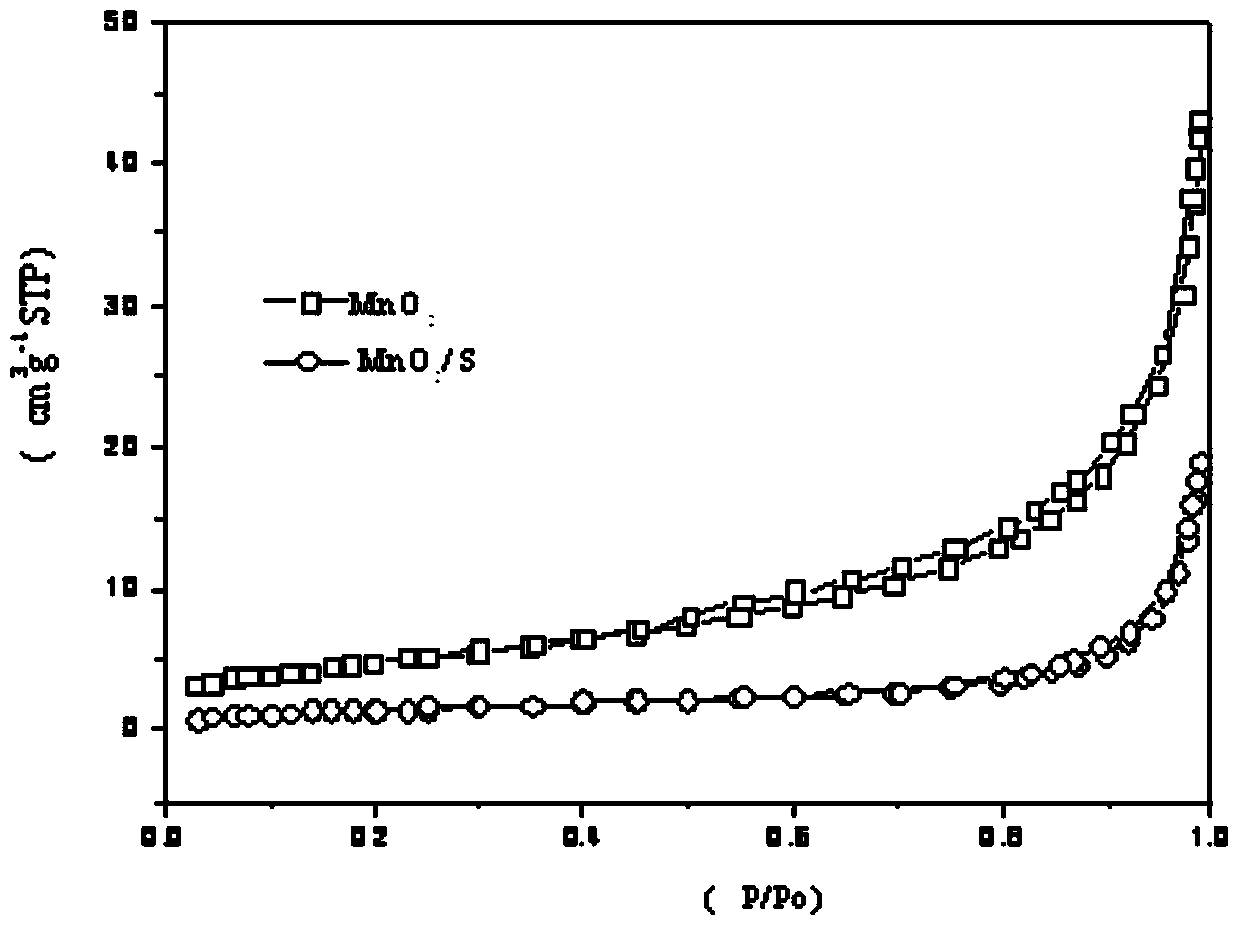

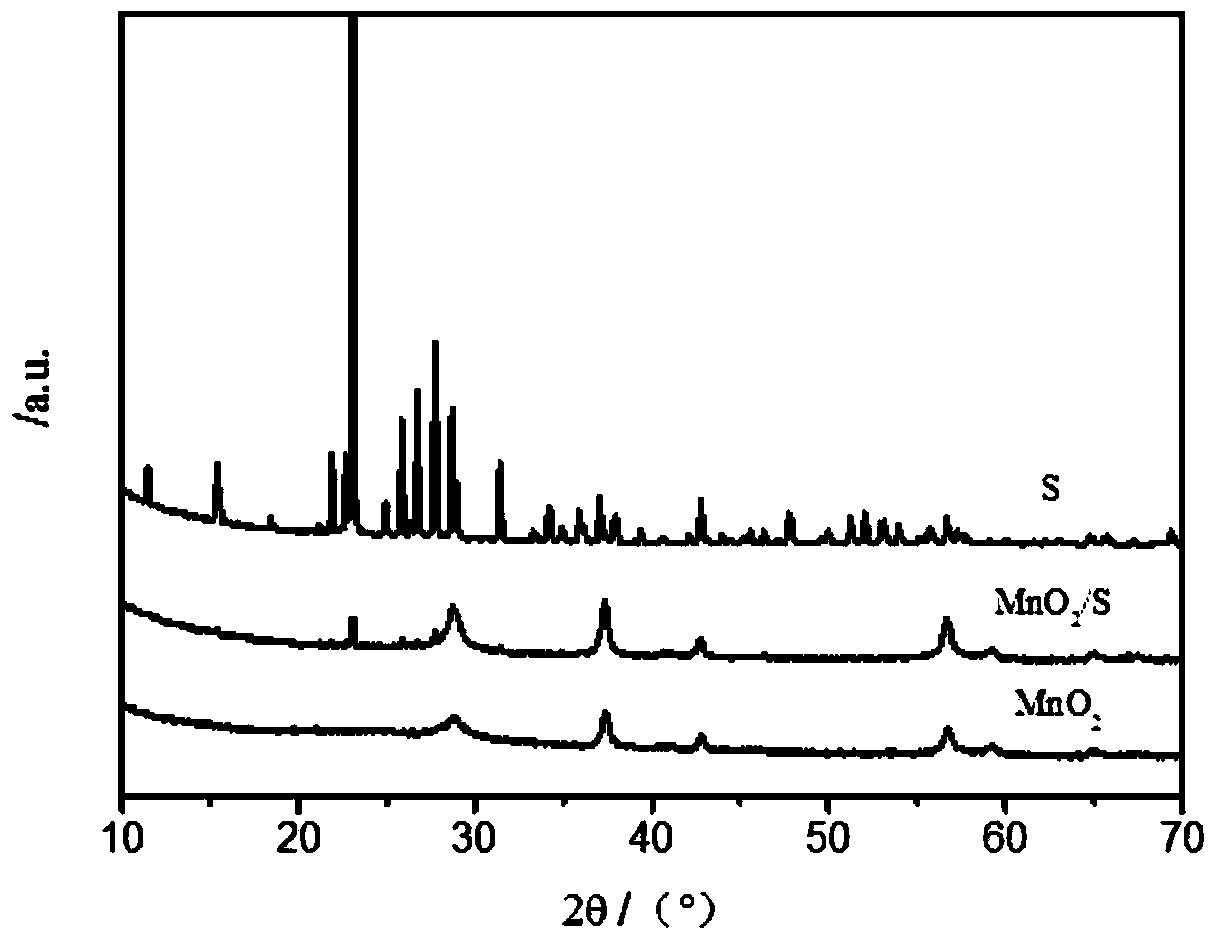

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

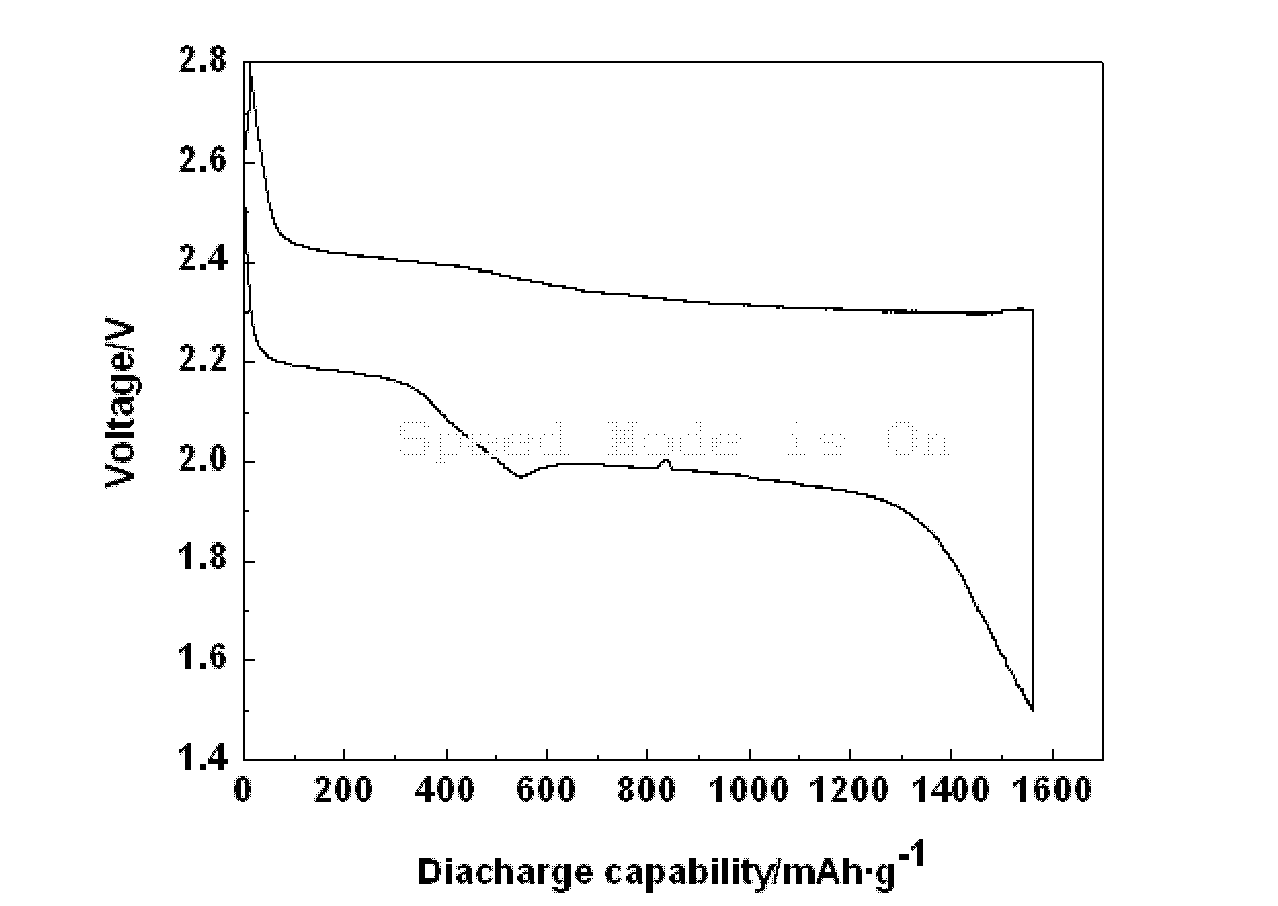

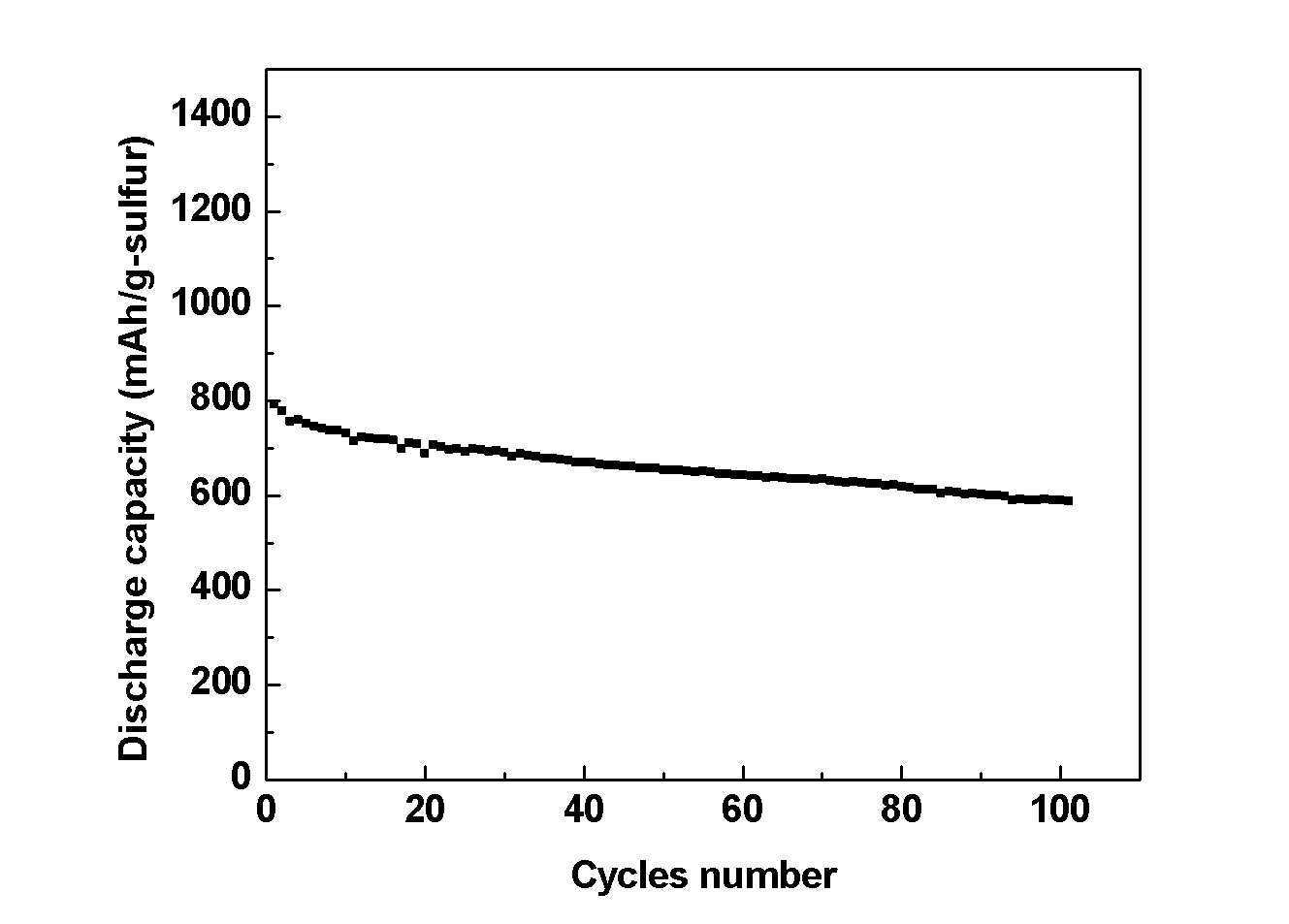

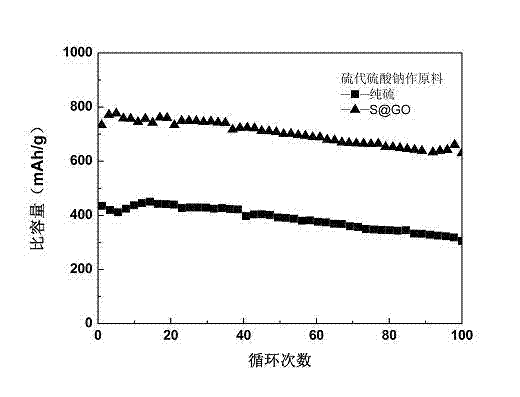

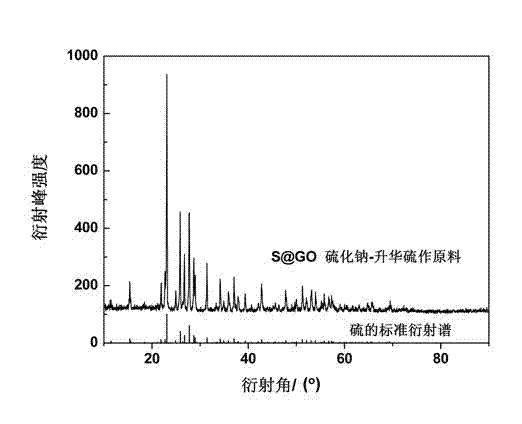

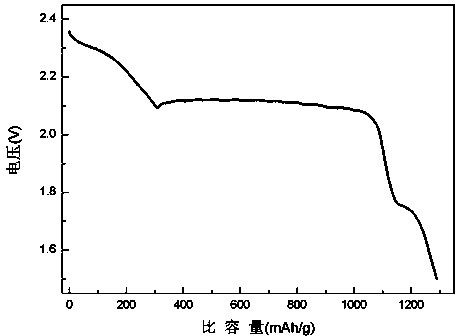

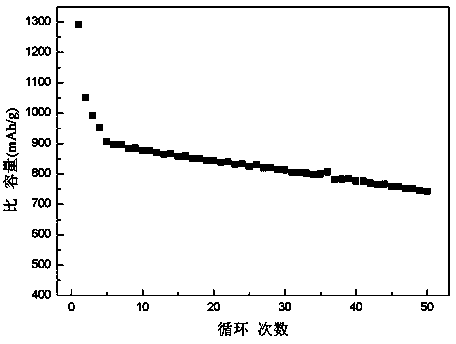

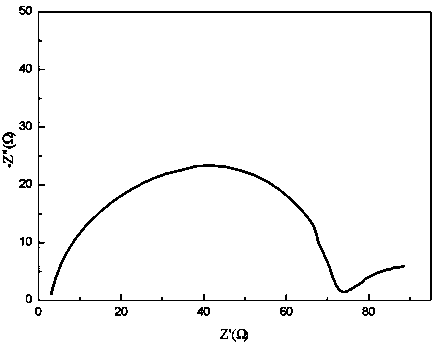

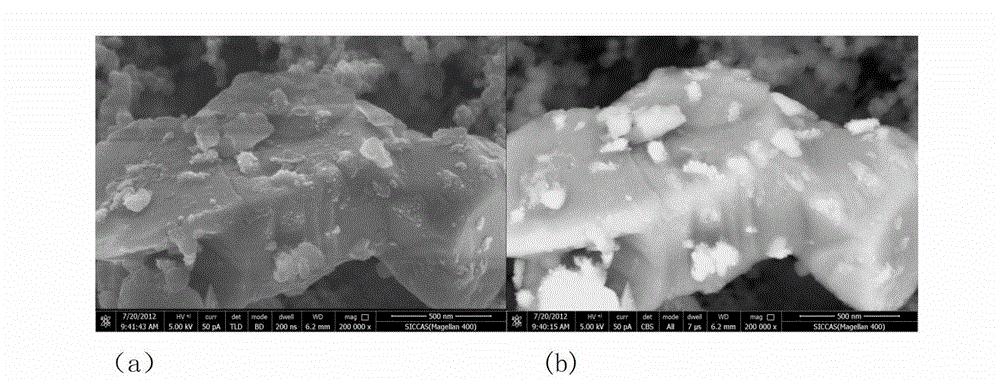

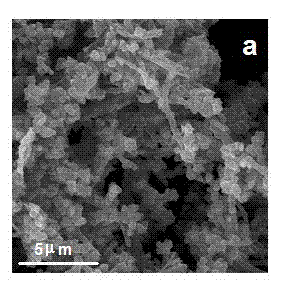

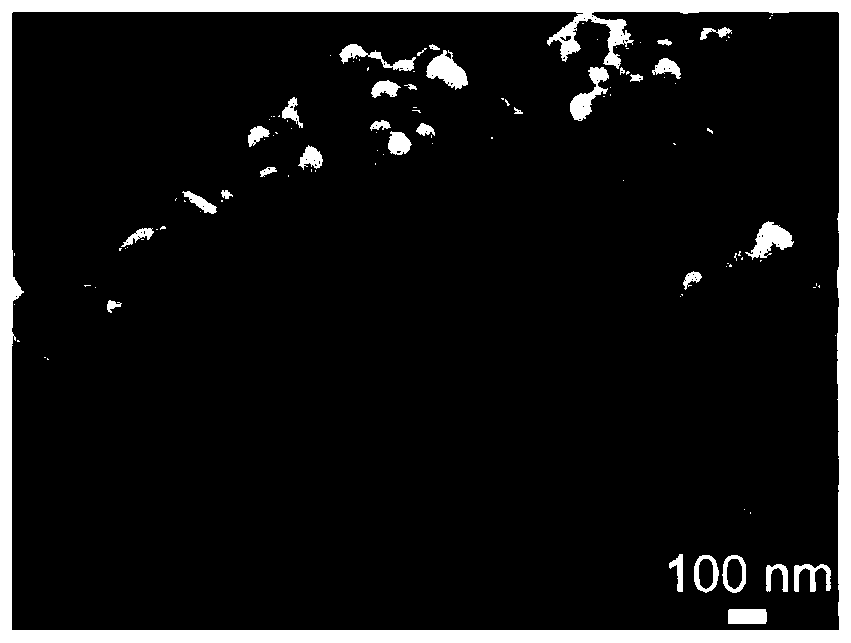

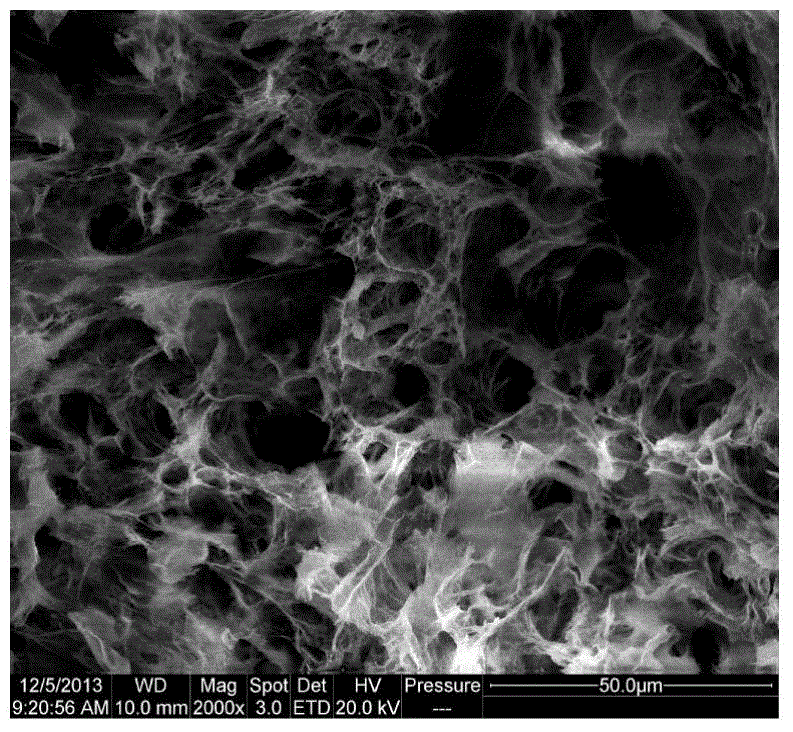

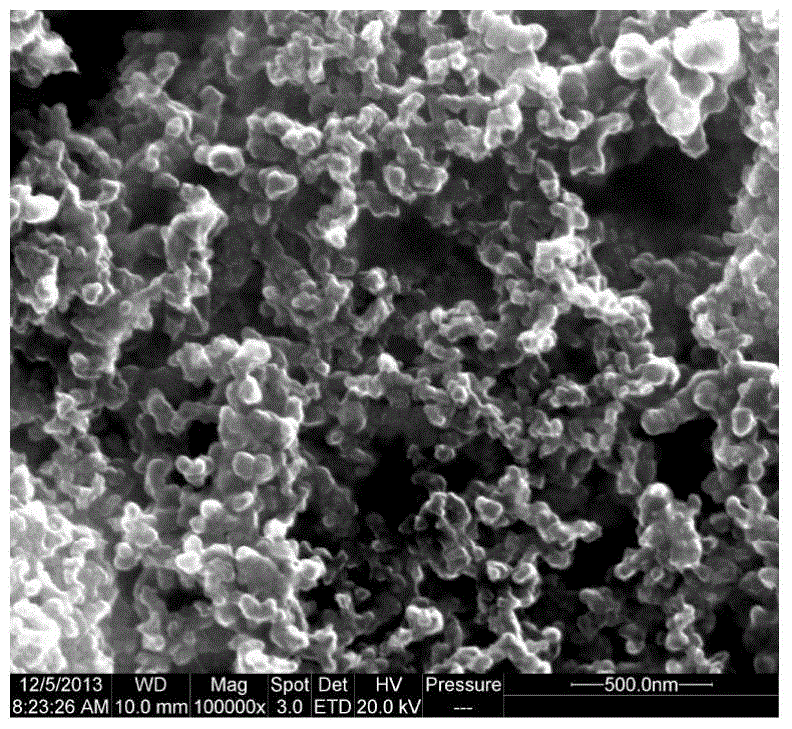

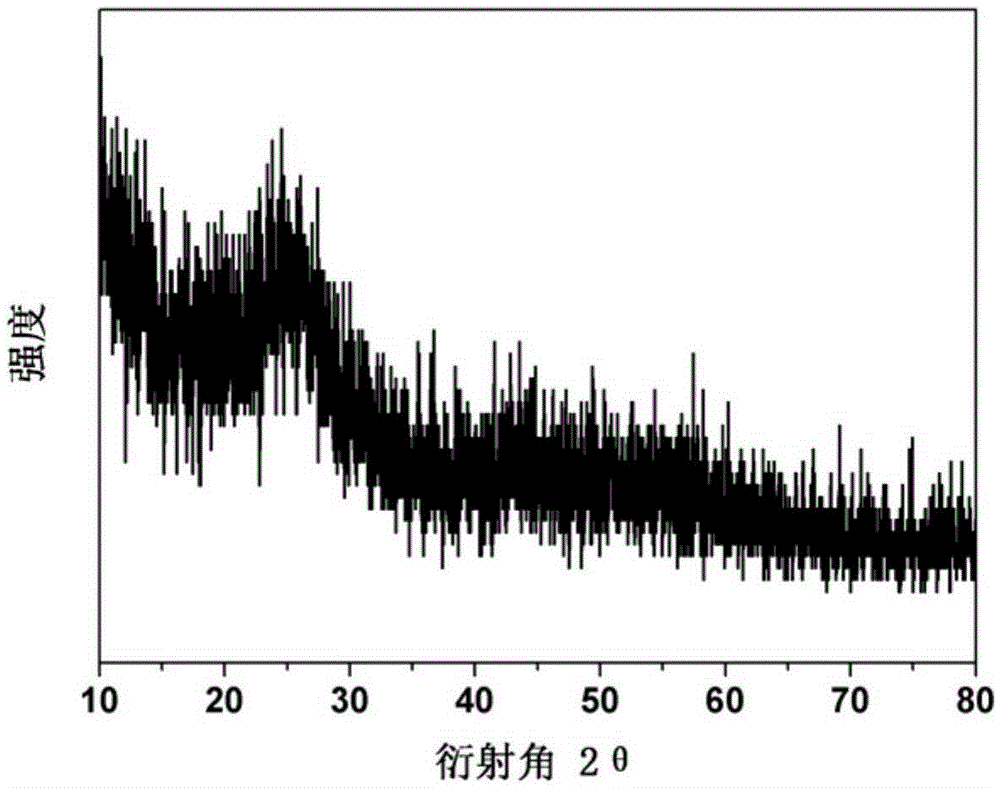

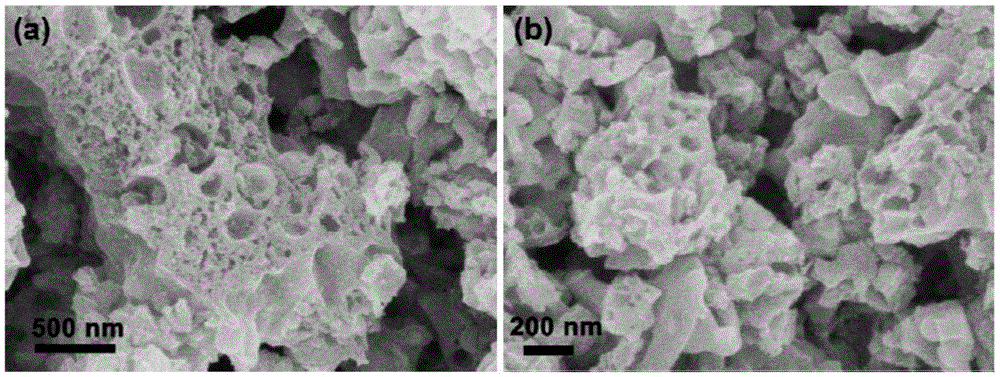

Method for preparing nano-sulfur / graphene oxide composite electrode material

The invention relates to a method for preparing a nano-sulfur / graphene oxide composite material with high specific capacity and belongs to the field of cross application of material synthesis and electrochemical power supplies. The nano-sulfur / graphene oxide composite material is applicable to an electrode material of a lithium sulfur secondary battery with the high specific capacity. The method is characterized by comprising the following steps of: synthesizing nano-sulfur particles by using a simple chemical method under the protection of a surfactant; and uniformly attracting graphene oxide and a carbon material to the surfaces of the nano-sulfur particles by interaction of the surfactant and the graphene oxide to form a core-shell type nano-sulfur / graphene oxide composite material. The graphene oxide and the carbon material coat a sulfur surface, so a sulfur electrode material is stable in structure, high in electric