Sulfur-series anode material, preparation method thereof and battery

A cathode material, sulfur system technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the above-mentioned chalcogenide cathode material, comprising:

[0046] Mix sulfur powder with M and carbon substrate, and carry out co-melting reaction under sealed conditions to obtain sulfur-based positive electrode materials;

[0047] The M is any one or more of selenium powder, antimony powder, iodine, red phosphorus, bismuth, tin;

[0048] The added amount of the carbon substrate is 0% to 80% of the total mass of raw materials, more preferably 0% to 70% of the total mass of raw materials. In some specific embodiments of the present invention, the added amount of the carbon substrate is 40% to 70% of the total mass of raw materials.

[0049] Wherein, the molar ratio of the sulfur powder to M is preferably (70:30)-(99.6:0.4), more preferably (9-99):1.

[0050] In the present invention, the carbon substrate is preferably any one or more of graphene, porous carbon material, carbon nanotube and CMK-3.

[005...

Embodiment 1

[0059] Embodiment 1 takes porous carbon material as substrate, prepares S 1-x Se x / C(x=0.1) material.

[0060] Take 5 grams of sulfur powder, 1.2 grams of selenium powder and 4 grams of porous carbon, mix them by wet ball milling for 24 hours, seal them in a 10mL reaction kettle, place them under a resistance crucible furnace, react at 220°C for 10 hours, and then cool naturally to Room temperature; S can be obtained after boiling the kettle 1-x Se x / C(x=0.1) material.

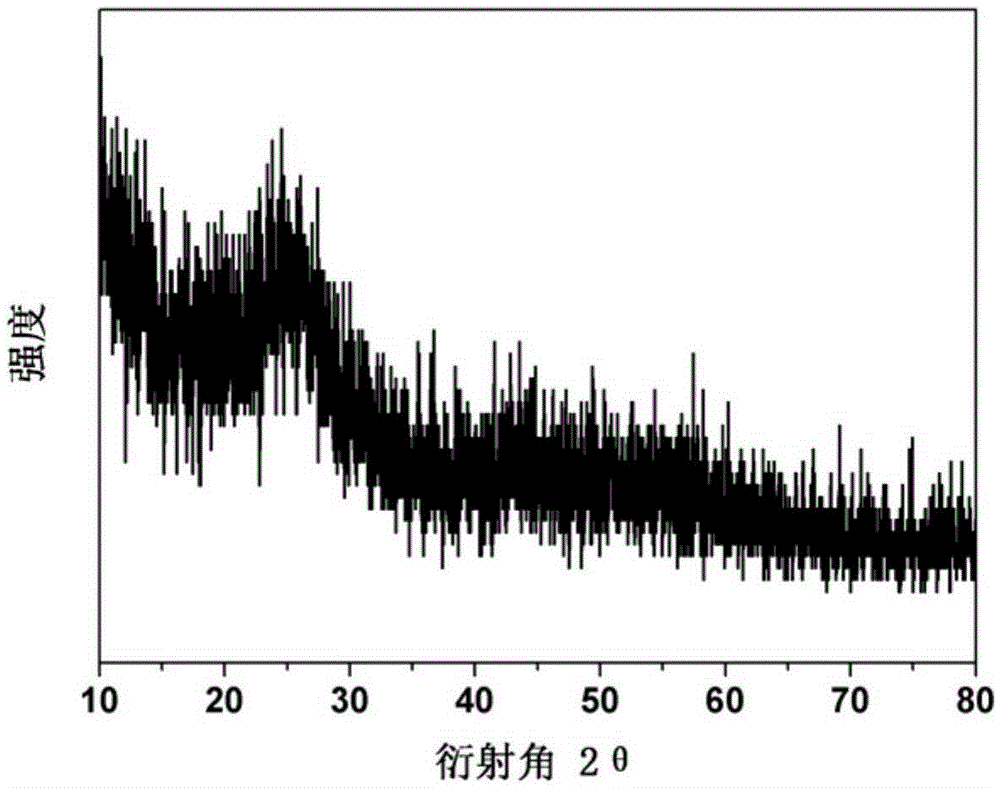

[0061] The S prepared by X-ray powder diffractometer 1-x Se x / C (x=0.1) material is subjected to X-ray diffraction analysis, figure 1 The S prepared for Example 1 of the present invention 1-x Se x / C (x=0.1) X-ray diffraction spectra of materials at different temperatures. Depend on figure 1 It can be seen that in the X-ray diffraction spectrum, there are only clearly visible amorphous diffraction peaks in the range of 2θ in the range of 10° to 80°, which proves that the material has an amorphous ...