conductivity and high in cycle performance. Environmentally-harmful materials are not employed, and the method can be implemented at low temperature, and is low in energy consumption in the synthesis process and low in equipment requirement. The synthesized material is high in charging / discharging capacity, non-toxic and harmless to a human body, and sulfur is abundant in nature, so the material has a good industrial prospect and can be applied to large-scale industrial production.

Owner:SHANGHAI UNIV

Sulfur electrode, and preparation and application thereof

ActiveCN102903887AImprove cycle stabilityIncrease profitNon-aqueous electrolyte accumulator electrodesCarbon compositesPorous carbon

A sulfur electrode, and preparation and application thereof. The sulfur electrode comprises a sulfur / carbon composite, a conductive agent and a binder, wherein the sulfur is an electrode active material. The content of sulfur / carbon composite in the electrode is 10-95%; a mass ratio of sulfur to porous carbon material in the sulfur / carbon composite is 1:0.05-19; the porous carbon material in the sulfur / carbon composite has conductivity greater than or equal to 0.1S / cm, specific surface area greater than or equal to 500 m<2> / g, and pore volume greater than or equal to 0.3cm<3> / g; and the pore structure comprises microporous and mesoporous. The porous carbon material is treated by an acid modification method, in which a mass fraction of acid is 1-50%. The sulfur electrode prepared by the method provided by the invention has advantages of high specific energy, excellent cycle stability, cheap and easily available electrode material, and simple and practical preparation method, and can be applied to a secondary battery.

Owner:中科派思储能技术有限公司

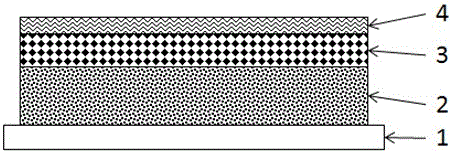

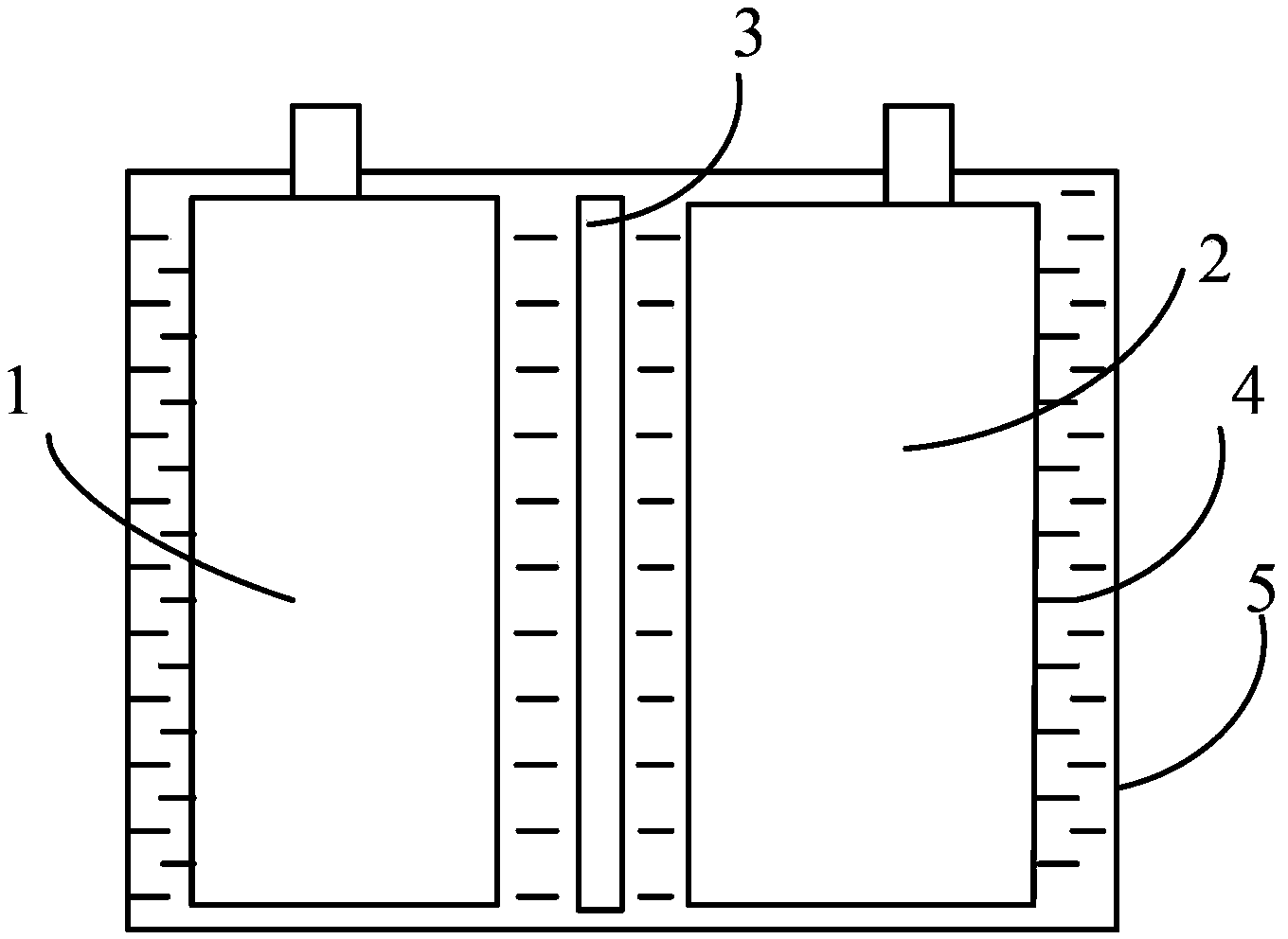

All-solid-state lithium-sulfur battery

ActiveCN106876783AImprove Coulombic efficiencyImprove cycle lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesSulfur electrodeAlloy

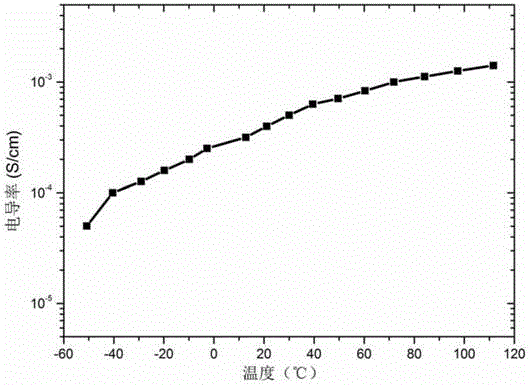

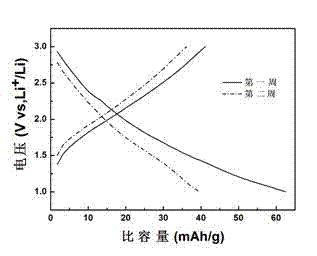

The invention discloses an all-solid-state lithium-sulfur battery. The all-solid-state lithium-sulfur battery comprises a sulfur positive electrode, a lithium or lithium alloy negative electrode, and a lithiated sulfoacid polymer solid electrolytic diaphragm; the solid electrolytic diaphragm is positioned between the sulfur positive electrode and the lithium or lithium alloy negative electrode; the sulfur positive electrode comprises a sulfur-containing active material, a conductive agent and a lithiated sulfoacid polymer; and the sulfur positive electrode, the lithiated sulfoacid polymer solid electrolyte and the lithium or lithium alloy negative electrode are assembled in a superimposition manner in sequence to form the battery. The room temperature ionic conductivity of the lithiated sulfoacid polymer solid electrolyte is greater than 10<-5>S / cm, and complexing of a lithium salt is not needed; the preparation method is simple; in addition, the room temperature ionic conductivity of the lithiated sulfoacid polymer solid electrolyte is better than that of a common inorganic-organic composite solid electrolyte; the sulfur positive electrode pole piece is prepared by adopting a polymer emulsion, and an efficient "sulfur / carbon / solid electrolyte" interface is established in the electrode, so that the activity of the sulfur electrode is improved and the battery with excellent performance is obtained; and in addition, the existing pole piece coating process and equipment can be utilized, and large scale production can be facilitated.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

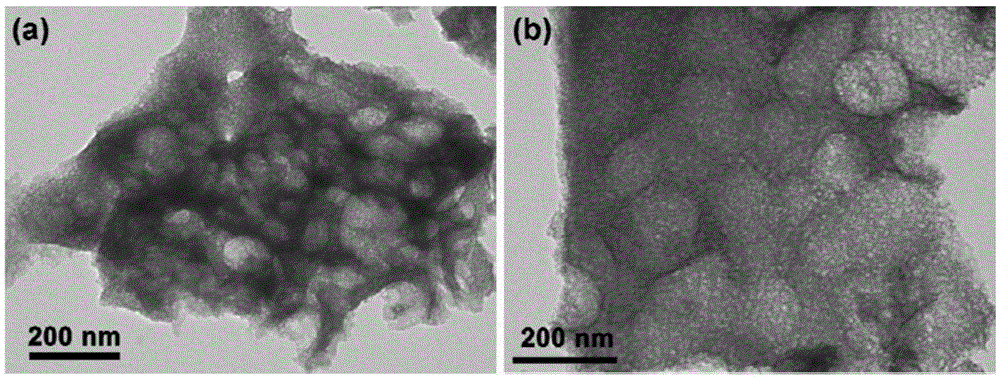

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

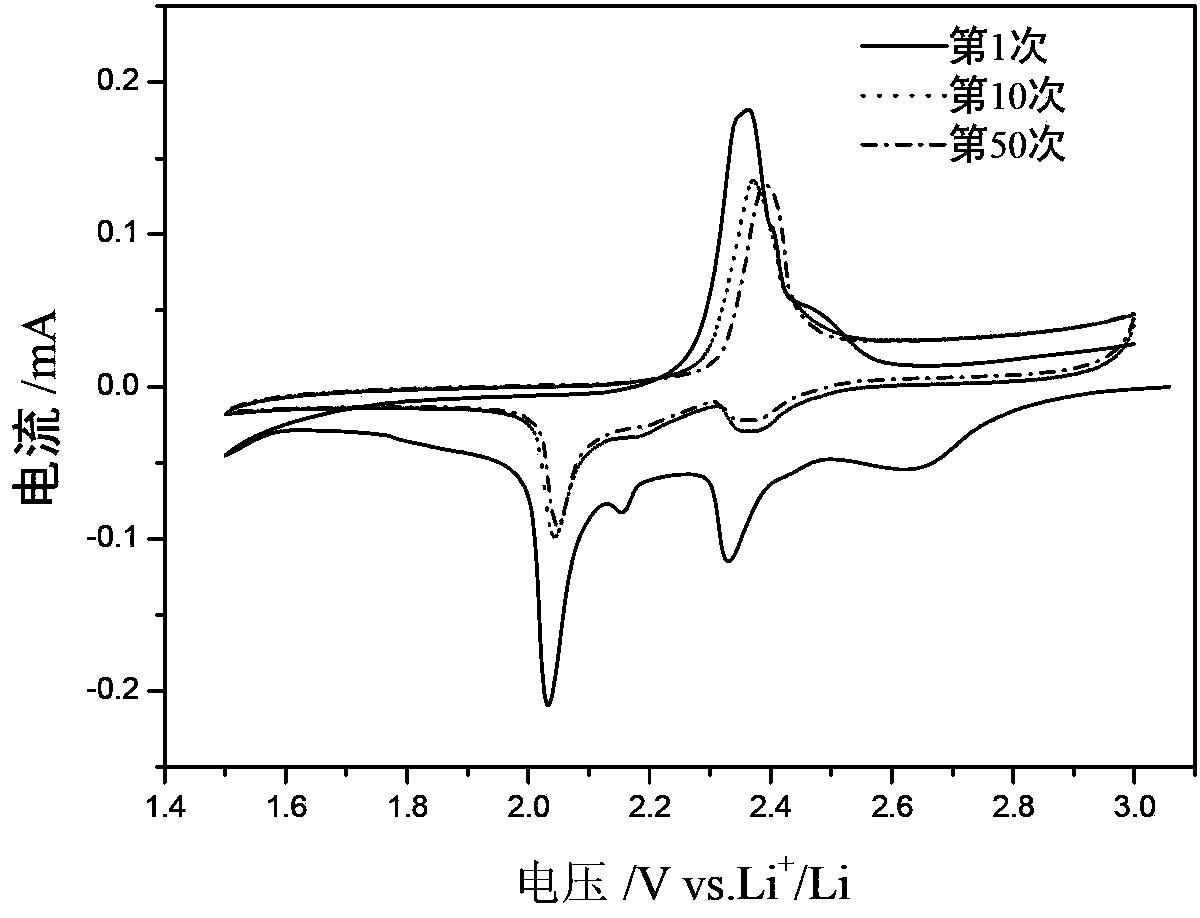

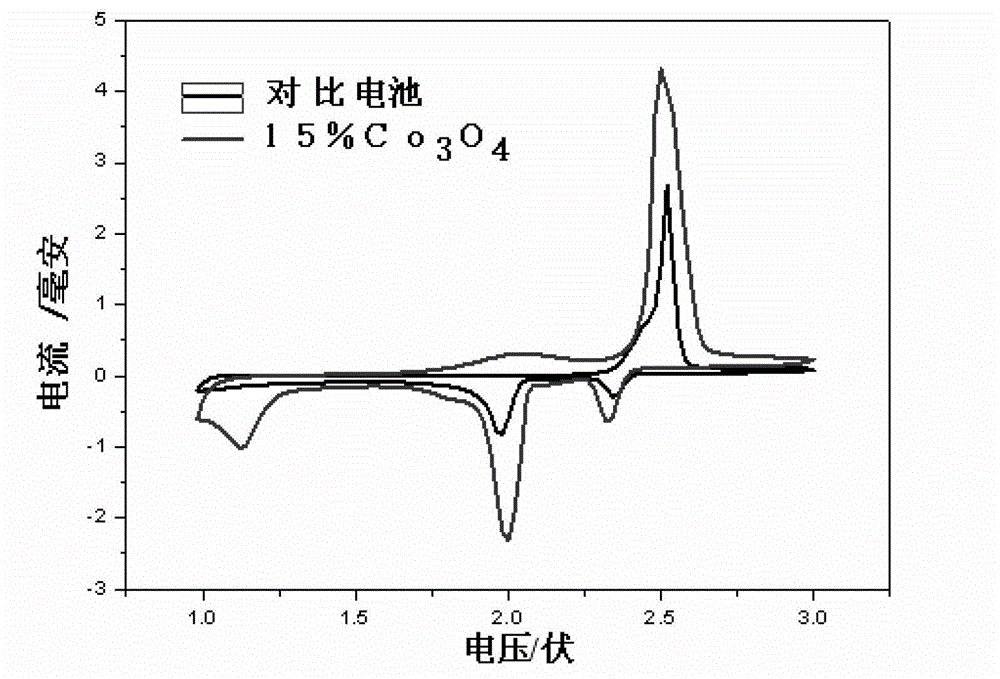

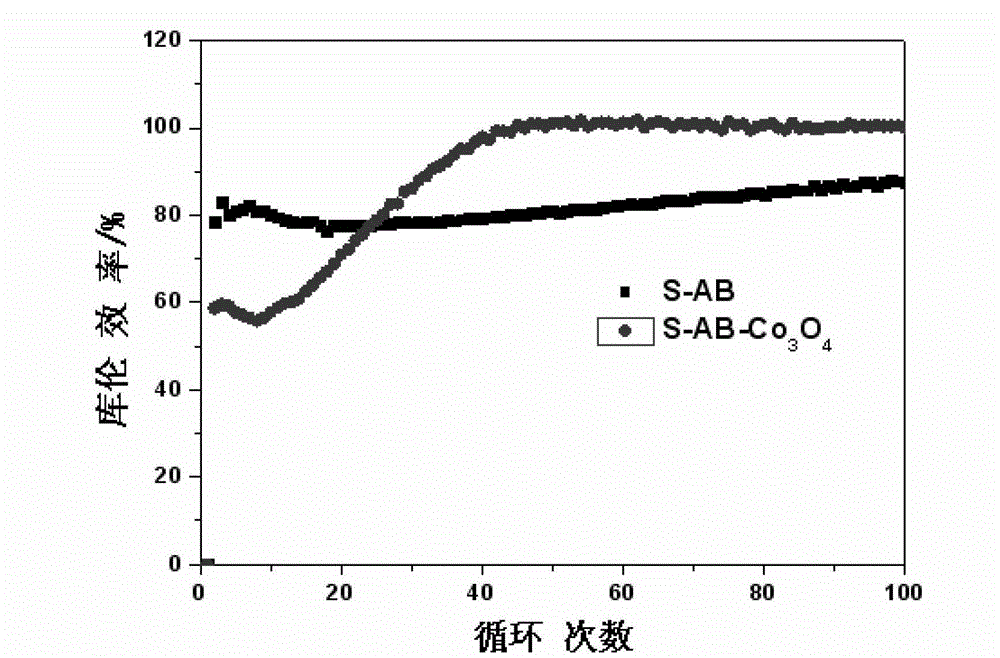

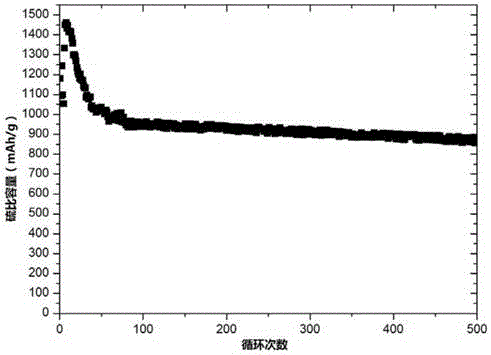

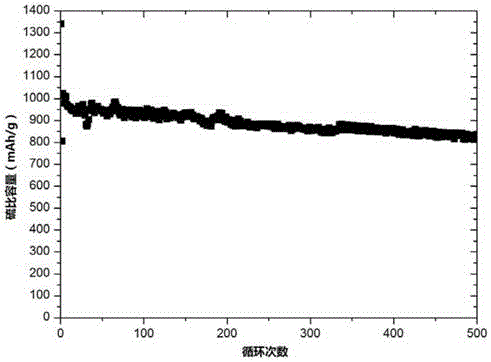

Positive pole composite system of lithium sulphur battery containing catalytic additive

InactiveCN102945966ANon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium–sulfur batteryNanoparticle

The invention provides a positive pole additive of a sulfur electrode, wherein the additive is an inorganic nanometer material with high specific surface area, and the size of a nanometer granule is 2-800 nanometers. The invention also provides a positive pole containing the positive pole additive and a battery. The positive pole additive and the obtained electric pole and battery which are provided by the invention have the advantages of high positive pole material conductivity and shuttle inhibition effect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Polymer composite solid electrolyte and preparation method and application thereof

ActiveCN106450424AImprove conductivityImprove cycle lifeCell electrodesSecondary cellsQuinoneSolid state electrolyte

The invention discloses a polymer composite solid electrolyte and a preparation method and application thereof. The polymer composite solid electrolyte is prepared from polyphenylene sulfide, a lithium salt and an organic quinones electron acceptor and is taken as a polymer composite solid electrolyte of a lithium-sulfur battery, the polymer composite solid electrolyte, carbon black and elemental sulfur are fabricated to a composite sulfur electrode material, and thus, a novel lithium-sulfur battery system is formed. The high-molecular polymer composite solid electrolyte provides a relatively good lithium ion migration passage, the lithium ion conductivity of a composite positive electrode material is improved, the high-molecular polymer composite solid electrolyte has certain rigidity and toughness, the volume change of a positive electrode after charge and discharge of the lithium-sulfur battery is buffered, the discharge specific capacity of the lithium-sulfur battery is improved, and the cycle lifetime of the lithium-sulfur battery is prolonged.