Embodiment 2

[0065] Take 5 grams of sulfur powder and 1.2 grams of selenium powder, mix them by wet ball milling for 24 hours, seal them in a 10mL reaction kettle, place them under a resistance crucible furnace, react at 200°C for 10 hours, and then cool naturally to room temperature; to get S 1-x Se x (x=0.1) Material.

[0066] The S prepared by X-ray powder diffractometer 1-x Se x (x=0.1) The material is subjected to X-ray diffraction analysis, and the results are shown in Figure 4 , Figure 4 The S prepared for Example 2 of the present invention 1-x Se x (x=0.1) X-ray diffraction spectra of materials at different temperatures. Depend on Figure 4 It can be seen that after the temperature is greater than 110 °C, the XRD of the product corresponds to a structure similar to monoclinic sulfur.

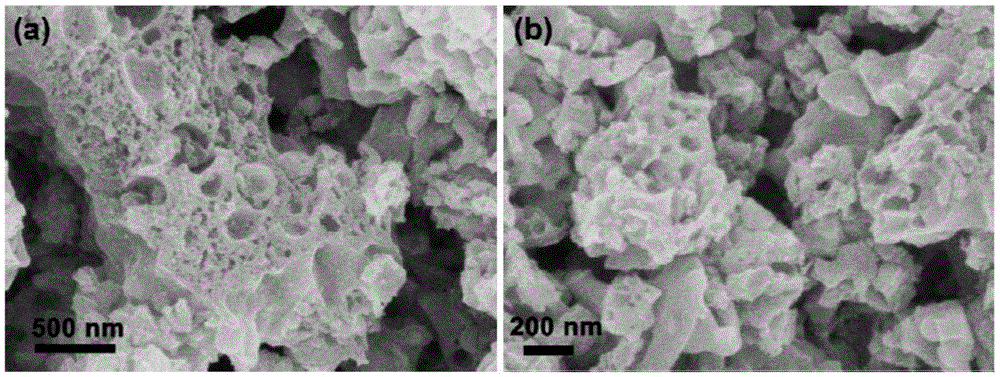

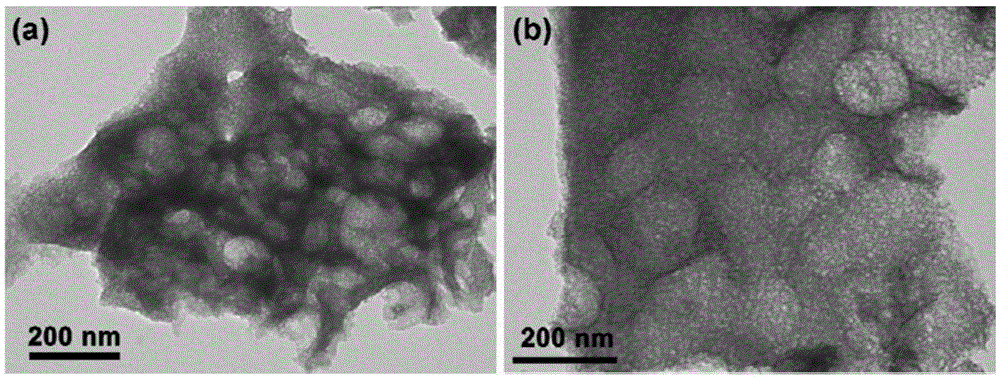

[0067] Adopt scanning electron microscope and transmission electron microscope to detect material structure, the result shows, the S prepared by the present invention 1-x Se x (x=0.1) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com