Owner:NANJING BOCHI NEW ENERGY CO LTD

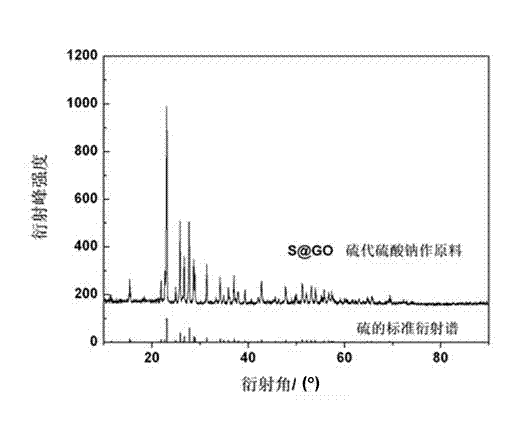

Preparation method for three-dimensional carbon nanotube/nitrogen-doped graphene/sulfur electrode slice

InactiveCN105609736AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsSulfur electrodeCarbon nanotube

The invention provides a preparation method for a three-dimensional carbon nanotube / nitrogen-doped graphene / sulfur electrode slice. The preparation method comprises the following steps of (1) adding the carbon nanotube, graphite oxide and polyacrylonitrile to N-methyl pyrrolidone, performing an ultrasonic reaction, coating an aluminium foil with mixed paste, and performing vacuum drying to obtain the electrode slice; (2) putting the obtained electrode slice into a muffle furnace under ammonia gas protection, heating to 400-500 DEG C, and naturally cooling; and (3) enabling the electrode slice obtained in the step (2) to be fully inserted into a Na2S2O3 solution, and slowly adding hydrochloric acid to the solution in a dropwise manner until the PH value of the solution reaches 6.5-7.5, taking out the electrode slice, and drying the electrode slice to obtain a positive plate. The electrode slice prepared by the invention can be directly used for the positive electrode of a lithium-sulfur battery without requiring a conductive agent and a binder, so that the cost of the electrode is greatly lowered.

Owner:钟玲珑

Sulfur/carbon composite material for lithium-sulfur secondary battery and preparation method thereof

InactiveCN102969481AHigh reactivityIncrease profitElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesCarbon compositesDischarge efficiency

The invention discloses a sulfur / carbon composite material for a lithium-sulfur secondary battery and a preparation method thereof. The composite material is formed by compositing a micro-pore carbon substrate with a lithium ion conduction property and elemental sulfur filled in the micro-pore structure. The carbon substrate is used as an electronic conductor in the composite material, and is further used as a lithium ion conductor, so that sulfur electrode reaction is directly carried out on a sulfur / carbon solid-solid interface in a conversion reaction manner without directly contacting with electrolyte. Therefore, the problem of circulation caused by that a polysulfide intermediate product is dissolved in the electrolyte can be solved. Compared with the other sulfur / carbon composite electrode, the composite material has the advantages of high electrochemical capacity, good circulation stability, high charging and discharging efficiency and the like; and meanwhile, the preparation method is simple and low in cost, and has a good application prospect.

Owner:WUHAN UNIV

Lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN110571418AMitigate the effects of volume expansionSuppression of the effects of volume expansionMaterial nanotechnologyFilament/thread formingFiberPolymer dissolution

The invention discloses a lithium-sulfur battery positive electrode material and a preparation method thereof. The method comprises the steps of providing a metal-organic framework material; dissolving the metal-organic framework material, a sulfur source and a polymer in a solvent, stirring for 1-12 hours, and controlling the temperature at 0-30 DEG C to obtain a spinning solution; carrying out electrostatic spinning on the spinning solution to obtain a polymer / metal organic framework film; sequentially carrying out pre-oxidation, carbonization and acid solution treatment on the film to obtain sulfur and nitrogen co-doped porous carbon nanofibers; and mixing the porous carbon nanofibers with sulfur powder, and heating and preserving heat for 1-12 hours in an inert atmosphere to obtain thelithium-sulfur battery positive electrode material. The sulfur and nitrogen co-doped porous carbon nanofiber prepared by adopting the preparation method has a large specific surface area and a rich pore structure. The lithium-sulfur battery positive electrode material serves as the positive electrode of a lithium-sulfur battery after being loaded with sulfur, which not only improves the conductivity of the sulfur electrode and relieves the influence caused by volume expansion of sulfur, but also can effectively inhibit the shuttle effect of sulfur.

Owner:SHENZHEN UNIV

Binder for lithium-sulfur battery and application of binder

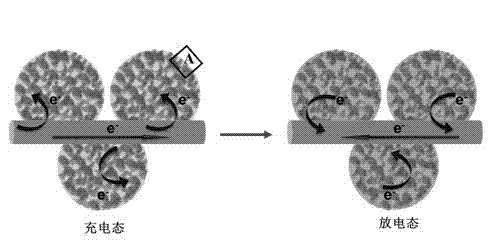

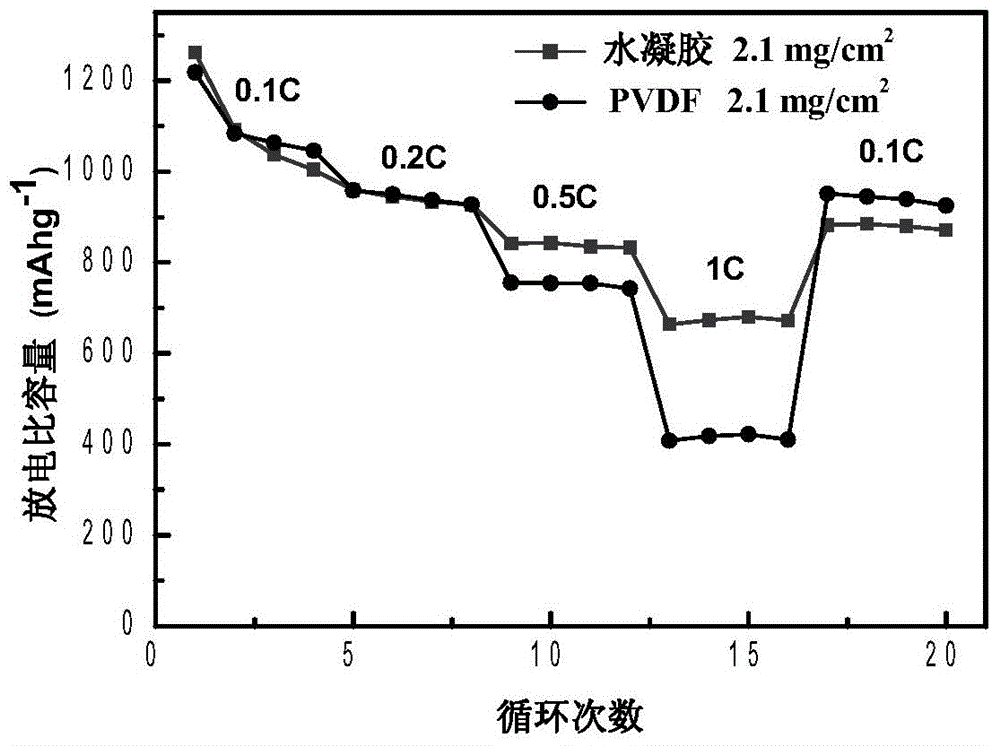

ActiveCN105226288AAddress volume expansionImprove cycle performanceCell electrodesLi-accumulatorsCross-linkBattery charge

The invention relates to a binder for a lithium-sulfur battery and an application of the binder. With gelatin and starch as the binder and hydrogel as a cross-linking agent, a lithium-sulfur battery electrode having a three-dimensional space mesh structure with mesoporous ducts is prepared. According to the prepared binder, the problems that the volume of the sulfur electrode expands, a plurality of intermediate products are generated during battery charging and discharging processes, the intermediate product lithium polysulfide (Li2Sx, x is less than or equal to 8 and greater than or equal to 4) is easily dissolved into organic electrolyte, and the shuttle effect is easy to generate can be solved. Therefore, the problem of relatively poor cyclicity of the lithium-sulfur battery can be solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

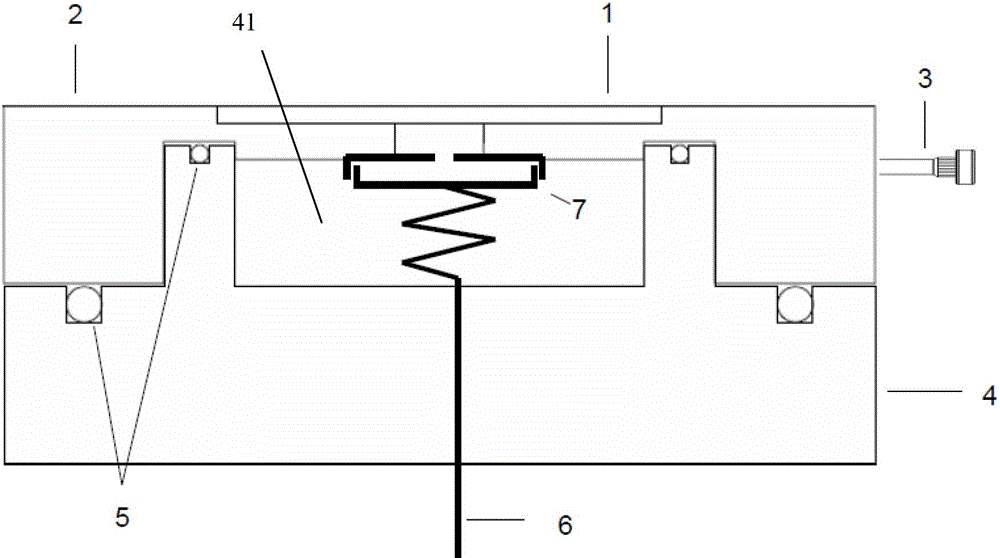

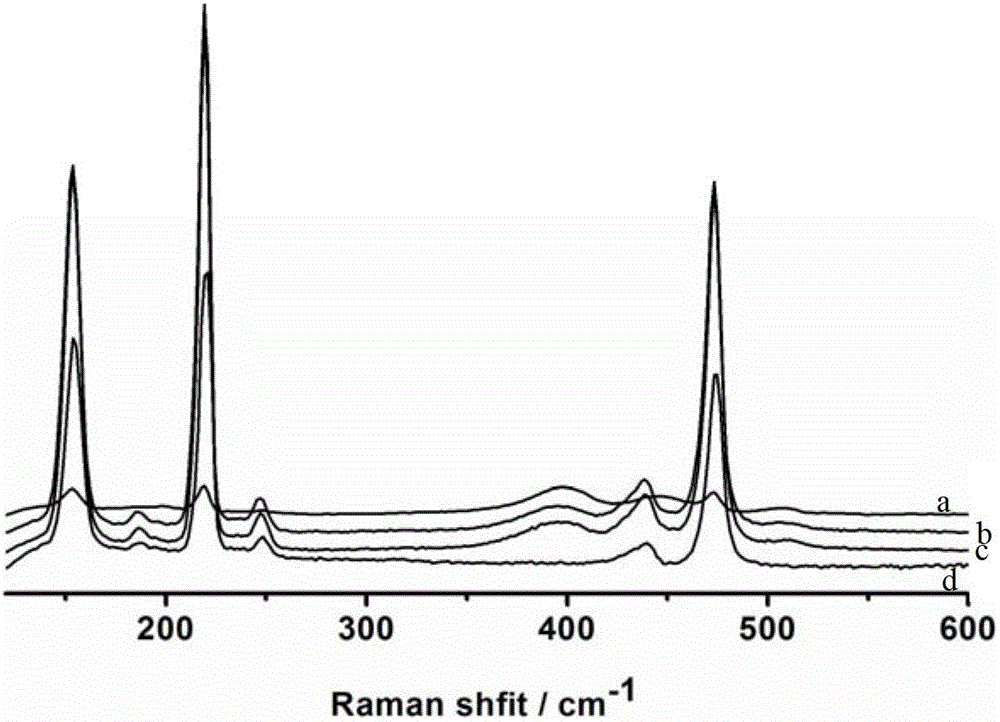

In-situ electrochemical-Raman combined testing device for non-aqueous system

InactiveCN103149192AGood Raman detection signalTo achieve the conditions required for the electrochemical reactionMaterial analysis by electric/magnetic meansRaman scatteringElectrical batterySulfur electrode

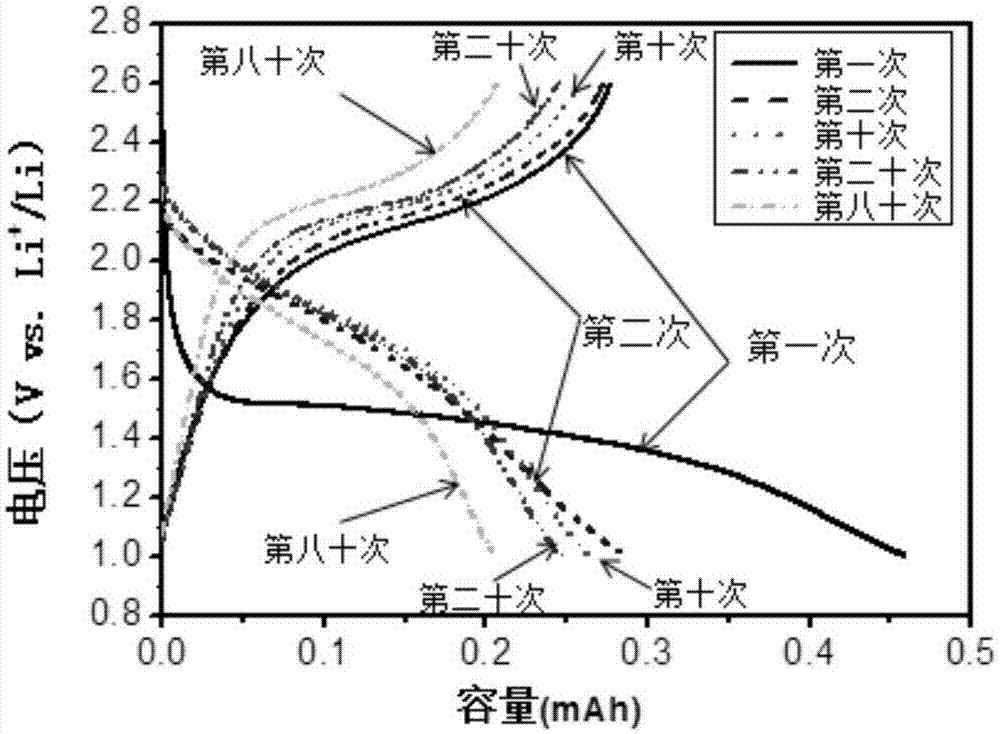

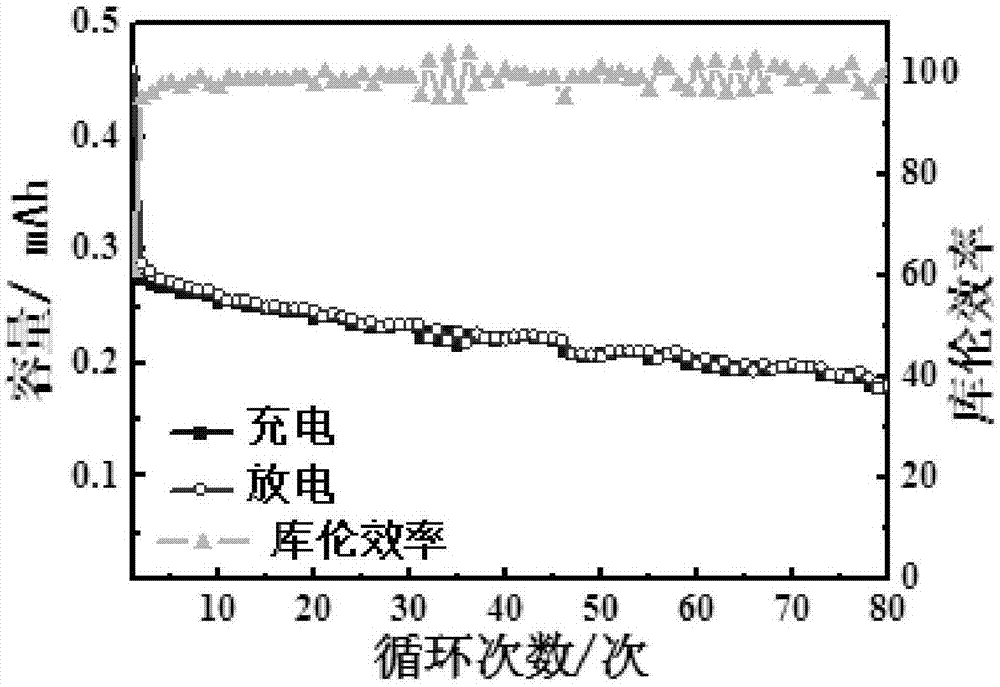

The invention relates to in-situ electrochemical spectral testing, and particularly relates to an in-situ electrochemical-Raman combined testing device for a non-aqueous system. The in-situ electrochemical-Raman combined testing device for the non-aqueous system can acquire the change information of structure and composition of a sulfur electrode in a charging and discharging process to facilitate deep understanding of the lithium storage mechanism and lithium storage property of a material and further to design and optimize the material. The in-situ electrochemical-Raman combined testing device comprises a metal cell body upper cover, an insulating non-conductive cell body lower cover, a work electrode binding post, a dual-O-shaped ring, a spring and a battery, wherein the middle part of the metal cell body upper cover is hollowed out; a piece of quartz glass serves as a window sheet; the metal cell body upper cover is connected with a work electrode of an electrochemical testing instrument through the work electrode binding post; a hollow cavity is kept inside the insulating non-conductive cell body lower cover; a spring serving as a counter electrode wire is arranged in the hollow cavity; the battery is arranged on the top of the spring; and the metal cell body upper cover and the insulating non-conductive cell body lower cover are sealed by the dual-O-shaped ring to form a closed electrolytic cell system.

Owner:XIAMEN UNIV

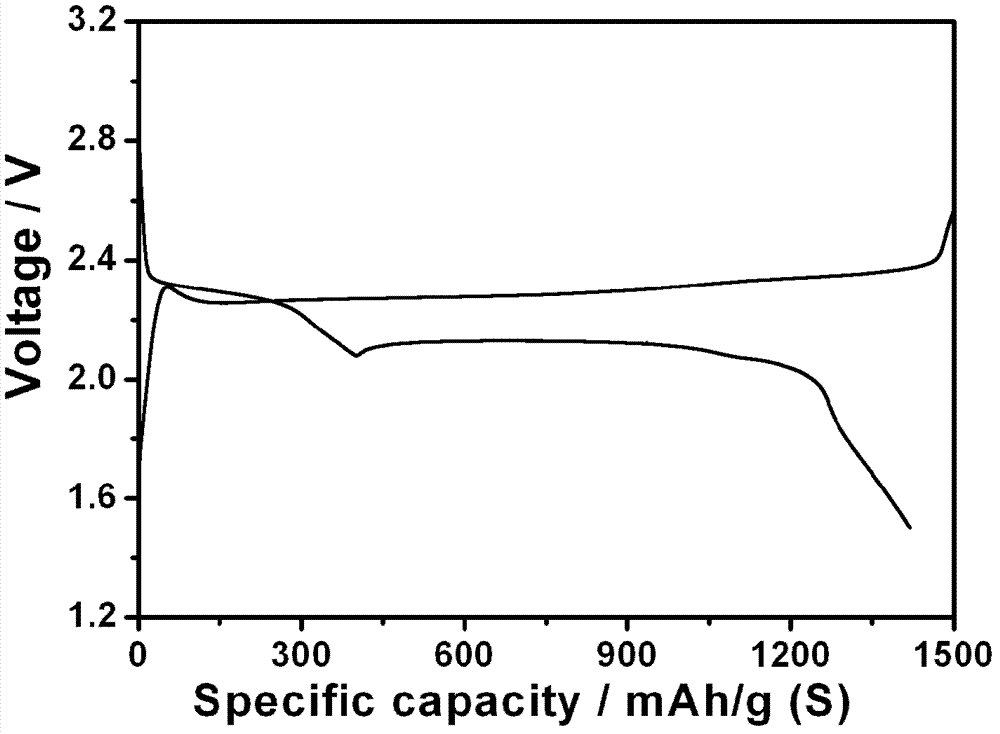

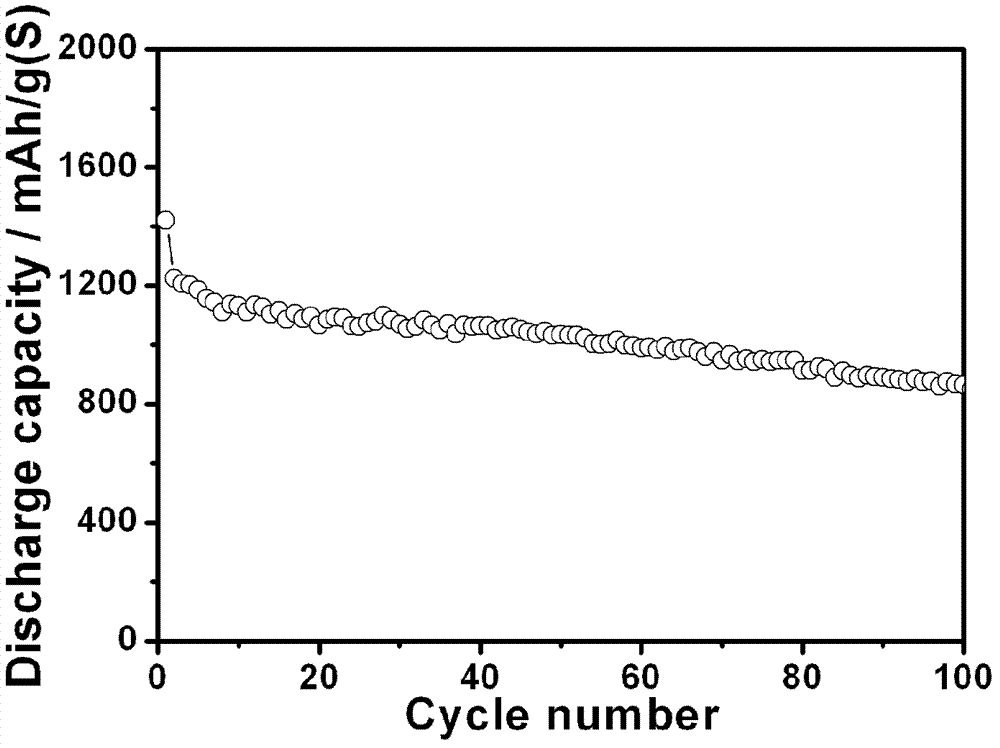

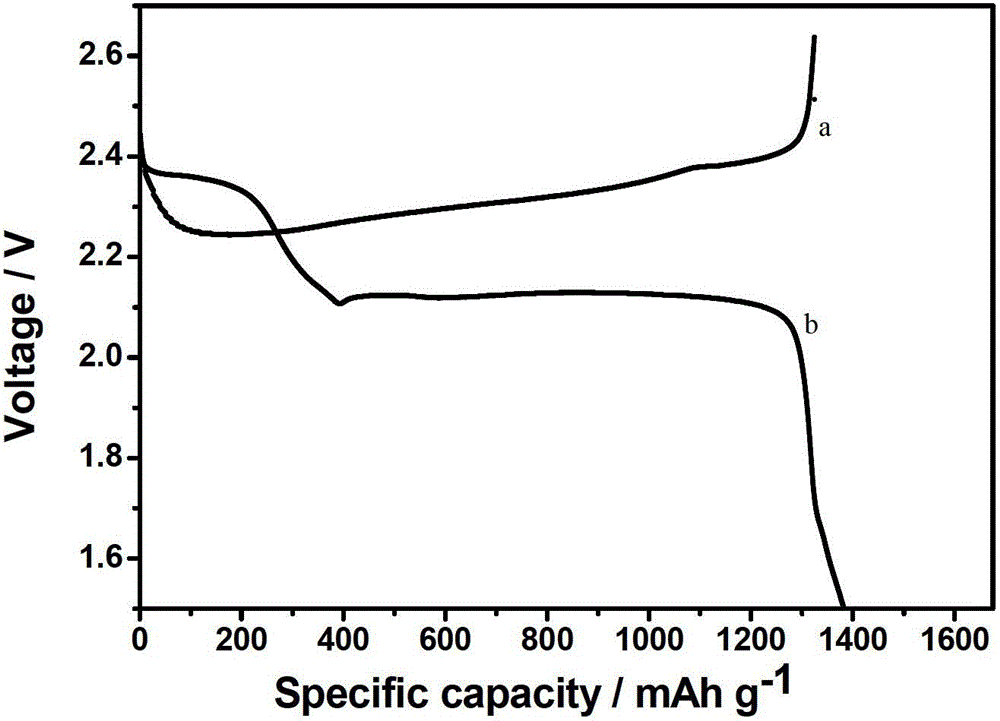

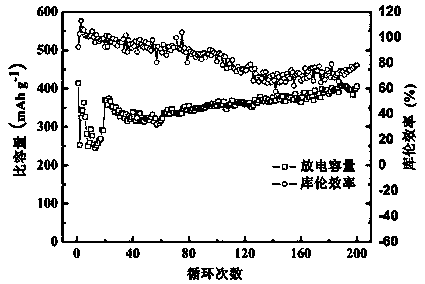

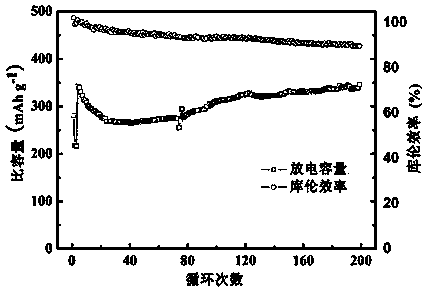

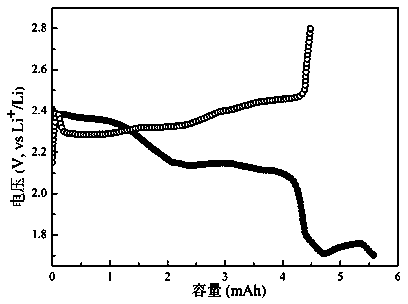

Preparation method and application of lithium-sulfur battery electrolyte solution

The invention discloses a preparation method and application of a lithium-sulfur battery electrolyte solution. The electrolyte solution mainly comprises an ether organic solvent, novel electrolyte (namely lithium polysulfide with different concentrations and different chemical compositions) and an additive. The specific preparation method of the electrolyte solution comprises the steps of taking a certain volume of ether organic solvent from a glove box, adding a certain amount of elemental sulfur and lithium polysulfide according to a stoichiometric ratio, sealing, then taking out of the glove box, and fully reacting after ultrasonic treatment; adding the additive LiNO3 into the electrolyte solution in the glove box, and standing to obtain the novel lithium-sulfur battery electrolyte solution. The electrolyte solution formula disclosed by the invention is suitable for different sulfur-based positive materials and is capable of obviously prolonging the cycle service life of a sulfur electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, preparation method of material and preparation method of positive electrode

ActiveCN104617283AInhibition of agglomerationImprove conductivityElectrode manufacturing processesFiberCarbon fibers

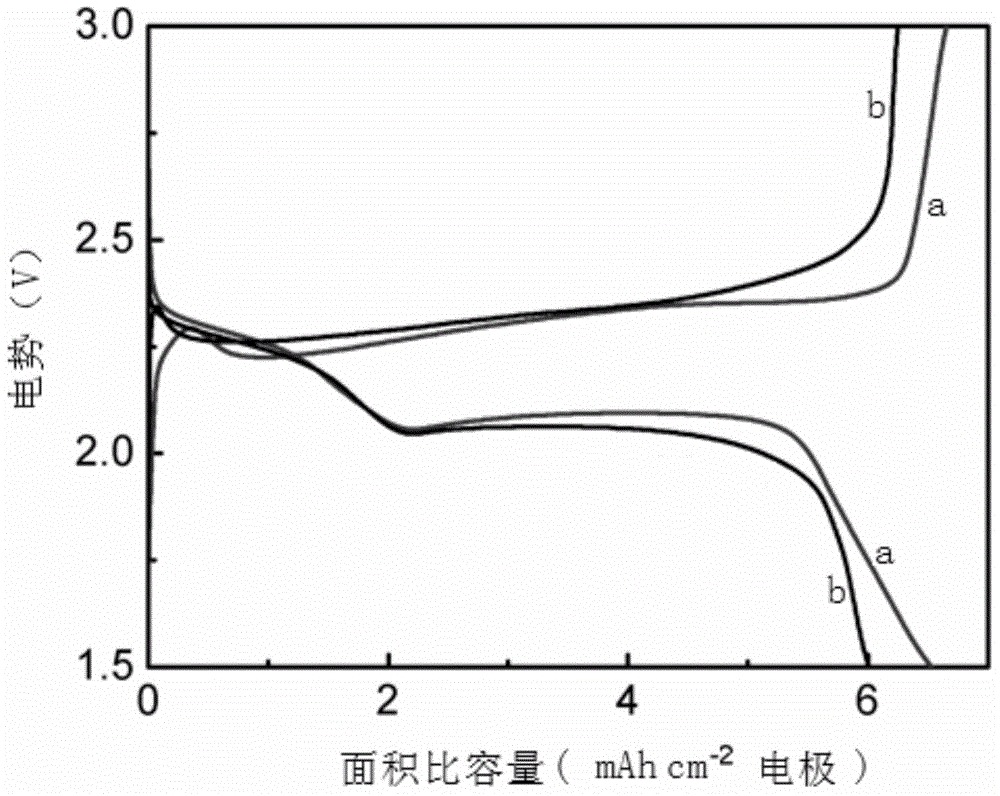

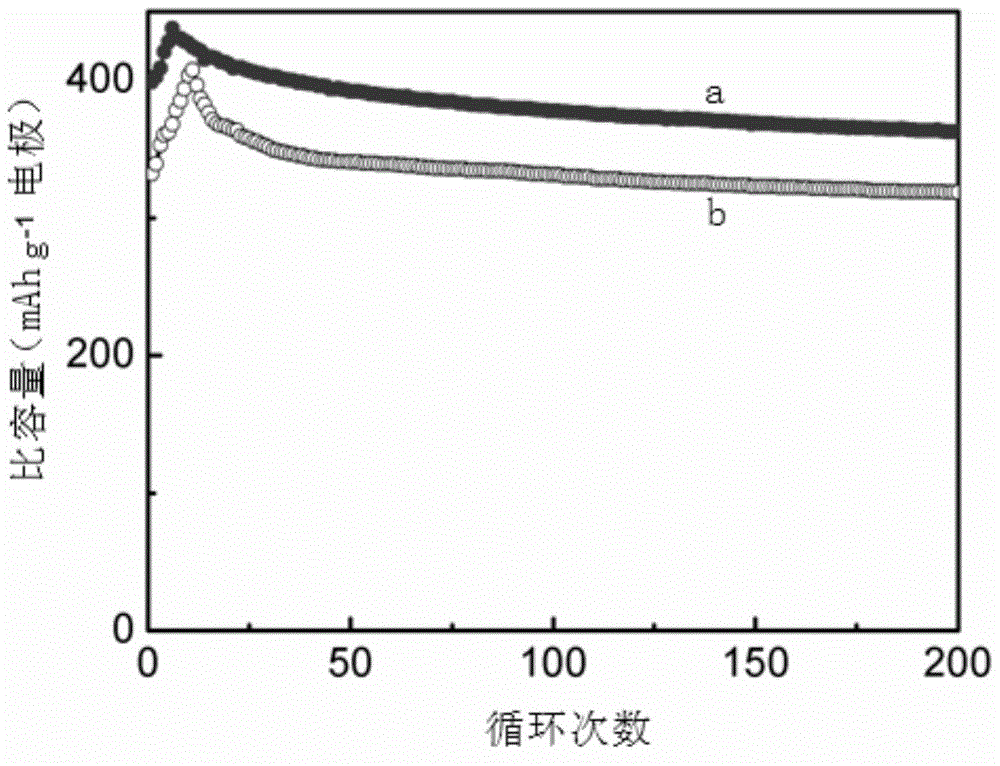

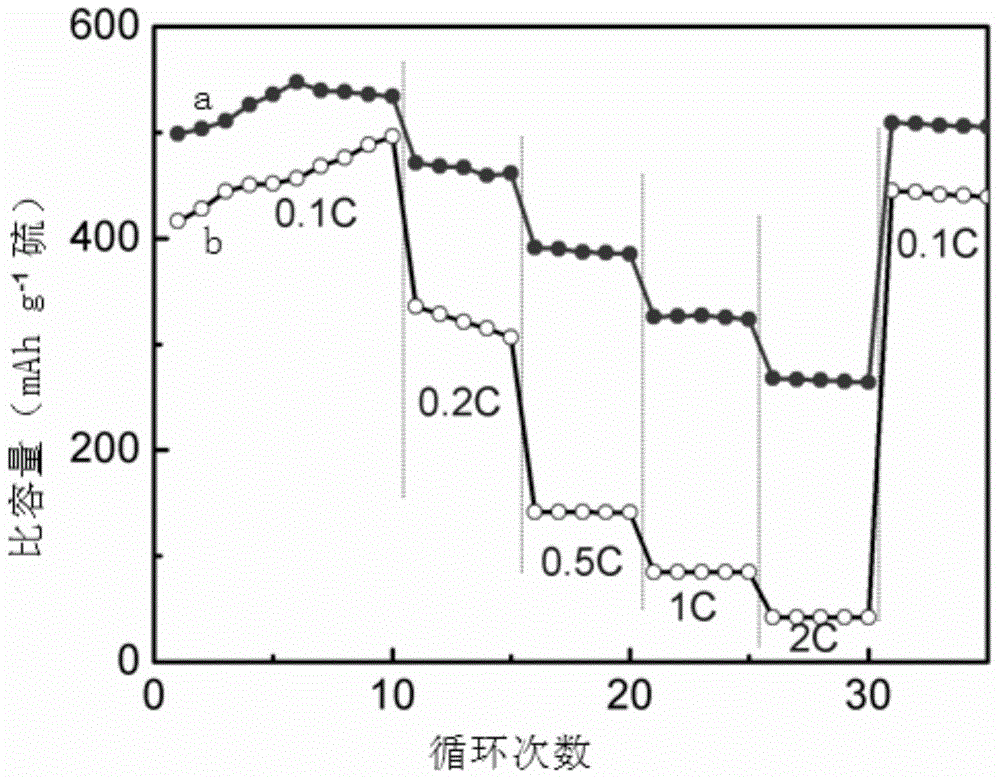

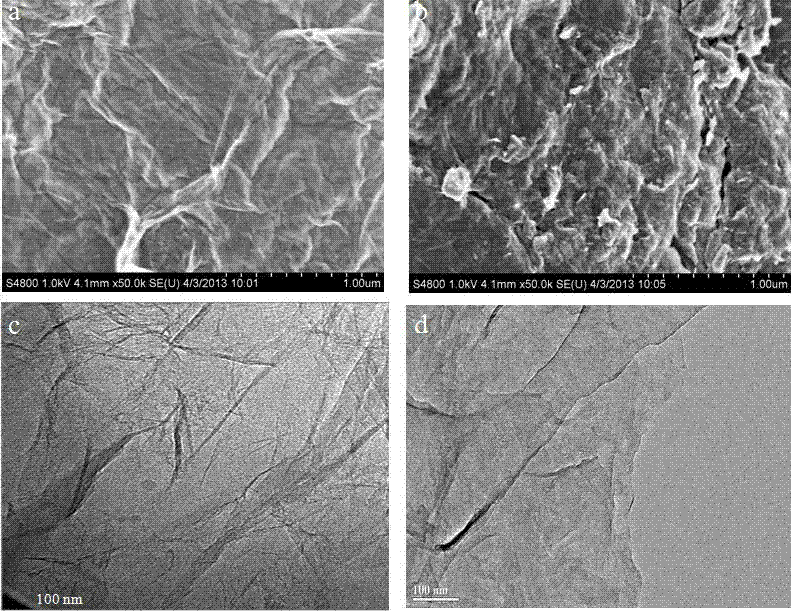

The invention discloses a lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, relates to a lithium-sulfur battery positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, and can be used for solving the technical problem that the conventional graphene-sulfur electrode is low in area specific capacity and bad in rate capability. The positive electrode material is formed by dispersing elemental sulfur in holes of carbon fiber modified spongy graphene. The preparation method of the positive electrode material comprises the following steps: adding carbon fibers into mixed liquid of graphene oxide dispersion liquid, carrying out hydro-thermal synthesis to obtain hydrogel and carrying out freeze-drying to obtain carbon fiber modified three-dimensional spongy graphene; cutting the carbon fiber modified three-dimensional spongy graphene into slices, sprinkling the elemental sulfur on the surfaces of the slices, placing the slices in a vacuum tank and heating to obtain the lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material. The positive electrode is prepared by slicing the positive electrode material and then pressing. The area specific capacity of the electrode material is up to 10 mAh / cm<2>, so that the electrode material can be applied to lithium ion batteries.

Owner:HARBIN INST OF TECH

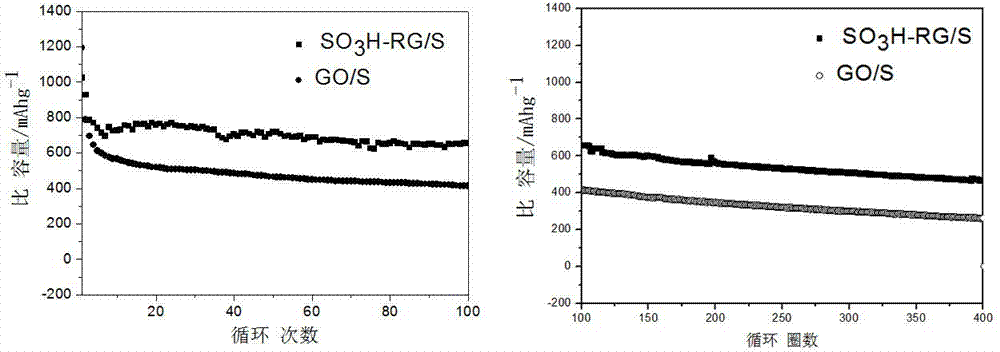

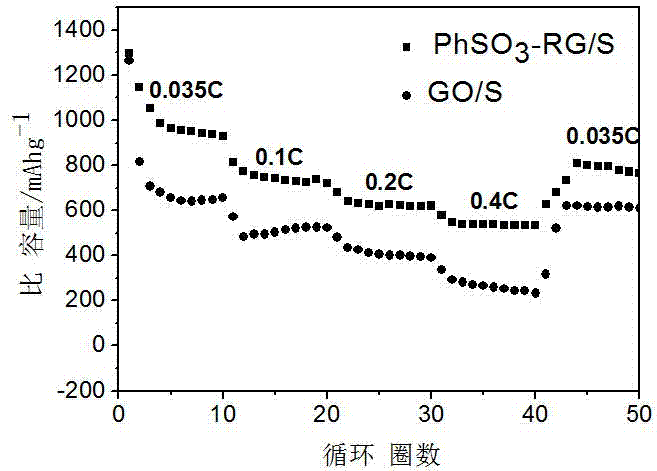

Additive-free sulfonated graphene/sulfur electrode slice and preparation method and application thereof

InactiveCN103682349AImprove conductivityIncrease stickinessLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentElectrical battery

The invention belongs to the technical field of lithium sulfur batteries and particularly relates to an additive-free sulfonated graphene / sulfur electrode slice and a preparation method and application thereof. The preparation method comprises the following steps: firstly, modifying graphene oxide to obtain sulfonated graphene with good water solubility and electrical conductivity; dispersing the sulfonated graphene in a sodium thiosulfate solution, adding a sulfuric acid solution and forming a sulfonated graphene / sulfur compound through a disproportionation reaction; carrying out size mixing on the compound through taking absolute ethyl alcohol as a solvent and coating a carbon-coated aluminum foil with the size to obtain the electrode slice which is applied to positive electrodes of the lithium sulfur batteries. The preparation method disclosed by the invention is simple in process and good in reproducibility; the raw material has excellent electrical conductivity and a certain viscosity, so that conductive carbon black and binder are not needed in the manufacturing of the electrode slice and the volume energy density of the positive electrode materials of the lithium sulfur batteries can be greatly increased; in addition, generated intermediate products can be prevented from being diffused into electrolyte, so that the shuttle effect is reduced, and the cycle performance and the rate performance of the lithium sulfur batteries are increased.

Owner:FUDAN UNIV

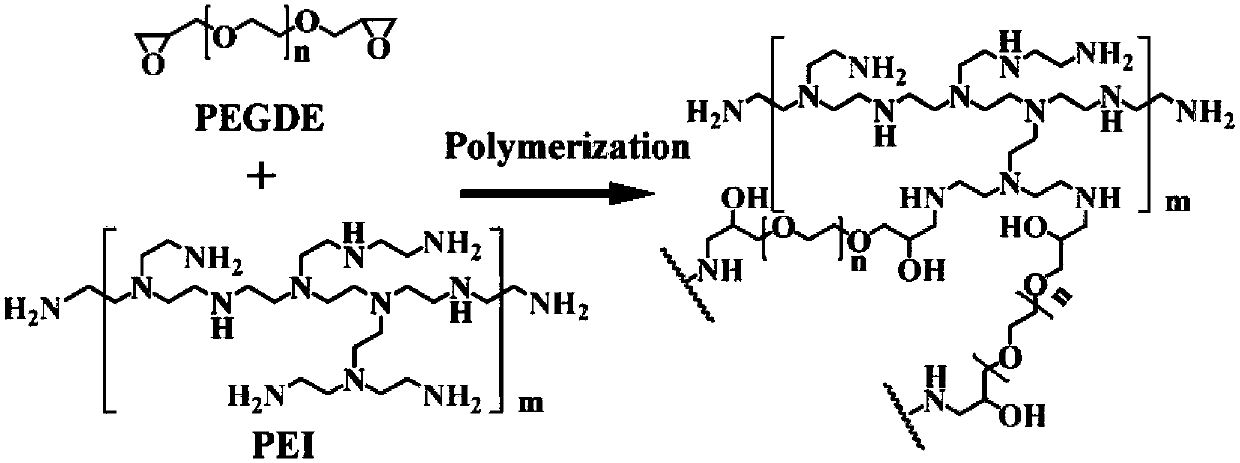

Polarity gel electrolyte and application thereof to solid-state lithium sulfur battery

ActiveCN108039511AFlow restrictionReduce risk of leakageLi-accumulatorsPolymer scienceLithium–sulfur battery

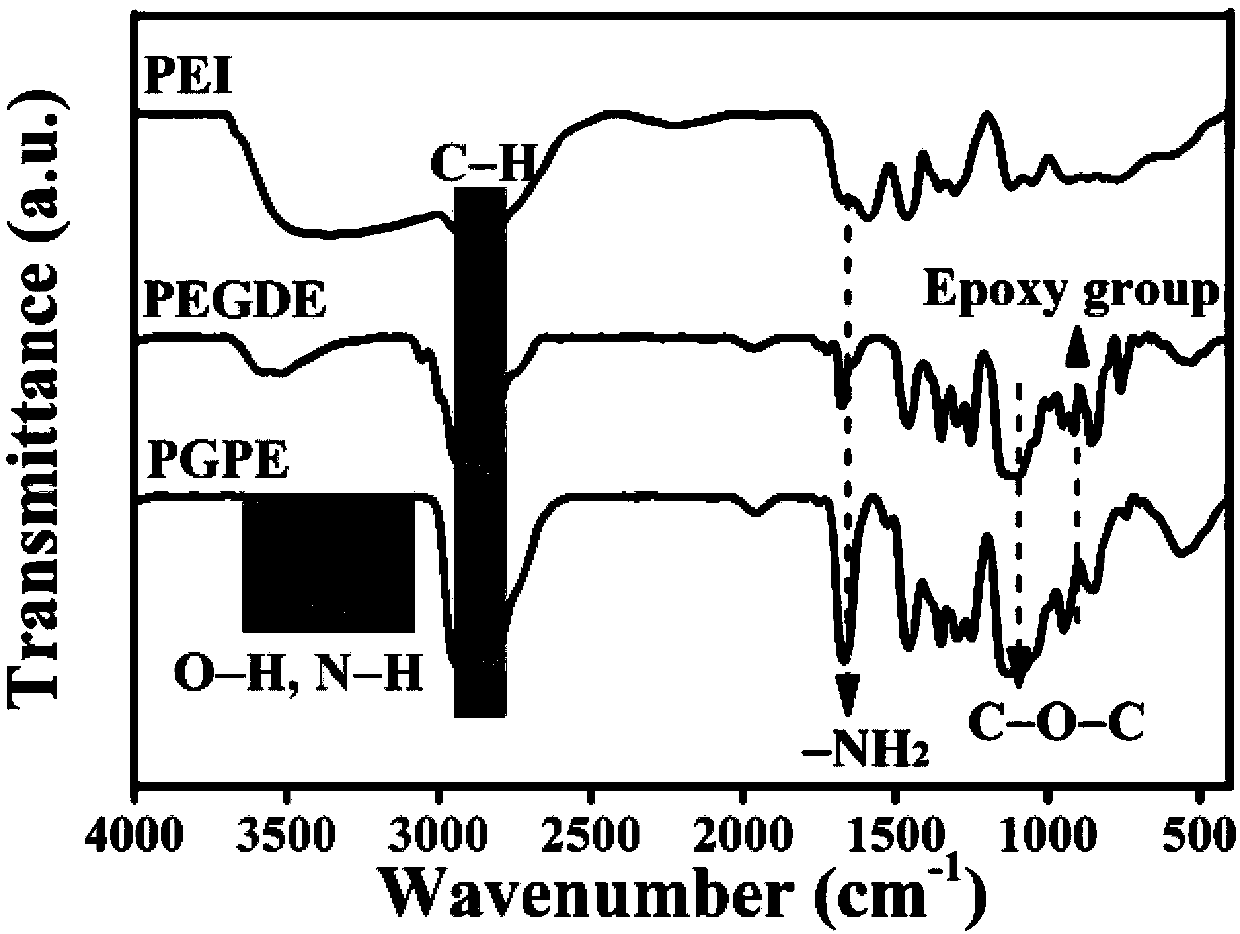

The invention relates to polarity gel electrolyte and application thereof to a solid-state lithium sulfur battery. The polarity gel electrolyte is prepared from a polymer matrix and liquid-state electrolyte formed in the polymer matrix, wherein the polymer matrix is prepared by polymerization reaction between a first organic matter containing at least two epoxy groups and a second organic matter containing at least two amino groups, and a molar ratio of the epoxy groups to the amino groups is 1 to (0.5 to 2). The polymer matrix not only can effectively limit flowing of the liquid-state electrolyte and reduce dangerousness of electrolyte leakage, but also can generate very strong interaction with polysulfide generated in a lithium sulfur battery circulation process and limit the polysulfidein a sulfur electrode very well; thus, performance of the lithium-sulfur battery is obviously improved.

Owner:苏州德加能源科技有限公司

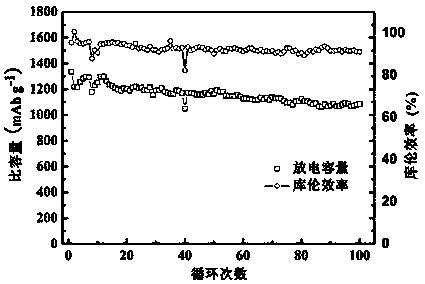

Preparation method of sulfur-containing electrode material

ActiveCN105304908AEasy accessImprove adsorption capacityElectrode carriers/collectorsLi-accumulatorsLithium–sulfur batteryLithium sulfur

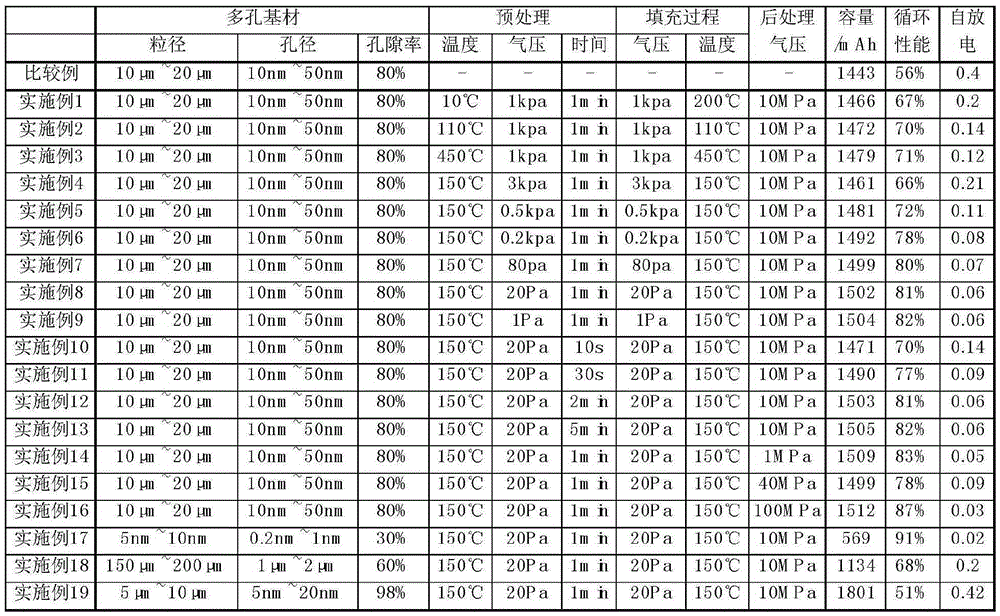

The invention belongs to the field of lithium-sulfur batteries, and particularly relates to a preparation method of a sulfur-containing electrode material. The method includes the three main steps of preprocessing of a porous matrix, filling of sulfur-containing components and preparation of the sulfur-containing electrode material. At the porous matrix preprocessing stage, gas components in the hole structure of the porous matrix are sufficiently discharged through long-time and high-vacuum processing, and enough space is preserved for filling of sulfur-containing components. In the mixing process of the sulfur-containing components and the porous matrix and before filling of the sulfur-containing components, the high vacuum degree is kept all the time, reserved space in the hole structure of the porous matrix can be kept, and the porous structure can be filled with enough sulfur-containing components.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

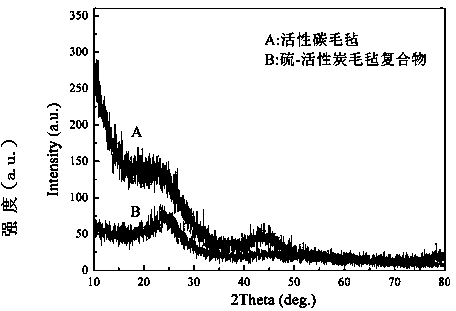

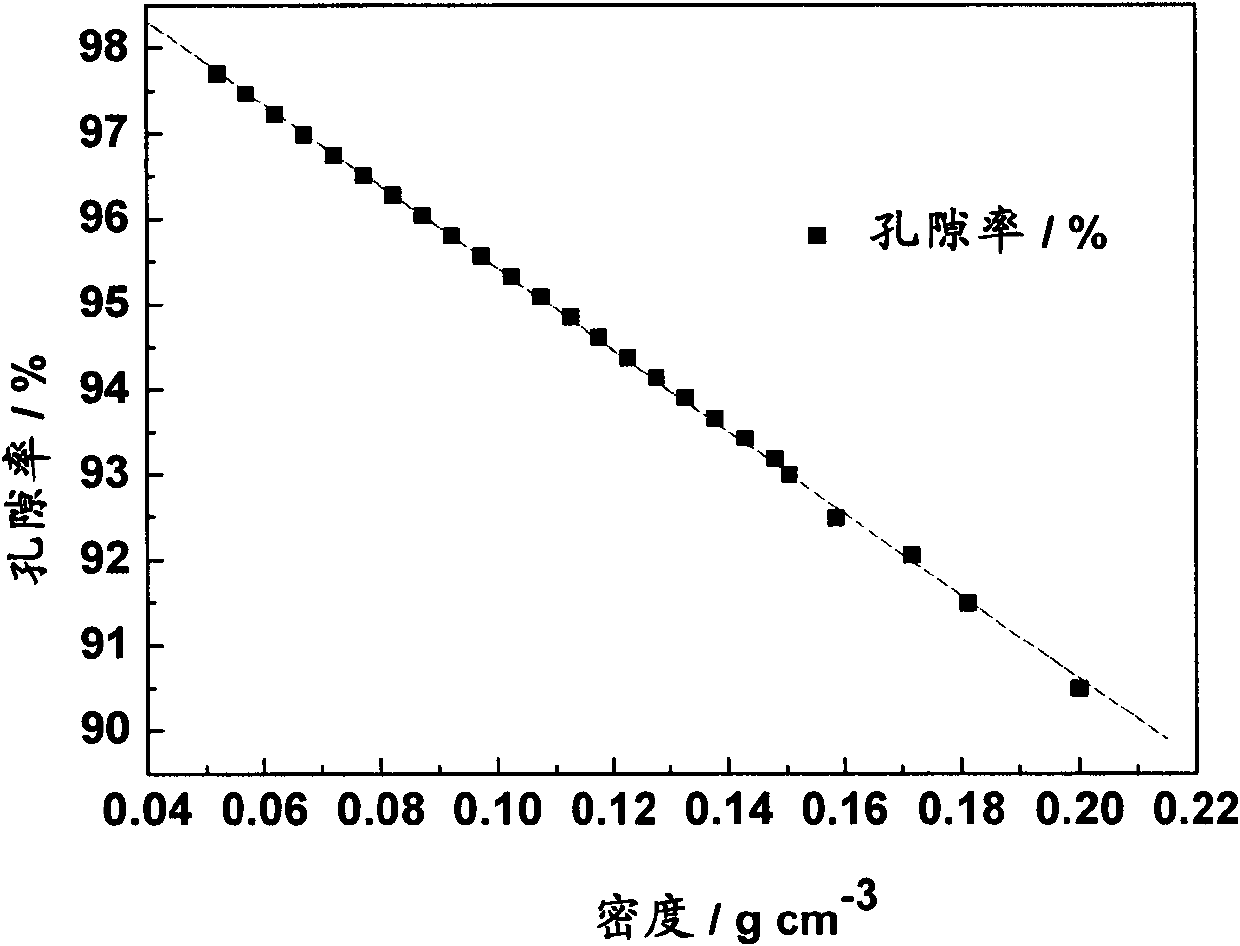

Sulfur-porous carbon felt composite positive material for lithium battery

InactiveCN103996828AHigh surface capacityGuaranteed cycle performanceCell electrodesLi-accumulatorsElectrical batteryPorous carbon

The invention relates to a sulfur-porous carbon felt composite positive material for a lithium battery. The composite positive material is a sulfur-porous carbon felt composite positive material which is obtained by compounding sulfur and a porous carbon felt. The porous carbon felt is active carbon felt or mesoporous carbon felt, and the sulfur content is 30 to 70 percent. The dissolving of polysulfide is limited by utilizing the porous structure of the carbon felt; in addition, different from the traditional porous carbon material, the carbon felt can partially or completely substitute adhesive and acetylene black, additional adhesive and acetylene black are not needed, the overall energy intensity of the electrode material can be effectively improved, when the composite electrode material is applied to a secondary lithium-sulfur battery, the discharging performance is good, and the surface capacity is high. Due to the characteristics of the structure, the carbon felt can be directly applied to a soft-packaging battery; and different from the traditional sulfur electrode which needs a pulping coating step, the practical prospect of the sulfur-porous carbon felt composite positive material is promising.

Owner:XUZHOU NORMAL UNIVERSITY

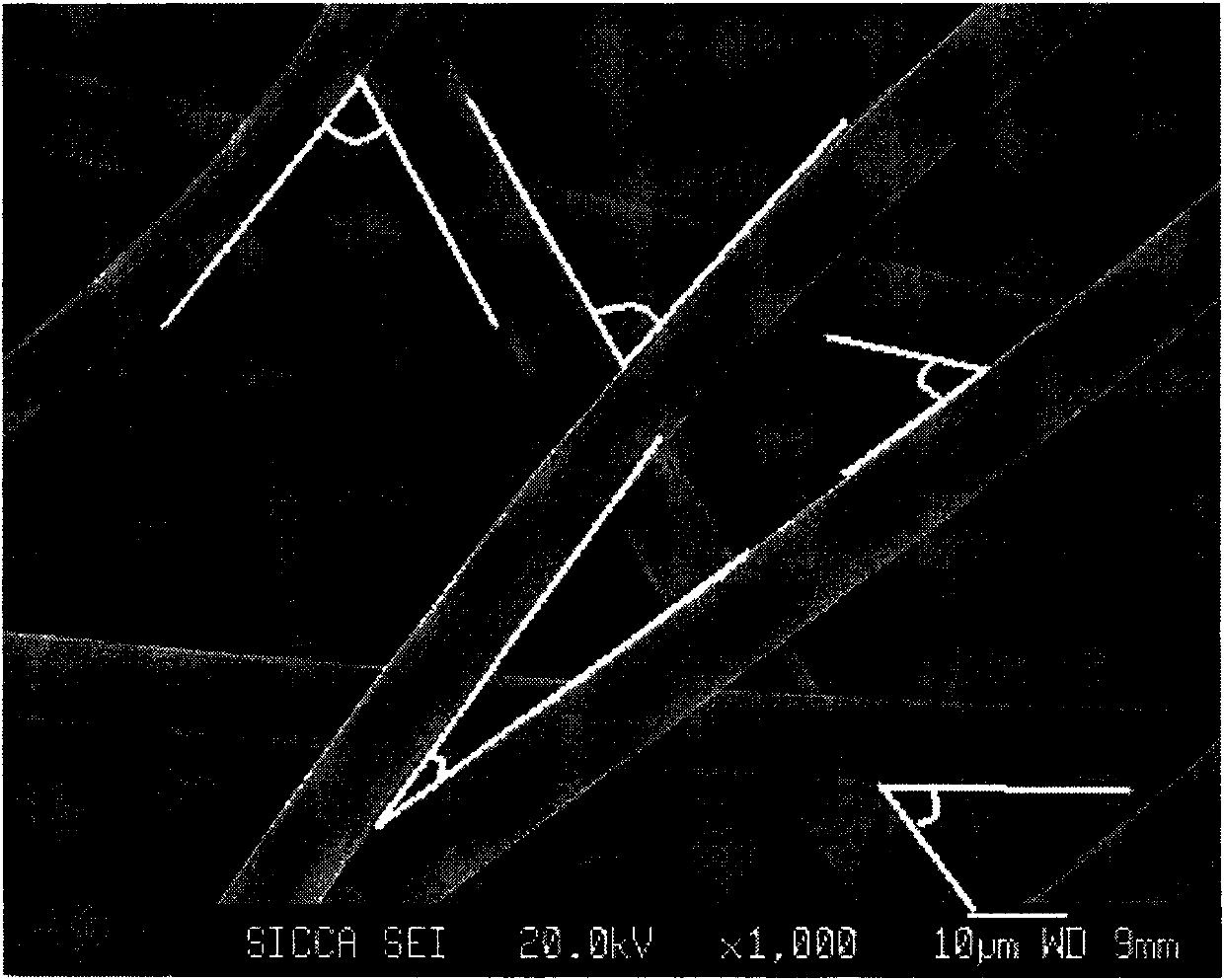

Stereo braiding-based carbon sulfur composite electrode for sodium sulfur battery

ActiveCN102142532ALower internal resistanceImprove power densityElectrode carriers/collectorsActive material electrodesCarbon fibersComposite electrode

The invention relates to a stereo braiding-based carbon sulfur composite electrode for a sodium sulfur battery. The carbon sulfur composite electrode is characterized by consisting of a graphite felt and high-purity sulfur, namely the carbon sulfur composite electrode consists of the porous graphite felt with adjustable carbon fiber crossing angles and combined fiber layers and the sulfur, wherein the sulfur in the composite electrode enters pores of the graphite felt after being melted with a penetration method. The graphite felt prepared by a stereo crossing braiding mode has the characteristics of high tensile strength and low elastic modulus; and by adjusting the crossing angles among the fibers, optimization of the sulfur on the wetting performance of the carbon felt is realized, theelectric conductivity of a sodium sulfur battery anode is improved, the contact performance of the sulfur electrode and ceramic electrolyte is enhanced, polarization is reduced, the working property of the anode in the battery is improved, and the performance (see embodiments) of the sodium sulfur battery is improved. The carbon sulfur composite electrode is particularly suitable for the sulfur pole of the high-power sodium sulfur battery.

Owner:上海电气企业发展有限公司

Positive electrode of lithium-sulfur battery and preparation method of positive electrode

ActiveCN106207088AImprove cycle performanceImprove the blocking effectNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium–sulfur batteryBlock effect

The invention discloses a positive electrode of a lithium-sulfur battery and a preparation method of the positive electrode. The positive electrode is composed of an aluminum foil and a coating layer arranged on the surface of the aluminum foil, wherein the coating layer is of a multilayered structure and is composed of elemental sulfur, a conducting agent and a binding agent; the sulfur content in all layers of the multilayered structure is distributed in a gradient shape from inside to outside; the sulfur content of the innermost layer is the highest and the outermost layer does not contain the sulfur. According to a gradient multilayered sulfur positive electrode structure provided by the invention, the innermost layer takes a carbon material with a high specific surface area and a high adsorption capability as the conducting agent and the sulfur fixation effect is enhanced; polysulfide ions can be adsorbed in the electrode as much as possible so that dispersion of the polysulfide ions toward a negative electrode side is alleviated; a surface containing does not contain a sulfur material and a sulfur diffusion space is provided; the planar carbon material is adopted so that the blocking effect on lithium polysulfide is enhanced; the lithium polysulfide is limited in an electrode space as much as possible, so that the structure provided by the invention can improve the circulating performance of the sulfur electrode to a certain extent.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Sulfur-series anode material, preparation method thereof and battery

ActiveCN105304877ASolve problems such as dissolutionFix compatibility issuesCell electrodesLi-accumulatorsCyclic processSulfur

The invention provides a sulfur-series anode material. The chemical formula is as indicated by formula (I) S<1-x>M<x> or formula (II) S<1-x>M<x> / C, wherein x is greater than 0 and less than 1; M is one or more of Se, Te, I, P, Bi and Sn. Compared with an existing sulfur anode material, the sulfur-series anode material can be used for effectively solving the problem that in the circulation process, an intermediate product of the sulfur anode material is dissolved, and excellent electrochemical performance is obtained. Meanwhile, the material can be applied to electrolyte of a conventional lithium ion battery, and the compatibility problem of a complete battery assembled with the material and other high-performance lithium ion battery electrode materials is further solved.

Owner:UNIV OF SCI & TECH OF CHINA

Graphene/sulfur composite material and preparation method thereof, battery positive electrode and preparation method thereof, and battery

InactiveCN103515608AAvoid churnImprove conductivityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSolubilitySulfur

The invention belongs to the field of electrochemistry, and discloses a graphene / sulfur composite material and a preparation method thereof, a battery positive electrode and a preparation method thereof, and a battery. The graphene / sulfur composite material comprises graphene and elemental sulfur at a mass ratio of (1-5):(5-9), moreover, the elemental sulfur is embedded into the microcellular structure of the graphene. According to the graphene / sulfur composite material provided by the invention, the elemental sulfur is embedded into the microcellular structure of the graphene, a graphene / elemental sulfur composite material is prepared, the microcellular structure of the graphene with high specific surface area can prevent loss of a discharging product of sulfur, so that the solubility is reduced; meanwhile, since the graphene has high conductivity and is fully contacted with the elemental sulfur, the conductivity of a sulfur electrode is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Positive electrode material for lithium-sulfur battery and preparation method for positive electrode material

ActiveCN105958045ADissolution inhibitionInhibit shuttleCell electrodesSecondary cellsHalogenLithium–sulfur battery

The invention discloses a positive electrode material for a lithium-sulfur battery. The positive electrode material comprises a carrier and active ingredients, wherein the carrier is a conductive carbon material, and a non-conductive halogen compound is loaded on the surface of the conductive carbon material. The invention also discloses a preparation method for the positive electrode material; the preparation method comprises the steps of mixing the halogen compound with a solvent A until the mixture is thick; blowing the mixture to the surface of the conductive carbon surface at a temperature of 100-200 DEG C under an inert gas to load the halogen compound on the surface of the conductive carbon material, and recording the product as the substrate; and enabling the active ingredients to be mixed with a solvent B to obtain a solution, adding the solution to the substrate in a dropwise manner, and drying to obtain the positive electrode material for the lithium-sulfur battery. The invention provides the positive electrode material for the lithium-sulfur battery; the conductive carbon material is compounded with the non-conductive halogen compound to be used as the carrier of the active ingredients, so that the dissolution of the lithium sulfide and the shuttle flying among the lithium-sulfur electrodes can be effectively restrained; and the capacity of the lithium-sulfur battery and the cycling times can be greatly increased.

Owner:ZHEJIANG UNIV

Preparation method of composite lithium-sulfur battery electrode material with three-dimensional conduction core-shell structure

ActiveCN110660985AHigh specific capacityPromote circulationPositive electrodesFibre chemical featuresSpinningLithium sulfur

The invention provides a preparation method of a composite lithium-sulfur battery electrode material with a three-dimensional conduction core-shell structure, which comprises the steps of dissolving polyacrylonitrile in an N, N-dimethylformamide solvent to obtain a sheath fluid; dissolving iron disulfide and polyvinylpyrrolidone into the N, N-dimethylformamide solvent to obtain a core fluid; respectively placing injectors filled with the core fluid and the sheath fluid on two injection pumps of an electrostatic spinning device for coaxial electrostatic spinning, collecting protofilament fibersjetted by electrospinning on a rolling shaft, then putting the obtained protofilament fibers into a muffle furnace with an air atmosphere for pre-oxidation, then carbonizing in a protective atmosphere of an inert gas to obtain an iron disulfide / carbon-coated carbon fiber composite material with a core-shell structure, immersing the obtained iron disulfide / carbon-coated carbon fiber composite material into dilute nitric acid, stirring, carrying out suction filtration, and drying to finally prepare the carbon-coated carbon fiber / sulfur composite lithium-sulfur battery electrode material with the three-dimensional conduction core-shell structure. The lithium-sulfur electrode material obtained by the invention has the characteristics of high capacity and good cycling stability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

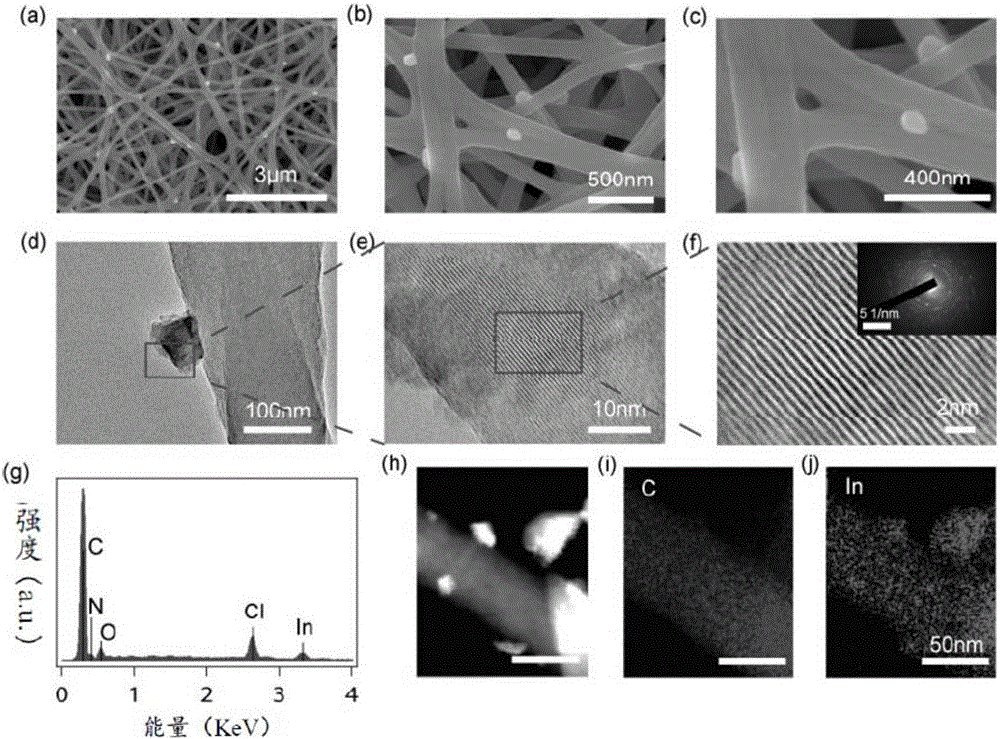

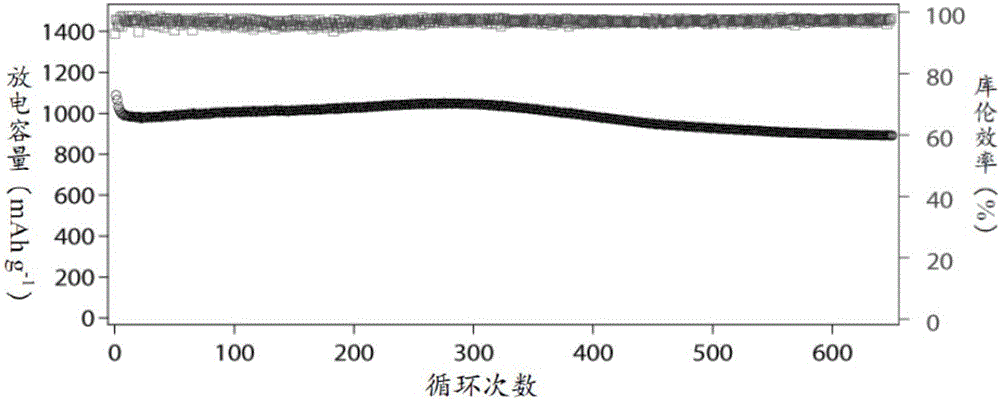

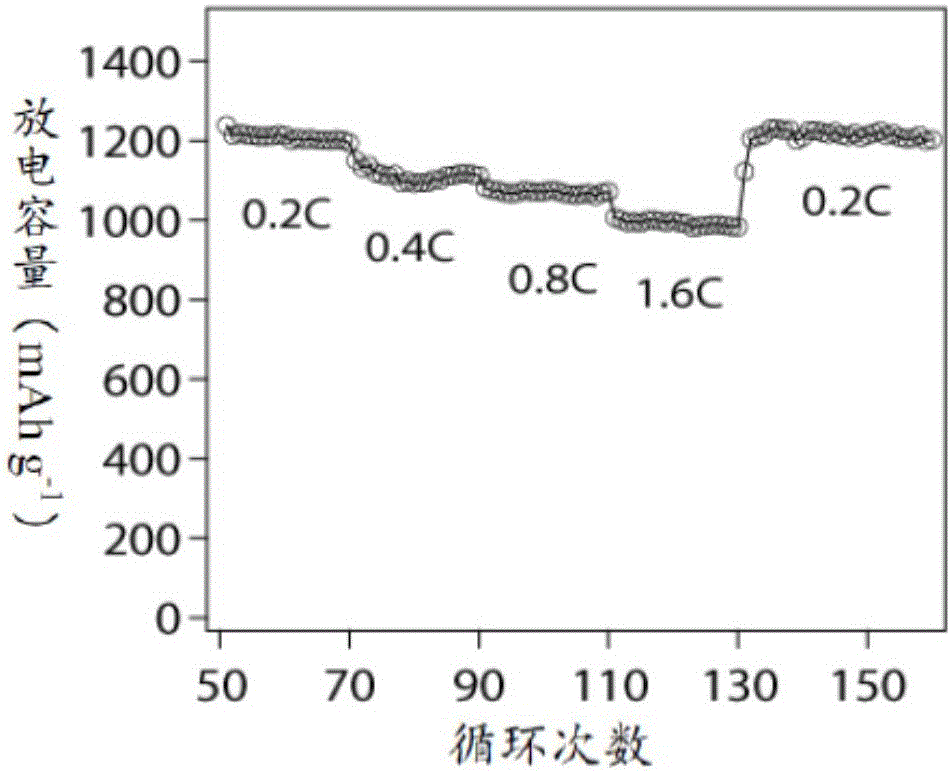

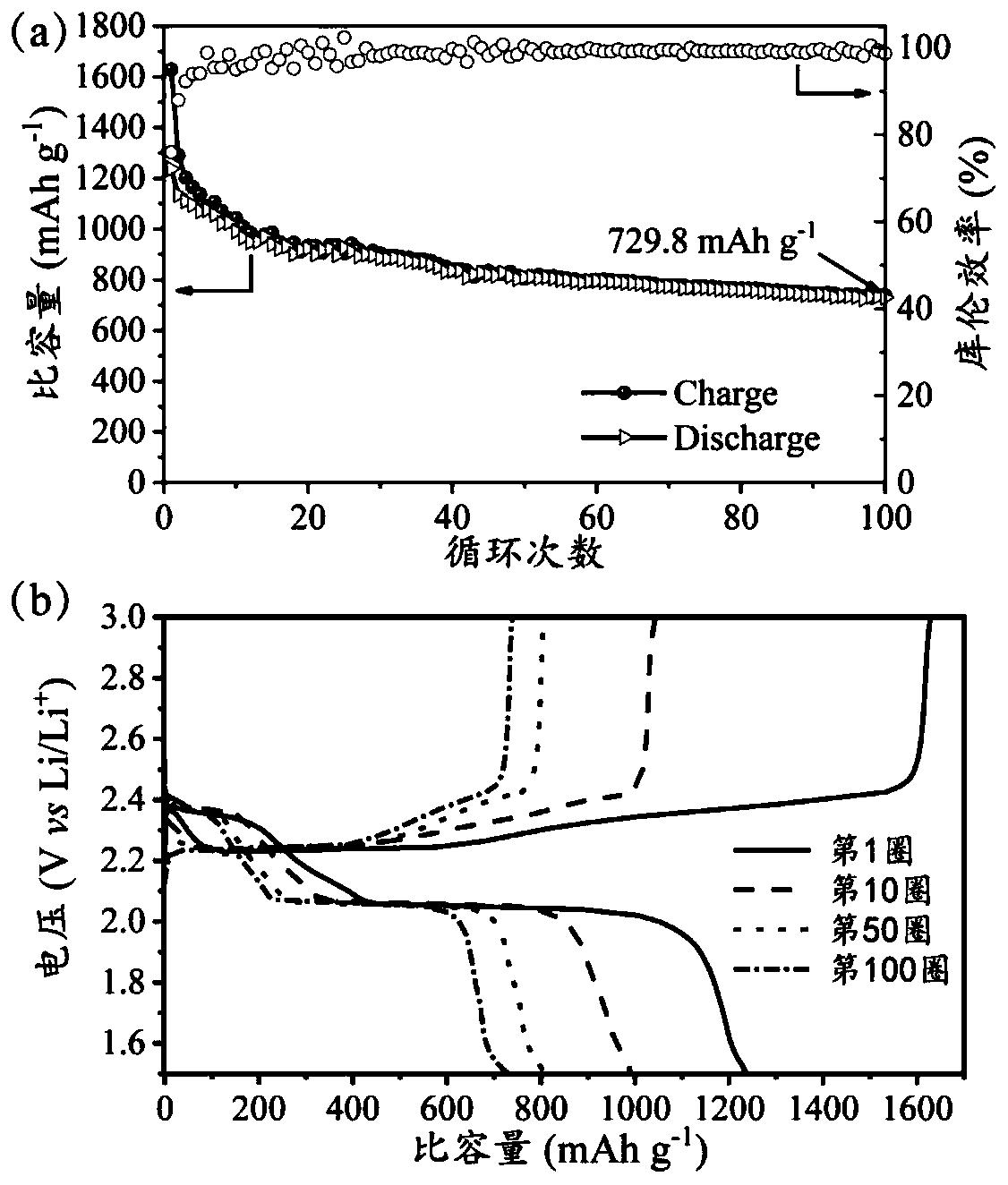

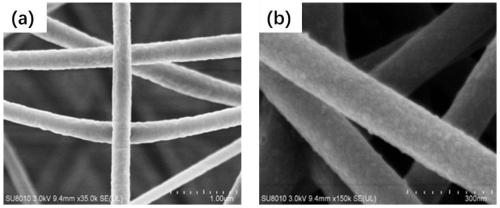

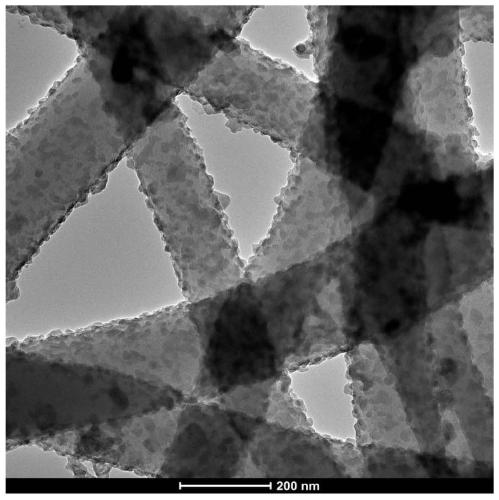

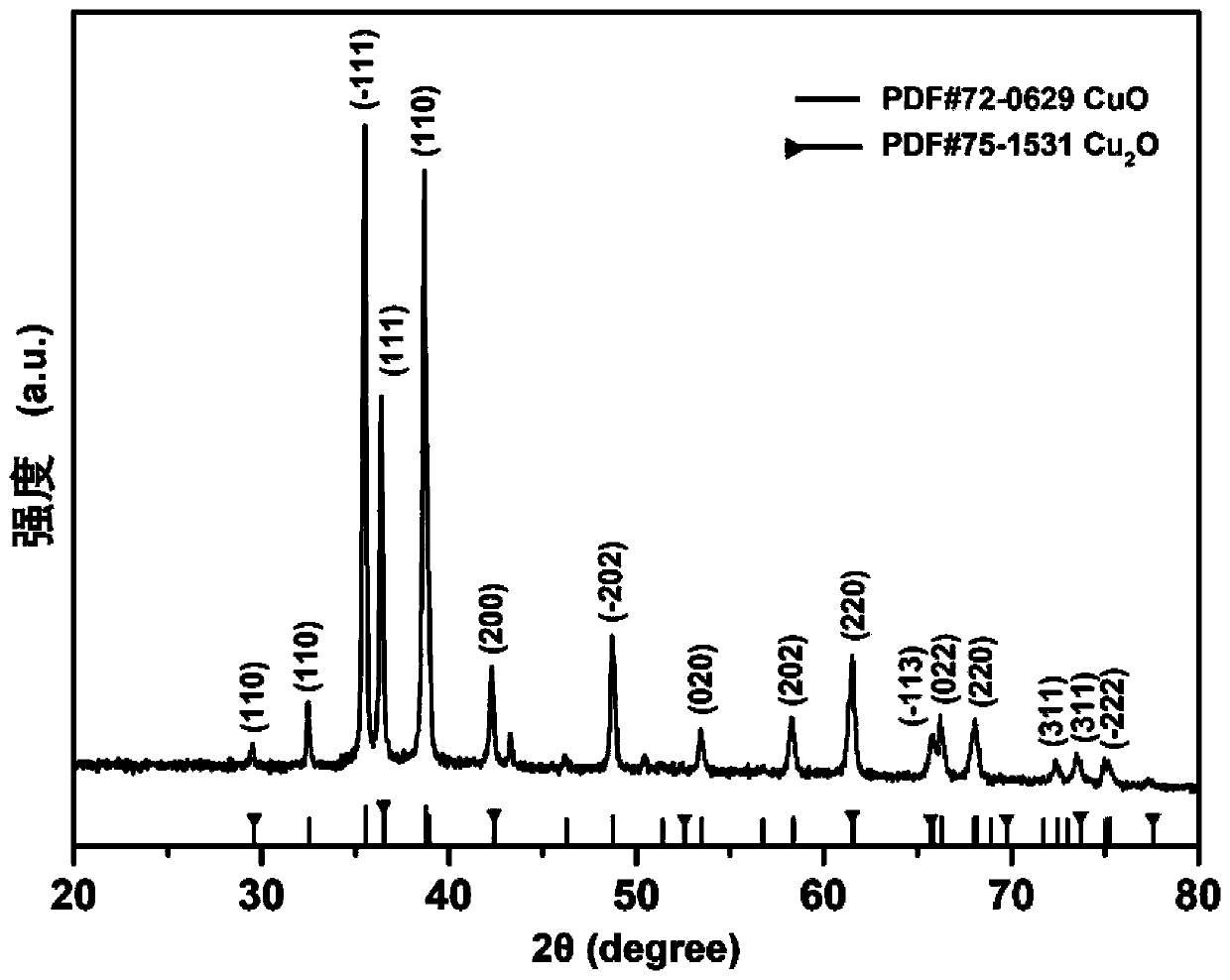

Copper oxide/carbon nanofiber/sulfur electrode material and preparation and application thereof

InactiveCN109888219AImprove cycle performanceImprove stabilityCell electrodesLi-accumulatorsN dimethylformamideLithium–sulfur battery

The invention relates to a copper oxide / carbon nanofiber / sulfur electrode material, and a preparation and an application thereof. The copper oxide / carbon nanofiber / sulfur electrode material is prepared by the following steps: adding polyacrylonitrile into an N,N-dimethylformamide solution of anhydrous copper acetate to obtain an electrostatic spinning solution, and performing electrostatic spinning to obtain a copper acetate / polyacrylonitrile nanofiber membrane; performing heat treatment to obtain a copper oxide / carbon nanofiber composite; and mixing the copper oxide / carbon nanofiber compositewith sublimed sulfur, and performing heat treatment. The copper oxide / carbon nanofiber obtained by the invention functions to adsorb polysulfide, and can improve the cycle performance and the stability of a lithium sulfur battery. The copper oxide / carbon nanofiber / sulfur electrode material provided by the invention has a broad application prospect in the field of electrode materials of the lithium sulfur battery.

Owner:DONGHUA UNIV

Lightweight flexible sulfur electrode, and preparation method and application thereof

InactiveCN109713310ALightweightImprove flexibilityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesCooking & bakingSulfur

The invention belongs to the technical field of novel batteries and in particular relates to a flexible sulfur electrode, a preparation method thereof and the application thereof in a metal (lithium / magnesium) sulfur battery. The invention provides a flexible sulfur electrode comprising elementary sulfur, conductive carbon black, copper sulfide CuSx (1 / 2<=x<=1) and a copper-carbon flexible film, wherein the elementary sulfur and the conductive carbon black are applied to the copper-carbon flexible film, and CuSx is generated in situ during a baking process. The preparation method of the flexible composite sulfur positive electrode of the invention is simple in process and easy to implement, provides a new idea for the preparation of a lightweight and highly-flexible metal (lithium / magnesium) sulfur battery, and is expected to be applied to a flexible metal (lithium / magnesium) sulfur battery in a large scale.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com